Electrodeposition method, electrodeposition solution and method for preparation of rare earth permanent magnetic material by electrodeposition

A technology of electrodeposition and surface deposition, which is applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, circuits, etc., can solve problems that are not suitable for industrial production, and achieve the effects of stable solution, high ion conductivity, and wide electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

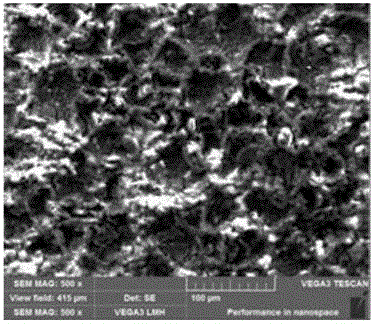

[0063] The cathode material in this example is: D7x3㎜R 2 FeMB (Neodymium Iron Boron) magnetic material, 10x10x1㎜ platinum sheet for anode. Electrodeposition liquid comprises the main salt that contains heavy rare earth element, the induction salt that induces heavy rare earth element deposition and the organic ionic liquid as solvent; Described main salt is the tetrafluoroborate of heavy rare earth element; In electrodeposition liquid, Tb( BF 4 ) 3 is 1mol / L, Fe(BF 4 ) 2 is 1.2mol / L, Co(BF 4 ) 2 0.6mol / L, the ionic liquid is 1-butyl-3-methylimidazolium tetrafluoroborate [EMIM]BF 4 . The electroplating conditions are: temperature 50°C, 1.9V constant voltage, electroplating time 300min, to obtain Fe-Co-Tb coating, such as figure 1 Shown; EDS analysis of its surface, the results are shown in Table 1.1. The heat treatment process is 900°C, cooling after holding for 150 minutes, then tempering at 480°C, cooling after holding for 150 minutes, the same heat treatment process...

Embodiment 2

[0070] The cathode material in this example is: D7x3㎜R 2 FeMB (Neodymium Iron Boron) magnetic material, 10x10x1㎜ platinum sheet for anode. Electrodeposition liquid comprises the main salt that contains heavy rare earth element, the induction salt that induces heavy rare earth element deposition and the organic ionic liquid as solvent; Described main salt is the tetrafluoroborate of heavy rare earth element; In electrodeposition liquid, Tb( BF 4 ) 3 is 0.5mol / L, Fe(BF 4 ) 2 is 1mol / L, Co(BF 4 ) 2 The 0.5mol / L ionic liquid is N-methylethylpyrrolidine tetrafluoroborate. The electroplating conditions are as follows: a temperature of 0°C, a constant voltage of 0.5V, and an electroplating time of 500 minutes to obtain a Fe-Co-Tb coating. The heat treatment process is 820 °C, cooling after 24 hours of heat preservation, and then tempering at 540 °C, cooling after heat preservation for 1 hour, and electrodeposited to R by the method of this example. 2 On the surface of FeMB, a...

Embodiment 3

[0074]The cathode material in this example is: D7x3㎜R 2 FeMB (Neodymium Iron Boron) magnetic material, 10x10x1㎜ platinum sheet for anode. Electrodeposition liquid comprises the main salt that contains heavy rare earth element, the induction salt that induces heavy rare earth element deposition and the organic ionic liquid as solvent; Described main salt is the tetrafluoroborate of heavy rare earth element; In electrodeposition liquid, Tb( BF 4 ) 3 is 0.2mol / L, Fe(BF 4 ) 2 0.5mol / L, Co(BF 4 ) 2 is 0.1mol / L, and the ionic liquid is 1-ethyl-3 methylimidazole bis-trifluoromethanesulfonimide salt. The electroplating conditions are as follows: a temperature of 200° C., a constant voltage of 2 V, and an electroplating time of 350 minutes to obtain a Fe-Co-Tb coating. The heat treatment process is 920 ° C, cooling after holding for 1 hour, then tempering at 480 ° C, cooling after holding for 10 hours, and electrodepositing to R by the method of this example. 2 On the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com