Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Good bonding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

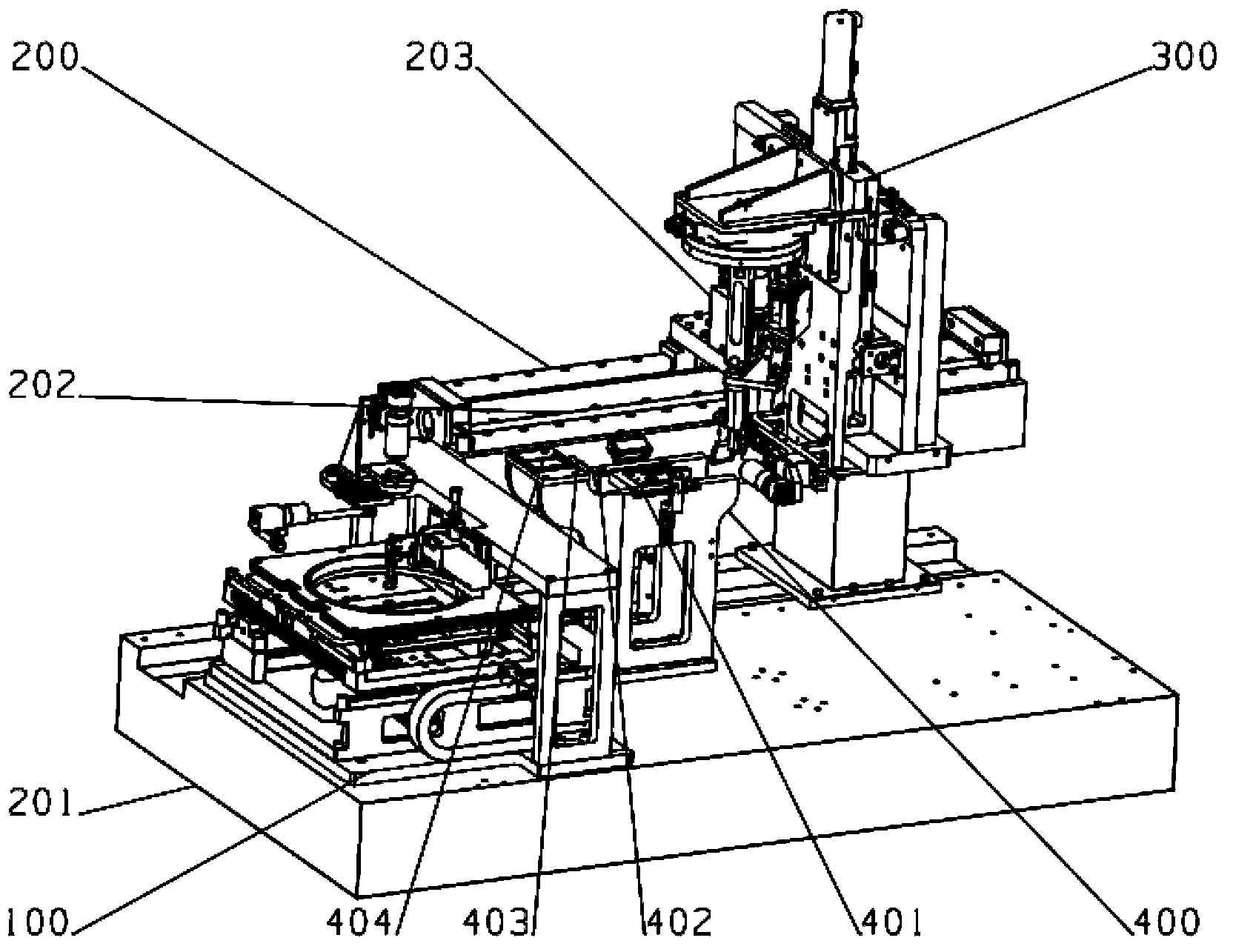

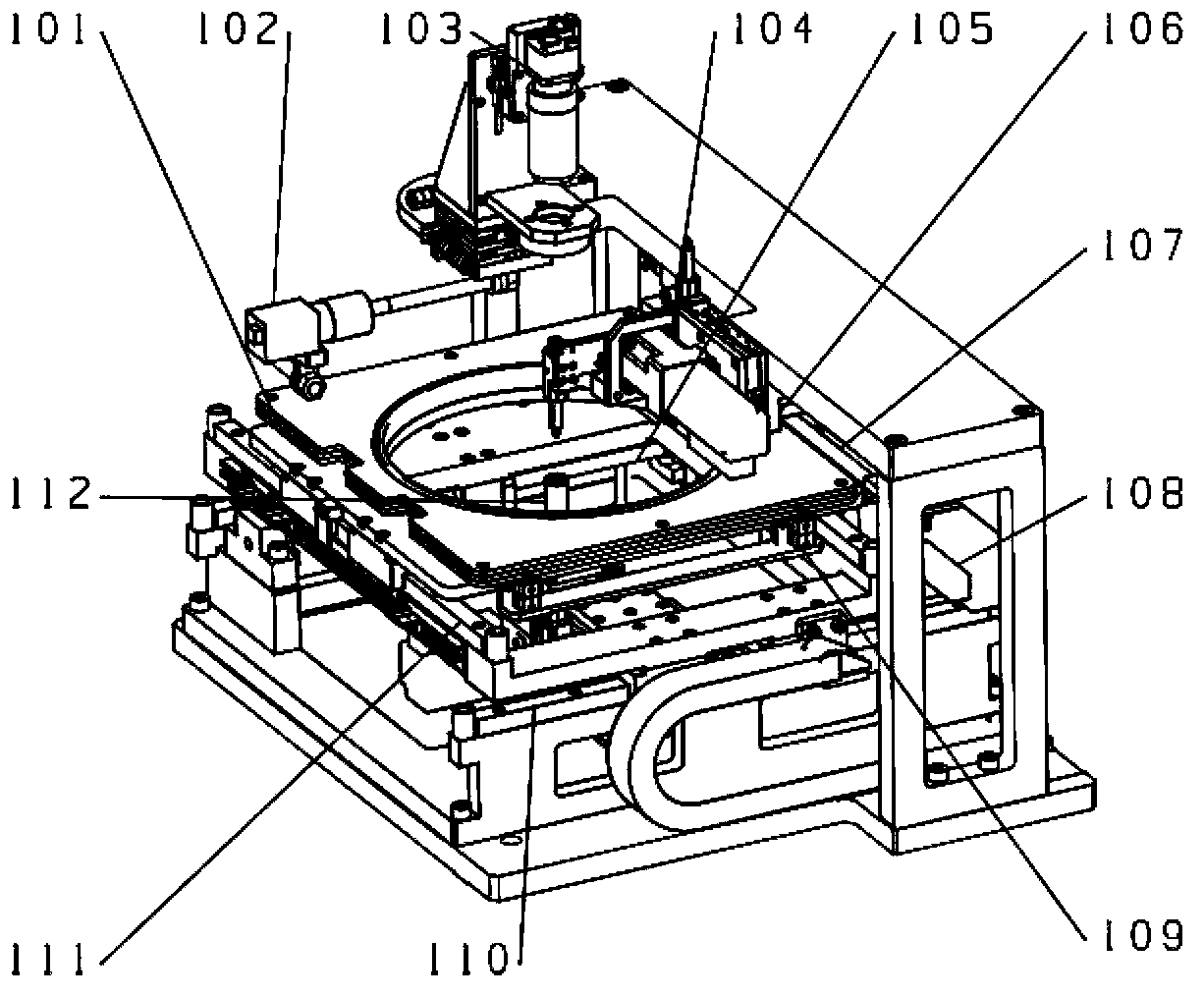

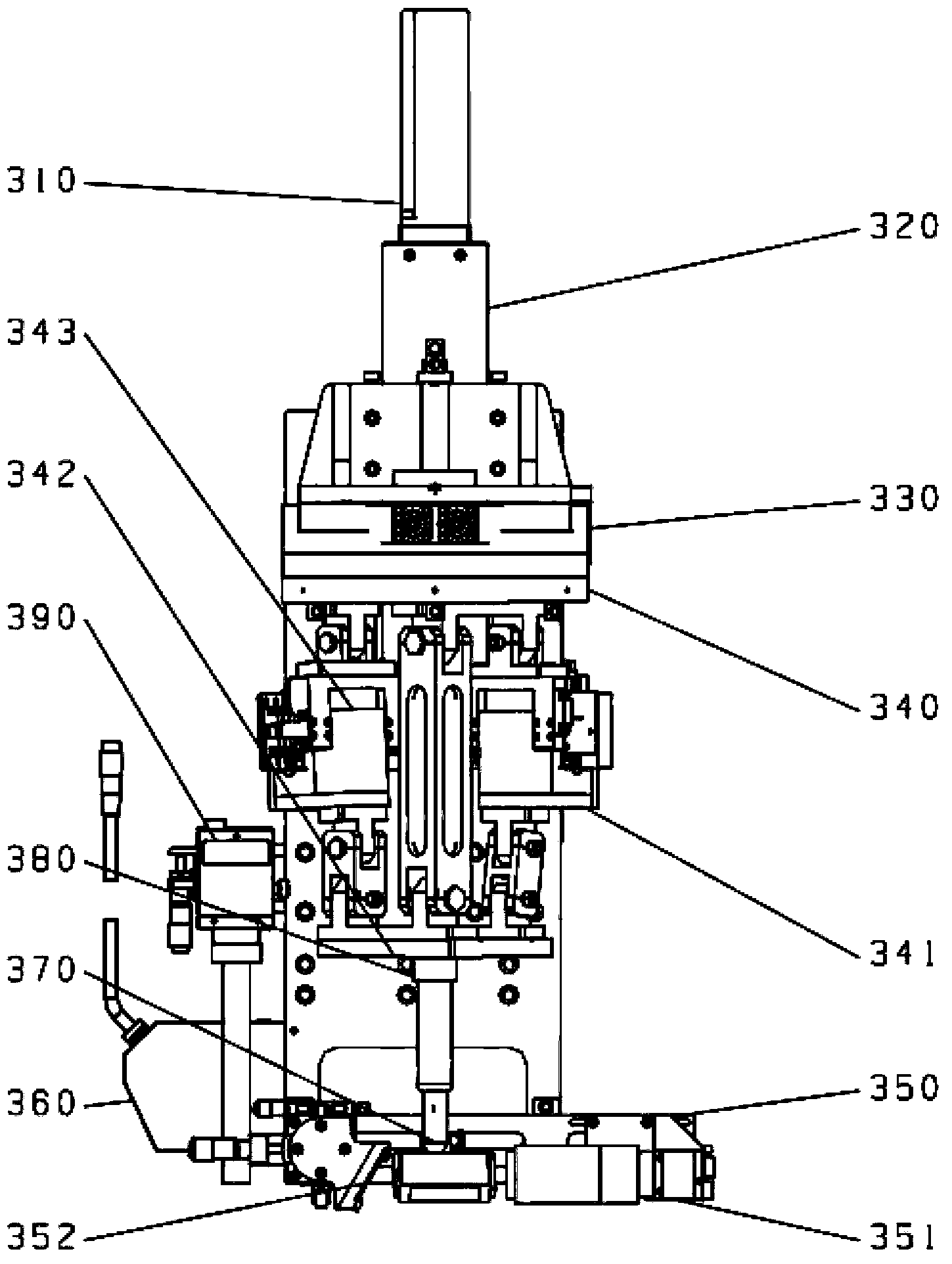

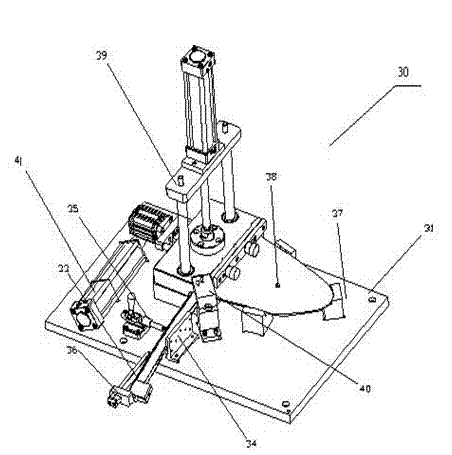

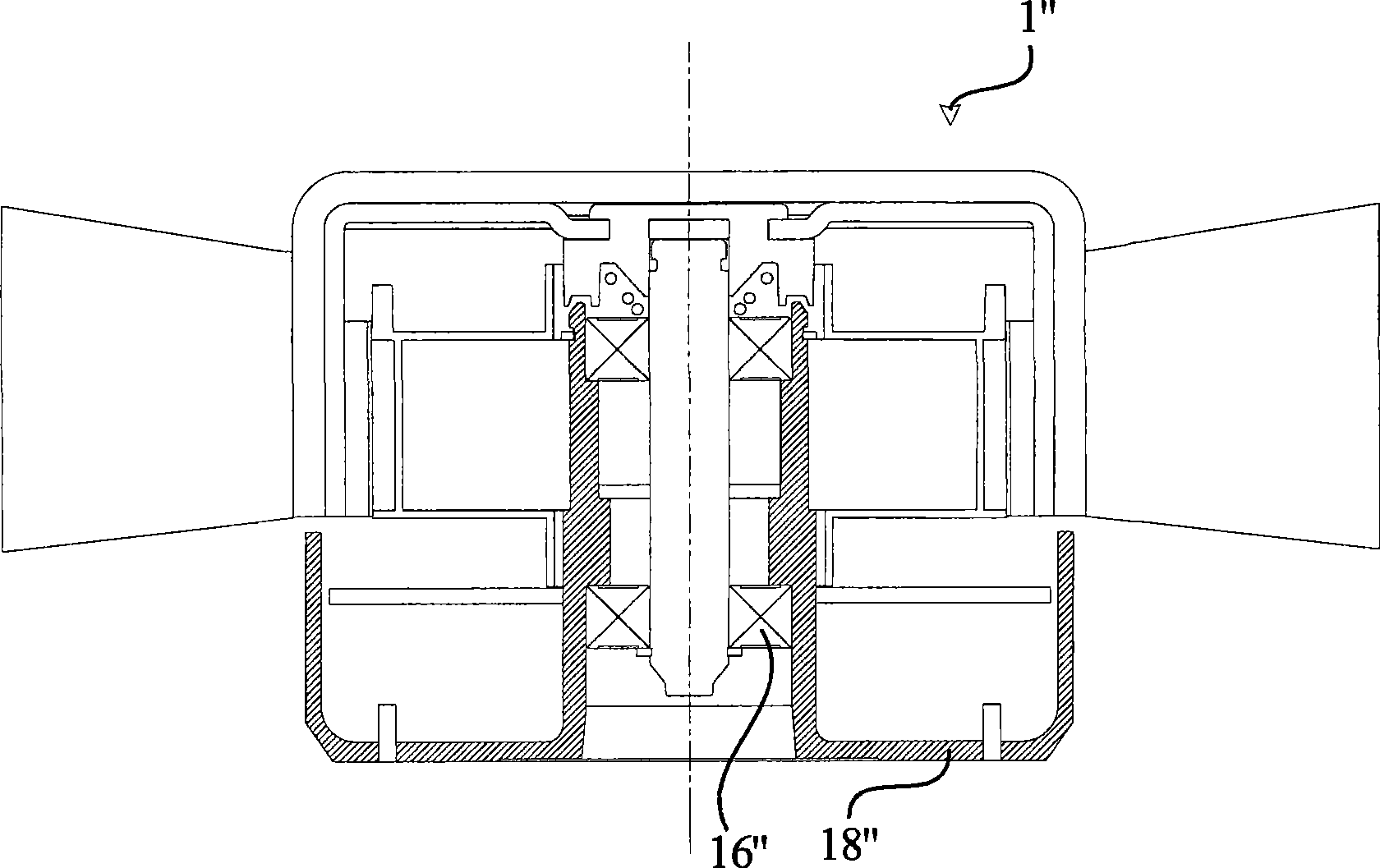

Back bonding platform for superchip

ActiveCN103367208ARigorous processHigh precisionSemiconductor/solid-state device manufacturingCircular discMicrometer

The invention discloses a back bonding platform for a superchip. The back bonding platform comprises a substrate, a chip peeling and overturning unit, an X-Y direction movement unit, a multi-degree of freedom bonding head and a mounting platform unit, wherein the chip peeling and overturning unit is used for respectively peeling and overturning a chip on a wafer disk and sending the chip to a to-be-picked position; the multi-degree of freedom bonding head is arranged on a supporting guide rail of the X-Y direction movement unit in a cantilever mode, and has functions of automatically levelling and aligning; the mounting platform unit is used for adsorbing the substrate and matched with the bonding head, so that the chip and the substrate are mutually positioned. In addition, in order to ensure the high-precision movement or matching of units, a plurality of vision positioning systems are configured in the back bonding platform. The back bonding platform can reach micrometer-level alignment accuracy, has the parallel adjusting accuracy of higher than 0.01 degree, and has the advantages of compact structure, convenience for operation and the like, so that the back bonding platform is particularly suitable for back bonding of the superchip.

Owner:HUAZHONG UNIV OF SCI & TECH

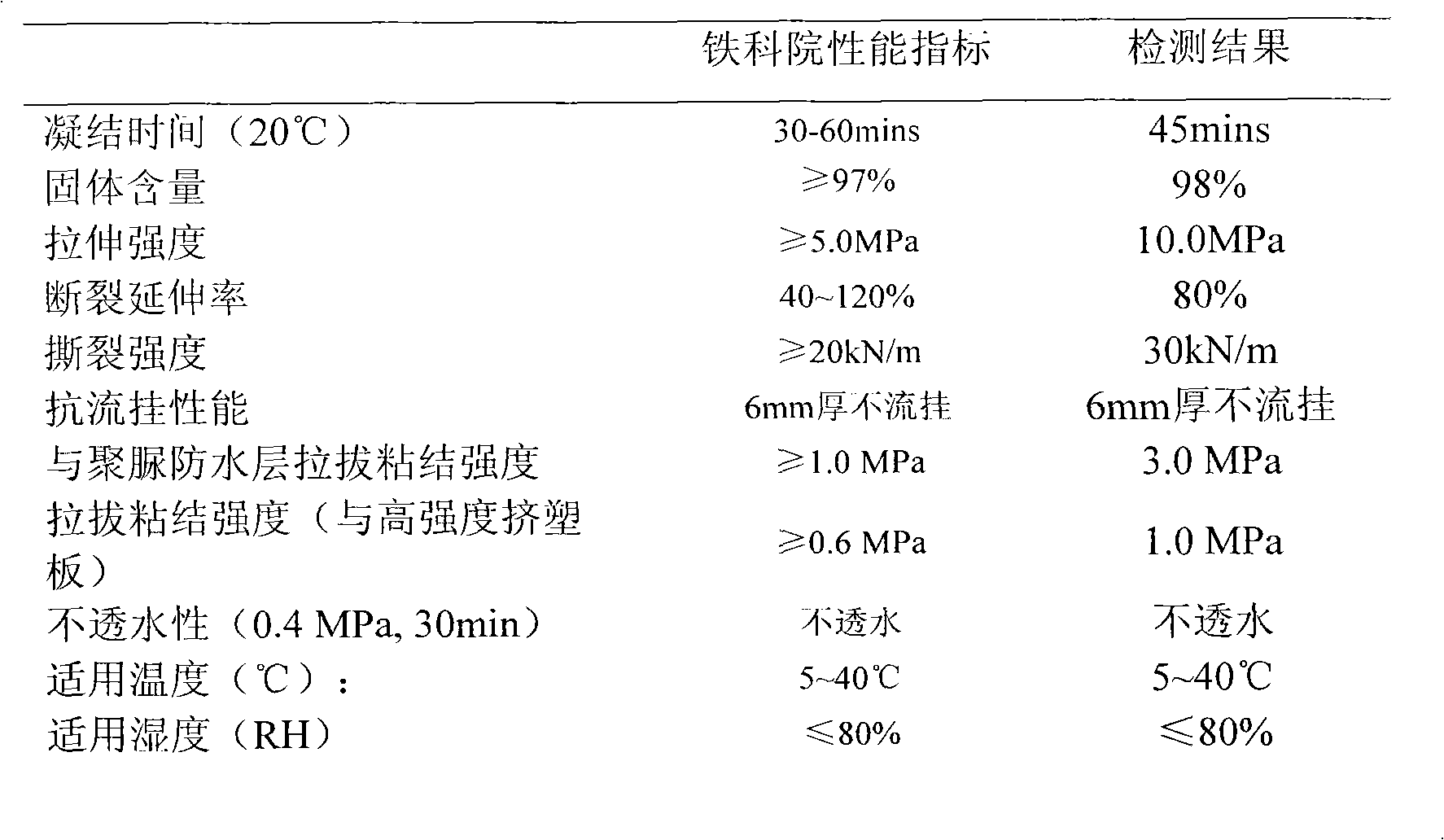

Polyurethane adhesive for bonding extruded sheet for high-speed railway and preparation method thereof

InactiveCN101921568AFast curingGood bonding effectNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryOrganosilicon

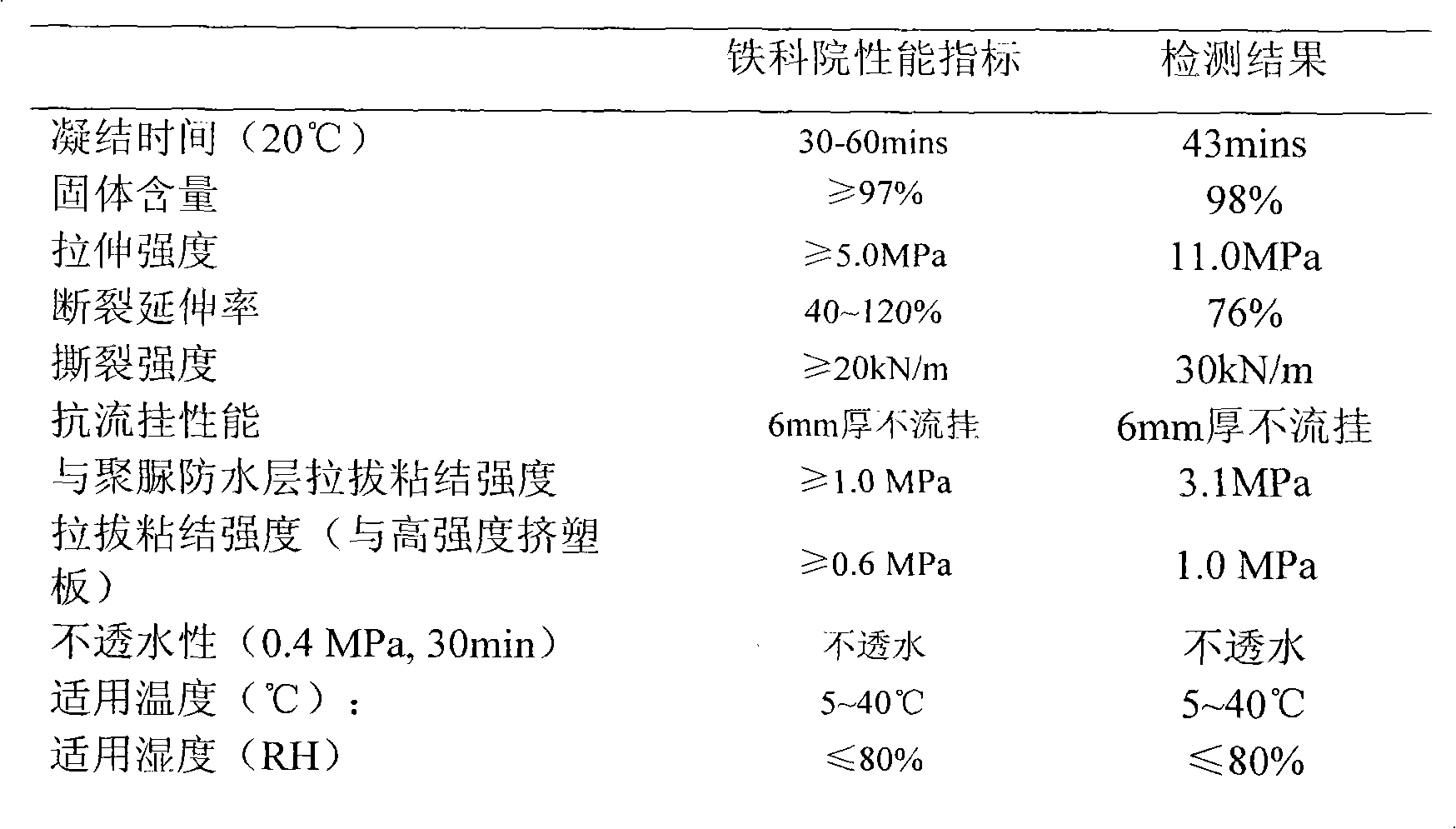

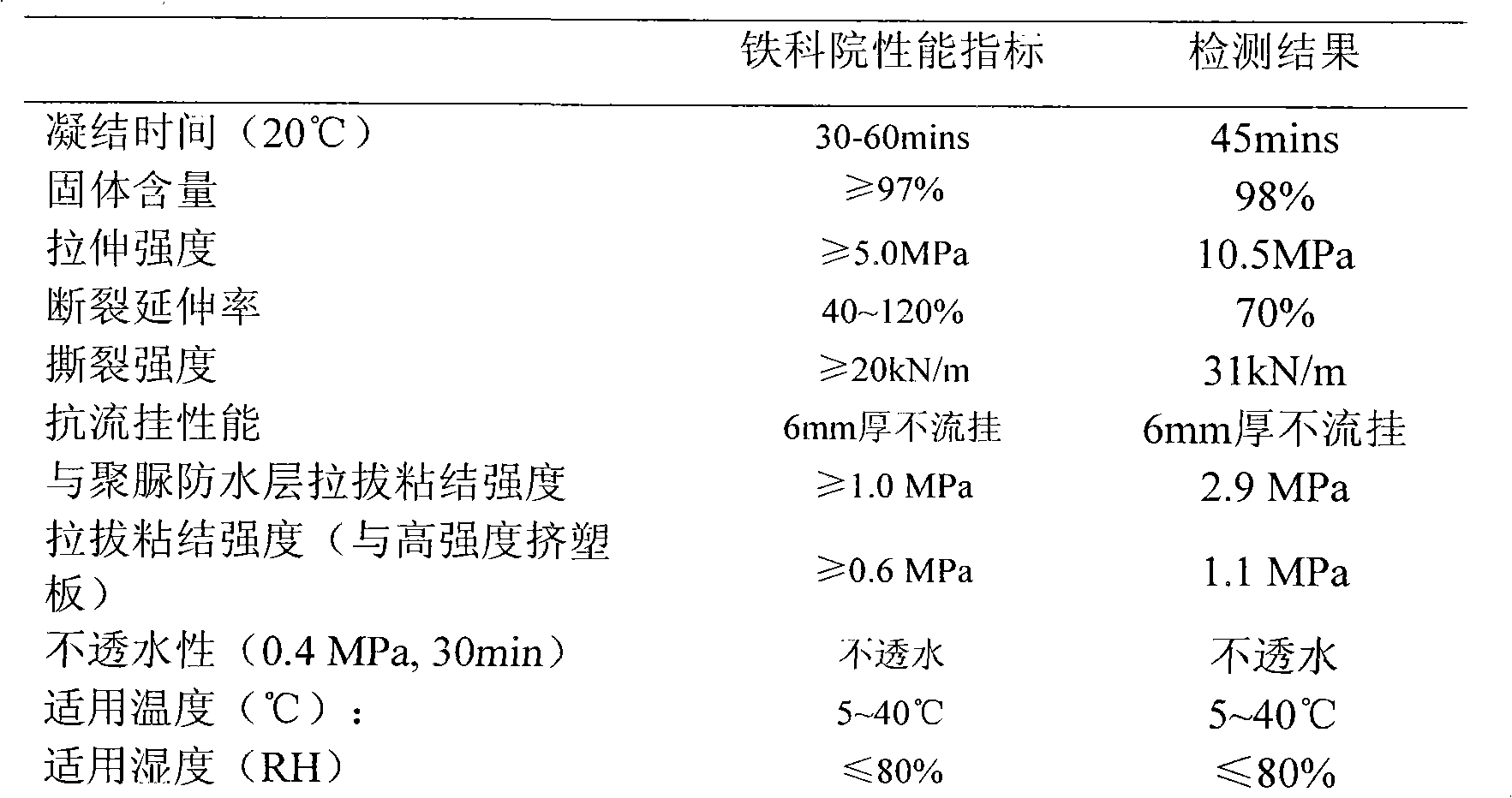

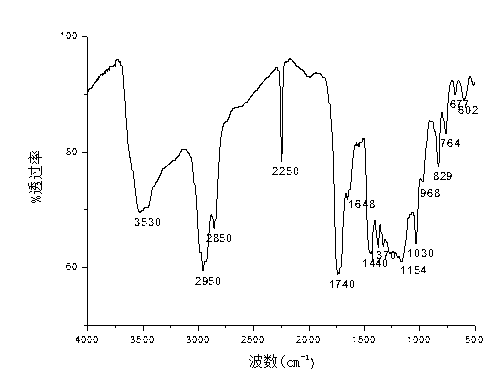

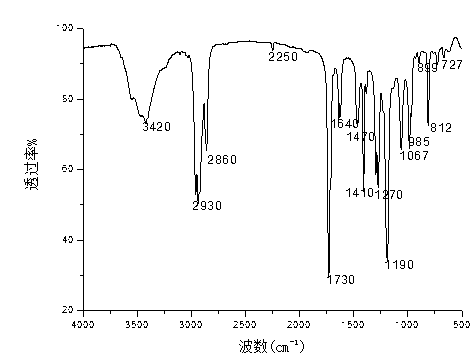

The invention discloses a polyurethane adhesive for bonding an extruded sheet for a high-speed railway and a preparation method thereof, which belong to the field of adhesive preparation. The method comprises the following steps of: compounding a terminal hydroxyl polyurethane perpolymer, obtained through the synthetic reaction of multiple trifunctional polyether polyols, bifunctional polyether polyols, methyl diphenylene diisocyanate or a derivative thereof and a thinner under certain conditions, with a small molecular chain extender, an anti-sagging auxiliary agent, a foam suppressor, a moisture absorbent, an inorganic filler and an organosilicon coupler to be used as the first component of the adhesive; and with polyisocyanate as the second component of the adhesive, proportionally compounding the two components to obtain the polyurethane adhesive. The adhesive prepared by the method has the characteristics of high curing speed, good bonding effect, high mechanical performance, sagging resistance, convenient construction and the like. No primer is applied, so that a good bonding effect is achieved between a concrete plate or a polyurea waterproof layer and a high-strength extruded sheet. The invention completely satisfies the technical standard and the criterion of a ballastless track technology.

Owner:BEIJING COMENS NEW MATERIALS

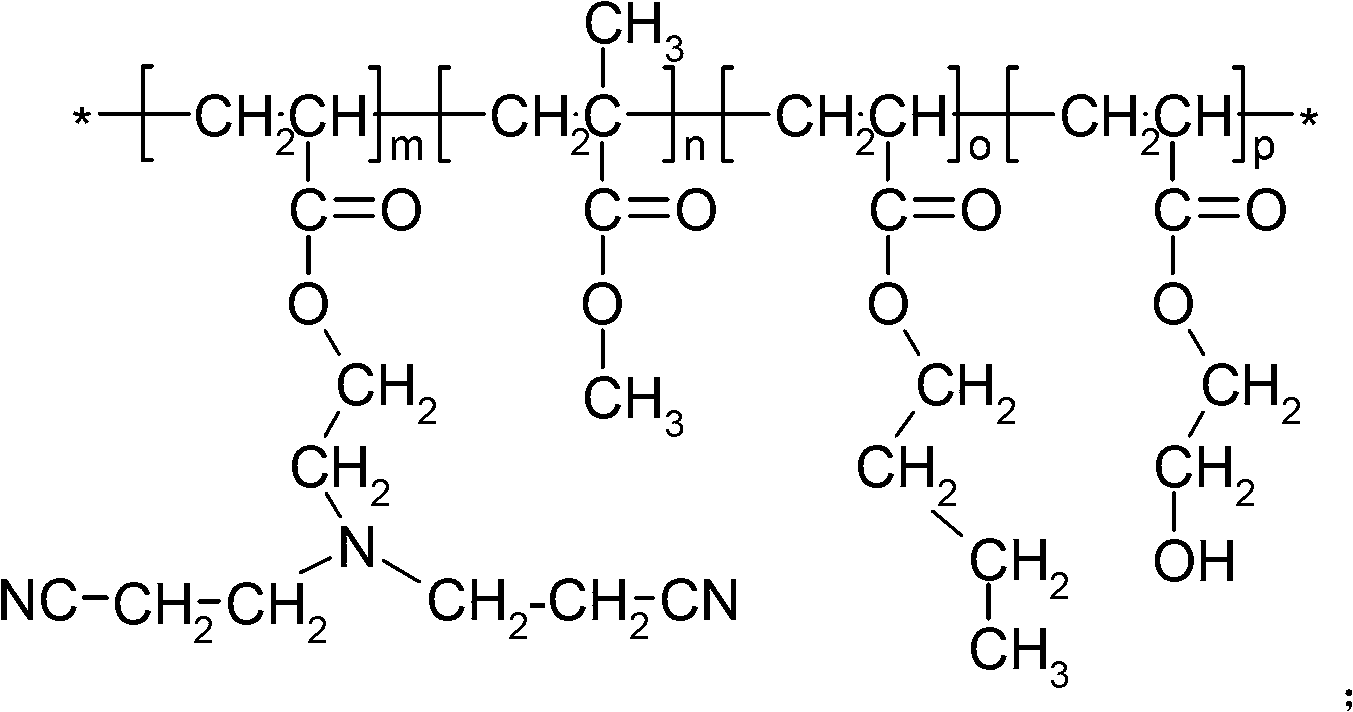

Macromolecule bonding agent and preparation method thereof

InactiveCN102977260AStrong forceThe polymerization reaction is easy to controlCarboxylic acid nitrile preparationOrganic compound preparationChemical synthesisPolymer science

The present invention discloses a macromolecule bonding agent and a preparation method thereof, and belongs to the technical field of chemical synthesis and propellant applications, wherein the obtained product can be adopted as a propellant bonding agent. According to the present invention, N,N-dicyanopropyl aminoethyl acrylate, methyl methacrylate, butyl acrylate and hydroxyethyl acrylate are subjected to copolymerization, wherein a copolymer function chain contains two cyanoalkyl groups, such that an absorption effect is strong; during product preparation, a reactivity ratio of the function monomer is close to reactivity ratios of other copolymerization monomers, such that the reaction is easily controlled; a good bonding effect can be achieved in propellant applications so as to provide a good mechanical property; and advantages of easily-obtained raw materials, easily-achieved preparation process and easy promotion and application are provided.

Owner:SUZHOU UNIV

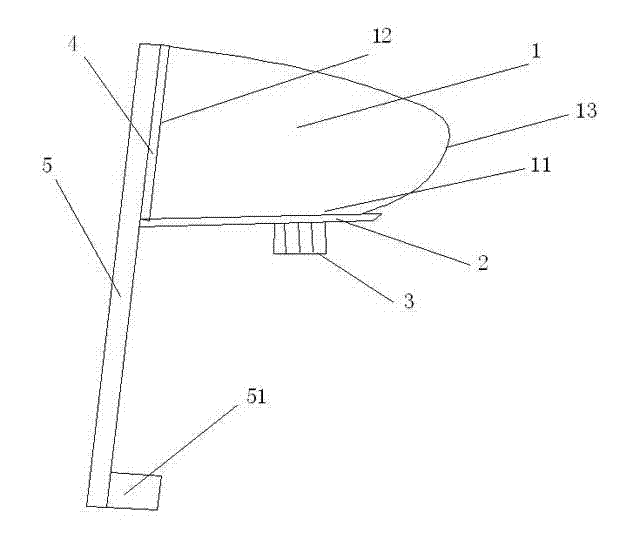

Production process and equipment for corner window glass edge-cladding assembly

ActiveCN102529650AGood bonding effectEnsure stabilityWindowsEngine sealsSecondary bondingEngineering

The invention relates to a production process and equipment for a corner window glass edge-cladding assembly, wherein the production process employs the bonding process for two times and is characterized by positioning by first tooling equipment firstly and then bonding the corner window glass with a positioning supporting iron block by single-component polyurethane glue; performing solidification after the first bonding; performing secondary bonding by second tooling equipment after finishing the solidification; during the secondary bonding, adjusting and fixing all the parts in place according to the designed limit requirements; injecting bi-component polyurethane into the clearance of each part by a high-pressure ejector so as to performing solidification; and finishing the processing of the corner window glass edge-cladding assembly after reaching to corresponding solidification time. The technical scheme of the invention makes full use of different bonding properties of the bi-component polyurethane glue and the single-component polyurethane glue to finish the processing by bonding for two times, and the bonding speed of the secondary bonding is accelerated by the high-pressure ejecting molding machine so as to achieve a good bonding effect. Therefore, the production process and the device for the corner window glass edging assembly are efficient and practical.

Owner:瀚德(中国)汽车密封系统有限公司

Gold and silver powder adhesive, preparation method thereof, wallpaper and textiles

ActiveCN103756601AGood bonding effectExcellent water resistance and high temperature resistanceEster polymer adhesivesIonTemperature resistance

The invention discloses a gold and silver powder adhesive. The gold and silver powder adhesive is prepared by using hard monomers, soft monomers, hydroxy ester containing monomers, (methyl)acrylic acid, multifunctional monomers, functional polymerizable monomers, emulsifying agents, initiators and deionized water as main raw materials and carrying out the processes of mixed monofunctional monomer pre-emulsification, seed reaction, monofunctional and multifunctional mixed monomer polymerization reaction and compounding. The solid content of the gold and silver powder adhesive is 30-50wt% of waterborne acrylate emulsion. Accordingly, the invention also discloses a method for preparing the gold and silver powder adhesive as well as wallpaper and textiles prepared by applying the gold and silver powder adhesive. The gold and silver powder adhesive has good adhesion, good water and high temperature resistance, strong covering power and high glossiness, and has the characteristics that the gold and silver powder adhesive is resistant to oxidation for a long time and does not discolor.

Owner:佛山市三水灏诚合成树脂有限公司

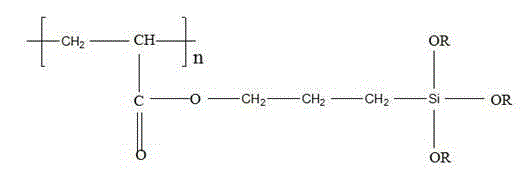

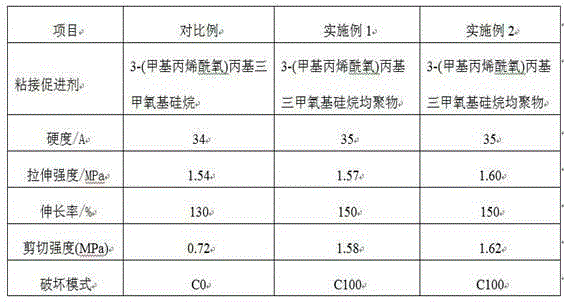

Adhesive mono-component addition silicone rubber adhesive and preparation method thereof

InactiveCN104449552AGood bondGood bonding effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesMono componentAluminium alloy

The invention discloses an adhesive mono-component addition silicone rubber adhesive. The adhesive mono-component addition silicone rubber adhesive is prepared from the following components in parts by weight: 100 parts of vinyl polydimethyl siloxane, 1-15 parts of hydrogen-containing polysiloxane, 5-30 parts of vapor-phase method silicon dioxide, 0.1-5 parts of platinum catalysts, 0.05-2 parts of inhibiting agents and 1-10 parts of adhesion promoters. Compared with mono-component addition silicone rubber prepared by methyl acryloyloxy alkoxy silane or acryloyloxy alkoxy silane monomer serving as an adhesive promoter, the mono-component addition silicone rubber prepared by homopolymer of methyl acryloyloxy alkoxy silane or acryloyloxy alkoxy silane monomer serving as the adhesive promoter has a good adhesion effect on aluminum alloy base materials.

Owner:TONSAN ADHESIVES INC

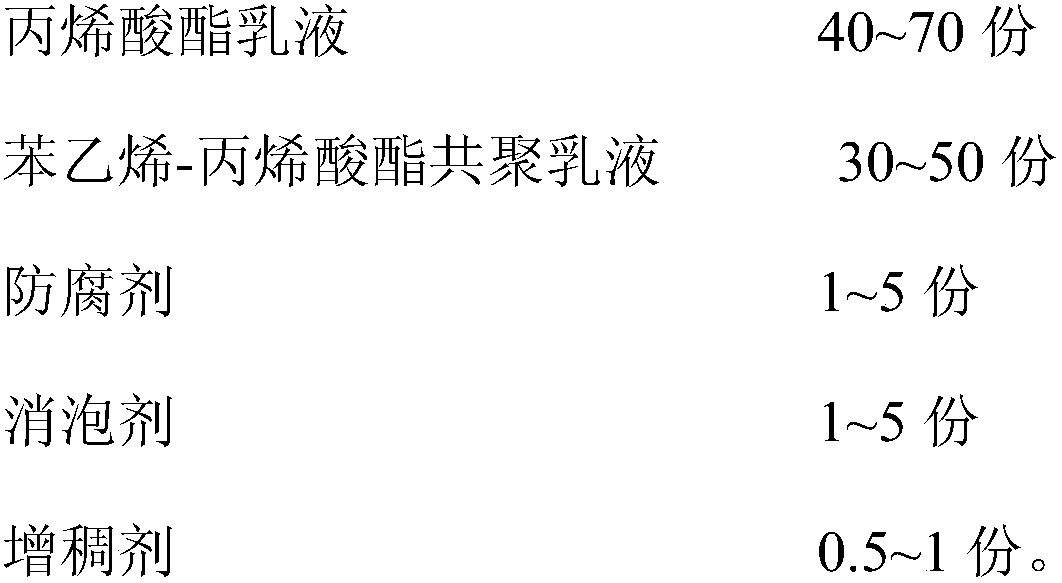

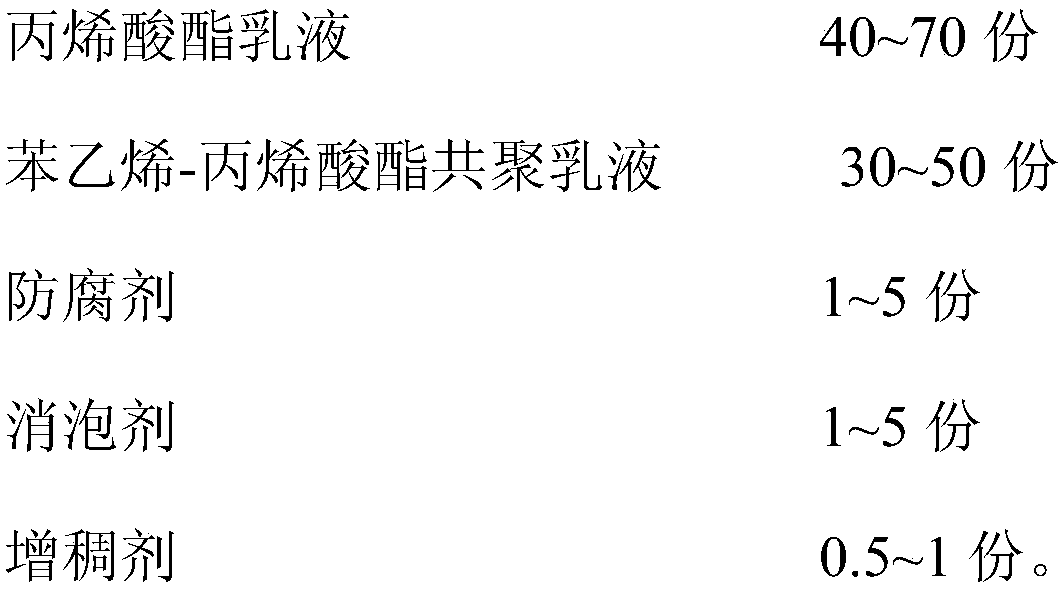

Double-component ceramic tile back adhesive

InactiveCN108048001AEasy constructionGood bonding effectNon-macromolecular adhesive additivesAmide/imide polymer adhesivesEmulsionBonding strength

The invention provides a double-component ceramic tile back adhesive. The double-component ceramic tile back adhesive comprises, by weight, 40-70 parts of acrylate emulsion, 30-50 parts of styrene-acrylate copolymer emulsion, 1-5 parts of preservatives, 1-5 parts of defoaming agent and 0.5-1 part of thickening agent. The double-component ceramic tile back adhesive has the advantages that the backadhesive is coordinated with cement mortar during use, a layer of back adhesive is plastered on the back of a ceramic tile, then the cement mortar is directly applied, and the ceramic tile is immediately adhered to a wall; the double-component ceramic tile back adhesive is convenient in construction, simple, efficient, good in adhering effect, capable of increasing bonding strength between the ceramic tile and the cement base material, capable of also increasing bonding strength between the cement base material and the wall, short in drying time, convenient and efficient in construction, and capable of avoiding the hollowing, peeling and falling off problems of ceramic tiles.

Owner:苏州启跃新材料科技有限公司

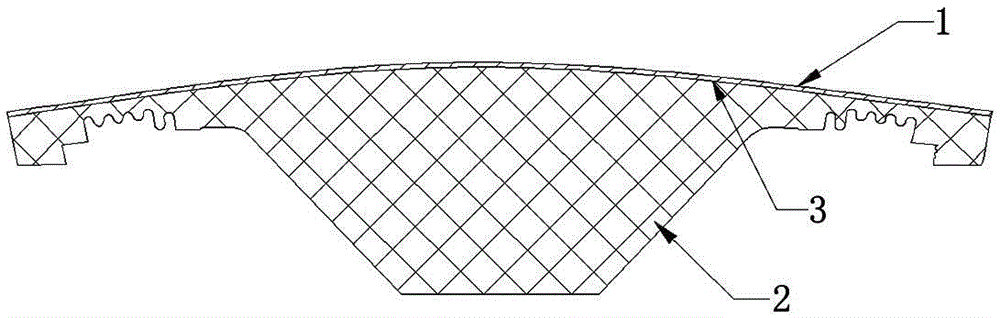

Polarized light 3D (three dimensional) lens and production method therefor

InactiveCN102928910AGood bonding effect3D effect is stableSynthetic resin layered productsCellulosic plastic layered productsPhysicsPressure sensitive

The invention relates to a polarized light 3D (three dimensional) lens and a production method for the polarized light 3D lens. The production method comprises the steps of producing a resin lens and producing a polarized light 3D film, wherein the resin lens is produced according to the following steps: the polarized light 3D film is put in a plastic ring, and a resin monomer is injected in a glass mould to be cured and released to form the lens. The polarized light 3D lens is characterized in that the polarized light 3D film is a polarized light 3D composite film, the polarized light 3D composite film is formed by compositing a PVA (polyvinyl acetate) polarized light film, a phase difference film and a TAC (triallyl cyanurate) film in sequence, or is formed by compositing the PVA polarized light film, the phase difference film and the PVA film in sequence, or is formed by compositing the PVA polarized light film, the phase difference film, the TAC film and the PVA film in sequence, and all the layers are bonded by taking pressure-sensitive adhesive or UV adhesive as a bonder so as to form the 3D composite film; and when the outer-layer film of the polarized light 3D composite film adopts the TAC film, the polarized light 3D composite film is subjected to chemical treatment, so as to obtain chemical reactive groups at the two sides of the polarized light 3D composite film.

Owner:SHANGHAI CONANT OPTICS CO LTD

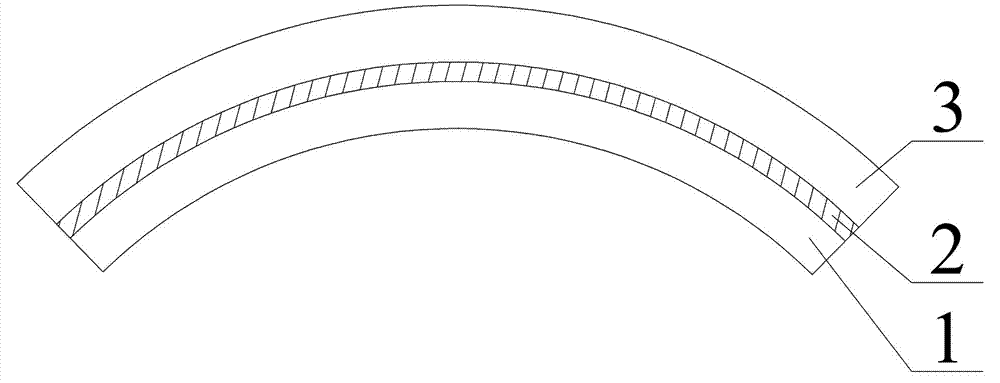

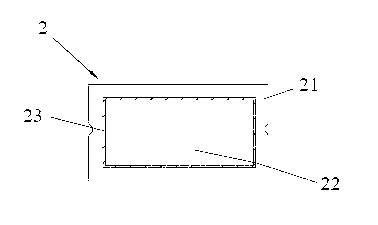

Electrical heater and fabricating method thereof, and vehicle

InactiveCN102843790AHigh bond strengthGood bonding effectAir-treating devicesHeater elementsHeat sinkThermal conductivity

The invention provides an electrical heater, comprising a frame, wherein multiple heat sink strips and multiple heating elements are arranged in the frame side by side, multiple heat sink strips and multiple heating elements are arranged at intervals, multiple heating elements comprise aluminum square tubes and PTC (positive temperature coefficient) thermistors installed in the aluminum square tubes, the aluminum square tubes are used for forming a first sandblasted surface with the surface which is connected with the heat sink strips, a thermal conductivity silica gel is arranged between the first sandblasted surface of the aluminum square tube and the adjacent heat sink strip, the aluminum square tube and the heat sink strips are bonded together by the thermal conductivity silica gel. The invention also provides a method for fabricating the electrical heater. The electrical heater has strong bond strength and good bond effect between the aluminum square tube and the adjacent heat sink strip, so that the heat conducting performance between the heating elements and the heat sink strips is excellent, the heat dissipation effect of the heat sink strips is good, and the frost removing, mist removing and heating effect are not affected even when the vehicle is used under the bumpy road condition for a long term.

Owner:BYD CO LTD

Binder composition applied to 3D printing and using method thereof

PendingCN112409790AGood bonding effectGood mechanical propertiesAdditive manufacturing apparatusActive agentSurface-active agents

The invention discloses a binder composition applied to 3D printing and a using method thereof. The binder composition comprises the following components in percentage by weight: 5-15% of a polymer, 1-5% of a stabilizer, 0.2-3% of a surfactant and 77-93.8% of a solvent. The using method of the binder composition comprises the step of transferring the binder composition to a spraying device of 3DPprinting equipment for powder 3D printing. The binder composition disclosed by the invention has a good binding effect on metal powder, ceramic powder and metal ceramic composite powder, and a printedgreen body material has good mechanical properties. According to the invention, rapid manufacturing of complex-structure products of metal, ceramic and metal ceramic composite materials is achieved,and production cost is saved.

Owner:JIHUA LAB

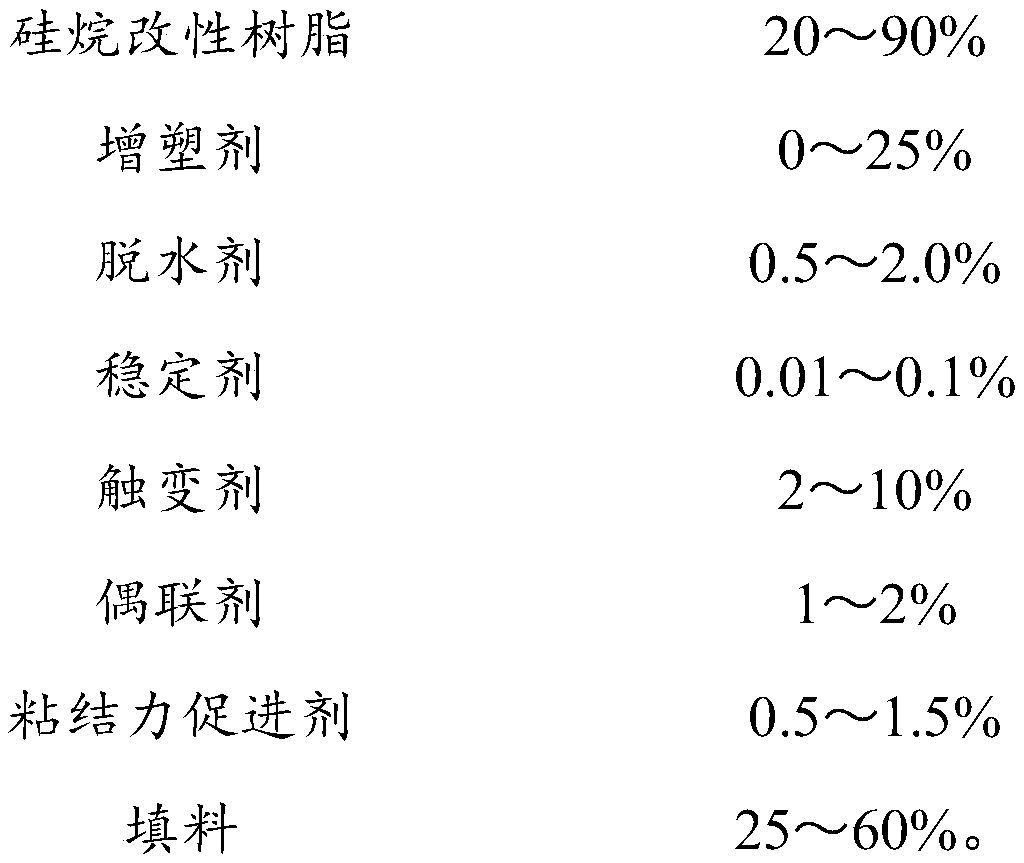

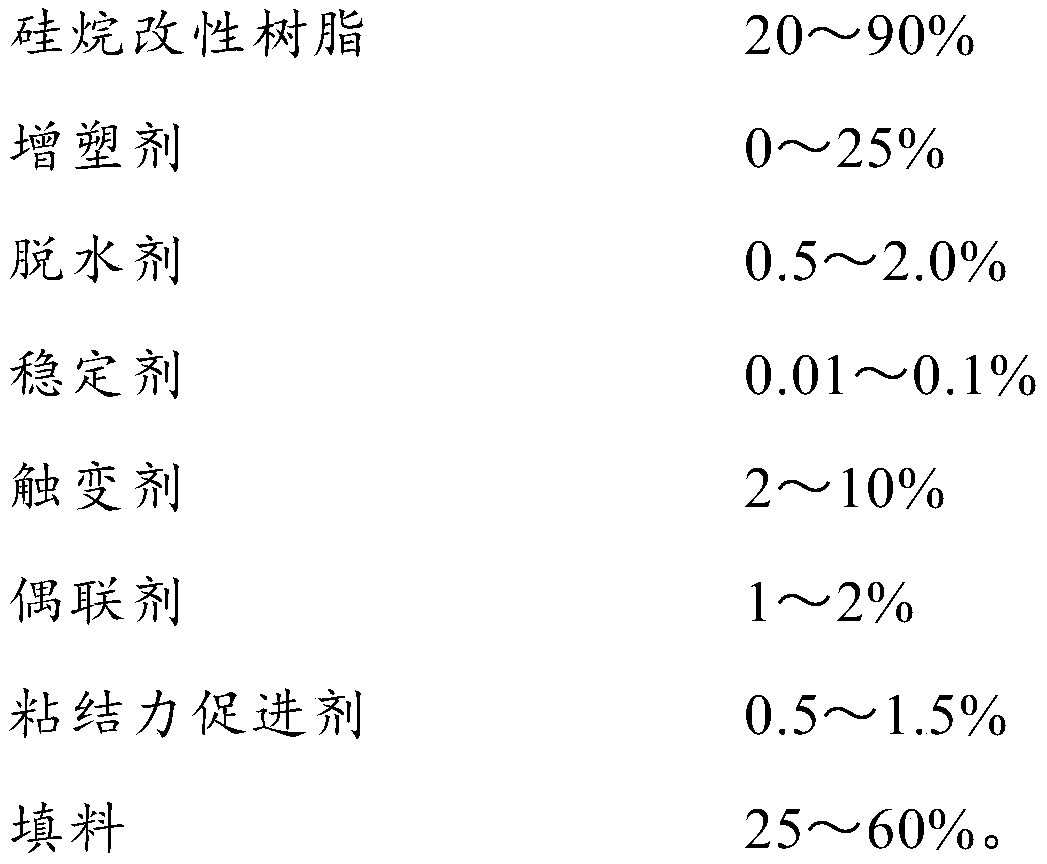

Silane modified polyether adhesion sealant

InactiveCN110564351AGood bondGood bonding effectNon-macromolecular adhesive additivesOther chemical processesChemistrySilanes

The invention provides a silane modified polyether adhesion sealant which is prepared from the following raw materials in percentage by mass: 20-90 percent of silane modified resin, 0-25 percent of aplasticizer, 0.5-2.0 percent of a dehydrating agent, 0.01-0.1 percent of a stabilizer, 2-10 percent of a thixotropic agent, 1-2 percent of a coupling agent, 0.5-1.5 percent of adhesion promoter and 25-60 percent of a filler. The silane modified polyether adhesion sealant is prepared by using the silane modified polyether resin as a main body with avoidance of use of an organic solvent, is wide inapplication range, is environmentally friendly and healthy and is simple and convenient in preparation and suitable for popularization and use.

Owner:苏州雅能新材料科技有限公司

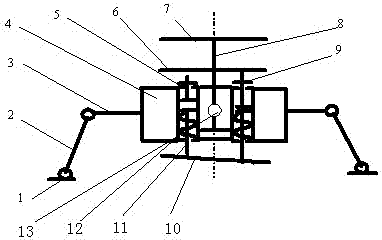

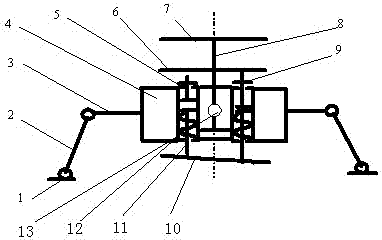

Resistance strain gauge paster compressing device with constant pressure

InactiveCN102506690AGood bonding effectEasy to excludeForce measurementElectrical/magnetic solid deformation measurementStrain gaugeEngineering

The invention relates to a resistance strain gauge paster compressing block with constant pressure. Two sides of a mounting mother block are respectively connected with magnetic absorption seats by virtue of a transverse support rod and a longitudinal support rod sequentially, compression bars a and b are respectively arranged in two mounting holes of the mounting mother block, length of the compression bar b is more than the length of the compression bar a, an auxiliary compression bar is respectively arranged below the compression bars a and b, rubber blocks are respectively arranged below the auxiliary compression bars, a compression bar spring is arranged outside each auxiliary compression bar, a pressing handle connecting rod is arranged at the middle part of the mounting mother block, and a pressing handle and an auxiliary pressing block are arranged above the pressing handle connecting rod. Locking screws are arranged between the mounting mother block and the pressing handle connecting rod. By using the spring structure of the compressing device, the compressing device maintains a certain constant pressure all the time when a paster is compressed, and pasting direction and position can be observed, if an error is found in the pasting direction and position, the pasting direction and position can be timely adjusted, and excessive adhesive and air during pasting can be conveniently removed, thus the pasting effect is better.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

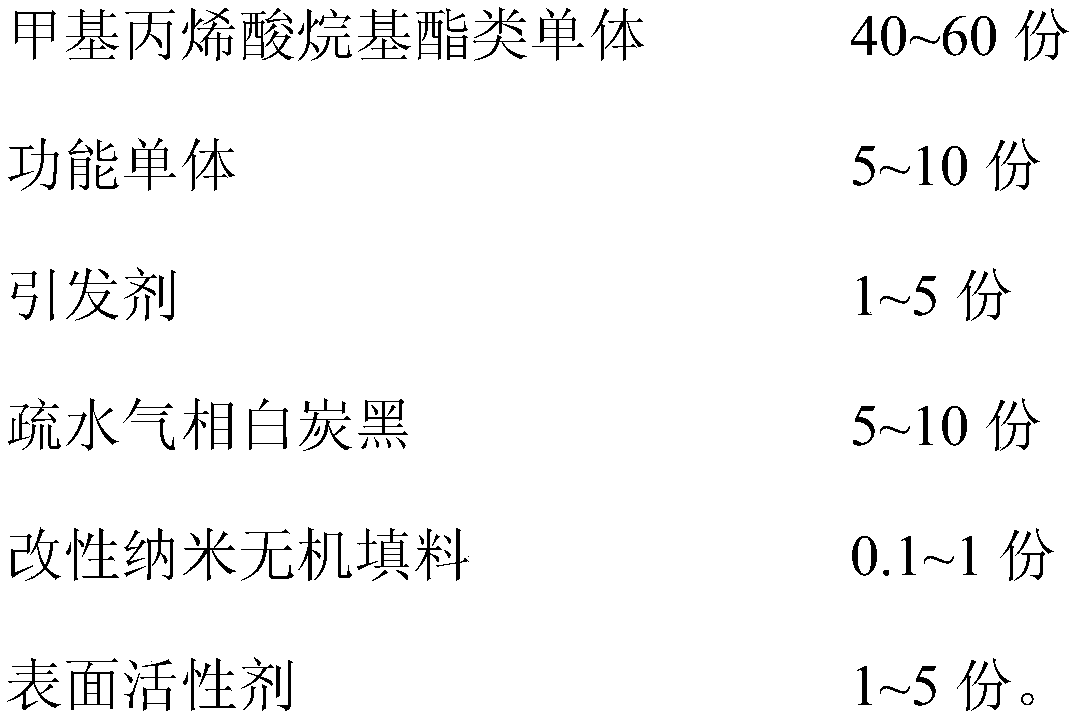

Composite pure waterborne hard-to-be-adhered material adhesive for packaging paper commodities and preparation method thereof

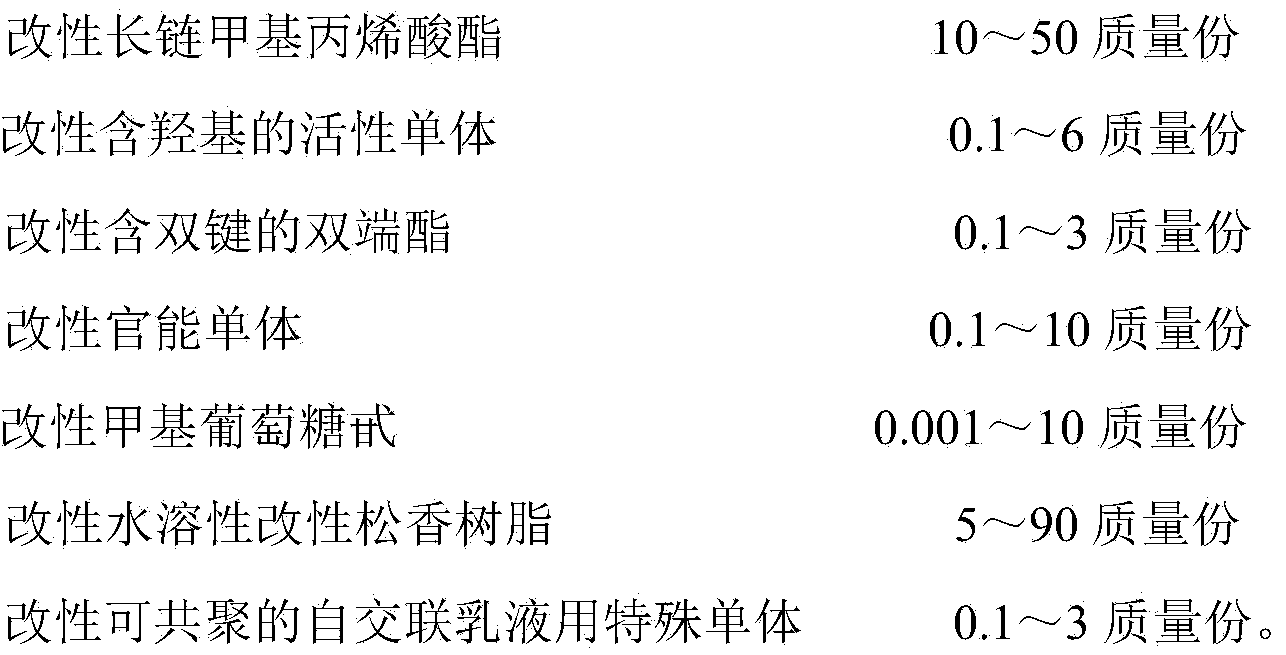

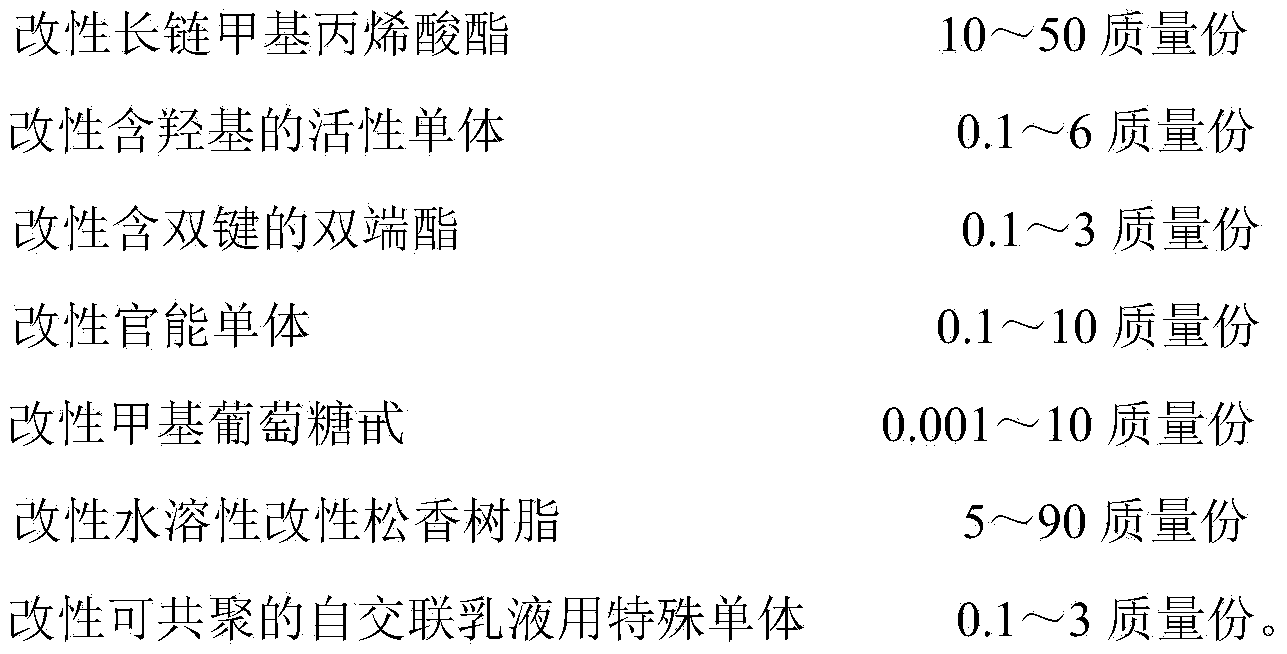

InactiveCN104178064AGood bonding effectNo bad smellEster polymer adhesivesRosin adhesivesFunctional monomerDouble bond

The invention relates to a composite pure waterborne hard-to-be-adhered material adhesive for packaging paper commodities and a preparation method thereof. The adhesive is prepared from a chain transfer agent, a reactive emulsifier, a thickener, an azo initiator, deionized water and a pH modifier, modified long-chain methacrylate, a modified active monomer containing hydroxyl, modified double-ended ester containing double bonds, a modified copolymerizable special monomer for a self-cross-linking emulsion, a modified functional monomer, modified methyl glucoside and modified water-soluble modified rosin resin, wherein the modified active monomer containing hydroxyl, the modified double-ended ester containing double bonds, the modified copolymerizable special monomer for a self-cross-linking emulsion, the modified functional monomer, the modified methyl glucoside and the modified water-soluble modified rosin resin are obtained under radiation of cobalt 60 gamma-ray. The preparation method comprises the steps of modifying the raw materials; preparing a pre-emulsion; preparing protection dispersed emulsion liquid; preparing seeds; preparing a copolymer emulsion and compounding the adhesive. The adhesive is odorless and has no toxic substances and meets the four quality standards in the terms of environment friendliness, water-temperature resistance, quick adhesion and persistent adhesivity standard and has good adhesion effect on the paper film which is not subjected to corona treatment and the non-polished UV oil coating.

Owner:常州天南化工有限公司

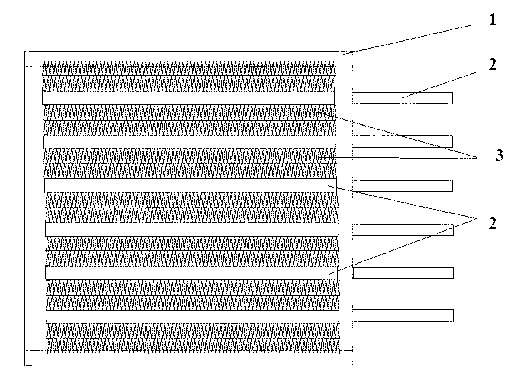

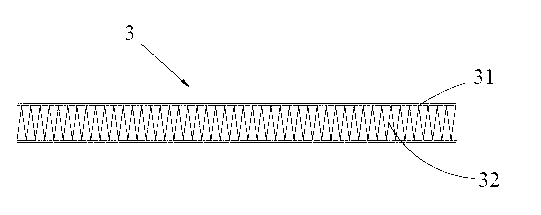

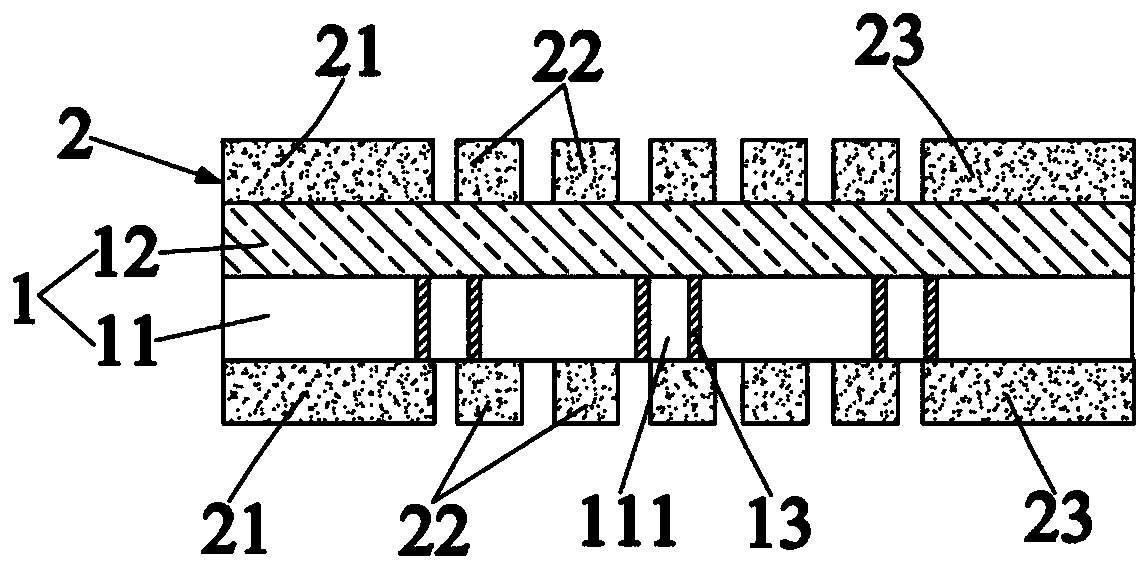

Lithium ion battery diaphragm and lithium ion battery containing same

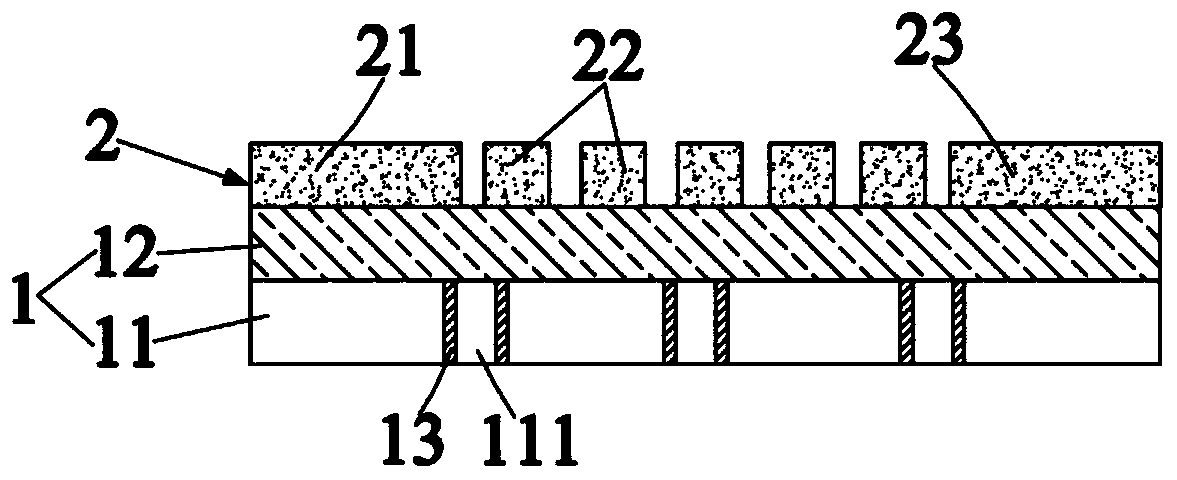

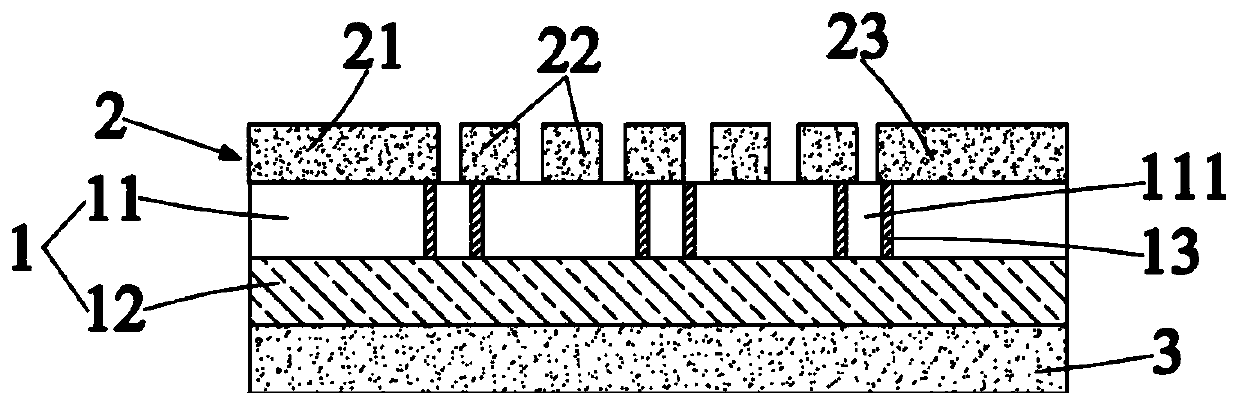

PendingCN110556495AImprove security risksGood bonding effectCell seperators/membranes/diaphragms/spacersSecondary cellsPolyolefinLithium electrode

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery diaphragm and a lithium ion battery containing the same. The lithium ion battery diaphragm comprises a heat-resistant composite base material layer. A first organic adhesive coating is arranged on one side of the heat-resistant composite base material layer. The heat-resistant composite base material layer comprises a base film and a ceramic layer arranged on the surface of the base film. The base film is provided with a plurality of pores, and a modified polyolefin coatingis attached to the pores. The first organic adhesive coating sequentially comprises a first complete coating area, a plaid intermittent coating area and a second complete coating area from the upper edge to the lower edge of the base film. Compared with the prior art, the lithium ion battery diaphragm can be fully infiltrated by the electrolyte and battery polarization can be reduced while good bonding performance and dimensional stability are achieved.

Owner:惠州锂威新能源科技有限公司

Novel wood floor adhesive

InactiveCN105368353AHigh adhesiveness and hot melt performanceGood bonding effectNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesN-Butyl acetateNatamycin

The invention discloses a novel wood floor adhesive. The novel wood floor adhesive comprises the following raw materials in parts by weight: 1.5-3.7 parts of silica sol, 0.8-1.7 parts of polyepoxy glyceryl ether, 2-3.7 parts of n-butyl acetate, 3-7 parts of asbestos powder, 0.6-1.5 parts of diisocyanate, 2-3.5 parts of urea, 1.3-3.5 parts of glycidyl trimethyl ammonium chloride-gliadin-glyoxal resin, and 0.5-2.7 parts of natamycin. Compared with the prior art, the novel wood floor adhesive has the advantages of no toxicity and no formaldehyde containing, has high adhesive property and hot melting property to the glycidyl trimethyl ammonium chloride-gliadin-glyoxal resin which is environmentally friendly, has the advantages of good bonding effect and long service life. The novel wood floor adhesive has the advantages of high bonding effect and good mechanical property, and has insect-prevention effect, combination of natamycin and urea can effectively prevent termite erosion and reduce possibility of insect pest, and a production method for the novel wood floor adhesive has the advantages of simple process, low production cost and easy popularization.

Owner:黄艳

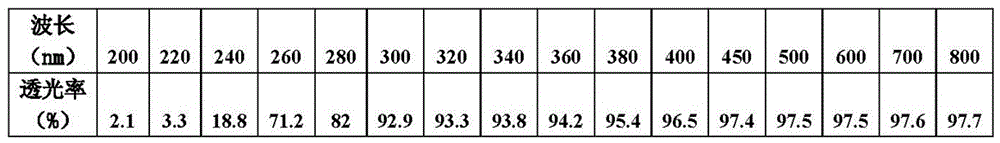

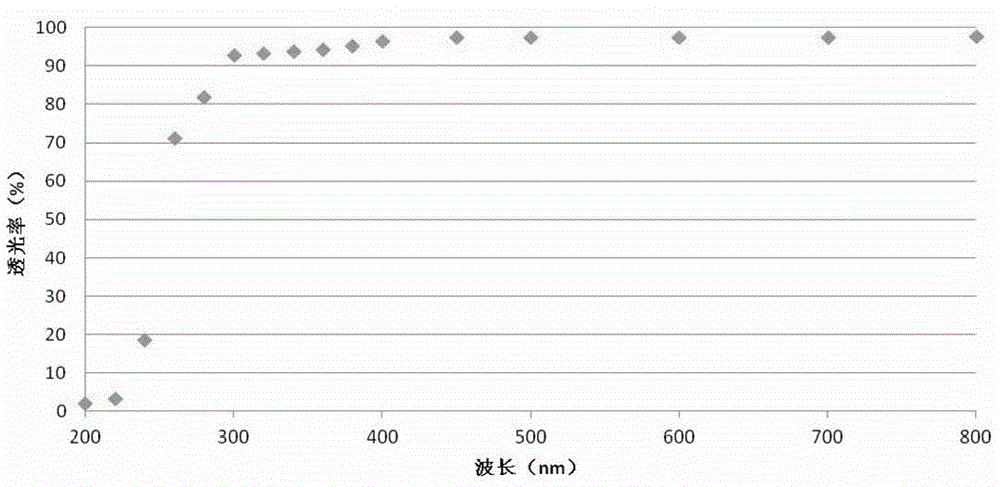

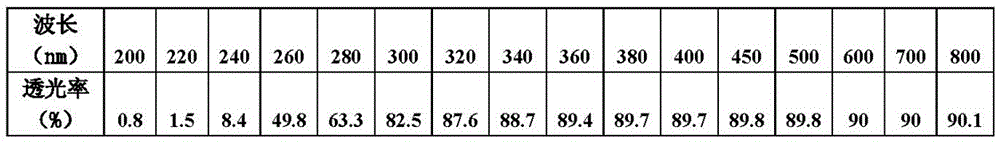

Ultraviolet (UV) light LED (light emitting diode) lamp bead packaging glue and preparation method thereof

InactiveCN106085344AReasonable formulaGood bonding effectNon-macromolecular adhesive additivesSemiconductor devicesOptical transmittanceLED lamp

The invention discloses an ultraviolet (UV) light LED (light emitting diode) lamp bead packaging glue and a preparation method thereof. The UV light LED lamp bead packaging glue comprises the following components of vinyl-terminated organic polysiloxane, liquid vinyl MQ silicon resin, linear methyl hydrogen polysiloxane, a platinum complex catalyst, an inhibitor and a tackifier. The ultraviolet LED lamp bead packaging glue has the advantages that the formula is reasonable, the bond energy of silicon oxygen bond of organosilicone main chain is high, the breaking is avoided under the condition of irradiation by high-energy UV light, and the sticking effect is good; the organosilicone can maintain higher transparency rate in the wider wavelength range, the high and low temperature-resistant and anti-aging properties are realized, the transparency is high, the forming property is good, the sticking property is good, the curing condition is mild, and the comprehensive property is better; the ultraviolet light LED lamp bead packaging glue is quickly prepared by the preparation method, the technological steps are simple and concise, the implementing is easy, and the productivity is high.

Owner:广东和天新材料科技有限公司

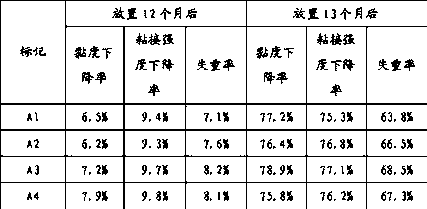

Preparation method of biodegradable copolyester hot melt adhesive

The invention discloses a preparation method of a hot melt adhesive, and concretely discloses a preparation method of a biodegradable copolyester hot melt adhesive. The method mainly comprises the following steps: 1, adding diacid formed by mixing terephthalic acid, m-phthalic acid, sebacic acid and , dioil formed by mixing butylene glycol and 1,3-propylene glycol and a catalyst into an esterification kettle, performing an esterification reaction at 160-205 DEG C, and ending the esterification reaction when the volume of water distilled from the esterification kettle is 95% or more of a theoretic water yield; and 2, adding an antioxidant into a product obtained in step 1, carrying out a condensation polymerization reaction at 230-240 DEG C under 100-150 Pa for 2.0 h, introducing nitrogen to release vacuum, and discharging the obtained product while hot to obtain the biodegradable copolyester hot melt adhesive. The biodegradable copolyester hot melt adhesive directly prepared through the synthesis method has a good bonding effect in a certain limitation period (such as twelve months), and can be rapidly degraded under natural conditions after the storage time exceeds the limitationperiod.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

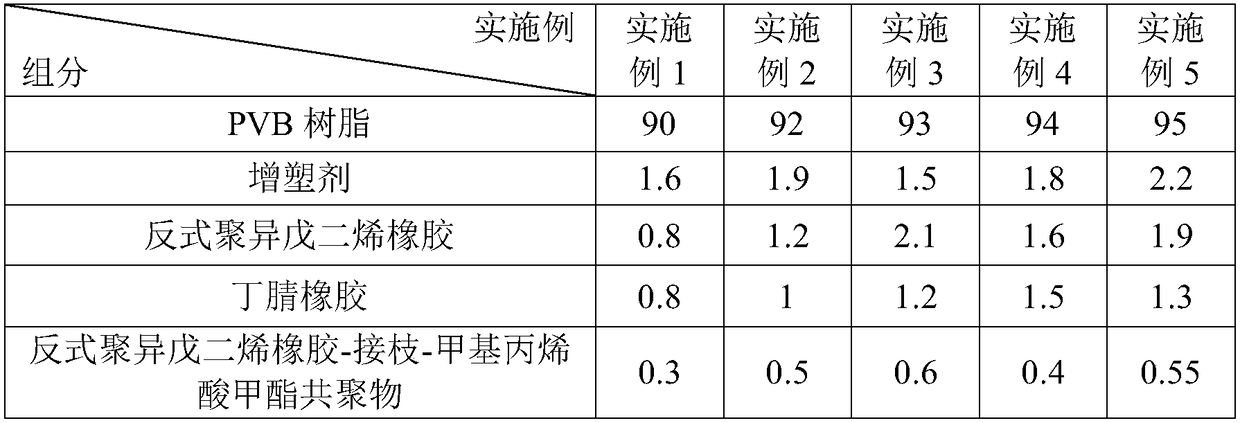

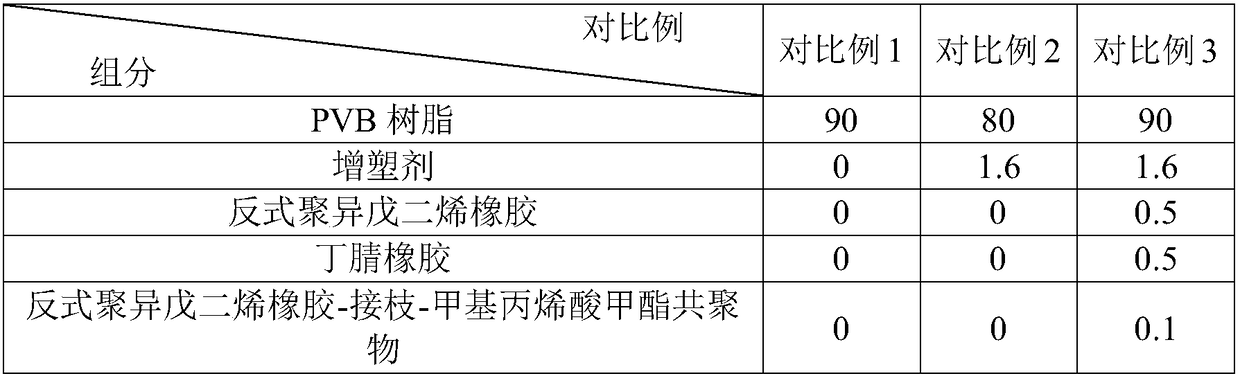

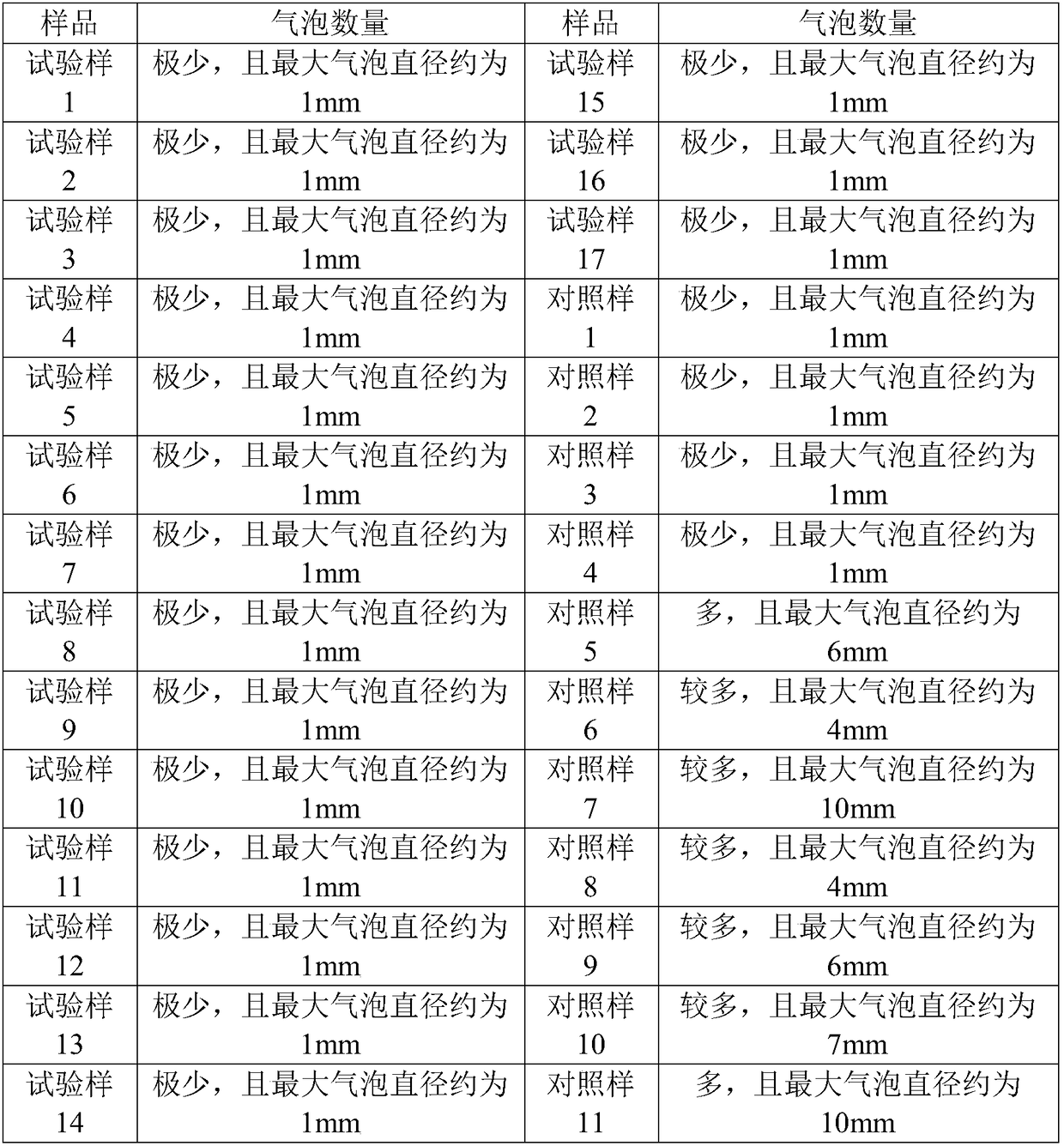

Production process of laminated glass

ActiveCN108312670AGood bonding effectGood adhesionSynthetic resin layered productsGlass/slag layered productsPlasticizerHot press

The invention discloses a production process of laminated glass and belongs to the technical field of glass. The process comprises the following steps: 1, cutting, abrasively cleaning and cleaning a massive glass raw material so as to obtain raw glass sheets; 2, putting a composite film into two layers or more layers of the raw glass sheets, cutting and removing excessive composite film part, andforming laminated glass; 3, preheating and pre-pressing on the laminated glass obtained in the step 2, softening the composite film, and performing hot press molding in an autoclave, thereby obtainingthe laminated glass. The composite film comprises PVB (Polyvinyl Butyral) resin, a plasticizer, trans-polyisoprene rubber-grafted methyl methacrylate copolymer. In the step 3, an operating temperature of hot press molding in the autoclave is 135-160 DEG C, the operating pressure is 1.3-1.6MPa, and the working time is 45-55 minutes. The composite film in the laminated glass disclosed by the invention has high bonding strength, so that the integrity of the laminated glass is excellent.

Owner:四川雄港玻璃有限公司

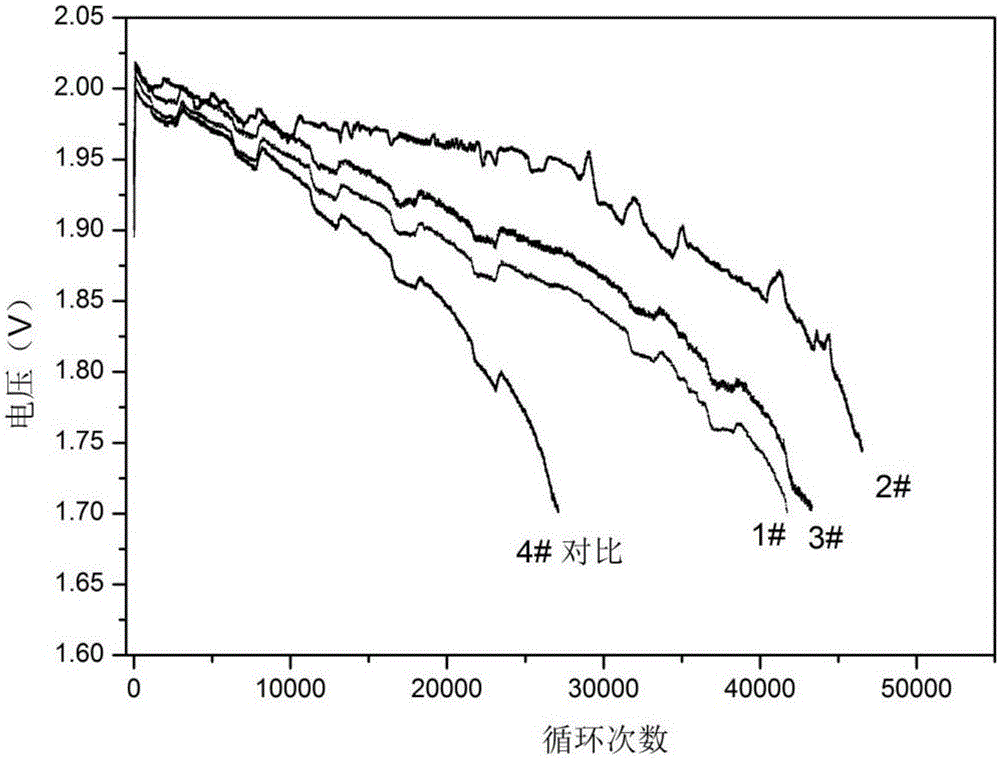

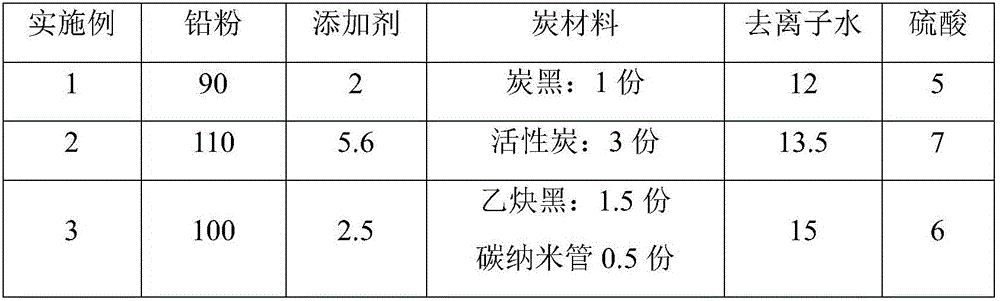

Lead-carbon battery negative plate and preparation method therefor

InactiveCN105845898AGood bonding effectIncrease migration rateLead-acid accumulator electrodesIonCyclic process

The invention provides a lead-carbon battery negative plate and a preparation method therefor. The negative plate comprises a plate grid and a negative electrode material for coating the plate grid, wherein the negative electrode material comprises an additive and more than one composite lead-carbon paste layer; and the carbon contents of the composite lead-carbon paste layers are gradually increased from the plate grid to the outer surface of the negative plate. According to the lead-carbon composite gradient negative plate obtained by the technical scheme of the invention, the corrosion layer formed between the plate grid and the lead paste is high in adhesion effect; a transmission channel with an excellent performance is established between the interior of the electrode and the external electrolyte, so that the migration rate of reaction ions is improved, and an effect of restraining negative electrode sulfation is achieved; the capability of charge acceptance of the prepared lead-carbon battery is improved by 1-2 times; the softening and falling off the negative electrode material in the cycle process are avoided; and the cycle life of the battery is prolonged.

Owner:CHINA ELECTRIC POWER RES INST +2

Non-gumming wear-resistant sole and preparation method thereof

The invention relates to a non-gumming wear-resistant sole by regulating the formula and process of various components of the sole. The non-gumming wear-resistant sole contains the following components in parts by weight: 30-50 parts of EVA (Ethylene-Vinyl Acetate), 10-20 parts of calcium stearate, 5-10 parts of nano calcium carbonate, 5-10 parts of zinc stearate, 20-30 parts of butadiene styrenerubber, 10-15 parts of ethylene-propylene-diene monomer, 5-8 parts of nano-titanium oxide, 1-3 parts of a vulcanizing agent, 2-5 parts of a bridging agent, 5-10 parts of a compatilizer, 2-8 parts of an anti-aging agent, 5-15 parts of epoxy resins, 5-15 parts of polyacrylate, 20-30 parts of polyvinyl alcohol and 2-5 parts of a foaming agent. Therefore, the prepared sole is excellent in mechanical property and excellent in high temperature resistance. The polyvinyl alcohol can achieve an excellent bonding effect, has high heat resistance, and achieves an excellent bonding effect when matched with polyacrylate.

Owner:浙江薪然鞋业集团有限公司

Preparation method of oxidized pellets with coarse-grain hematite as main raw material

The invention relates to a preparation method of oxidized pellets with coarse-grain hematite as a main raw material. The technical scheme of the invention is as follows: uniformly mixing 60-70 percent by weight of coarse-grain hematite, 20-30 percent by weight of fine-grain iron-containing raw material, 2-6 percent by weight of organic binding agent and 5-8 percent by weight of water, and carrying out pressure forming to obtain ellipsoidal green-balls; and roasting the ellipsoidal green-balls at 1150-1200 DEG C for 15-30min to obtain the oxidized pellets, wherein the coarse-grain hematite is ground hematite or pelletized return fines and has the grain diameter of being less than or equal to 6mm; the fine-grain iron-containing raw material is electric precipitation dust in the smelting process of iron ore concentrate or steel; the organic binding agent is prepared by mixing starch, inorganic sodium salt, borate and water according to a mass ratio of 1: (0.04-0.15): (0.02-0.10): (4.0-5.0); and forming equipment is a double-roll ball press machine, wherein the forming pressure is 10-30MPa. The preparation method disclosed by the invention has the advantages of strong adaptability to raw material granularity, simple process, low energy consumption, low production cost and high quality of oxidized pellets.

Owner:WUHAN UNIV OF SCI & TECH

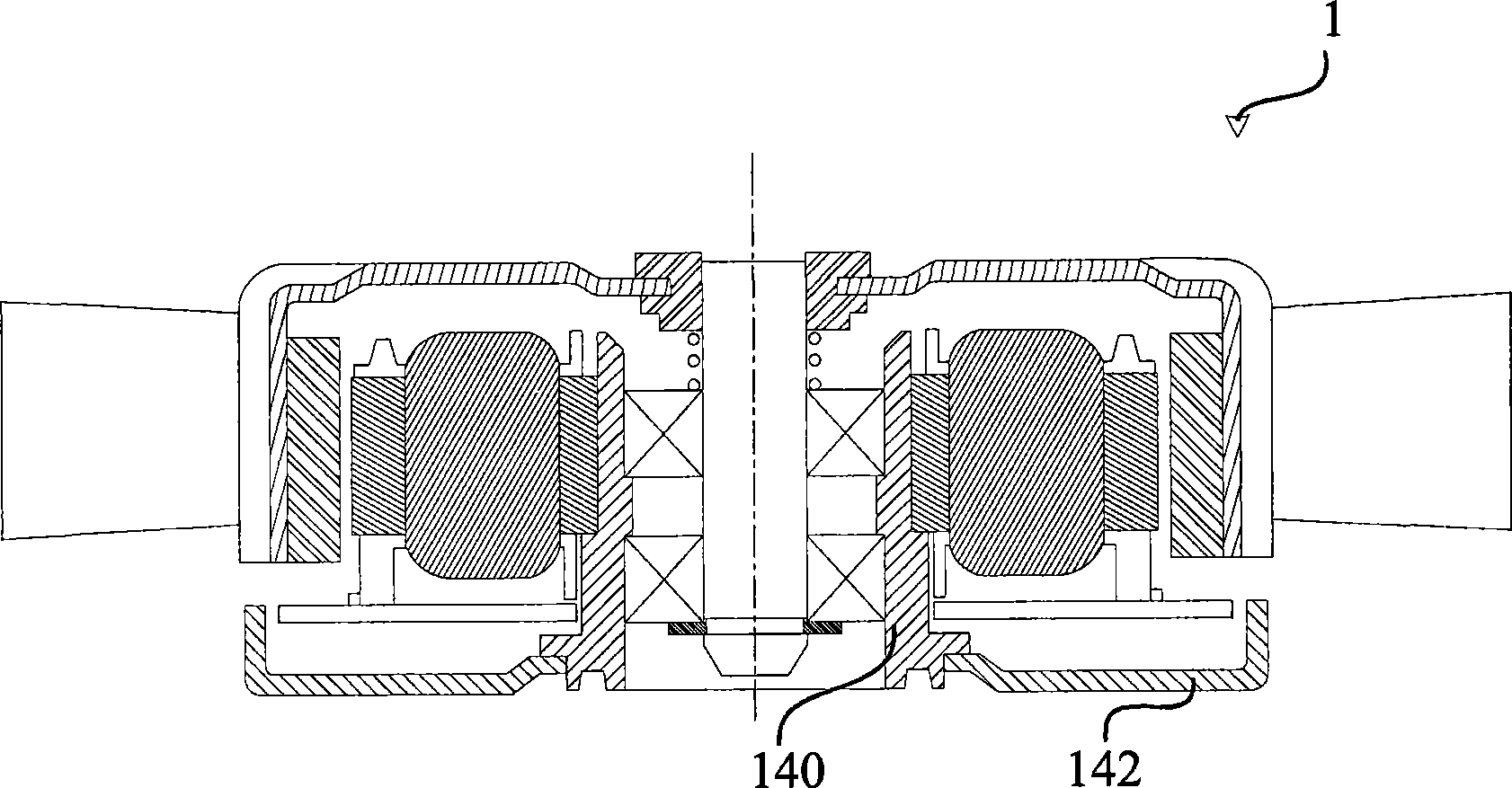

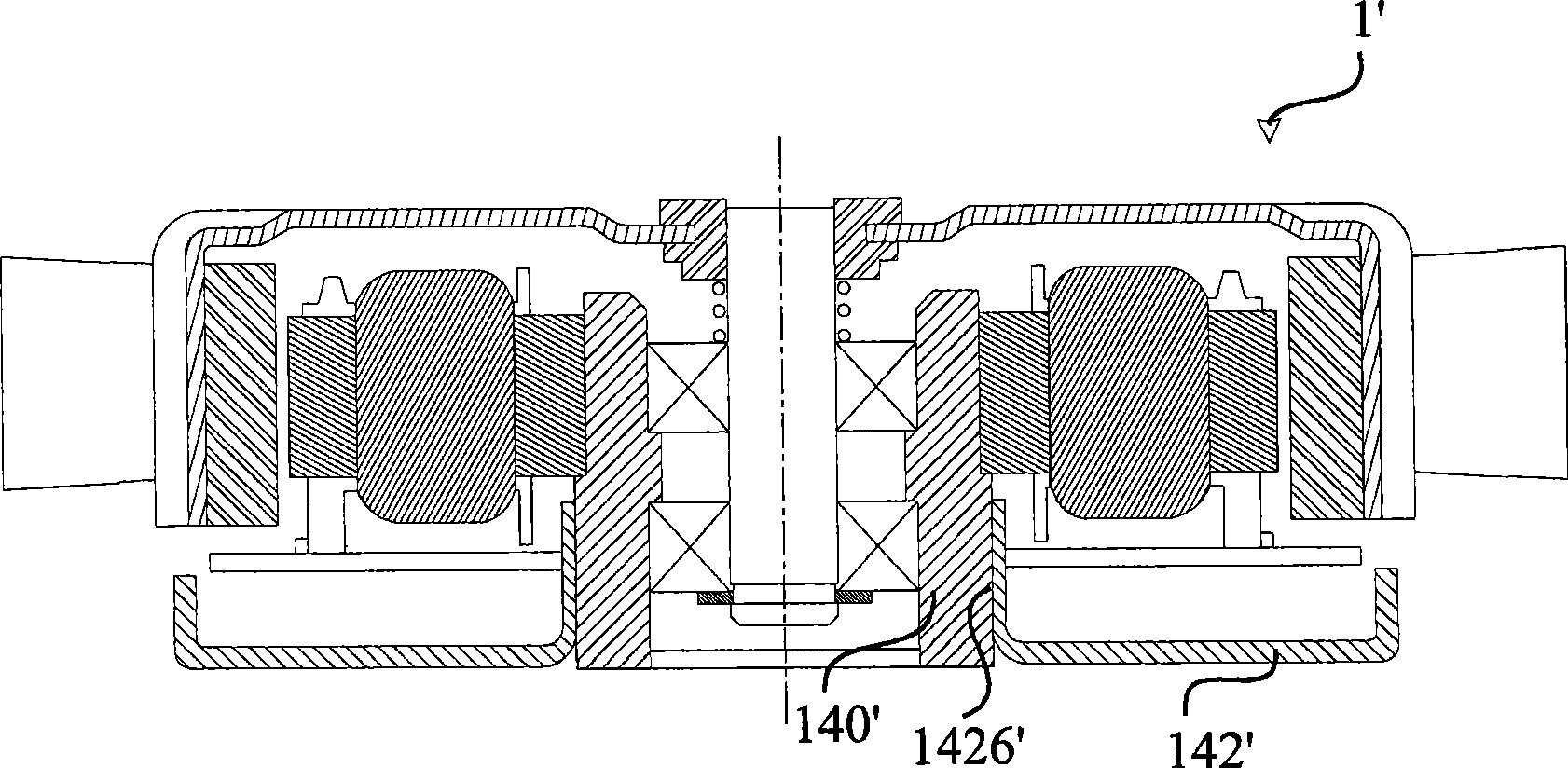

Fan and stator holder thereof

InactiveCN101469720AGood bonding effectImprove base strengthPump componentsPump installationsStatorEngineering

The present invention discloses a fan stator permanent seat which is used to bear a stator structure of a fan, wherein the fan stator permanent seat includes a plastic rubber bearing sleeve and a metal base plate. The metal base plate is provided with a interconnecting piece which is covered by the plastic rubber bearing sleeve.

Owner:DELTA ELECTRONICS INC

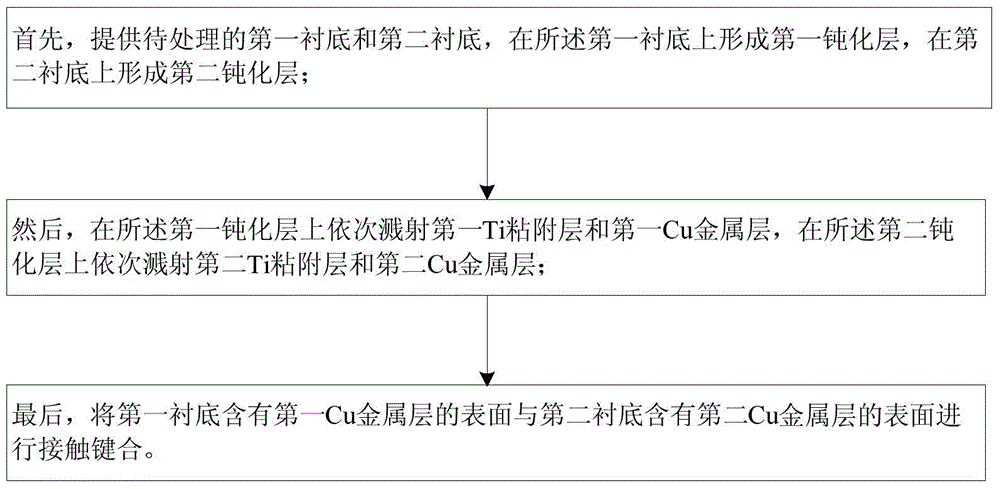

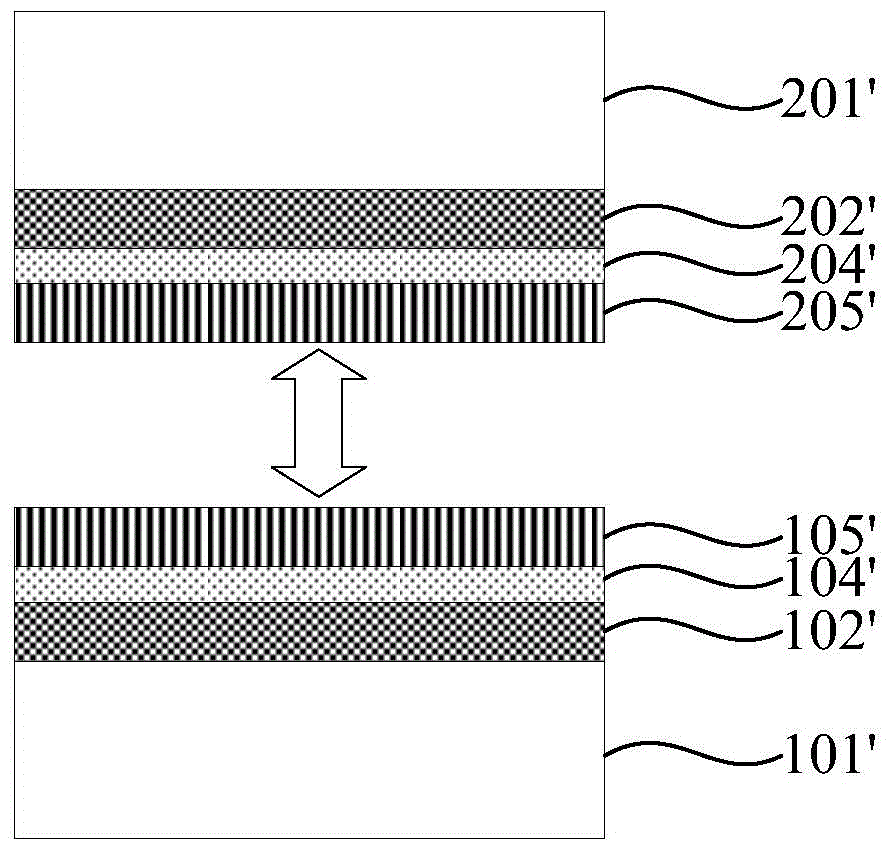

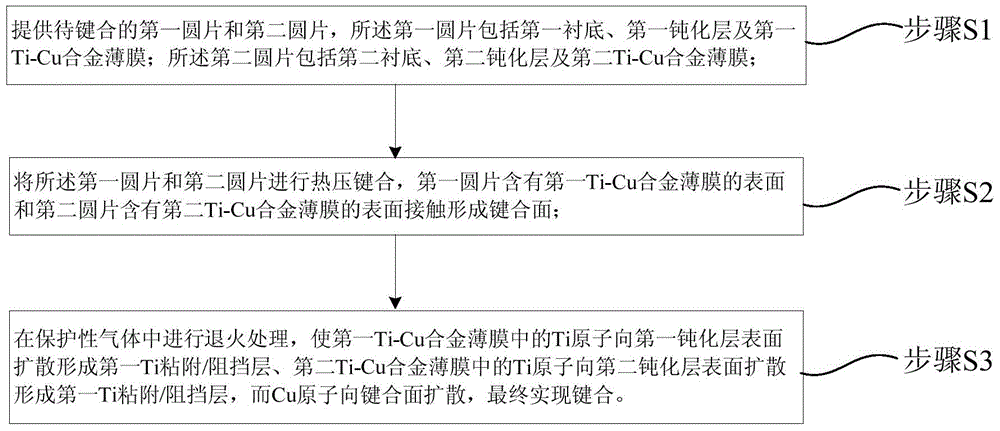

Copper-copper metal thermal pressing bonding method

InactiveCN104465428AGood bonding effectImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveTi-Cu alloy

The invention provides a copper-copper metal thermal pressing bonding method. The method at least comprises the following steps: first of all, providing a first wafer to be bonded and a second wafer to be bonded, wherein the first water comprises a first substrate, a first passivation layer and a first Ti-Cu alloy film, and the second wafer comprises a second substrate, a second passivation layer and a second Ti-Cu alloy film; then, performgin thermal pressing bonding on the surface of the first Ti-Cu alloy film of the first wafer and the surface of the second Ti-Cu alloy film of the second wafer; and finally, performing annealing processing in a protective gas to enable Ti atoms in the first Ti-Cu alloy film to diffuse towards the surface of the first passivation layer and Ti atoms in the second Ti-Cu alloy film to diffuse towards the surface of the second passivation layer so as to finally form Ti adhesive / barrier layers on the surfaces of the first passivation layer and the second passivation layer, and Cu atoms diffusing towards a bonding surface so as to realize bonding. According to the method provided by the invention, before the bonding, what is needed is only to respectively perform co-sputtering on the two substrates for once, such that the sputtering frequency is reduced by half, the process is relatively simple, the reliability is good, the technical cost is quite low, and finally, the Ti adhesive / barrier layer are formed through diffusion after the annealing processing, and the copper bonding effect is better.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Acrylic glue and manufacturing process of composite acrylic plate using same

InactiveCN110079253AFast curingGood bonding effectSynthetic resin layered productsLaminationEthyl acetateEthyl ester

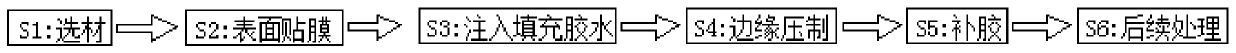

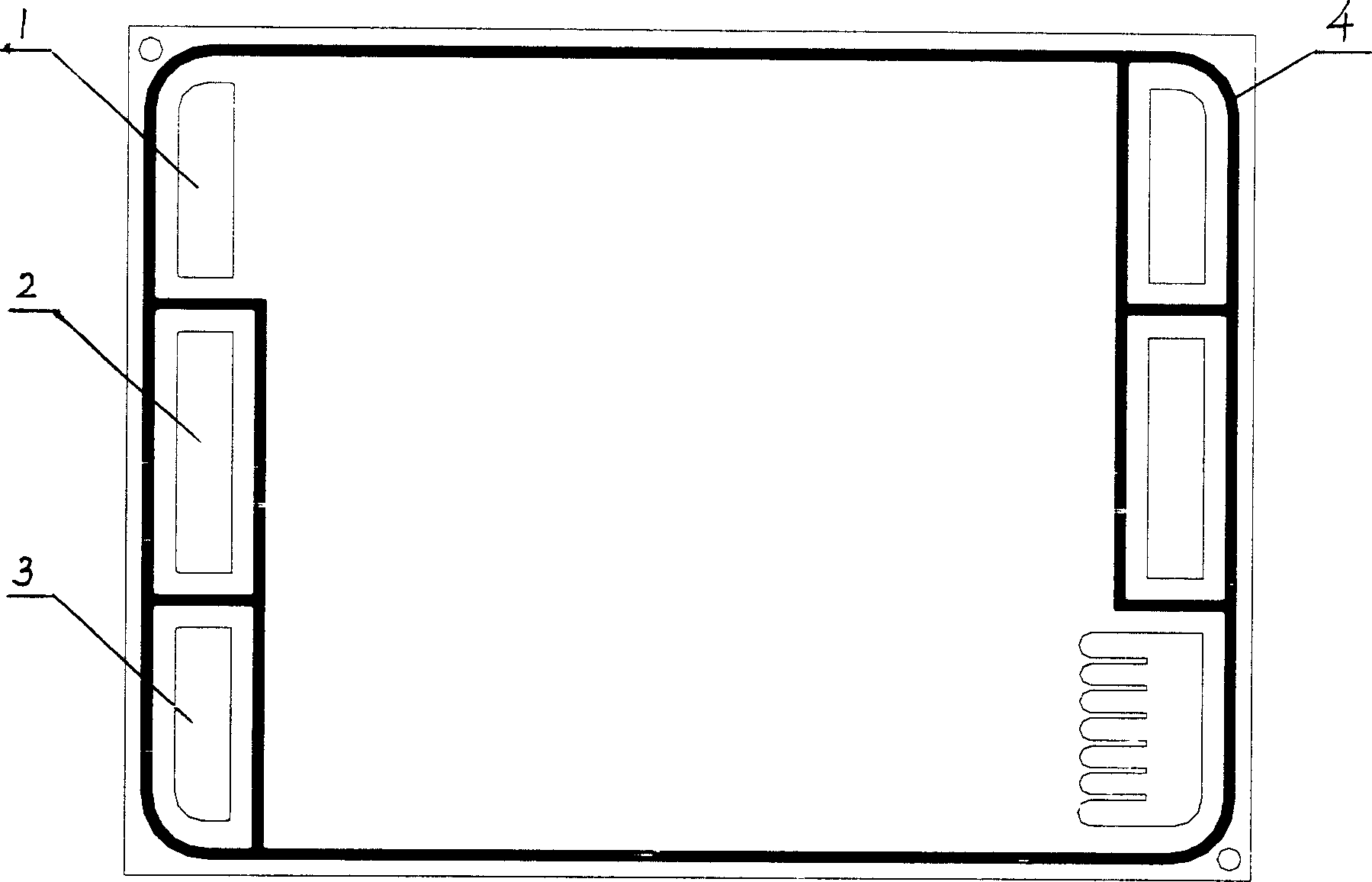

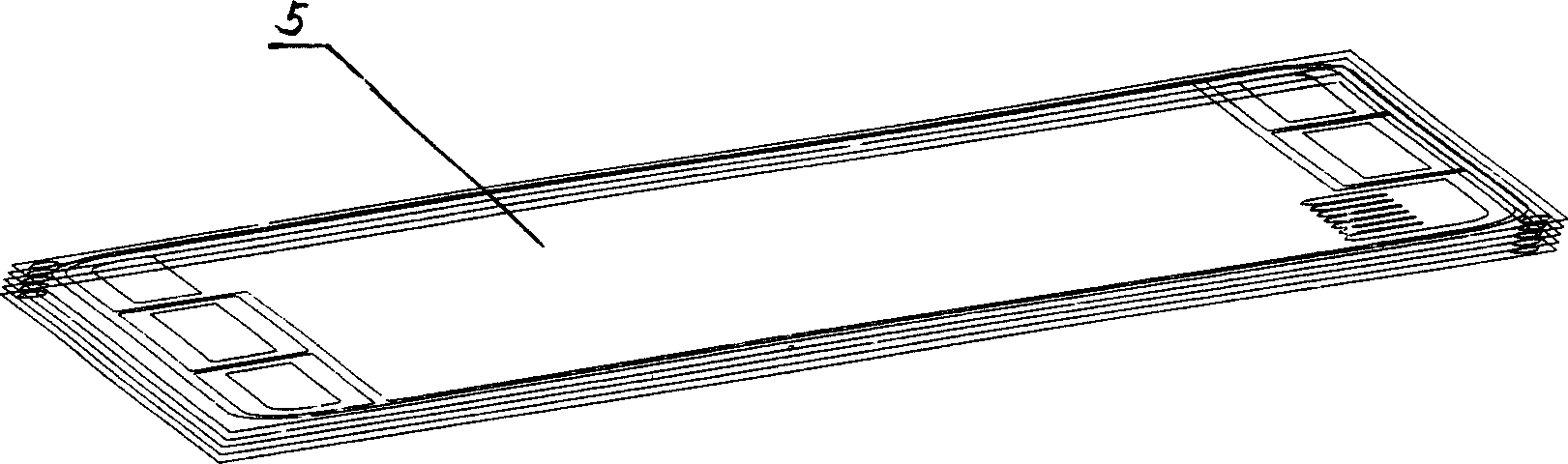

The invention provides acrylic glue. The acrylic glue comprises the following raw materials in parts by weight: 10 to 25 parts of PMMA resin, 40 to 60 parts of ethyl acetate, 20 to 35 parts of dichloromethane, 0.005 to 0.02 part of a curing agent, 0.3 to 0.7 part of a light diffusant and 0.1 to 0.25 part of trichloromethane. A composite acrylic plate manufactured by the acrylic glue comprises a bottom layer plate, a glue layer and an upper layer plate; and the glue layer is formed after the acrylic glue is solidified; a gap between the bottom layer plate and the upper layer plate is filled with the glue layer. The manufacturing process of the composite acrylic plate comprises the following steps: S1, selecting materials; S2, sticking a film on the surface; S3, injecting filling glue; S4, performing edge pressing; S5, supplementing glue; and S6, performing subsequent treatment. The acrylic glue provided by the invention has the advantages of high curing rate, excellent adhesion effect,less possibility of cracking and no bubble and crystallization defects during adhesion; and the composite acrylic plate manufactured by the acrylic glue through adhesion has stronger transmitting brightness and can reduce the energy consumption of a light source compared with a traditional composite acrylic plate.

Owner:东莞市德宝展示用品有限公司

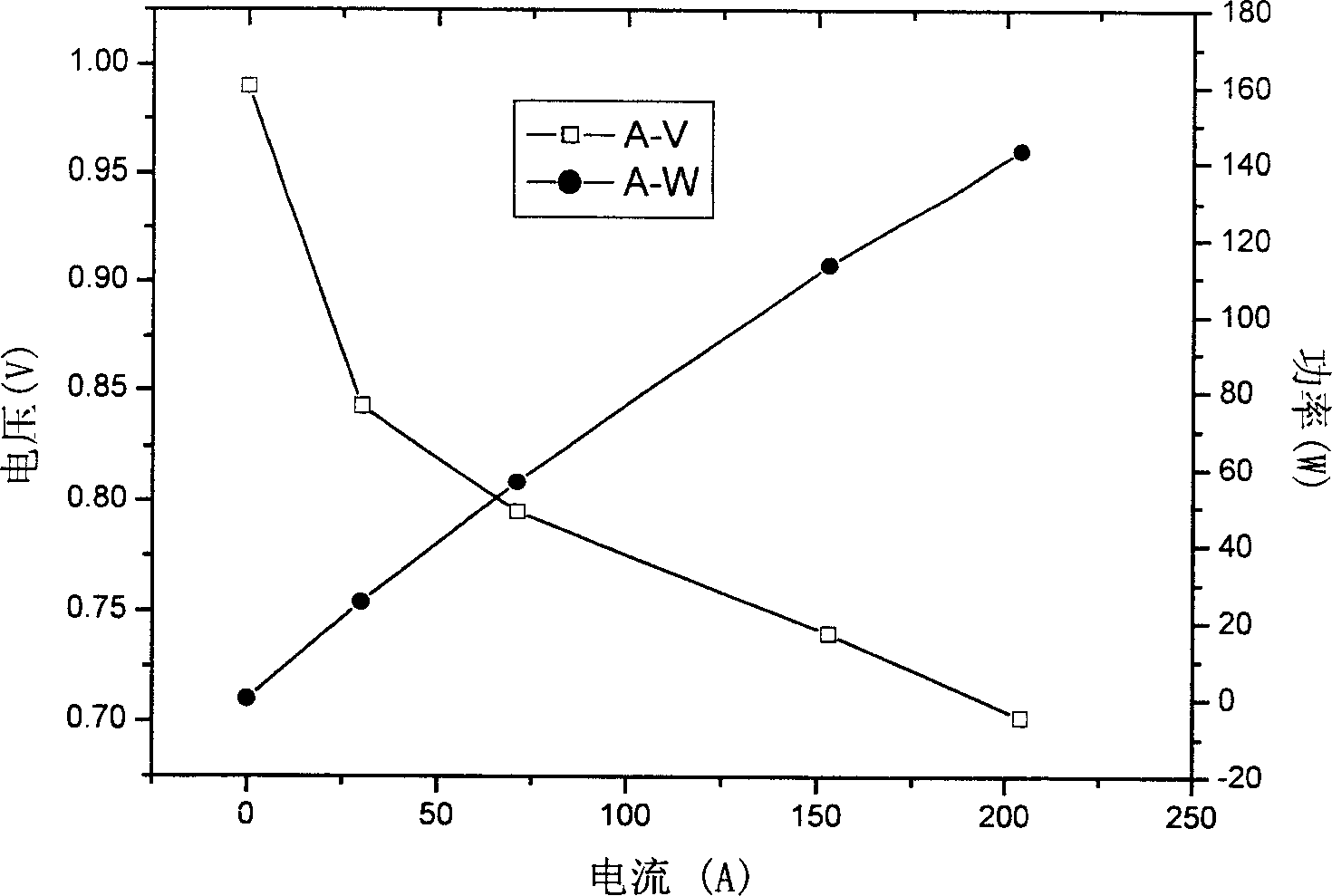

Metal bipolar plate used for proton exchange film fuel cell and preparative method

ActiveCN1812171AGood bonding effectStrong and reliable sealingCell electrodesCollectors/separatorsPhosphoric acidAdhesive

This invention relates to a kind of metal double-polar plate and its producing method used in proton exchanging membrane fuel cell under special situation. The said double-polar plate is arranged with gas and liquid chamber. A layer of potted line is evenly cemented at working area circumference of double-polar plate and circumference of gas, liquid chamber. The producing method of the said double-polar plate is: adhesive phosphoric acid, which weight percent is no less than 85%, is evenly smeared on working area circumference of double-polar plate and circumference of gas, liquid chamber. Conductive adhesive is evenly cemented around the double-polar plate as potted line. The pressure and temperature are produced on vulcanizing machine. The pressure is controlled below 0.1MPa. The temperature of vulcanizing machine is controlled between 150DEG C-240DEG C. This invention resolves question of sealing between gas chamber and gas chamber, gas chamber and environment in battery.

Owner:中钛国创(青岛)科技有限公司

Crack-resistant long-life door and window joint filling and sealing mortar manufacturing method

The invention discloses a crack-resistant long-life door and window joint filling and sealing mortar manufacturing method. A problem that comprehensive performances of present cement mortars often cannot reach demands when the cement mortars are used in the door and window joint filling treatment is solved. The method comprises the following steps: 1, preparing an active mixed solid material: uniformly mixing active silica, quartz sand, diatomite, an air entraining agent, a water reducer and hydrophobic powder; 2, preparing a mixed solution: dissolving a K-11 mortar crack resisting agent in a proper amount of water, wherein the addition amount of water is 30-40% of the amount of cement; and 3, preparing a mortar: respectively injecting the mixed solution, cement and the active mixed material into a double shaft mixer in a stirring state through a water pump and an injection machine according to a certain ratio, and uniformly stirring to prepare the cement mortar. The cement mortar prepared in the invention has the advantages of excellent waterproof effect, good bonding effect, excellent crack resistance and long service life.

Owner:SICHUAN YAHAO REAL ESTATE DEV

Method for veneering at surface of wood-plastic composite material

The invention discloses a method for veneering at the surface of a wood-plastic composite material, relates to a veneer decorating method of the wood-plastic composite material, and aims at solving the problems of difficult veneering at the surface of the traditional polyolefin wood-plastic composite material, complicated process and high cost. The method comprises the following steps of: 1, preheating; 2, preparing a veneer sheet; and 3 cooling and finalizing the design to finish veneering. The veneering method disclosed by the invention is simple and convenient to operate, high in surface bonding strength, and economical in energy source. By adopting the method disclosed by the invention, auxiliary facilities such as coating equipment and glue preparation equipment are not needed; a special adhesive is not used; and special surface treatment is also not needed, so that the cost is reduced. The wood-plastic composite material adopts non-polar thermoplastic plastic as a substrate, and does not generate incompatibility with polar lignocellulosic materials; and the wood-plastic composite material and the polar lignocellulosic materials cannot be firmly bound together by common adhesive easily. According to the method, a surface decorative material and the wood-plastic composite material are firmly spliced by using wood-plastic matrix plastic and a coupling agent with bipolar groups. Therefore, the method can be used for carrying out veneering decoration on the surface of the wood-plastic composite material.

Owner:NORTHEAST FORESTRY UNIVERSITY

Carboxyl rubber adhesive

InactiveCN102850976AGood bonding effectGood adhesionNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesKetoneCarboxylic group

The present invention provides a carboxyl rubber adhesive, which comprises the following components, by weight, 3-5 parts of a carboxyl nitrile rubber, 60-70 parts of methyl ethyl ketone, 20-30 parts of a phenolic resin, 1-2 parts of a coumatone resin, 0.5-1 part of magnesium oxide, 1-2 parts of carbon black, 0.03 part of sulfur, 0.03 part of an accelerator D, and 0.03 part of an anti-aging agent D. The carboxyl rubber adhesive of the present invention has the following technical effects that: the carboxyl rubber adhesive can be used for adhesion of a rubber and a metal, and has a good adhesion effect.

Owner:NANTONG HONGYU CHEM

Rubber and polytetrafluoroethylene bonding method

The invention discloses a rubber and polytetrafluoroethylene bonding method. The rubber and polytetrafluoroethylene bonding method comprises the following steps of: (1) treating the one-sided surface of a turned polytetrafluoroethylene film in a sodium naphthalene treating fluid so as to eliminate free ions on the surface of the polytetrafluoroethylene film and increase surface roughness; (2) coating the one-sided surface, treated by the sodium naphthalene treating fluid, of the polytetrafluoroethylene film with diluted Chemlok 205 base coat, and after completing coating, carrying out drying for 30 minutes in a thermostatic chamber with the temperature of 60 DEG C; (3) coating the dried Chemlok 205 base coat with diluted Chemlok 252X finishing coat, and after completing coating, carrying out drying for 30 minutes in the thermostatic chamber with the temperature of 60 DEG C or carrying out drying for 2 hours at a normal temperature; and (4) putting the polytetrafluoroethylene film treated in the step (3) in a rubber mold, and carrying out sustained pressurization for 600 seconds at the temperature of 160 DEG C+ / -5 under the pressure of 16+ / -1Mpa so as to enable the rubber and the polytetrafluoroethylene to be tightly bonded in a heat vulcanization process, so that the service life of rubber structural components is prolonged.

Owner:SHANGHAI BEST RING TECH

High-power LED heat-dissipation ceramic aluminum nitride substrate containing toughening carbon nanofibers

The invention discloses a high-power LED heat-dissipation ceramic aluminum nitride substrate containing toughening carbon nanofibers. The ceramic substrate uses mixed ionic liquid and deionized water as a solvent medium to replace a toxic organic solvent in a traditional tape casting process, and the dispersibility and associativity of the raw materials are improved. In addition, the high-power LED heat-dissipation ceramic aluminum nitride substrate uses aluminum silicon sol-polyvinyl alcohol as a binder, and the effective components can reduce the oxygen content of sintering atmosphere and improve the purity of aluminum nitride lattices to obtain good heat-conducting property. The added carbon nanofibers can effectively improve the crack resistance strength and fracture toughness of a composite ceramic body and improve the defects of traditional aluminum nitride ceramics. The ceramic aluminum nitride substrate obtains good heat conductivity effect and excellent mechanical properties under the lower sintering temperature, greatly prolongs the service life of chips when being used as a high-power LED chip substrate and has good market efficiency.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com