Effective plant component extracting process

A technology of plant active ingredients and active ingredients, applied in the direction of solid solvent extraction, etc., can solve the problems of low extraction efficiency of plant active ingredients, solvent pollution of the environment, active ingredients, and low bioavailability of active ingredients, so as to shorten the crushing time and reduce separation Effect of extraction step, easier deagglomeration and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Acanthopanax 500g, pretreated, impurity removed, dried until the water content is not higher than 20%, coarsely crushed to 60 mesh, added 10g of Na 2 CO 3 , crushed by planetary mill to get processed powder N 1 .

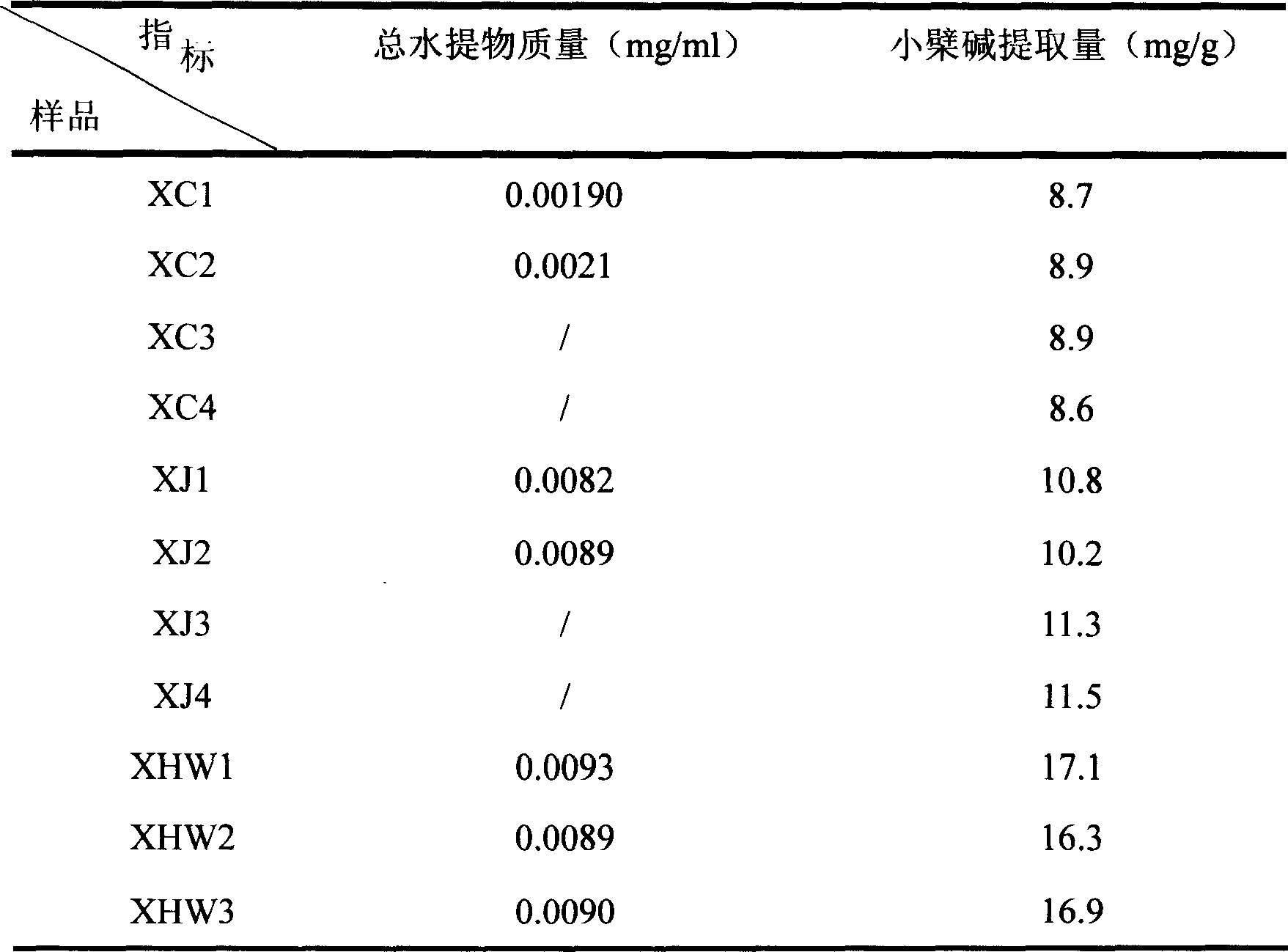

[0025] Weigh each portion of 5g processed powder N 1 60 meshes of Acanthopanax senticosus (GC) were conventionally crushed, respectively added with 50 ml of distilled water and 20% ethanol, and extracted at room temperature for 48 hours. After filtering with gauze and absorbent cotton, place the water extract and 20% alcohol extract in a 50°C water bath to evaporate to dryness, and weigh them respectively. The yield is shown in Table 1:

[0026] Table 1

[0027] sample

Embodiment 2

[0029] Acanthopanax 500g, pretreated, impurity removed, dried until the moisture content is not higher than 20%, coarsely crushed to 60 mesh, added 20g of NaHCO 3 , crushed by planetary mill to get processed powder N 2 .

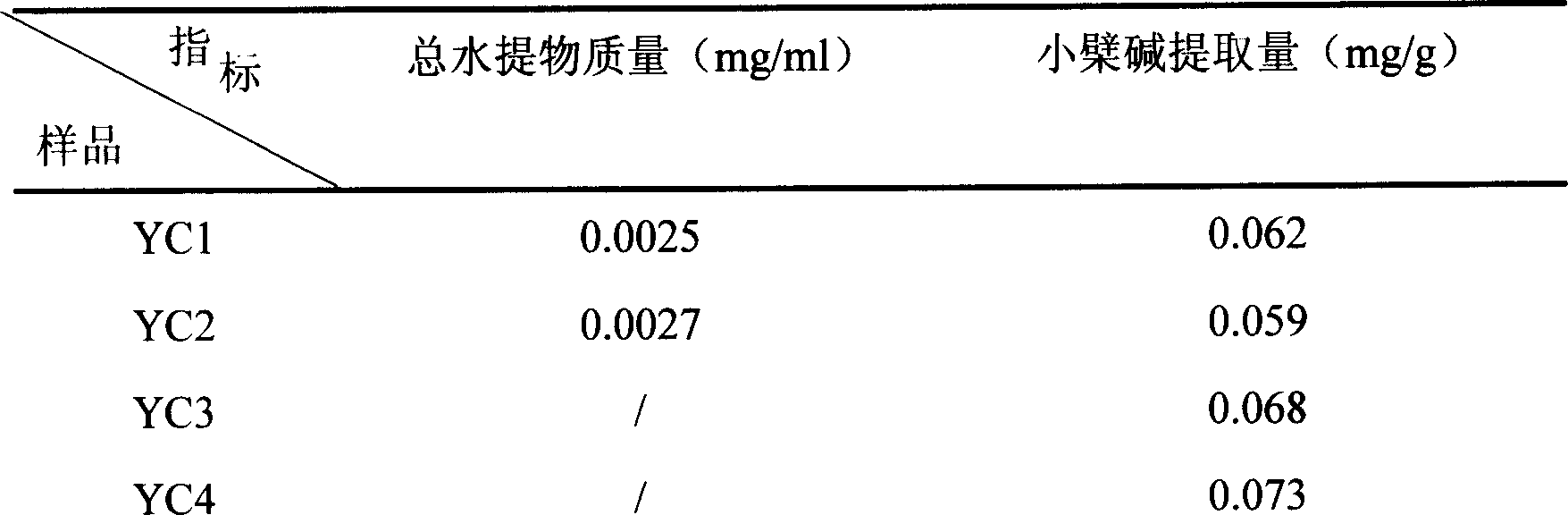

[0030] Weigh each 5g processing powder N 2 60 meshes of Acanthopanax senticosus (GC) were conventionally crushed, respectively added with 50 ml of distilled water and 20% ethanol, and extracted at room temperature for 48 hours. After filtering with gauze and absorbent cotton, place the water extract and 20% alcohol extract in a 50°C water bath to evaporate to dryness, and weigh them respectively. The yield is shown in Table 2:

[0031] Table 2

[0032] sample

Embodiment 3

[0034] Acanthopanax 500g, pretreated, impurity removed, dried until the water content is not higher than 20%, coarsely crushed to 60 mesh, added 5 grams of NaOH, crushed by a planetary mill, and processed powder N 3 .

[0035] Weigh each portion of 5g processing powder N 3 60 meshes of Acanthopanax senticosus (GC) were conventionally crushed, respectively added with 50 ml of distilled water and 20% ethanol, and extracted at room temperature for 48 hours. After filtering with gauze and absorbent cotton, place the water extract and 20% alcohol extract in a 50°C water bath to evaporate to dryness, and weigh them respectively. The yield is shown in Table 3:

[0036] table 3

[0037] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com