Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

644results about How to "Fast deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

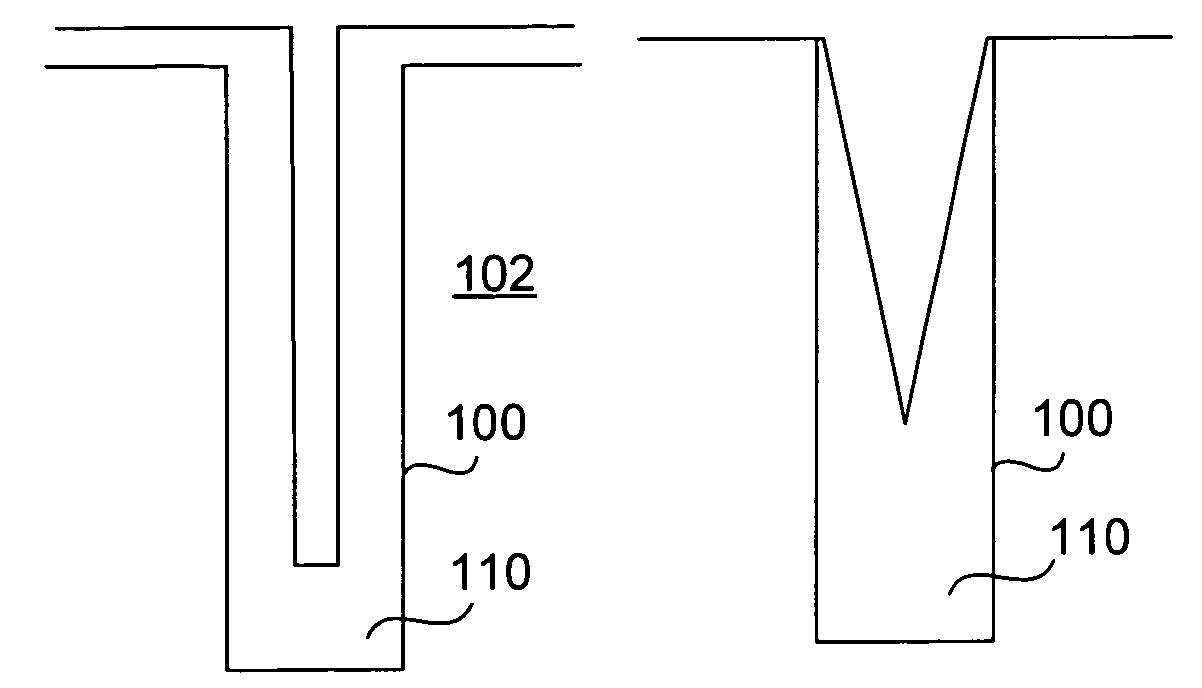

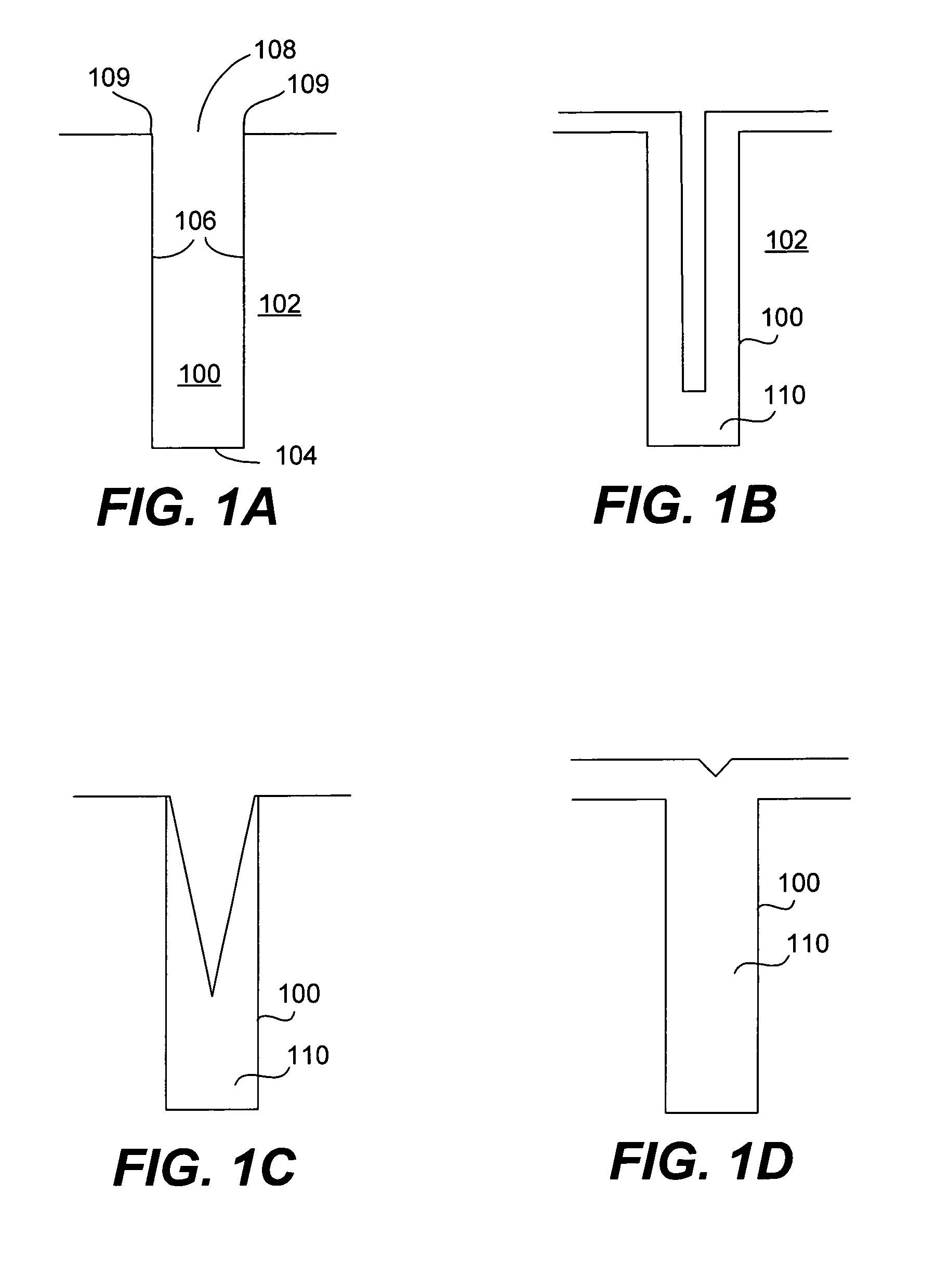

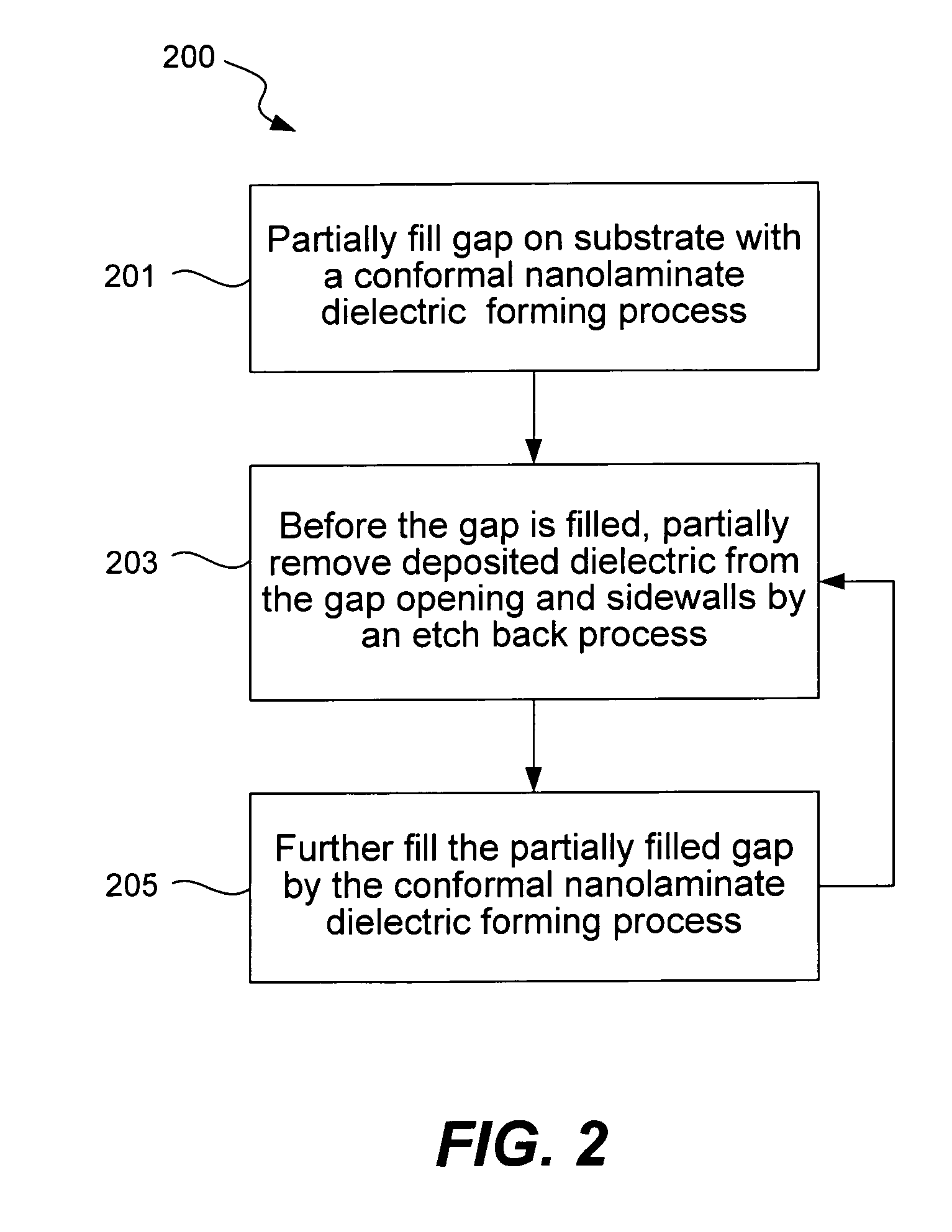

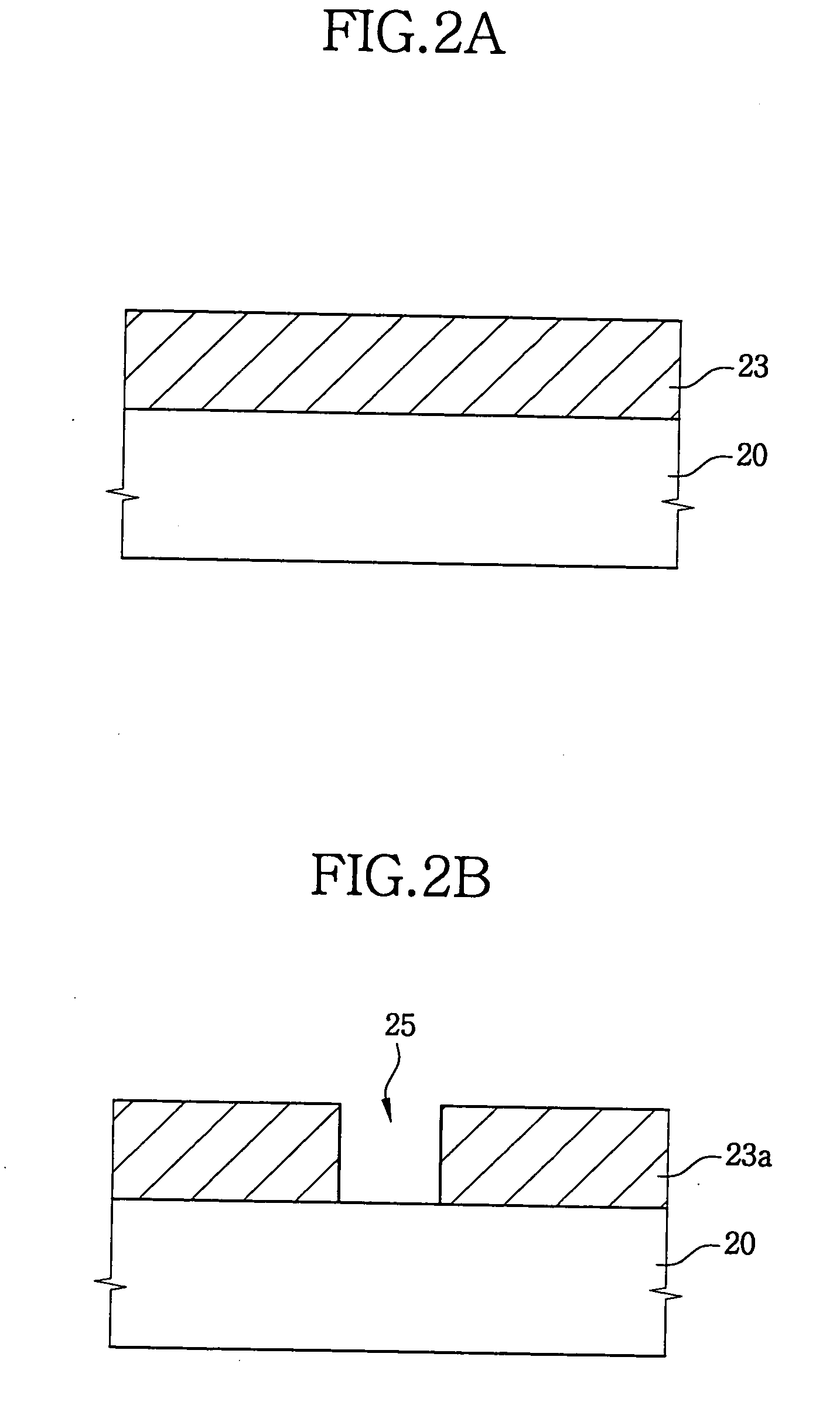

Conformal nanolaminate dielectric deposition and etch back gap fill process

InactiveUS7482247B1Reduce morbidityHigh aspect ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricEngineering

Conformal nanolaminate dielectric deposition and etch back processes that can fill high aspect ratio (typically at least 5:1, for example 6:1), narrow width (typically sub 0.13 micron, for example 0.1 micron or less) gaps with significantly reduced incidence of voids or weak spots involve the use of any suitable confirmal dielectric deposition technique and a dry etch back. The etch back part of the process involves a single step or an integrated multi-step (for example, two-step) procedure including an anisotropic dry etch followed by an isotropic dry etch. The all dry deposition and etch back process in a single tool increases throughput and reduces handling of wafers resulting in more efficient and higher quality nanolaminate dielectric gap fill operations.

Owner:NOVELLUS SYSTEMS

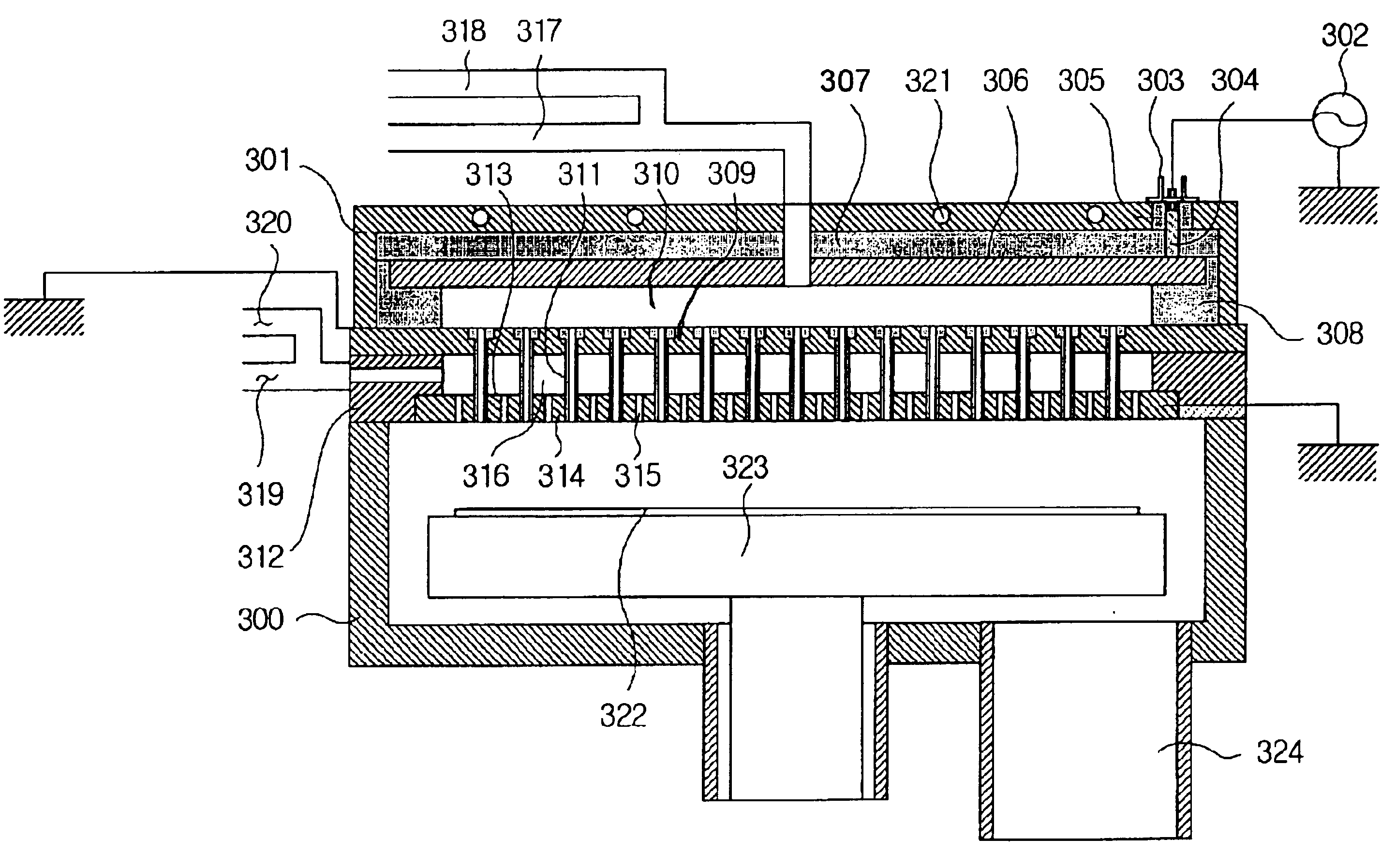

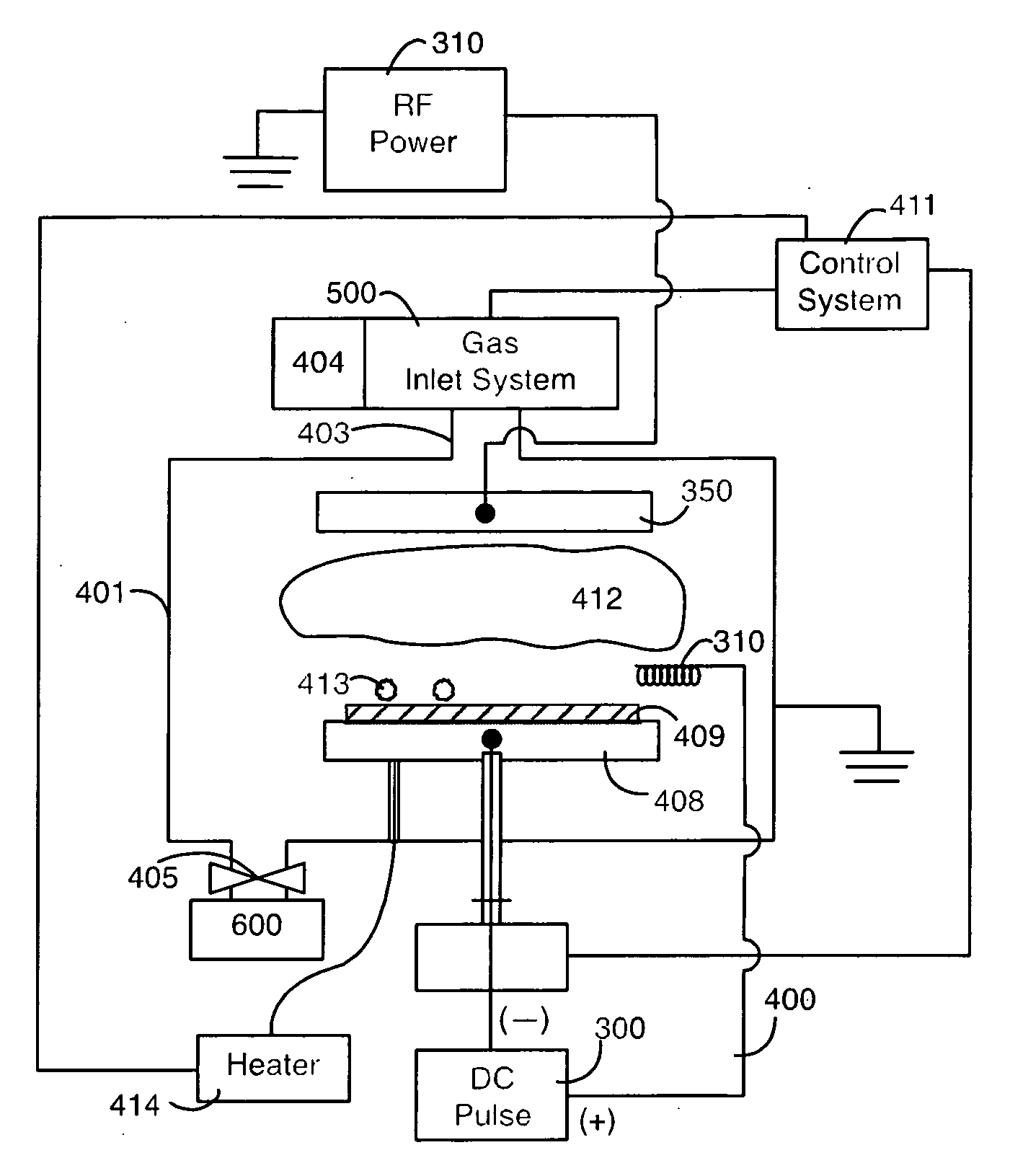

Plasma chemical vapor deposition apparatus

InactiveUS6886491B2Avoid damageExcellent step coverage and film quality characteristicSemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectric power systemEngineering

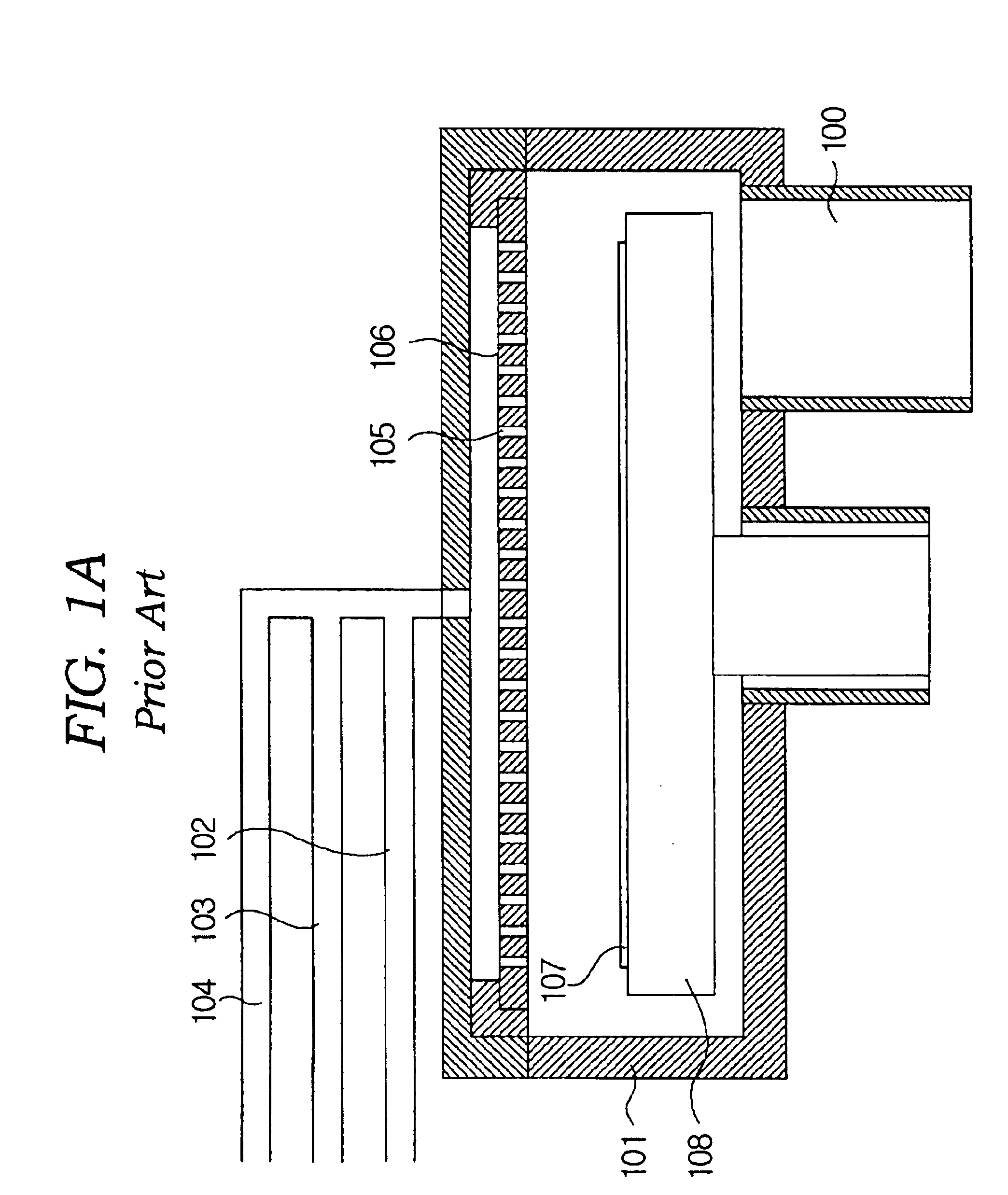

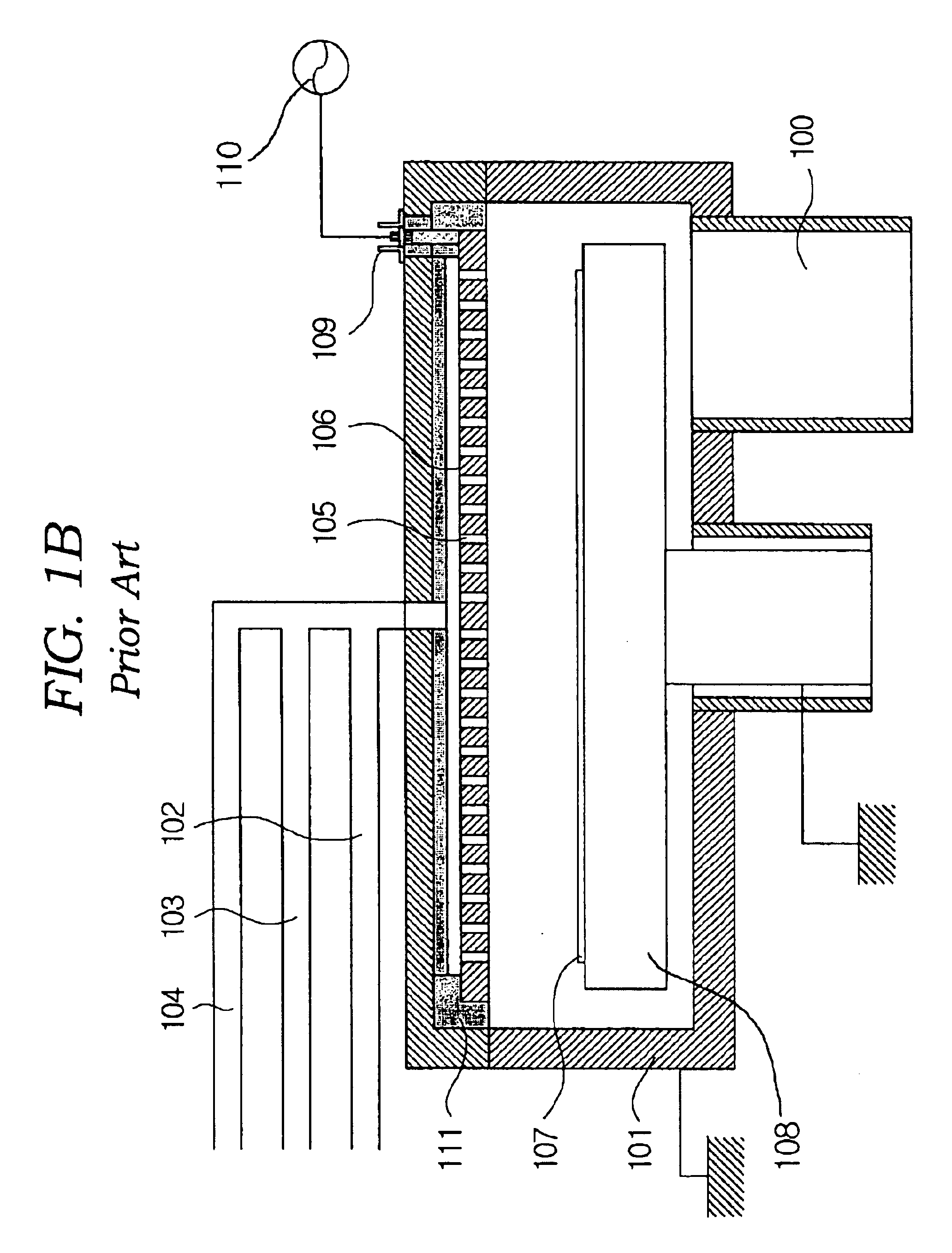

The present invention relates to chemical vapor deposition apparatus. In the chemical vapor deposition apparatus, an RF power source connection portionconnected to an external RF power source is installed on an upper side of a chamber; an RF electrode plate is installed within the chamber to be spaced with a predetermined gap from an inner upper surface of the chamber and to be spaced with a predetermined gap from a showerhead disposed below the RF electrode plate; plasma is generated in a first buffer portion, which is defined by a gap between the RF electrode plate and an upper surface of the showerhead, by means of the electric power applied from the external RF power source to the RF electrode plate; the showerhead is divided into two sections in a vertical direction and a second buffer portion is defined by a space between the two sections; reactant gases are supplied to the first buffer portion in which the plasma is generated; and source gases are supplied to the second buffer portion.

Owner:WONIK IPS CO LTD

Method for forming a wiring of a semiconductor device, method for forming a metal layer of a semiconductor device and apparatus for performing the same

InactiveUS20050059240A1Good step coverageThe process parameters are simpleSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical reactionDevice material

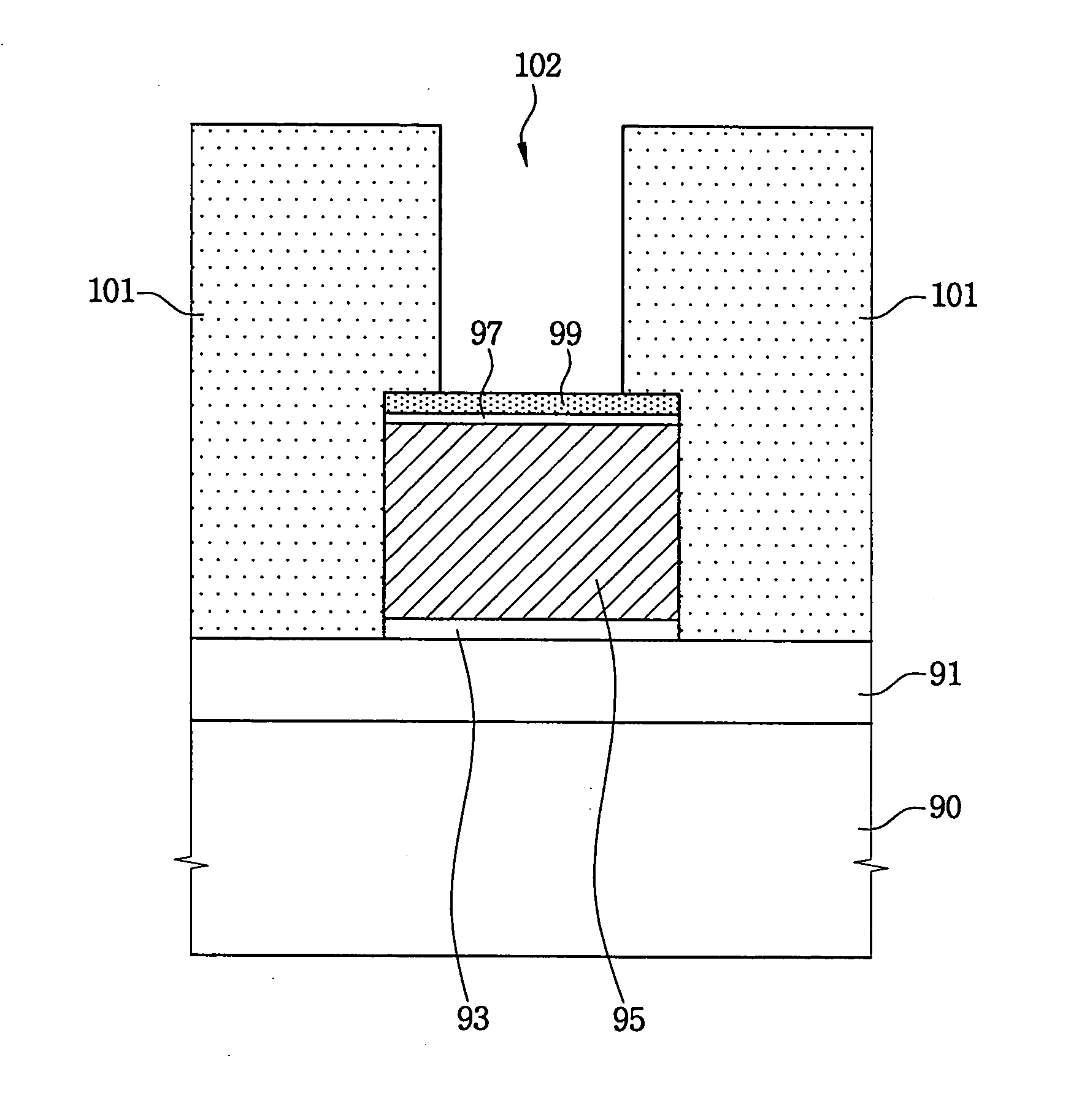

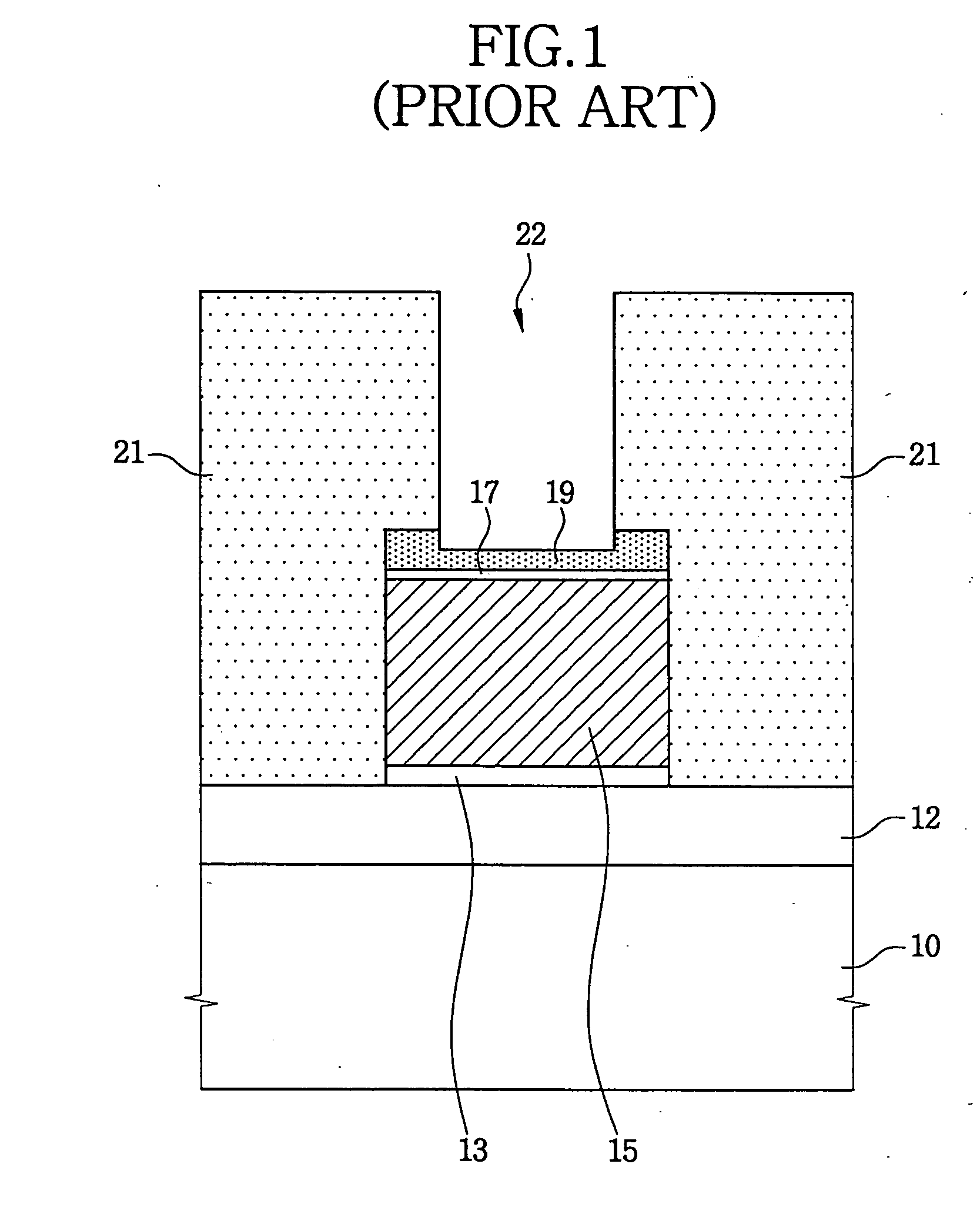

In a method for forming a wiring of a semiconductor device using an atomic layer deposition, an insulating interlayer is formed on a substrate. Tantalum amine derivatives represented by a chemical formula Ta(NR1)(NR2R3)3 in which R1, R2 and R3 represent H or C1-C6 alkyl group are introduced onto the insulating interlayer. A portion of the tantalum amine derivatives is chemisorbed on the insulating interlayer. The rest of tantalum amine derivatives non-chemisorbed on the insulating interlayer is removed from the insulating interlayer. A reacting gas is introduced onto the insulating interlayer. A ligand in the tantalum amine derivatives chemisorbed on the insulating interlayer is removed from the tantalum amine derivatives by a chemical reaction between the reacting gas and the ligand to form a solid material including tantalum nitride. The solid material is accumulated on the insulating interlayer through repeating the above processes to form a wiring.

Owner:SAMSUNG ELECTRONICS CO LTD

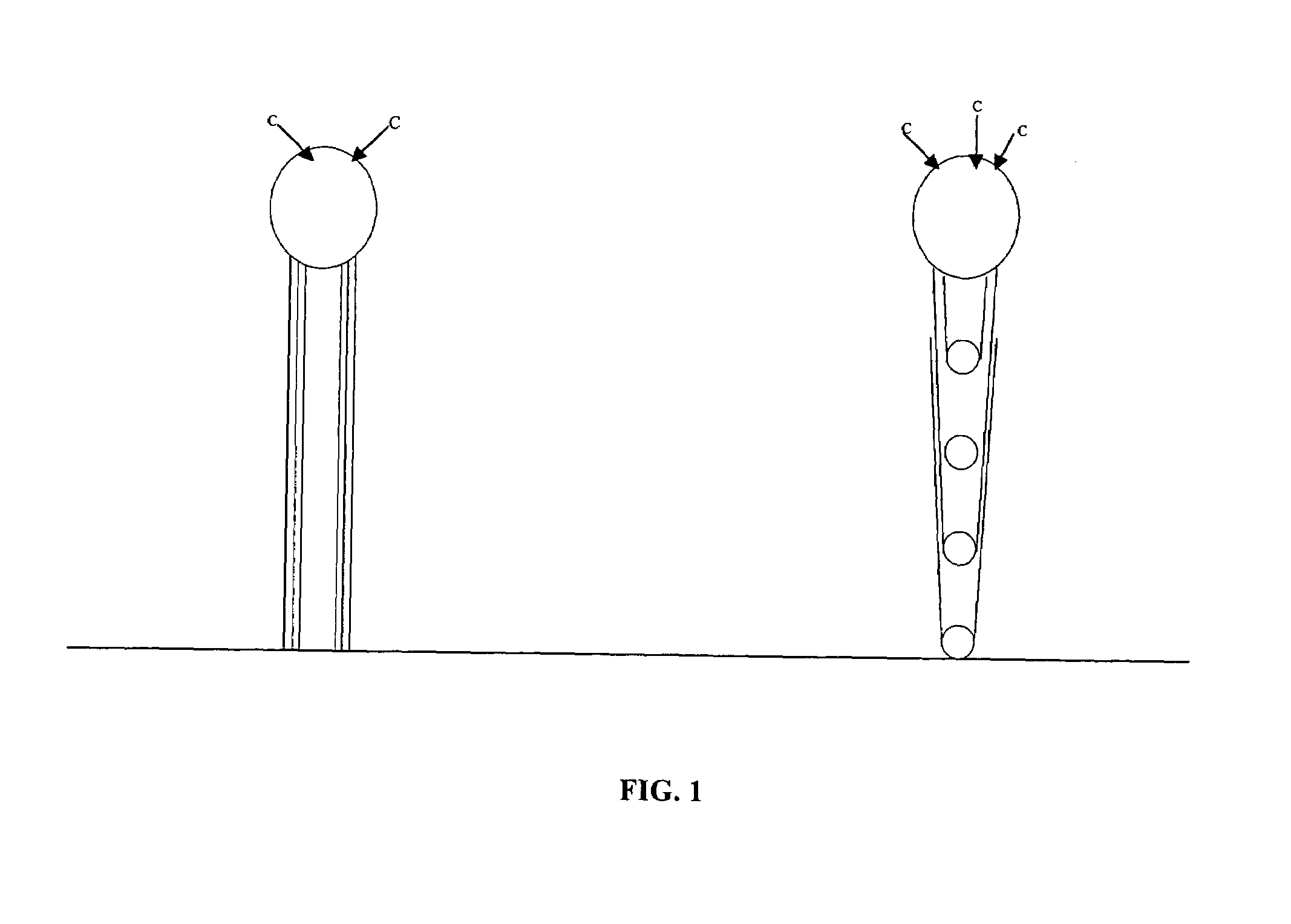

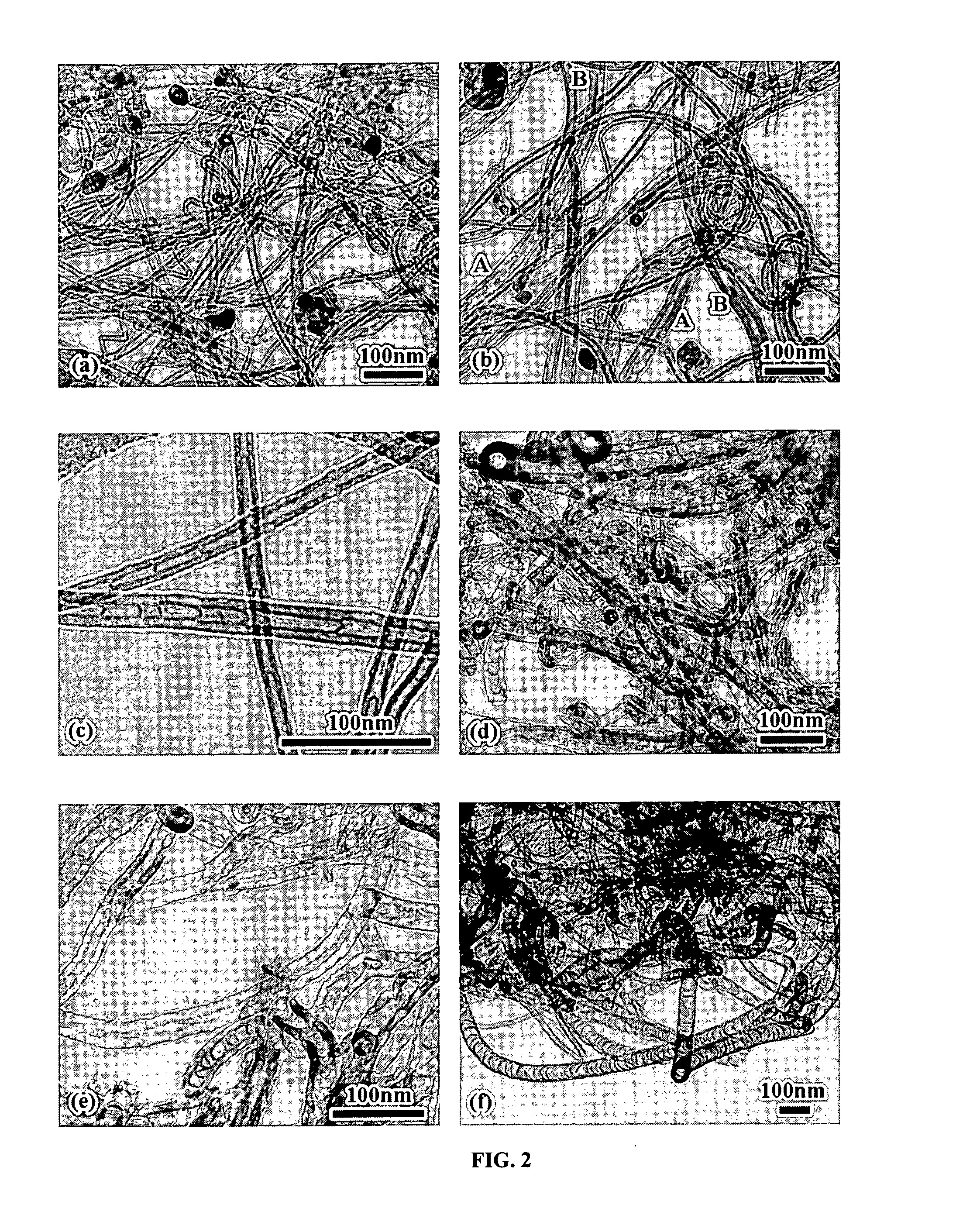

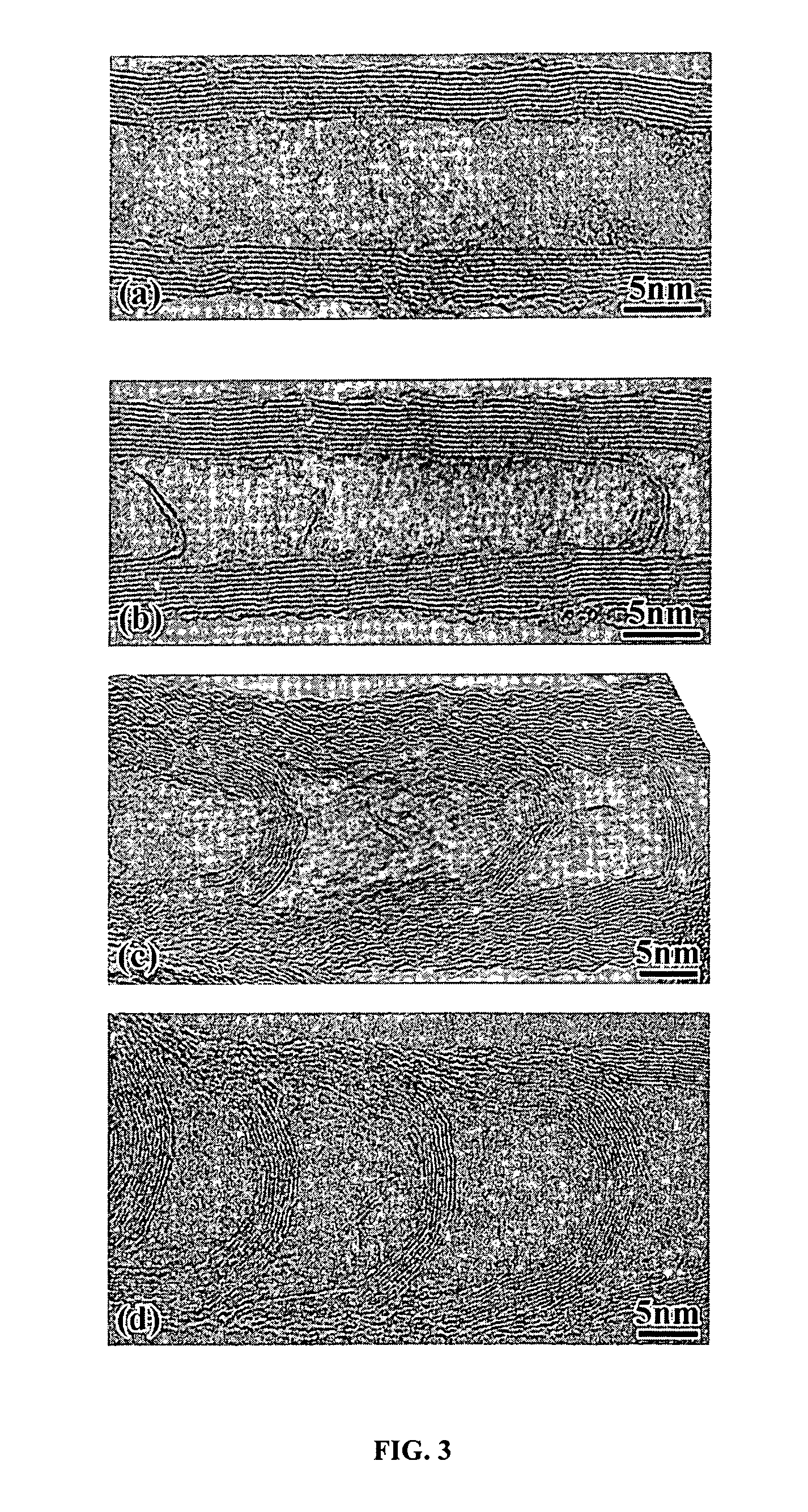

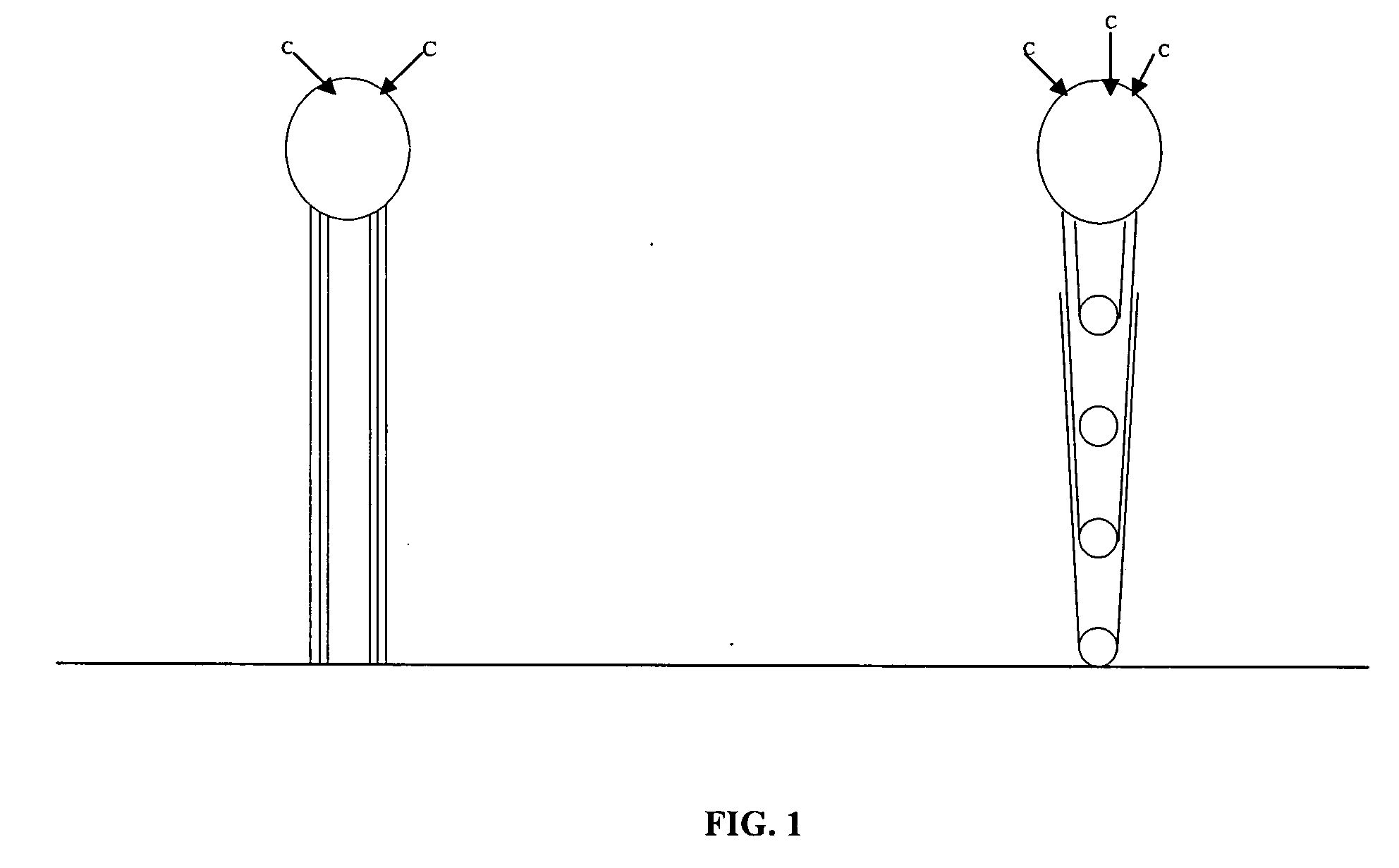

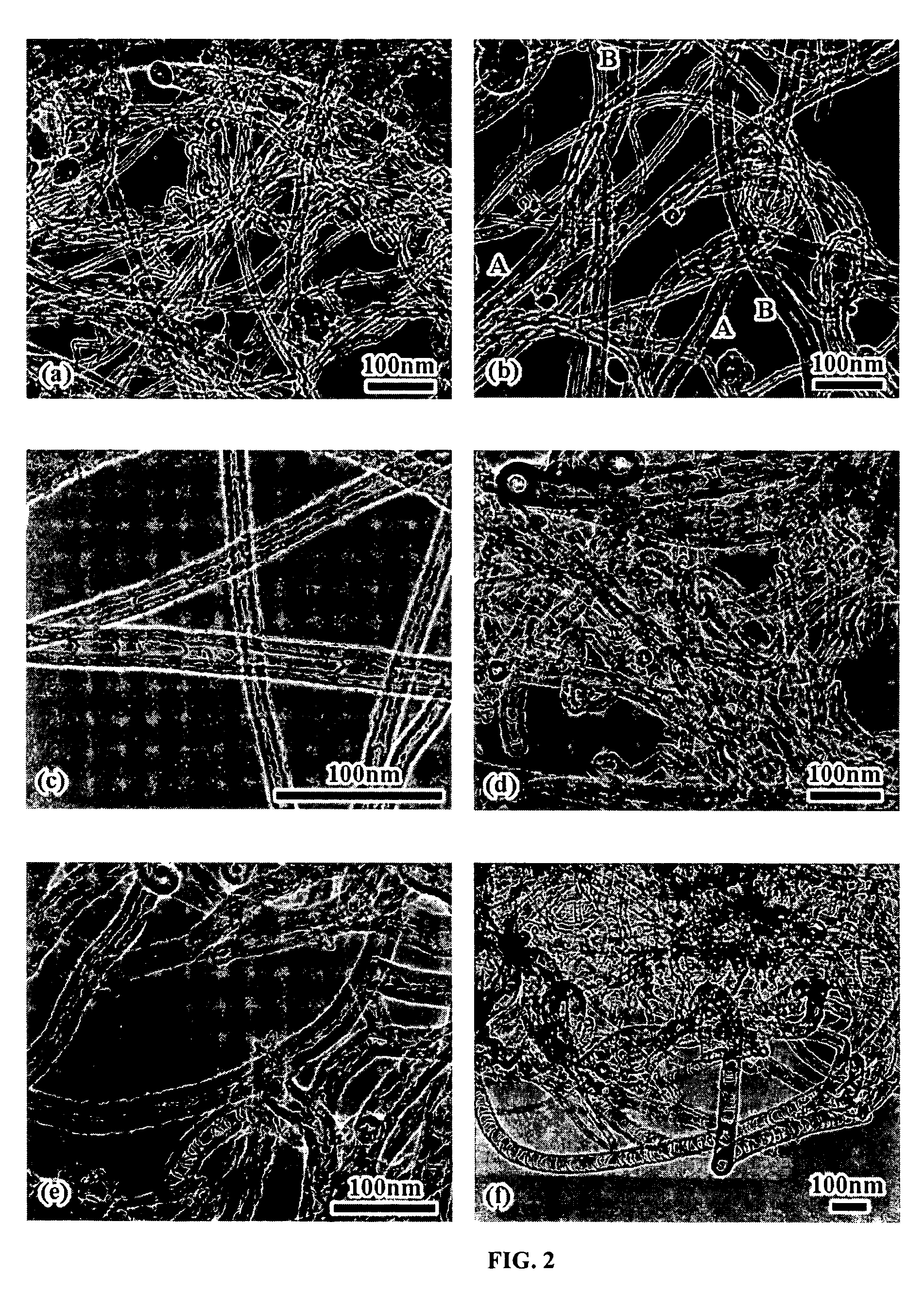

Varied morphology carbon nanotubes and method for their manufacture

InactiveUS7157068B2Increased yieldPromote catalyst activityMaterial nanotechnologyCarbon compoundsCarbon nanotubeMaterials science

Owner:TRUSTEES OF BOSTON COLLEGE THE

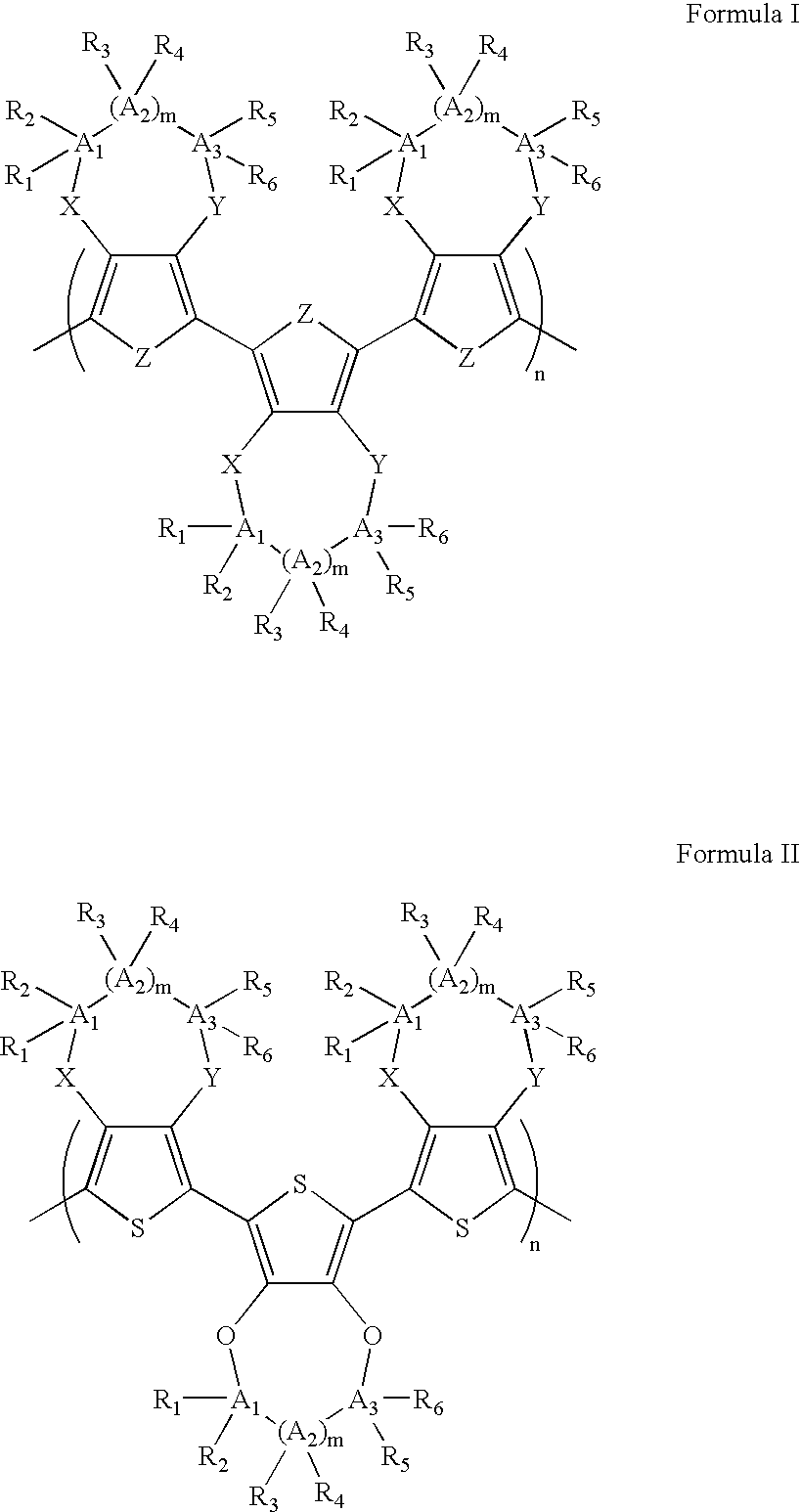

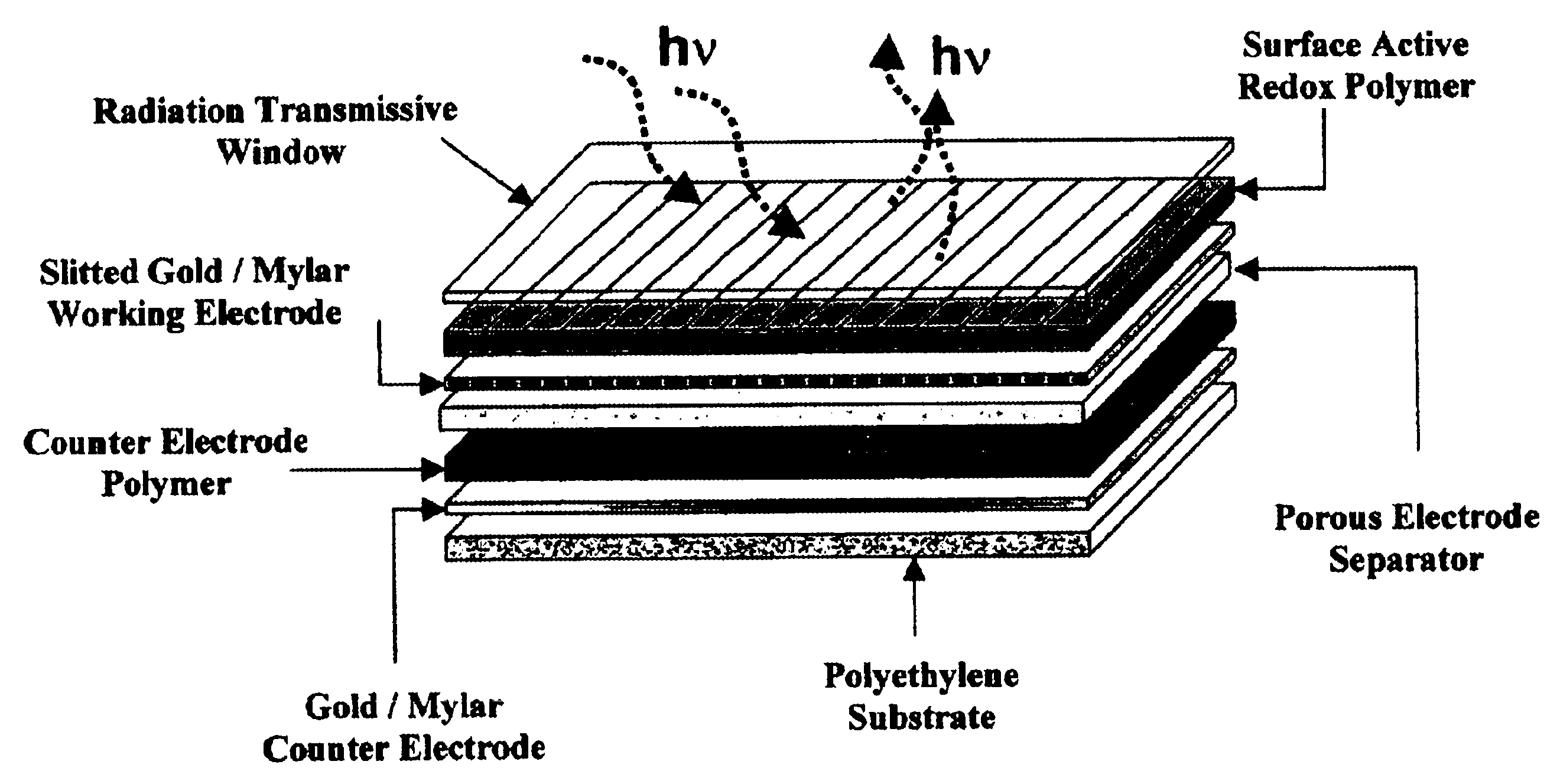

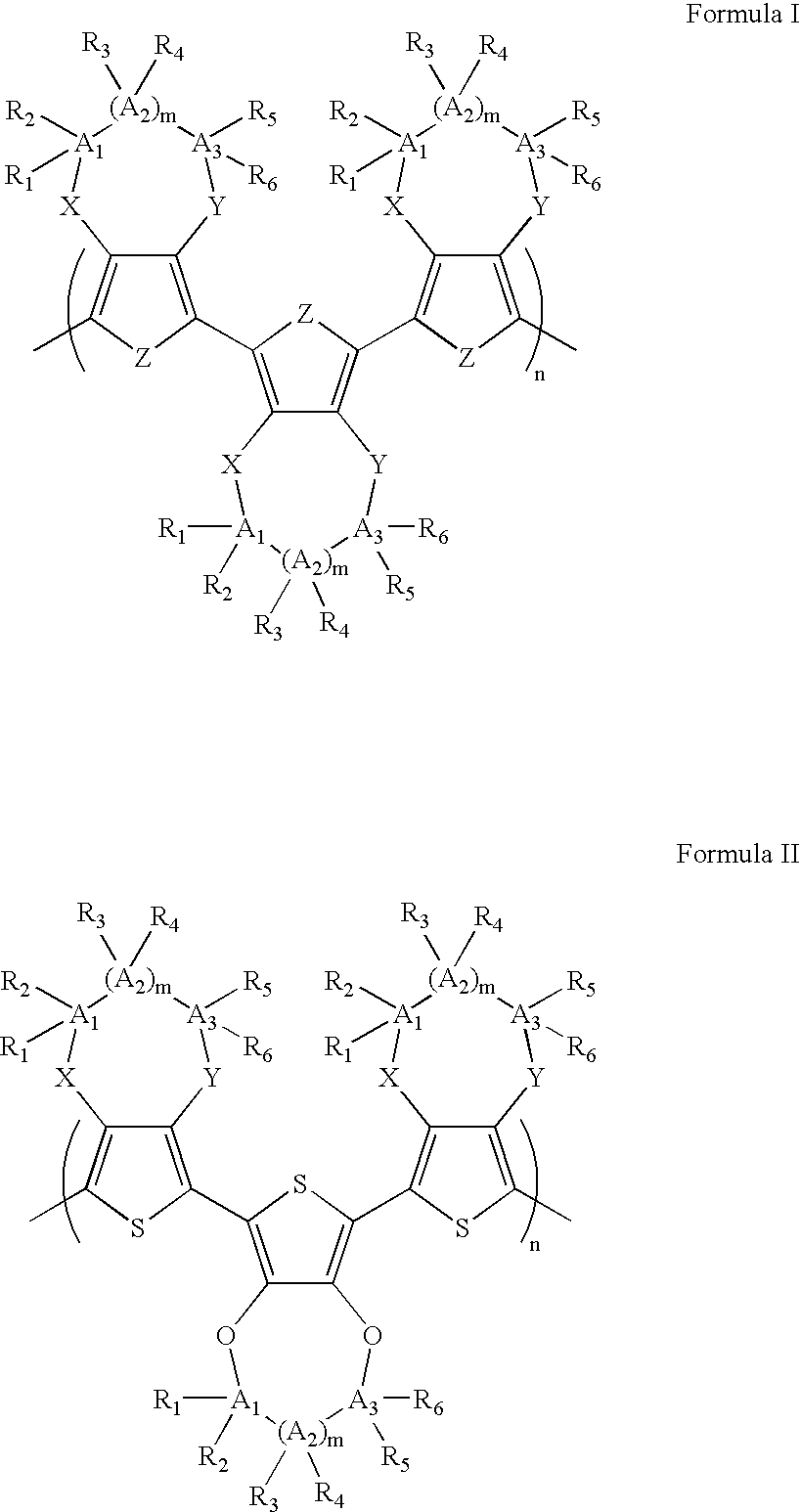

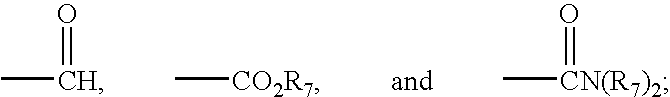

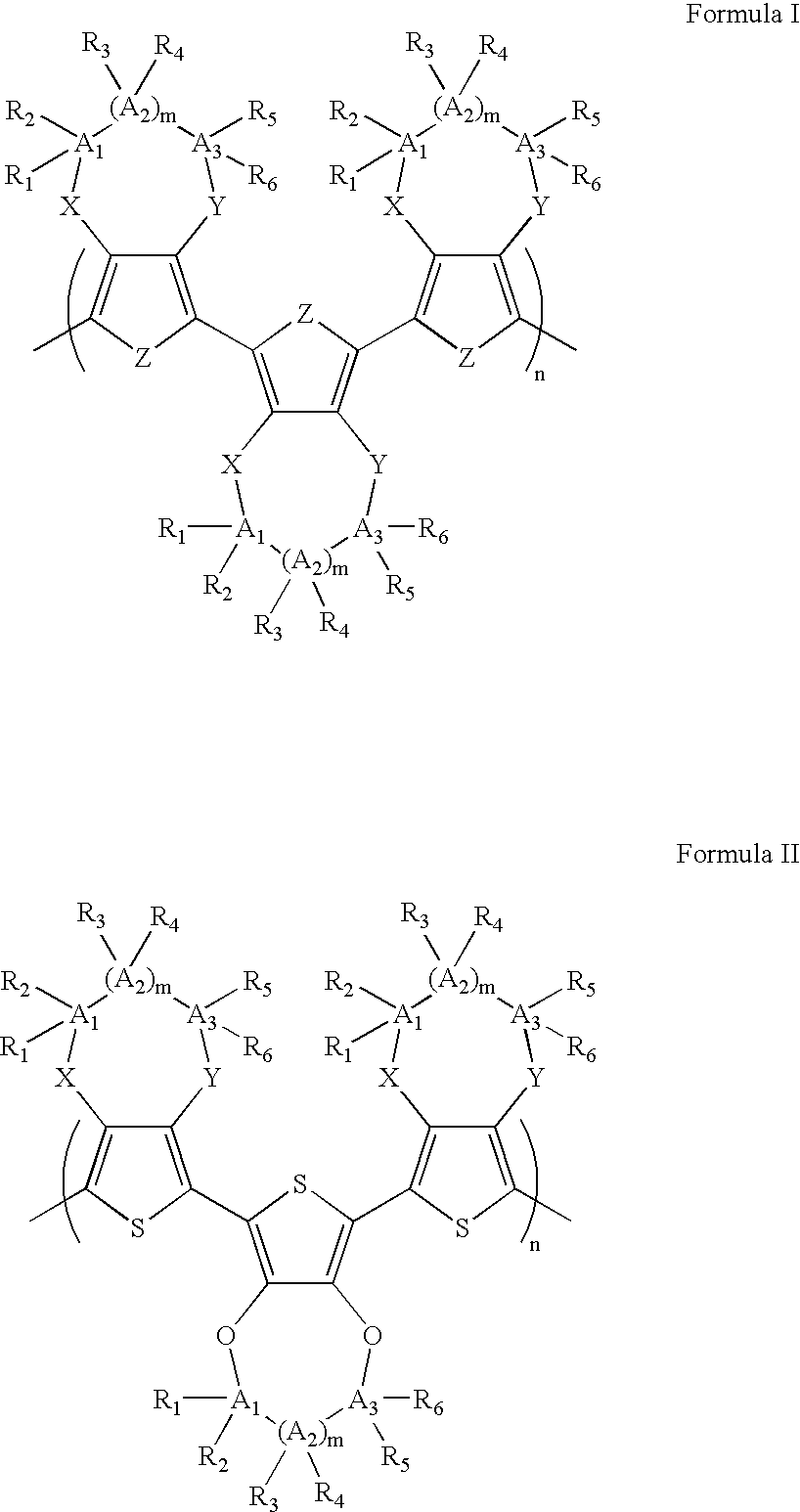

Electrochromic polymers and polymer electrochromic devices

InactiveUS6791738B2Increase the gapLess structural defectsPhotosensitive materialsElectrography/magnetographyPolymer scienceGas phase

The subject invention pertains to electrochromic polymers and polymer electrochromic devices. In a specific embodiment, two complementary polymers can be matched and incorporated into dual polymer electrochromic devices. The anodically coloring polymers in accordance with the subject invention can allow control over the color, brightness, and environmental stability of an electrochromic window. In addition, high device contrast ratios, high transmittance changes, and high luminance changes can be achieved, along with half-second switching times for full color change. Also provided are electrochromic devices such as advertising signage, video monitors, stadium scoreboards, computers, announcement boards, warning systems for cell phones, warning / information systems for automobiles, greeting cards, electrochromic windows, billboards, electronic books, and electrical wiring. The subject invention also provides for the use of complementary electrochromic polymers in the manufacture of electrochromic devices. In some embodiments, the devices of the invention can be prepared using metal vapor deposition or line patterning.

Owner:FLORIDA UNIV OF A FLORIDA

Electrochromic polymers and polymer electrochromic devices

InactiveUS20030174377A1Increase the gapLess structural defectsPhotosensitive materialsElectrography/magnetographyPolymer scienceGas phase

The subject invention pertains to electrochromic polymers and polymer electrochromic devices. In a specific embodiment, two complementary polymers can be matched and incorporated into dual polymer electrochromic devices. The anodically coloring polymers in accordance with the subject invention can allow control over the color, brightness, and environmental stability of an electrochromic window. In addition, high device contrast ratios, high transmittance changes, and high luminance changes can be achieved, along with half-second switching times for full color change. Also provided are electrochromic devices such as advertising signage, video monitors, stadium scoreboards, computers, announcement boards, warning systems for cell phones, warning / information systems for automobiles, greeting cards, electrochromic windows, billboards, electronic books, and electrical wiring. The subject invention also provides for the use of complementary electrochromic polymers in the manufacture of electrochromic devices. In some embodiments, the devices of the invention can be prepared using metal vapor deposition or line patterning.

Owner:FLORIDA UNIV OF A FLORIDA

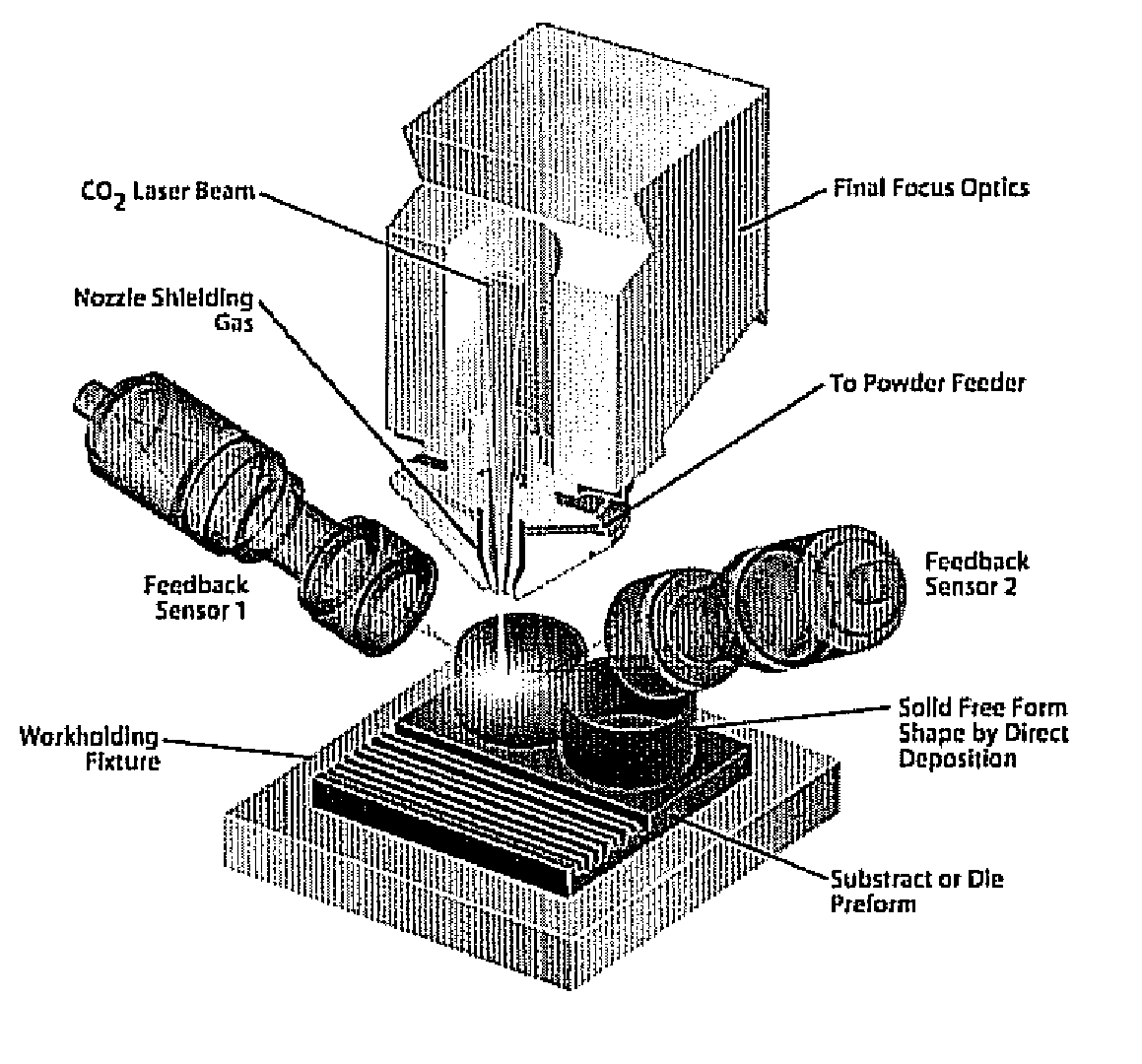

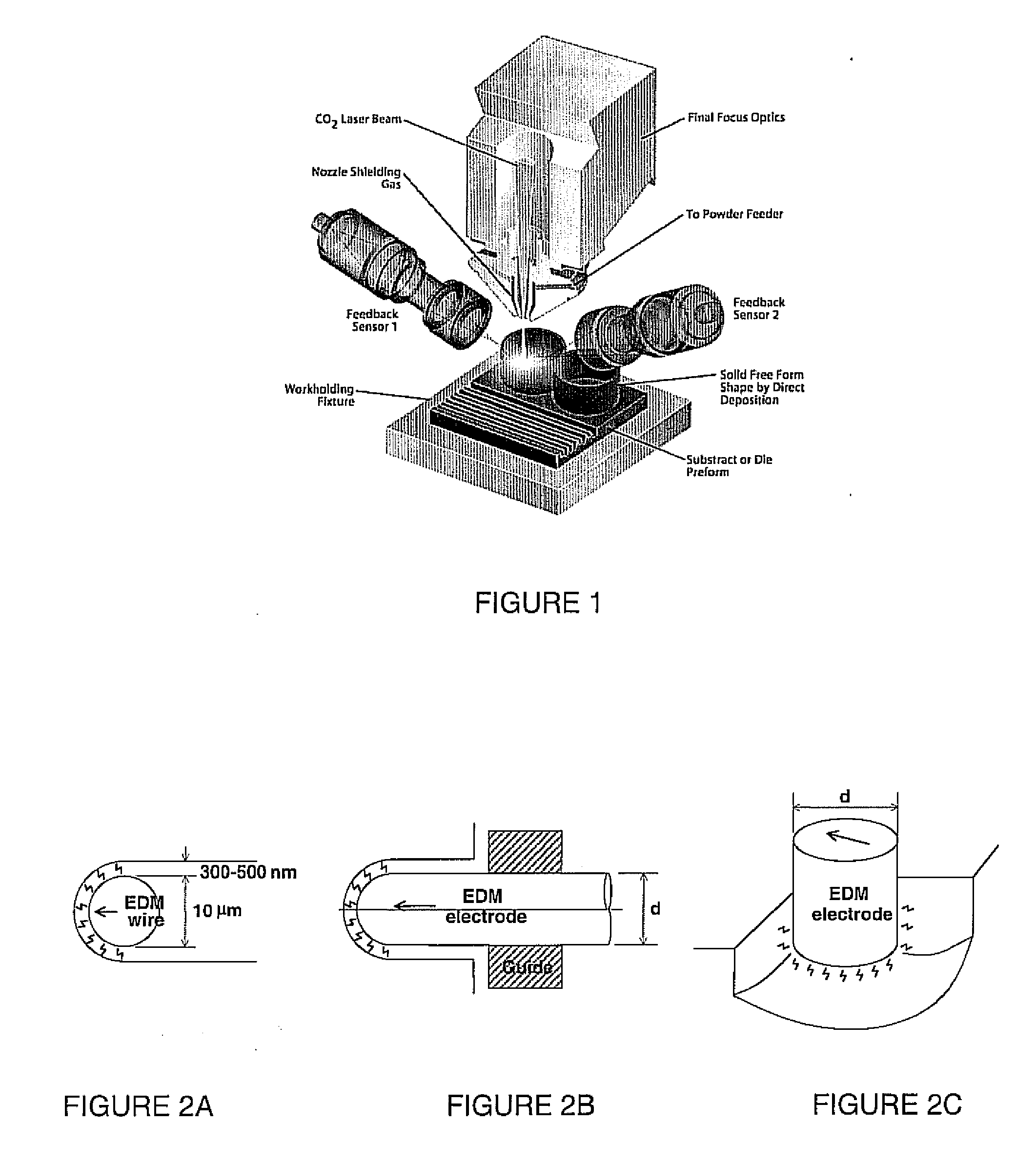

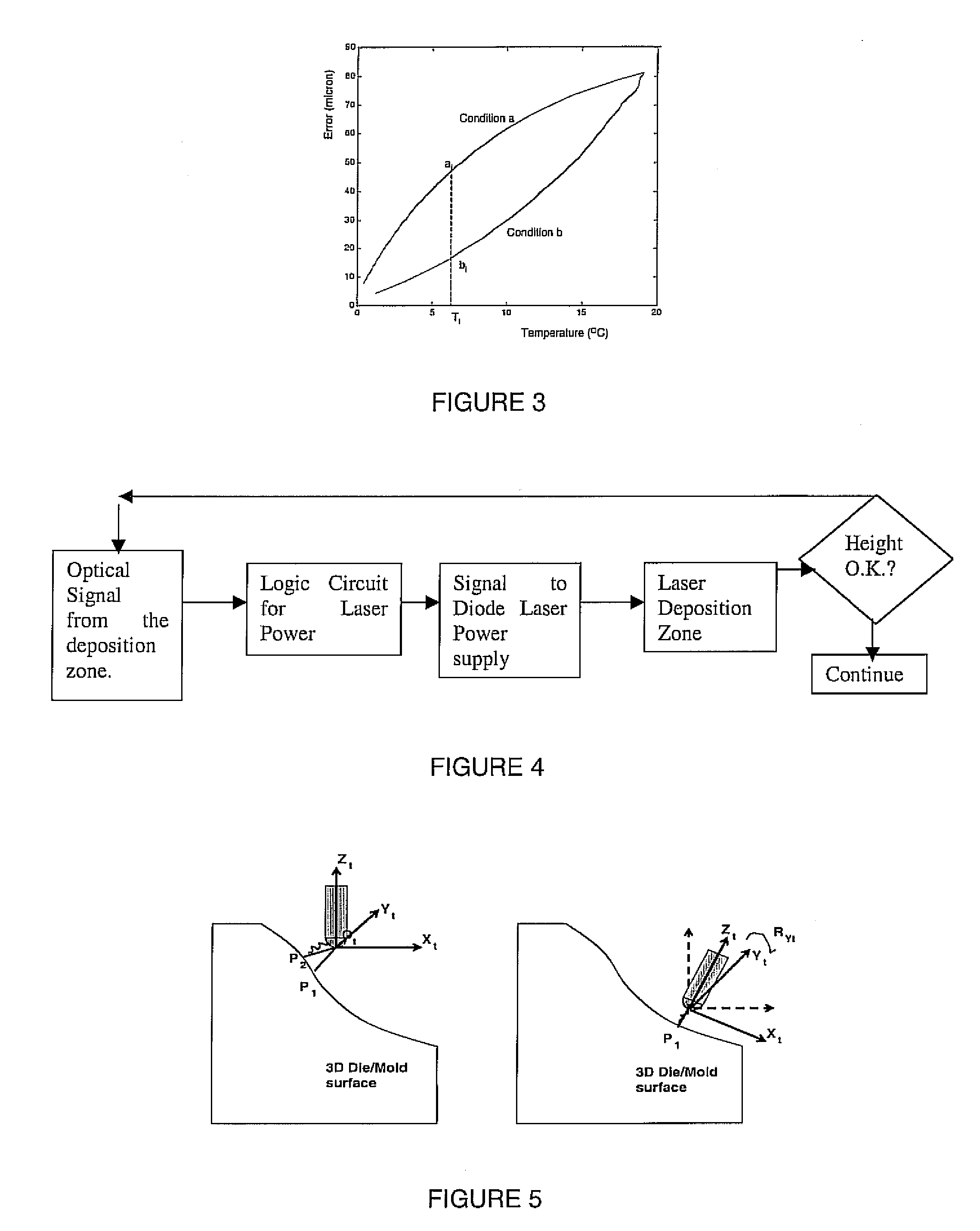

High-speed, ultra precision manufacturing station that combines direct metal deposition and edm

ActiveUS20070205184A1Fast transferImprove efficiencyAdditive manufacturing apparatusElectric discharge heatingEngineeringWorkstation

A direct-metal deposition (DMD) processing stage and a 5DOF (degree of freedom) dry micro-EDM (mEDM) stage are integrated to provide the submicron scale resolution necessary for the ultra-precision processing of work pieces. The DMD processing stage includes optical feedback for dimensional control utilizing a high-power, fiber-coupled diode laser with fast response time and small beam parameter product. The electrical discharge machining (EDM) stage is a dry EDM stage using an inert gas with appropriate dielectric properties to perform the surface finishing operations. The system further includes one or more surface treatment operations to obtain a desired level of surface hardness or wear resistance and / or to minimize the distortion induced in treating the surface.

Owner:DM3D TECH

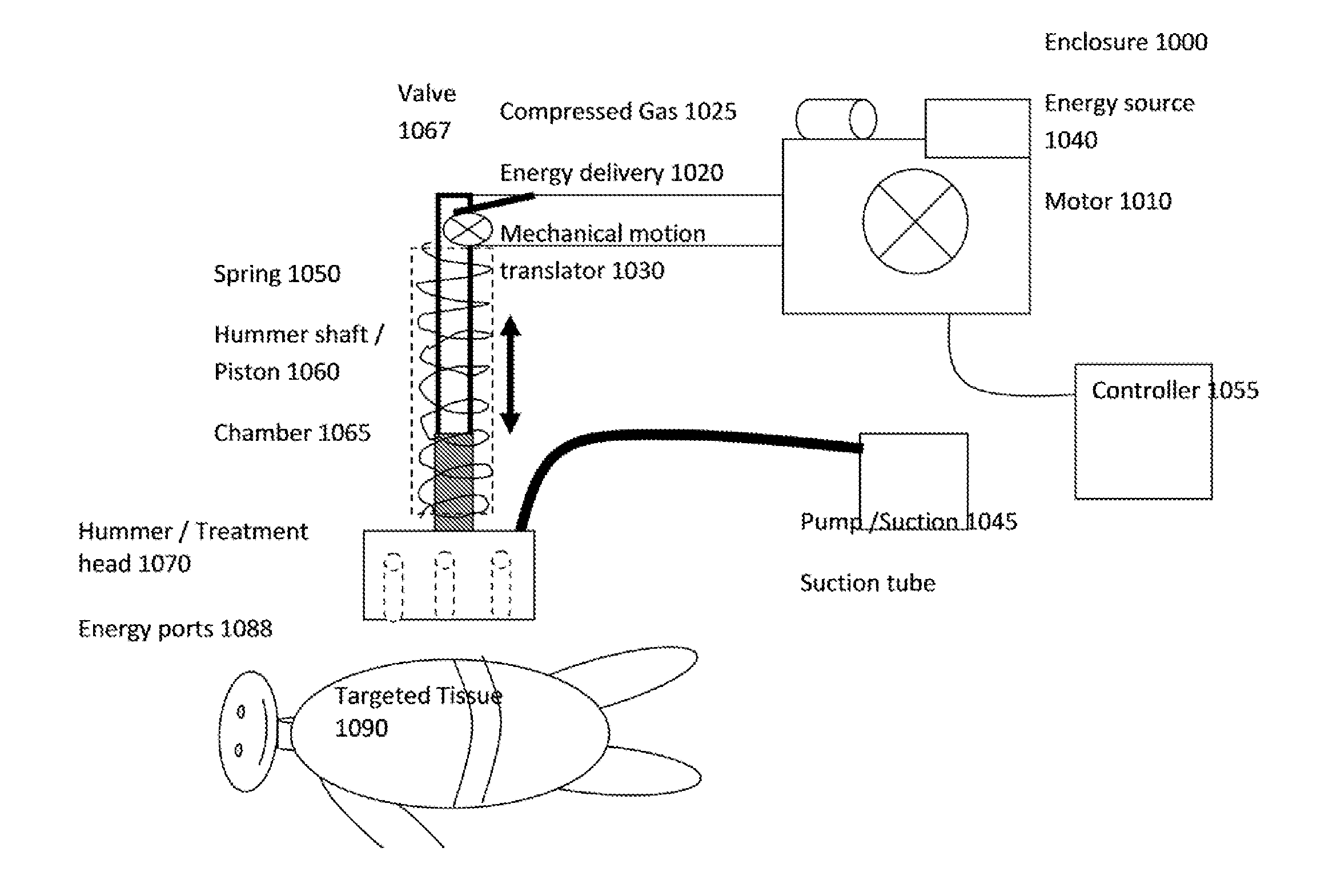

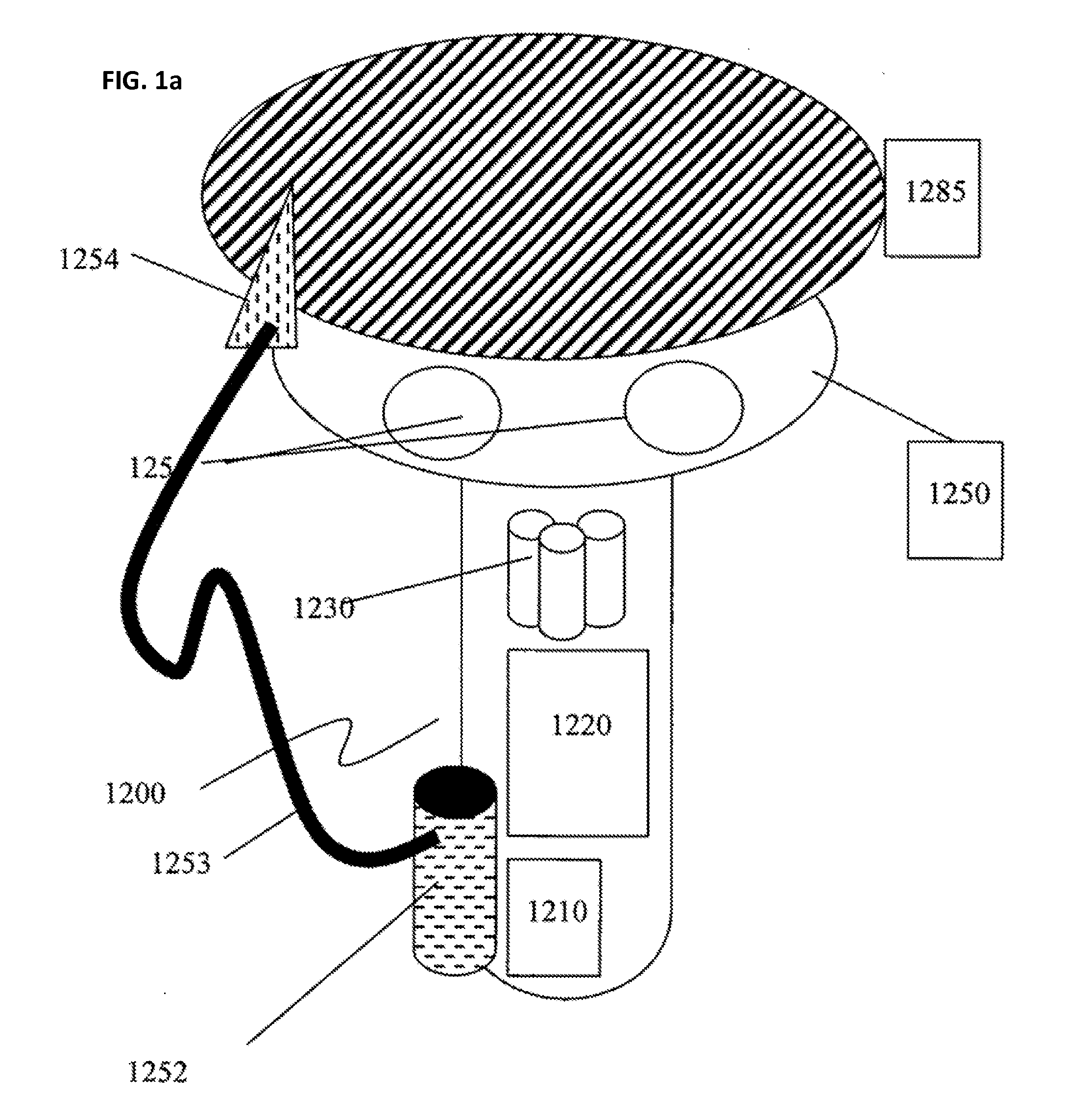

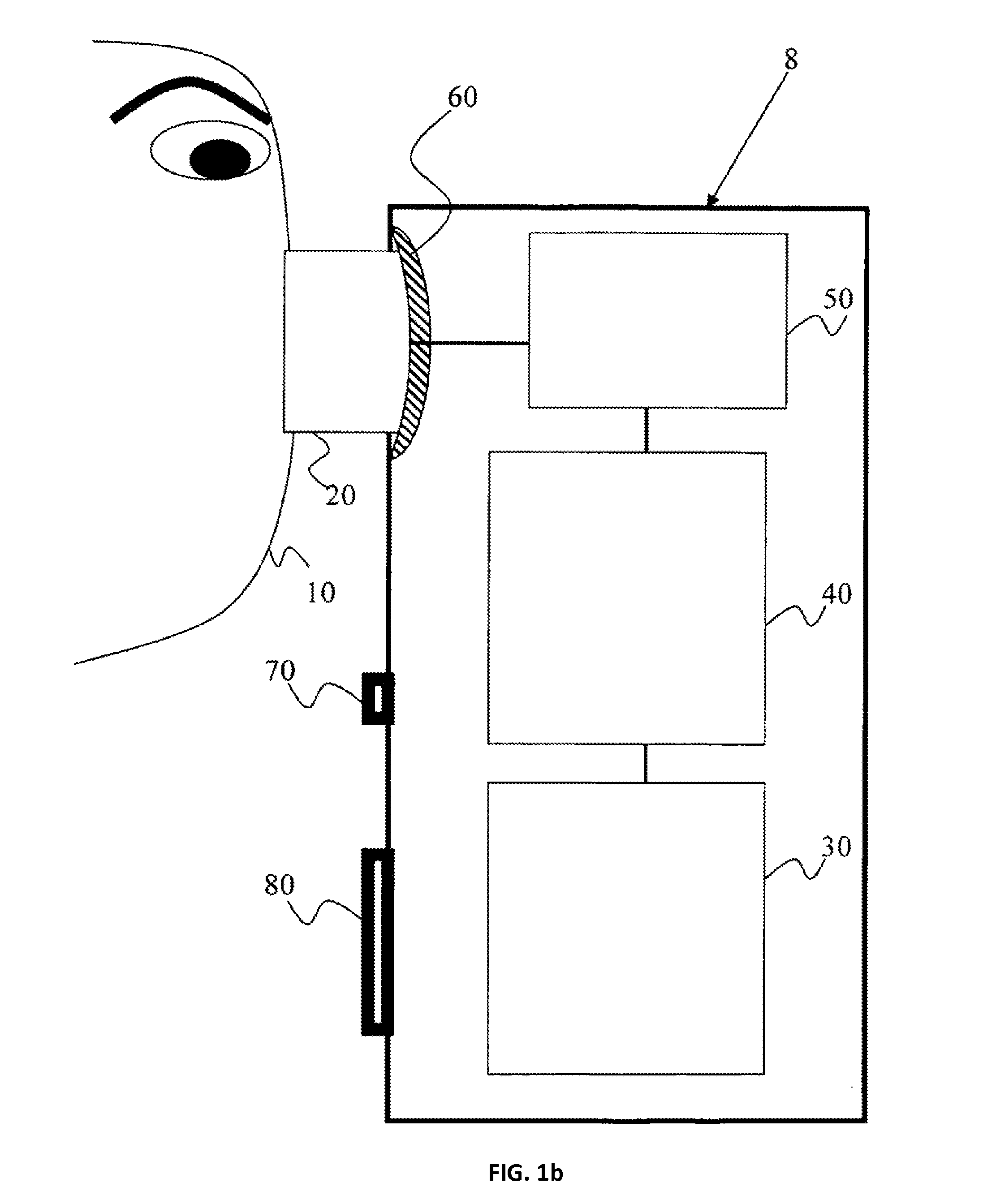

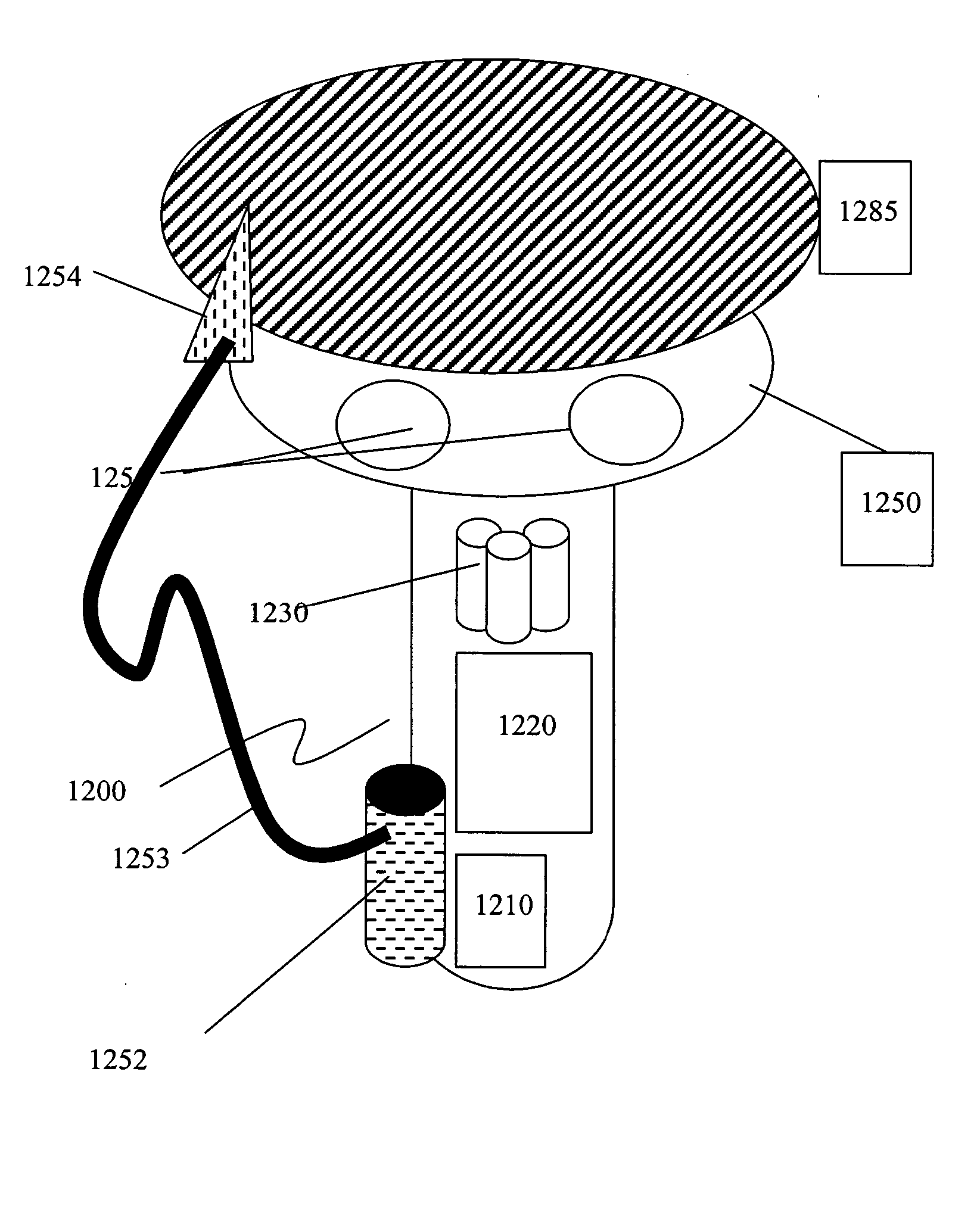

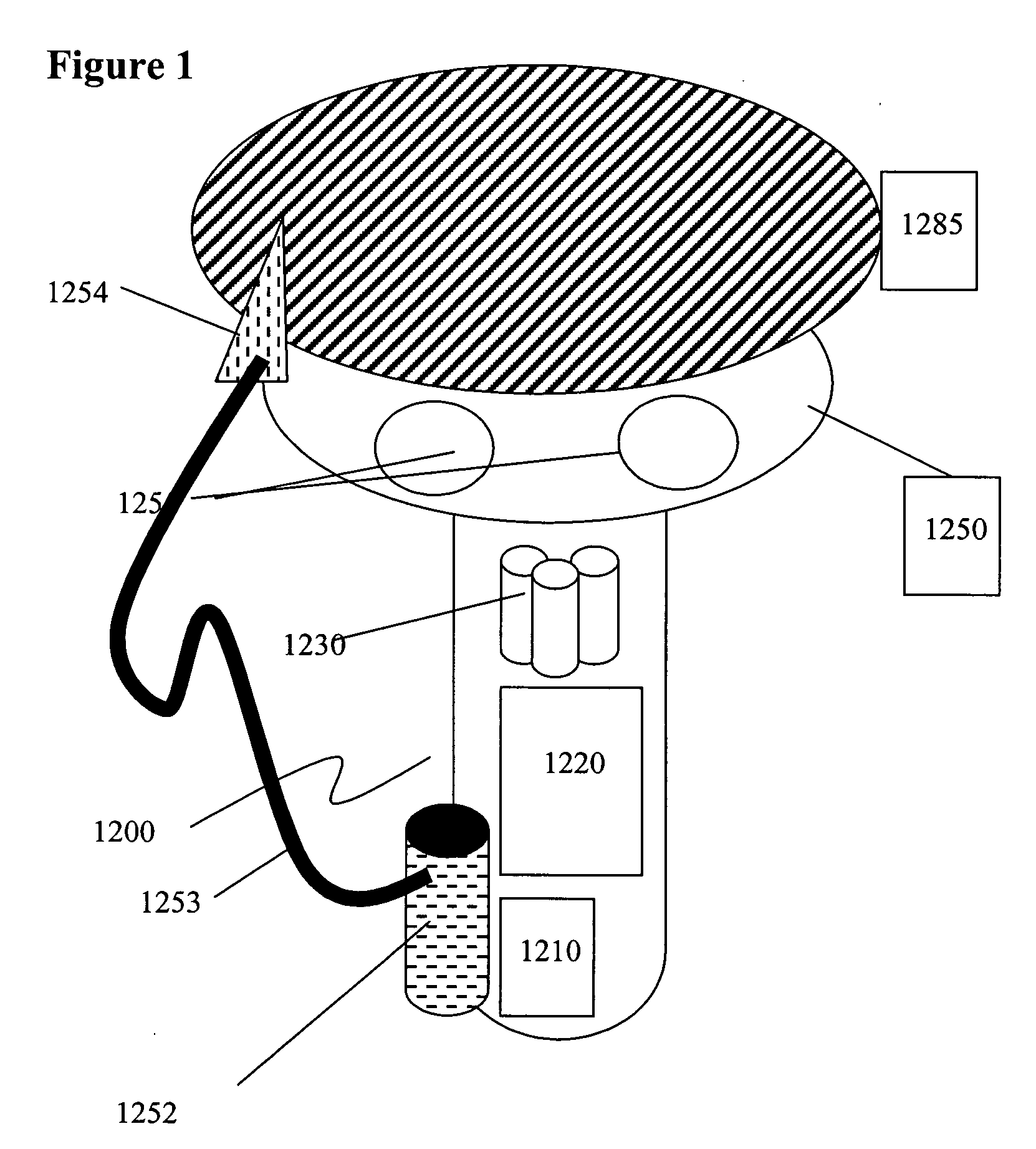

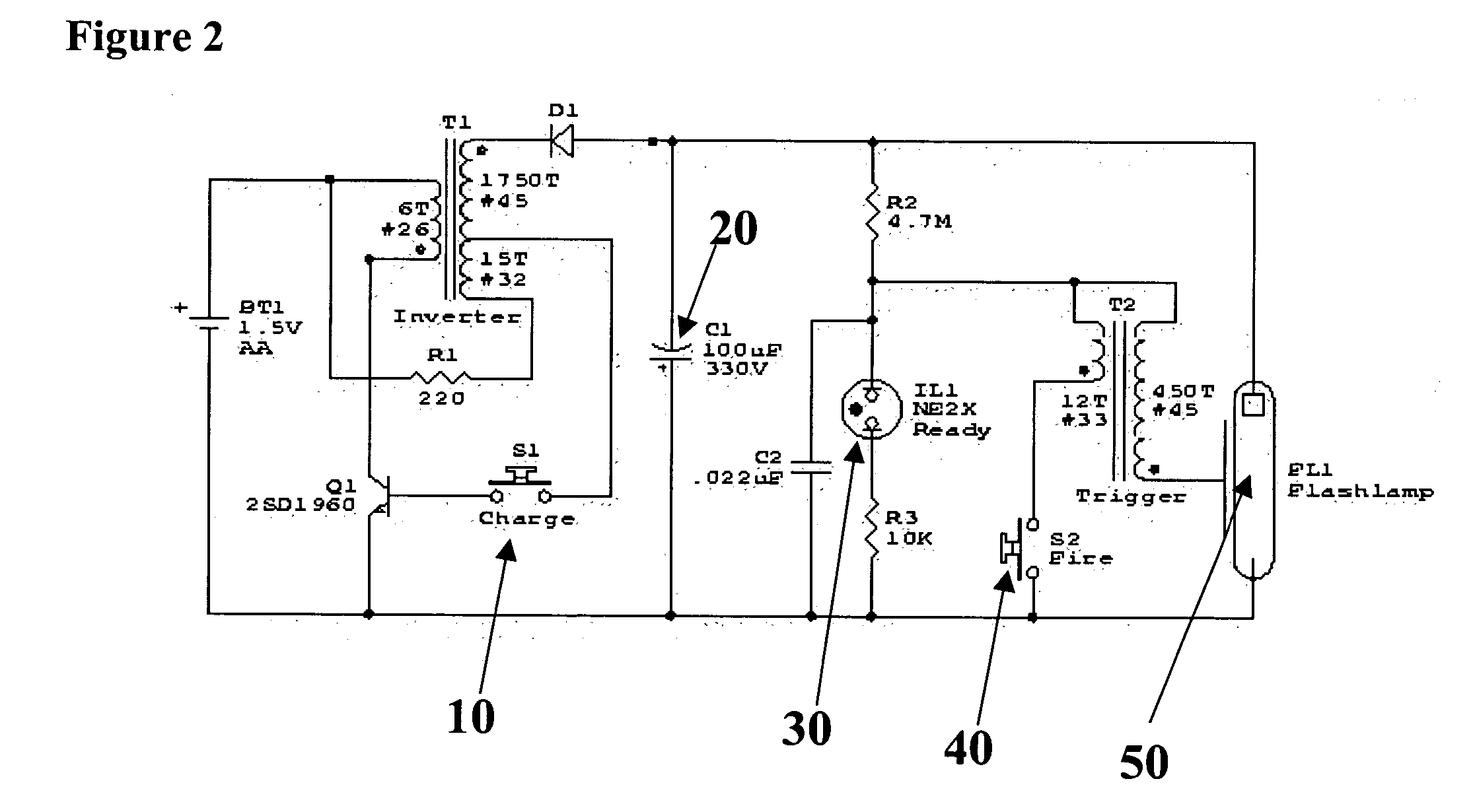

Device and method for treating medical, skin, and hair disorders with energy

InactiveUS20130184693A1Low costRapid deposition of energySurgical instrument detailsLight therapyLight sourceDisease

A device and a method for thermal treatments of target material with various thermal interactions are disclosed. A device for treating hair on the skin comprises a treatment head coupled to a housing; a hair remover for removing the hair from a target area of the skin; a light source for transmitting a predetermined amount of energy to the skin. A device and method for treatment of tissue. The device comprises of an energy source for treatment of surface and subsurface tissue, And of a mechanical source of energy for mechanically deforming the treated tissue. Both the Mechanical Energy (ME) and the Treatment Energy (TE) may be either continuously operating (CO) or modulated in time and space.

Owner:NEEV JOSEPH

Device and method for treating skin disorders with thermal energy

InactiveUS20060074468A1Low costEffective treatmentSurgical instruments for heatingLight therapyThermal energyCutaneous condition

A device and a method for thermal treatments of target material with various thermal interactions are disclosed. A preferred treatment includes Thermal Heat Shuttle that transports a predetermined known quota of energy to the target surface. In particular, the launching of thermal energy quanta from various energy sources in lumps of energy quanta and leading to the treatment and healing of a variety of skin conditions are disclosed.

Owner:NEEV JOSEPH

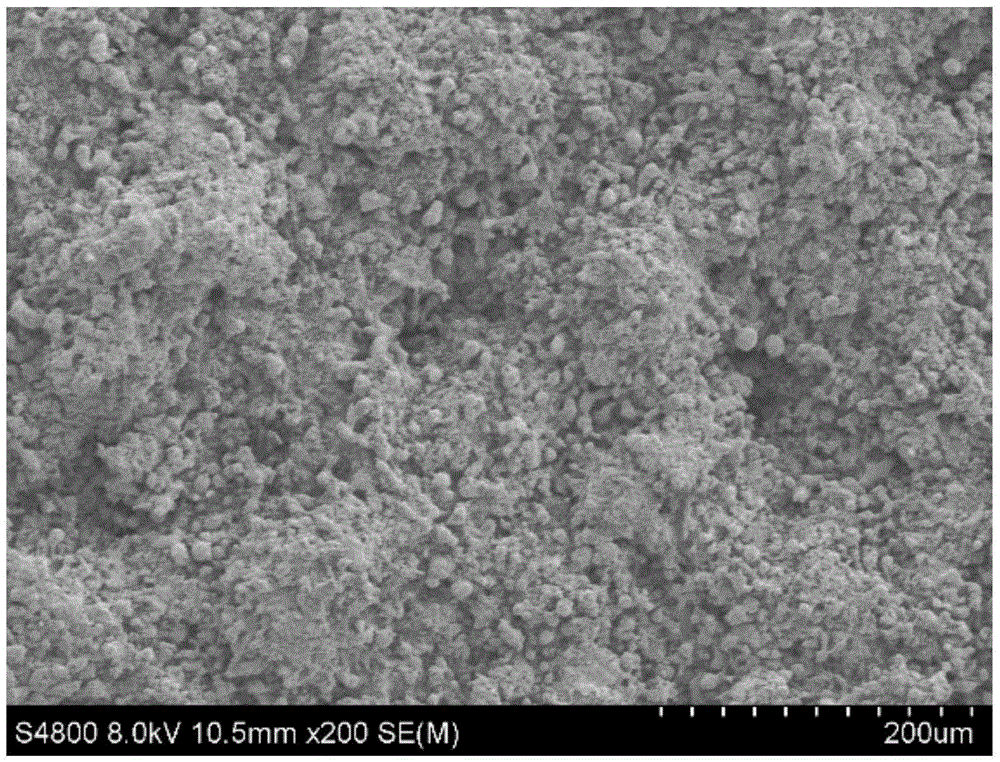

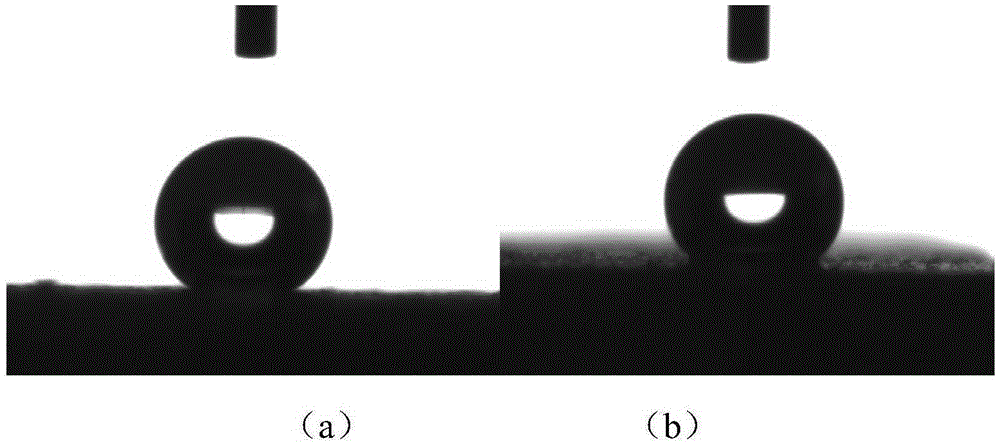

Method for preparing wear-resisting super-hydrophobic coating through cold spraying technology and product of method

ActiveCN105386032APreserve physicochemical propertiesFast depositionPressure inorganic powder coatingWear resistanceRolling angle

The invention discloses a method for preparing a wear-resisting super-hydrophobic coating through a cold spraying technology and a product of the method. The method comprises the following steps that firstly, the surface of a base body is roughened; secondly, sprayed powder is modified with low-surface-energy matter; and thirdly, the wear-resisting super-hydrophobic coating is prepared on the surface of the base body through the cold spraying technology. The static contact angle of the coating prepared through the method can be 150-180 degrees, the rolling angle of the coating is smaller than 10 degrees, and good super-hydrophobicity is achieved. According to the method, the product of a non-stick pan is prepared and has good wear resistance and non-stick performance, and compared with non-stick pans in the market, the product is more resistant to wear and has the great competitive potential in the field. In addition, the method can be used for preparing different wear-resisting super-hydrophobic coatings based on different base materials (such as metal, ceramic, glass and plastic), and the application range is wide.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Diamond wire saw production method of surface modified diamond

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

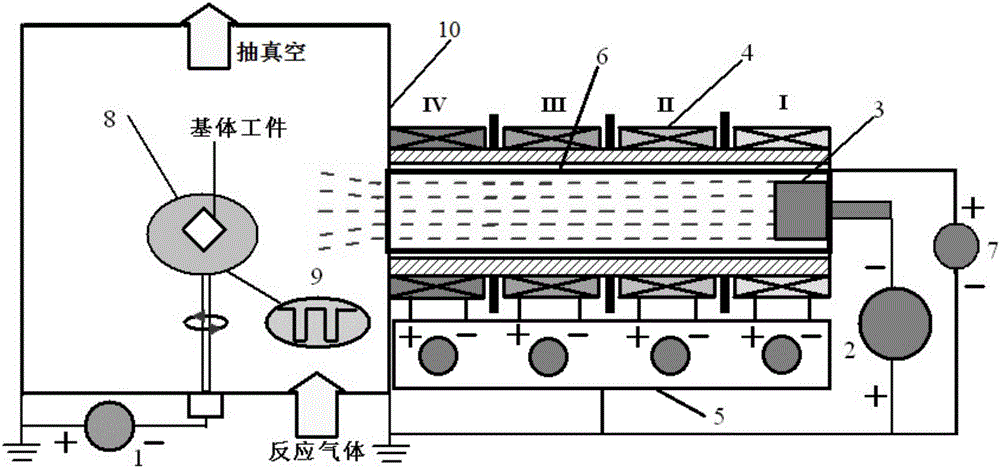

Multi-stage magnetic field arc ion plating method for lining positive bias straight pipe

InactiveCN105925940AReduce lossImprove transmission efficiencyVacuum evaporation coatingSputtering coatingPhysicsElectric arc

The invention discloses a multi-stage magnetic field arc ion plating method for a lining positive bias straight pipe, and belongs to the technical field of material surface treatment. The problems that in a multi-stage magnetic field filtering device, pollution to the inner wall of a pipeline due to macroparticles needs to be removed, and losses are caused in the plasma transmitting process need to be solved. The method comprises the steps that firstly, a workpiece to be coated is arranged on a sample table in a vacuum chamber, and a related power source is powered on; and secondly, film deposition is conducted, when the vacuum degree in the vacuum chamber is smaller than 10-4Pa, work gas is guided in, the air pressure is adjusted, a coating power source is started, meanwhile, energy of plasmas is adjusted through a grid bias power supply, the macroparticle defect is further eliminated through a lining positive bias straight pipe device, the transmission efficiency of the arc plasmas is guaranteed through the lining positive bias straight pipe device, needed technology parameters are set, and film deposition is conducted.

Owner:魏永强

Varied morphology carbon nanotubes

InactiveUS20080118426A1Increase productionHigh catalytic activityMaterial nanotechnologyCarbon compoundsCarbon nanotubeMaterials science

Owner:TRUSTEES OF BOSTON COLLEGE THE

Explosive painting process of preparing heat barrier coating

InactiveCN1416964AImprove bindingFast depositionLiquid surface applicatorsMolten spray coatingHardnessAlloy

The present invention is explosive coating process of preparing heat barrier coatings. Of the coating, the connecting layer comprises MCrAlY alloy system, where M is Ni and / or Co; and the ceramic layer has the ZrO2-8Y2O3 components. The specific operations include hexahedral explosive coating controlling the base material temperature at 100-200 deg.c, coating the connecting layer and the ceramic layer successively to obtain the heat barrier coatings. The specific operation parameters for forming the connecting layer and the ceramic layer are provided. Between the connecting layer and the ceramic layer, one transition layer including two components of both connecting layer and ceramic layer may be increased. The present invention may obtain completely antioxidant coatings with high hardness and high heat insulating effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

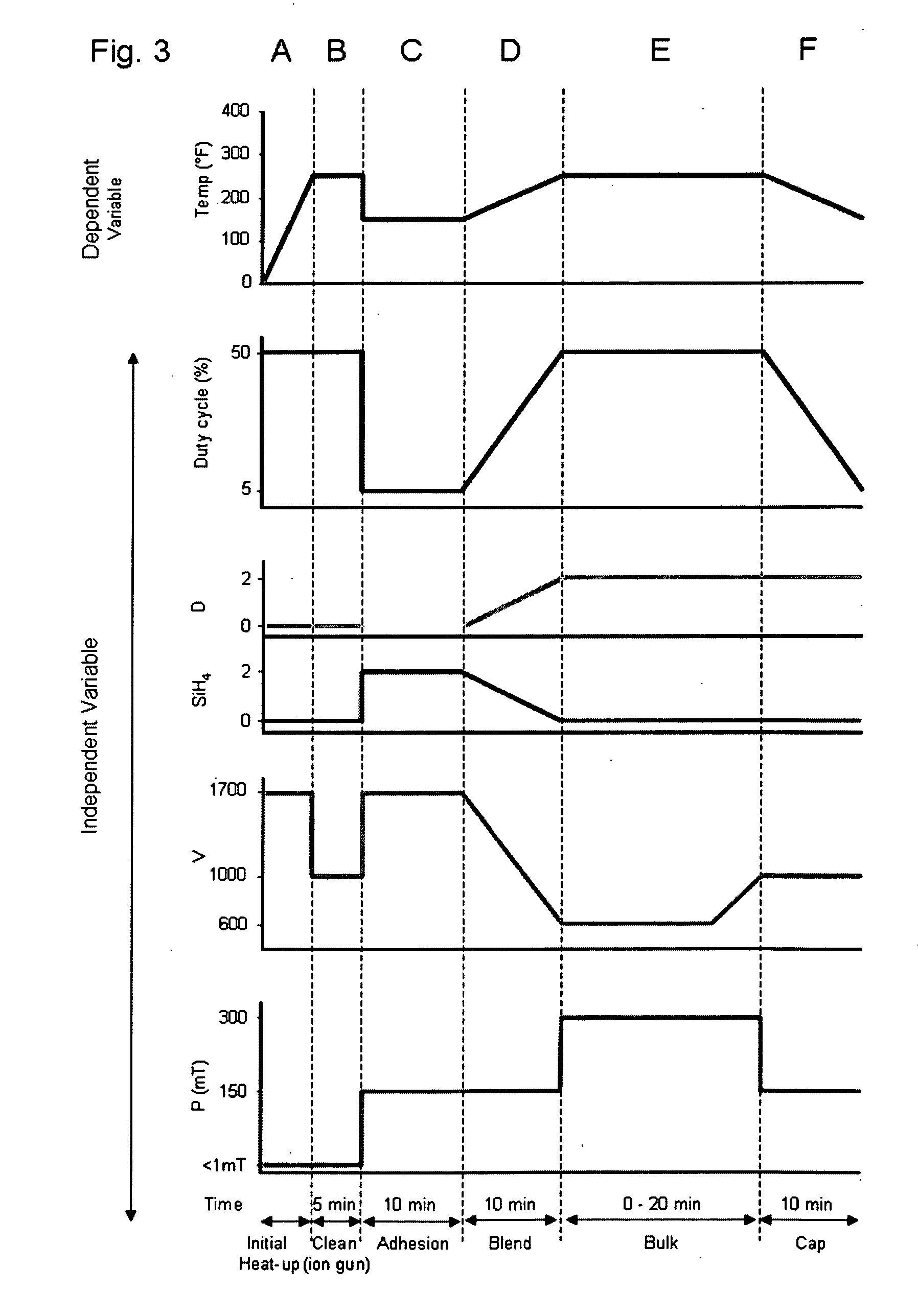

Method for producing amorphous carbon coatings on external surfaces using diamondoid precursors

InactiveUS20090029067A1Desirable mechanical and tribological propertyFast depositionChemical vapor deposition coatingPlasma techniqueGas phaseRefractive index

The invention relates to a method for forming high sp3 content amorphous carbon coatings deposited by plasma enhanced chemical vapor deposition on external surfaces. This method allows adjustment of tribological properties, such as hardness, Young's modulus, wear resistance and coefficient of friction as well as optical properties, such as refractive index. In addition the resulting coatings are uniform and have high corrosion resistance. By controlling pressure, type of diamondoid precursor and bias voltage, the new method prevents the diamondoid precursor from fully breaking upon impact with the substrate. The diamondoid retains sp3 bonds which yields a high sp3 content film at higher pressure. This enables a faster deposition rate than would be possible without the use of a diamondoid precursor.

Owner:CHEVROU USA INC

Chemical-copper plating liquid and copper plating production process

ActiveCN101654797AImprove bindingApplicable functionLiquid/solution decomposition chemical coatingPorosityCopper plating

The invention relates to chemical-copper plating liquid and a copper plating production process, which are used for copper plating of tubular steel and iron pieces and non-metal pieces, and are characterized in that: the chemical-copper plating liquid consisting of copper sulphate, a retarder, a complexant, a reductant and deionized water is used to pretreat a workpiece and then the workpiece is subjected to chemical-copper plating; an anode is 0.3 percent phosphor-containing copper plate; the area ratio of the anode and the cathode is 2:1; the current intensity in the cathode is 0.5 to 4A / dm<2>; the pH value of the copper plating liquid is 1.0 to 3.0; the temperature of the copper plating liquid is normal temperature; and the carrying capacity is 1 to 4dm<2> / kg; the copper plating time is8 to 10 minutes. The liquid and the process have the advantages of firm bonding between cladding and a substrate, stable process, high impurity resistance, long service life, crystalline simple copper cladding, fine cladding crystallization, low porosity, high anticorrosion performance, simple operation, convenient maintenance, no formaldehyde, no damages to human bodies and environment and environmentally-friendly product.

Owner:河北聚贤环保科技股份有限公司

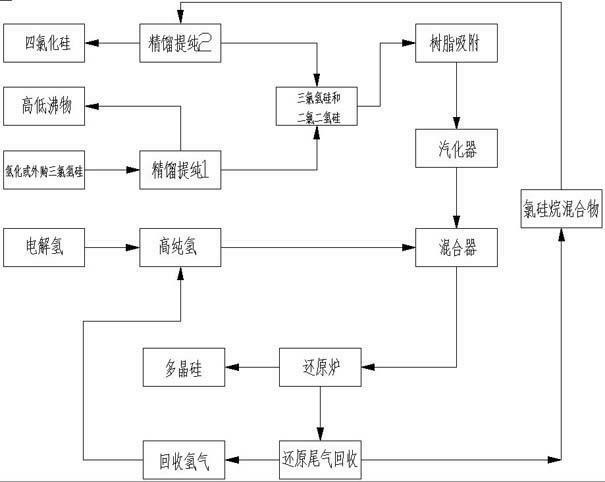

Method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon

InactiveCN102642834ASolve processing problemsReduce investmentSiliconPhysical chemistryMixed materials

The invention discloses a method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon. After trichlorosilane produced by hydrogenation of silicon tetrachloride or purchased outside is rectified and purified, the rectified and purified trichlorosilane is mixed with recycled trichlorosilane and dichlorosilane mixed materials, the volume percent of dichlorosilane in the mixed raw materials is controlled to be between 3% and 15%, preferably between 5% and 10%, then impurity removal by adsorption and vaporization operation are performed, vaporized chlorosilane mixed gas and high-purity hydrogen are mixed according to mole ratio of 1:2 to 1:10, preferably 1:4 to 1:6, and finally the vaporized chlorosilane mixed gas and the high-purity hydrogen enter into a reduction furnace to produce the polycrystalline silicon. After reactions, tail gas undergoes low-temperature condensation recycle, chlorosilane obtained by recycle is sent to a rectification process to perform separation of silicon tetrachloride and impurities, and the trichlorosilane and dichlorosilane mixed raw materials are obtained. The method makes full use of byproduct dichlorosilane in the polycrystalline silicon production process to improve sedimentation velocity of silicon and reduce power consumption and material consumption, simultaneously can reduce treatment cost and loss of silicon, and improves trichlorosilane utilization rate.

Owner:雅安永旺硅业有限公司

Preparation method of electroplating diamond fret saw

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

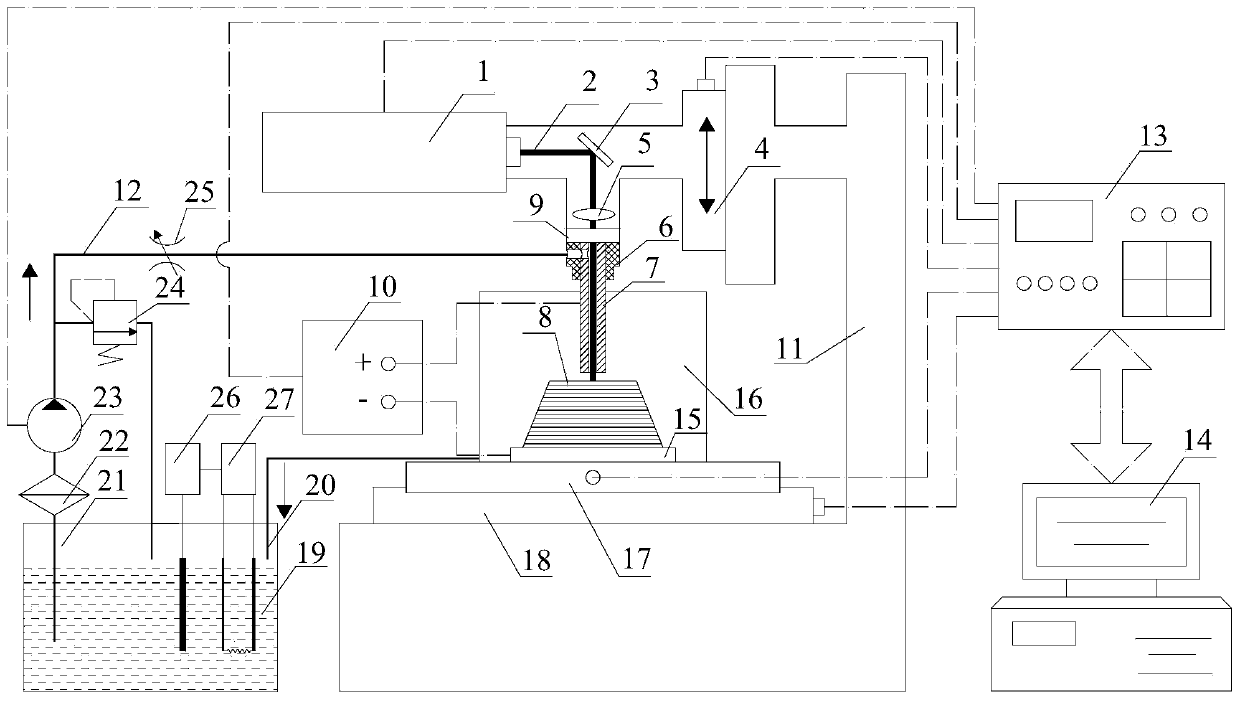

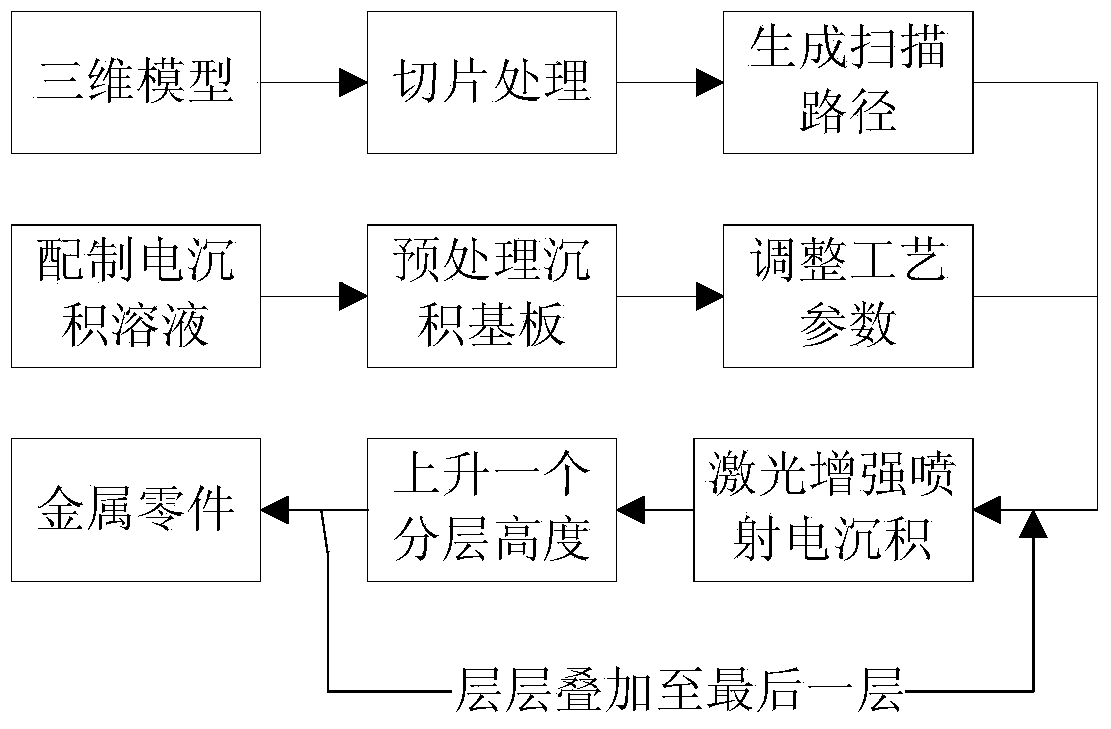

Laser-reinforced jet-electrodeposition rapid-prototyping processing apparatus and method

The invention discloses a laser-reinforced jet-electrodeposition rapid-prototyping processing apparatus and method. An anode is connected with a laser generation mechanism, an eye shield is located between the laser generation mechanism and the anode, a cathode is a deposition substrate which is arranged in a deposition groove, and a power supply is connected with the cathode and the anode; a Z-axis mobile platform is connected with the anode and the laser generation mechanism, and an X-axis mobile platform and a Y-axis mobile platform are successively arranged below the deposition groove; the liquid inlet end of a constant temperature liquid storage mechanism is connected with the anode, the liquid returning end of the constant temperature liquid storage mechanism is connected with the deposition groove, and a controller is connected with the laser generation mechanism, the power supply, the X-axis mobile platform, the Y-axis mobile platform, the Z-axis mobile platform and the constant temperature liquid storage mechanism. According to the invention, a high-energy density laser beam and a high-speed electrodeposition solution are synchronously jetted to the surface of the cathode through a tubular passive anode centre bore, combination of laser reinforced electrodeposition technology and electrodeposition solution injection is realized, and a high deposition speed is obtained.

Owner:TONGLING UNIV

High-hardness and high-corrosion-resistance high-entropy alloy nitride coating and preparation method thereof

ActiveCN108220880AImprove corrosion resistanceIncrease productivityVacuum evaporation coatingSputtering coatingHigh entropy alloysHardness

The invention provides a high-hardness high-corrosion-resistance high-entropy alloy nitride coating. The molecular formula of the high-hardness high-corrosion-resistance high-entropy alloy nitride coating is (AlCrTiZrNbV)N. The invention further provides a preparation method of the coating. The method comprises the steps of firstly, cleaning a matrix and then conducting ion cleaning; secondly, sending the treated matrix to a sputtering chamber to deposit a TiN transition coating, controlling a Ti target material through a DC cathode and depositing the TiN transition coating of 100-200 nm; andthirdly, depositing a TiAlN transition coating on the TiN transition coating and depositing the (AlCrTiZrNbV)N coating on the TiAlN transition coating. The (AlCrTiZrNbV)N coating obtained through thepreparation method has high hardness exceeding 35 GPa and also has excellent corrosion resistance. The coating has the characteristics of being simple in production process, high in deposition speed,low in cost and the like and also has the advantages of being high in production efficiency, low in energy consumption and low in equipment requirement.

Owner:SHANGHAI NEWARC COATING TECH CO LTD

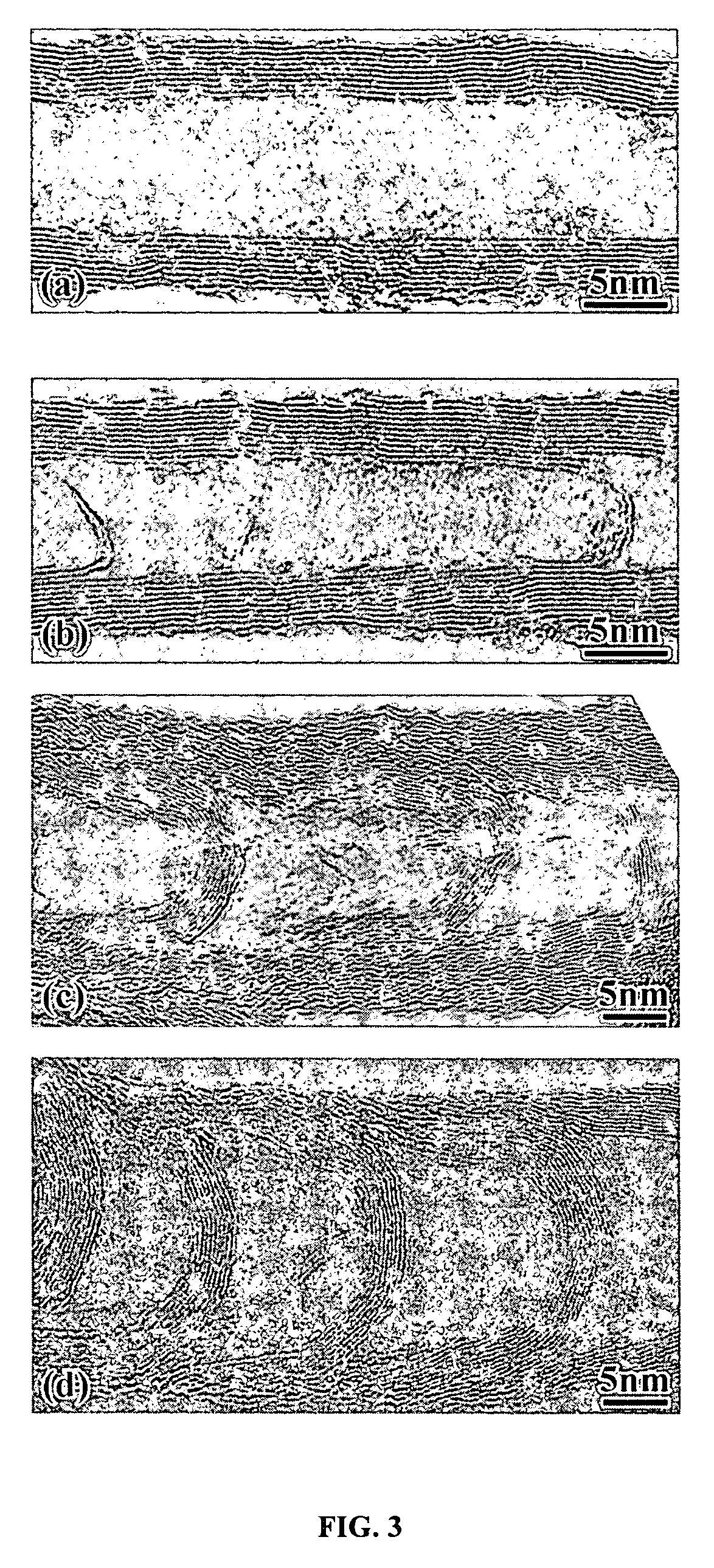

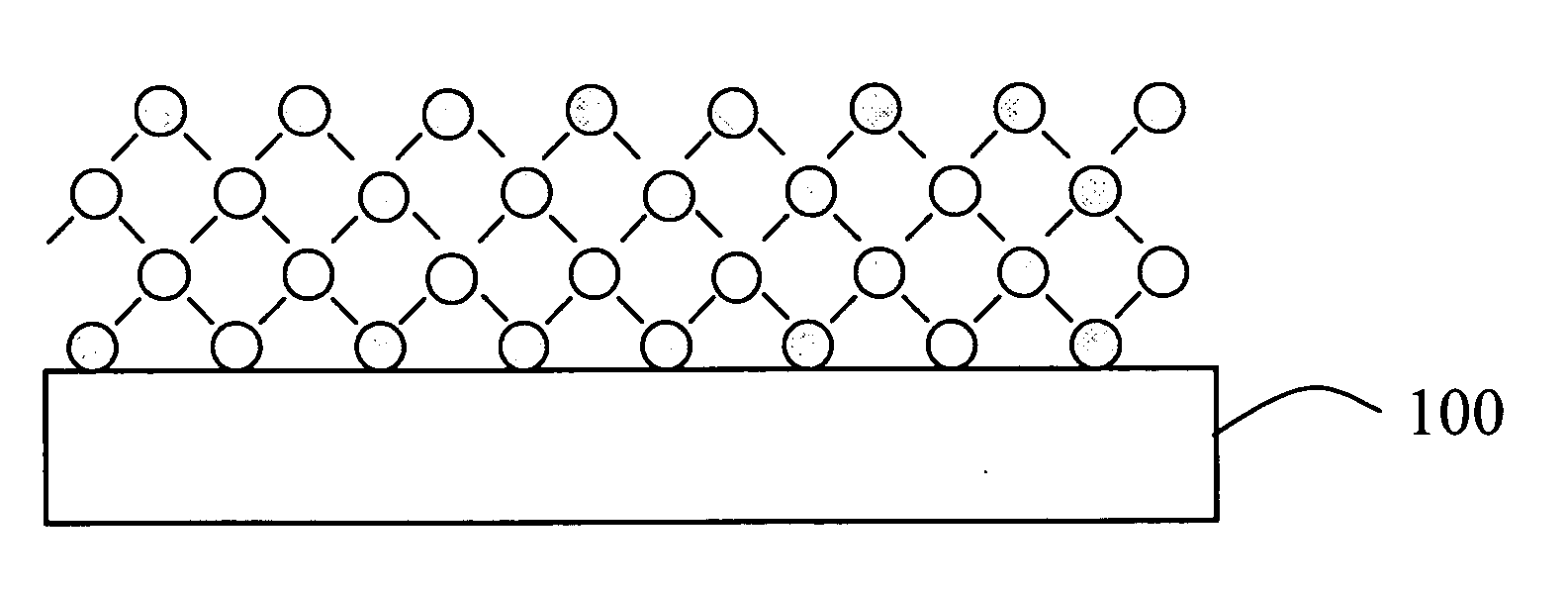

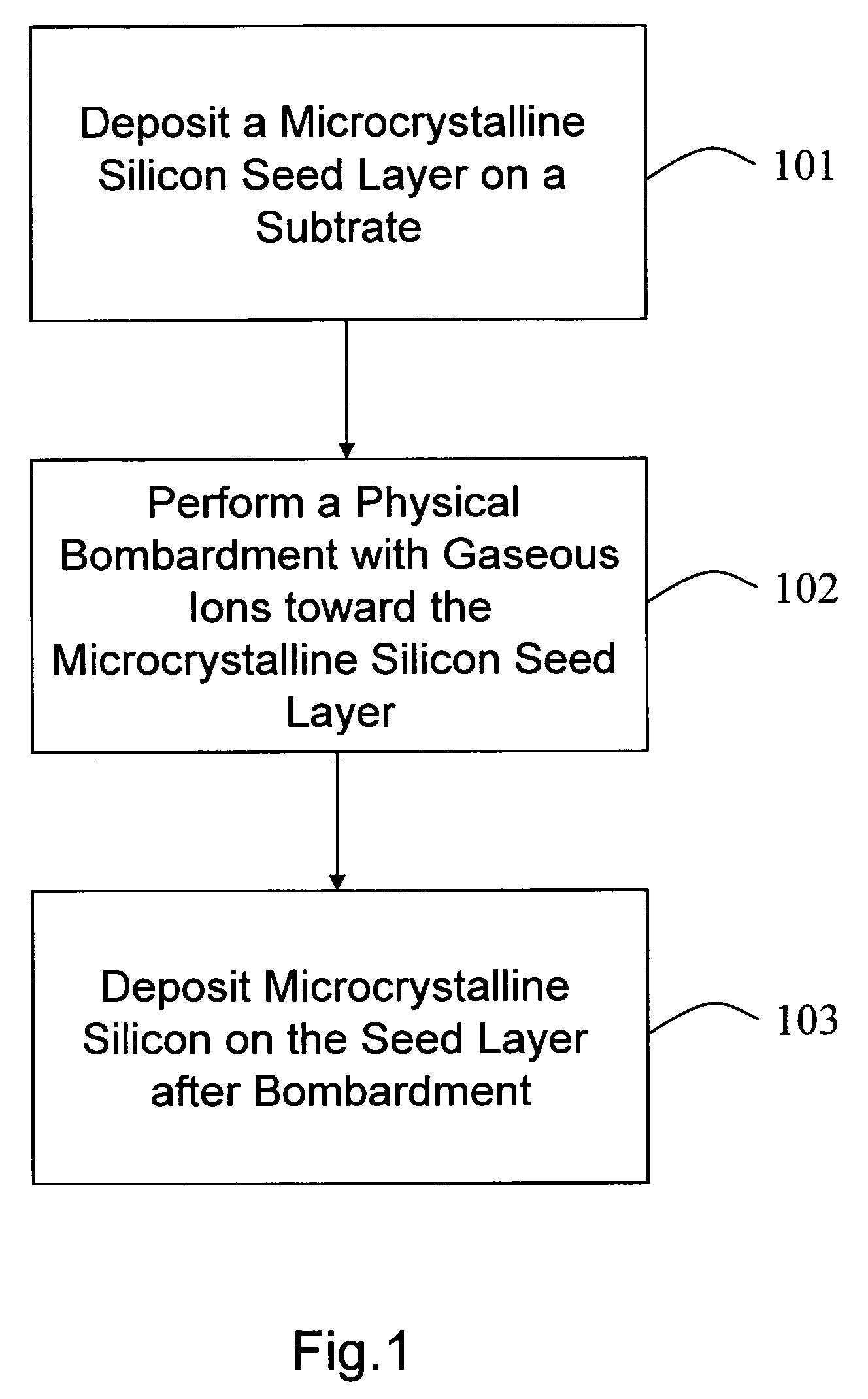

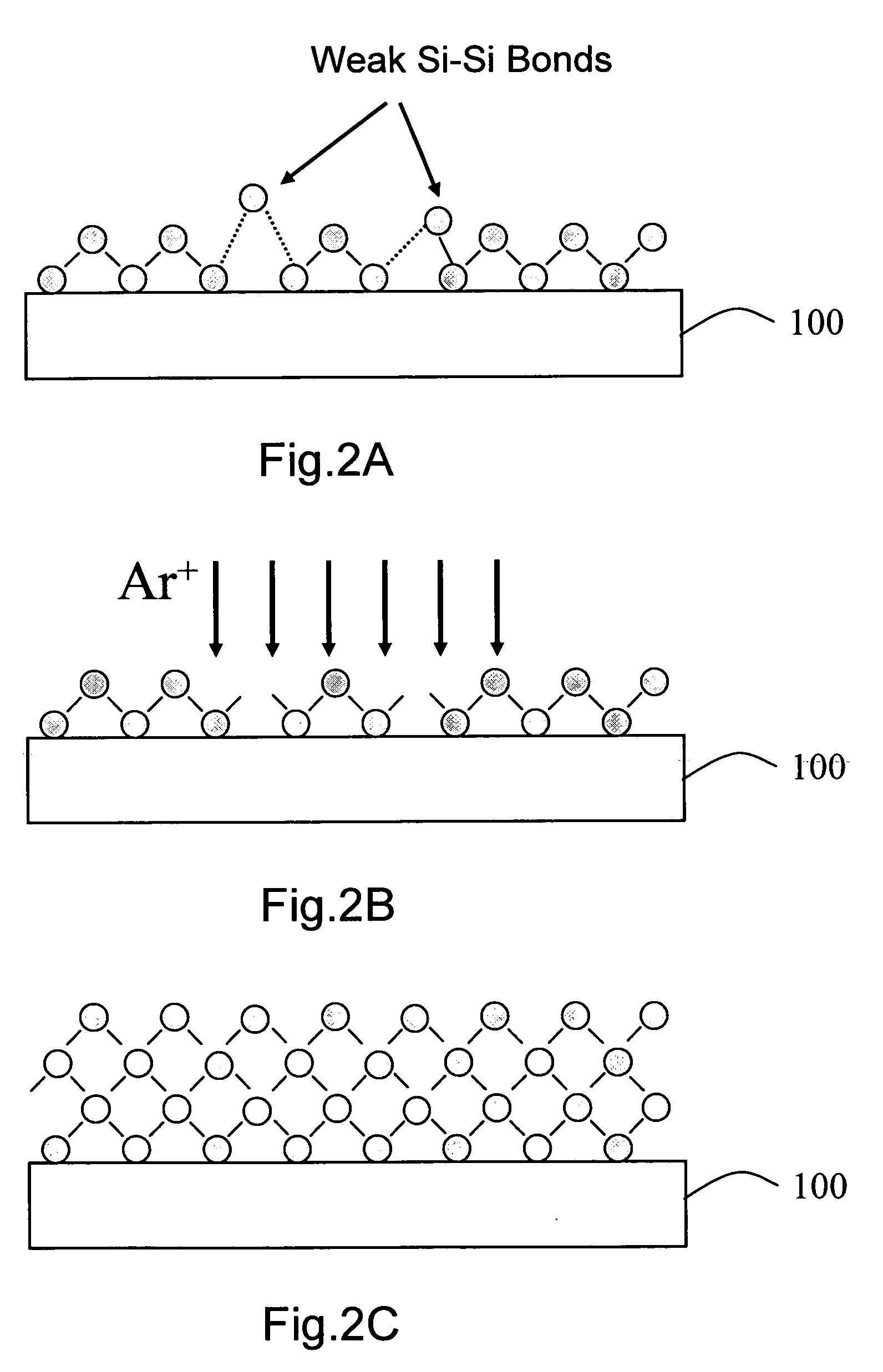

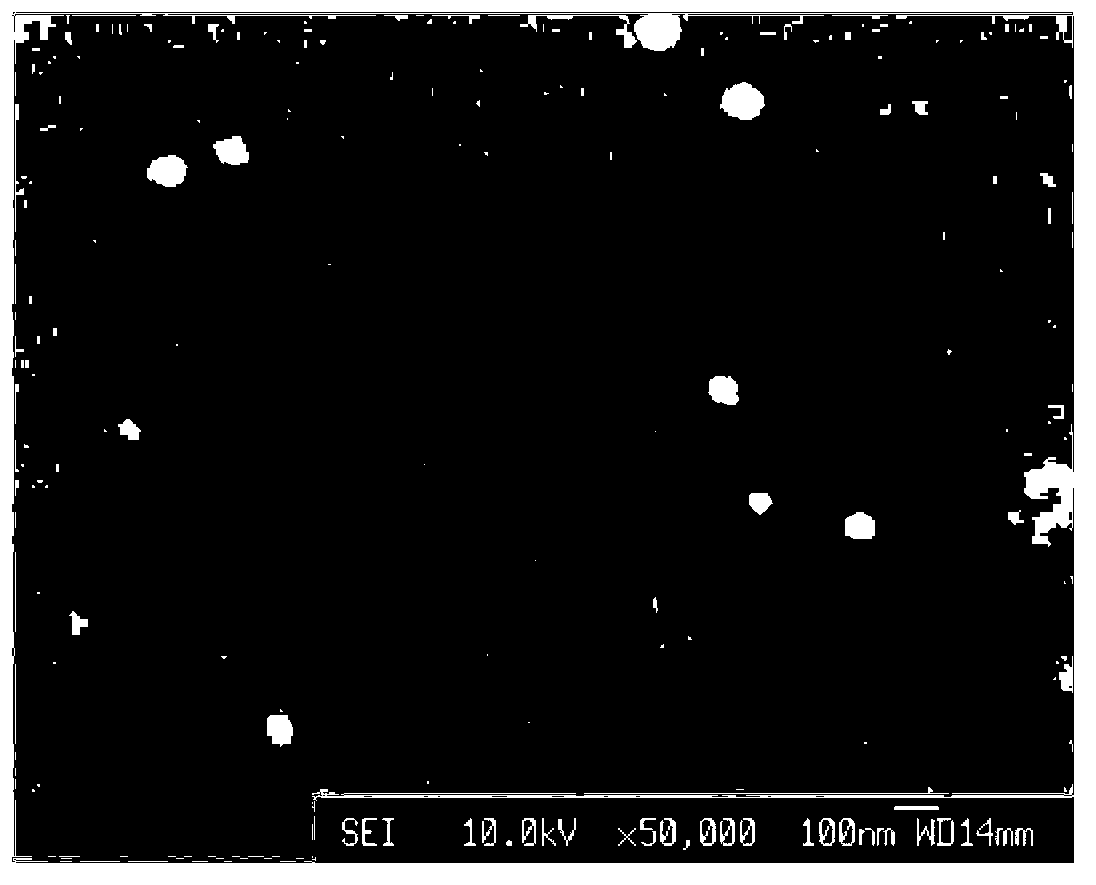

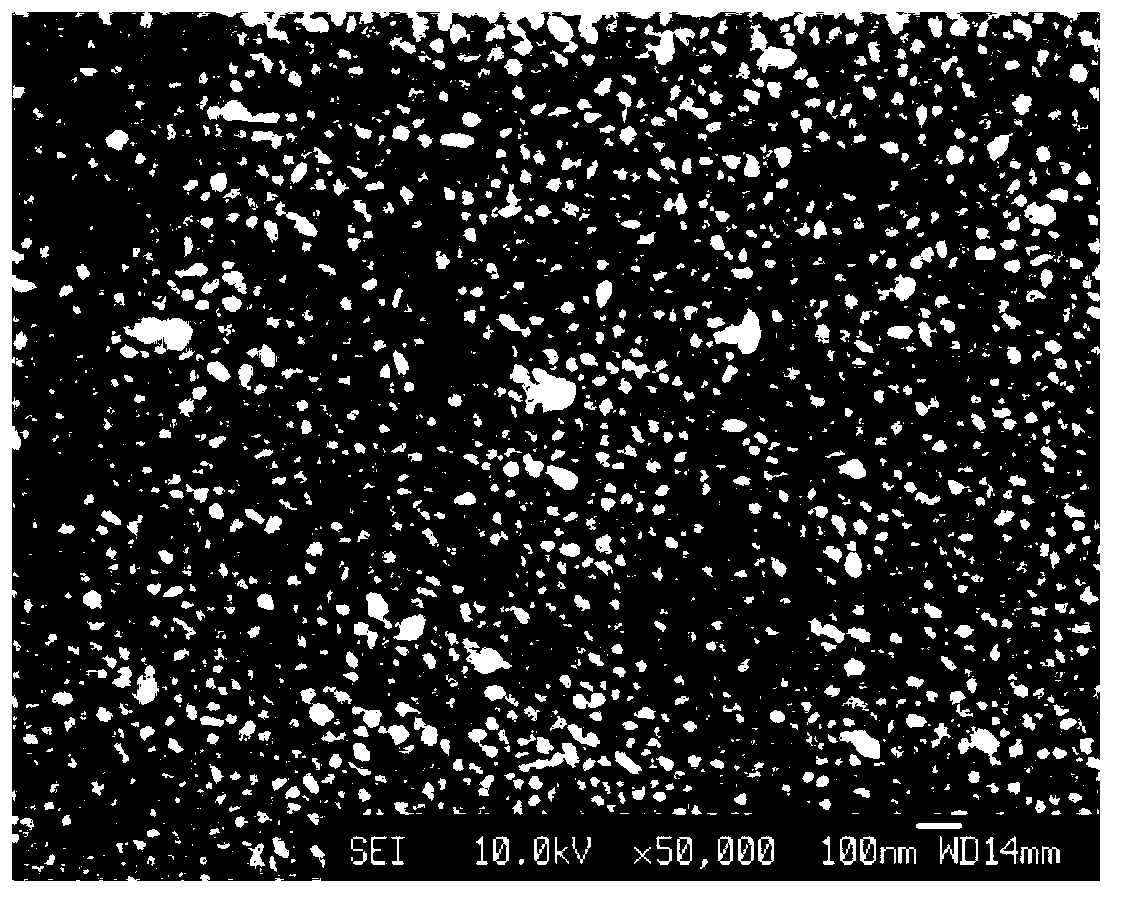

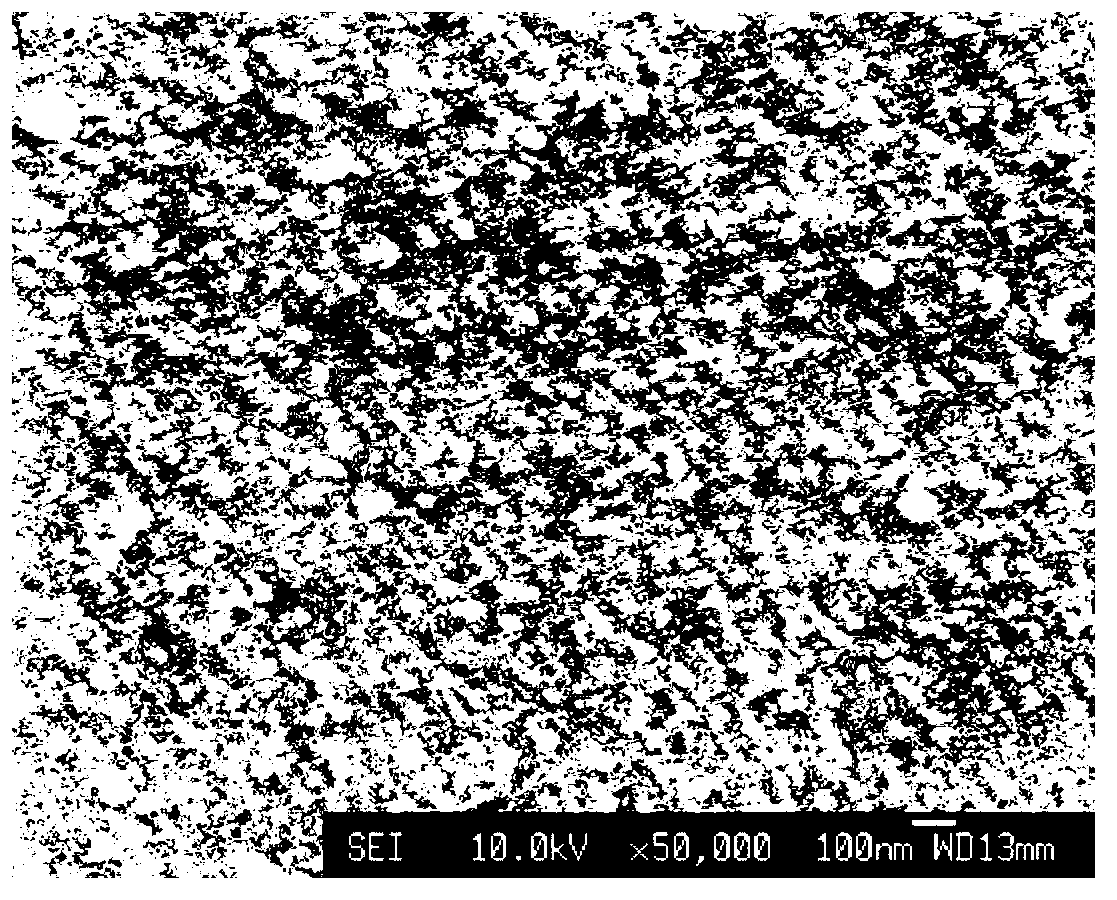

Method for forming a microcrystalline silicon film

InactiveUS20090029532A1Improve the crystallization processFast depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThree stageOptoelectronics

This invention provides a method for forming a microcrystalline silicon film, which employs a three-stage deposition process to form a microcrystalline film. A microcrystalline silicon seed layer is formed on a substrate. Gaseous ions are used to bombard a surface of the microcrystalline silicon seed layer. Microcrystalline silicon is formed on the microcrystalline silicon seed layer after the bombardment to a predetermined thickness.

Owner:IND TECH RES INST

Electrodeposition method, electrodeposition solution and method for preparation of rare earth permanent magnetic material by electrodeposition

InactiveCN105839152AFast depositionSave time in electrodeposition processInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementTetrafluoroborate

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

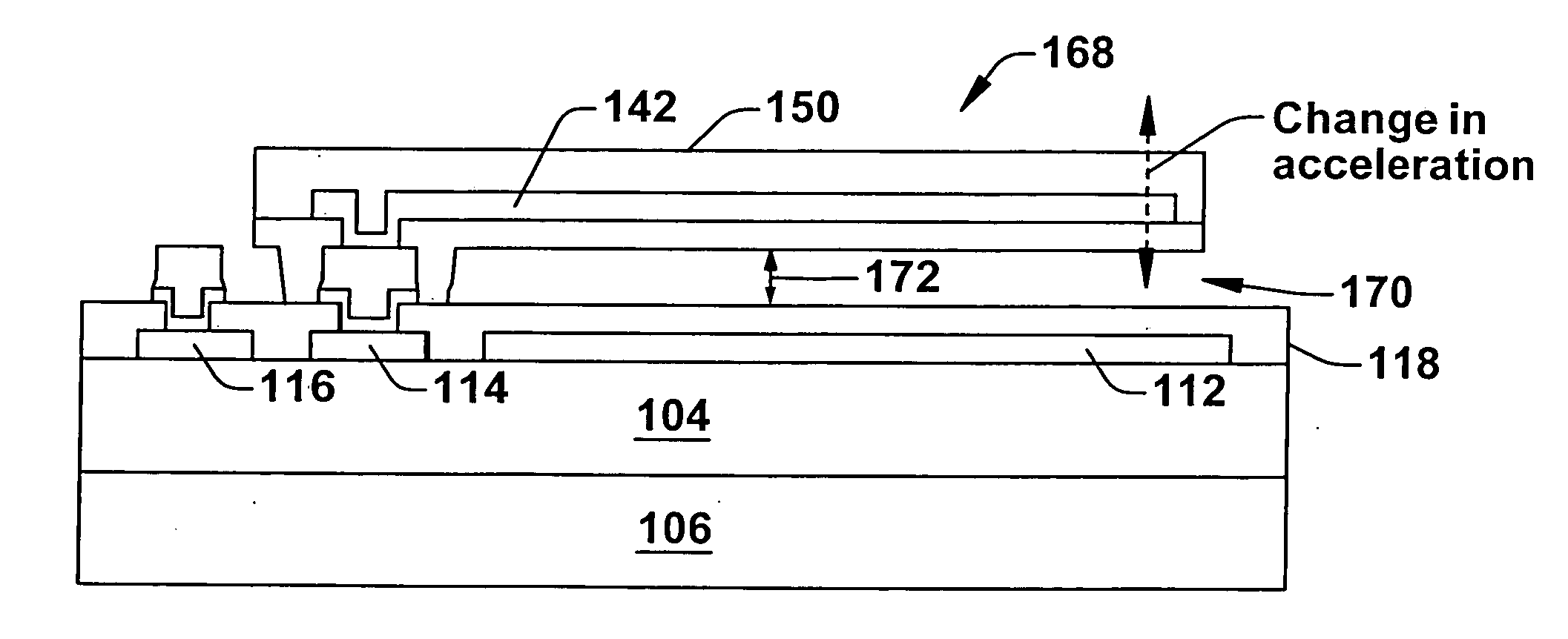

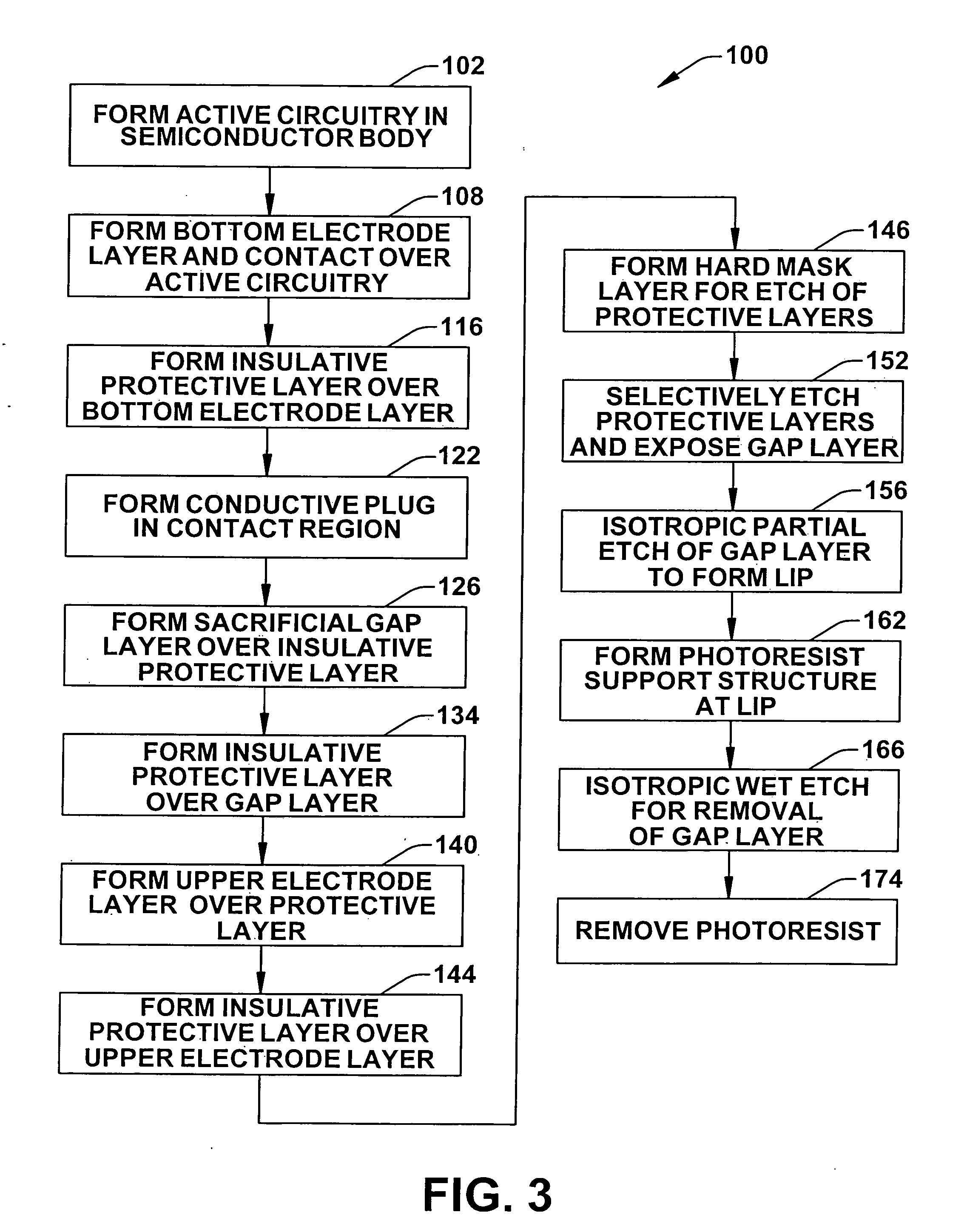

Semiconductor device and fabrication method thereof

ActiveUS20070172975A1Fast depositionEasy to useTransducer detailsSolid-state devicesDevice materialEngineering

A method of forming a MEMS structure over active circuitry in a semiconductor body includes forming active circuitry in a semiconductor body, and forming the MEMS structure over the active circuitry, wherein at least a portion of the MEMS structure spatially overlaps the active circuitry.

Owner:TEXAS INSTR INC

Bipolar plate of fuel cell and method for preparing carbon titanium nanocomposite film on surface thereof

The invention discloses a bipolar plate of a fuel cell and a method for preparing a carbon titanium nanocomposite film on the surface thereof, belongs to the technical field of surface modification of metallic materials and fuel cells, and relates to a bipolar plate of a regenerative fuel cell and a proton exchange membrane fuel cell and a preparation technology of a surface modified film of the bipolar plate. The bipolar plate consists of a metal thin plate substrate and carbon titanium nanocomposite films which are formed on the surfaces at two sides of the substrate, wherein the metal thin plate substrate is a titanium plate and a stainless steel plate; the carbon titanium nanocomposite film is an amorphous and nanocrystalline composite film which is prepared on an amorphous carbon substrate with an arc ion film plating method and on which titanium and titanium carbide nanocrystals are distributed; the thickness of the film is of micron dimension; and the size of the crystal grains of the nanocrystals is of micron dimension. The invention has the effects and advantages that: the bipolar plate is low in manufacturing cost, has prominent composite performance such as corrosion resistance, conductivity, hydrophobicity and the like, can be used for replacing a noble metal bipolar plate and a graphite bipolar plate, and can be used as a cell bipolar plate of the proton exchange membrane fuel cell and an electrolytic cell bipolar plate of the regenerative fuel cell.

Owner:DALIAN UNIV OF TECH

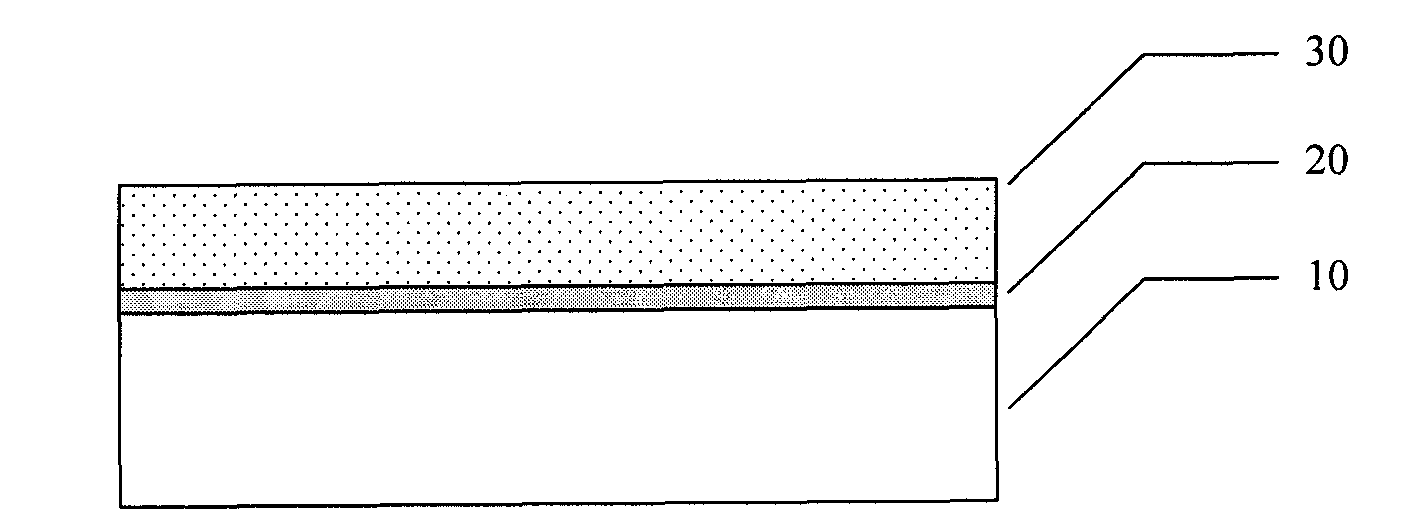

Platinum-group metal coating on surface of refractory metal and preparation method thereof

InactiveCN101787514AFast depositionThickness is easy to controlVacuum evaporation coatingSputtering coatingVacuum furnaceGrowth orientation

The invention provides a platinum-group metal coating 30 for refractory metal 10; a 0.2 to 2mu m transition layer 20 is arranged between the platinum-group metal coating 30 and the refractory metal base material 10; in the transition layer 20, from one side of the base material of the refractory metal 10 to one side of the platinum-group metal coating 30, the platinum-group metal elements are sequentially increased until the transition layer 20 ends, the content of the platinum-group metal elements reaches 100 percent, and the thickness of the platinum-group metal coating 30 is within 100mu m. The invention provides a method of preparing the platinum-group metal coating 30 on the surface of the refractory metal 10. The method is carried out in a vacuum furnace, uses platinum-group metal as a target, the target voltage is between 0 and -1200V, the refractory metal serves as the base material, and the voltage is between 0 and -900V. Argon serves as the working atmosphere, when the vacuum indoor pressure reaches 15 to 55Pa, a DC power supply is connected, and finally the platinum-group metal coating with preferred growth orientation is finally formed through continuous sputtering and anti-sputtering, absorption and desorption.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

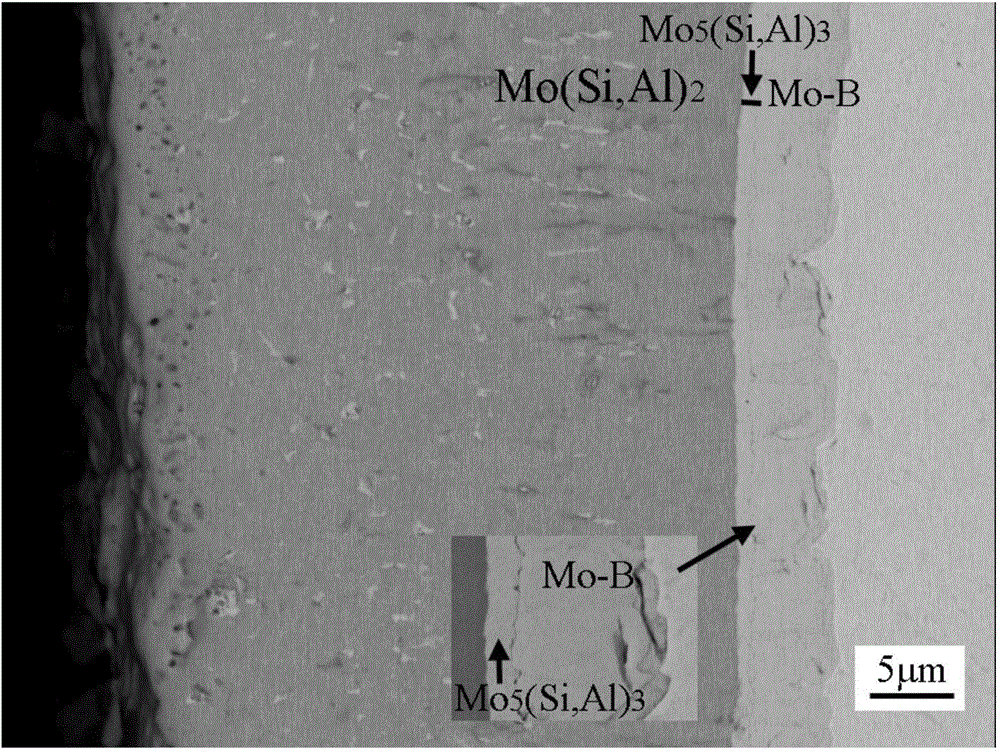

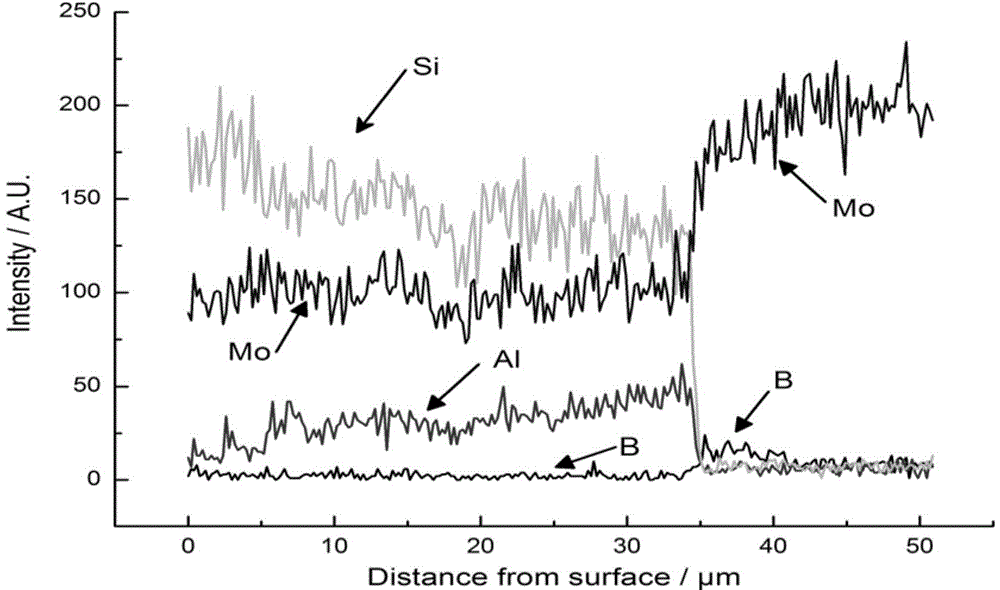

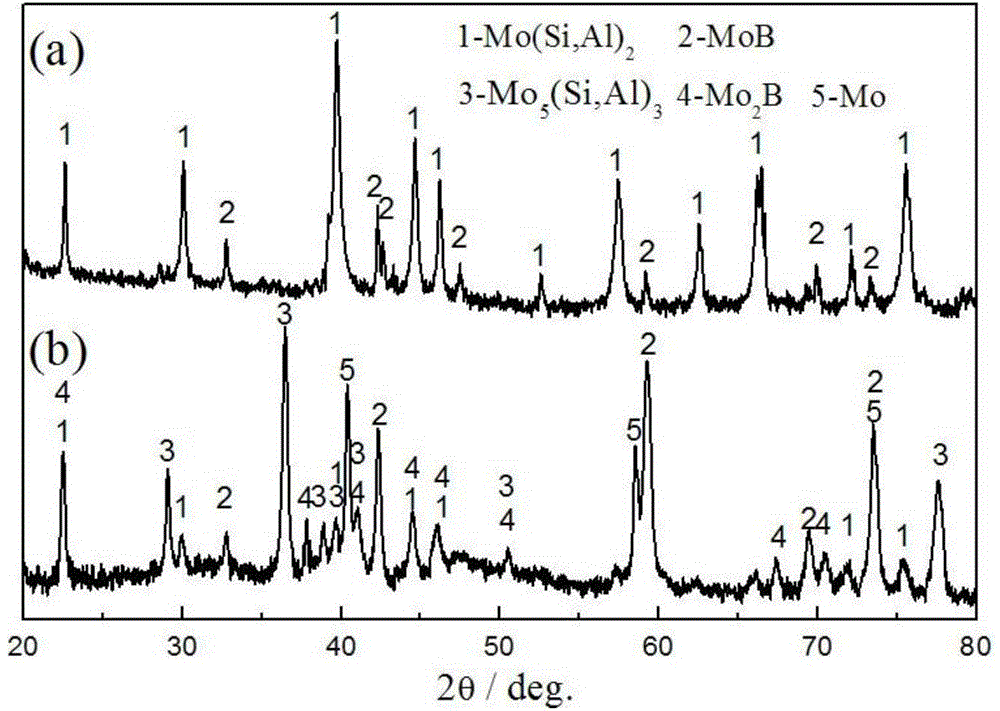

Method for preparing anti-oxidation permeated layer on surface of molybdenum or molybdenum alloy

InactiveCN104831231ASlow degradationFast depositionSolid state diffusion coatingAlloy substrateMegasonic cleaning

The invention discloses a method for preparing an anti-oxidation permeated layer on the surface of molybdenum or a molybdenum alloy. The method comprises the following steps: I, polishing the surface of molybdenum or the molybdenum alloy so as to remove oxidized skin on the surface, performing ultrasonic washing, and drying; II, preparing a coating permeation agent; and III, coating molybdenum or the molybdenum alloy into a crucible with the permeation agent, sealing the crucible and putting the crucible into a high-temperature furnace, performing heat-preservation treatment for 1-20 hours at 1000-1500 DEG C in the presence of argon, and performing furnace cooling till the room temperature, thereby obtaining the anti-oxidation permeated layer on the surface of molybdenum or the molybdenum alloy. As the high-temperature furnace is adopted to perform heat-preservation treatment on molybdenum or the molybdenum alloy coated in the permeation agent, the anti-oxidation permeated layer of a multi-layer structure can be formed on the surface of molybdenum or the molybdenum alloy, and the anti-oxidation permeated layer is high in adaptability to the shape of a molybdenum or molybdenum alloy substrate, uniform in thickness of permeated layer, slow in degradation speed of the permeated layer, and has the advantages of simplicity in operation and rapid permeated layer deposition speed.

Owner:CHANGAN UNIV

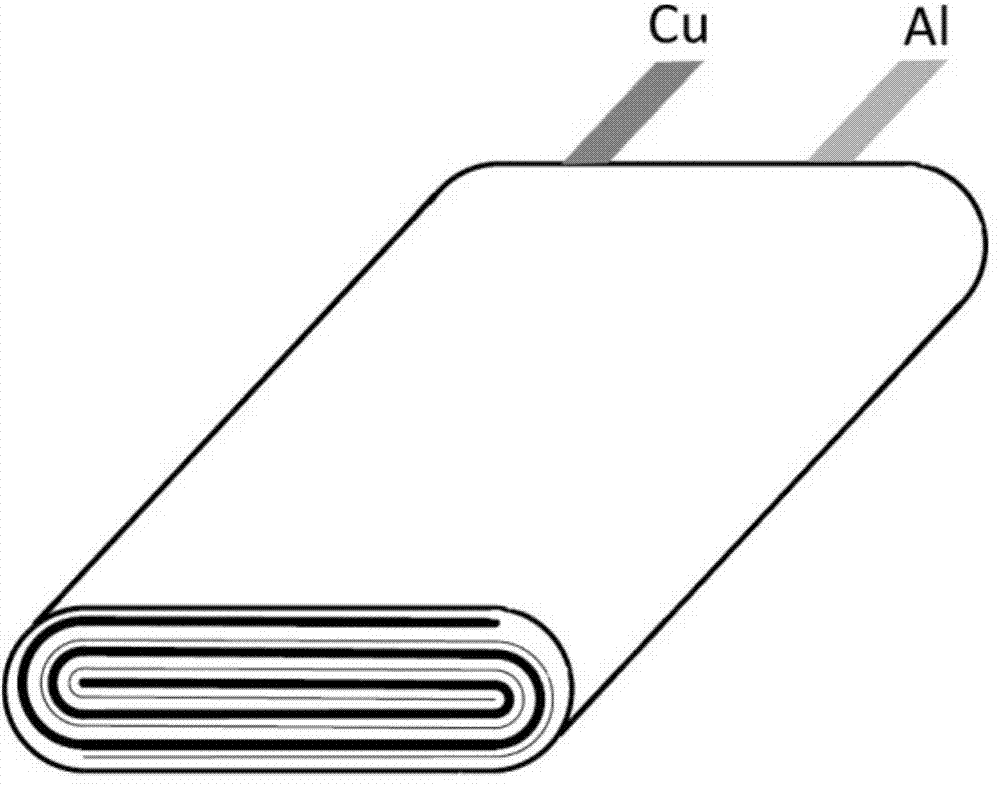

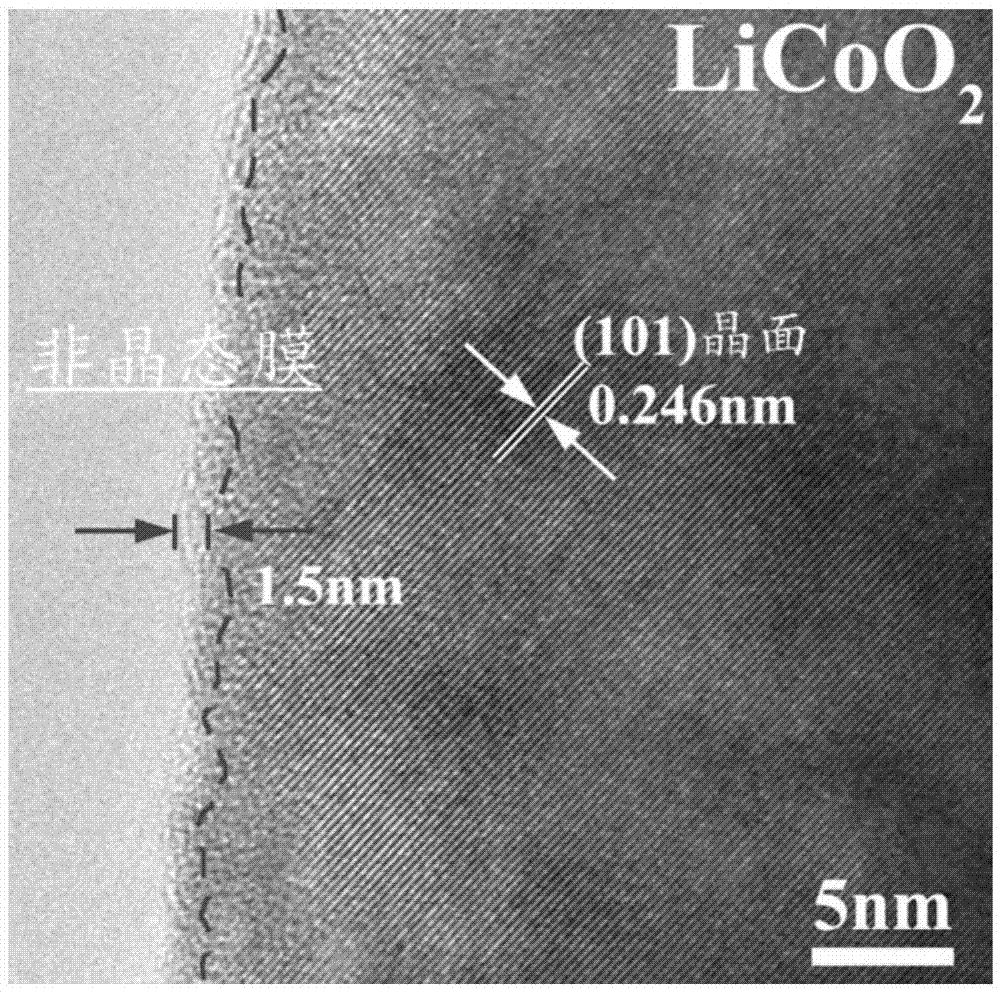

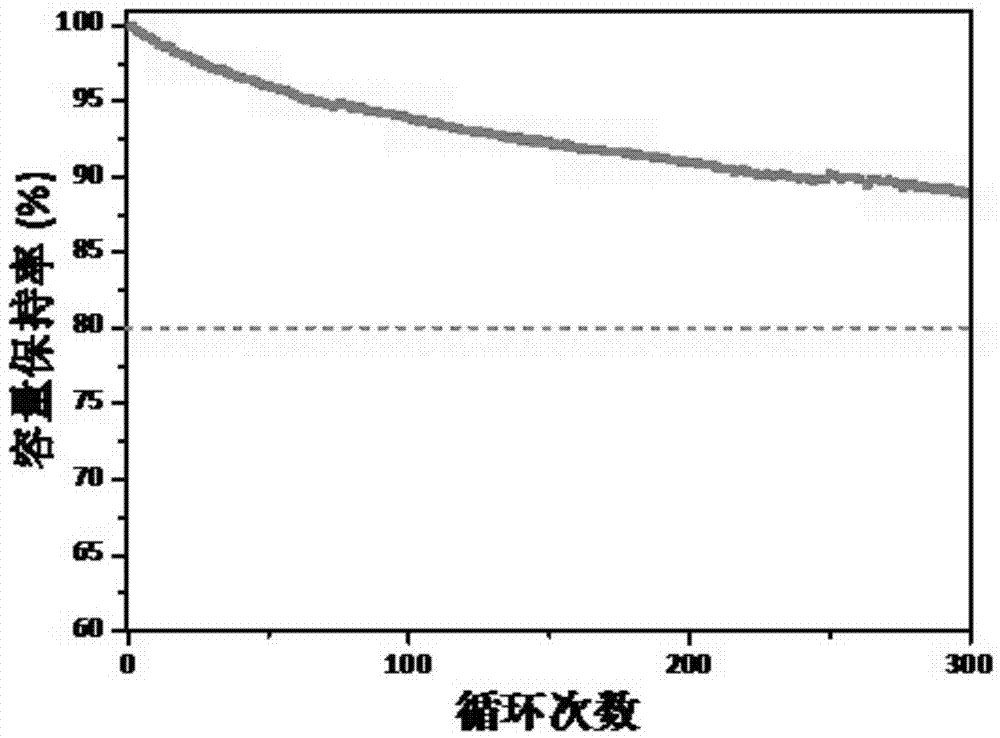

Lithium ion battery and manufacturing method thereof

ActiveCN103928704AGood high temperature storage performanceExcellent high temperature cycle performanceFinal product manufactureSecondary cellsHigh temperature storageElectrical battery

The invention provides a lithium ion battery. The lithium ion battery comprises a sealed packaging piece, and an electrode set and electrolyte which are arranged in the sealed packaging piece, wherein the electrode set comprises an anode piece, a cathode piece and a separation membrane arranged between the anode piece and the cathode piece; the lithium ion battery further comprises nano protection layers; the nano protection layers are arranged on the surface of the anode piece, the surface of the cathode piece and the surface of the separation membrane of the lithium ion battery; the thickness of each nano protection layer is 0.2-10nm. According to the lithium ion battery, a plasma enhanced type atom layer deposition layer is used for putting a wound battery core into a reaction cavity; meanwhile, the nano protection layers are uniformly plated on the surface of the anode piece, the surface of the cathode piece and the surface of the separation membrane, so that the lithium ion battery has excellent high-temperature storage performance, high-temperature cycle performance and safety performance; the lithium ion battery has the advantages of simple preparation method, low reaction temperature, small energy consumption, controllable thickness, wide reaction precursors, rapid deposition speed and capability of being produced in a large batch.

Owner:安普瑞斯(无锡)有限公司

Composite plating Ni - P - SiC in high phosphor, and preparation method

InactiveCN101050525AHigh hardnessEvenly distributedLiquid/solution decomposition chemical coatingPhosphorHardness

This invention relates to a process for preparing wear- and corrosion-resistant high-phosphorus Ni-P-SiC composite plating layer. The addition of SiC particles into the Ni-P-SiC composite plating layer can improve the hardness and wear resistance of the plating layer, thus can improve the wear resistance of mechanical parts and prolong their service life. The plating solution has such advantages as high stability, high bath plating temperature, high deposition speed and easy control. The obtained high-phosphorus Ni-P-SiC composite plating layer has a high bonding strength with the matrix, and has excellent wear and corrosion resistance.

Owner:SHANDONG UNIV

Method for preparing tungsten trioxide (WO3) electrochromic films

InactiveCN103246119AUniform depositionUniform dense depositionNon-linear opticsRadio frequency magnetron sputteringIndium tin oxide

WO3 films have the advantages of being large in visible light transmissivity adjusting range, high in coloration efficiency, short in response time, good in circulation stability, friendly to environment and the like. Electrochromic devices based on WO3 films can be widely used on buildings, automobiles and the like to serve as energy-saving smart windows. The invention relates to a WO3 photoelectric functional material and provides a method for preparing WO3 electrochromic films which are good in film quality, uniform in thickness and short in color-changing response time. According to the method, WO3 serves as a target, and electrochromic WO3 films are prepared on transparent conductive indium tin oxide (ITO) glass substrates through a radio frequency magnetron sputtering method. The method is simple in preparation process, easy to control, good in repeatability, stable in deposition rate and capable of being produced on a large scale conveniently.

Owner:NANJING UNIV OF SCI & TECH

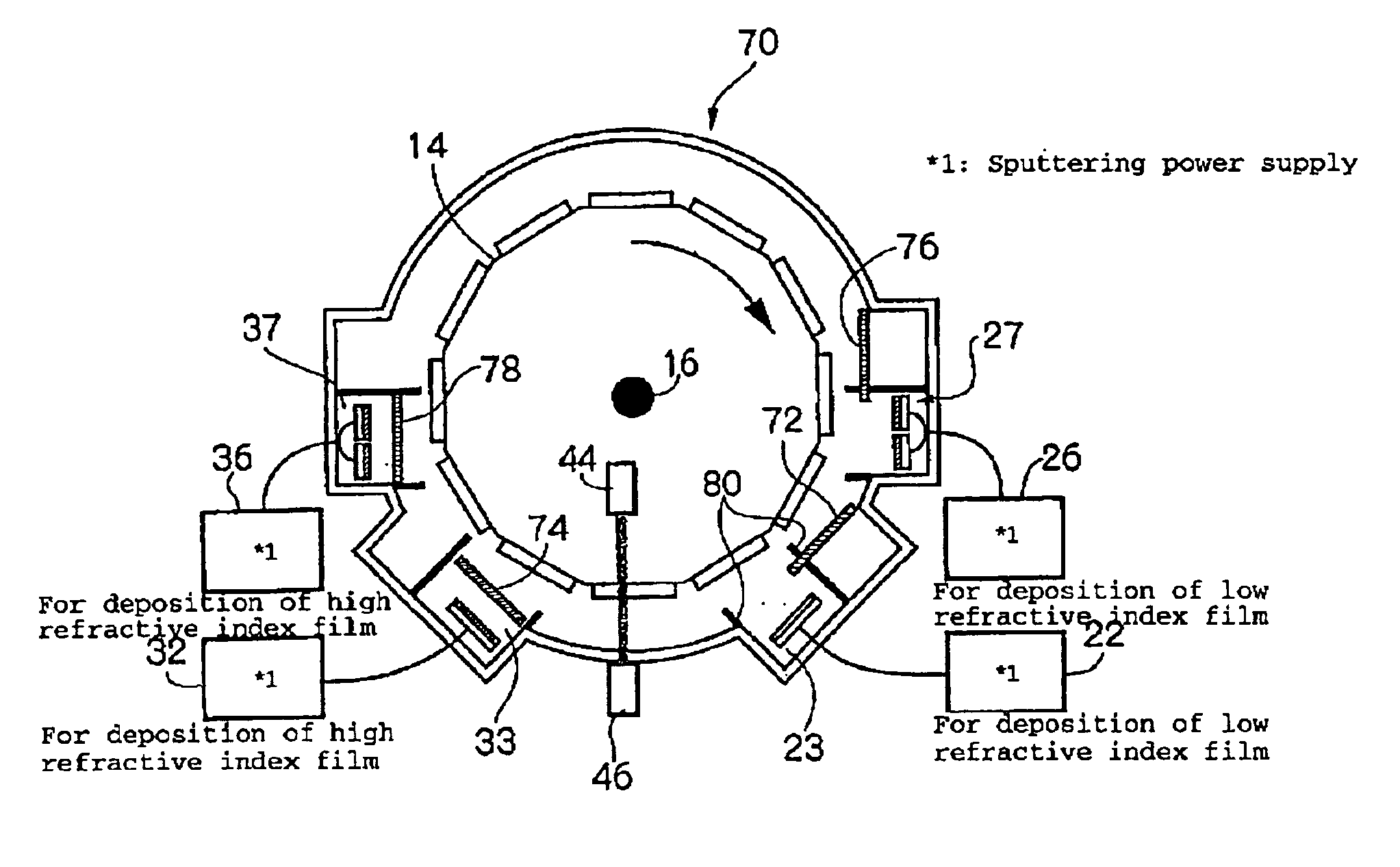

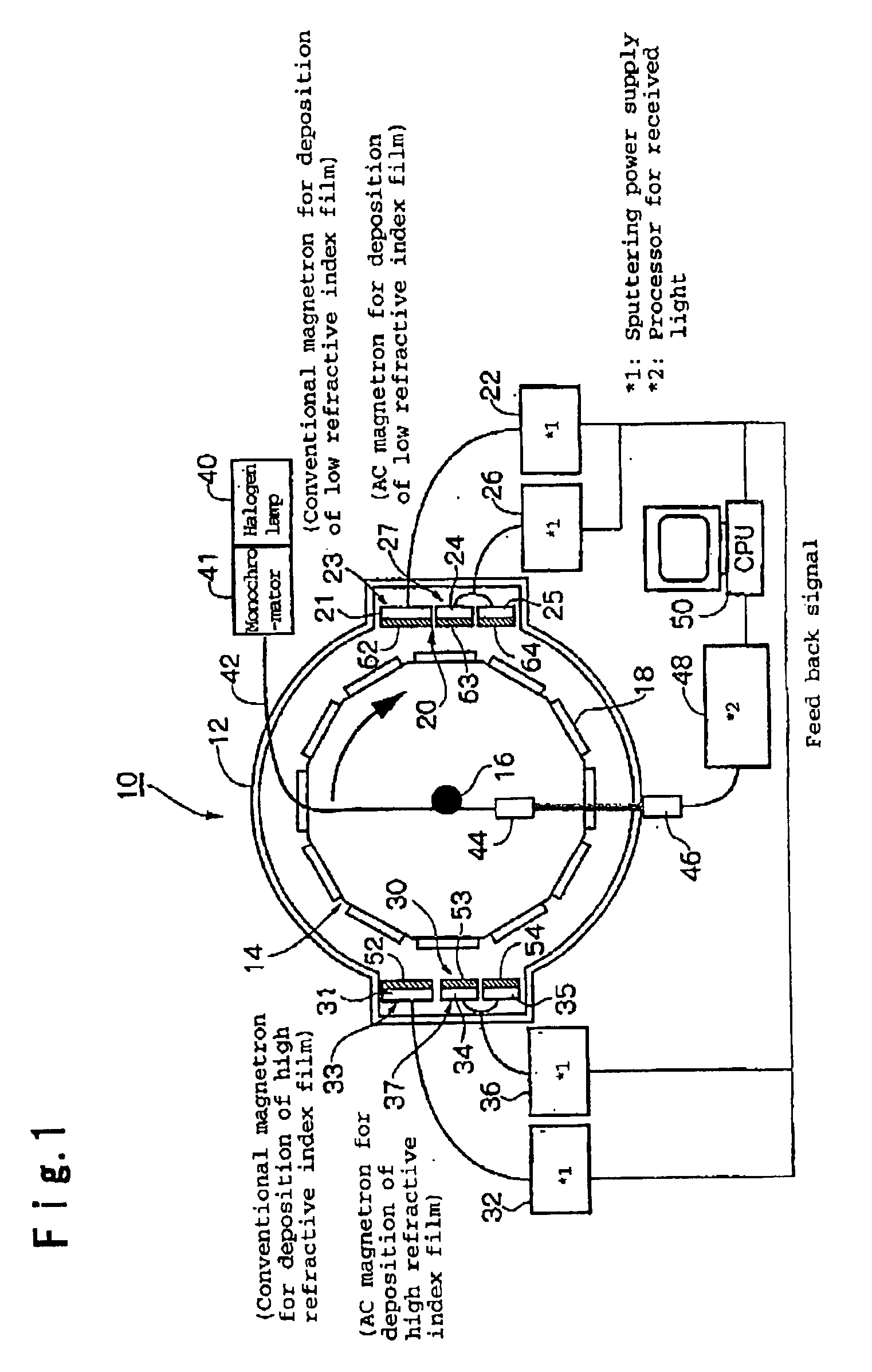

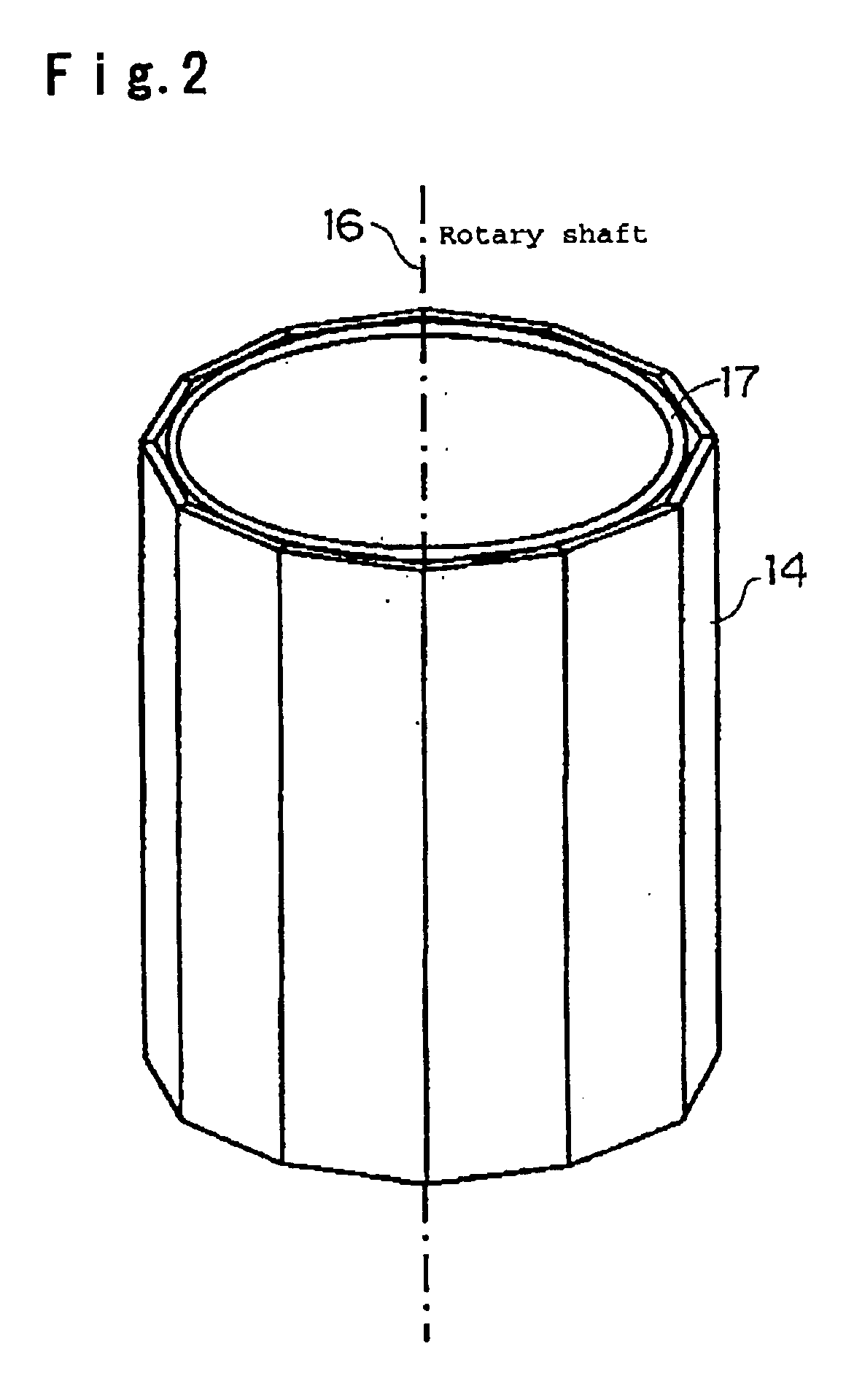

Sputtering apparatus and sputter film deposition method

InactiveUS6863785B2Rapid film deposition filmRapid film film thickness controlCellsElectric discharge tubesProduction rateSputtering

A sputtering apparatus and a sputter film deposition method, which includes a conventional magnetron and an AC magnetron for deposition of a low refractive index film, and a conventional magnetron and an AC magnetron for deposition of a high refractive index film, performs film deposition by each of the AC magnetrons until having achieved 90% of a designed film thickness, and then performs the film deposition only by each of the conventional magnetrons, and which can control the film thickness with high precision and have excellent productivity.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com