Copper alloy with excellent flexibility and its production method

A manufacturing method, a technology of titanium-copper alloy, applied in the field of copper alloy and its manufacturing, can solve the problems of residual precipitates, decreased material bendability, large grains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

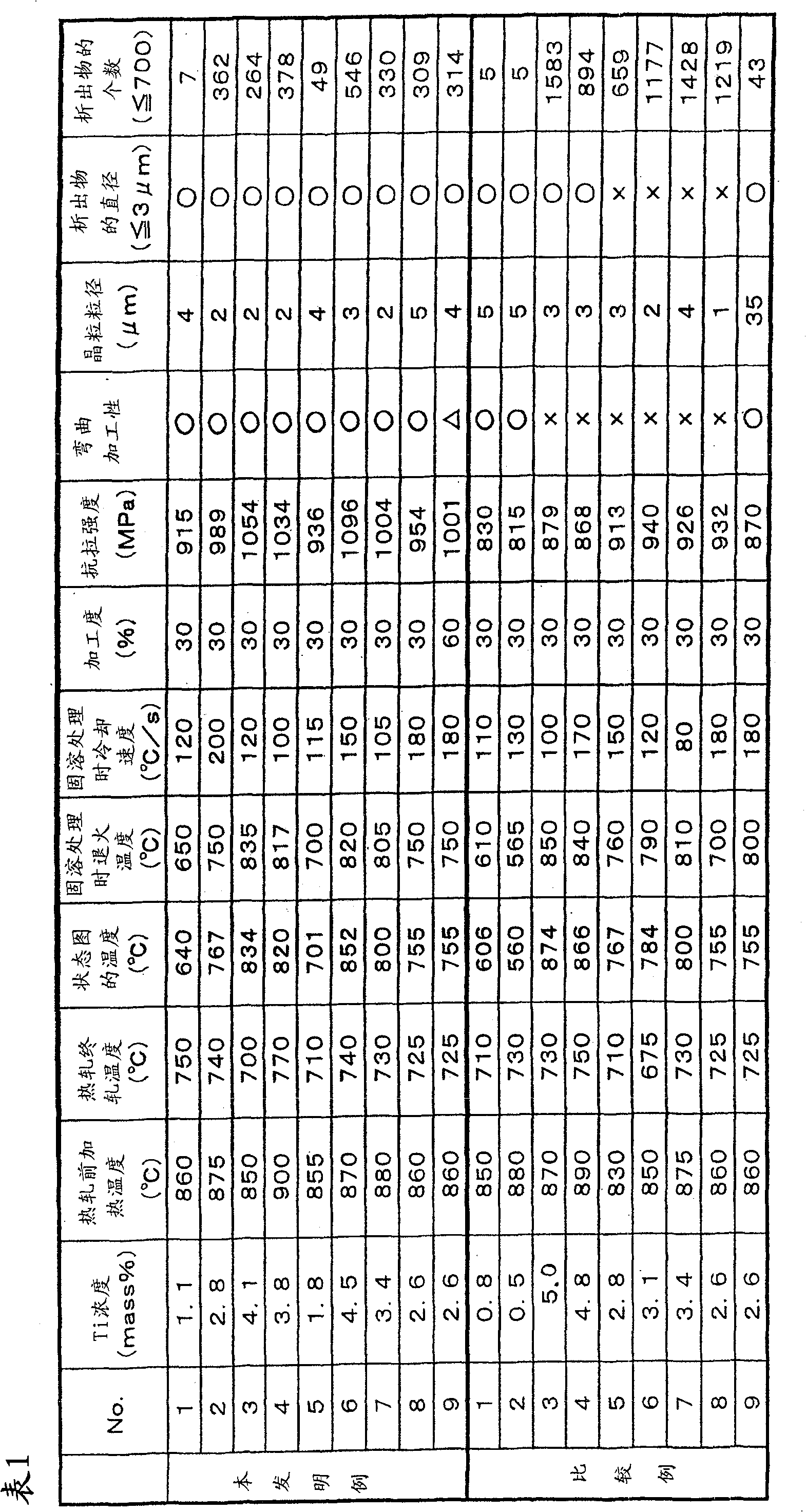

[0040]Electrolytic copper or oxygen-free copper was used as raw material, and ingots (thickness 20 mm) of various compositions shown in Table 1 were cast in a high-frequency vacuum melting furnace. Next, this ingot was hot-rolled at the temperature described in Table 1 to a thickness of 8 mm, and the scale on the surface was planarized, followed by cold rolling to obtain a plate with a thickness of 0.43 mm. In the subsequent solution treatment, each composition was annealed at the temperature shown in Table 1 for 30 seconds, and then cooled to room temperature at the cooling rate shown in Table 1.

[0041] Then, after cold rolling (thickness: 0.3 mm) at a working degree of 30%, aging treatment was performed on the condition that the highest strength could be obtained for each test material. Here, for Example No. 9 in the table, in order to observe the influence of the working degree on the bendability of the material, the final working degree was determined at 60%.

[0042] E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com