Macromolecule bonding agent and preparation method thereof

A technology of bonding agent and macromolecule, which is applied in the field of macromolecular bonding agent and its preparation, can solve the problems of large difference in polymerization reactivity ratio and difficult control of reaction, and achieve excellent mechanical properties and excellent bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

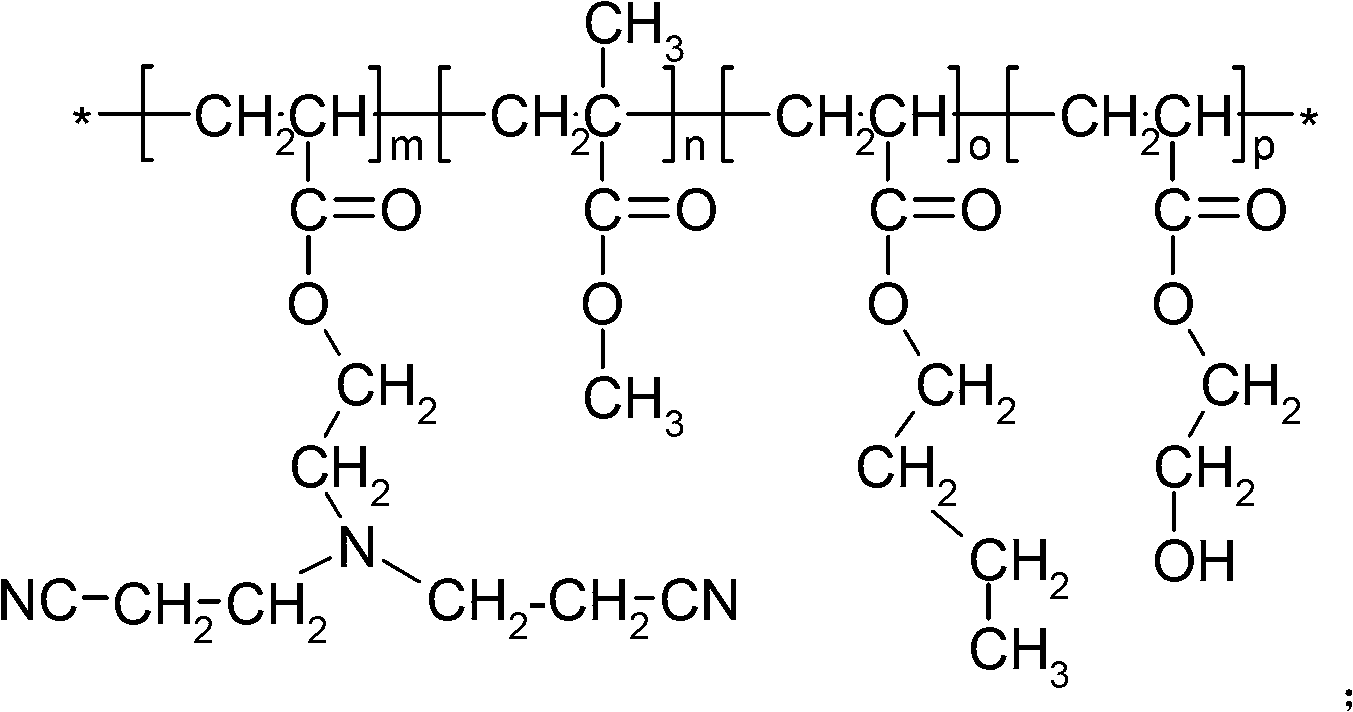

Method used

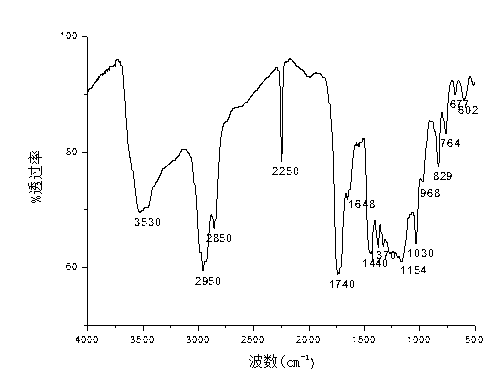

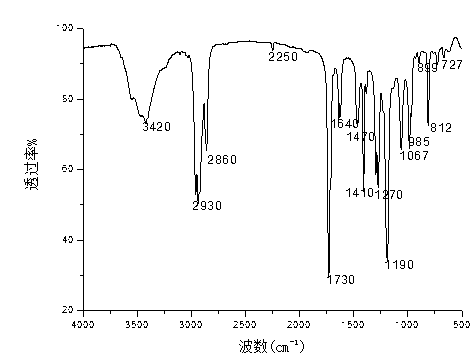

Image

Examples

Embodiment 1

[0034] The four-neck flask was equipped with mechanical stirring, reflux condenser, thermometer and addition funnel, and was cooled with ice water. First add 305 grams of aminoethanol and 980 grams of distilled water, and after cooling to 0-15°C, slowly add 583 grams of acrylonitrile dropwise. The reaction is exothermic, and the rate of addition is controlled so that the temperature of the reaction solution does not exceed 35°C. After the addition is complete, the reaction is continued with natural stirring for 6 hours.

[0035] After stopping the reaction, the reaction solution was transferred to a distillation apparatus, and water and unreacted raw materials were evaporated under reduced pressure at a temperature of 110° C. and a vacuum of 10 mmHg to obtain a total of 802.2 grams of crude product. The crude product was rectified at a temperature of 160°C and a vacuum of 2 to 3mmHg, and a total of 760.6 grams of colorless liquid intermediates with a boiling point of 152 to 15...

Embodiment 2

[0049] In a three-necked flask equipped with electromagnetic stirring, a reflux condenser, a thermometer and an addition funnel, add 630 g of ethyl acetate, 6.5 g of n-dodecanethiol, and 6.2 g of azobisisobutyronitrile, and stir to dissolve. The temperature was raised to 65 oC, and the above-mentioned mixed monomers were added dropwise, and the addition was completed in 30 minutes. After adding, keep warm at 75oC for 3h.

[0050] After the reaction was completed, the solvent was distilled off under reduced pressure at 60° C. and a vacuum of 10 mmHg, and the distillation time was such that no solvent distilled out. Finally, 610.2 g of the orange viscous macromolecular bonding agent product was obtained, with a yield of 98.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com