Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Reduce the pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

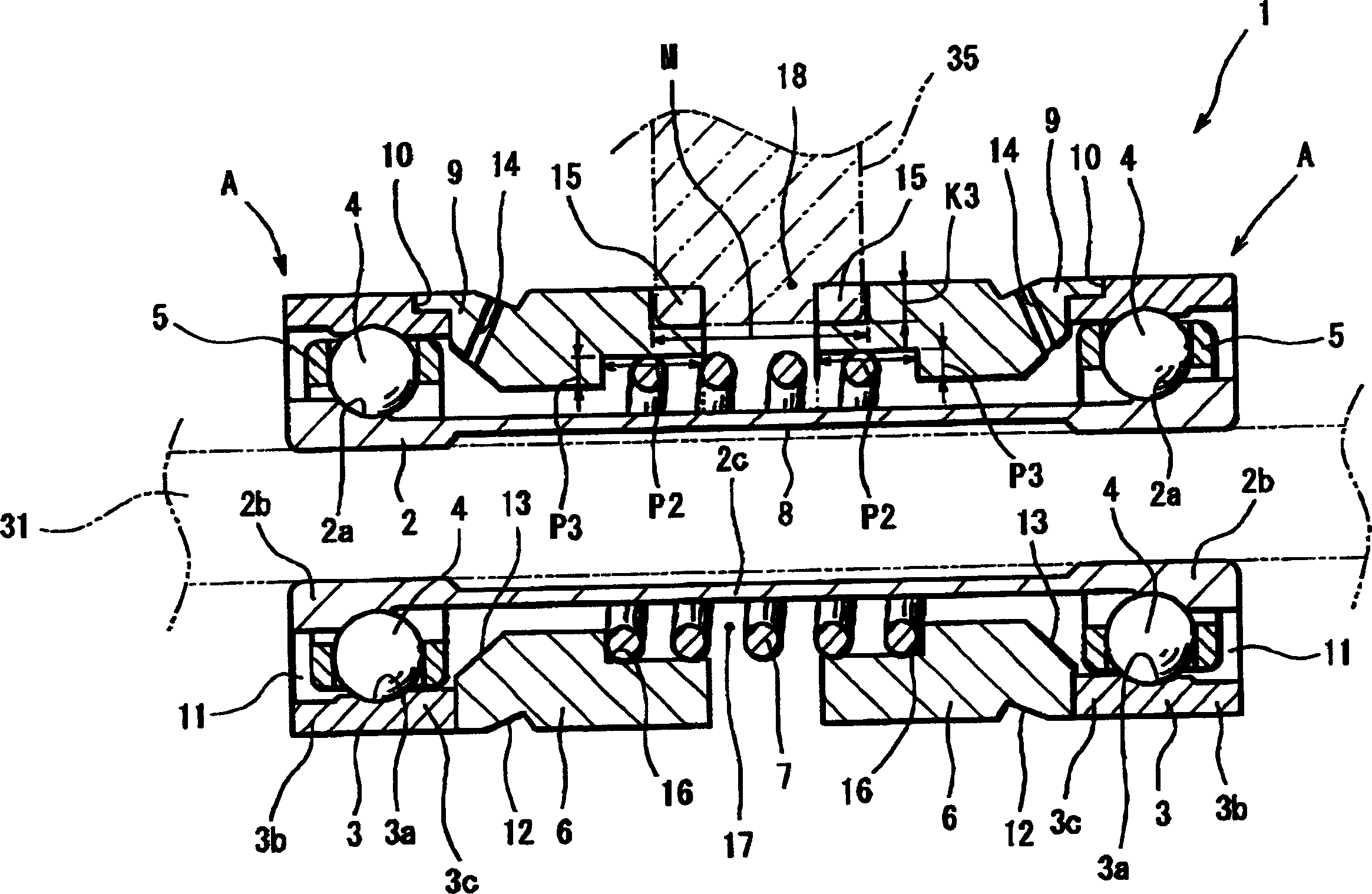

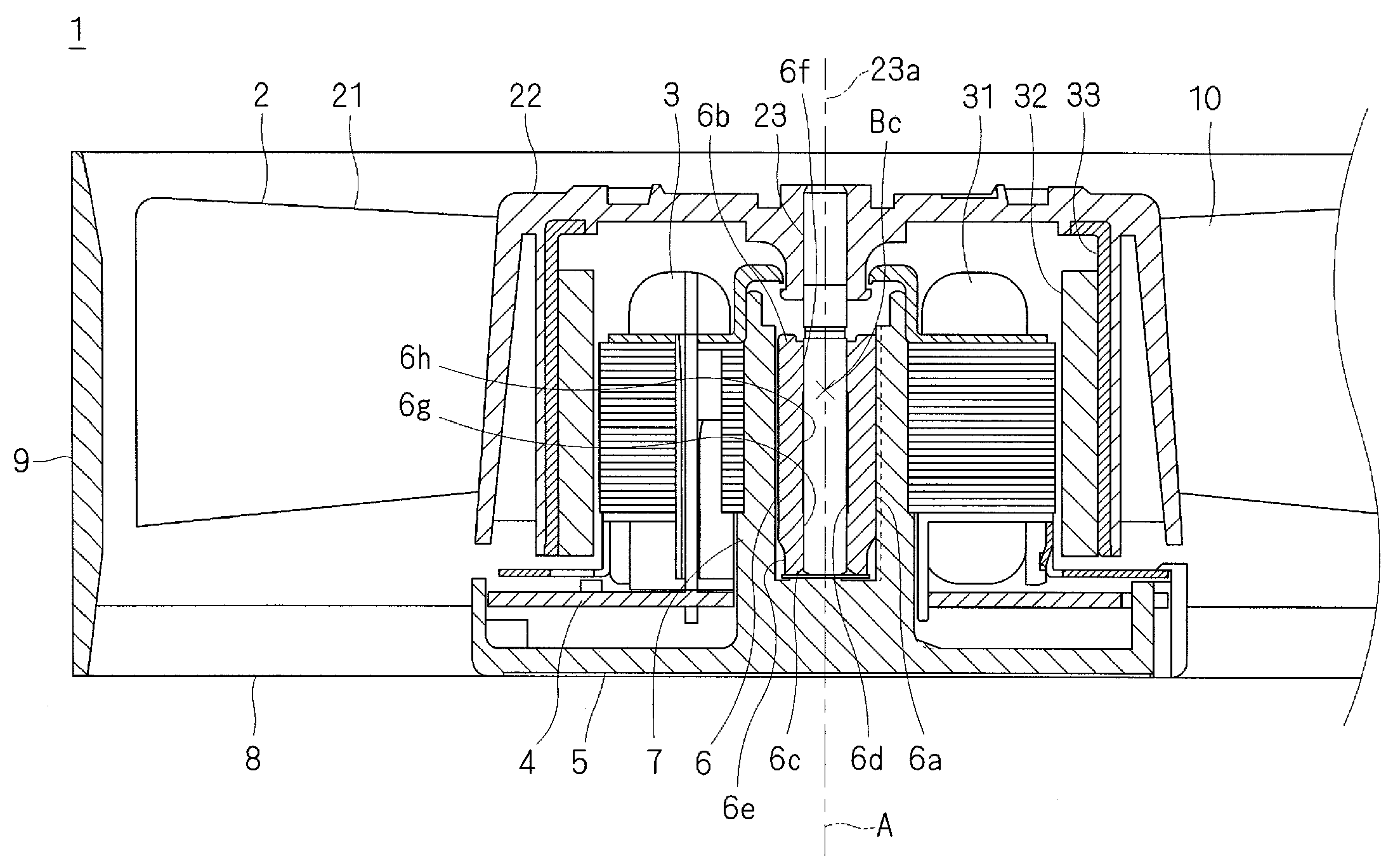

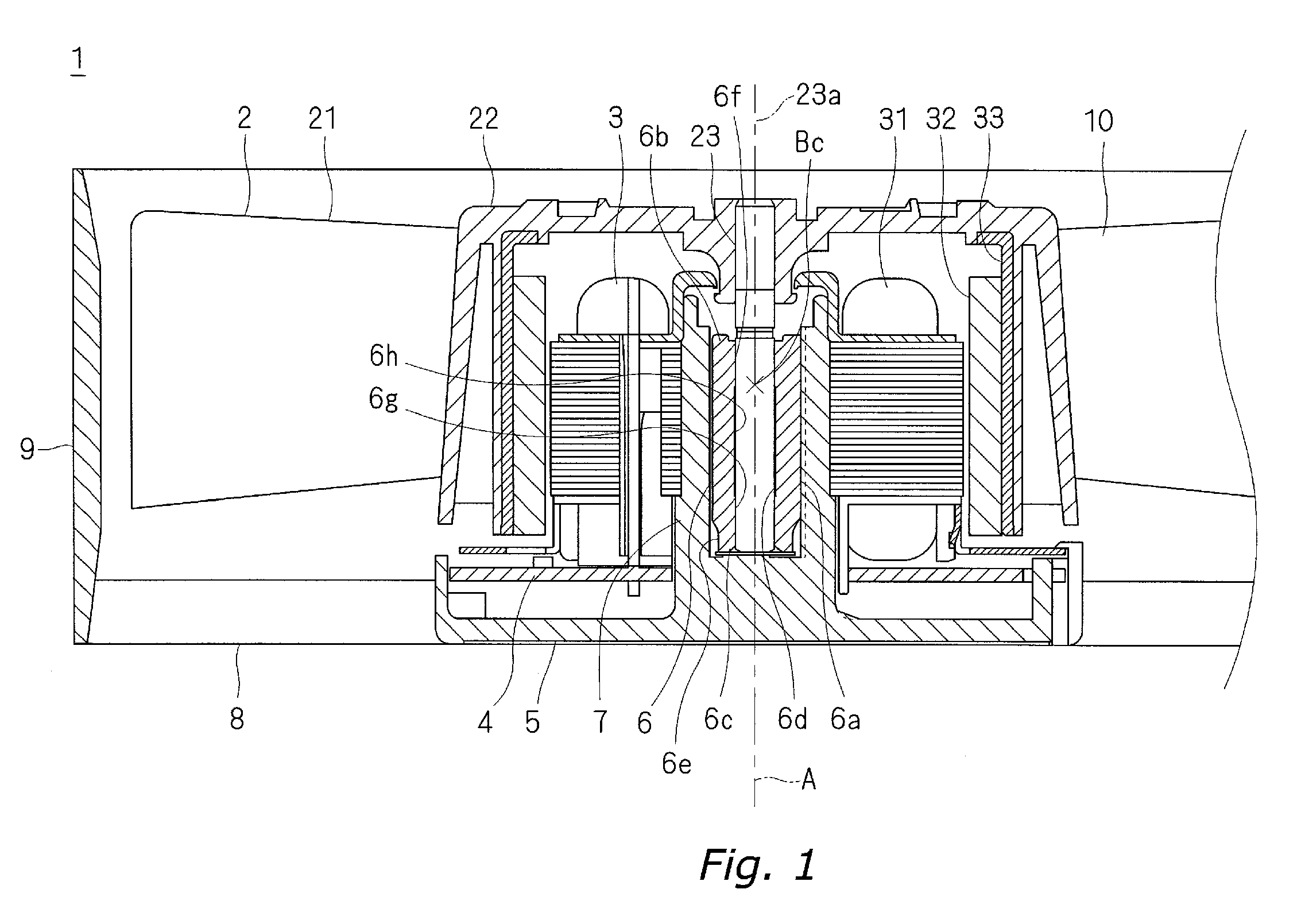

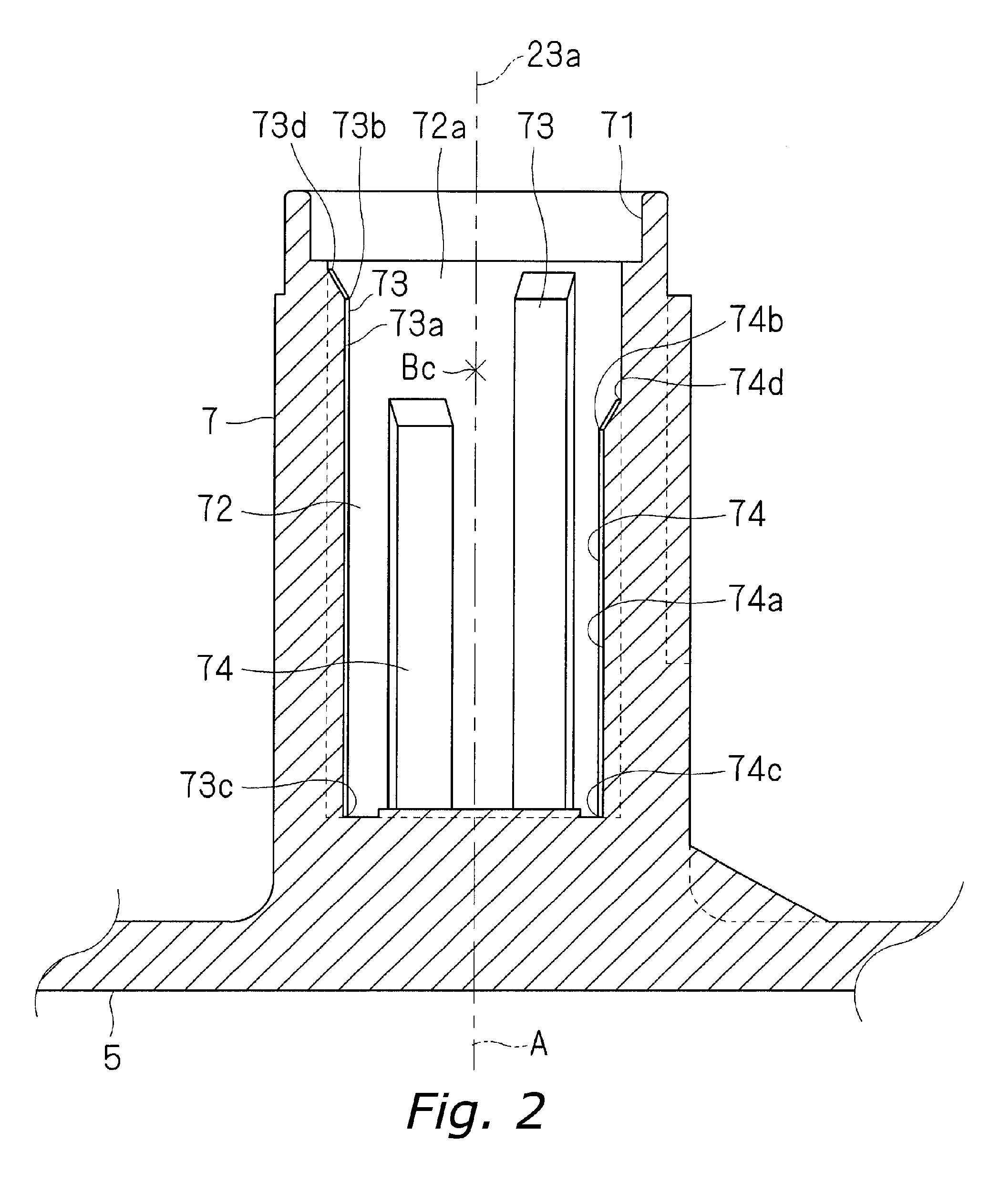

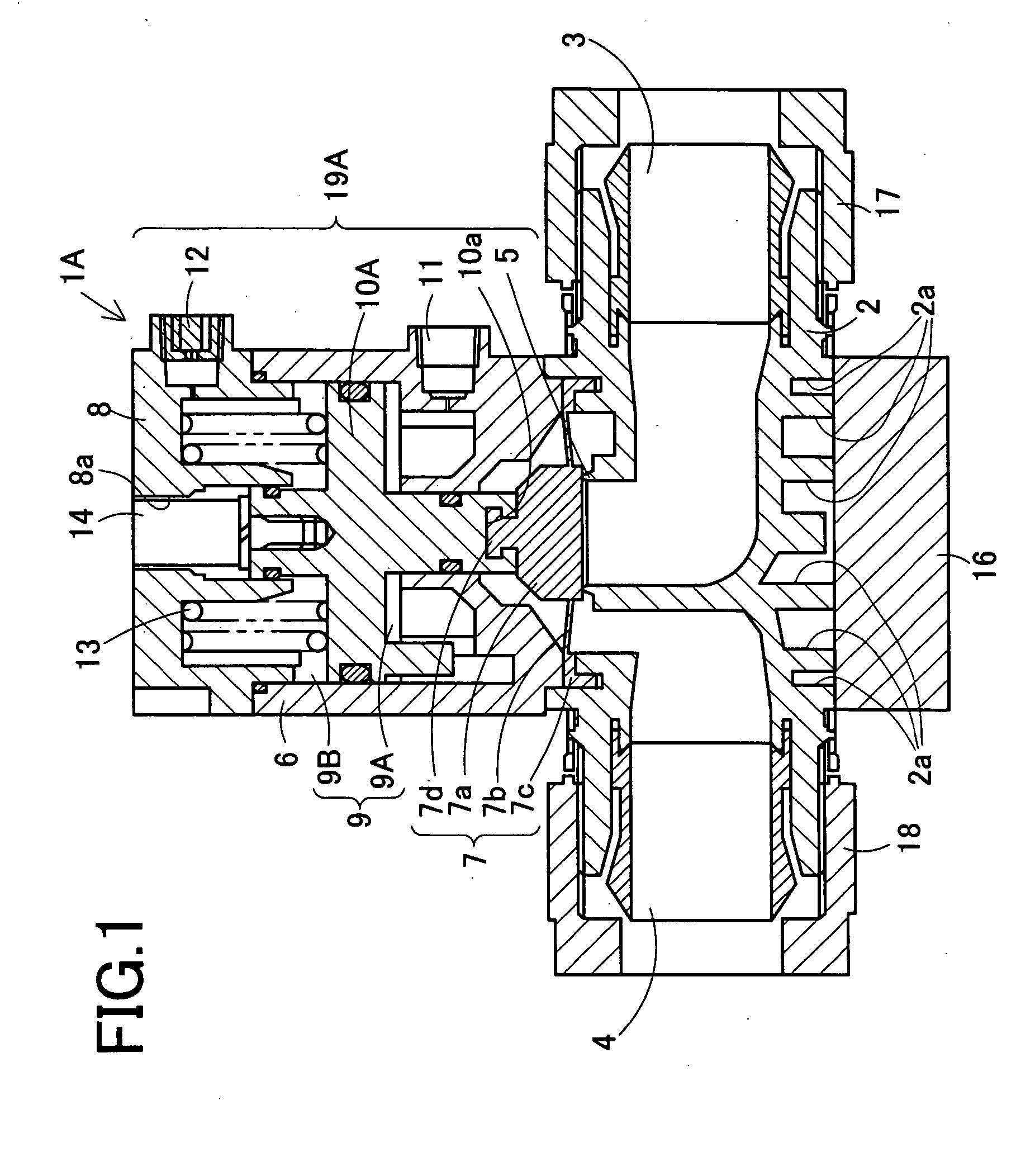

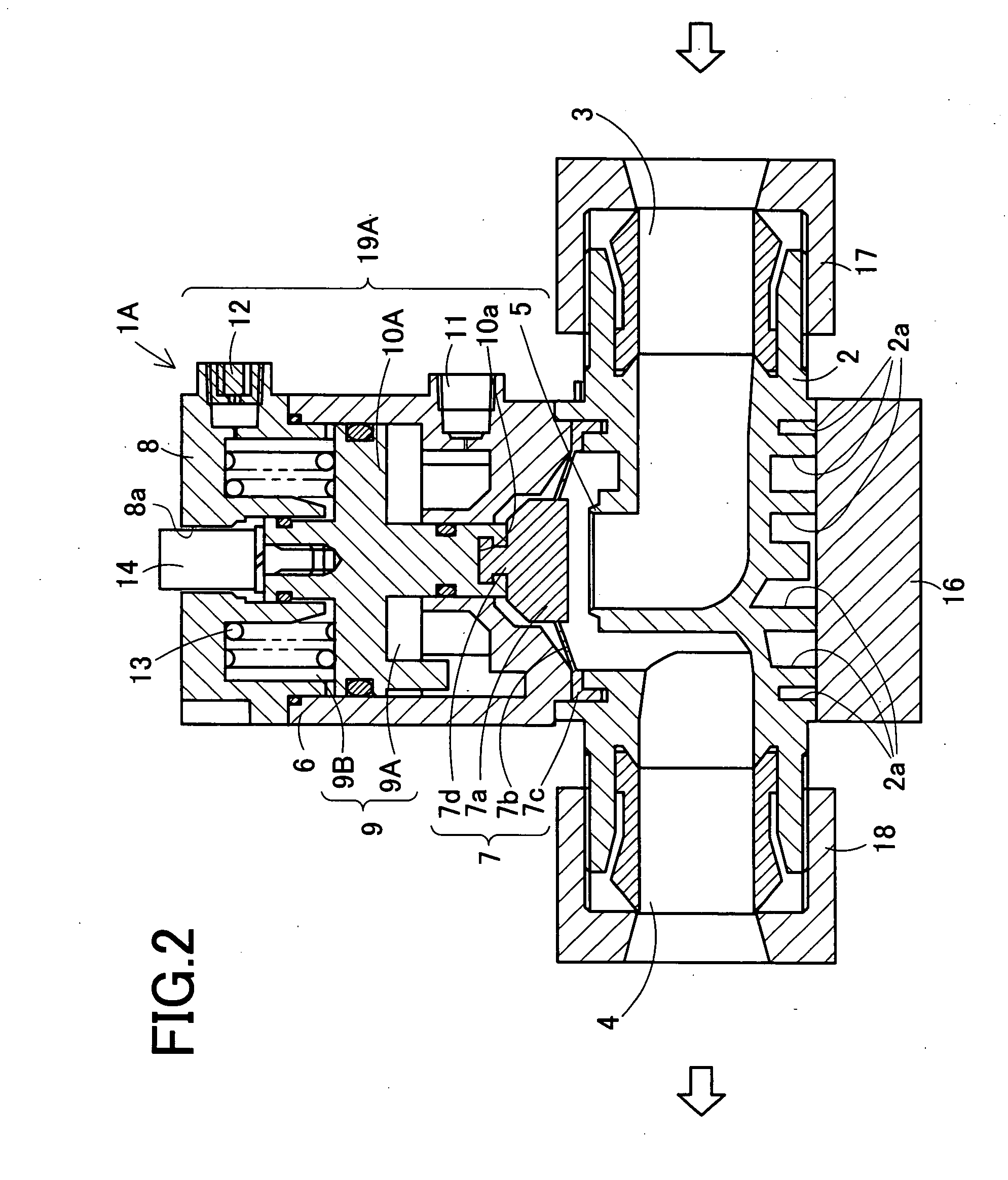

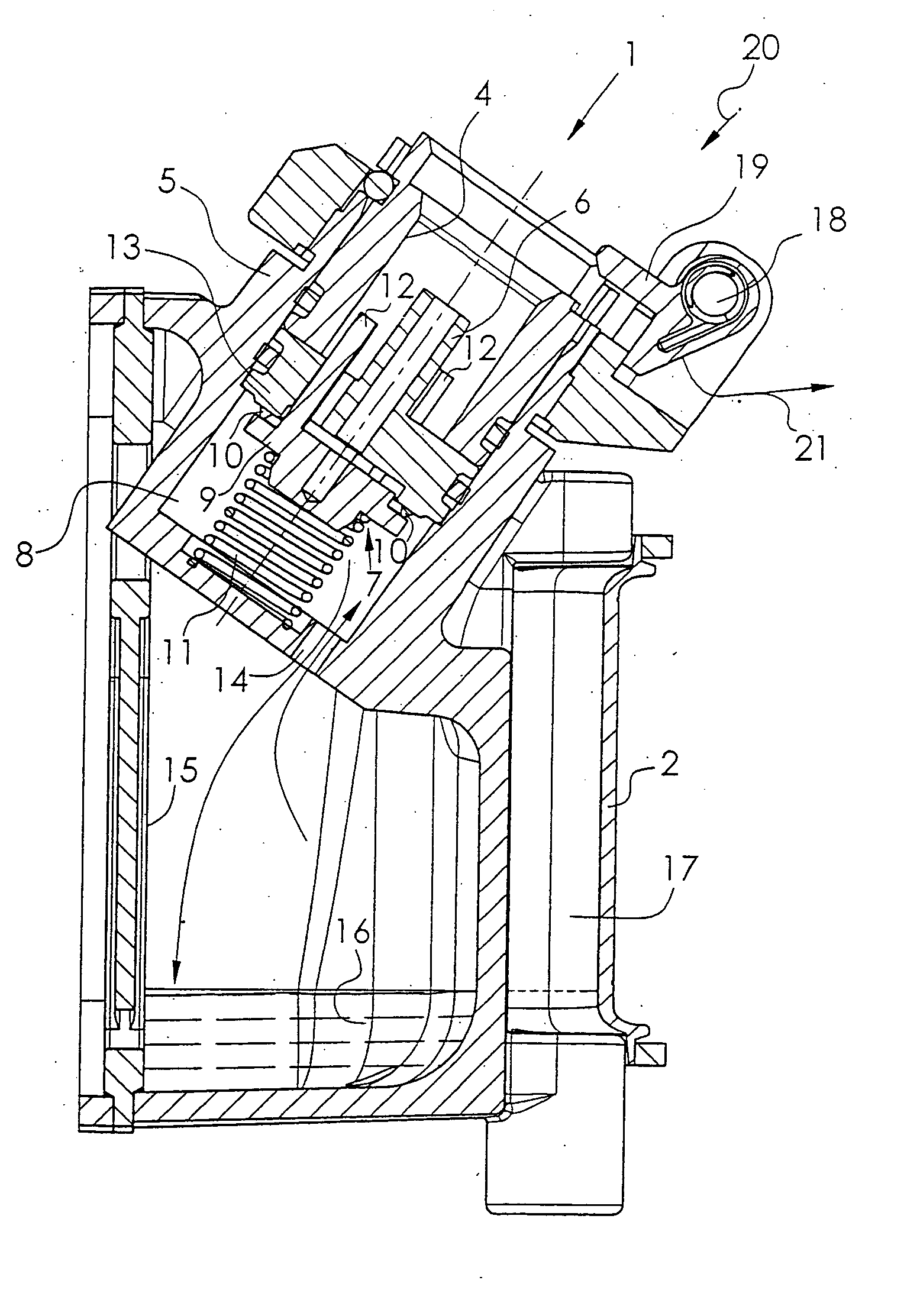

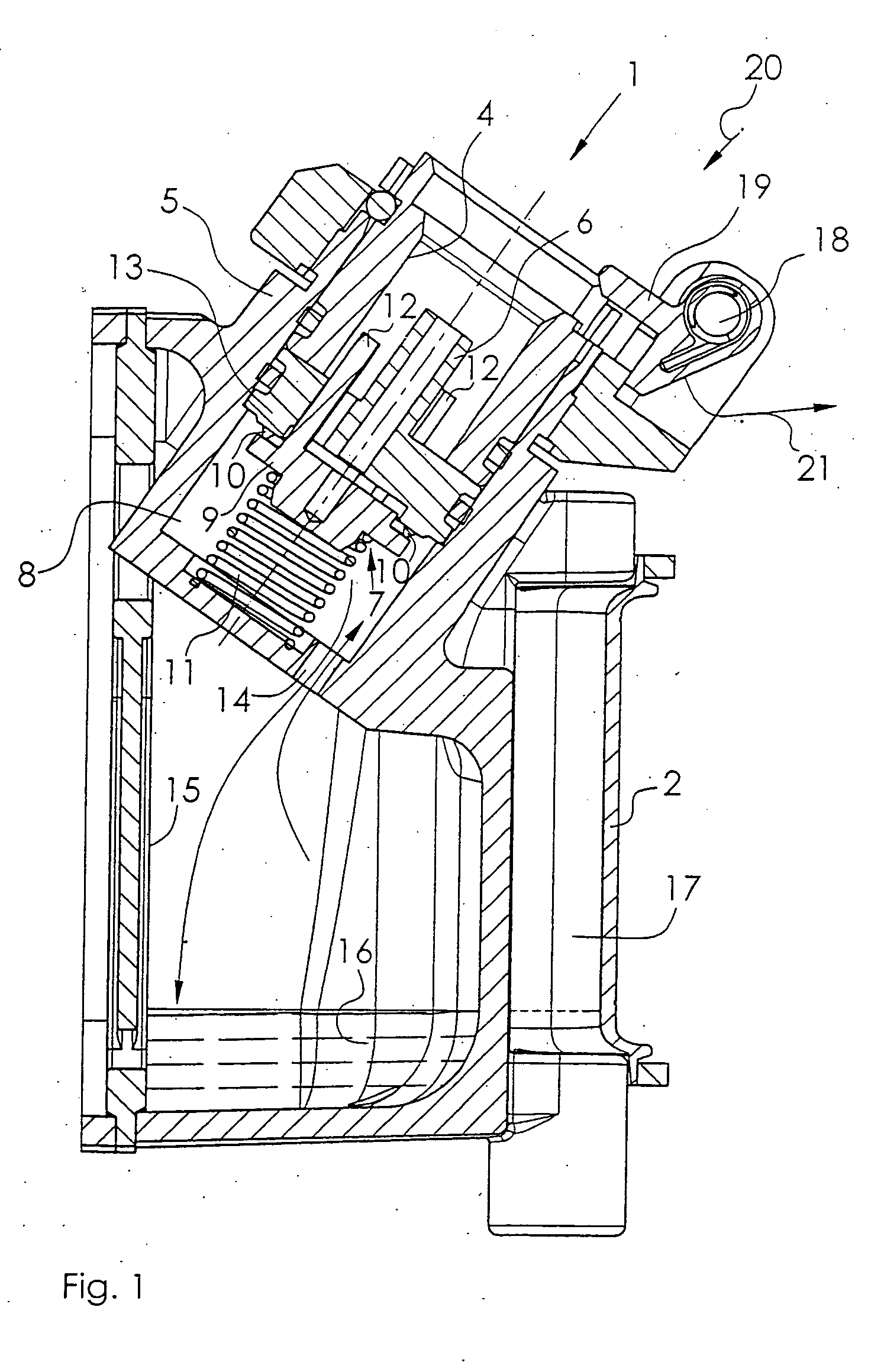

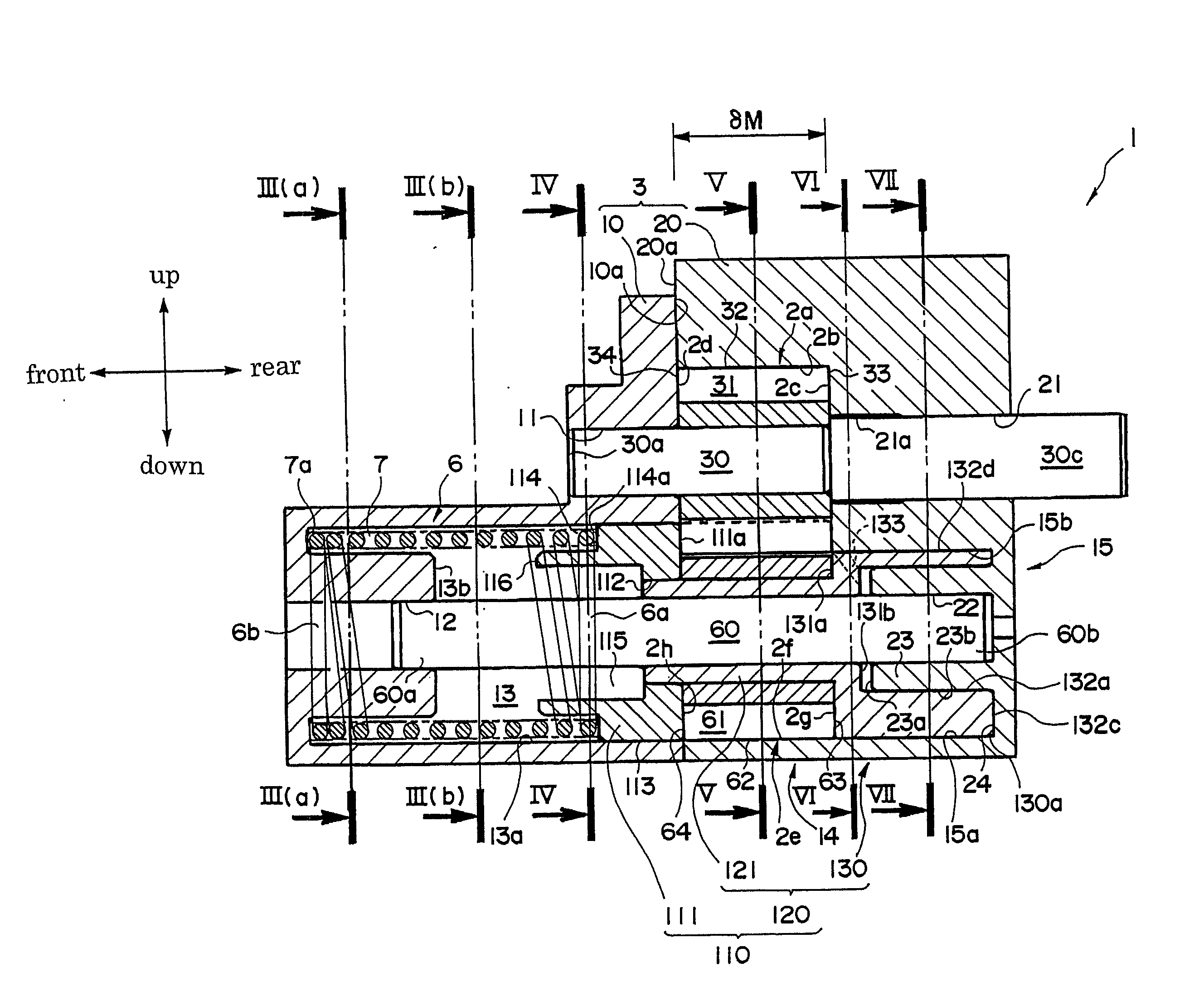

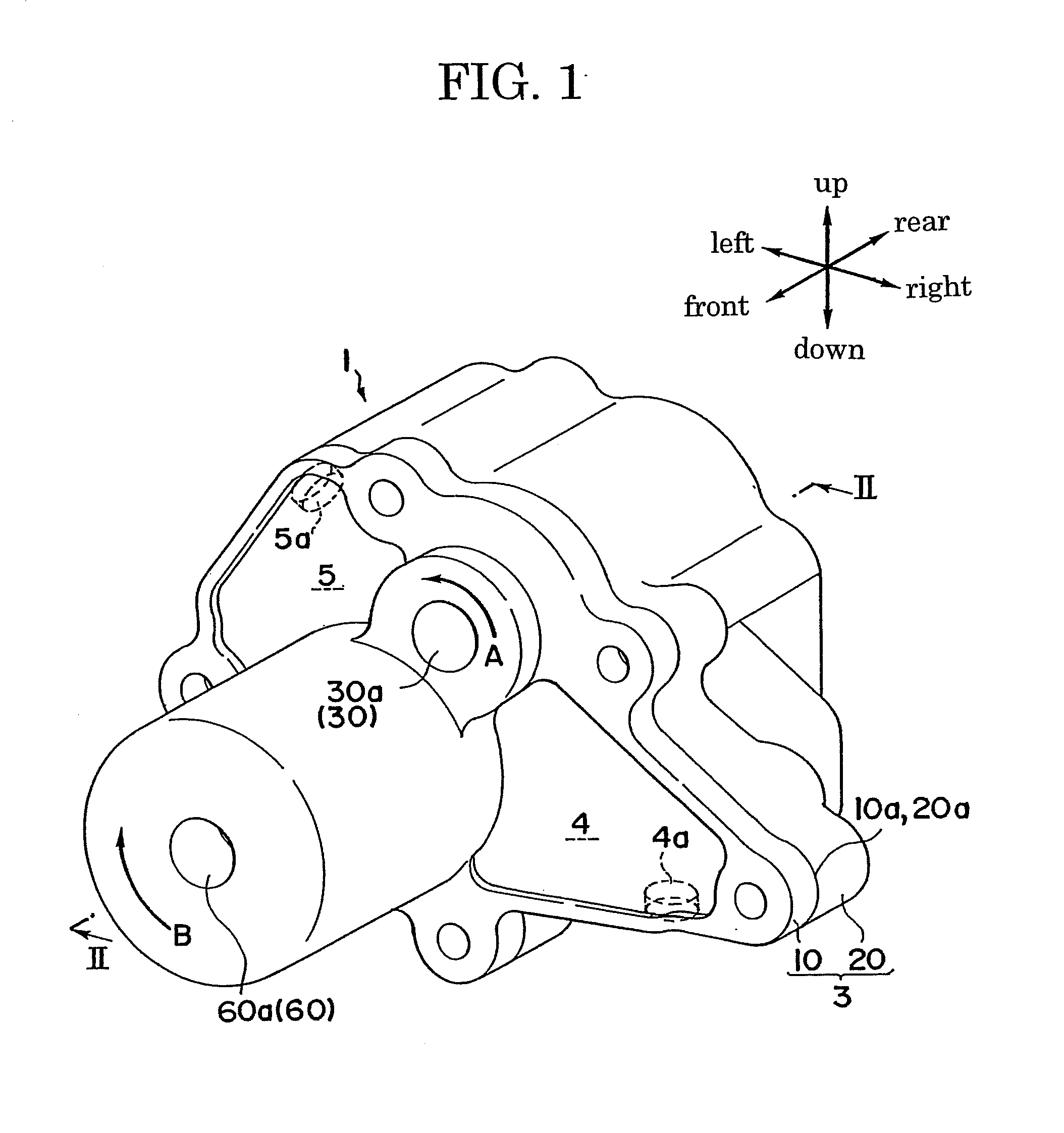

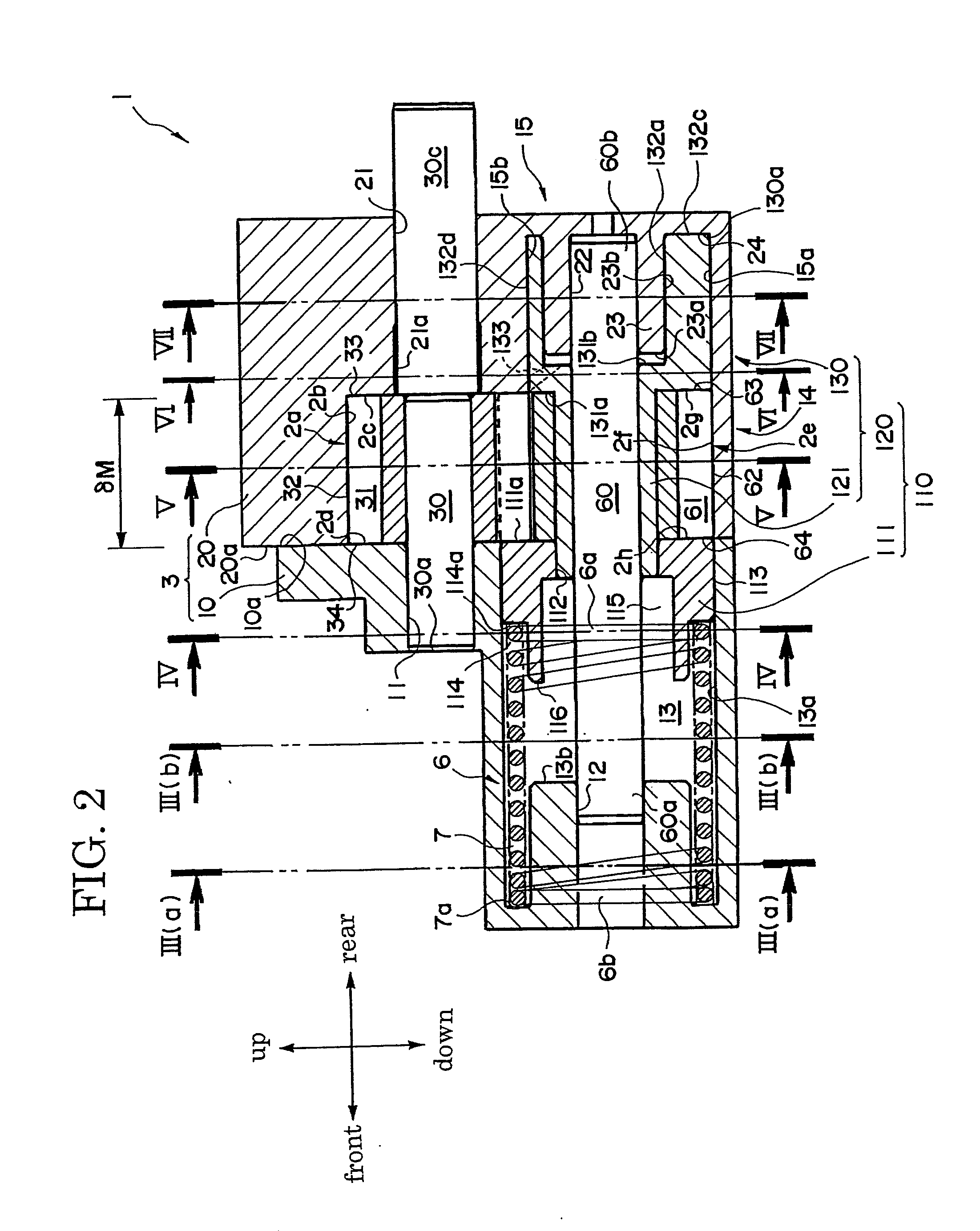

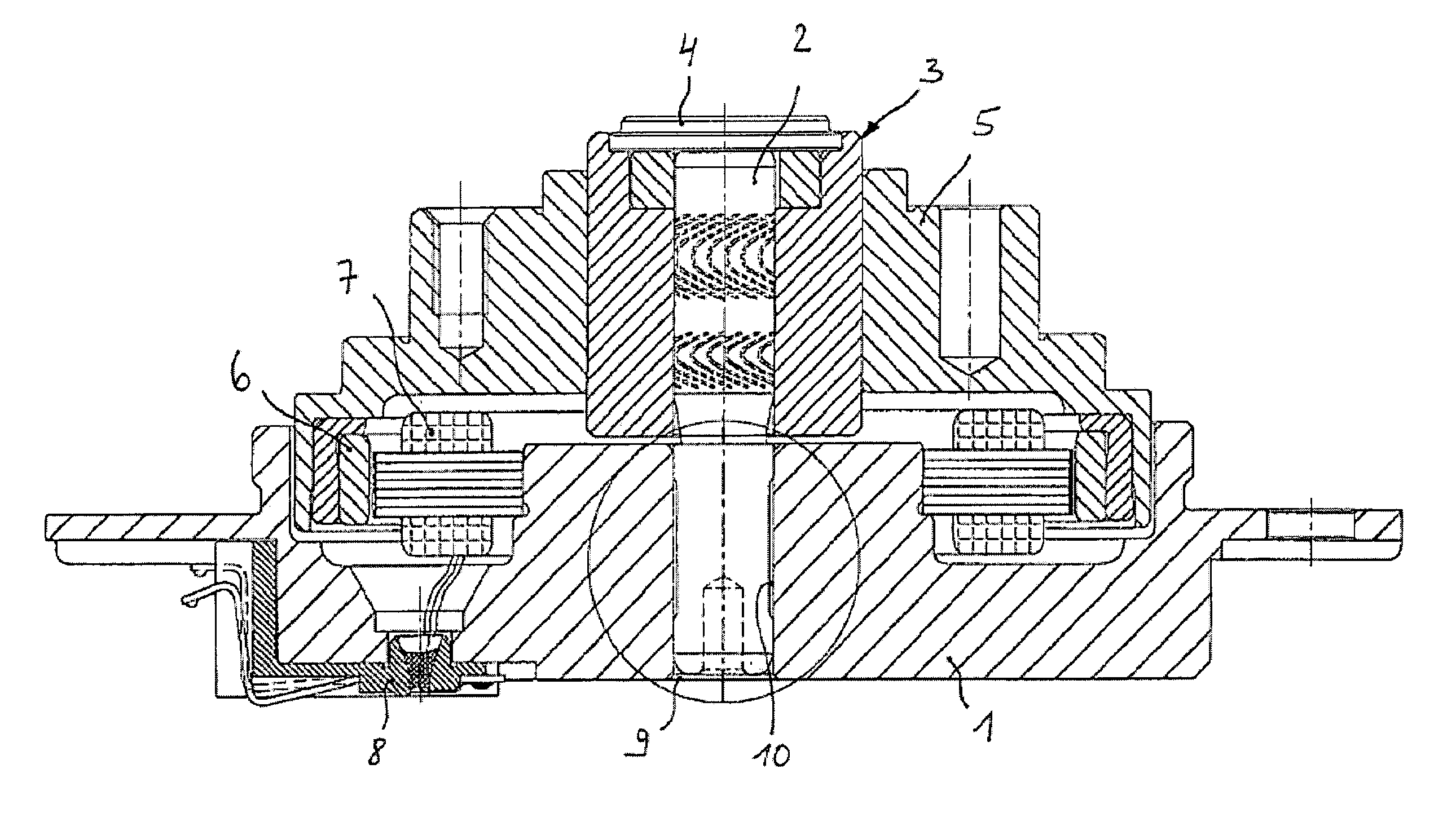

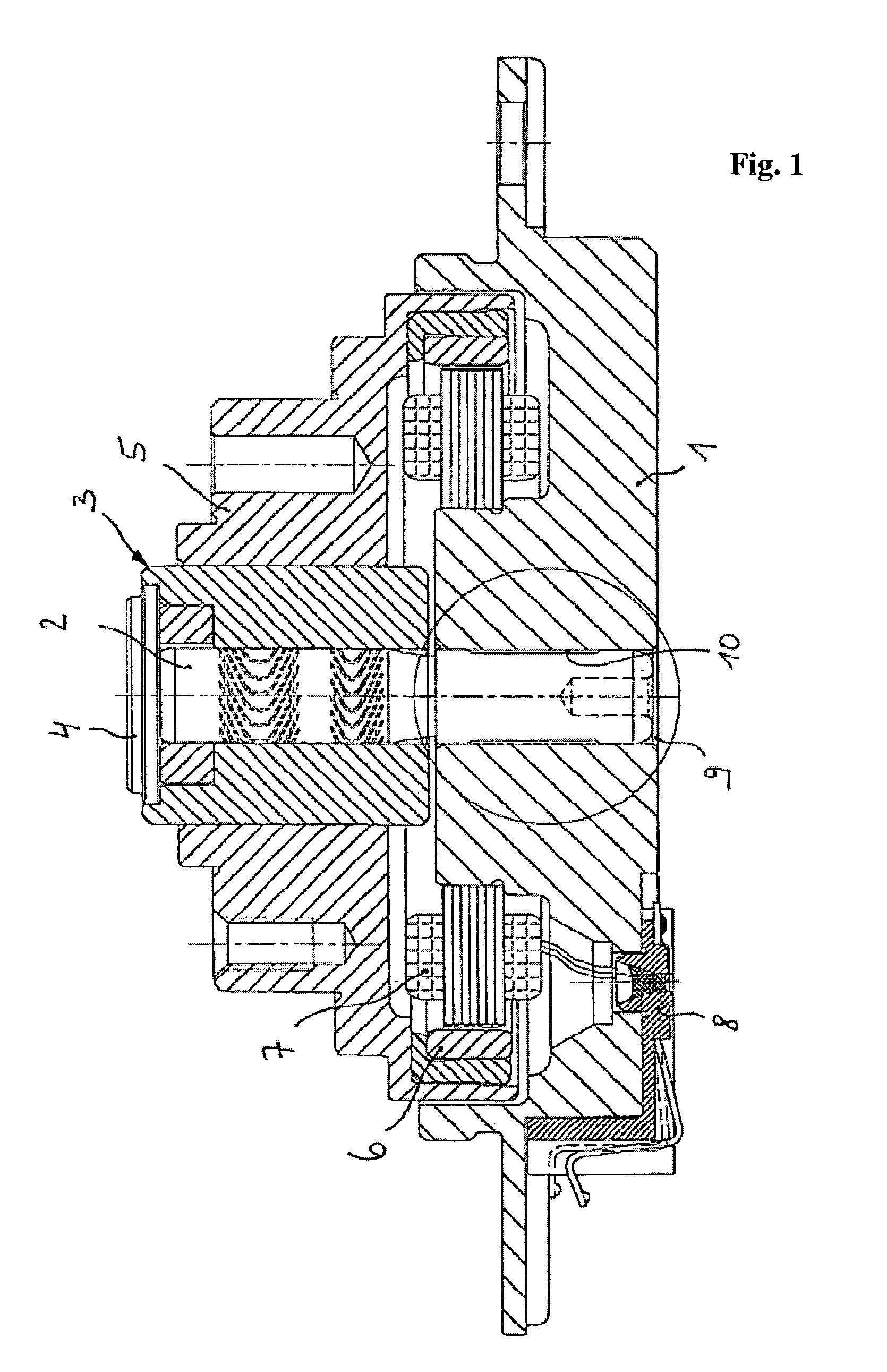

Bearing device for turbocharger

InactiveCN1890475AReduce the pressing forceAvoid indentationRolling contact bearingsBearing assemblyFree rotationTurbocharger

A turbocharger bearing assembly is disposed in a housing for rotatably supporting an intermediate portion of a rotary shaft of a turbocharger. A pair of outer rings formed with outer raceways are mounted to opposite ends of a substantially cylindrical inner ring formed with inner raceways, thereby constituting a bearing unit including two angular bearings. Thus, the number of assembly steps is reduced to facilitate an assembly work. A pair of sleeves are inserted in a gap defined between the outer rings. The sleeve is formed with an engaging portion on an outer periphery thereof for restricting its rotation relative to the housing and the outer ring. This makes it easy to position the bearing in the housing.

Owner:JTEKT CORP

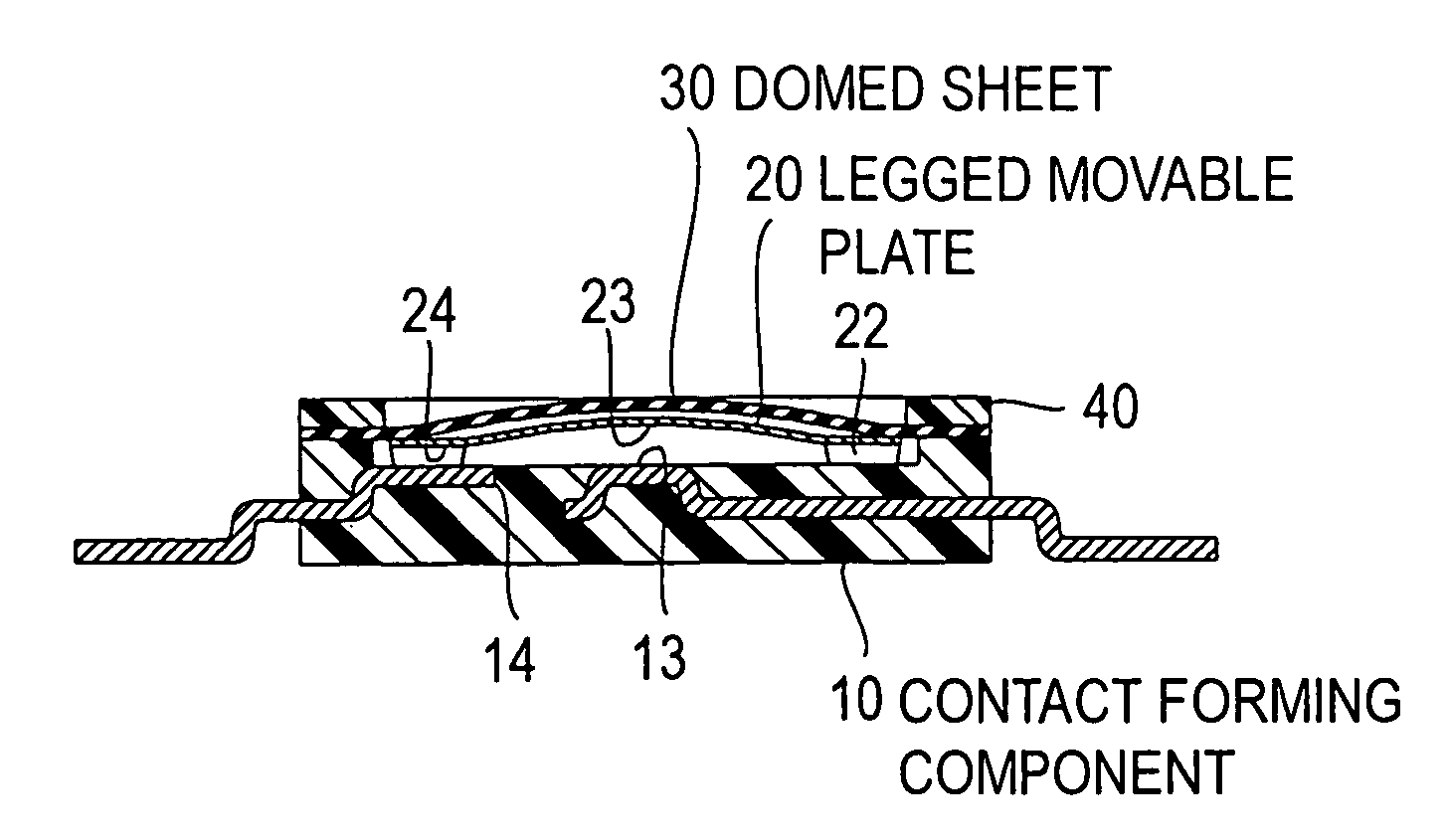

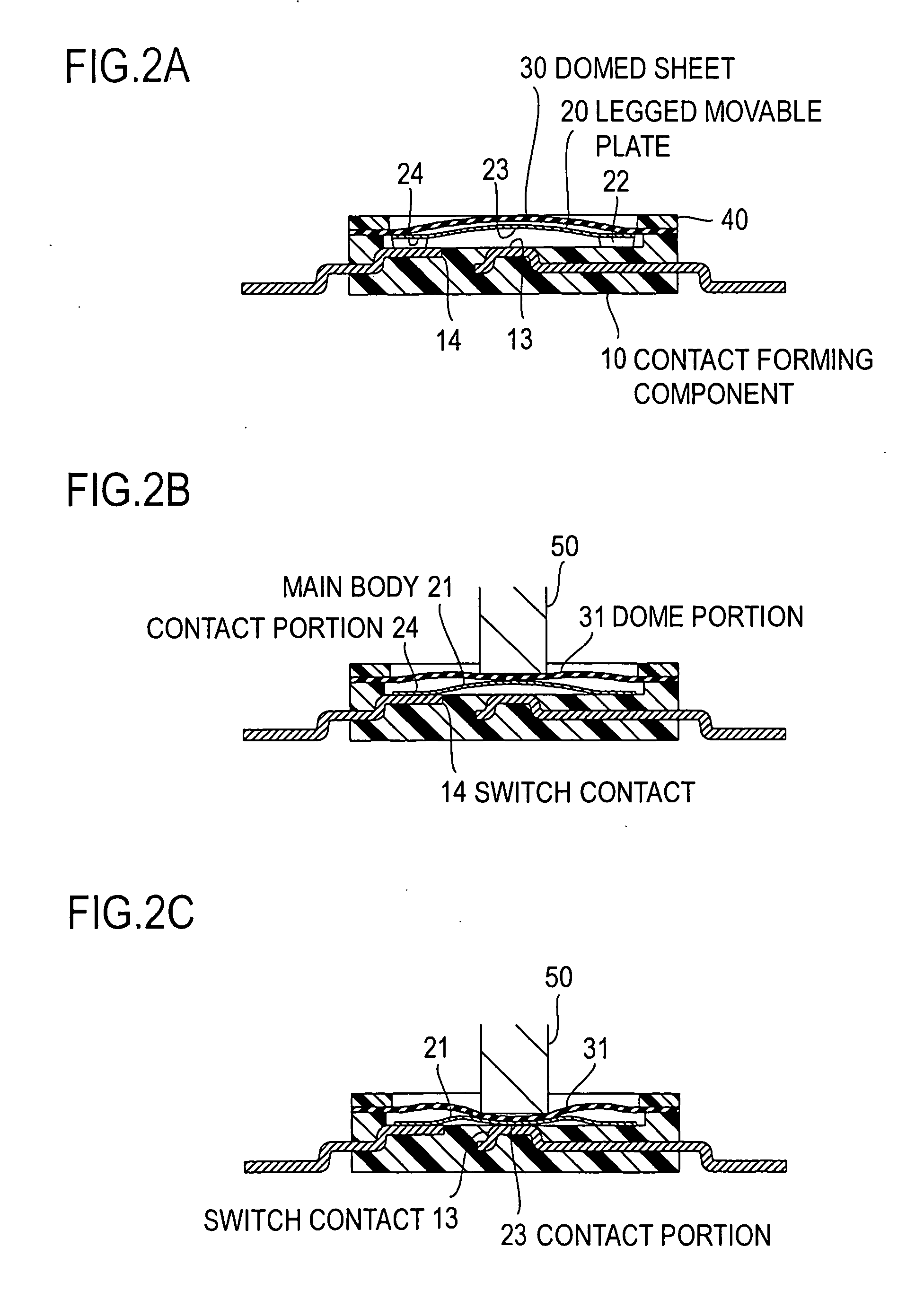

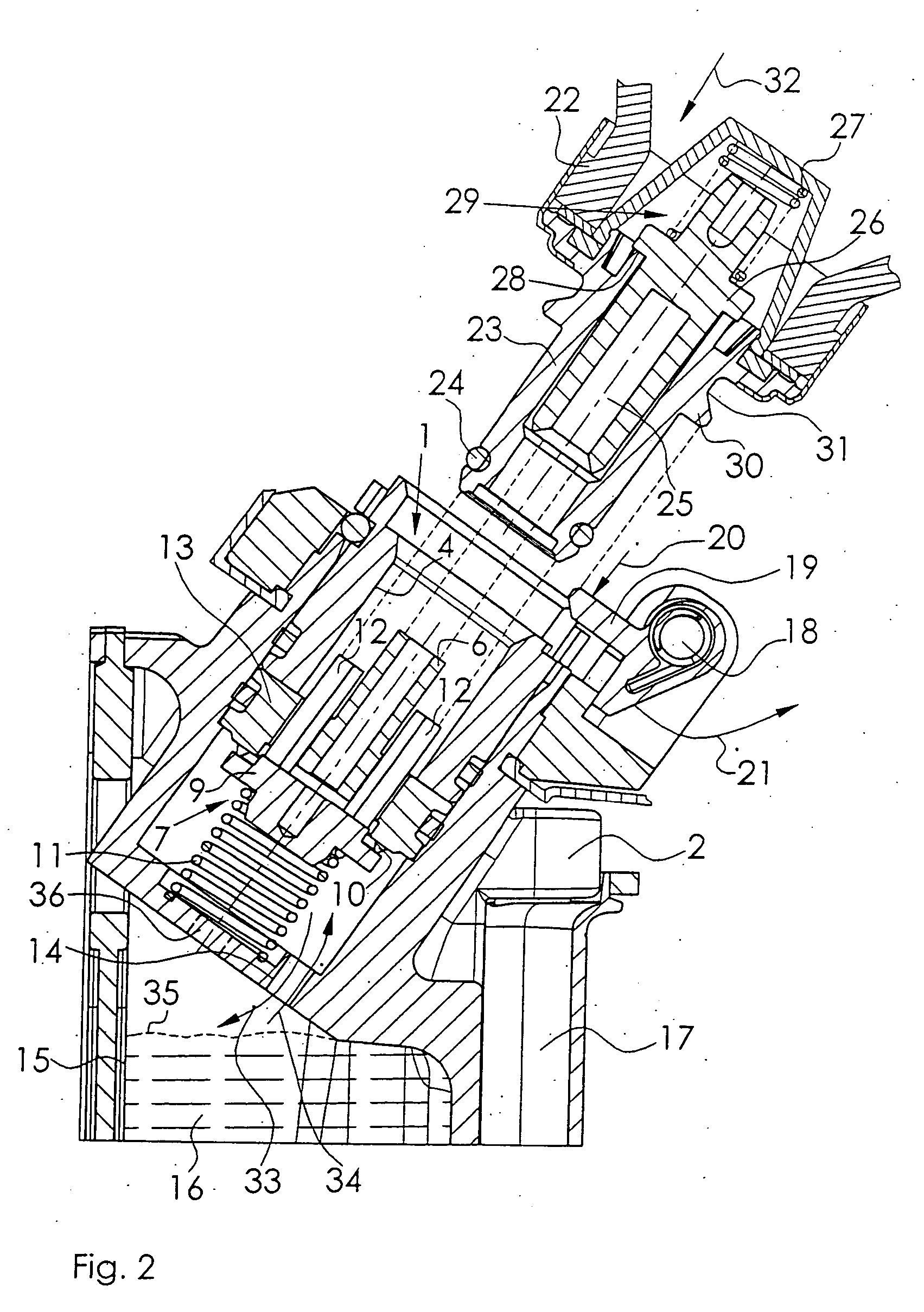

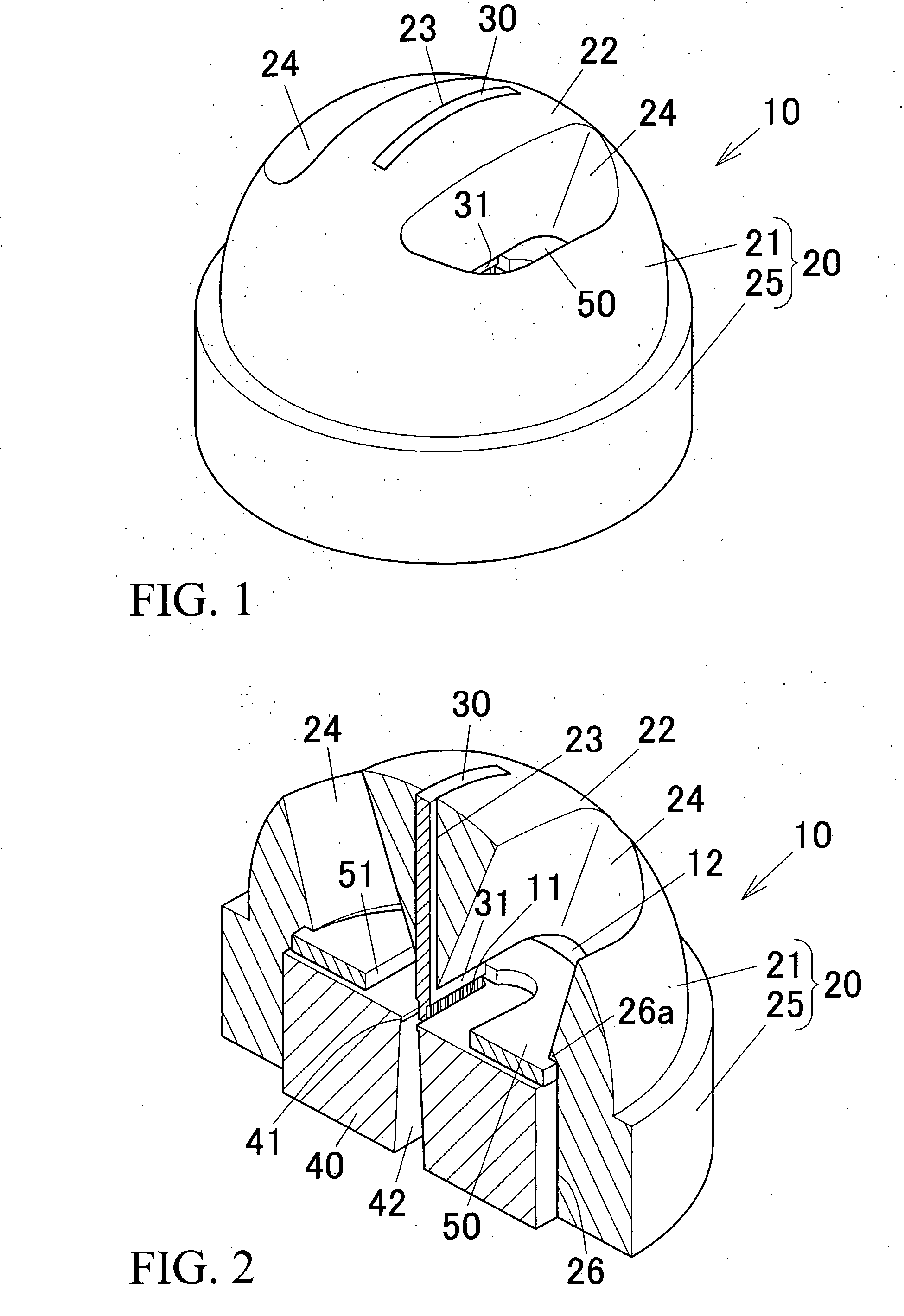

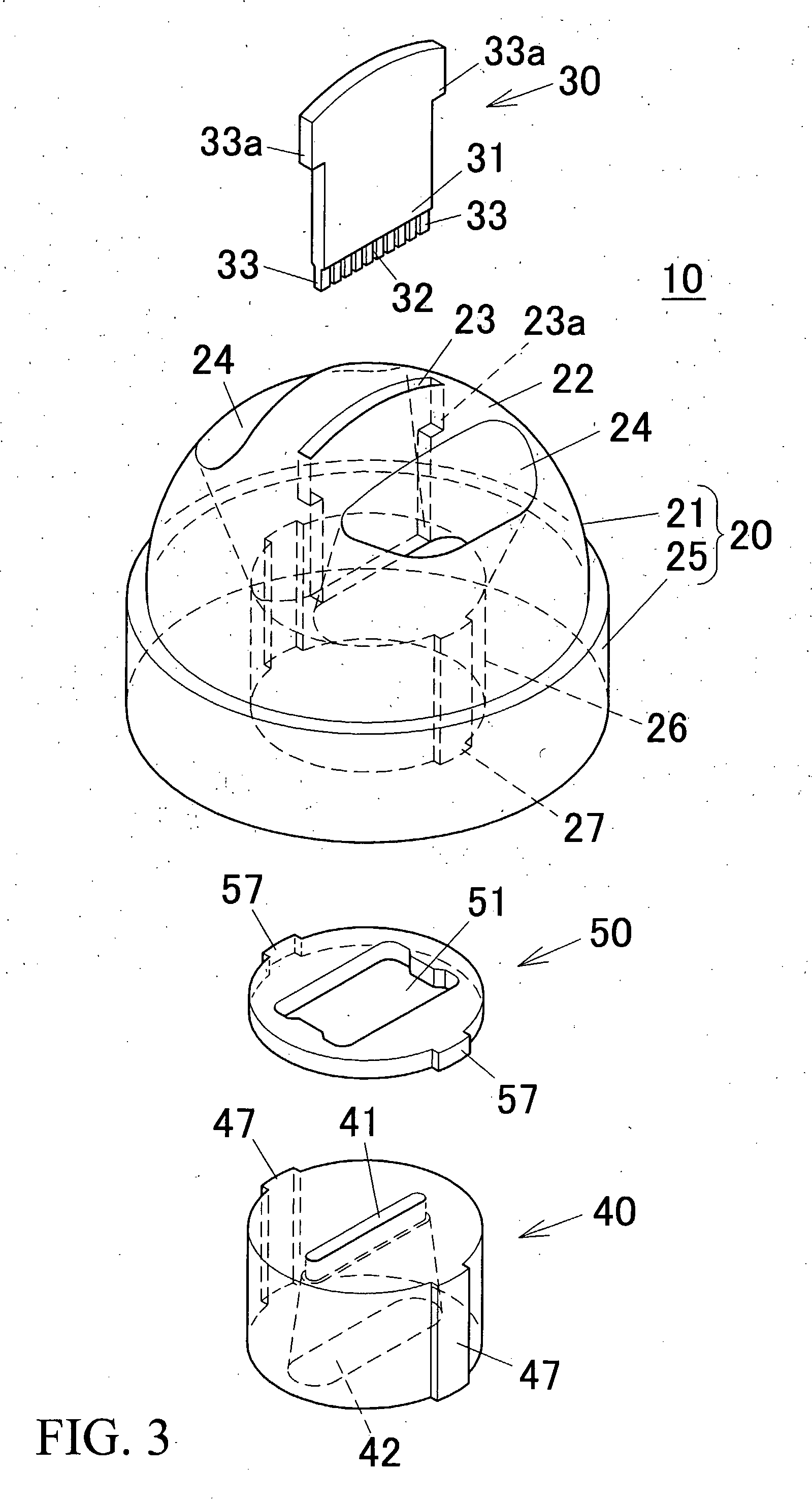

Dome-Shaped Contact and Multi-Step Operation Electrical Switch Incorporating the Same

InactiveUS20080164133A1Guaranteed uptimeReduce the pressing forceContact surface shape/structureSnap-action arrangementsMiniaturizationEngineering

Owner:JAPAN AVIATION ELECTRONICS IND LTD

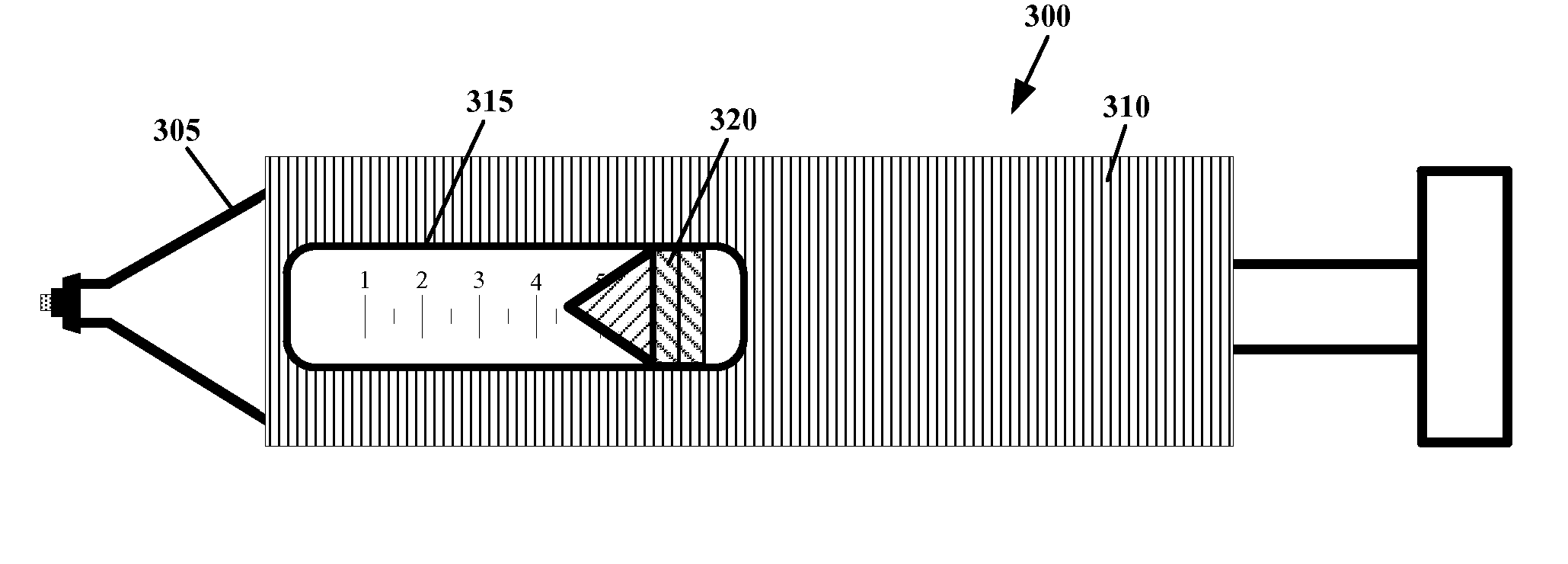

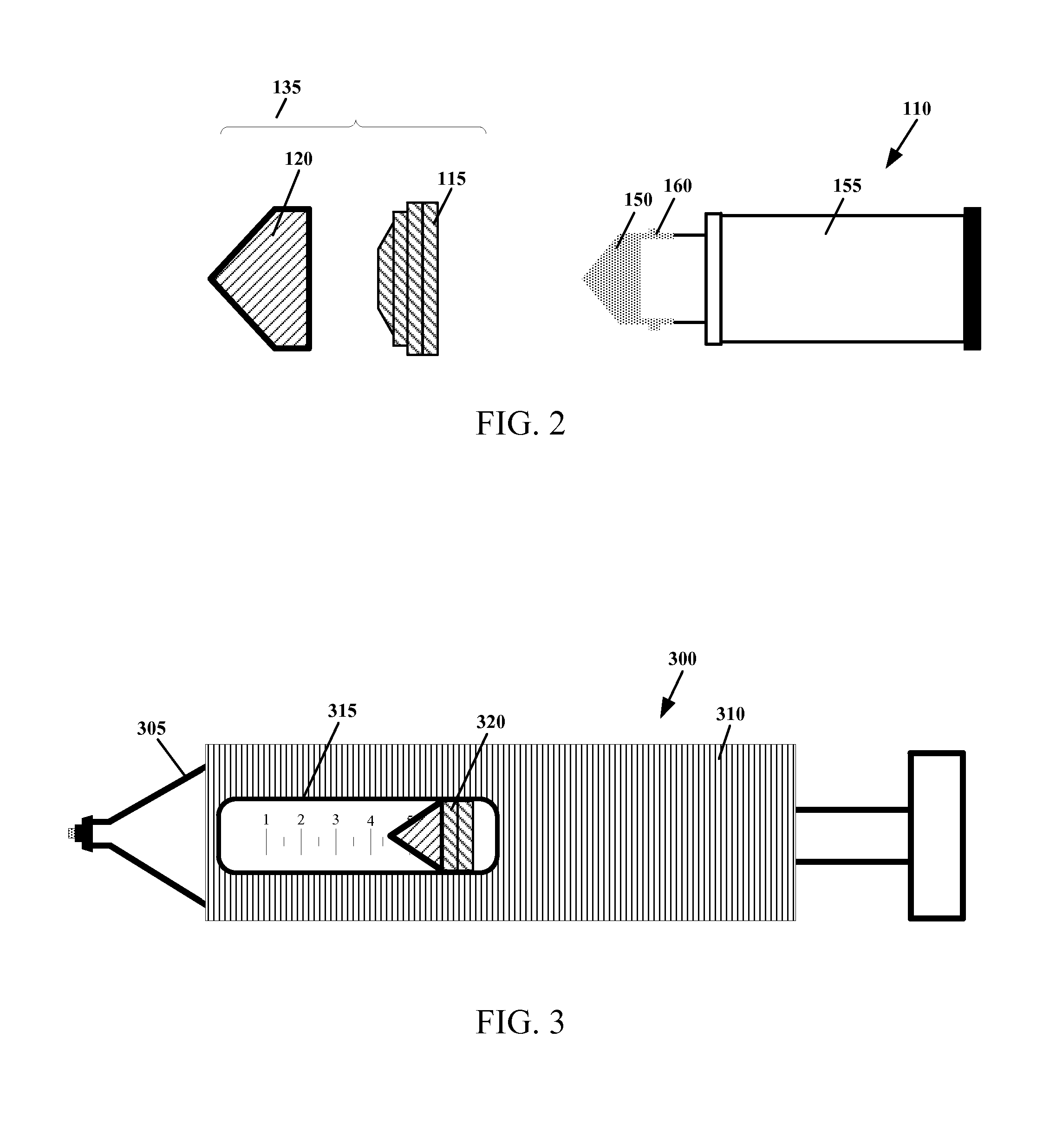

Information sensing syringe

InactiveUS20140249410A1Reduce distanceIncrease distanceAutomatic syringesMedical devicesFluid controlPinch valve

Syringe systems and flow control systems configured to detect information associated with a liquid material are described. The syringe systems may include a syringe body for housing the liquid material and an injector piston for expelling the liquid material out of the syringe through a discharge outlet at a distal end of the syringe body. Components of the syringe, such as an injector piston, may include sensors configured to measure and / or detect a property of the liquid material, such as concentration, pH, or radioactivity. The flow control system may include a pinch valve and a platen arranged about a fluid delivery channel. Flow within the fluid delivery channel may be controlled by increasing (squeezing the fluid delivery channel) or decreasing the distance between the pinch valve and the platen. Components of the flow control system may include detectors configured to detect properties of fluid in the fluid control channel.

Owner:BAYER HEALTHCARE LLC

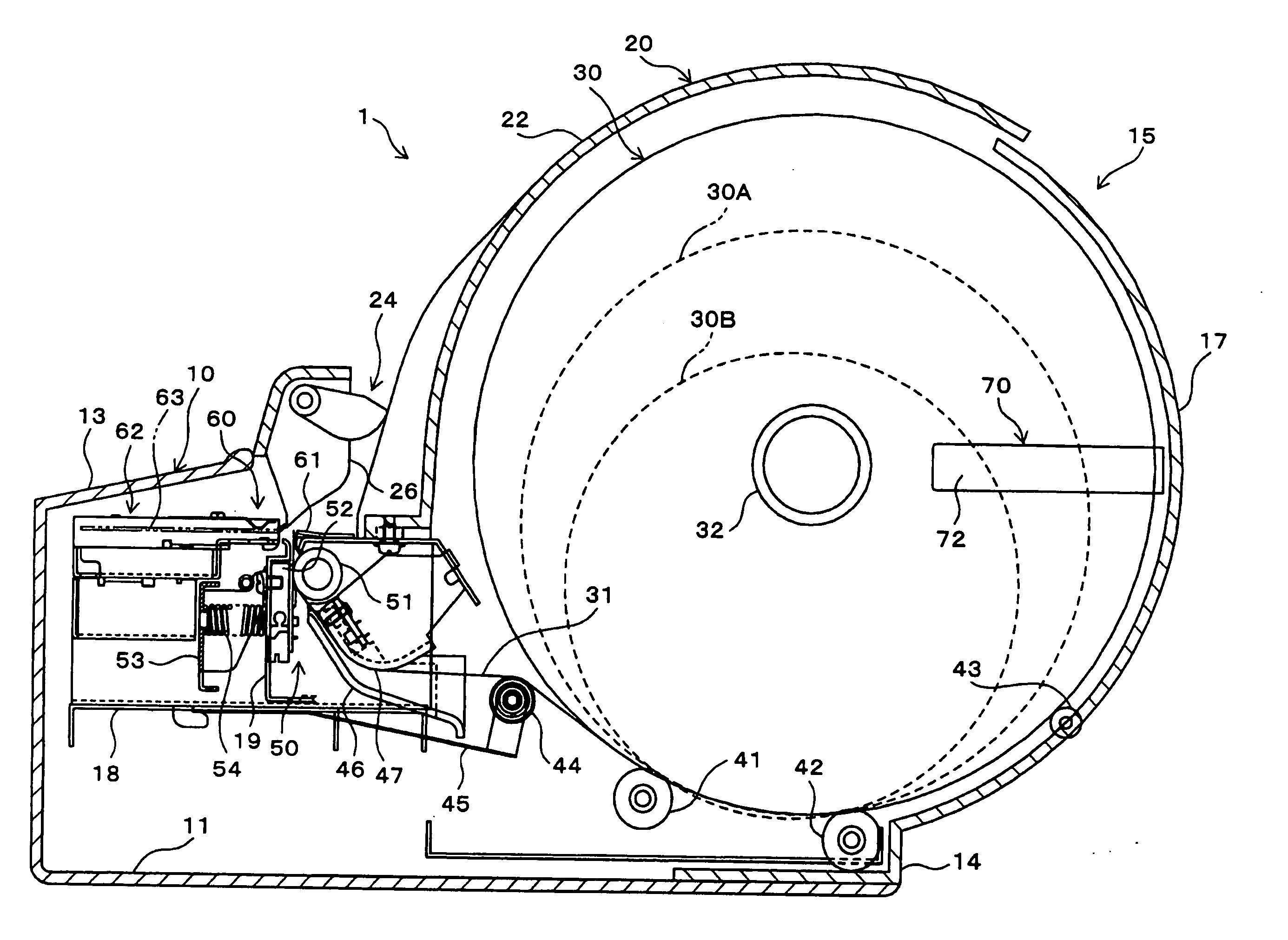

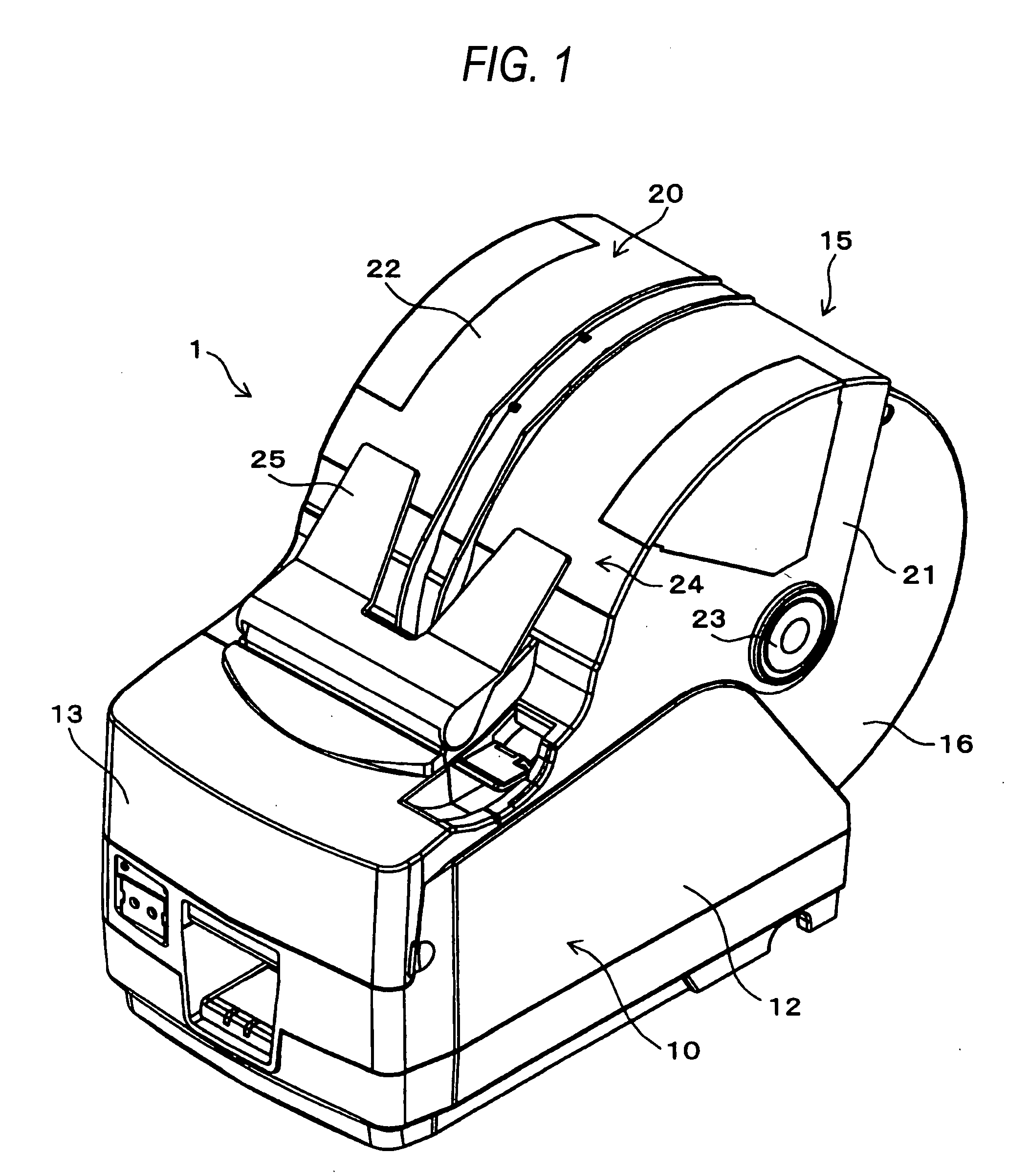

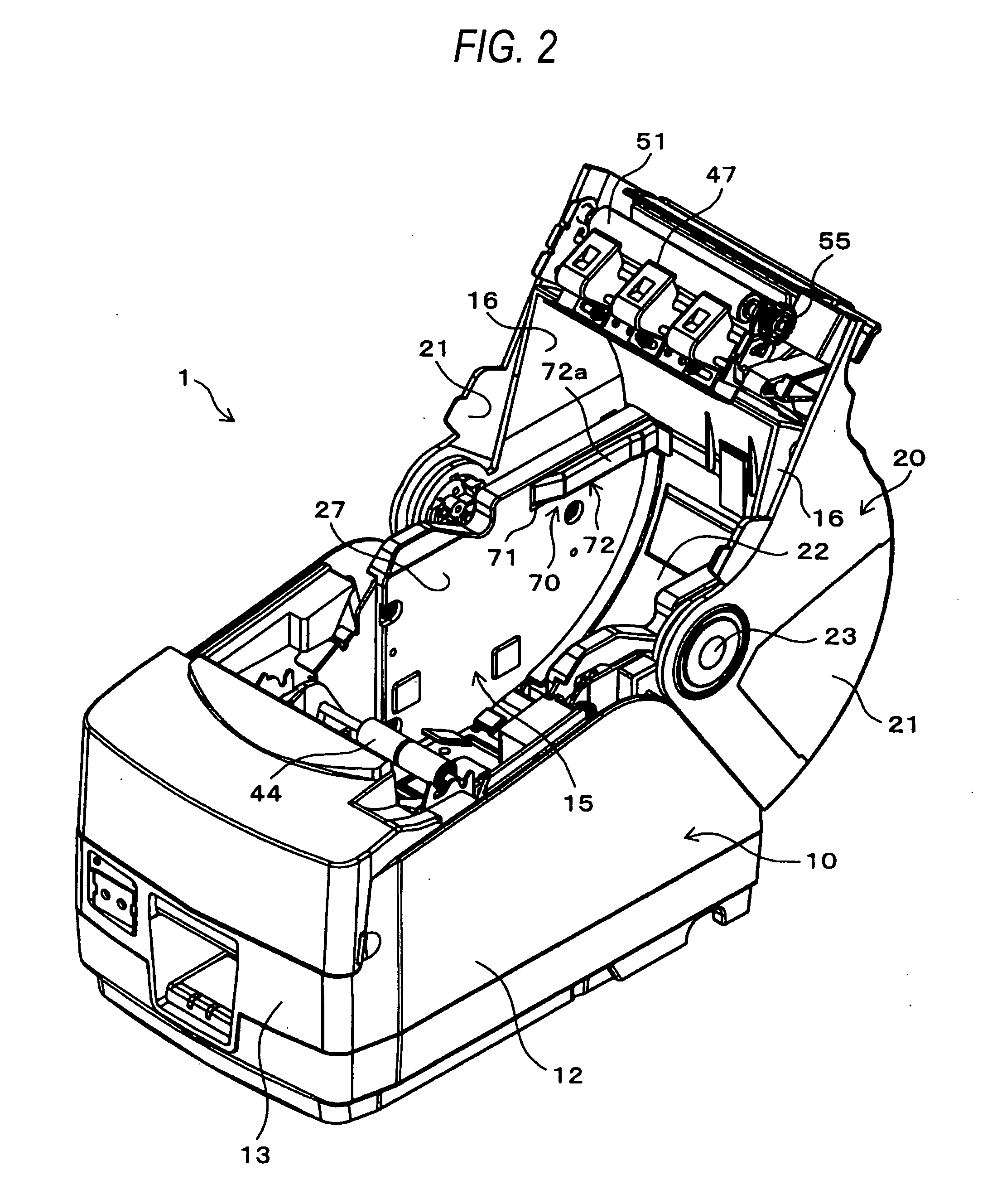

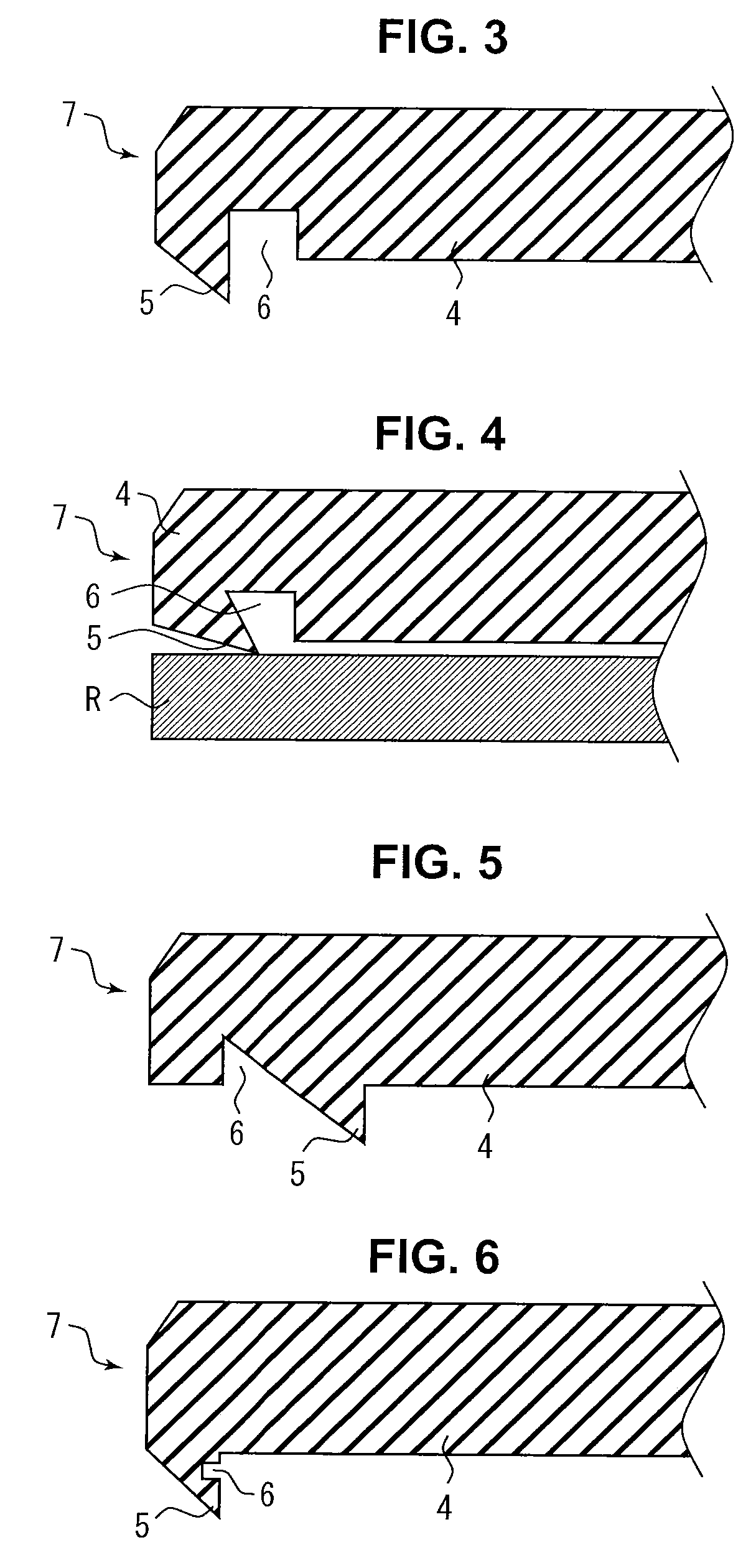

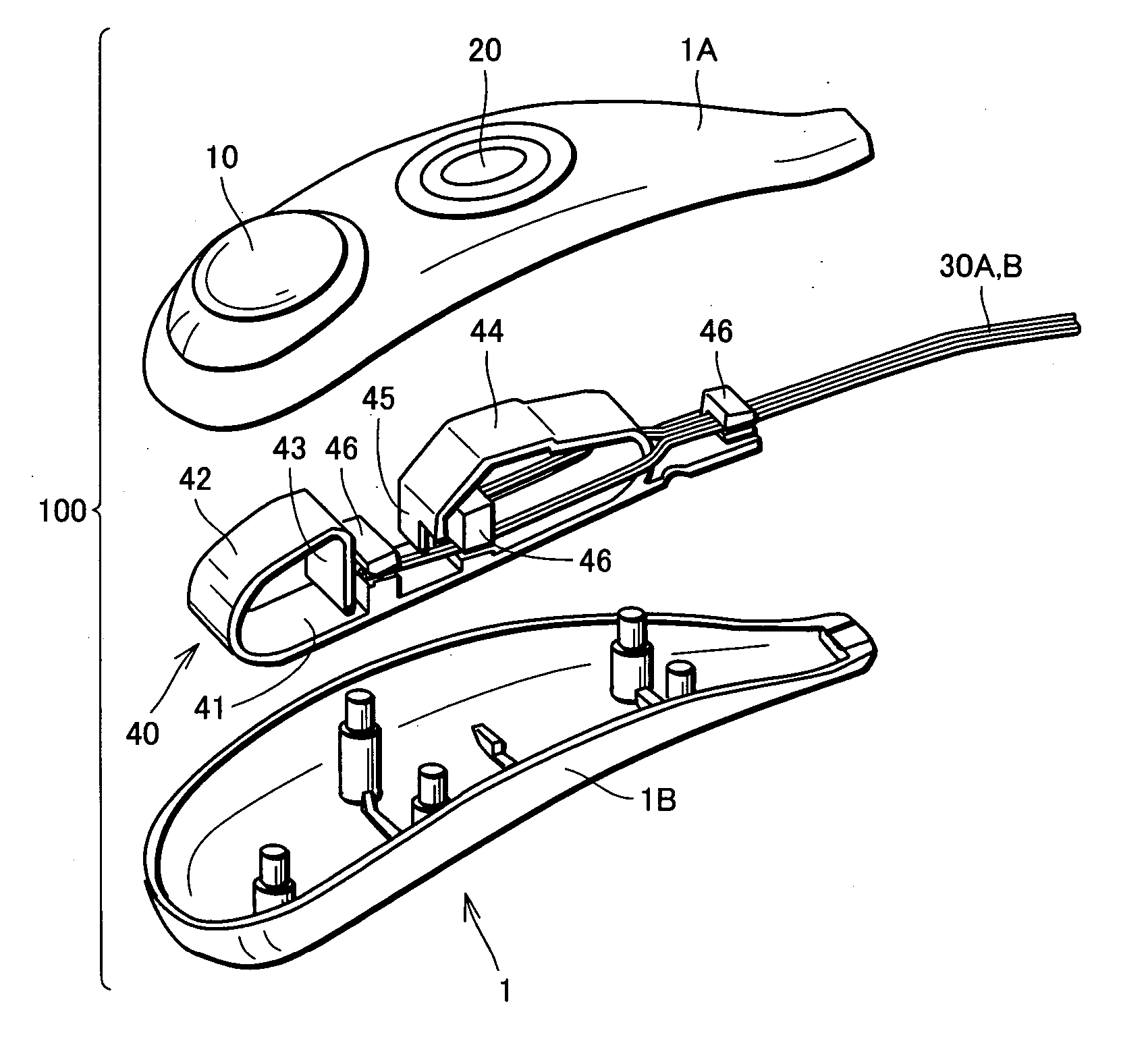

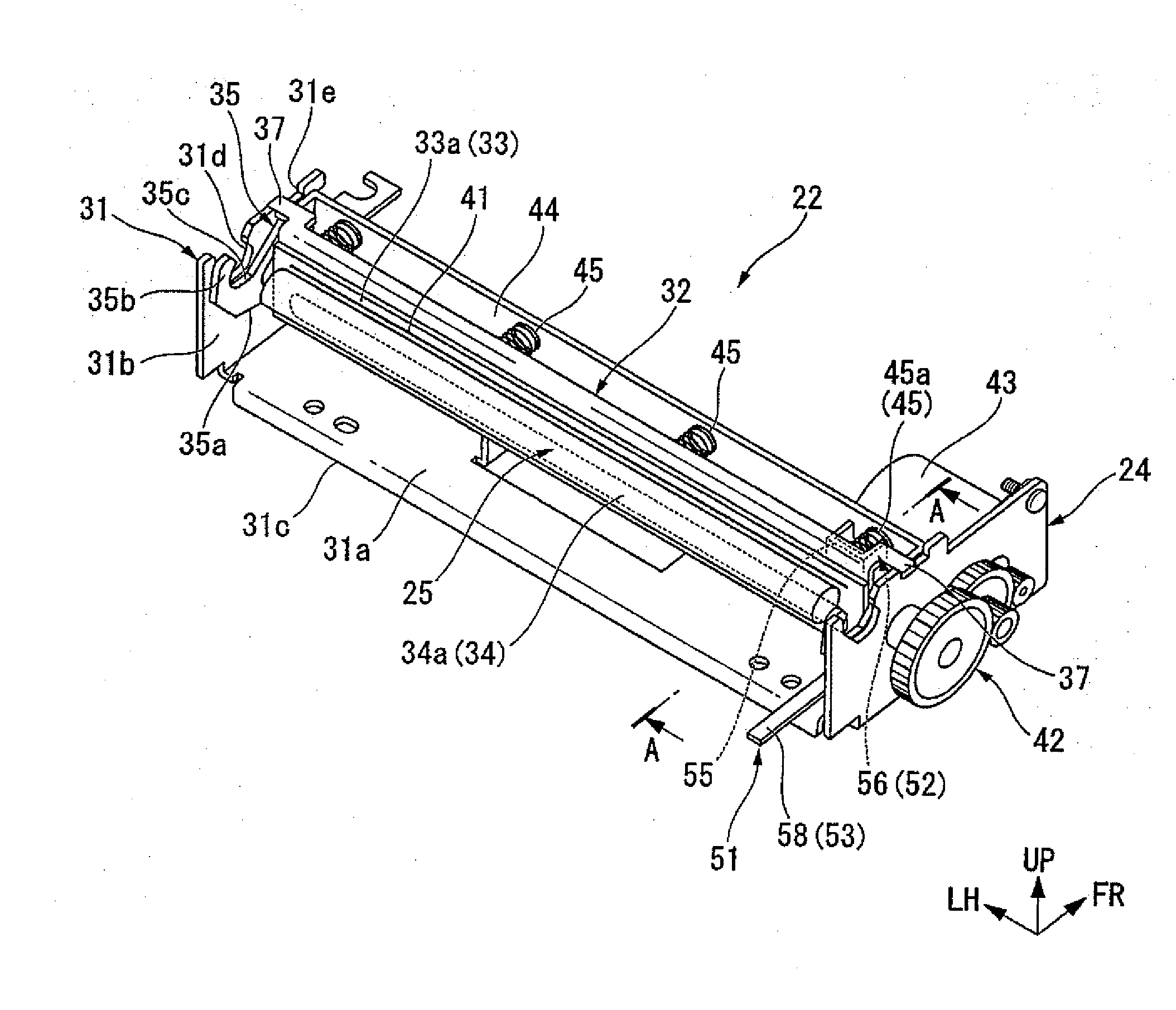

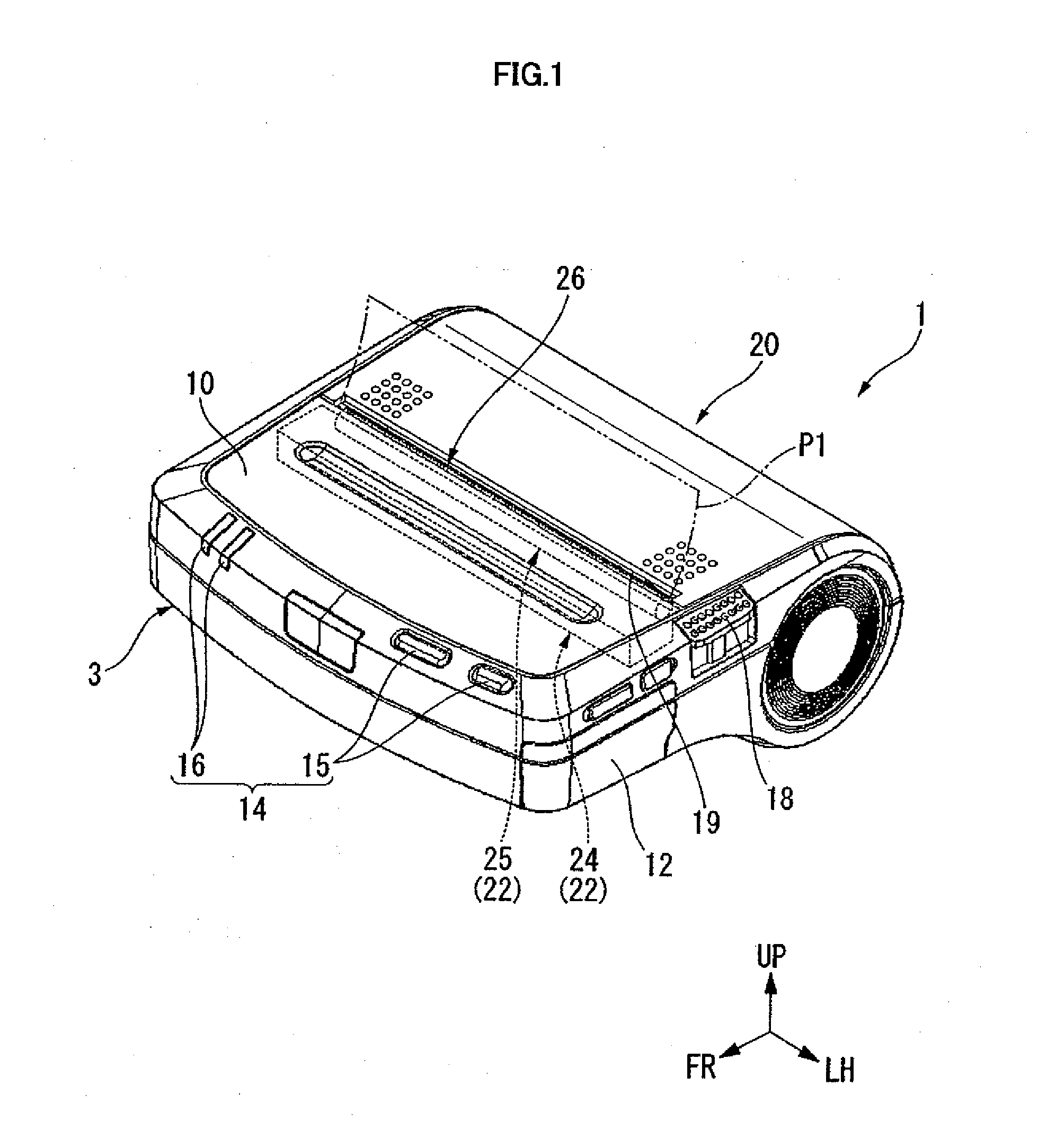

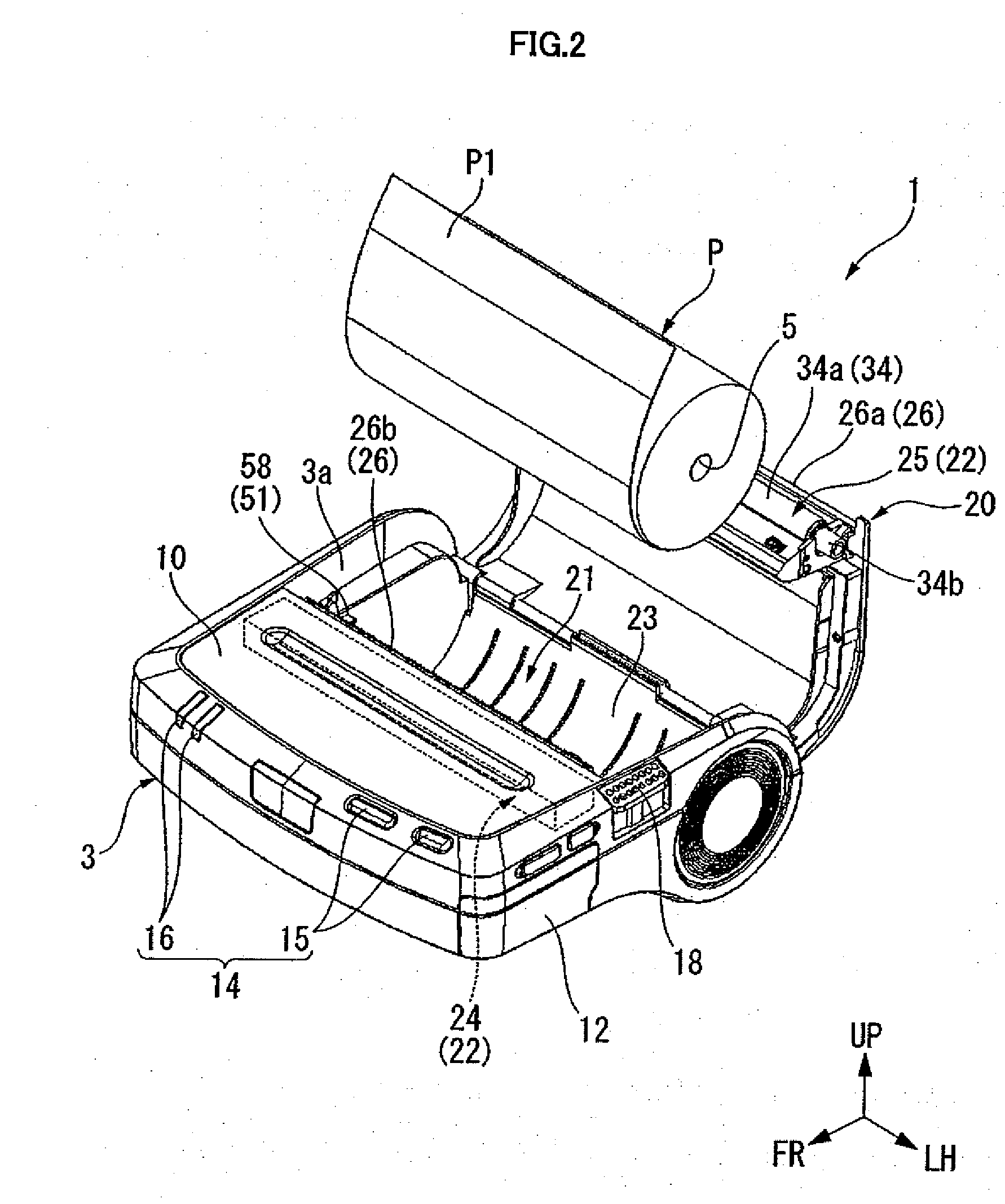

Roll paper holding mechanism and printer

InactiveUS20050232677A1Guaranteed uptimeAvoid inertia forceOther printing apparatusWebs handlingRolling paperCoil spring

Pressing plates press side faces of a roll paper loaded into a roll paper holder unit of the drop-in type, thereby preventing overrun of the roll paper caused by an inertia force from occurring. Each of the pressing plates is urged by two coil springs which are placed respectively on inner and outer circumference sides of the roll paper. The coil spring on the outer circumference side has a higher elasticity than the coil spring on the inner circumference side. According to the configuration, the pressing force of the pressing plates due to the elasticity of the coil springs is gradually reduced in accordance with reduction of a diameter of the roll paper.

Owner:STAR MICRONICS

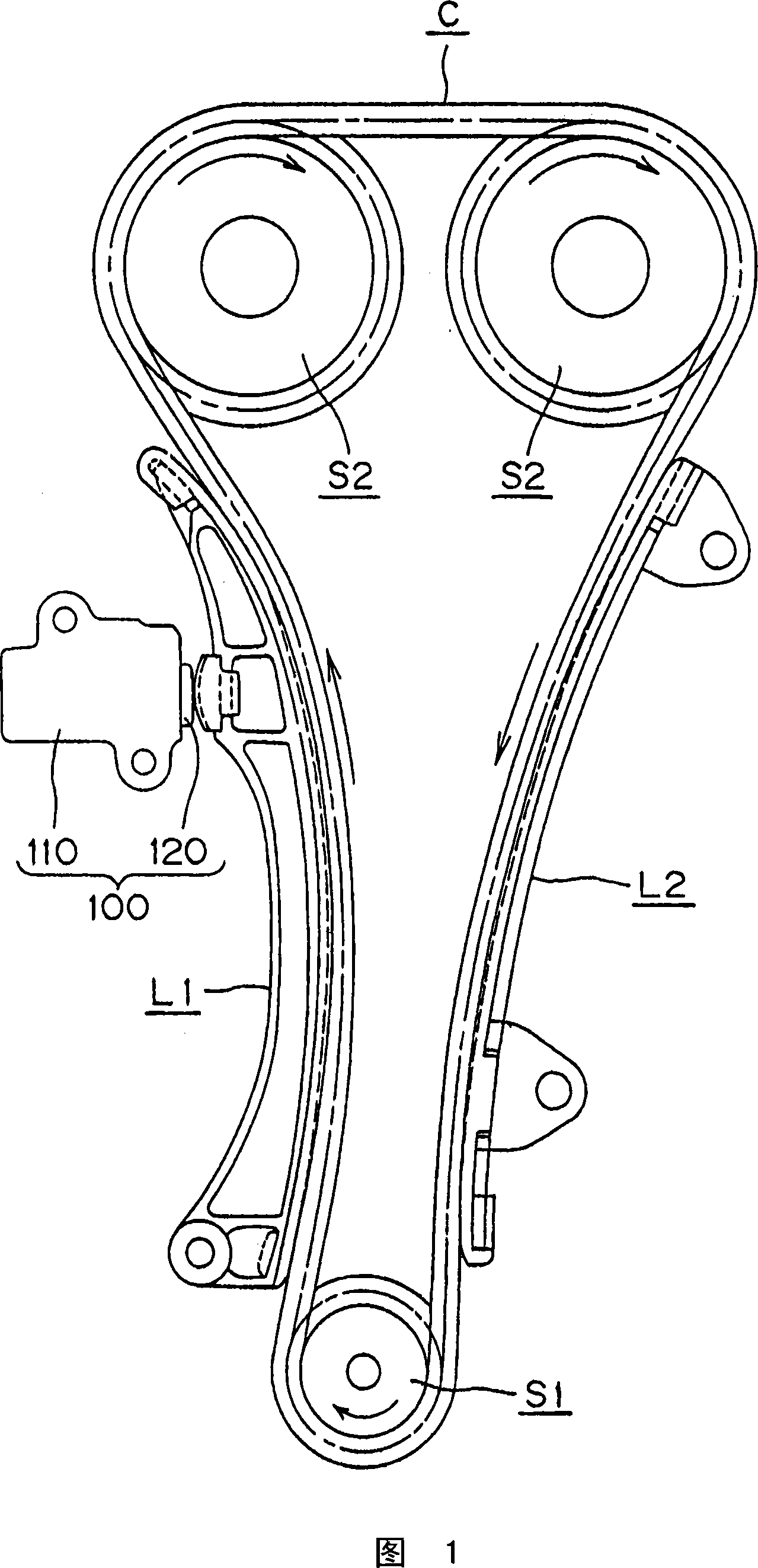

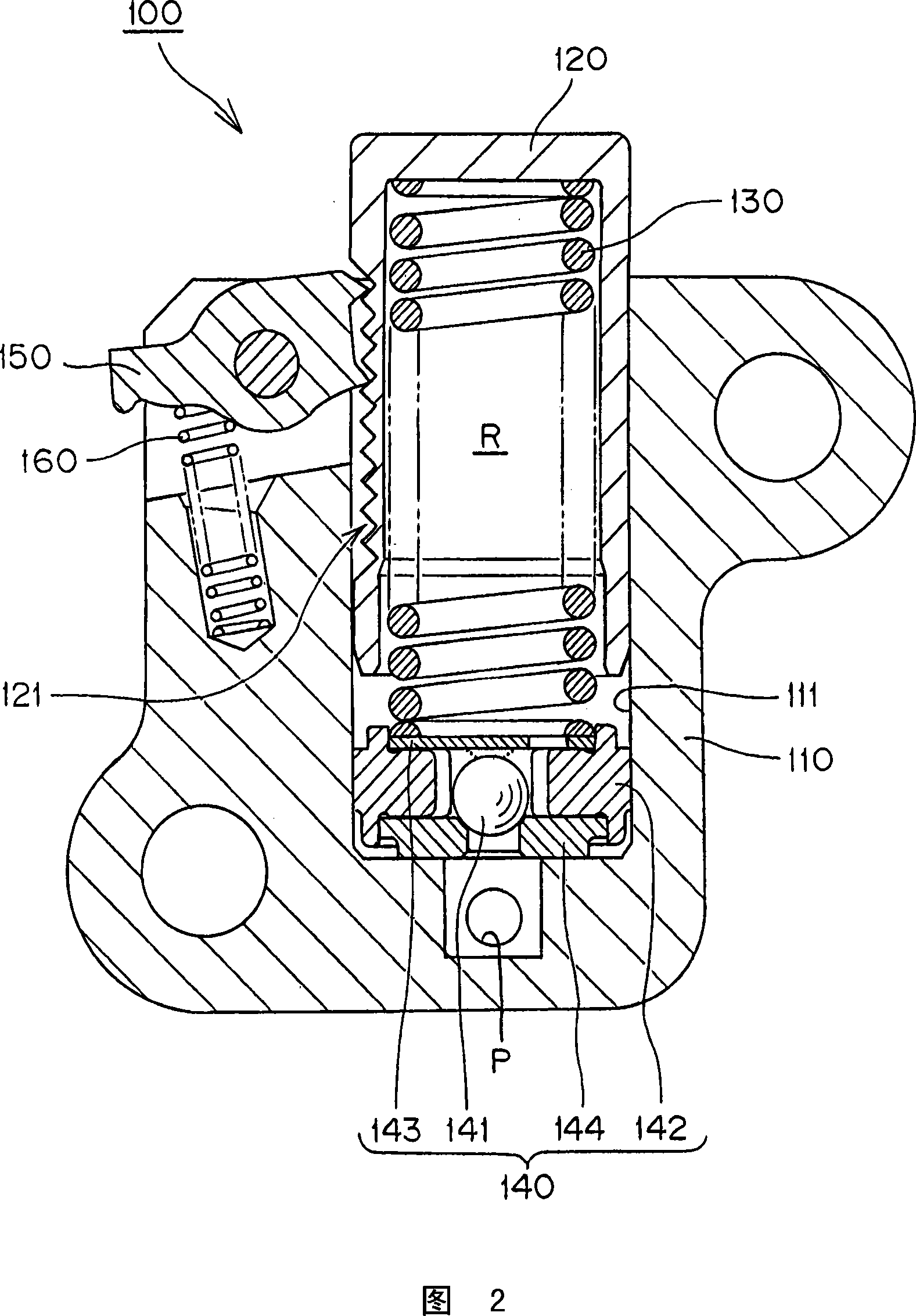

Hydraulic tensioner

A check valve unit in a hydraulic tensioner comprises a check ball, a steel ball guide having an inner wall allowing a limited range of longitudinal movement of the ball but restricting its lateral movement, a steel retainer attached to the high pressure oil chamber side of the ball guide, and a steel ball seat attached to the oil supply side of the ball guide. Bulged portions formed on an outer surface of the ball guide are press-fit into the plunger-accommodating hole of the tensioner.

Owner:TSUBAKIMOTO CHAIN CO

Bearing structure, motor, and fan apparatus

ActiveUS20100054965A1Reduce distortionSimple structurePump componentsShaftsBiomedical engineeringElectric motor

Owner:NIDEC CORP

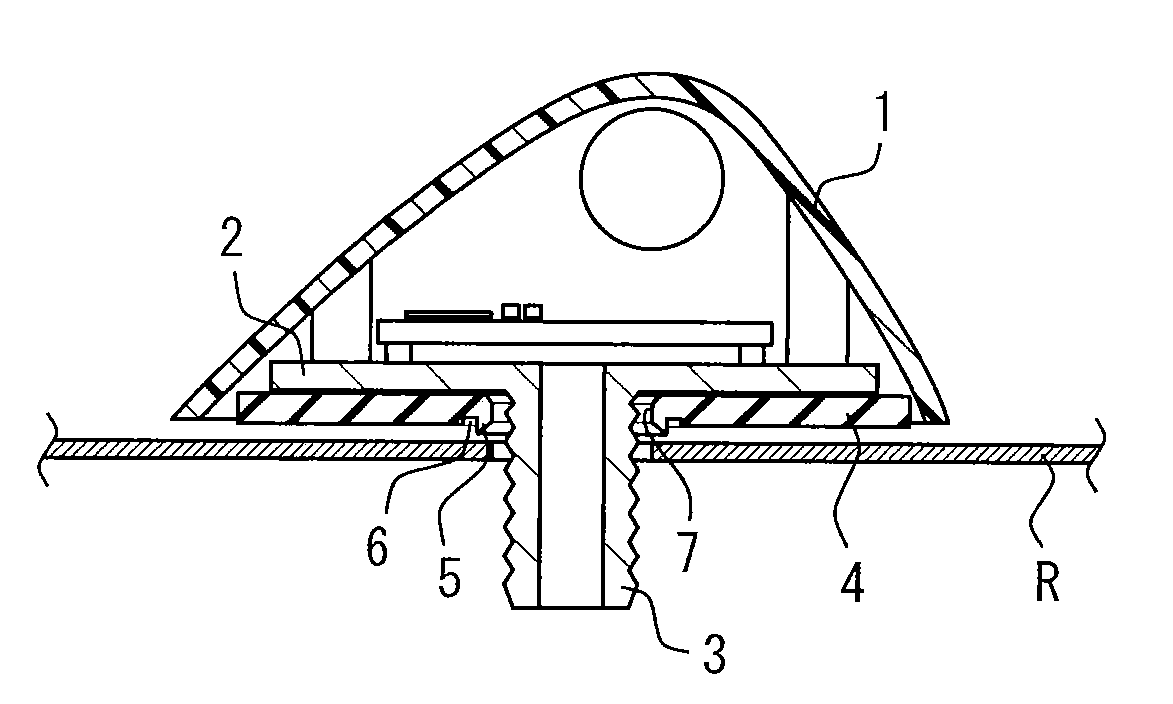

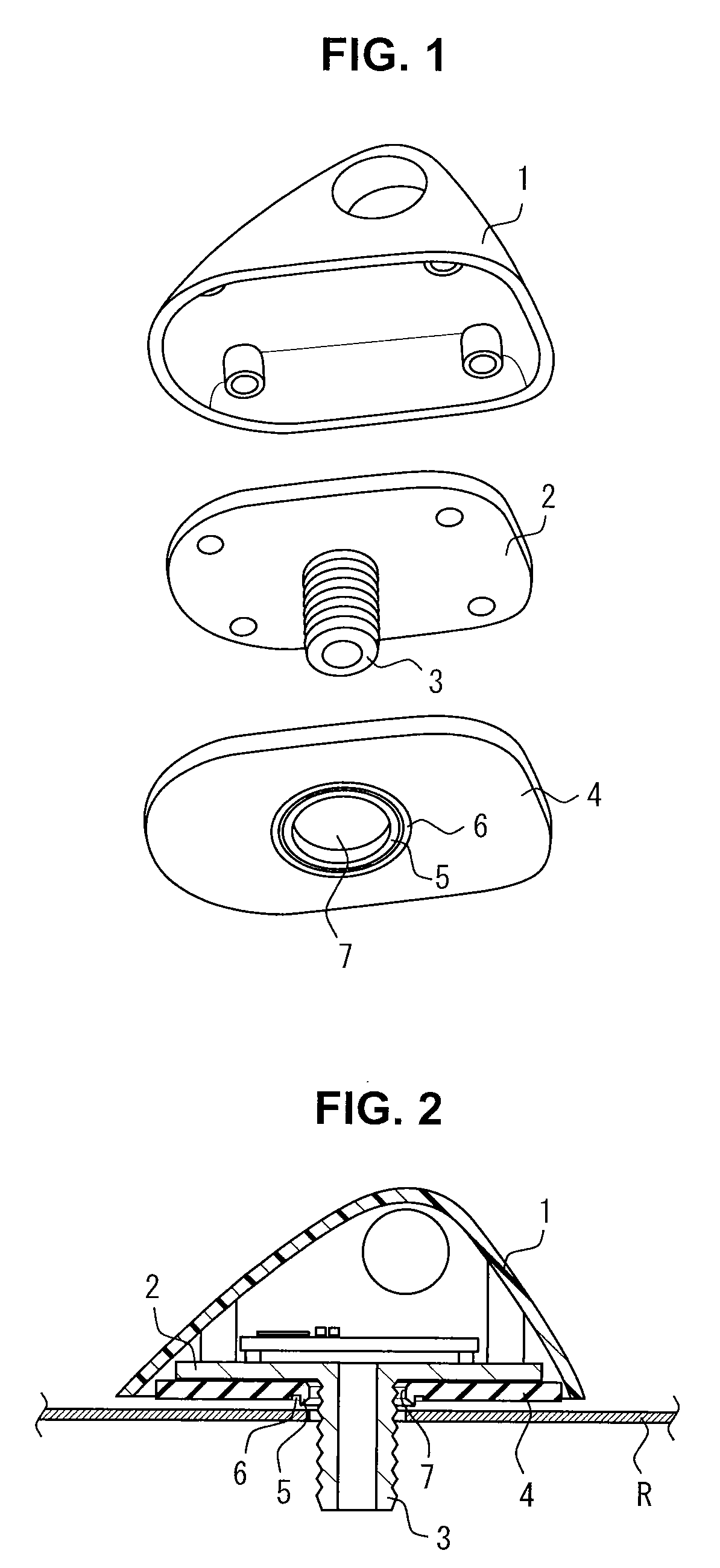

Vehicle Roof Mount Antenna

ActiveUS20100007566A1Satisfactory waterproofnessSatisfactory dustproofnessSimultaneous aerial operationsAntenna supports/mountingsEngineeringMechanical engineering

The vehicle roof mount antenna to be detachably mounted on a vehicle roof is mainly constituted by an antenna cover 1, an antenna base 2, a boss 3, a pad 4, an annular rib 5, and an annular groove portion 6. The pad 4 has a boss hole 7 through which the boss 3 penetrates and is disposed between the antenna base 2 and the vehicle roof R. The annular rib 5, which is made of an elastic material, is provided on the vehicle roof R side surface of the pad 4. When the vehicle roof mount antenna is fixed to the vehicle roof R, the annular rib 5 is inclined from the boss hole 7 toward a periphery of the pad 4. The annular groove portion 6 is provided at a position where the pressing force of the annular rib 5 against the vehicle roof R can be reduced.

Owner:HARADA IND CO LTD

Chemical liquid valve

InactiveUS20060145107A1Stable sealing strengthStop the flowSpindle sealingsDiaphragm valvesEngineeringPiston rod

A chemical liquid valve is arranged such that a diaphragm coupled to a piston rod is brought into / out of contact with a valve seat provided between an inlet port and an outlet port. To achieve a chemical liquid valve providing stable sealing strength, the diaphragm includes an engagement part whose top end is formed in semispherical shape, which is inserted and engaged in a recess of the piston rod so that the engagement part of the diaphragm comes into point contact with an inner wall of the recess of the piston rod. Thus, the piston rod swingably holds the diaphragm.

Owner:CKD

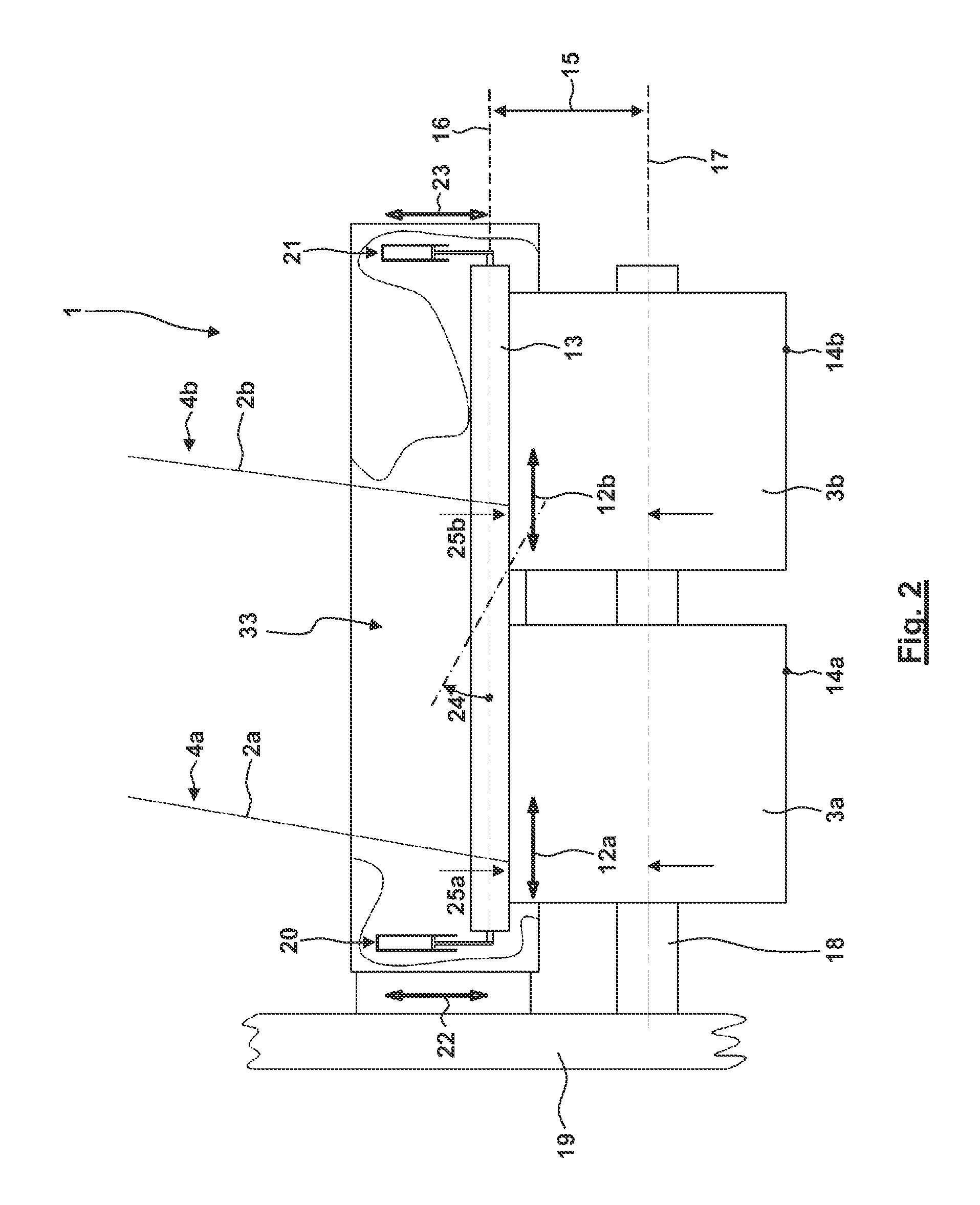

Filling device for an anesthetic evaporator

ActiveUS20060048842A1Increase capacityReduce the pressing forceRespiratorsSolid materialEngineeringAnaesthetic vaporizer

A filling device for an anesthetic evaporator has filling of an anesthetic evaporator is possible. To accomplish the object, an additional vent hole (36), which is opened immediately after the filling in order for excess anesthetic volume to be able to flow out of the filling device into the anesthetic tank (15) of the anesthetic evaporator (2), is provided within the filling device above a fluid channel (14), via which both the gas and liquid exchange takes place during the filling.

Owner:DRAGERWERK AG

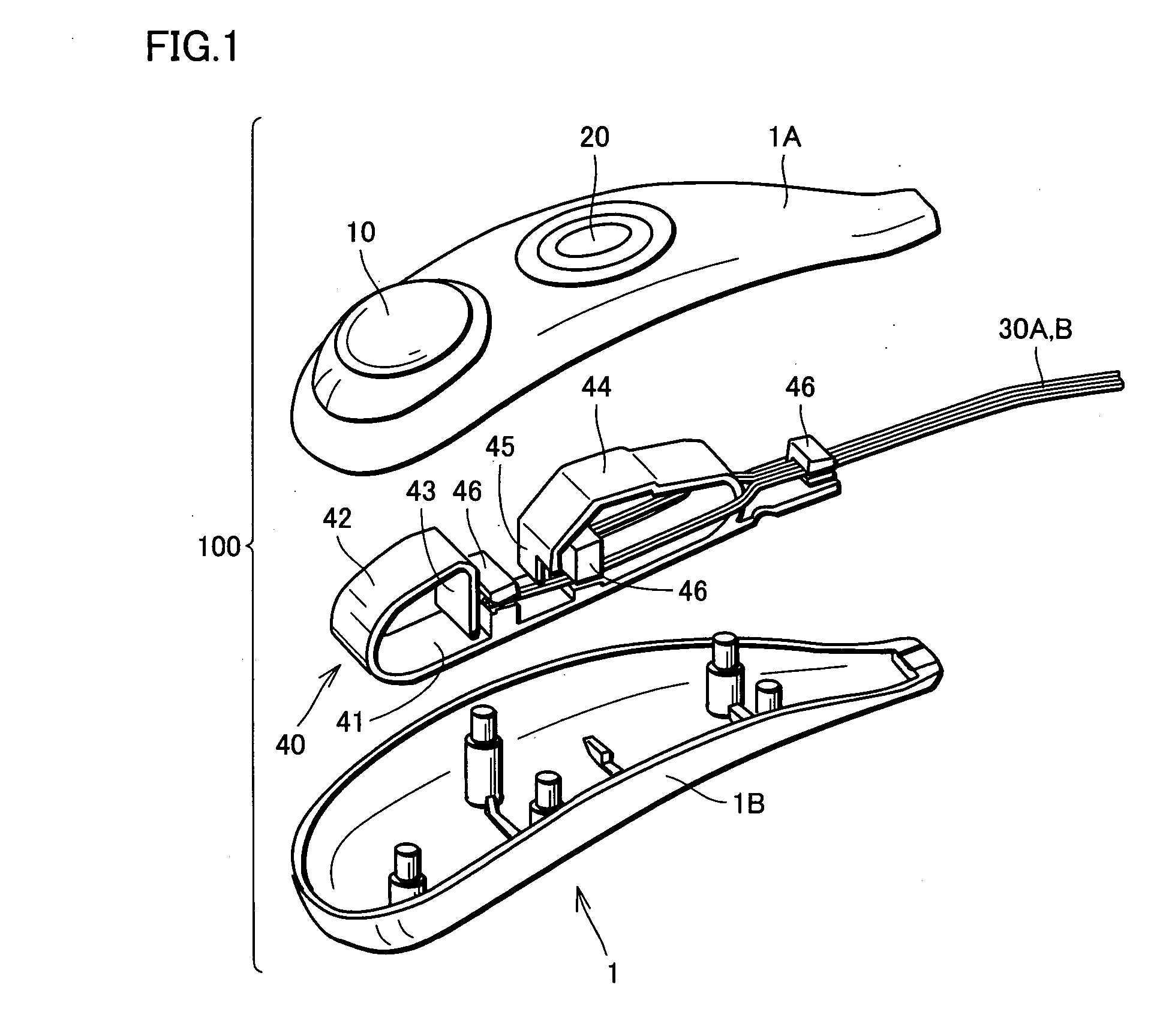

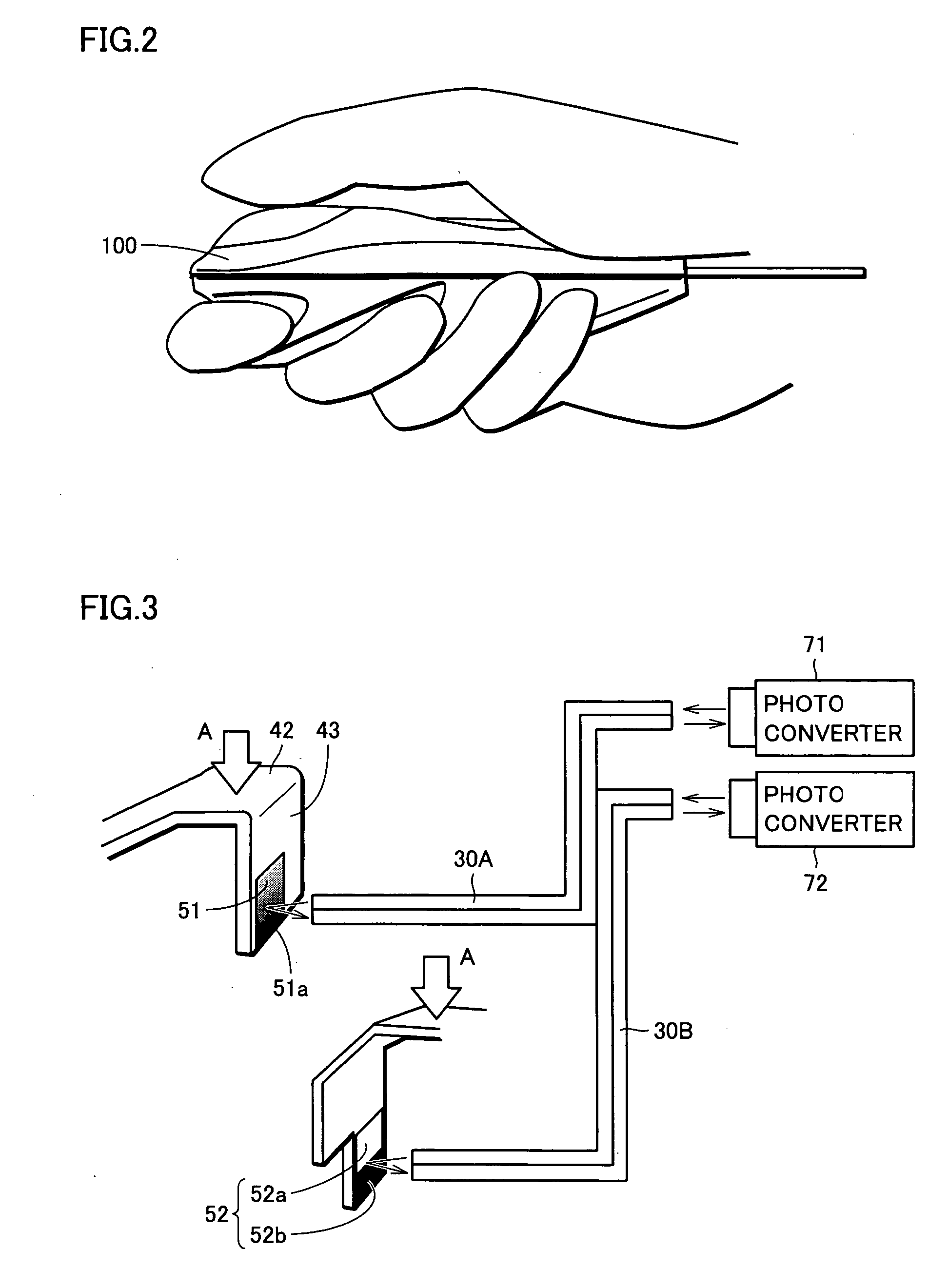

Variable hand switch

InactiveUS20060213756A1Continuous controlGuaranteed uptimeElectronic switchingElectric switchesEngineeringMechanical engineering

Owner:TAKACHI KEN

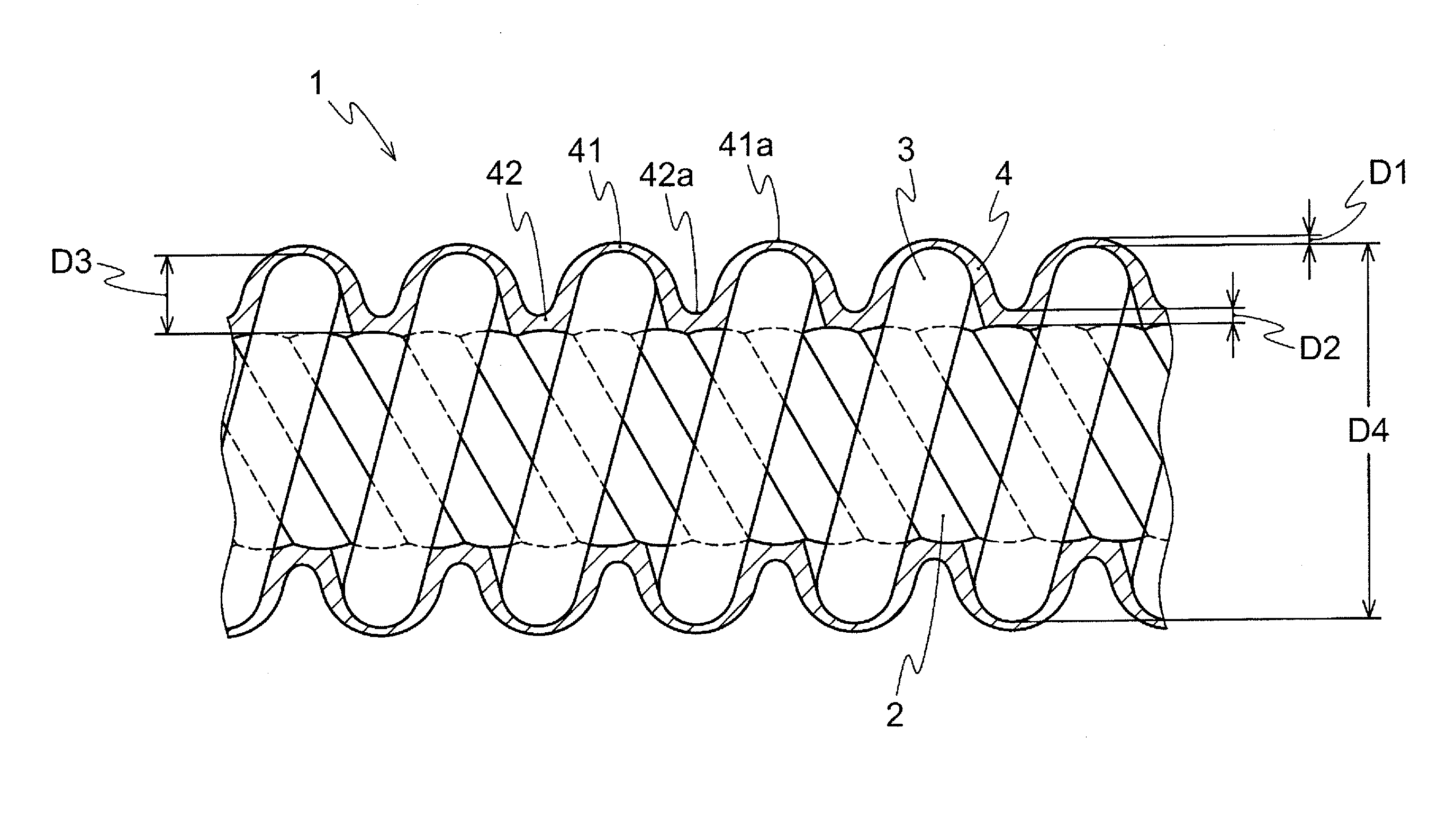

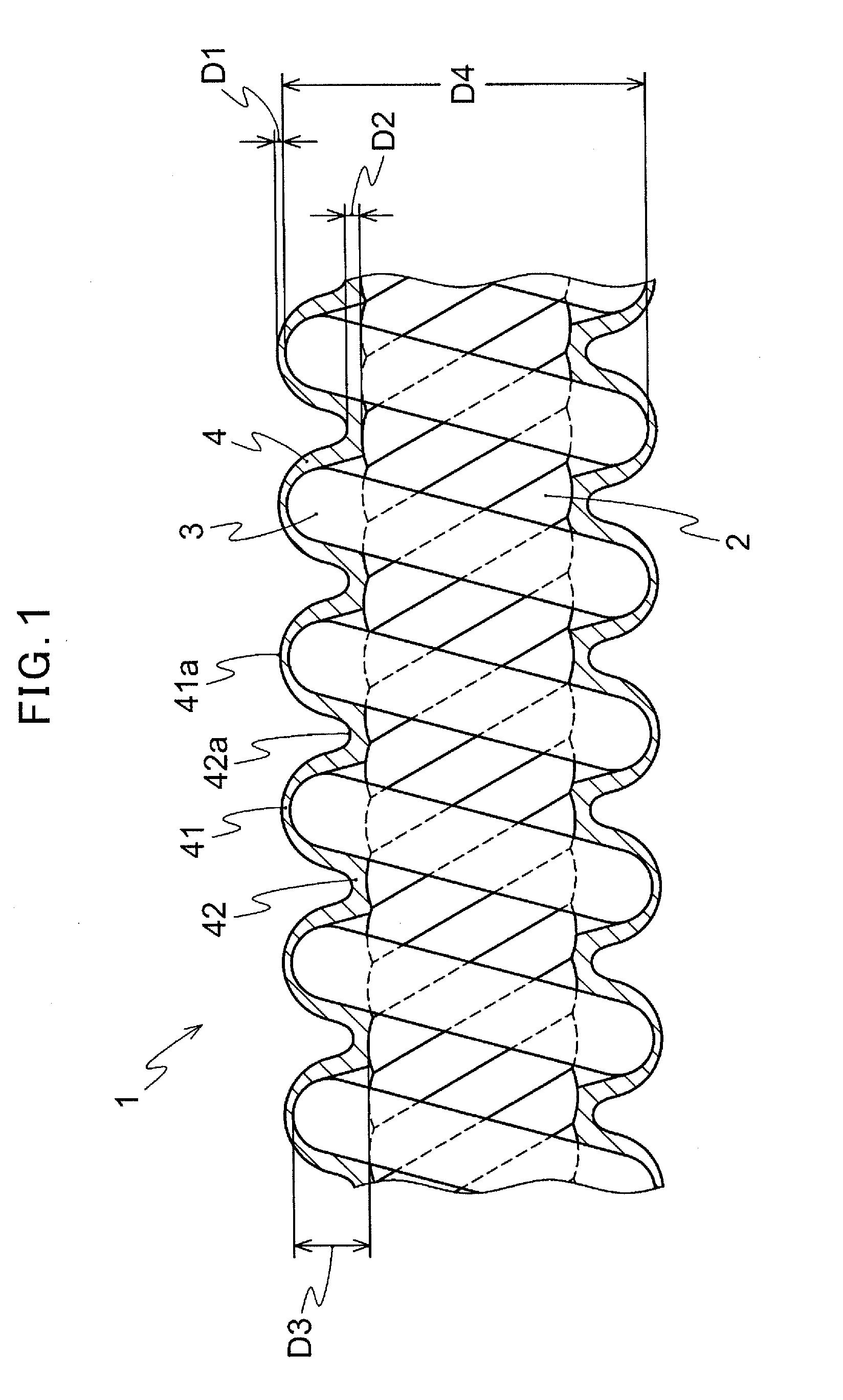

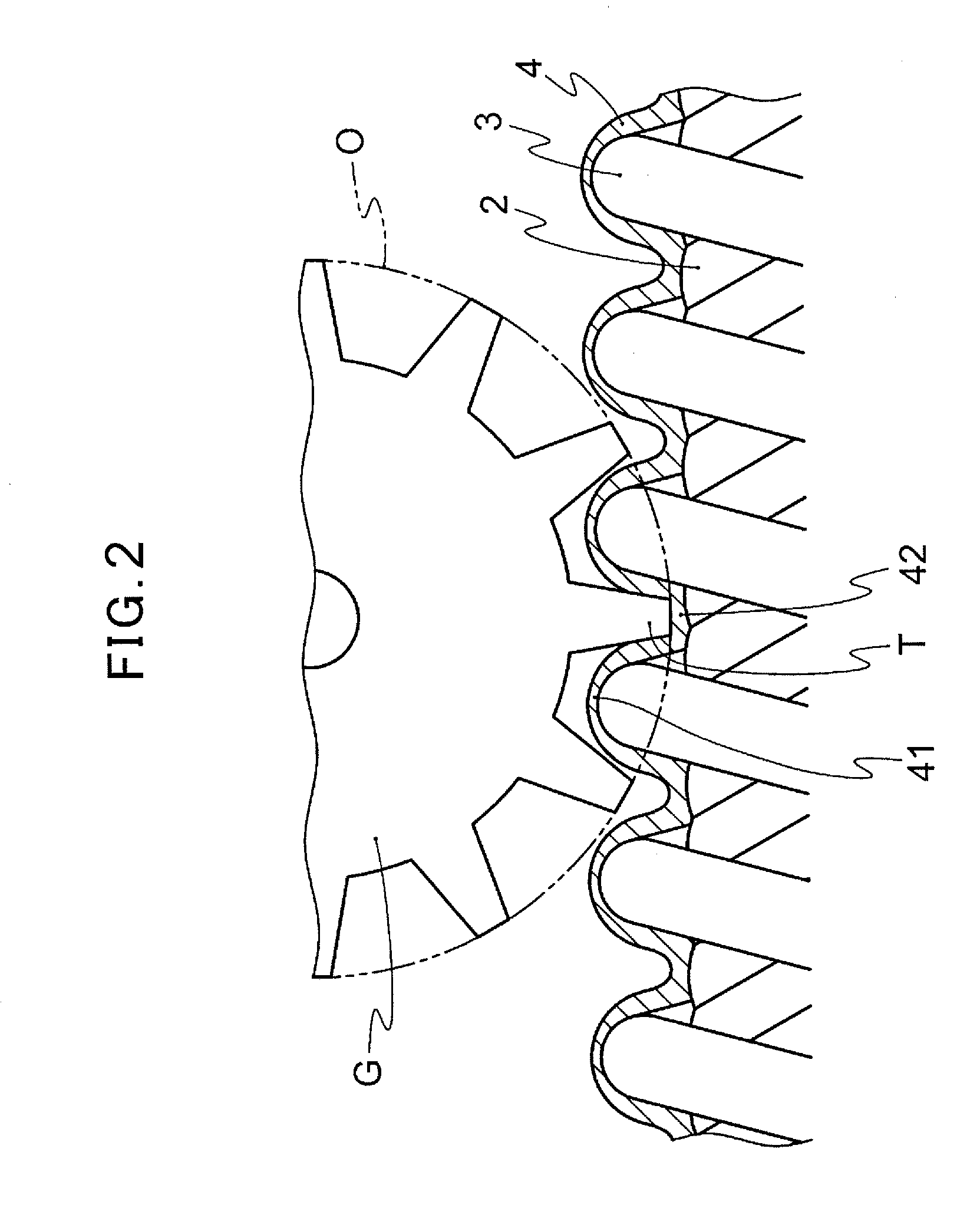

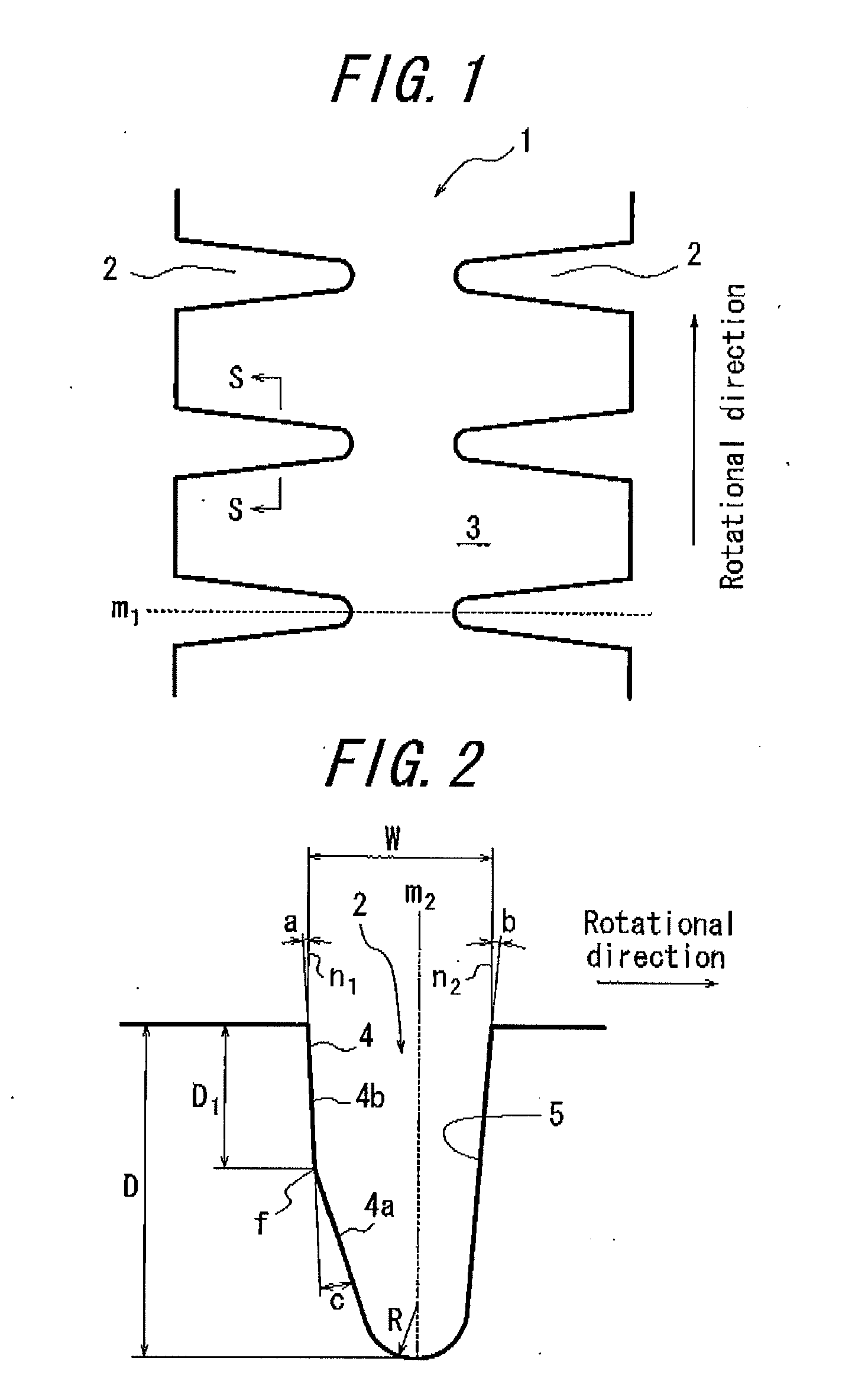

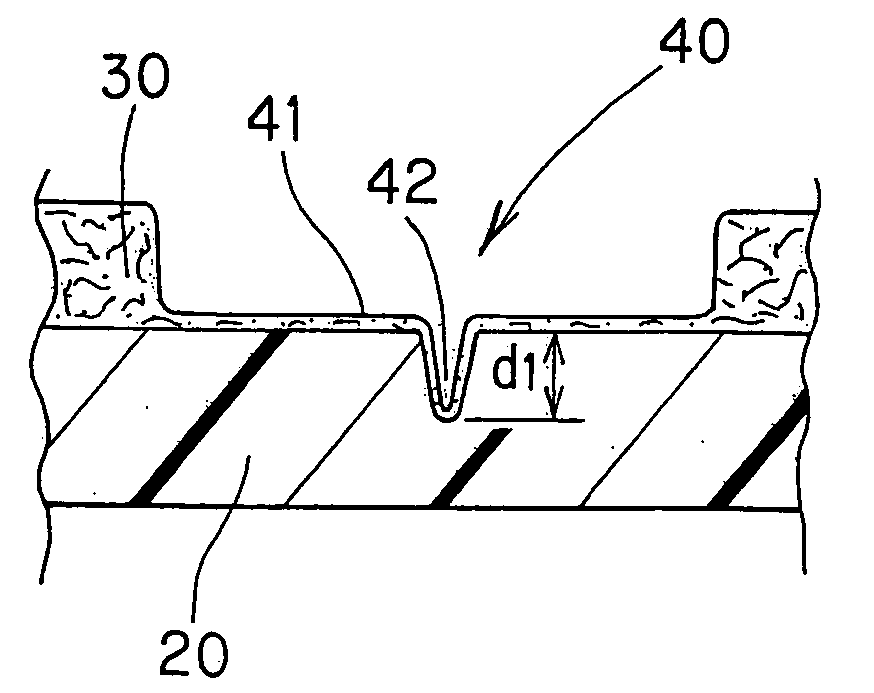

Toothed cable

InactiveUS20120277047A1Avoid attenuationInhibit the generation of cracksRopes and cables for vehicles/pulleyDriving beltsEngineeringElectrical and Electronics engineering

The present invention has an object of providing a toothed cable 1 not to cause an unnecessary load on a motor or the like, not to cause tear in the cover layer and to have excellent durability. The present invention provides a toothed cable 1 comprising a core cable 2, and a tooth line 3 helically wound on the outer periphery of the core cable 2. The toothed cable 1 further comprises a cover layer 4 covering the outer surface of the core cable 2 and the tooth line 3 with a resin continuously. This toothed cable 1 has helical convex portions 41 formed by covering the tooth line 3 with the resin and helical concave portions 42 formed by covering intervals in the tooth line with the resin, and the covered layer 4 is in contact with the core cable 2 and the tooth line 3.

Owner:HI-LEX CORPORATION

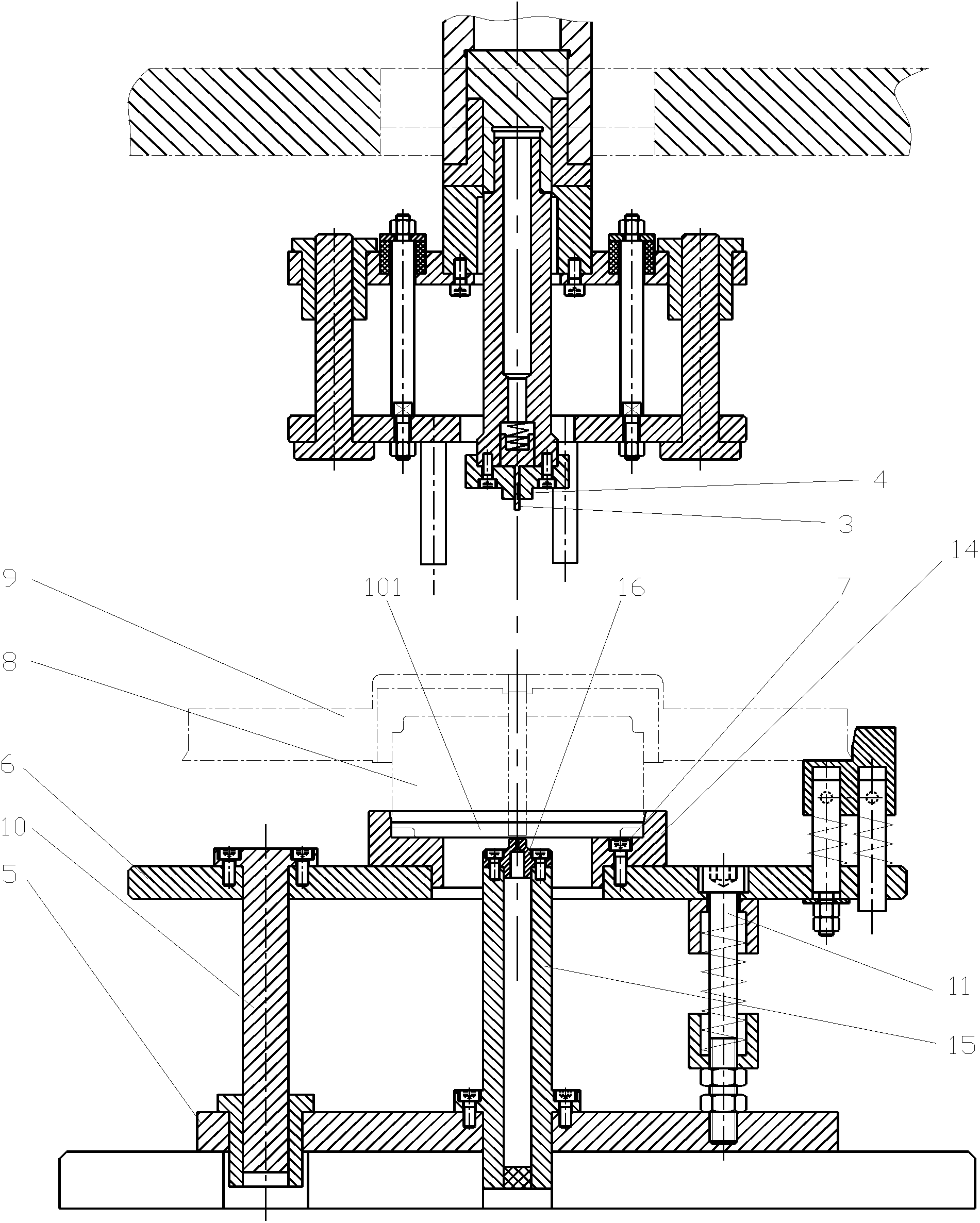

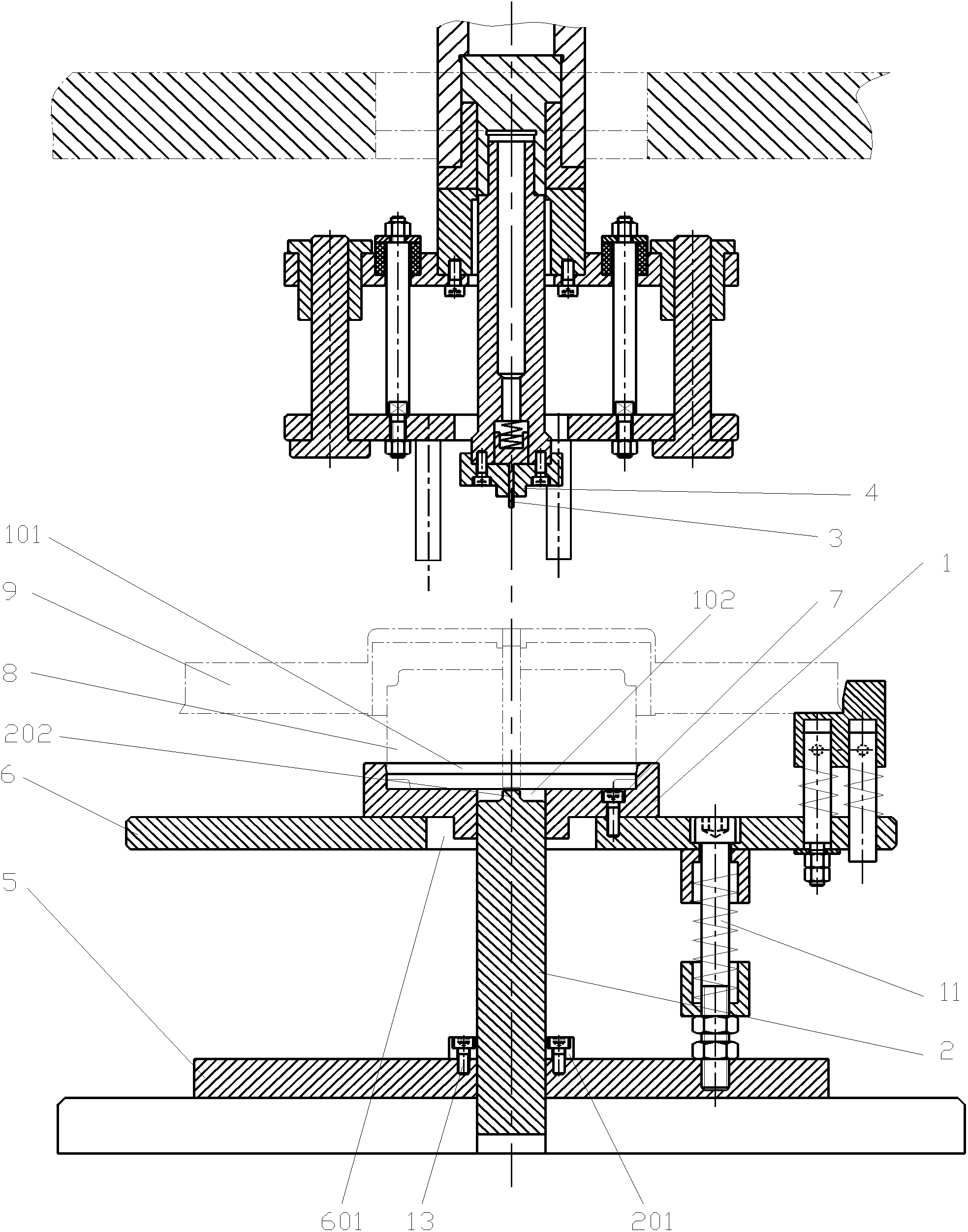

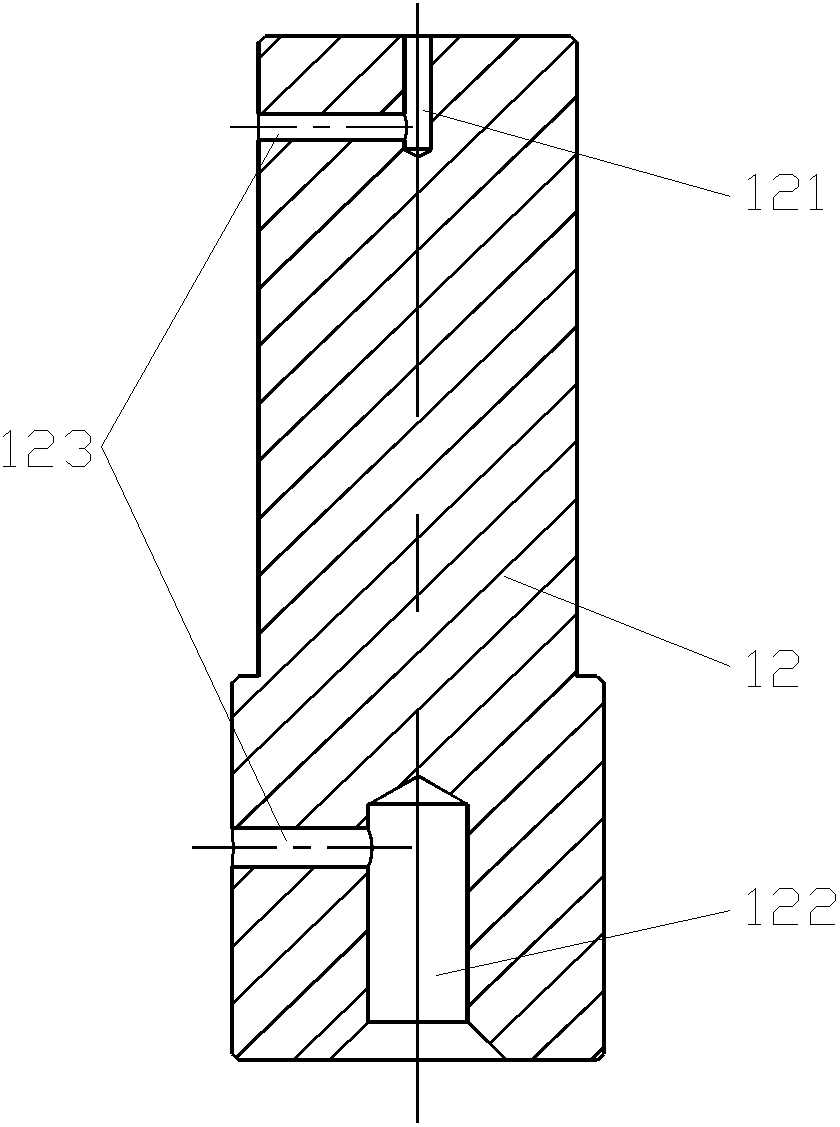

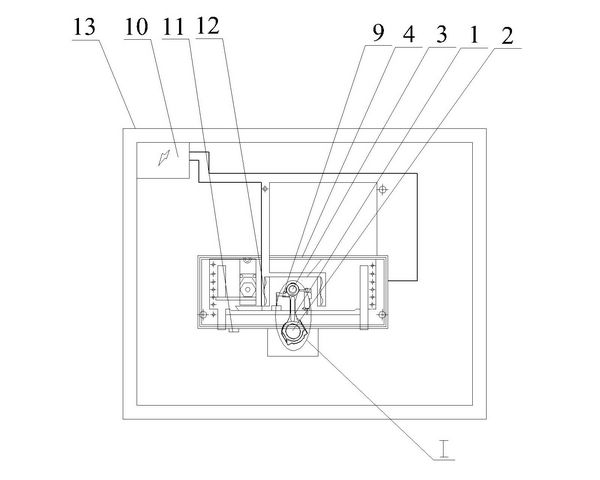

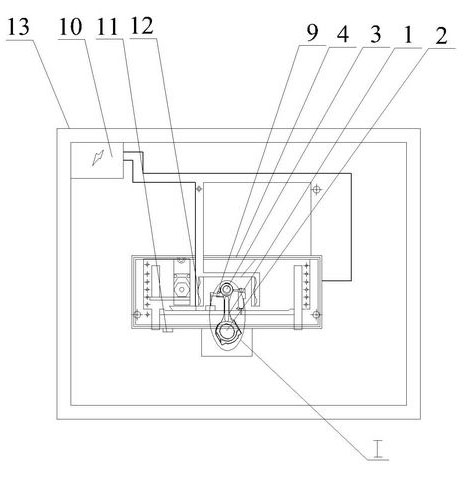

Improved structure of cooling fan compression joint device

ActiveCN102528426AGuaranteed positioning accuracyThe pressing process is stableMetal working apparatusEngineeringRejection rate

The invention relates to an improved structure of a cooling fan compression joint device. A liftable supporting plate is arranged in parallel above a horizontal base. The center of the supporting plate is provided with a mounting hole. A lower clamp which is of a step disk shape is arranged above the supporting plate. The small end of the lower clamp extends into the mounting hole. The outer diameter of the small end of the lower clamp is less than the aperture of the mounting hole on the supporting plate. The big end of the lower clamp is provided with a motor positioning cavity. The center of the small end of the lower clamp is provided with a through hole. The through hole is communicated with the motor positioning cavity. A vertical ejector rod is arranged in the through hole of the lower clamp. The ejector rod is in clearance fit with the through hole. The center of the end face of the upper end of the ejector rod protrudes to form an ejector head. An upper guide pin capable of vertically lifting and descending is coaxially arranged above the lower clamp. A device is provided with a vertical centering rod. The upper and lower end faces of the vertical centering rod are respectively provided with coaxial centering holes. The coaxiality of the upper guide pin and the lower clamp is detected before press mounting by utilizing the centering rod, so that the press mounting process is ensured stable, the interference is uniform, the pressure is reduced, the press mounting alarm is reduced and the rework rate and the rejection rate are reduced, and thus, the cost is reduced.

Owner:SHANGHAI BROSE AUTOMOTIVE COMPONENTS

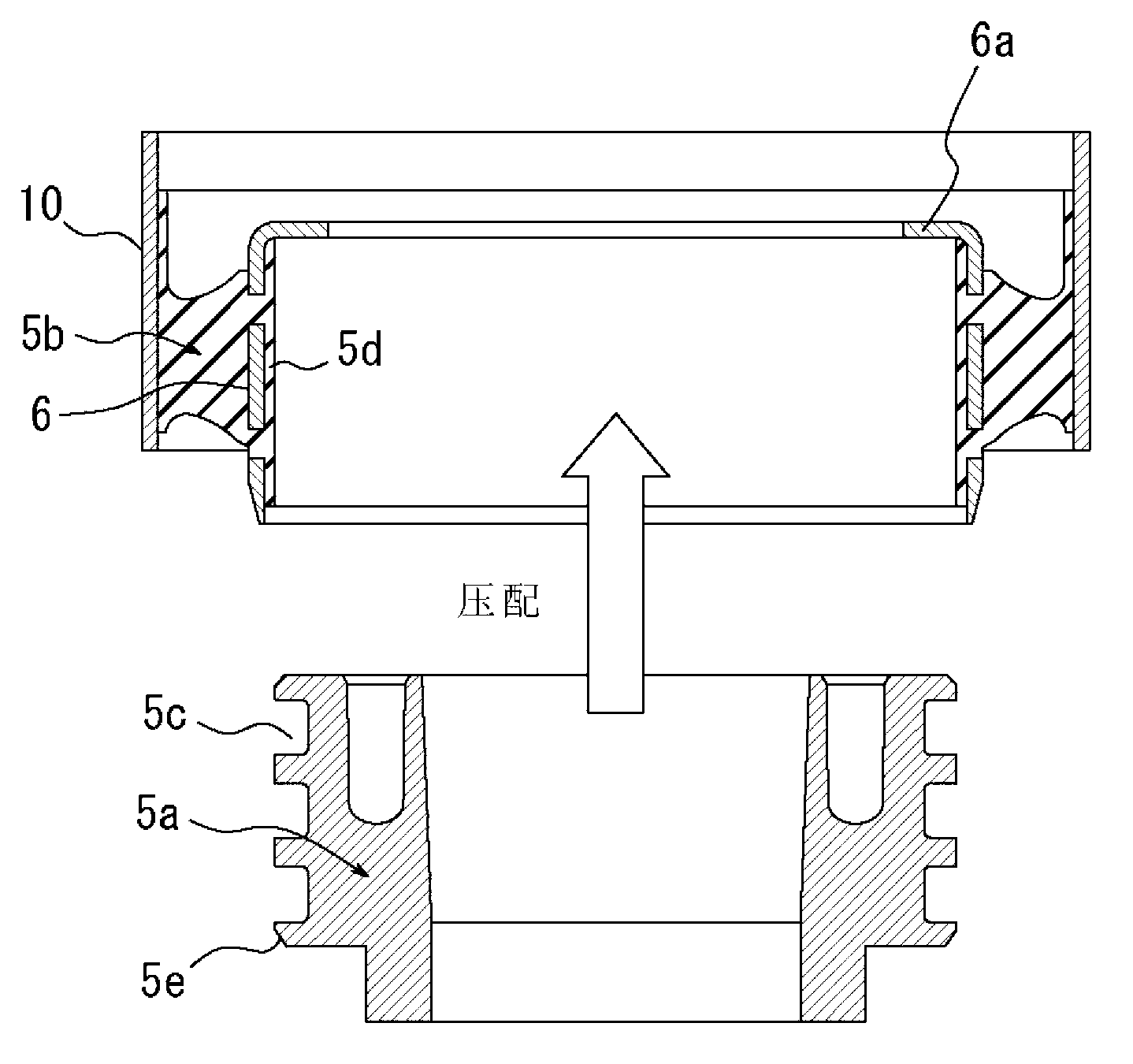

Liquid seal anti-vibration device and manufacturing method thereof

ActiveCN102884338AAvoid deformationIncrease the vibration reduction functionSpringsSprings/dampers manufactureMechanical engineeringEngineering

The disclosed liquid seal anti-vibration device is provided with: an inner tube (1) and outer tube (2); rubber bodies (3, 4) connecting said inner and outer tubes (1, 2) in a liquid-tight manner at two positions separated in the axis direction; a partition wall which, disposed between the two rubber bodies (3, 4), divides into two parts in the axis direction the space between the inner and outer tubes and which comprises an annular rigid member (5a) and an elastic member (5b); liquid chambers (8, 9) formed by sealing a noncompressible fluid in each of the spaces formed by the partition wall (5); and a restricted passage (7) allowing communication between the two liquid chambers (8, 9) formed by the partition wall (5). The aforementioned partition wall (5) is configured from the annular rigid member (5a), which protrudes from the inner tube (1) towards the outer tube side, and from the elastic member (5b), which connects said annular rigid member (5a) to the outer tube (2). The aforementioned restricted passage (7) is configured from one or multiple passage grooves (5c), which, formed on the outer peripheral surface of the annular rigid member (5a), extend at least one time around the circumference thereof, and from a bounding rigid tube member (6) which, attached to the aforementioned elastic member (5b), seals the openings of the passage grooves (5c) via a seal member (5d) in a liquid-tight manner.

Owner:BRIDGESTONE CORP

Gear pump

ActiveUS20100086422A1Operational reliability is increasedEfficient variabilityOscillating piston enginesEngine of counter-engagement typeGear pumpGear wheel

An oil pump includes a drive gear, which rotates with a drive shaft, a driven gear, which meshes with the drive gear and is supported rotatable on a driven shaft, and a casing having a pump chamber, which accommodates the drive gear and the driven gear. The casing of the gear pump is provided with an intake port and a discharge port, which are in fluid communication with the pump chamber, so that oil is sucked through the intake port and discharged through the discharge port. A gear holder is provided in the casing such that the gear holder supports the driven gear rotatable and holds both sides of the driven gear while the gear holder itself is being supported axially movable by the driven shaft. The gear holder holding the driven gear moves axially by receiving a biasing force and also a pressing force acting against the biasing force.

Owner:TBK

Printer

ActiveUS20120242772A1Reduce the pressing forceReduce pressing forceRecording apparatusPower drive mechanismsRelease pressEngineering

The printer includes: a thermal head including a large number of heating elements and being arranged along a width direction of a thermal paper to be drawn from a roll sheet; a platen roller arranged opposite to the thermal head, for sending out the thermal paper by rotating in a state of sandwiching the thermal paper between the thermal head and the platen roller; and an elastic member provided on an opposite side of the platen roller with respect to the thermal head, for pressing the thermal head toward the platen roller, in which the elastic member is provided with a pressing force releasing mechanism for separating the elastic member from the thermal head according to a width of the roll sheet to be fed, and for releasing pressing of the thermal head by the elastic member.

Owner:SEIKO INSTR INC

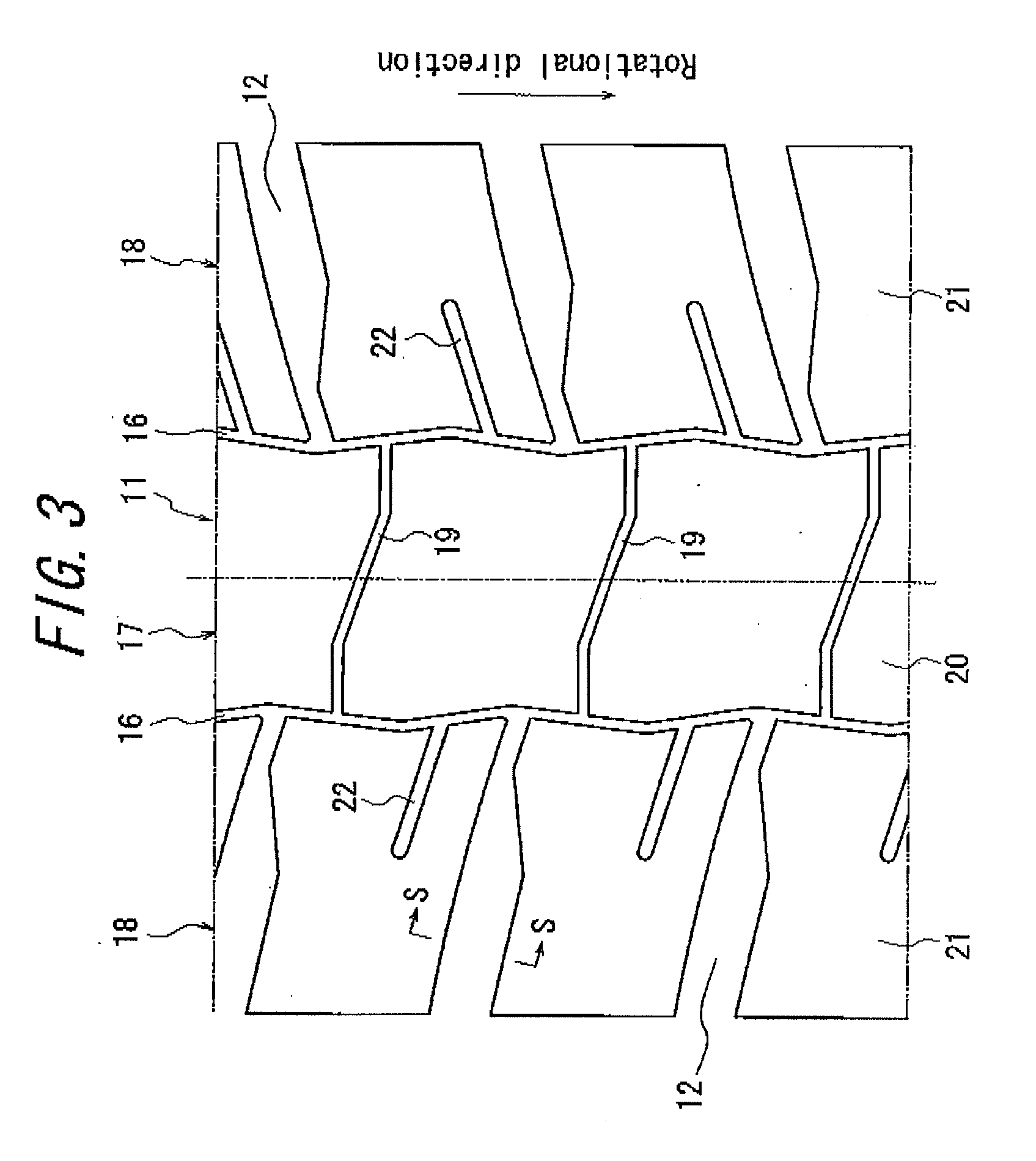

Pneumatic radial tire for heavy load

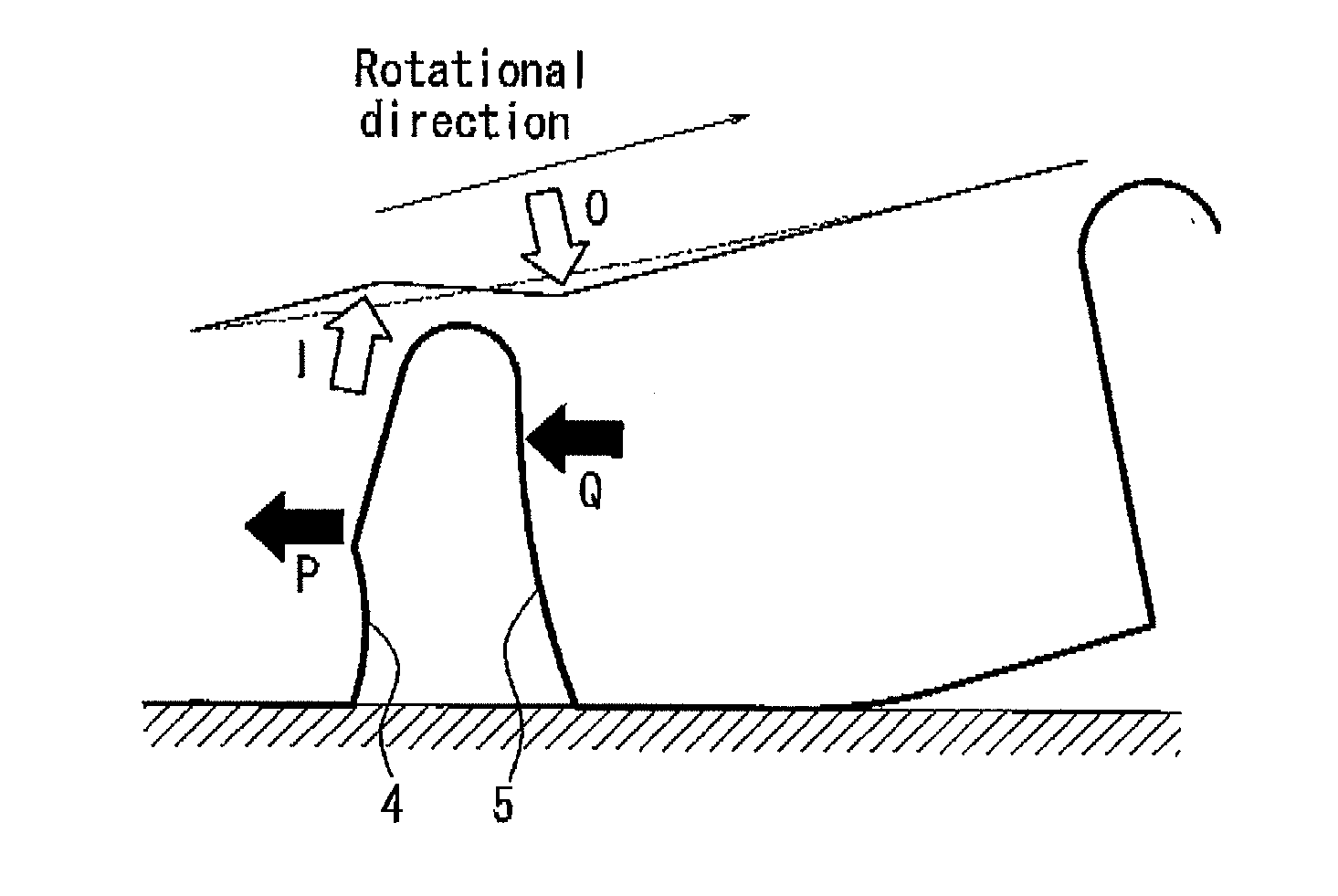

InactiveUS20110017375A1Degraded road surfaceNarrow widthTyre tread bands/patternsNon-skid devicesGroove widthRoad surface

The present invention provides a pneumatic radial tire for heavy load, having lug grooves in respective side regions of a tread surface, in which tire an amount of slip of the trailing edge of each of land portions defined by the lug grooves, with respect to a road surface, when the tire is rotated with load applied thereon is advantageously reduced without causing decrease in partial wear resistance of the land portions at a road contact surface thereof and generating cracks at the lug groove bottom. The pneumatic radial tire for heavy load, having a plurality of lug grooves 2 provided in respective side regions of a tread surface 1 to extend in the tread width direction, open at respective side edges of the tread surface 1, and define land portions 3 therebetween, is characterized in that: in a cross section of each lug groove 2 in the width direction thereof, only a groove wall 4 on the step-in side of each land portion 3 is bent at at least one bent point in the depth direction of the corresponding lug groove 2 such that a portion 4a of the groove wall, located on the inner side in the radial direction than the bent point f, is tilted in a direction that narrows a groove width.

Owner:BRIDGESTONE CORP

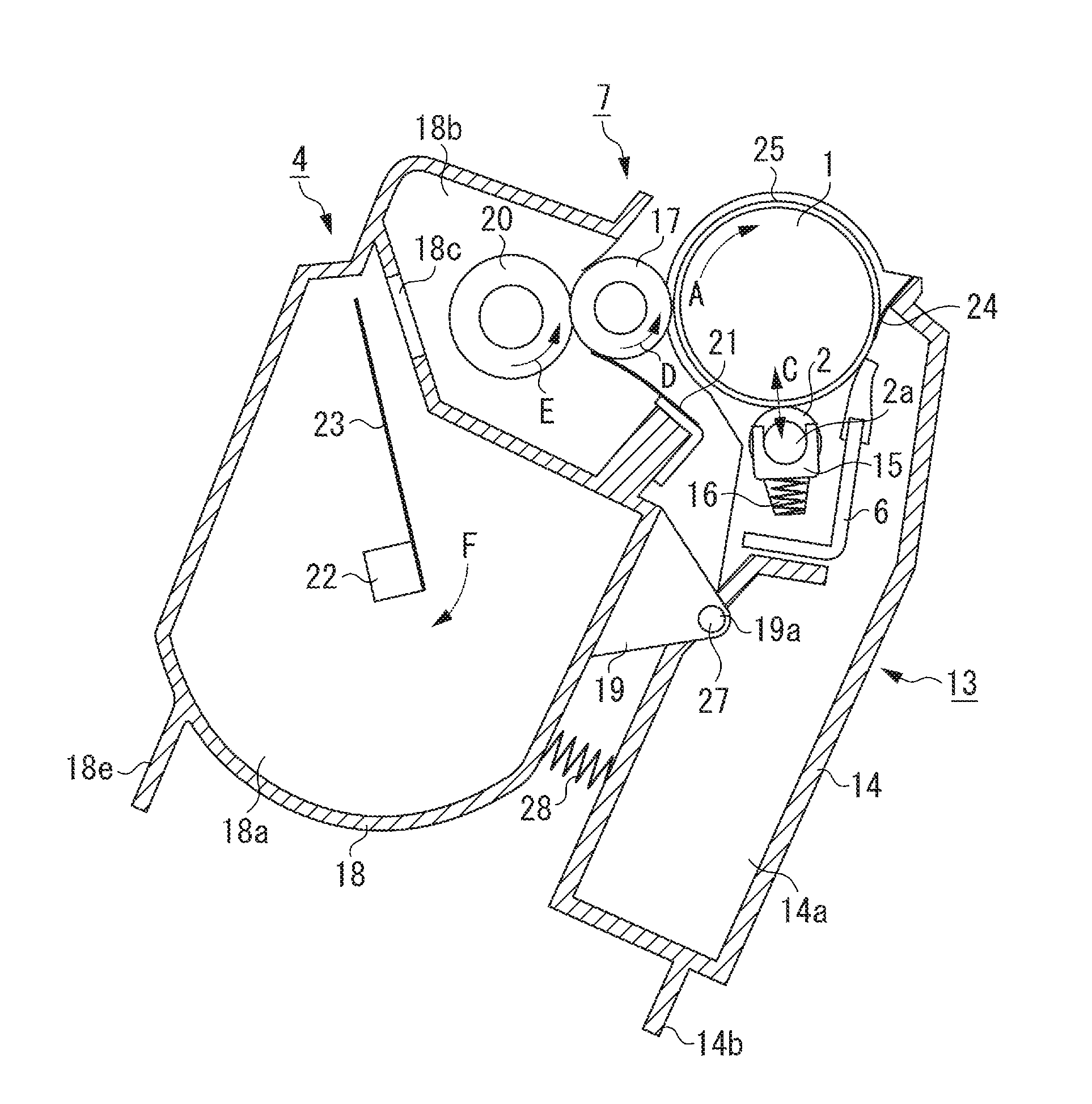

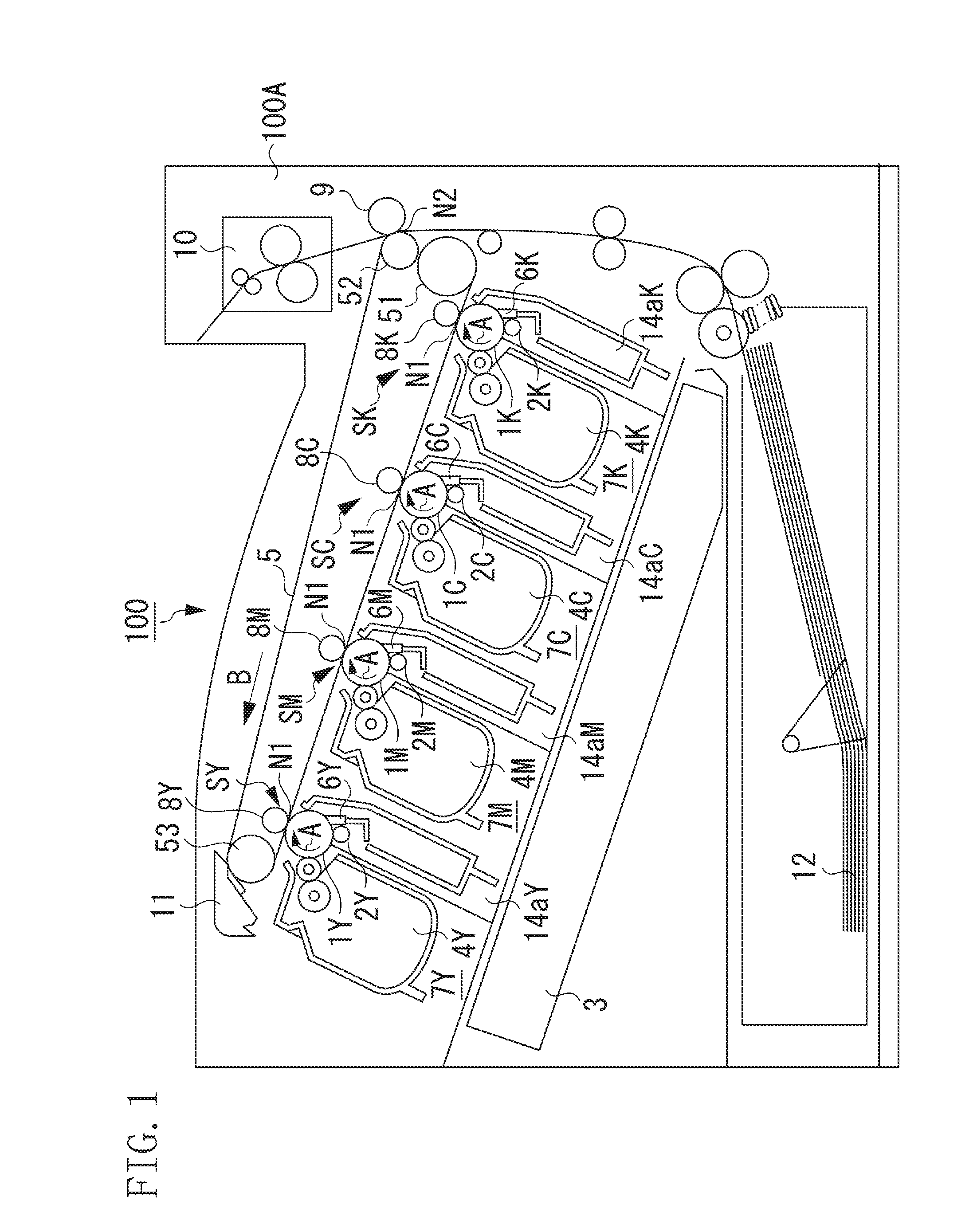

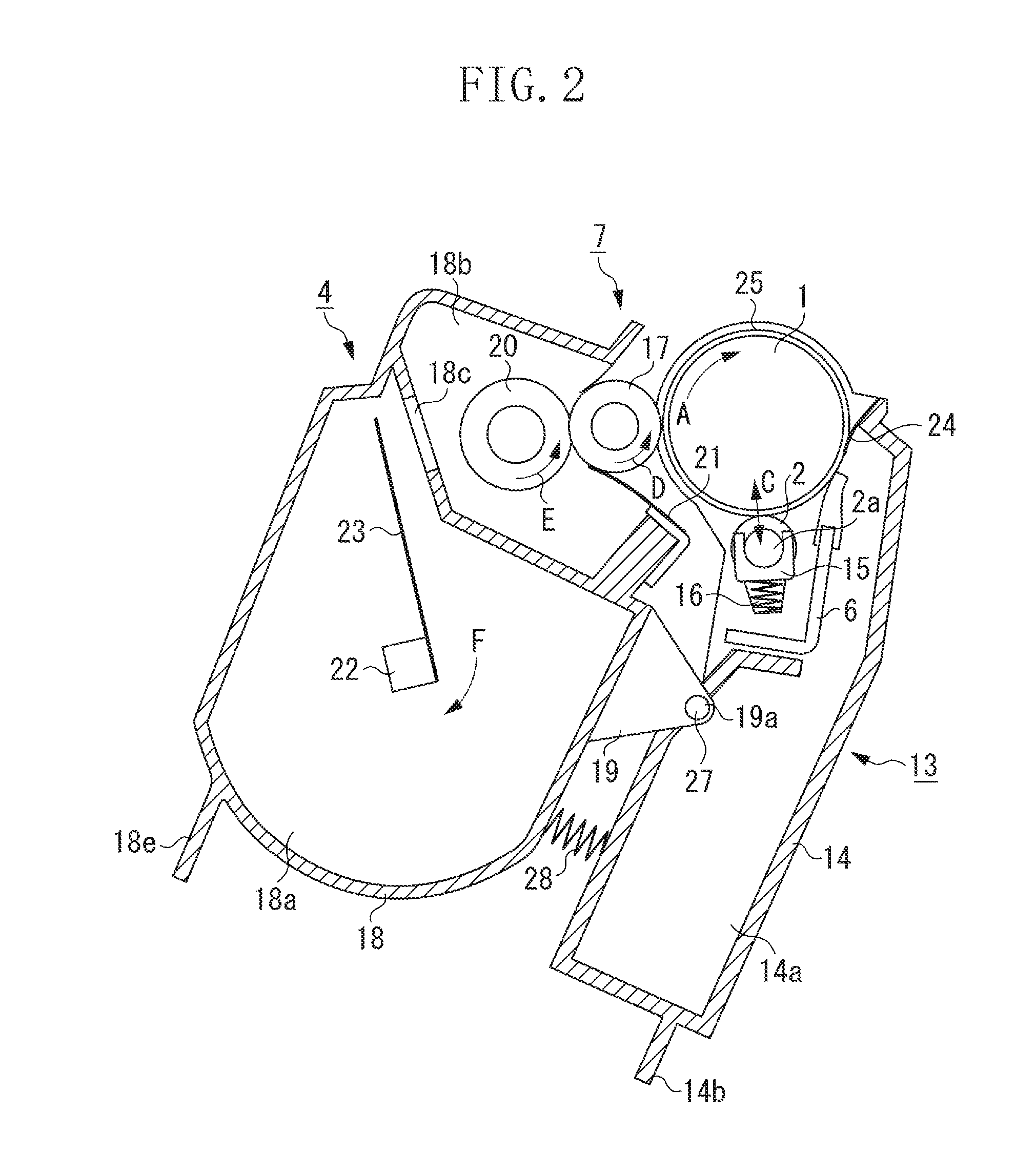

Process cartridge and electrophotographic image forming apparatus

InactiveUS20120275815A1Reduce the pressing forceSimple configurationElectrographic process apparatusEngineeringMechanical engineering

Owner:CANON KK

Hot pressing bush device and hot pressing process of connecting rod piston pin hole

InactiveCN102029502AImprove fitReduce the pressing forceMetal working apparatusEngineeringElectric control

The invention discloses a hot pressing bush device and a hot pressing process of a connecting rod piston pin hole, which are applied to a hot pressing bush of the connecting rod piston pin hole. A press mounting system and an infrared sensing thermodetector are arranged in a high-frequency heating furnace; the high-frequency heating furnace and the press mounting system are controlled by an electric control system respectively; both sides of the press mounting system are provided with high-frequency induction coils; a connecting rod is positioned on a press mounting system panel; a guide sleeve is fixed in the press mounting system; a bush is sleeved on a press-in shaft; axial motion of the press-in shaft and a positioning mandrel is controlled by the electric control system respectively;and a protective cap is arranged at the periphery of the high-frequency heating furnace. During press mounting, a connecting rod piston pin hole end is put into the high-frequency heating furnace andthe high-frequency induction coil and the infrared sensing thermodetector are used for heating and monitoring quickly. When a set temperature is reached, heating is stopped and press mounting is performed on the connecting rod piston pin hole by the press mounting system. The host pressing bush is adopted and the jointing degree between the bush and the piston pin hole is close to 100 percent, sothat the press-in force of the bush is lowered, an outer wall is prevented from being broken by press-in of the bush and safe operation of an engine is ensured.

Owner:襄阳长源东谷实业股份有限公司 +1

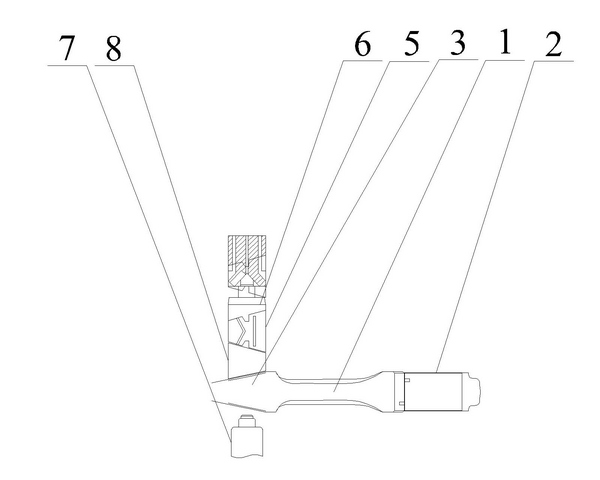

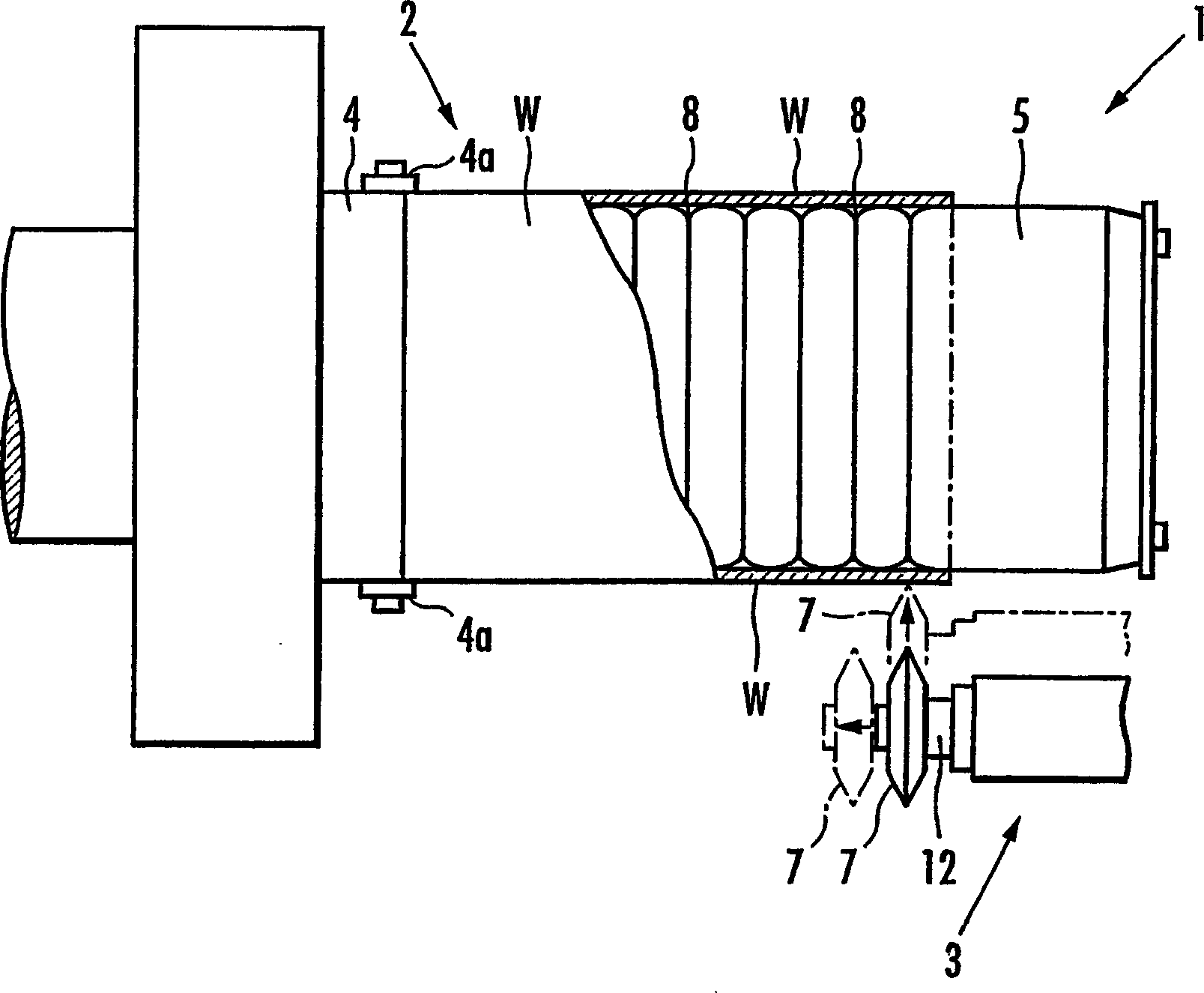

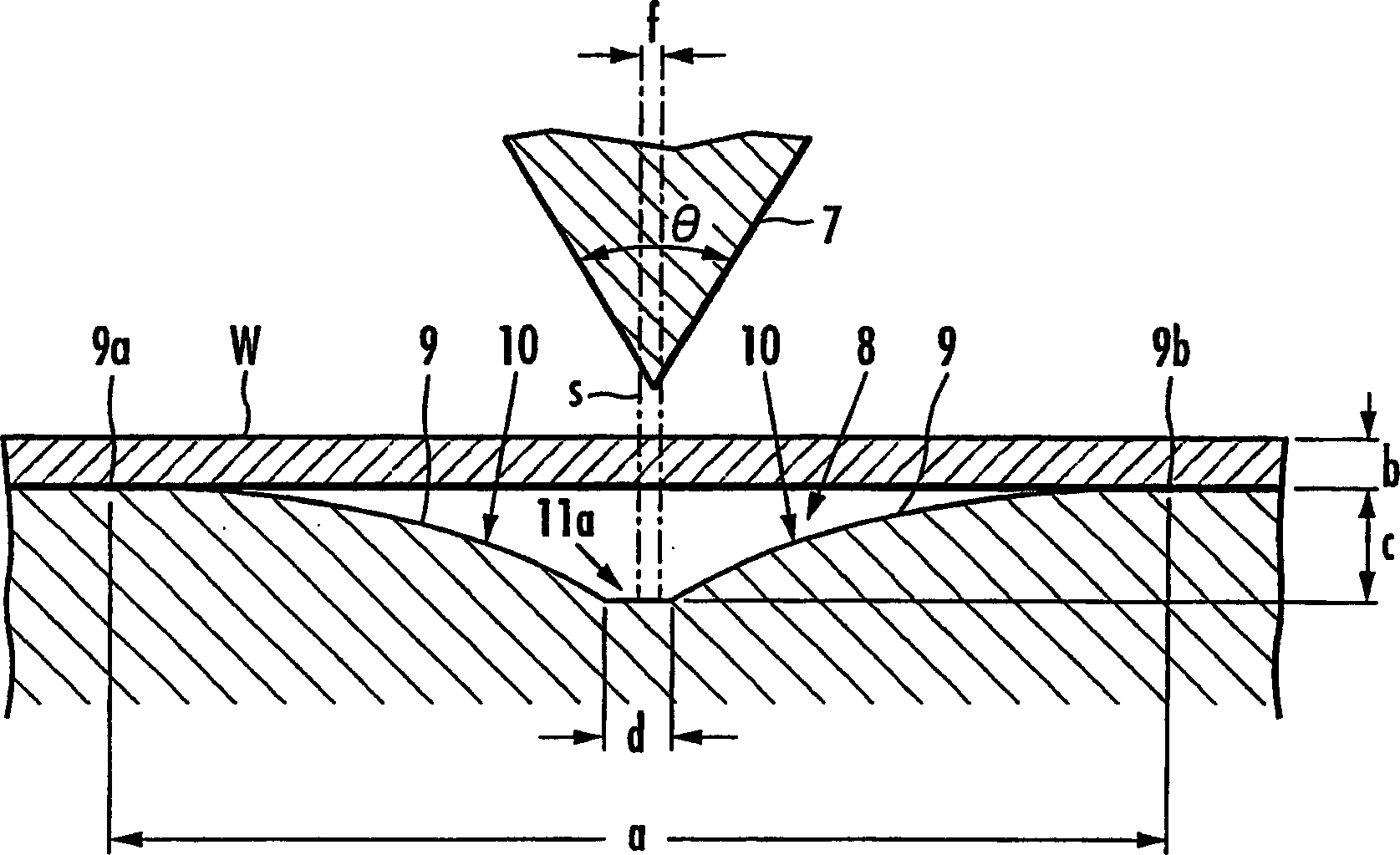

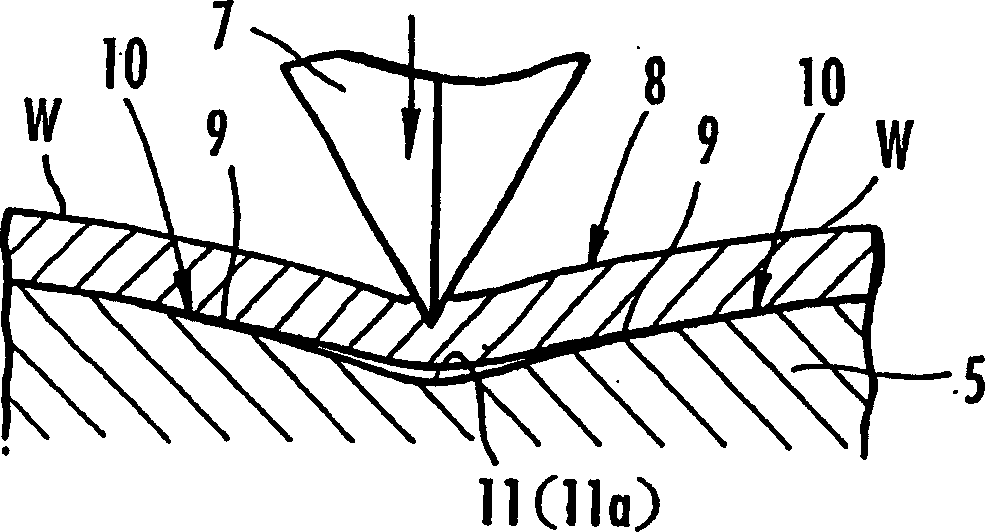

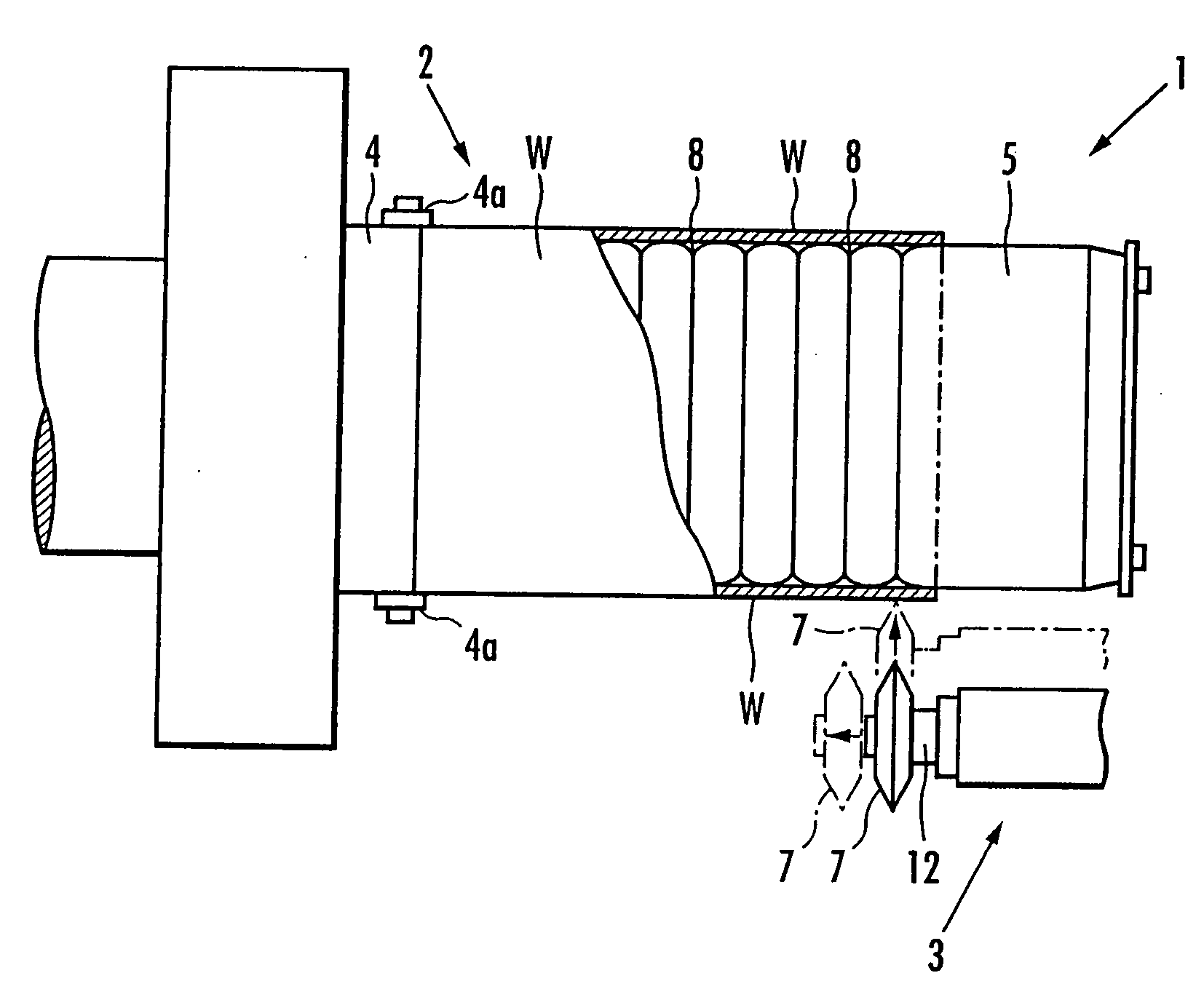

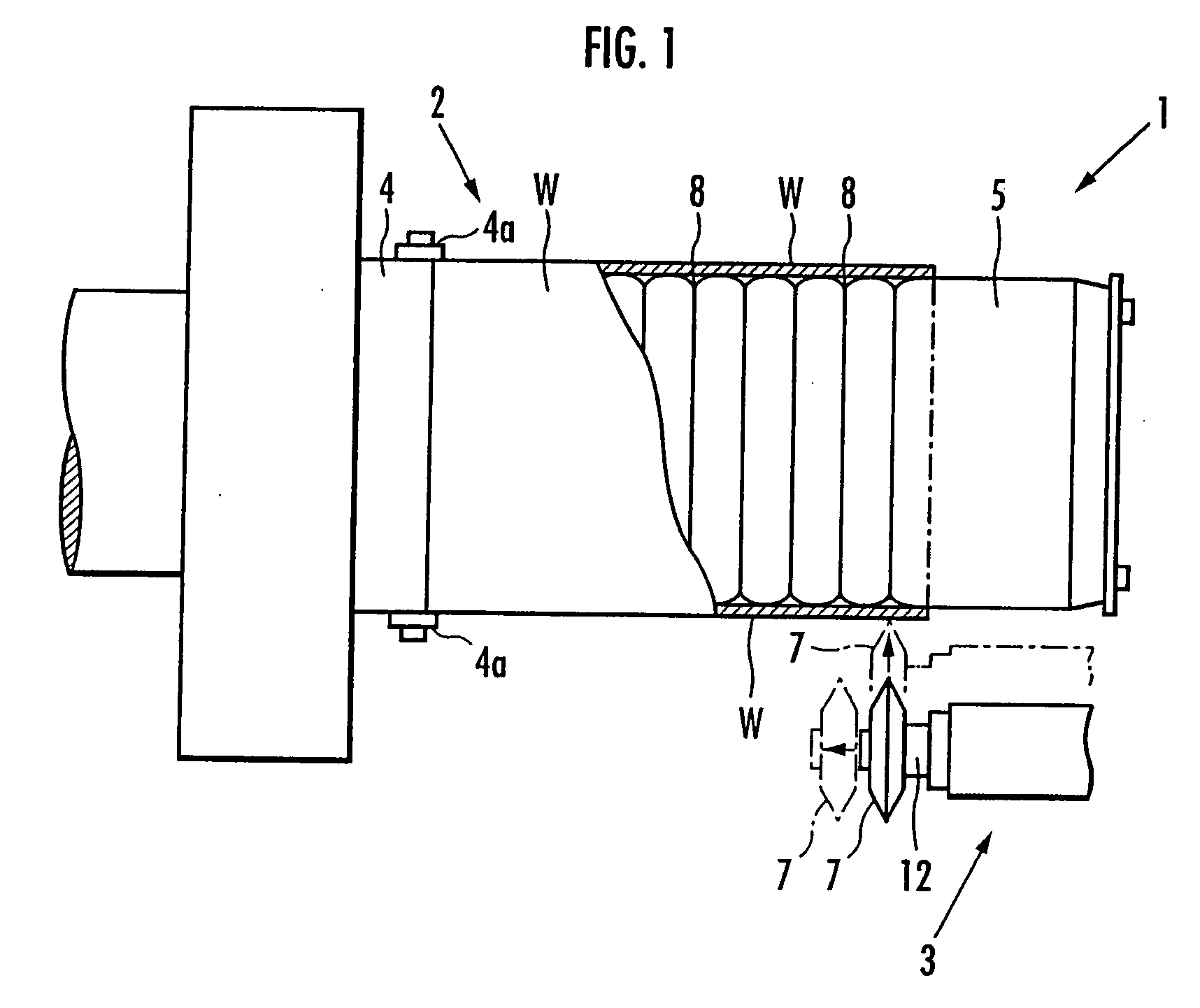

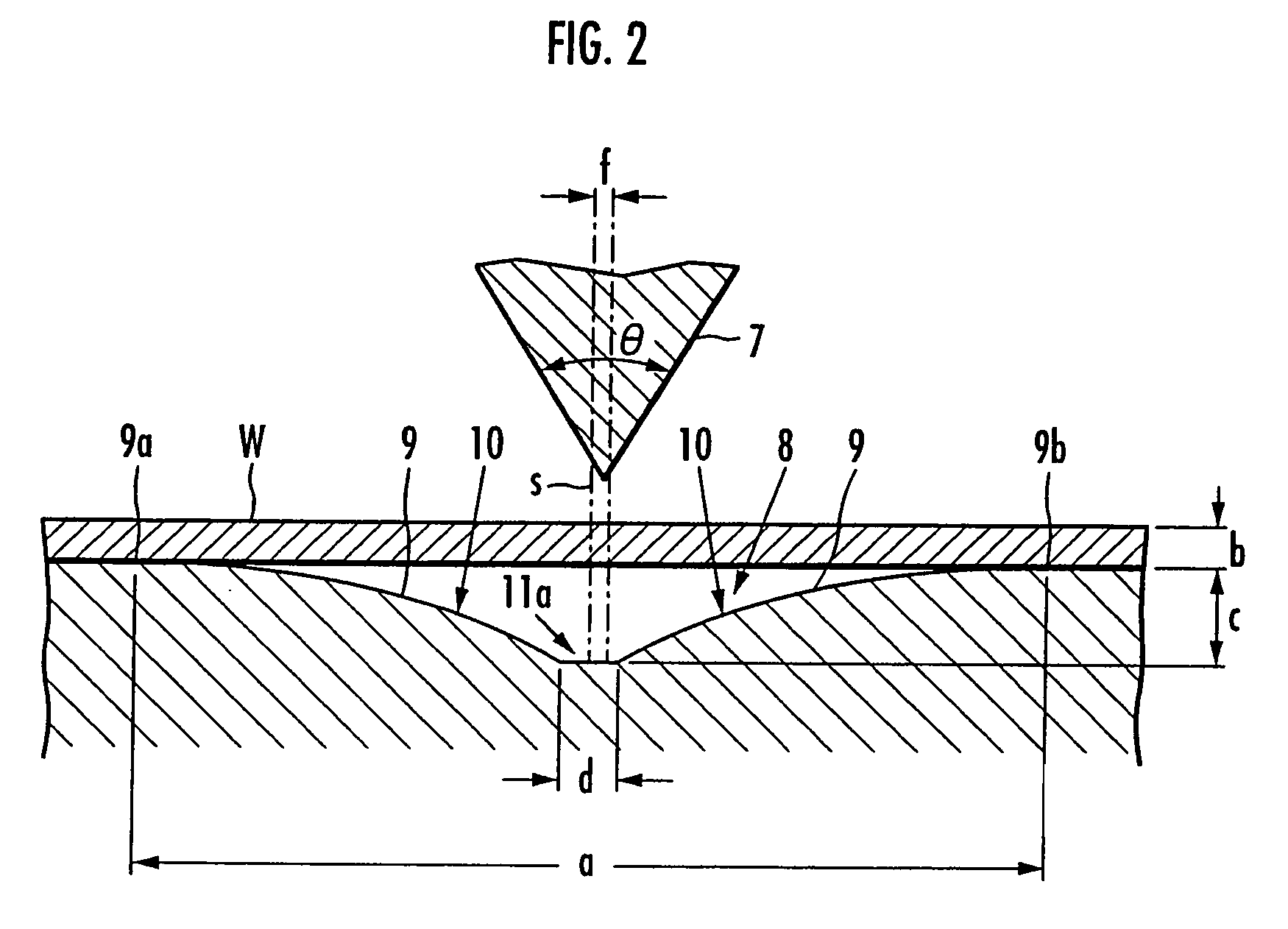

Cutting device for thin metallic plate

InactiveCN1771105AReduce the pressing forceCut off is really reliableTube shearing machinesShearing machine accessoriesGranularityEngineering

To provide a cutting device for a thin metal plate which can shorten the time for shaping the cut edge, improve manufacturing efficiency, and prolong the life of the cutter. The cutting device for cutting a metal thin plate (W) with a predetermined width is provided with a shear blade (7) made of a metal harder than the thin plate (W) and having a blade angle in the range of 50° to 90°. A contact tool (5) is provided with a groove (8) opposite to the shearing blade (7) and in contact with the inner side of the sheet (W). Set the spacing dimension (a) of the upper edge (9a, 9b) of the inner side wall (9) of the groove portion (8) as 15 to 30 times the plate thickness dimension (b) of the thin plate (W), and the groove portion (8) The depth dimension (c) of the deepest part (11) is set to 1 to 3 times the plate thickness dimension (b) of the thin plate (W). Curved surfaces (10) are provided on both inner side walls (9) of the groove portion (8), and the radius of curvature thereof is set to 15 to 50 times the thickness dimension (b) of the thin plate.

Owner:HONDA MOTOR CO LTD

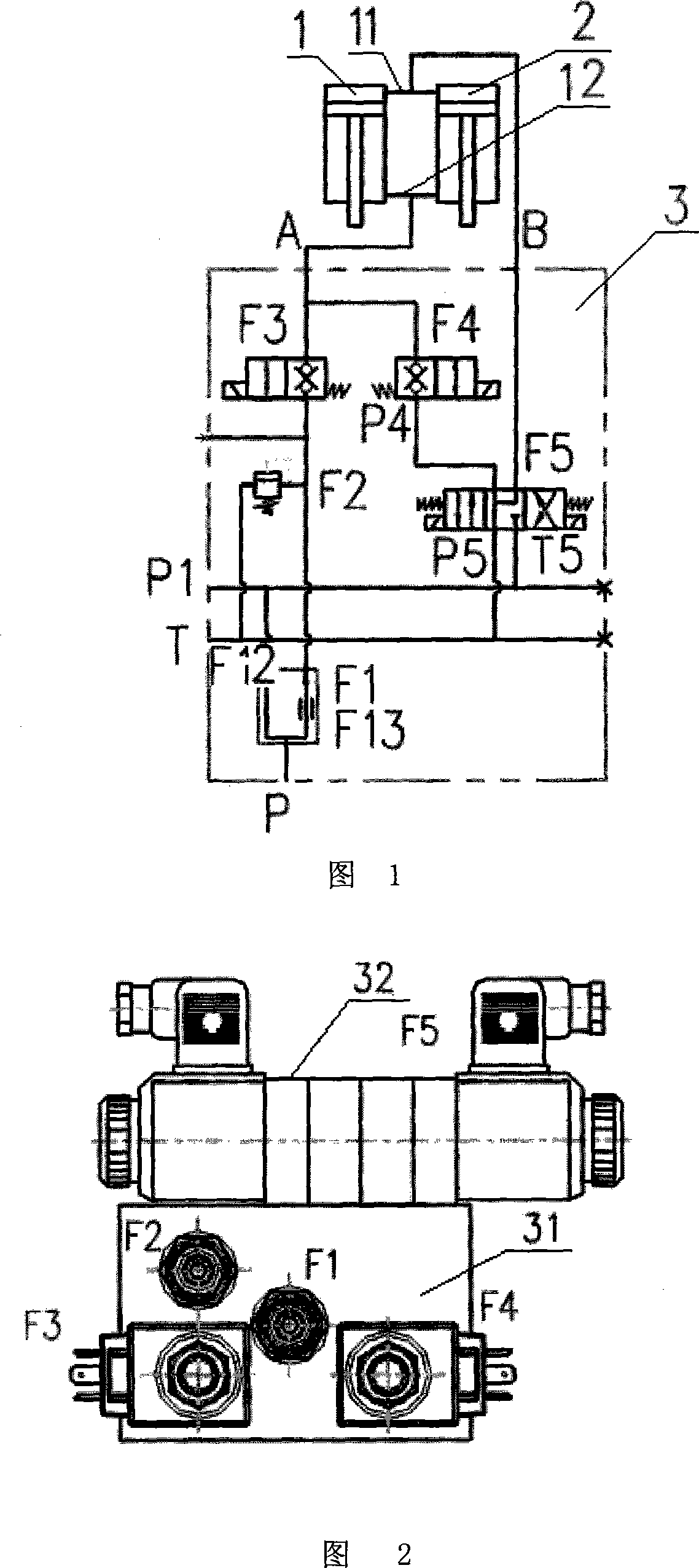

Hydraulic system for floating of scraper of pavement milling machine

ActiveCN104500485AAchieve improvementAchieve lockingServomotor componentsServomotorsFuel tankEngineering

The invention discloses a hydraulic system for the floating of a scraper of a pavement milling machine. The hydraulic system comprises a scraper oil cylinder with a piston rod which is vertically arranged downwards, wherein the piston rod of the scraper oil cylinder is connected with the scraper which is horizontally arranged; two oil paths are led from an upper cavity of the scraper oil cylinder, one path is communicated with a first oil port (A) of a three-position four-way electromagnetic reversing valve (5), and the other path is communicated with an oil tank through a throttling valve (4); a lower cavity of the scraper oil cavity is divided into two paths after passing through a two-position two-way electromagnetic valve (6), one path is communicated with a second oil port (B) of the three-position four-way electromagnetic reversing valve (5), and the other is communicated with an oil outlet of a three-way pressure reducing valve (3); an oil inlet (P) of the three-position three-way electromagnetic reversing valve (5) is communicated with the oil tank through an auxiliary pump (1), and an oil outlet(T) of the three-position three-way electromagnetic reversing valve (5) is communicated with the oil tank; an oil inlet of the three-way pressure reducing valve (3) is communicated withthe oil tank through an oil supplementing pump (2). The hydraulic system for the floating of the scraper of the pavement milling machine is simple in structure, safe and reliable.

Owner:柳工无锡路面机械有限公司

Cutting device for thin metallic plate

InactiveUS20060169115A1Increase contact timeDeficient in their formTurning machine accessoriesTube shearing machinesHardnessMetal

A cutting device for a thin metallic plate is provided which shortens time for shaping or the like on a cut edge to improve manufacturing efficiency, and increases the life of a cutter. The cutting device for cutting a thin metallic plate W with a predetermined width includes a shearing cutter 7 which is made of a metal having a higher hardness than the thin plate W and has a blade angle of 50 to 90°. A contacting member 5 is provided which includes a groove 8 facing the shearing cutter 7 and makes contact with the back side of the thin plate W. In the groove 8, an interval a between upper edges 9a and 9b of inner walls 9 is set at 15 to 30 times a thickness b of the thin plate W. A depth c of a deepest portion 11 in the groove 8 is set at one to three times the thickness b of the thin plate W. The inner walls 9 of the groove 8 include curved surfaces 10, each of which has a curvature radius of 15 to 50 times the thickness b of the thin plate.

Owner:HONDA MOTOR CO LTD

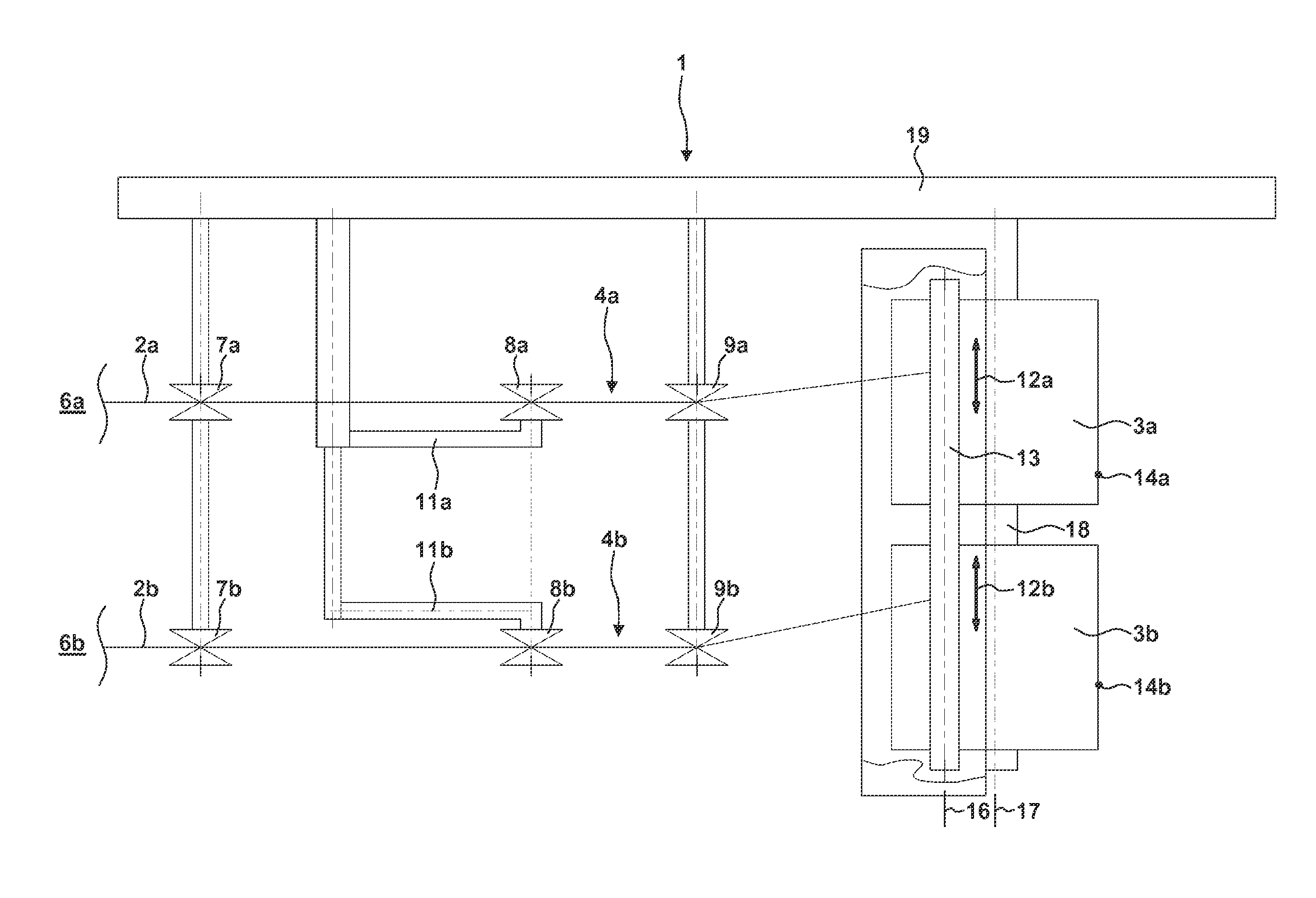

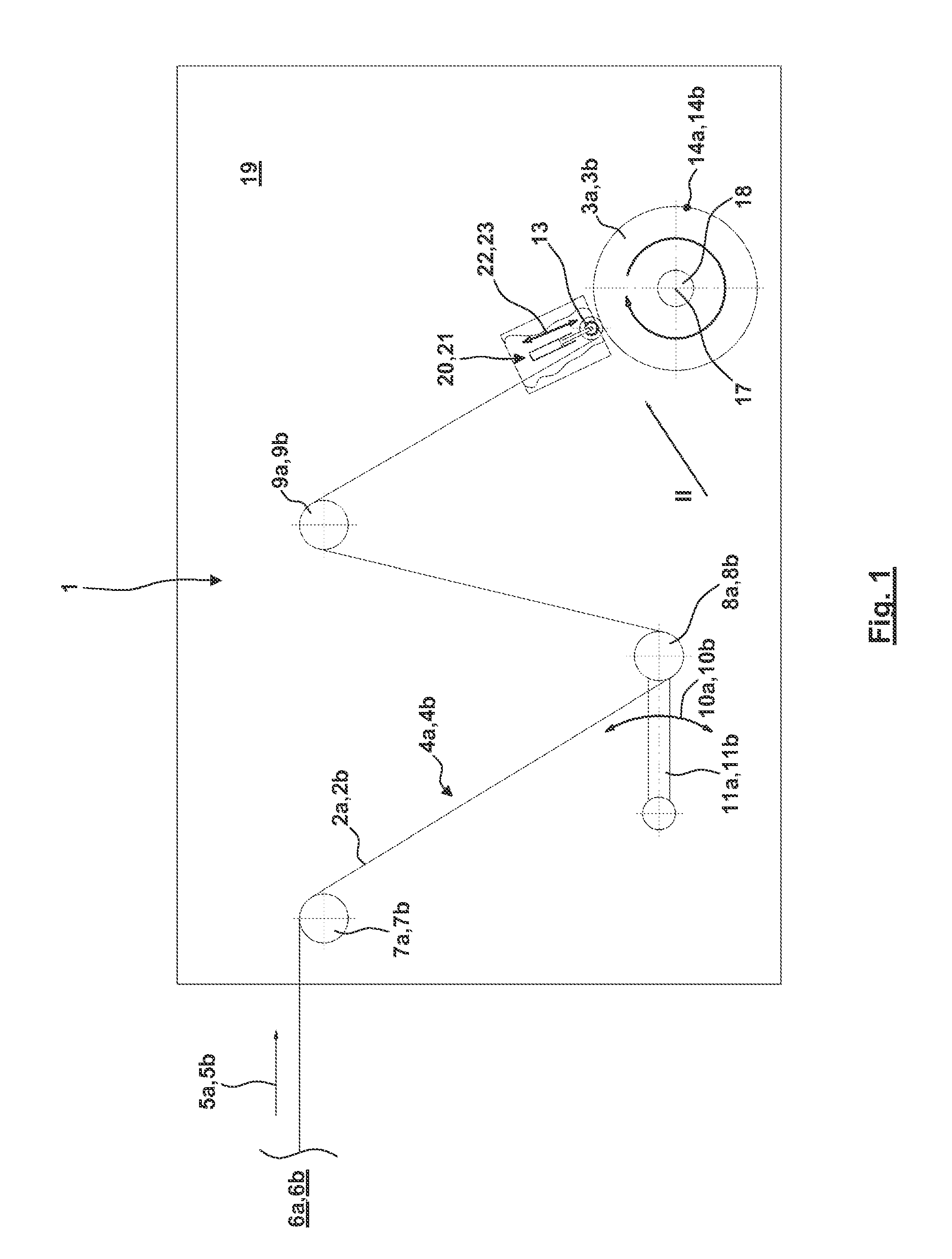

Winding Machine and Method for Controlling the Winding Machine

InactiveUS20130037647A1Increase pressureReduce deflectionFilament handlingTension measurementWinding machineControl signal

The invention relates to a winding machine. Winding material is continuously fed along feeding paths to two wound packages. A control signal is generated for actuating actuators. The actuators change the pressing force pressing a pressure roller at at least one wound package. The control signal depends on a tension of the winding material. In case that the tension of the winding material in a path to a wound package exceeds a predetermined tension the pressing force of the pressure roller at the associated wound package is increased. Accordingly the radius of the outer surface of the associated wound package is reduced. This reduction is intended for counteracting the undesired increase of the tension in the winding material.

Owner:GEORG SAHM GMBH & CO KG

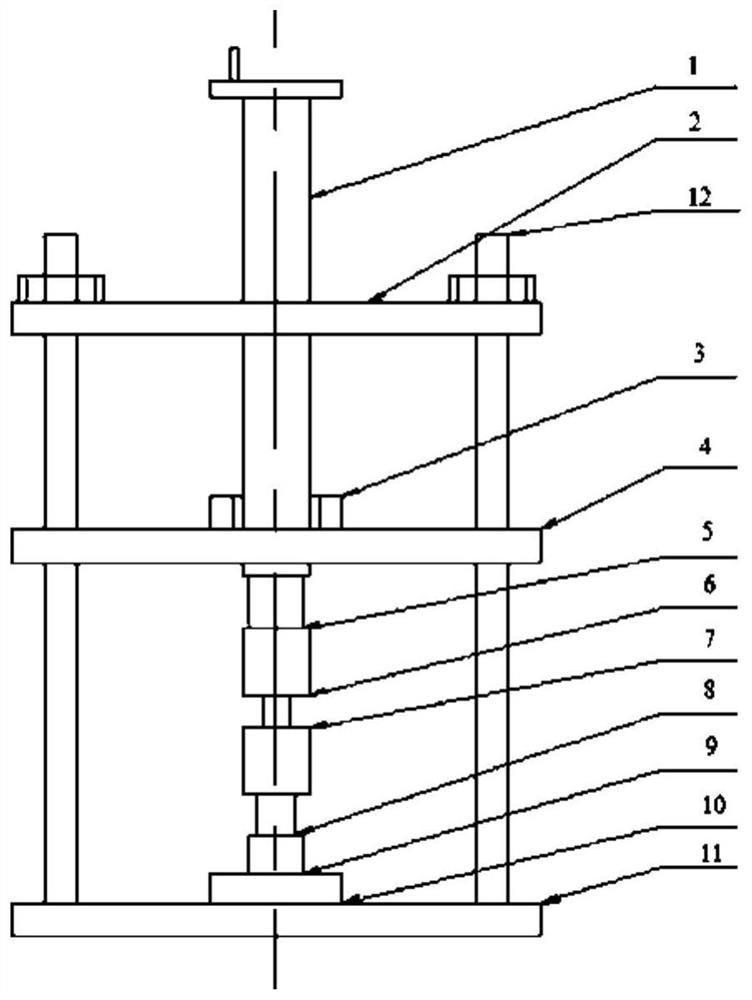

Interference fit part assembling and disassembling device applying ultrasonic vibration and using method

PendingCN112171247AReduce the pressing forceReduce damageMetal working apparatusPhysicsMachine press

The invention belongs to the field of ultrasonic vibration and mechanical engineering, and discloses an interference fit part assembling and disassembling device applying ultrasonic vibration and a using method. The interference fit part assembling and disassembling device comprises a press, an ultrasonic generation device, a sleeve mechanism and a vibration mechanism, wherein the press is a mechanical press with lifting threads, the ultrasonic generation device is connected with the sleeve mechanism through a flange plate by using bolts, the vibration mechanism is connected with the sleeve mechanism through a lower end cover and a flange plate by using bolts, a bottom cross beam is arranged at the bottom of a device body, and a fastening seat is arranged on the bottom cross beam. According to the interference fit part assembling and disassembling device applying ultrasonic vibration and the using method, the press-fitting force during assembling and the pressure value required duringdisassembling are effectively reduced, the damage to the contact surface of a part is reduced, the working efficiency and the operation safety are improved, and the labor intensity is reduced.

Owner:SANY HEAVY EQUIP

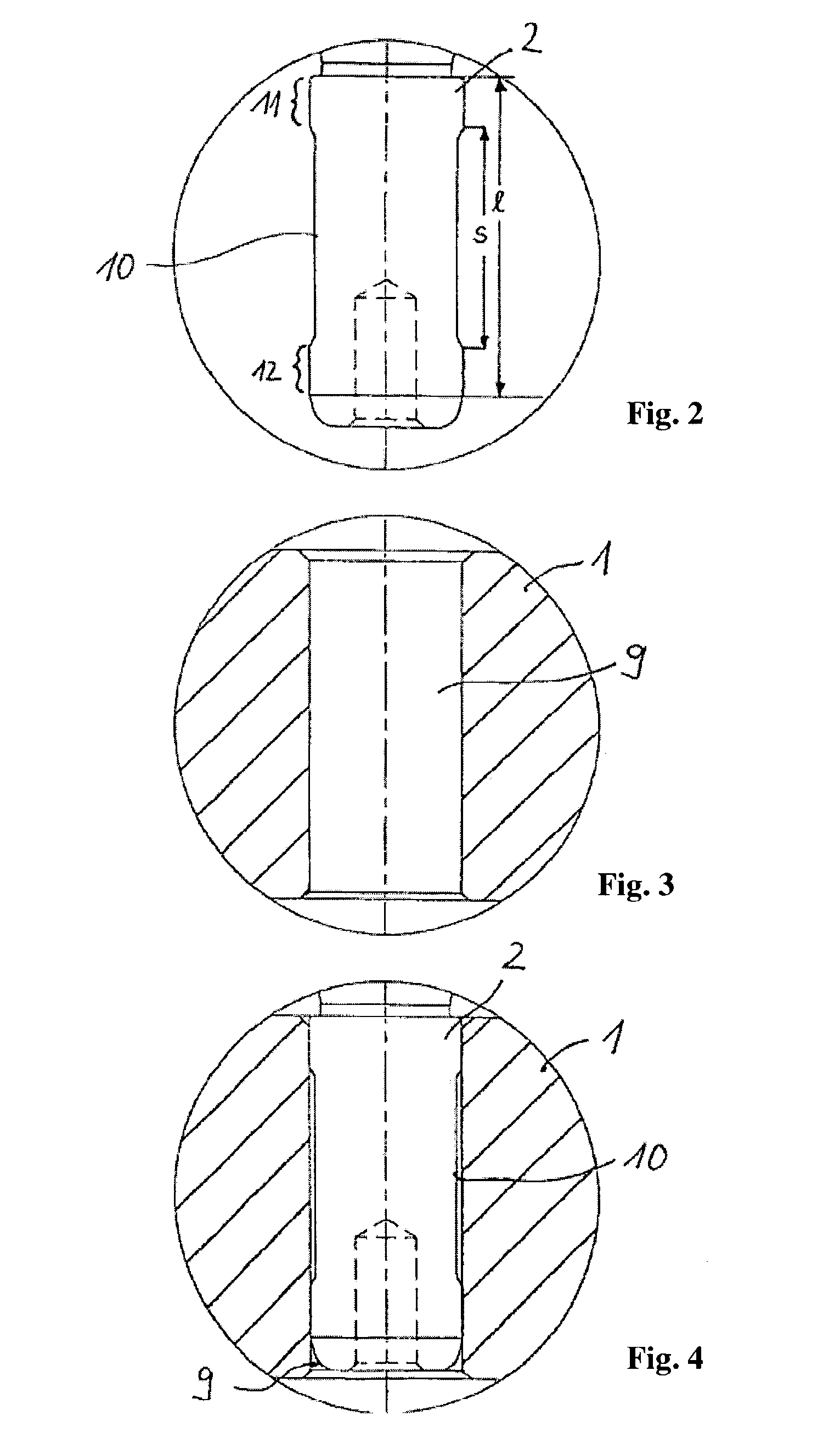

Spindle motor for hard disk drives

ActiveUS7068466B2Improve retentionReduce harmShaftsRecord information storageHard disc driveEngineering

A spindle motor for use in hard disk drives having a base plate, a stationary shaft, a rotationally driven rotor, and a bearing system rotationally supporting the rotationally driven rotor. The shaft is fixedly mounted on the base plate. The base plate includes a drilled hole for insertion of a portion of the shaft such that this shaft's portion and the inner surface of the hole define a joint length l, when this portion is pressed into the drilled hole. The shaft has at least one notch located along the shaft's circumference and interrupting the joint length l.

Owner:MINEBEAMITSUMI INC

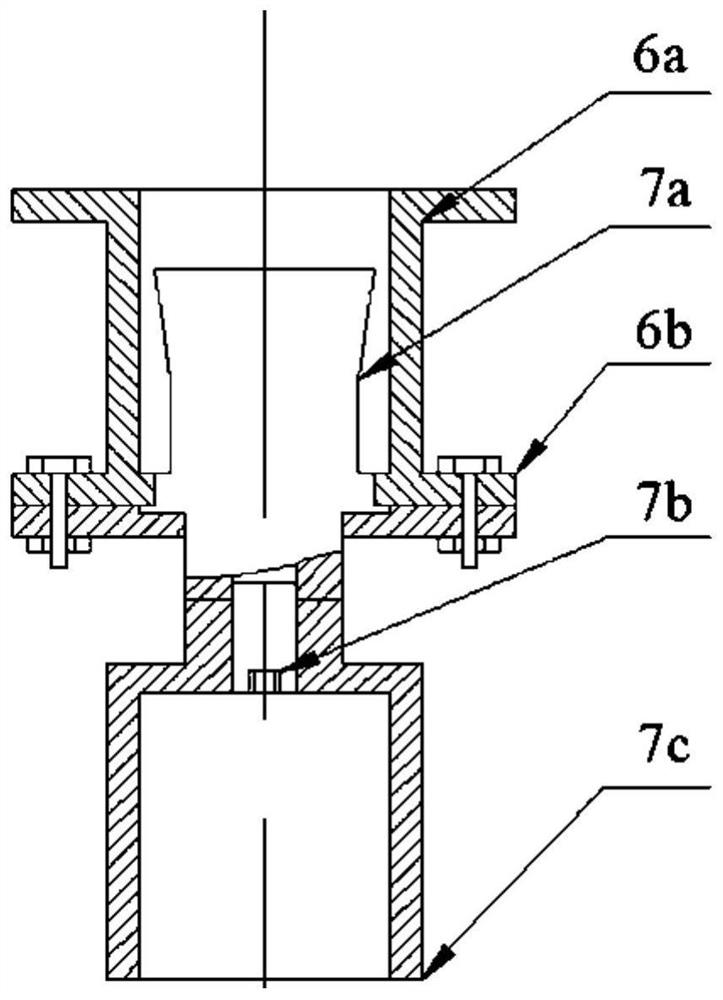

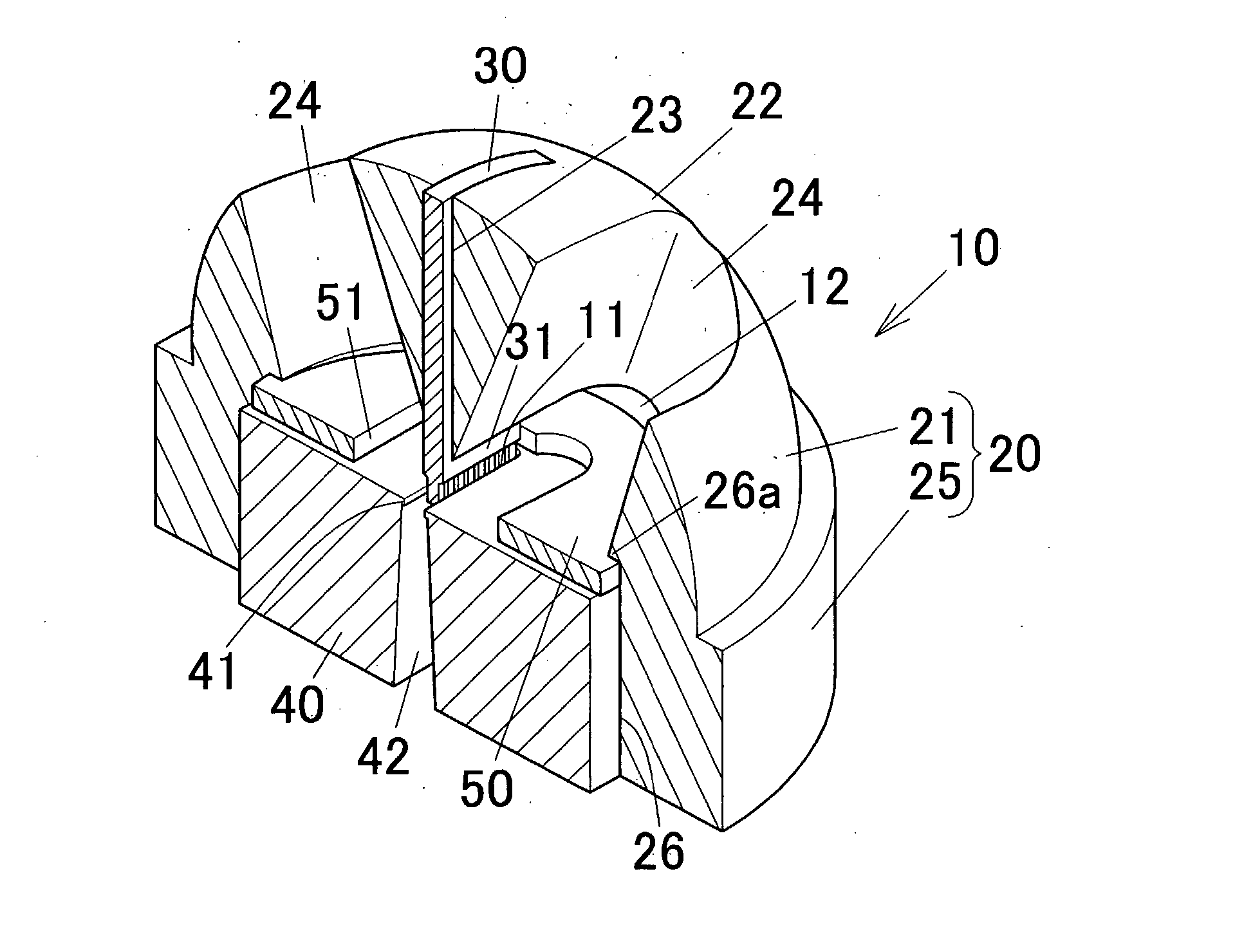

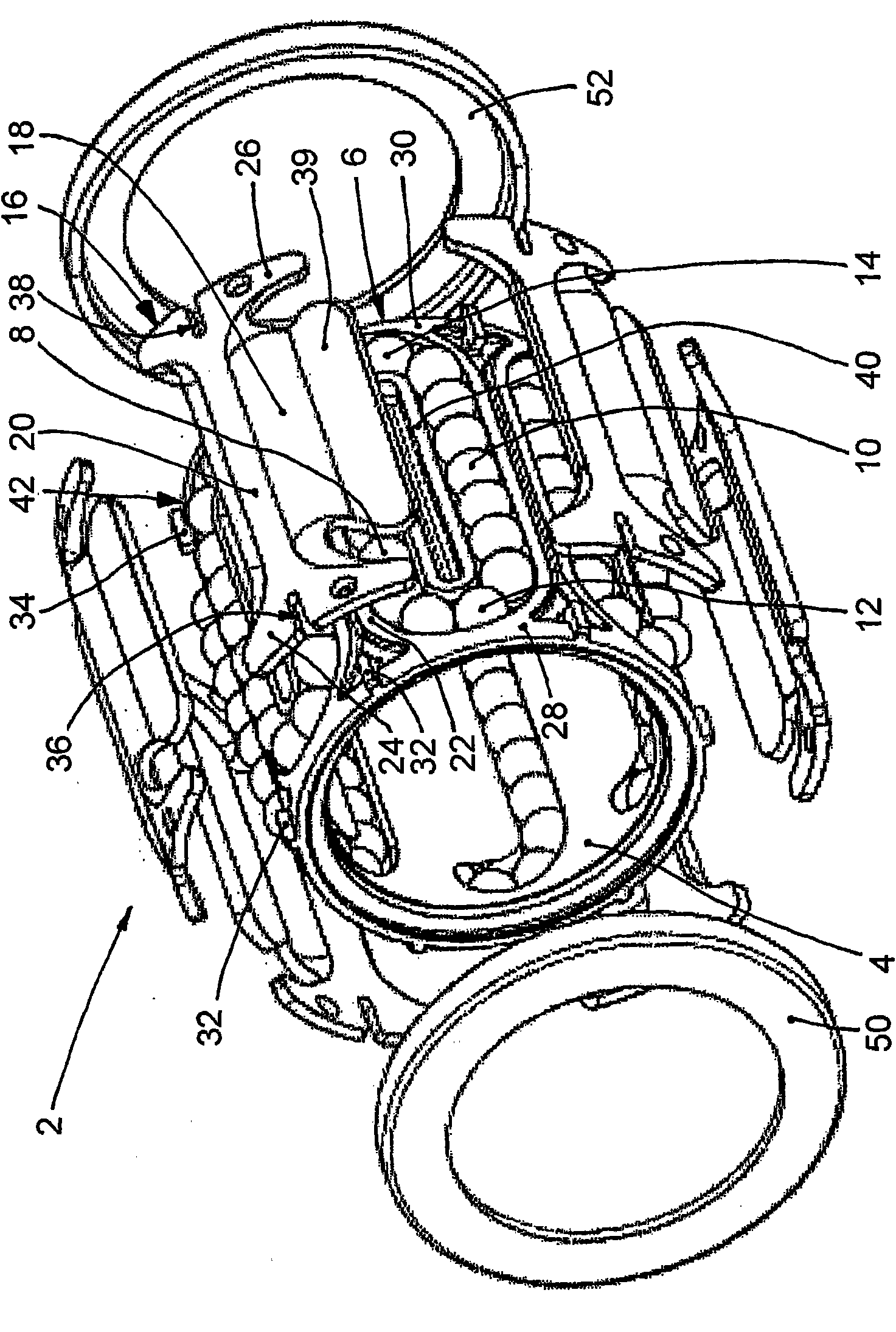

Extrusion Die for Metallic Material

InactiveUS20070283736A1Reduce the pressing forceSolve the lack of durabilityExtrusion diesMetallic materialsMetal

In some preferred embodiments, an extrusion die for metallic material capable of obtaining a high quality extruded article can be provide while securing sufficient strength and durability. The extrusion die is provided with a die holding case 20 having a dome portion 21 with an external surface functioning as a metallic material pressure receiving surface 22, the metallic material pressure receiving surface 22 being disposed so as to face rearward, a male die 30 held in the die holding case 21, and a female die 40 held in a front portion of the die holding case 20. The metallic material pressure receiving surface 22 is formed into a convex configuration, and a porthole 24 is formed in the dome portion 21. The central axis A2 of the porthole 24 is inclined to the central axis A1 of the die holding case 20. The metallic material pressed against the metallic material pressure receiving surface 22 is introduced into the die holding case 20 through the porthole 24 and passes through the extrusion hole 11.

Owner:SHOWA DENKO KK

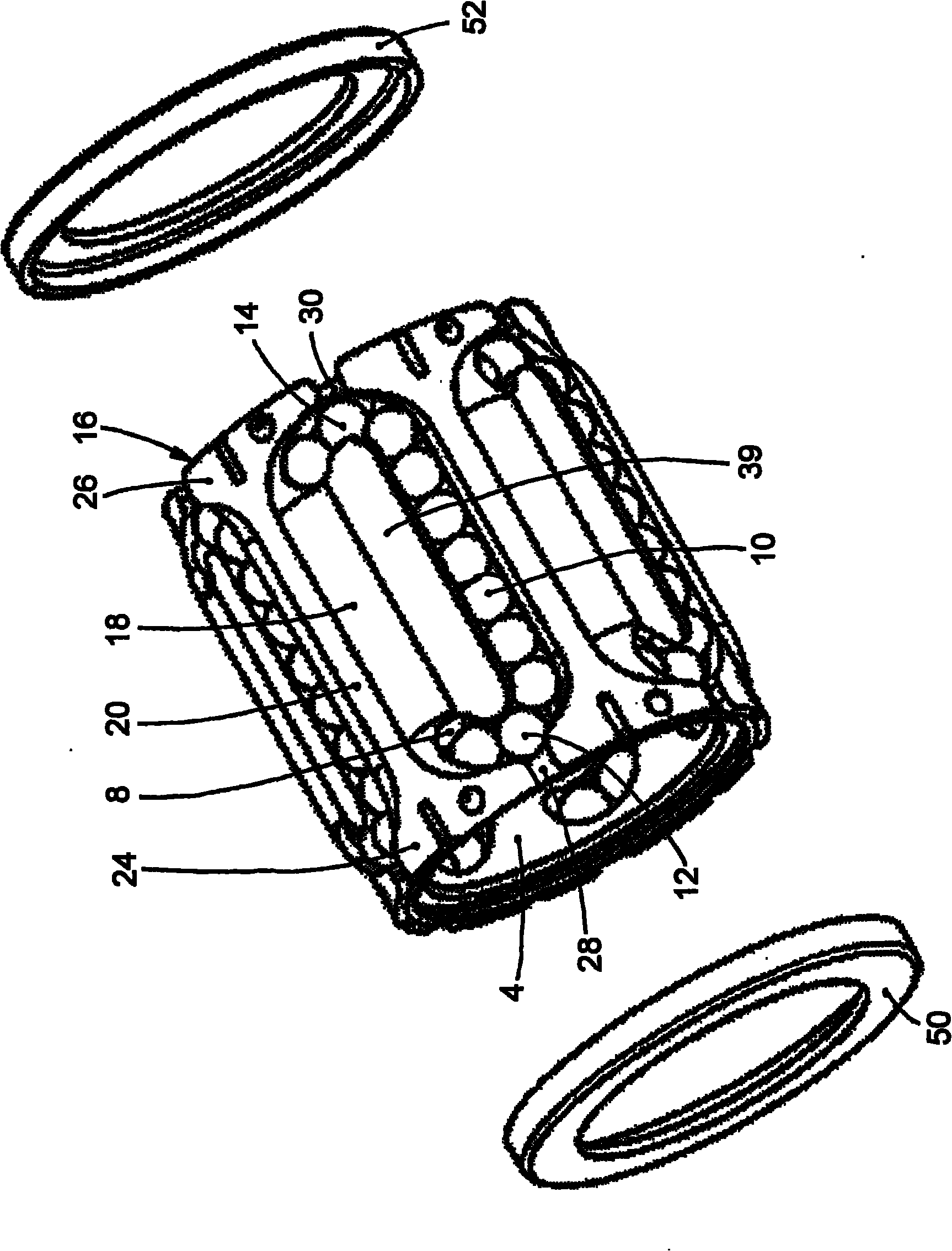

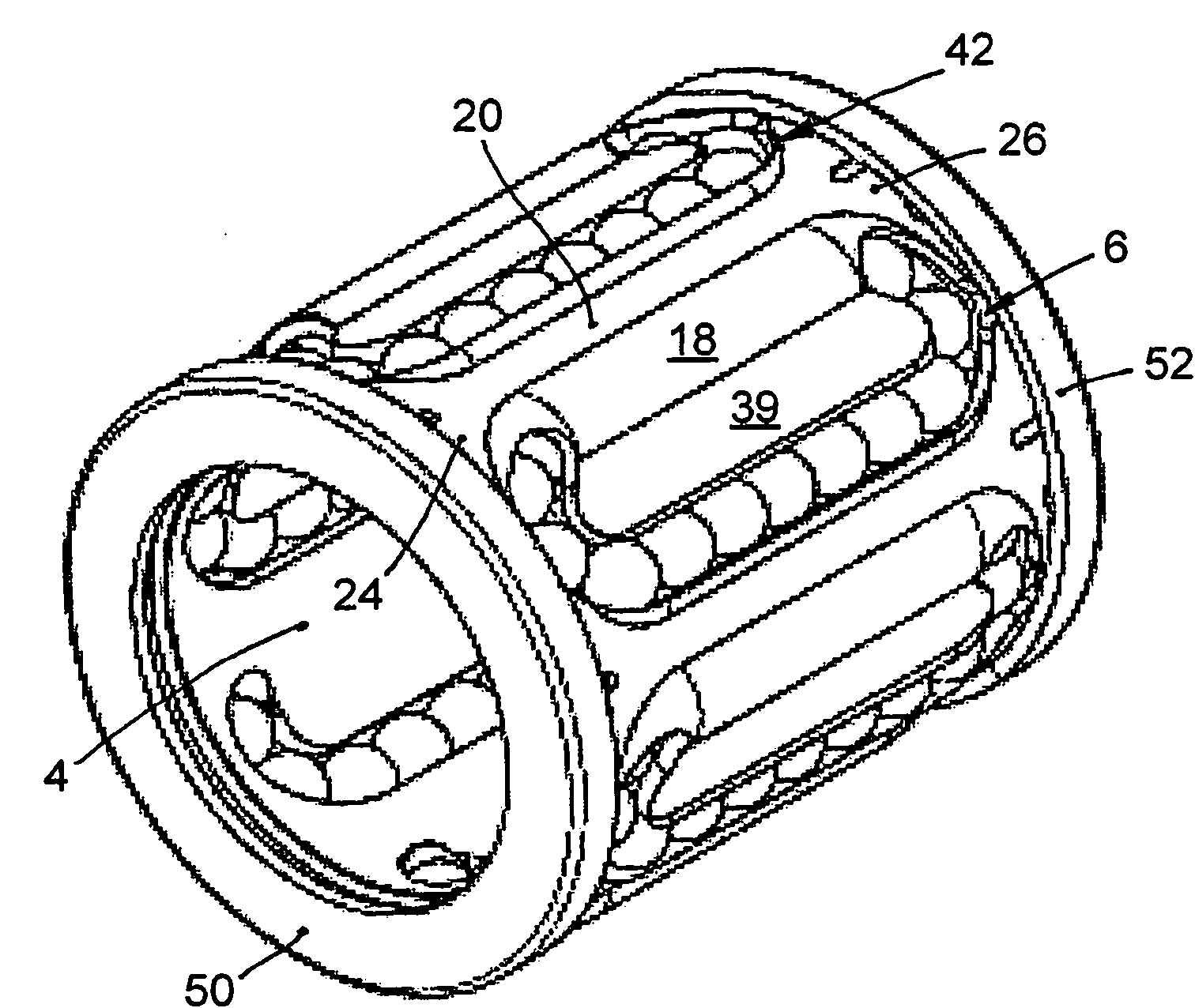

Linear ball bearing

InactiveCN101772653ARadial structure height reductionGuaranteed exact positionLinear bearingsBall bearingSupport surface

The present invention relates to a linear ball bearing (2) comprising a substantially sleeve-like cage (4) for receiving a plurality of axial ball loops (6) that are distributed across the circumference of the cage, wherein each ball loop has a first ball channel that is open radially to the inside and to the outside for the row of the carrying ball (8), and a second ball channel, open radially towards the outside for the row of the non-carrying balls (10) and comprises deflection channels that connect the ball channels of a ball loop (6) to each other, and wherein at least the first ball channel is covered on the outside by a load-bearing carrier plate (16). Individual support surfaces (20, 39) are provided on the carrier plates (16), said surfaces resting on predetermined support regions (22, 40) on the outer lateral surface of the cage (4). The carrier plates (16) are positioned via interacting positioning means (32, 34; 36, 38) in the predetermined positions thereof on the cage (4). The carrier plates (16) resting against the cage (4) are fixed to the cage (4) via holding rings (50, 52) that are slid over the carrier plates.

Owner:SCHAEFFLER TECH AG & CO KG

Hydraulic tensioner

The invention provides a hydraulic tensioner. A check valve unit has no elastic deformation or expansion caused by high-pressure in high-pressure oil chamber or high-temperature change in engine indoor, and can play a role of a check valve, furthermore, the check valve unit can be simply and firmly mounted on a case mainbody. The check valve unit (140) in a hydraulic tensioner (100) comprises: a check ball (141) allowing a limited range of pressure oil flow; a steel ball guide (142) having an inner wall allowing movement of a ball non-return valve; a steel retainer (143) attached to the high pressure oil chamber side of the ball guide (142); and a steel ball seat (144) attached to the oil supply side of the ball guide (142); bulged portions (142c) formed on an outer surface of the ball guide (142) are press-fit into the plunger-accommodating hole 111 of the tensioner.

Owner:TSUBAKIMOTO CHAIN CO

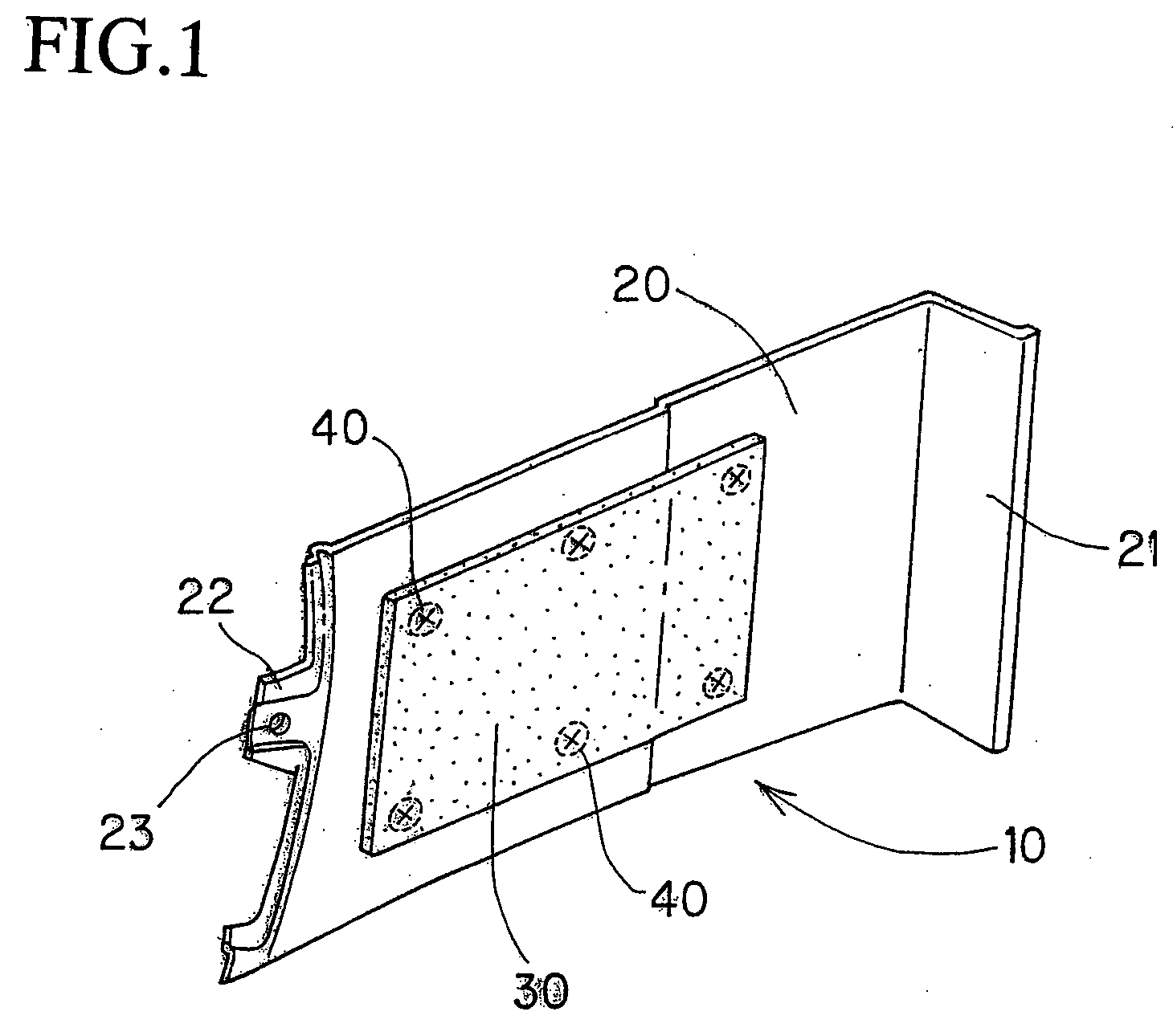

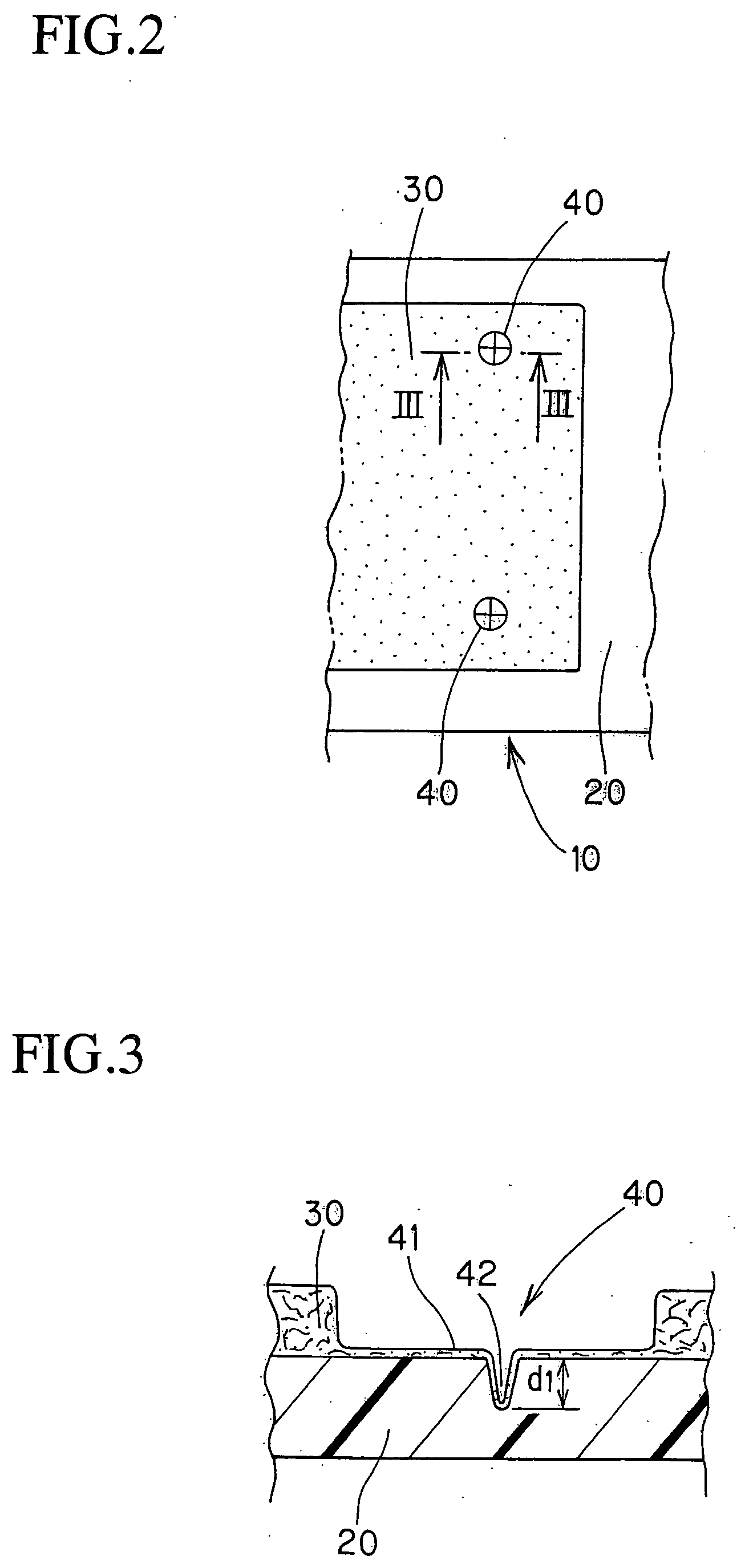

Fibrous mat fixing structure

InactiveUS20060141221A1High bonding strengthWell formedLayered productsPedestrian/occupant safety arrangementUltrasonic weldingEngineering

A fibrous mat fixing structure in which a fibrous mat such as a non-woven fabric mat 30 is integrally attached to a resin molding 20 by ultrasonic welding is designed to reduce the working time and simplify working facilities while preventing any considerable surface defect such as irregularities in the surface of the resin molding 20. A luggage room side trim (sound absorbing member for a vehicle) 10 has a fibrous mat such as a non-woven fabric mat 30 welded and integrally attached to a luggage room side trim main molding by an ultrasonic horn 50. A sharp projecting thread 52 is formed on a flat pressing surface 51 of the ultrasonic horn 50. A V-groove 42 which bites into the resin molding 20 is formed in a weld portion 40 of the non-woven fabric mat 30 together with a flat weld surface 41, thereby enabling fibers in the non-woven fabric mat 30 to easily bite into the molten surface of the resin molding 20. A resulting anchoring effect can be expected and the V-groove 42 can be formed in a short time in the resin molding 20, thus improving the operability while preventing occurrence of a defect in appearance.

Owner:KASAI KOGYO CO LTD

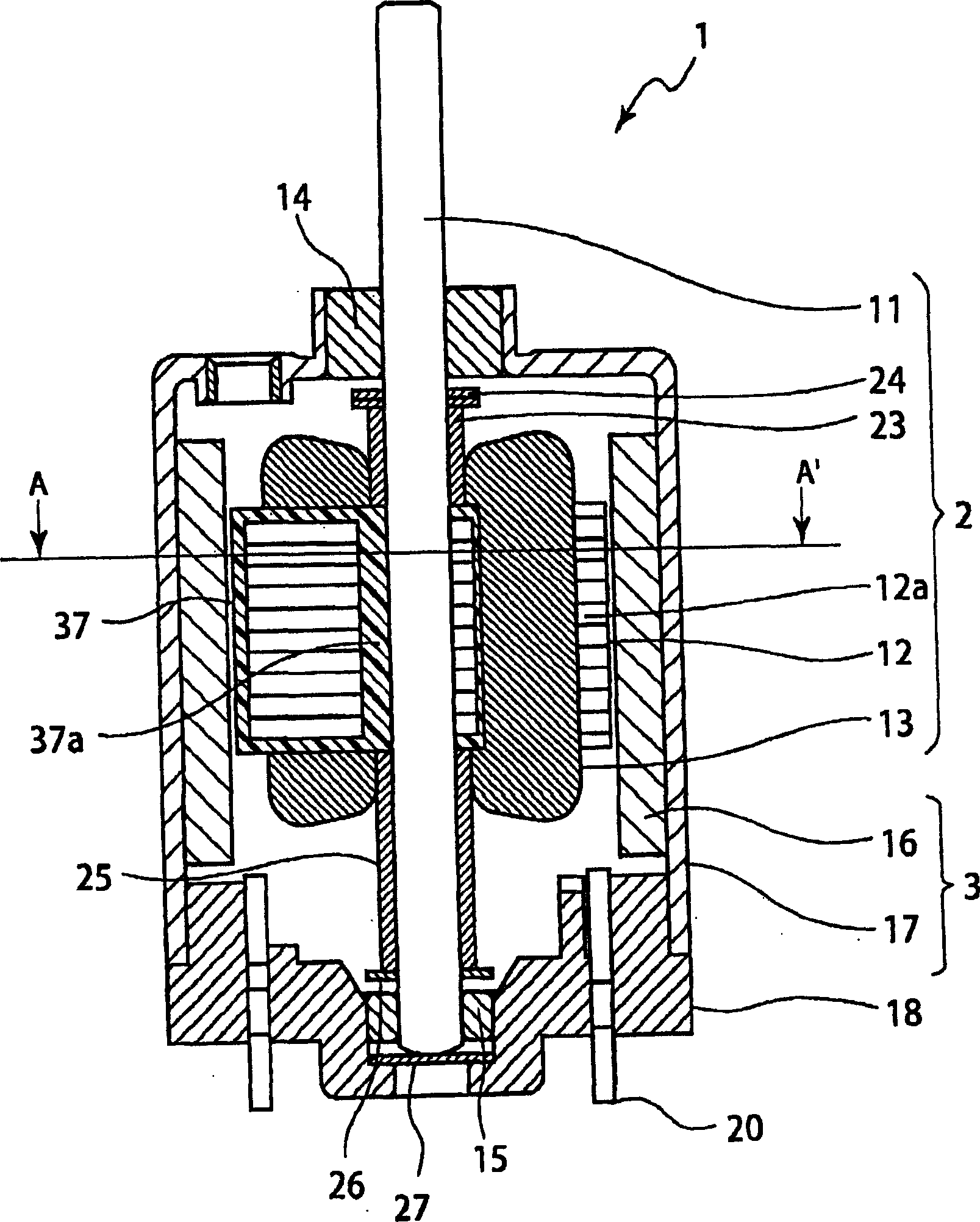

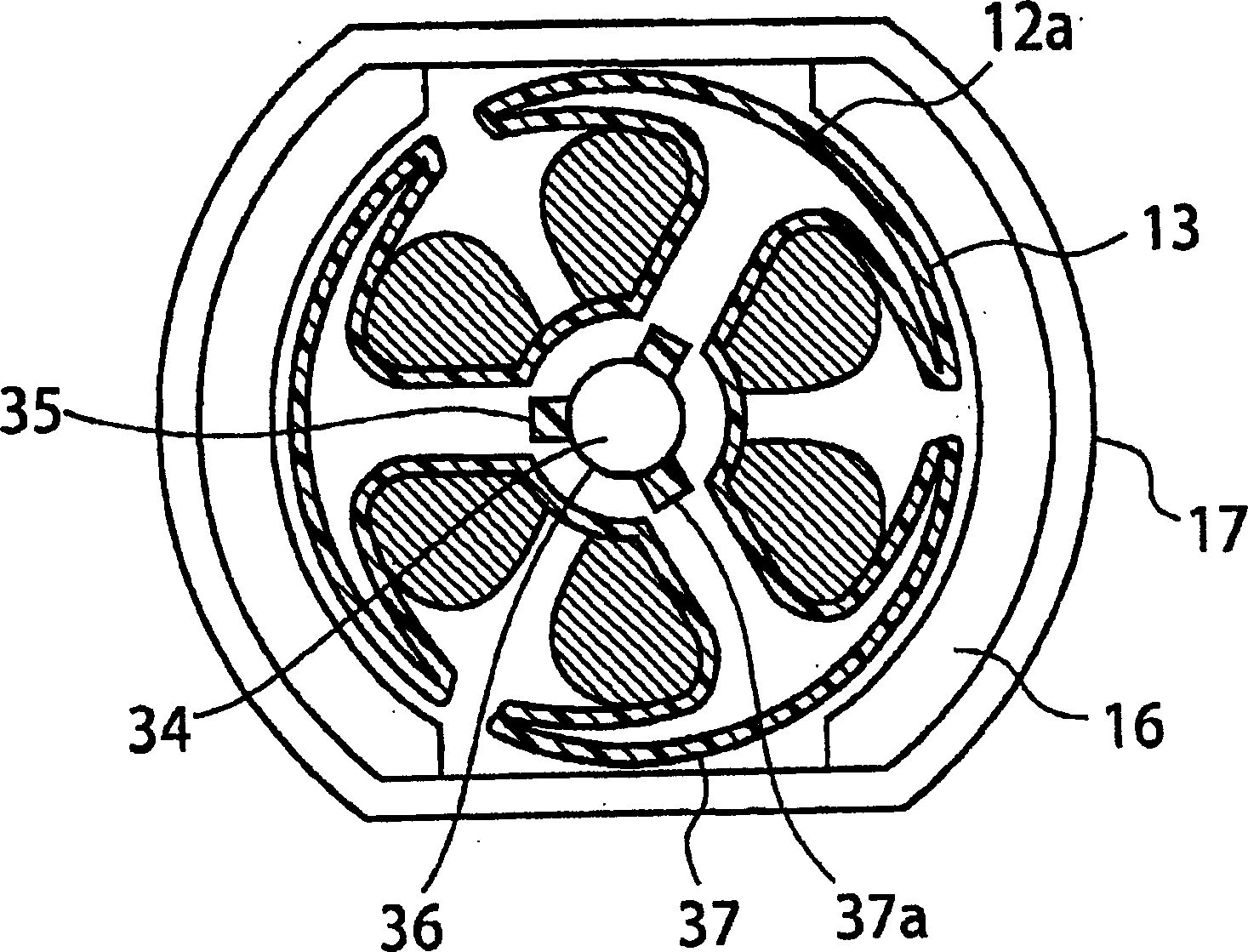

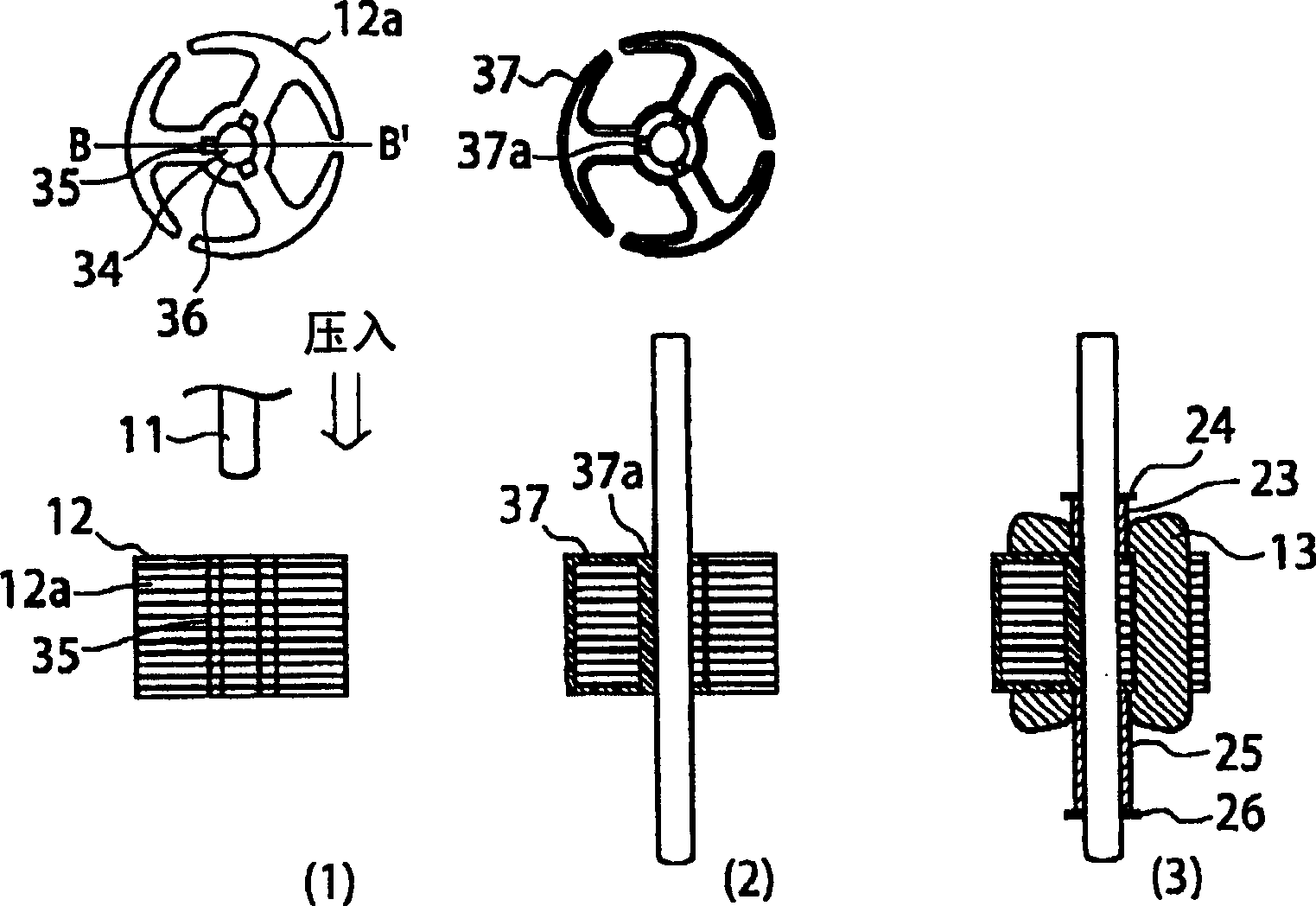

Rotor iron core of motor and small motor

InactiveCN1783651AAvoid deformationCurb bendingWindings insulation shape/form/constructionMagnetic circuit rotating partsElectric machineEngineering

The present invention provides a rotor core in which the rotating shaft of a motor used in information equipment and the like is not bent or damaged when the rotating shaft core is pressed into the core. The through hole (34) of the iron core sheet (12a) is provided with a press-fit part (36) and a gap part (35), and the rotating shaft (11) is pressed into the iron core (12) formed by laminating the iron core sheet (12a). A resin film (37a) joining the rotating shaft (11) and the core (12) is formed on the gap portion (35), thereby forming a rotor core that suppresses bending and damage of the rotating shaft (11), and provides a small, low-noise, Motor with high reliability.

Owner:SANKYO SEIKI MFG CO LTD

Floating hydraulic system for end gate of pavement milling and planning machine

InactiveCN101205938AReduce the pressing forceEnsure reasonable pressureServomotor componentsServomotorsEngineeringRoad surface

The invention provides an end door floating hydraulic system of a pavement milling machine, which relates to a hydraulic system of the pavement milling and planning machine. The invention comprises a priority governor valve, an overflow valve, a first normal close two-position electromagnetic valve, a second normal close two-position electromagnetic valve, a three-position electromagnetic reversing clapper and an end door lift cylinder, wherein, a system high pressure oil outlet is connected with an oil inlet of the priority governor valve; a priority oil outlet of the priority governor valve is communicated with an oil inlet of the overflow valve, and communicated with an oil inlet of the first normal close two-position electromagnetic valve; a hydraulic fluid port of the three-position electromagnetic reversing clapper is communicated with an oil inlet of the second normal close two-position electromagnetic valve; an oil outlet of the second normal close two-position electromagnetic valve is connected with an oil outlet of the first normal close two-position electromagnetic valve, and then is communicated and connected with an oil conduit with a rod chamber of the end door lift cylinder via the hydraulic fluid port; the hydraulic fluid port of the three-position electromagnetic reversing clapper is communicated and connected with an oil conduit without rod chamber of the end door lift cylinder via the hydraulic fluid port. The invention fulfills simple structure, reliable performance, and aims of regulating the pressing force of the end door of the pavement milling machine to the pavement.

Owner:ZHENJIANG HUACHEN HUATONG ROAD MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com