Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

594results about How to "Improve the plating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing hot-dip galvanized steel sheet having high strength and also being excellent in formability and galvanizing property

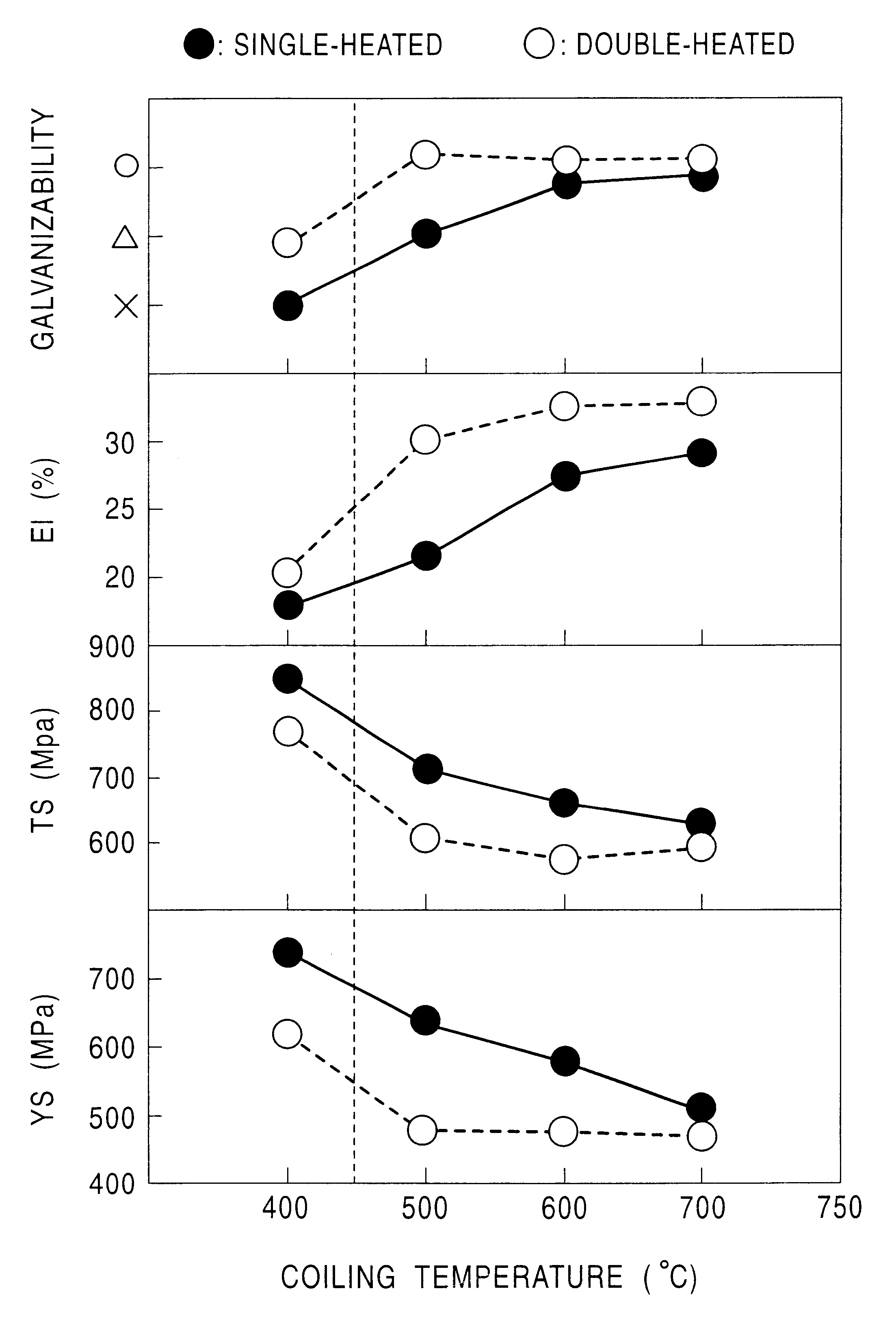

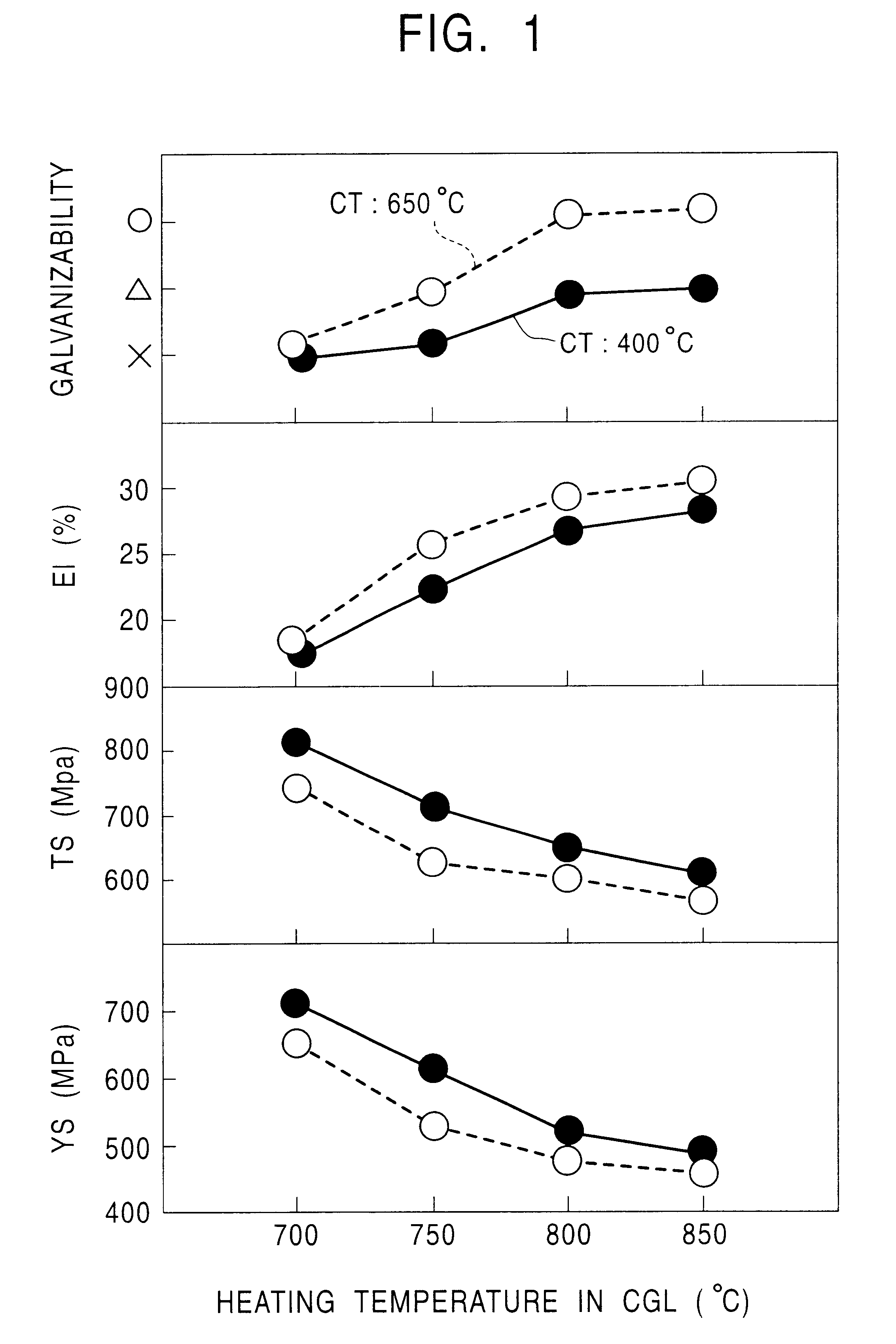

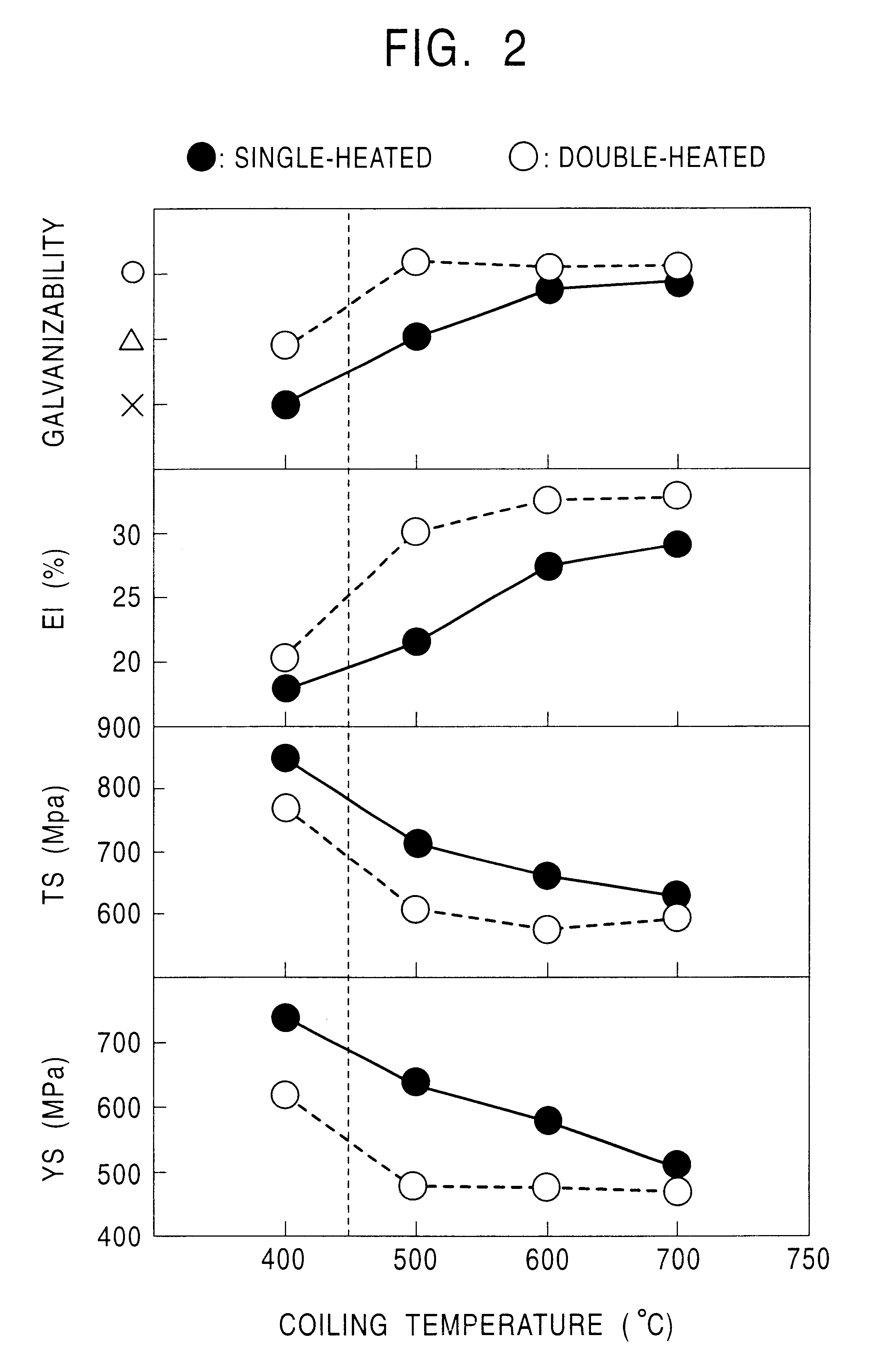

InactiveUS6537394B1Satisfactory workabilityHigh strengthHot-dipping/immersion processesFurnace typesSheet steelBand shape

A hot-dip galvanized high-strength steel sheet having superior workability and galvanizability containing:0.01% to 0.20% by weight of C;1.0% by weight or less of Si;more than 1.5% to 3.0% by weight of Mn;0.10% by weight or less of P;0.05% by weight or less of S;0.10% by weight or less of Al;0.010% by weight or less of N;0.010% to 1.0% by weight in total of at least one element selected from the group consisting of Ti, Nb, and V; andthe balance being Fe and incidental impurities;in which the steel sheet has the metal structure in which the areal rate of the ferrite phase is 50% or more, the ferrite phase has an average grain diameter of 10 mum or less, and the thickness of a band-like structure composed of the second phase satisfies the relationship Tb / T<=0.005, where Tb is the average thickness in the sheet thickness direction of the band-like structure and T is the thickness of the steel sheet, and a method for producing the same. To provide a method for producing a hot-dip galvanized high-strength steel sheet in which superior workability and high strength are obtained and moreover satisfactory galvanizability is obtained when galvanizing is performed using facilities such as a continuous galvanizing line.

Owner:KAWASAKI STEEL CORP

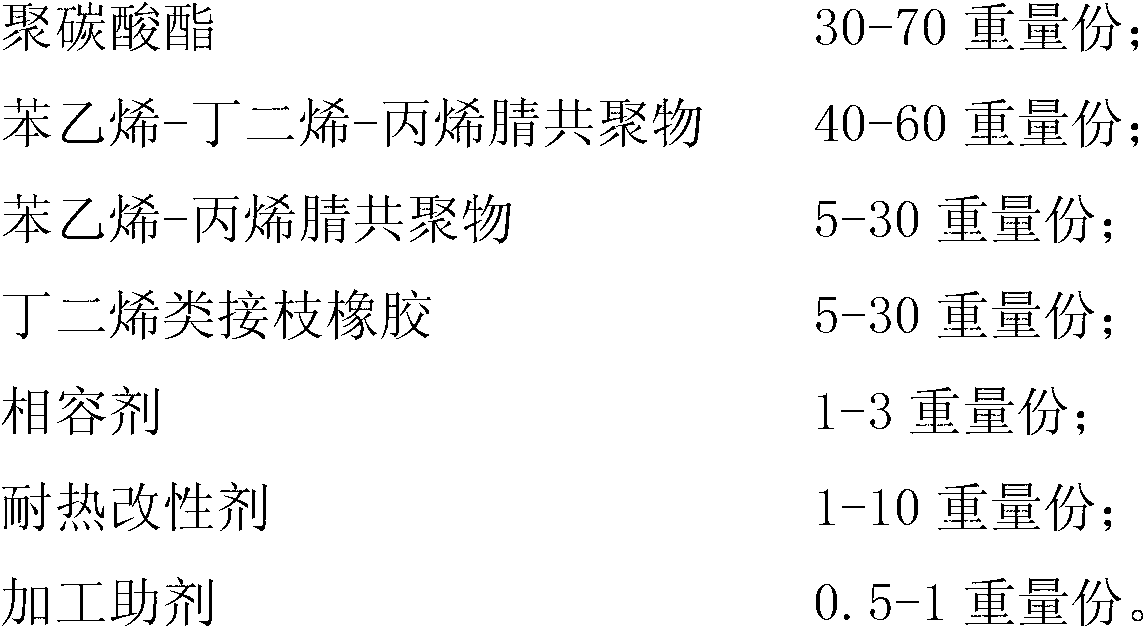

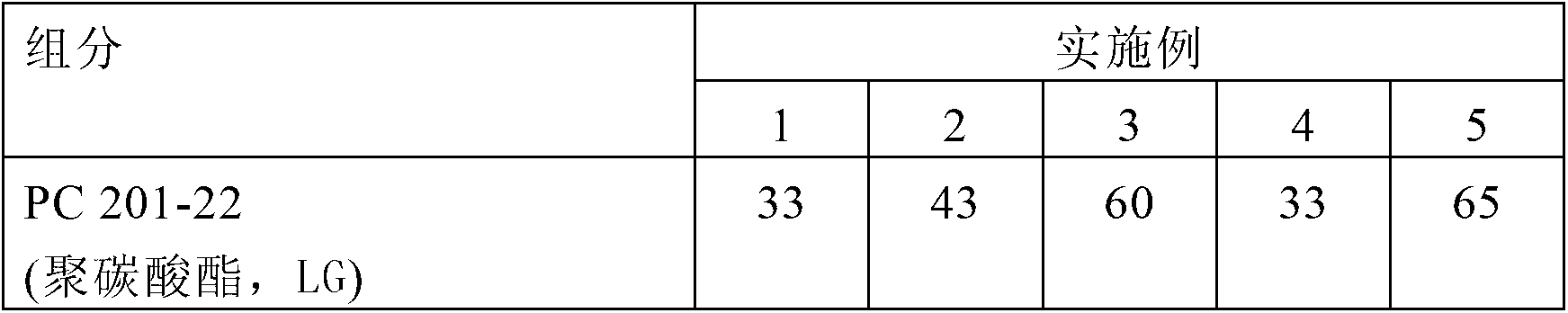

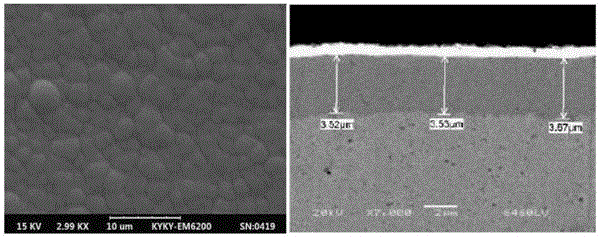

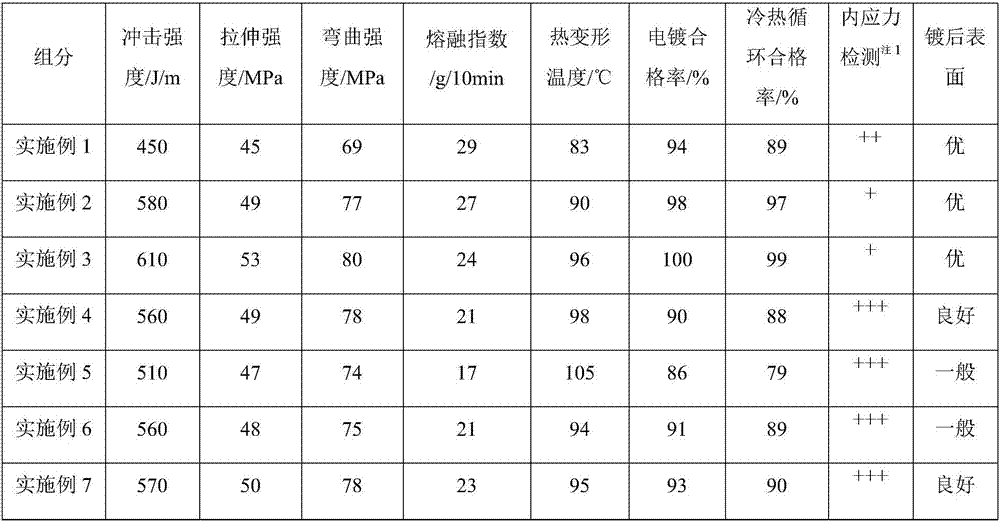

Electroplating PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

The invention provides an electroplating PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material and a preparation method thereof. The electroplating PC / ABS alloy material comprises the following components in parts by weight: 30-70 parts of PC, 40-60 parts of ABS, 5-30 parts of styrene-acrylonitrile copolymer, 5-30 parts of butadiene graft rubber, 1-3 parts of compatilizer, 1-10 parts of heat-resistance modifier and 0.5-1 part of processing assistant. The alloy material provided by the invention has the advantages of favorable electroplating properties, excellent mechanical properties and favorable heat resistance, and can be used for designing automobile internal and external ornaments, including heat dissipation grids, door grips, vehicle logos, instrument panel decorating strips and the like.

Owner:中广核俊尔(上海)新材料有限公司

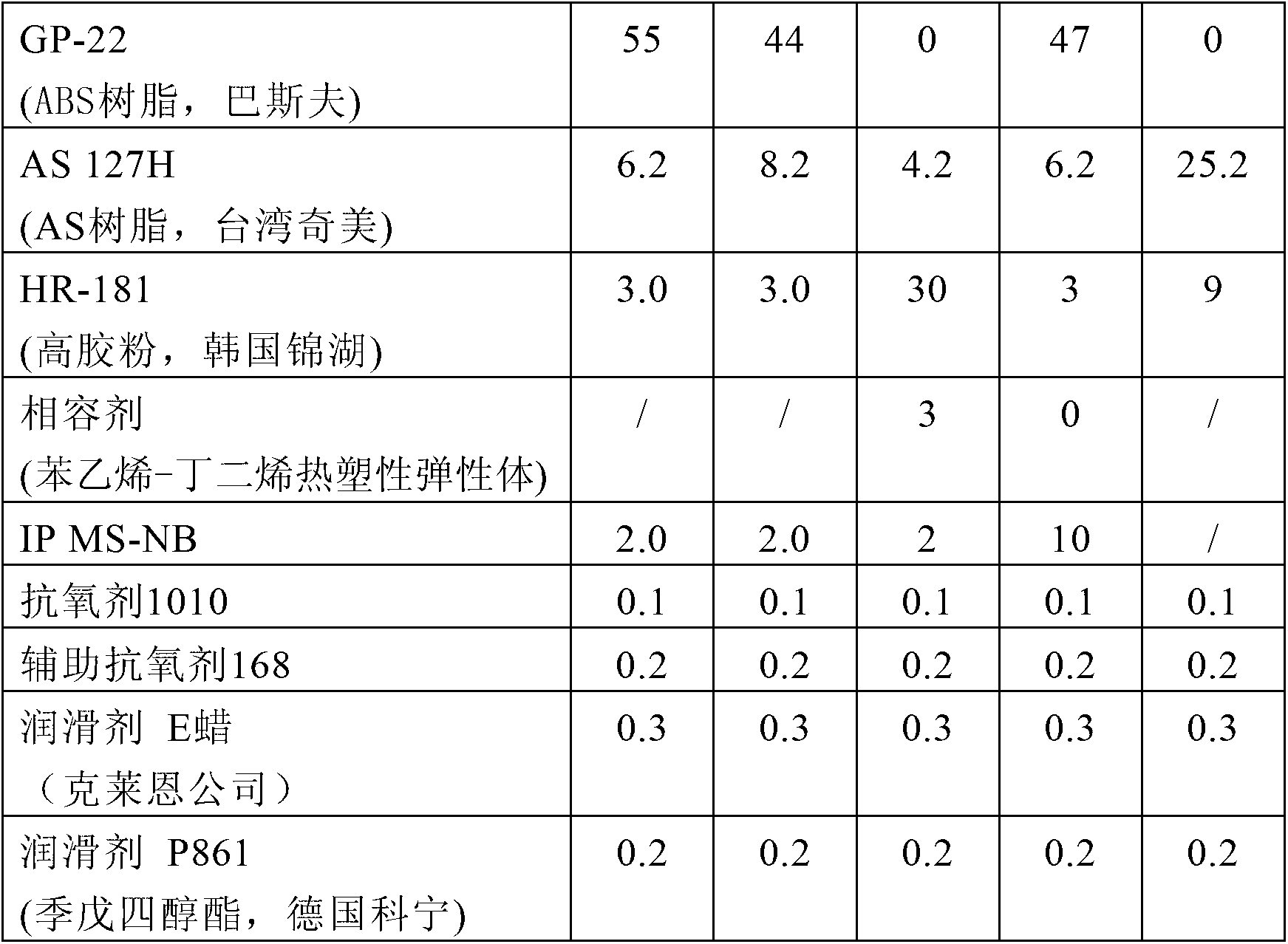

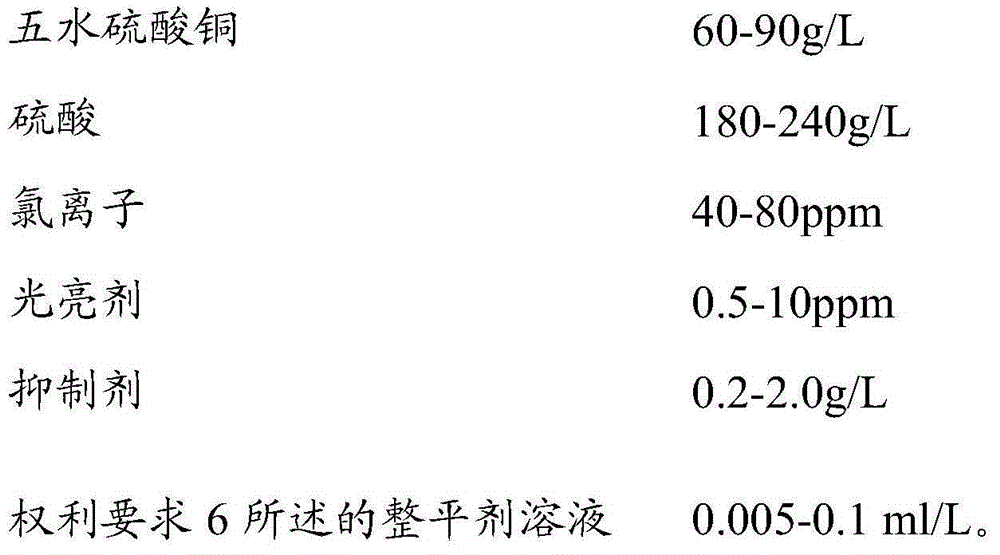

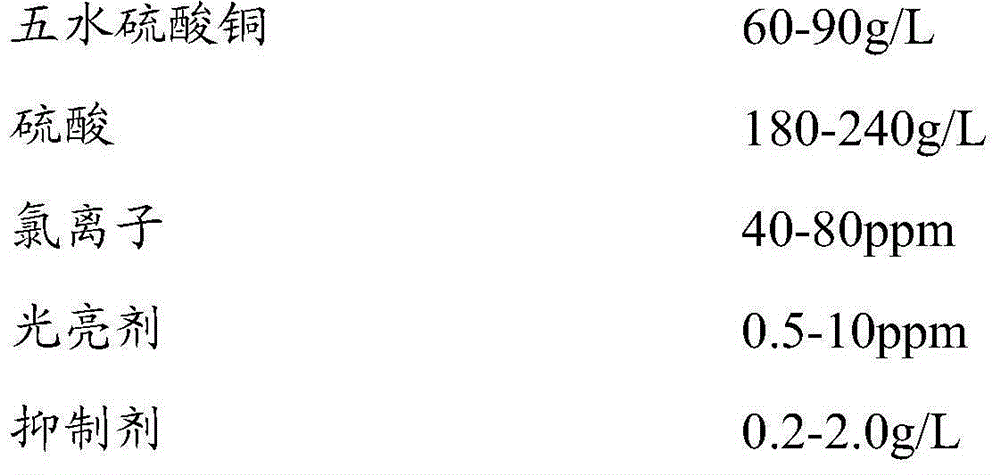

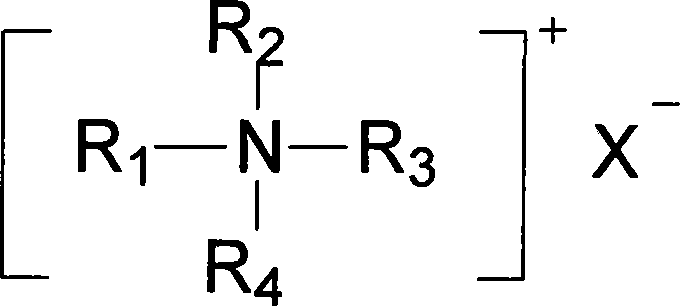

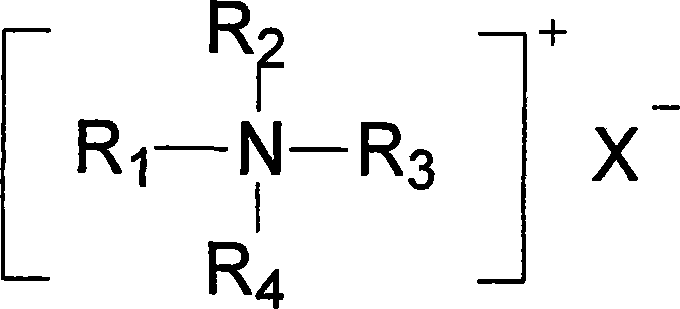

Leveling agent solution and preparation method and application thereof

ActiveCN105002527AHas a leveling effectHas a bright effectAlkyl transferNitrogenous heterocyclic compound

The invention relate to a leveling agent solution and a preparation method and application thereof. The leveling agent solution is obtained in the mode that a nitrogenous heterocyclic compound and a diepoxide compound are polymerized and then 1,3-propane sultone is used for an alkylation reaction. The leveling agent solution, a brightener and an inhibitor are used together, and a good electroplating effect can be obtained in electroplating of circuit board through holes.

Owner:GUANGDONG GUANGHUA SCI TECH

Additive for heat zinc coating auxiliary agent

InactiveCN101126142AHigh activityIncrease profitHot-dipping/immersion processesSlagSurface-active agents

The invention provides an additive used in hot-dip galvanizing assistant plating agent, belonging to the technical field of metal material plating. The invention is used for solving the problem of assistant plating efficiency. The technical proposal of the invention is that the additive is a de-ionized water solution; the water solution contains cation surface active agent and organic solvent of the long chain alkyl; the content of the long chain alkyl cation surface active agent is 100 to 800 gram per liter; the organic solvent can be ethanol, isopropyl alcohol, acetone or one of nickel and N-dimethyl formamide, with adding content of 30 to 160 gram per liter. The invention has the advantages that the assistant plating agent is made and the made element have a plating face with excellent wettability and compatibility, which can increase the activity and the utilization rate, improve the assistant plating efficiency, prevent plated element from escaping, prevent the plated element which is assistant plated from being secondarily oxidized in air, reduce zinc slag, prevent the zinc liquid from splashing and increase the surface quality of the made element. Furthermore, the invention can be directly added into the assistant agent, and then is evenly mixed, with the character of easy operation. The invention is not limited by the temperature of the assistant plating agent so that the invention can be used under room temperature.

Owner:陈冬

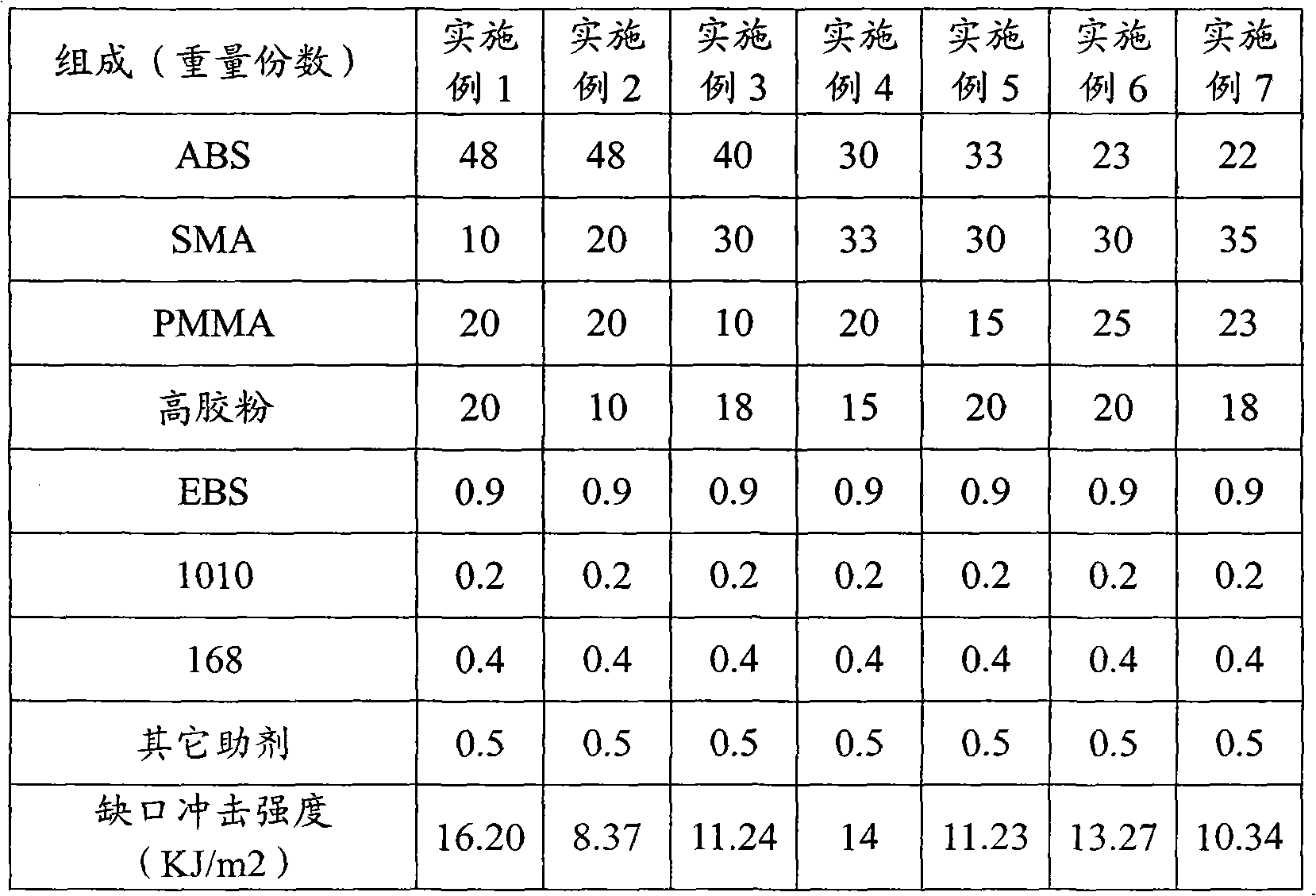

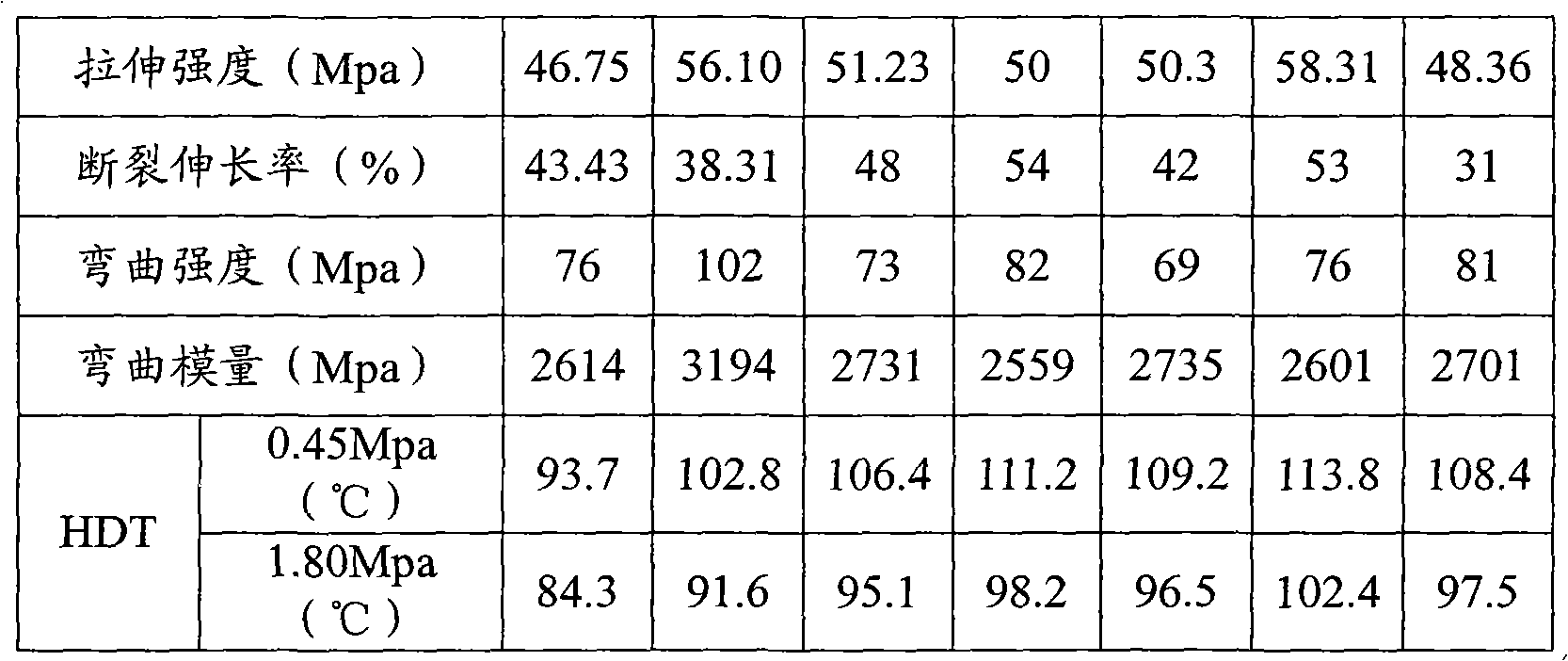

Heat-resisting ABS modified material and preparation method thereof for plating

ActiveCN101768320AImprove heat resistance of ABSImproves flow and flexural strengthPolybutyl methacrylateFlexural strength

The invention discloses a heat-resisting ABS modified material and a preparation method thereof for plating; the heat-resisting ABS modified material for plating is prepared by raw materials of acrylonitrile-butadiene-styrene copolymer (ABS), styrene-maleic anhydride copolymer (SMA), poly methyl methacrylate (PMMA), toughened rubber powder, antioxidant, a dispersing agent and other additives; the preparation method includes that: the raw materials are mixed and fed to a double-screw extruder for granulation, so as to obtain end products. The ABS modified material not only has high deformation temperature (HDT), but also has good plating effect, better impact toughness and flexural strength, and is applicable to parts requiring heat resistance and baking finish treatment.

Owner:徐东

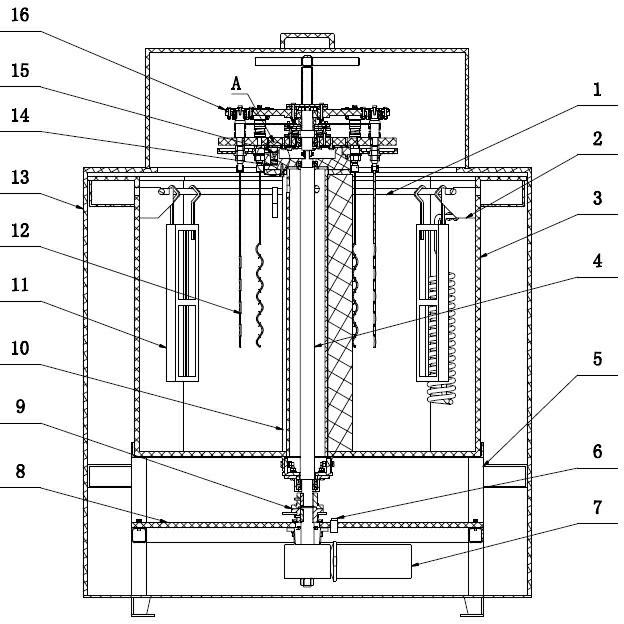

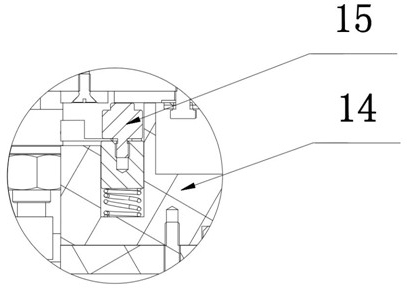

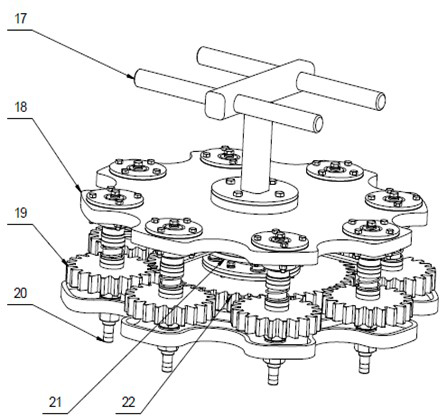

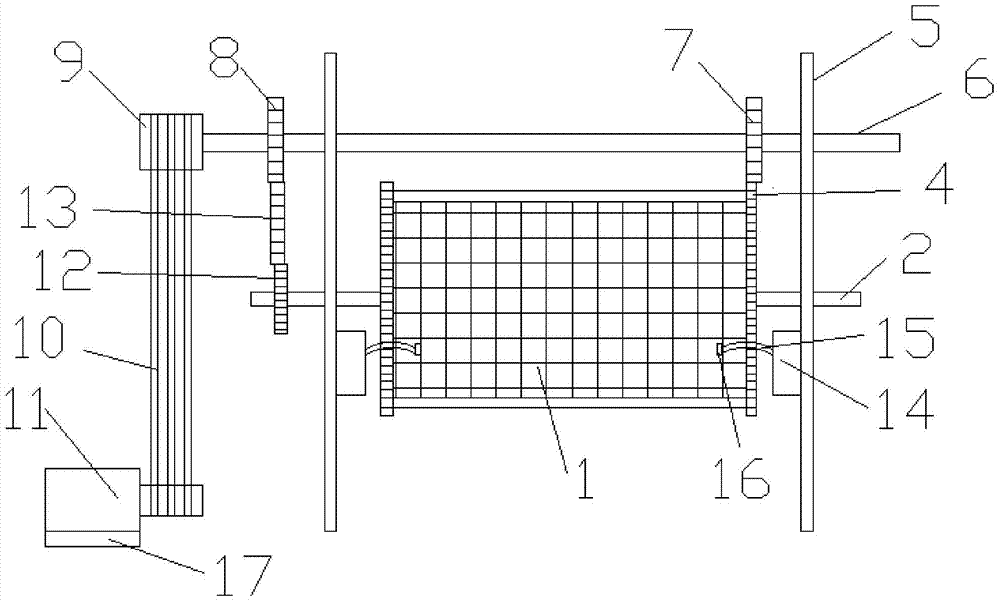

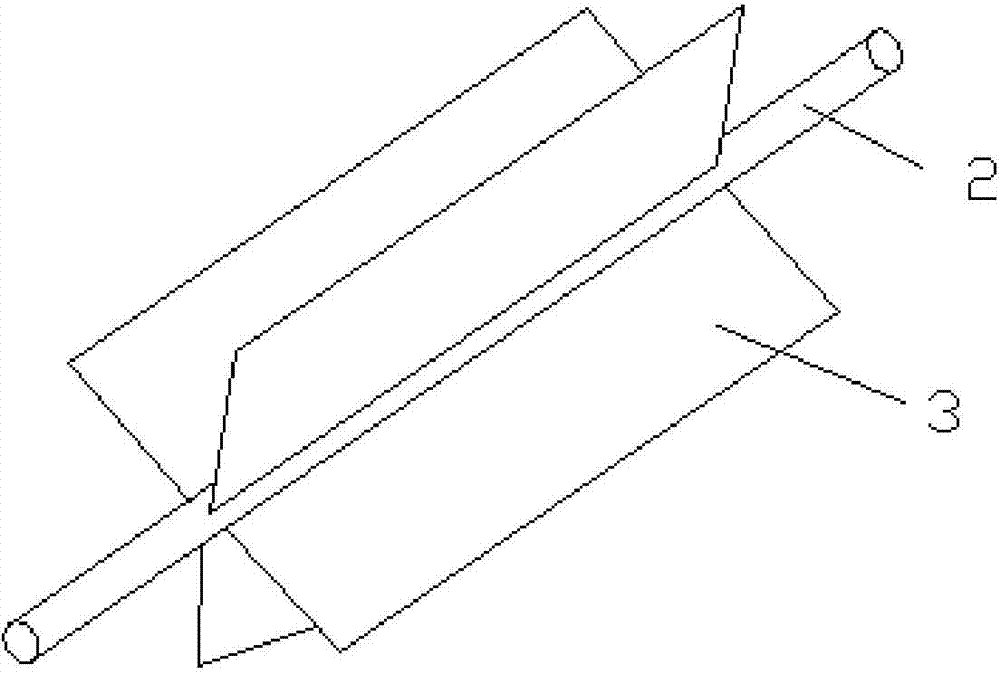

Rotary electroplating device

ActiveCN102505137AImprove uniformityGood plating effectElectrolysis componentsRotational axisReduction drive

The invention discloses a rotary electroplating device, comprising an electroplating groove, a driving mechanism located on an electroplating groove bracket and a conductive system for electroplating. The driving mechanism comprises a motor reducer, a shaft coupler and a center rotating shaft. The shaft coupler is connected with the lower end of the center rotating shaft; and the upper end of the center rotating shaft upwards stretches out the electroplating groove and is connected with a rotary disc system capable of rotating along with the center rotating shaft. The rotary disc system comprises a rotary flange disc with a system center shaft, and a gear mechanism which can be driven by the center rotating shaft to rotate and is connected on the rotary flange disc. According to the rotary electroplating device disclosed by the invention, not only the revolution of a working piece around the center rotating shaft but also the autorotation of the working piece exist in the solution by a planet gear mechanism. Therefore, the uniformity of a plating layer of the working piece is further improved in a manner of combining the revolution with the autorotation. The electroplating effect is good for the complex working pieces, particularly shell parts, and the uniform plating layer can be obtained simultaneously.

Owner:HENGLI ELETEK

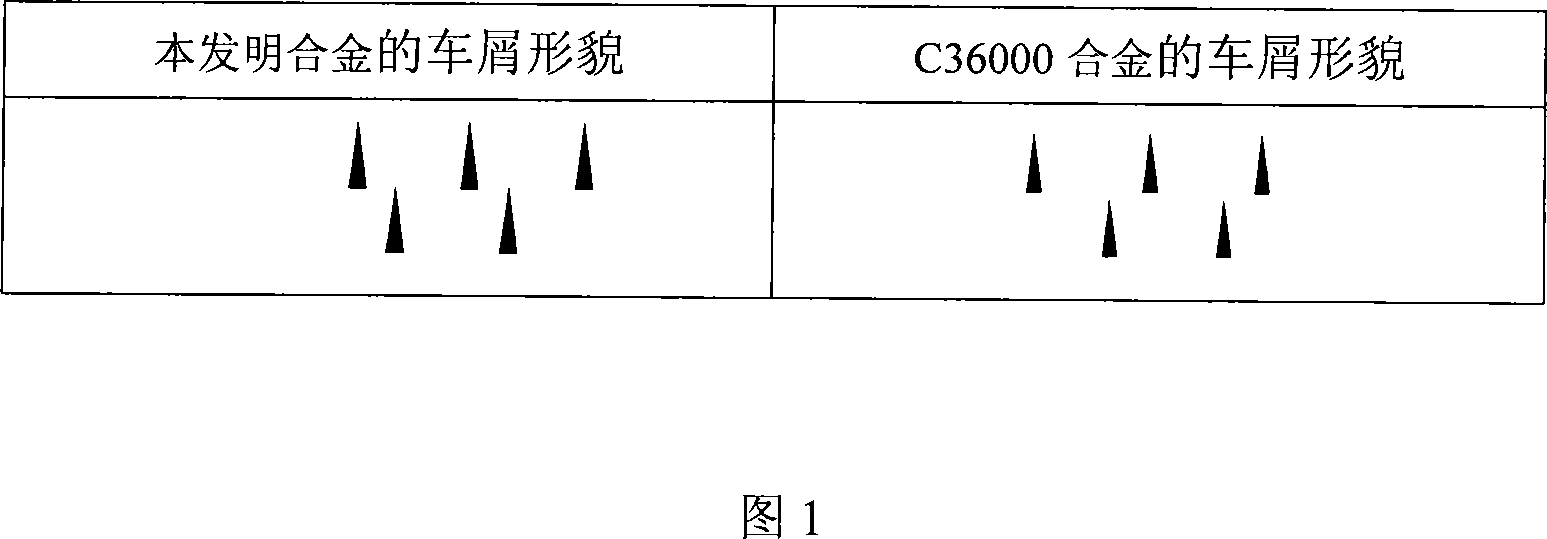

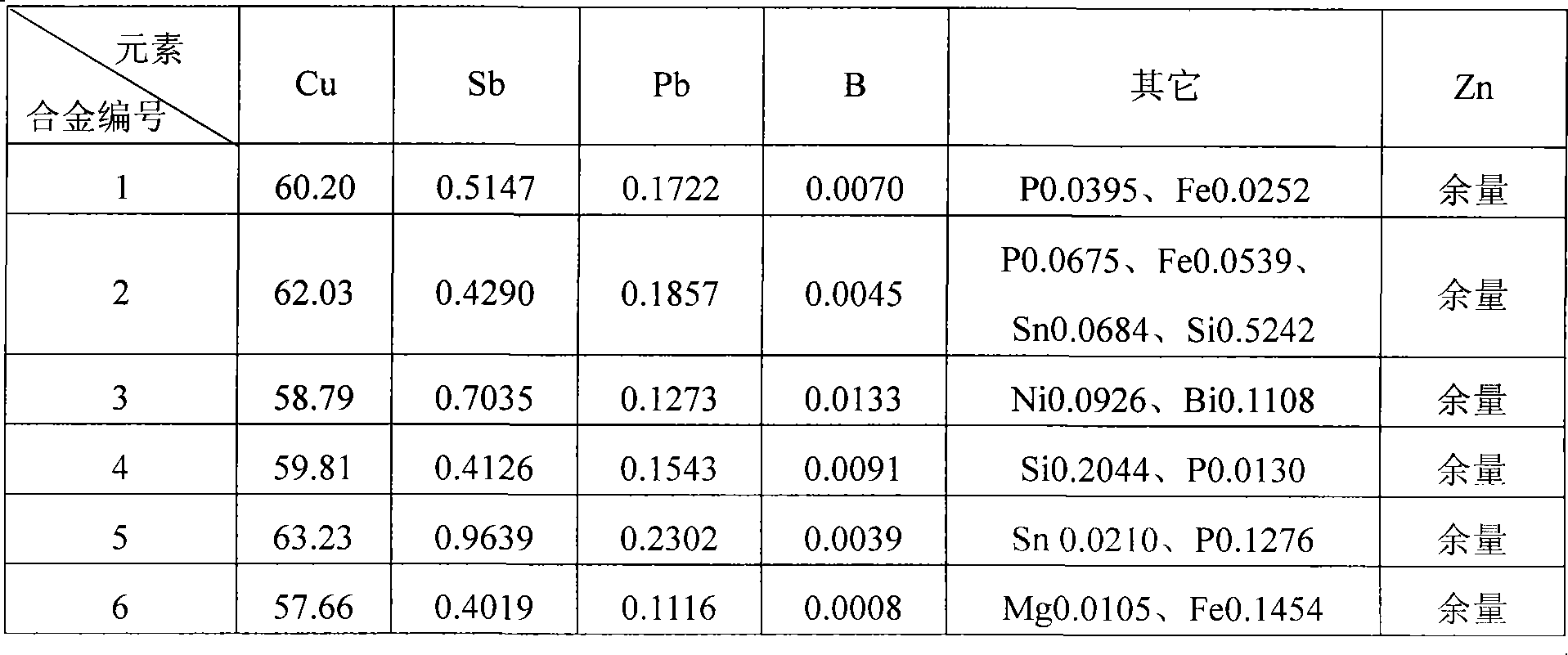

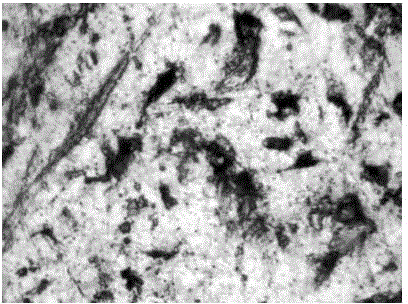

Low-lead-boron easy-cutting antimony brass alloy and method for manufacturing same

ActiveCN101113501AImprove mechanical propertiesExcellent thermoformabilityMechanical propertyImpurity

The invention discloses a low lead and boron easy-cutting antimony brass alloy and a preparation method thereof. The chemical components of the low lead brass alloy are that: 55-65wt percent of copper, 0.4-1.2wt percent of antimony, 0.1-0.3wt percent of lead, 0.0003-0.05 wt percent of boron, 0.05-1.5wt percent of other components, wherein, the other components comprise at least one of the elements of: magnesium, iron, tin, nickel, silicon, bismuth and phosphorus, the other elements are zinc and inevitable impurities. The production method is that: the low lead and boron easy-cutting antimony brass alloy is treated by an alloying treatment and is smelted by a cover protection method to ensure the metal antimony, boron to become intermetallic compound through fast solid solution in the melten brass; the bass casting ingots are made by continuous casting under 1020 DEG C; the bass casting is pressed under a large pressing ratio under the temperature between 680 DEG C and 750 DEG C, anneal in the middle thermal treatment is under 450-650 DEG C according to cold process conditions, when the temperature is below 400 DEG C, anneal for eliminating stress is made. The invention has the advantages that the products have good mechanical, thermoforming, corrosion resistance, polishing and electroplating performance, and successfully solves the problems of singularity of waste chips, recovery of variety of components and comprehensive utilization and recycling. The recovery can be singularity or be comprehensive such as comprehensive recovery of the waste chips of the Cu-Zn-Si system, Cu-Zn-Bi system and Cu-Zn-Sb system alloy. At the same time the lead and brass waste chips can also be partly recovered and utilized.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Whole sulphate type trivalent chromium plating solution and electroplating method using the same

The invention relates to full sulfate type trivalent chromium electroplating solution. The electroplating solution includes chromic sulfate, potassium sulfate and / or sodium sulfate, boracic acid, complexing agent and water, wherein, the electroplating solution also includes additive A and additive B, the additive A is selected from one or more of OP emulsifier, water soluble borofluoride, water soluble silico fluoride, vinyl diamine acetic acid, cystine, 1,4-butynediol, thiourea and glycol; the additive B is selected from one or more of O-Sulfonylbenaylsuamine, glycerine, water soluble sulphosuccinate, Docusate sodium and water soluble alkyl ether sulfate. The electroplating solution provided by the invention ensures the current density scopes of the coating and the luminous area to be both improved to a great extent.

Owner:BYD CO LTD

Hard aluminum alloy for metal die casting of precision electronic product structural member

The invention discloses a hard aluminum alloy for metal die casting of a precision electronic product structural member. The hard aluminum alloy is prepared by antigravity metal die casting and natural ageing heat treatment. The hard aluminum alloy comprises, by mass, 21-30% of zinc, 5.7-7.2% of silicon, 2.0-2.4% of copper, 0.17-0.35% of manganese, 0.2-0.6% of trace alloy element and the balance aluminum and unavoidable impurities with iron content of 0.27% or less. The invention also discloses a preparation method of the hard aluminum alloy. The hard aluminum alloy can be prepared by high precision die casting, has high strength, can be subjected to high quality surface treatment, can be used for production of a high precision structural member of small, thin and light electronic products, and is suitable for large parts of spaceflight and aviation, automobiles, high-speed railway, steamships and yachts and daily hardware products.

Owner:陈灿

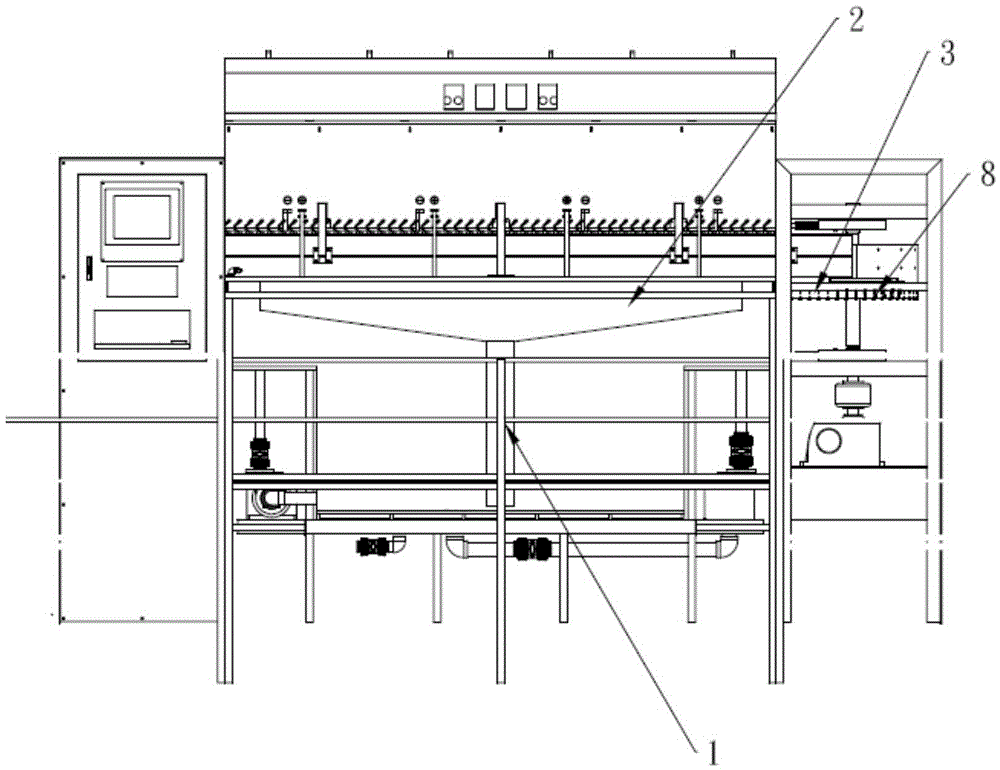

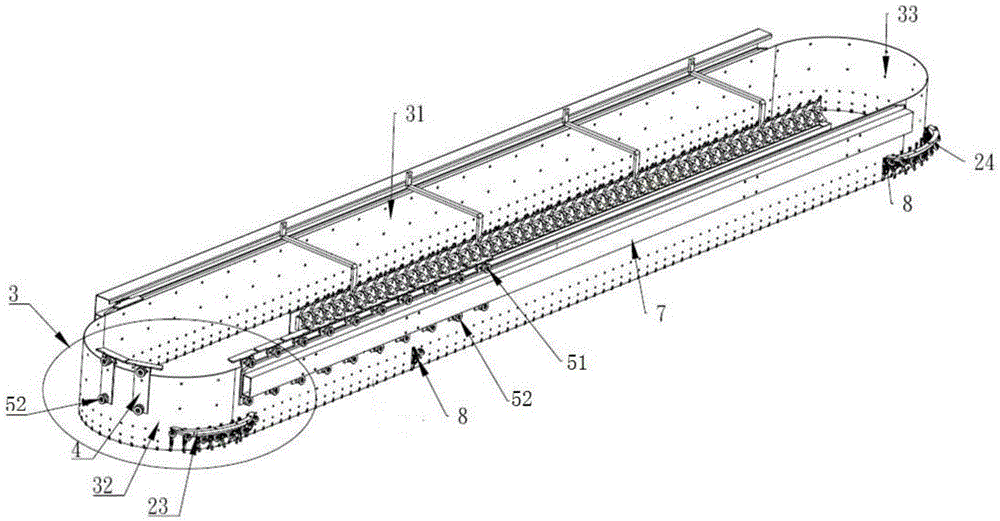

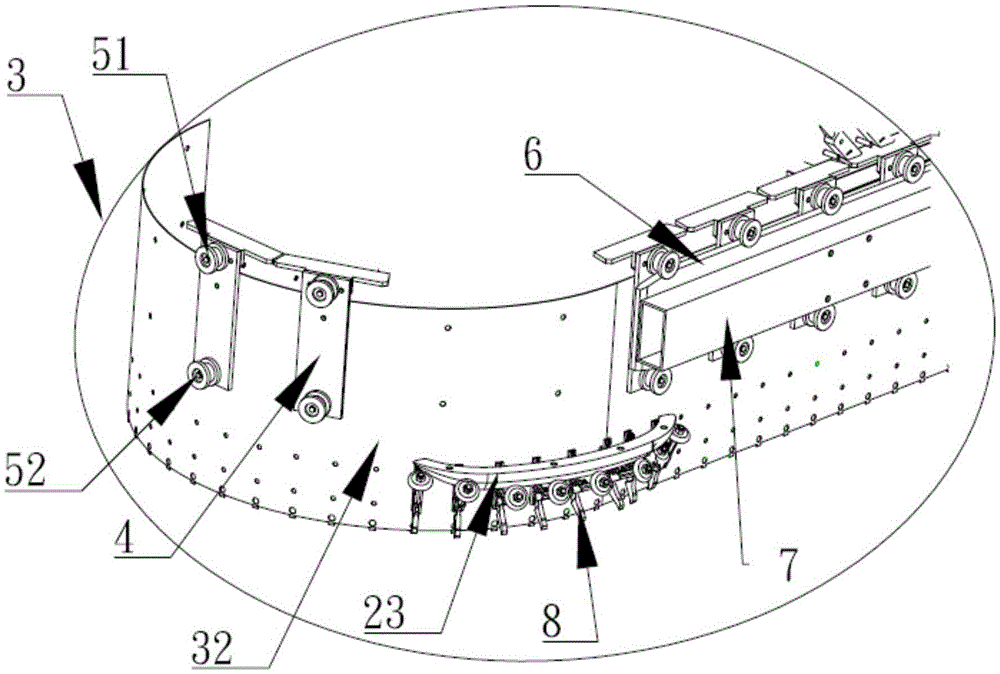

Electroplating device and continuous vertical electroplating production line

ActiveCN105648512AUniform platingEasy to operateElectrolysis componentsCharge manipulationProduction lineEngineering

The invention discloses an electroplating device and a continuous vertical electroplating production line. The electroplating device comprises a rack, an electroplating bath arranged on the rack, a conveying belt arranged in the electroplating bath, a drive mechanism for driving the conveying belt to drive a substrate fixed to the bottom of the conveying belt to move in the electroplating bath and a limiting mechanism arranged on the rack. The continuous vertical electroplating production line comprises a continuous feeding system, the electroplating device and a continuous collecting system. In the moving process of the conveying belt, downward movement of the conveying belt can be limited by the limiting mechanism, so that the conveying belt is kept running at the same height in the electroplating bath all the time, then the substrate fixed to the edge of the bottom of the conveying belt runs at the same height, it is ensured that the substrate is evenly electroplated in the electroplating bath, and the electroplating performance of the electroplating device is improved.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Resin composition for direct metal plating, molded article, and metal-plated molded article

ActiveUS20090226727A1Improve the plating effectImprove impact resistanceSynthetic resin layered productsSurface reaction electrolytic coatingShell moldingAlloy

The objective of the present invention is to provide a resin composition for direct plating whose plating performance such as depositibility and appearance after forming a metal film including copper film and the like by electroplating in direct plating method is excellent, a molded article comprising this composition, and a plated article having a metal film or an alloy film, formed by direct plating. The present composition is a thermoplastic resin composition containing a rubber-reinforced vinyl-based resin and the rubber-reinforced vinyl-based resin comprises a diene-based rubbery polymer [a1] and an ethylene•α-olefin-based rubbery polymer [a2], the total amount of the diene-based rubbery polymer [a1] and the ethylene•α-olefin-based rubbery polymer [a2] is from 3 to 30% by mass based on the thermoplastic resin composition, and the ratio of the ethylene•α-olefin-based rubbery polymer [a2] to the total amount is from 0.01 to 0.4.

Owner:TECHNO UMG CO LTD

Magnesium-lithium alloy surface electrocoppering solution and magnesium-lithium alloy surface electrocoppering treatment method

InactiveCN102776535AImprove manufacturing speedImprove corrosion resistanceCopper platingPhytic acid

The invention provides magnesium-lithium alloy surface electrocoppering solution and a magnesium-lithium alloy surface electrocoppering treatment method. The method comprises the following steps that (1) the magnesium-lithium alloy surface is subjected to pretreatment; (2) the activation is carried out under the room temperature and ultrasonic conditions; (3) the zinc galvanizing is carried out at the temperature being 40 to 60 DEG C; and (4) the electrocoppering is carried out in copper plating solution; the electrocoppering solution consists of 50 to 70g / L of cupric pyrophosphate, 300g / L of potassium pyrophosphate, 40g / L of dipotassium phosphate, 40g / L of potassium sodium tartrate, 0.1 g / L of citric acid, 0.1g / L of phytic acid, 0.02 g / L of vanillin and the balance water; and the electrocoppering comprises the following conditions that the pH is 8 to 9, the temperature is 30 to 50 DEG C, the voltage is 2 to 4V, the current is 0.02 to 0.04 A, and the time is 20 to 40 minutes. The plating layer has the performance which is not reached by the existing magnesium-lithium alloy surface treatment method, meanwhile, the plating layer forming is fast, the plating layer forming speed is accelerated, the surface treatment efficiency is improved, the operation is simple and convenient, the production efficiency is high, and the large-scale popularization and the application are favorably realized.

Owner:HARBIN ENG UNIV

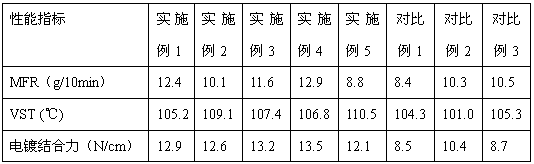

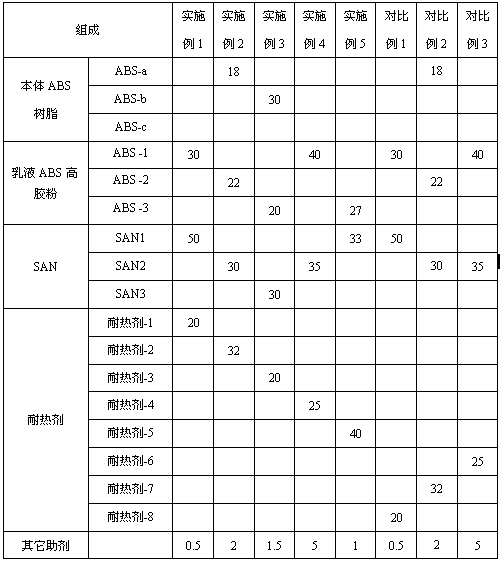

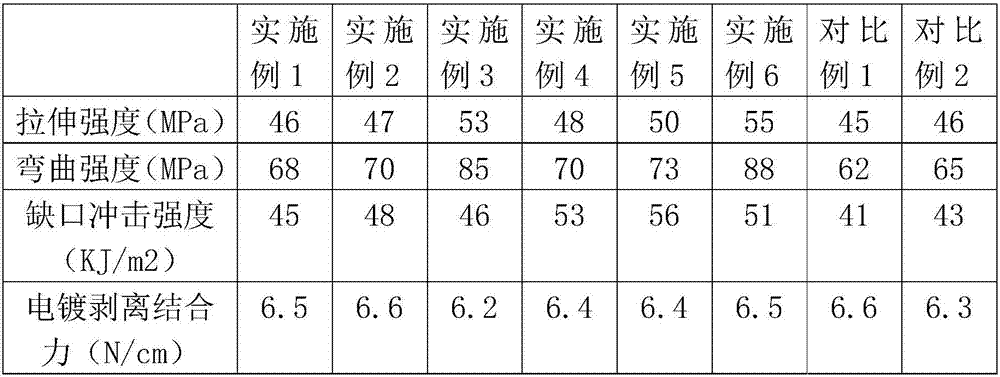

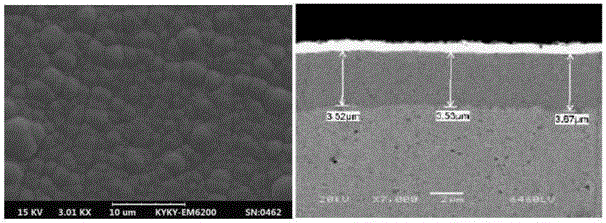

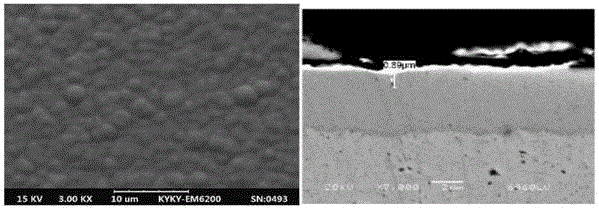

Heat-resisting ABS (Acrylonitrile-Butadiene-Styrene) resin applicable to electroplating and preparation method thereof

The invention relates to heat-resisting ABS (Acrylonitrile-Butadiene-Styrene) resin applicable to electroplating and a preparation method thereof. The heat-resisting ABS resin is prepared from the following ingredients in parts by weight: 0-30 parts of mass ABS resin, 20-40 parts of emulsion ABS rubber powder, 30-50 parts of styrene-acrylonitrile copolymer, 20-40 parts of heat resisting agent and 0.5-5 parts of other assistants, wherein the heat resisting agent is a quadripolymer based on four monomers including an N-phenyl maleimide monomer, an alpha-methyl styrene monomer, a styrene monomer and an acrylonitrile monomer, the weight percentage of the N-phenyl maleimide monomer is 5-20%, the weight percentage of the alpha-methyl styrene monomer is 40-70%, the weight percentage of the styrene monomer is 10-45%, the weight percentage of the acrylonitrile monomer is 10-45%, and the glass-transition temperature is 145-165 DEG C. According to the heat-resisting ABS resin applicable to electroplating and the preparation method thereof, through reasonably selecting the heat resisting agent, the heat resistance and plated layer binding force of the ABS resin are improved; and a heat-resisting master batch is not required to be prepared during preparation, so that the preparation is simple and easy to operate.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

High-strength electroplating PC/ABS alloy material and preparation method thereof

The invention discloses a high-strength electroplating PC / ABS alloy material and a preparation method thereof. The high-strength electroplating PC / ABS alloy material is prepared by comprising the following raw materials in parts by weight: 40-60 parts of PC, 40-60 parts of ABS, 5-10 parts of ABS-g-MAH compatilizer, 1-5 parts of GMA toughening agent, 0.5-1 part of nano calcium carbonate, 0.2-0.5 part of antioxidant 168, and 0.2-0.5 part of lubricant. By adding GMA toughening agent, and nano calcium carbonate in preparation of the PC / ABS alloy material, the modified PC / ABS alloy has higher tensile strength and bending strength, and the PC / ABS alloy material has excellent rigidity; the impact strength of the electroplating PC / ABS alloy material can be improved synergistically by the GMA toughening agent and ABS-g-MAH compatilizer, and the electroplating PC / ABS alloy material has impact toughness of excellent rigidity; and the electroplating PC / ABS alloy material added with GMA toughening agent and nano calcium carbonate does not influence the electroplating performance, and is especially applicable to automobile outer door electroplating handles and inner door electroplating clasping hands and other products which are frequently subjected to drawing force.

Owner:南京跃贝新材料科技有限公司

Plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing

ActiveCN101597732AGood interface wettabilityGood compatibilityHot-dipping/immersion processesAlcoholEther

The invention discloses a plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing which comprises the following components in percentage by weight: 20-25% of fatty alcohol-polyoxyethylene ether, 20-26% of dodecyl phenyl polyoxyethyleneether, 8-14% of polyoxyethylene octylphenol ether, 3-6% of triethanolamine, 0.8-1.5% of carbamide and 30-36% of methyl alcohol. The method comprises the following steps: weighing the raw materials according to the proportioning of the additive, mixing and stirring the raw materials evenly to form the additive of the invention, adding the stock solution of the plating assistant agent additive of the invention into a slot according to a proportion that the amount of the added stock solution of the plating assistant agent additive accounts for 0.1-0.2% of the plating assistant agent bath solution, stirring evenly, and being able to use at the temperature of 70-75 DEG C. By adding the additive of the invention into the plating assistant agent, the wettability and the infiltrative of the plating assistant agent can be effectively enhanced, the plating effect on the surface of the steel wire is improved, and the plating leakage of the steel wire zinc plating is avoided.

Owner:巩义市恒星金属制品有限公司

Novel electroplating roller

InactiveCN104499035AIncrease current flowQuality improvementElectrolysis componentsBlade plateDrive wheel

The invention relates to a novel electroplating roller, which comprises a roller, the roller comprises a roller body and an end cap, an end cap gear sleeves peripheral part of the end cap, a center rotating shaft is arranged in the roller, two ends of the center rotating shaft are connected to a support column in a movable mode, a plurality of blade plates are arranged on the center rotating shaft, a rotating shaft gear sleeves one side of the center rotating shaft, a rotation shaft is arranged over the roller, two ends of the rotation shaft are connected to the support column in the movable mode, a driving gear 1 and a driving gear 2 sleeve the rotation shaft, the driving gear 1 is engaged with the end cap gear, a driven gear is arranged between the driving gear 2 and the rotating shaft gear, the driven gear is respectively engaged with the driving wheel 2 and the rotating shaft, one end of the rotation shaft is connected to a belt pulley, the belt pulley is connected to a motor through the belt, a cathode connector is arranged on the support column, a cathode contact is arranged in the roller, and the cathode connector is connected to the cathode contact through a lead. The novel electroplating roller increases the electroplating efficiency, the parts are rotated in the electroplating roller, so that backlogging is difficult, and the parts are uniformly electroplated.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Compound cyanide-free gold plating solution and preparation method thereof

ActiveCN105937028APrevent spontaneous reactionsExtended service lifeLiquid/solution decomposition chemical coatingPh bufferingCyanide

The invention relates to the technical field of light industry and chemical materials, in particular to a compound cyanide-free gold plating solution and a preparation method thereof. The compound cyanide-free gold plating solution is characterized by being composed of cyanide-free gold salt, soft base type coordination agents, non-soft base type coordination agents, reducing agents, impurity shielding agents, additives, pH buffering agents and water, wherein the content of the cyanide-free gold salt is 0.8-6g / L, the content of the soft base type coordination agents is 8-50g / L, the content of the non-soft base type coordination agents is 3-20g / L, the content of the reducing agents is 1-10g / L, the content of the impurity shielding agents is 5-20g / L, the content of the additives is 1-10g / L and the content of the pH buffering agents is 10-40g / L. The compound cyanide-free gold plating solution is small in corrosion to nickel layers and has the advantages that the stability is good, the plating effect is good and the utilization rate of the gold salt is high. The preparation method has the advantages of being simple and low in production cost.

Owner:SHENZHEN RONGWEIYE ELECTRONICS +1

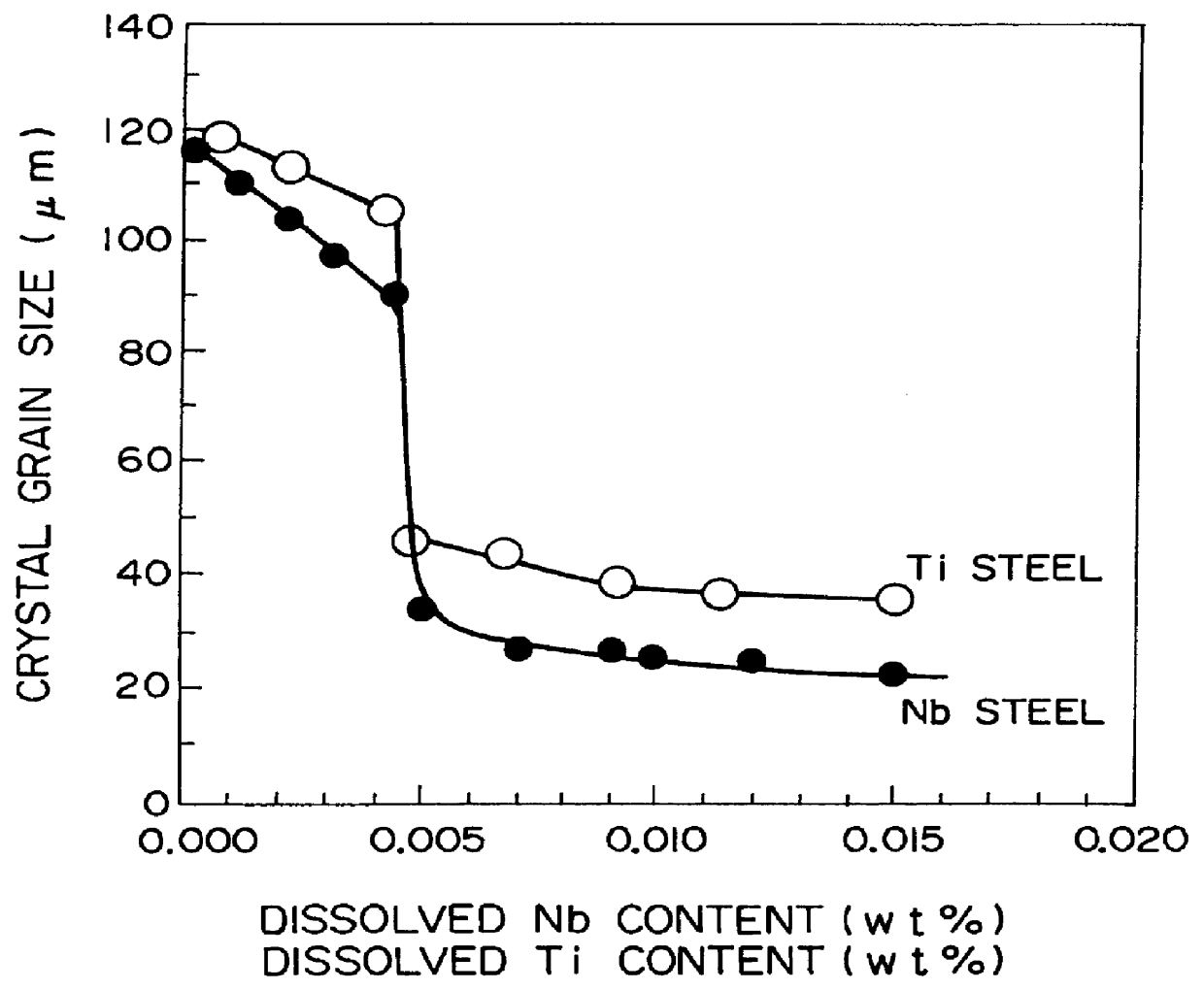

Steel sheet for double wound pipe and method of producing the pipe

InactiveUS6110299AImprove metal performanceGood molding effectFurnace typesHeat treatment furnacesReduction rateSheet steel

PCT No. PCT / JP97 / 04289 Sec. 371 Date Jun. 24, 1998 Sec. 102(e) Date Jun. 24, 1998 PCT Filed Nov. 25, 1997 PCT Pub. No. WO98 / 24942 PCT Pub. Date Jun. 11, 1998A steel sheet for double-rolled tubes has excellent formability, and excellent strength and toughness after forming and heat treatment of a tube because of suppressed coarsening of the ferrite grain size and a method for making the same comprises: hot finish-rolling of a steel material containing C: 0.0005-0.020 wt %, and one or two of Nb: 0.003-0.040 wt %, and Ti: 0.005-0.060 wt % at a final temperature of 1,000-850 DEG C., coiling at 750 DEG C. or less, cold rolling, continuous annealing at 650 DEG C.-850 DEG C. for 20 seconds or less, and second cold-rolling at a rolling reduction rate of 20% or less, so that at least one of Nb and Ti is present in a solid solution state in an amount of 0.005 wt % or more, and the crystal grain size in the ferrite structure is in the range of 5 to 10 mu m.

Owner:KAWASAKI STEEL CORP

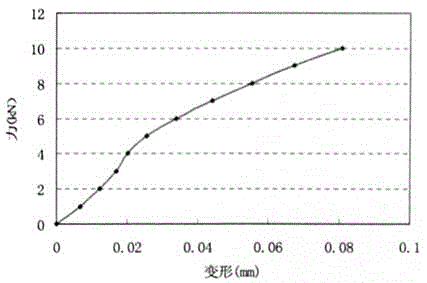

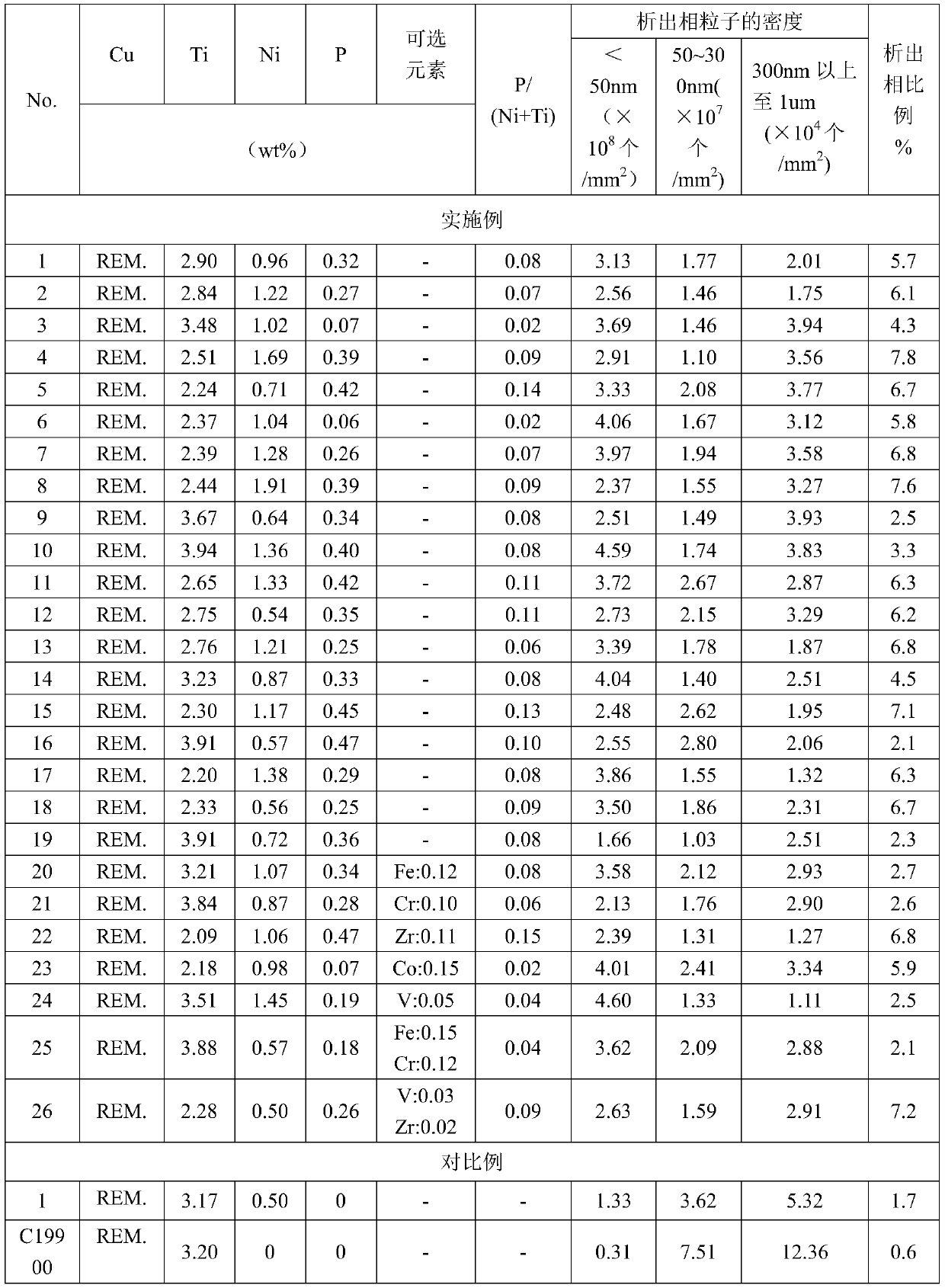

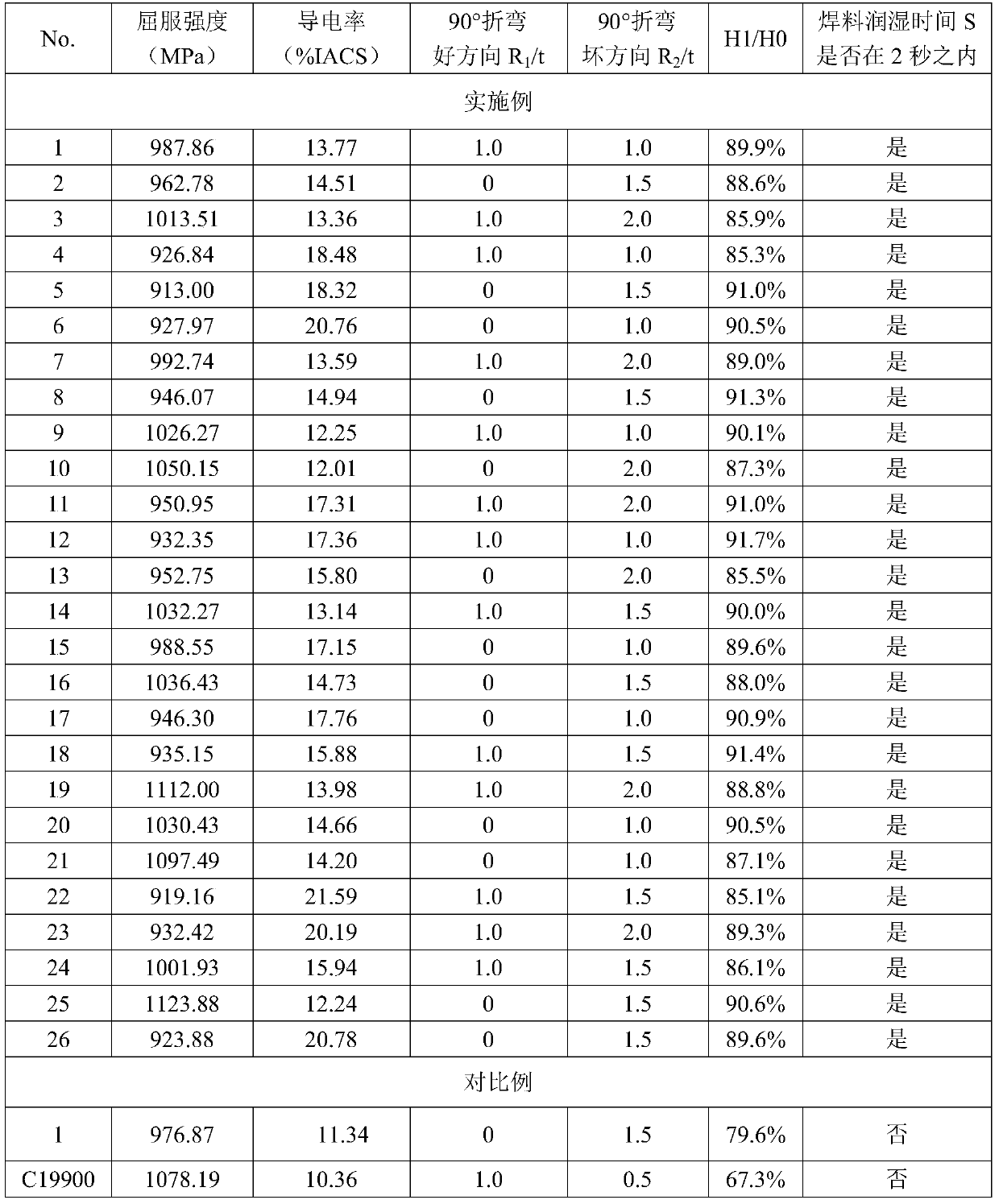

Aging-reinforced titanium-copper alloy and preparation method thereof

The invention relates to an aging-reinforced titanium-copper alloy. The aging-reinforced titanium-copper alloy is characterized by being prepared from the compositions in percentage, by weight, 2.0-4.0% of Ti, 0.5-2.0% of Ni, 0.05-0.5% of P and the balance copper and unavoidable impurities. By controlling the matching ratio of Ni to P to Ti, the yield strength of the aging-reinforced titanium-copper alloy is up to 900-1150 MPa, the conductivity is up to 12-22% IACS, and excellent bending machinability, high-temperature softening resistance and welding properties are obtained. The aging-reinforced titanium-copper alloy is especially applicable to the fields of connectors, terminals, relays and the like.

Owner:NINGBO POWERWAY ALLOY MATERIAL +1

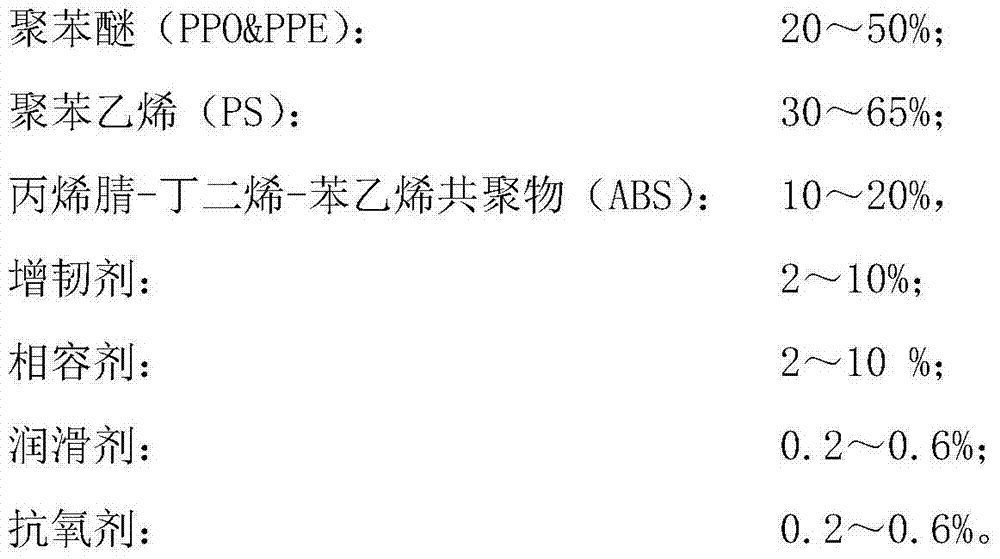

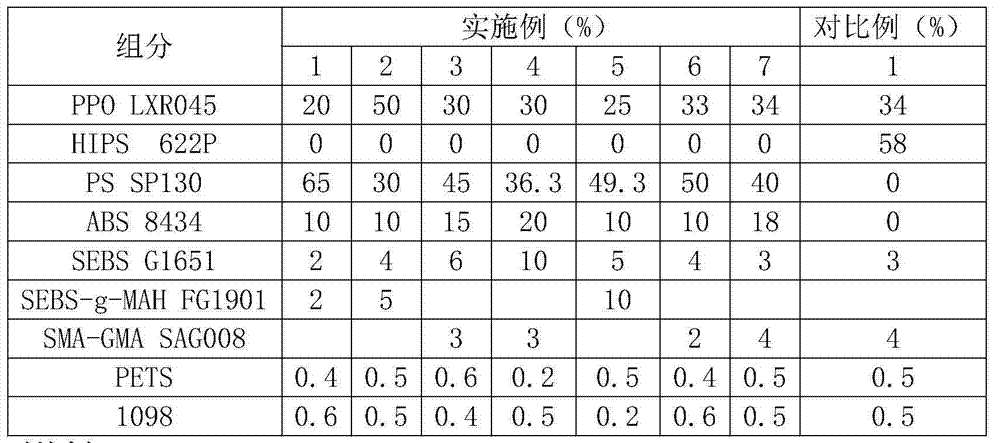

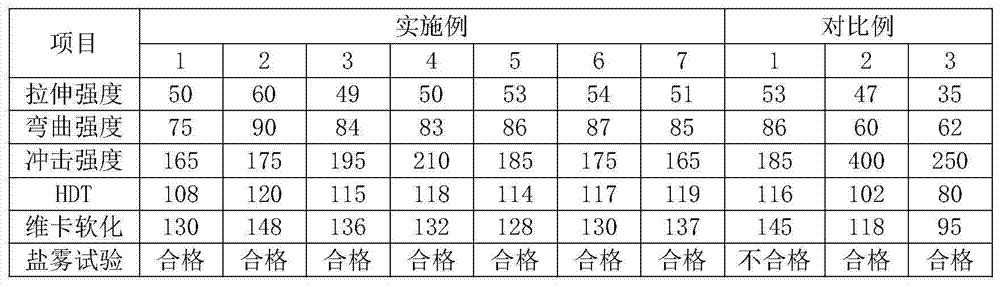

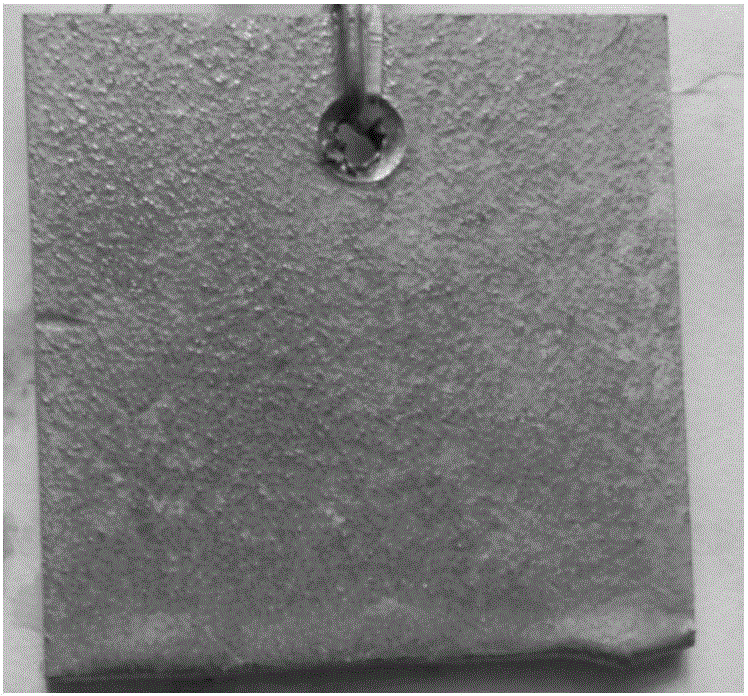

High-temperature-resistant platable polyphenylether alloy material and preparation method thereof

InactiveCN104262806AImprove temperature resistanceNot easily deformedPolystyreneAcrylonitrile butadiene styrene

The invention discloses a high-temperature-resistant platable polyphenylether alloy material and a preparation method thereof. The material comprises the following components in percentage by mass: 20-50% of polyphenylether, 30-65% of polystyrene, 10-20% of acrylonitrile-butadiene-styrene copolymer, 2-10% of toughener, 2-10% of compatilizer, 0.2-0.6% of lubricant and 0.2-0.6% of antioxidant. The invention also discloses a preparation method of the alloy. The preparation method comprises the following steps: weighing the raw materials in percentage by weight, mixing the raw materials in a high-speed mixer, and carrying out extrusion granulation with a double screw extruder. The high-temperature-resistant platable polyphenylether alloy material has the advantages of excellent heat resistance, excellent plating properties, favorable dimensional stability and favorable hydrolysis resistance, can satisfy the requirements of high-temperature plating, and is applicable to automobile wheel cowls, domestic and industrial water valves, bath accessories, electronic and electric appliance accessories and the like.

Owner:SHANGHAI SUNNY

Electroplating process for zinc alloy

InactiveCN105714346AElectroplating process method is simpleGood plating effectWax removalStrong acids

The invention discloses an electroplating process for zinc alloy. The electroplating process is characterized by comprising the following steps: 1) polishing, wherein a finished zinc alloy die-casting unavoidably has flashes, burrs, impressions and the like and has to undergo polishing so as to obtain good appearance; 2) cold wax removal; 3) ultrasonic wax removal; 4) ultrasonic oil removal, wherein the zinc alloy can directly undergo electrolysis for oil removal if the surface of the zinc alloy is not full of oil stains, good ultrasonic oil removal effect can be obtained for parts with a great number of oil stains, complicated shapes, grooves or blind holes, and the pH value of oil removing powder should not be too high because strong base exerts fast dissolving effect on aluminum, which leads to dissolving-out of shrinkage cavities in the surfaces of the parts, and the shrinkage cavities influence bonding force if not thoroughly cleaned in the process of electroplating; 5) oil removal through electrolysis of a negative electrode; 6) oil removal through electrolysis of a positive electrode; and 7) activation, wherein the zinc alloy is normally activated in a hydrofluoric acid solution or in a hydrofluoric acid-sulfuric acid solution, activation salt is also commercially available, and since zinc is amphoteric metal and is prone to dissolving and corrosion in strong acid and strong base, activation is normally carried out in weak acid.

Owner:CHONGQING XUXINYUE NC MACHINERY CO LTD

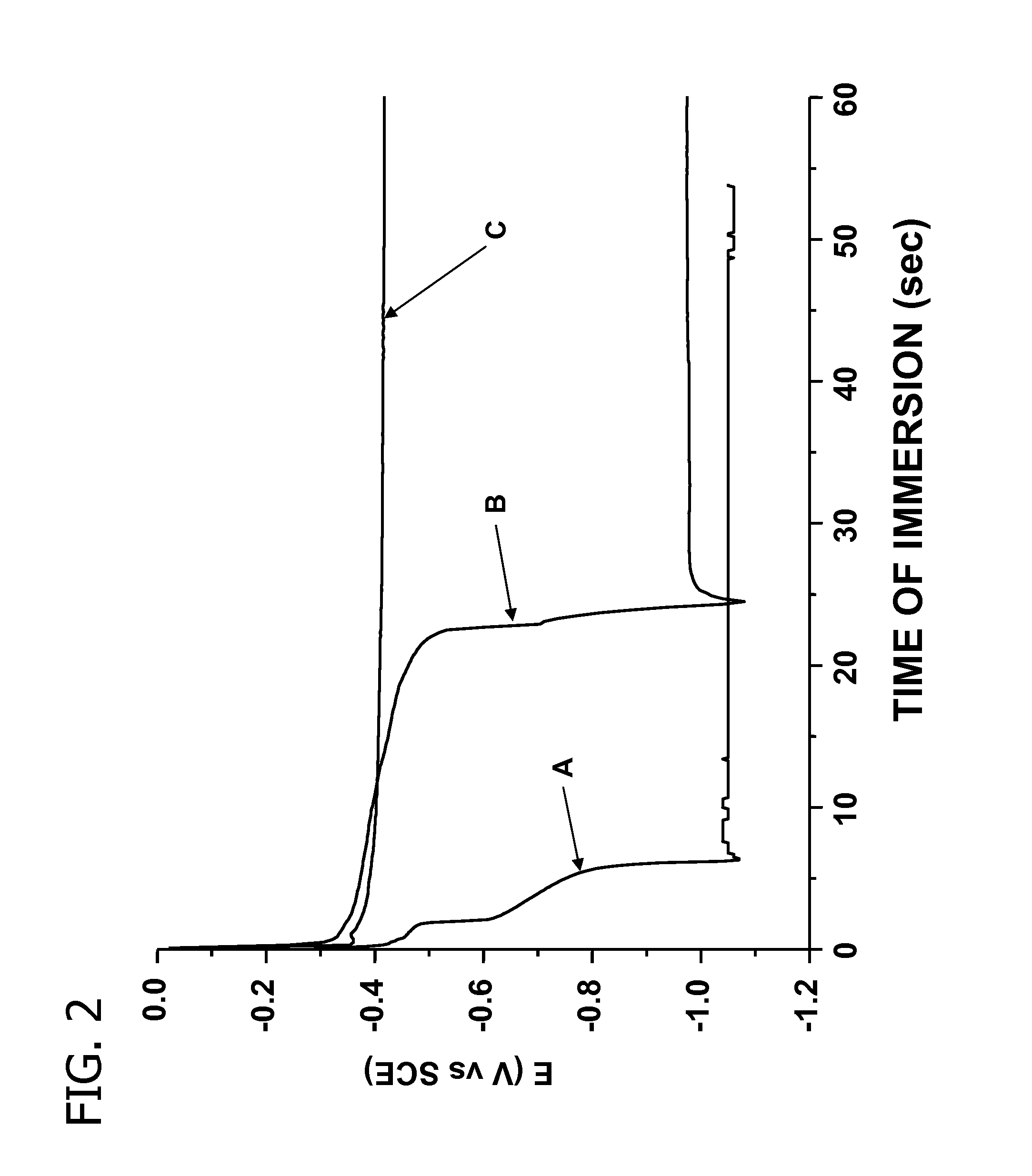

Near neutral pH cleaning/activation process to reduce surface oxides on metal surfaces prior to electroplating

InactiveUS7270734B1Improve the plating effectIncrease currentSemiconductor/solid-state device manufacturingPrinted circuit manufactureNeutral phBiological activation

The invention relates to a method for electroplating a metal deposit on electroplatable portions of composite articles that have both electroplatable and non-electroplatable portions. In this method, the invention is an improvement which comprises treating the articles prior to electroplating to provide the electroplatable portions with enhanced electroplatability. This is achieved by passing a current though a near neutral pH solution that contains a conductivity agent and a buffer to reduce or remove surface oxides and contaminants from such portions without deleteriously affecting the non-electroplatable portions of the articles. When the treated surfaces are subsequently subjected to metal plating, a uniform, smooth metal deposit is achieved.

Owner:TECHNIC INC

Plating assistant agent for zinc-aluminum-nickel-rare earth-alloy hot-dip plating and technological method

InactiveCN105908113AHigh activityIncrease profitHot-dipping/immersion processesHexamethylenetetramineActive agent

The invention provides a plating assistant agent for zinc-aluminum-nickel-rare earth-alloy hot-dip plating and a technological method. The plating assistant agent comprises the following components of an A solution containing zinc chloride, ammonium chloride, stannous chloride and urotropin and a B solution containing ethyl alcohol, a nonionic surfactant and a cationic surfactant, wherein the plating assistant agent is obtained by mixing the A solution and the B solution. By using the plating assistant agent, skip plating can be effectively avoided; and the surface quality of a plating layer is obviously improved; the yield of a plated article is improved; and the corrosion-resistance of the plating layer can be obviously improved. The plating assistant agent does not contain fluorinion which is harmful to the environment, and requirement of environment protection is met.

Owner:CHANGAN UNIV

Electroplating PC/ABS alloy material and preparation method and application thereof

The invention provides an electroplating PC / ABS alloy material and a preparation method and application thereof. The PC / ABS alloy material comprises, by weight, 25-85 parts of polycarbonate (PC), 15-75 parts of styrene-butadiene-acrylonitrile copolymer (ABS), 0.1-20 parts of organic microspheres and 0-3 parts of additive. In the preparation process, PC, ABS, the organic microspheres and other additives are added into a high-speed mixer to be uniformly mixed and then added into a double-screw extruder together for extrusion, and granulation is carried out through a granulator. The method is simple and feasible; the organic microspheres are added, and on the premise that the strength of a matrix is guaranteed, the flowability of the PC / ABS alloy material is improved, the internal stress of the material is reduced, and the electroplating qualified rate and the pass percentage of cold and hot cycling are increased; besides, the organic microspheres can be subjected to coarsening and etching together with a rubber phase, more etching points are provided, and better electroplating performance is obtained.

Owner:WANHUA CHEM GRP CO LTD

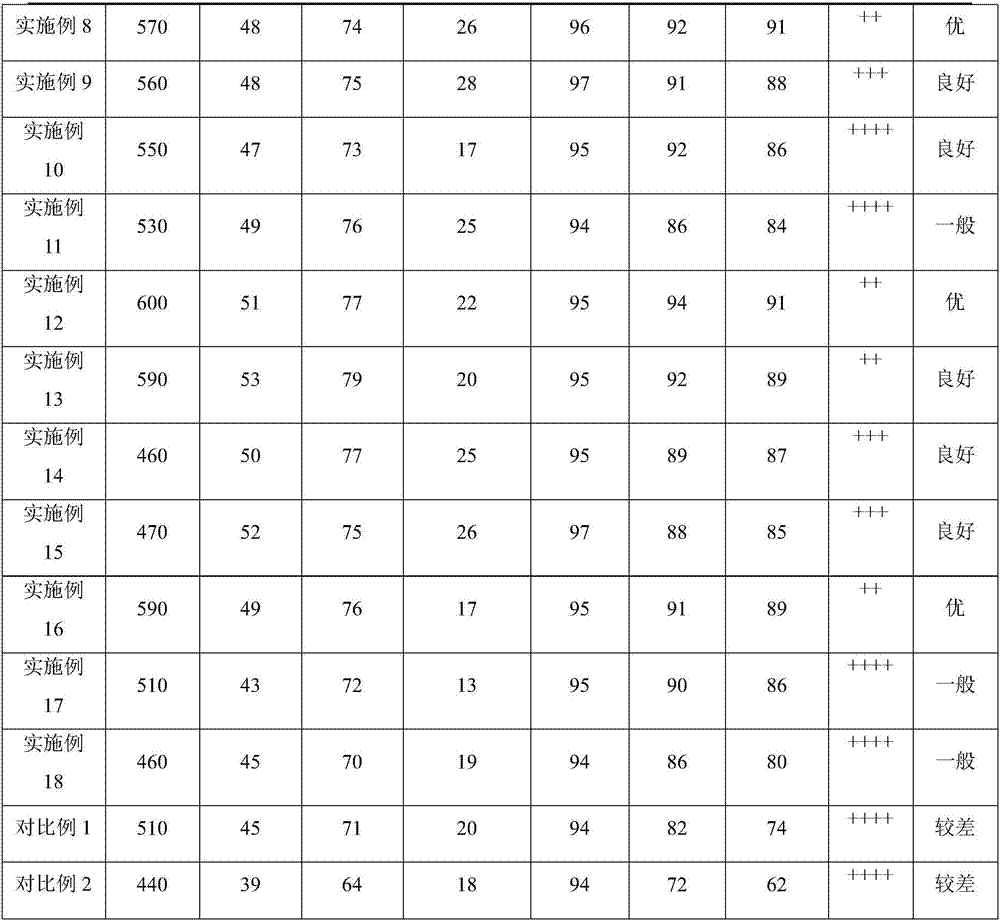

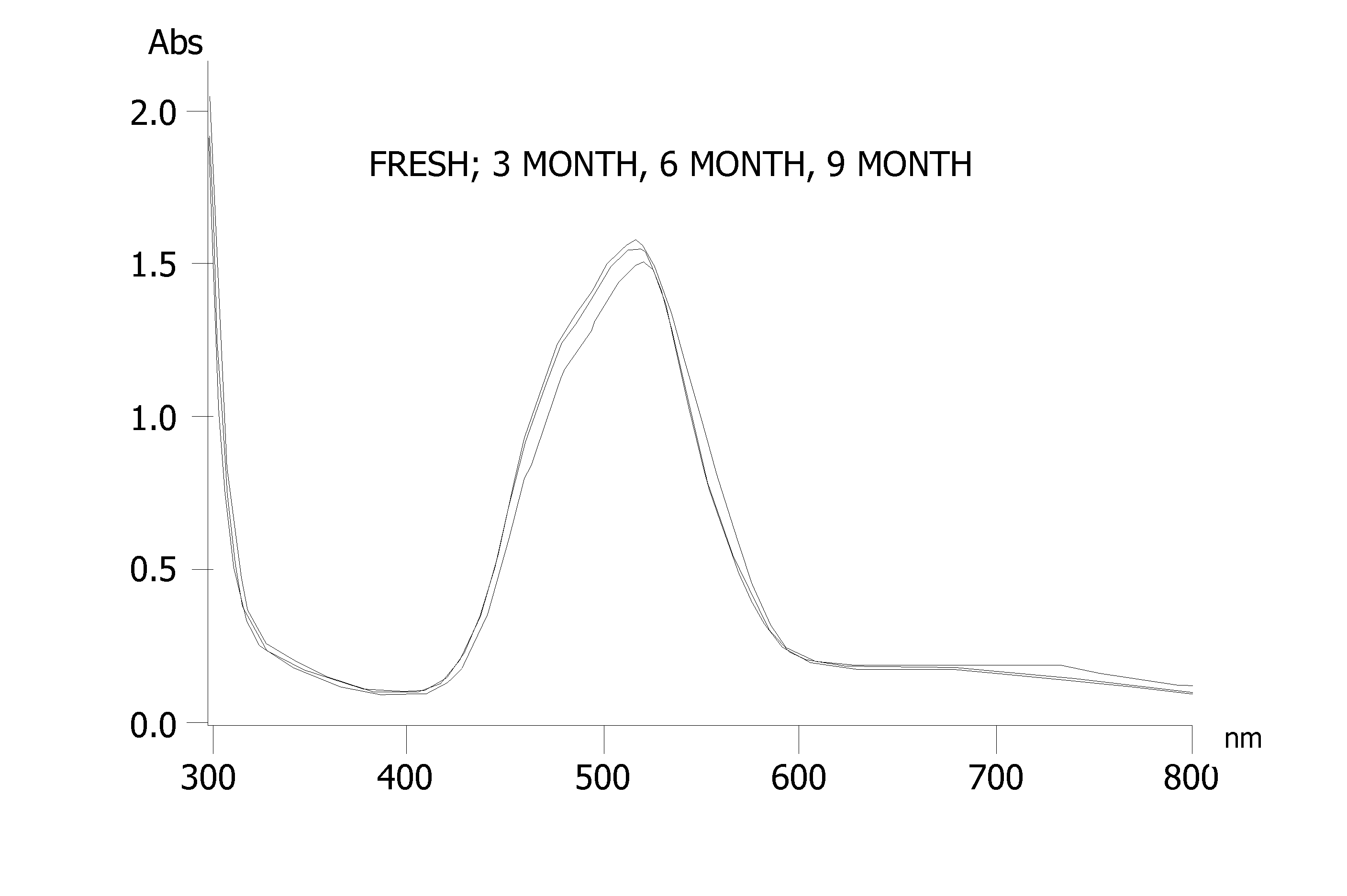

Manufacture of electroless cobalt deposition compositions for microelectronics applications

InactiveUS20080090414A1Improve performanceExtended shelf lifeAnodisationSemiconductor/solid-state device manufacturingAlloyElectroless deposition

A method of preparing an aqueous electroless deposition composition for electrolessly depositing Co or a Co alloy onto a substrate in manufacture of microelectronic devices by treating water or an aqueous electroless deposition composition with a deoxygenating treatment to reduce the oxygen concentration.

Owner:MACDERMID ENTHONE INC

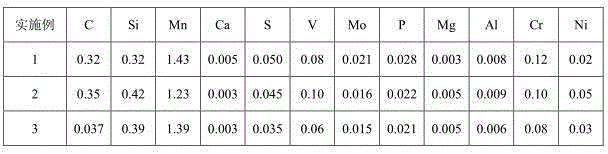

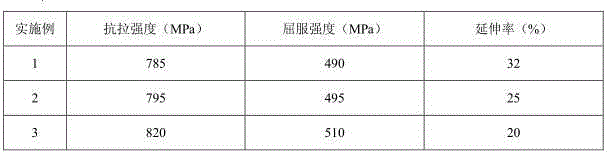

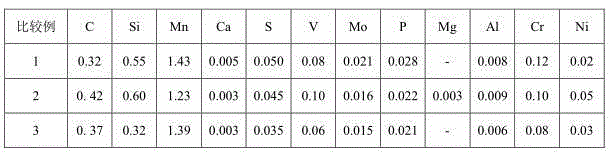

Yoke product and preparation method thereof

ActiveCN104696379AReduce consumptionReduce manufacturing costHot-dipping/immersion processesYielding couplingSlow coolingMachining

The invention relates to a yoke product and a preparation method thereof. The preparation method comprises the following steps: performing roll forging blanking; performing forging formation; performing magnetic powder inspection; performing mechanical processing. The steps do not comprise thermal refining; in the step of forging formation, semifinished products obtained after roll forging blanking are heated to 1180-1230 DEG C, the preforging temperature is 1180-1230 DEG C, the final forging temperature is 930-980 DEG C, the cooling speed after final forging is controlled to be 2.5-3.5 DEG C / s, and after the temperature drops to 420-450 DEG C, slow cooling is performed. According to the yoke product disclosed by the invention, after treated by forging and mechanical processing, the properties of parts finally satisfy using requirements, the manufacturing cost is reduced, the consumption of energy sources is obviously reduced, and the production efficiency is improved. The prepared yoke product has the characteristics that the tensile strength can be 780-900 MPa, the yield strength can be 480-550 MPa, and the elongation percentage can be up to 16-40%.

Owner:SHANDONG JINMA INDAL GROUP

Machining method for aluminum alloy turbine blade of aero-engine

The invention discloses a machining method for an aluminum alloy turbine blade of an aero-engine, and belongs to the technical field of machining for turbine blades of aero-engines. The machining method comprises the following steps: casting the aluminum alloy turbine blade, carrying out film hole machining through a machining method of ultrafast laser annular cutting and spiral scanning, and removing a remelted layer through abrasive particle flow machining and a melted layer removal solution. According to the machining method disclosed by the invention, the film hole machining is carried outthrough the machining method of ultrafast laser annular cutting and spiral scanning, so that the heat effect can be greatly reduced and the surface integrity is improved, the machined film hole has few burrs, grooves and micro-cracks, and the maximum thickness of the remelted layer is not greater than 25[mu]m. Abrasive particles uniformly grind the surface or the corners of a channel under a pressure effect, so that allowance can be removed, the effects of deburring, chamfering and polishing can also be acted, the remelted layer can also be effectively reduced, a hole diameter increment is controlled to be 0.02mm to 0.04mm, and the remelted layer and the micro-cracks can be effectively controlled. The remelted layer is further removed through the remelted layer removal solution, so that no remelted layer residue at the inlet-outlet of the film hole can be achieved.

Owner:安徽恒利增材制造科技有限公司

High-density and high-precision printed circuit board copper electroplating process

InactiveCN103806031AIntense and even stirring actionGuaranteed cleanlinessPrinted circuit manufactureNumerical controlUltrasonic assisted

The invention belongs to the field of electroplating, and especially relates to a high-density and high-precision printed circuit board copper electroplating process used during a copper plating process in circuit board production manufacturing. According to the present invention, the electroplating solution comprises a copper sulfate solution and a dispersant; the high-density and high-precision printed circuit board copper electroplating process is characterized in that a plating tank added with a copper plating solution is placed in a numerical control ultrasonic generator, a prepared printed circuit board is placed into the plating solution, and ultrasonic waves with a certain power are applied during the electroplating process to enhance electroplating; and ultrasonic waves are adopted to enhance copper electroplating, such that the obtained plating layer has characteristics of delicate appearance, good gloss, uniform grain, tight covering and excellent comprehensive performance, and provides good bonding force and good corrosion resistance compared with the plating layer obtained through the treatment with no ultrasonic wave assisted effect.

Owner:WUXI XINSANZHOU STEEL

Long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping

ActiveCN105648377AReduce performanceWill not use reduced effectHot-dipping/immersion processesAlkali freeSurface-active agents

The invention discloses a long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping. The plating assistant agent is prepared from the following raw materials in percentage by weight: 25 percent to 35 percent of ZnCl2, 2 percent to 10 percent of KF, 5 percent to 15 percent of CaCl2, 4.5 percent to 8.5 percent of AgCl, 2 percent to 3.5 percent of alkali-free SP binary compound flooding dispersing agent, 0.1 percent to 0.5 percent of compound surface active agent and the balance water. Through a reasonable formula of the plating assistant agent, a zinc-aluminum-magnesium alloy coating is obtained on the surface of a steel and iron material substrate by utilizing hot dipping; the coating and the steel and iron material substrate separately keep original performance; the coating is compact in structure and free of skip plating, and zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance can be formed. The plating assistant agent is low in cost, can be easily produced industrially, and can be widely suitable for hot dipping long-ageing reusable zinc-aluminum-magnesium alloy plating solution of which the Al content is 5 percent to 22 percent and the Mg content is 2 percent to 6 percent.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

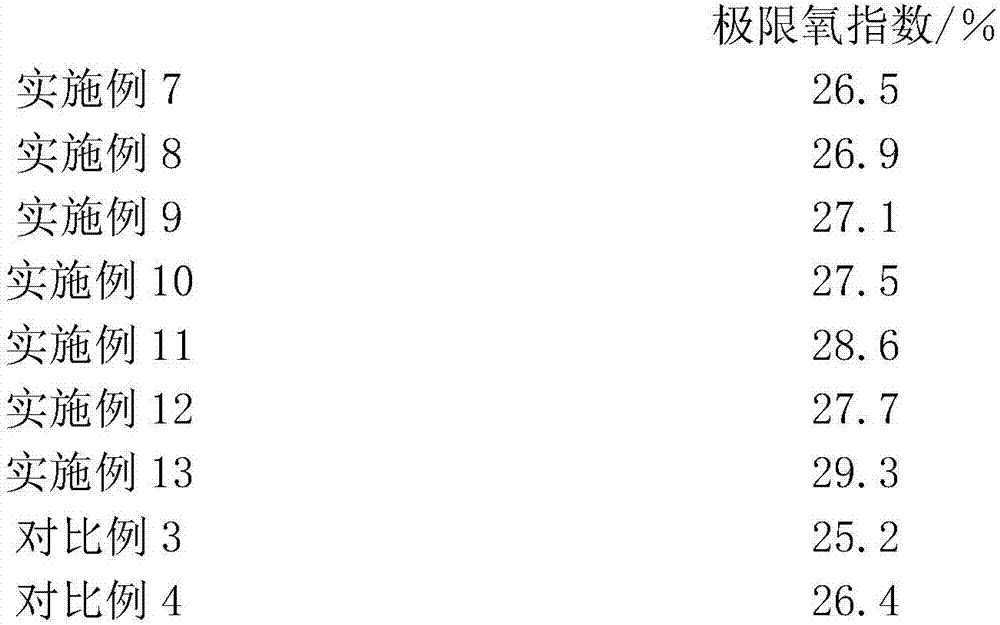

Preparation method of flame-retardant electroplating ABS for shell of electronic apparatus

ActiveCN104277410AMeet the requirements of flame retardancyImprove temperature resistanceFlame resistanceAnoxomer

The invention discloses a flame-retardant electroplating ABS for the shell of an electronic apparatus. The flame-retardant electroplating ABS is prepared by using the following components, by weight, 65-85 parts of ABS, 10-30 parts of a flame retardant, 1-5 parts of a filler, 0.1-0.5 parts of an antioxidant and 0.1-0.3 parts of a lubricant. The invention also discloses a preparation method of the flame-retardant electroplating ABS (acrylonitrile butadiene styrene copolymer) for the shell of the electronic apparatus. The flame-retardant electroplating ABS for the shell of the electronic apparatus can be obtained by controlling the content of the filler and a rubber phase in a system. The flame-retardant electroplating ABS for shell of the electronic apparatus meets the flame retardation requirements of electroplating and electronic products. The increase of the filler benefits the heat resistance and the flame retardation of the ABS material, reduces the cost, and makes the flame retardant ABS material have an electroplating etching property.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com