Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2223results about "Shaft assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

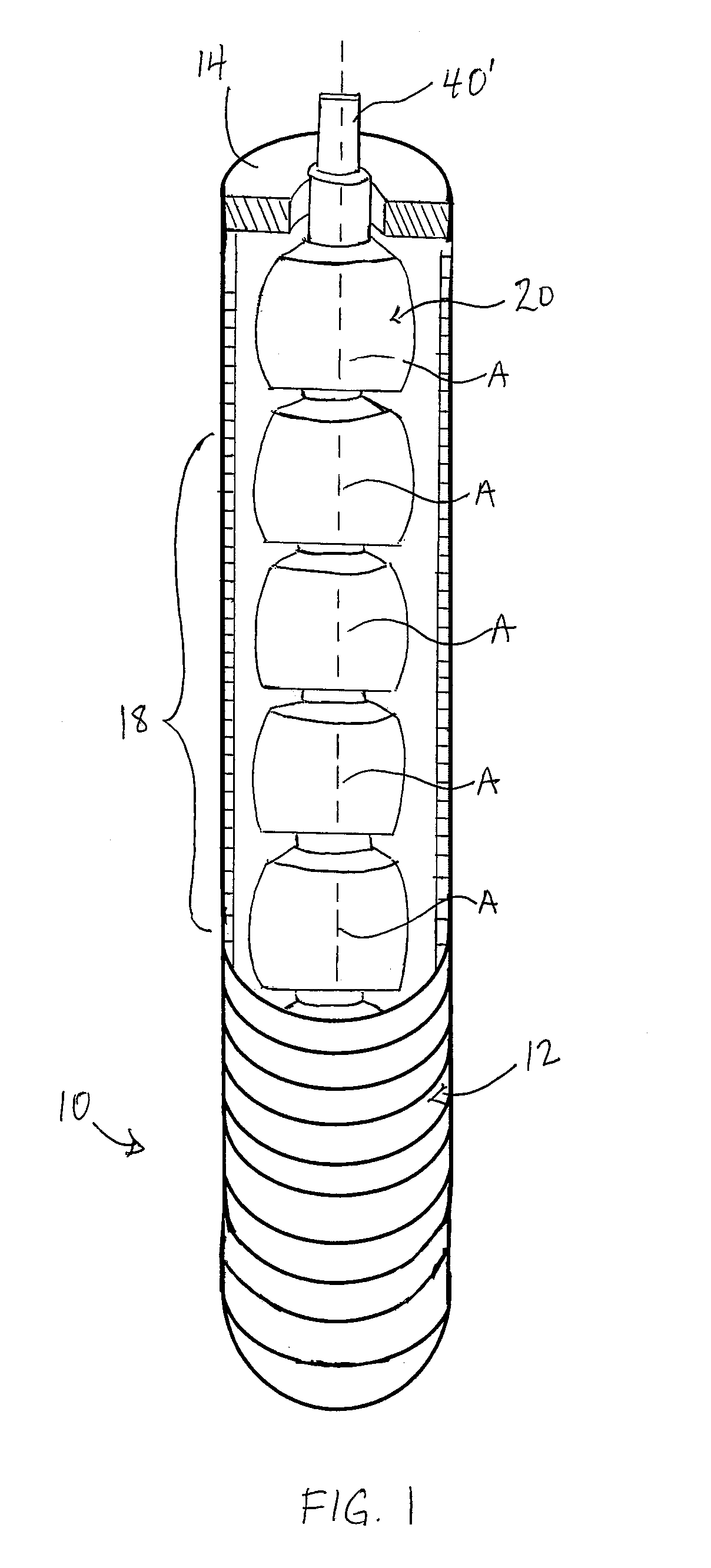

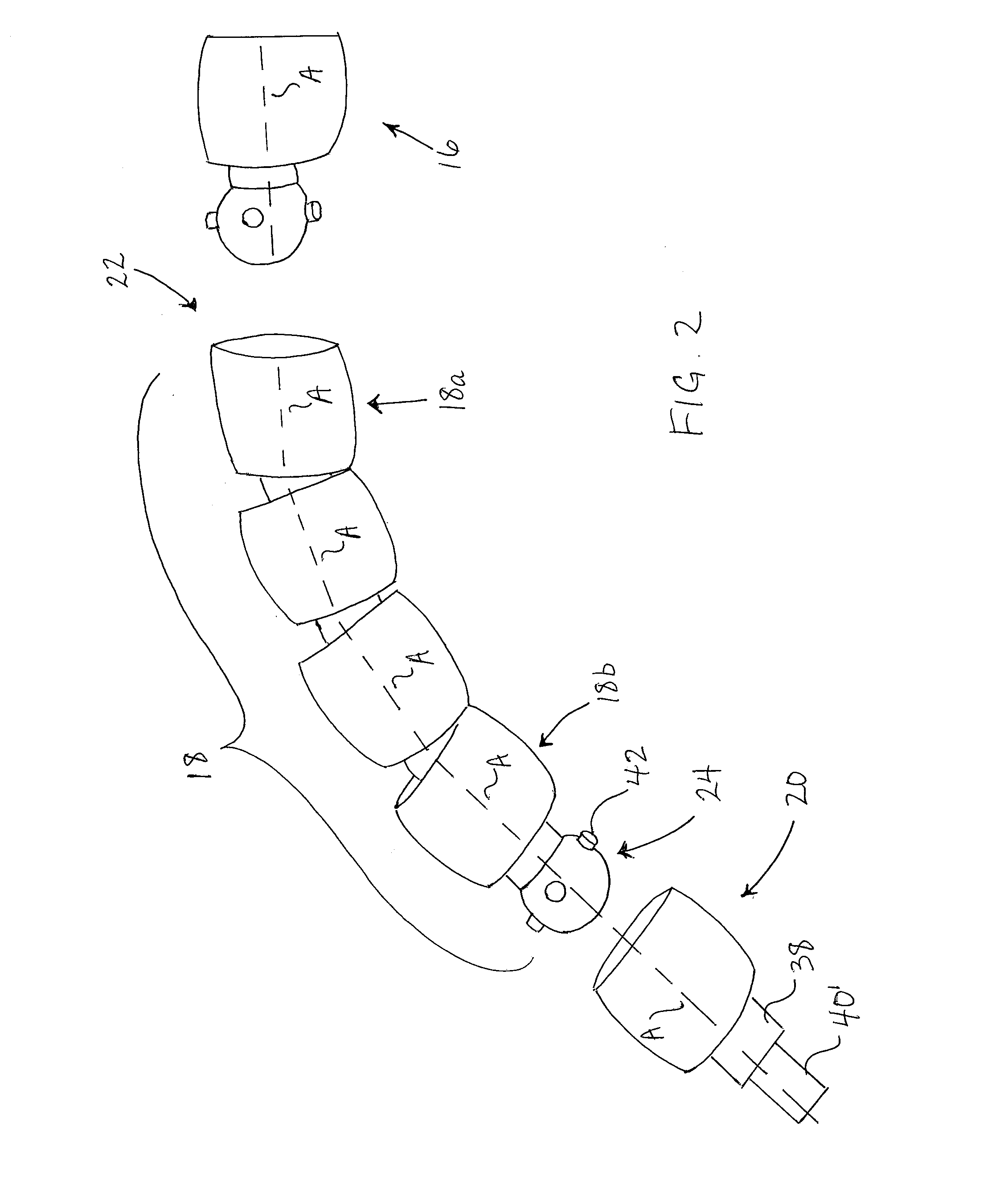

Elongate Flexible Torque Instruments And Methods Of Use

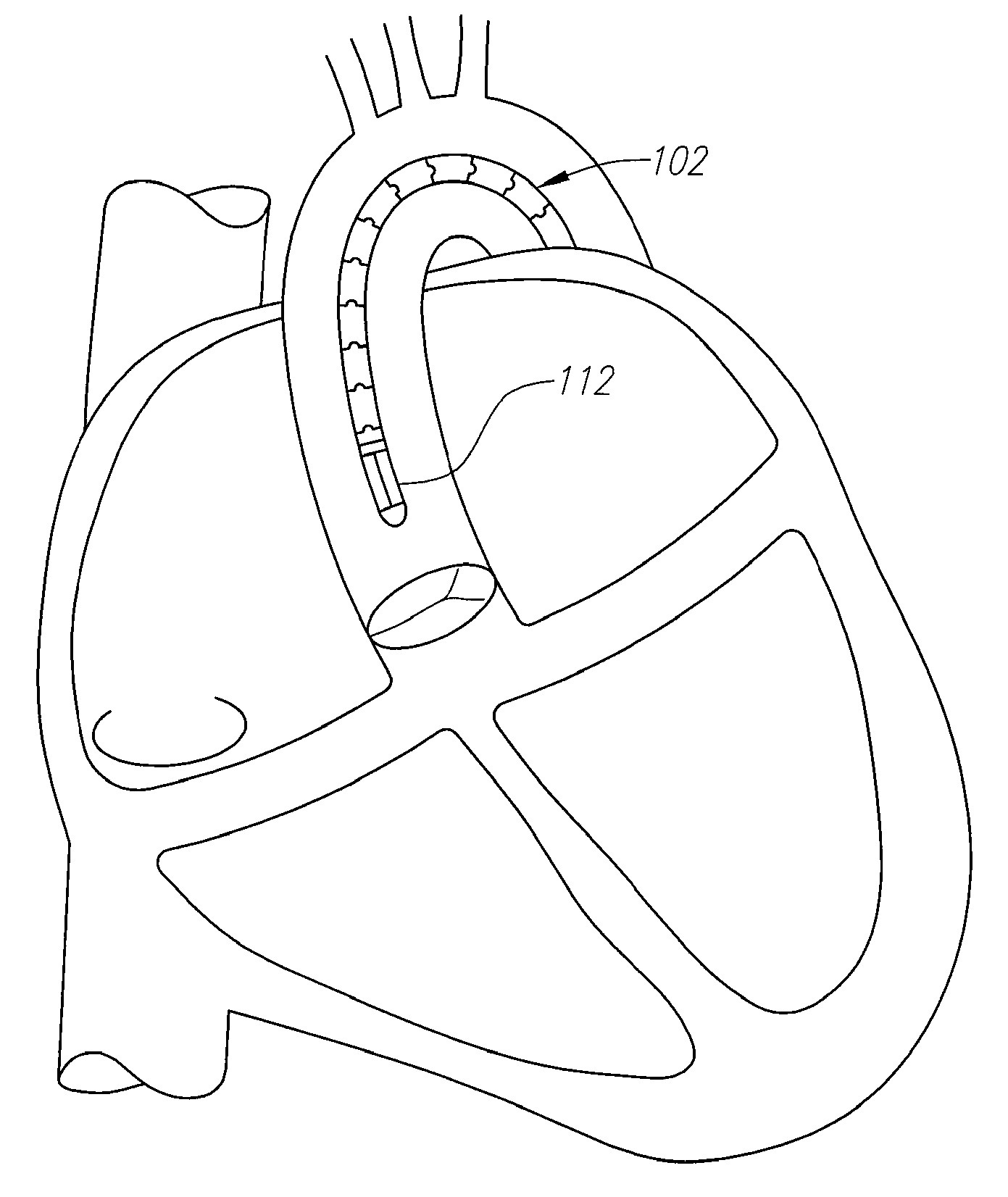

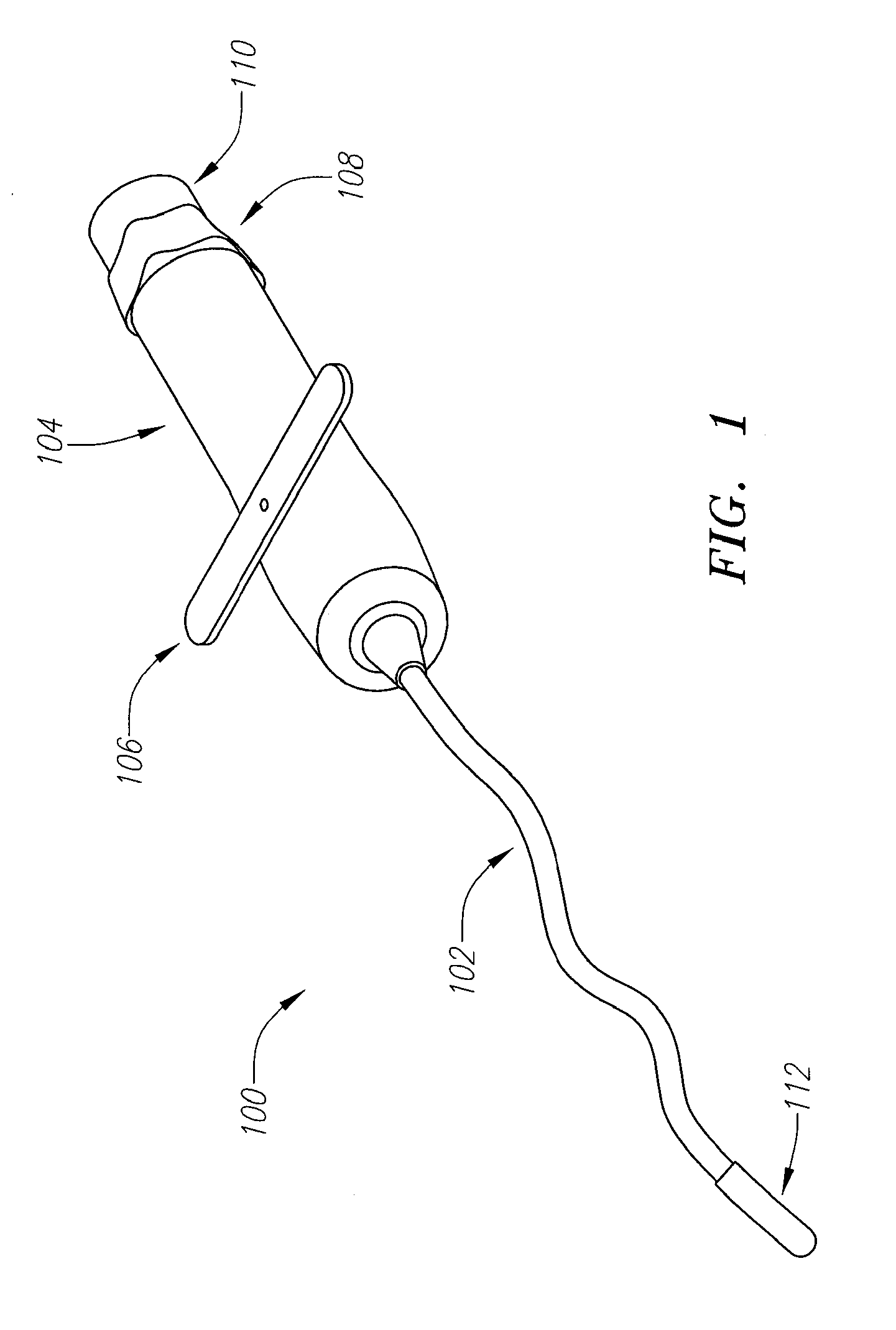

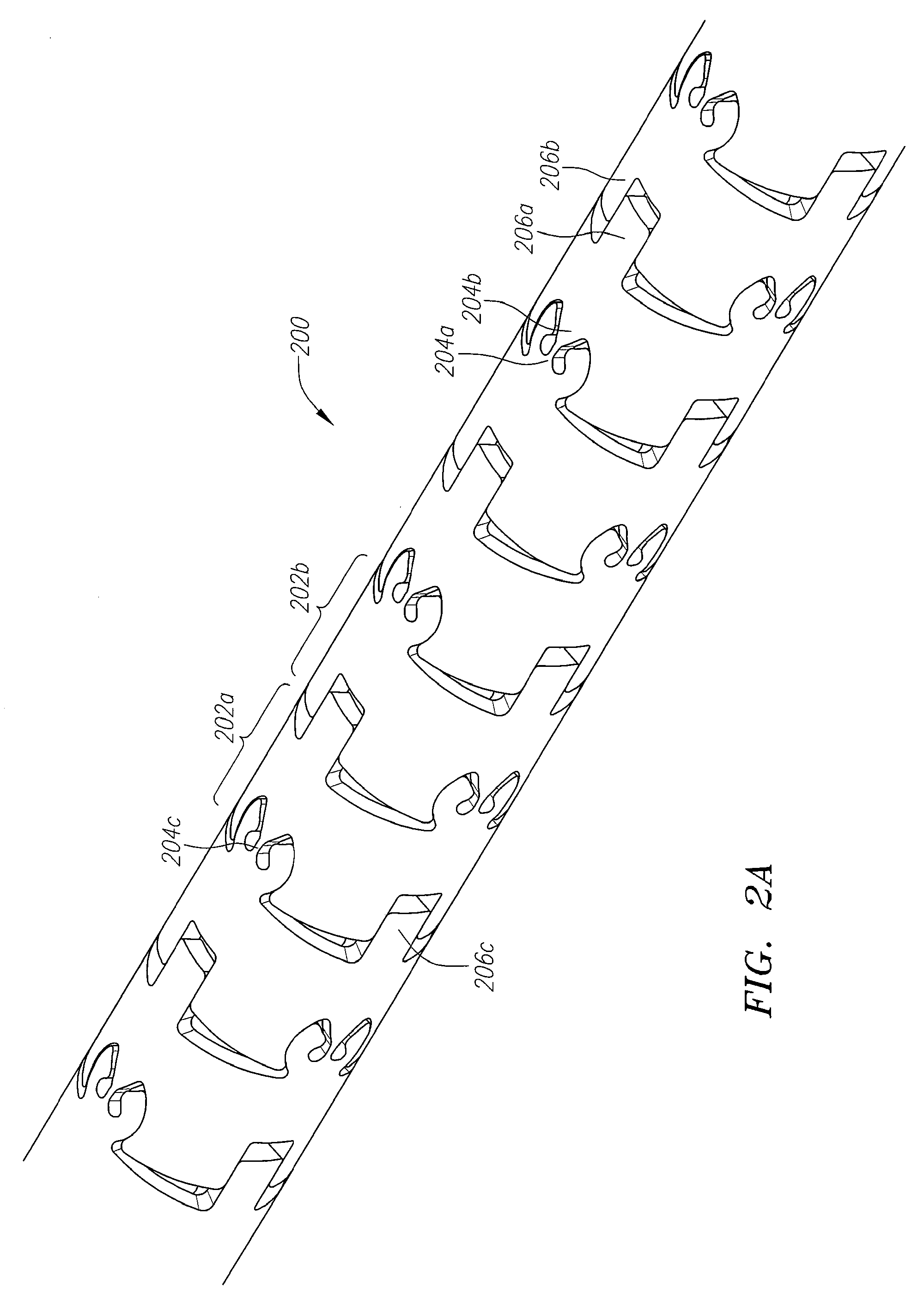

Torque shafts and other related systems and methods are described herein. In one embodiment, the torque shafts are both flexible and capable of transmitting torque. An apparatus for transmission of torque includes an elongate body, comprising a plurality of joint segments, each joint segment configured to pivot with respect to an adjacent segment and being further configured to have at least two link elements.

Owner:AORTX

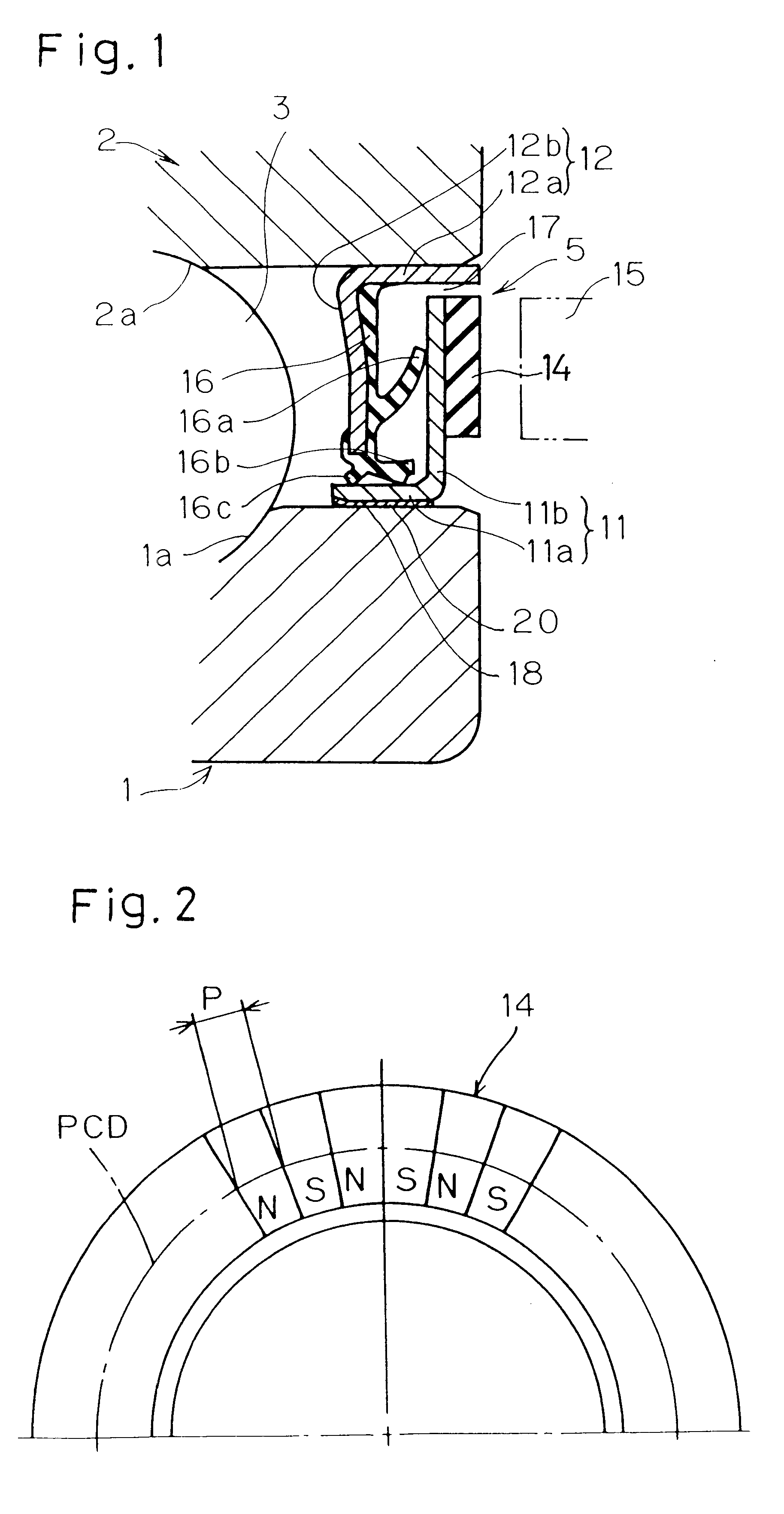

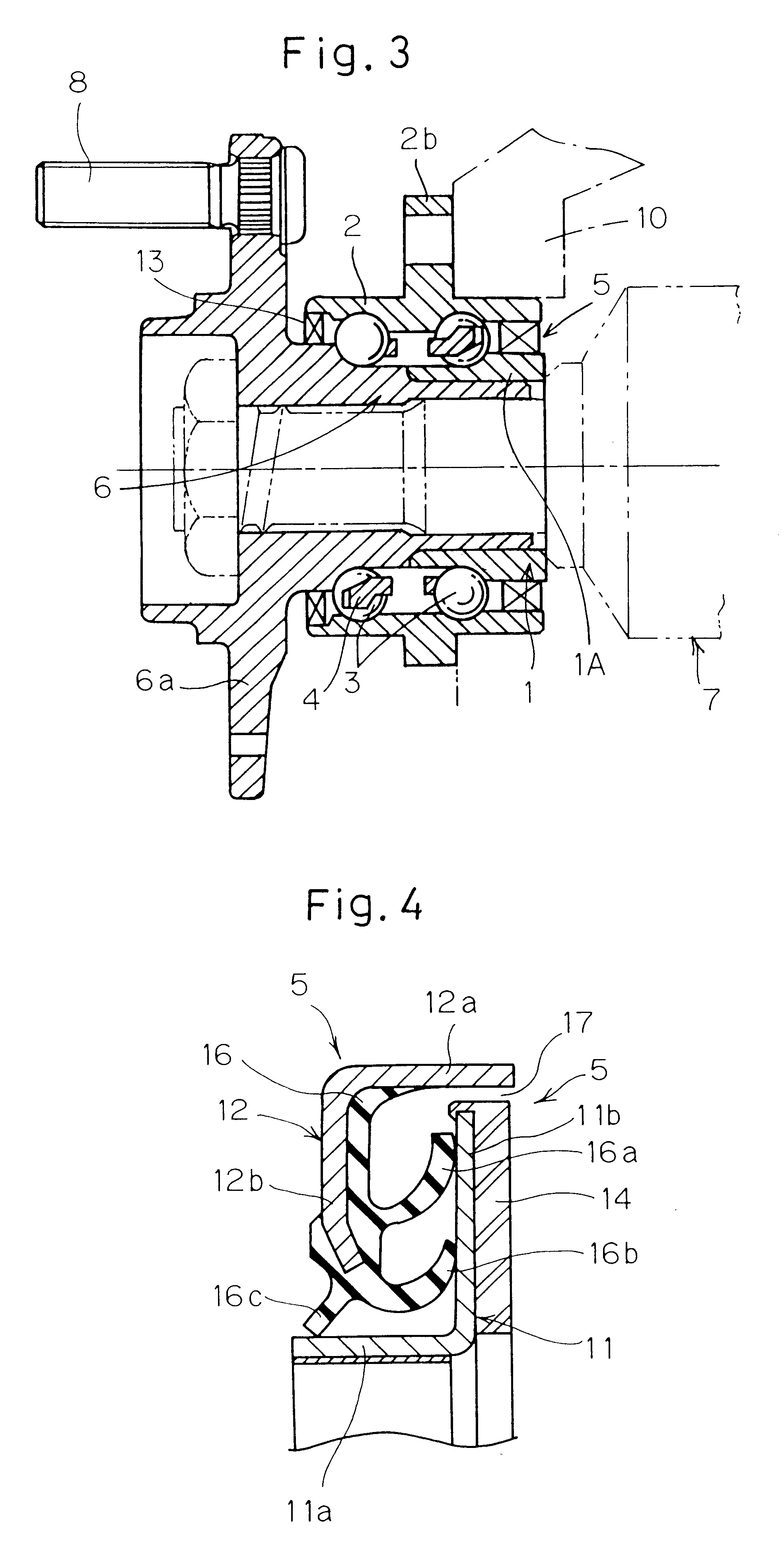

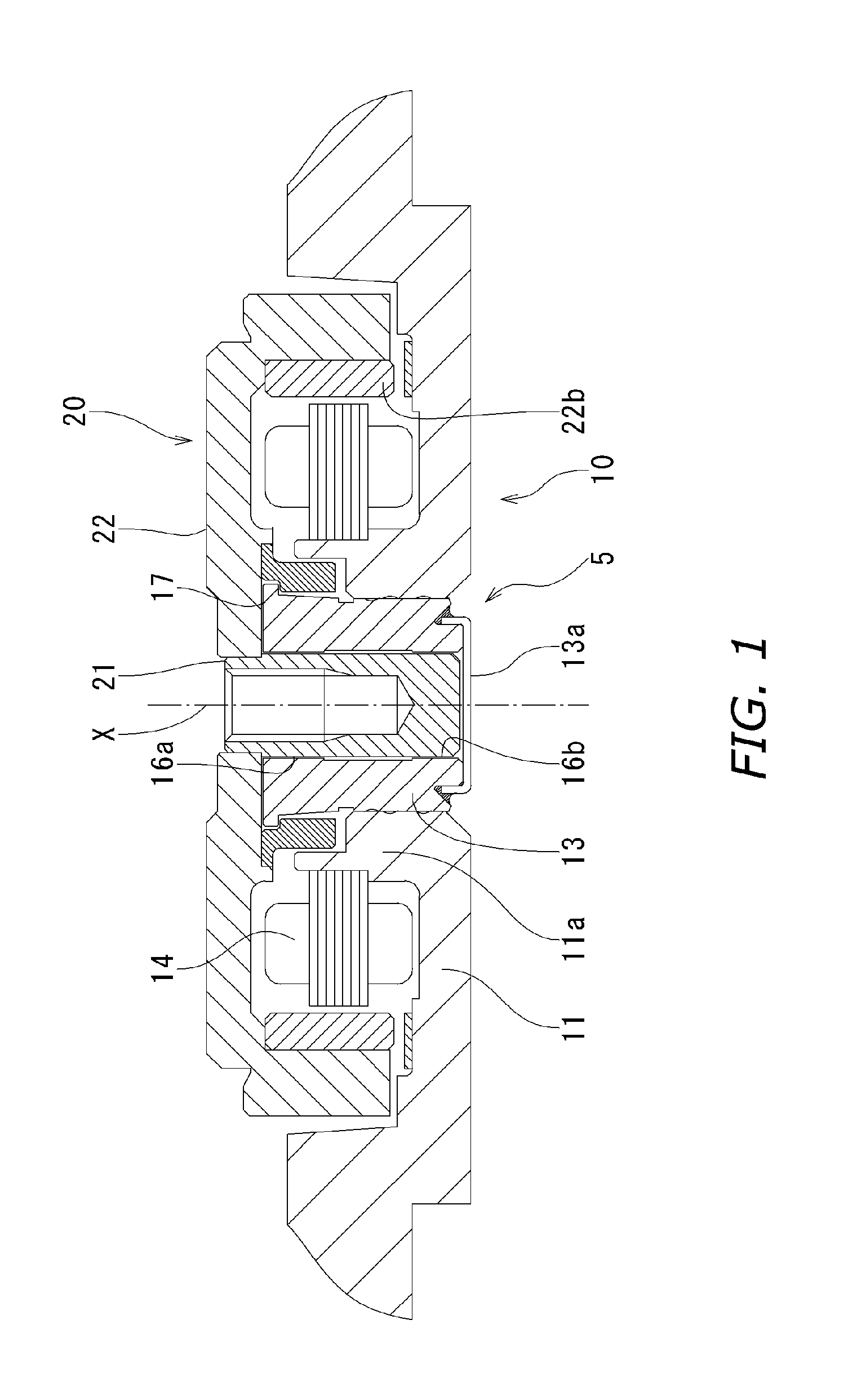

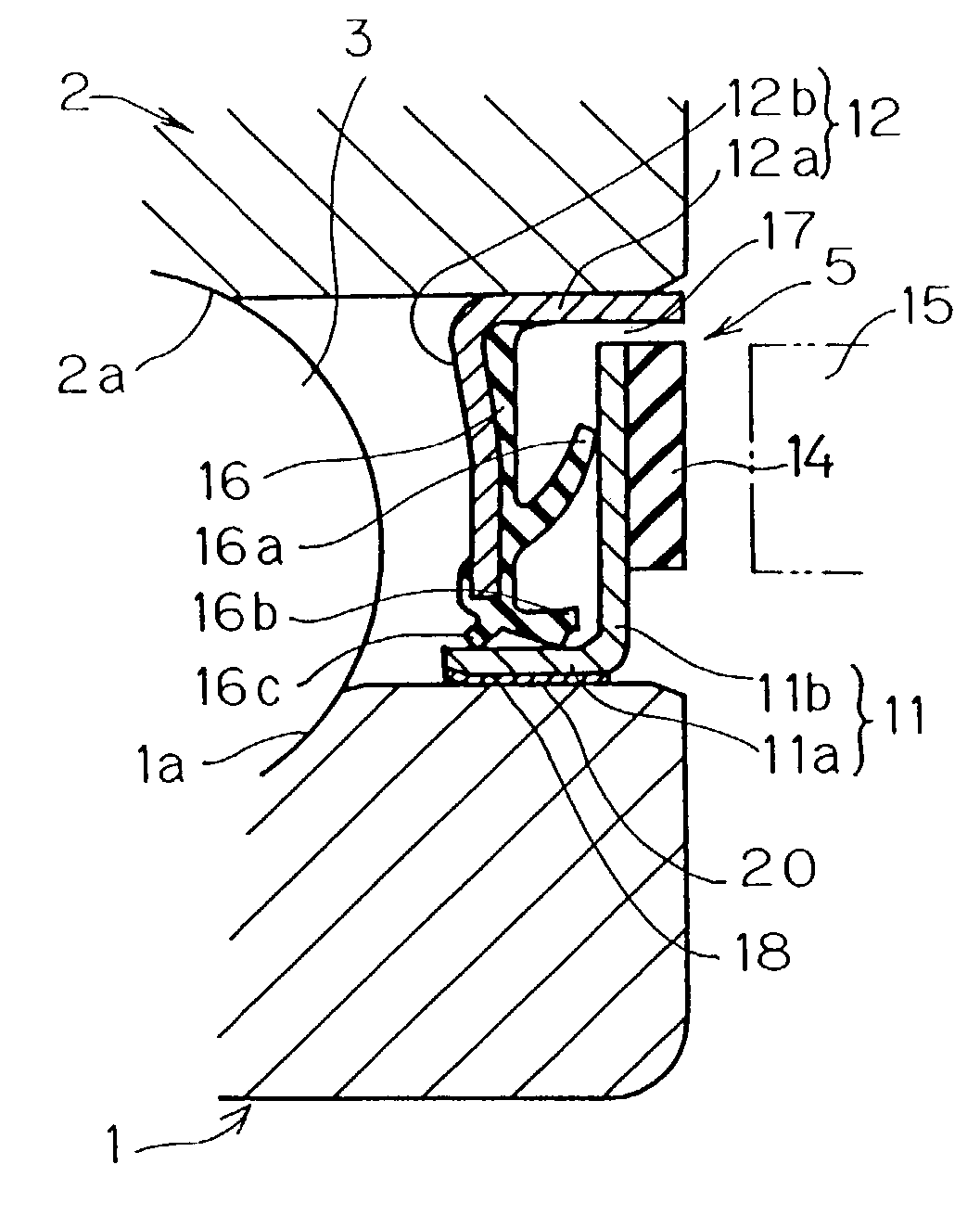

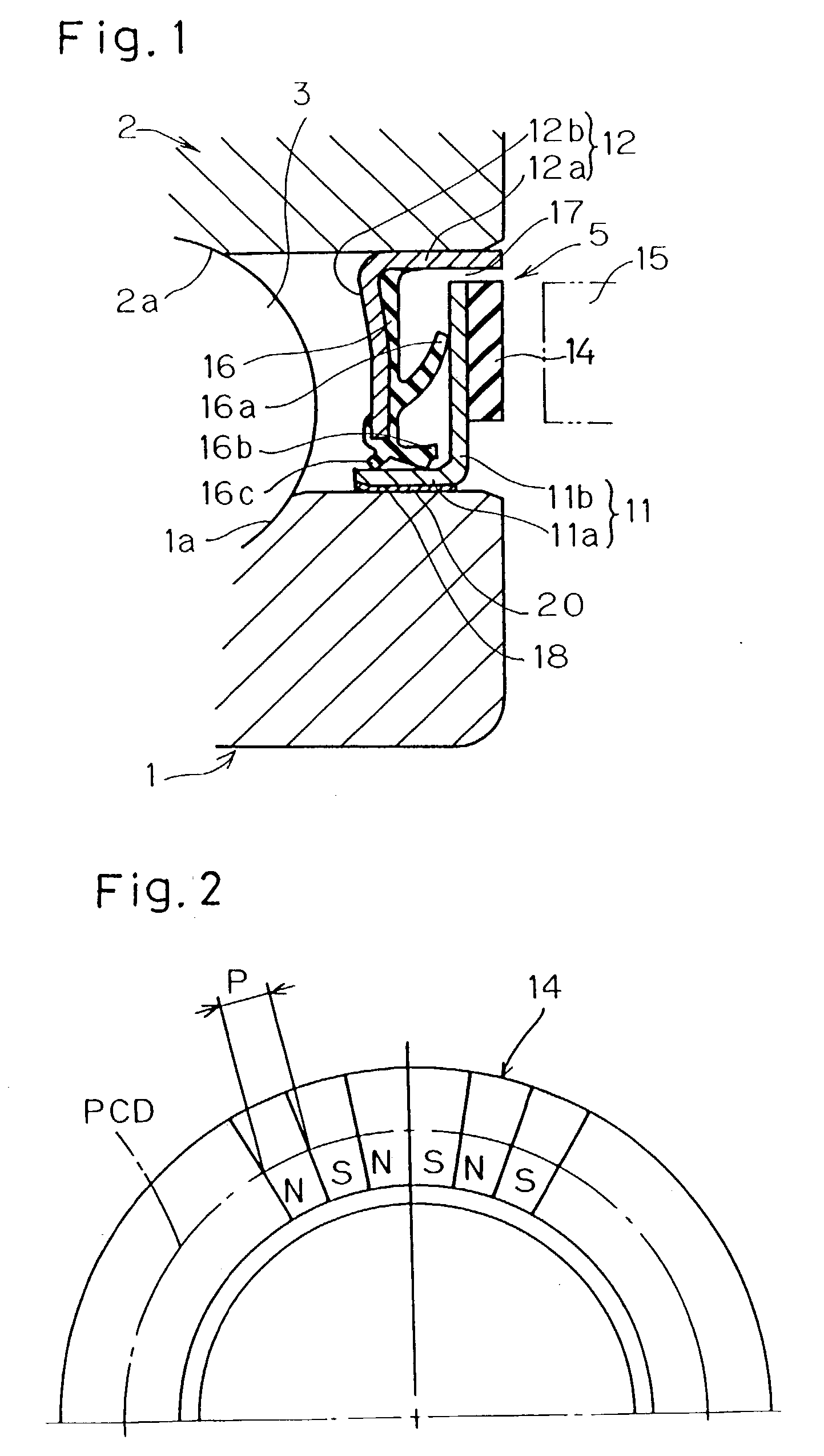

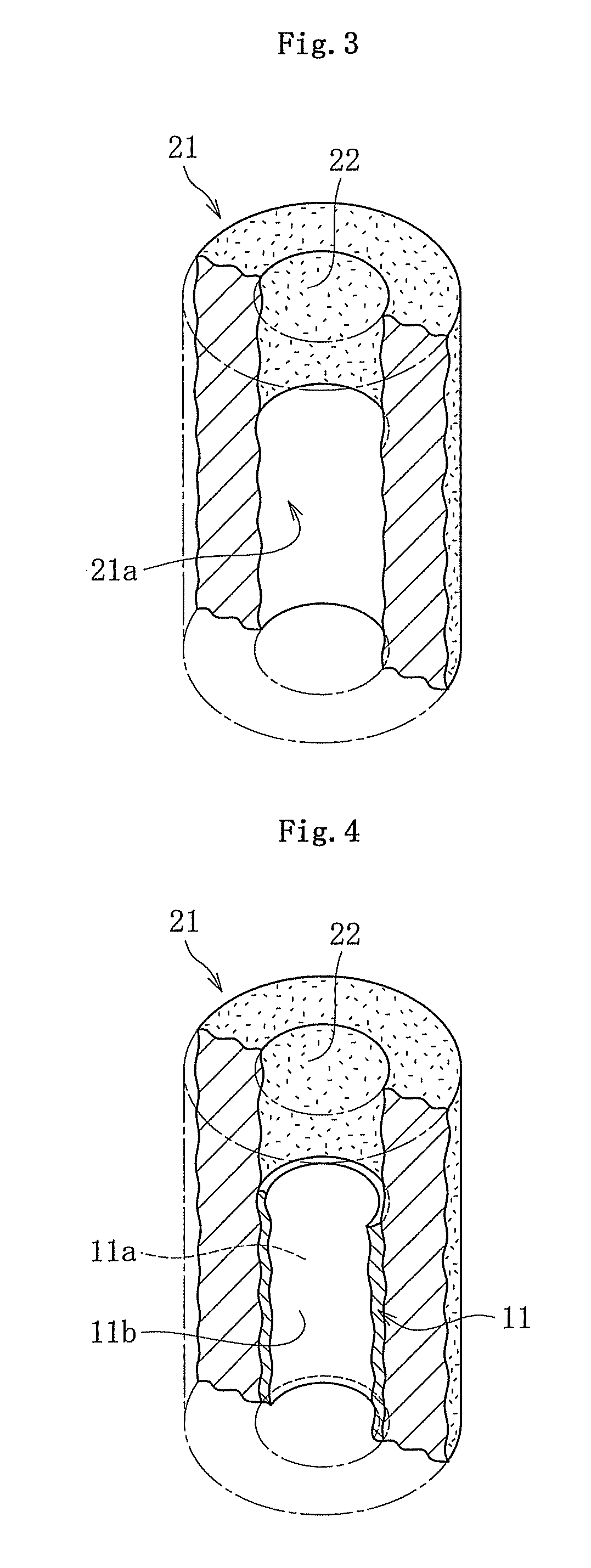

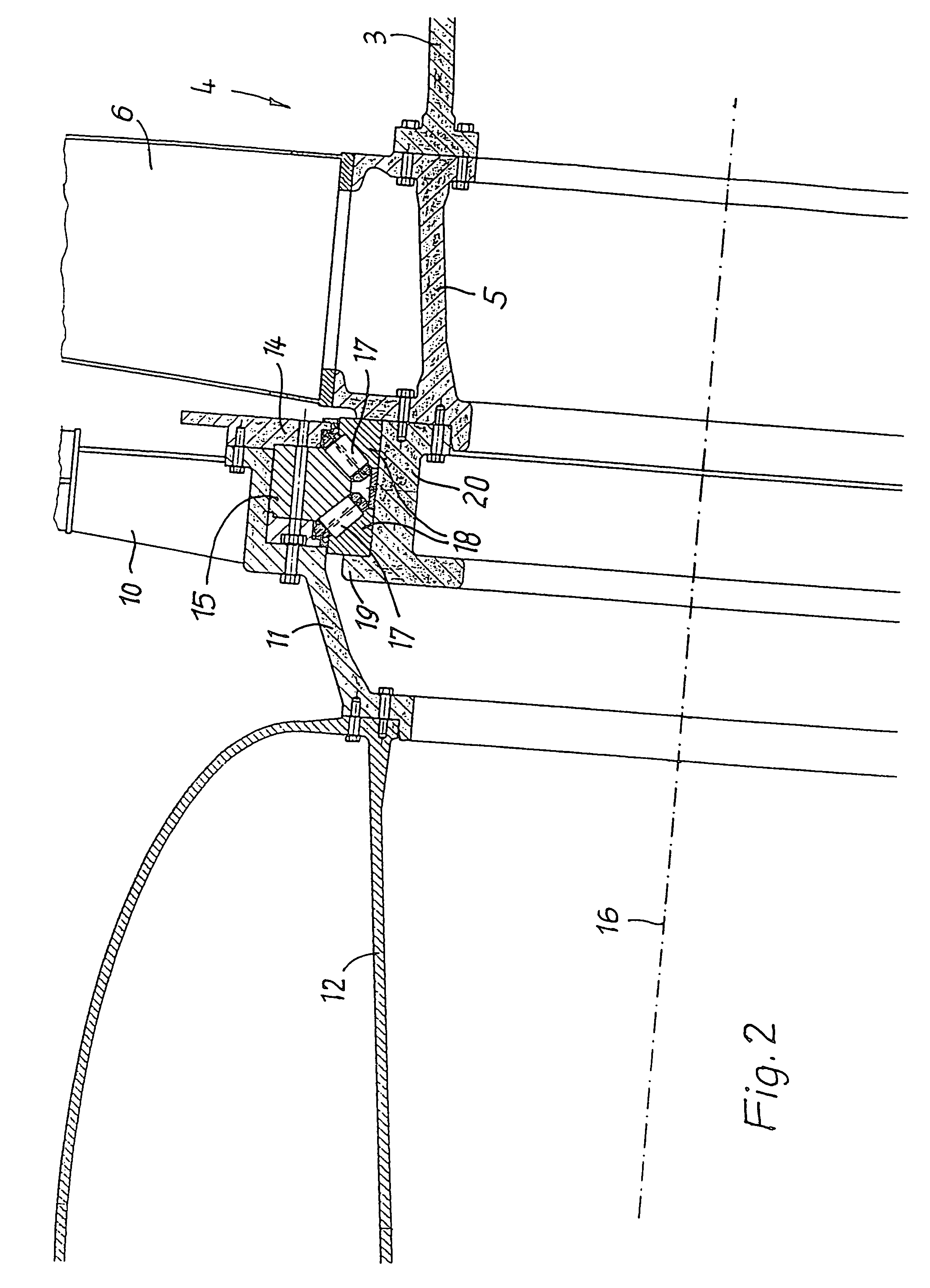

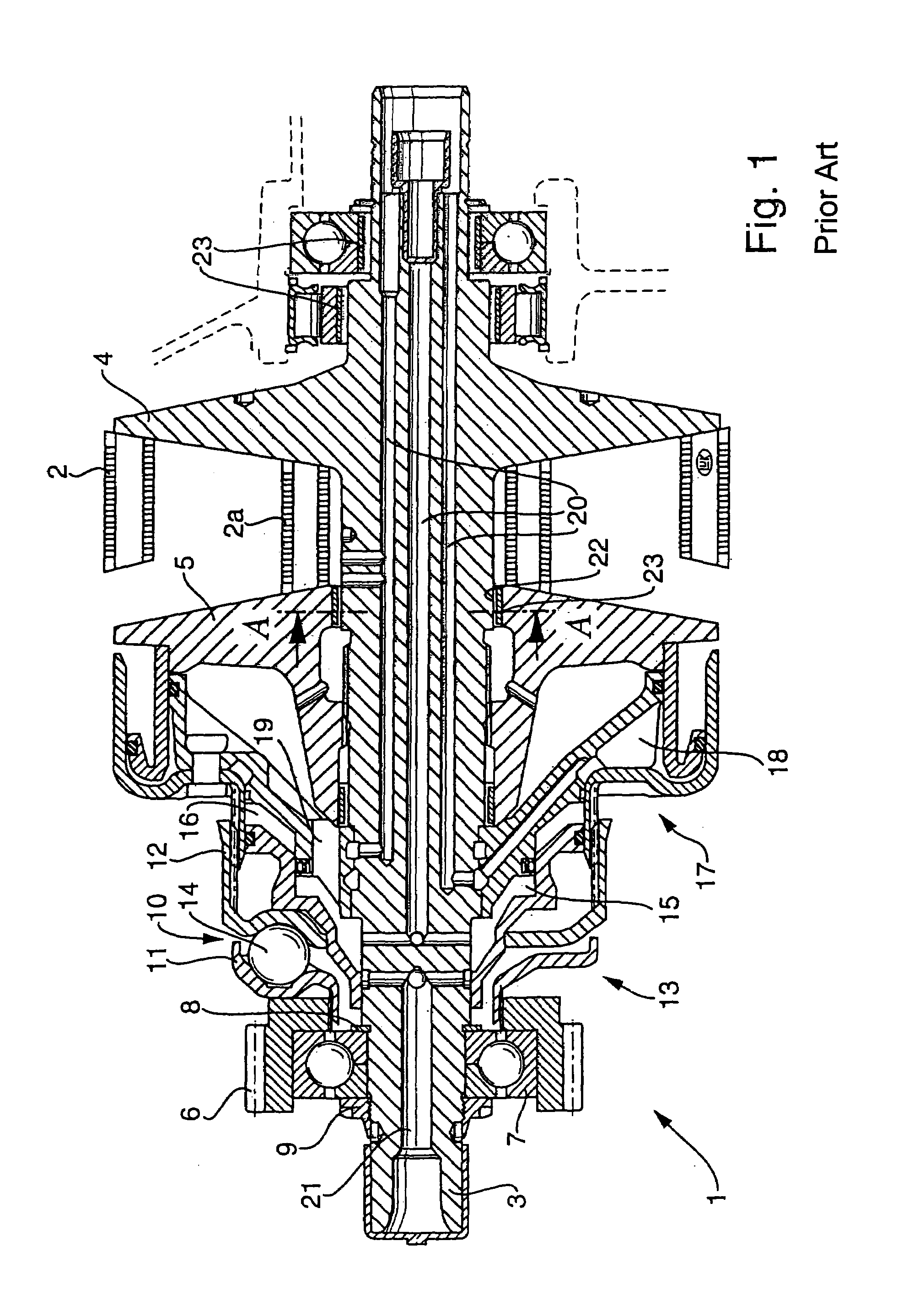

Wheel bearing and sealing device therefor

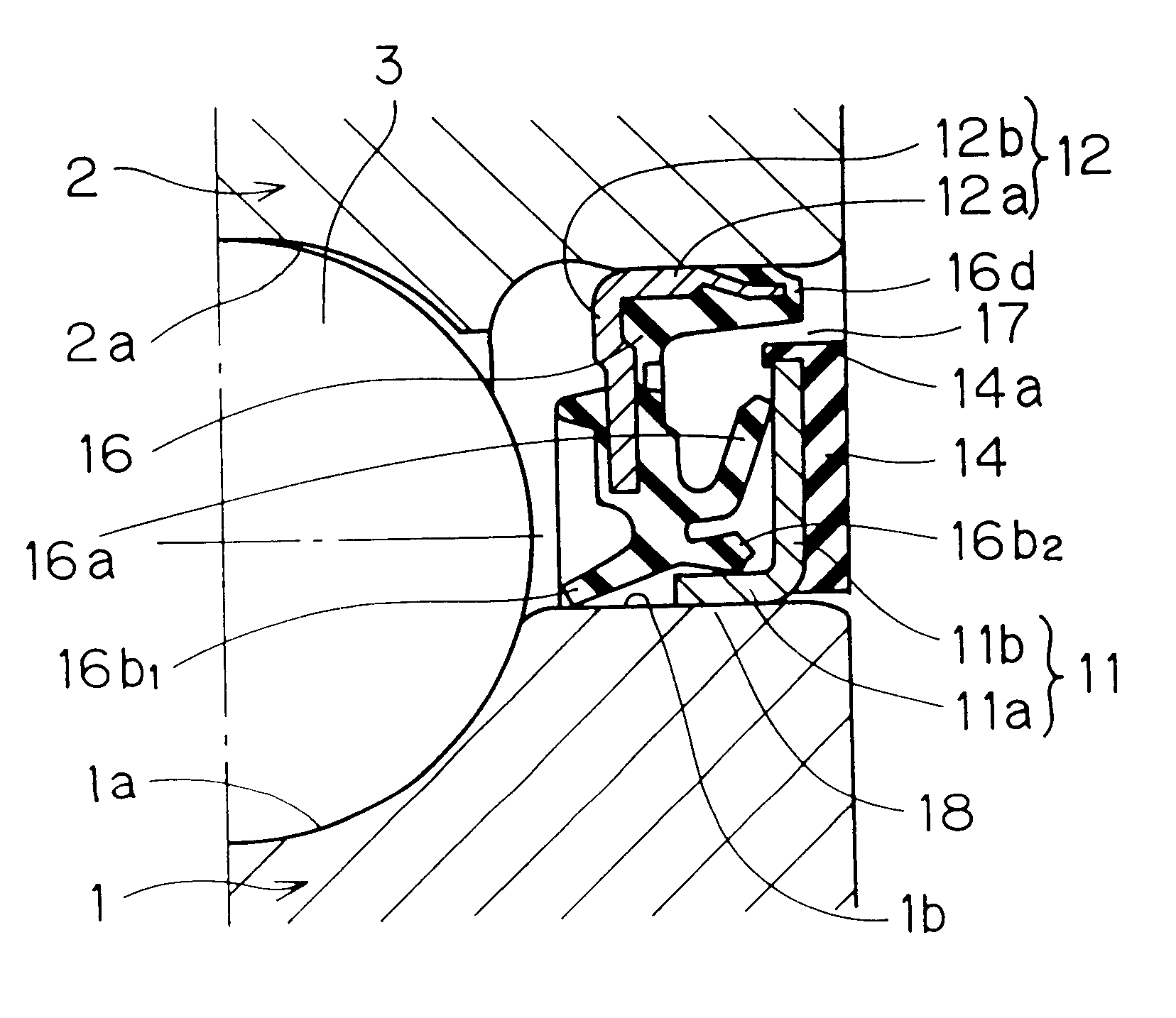

A wheel bearing includes a sealing device 5 positioned between inner and outer members 1 and 2. This sealing device 5 includes an elastic member 14, which eventually forms an encoder grid and is provided on a first annular sealing plate 11. A second annular sealing plate 12 is provided with sealing lips 16a to 16c. An engagement 18 between a cylindrical wall 11a of the first annular sealing plate 11 and the inner member 1 is provided with an elastic member 20 made of a material dissimilar to that for the elastic material 14. This elastic member 20 may be a rubber coated layer, resin paint layer, a thin film of adhesive material or a ring-shaped rubber member. Thereby, any possible ingress of water across an engagement surface of the annular sealing plate is prevented, accompanied by increase of the lifetime of the bearing, with no problem associated with separation and displacement of the annular sealing plates. The magnetic flux density can also be easily secured.

Owner:NTN CORP

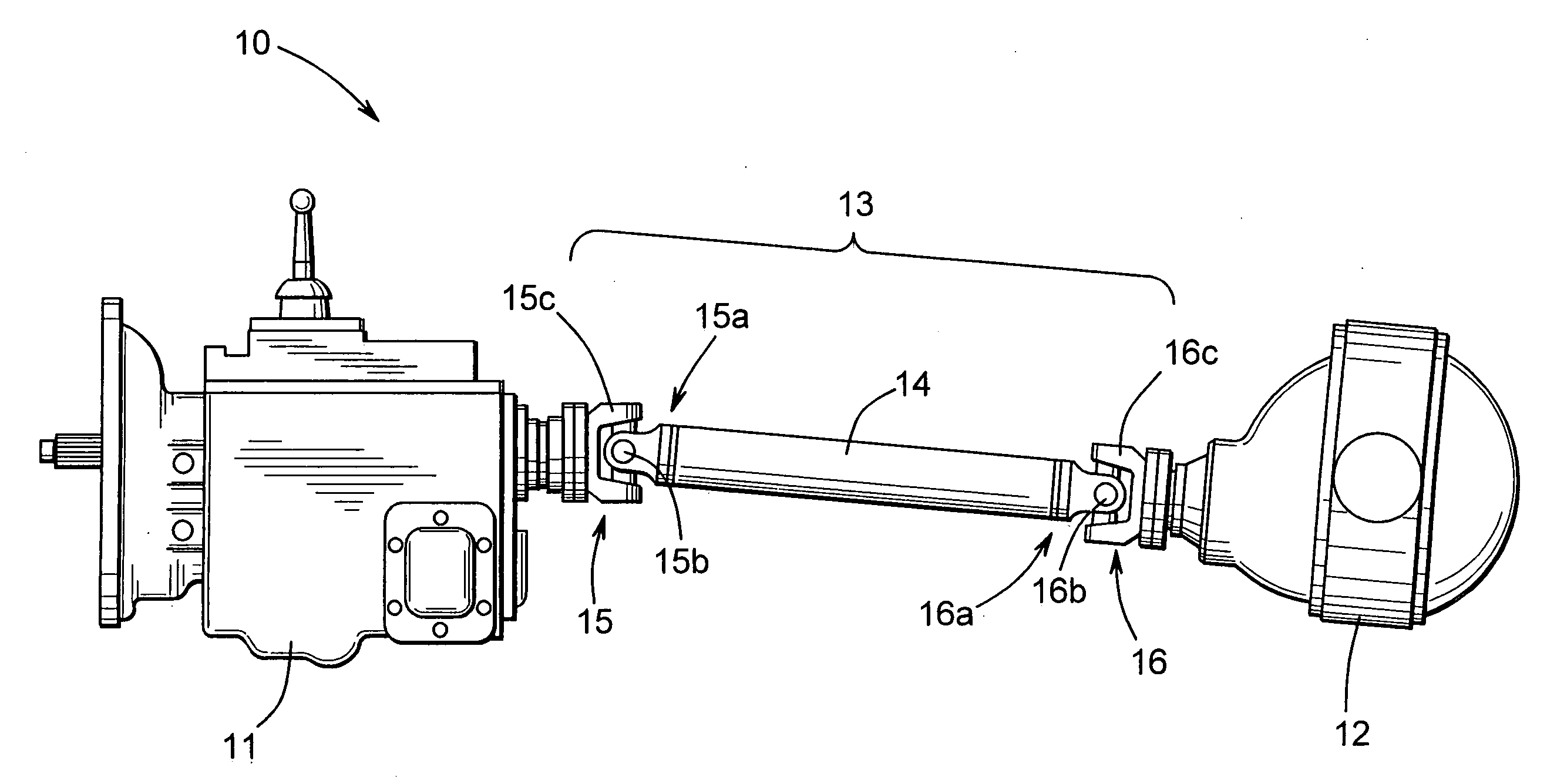

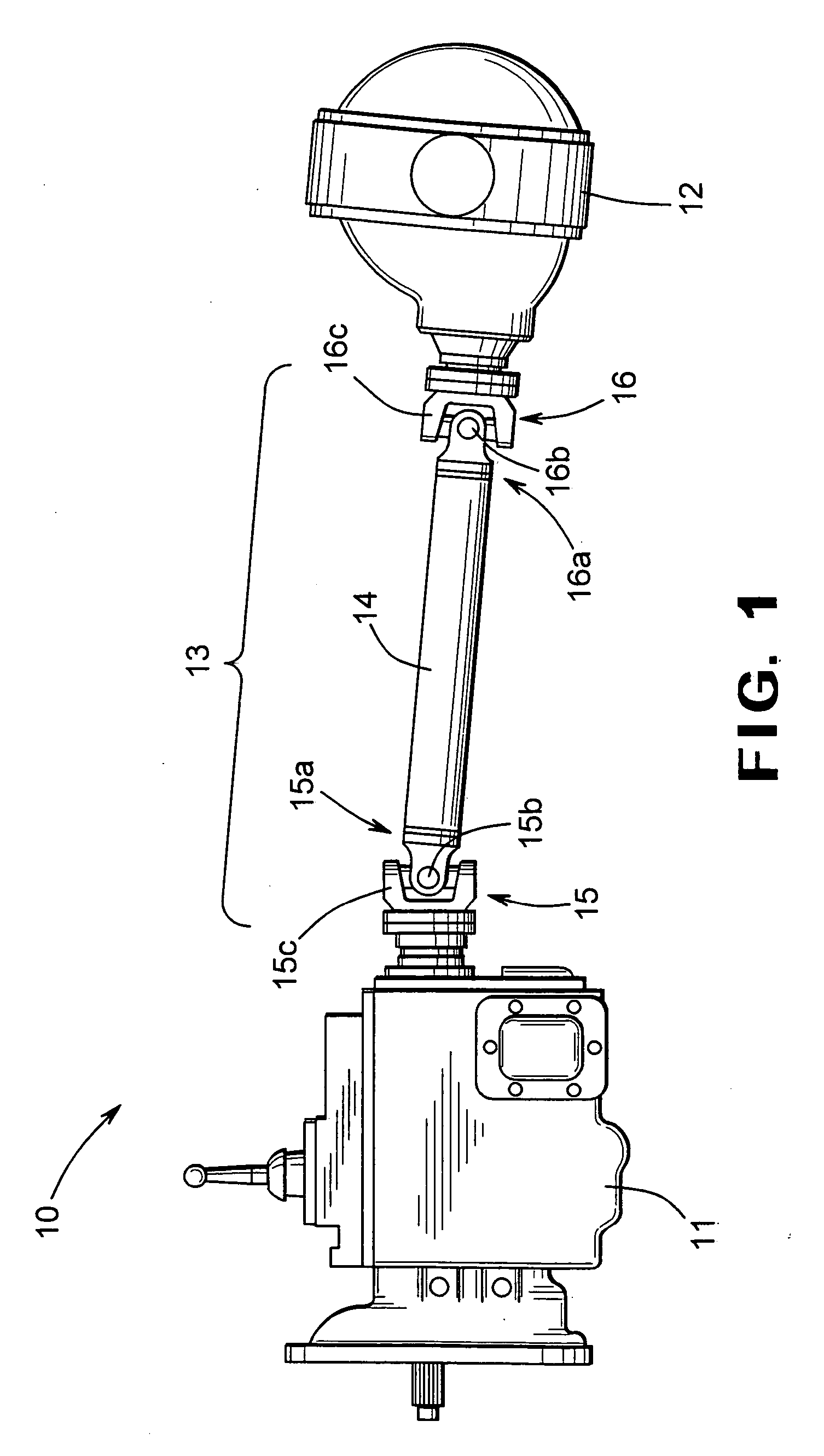

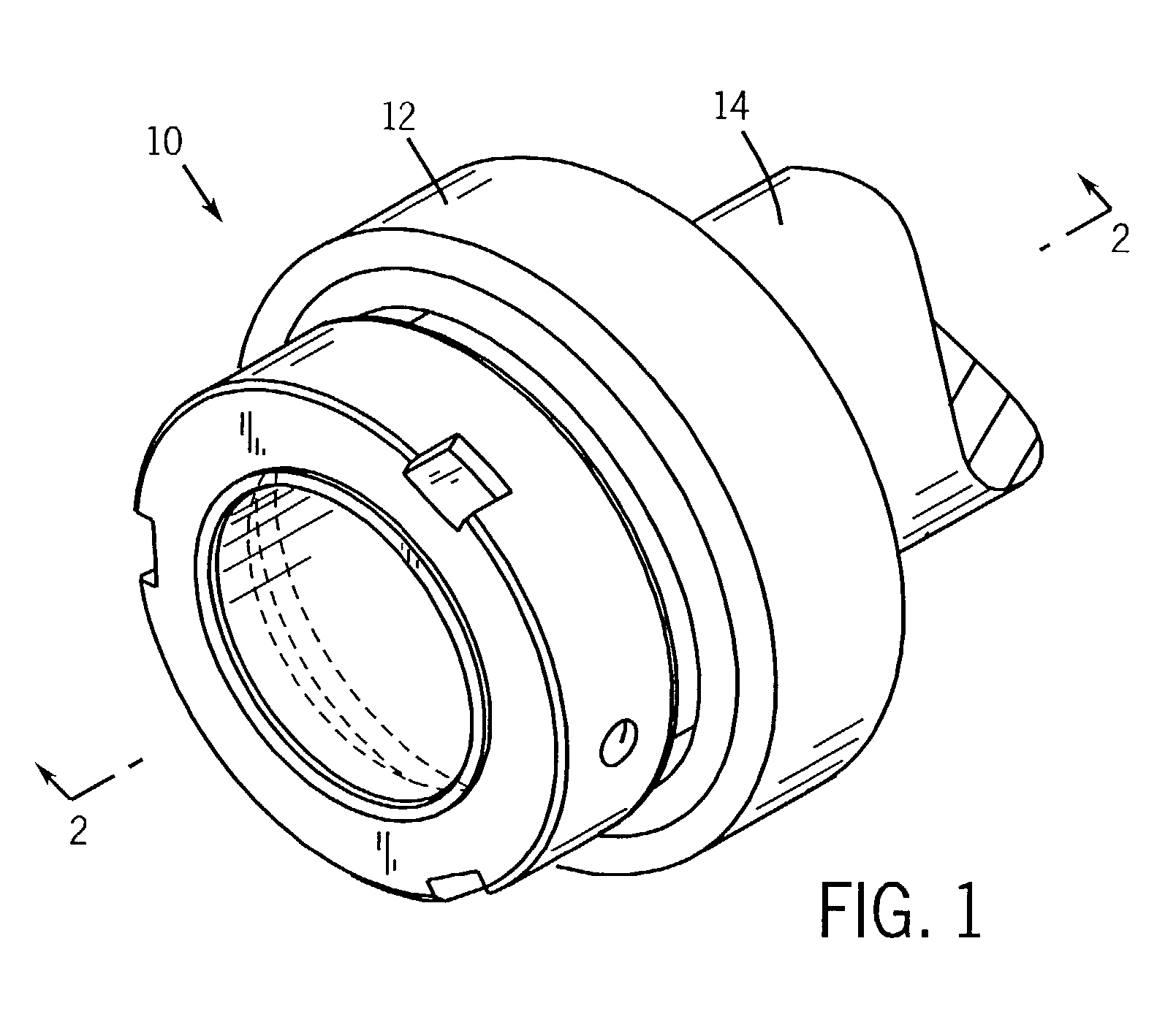

Driveshaft assembly and method of manufacturing same

InactiveUS20070066406A1Protection from damageSimple structureClutchesYielding couplingEngineeringMagnetic pulse welding

A driveshaft assembly includes a yoke including a body portion, a pair of opposed yoke arms that extends generally in a first axial direction from the body portion, and a neck portion that extends generally in a second axial direction from the body portion. A driveshaft tube is secured to the neck portion of the yoke, such as by magnetic pulse welding. A ring is secured to the body portion of the yoke, such as by press fitting, and a balance weight is secured to the ring, such as by welding.

Owner:DANA AUTOMOTIVE SYST GRP LLC

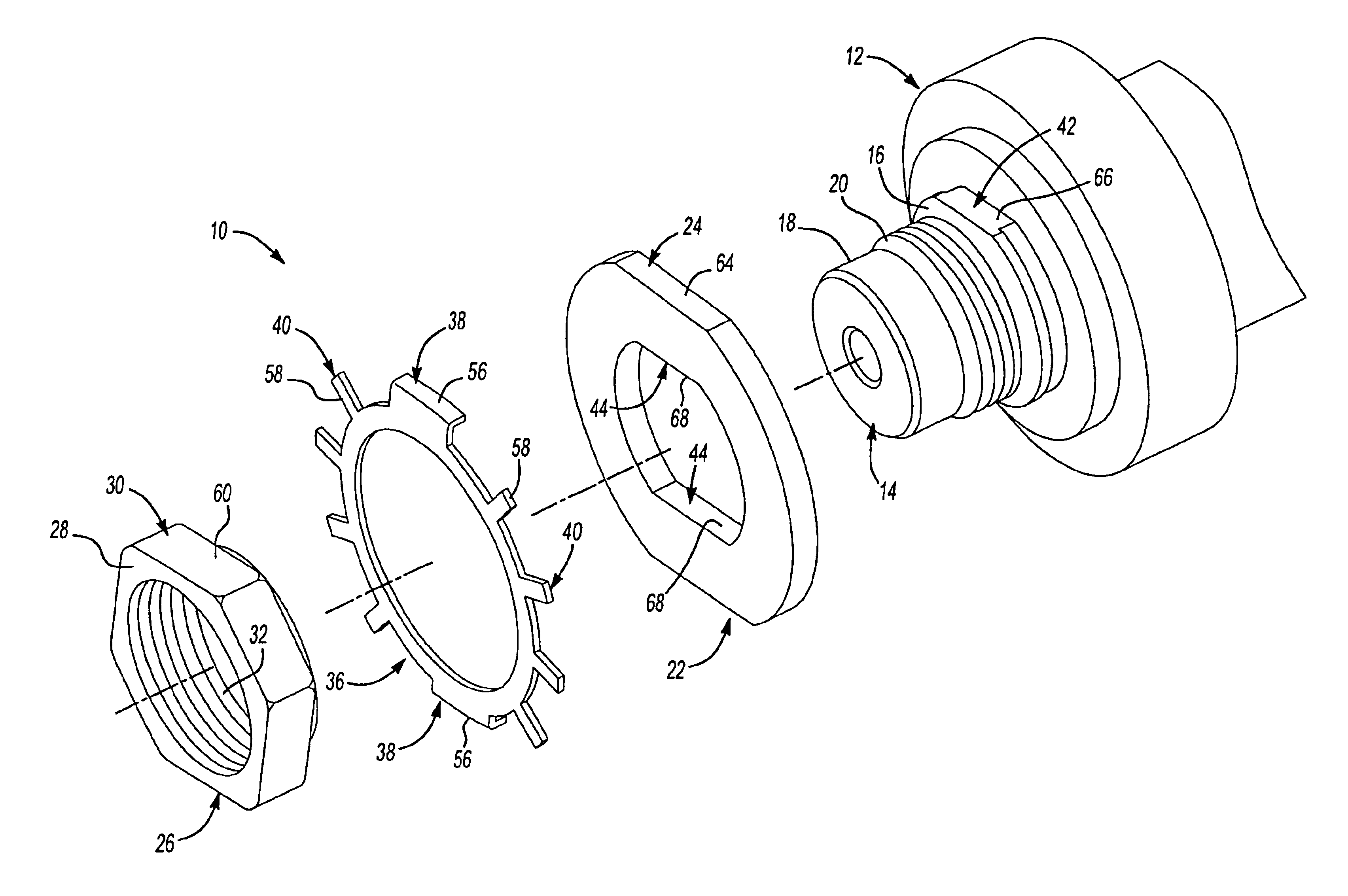

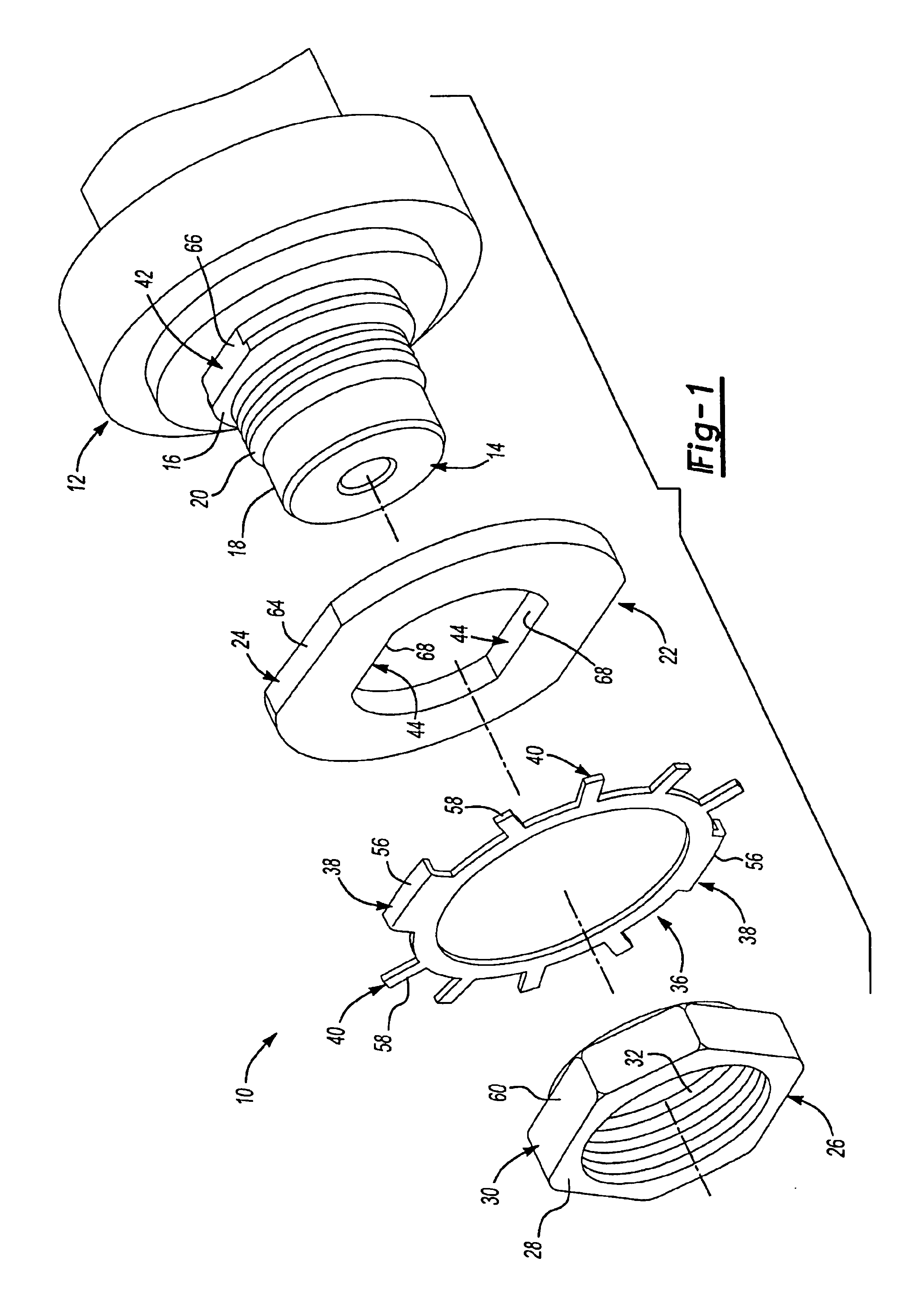

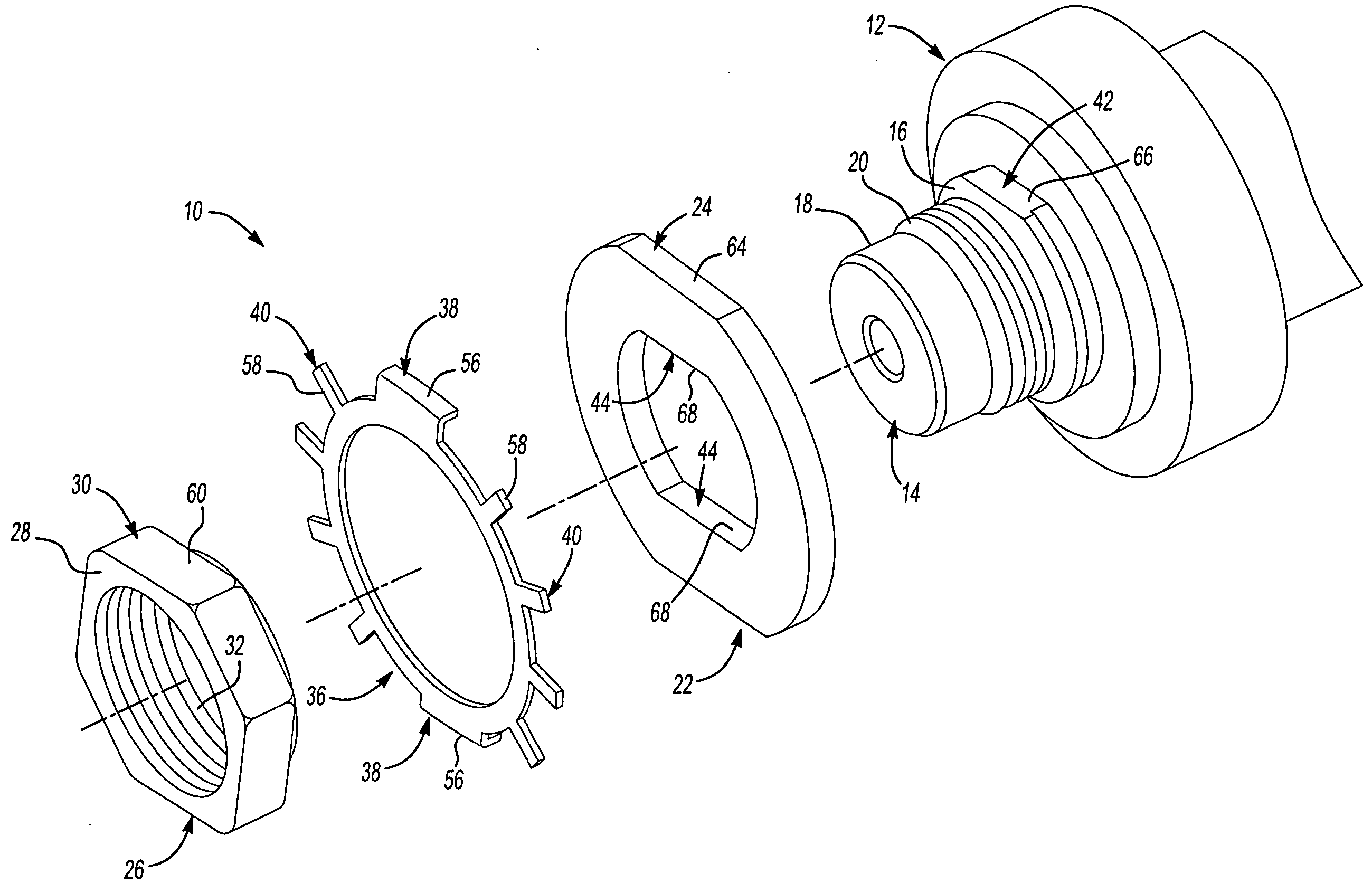

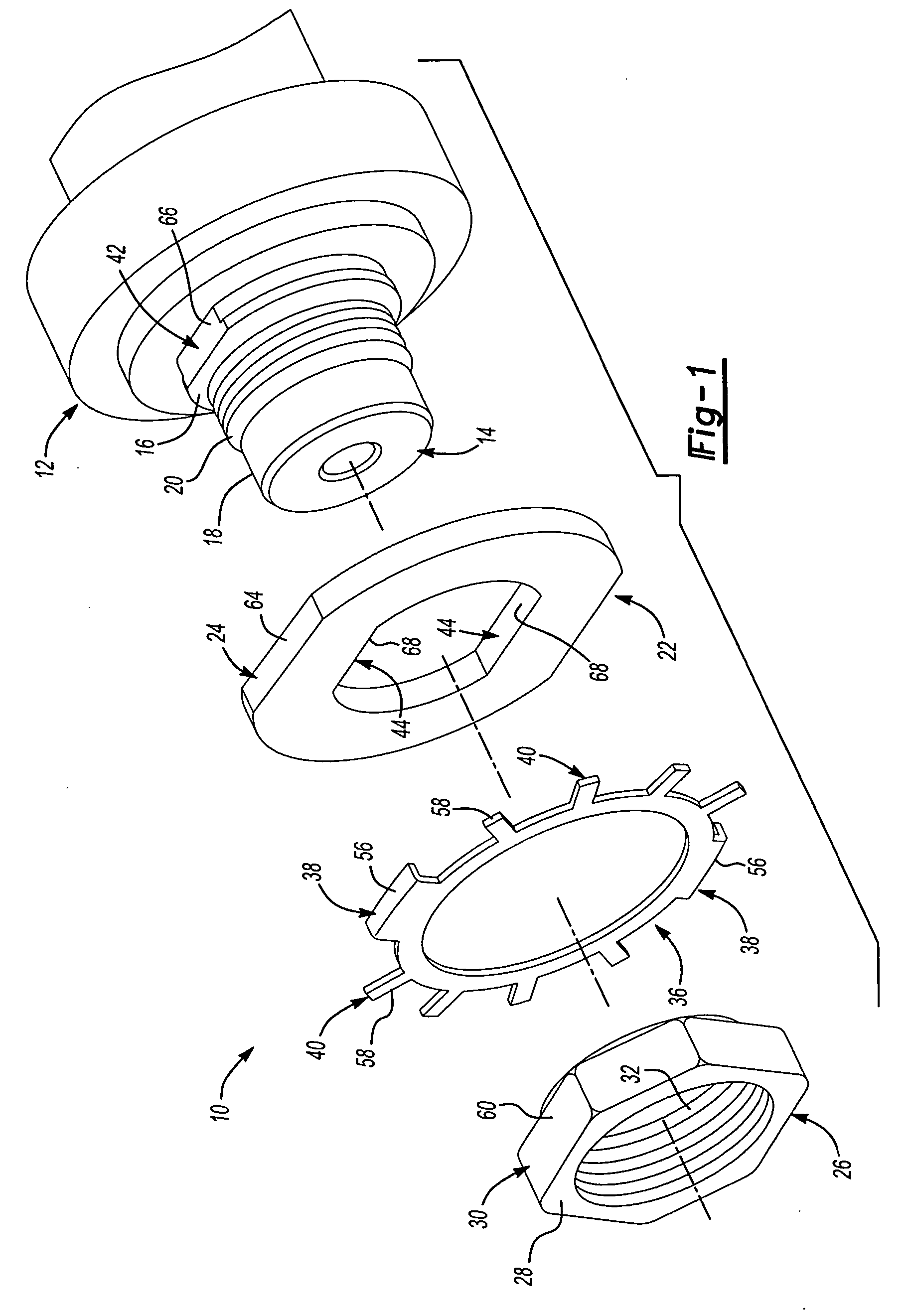

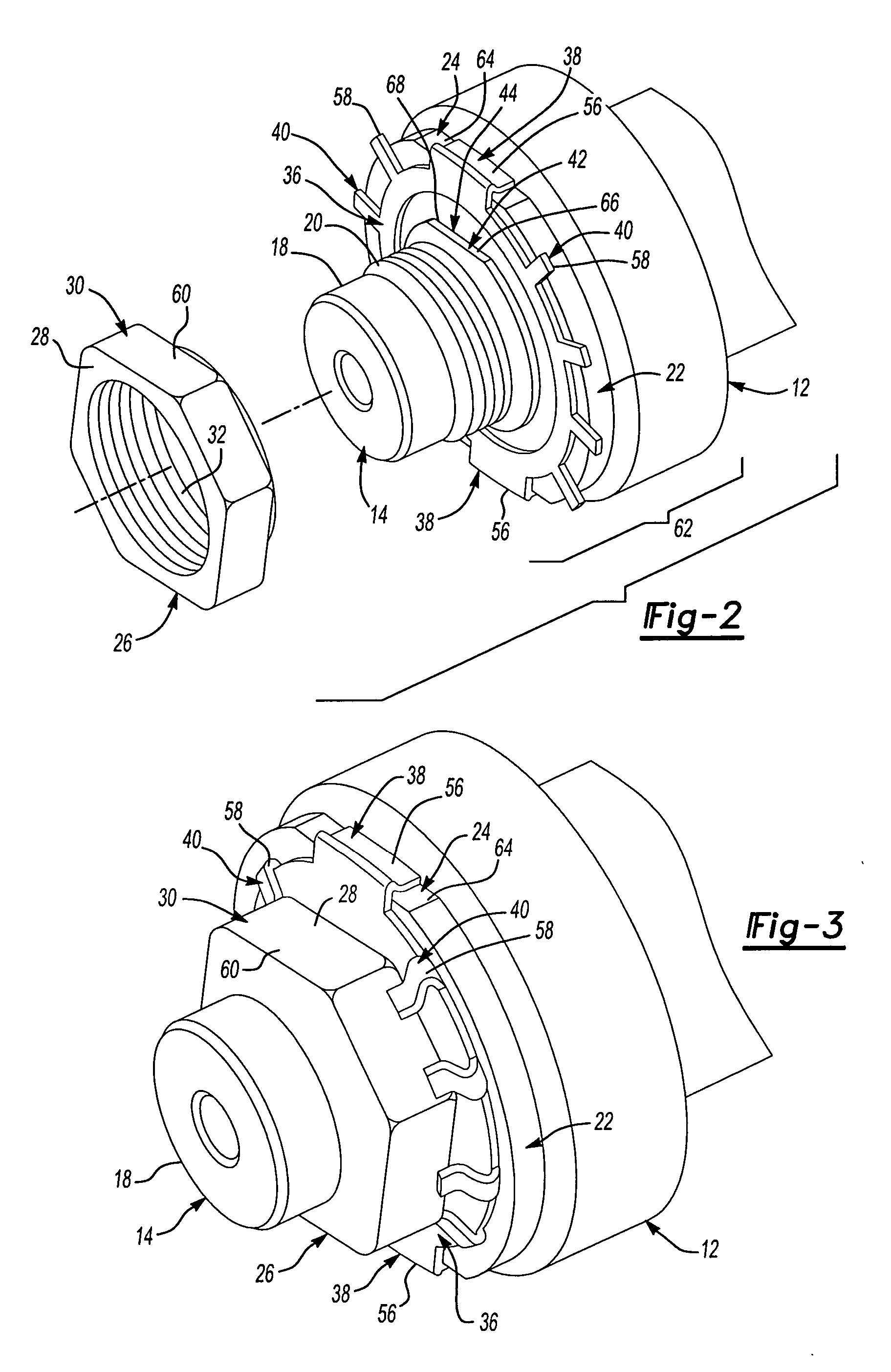

Combination lock washer and spindle bearing assembly

The present invention relates to a connection between a spindle and a bearing assembly to retain the bearing assembly on the spindle. A combination lock washer and spindle bearing assembly is provided to include a spindle, thrust washer, lock washer and nut in which the lock washer simultaneously locks the inner thrust washer and an outer spindle nut. According to the present invention, the thrust washer, lock washer and nut may be oriented at any angle relative to one another allowing for infinite bearing adjustment positions.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

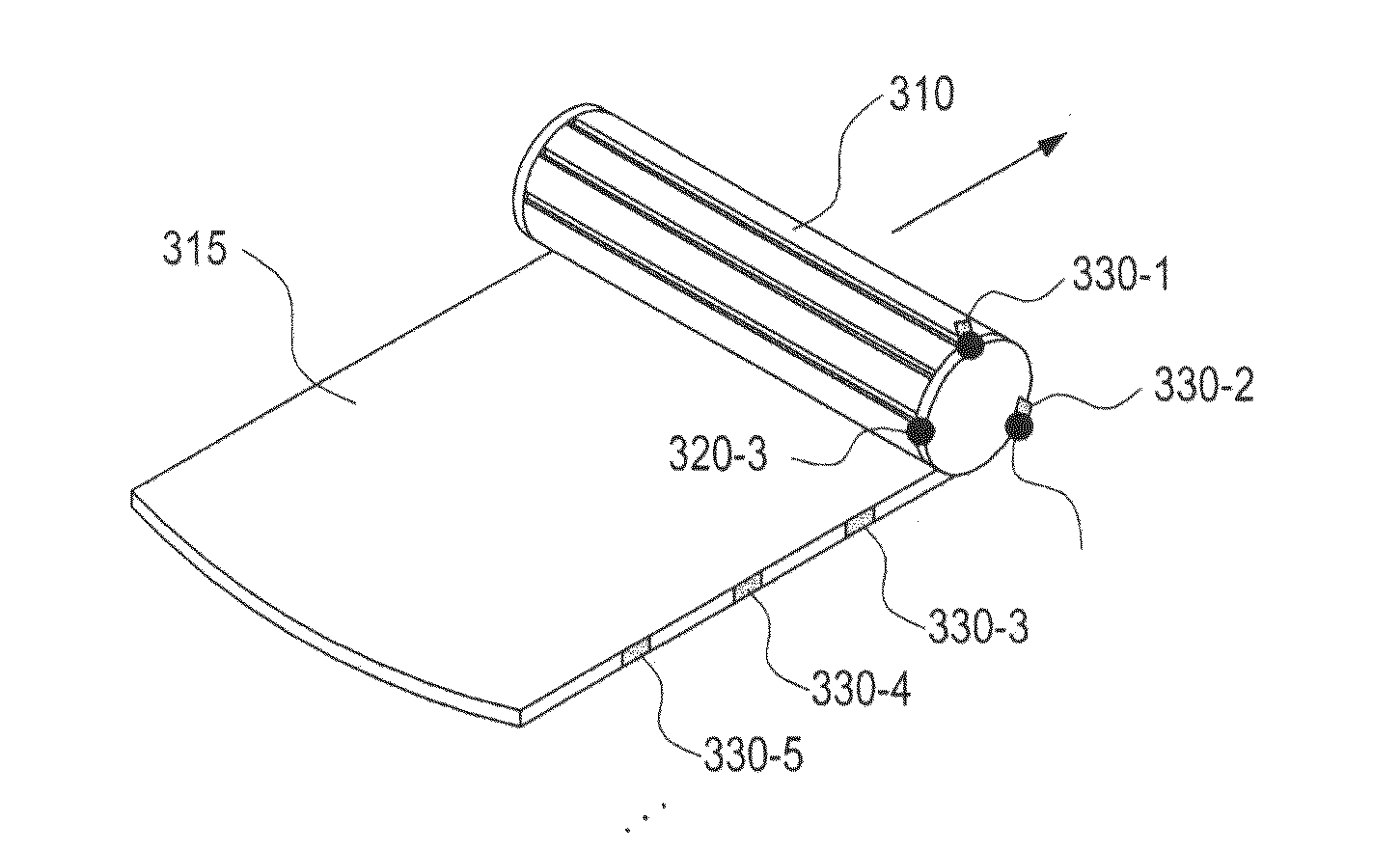

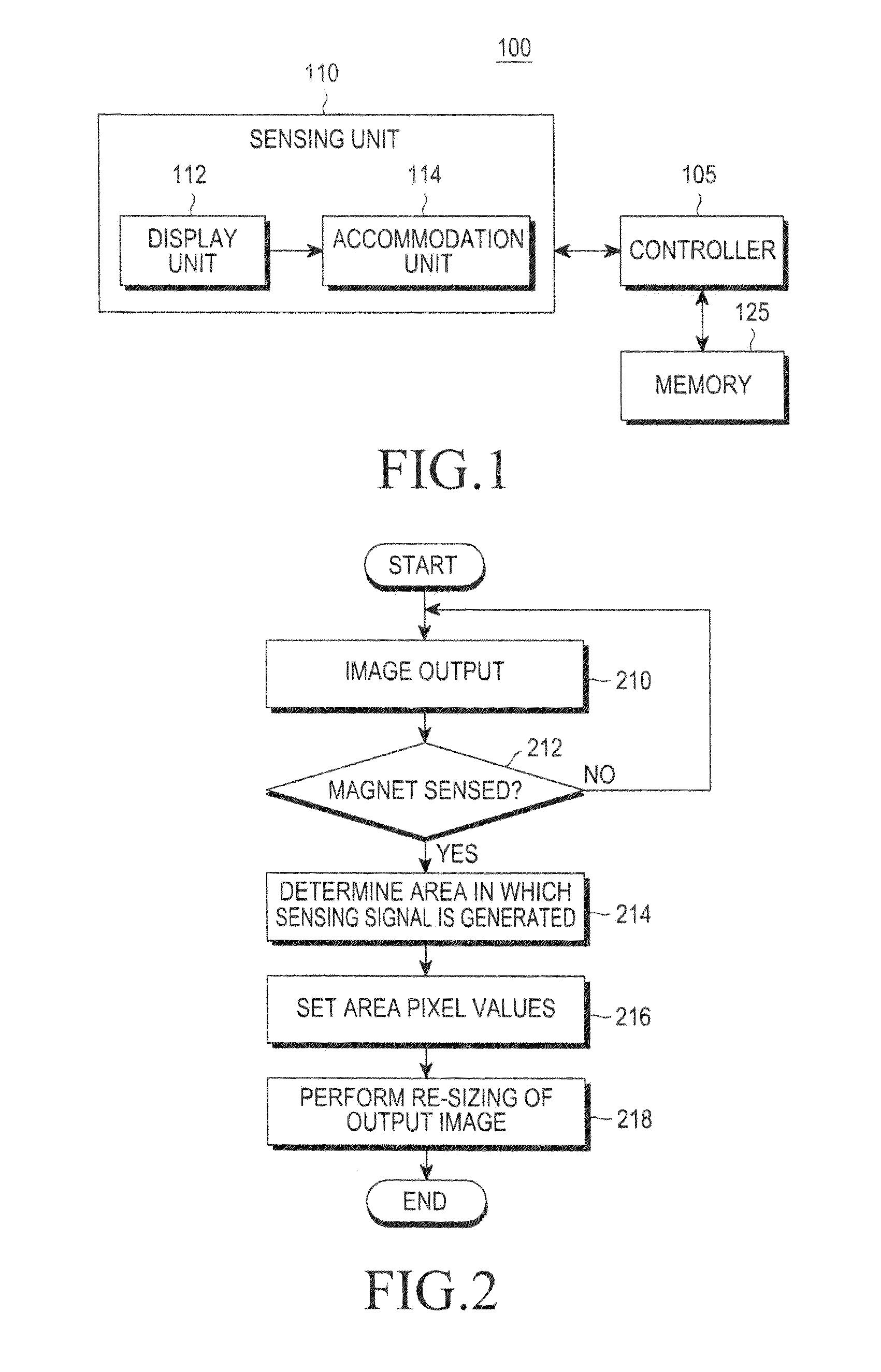

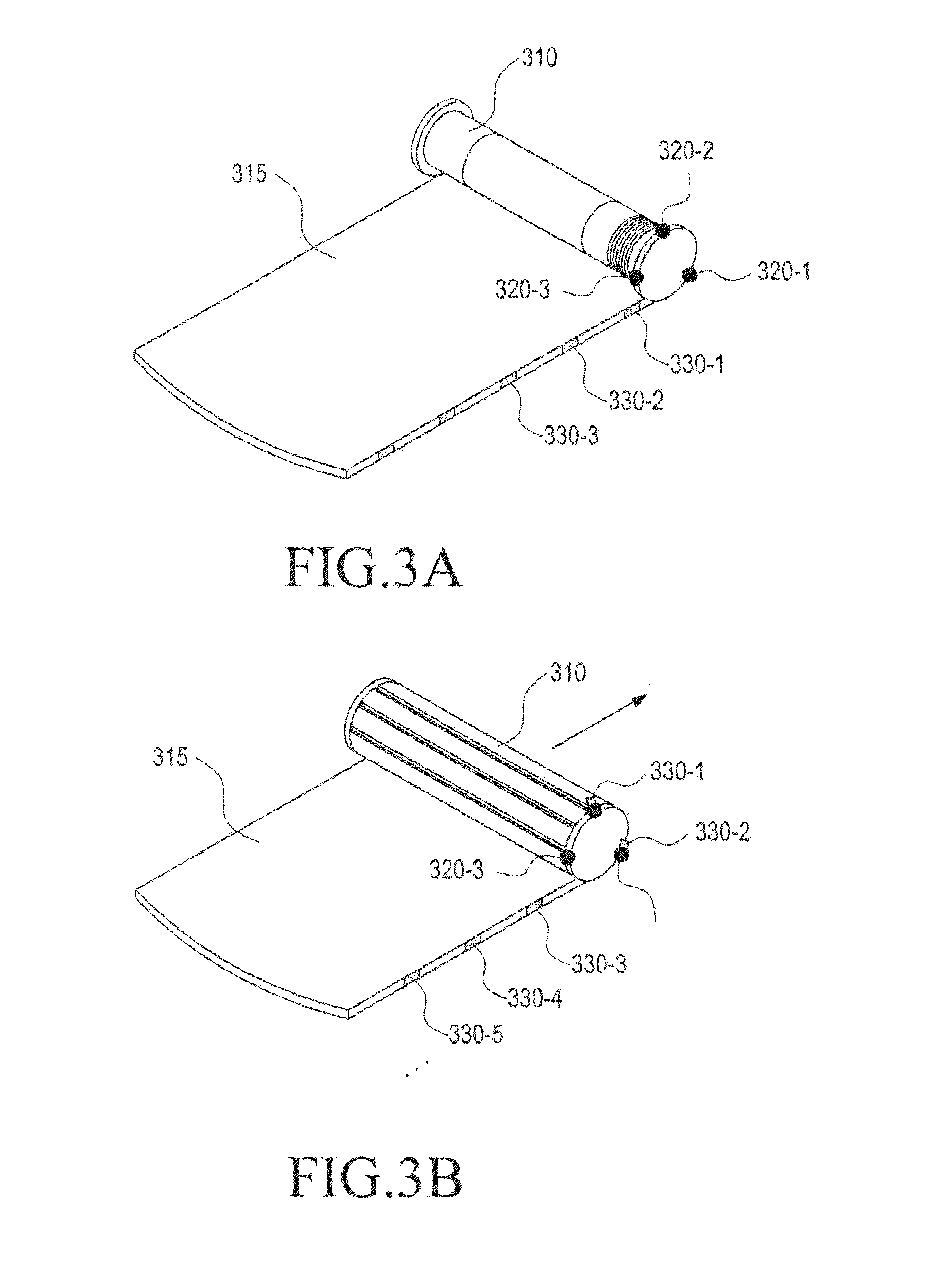

Display apparatus and method for portable terminal

ActiveUS20110227855A1Prevent unnecessary current consumptionPower managementBearing assemblyFlexible displayBiomedical engineering

A display apparatus for a portable terminal includes an expandable flexible display unit, a sensing unit including of a plurality of magnets and a plurality of sensors sensing the magnets to sense an amount of display unit area accommodated in an accommodation unit of the display unit, and a controller setting pixel values according to sensed amount of the display unit area.

Owner:SAMSUNG ELECTRONICS CO LTD

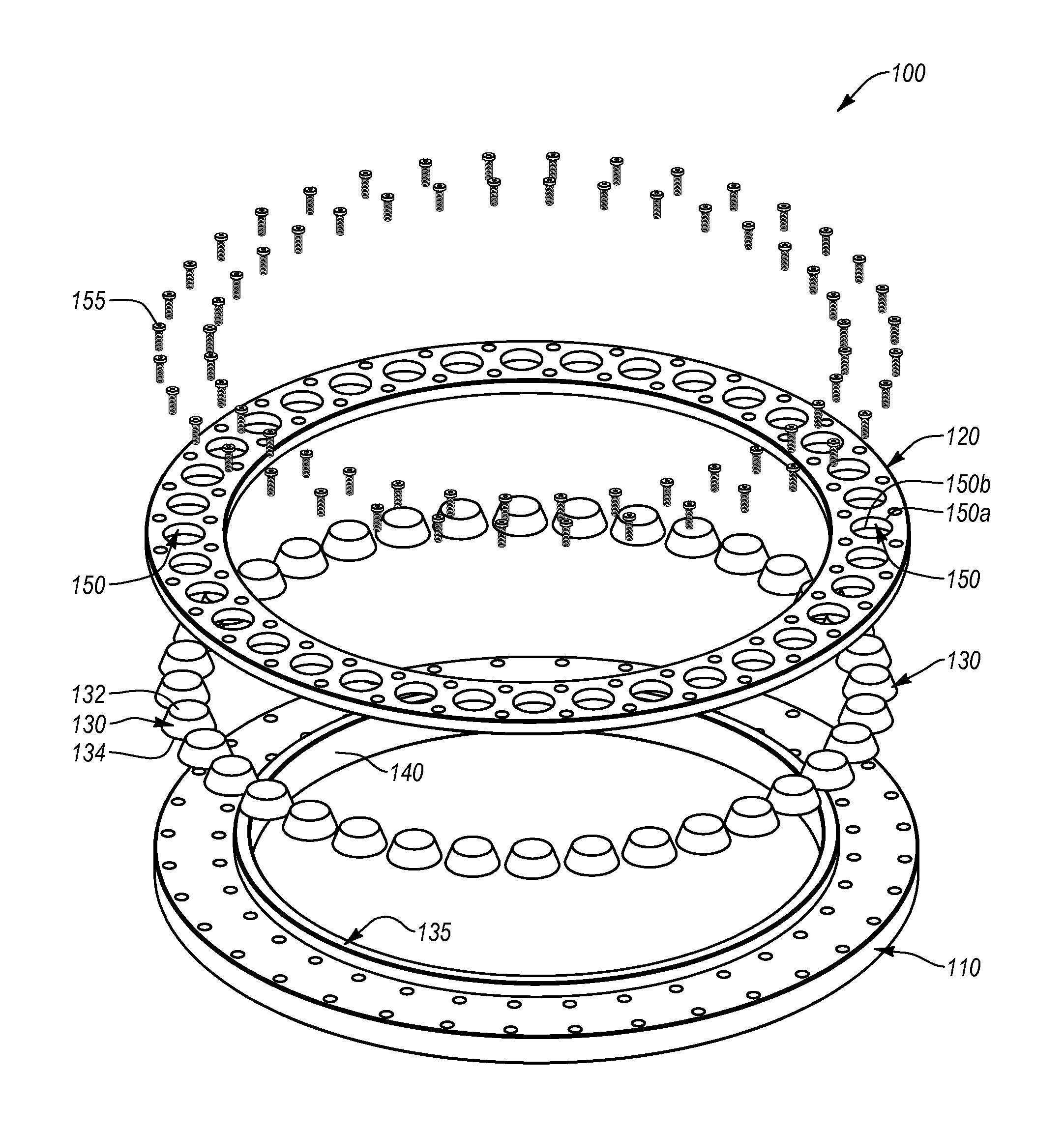

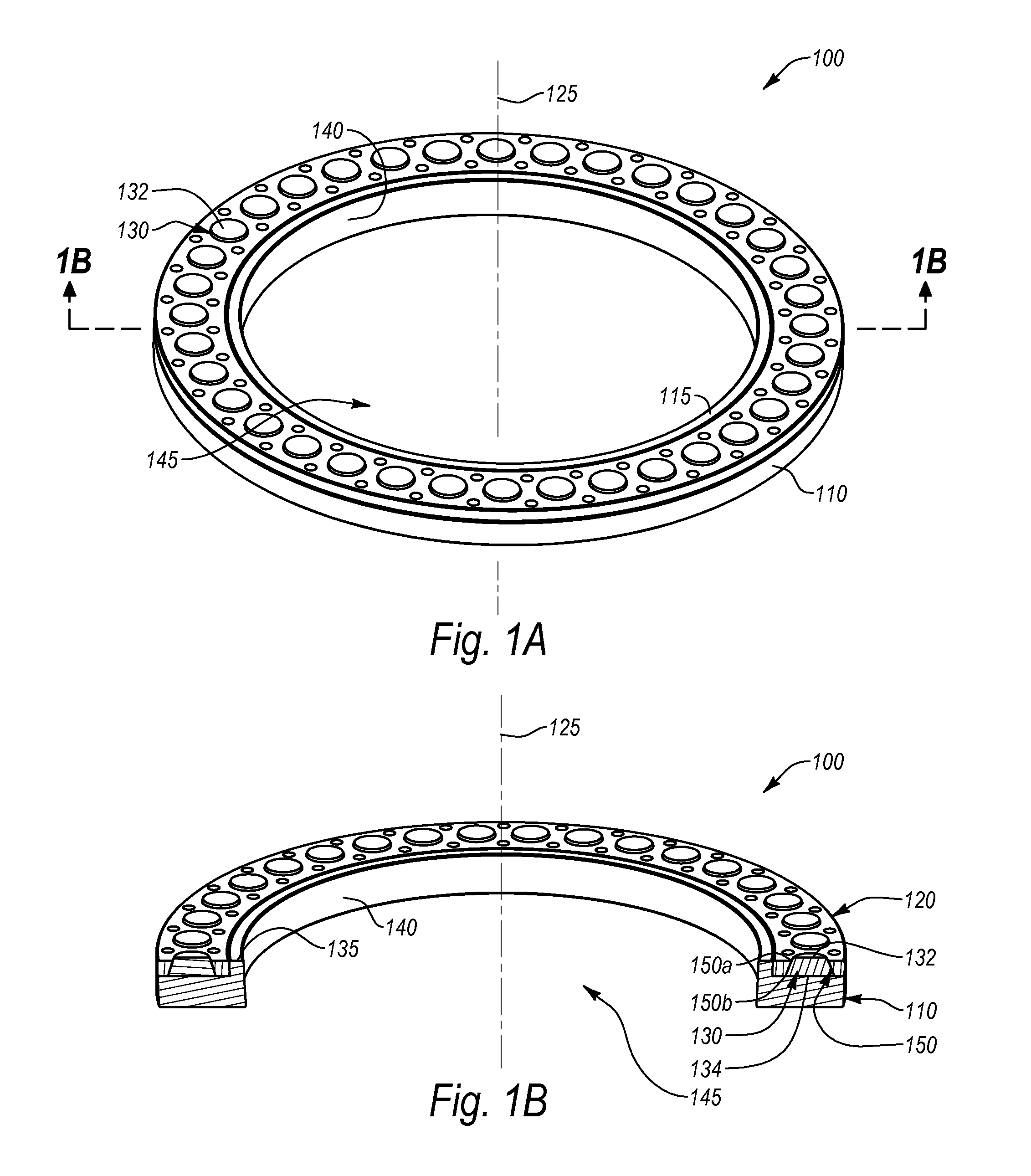

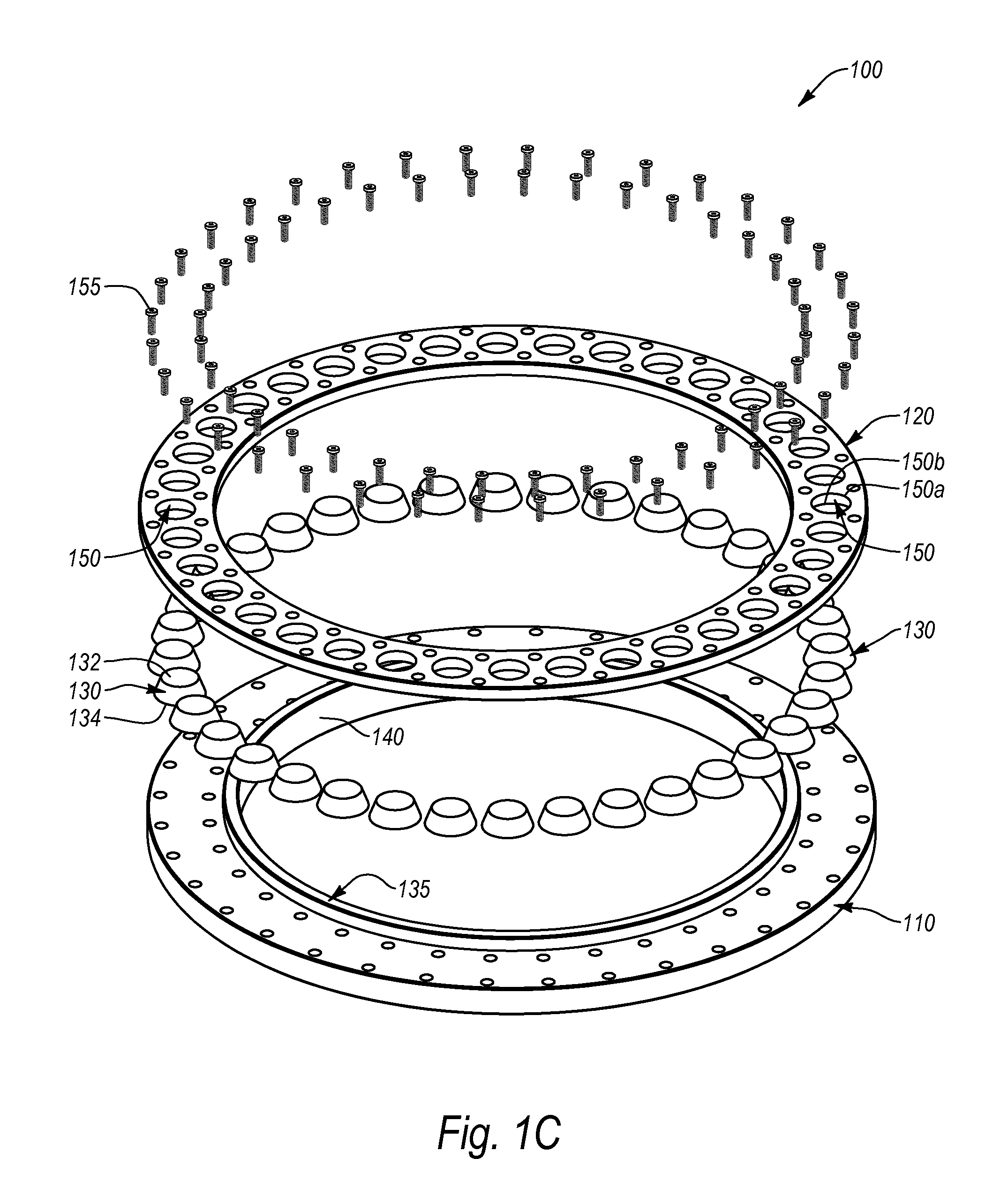

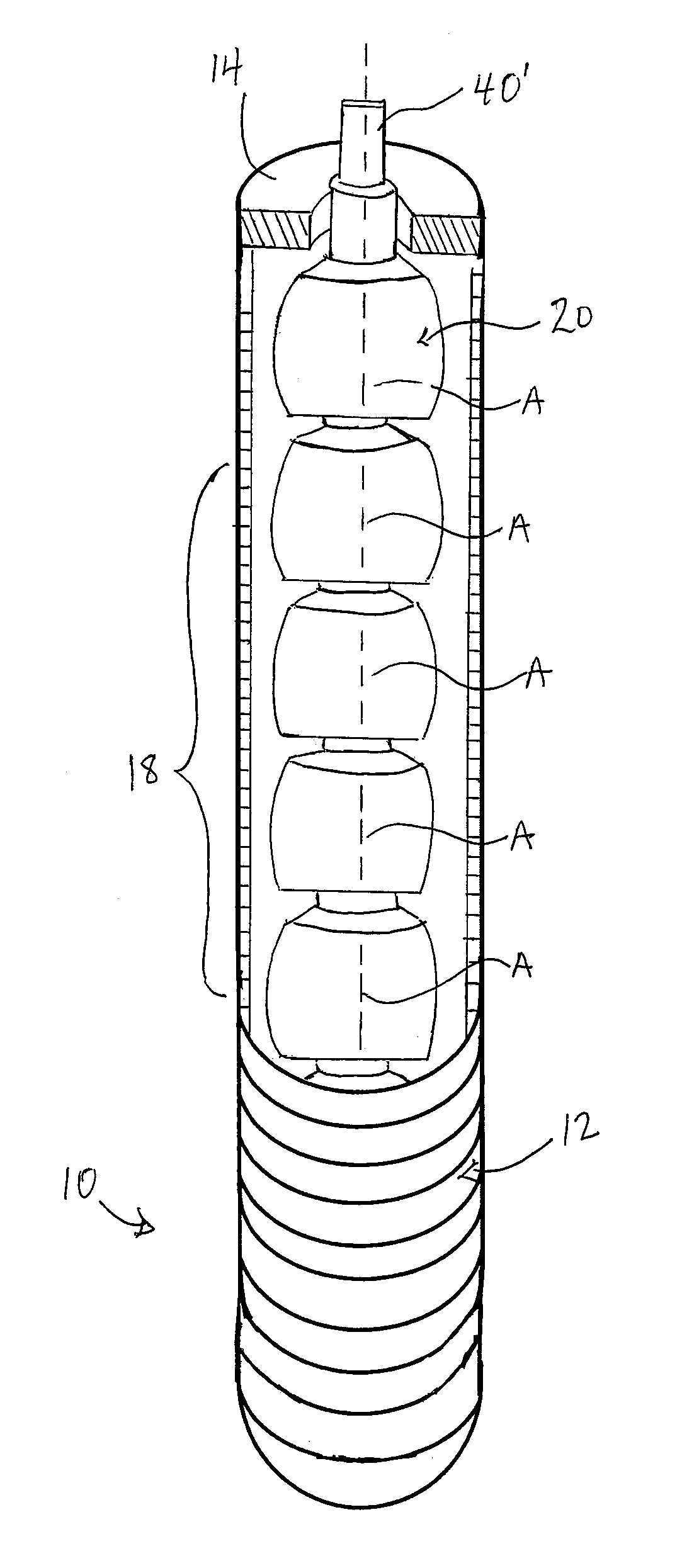

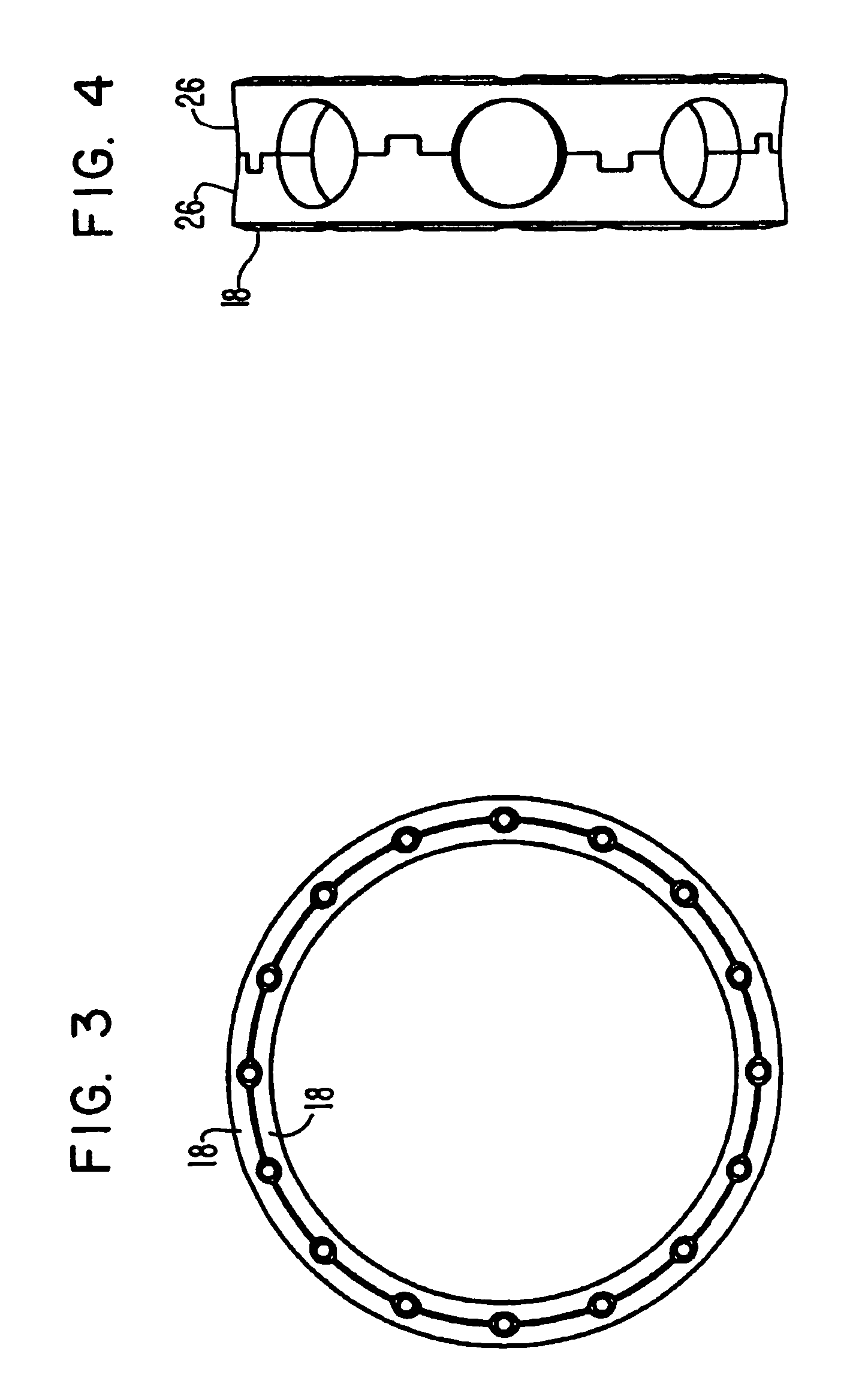

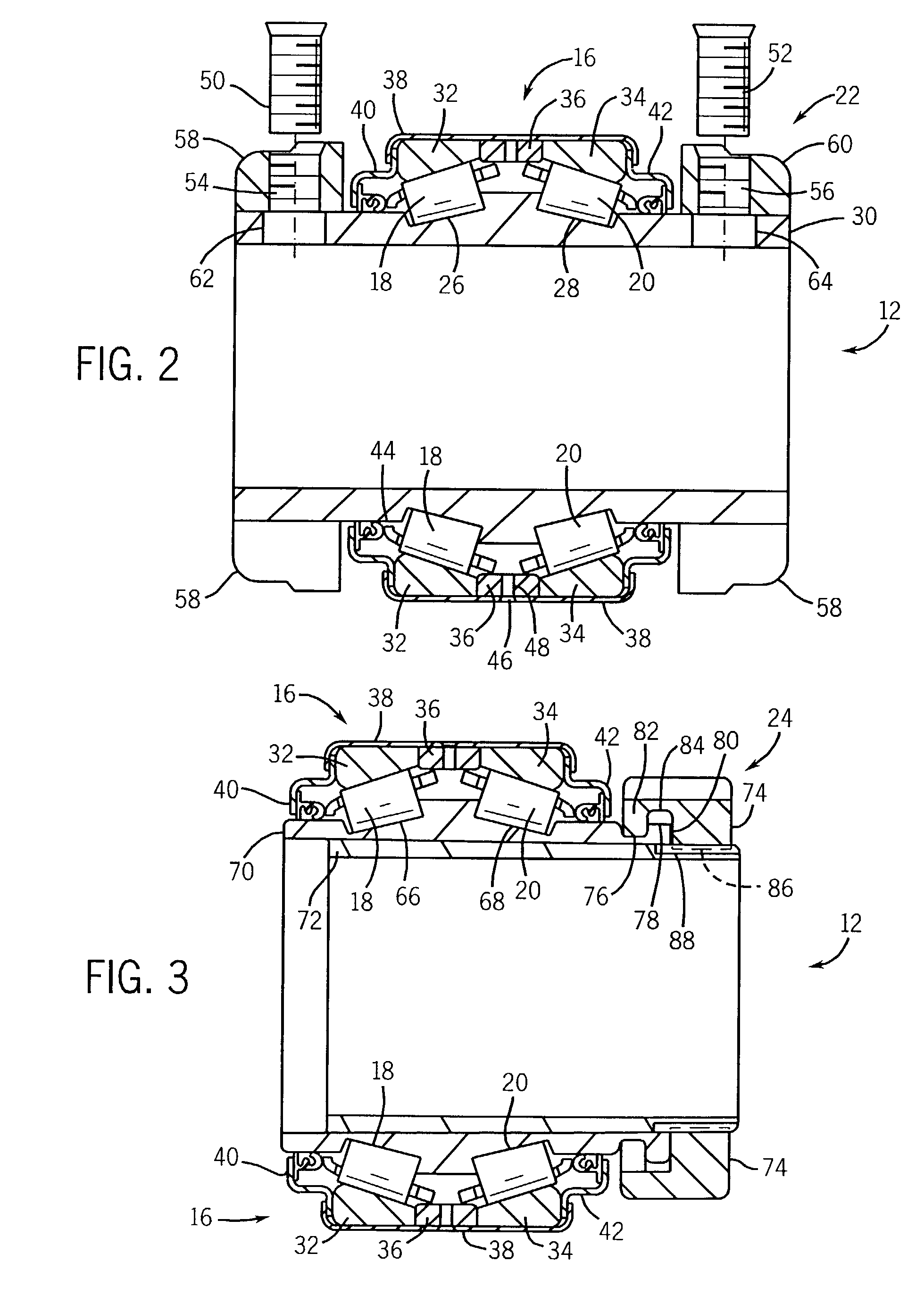

Bearing Assemblies, Bearing Apparatuses Using the Same, and Related Methods

Various embodiments relate to bearing assemblies configured to enable removal and replacement of superhard bearing elements, and bearing apparatuses that may utilize such bearing assemblies. The disclosed bearing assemblies may be used in a number of applications, such as downhole motors in subterranean drilling systems, directional drilling systems, roller-cone drill bits, and many other applications. In an embodiment, a bearing assembly includes a support ring and a retention ring assembled with the support ring. The retention ring includes a plurality of through holes. The bearing assembly further includes a plurality of superhard bearing elements, with each superhard bearing element inserted partially through and projecting from a corresponding one of the through holes of the retention ring. The retention ring and each superhard bearing element are collectively configured to restrict displacement of each superhard bearing element beyond a selected position in a direction away from the support ring.

Owner:US SYNTHETIC CORP

Combination lock washer and spindle bearing assembly

The present invention relates to a connection between a spindle and a bearing assembly to retain the bearing assembly on the spindle. A combination lock washer and spindle bearing assembly is provided to include a spindle, thrust washer, lock washer and nut in which the lock washer simultaneously locks the inner thrust washer and an outer spindle nut. According to the present invention, the thrust washer, lock washer and nut may be oriented at any angle relative to one another allowing for infinite bearing adjustment positions.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

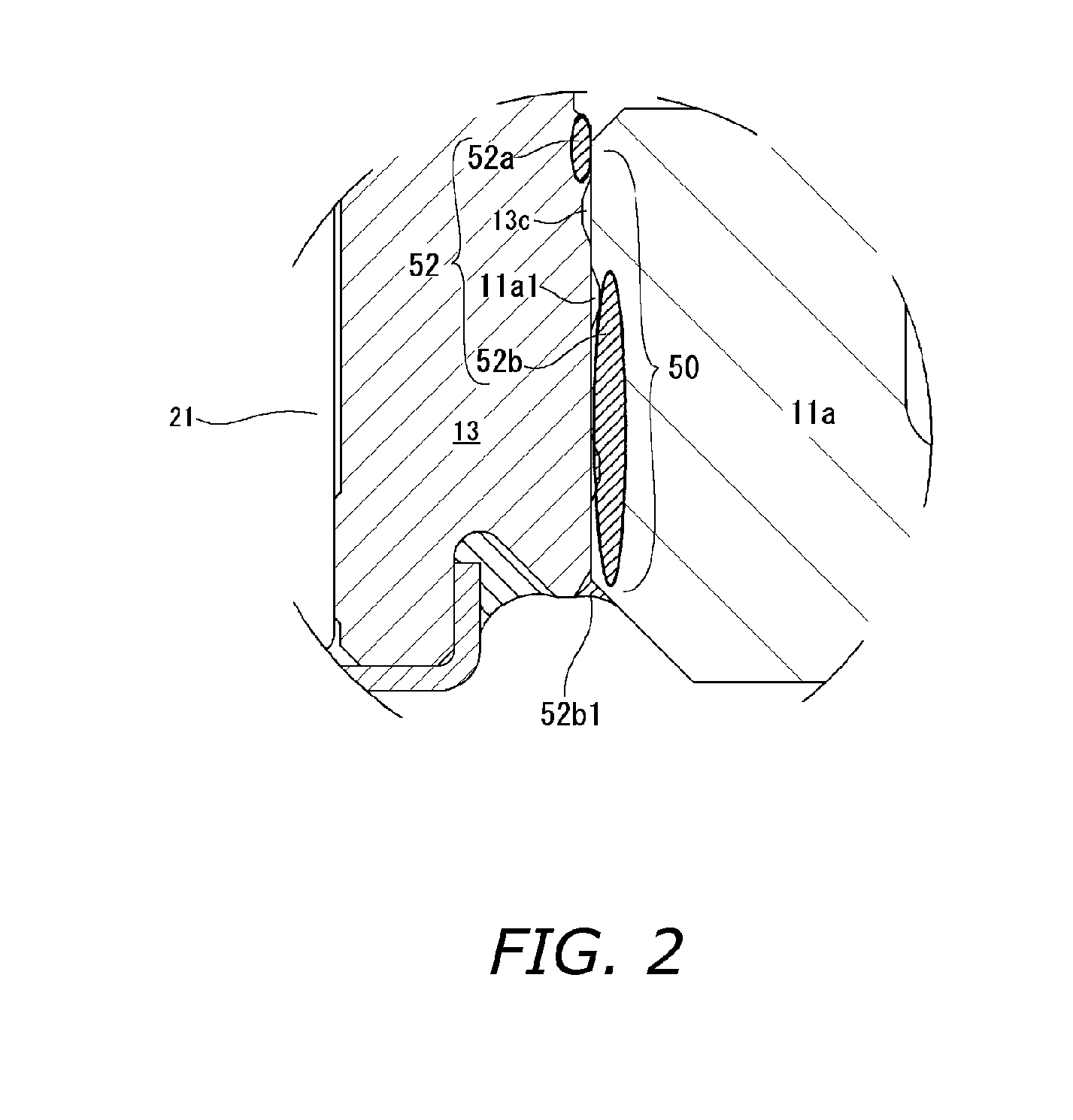

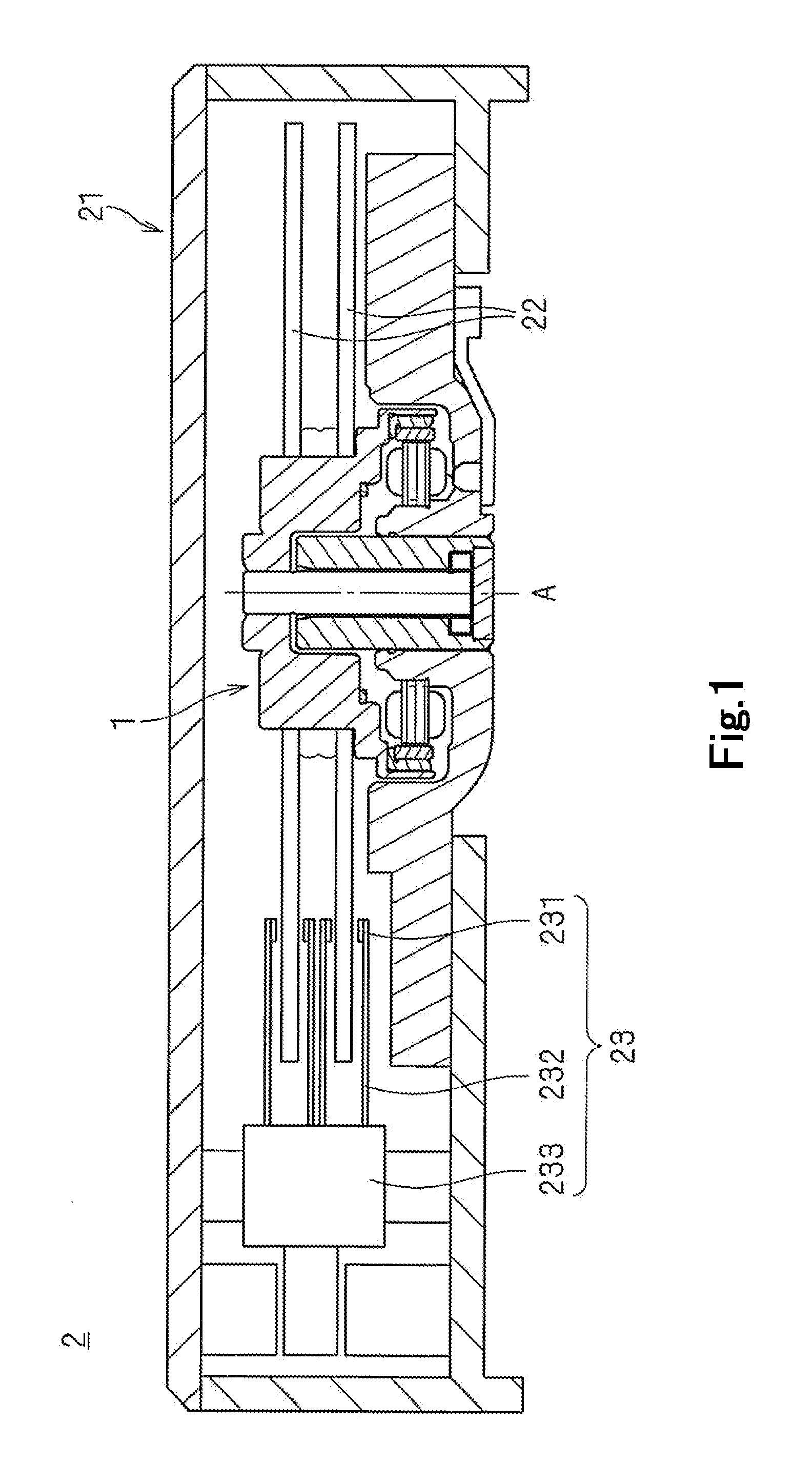

Motor unit, manufacturing method therefor and recording disk driving apparatus

ActiveUS7088023B1Increase production capacityHigh bonding strengthBearing assemblyShaft assemblyAdhesiveEngineering

In a motor unit as an example of the invention, a bearing assembly 5 is securely held on an inner circumferential portion of a hollow cylindrical section 11a of a first housing member 11 with an adhesive section 52 interposed therebetween. The adhesive section 52 includes: a first adhering subsection 52a in which an anaerobic adhesive is present and a second adhering subsection 52b in which an externally stimulated curing type adhesive cured by heating or ultraviolet irradiation is present. Inserting the bearing assembly 5 into the hollow cylindrical section 11a produces a temporarily fixed state by the first adhering subsection 52a, thereby enabling the external stimulated curing type adhesive to be stably cured in the temporarily fixed state.

Owner:NIPPON DENSAN CORP

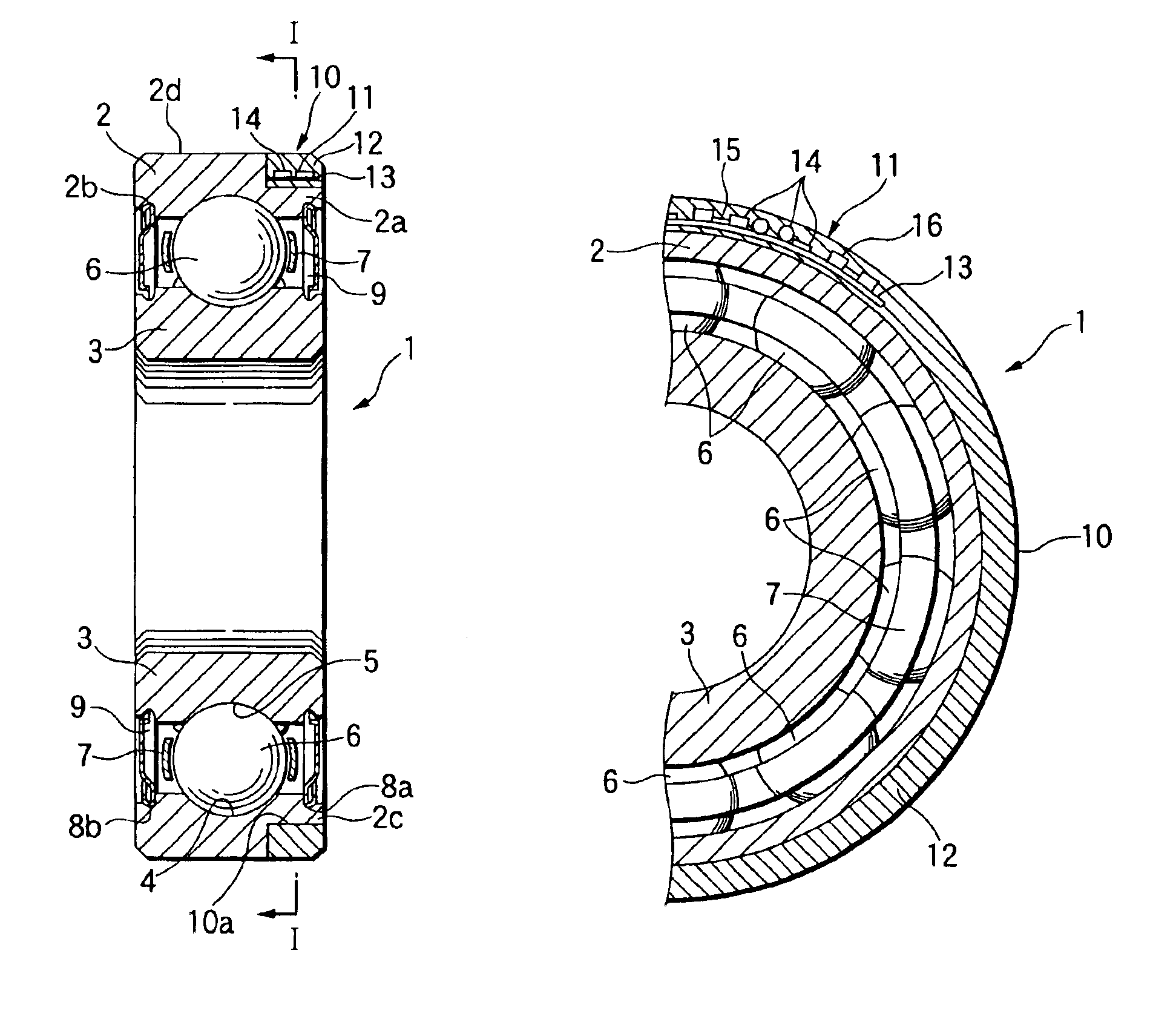

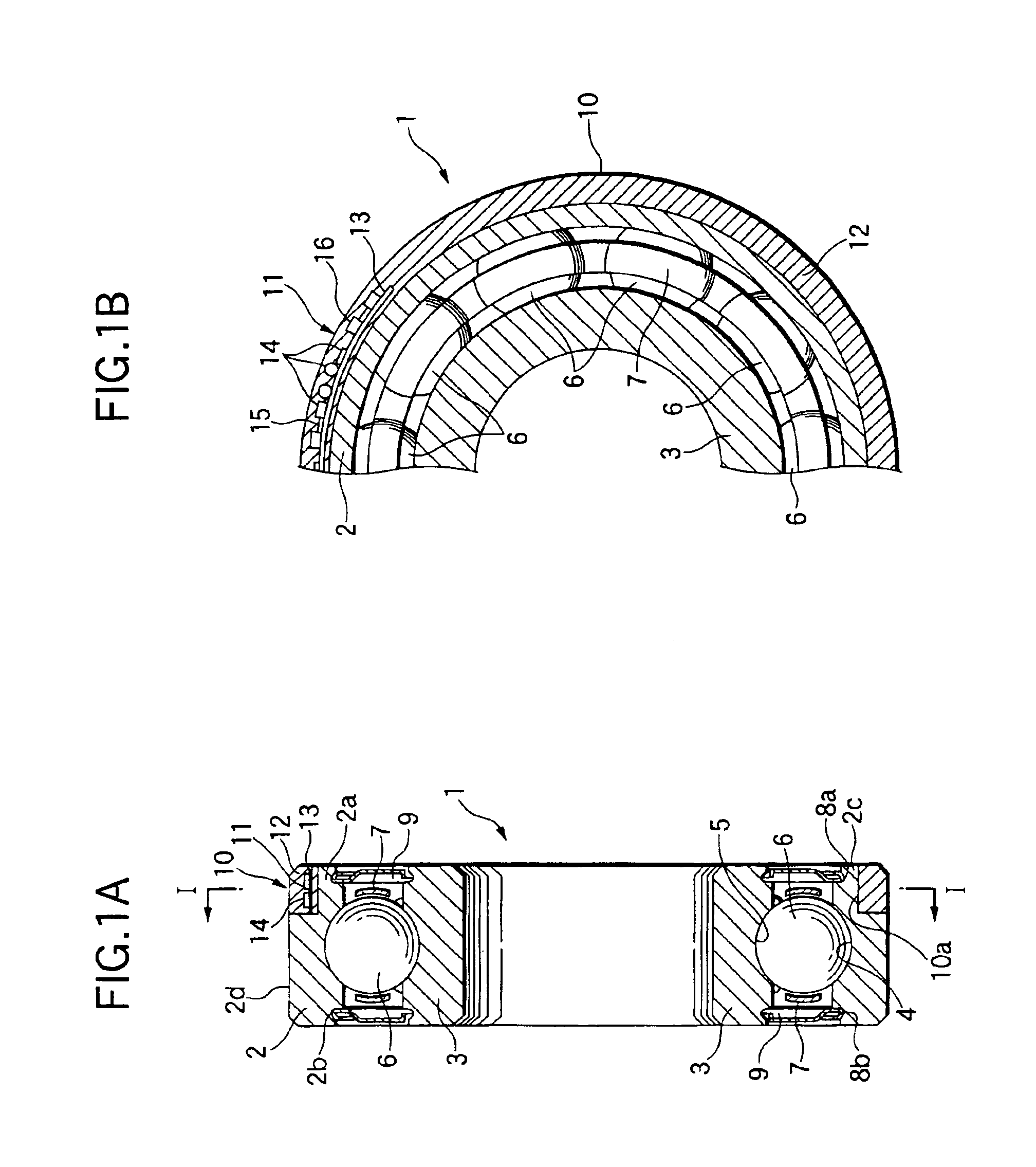

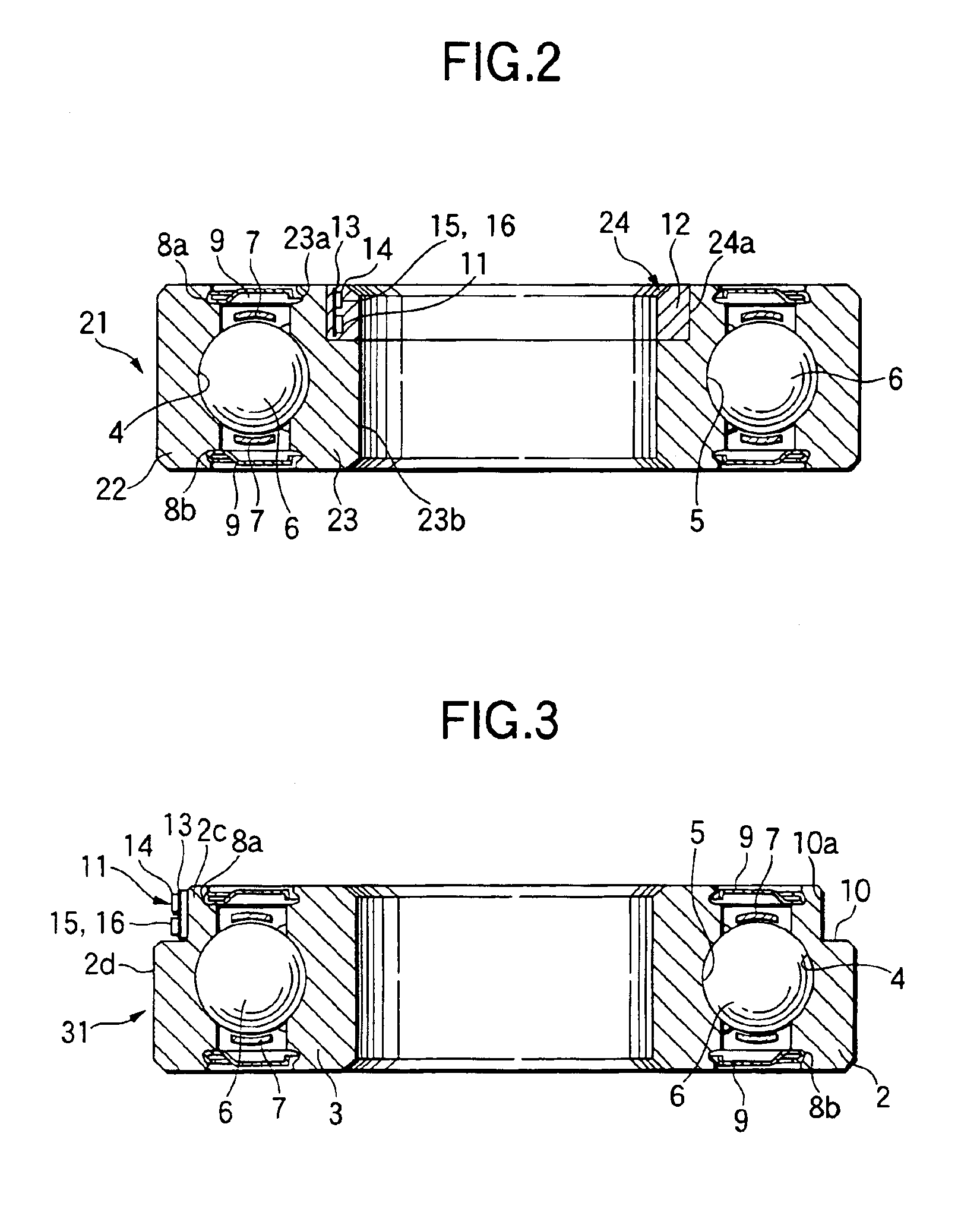

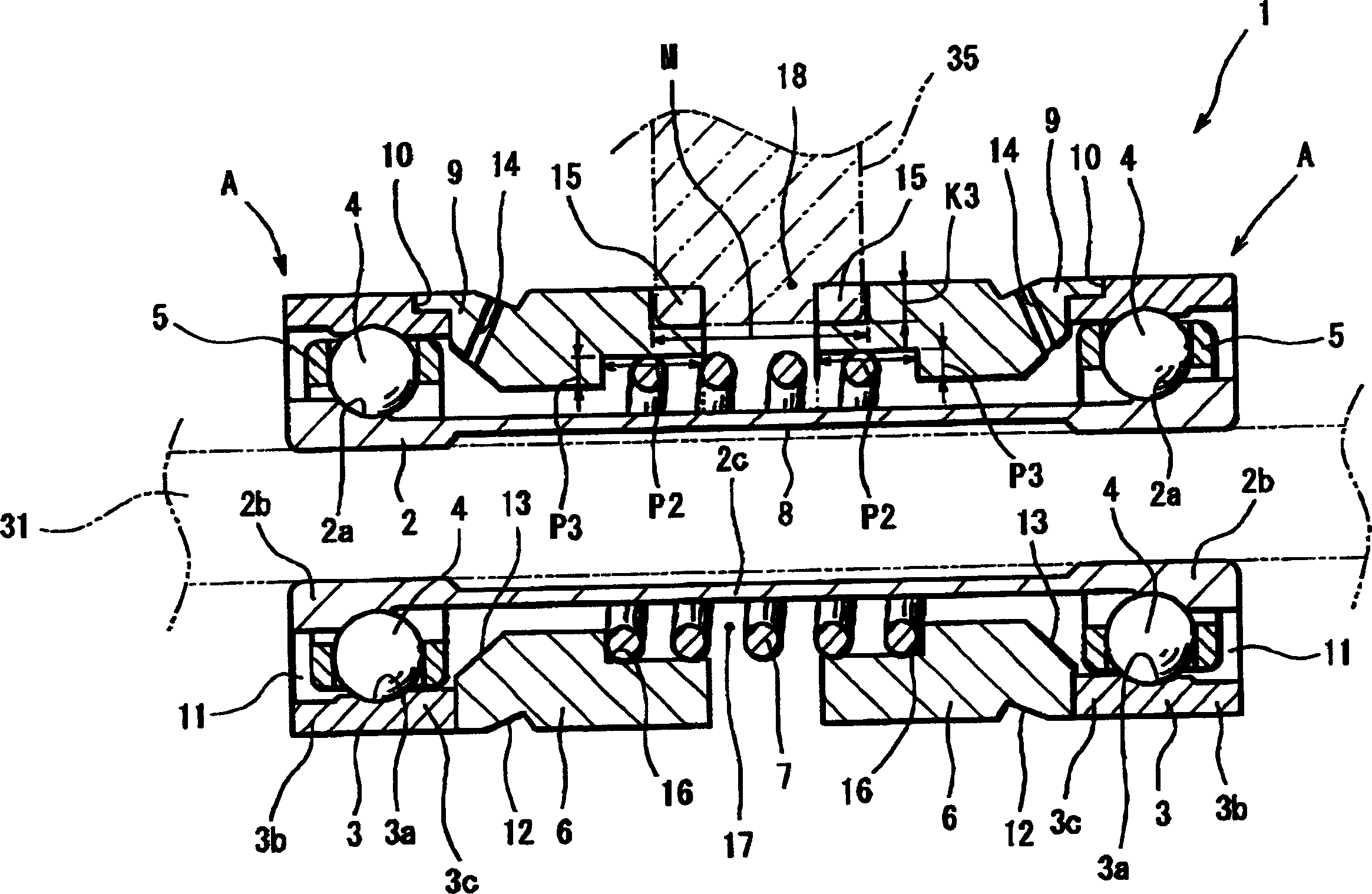

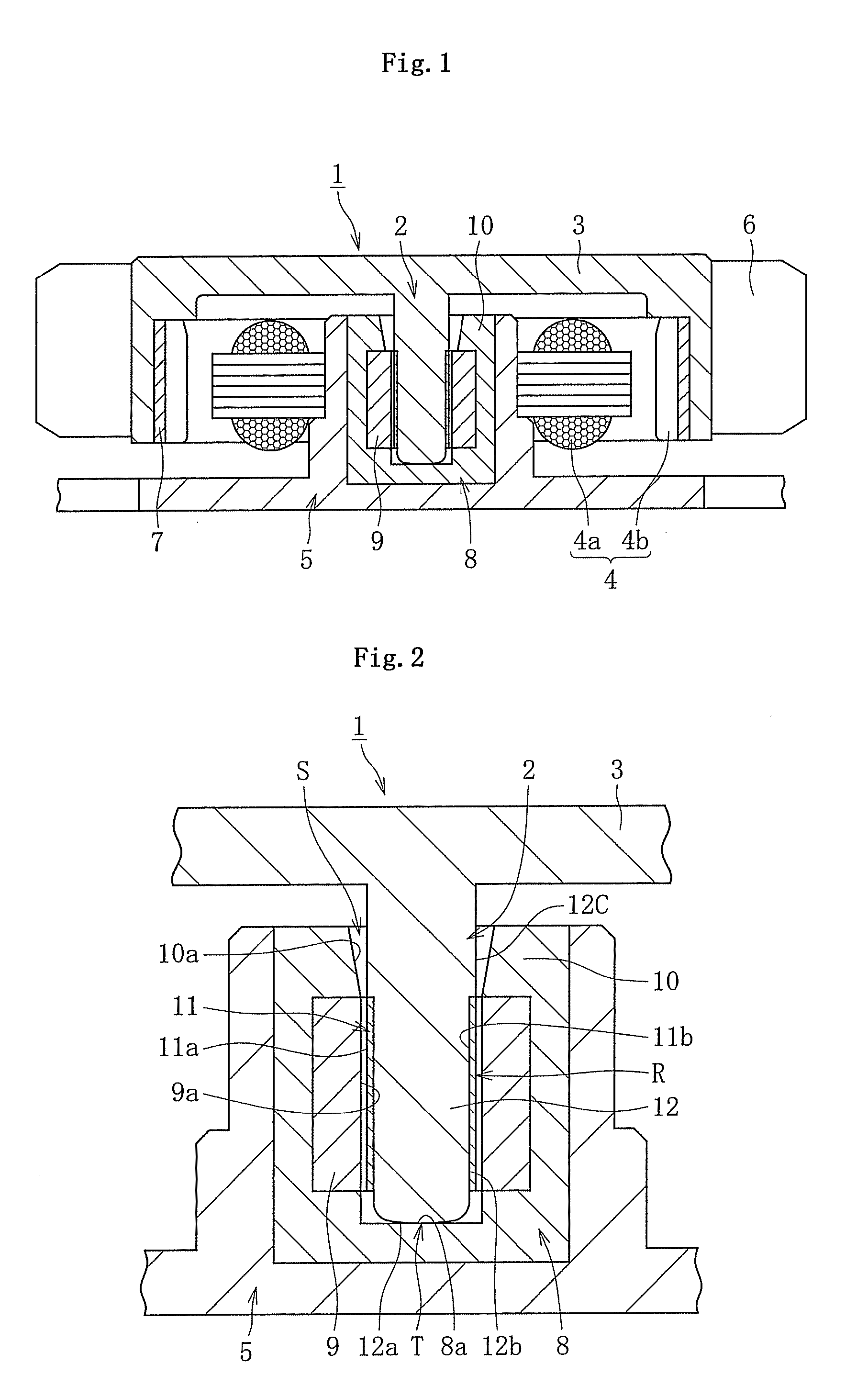

Rolling bearing device and ring with sensor for the rolling bearing device

InactiveUS6948856B2Minimize formationGood adhesionBearing assemblyBall bearingsRolling-element bearingElectrical and Electronics engineering

Owner:NSK LTD

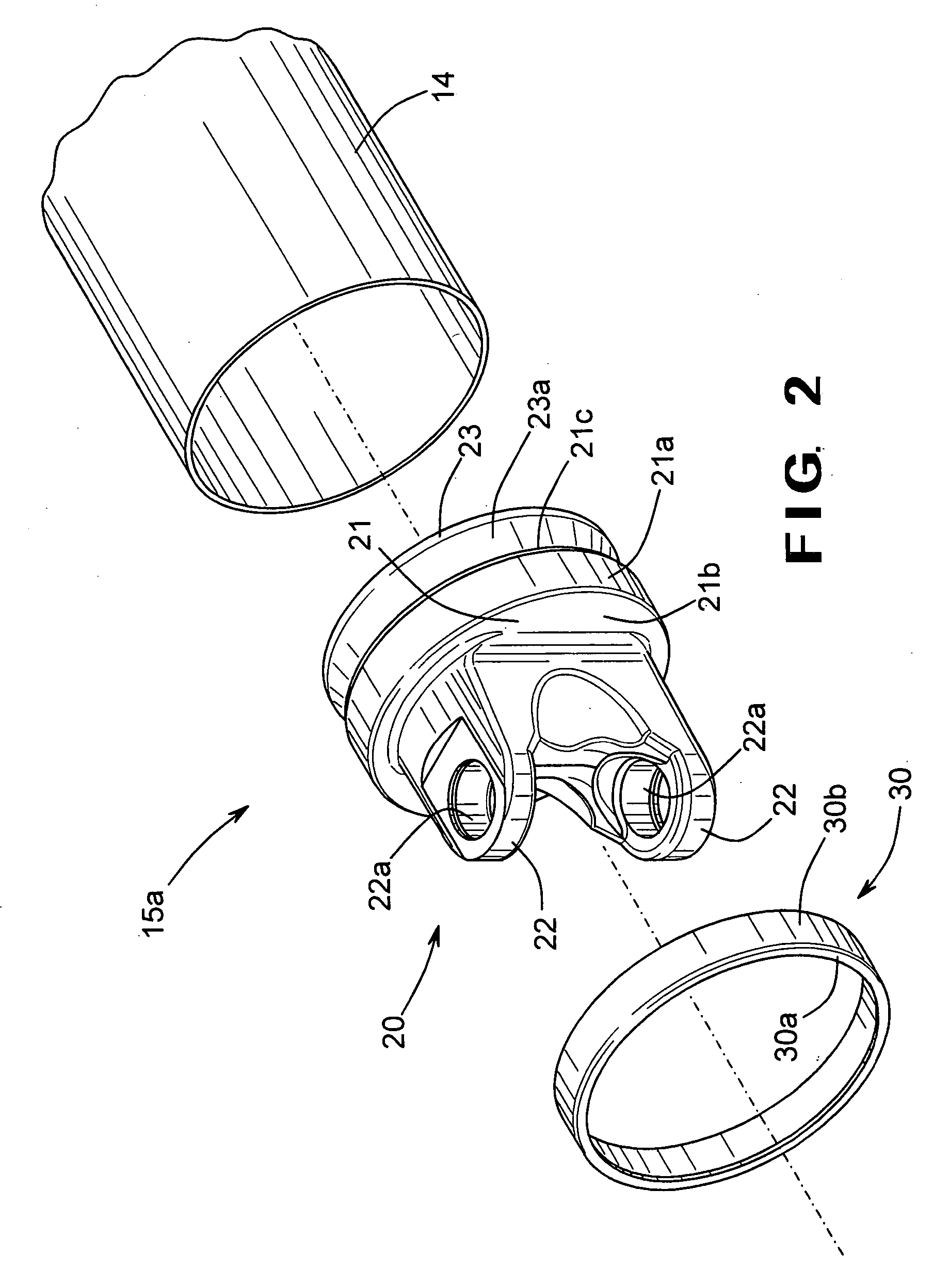

Flexible Transmission Device for Tool Extensions and the Like

InactiveUS20140069240A1Smooth transitionContour smoothingYielding couplingBearing assemblyBall and socket jointFastener

Owner:DAUVIN JAE E +1

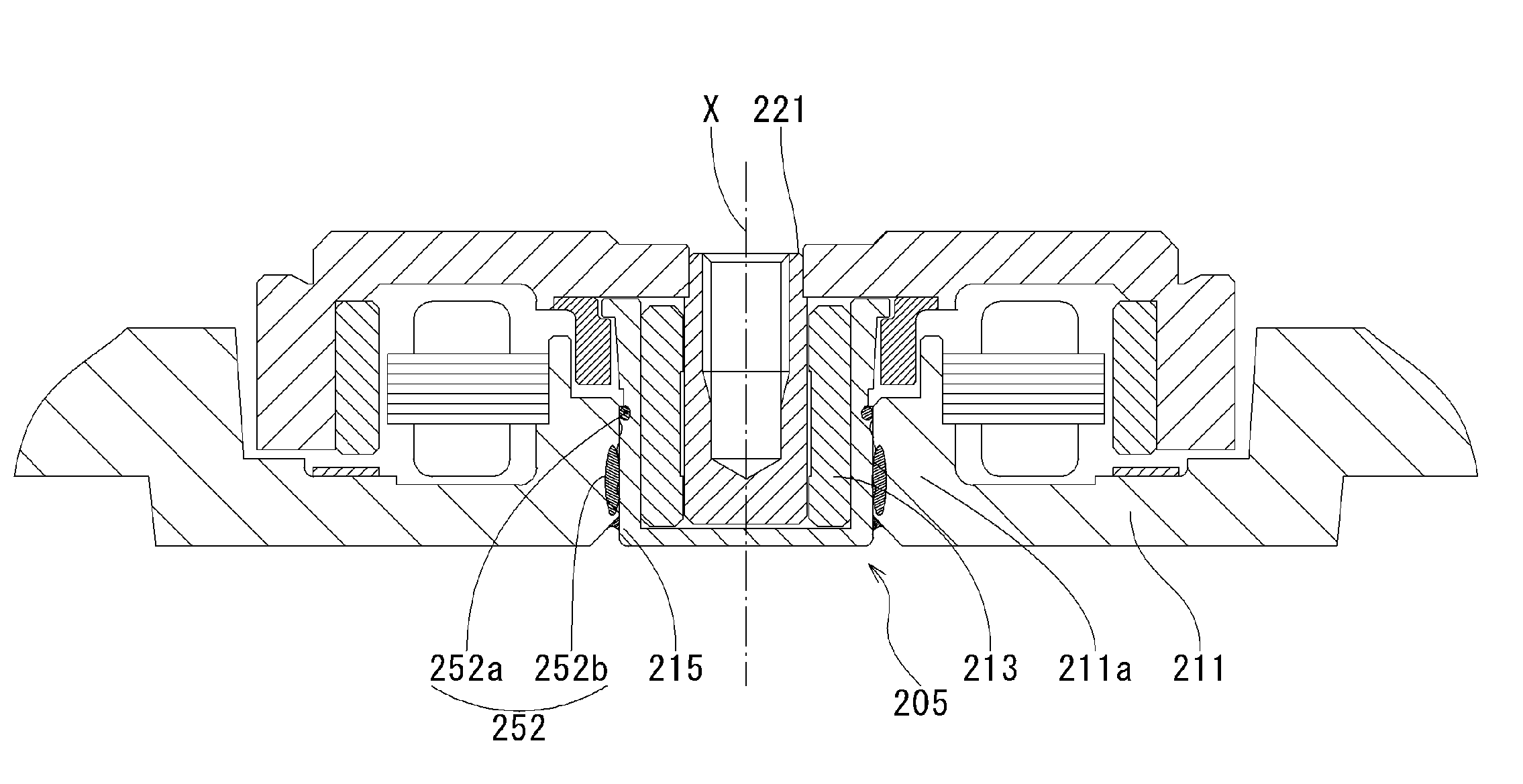

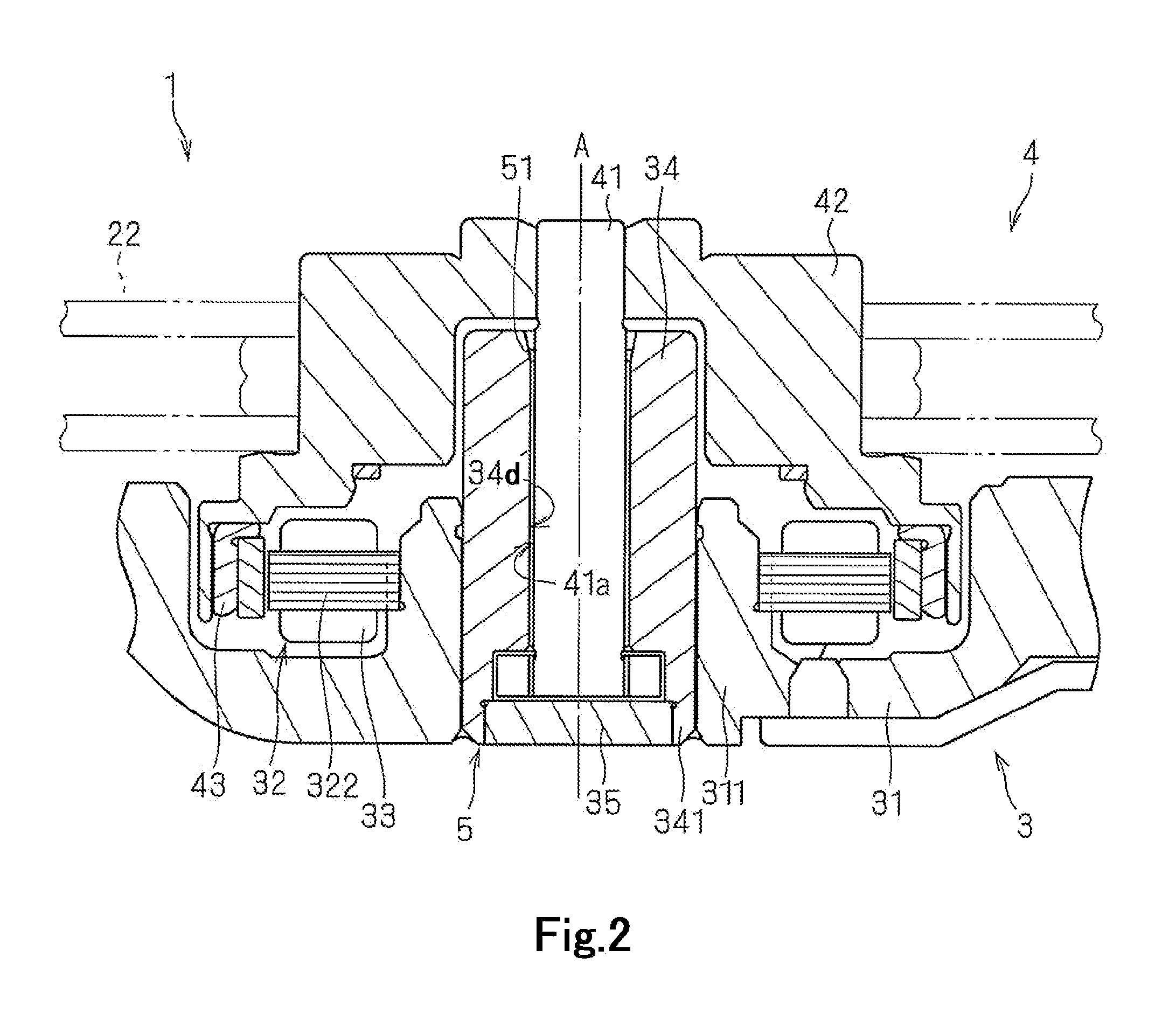

Bearing device for turbocharger

InactiveCN1890475AReduce the pressing forceAvoid indentationRolling contact bearingsBearing assemblyFree rotationTurbocharger

A turbocharger bearing assembly is disposed in a housing for rotatably supporting an intermediate portion of a rotary shaft of a turbocharger. A pair of outer rings formed with outer raceways are mounted to opposite ends of a substantially cylindrical inner ring formed with inner raceways, thereby constituting a bearing unit including two angular bearings. Thus, the number of assembly steps is reduced to facilitate an assembly work. A pair of sleeves are inserted in a gap defined between the outer rings. The sleeve is formed with an engaging portion on an outer periphery thereof for restricting its rotation relative to the housing and the outer ring. This makes it easy to position the bearing in the housing.

Owner:JTEKT CORP

Wheel bearing and sealing device therefor

A wheel bearing includes a sealing device 5 positioned between inner and outer members 1 and 2. This sealing device 5 includes an elastic member 14, which eventually forms an encoder grid and is provided on a first annular sealing plate 11. A second annular sealing plate 12 is provided with sealing lips 16a to 16c. An engagement 18 between a cylindrical wall 11a of the first annular sealing plate 11 and the inner member 1 is provided with an elastic member 20 made of a material dissimilar to that for the elastic material 14. This elastic member 20 may be a rubber coated layer, resin paint layer, a thin film of adhesive material or a ring-shaped rubber member. Thereby, any possible ingress of water across an engagement surface of the annular sealing plate is prevented, accompanied by increase of the lifetime of the bearing, with no problem associated with separation and displacement of the annular sealing plates. The magnetic flux density can also be easily secured.

Owner:NTN CORP

Spindle motor, disk drive apparatus using spindle motor, and method of manufacturing spindle motor

A spindle motor includes a shaft arranged in an upward / downward direction along a central axis; a base member including a substantially cylindrical holder portion arranged around the central axis; a bearing unit arranged radially inward of the holder portion; and a rotating portion arranged above the base member to rotate about the central axis. The rotating portion preferably includes a mounting surface on which a disk is to be mounted. An adhesive containing an electrically conductive material and an adhesive containing an externally stimulated curing material and / or an anaerobic curing material are arranged in a clearance space defined between an inner circumferential surface of the holder portion and an outer circumferential surface of the bearing unit. The adhesive containing the electrically conductive material is arranged above the adhesive containing the externally stimulated curing material and / or the anaerobic curing material.

Owner:NIPPON DENSAN CORP

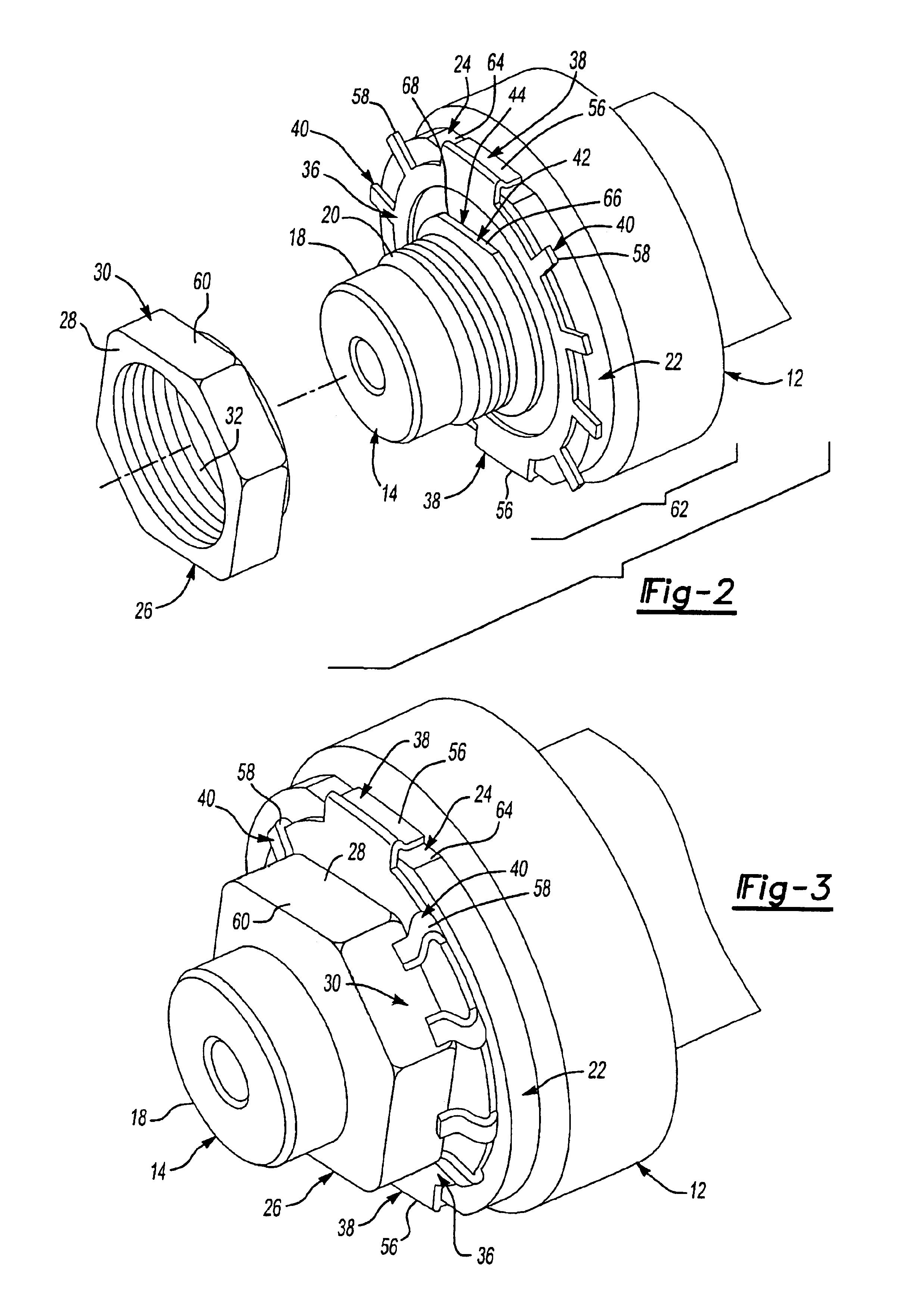

Axle spindle nut assembly for heavy-duty vehicles

ActiveUS8016531B2Eliminate and minimize possibilityReduce the amount requiredRolling contact bearingsBearing assemblyHeavy dutyMechanical engineering

An axle spindle nut assembly secures a wheel end assembly on an axle spindle. The wheel end assembly includes outboard and inboard outboard bearings that are immovably mounted on the axle spindle, and a wheel hub which is rotatably mounting on the bearings. The spindle nut assembly includes a nut that threads onto an outboard end of the axle spindle, and is tightened against the outboard bearing to a selected torque level. The nut includes an outboard surface that is formed with a plurality of features. A washer is formed with a tab that engages a keyway of the axle spindle outboardly of the nut, and with a plurality of mating features that mechanically engage the features formed in the outboard surface of the nut to prevent substantial rotation of the nut after the nut has been tightened to the selected torque level.

Owner:HENDRICKSON USA L L C

Motor with a stationary shaft with formed knurled grooves on shaft and/or housing

InactiveUS6630758B2Prevent occurrence of abnormalityAvoid it happening againBearing assemblyBall bearingsRolling-element bearingEngineering

A motor comprises a rotor, a stator, and a shaft wherein one of the stator and the rotor is provided with a housing, a rolling bearing is provided between the housing and the shaft and having an inner race and outer race, the inner race is fixed to the shaft through adhesion between the outer peripheral surface of the shaft and the inner peripheral surface of the inner race, the outer race is fixed to the housing through press-fitting, and the outer peripheral surface of the shaft is formed with knurled grooves, where the number (P) of the knurled grooves in the circumferential direction and the number (Z) of the rolling members in the rolling bearing are in the relations of P≢n Z and P≢nZ±1 where n is a positive integer.

Owner:NSK LTD

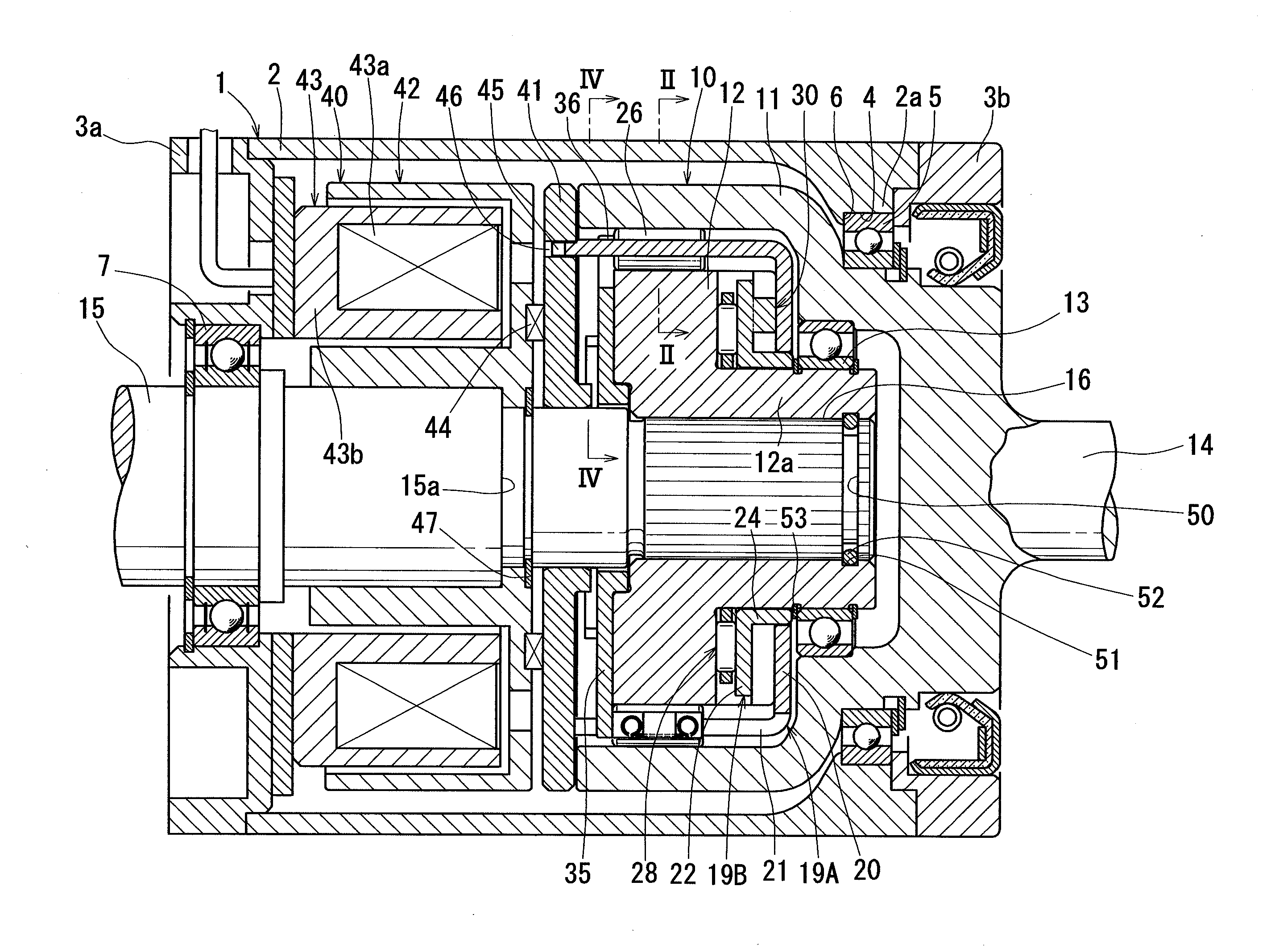

Rotation transmission device

InactiveUS20100314212A1Increase circumferential widthMinimize playBearing assemblyShaft assemblyCamFlange

A rotation transmission device is provided which is small in play in the rotational direction, can be idled with high reliability and is high in torque capacity.An axially movable control retainer 19A and a rotatable rotary retainer 19B are mounted between an outer ring 11 having a cylindrical surface 17 on its inner periphery and an inner ring 12 having cam surfaces on its outer periphery. An opposed pair of rollers 26 and a coil spring 27 for biasing the pair of rollers 26 away from each other are received in each pocket 25 defined between bridges 21 and 23 of the respective retainers 19A and 19B. A torque cam 30 is provided between flanges 20 and 22 of the control retainer 19A and the rotary retainer 19B, respectively. An armature 41 is coupled to the bridges 21 of the control retainer 19A. An electromagnet 43 is provided to face a rotor 42 that axially faces the armature 41 so that when the electromagnet 43 is energized, the control retainer 19A moves toward the rotor 42, and the control retainer 19A and the rotary retainer 19B rotate relative to each other in the direction to reduce the circumferential width of the pockets 25, thereby disengaging the opposed pairs of rollers 26. When the electromagnet 43 is deenergized, the control retainer 19A moves away from the rotor 42 under the biasing force of the separation spring 44, and the control retainer 19A and the rotary retainer 19B rotate relative to each other in the direction to increase the circumferential width of the pockets 25, thereby engaging the opposed pairs of rollers 26.

Owner:NTN CORP

Fluid dynamic bearing device

InactiveUS20090046960A1Improve carrying capacityLow costBearing assemblyShaft assemblyEngineeringMechanical engineering

Owner:NTN CORP

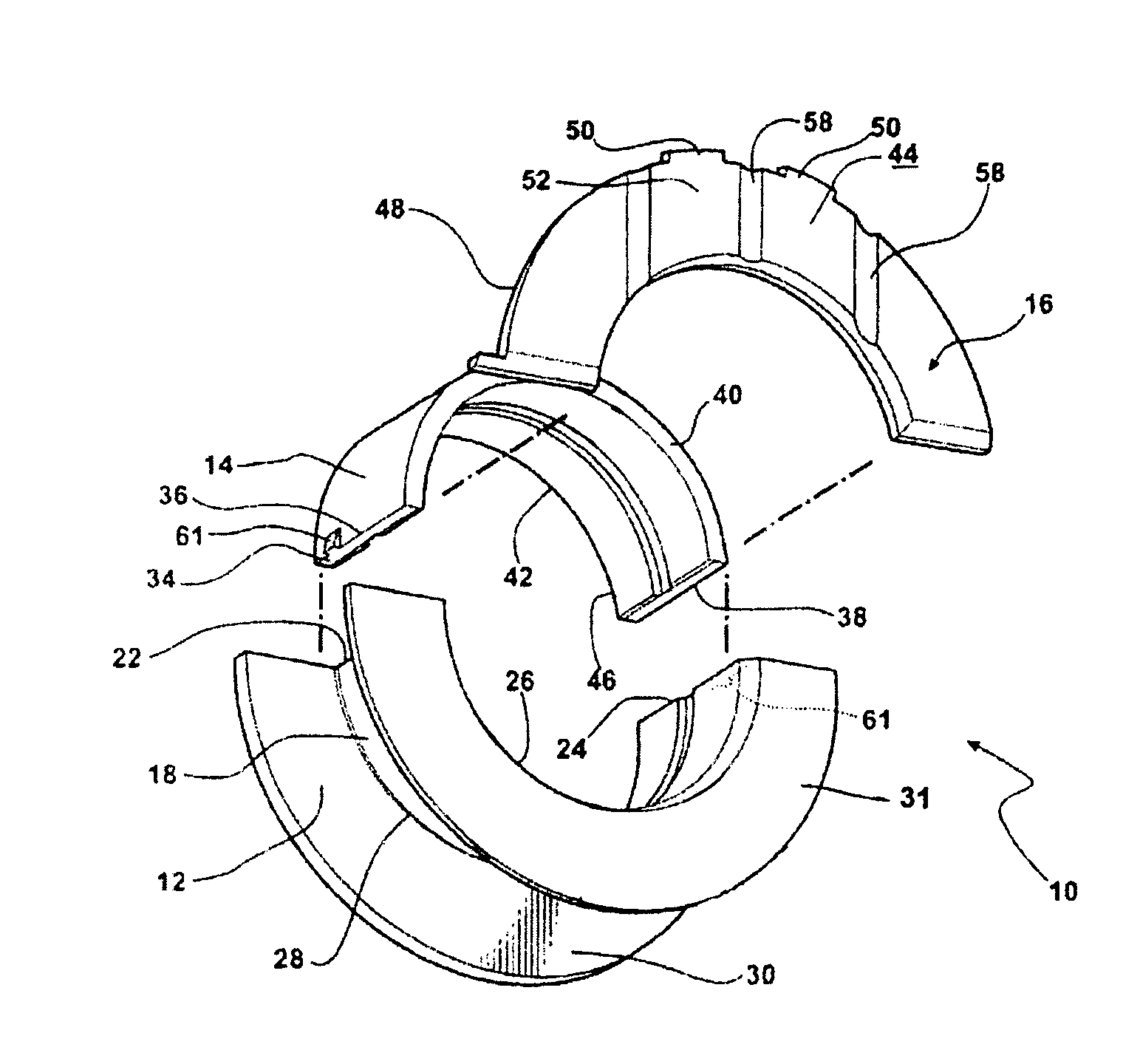

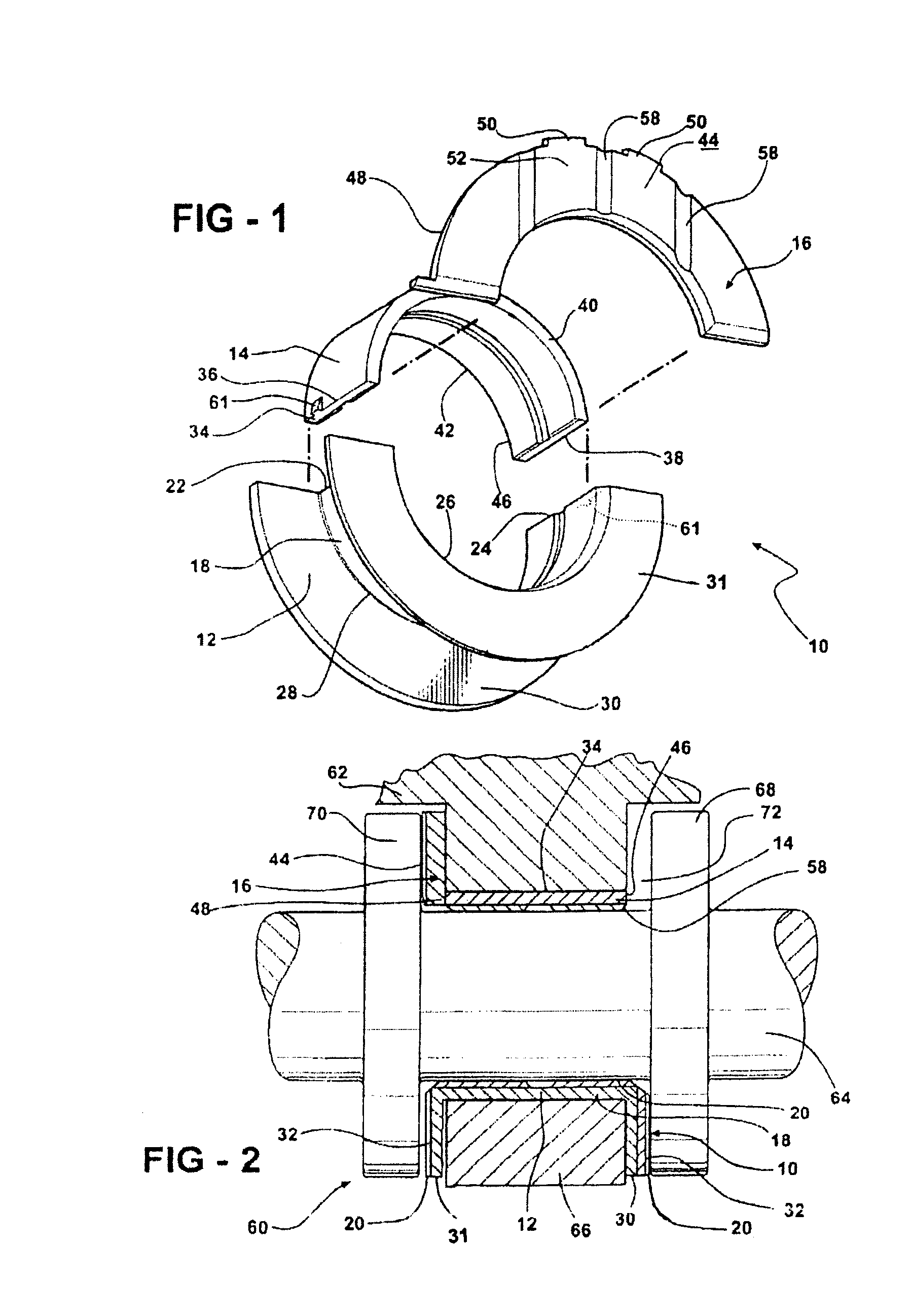

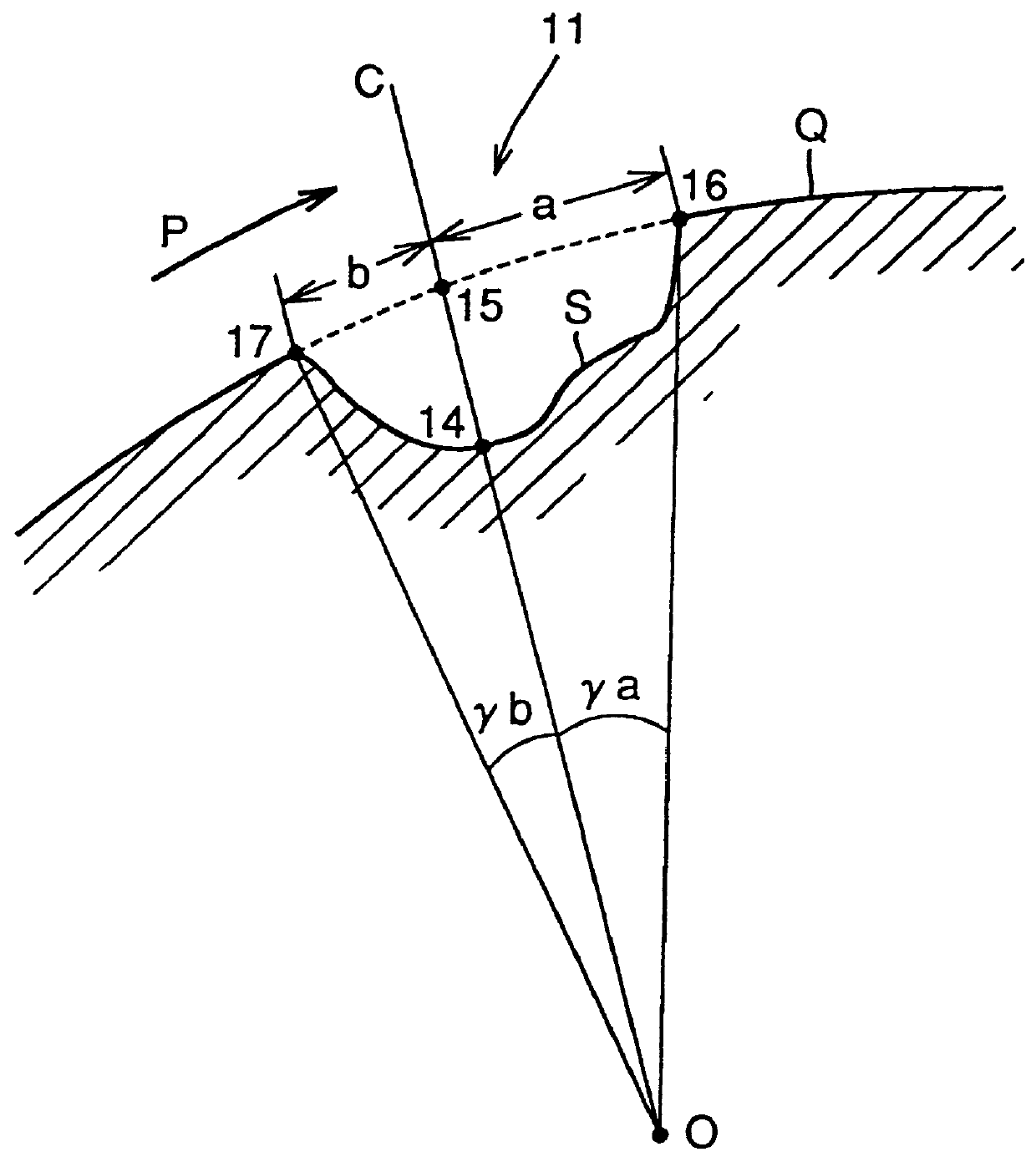

Thrust bearing assembly

InactiveUS7134793B2Reduce manufacturing costExpensive to manufactureBearing assemblyCrankshaft bearingsThrust bearingFree edge

The subject invention provides a thrust bearing assembly having only three thrust flanges in total. One portion of the thrust bearing assembly comprises a main bearing having an arcuate bearing shell with a concave inner surface and a convex outer surface. A thrust washer having hydrodynamic features abuts one of the edges of the main bearing and extends radially outwardly from the outer surface thereof forming a thrust surface. The other of the edges of the main bearing is free of a flange. The free edge of the main bearing is preferably spaced inward from other thrust surfaces and the edge has a substantially narrower width than the other thrust surfaces. The other portion of the assembly may include a traditional thrust bearing having one thrust flange with hydrodynamic features and another thrust flange free of hydrodynamic features, both extending radially outwardly therefrom or may include another main bearing abutting a pair of thrust washers, one having hydrodynamic features and one free of hydrodynamic features, extending radially outwardly from the other main bearing. In either configuration, the thrust flange or thrust washer that is free of hydrodynamic features is opposite the thrust washer having hydrodynamic features of the main bearing.

Owner:FEDERAL MOGUL WORLD WIDE LLC

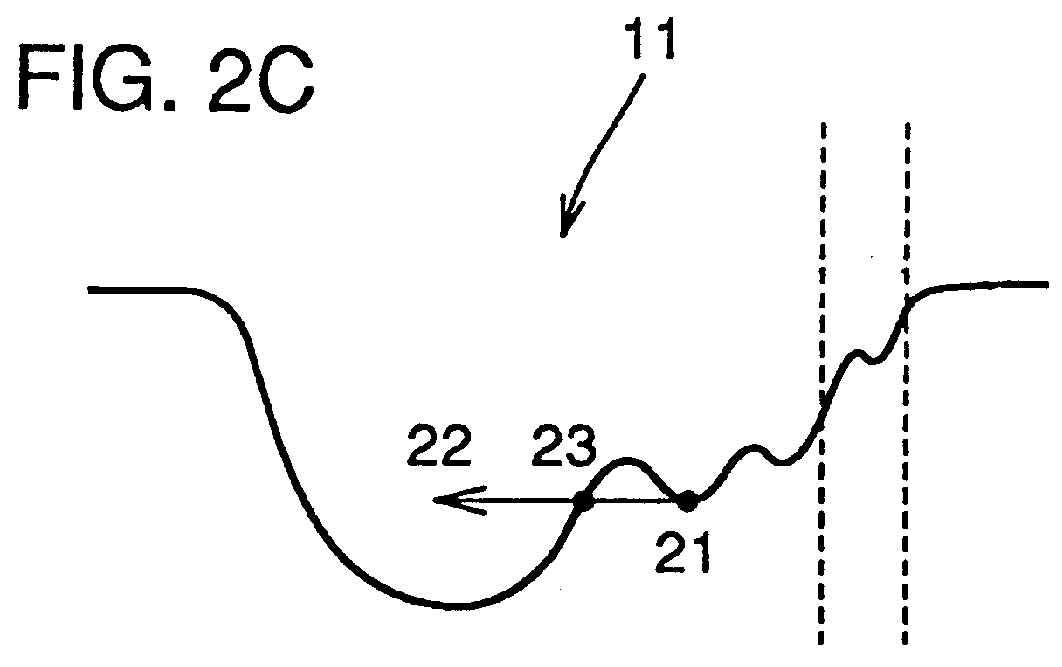

Dynamic pressure pneumatic bearing structure and method of manufacturing the same

PCT No. PCT / JP98 / 00739 Sec. 371 Date Oct. 28, 1998 Sec. 102(e) Date Oct. 28, 1998 PCT Filed Feb. 23, 1998 PCT Pub. No. WO98 / 38433 PCT Pub. Date Sep. 3, 1998Provided is a hydrodynamic gas bearing structure which can prevent occurrence of whirl not only in high-speed rotation but also in low-speed rotation, reduces such frequency that a floating rotational frequency in starting or stoppage of rotation increases, and is capable of shifting the floating rotational frequency to a low rotational frequency side. The hydrodynamic gas bearing structure comprises a shaft body (1) and a bearing body (2). A groove (11) is formed on the outer peripheral surface of the shaft body (1). The groove (11) consists of at least two concave parts, whose depths substantially differ from each other, which are formed serially in the circumferential direction, and has a circumferentially asymmetrical shape in a cross section perpendicular to the axis. The circumferential distance a between the intersection point (15) of a line (C) connecting the deepest point (14) of the groove (11) and the center (O) of the shaft body (1) and the outer peripheral line (Q) of the shaft body (1) and one edge (16) of the groove (11) positioned downward an air current (P) generated in rotation in relation to the intersection point (15) is larger than the circumferential distance b between the intersection point (15) and the other edge (17) of the groove (11) positioned upstream the air current (P) in relation to the intersection point (15). The ratio (d2 / d1) of the mean depth d2 of a relatively shallow part of the groove (11) to the mean depth d1 of a relatively deep part of the groove (11) is less than 0.3. The hydrodynamic gas bearing structure is suitable for employment for a rotation driving part of a magnetic recording apparatus or a laser beam printer.

Owner:SUMITOMO ELECTRIC IND LTD

Rolling bearing device and ring with sensor for the rolling bearing device

InactiveUS20050259903A1Minimize formationGood adhesionBearing assemblyBall bearingsRolling-element bearingClassical mechanics

Owner:NSK LTD

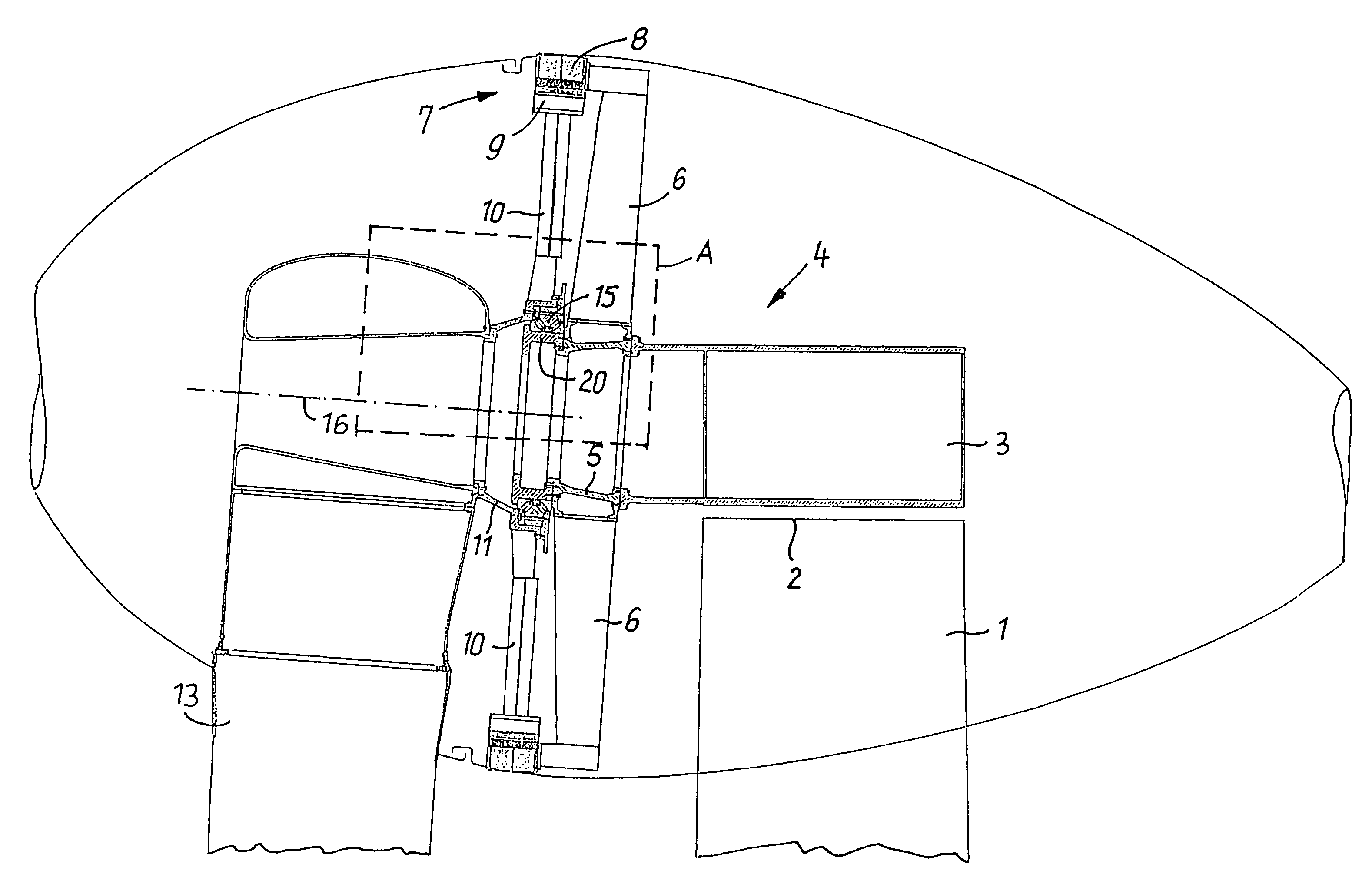

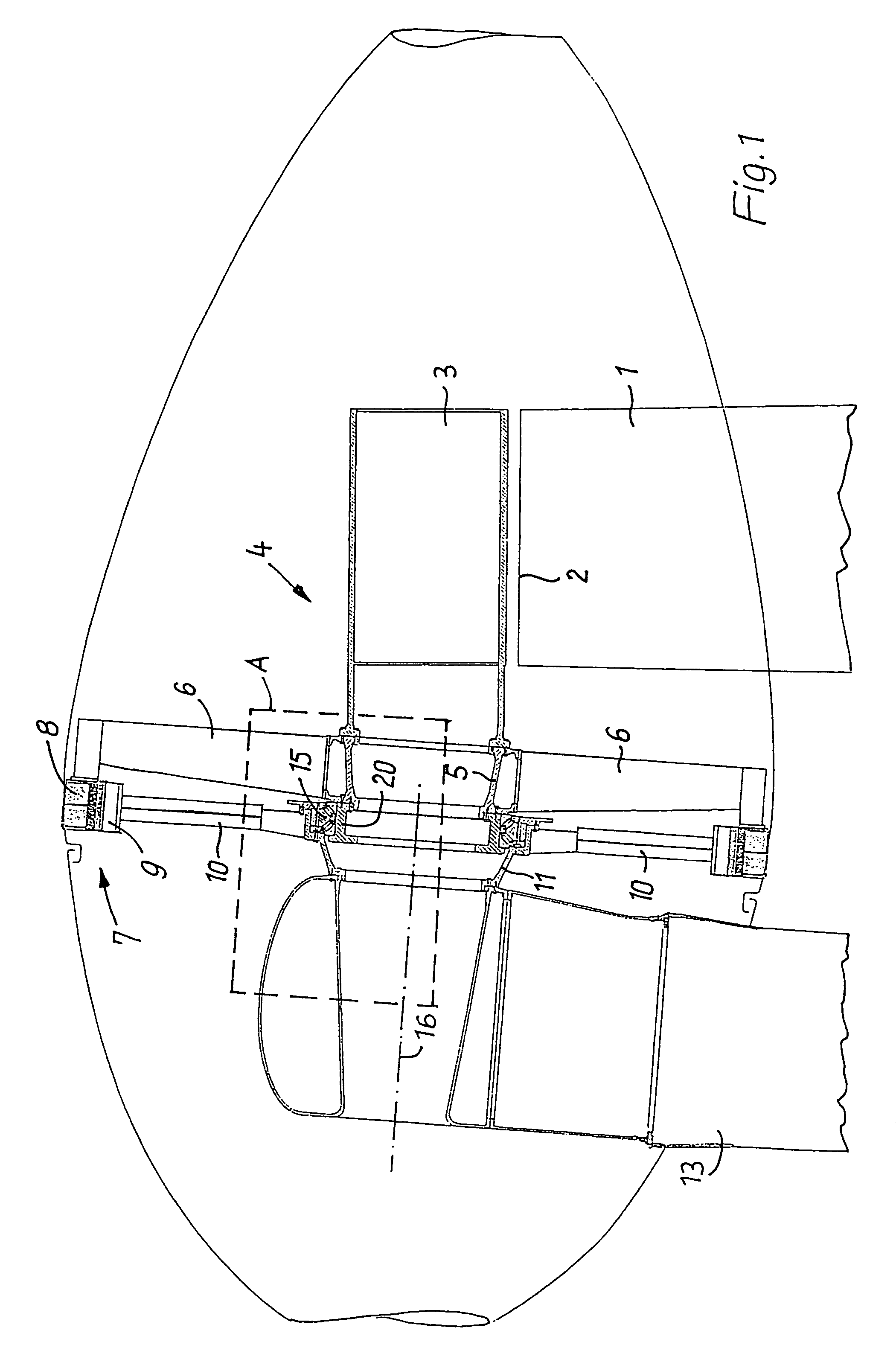

Wind energy unit comprising a hollow shaft for rotor hub and generator

InactiveUS7084522B2Reduce weightReduced moment loadInfluencers using Magnus effectRoller bearingsWind forceWind power

In a wind power installation with a (hollow) axis tube member and a hollow shaft mounted thereon for the rotor there is provided only a single bearing which also carries moments, between the axis tube member and the hollow shaft, whereby the parts of the machine which are to be fixed to the machine carrier and thus on the top of the pylon are of a markedly lower weight without the required orientation between the rotating and stationary parts of the electrical generator being adversely affected. In that arrangement the rotating part of the generator is radially aligned substantially with the bearing. The bearing to be used is in particular a twin-row inclined roller bearing with rows of rollers arranged at an angle of about 45° relative to each other.

Owner:WOBBEN ALOYS

Bearing retainer assembly and method

A bearing assembly and method includes a two-piece ball bearing retainer. The retainer has a first set of fluid passage apertures penetrating into ball bearing sockets, and has a supplemental set of fluid passage apertures penetrating from one side of the retainer to the other. The two halves can be snap fit together.

Owner:SPX FLOW INC

Bearing assembly

A bearing assembly comprises a bearing race received in a bore of a housing comprising a deformable housing material. The bearing race includes one or more recesses formed on a surface thereof disposed proximate the housing. Each recess receives housing material that has been deformed locally therein after the bearing race is received in the bore to prevent both rotational and axial motion of the bearing race relative to the housing.

Owner:VISTEON GLOBAL TECH INC

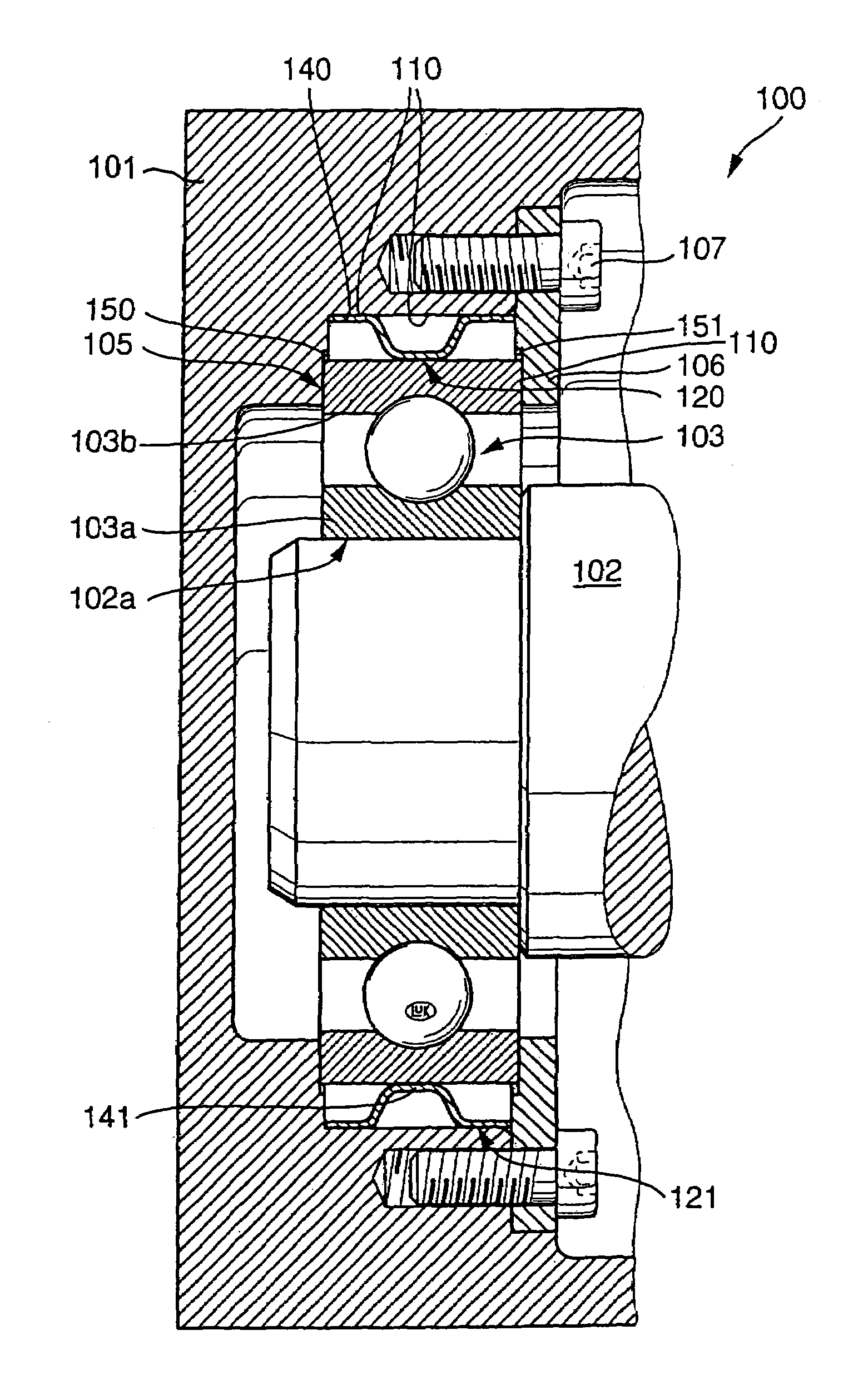

Bearing insert with controlled endplay

A system and method is provided to accommodate positional variations in a bearing assembly, which has a clearance adjustment assembly for setting the roller clearance therein. The bearing assembly has multiple rows of tapered rollers disposed circumferentially between an inner sleeve and the clearance adjustment assembly, which is secured by an outer retaining sleeve. The clearance adjustment assembly has at least one clearance adjustment ring disposed adjacent multiple tapered support rings, which extend circumferentially about the multiple rows of tapered rollers. In the bearing assembly, the at least one clearance adjustment ring forces the multiple tapered support rings against the multiple rows of tapered rollers to set the desired roller clearance. Accordingly, the bearing assembly can accommodate expansion, contraction, and angular variations in the system.

Owner:BALDOR ELECTRIC COMPANY

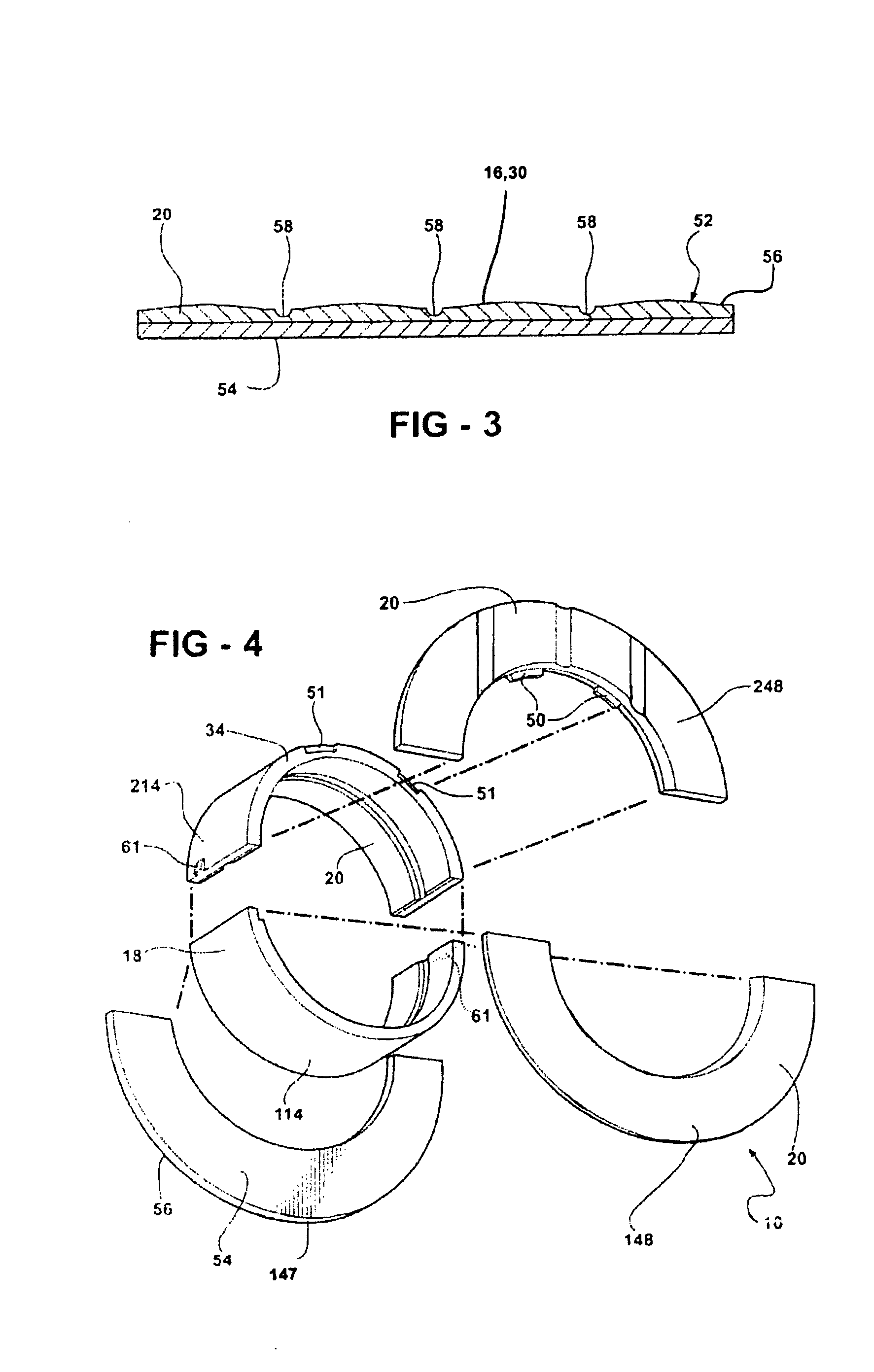

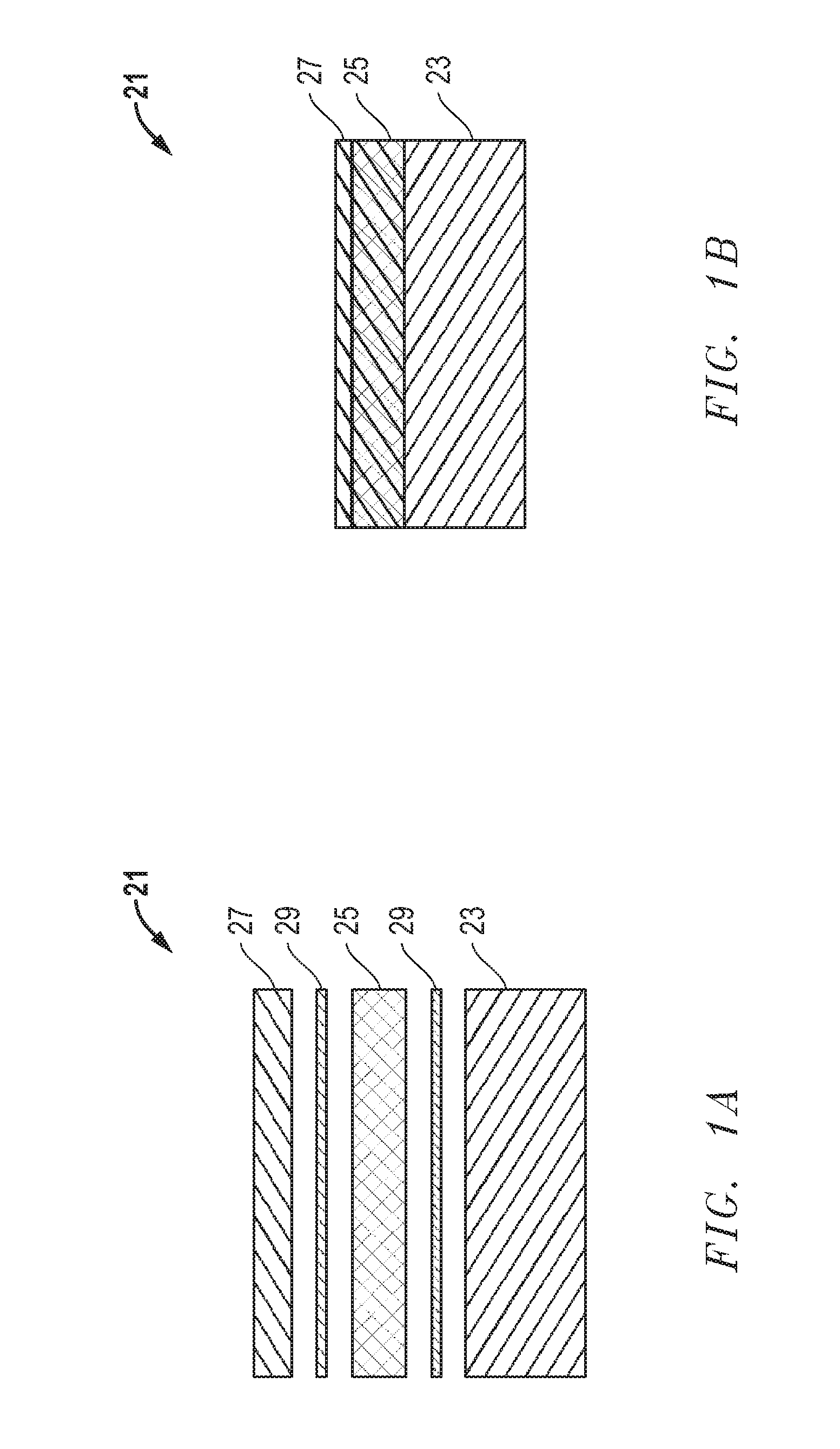

Maintenance-free bearing with tolerance compensation properties against wear and misalignment

A system for elastically compensating for wear, thermal expansion and misalignment comprises a ring located between a housing and a pin in the bore of the housing. The ring has a backing layer, an expanded grid structure having a plurality of openings, a low friction layer penetrated into the openings of the expanded grid structure, and adhesive for bonding the backing layer, expanded grid structure and low friction layer together to provide elastic deformation of the ring between the housing and pin.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS PAMPUS GMBH

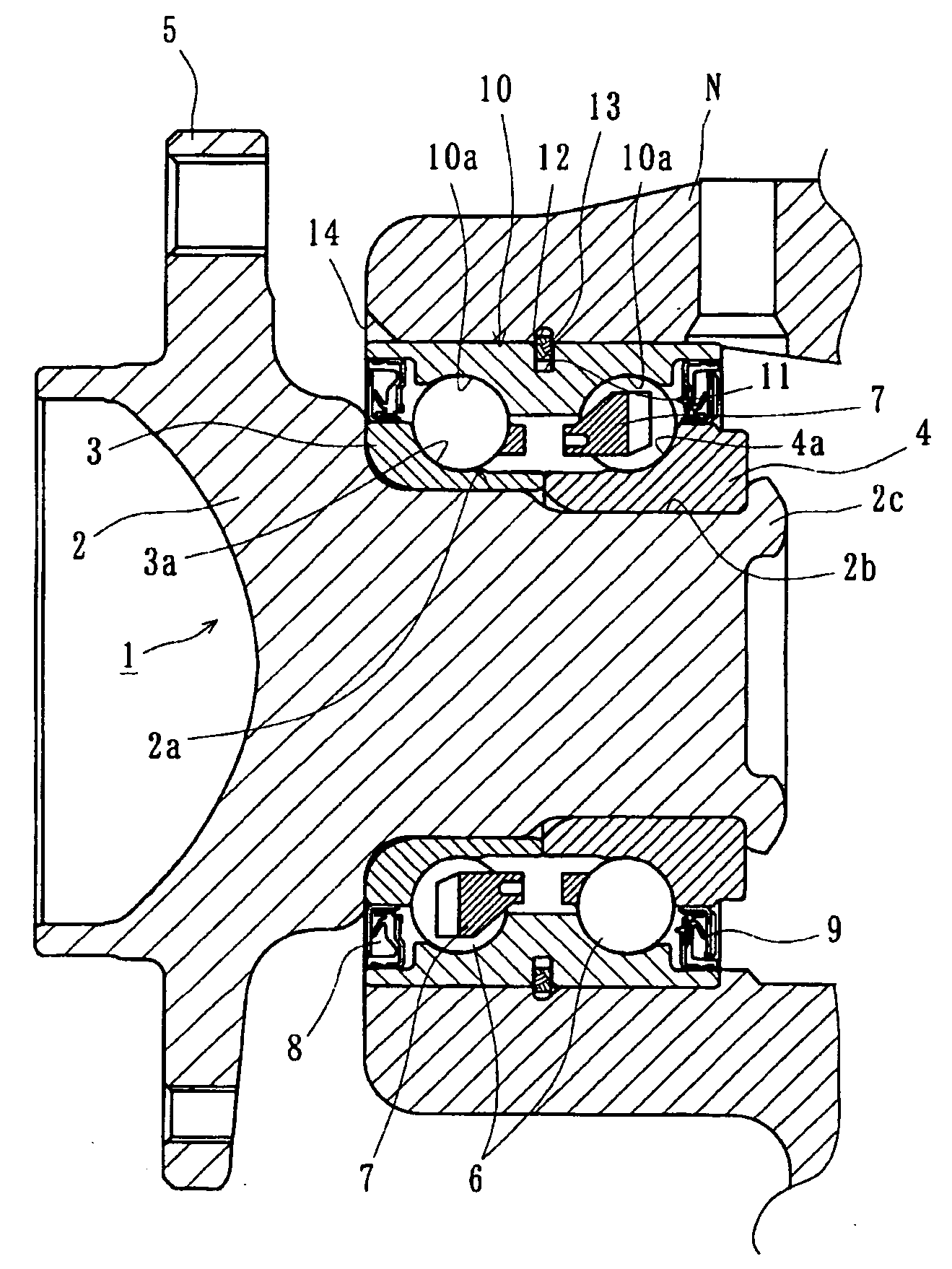

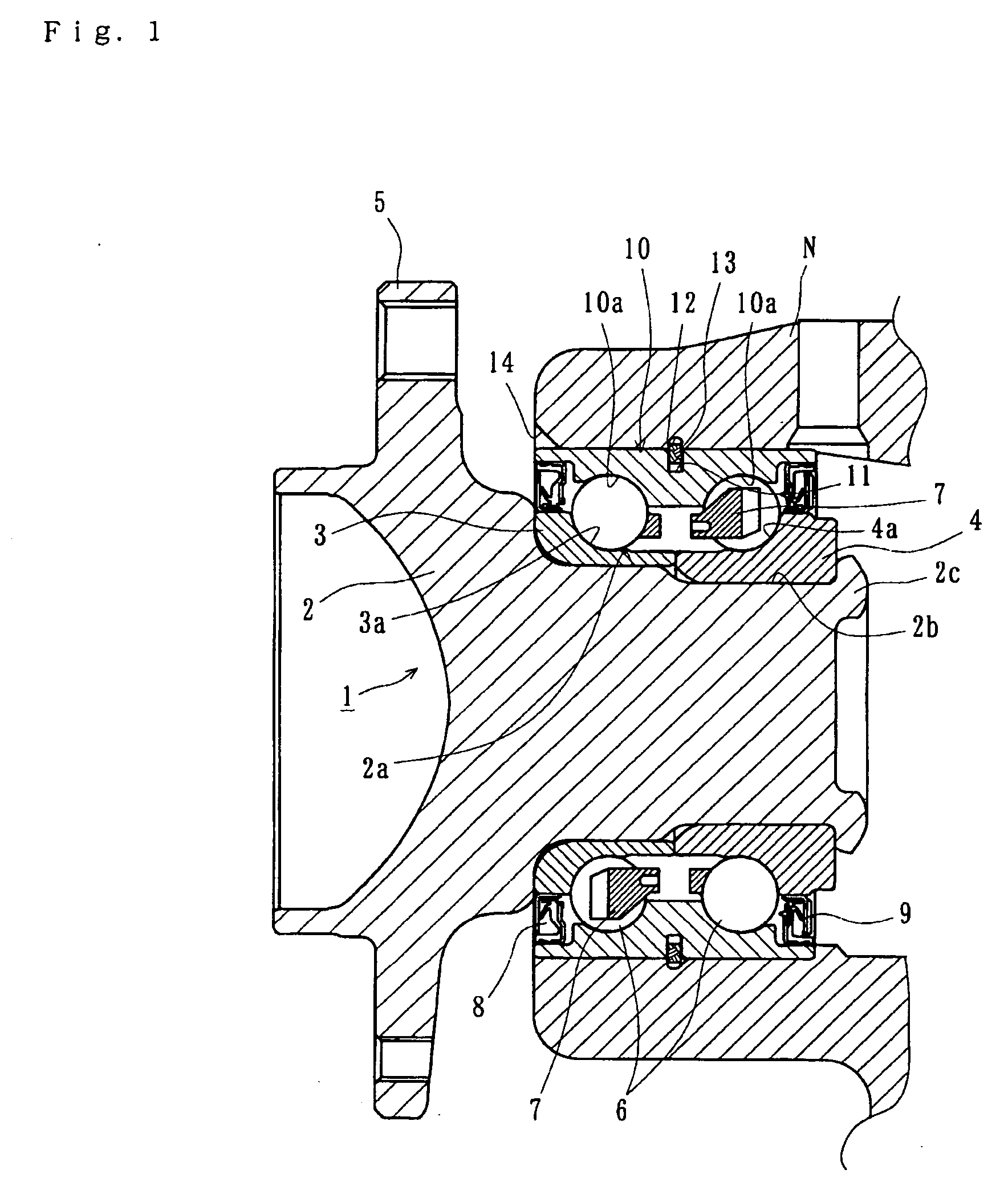

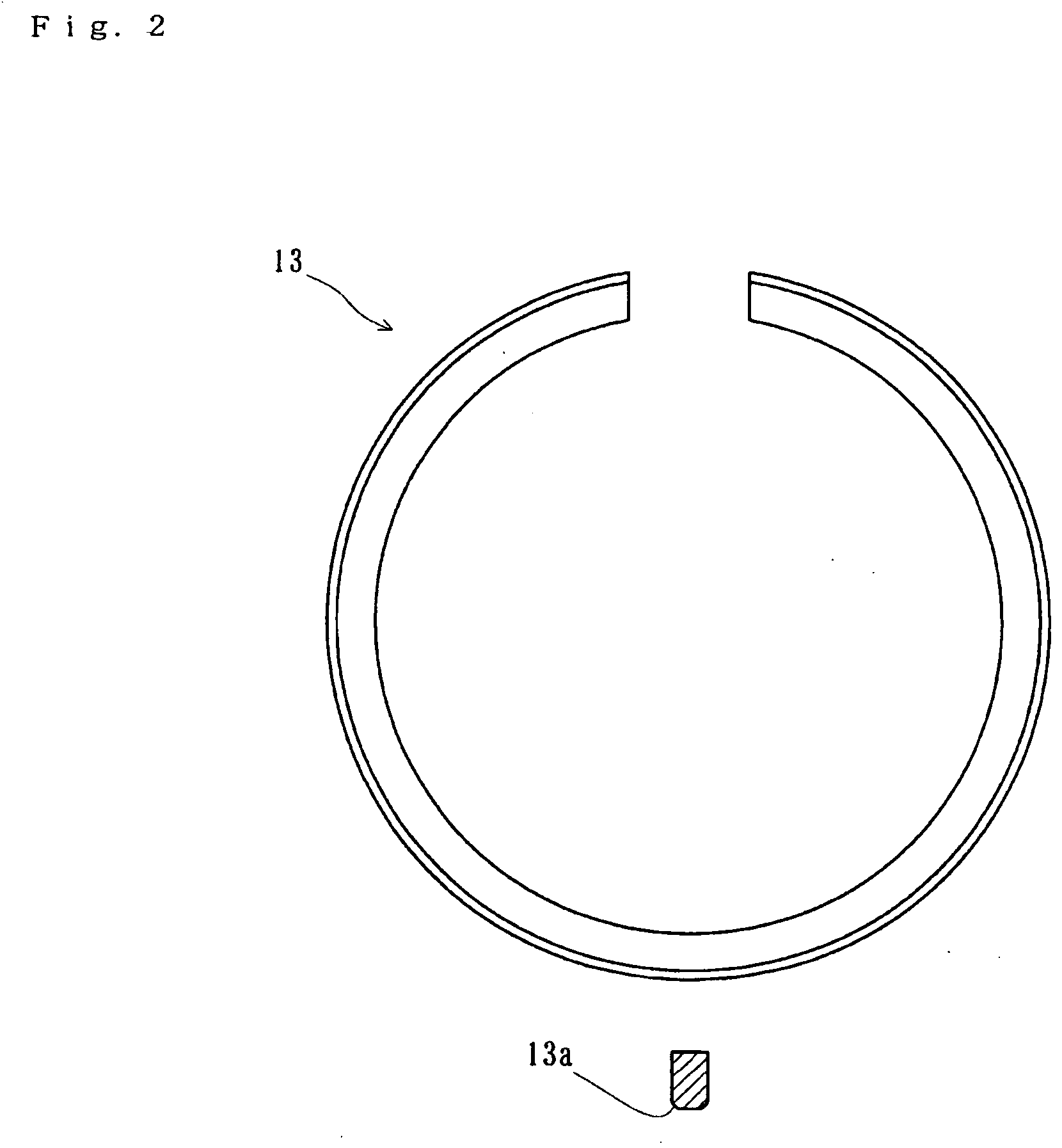

Bearing apparatus for a wheel of vehicle

InactiveUS20050105840A1Easily destructedSimplify disassemblyRolling contact bearingsBearing assemblyMan-hourEngineering

A vehicle wheel bearing apparatus is simple to assemble and disassemble which reduces the man-hour in manufacturing and its manufacturing cost. The bearing apparatus has an inner member (1) including a wheel hub (2) integrally formed with a wheel mounting flange (5) at one end. Axially extending cylindrical portions (2a) and (2b) axially extend from the wheel mounting flange (5). Inner rings (3) and (4) are fitted on the axially extending cylindrical portions (2a) and (2b). An outer member (10) is fitted in a knuckle N which forms a part of a suspension apparatus. Double row rolling elements (6) and (6) are arranged between the inner and outer members (1) and (10). The wheel hub wheel, (2) is rotatably supported by the knuckle N. Annular stop ring grooves (11) and (12) are formed, respectively, on the outer circumferential surface of the outer member (10) and the inner circumferential surface of the knuckle N. A stop ring (13), with a predetermined shearing strength of 20˜200 MPa, is fitted in the stop ring grooves (11) and (12).

Owner:NTN CORP

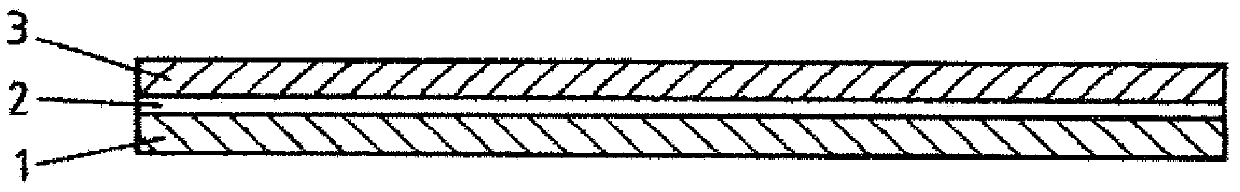

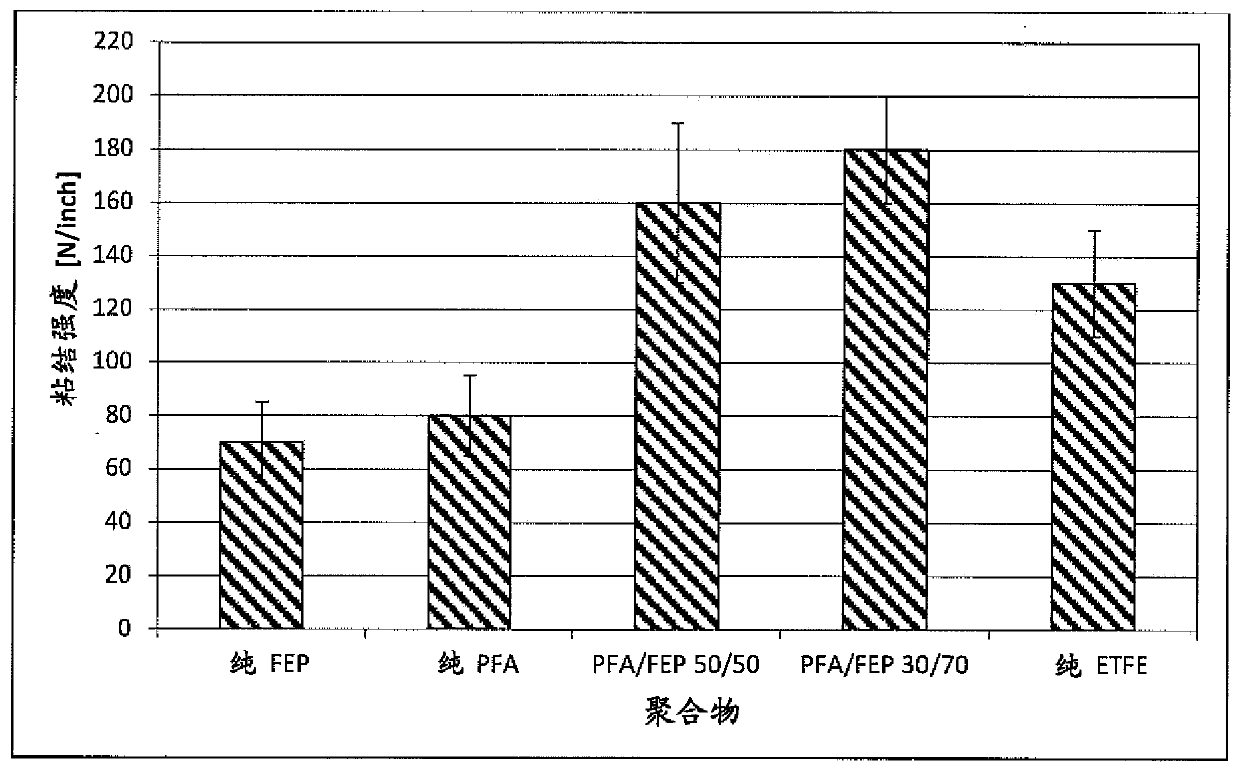

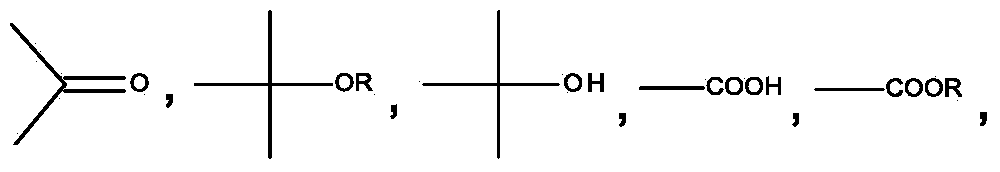

Maintenance-free slide bearing with FEP or PFA in the adhesive layer

Slide bearings and methods of producing slide bearings are disclosed. The slide bearing has a metal support, an adhesive layer and a sliding layer. The adhesive layer is applied directly to the metal support. The adhesive layer comprises a blend of at least two fluoropolymers P1 and P2, wherein P1 is selected from perfluoroalkoxyethylene (PFA) or tetrafluoroethylene-hexafluoropropylene (FEP). P2 is different from P1 and can be a fluoropolymer.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Quick-action fastening system for actuating-pull mechanisms and a spring for a fastening system

InactiveUS6178844B1Prevent exitEasy to installSnap fastenersBearing assemblyMobile vehicleEngineering

A quick-action fastening system for actuating systems, preferably for motor vehicles, and a spring of the quick-action fastening system. The quick-action fastening system has a spring arranged between a fastening plate and the end part of a cable sheathing. The spring braces the end part directly against the actuating plate and has regions by which it secures the end part on the fastening plate radially and axially and prevents the actuating plate from being withdrawn.

Owner:KONGSBERG AUTOMOTIVE AB (SE)

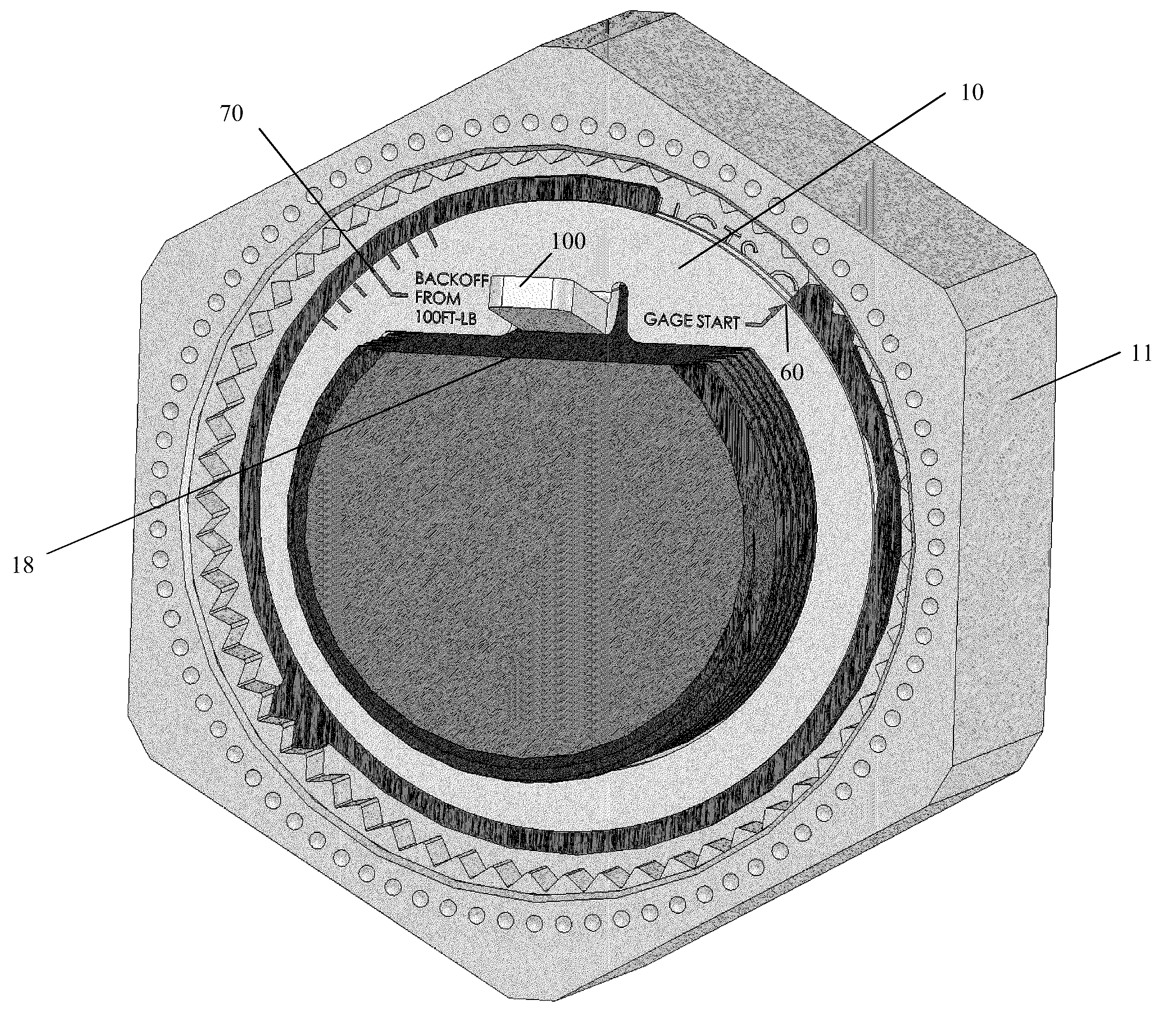

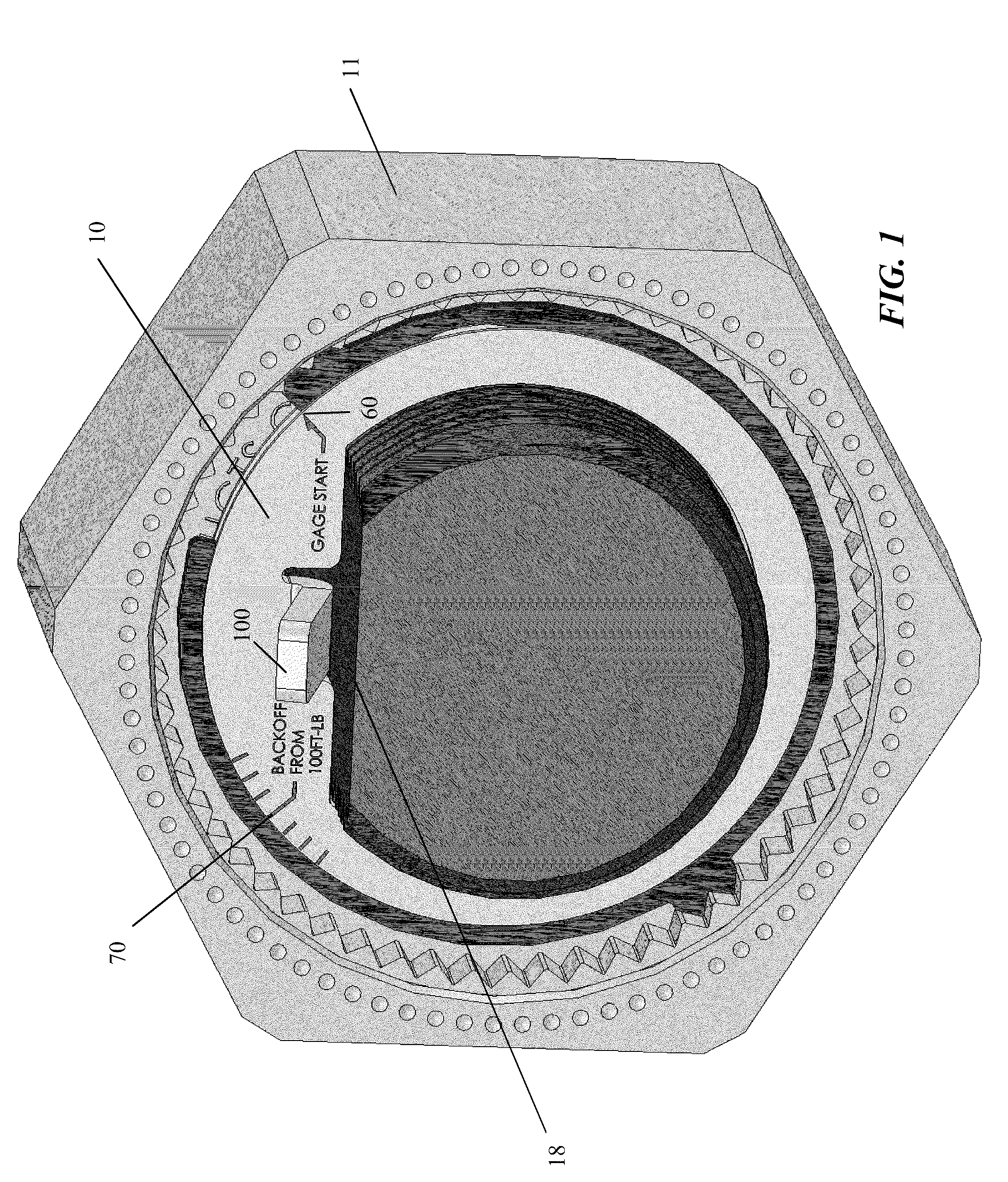

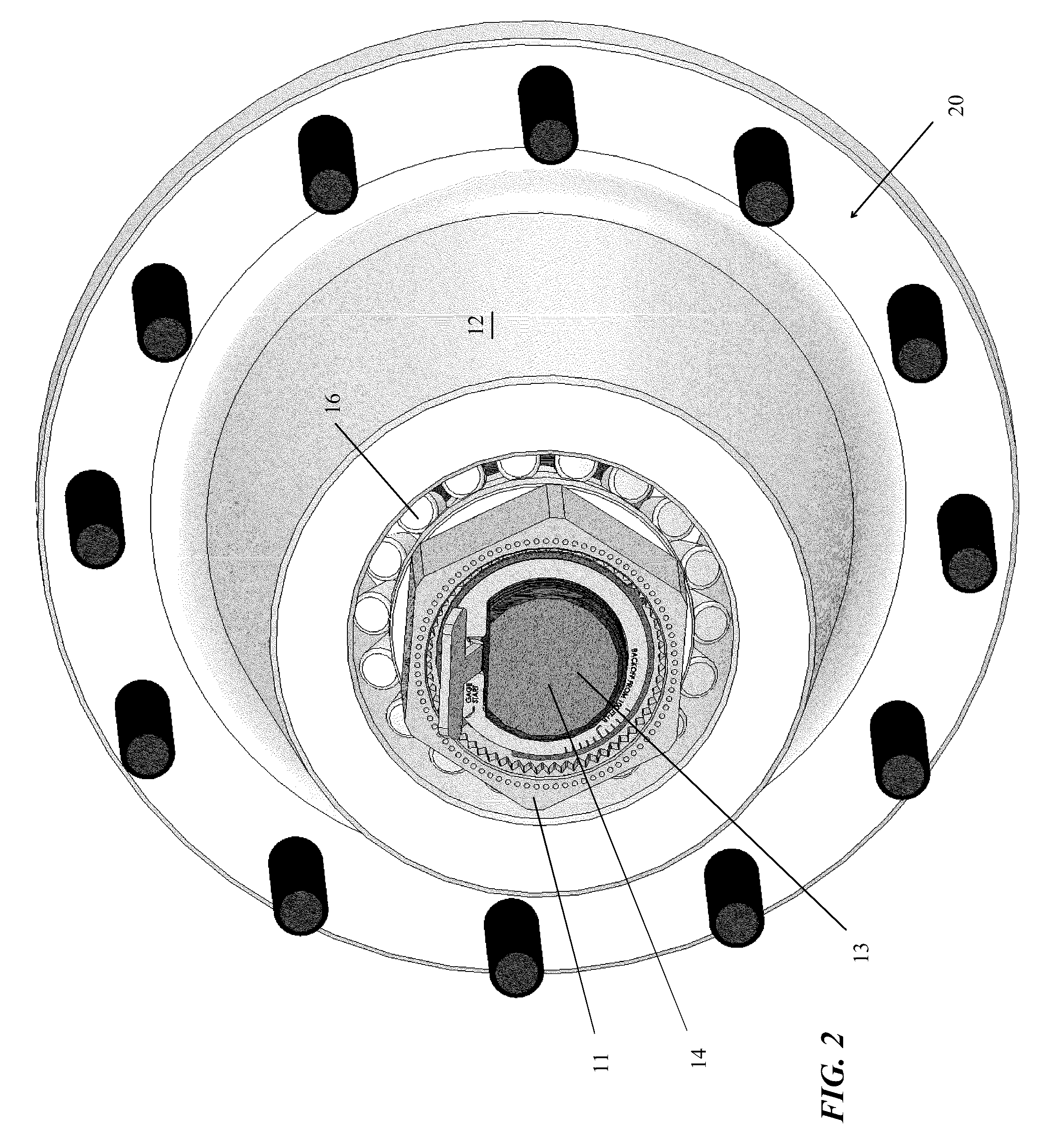

Systems and methods for preloading a bearing and aligning a lock nut

Owner:TEMPER AXLE PROD +1

Bearing assembly

A bearing assembly including a bearing having an outer bearing ring and an inner bearing ring. The outer bearing ring is axially received in a bearing-receiving recess that includes a substantially cylindrical inner wall. An element that is radially flexible is located between at least one of the outer bearing ring and the inner wall of the recess, and the inner bearing ring and a rotatable member that is rotatably carried in the bearing assembly. The flexible element includes at least one annular element that is undulated in the radial direction, or is provided with projections. Flexible elements can also be disposed against a side surface of the bearing ring for damping axial vibrations.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com