Method for preparing high-temperature superconducting coating conductor LaSrMnO3 buffering layer film

A technology of coated conductors and high-temperature superconductors, which is applied in the manufacture/processing of superconductor devices, and can solve problems such as quenching of superconducting layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

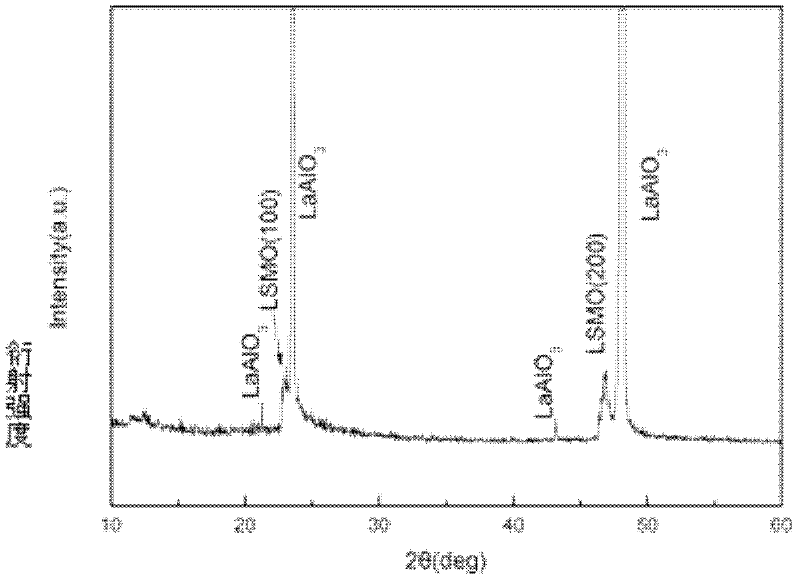

[0027] The first specific embodiment of the present invention is a method for preparing a high-temperature superconducting coated conductor La 0.7 Sr 0.3 MnO 3 The method for buffer layer thin film, its step is:

[0028] a, preparation of anhydrous solution: analytically pure lanthanum oxide (La 2 o 3 ) is dissolved in acetic acid according to the ratio of cation ratio La:Sr:Mn=0.7:0.3:1 (the molar ratio of acetic acid to cation is 10:1). After the solution is completely dissolved, the solution is placed in an infrared drying oven, and taken out after the solution is dried into a white solid (ie, lanthanum acetate). Strontium acetate and manganese acetate are mixed and dissolved in propionic acid with the prepared white solid according to the ratio of the above-mentioned cation ratio La:Sr:Mn=0.7:0.3:1 to form an anhydrous solution;

[0029] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a for ultrasonic dissolution to form a viscous...

Embodiment 2

[0036] The preparation method of this example consists of the following steps in turn:

[0037] a, preparation of anhydrous solution: analytically pure lanthanum oxide (La 2 o 3 ) is dissolved in acetic acid according to the ratio of cation ratio La:Sr:Mn=0.7:0.3:1 (the molar ratio of acetic acid to cation is 10:1). After the solution is completely dissolved, the solution is placed in an infrared drying oven, and taken out after the solution is dried into a white solid (ie, lanthanum acetate). Strontium acetate and manganese acetate are mixed and dissolved in propionic acid with the prepared white solid according to the ratio of the above-mentioned cation ratio La:Sr:Mn=0.7:0.3:1 to form an anhydrous solution;

[0038] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a for ultrasonic dissolution to form a viscous colloid. The addition of polyvinyl butyral (PVB) accounts for 3% of the total mass of the colloid

[0039] c. Colloid coating...

Embodiment 3

[0045] The preparation method of this example consists of the following steps in turn:

[0046] a, preparation of anhydrous solution: analytically pure lanthanum oxide (La 2 o 3 ) is dissolved in acetic acid according to the ratio of cation ratio La:Sr:Mn=0.7:0.3:1 (the molar ratio of acetic acid to cation is 10:1). After the solution is completely dissolved, the solution is placed in an infrared drying oven, and taken out after the solution is dried into a white solid (ie, lanthanum acetate). Strontium acetate and manganese acetate are mixed and dissolved in propionic acid with the prepared white solid according to the ratio of the above-mentioned cation ratio La:Sr:Mn=0.7:0.3:1 to form an anhydrous solution;

[0047] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a for ultrasonic dissolution to form a viscous colloid. The addition of polyvinyl butyral (PVB) accounts for 2% of the total mass of the colloid

[0048] c. Colloid coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com