Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

313 results about "Patterned media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

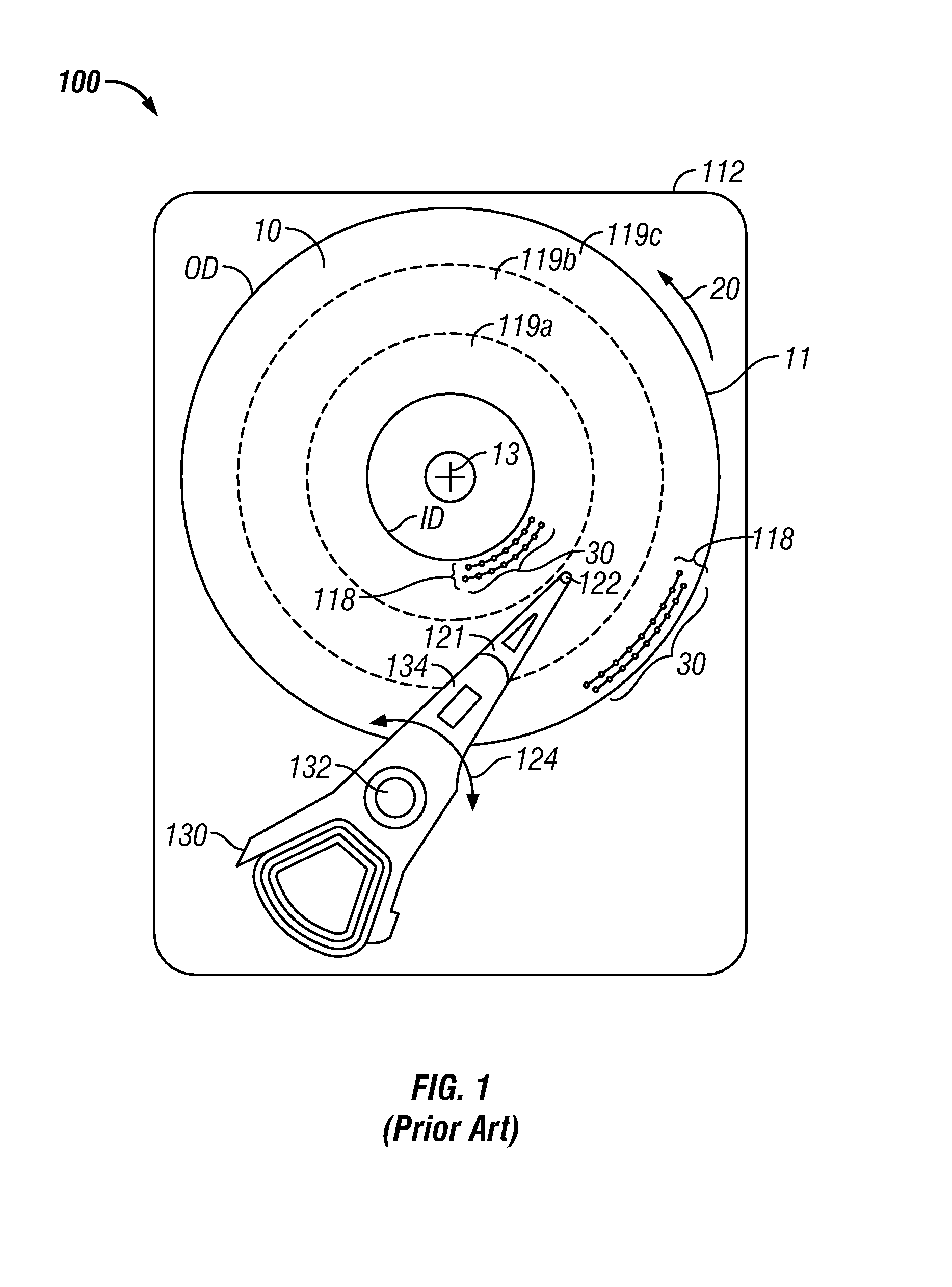

Patterned media (also known as bit-patterned media or BPM) is a potential future hard disk drive technology to record data in magnetic islands (one bit per island), as opposed to current hard disk drive technology where each bit is stored in 20-30 magnetic grains within a continuous magnetic film. The islands would be patterned from a precursor magnetic film using nanolithography. It is one of the proposed technologies to succeed perpendicular recording due to the greater storage densities it would enable. BPM was introduced by Toshiba in 2010.

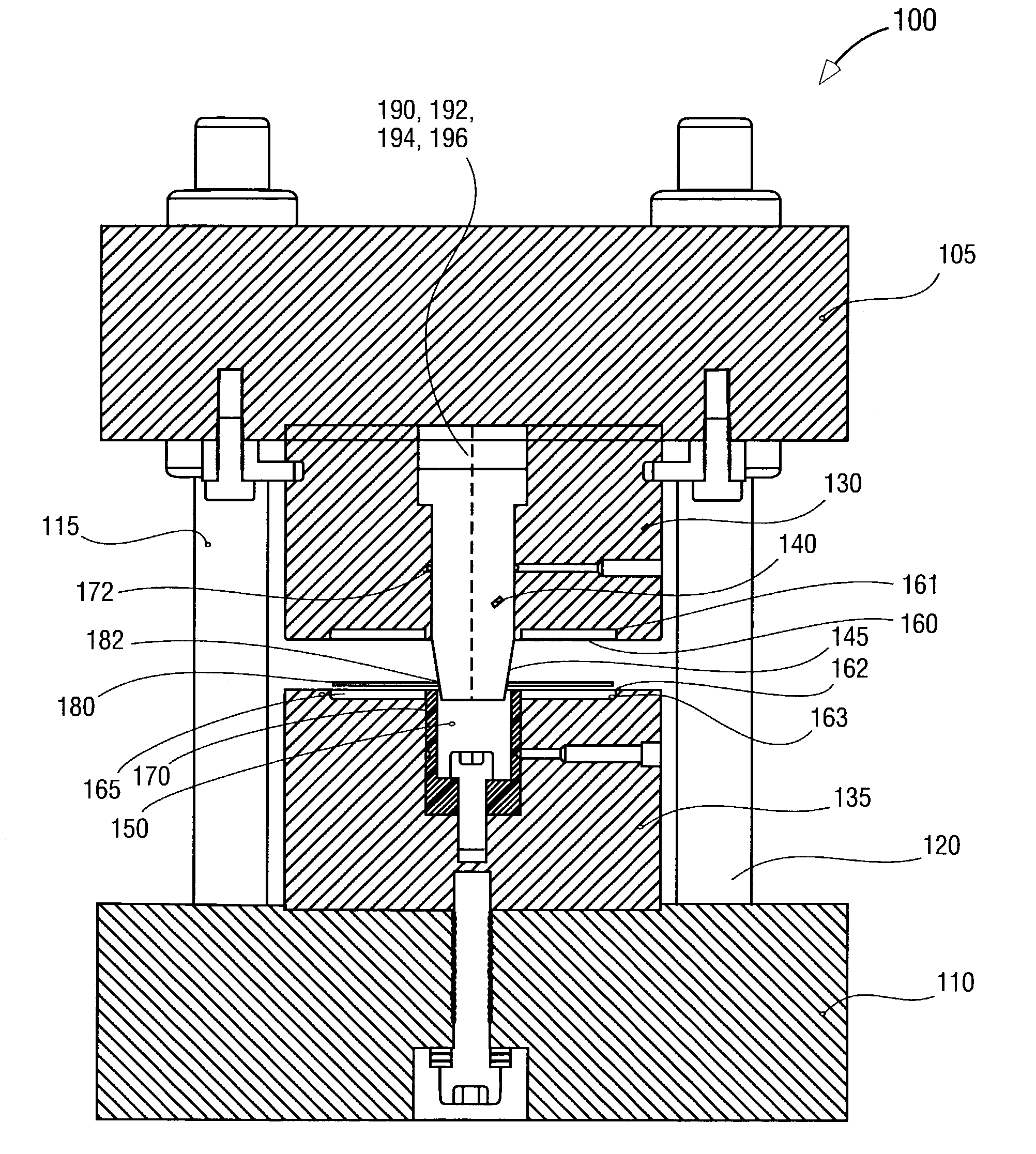

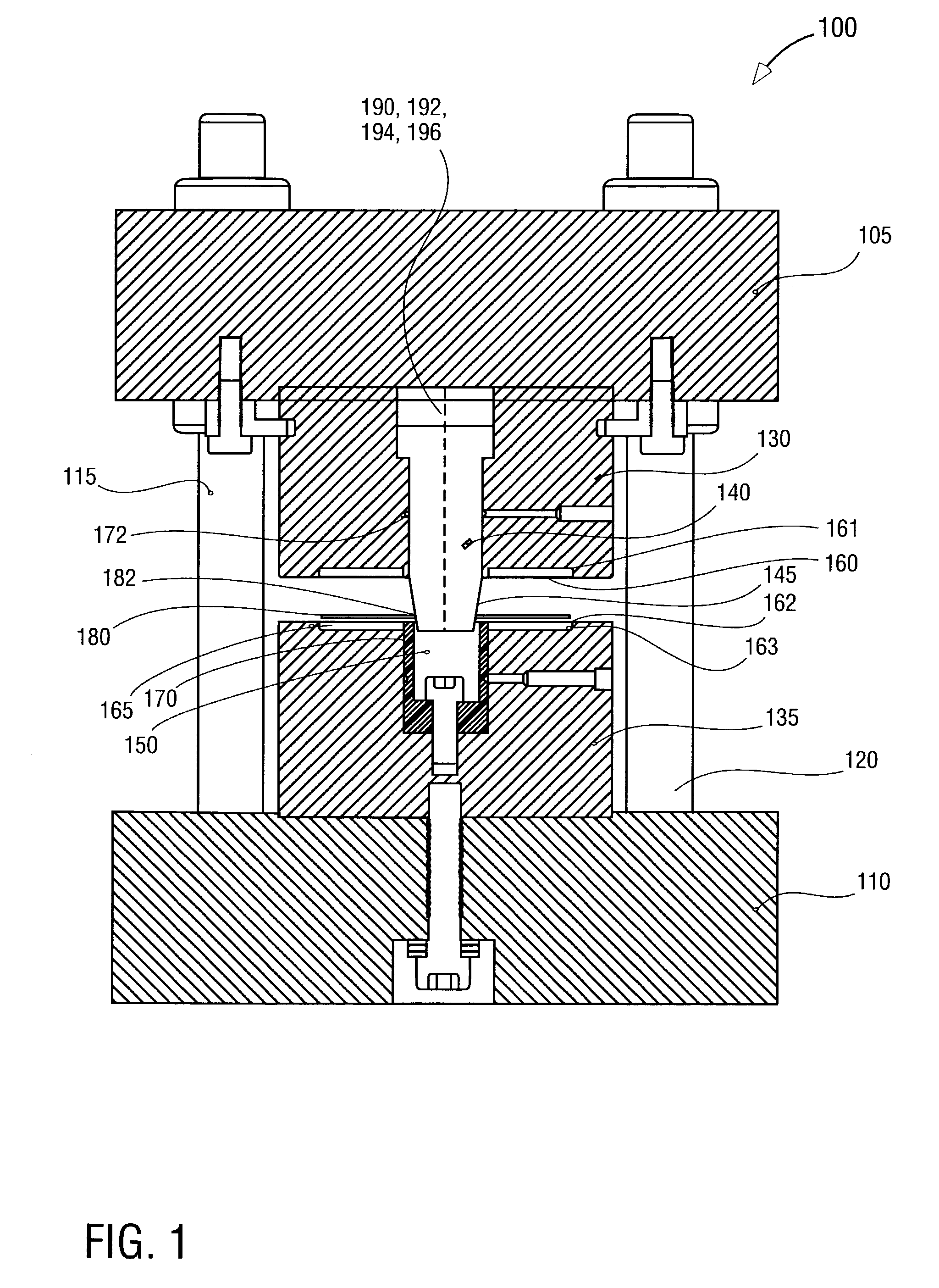

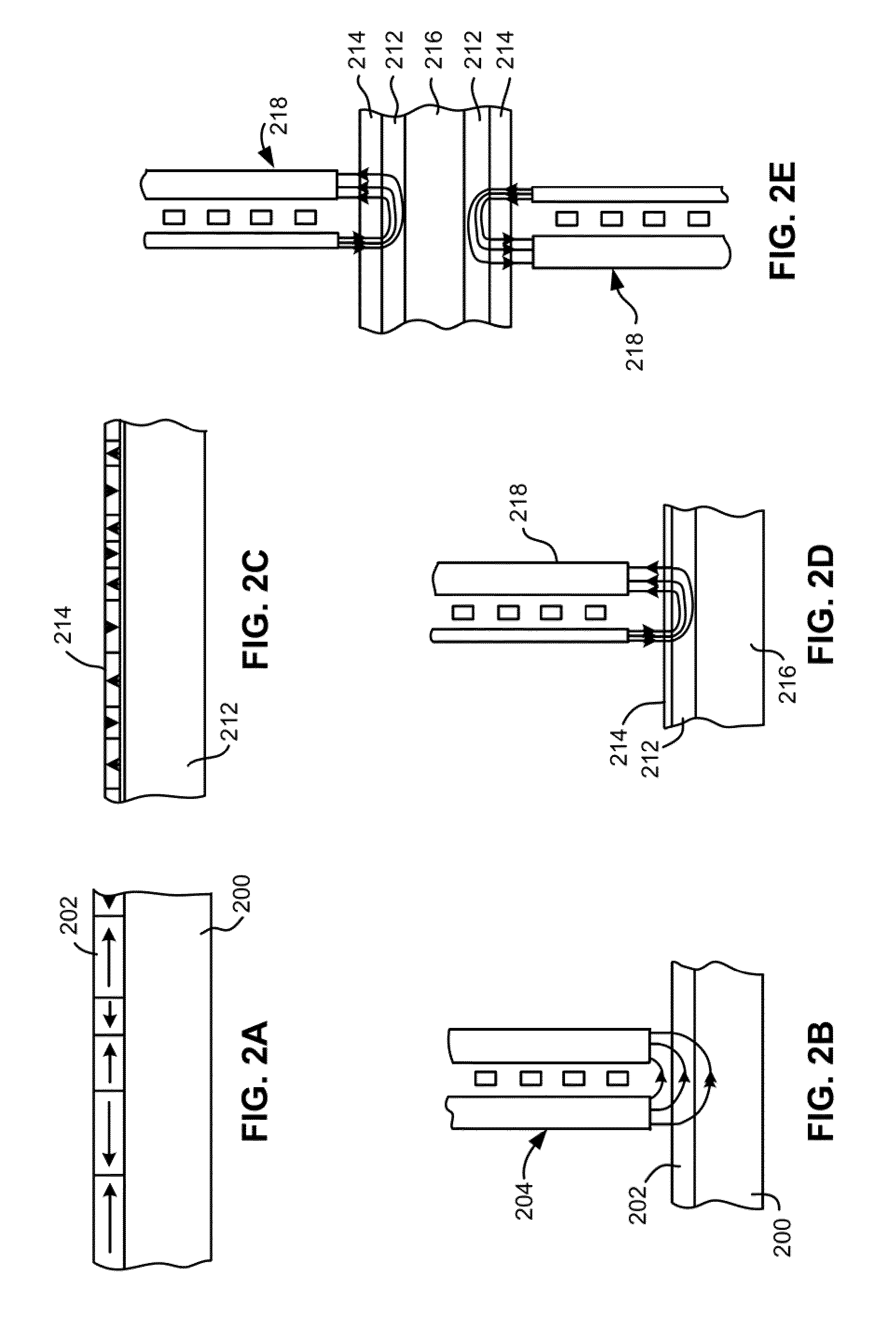

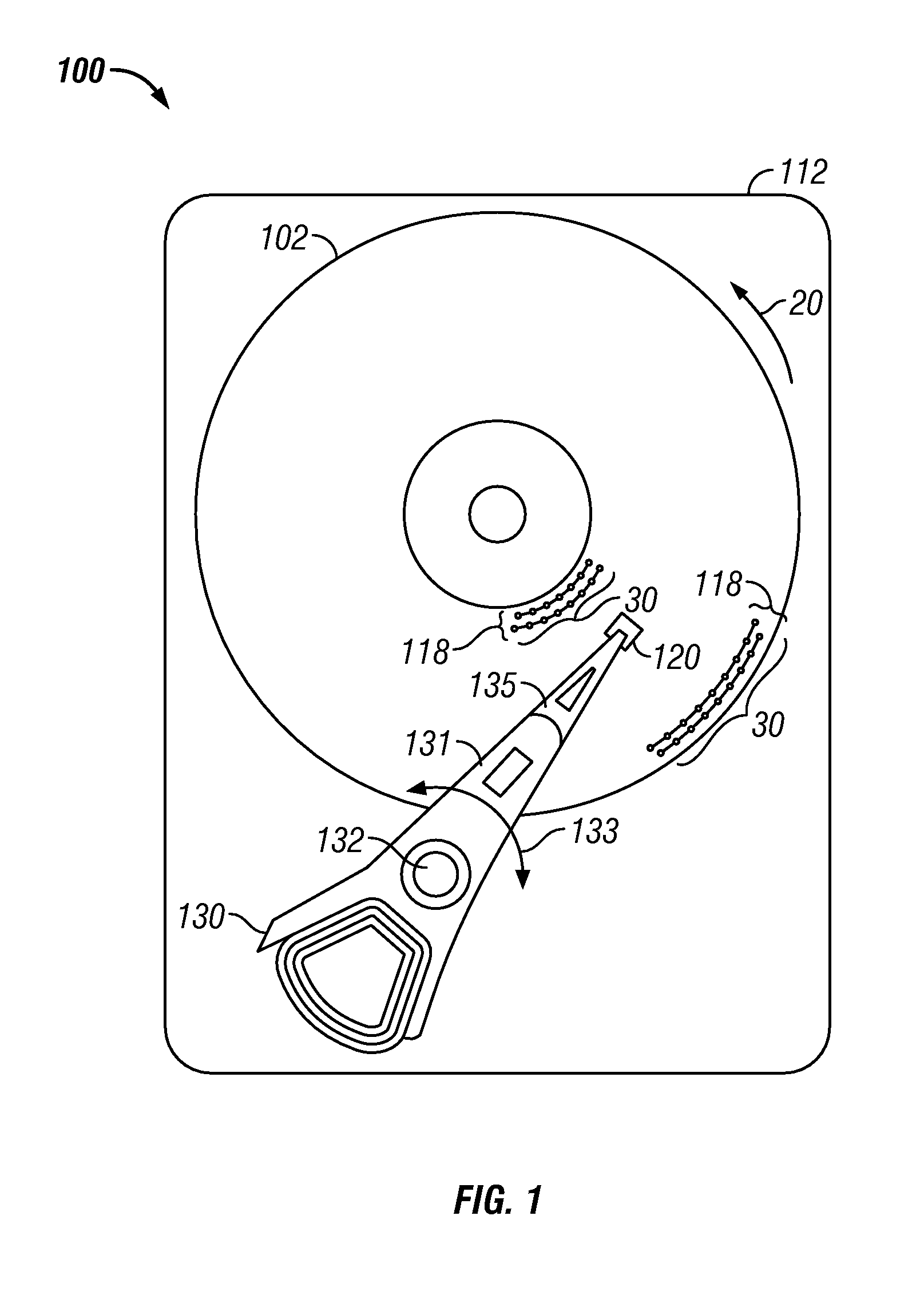

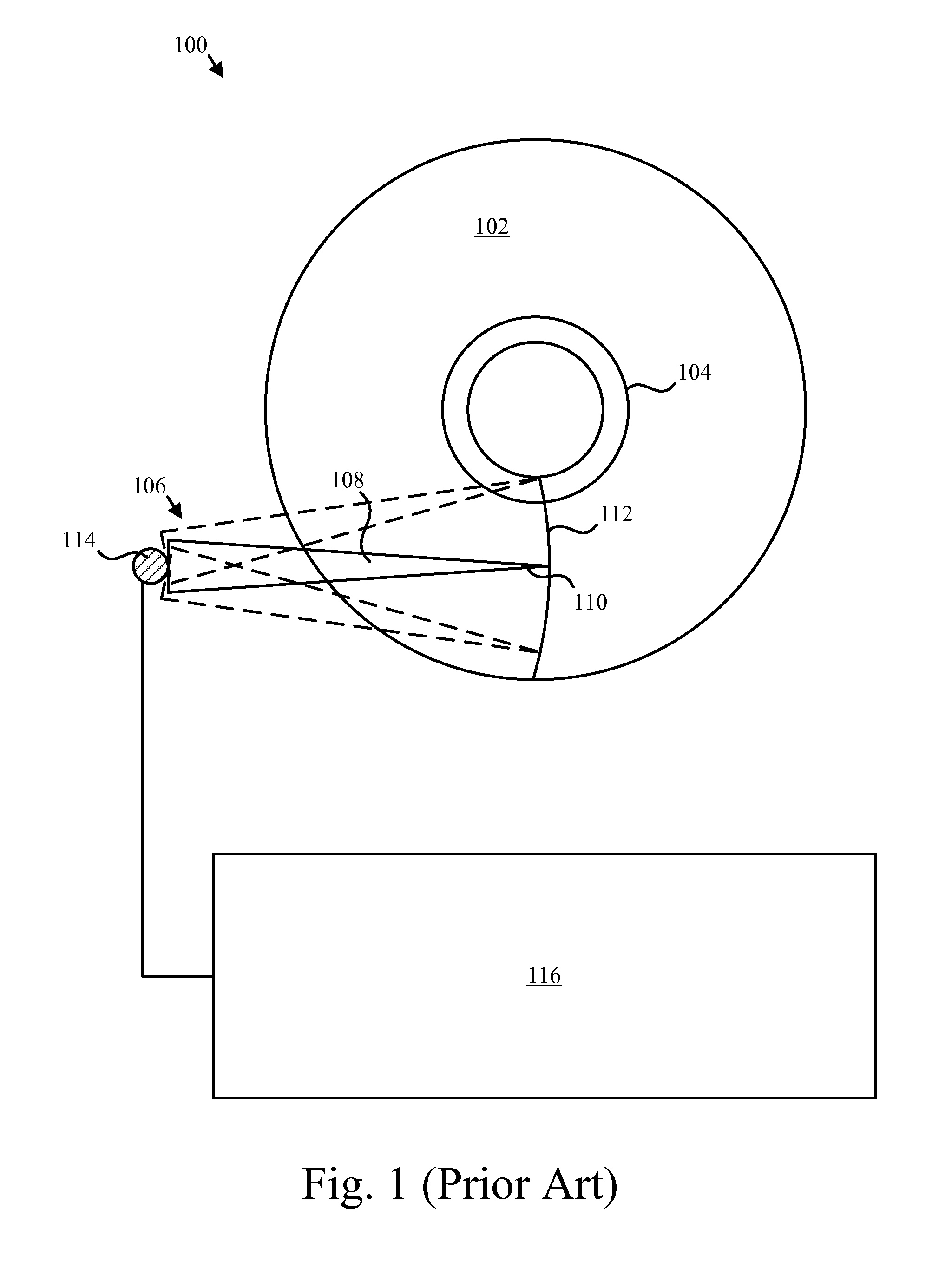

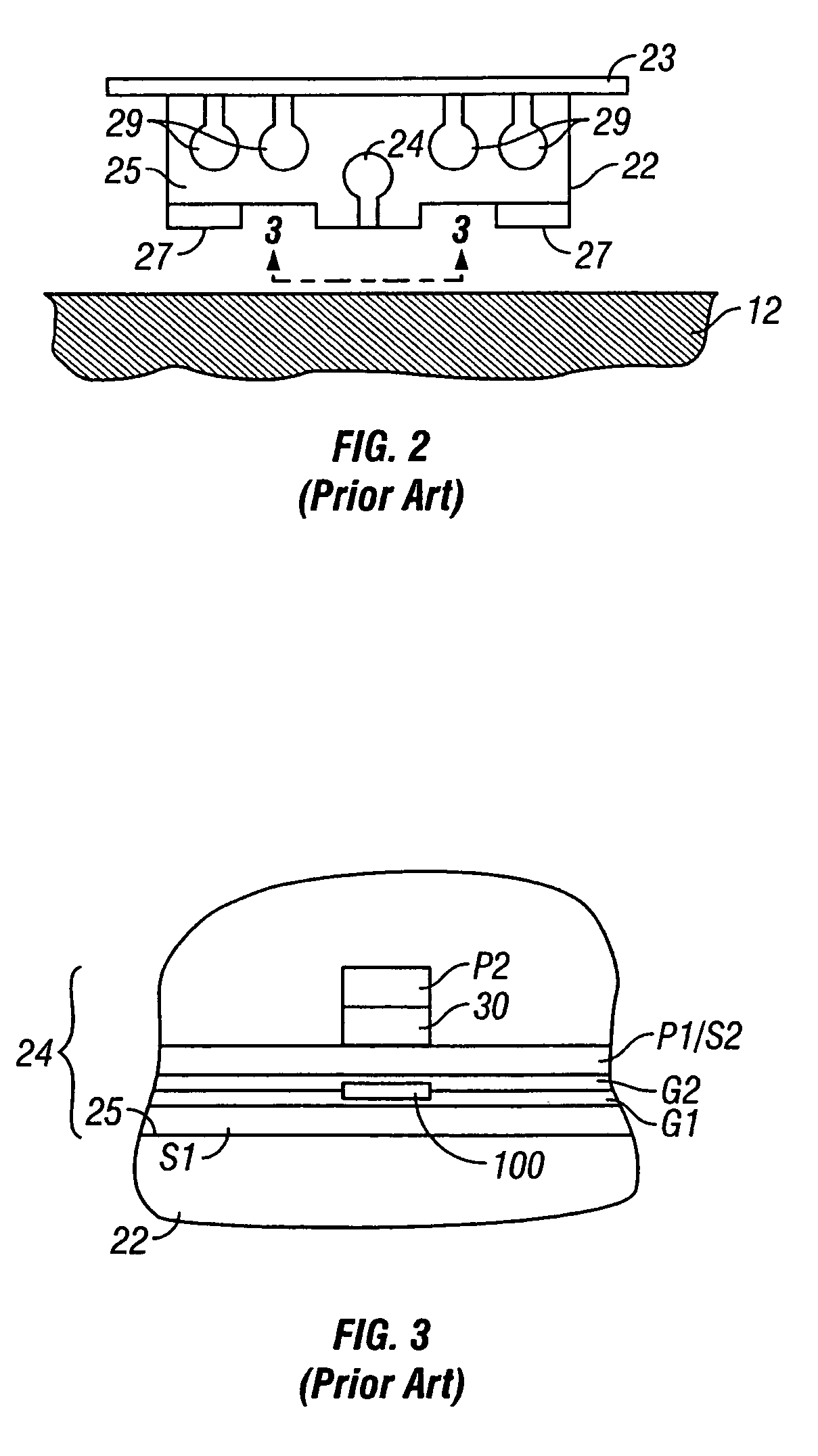

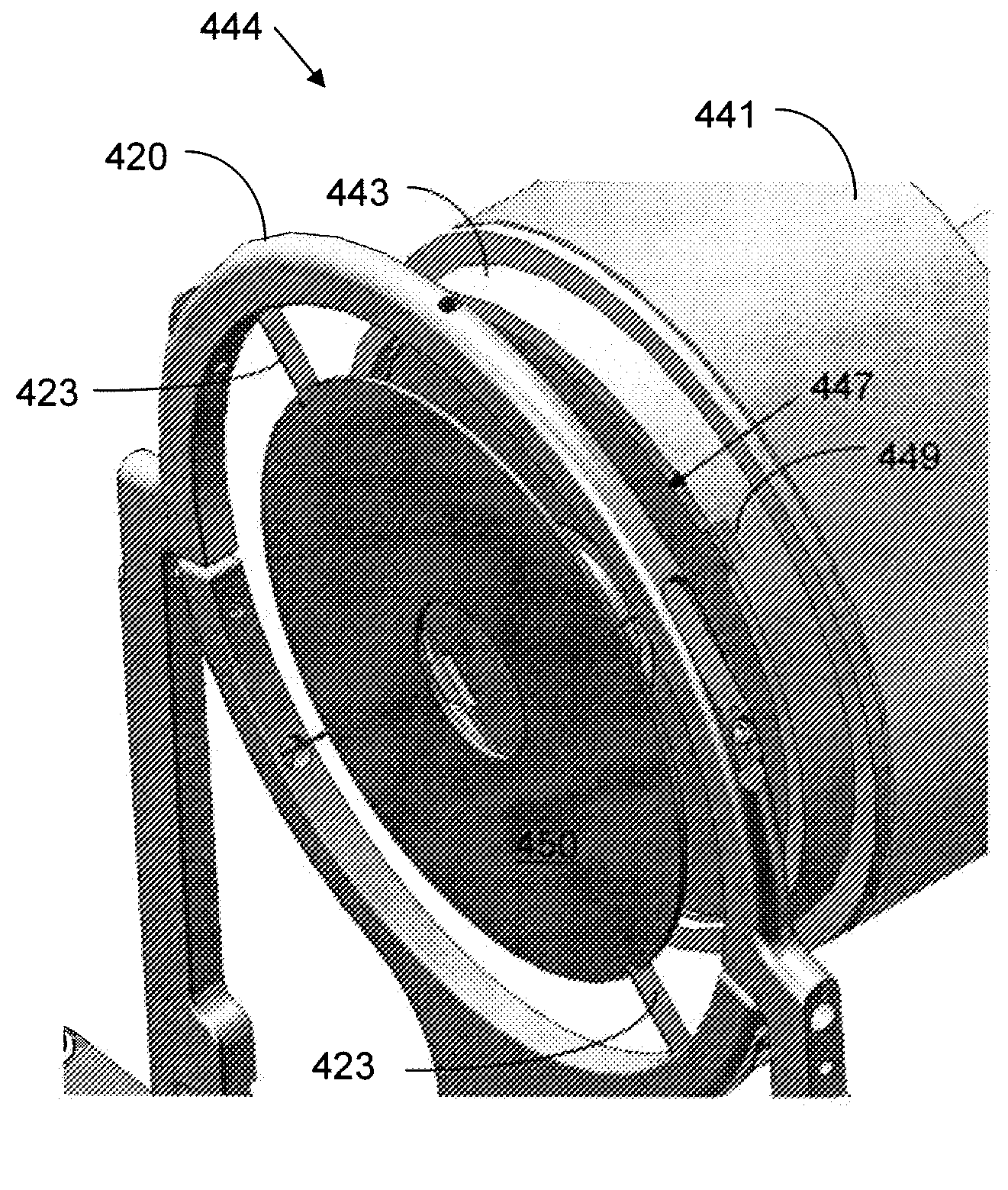

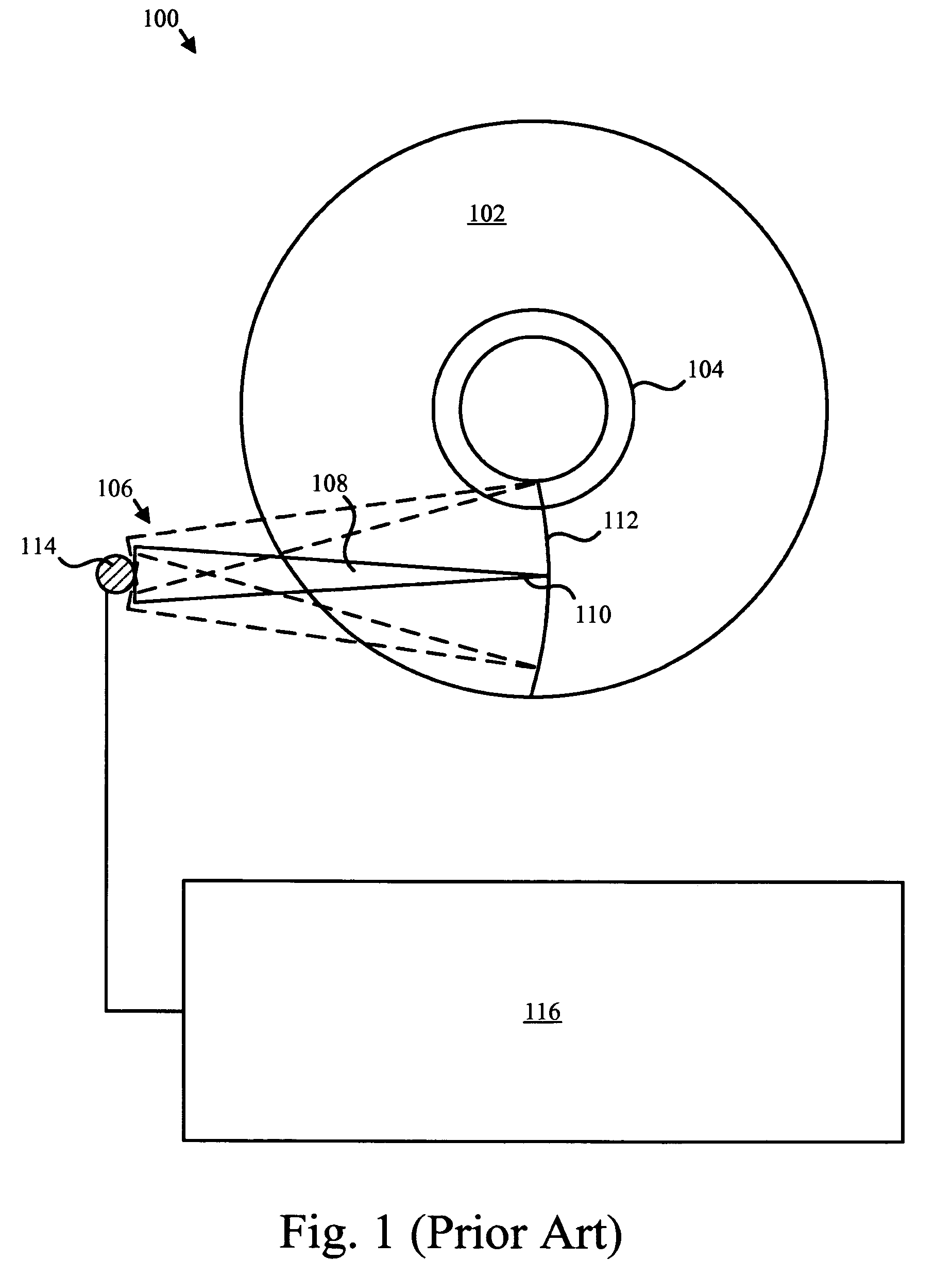

Disk alignment apparatus and method for patterned media production

An apparatus and method for aligning a disk with an imprinting surface are described. In one embodiment, the apparatus has a die which includes an air-bearing mandrel having a tapered nose to engage an ID of the disk, a circular imprinting surface having a centerline concentric with the air-bearing mandrel, and an air-bearing cavity to position the disk. The axial movement of the top die towards the bottom die guides the ID of the disk into coincident alignment with the centerline of the top die.

Owner:WD MEDIA

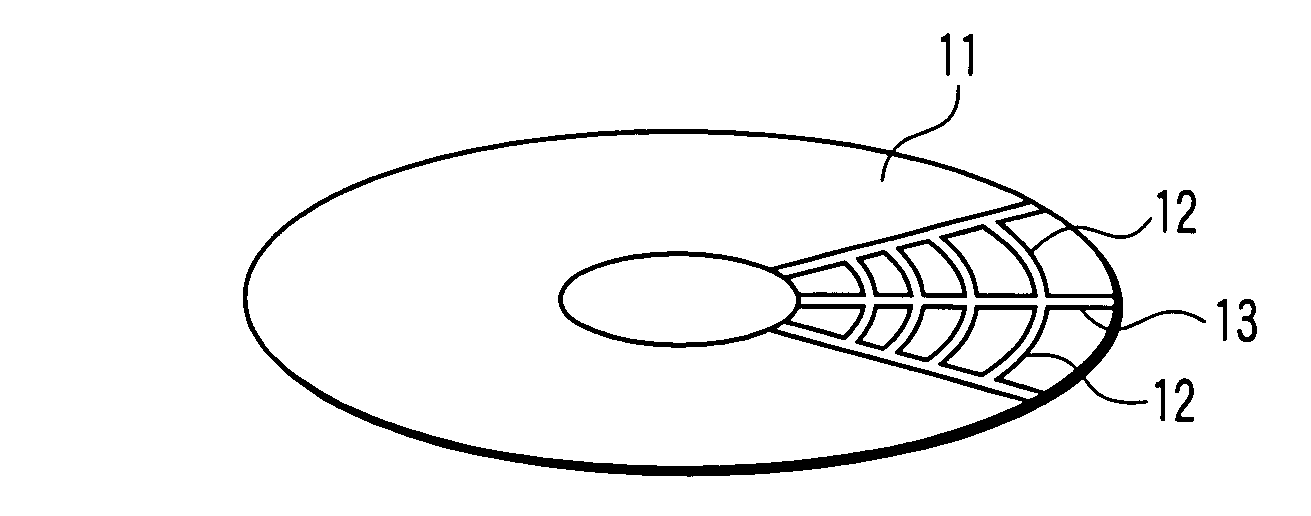

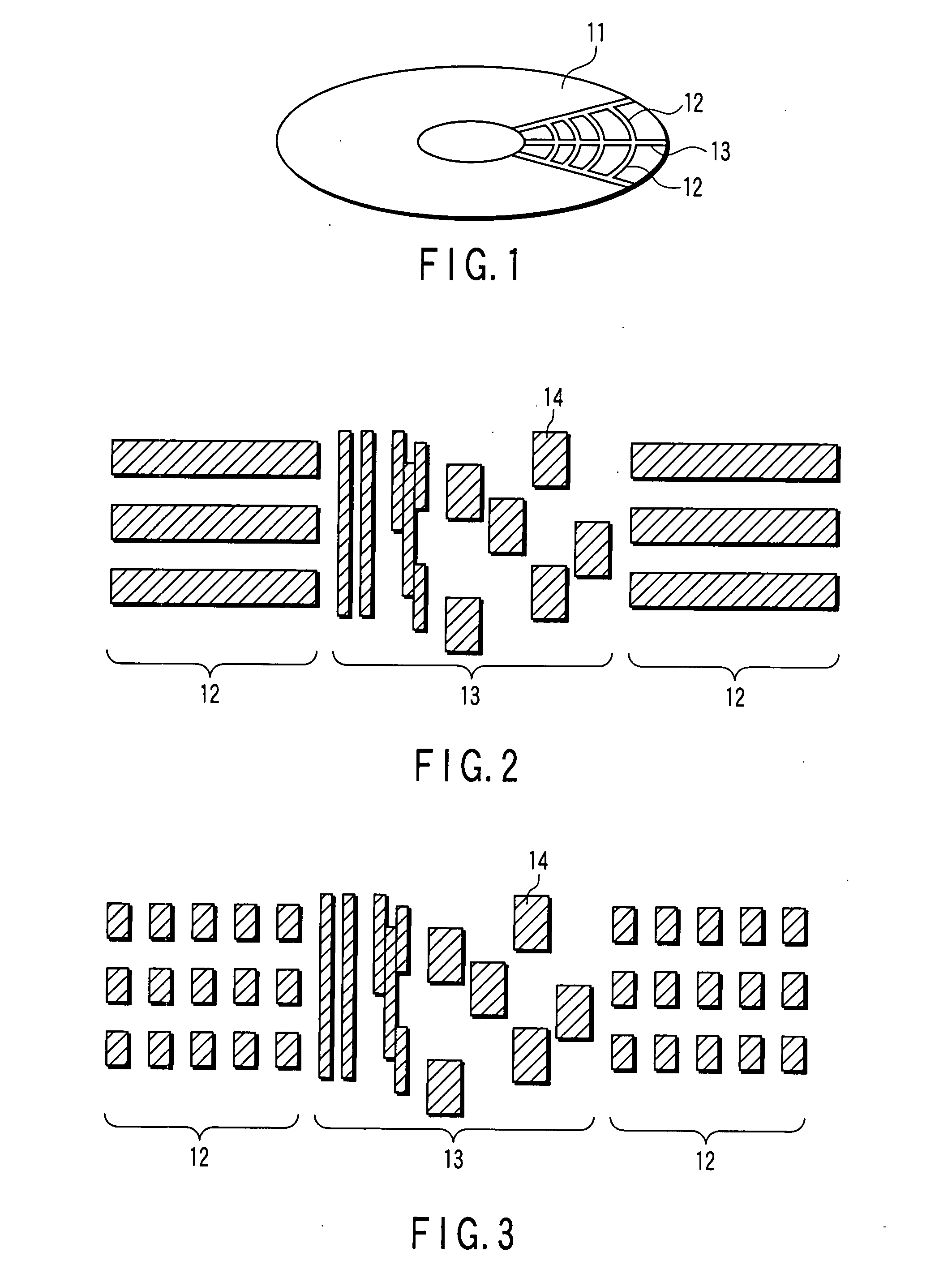

Method using block copolymers for making a master mold with high bit-aspect-ratio for nanoimprinting patterned magnetic recording disks

ActiveUS20090308837A1Decorative surface effectsSemiconductor/solid-state device manufacturingResistEngineering

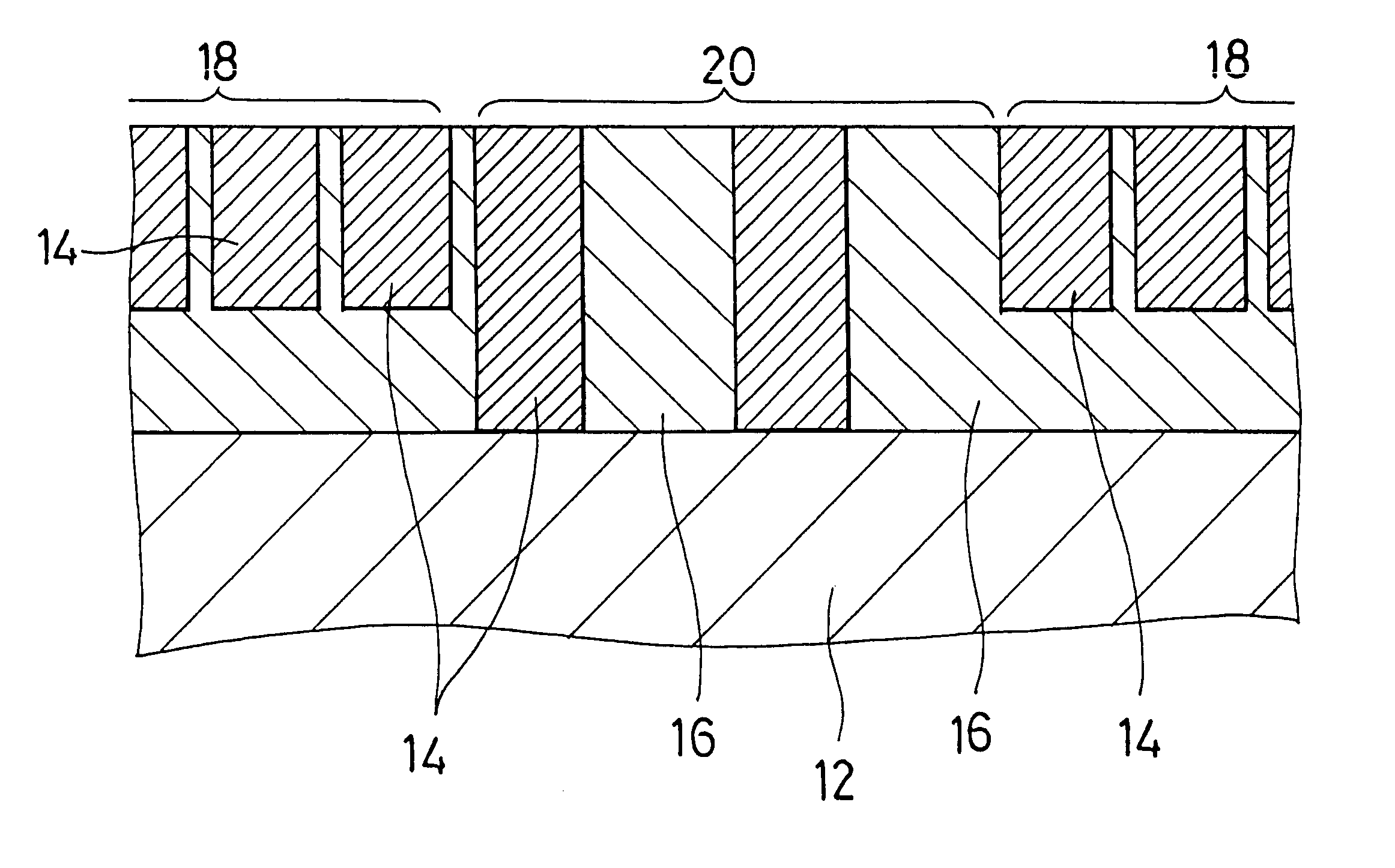

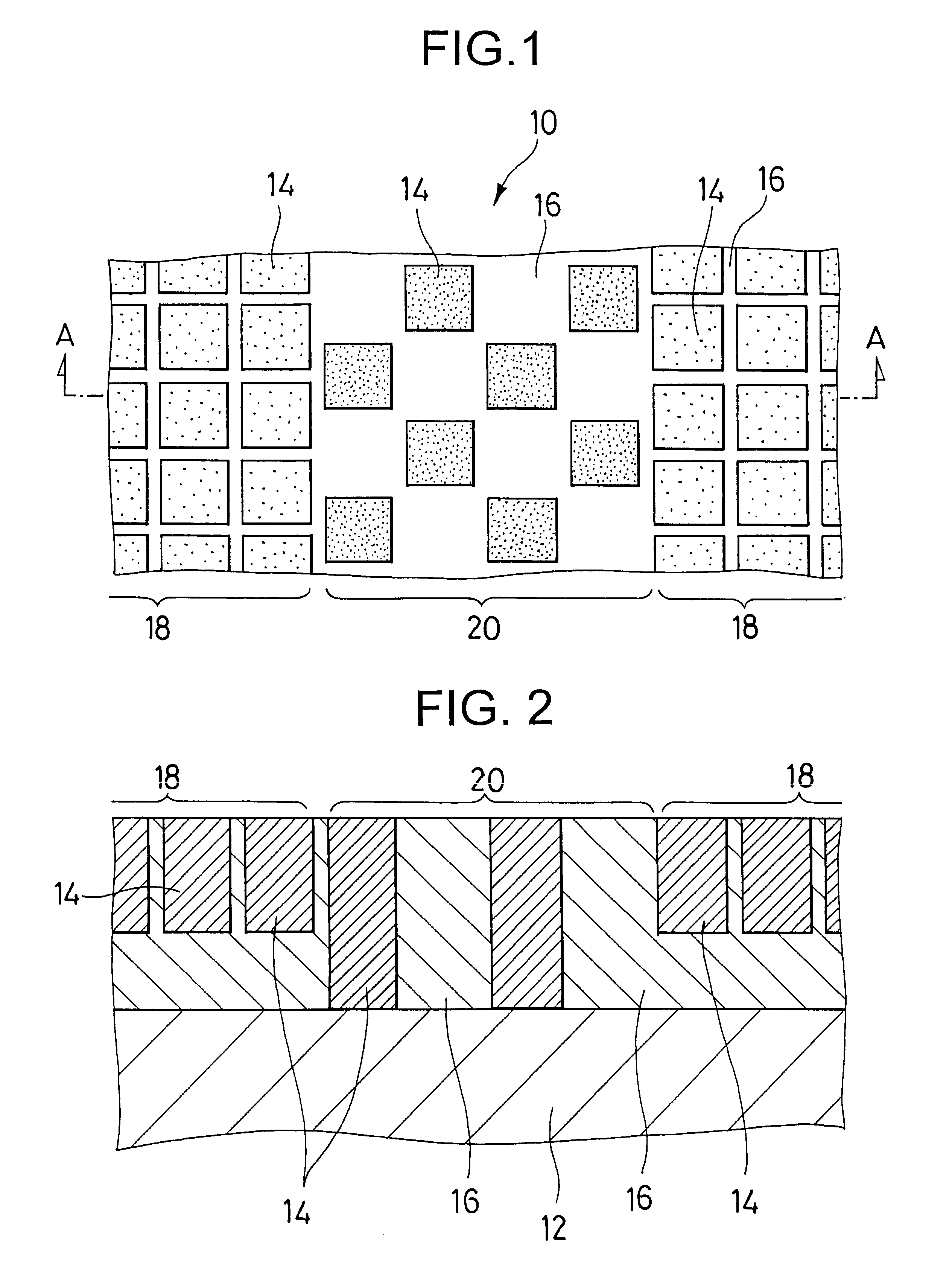

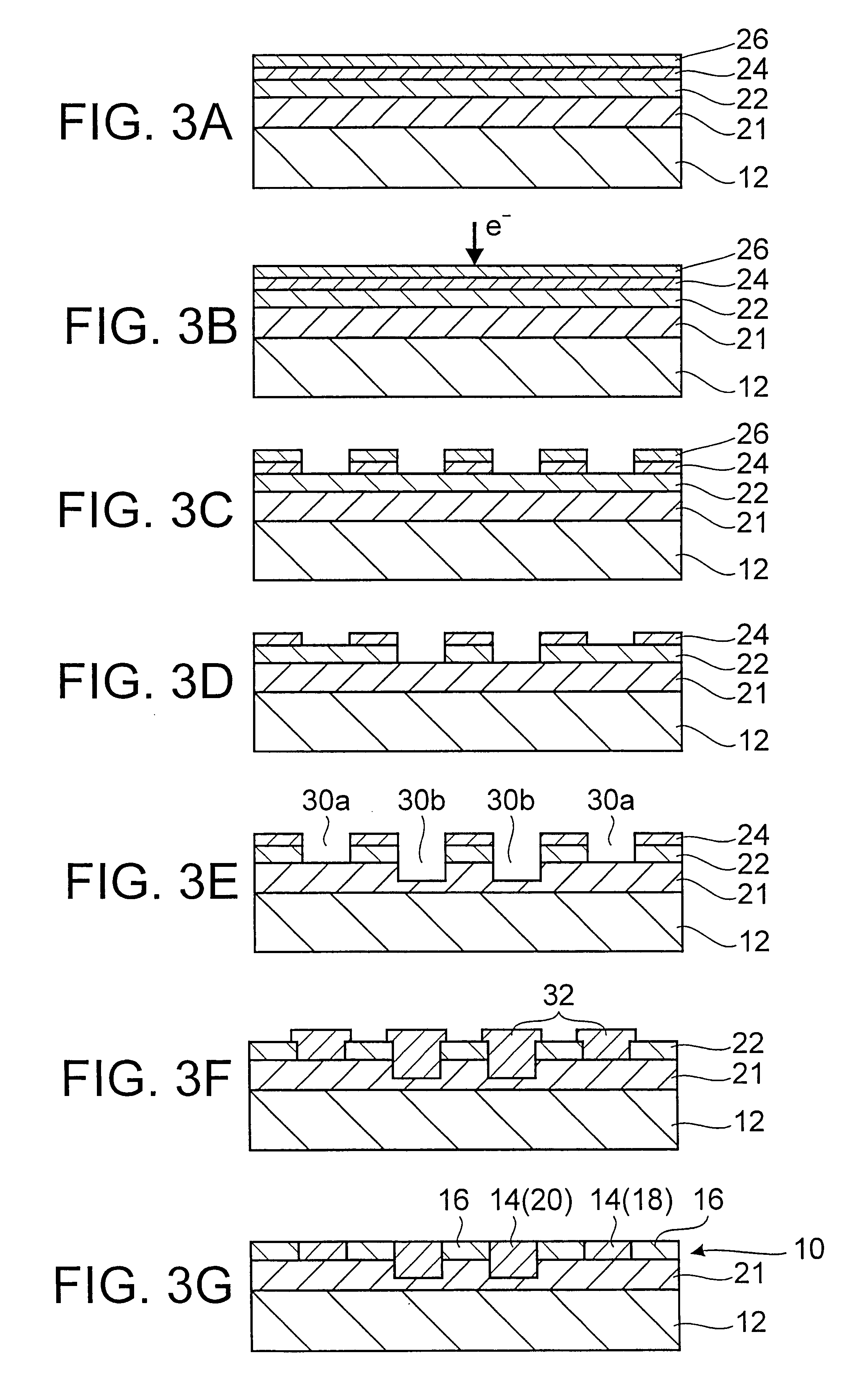

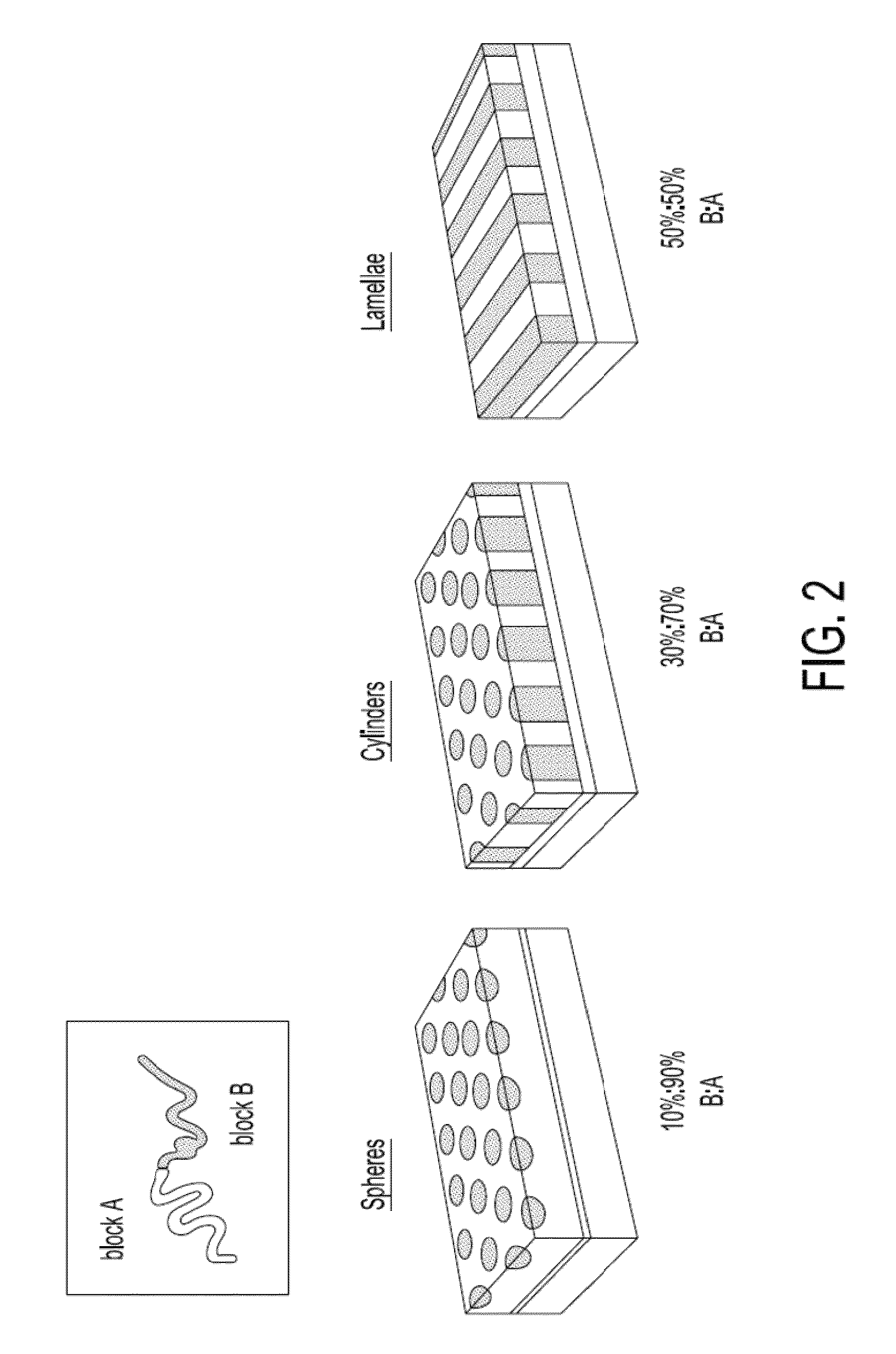

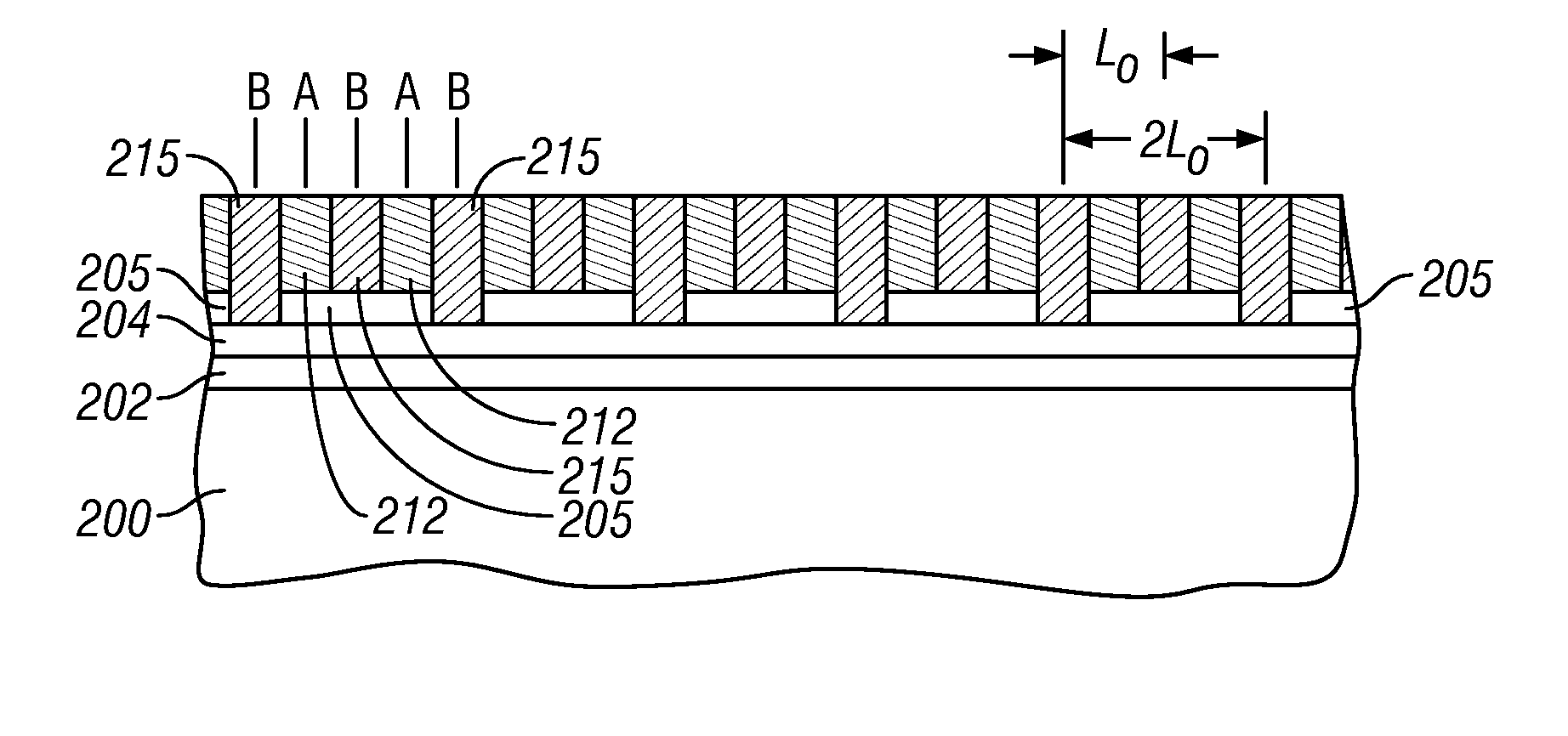

The invention is a method for making a master mold to be used for nanoimprinting patterned-media magnetic recording disks. The method uses conventional optical or e-beam lithography to form a pattern of generally radial stripes on a substrate, with the stripes being grouped into annular zones or bands. A block copolymer material is deposited on the pattern, resulting in guided self-assembly of the block copolymer into its components to multiply the generally radial stripes into generally radial lines of alternating block copolymer components. The radial lines of one of the components are removed and the radial lines of the remaining component are used as an etch mask to etch the substrate. Conventional lithography is used to form concentric rings over the generally radial lines. After etching and resist removal, the master mold has pillars arranged in circular rings, with the rings grouped into annular bands.

Owner:WESTERN DIGITAL TECH INC

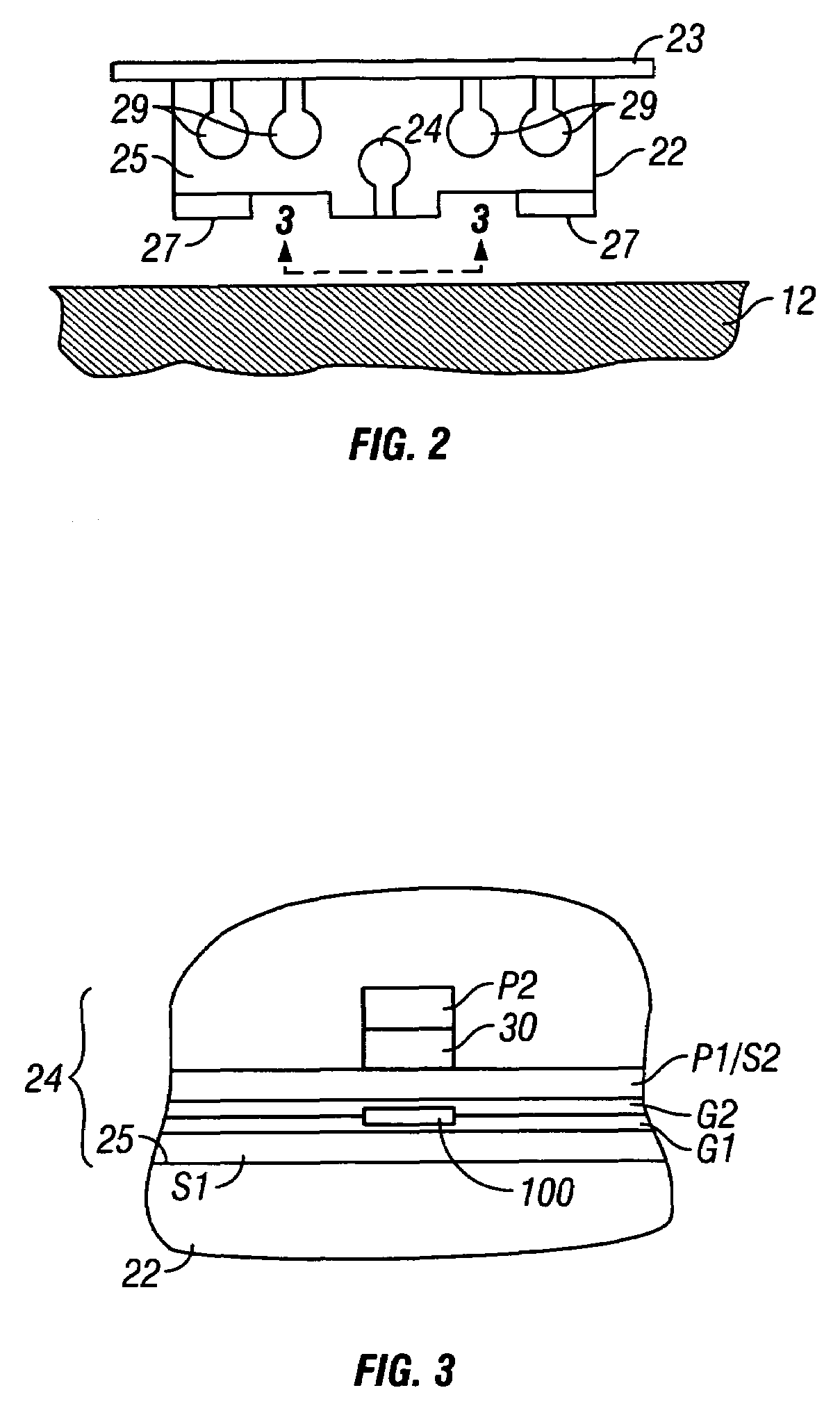

Joint design of thermally-assisted magnetic recording head and patterned media for high optical efficiency

ActiveUS20110096431A1Combination recordingPatterned record carriersHeat-assisted magnetic recordingEngineering

A system according to one embodiment includes a magnetic recording medium having a magnetic layer with features in a discrete track configuration or a bit patterned configuration and an underlayer adjacent the magnetic layer, the underlayer comprising a material capable of forming surface plasmon resonance; and a magnetic head having: a writer for writing to the medium; and a near-field transducer for heating the medium for thermally assisted recording. Additional systems and methods are also presented.

Owner:WESTERN DIGITAL TECH INC

Magnetic recording medium

InactiveUS6420058B1Improve coercive forceAvoid erasureProtective coatings for layersMagnetic materials for record carriersNon magneticPatterned media

The invention aims to prevent inadvertent rewriting or erasure of servo information in a patterned medium based on the perpendicular recording mode. The magnetic recording medium of the invention includes recording tracks each having an array of unit minute recording portions of a magnetic material separated by non-recording portions of a nonmagnetic material. The recording tracks include data regions and servo regions. The unit minute recording portions in the data regions have substantially the same surface area as the unit minute recording portions in the servo regions. The invention satisfies ARS / ARD>=1.5 provided that the unit minute recording portion has an aspect ratio which is the thickness divided by the square root of the surface area, the unit minute recording portion in the data region has an aspect ratio ARD, and the unit minute recording portion in the servo region has an aspect ratio ARS.

Owner:TDK CORPARATION

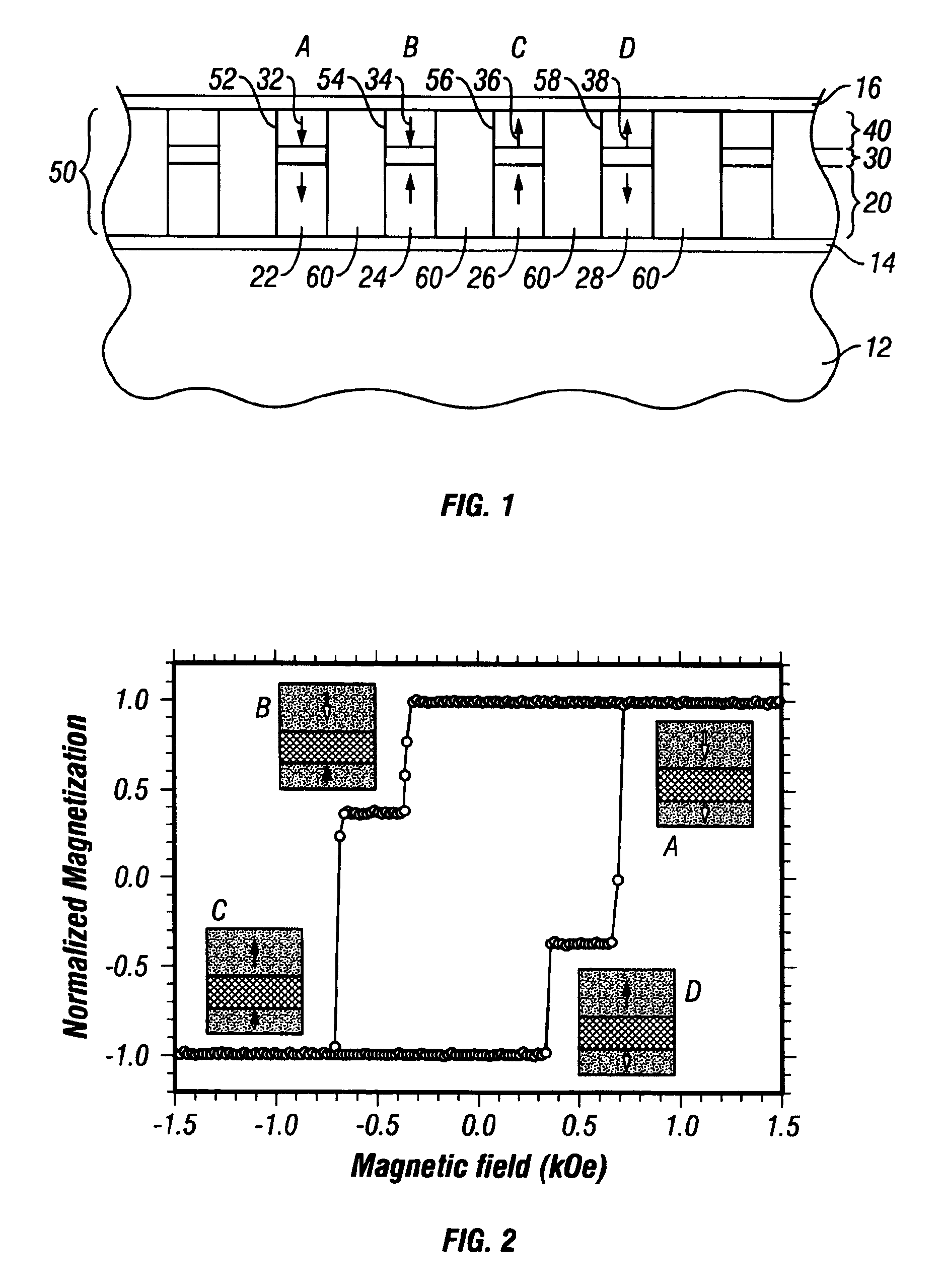

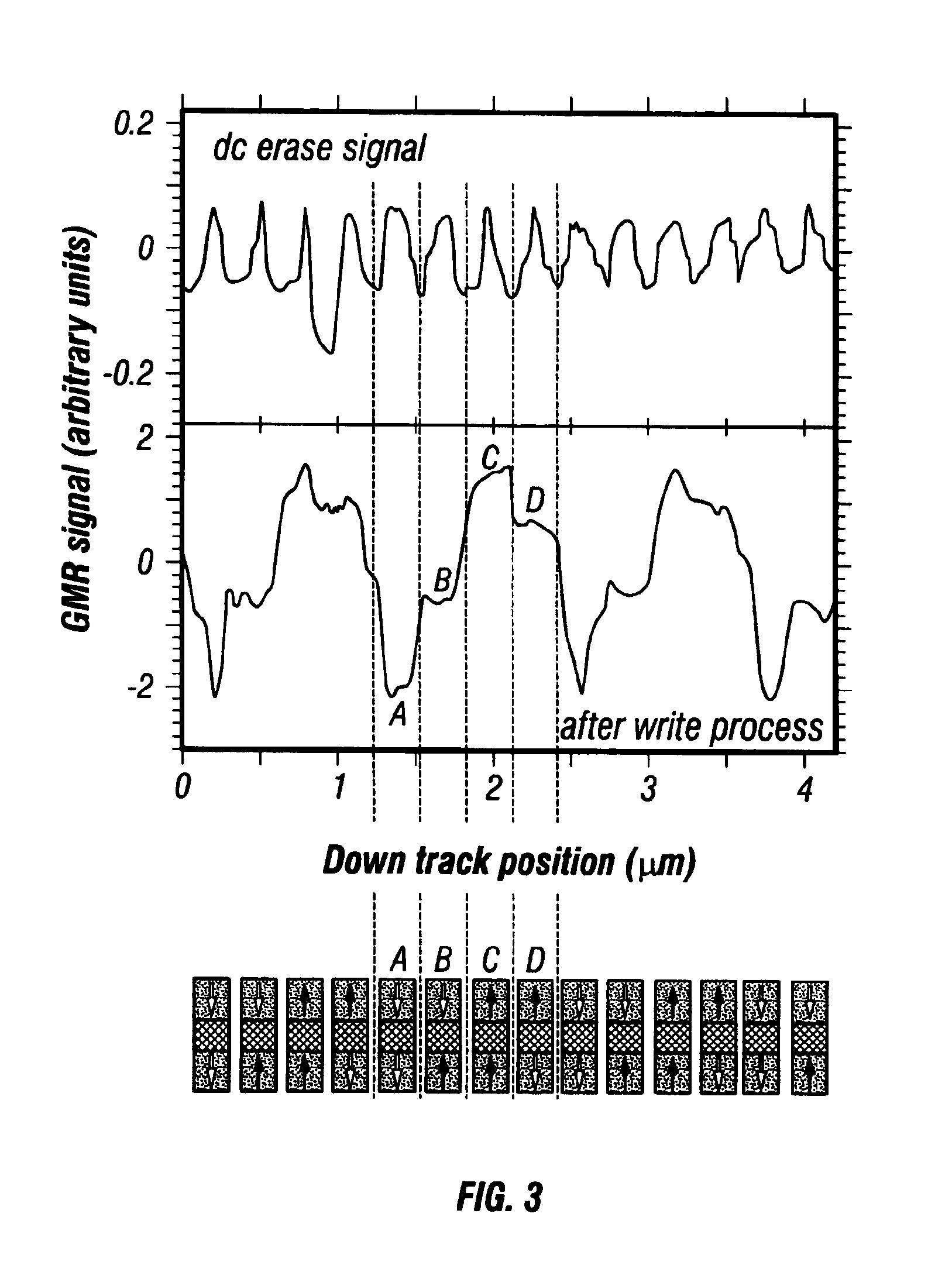

Method for magnetic recording on patterned multilevel perpendicular media using thermal assistance and fixed write current

ActiveUS6865044B1Improve noiseImprove recording densityNanoinformaticsPatterned record carriersPatterned mediaElectrical current

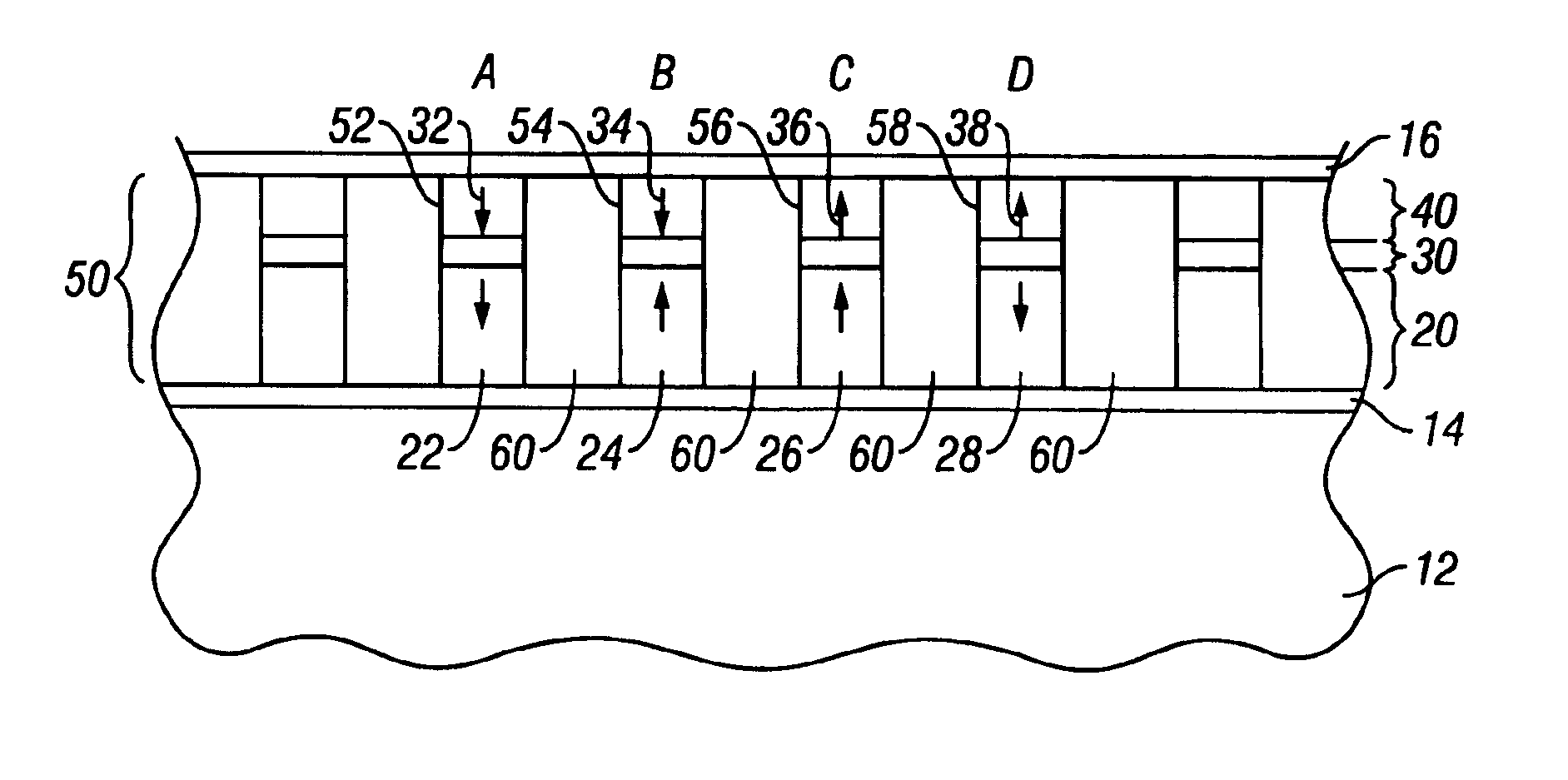

A method for magnetic recording uses a fixed write current with thermal assistance to record on a patterned perpendicular magnetic recording medium. The patterned medium has magnetic blocks or islands, each of which contains a stack of individual magnetic cells to provide multilevel recording. Each cell in an island is formed of a material or set of materials to provide the cell with perpendicular magnetic anisotropy and is a single magnetic domain. Each cell is magnetically decoupled from the other cells in its island by nonmagnetic spacer layers. Thus each cell can have a magnetization (magnetic moment) in one of two directions (into or out of the plane of the layer making up the cell), and this magnetization is independent of the magnetization of the other cells in its island. This permits multiple magnetic levels or states to be recorded in each magnetic island.

Owner:WESTERN DIGITAL TECH INC

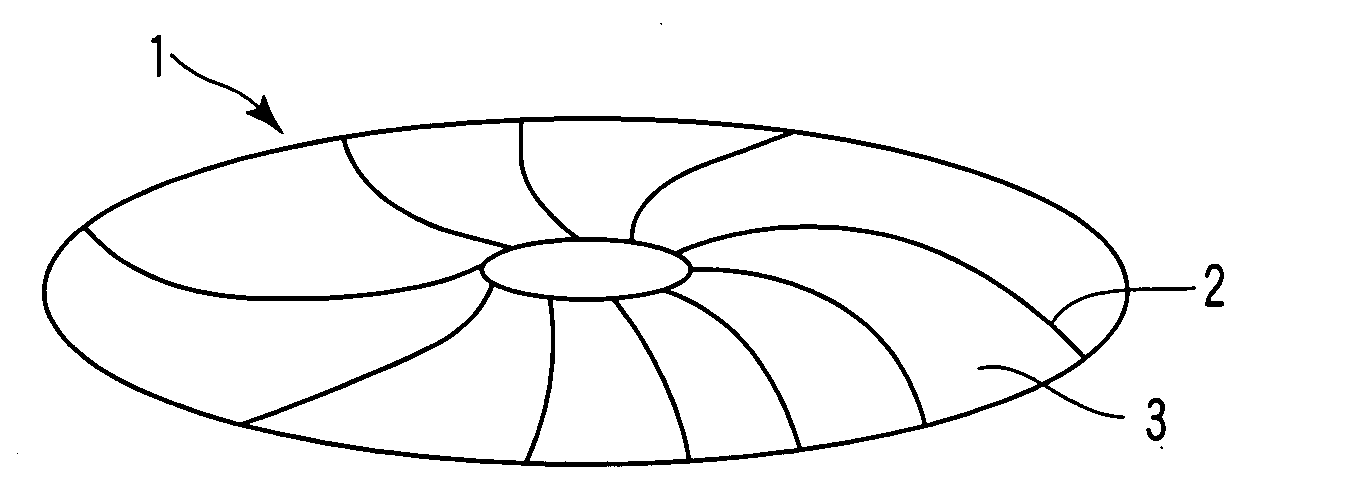

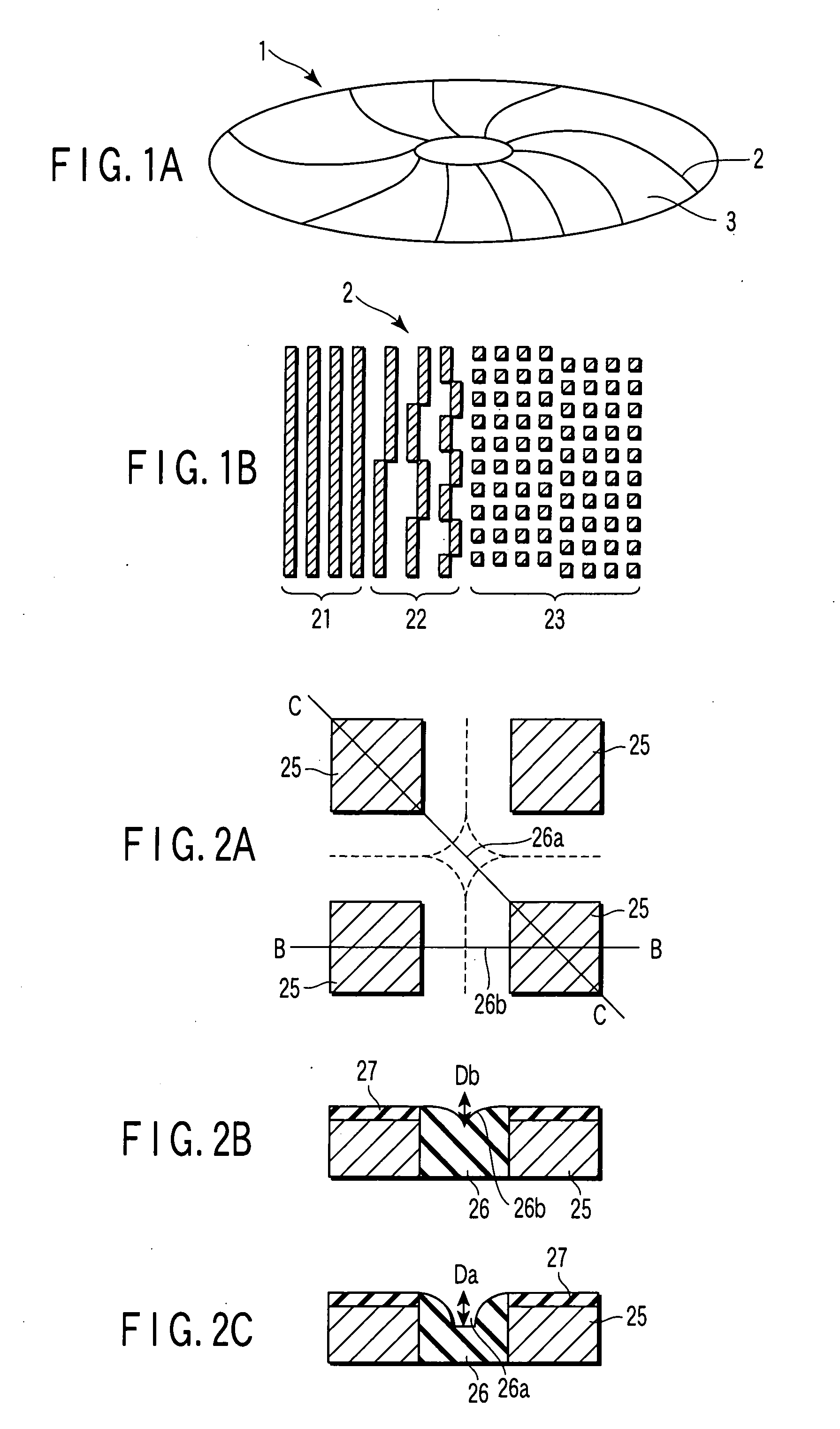

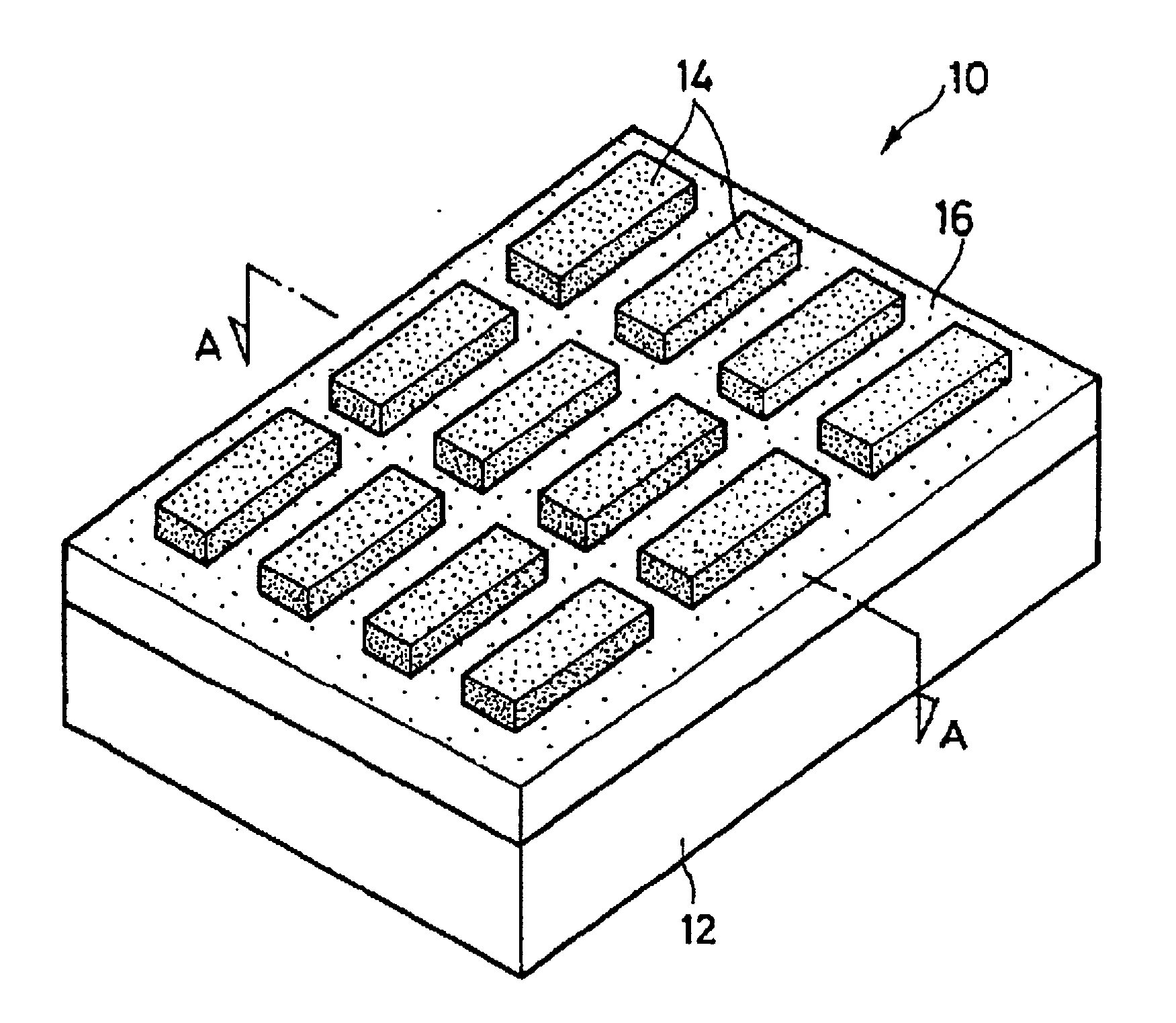

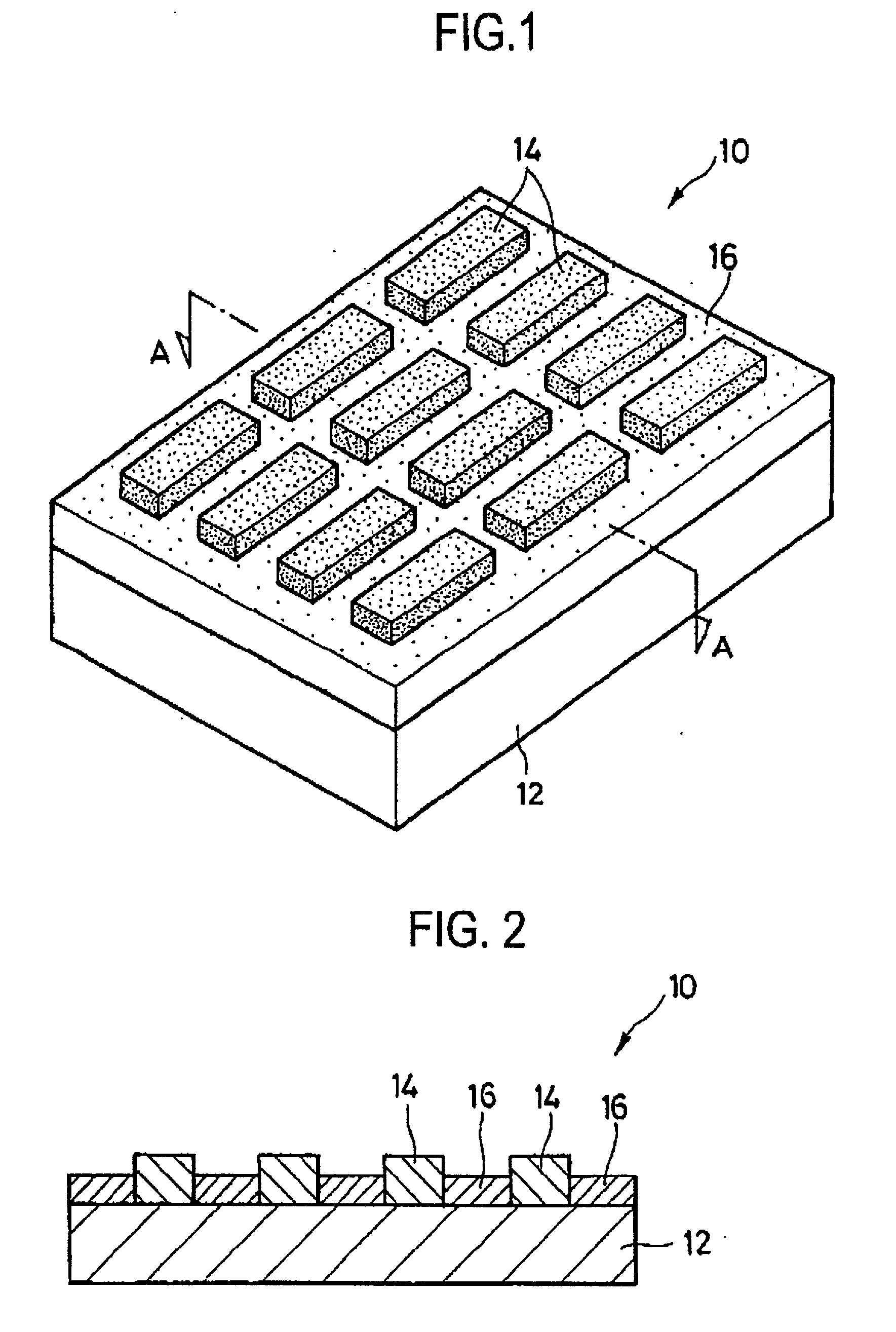

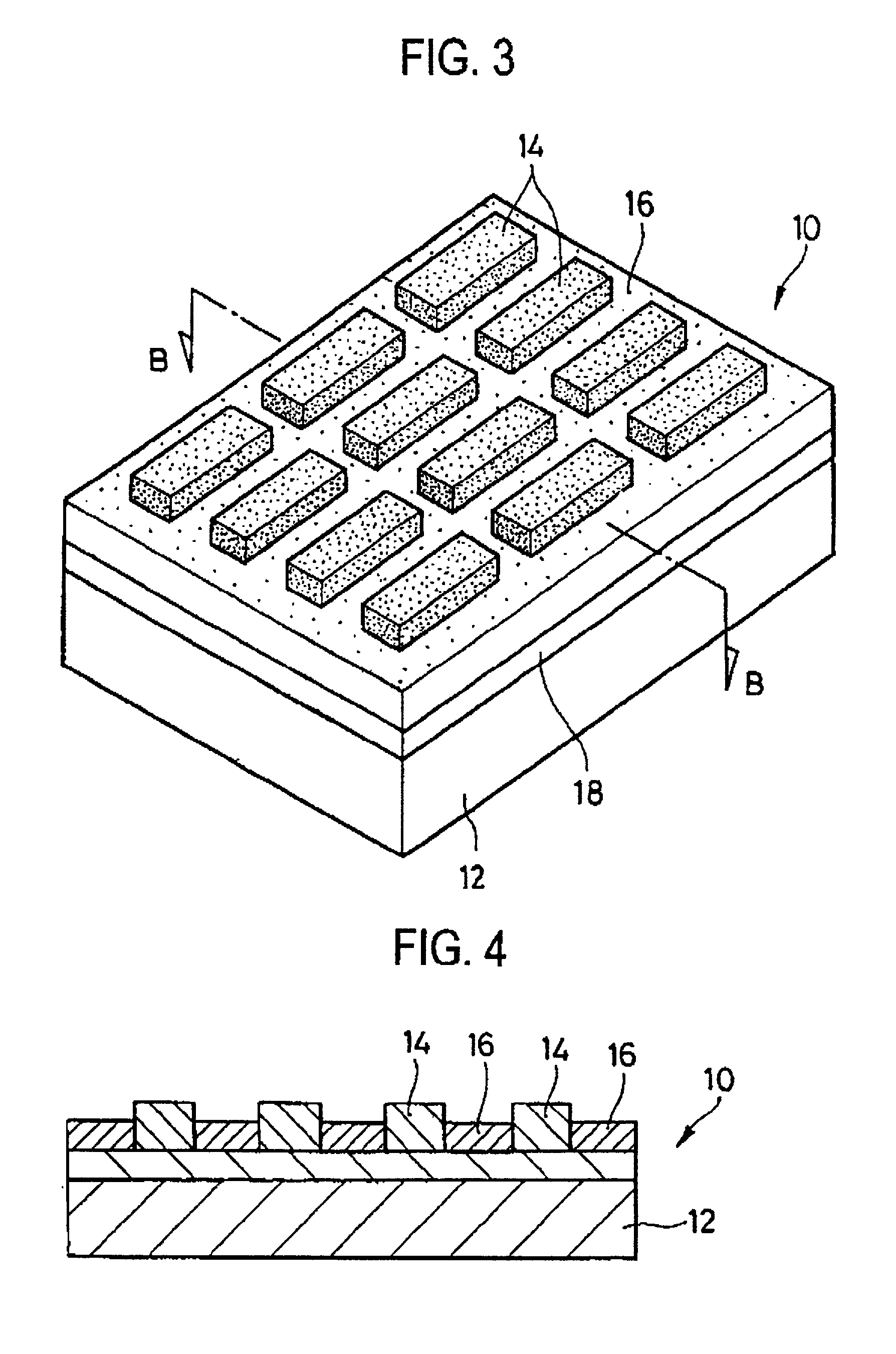

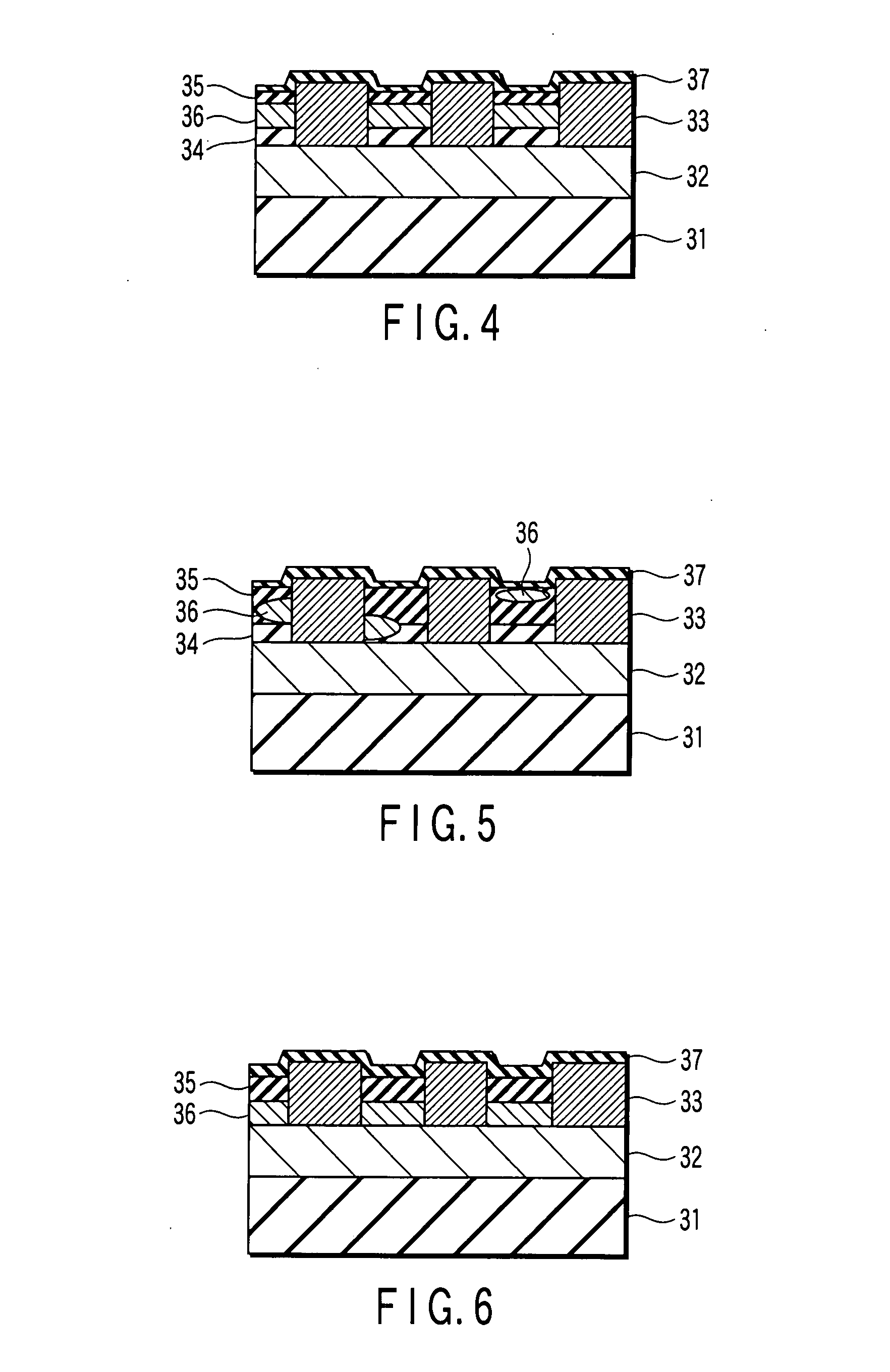

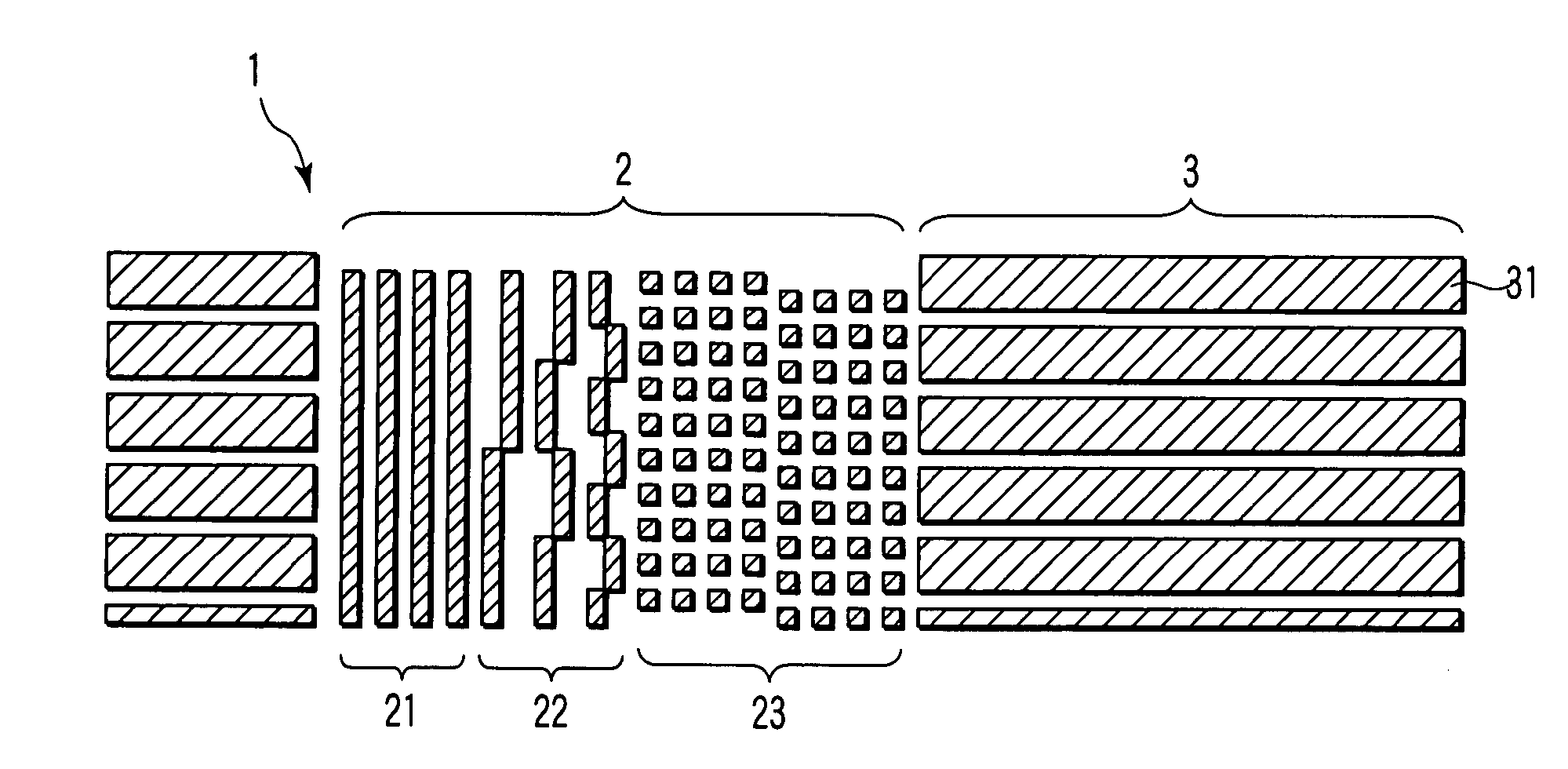

Patterned media and method of manufacturing the same, and magnetic recording apparatus

A patterned media has a substrate, and a magnetic recording layer on the substrate including protruded magnetic patterns and a nonmagnetic material filled in between the protruded magnetic patterns. In the patterned media, a depth Db and a depth Da, which are defined that Db is a depth from a surface of the magnetic patterns to a surface of the nonmagnetic material filled in a first central part between the magnetic patterns adjacent to each other in a cross-track direction or a down-track direction, and Da is a depth from a surface of the magnetic patterns to a surface of the nonmagnetic material filled in a second central part in a portion surrounded by the magnetic patterns, have a relationship that the depth Da is greater than the depth Db.

Owner:KK TOSHIBA

Joint design of thermally-assisted magnetic recording head and patterned media for high optical efficiency

ActiveUS8031561B2Combination recordingPatterned record carriersHeat-assisted magnetic recordingPatterned media

A system according to one embodiment includes a magnetic recording medium having a magnetic layer with features in a discrete track configuration or a bit patterned configuration and an underlayer adjacent the magnetic layer, the underlayer comprising a material capable of forming surface plasmon resonance; and a magnetic head having: a writer for writing to the medium; and a near-field transducer for heating the medium for thermally assisted recording. Additional systems and methods are also presented.

Owner:WESTERN DIGITAL TECH INC

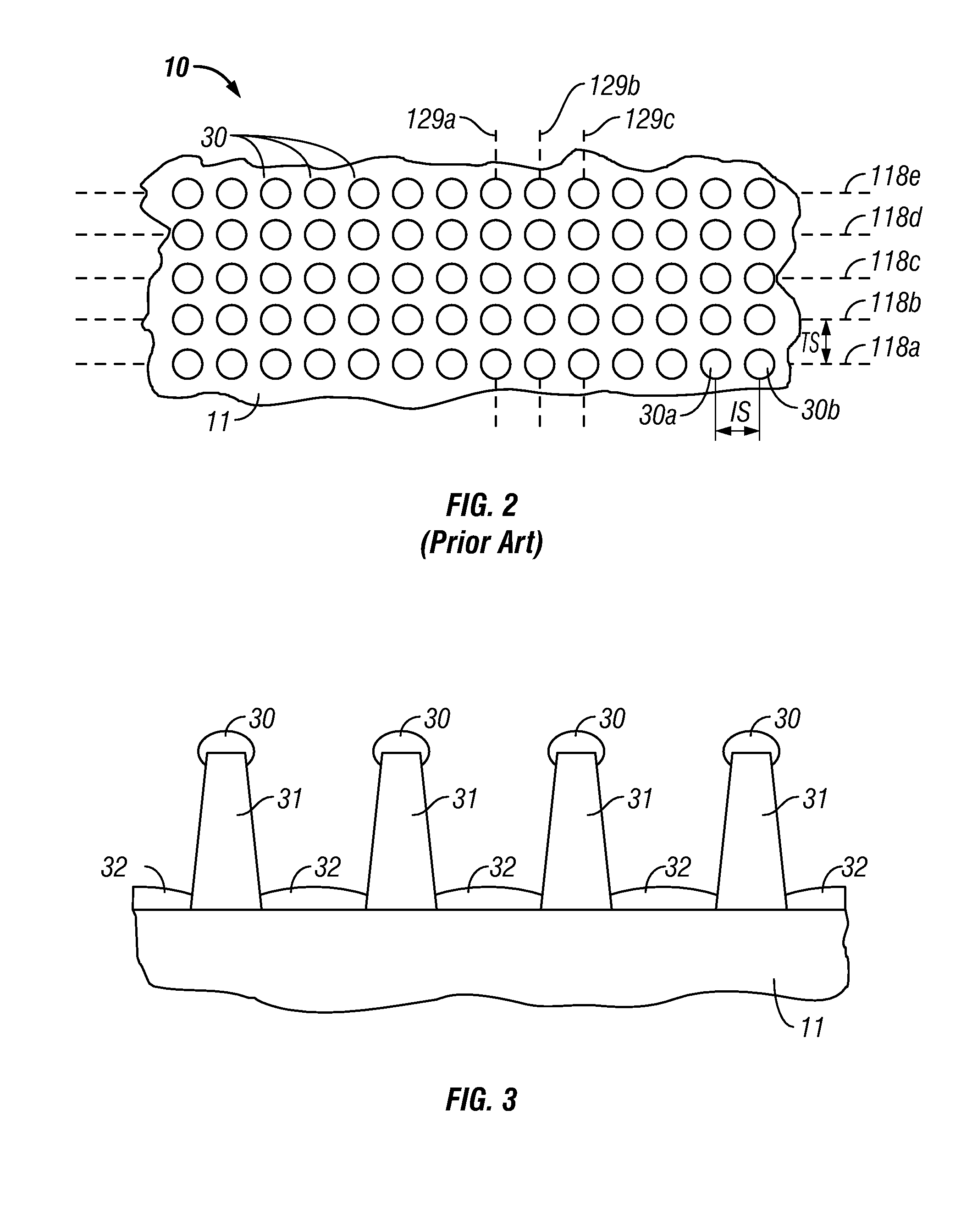

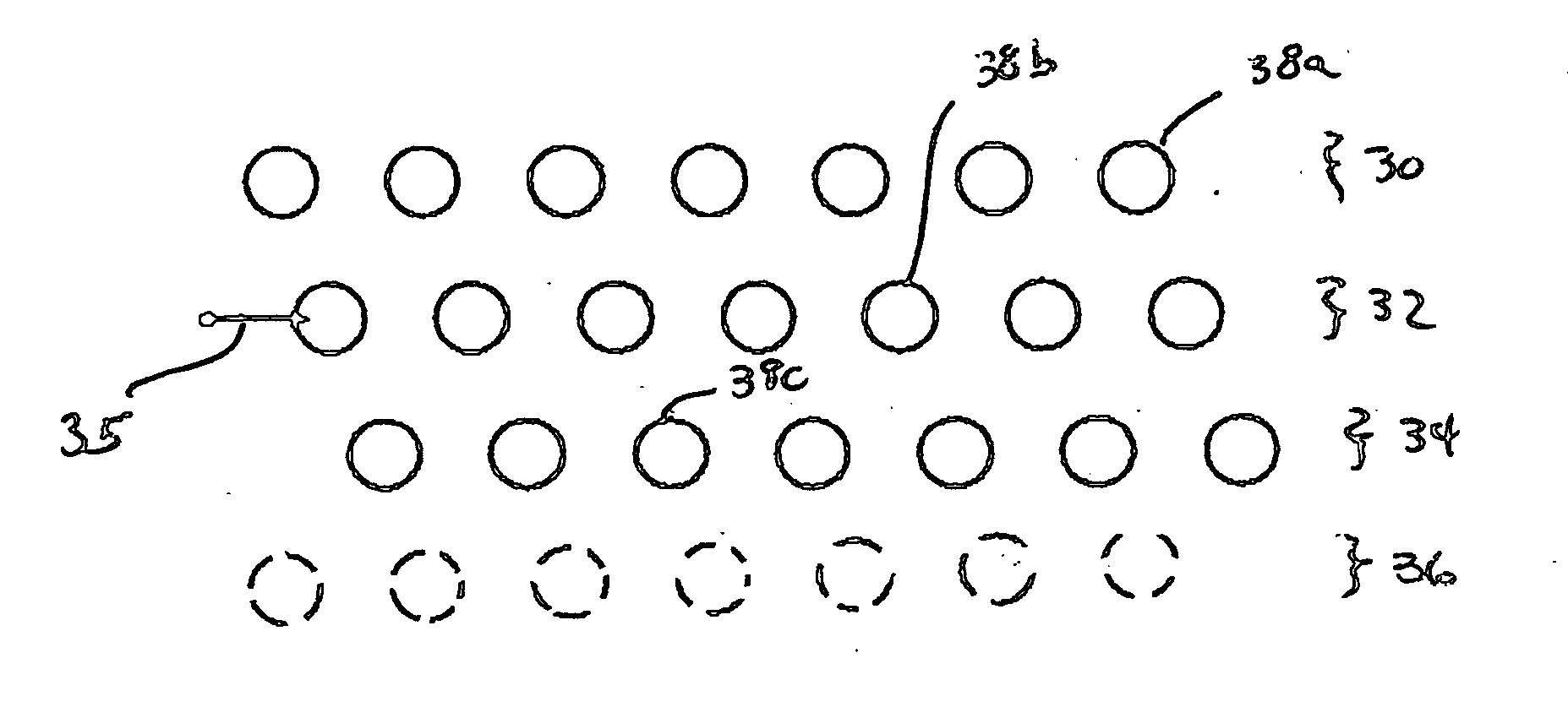

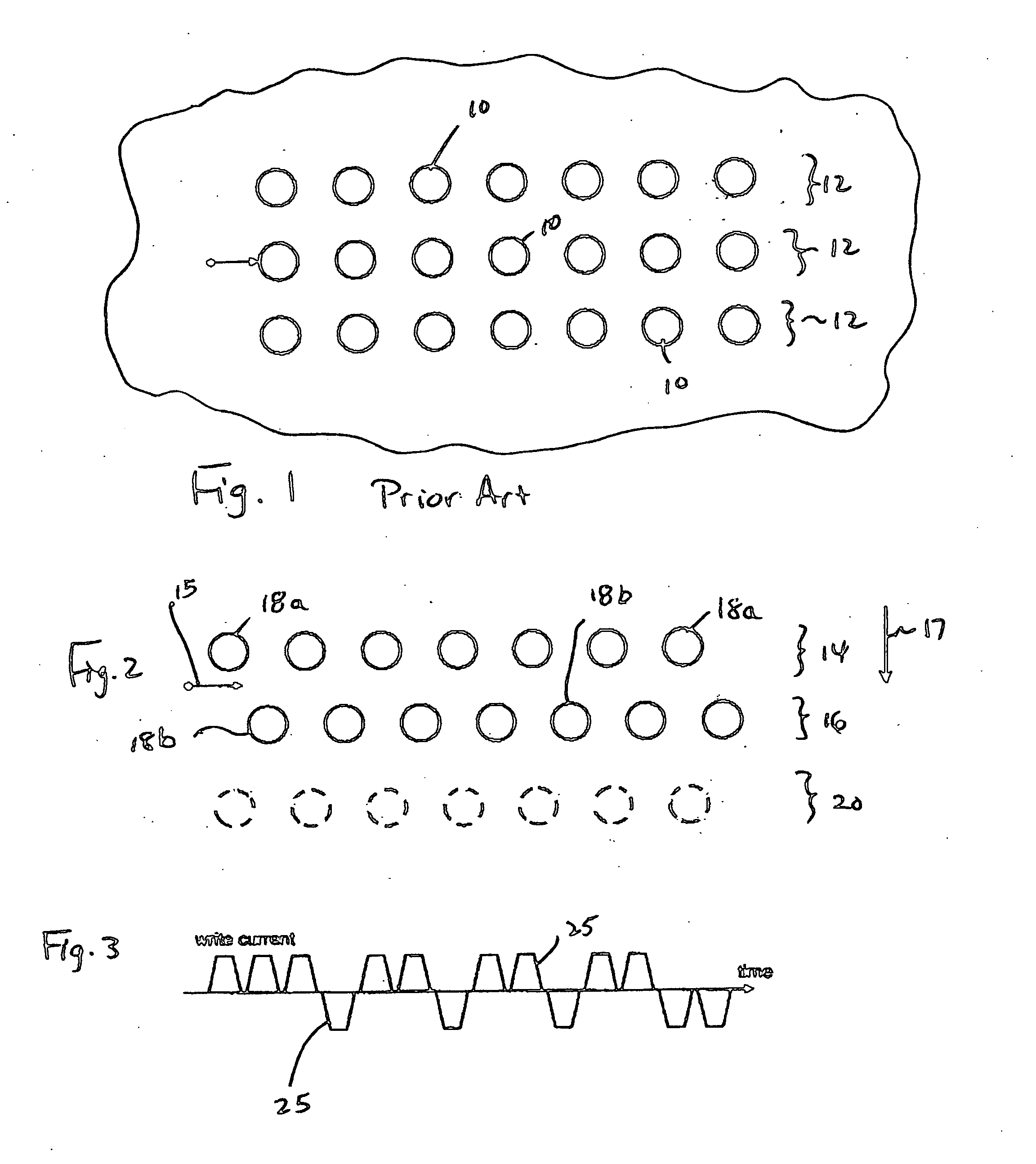

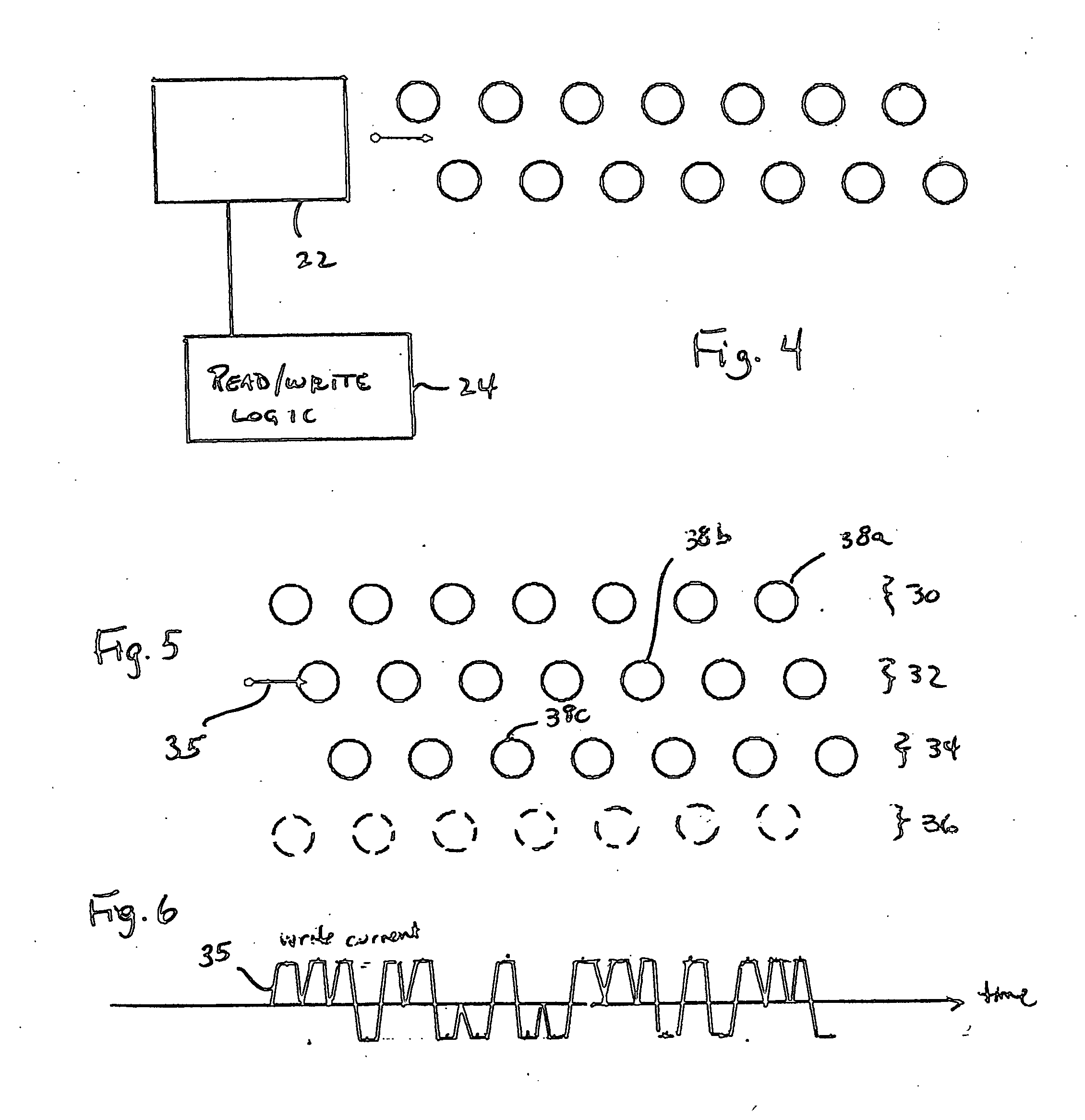

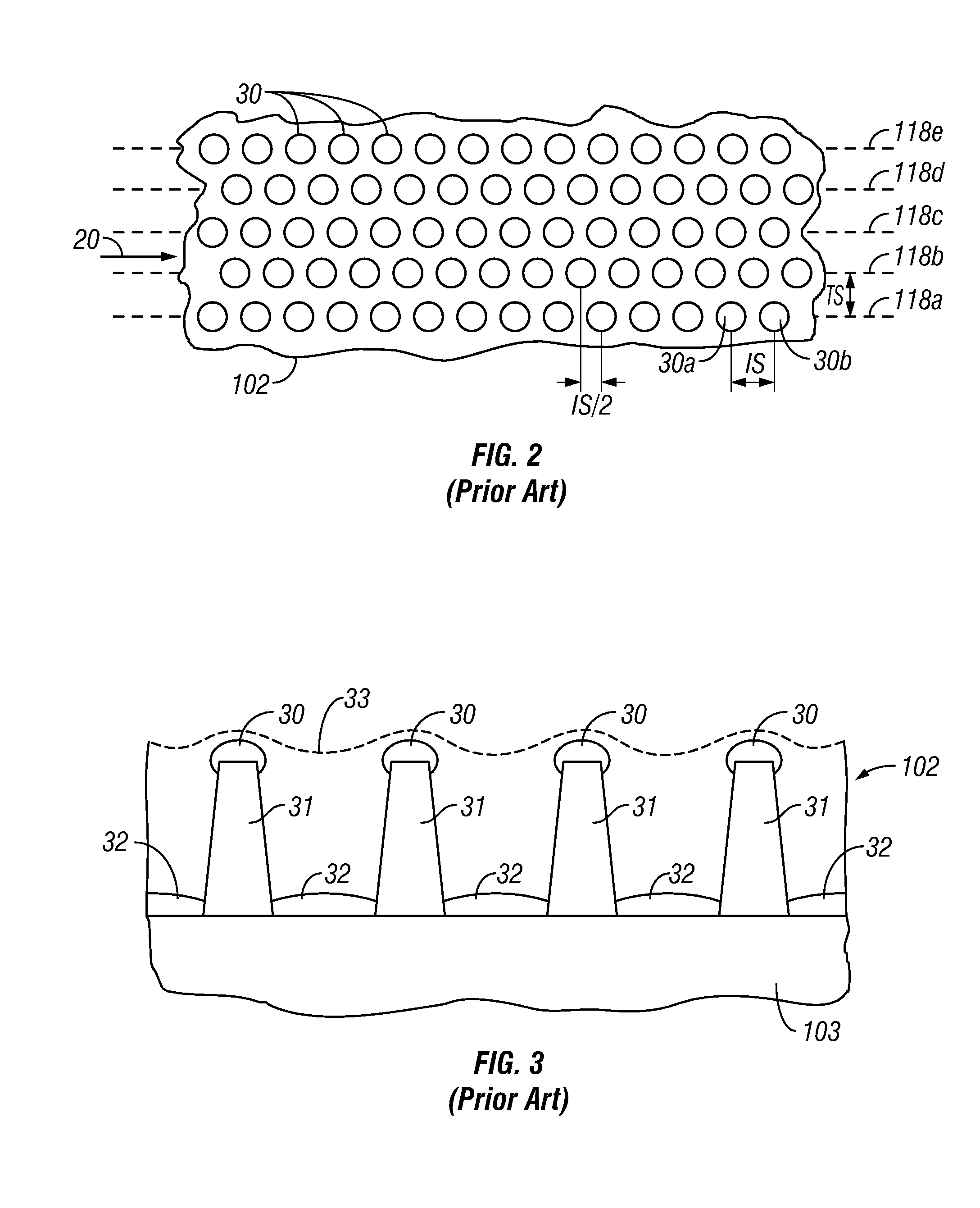

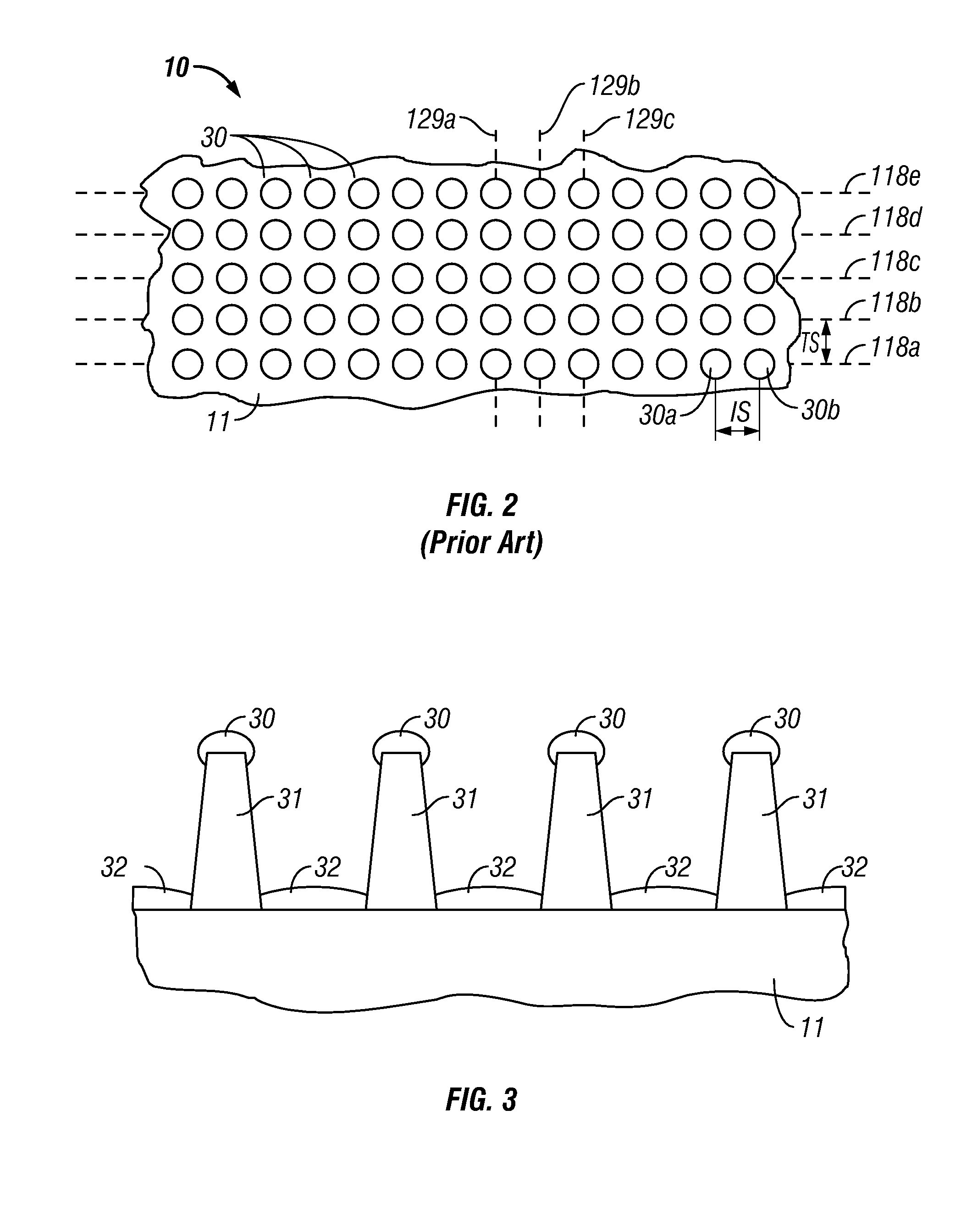

Data storage device with bit patterned media with staggered islands

InactiveUS20070258161A1Great bit aspect ratioLoss of areal densityNanoinformaticsPatterned record carriersData recordingRecording density

A data recording device employs a bit patterned data recording medium that has an array of rows that are offset to one another. The rows are offset such that the bits are staggered in a direction that is normal to the direction in which the rows extend. The increased bit aspect ratio of the staggered bit pattern recording medium increases the linear recording density and enables a higher data recording rate.

Owner:SEAGATE TECH LLC

Magnetic recording medium

InactiveUS20020135939A1Avoid stickingEliminate needNanoinformaticsPatterned record carriersEngineeringSurface level

Owner:TDK CORPARATION

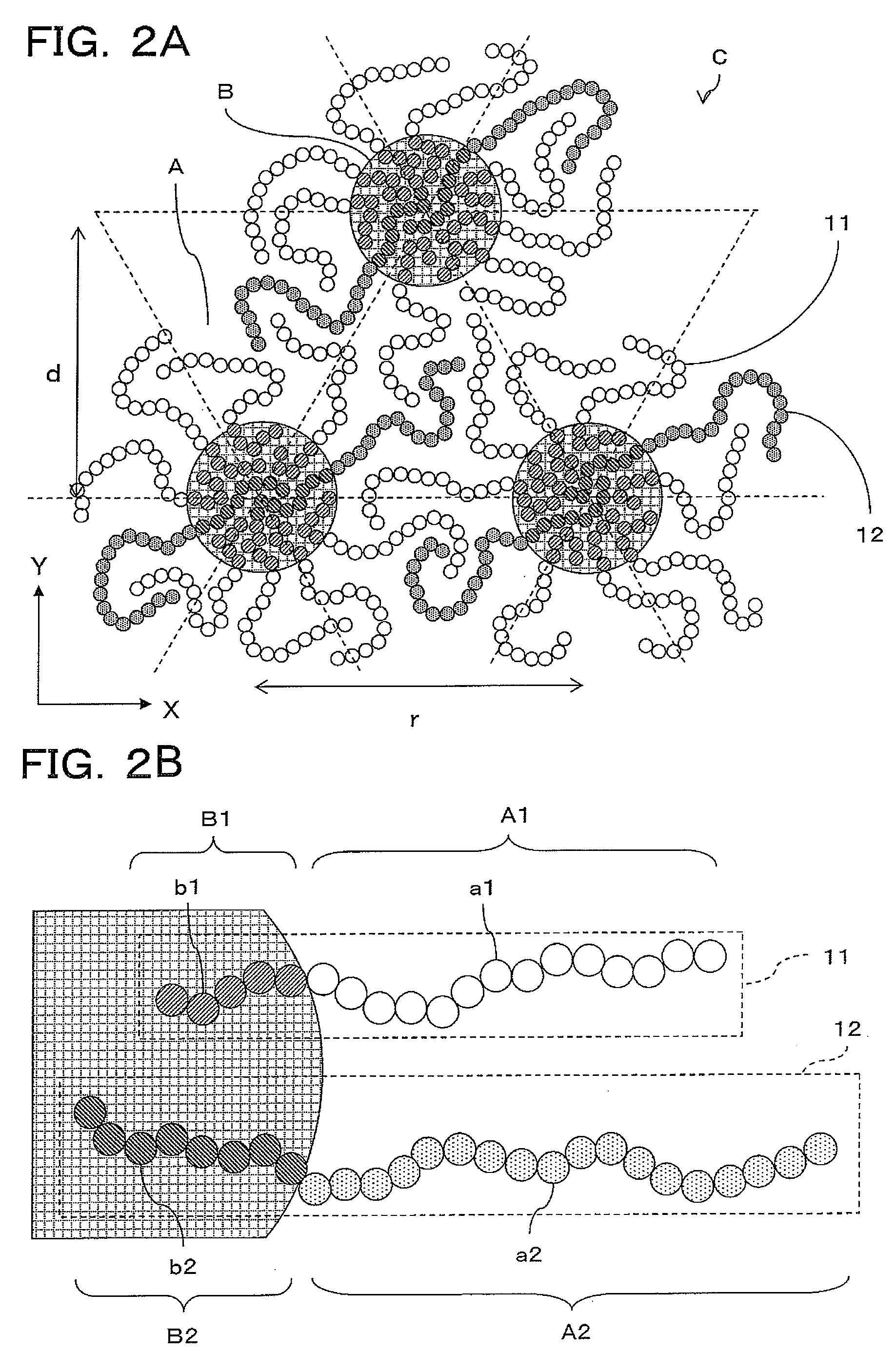

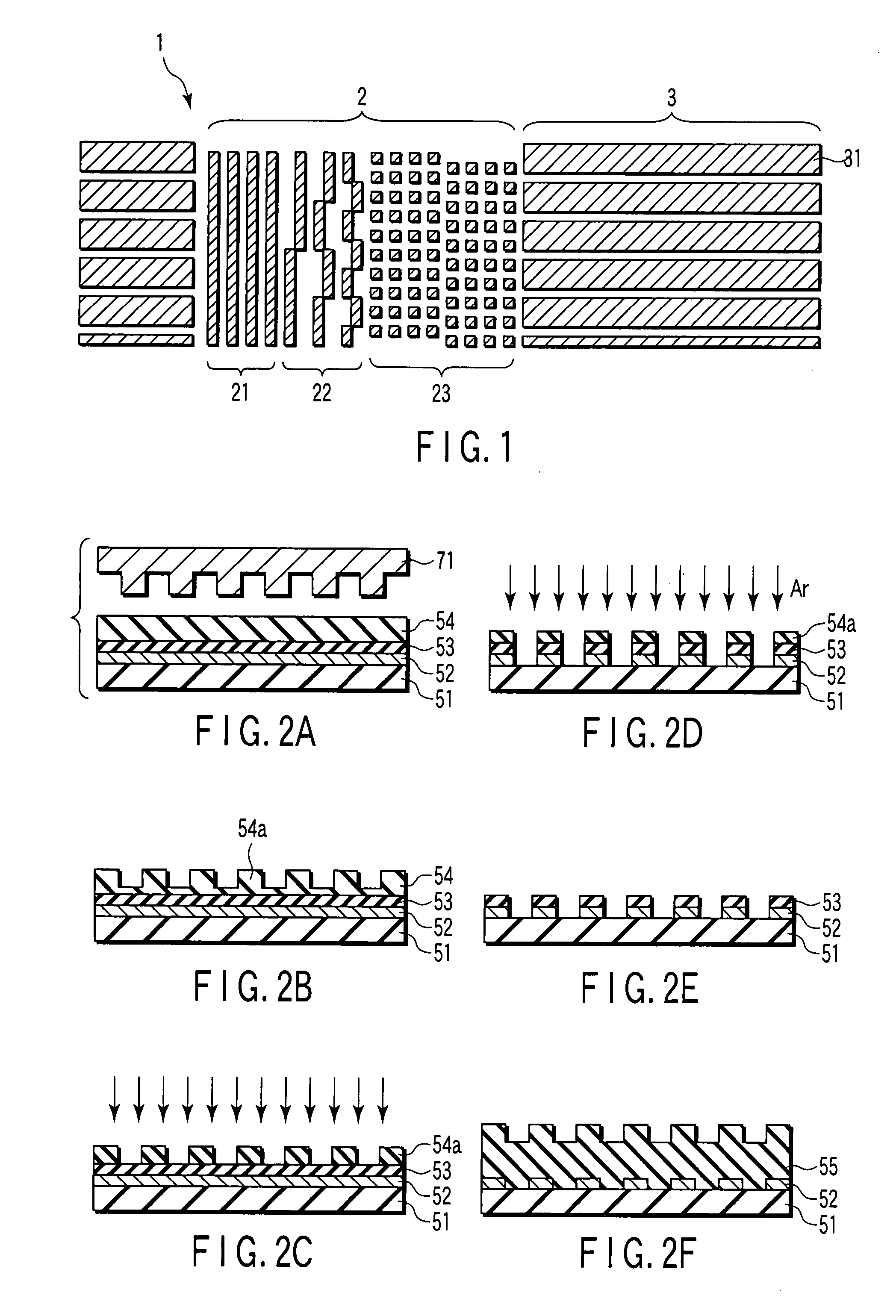

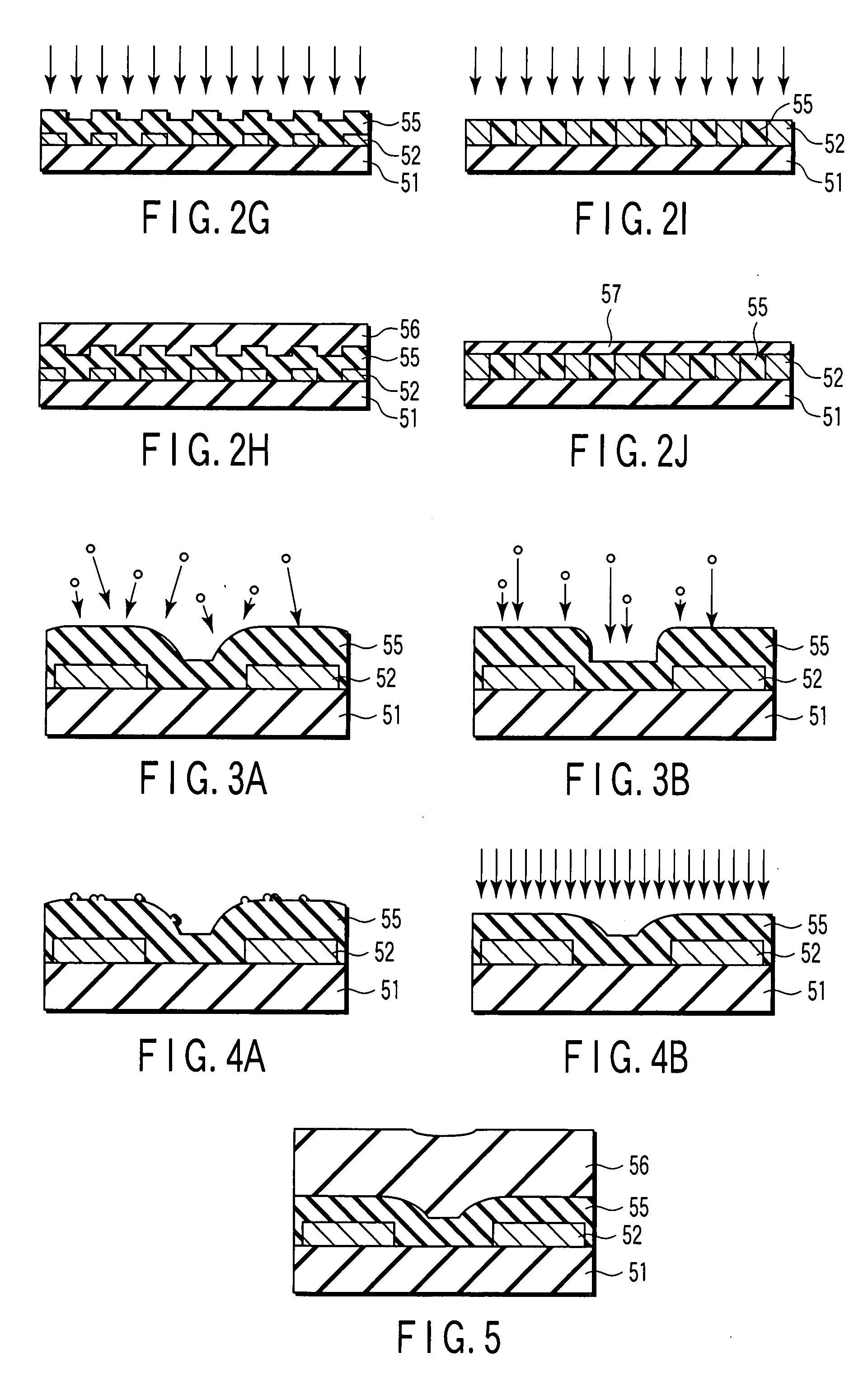

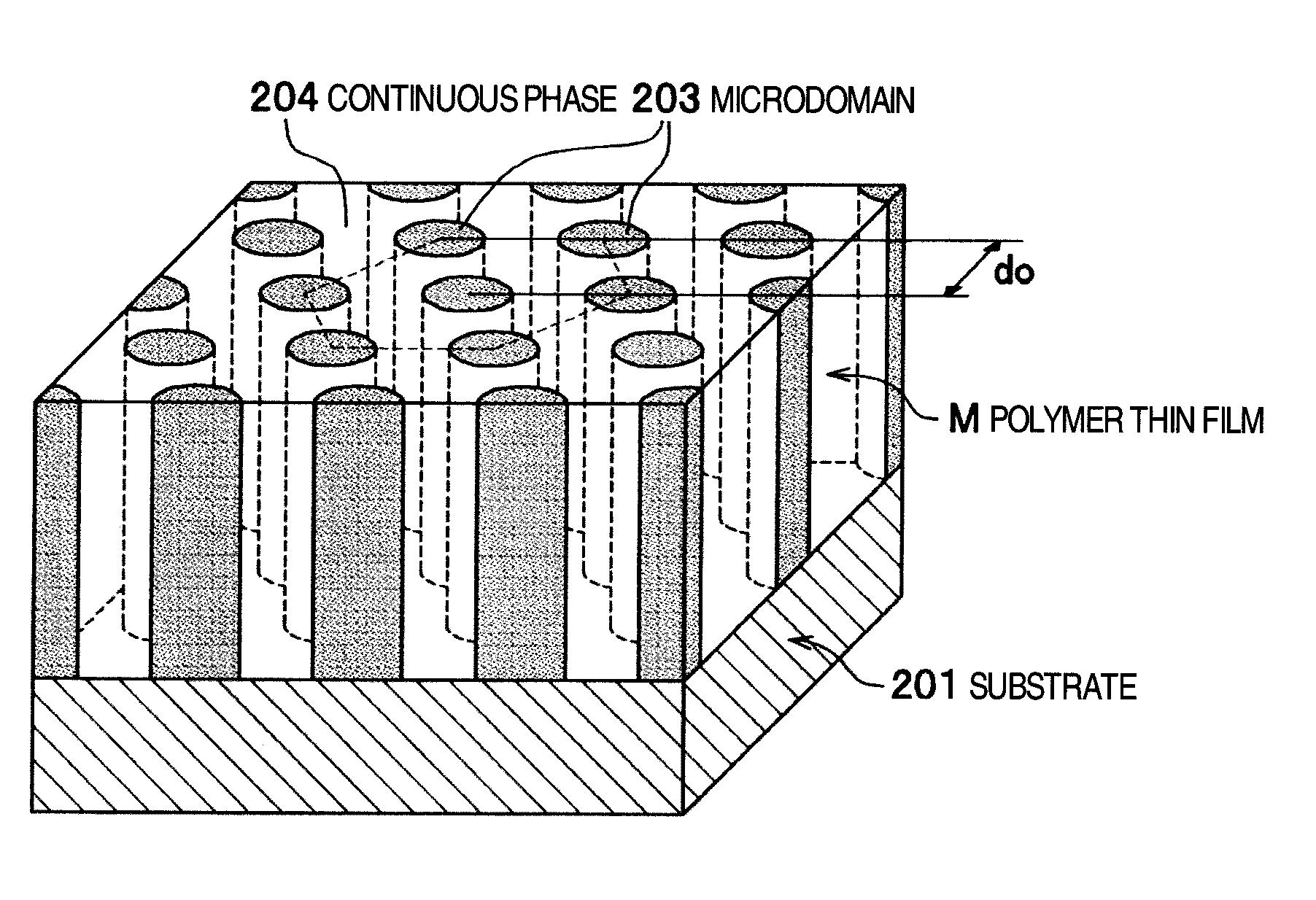

Polymer Thin Film, Patterned Substrate, Patterned Medium for Magnetic Recording, and Method of Manufacturing these Articles

ActiveUS20080233435A1Magnetic materials for record carriersBase layers for recording layersPolymer sciencePolymer thin films

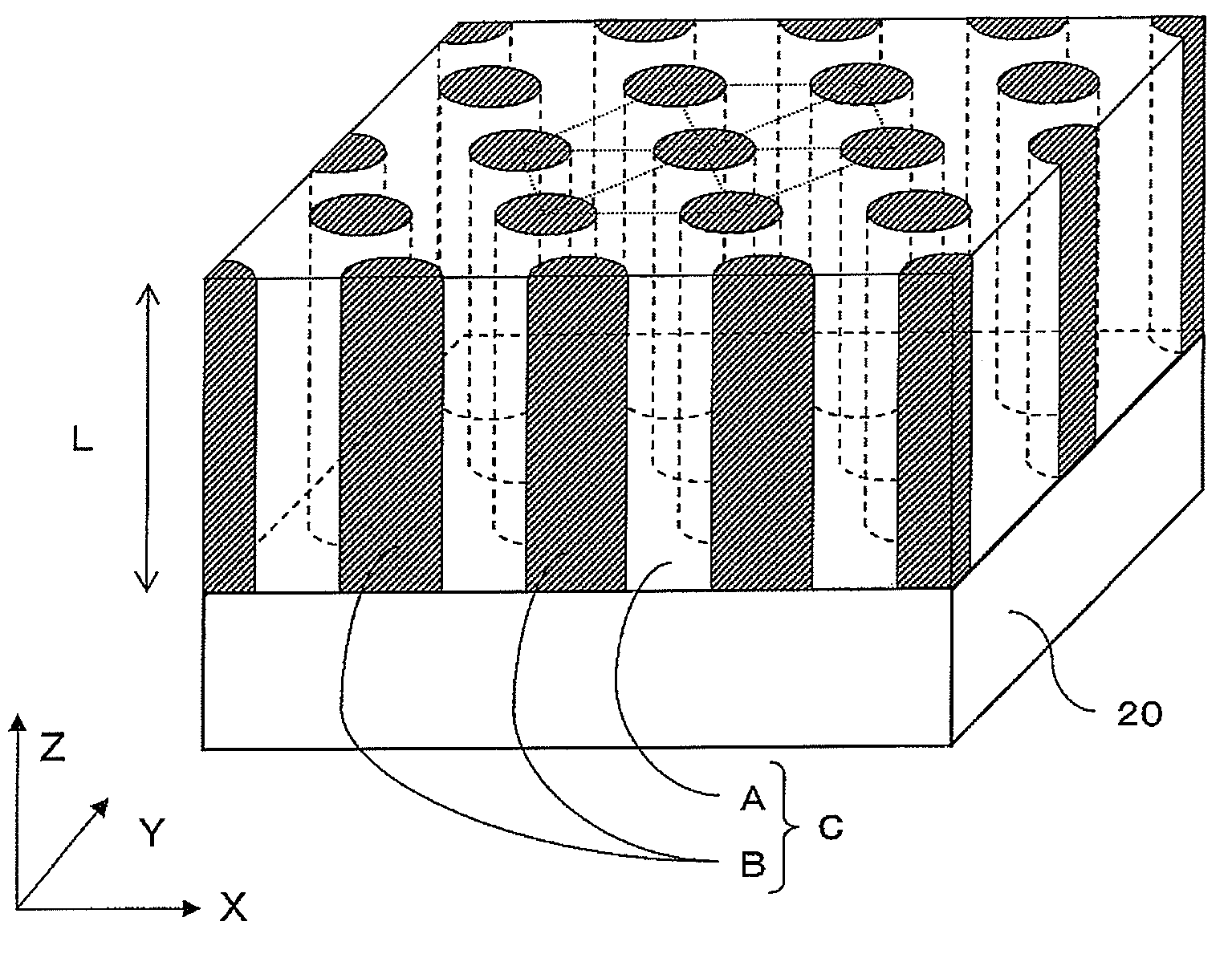

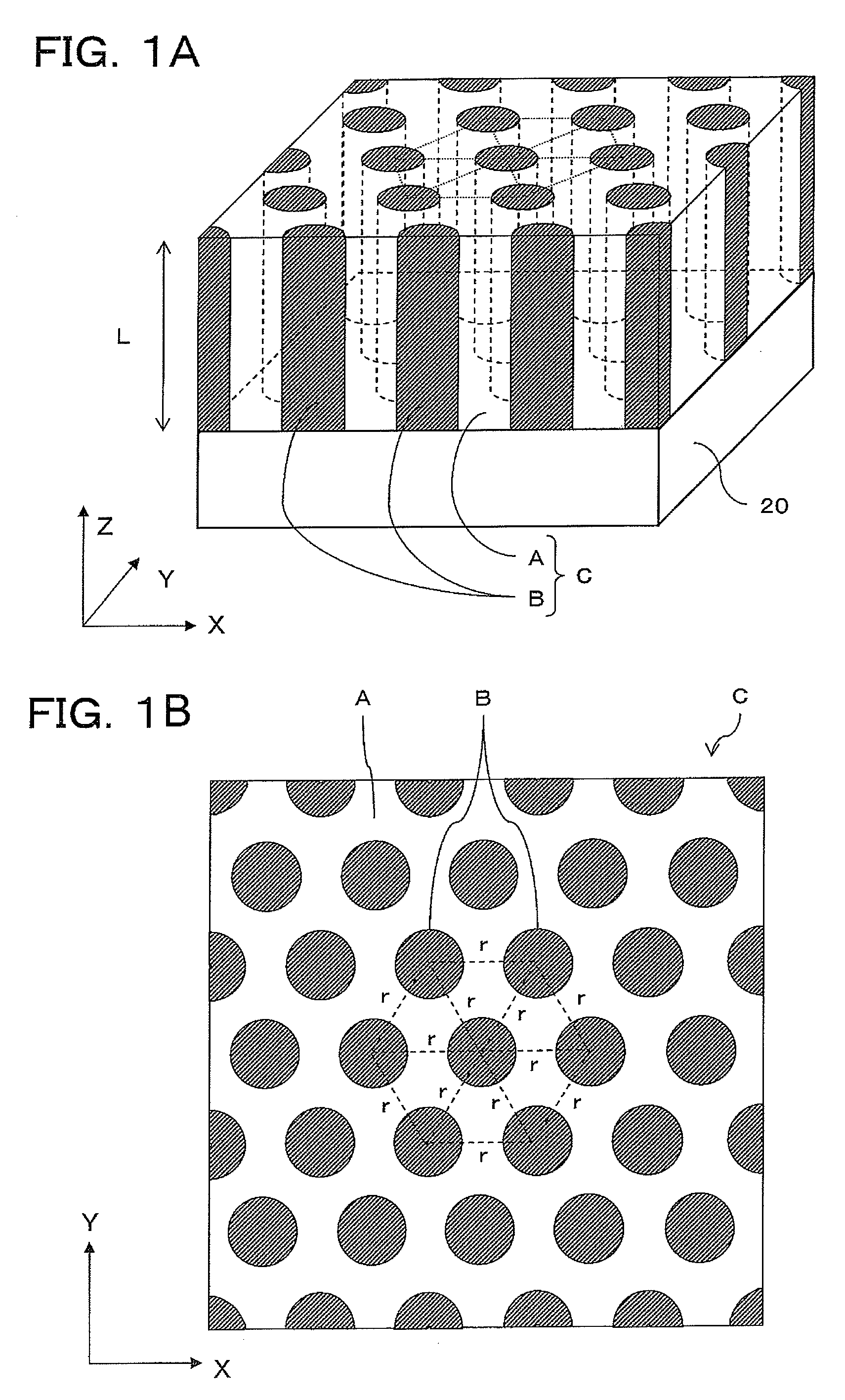

A polymer thin film in which cylindrical phases are distributed in a continuous phase and are oriented in a pass-through-direction of the film includes at least: a first block copolymer including at least a block chain A1, as a component of the continuous phase, composed of polymerized monomers a1, and a block chain B1, as a component of the cylindrical phases, composed of polymerized monomers b1; and a second block copolymer including at least a block chain A2, as a component of the continuous phase, composed of polymerized monomers a2, and a block chain B2, as a component of the cylindrical phases, composed of polymerized monomers b2, with the second copolymer having a degree of polymerization different from that of the first copolymer. A film thickness of the polymer thin film and an average center distance between adjacent cylindrical phases have a relation represented by a predetermined expression.

Owner:HITACHI LTD

Patterned media, method of manufacturing the same, and magnetic recording/reproducing apparatus

InactiveUS20070281078A1Increase etch rateRecord information storageCoatingsEngineeringPatterned media

According to one embodiment, a patterned media includes a magnetic film processed into patterns for tracks, servo zones or data zones, and a nonmagnetic filling material filled between patterns of the magnetic film for the tracks, servo zones or data zones and including a base material and a barrier material formed of a metal that does not constitute the base material.

Owner:KK TOSHIBA

Method of manufacturing patterned media

According to one embodiment, there is provided a method of manufacturing a patterned media having a substrate and a magnetic recording layer on the substrate including protruded magnetic patterns and a nonmagnetic material filling recesses between the magnetic patterns. The method includes depositing a first nonmagnetic material to fill the recesses between the magnetic patterns, carrying out surface reforming of the first nonmagnetic material, depositing a second nonmagnetic material on the first nonmagnetic material, and etching back the second and first nonmagnetic materials.

Owner:KK TOSHIBA

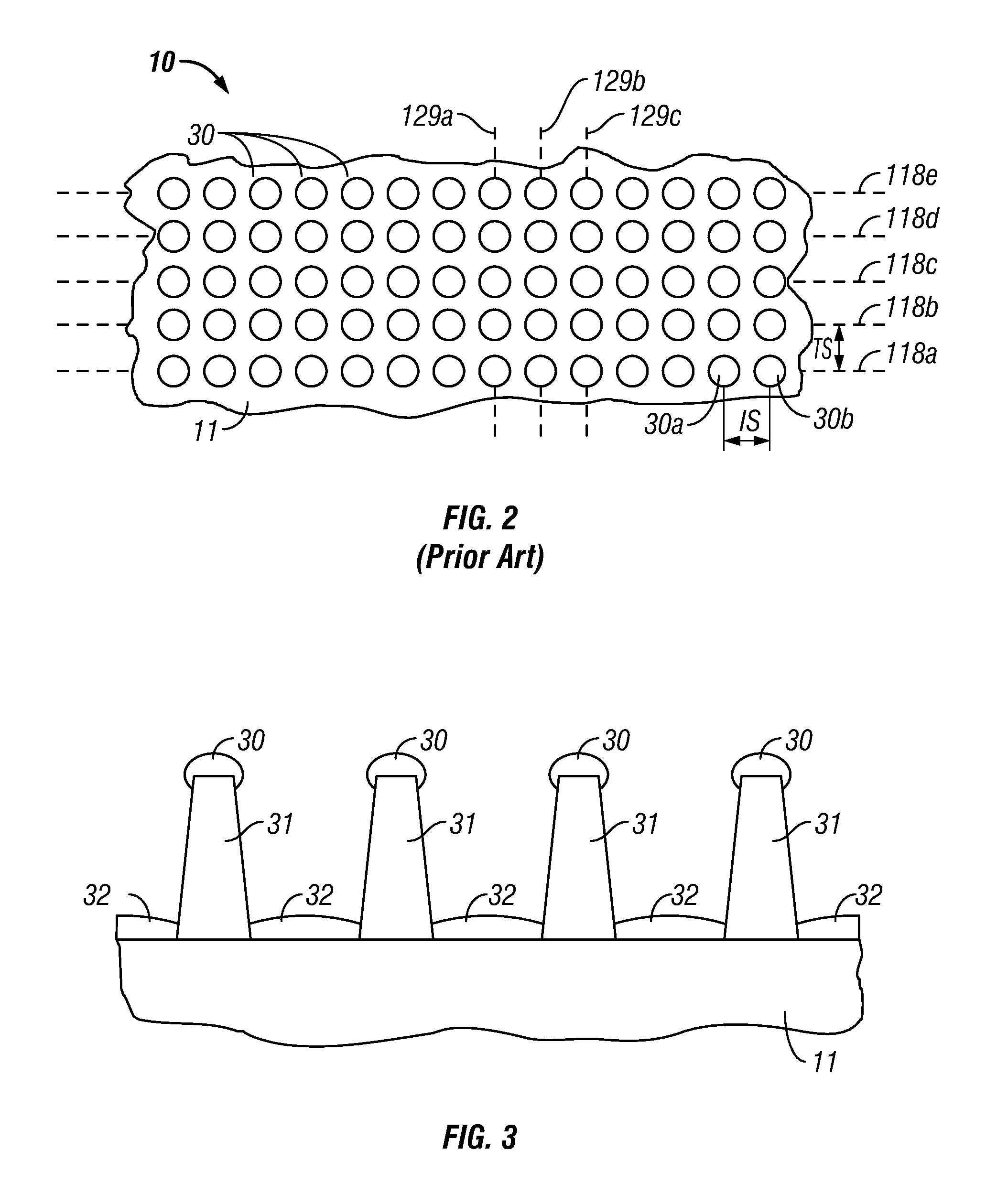

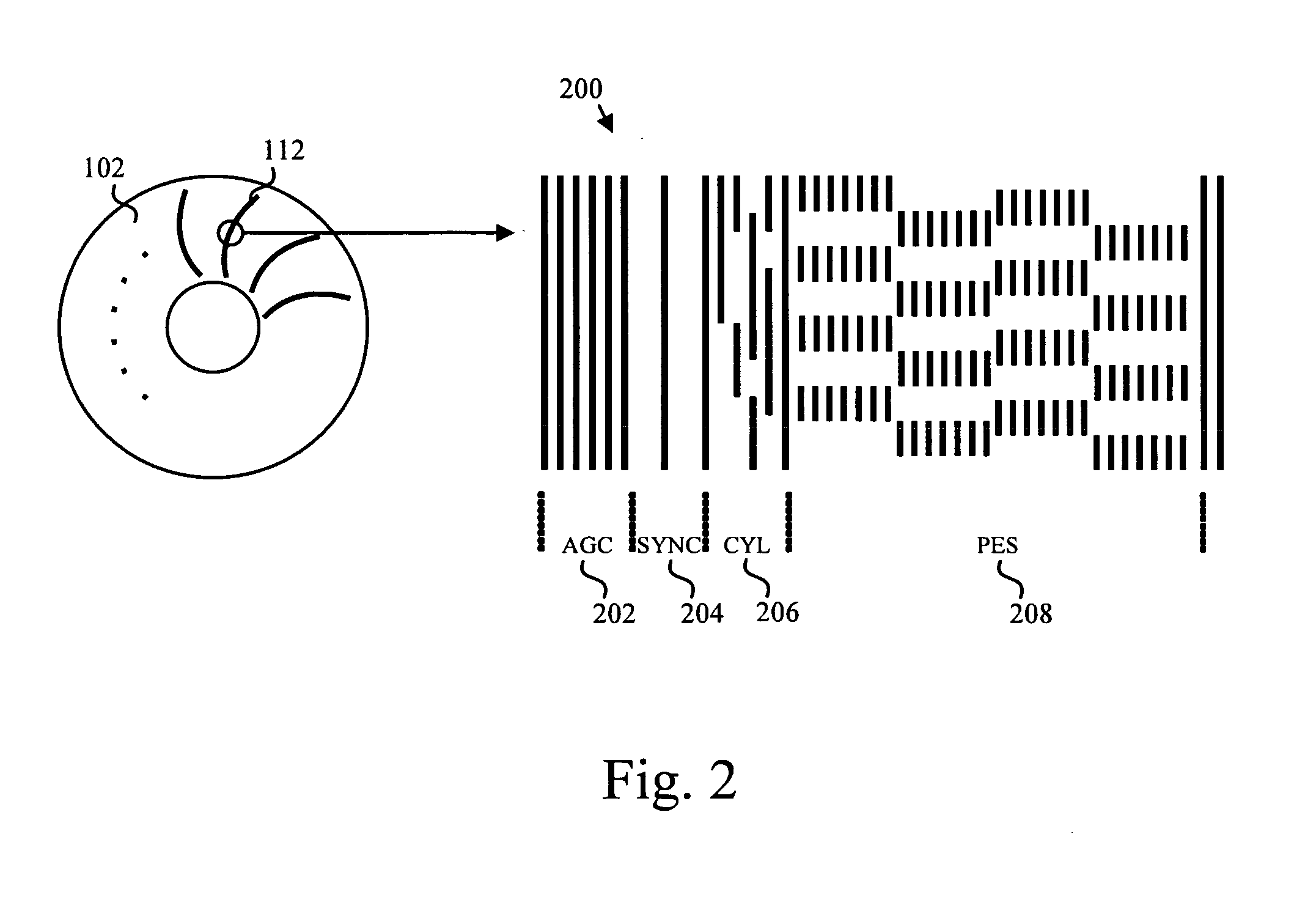

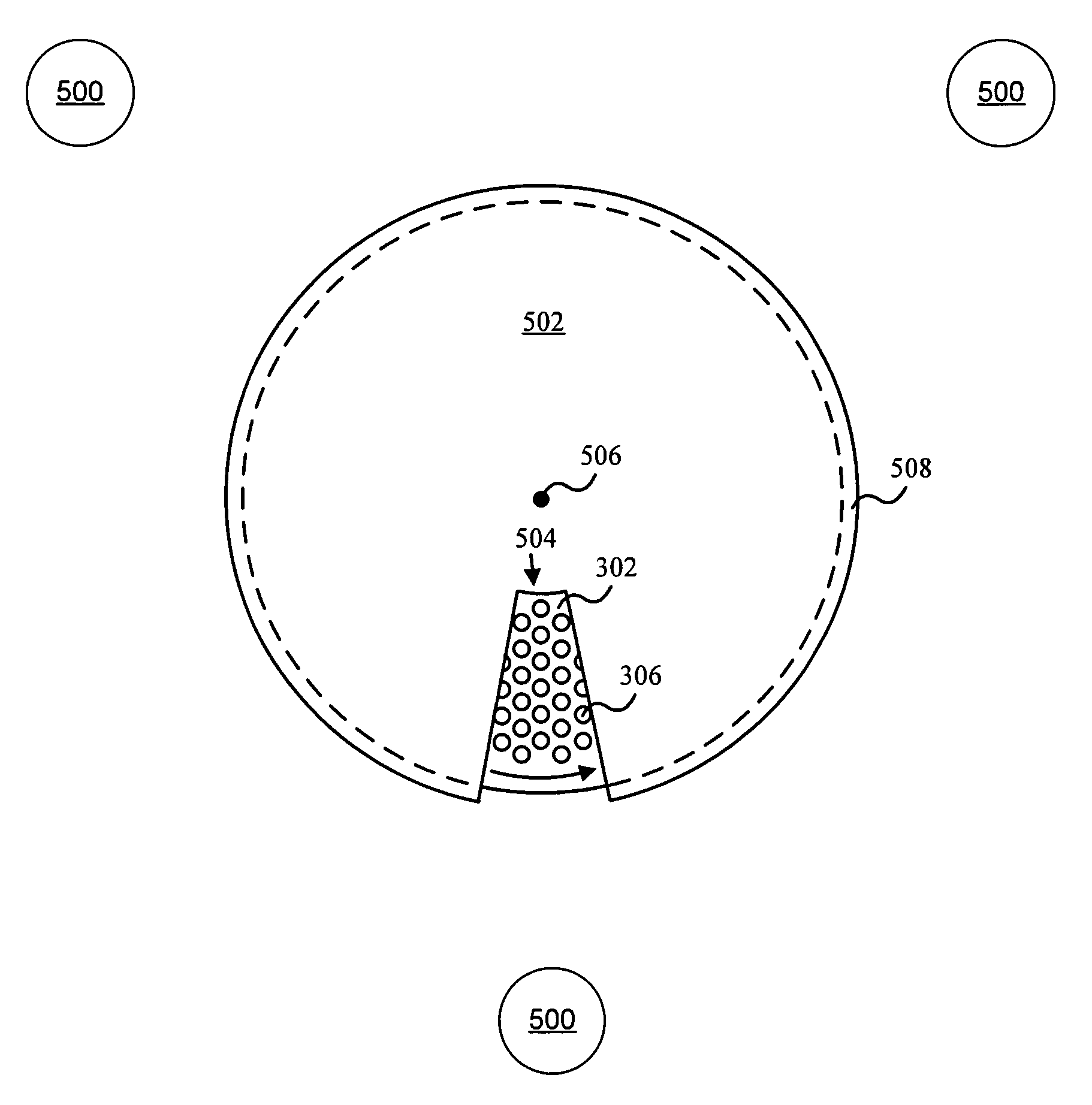

Patterned-media magnetic recording disk with optical contrast enhancement and disk drive using optical contrast for write synchronization

ActiveUS20100091618A1Increase contrastCombination recordingPatterned record carriersRadiation exposureNon magnetic

A patterned-media magnetic recording disk drive uses an optical system for clocking the write data and a patterned-media disk that has discrete magnetizable data islands with nonmagnetic spaces between the islands, wherein the nonmagnetic spaces contain optical contrast material. The optical contrast material may be optically absorptive material, fluorescent material, or a metal layer that generates surface plasmons when excited by radiation of a specific wavelength. Radiation from a primary radiation source is directed to a near-field transducer maintained near the disk surface and a radiation detector detects radiation reflected back from the transducer. If the disk has fluorescent material or a metal layer in the nonmagnetic spaces, then a secondary radiation source irradiates the fluorescent material or metal layer with radiation of a specific wavelength to cause the fluorescent material to emit radiation or the metal layer to generate surface plasmons. As the disk rotates, reflected optical power from the transducer varies depending on whether an island or space is under the transducer. The output signal from the radiation detector output controls the write clock.

Owner:WESTERN DIGITAL TECH INC

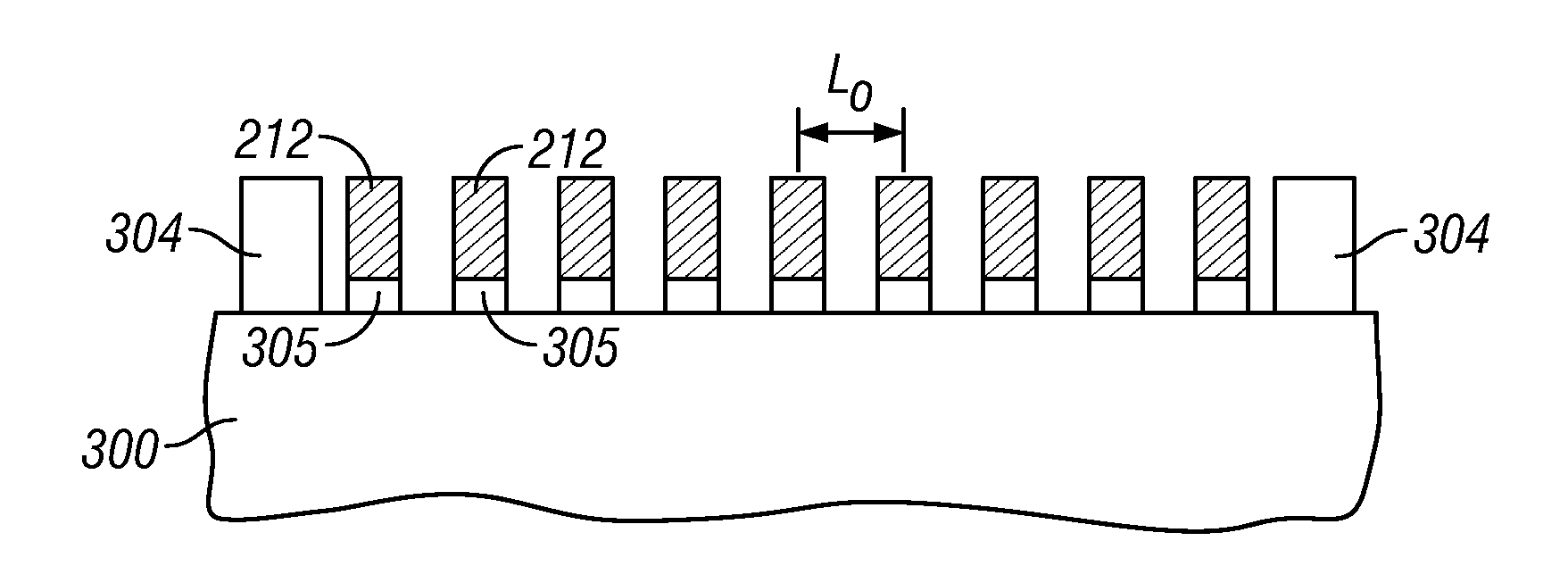

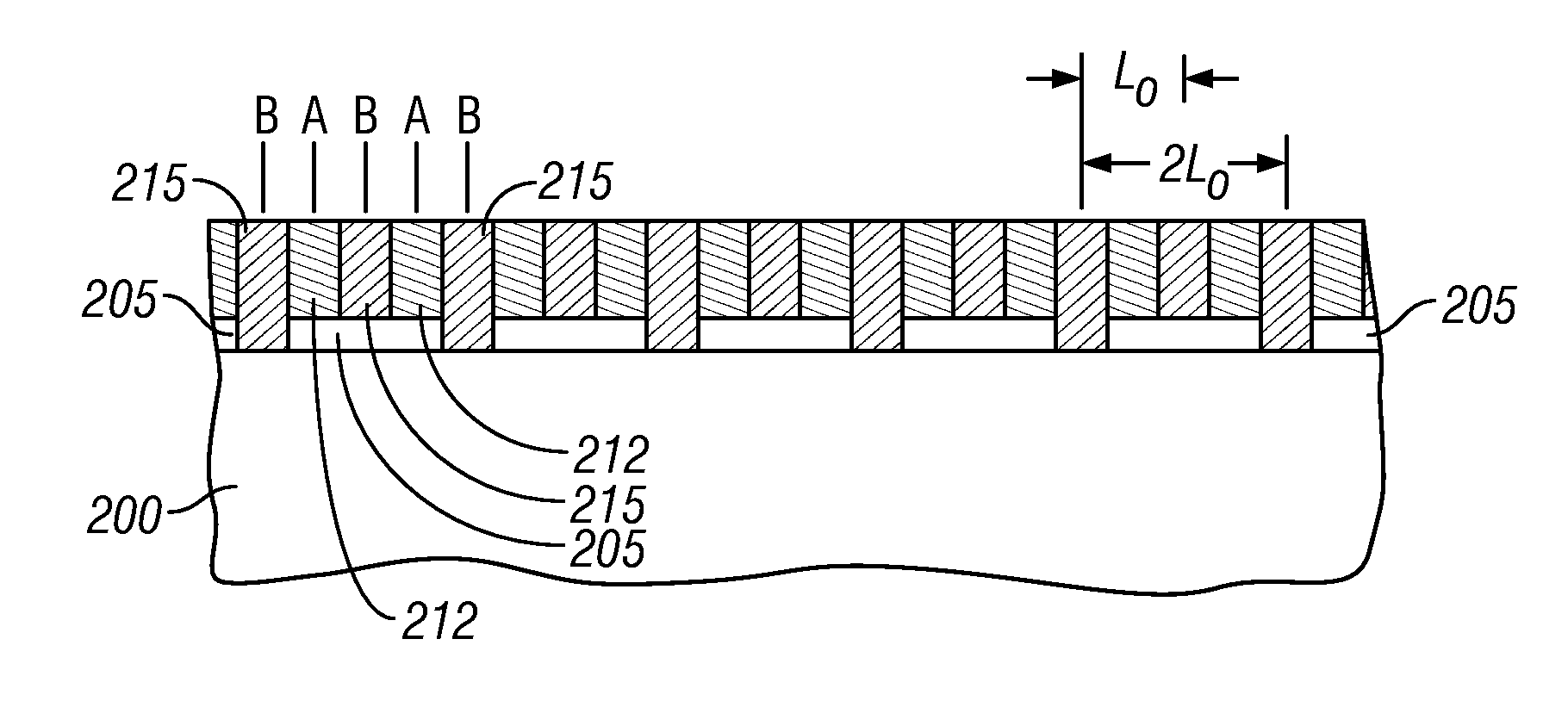

Method using block copolymers for making a master mold with high bit-aspect-ratio for nanoimprinting patterned magnetic recording disks

InactiveUS7976715B2Magnetic materials for record carriersDecorative surface effectsResistLithographic artist

A method for making a master mold that is used in the nanoimprinting process to make patterned-media disks with patterned data islands uses guided self-assembly of a block copolymer into its components. Conventional or e-beam lithography is used to first form a pattern of generally radial stripes on a substrate, with the stripes being grouped into annular zones or bands. A block copolymer material is then deposited on the pattern, resulting in guided self-assembly of the block copolymer into its components to multiply the generally radial stripes into generally radial lines. Various methods, including conventional lithography, guided self-assembly of a second block copolymer, and e-beam lithography, are then used to form concentric rings over the generally radial lines. After etching and resist removal, the master mold has a pattern of either pillars or holes, depending on the method used.

Owner:WESTERN DIGITAL TECH INC

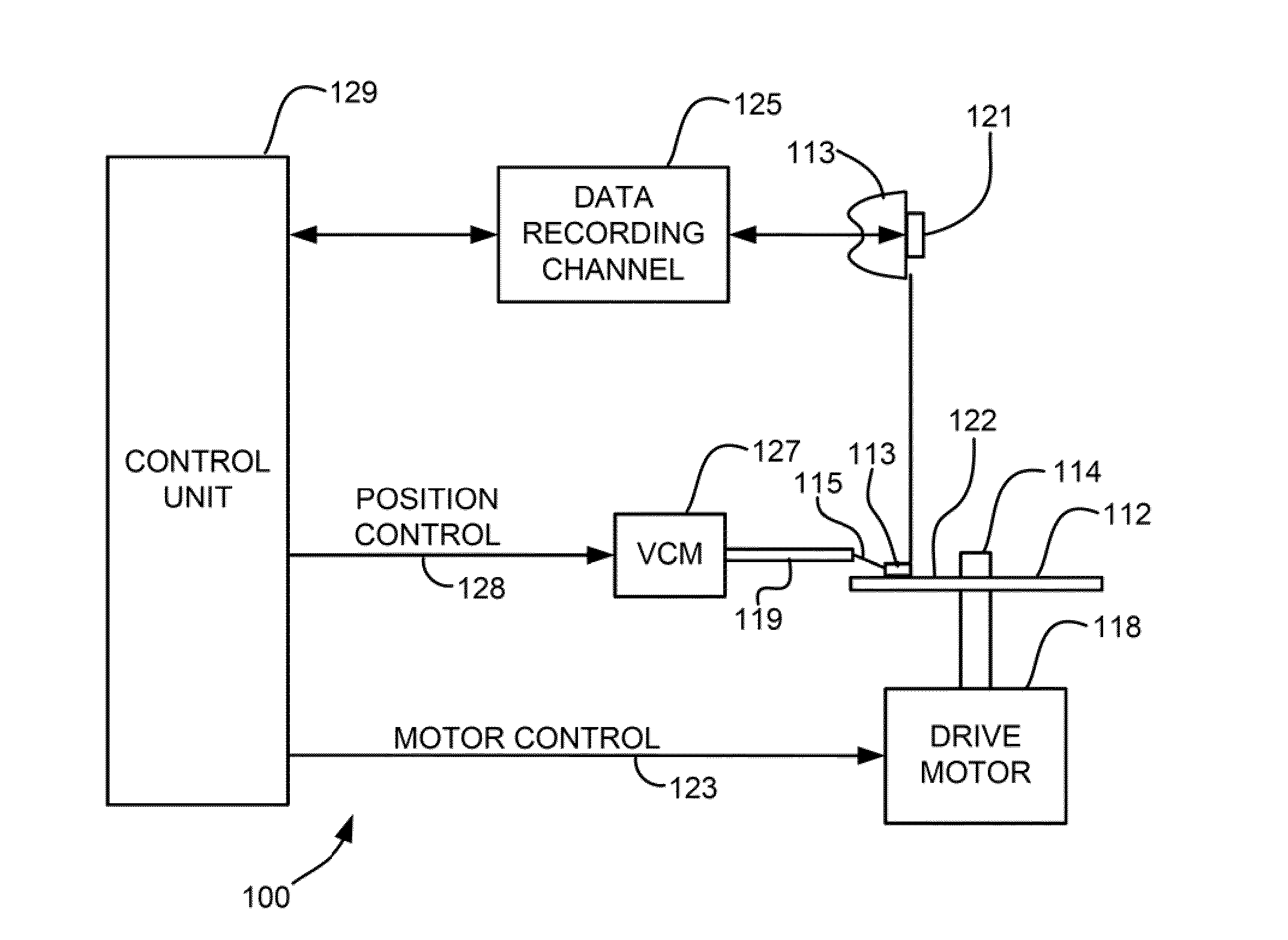

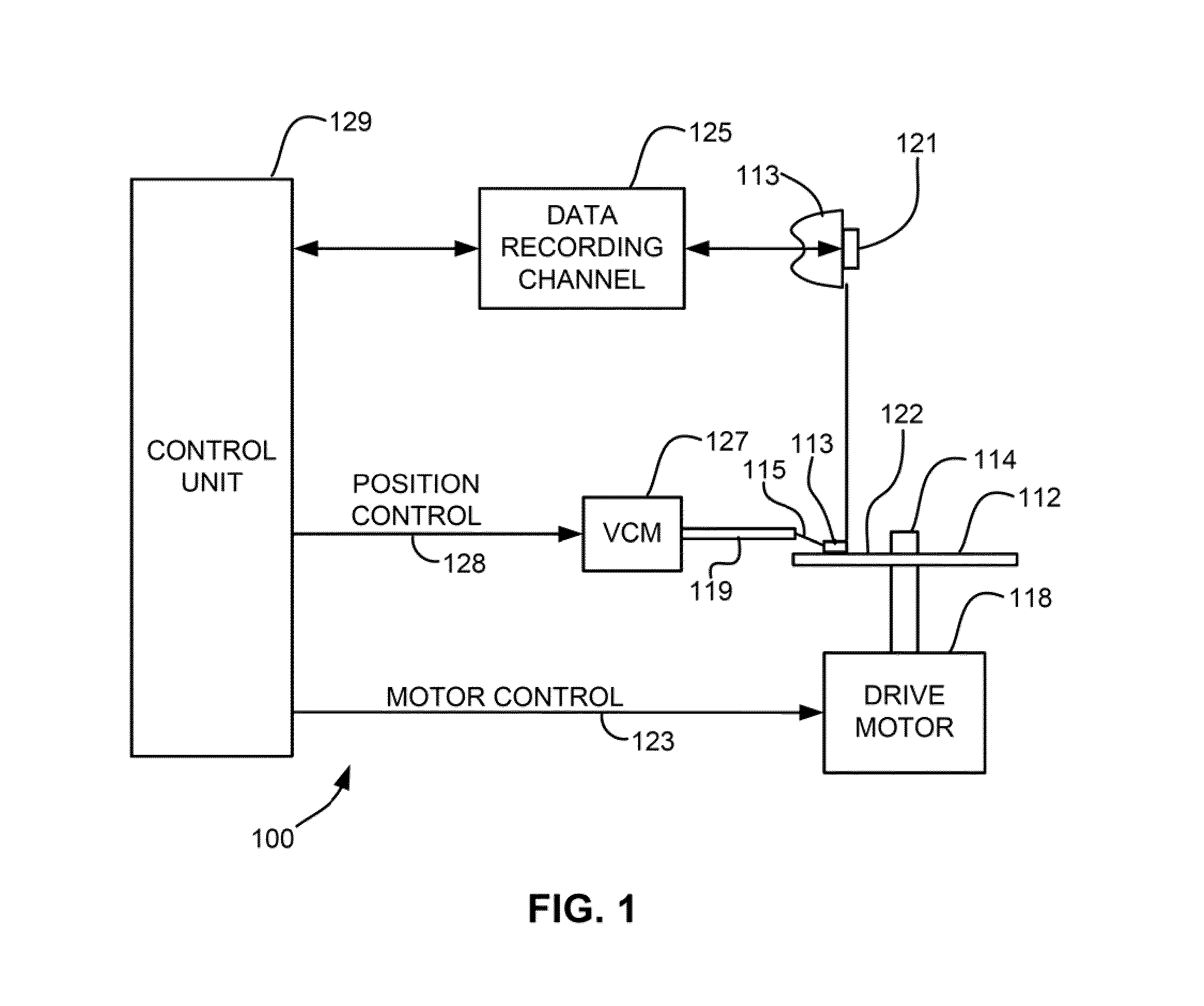

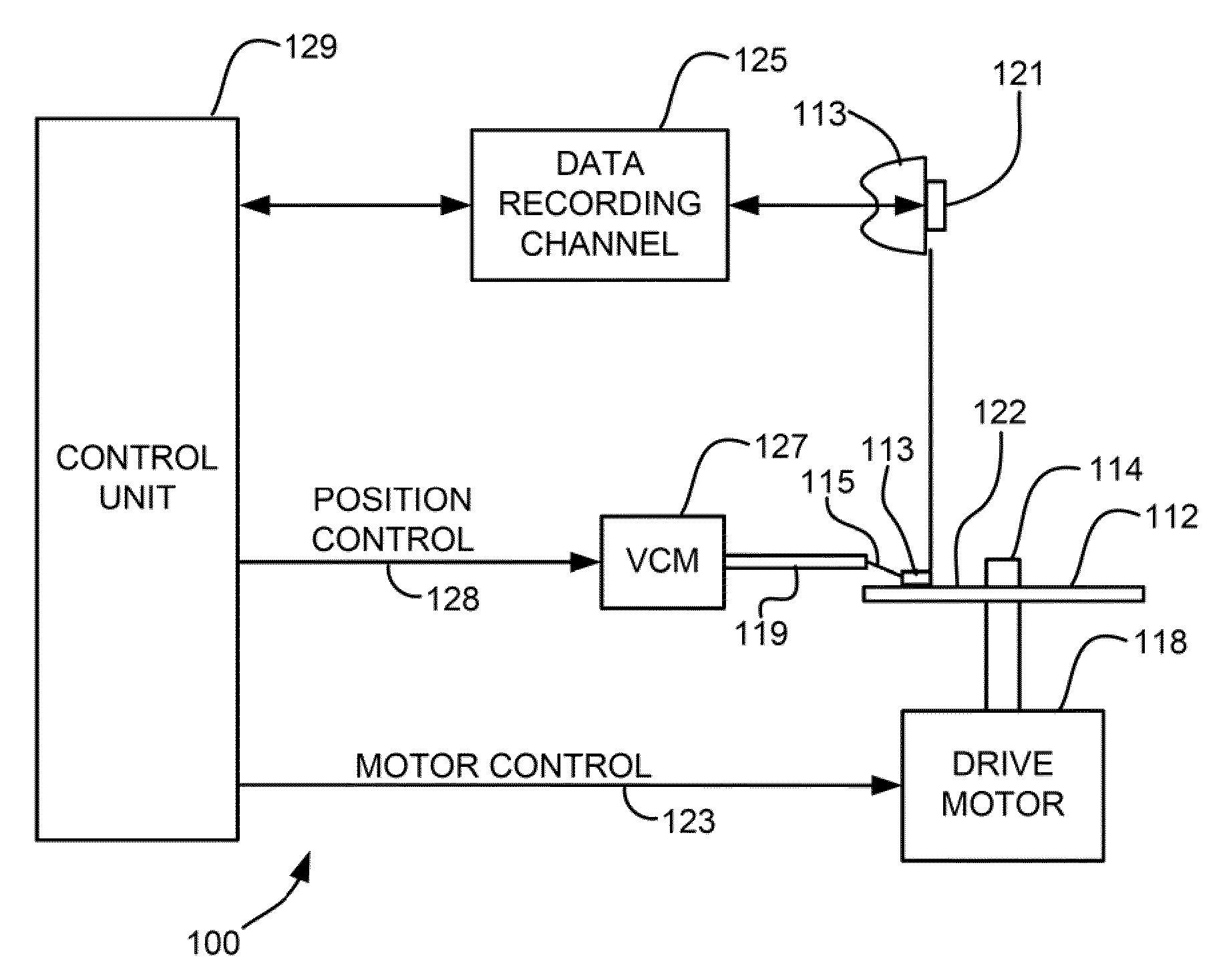

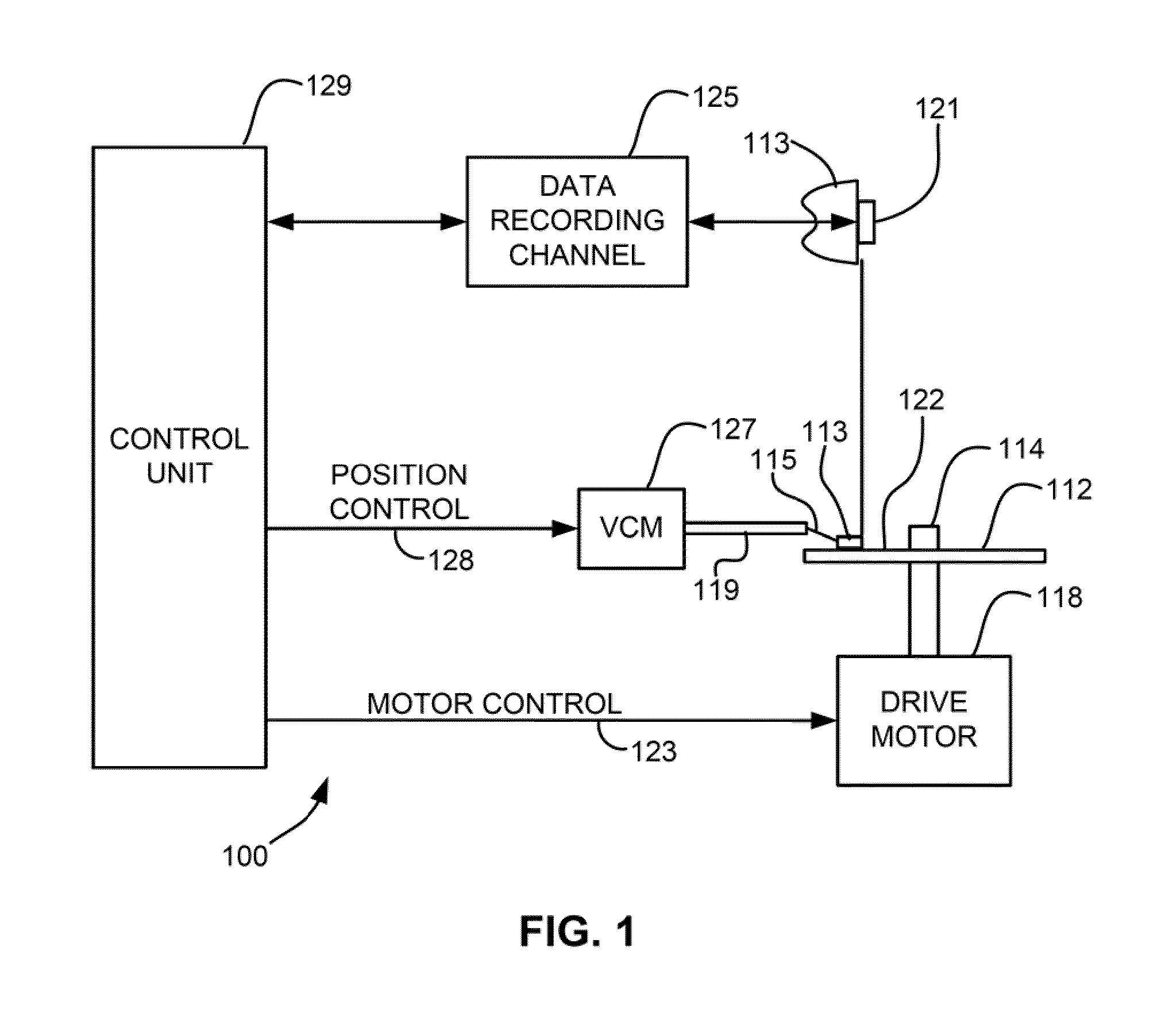

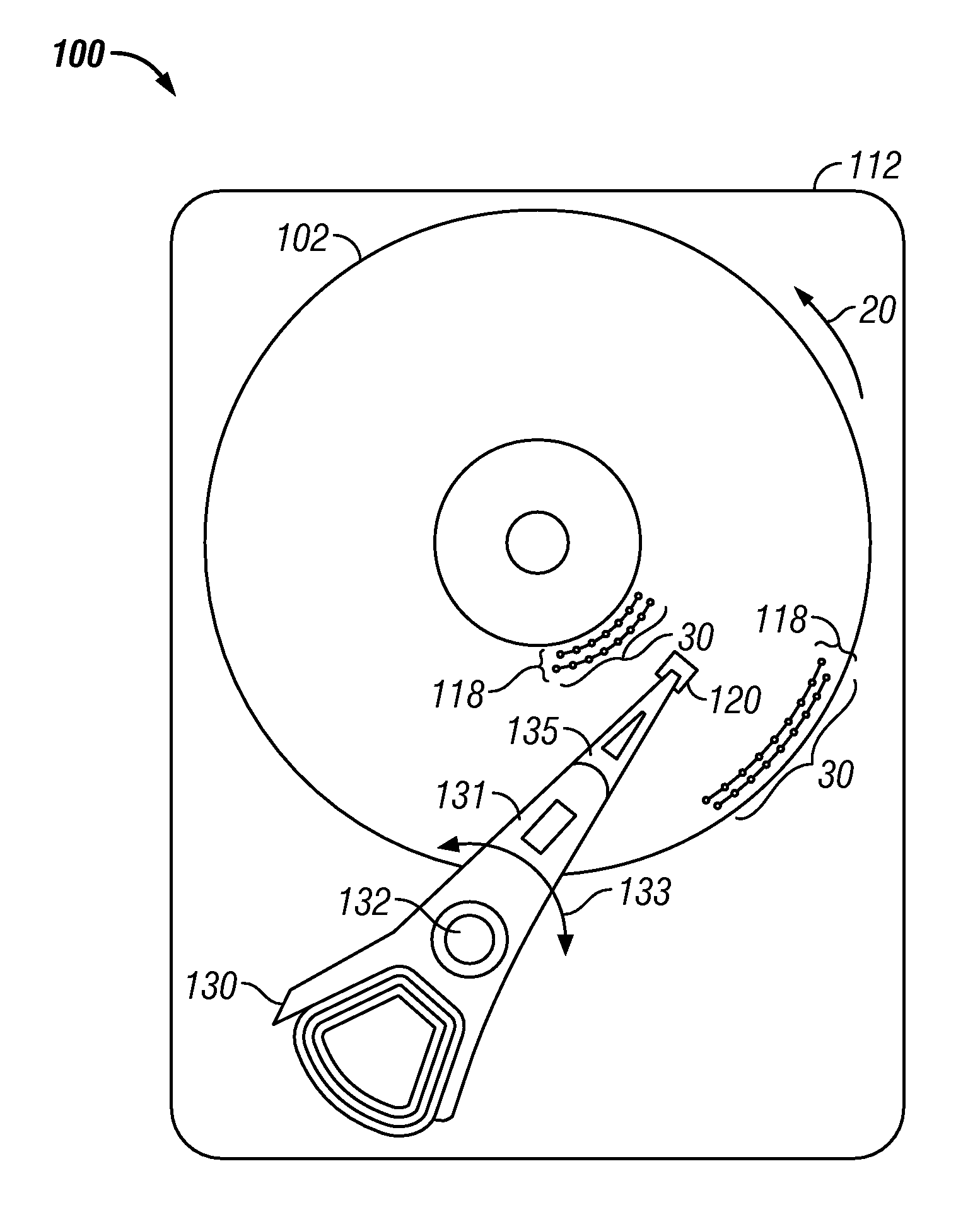

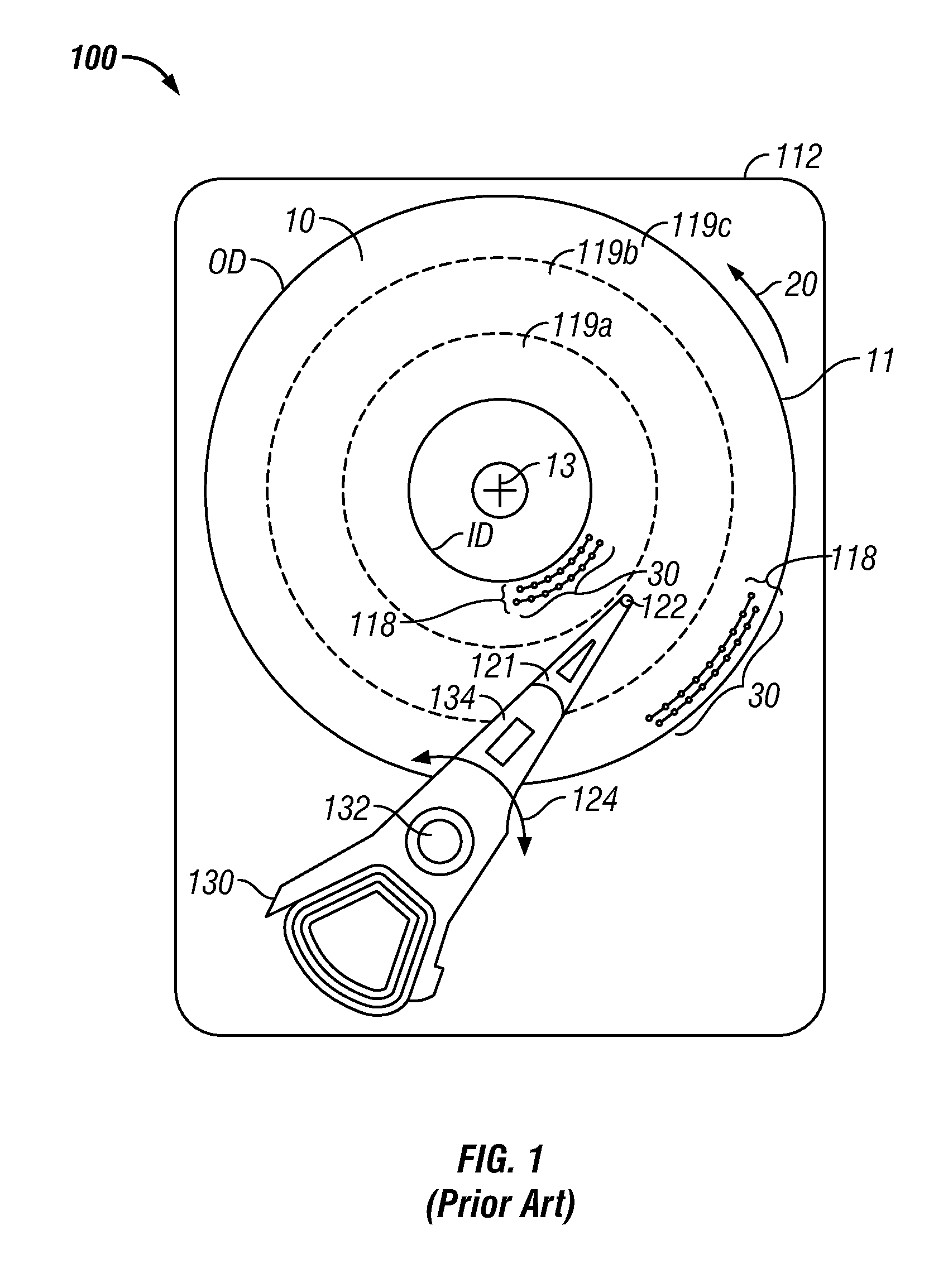

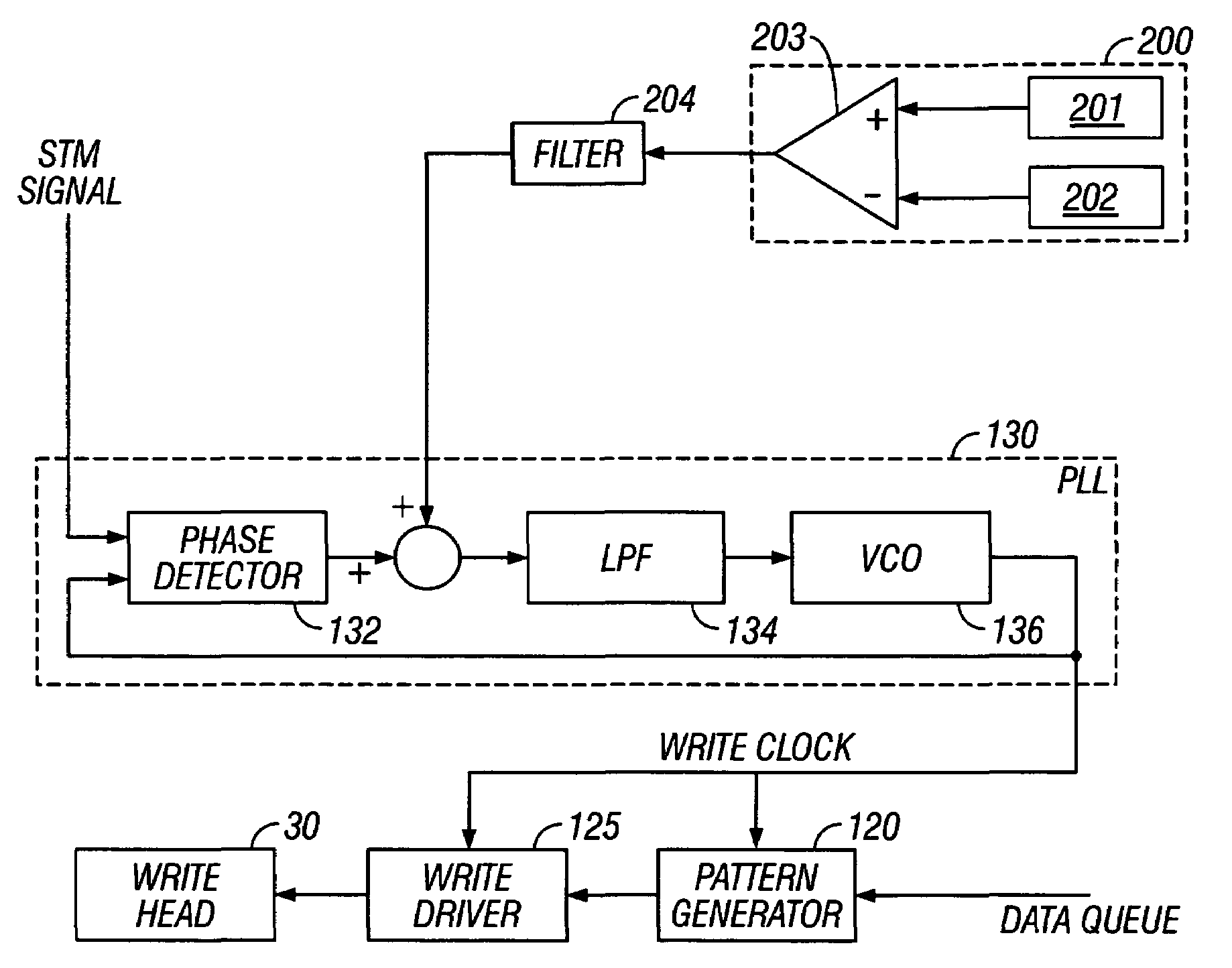

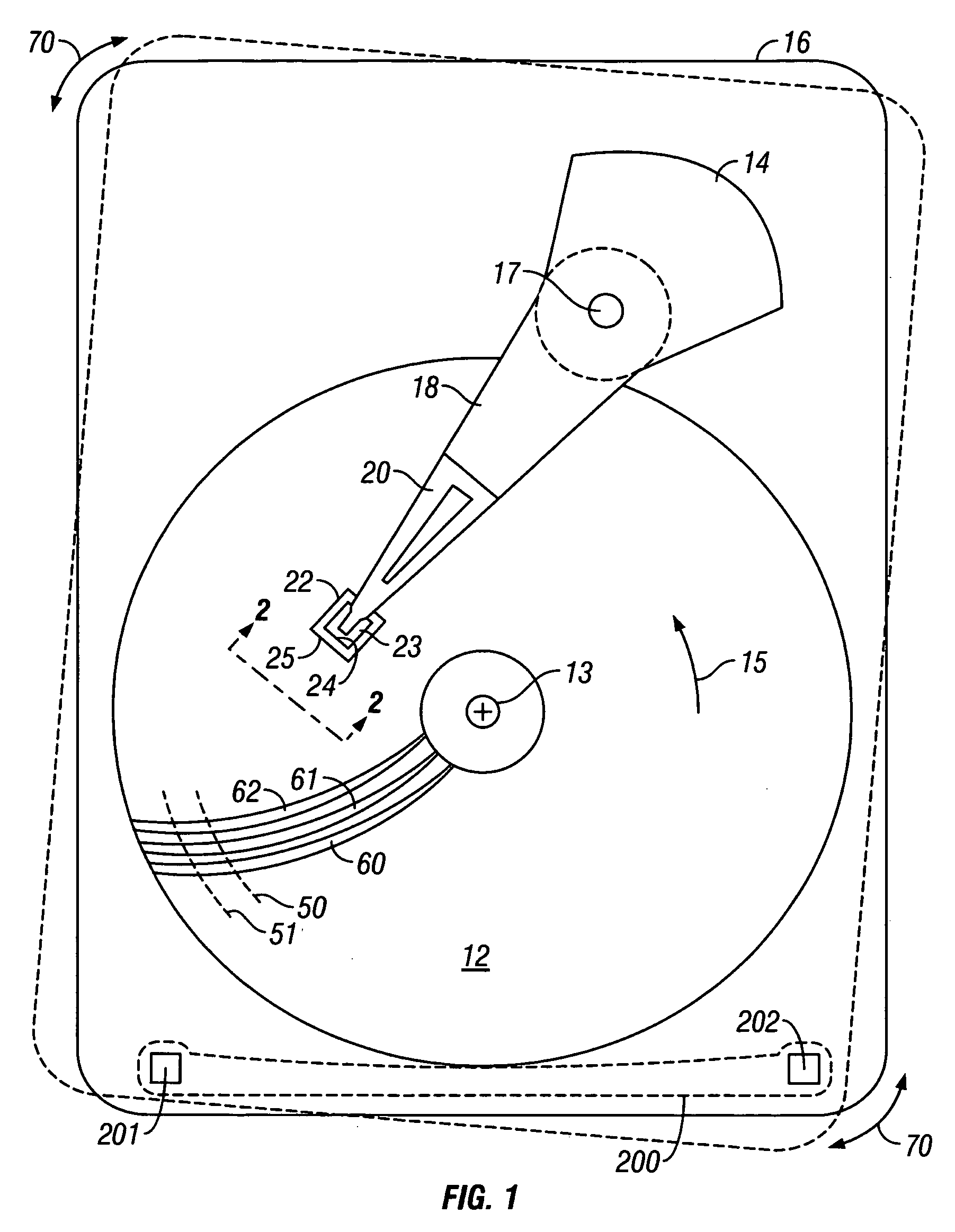

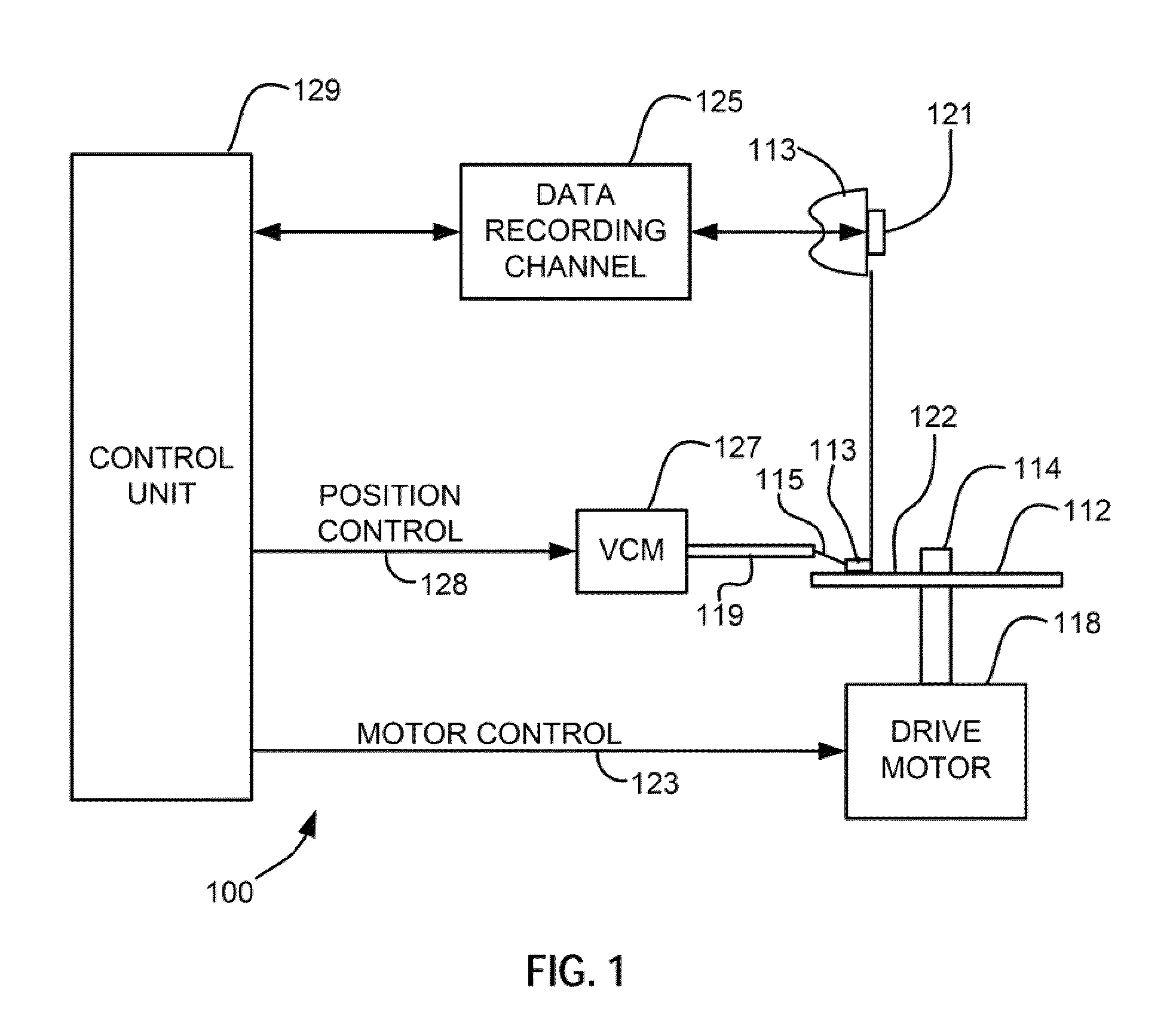

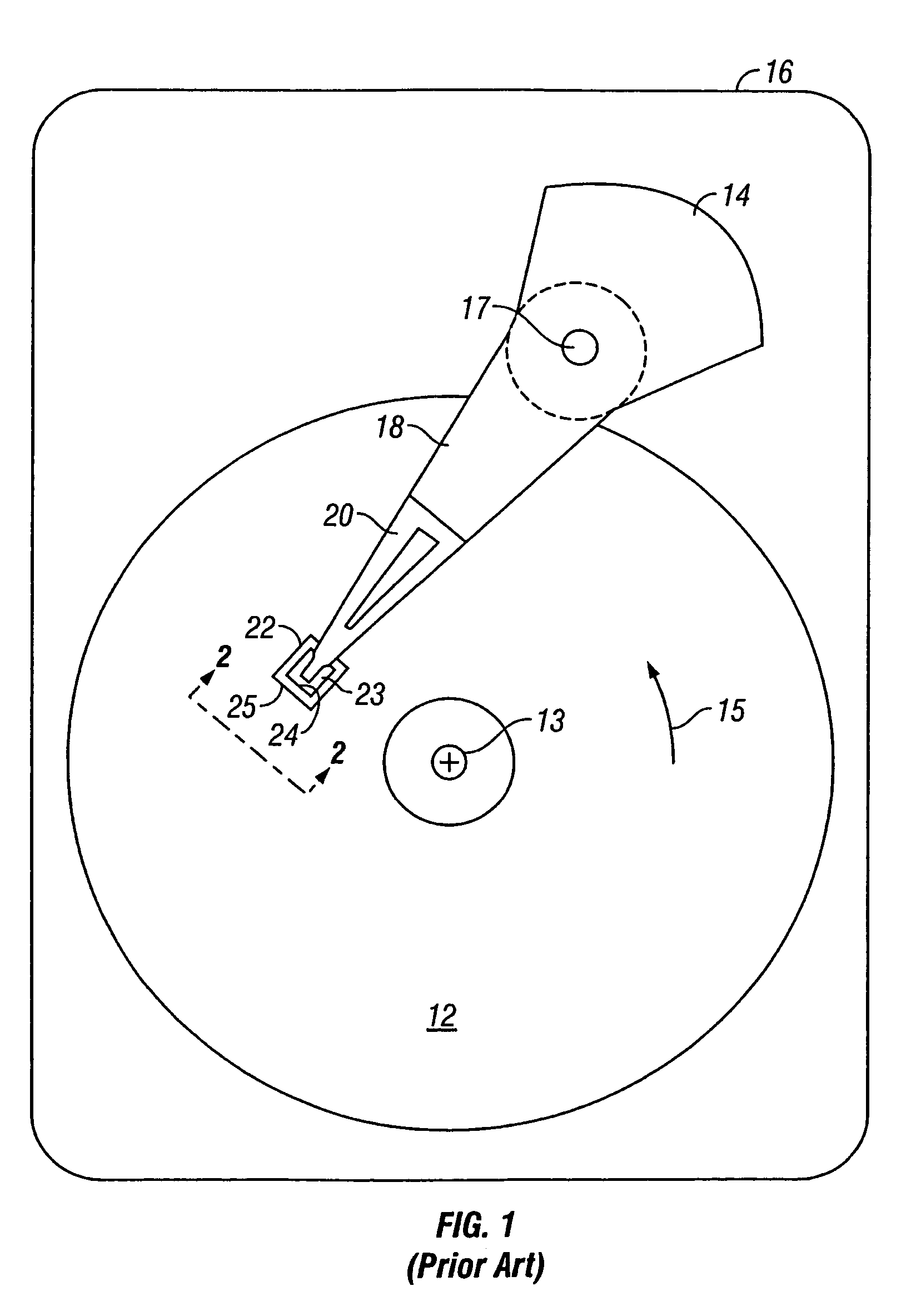

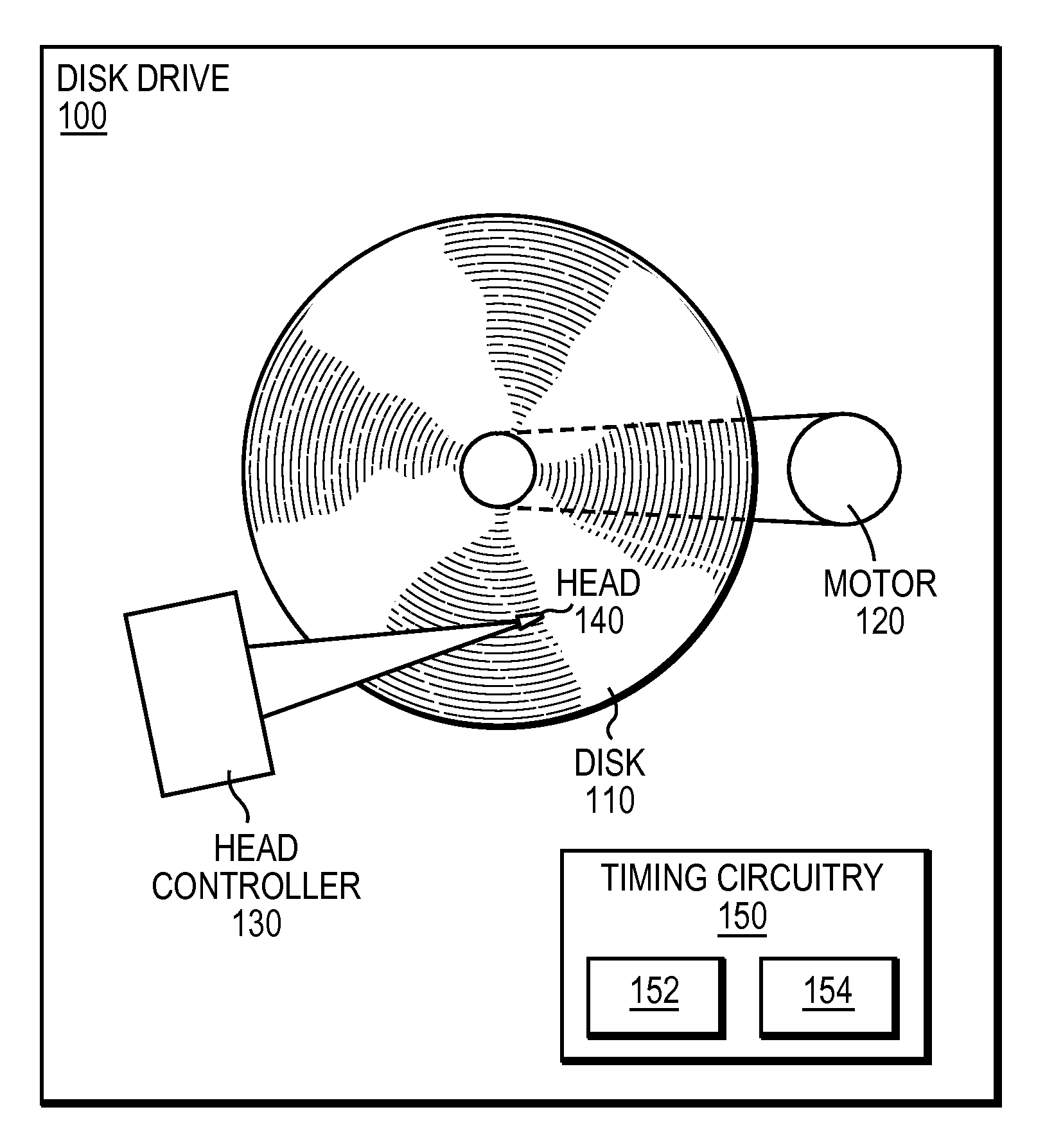

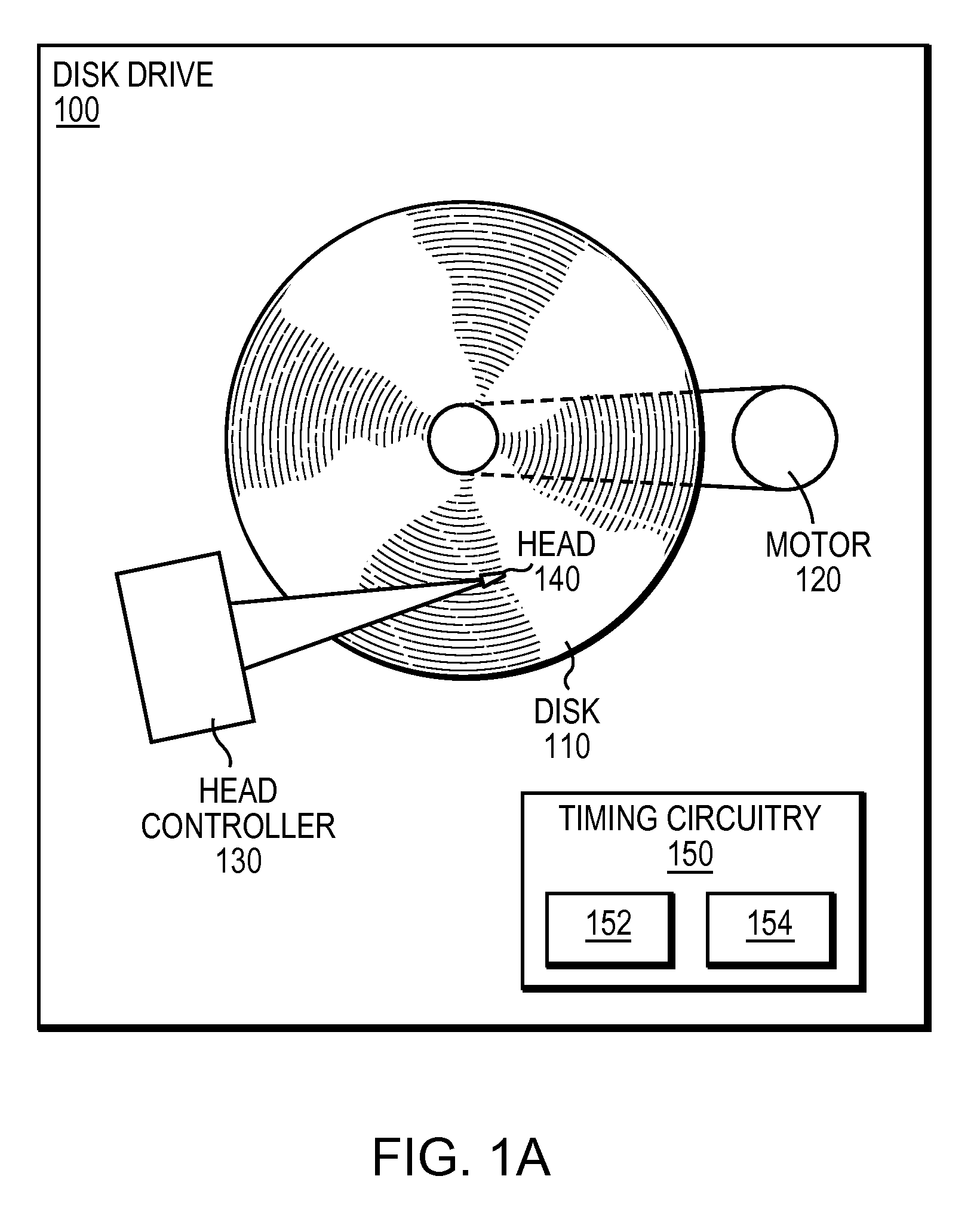

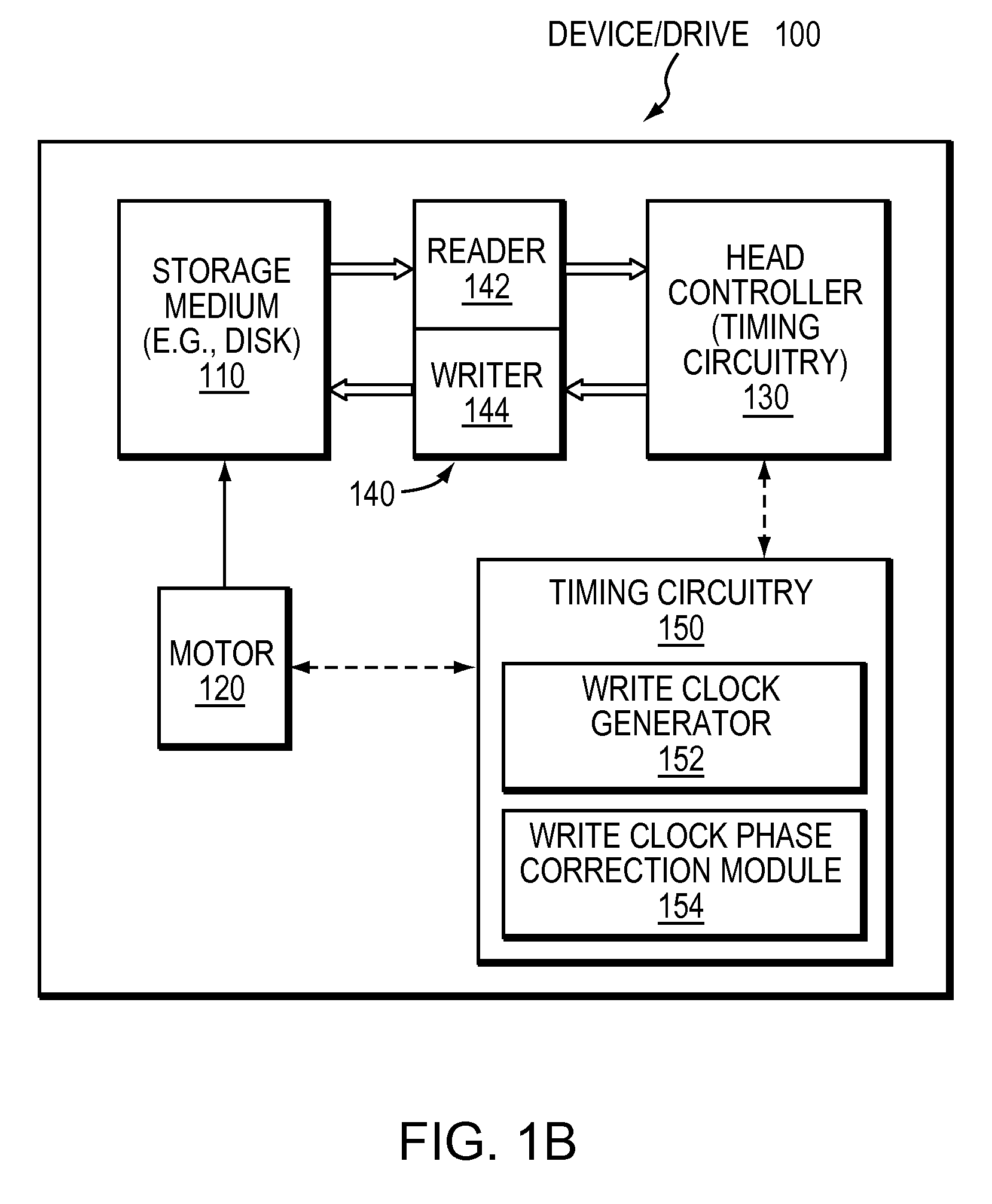

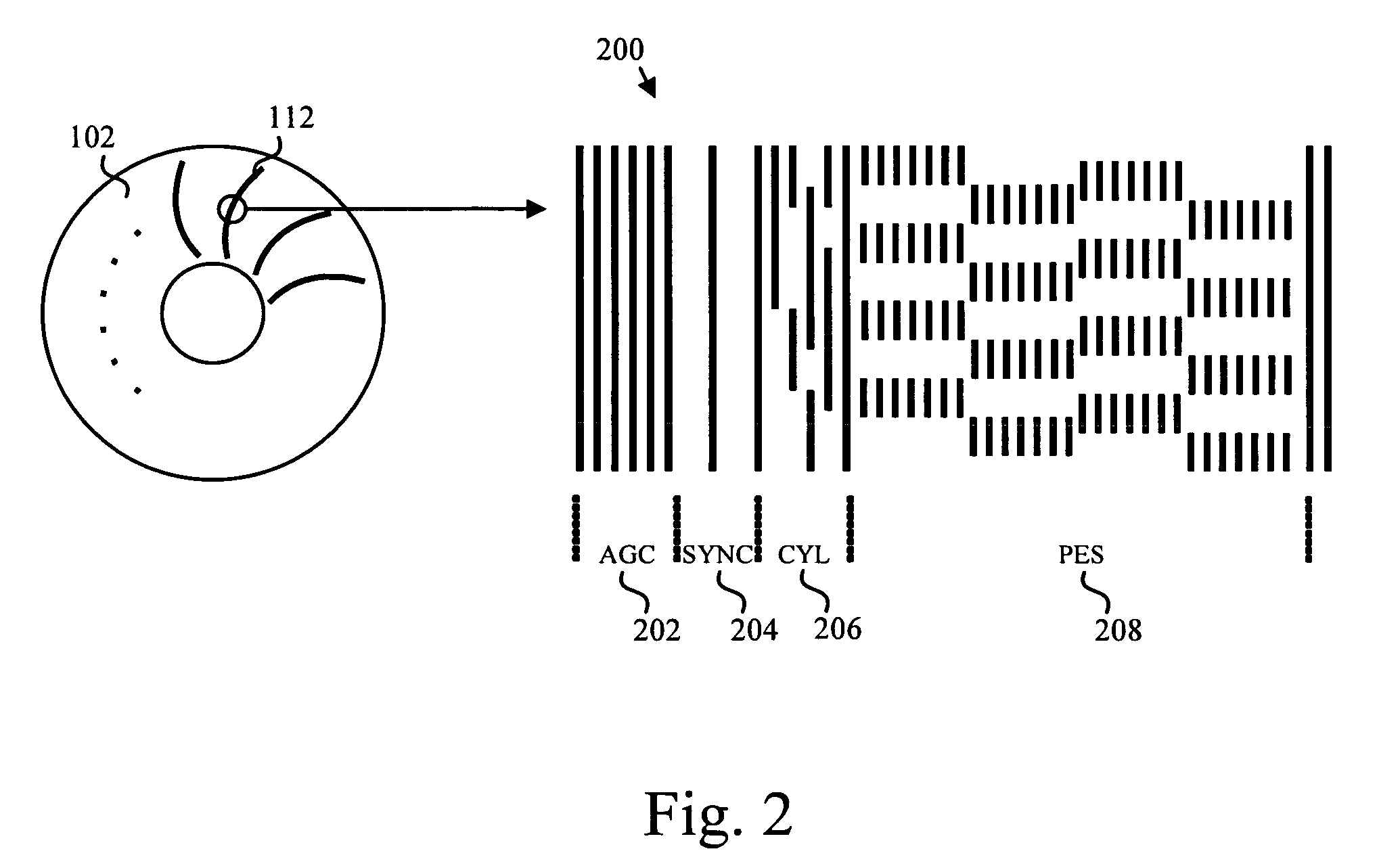

Magnetic recording disk drive with patterned media and compensation for write-clock timing error caused by rotational disturbances

InactiveUS7133229B2Disc-shaped record carriersDriving/moving recording headsPhase detectorRotational vibration

A magnetic recording disk drive has a patterned magnetic recording disk with data blocks of magnetizable material separated by nonmagnetic regions, a write-clock-generation circuit for timing write pulses to the write head, and a rotational vibration sensor that adjusts the timing of the write pulses to correct for errors caused by rotational disturbances to the disk drive. The write-clock-generation circuit receives a reference clock signal synchronized to disk rotation and multiplies it to generate a higher-frequency write-clock signal. The write-clock-generation circuit includes a phase detector that compares the phase of the reference clock signal and the write-clock signal and provides an error signal. The output of the rotational vibration sensor is summed with the phase detector error signal to compensate for disk rotation speed changes caused by rotational disturbances.

Owner:WESTERN DIGITAL TECH INC

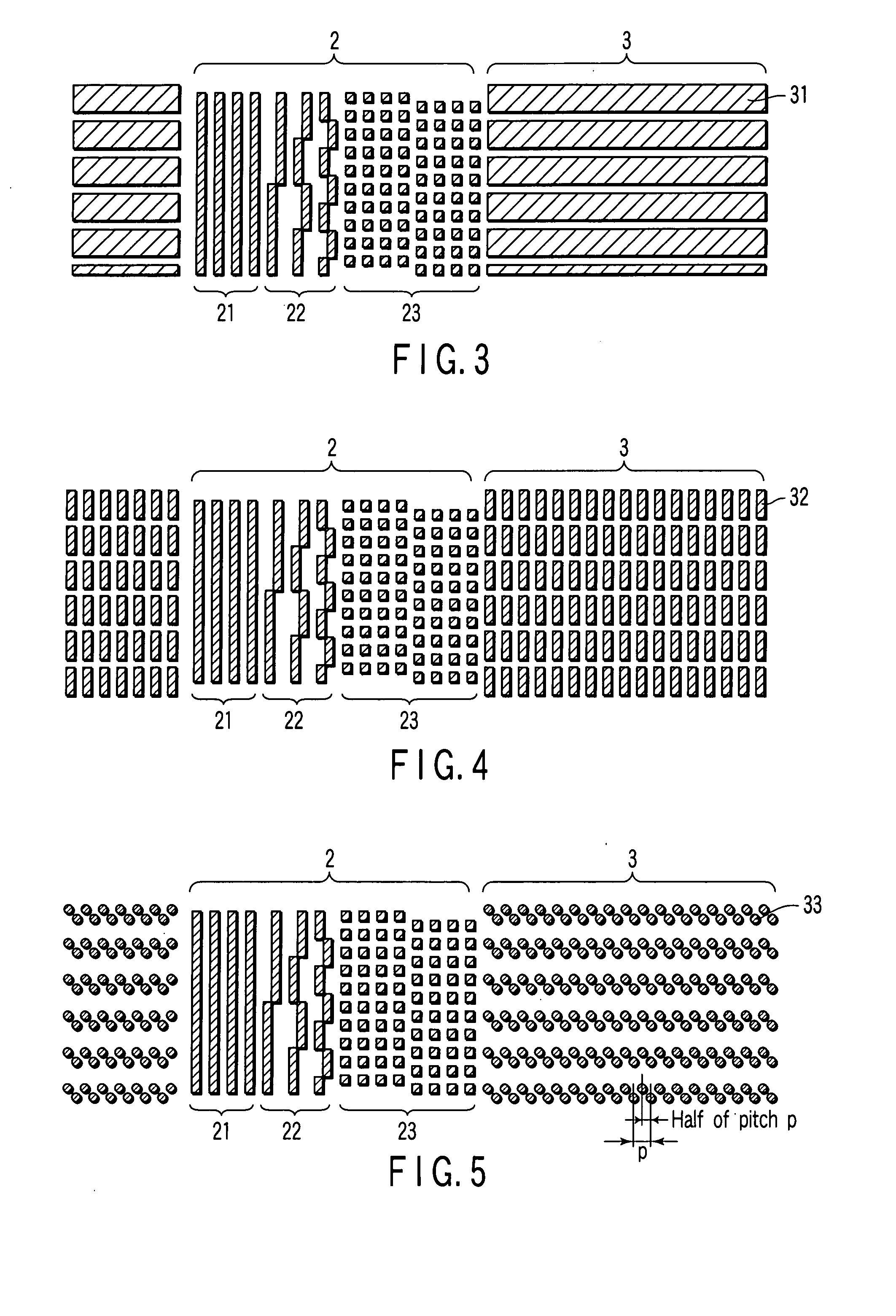

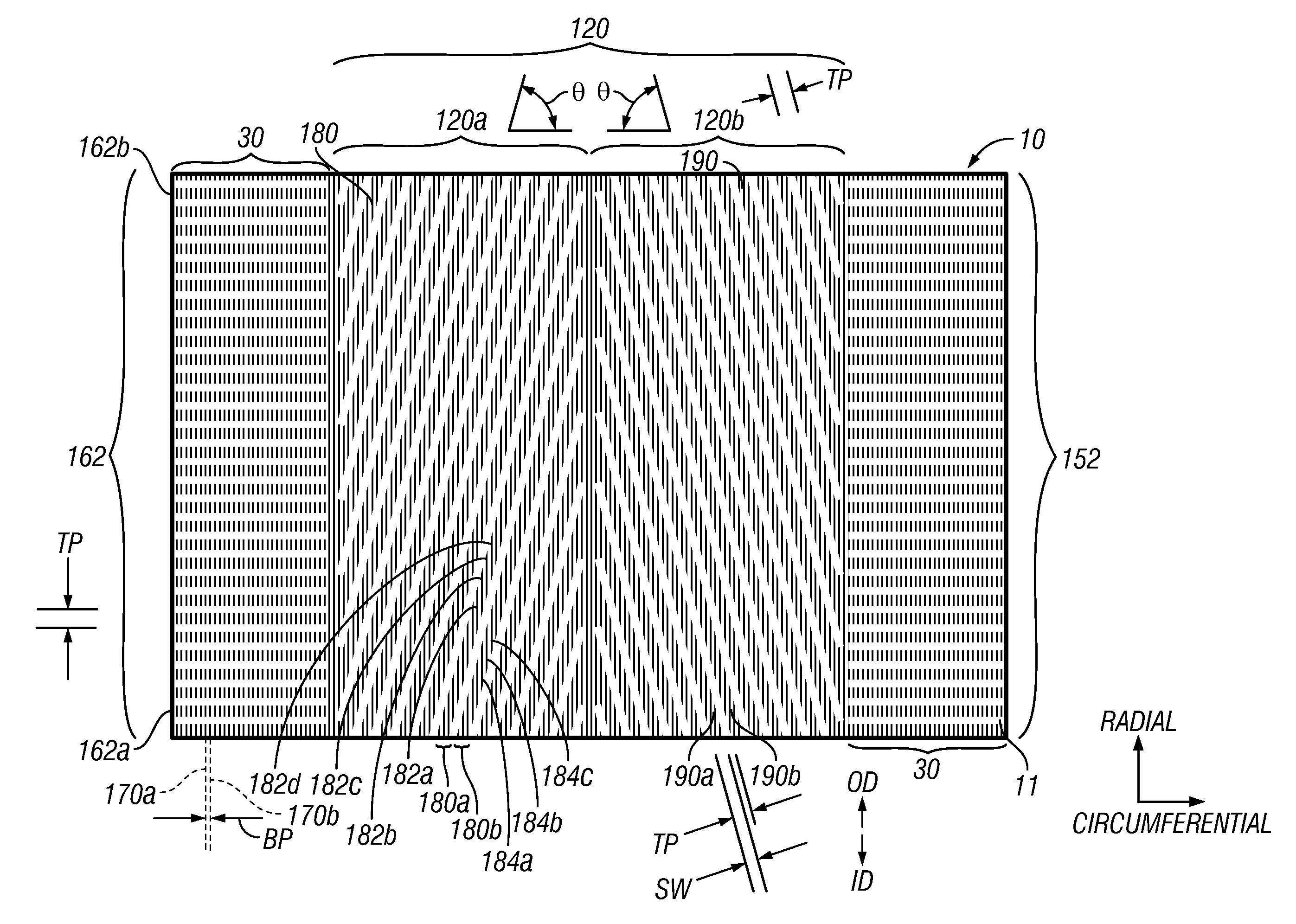

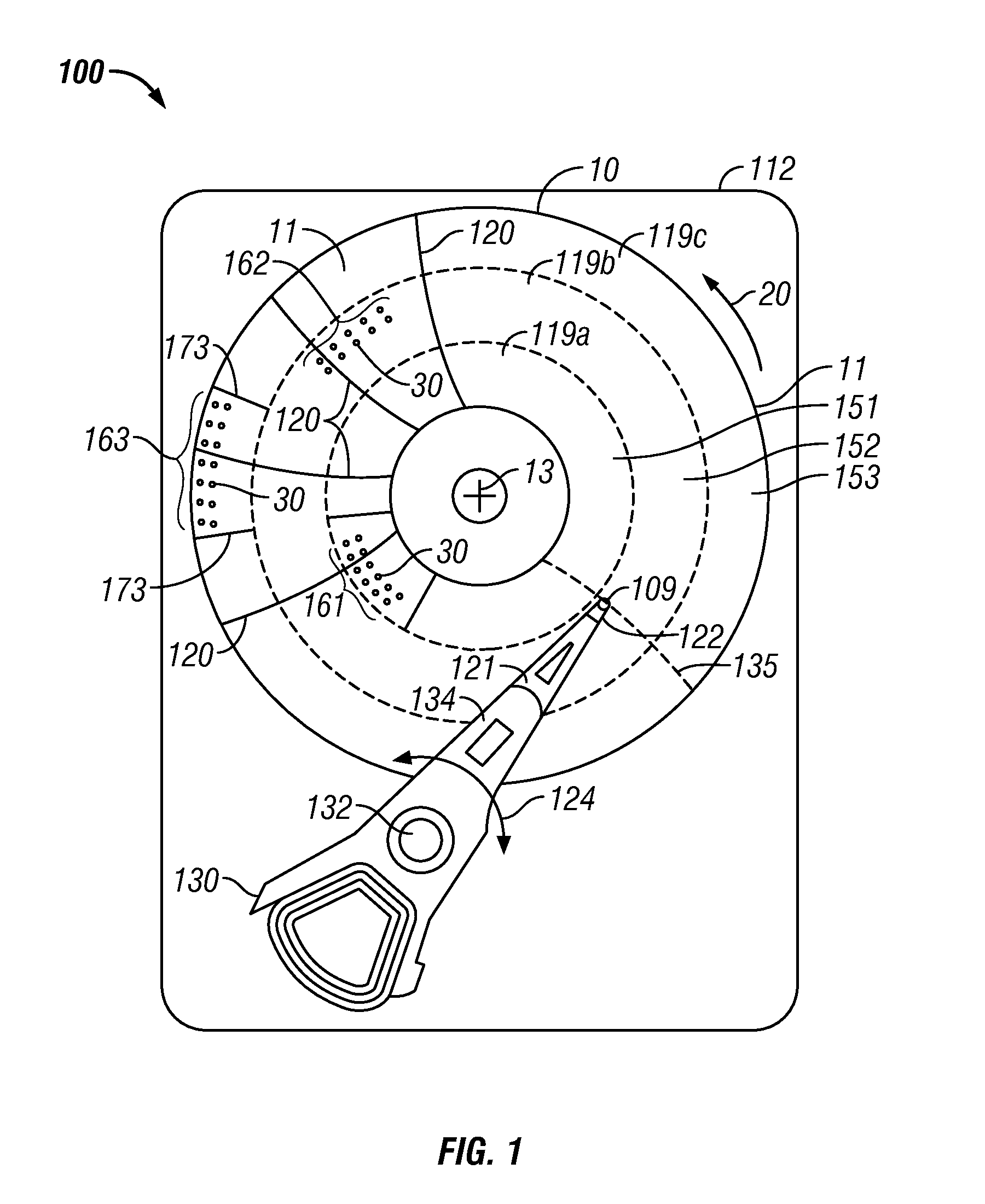

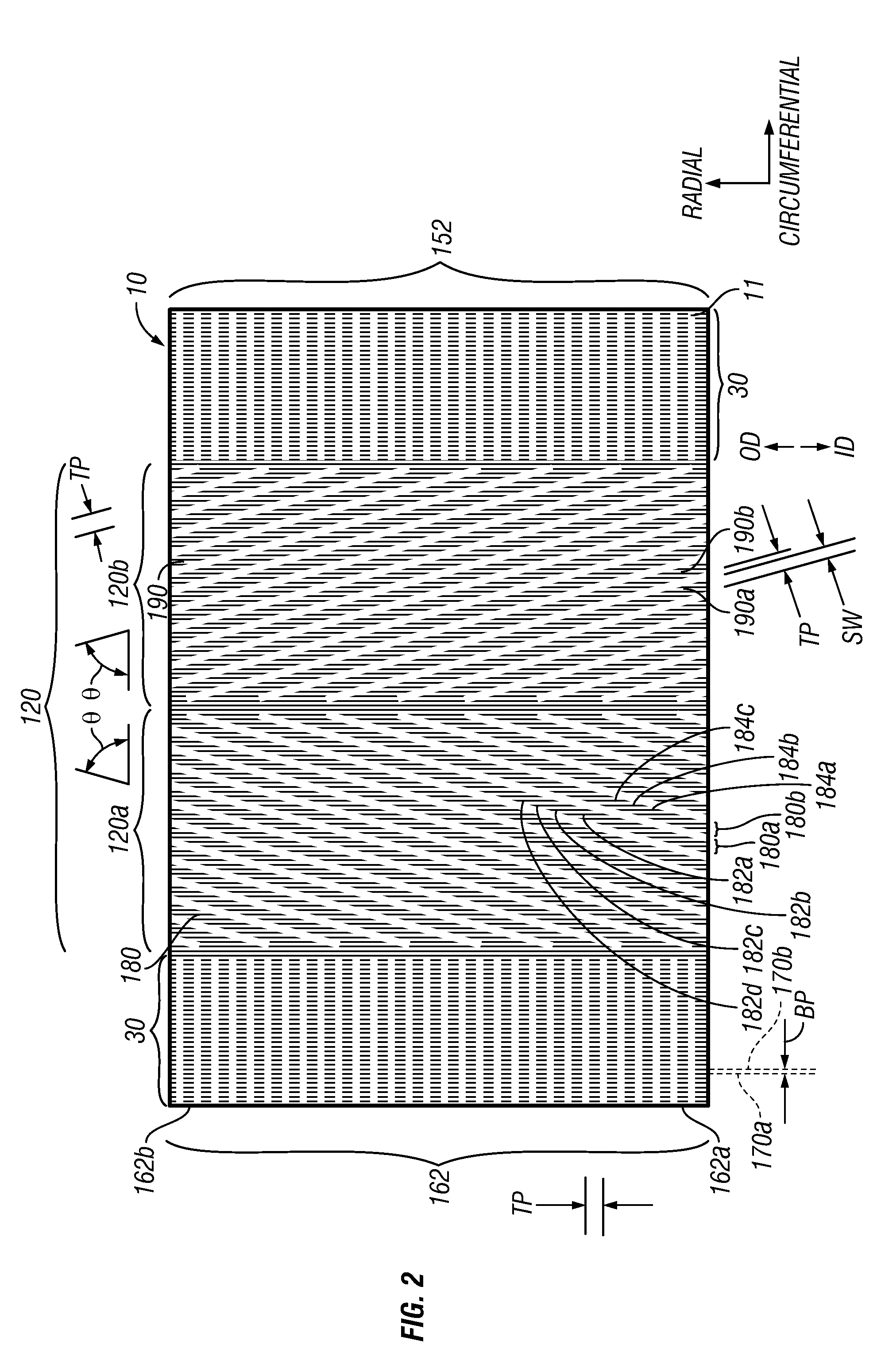

Patterned magnetic recording disk with patterned servo sectors having chevron servo patterns

ActiveUS8059350B2Precise positioningDecorative surface effectsRecord information storageControl theoryPatterned media

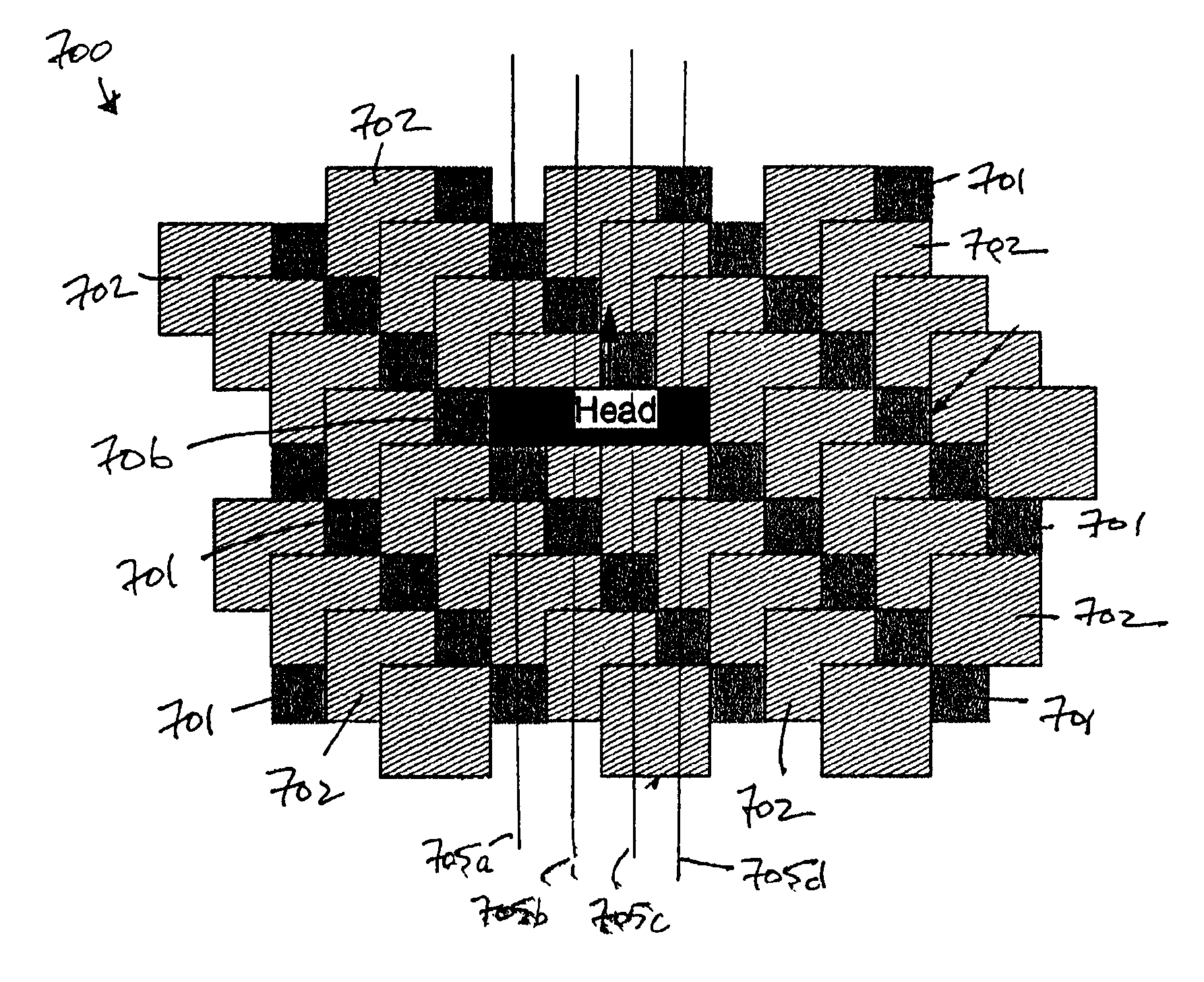

A patterned-media perpendicular magnetic recording disk has patterned servo regions and is nanoimprinted from a master mold made using directed self-assembly of block copolymers. The disk has patterned concentric circular data tracks of discrete data islands, with the tracks having a track pitch in the radial or cross-track direction. The disk also has patterned servo sectors extending generally radially across the patterned data tracks. The servo pattern is a chevron pattern of slanted or non-radial stripes that have a stripe pitch in the cross-stripe direction substantially equal to the track pitch. As a result of the method of making the master mold, the nanoimprinted disk has a chevron servo pattern with non-radial stripes that are magnetized segments of radial lines separated by nonmagnetic spaces.

Owner:WESTERN DIGITAL TECH INC

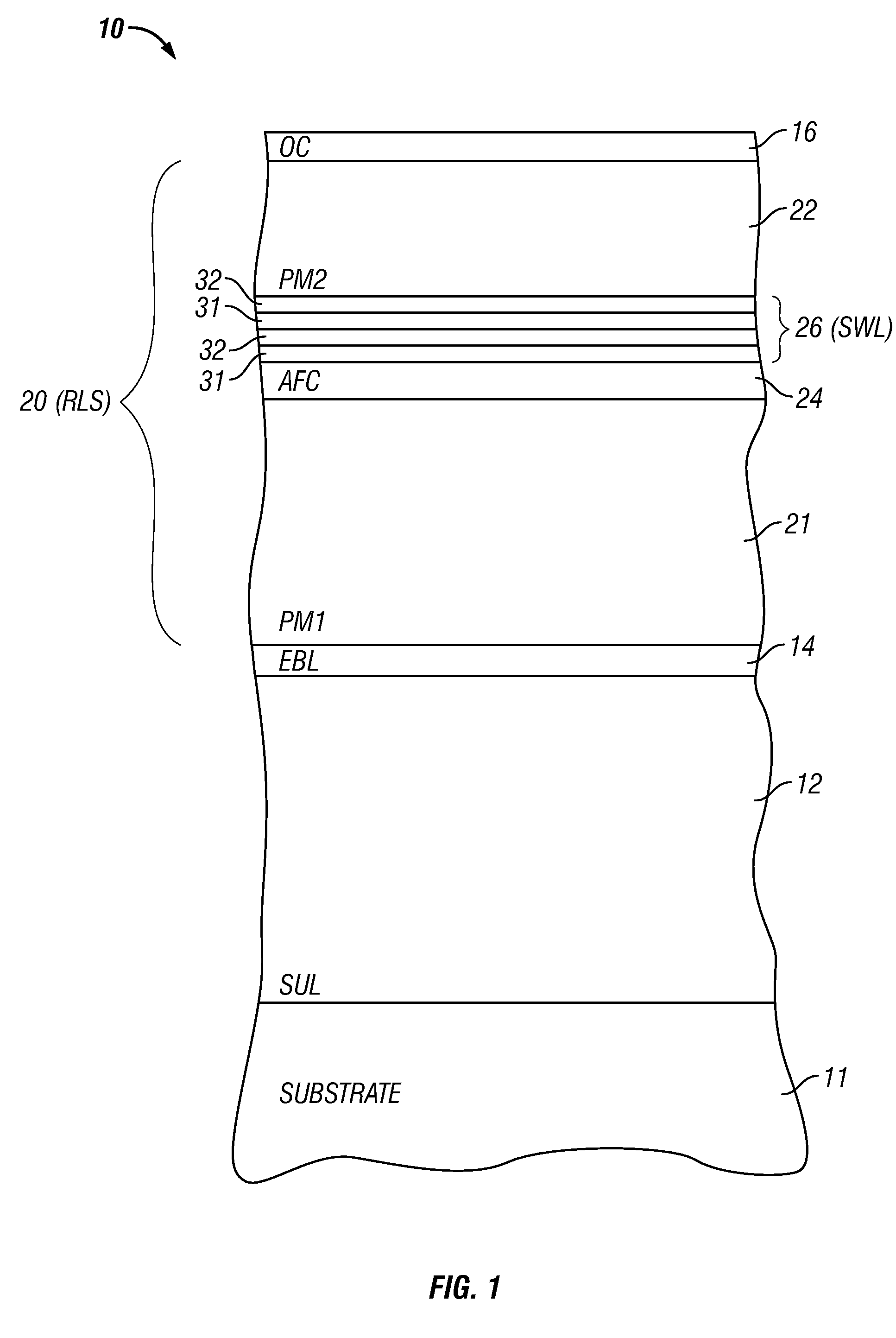

Perpendicular magnetic recording medium and system with low-curie-temperature multilayer for heat-assisted writing and/or reading

ActiveUS20090226762A1Strong readback signalData augmentationRecord information storageManufacture of flux-sensitive headsAntiferromagnetic couplingMagnetization

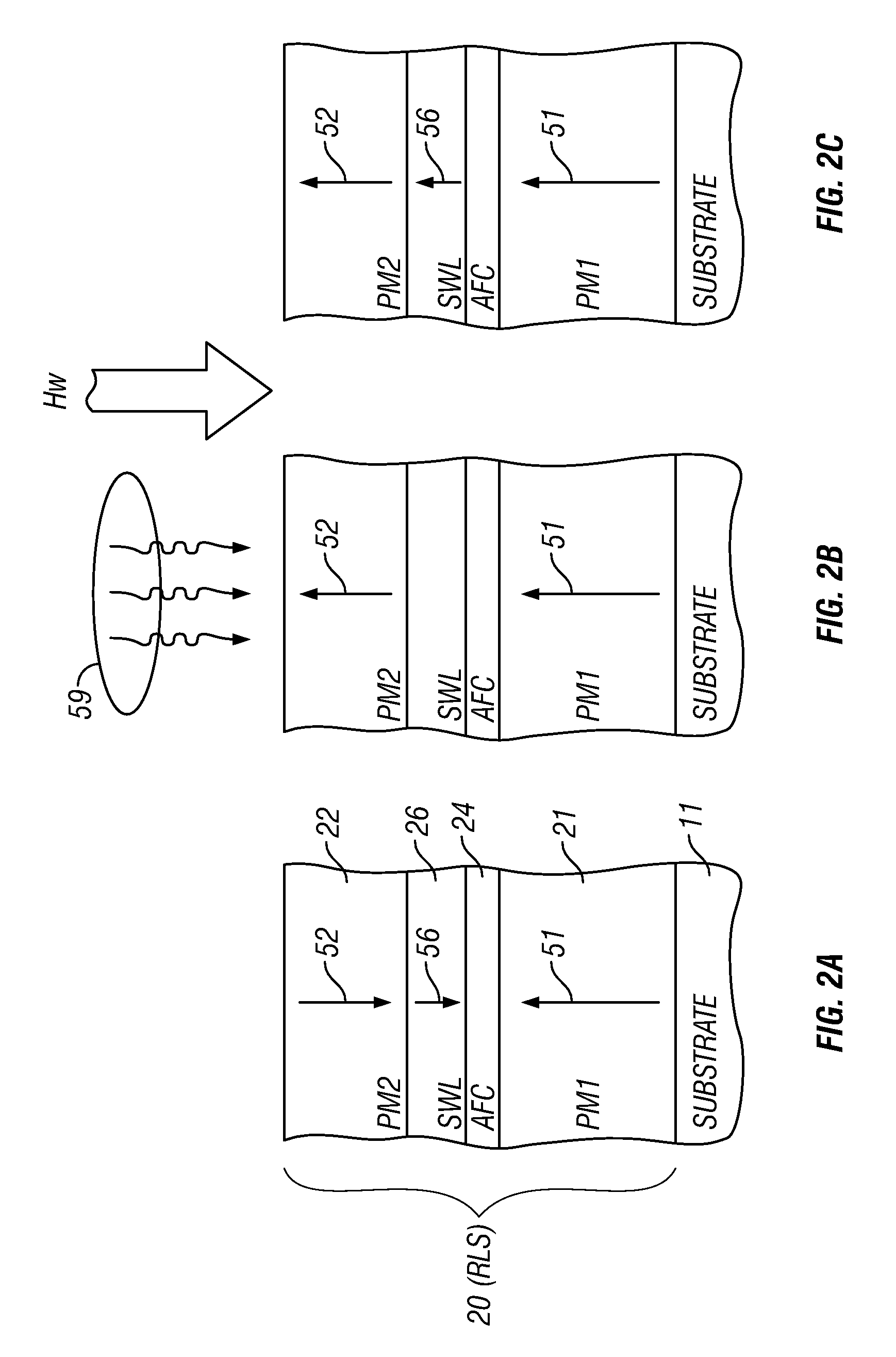

A perpendicular magnetic recording medium, usable for either continuous or patterned media, has a recording layer structure (RLS) of first and second perpendicular magnetic layers (PM1, PM2) and an antiferromagnetically coupling (AFC) layer and a ferromagnetic switching layer (SWL) between PM1 and PM2. The magnetic recording system uses heat to assist in the reading and / or writing of data. The SWL is a Co / Ni multilayer with a Curie temperature (TC-SWL) less than the Curie temperatures of PM1 and PM2. At room temperature, there is ferromagnetic coupling between SWL and the upper ferromagnetic layer (PM2) so that the magnetizations of SWL and PM2 are parallel, and antiferromagnetic coupling between SWL and the lower ferromagnetic layer (PM1) across the AFC layer so that the magnetization of PM1 is aligned antiparallel to the magnetizations of SWL and PM2. When the SWL is heated to above TC-SWL it is no longer ferromagnetic, there is no antiferromagnetic coupling between the SWL and PM1 across the AFC layer, and the magnetizations of PM1 and PM2 become aligned parallel.

Owner:WESTERN DIGITAL TECH INC

Patterned media having offset tracks

InactiveUS6937421B2Improve performanceNanoinformaticsRecord information storagePatterned mediaOptical medium

An information recording system includes a storage medium, such as a magnetic or an optical medium, that is formed to have a plurality of adjacent tracks. Each track includes a plurality of storage elements that are arranged substantially along the track in a regular manner. A head disposed in proximity to the storage medium and has a width that spans at least two adjacent tracks. The storage elements are further arranged substantially along first and second axes, such that the first and second axes are substantially perpendicular to each other and are each substantially oriented 45° from an along-track direction associated with a track. The head reads and / or writes information from at least two adjacent tracks spanned by the head.

Owner:IBM CORP

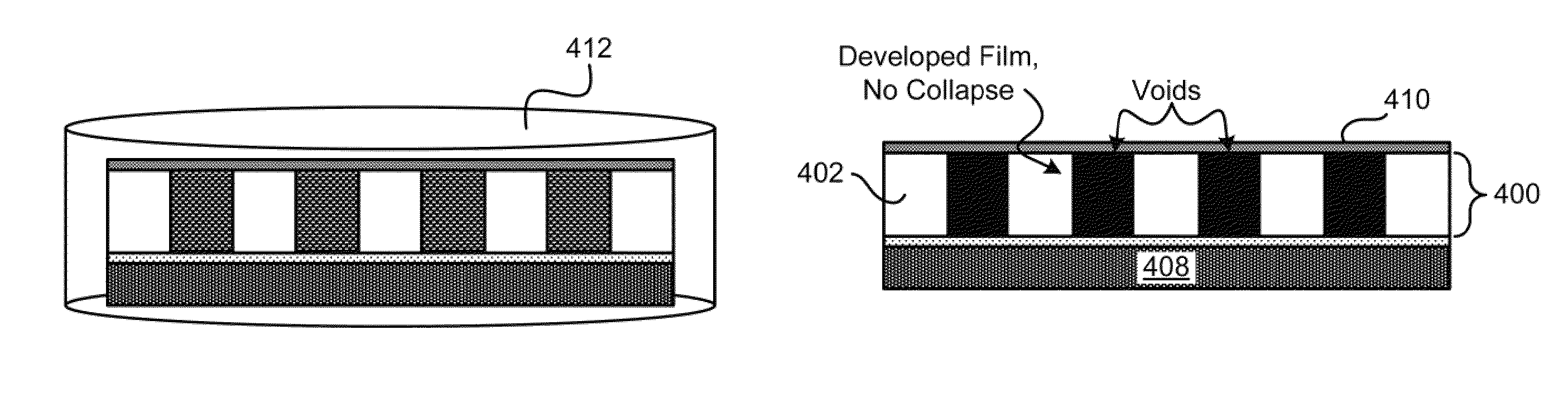

Supporting membranes on nanometer-scale self-assembled films

Block copolymer lithography has emerged as an alternative lithographic method to achieve large-area, high-density patterns at resolutions near or beyond the limit of conventional lithographic techniques for the formation of bit patterned media and discrete track media. In one embodiment, a structure comprises a plurality of nanostructures extending upwardly from a substrate and a porous membrane extending across upper ends of the plurality of nanostructures. A method, according to another embodiment, comprises forming a block copolymer layer on a substrate, inducing self assembly of the block copolymer layer, selectively degrading a block polymer from the block copolymer layer, forming a porous membrane over the block copolymer layer, and removing a portion of the block copolymer layer for defining a plurality of nanostructures extending upwardly from the substrate after forming the porous membrane over the block copolymer layer. Other systems and methods are disclosed as well.

Owner:WESTERN DIGITAL TECH INC

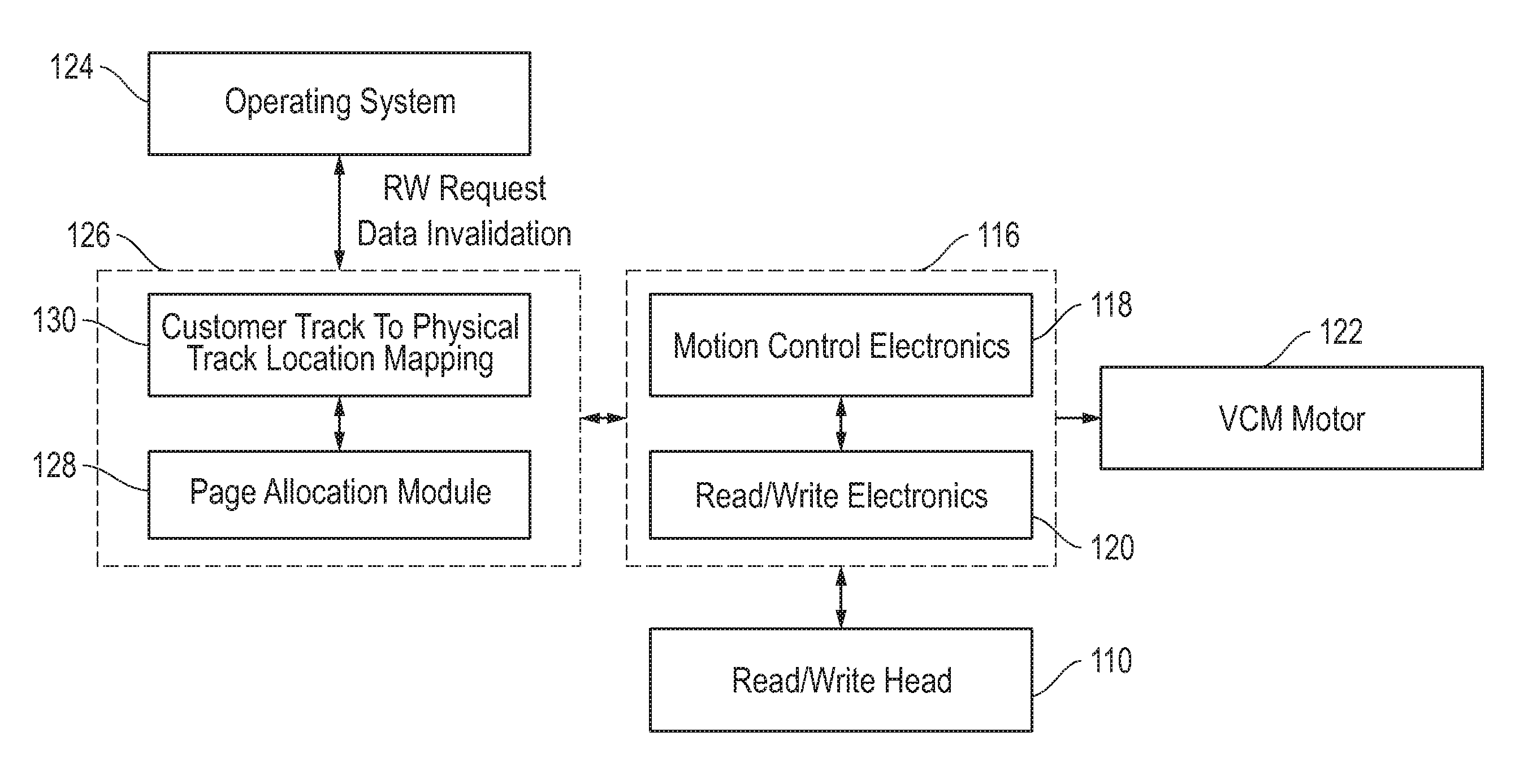

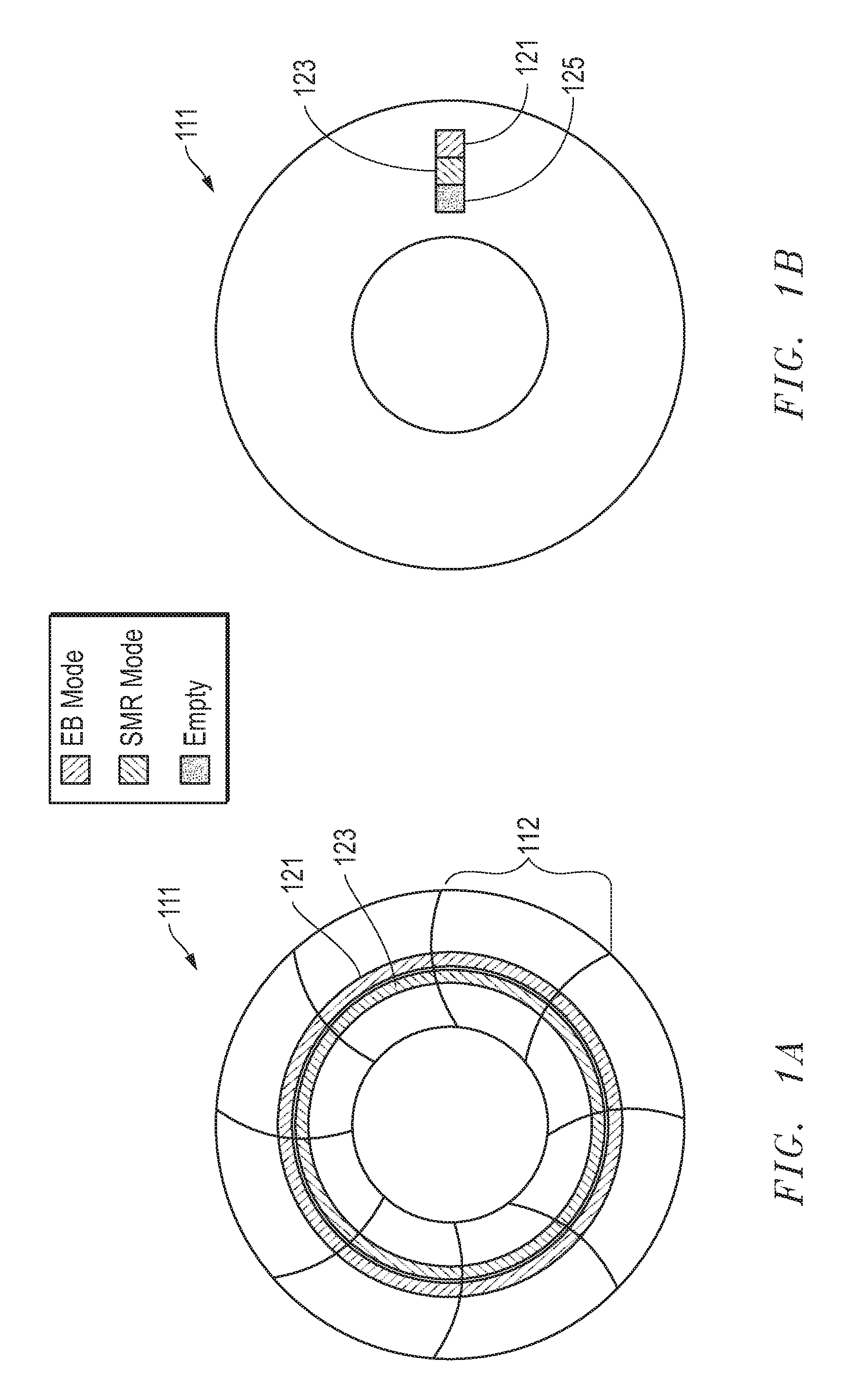

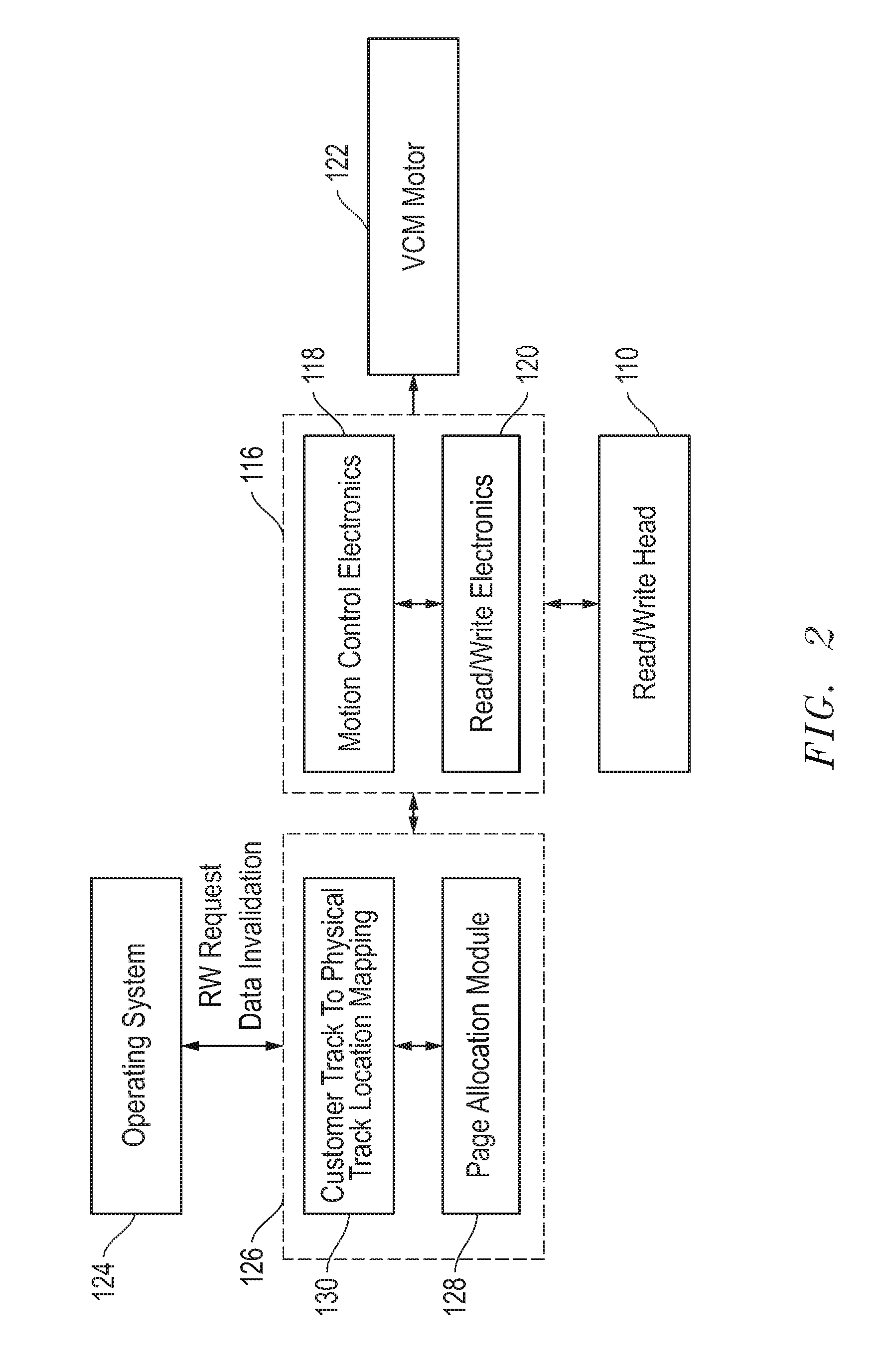

System, method and apparatus for storage architecture for bit patterned media using both erase band and shingled magnetic recording

ActiveUS20120099216A1Improve performanceFilamentary/web record carriersPatterned record carriersHard disc driveShingled magnetic recording

Storage architecture for bit patterned media uses both erase band and shingled magnetic recording. A hard disk drive may comprise a disk having bit patterned media with a plurality of data tracks arrayed in architecture pages having at least one of erase band mode (EBM), shingled mode (SM) and unallocated space. An actuator has a head for writing data to the data tracks of the bit patterned media. A control system monitors, reallocates and reconfigures the architecture pages from EBM, SM or unallocated space to a different one of EBM, SM or unallocated space to enhance performance of the hard disk drive.

Owner:WESTERN DIGITAL TECH INC

Method using block copolymers for making a master mold with high bit-aspect-ratio for nanoimprinting patterned magnetic recording disks

ActiveUS8119017B2Decorative surface effectsSemiconductor/solid-state device manufacturingResistLithographic artist

The invention is a method for making a master mold to be used for nanoimprinting patterned-media magnetic recording disks. The method uses conventional optical or e-beam lithography to form a pattern of generally radial stripes on a substrate, with the stripes being grouped into annular zones or bands. A block copolymer material is deposited on the pattern, resulting in guided self-assembly of the block copolymer into its components to multiply the generally radial stripes into generally radial lines of alternating block copolymer components. The radial lines of one of the components are removed and the radial lines of the remaining component are used as an etch mask to etch the substrate. Conventional lithography is used to form concentric rings over the generally radial lines. After etching and resist removal, the master mold has pillars arranged in circular rings, with the rings grouped into annular bands.

Owner:WESTERN DIGITAL TECH INC

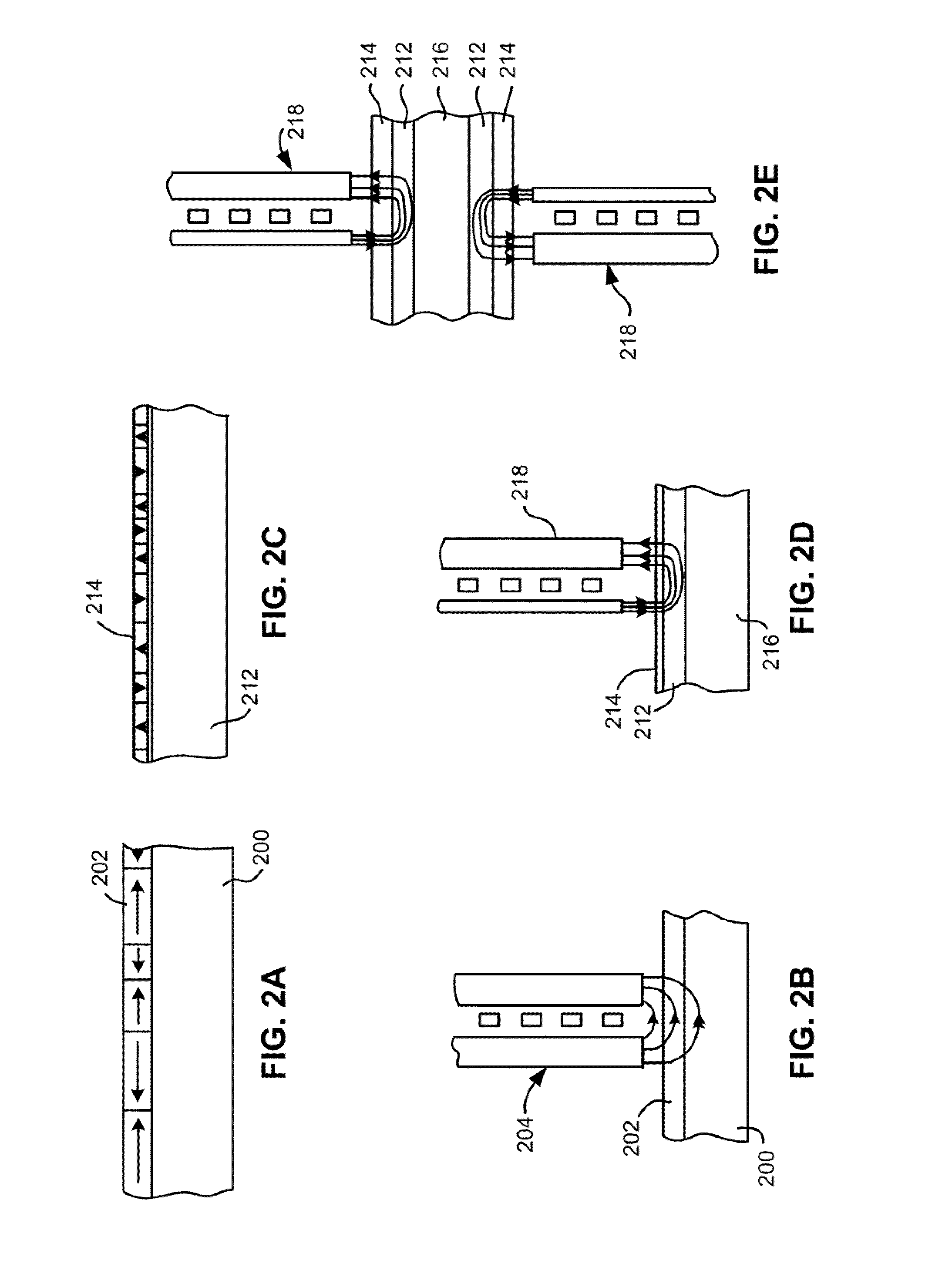

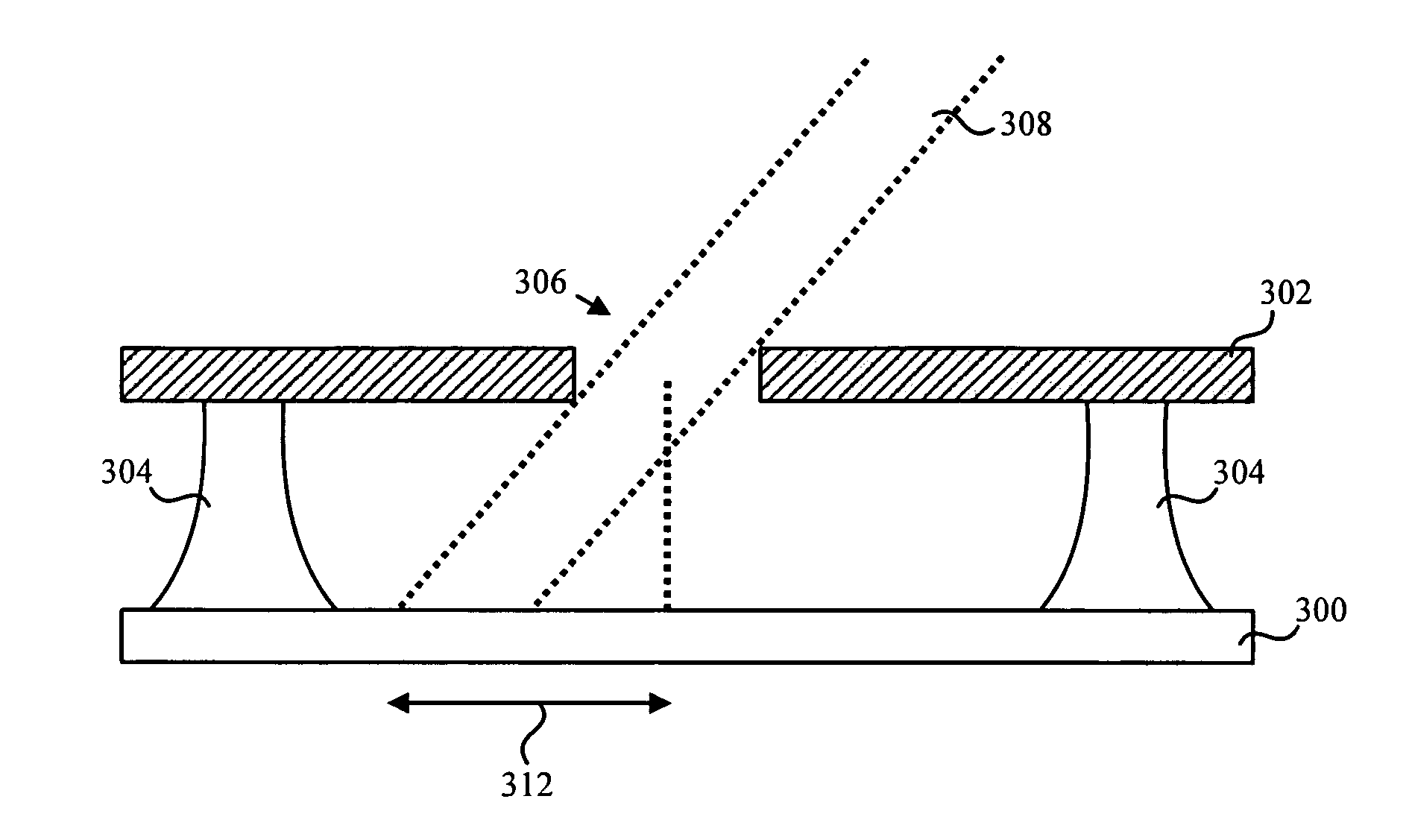

Apparatus, method and system for fabricating servo patterns on high density patterned media

An apparatus, system, and method are disclosed for utilizing a “shadow mask” approach to fabricate servo patterns on high density patterned media. The apparatus may include a deposition mask having a plurality of apertures generated by a conventional lithographic process. Material may be deposited onto a substrate through the deposition mask apertures from at least one deposition source oriented at unique deposition angles. In this manner, each aperture may correspond to multiple deposition locations. Apertures may be precisely dimensioned and positioned to create servo pattern features from the resulting deposition locations. The deposition mask may also include a plurality of bit pattern apertures adapted to direct a material to a plurality of deposition locations on the substrate, the deposition locations forming a bit pattern concurrent with formation of a servo pattern.

Owner:WESTERN DIGITAL TECH INC

Apparatus system and method for variable data density patterned media

An apparatus, system, and method are disclosed for variable data density patterned media. The apparatus includes a patterned media recording surface comprising a plurality of sectors. Each sector may include a synchronization region configured to generate a signal in a read head, a first data region with a first data density configured to generate a signal with a first frequency, and at least a second data region with a second data density configured to generate a signal with a second frequency. The system includes a hard disk drive and the apparatus. The method includes sensing a signal in a read head, synchronizing the frequency and phase of a write clock with a predetermined frequency and phase of a synchronization region, and modifying the frequency of the write clock after a period of time determined in response to at least one physical characteristic of the disk.

Owner:WESTERN DIGITAL TECH INC

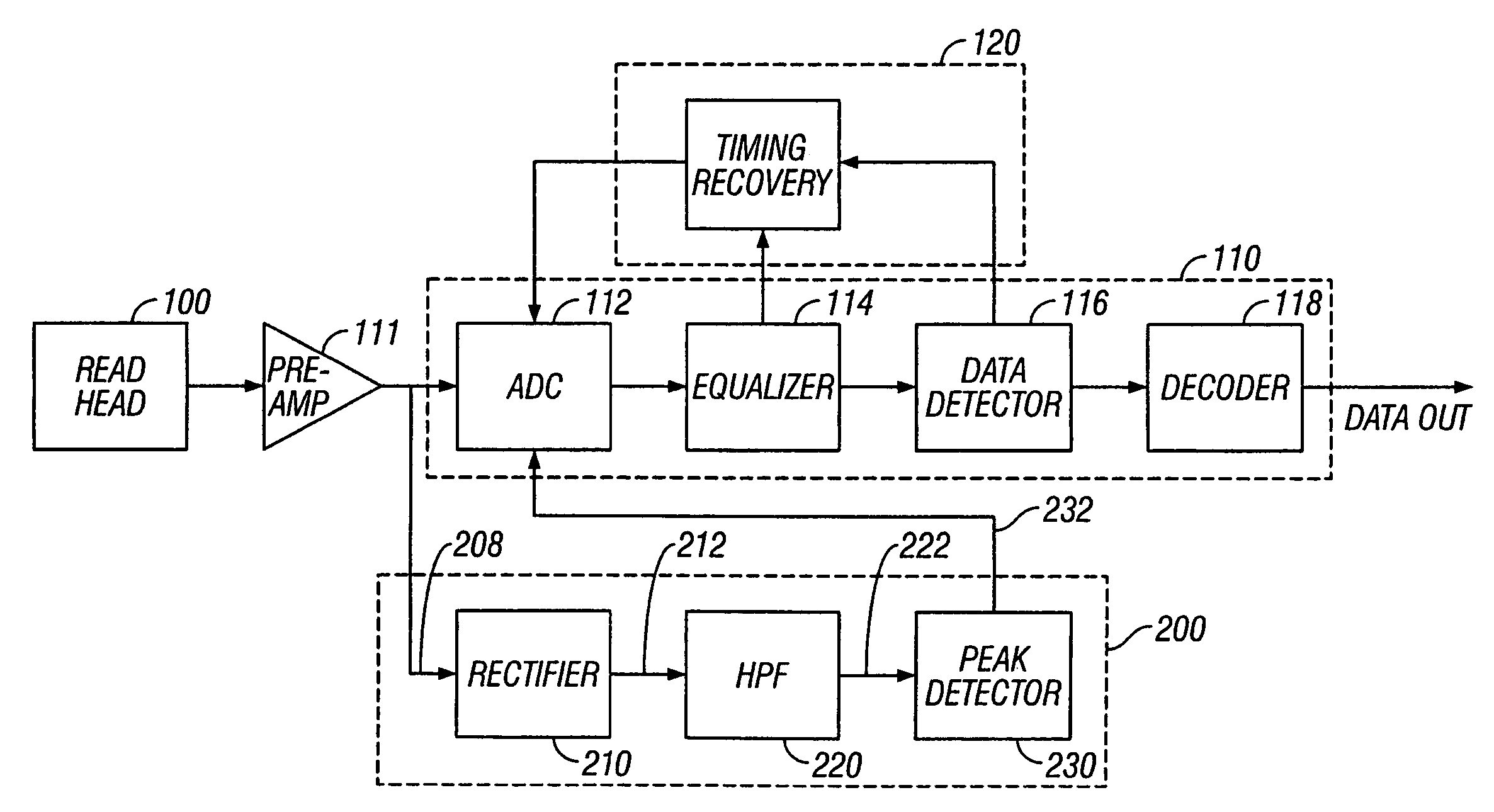

Magnetic recording disk drive with patterned media and circuit for generating timing pulses from the pattern

A magnetic recording disk drive has a patterned magnetic recording disk with data blocks of magnetizable material separated by nonmagnetic regions, a read head for reading the magnetized data blocks and generating a readback signal, and a timing circuitry that generates from the readback signal a series of timing pulses. When the read head is over a nonmagnetic region the readback signal is significantly reduced, and this signal reduction is detectable to determine the position of the nonmagnetic regions. The timing circuitry includes a rectifier that rectifies the readback signal, a highpass filter that filters the rectified signal at the frequency of the data blocks, and a peak detector that detects the peaks of the filtered signal and generates a series of timing pulses, each pulse representing a nonmagnetic region. The timing pulses can be used for marking the bit boundaries in the digital data sequence that is output from the read channel or as the write clock signal to the write head for magnetizing the data blocks.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

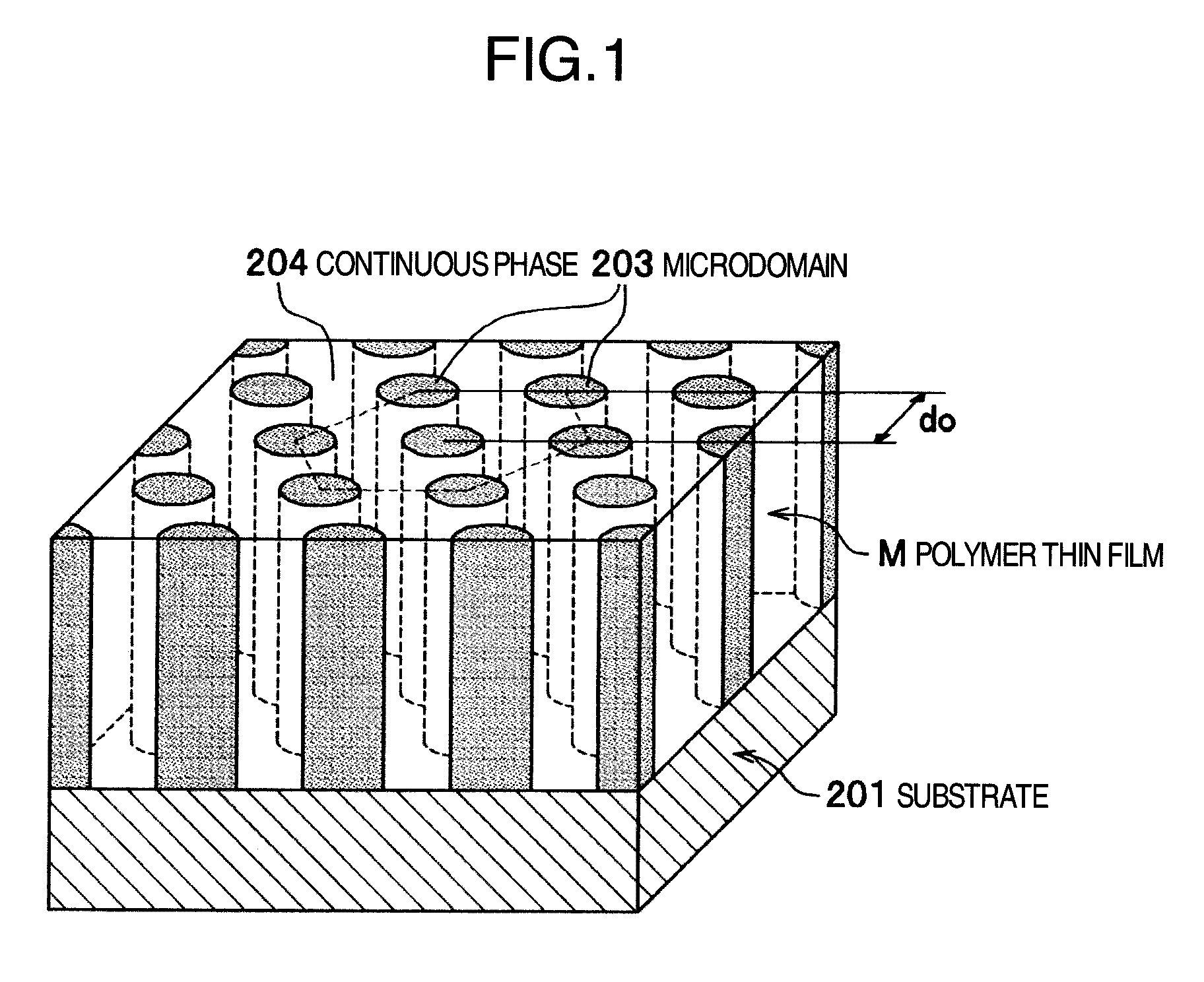

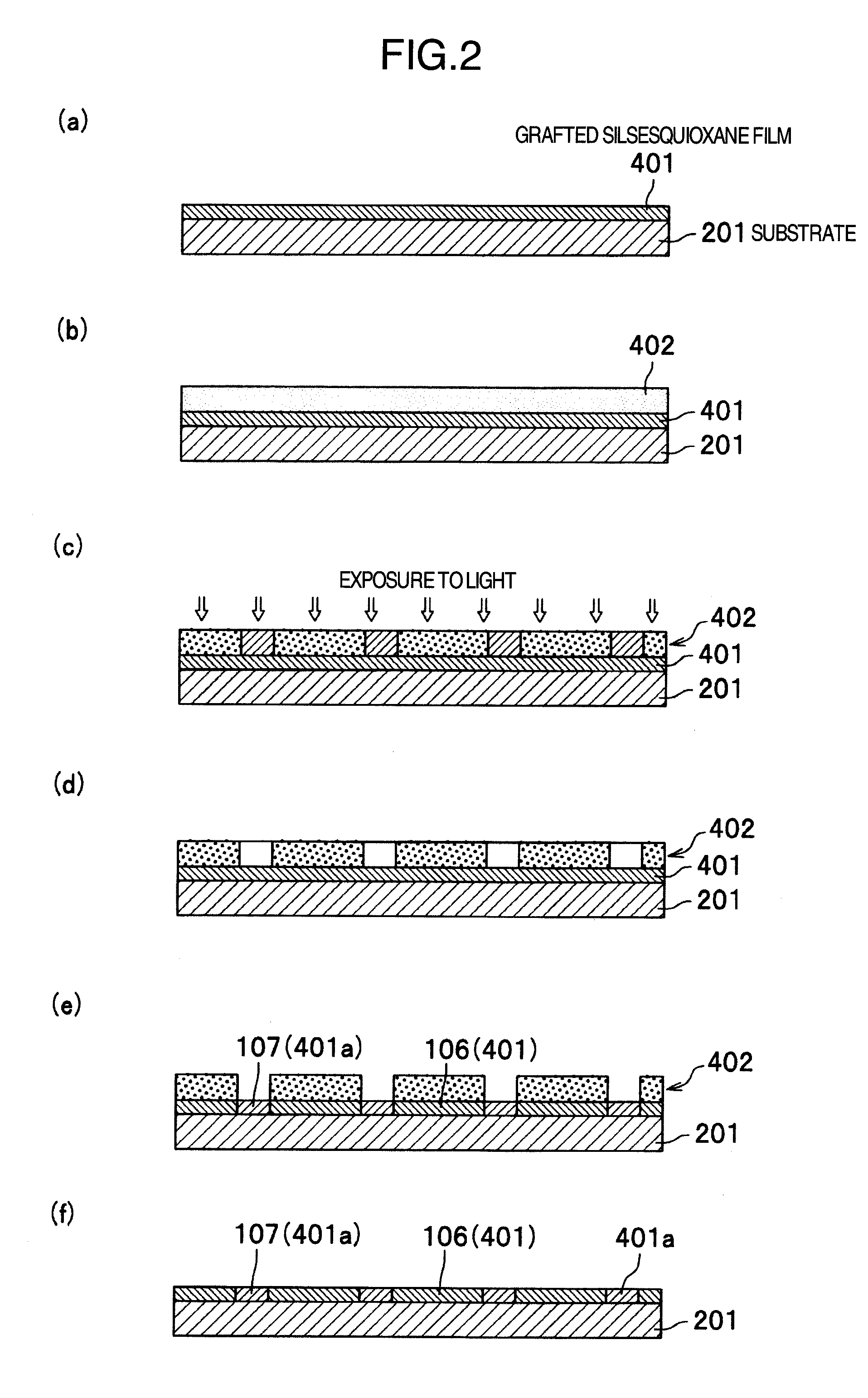

Polymer thin film, patterned media, production methods thereof, and surface modifying agents

InactiveUS20110281085A1Simple structureImprove regularityLayered productsDecorative surface effectsFine structurePolymer science

The objects of the present invention are to provide a polymer thin film having finer structure than the conventional product, excellent regularity over a wide range and only limited defects, patterned media, methods for producing the thin film and patterned media, and surface modifying agent used in these production methods.The method of the present invention is for producing a polymer thin film with a plurality of microdomains regularly arranged in a continuous phase by microphase separation on a substrate, comprising steps for forming a grafted silsesquioxane film on the substrate, and for forming a pattern different in chemical properties from the grafted silsesquioxane film in such a way that the pattern corresponds to the microdomain arrangement.

Owner:HITACHI LTD

Write synchronization phase calibration for storage media

InactiveUS20100202079A1Modification of read/write signalsPatterned record carriersPhase correctionPatterned media

A technique is described for write synchronization phase calibration for storage media (e.g., bit patterned media). In one embodiment, a calibration write clock signal may be generated at a frequency offset from a nominal dot frequency of a bit patterned storage media. A periodic signal that was written to the media synchronous to the calibration write clock signal may then be read and mixed with a reference periodic signal at the nominal dot frequency to obtain a difference signal. This difference signal may be demodulated to determine a phase correction for write synchronization to the media.

Owner:SEAGATE TECH LLC

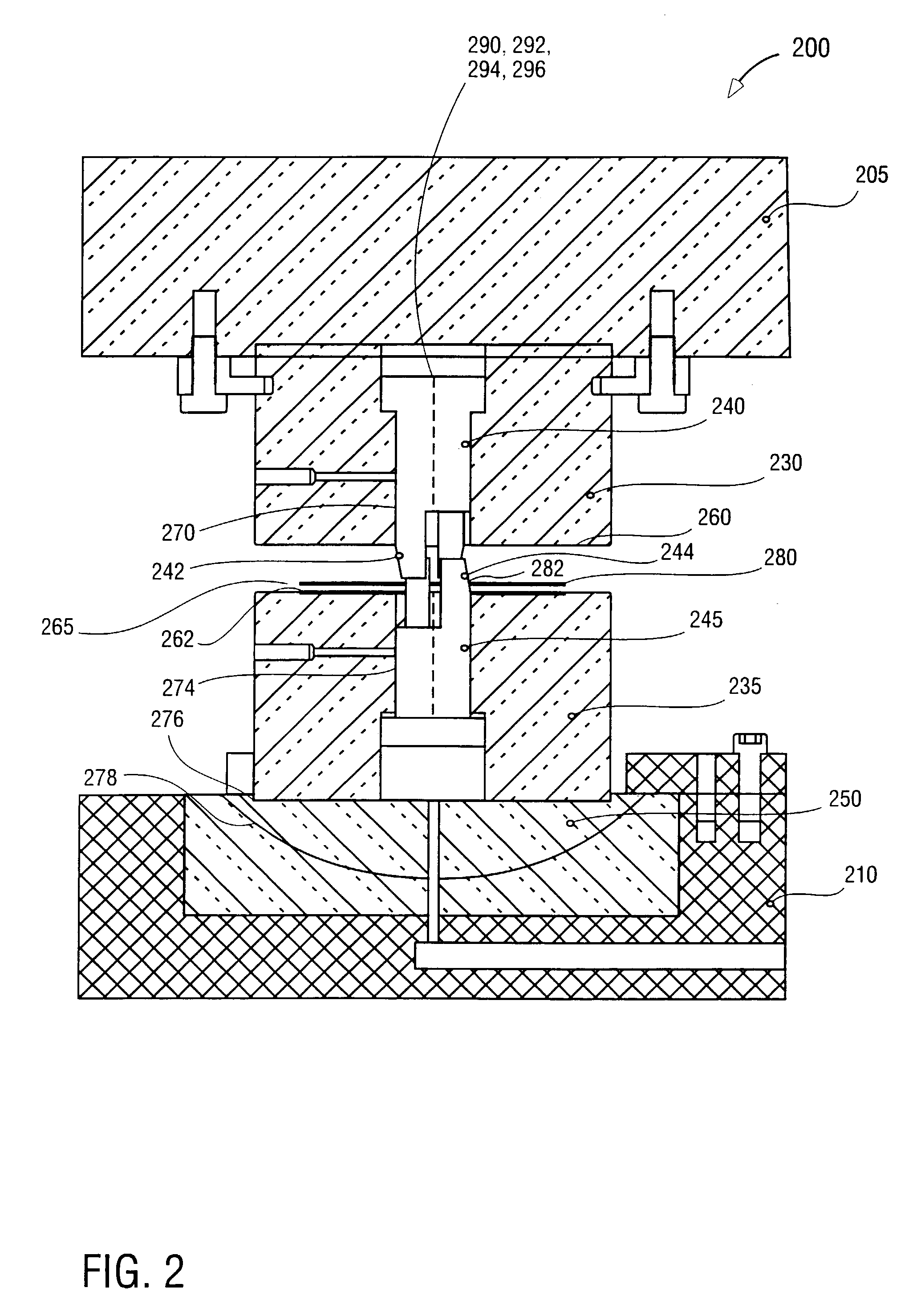

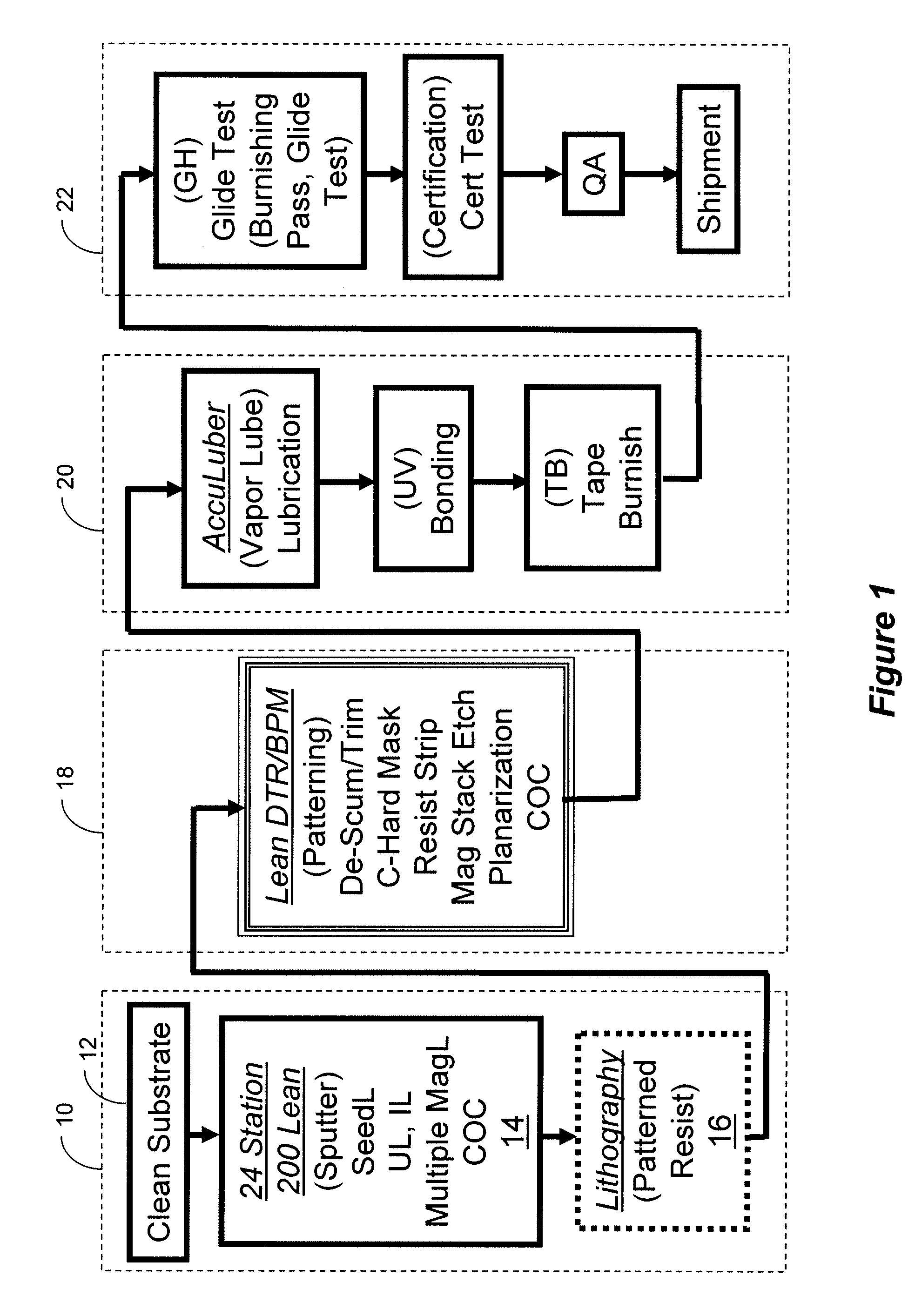

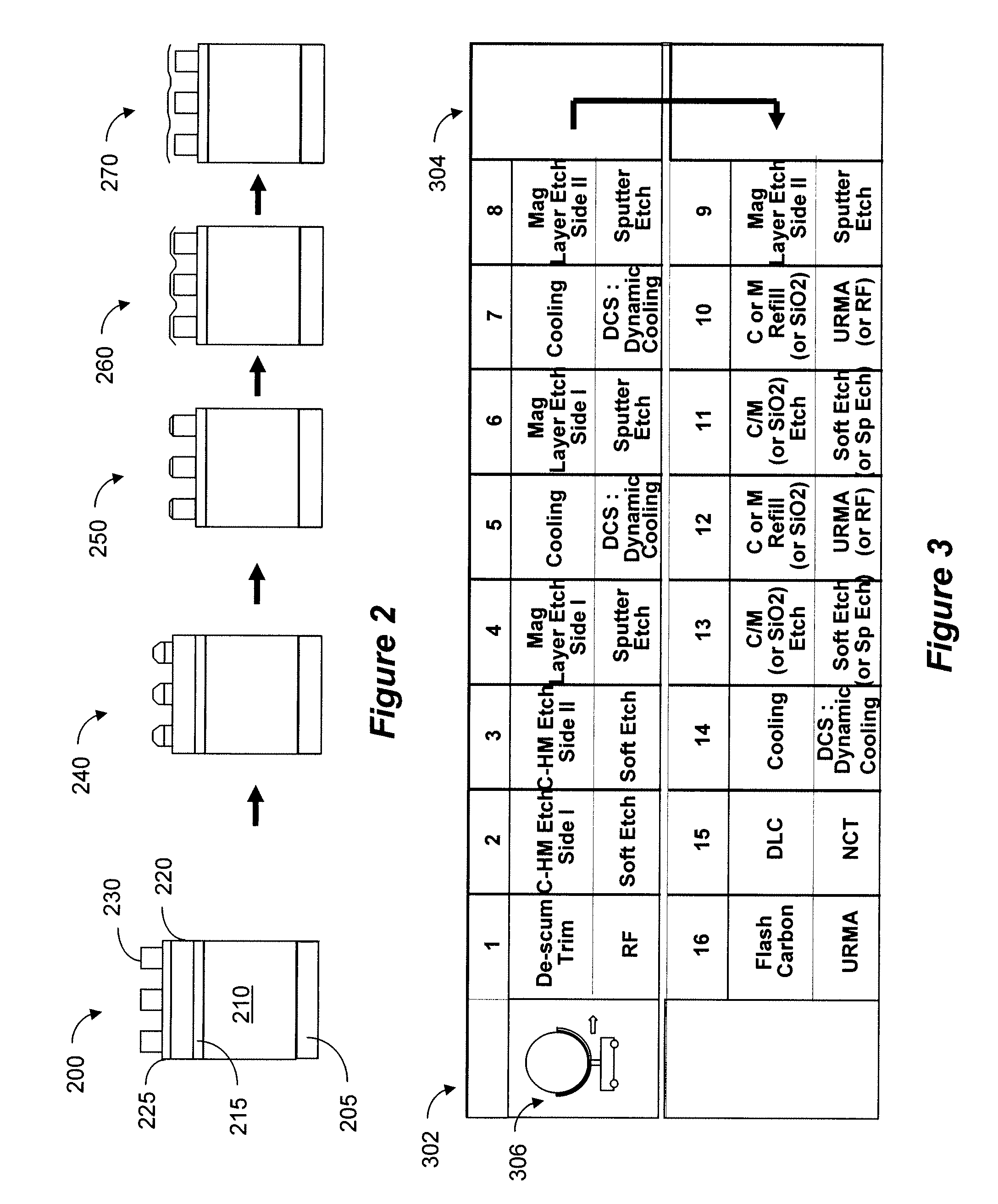

System and method for commercial fabrication of patterned media

A system is provided for etching patterned media disks for hard drive. The modular system may be tailored to perform specific processes sequences so that a patterned media disk is fabricated without removing the disk from vacuum environment. In some sequence the magnetic stack is etched while in other the etch is performed prior to forming the magnetic stack. In a further sequence ion implantation is used without etching steps. For etching a movable non-contact electrode is utilized to perform sputter etch. The cathode moves to near contact distance to, but not contacting, the substrate so as to couple RF energy to the disk. The substrate is held vertically in a carrier and both sides are etched serially. That is, one side is etched in one chamber and then in the next chamber the second side is etched.

Owner:INTEVAC

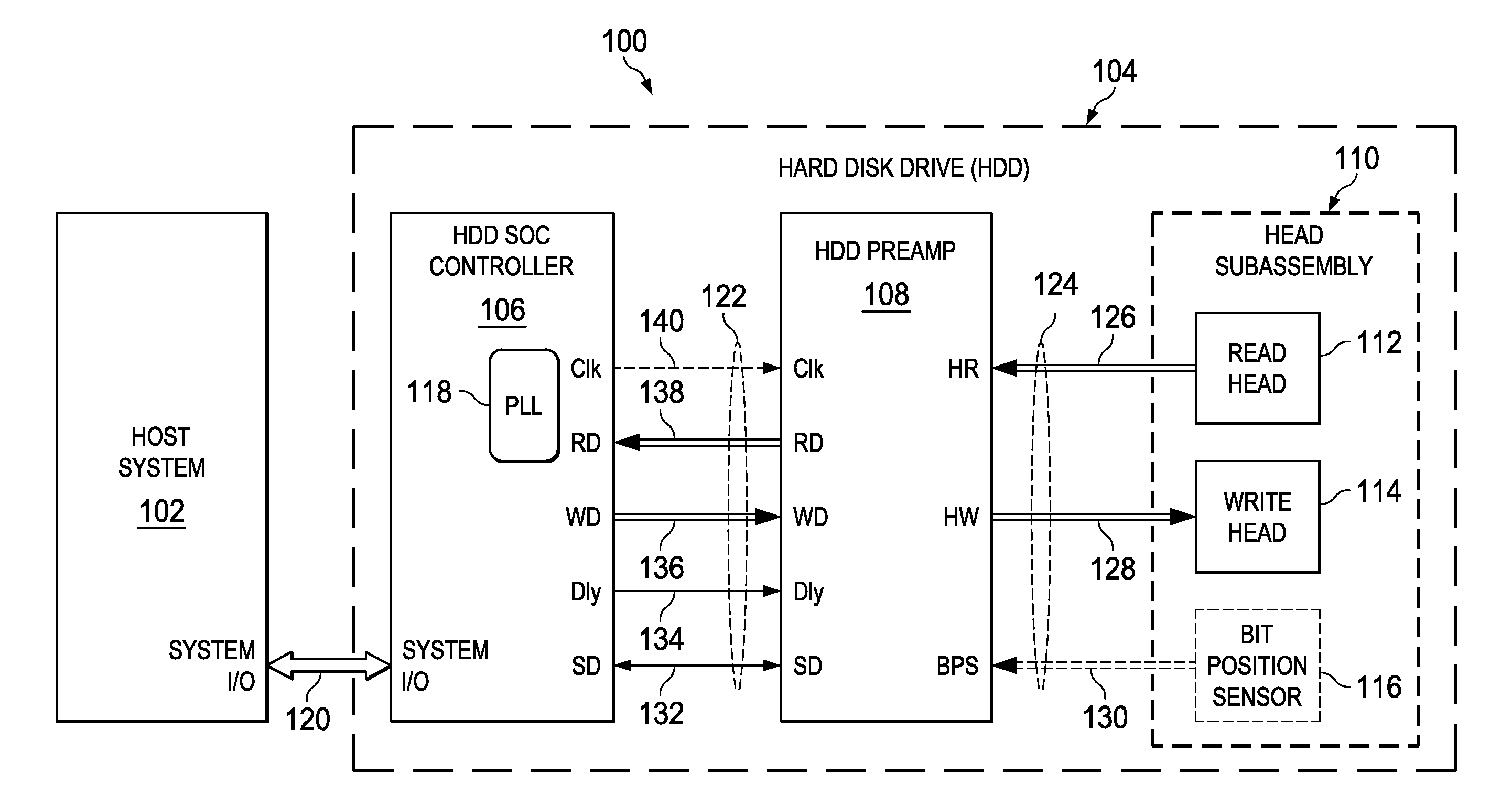

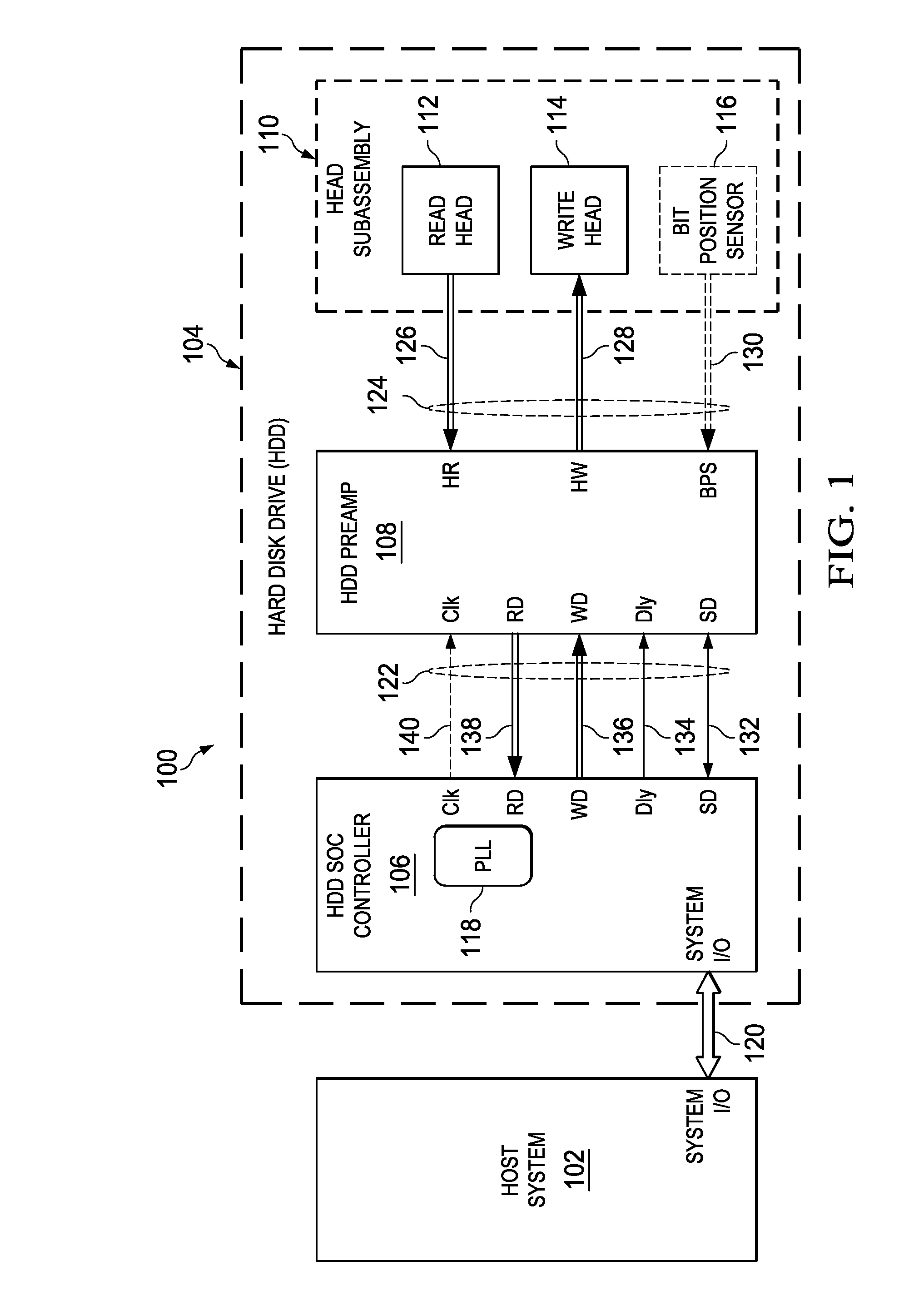

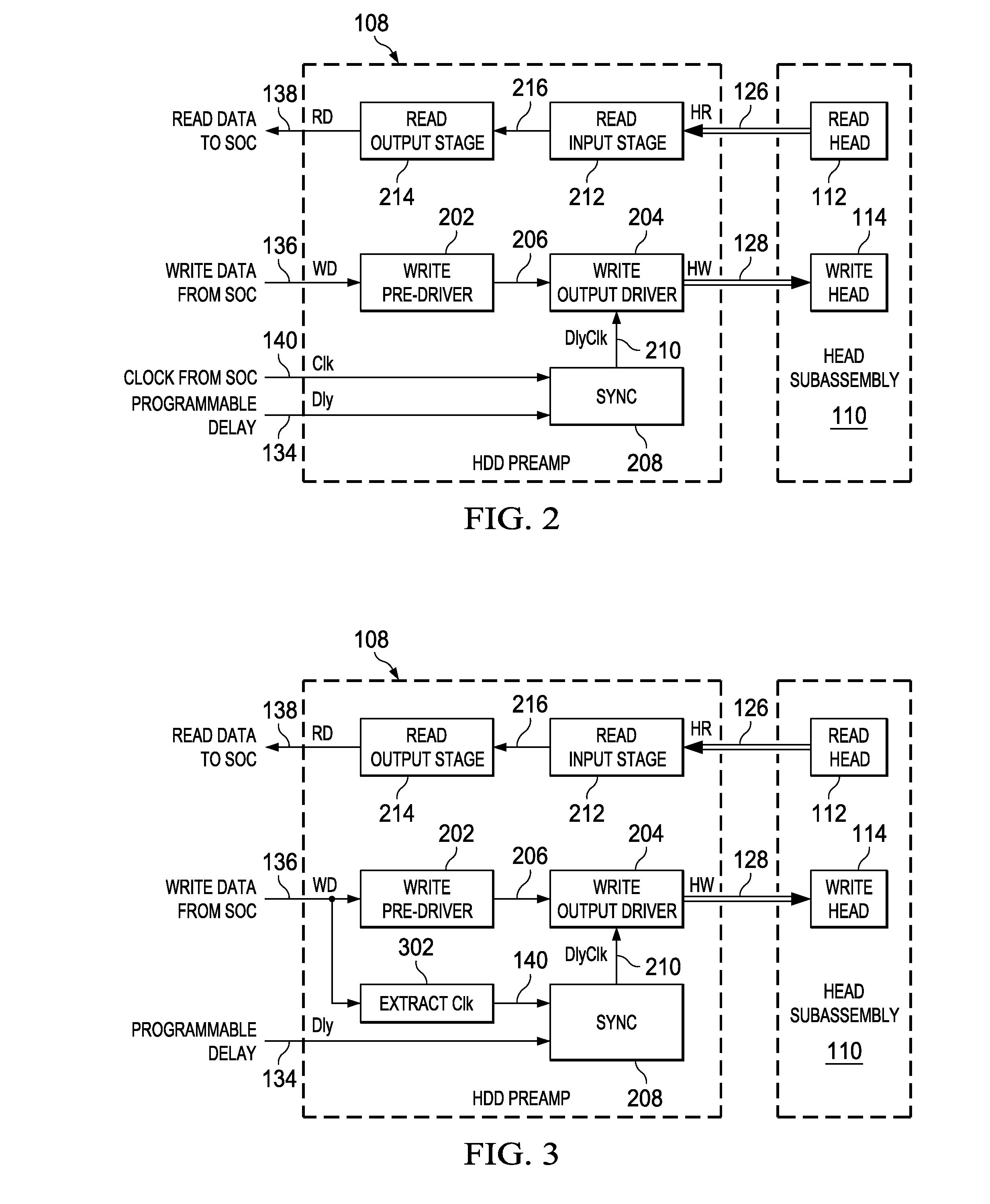

Preamplifier and method for synchronization with bit patterned media

ActiveUS20100246048A1Accurate timingReduce time uncertaintyPatterned record carriersNanoinformaticsAudio power amplifierMagnetic storage

A preamplifier and method writes data synchronized with the passing of a write head in a magnetic storage device over bit islands in discrete patterned recording media. The preamplifier contains a write pre-driver that conditions write data, a synchronization circuit that accepts a delay offset value and a write clock and produces a delayed clock, and a write output driver that is gated by the delayed clock to produce write pulses for magnetizing the bit islands. Gating the write output driver using the delayed clock results in more accurate synchronization than delaying the write data into the preamplifier due to the reduction of the overall length and variability of interconnects and transistors in the intervening circuitry. Write clock generation circuitry, as well as bit position sensor circuitry for use with bit position signals produced by a read head or by a separate bit position sensor, are optionally integrated into the preamplifier, close to the write output driver and write head, for further improvements in delay accuracy and stability. Write pulses produced by the preamplifier are thus well aligned with the bit islands, resulting in higher magnetization and an improved bit error rate.

Owner:TEXAS INSTR INC

Apparatus, method and system for fabricating servo patterns on high density patterned media

An apparatus, system, and method are disclosed for utilizing a “shadow mask” approach to fabricate servo patterns on high density patterned media. The apparatus may include a deposition mask having a plurality of apertures generated by a conventional lithographic process. Material may be deposited onto a substrate through the deposition mask apertures from at least one deposition source oriented at unique deposition angles. In this manner, each aperture may correspond to multiple deposition locations. Apertures may be precisely dimensioned and positioned to create servo pattern features from the resulting deposition locations. The deposition mask may also include a plurality of bit pattern apertures adapted to direct a material to a plurality of deposition locations on the substrate, the deposition locations forming a bit pattern concurrent with formation of a servo pattern.

Owner:WESTERN DIGITAL TECH INC

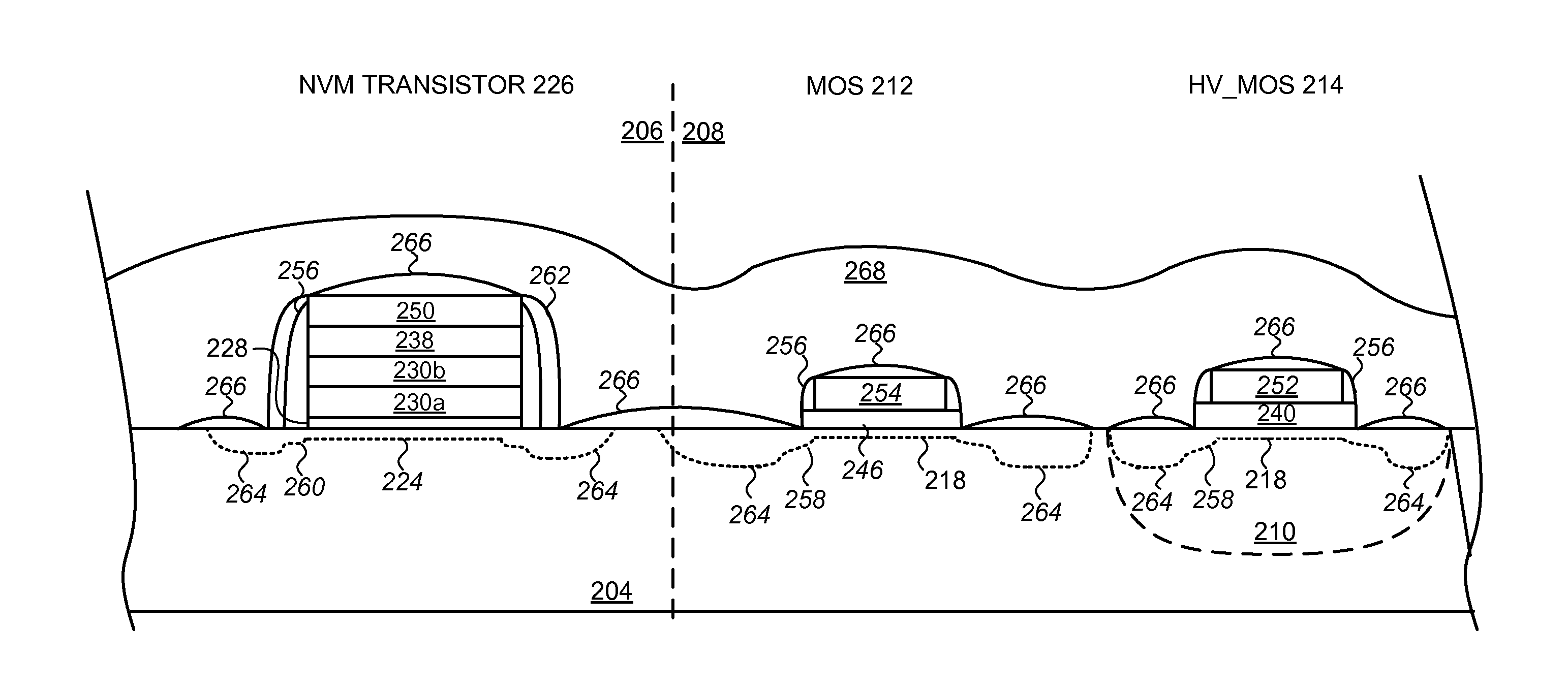

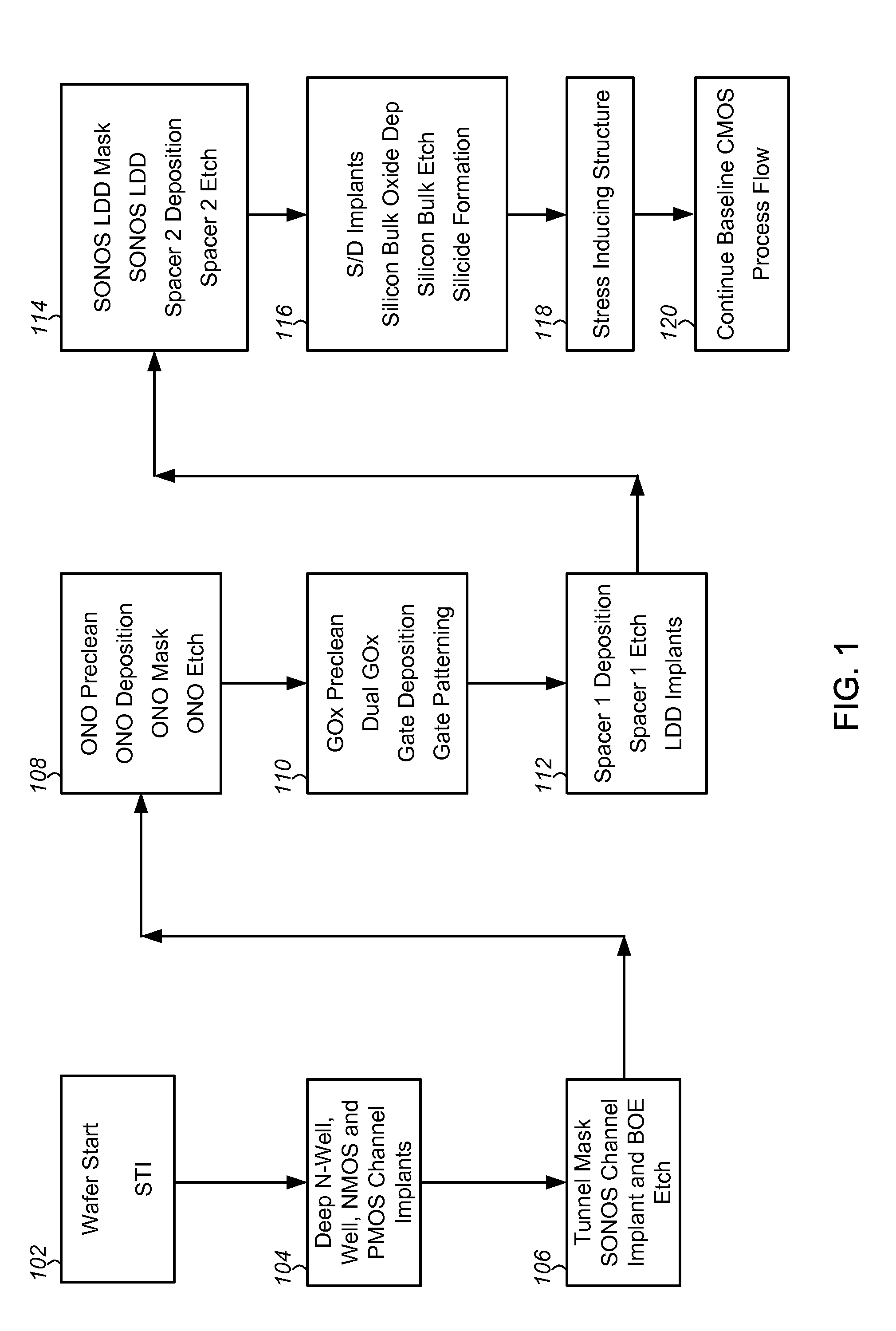

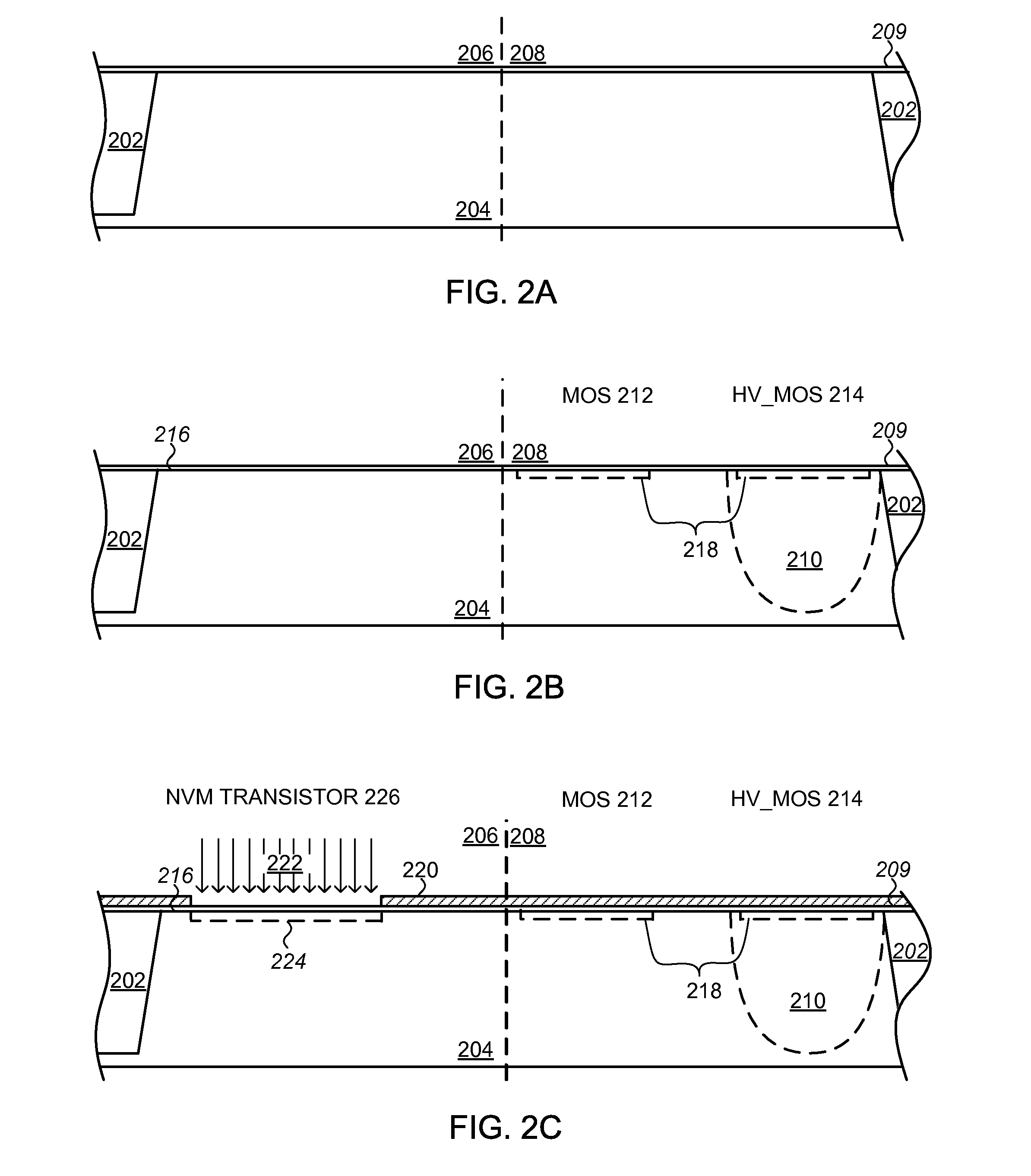

Embedded sonos based memory cells

Memory cells including embedded SONOS based non-volatile memory (NVM) and MOS transistors and methods of forming the same are described. Generally, the method includes: forming a dielectric stack on a substrate, the dielectric stack including a tunneling dielectric on the substrate and a charge-trapping layer on the tunneling dielectric; patterning the dielectric stack to form a gate stack of a NVM transistor of a memory device in a first region of the substrate while concurrently removing the dielectric stack from a second region of the substrate; and performing a gate oxidation process of a baseline CMOS process flow to thermally grow a gate oxide of a MOS transistor overlying the substrate in the second region while concurrently growing a blocking oxide overlying the charge-trapping layer. In one embodiment, Indium is implanted to form a channel of the NVM transistor.

Owner:LONGITUDE FLASH MEMORY SOLUTIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com