Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100 results about "Strontium acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick Answer. The formula for strontium acetate is Sr(C2H3O2)2. This formula can also be written as SrC4H6O4. Strontium acetate has a molecular weight of 205.71 grams per mole.

Medical titanium with a trace element slow-release function or titanium alloy implant material as well as preparation method and application of same

InactiveCN102908661AImprove biological activityIncrease success rateSurface reaction electrolytic coatingSuperimposed coating processElectrolytic agentTitanium metal

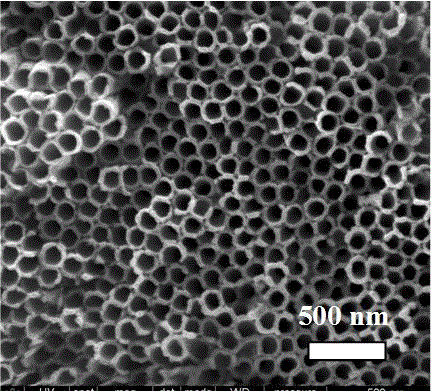

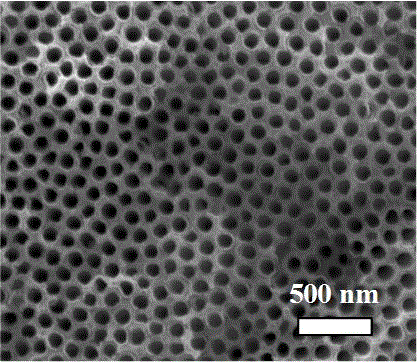

The invention relates to medical titanium with a trace element slow-release function or a titanium alloy implant material as well as a preparation method and an application of the medical titanium. The invention adopts the technical scheme that the preparation method comprises the following steps: putting a polished titanium-containing metal sheet into an electrolyte as an anode for anodic oxidation; flushing and drying the titanium-containing metal sheet subjected to anodic oxidation, carrying out heat treatment for 1-3 hours at a temperature of 100-500 DEG C, naturally cooling and ultrasonically cleaning and drying; and putting the dried titanium-containing metal sheet into one of or mixed solution of more than any two strontium hydroxide, strontium acetate, zinc acetate or magnesium acetate, carrying out hydrothermal reaction for 0.5-12 hours in a closed container at a temperature of 100-300 DEG C, naturally cooling, taking out, cleaning and drying, and carrying out heat treatment for 1-3 hours at a temperature of 450-550 DEG C to obtain the medical titanium with the trace element slow-release function or the titanium alloy implant material. The medical titanium or the titanium alloy implant material as well as the preparation method and the application thereof have the beneficial effects that the preparation method is simple and reliable, the loading quantity and the release amount of trace elements of the medical titanium in a nano tube are controllable, the medical titanium and the biological activity on the alloy surface can be better promoted, and the application prospect is good in the medical implant material.

Owner:WUHAN UNIV OF SCI & TECH

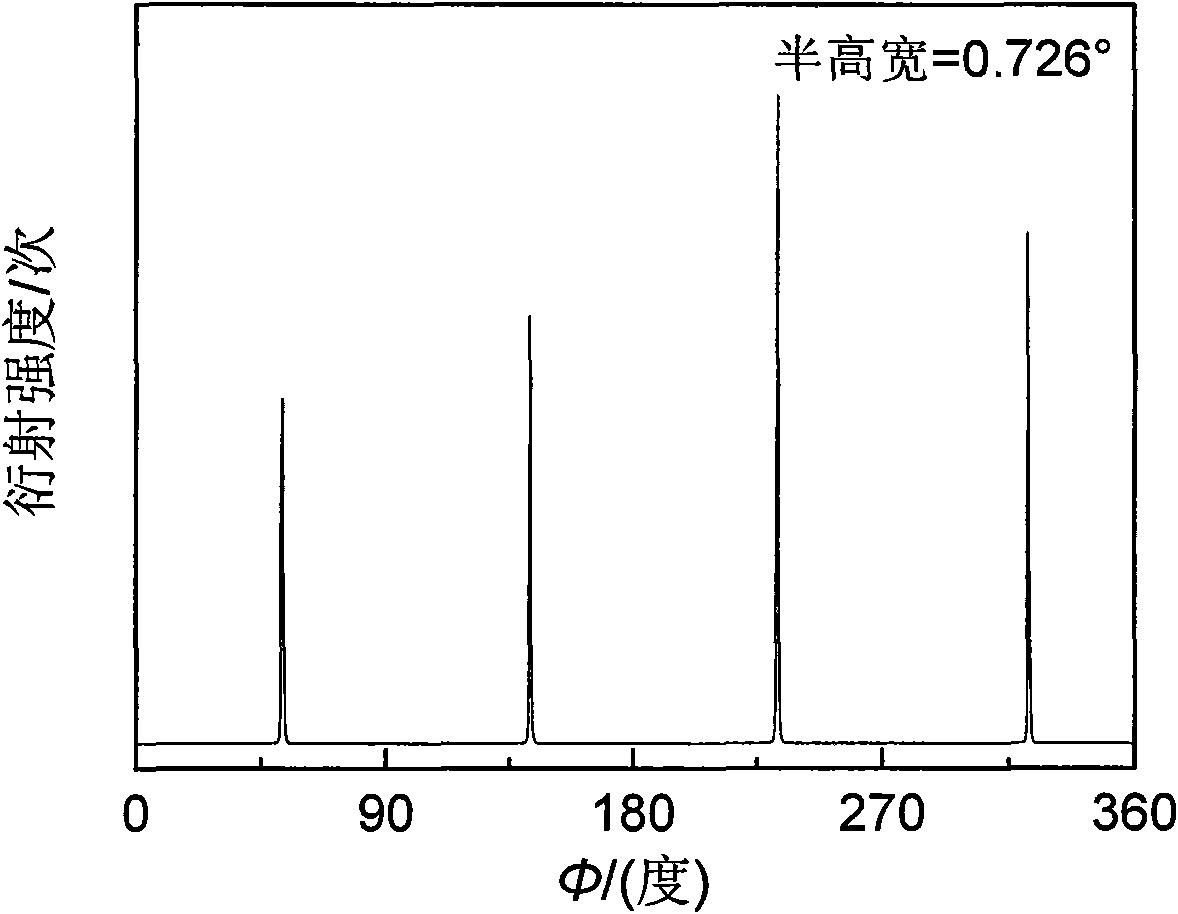

Method for preparing high-temperature superconducting coating conductor LaSrMnO3 buffering layer film

InactiveCN102509763ALow priceEasy to useSuperconductor device manufacture/treatmentMANGANESE ACETATEElectrical conductor

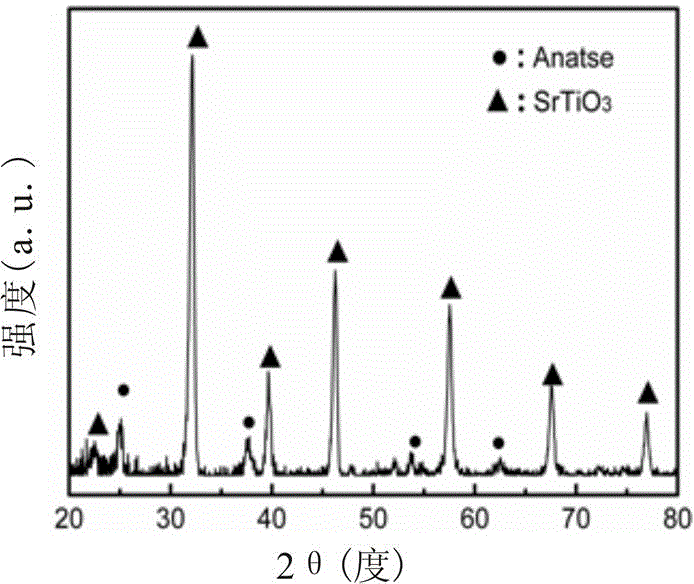

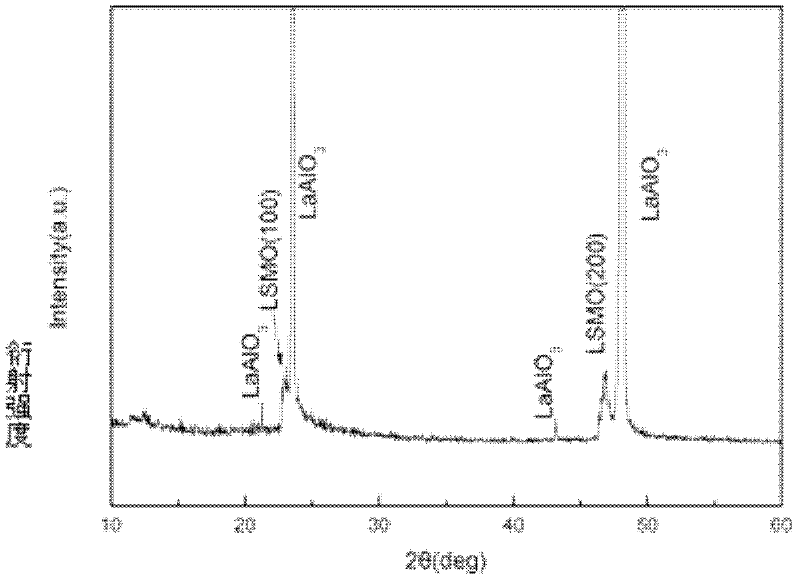

The invention discloses a method for preparing a high-temperature superconducting coating conductor La0.7Sr0.3MnO3 buffering layer film, and belongs to the technical field of high-temperature superconducting materials preparation. The film prepared by the method is smooth and compact, and is favorable in texture, and triplex functions of La0.7Sr0.3MnO3 as a conducting buffering layer film, namely isolation, extension and electric current transmission, can be adequately exerted. The method comprises the following steps: dissolving analytically pure lanthanum oxide (La2O3) in acetic acid (the mol ratio of the acetic acid to cations being 10: 1) in a cation ratio of La: Sr: Mn=0.7: 0.3: 1; after the analytically pure lanthanum oxide is completely dissolved, putting the obtained solution in an infrared drying box, and after the solution is baked into a white solid, taking out the white solid; mixing and dissolving strontium acetate and manganese acetate with the prepared white solid (namely lanthanum acetate) in propionic acid in the cation ratio of La: Sr: Mn=0.7: 0.3: 1 to form an anhydrous solution; adding polyvinyl butyral (PVB) in the anhydrous solution to prepare into a colloid with good film forming property; and coating the colloid on a substrate, drying the coated substrate, and then, putting the dried substrate in a sintering furnace to be sintered to form a phase, so as to obtain a lanthanum-strontium-manganese oxide La0.7Sr0.3MnO3 high-temperature superconducting coating conductor buffering layer. The cost of the method is low; the manufacturing process is simple; the operation is easy to control; and the environment is not polluted.

Owner:SOUTHWEST JIAOTONG UNIV

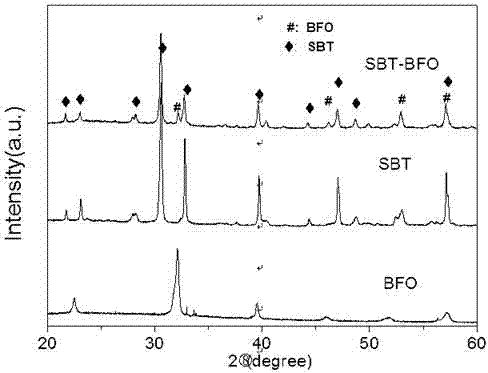

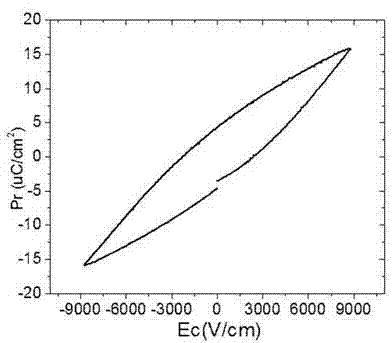

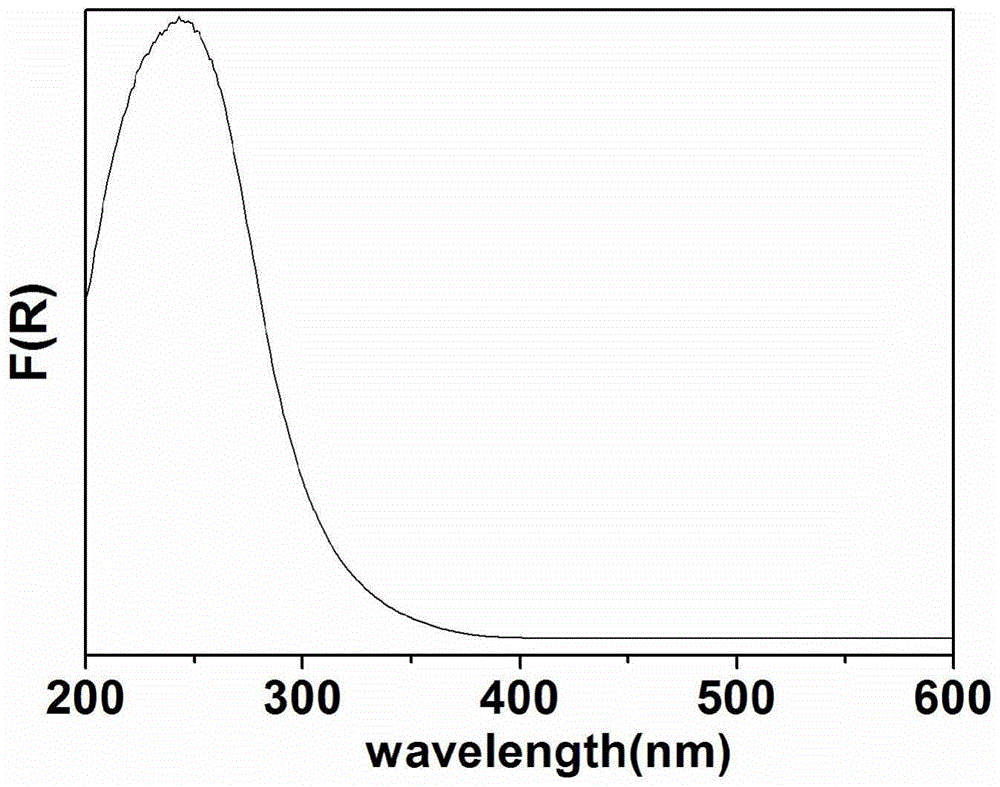

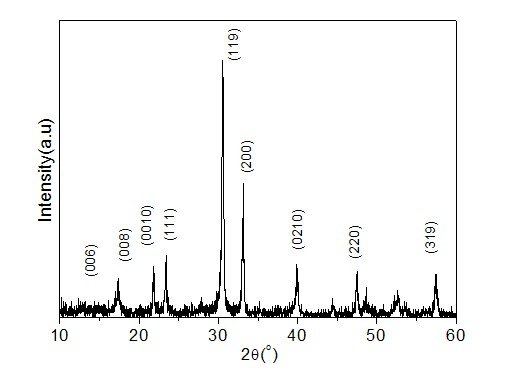

Bismuth ferrite-strontium bismuth titanatemultiferroic composite film and preparation method thereof

InactiveCN103496747AControl UniformityLow preparation temperatureIron compoundsBismuth compoundsLeakage current densityNitrate

The invention belongs to the technical field of electronic ceramics, and specifically relates to a bismuth ferrite-strontium bismuth titanatemultiferroic composite film and a preparation method thereof. The bismuth ferrite-strontium bismuth titanatemultiferroic composite film comprises the following raw materials: ferric nitrate, bismuth nitrate, tetrabutyltitanate and strontium acetate. The bismuth ferrite-strontium bismuth titanatemultiferroic composite film has stable structure, and is substantially reduced in leakage current density and strengthened in ferroelectric performance.

Owner:SHANDONG JIANZHU UNIV

Preparation of red strontium sulphide long afterglow material

InactiveCN101328405AEasy to controlWell mixedLuminescent compositionsSolubilitySurface-active agents

The invention discloses a method for preparing a red strontium sulphide long afterglow material, comprising a hydrothermal coprecipitation method which comprises the following steps that: (a) water-solubility strontium salt, water-solubility europium salt, water-solubility dysprosium salt, carbamide and water are weight according to the mol ratio of 1: between 0.01 and 0.05: between 0.01 and 0.05: between 4 and 6: between 28 and 32 and are put inside a container to be stirred and dissolved, the mixture is insulated in a sealing state at a temperature of between 80 and 160 DEG C for 5 to 24 hours so that a precursor is obtained; (b) the precursor is subject to filtering and annealing at a temperature of between 900 and 1200 DEG C in the reaction environment for 0. 5 to 2 hours so that the red strontium sulphide long afterglow material is prepared; the water-solubility strontium salt is strontium nitrate or strontium chloride or strontium acetate, the water-solubility europium salt is europium nitrate, europium chloride or polyimide, the water-solubility dysprosium salt is dysprosium nitrate or dysprosium chloride or dysprosium acetate, and a surface active agent is added according to the mol ratio of the water-solubility strontium salt to the surface active agent of 1: between 0.0001 and 0.0003. The method is widely applied to the fields such as building decoration, traffic transportation, military facilities, fire emergency service and goods for everyday consumption.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

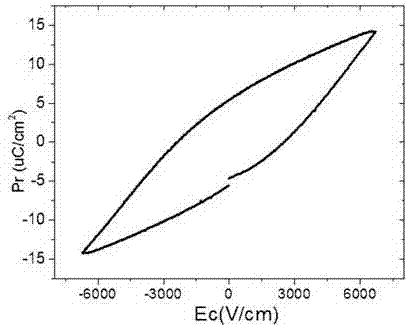

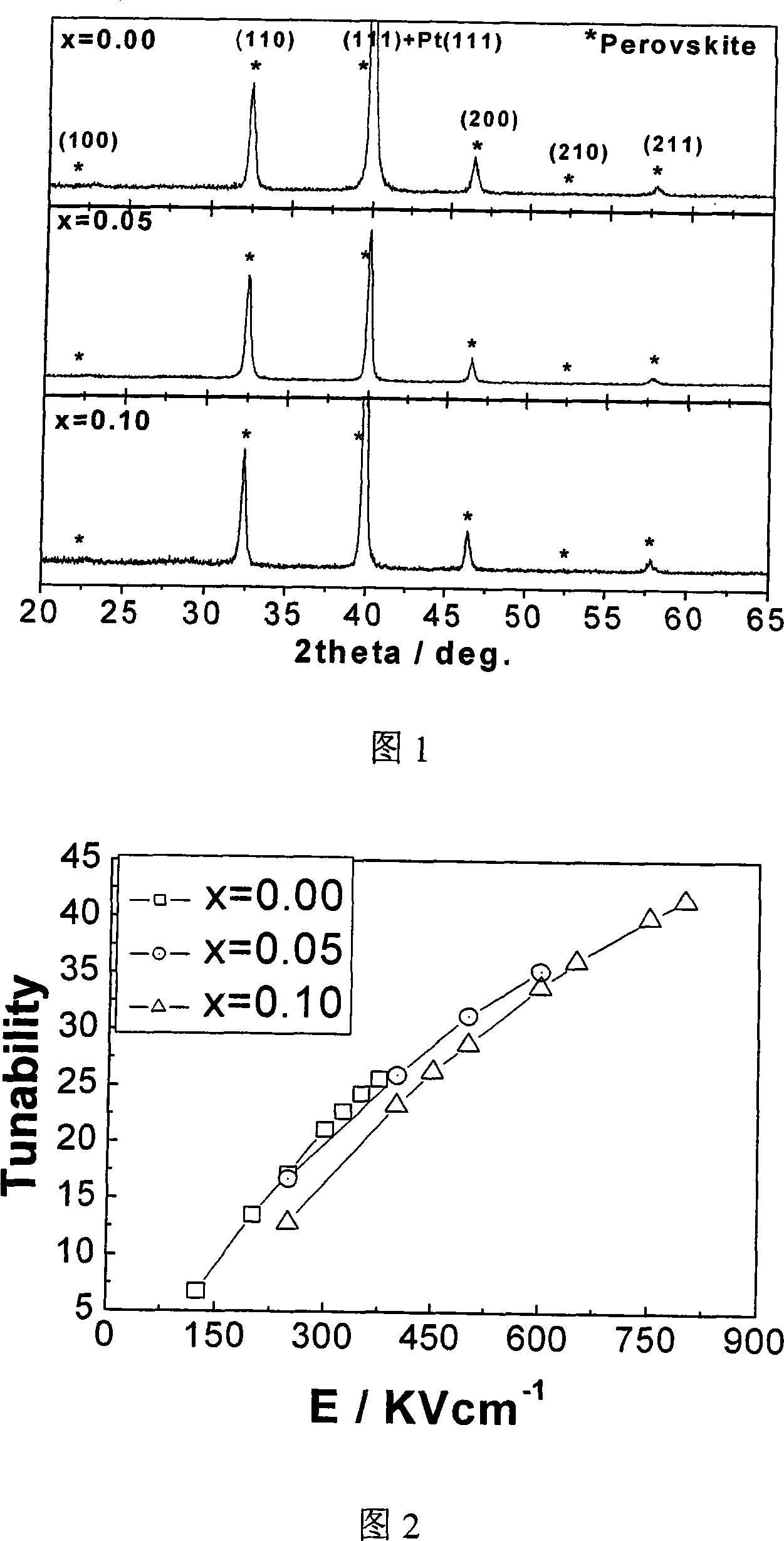

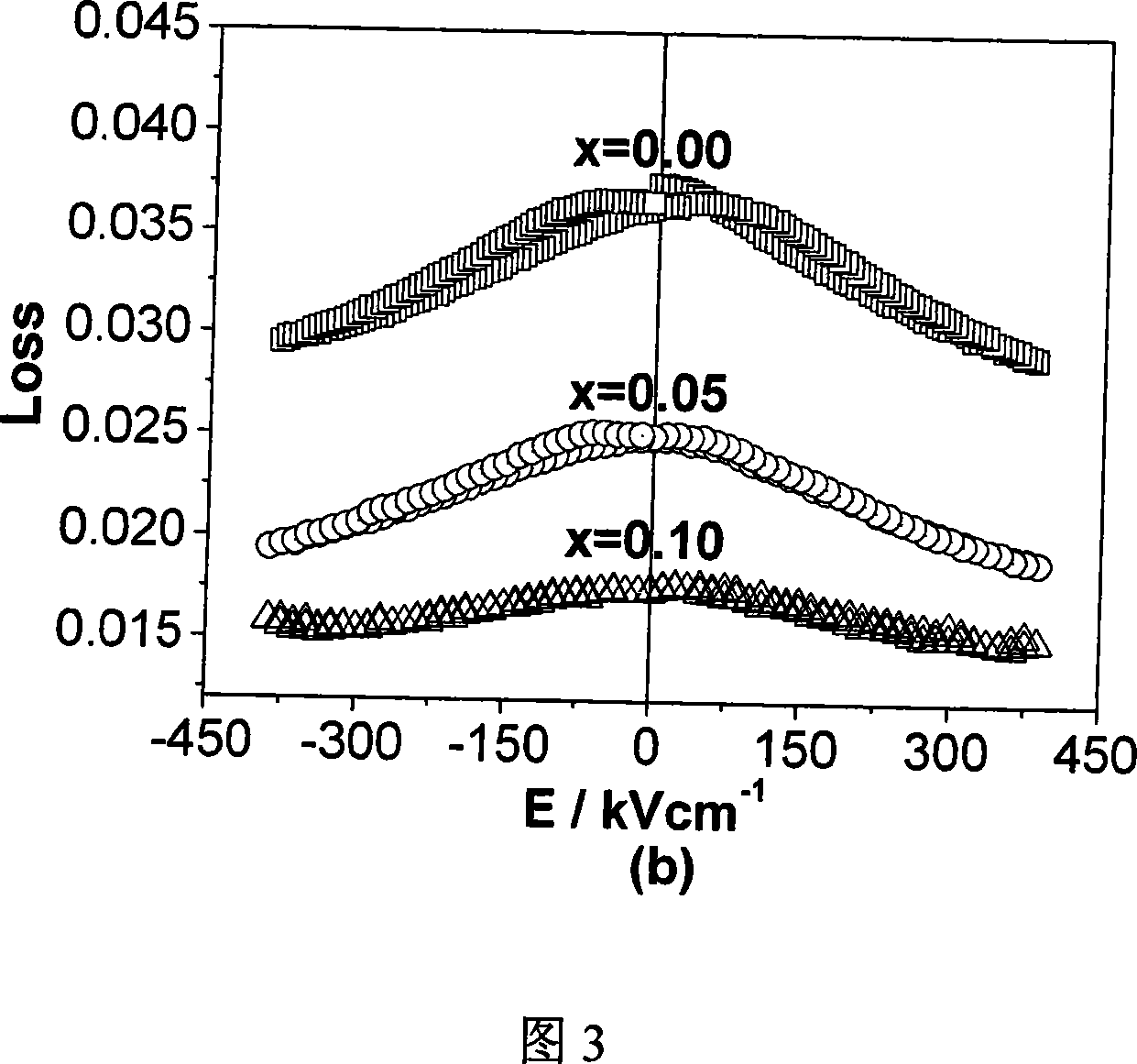

Method for preparing micro-wave dielectric adjustable strontium bismuth titanate film

The invention discloses a preparation method of strontium bismuth titanate microwave dielectric tunable membrane with perovskite structure. The Sol-Gel technique is adopted; the pure strontium acetate, the bismuth nitrate and the tetrabutyl titanate are the starting materials; the glacial acetic acid and the glycol ether are the solvent, the acetylacetone is the stabilizing agent, and the strontium bismuth titanate sol with chemical compound of BixSr1-1.5xTiO3 is synthesized. With the rapid thermal process technique, the strontium bismuth titanate membrane is with perovskite structure is produced on the uropatagia. By utilizing the microstructure modification of the strontium bismuth titanate membrane, the dielectric loss of the membrane is decreased while the tunable character of the membrane is not decreased, the quality factor of the membrane is improved, and a practical microwave dielectric tunable membrane of novel type is obtained thereby.

Owner:XI AN JIAOTONG UNIV

Rare earth-doped srstrontium cerate nano crystal ceramic preparing method

The present invention for ceramics of rare earth doped with strontium cerate nano crystal mainly adopts sol-gel method, to prepare the solution with a certain concentration by using cerous nitrate, strontium nitrate or strontium acetate and rare earth oxide as raw material, the weight ratio of them is dependent on the composition of ceramics to be prepared, the composition of the ceramics is SrCe1-xRExO3, in which the range of x value is 0.02-0.20, the concentraitons of cerous nitrate, strontium nitrate or strontium acetate are 0.2-2 mol / L respectively, using citric acid as complex builder, the added quantity of citric acid is 1.5-2.5 times the said solution, under stirring or ultrasonic vibration, heating in wate bath with 50-80 deg.C, regulating pH value to obtain transparent gel, drying to obtain opaque dried gel.

Owner:SHANGHAI UNIV

Preparation of nano crystal film of rare earth doped strontium cerate

InactiveCN1584114AImprove compactnessImprove conductivityPolycrystalline material growthSolid/suspension decomposition chemical coatingWater bathsRare earth

A method for preparing rare earth doped strontium cerate nanometer crystal thin film by organic polymer presoma method is disclosed. It is prepared by: preparing initial solution with cerous nitrate, strontium nitrate or strontium acetate, rare earth oxide as raw materials, determining the proportion by prepared thin film composition, the composition of thin film is SrCe1-xRExO3, the range of x volume is 0.02-0.20, concentration of initial solution is 0.1-0.4mol / L, taking ethylene as complexant, the adding account of ethylene is 2-6 times of metal ionic total account, mixing and supersonic oscillating, heating in water bath under 50-100deg.C, adjusting PH value, the system being heated reacting to produce organic polymer, film coating with 1500-3000rpm circulating speed on required chip by glue equalizer when viscosity reaching 100-300cP, infrared drying or vacuum drying, second film coating, drying until reaching the required thickness, and producing nanometer crystal thin film under 900deg.C reacting.

Owner:SHANGHAI UNIV

Medical biological fluorine anti-caries dressing and preparation method thereof

ActiveCN104288466AAvoid bleedingWith desensitization and analgesiaDigestive systemPharmaceutical non-active ingredientsBleeding gumGlycerol

The invention relates to the technical field of anti-caries functional dressings, particularly to a medical biological fluorine anti-caries dressing and a preparation method thereof. The medical biological fluorine anti-caries dressing is composed of modified chitosan, sorbitol, glycerol, silica, sodium fluoride, aluminium hydroxide, zinc citrate, peppermint oil, strontium acetate, a garlic extracting solution and carbomer. The medical biological fluorine anti-caries dressing can prevent caries, remove scales on the surfaces of teeth, maintain cleaning of an oral cavity, can effectively prevent gingivitis, periodontitis and bleeding gums and also has the efficacies of desensitization, analgesia, ozostomia removal and the like, so that the medical biological fluorine anti-caries dressing comprehensively maintains health of teeth and the oral cavity and has the characteristics of high safety, non toxic or side effect, and good convenience in use.

Owner:GUANGXI XINYE BIOLOGICAL TECH

Process for preparing niobium-doped strontium titanate film

A preparation method for niobium-doped strontium titanate thin film comprises the following steps: a)the preparation of niobium-citric acid glycol solution; putting the niobium oxide in hydrofluoric acid to form niobium oxide solution at 70-85 DEG C, then adding ammonia dropwise and aging the solution for 4 to 6 hours; after filtering, taking out the sediment and washing the sediment with dilute ammonia; after drying, the sediment is dissolved into the ethylene glycol solution of the citric acid at 60-80 DEG C. b)the preparation of precursor solution; based on molar ratio, Sr2+: Ti4+: Nb5+ is equal to 1:1-x: x, while x is equal to 0.1- 0.005; measuring and taking strontium acetate, tetrabutyl titanate and the niobium-citric acid glycol solution in the step a; dissolving the strontium acetate into water to get a solution A; adding acetylacetone dropwise into butyl titanate, and then adding ethylene glycol ether solvent to get a solution B; mixing the solution A with the solution B, and then adding the niobium-citric acid glycol solution into the mixed solution, followed by 1-4: 1 of ethylene glycol and glycerol, so that the concentration of the solution can reach Sr2+ ion 0.15-0.40 mol / L. c)thermal decomposition and sintering. The method uses cheap raw materials and has simple production technology and low production costs, which facilitates commercial applications.

Owner:SOUTHWEST JIAOTONG UNIV

Barium strontium titanate dielectric film prepared through micro-arc oxidation and method thereof

InactiveCN102304744ASimple technical processLess investmentSurface reaction electrolytic coatingElectrolytic agentBarium strontium titanate

The invention discloses a barium strontium titanate dielectric film prepared through micro-arc oxidation and a method thereof. The method comprises the following steps: preparing electrolyte from barium acetate or strontium acetate or mixture thereof, wherein the molar concentration of the barium acetate solution is 0-2.0 mol / L and the molar concentration of the strontium acetate is 0-1.2 mol / L; treating with a direct-current pulse power supply for 6-60 min, wherein the current density is 10-50 A / dm<2>, the pulse frequency is 50-250 Hz, and the duty cycle is 60%-95%; connecting a titanium substrate with an anode, and keeping the temperature of the electrolyte at 50-60 DEG C during the reaction; and taking down the treated titanium after the reaction, washing with distilled water and drying. The method has simple working procedures and high film-forming speed; and the film and the titanium (Ti) substrate are in metallurgical bonding, and the film has excellent dielectric properties.

Owner:SOUTH CHINA UNIV OF TECH

Perovskite type catalyst prepared by sol-gel weak oxidation calcination and method

PendingCN112058272AWell mixedThe right concentration of oxygen vacanciesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a perovskite type catalyst prepared by sol-gel weak oxidation calcination and a method. The method comprises the following steps of: dissolving lanthanum nitrate, strontium acetate hemihydrate, cobalt nitrate hexahydrate, manganese acetate tetrahydrate, a composite complexing agent ethylenediaminetetraacetic acid and citric acid with deionized water to prepare sol, and adjusting the pH value by using an adjusting agent in the sol forming process to make the pH value in a range of 6-7; evaporating sol moisture through heating or water bath to form gel, and drying the gelat 250 DEG C for 5 hours to obtain dry gel; and calcining the dry gel for 4-6 hours at 900-1000 DEG C under a weak oxidation condition, cooling, taking out, and grinding into powder, thereby obtaining the perovskite (La0.5Sr0.5) (Co0.8Mn0.2)O3-lambda oxide catalyst. The preparation process is simple, damage to equipment and the environment is small, and the prepared catalyst has excellent, stableand reliable catalytic activity.

Owner:TIANJIN UNIV

Method for preparing strontium titanate film having spherical grain accumulated porous structure

InactiveCN102390935AOvercoming Synthetic DifficultiesOvercoming complexitySolid/suspension decomposition chemical coatingPolymer sciencePore distribution

The invention belongs to the technical field of a functional material and particularly relates to a method for preparing a strontium titanate film having a spherical grain accumulated porous structure. A sol gel template process is adopted in the method. The method comprises the following steps: dropwise adding a strontium acetate solution having a certain concentration in a tetrabutyl titanate alcohol solution at a speed of (0.25-2) milliliters per minute; continuously stirring at a speed of (500-1000) revolutions per minute; after finishing titration for 0.5-1.5 hours, adding a non-ionic surface active agent; stirring again till obtaining a uniform, stable, layering-free and 0.1-0.5mol / L strontium titanate sol; after ageing, utilizing a spinning method or dipping drawing method to coat a film on a substrate; and drying and calcinating, thereby obtaining the strontium titanate film having the spherical grain accumulated porous structure. The method provided by the invention has the characteristics of simple production process, less equipment investment, low cost, easiness for operation and excellent repeatability. According to the method, a spherical grain accumulated three-dimensional porous film, which has the characteristics of big specific surface area, uniform pore distribution and excellent interpenetration, can be obtained.

Owner:SHENYANG POLYTECHNIC UNIV

Catalyst for degrading antibiotics in water through photocatalysis as well as preparation method and application of catalyst

ActiveCN104607175ASimple processEasy to controlWater/sewage treatment by irradiationWater contaminantsPtru catalystEthylic acid

The invention discloses a catalyst for degrading antibiotics in water through photocatalysis as well as a preparation method and an application of the catalyst. The preparation method comprises steps as follows: 1), preparation of a nano-powder precursor solution : strontium acetate, antimony pentoxide and 65-75 ml of deionized water are stirred and mixed at the room temperature, the mole ratio of strontium acetate to antimony pentoxide is (1.35-2) :1, the PH is adjusted to 1-5 through 2-6 mol / L of nitric acid, and the nano-powder precursor solution is obtained; (2), preparation of nano-powder under the hydrothermal condition: the nano-powder precursor solution is placed in a 100 ml of high-pressure reaction kettle, is heated to the temperature of 100-200 DEG C at the speed of 1-5 DEG C / min, has a hydrothermal reaction for 6-48 h, is naturally cooled to the room temperature after the reaction ends, and then is taken out, a product is cleaned for 3-5 times with deionized water and absolute ethyl alcohol and put in a drying box to be dried at the temperature of 60-80 DEG C, and a photocatalyst is obtained. The photocatalyst prepared with the preparation method and used for degrading antibiotics in water through photocatalysis can be used for photocatalysis treatment on antibiotics in sewage, and the degradation rate is higher than 89%.

Owner:FUJIAN NORMAL UNIV

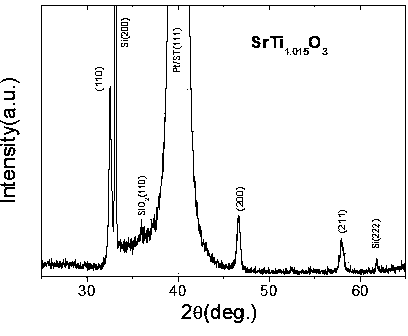

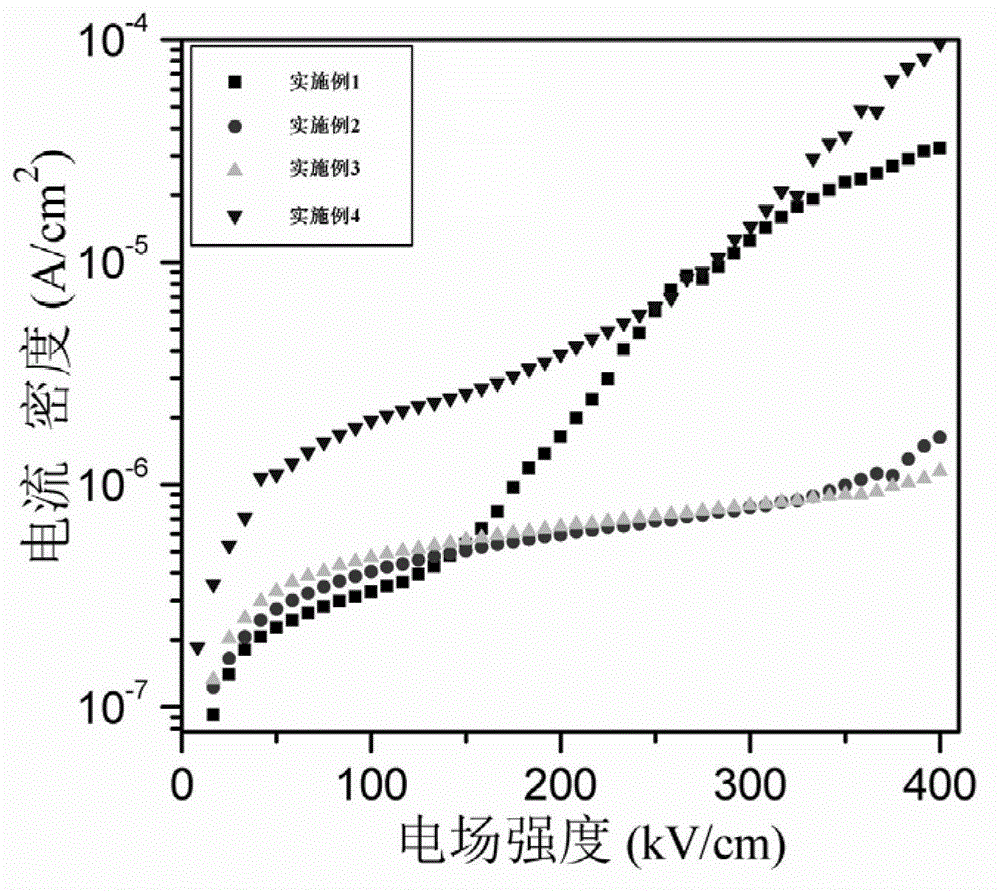

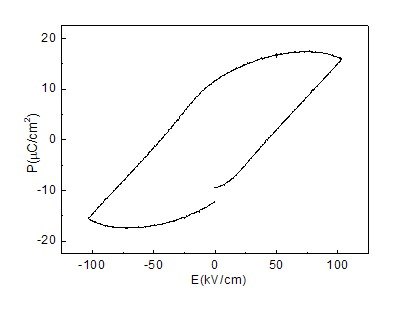

Self-doped strontium titanate ferroelectric film and preparation method thereof

A self-doped strontium titanate ferroelectric film and a preparation method thereof. The self-doped strontium titanate ferroelectric film is composed of a material with a molecular formula of SrTi1+xO3, wherein the value range of x is 0.015-0.02. The preparation method of the film comprises the following steps: weighing strontium acetate, tetrabutyl titanate, and acetylacetone according to a mole ratio of 1:(1.015-1.02):0.7, completely dissolving strontium acetate in acetic acid, then adding ethylene glycol monomethyl ether, tetrabutyl titanate, and acetylacetone, diluting the solution with ethylene glycol monomethyl ether to obtain a mole concentration of strontium acetate of 0.3 mol / L, stirring to obtain a solution C; dropping the solution C on a substrate in a spin coater, performing spin coating, drying and thermolysis till the thickness of the SrTi1+xO3 dry film reaches 300 nm, and performing annealing to obtain the SrTi1+xO3 film. According to the invention, ferroelectricity is induced by excessive Ti and in an anoxic atmosphere, and ferroelectric hysteresis loops are measured at a temperature above zero or even at room temperature; no introduction of other element is necessary, and the method is simple.

Owner:HENAN UNIV OF SCI & TECH

Mn-doped sodium bismuth titanate-potassium bismuth titanate-strontium titanate ternary series piezoelectric film material and preparation method thereof

The invention relates to a Mn-doped sodium bismuth titanate-potassium bismuth titanate-strontium titanate ternary series piezoelectric film material and a preparation method thereof. According to 0.95(0.8Bi<1 / 2>Na<1 / 2>TiO3-0.2Bi<1 / 2>K<1 / 2>)TiO3-0.05SrTiO3(BNT-BKT-ST)+xmol%Mn with the x being 0-1.0%, bismuth nitrate, sodium acetate, potassium acetate, strontium acetate, manganese acetate, titanium isopropylate, acetic acid and glycol ether are adopted, acetylacetone and aqueous ammonia are adopted as raw materials, and a Pt / Ti / SiO2 / Si substrate is coated in a spin-coating manner by adoption a sol-gel method so as to prepared sodium bismuth titanate-potassium bismuth titanate-strontium titanate ternary series piezoelectric film with a single perovskite structure. The piezoelectric coefficient d<33> of the film can reach 93 pm / V. By Mn doping, the leak current of the sodium bismuth titanate-potassium bismuth titanate-strontium titanate ternary type piezoelectric film is decreased and resistance to pressure is enhanced. The film reaches performances of traditional lead piezoelectric film and has good application prospect in microactuators and actuators.

Owner:TONGJI UNIV

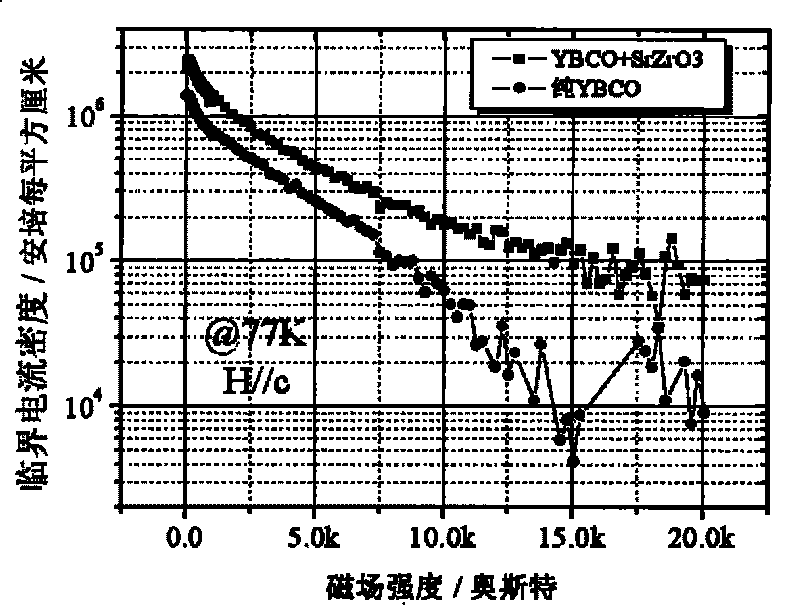

SrZrO3 doped YBCO thin film and preparation method thereof

InactiveCN101320604BLow costFast depositionSuperconductors/hyperconductorsSuperconductor devicesOrganic compoundChemistry

A SrZrO3 doped YBCO film and a preparation method thereof belong to the technology field of the preparation of the superconducting material with high-temperature coat. The original PLD method has the defect that the equipment is complicated, the cost is high and the proportion of the dopant is not easy to control. The film provided by the invention consists of 1 to 15 molar percent of SrZrO and 85 to 99molar percent of YBCO. The invention prepares YBCO precursor solution by the deposition method of trifluoroacetic acid and metal-organic compound; the YBCO precursor solution and the propionatesolution comprising strontium acetate and zirconium acetylacetone are mixed to obtain the SrZrO3 doped YBCO precursor solution; then the SrZrO3 doped YBCO precursor solution is spin-coated or dip-coated on the base, and the base is sintered under the wet oxygen atmosphere and below 400 DEG C; finally the base is high-temperature sintered under the wet ArO2 mixing atmosphere and between 750 to 850DEG C to obtain the SrZrO3 doped YBCO film. The film of the invention has the advantages of higher critical current density, higher critical conversion temperature and biaxial texture in the magneticfiled, simple equipment and low cost.

Owner:BEIJING UNIV OF TECH

Attapulgite/nano-strontium-titanate/nano-tin-oxide photocatalysis silicone-acrylic coating preparation method

InactiveCN107033708AImprove photocatalytic performanceGood weather resistanceCoatingsPliabilityAcrylic coating

The invention discloses an attapulgite / nano-strontium-titanate / nano-tin-oxide photocatalysis silicone-acrylic coating preparation method. Tin tetrachloride, strontium acetate and tetrabutyl titanate serve as raw materials, nano-tin-oxide and nano-strontium-titanate are loaded on the surface of attapulgite by a sol-gel method, the attapulgite is modified by photocatalysis, a prepared attapulgite loaded strontium-titanate / tin-oxide composite nano-material has excellent thickening property, leveling property and photocatalysis activity and then serves as a thickening agent and a photocatalyst for preparing a silicone-acrylic coating, and the prepared silicone-acrylic coating has excellent photocatalysis property, good weather resistance, water resistance, chemical resistance, stain resistance, flexibility and adhesiveness.

Owner:ANHUI BOSHUO TECH

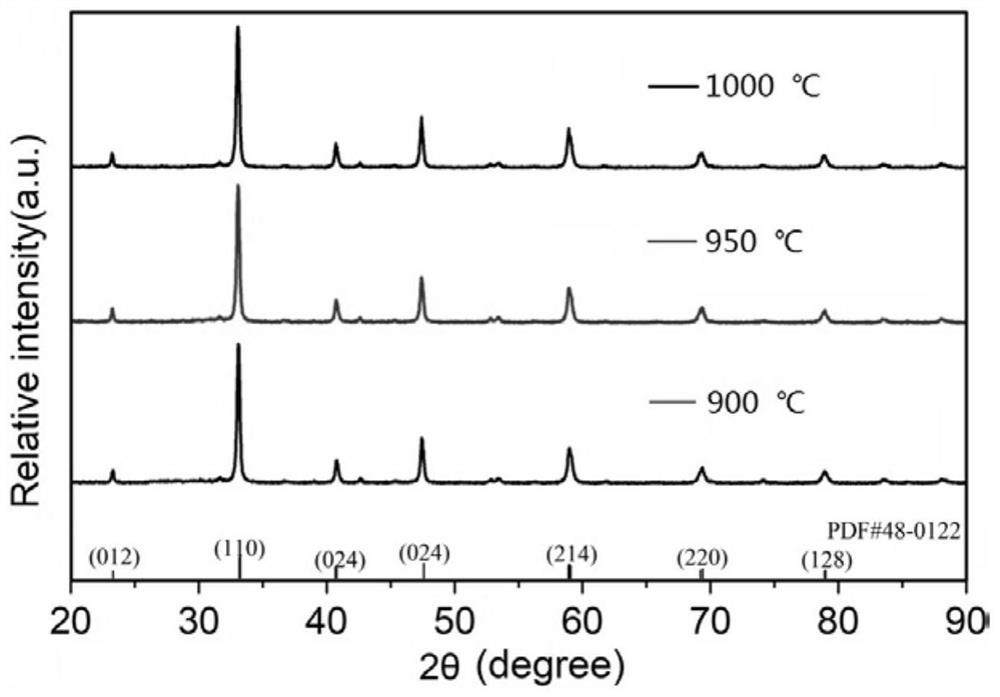

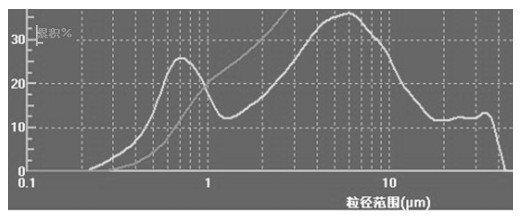

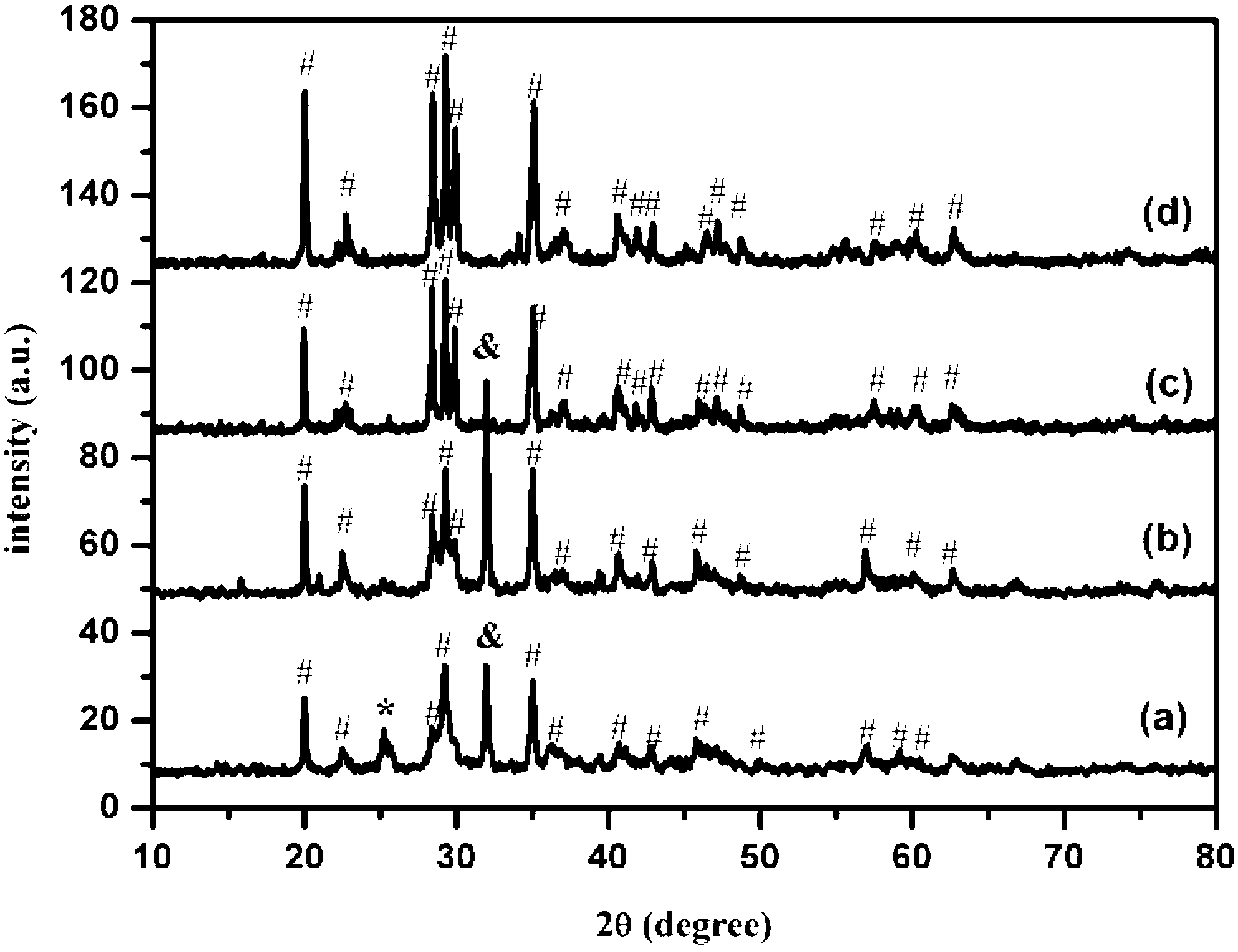

Rapid preparation method of perovskite structure polycrystalline nanopowder with chemical formula ca0.4sr0.6bi4ti4o15

InactiveCN102267721ANarrow size distributionUniform compositionNanotechnologyBismuth compoundsStrontium acetateTitanium

The invention relates to a preparation method of perovskite-structure polycrystalline nanopowder, in particular to a quick preparation method of perovskite-structure polycrystalline nanopowder with a chemical formula of Ca0.4Sr0.6Bi4Ti4O15. The invention aims to provide a quick preparation method of Ca0.4Sr0.6Bi4Ti4O15 powder; and the method has the advantages of simple technique and low cost, and the preparation process is convenient to operate and control. The aim of the invention is realized by the following technical scheme: acetylacetone, tetrabutyl titanate, strontium acetate, bismuth nitrate, calcium nitrate and ethylene glycol are used as raw materials and a sol-gel method is adopted for synthesis. The invention has the following beneficial effects: the particle size of the perovskite-structure high-purity superfine powder which is prepared directly and quickly is 1-10mu m, the particles are nearly spherical, the size distribution range is narrow and the components are uniform.

Owner:SHANDONG JIANZHU UNIV

Preparation method of rare-earth modified attapulgite composite nanomaterial loaded with strontium titanate/stannic oxide/zinc sulfide

InactiveCN107081159AAdjust the band structureWide spectral response rangeHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsStrontium titanateRare-earth element

The invention discloses a preparation method of a rare-earth modified attapulgite composite nanomaterial loaded with strontium titanate / stannic oxide / zinc sulfide. The preparation method comprises the following steps: adopting tin tetrachloride, strontium acetate and tetrabutyl titanate as raw materials, adding lanthanum chloride and europium sulfate as a rare-earth modifier, correspondingly obtaining rare-earth lanthanum modified gel A and rare-earth europium modified gel B by adopting a sol-gel method, then adopting zinc acetate, thioacetamide and yttrium nitrate as raw materials, adopting a hydro-thermal synthesis method to prepare yttrium-doped nanometer zinc sulfide, then mixing the gel A, the gel B, the purified attapulgite and the yttrium-doped nanometer zinc sulfide, drying, and calcining to obtain three rare-earth elements of lanthanum, europium and yttrium modified attapulgite composite nanomaterial loaded with strontium titanate / stannic oxide / zinc sulfide. The spectral response range of the attapulgite composite nanomaterial loaded with strontium titanate / stannic oxide / zinc sulfide is broadened, and the excellent photocatalytic performance is shown under the visible light and sunlight.

Owner:ANHUI BOSHUO TECH

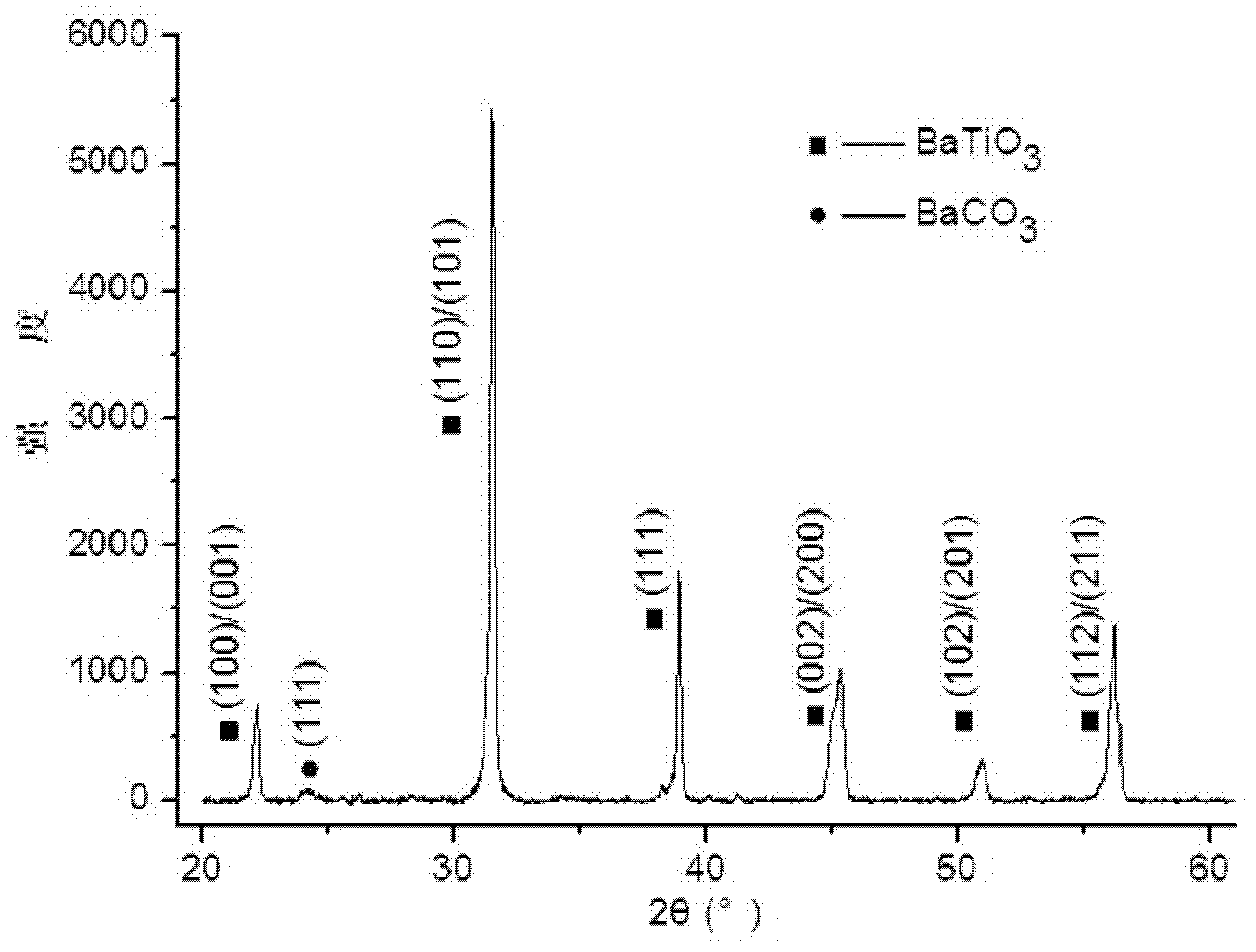

Preparation method of bismuth layer structure ferroelectric ceramic material with chemical formula srbi2ti2o9 for preparing thin film

InactiveCN102267811AEvenly dopedEasy to uniform quantitative dopingHigh voltage capacitorsStrontium acetate

The invention relates to a preparation method of a bismuth layer structured ferroelectric material, and concretely relates to a preparation method of a bismuth layer structured ferroelectric ceramic material of chemical formula of SrBi2Ti2O9 for preparing films. A purpose of the invention is to prepare the bismuth layer structured ferroelectric ceramic material which can replace a PZT material. The purpose of the invention is realized by adopting the following technical scheme that the material is synthesized by adopting a sol-gel process with tetrabutyl titanate, acetylacetone, bismuth nitrate, strontium acetate and glycol as raw materials. The preparation method of the present invention has advantages that: the material performs a high temperature dielectric property, high piezoelectriccoefficient and a good ferroelectric property, can replace lead ferroelectric materials under a high temperature, and can be applied to fields of high voltage capacitors, ferroelectric memories, piezoelectric ceramic oscillators and the like.

Owner:SHANDONG WOMENS UNIV

MOD method for preparing LSCO conductive film on biaxial texture NiW alloy

InactiveCN101649451ADiffusion barrierPrevent oxidationSuperconductors/hyperconductorsLiquid/solution decomposition chemical coatingPropanoic acidOxygen

The invention relates to an MOD method for preparing an LSCO conductive film on biaxial texture NiW alloy, which belongs to the technical field of superconducting materials. The method comprises the following steps: dissolving strontium acetate, lanthanum acetate and cobaltous acetate into propionic acid step by step and adding acetylacetone to prepare precursor solution; coating the precursor solution on a biaxial texture NiW base band by a glue homogenizing machine; then carrying out pyrolysis processing and carrying out coating and pyrolysis processing again; and carrying out crystallization reaction. The prepared LSCO film has the thickness of 500-700nm, obstructs the diffusion process of a Ni element to a YBCO layer and favorably prevents the oxidation of an NiW substrate; and the electrical resistivity of the film, which is detected by a four-lead method can reach 1.1*10<-4>omega*m in a liquid nitrogen temperature zone. Compared with the traditional process, the invention reducesthe number of buffer layers, thereby reducing the preparation process and the manufacture cost of a YBCO / buffer / NiW composite material.

Owner:NORTHEASTERN UNIV

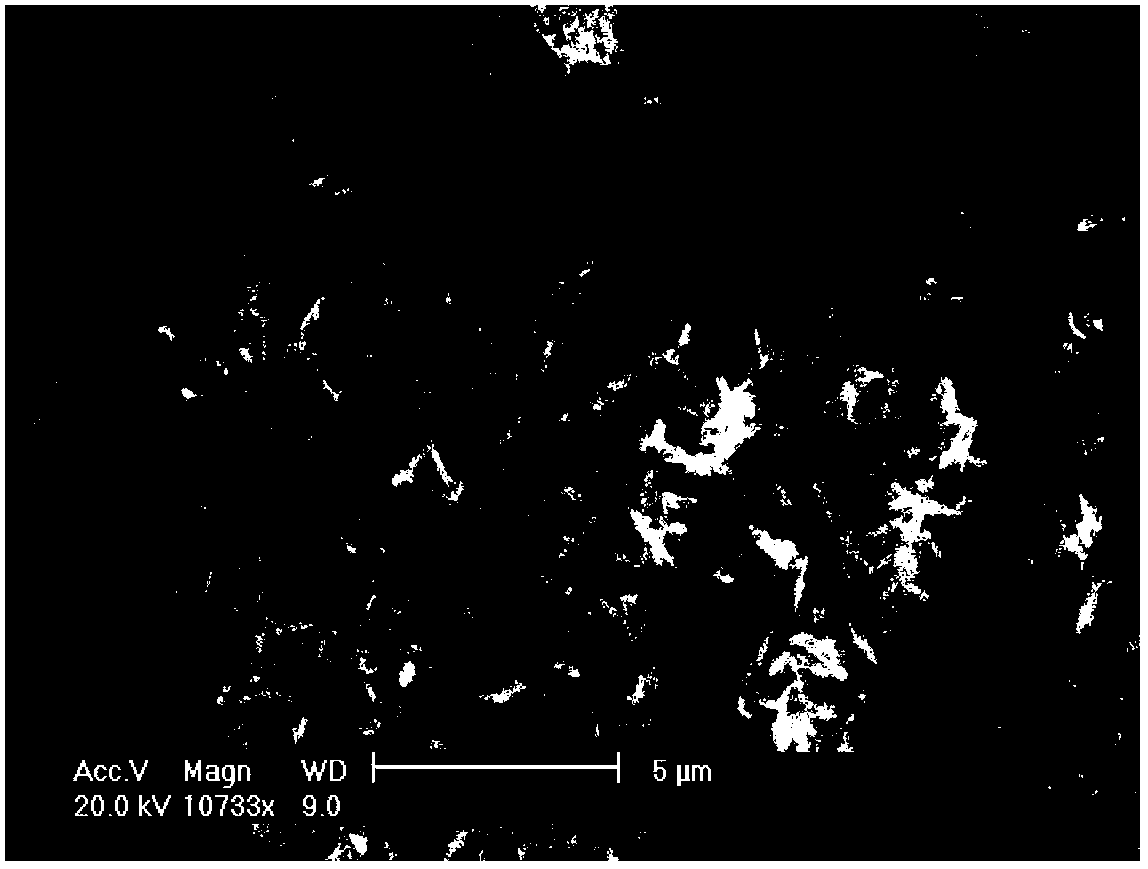

Preparation method of strontium bismuth tantalite nanometer line

InactiveCN101319393ASimple processPolycrystalline material growthSingle crystal growth detailsNanowireStrontium acetate

The invention provides a method for preparing a strontium bismuth tantalum nanowire, relating to a nanowire preparation method. The method solves the problem that the strontium bismuth tantalum nanowire can not be prepared by the prior art. The preparation method comprises the following steps that: 1. strontium acetate, bismuth subnitrate and tantalum ethoxide are weighed to prepare an SBT precursor sol; 2. the electrophoretic deposition is performed; 3. the calcination process is performed; and 4. the nanowire with a template is put in a sodium hydrate solution so that the strontium bismuth tantalum nanowire is prepared. The method realizes the synthesis of the strontium bismuth tantalum nanowire by adopting the method of electrophoretic deposition through the SBT sol. The method is simple, has simple devices and can accurately control the length of the nanowire.

Owner:HARBIN INST OF TECH

Method for preparing high-temperature superconductive coated conductor SrZrO3 buffer film

InactiveCN102176349AGood chemical compatibilityBlock interdiffusionSuperconductors/hyperconductorsSuperconductor devicesPropanoic acidElectrical conductor

The invention discloses a method for preparing a high-temperature superconductive coated conductor SrZrO3 buffer film, relating to the technical field of high-temperature superconductive material preparation. The film prepared by the method has excellent chemical compatibility and can effectively prevent Ni and Cu in ReBCO from mutual diffusion. The method comprises the following steps: dissolving strontium acetate and acetyl acetone zirconium in propionic acid to form an anhydrous solution; adding PVB in the anhydrous solution to prepare gel with good film forming performance; coating the gel on a substrate, drying, and sintering into a phase in a sintering furnace to finally obtain the high-temperature superconductive coated conductor SrZrO3 buffer film.

Owner:SOUTHWEST JIAOTONG UNIV

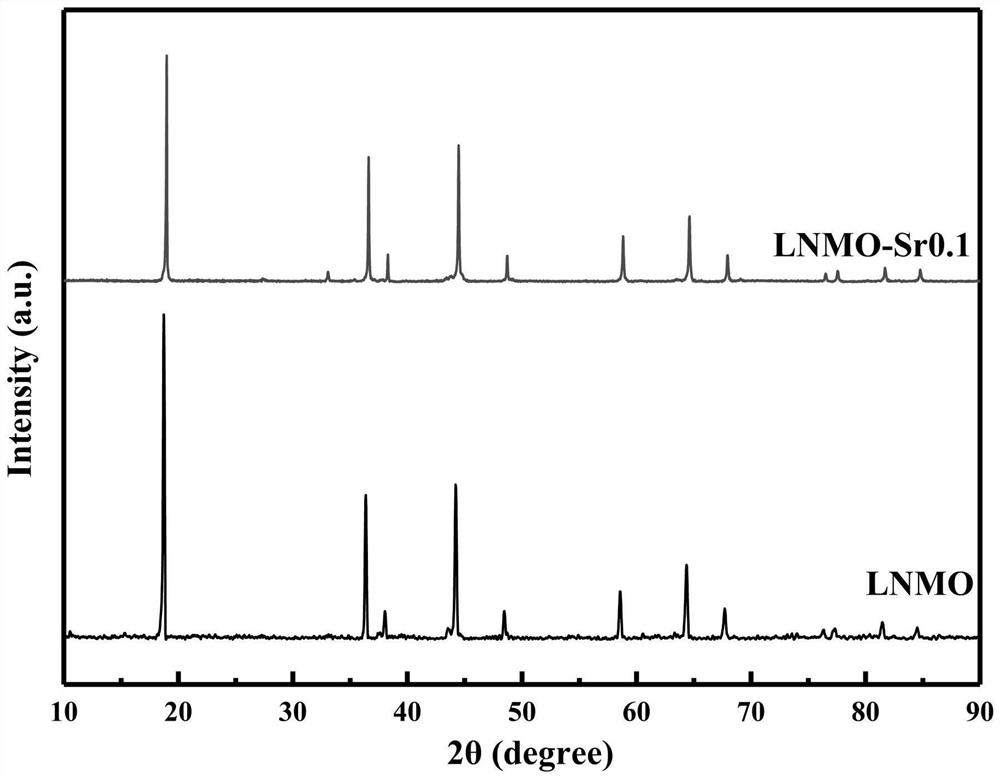

Modification method for doping and synthesizing binary lithium nickel manganese oxide positive electrode material

PendingCN112751026ASimple preparation processLow costSecondary cellsPositive electrodesMANGANESE ACETATEAir atmosphere

The invention discloses a modification method for doping and synthesizing a binary lithium nickel manganese oxide positive electrode material. The modification method comprises the following steps of: (1) dissolving lithium acetate, nickel acetate, manganese acetate and strontium acetate in deionized water to obtain an acetate solution; (2) dissolving citric acid in ethylene glycol to obtain a citric acid-ethylene glycol solution; (3) adding the acetate solution into the citric acid-ethylene glycol solution, heating and stirring the mixed solution until the solution becomes green gel; and (4) drying the green gel, grinding the product, and sintering the ground product in an air atmosphere to obtain the binary lithium nickel manganese oxide positive electrode material. The modification method is a synthesis process which is relatively low in cost, simple to operate and high in benefit, and has the advantages that Sr<2+> doping is realized, the structural stability is enhanced, side reactions on the surface of the material are inhibited, and the cycle performance of the material is greatly improved.

Owner:GUIZHOU UNIV

Preparation method of attapulgite-loaded nano-sized strontium titanate

InactiveCN107138145ALarge specific surface areaEfficient and fast adsorption and decompositionGas treatmentOther chemical processesBenzeneStrontium titanate

The invention discloses a preparation method of attapulgite-loaded nano-sized strontium titanate. The preparation method comprises the following steps: weighing strontium acetate and tetrabutyl titanate according to a molar ratio of 1: 1, then dissolving strontium acetate into distilled water to obtain a solution A, and dissolving tetrabutyl titanate into isopropanol to obtain a solution B; while magnetically stirring, dropwise adding the solution A into the solution B, continuing stirring for 2-4 min, standing and aging, then adding purified attapulgite, stirring for 10-15 min, filtering, placing for 1-2 days, drying till a constant weight, presintering for 1-3 h at 200-250 DEG C, increasing the temperature to 380-420 DEG C, keeping the constant temperature for 2-4 h, then increasing the temperature to 590-630 DEG C, keeping the constant temperature for 1-2 h, then increasing the temperature to 770-810 DEG C, keeping the constant temperature for 0.5-1 h, naturally cooling, and taking out on the next day. Attapulgite-loaded nano-sized strontium titanate can efficiently and rapidly adsorb and decompose formaldehyde, benzene, ammonia, TVOC and other harmful gases so as to achieve purifying, disinfecting, deodorizing and sterilizing purposes.

Owner:ANHUI BOSHUO TECH

High-brightness nano strontium-aluminate long-afterglow luminous material and preparation method and application thereof

InactiveCN102703068ACalcination temperature is lowSave energyLuminescent compositionsEuropiumAluminum Acetate

The invention discloses high-brightness nano strontium-aluminate long-afterglow luminous material and a preparation method and application thereof; the preparation method comprises the following steps: mixing strontium acetate semihydrate, aluminum acetate basic, europium acetate, dysprosium acetate and urea according to a mol ratio (0.005-0.02): (0.01-0.04): (0.0004-0.0008): (0.0008-0.0012): (0.02-0.08) and preparing the high-brightness nano strontium-aluminate long-afterglow luminous material through an alcohol-heat synthesis-burning method. Compared with a traditional high-temperature solid-phase method, pure-phase SrA12O4:Eu<2+>,Dy<3+> can be obtained at 1150 degrees centigrade by the preparation method provided by the invention; a burning temperature is reduced greatly; energy source is saved; prepared strontium-aluminate long-afterglow luminous material has good luminous strength and relatively long afterglow time; the preparation method provided by the invention is characterized by safe and nontoxic use, simple and easy operation, low cost, high efficiency and easy industrial application.

Owner:JINAN UNIVERSITY

Barium strontium titanate multilayered film, and preparation method thereof

InactiveCN102229265ASimple preparation equipmentSimple processLayered productsTitanium compoundsStrontium titanateBarium strontium titanate

The invention discloses a barium strontium titanate multilayered film, and a preparation method thereof. According to the invention, barium acetate, strontium acetate and tetrabutyl titanate with certain molar ratios are dissolved into an acetic acid solution, an ethylene glycol methyl ether solution and an acetylacetone solution, such that stable precursory sols with different barium-strontium ratios are prepared. Sol distribution processes and heat treatment processes are alternatively carried out upon substrates such as silicon-based platinum, until a required thickness is reached. According to the invention, the barium strontium titanate multilayered structure is prepared with a chemical solution deposition method. With the method, a film material with high tuning rate and low dielectric loss can be obtained. The film can be used in microwave tuning devices.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

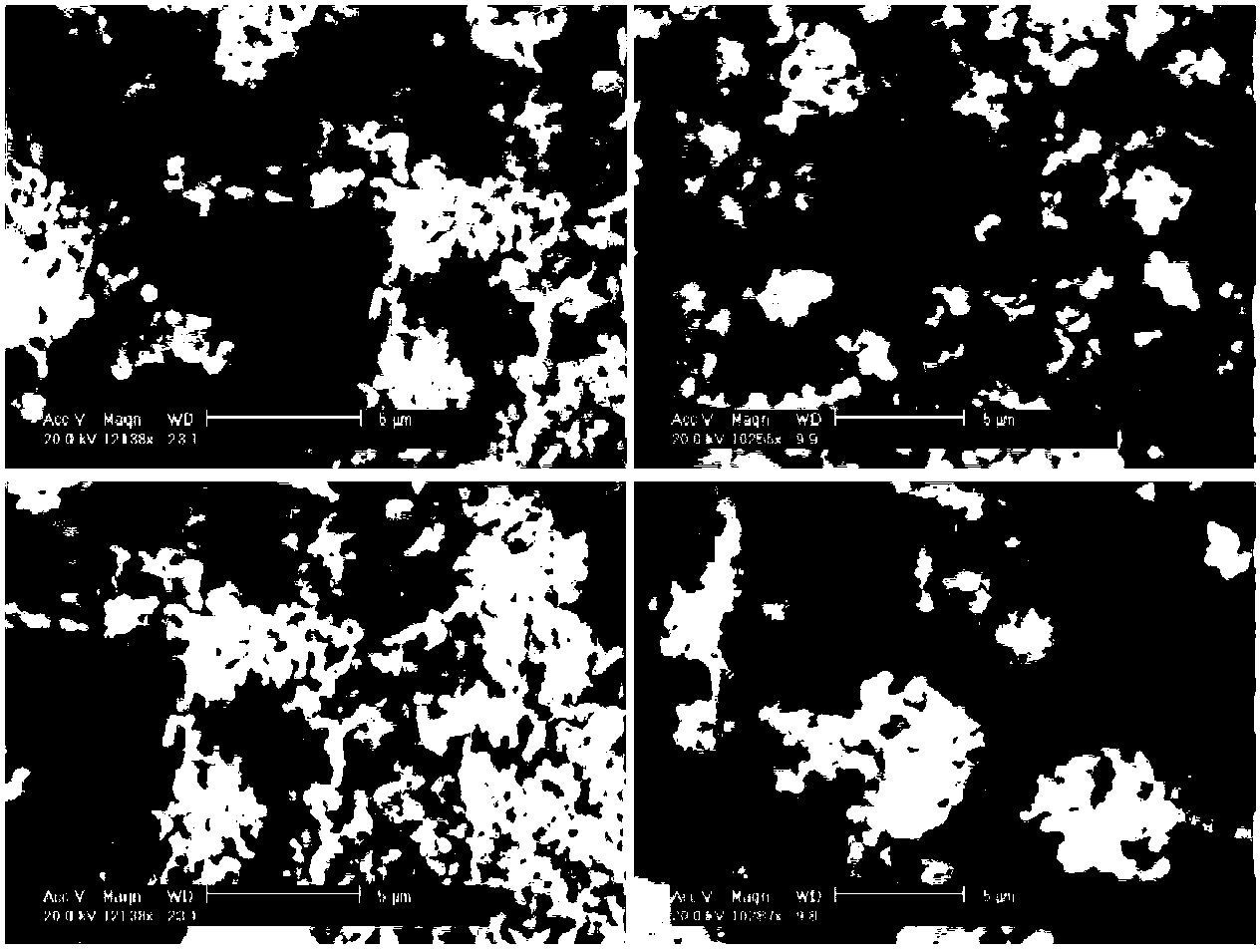

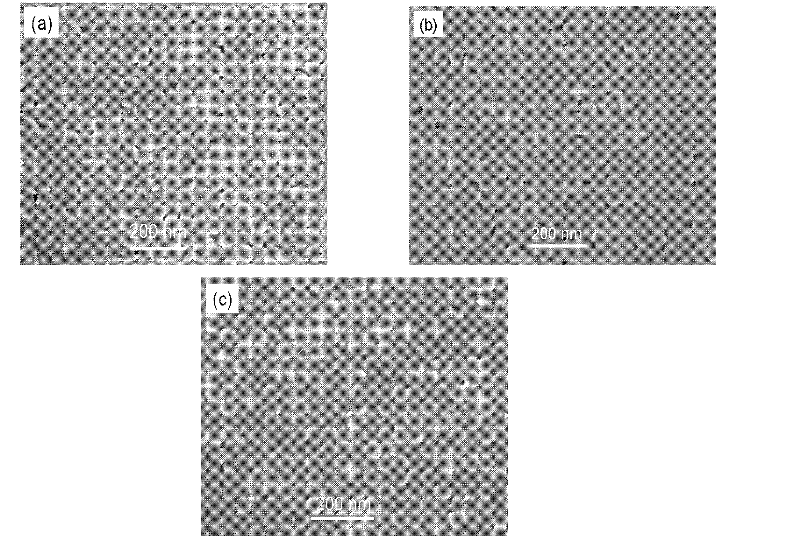

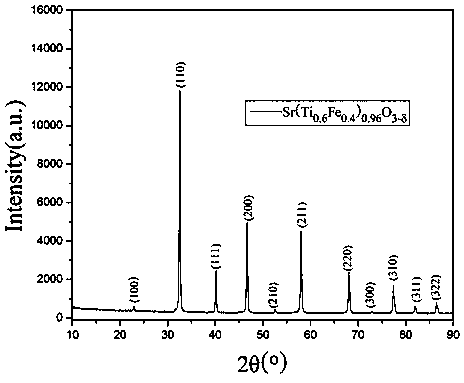

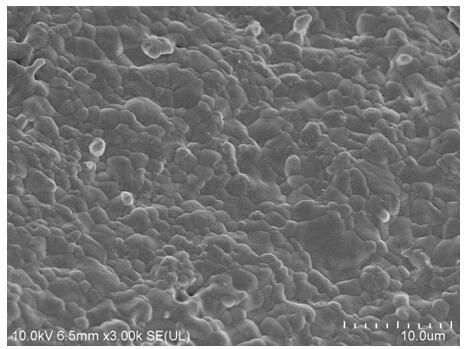

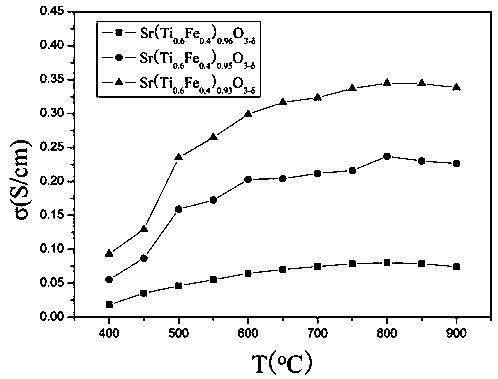

B-site vacancy Fe-doped strontium titanate and preparation method thereof

InactiveCN110483036ALow costUniform particle size distributionCell electrodesStrontium titanateAlcohol

The invention relates to B-site vacancy Fe-doped strontium titanate and a preparation method thereof, and belongs to the technical field of functional materials. The molecular formula of the B-site vacancy Fe doped strontium titanate is Sr (Ti0. 6Fe0. 4) < 1-x > O < 3-delta >, wherein the B-site vacancy amount is x, A / B is greater than 1, A is the molar weight of Sr, and B is the total molar weight of Ti and Fe. The preparation method comprises the following steps: synthesizing precursor powder by adopting a sol-gel method: dissolving strontium acetate, ferric oxide and tetrabutyl titanate which serve as raw materials into isopropanol and absolute ethyl alcohol according to a molecular formula molar ratio, and sufficiently stirring on a magnetic stirrer for 40 minutes to form sol; standingfor 12 hours, and layering to form wet gel; putting into a drying box, drying at 60 DEG C to form fluffy dry gel, and grinding to obtain precursor powder; and calcining the obtained precursor powderat 1100 DEG C for 10 hours to obtain the B-site vacancy Fe-doped strontium titanate powder. The purpose of the method is to improve the conductivity and catalytic activity of the material by doping pure SrTiO3.

Owner:KUNMING UNIV OF SCI & TECH

Hole sealing agent for hole sealing of CTP plate and using method thereof

ActiveCN107604413AImprove hydrophilicityStrong printing forceSurface reaction electrolytic coatingCobalt acetateSodium acetate

The invention discloses a hole sealing agent for hole sealing of a CTP plate. The hole sealing agent is composed of, by mass, 5%-15% of main agents, 0.2%-3% of assistants and the balance water, wherein the main agents are one or more of sodium acetate, nickel acetate, cobalt acetate and strontium acetate, and the assistants are one or more of citric acid, phosphoric acid, sodium fluoride and sodium dihydrogen phosphate. The hole sealing agent is moderate in price and convenient to operate and control, and the performance of screen dot reduction, hydrophilicity, pressrun and the like of the CTPplate subjected to hole sealing treatment through the hole sealing agent is excellent. The invention further provides a using method of the hole sealing agent for hole sealing of the CTP plate. The hole sealing agent prepared from the raw materials is sprayed on an anodized aluminum plate for 5-25 s at the temperature of 35-55 DEG C, then the aluminum plate is cleaned through deionized water, andthus hole sealing treatment of the aluminum plate is completed. Operation is easy, and a shutdown staining failure widely occurring in existing CTP plates can be effectively solved.

Owner:HUANGSHAN YINJIANG TECH

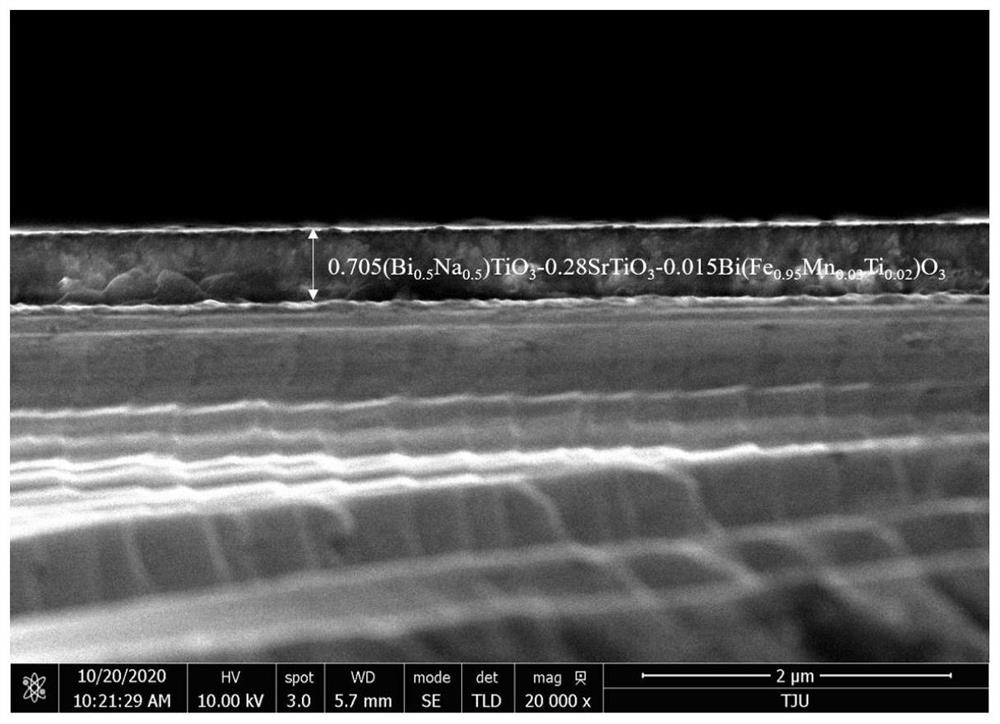

Sodium bismuth titanate-based lead-free piezoelectric film and preparation method thereof

ActiveCN113213920AHigh polarizationTypical perovskite structureSodium acetateMANGANESE ACETATE TETRAHYDRATE

The invention relates to a sodium bismuth titanate-based lead-free piezoelectric film and a preparation method thereof, and belongs to the field of electronic functional materials and devices. The preparation method provided by the invention comprises the following steps: step 1, adding bismuth nitrate, sodium acetate and strontium acetate into a solvent, and stirring to obtain a solution A; step 2, dissolving acetylacetone, tetrabutyl titanate, ferric nitrate nonahydrate and manganese acetate tetrahydrate in a solvent, stirring and heating to obtain a solution B; step 3, mixing the solution A with the solution B, and performing pretreatment to obtain a mixed solution C; and step 4, coating a treated substrate with the mixed solution C by using a spin coating method, and performing high-temperature treatment to obtain the (0.72-x)(Bi0. 5Na0. 5) TiO3-0. 28SrTiO3-xBi (Fe0. 95Mn0.03Ti0.02)O3 ternary system sodium bismuth titanate-based lead-free piezoelectric film. Therefore, the piezoelectric film prepared by the method is flat and smooth in surface, has a typical perovskite structure, relatively high polarization intensity and excellent piezoelectric performance; and meanwhile, the inverse piezoelectric coefficient can reach 179.7 picometer / volt to the maximum, and the method has very important significance for developing a high-performance lead-free piezoelectric film.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com