Medical titanium with a trace element slow-release function or titanium alloy implant material as well as preparation method and application of same

A technology of trace elements and implant materials, used in metal material coating technology, electrolytic coatings, medical science and other directions, can solve problems such as implant surgery failure, improve the success rate, enhance the ability of bone healing and osseointegration, The effect of simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

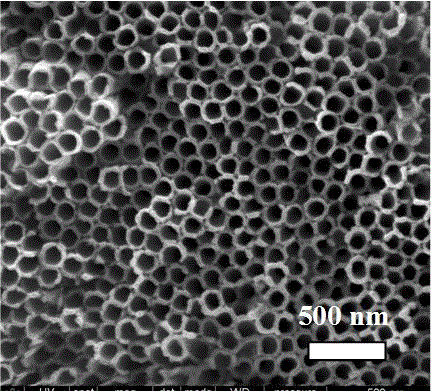

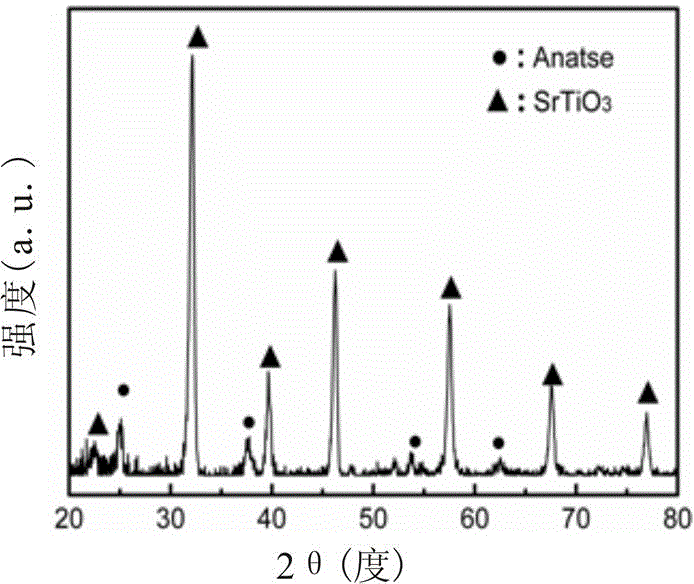

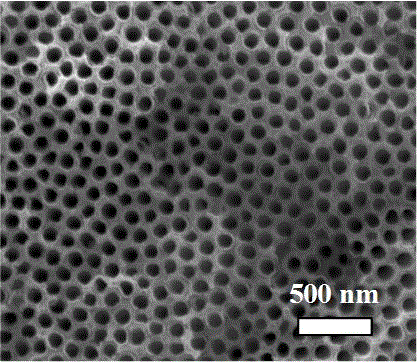

[0047] A medical titanium or titanium alloy implant material with the slow-release function of trace element Sr and a preparation method thereof. Put the titanium-containing metal sheet as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40-60V, and the anodic oxidation time is 0.5-4 hours; then the anodized titanium-containing metal sheet is rinsed and dried at 100 Heat treatment at ~300℃ for 1~3 hours, after natural cooling, ultrasonic cleaning and drying, then place in 0.005~0.015 mol / L strontium hydroxide solution, hydrothermal reaction in a closed container at 100~200℃ for 0.5~ 3h, cool naturally, take it out, wash and dry, then heat treatment at 450-550°C for 1~3h, a kind of nanotube biological coating with trace element Sr slow-release function is obtained on the surface of titanium-containing metal sheet, which continuously releases trace elements Sr (such as Figure 7 shown), can promote cell proliferation and cell differentiation t...

Embodiment 2

[0049] A medical titanium or titanium alloy implant material with the slow-release function of trace element Sr and a preparation method thereof. Put the titanium-containing metal sheet as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 40-60V, and the anodic oxidation time is 0.5-4 hours; then the anodized titanium-containing metal sheet is rinsed and dried at 200 Heat treatment at ~500°C for 1~3 hours, after natural cooling, ultrasonic cleaning and drying, then place in 0.015~0.025 mol / L strontium hydroxide solution, hydrothermal reaction in a closed container at 150~300°C for 1~ 6h, cool naturally, take it out, wash and dry, heat treatment at 450-550°C for 1~3h, and get a kind of nanotube biological coating with trace element Sr slow release function on the surface of titanium-containing metal sheet, which continuously releases trace elements Sr can promote cell proliferation and cell differentiation to a certain extent, improve the biolo...

Embodiment 3

[0051] A medical titanium or titanium alloy implant material with the slow-release function of trace element Sr and a preparation method thereof. Put the titanium-containing metal sheet as an anode into the electrolyte for anodic oxidation, the anodic oxidation voltage is 20-40V, and the anodic oxidation time is 0.5-4 hours; then the anodized titanium-containing metal sheet is rinsed and dried at 100 Heat treatment at ~300℃ for 1~3 hours, after natural cooling, ultrasonic cleaning and drying, then place in 0.005~0.015 mol / L strontium hydroxide solution, hydrothermal reaction in a closed container at 100~200℃ for 0.5~ 3h, cool naturally, take it out, wash and dry, then heat treatment at 450-550°C for 1~3h, a kind of nanotube biological coating with trace element Sr slow-release function is obtained on the surface of titanium-containing metal sheet, which continuously releases trace elements Sr can promote cell proliferation and cell differentiation to a certain extent, improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com