Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Ti-Cu alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Of the Ti–Cu alloys tested, the 5 and 10% Cu alloys had significantly higher strength than the rest. The 10% Cu alloy exhibited the lowest mean elongation. CP Ti and the 0.5 and 1% Cu alloys showed higher ductility. The bulk hardness of all the cast Ti–Cu alloys, except for the 10% Cu alloy, and CP Ti was approximately the same.

Nanoporous TiO2 film on Ti-Cu alloy surface and its preparation method

InactiveCN102522573AEvenly distributedAvoid destructionFinal product manufactureCollectors/separatorsTi-Cu alloyVoltage source

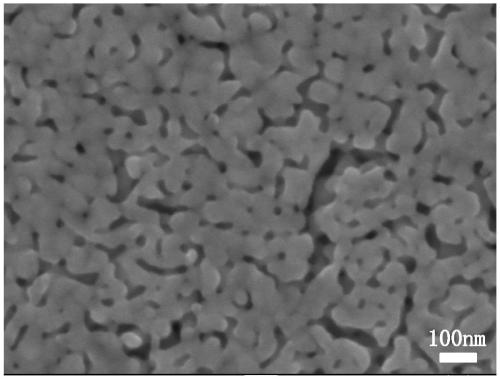

The invention discloses a nanoporous TiO2 film on a Ti-Cu alloy surface. With thickness of 5 micrometers, the film has a smooth surface which is not damaged, and the nanopores present an interconnected bicontinuous structure appearance. With an aperture of 50-100nm, the nanopores are in uniform distribution. The preparing method of the film consists of: preparing an amorphous Ti30Cu70 alloy strip; coating the two sides of the strip with silica gel; preparing a 30 mass percent nitric acid solution as an electrolyte solution, utilizing a voltage source meter or an electrochemical workstation to conduct a pulsed dealloying process, with the parameters set as the following: an initial voltage of 1V, a pulse amplitude of 300-400mV, a pulse voltage applying time of 0.5s, a stopped voltage applying time of 0.5-1.0s, a cycle period of 7022-10800 times, and an electrode area of 0.8cm<2>. The preparation method of the invention has the advantages of simple preparation process, low cost, no ''impurity'' introduced during preparation, and no danger, thus being suitable for large area production and application.

Owner:TIANJIN UNIV

Preparation method of anti-microbial type medical porous Ti-Cu alloy having bioactivity

A preparation method of an anti-microbial type medical porous Ti-Cu alloy having bioactivity comprises the steps of (1) preparing powder, wherein titanium powder, copper powder and magnesium powder are mixed according to a certain mass percentage ratio; (2) conducting ball milling, wherein the mixed powder is placed in a stainless steel ball mill tank for ball milling; (3) conducting blank pressing, wherein the ball milled powder material is mold-pressed into a pressed blank at the pressure of 500-1000 MPa; (4) conducting furnace charging, wherein the obtained pressed blank and a microwave-assisted heating material are placed in a polycrystal mullite fiber heat preservation barrel, and the polycrystal mullite fiber heat preservation barrel is placed in a microwave sintering furnace; (5) obtaining the ideal anti-microbial type medical porous Ti-Cu alloy having the bioactivity through microwave sintering. The preparation method of the anti-microbial type medical porous Ti-Cu alloy havingthe bioactivity has the technical effects that the preparation method is easy and convenient to perform, the sintering period is short, the energy consumption is small, the preparation method is suitable for industrial production, the sintered porous Ti-Cu alloy has excellent bioactivity and anti-microbial property and can be used as repair and substitute materials of bones, joints, artificial tooth roots and other hard tissue.

Owner:NANCHANG HANGKONG UNIVERSITY

Aging-reinforced titanium-copper alloy and preparation method thereof

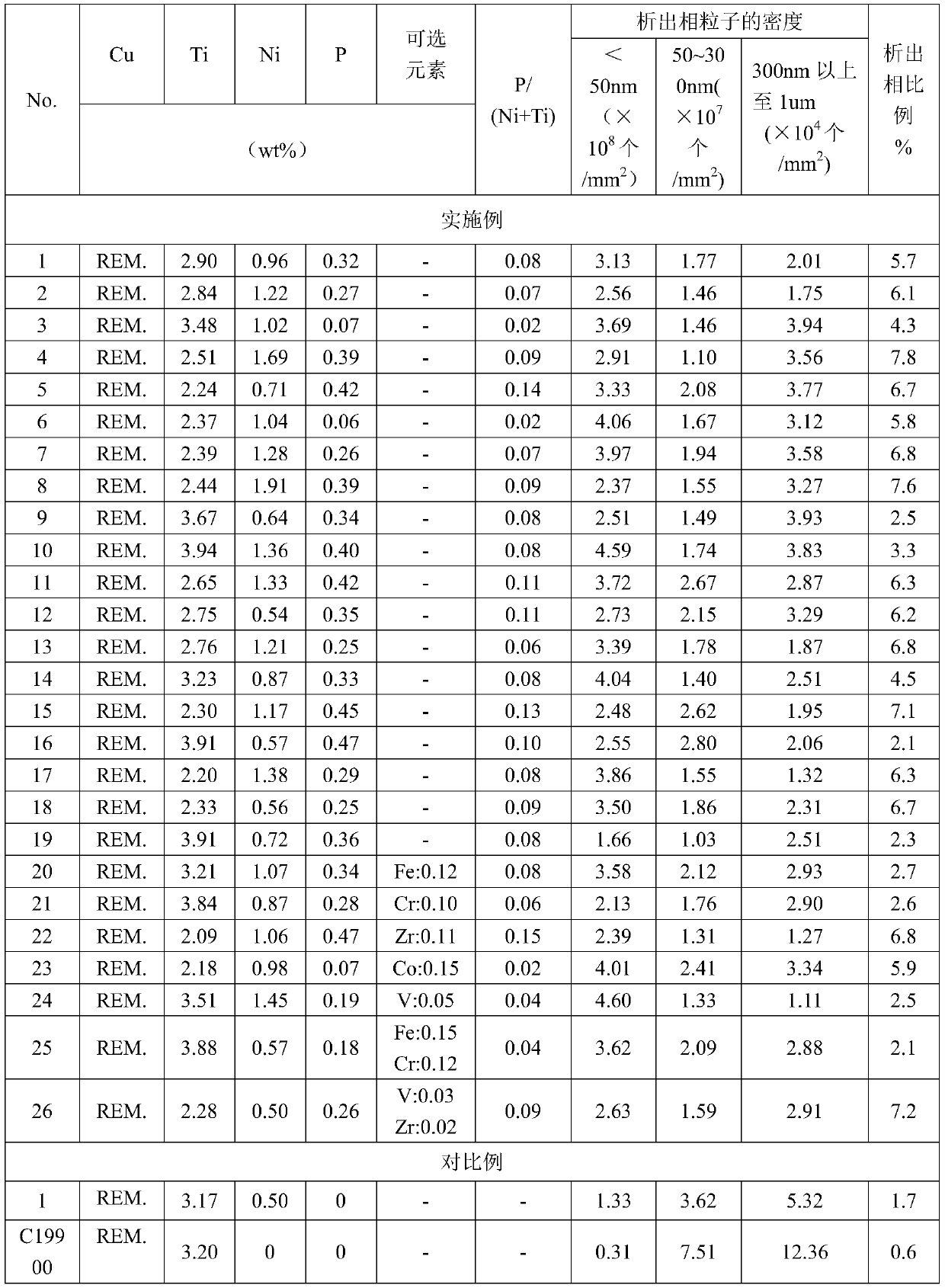

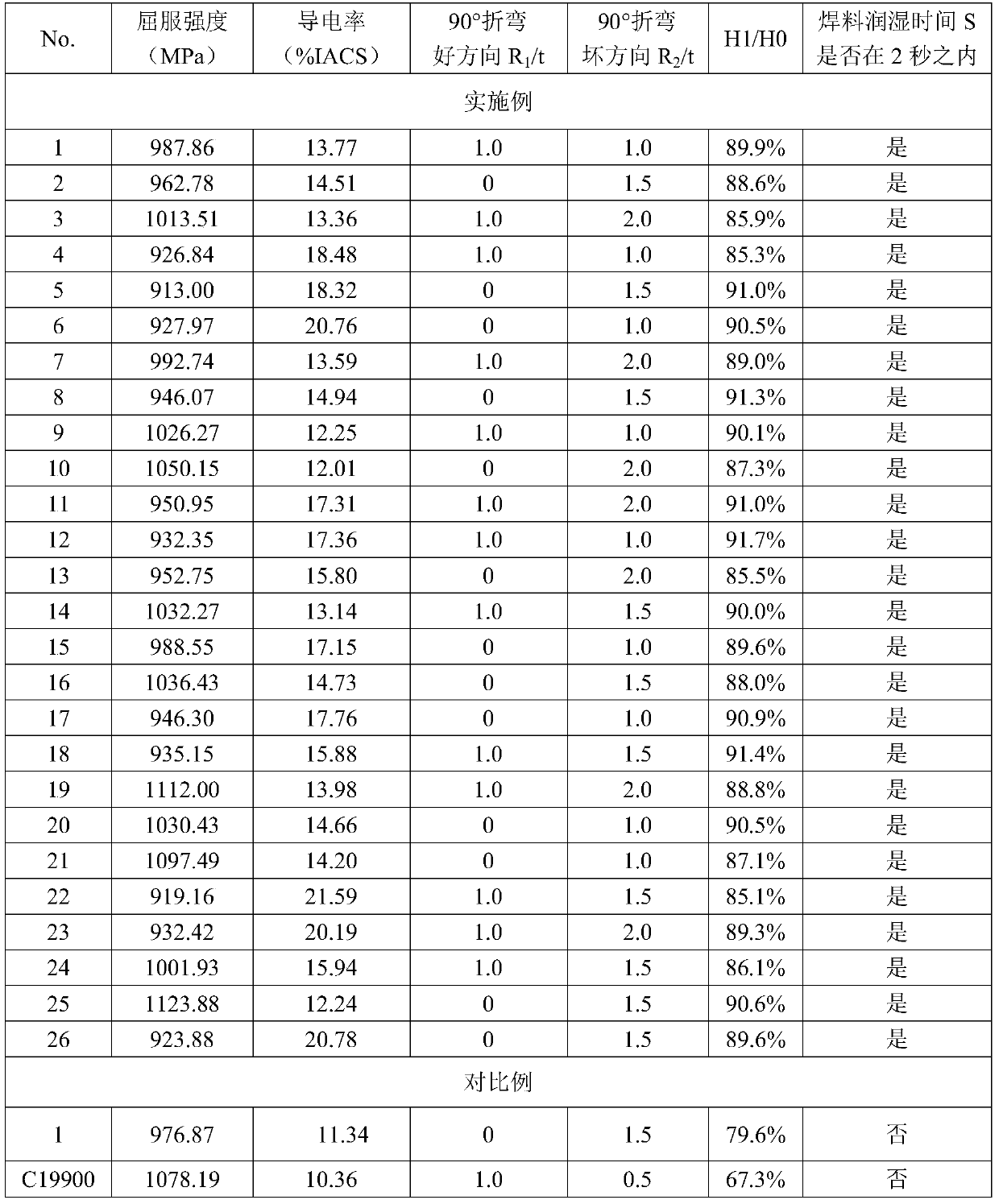

The invention relates to an aging-reinforced titanium-copper alloy. The aging-reinforced titanium-copper alloy is characterized by being prepared from the compositions in percentage, by weight, 2.0-4.0% of Ti, 0.5-2.0% of Ni, 0.05-0.5% of P and the balance copper and unavoidable impurities. By controlling the matching ratio of Ni to P to Ti, the yield strength of the aging-reinforced titanium-copper alloy is up to 900-1150 MPa, the conductivity is up to 12-22% IACS, and excellent bending machinability, high-temperature softening resistance and welding properties are obtained. The aging-reinforced titanium-copper alloy is especially applicable to the fields of connectors, terminals, relays and the like.

Owner:NINGBO POWERWAY ALLOY MATERIAL +1

Generator rotor slot wedge manufactured by beryllium-nickel-titanium-copper alloy

InactiveCN101078070ARaise room temperatureImprove mechanical propertiesManufacturing dynamo-electric machinesManganeseTi-Cu alloy

A kind of rotor slot wedge of dynamotor made of Be-Ni-Ti-Cu alloy, the character of it is: the weight percent of the main components are Be 0.10-0.30%, Ni 1.50-2.50%, Ti 0.40-0.60%, Cr 05-0.15%; the weight percent of impure elements: Mn<=0.04%, Pb<=0.01%, Zn<=0.50%, Fe<=0.20%, Sn<=0.20%, Al<=0.04%, Bi<=0.005%, Mg<=0.005%, the rotor slot wedge of dynamotor is made out by smelting, cast, hot forging, cold-forming, heat treatment, and machining technology. The advantage of this patent is that it owns great mechanical property both at normal temperature and high temperature, and great electric ability, the cost of it is low, and it is easy to confect, and the internal soundness is well, and the percent of pass at supersonic flaw detecting is high.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Heat interface material and its producing method

InactiveCN1684251AImprove thermal conductivityImprove thermal efficiencySide-by-side/stacked arrangementsSemiconductor/solid-state device detailsShape-memory alloyTi-Cu alloy

This invention provides a thermal interface material including a film and a heat conduction glue closely adhered to said film, among which, said film is composed of a shape memory alloy possibly containing the nm Ni Ti Cu alloy formed on the base surface by vacuum sputter deposition. In addition, this invention also relates to a manufacturing method for the material. Said material contains nm alloy films with a shape memory function, which can resume the original deposited shape under a heat source temperature to increase the contact area with the radiation device, so the material has fine heat conductivity and conduction efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Titanium dioxide nano thin film composite material and constant-current preparation method thereof

InactiveCN102534742AUniform distribution of poresLow implementation costElectrolysisPore distribution

The invention discloses a titanium dioxide nano thin film composite material and a constant-current preparation method of the composite material. The constant-current preparation method comprises the steps of: placing an amorphous Ti-Cu alloy in an electrolysis solution, and carrying out dealloying process by utilizing a three-electrode system and adopting a constant-current method, wherein a netted platinum electrode is used as a counter electrode, a saturated calomel electrode is used as a reference electrode, the amorphous alloy Ti-Cu is used as a working electrode, the current density is 0.8-2mA / cm<2>, the dealloying time is 3600-10800s, the electrolysis solution is 20-50wt% nitric acid aqueous solution, and the electrolysis solution temperature is 50-80 DEG C. According to the technical scheme disclosed by the invention, Ti-Cu amorphous alloy strips are placed in the electrolysis solution, and dealloying is carried out by three-electrode system reaction, thus a nano porous thin film structure with uniform pore distribution is prepared, the implementation cost is low, the operation is simple and convenient, the reaction temperature is low and the method is an efficient and economical synthesis method.

Owner:TIANJIN UNIV

Material of titanium copper alloy, and production method

This invention discloses a method for producing Ti-Cu alloy material. The Ti-Cu alloy material is produced from Ti 5.8-6.1% and Cu 93.9-94.2% by smelting, casting, and rolling. Besides, a third element (one of Al, Fe, Cr and Cd) 0.5-1% can also be added to form a ternary metal. The method comprises: smelting the above components, casting, homogenizing, hot-rolling, quenching, washing with acid, cold-rolling, and aging. The obtained Ti-Cu alloy material has such advantages as high strength, high elasticity, high wear resistance, high corrosion resistance, and high weldability.

Owner:赵景财 +1

Copper-titanium alloys excellent in strength, conductivity and bendability, and method for producing same

InactiveUS20060011275A1High strengthImprove conductivityTitaniumElectrical resistivity and conductivity

The present invention provides a titanium copper alloy excellent in strength, electrical conductivity and bendability, characterized in that it consists essentially of 1.5 to 2.3% by mass of Ti, balance Cu and inevitable impurities; said alloy having a 0.2% yield strength of 750 MPa or greater; an electrical conductivity of 17% IACS or greater; and a relationship represented by the formula:MBR / t≦0.04×YS−30,in which, YS is a 0.2% yield strength (MPa), and MBR / t is a ratio of a minimum bending radius (MBR; mm) for no cracking when said alloy is subjected to W bend test according to JIS H3130 standard along a transverse direction to a rolling direction, to a thickness (t; mm) of test piece.

Owner:JX NIPPON MINING & METALS CO LTD

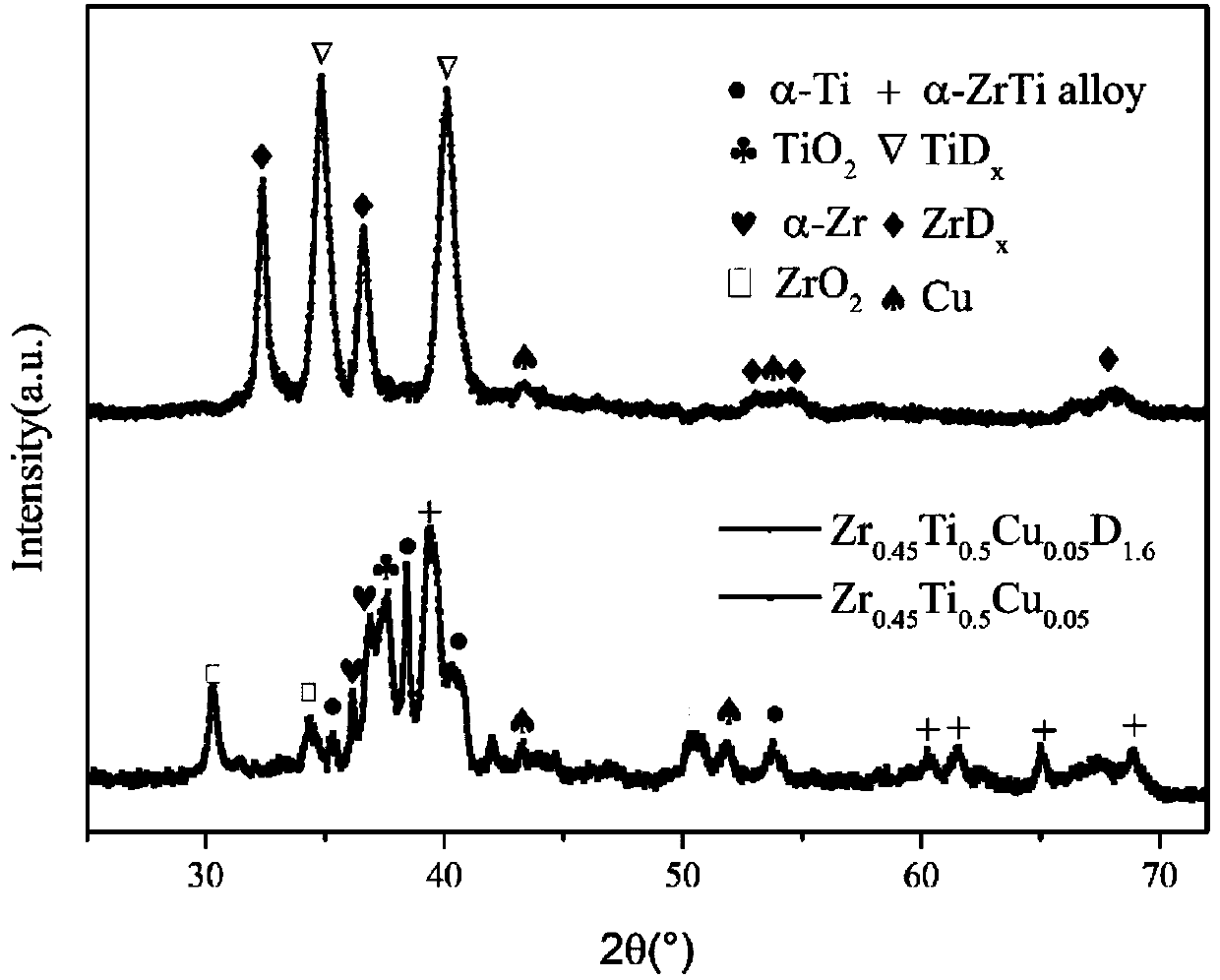

Nano-porous material prepared through selective corrosion of Zr-Ti-Cu alloy and preparation method thereof

The invention discloses a nano-porous material prepared through selective corrosion of a Zr-Ti-Cu alloy and a preparation method thereof. The material takes ZrxTiyCuz as a substrate, wherein x, y andz refer to atom percentage; x is more than 0 and less than 50; y is more than 0 and less than 50; z=50; and x+y=50. A nano-porous copper layer of the porous material is 1 to 3[mu]m in thickness, 20 to40nm in ligament width, and 11 to 30nm in aperture size. In the preparation method, a chemical dealloying method is adopted after smelting; Ti and Zr atoms are removed through selective corrosion with HF acid; and copper atoms are diffused, recombined and agglomerated to form a three-dimensional dual-continuous nano-porous material with a uniform netlike structure. Compared with the prior art, the preparation method only uses a HF solution without any other acid, so that the operation steps are simplified.

Owner:HEBEI UNIV OF TECH

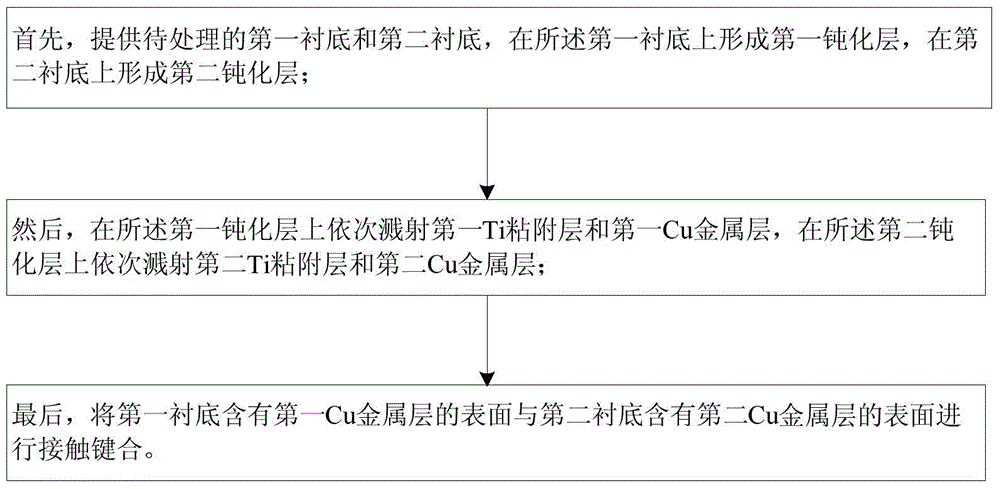

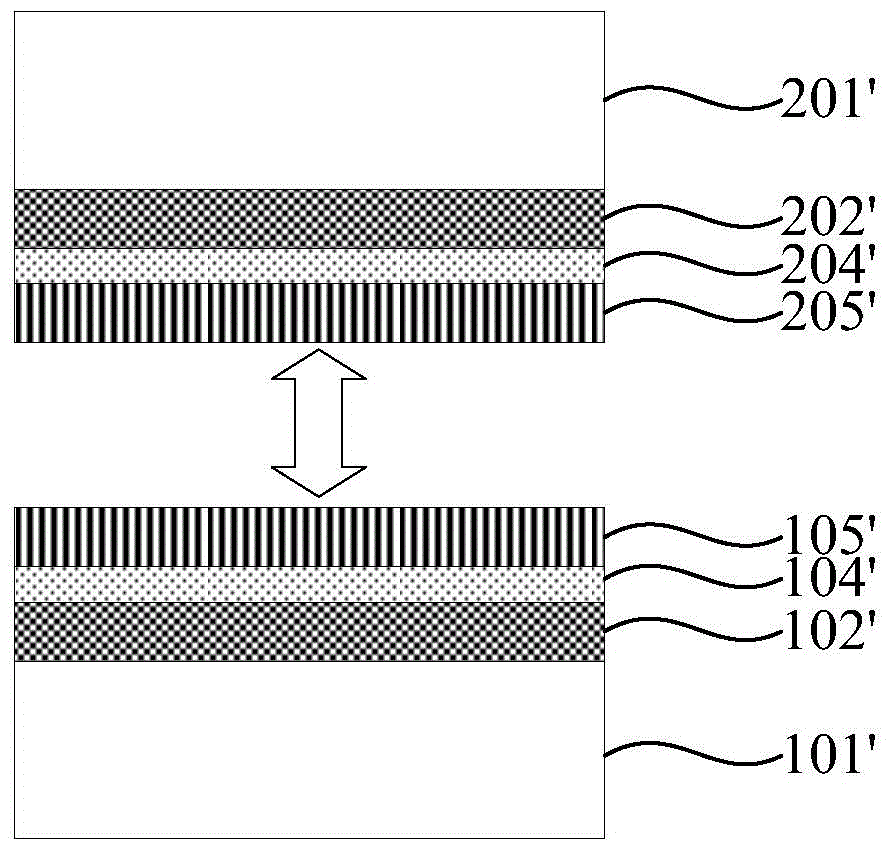

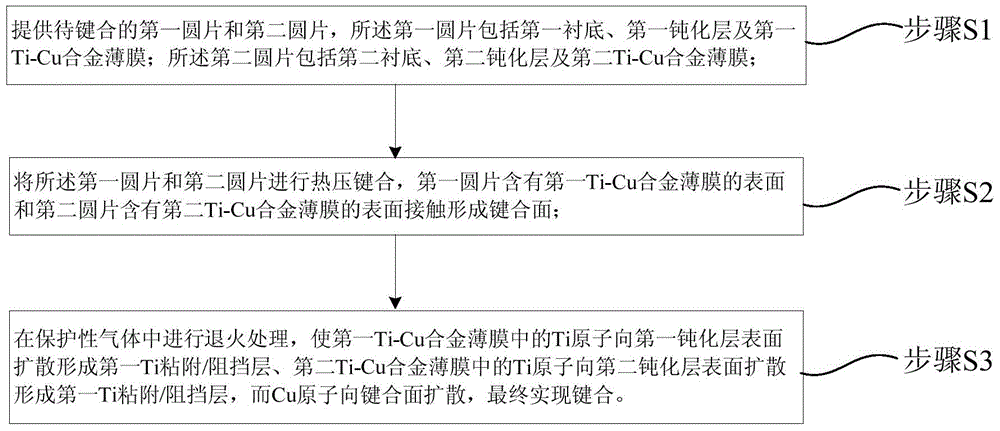

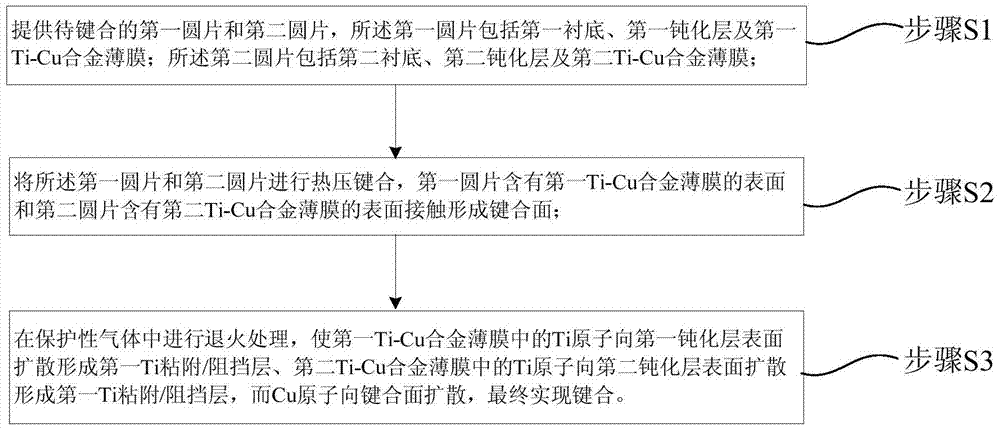

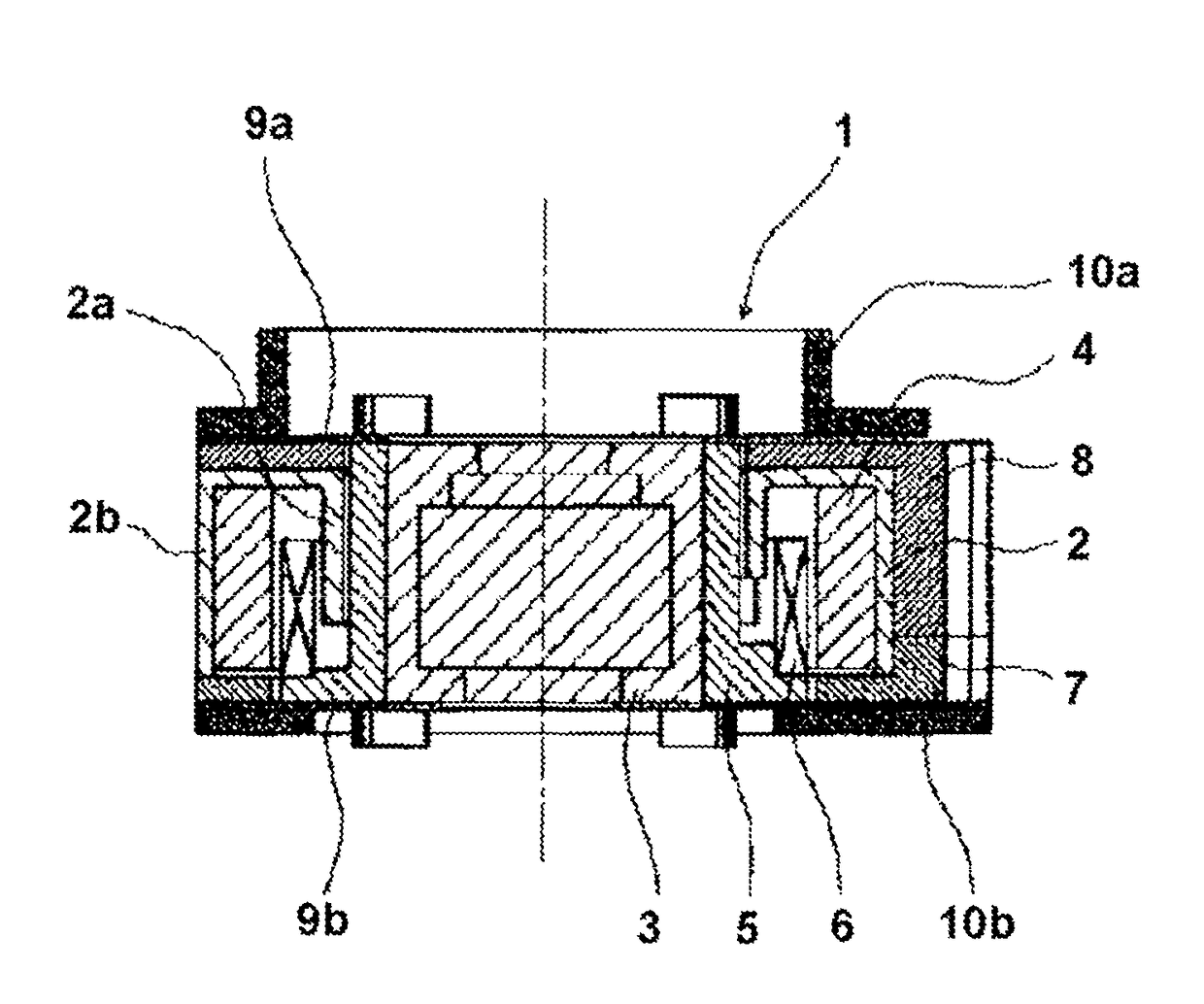

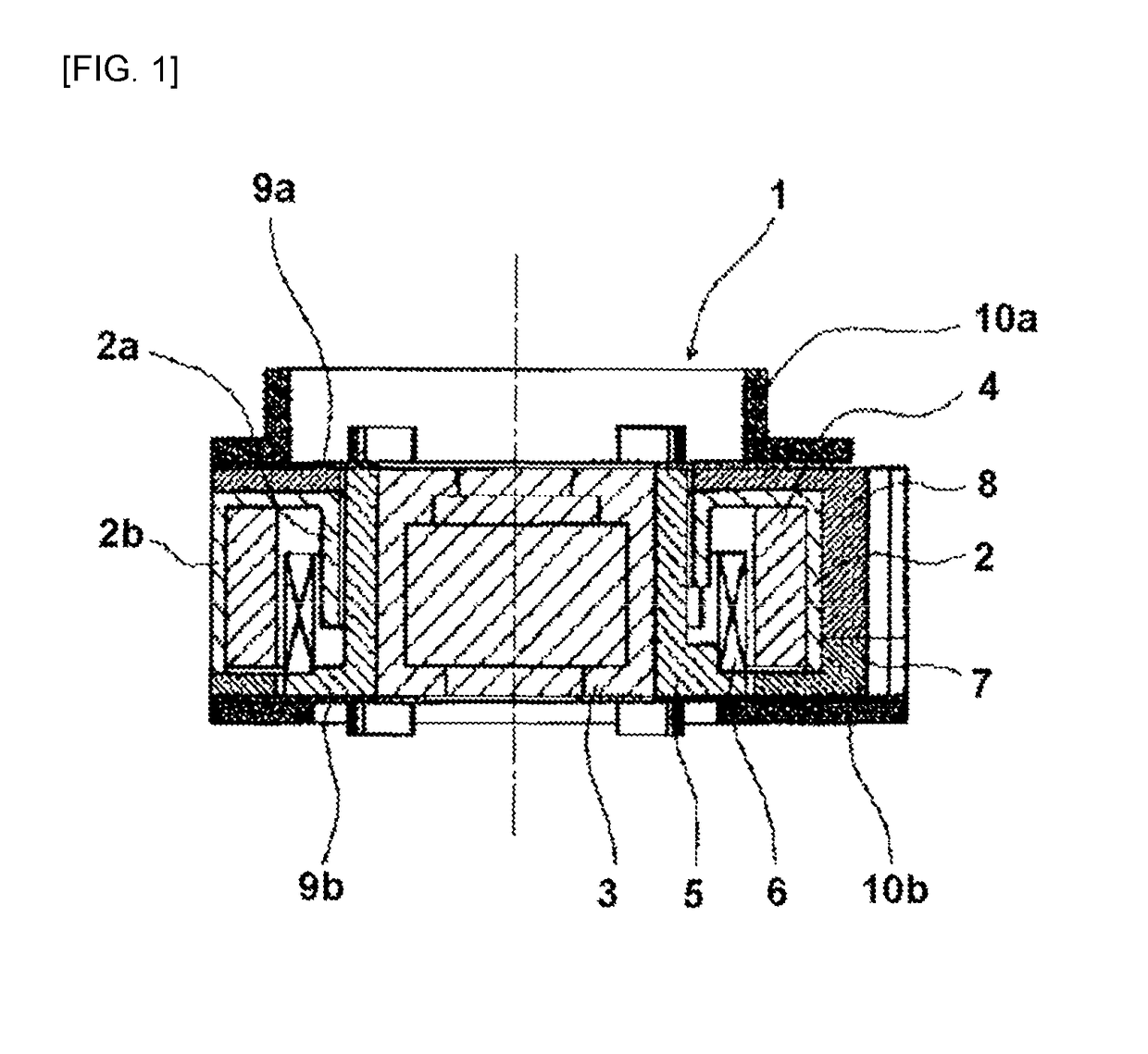

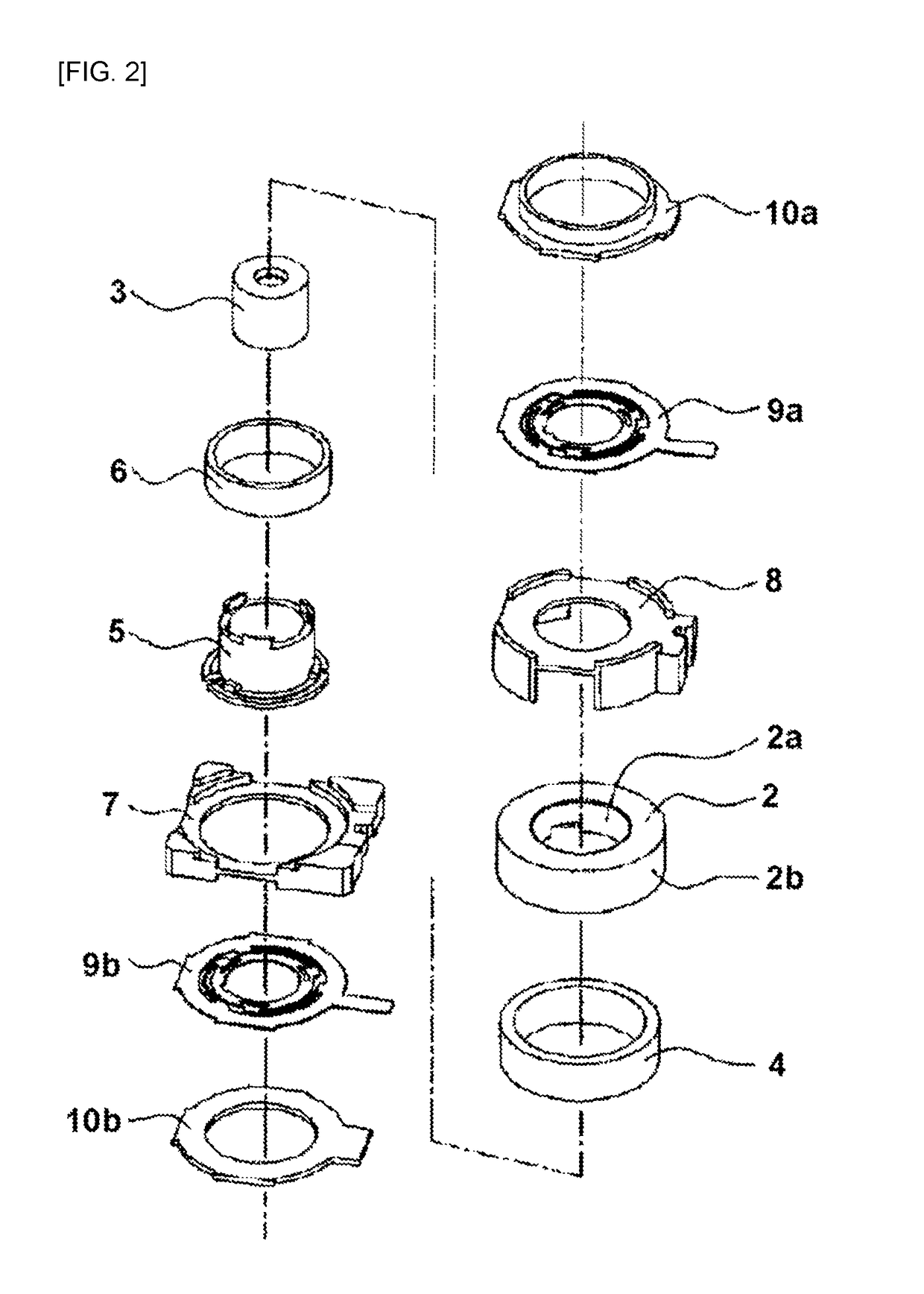

Copper-copper metal thermal pressing bonding method

InactiveCN104465428AGood bonding effectImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveTi-Cu alloy

The invention provides a copper-copper metal thermal pressing bonding method. The method at least comprises the following steps: first of all, providing a first wafer to be bonded and a second wafer to be bonded, wherein the first water comprises a first substrate, a first passivation layer and a first Ti-Cu alloy film, and the second wafer comprises a second substrate, a second passivation layer and a second Ti-Cu alloy film; then, performgin thermal pressing bonding on the surface of the first Ti-Cu alloy film of the first wafer and the surface of the second Ti-Cu alloy film of the second wafer; and finally, performing annealing processing in a protective gas to enable Ti atoms in the first Ti-Cu alloy film to diffuse towards the surface of the first passivation layer and Ti atoms in the second Ti-Cu alloy film to diffuse towards the surface of the second passivation layer so as to finally form Ti adhesive / barrier layers on the surfaces of the first passivation layer and the second passivation layer, and Cu atoms diffusing towards a bonding surface so as to realize bonding. According to the method provided by the invention, before the bonding, what is needed is only to respectively perform co-sputtering on the two substrates for once, such that the sputtering frequency is reduced by half, the process is relatively simple, the reliability is good, the technical cost is quite low, and finally, the Ti adhesive / barrier layer are formed through diffusion after the annealing processing, and the copper bonding effect is better.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

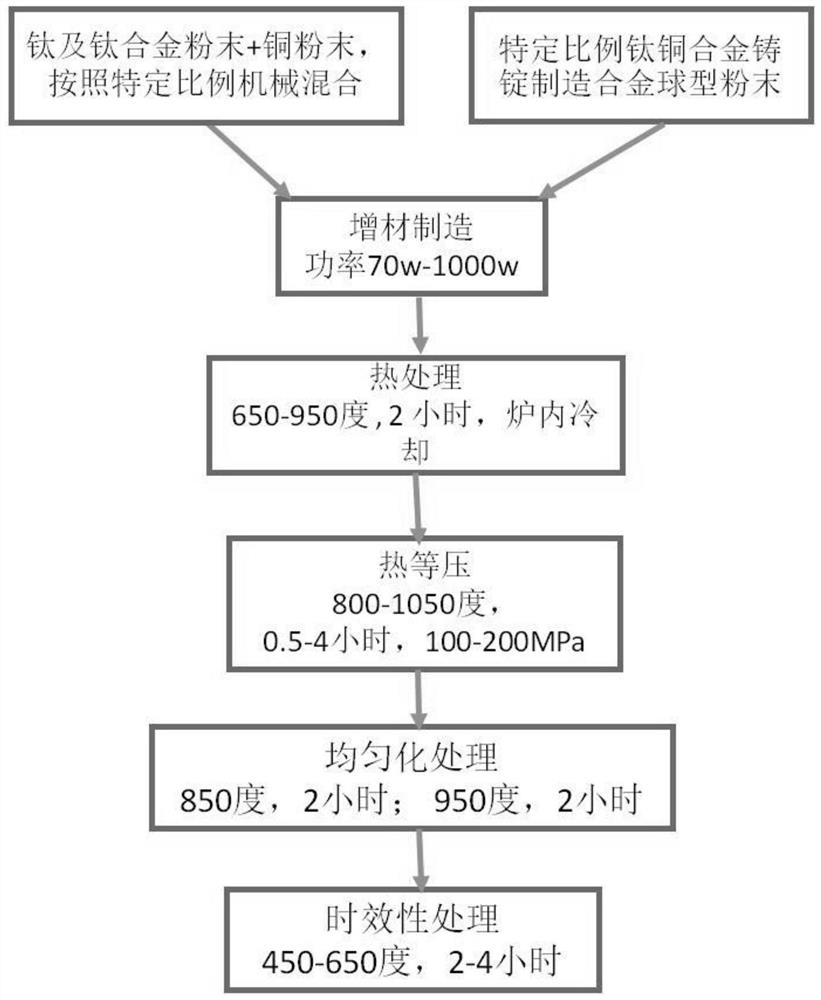

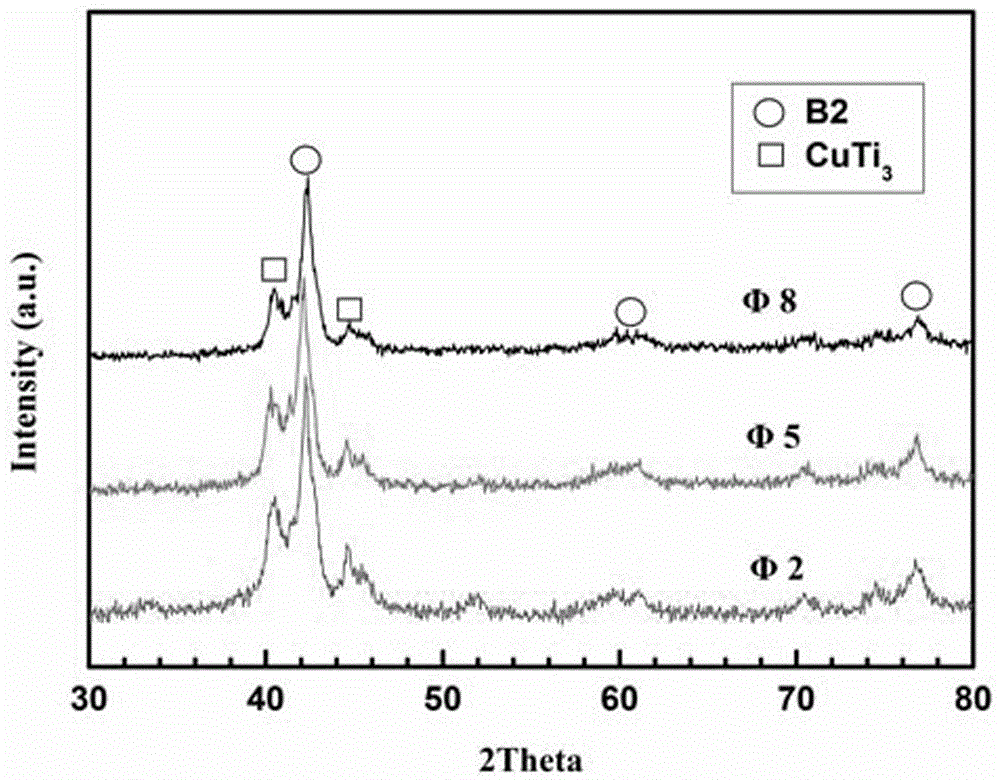

Antibacterial material additive material, preparation method and application

InactiveCN113172237ALong-acting antibacterialBalance of Mechanical PropertiesAdditive manufacturing apparatusTissue regenerationMetallic materialsTi-Cu alloy

The invention belongs to the technical field of metal materials, and discloses an antibacterial material additive material, a preparation method and application. Titanium or titanium alloy spherical powder and copper spherical powder are mixed according to a specific proportion, or a titanium-copper alloy ingot in a specific proportion is utilized, and spherical alloy powder is prepared through a plasma rotating electrode and a plasma atomization or gas atomization method; raw material powder is processed by using a laser melting or electron beam additive manufacturing technology; heat treatment is carried out on a processed product, the product is cooled in a furnace, and then hot isobaric treatment is carried out; homogenization treatment is carried out; and timeliness processing is carried out. According to the alloy additive manufacturing production method and a post-treatment process, compared with an antibacterial coating, common titanium and titanium alloy can have a long-acting antibacterial effect. A mixed material in a specific proportion can be processed by utilizing the advantages of additive manufacturing, a traditional titanium-based material is endowed with the antibacterial characteristic, and the mechanical property and the antibacterial effect of a part can be balanced through the post-treatment process.

Owner:广州柔岩科技有限公司

Preparation method of Ni-Ti-Cu alloy tooth arch wires

The invention discloses a preparation method of Ni-Ti-Cu alloy tooth arch wires. The material of the tooth arch wires is a Ni-Ti-Cu alloy and comprises, by weight, 50.14% of Ni, 43.54% of Ti and 6.26% of Cu. Ni-Ti-Cu cast ingots are prepared by adoption of vacuum self-consuming electric arc smelting, and then forging, rolling, wire drawing and sizing are conducted to prepare the Ni-Ti-Cu tooth arch wires. The method has the advantages that stress needed by martensite phase variant reorientation is low, thus martensite variant reorientation is easily conducted, and deformation stress or the yield strength under the martensite state is lowered; through adding of the Cu, the yield strength of a base phase B2 can be improved, so that the yield strength difference of the base phase and a martensite phase is increased, and phase change cyclic behavior of the base phase is reinforced; the Ni-Ti-Cu alloy is small in super-elasticity stress lagging and thus is a good super-elasticity material; and in Ni-Ti-Cu, the content of the Cu is, by atom percentage, 5-10% so as to replace Ni, and the raw material cost can further be greatly reduced.

Owner:广州市帕菲克义齿科技有限公司

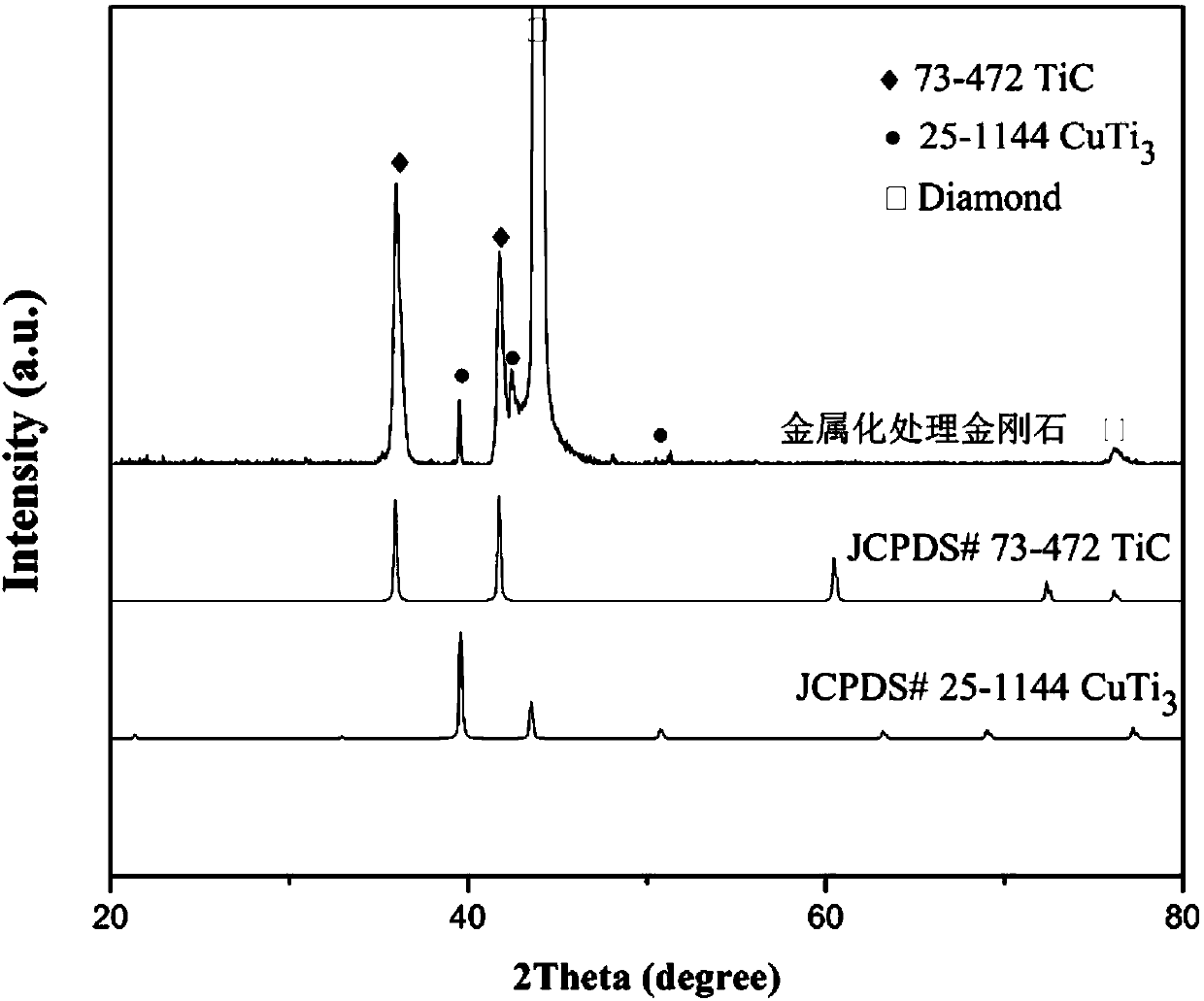

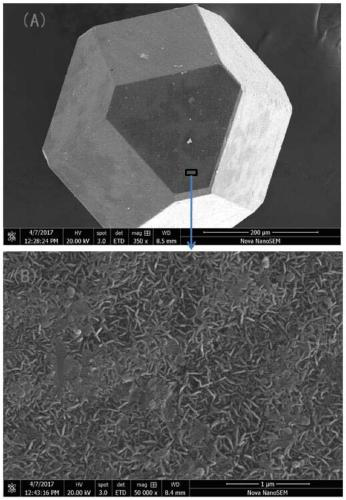

Diamond-magnesium composite heat-radiation material as well as preparation method and application thereof

The invention discloses a diamond-magnesium composite heat-radiation material as well as a preparation method and the application thereof. A gradient layer from titanium carbide to a titanium copper alloy is generated on the surface of a diamond to modify and improve interface combination of the diamond and a magnesium substrate, a light diamond-magnesium composite heat-radiation material with high heat conductivity is rapidly synthesized by using a discharge plasma sintering technique, so that the problem of heat radiation caused along with increase of sealing density, of a device of the electronic sealing field, is effectively solved.

Owner:HENAN HUANGHE WHIRLWIND CO LTD

A kind of diamond-magnesium composite heat dissipation material and its preparation method and application

The invention discloses a diamond-magnesium composite heat-radiation material as well as a preparation method and the application thereof. A gradient layer from titanium carbide to a titanium copper alloy is generated on the surface of a diamond to modify and improve interface combination of the diamond and a magnesium substrate, a light diamond-magnesium composite heat-radiation material with high heat conductivity is rapidly synthesized by using a discharge plasma sintering technique, so that the problem of heat radiation caused along with increase of sealing density, of a device of the electronic sealing field, is effectively solved.

Owner:HENAN HUANGHE WHIRLWIND CO LTD

Titanium-copper alloy having excellent conductivity and method of producing the same

The present invention provides a titanium-copper alloy having high strength and excellent conductivity as a copper alloy comprising: three to four percent by mass of Ti, residual Cu, and inevitable impurities, wherein the area percentage (S(%)) of a Cu—Ti intermetallic compound phase observed in a section perpendicular to the rolling direction is represented by the following formula: S(%)≧8.1×[Ti]−17.7 where [Ti] represents the Ti content in percent by mass. A method for producing the same is also provided.

Owner:JX NIPPON MINING & METALS CO LTD

Titanium-copper alloy explosion-proof material and preparation method thereof

The invention discloses a titanium-copper alloy explosion-proof material and a preparation method thereof. The material comprises the following components of, in percentage by weight, 30%-40% of titanium-copper alloy, and 60%-70% of graphene; and the titanium-copper alloy comprises the following components of, in percentage by atomic weight, 60%-65% of titanium, 30% of copper, and 5%-10% of nickel. The preparation method comprises the following steps of 1) taking high-purity titanium, copper and nickel as raw material, carrying out high-temperature smelting in an argon atmosphere, grinding toremove oxide skin, and grinding into powder to obtain alloy powder; 2) preparing natural graphite or artificial graphite into powdery graphene; and 3) mixing part of the alloy powder with powdery graphene, loading the mixture into a mold, and sintering to obtain a preform; and placing the preform into a crucible, vacuumizing, heating the remaining alloy powder to be molten, introducing the alloy melt to permeate the preform, and cooling to room temperature. The titanium-copper alloy and the graphene are prepared into the explosion-proof material in the modes of combined mixed sintering, alloymelt infiltration and the like, the overall strength of the material can be improved, and the explosion-proof material has excellent explosion-proof performance.

Owner:CANGZHOU BOHAI SAFETY & SPECIAL TOOLS GRP

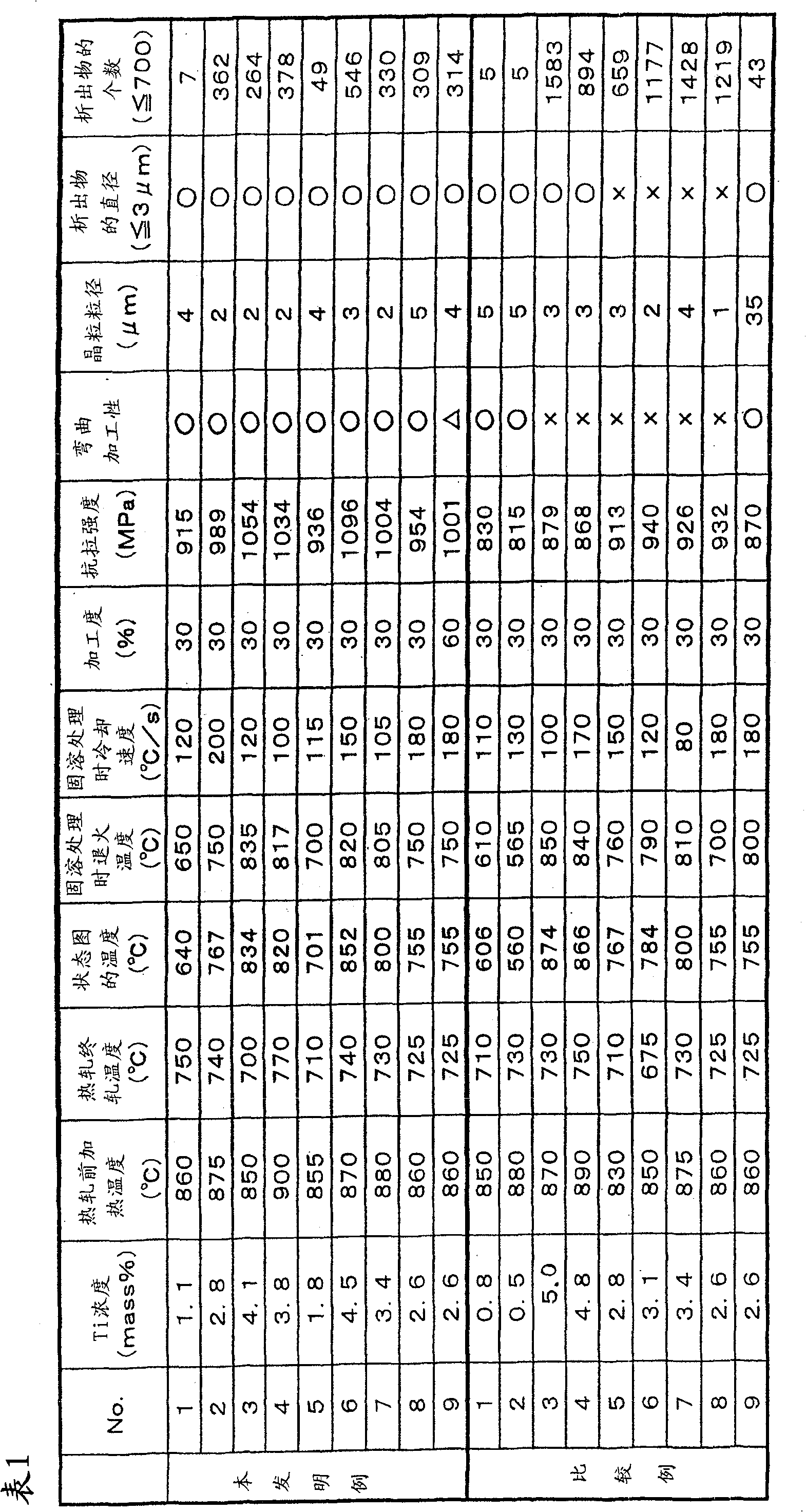

Copper alloy with excellent flexibility and its production method

An object of the present invention is to provide a titanium-copper alloy having excellent strength and good bendability. The titanium-copper alloy is characterized in that it contains 1.0 to 4.5% by mass of Ti, the rest is composed of Cu and unavoidable impurities, and the diameter of the intermetallic compound of Cu and Ti precipitated in the alloy is 3 μm or less, and in the vertical The average number of intermetallic compounds of Cu and Ti with a size of 0.2 to 3 μm precipitated in the alloy in the cross section of the rolling direction is 700 or less per 1000 μm 2 , and the grain size is 10 μm or less.

Owner:JX NIPPON MINING & METALS CORP

A kind of preparation method of titanium-copper alloy material

Owner:CHANGCHUN AERMASI SCI & TECH

A copper-copper metal thermocompression bonding method

InactiveCN104465428BImprove bonding effectImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingSputteringTi-Cu alloy

The present invention provides a copper-copper metal thermocompression bonding method, the method at least includes the steps of: first providing a first wafer to be bonded and a second wafer, the first wafer includes a first substrate , the first passivation layer and the first Ti-Cu alloy thin film, the second wafer includes a second substrate, the second passivation layer and the second Ti-Cu alloy thin film; The surface of the first Ti-Cu alloy film and the surface of the second Ti-Cu alloy film of the second disc are bonded by thermocompression; finally annealing is carried out in a protective gas to make the Ti atoms in the first Ti-Cu alloy film Diffusion to the surface of the first passivation layer, the Ti atoms in the second Ti-Cu alloy film diffuse to the surface of the second passivation layer, and finally form a Ti adhesion / barrier layer on the surface of the first and second passivation layer, and Cu atoms diffuse to the bonding surface to realize bonding. The method of the present invention only needs to co-sputter the two substrates once before bonding, the number of sputtering is reduced by half, the process is relatively simple, the reliability is good, and the process cost is low. Finally, the annealing treatment is diffused to form Ti Adhesion / barrier layer and enables better copper bonding.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

High-strength titanium-copper alloy rod suitable for conductive elastic components and preparation method

ActiveCN109338149BImproved hot and cold processing performanceImprove mechanical propertiesConductive materialMetal/alloy conductorsTi-Cu alloyElectro conductivity

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

A kind of aging strengthened titanium-copper alloy and preparation method thereof

The invention relates to an aging-reinforced titanium-copper alloy. The aging-reinforced titanium-copper alloy is characterized by being prepared from the compositions in percentage, by weight, 2.0-4.0% of Ti, 0.5-2.0% of Ni, 0.05-0.5% of P and the balance copper and unavoidable impurities. By controlling the matching ratio of Ni to P to Ti, the yield strength of the aging-reinforced titanium-copper alloy is up to 900-1150 MPa, the conductivity is up to 12-22% IACS, and excellent bending machinability, high-temperature softening resistance and welding properties are obtained. The aging-reinforced titanium-copper alloy is especially applicable to the fields of connectors, terminals, relays and the like.

Owner:NINGBO POWERWAY ALLOY MATERIAL +1

A kind of low modulus, high anti-corrosion ternary ni-ti-cu alloy and preparation method thereof

The invention discloses a low-modulus, high-corrosion-resistant ternary Ni-Ti-Cu alloy and a preparation method thereof. Its main technical scheme is: Ni-Ti-Cu alloy prepared under the conditions of adding Cu element and rapid solidification 26 Ti 49 Cu 25 The elastic modulus of the alloy is around 60 GPa. The present invention has the following beneficial effects: the cooling rate of the present invention using the water-cooled copper crucible method is much lower than other rapid cooling conditions (strip technology), and it is easier to realize in actual industrial production; Cu can play a passivation role on the alloy surface , thereby improving the corrosion resistance of the alloy. In addition, the Cu of the ternary Ni‑Ti‑Cu alloy can be slowly released from the vascular stent, which can play a good role in reducing restenosis symptoms after heart valve surgery.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

High-flexibility copper rod and preparation method thereof

InactiveCN113088754AEliminate hot brittlenessGood flexibilityMetallic material coating processesHeat resistanceTi-Cu alloy

The invention discloses a high-flexibility copper rod and a preparation method thereof. Copper and titanium are compounded to prepare a copper-based alloy, the flexibility and strength of the material are improved, zirconium is added in the compounding process, titanium is dissolved in the copper in a solid mode, meanwhile, diffusion of the titanium element on a grain boundary can be hindered through addition of zirconium, and thus the heat resistance of the titanium-copper alloy is remarkably improved; the titanium-copper alloy and boron are crushed and then sintered under high pressure, so that secondary recombination of the grain boundary is performed, the boron located at the grain boundary inhibits continuous precipitation of beta-Cu4Ti at the grain boundary during sintering, intergranular fracture is reduced, and the flexibility is improved; the addition of the Mg-Zn-Al alloy inhibits non-uniform nucleation of an equilibrium phase of the titanium-copper alloy at the grain boundary, twin boundary, dislocation and other defects, so that grains are more regular, meanwhile, distribution of a second phase is improved, the hot brittleness of the alloy is eliminated, the metal strength is improved, and the mechanical property of the alloy is improved.

Owner:JIANGXI ZHONGSHENG METAL

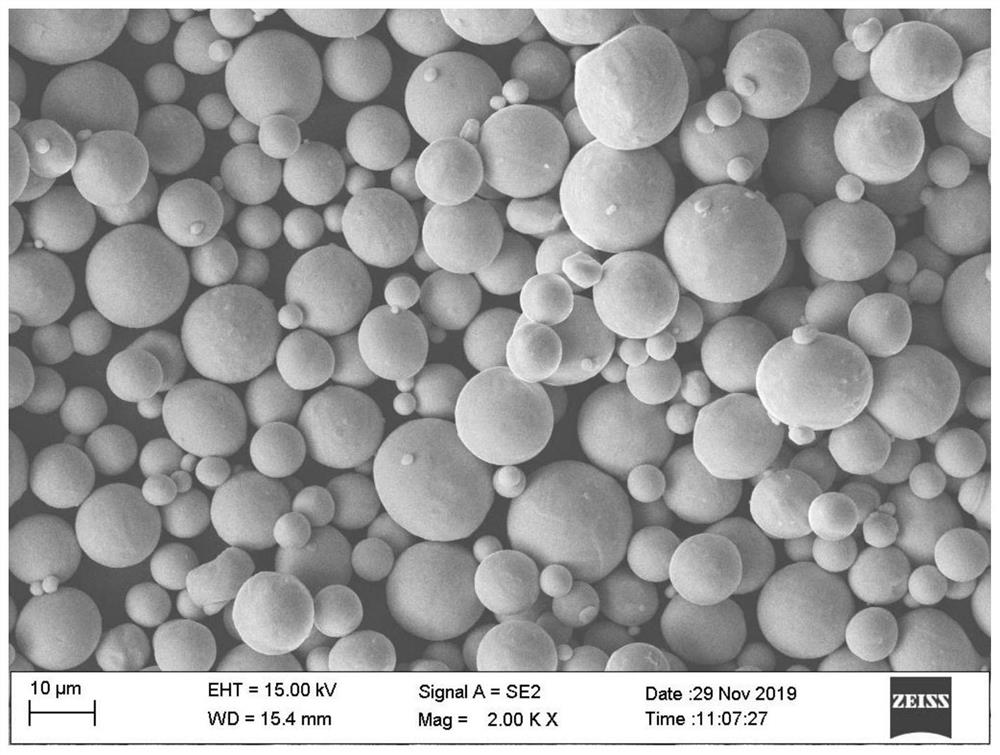

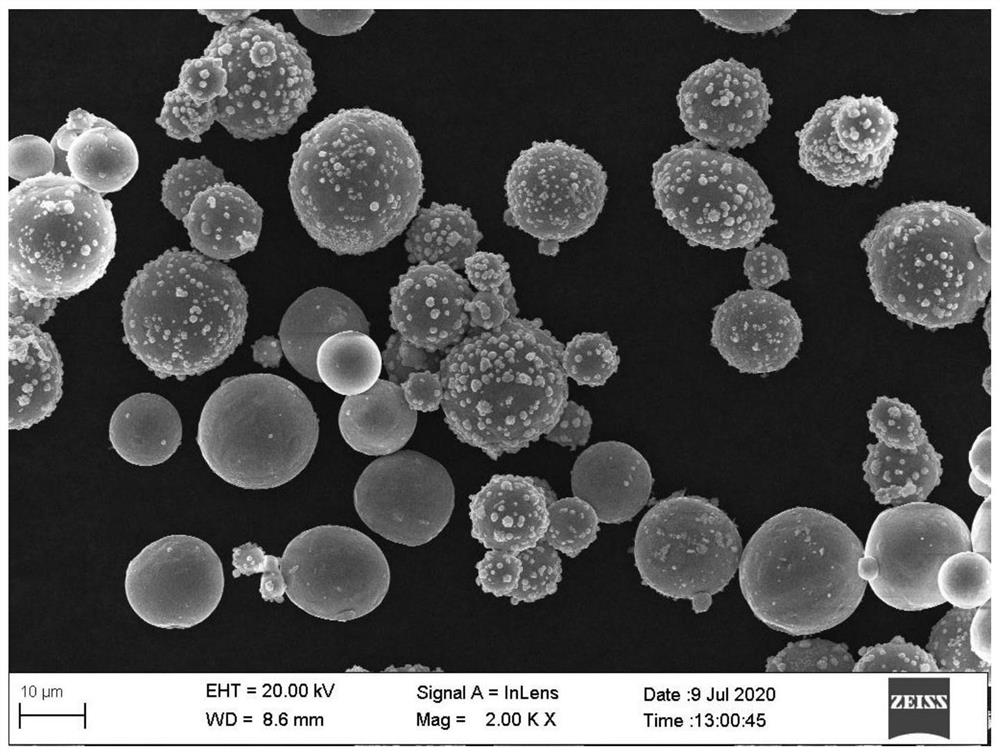

Biomedical titanium-copper microsphere assembly type microsphere powder, biomedical titanium-copper alloy and preparation process

ActiveCN112846172AUniform tissueHigh strengthTransportation and packagingMetal-working apparatusMicrosphereTi-Cu alloy

The invention relates to biomedical titanium-copper microsphere assembly type microsphere powder, biomedical titanium-copper alloy and a preparation process. According to the biomedical titanium-copper microsphere assembly type microsphere powder provided by the invention, a body is spherical titanium powder particles, a plurality of cellular copper particles uniformly coat the spherical surface of the body to form a microsphere collection, wherein the particle size of the spherical titanium powder particles is less than 35 microns, and the particle size of the copper particles is less than 3 microns. The titanium-copper alloy prepared from the microsphere powder is composed of an alpha-Ti matrix phase and a Ti2Cu phase, the Ti2Cu phase is finely dispersed and uniformly distributed in the alpha-Ti matrix phase, then the antibacterial property of the material can be improved, the density of the titanium-copper alloy reaches 98% or above, and the compressive yield strength reaches 860 MPa. The preparation process provided by the invention is simple, the production efficiency is high, the alloy cost is relatively low, meanwhile, the nonuniformity of components of the titanium-copper alloy in the traditional preparation method can be obviously improved, and then the mechanical property and the antibacterial property are improved.

Owner:JIANGXI UNIV OF SCI & TECH

Rare earth nitride dispersion strengthened titanium-doped copper alloy and preparation method thereof

The invention discloses a rare earth nitride dispersion strengthening titanium-doped copper alloy and a preparation method thereof. The copper alloy is composed of copper, rare earth nitride and titanium. The copper alloy comprises, by mass, 70%-80% of copper, 0.1%-8% of rare earth nitride and the balance titanium. The method comprises the following steps: blowing rare earth nitride particles into a copper melt, stirring until the rare earth nitride particles are uniformly mixed, spraying titanium powder into a copper alloy melt, cooling the copper alloy melt, carrying out pressure casting to obtain a green body sample, and carrying out degassing and thermal aging treatment on the green body. The copper alloy prepared by the invention has the characteristics of high hardness, high wear resistance and high electric conductivity and heat conductivity.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

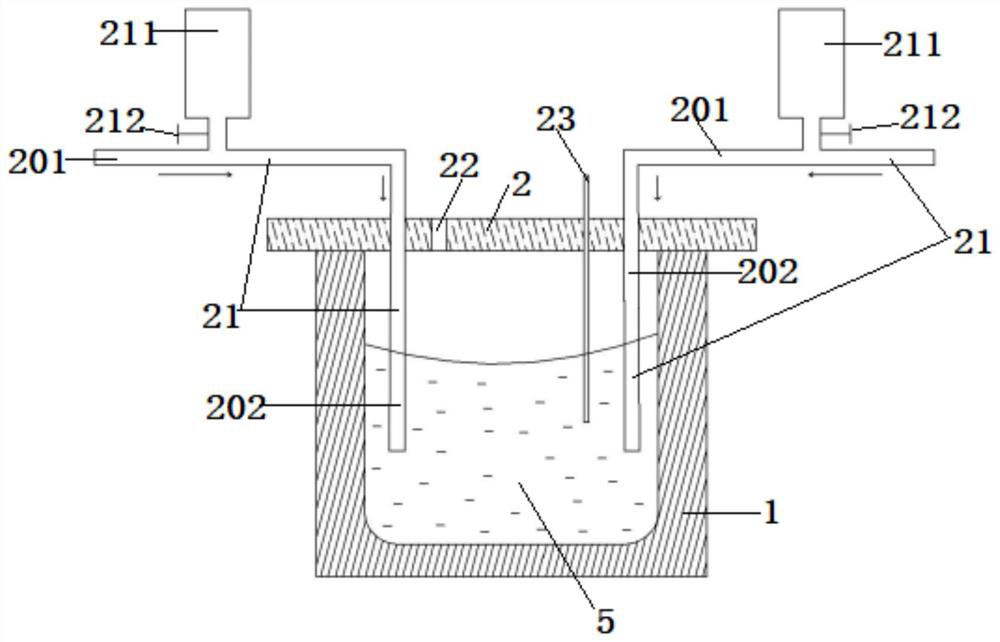

Preparation process of hydrogen-storage crack-free zirconium-titanium-copper alloy electrode wafer

ActiveCN107739859AReduce body gainReduce hydrogen embrittlementSolid state diffusion coatingElectromagnetic inductionMetal

The invention discloses a preparation process of a hydrogen-storage crack-free zirconium-titanium-copper alloy electrode wafer. The preparation process comprises the steps of 1, adopting metallic titanium, metallic zirconium and metallic copper as raw materials, and preparing a zirconium-titanium-copper alloy through a water-cooling copper crucible electromagnetic induction vacuum suspension smelting method according to the mixing ratio of the raw materials; 2, machining a zirconium-titanium-copper alloy ingot obtained in step 1 into a sample in a certain shape and of a certain size, and conducting a series of treatment on the surface of the zirconium-titanium-copper alloy ingot; and 3, conducting a hydrogen absorption reaction on the zirconium-titanium-copper alloy sample obtained in step2, so that a finished product is obtained. The preparation process starts with the more essential materials and focuses on developing an alloy material excellent in performance; and the alloy material can reduce the bulking and hydrogen embrittlement effects generated due to hydrogenation in the hydrogen absorption process through the pinning effect of certain microelements.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Preparation method of crack-free nickel-titanium-copper alloy for additive manufacturing

ActiveCN114669751AHigh densityGood formabilityAdditive manufacturing apparatusIncreasing energy efficiencyCrack freeLap joint

A preparation method of a crack-free nickel-titanium-copper alloy for additive manufacturing comprises the steps that firstly, the hot crack trend in a target alloy component range is calculated, the alloy component with the lowest hot crack trend is selected for burdening and smelting, and nickel-titanium-copper alloy powder is prepared through a gas atomization method; designing a'grid lap joint 'parameter optimization structure, modeling the'grid lap joint' parameter optimization structure and a part structure, designing a position and a support, and slicing; keeping the original coordinates of the model unchanged, setting a printing path and a scanning strategy, inputting process parameters, and copying a set project file into SLM equipment; debugging equipment, firstly printing a sheet layer to form a new substrate, and then printing a part; when the temperature of the substrate is reduced to 70 DEG C or below, the substrate with the printing piece is taken down and placed in a furnace for heat preservation; and finally, the printed piece is cut off from the base plate and ground, and the nickel-titanium-copper alloy is obtained. According to the nickel-titanium-copper alloy and the preparation method thereof, printing cracks are eliminated through component design, process parameter optimization and structural design, and the nickel-titanium-copper alloy high in density, good in formability and excellent in comprehensive performance is prepared.

Owner:CENT SOUTH UNIV

Titanium-copper alloy having plating layer

ActiveUS10092970B2Improve adhesionHigh bonding strengthProjector focusing arrangementSoldering apparatusTi-Cu alloyUltimate tensile strength

There is provided a titanium-copper alloy in which the adhesion strength with solder can be increased. The titanium-copper alloy comprises a base material and a plating layer provided on a surface of the base material, wherein the base material contains 1.5 to 5.0% by mass of Ti with a balance consisting of copper and unavoidable impurities, and the plating layer is selected from the group consisting of a Ni plating layer, a Co plating layer, and a Co—Ni alloy plating layer.

Owner:JX NIPPON MINING & METALS CORP

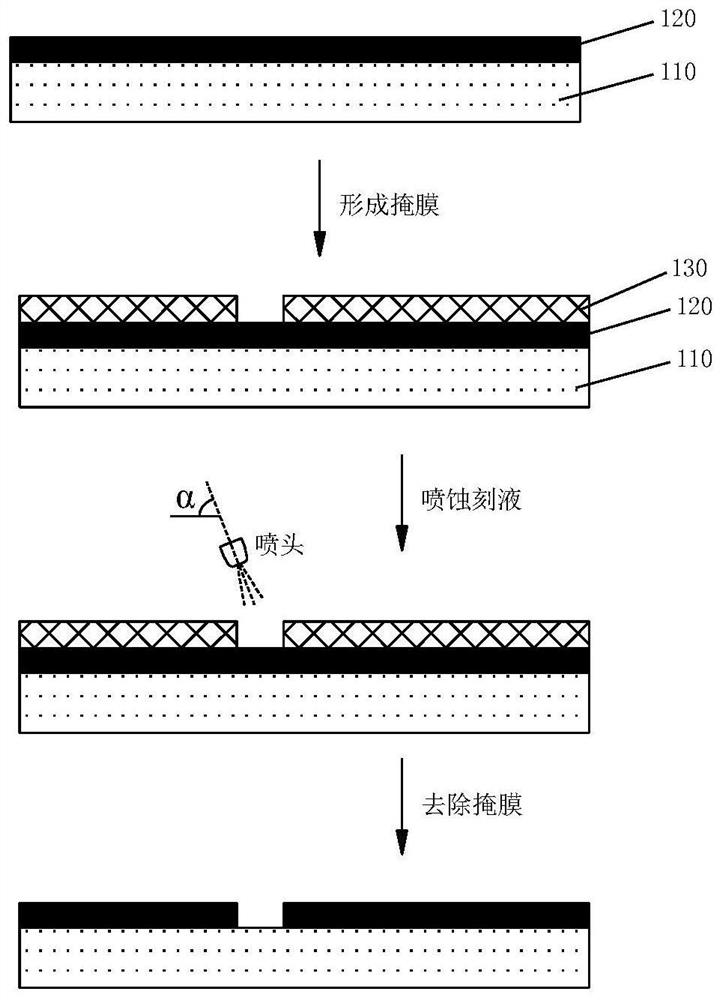

Titanium-copper alloy etching solution and etching method

The invention discloses a titanium-copper alloy etching solution and an etching method. The etching solution comprises inorganic acid, copper salt and a corrosion inhibitor. The inorganic acid is used for providing hydrogen ions in an acidic environment, and the acidic environment is beneficial to excitation of oxidability of copper ions in the copper salt, so that the copper ions react with the titanium-copper alloy, and etching of the titanium-copper alloy is achieved. After the copper salt is dissolved, copper ions have strong oxidizing property in an acid environment and can react with the titanium-copper alloy, so that etching of the titanium-copper alloy is realized. The corrosion inhibitor is added into the etching solution, the corrosion inhibitor can be dissolved in the etching solution and has good affinity with the titanium-copper alloy, the corrosion inhibitor can be attached to the side wall of the titanium-copper alloy in the etching process, contact between the side wall and the etching solution is reduced, then lateral erosion is reduced, and the etching precision is improved.

Owner:AKM ELECTRONICS INDAL PANYU

High-strength titanium-copper alloy strip suitable for conductive elastic components and preparation method thereof

The invention discloses a high-strength titanium-copper alloy strip applicable to a conducting elastic element and a preparation method and belongs to the technical field of titanium-copper alloy strips. The high-strength titanium-copper alloy strip comprises the chemical components including, by weight, 0-0.01% of C, 2.6-3.4% of Ti, 0.001-0.2% of Ce, not greater than 0.3% of the sum of W, Ta, Hfand Fe, and the balance Cu and inevitable impurities. According to the end product performance, the tensile strength is 1149-1230 MPa, the yield strength is 1028-1100 MPa, the heat conductivity coefficient is 92-125 W / (m*DEG C), the specific conductance is 19-27 % IACS, the grain size is 2-15 mum, and the hardness is 320-370 HV. The alloy production process comprises the steps including vacuum smelting, forging, hot rolling, cold rolling, annealing, finished product rolling, ageing, stress relieving annealing and the like. The high-strength titanium-copper alloy strip applicable to the conducting elastic element and the preparation method have the advantages that matching of the high strength, high heat conductivity and high specific conductance of the alloy stirp meets the requirements for strength and heat dissipating performance of the conducting elastic element.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com