Polylactic acid foaming composite material as well as preparation method and application thereof

A technology of polylactic acid foaming and composite materials, which is applied in the field of biodegradable foaming materials, can solve problems such as difficulty in obtaining stable shape foamed products, low melt strength of polylactic acid resin, and inability to achieve lightweight products, etc., to achieve Improvement of low melt strength and low elasticity, ease of control, ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] S11 Dissolve zinc acetate and phenylalanine in a mixed solution of ethanol and distilled water, stir and reflux in an oil bath at 70°C for 3 hours, continue the reaction and a large amount of white precipitate will appear, cool naturally to room temperature after the reaction, and the lower layer is powder solid, the upper layer was a yellow liquid, suction filtered, the filter paper was washed three times with ethanol and distilled water, and dried in a vacuum oven at 60°C for 24 hours to obtain a white powder, which was the bio-based nucleating agent.

[0041]S12 Mix 100 parts by mass of polylactic acid resin, 10 parts by mass of polyadipate-terephthalate-butylene glycol ester, 0.5 parts by mass of chain extender, 0.1 part by mass of lubricant and 0.5 parts by mass of bio-based nucleating agent, The polylactic acid foaming masterbatch is prepared by extruding, pulling, and pelletizing.

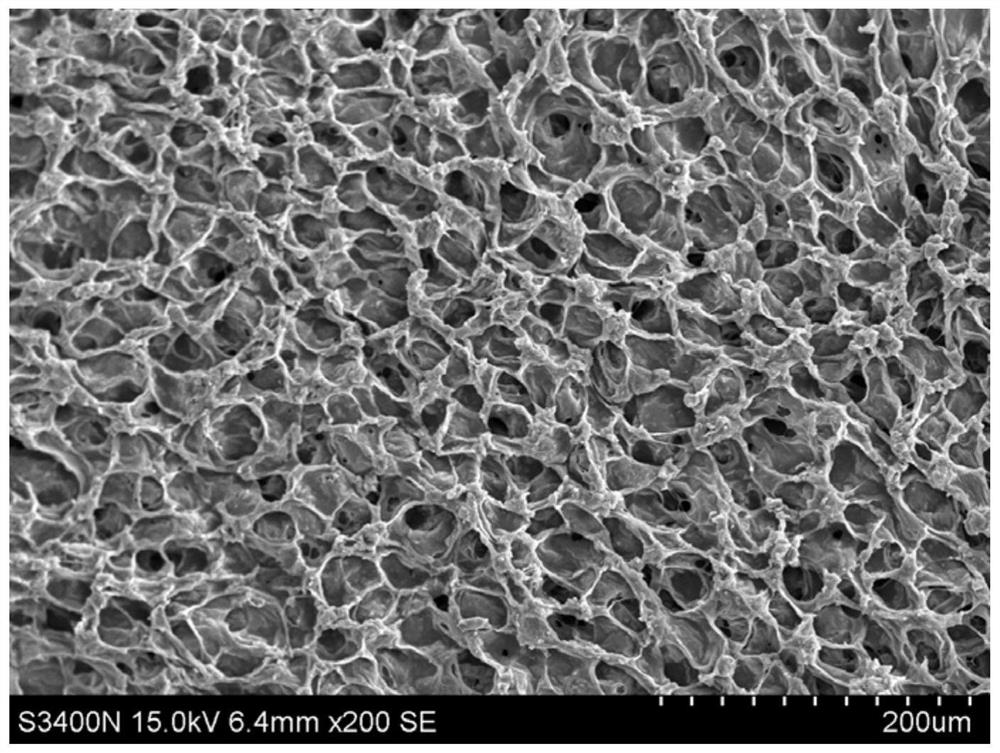

[0042] S13 Put the polylactic acid foaming masterbatch into the autoclave, feed s...

Embodiment 2

[0045] S21 Dissolve zinc acetate and proline in a mixed solution of ethanol and distilled water, stir and reflux in an oil bath at 70°C for 3 hours, continue the reaction and a large amount of white precipitate will appear, after the reaction is completed, naturally cool to room temperature, and the lower layer is in powder form Solid, the upper layer is a yellow liquid, suction filtered, the filter paper is repeatedly washed with ethanol and distilled water three times, and dried in a vacuum oven at 60°C for 24 hours to obtain a white powder, which is the bio-based nucleating agent.

[0046] S22 by mixing 100 parts by mass of polylactic acid resin, 10 parts by mass of polyadipate-terephthalate-butylene glycol ester, 0.8 parts by mass of chain extender, 0.3 parts by mass of lubricant and 0.5 parts by mass of bio-based nucleating agent, Extrusion, traction, pelletizing to prepare polylactic acid foam masterbatch

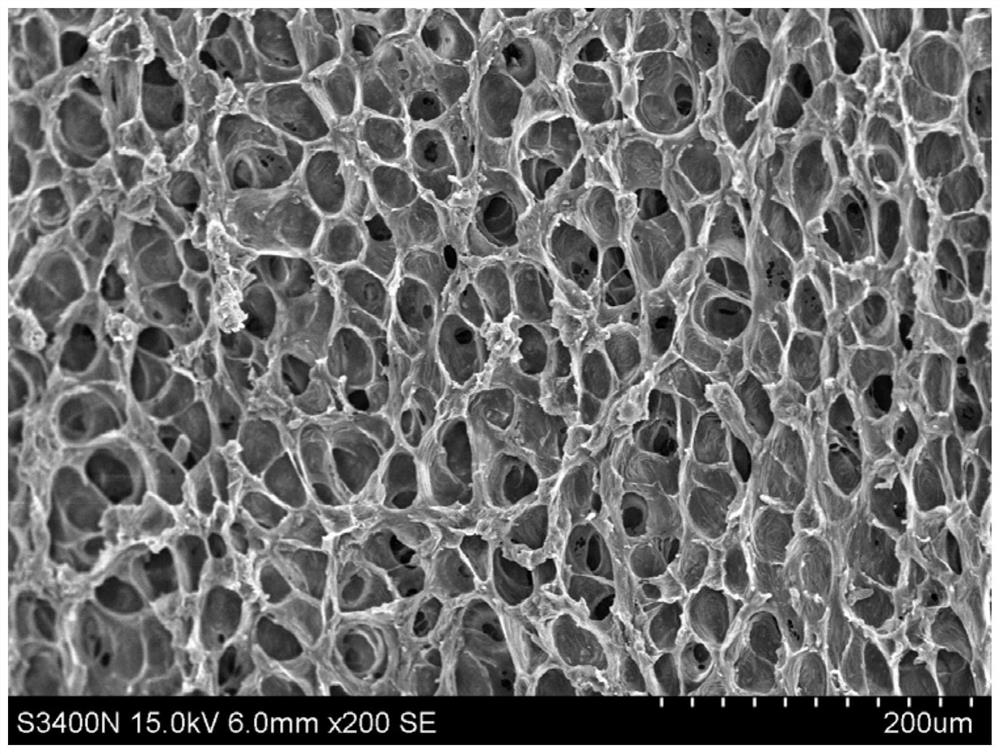

[0047] S23 Put the polylactic acid foaming masterbatch into the ...

Embodiment 3

[0050] S31 Dissolve zinc acetate and alanine in a mixed solution of ethanol and distilled water, stir and reflux in an oil bath at 70°C for 3 hours, continue the reaction and a large amount of white precipitate will appear, cool to room temperature naturally after the reaction, the lower layer is powdery Solid, the upper layer is a yellow liquid, suction filtered, the filter paper is repeatedly washed with ethanol and distilled water three times, and dried in a vacuum oven at 60°C for 24 hours to obtain a white powder, which is the bio-based nucleating agent.

[0051] S32 mixes 100 parts by mass of polylactic acid resin, 10 parts by mass of polyadipate-terephthalate-butylene glycol ester, 1 part by mass of chain extender, 0.5 part by mass of lubricant and 0.5 part by mass of bio-based nucleating agent, The polylactic acid foaming masterbatch is prepared by extruding, pulling, and pelletizing.

[0052] S33 Put the polylactic acid foaming masterbatch into the autoclave, feed sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com