Polyurethane adhesive for bonding extruded sheet for high-speed railway and preparation method thereof

A polyurethane adhesive, high-speed railway technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of no extruded board adhesive, construction technology and insufficient bonding strength, etc. To achieve the effect of good bonding effect, good elasticity and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

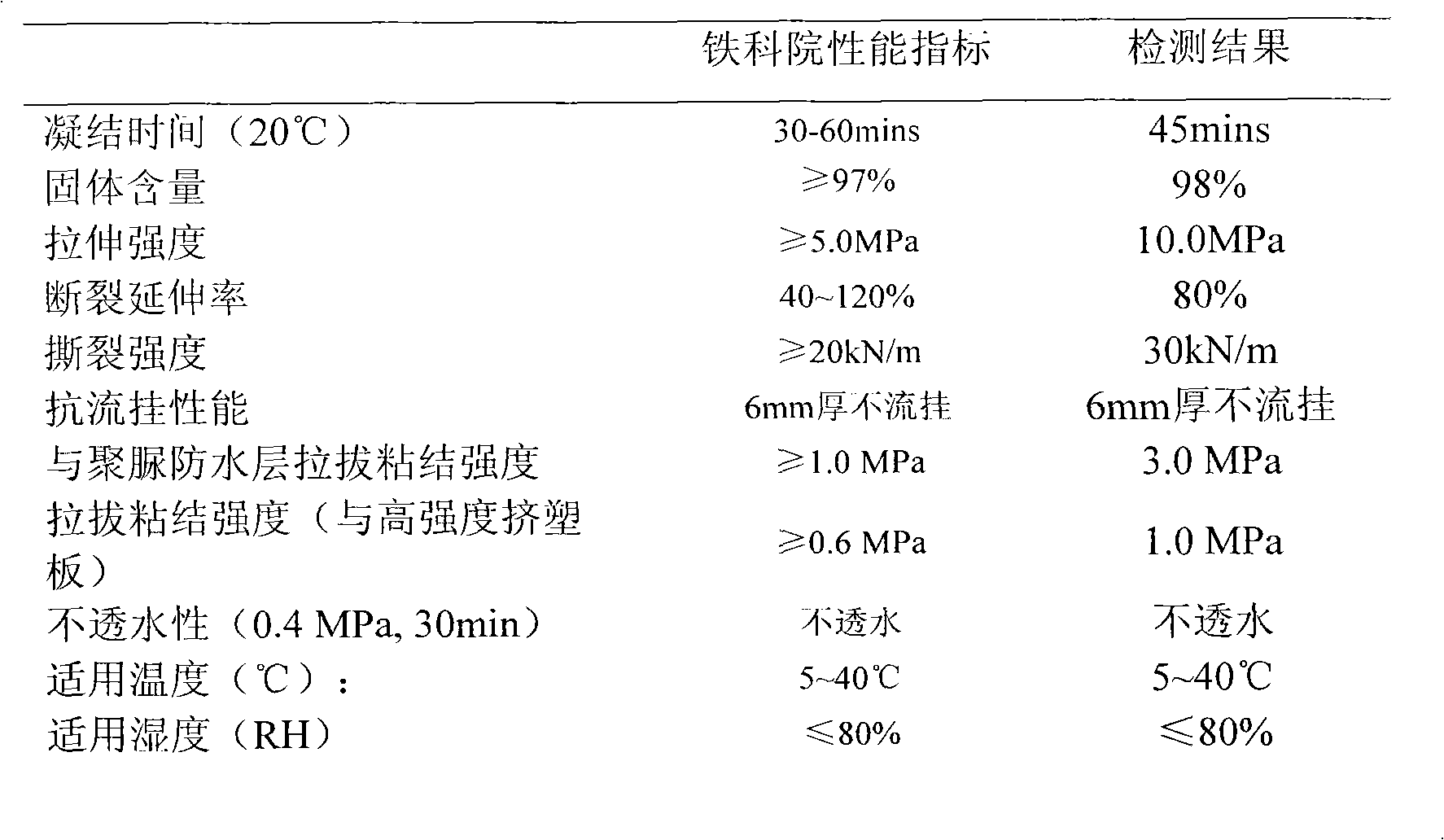

Embodiment 1

[0026] This embodiment provides a polyurethane adhesive, the adhesive is suitable for the adhesive of high-speed railway ballastless track extruded board bonding, the adhesive has a good bonding effect on the concrete board or polyurea waterproof layer and high-strength extruded board, the The adhesive is compounded by the first component and the second component at a mass ratio of 2.85-3.15:1. The isocyanate content of the adhesive is 23%-28% by mass, and the viscosity is 200% at 25°C. ~400mPa·s; Among them, the first component is composed of 30-60% of hydroxyl-terminated polyurethane prepolymer, 5-10% of diluent, 1-3% of small molecule chain extender, and 30-60% of inorganic filler in terms of mass percentage. 60%, anti-sag additive 1-3%, hygroscopic agent 1-3%, defoamer 0.2-0.5% and silicone coupling agent 0.5-2% as raw materials, the combination made by mixing all raw materials evenly thing;

[0027] The hydroxyl-terminated polyurethane prepolymer in the first component i...

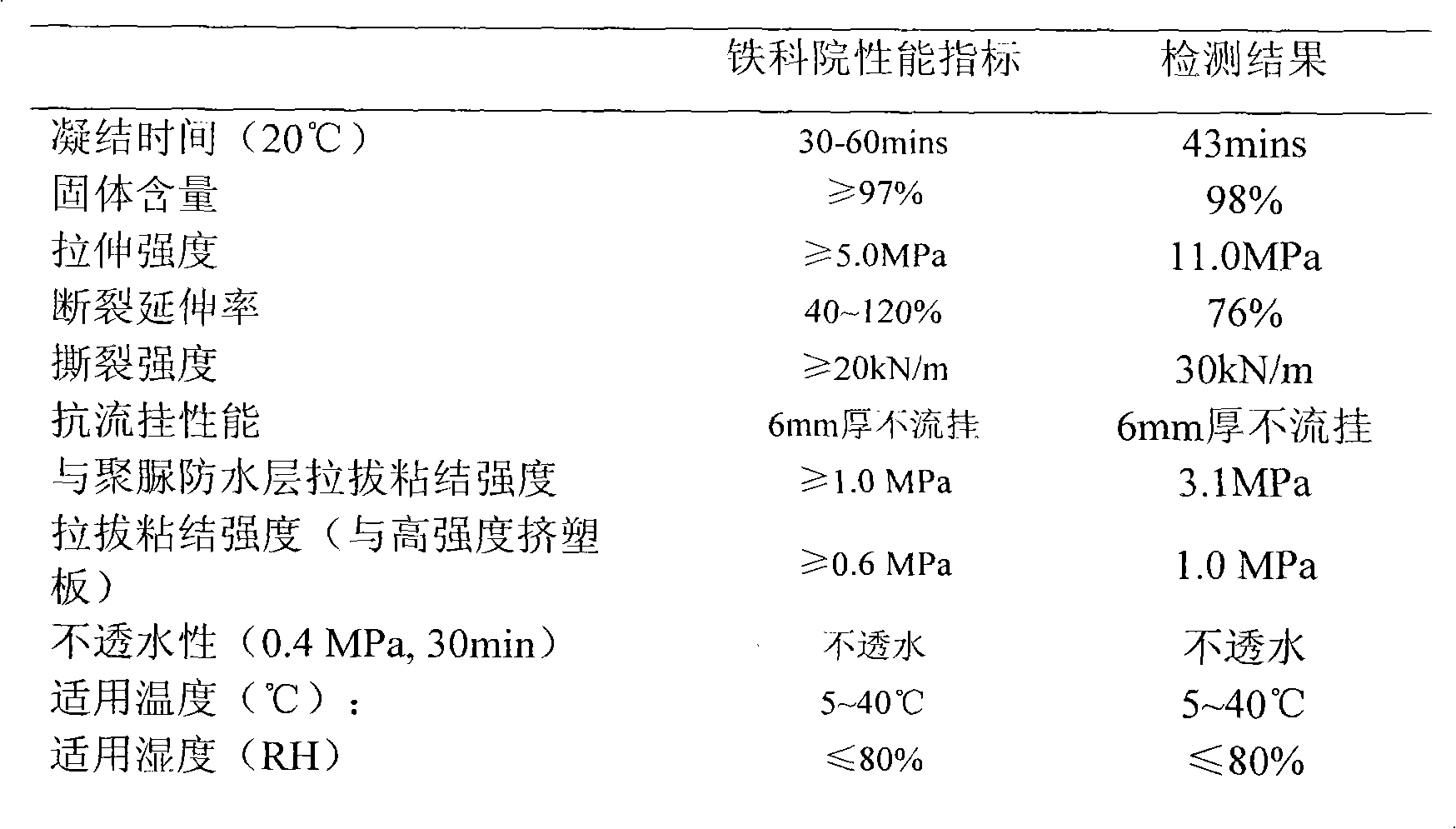

Embodiment 2

[0054] This example provides a method for preparing a polyurethane adhesive, which is an adhesive suitable for bonding extruded boards in ballastless tracks of high-speed railways, and is applied to concrete slabs or polyurea waterproof layers and high-strength extruded boards. Bonding to achieve a good bonding effect, the preparation method specifically includes:

[0055] Preparation of hydroxyl-terminated polyurethane prepolymer:

[0056] Get raw materials according to the following ratio:

[0057] Raw material ratio (parts by mass)

[0058] Polyether trihydric alcohol (molecular weight is 500) 50

[0059] Polyether diol (molecular weight is 400) 12

[0060] Dioctyl phthalate 23

[0061] Diphenylmethane diisocyanate 15;

[0062] Preparation method: Add 50 parts by mass of polyether triol and 12 parts by mass of polyether diol into a synthesis reaction kettle, raise the temperature to 50°C, turn off the heating, and add 15 parts by mass of diphenylmethane diisocyanate Q...

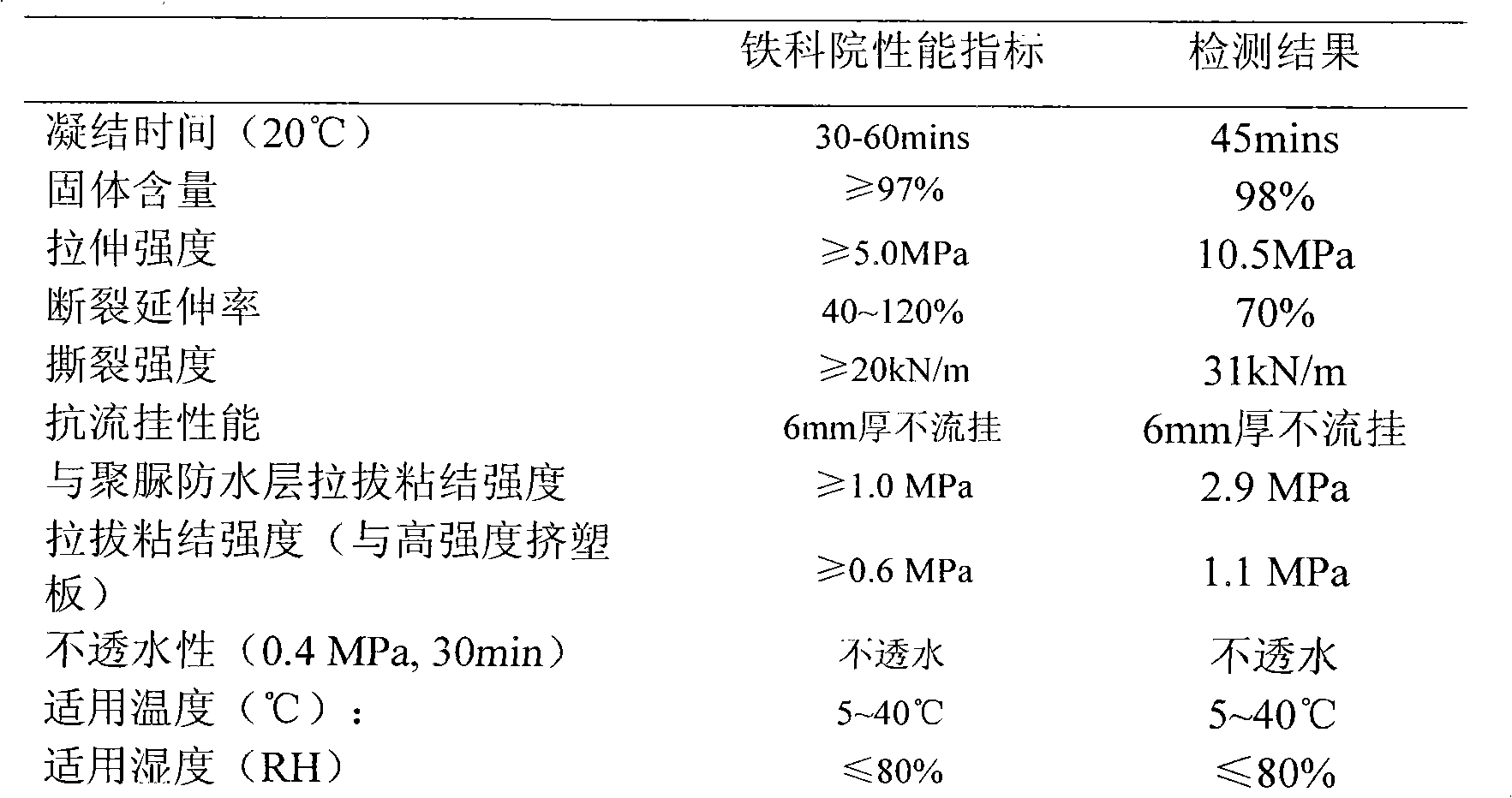

Embodiment 3

[0092] This example provides a method for preparing a polyurethane adhesive, which is an adhesive suitable for bonding extruded boards in ballastless tracks of high-speed railways, and is applied to concrete slabs or polyurea waterproof layers and high-strength extruded boards. Bonding to achieve a good bonding effect, the preparation method specifically includes:

[0093] Preparation of hydroxyl-terminated polyurethane prepolymer:

[0094] Get raw materials according to the following ratio:

[0095] Raw material ratio (parts by mass)

[0096] Polyether trihydric alcohol (molecular weight is 800) 60

[0097] Polyether diol (molecular weight is 2000) 15

[0098] Diisononyl phthalate 15

[0099] Carbodiimide-modified diphenylmethane diisocyanate 10;

[0100] Preparation method: Add 60 parts by mass of polyether triol and 10 parts by mass of polyether diol into a synthesis reaction kettle, raise the temperature to 50°C, turn off the heating, and modify 15 parts by mass of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com