Secondary cell and its manufacturing method

A secondary battery and manufacturing method technology, which is applied in secondary battery manufacturing, secondary battery, electrode manufacturing, etc., can solve the problems of reduced electrolyte impregnation and uneven distribution of electrolyte, and achieves excellent impregnation and cycle characteristics and excellent reliability, the effect of suppressing internal short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

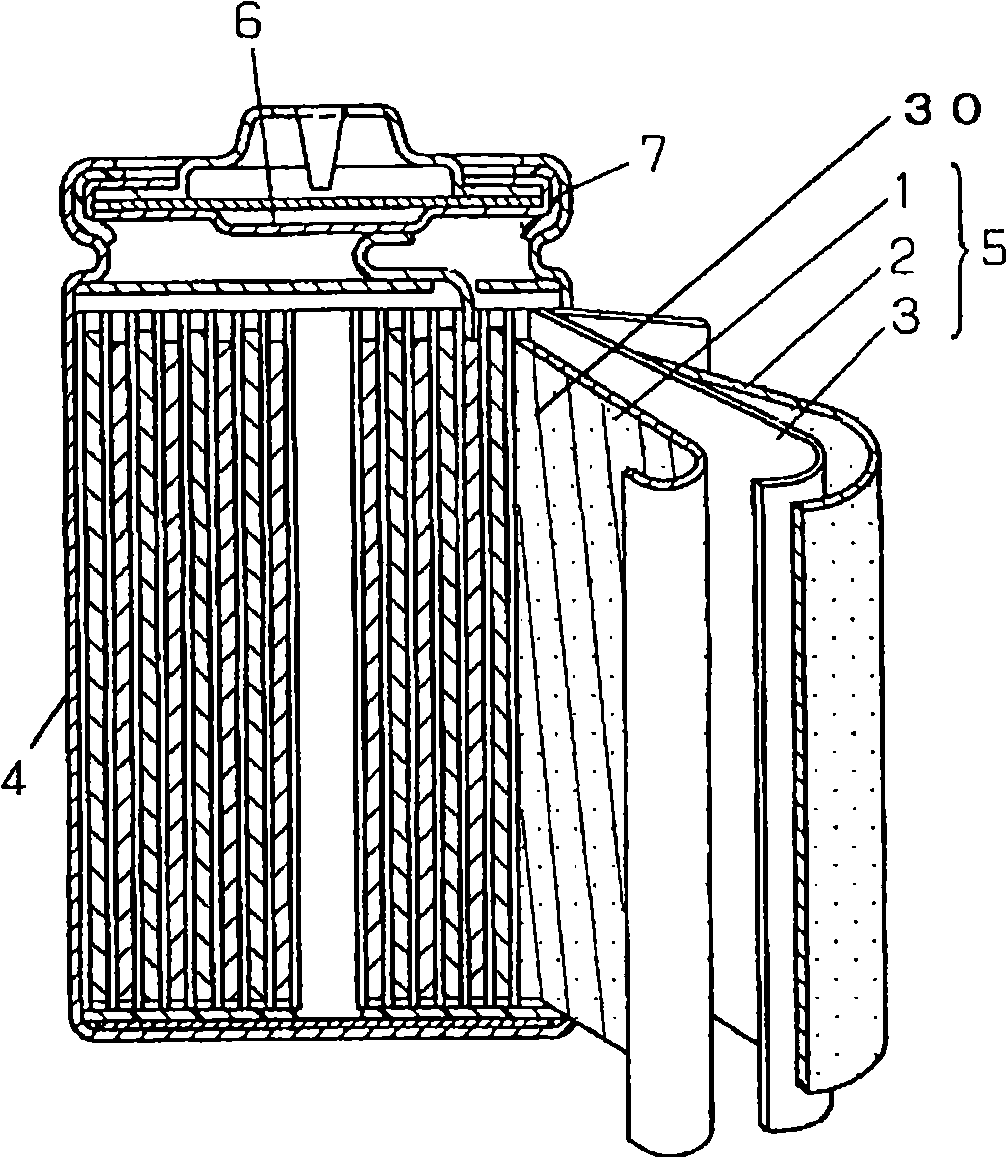

[0099] First, 100 parts by weight of lithium cobaltate as an active material, 2 parts by weight of acetylene black as a conductive agent relative to 100 parts by weight of an active material, and 2 parts by weight of acetylene black as a binder relative to 100 parts by weight of an active material The polyvinylidene fluoride of the agent was stirred and kneaded with an appropriate amount of N-methyl-2-pyrrolidone, thereby preparing a positive electrode mixture slurry. This positive electrode mixture slurry was coated on a current collector made of aluminum foil with a thickness of 15 μm, dried, and press-worked to a total thickness of 170 μm.

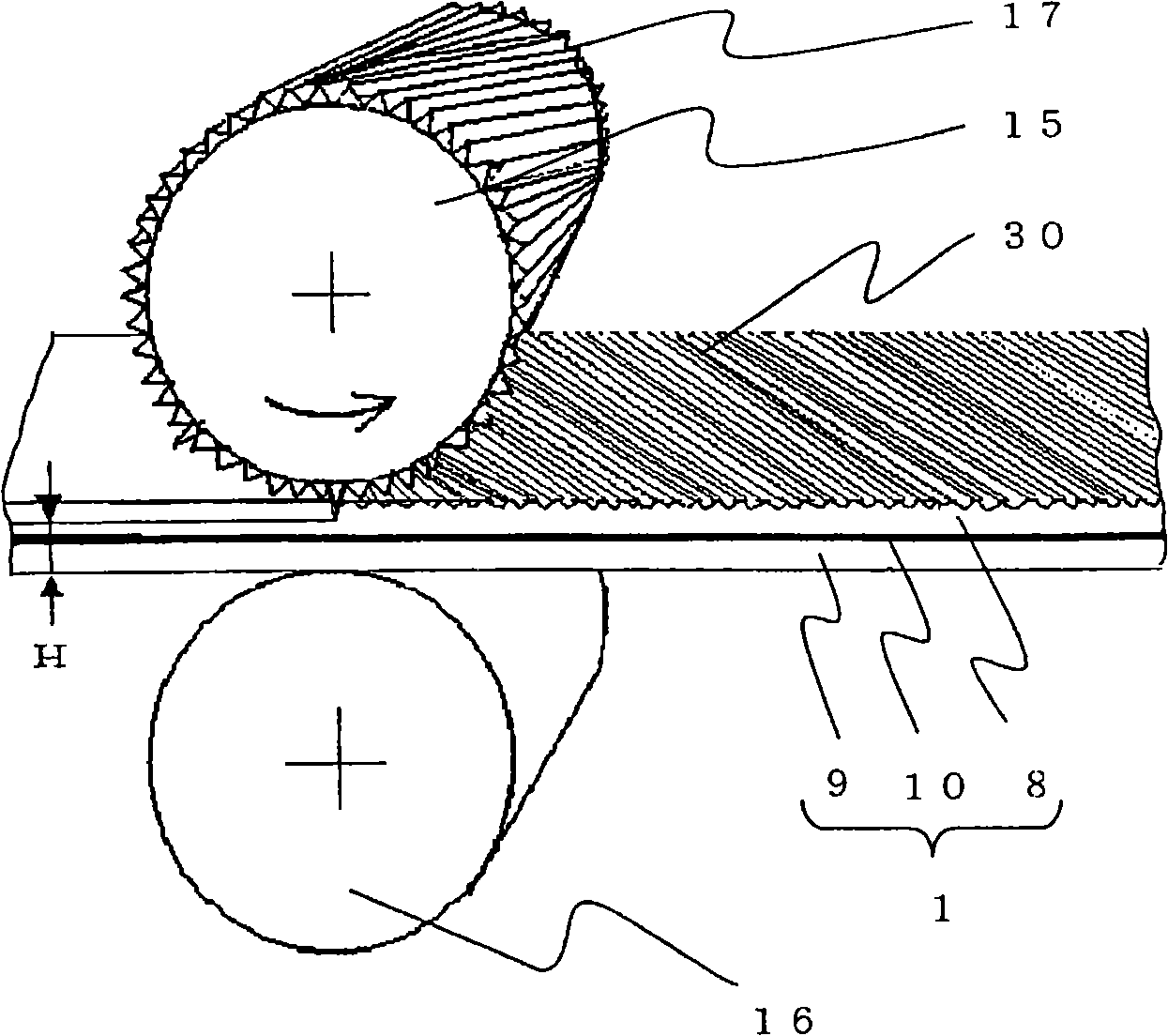

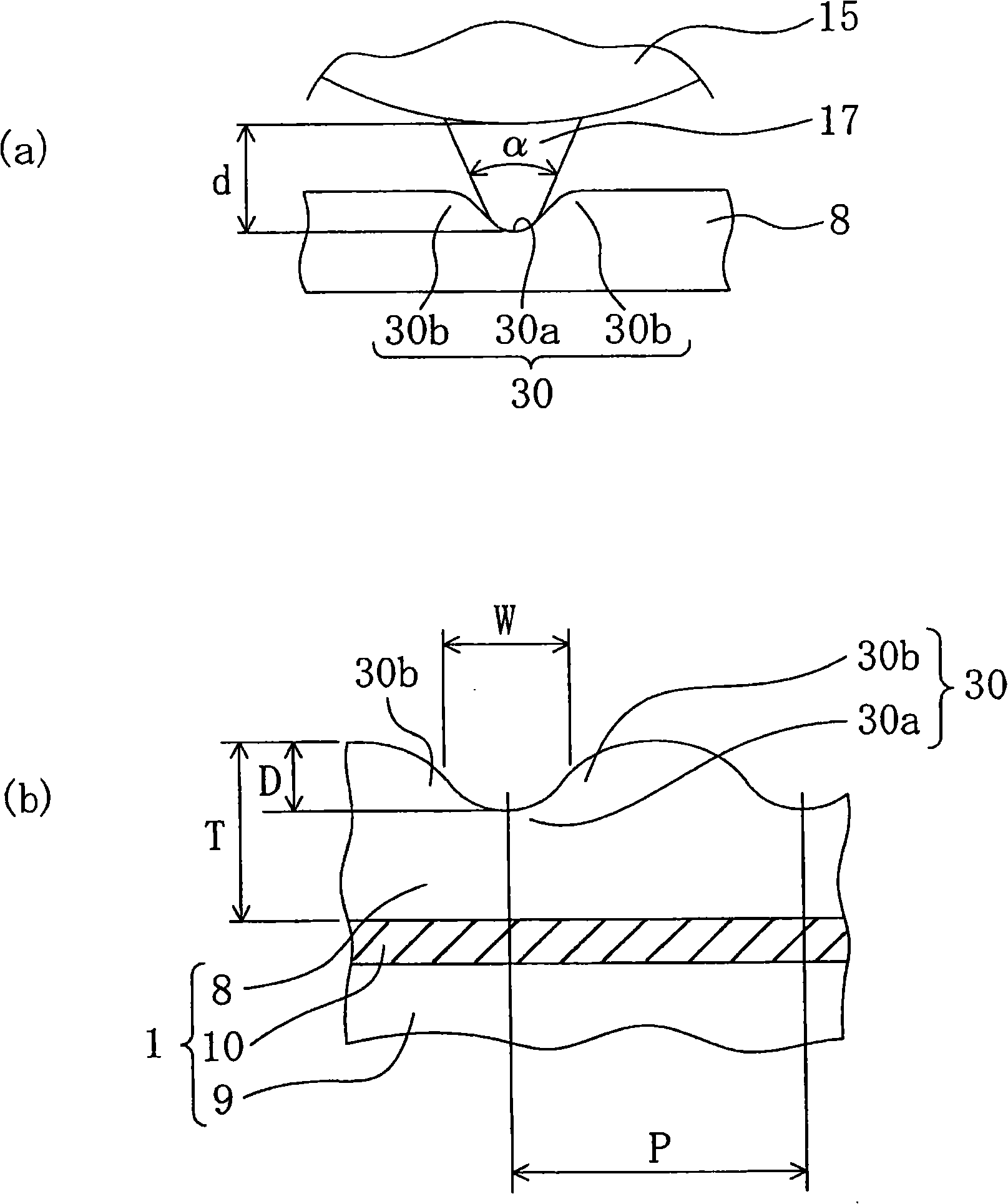

[0100] Secondly, if image 3 As shown in (a), prepare the upper roll 15 formed with the convex portion 17 having a tip angle α of 115° and a height d of 25 μm inclined at an angle of 45° with respect to the central axis of the upper roll 15, and one without the convex portion. Lower roll 16, such as figure 2 As shown, the press-worke...

Embodiment 2

[0106] An electrode group was produced in the same manner as in Example 1, except that grooves 30 were formed on both surfaces of the positive electrode plate 1 using the same roll as the upper roll 15 used in Example 1 as the lower roll 16 . In addition, the grooves 30 formed on both sides of the positive electrode plate 1 are as Figure 6 As shown in (a), an inclination angle of 45 degrees is formed with respect to the longitudinal direction of the positive electrode plate 1 , and the phases are symmetrical on both sides of the positive electrode plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com