Novel electroplating roller

A technology of electroplating rollers and rollers, which is applied in the direction of electrolysis process and electrolysis components, etc., which can solve problems such as easy backlog, low plating efficiency, uneven plating of parts, etc., to increase current flow, improve quality, and avoid missing plating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

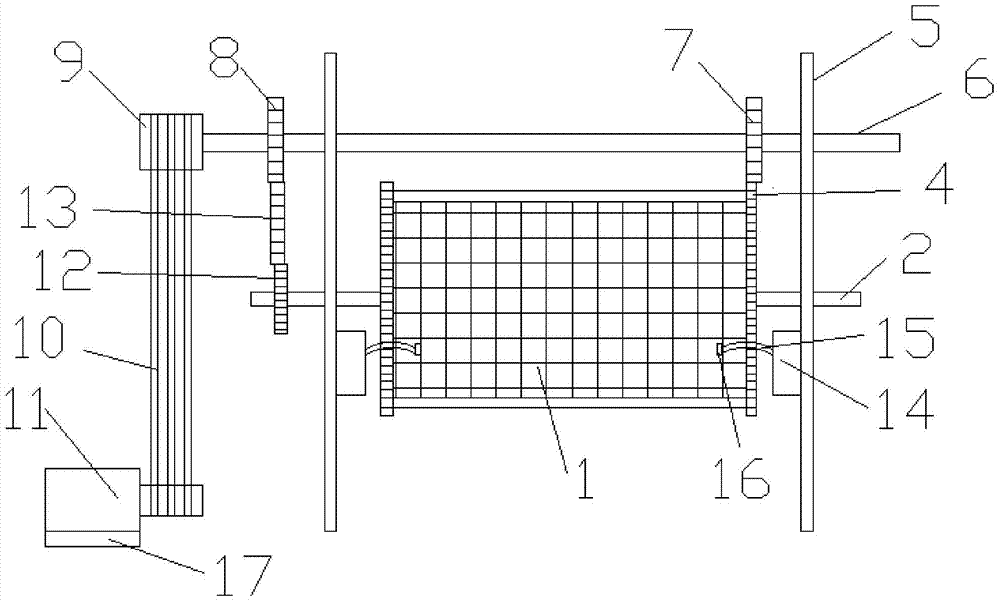

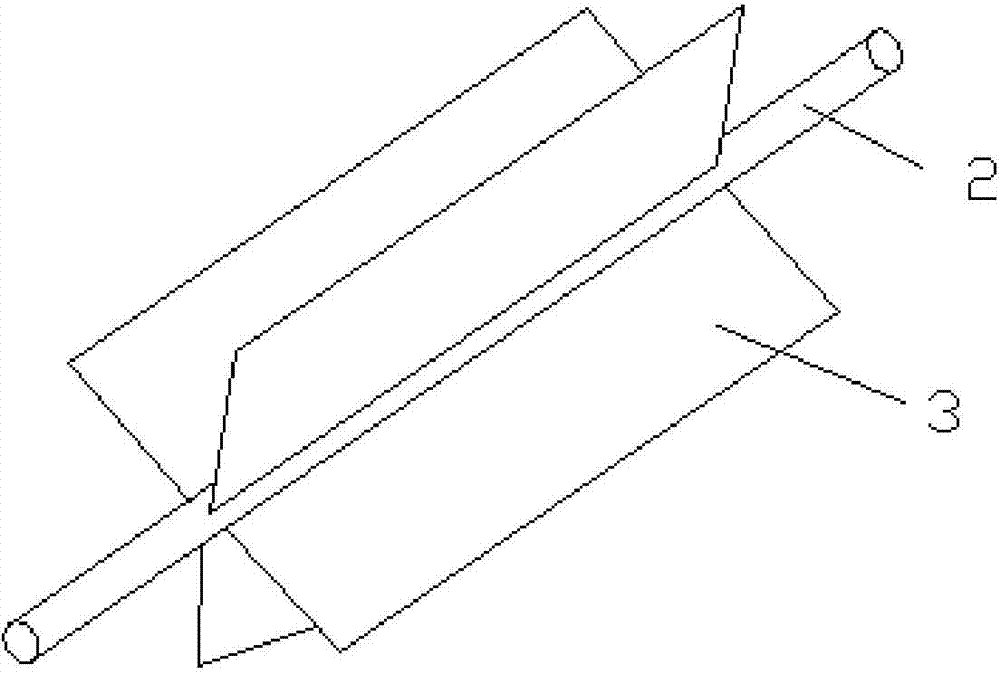

[0026] figure 1 , figure 2 The new type of electroplating drum shown includes a drum 1. The drum 1 includes a drum body and an end cover. The end cover is covered with an end cover gear 4. The drum 1 is provided with a central rotating shaft 2, and the two ends of the central rotating shaft 2 protrude from the drum 1 and The supporting column 5 is movably connected, and several blade plates 3 are arranged on the central rotating shaft 2, and a rotating shaft gear 12 is set on one side of the central rotating shaft 2, and a rotating shaft 6 is arranged above the drum 1, and the two ends of the rotating shaft 6 pass through the supporting column 5, and are connected with the supporting The column 5 is movably connected, the rotating shaft 6 is covered with a driving gear 1 7 and a driving gear 2 8, the driving gear 1 7 is arranged above the end cover gear 4, and is engaged with the end cover gear 4, and the driving gear 2 8 is arranged on the rotating shaft gear 12 On the top,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com