Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145results about How to ""Increased yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

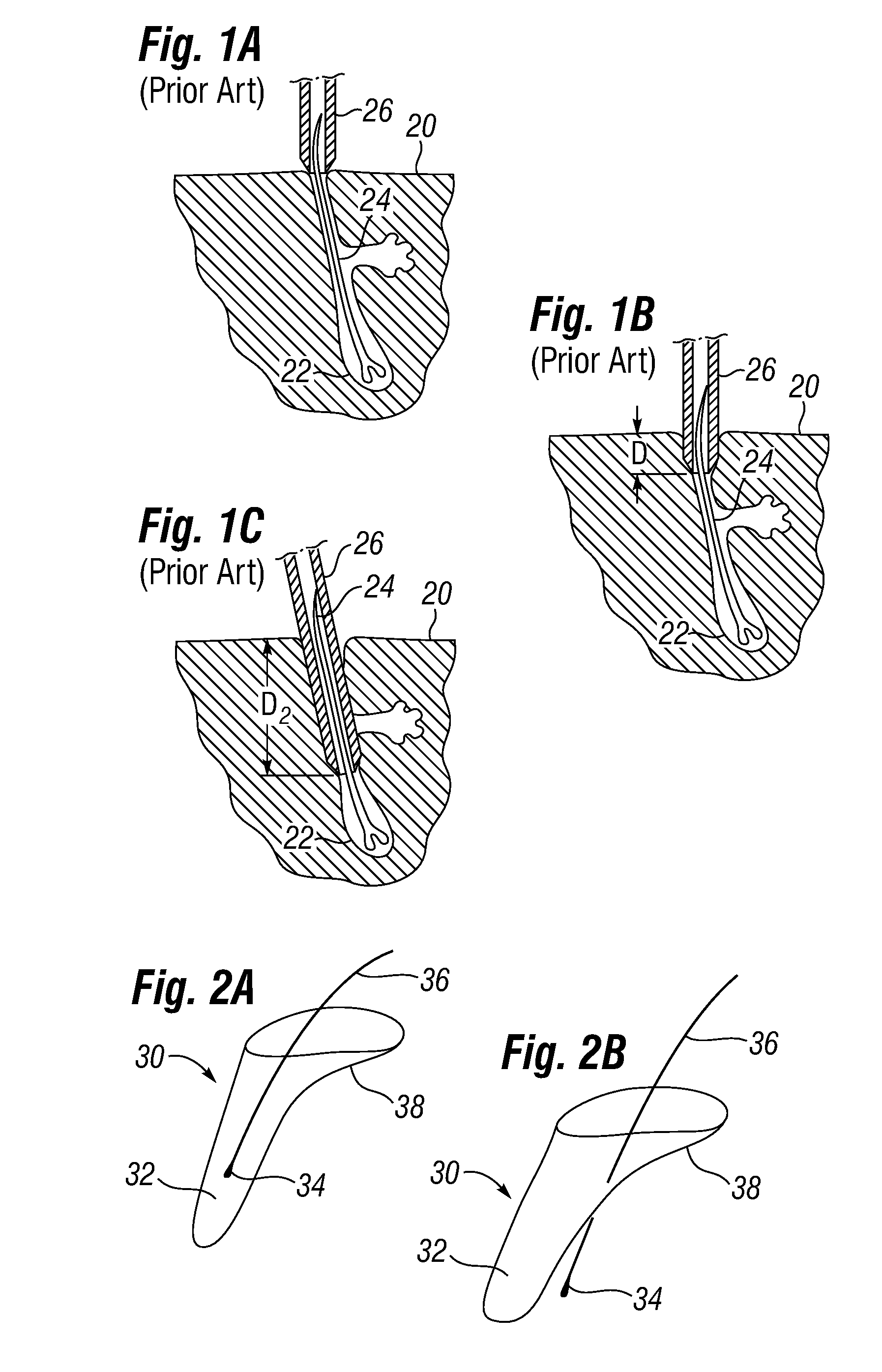

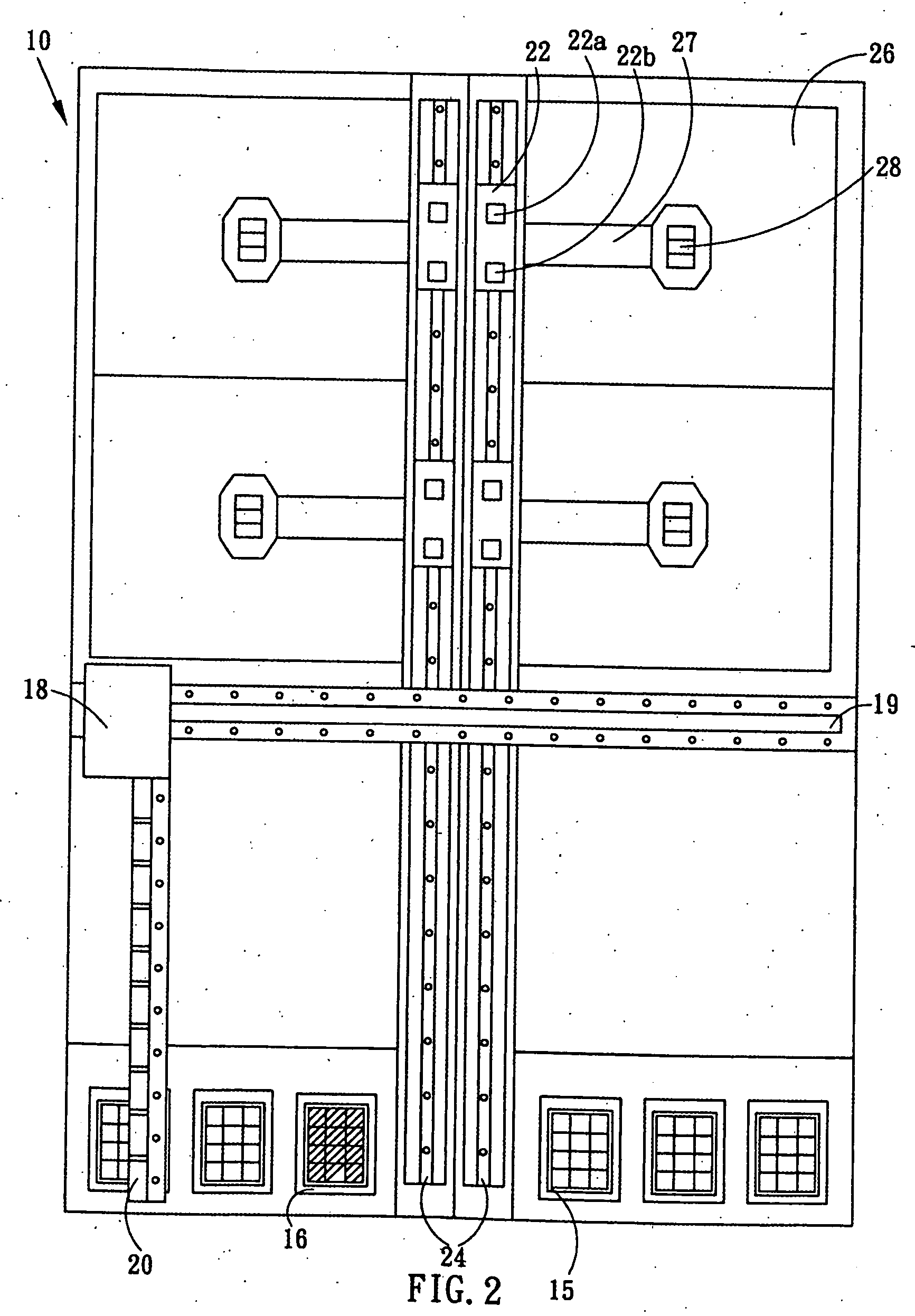

Biological unit removal tools with retention mechanism

ActiveUS20080234602A1Increased yieldIncrease productionHair-singeingSkin implantsBiological unitBiomedical engineering

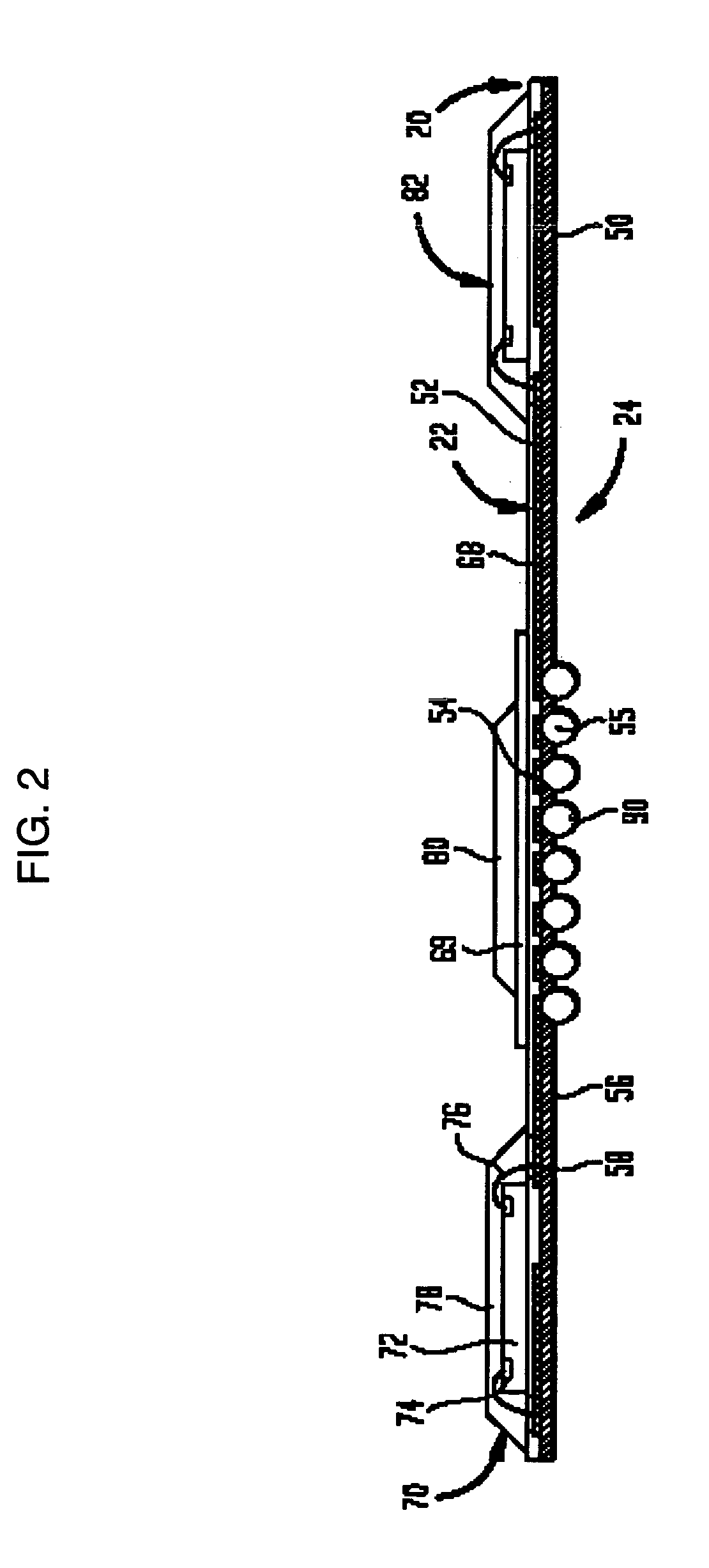

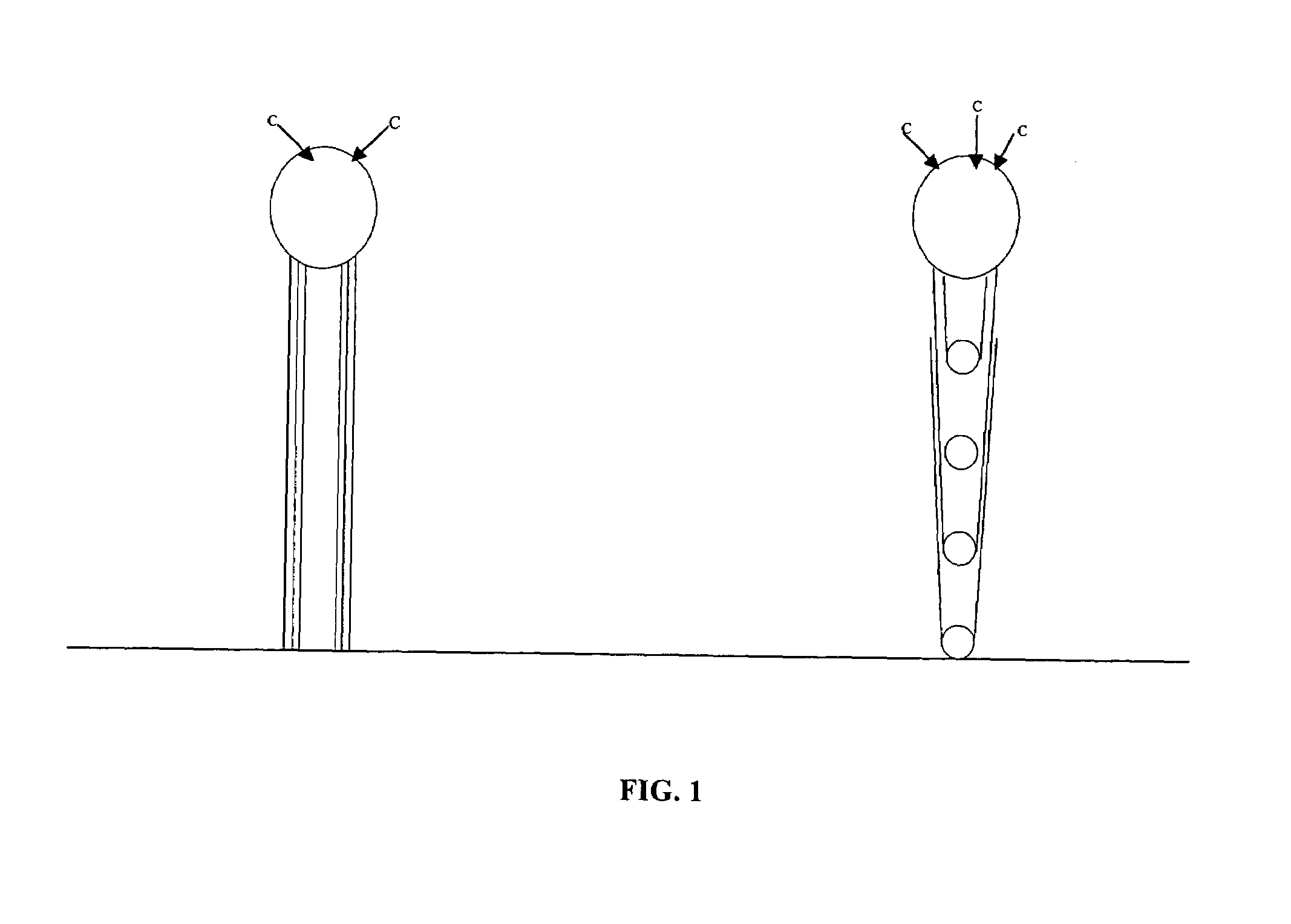

Tools and methods are provided for removing biological units from a body surface utilizing a removal tool. The tools may incorporate retention members and mechanisms configured to impede movement of the biological unit in the direction of a distal end of the tool and to improve retention of the biological unit in the tool. Some of the retention members are stationary and some are movable within the lumen of the biological unit removal tools. The distal tips of the tools are desirably configured to reduce the chance of transection of a biological unit, such as by including both cutting segments and blunt relief segments. A number of dual concentric tube embodiments permit a division of removal functions. Distal fluid or gas delivery may supplement a vacuum in a luminal space to help extract biological units from surrounding tissue.

Owner:VENUS CONCEPT INC

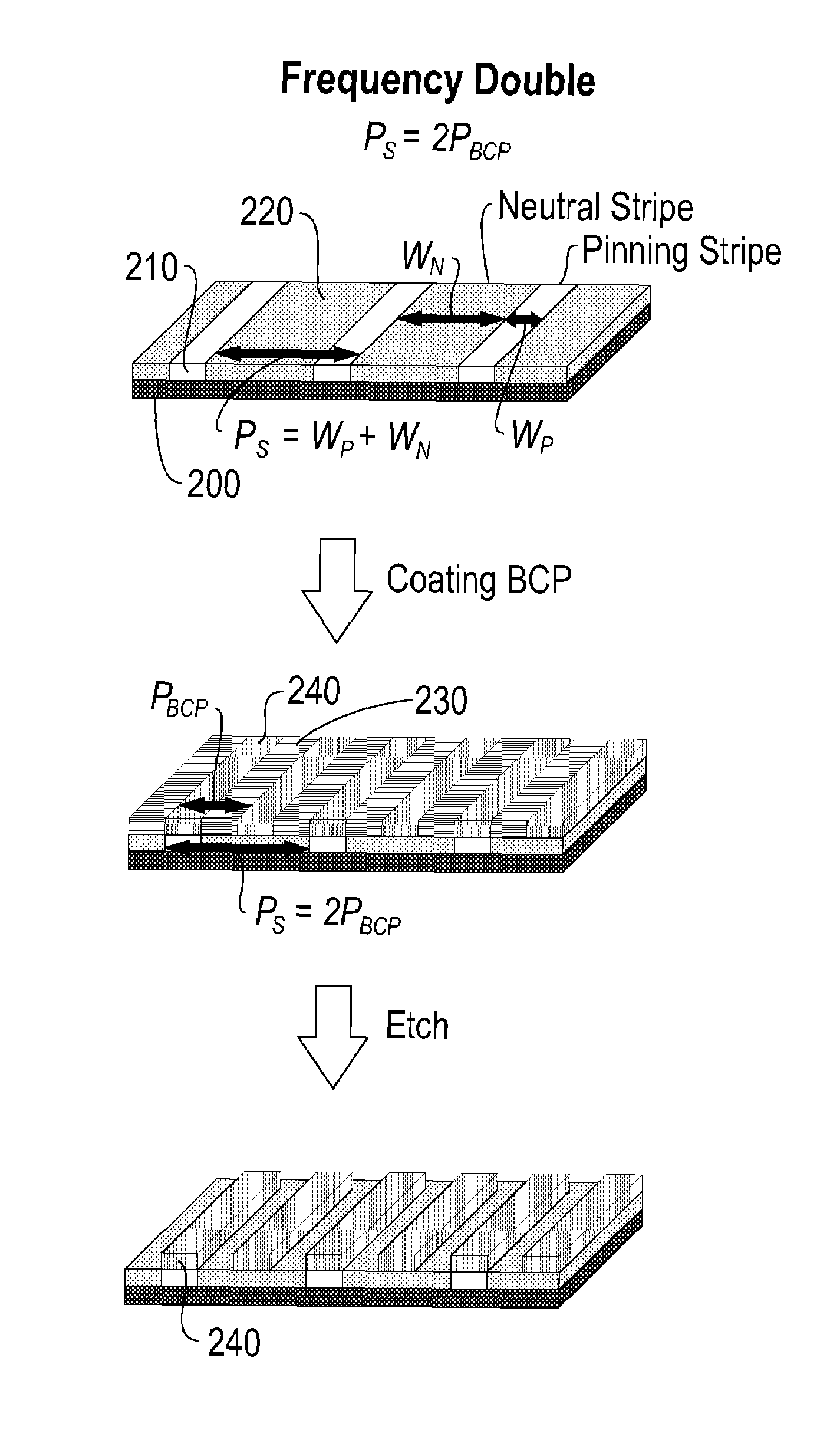

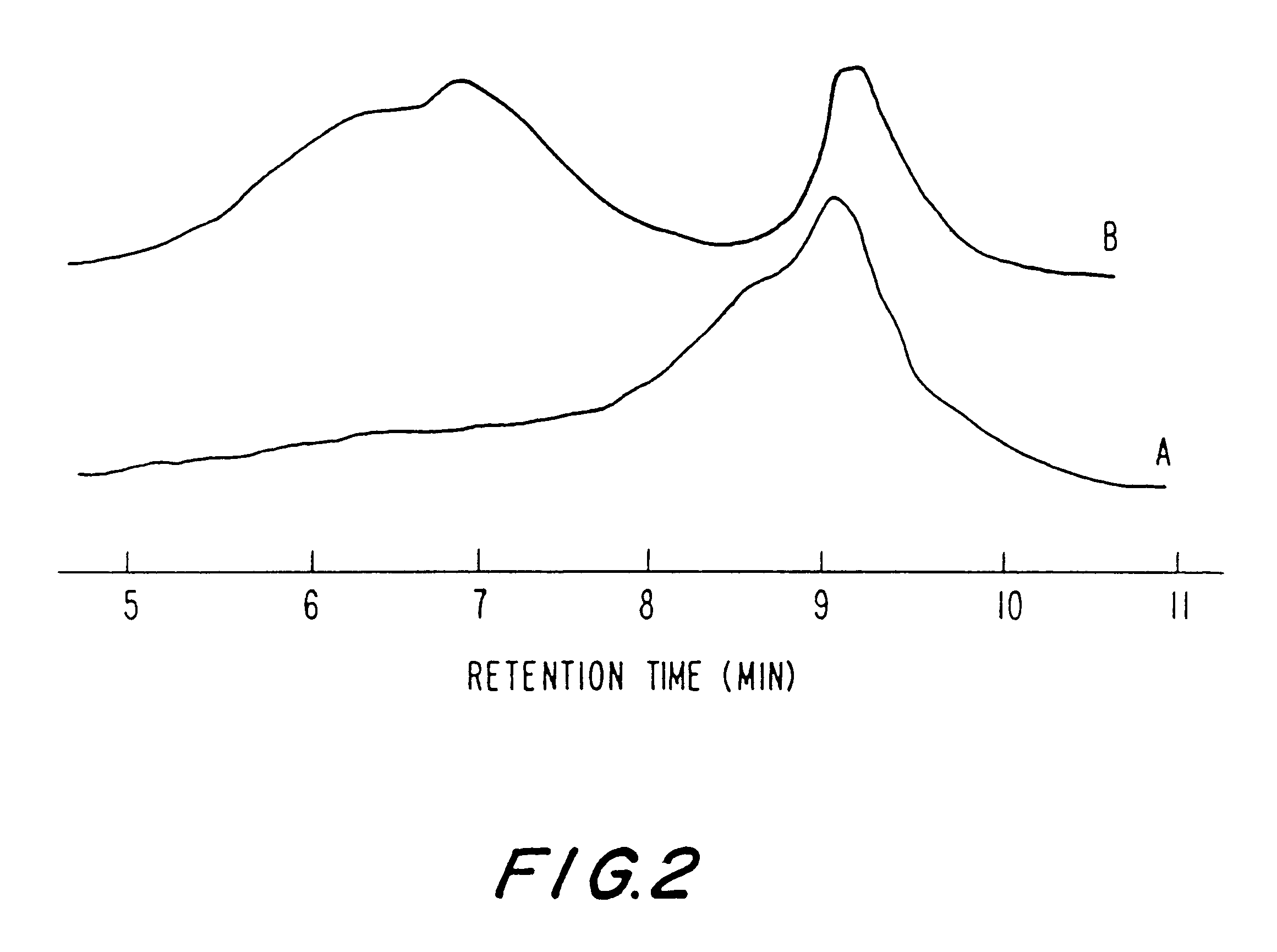

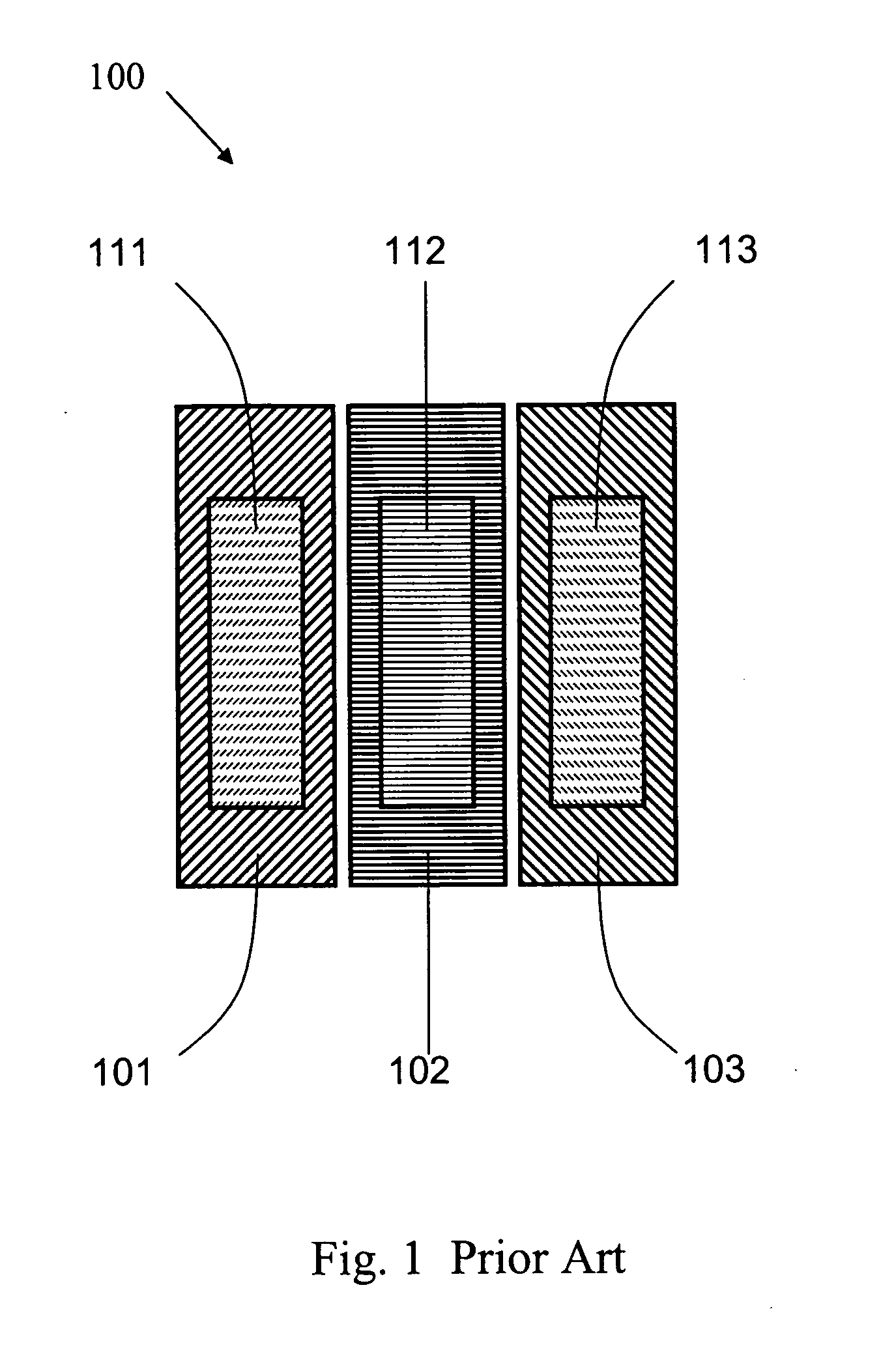

Method of forming polymer features by directed self-assembly of block copolymers

ActiveUS7521094B1Increased yieldDecrease cycle timeNanoinformaticsPhotomechanical apparatusDirected self assemblyMolecular physics

Disclosed herein is a method of forming polymer structures comprising applying a solution of a diblock copolymer assembly comprising at least one diblock copolymer that forms lamellae, to a neutral surface of a substrate having a chemical pattern thereon, the chemical pattern comprising alternating pinning and neutral regions that are chemically distinct and which have a chemical pattern spatial frequency given by the number of paired sets of pinning and neutral regions along a given direction on the substrate; and forming domains comprising blocks of the diblock copolymer. The domains form by lateral segregation of the blocks. At least one domain has an affinity for the pinning regions and forms on the pinning region, the domains so formed on the pinning region are aligned with the underlying chemical pattern, and domains that do not form on the pinning region form adjacent to and are aligned with the domains formed on the pinning regions. In this way, a structure comprising repeating sets of domains is formed on the chemical pattern with a spatial frequency given by the number of repeating sets of domains in the given direction, that is at least twice that of the chemical pattern spatial frequency. Methods of forming the chemical patterns, and pattern transfer methods using patterned domains, are also disclosed.

Owner:GLOBALFOUNDRIES US INC

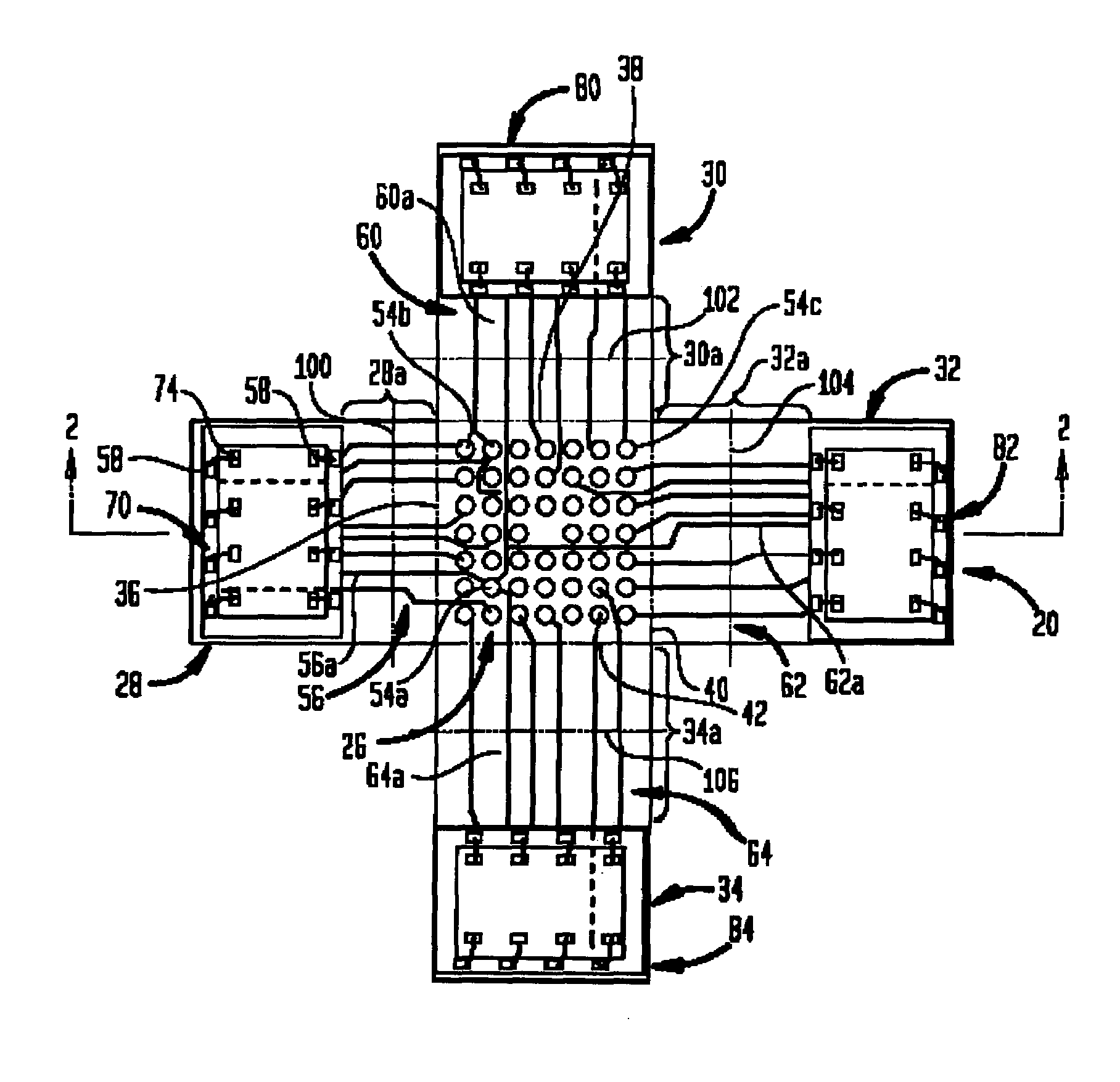

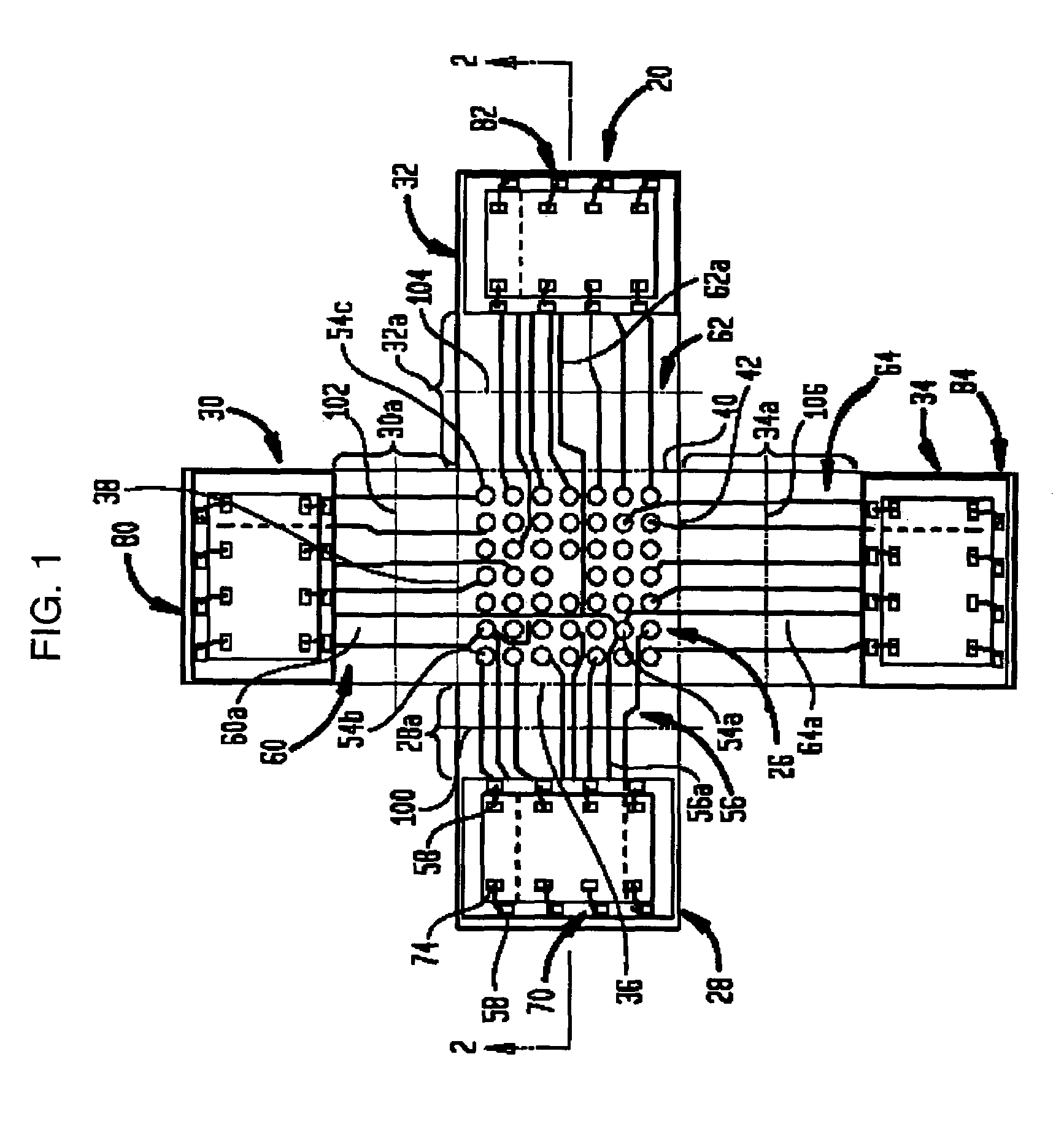

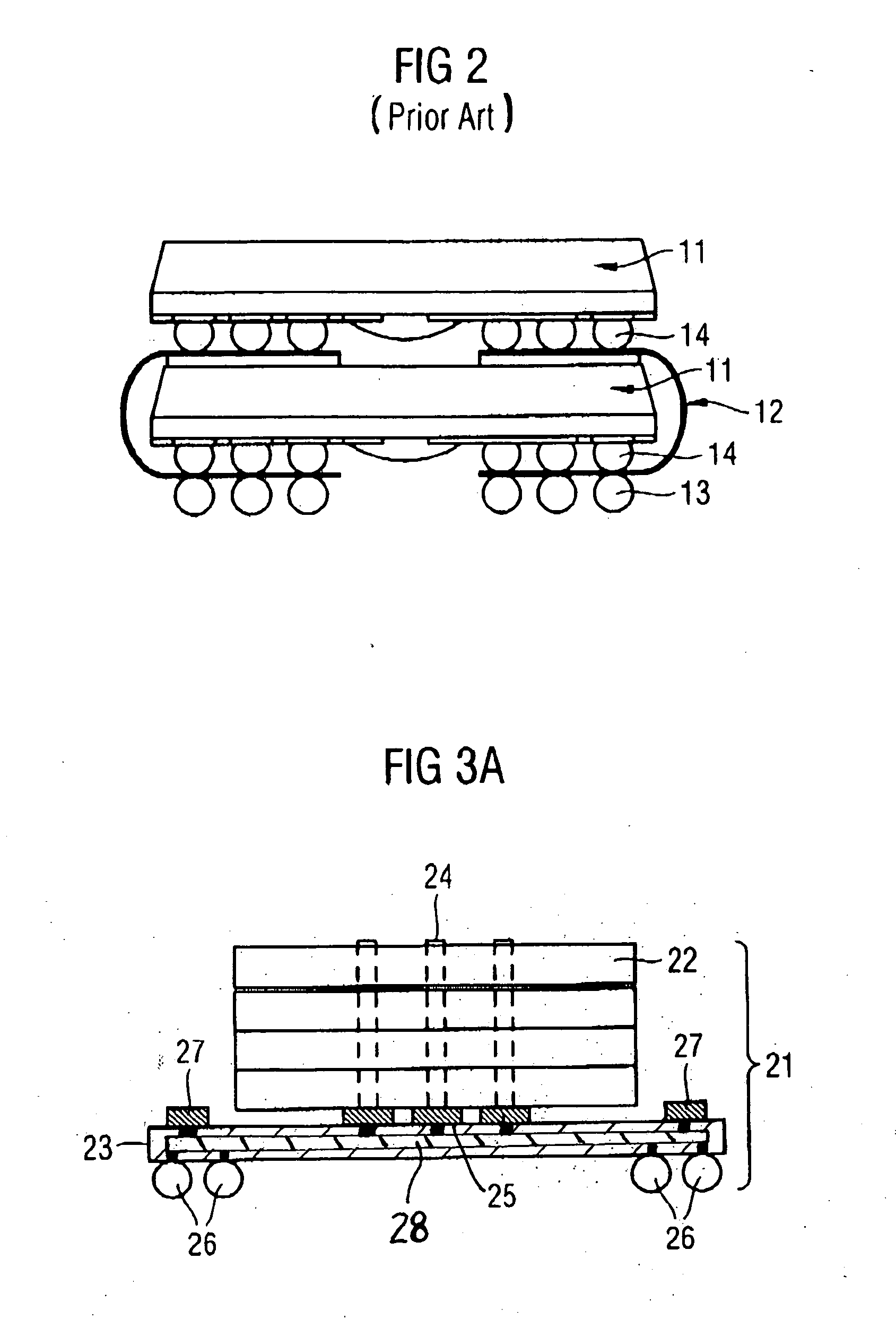

Assemblies having stacked semiconductor chips and methods of making same

InactiveUS7071547B2Relieve mechanical stressIncreased yieldSemiconductor/solid-state device detailsSolid-state devicesMicroelectronicsEngineering

A stacked microelectronic assembly comprises a continuous sheet including a core panel and a plurality of side panels, each having a folded portion that connects the side panel to an edge of the core panel. At least two of the panels are at least partially horizontally aligned with one another in a stack. During manufacture of a stacked microelectronic assembly, failed microelectronic elements are identified and associated side panels thereof are simply cut-off. This results in the production of a usable stacked microelectronic assembly albeit of reduced capacity, or reduced functionality.

Owner:TESSERA INC

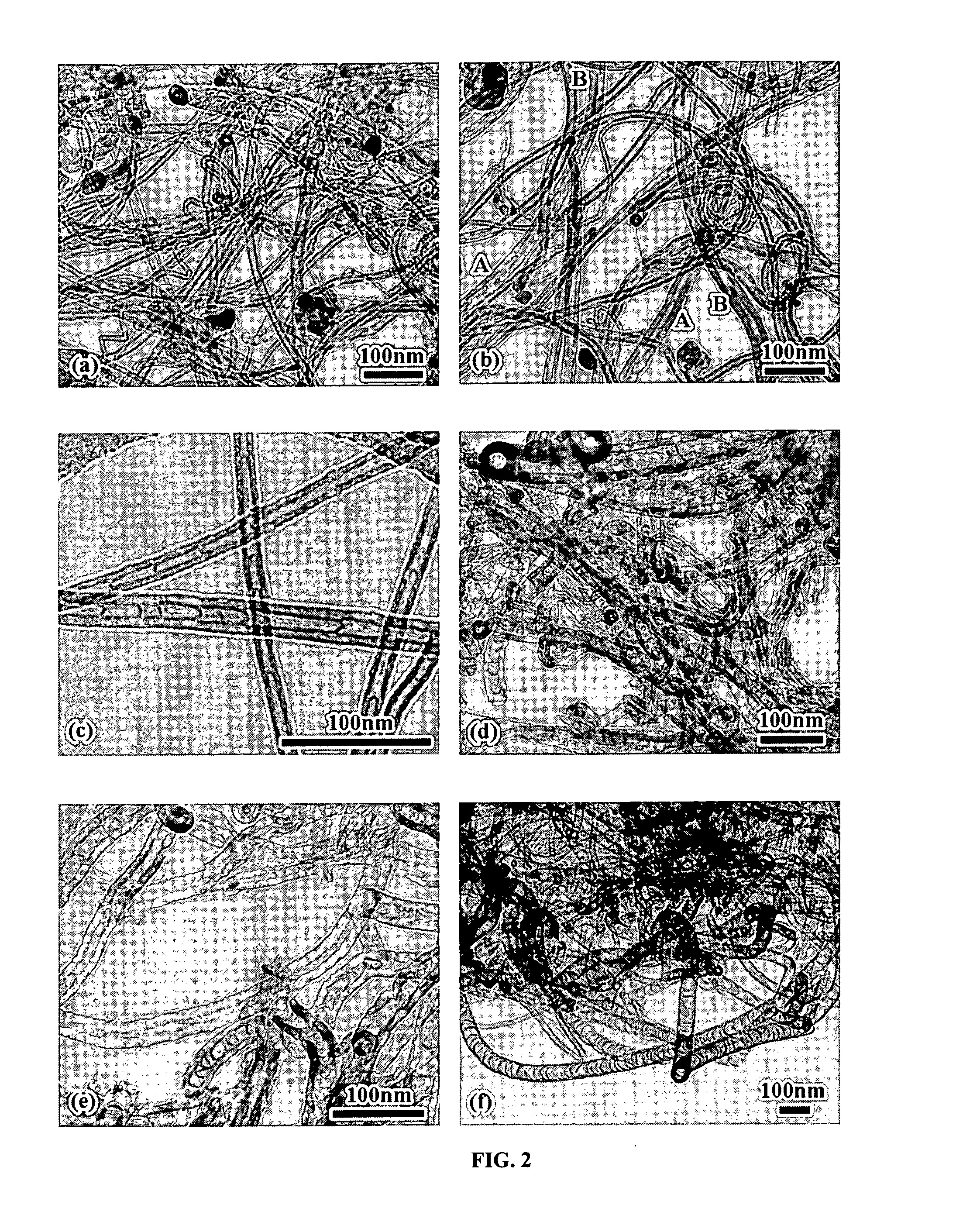

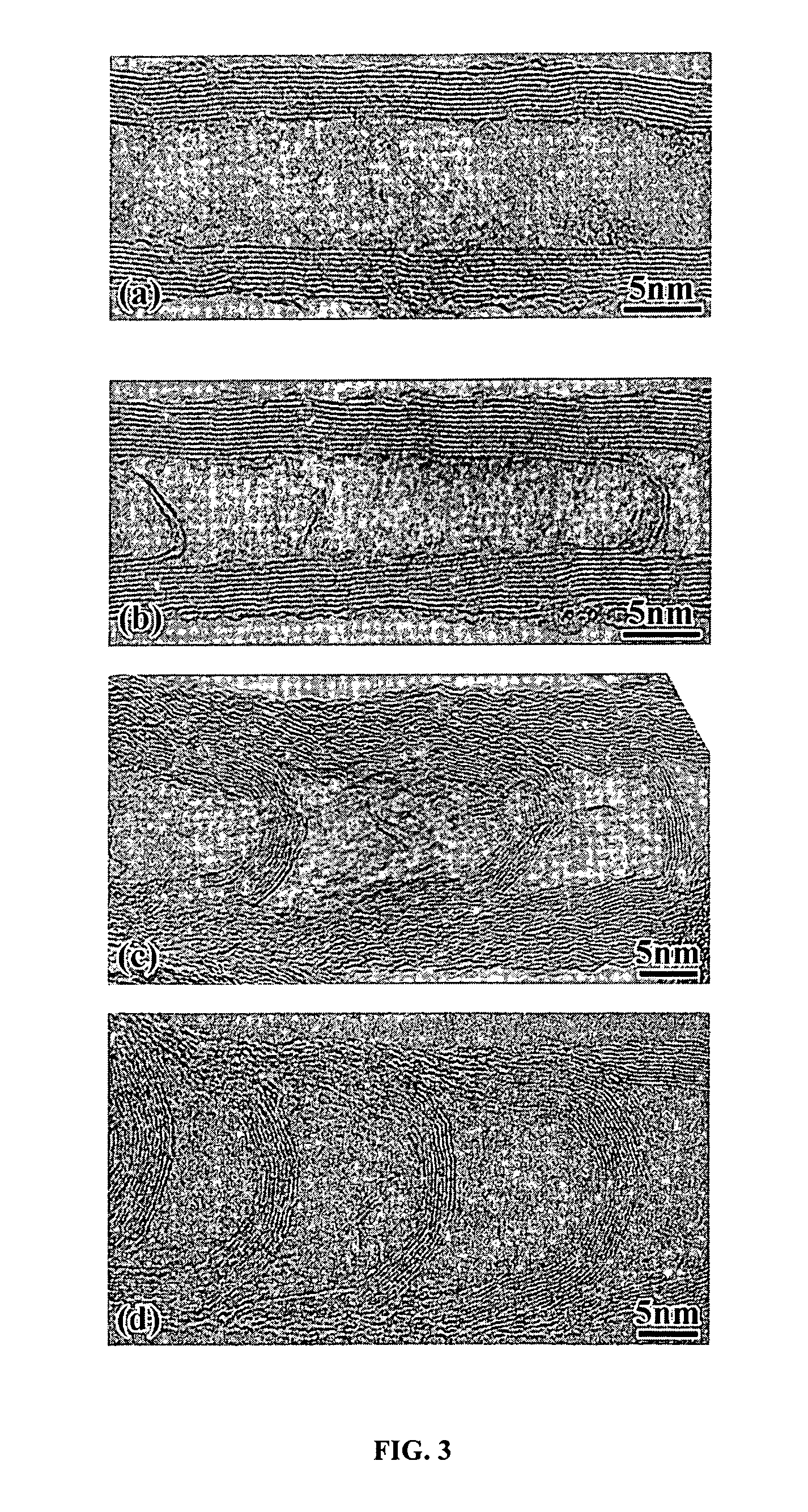

Varied morphology carbon nanotubes and method for their manufacture

InactiveUS7157068B2Increased yieldPromote catalyst activityMaterial nanotechnologyCarbon compoundsCarbon nanotubeMaterials science

Owner:TRUSTEES OF BOSTON COLLEGE THE

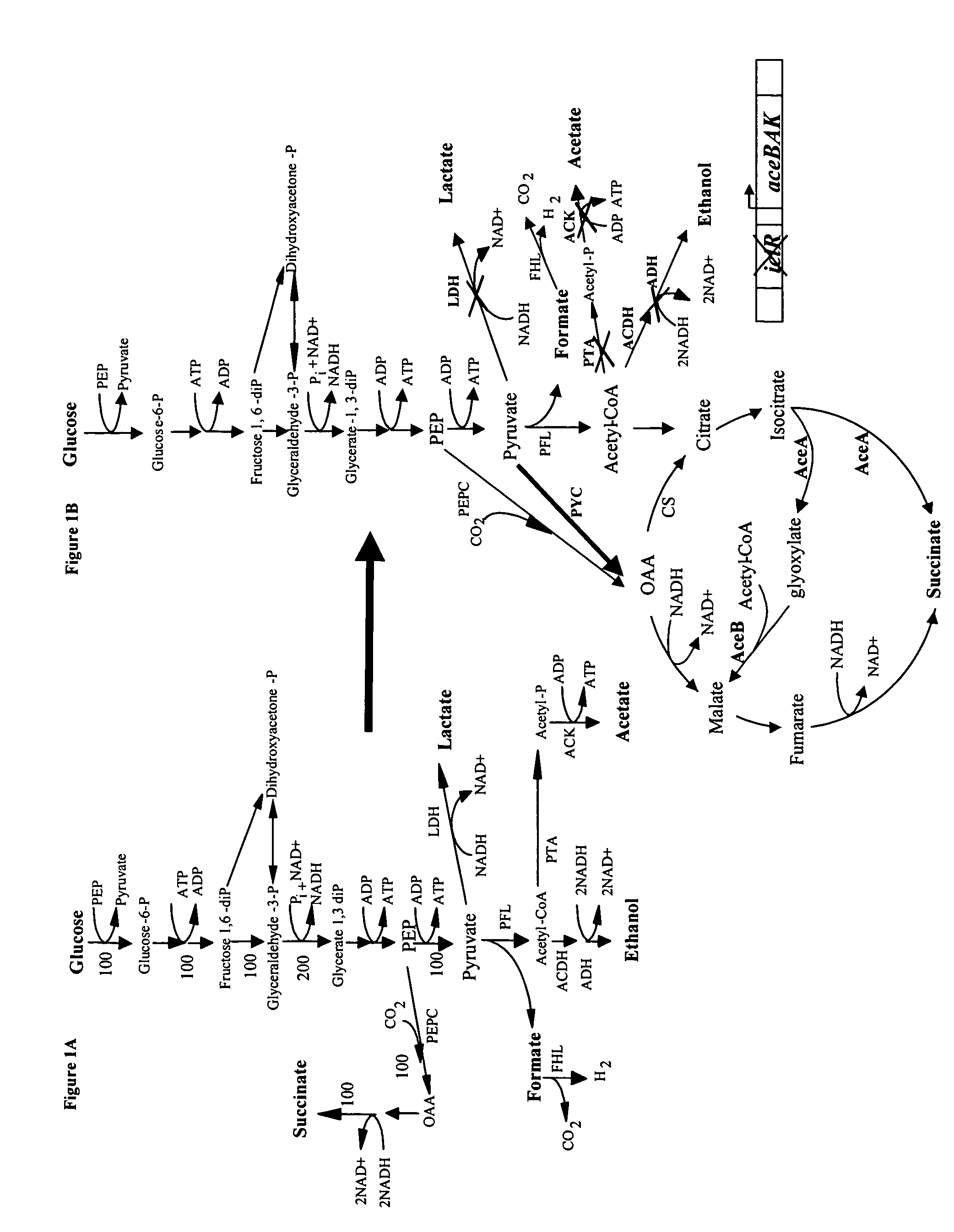

Mutant E. coli strain with increased succinic acid production

ActiveUS20060046288A1Improve productionIncreased yieldBacteriaFermentationMutant strainAnaerobic digestion

The invention relates to a mutant strain of bacteria, which either lacks or contains mutant genes for several key metabolic enzymes, and which produces high amounts of succinic acid under anaerobic conditions.

Owner:RICE UNIV

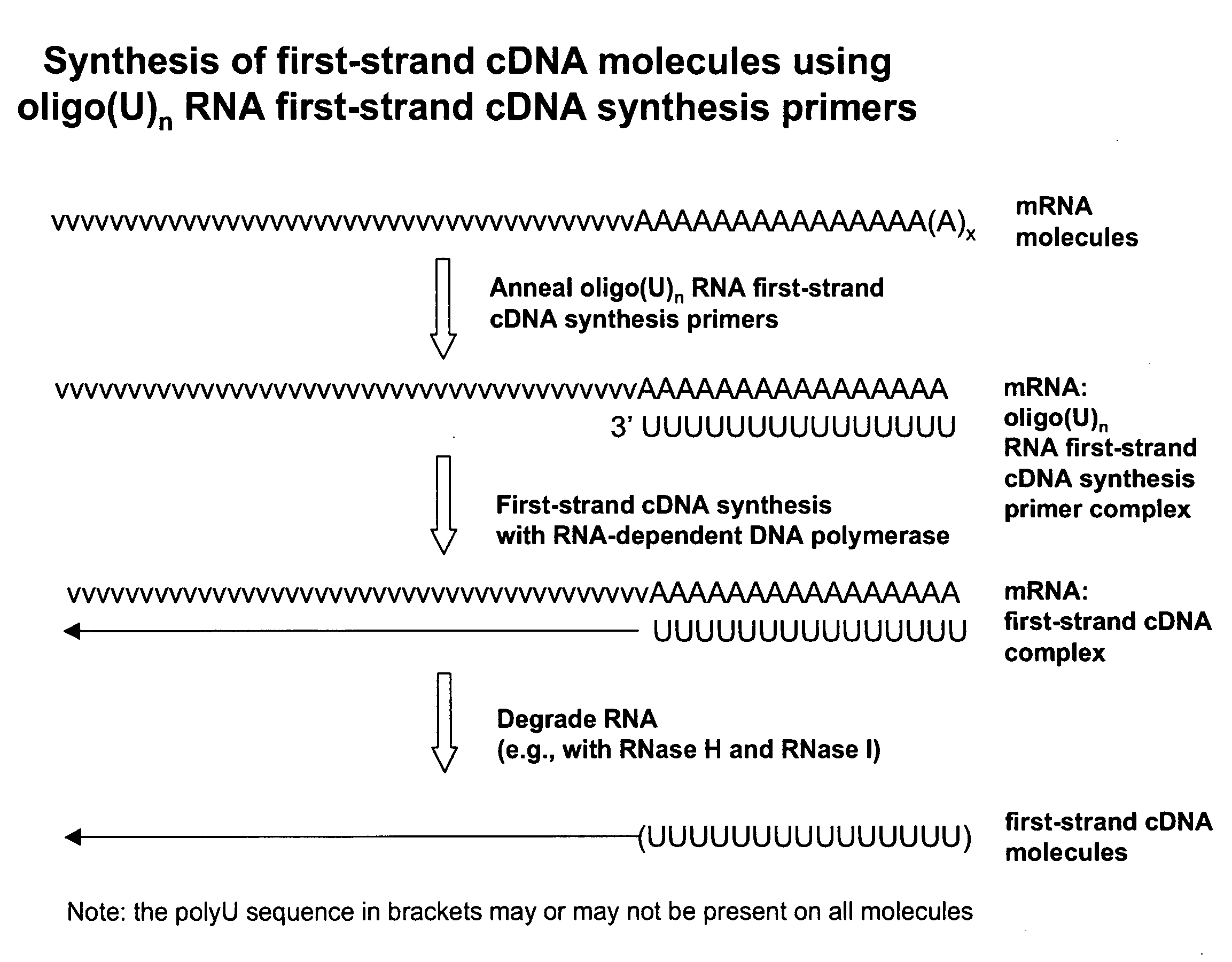

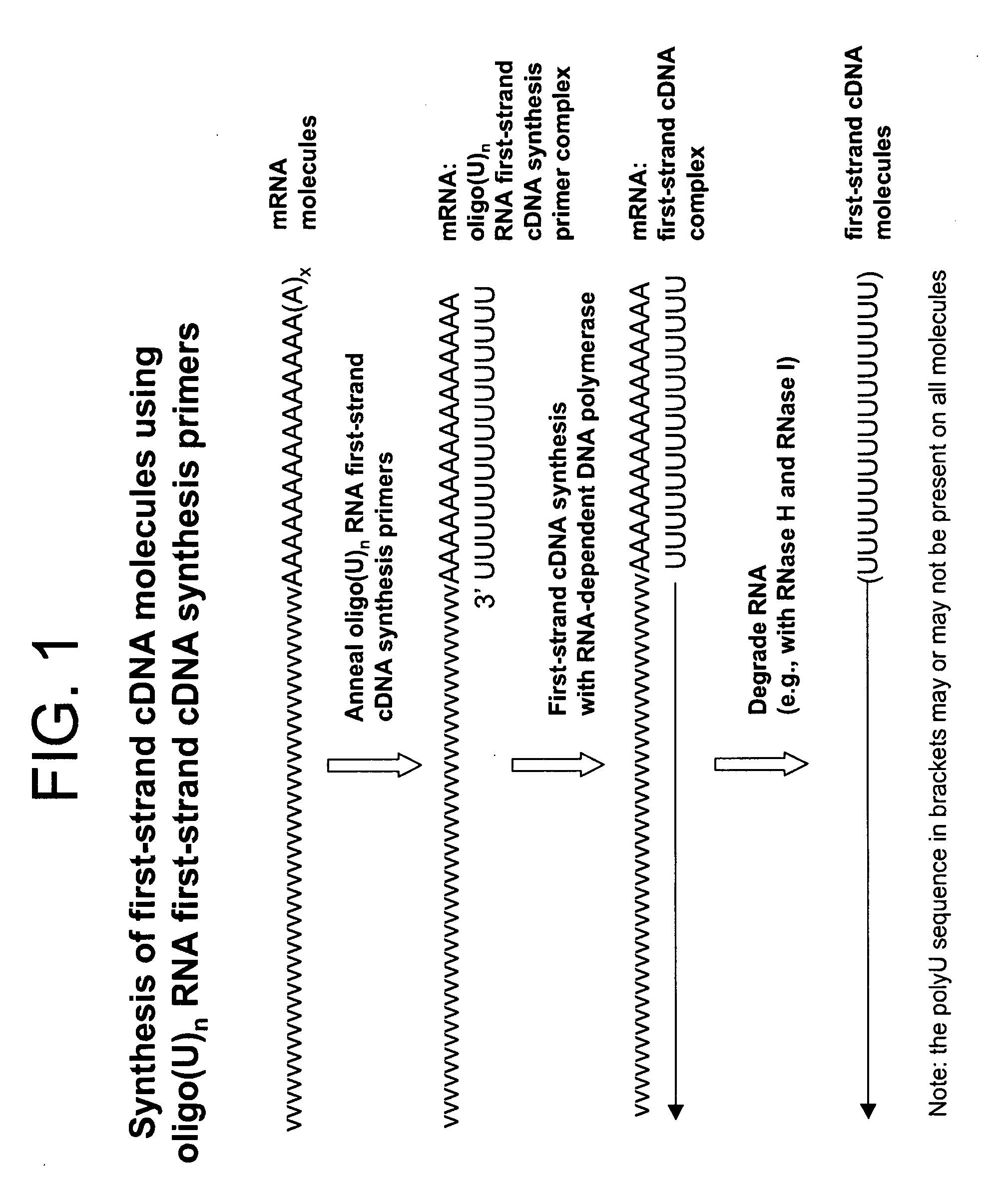

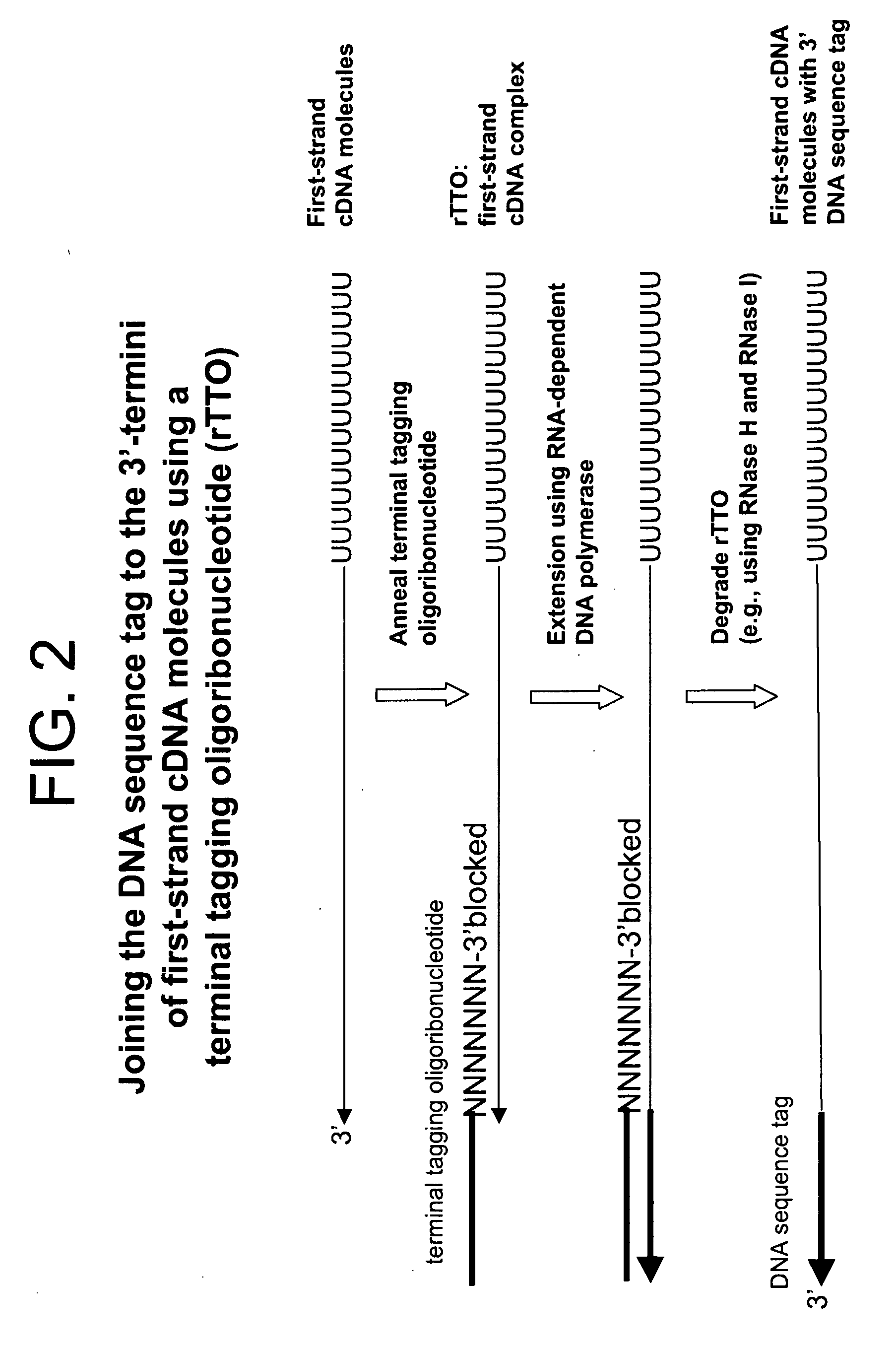

Copy DNA and sense RNA

ActiveUS20090053775A1Increased yieldLoss of productionMicrobiological testing/measurementTransferasesRibonucleotide synthesisOligoribonucleotides

The present invention relates generally to methods, compositions and kits for synthesizing sense RNA molecules from one or more RNA molecules of interest in a sample. In exemplary embodiments, the methods use a terminal tagging oligoribonucleotide (rTTO) to join a DNA sequence tag to the 3′-termini of first-strand cDNA molecules. The use of an rTTO comprising ribonucleotides results in decreased oligonucleotide-derived background synthesis of RNA in the absence of sample RNA and, surprisingly and unexpectedly, also results in significantly increased yields of sense RNA molecules that exhibit sequences that are substantially identical to those of the RNA molecules of interest in the sample. The sense RNA molecules also have an RNA sequence tag on their 5′-termini that is useful for fixing the lengths of sense RNA molecules that are synthesized in a second or subsequent round.

Owner:CELLSCRIPT

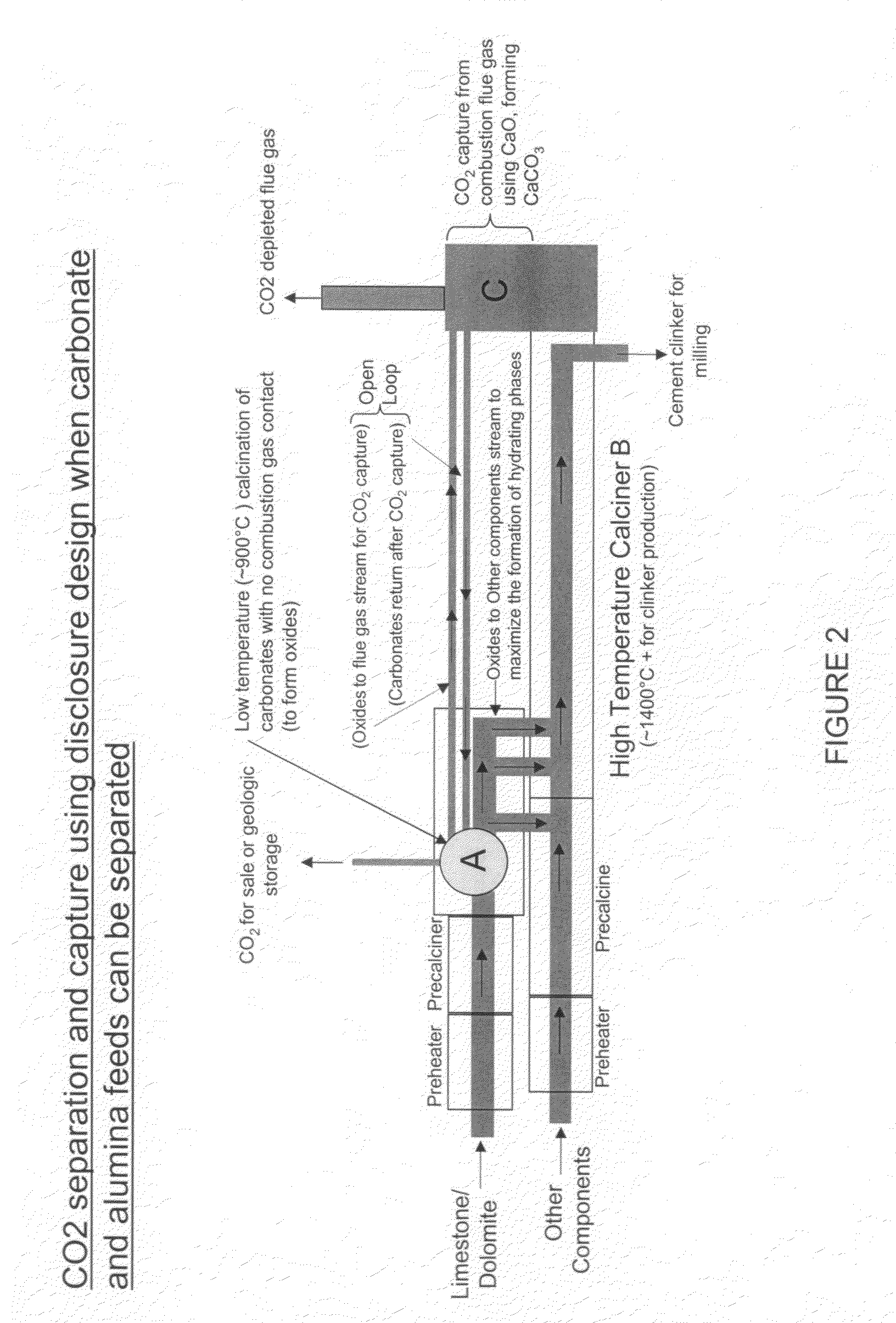

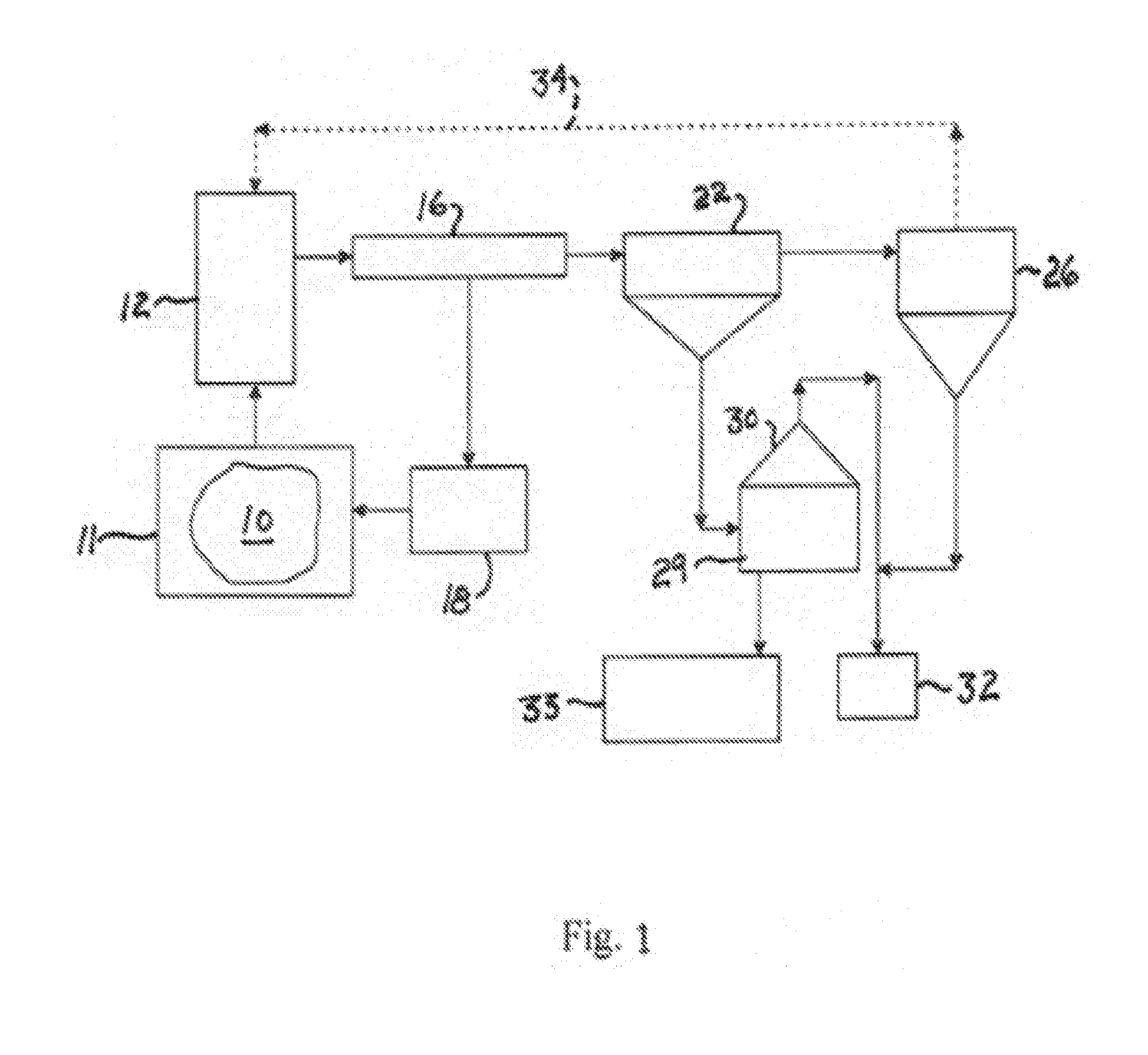

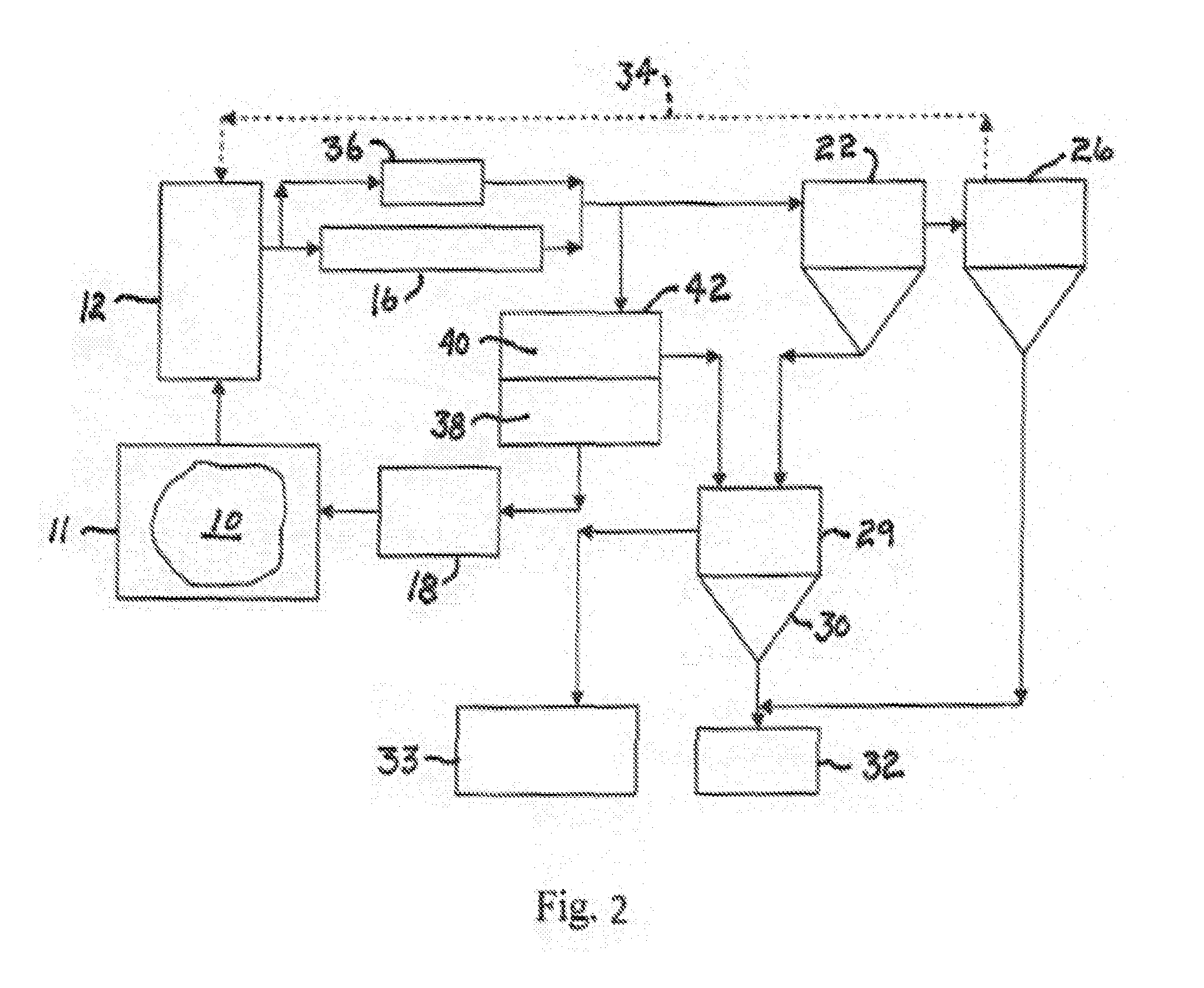

Carbon dioxide capture from a cement manufacturing process

ActiveUS20100319586A1Low formation temperatureIncreased yieldExhaust apparatusSilencing apparatusFlueCarbon dioxide

A process of manufacturing cement clinker is provided in which a clean supply of CO2 gas may be captured. The process also involves using an open loop conversion of CaO / MgO from a calciner to capture CO2 from combustion flue gases thereby forming CaCO3 / CaMg(CO3)2. The CaCO3 / CaMg(CO3)2 is then returned to the calciner where CO2 gas is evolved. The evolved CO2 gas, along with other evolved CO2 gases from the calciner are removed from the calciner. The reactants (CaO / MgO) are feed to a high temperature calciner for control of the clinker production composition.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS +1

Proteinoid carriers and methods for preparation and use thereof

InactiveUS6413550B1High yieldIncreased yieldOrganic active ingredientsCosmetic preparationsDecompositionGastrointestinal tract

Improved proteinoid carriers and methods for their preparation and use as oral delivery systems for pharmaceutical agents are described. The proteinoid carriers are soluble within selected pH ranges within the gastrointestinal tract and display enhanced stability towards at least one of photolysis or decomposition over time. The proteinoid carriers are prepared from proteinoids having between 2 and 20 amino acids and having a molecular weight of between about 250 and 2400 daltons.

Owner:NOVO NORDISK NORTH AMERICA OPERATIONS AS

Dicing die-bonding film

InactiveUS20100029059A1Increased yieldExcellent in pickup propertyLamination ancillary operationsFilm/foil adhesivesPressure sensitiveFree-radical reaction

The present invention is a dicing die-bonding film having a dicing film having a pressure-sensitive adhesive layer on an ultraviolet-ray transmitting base and a die-bonding film provided on the pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer is formed by laminating the die-bonding film onto a pressure-sensitive adhesive layer precursor formed from an acrylic polymer comprising an acrylic ester as a main monomer, a hydroxyl group-containing monomer at a ratio in the range of 10 to 40 mol % with respect to 100 mol % of the acrylic ester, and an isocyanate compound having a radical reactive carbon-carbon double bond within a molecular at a ratio in the range of 70 to 90 mol % with respect to 100 mol % of the hydroxyl group-containing monomer, and then curing by irradiating with an ultraviolet ray from the base side, and the die-bonding film is formed from an epoxy resin.

Owner:NITTO DENKO CORP

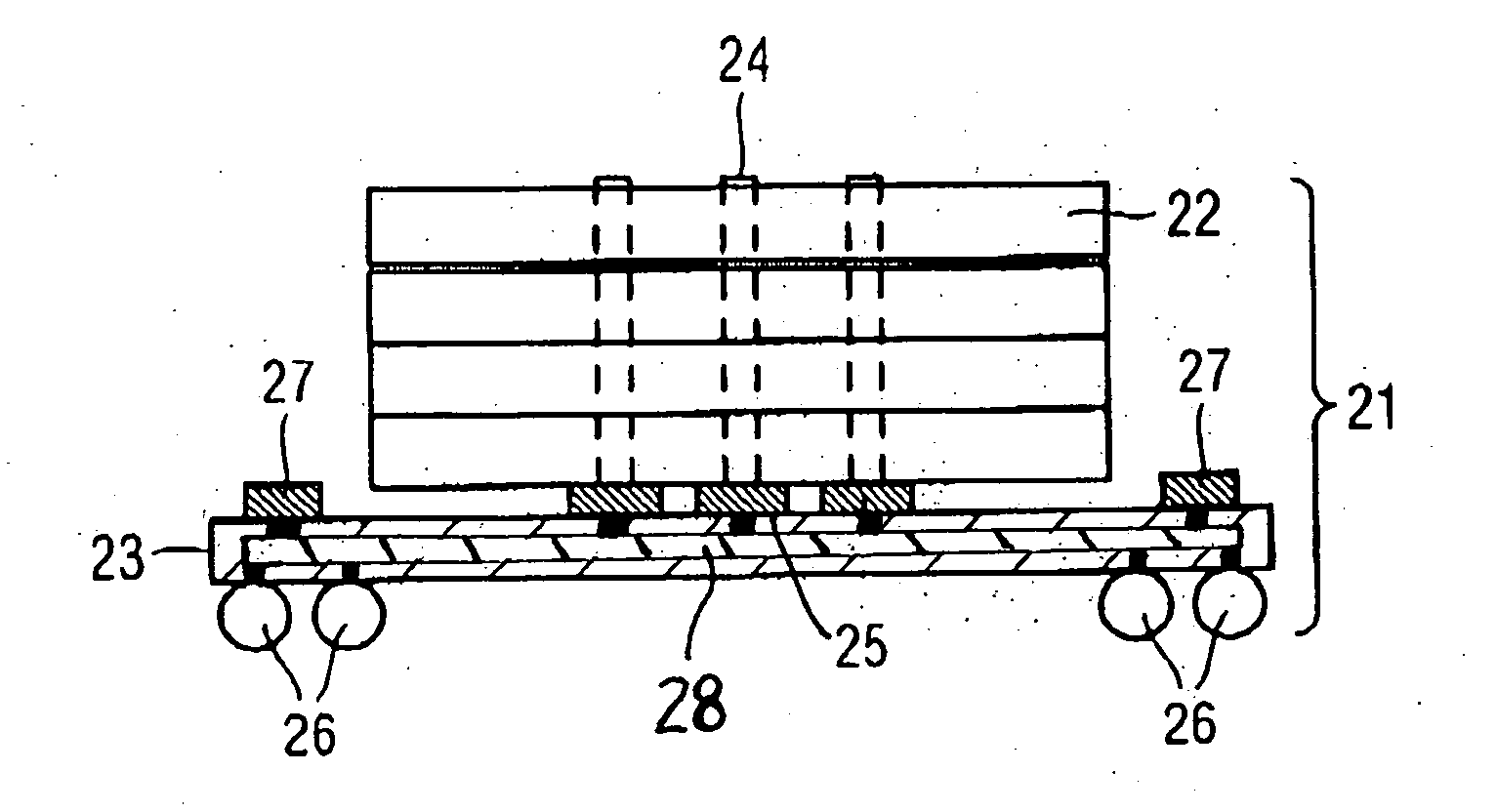

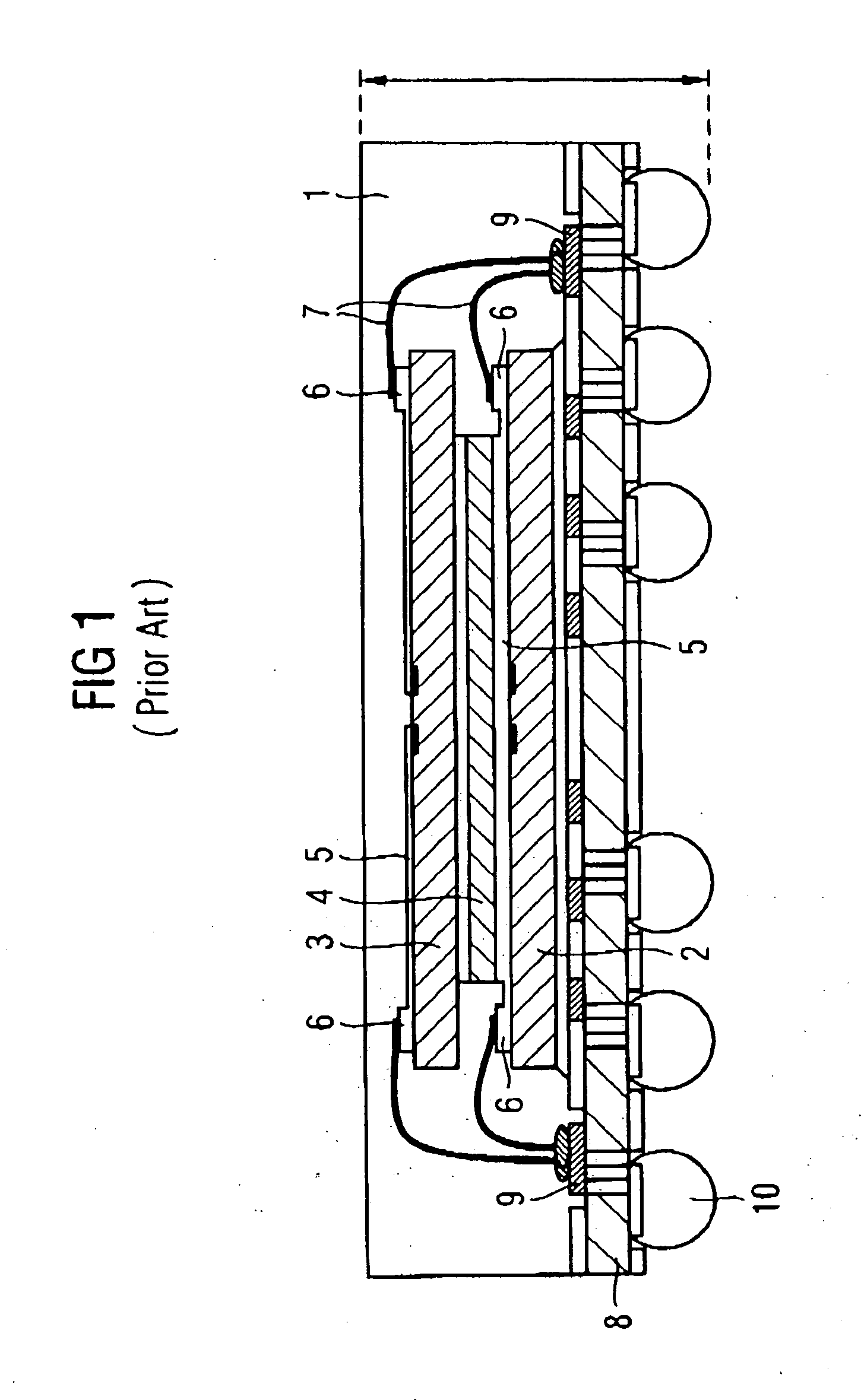

Multi-chip device and method for producing a multi-chip device

InactiveUS20060286822A1Increased memory capacityIncreased yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringContact element

The present invention relates to a multi-chip device comprising a plurality of chip stacks each including a plurality of single chips stacked on each other, wherein the stacked single chips are electrically interconnected by one or more through-chip-connection extending through at least one of the single chips and a substrate providing one or more first contact elements each of which is in contact with one of the through-chip-connections and providing one or more second contact elements being in electrical contact with the first contact elements, wherein the plurality of chip stacks are stacked onto each other and wherein the second contact elements of one of the chip stacks each being arranged to be in contact to one or more third contact elements of an adjacent one of the chip stacks.

Owner:POLARIS INNOVATIONS

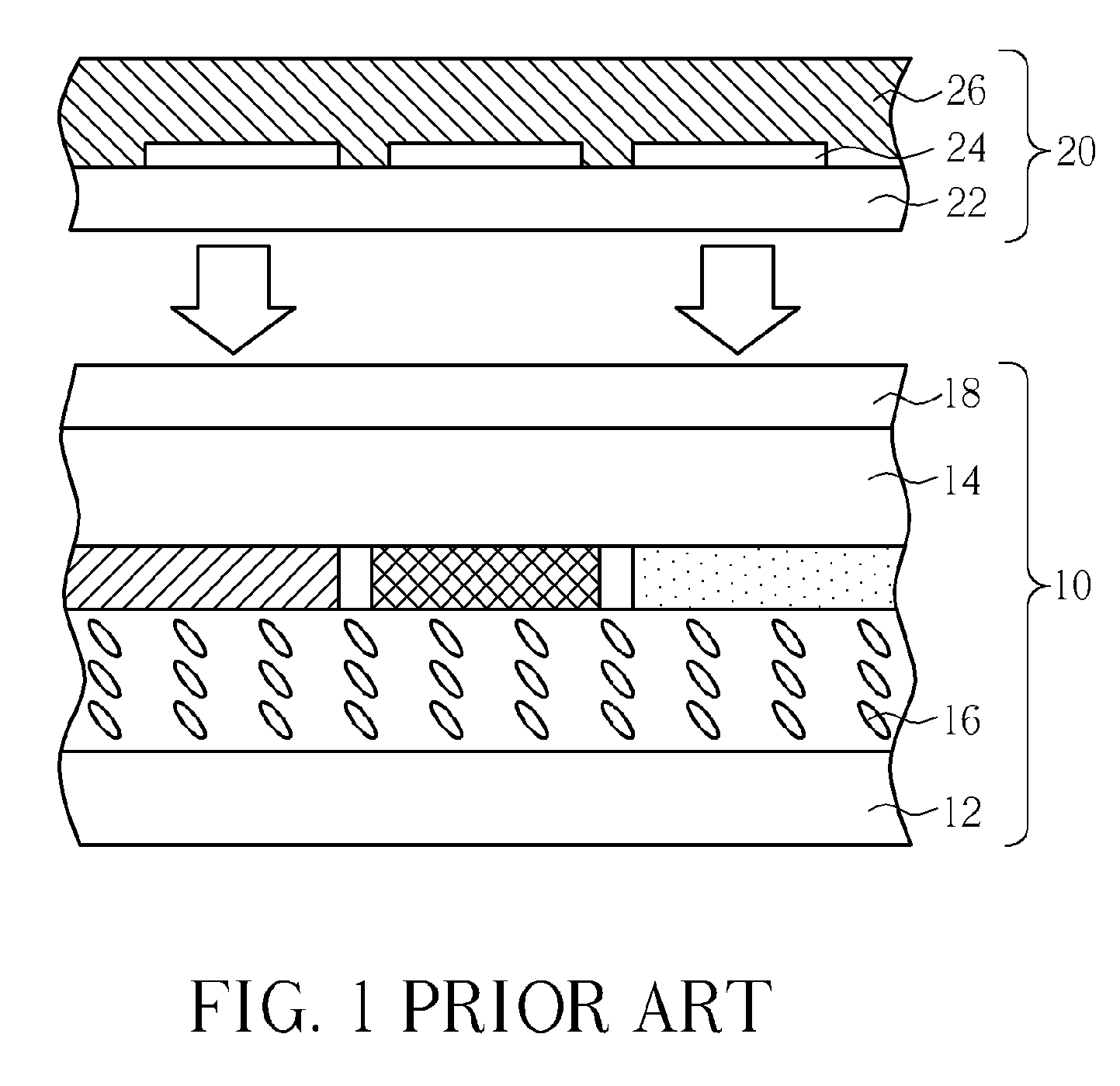

Transflective liquid crystal display

InactiveUS20070242014A1Manufacturing cost be reduceIncreased yieldStatic indicating devicesNon-linear opticsSystem structureLiquid-crystal display

The apparatus, methods, system and devices of the present invention provides transflective LCD system structure wherein each pixel is composed of at least three reflective sub-pixels and at least one transmissive sub-pixel. The reflective sub-pixels have a color filter layer for displaying color reflective images and the transmissive sub-pixel it is driven by color sequential imaging method for displaying a color transmissive image. The configuration of the sub-pixels and the location of the sub-pixel electronics increases the aperture ratio of both transmissive sub-pixel and reflective sub-pixel to improve the image brightness and lower the overall power consumption of the device.

Owner:INNOLUX CORP +1

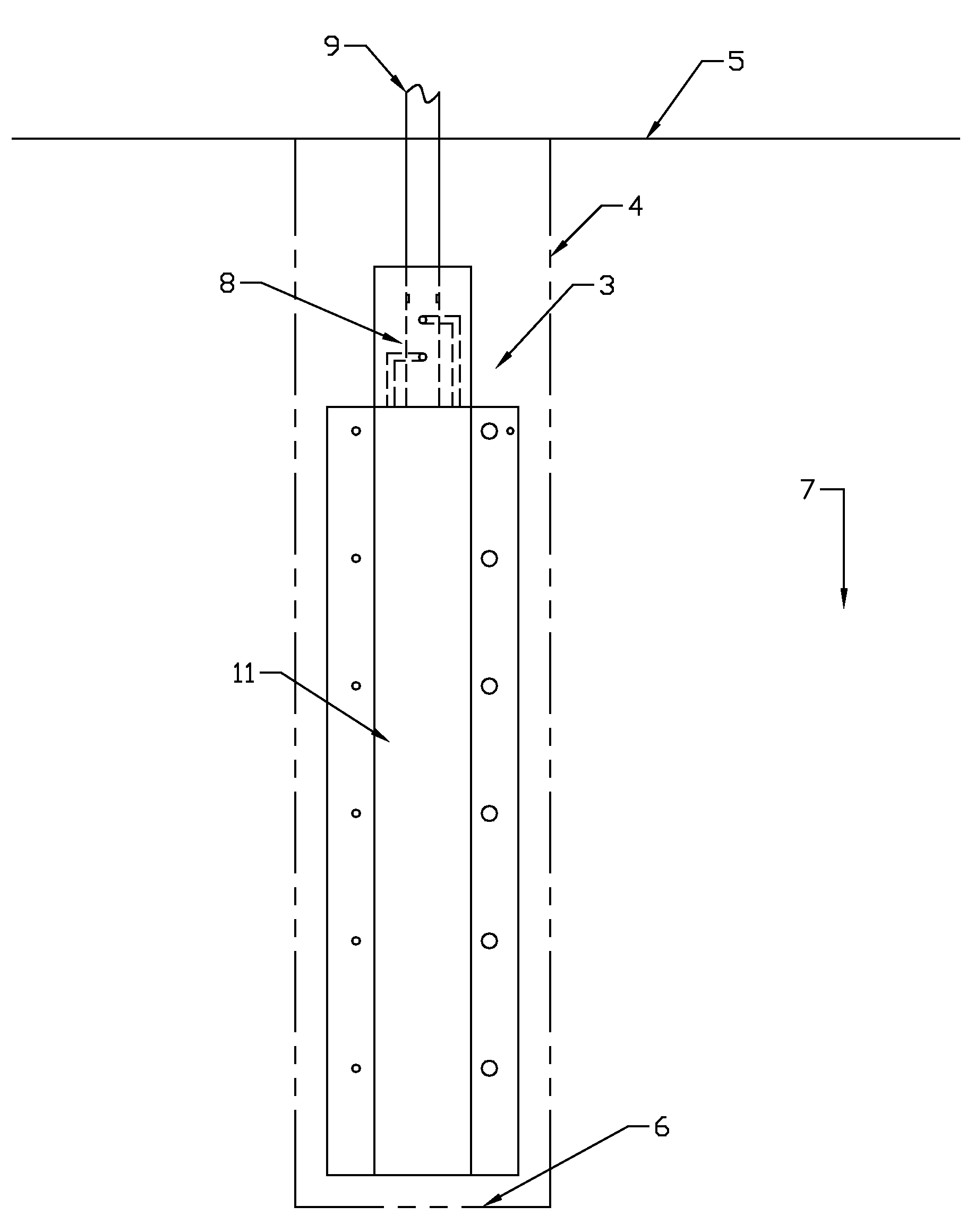

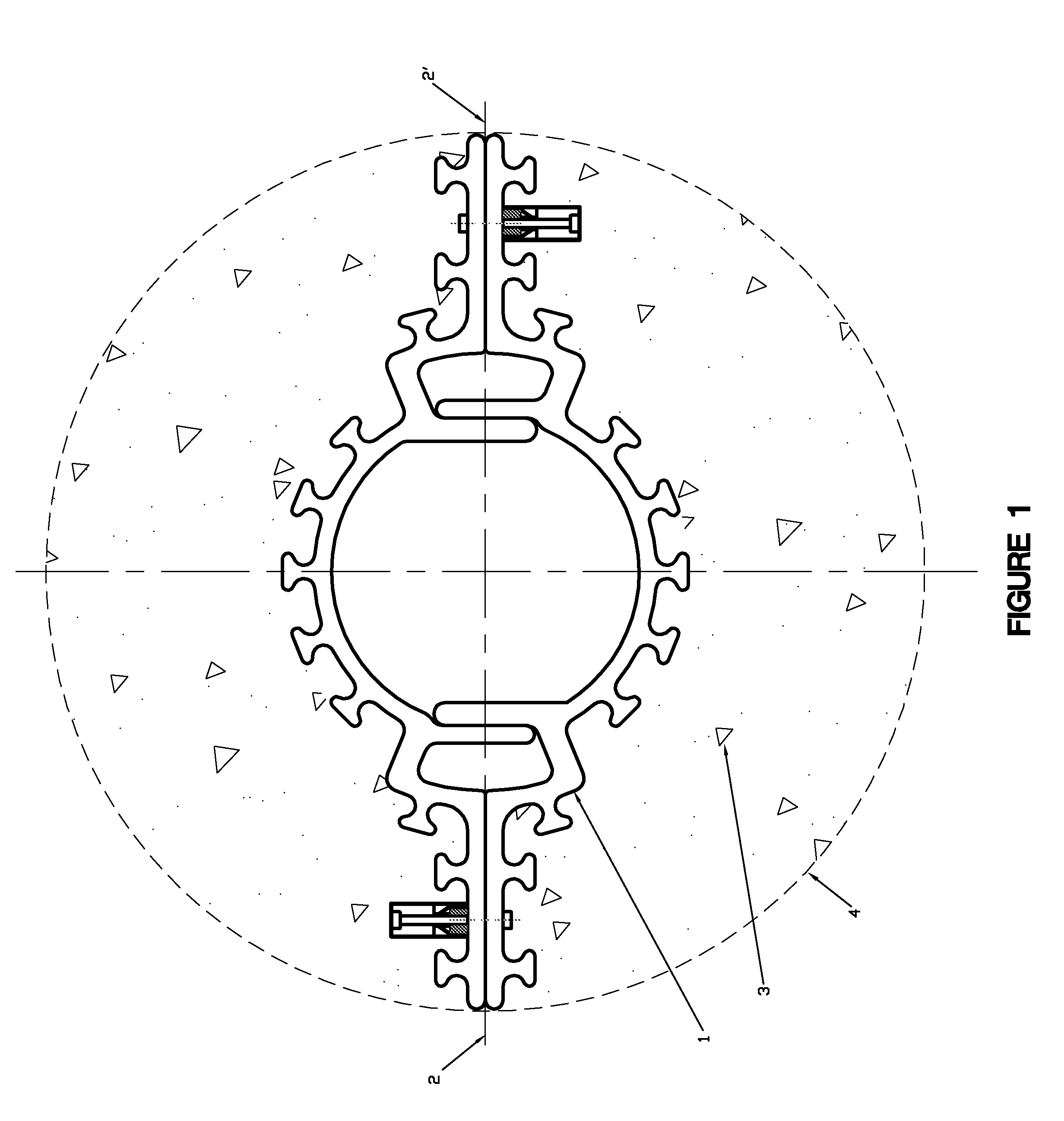

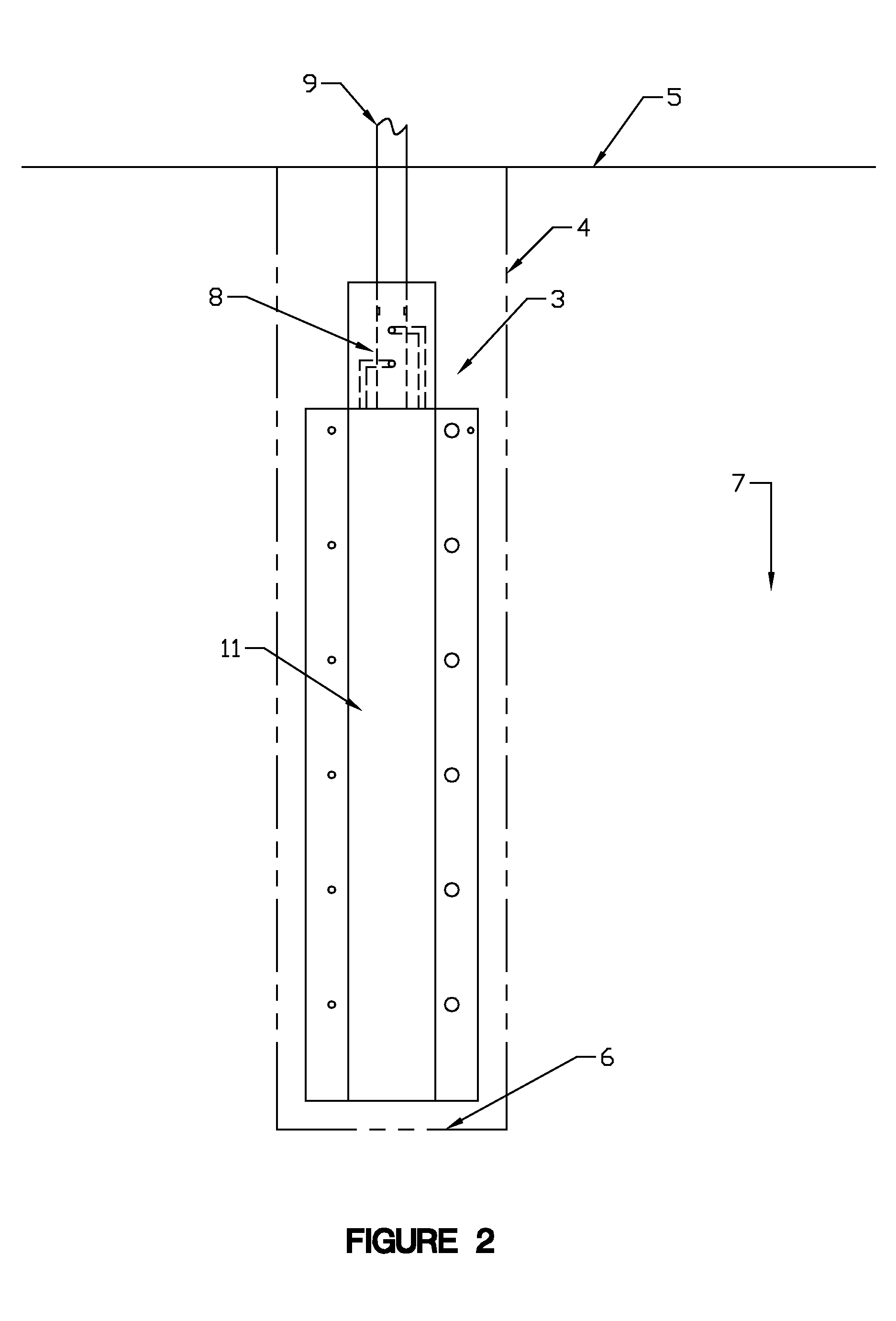

Hydraulic Fracture Initiation and Propagation Control in Unconsolidated and Weakly Cemented Sediments

InactiveUS20070199704A1Increased yieldReduce flowFluid removalSealing/packingMultiple fracturesPetroleum

A method and apparatus for initiating and propagating a vertical hydraulic fracture in unconsolidated and weakly cemented sediments from a single bore hole to control the fracture initiation plane and propagation of the hydraulic fracture, enabling greater yield and recovery of petroleum fluids from the formation. An injection casing with multiple fracture initiation sections is inserted and grouted into a bore hole. A fracture fluid carrying a proppant is injected into the injection casing and opens the fracture initiation sections to dilate the formation in a direction orthogonal to the required fracture azimuth plane. Propagation of the fracture is controlled by limiting the fracture fluid injection rate during fracture initiation and propagation and maintaining a minimum fracture fluid viscosity. The injection casing initiation section remains open after fracturing providing direct hydraulic connection between the production well bore, the permeable proppant filled fracture and the formation.

Owner:GEOSIERRA

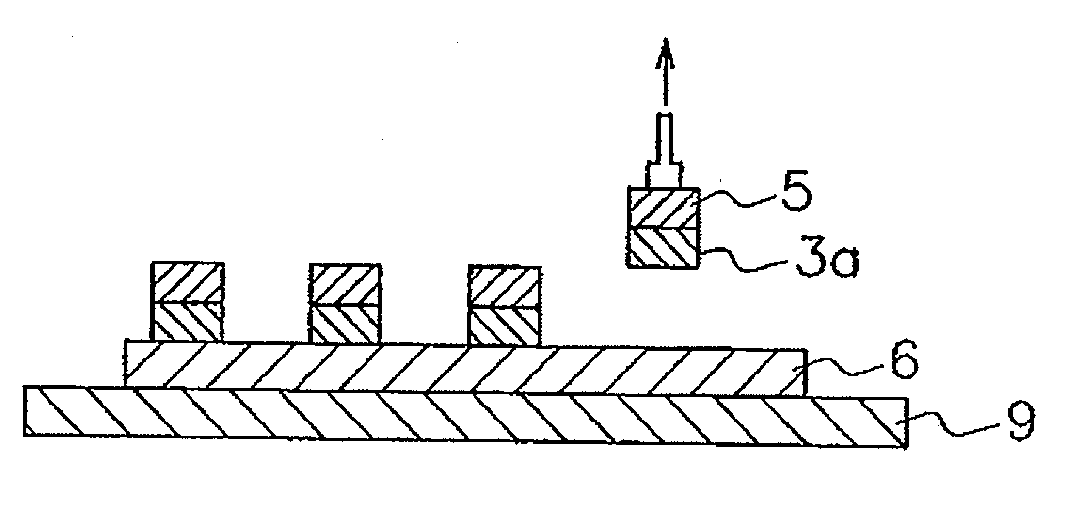

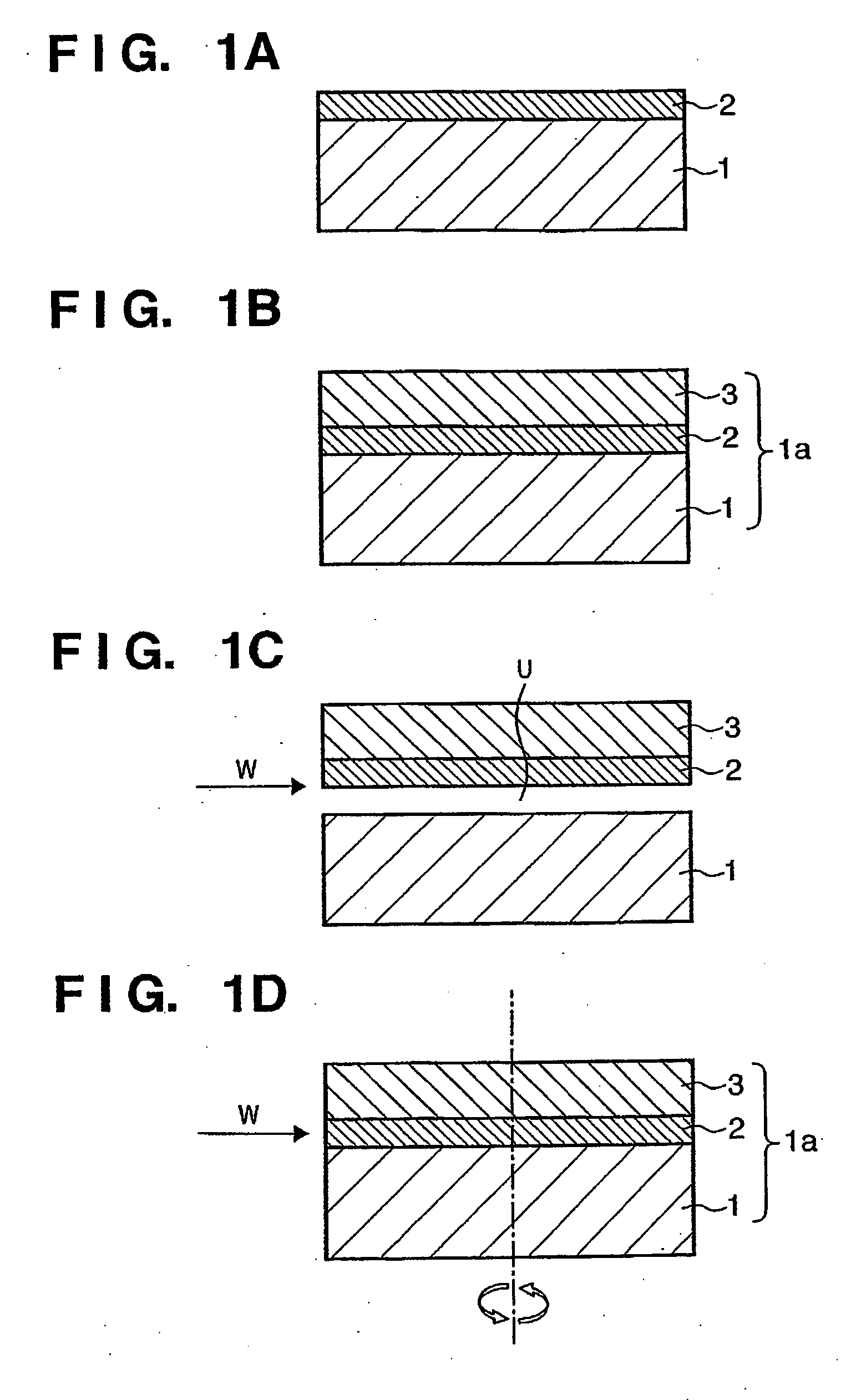

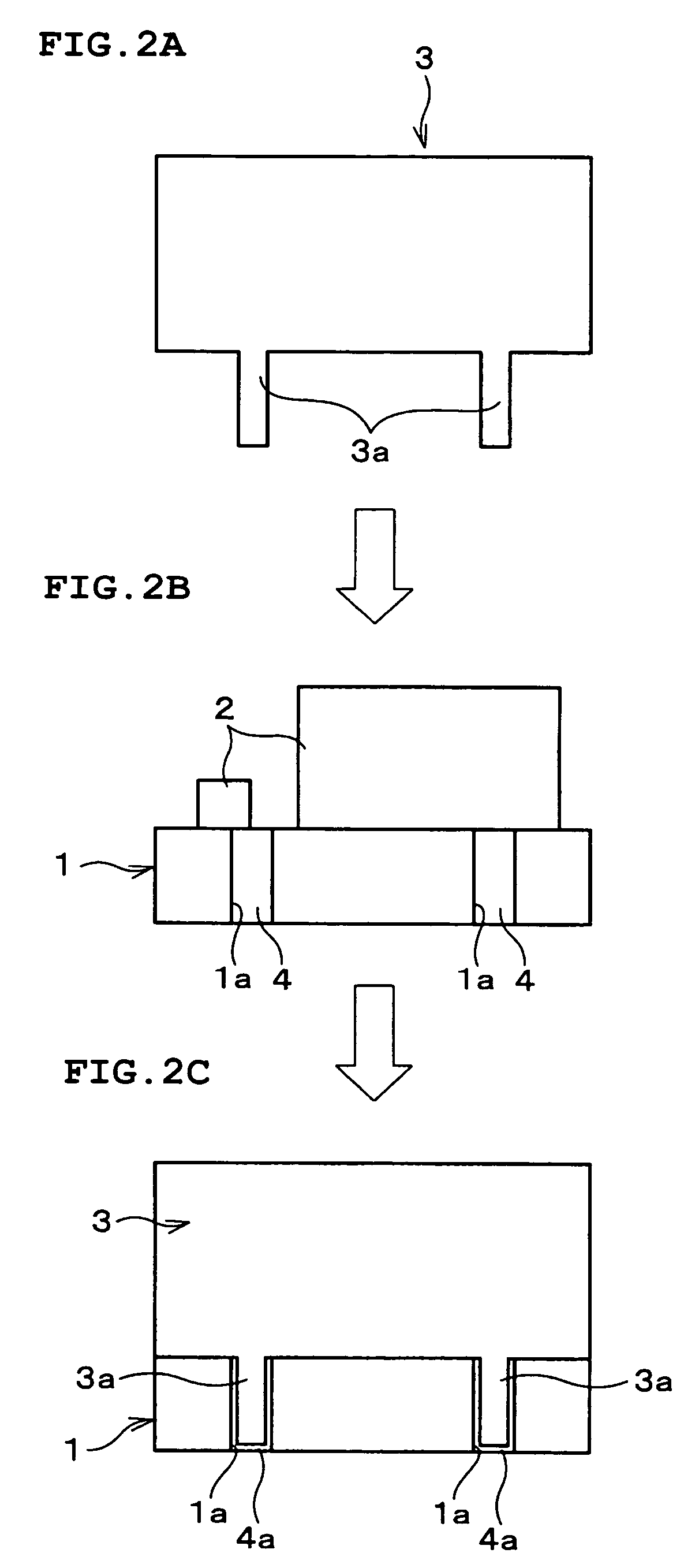

Semiconductor film manufacturing method and substrate manufacturing method

ActiveUS20060246688A1Increased yieldIncrease throughputSemiconductor/solid-state device manufacturingSemiconductor lasersEngineeringSemiconductor

This invention provides a semiconductor film manufacturing method using a new separation technique and applications thereof. The semiconductor film manufacturing method of this invention includes a separation layer forming a step of hetero-epitaxially growing a separation layer (2) on a seed substrate (1), a semiconductor film forming step of forming a semiconductor film (3) on the separation layer (2), and a separation step of separating, by using the separation layer (2), the semiconductor film (3) from a composite member (Ia) formed in the semiconductor film forming step.

Owner:CANON KK

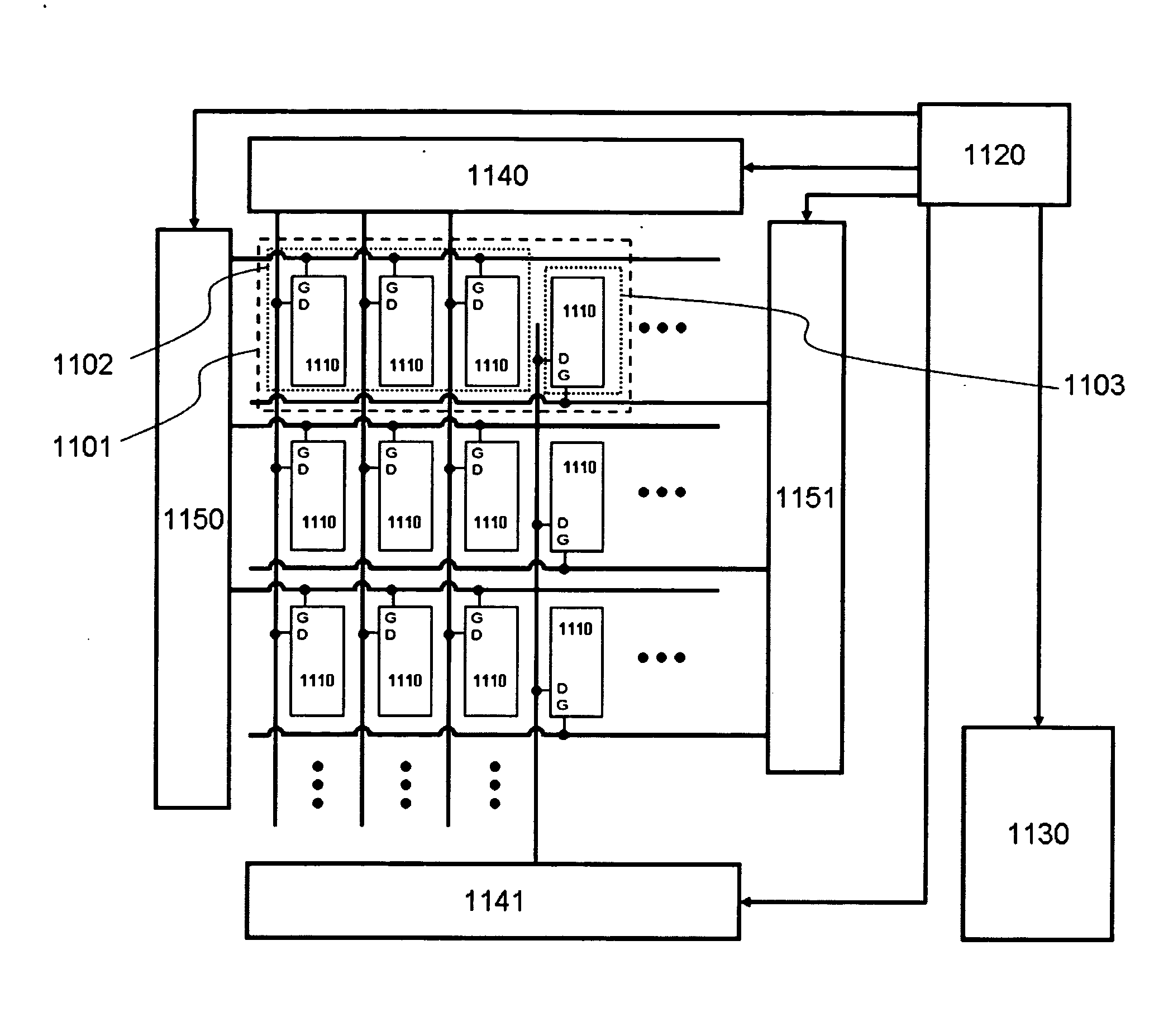

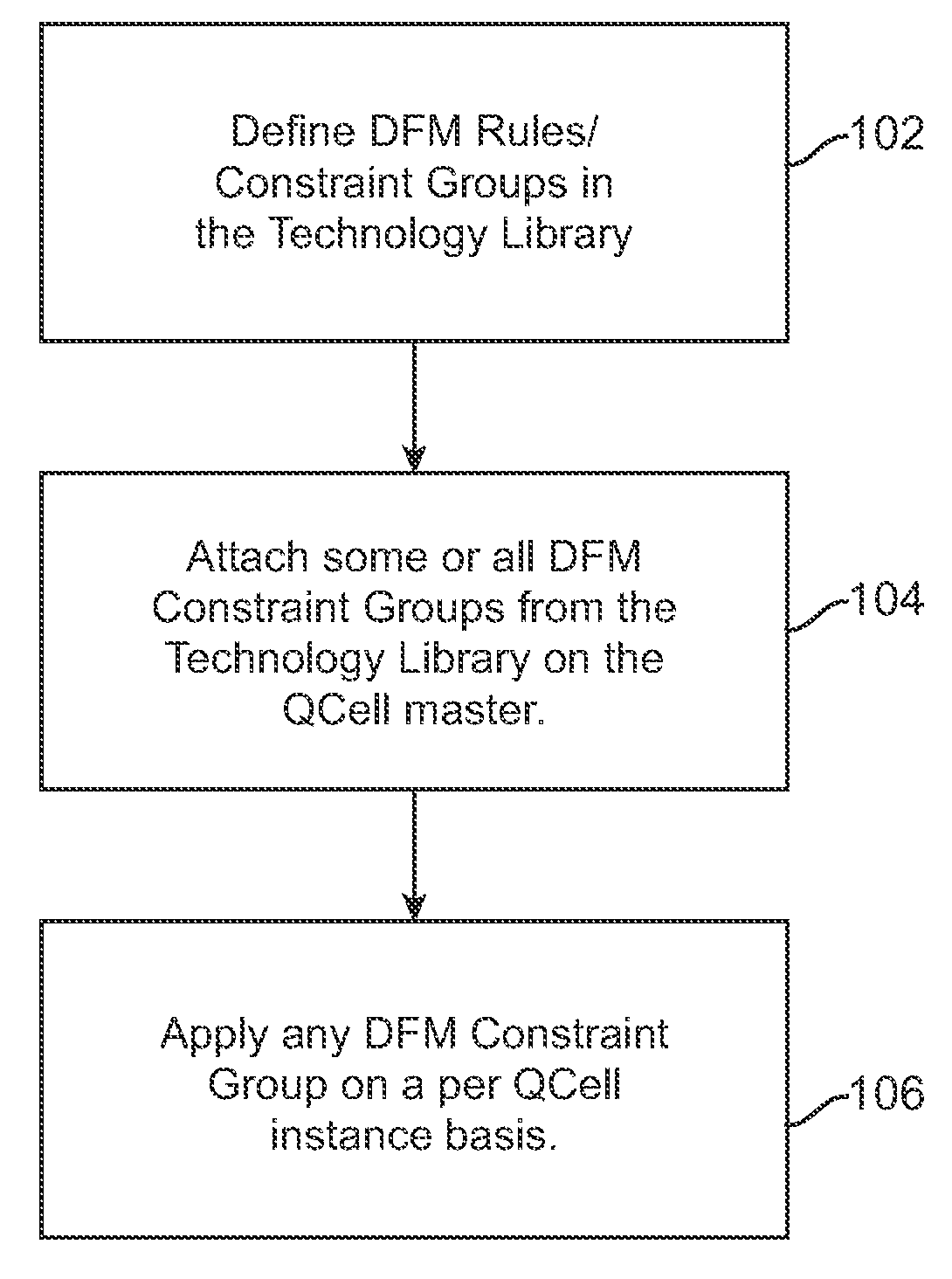

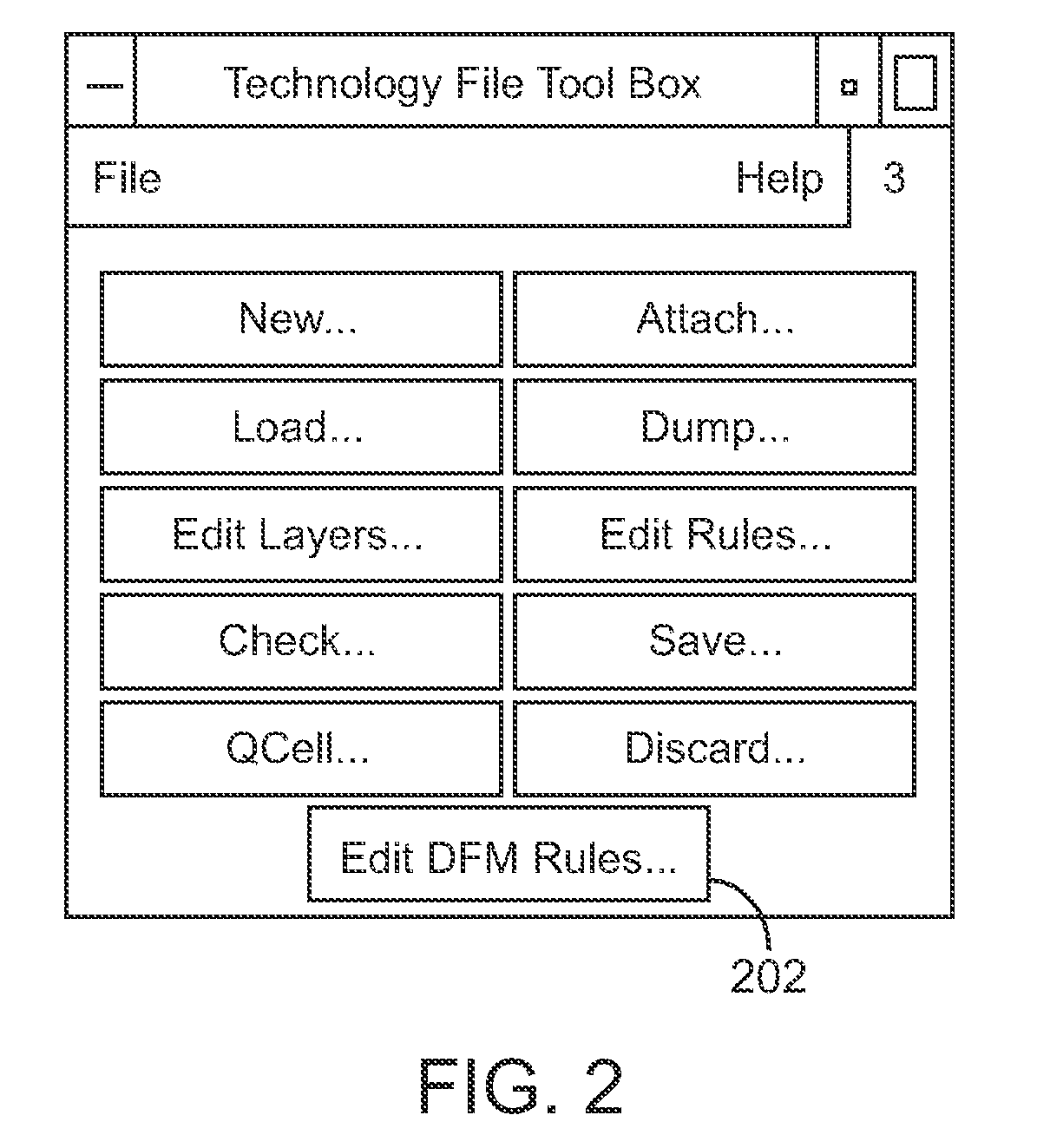

Method and mechanism for implementing DFM aware cells for an electronic design

InactiveUS7506277B1Increased yieldImprove productivityCAD circuit designProgram controlProduction rateElectronic design

An improved method, system, computer program product, and electronic design structures which provides the flexibility to IC designers to be able to relax the design rules to increase the yield and improve the layout productivity is disclosed. In some disclosed approaches, automated interactive aids and batch tools are provided which can assist in optimizing the final layouts for yield at the initial placement and / or routing stages for optimizing yield. Provided in some disclosed approaches are automated capability to layout designers at the mos devices level to configure mos devices as per different DFY recommendations from the foundry without negative effects on the overall chip area (or cell size). The design rules may be relaxed selectively on an instance basis and wherever possible or desirable.

Owner:CADENCE DESIGN SYST INC

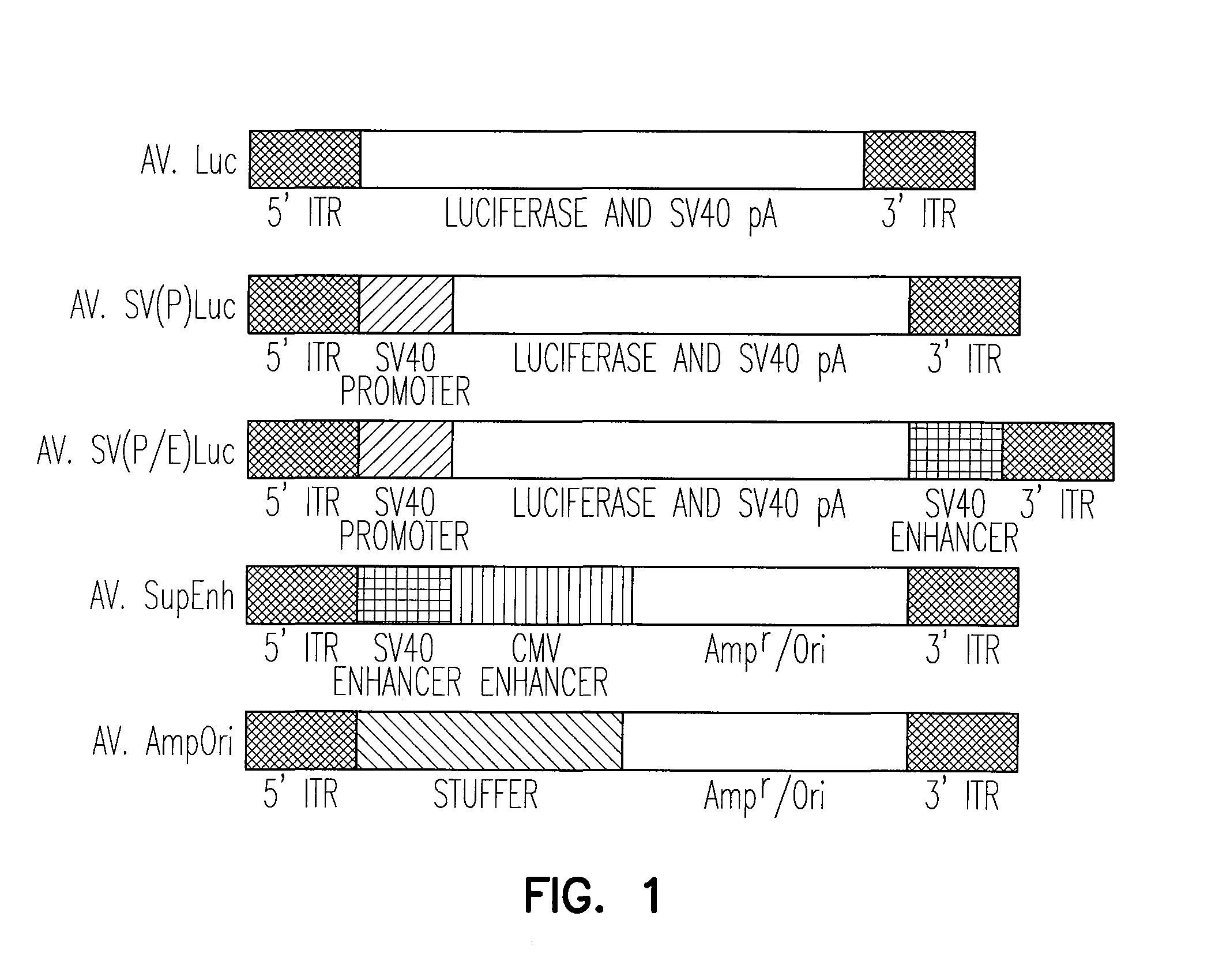

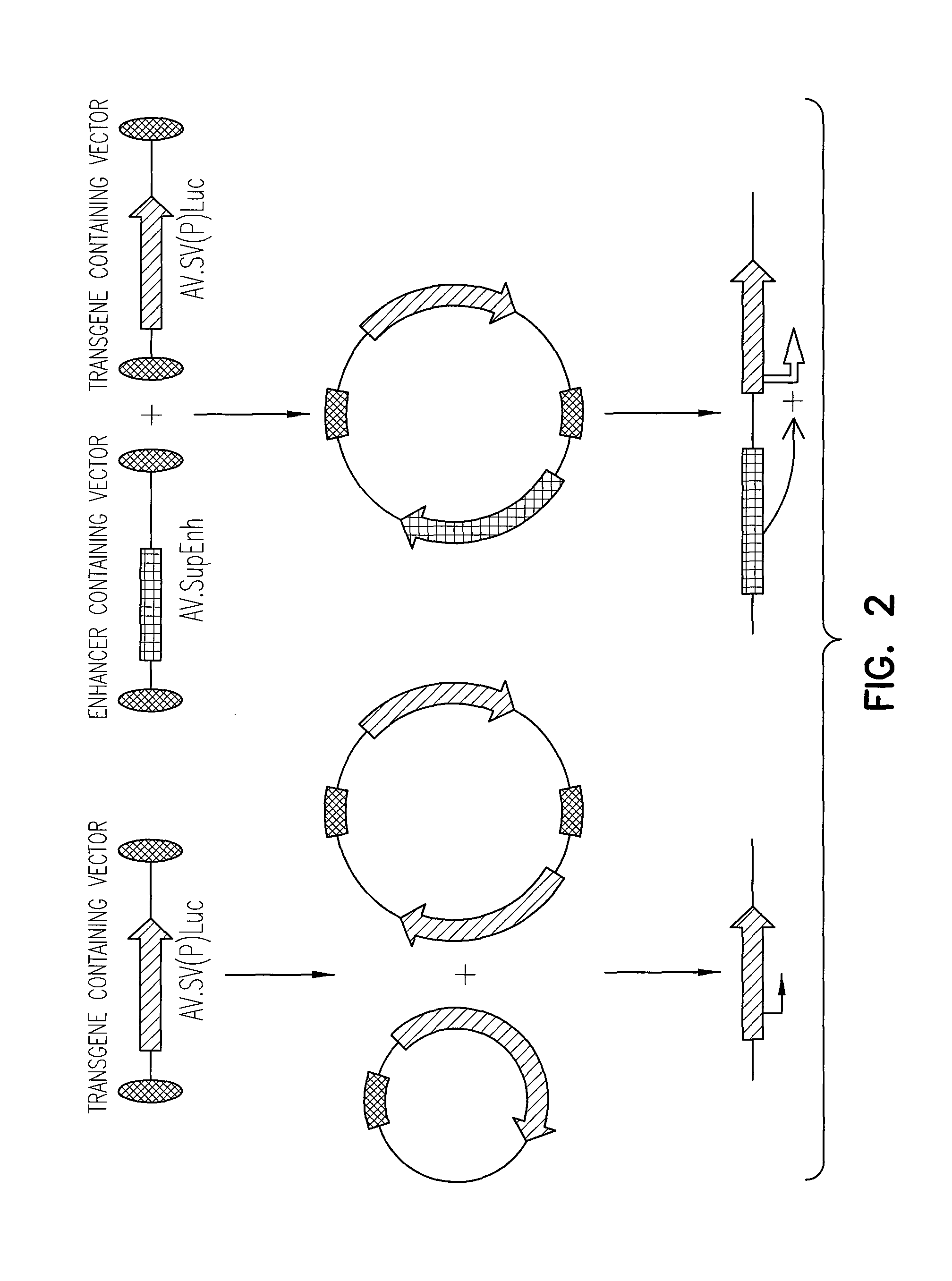

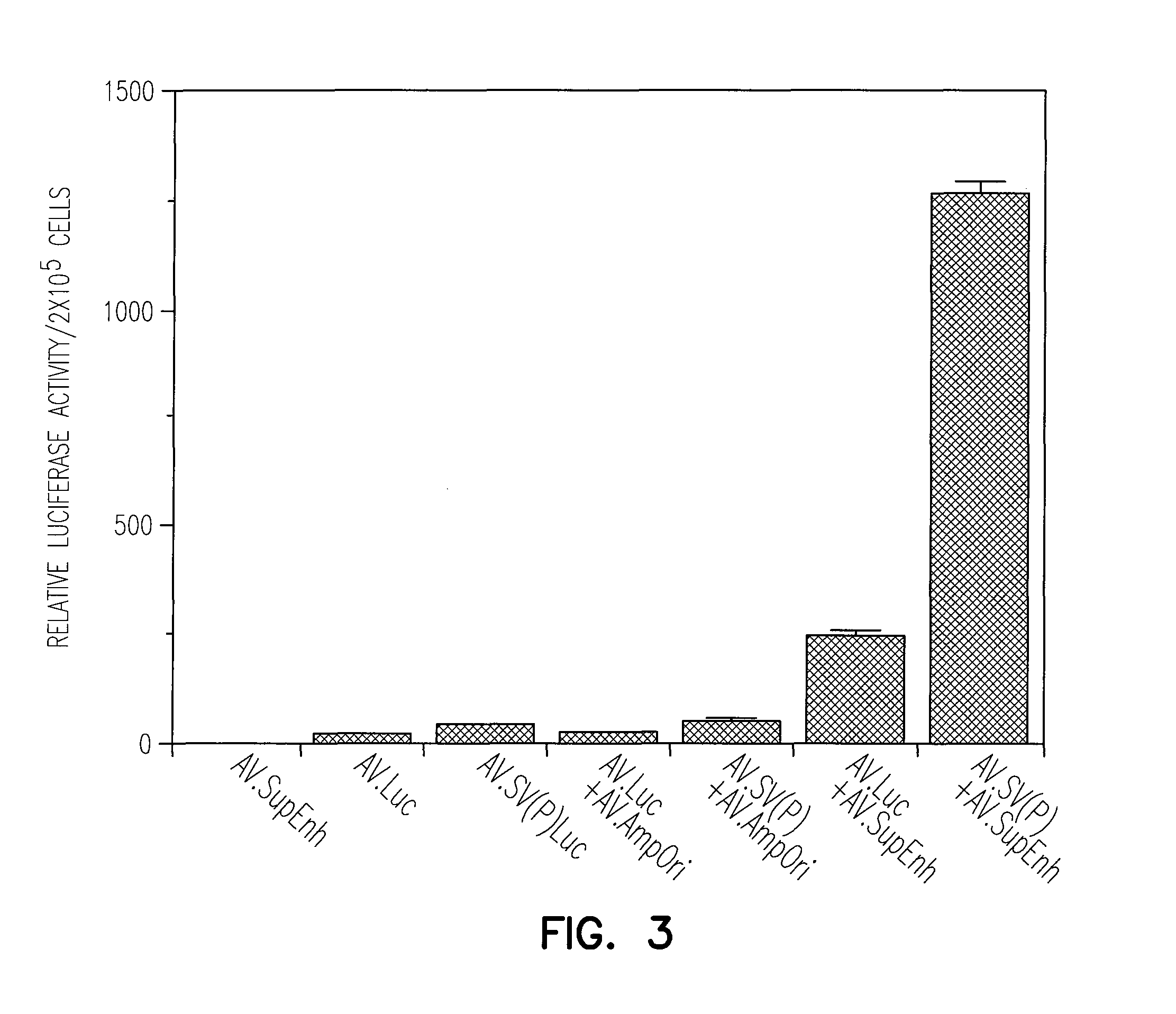

Adeno-associated virus vectors with intravector heterologous terminal palindromic sequences

InactiveUS8241622B2Increased yieldReduce capacityAntibacterial agentsBiocideAdeno-associated virusVirology

The invention provides recombinant AAV vectors, at least one of which has heterologous terminal palindromic sequences, and methods of using those vectors.

Owner:UNIV OF IOWA RES FOUND

Reticle cleaning method for a lithography tool and a reticle cleaning system thereof

InactiveUS20110180108A1Enhance qualityIncreased yieldSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringReticle

A reticle cleaning method for a lithography tool, wherein an inspection apparatus deployed in the lithography tool is used to perform the cleaning procedure on reticle in the EUV reticle pod, the reticle cleaning method comprising: transporting the EUV reticle pod to the upper chamber of the inspection apparatus; forming vacuum in the upper chamber of the inspection apparatus; transporting the inner box of the EUV reticle pod to the lower chamber of the inspection apparatus; forming vacuum in the lower chamber of the inspection apparatus; performing the cleaning process multiple times for gas filling and vacuum exhausting, wherein an inert gas is provided for the process of gas filling to be performed multiple times on the inner box to allow the particles in the inner box to be brought away by the flow field formed by the inert gas in the inner box; and transporting the inner box to a reticle library.

Owner:GUDENG PRECISION IND CO LTD

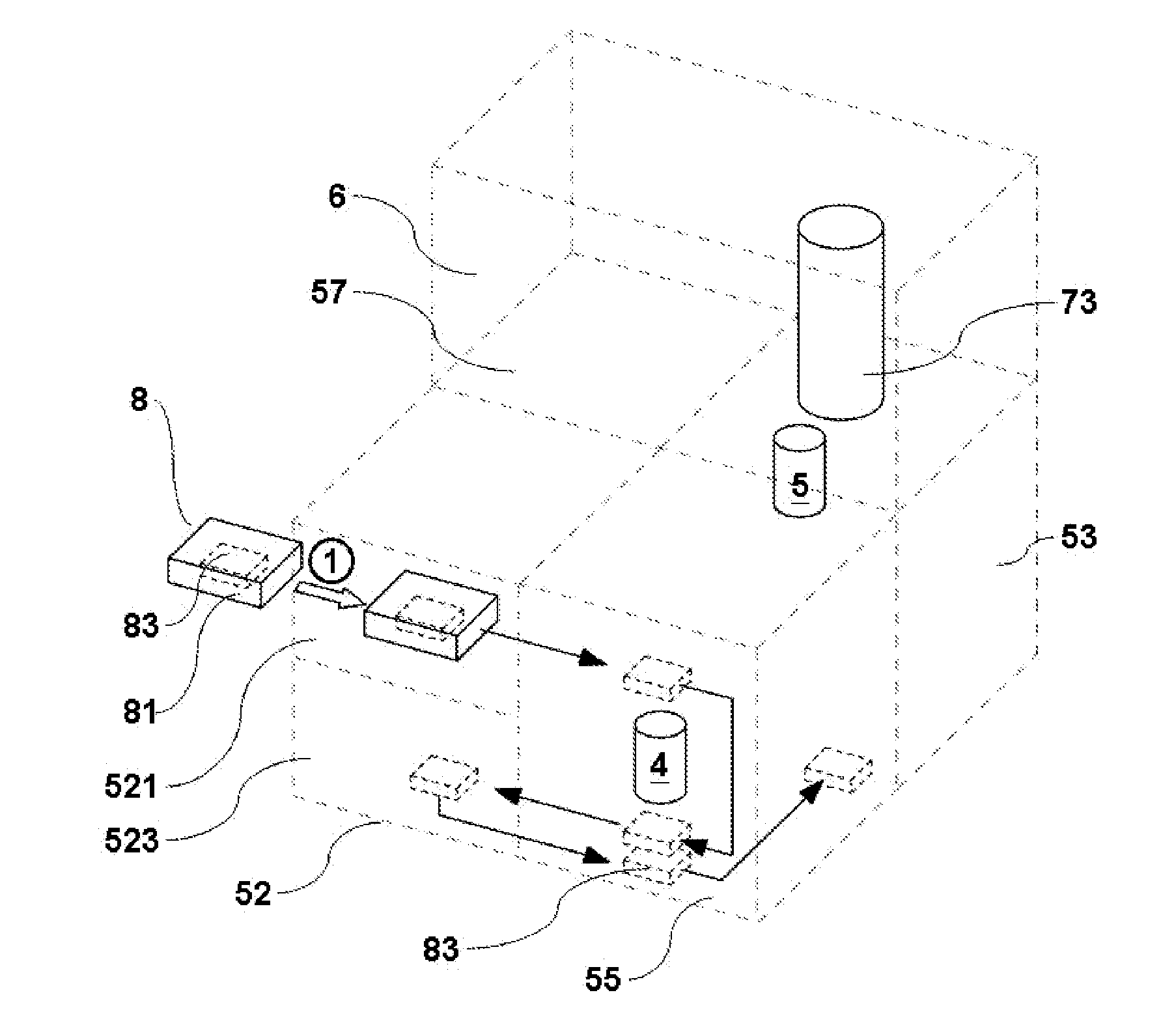

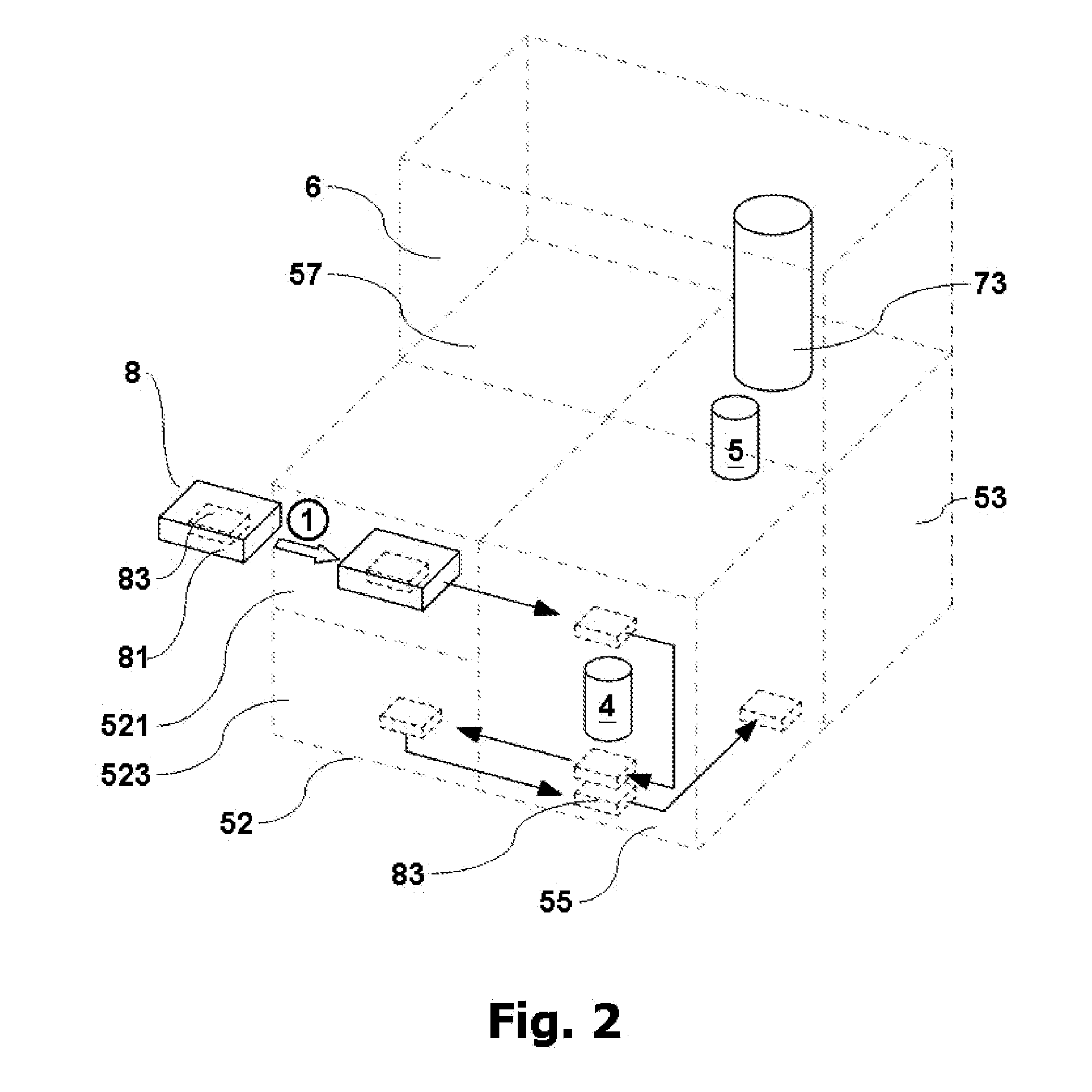

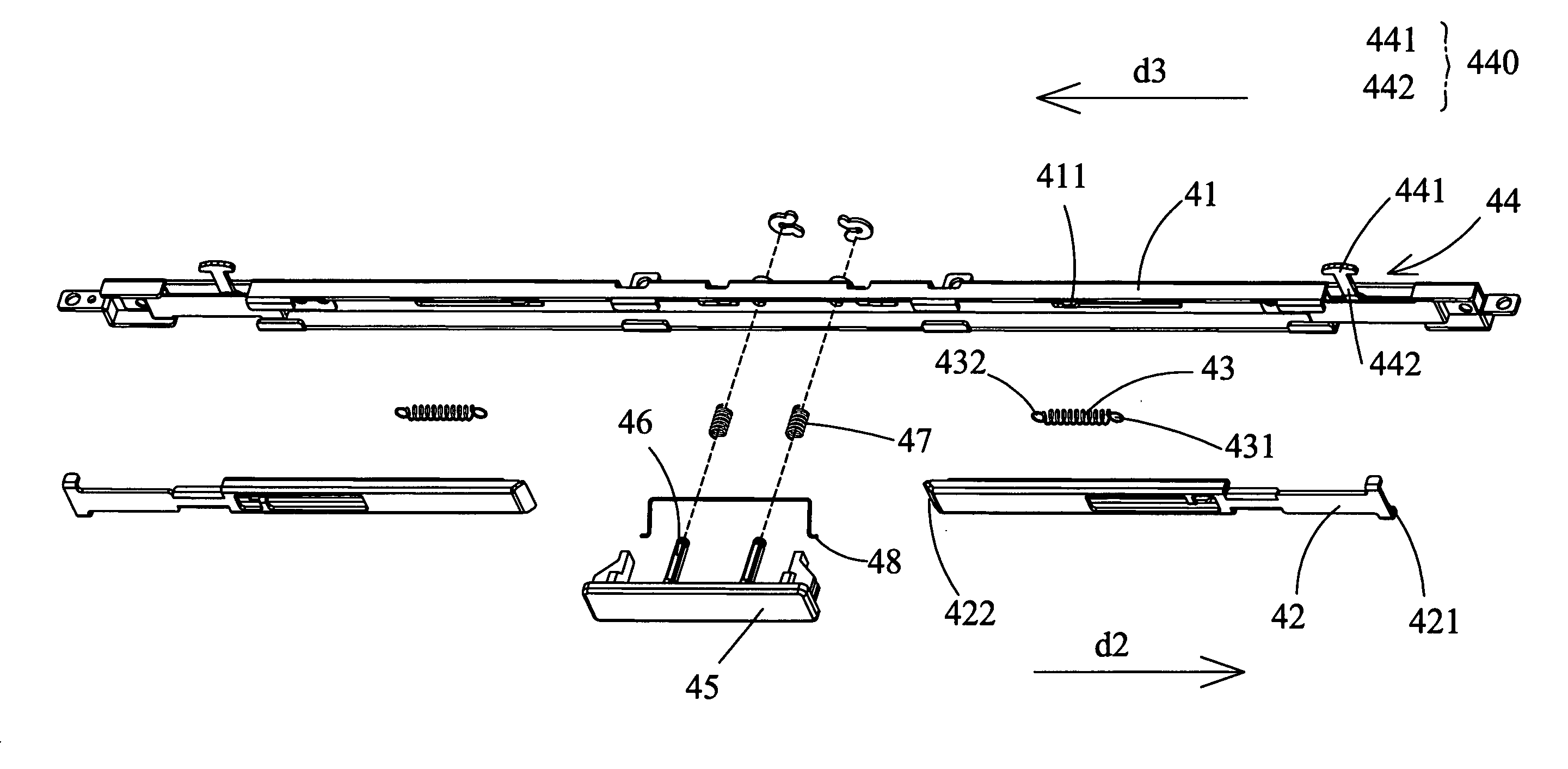

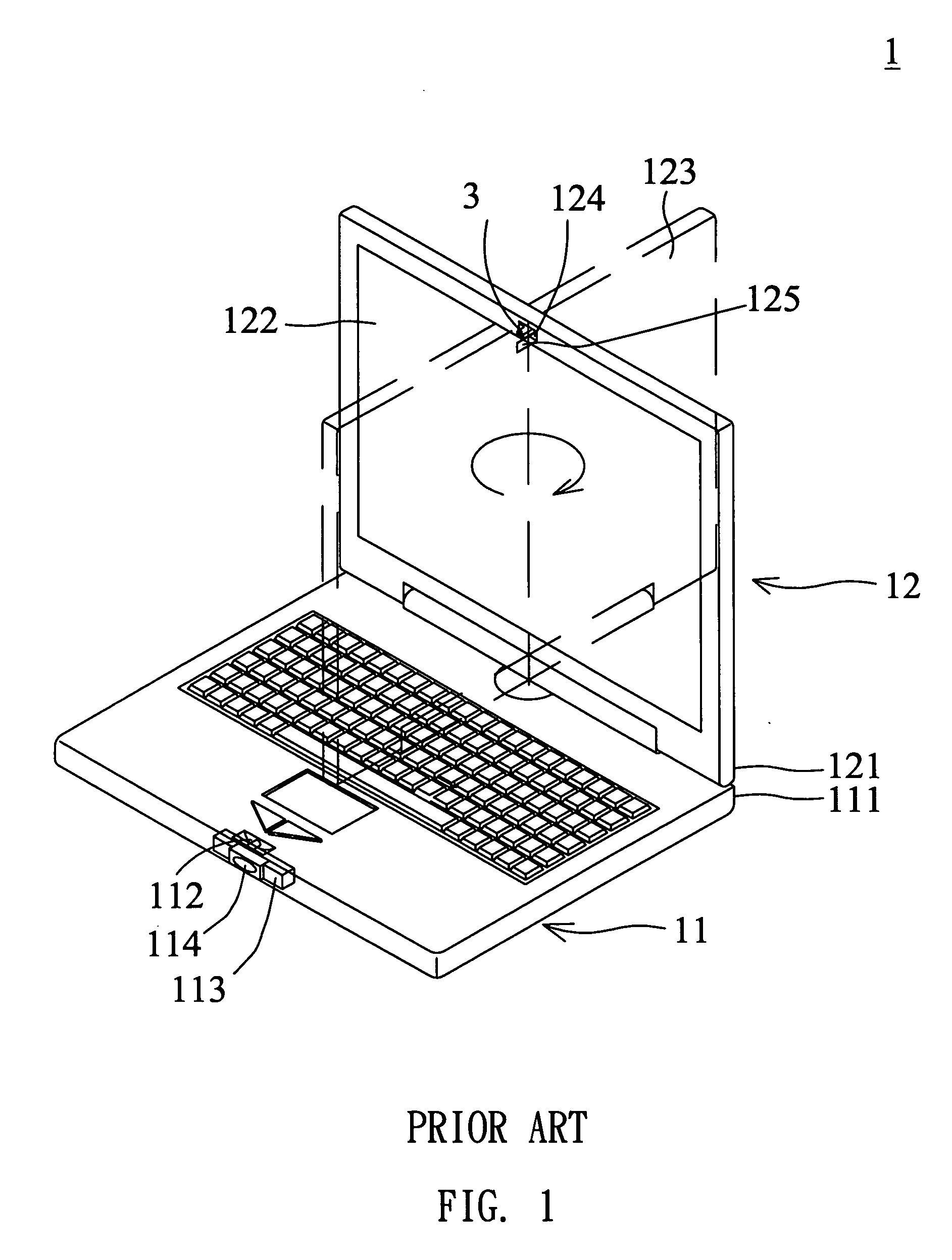

Latch structure

ActiveUS20050180562A1Shorten fabrication timeIncreased yieldInterconnection arrangementsWing fastenersEngineeringElectrical and Electronics engineering

A latch structure includes a base, a connecting unit, a first elastomer, at least one hook unit and a button. In this case, the connecting unit has a first side and a second side, and the connecting unit is disposed on the base. The first elastomer has a first end and a second end. The first end connects to the connecting unit and the second end connects to the base. At least one hook unit is located at the first side of the connecting unit. The hook unit has a moving member with a hook portion and a connecting portion, and the hook portion locates in a first site. The button is located at the second side of the connecting unit. When the hook portion does not locate in the first site, the button moves toward a first direction, the button pushes the connecting unit in a second direction, and the connecting unit touches the connecting portion. Accordingly, the hook portion turns to the first site.

Owner:ASUSTEK COMPUTER INC

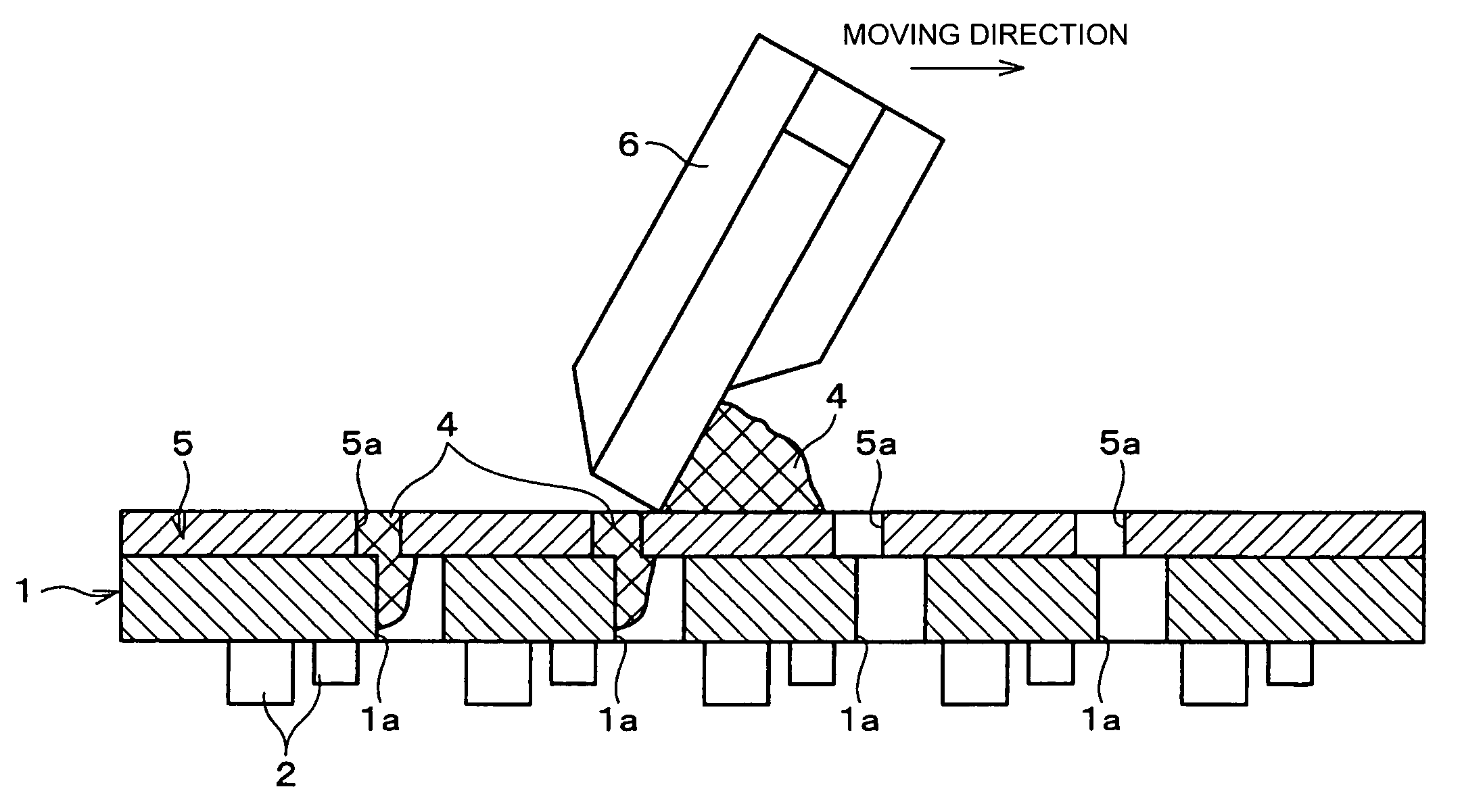

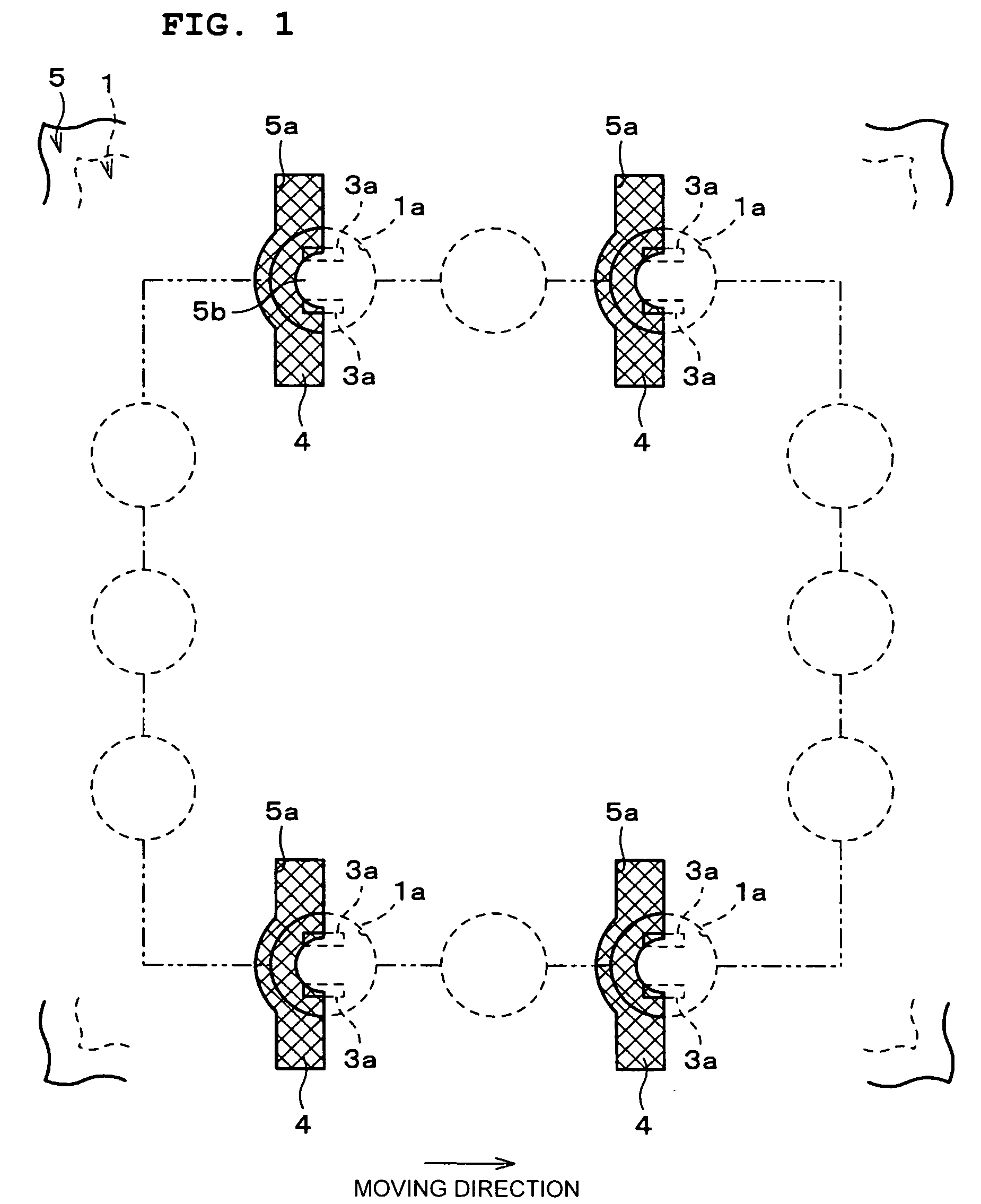

Method for manufacturing electronic component

ActiveUS7223316B2Increased yieldIncrease productionLiquid surface applicatorsSemiconductor/solid-state device detailsSolder pasteEngineering

A method for manufacturing an electronic component includes the steps of inserting tabs of a cover into through holes formed in a circuit board having mounting elements on the front surface thereof, disposing a print mask having openings at positions corresponding to the through holes on the back surface of the circuit board, and supplying solder cream to the through holes through the openings by placing the solder cream on the print mask and moving the solder cream in a predetermined direction with a squeegee. The print mask is provided with projections which project upstream in the moving direction of the solder cream in openings of the print mask, and the openings are shifted upstream in the moving direction of the solder cream. In addition, the tabs are inserted into the through holes such that the width direction of the tabs is along the moving direction of the solder cream.

Owner:MURATA MFG CO LTD

Process for obtaining oils, lipids and lipid-derived materials from low cellulosic biomass materials

InactiveUS20130206571A1Easily recoverableIncreased yieldDirect heating destructive distillationBiofuelsSolventTar

The present invention concerns low energy requiring methods for processing low cellulosic biomass materials into oil, char and liquid components. One method comprises the steps of subjecting the biomass to hydrothermal carbonization under specified reaction conditions for producing a combined char and oil fraction as well as an aqueous fraction, separating the combined oil and char fraction from the aqueous fraction by filtration; separating the combined oil and char fraction into individual oil and char fractions using an organic solvent for forming an oil depleted char fraction and a liquid oil and solvent solution, and separating the liquid oil and solvent solution into individual oil and solvent fractions by distillation.

Owner:HEILMANN STEVEN M +7

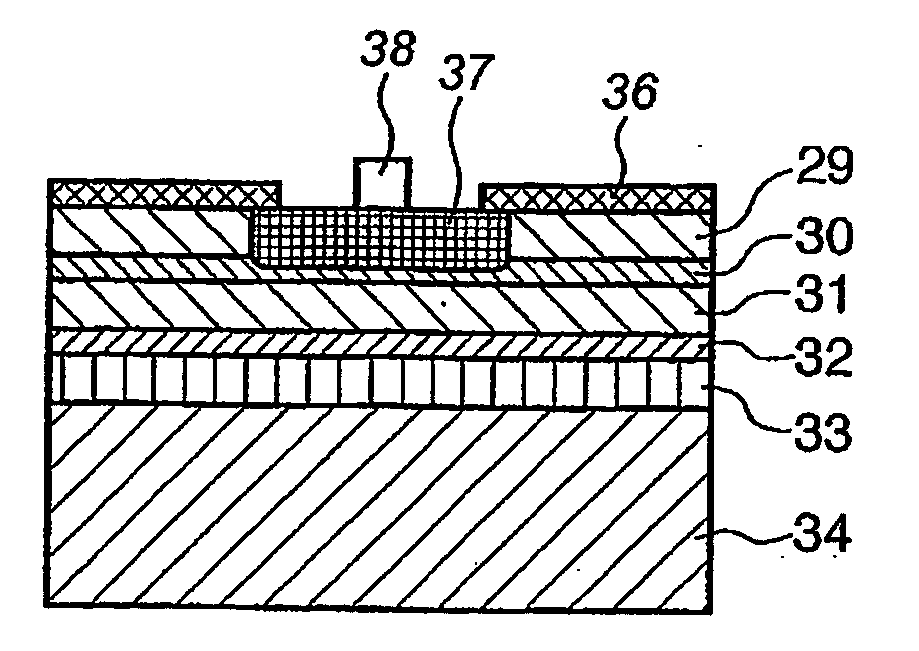

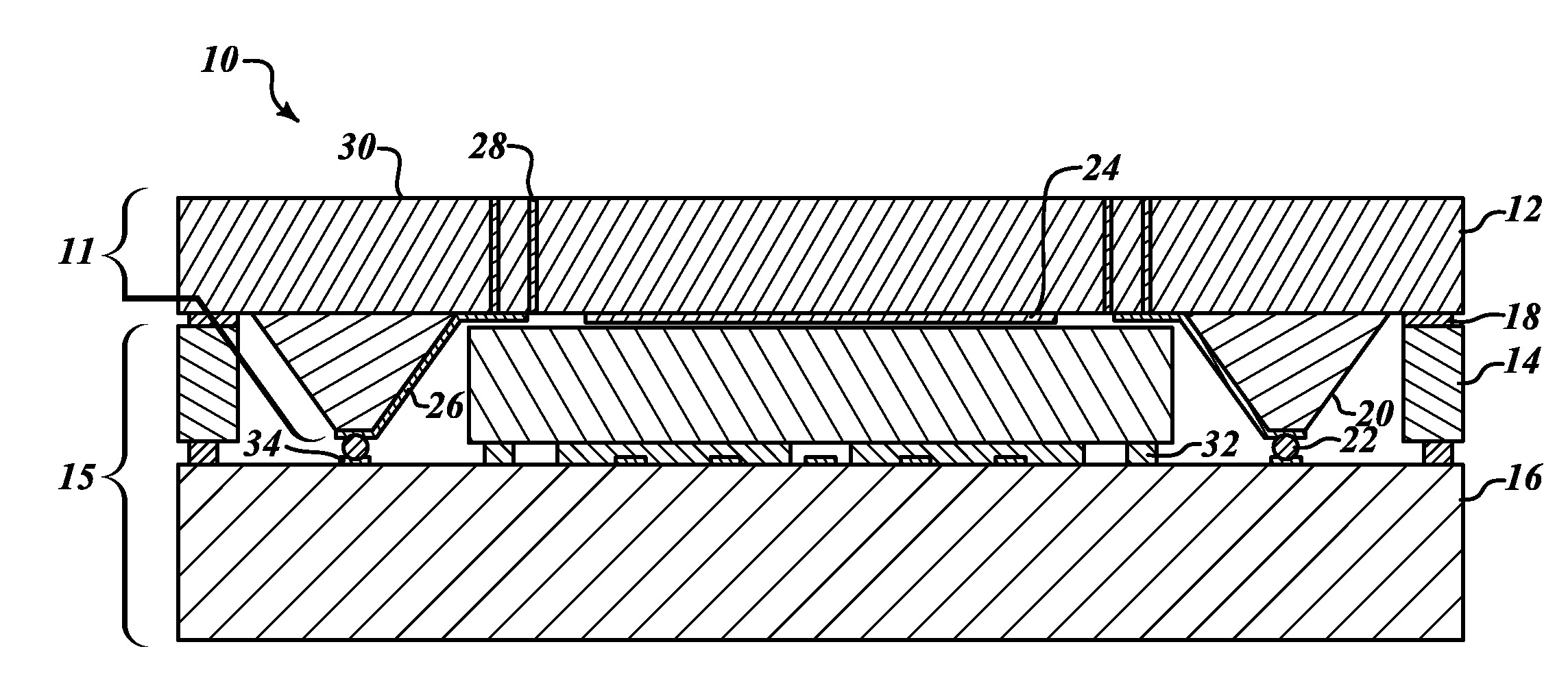

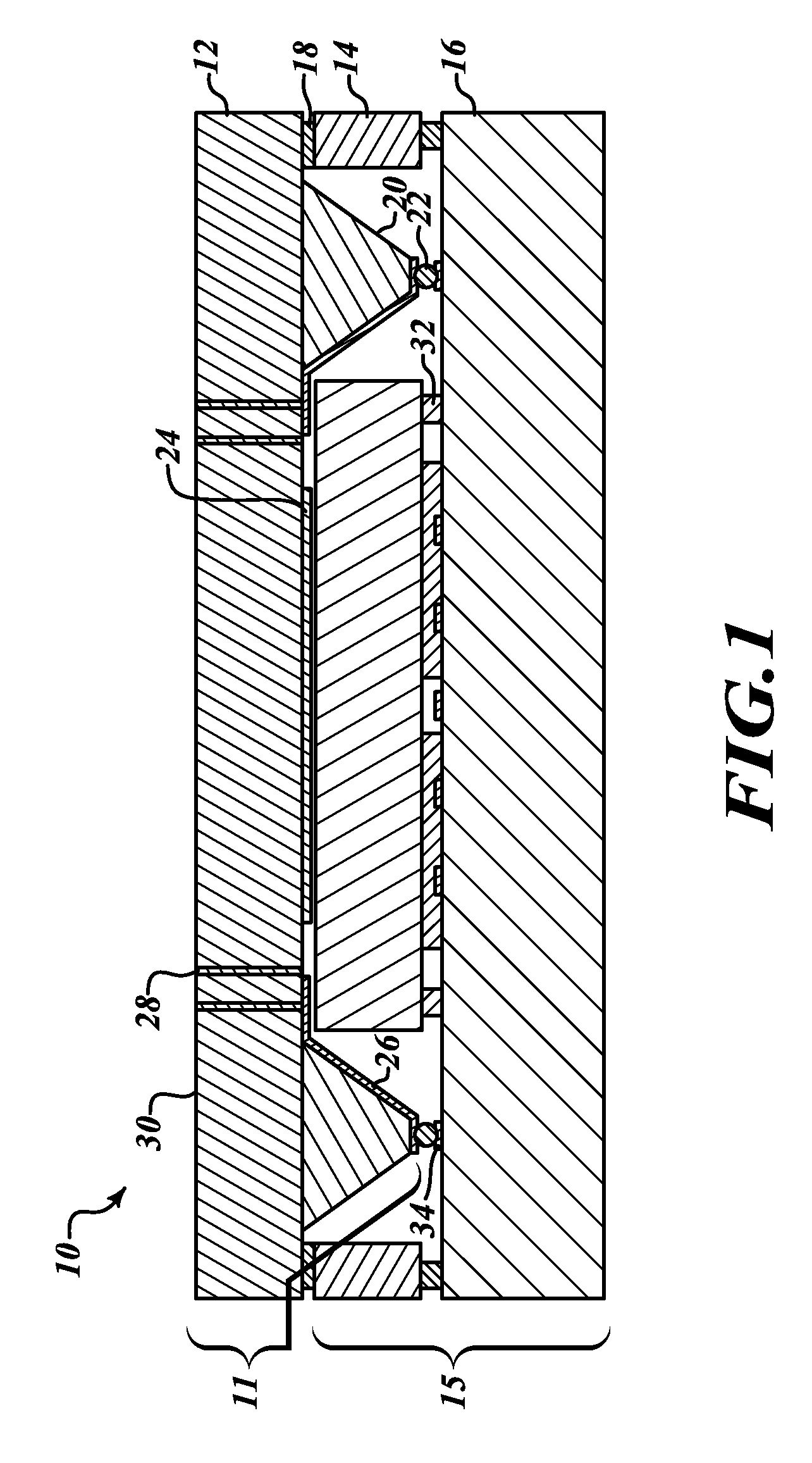

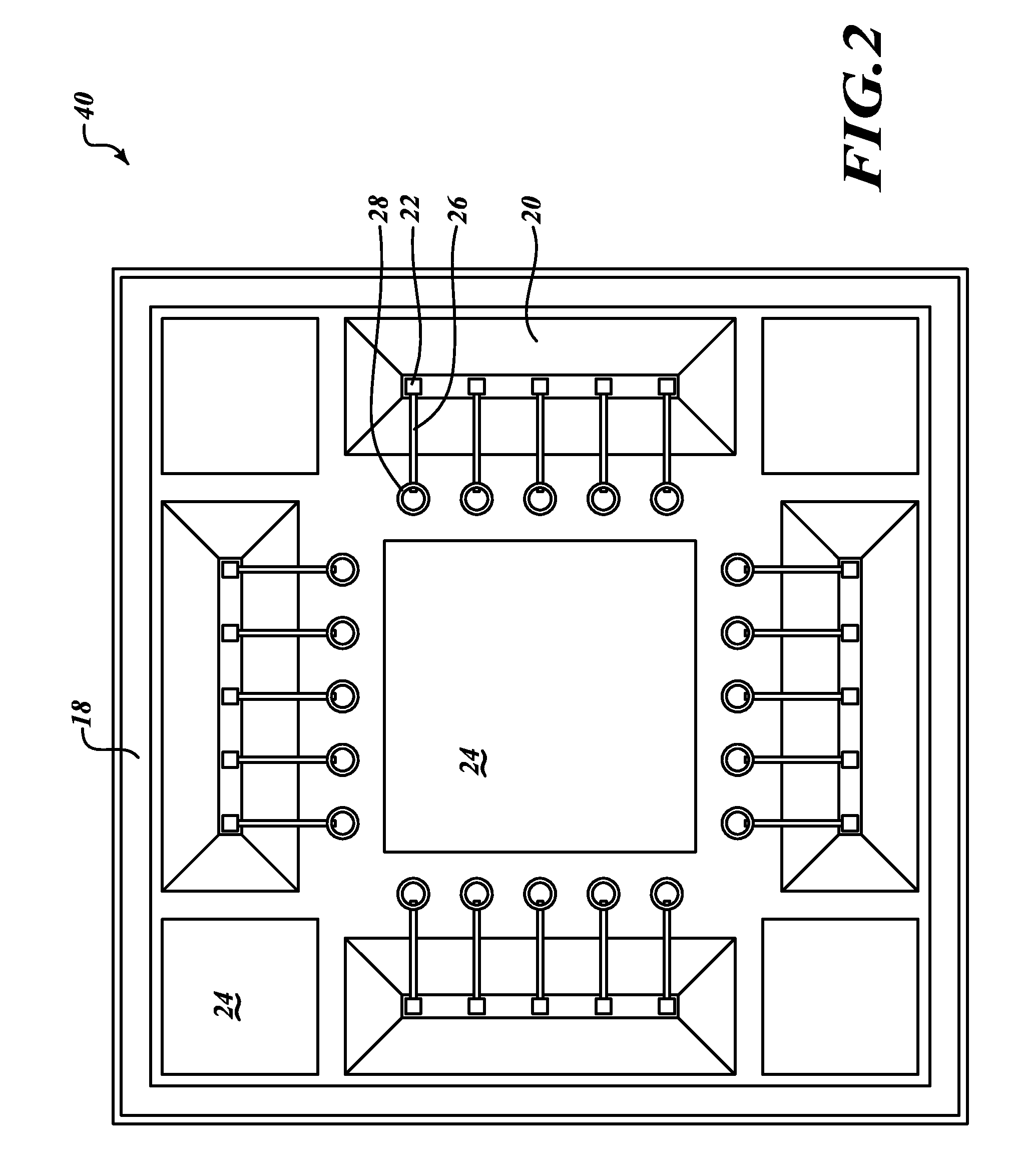

Systems and methods for implementing a wafer level hermetic interface chip

InactiveUS20100084752A1Increased yieldFacilitate hermetic sealSemiconductor/solid-state device detailsSolid-state devicesExternal circuit

Systems and methods for enabling hermetic sealing at the wafer level during fabrication of a microelectromechanical sensor (MEMS) device. The MEMS device has a specialized hermetic interface chip (HIC) that facilitates a stable hermetic sealing process. The HIC includes a plurality of vias in a substrate layer, a plurality of mesas having etched portions, a seal ring, a plurality of conductive leads on a first side of the HIC, and a plurality of conductive leads on a second side of the HIC. The plurality of conductive leads on the first side of the HIC feeds from the etched portions of the plurality of mesas through the plurality of vias in the substrate layer to the plurality of conductive leads on the second side of the HIC. The conductive leads are capable of connecting an external circuit to the MEMS device.

Owner:HONEYWELL INT INC

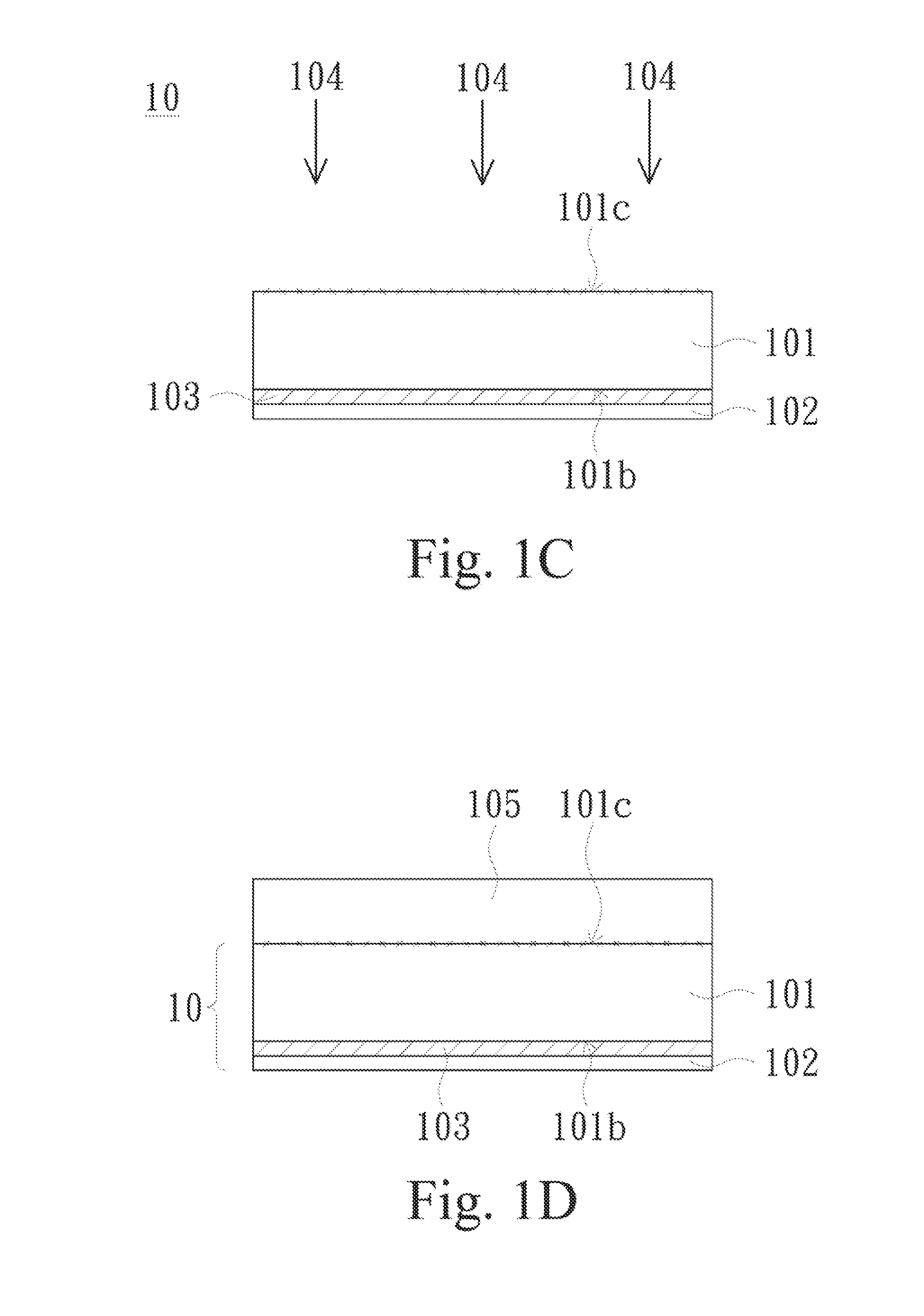

Metal substrate and method of manufacturing the same

ActiveUS20150257253A1Increased yieldIncrease productivity and efficiencyRecord information storageMagnetic recordingMetal substrateOptoelectronics

A metal substrate includes a first insulating substrate, a second insulating substrate, a first metal layer, a second metal layer and a release layer. The first insulating substrate has a first modified surface and a second surface opposite to the first modified surface. The first metal layer faces the second surface. The release layer is bonded on the first modified surface. The second insulating substrate is bonded on a side of the release layer, such that the release layer is between the first modified surface and the second insulating substrate. The second metal layer is disposed on a side of the second insulating substrate, such that the second insulating substrate is between the release layer and the second metal layer. An original surface roughness of the first modified surface has a variation substantially less than 10% after the first modified surface is released from the release layer.

Owner:AZOTEK

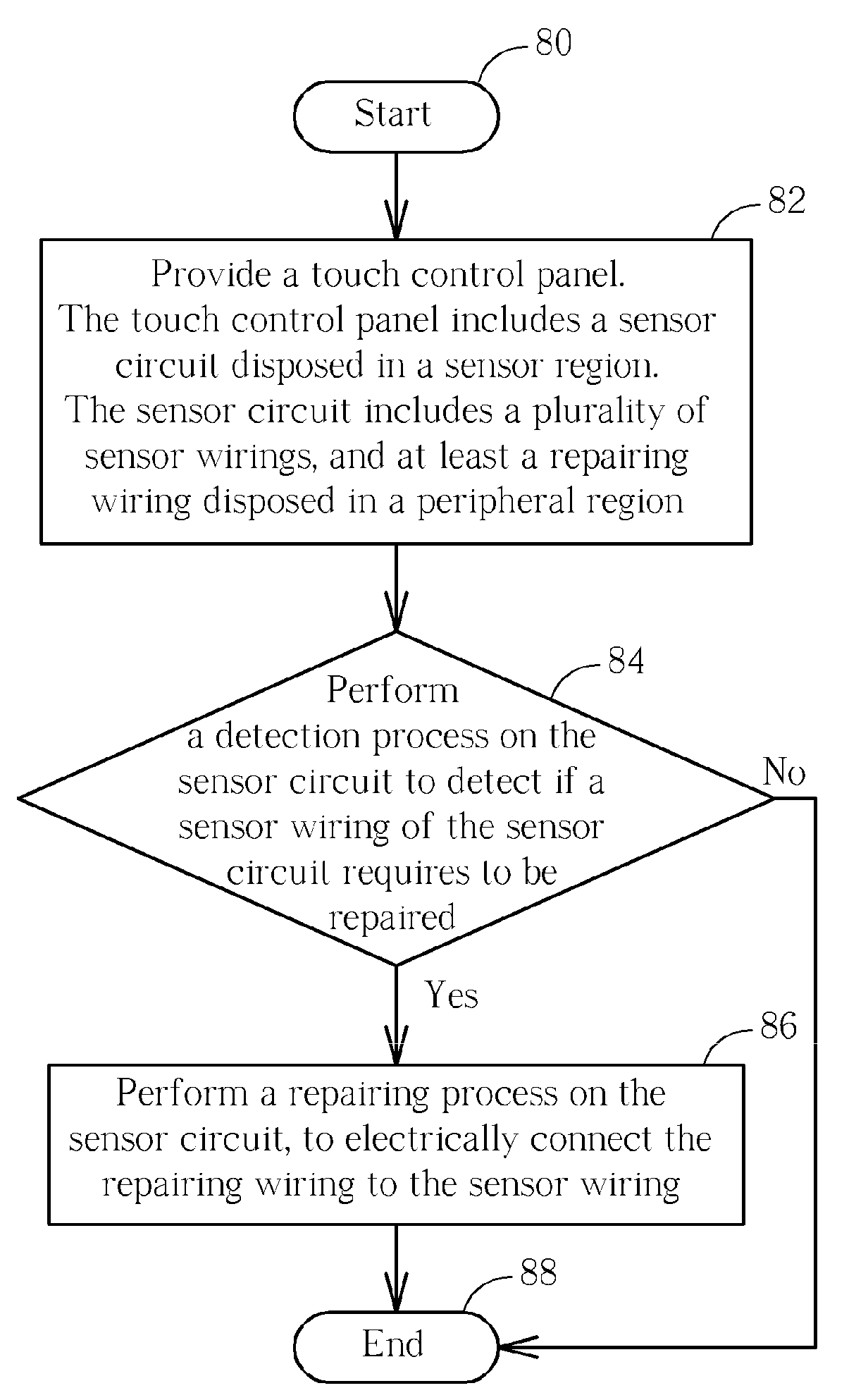

Repairable touch control device and method of repairing touch control panel

ActiveUS20100007615A1Increased yieldCost reductionInput/output processes for data processingEngineeringElectrical and Electronics engineering

A repairable touch control device includes a substrate, a sensor circuit, and at least a repairing wiring. The substrate includes a sensor region, and a peripheral region. The sensor circuit, which includes sensor wirings, is disposed in the sensor region. The repairing wiring is disposed in the peripheral region for repairing the sensor wirings.

Owner:AU OPTRONICS CORP

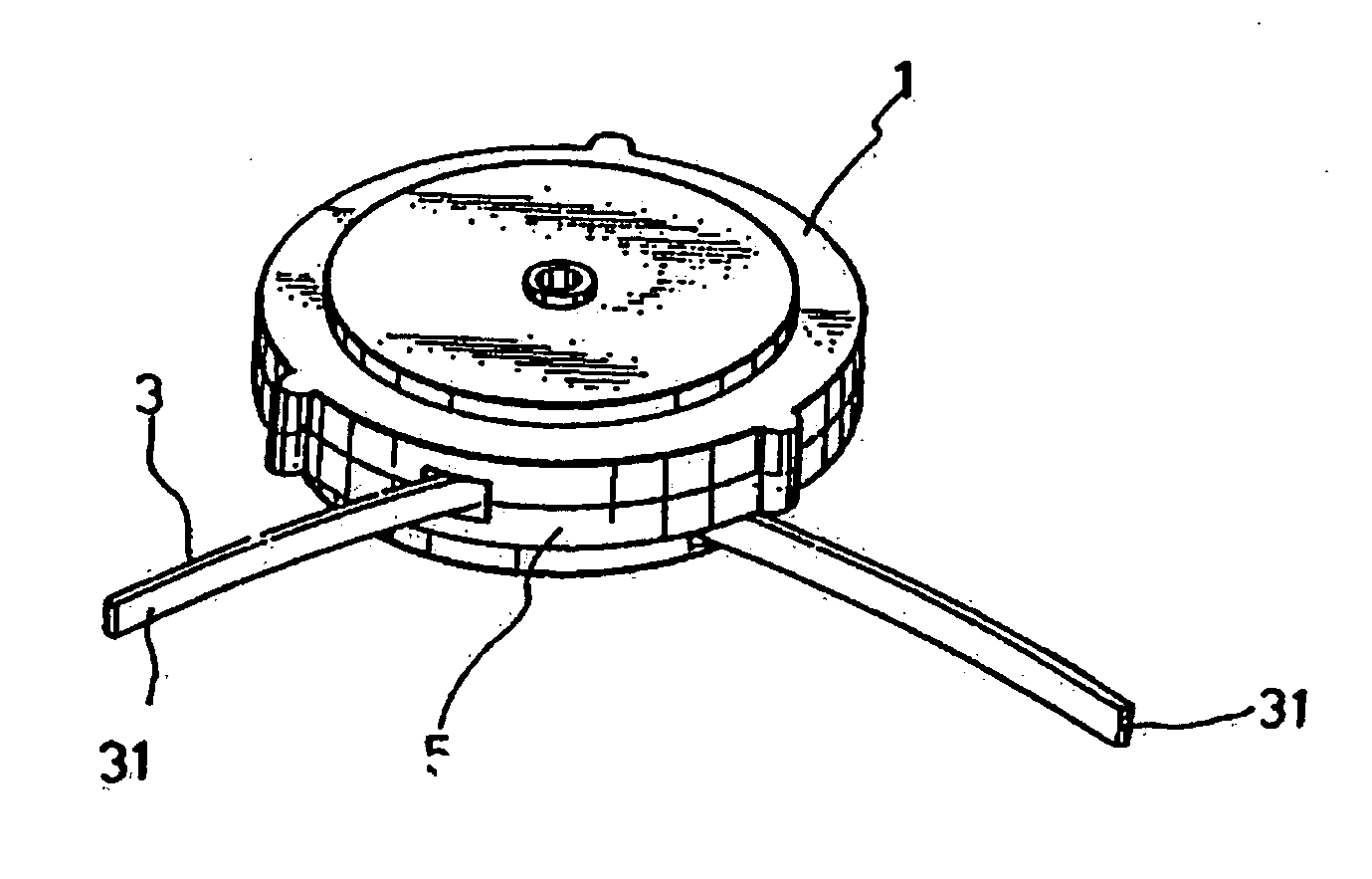

Structure of a single-pull reel

InactiveUS20090101743A1Increased yieldMuscle operated startersMachines/enginesEngineeringCoil spring

A single-pull reel which includes a bottom cover having a center axle, a top cover engageable with the bottom cover; a cord-rotating disc having a top portion provided with a circular flange which is divided into a plurality of sections by a plurality of slots, a clamping member being provided behind one of the sections to form a passage therebetween and having a plurality of serrated teeth at an inner side against the one of the sections, the bottom portion being provided with a multi-operation urging track, a spiral spring having an inner end engaged with a notch of the axle and an outer end bent into a hook to engage with one of the sections of the cord-rotating disc, a cord, and a peg positioning structure comprising a peg and a pulling spring.

Owner:ACROX TECH

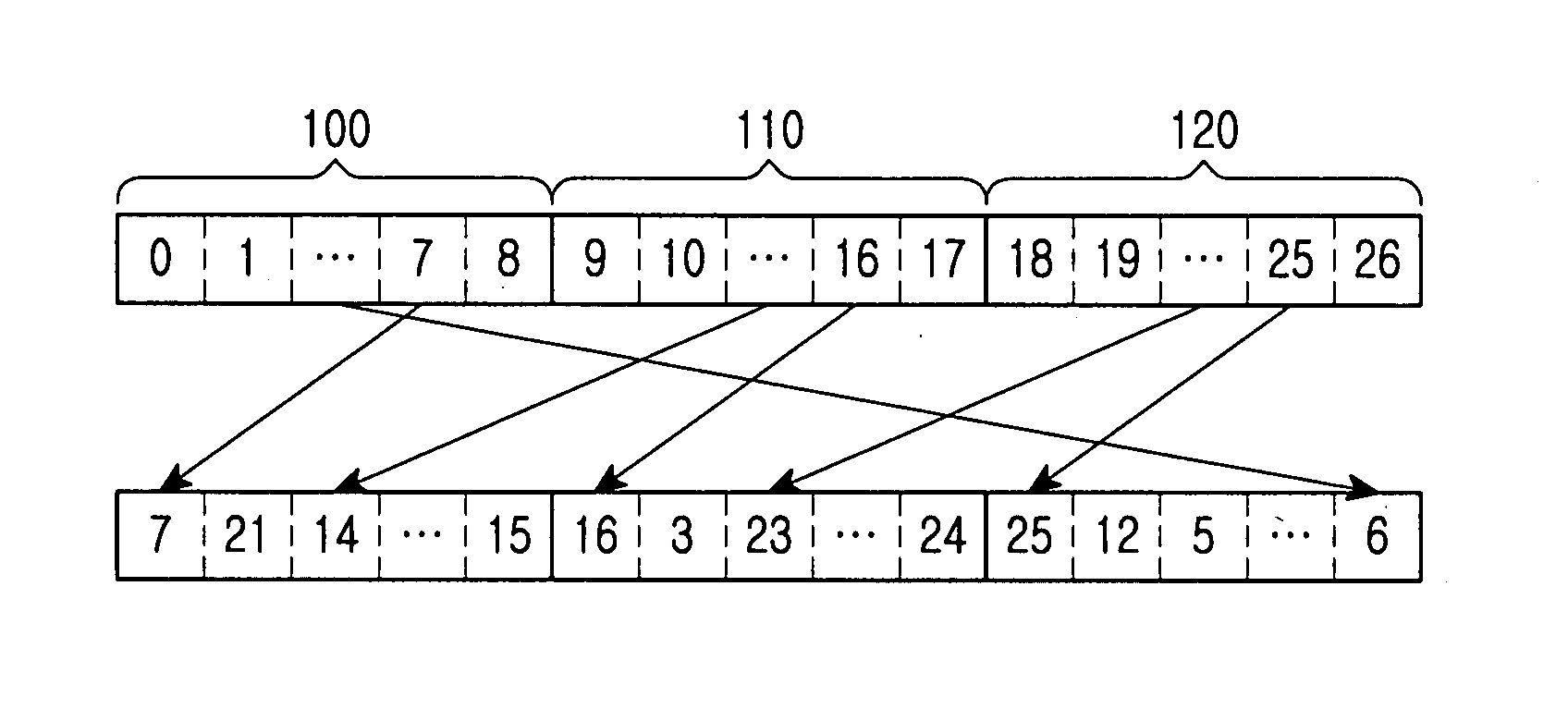

Parallel interleaving apparatus and method

InactiveUS20080109618A1Increased yieldIncrease productionMemory adressing/allocation/relocationCode conversionParallel computing

Provided is a parallel interleaving method and apparatus. The parallel interleaving method includes dividing input information bits into a predetermined number of sub-blocks and interleaving the information bits divided into the sub-blocks according to a predetermined first interleaving rule.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Production Process of Granular Poly(Arylene Sulfide)

The invention provides a production process of a granular poly(arylene sulfide) by polymerizing a sulfur source and a dihalo-aromatic compound in an organic amide solvent by a polymerization process containing a phase-separation polymerization step, wherein the production process contains a step I of adding an aromatic compound in a proportion of 0.01 to 20 mol per 100 mol of the organic amide solvent into the liquid phase containing the organic amide solvent and a formed polymer within the polymerization reaction system, said liquid phase being in the phase-separated state, after the phase-separation polymerization step; a step II of cooling the liquid phase within the polymerization reaction system; and a step III of collecting the formed polymer from the liquid phase.

Owner:KUREHA KAGAKU KOGYO KK

Compositions and processes for fracturing subterranean formations

ActiveUS20110005969A1Increased yieldLiquid organic insulatorsFluid removalChemistryFluid composition

The present invention is directed to novel additives packages, to fluid compositions including the additives, to methods of using the fluid compositions and the additives package, to methods of recovering hydrocarbons, and to petroleum products made from hydrocarbons derived from these methods. The novel additives packages may be used in a fluid composition for fracturing a subterranean. The additives package of the present invention include one or more gelling agents; one or more cross-linking agent; and one or more high temperature stabilizers; wherein the additives package further comprises one or more ingredients selected from the group consisting of a clay stabilizer, a metallic base, a cross-link retarder, and a gel breaker, and any combination thereof; and wherein the additives package optionally includes a diluent.

Owner:GIFFIN CLAUDINE

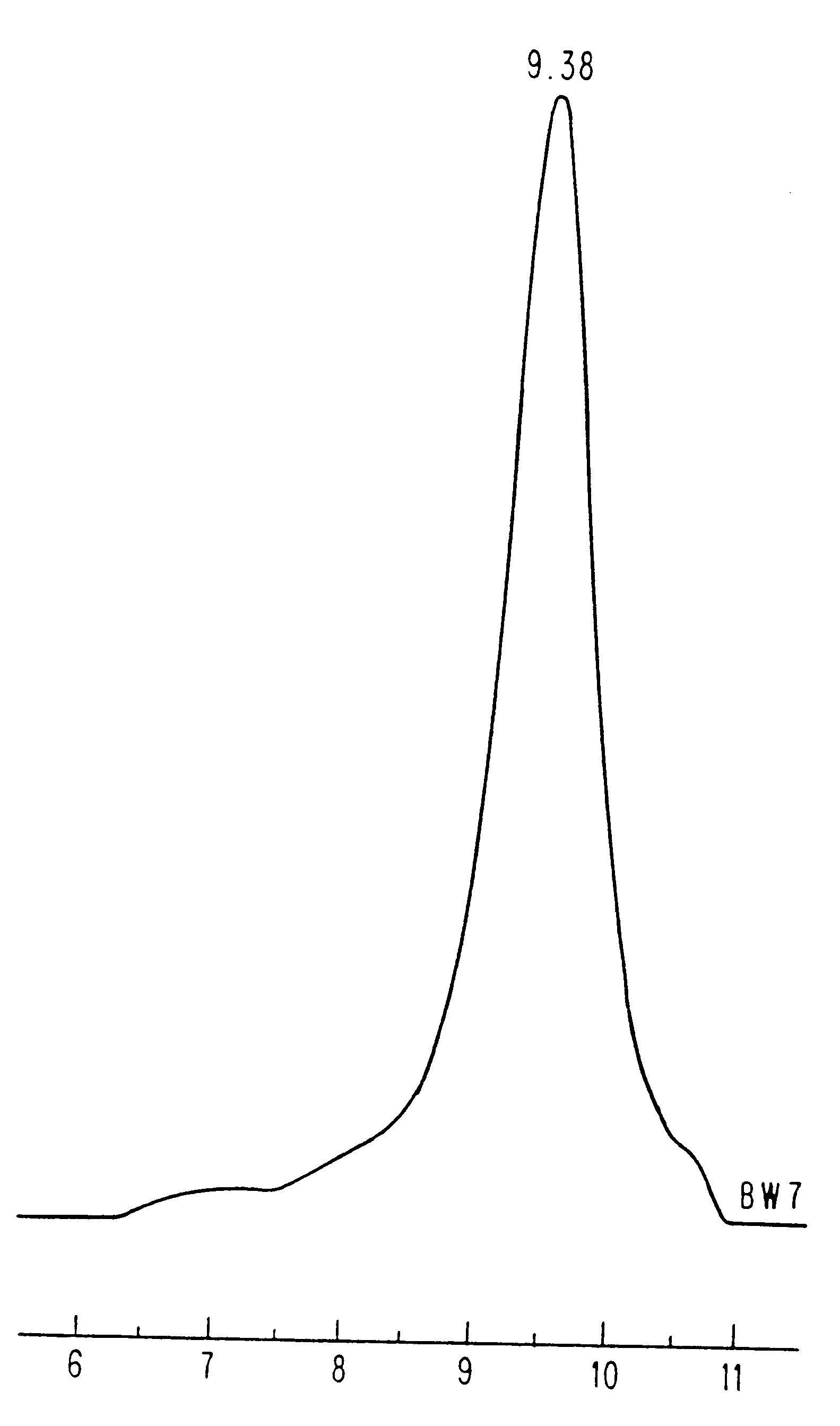

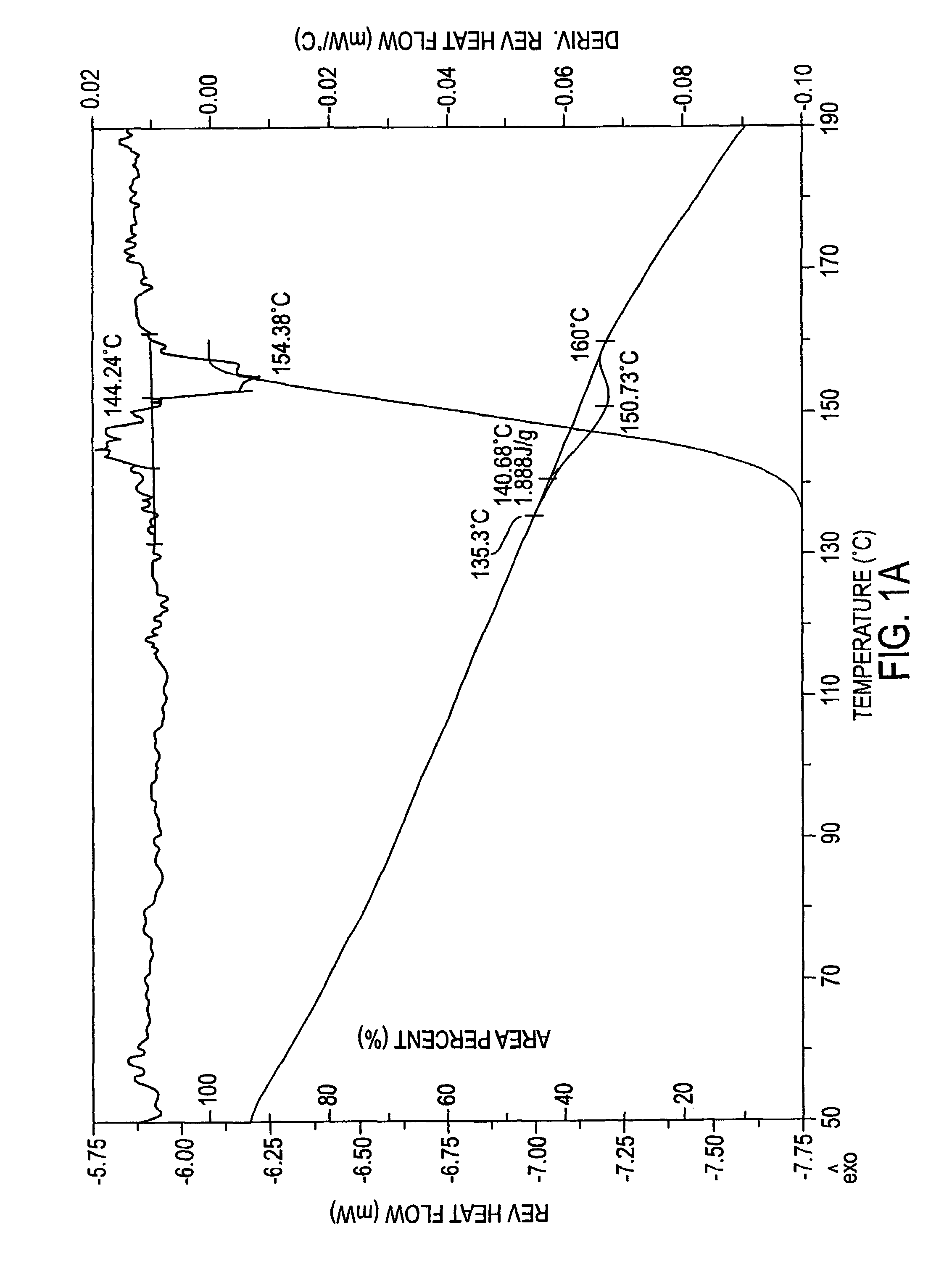

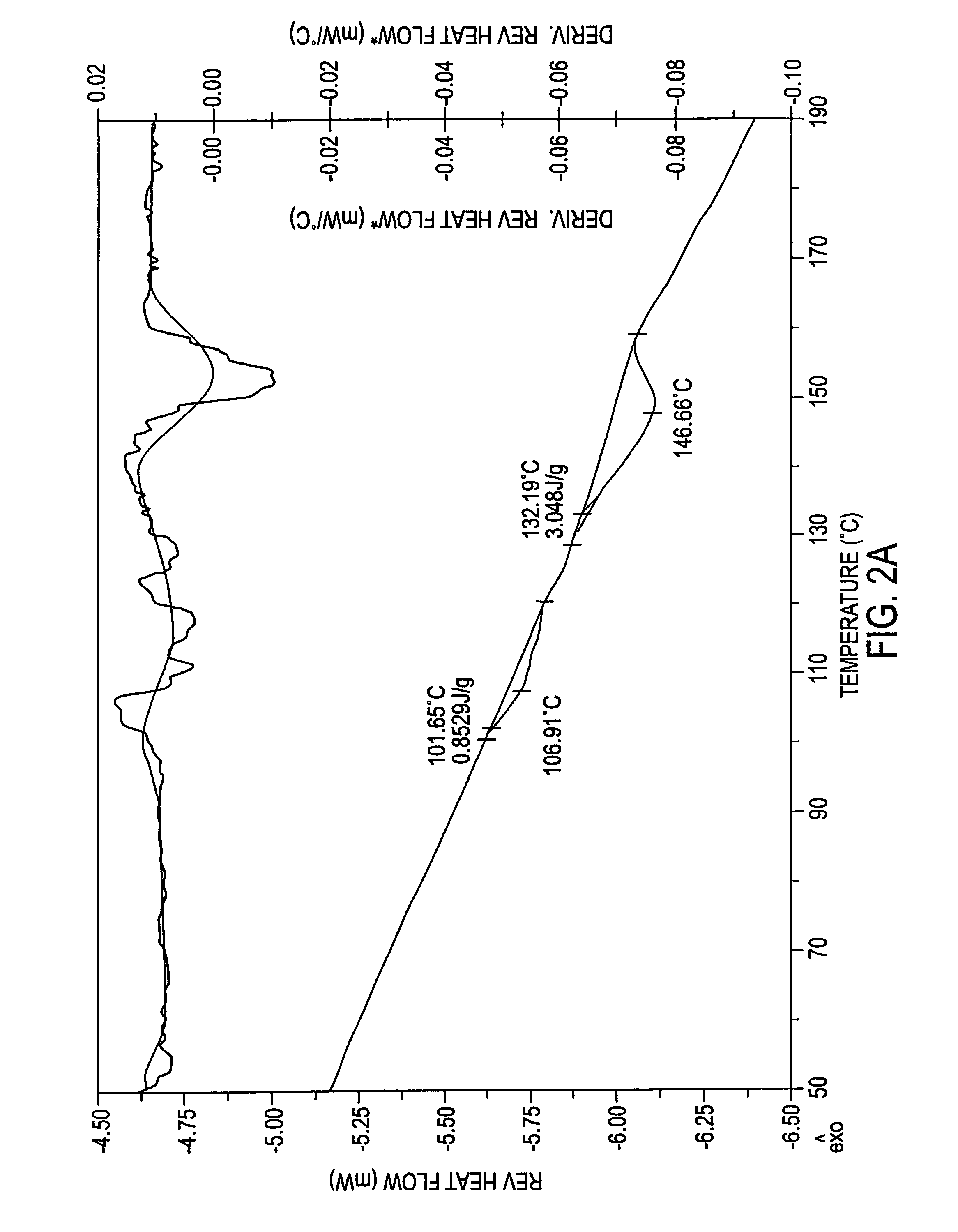

Process for making enzyme-resistant starch for reduced-calorie flour replacer

An enzyme resistant starch type III having a melting point or endothermic peak of at least about 140° C. as determined by differential scanning calorimetry (DSC) is produced in yields of at least about 25% by weight, based upon the weight of the original starch ingredient. A gelatinization stage, nucleation / propagation stage, and preferably a heat-treatment stage are used to produce reduced calorie starch-based compositions which contain the enzyme resistant starch type III. The high melting point of the enzyme resistant starch permits its use in baked good formulations without substantial loss of enzyme resistance upon baking. A gelatinized, starch-based bulking agent having at least 30% by weight of the enzyme-resistant starch may be used in bar-type, extruded, sheeted, or rotary molded food products. The melting enthalpy of the bulking agent may be from about 0.5 to about 4 Joules / g and its water-holding capacity may be less than 3 grams.

Owner:INTERCONTINENTAL GREAT BRANDS

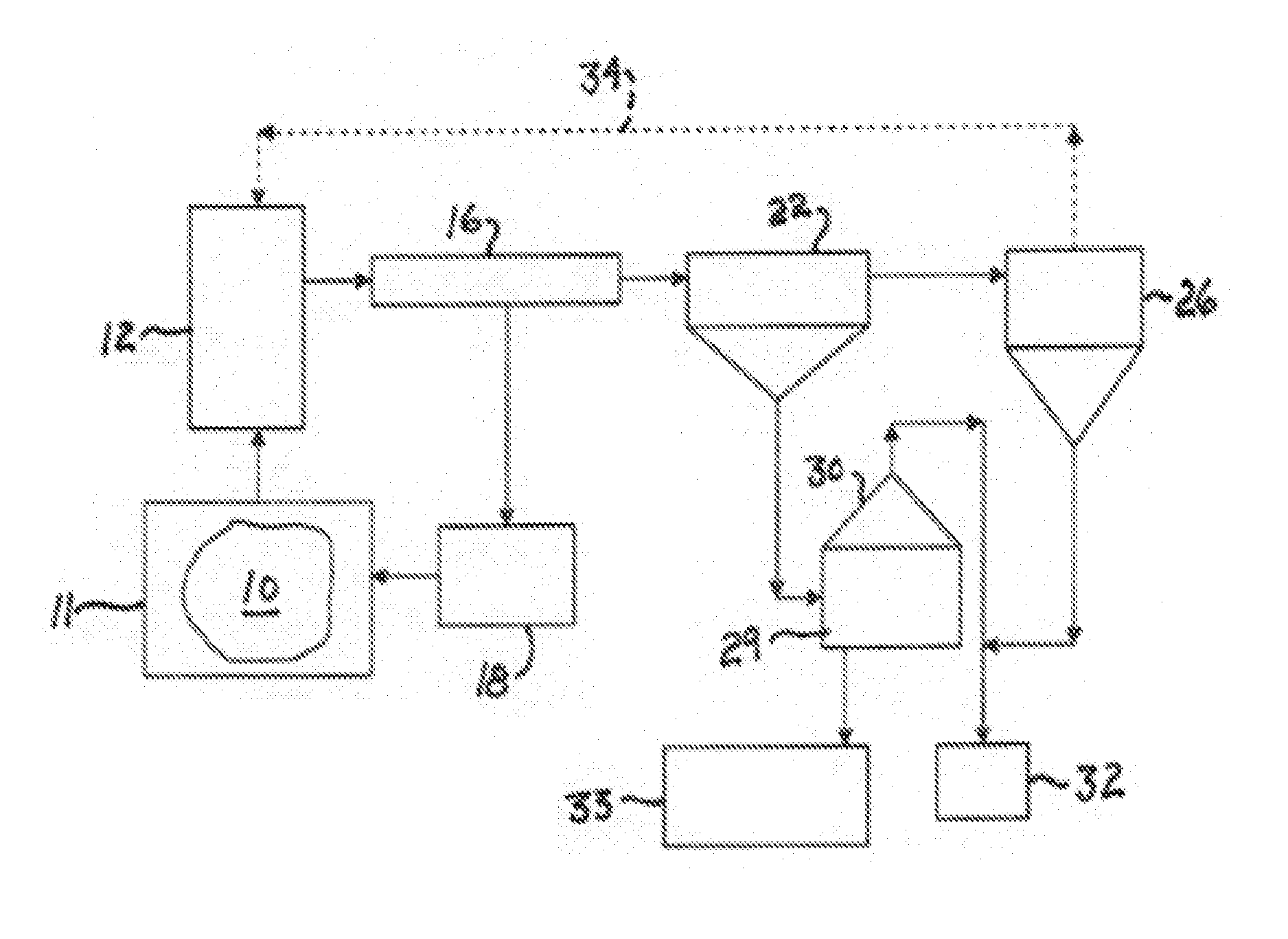

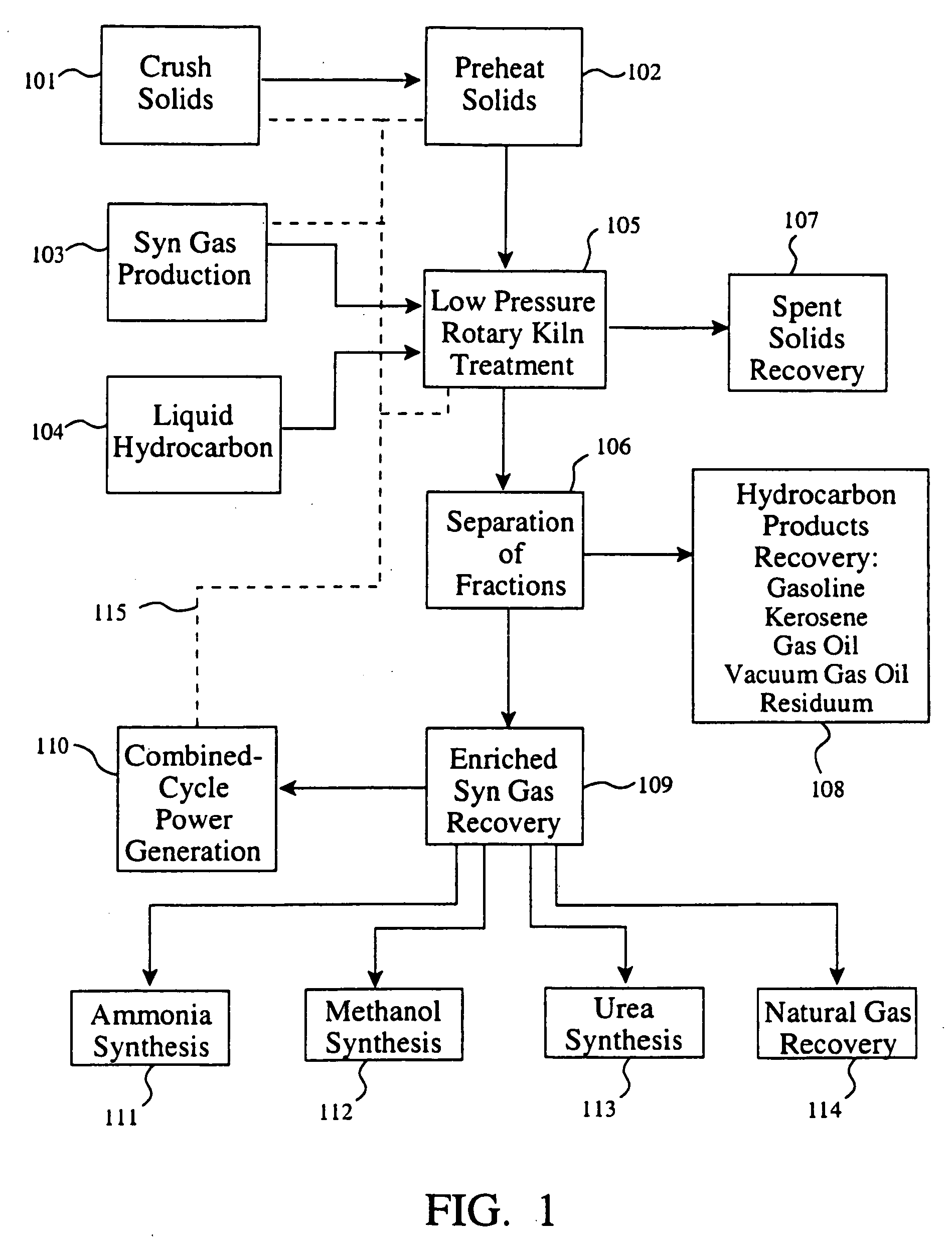

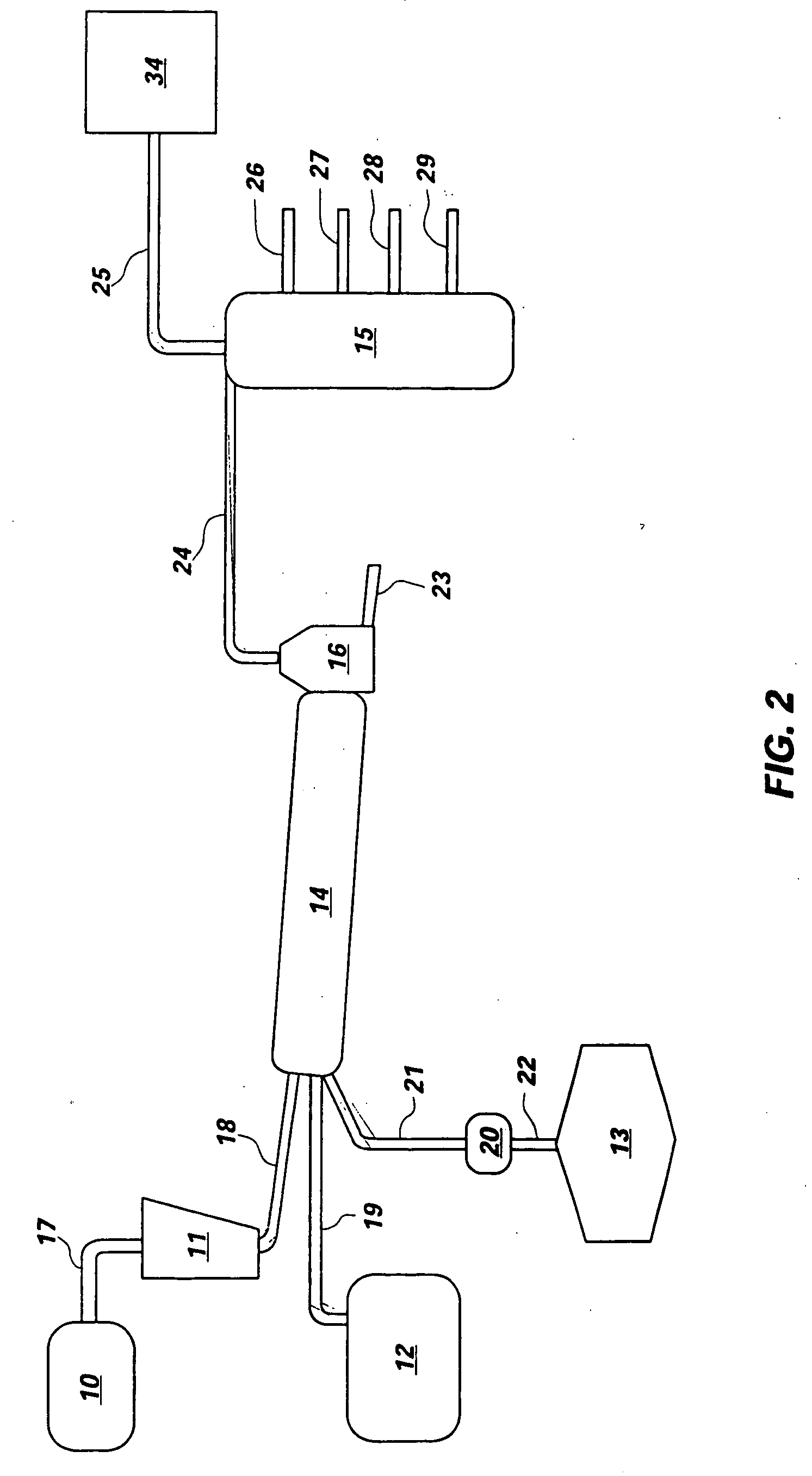

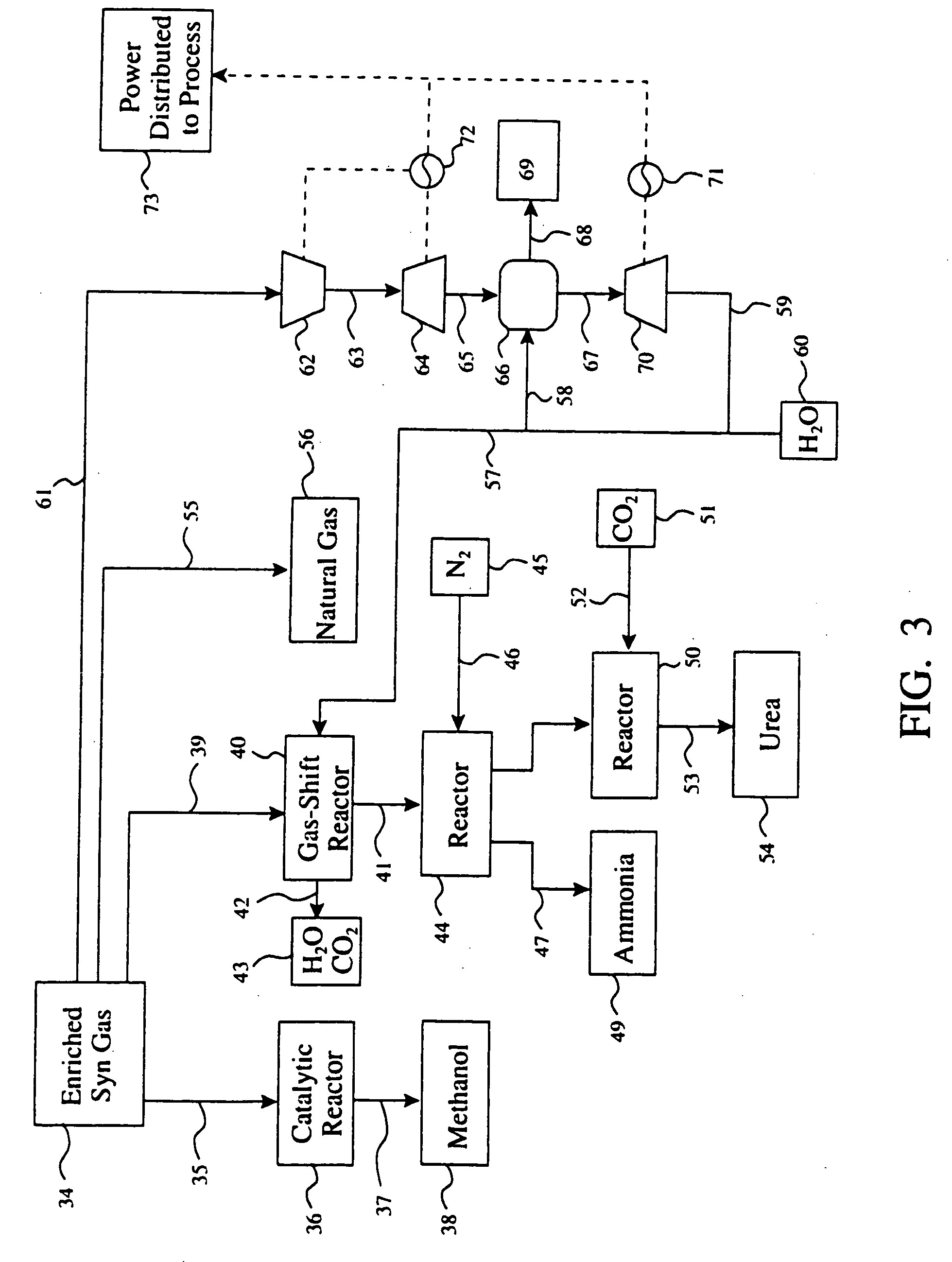

Process for the recovery of hydrocarbon fractions from hydrocarbonaceous solids

InactiveUS20050173305A1Increased yieldMinimizes burnLiquid hydrocarbon mixture productionLiquid-gas reaction processesChemistryCarbon dioxide

Process and apparatus for extraction of oil and hydrocarbons from crushed hydrocarbonaceous solids (101), such as oil shale, involving the pyrolyzing of the crushed solids (101) with liquid hydrocarbon (104) and hot gas such as syn gas (103) rich in hydrogen, carbon dioxide and carbon monoxide or a solid hydrocarbon such as gilsonite. Crushed hydrocarbonaceous solids are treated with a hydrocarbon and hot gas in a rotary kiln (105) where the crushed solids are cascaded into the hot gas for sufficient time to strip the volatile liquids and gases found in the solids, removing the vaporized liquids, enriched hot gas and spent crushed solids from the kiln, fractionating the vaporized liquids (106) and enriched syn gas into the desired fractions. Use of hot syn gas is particularly suited for use in conjunction with combined-cycle electricity generation (110) and in the preparation of various by-products. The process efficiently recycles heat and energy to reduce harmful atmospheric emissions and reliance on external energy sources.

Owner:SMITH ANTHON L

Electronic component testing apparatus

InactiveUS20070018673A1Increased yieldProbability decreaseIndividual semiconductor device testingEngineeringInput/output

Owner:KING YUAN ELECTRONICS

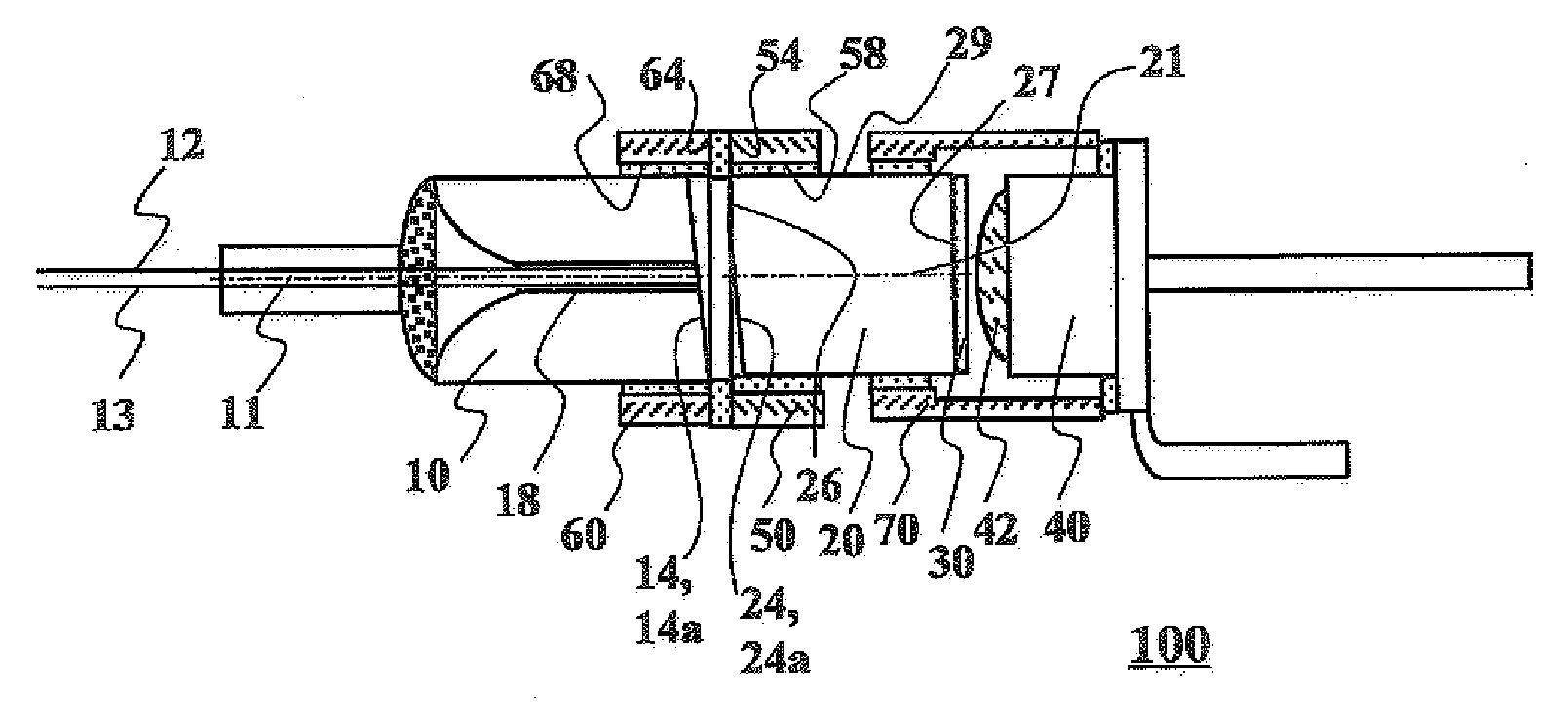

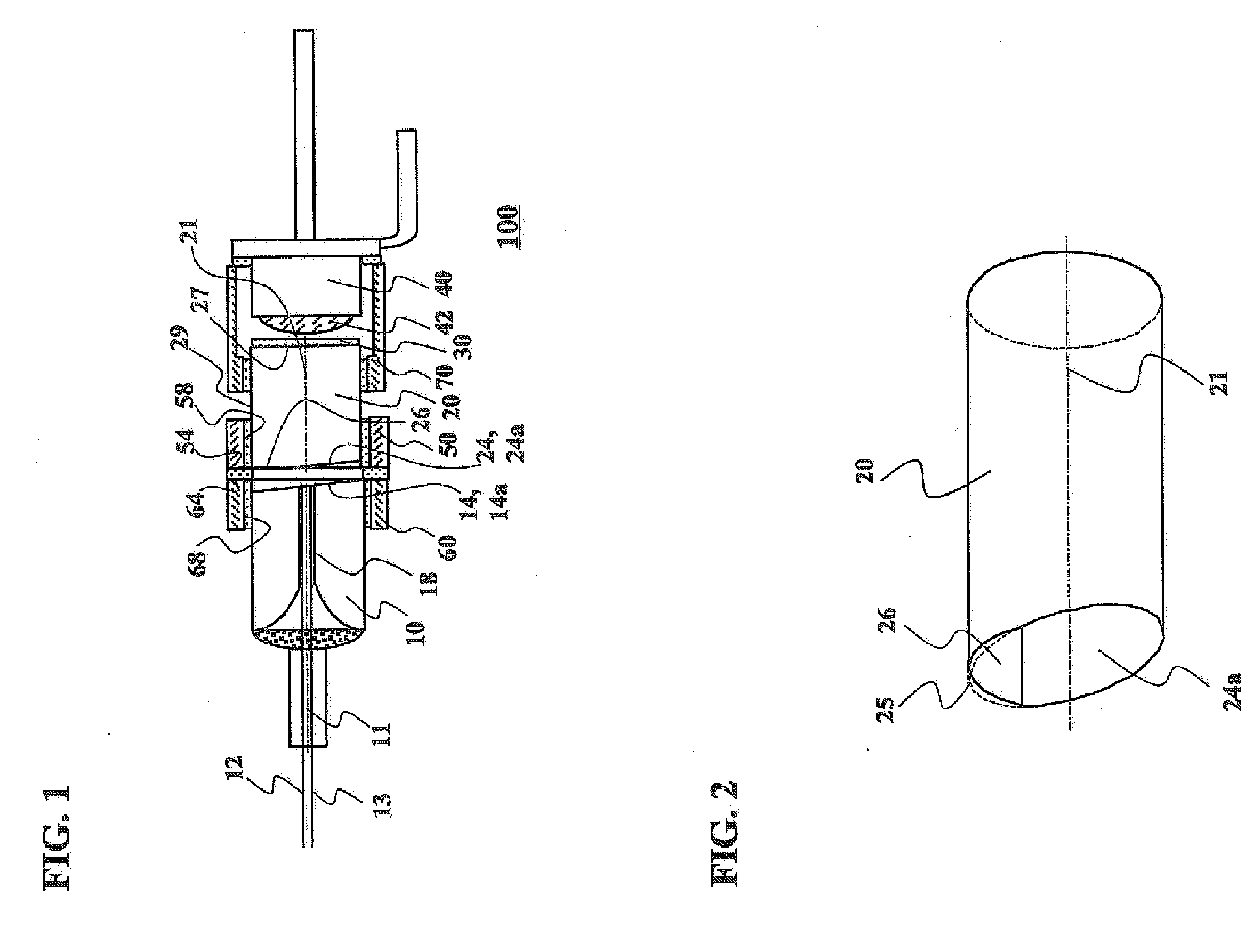

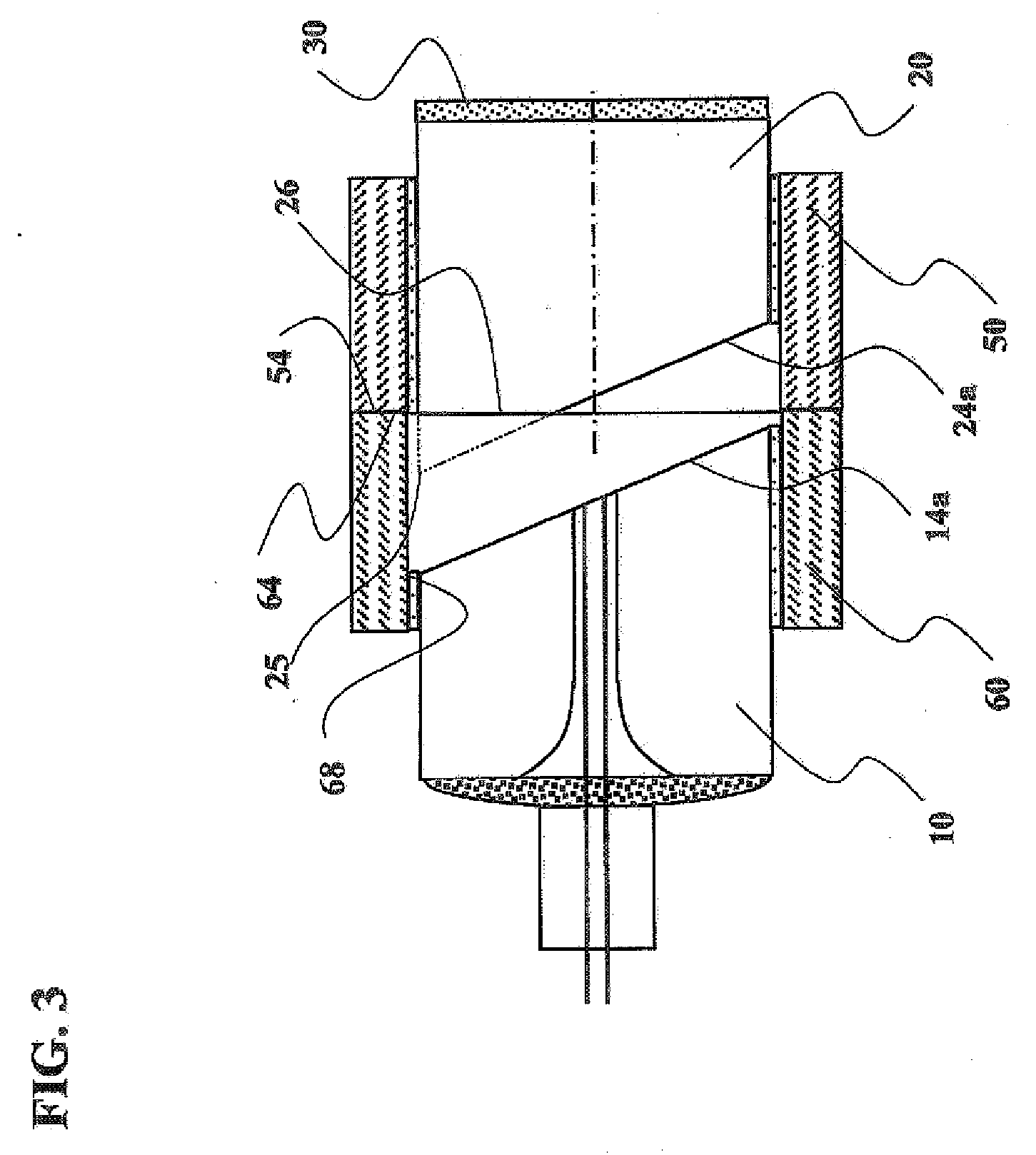

Optical Power Monitor and its Manufacturing Method

An optical power monitor comprising a pig-tail fiber and a GRIN lens opposed to each other with a spacing and each having an end face (angled face) angled with respect to the axis, being low on reflection loss and able to be easily assembled. The pig-tail fiber and the GRIN lens are fixed in respective sleeves having axial end faces adhered to each other. At least one of the pig-tail fiber and the GRIN lens has an arc-segmental end face directed in its axial direction at the tip of its angled face. The arc-segmental end face is positioned in the same plane as the axial end face of the sleeve of the one. The axis of the sleeve of the one is kept vertical to the axial end face of the sleeve of the one. It can be prevented that the axial tip of the other enters the sleeve of the one and comes into contact with an inner wall of the sleeve of the one. Therefore, the assembling man-hours needed to adjust their relative positions can be reduced, and the assembling yield can be improved.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com