A kind of diamond-magnesium composite heat dissipation material and its preparation method and application

A composite heat dissipation material, diamond technology, applied in the field of diamond-magnesium composite heat dissipation material and its preparation, can solve the problems of large interface thermal resistance, high density, high brittleness, etc., and achieve the effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

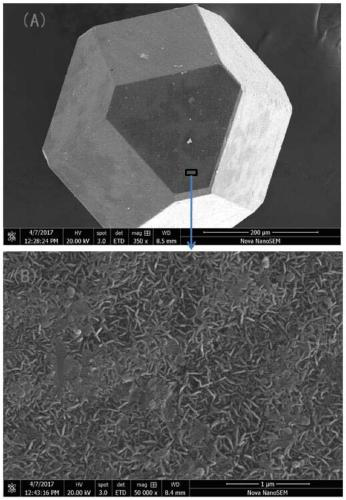

Image

Examples

Embodiment 1

[0036] In this embodiment, a diamond-magnesium composite heat dissipation material, the preparation process is as follows:

[0037] The preparation of diamond particles modified by the surface gradient layer, the specific process is: pretreatment of diamond raw materials, diamond surface pretreatment process: ultrasonic cleaning of acetone solution for 20 minutes---absolute ethanol ultrasonic cleaning for 20 minutes---deionized water washing to neutral Properties---wash with dilute nitric acid solution for 15 minutes---wash with deionized water until neutral---dry fully. After pickling, roughening and cleaning, clean diamonds are obtained; and mixed molten salt is prepared, specifically, sodium chloride and potassium chloride are mixed evenly according to the mass ratio of 2:1 to obtain mixed molten salt; according to the mass The ratio is 1:12:0.6:0.2, respectively weighing diamond, mixed molten salt, metal copper powder with a particle size of 1000 nm and titanium powder wit...

Embodiment 2

[0042] In this embodiment, a diamond-magnesium composite heat dissipation material, the preparation process is as follows:

[0043] The preparation of diamond particles modified by the surface gradient layer, the specific process is: pretreatment of diamond raw materials, roughening and cleaning by pickling, to obtain clean diamonds; and preparation of mixed molten salt, specifically sodium chloride and chloride Potassium is mixed evenly according to the mass ratio of 2:1 to obtain mixed molten salt; according to the mass ratio of 1:10:0.08:0.5, respectively weigh diamond, mixed molten salt, and metal copper powder with a particle size of 30 nanometers and titanium powder with a particle size of 80 nanometers. After mixing these four substances evenly, they were kept in a tube furnace at 900°C under a nitrogen atmosphere for 80 minutes. After cooling to room temperature with the furnace, they were taken out and cleaned and dried to obtain a surface gradient layer modification. ...

Embodiment 3

[0047] In this embodiment, a diamond-magnesium composite heat dissipation material, the preparation process is as follows:

[0048] The preparation of diamond particles modified by the surface gradient layer, the specific process is: pretreatment of diamond raw materials, roughening and cleaning by pickling, to obtain clean diamonds; and preparation of mixed molten salt, specifically sodium chloride and chloride Potassium is mixed evenly according to the ratio of mass ratio of 2:1 to obtain mixed molten salt; according to the ratio of mass ratio of 1:15:0.15:0.1, respectively weigh diamond, mixed molten salt, and metal copper powder with a particle size of 30 nanometers and titanium powder with a particle size of 30 nanometers. After mixing these four substances evenly, heat them in a tube furnace at 920°C under a nitrogen atmosphere for 45 minutes, and take them out after cooling to room temperature with the furnace. After cleaning and drying, a surface gradient layer modifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com