Heat-resisting ABS (Acrylonitrile-Butadiene-Styrene) resin applicable to electroplating and preparation method thereof

An ABS resin, heat-resistant technology, applied in the polymer field, can solve the problems of many volatile substances, weakening processing performance, increasing energy consumption and equipment loss, etc. The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

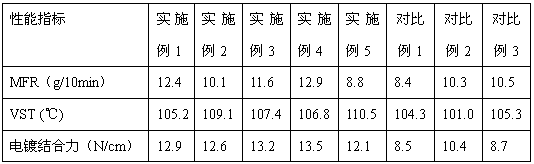

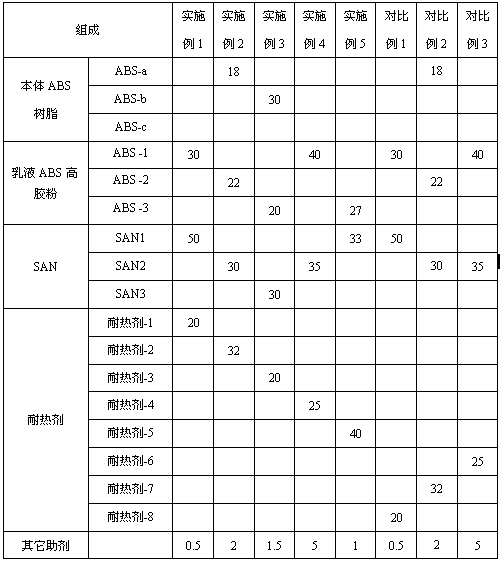

Examples

Embodiment 1

[0039] (1) Weigh each component according to the weight ratio in Table 1;

[0040](2) Pre-mix the bulk method ABS resin, emulsion method ABS rubber powder, heat-resistant agent and other additives in a high-speed mixer for 20 minutes;

[0041] (3) The above-mentioned mixed mixture is fed from the main feed of the twin-screw extruder, and the sample is obtained through melt extrusion, cooling, drying, and pelletizing. The screw diameter of the twin-screw extruder is 35 mm, and the aspect ratio is 44. The extruder has a total of 10 temperature control zones from the feed port to the die, of which the temperature control of the 1st to 3rd zones is 180-200 °C; the temperature control of the 4th to 7th zones is 230-250 °C; It is 220-240°C. The two vacuuming positions of the extruder are respectively set in the fourth and ninth zones, and the vacuum degree is 0.06-0.094MPa. The screw speed was set at 100-160 rpm.

Embodiment 2

[0043] The weight ratio of raw materials is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0045] The weight ratio of raw materials is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com