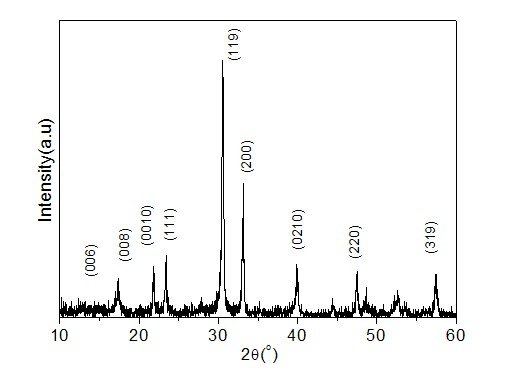

Rapid preparation method of perovskite structure polycrystalline nanopowder with chemical formula ca0.4sr0.6bi4ti4o15

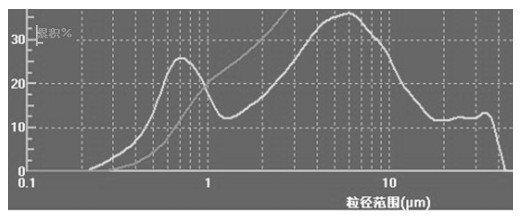

A perovskite structure, nano-powder technology, applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., can solve the problem of slow volatilization of organic solvents, long drying cycle of powder, difficulty in accurately controlling the particle size of nano-powder and Particle size distribution and other issues, to achieve the effect of uniform composition and narrow size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chemical formula is Ca 0.4 Sr 0.6 Bi 4 Ti 4 o 15 The rapid preparation method of the perovskite structure polycrystalline nanopowder, the specific steps are as follows:

[0025] (1) Prepare solution A with tetrabutyl titanate and acetylacetone at a ratio of 1:1 by volume: take 50ml of tetrabutyl titanate, use 50ml of acetylacetone as a chelating agent, and use a pipette to slowly dissolve 50ml of acetylacetone Slowly drop into the tetrabutyl titanate solution, and at the same time, in order to keep the temperature of the solution constant, put the beaker containing the solution in ice water at 0°C after mixing, and keep stirring the mixed solution to prevent the heat generated during the chelation process Hydrate the mixed solution; fully stir the mixed solution on a magnetic stirrer for 12 hours to obtain a clear yellow-brown transparent A solution;

[0026] (2) Weigh 77g of bismuth nitrate, 5g of strontium acetate, and 3.5g of calcium nitrate into 100ml of so...

Embodiment 2

[0031] Step (4) The drying temperature is 70°C, and the other conditions are the same as in Example 1.

Embodiment 3

[0033] Step (4) The drying temperature is 80°C, and the other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com