Hot pressing bush device and hot pressing process of connecting rod piston pin hole

A piston pin hole and connecting rod technology, which is applied in the field of auto parts manufacturing, can solve the problems of easy straining of the bushing, high pressure of the bushing, falling off of the bushing, etc., and achieve the effect of ensuring safe operation and avoiding straining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

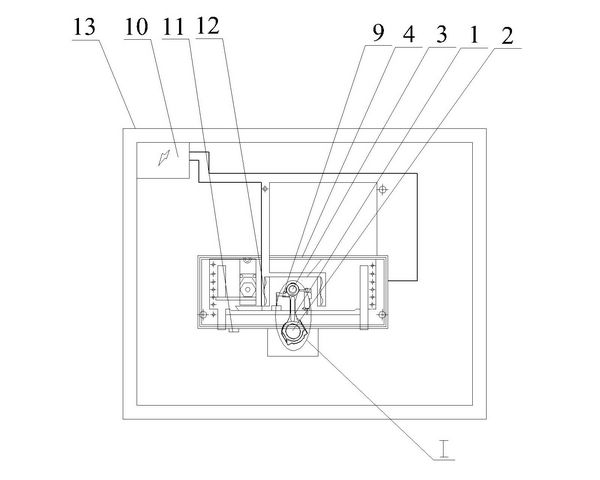

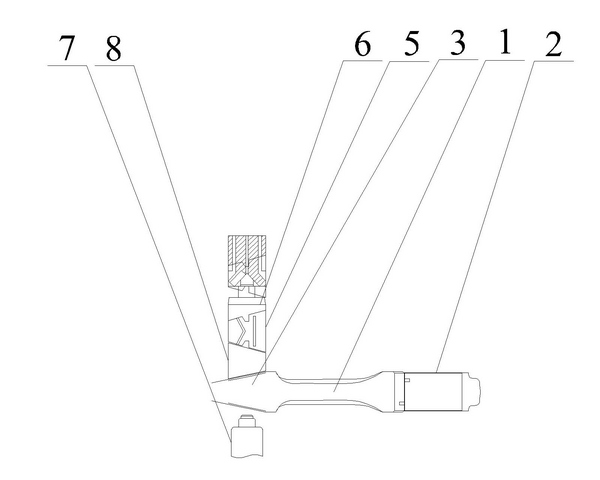

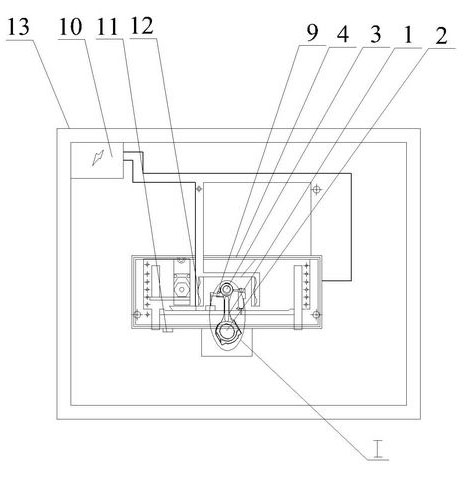

[0018] like figure 1 , figure 2 shown, where figure 2 only draw figure 1 of Side view of the axial press-fit part. There are crankshaft holes 2 and piston pin holes 3 at both ends of the connecting rod 1, and a pressing system 9 is installed in the high-frequency heating furnace 4; the temperature sensor part of the infrared sensor thermometer 11 is installed in the high-frequency heating furnace 4, and In order to sense the actual heating temperature in the high-frequency heating furnace 4, the display of the infrared sensor thermometer 11 is located outside the high-frequency heating furnace 4 to visually display the temperature in the furnace. The high-frequency heating furnace 4 is automatically controlled by the electrical control system 10 The two sides of the press-fit system 9 are equipped with high-frequency induction coils 12, the connecting rod 1 is positioned on the workbench of the press-fit system 9, and the guide sleeve 8 is fixed in the press-fit system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com