Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

302 results about "Directed self assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

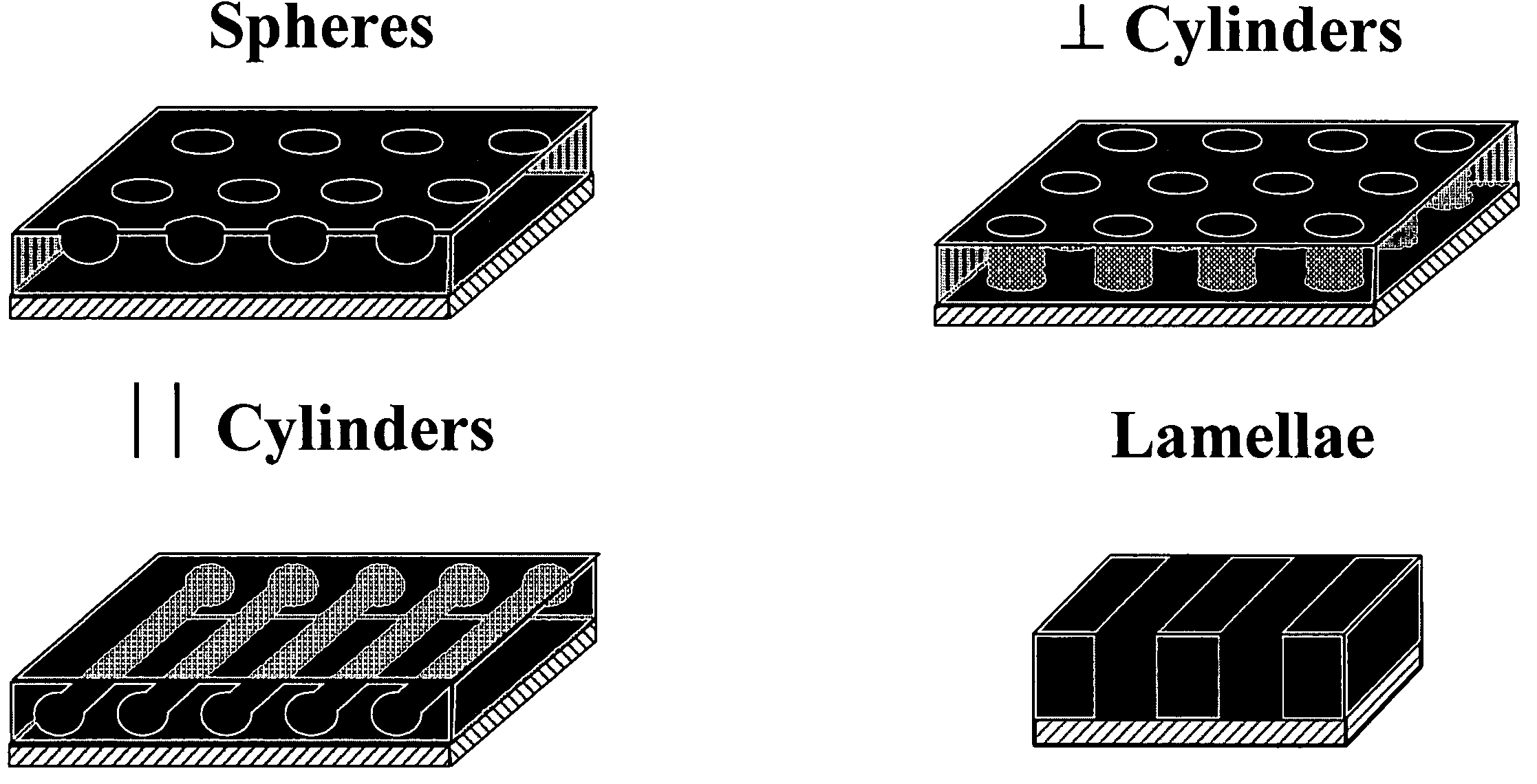

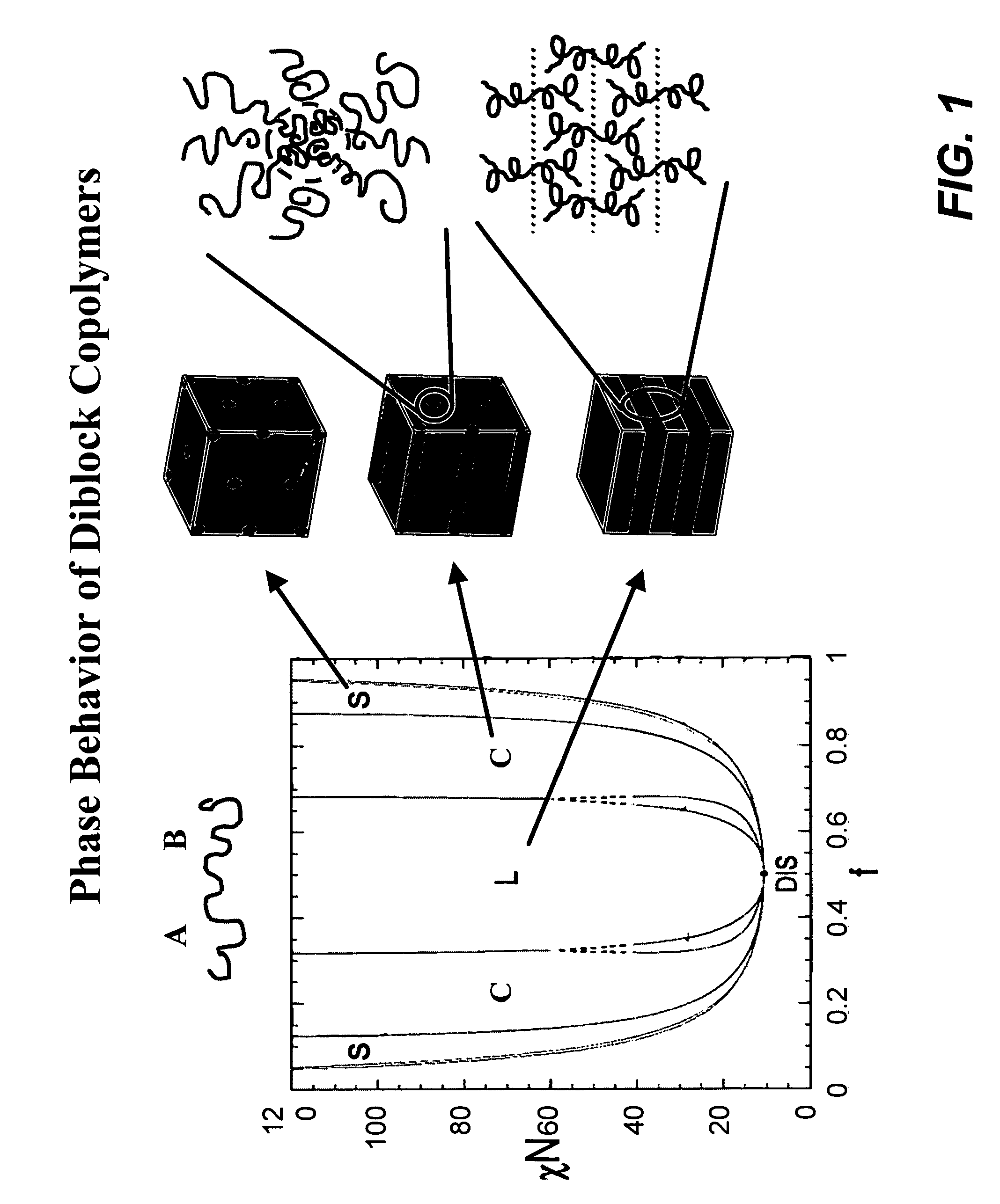

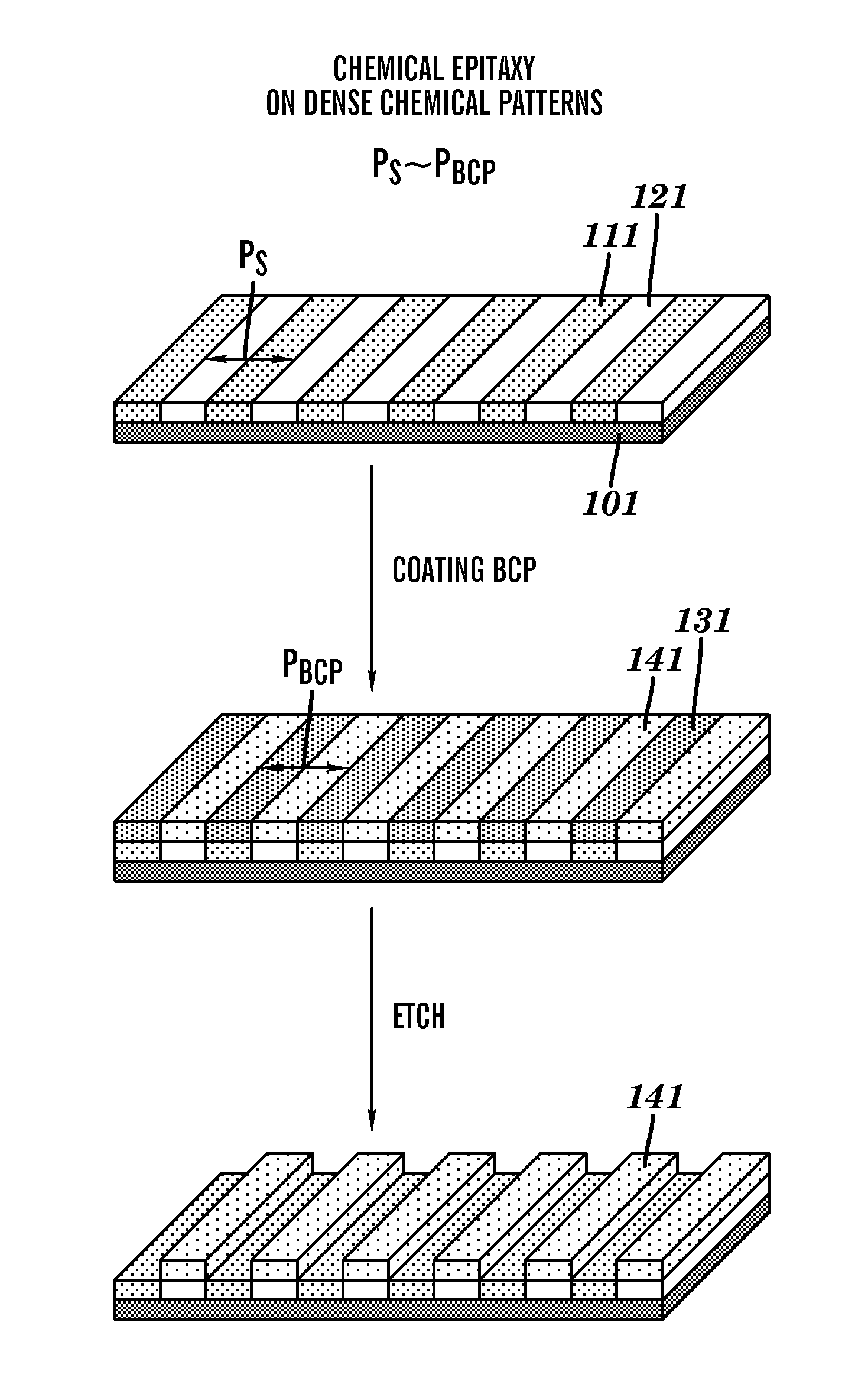

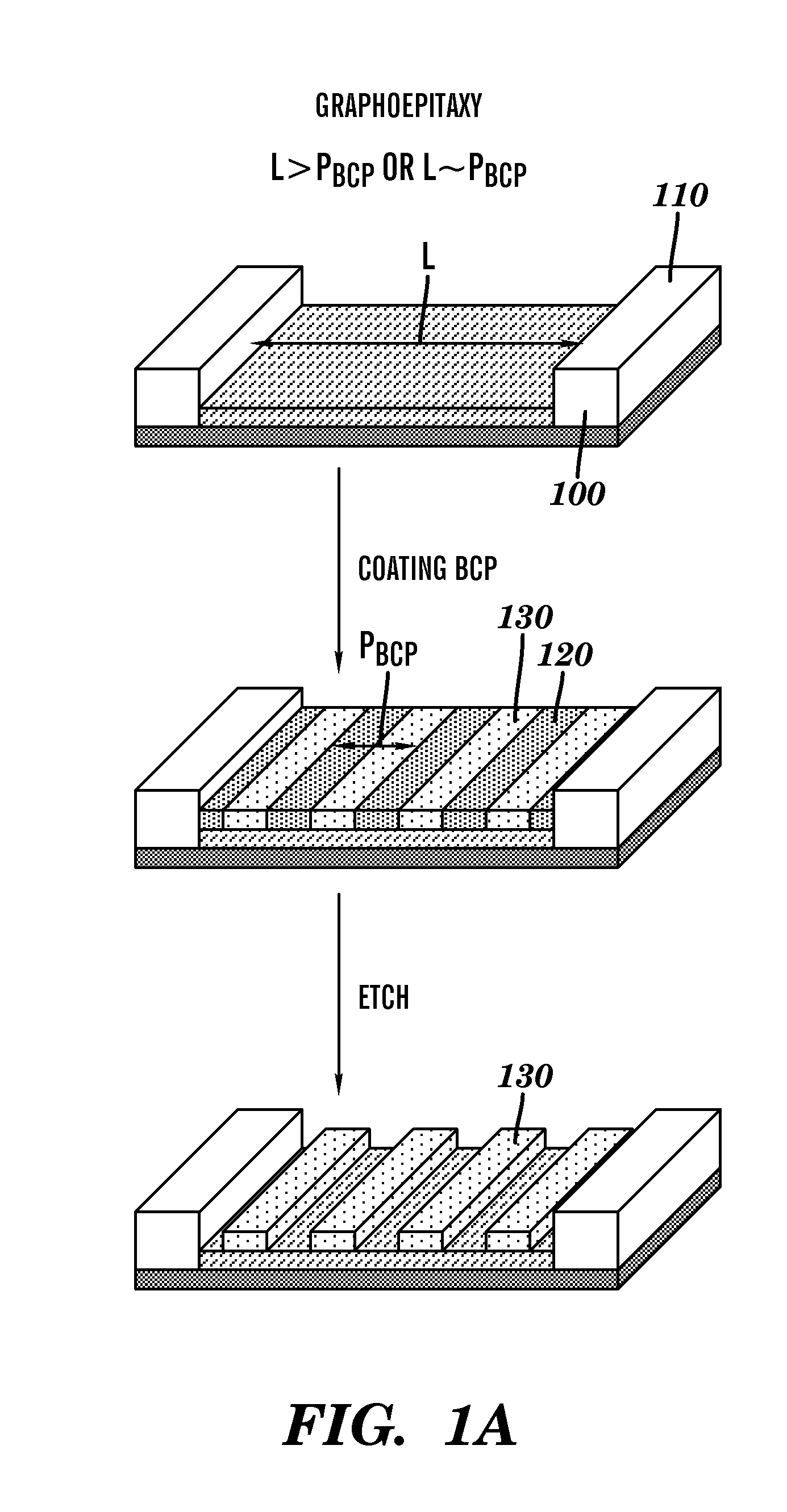

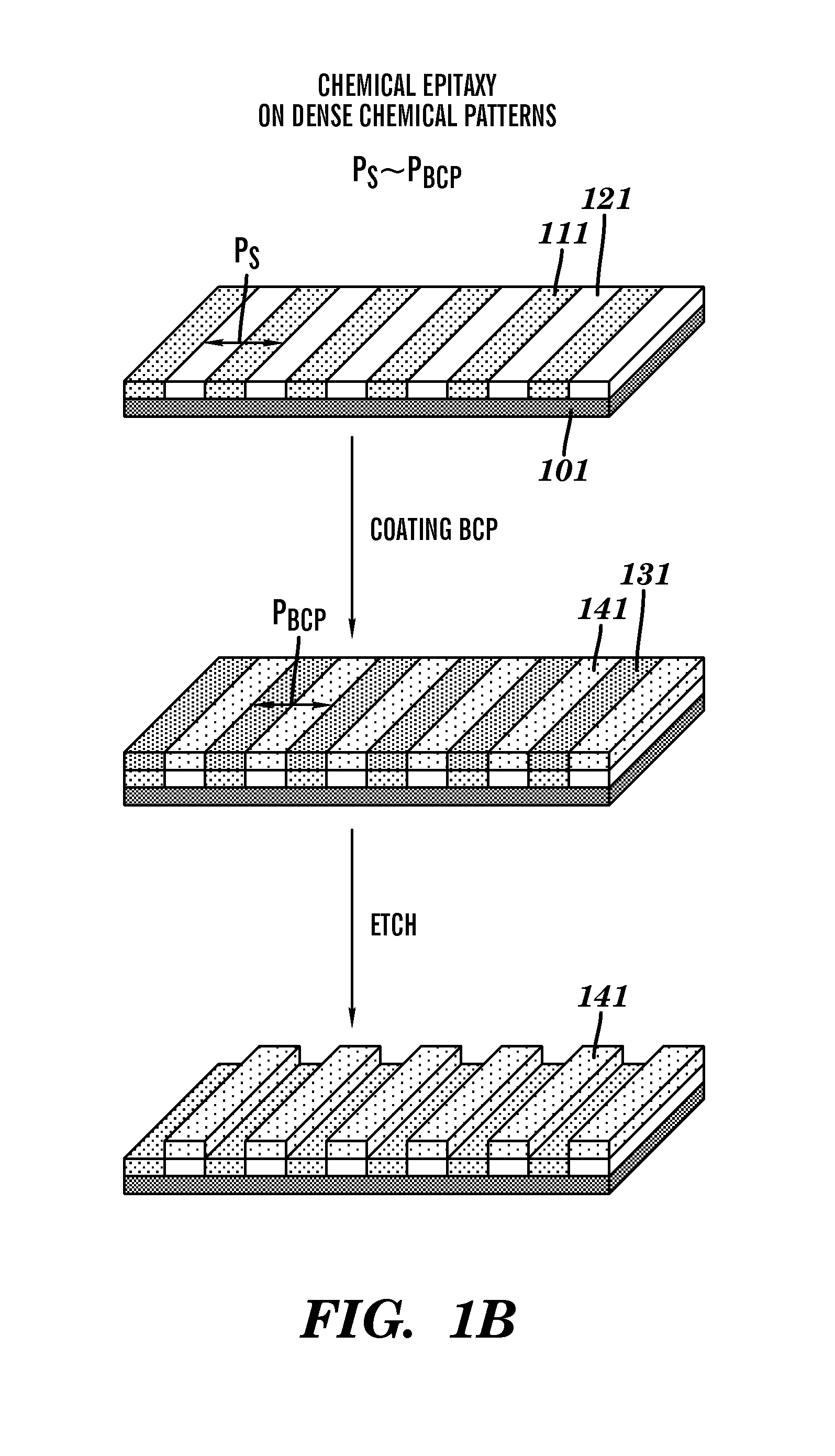

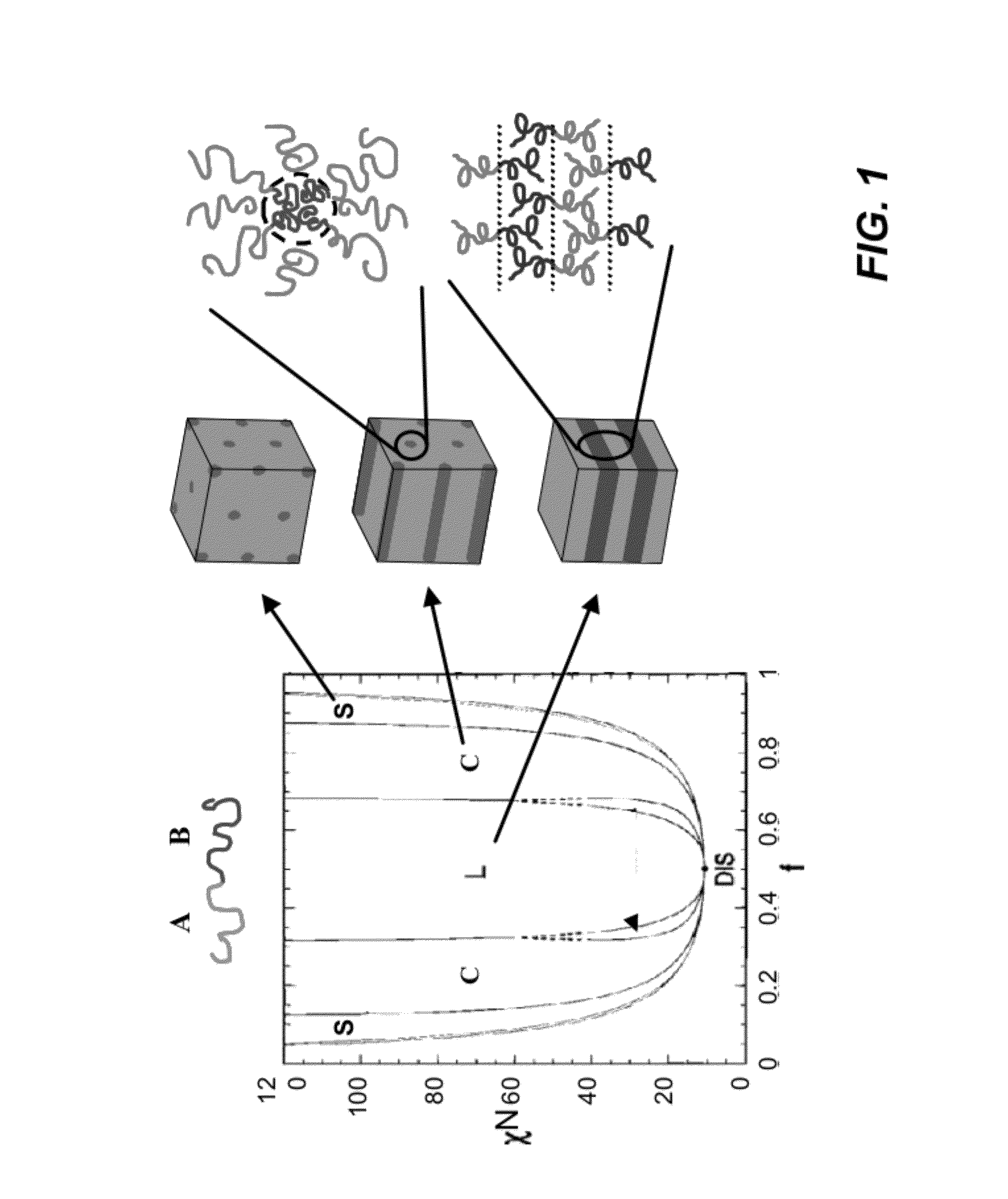

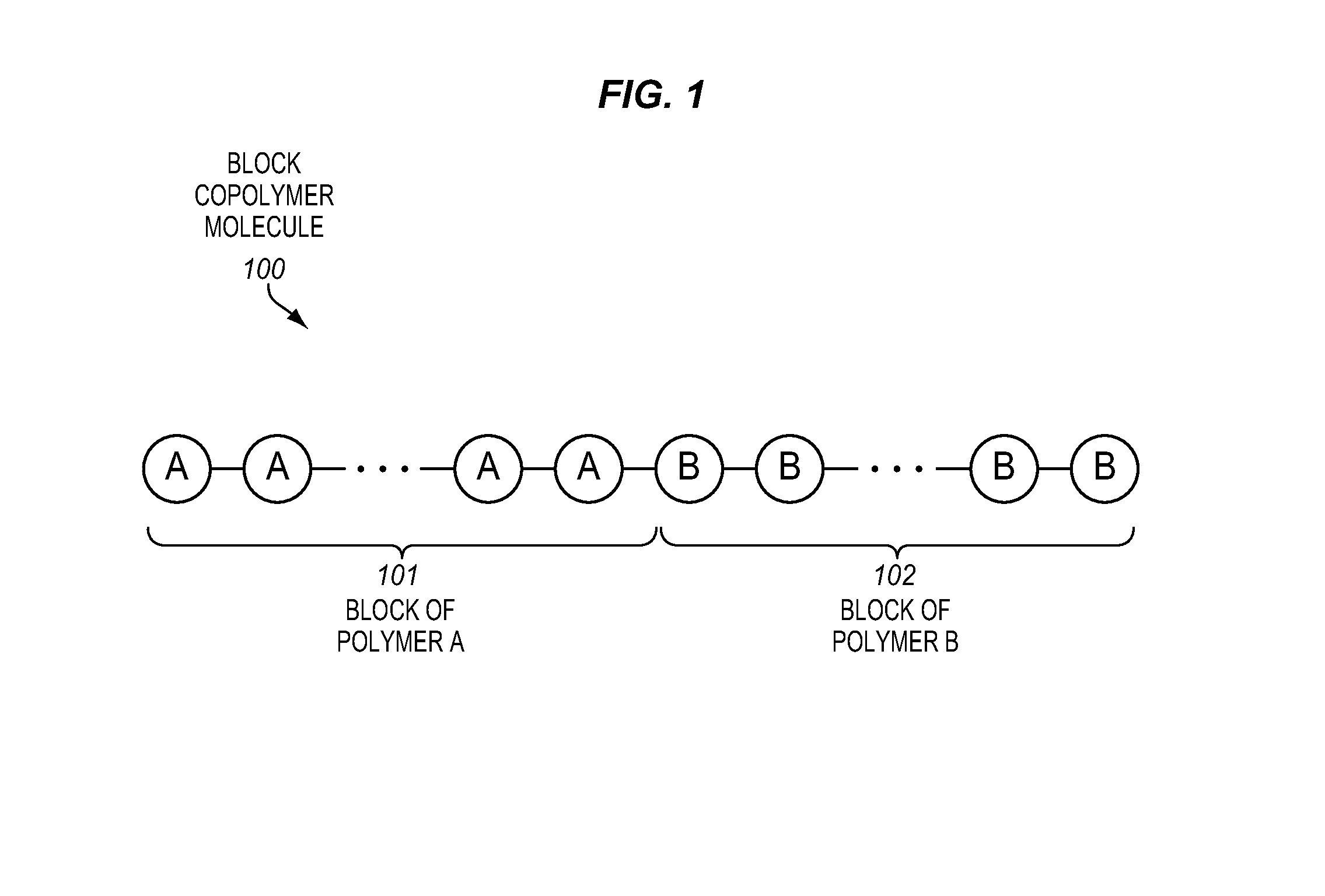

Directed self-assembly. Directed self-assembly (DSA) is a type of directed assembly which utilizes block co-polymer morphology to create lines, space and hole patterns, facilitating for a more accurate control of the feature shapes.

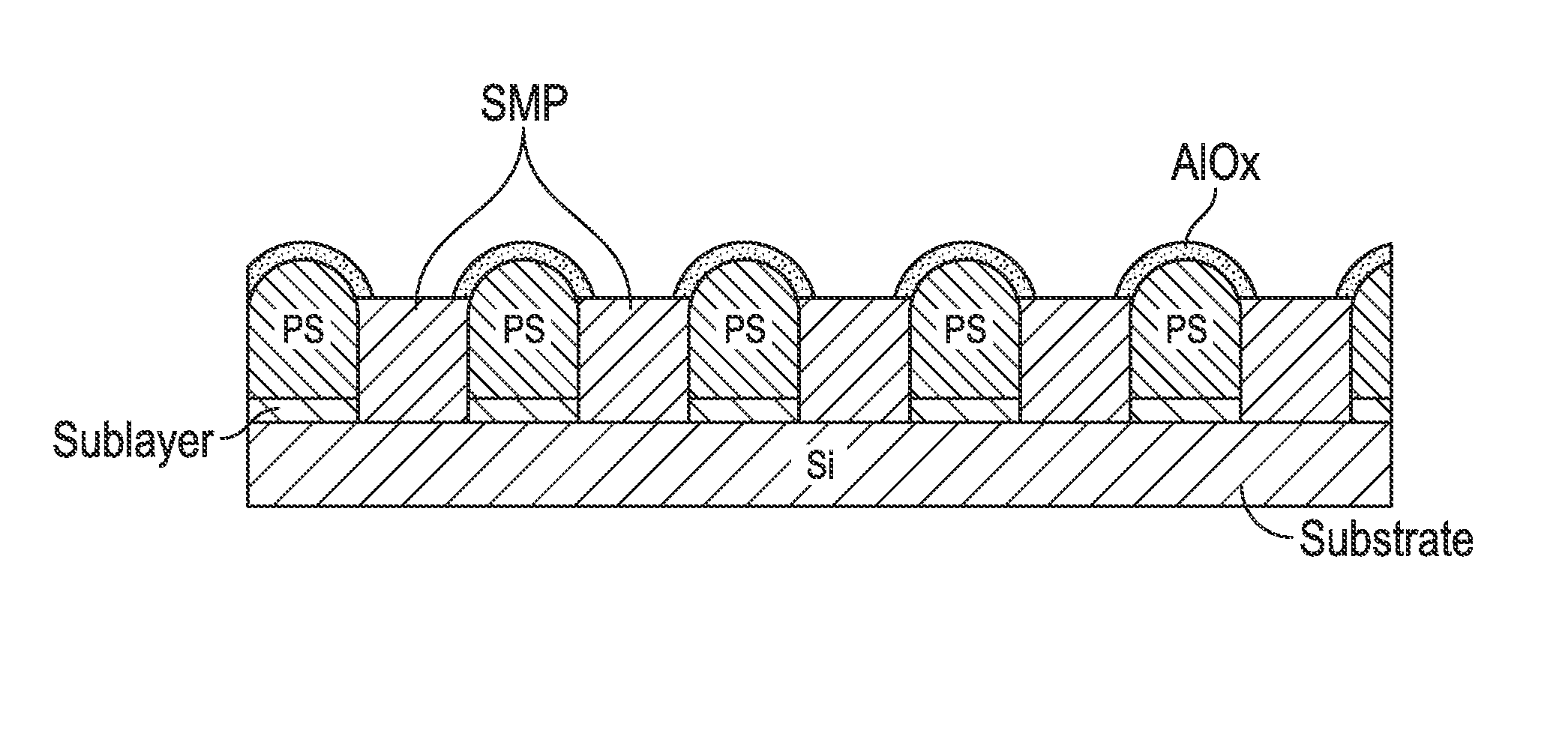

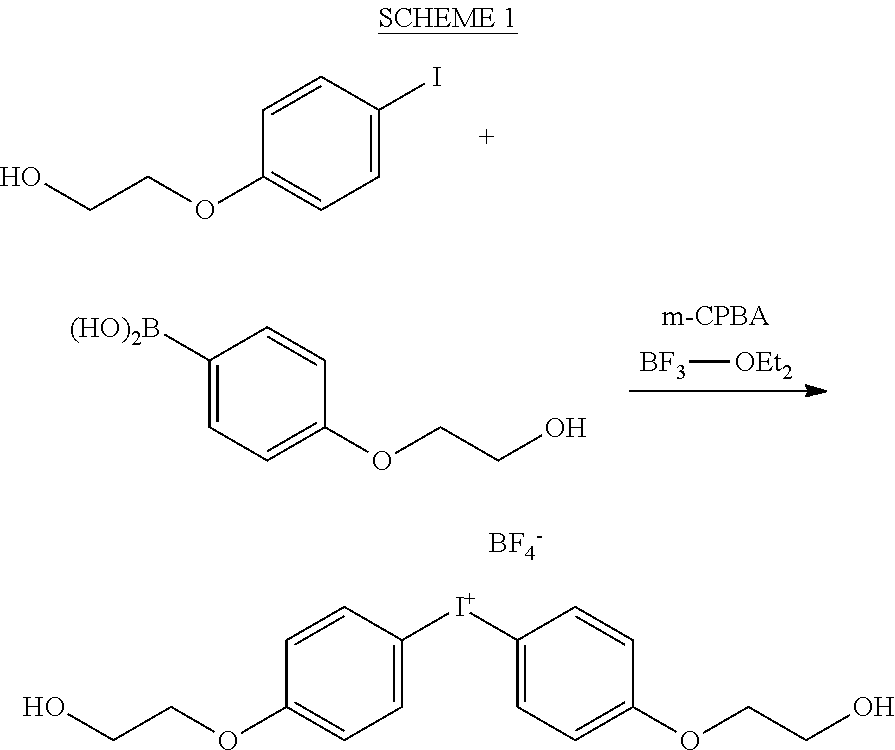

Method for making a chemical contrast pattern using block copolymers and sequential infiltration synthesis

ActiveUS20140346142A1Decorative surface effectsPhotomechanical apparatusInorganic materialsAtomic layer deposition

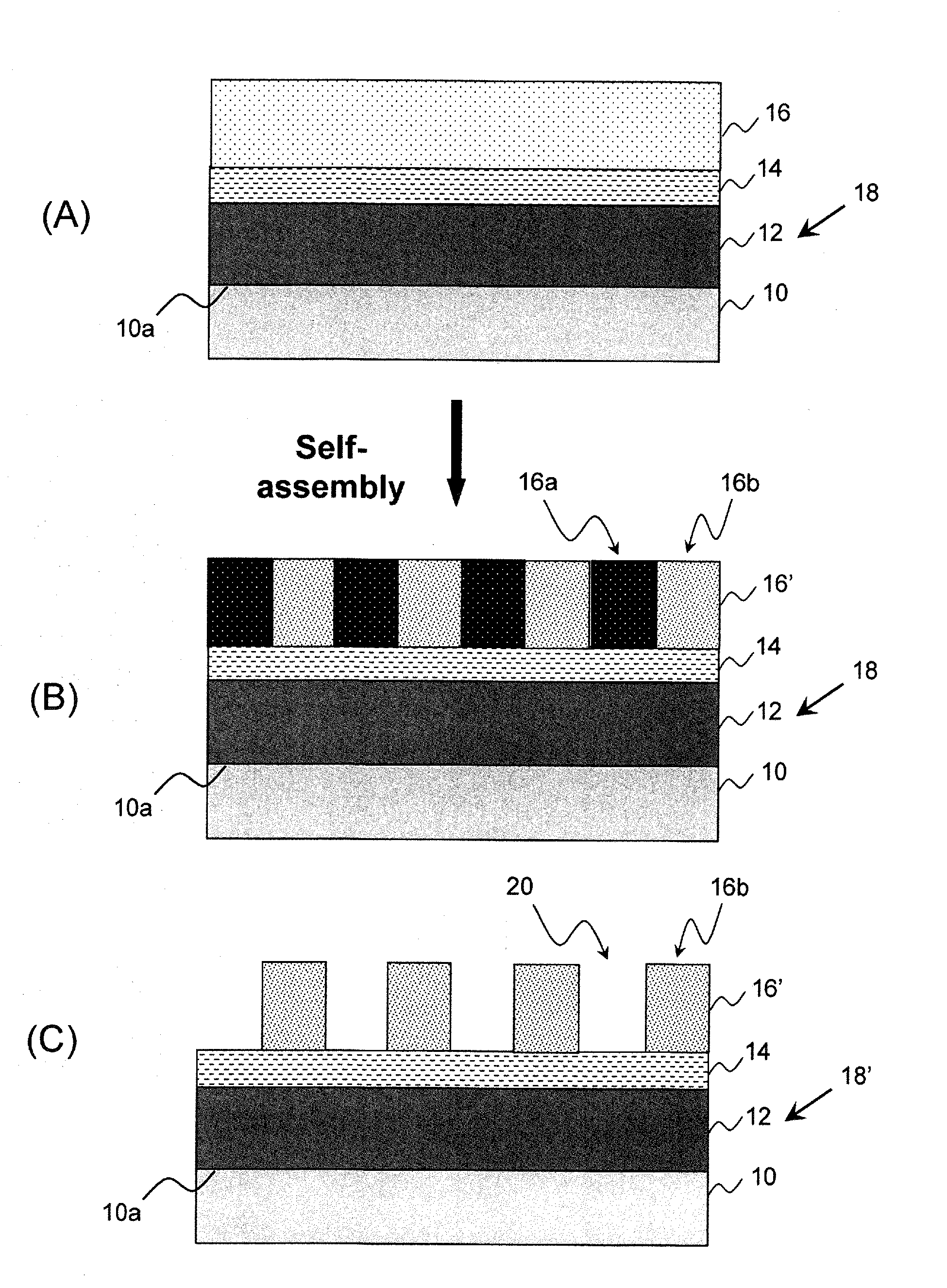

A method for making a chemical contrast pattern uses directed self-assembly of block copolymers (BCPs) and sequential infiltration synthesis (SIS) of an inorganic material. For an example with poly(styrene-block-methyl methacrylate) (PS-b-PMMA) as the BCP and alumina as the inorganic material, the PS and PMMA self-assemble on a suitable substrate. The PMMA is removed and the PS is oxidized. A surface modification polymer (SMP) is deposited on the oxidized PS and the exposed substrate and the SMP not bound to the substrate is removed. The structure is placed in an atomic layer deposition chamber. Alumina precursors reactive with the oxidized PS are introduced and infuse by SIS into the oxidized PS, thereby forming on the substrate a chemical contrast pattern of SMP and alumina. The resulting chemical contrast pattern can be used for lithographic masks, for example to etch the underlying substrate to make an imprint template.

Owner:WESTERN DIGITAL TECH INC

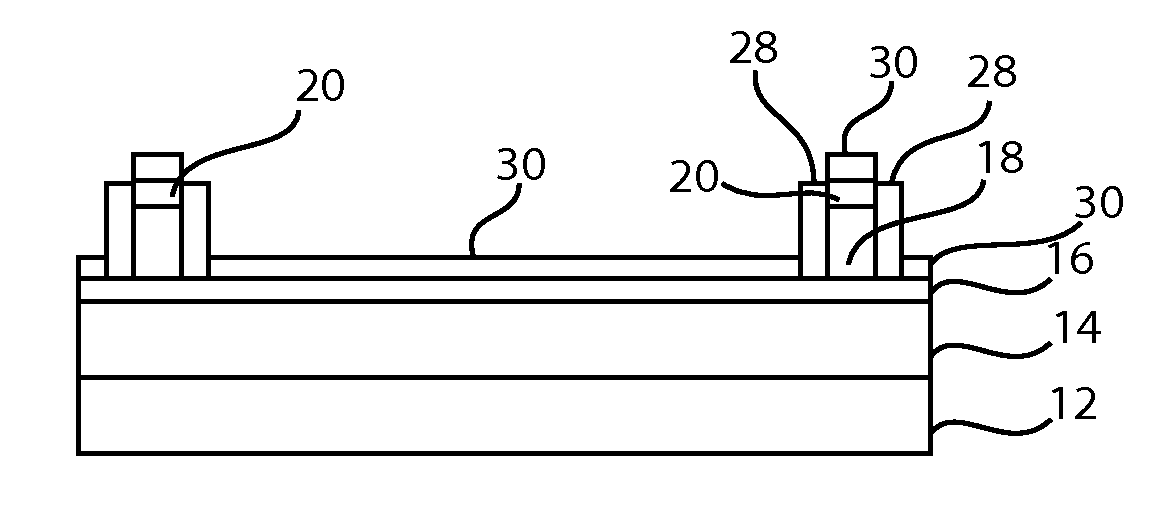

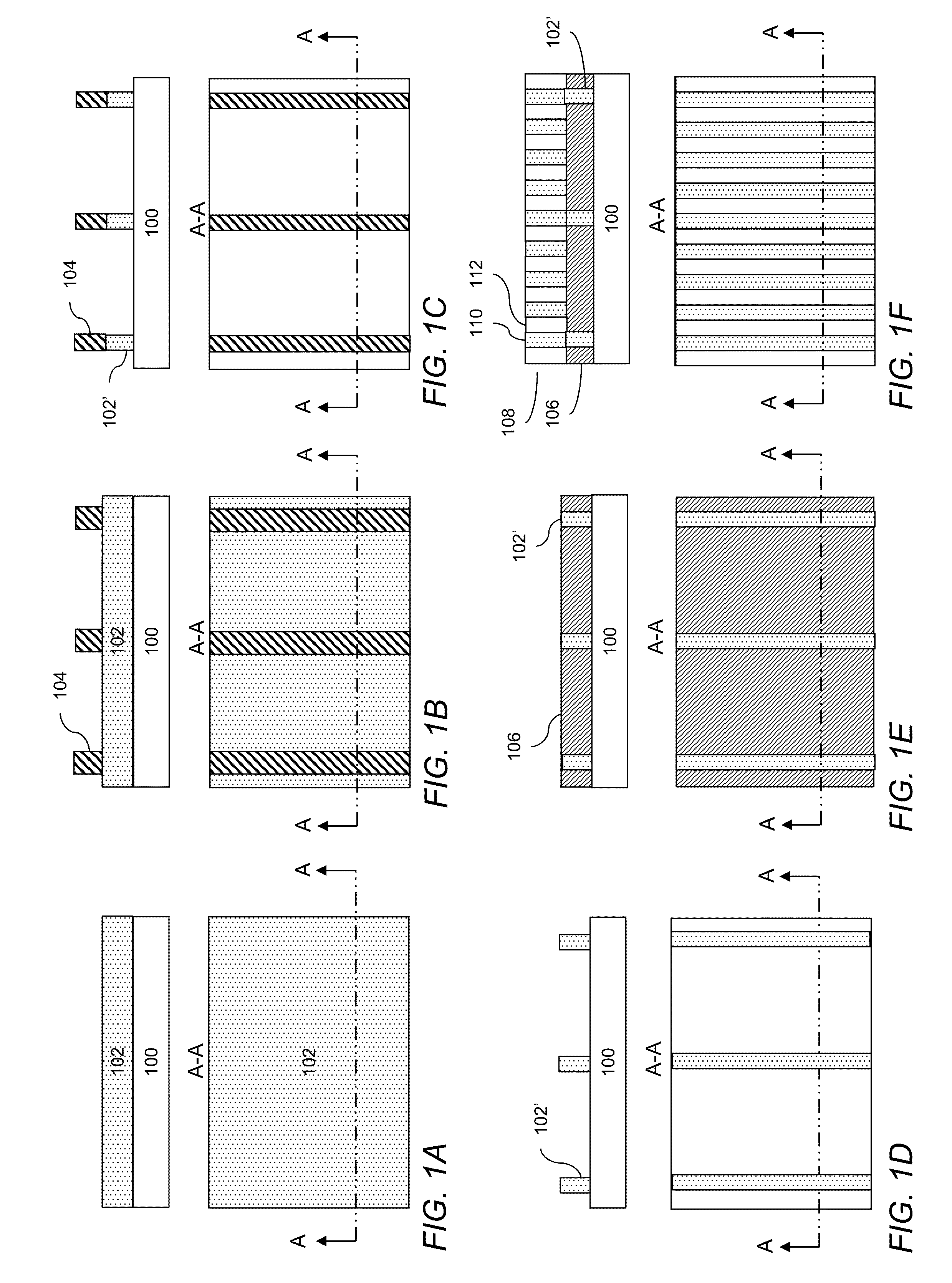

Dsa grapho-epitaxy process with etch stop material

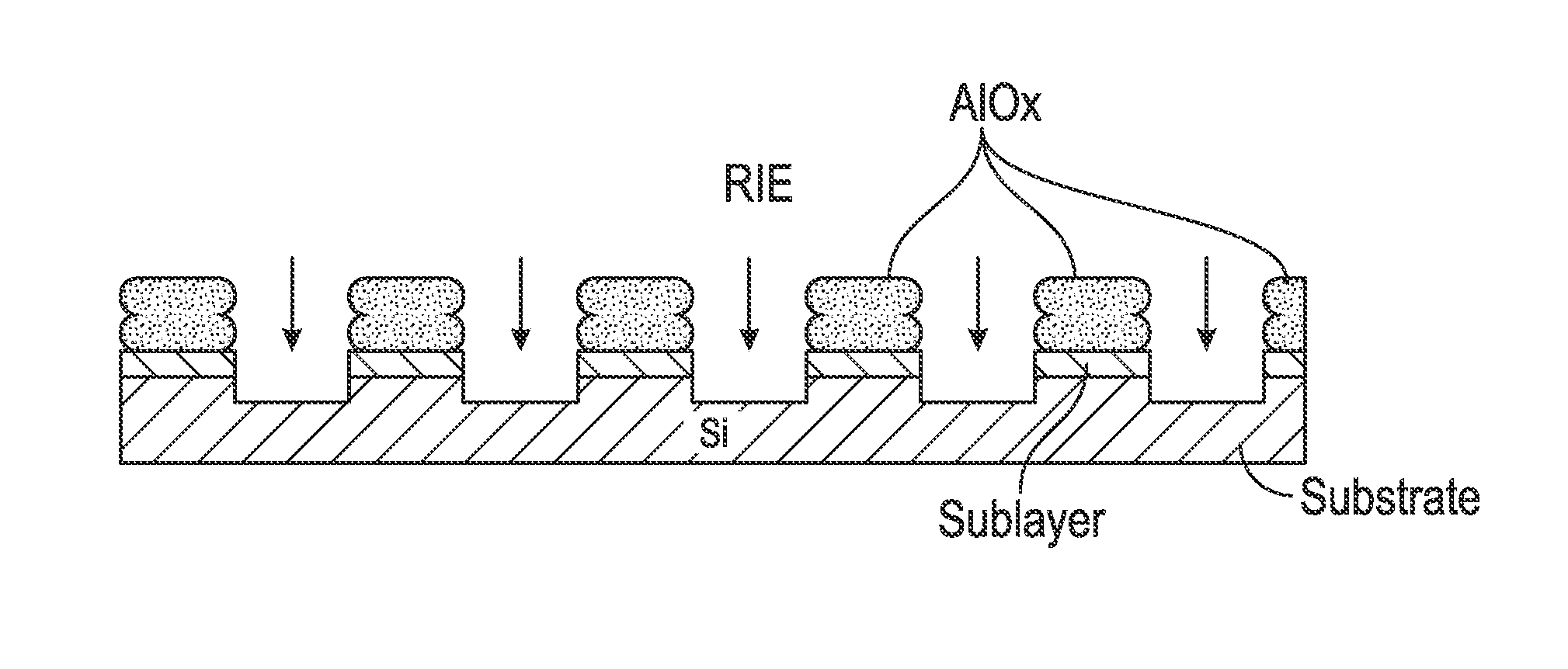

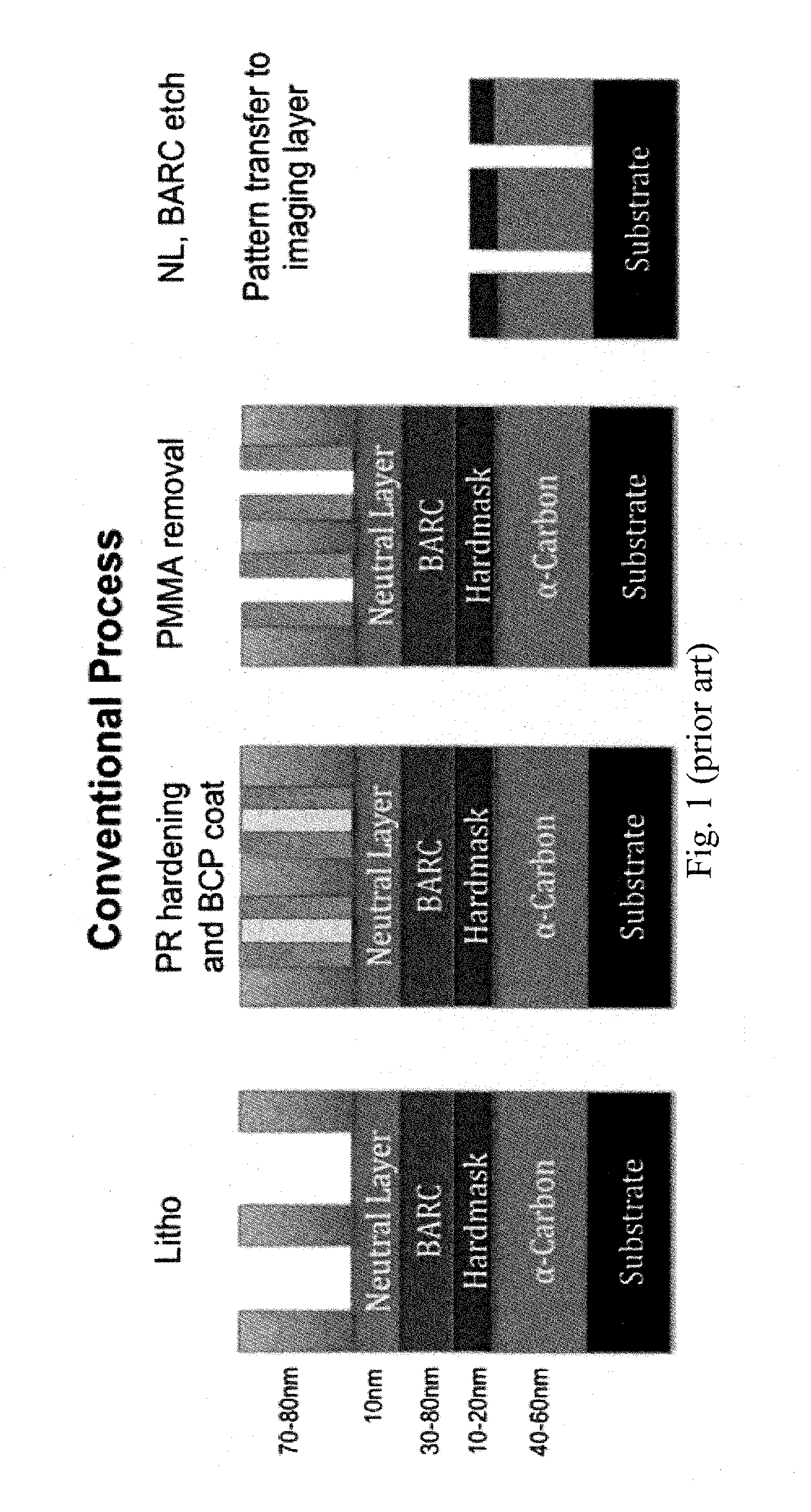

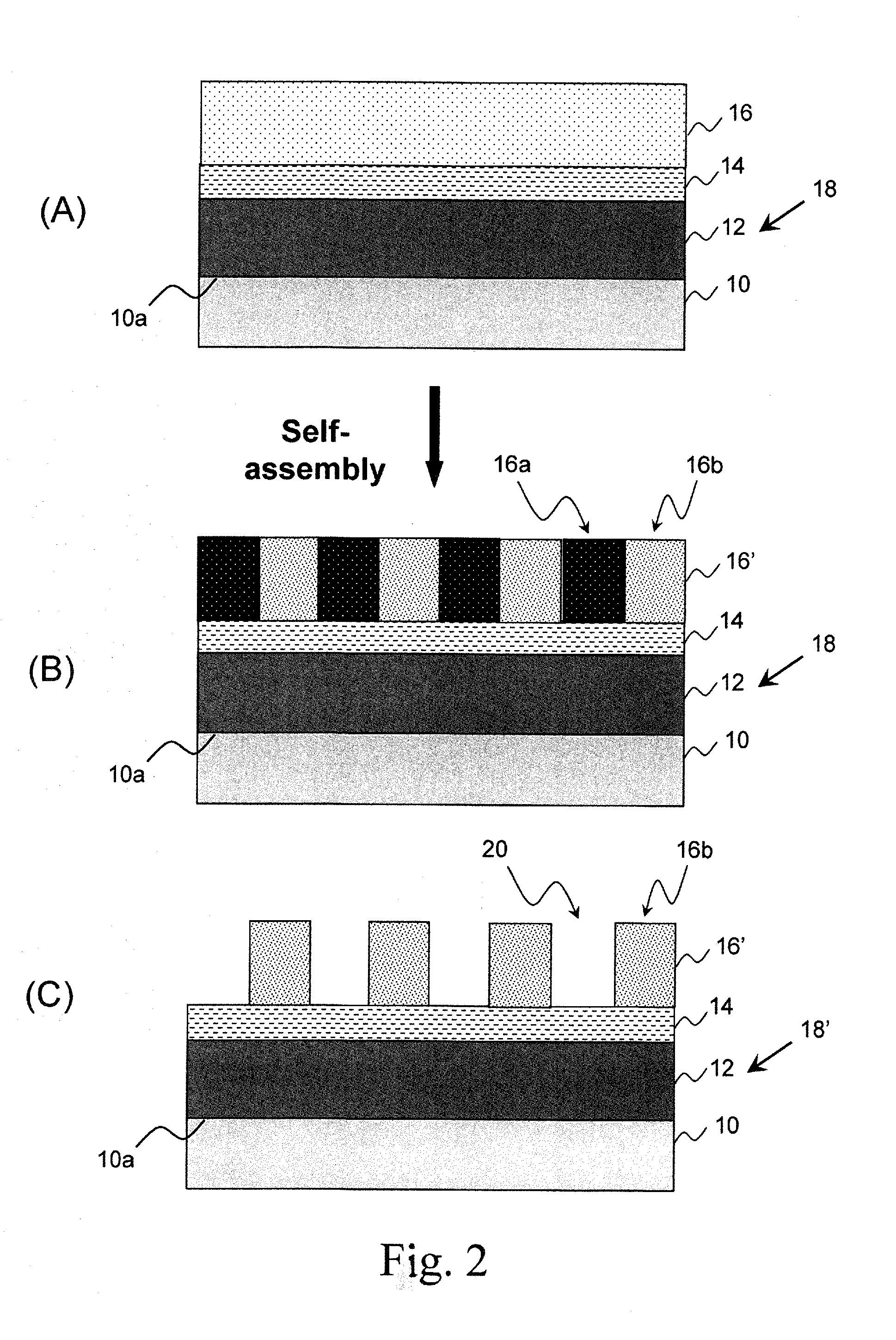

InactiveUS20140256145A1Reduce widthForming accuratelySemiconductor/solid-state device manufacturingResistReactive-ion etching

A method for defining a template for directed self-assembly (DSA) materials includes forming an etch stop layer on a neutral material, forming a mask layer on the etch stop layer and forming an anti-reflection coating (ARC) on the mask layer. A resist layer is patterned on the ARC using optical lithography to form a template pattern. The ARC and the mask layer are reactive ion etched down to the etch stop layer in accordance with the template pattern to form a template structure. The ARC is removed from the mask layer and the template structure is trimmed to reduce a width of the template structure. A wet etch is performed to remove the etch stop layer to permit the neutral material to form an undamaged DSA template for DSA materials.

Owner:IBM CORP

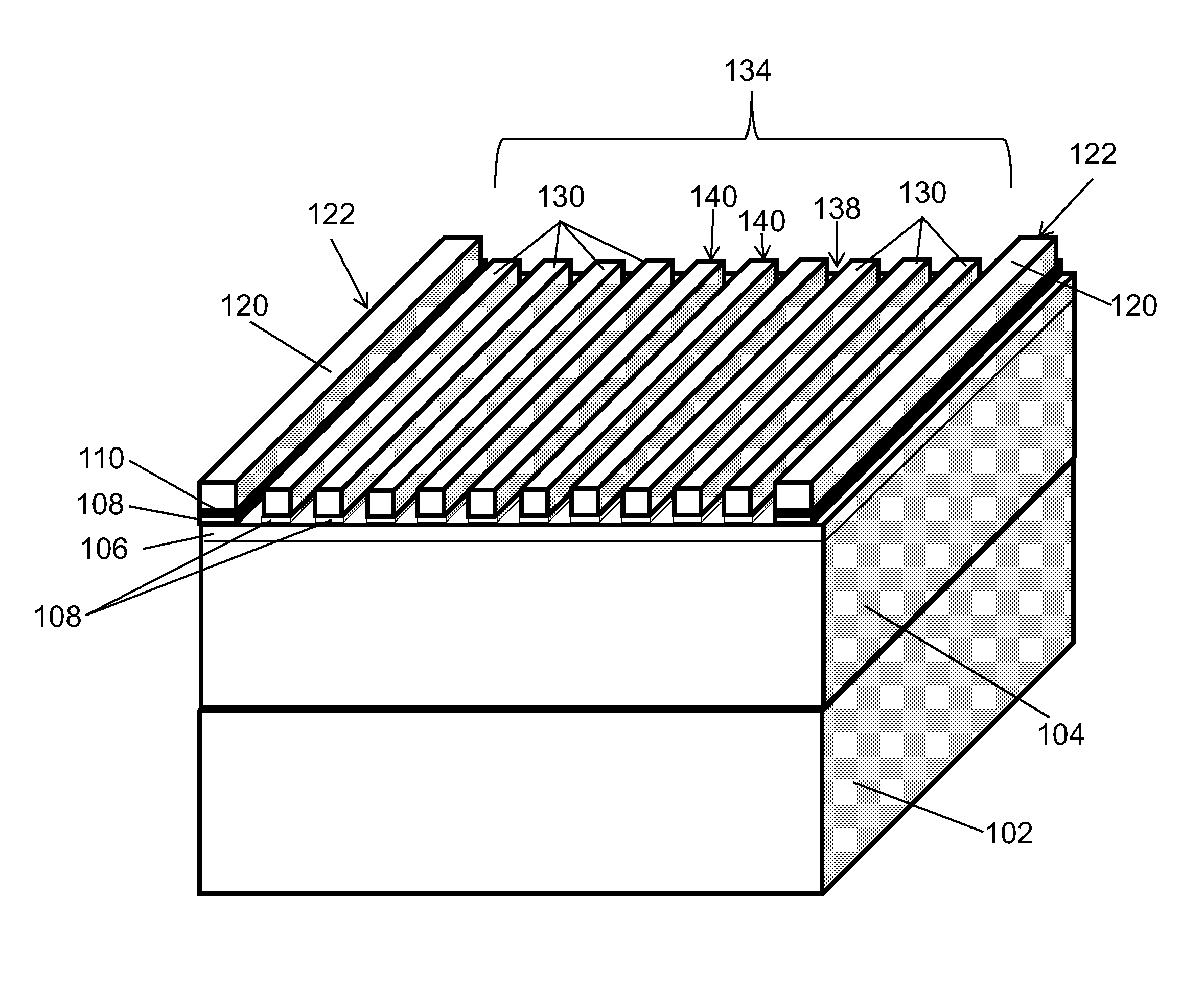

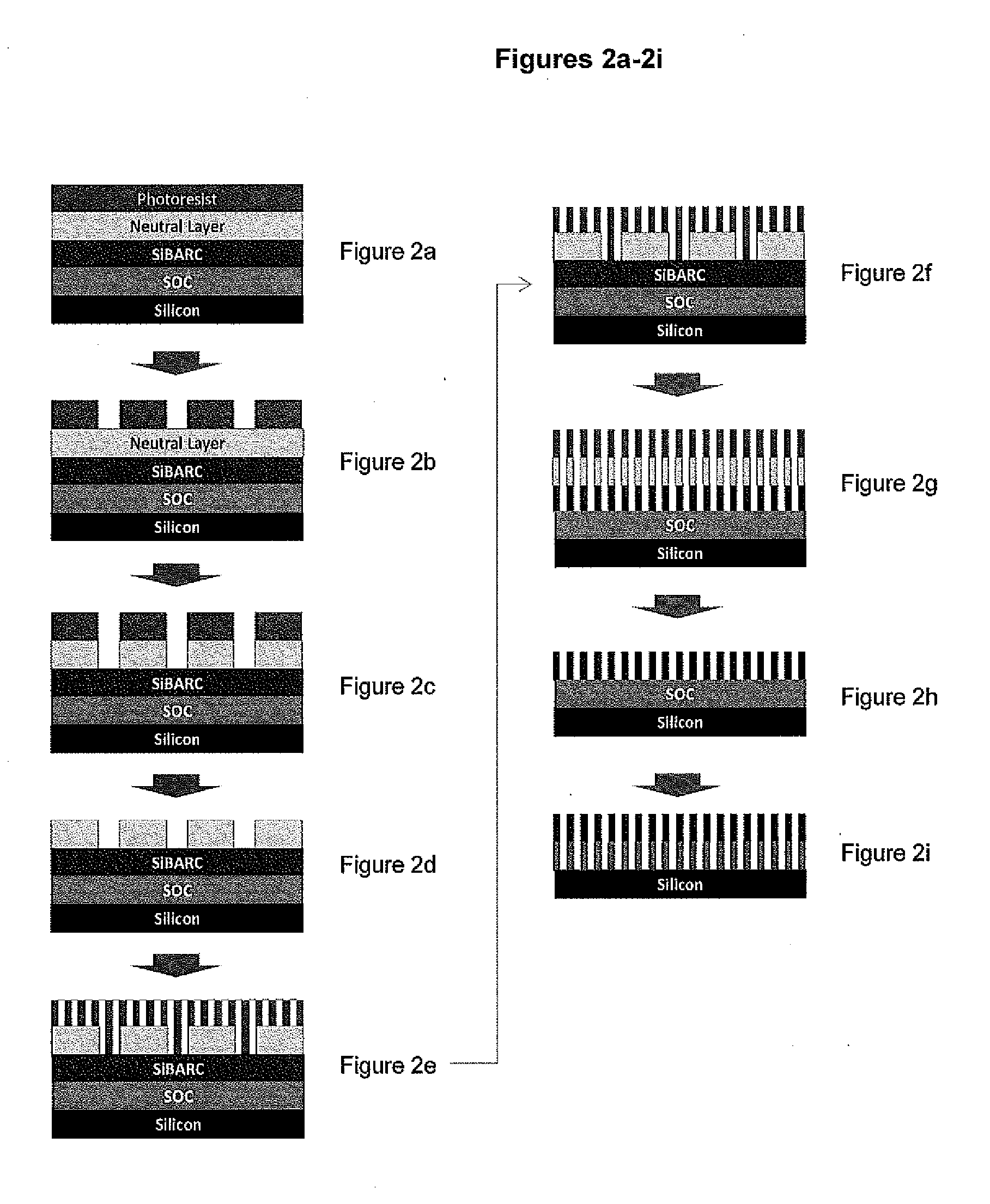

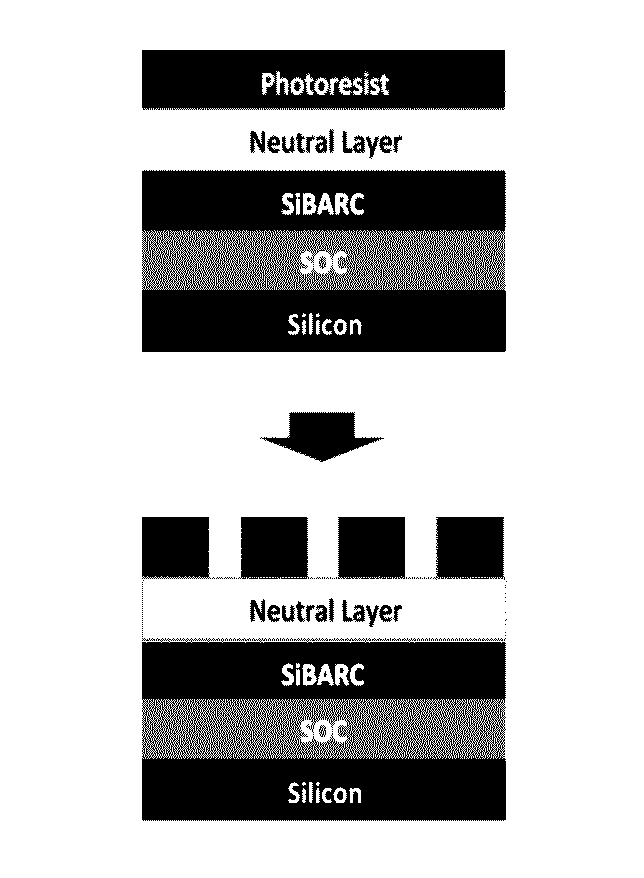

Silicon hardmask layer for directed self-assembly

ActiveUS20130273330A1Easy alignmentHigh surface energyFixed microstructural devicesDecorative surface effectsChemistryDirected self assembly

Compositions for directed self-assembly patterning techniques are provided which avoid the need for separate anti-reflective coatings and brush neutral layers in the process. Methods for directed self-assembly are also provided in which a self-assembling material, such as a directed self-assembly block copolymer, can be applied directly to the silicon hardmask neutral layer and then self-assembled to form the desired pattern. Directed self-assembly patterned structures are also disclosed herein.

Owner:BREWER SCI

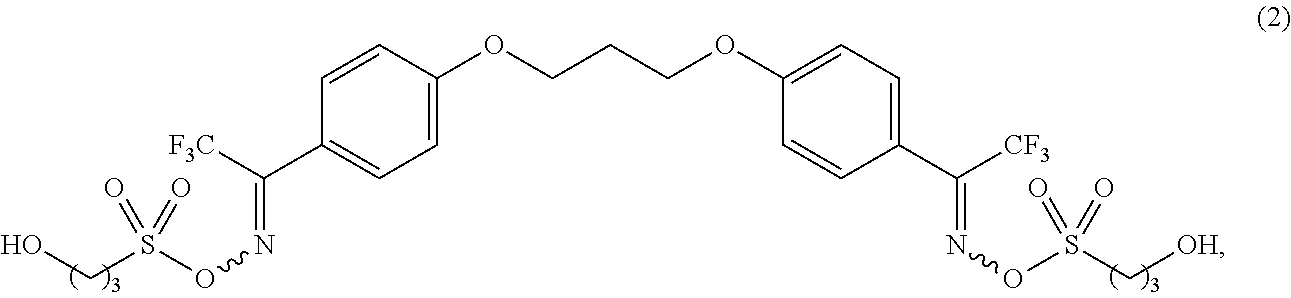

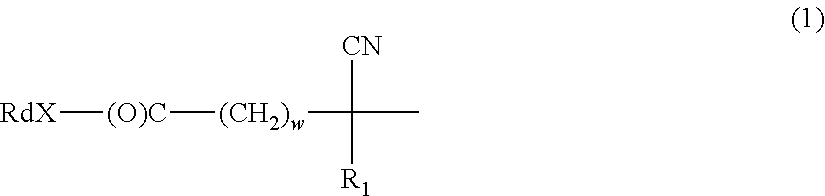

Compositions of neutral layer for directed self assembly block copolymers and processes thereof

ActiveUS20130078576A1High resolutionHigh pattern definitionElectric discharge tubesNanoinformaticsPolymer scienceMoiety

The present invention relates to novel neutral layer compositions and methods for using the compositions. The neutral layer composition comprises at least one random copolymer having at least one unit of structure (1), at least one unit of structure (2) and at least one unit of structure (3)where R1 is selected from the group consisting of a C1-C8 alkyl, C1-C8 fluoroalkyl moiety, C1-C8 partially fluorinated alkyl, C4-C8 cycloalkyl, C4-C8 cyclofluoroalkyl, C4-C8 partially fluorinated cycloalkyl, and a C2-C8 hydroxyalkyl; R2, R3 and R5 are independently selected from a group consisting of H, C1-C4 alkyl, CF3 and F; R4 is selected from the group consisting of H, C1-C8 alkyl, C1-C8 partially fluorinated alkyl and C1-C8 fluoroalkyl, n ranges from 1 to 5, R6 is selected from the group consisting of H, F, C1-C8 alkyl and a C1-C8 fluoroalkyl and m ranges from 1 to 3.

Owner:MERCK PATENT GMBH

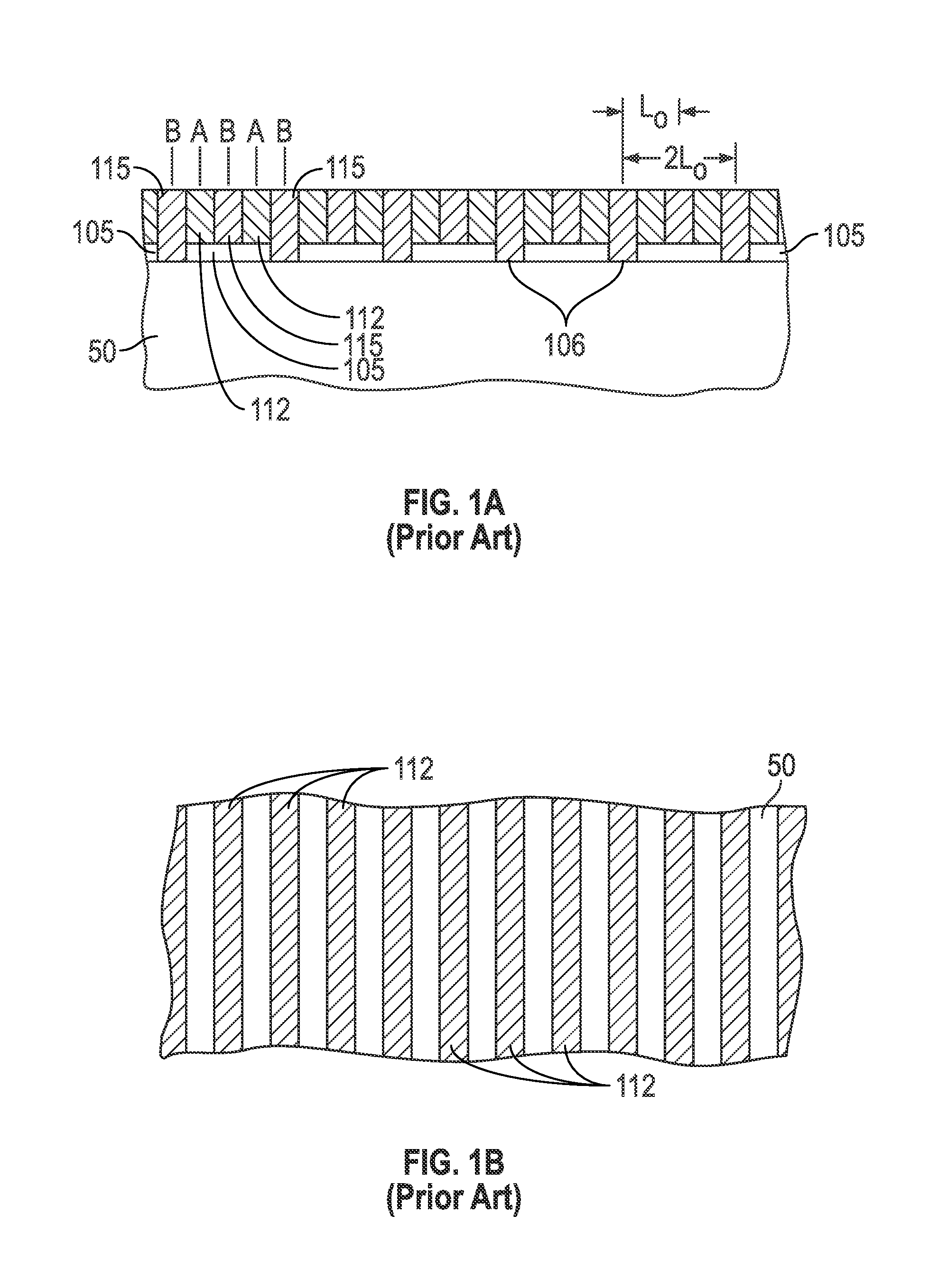

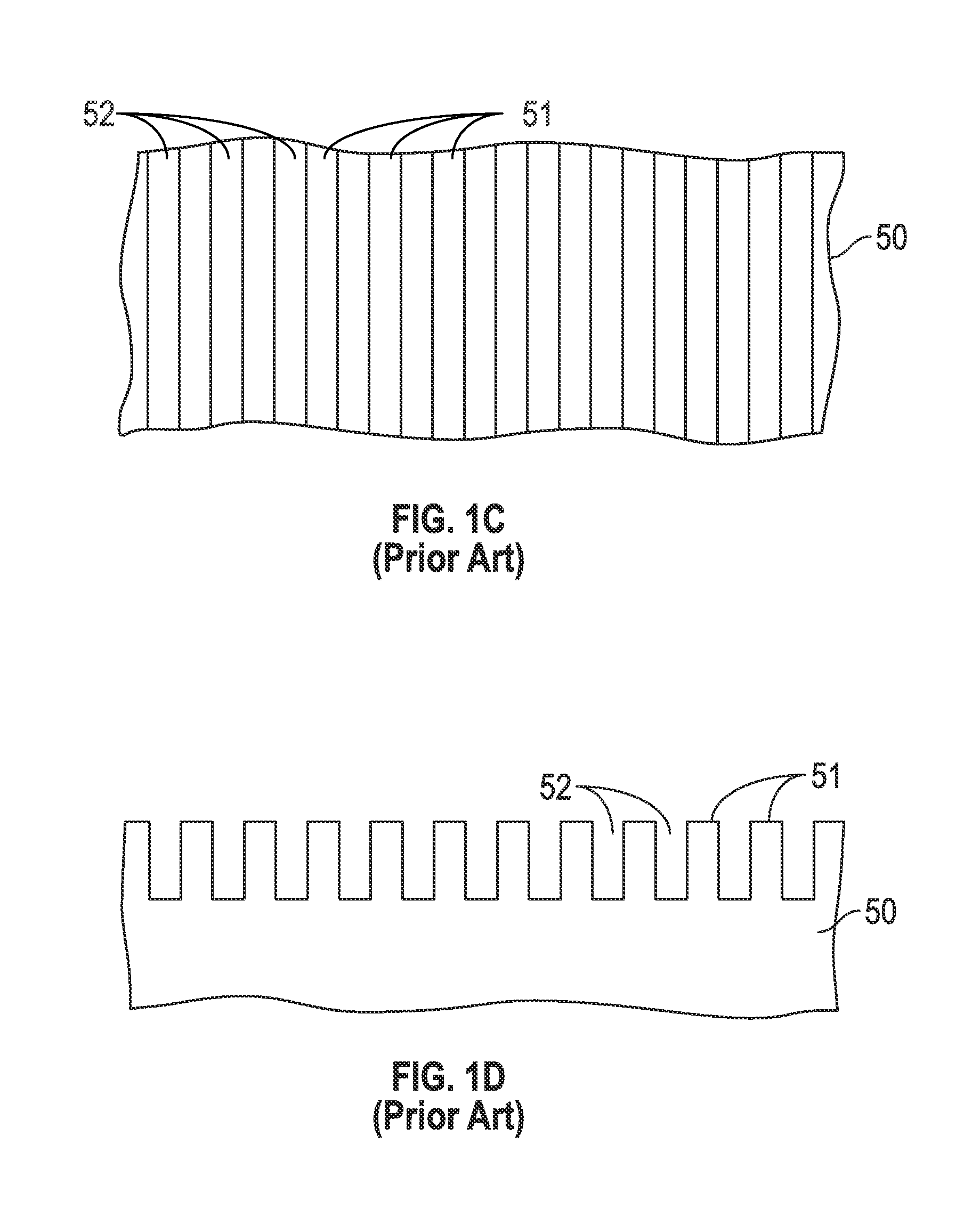

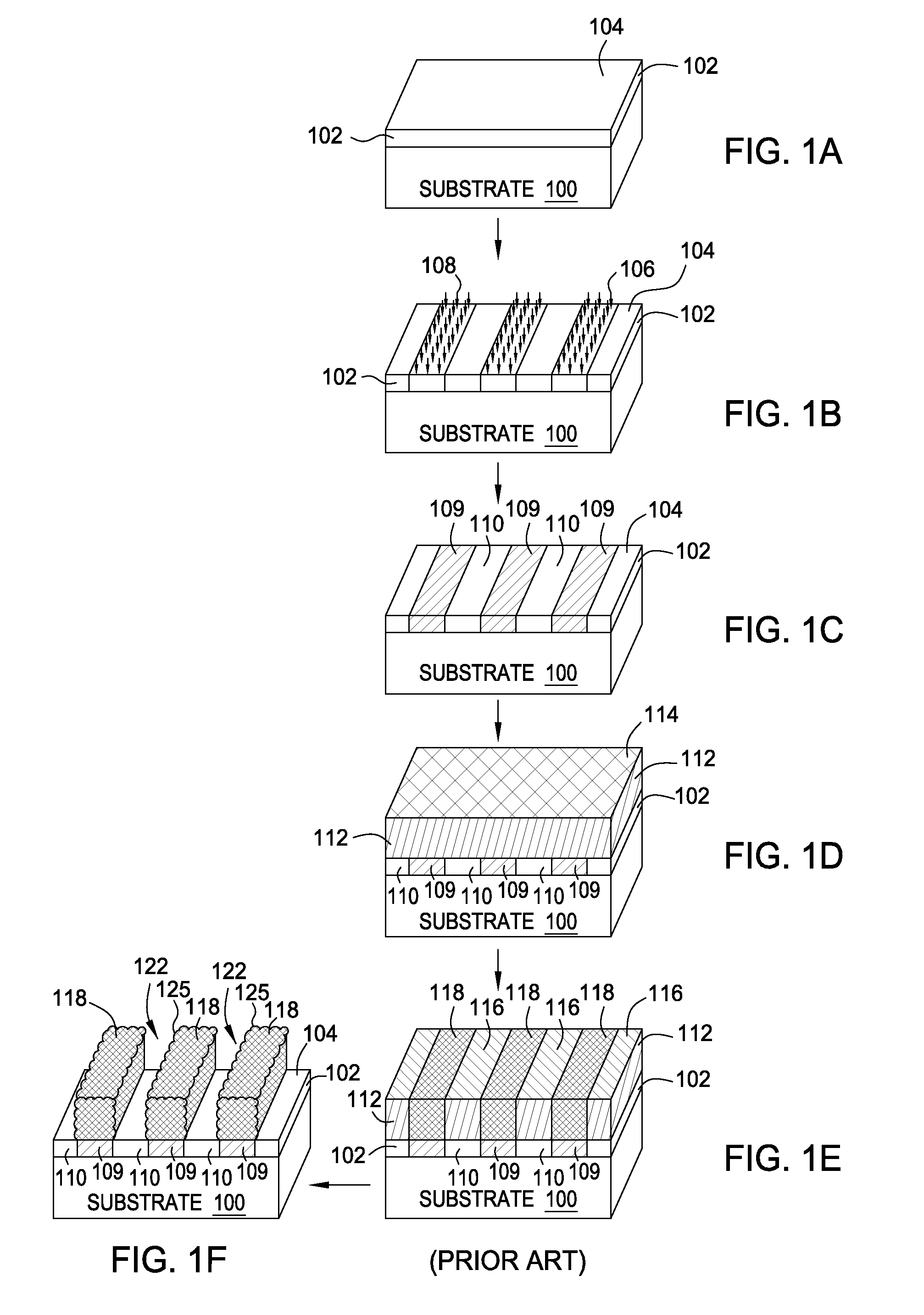

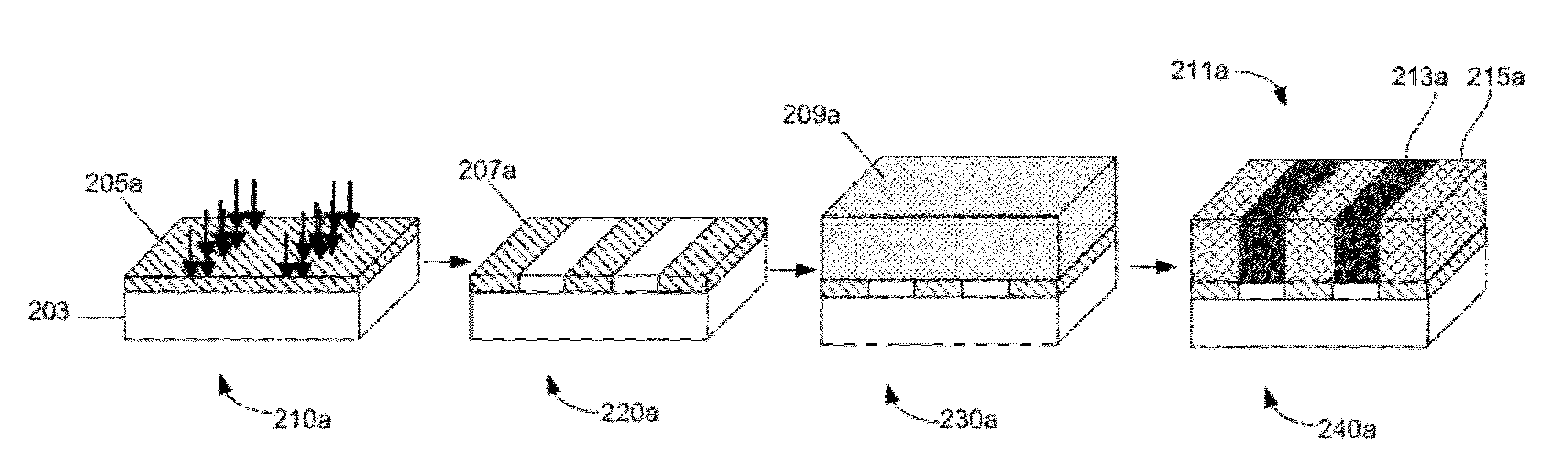

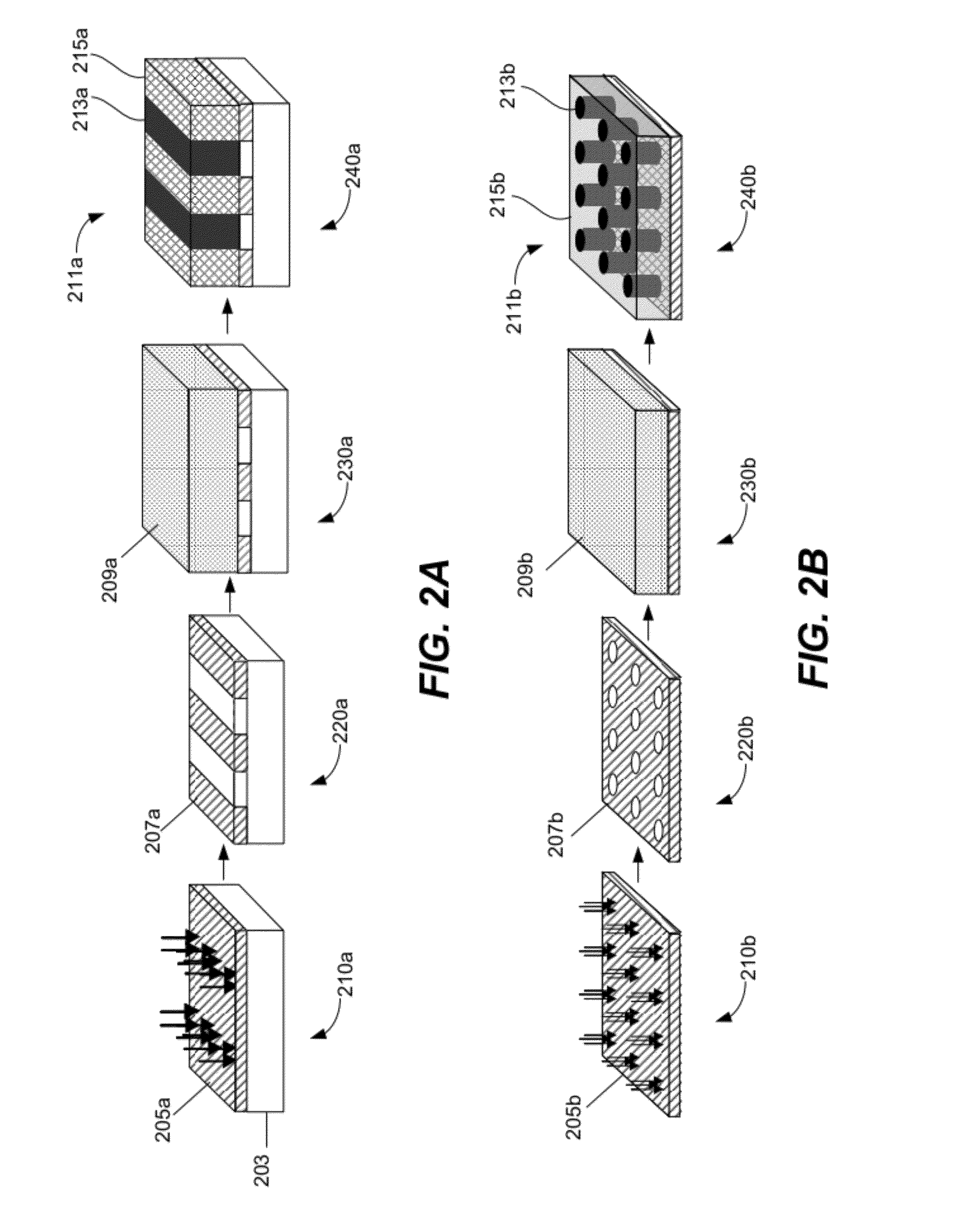

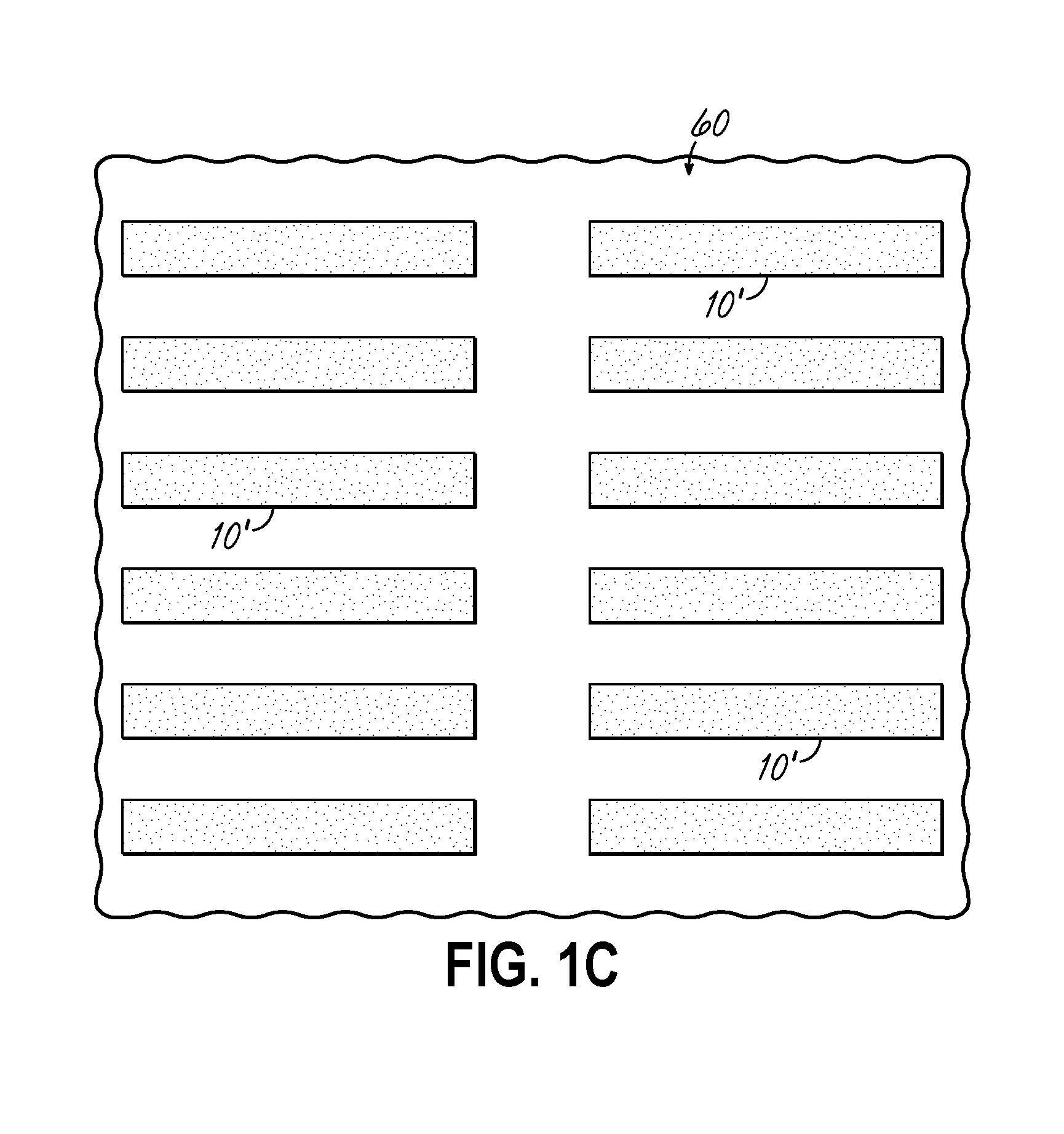

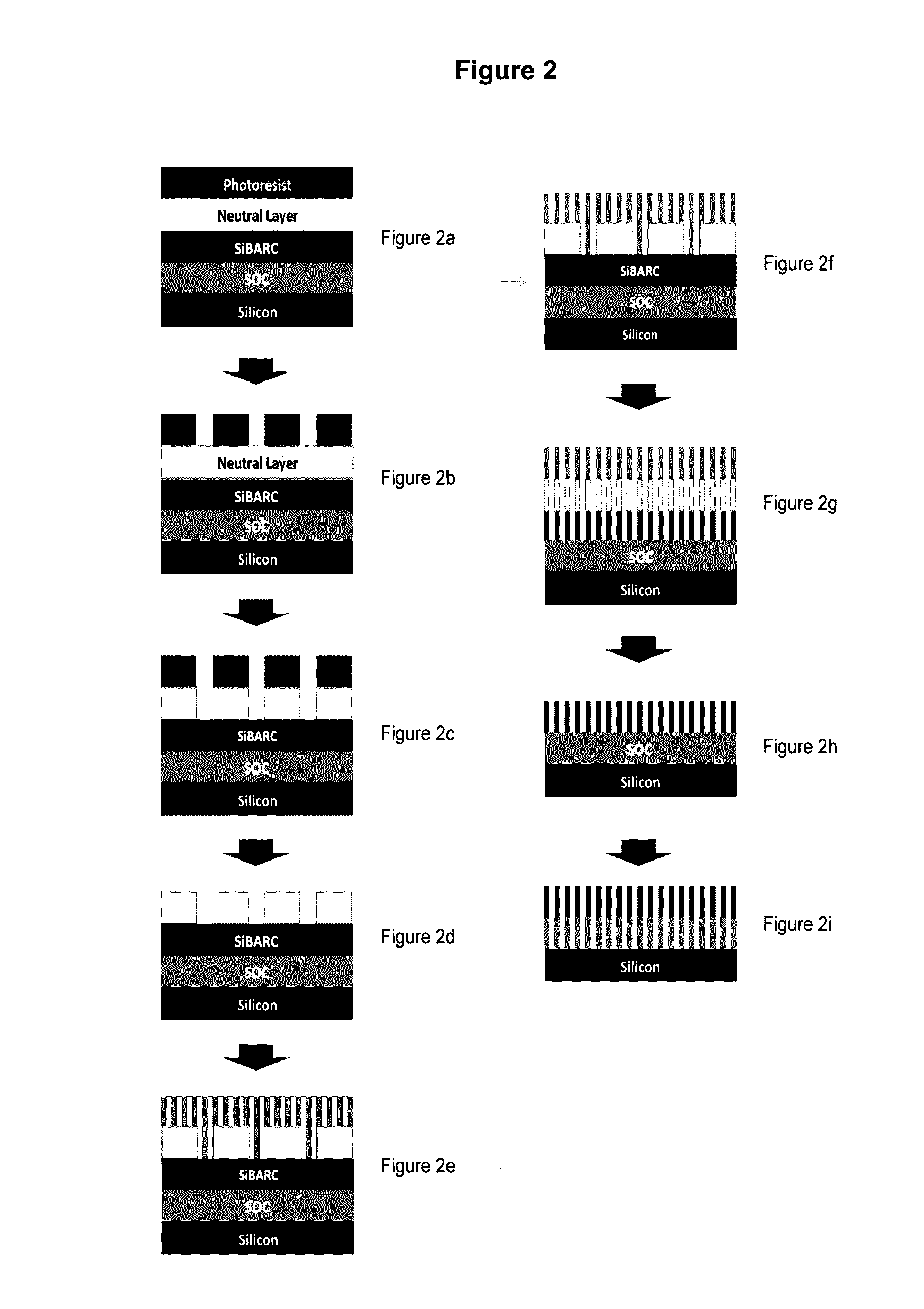

Directed block copolymer self-assembly patterns for advanced photolithography applications

InactiveUS20140357083A1Electric discharge tubesSemiconductor/solid-state device manufacturingPhotoresistSelf-assembly

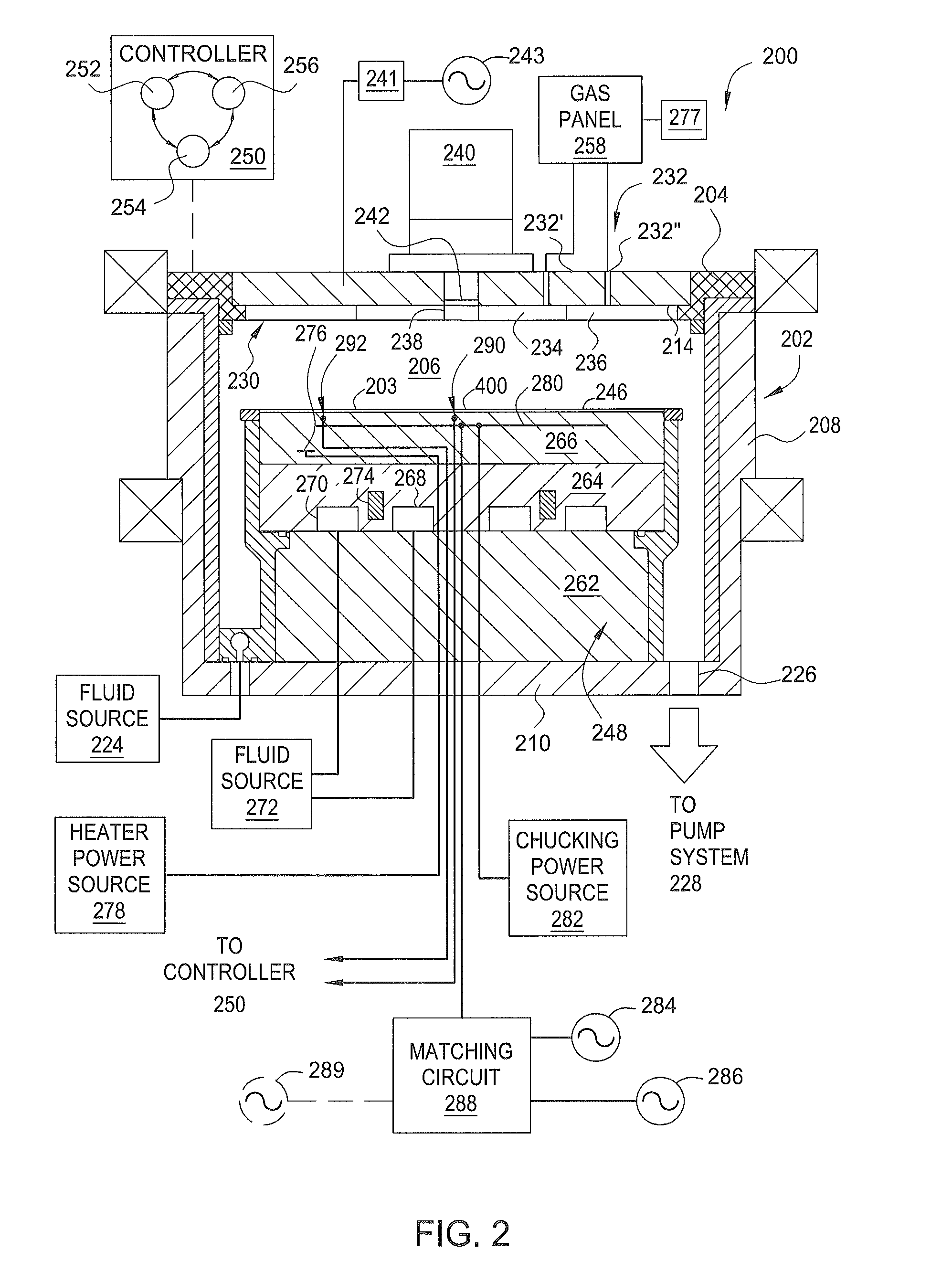

Embodiments of methods and an apparatus for utilizing a directed self-assembly (DSA) process on block copolymers (BCPs) to form a defect-free photoresist layer for feature transfer onto a substrate are provided. In one embodiment, a method for performing a dry development process includes transferring a substrate having a layer of block copolymers disposed thereon into an etching processing chamber, wherein at least a first type and a second type of polymers comprising the block copolymers are aggregated into a first group of regions and a second group of regions on the substrate, supplying an etching gas mixture including at least a carbon containing gas into the etching processing chamber, and predominately etching the second type of the polymers disposed on the second groups of regions on the substrate in the presence of the etching gas mixture.

Owner:APPLIED MATERIALS INC

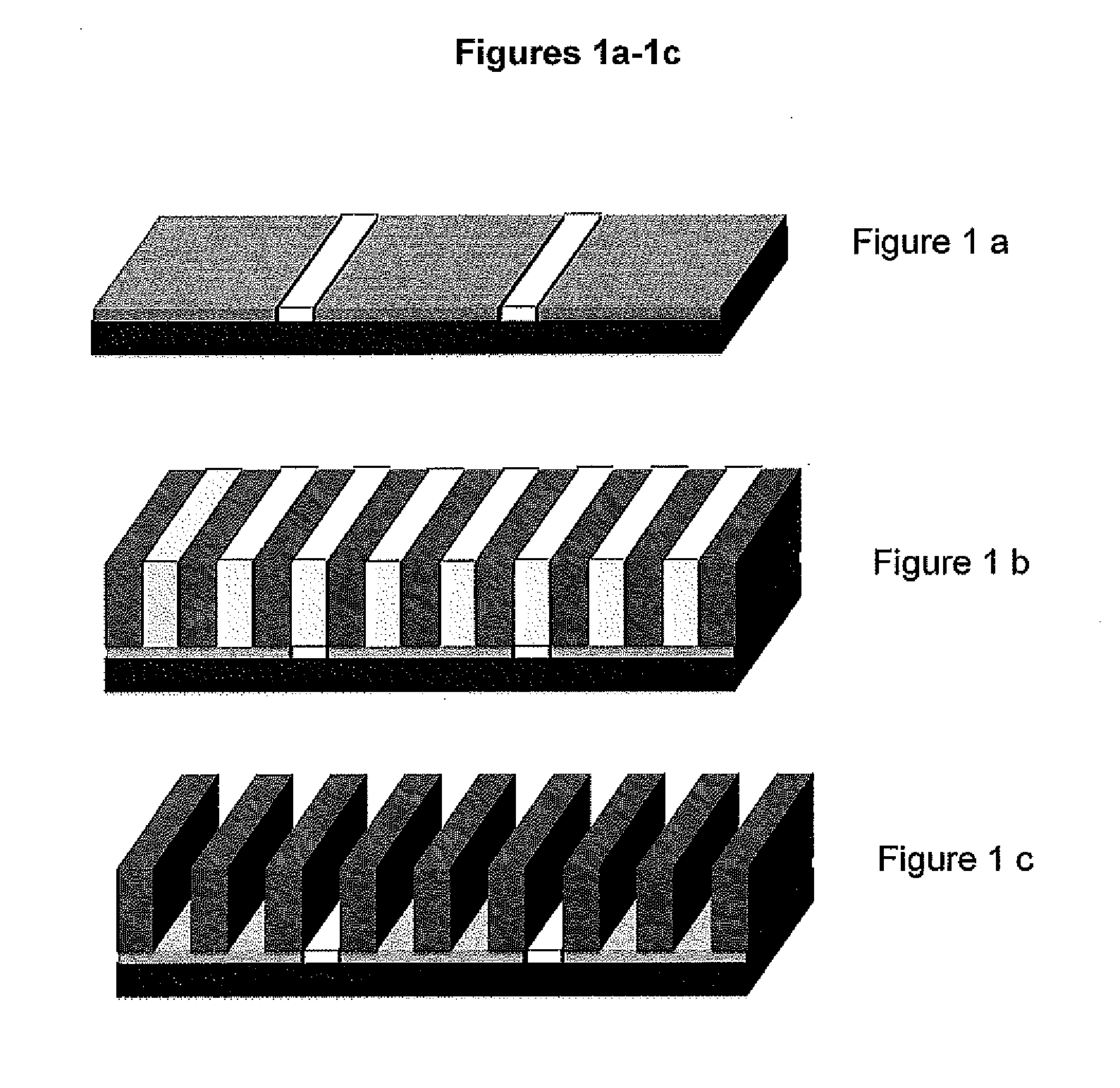

Directed assembly of triblock copolymers

Methods of directed self-assembly of multi-block (i.e., triblock and higher-order) copolymers on patterned substrates and related compositions are provided. According to various embodiments, the methods involve depositing copolymer materials on substrates configured to drive the assembly of micro-phase separated films that exhibit the same morphology as that copolymer materials in the bulk. In certain embodiments, binary patterns are used to drive the triblock copolymer films. The binary two-dimensional surface patterns are transformed into three-component and three-dimensional structures throughout the thickness of the overlying copolymer films.

Owner:WISCONSIN ALUMNI RES FOUND

Method of forming polymer features by directed self-assembly of block copolymers

Disclosed are methods of forming polymer structures comprising: applying a solution of a block copolymer assembly comprising at least one block copolymer to a neutral substrate having a chemical pattern thereon, the chemical pattern comprising alternating pinning and neutral regions that are chemically distinct and have a first spatial frequency given by the number of paired sets of pinning and neutral regions along a given direction on the substrate; and forming domains of the block copolymer that form by lateral segregation of the blocks in accordance with the underlying chemical pattern, wherein at least one domain of the block copolymer assembly has an affinity for the pinning regions, wherein a structure extending across the chemical pattern is produced, the structure having a uniform second spatial frequency given by the number of repeating sets of domains along the given direction that is at least twice that of the first spatial frequency.

Owner:GLOBALFOUNDRIES U S INC

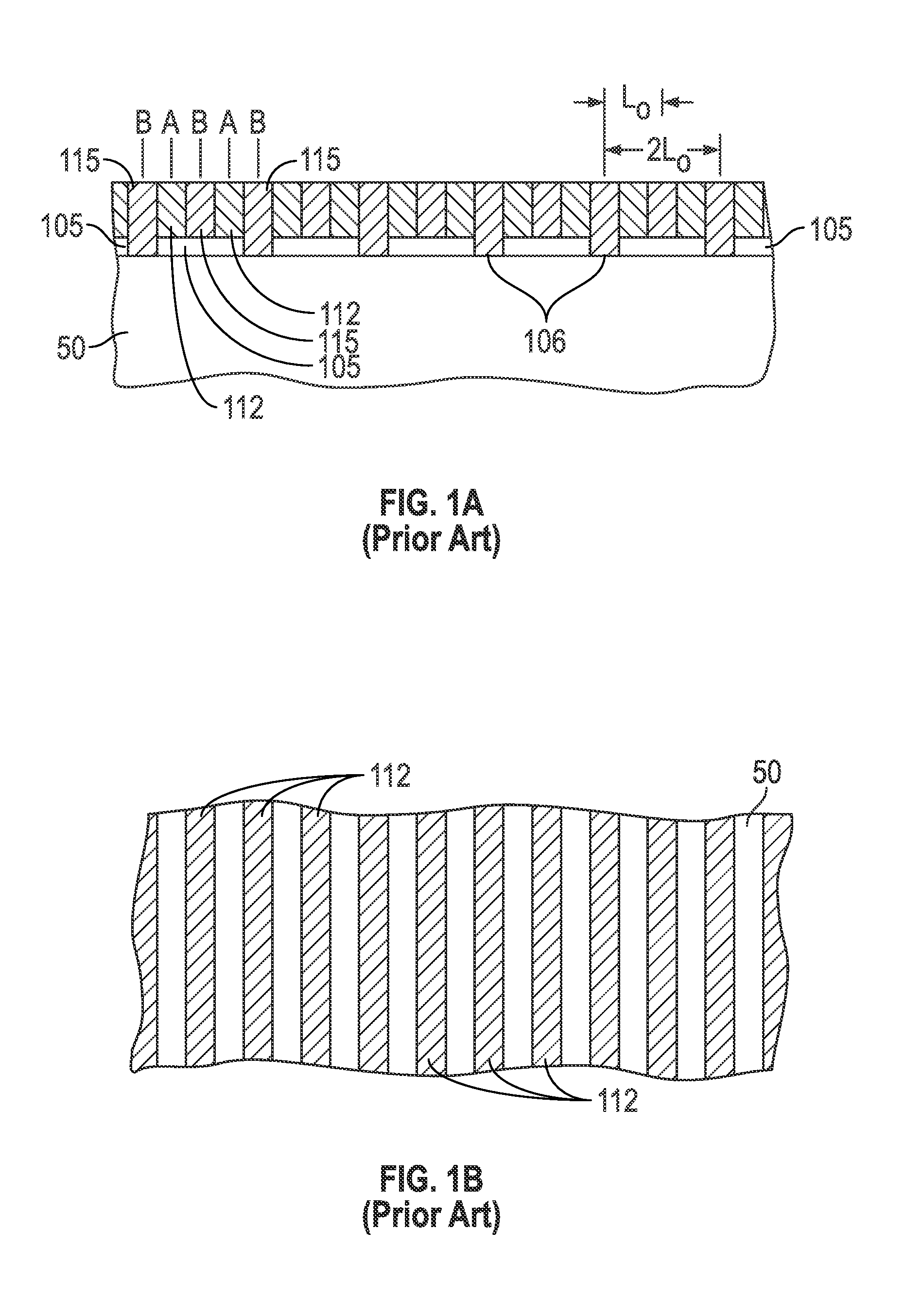

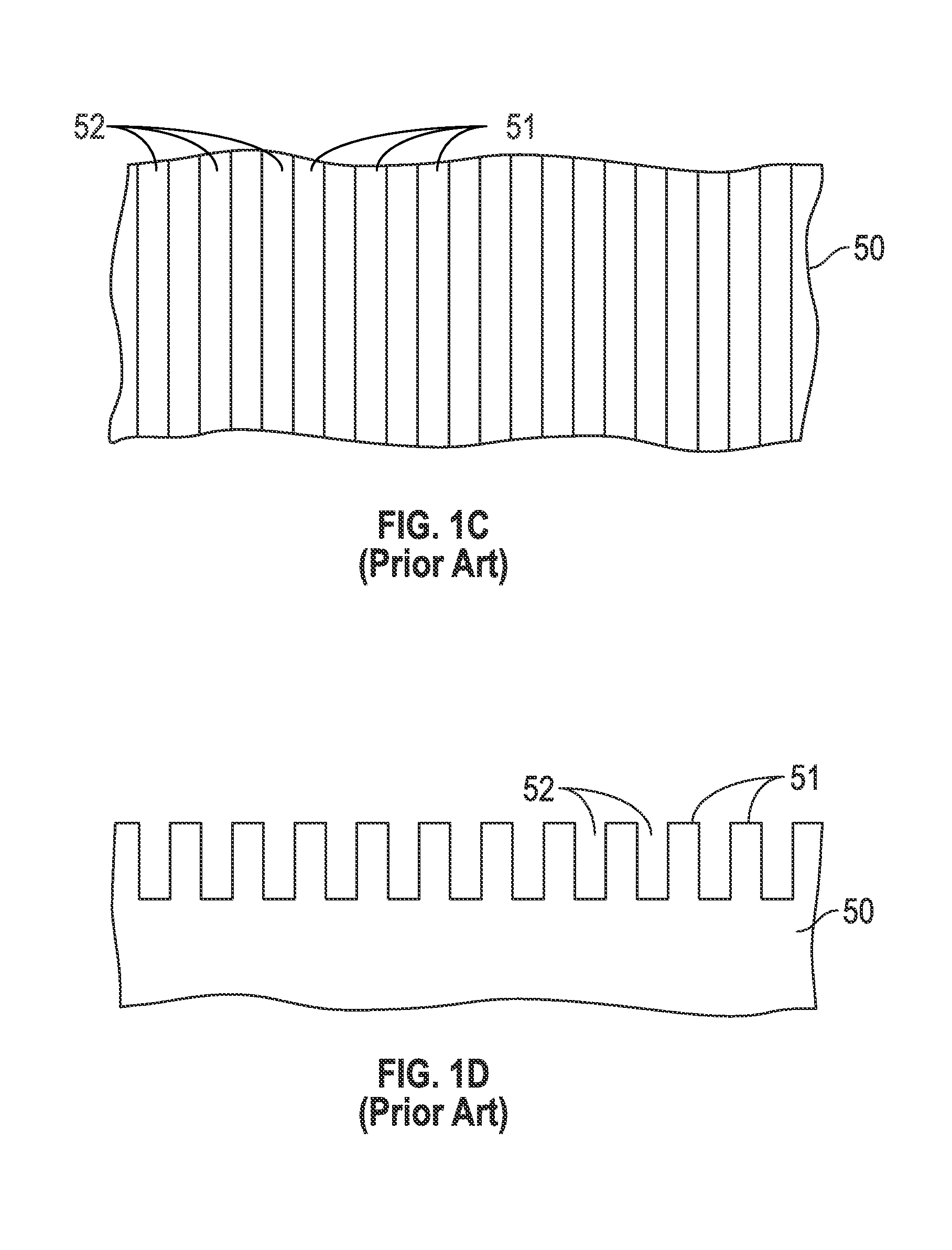

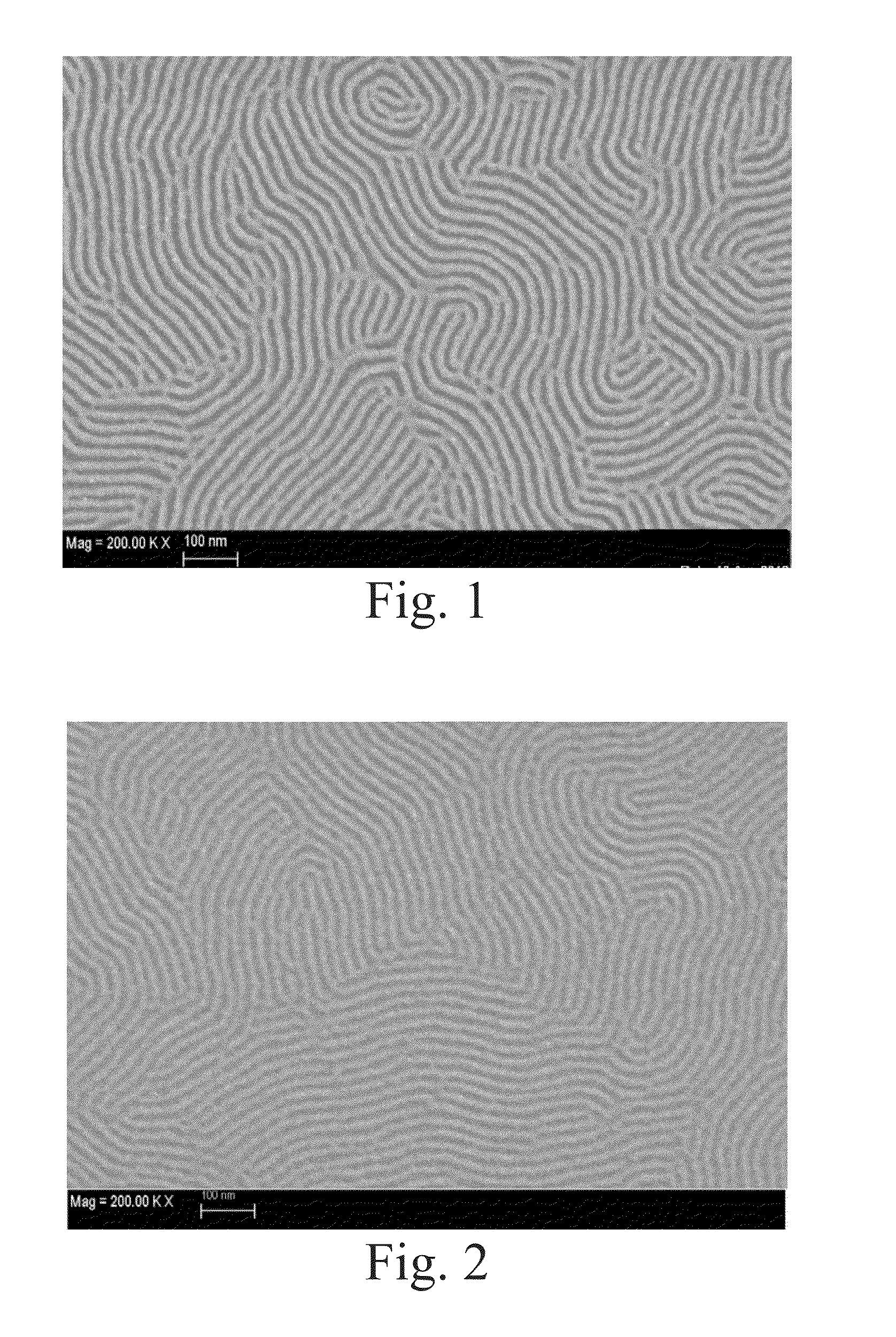

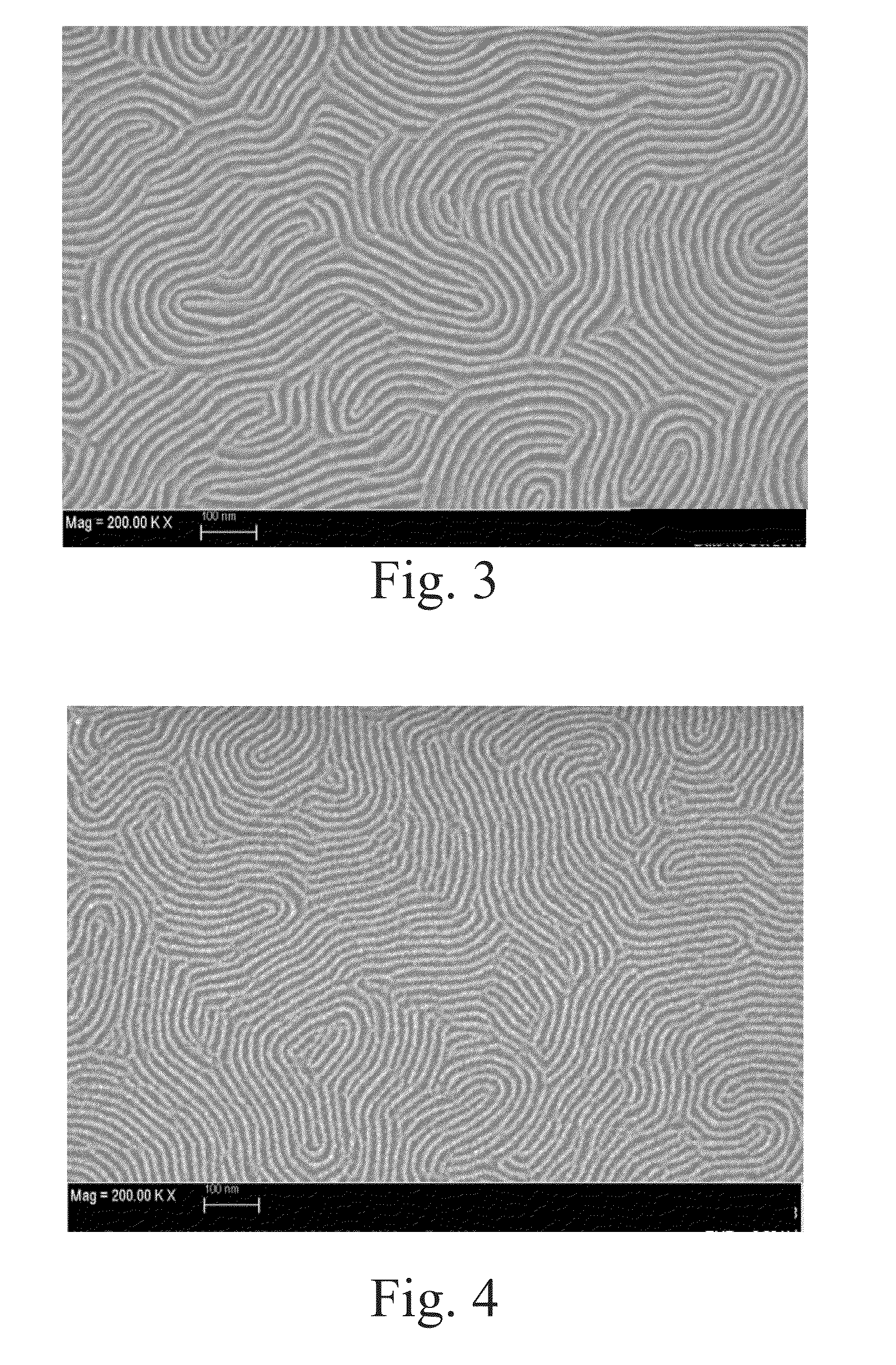

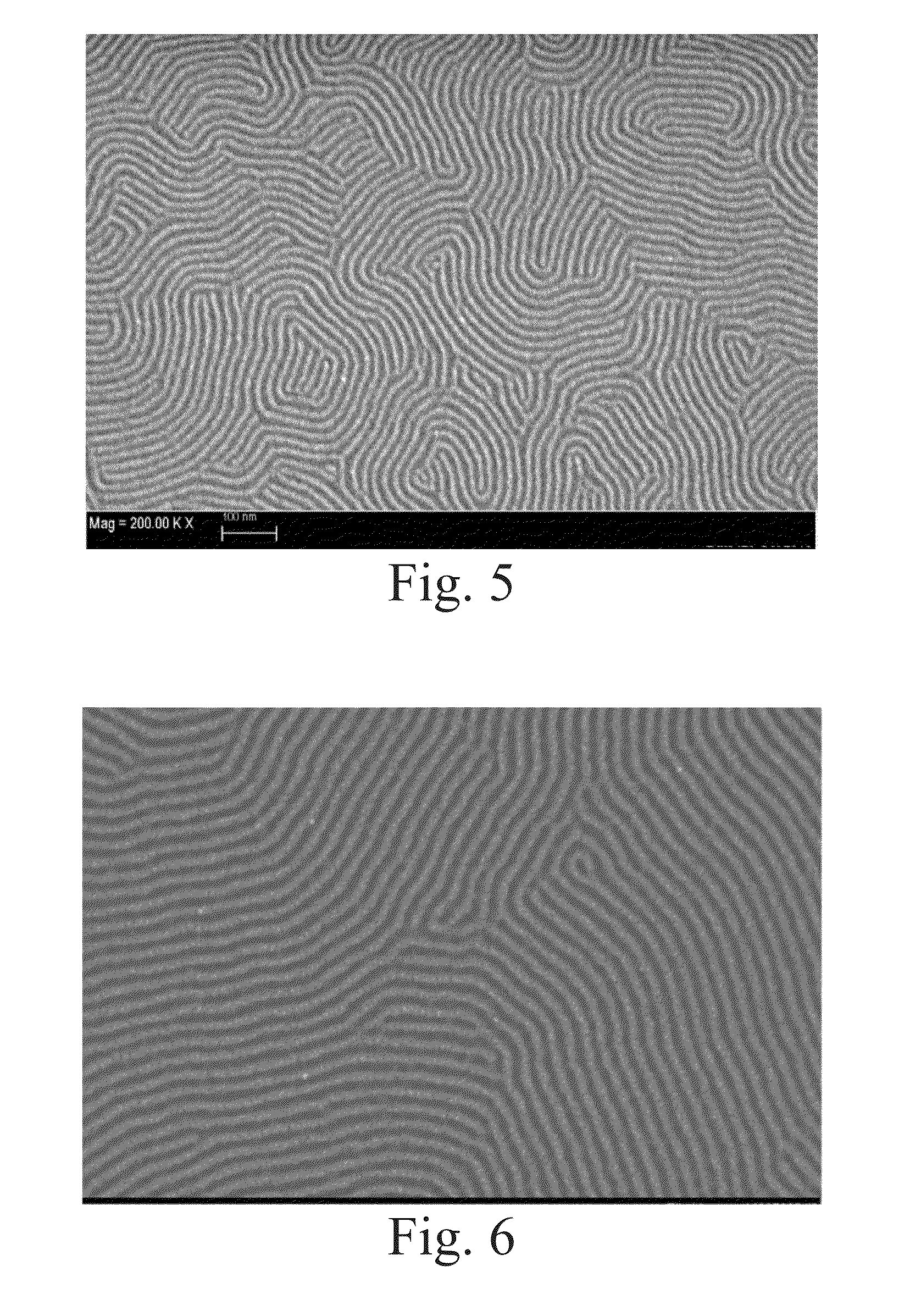

Solvent annealing block copolymers on patterned substrates

ActiveUS20120202017A1High degreeImproved size controlMaterial nanotechnologyDecorative surface effectsImage resolutionLine width

Provided herein are block copolymer thin film structures and methods of fabrication. Aspects described herein include methods of directed self-assembly of block copolymers on patterns using solvent annealing, and the resulting thin films, structures, media or other compositions. According to various embodiments, solvent annealing is used direct the assembly of block copolymers on chemical patterns to achieve high degrees of pattern perfection, placement of features at the precision of the lithographic tool used to make the chemical pattern, improved dimensional control of features, improved line edge and line width roughness, and resolution enhancement by factors of two to four or greater.

Owner:WISCONSIN ALUMNI RES FOUND

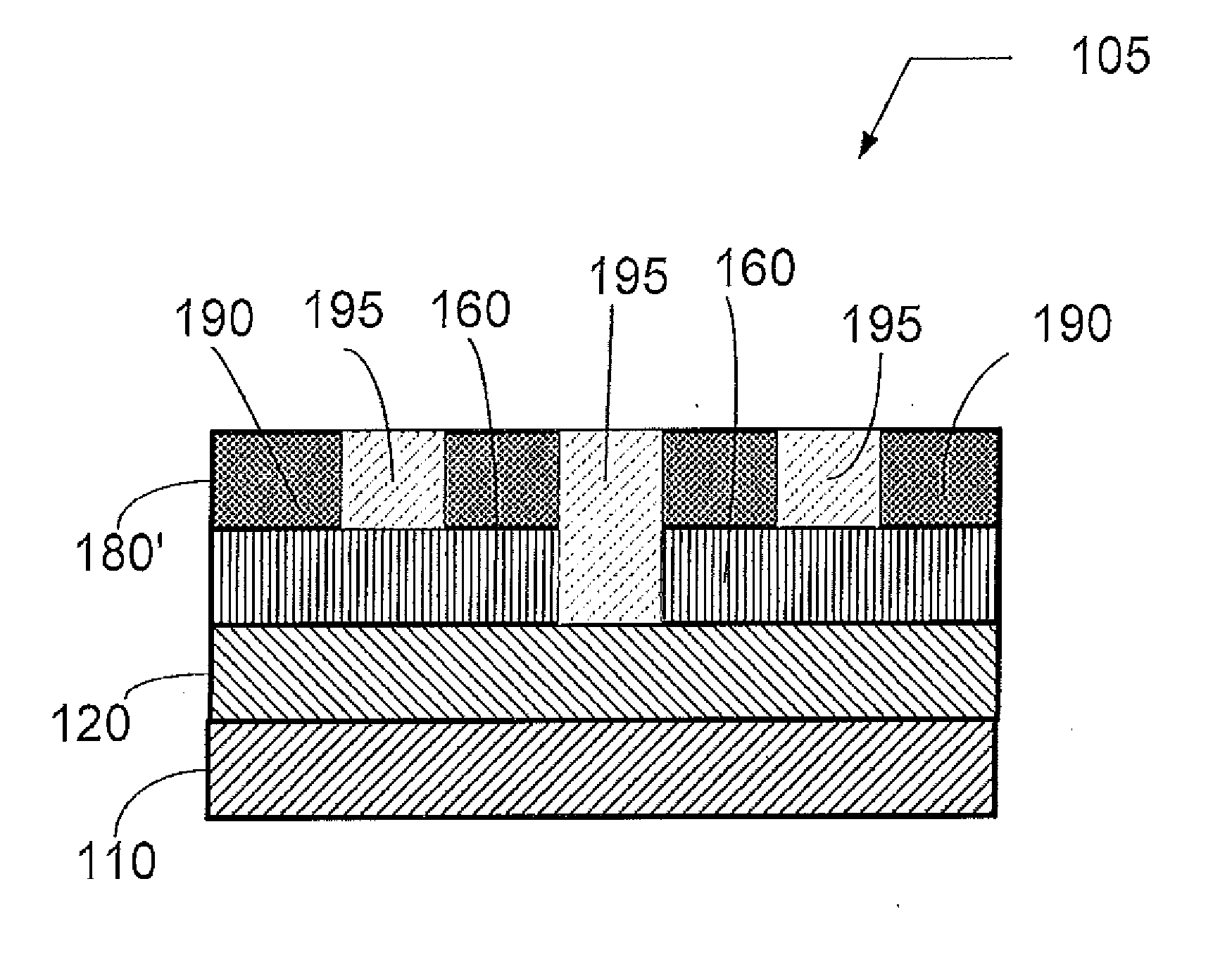

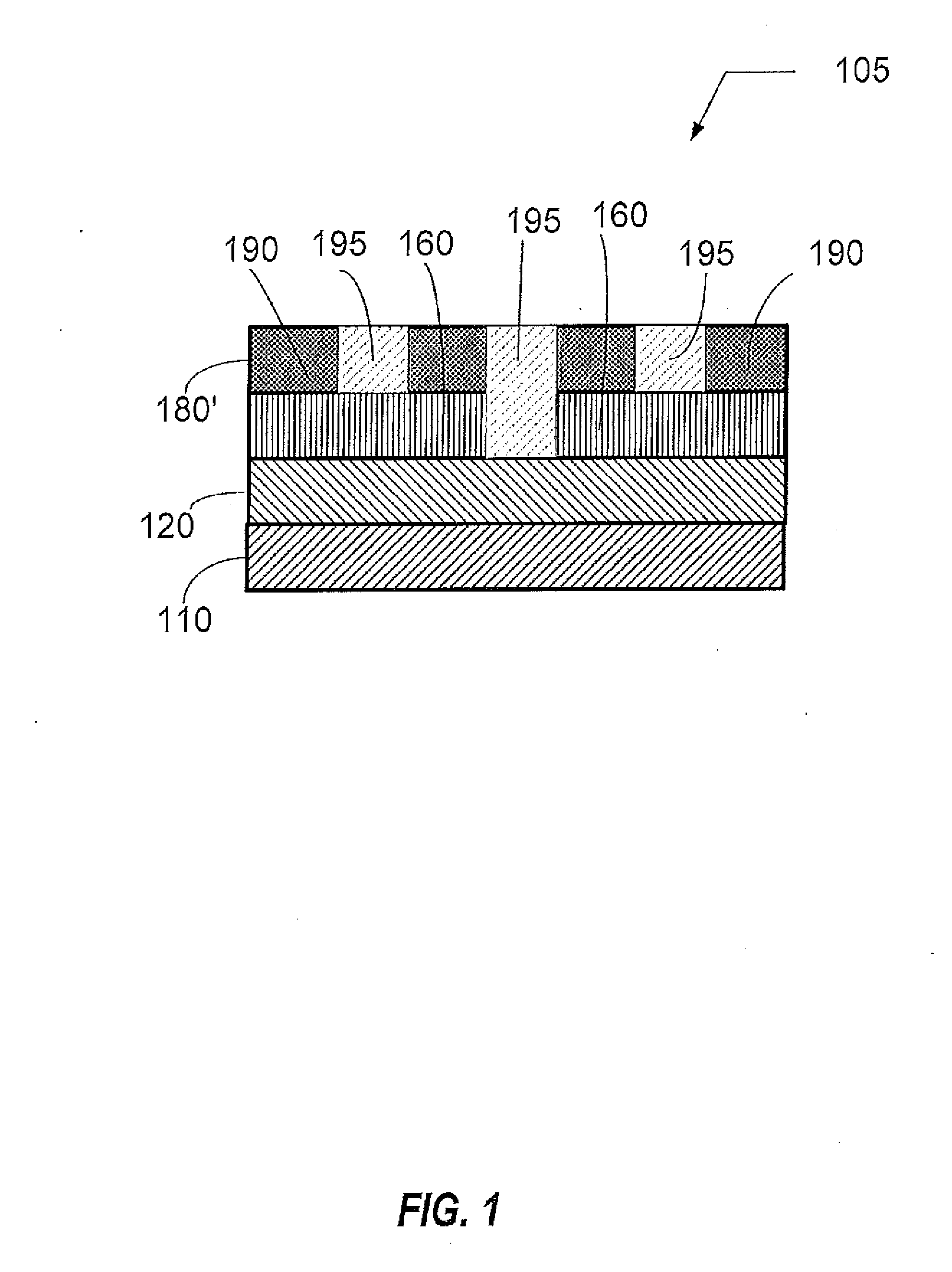

Topography minimization of neutral layer overcoats in directed self-assembly applications

A method is provided for patterning a layered substrate that includes loading a substrate into a coater-developer processing system; coating the substrate with a photoresist material layer; patterning the photoresist material layer to form a photoresist pattern; transferring the substrate to a deposition processing system; and depositing a neutral layer over the photoresist pattern and exposed portions of the substrate. The neutral layer can deposited using a gas cluster ion beam (GCIB) process, or an atomic layer deposition (ALD) process, which has minimal topography. The method may further include lifting off a portion of the neutral layer deposited over the photoresist pattern to expose a neutral layer template for subsequent directed self-assembly (DSA) patterning; depositing a DSA material layer over the neutral layer template; baking the DSA material layer to form a DSA pattern; and developing the DSA material layer to expose the final DSA pattern for subsequent feature etching.

Owner:TOKYO ELECTRON LTD

Selective deposition using hydrophobic precursors

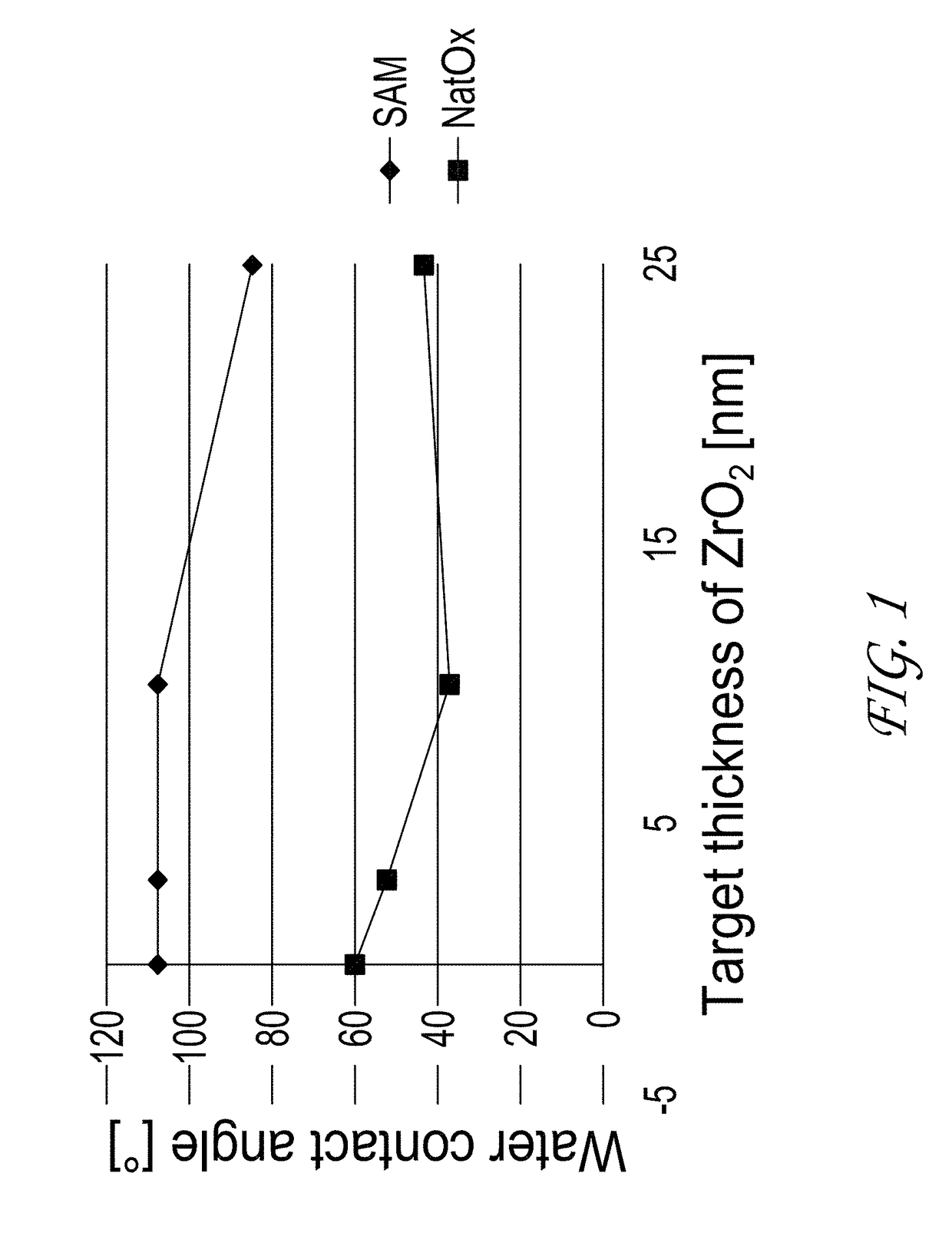

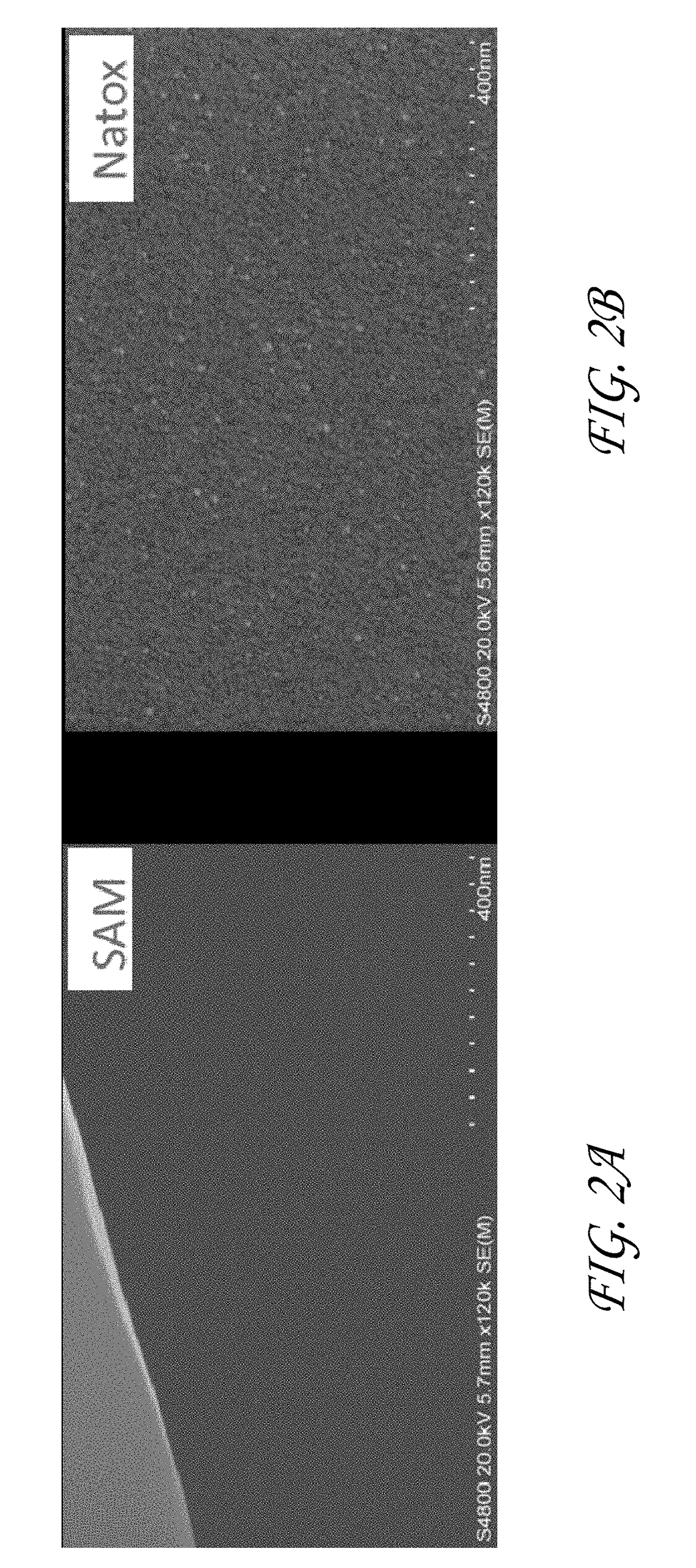

ActiveUS20170323776A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSelf-assembled monolayerGas phase

Vapor deposition processes are provided in which a material is selectively deposited on a first surface of a substrate relative to a second organic surface. In some embodiments a substrate comprising a first surface, such as a metal, semi-metal or oxidized metal or semi-metal is contacted with a first vapor phase hydrophobic reactant and a second vapor phase reactant such that the material is deposited selectively on the first surface relative to the second organic surface. The second organic surface may comprise, for example, a self-assembled monolayer, a directed self-assembled layer, or a polymer, such as a polyimide, polyamide, polyuria or polystyrene. The material that is deposited may be, for example, a metal or metallic material. In some embodiments the material is a metal oxide, such as ZrO2 or HfO2. In some embodiments the vapor deposition process is a cyclic chemical vapor deposition (CVD) process or an atomic layer deposition (ALD) process. In some embodiments the material is deposited on the first surface relative to the second surface with a selectivity of greater than about 50%, greater than about 60%, greater than about 70%, greater than about 80%, greater than about 90% or greater than about 95%.

Owner:ASM IP HLDG BV

Compositions of neutral layer for directed self assembly block copolymers and processes thereof

ActiveUS8691925B2High resolutionHigh pattern definitionElectric discharge tubesNanoinformaticsStructural unitDirected self assembly

The present invention relates to novel neutral layer compositions and methods for using the compositions. The neutral layer composition comprises at least one random copolymer having at least one unit of structure (1), at least one unit of structure (2) and at least one unit of structure (3)where R1 is selected from the group consisting of a C1-C8 alkyl, C1-C8 fluoroalkyl moiety, C1-C8 partially fluorinated alkyl, C4-C8 cycloalkyl, C4-C8 cyclofluoroalkyl, C4-C8 partially fluorinated cycloalkyl, and a C2-C8 hydroxyalkyl; R2, R3 and R5 are independently selected from a group consisting of H, C1-C4 alkyl, CF3 and F; R4 is selected from the group consisting of H, C1-C8 alkyl, C1-C8 partially fluorinated alkyl and C1-C8 fluoroalkyl, n ranges from 1 to 5, R6 is selected from the group consisting of H, F, C1-C8 alkyl and a C1-C8 fluoroalkyl and m ranges from 1 to 3.

Owner:MERCK PATENT GMBH

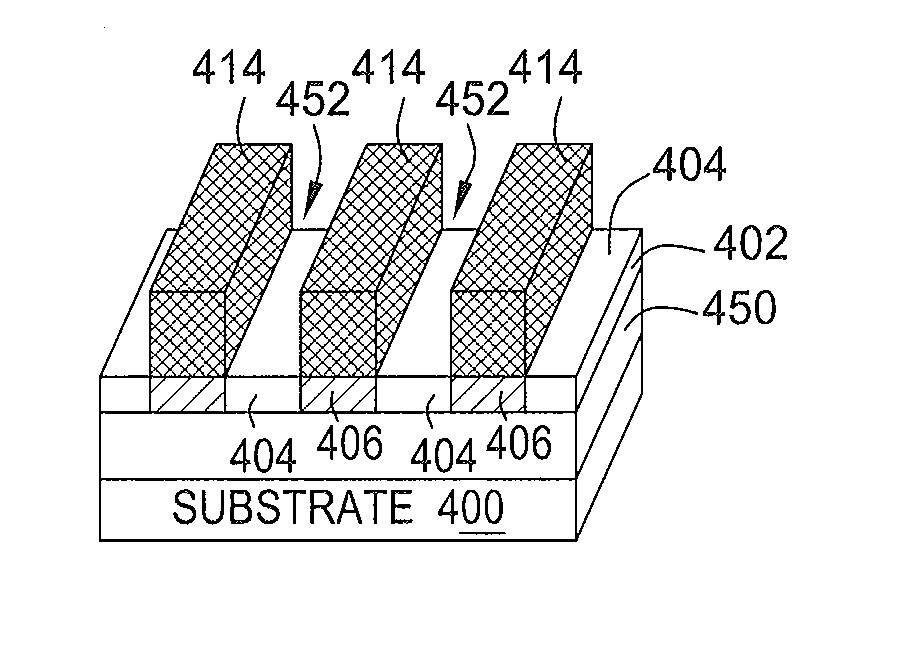

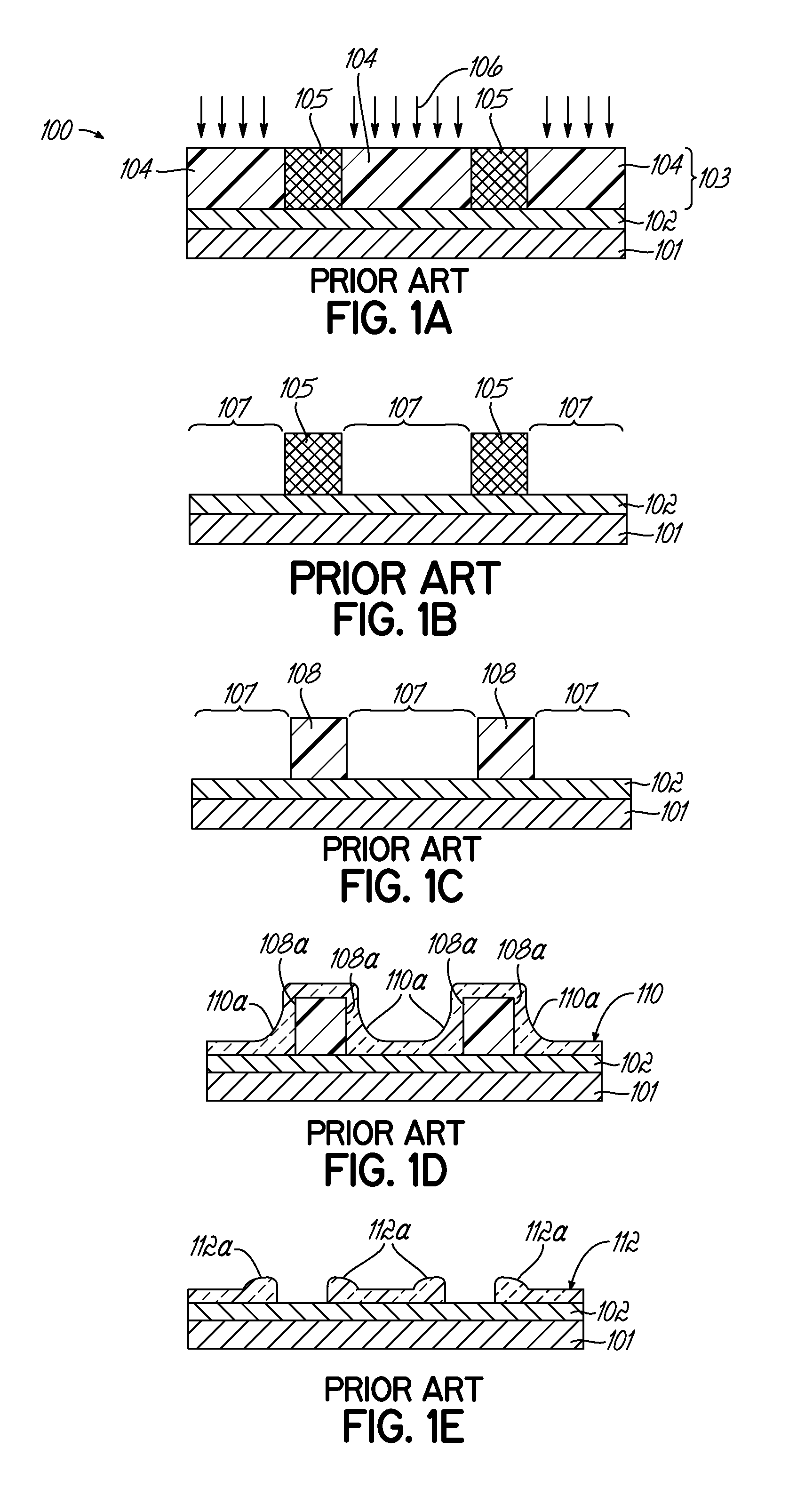

Grapho-epitaxy DSA process with dimension control of template pattern

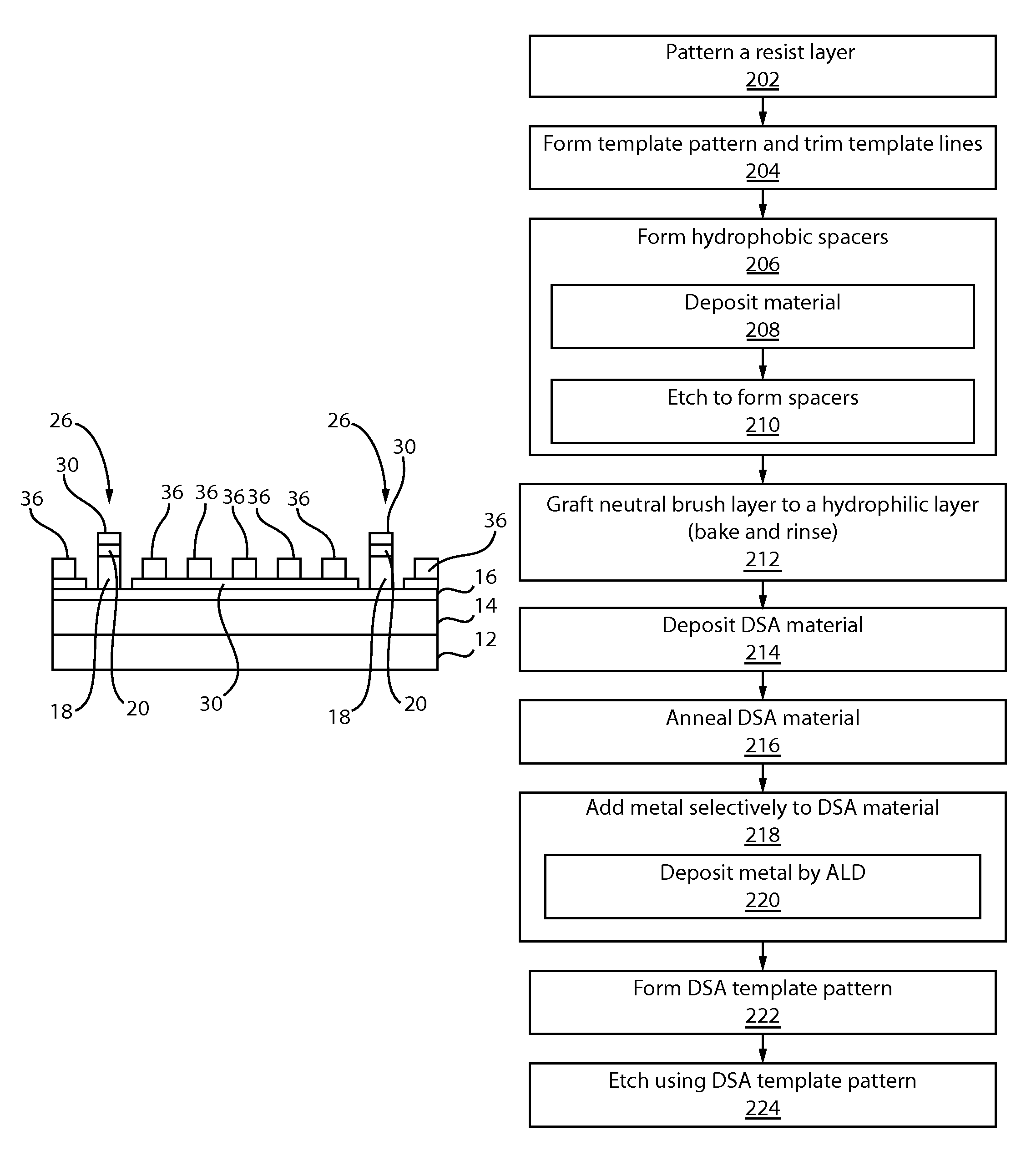

InactiveUS8853085B1Photomechanical apparatusSemiconductor/solid-state device manufacturingResistGobio gobio obtusirostris

A method for defining a template for directed self-assembly (DSA) materials includes patterning a resist on a stack including an ARC and a mask formed over a hydrophilic layer. A pattern is formed by etching the ARC and the mask to form template lines which are trimmed to less than a minimum feature size (L). Hydrophobic spacers are formed on the template lines and include a fractional width of L. A neutral brush layer is grafted to the hydrophilic layer. A DSA material is deposited between the spacers and annealed to form material domains in a form of alternating lines of a first and a second material wherein the first material in contact with the spacers includes a width less than a width of the lines. A metal is added to the domains forming an etch resistant second material. The first material and the spacers are removed to form a DSA template pattern.

Owner:ELPIS TECH INC

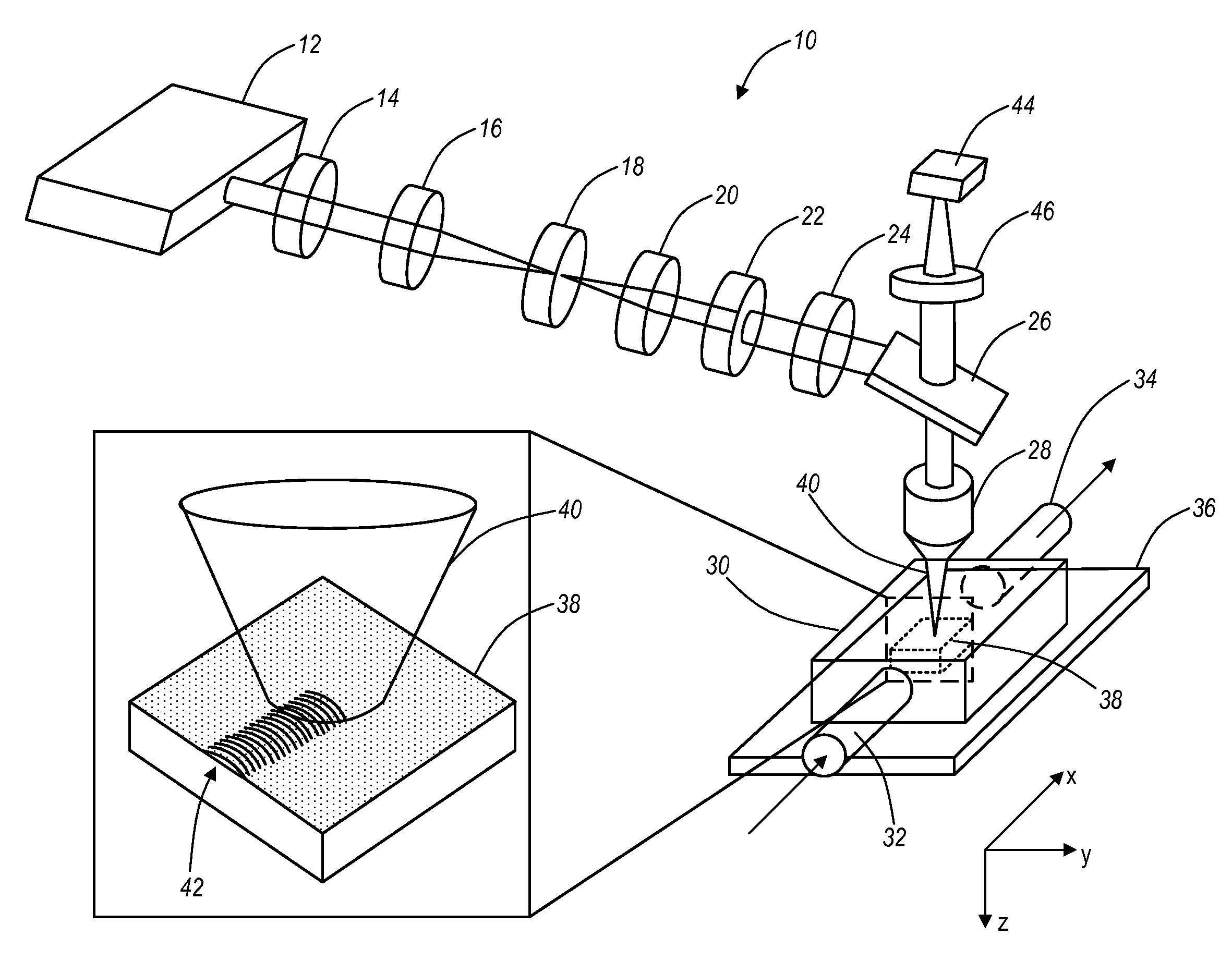

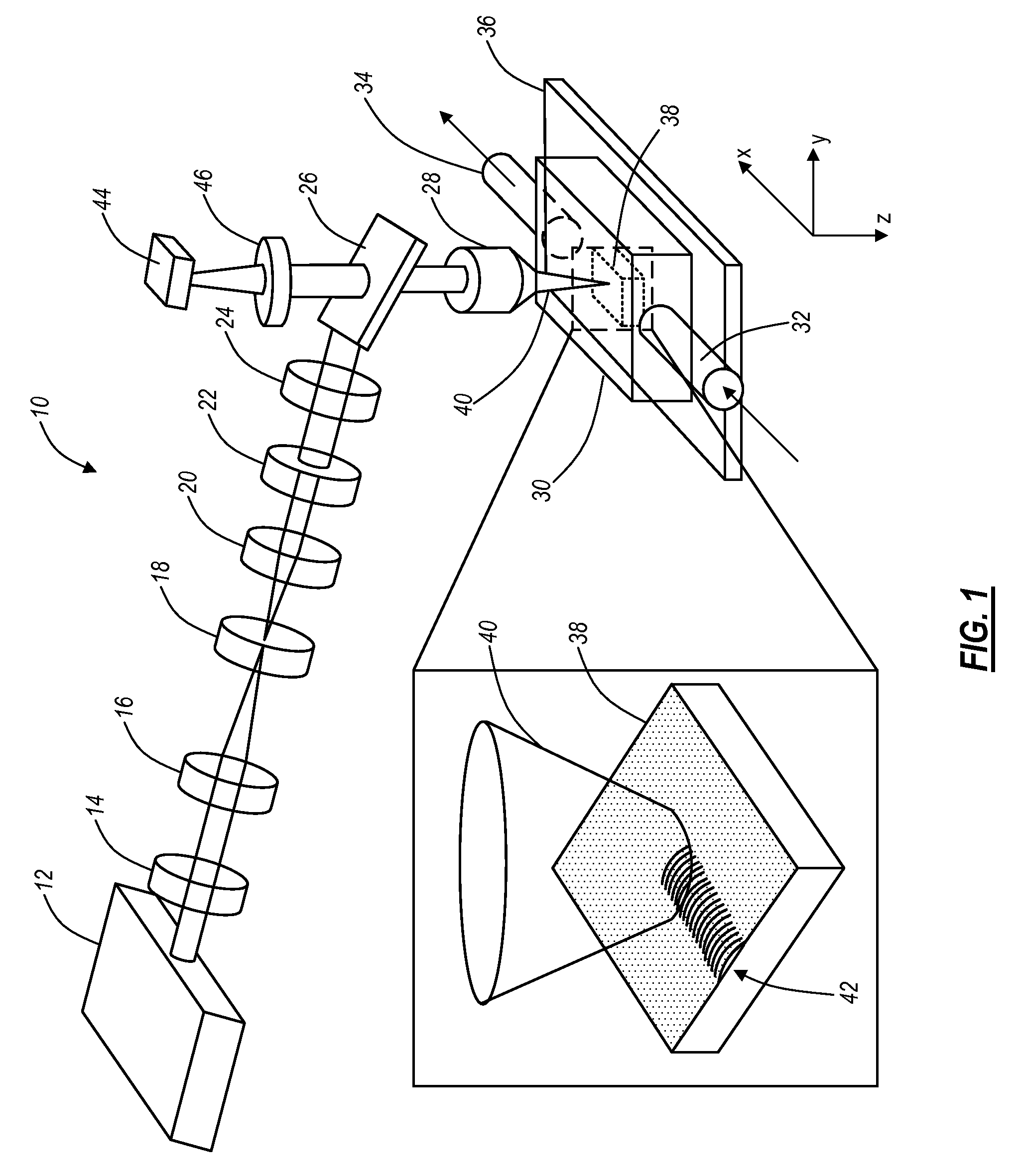

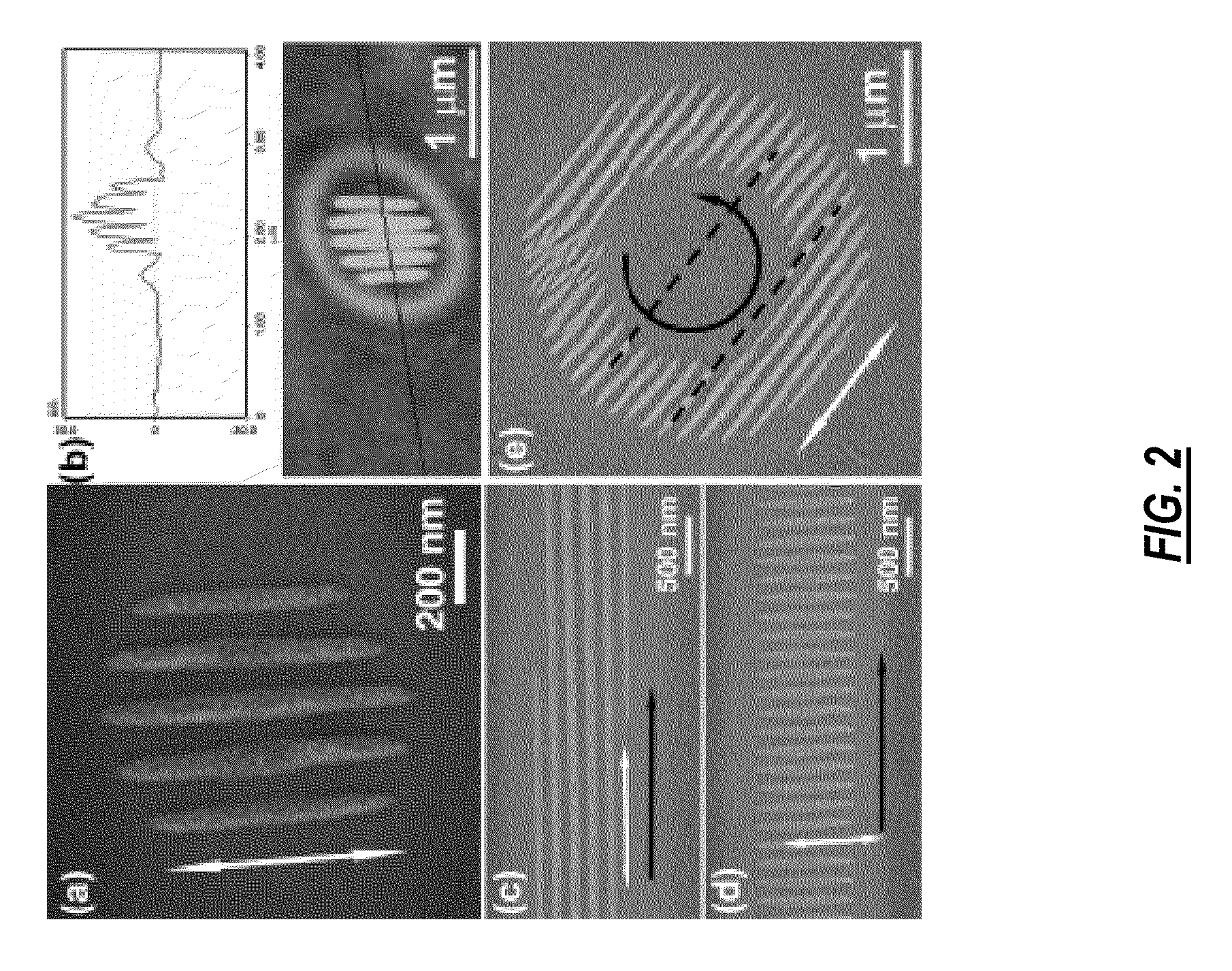

Light-induced directed self-assembly of periodic sub-wavelength nanostructures

ActiveUS20090214885A1Small feature sizeExcellent long-range orderCasting plantsNanoinformaticsWavelengthNanostructure

In various exemplary embodiments, the present invention provides a system for the light-induced directed self-assembly (LIDSA) of periodic sub-wavelength nanostructures, including: a light source for delivering a beam of photons; a reaction chamber disposed adjacent to the light source; a gas including one or more precursor materials disposed within the reaction chamber; and a substrate disposed within the reaction chamber, wherein the substrate is positioned and configured to receive the beam of photons; wherein the beam of photons causes a periodic sub-wavelength nanostructure of one or more constituents of the one or more precursor materials to form on a surface of the substrate. In various exemplary embodiments, the present invention also provides an associated method.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

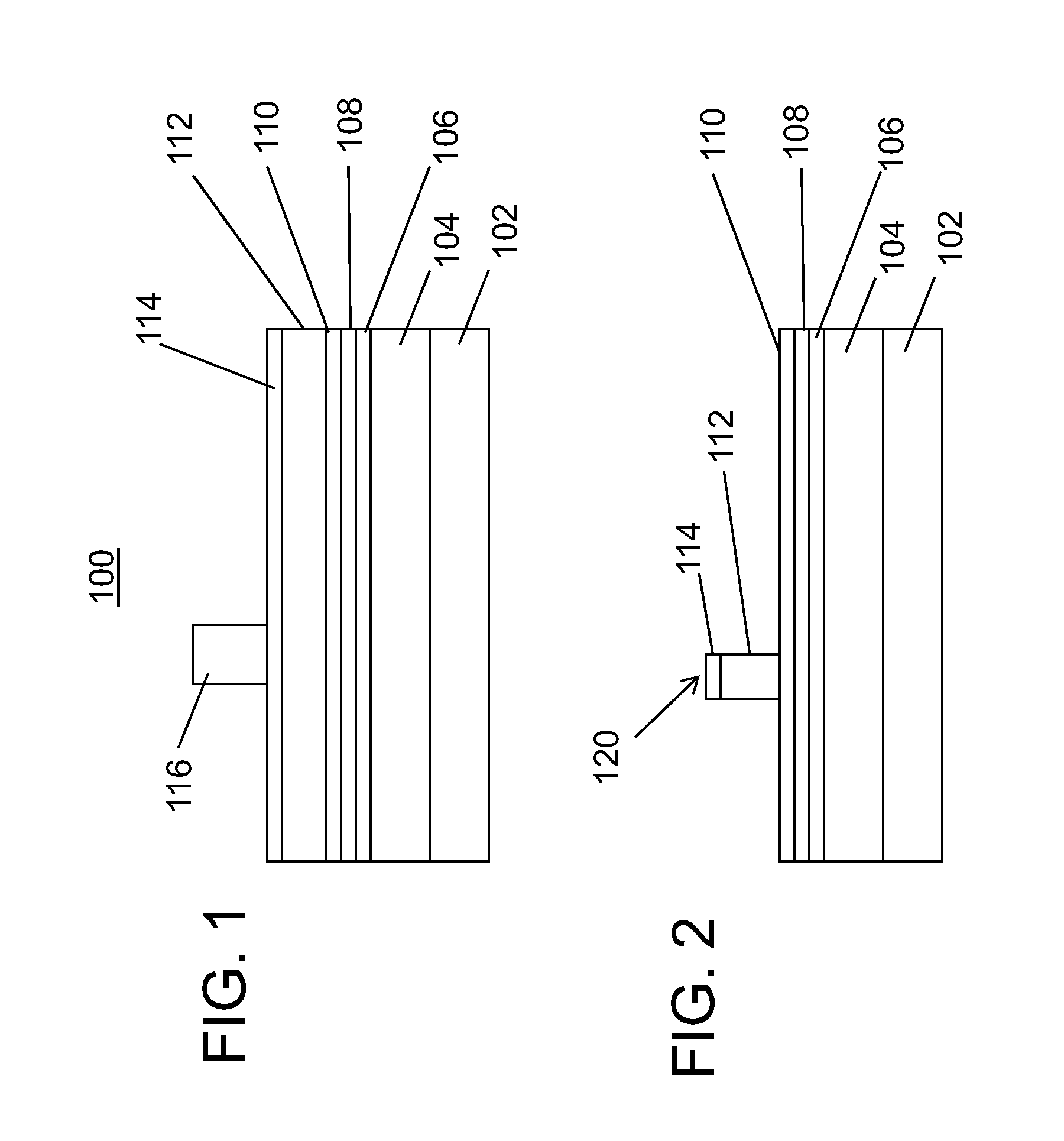

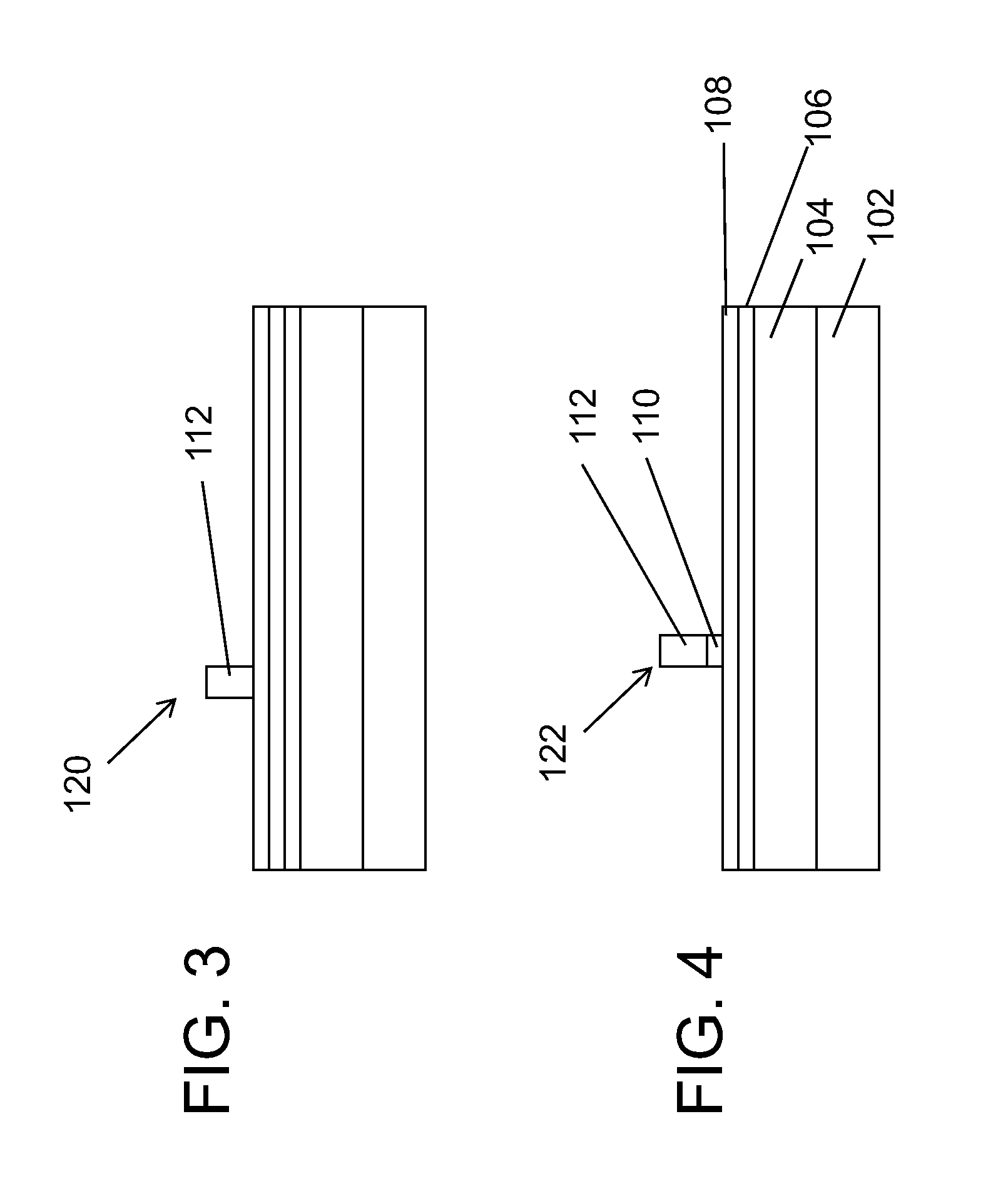

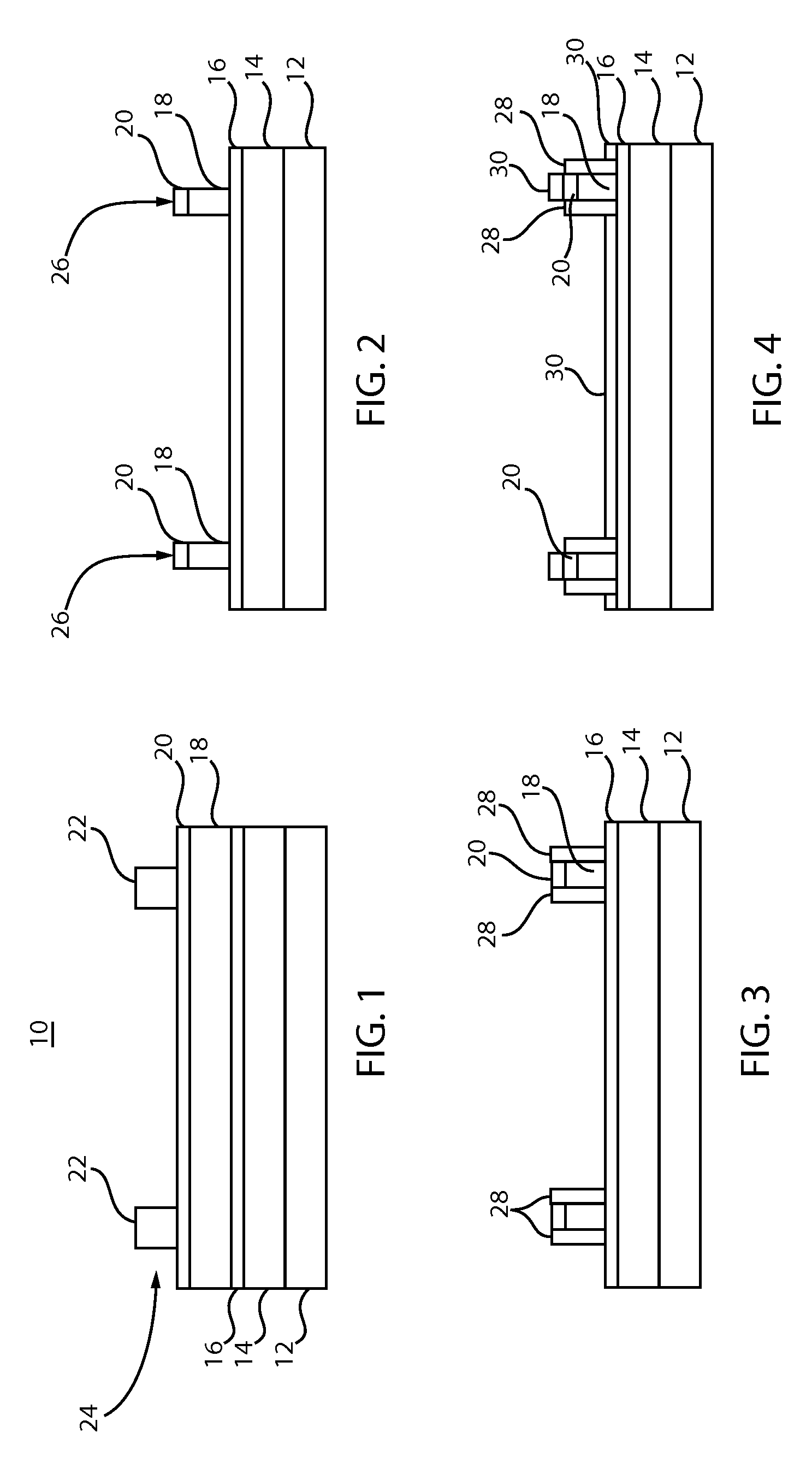

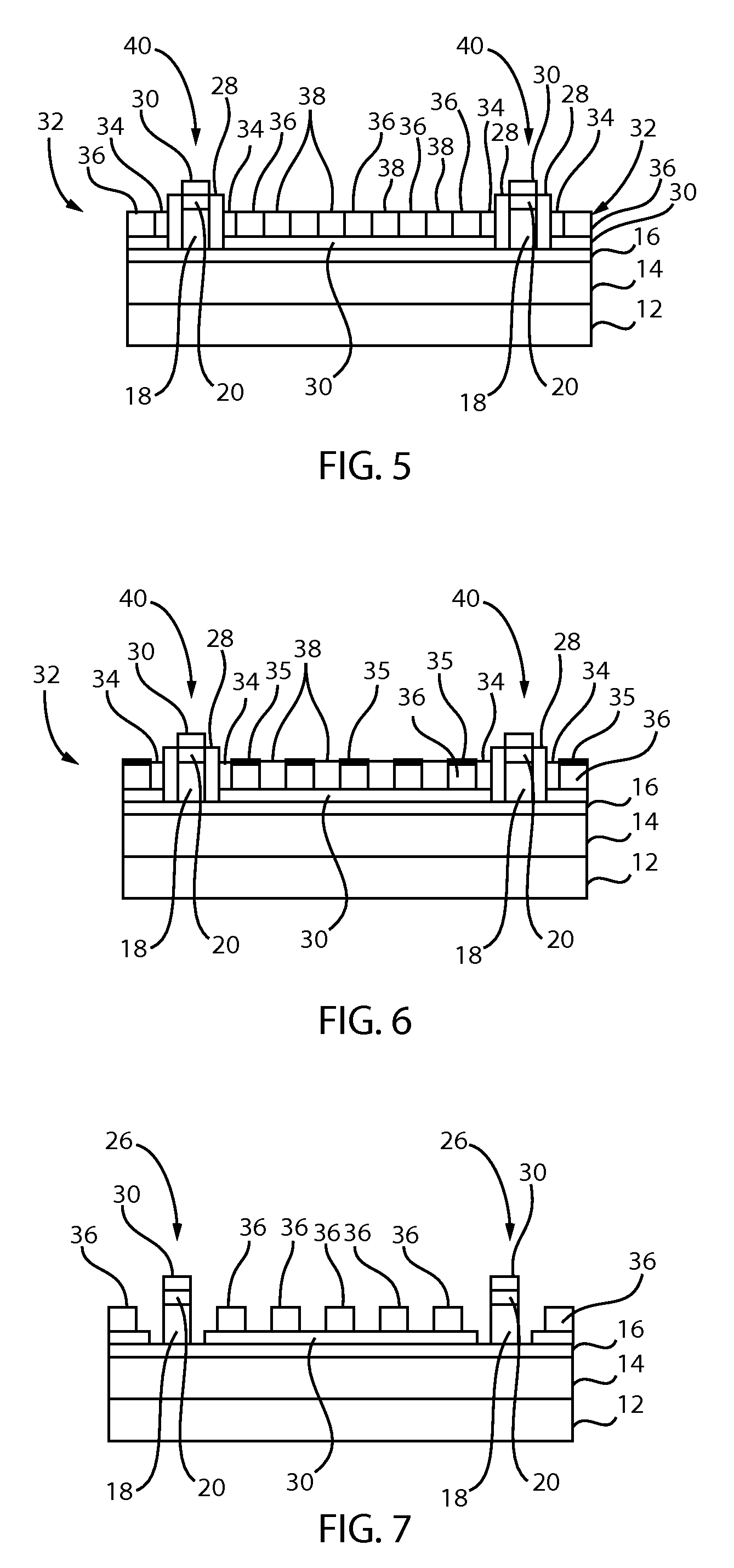

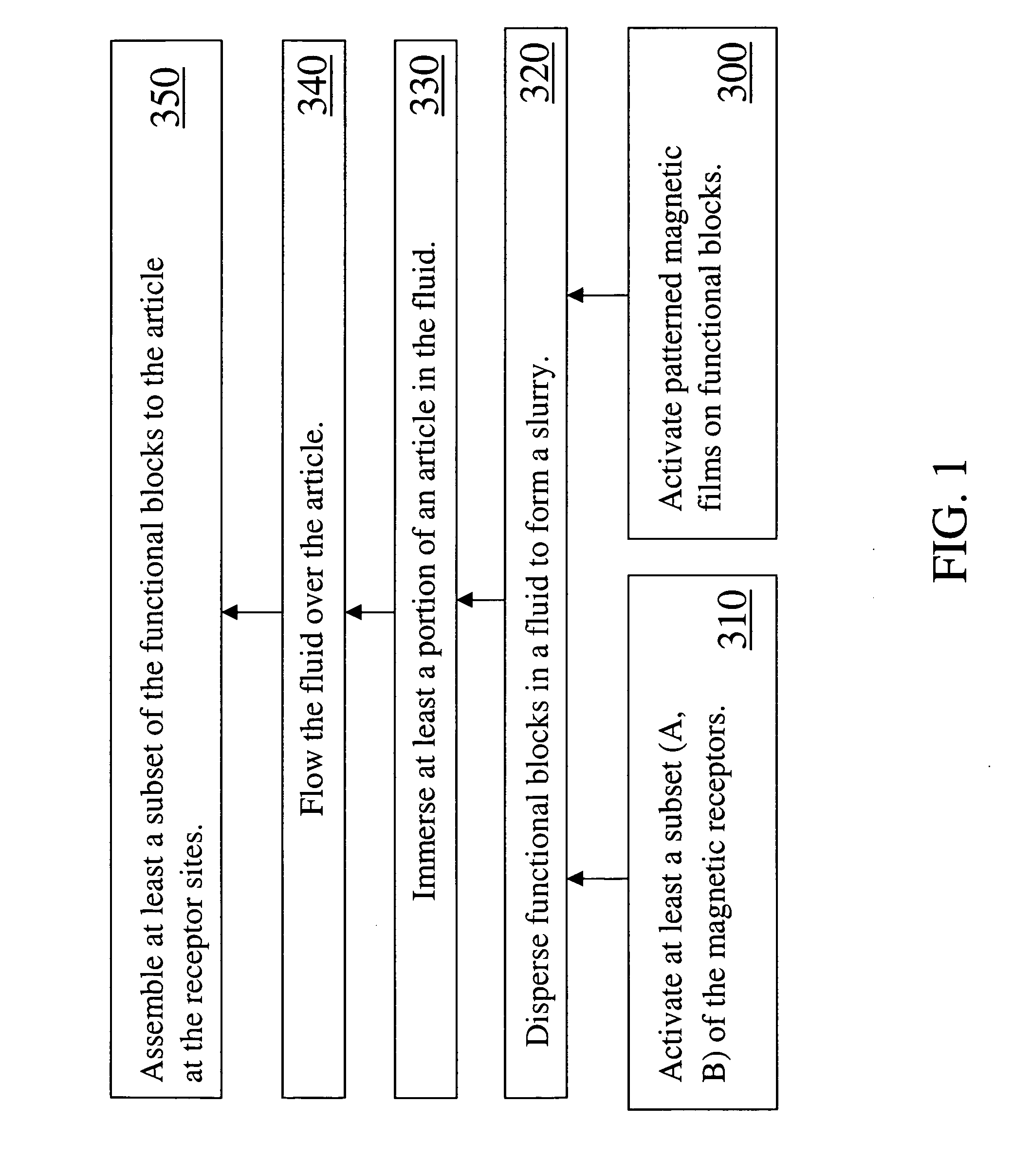

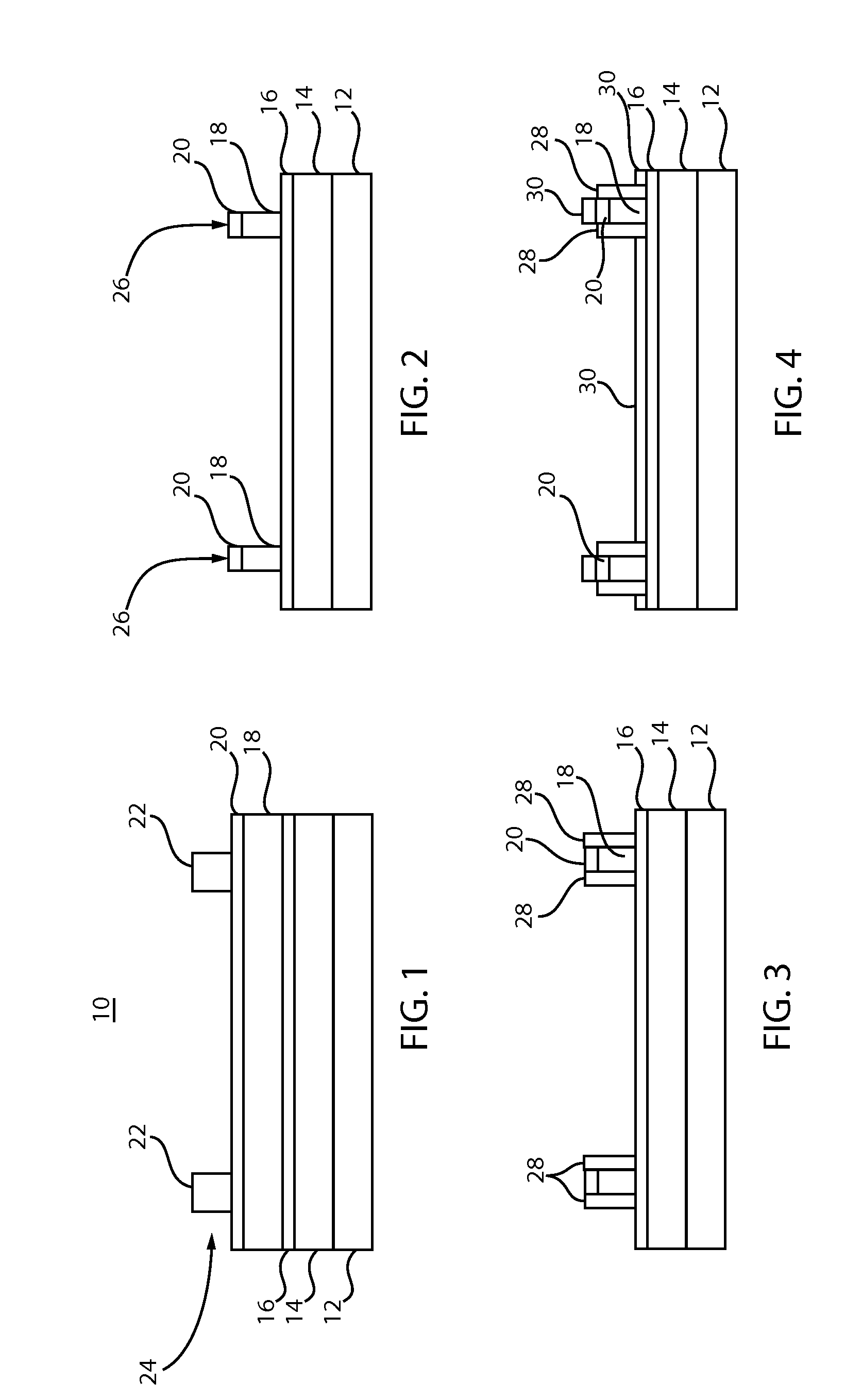

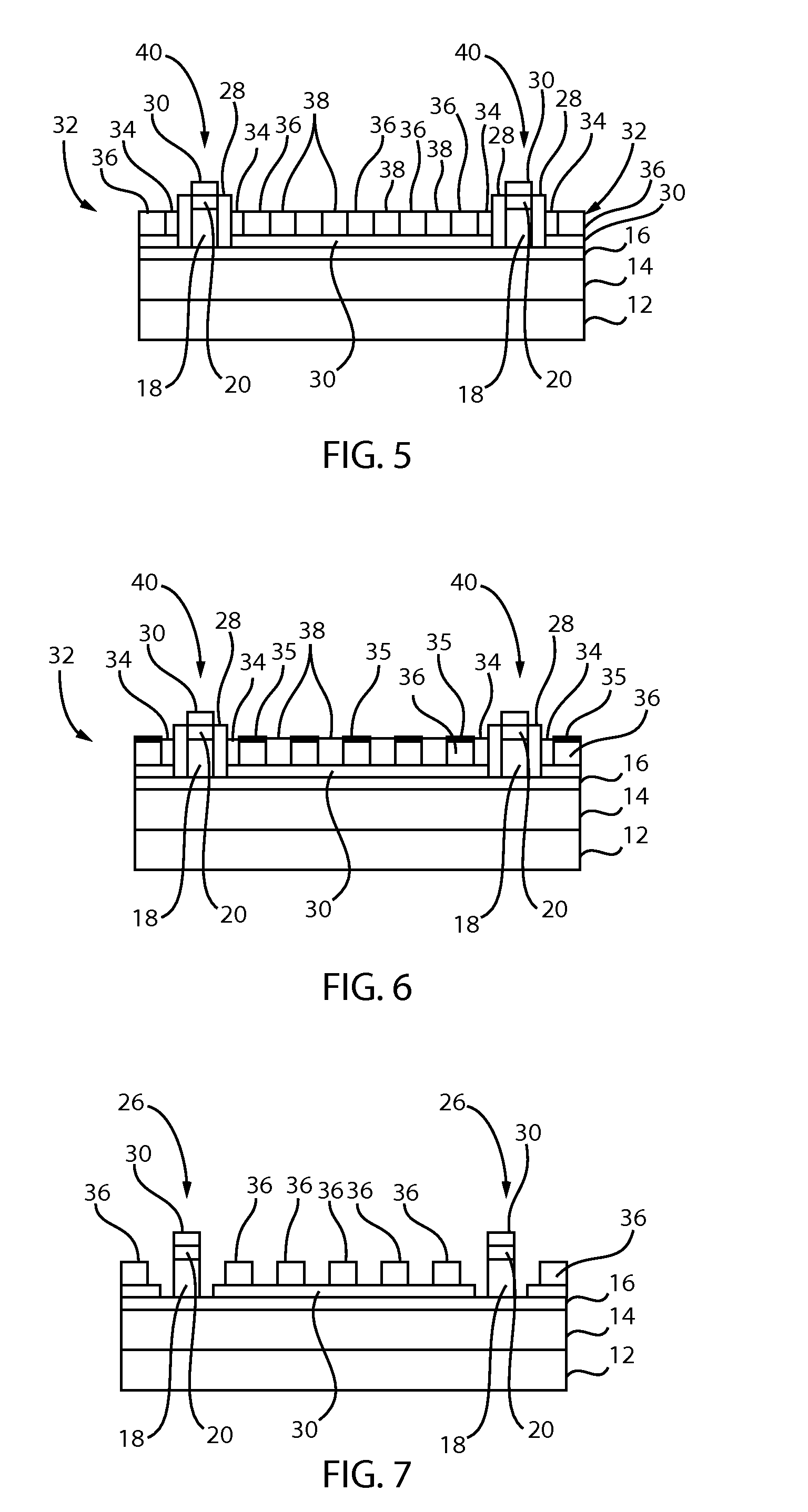

Methods for magnetically directed self assembly

ActiveUS20070087472A1Easy to assemblePrinted circuit assemblingWriting implementsDirected self assemblyEngineering

A fluidic assembly method includes dispersing a number of functional blocks in a fluid to form a slurry. Each of the functional blocks includes at least one element and a patterned magnetic film comprising at least one region. The fluidic assembly method further includes immersing at least a portion of an article in the fluid. The article includes a substrate, a number of receptor sites disposed on the substrate and a number of magnetic receptors, each of the magnetic receptors being disposed within a respective one of the receptor sites. A method of manufacturing an assembly includes disposing a number of functional blocks over at least a portion of an article, agitating the functional blocks relative to the article and assembling at least a subset of the functional blocks to the magnetic receptors on the article.

Owner:GENERAL ELECTRIC CO

Method for making a chemical contrast pattern using block copolymers and sequential infiltration synthesis

ActiveUS8900467B1Decorative surface effectsVacuum evaporation coatingAtomic layer depositionDirected self assembly

A method for making a chemical contrast pattern uses directed self-assembly of block copolymers (BCPs) and sequential infiltration synthesis (SIS) of an inorganic material. For an example with poly(styrene-block-methyl methacrylate) (PS-b-PMMA) as the BCP and alumina as the inorganic material, the PS and PMMA self-assemble on a suitable substrate. The PMMA is removed and the PS is oxidized. A surface modification polymer (SMP) is deposited on the oxidized PS and the exposed substrate and the SMP not bound to the substrate is removed. The structure is placed in an atomic layer deposition chamber. Alumina precursors reactive with the oxidized PS are introduced and infuse by SIS into the oxidized PS, thereby forming on the substrate a chemical contrast pattern of SMP and alumina. The resulting chemical contrast pattern can be used for lithographic masks, for example to etch the underlying substrate to make an imprint template.

Owner:WESTERN DIGITAL TECH INC

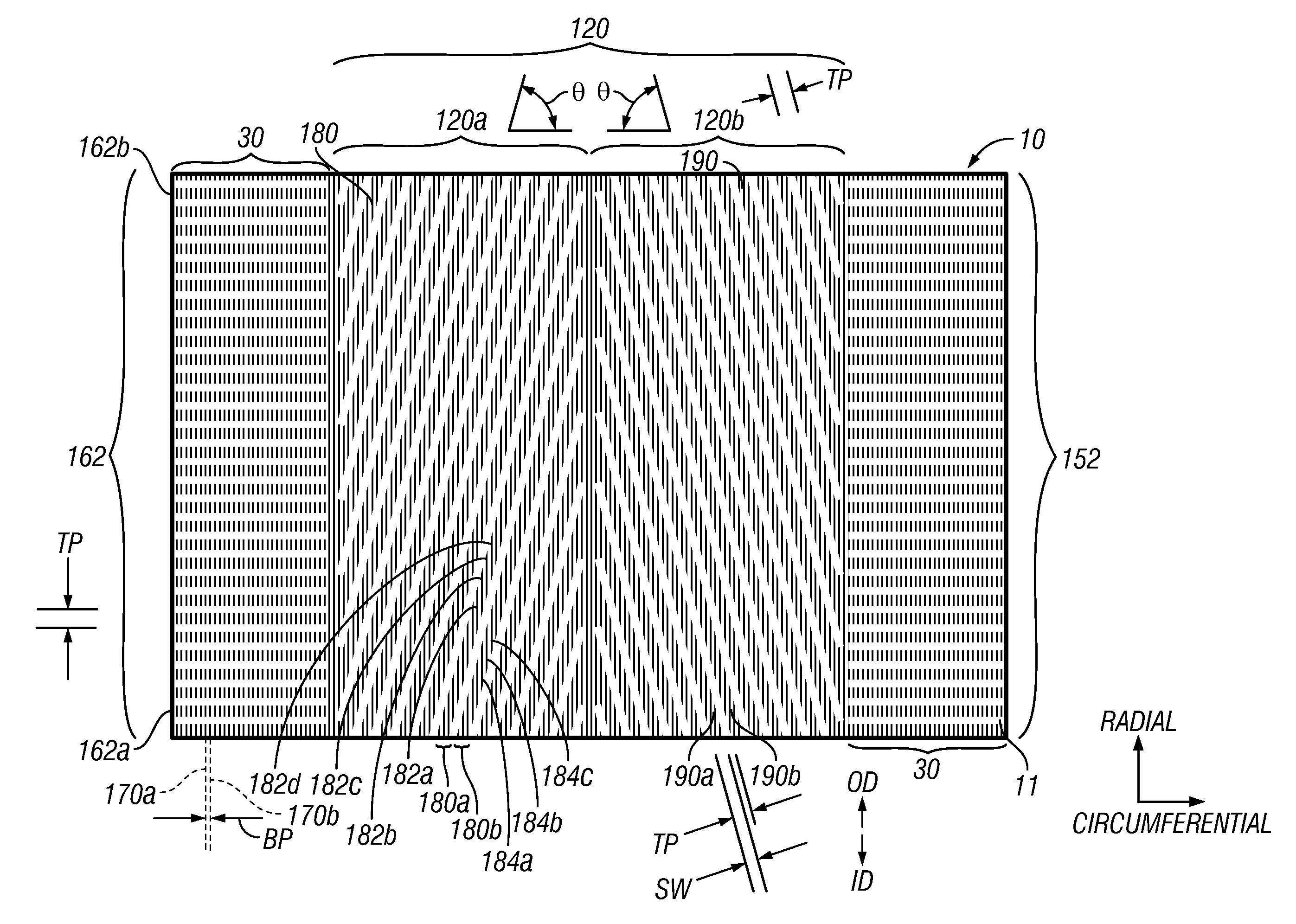

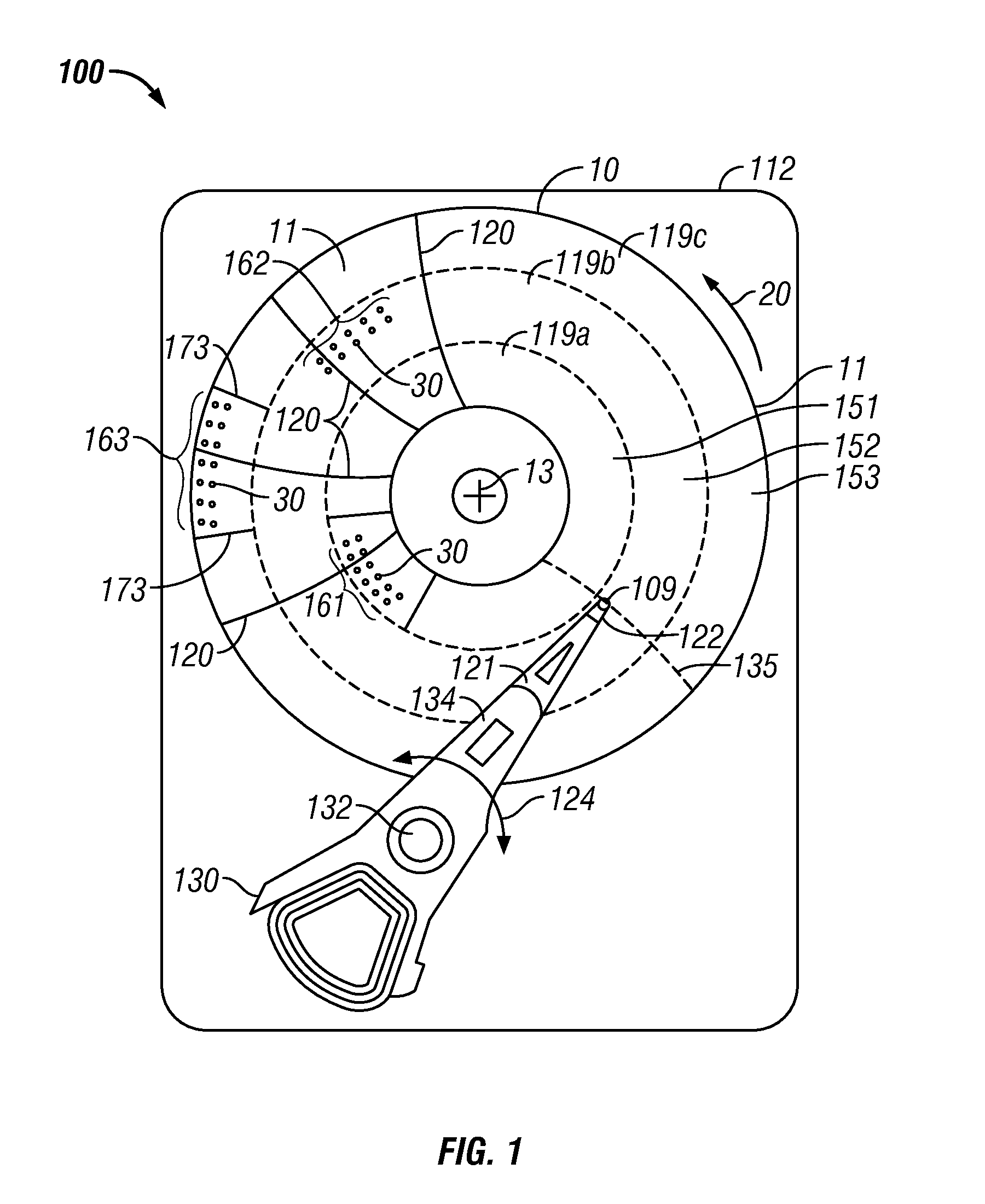

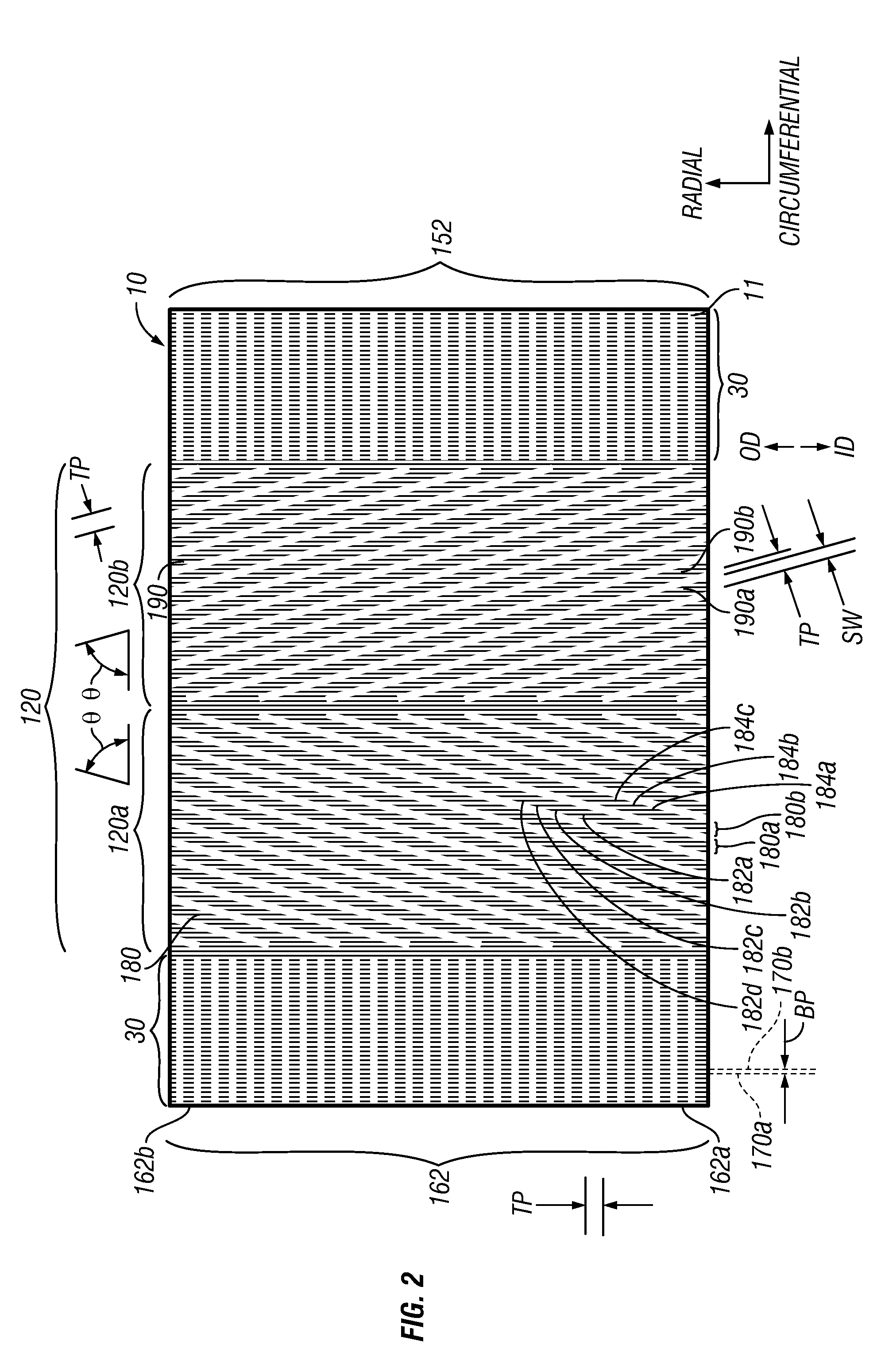

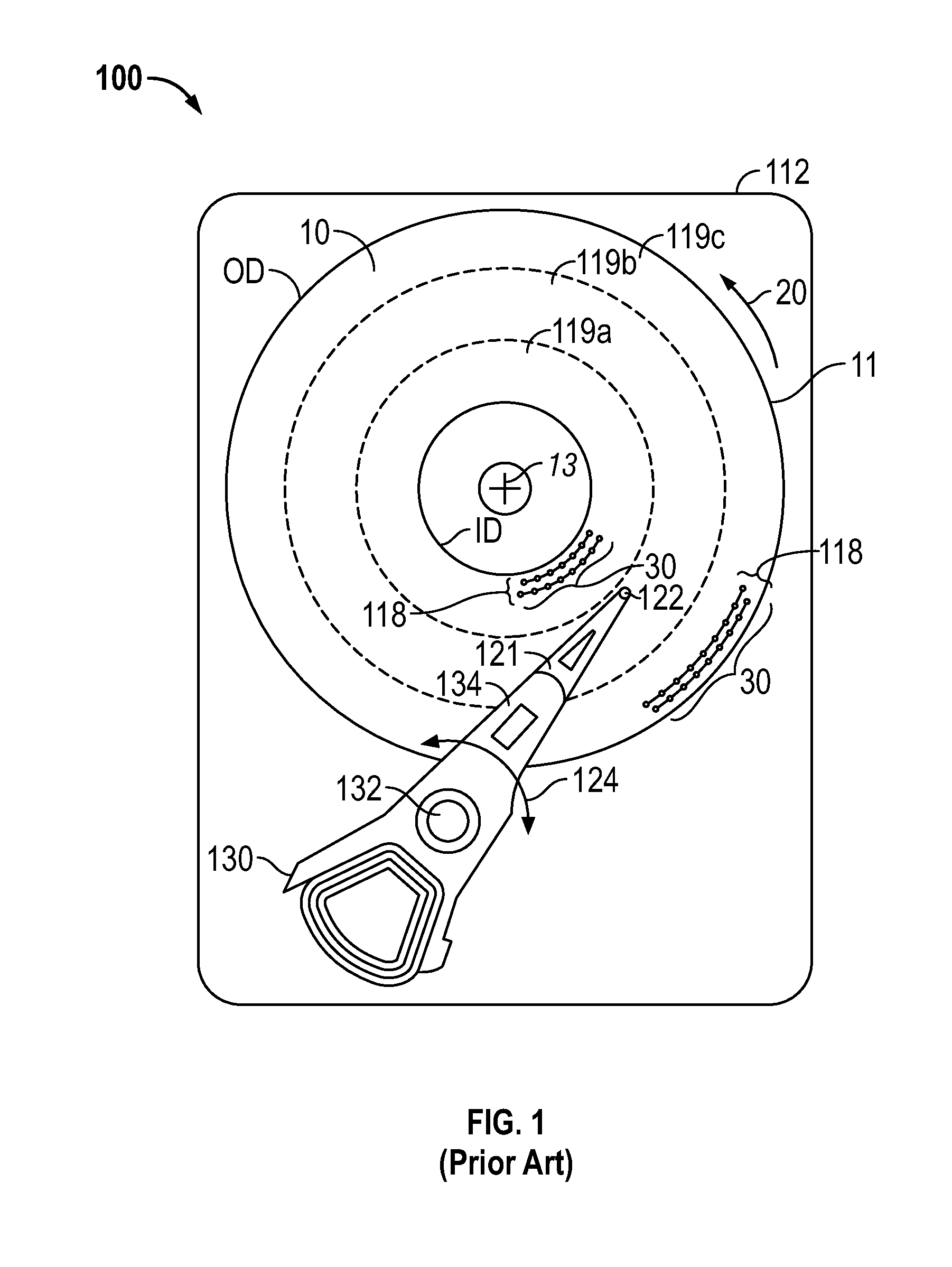

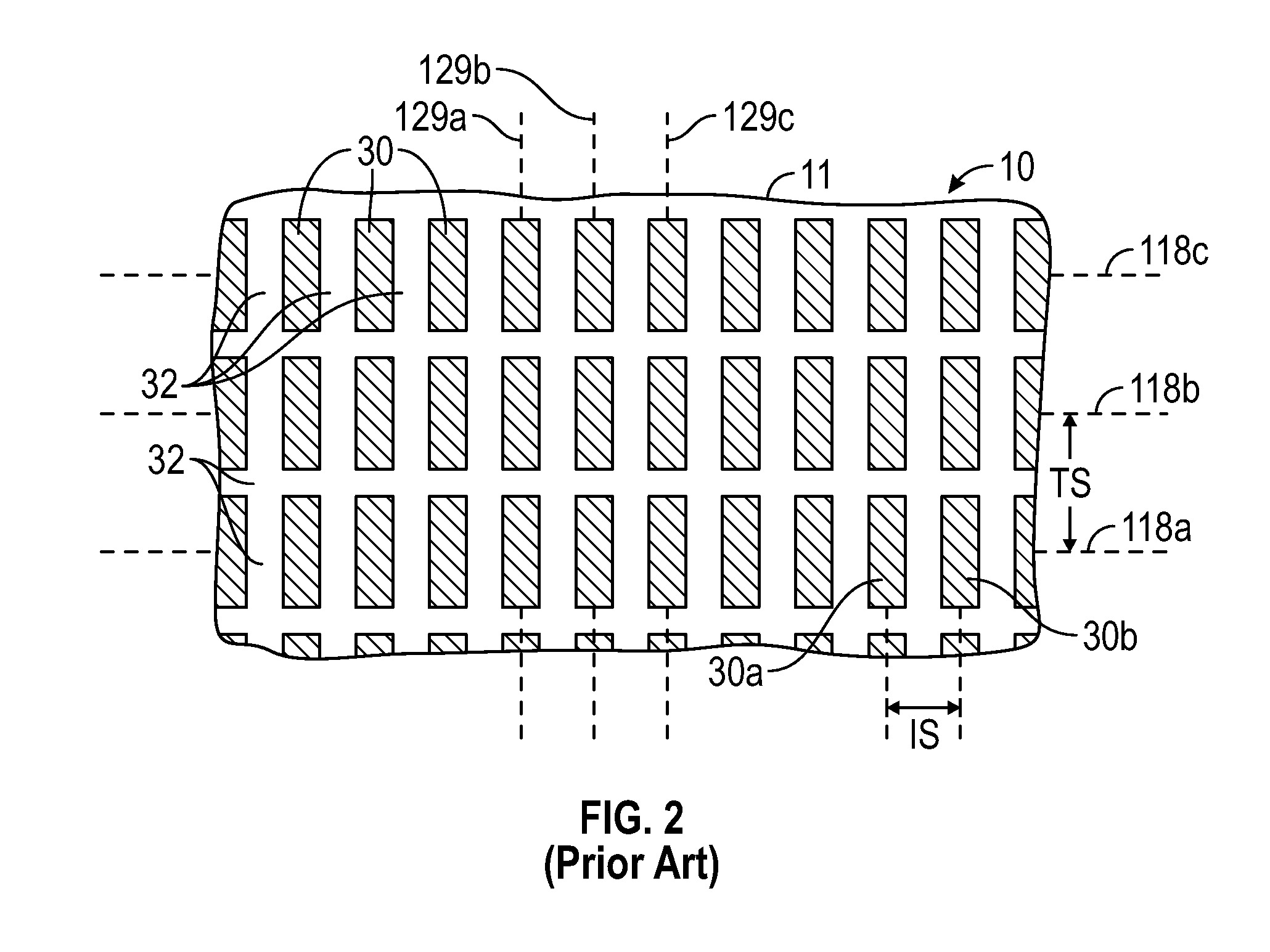

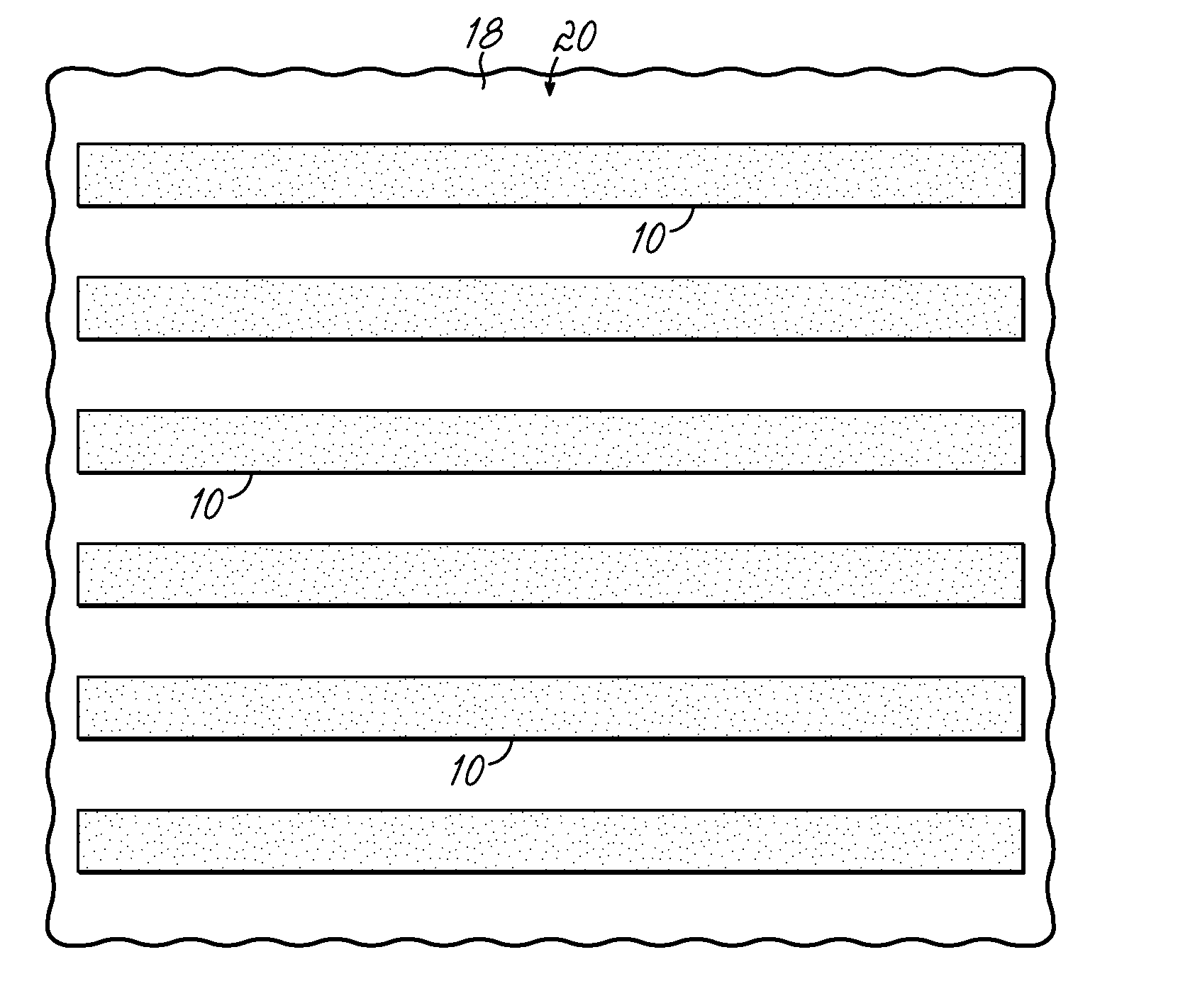

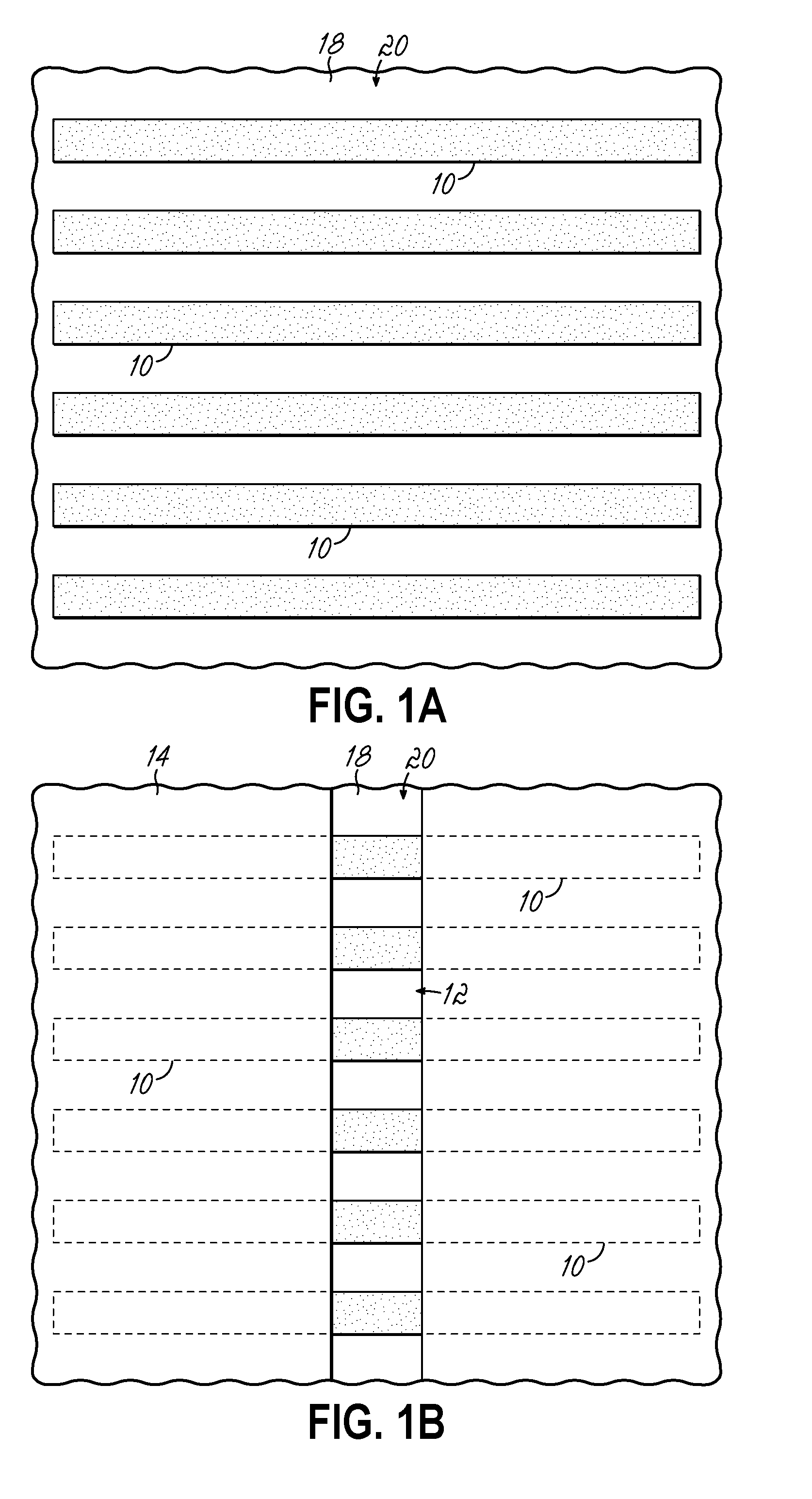

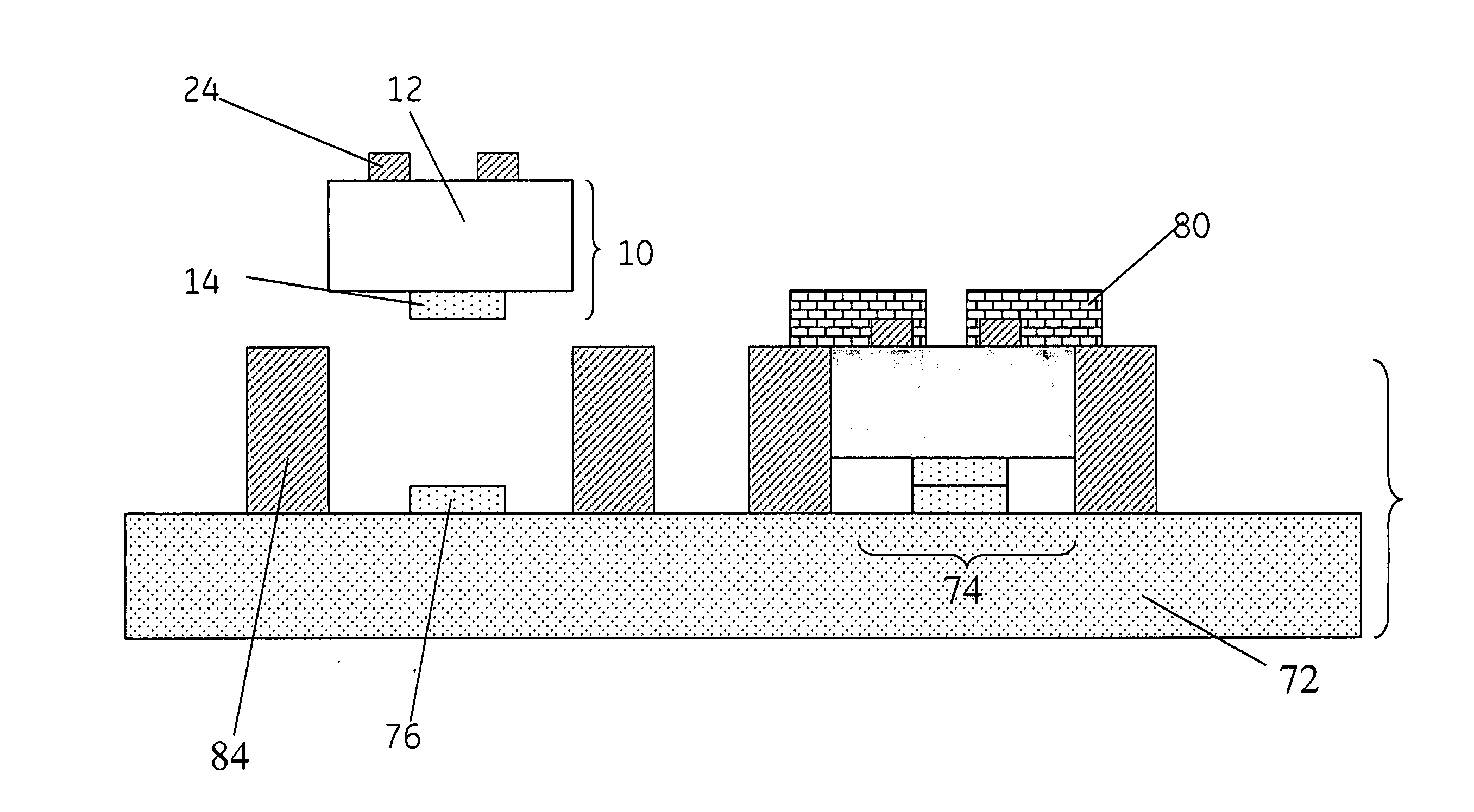

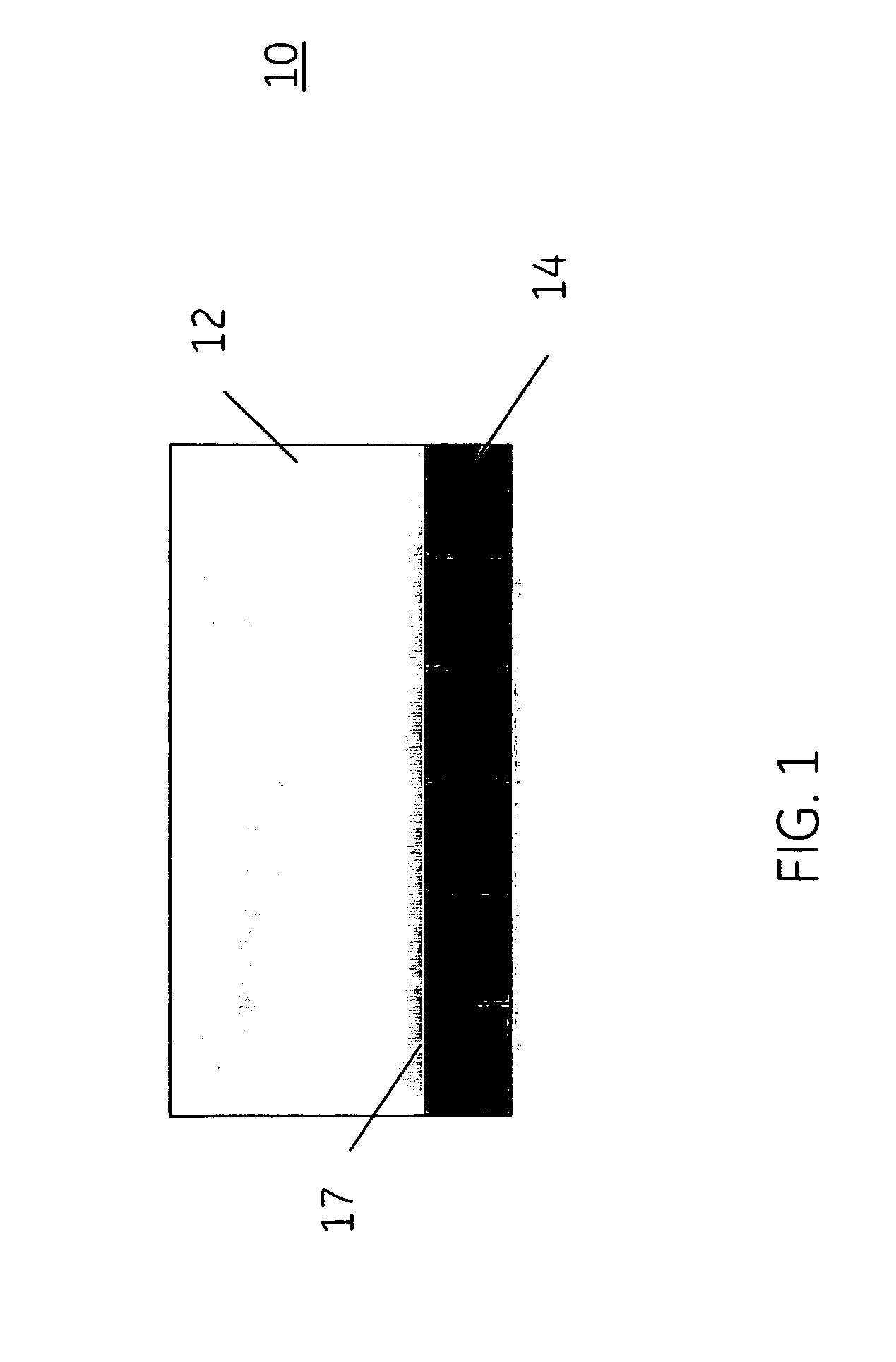

Patterned magnetic recording disk with patterned servo sectors having chevron servo patterns

ActiveUS8059350B2Precise positioningDecorative surface effectsRecord information storageControl theoryPatterned media

A patterned-media perpendicular magnetic recording disk has patterned servo regions and is nanoimprinted from a master mold made using directed self-assembly of block copolymers. The disk has patterned concentric circular data tracks of discrete data islands, with the tracks having a track pitch in the radial or cross-track direction. The disk also has patterned servo sectors extending generally radially across the patterned data tracks. The servo pattern is a chevron pattern of slanted or non-radial stripes that have a stripe pitch in the cross-stripe direction substantially equal to the track pitch. As a result of the method of making the master mold, the nanoimprinted disk has a chevron servo pattern with non-radial stripes that are magnetized segments of radial lines separated by nonmagnetic spaces.

Owner:WESTERN DIGITAL TECH INC

Chemi-epitaxy in directed self-assembly applications using photo-decomposable agents

ActiveUS20140272723A1NanoinformaticsPhotomechanical exposure apparatusReaction temperatureCrosslinked polymers

A method of forming a layered substrate comprising a self-assembled material is provided. The method includes forming a first layer of material on a substrate, forming a layer of a radiation sensitive material on the first layer of material, imaging the layer of the radiation sensitive material with patterned light, heating the layer of the radiation sensitive material to a temperature at or above the cross-linking reaction temperature, developing the imaged layer, and forming the block copolymer pattern. The radiation sensitive material comprises at least one photo-sensitive component selected from (a) a photo-decomposable cross-linking agent, (b) a photo-base generator, or (c) a photo-decomposable base; and a cross-linkable polymer, wherein imaging by the patterned light provides a pattern defined by a first region having substantial portions of a decomposed photo-sensitive component surrounded by regions having substantial portions of intact photo-sensitive component.

Owner:TOKYO ELECTRON LTD

High-chi block copolymers for directed self-assembly

ActiveUS20150197594A1Easy alignmentSurface energyDecorative surface effectsDuplicating/marking methodsOrganic chemistryDirected self assembly

Compositions for directed self-assembly (DSA) patterning techniques are provided. Methods for directed self-assembly are also provided in which a DSA composition comprising a block copolymer (BCP) is applied to a substrate and then self-assembled to form the desired pattern. The block copolymer includes at least two blocks and is selected to have a high interaction parameter (χ). The BCPs are able to form perpendicular lamellae by simple thermal annealing on a neutralized substrate, without a top coat. The BCPs are also capable of micro-phase separating into lines and spaces measuring at 10 nm or smaller, with sub-20-nm L0 capability.

Owner:BREWER SCI

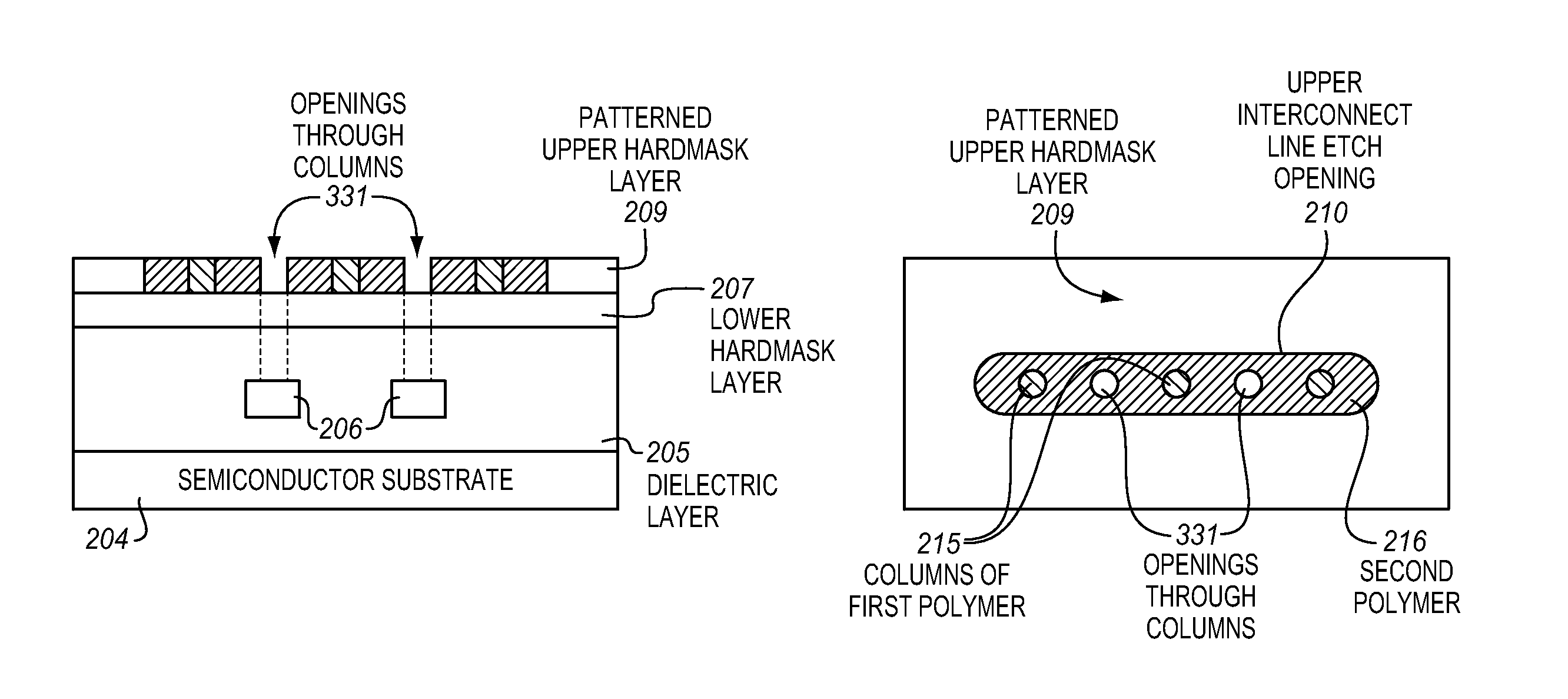

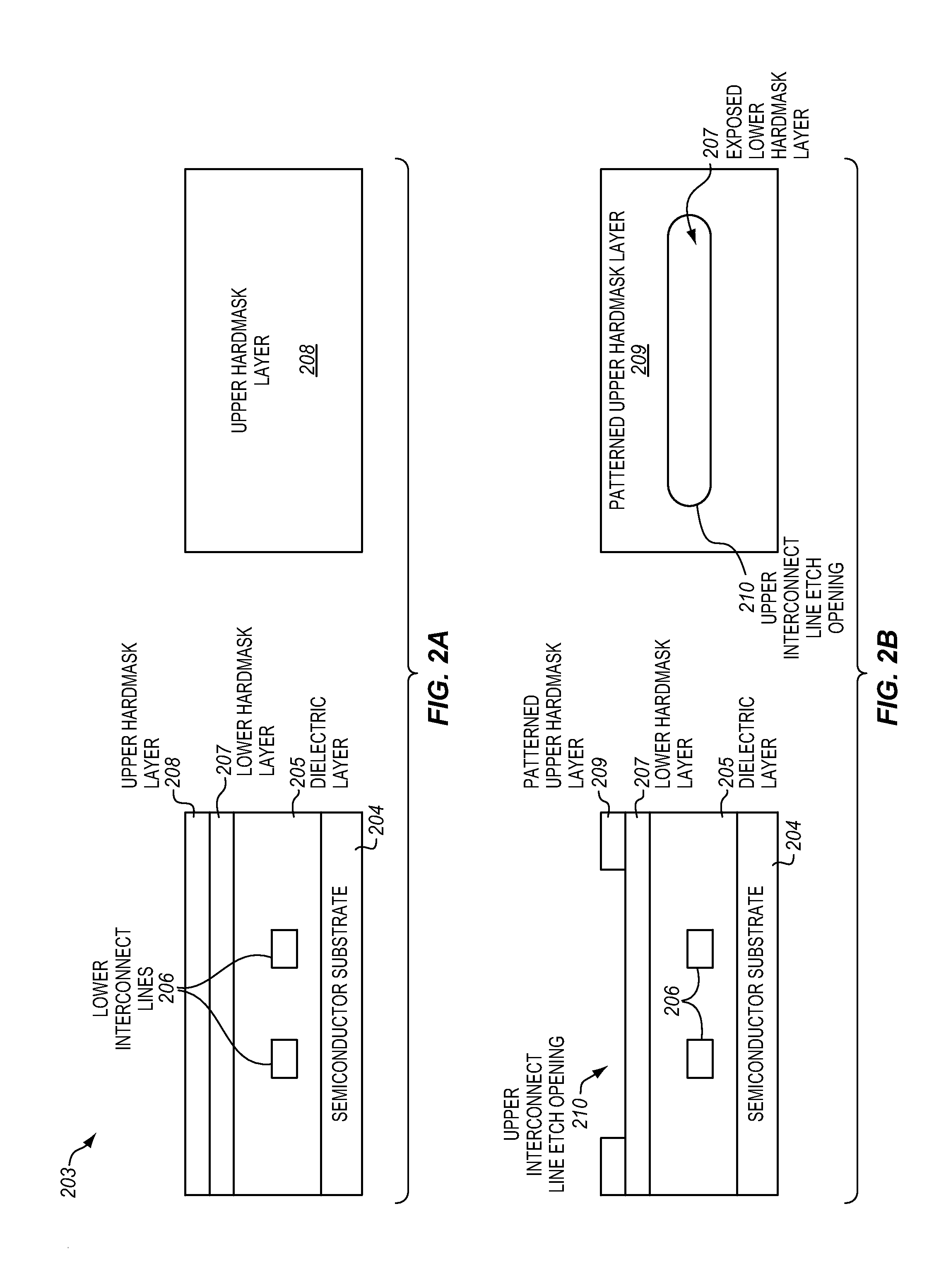

Directed self assembly of block copolymers to form vias aligned with interconnects

InactiveUS20140091476A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

A method of an aspect includes forming an interconnect line etch opening in a hardmask layer. The hardmask layer is over a dielectric layer that has an interconnect line disposed therein. The interconnect line etch opening is formed aligned over the interconnect line. A block copolymer is introduced into the interconnect line etch opening. The block copolymer is assembled to form a plurality of assembled structures that are spaced along a length of the interconnect line etch opening. An assembled structure is directly aligned over the interconnect line that is disposed within the dielectric layer.

Owner:INTEL CORP

Grapho-epitaxy dsa process with dimension control of template pattern

InactiveUS20140315390A1Photomechanical apparatusSemiconductor/solid-state device manufacturingResistGobio gobio obtusirostris

A method for defining a template for directed self-assembly (DSA) materials includes patterning a resist on a stack including an ARC and a mask formed over a hydrophilic layer. A pattern is formed by etching the ARC and the mask to form template lines which are trimmed to less than a minimum feature size (L). Hydrophobic spacers are formed on the template lines and include a fractional width of L. A neutral brush layer is grafted to the hydrophilic layer. A DSA material is deposited between the spacers and annealed to form material domains in a form of alternating lines of a first and a second material wherein the first material in contact with the spacers includes a width less than a width of the lines. A metal is added to the domains forming an etch resistant second material. The first material and the spacers are removed to form a DSA template pattern.

Owner:ELPIS TECH INC

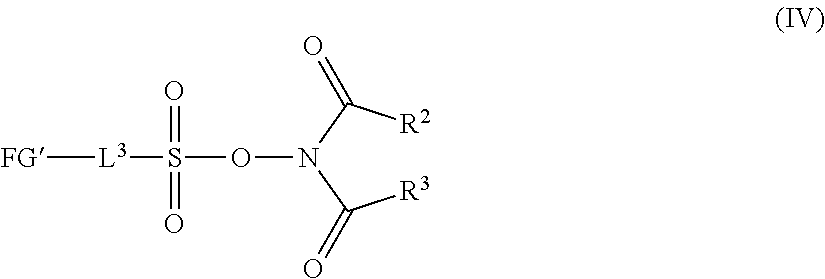

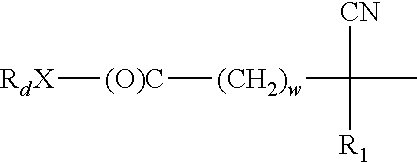

Neutral layer polymer composition for directed self assembly and processes thereof

ActiveUS8835581B2Low costReliable incorporationAzo dye preparationMonoazo dyesNitrogenCombinatorial chemistry

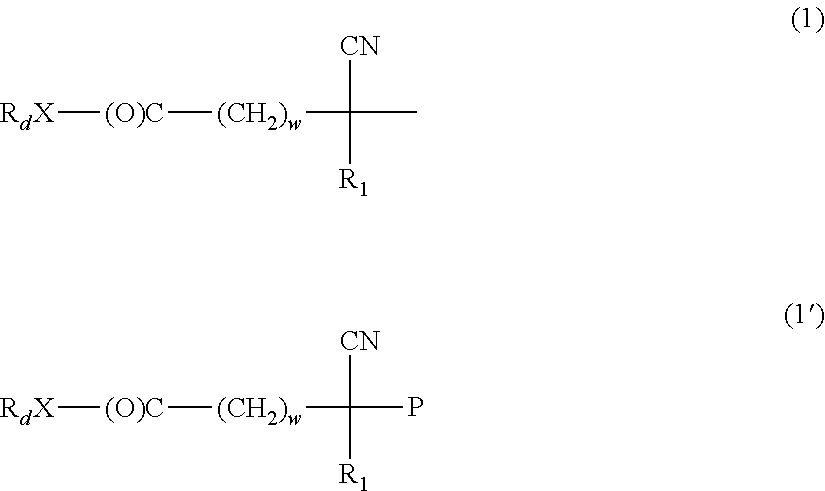

The present invention relates to a novel polymeric composition comprising a novel polymer having two or more repeat units and a terminus having the structure (1):wherein R1 represents a C1-C20 substituted or unsubstituted alkyl group, w is a number from 1-8, X is oxygen (O) or nitrogen (N), and Rd is a reactive group. The invention also relates to a process for forming a pattern using the novel polymeric composition. The invention further relates to a process of making the novel polymer.

Owner:MERCK PATENT GMBH

Etch process for reducing directed self assembly pattern defectivity using direct current positioning

ActiveUS20140370718A1Reducing directed self-assembly pattern defectivityReduce defectsPhotomechanical apparatusSemiconductor/solid-state device manufacturingProcess compositionElectron

A method for preparing a patterned directed self-assembly layer for reducing directed self-assembly pattern defectivity using direct current superpositioning is provided. A substrate having a block copolymer layer overlying a first intermediate layer, said block copolymer layer comprising a first phase-separated polymer defining a first pattern and a second phase-separated polymer defining a second pattern in said block copolymer layer is provided. A first plasma etching process using plasma formed of a first process composition to remove said second phase-separated polymer while leaving behind said first pattern of said first phase-separated polymer is performed. A second plasma etching process to transfer said first pattern into said first intermediate layer using plasma formed of a second process composition is performed. In an embodiment, said first phase-separated polymer is exposed to an electron beam preceding, during, or following said first plasma etching process, or preceding or during said second plasma etching process.

Owner:TOKYO ELECTRON LTD

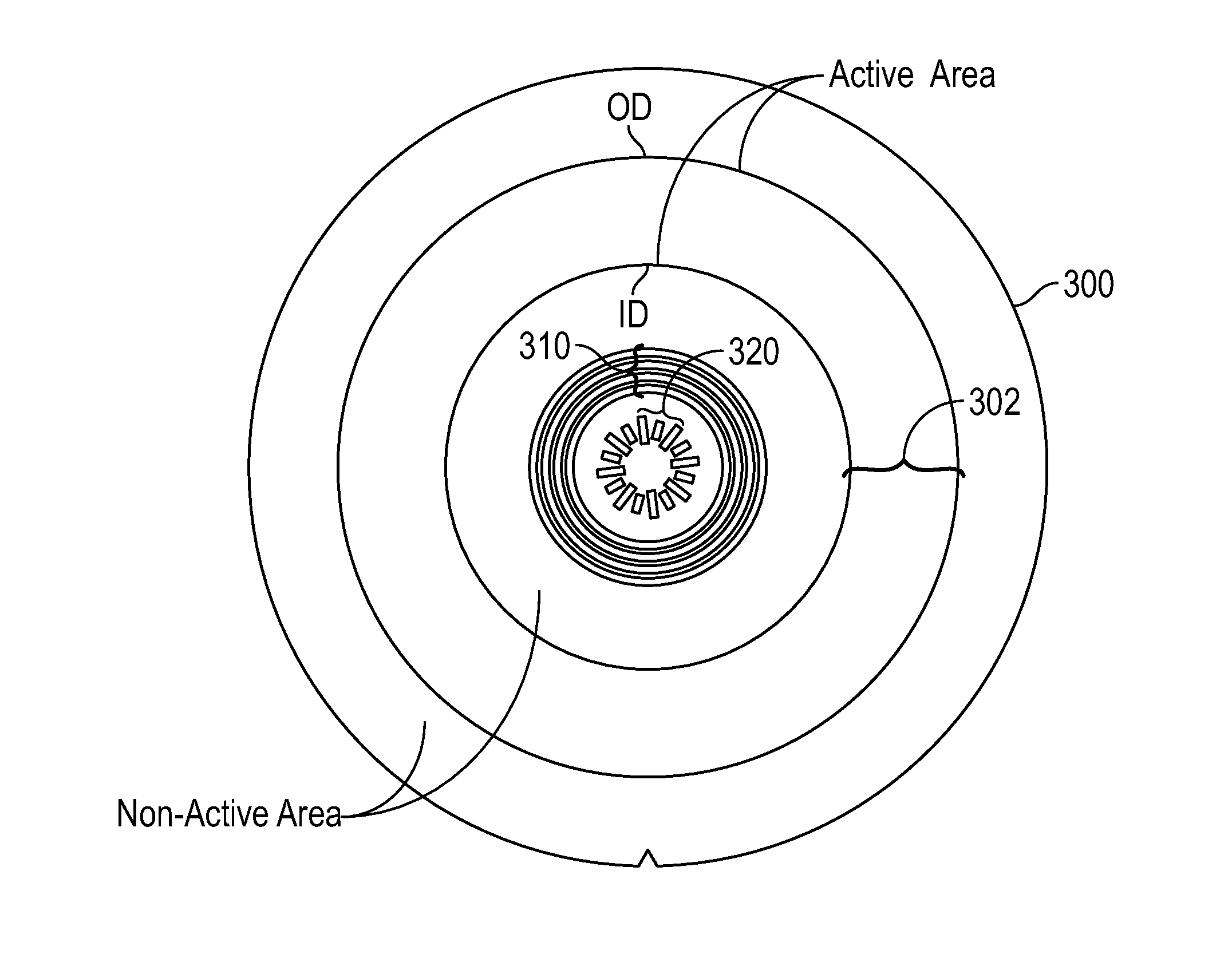

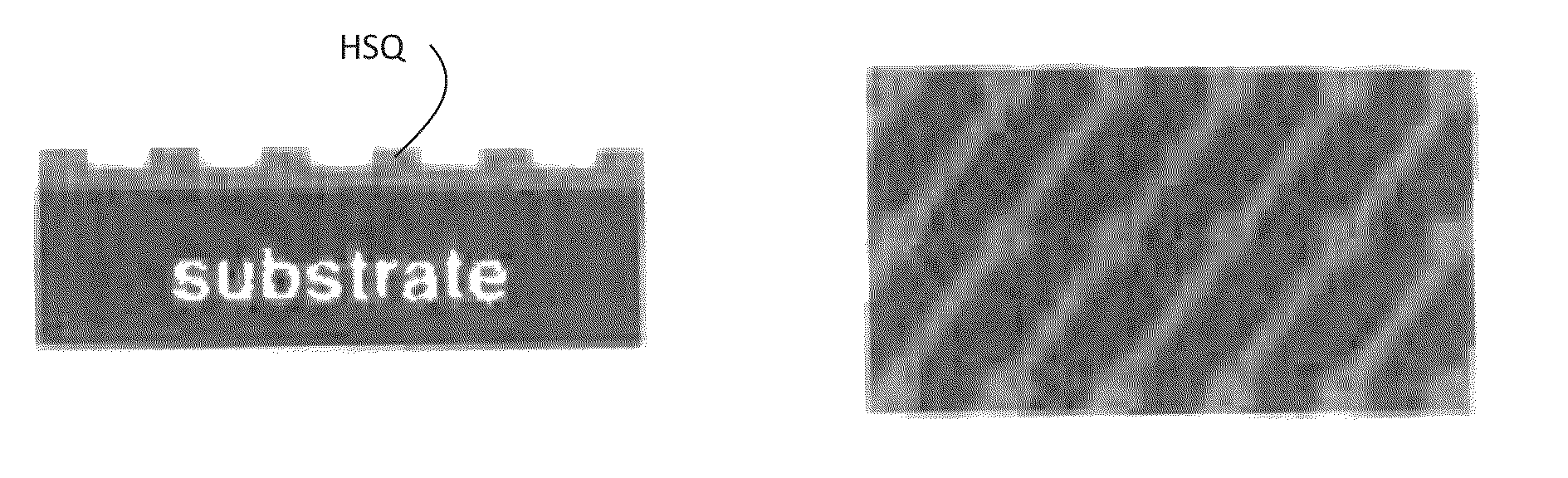

Imprint template with optically-detectable alignment marks and method for making using block copolymers

A method using directed self-assembly of block copolymers (BCPs) for making an imprint template has the required patterns for both the features in the template's active area and the optically-detectable alignment marks in the template's non-active area. A chemical contrast pattern defined by a lithographic technique forms patterns of lines in both the active area and non-active area, as well as patterns of featureless gap regions in the non-active area. The pattern of lines has the BCP components aligned as lamellae perpendicular to the substrate, while the pattern of featureless gap regions has the BCP components aligned as lamellae parallel to the substrate. The patterns of lines and featureless gap regions in the non-active area define the optically detectable alignment marks. One of the BCP components is removed, leaving the other BCP component as an etch mask to fabricate the imprint template.

Owner:WESTERN DIGITAL TECH INC

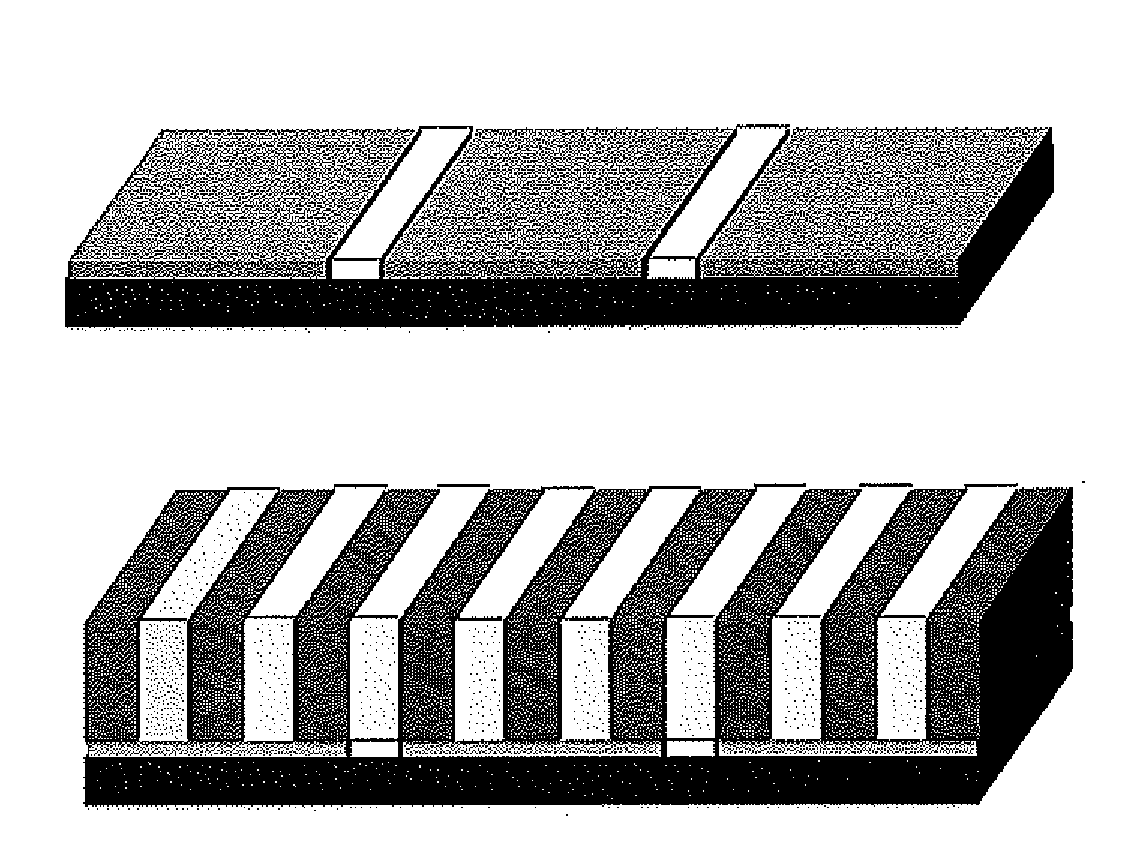

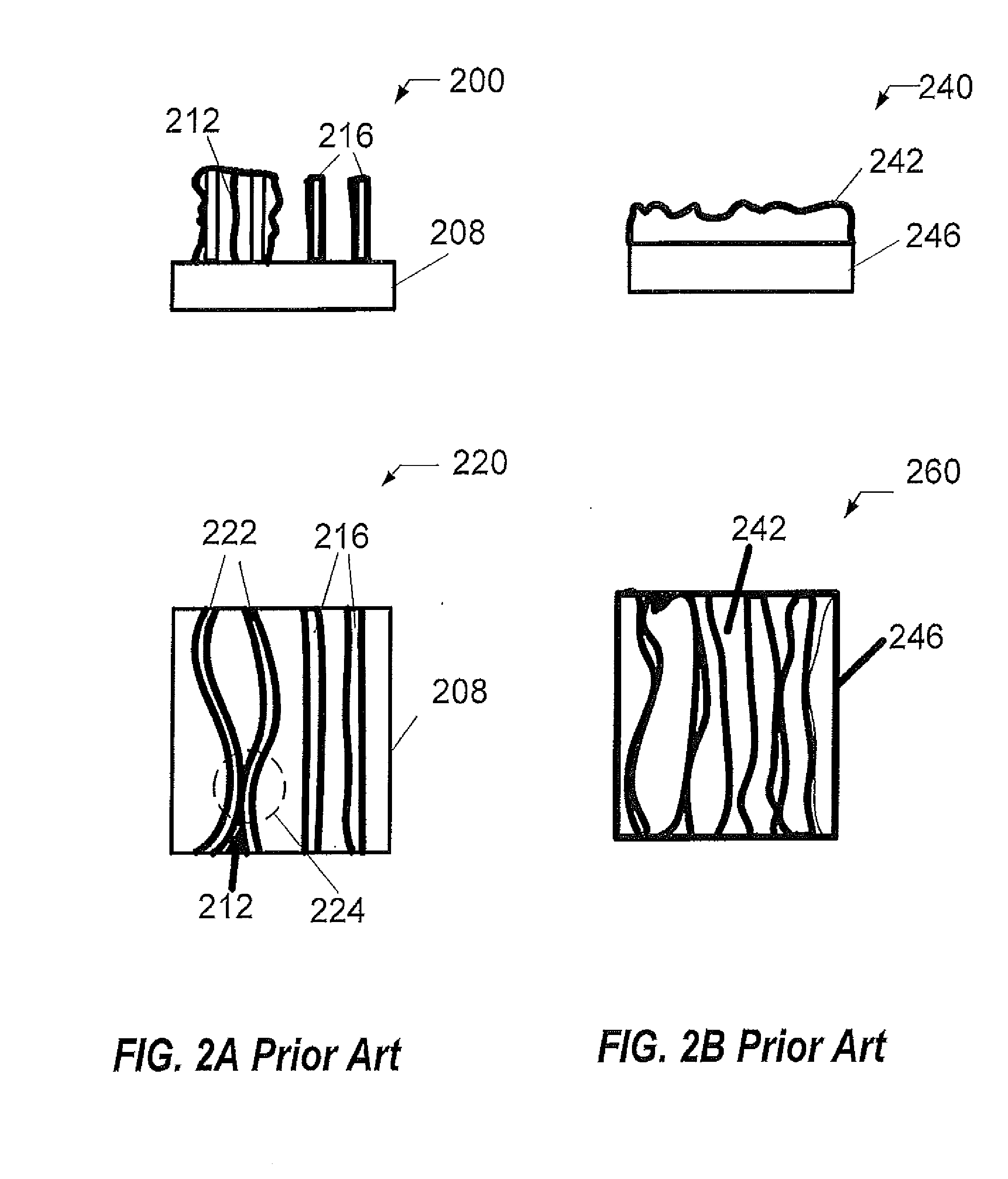

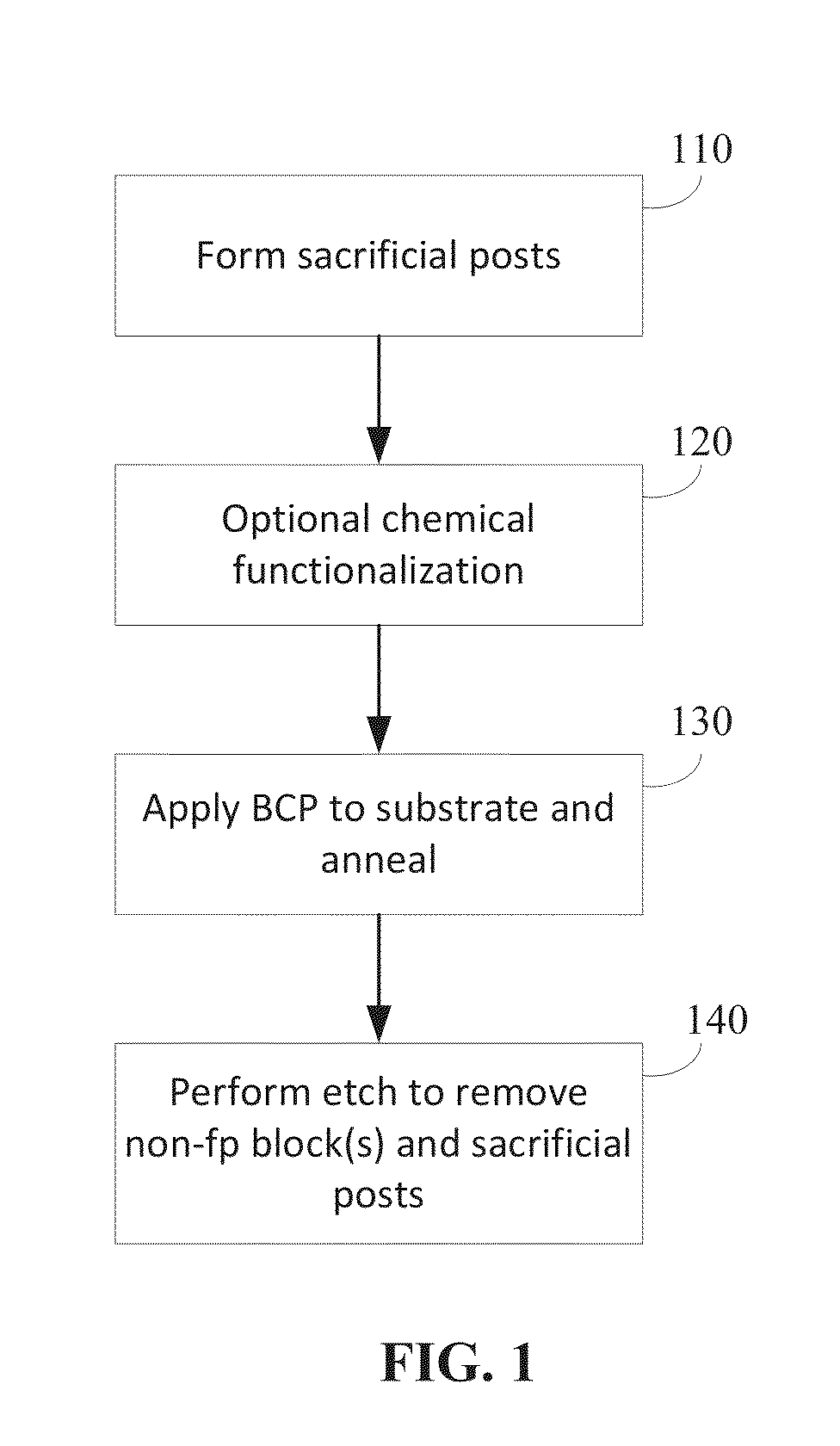

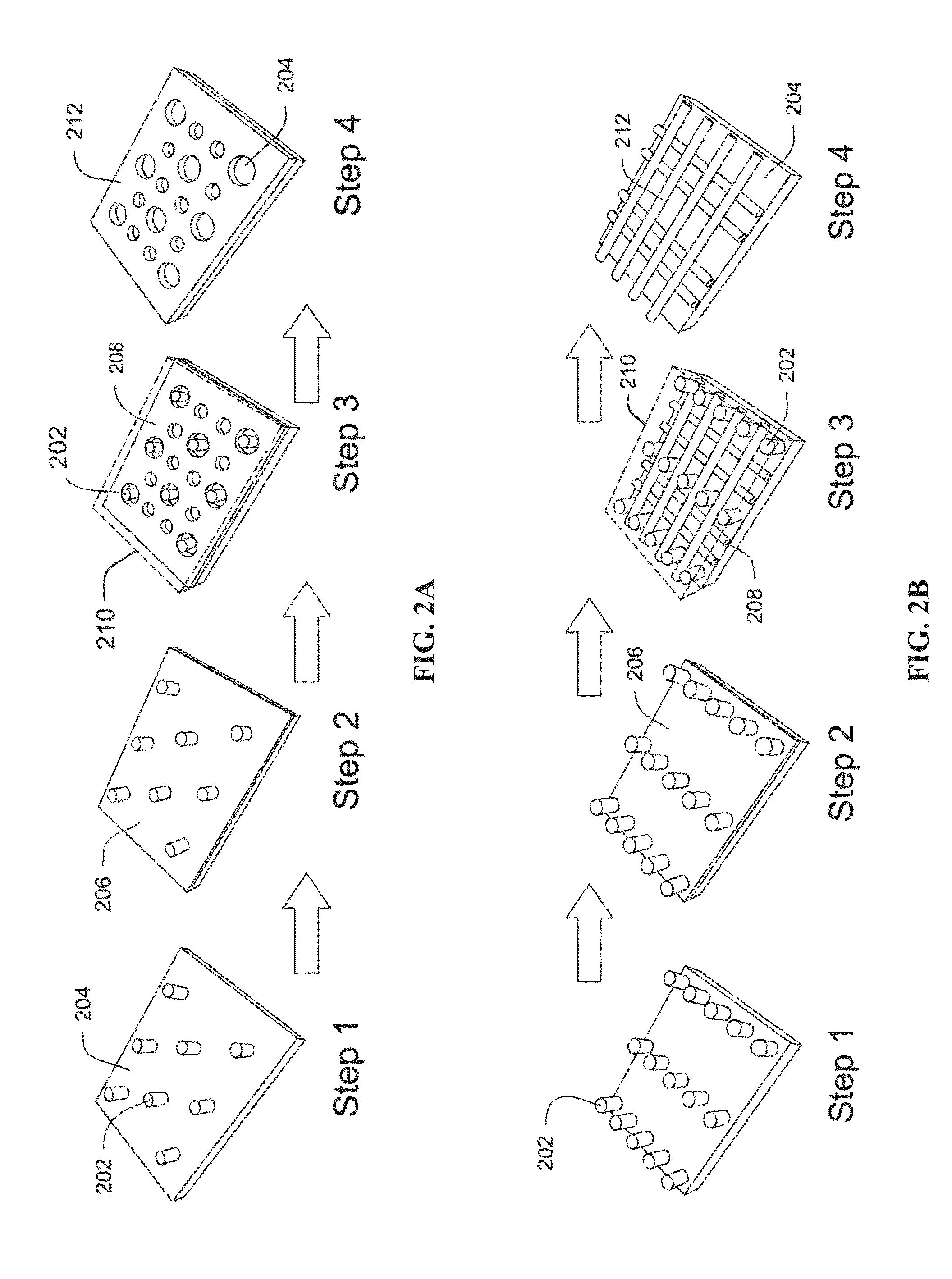

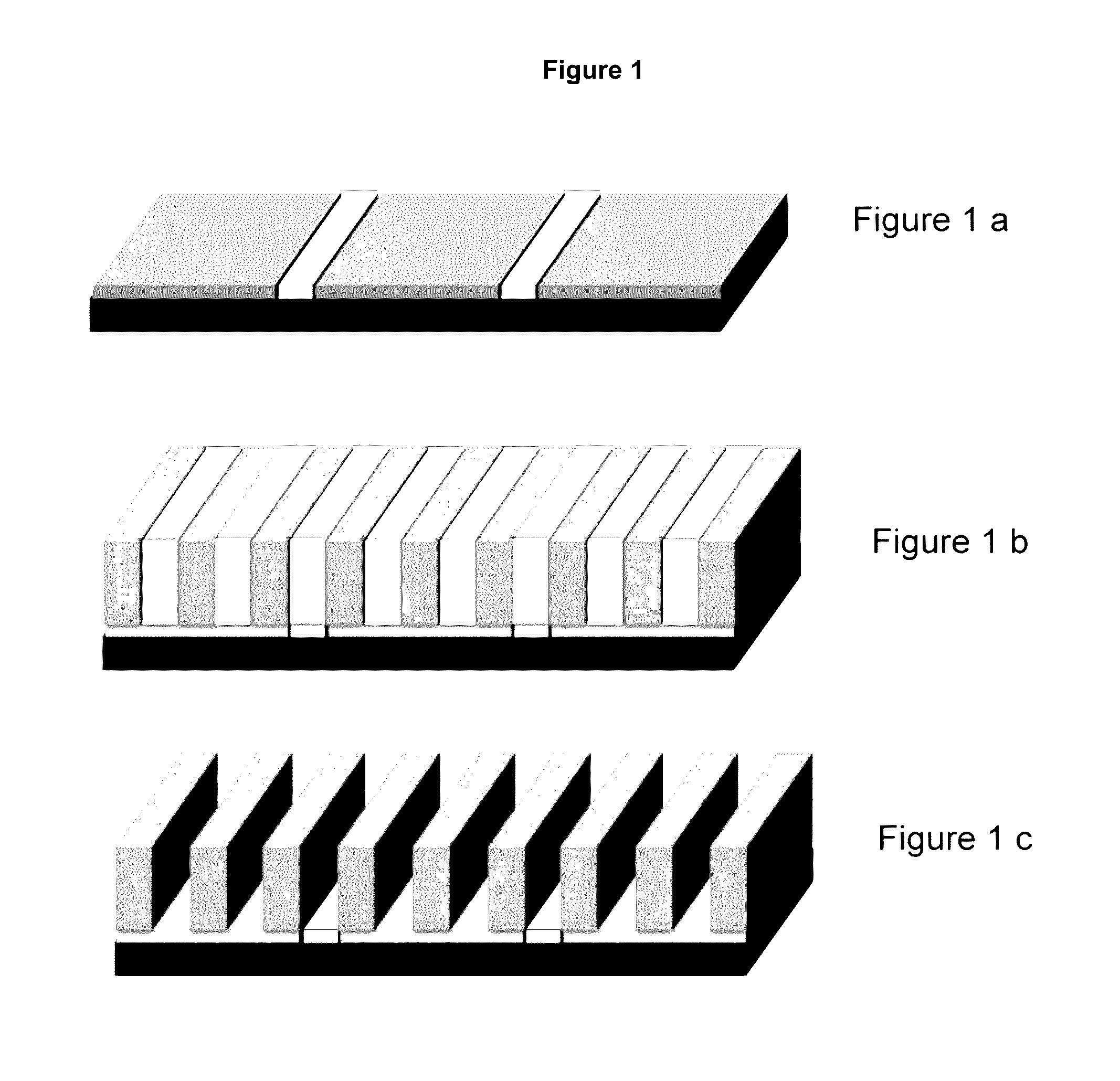

Removable templates for directed self assembly

ActiveUS20130244439A1Photomechanical apparatusSemiconductor/solid-state device manufacturingPolystyreneEngineering

A sacrificial-post templating method is presented for directing block copolymer (BCP) self-assembly to form nanostructures of monolayers and bilayers of microdomains. The topographical post template can be removed after directing self-assembly and, therefore, is not incorporated into the final microdomain pattern. The sacrificial posts can be a material removable using a selective etchant that will not remove the material of the final pattern block(s). The sacrificial posts may be removable, at least in part, using a same etchant as for removing one of the blocks of the BCP, for example, a negative tone polymethylmethacrylate (PMMA) when a non-final pattern block of polystyrene is removed and polydimethylsiloxane (PDMS) remains on the substrate.

Owner:MASSACHUSETTS INST OF TECH

Use of grapho-epitaxial directed self-assembly to precisely cut lines

ActiveUS20150108087A1Decorative surface effectsSemiconductor/solid-state device manufacturingEngineeringTopography

A method for forming a patterned topography on a substrate is provided. The substrate is initially provided with an exposed plurality of lines formed atop. An embodiment of the method includes aligning and preparing a first directed self-assembly pattern (DSA) pattern immediately overlying the plurality of lines, and transferring the first DSA pattern to form a first set of cuts in the plurality of lines. The embodiment further includes aligning and preparing a second DSA pattern immediately overlying the plurality of lines having the first set of cuts formed therein, and transferring the second DSA pattern to form a second set of cuts in the plurality of lines. The first and second DSA patterns each comprise a block copolymer having a hexagonal close-packed (HCP) morphology and a characteristic dimension Lo that is between 0.9 and 1.1 times the spacing between individual lines of the plurality of lines.

Owner:TOKYO ELECTRON LTD

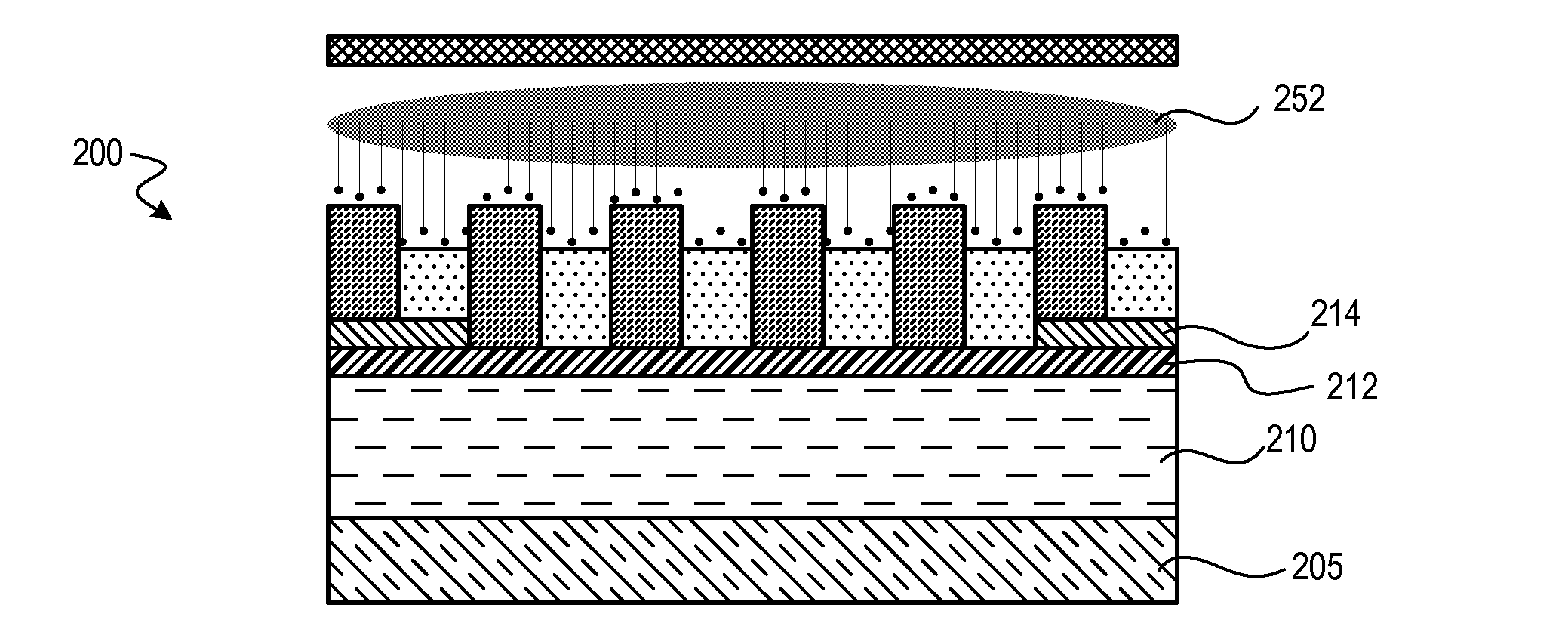

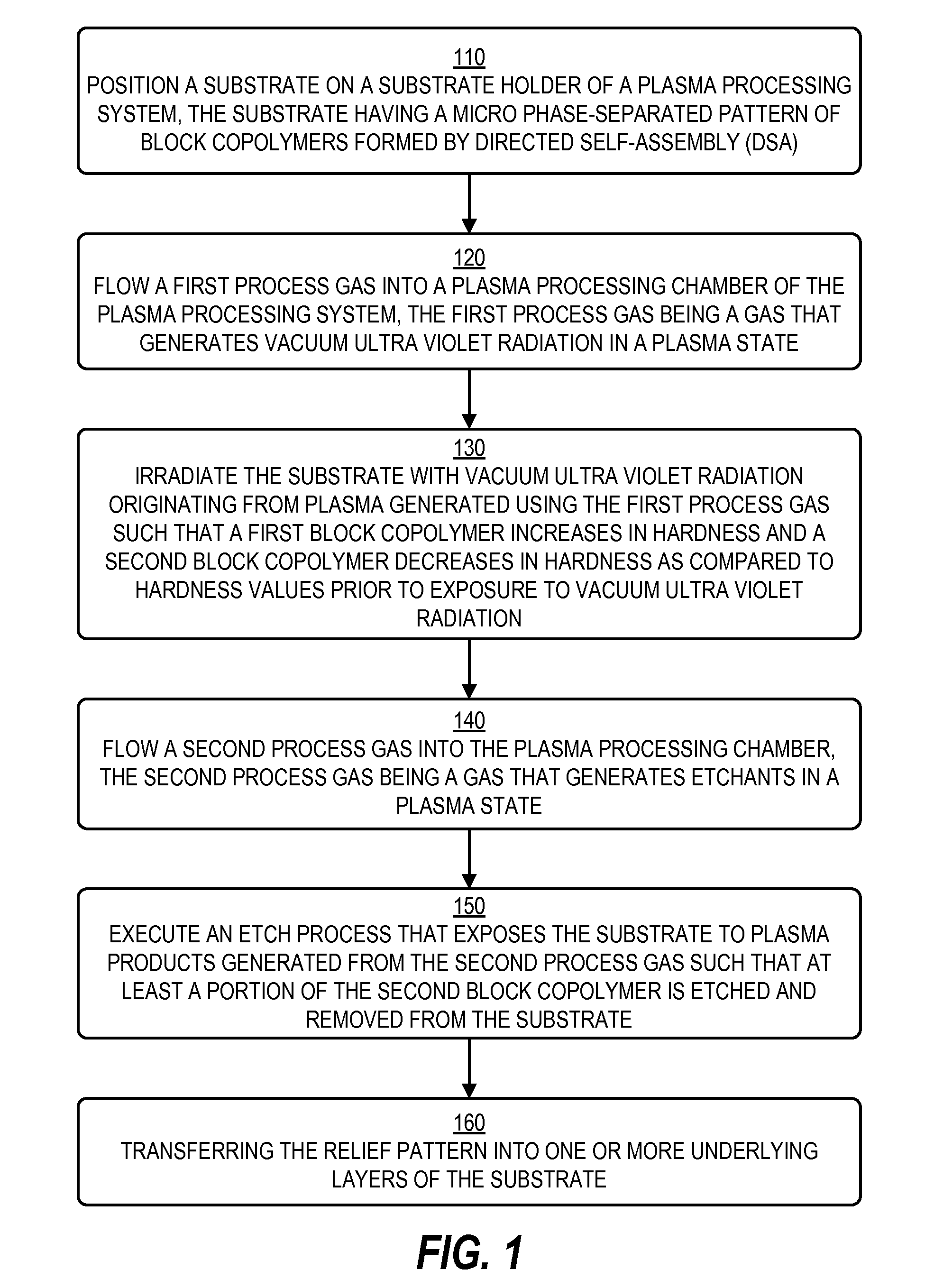

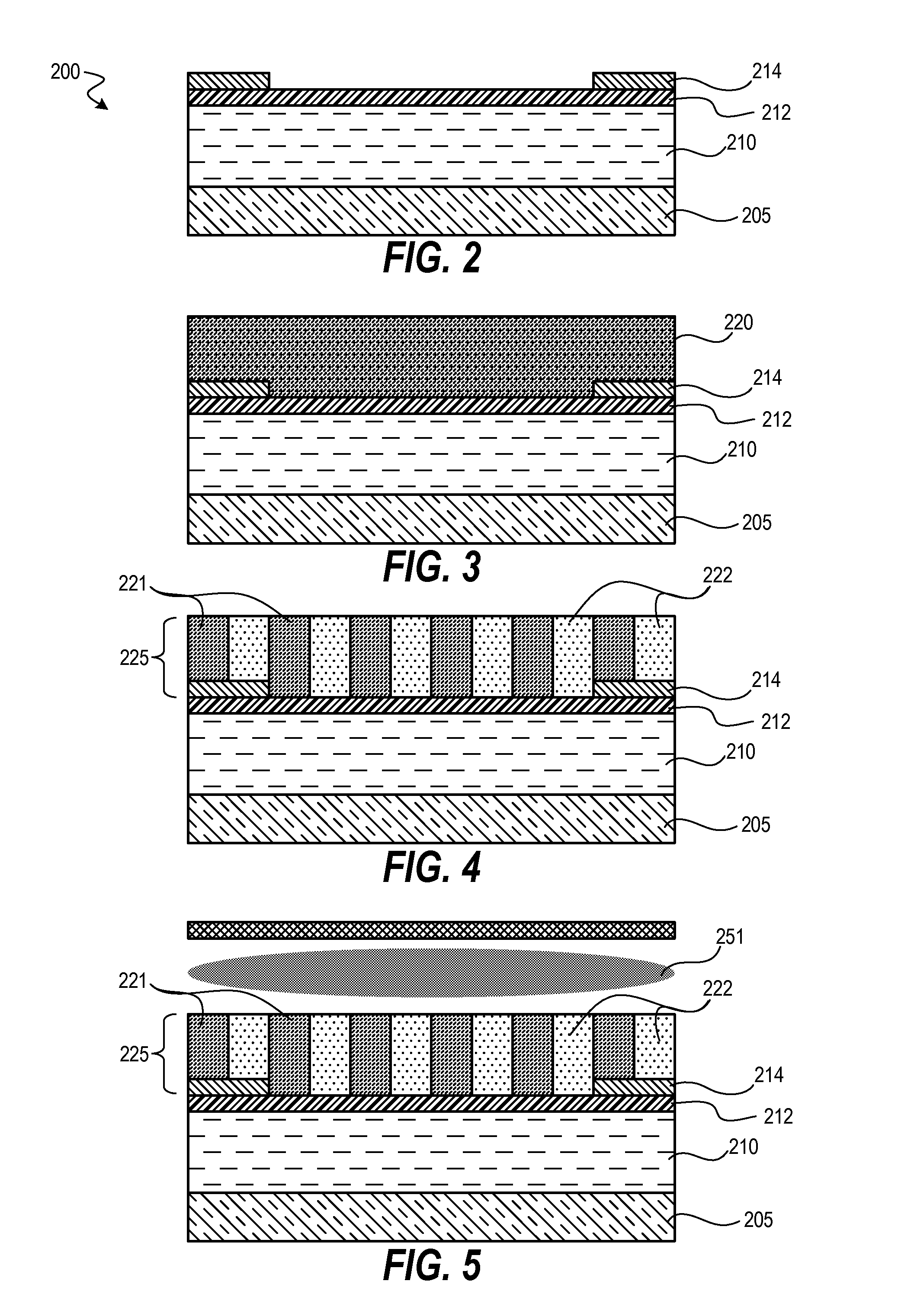

Method for Directed Self-Assembly and Pattern Curing

ActiveUS20160042971A1Improve etch selectivityEfficient etchingSemiconductor/solid-state device manufacturingProcess systemsLight exposure

Techniques disclosed herein include methods for DSA patterning and curing of DSA patterns. Techniques include curing phase-separated block copolymers using vacuum ultraviolet (VUV) light exposure at wavelengths from about 100 nanometers to 170 nanometers. VUV light can be generated using a plasma process system and from energizing various VUV-generating process gasses. A VUV curing step is executed (fully or partially) prior to executing an etch process to etch away one of the block copolymers. Such VUV exposure can selectively harden one block copolymer while weakening another block copolymer. This hardening and weakening increases etch selectivity enabling more effective etching and results in better patterns.

Owner:TOKYO ELECTRON LTD

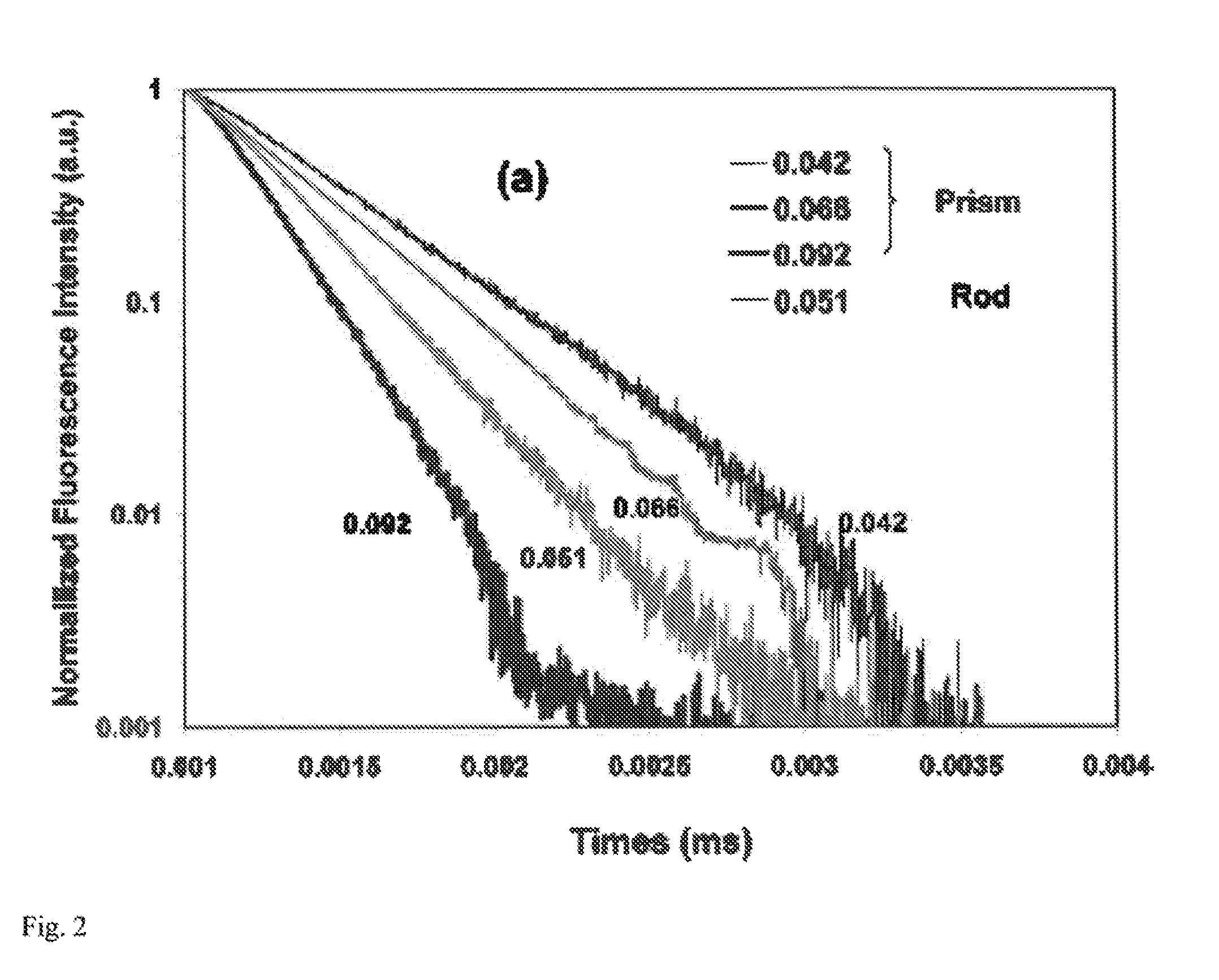

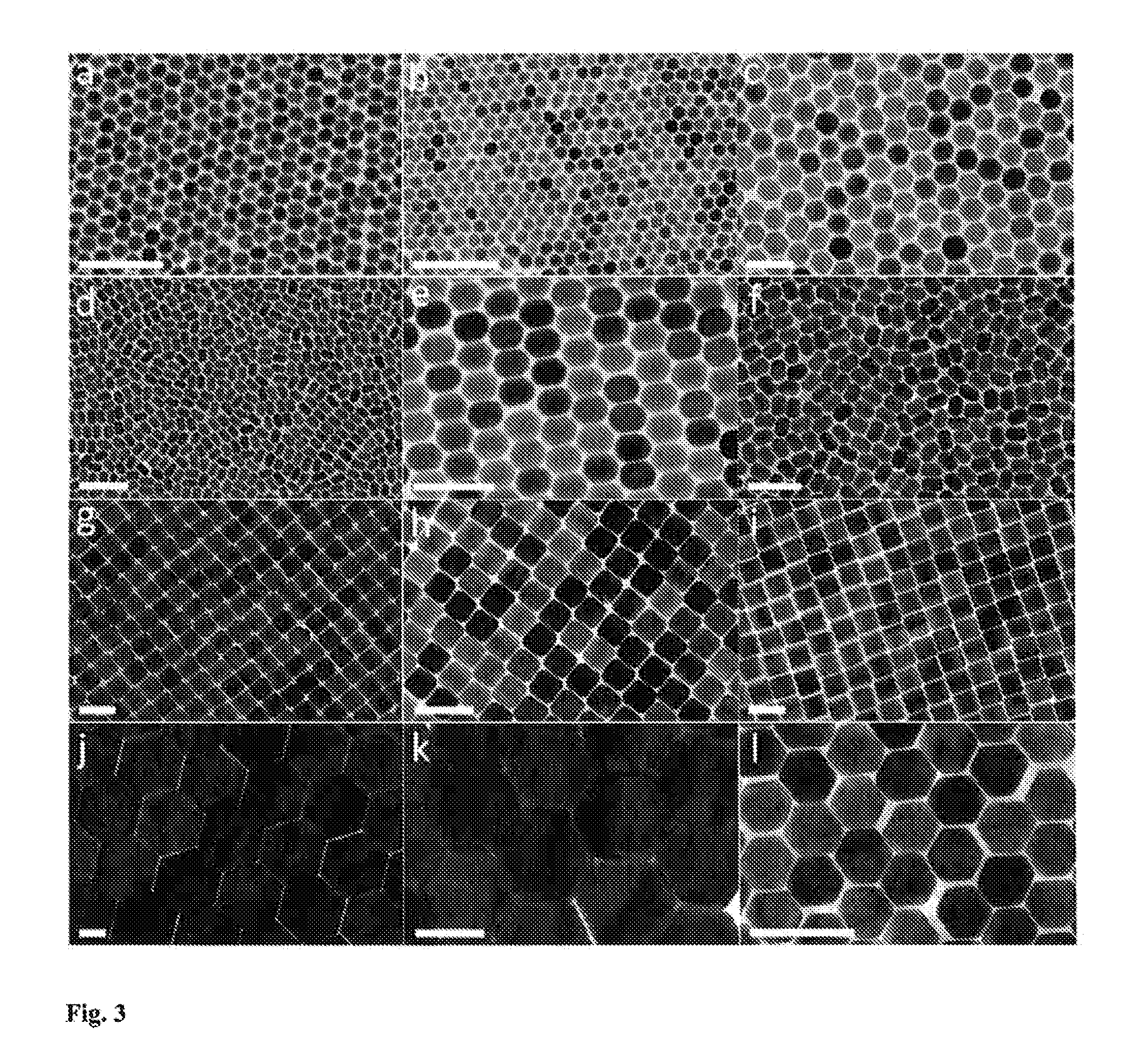

Morphologically and size uniform monodisperse particles and their shape-directed self-assembly

ActiveUS9181477B2Increase in sizeQuench reactionMaterial nanotechnologyFrom normal temperature solutionsRare earthLanthanide

Monodisperse particles having: a single pure crystalline phase of a rare earth-containing lattice, a uniform three-dimensional size, and a uniform polyhedral morphology are disclosed. Due to their uniform size and shape, the monodisperse particles self assemble into superlattices. The particles may be luminescent particles such as down-converting phosphor particles and up-converting phosphors. The monodisperse particles of the invention have a rare earth-containing lattice which in one embodiment may be an yttrium-containing lattice or in another may be a lanthanide-containing lattice. The monodisperse particles may have different optical properties based on their composition, their size, and / or their morphology (or shape). Also disclosed is a combination of at least two types of monodisperse particles, where each type is a plurality of monodisperse particles having a single pure crystalline phase of a rare earth-containing lattice, a uniform three-dimensional size, and a uniform polyhedral morphology; and where the types of monodisperse particles differ from one another by composition, by size, or by morphology. In a preferred embodiment, the types of monodisperse particles have the same composition but different morphologies. Methods of making and methods of using the monodisperse particles are disclosed.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA +1

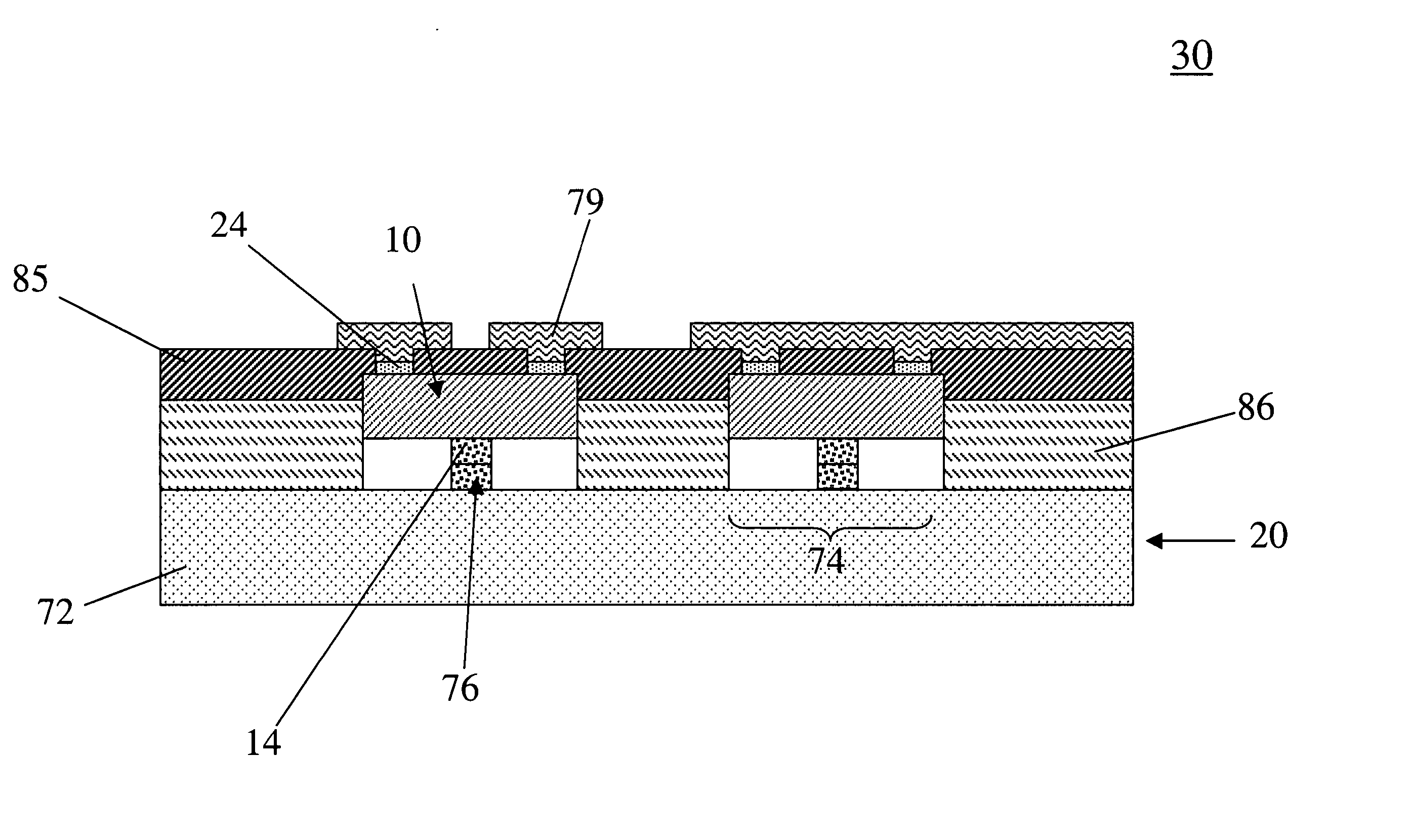

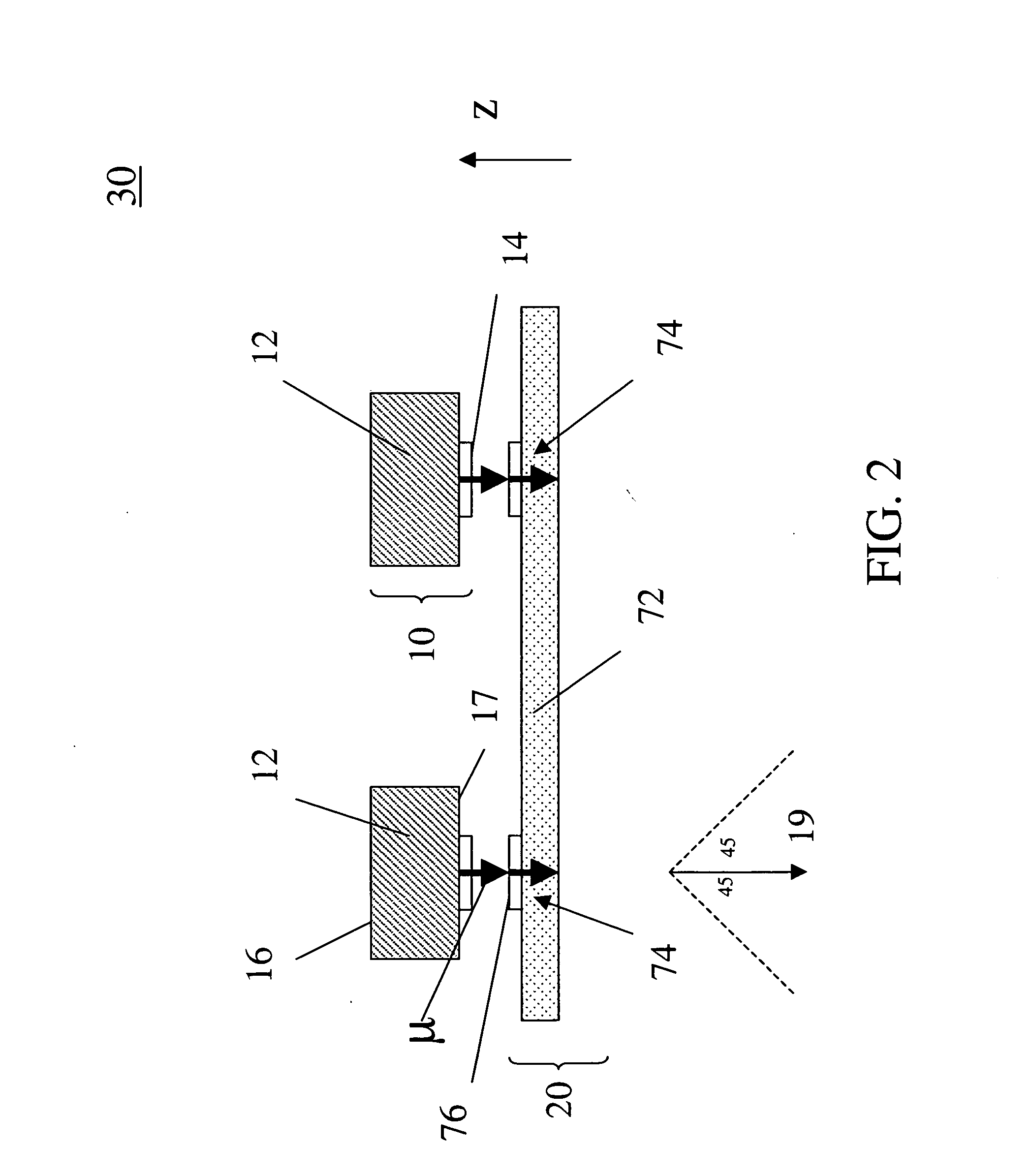

Articles and assembly for magnetically directed self assembly and methods of manufacture

A functional block for assembly includes at least one element and a magnetic film attached to the element and having a magnetic remanence (MR / MS) of less than about 0.2, having a coercive field (Hc) of less than about 100 Oersteds (100 Oe) and having a permeability (μ) of greater than about two (2). At least one element is selected from the group consisting of a semiconductor device, a passive element, a photonic bandgap element, a luminescent material, a sensor, a micro-electrical mechanical system (MEMS), an energy harvesting device and combinations thereof. An article for assembly includes a substrate and a patterned magnetic film disposed on the substrate and defining at least one receptor site. The patterned magnetic film is magnetized primarily in a longitudinal direction and is characterized by a BH product of greater than about 1 megaGauss Oe.

Owner:GENERAL ELECTRIC CO

Directed self-assembly pattern formation methods and compositions

ActiveUS20150287592A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusData memoryDirected self assembly

A method of forming a pattern by directed self-assembly, comprising: (a) providing a semiconductor substrate comprising one or more layers to be patterned; (b) applying a crosslinkable underlayer composition over the one or more layers to be patterned to form a crosslinkable underlayer, wherein the crosslinkable underlayer composition comprises a crosslinkable polymer comprising a first unit of the following general formula (I-A) or (I-B):wherein: P is a polymerizable functional group; L is a single bond or an m+1-valent linking group; X1 is a monovalent electron donating group; X2 is a divalent electron donating group; Ar1 and Ar2 are trivalent and divalent aryl groups, respectively, and carbon atoms of the cyclobutene ring are bonded to adjacent carbon atoms on the same aromatic ring of Ar1 or Ar2; m and n are each an integer of 1 or more; and each R1 is independently a monovalent group; (c) heating the crosslinkable underlayer to form a crosslinked underlayer; (d) forming a self-assembling layer comprising a block copolymer over the crosslinked underlayer; and (e) annealing the self-assembling layer. The methods and compositions find particular applicability in the manufacture of semiconductor devices or data storage devices for the formation of high resolution patterns.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC +1

Compositions and processes for self-assembly of block copolymers

ActiveUS9574104B1High resolutionHigh pattern definitionOrganic chemistryNanoinformaticsCross-linkEnd-group

The present invention relates to novel copolymers containing cross-linkable and graft-able moieties, novel compositions comprised of these novel copolymers and a solvent, and methods for using these novel compositions to form neutral layer films which are both cross-linked and grafted on the substrate which are used in processes for aligning microdomains of block copolymers (BCP) on this neutral layer coated substrate such as self-assembly and directed self-assembly. The novel compositions are comprised of at least one novel random copolymer comprised of least one unit of structure (1), at least one unit of structure (2) at least one unit of structure (3) one H end group and one end group having structure (1′);where R1 is selected from the group consisting of a C1-C8 alkyl, C1-C8 fluoroalkyl, C1-C8 partially fluorinated alkyl moiety, C4-C8 cycloalkyl, C4-C8 cyclofluoroalkyl, C4-C8 partially fluorinated cycloalkyl, and a C2-C8 hydroxyalkyl; R2, R3 and R5 are independently selected from a group consisting of H, C1-C4 alkyl, CF3 and F; R4 is selected from the group consisting of H, C1-C8 alkyl, C1-C8 partially fluorinated alkyl moiety and C1-C8 fluoroalkyl, n ranges from 1 to 5, R6 is selected from the group consisting of H, F, C1-C8 alkyl and a C1-C8 fluoroalkyl and m ranges from 1 to 3, and n′ ranges from 1 to 5, and n″ ranges from 1 to 5, n′″ ranges from 1 to 5, R7 is a C1 to C8 alkyl and X is —CN, or an alkyloxycarbonyl moiety R8—O—(C═O)— where R8 is a C1 to C8 alkyl and represent the attachment point of the end group to the polymer. The novel polymers, compositions and processes are useful for fabrication of electronic devices.

Owner:MERCK PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com