Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

288results about How to "Curb bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

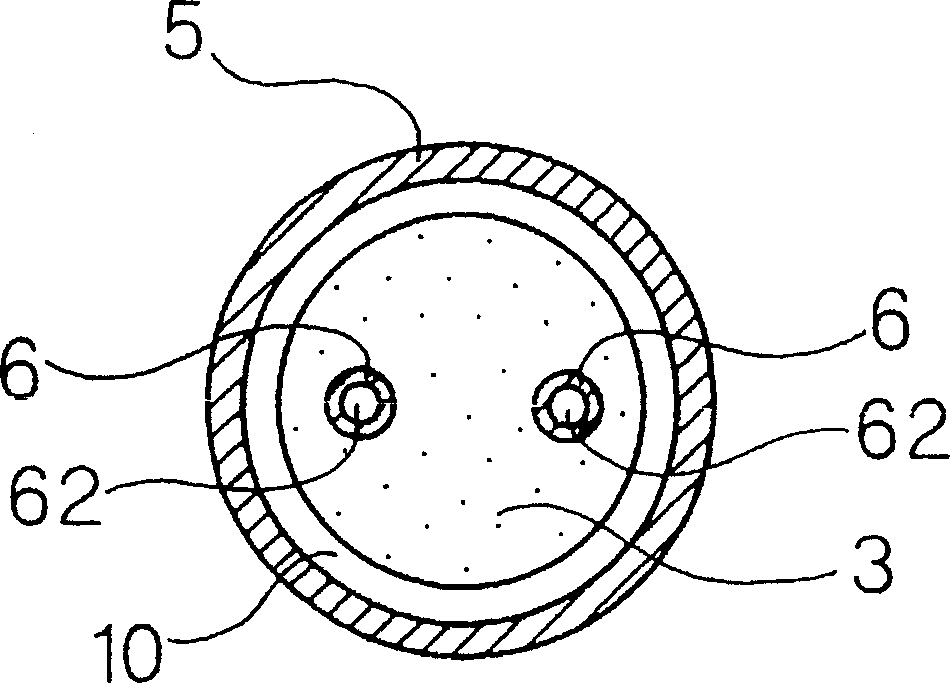

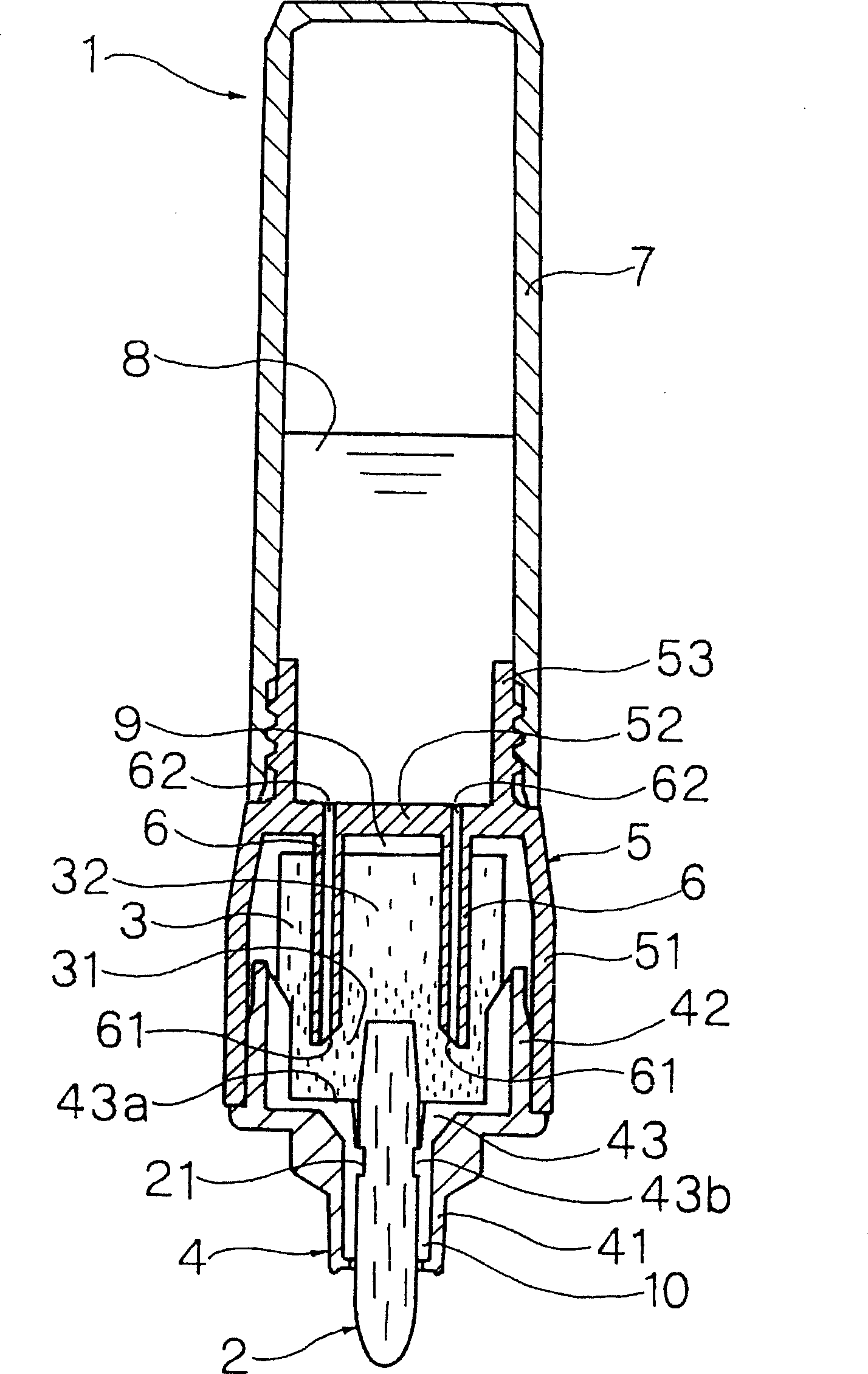

Direct-fluid-supply writing implement

The invention aims to provide a direct fluid type writing implement which has no possibility of the ink in an ink tank leaking from the penpoint side, get ready for writing in a short time by a quick change of air and the ink at the initial discharge of the ink, and moreover can simplify the structure. The direct fluid type writing implement comprises the penpoint, an ink occluding body connected to the rear end of the penpoint, the ink tank disposed in the rear of the ink occluding body and storing the ink directly and communication pipes connecting the ink tank with the ink occluding body. The communication pipes are provided in a plurality. The respective front ends of the communication pipes are opened. The ink occluding body has a high-density part and a low-density part connected to the high-density part in the rear of this part. The respective front ends of the communication pipes and the rear end of the penpoint are connected to the high-density part.

Owner:THE PILOT INK CO LTD

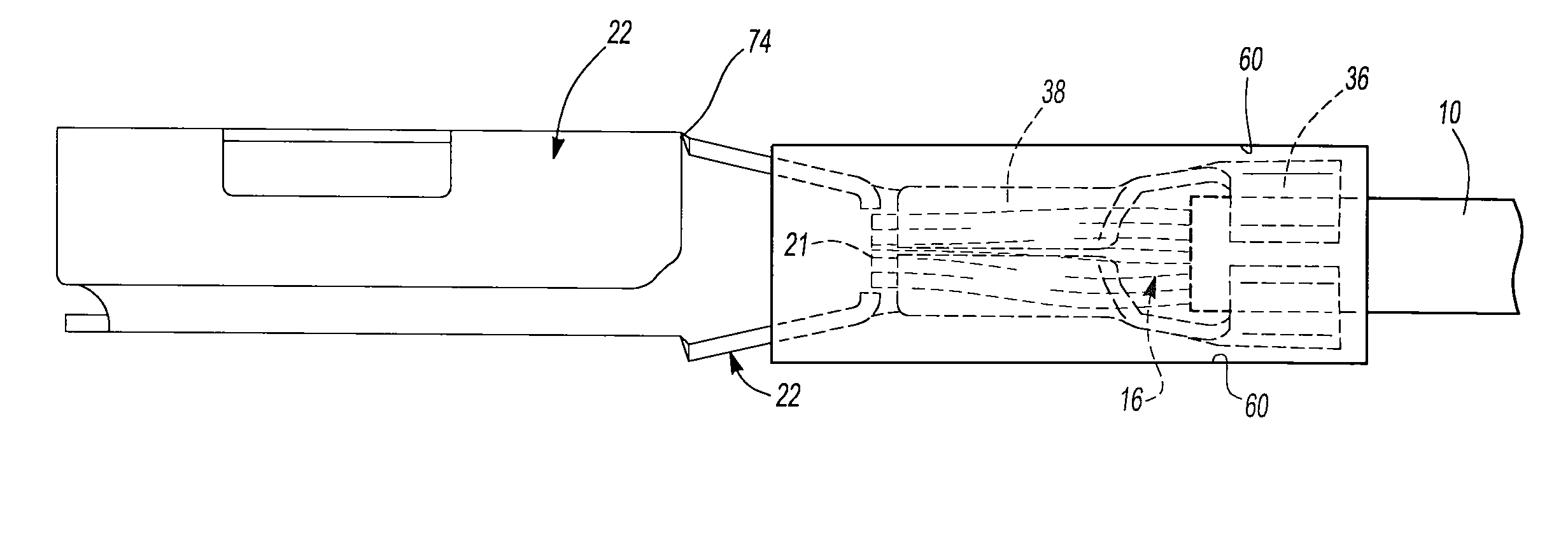

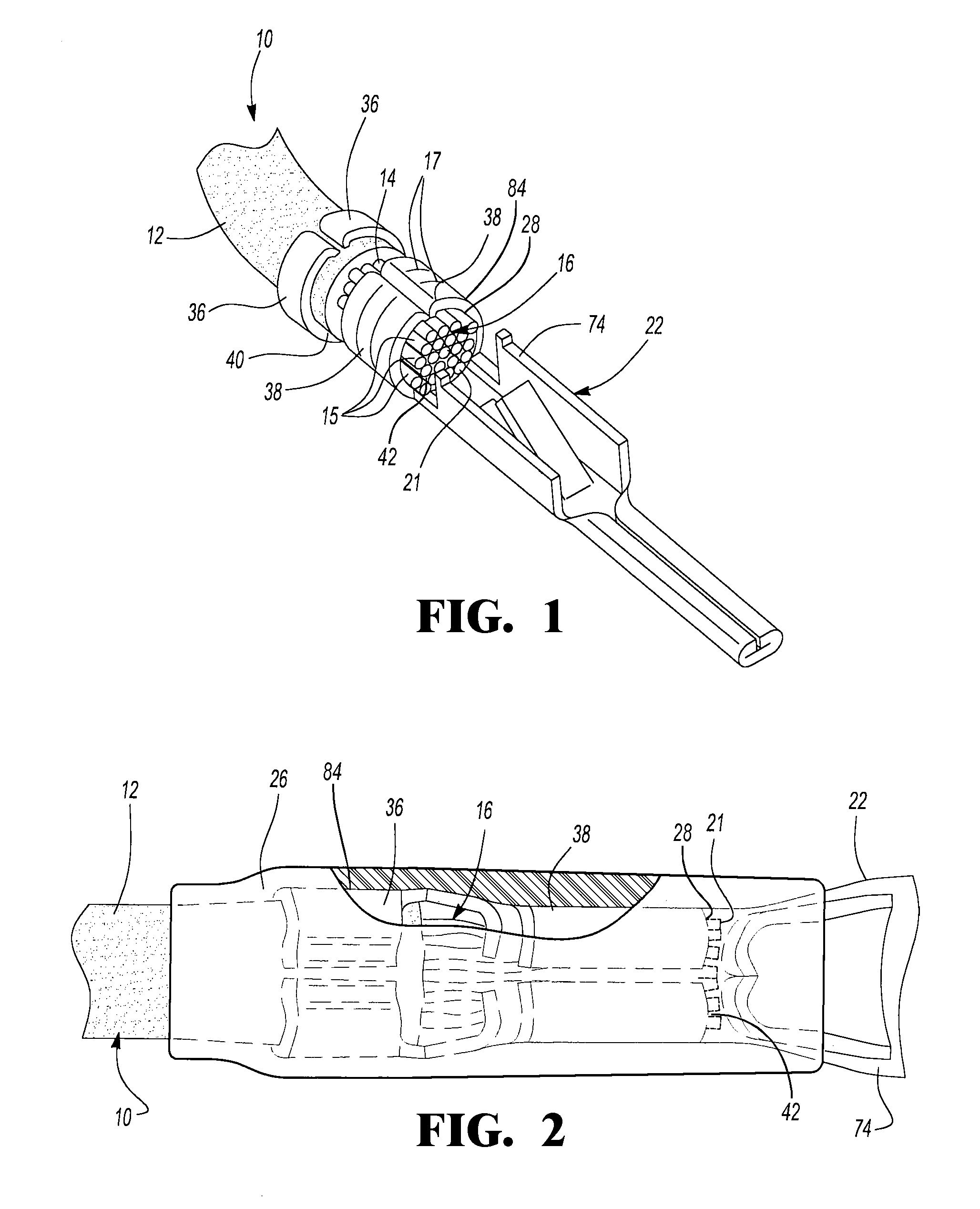

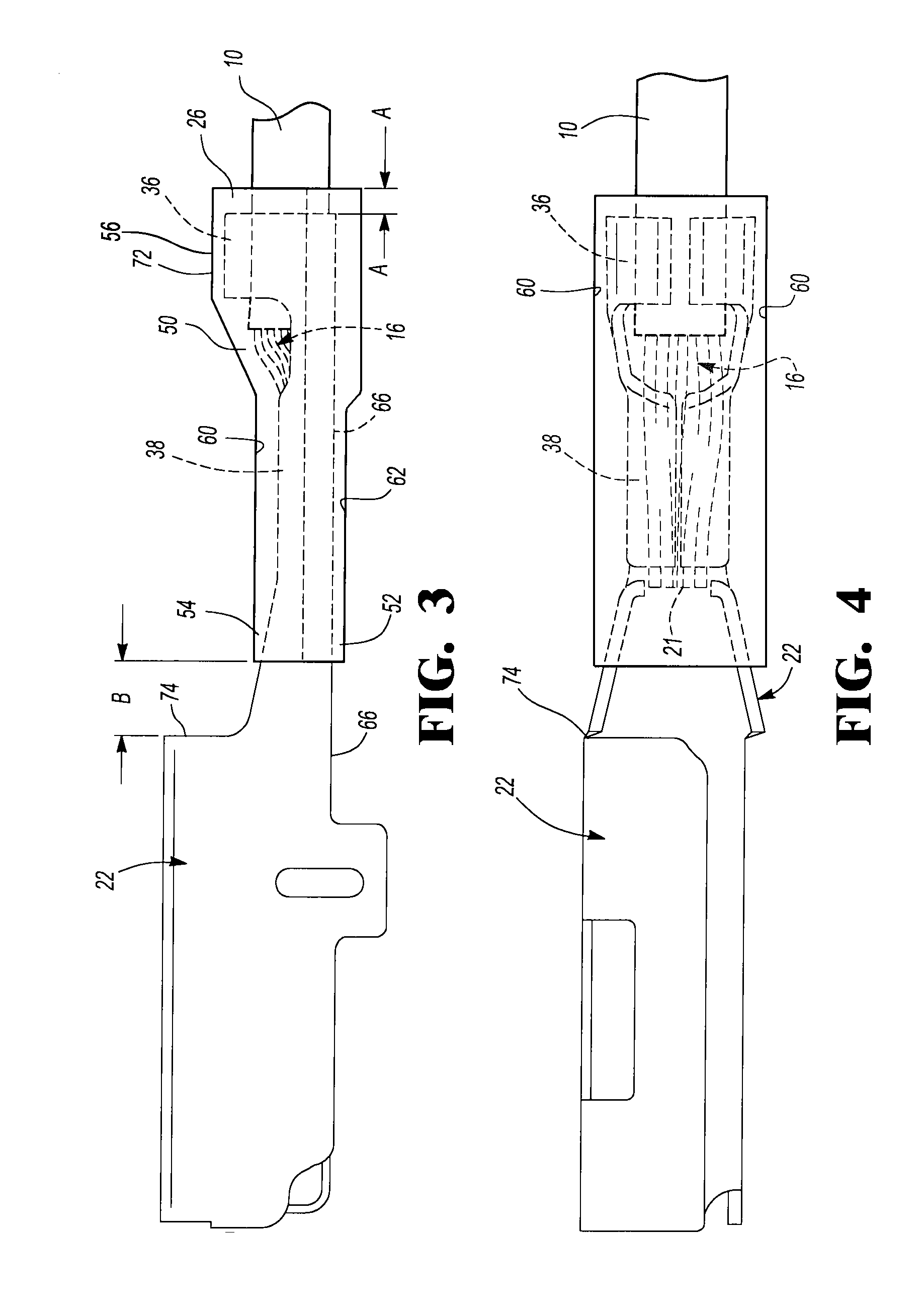

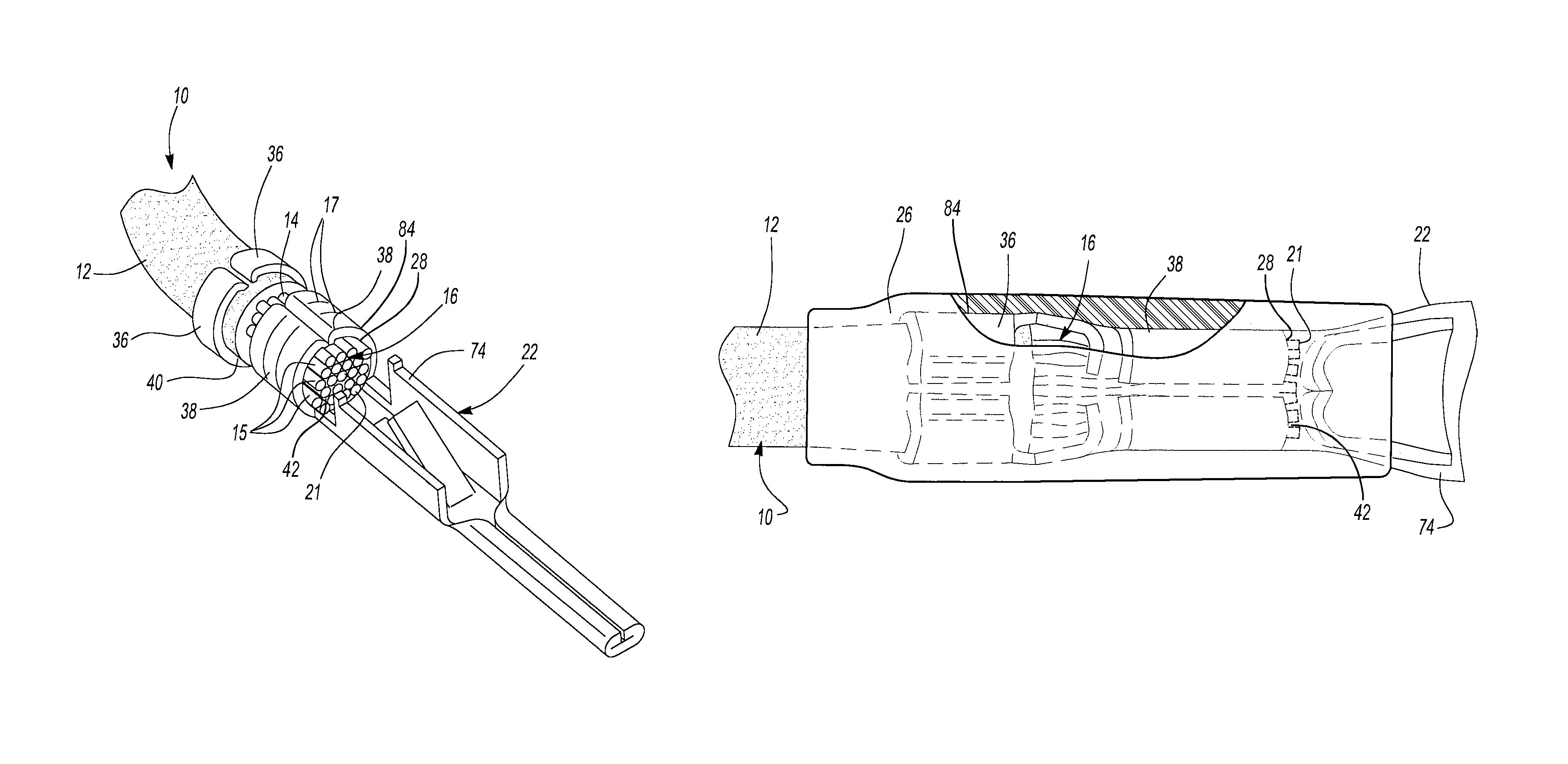

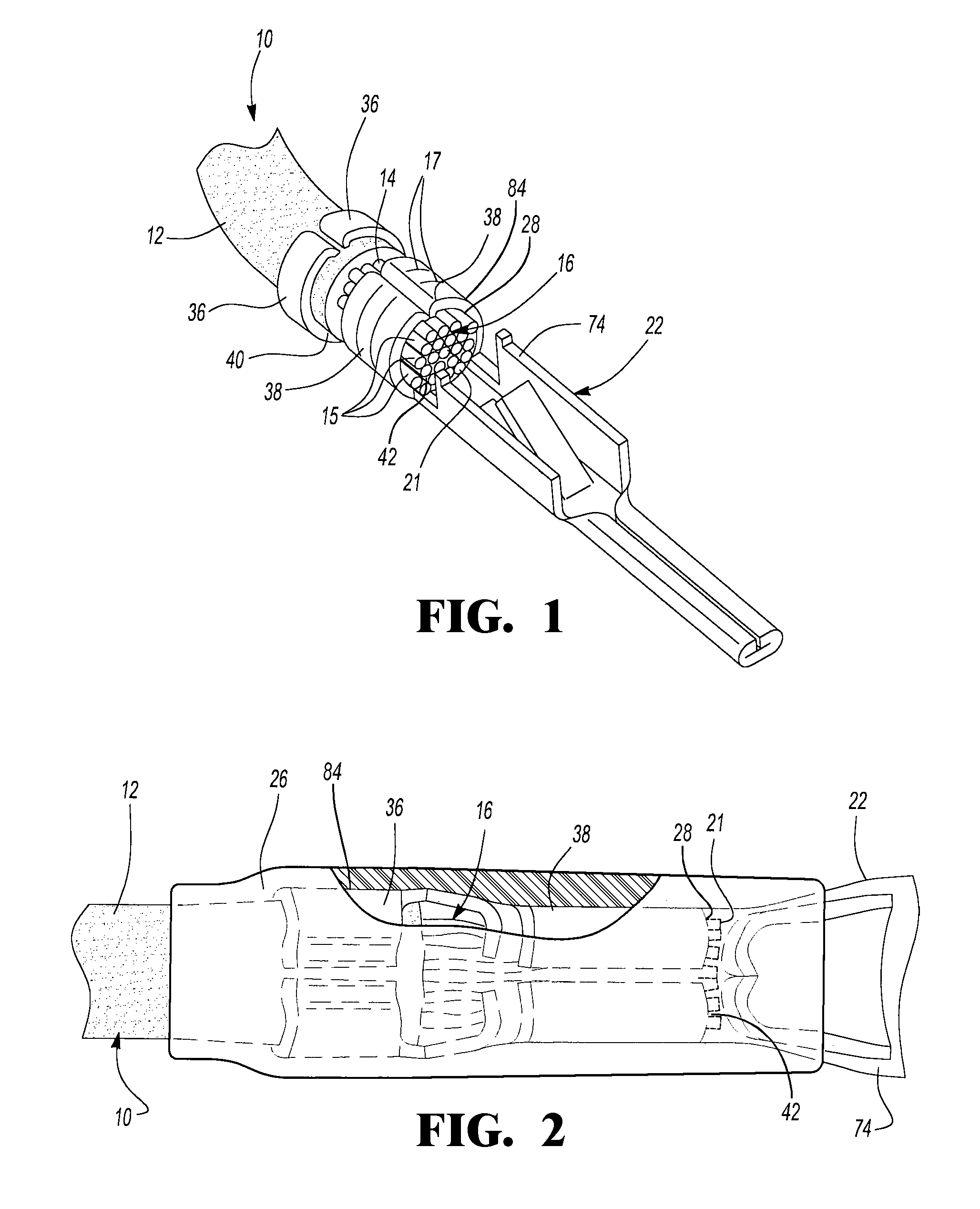

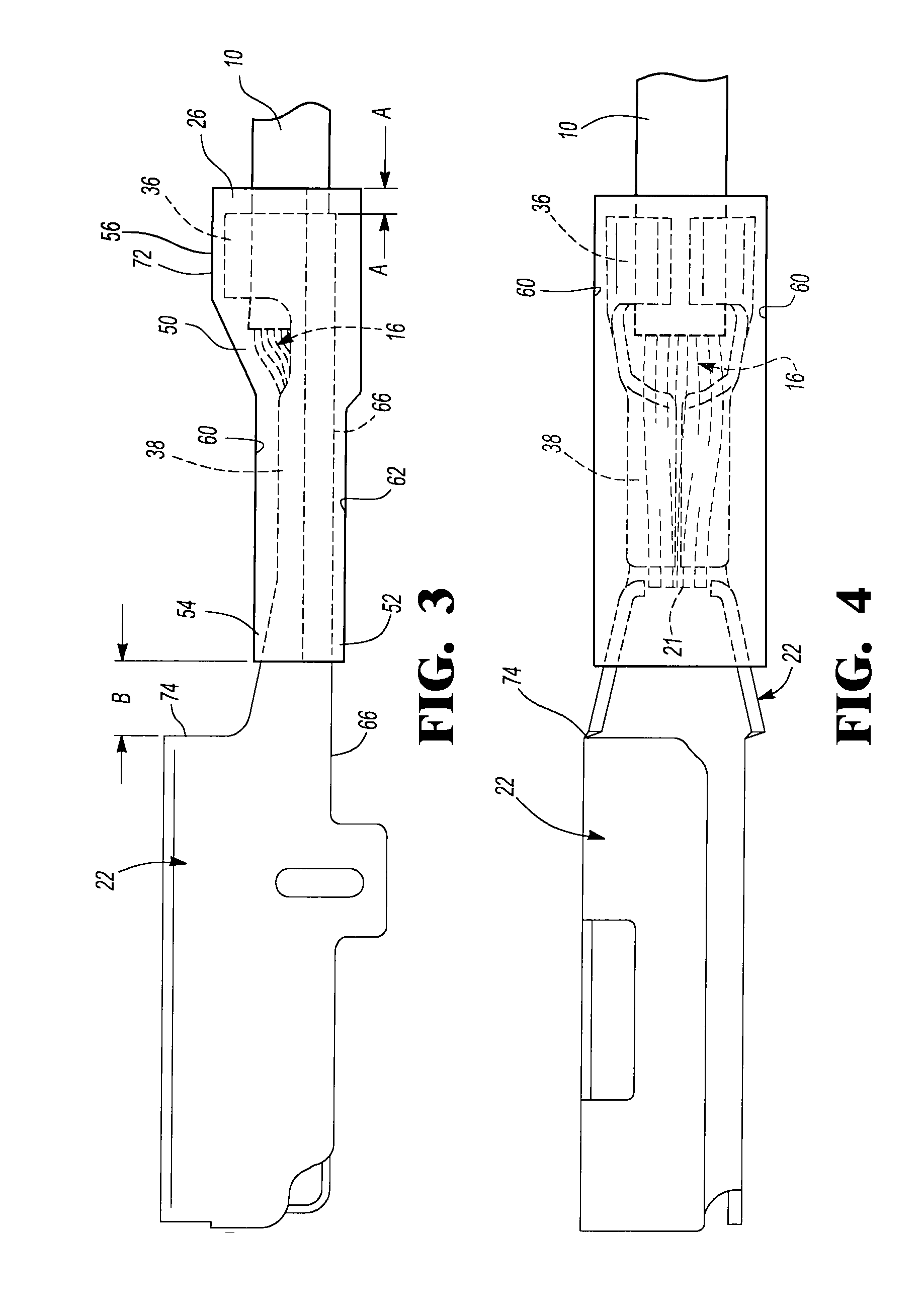

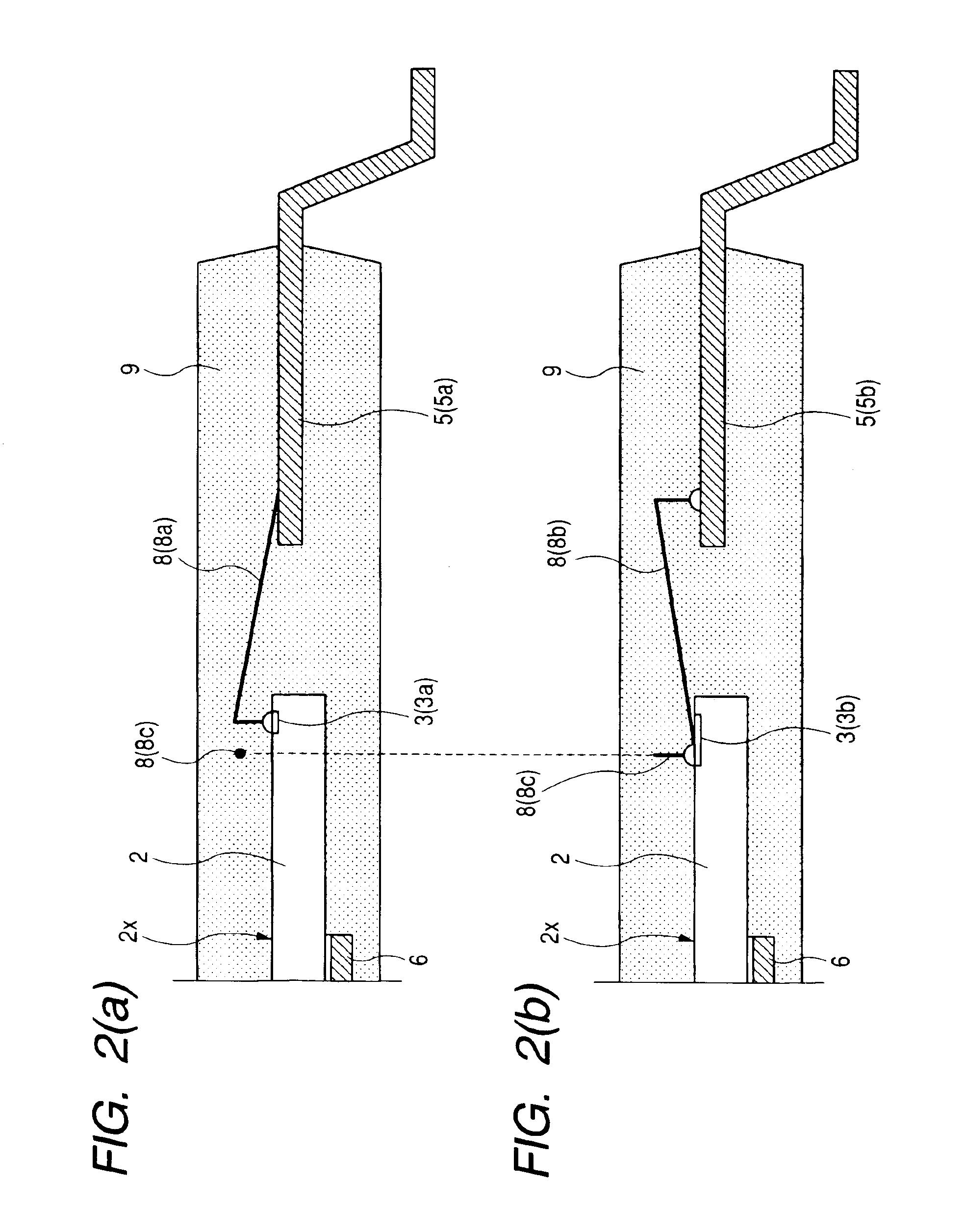

Electrical terminal connection with molded seal

InactiveUS20110070770A1Curb bendingImprove sealingContact member assembly/disassemblyDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectricityElectrical connection

A corrosion resistant electrical connection structure has an electrically conductive cable with an electrically conductive core and an insulative outer cover. An electrically conductive terminal is electrically connected to a lead of the core that extends beyond the insulative outer cover. A molded hot melt seal seals the lead of the core and the terminal interface section from ambient electrolytes. In an exemplary embodiment, the core is made from aluminum or an aluminum alloy and the terminal is made from a copper alloy.

Owner:APTIV TECH LTD

Electrical terminal connection with molded seal

InactiveUS8360803B2Curb bendingImprove sealingContact member assembly/disassemblyDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical connectionHot melt

A corrosion resistant electrical connection structure has an electrically conductive cable with an electrically conductive core and an insulative outer cover. An electrically conductive terminal is electrically connected to a lead of the core that extends beyond the insulative outer cover. A molded hot melt seal seals the lead of the core and the terminal interface section from ambient electrolytes. In an exemplary embodiment, the core is made from aluminum or an aluminum alloy and the terminal is made from a copper alloy.

Owner:APTIV TECH LTD

Light deflector, optical scanning device and image forming apparatus

ActiveCN104216109AShake suppressionCurb bendingElectrographic process apparatusOptical elementsEngineeringMechanical engineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

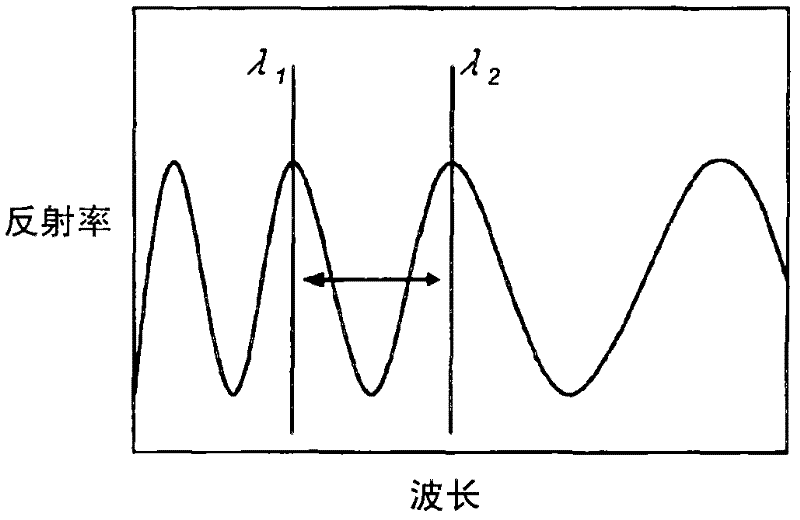

Optical film, polarizing plate, image display device, and method for manufacturing optical film

InactiveCN102445720ACurb bendingInterference inhomogeneity suppressionElectroluminescent light sourcesSolid-state devicesRefractive indexPolarizer

An optical film contains a transparent base material having thereon a hard coat layer formed of a hard coat layer forming composition containing the specific components, wherein a refractive index of the hard coat layer is 1.45 or more and not more than 1.55; and in the hard coat layer forming composition, a content of the component (a) is a content of the component (b) or more.

Owner:FUJIFILM CORP

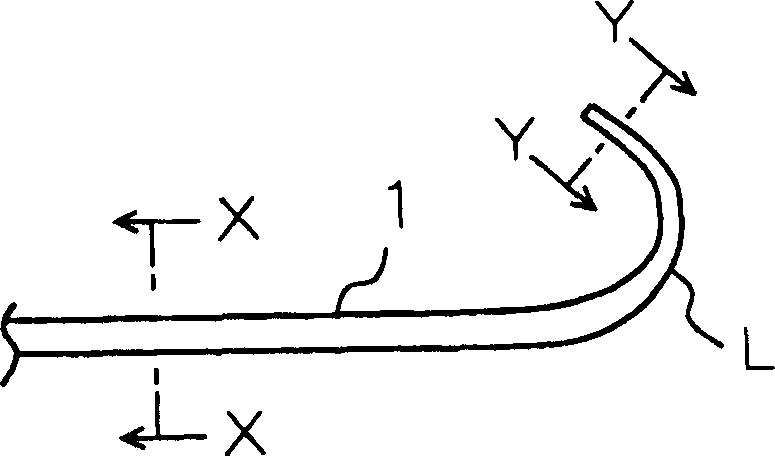

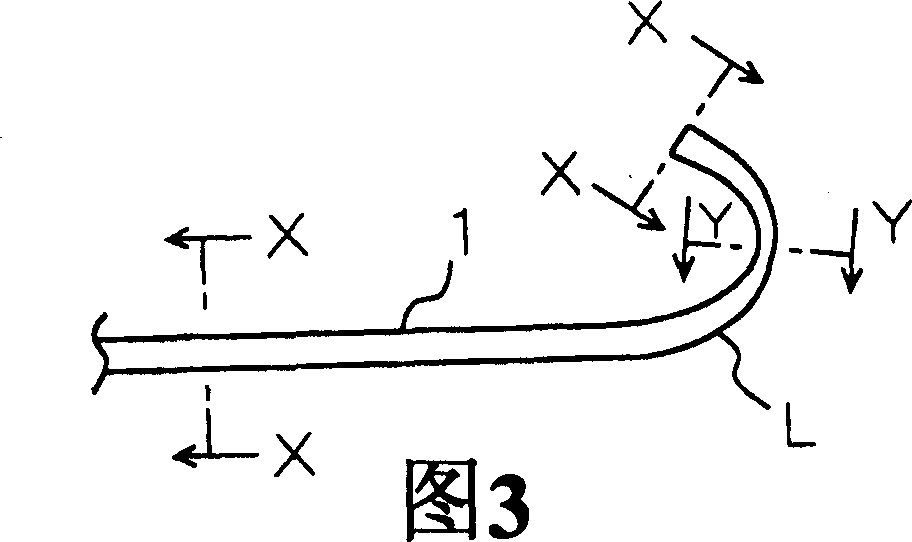

Guide wire for medical treatment

The aim of the invention is to guide wire for medical treatment capable of being easily introduced into a blood vessel from a blood vessel guide port at a femoral, a brachium, or a radial, easily meandered in the blood vessel, and hard to be erroneously advanced into the blood vessel at a branched part, comprising a metal core covered with a resin having a tip part bent in a smooth curved shape, characterized in that the diameter of the guide wire including a resin layer is 0.46 to 1.02 mm, an angle formed by the extension line of the tip part of the guide wire relative to a wire base line is 40 to 70 DEG , and the width dimension of the curved part is 2 mm or longer to less than 10 mm.

Owner:JAPAN STENT TECH CO LTD

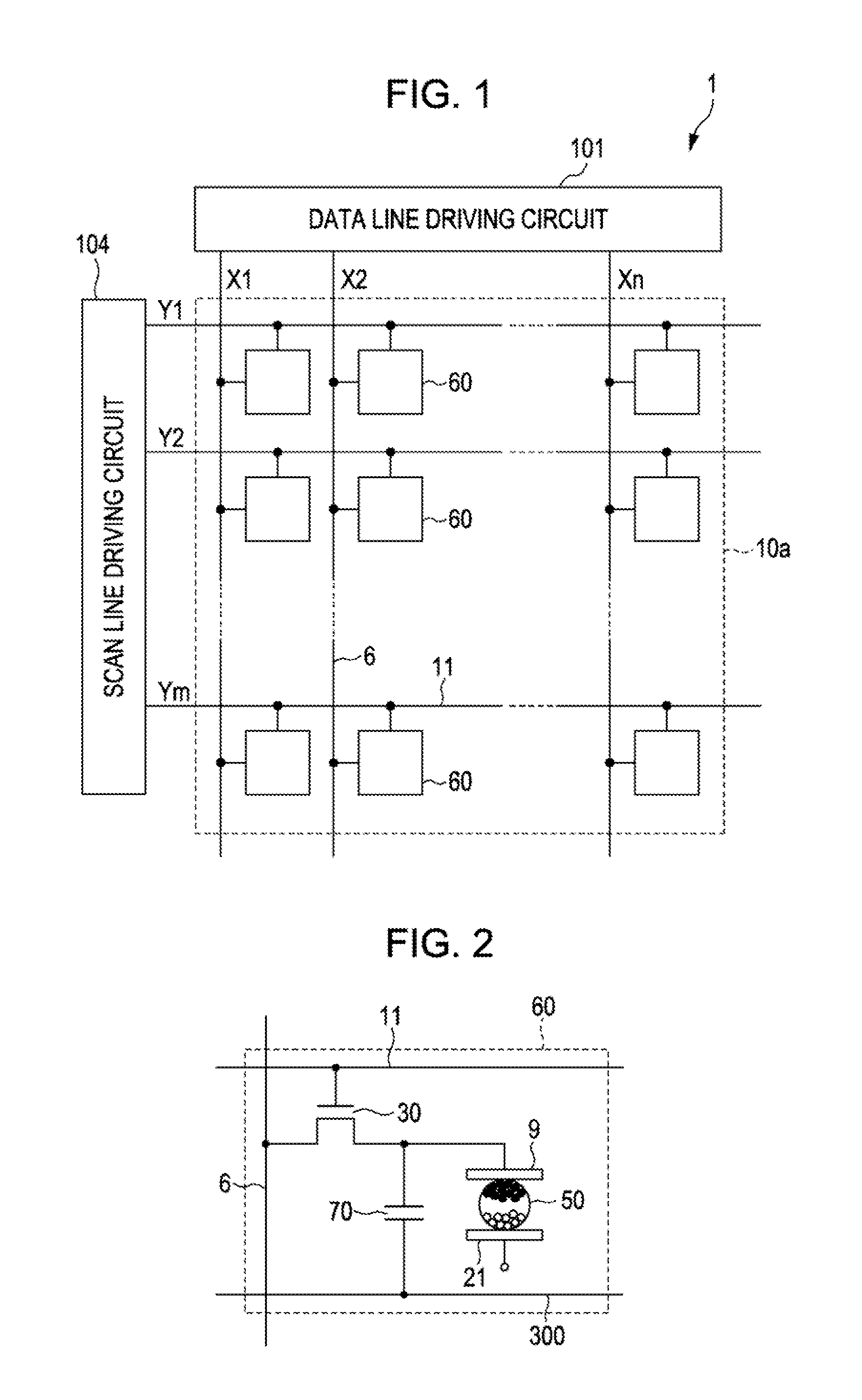

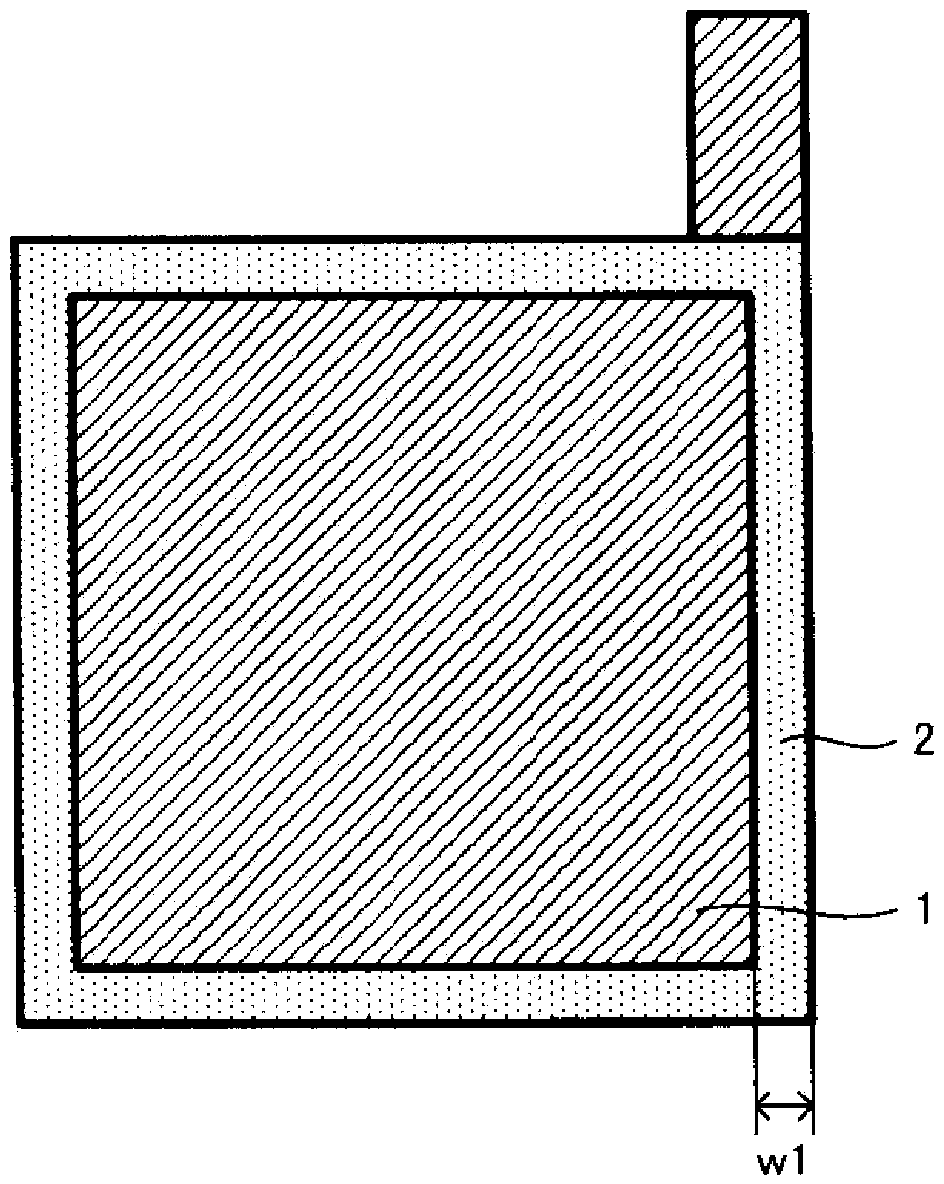

Substrate for semiconductor device, method of manufacturing the same, semiconductor device and electronic device

ActiveUS20110114971A1Curb bendingLow costSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorTransistor

A substrate for a semiconductor device is provided, including: a substrate; a transistor, formed on the substrate, that includes a semiconductor layer, and a gate electrode disposed so as to be opposed to the semiconductor layer with a gate insulating film interposed therebetween; and an underlying film disposed below the semiconductor layer, as an underlayer of the transistor, and formed in an island shape so as to at least partially overlap the semiconductor layer, in a plan view of the substrate.

Owner:E INK CORPORATION

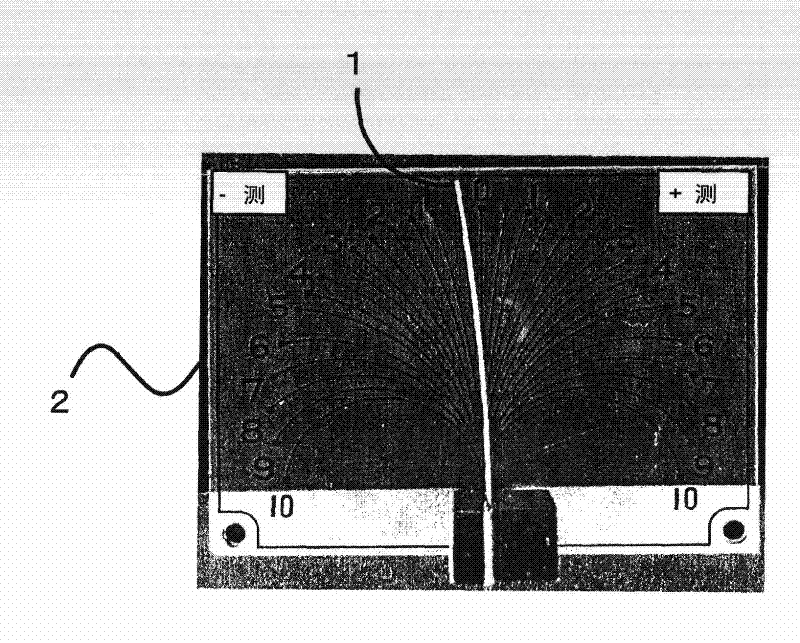

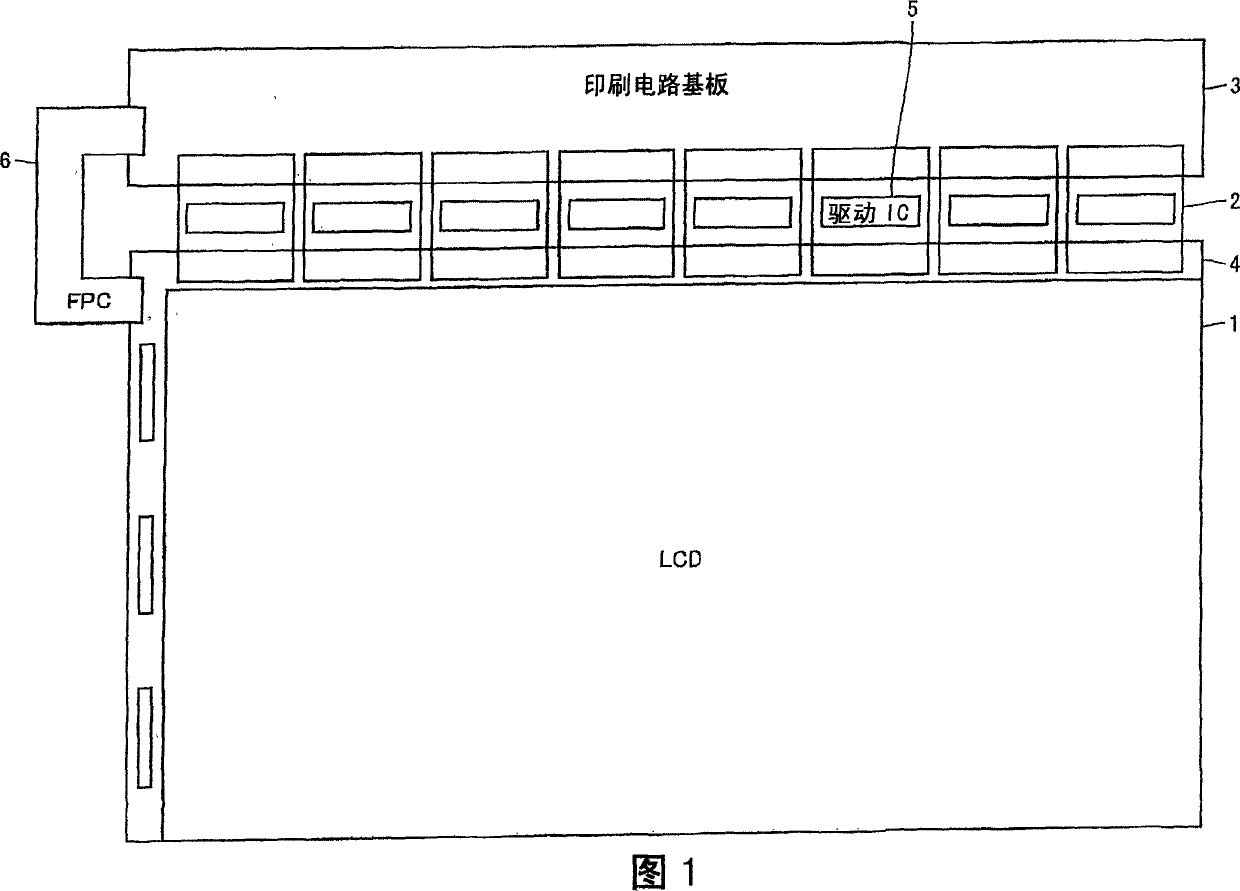

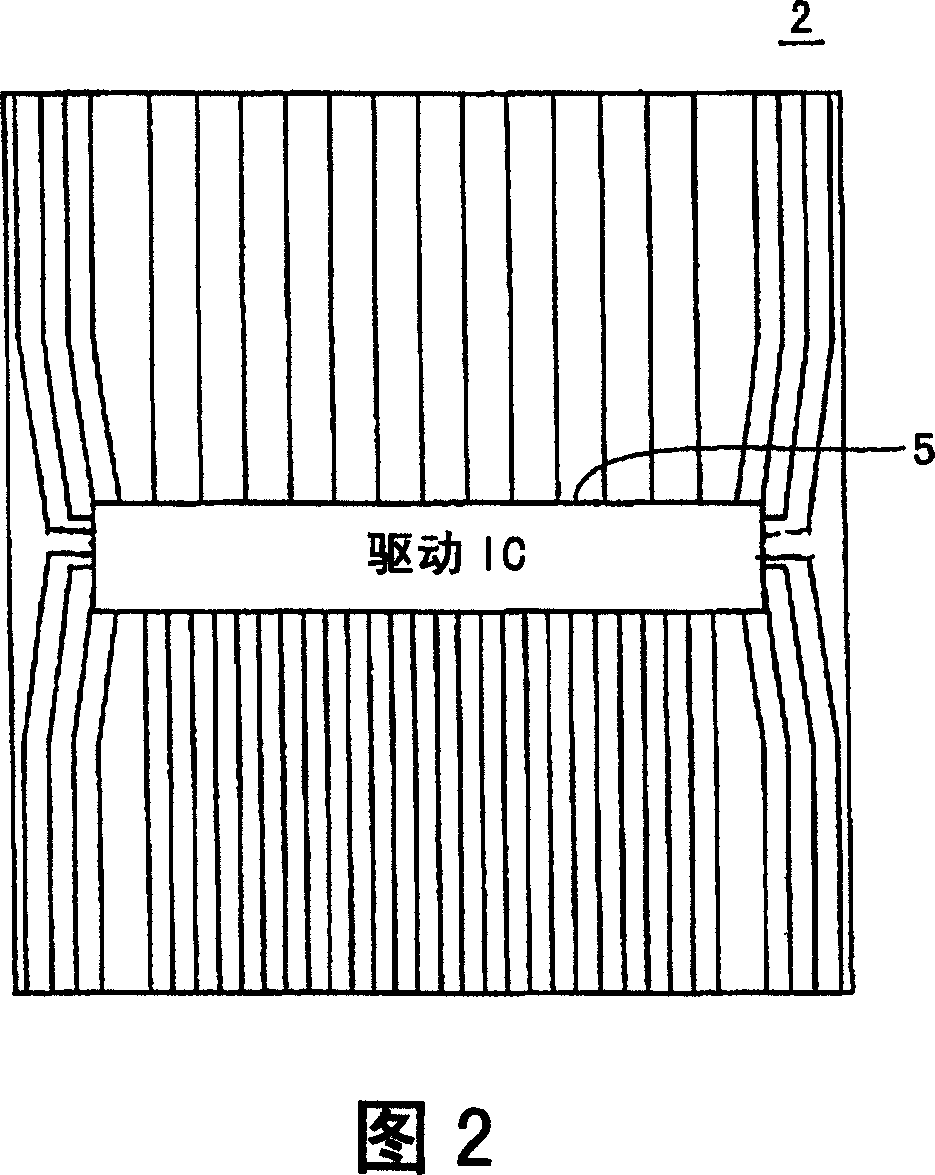

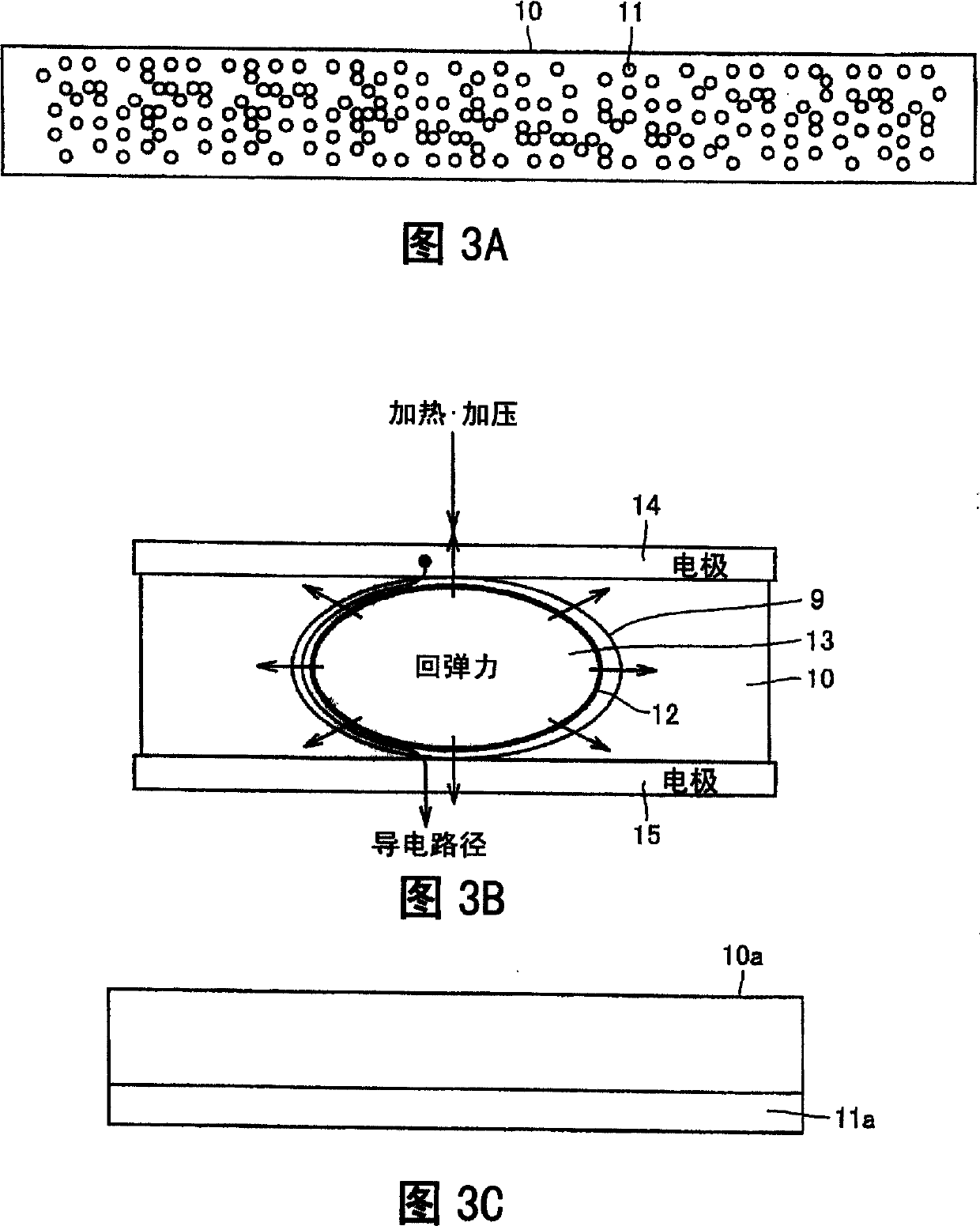

Bonding method and apparatus

InactiveCN1818754ACurb bendingSuppression of inhomogeneityStatic indicating devicesAdhesive processes with adhesive heatingAnisotropic conductive filmAdhesive

The invention provides a bonding device capable of shortening a bonding time and performing high speed and accurate mounting by irradiating a laser to an anisotropic conductive film (ACF) which is a mounting adhesive. Laser generated from a laser generator is reflected by a laser mirror, passes through an array substrate (glass substrate) through a backup glass, and then, directly irradiated to an ACF in a pinpoint manner. The laser from the laser generator is set to have a wavelength whose transmittance of transmitting the TCP and the array substrate having the ACF inserted therebetween is higher than that of the other wavelength. The ACF is welded by this laser irradiation, so that the TCP and the array substrate are bonded to each other.

Owner:ORMON CORP

Pressure-sensitive adhesive sheets for wafer grinding and warp inhibiting

The present invention relates to a pressure-sensitive adhesive sheet for semiconductor wafer processing, which includes a substrate and a pressure-sensitive adhesive layer disposed on the substrate, the pressure-sensitive adhesive sheet or said substrate having a thermal shrinkage ratio of 2% or lower after having been allowed to stand at 60 DEG C. for 10 minutes. This pressure-sensitive adhesive sheet preferably has a degree of elongation of 2% or lower in a silicon wafer application test of the pressure-sensitive adhesive sheet. According to this pressure-sensitive adhesive sheet, the back side of a semiconductor wafer can be ground to an extremely small thickness without bending the wafer.

Owner:NITTO DENKO CORP

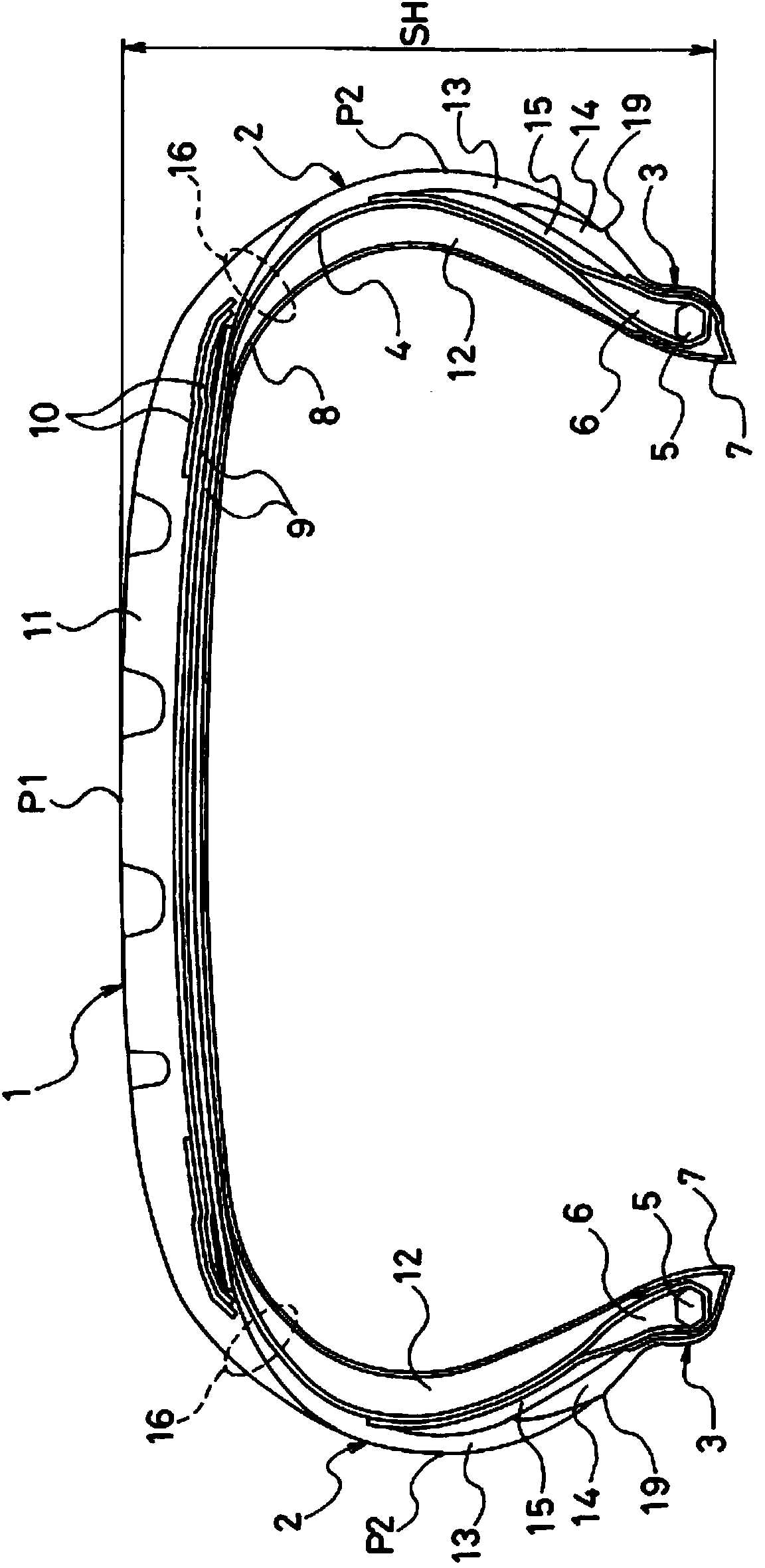

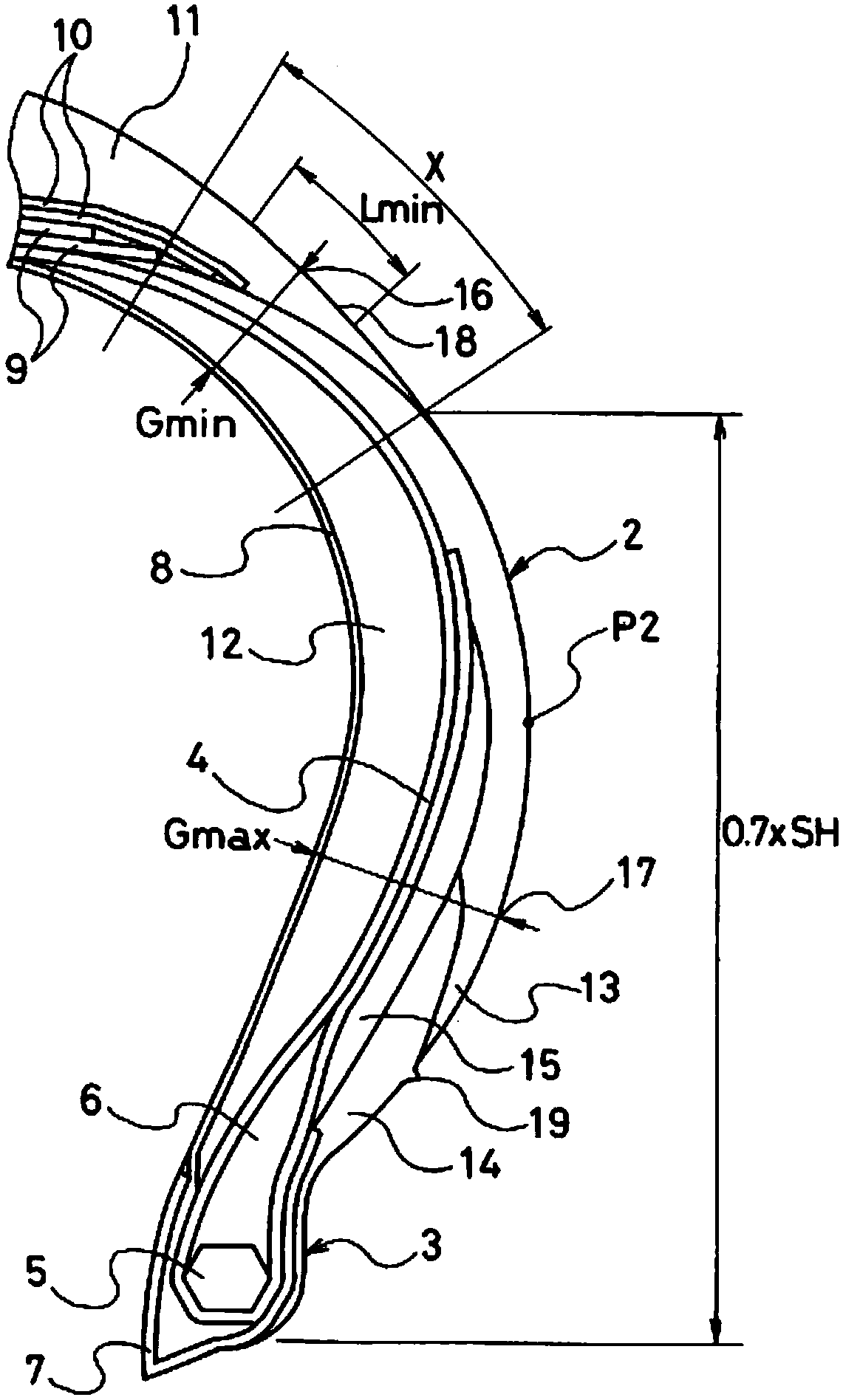

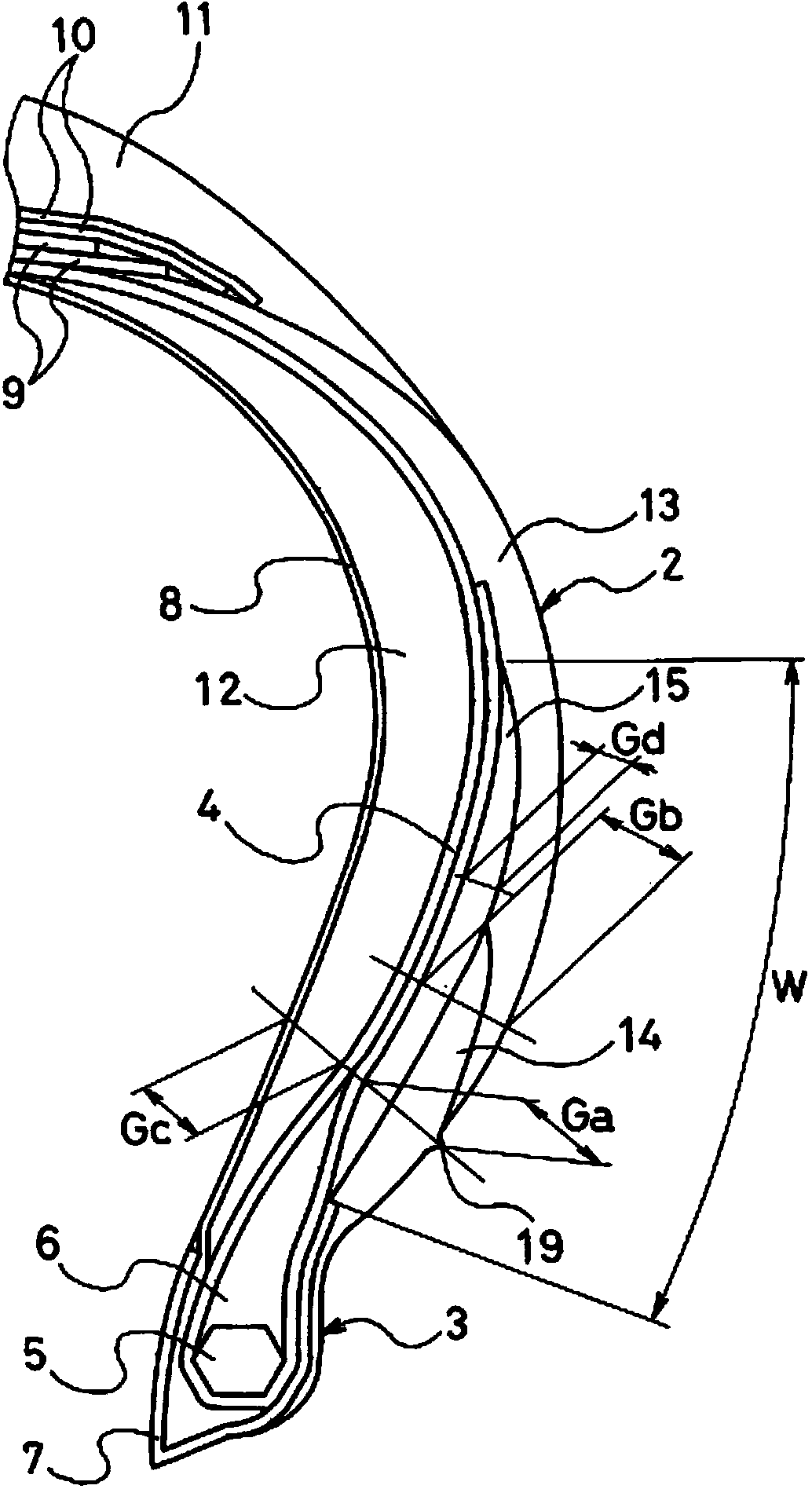

Run-flat tire

ActiveCN104321209AAvoid breakingIncreased durabilitySpecial tyresPneumatic tyre reinforcementsEngineeringRun-flat tire

Provided is a run-flat tire that achieves high levels of both run-flat durability and ride comfort, and minimizes weight increase. In a sidewall-reinforced run-flat tire, the minimum thickness section being positioned between the belt layer end section and the tire cross-sectional height (SH) 70% position, the relationship between the thickness (Gmin) of the minimum-thickness section and the thickness (Gmax) of the maximum thickness section (17) is defined as 0.5 × Gmax ≤ Gmin ≤ 0.8 × Gmax; the relationship between the length (Lmin) of the thin region and the tire cross-sectional height (SH) is defined as 0.18 × SH ≤ Lmin ≤ 0.26 × SH; the relationship between the weight (Wr) of the sidewall-reinforcement layer, the tire total weight (Wt), and the tire oblateness (R) is defined as 0.08 × Wt × (1 - 0.2 × (1 - R / 50)) ≤ Wr ≤ 0.18 × Wt × (1 - 0.2 × (1 - R / 50)); the relationship between the thickness (Ga) at the rim-check line of the outer-side rubber portion outward of the carcass layer, and the maximum thickness (Gb) thereof, is defined as 0.8 × Gb ≤ Ga ≤ 1.0 × Gb; and the relationship between the thickness (Gc) at the rim-check line of the inner-side rubber portion inward of the carcass layer and the thickness (Ga) is defined as 0.7 × Ga ≤ Gc ≤ 1.0 × Ga.

Owner:THE YOKOHAMA RUBBER CO LTD

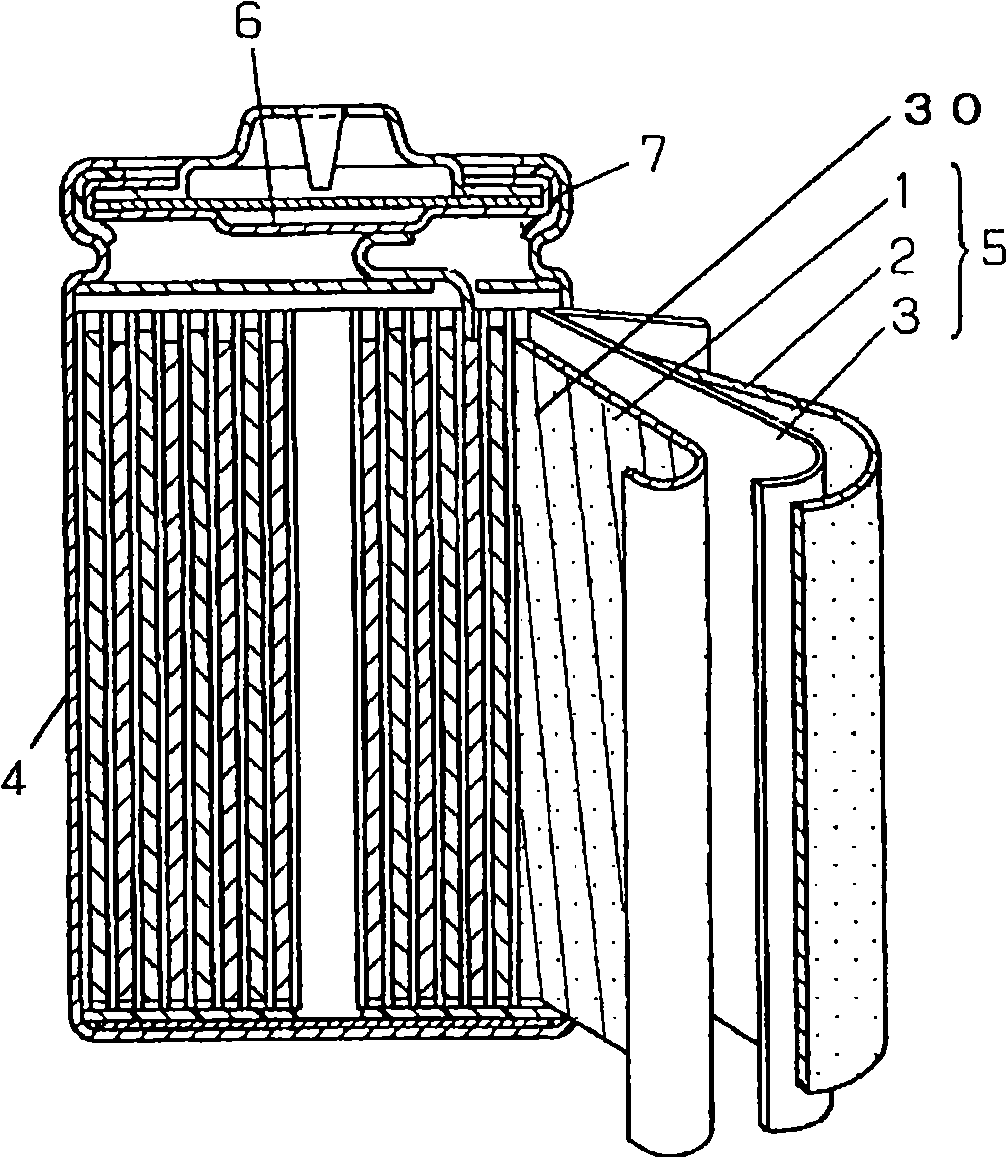

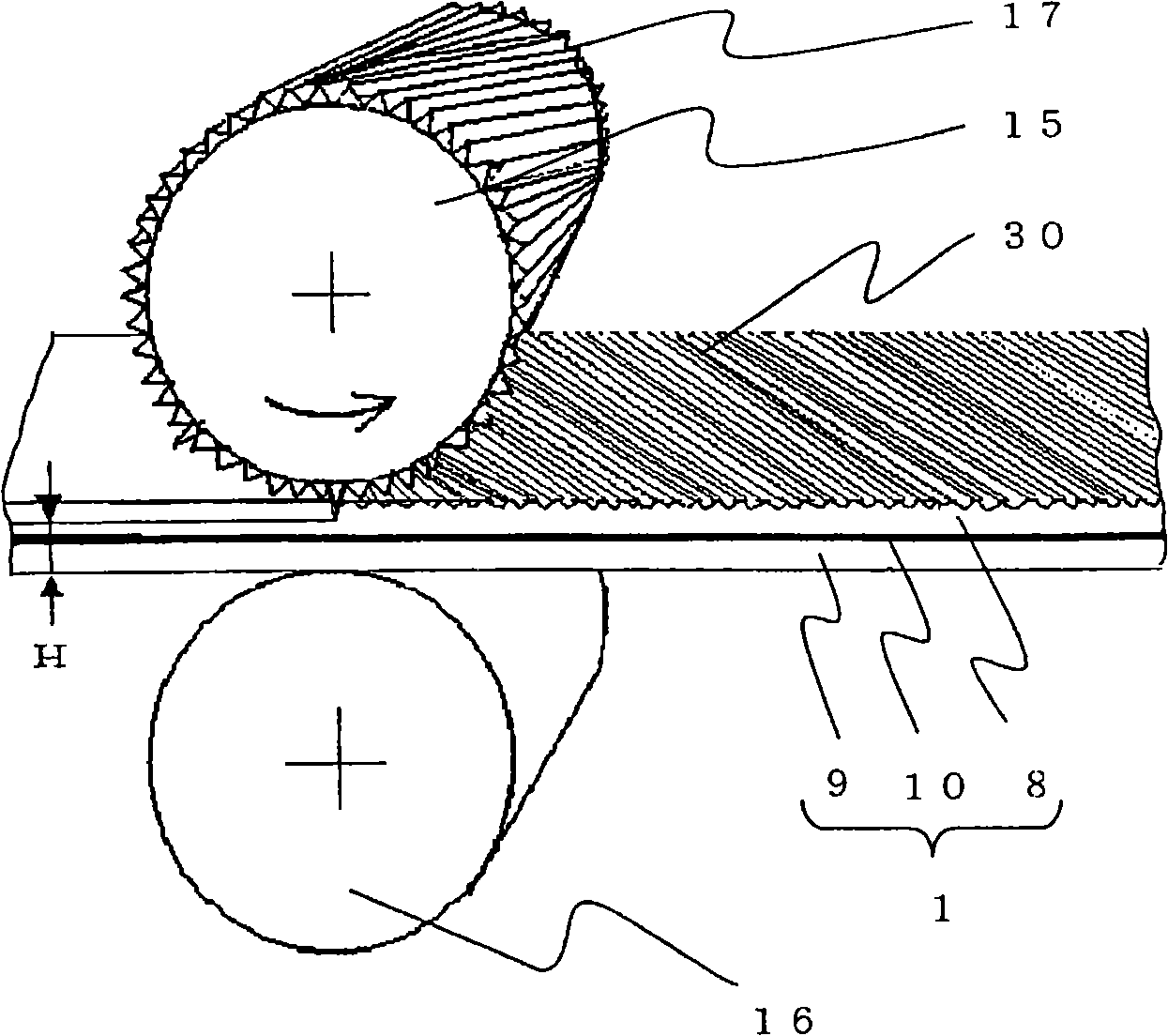

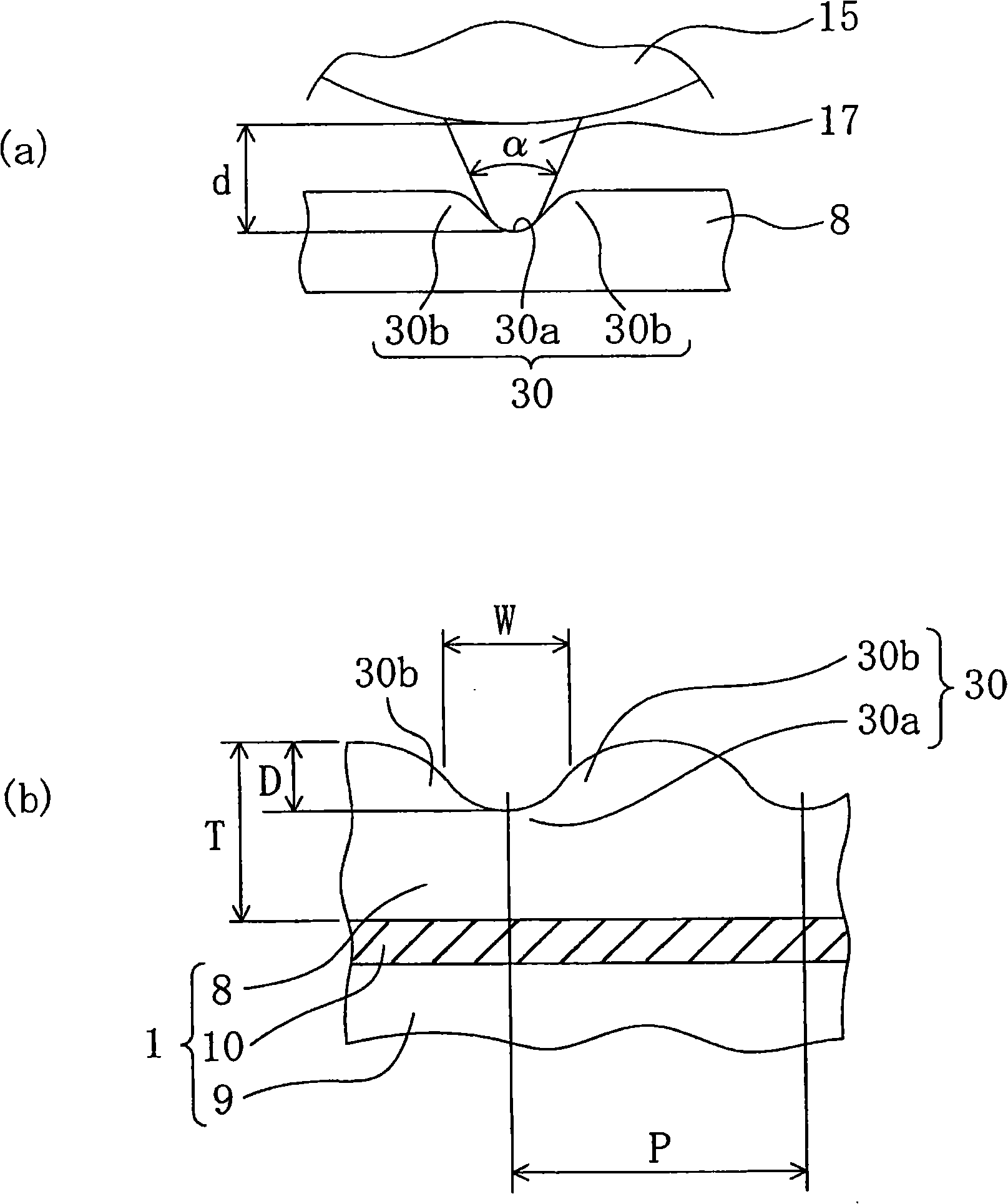

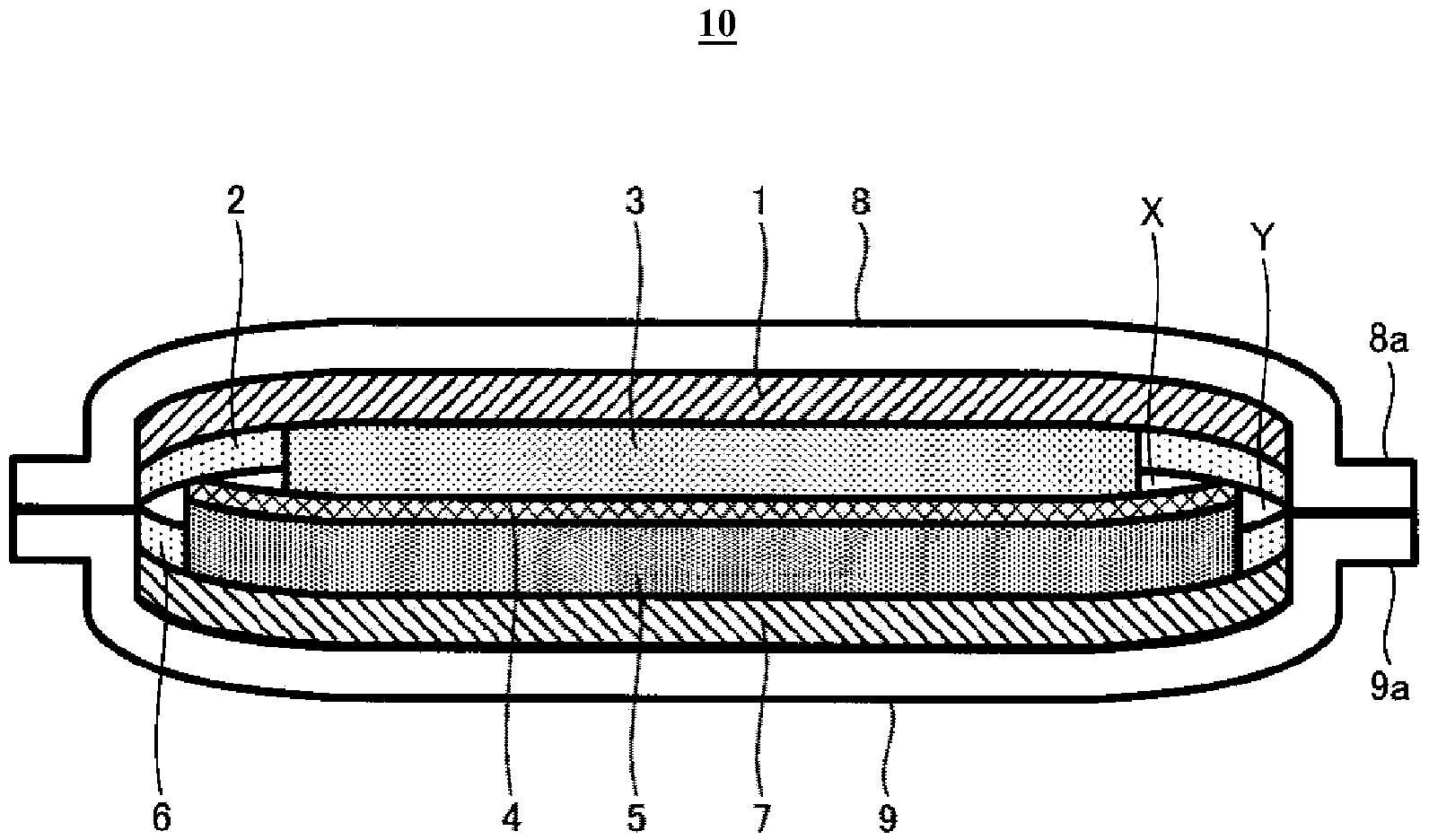

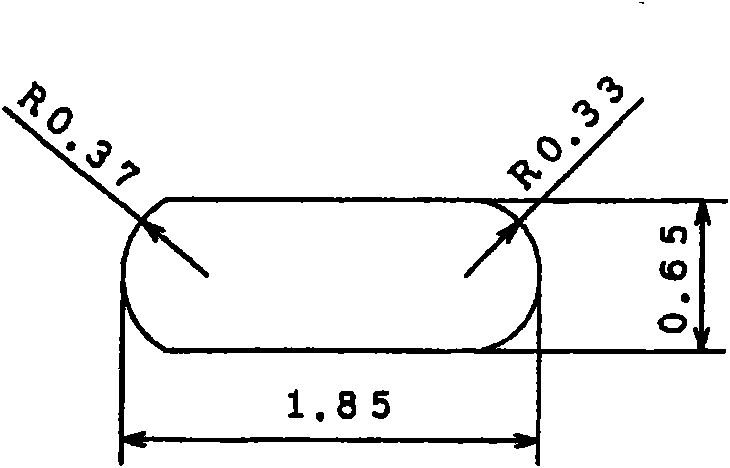

Secondary cell and its manufacturing method

InactiveCN101517816ACurb bendingInhibit sheddingElectrode rolling/calenderingFinal product manufactureBiomedical engineeringElectrode

The invention relates to a secondary cell which has an electrode group (5) fabricated by winding positive and negative electrode sheets (1, 2) each comprising a current collector (1) and mix layers (8, 9) formed on the current collector and containing active materials and a separator (3) interposed between the electrode sheet. Grooves (30) are formed in the surface of the mix layers (8, 9) of at least one of the positive and negative electrode sheets (1, 2). Each groove (30) has curvatures at the end portions (30b) of the side surfaces and the central portion (30a) of the bottom surface. The grooves (30) are continuously formed in the surfaces of the mix layers (8, 9) for on both sides of the electrode sheet (1) at intervals of 200 [mu]m or less along the length direction of the electrode sheet (1). The phases of the grooves(30) are shifted from one another.

Owner:PANASONIC CORP

Inflated tyre and vulcanized metal die thereof

InactiveCN1397440AThe effect of suppressing lodgingCurb bendingTyresTyre tread bands/patternsEngineeringDepth direction

A pneumatic tire comprises a tread portion comprising tread elements each provided with a sipe (4), the sipe (4) having an open top end and a bottom, and in a range from the open top to a certain depth, a configuration of the sipe in a plane parallel with the tread face comprising a zigzag part oscillating in the longitudinal direction of the sipe in the course from the open top to said certain depth.

Owner:SUMITOMO RUBBER IND LTD

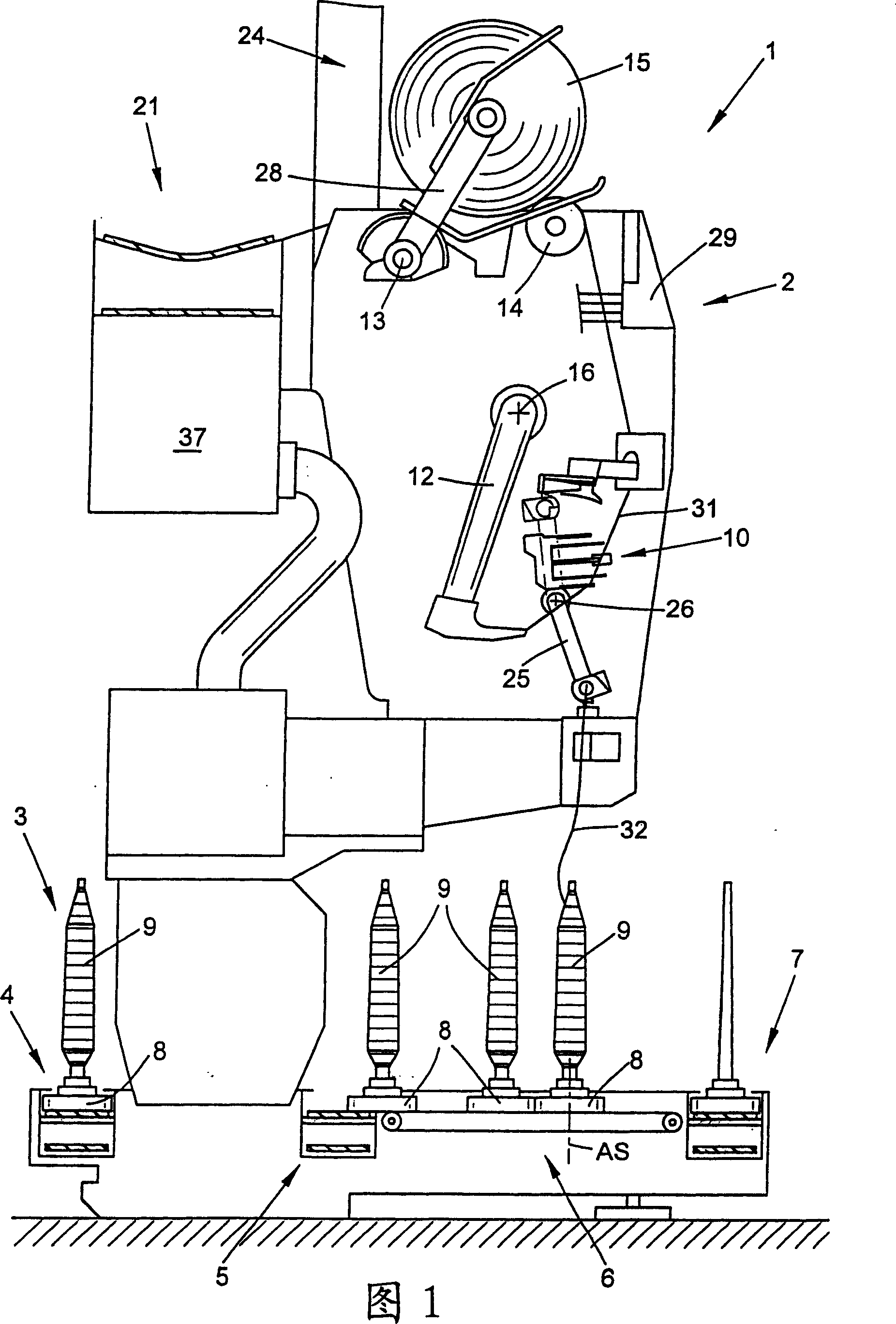

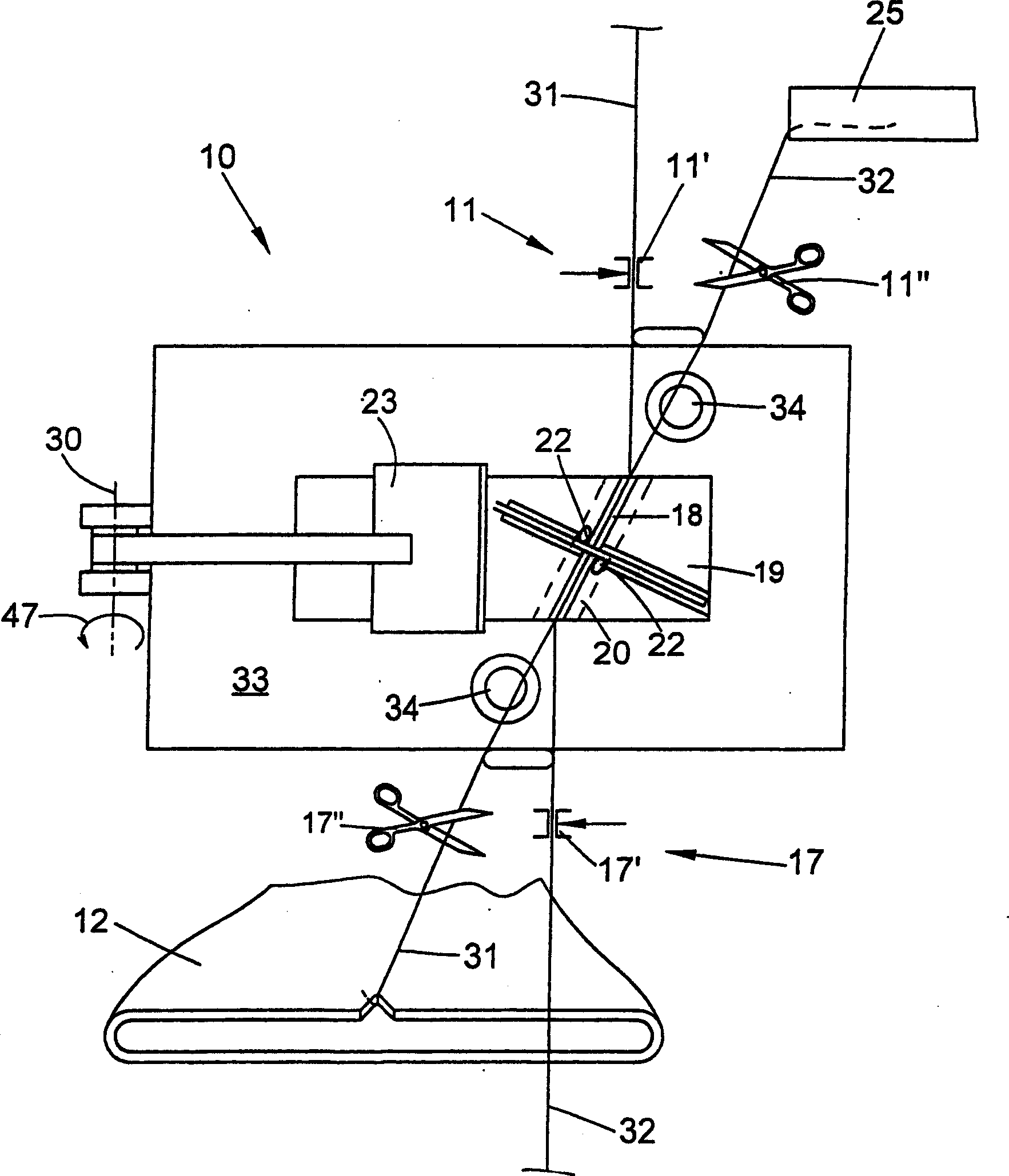

Apparatus for splicing yarns pneumatically

InactiveCN1629375AUniform appearanceAvoid interferenceFilament handlingPiercing arrangementsYarnEngineering

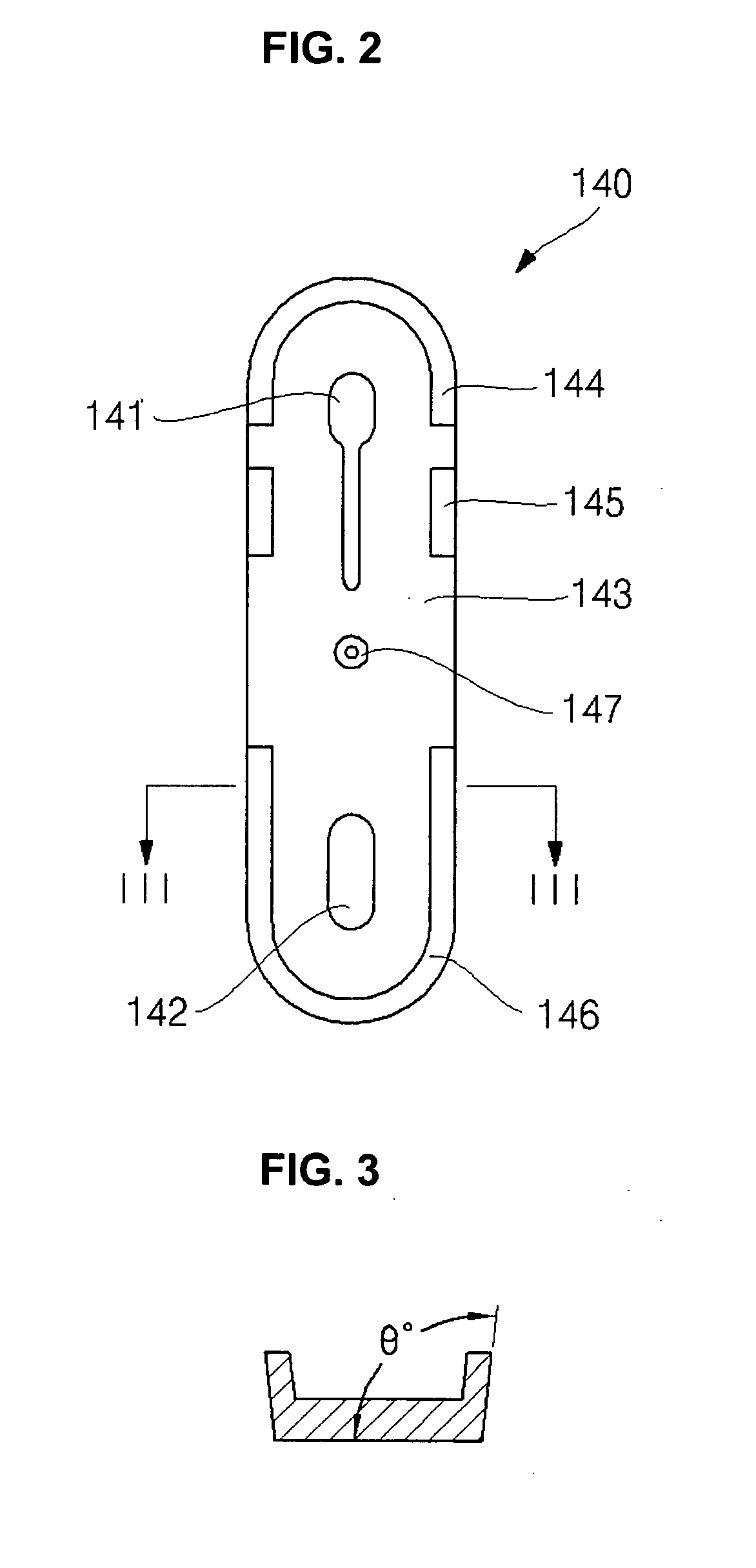

The invention relates to a yarn splicing device for pneumatically joining yarns, especially elastic yarns, with a splicing body having a vacuum-loadable splicing channel which can be operated by means of a The covering element is closed and, moreover, a support is arranged in the region of the splicing channel, which supports the fixing of the yarn ends. According to the invention, it is provided that the supporting element consists of a spring wire (36) and a cover element (23), wherein the spring wire (36) is positioned in an opposite position in the spliced body (19). In the groove (35) that moves angularly in the splicing channel (20), that is, the yarn ends (31, 32) to be spliced are clamped between the covering element (23) and the spring wire ( 36) Between.

Owner:SAURER GMBH & CO KG

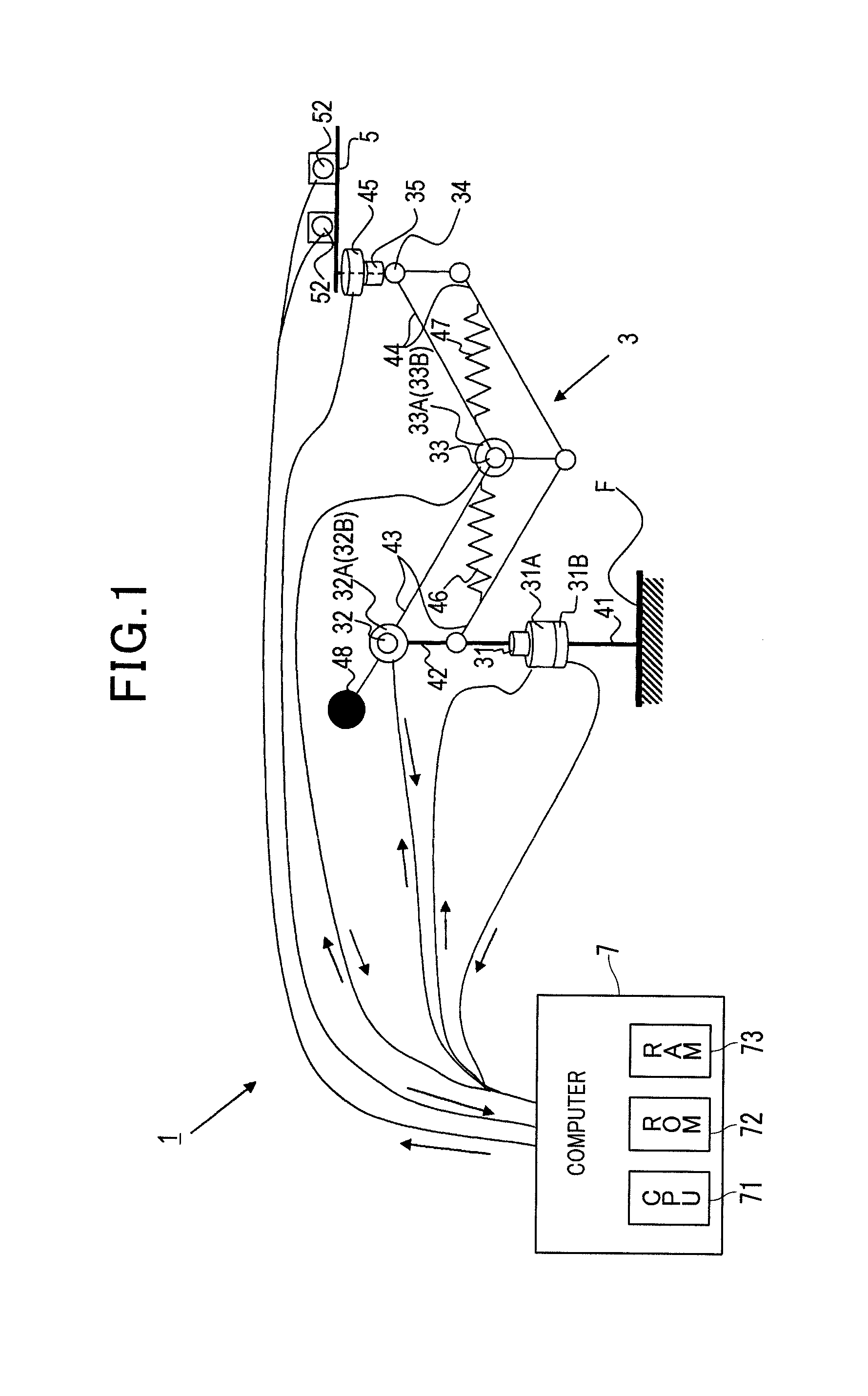

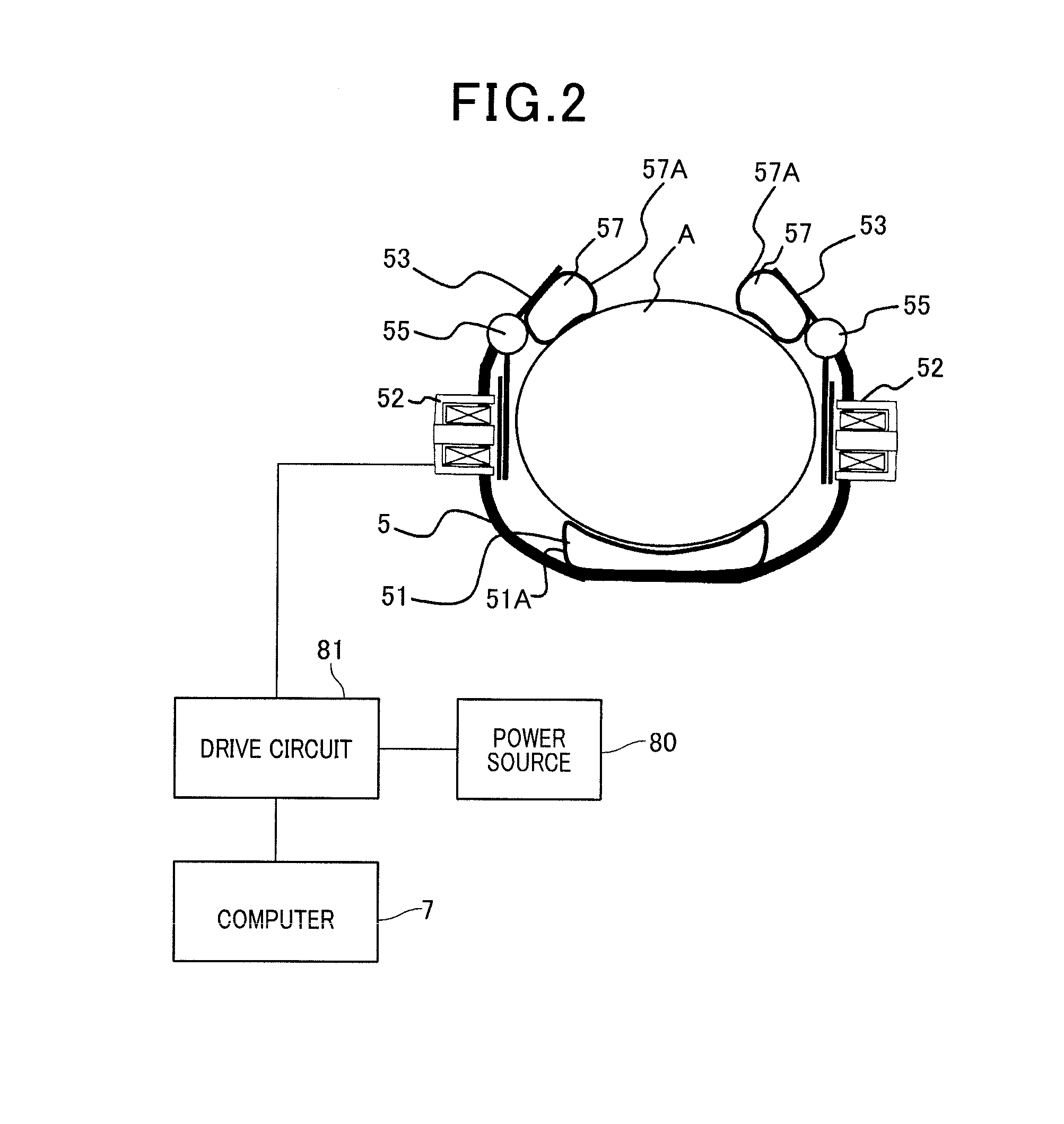

Apparatus for supporting body part of worker

InactiveUS20140014804A1Easily recognizeErroneous operation of apparatusDiagnosticsSurgeryBody segmentMechanical engineering

An apparatus for supporting a worker's body part, for example a surgeon's arm, is provided. The body part is supported by a base movably supported by a support. The apparatus has a free mode and a limitation mode, which are switchable. When it is determined that the body part is attempting to move the base or a fastening member, the operating mode is switched to the free mode. When it is determined that the body part is not attempting to move the base or the fastening member, the operating mode is switched to the limitation mode. The free mode allows the fastening member to fasten the body part on the base and allows a brake to release limitations to the motions of the base. The limitation mode allows the fastening member to release the body part from being fastened and allows the brake to limit the motions of the base.

Owner:DENSO CORP +2

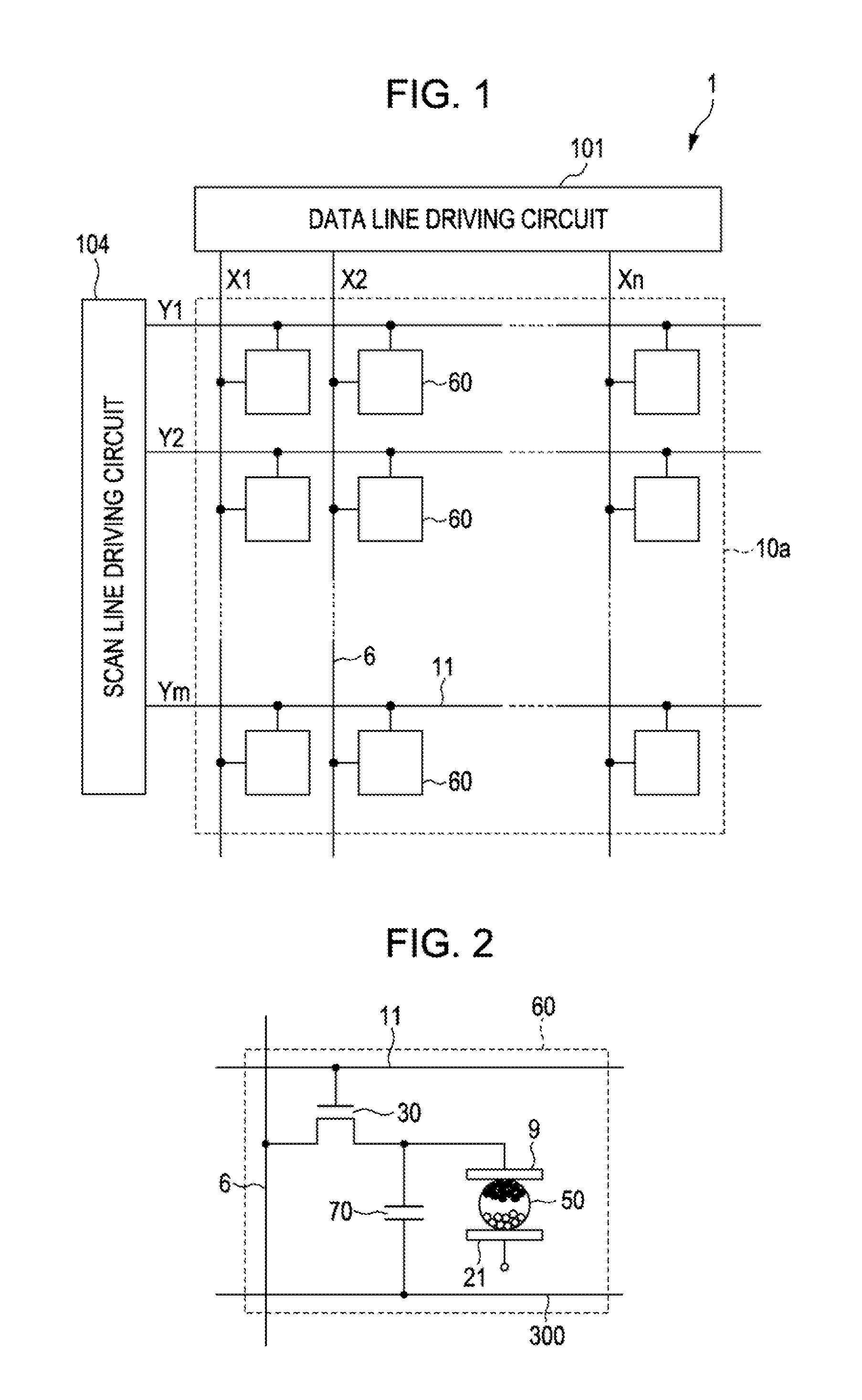

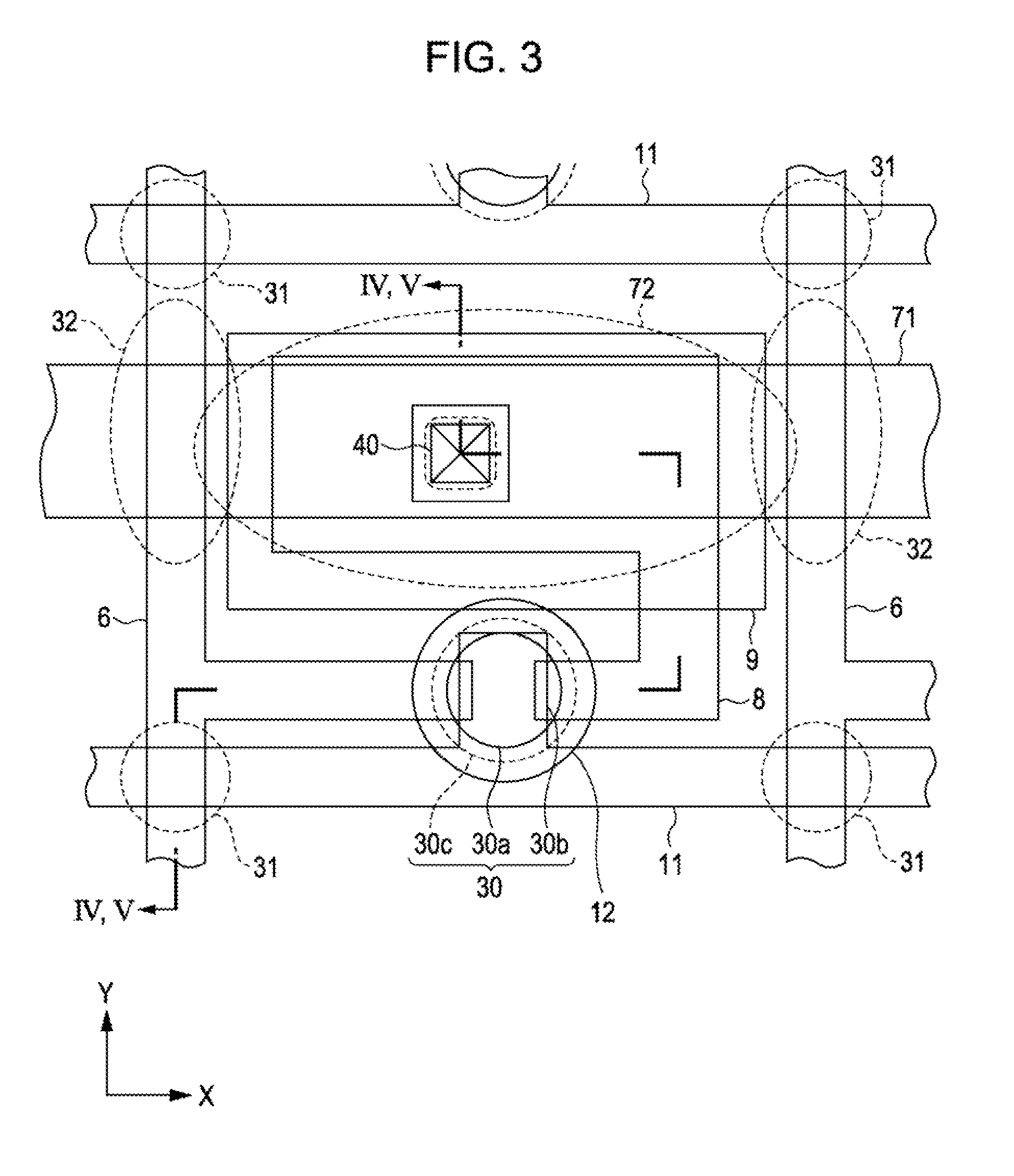

Substrate for semiconductor device including an island-shaped underlying film overlapping a transistor, method of manufacturing the same, semiconductor device and electronic device

ActiveUS8330194B2Curb bendingLow costSolid-state devicesSemiconductor/solid-state device manufacturingElectronSemiconductor

A substrate for a semiconductor device is provided, including: a substrate; a transistor, formed on the substrate, that includes a semiconductor layer, and a gate electrode disposed so as to be opposed to the semiconductor layer with a gate insulating film interposed therebetween; and an underlying film disposed below the semiconductor layer, as an underlayer of the transistor, and formed in an island shape so as to at least partially overlap the semiconductor layer, in a plan view of the substrate.

Owner:E INK CORPORATION

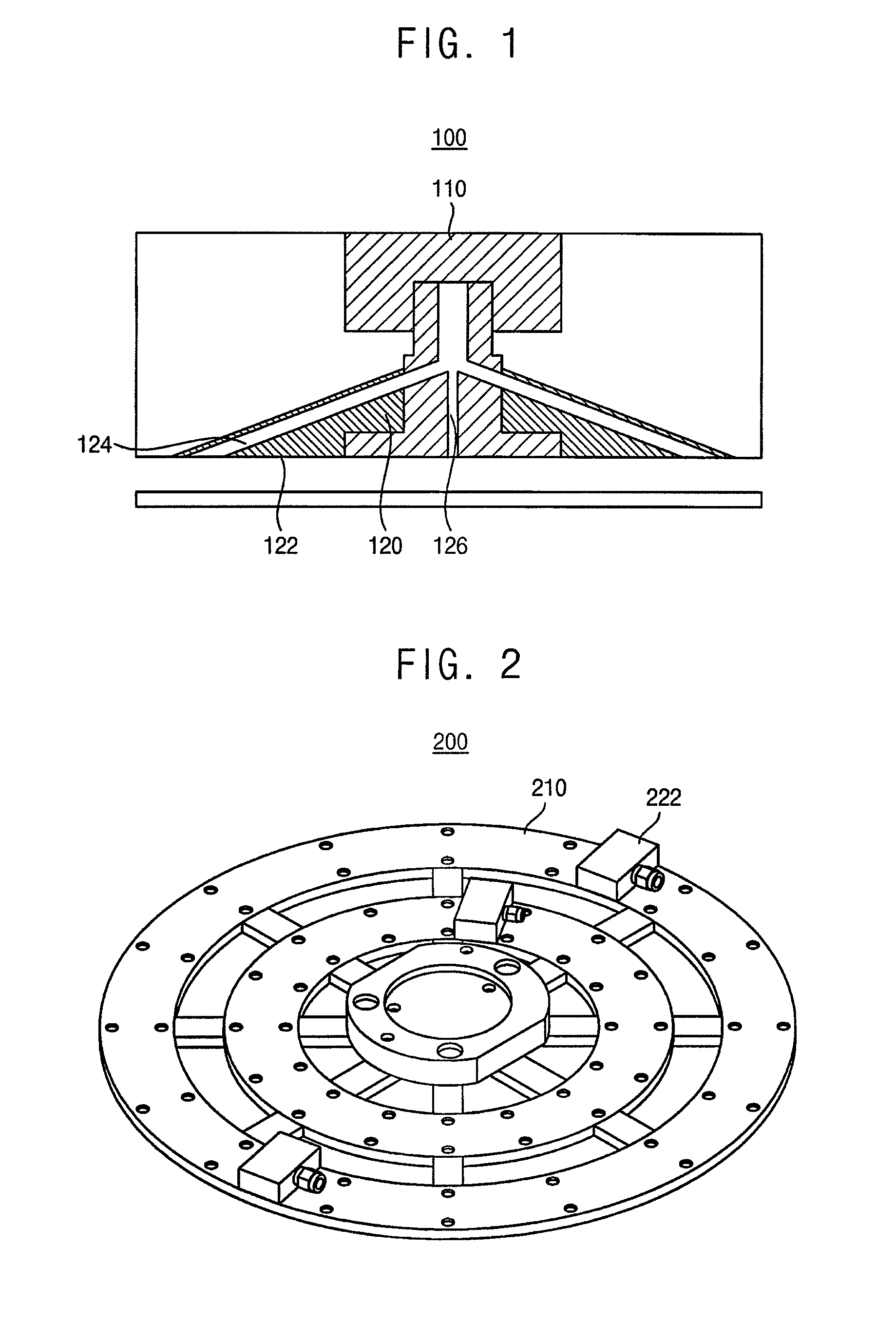

Process and apparatus for producing single crystal

InactiveUS20070020872A1Easy temperatureImprove efficiencyPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalSingle crystal growth

Disclosed are a production apparatus and a production process in which a thick and high-quality single crystal film can be formed on both sides of a colored substrate. Both single crystal growth surfaces of a colored substrate which has been fixed through a substrate holder within a reactor are substantially evenly heated by at least one pair of infrared irradiation devices each comprising an infrared generating source and a reflecting mirror to produce a single crystal.

Owner:CRYSTAL SYST

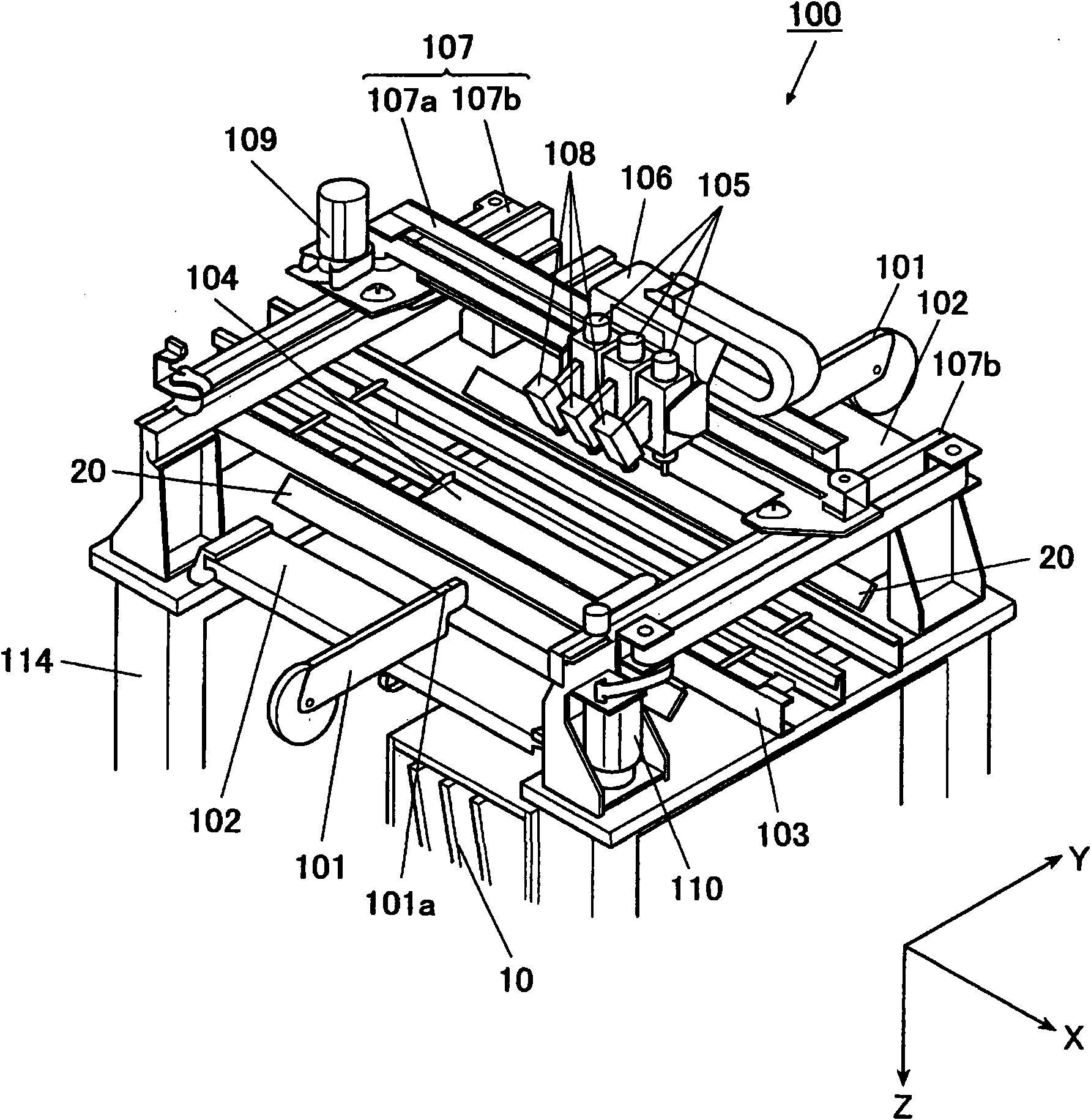

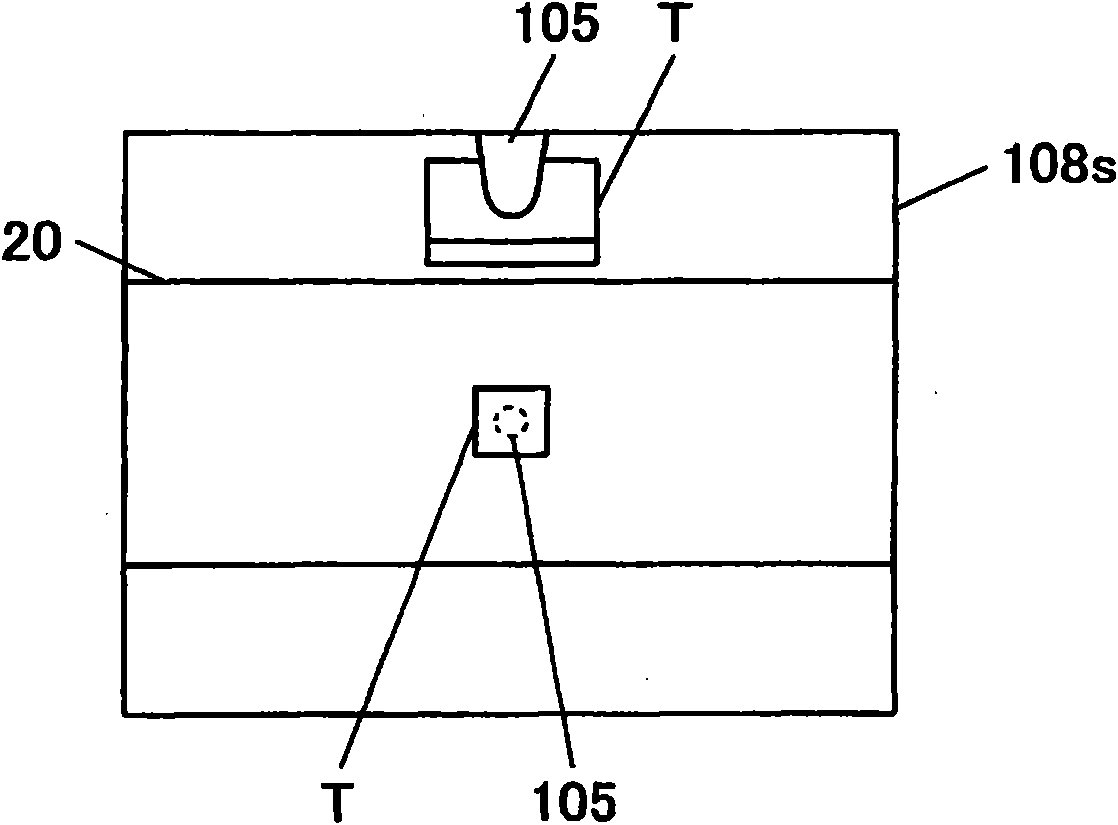

Electronic parts installation apparatus

ActiveCN101902902AEasy to processRestrains bending and twistingElectrical componentsEngineeringNozzle

The present invention provides an electronic parts installation apparatus, capable of stably and accurately recognizing hold mode of the electronic parts. The apparatus includes a substrate holding part; a member supply part for supplying the electronic parts; a loading head having an adsorption nozzle; a loading head shifting mechanism capable of locating the loading head arbitrarily; a filming unit arranged on the loading head to film the electronic part absorbed by the adsorption nozzle; a filming reflection mirror extended between the member supply part and the substrate holding part and having only one reflecting plane; and an image processing device for judging the position and angle of the absorbed electronic part relative to the absorption nozzle according to the filming image of the electronic part obtained through reflection of the filming reflection mirror, wherein the reflecting plane of the filming reflection mirror is an inclined plane which adopts a bisecting line between a central line of the adsorption nozzle and the line of sight of the filming unit as its perpendicular line.

Owner:JUKI CORP

Endoscopically inserting surgical tool

An endoscopically inserting surgical tool is composed of an elongated flexible cord to be passed through a tool guide channel on an endoscope, and a tool action mechanism mounted on a fore distal end of the flexible cord to be projected out of the tool guide channel. The flexible cord has such a length that, when the tool action mechanism is projected out of a tool exit opening at the end of the tool guide channel, a proximal end portion of the flexible cord still remains outside and rearward of a tool entrance way which is provided on a manipulating head grip of the endoscope as an approach to the tool guide channel. A proximal end portion of the flexible cord is gripped in a rotary tool adjustor which is manipulable to turn the tool action mechanism clockwise or counterclockwise together with the flexible cord in the tool guide channel of the endoscope.

Owner:FUJIFILM CORP

Solid cell

ActiveCN103620856ASuppress short circuitInhibition of short circuit conditionsCell seperators/membranes/diaphragms/spacersFinal product manufactureInsulation layerOptoelectronics

A primary objective of the present invention is to provide a solid cell with which it is possible to alleviate short-circuits between electrodes. The present invention is a solid cell, comprising a first electrode layer, a second electrode layer, and a solid electrolyte layer which is positioned between the first electrode layer and the second electrode layer. A first insulation layer is positioned upon the exterior circumference of the first electrode layer. The size of the stack face of the first electrode layer, taking the stack direction of the first electrode layer, the solid electrolyte layer, and the second electrode layer as the direction of the normal thereof, is smaller than the size of the stack face of the solid electrolyte layer. When viewed from the stack direction, the outer edge of the solid electrolyte layer is located upon the exterior circumference of the first electrode layer, and the outer edge of the first insulation layer is located on the exterior circumference of the solid electrolyte layer. The first electrode layer, the first insulation layer, and the solid electrolyte layer are positioned such that the outer edge of the first insulation layer and the end parts of the solid electrolyte layer make contact.

Owner:TOYOTA JIDOSHA KK

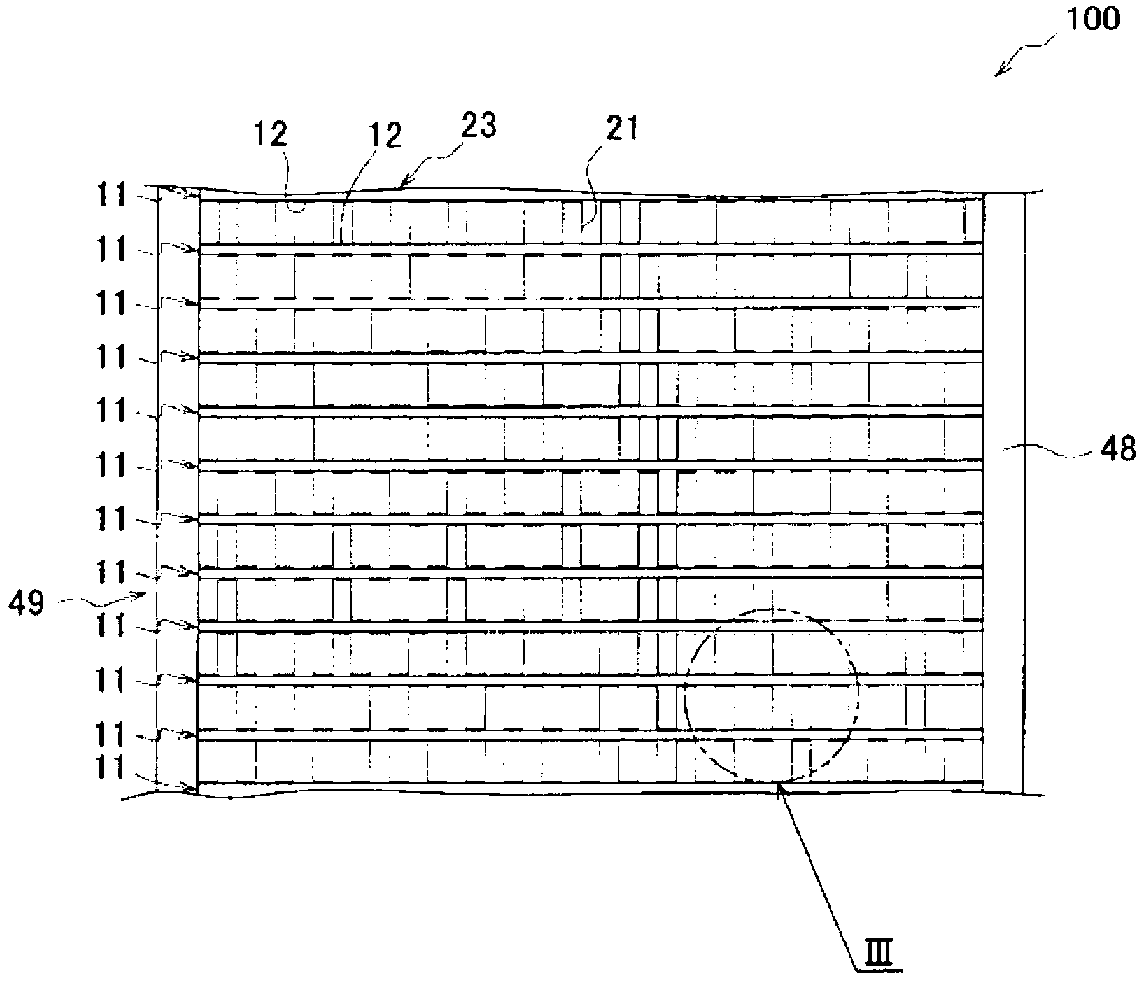

Display device and TV receiver

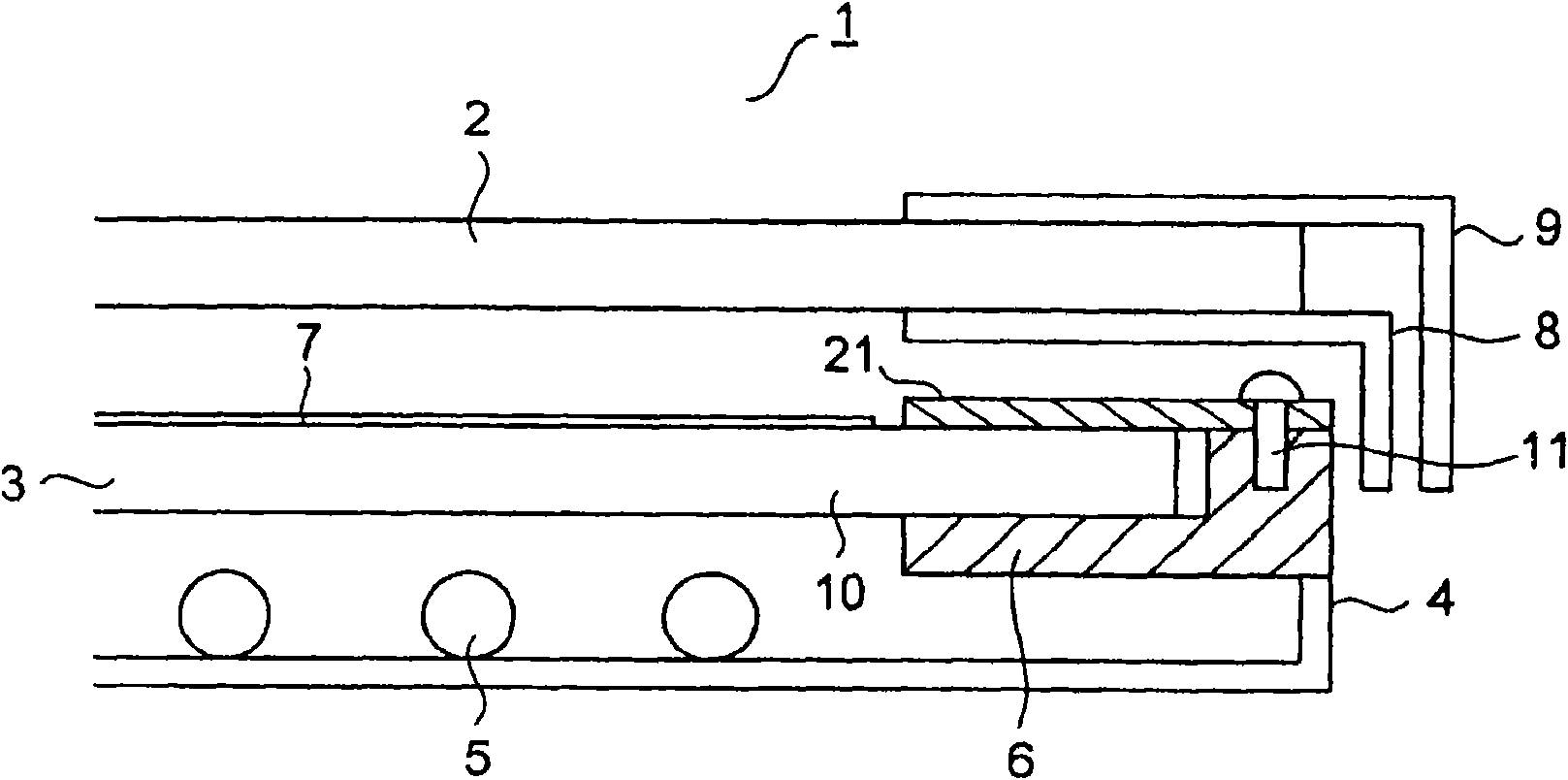

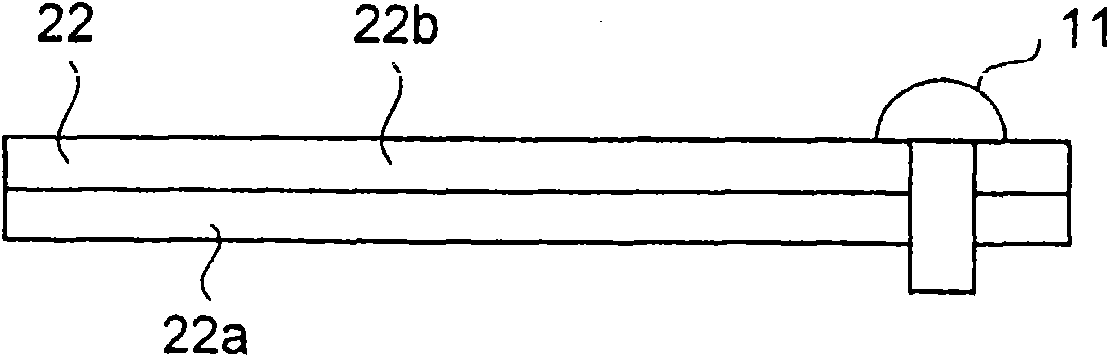

InactiveCN101681058ACurb bendingScalable configurationTelevision system detailsElectric lightingDisplay deviceEngineering

A display device has a light source (5), a diffusion plate (10) for diffusing light emitted from the light source, a support base (6) for supporting the diffusion plate, an optical sheet (7) placed onthe diffusion plate, a diffusion plate retainer (21) attached to the support base and holding the diffusion plate between itself and the support base by pressing the diffusion plate while avoiding the optical sheet, and a display panel (2) facing the diffusion plate. A warp of the diffusion plate (10) due to a temperature rise can be suppressed by pressing the diffusion plate (10) by using the highly rigid diffusion plate retainer (21). Because the optical sheet (7) is not pressed by the diffusion plate retainer (21), the optical sheet (7) can be placed so as to be able to expand and retract.Therefore, wrinkles in the optical sheet due to a temperature rise can be prevented. Consequently, even if the diffusion plate (10) is increased in size, an excellent display image can be obtained.

Owner:SHARP KK

Endoscopically inserting surgical tool

An endoscopically inserting surgical tool is composed of an elongated flexible cord to be passed through a tool guide channel on an endoscope, and a tool action mechanism mounted on a fore distal end of the flexible cord to be projected out of the tool guide channel. The flexible cord has such a length that, when the tool action mechanism is projected out of a tool exit opening at the end of the tool guide channel, a proximal end portion of the flexible cord still remains outside and rearward of a tool entrance way which is provided on a manipulating head grip of the endoscope as an approach to the tool guide channel. A proximal end portion of the flexible cord is gripped in a rotary tool adjustor which is manipulable to turn the tool action mechanism clockwise or counterclockwise together with the flexible cord in the tool guide channel of the endoscope.

Owner:FUJIFILM CORP

Special-shaped wire section forming device

Owner:HITACHI METALS LTD

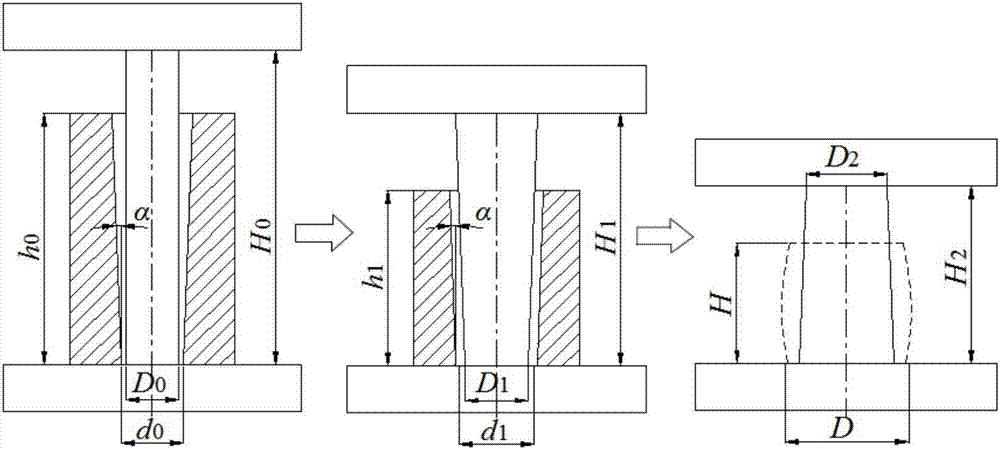

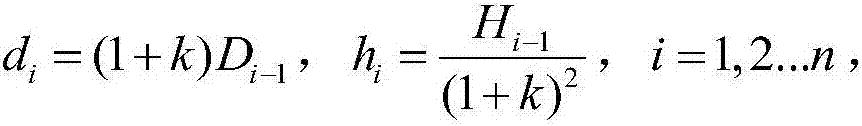

Upsetting forming method of ultra-large height-diameter ratio metal blank

ActiveCN106964735AStable and uniform deformationQuality improvementMetal-working apparatusInstabilityDiameter ratio

The invention provides an upsetting forming method of an ultra-large height-diameter ratio metal blank. The method comprises the following steps that (1), according to the initial blank size, the mold interior upsetting blank diameter increasing rate and the free upsetting blank height-diameter ratio, the mold interior upsetting pass is determined to plan the upsetting technological process; (2), according to the target size of an upsetting forming part, the free upsetting blank height-diameter ratio and the mold interior upsetting blank diameter increasing rate, the upsetting ratios of all upsetting passes are determined; (3), an annular mold with the demolding slope is adopted for mold interior upsetting, the main working size can be determined by means of the method that the upsetting blank sizes of all the passes are calculated according to the upsetting ratios of all the passes; and (4), upsetting forming is conducted, specifically, upsetting of all the passes is sequentially conducted through a press machine and a mold according to the planned upsetting process, and finally the needed upsetting forming part is obtained. According to the upsetting forming method of the ultra-large height-diameter ratio metal blank, the phenomenon of upsetting instability of the ultra-large height-diameter ratio blank can be effectively avoided, upsetting bending of the blank is avoided, upsetting deformation uniformity can be adjusted and controlled, and the upsetting capacity is lowered, so that the effects of upsetting quality improving, upsetting energy consumption reducing and device upsetting size range enlarging are achieved.

Owner:WUHAN UNIV OF TECH

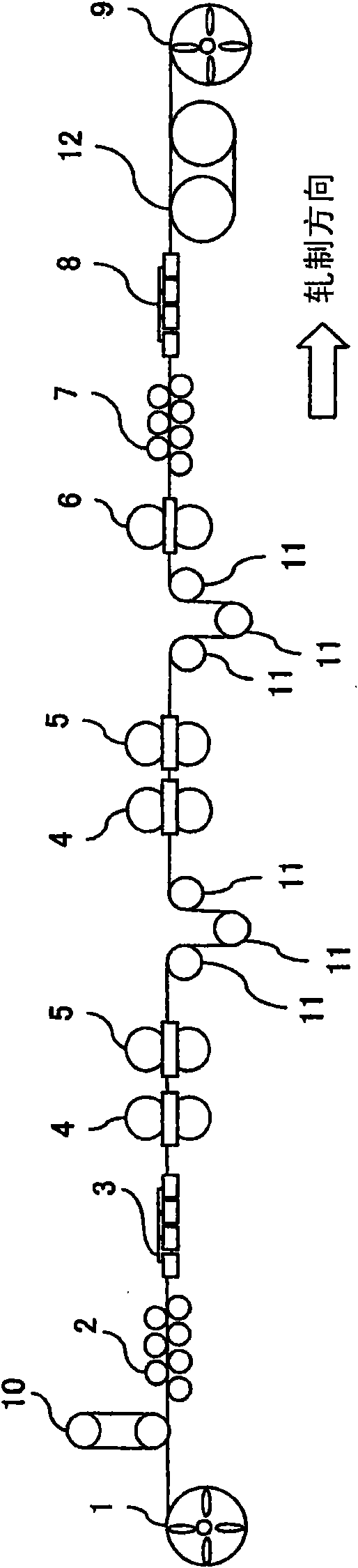

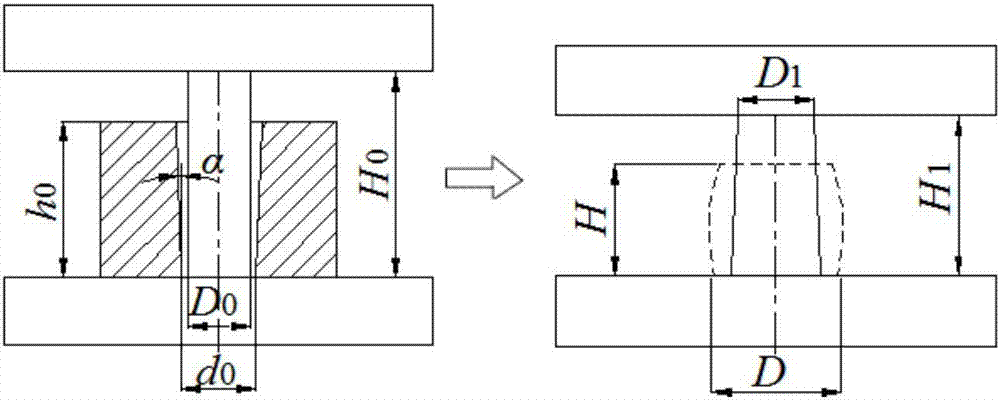

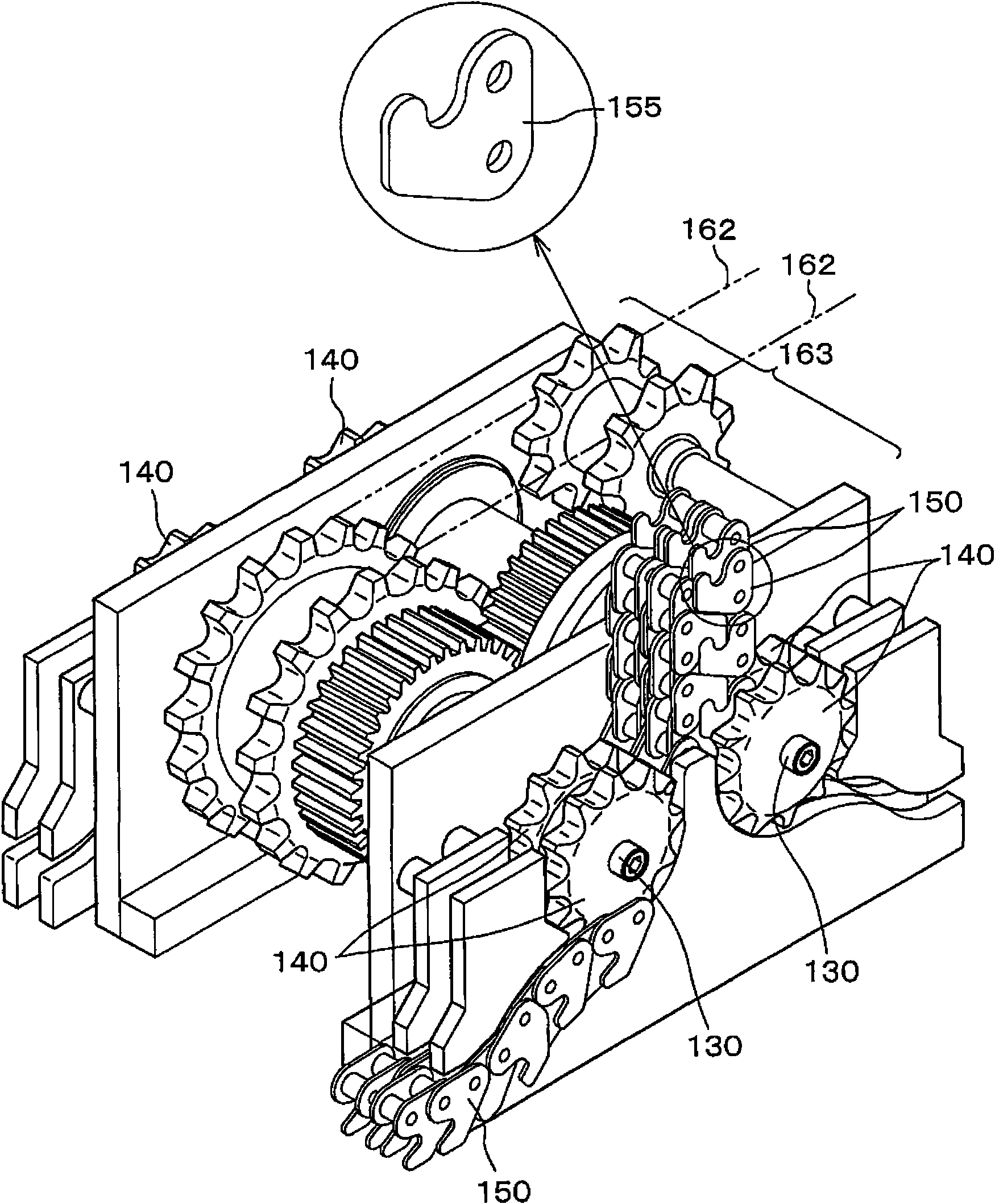

Engagement chain type driving device

ActiveCN101670991ARealize advance and retreat actionsCurb bendingPortable liftingLifting framesEngineeringSprocket

The invention provides an engagement chain type driving device which can realize the advance and retreat drive without the auxiliary guide mechanism, and can realize the reduction in size and light, and ensure the high free degree for the design of other parts, the arrangement position of the devices, and the like, and can make the maintenance easy and reduce the coveying load of the workpieces, at the same time, when the suepension or suspension arm supporting is adopted, the auxiliary guide mechanism is also not required. The invention relates to an engagement chain type driving device including a pair of driving sprockets, a pair of engagement chains, and a driving source, wherein the inner tooth plates and outer tooth plates being brought opposite to each other and into contact with each other when the engagement chains are integrated by the pair of driving sprockets, such that the flat surfaces hold the chain engagement position.

Owner:TSUBAKIMOTO CHAIN CO

Secondary battery and the fabrication method thereof

ActiveUS20070190411A1Improve efficiencySuppress bendingConveyorsFinal product manufactureEngineeringElectrical and Electronics engineering

A secondary battery, which has no raw material injection spot and a burr on a lower surface of the insulating member. The sidewalls are formed on the opposite side to the side on which bending stress is applied, and the sidewalls act as a structural resistor, which result in preventing the plate from bending. The insulating member inserted into the container has an inversely stepped part to keep the insulating member from escaping from the container. A fabrication method of the secondary battery whereby an insulating member is prepared by inserting a raw material from the side on which the sidewall is to be formed into a mold and solidifying the inserted raw material, the insulating member is positioned over the electrode assembly inserted into a container, and a cap is coupled to an opening of the container with the insulating member positioned over the electrode assembly.

Owner:SAMSUNG SDI CO LTD

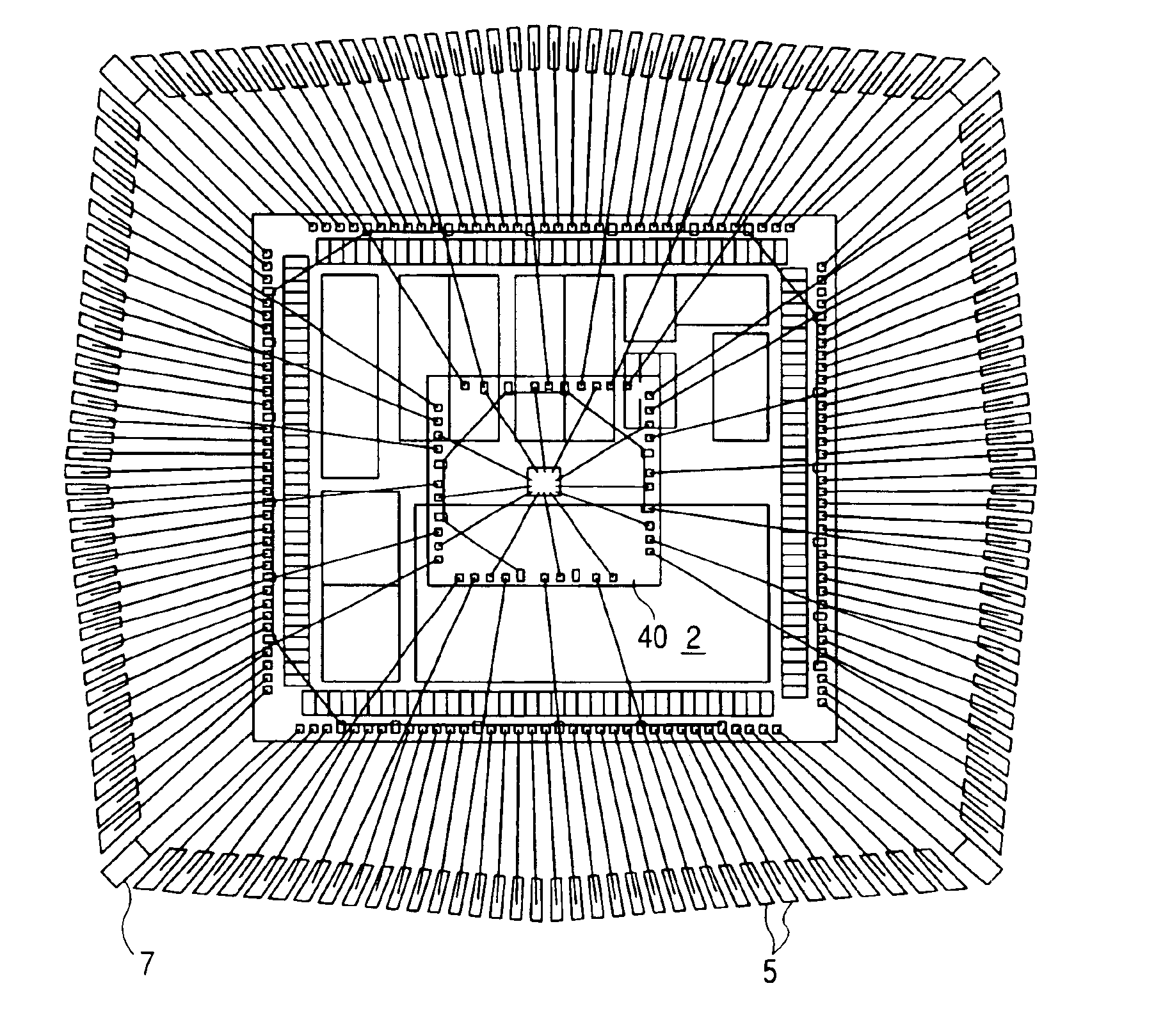

Semiconductor device

InactiveUS6930380B2Reduce in quantityCurb bendingTransistorSemiconductor/solid-state device detailsSemiconductor chipEngineering

A semiconductor device includes a semiconductor chip, a plurality of bonding pads which are formed on a main surface of the semiconductor chip and include first power source bonding pads, second power source bonding pads and a plurality of signal bonding pads, a plurality of leads which are arranged around the semiconductor chip and include first power source leads and a plurality of signal leads, a plurality of bonding wires which include first bonding wires for connecting the first power source bonding pads with the first power source leads, second bonding wires for connecting the first bonding pads with second bonding pads and third bonding wires for connecting the plurality of signal bonding pads with the plurality of signal leads, and a sealing body which seals the semiconductor chip, the plurality of bonding wires and some of the plurality of leads.

Owner:RENESAS ELECTRONICS CORP +1

Bending processing method of heat exchanger

ActiveCN102699155APrevent bucklingReduce intensityEvaporators/condensersTubular elementsEngineeringContact position

The invention discloses a bending processing method of a heat exchanger. According to the method, the heat exchanger can be bent only by holding a position of a holding part of the heat exchanger and enabling the holding part to bend according to a ruled track through controlling gestures of the holding part without using a bending mould. At this moment, a contact position of a free part of the heat exchanger which is not held and a guide part is determined by a reacting force generated during the bending process, and no limitation force is generated by the free part which is not held, so that buckling generated by the heat exchanger during the bending process can be avoided. The bending processing method of the heat exchanger, disclosed by the invention, can suppress deformation and buckling of heat transfer fins.

Owner:SHANGHAI JIAO TONG UNIV +1

Nozzle for holding a substrate and apparatus for transferring a substrate including the same

InactiveUS20110042983A1Lower its compressed pressureReduce pressureGripping headsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A nozzle for holding a substrate may include a nozzle head and a nozzle body. The nozzle head may provide the substrate with compressed air. The nozzle body may be connected to the nozzle head. The nozzle body may be arranged facing the semiconductor substrate. The nozzle body may have a substantially flat supporting surface which provides a uniform gap between the substrate and the nozzle body. The nozzle body may have a first passageway which allows the compressed air to pass through toward the substrate to form a vacuum between the substantially flat supporting surface and the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

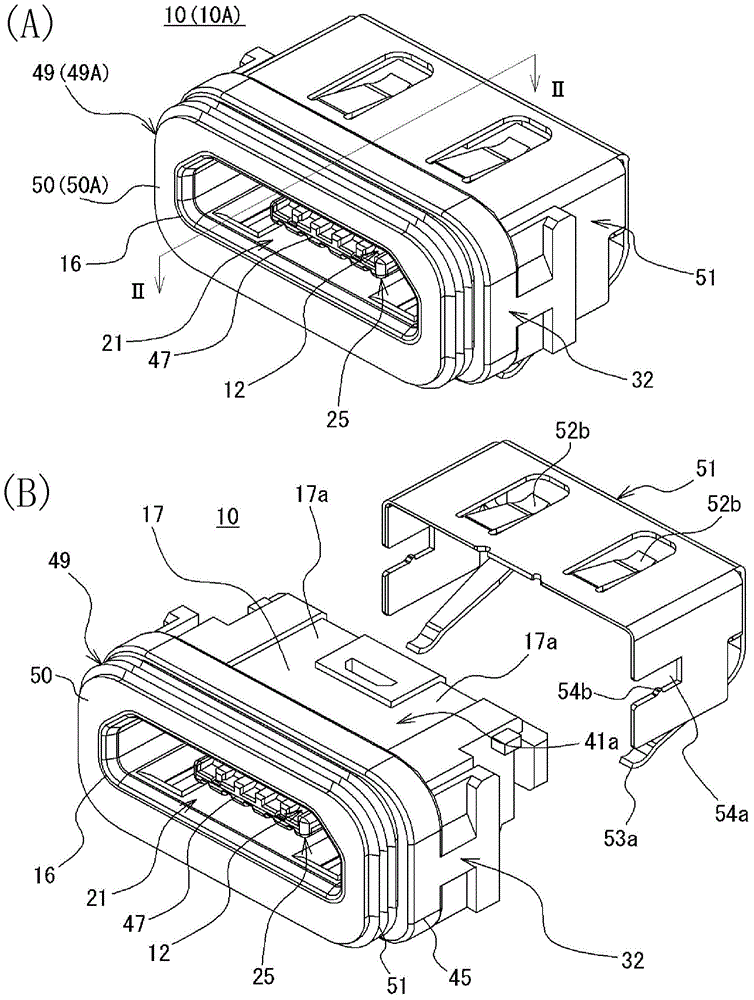

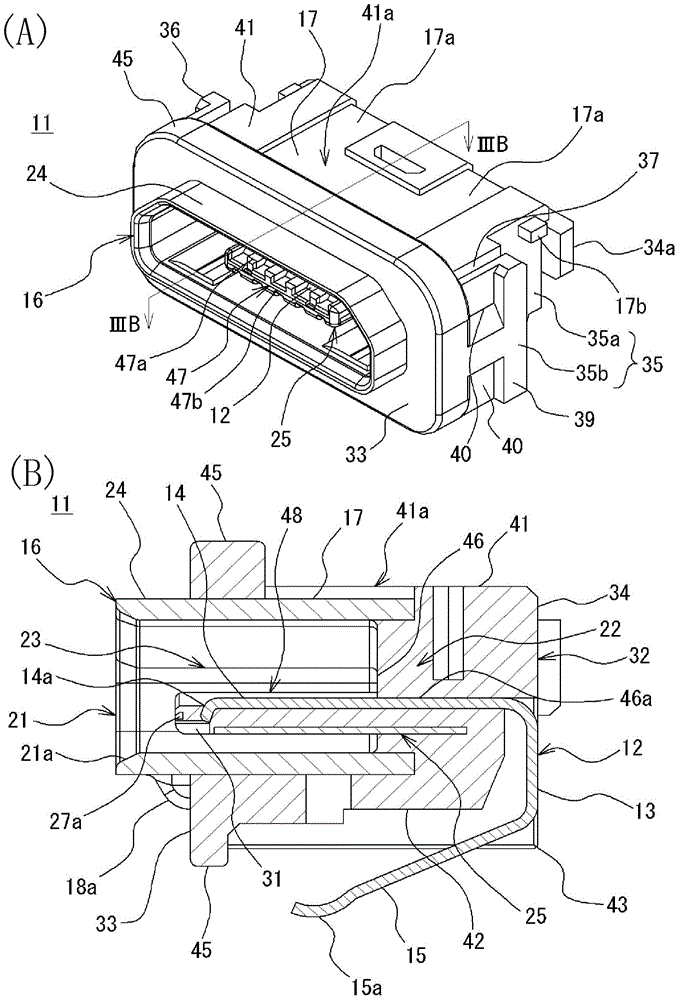

Waterproof connector and manufacturing method thereof

InactiveCN104103949AWell formedCurb bendingContact member cases/bases manufactureContact member assembly/disassemblyBiomedical engineering

Owner:JST MFG CO LTD

Method for manufacturing impact absorber for vehicle

InactiveCN101176964AHigh tensile strengthMeet the intensityFurnace typesBumpersRoll formingInduction hardening

Owner:AISIN SEIKI KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com