Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

196results about How to "Fast crystallization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing Beta molecular sieve by organic-free template

InactiveCN101249968AFast crystallization rateSynthesis fastCrystalline aluminosilicate zeolitesMolecular sieveAlumina gel

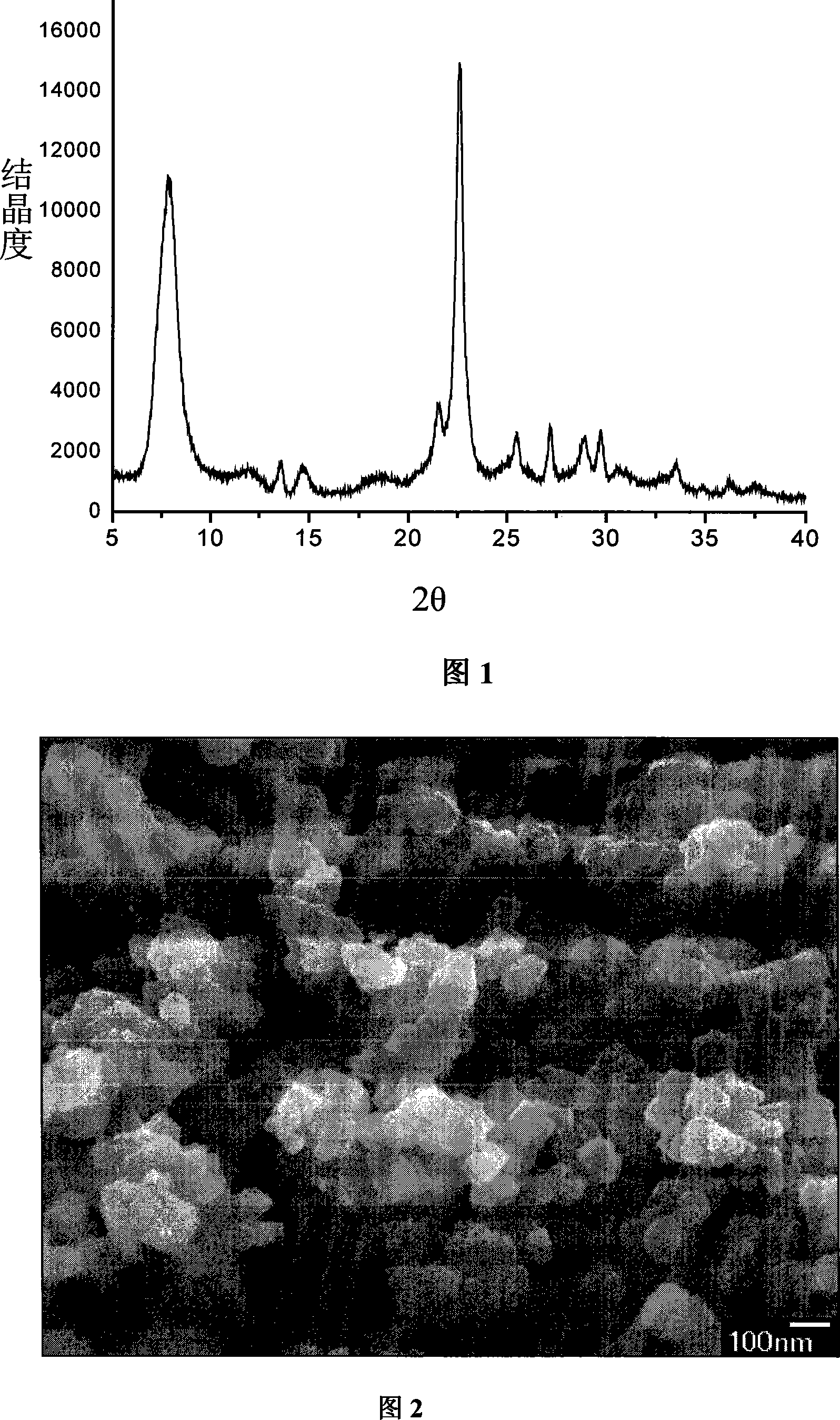

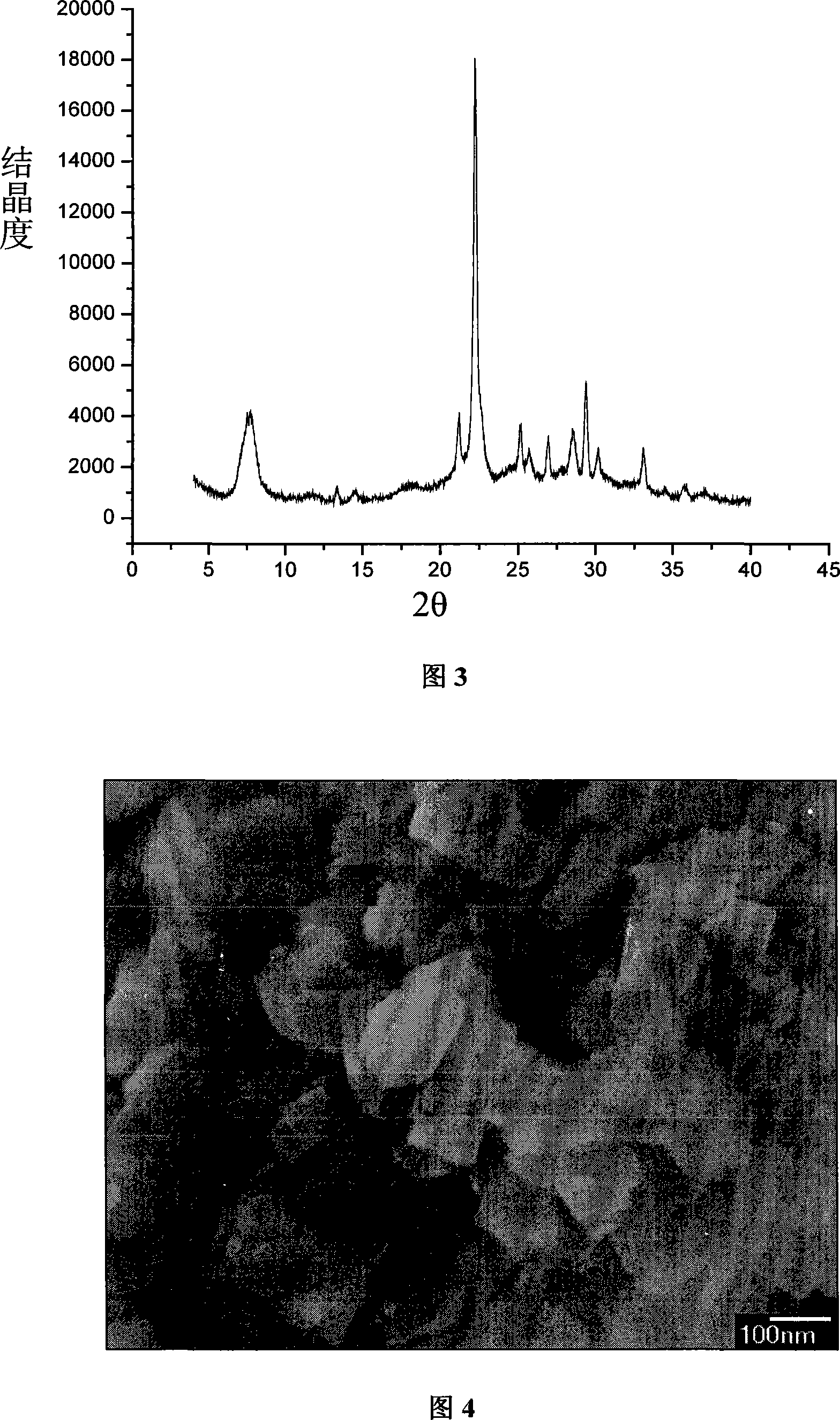

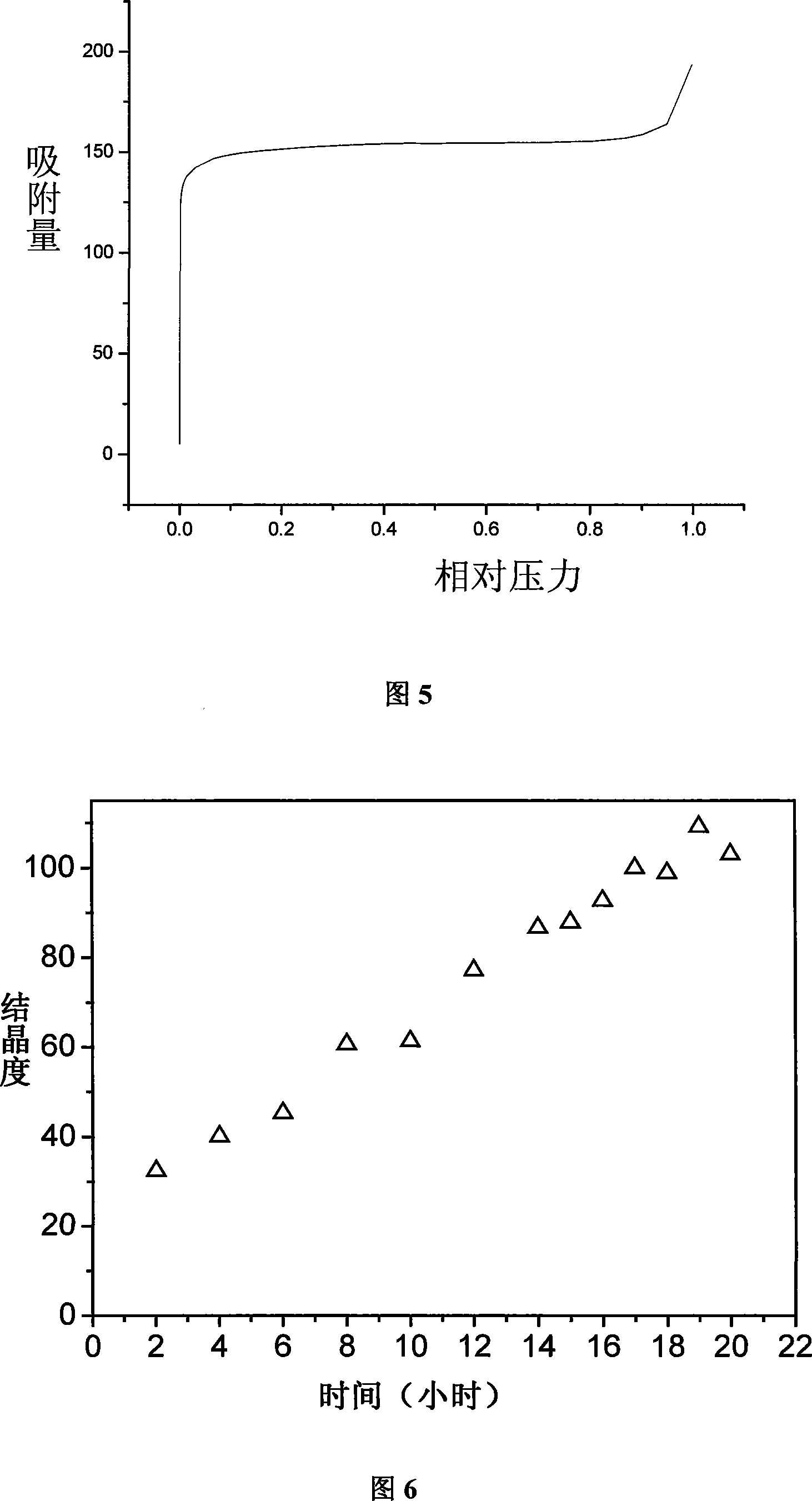

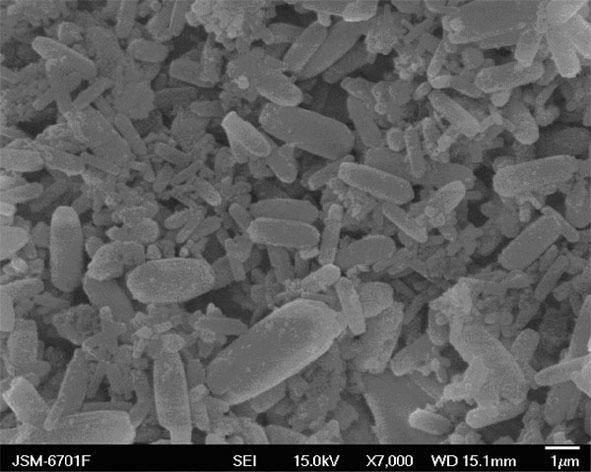

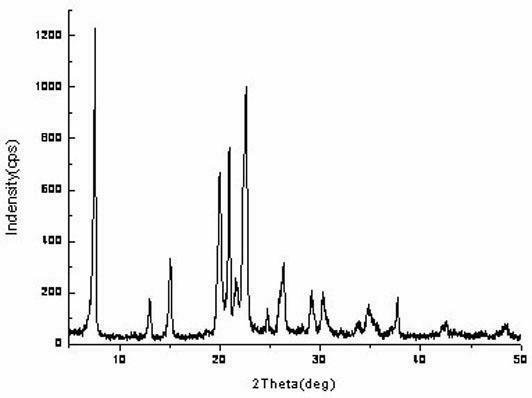

The invention relates to a method of synthesizing Beta molecular sieve without organic templates, which belongs to the technical field of catalytic chemistry. The steps of the invention comprise mixing alkali oxide sources, alumina sources, silica sources and water, stirring and synthesizing initial silica-alumina gel, then adding with Beta zeolite crystal seed, crystallizing 12-24 hours under the temperature of 100-180 DEG C and hydro-thermally synthesizing the Beta molecular sieve, SiO2 / Al2O3 of the Beta zeolite crystal seed equals 22-25, and the quality of addition quantity is 5%-20% of the silica sources. The method of the invention suits requirements of applying zeolite molecular sieve in industry, not only can directly synthesize high crystallinity crystal of the Beta molecular, but also can increase crystallizing speed of the molecular and reduce manufacturing cost. Because the synthesis process doesn't use any organic templates without roasting, thereby a pore path is unimpeded, and environmental pollution and relatively consumption are avoided.

Owner:JILIN UNIV

Process for preparing SAPO molecular sieve

ActiveCN101284673AStir wellSynthesis speedMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveState of art

The invention relates to a method for preparing a SAPO molecular sieve and mainly solves the problem that the SAPO molecular sieve has low crystallization speed and low production capacity in the prior art. The method comprises the following steps: (a) evenly mixing a phosphorous source, an aluminum source, a silicon source and water to form a crystallized solution I; (b) adding small-grain solid seed crystals with the diameter of the crystals being less than 1 micron to the crystallized solution I to form a crystallized solution II; (c) subjecting the crystallized solution II to hydrothermal crystallization at the temperature of 110 DEG C to 260 DEG C for at least 0.1 hours to obtain the SAPO molecular sieve; and d) recycling the molecular sieve product. By the technical proposal, the problem in the prior art is well solved, so that the method can be used in the process of preparing alkenes catalyst with oxygenated chemicals.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glass fiber enhanced PET/PBT (Polyethylene Terephthalate)/(Polybutylene Terephthalate) alloy with high glossiness and low warping degree and preparation method thereof

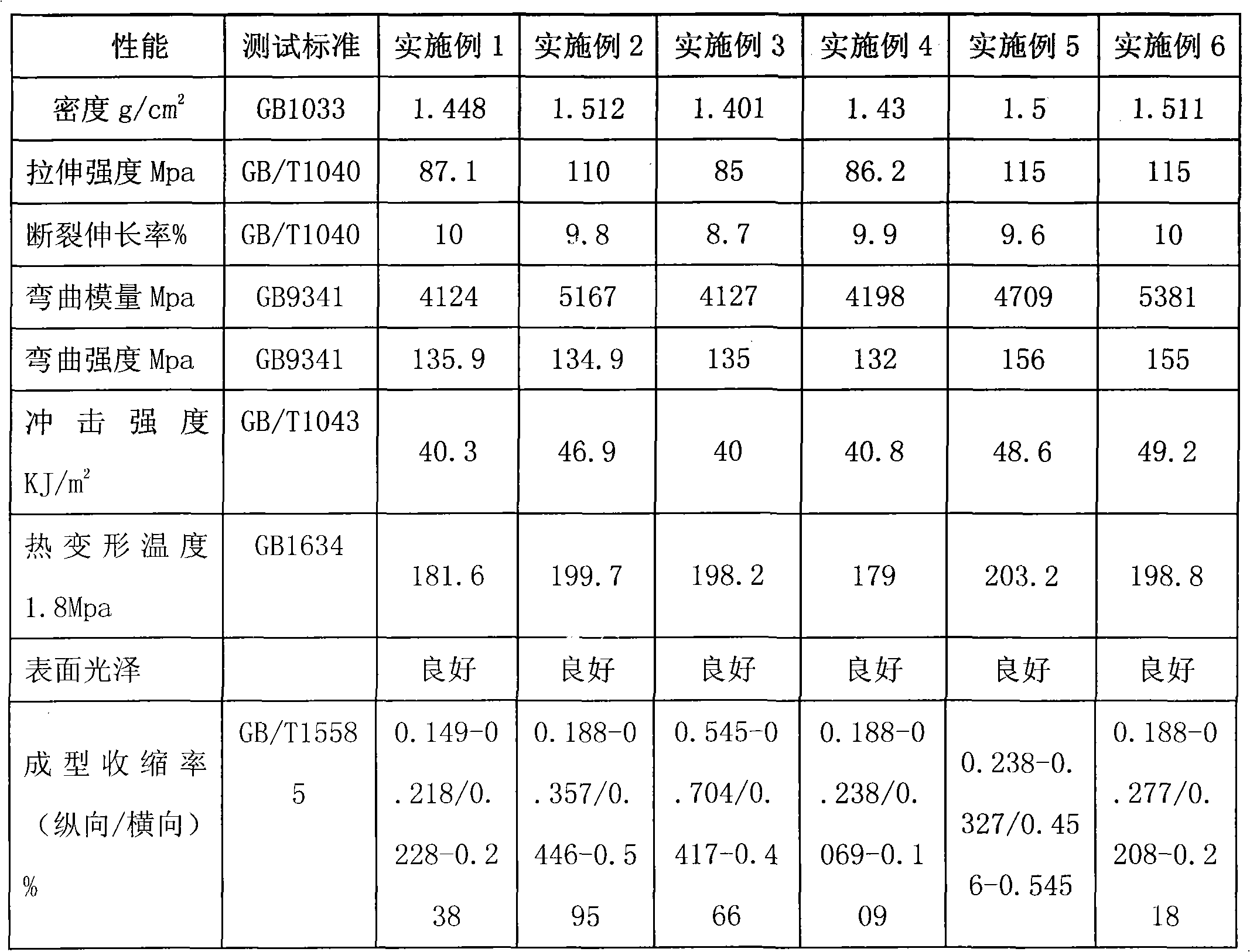

The invention discloses a glass fiber enhanced PET / PBT (Polyethylene Terephthalate) / (Polybutylene Terephthalate) alloy with high glossiness and low warping degree and a preparation method thereof. The PET / PBT alloy comprises the following components by mass percentage content: 15-60% of PBT, 19-60% of PET, 3-10% of compatilizer, 0.3-0.9% of antioxygen, 0.5-1% of nucleating accelerating agent, 3-8% of composite nucleating agent, 10-30% of glass fiber and 0.4-1% of processing aid. According to the invention, the PET and the PBT are fused to obtain the PET / PBT alloy, and the PET / PBT alloy has the advantages of quick crystallizing speed rate, good physical performance, high distortion temperature, high surface glossiness, low contractibility rate, stable dimension, low warping degree and lower cost; and the PET / PBT alloy of the invention can be used for completely replacing the bakelite powder under a specific occasion.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

Polyether ester elastomer composition

InactiveUS20080103217A1Fast crystallizationEffectively utilize the polymerOther chemical processesMixing methodsElastomerFiber

Disclosed are polyether ester elastomer compositions having polytrimethylene ether ester soft segments and polyethylene ester hard segments and containing a nucleating agent. Shaped articles can be made from these compositions, particularly molded articles, films and fibers.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of SAPO-34 molecular sieve membrane

ActiveCN104150504AFast crystallization rateImprove uniformityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sievePermeation

The invention provides a preparation method of a SAPO-34 molecular sieve membrane. The method is characterized in that a specific zeolite molecular sieve is employed as a silicon source. A continuous compact SAPO-34 molecular sieve thin film is formed on a surface of a porous ceramic supporting body, namely, a layer of the SAPO-34 molecular sieve membrane is grown on the porous ceramic supporting body with a crystalline state zeolite molecular sieve being the silicon source. A structure unit of the molecular sieve is same as that of SAPO-34. Crystal nucleus are provided for crystallization of a SAPO-34 molecular sieve and a synthesis time of the membrane is shortened. In addition, the content of silicon in the SAPO-34 molecular sieve membrane can be adjusted within a large range. The membrane has a preferable selectivity on CO2 and a high permeation flux and separation selectivity when being used for separating mixing systems of CO2 / CH4.

Owner:NANJING MEMBRANE IND TECH RES INST CO LTD

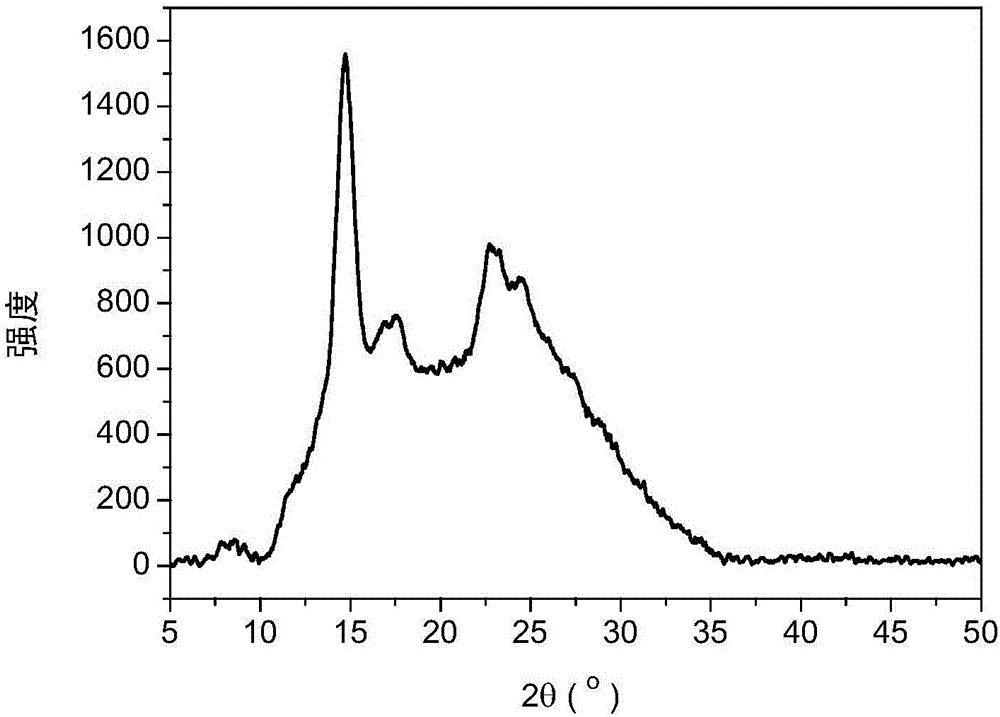

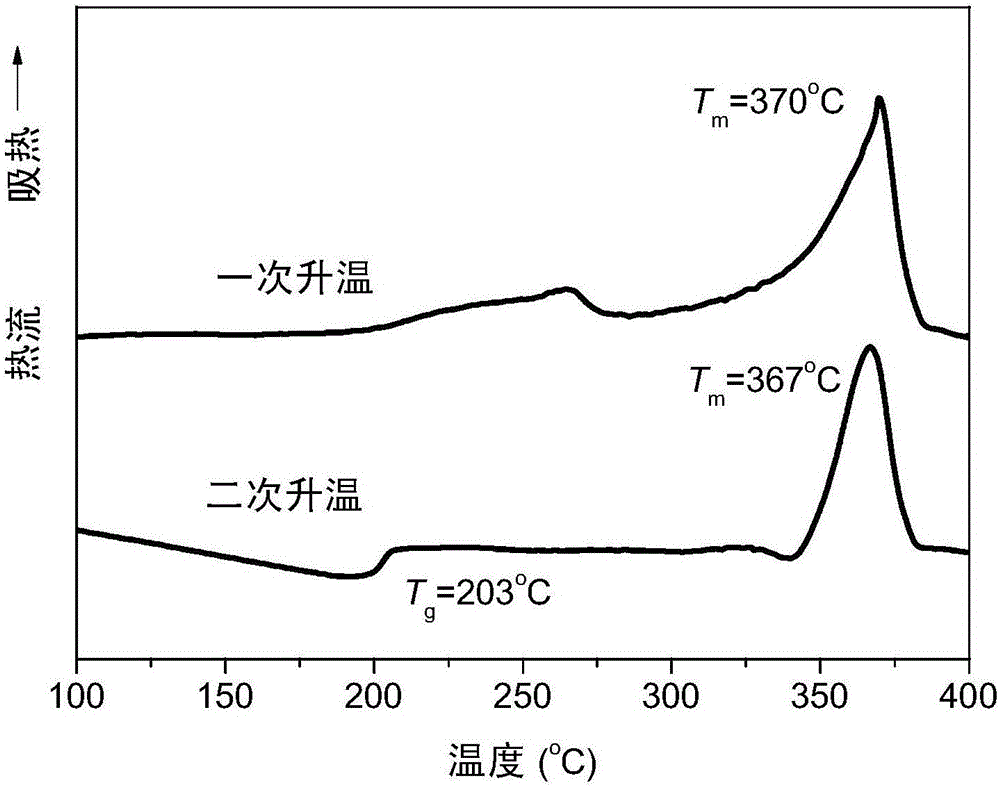

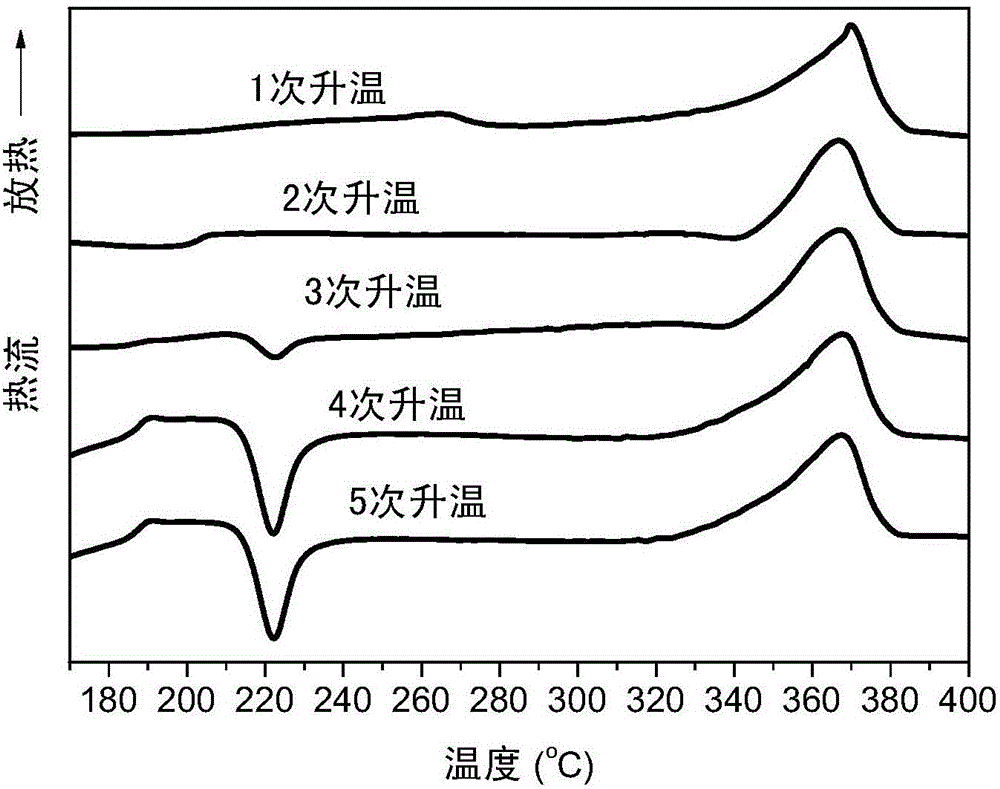

Crystalline copolymer polyimide resin low in melt viscosity and prone to melt processing and application

ActiveCN106167547AReduce melt viscosityHigh thermal decomposition temperatureCoatingsAdhesivesPolymer scienceAdhesive

The invention discloses crystalline copolymer polyimide resin low in melt viscosity and prone to melt processing. The crystalline copolymer polyimide resin is prepared from aromatic dianhydride monomers, aromatic diamine monomers and capping agent by means of condensation polymerization, mixtures of 3,3',4,4'-triphenyldiether tetracarboxylic acid dianhydride and other dianhydrides are taken as aromatic dianhydride monomers, and phthalic anhydride is taken as capping agent. The copolymer polyimide resin has high glass transition temperature, good heat stability, low melt viscosity, excellent repeated melt crystallization capacity and easy-melting processability, the melting range is 320-380 DEG C, and the polymer has broad application in preparation of materials such as composite material matrix resin, high-temperature adhesives, powder coating, high-performance films, 3D-printing polymer powder and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

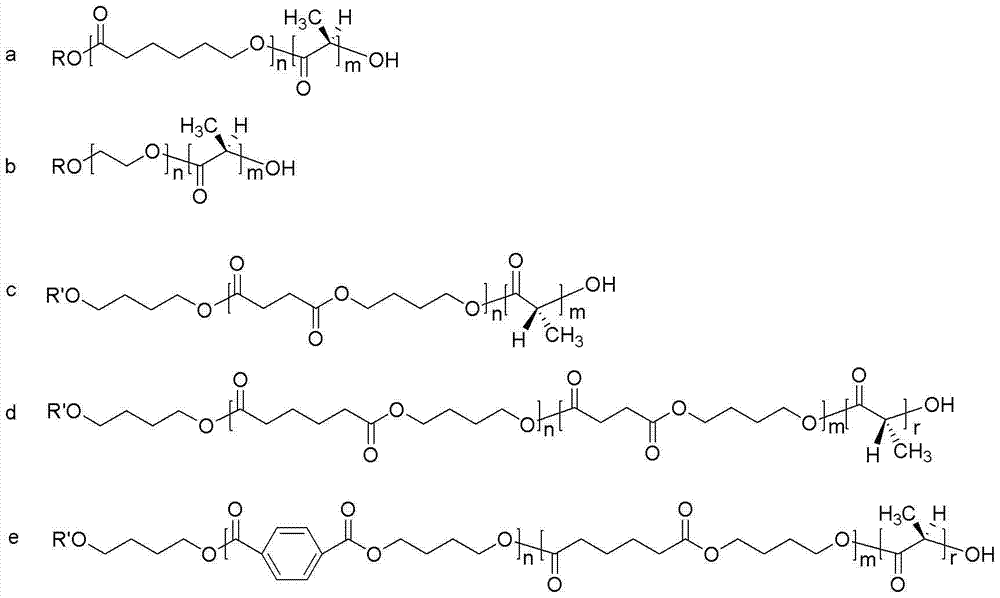

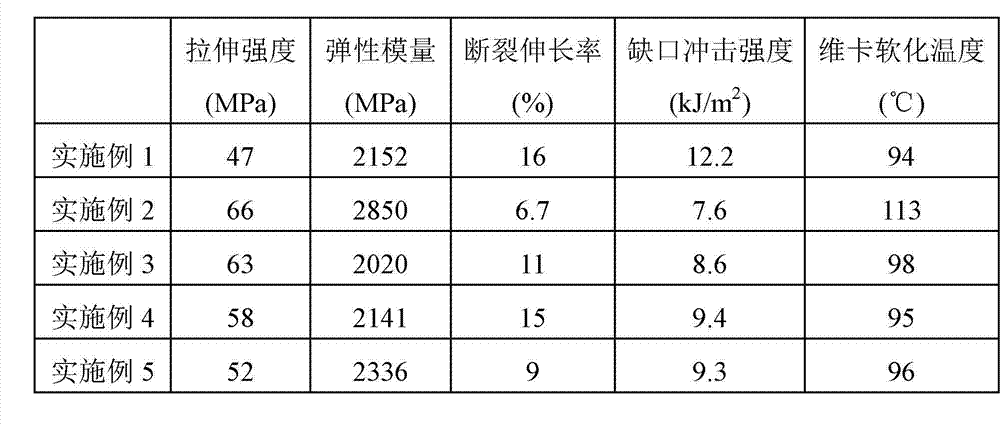

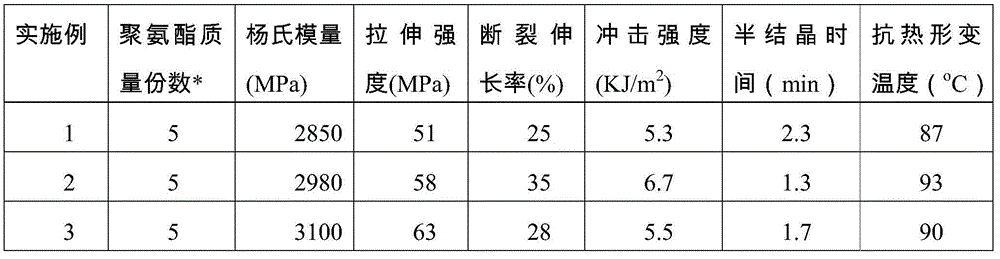

Polylactic resin composition with high heat resistance and high flexibility and preparation method of composition

InactiveCN102924892AHigh heat resistance and high toughnessImprove toughnessPolymer scienceHeat resistance

The invention discloses a polylactic resin composition with high heat resistance and high flexibility and a preparation method of the composition, solving the problem that polylactic resin with high heat resistance and high flexibility does not exist in the prior art. The polylactic resin composition consists of the following components in parts by weight: 50 to 99.5 weight parts of poly-L-lactic acid homopolymer and 0.5 to 50 weight parts of poly-D-lactic acid copolymer, wherein the poly-D-lactic acid copolymer is prepared from poly-D-lactic acid and a polymer with a flexible chain structure. The invention also provides the preparation method of the polylactic resin composition with high heat resistance and high flexibility. The preparation method is simple and suitable for industrialized production; and the prepared polylactic resin composition has high flexibility and heat resistance, the elongation at break reaches 16 percent, the notch impact strength reaches 12.2kJ / m<2>, and the vicat softening temperature reaches 113 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

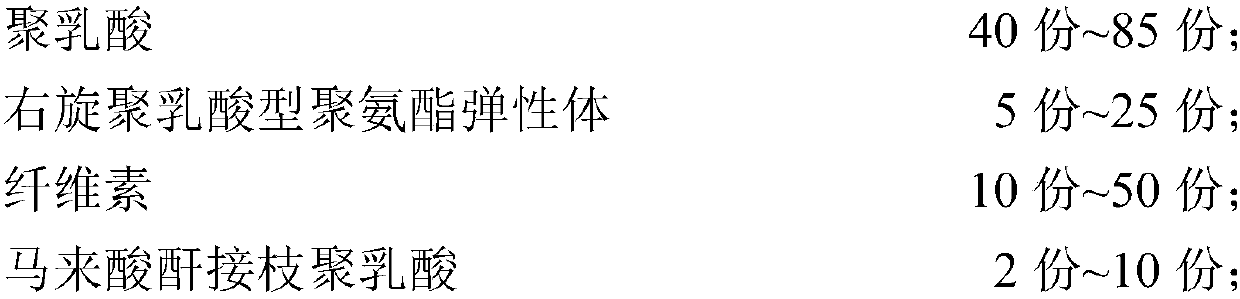

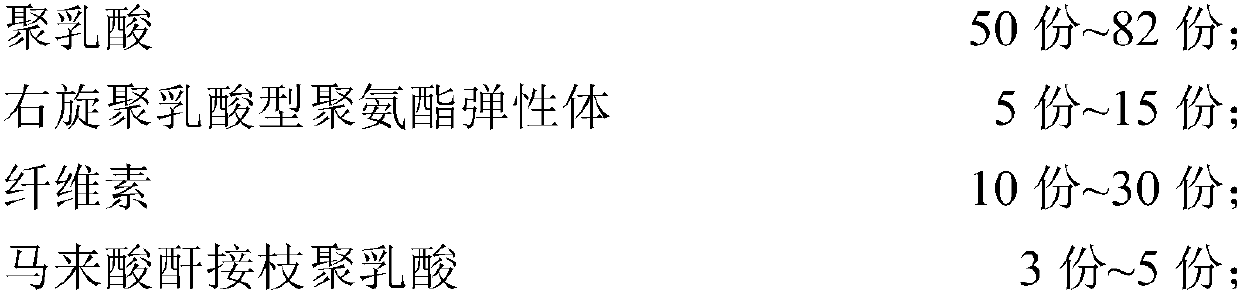

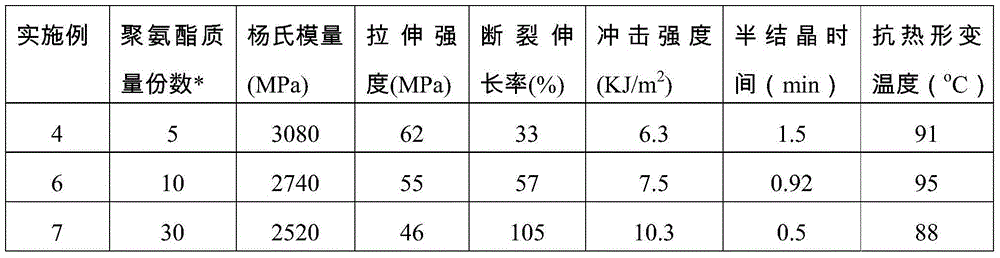

Polylactic acid/cellulose bio-based degradable composite material and preparation method thereof

The invention discloses a polylactic acid / cellulose bio-based degradable composite material and a preparation method thereof. The polylactic acid / cellulose bio-based degradable composite material is prepared from the following raw materials in parts by weight: 40-85 parts of polylactic acid, 5-25 parts of a dextral polylactic acid-type polyurethane elastomer, 2-10 parts of maleic anhydride graftedpolylactic acid and 10-50 parts of cellulose, wherein the number average molecular weight of the polylactic acid is 100000-300000. The polylactic acid / cellulose bio-based degradable composite material is safe, non-toxic, biodegradable and excellent in mechanical properties. The preparation method comprises the following steps: uniformly mixing components, then adding into a twin-screw extruder, performing melt blending, drawing into strips, pelletizing, and drying to obtain the composite material. The preparation method is simple, easy to control, strong in operability and easy to implement,the production cost is low, and the industrial mass production is easy; the prepared composite material can be applied to the field of interior trim parts, films, fibers or other specially shaped materials and the like.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

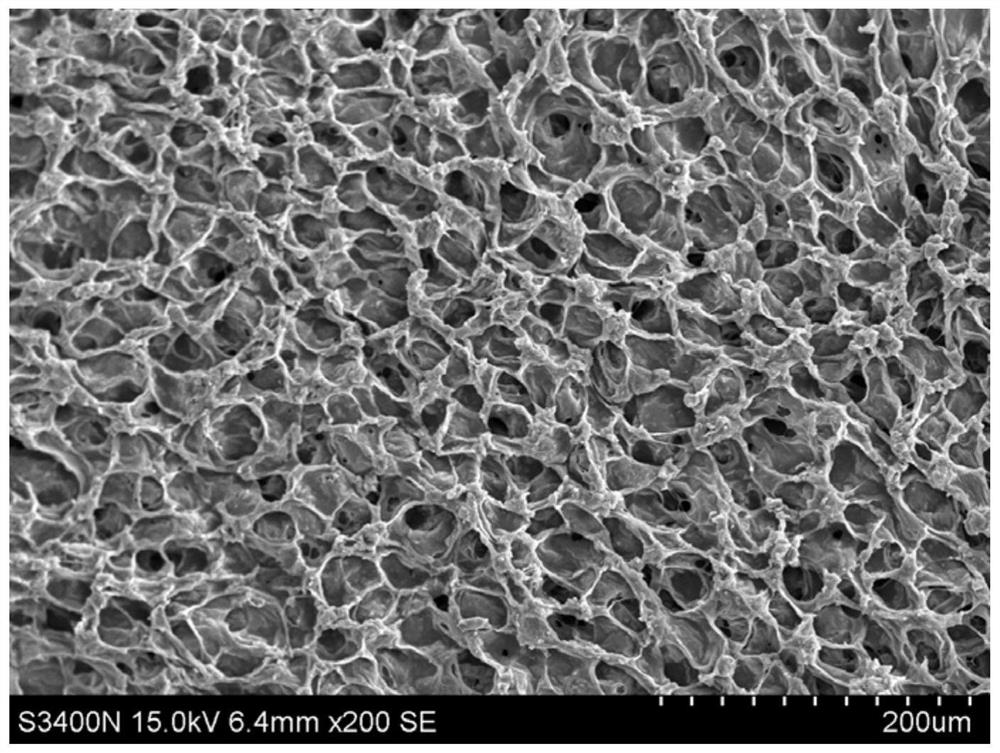

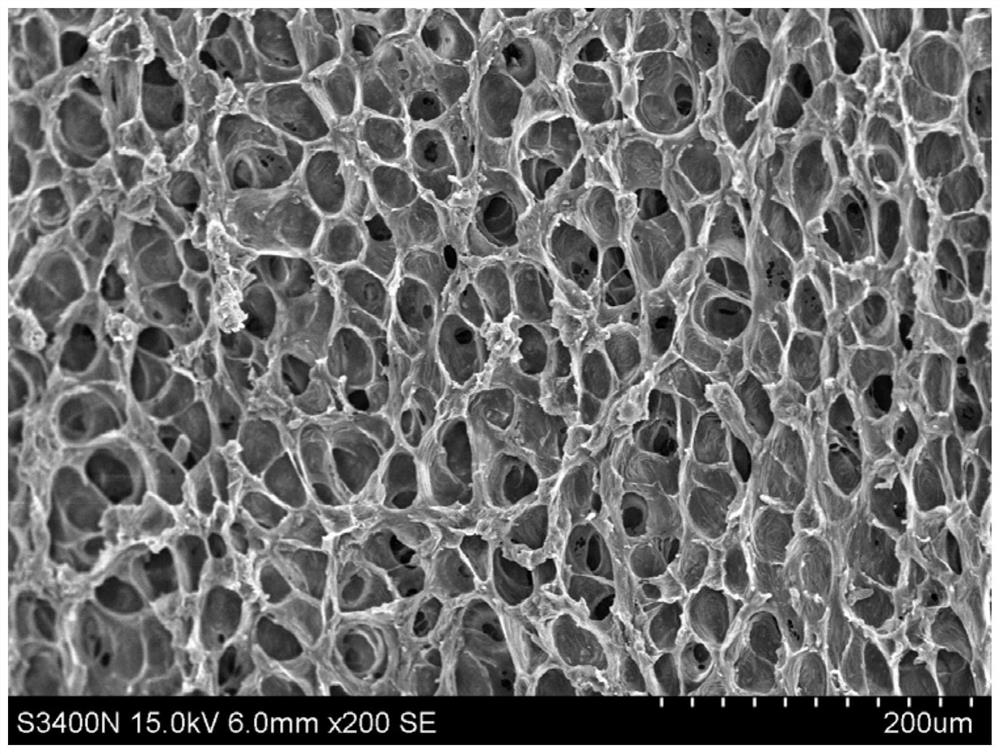

Three-dimensional ordered monodisperse macroporous material, and its preparing method and functionizing method

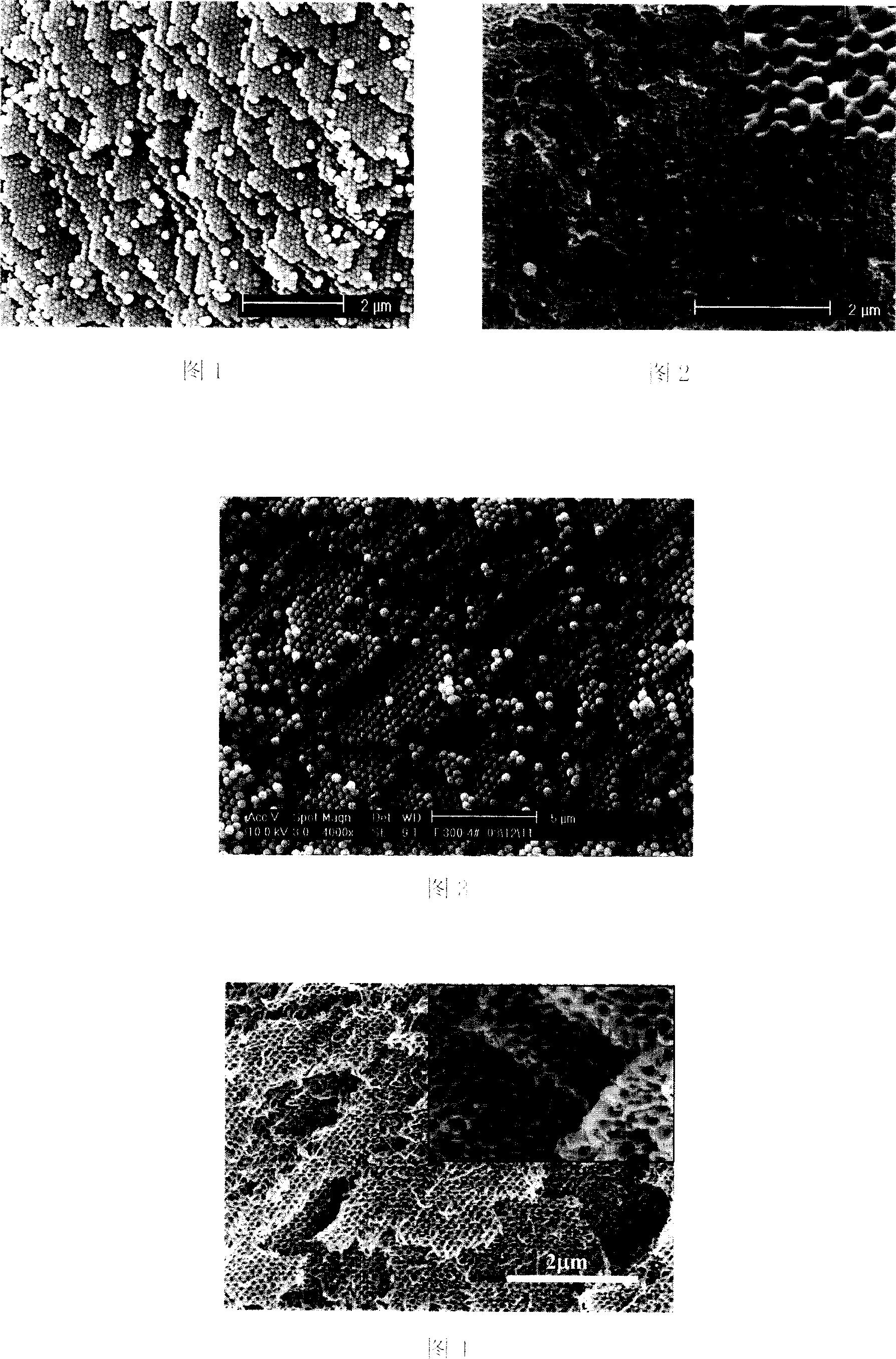

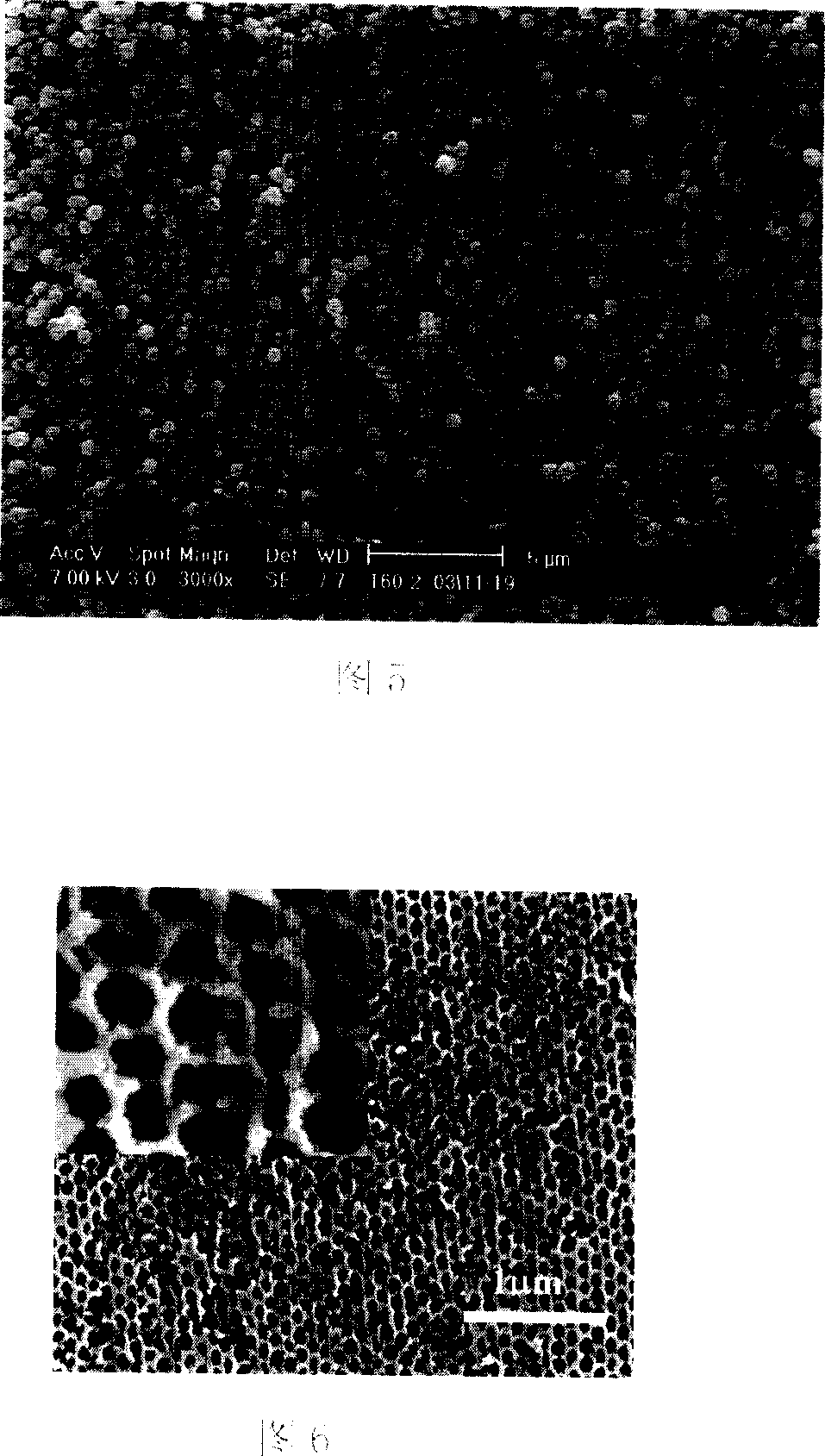

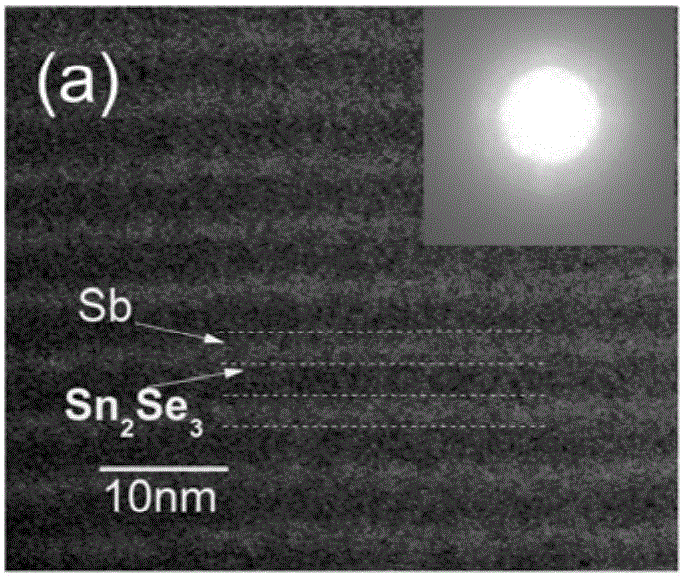

InactiveCN1935857AHigh melting pointFast crystallization ratePolyvinyl alcoholCoordination polymerization

The invention relates to three-dimensional order mono-disperse macropore material and its preparation method and functionalizing method. The three-dimensional order mono-disperse macropore material has 91%-98% syndiotactic polyvinyl alcohol arene, 80 nm-1000 nm average aperture. Its preparation method includes the following steps: using colloid crystal mold board method to make three-dimensional order mono-disperse macropore polyvinyl alcohol without water and oxygen by coordination polymerization; using copolymerization or chloromethylation to functionalize. It has the advantages of high melting point, quick crystallization rate, strong chemical resistance, good size stability, processing surface chemical modification, and wide application prospect in sensor, photon chip, photon band gap material preparation etc.

Owner:HEBEI UNIV OF TECH

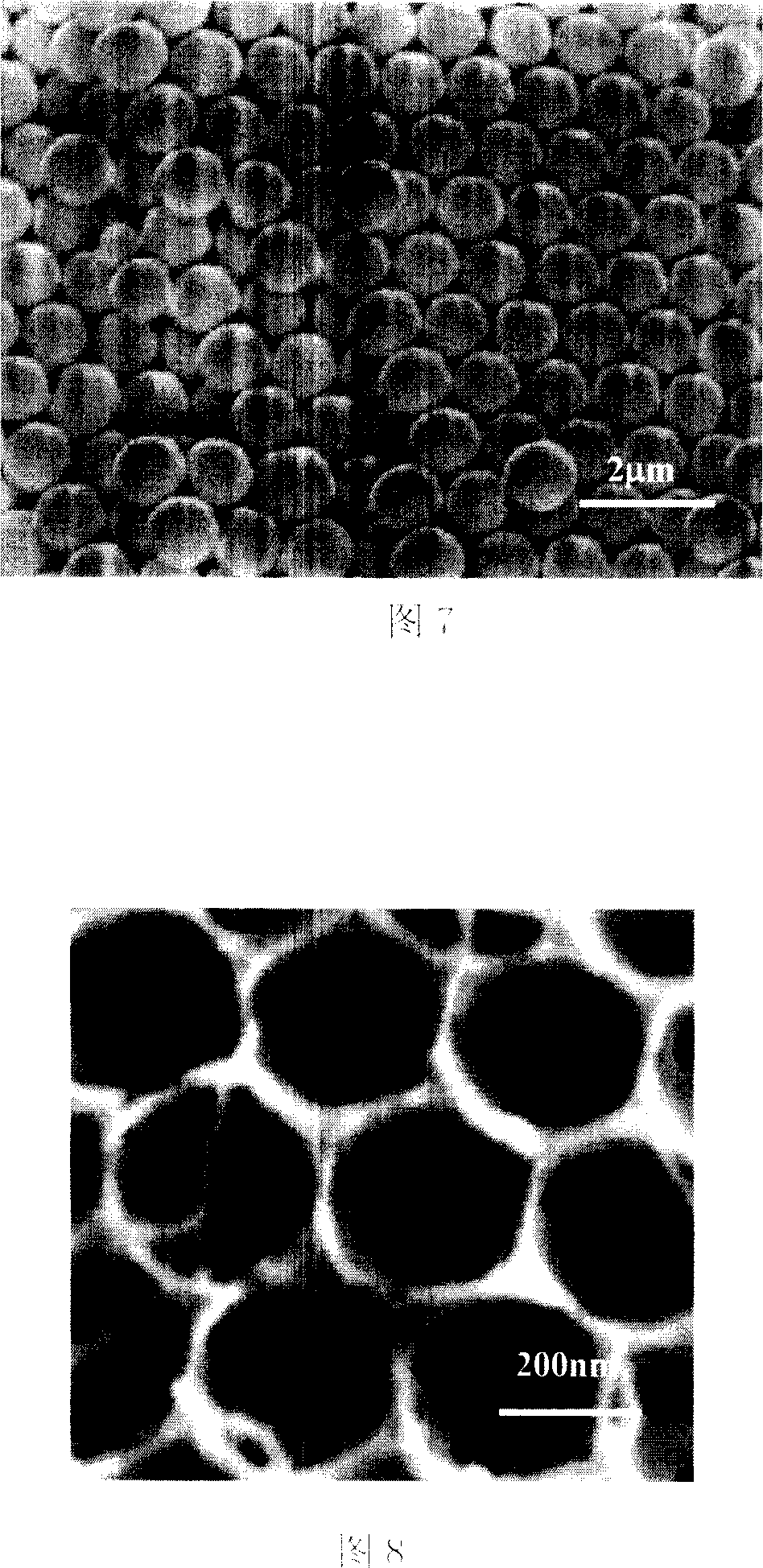

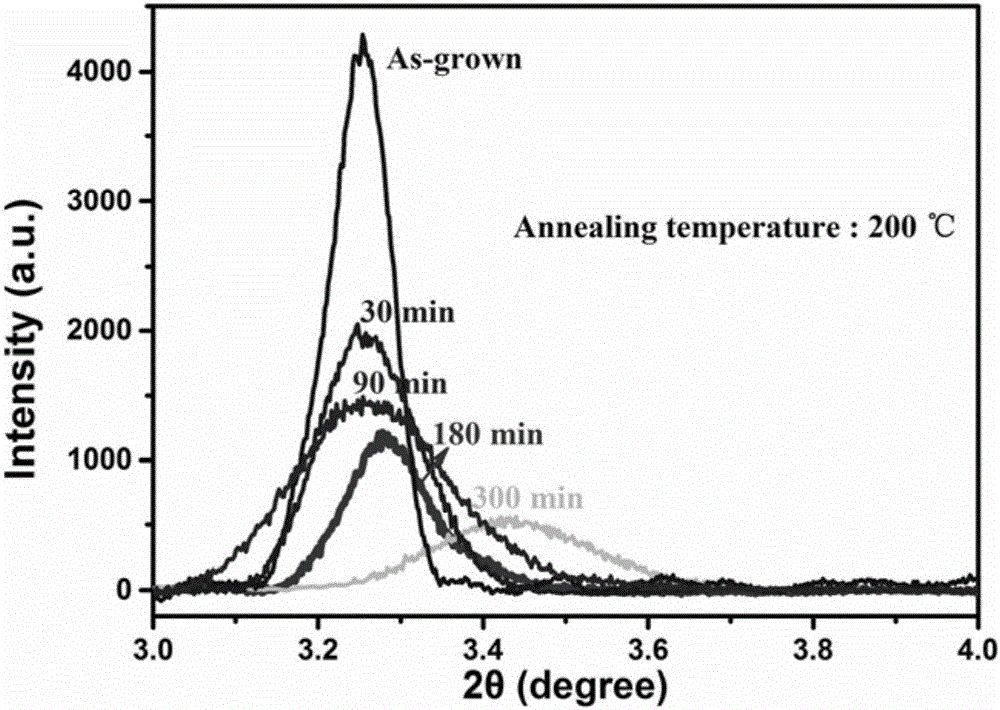

Multilayer nanometer composite phase-transition thin film material and preparation method and application thereof

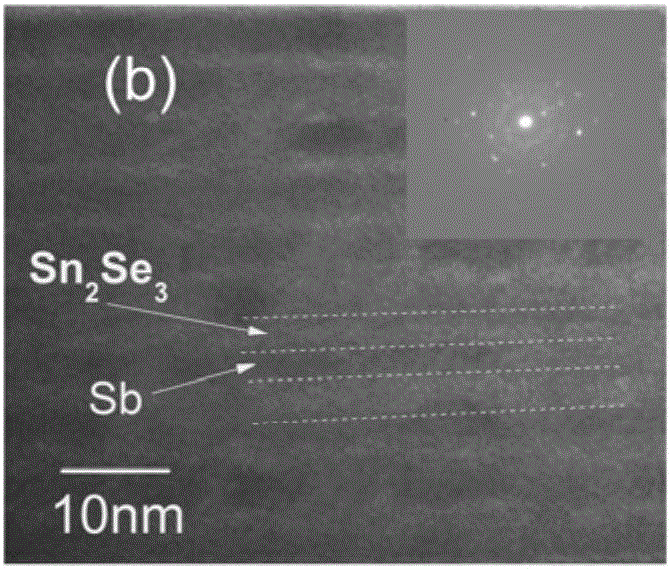

ActiveCN105679934ALow thermal conductivityReduce lossElectrical apparatusVacuum evaporation coatingThermal stabilityPhase-change material

The invention discloses a multilayer nanometer composite phase-transition thin film material and a preparation method and application thereof. The material is formed by arranging Sn2Se3 film layers and Sb film layers alternatively, one Sn2Se3 film layer and one Sb film layer serve as an alternative period, and the Sn2Se3 layer in the latter alternative period is deposited on the Sb layer in the former alternative period. A general formula of the film structure of the film material is [Sn2Se3(a) / Sb(b)]x, a represents the thickness of the single Sn2Se3 film layer, b represents the thickness of the single Sb film layer, a is greater than or equivalent to 1nm and lower than or equivalent to 50nm, b is greater than or equivalent to 1nm and lower than or equivalent to 50nm, x represents the number of alternative periods or layers of the Sn2Se3 film layers and Sb film layers, and x is a positive integer. The phase-transition thin film material uses Sb as a crystallization induction layer to accelerate phase transition of the phase-transition material, and advantages of low melting point and high thermal stability of Sn2Se3 are used; and the clamping effect of multiple interfaces in the multilayer nanometer composite structure is used to reduce the size of crystal grains, and further to shorten the crystallization time, inhibit crystallization, improve the thermal stability and accelerate phase transition.

Owner:昆山模之特电子材料有限公司

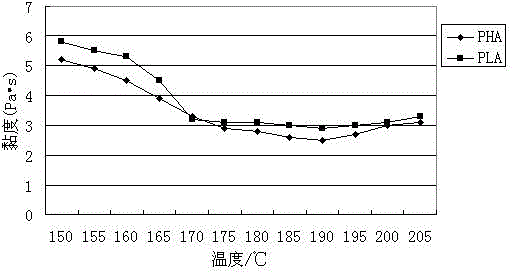

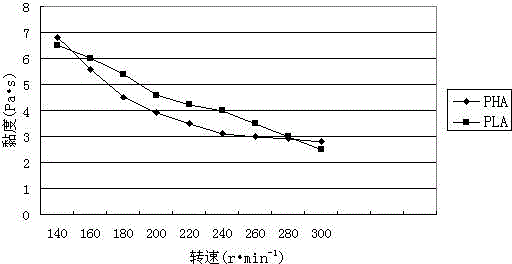

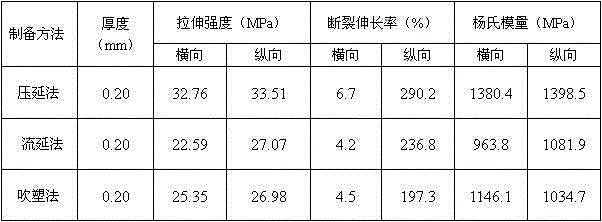

Degradable PHA/PLA mixture film and preparation method thereof

The invention discloses a degradable PHA / PLA mixture film and a preparation method thereof. The degradable PHA / PLA mixture film comprises, by weight, 30-40 parts of PHA resin and 60-70 parts of PLA resin. Based on the total weight of the PHA and PLA, the degradable PHA / PLA mixture film comprises, by weight, 4.5-12% of a plasticizer, 0.8-1.5% of an inorganic filling material, 0.2-0.7% of an anti-oxidant, 0.3-0.5% of a lubricant and 0.1-0.3% of an antistatic agent. The PHA resin and PLA resin are ground to form powder, the power and other auxiliary agents are blended, are fed into an extruder and are subjected to fusion plasticization, and the extruded product is subjected to calendaring slice formation, taking-away, stretching, cooling, traction, reeling and cutting. The preparation method has simple and easy processes. The degradable PHA / PLA mixture film has performances satisfying usage requirements on a card-based industry, a printing industry and a package industry.

Owner:江苏华信高新材料有限公司

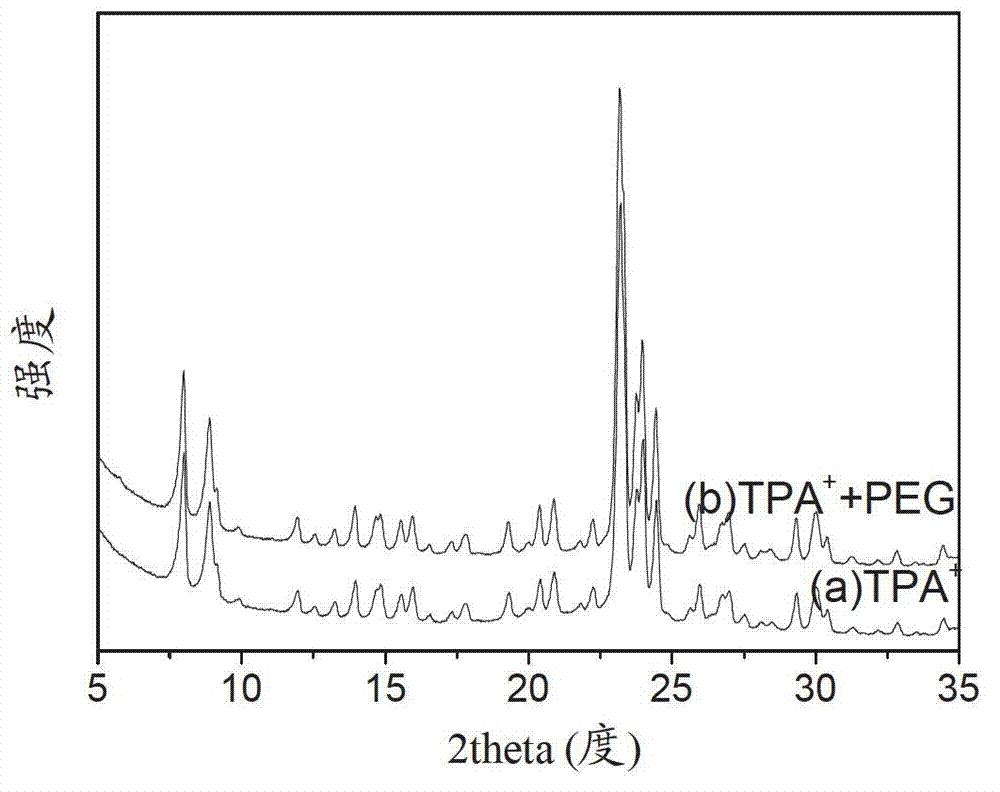

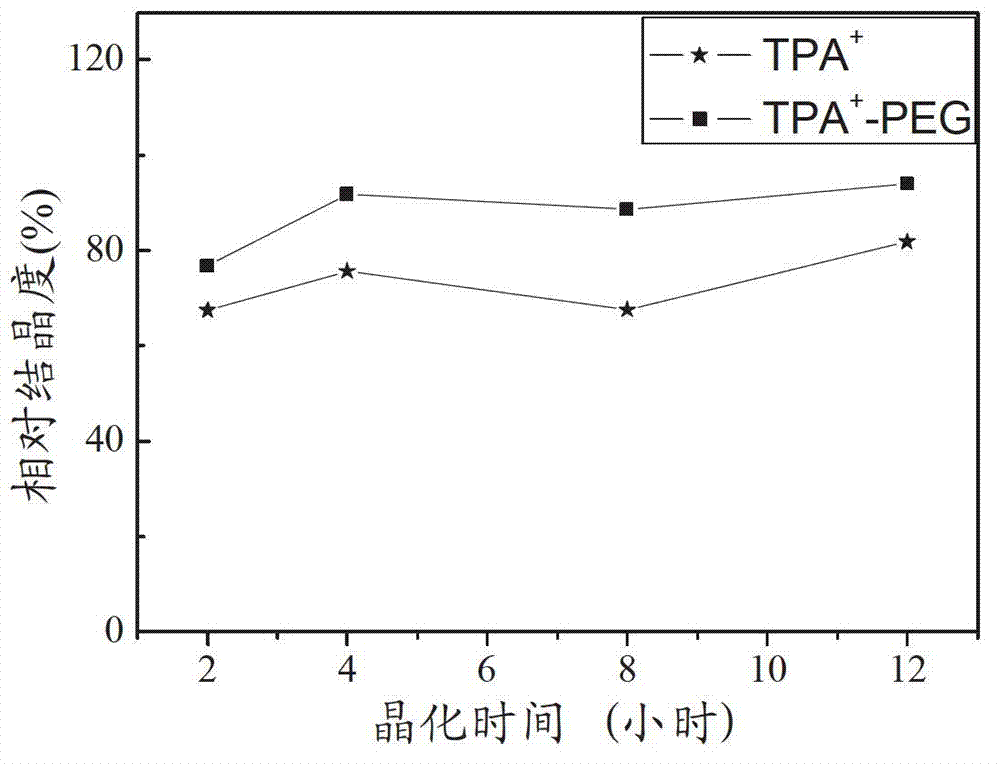

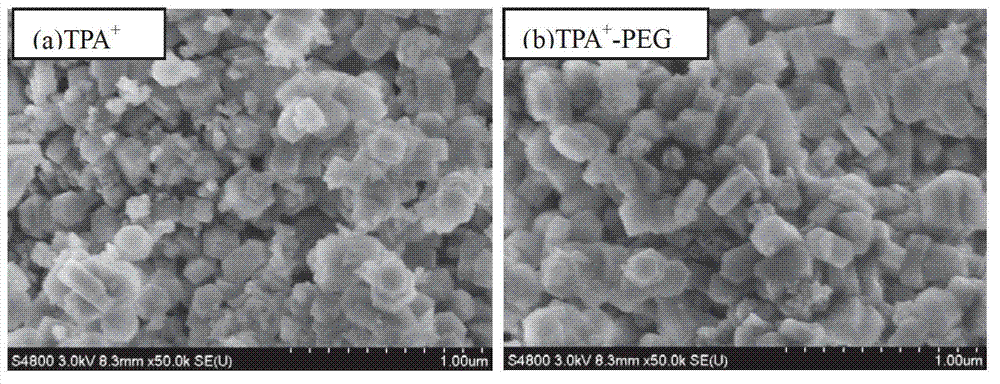

Pentasil type zeolite molecular sieve synthetic method

InactiveCN102963907APromote crystallizationReduce dosagePentasil aluminosilicate zeoliteMolecular sieveCrystallinity

The invention belongs to the field of molecular sieve catalytic materials and discloses a pentasil type zeolite molecular sieve synthetic method. The pentasil type zeolite molecular sieve synthetic method comprises the following steps of mixing an aluminum-source compound, an alkali-source compound, a silicon-source compound, an additive, an organic template agent and water, and uniformly stirring to form a reaction mixture; and carrying out hydrothermal crystallization, filtering, washing and drying to obtain pentasil type zeolite molecular sieve, wherein the additive is polyether type compound. The pentasil type zeolite molecular sieve synthetic method disclosed by the invention has the advantages of high crystallization speed, low cost, low template agent consumption and the like, and the synthesized pentasil type zeolite molecular sieve has high degree of crystallinity and purity.

Owner:EAST CHINA NORMAL UNIV

Calcium sulfate whisker modified polypropylene composite material and preparation method thereof

The invention discloses a calcium sulfate whisker modified polypropylene composite material and a preparation method thereof. The calcium sulfate whisker modified polypropylene composite material is prepared from the following raw materials in part by weight: 100 parts of polystyrene (PP), 10 to 40 parts of calcium sulfate whisker, 10 to 20 parts of styrene butadiene styrene (SBS), 10 to 20 partsof ethylene vinyl acetate (EVA), 0.1 to 0.3 part of divinylbenzene (DVB), 0.5 to 2 parts of benzoyl hydrazine and 1 to 3 parts of titanate coupling agent. The preparation method comprises the following steps of: mixing the calcium sulfate whisker and the titanate coupling agent in a high speed mixer for 5 to 12 minutes; mixing other raw materials and the modified calcium sulfate whisker in the high speed mixer for 5 to 10 minutes; and extruding and pelletizing the obtained mixture in a double-screw extruder. The calcium sulfate whisker modified polypropylene composite material has high impactstrength and toughness, and is particularly suitable for manufacturing various electrical equipment shells requiring high strength.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

Quick synthesis method of heteroatomic aluminophosphate molecular sieve SAPO-5 in eutectic body

InactiveCN102583436AFast crystallization rateMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveO-Phosphoric Acid

The invention relates to a quick synthesis method of heteroatomic aluminophosphate molecular sieve SAPO-5 in an eutectic body, which comprises the following steps that: A) the eutectic body, an aluminum source and a silicon source are uniformly blended, then phosphoric acid and hydrofluoric acid are added into the mixture, the prepared mixture (according to the mol ratio) is that: aDES: bP2O5: Al2O3: cHF: dSiO2, wherein a= 54 to 162, b=1.0 to 2.0, c=0.45 to 0.93, d=0.2 to 0.8, the mixture is heated under the temperature of 120 to 125 DEG C, so the mixture is uniformly blended; B) the mixture obtained in step A is heated under the radiation of microwaves to 160 to 180 DEG C, and then the mixture is crystallized for 15 to 60 minutes under a normal pressure; and C) the reaction mixture obtained in step B is cooled to the room temperature and is subjected to vacuum filtration, products are repeatedly washed by water and acetone and are dried under the temperature of 80 to 100 DEG C, so a powder product of the heteroatomic aluminophosphate molecular sieve SAPO-5 is obtained.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

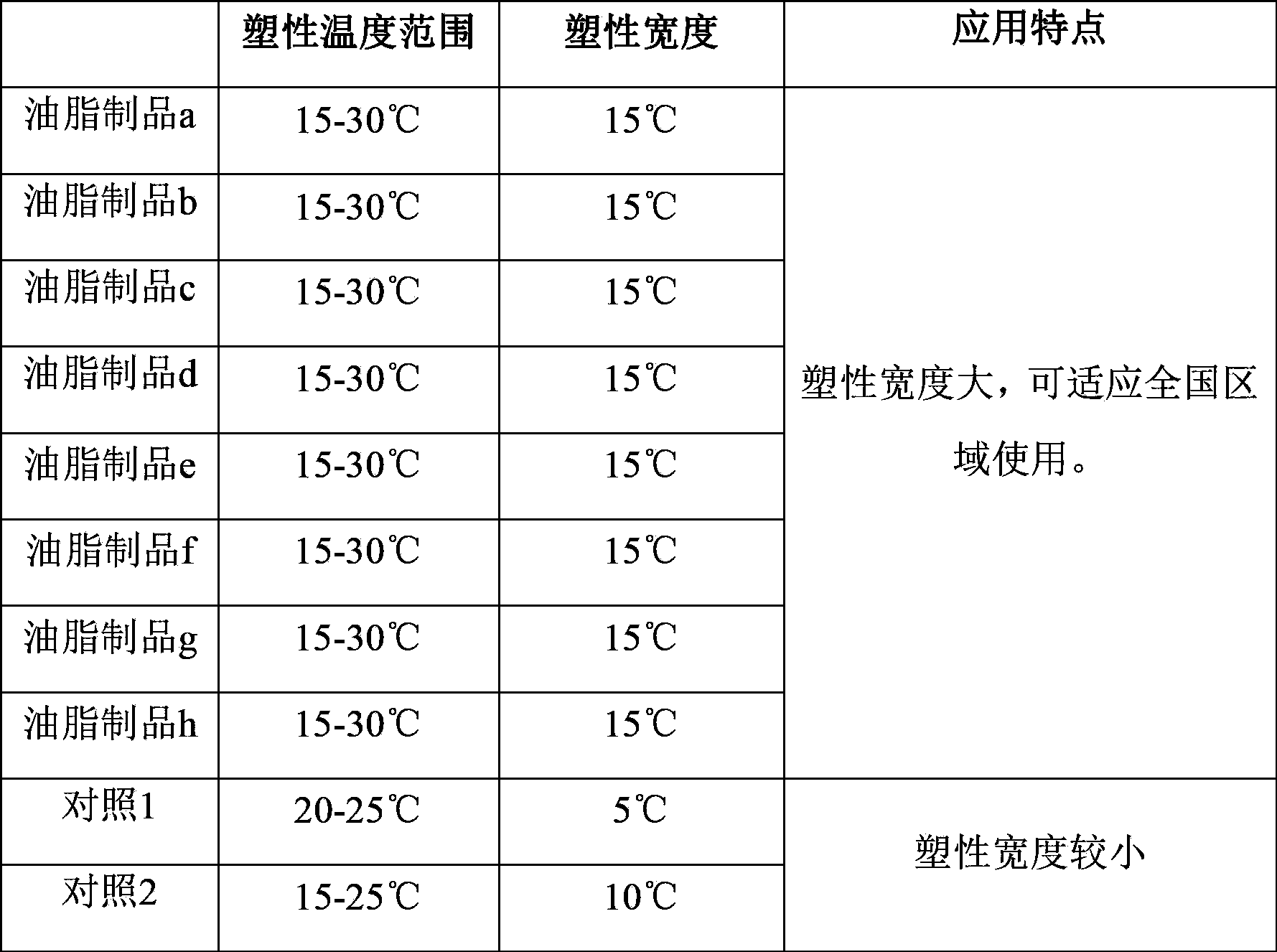

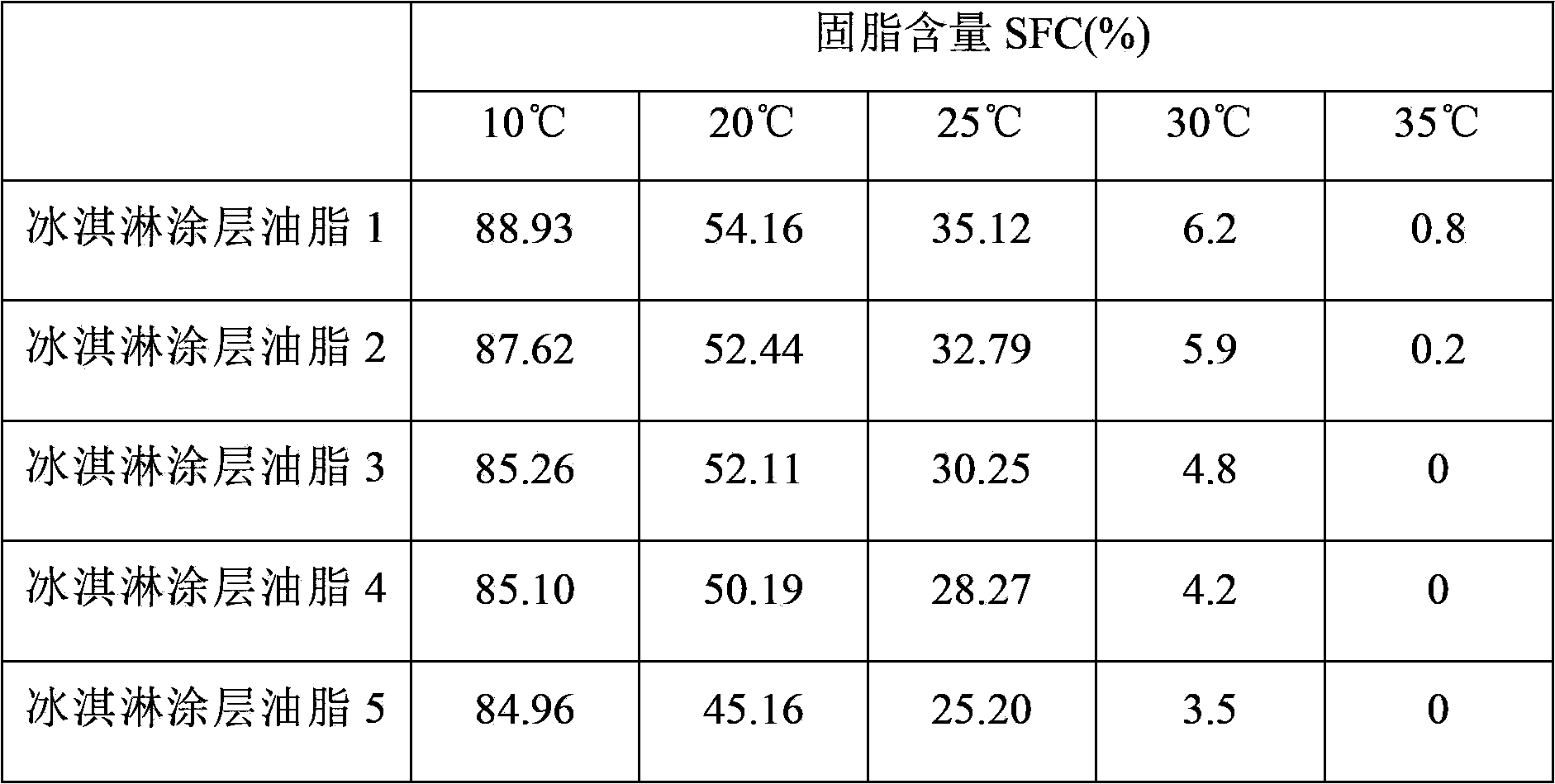

Grease composition and plastic grease product

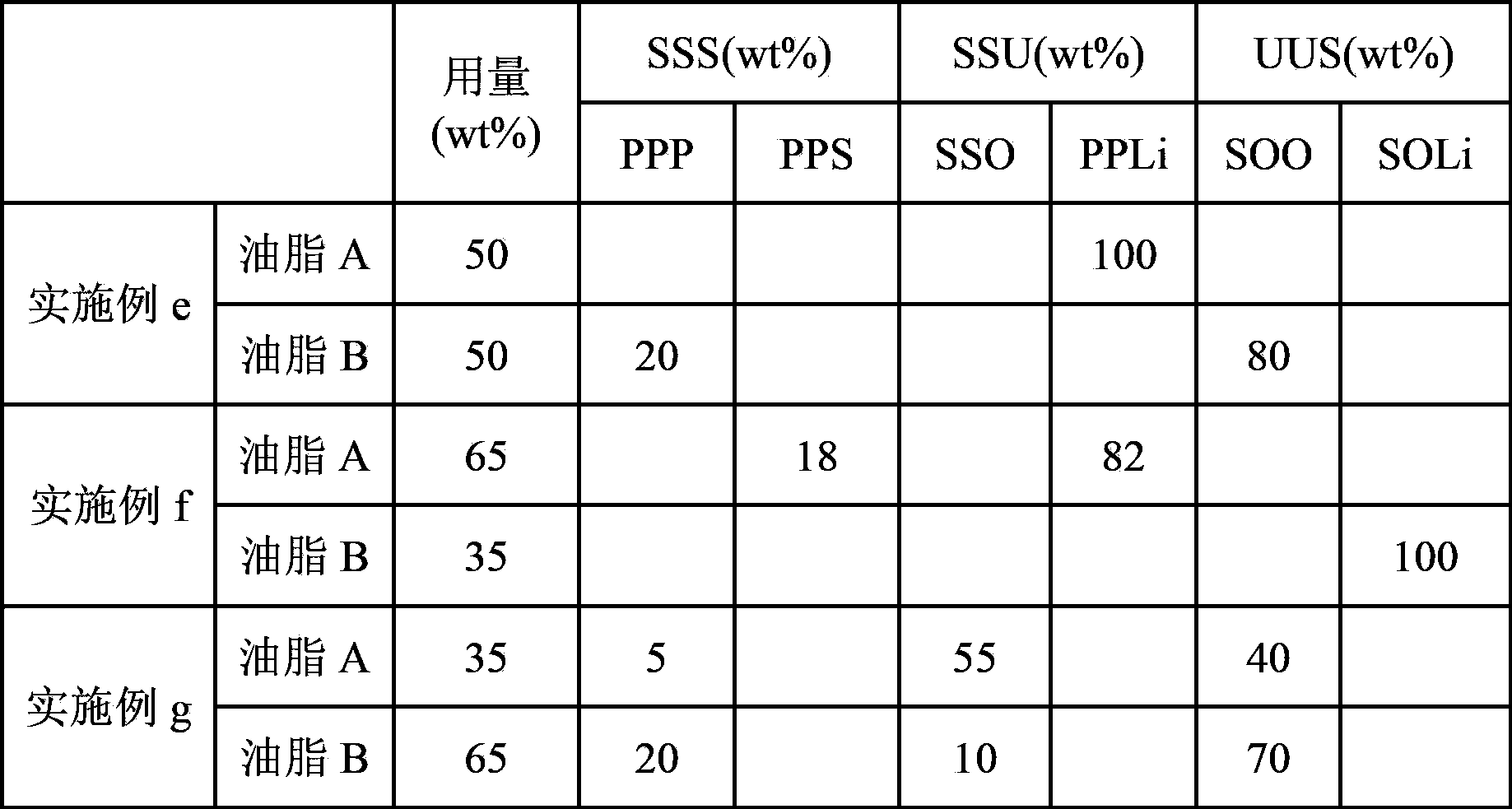

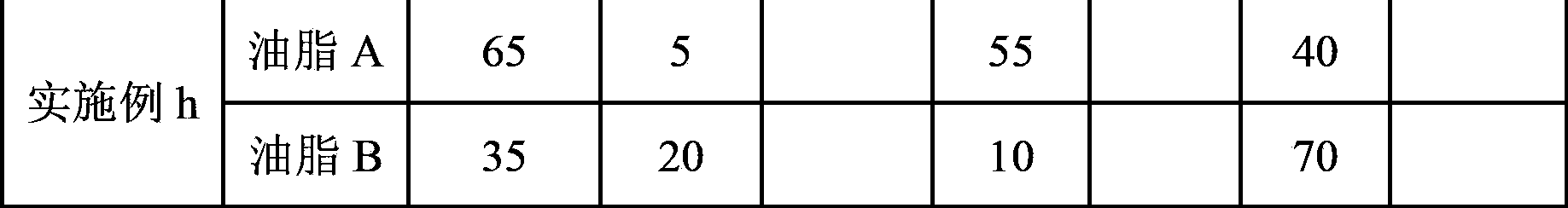

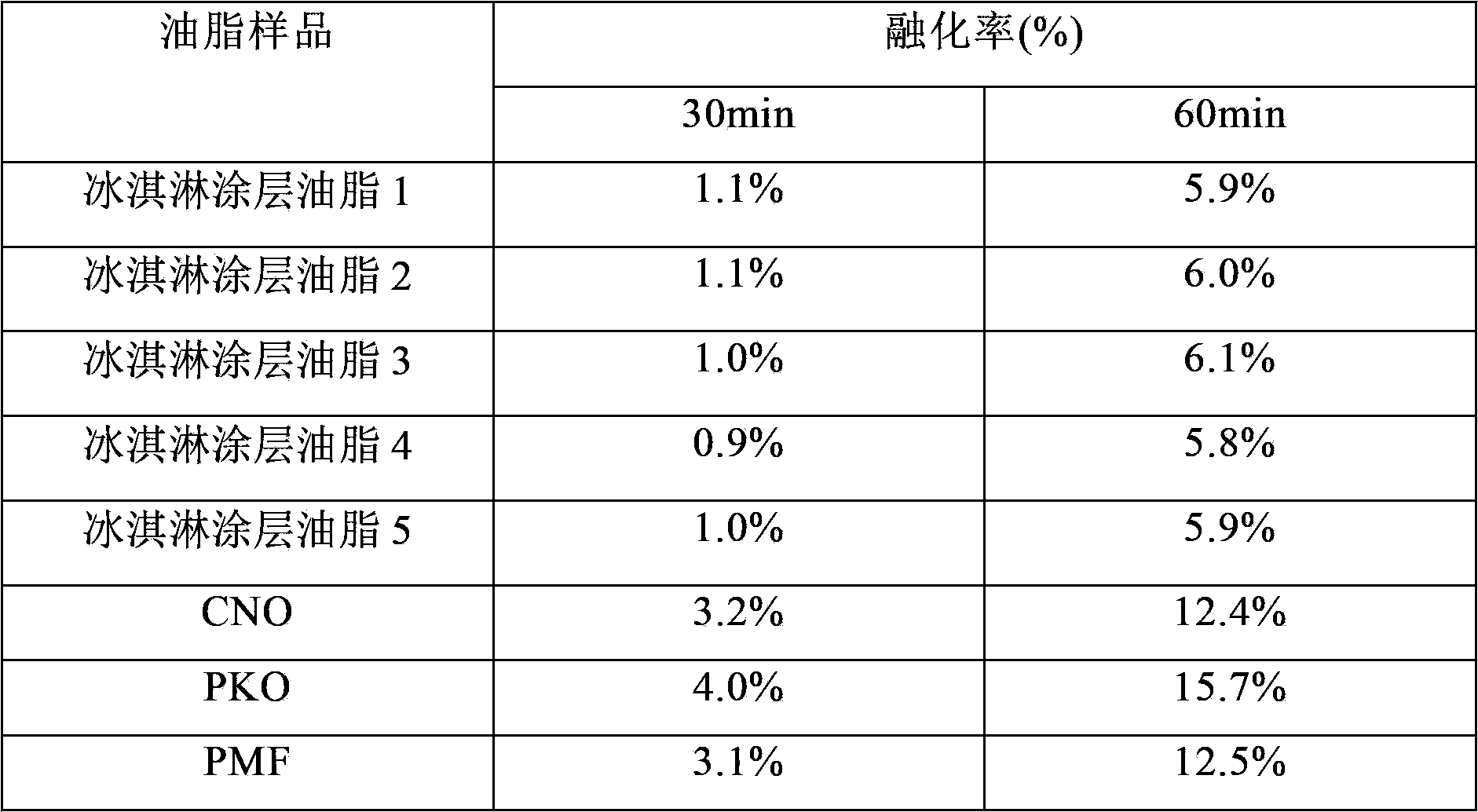

ActiveCN103891921AFast crystallization rateWide range of plasticityEdible oils/fats production/working-upOil and greaseTriglyceride

The invention provides a grease composition. The grease composition comprises, based on the weight of total triglycerides, more than 25.5 wt% of 1,2-disaturated-3-unsaturated triglyceride (SSU), more than 33.1% of 1,2-diunsaturated-3-saturated triglyceride (UUS), more than 9.2 wt% of trisaturated triglyceride (SSS), and less than 10 wt% of triunsaturated triglyceride (UUU), wherein the S is saturated fatty acid and the U is unsaturated fatty acid. The invention also provides a preparation method of a plastic grease product. The method includes subjecting the grease composition to rapid cooling, kneading and curing processing. The plastic grease product prepared by the method has advantages of wide plasticity temperature range, high crystallization rate, high expansion rate, and the like.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

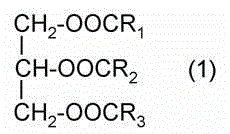

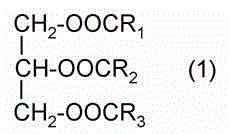

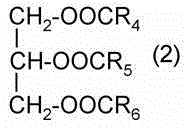

Oil composition, preparation method thereof and foodstuffs

ActiveCN105795000AFast crystallization rateShorten production timeDough treatmentCocoaOil and greaseChemical composition

The invention relates to an oil composition, a preparation method thereof and foodstuffs. The oil composition is characterized in that the oil composition comprises triglyceride whose weight is not less than 30% of the total weight as shown in the following general formula (1); in the general formula (1), definitions of R1, R2, and R3 are shown in the specification. The composition does not contain trans-fatty acids, crystallization rate is higher, long time cooling and solidification for shaping at low temperature are not needed, production time is reduced, the composition has a cool mouthfeel without pasty mouthfeel, and the composition melts fast.

Owner:嘉里特种油脂(上海)有限公司

Method for synthesizing P-Al molecular sieve by microwave heating

InactiveCN100410172CFast crystallization rateNo emissionsMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveOrganic solvent

The invention discloses a synthesizing method of amblygonite molecular sieve, which comprises the following steps: A) heating ionic liquid to 10-150 deg.c; adding phosphor source and aluminum source to blend evenly; adding mineralizer to mix evenly; producing molar proportion at 0.5-1.0 a, 0.1-100 b and 0.01-2 c for aP2O5:Al2O3:b ionic liquid : c mineralizer; B) heating step A compositions to 100-300 deg.c through microwave irradiation; crystallizing for 1-200 min under normal pressure or self-pressure; C) cooling step B composition to indoor temperature; filtering; washing filtrate through water or organic solvent; drying at 80-110 deg.c to produce powder-shaped product. The invention is rapid to synthesize the molecular sieve, which saves cost effectively.

Owner:PETROCHINA CO LTD +1

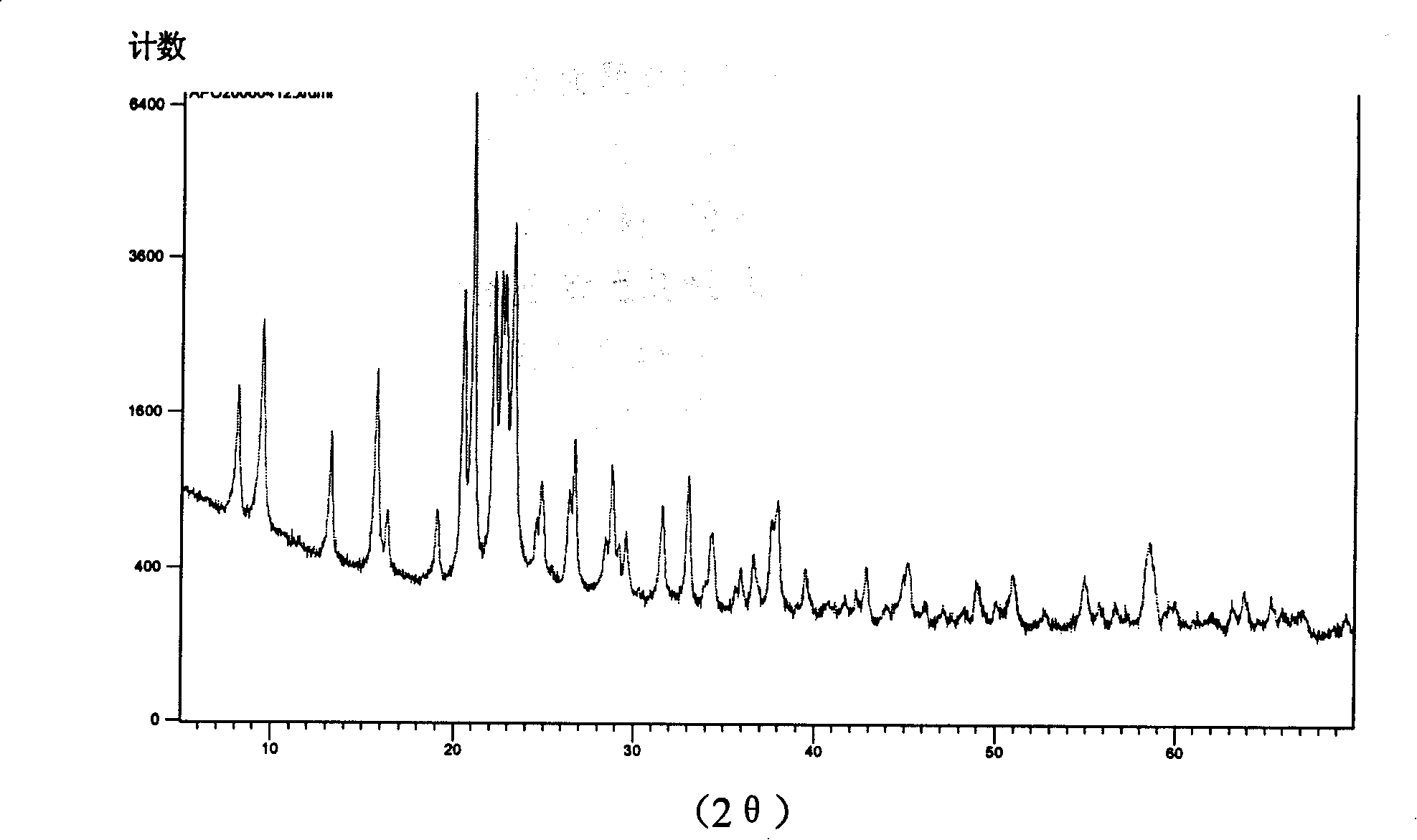

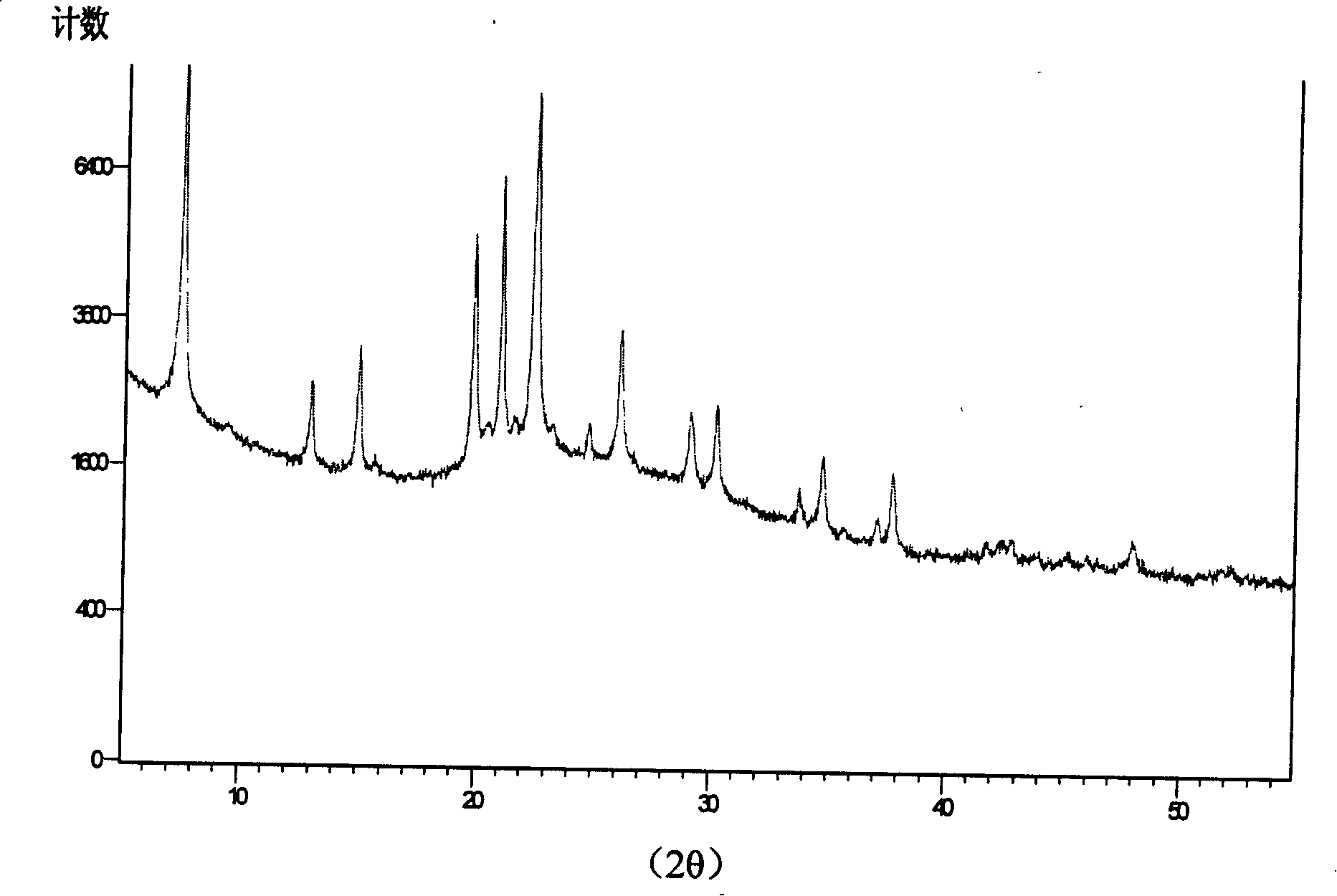

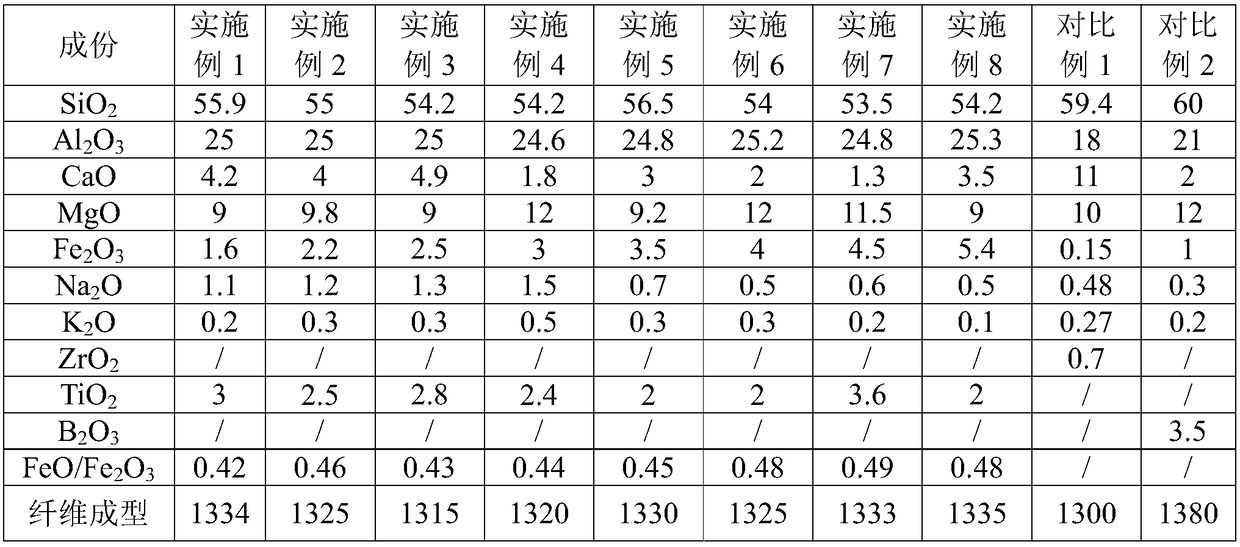

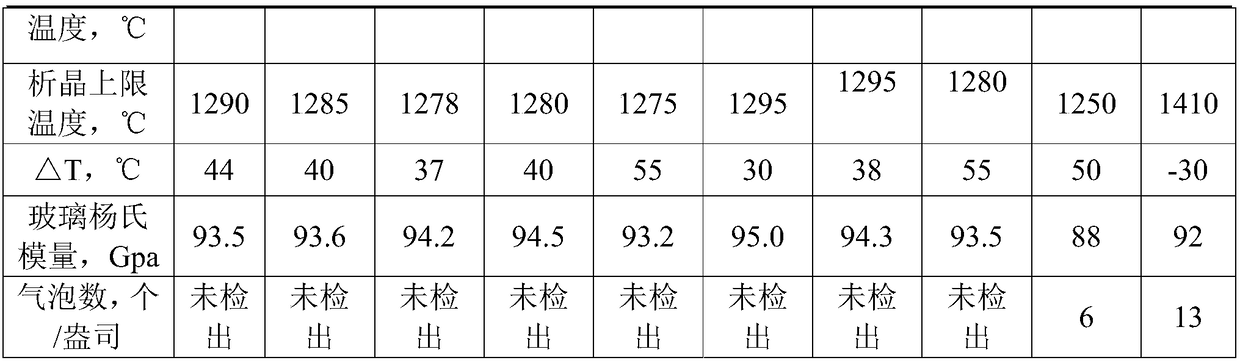

High-modulus glass fiber composition based on basalt

The invention belongs to the technical field of glass fibers and in particular relates to a high-modulus glass fiber composition based on basalt. The composition comprises the following components: 53.0-60.0% of SiO2, 24.5-28.0% of Al2O3, 8.0-15.0% of MgO, 1.5-5.5% of Fe2O3, 2.0-4.0% of TiO2, greater than 0% and less than or equal to 5.0% of CaO, greater than 0% and less than or equal to 1.5% of Na2O and greater than 0% and less than or equal to 0.5% of K2O. The glass fiber composition provided by the invention has a modulus of 93-95GPa. The glass fiber composition is prepared from a basalt mineral raw material and a common glass fiber mineral raw material, a large ratio of a Fe2O3 component is introduced, and particularly FeO / Fe2O3 is less than or equal to 0.6, so that the glass fiber hasthe properties of specific high strength, high modulus and the like of a basalt glass fiber, and has the advantage of high-efficiency industrial production of glass fibers.

Owner:TAISHAN FIBERGLASS INC

Polylactic acid foaming composite material as well as preparation method and application thereof

The invention belongs to the technical field of biodegradable foaming materials, and discloses a polylactic acid foaming composite material as well as a preparation method and application thereof. The polylactic acid foaming composite material comprises the following components in parts by weight: 100 parts of polylactic acid resin, 5-15 parts of other biodegradable materials, 0.5-3 parts of a bio-based nucleating agent, 0.5-4 parts of a chain extender and 0.1-1 part of a lubricant. The preparation method comprises the steps of mixing, extruding, drawing and pelletizing the components to prepare a polylactic acid foaming master batch; and putting the polylactic acid foaming master batch into a high-pressure reaction kettle, introducing a fluid serving as a foaming agent into the high-pressure reaction kettle, controlling the temperature of the high-pressure reaction kettle to be 40-200 DEG C and the pressure of the high-pressure reaction kettle to be 8-20 MPa, keeping the temperature and the pressure for 30-120 minutes, releasing gas in the reaction kettle, reducing the pressure to normal pressure, and taking out polylactic acid foaming particles from the reaction kettle, so as to obtain the particles, namely, the polylactic acid foaming composite material.

Owner:GUANGDONG UNIV OF TECH

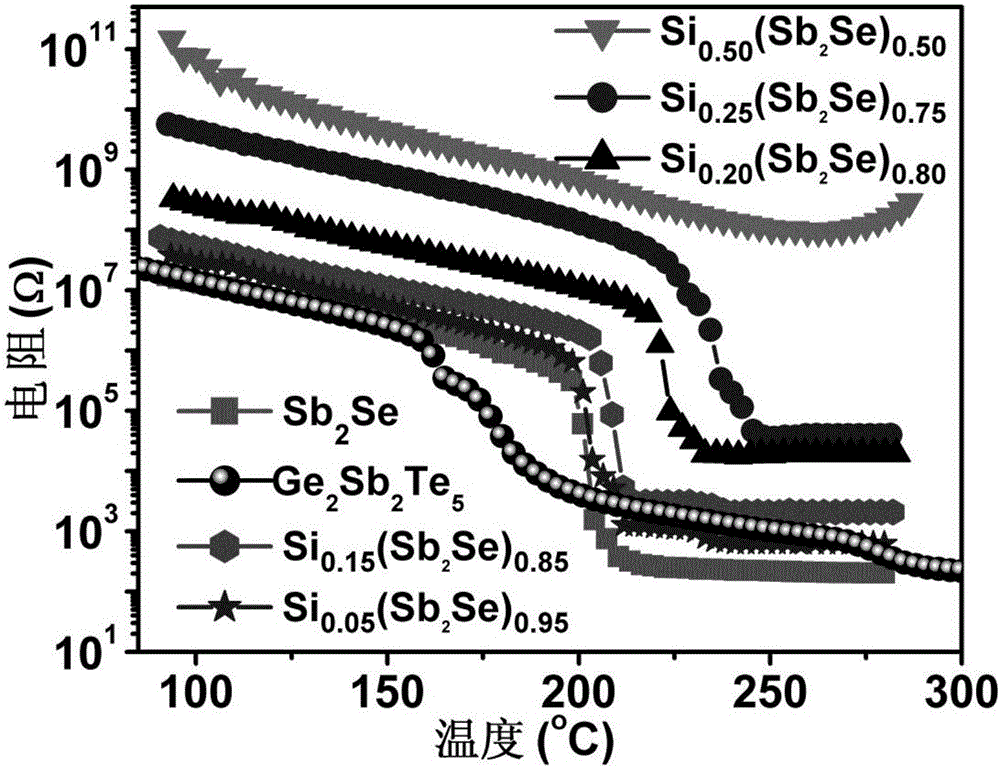

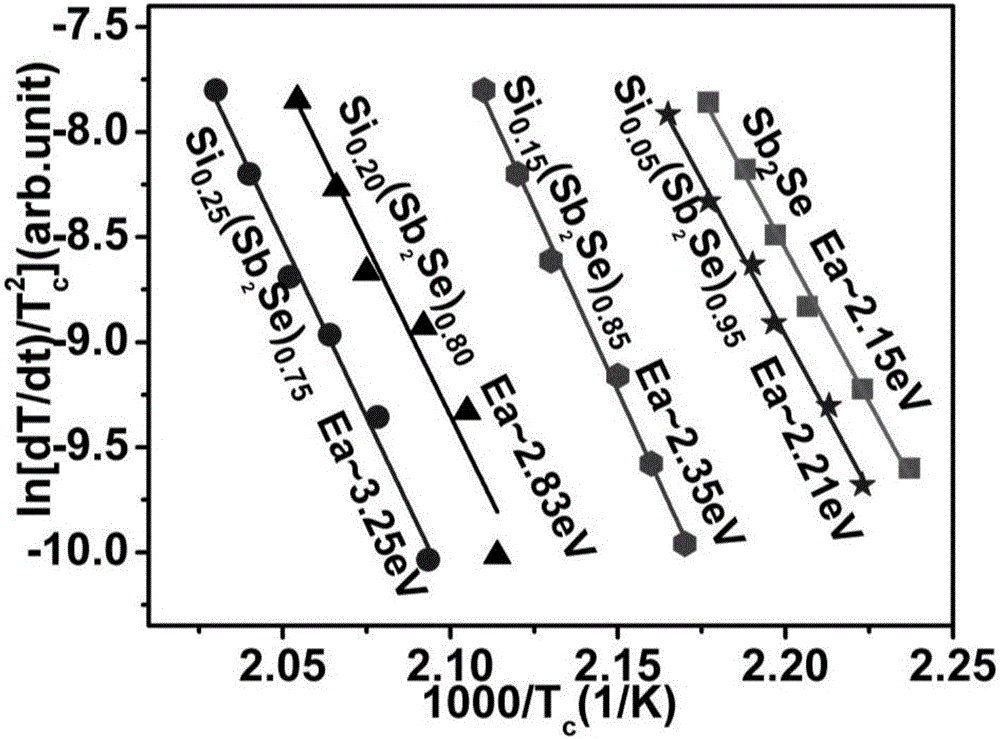

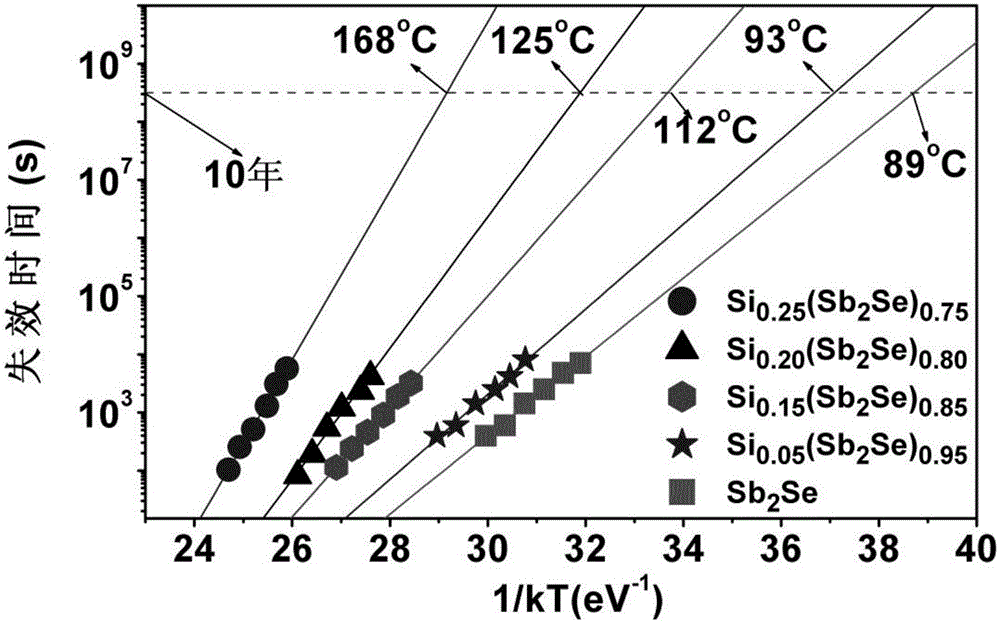

Si-Sb-Se nano phase-change thin film material and preparation method and application thereof

InactiveCN106374043AImprove thermal stabilityFast phase changeElectrical apparatusVacuum evaporation coatingChemical compositionSemiconductor materials

The invention belongs to the field of semiconductor materials, and discloses an Si-Sb-Se nano phase-change thin film material. A general formula of a chemical composition of the phase-change thin film material is Si<x>(Sb<2>Se)<1-x>, wherein x is smaller than 0.50 and greater than or equal to 0.05; the proportion of an ingredient Si in the Si<x>(Sb<2>Se)<1-x> is controlled through the diameters of stacked Si sheets; and the Si-Sb-Se nano phase-change thin film material is formed by deposition through a room-temperature high-vacuum magnetron sputtering method. The Si-Sb-Se nano phase-change thin film material provided by the invention does not contain a Te element and belongs to an environment-friendly material; and meanwhile, Si-Sb-Se also has ultra-high thermal stability, relatively low power consumption and a high phase change speed, is an ideal phase-change storage material and has a relatively good market application prospect.

Owner:JIANGSU UNIV OF TECH

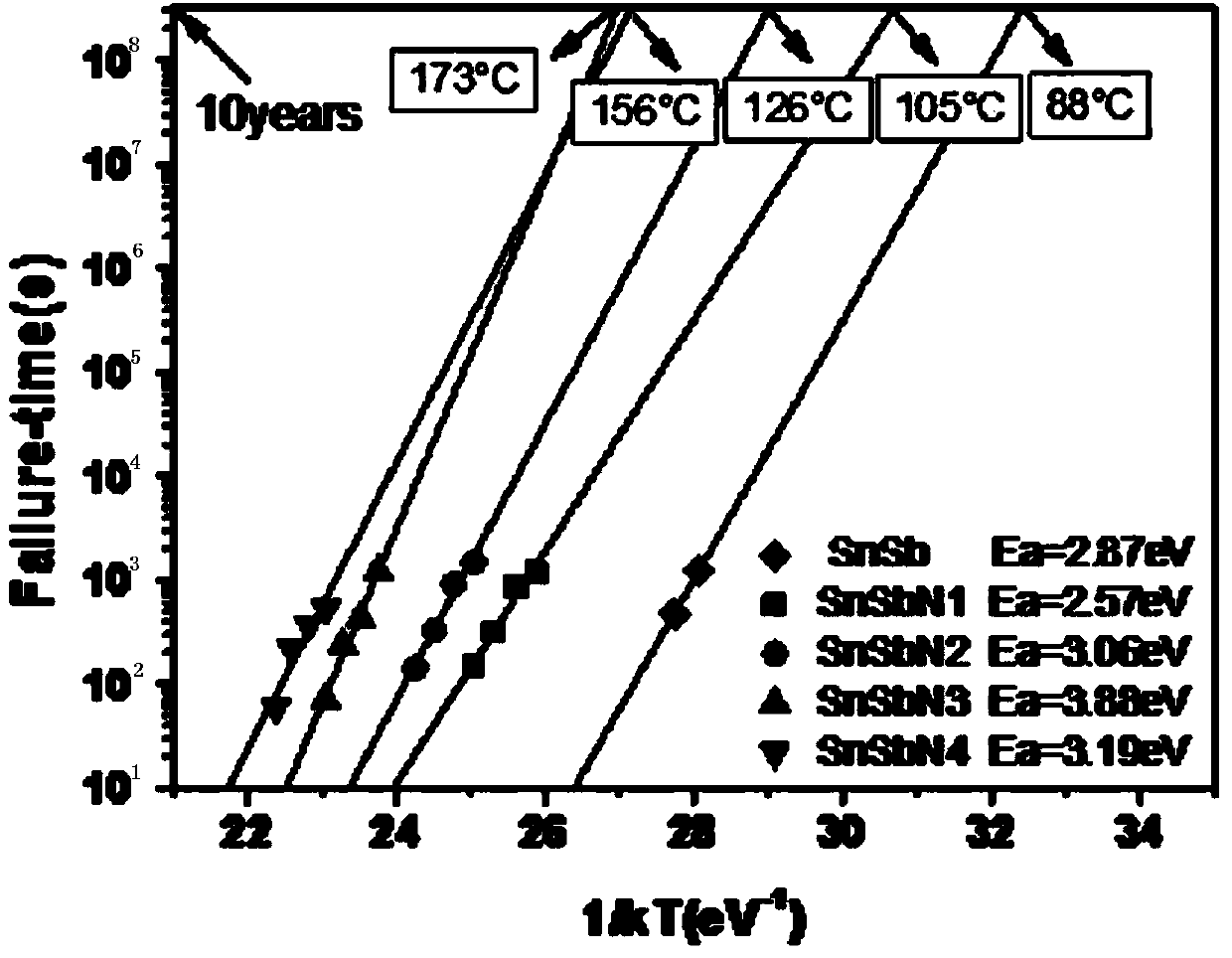

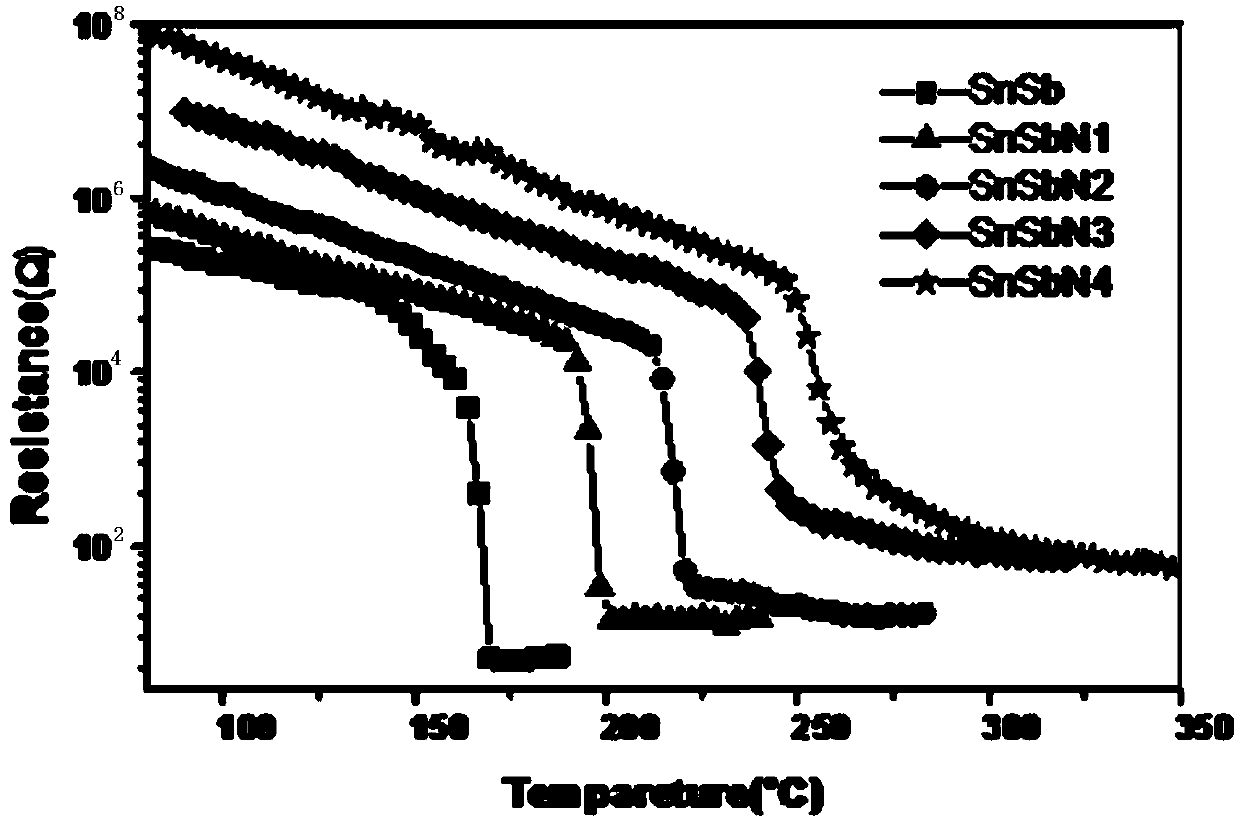

Nitrogen-doped nano-film material applied to quick high-stability phase transition storage and preparation method

The invention discloses a nitrogen-doped nano-film material applied to a quick high-stability phase transition storage. The nitrogen-doped nano-film material is characterized in that the chemical fomula is Sn15Sb85Nx, wherein x is the nitrogen flow rate based on the unit of sccm; the nitrogen-doped Sn15Sb85 is prepared by the room-temperature magnetron sputtering method; argon and nitrogen are charged at the same time during performing magnetron sputtering and depositing for the Sn15Sb85 film. The preparation method is characterized in that nitrogen-doped Sn15Sb85 nano phase transition thin materials with different N atom contents can be obtained by controlling the flow rate of Ar and N2; other preparation conditions cannot be ignored, which certainly influences the content and size of N atoms in the final nitrogen-doped Sn15Sb85 nano phase transition film material. The nitrogen-doped Sn15Sb85 nano film material can be applied to the phase transition storage and is high in crystallization temperature and crystallization resistance, and the heat stability of PCRAM can be greatly improved.

Owner:JIANGSU UNIV OF TECH

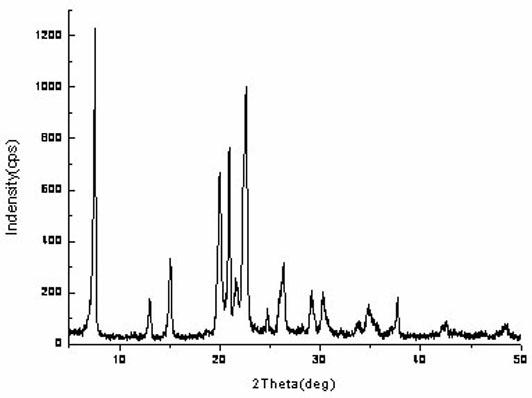

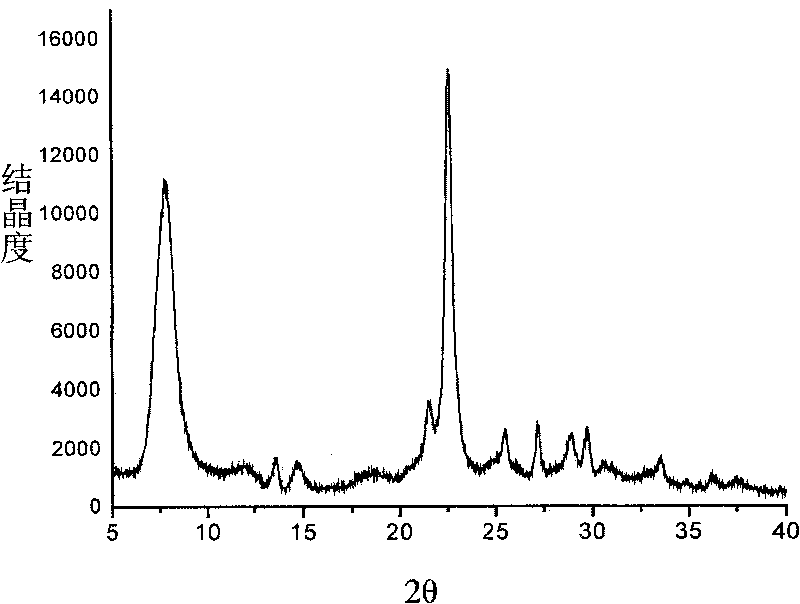

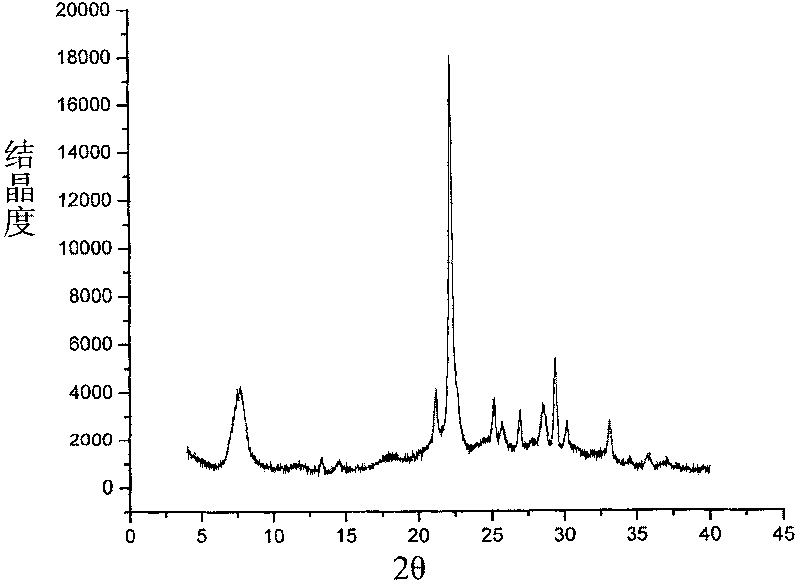

Method for synthesizing Beta molecular sieve by organic-free template

InactiveCN101249968BFast crystallization ratePollution does not causeCrystalline aluminosilicate zeolitesMolecular sieveAlkali metal oxide

The invention relates to a method of synthesizing Beta molecular sieve without organic templates, which belongs to the technical field of catalytic chemistry. The steps of the invention comprise mixing alkali oxide sources, alumina sources, silica sources and water, stirring and synthesizing initial silica-alumina gel, then adding with Beta zeolite crystal seed, crystallizing 12-24 hours under thetemperature of 100-180 DEG C and hydro-thermally synthesizing the Beta molecular sieve, SiO2 / Al2O3 of the Beta zeolite crystal seed equals 22-25, and the quality of addition quantity is 5%-20% of thesilica sources. The method of the invention suits requirements of applying zeolite molecular sieve in industry, not only can directly synthesize high crystallinity crystal of the Beta molecular, butalso can increase crystallizing speed of the molecular and reduce manufacturing cost. Because the synthesis process doesn't use any organic templates without roasting, thereby a pore path is unimpeded, and environmental pollution and relatively consumption are avoided.

Owner:JILIN UNIV

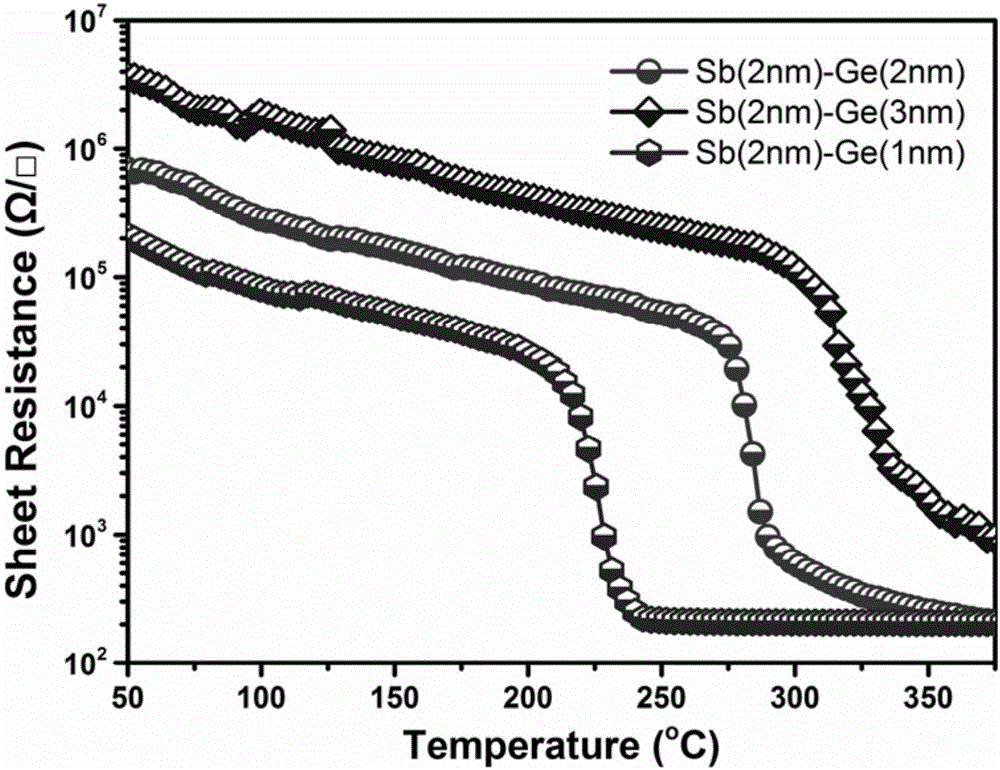

Antimony-germanium multilayer nano-composite phase-change material and preparation and application thereof

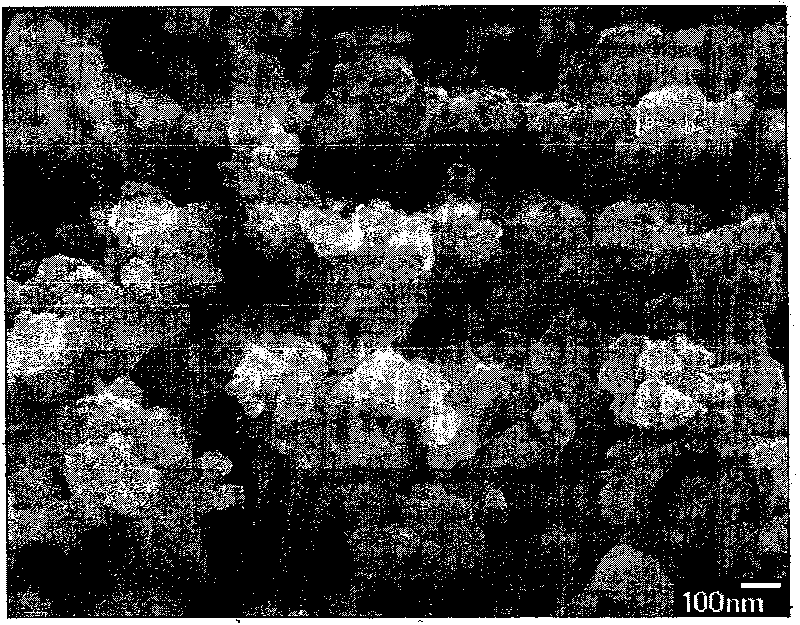

InactiveCN106601908AImprove thermal stabilityHigh thermal stabilityMaterial nanotechnologyElectrical apparatusFilm materialStorage material

The invention relates to an antimony-germanium multilayer nano-composite phase-change material and preparation and application thereof. The composite phase-change material comprises a multilayer film structure formed by alternative arrangement of Sb films and Ge films, the thickness of the Sb film is 1-3 nm, and the thickness of the Ge film is 0.5-3.5 nm. By employing a magnetron sputtering method, multiple layers of Sb films and Ge films are alternatively deposited on a SiO2 / Si (100) substrate by regarding Sb and Ge as sputtering target materials and regarding Ar as the sputtering gas, and the Sb / Ge nano-composite multilayer phase-change film material is obtained. Compared with the prior art, according to the Sb / Ge nano-composite multilayer phase-change film, the thermal stability is high, and the saving time of data can be increased; crystalline and amorphous resistances are higher, and the operation power consumption of a PCRAM can be reduced; and compared with the conventional phase-change storage material, the thermal stability is improved, and the crystallization speed is accelerated.

Owner:TONGJI UNIV

Preparation method of ZSM-5 molecular sieve

ActiveCN103848437ASuitable for industrial production applicationsHigh crystallinityPentasil aluminosilicate zeoliteNanotubeZSM-5

The invention discloses a preparation method of a ZSM-5 molecular sieve. The preparation method comprises the following steps: (1) mixing a substance containing elements in the IVA group, a substance containing elements in the IIIA group, alkali metal hydroxides, a crystal seed, and water so as to obtain a gel liquid; (2) carrying out an aging treatment on the gel liquid obtained in the step (1) for 0 to 240 hours; (3) crystallizing the aged mixture at a temperature of 120 to 180 DEG C so as to obtain the ZSM-5 molecular sieve; wherein the crystal seed is a ZSM-11 molecular sieve having a grafted nanotube shape. The preparation method is carried out in a template-free system, and utilizes a ZSM-11 molecular sieve, whose phase is different from that of target ZSM-5 molecular sieve, to prepare a ZSM-5 molecular; thus the morphology and size of the obtained ZSM-5 molecular sieve can be controlled just through adjusting the morphology of ZSM-11 molecular sieve taken as the crystal seed, the ZSM-5 molecular sieve has a pure phase and a high crystallization degree, and the crystallization speed of the preparation method is faster than that of conventional methods taking ZSM-5 as the crystal seed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

SiO2 doped Sb nano phase change film material, and preparation method and application of film material

InactiveCN106953006AEasy to prepareProcess parameters are easy to control effectivelyMaterial nanotechnologyElectrical apparatusChemical compositionRandom access memory

The invention discloses an SiO2 doped Sb nano phase change film material, and a preparation method and an application of the film material. A chemical composition of the SiO2 doped Sb nano phase change film material is (SiO2)xSb1-x, wherein x is greater than or equal to 0.22 and less than or equal to 0.40; and the film material is deposited by a magnetron sputtering method. The prepared SiO2 doped Sb nano phase change film material has a high crystallization temperature, can effectively improve thermal stability of a PCRAM (Phase Change Random Access Memory), has a high crystallization speed, and can greatly increase a memory speed of the PCRAM.

Owner:JIANGSU UNIV OF TECH

Method for synthesis of high silica-alumina ratio ultrafine NaY molecular sieve

ActiveCN104743572ARealize full recyclingReduce consumptionFaujasite aluminosilicate zeoliteMolecular sieveHigh silica

The invention discloses a method for synthesis of a high silica-alumina ratio ultrafine NaY molecular sieve. The method comprises the following steps of collecting a crystallization mother liquor of a high silica-alumina ratio ultrafine NaY molecular sieve, adding inorganic acid and soluble aluminum salt solution into the crystallization mother liquor so that pH is adjusted and silica-alumina gel precipitates are formed, filtering the precipitates to obtain silica-alumina gel filter cake with a SiO2 / Al2O3 ratio of 17-85, preparing a guiding agent from a part of or all the filter cake, adding reaction gel with a silicon source, an aluminum source and water into the guiding agent, and carrying out at least three programming calefactive control crystallization processes under full dynamic conditions. The NaY molecular sieve has average crystal grain sizes of 100-500nm and a skeleton silica-alumina ratio (SiO2 / Al2O3) higher than 6.7. The method realizes silicon source complete cycle utilization.

Owner:陕西煤化工技术工程中心有限公司 +1

Preparation method and application of Raney Ni catalyst suitable for methanation of fixed bed

InactiveCN104084219AImprove conversion rateHigh selectivityGaseous fuelsRaney catalystsMethanationFixed bed

The invention discloses a Raney Ni catalyst suitable for methanation of a fixed bed. The Raney Ni catalyst is characterized in that the Ni content is 86wt%-95wt% and the specific surface area is between 85 and 180 m<2> / g. The Raney Ni catalyst suitable for methanation of the fixed bed has the advantages that the particle size is uniform, the mechanical strength is high, the catalytic activity is good and the Raney Ni catalyst is suitable for large-scale production.

Owner:SEDIN ENG

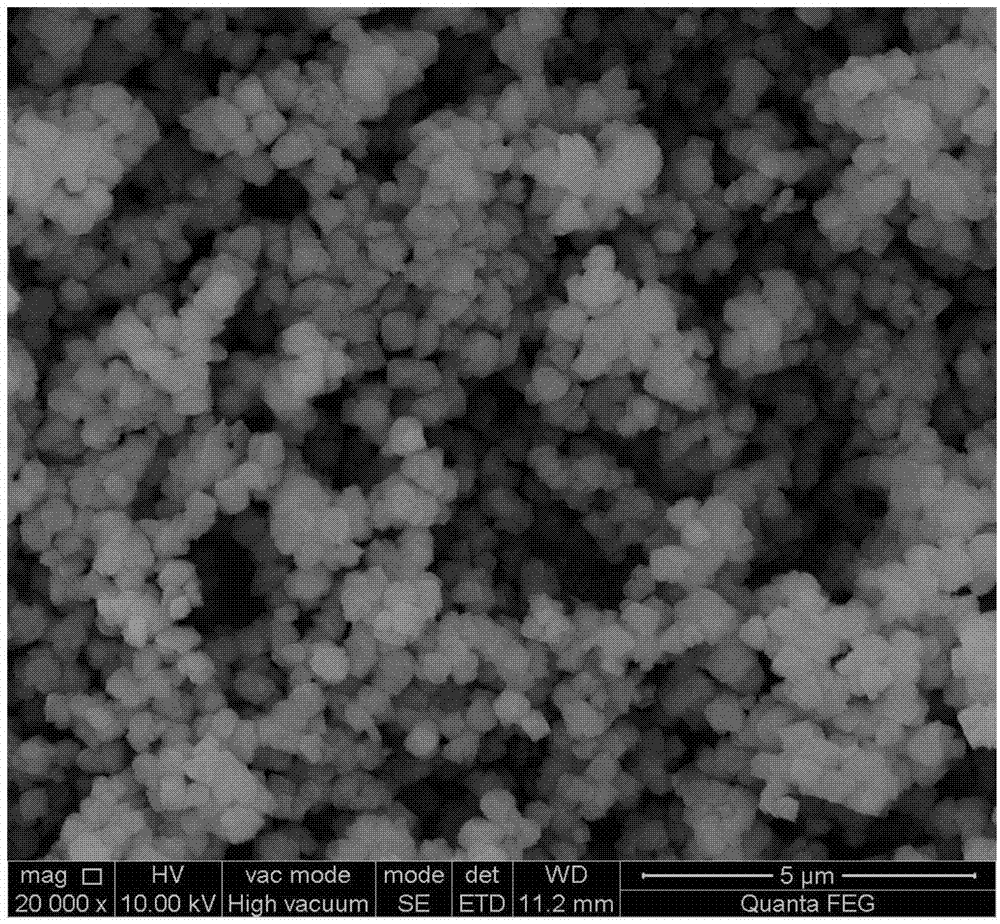

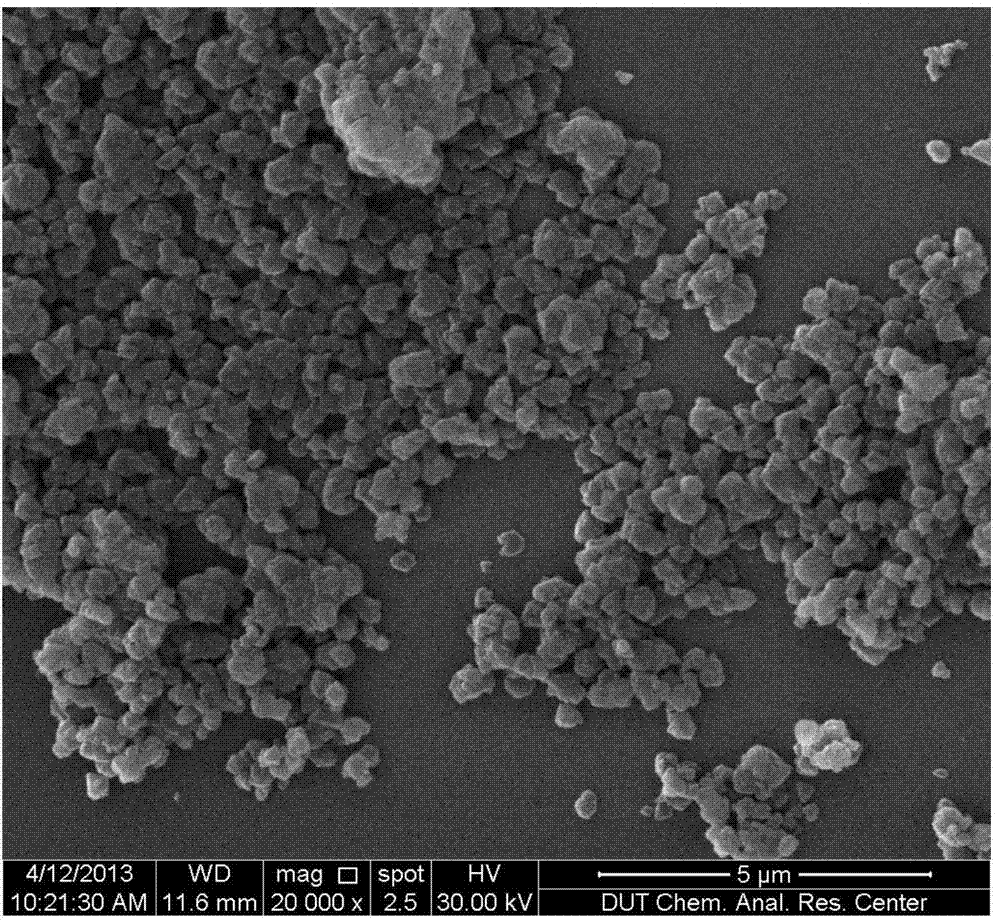

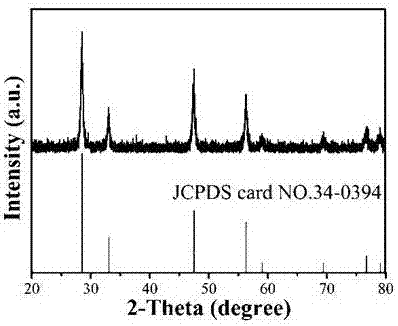

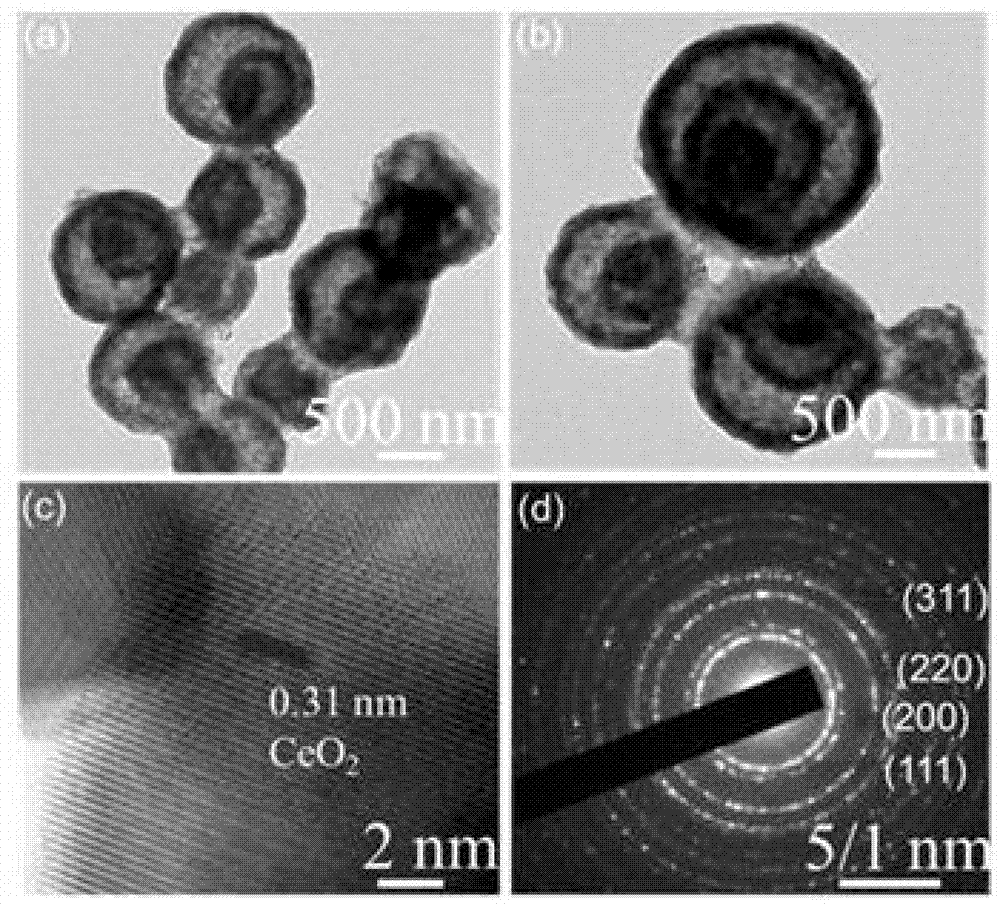

Preparation method of cerium dioxide nano hollow sphere

InactiveCN107043121AEfficient synthesisHigh purityRare earth metal oxides/hydroxidesMicroballoon preparationCerium nitrateHigh energy

The invention relates to a preparation method of cerium dioxide nano hollow sphere. The method is characterized in that cerium nitrate and pyridine-2,5-dicarboxylic acid are respectively dissolved in absolute ethyl alcohol and DMF, volume ratio of two solvents is 1:1, and a Ce(NO3)3 solution with the concentration of 0.01-0.2 mol / L is prepared after mixing stirring. The average particle size of the synthesized CeO2 nano hollow sphere having a multilayer core-shell structure is 300 nm, the distribution is uniform, multi-shell CeO2 has the porous core-shell hollow structure and has wide important latent application, such as for absorbing pollutant in sewage and sensing gas; and the method has the advantages of uniform heating, high products purity, high energy utilization rate, short reaction time, and clean heating environment.

Owner:JIANGXI NORMAL UNIV

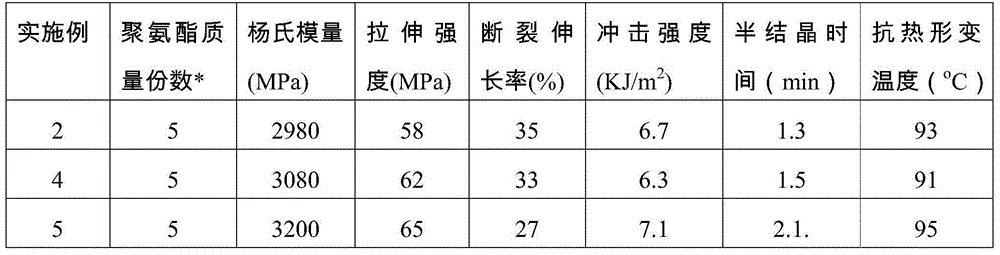

Polylactide-type polyurethane-modified polylactic acid alloy and preparation method thereof

The invention provides a preparation method of a polylactide-type polyurethane-modified polylactic acid alloy. The preparation method comprises the following steps: a. dissolving D-polylactide polylol, diisocyanate and a catalyst in a mole ratio of 1:(3-5):(0.001-0.01) in a solvent, and reacting in a protective gas atmosphere at 50-100 DEG C to obtain a prepolymer; b. adding a chain extender into the prepolymer, and carrying out chain extension to obtain a D-polylactide polylol polyurethane elastomer, wherein the mole ratio of the chain extender to the D-polylactide polylol is (2-4):1; and c. premixing 60-99.5 parts by mass of polylactic acid and 0.5-40 parts by mass of D-polylactide polylol polyurethane elastomer, and carrying out melt extrusion at 175-190 DEG C through a double-screw extruder. The invention also provides a polylactide-type polyurethane-modified polylactic acid alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com