MOD method for preparing LSCO conductive film on biaxial texture NiW alloy

A technology of lanthanum strontium cobalt oxide and conductive thin film is applied in the field of YBCO superconducting tape to achieve the effects of reducing manufacturing cost, preventing oxidation and simplifying quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

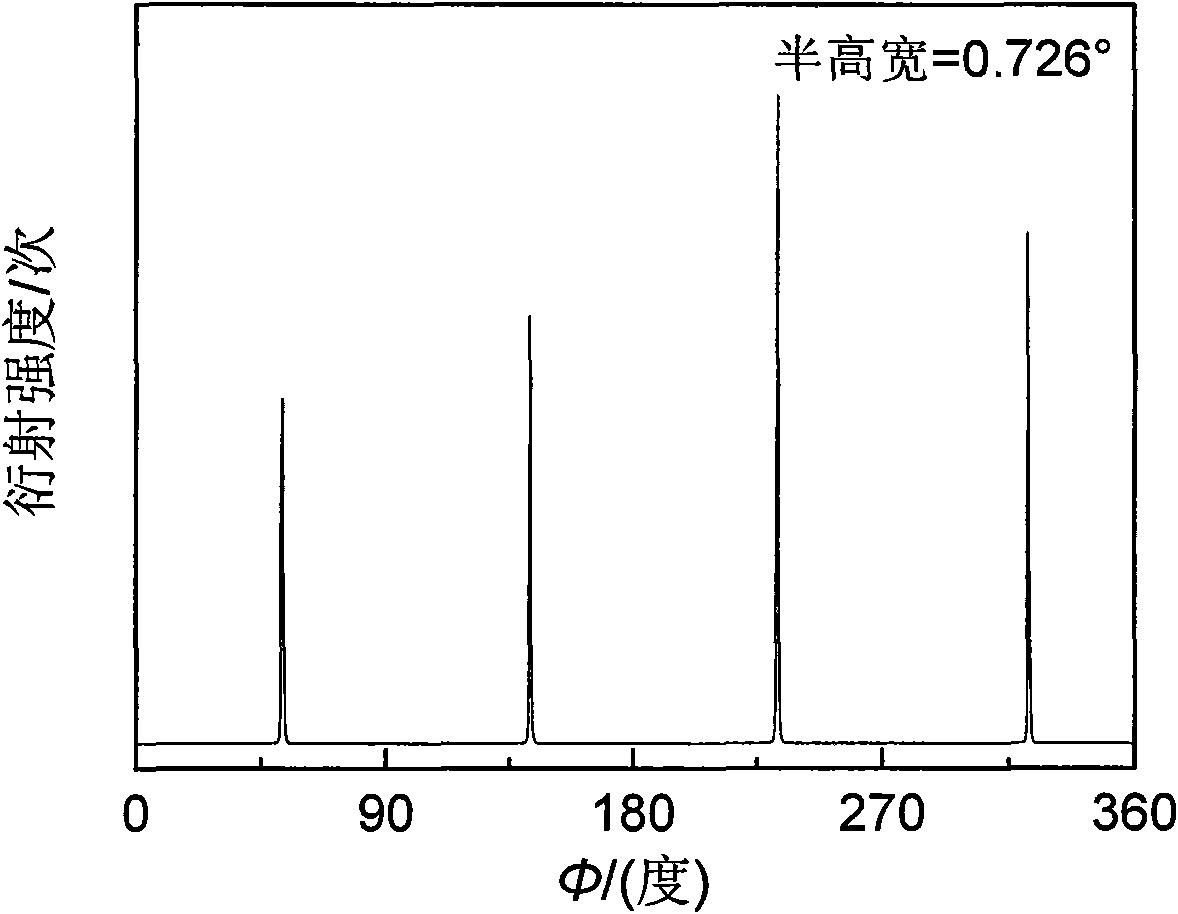

Image

Examples

Embodiment 1

[0024] The process steps of preparing lanthanum strontium cobalt oxide conductive thin film on biaxially textured NiW alloy by MOD method are as follows.

[0025] Strontium acetate (C 4 h 6 SrO 4 ), lanthanum acetate (C 6 h 9 LaO 6 1.5H 2 O) and cobalt acetate (C 4 h 6 CoO 4 4H 2 O) Three kinds of salts are dissolved step by step into propionic acid (C 2 h 5 COOH), a mixed solution of strontium acetate, lanthanum acetate and cobalt acetate was prepared. which is:

[0026] Strontium acetate (C 4 h 6 SrO 4 ) into propionic acid (C 2 h 5 COOH), stirring to dissolve, and adding lanthanum acetate (C 6 h 9 LaO 6 1.5H 2 (0), stirring and dissolving, then adding cobalt acetate (C) in the propionic acid solution of strontium acetate and lanthanum acetate obtained 4 h 6 CoO 4 4H 2 O), stirred to dissolve.

[0027] Control the molar ratio of lanthanum acetate, strontium acetate and cobalt acetate three kinds of salts to be lanthanum acetate: strontium acetate: c...

Embodiment 2

[0037] The process steps of preparing lanthanum strontium cobalt oxide conductive thin film on biaxially textured NiW alloy by MOD method are as follows.

[0038] Strontium acetate (C 4 h 6 SrO 4 ), lanthanum acetate (C 6 h 9 LaO 6 1.5H 2 O) and cobalt acetate (C 4 h 6 CoO 4 4H 2 O) Three kinds of salts are dissolved step by step into propionic acid (C 2 h 5 COOH), a mixed solution of strontium acetate, lanthanum acetate and cobalt acetate was prepared. which is:

[0039] Strontium acetate (C 4 h 6 SrO 4 ) into propionic acid (C 2 h 5 COOH), stirring to dissolve, and adding lanthanum acetate (C 6 h 9 LaO 6 1.5H 2 (0), stirring and dissolving, then adding cobalt acetate (C) in the propionic acid solution of strontium acetate and lanthanum acetate obtained 4 h 6 CoO 4 4H 2 O), stirred to dissolve.

[0040] Control the mol ratio of lanthanum acetate, strontium acetate and cobalt acetate three kinds of salts to be lanthanum acetate: strontium acetate: cob...

Embodiment 3

[0048] The process steps of preparing lanthanum strontium cobalt oxide conductive thin film on biaxially textured NiW alloy by MOD method are as follows.

[0049] Strontium acetate (C 4 h 6 SrO 4 ), lanthanum acetate (C 6 h 9 LaO 6 1.5H 2 O) and cobalt acetate (C 4 h 6 CoO 4 4H 2 O) Three kinds of salts are dissolved step by step into propionic acid (C 2 h 5 COOH), a mixed solution of strontium acetate, lanthanum acetate and cobalt acetate was prepared. which is:

[0050] Strontium acetate (C 4 h 6 SrO 4 ) into propionic acid (C 2 h 5 COOH), stirring to dissolve, and adding lanthanum acetate (C 6 h 9 LaO 6 1.5H 2 (0), stirring and dissolving, then adding cobalt acetate (C) in the propionic acid solution of strontium acetate and lanthanum acetate obtained 4 h 6 CoO 4 4H 2 O), stirred to dissolve.

[0051] Control the molar ratio of lanthanum acetate, strontium acetate and cobalt acetate three kinds of salts to be lanthanum acetate: strontium acetate: c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com