Biomedical titanium-copper microsphere assembly type microsphere powder, biomedical titanium-copper alloy and preparation process

A biomedical and preparation technology, applied in the biomedical field, can solve the problems of titanium-copper alloys that are difficult to achieve alloy homogenization, biomaterials are not sintered densely, and alloy distribution is uneven, and achieve excellent biocompatibility and antibacterial properties , short preparation time and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

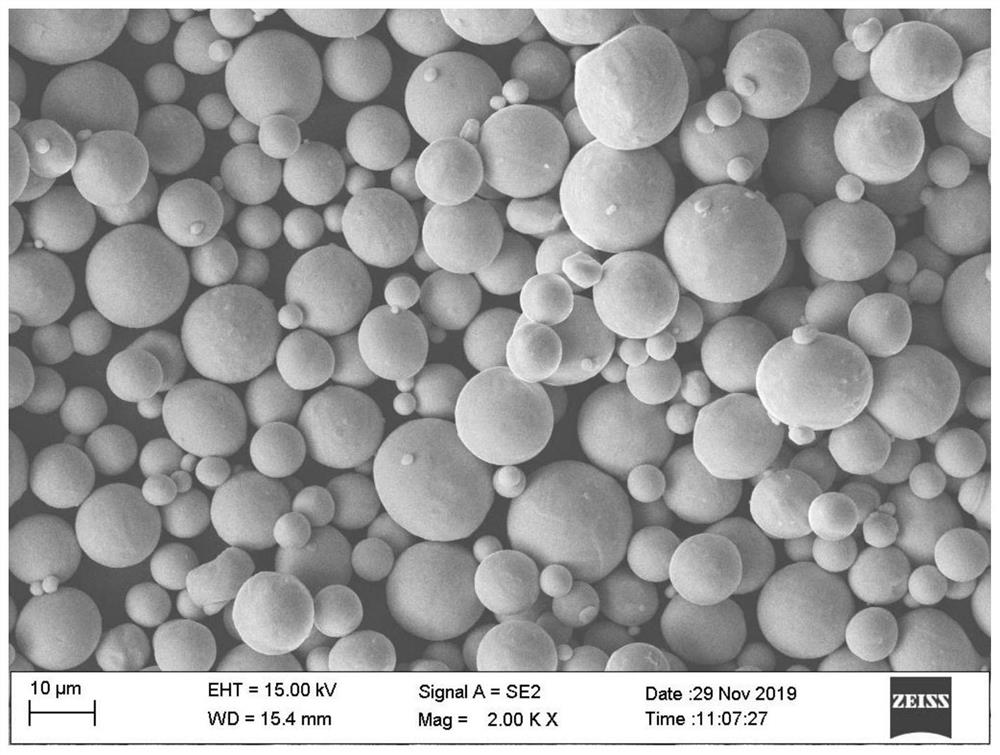

[0047] Add 8g of spherical titanium powder (purity 99%) with a particle size of less than 35 microns to 1mol / L sodium hydroxide solution, put it into a constant temperature water bath and heat it to 40°C, and use magnetic stirring to continuously carry out gentle stirring. degreasing and deoxidizing film at 30 rpm for 20 min; filter the powder with a centrifuge, wash with deionized water for 3 times, wash with ethanol for 2 times, and then put it in a vacuum oven at 100°C for drying with a vacuum degree of 1Pa, the time is 10min;

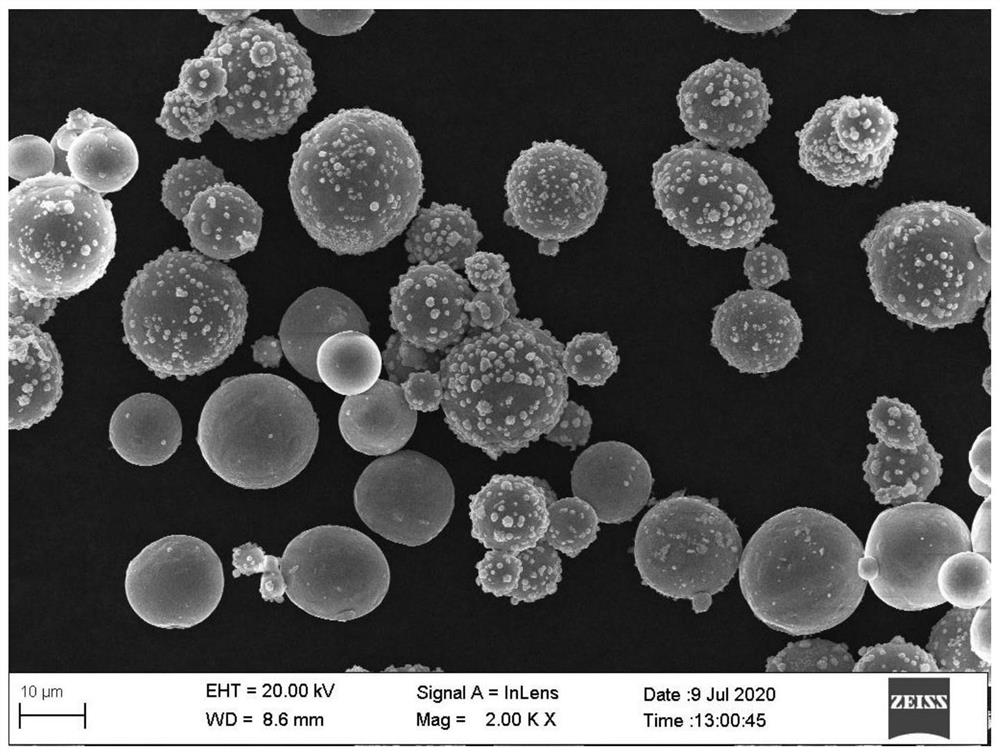

[0048] Configure 200ml electroless copper plating solution, the formula of the plating solution is copper sulfate 9.75g / L; formaldehyde 12.0 ml / L; potassium sodium tartrate 25.0g / L; bipyridine 10ml / L; pH value 12-12.5; Take the dried 8g powder and add it to the prepared chemical plating solution, heat it to 45°C in a constant temperature water bath, keep it warm and stir it continuously with magnetic stirring. The stirring speed is 30rpm, and the pl...

Embodiment 2

[0053] Add 8g of spherical titanium powder (purity 99%) with a particle size of less than 35 microns to 1mol / L sodium hydroxide solution, put it into a constant temperature water bath and heat it to 40°C, and use magnetic stirring to continuously carry out gentle stirring at a stirring speed of 40rpm , remove oil and oxide film for 20 minutes; filter the powder with a centrifuge, wash with deionized water for 3 times, wash with ethanol for 2 times, and then put it in a vacuum drying oven at 100°C for 10 minutes;

[0054] Configure 200ml electroless copper plating solution, the formula of the plating solution is copper sulfate 9.75g / L; formaldehyde 12.0 ml / L; potassium sodium tartrate 25.0g / L; bipyridine 10ml / L; pH value 12-12.5; Take the dried 8g powder and add it to the prepared chemical plating solution, heat it to 45°C in a constant temperature water bath, keep it warm, and use magnetic stirring to continuously carry out gentle stirring. The stirring speed is 30rpm, and the ...

Embodiment 3

[0059] Add 8g of spherical titanium powder (purity 99%) with a particle size of less than 35 microns to 1mol / L sodium hydroxide solution, put it into a constant temperature water bath and heat it to 40°C, and use magnetic stirring to continuously carry out gentle stirring at a stirring speed of 40rpm , degreasing and deoxidizing film for 20 minutes; and cleaning 3 times with deionized water, 2 times with ethanol, and then drying in a vacuum oven at 100 °C for 10 minutes;

[0060] Configure 200ml electroless copper plating solution, the formula of the plating solution is copper sulfate 9.75g / L; formaldehyde 12.0 ml / L; potassium sodium tartrate 25.0g / L; bipyridine 10ml / L; pH value 12-12.5; Take the dried 8g powder and add it to the prepared chemical plating solution, heat it to 45°C in a constant temperature water bath, keep it warm, and stir it continuously with magnetic stirring. The stirring speed is 30rpm, and the plating time is 90min. The whole process Use sodium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com