Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Ternary eutectic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

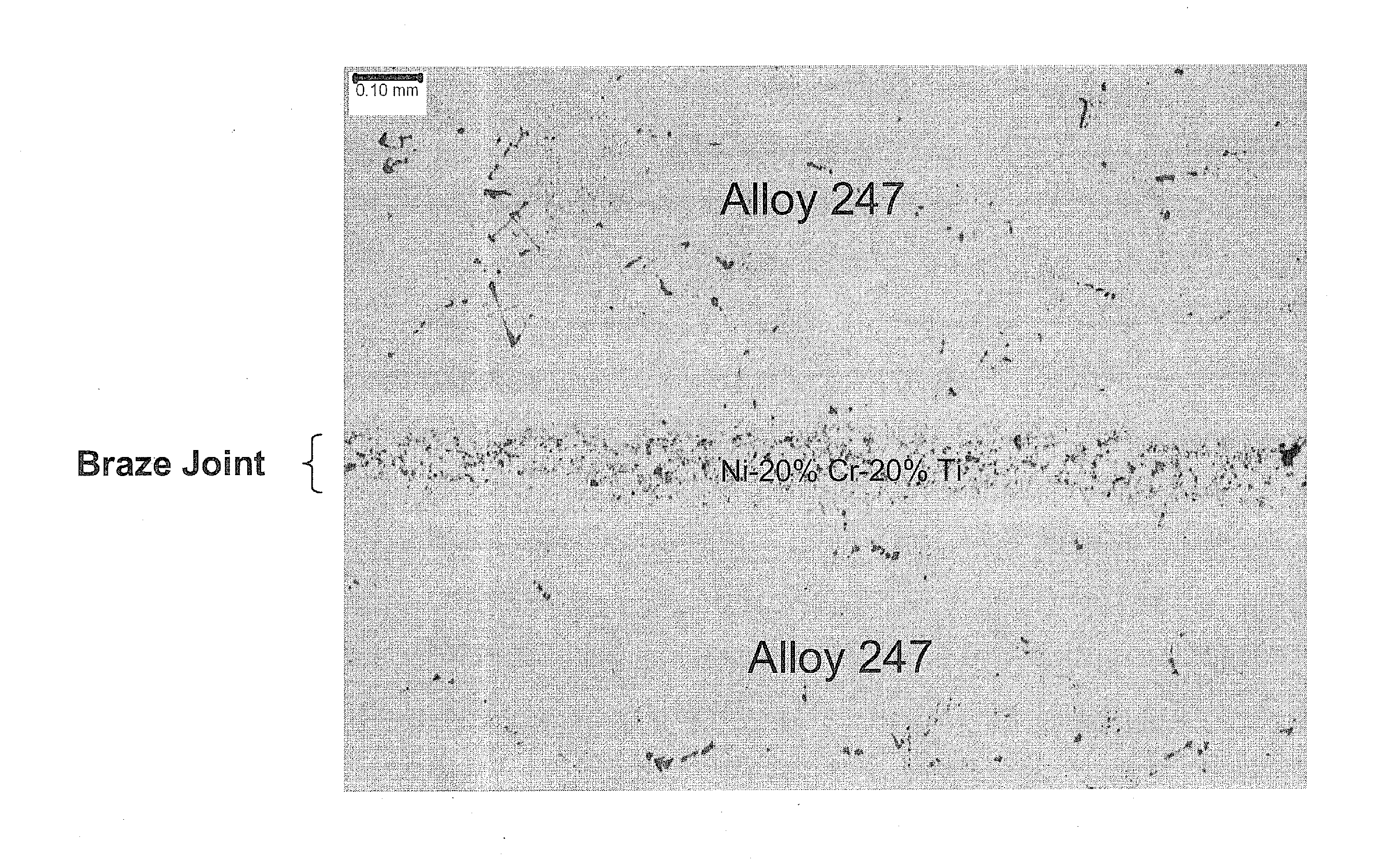

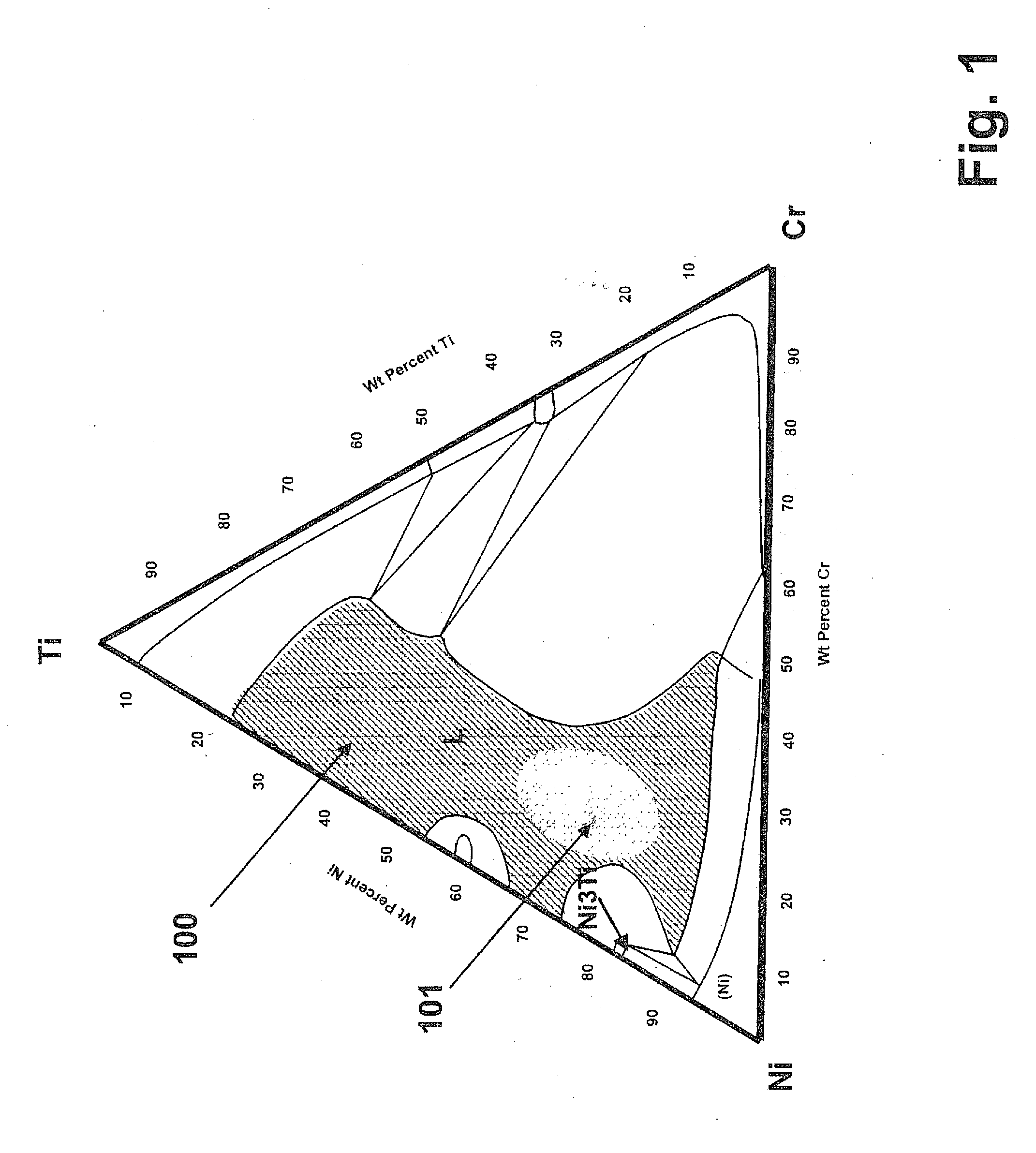

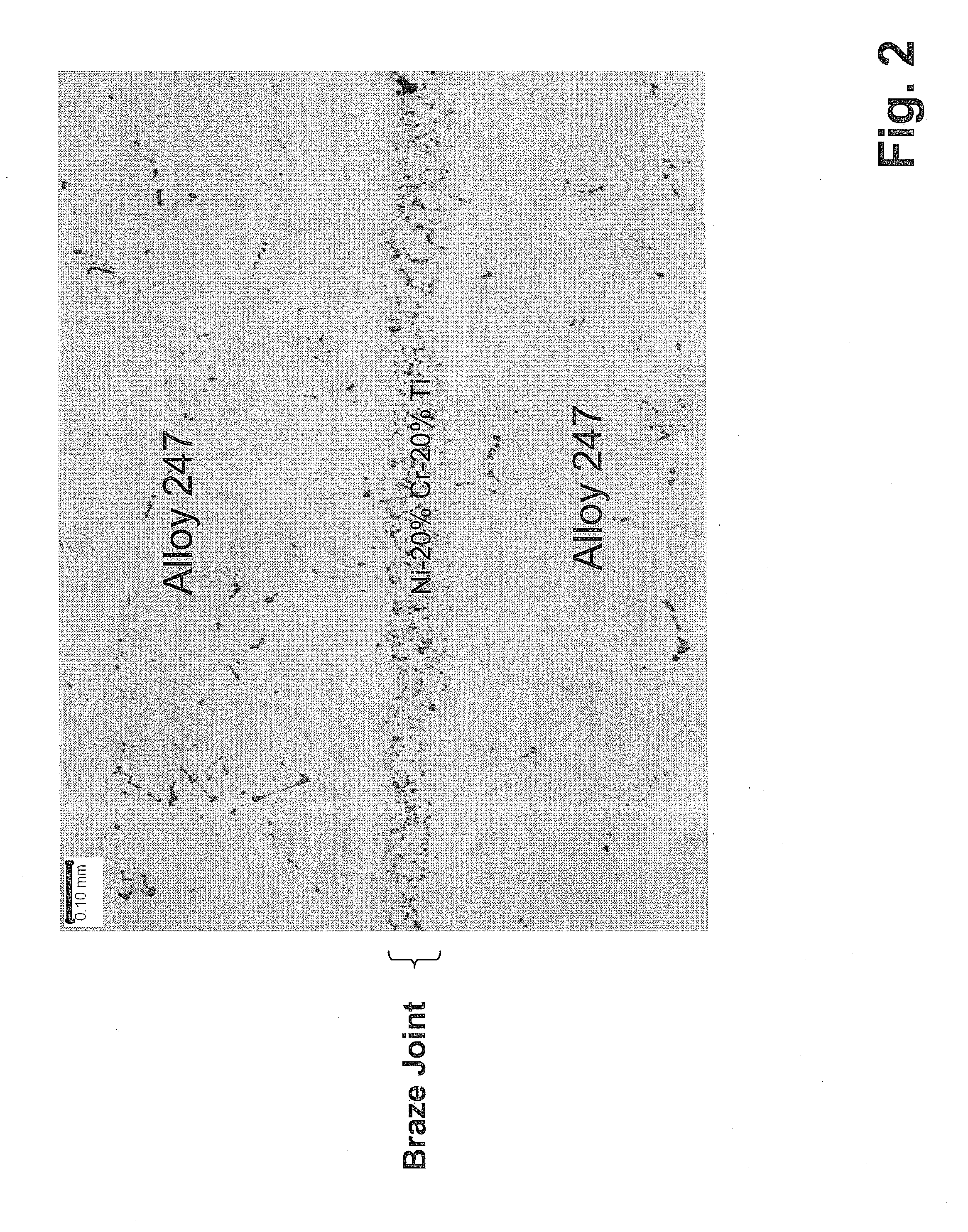

Ni-ti-cr near ternary eutectic alloy for gas turbine component repair

ActiveUS20140007988A1Reduce eliminateReduce the temperatureTurbinesBlade accessoriesTurbine bladeRepair material

A ternary near eutectic alloy of Ni, Ti, Cr is described having a relatively low melting temperature of approximately 1230 deg. C. or less, suitable for fusing cracks in turbine blades and vanes without substantial risk of cracking during the repair process. Such an alloy is suitable for low temperature joining or repair of turbine blades since it contains the same components as typical turbine blades and vanes without foreign elements to lower the melting point of the repaired material or adversely affect the mechanical properties of the repaired component. Exclusion of boron eliminates the formation of brittle boron compounds, detrimental to the properties of the repair or seam.

Owner:SIEMENS ENERGY INC

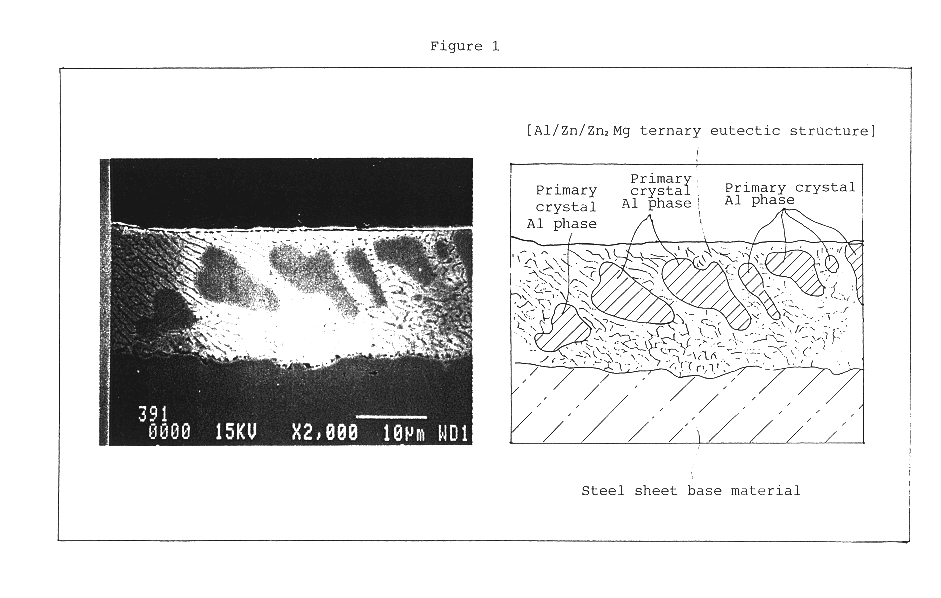

Hot-dip Zn-A1-Mg plated steel sheet good in corrosion resistance and surface appearance and method of producing the same

InactiveUS6379820B1Increase resistanceFine surfaceHot-dipping/immersion processesLiquid surface applicatorsSheet steelImpurity

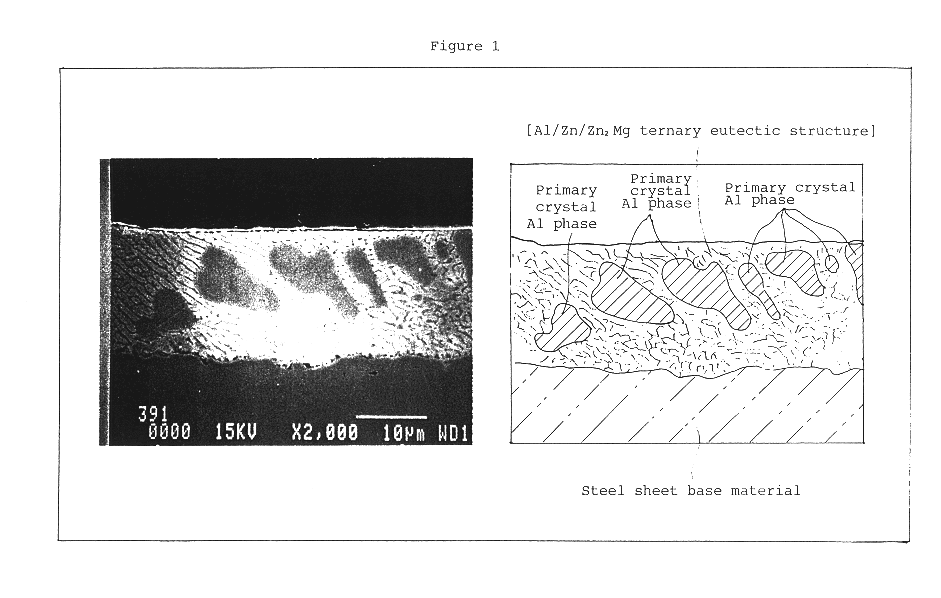

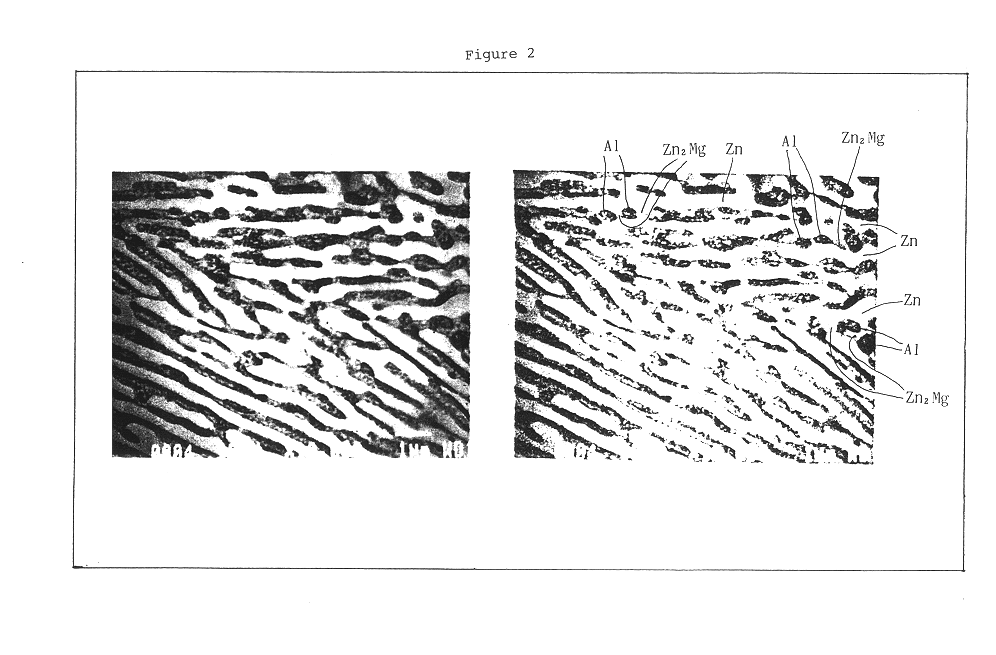

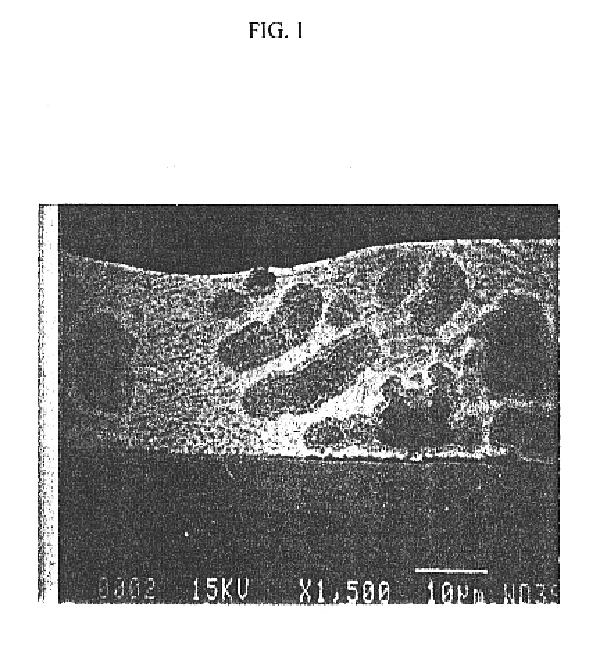

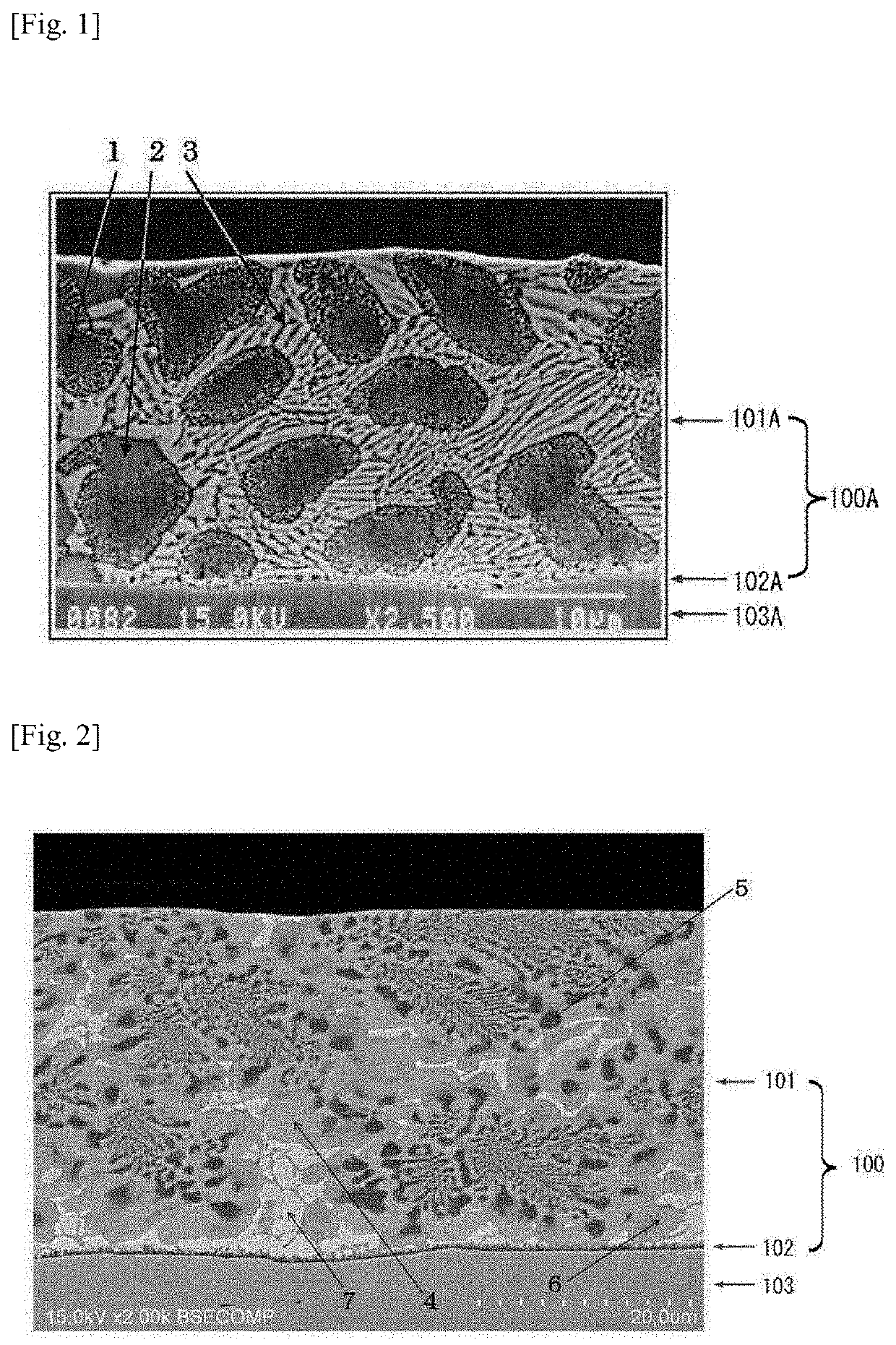

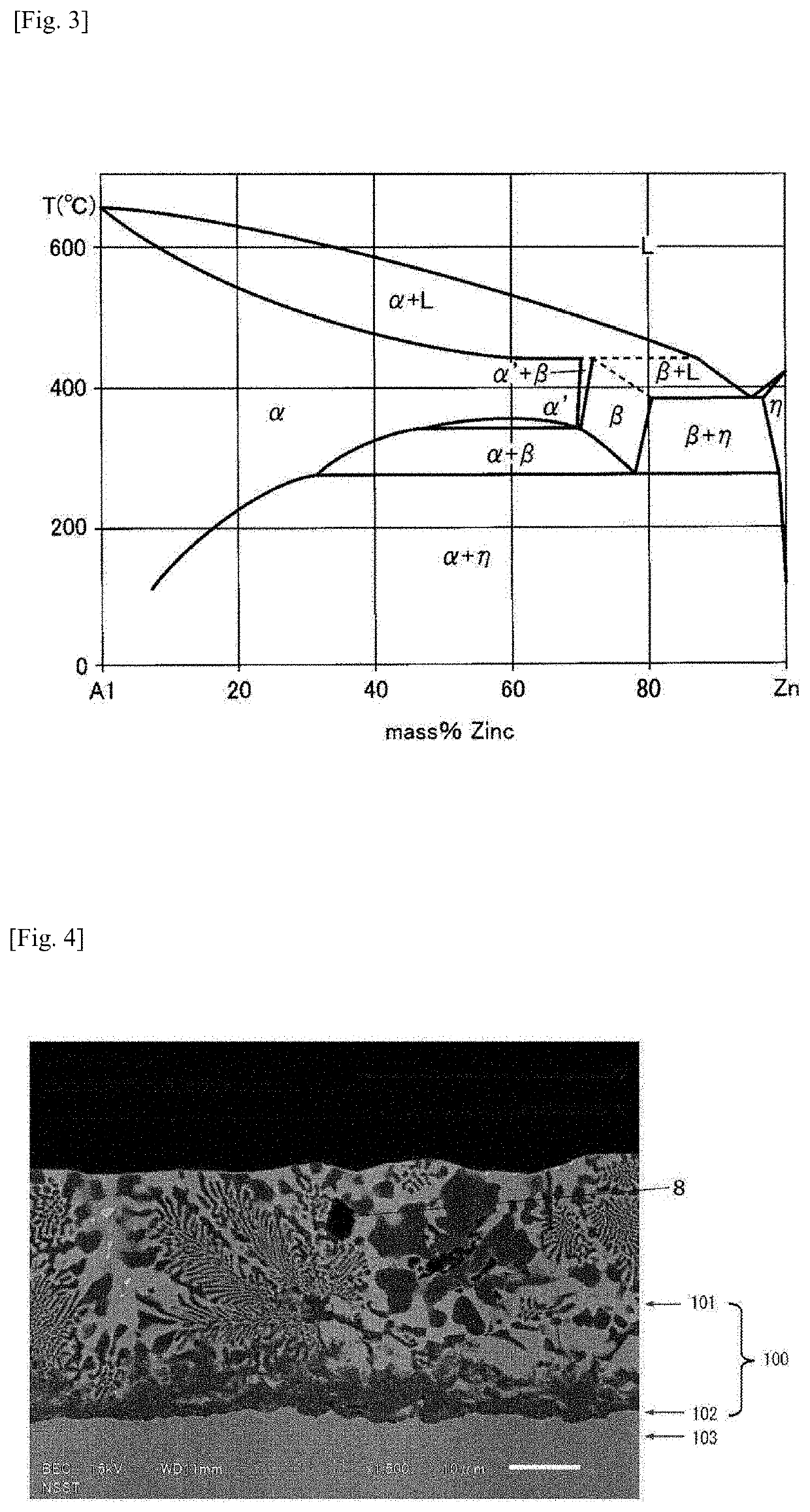

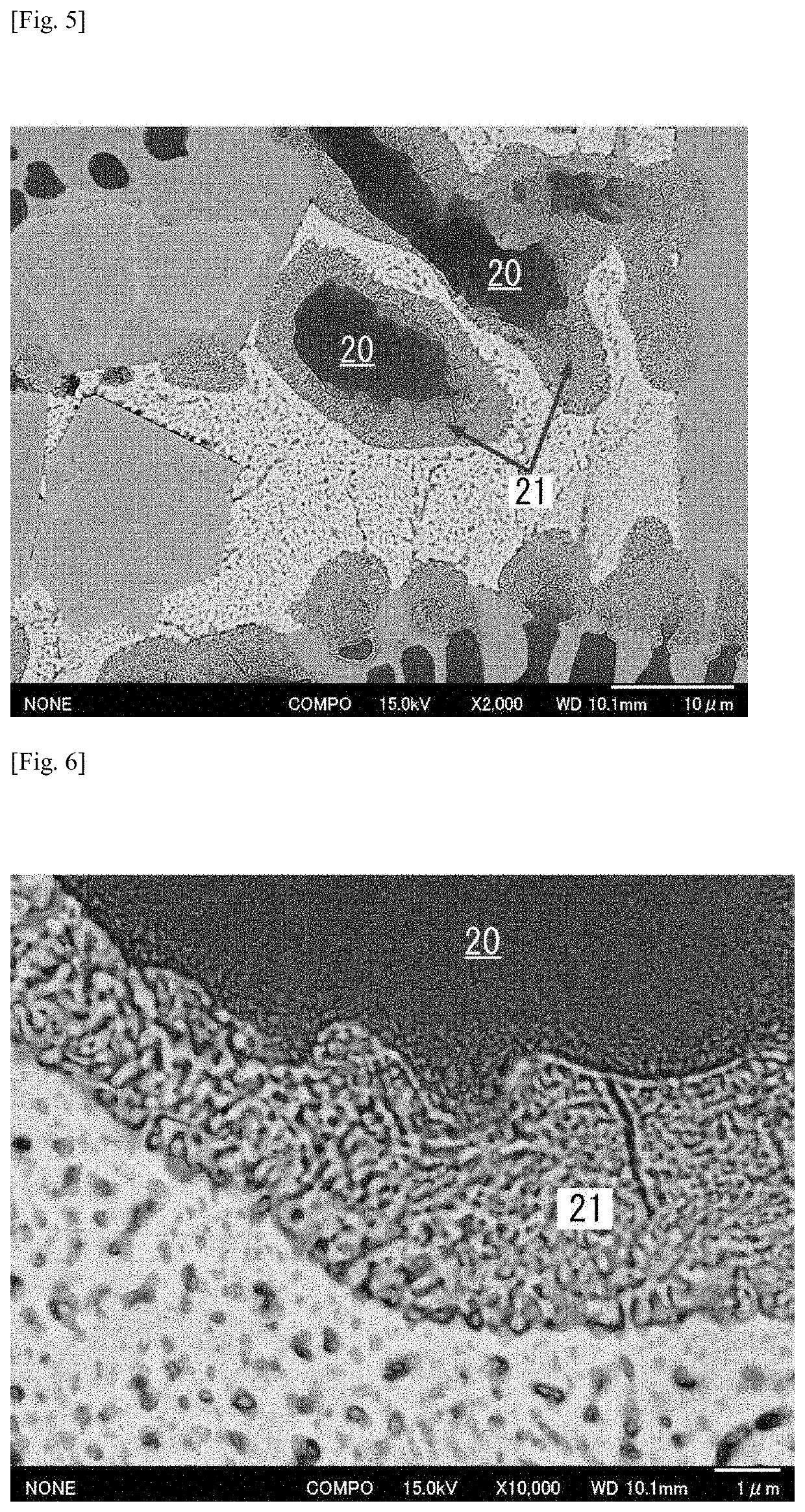

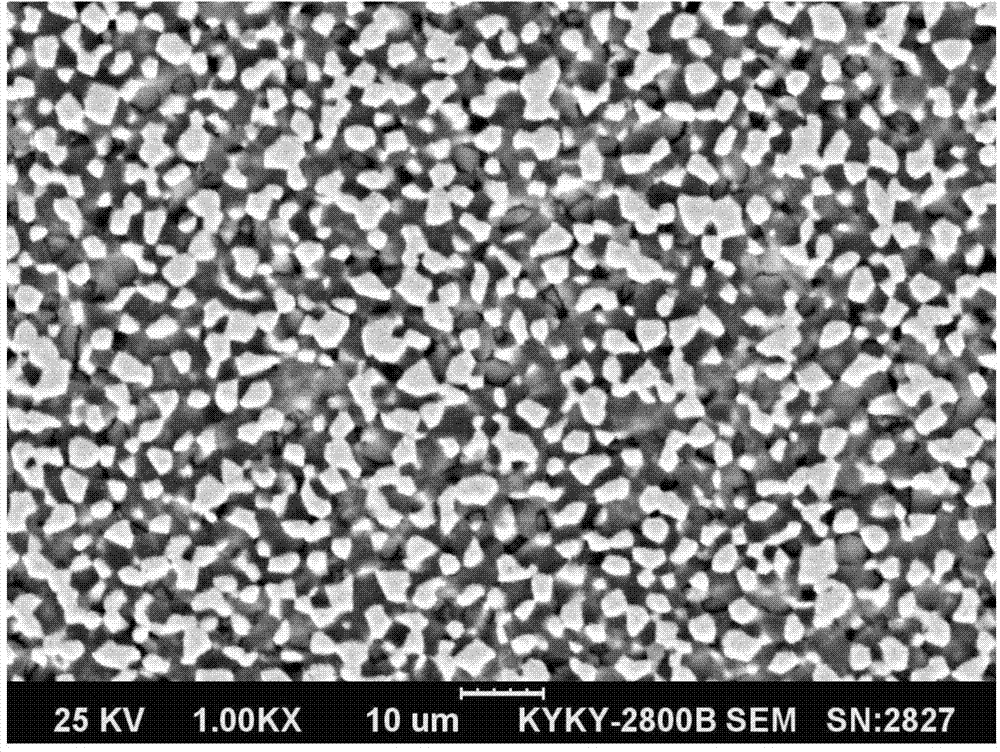

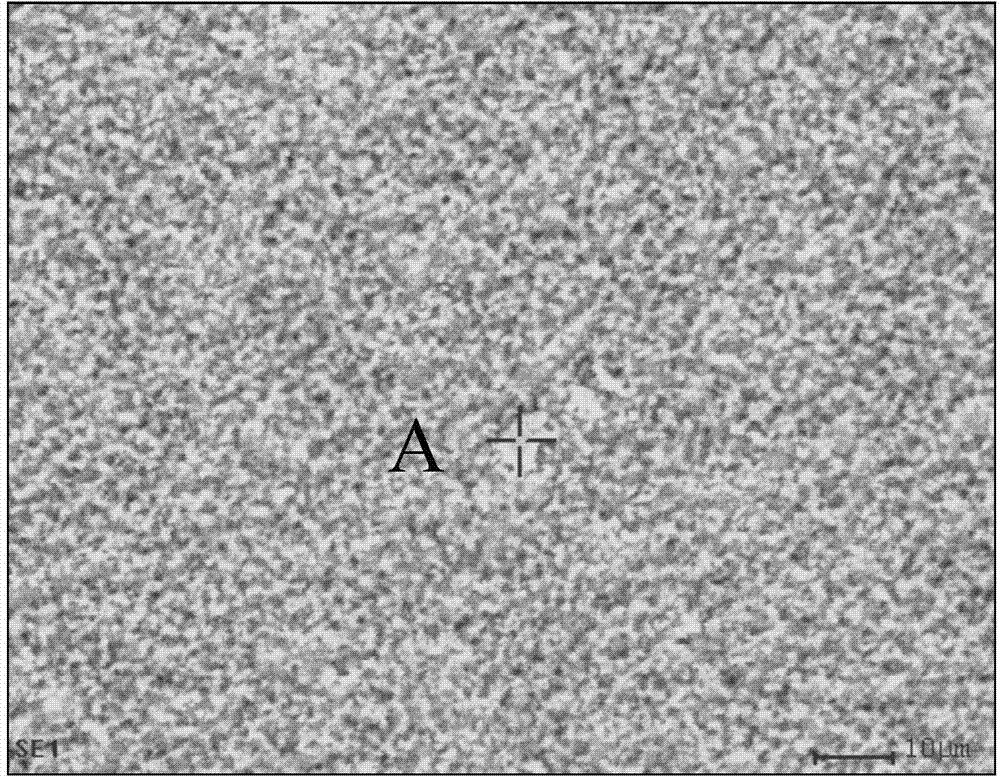

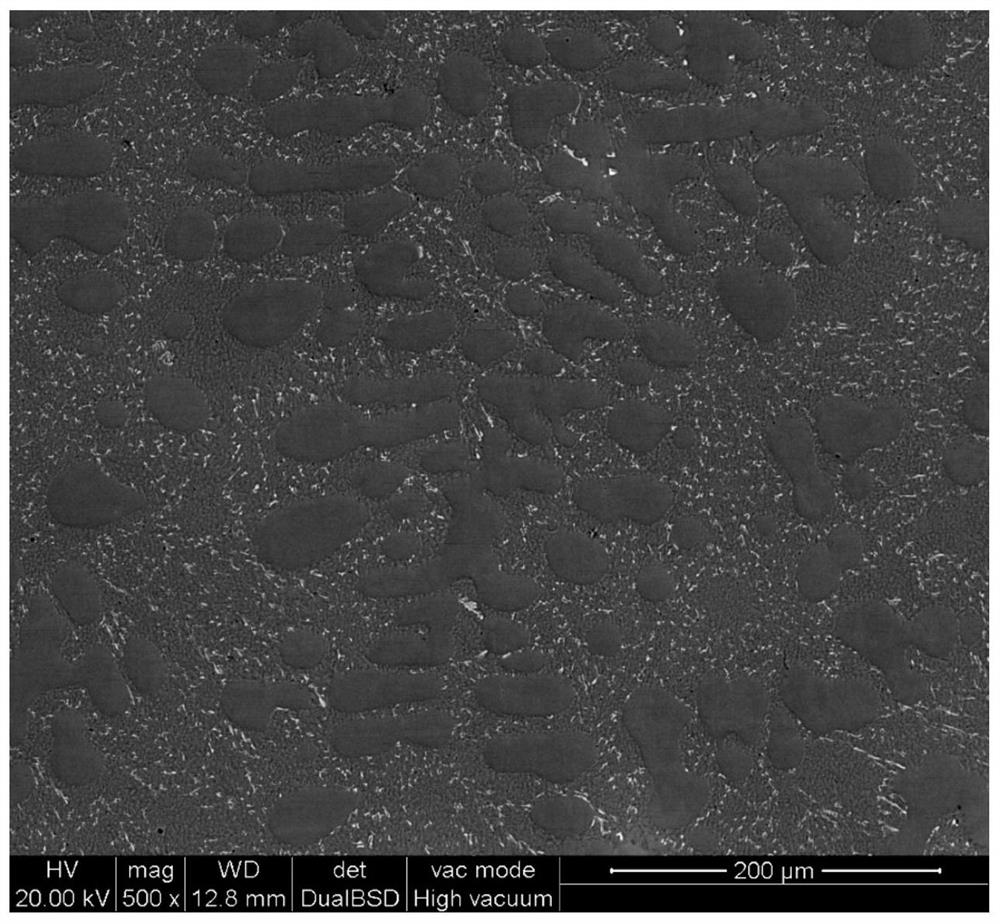

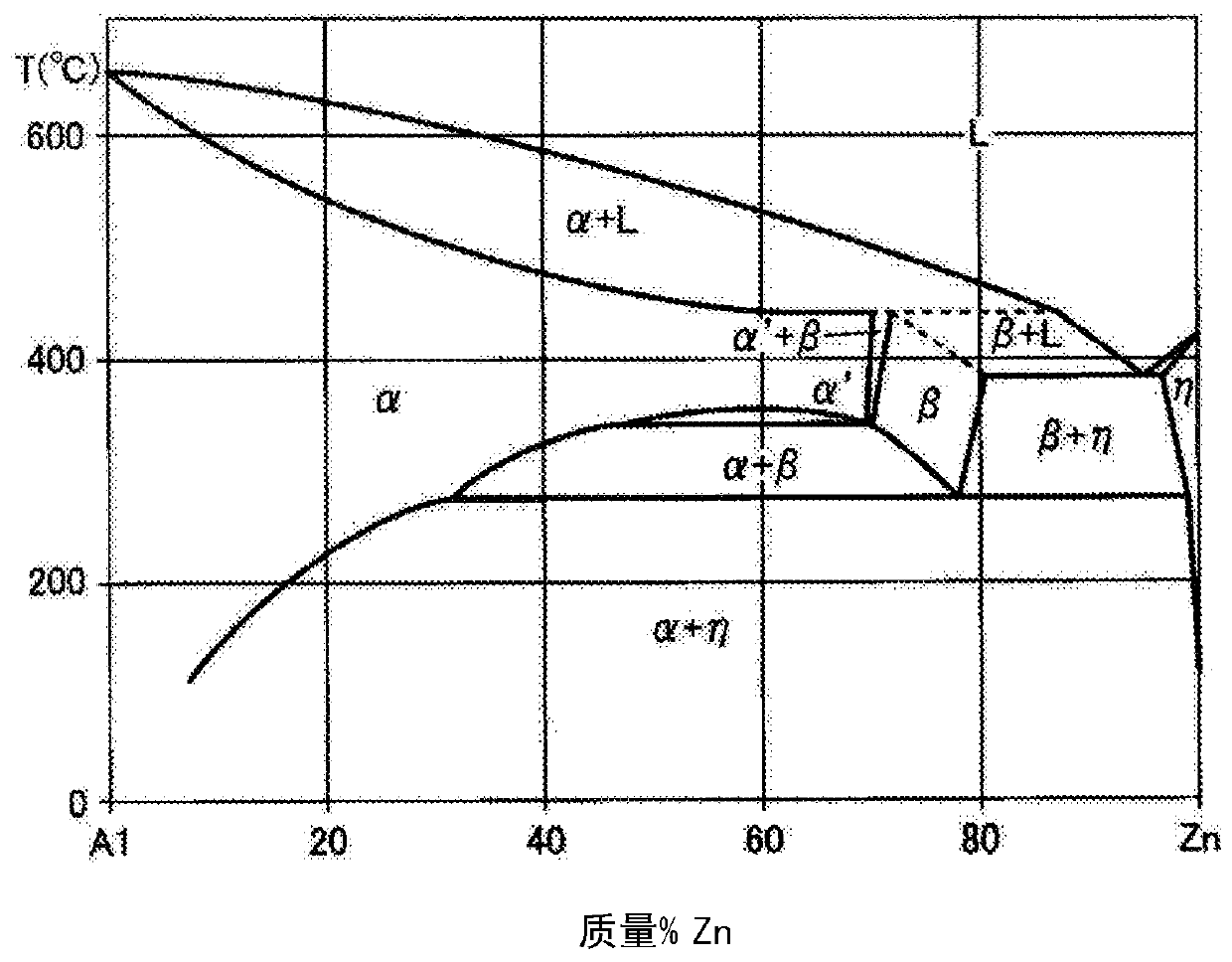

A hot-dip Zn-Al-Mg plated steel sheet good in corrosion resistance and surface appearance that is a hot-dip Zn-base plated steel sheet obtained by forming on a surface of a steel sheet a hot-dip Zn-Al-Mg plating layer composed of Al: 4.0-10 wt. %, Mg: 1.0-4.0 wt. % and the balance of Zn and unavoidable impurities, the plating layer having a metallic structure including a primary crystal Al phase or a primary crystal Al phase and a Zn single phase in a matrix of Al / Zn / Zn2Mg ternary eutectic structure. To obtain a plating layer possessing this metallic structure, the cooling rate of the plating layer adhering to a steel strip extracted from a plating bath and the plating bath temperature are appropriately controlled in a continuous hot-dip plating machine and / or appropriate amounts of Ti and B are added to the bath. Occurrence of a stripe pattern peculiar to this plated steel sheet is controlled by morphology control of a Mg-containing oxide film up to solidification of the plating layer or by adding an appropriate amount of Be to the plating bath.

Owner:NISSHIN STEEL CO LTD

Plating assistant agent for zinc aluminum magnesium alloy hot dipping for steel wire

ActiveCN103510031AImprove bindingInhibit sheddingHot-dipping/immersion processesMg alloysActive agent

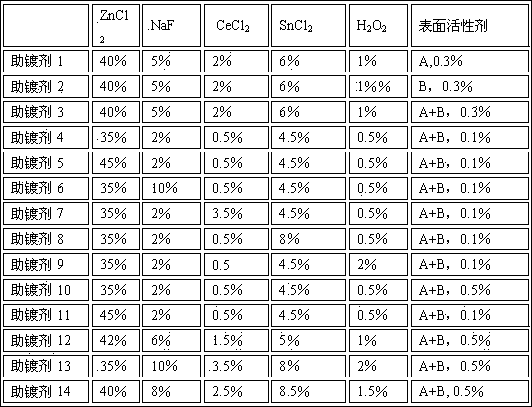

The invention relates to a plating assistant agent for zinc-aluminum-magnesium alloy hot dipping for a steel wire and belongs to the technical field of steel and iron material surface plating processes. The plating assistant agent is composed of 35-45 percent of ZnCl2, 2-10 percent of NaF2, 0.5-3.5 percent of CeCl2, 4.5-8.5 percent of SnCl2, 0.5-2 percent of H2O2, 0.1-05 percent of a surfactant and water in balancing amount. The surfactant is fatty alcohol ether sodium sulfate and / or sodium dodecyl sulfate. According to the invention, through a reasonable plating assistant agent formula, zinc-aluminum-magnesium alloy plating is obtained on the surface of the steel wire through hot dipping. The plating and the steel wire keep original performance respectively, more than 99.9 percent of a metallurgical bonding interface is obtained, the plating is compact in structure, plating leakage is avoided, and a zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance is formed. The corrosion resistance performance of the alloy plating is 2-4 times than that of normal hot-dipped pure zinc plating. The plating assistant agent is low in cost, can be used repeatedly and facilitates industrial production.

Owner:STATE GRID CORP OF CHINA +1

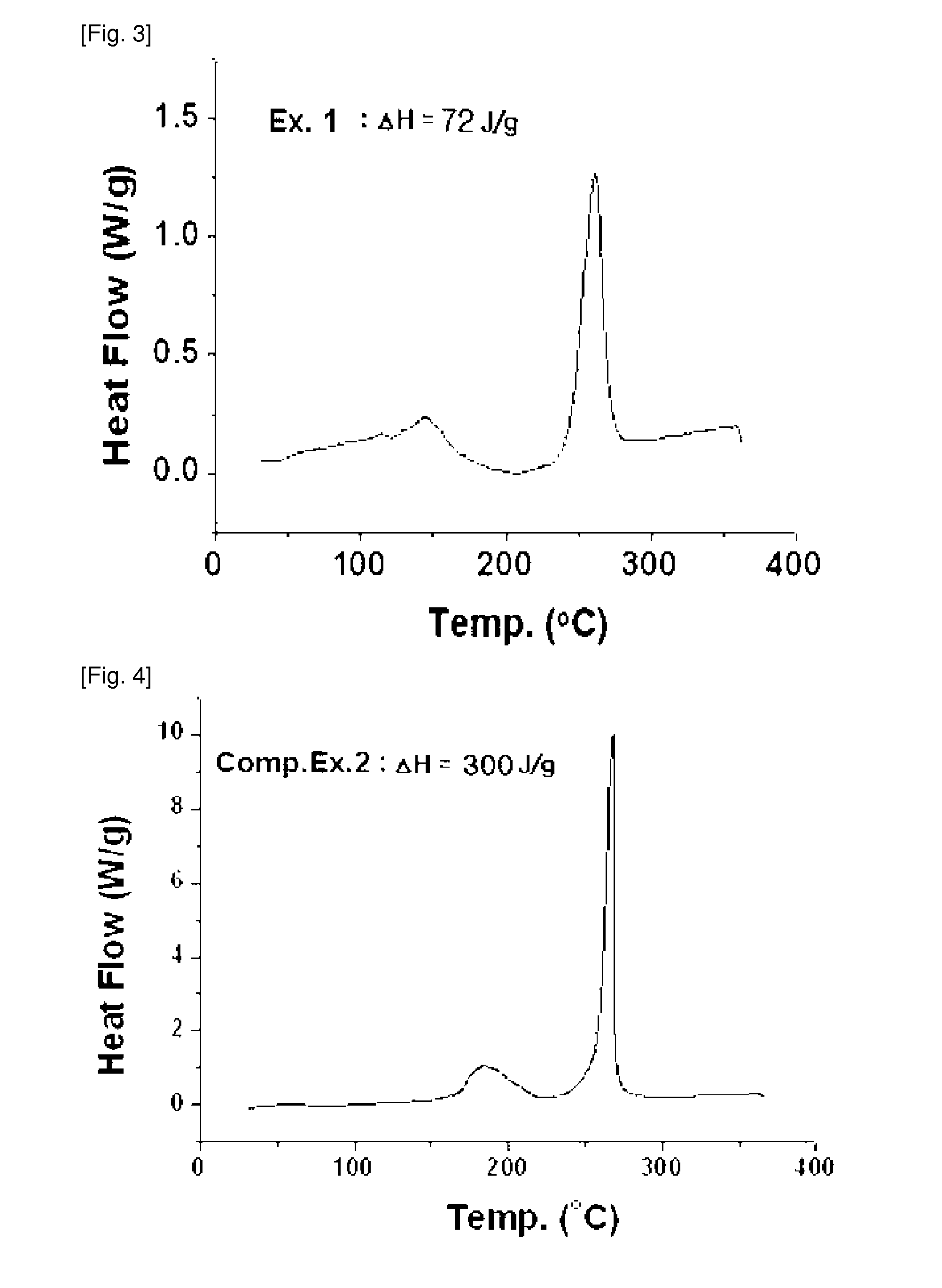

Zn-Al-Mg hot-dip steel plate with high corrosion resistance, and production method thereof

ActiveCN109536864AWon't dissolveDoes not dissolveHot-dipping/immersion processesSheet steelChemical composition

The invention discloses a Zn-Al-Mg hot-dip steel plate with high corrosion resistance, and a production method thereof. The Zn-Al-Mg hot-dip steel plate comprises a baseplate and a coating on the baseplate, and is characterized in that the chemical components of the coating comprise, by mass, 1.8%-2.3% of Al, 1.2%-1.8% of Mg, 0.01%-0.08% of Re, 0.003%-0.008% of Cu and the balance Zn and other inevitable impurities, wherein the Cu is added to plating solutions in a nanometer form during melting of the plating solutions. The Cu in the coating of the steel plate is added in a nano-copper form during melting of the plating solutions; since the temperature of Zn liquid is lower during adding of the Cu, the shape of Cu particles can be ensured; by taking advantage of the characteristic of fine dispersion of the Cu particles, the Cu particles play a role in strengthening of precipitation, so that the hardness of the coating is improved; and by adding of rare earth Re, the coating structure can be fined, and the fluidity of the plating solutions is improved, so that the corrosion resistance of the coating can be improved effectively. The coating structure of a product obtained with the method is primary Zn, Zn / MgZn2 binary eutectic, Zn / Al / MgZn2 ternary eutectic and nano-copper; and the corrosion resistance is equal to 10-15 times the corrosion resistance of a pure zinc plate of the same thickness.

Owner:HEBEI IRON AND STEEL

Secondary battery comprising ternary eutectic mixtures and preparation method thereof

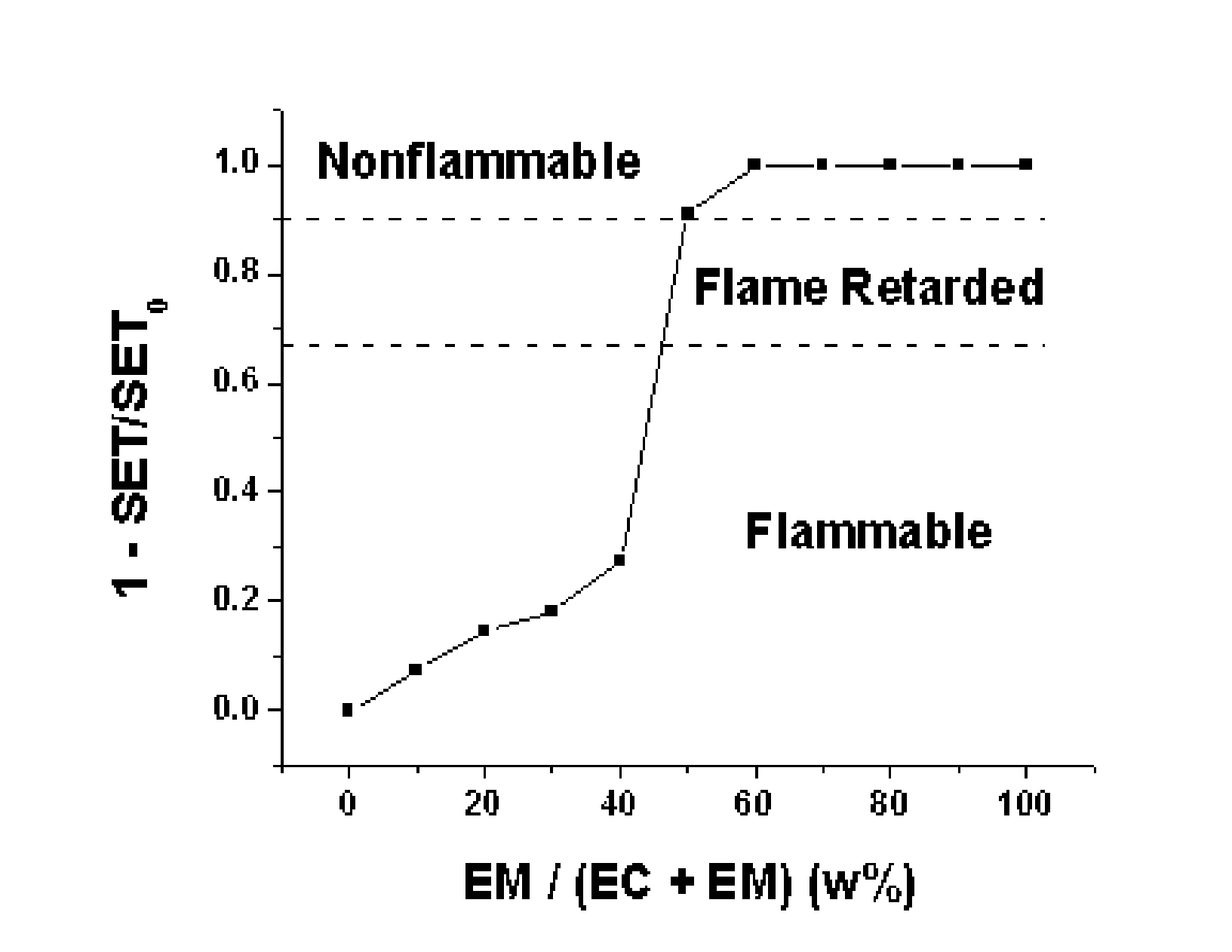

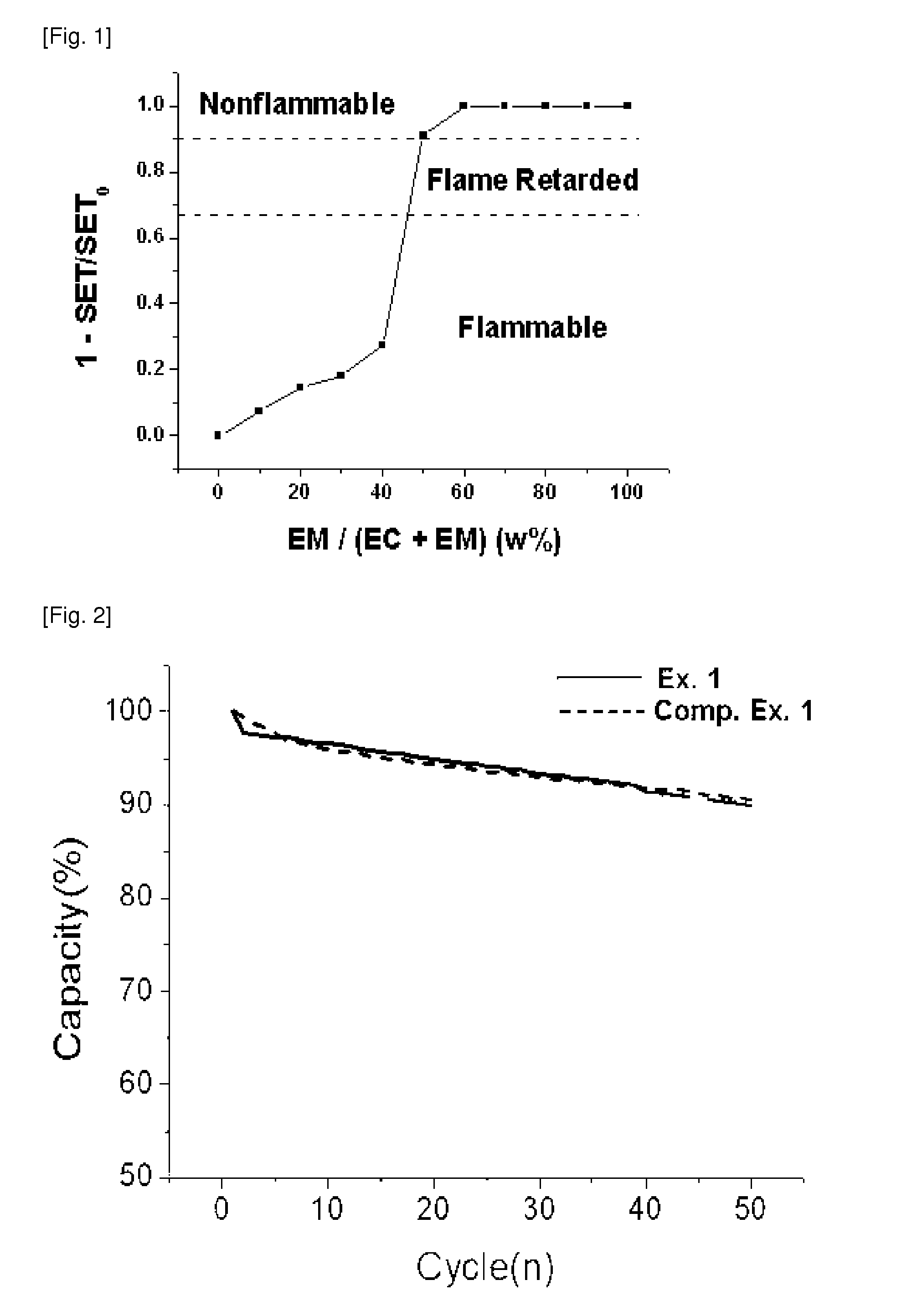

ActiveUS20100196766A1Good chemical and thermal stabilityAlkaline accumulatorsElectrode manufacturing processesLithiumElectrochemical window

Disclosed is a secondary battery including a cathode, an anode, a separator, and an electrolyte, wherein the electrolyte includes a ternary eutectic mixture prepared by adding (c) a carbonate-based compound to a eutectic mixture containing (a) an amide group-containing compound and (b) an ionizable lithium salt, and the carbonate-based compound is included in an amount of less than 50 parts by weight based on 100 parts by weight of the electrolyte. The use of the disclosed ternary eutectic mixture having flame resistance, chemical stability, high conductivity, and a broad electrochemical window, as the electrolyte material, improves both the thermal stability and quality of the battery.

Owner:LG ENERGY SOLUTION LTD

SnBiSb-series low-temperature lead-free solder and preparation method thereof

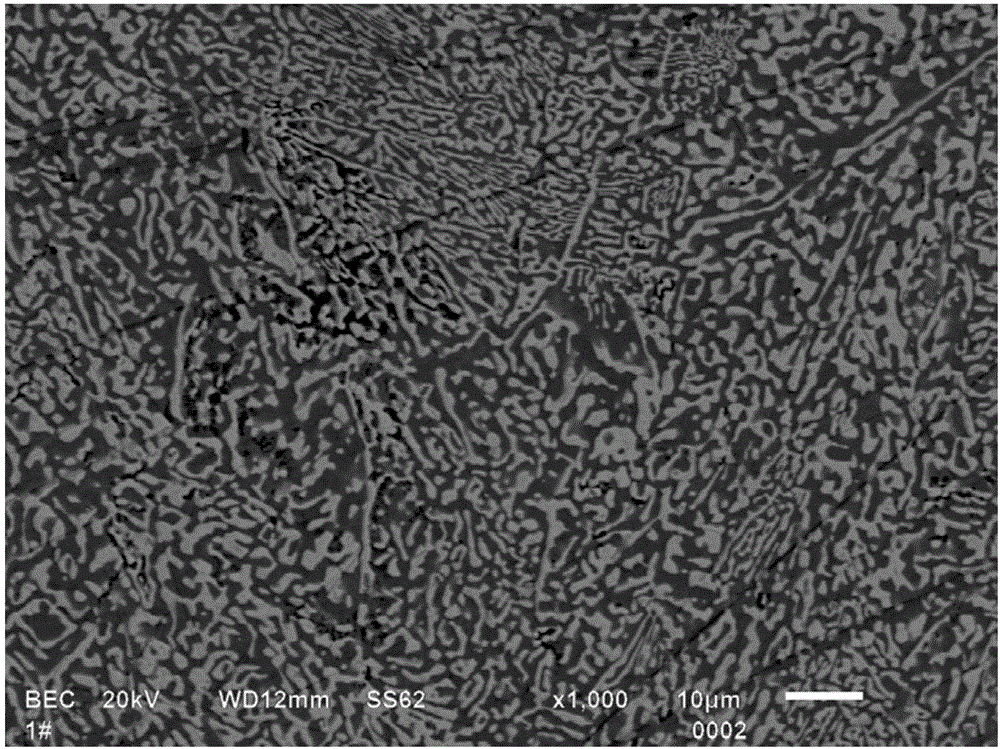

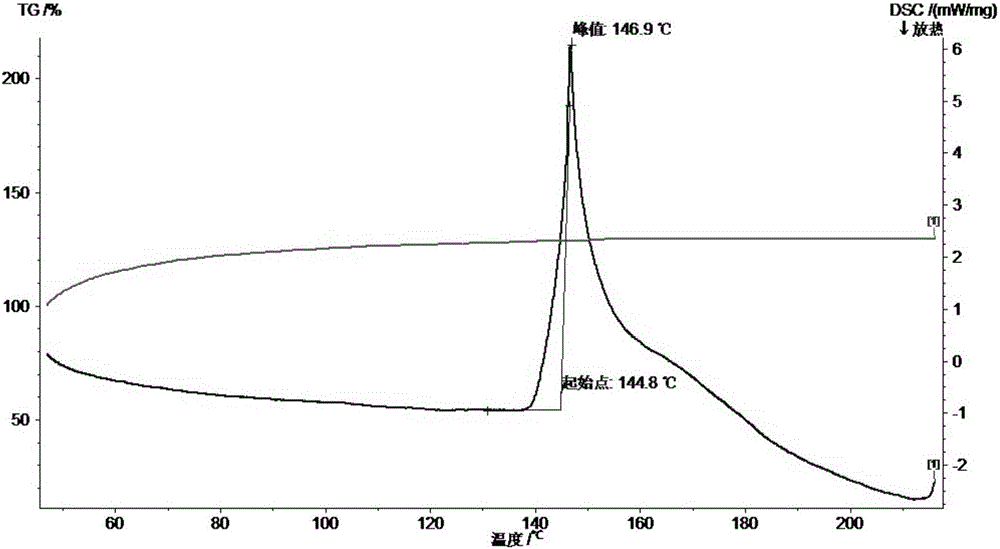

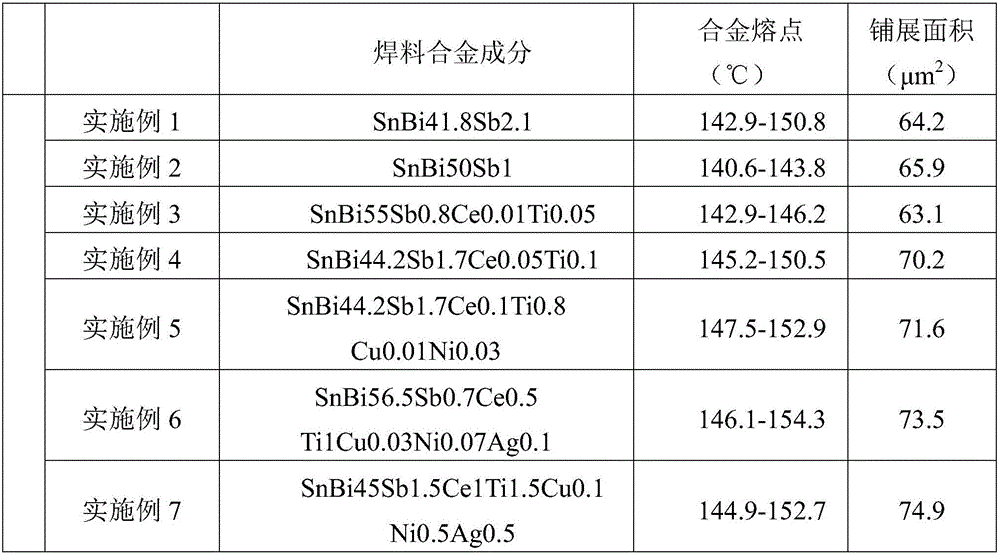

ActiveCN106216872AFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMechanical properties of carbon nanotubes

The invention discloses SnBiSb-series low-temperature lead-free solder and a preparation method thereof, and belongs to the technical field of low-temperature soft solder. The SnBiSb-series low-temperature lead-free solder consists of the following components in percentage by weight: 32.8-56.5% of Bi, 0.7-2.2% of Sb, the balance Sn, wherein weight percentage of Bi and Sb meets a relation b=0.006 a<2>-0.0672a+19.61+c, a is weight percentage of Bi, b is weight percentage of Sb, and c is greater than or equal to c, and smaller than or equal to 1.85. The invention further discloses a preparation method for the lead-free solder. Solder alloy of the SnBiSb-series low-temperature lead-free solder is a ternary eutectic or near-elliptic eutectic structure, is low in melting point, has excellent mechanical property and reliability, and is suitable for the low-temperature solder field.

Owner:BEIJING COMPO ADVANCED TECH

Dissimilar metal joining method for magnesium alloy and steel

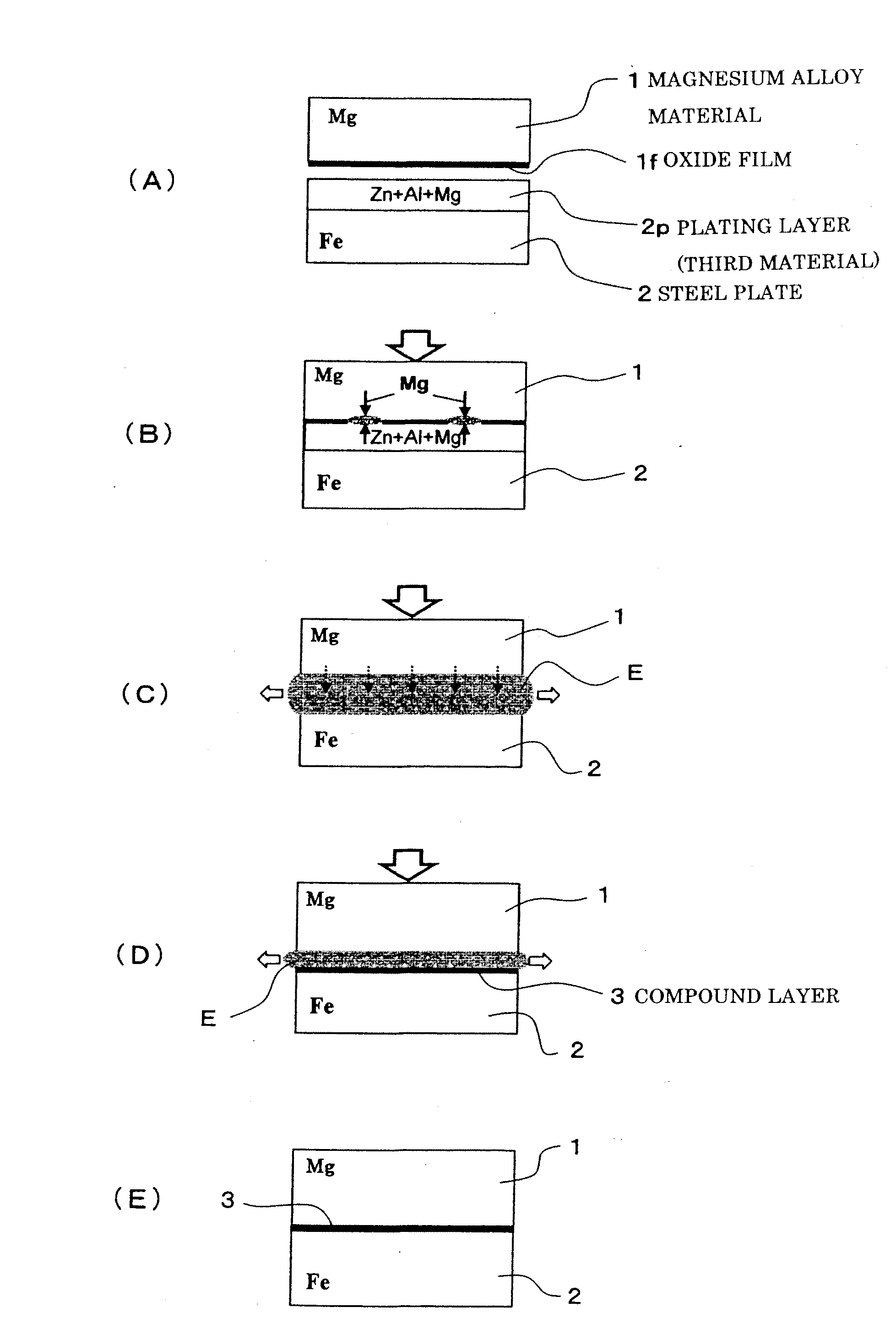

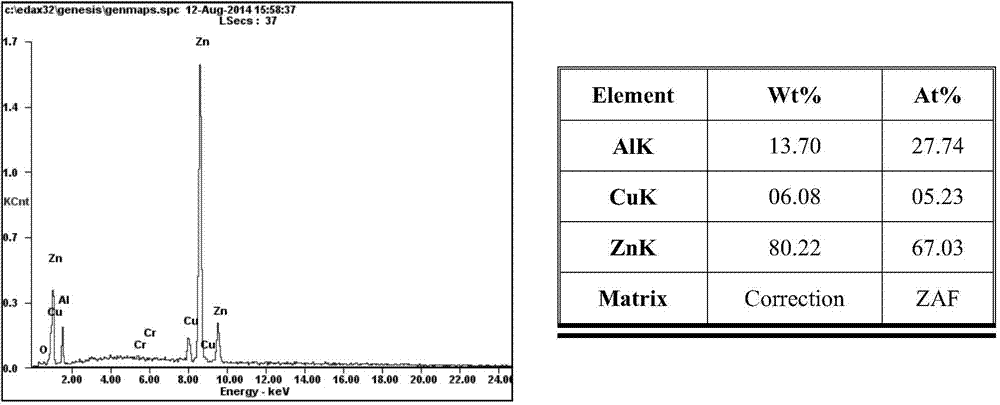

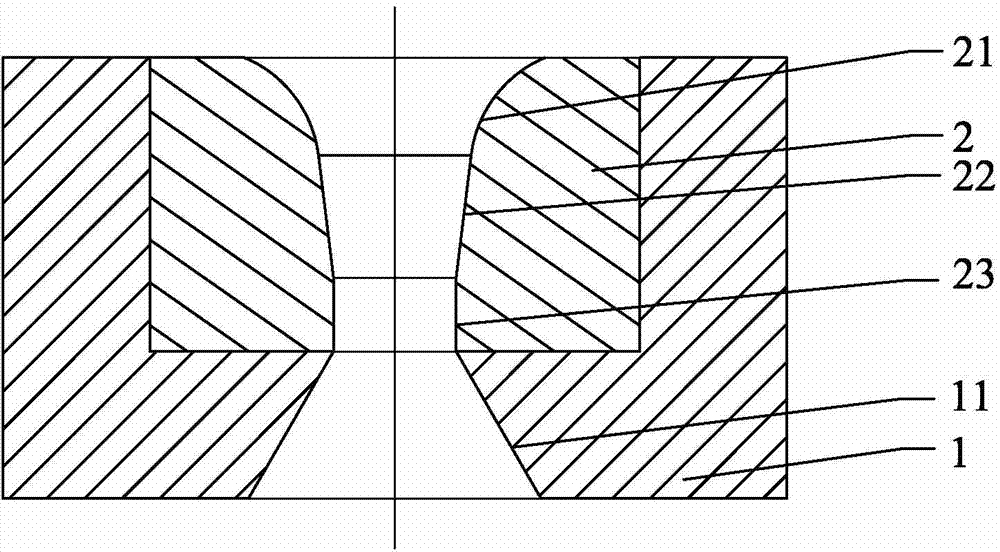

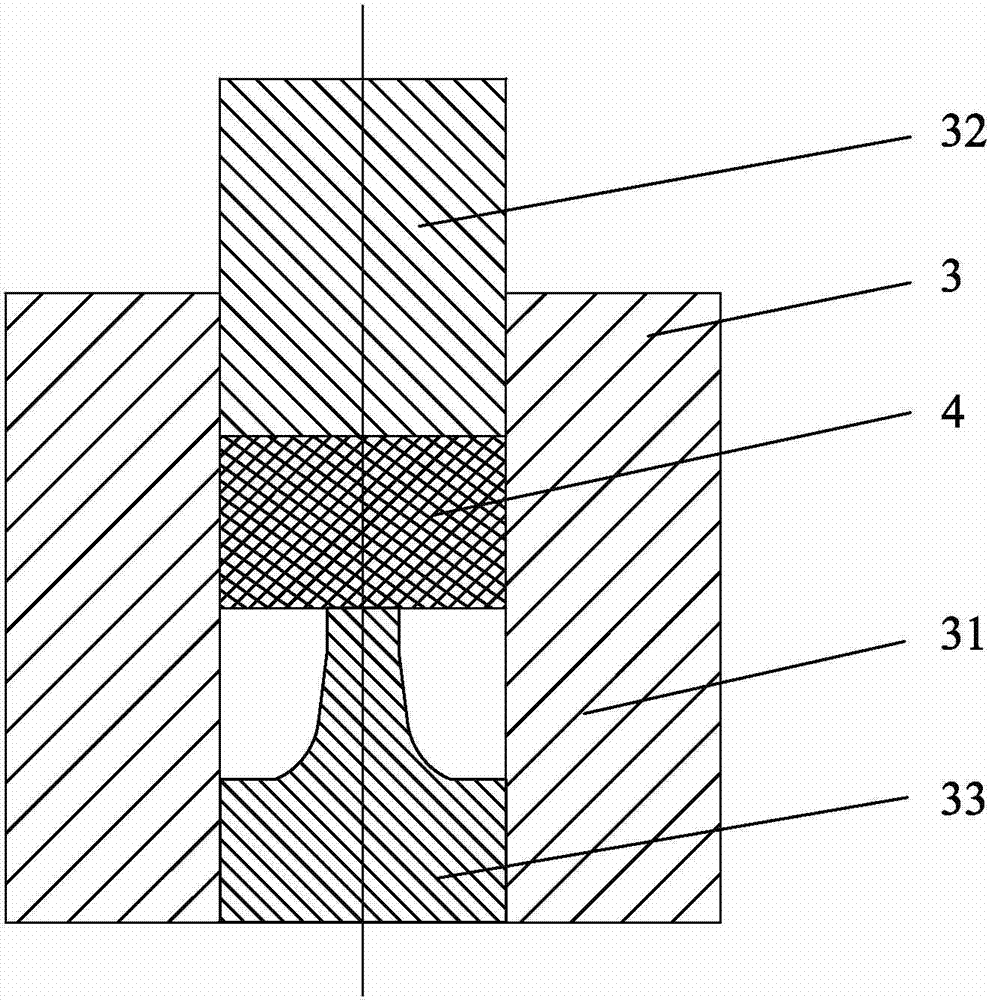

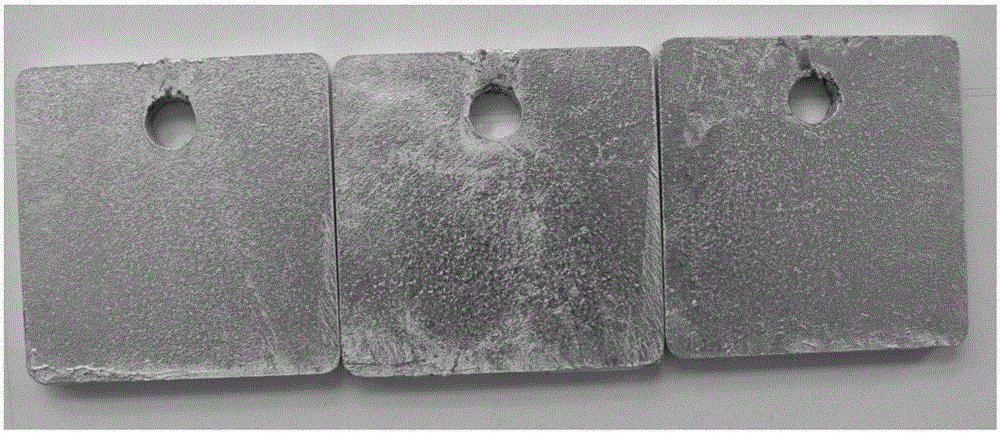

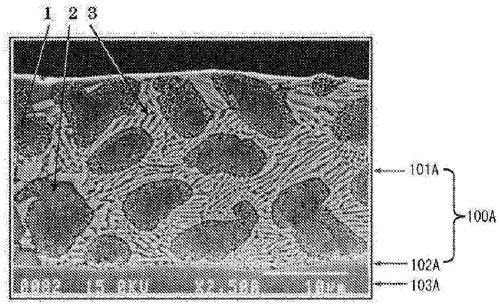

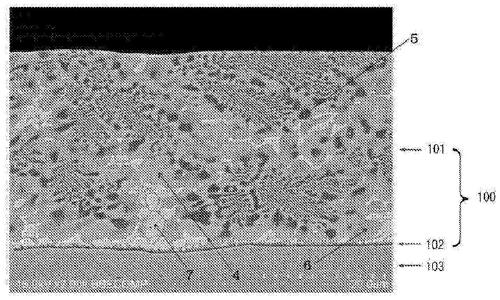

ActiveUS20110159313A1Easy to disassembleCooking-vessel materialsSoldering apparatusSheet steelIntermetallic

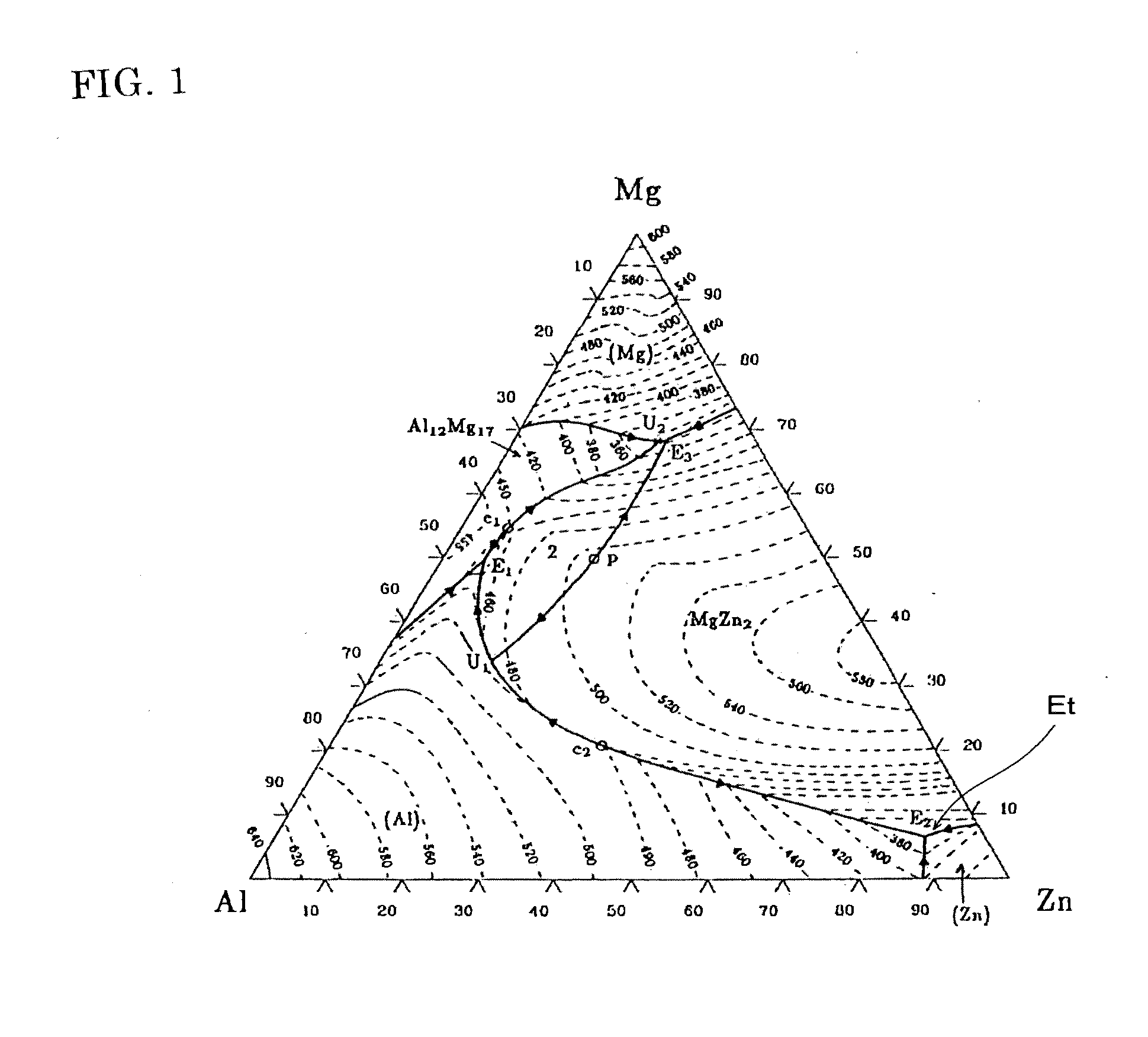

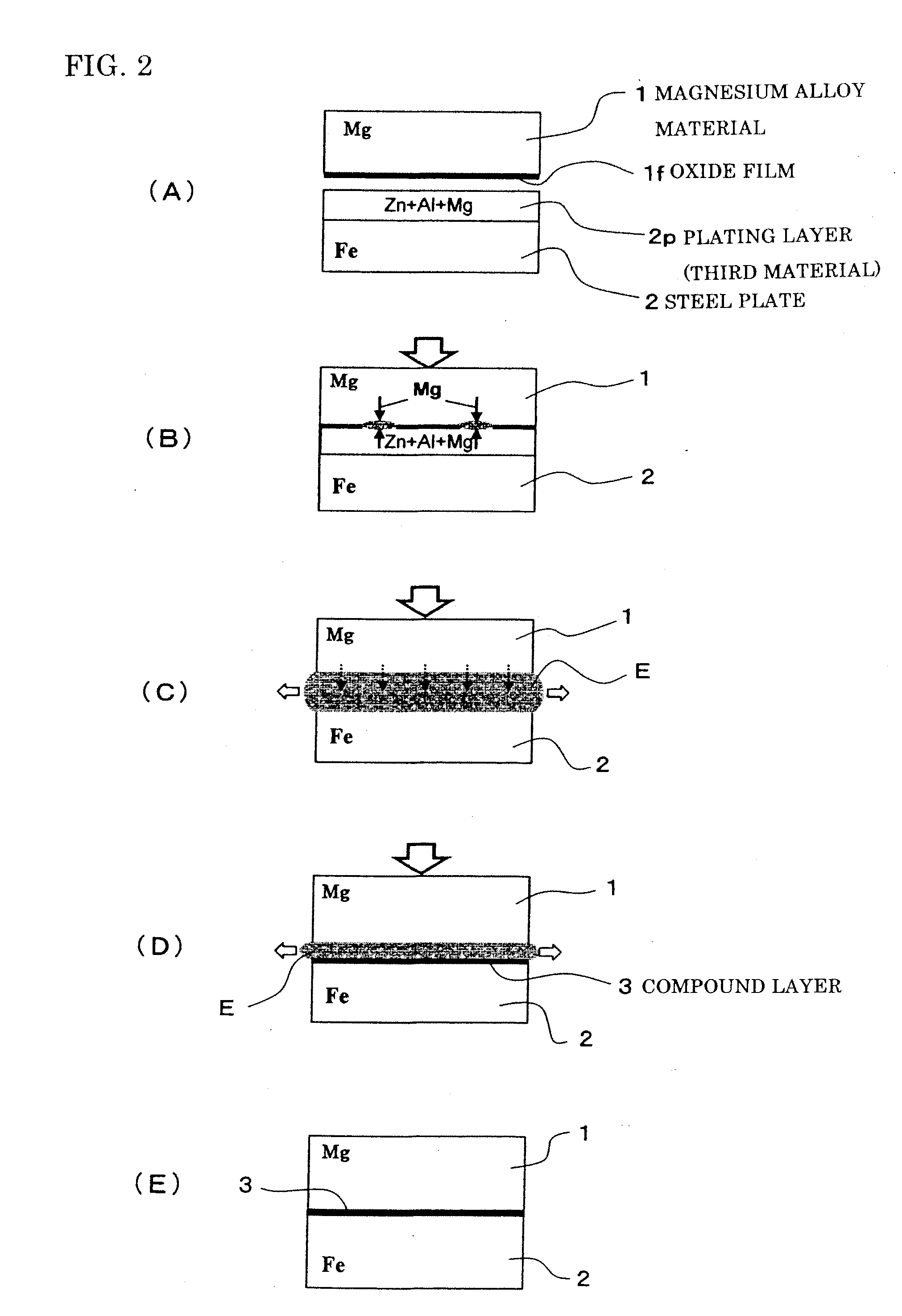

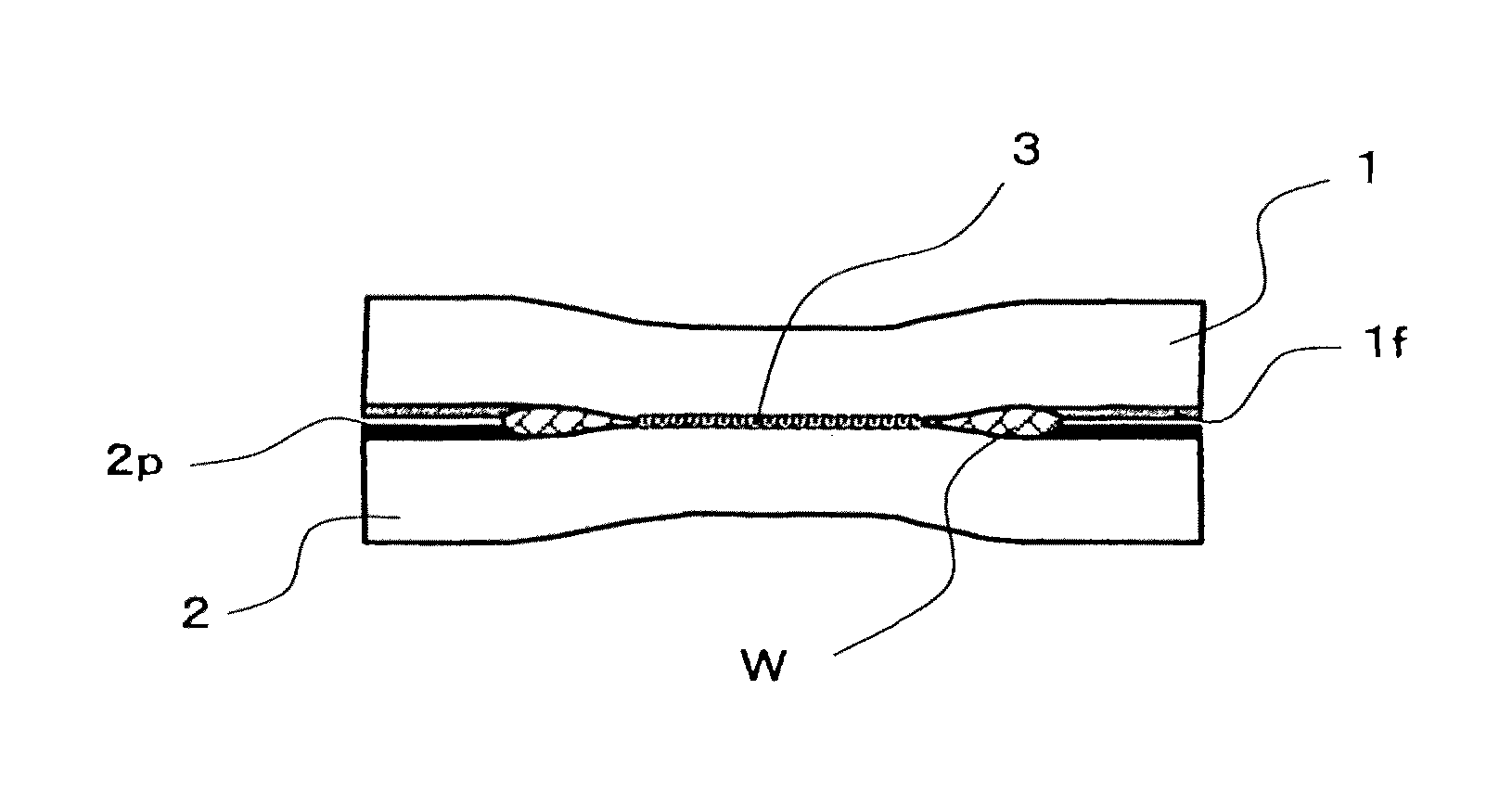

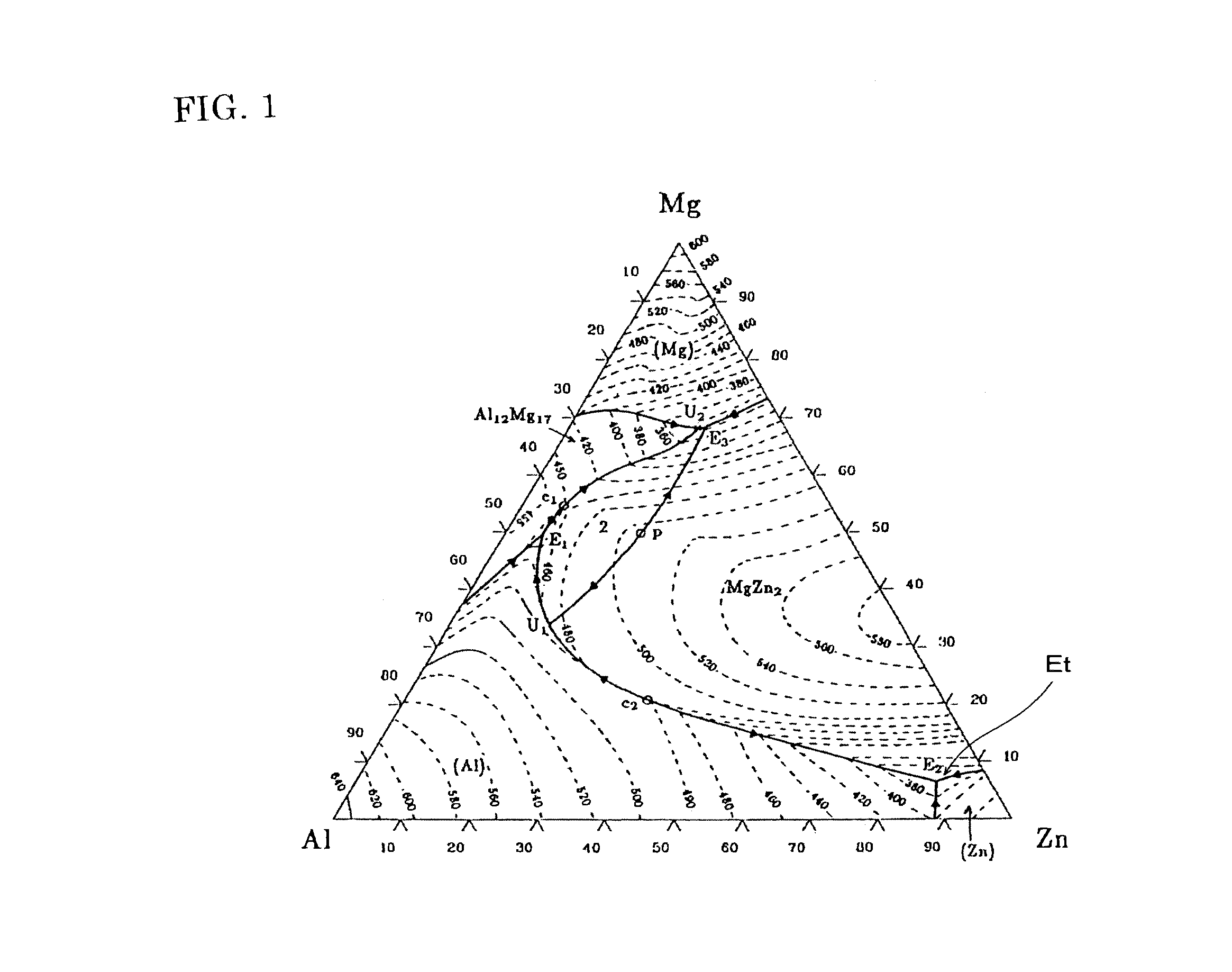

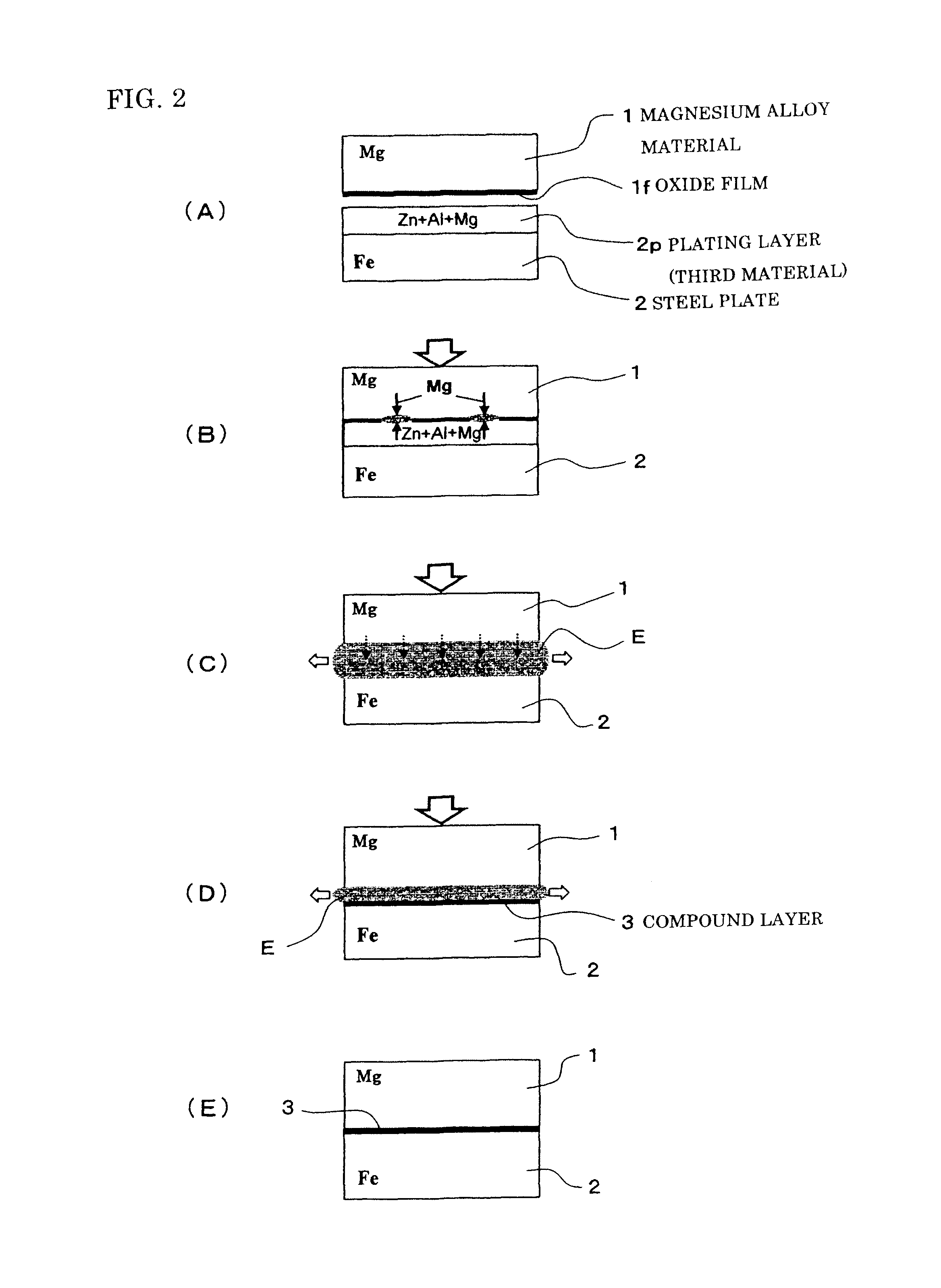

[Object] To provide a joining method for dissimilar metals which are magnesium alloy and steel and difficult to be metallurgically directly joined to each other while oxide film is present at a joining surface.[Solving Means] In order to join magnesium alloy material 1 and steel plate 2 to each other, a galvanized steel plate to which Zn—Al—Mg alloy plating (a third material) is applied is used as the steel plate 2. When joining is made, ternary eutectic melting of Al—Mg—Zn is caused, so that it is discharged together with oxide film 1f and impurities from the joining interface while Al—Mg intermetallic compound such as Al3Mg2 and Fe—Al intermetallic compound such as FeAl3 are formed, thereby joining the newly generated surfaces of the magnesium alloy material 1 and the steel plate 2 to each other through a compound layer 3 containing these intermetallic compounds.

Owner:NISSAN MOTOR CO LTD

Dissimilar metal joining method for magnesium alloy and steel

ActiveUS9174298B2Easy to disassembleCooking-vessel materialsSoldering apparatusSheet steelIntermetallic

[Object] To provide a joining method for dissimilar metals which are magnesium alloy and steel and difficult to be metallurgically directly joined to each other while oxide film is present at a joining surface.[Solving Means] In order to join magnesium alloy material 1 and steel plate 2 to each other, a galvanized steel plate to which Zn—Al—Mg alloy plating (a third material) is applied is used as the steel plate 2. When joining is made, ternary eutectic melting of Al—Mg—Zn is caused, so that it is discharged together with oxide film 1f and impurities from the joining interface while Al—Mg intermetallic compound such as Al3Mg2 and Fe—Al intermetallic compound such as FeAl3 are formed, thereby joining the newly generated surfaces of the magnesium alloy material 1 and the steel plate 2 to each other through a compound layer 3 containing these intermetallic compounds.

Owner:NISSAN MOTOR CO LTD

Method for obtaining aluminum oxide-based ternary melt grown ceramic tissue morphology

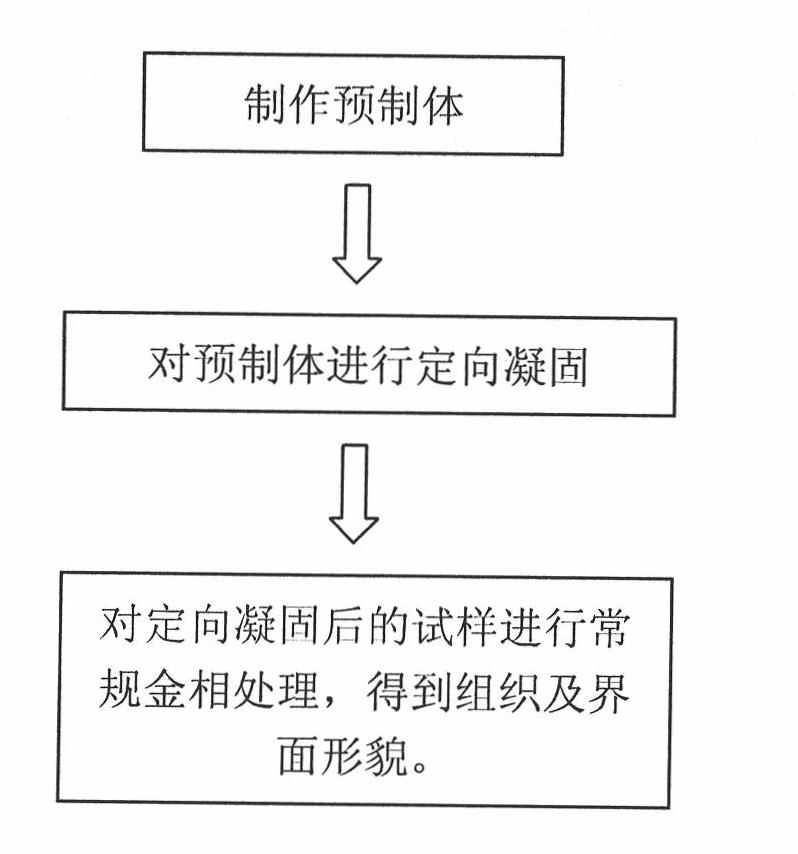

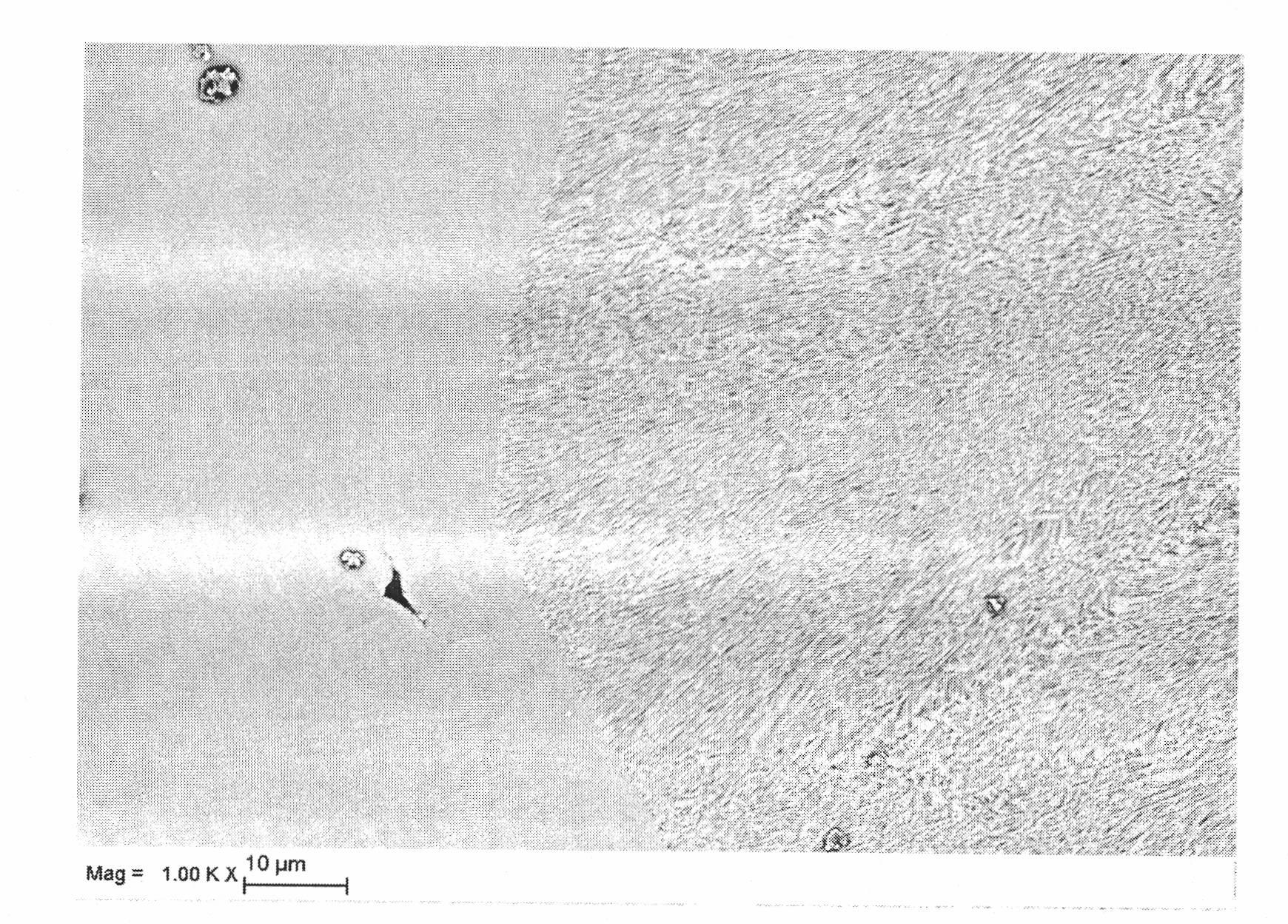

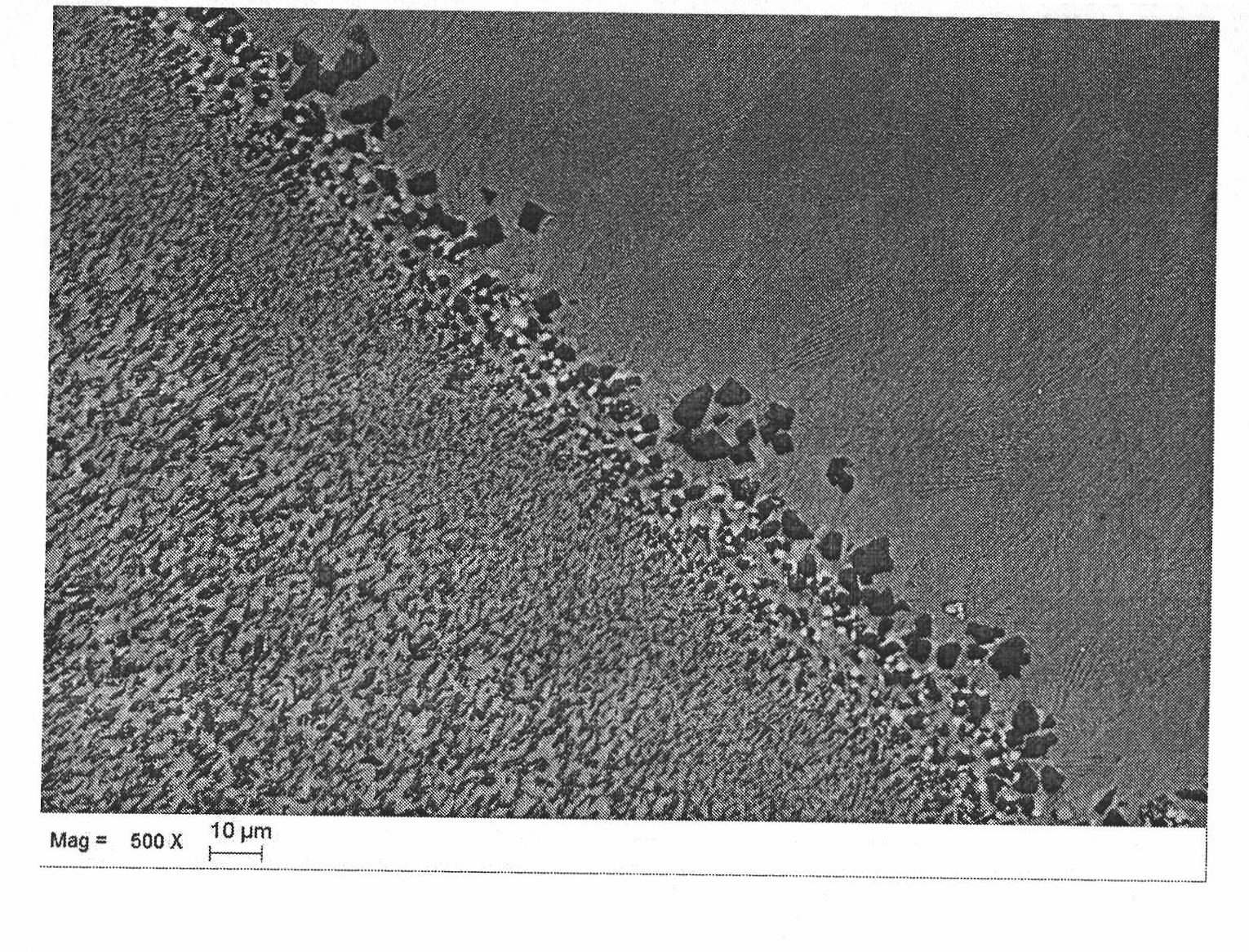

ActiveCN102153334AIncrease superheatIncreasing the temperature gradient of the solid phaseZone meltingLiquid metal

The invention discloses a method for obtaining aluminum oxide-based ternary melt grown ceramic tissue morphology, which comprises the following steps of: combining zone melting and liquid metal cooling, and performing directional solidification on a plurality of precast bodies formed by using aluminum oxide, yttrium oxide and zirconium oxide respectively; and taking the longitudinal sections and the transverse sections of the directional solidified precast bodies, performing conventional metallographic treatment, and performing surface metal spraying to obtain tissue morphology and interface morphology of the aluminum oxide-based ternary eutectic oxide melt grown ceramic at different growth rates. In the directional solidification, the withdrawing rate is 1 to 10,000mum / s, and the laser power is 200 to 1,500W. The obtained directional solidification tissues are greatly different from the tissues in a melting zone and have no obvious tissue transition zone, and the interface morphologyis preserved perfectly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

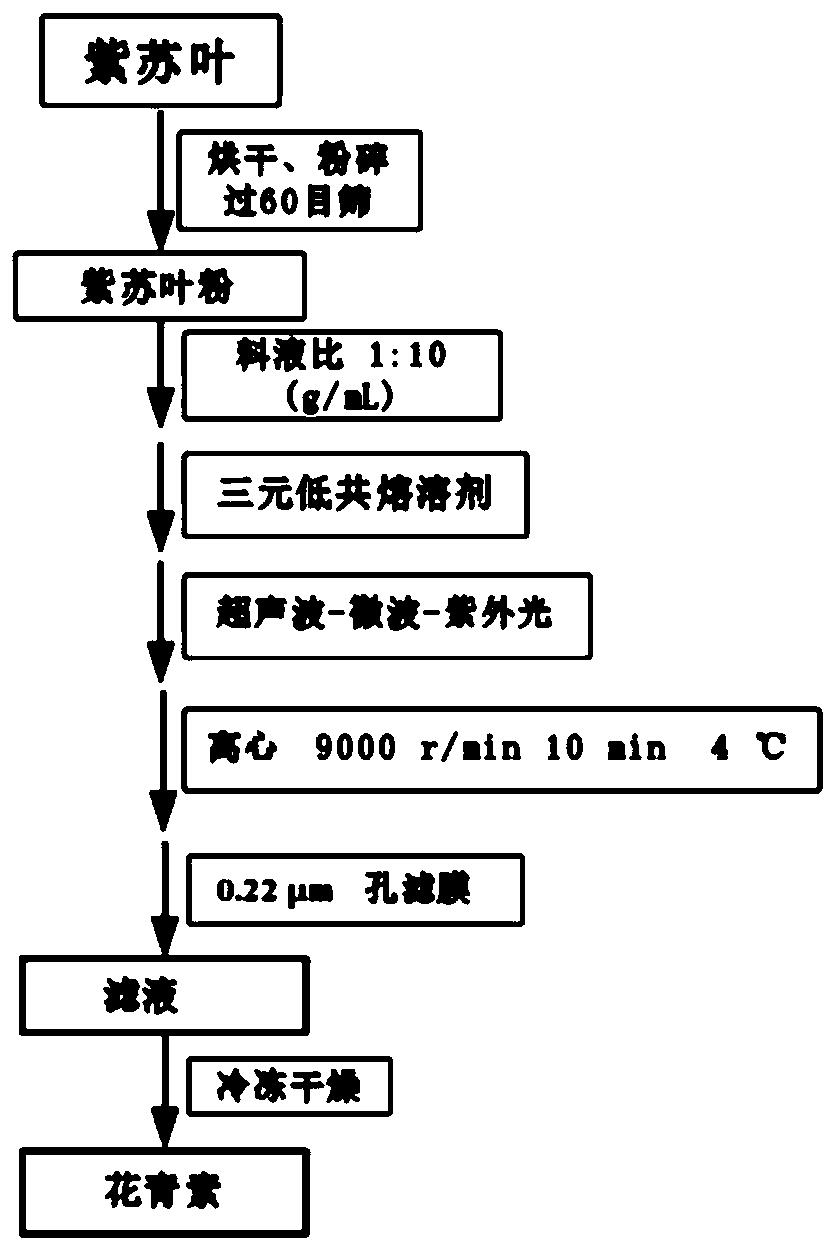

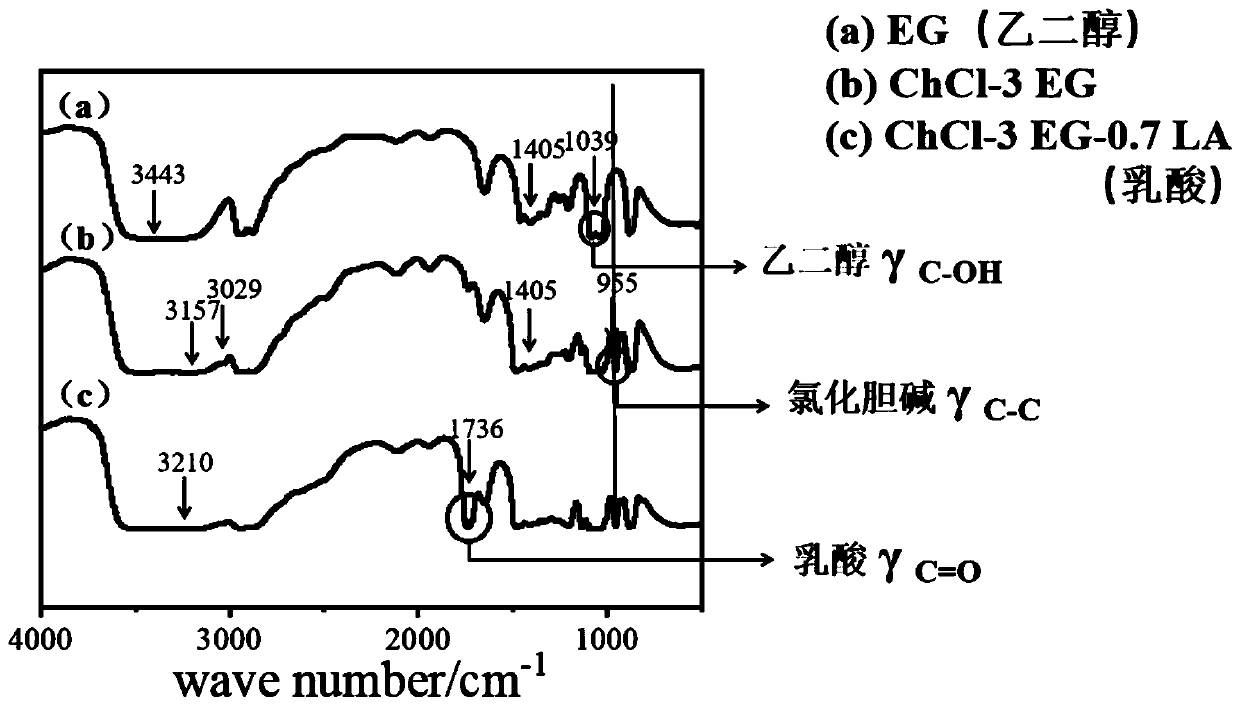

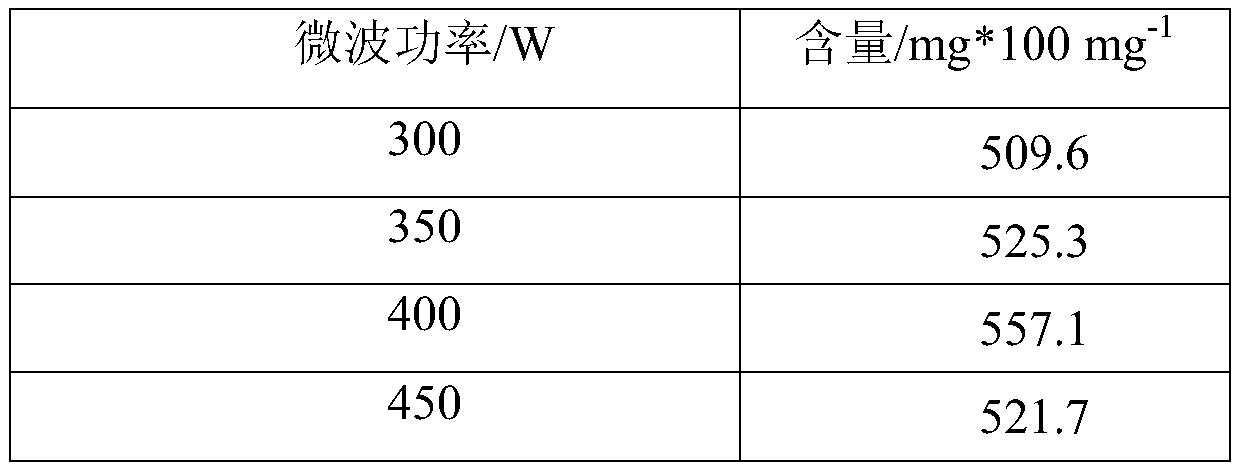

Method for extracting Perilla frutescens leaf anthocyanin by using a ternary eutectic solvent

ActiveCN110590730AReduce lossIncrease contentOrganic chemistryUltraviolet lightsPerilla frutescens leaf

The invention discloses a Perilla frutescens leaf anthocyanin extraction method, and particularly relates to preparation of an eutectic solvent, and a method for ultrasonic wave-microwave-ultravioletlight assisted extraction of anthocyanin, wherein the eutectic solvent has advantages of diversified structure, biodegradability, environmental protection, easy preparation, renewable property, low melting point and the like, is an environmentally-friendly solvent, and can effectively reduce the solvent loss and obviously increase the content of anthocyanin at a low dosage; and the disadvantages of the single wave can be overcome through the ultrasonic wave-microwave-ultraviolet light combination, such that the method is an emerging technology integrating the advantages of ultrasonic wave extraction and microwave extraction, the solvent can penetrate through plant matrixes easily, and the effective components can be dissolved in the solvent easily.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Silicon carbide granules reinforced aluminium base composite material connection method

InactiveCN1654155AAvoid damageSurface pretreatment requirements are not highWelding/cutting media/materialsSoldering mediaSlurryPre treatment

The present invention relates to the connection method of SiC particle reinforced Al-base composite material (SiCp / Al), and is especially instantaneous liquid phase diffusion connecting technology of SiCp / Al. The present invention realizes the metallurgical combination between samples with mixed Al, Ag, Cu and Ti powder as the intermediate layer, and through the ternary eutectic reaction of Al, Ag and Cu and certain time of component diffusion and homogenization. The technological process includes compounding the intermediate layer, surface treatment of the mother material to be connected, setting the mixed powder slurry compounded with anhydrous alcohol to the surface of the mother material, heating in vacuum furnace for certain time and cooling in the furnace. The said process can connect SiCp / Al parts with complicated structure and has the features of low connection temperature, less damage to mother material, etc.

Owner:UNIV OF SCI & TECH BEIJING

Steel sheet hot dip coated with Zn-Al-Mg having high Al content

InactiveUS6709770B2Improve corrosion resistanceQuality improvementHot-dipping/immersion processesDomestic articlesSheet steelCrystal structure

A high Al hot-dip Zn-Al-Mg plated steel sheet is obtained by forming on a steel sheet surface a hot-dip plating layer comprising, in mass %, Al: more than 10 to 22% and Mg: 1-5%, and, optionally, Ti: 0.002-0.1%, B: 0.001-0.045% and Si: 0.005-0.5%. The plating layer exhibits a metallic structure of [primary crystal Al phase] mixed in a matrix of [Al / Zn / Zn2Mg ternary eutectic crystal structure]. Substantially no Zn11Mg2 phase is present in the metallic structure of the plating layer.

Owner:NISSHIN STEEL CO LTD

Metallic coated steel product

ActiveUS20200002798A1Improve corrosion resistanceHot-dipping/immersion processesChromatisationMetal coatingHeat-affected zone

Provided is a metallic coated steel product which is less likely to experience LME and blowhole formation and is likely to exhibit an improved corrosion resistance at welding heat affected zones. The metallic coated steel product is a hot-dip metallic coated steel product including a steel product and a plating layer that is provided on a surface of the steel product and includes a Zn—Al—Mg alloy layer. In a cross-section of the Zn—Al—Mg alloy layer an area fraction of MgZn2 phase is from 45 to 75%, a total area fraction of MgZn2 and Al phases is not less than 70%, and an area fraction of Zn—Al—MgZn2 ternary eutectic structure is from 0 to 5%; and the plating layer has a predetermined chemical composition.

Owner:NIPPON STEEL CORP

High-strength deformable zinc-based alloy material

The invention discloses a high-strength deformable zinc-based alloy material which consists of the following components in percentage by weight: 5wt%-15wt% of Cu, 7wt%-20wt% of Al, 0.01wt%-1.5wt% of Mg, 0.01wt%-2.0wt% of Cr and the balance of Zn and inevitable impurities. A microstructure of the zinc-based alloy material comprises a tiny and uniformly-distributed primary phase Epsilon, an aluminum-rich Al-Zn-Cu ternary tiny eutectoid structure and a zinc-rich Zn-Al-Cu ternary eutectic structure. The alloy material disclosed by the invention is higher than 500MPa in tensile strength, higher than 120 in HV hardness, higher than 10% in ductility and higher than 26% IACS in electric conductivity, is also good in machining properties, and can be applied to industries of power plugs, electronic and electric products, communication connectors and the like as a substitute product of traditional copper alloy, especially traditional lead brass.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Mosaic ceramic drawing die and making method thereof

ActiveCN103586296AGood mechanical propertiesGood high temperature superplasticityDrawing diesHardnessWear resistance

The invention discloses a mosaic ceramic drawing die and a making method thereof. The mosaic ceramic drawing die is characterized in that the mosaic ceramic drawing die comprises a die core and a die sleeve; the die core comprises an inlet zone, a work zone and a sizing zone which are coaxial, are smoothly connected, and are obtained through a superplastic extrusion molding method, and the material of the die core is an alumina-based ternary eutectic ceramic; and the die sleeve comprises a die core accommodating zone for fixing the die core, and an outlet zone smoothly connected with the sizing zone. The drawing die core is formed through the superplastic extrusion molding by utilizing the superplasticity of the alumina-based ternary eutectic ceramic, and is inlaid in the die sleeve to compose the mosaic ceramic drawing die. The die core has a high hardness and wear and high temperature resistances, and can substantially improve the service life of the drawing die; and the superplastic molding method is suitable for the batch production, and the whole drawing die adopts a mosaic structure, so the production cost of the whole drawing die is reduced.

Owner:DALIAN UNIV OF TECH

Inorganic phase-change composite material and preparation method thereof

ActiveCN108467711AImprove corrosion resistanceReduced phase transition temperature rangeHeat-exchange elementsSodium acetateSodium stearate

The invention discloses an inorganic phase-change composite material and a preparation method of the material. The phase-change material comprises a main heat agent, a nucleator, a pH (potential of hydrogen) regulator, a corrosion inhibitor, a heat conduction agent and water, wherein the mass of the nucleator is 3-6% of that of the main heat agent; the mass of the pH regulator is 0-3% of that of the main heat agent; and the mass of the corrosion inhibitor is 0.5-2% of that of the main heat agent. Eutectic salt is prepared by a high-temperature hydrothermal reaction of sodium acetate, calcium chloride and sodium stearate in the pH regulator; a phase change temperature scope of the eutectic salt is reduced to 5-10 DEG C; a prepared product directly generates a self-organization framework toform the jelly-like eutectic salt, so that a thickening agent and a setting agent are not required to be added in a system; a degree of supercooling of the product is greatly reduced; and furthermore,since the ternary eutectic salt has a special structure, the ternary eutectic salt has the advantages of low lamination and supercooling possibility of an organic phase-change material and a high potential heat value of an inorganic phase-change material.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping

ActiveCN105648377AReduce performanceWill not use reduced effectHot-dipping/immersion processesAlkali freeSurface-active agents

The invention discloses a long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping. The plating assistant agent is prepared from the following raw materials in percentage by weight: 25 percent to 35 percent of ZnCl2, 2 percent to 10 percent of KF, 5 percent to 15 percent of CaCl2, 4.5 percent to 8.5 percent of AgCl, 2 percent to 3.5 percent of alkali-free SP binary compound flooding dispersing agent, 0.1 percent to 0.5 percent of compound surface active agent and the balance water. Through a reasonable formula of the plating assistant agent, a zinc-aluminum-magnesium alloy coating is obtained on the surface of a steel and iron material substrate by utilizing hot dipping; the coating and the steel and iron material substrate separately keep original performance; the coating is compact in structure and free of skip plating, and zinc-aluminum-magnesium ternary eutectic with excellent corrosion resistance can be formed. The plating assistant agent is low in cost, can be easily produced industrially, and can be widely suitable for hot dipping long-ageing reusable zinc-aluminum-magnesium alloy plating solution of which the Al content is 5 percent to 22 percent and the Mg content is 2 percent to 6 percent.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance

ActiveCN108690944AImprove corrosion resistanceImprove surface conditionHot-dipping/immersion processesFurnace typesCorrosionCoating

The invention discloses a manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance. The manufacturing method comprises the following steps: increasing the oxygen partial pressure in an annealing furnace to 30-80 ppm when basic strip steel enters a preheating section of the annealing furnace, wherein the dew point of the preheating furnace is 0-50DEG C, the furnace pressure of the annealing furnace is 300-500 Pa, and the preheating temperature is 500-700 DEG C; controlling the dew point of a soaking section at 30 DEG C below zero to 30 DEG Cafter the basic strip steel enters the soaking section, wherein the hydrogen content in percent by volume is 15-25%; and finally, controlling the cooling speed at 20-100 DEG C / s for cooling, wherein the basic strip steel enters a zinc pot to produce Mg-containing hot dipped steel plates. Mg-enriched ternary eutectic phase sheets in coatings of the steel plates are small in interlayer spacing, relatively short and uniform in distribution, Mg-containing oxides are unlikely produced, and the hot dipped steel plates have high corrosion resistance and good blacken resistance. In a severe environment, the corrosion resistance of the coatings is 2-3 times of that of conventional hot dipped steel plates, or the corrosion resistance is even higher, and the quality of the surface tissues of the coatings is good.

Owner:武汉钢铁有限公司

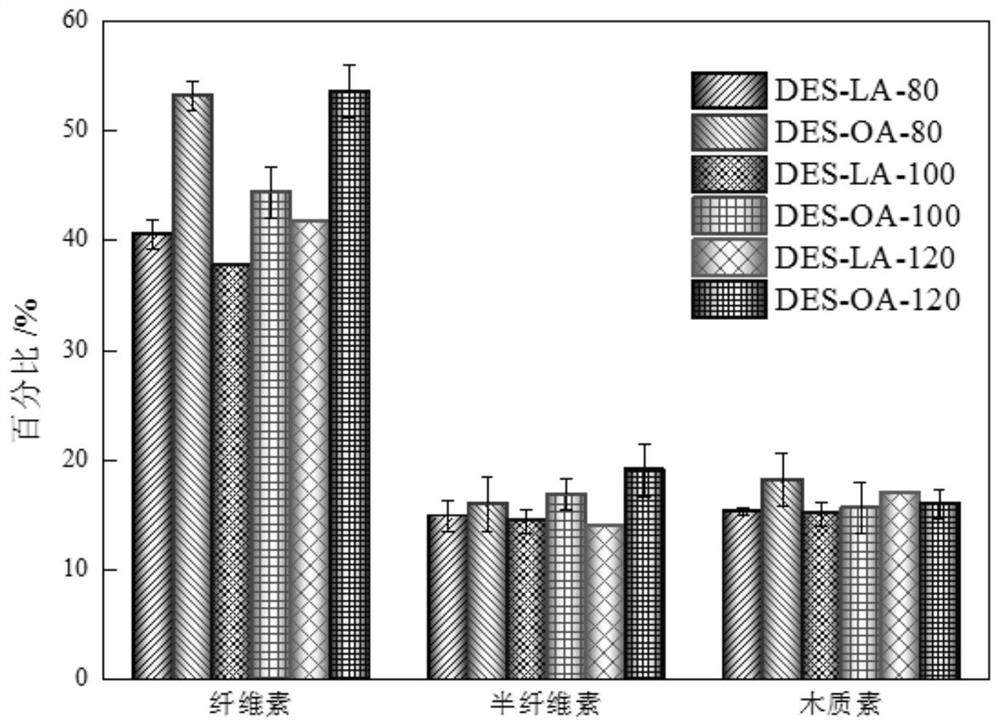

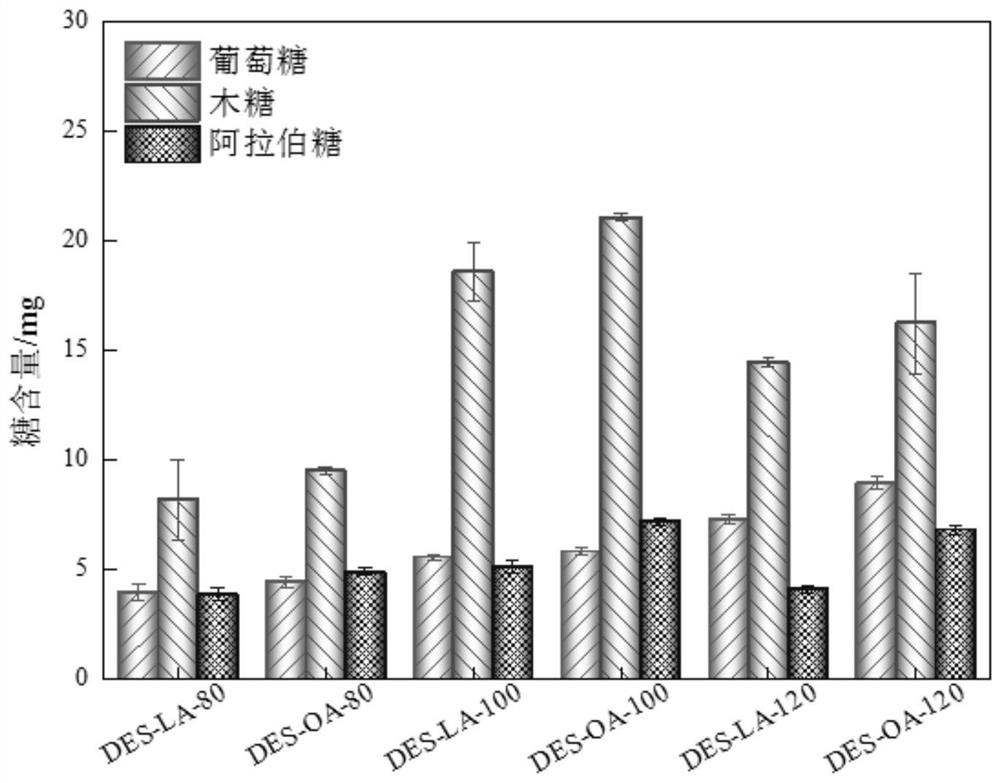

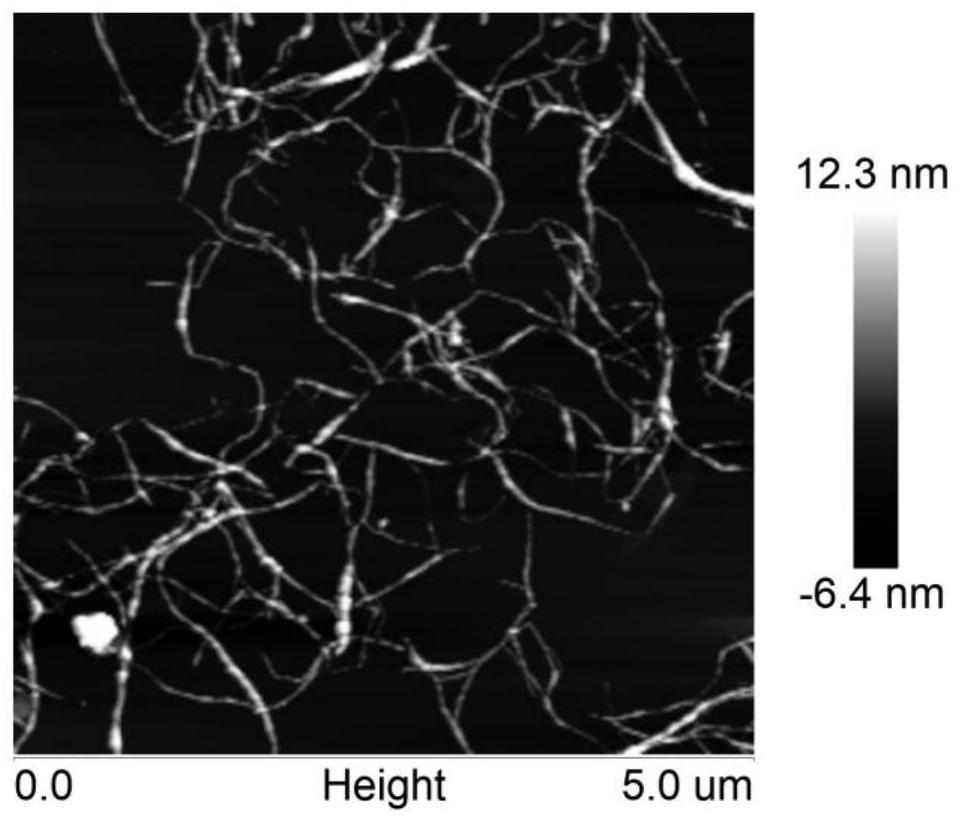

Method for preparing nanocellulose microfibrils through pretreatment of ternary eutectic solvent

ActiveCN112853794ASimple and fast operationImprove preprocessing effectPaper material treatmentFreeze-dryingPhysical chemistry

The invention discloses a method for preparing nanocellulose microfibrils through pretreatment of a ternary eutectic solvent, which belongs to the technical field of biomass nanocellulose preparation. The method comprises the following steps of firstly, pretreating lignocellulose biomass by using a ternary eutectic solvent, and separating to obtain a component rich in cellulose, preparing a 1wt% solution from a cellulose-rich component, centrifuging to obtain a nanocellulose suspension, carrying out high-strength ultrasonic treatment to fibrillate nanofibers, and freeze-drying to obtain the nanocellulose microfibril. The particle size range of the prepared nanocellulose microfibril is 26.84-61.26 nm, the removal rate of lignin reaches 56.28%, the effect is remarkable, operation is easy, the condition is mild, the cost is low, and pollution is small; and meanwhile, the used eutectic solvent is very environment-friendly, meets the standard of green chemical production, and has a relatively good practical application value.

Owner:JIANGSU UNIV

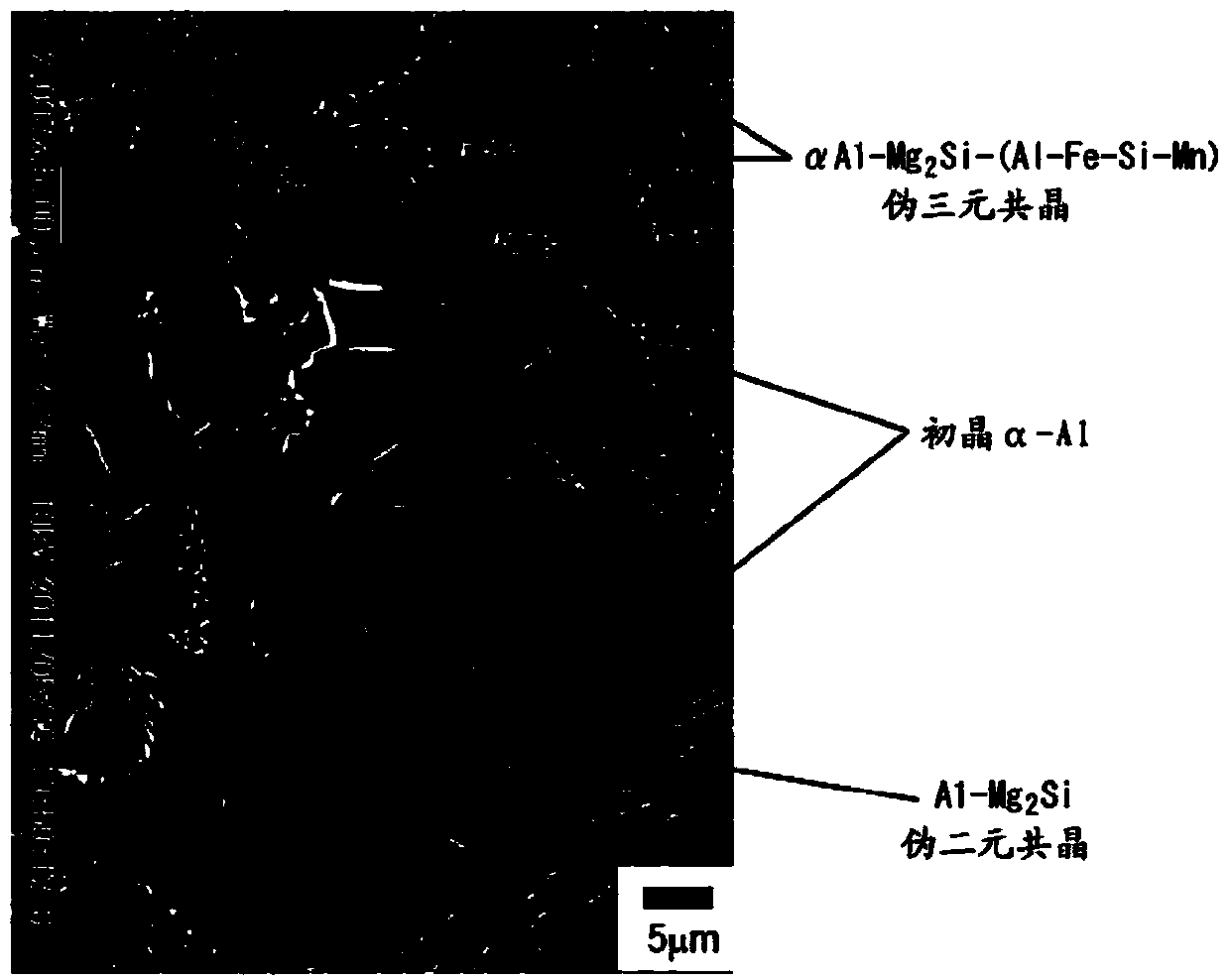

Al-based plated steel material and method for producing same

ActiveCN103975089AImprove corrosion resistanceHot-dipping/immersion processesThin material handlingImpurityArea ratio

This invention addresses the problem of providing an Al-based plated steel material having excellent corrosion resistance compared with a conventional product, and a method for producing the same. As a means for solving the problem, this invention forms on the surface of a steel material a plated layer containing by mass 6-10% Mg, 3-7% Si, 0.2-2% Fe, and 0.02-2% Mn, the remainder comprising Al and unavoidable impurities, and forms a alphaAl-Mg2Si-(Al-Fe-Si-Mn) pseudo-ternary eutectic structure having an area ratio of at least 30% within the plated layer.

Owner:JFE STEEL CORP +1

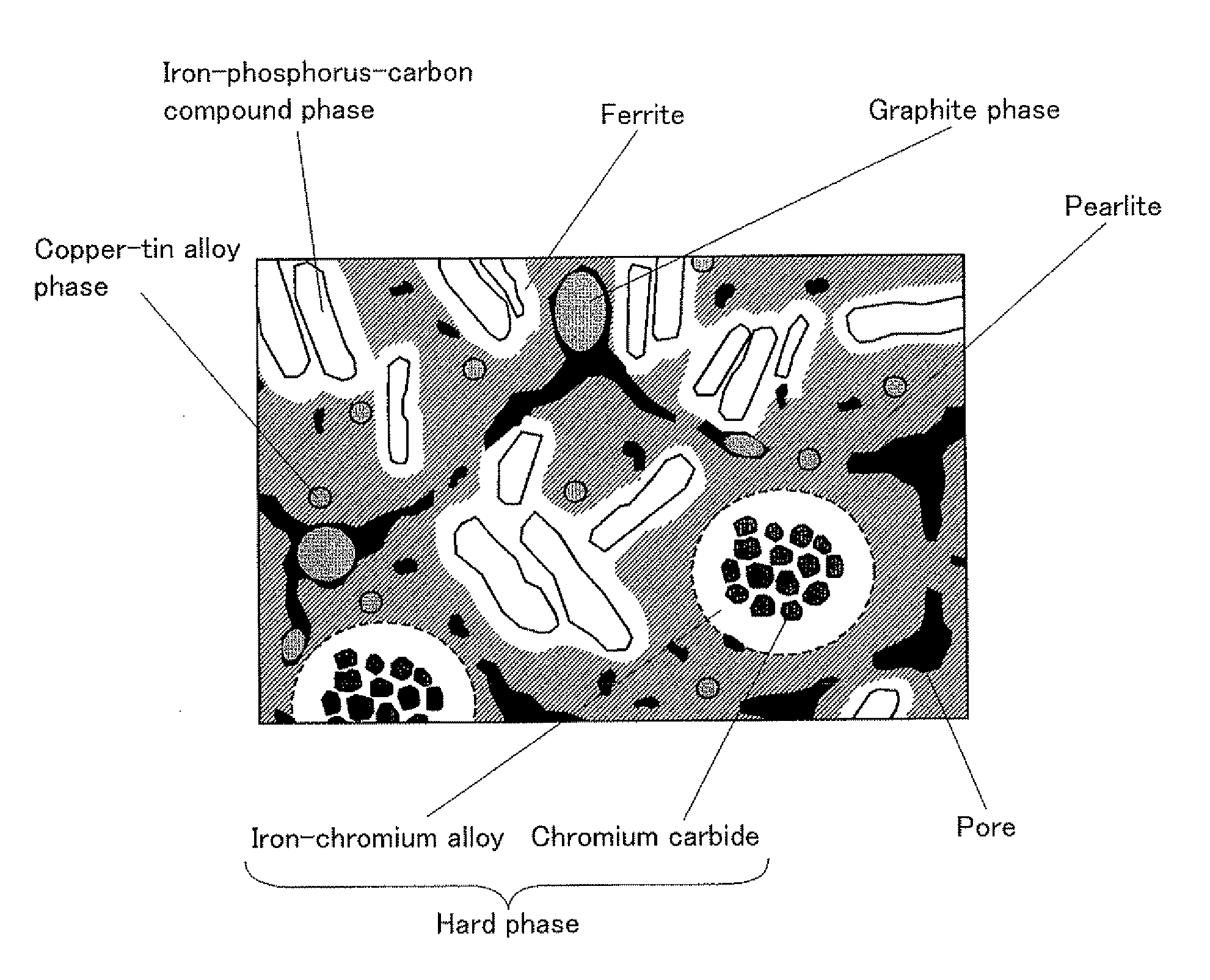

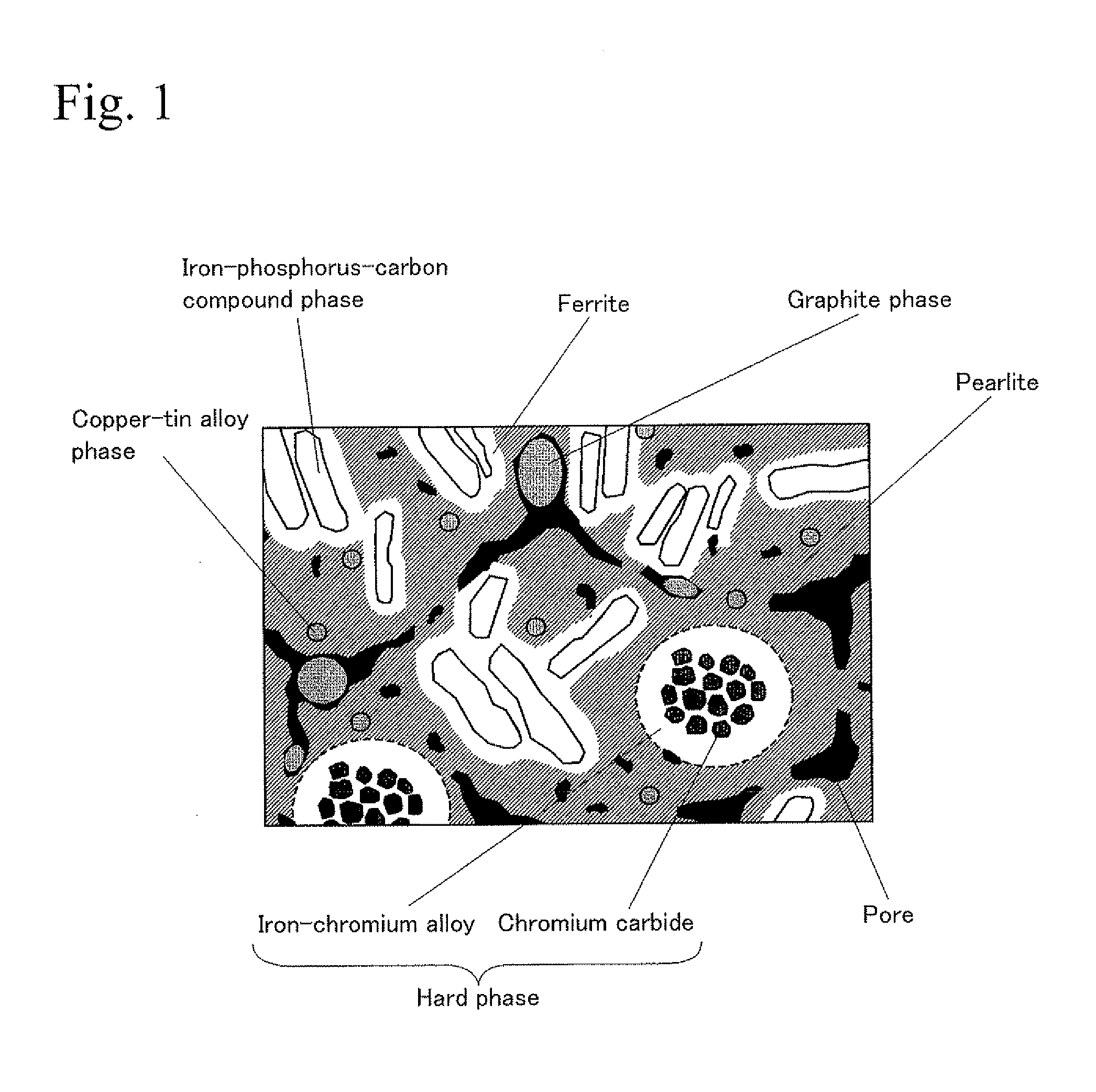

Sintered valve guide and production method therefor

A sintered valve guide exhibits a metallic structure having a mixed structure and a hard phase in which hard particles are dispersed in an alloy matrix. The mixed structure consists of pearlite, an Fe—P—C ternary eutectic phase, a ferrite phase, a copper phase, and pores, and the mixed structure consists of, by mass %, 0.075 to 0.525% of P, 3.0 to 10.0% of Cu, 1.0 to 3.0% of C, and the balance of Fe and inevitable impurities. The hard phase is dispersed at 2 to 15 mass % in the mixed structure.

Owner:RESONAC CORP

Single plating type zinc-aluminum-magnesium-rare earth protection coating with high corrosion resistance and preparation technology

ActiveCN105063532AGood lookingAchieve surface single platingHot-dipping/immersion processesRare earthAlloy coating

The invention discloses a single plating type zinc-aluminum-magnesium-rare earth protection coating with high corrosion resistance and a preparation technology. According to the single plating type zinc-aluminum-magnesium-rare earth protection coating technology, a zinc-aluminum-magnesium alloy coating can be acquired on a metal surface with a single hot dipping method; respective original performance of the coating and a metal matrix are kept, but the coating and the metal matrix form a metallurgical bonding interface of more than 99.9%, meanwhile, the coating is compact in structure, has stable components and excellent corrosion resisting performance and avoids skip plating, and salt-spray corrosion reaches 2,060 h; the corrosion resistance of the alloy coating is better than that of a common hot dipping pure-zinc coating, and the service life is prolonged. The single plating type technology can be reused and applicable to industrial production, overcomes defects that assistant plating of metal and a zinc-aluminum-magnesium alloy liquid is difficult, an excellent metallurgical bonding interface between the metal and the zinc-aluminum-magnesium alloy liquid is difficult to form, the probability of skip plating is high and the like, and can be widely applicable to preparation of a zinc-aluminum-magnesium alloy plating solution containing 5%-12% of Al and 1%-6% of Mg on the metal surface; a prepared co-penetrated layer forms Zn / Al / MgZn2 ternary eutectic and multiple types of binary eutectic, and the eutectic is the major reason for guaranteeing high corrosion resistance of the co-penetrated layer.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

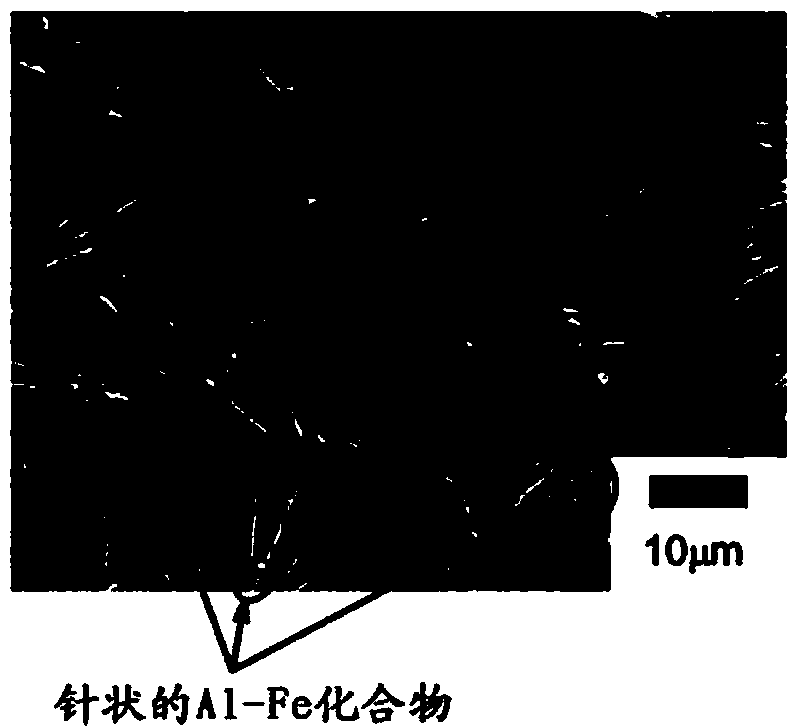

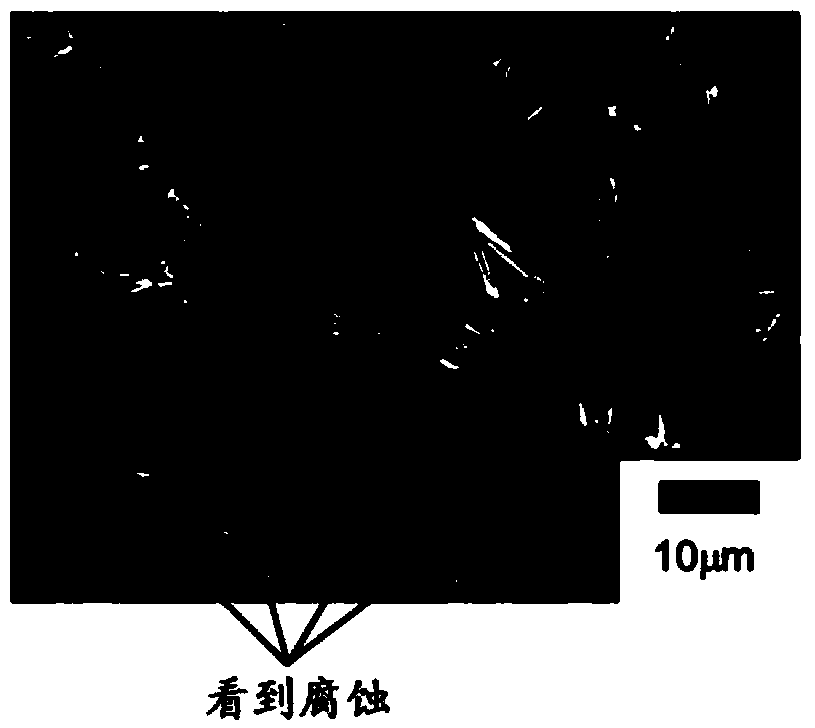

Zn-containing medium-strength high-ductility die-cast aluminum alloy and preparation method thereof

The invention discloses a Zn-containing medium-strength high-ductility die-cast aluminum alloy and a preparation method thereof, and belongs to the field of metal materials. The invention provides a casting aluminum alloy material which is medium in strength, is high in ductility, is free of thermal treatment and is suitable for die-cast formation as well as a preparation method thereof. The medium-strength high-ductility die-cast aluminum alloy consists of the following chemical components in percentage by weight: 10.0-13.0% of Si, 4.1-7.1% of Zn, 0.5-0.8% of Fe, 0.1-0.4% of Mn, 0.02-0.04% ofSr, less than or equal to 0.01% of Mg, less than or equal to 0.01% of Cu, less than or equal to 0.15% of other impurity elements, and the balance of Al. The preparation method comprises the followingsteps: smelting, sampling to rest, regulating alloy components, adding intermediate alloy to refine, de-slagging and casting. Through thermodynamic calculation, content range of Si, Fe and Mn of ternary eutectic Al-Si-Al(FeMn)Si is determined to reduce adverse effects, on alloy plasticity, of Mn and Fe; and Sr is the most common and effective eutectic silicon modifier, so that eutectic silicon ispromoted to convert to fine fibers from thick faller gills, and therefore, alloy plasticity is further improved.

Owner:肇庆南都再生铝业有限公司 +2

Ni-Al-RE TERNARY EUTECTIC ALLOY AND PREPARATION METHOD THEREOF

A Ni—Al-RE ternary eutectic alloy and a preparation method thereof are provided. The alloy is composed of the following elements by weight percent, aluminum (Al) of 2.50% to 19.50%, rare earth (RE) of 1.30% to 20.0%, other impurity elements being less than or equal to 0.10%, and the rest being nickel (Ni). The microstructure of the alloy is in a completely eutectic form, and the density is 6.8 to 7.1 g / cm3. Raw materials are prepared according to the ratio, and are placed into a vacuum induction smelting furnace; the smelting furnace is vacuumized to 10−5 Pa, power is increased to ensure complete melting of the raw materials, and the molten alloy melt is poured into an iron mold to obtain alloy ingots. The eutectic phase in the microstructure of the alloy in the disclosure has high hardness.

Owner:SHANGHAI JIAO TONG UNIV +1

Plated steel

ActiveCN110234780AInhibition formationImprove corrosion resistanceHot-dipping/immersion processesChromatisationChemical compositionAlloy

Provided is a plated steel which curbs LME and the formation of blowholes, and which improves the corrosion resistance of welding heat-affected zones. This plated steel is hot-dipped plated steel comprising steel and a plating layer which includes a Zn-Al-Mg alloy layer which is positioned on the surface of the steel. In a cross section of the Zn-Al-Mg alloy layer, the surface area percentage of MgZn2 phase is 45-75%, the total surface area percentage of MgZn2 phase and Al phase is at least 70%, and the surface area percentage of the Zn-Al-MgZn2 ternary eutectic structure is 0-5%. The platinglayer has a predetermined chemical composition.

Owner:NIPPON STEEL CORP

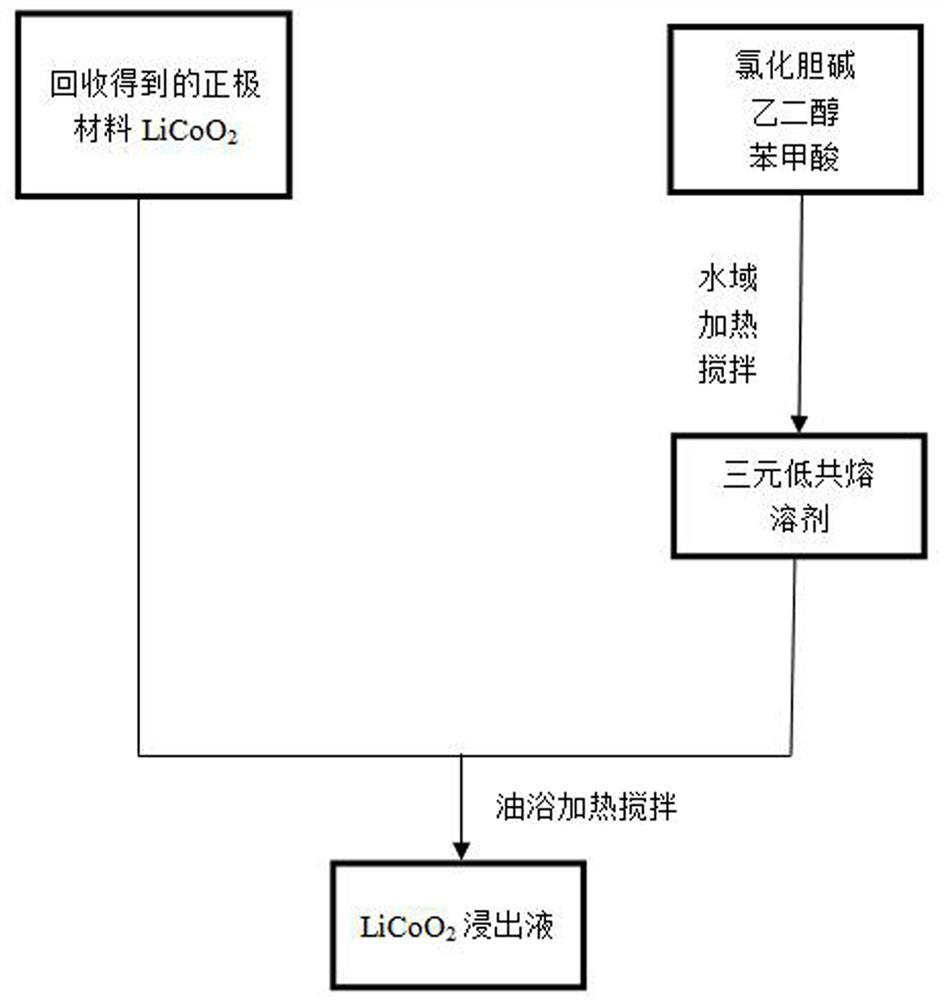

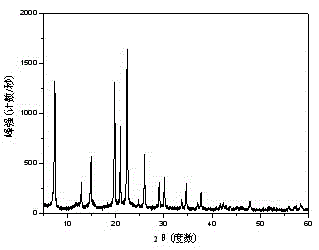

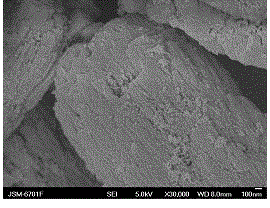

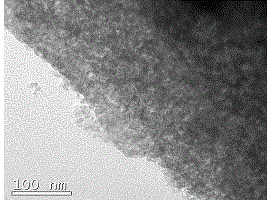

Method for recycling lithium battery positive electrode material LiCoO2 by ternary eutectic solvent system

ActiveCN114122555AEfficient leachingLow viscosityWaste accumulators reclaimingBattery recyclingBenzoic acidPhysical chemistry

The invention belongs to the field of battery recovery and eutectic solvents, and relates to a method for recovering a lithium battery positive electrode material LiCoO2 by a ternary eutectic solvent system. According to the invention, choline chloride, ethylene glycol and benzoic acid are mixed according to a molar ratio of 1: (1.9-1.5): (0.1-0.5) to prepare a ternary eutectic solvent system, and the prepared ternary eutectic solvent is low in viscosity, good in fluidity, low in recovery cost and environment-friendly. The ternary eutectic solvent system prepared by the method can efficiently and quickly recover cobalt and lithium in the battery positive electrode material, the leaching time is shortened, and the leaching efficiency of cobalt and lithium is improved.

Owner:SHENYANG LIGONG UNIV

Preparation method of hierarchical-pore CoAlPO-5 molecular sieve

InactiveCN103818926AFast crystallization rateChange the spatial structureMolecular-sieve and base-exchange phosphatesTetramethylammonium bromidePhosphoric acid

The invention relates to a preparation method of a hierarchical-pore CoAlPO-5 molecular sieve. The preparation method comprises the following steps: (1) uniformly mixing a succinic acid-choline chloride-tetraethylammonium bromide ternary eutectic mixture EM, aluminium isopropoxide and cobalt acetate tetrahydrate, then adding a proper amount of phosphoric acid and hydrofluoric acid so as to obtain a mixed system of a:Co2O3.Al2O3.b:P2O5.c:HF.d:EM, wherein coefficients are accounted in molar ratio that a is equal to 0.2-0.6, b is equal to 1.1-2.2, c is equal to 0.45-1.35 and d is equal to 62.0-124.0, and heating to 120 DEG C, so as to be mixed uniformly to obtain the mixture; (2) heating the mixture to 175 DEG C, carrying out crystallization for 15 minutes at an ordinary pressure or a self-generated pressure; (3) cooling the crystallization product to a room temperature, carrying out centrifugal washing repeatedly with water and acetone, and drying for 2 h at 90 DEG C so as to obtain a powder product of the hierarchical-pore CoAlPO-5 molecular sieve.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for preparing Al2O3-GdAlO3-ZrO2 ternary eutectic ceramic by selective laser melting

A selective laser melting method of blocky ternary eutectic oxide ceramic adopts a CO2 laser selective melting method, the scanning rate and the laser power of the CO2 laser selective melting method are controlled within ranges shown in the specification, and a melt material in a laser scanning area obtains higher supercooling degree, the nucleation rate is increased, so that the eutectic structure is refined, and the mechanical properties of a sample is improved. The large-size blocky Al2O3-GdAlO3-ZrO2 eutectic ceramic is obtained through preparation, and the size of the prepared Al2O3-GdAlO3-ZrO2 eutectic ceramic reaches 20*18*3.5 mm<3> after the Al2O3-GdAlO3-ZrO2 eutectic ceramic is subjected to linear cutting. The scanning rate can reach 5000 mm / s at most, the energy absorption rate ofthe ceramic material to a CO2 laser is high, and complete melting and solidification forming of the oxide ceramic material are better facilitated. Meanwhile, a laser beam selectively melts and solidifies a powder layer according to a path and parameters set by a computer, layer-by-layer stacking is carried out, and a solidified eutectic ceramic sample with a large size and a complex shape can beprepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for improving mechanical properties of aluminum alloy castings

InactiveUS20150252460A1Avoid deformationAvoid overall overheatingPretreated surfacesSpecial surfacesSolution treatmentMechanical property

The present invention discloses a method for improving mechanical properties of aluminum alloy casting. The advantages of the present invention lie in: combining heat-treatment with thermal painting; dividing the solution treatment of conventional T6 heat treatment process into two separate solution treatments, which avoids deformation and overheating of the casting due to melting of the ternary eutectic structures with low melting point, thereby improving efficiency of the heat-treatment and lowering the amount of energy consumed and the cost of production.

Owner:CITIC DICASTAL

Solder and production method thereof

InactiveCN105269178AMeet job requirementsLow priceWelding/cutting media/materialsSoldering mediaManufacturing technologyAlloy

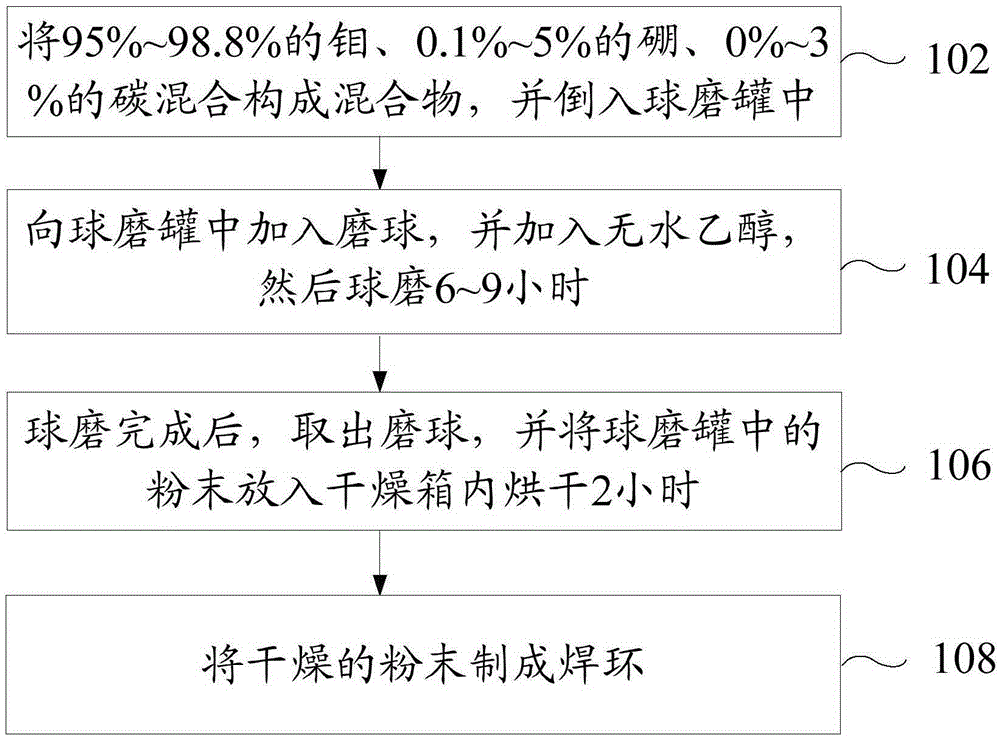

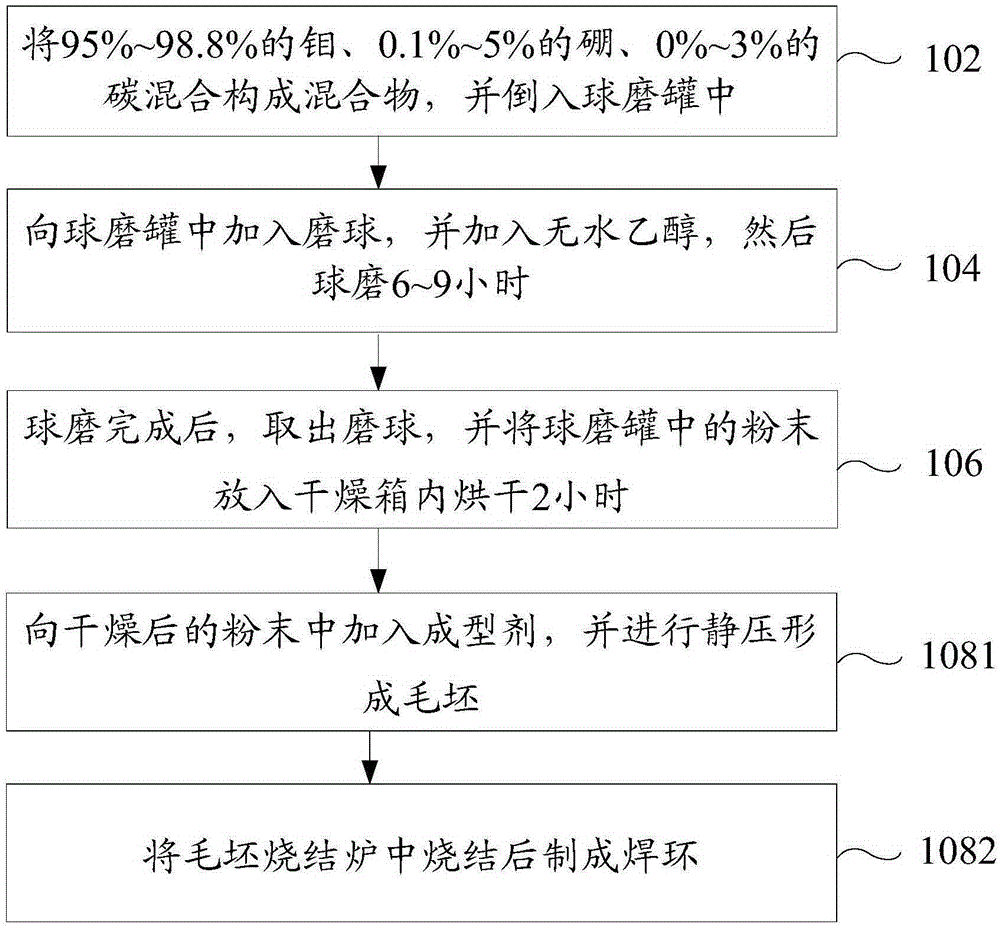

The invention provides solder and a production method thereof. The solder is composed of, by mass, 0.1%-5% of boron, 95%-98.8% of molybdenum and 0%-3% of carbon. According to the solder, a small amount of boron or the mixture of boron and carbon is added into high-temperature molybdenum alloy solder, so the solder is low in price and simple in manufacturing technology. Binary or ternary eutectic alloy solder is formed after the solder is subject to ball milling, so the working requirements of magnetron cathode components can be completely satisfied.

Owner:GUANGDONG WITOL VACUUM ELECTRONICS MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com