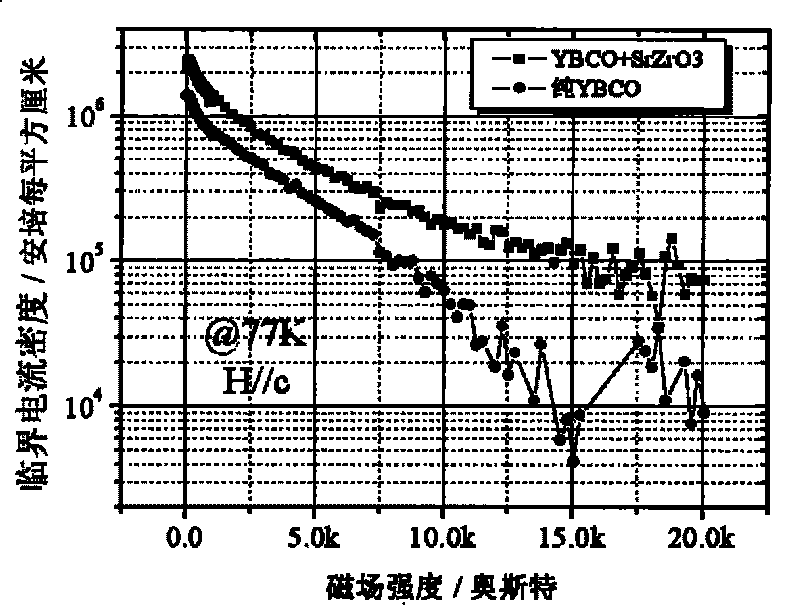

SrZrO3 doped YBCO thin film and preparation method thereof

A thin film and coating technology, applied in the field of high-temperature superconducting material preparation, can solve the problems of complex equipment, high cost, high vacuum, etc., and achieve the effects of fast deposition speed, easy control, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Dissolve 0.01mol yttrium acetate, 0.02mol barium acetate and 0.03mol copper acetate in deionized water, then add 11ml trifluoroacetic acid for complexation, then evaporate and concentrate at 50°C to obtain a blue transparent colloidal liquid, dilute with methanol , to obtain a 1.0mol / L YBCO precursor solution;

[0028] Dissolve strontium acetate and zirconium acetylacetonate in propionic acid at a molar ratio of 1:1 to obtain SrZrO with a total metal ion concentration of 1.0 mol / L 3 Precursor solution;

[0029] Press SrZrO 3 : The molar percentage of YBCO is 1% and SrZr0 3 The precursor solution is mixed with the YBCO precursor solution to obtain SrZrO 3 Doped YBCO precursor solution;

[0030] 2) SrZrO was coated by spin coating 3 The doped YBCO precursor solution is coated on the substrate to obtain a wet film, the coating film rotation speed is 3000 rpm, and the film coating time is 3 minutes;

[0031] 3) The wet film is pre-fired at a low temperature in wet ...

Embodiment 2

[0035] 1) Dissolve 0.005mol yttrium acetate, 0.01mol barium acetate and 0.015mol copper acetate in deionized water, then add 5.5ml trifluoroacetic acid for complexation, then evaporate and concentrate at 50°C to obtain a blue transparent colloidal liquid, and use methanol Dilute to obtain 1.5mol / L YBCO precursor solution;

[0036]Dissolve strontium acetate and zirconium acetylacetonate in propionic acid at a molar ratio of 1:1 to obtain SrZrO with a total metal ion concentration of 0.5 mol / L 3 Precursor solution;

[0037] Press SrZrO 3 : The molar percentage of YBCO is 6% SrZrO 3 The precursor solution is mixed with the YBCO precursor solution to obtain SrZrO 3 Doped YBCO precursor solution;

[0038] 2) SrZrO was coated by spin coating 3 The doped YBCO precursor solution is coated on the substrate to obtain a wet film, the coating film rotation speed is 4000 rpm, and the film coating time is 2 minutes;

[0039] 3) The wet film is pre-fired at a low temperature in wet oxy...

Embodiment 3

[0043] 1) Dissolve 0.01mol yttrium acetate, 0.02mol barium acetate and 0.03mol copper acetate in deionized water, add 11ml of trifluoroacetic acid for complexation, evaporate and concentrate at 50°C to obtain a blue transparent colloidal liquid, and use methanol Dilute to obtain 2mol / L YBCO precursor solution;

[0044] Dissolve strontium acetate and zirconium acetylacetonate in propionic acid at a molar ratio of 1:1 to obtain SrZrO with a total metal ion concentration of 0.1mol / L 3 Precursor solution;

[0045] Press SrZrO 3 : The molar percentage of YBCO is 10% SrZrO 3 The precursor solution is mixed with the YBCO precursor solution to obtain SrZrO 3 Doped YBCO precursor solution;

[0046] 2) SrZrO was coated by spin coating 3 The doped YBCO precursor solution is coated on the substrate to obtain a wet film, the coating film rotation speed is 6000 rpm, and the film coating time is 1 minute;

[0047] 3) The wet film is pre-fired at a low temperature in wet oxygen below 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com