Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

511results about "Piercing arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

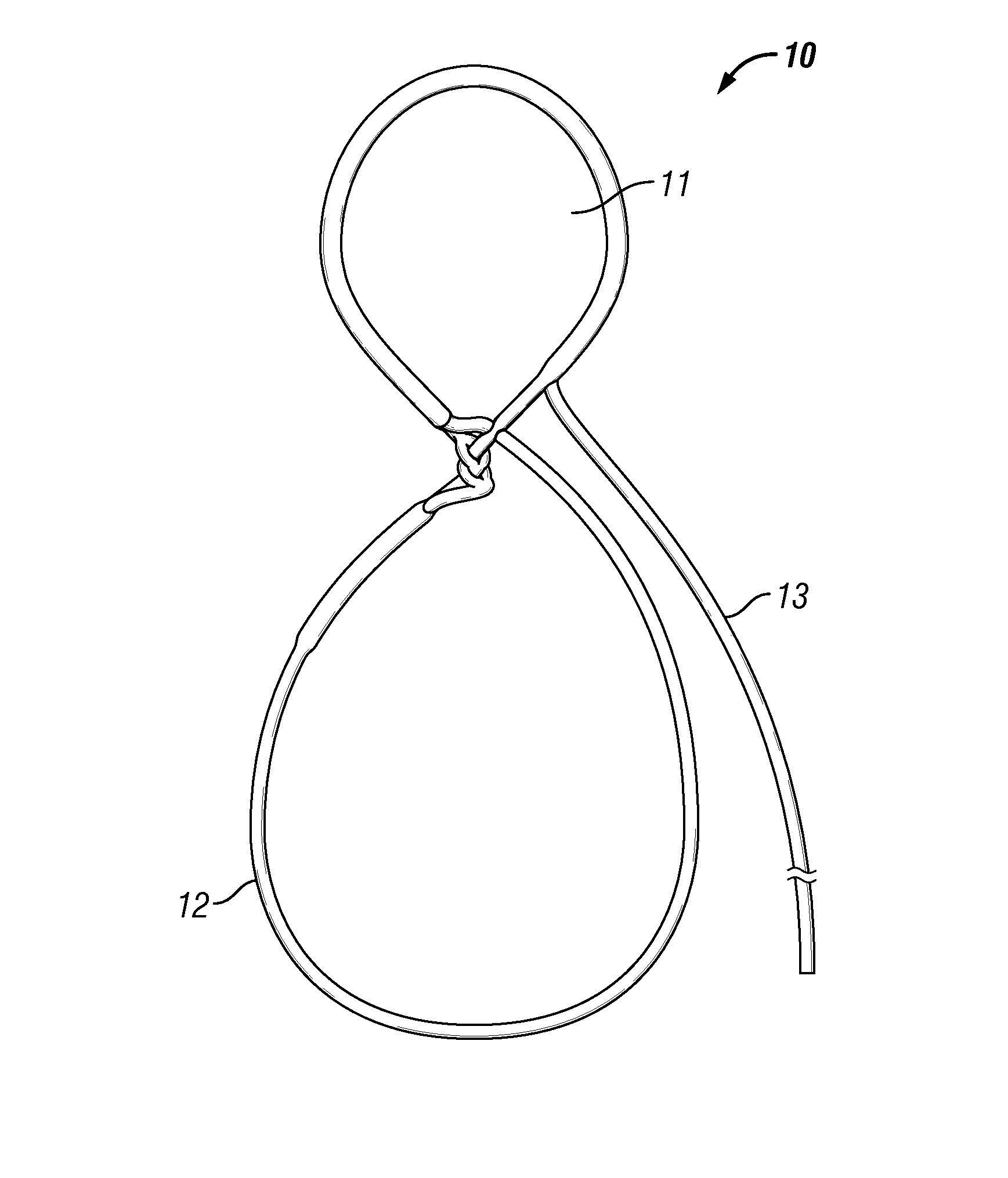

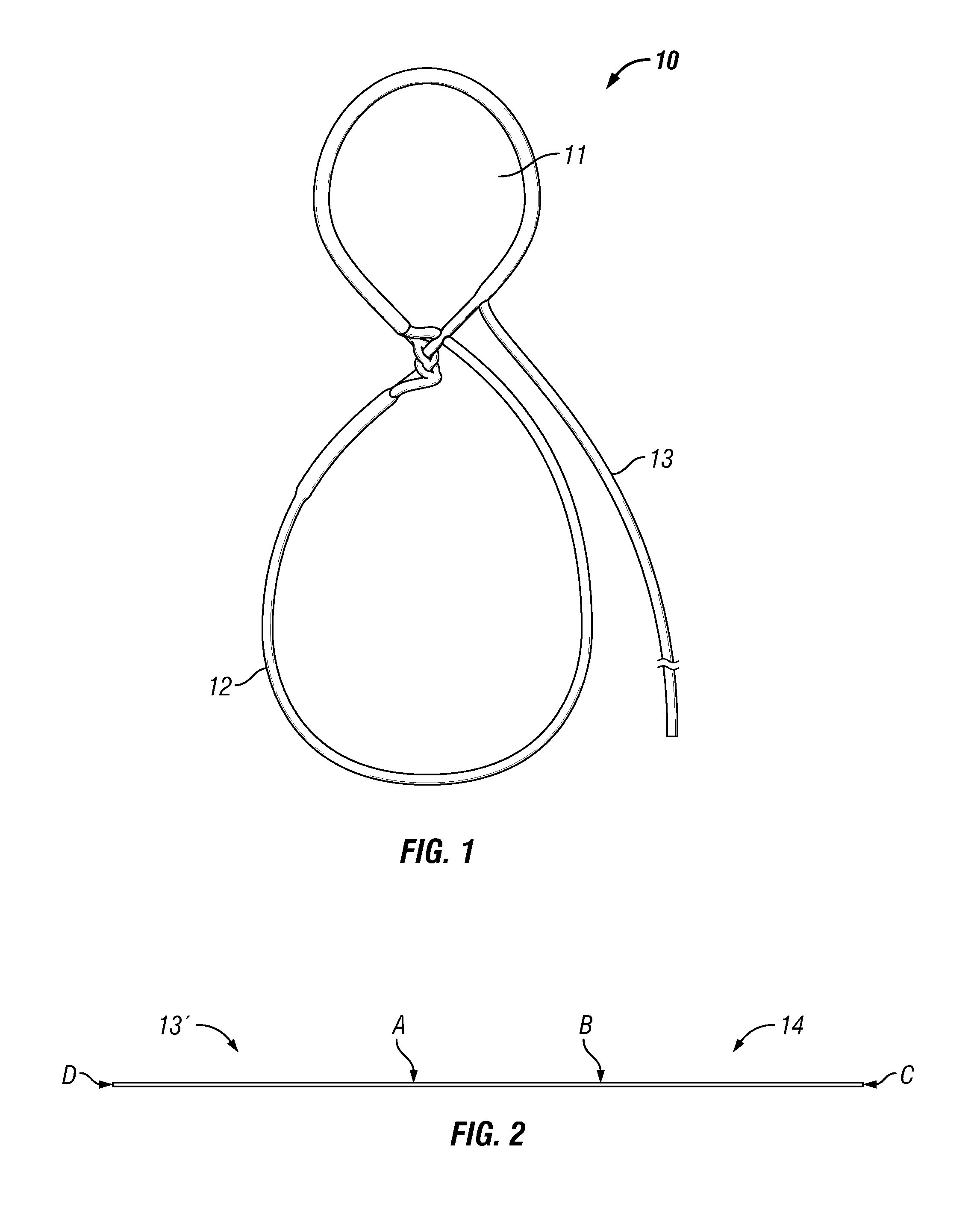

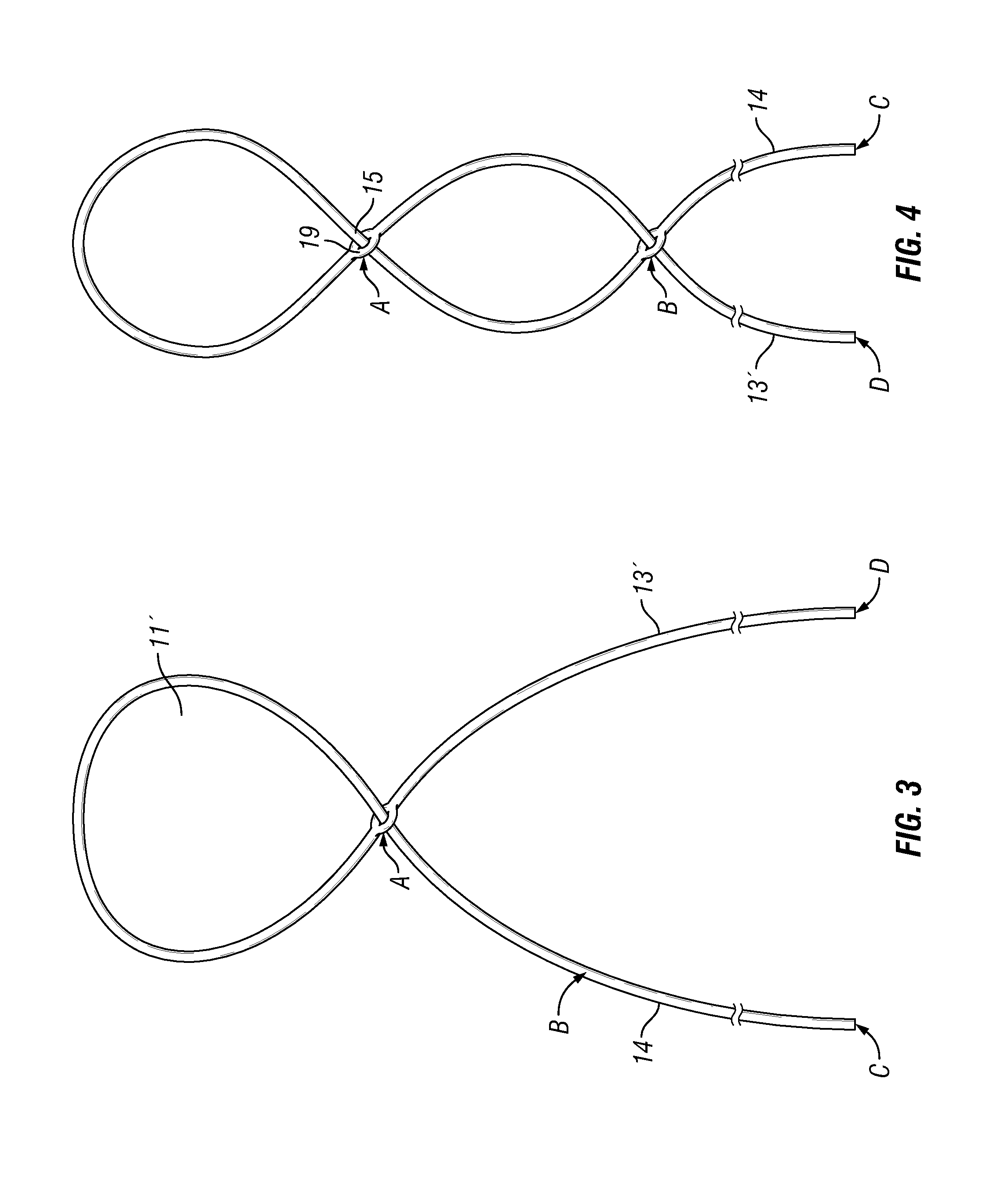

Adjustable continuous filament structure and method of manufacture and use

ActiveUS20140277121A1Simplified and reliable useReduce adjustmentSuture equipmentsSurgical needlesEngineeringMechanical engineering

A method of assembling an adjustable continuous filament assembly whereby a single length of filament is spliced to form a nonadjustable portion and a single free segment. The single free segment is introduced into the inner core of the nonadjustable portion at a first position. The single free segment is passed through at least a portion of the inner core of the nonadjustable portion. The single free segment is withdrawn from the nonadjustable portion at a second position, thereby forming an adjustable portion secured to the nonadjustable portion and adjustable by the single free segment.

Owner:STRYKER CORP +1

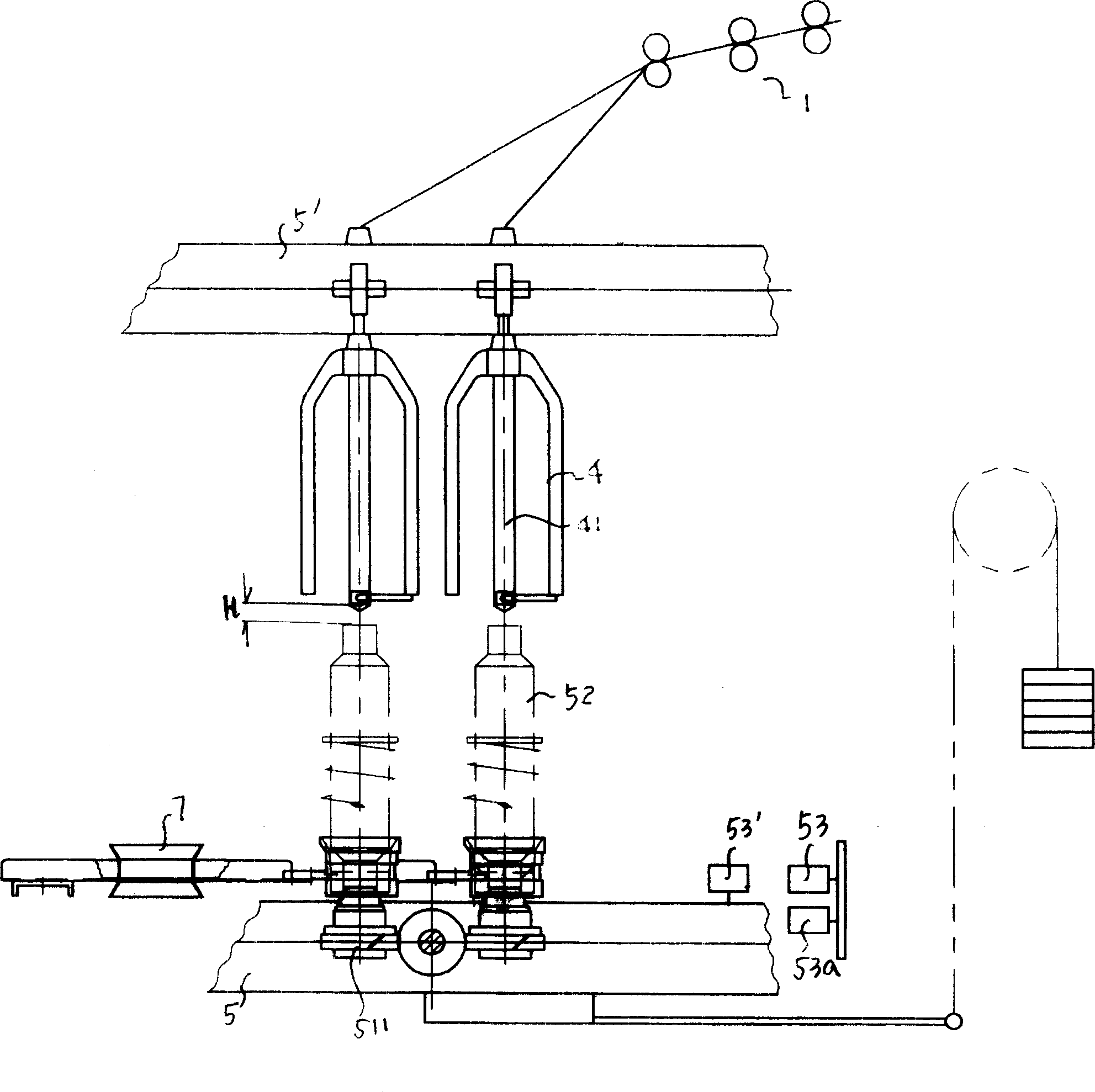

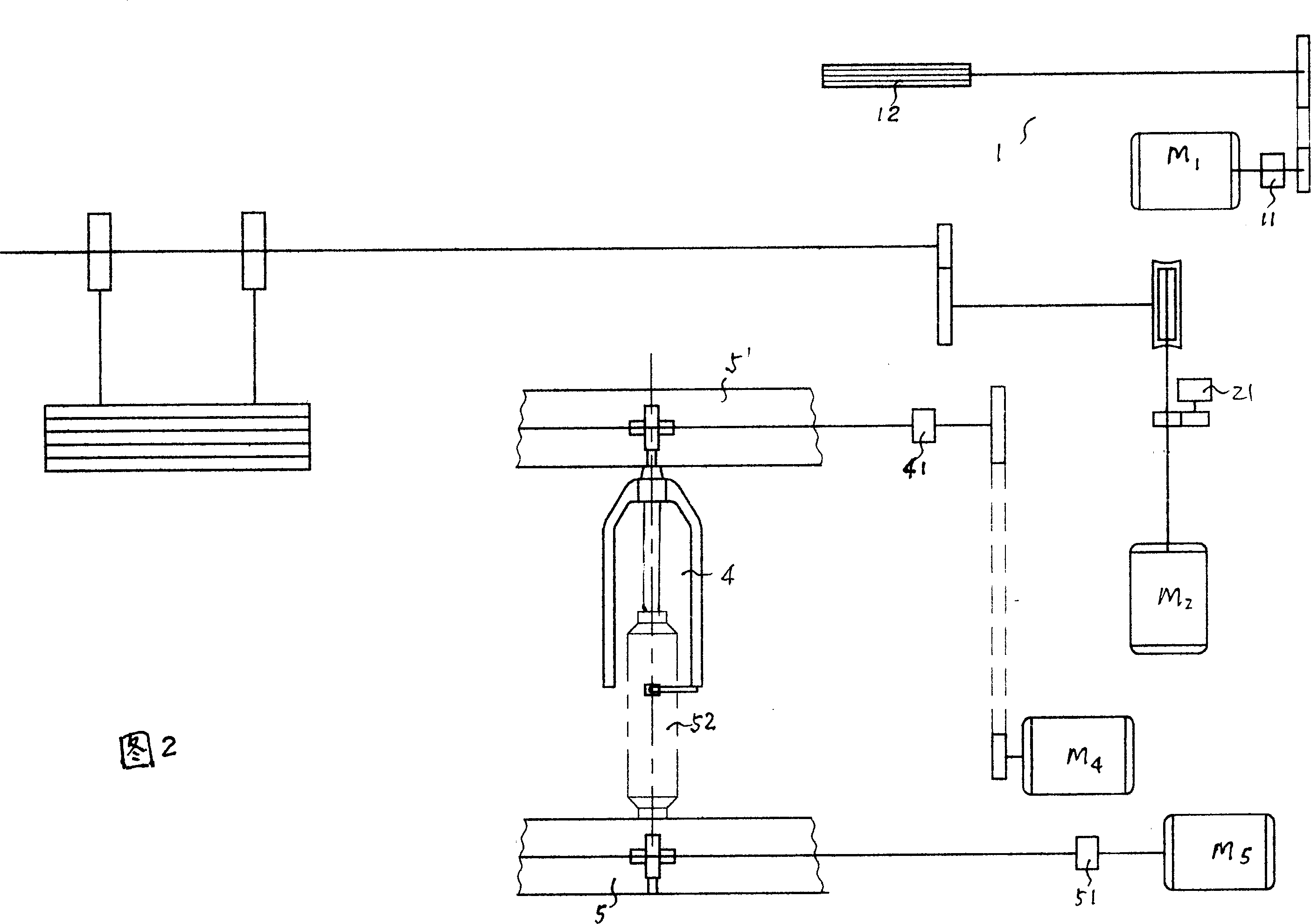

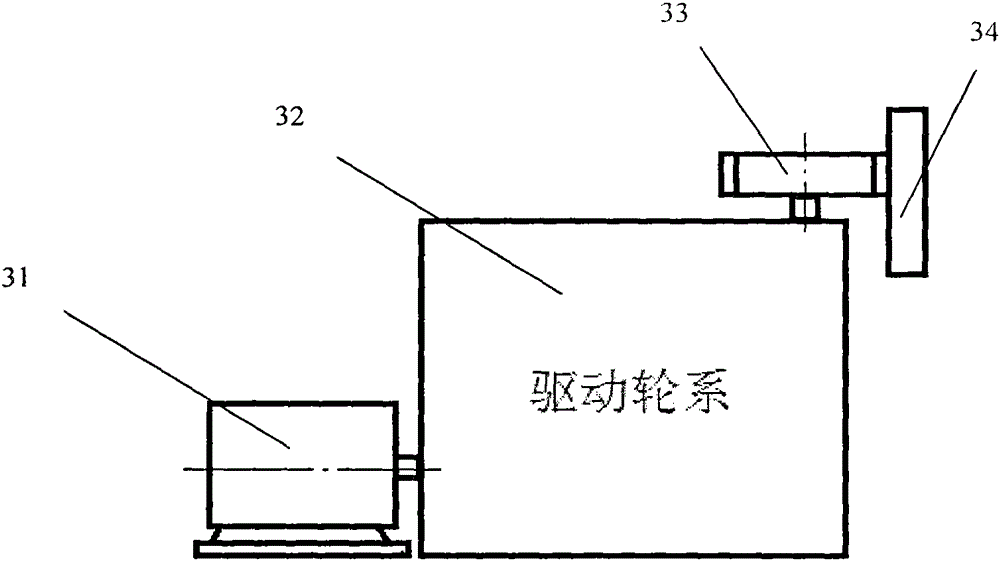

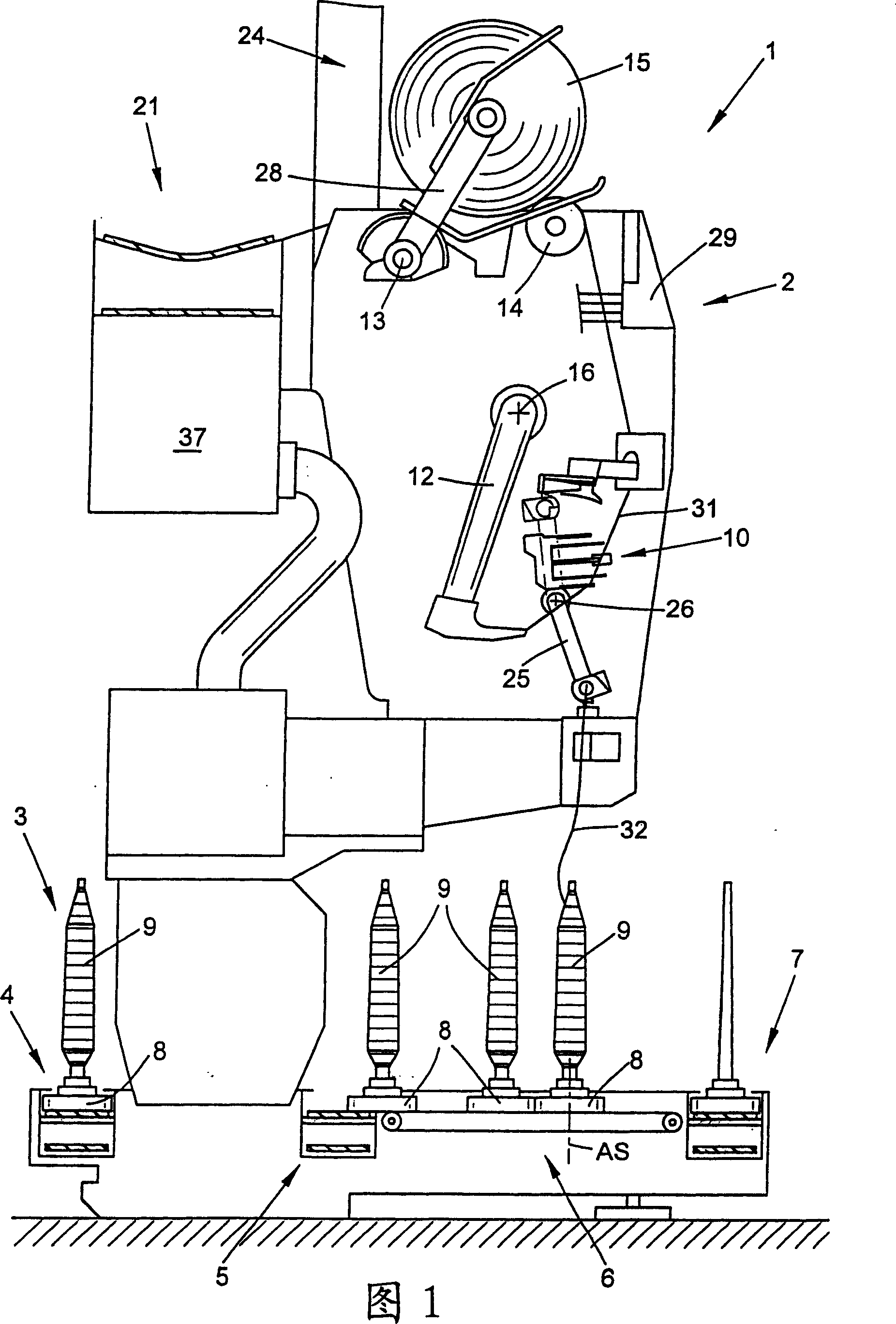

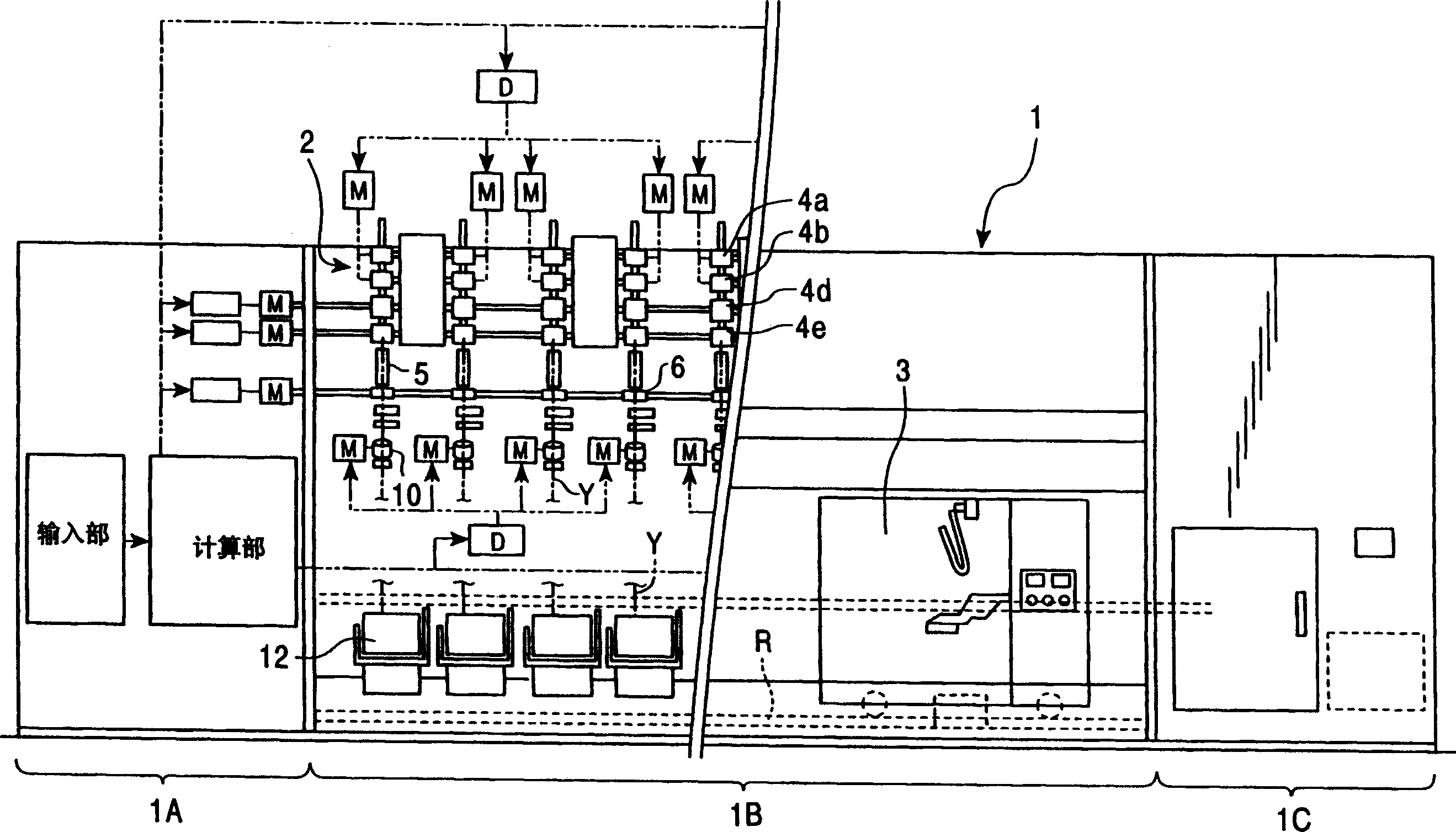

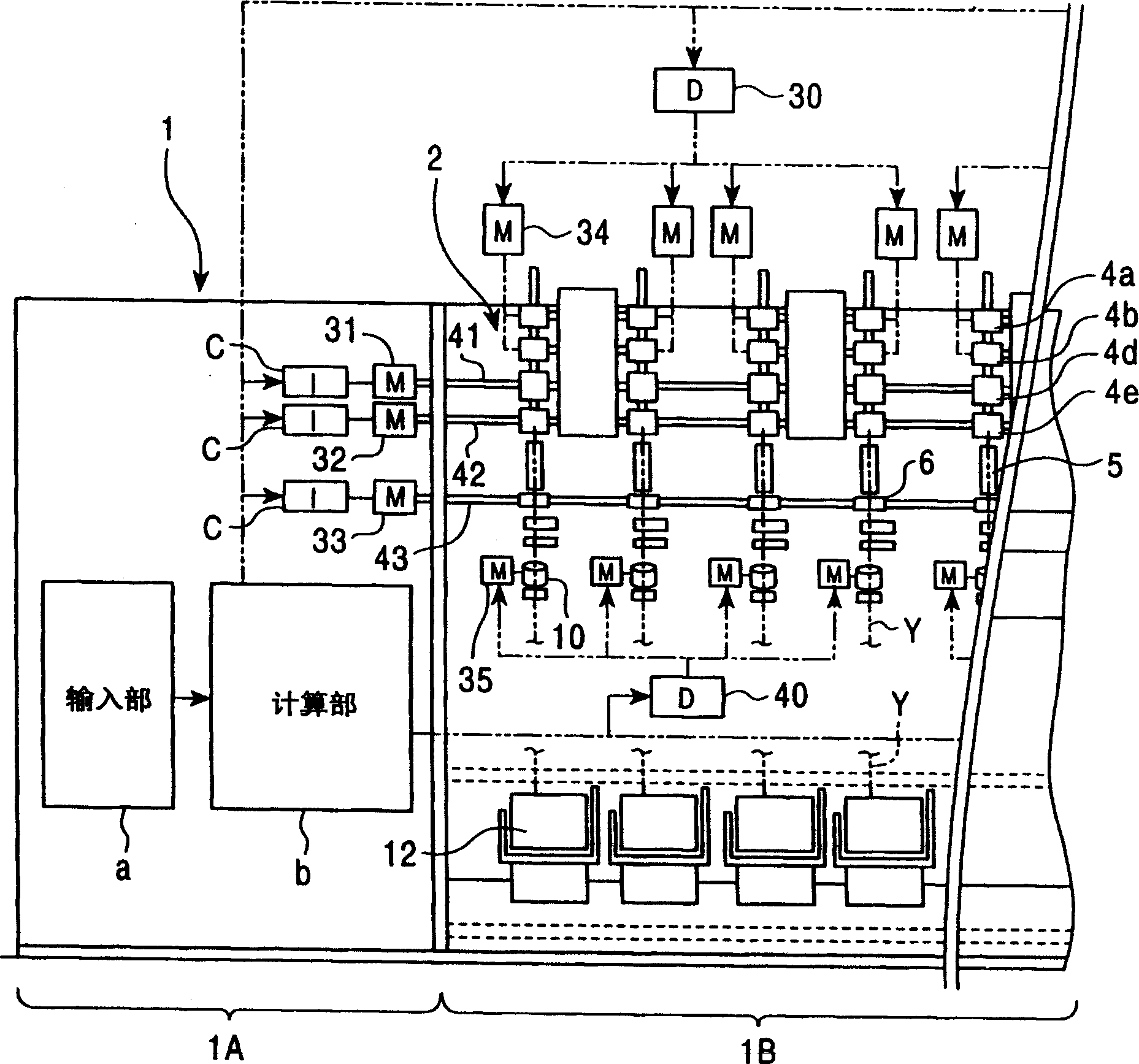

Method and device for automatic spinning repiece

InactiveCN1488798AOptimize structural configurationReduce twistPiercing arrangementsContinuous wound-up machinesYarnLow speed

The present invention relates to an automatic spinning new end forming method and its equipment. The roving machine utilizes the coder positioned at the drafting portion position to detect the full-yarn length when the bobbin can be fulled, and makes the roving machine spin to a certain length in low speed, after the roving is spun to a certain length, makes the roving machine operate in low speed, at the moment makes the spindle rail stop lifting movement and makes the yarn be in said height position, winds 2-3 turns of halching and makes the spindle rail be quickly lowered to form large thread pitch wind so as to make the roving do not take-off in its transportation process; changes the speed ratio of flywer and roller so as to reduce roving twist, and obtain undertwisted roving, and when the ultralowering of spindle rail is made to place, the yarn is stretch-broken to produce fuzzy fibre whose length can be suitable for secondary automatic spinning new end formation.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

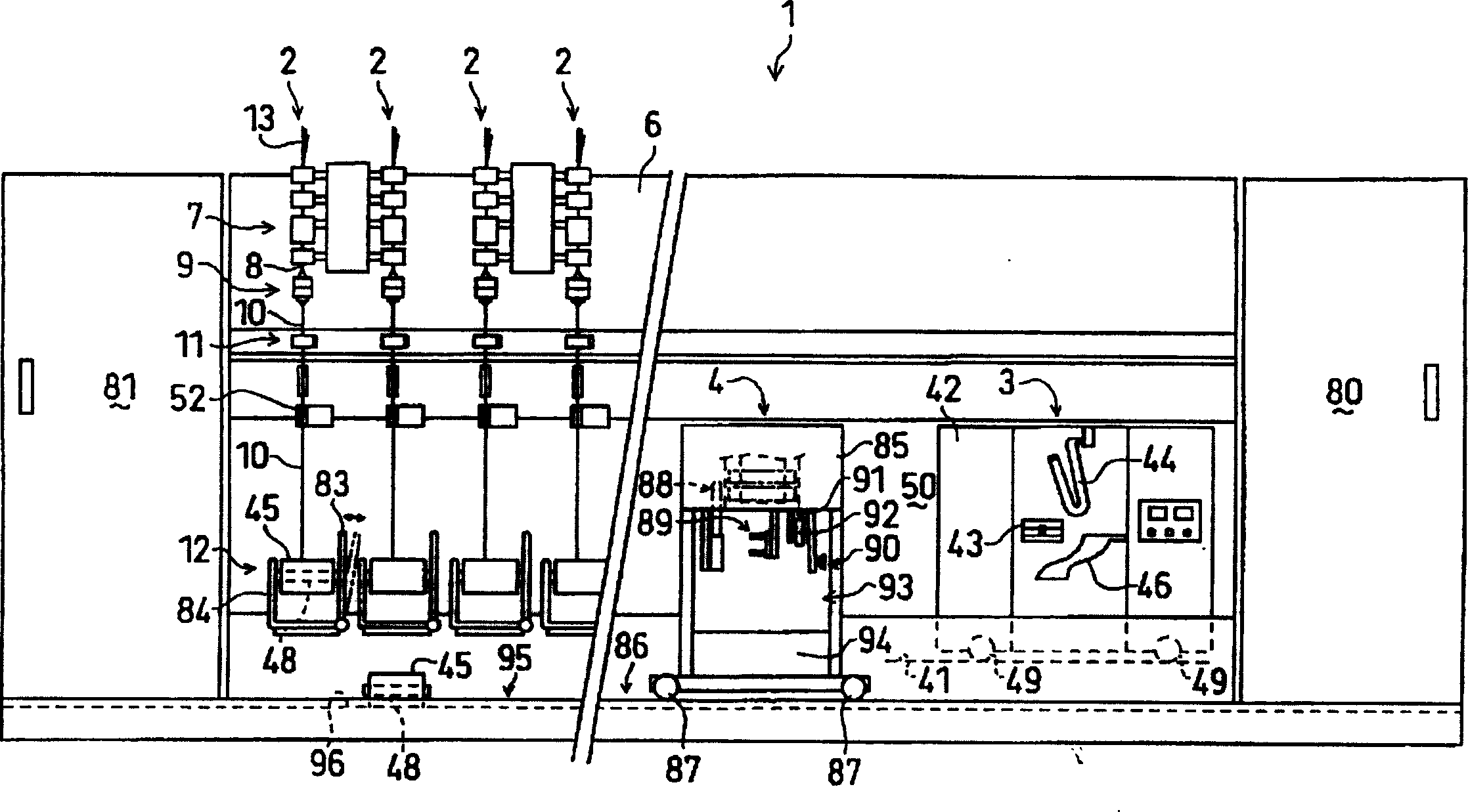

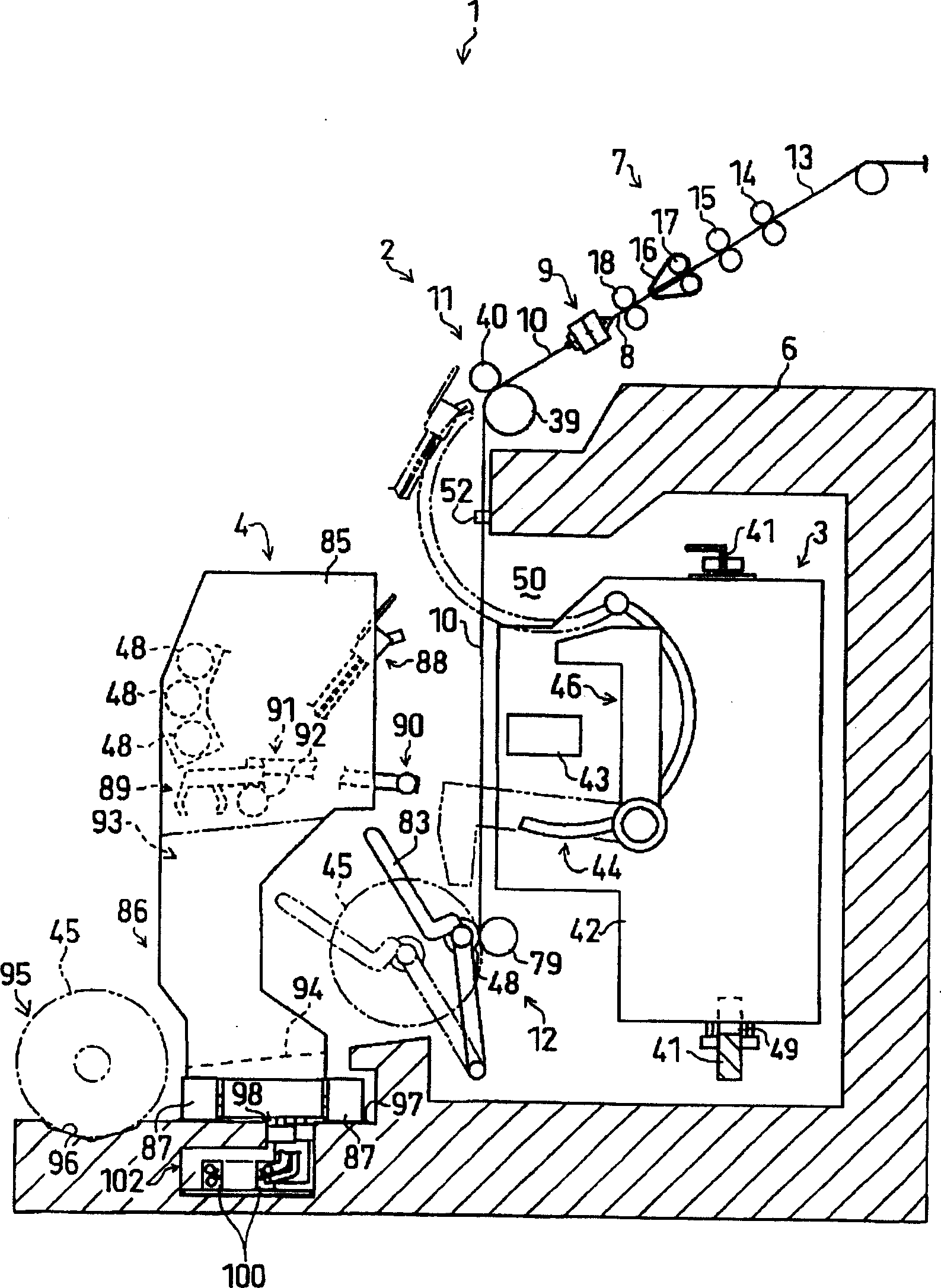

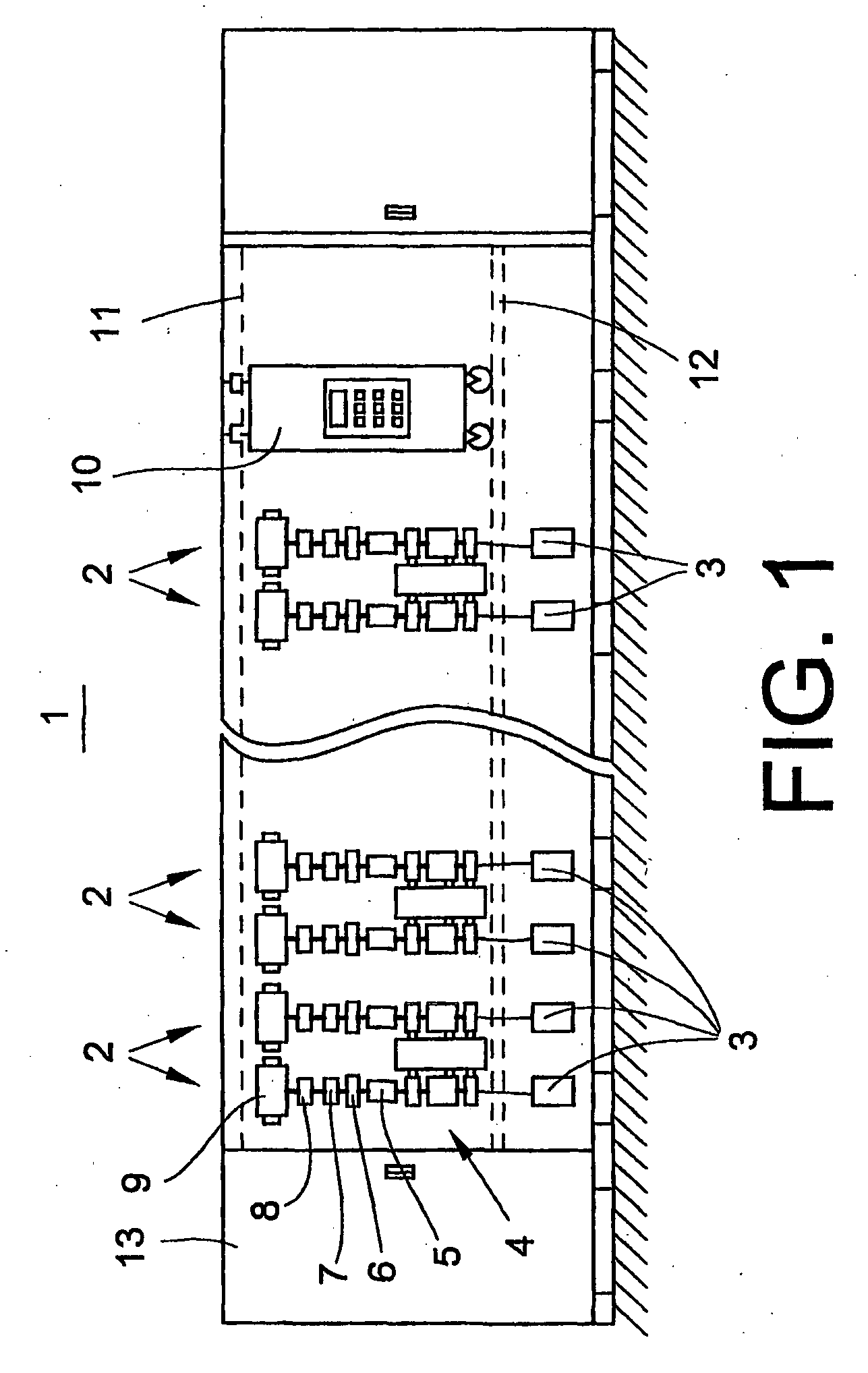

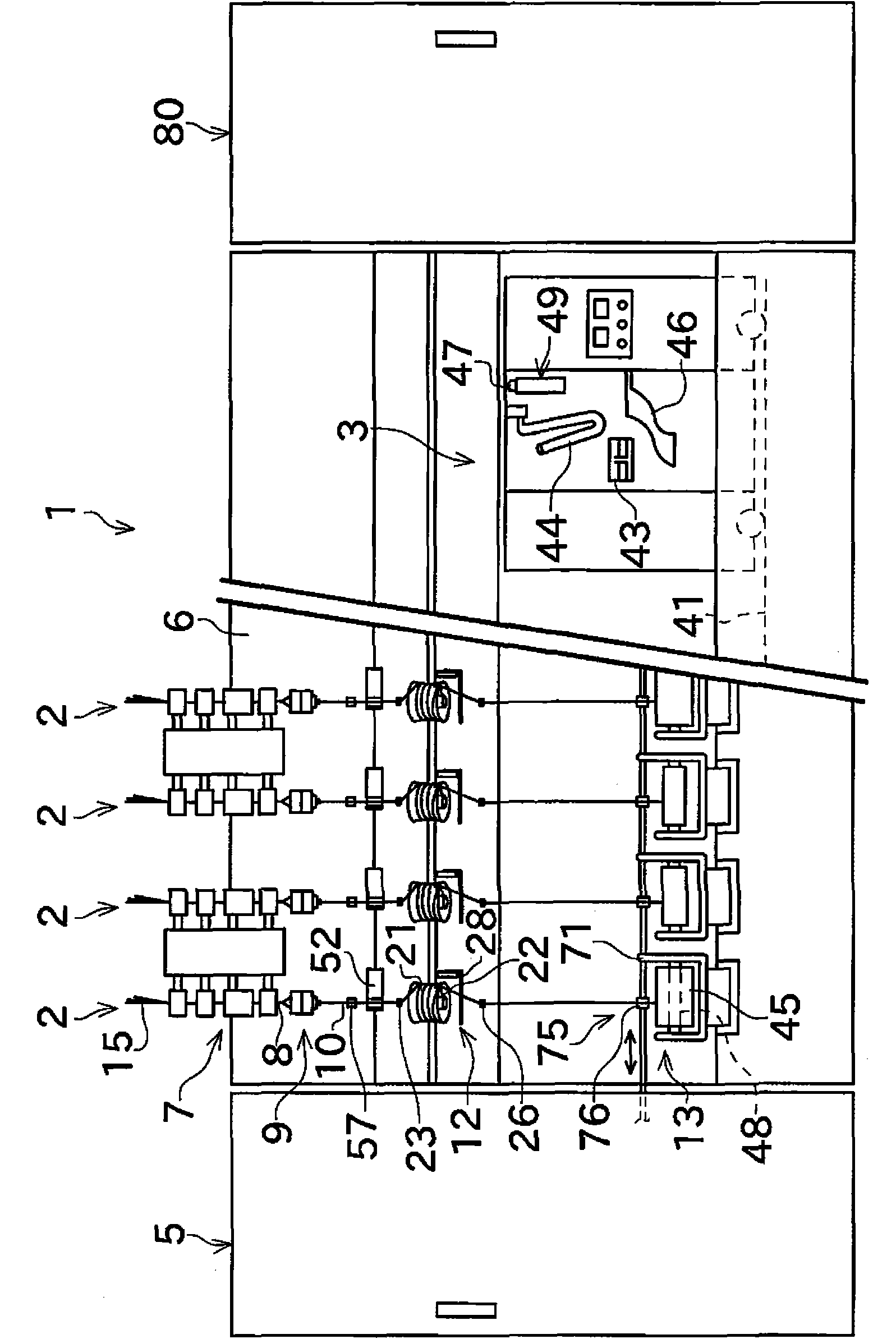

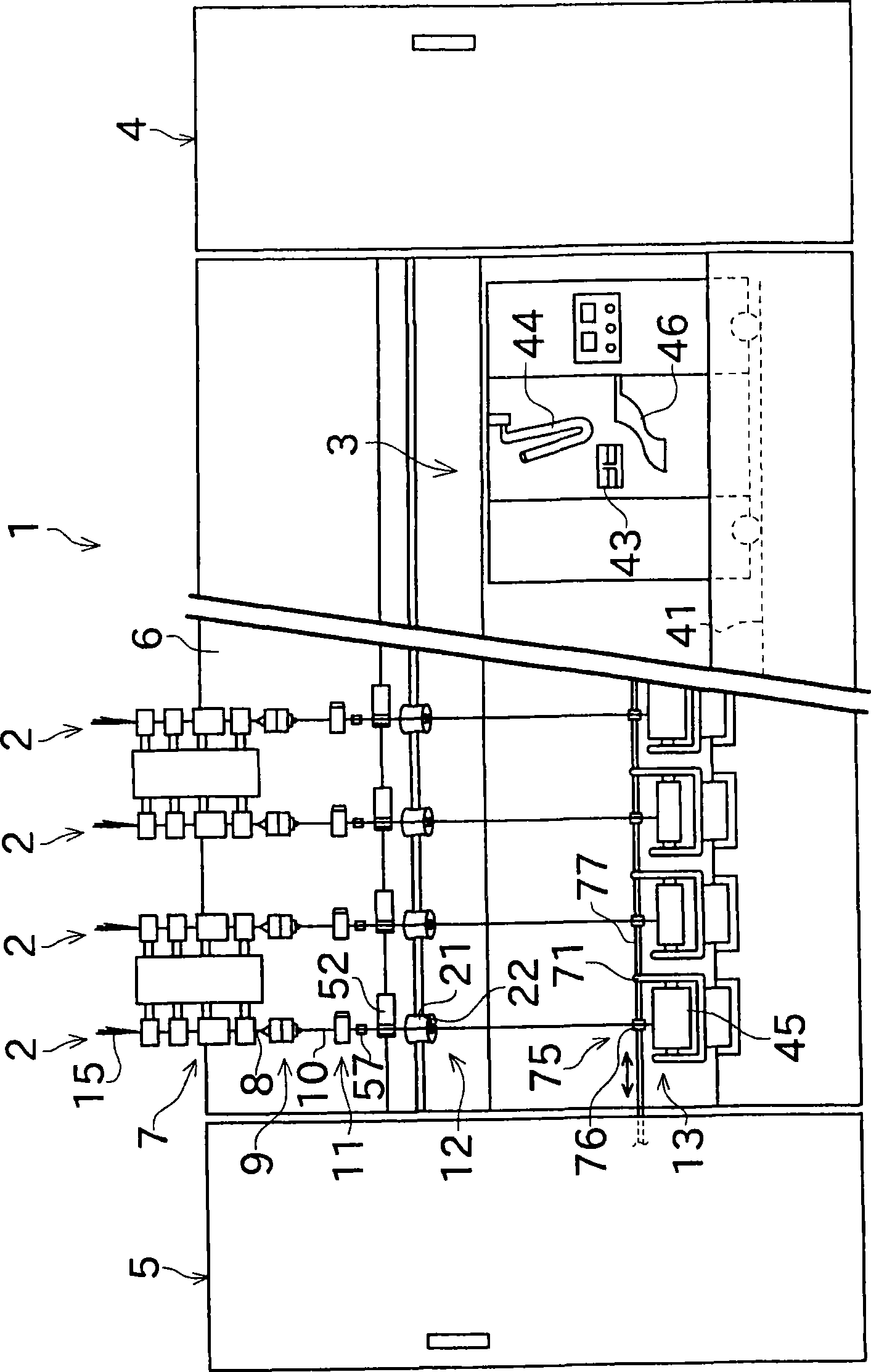

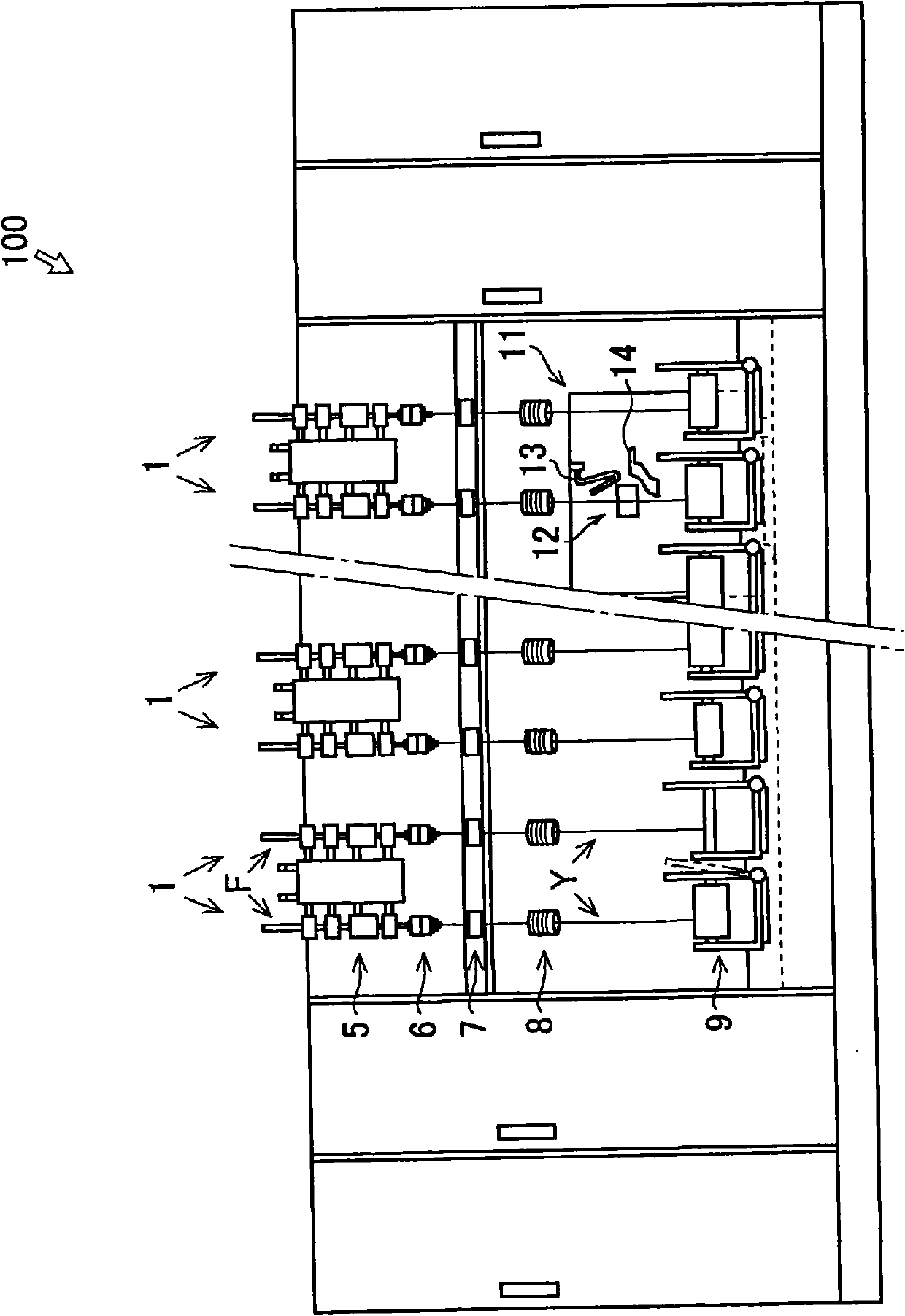

Textile machinery

ActiveCN1651622AEasy to recycleLess burden postureFilament handlingPiercing arrangementsYarnEngineering

To provide a textile machine enabling easy doffing of a full package 45. The textile machine 1 has a plurality of yarn-processing units 2 capable of forming a package 45 and placed in a row. The machine is provided with a doffing truck 4 traveling between the units along the direction of the yarn processing unit row and transferring the full package 45 to a storage area 95. The traveling path 86 of the doffing truck 4 is placed between the storage area 95 of the full package 45 and the yarn processing unit 2 in a direction perpendicular to the direction of the yarn processing unit row (the lateral direction in the selected figure). When the yarn running side of the yarn processing unit 2 is taken as the front side, the traveling path 86 of the doffing truck 4 and the storage area 95 are placed at the front side.

Owner:MURATA MASCH LTD

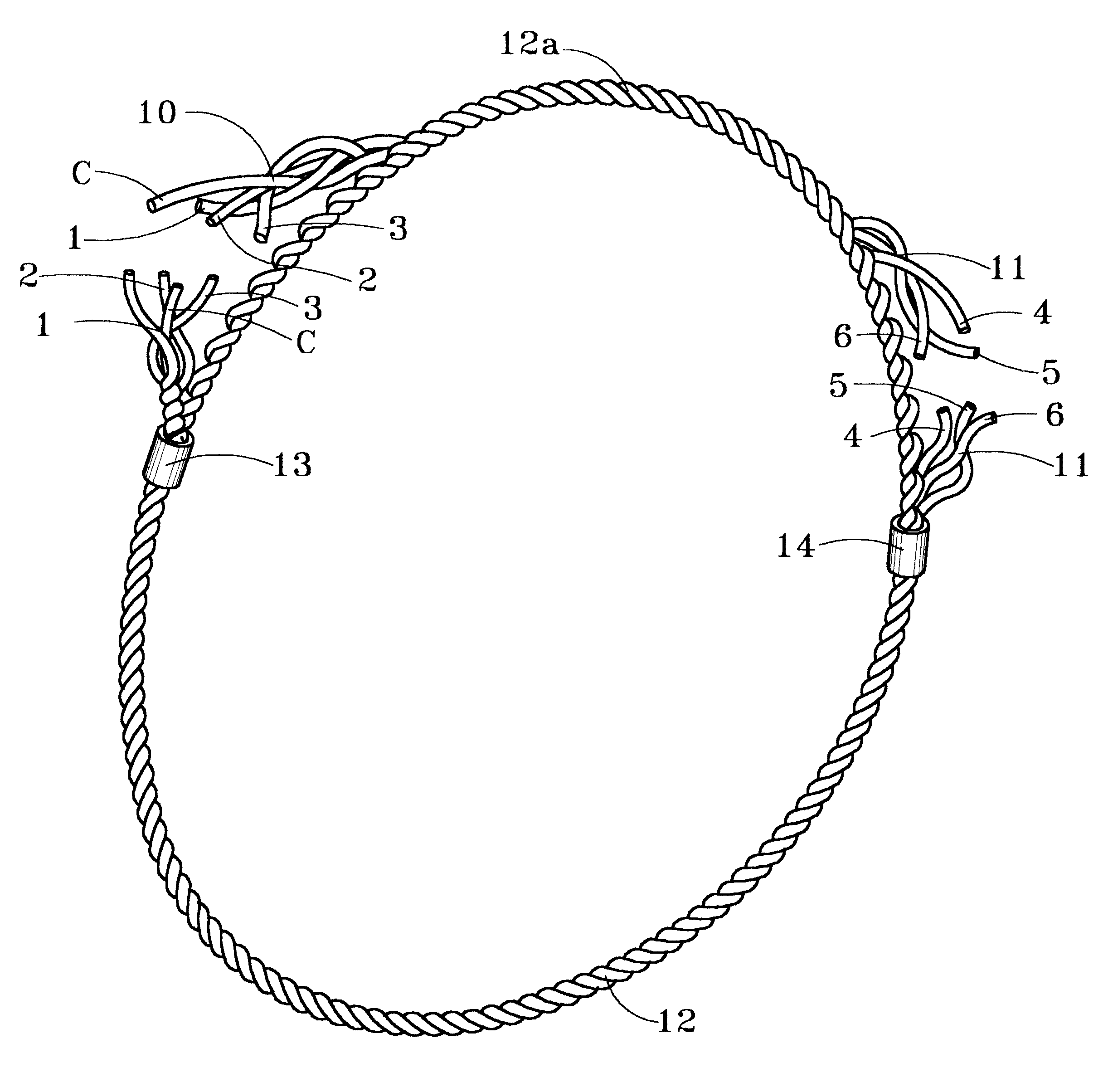

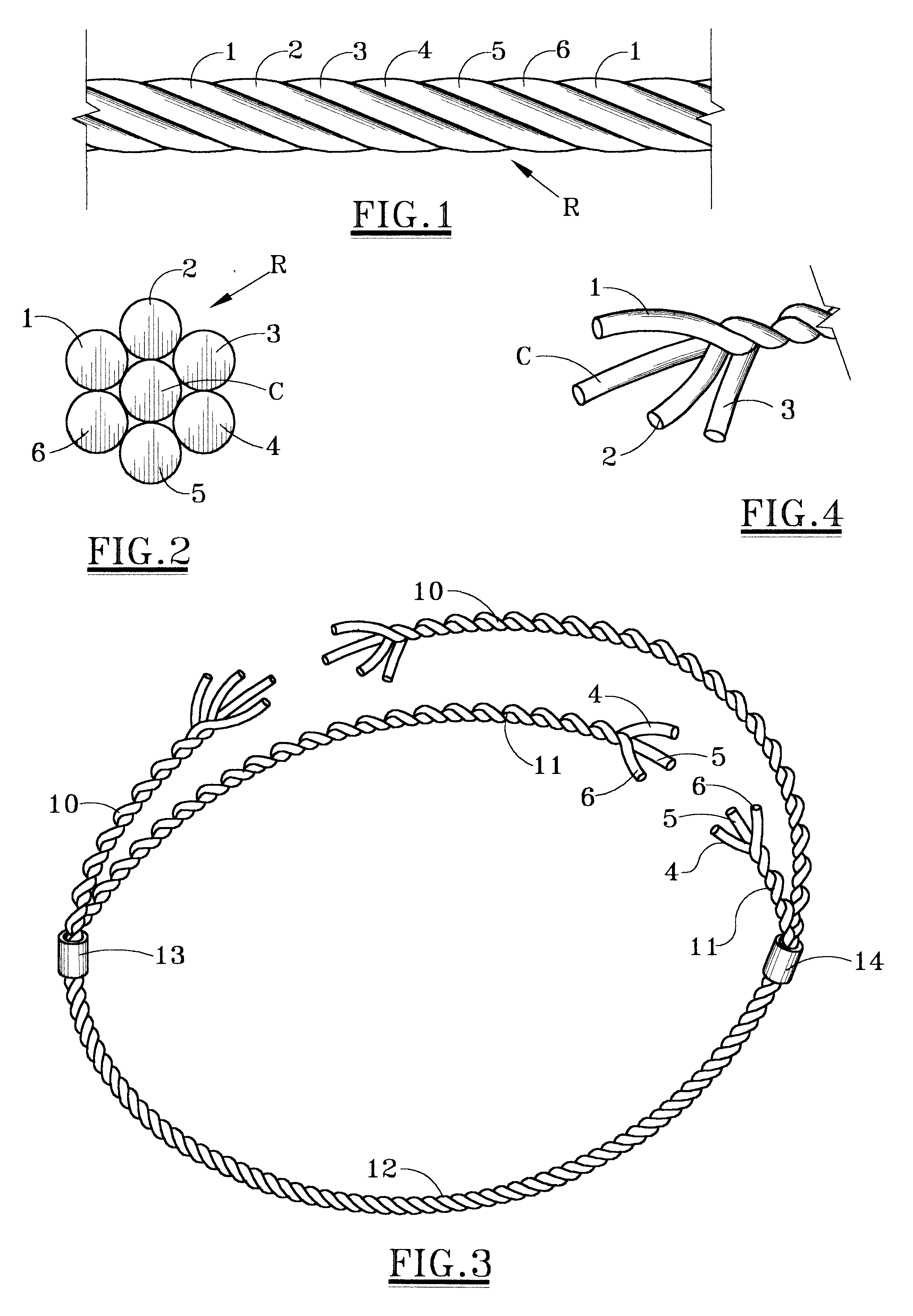

Wire rope sling and methods of making same

A wire rope sling made of wire rope having a core and multiple strands of wire helically laid around the core and cut from a predetermined length. Approximately half of the strands of wire are separated from the core and the remaining strands of wire, shifted, relative to the core, a predetermined distance and rewoven with the core and remaining strands of wire into a continuous loop. A splicing sleeve surrounds first and second ends of the approximately half of the strands and a continuous section of the core and remaining strands in a tightly engaged manner and another splicing sleeve surrounds first and second ends of the core and the remaining strands and a continuous section of the approximately half of the strands in a tightly engaged manner.

Owner:HOLLOWAY HOUSTON

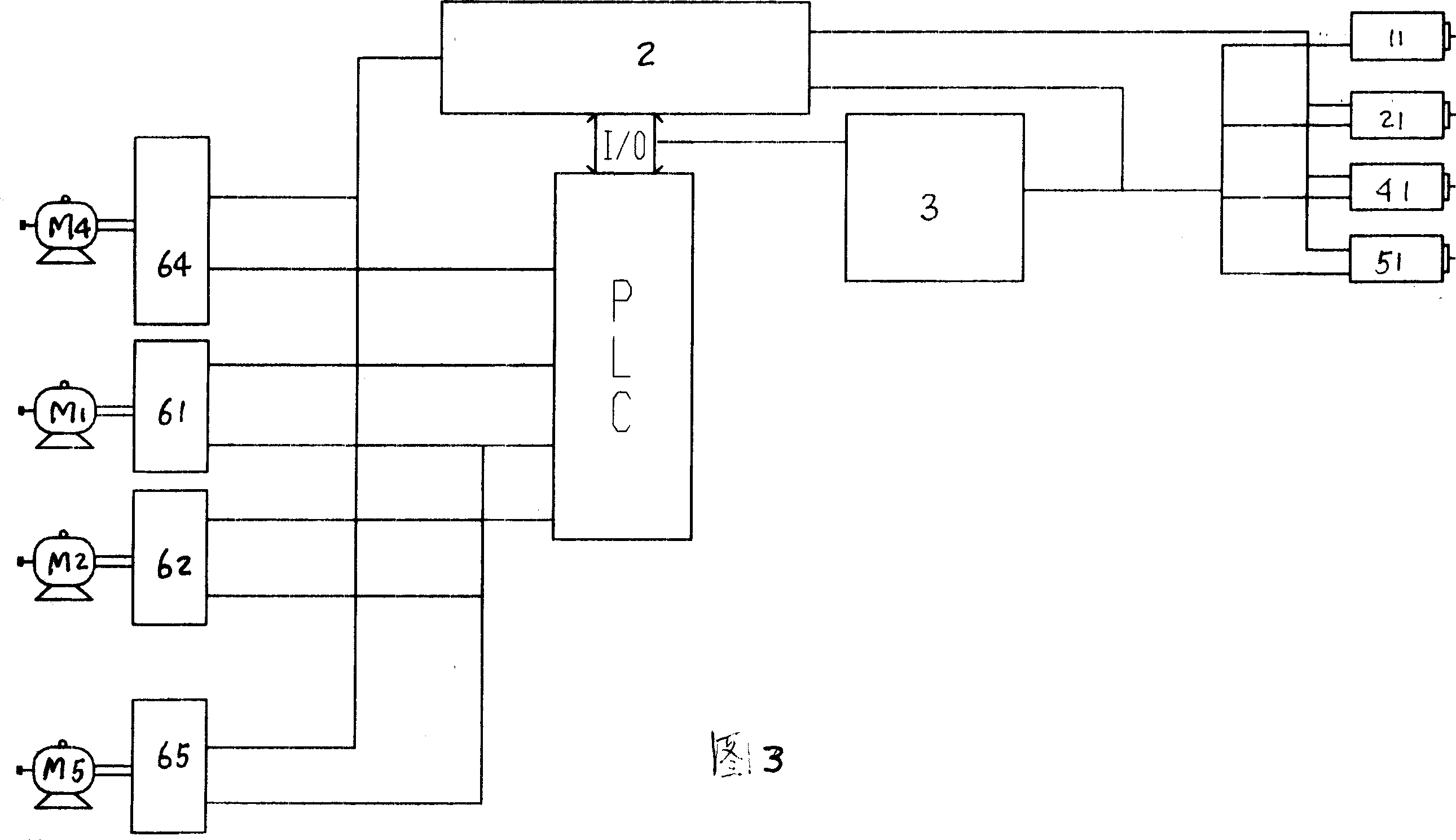

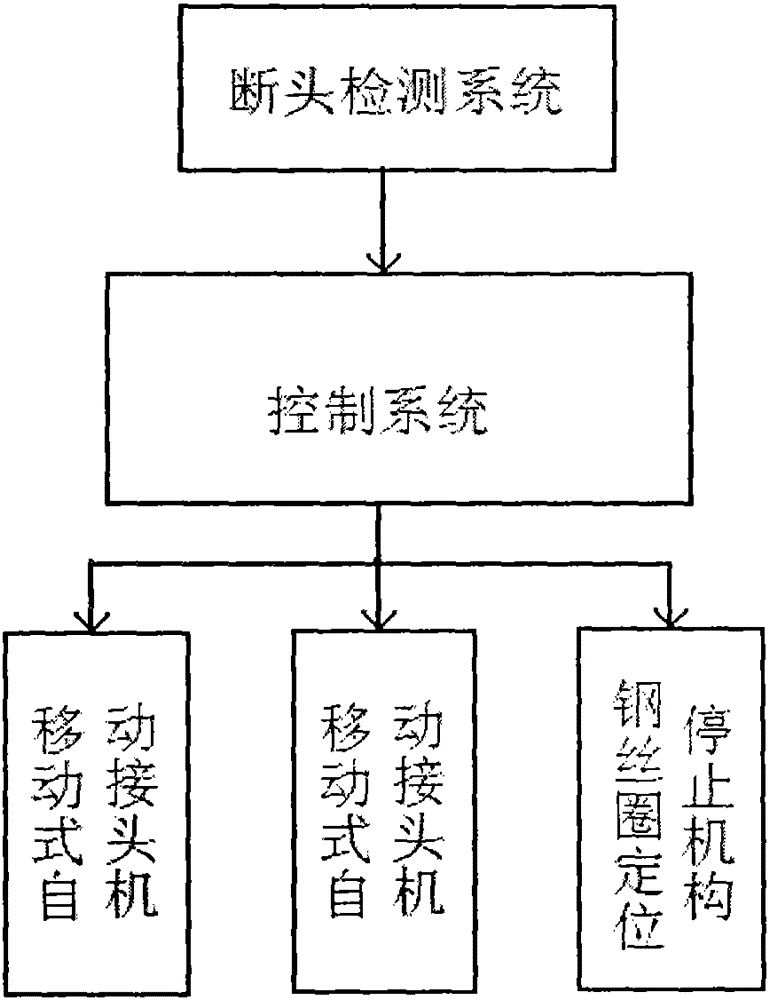

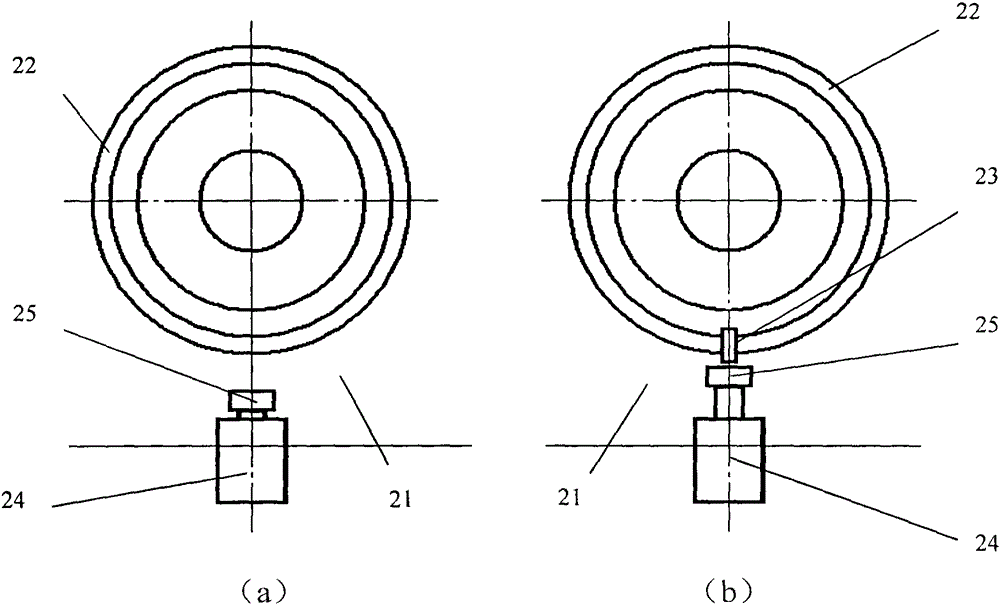

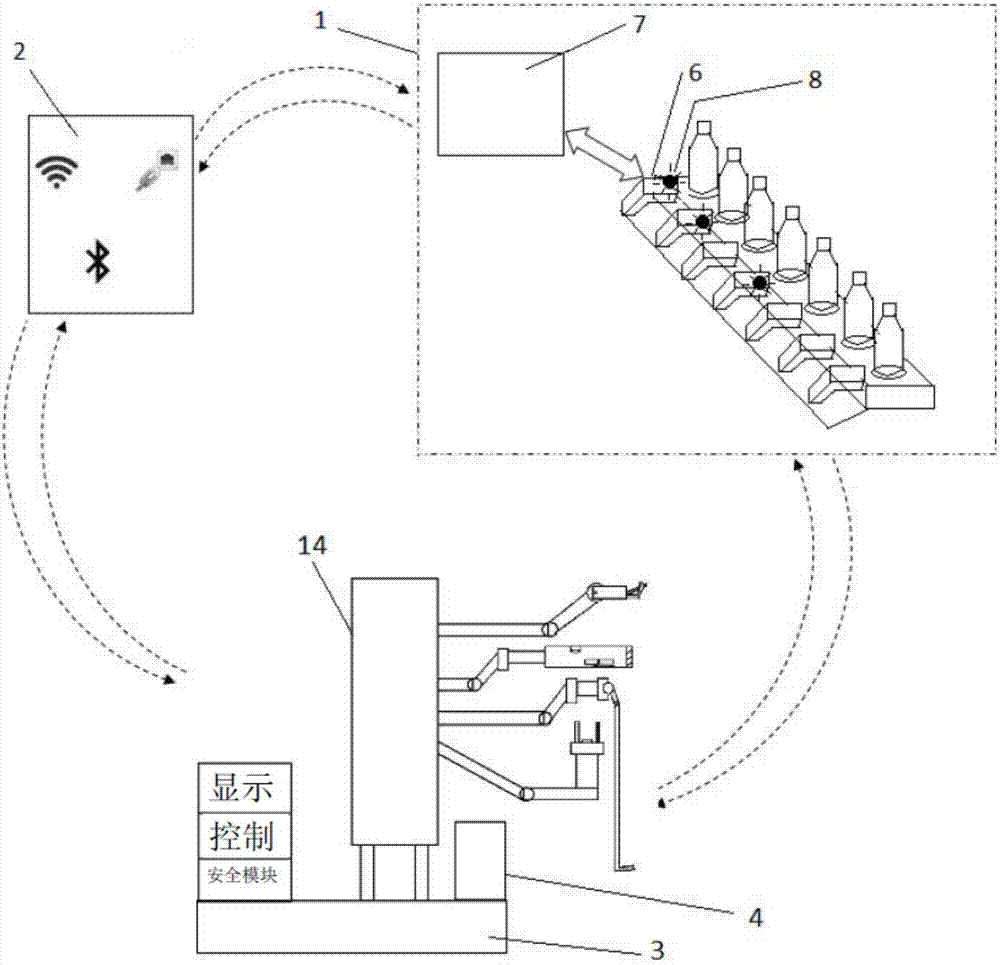

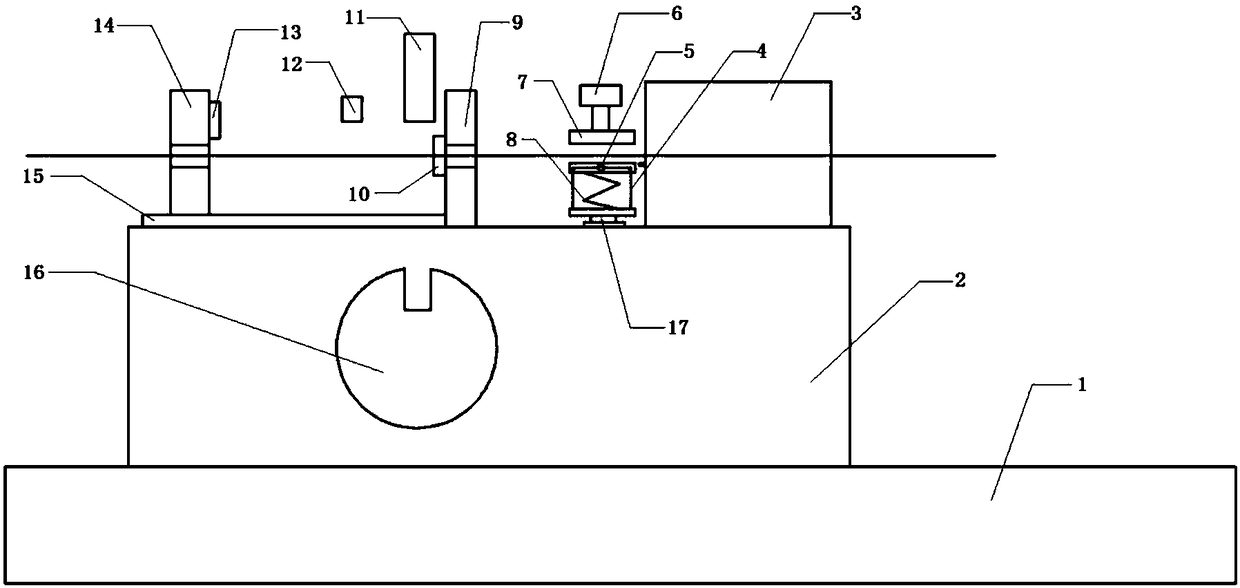

Method and device for automatically and intelligently piecing ring-spun yarn broken ends

The invention relates to a method and device for automatically and intelligently piecing ring-spun yarn broken ends. In a spinning machine, a combination of a broken ends detection system, a movable type automatic piecing machine, a ring traveller positioning and stop mechanism and a control system formed by a single-chip microcomputer or a PLC is adopted, wherein spinning end breaking signals of every single spindle of the spinning machine are detected in real time through a sensor of the broken ends detection system, and the spinning end breaking signals from the broken ends detection system are received by the single-chip microcomputer or the PLC control system; the spinning end breaking signals are processed by the single-chip microcomputer or the PLC control system and are sent to the movable type automatic piecing machine and the ring traveller positioning stop mechanism, the spinning end breaking signals are received by the ring traveller positioning stop mechanism, a ring traveller controlling the spindle position of the broken ends is stopped and positioned exactly in front of a steel collar ring rail, the movable type automatic piecing machine relates to the steps: receiving the spinning end breaking signals, automatically moving to the spindle position of the broken ends, controlling a spindle with the broken ends, unwinding and guiding a yarn of a spool, clamping the yarn in the ring traveler and a yarn guide, controlling the feeding speed of the guiding yarn, and piecing the yarn and a fiber strand which is outputted by a front roller or a yarn guiding roller of compact spinning together; the unmanned intelligent mechanical operation of piecing the broken ends is realized during the spinning process of the ring-spun yarn.

Owner:徐州锦业纺织科技有限公司

Method and device for automatically and intelligently piecing ring-spun yarn broken ends with guiding yarn

The invention relates to a method and device for automatically and intelligently piecing ring-spun yarn broken-ends with a guiding yarn. In a spinning machine, a combination of a broken ends detection system, a movable type automatic piecing machine, a ring traveller positioning and stop mechanism and a control system formed by a single-chip microcomputer or a PLC is adopted, wherein spinning end breaking signals of every single spindle of the spinning machine are detected in real time through a sensor of the broken ends detection system, and the spinning end breaking signals from the broken ends detection system are received by the single-chip microcomputer or the PLC control system; the spinning end breaking signals are processed by the single-chip microcomputer or the PLC control system and are sent to the movable type automatic piecing machine and the ring traveller positioning stop mechanism, the spinning end breaking signals are received by the ring traveller positioning stop mechanism, a ring traveller controlling the spindle position of the broken ends is stopped and positioned exactly in front of a steel collar ring rail, the movable type automatic piecing machine relates to the steps: receiving the spinning end breaking signals, automatically moving to the spindle position of the broken ends, controlling a spindle with the broken ends, unwinding and guiding a yarn of a spool, clamping the yarn in the ring traveler and a yarn guide, piecing the yarn and a guiding yarn of same quality, same material and same size together, controlling the feeding speed of the guiding yarn, and piecing the yarn and a fiber strand which is outputted by a front roller or a yarn guiding roller of compact spinning together; the unmanned intelligent mechanical operation of piecing the broken ends is realized during the spinning process of the ring-spun yarn.

Owner:桐乡市金隆丝业丝线有限公司

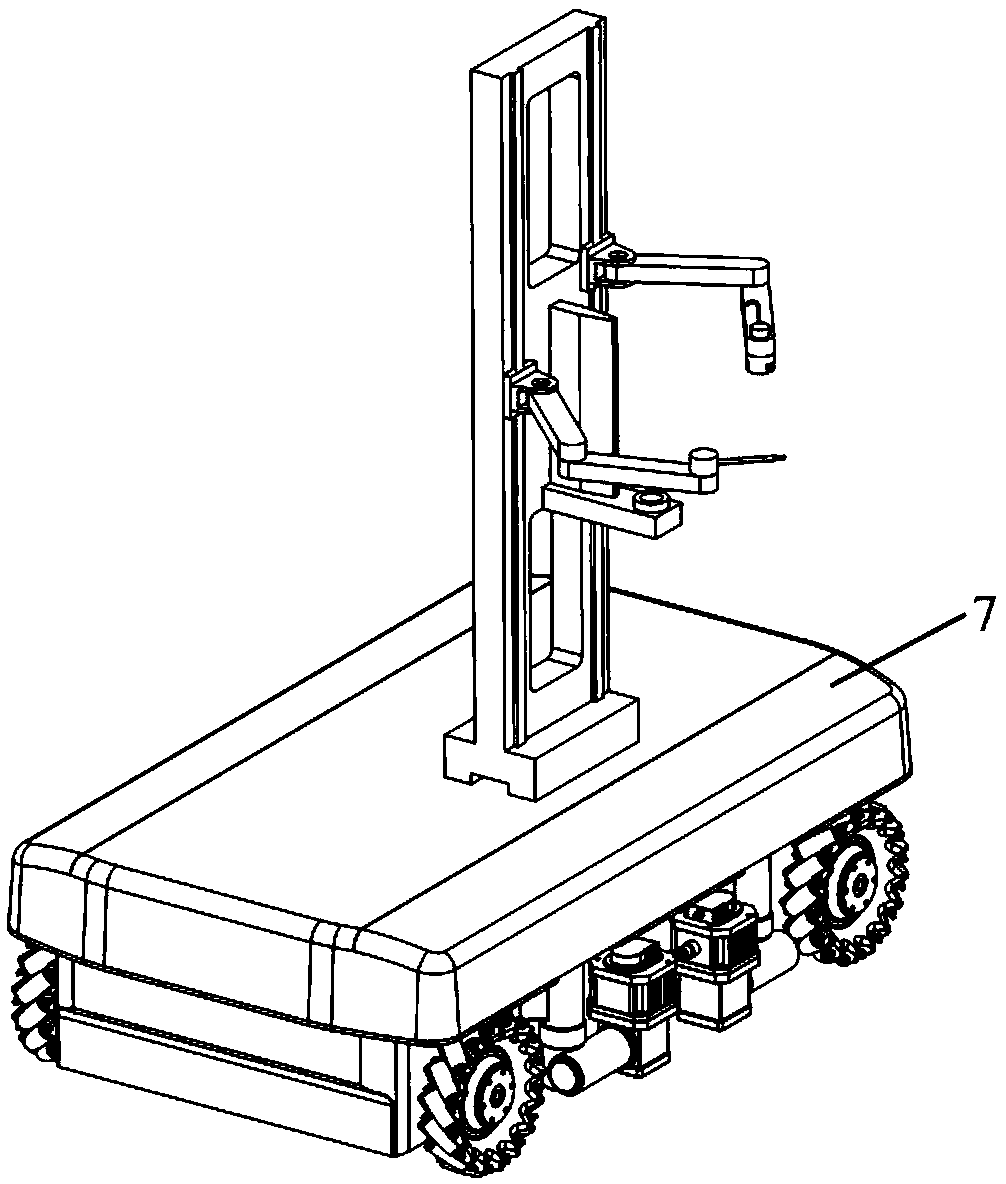

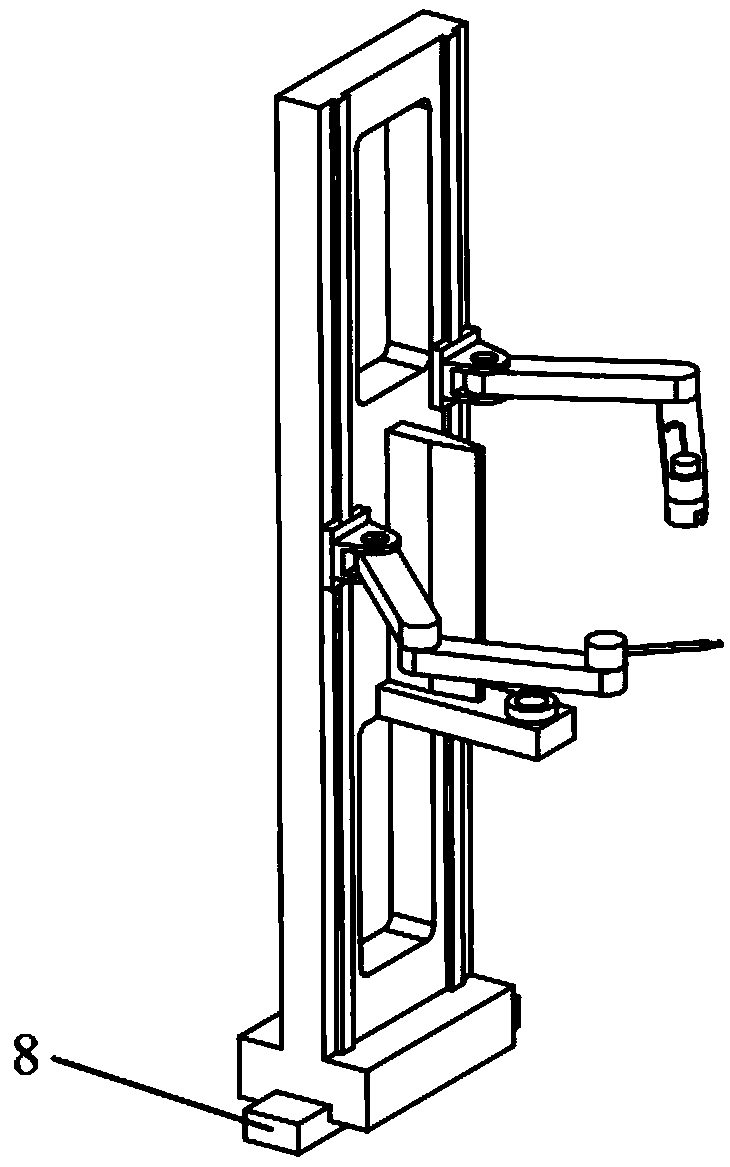

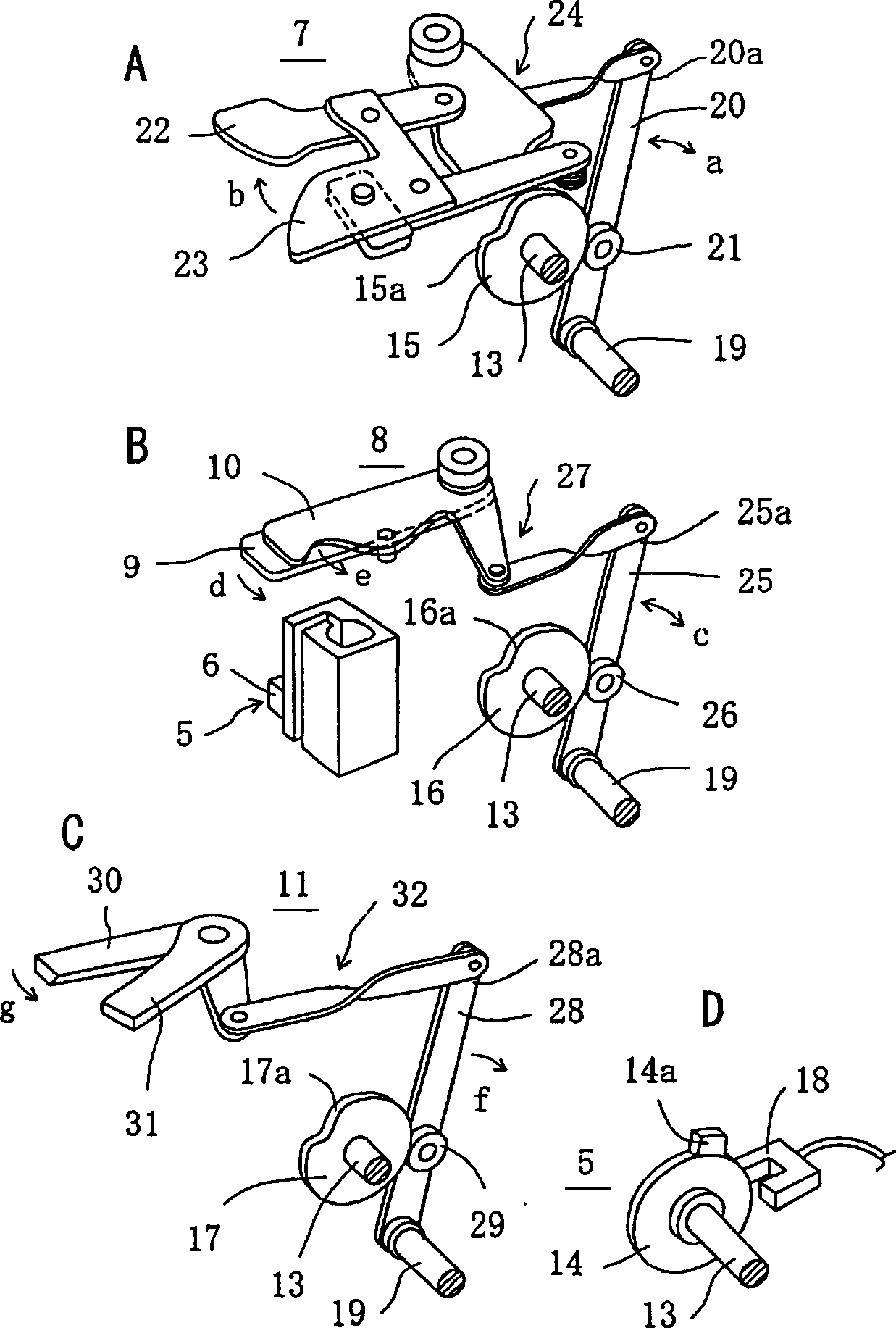

Automatic jointing robot of ring throstle and method

The invention relates to an automatic jointing robot of a ring throstle and a method. The automatic jointing robot of the ring throstle is applied to the ring throstle and comprises a rack, a right arm assembly, a left arm assembly and a yarn head seeking assembly, wherein the right arm assembly and the left arm assembly are used for cooperating with each other to complete the jointing operation of the ring throstle, the yarn head seeking assembly is used for seeking the broken heads of yarns on the ring throstle, a yarn clamping device assembly is arranged on the right arm assembly, and a catching and locating assembly is arranged on the left arm assembly; the right arm assembly and the left arm assembly are slidably connected with the rack and reciprocatingly move on the rack; the yarn head seeking assembly is fixedly connected to the rack and located between the right arm assembly and the left arm assembly; through the robot, the method that a bobbin is pulled from a spindle to seekthe broken heads is achieved, the reliability of seeking yarn heads is improved, and therefore the total efficiency of jointing is increased; the adopted robot only has two mechanical arms capable offlexibly moving in the vertical direction, the structure is simplified, and the jointing operation can be conveniently conducted in narrow jointing space.

Owner:国机智能技术研究院有限公司

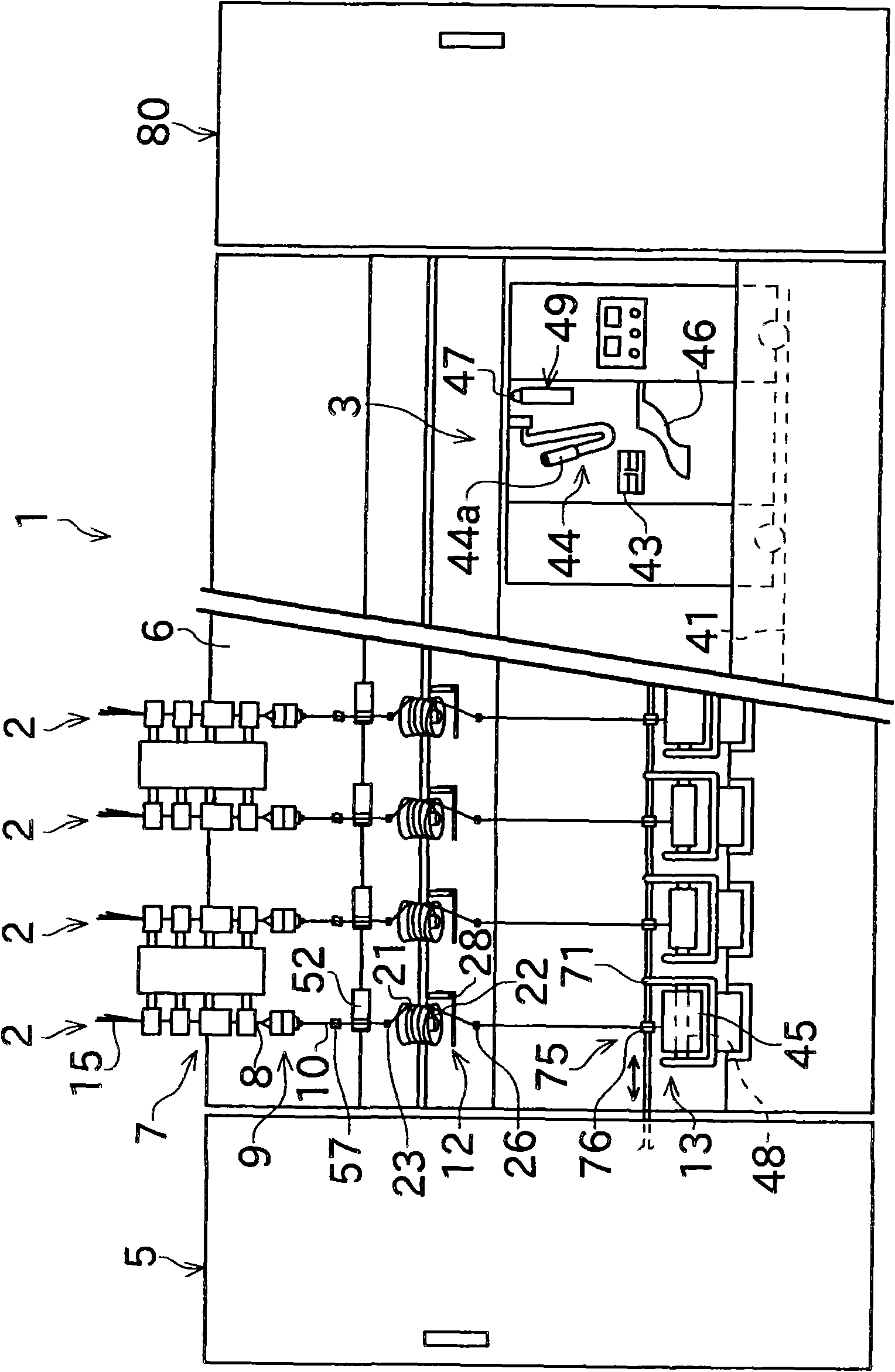

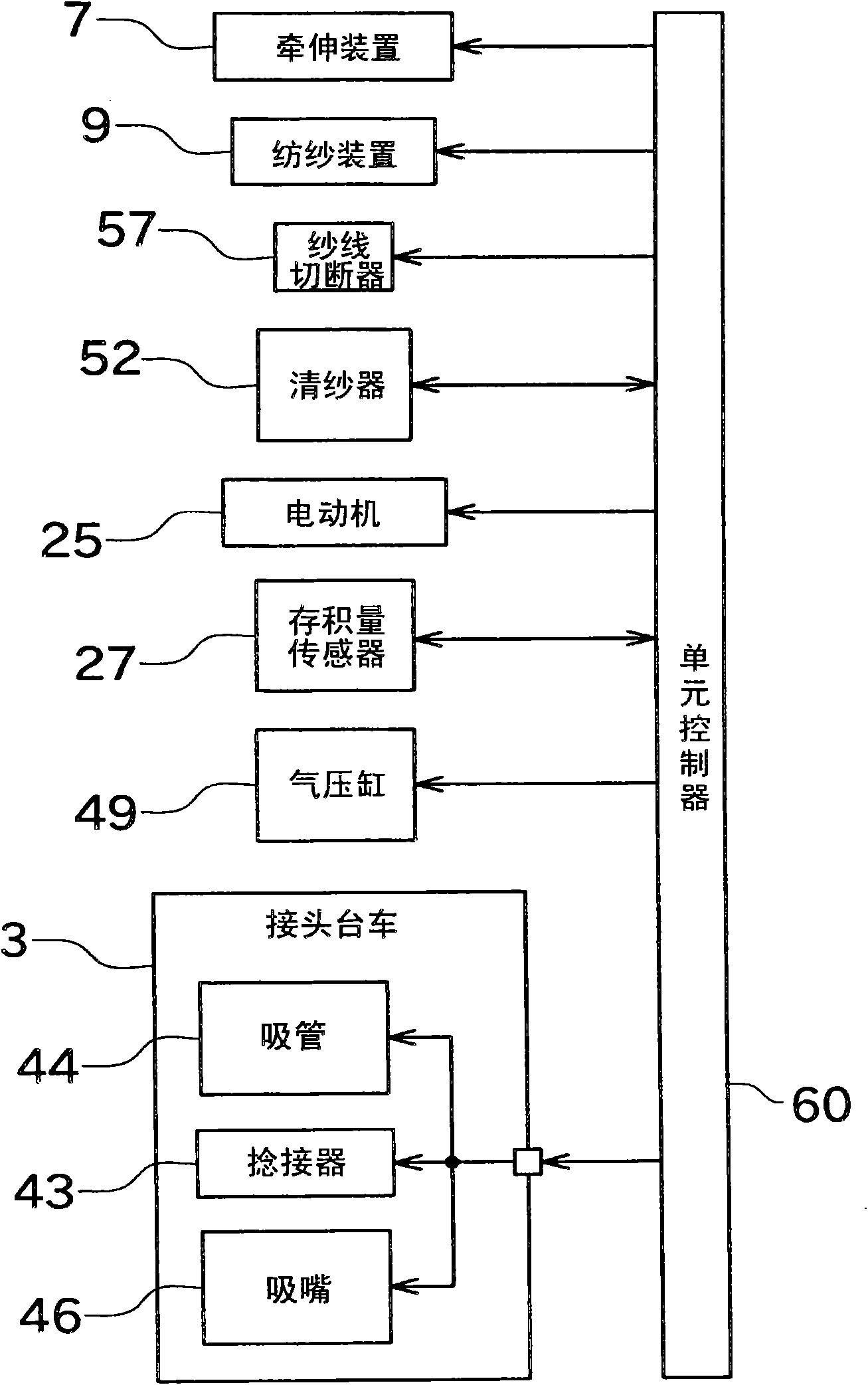

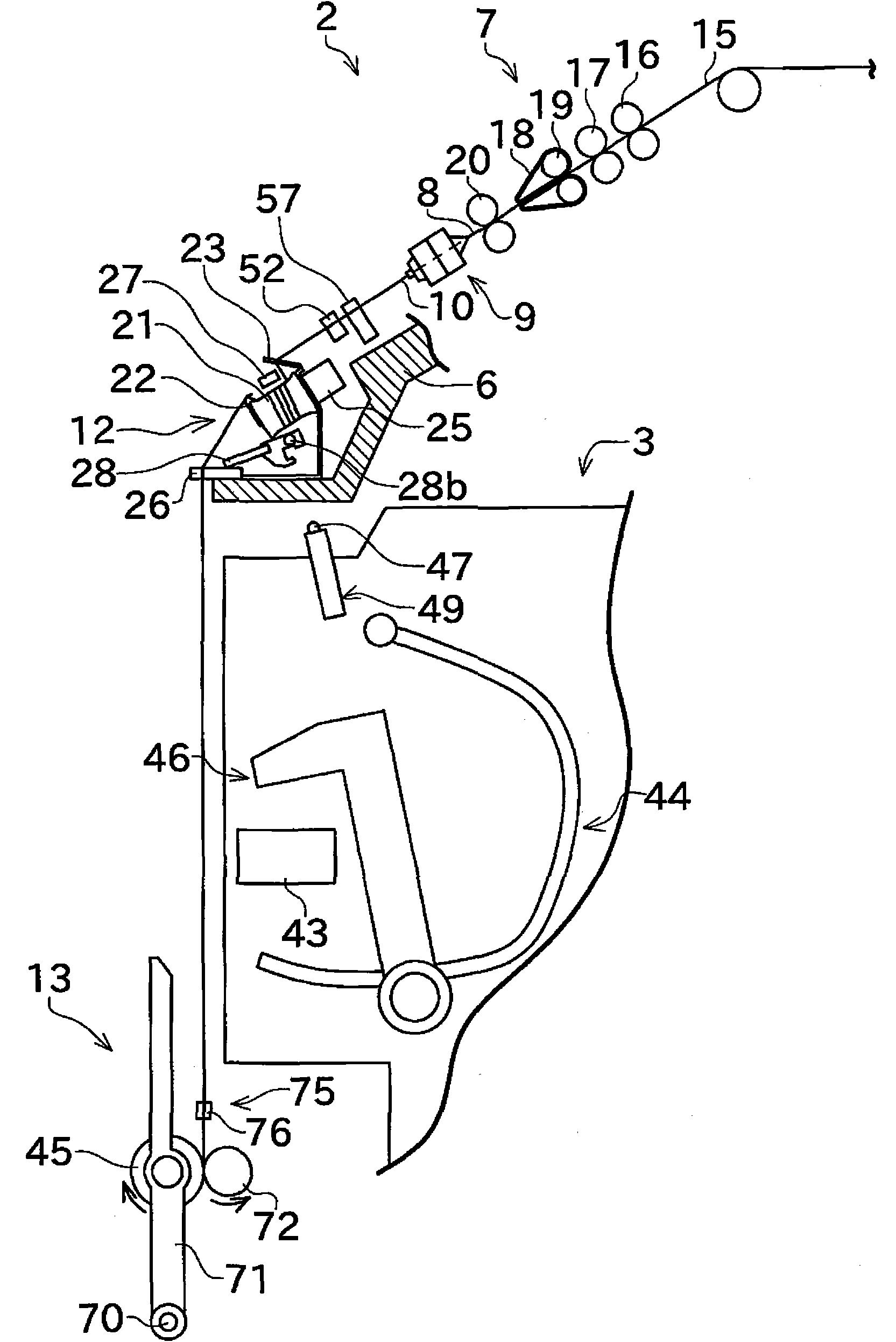

Spinning machine

ActiveCN101994176AImprove operational efficiencyReduce failurePiercing arrangementsFilament handlingYarnPulp and paper industry

The present invention provides a spinning machine, including a yarn accumulating roller (21), a yarn hooking member, a yarn removing lever (28), a suction pipe (44), and a unit controller. The hooking member can wind a spun yarn (10) around the yarn accumulating roller (21). The yarn removing lever (28) can remove the spun yarn (10) from the yarn hooking member. The suction pipe (44) can catch a yarn end of the spun yarn (10) and includes a twisting nozzle capable of applying twists to the caught spun yarn (10). The unit controller controls the twisting nozzle to operate while the spun yarn (10) caught by the suction pipe (44) is being wound around the yarn accumulating roller (21), and controls the twisting nozzle to stop before the yarn removing lever (28) removes the spun yarn (10) from the yarn hooking member.

Owner:MURATA MASCH LTD

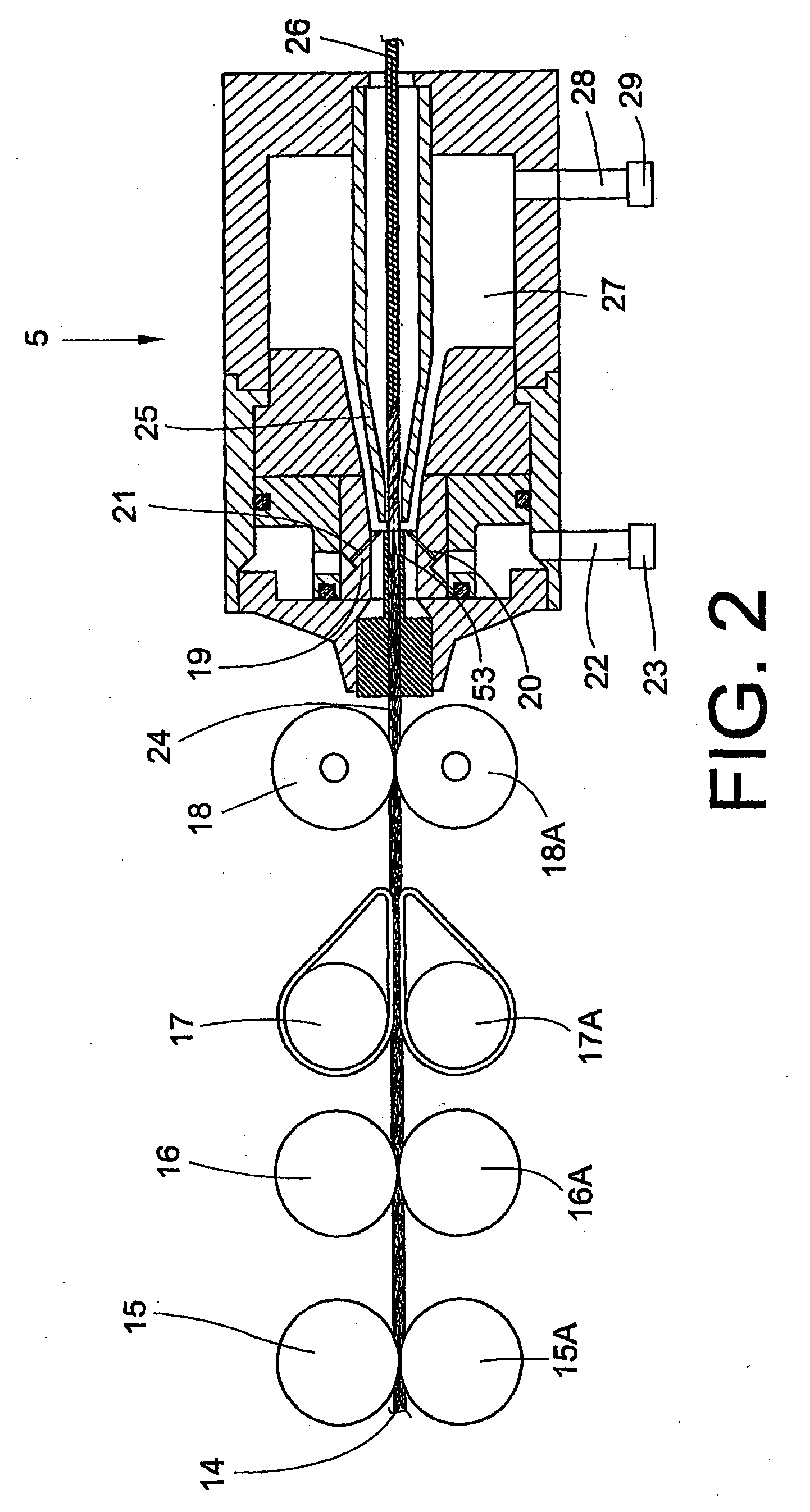

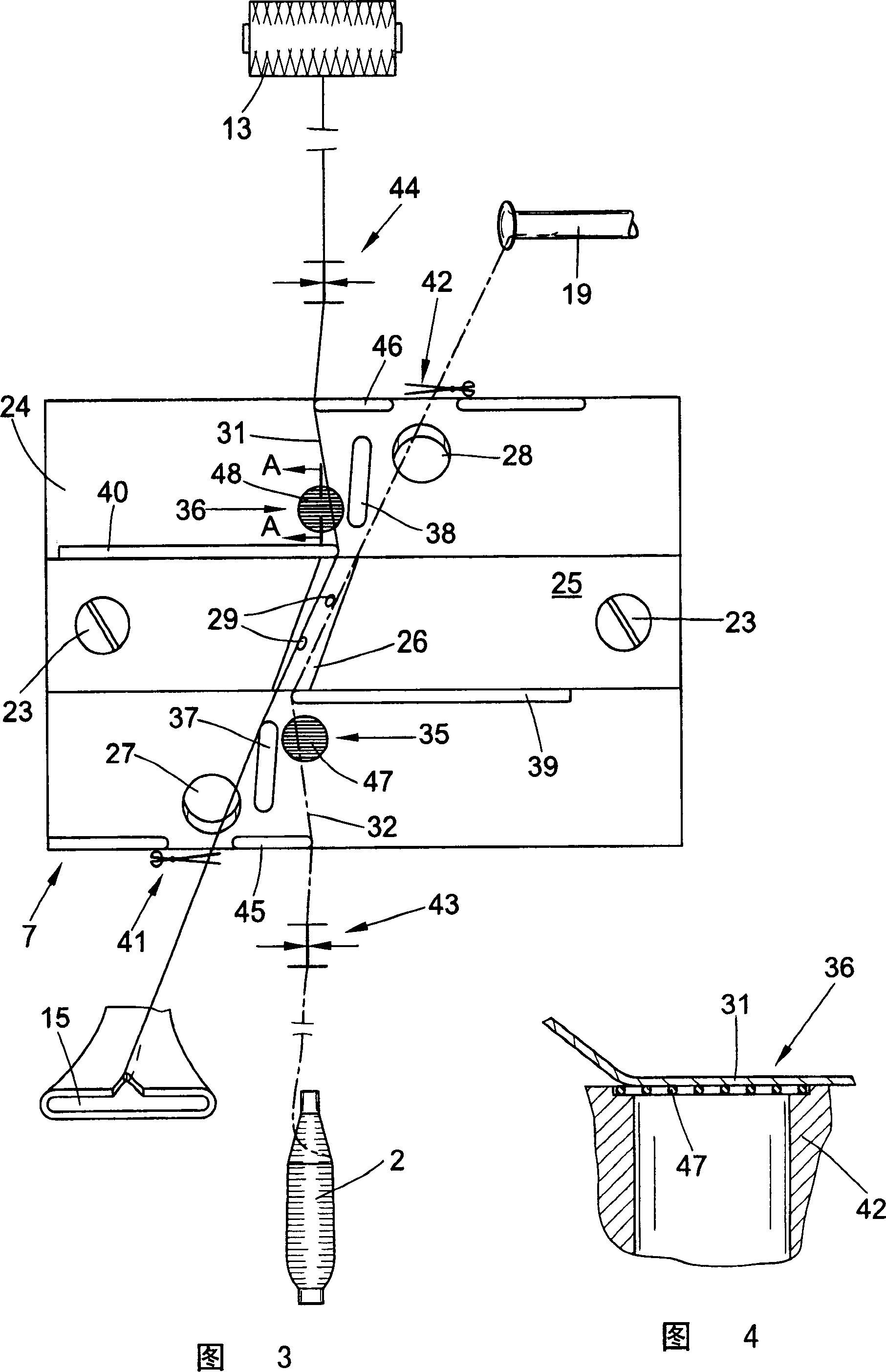

Joining method on a jet spinning machine, spinning device and jet spinning machine

InactiveUS20090094958A1Eliminate disadvantagesReduce in quantityPiercing arrangementsDrafting machinesEngineeringScrew thread

A joining method wherein fibers of a fiber band are wound around an auxiliary thread threaded into a spinning device and drawn through a spinning cone. The newly spun thread is separated from the auxiliary thread and connected to the end of an upper thread. A spinning device is provided for a jet spinning machine for carrying out such method, comprising a first clamping device for temporary clamping of the upper thread and a second clamping device for temporary clamping of the auxiliary thread. A jet spinning machine for carrying out the method has a mechanism for storing the auxiliary thread and the newly spun thread, a mechanism for separating the auxiliary thread from the newly spun thread, and a splicing mechanism for connecting the newly spun thread to the upper thread, all arranged only on at least one operating carriage displaceable along multiple spinning stations.

Owner:SAURER INTELLIGENT TECH AG

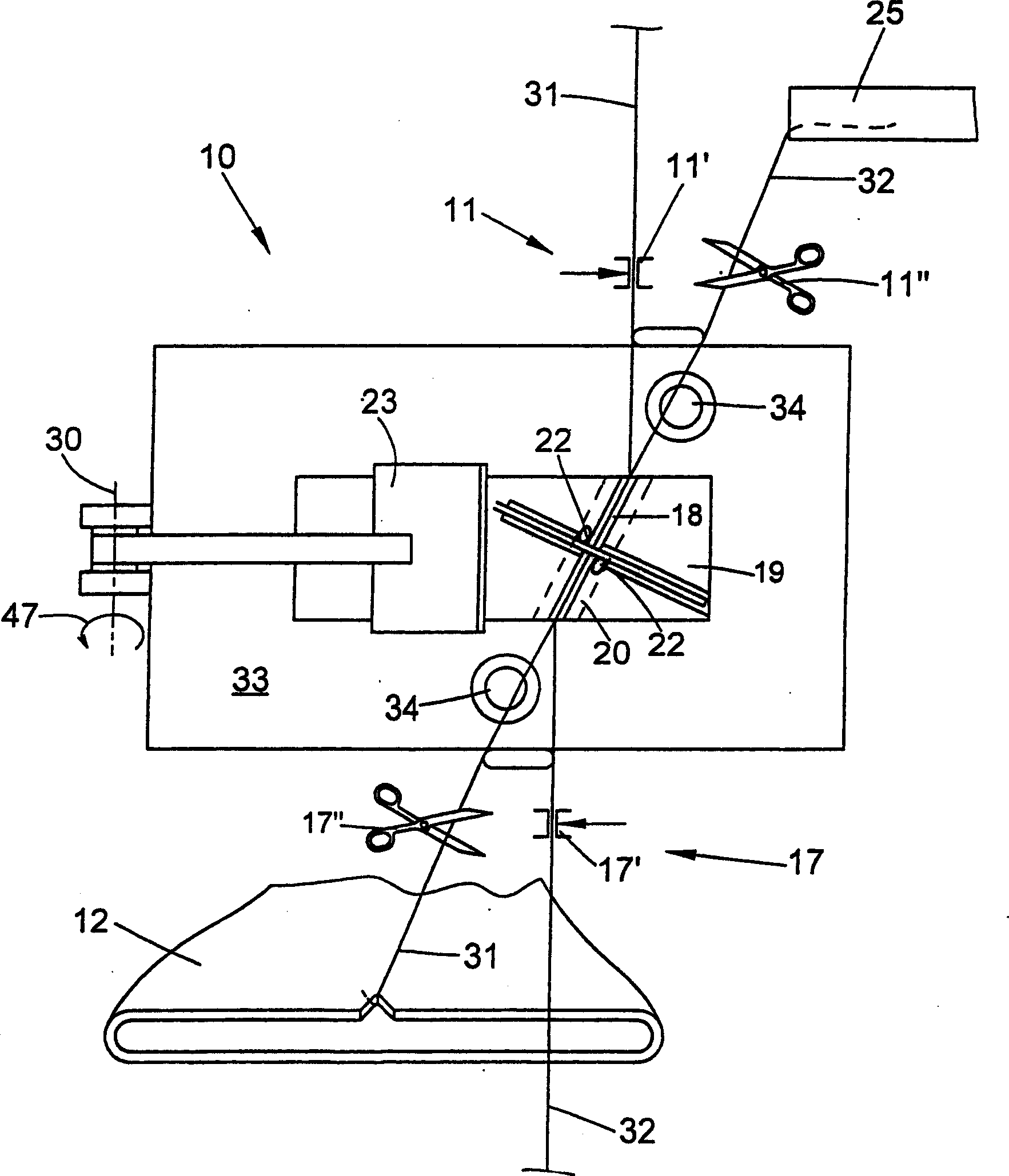

Method for optimizing pneumatic connecting line or yarn and corresponding equipment

InactiveCN101165241AFilament handlingPiercing arrangementsYarnElectrical and Electronics engineering

A method for optimizing pneumatic connecting line or yarn includes the following steps: lines (12, 15)needed connecting are led into connecting cavity (11) of pneumatic connecting device (10); the lines (12, 15) entering into device (10) are locked; the ends of the lines (12, 15) are cut off; the ends of the lines (12, 15) are untwisted; the lines (12, 15) are dragged on the direction of connecting cavity (11) and cut off, the ends of the lines are open; the connecting is executed by compressing air, wherein, at least one step capable of adjusting measurement to intercept lines (12, 15) by at least two intercepting lever (32, 33) executes on the downstream of leading-points (20, 21) between the leading step and the untwisting step to extend the path of the lines (12, 15) and change the length of the ends of the lines (12, 15) outspread. The invention also relates to a device for executing the method.

Owner:MEDSAN SPA

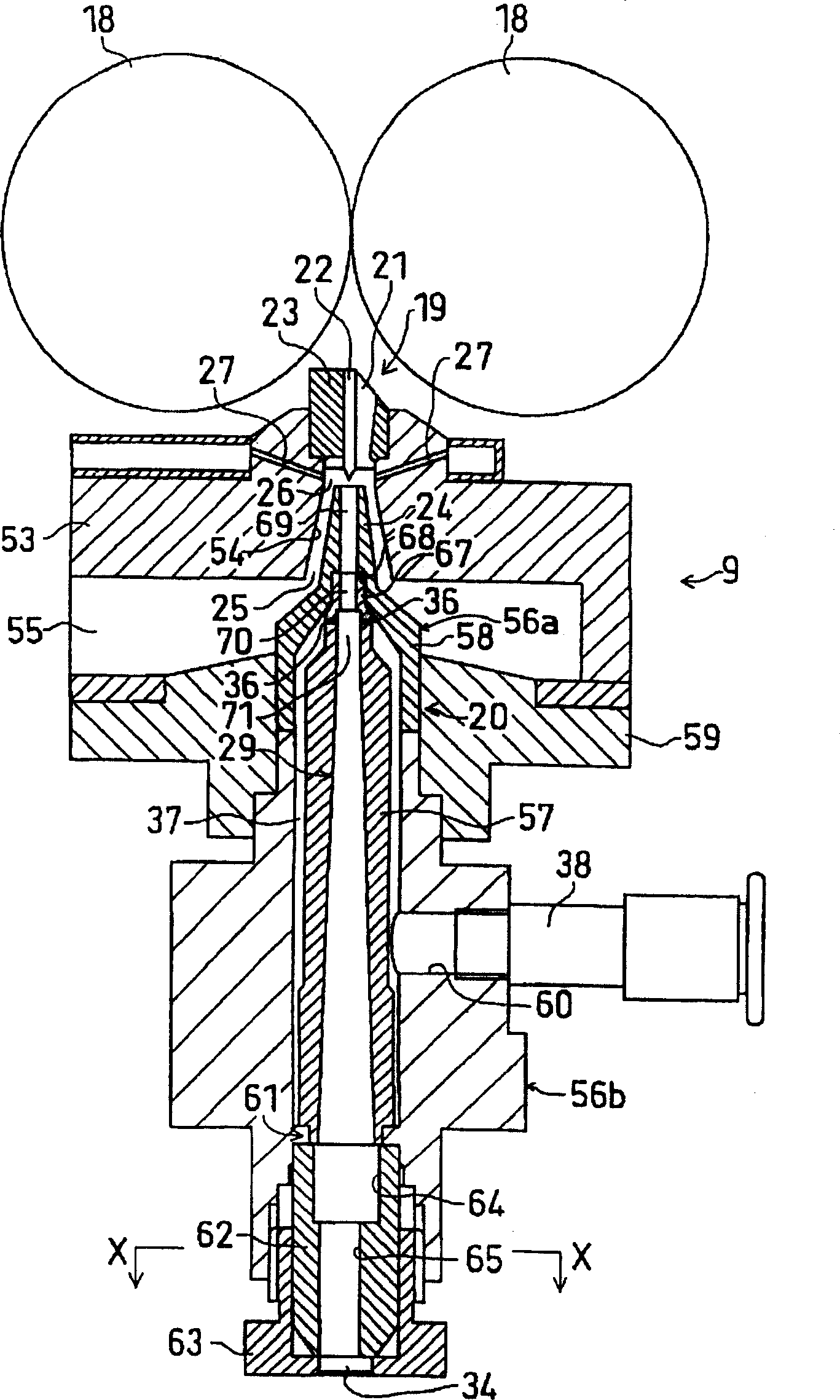

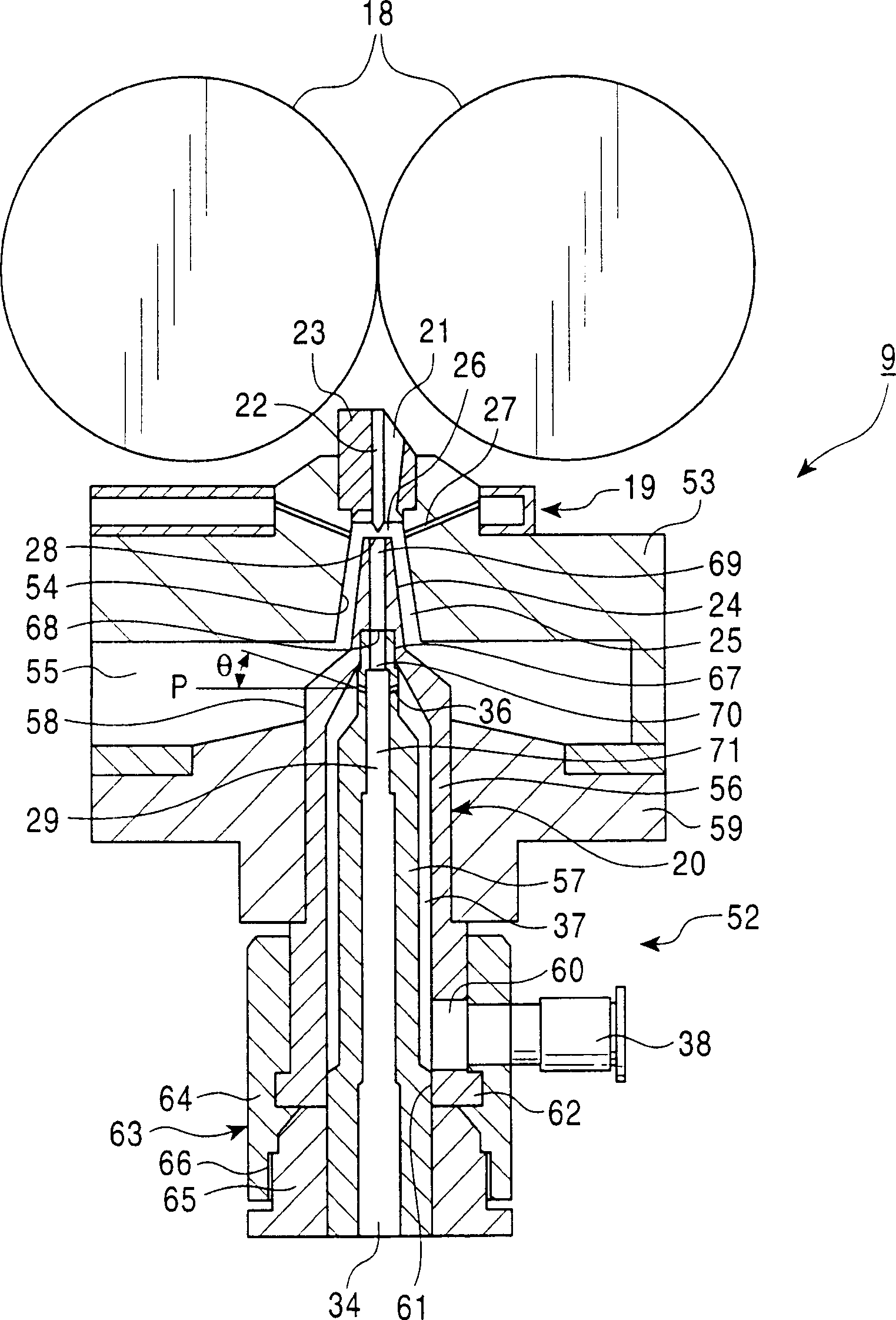

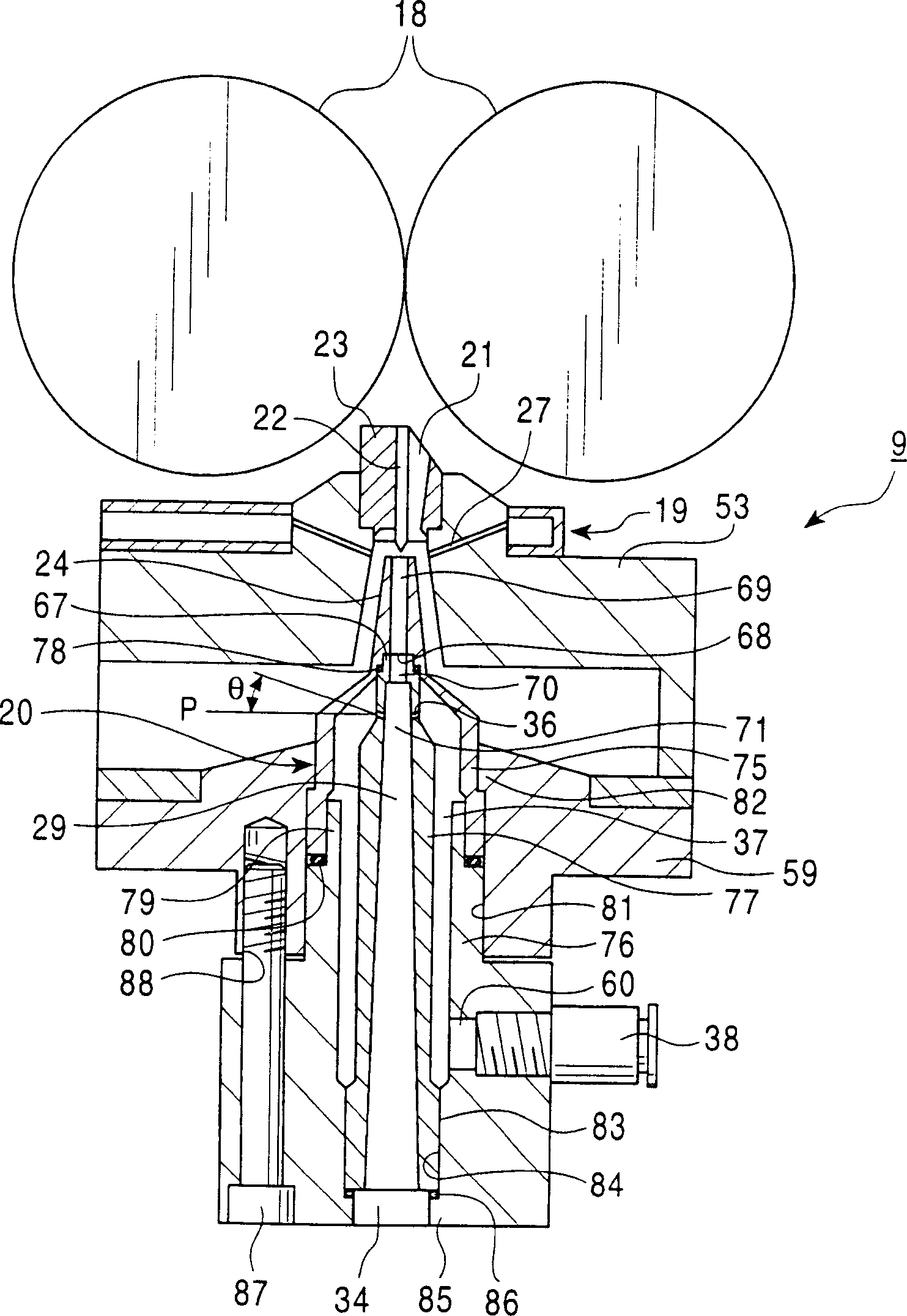

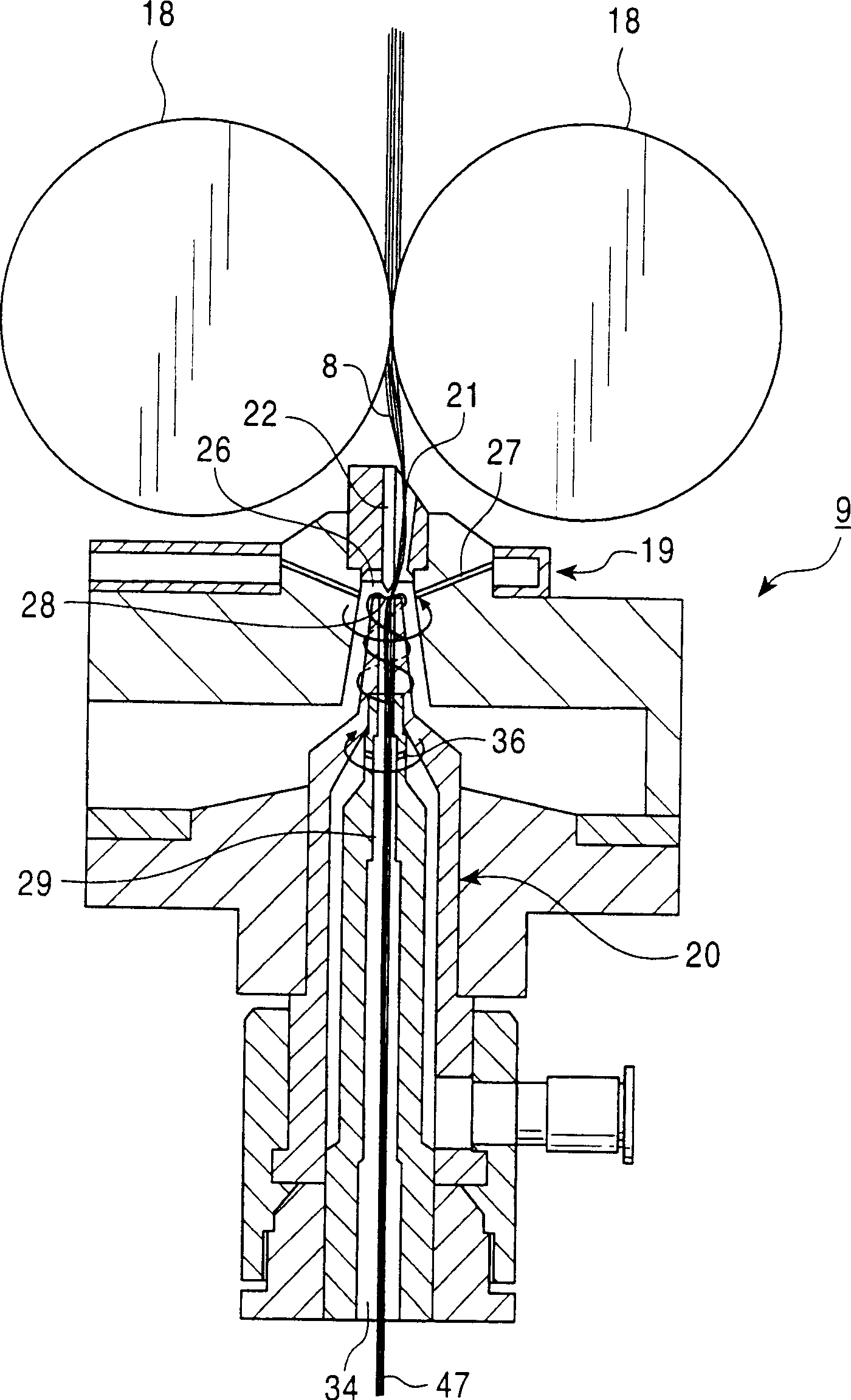

Spinning devices

InactiveCN1407153AAvoid yarn breakageIncrease success ratePiercing arrangementsContinuous wound-up machinesEngineeringYarn strength

The invention provides a high-speed spinning by increasing success rates of the taking-out of a yarn and the piecing of the yarn. This spinning frame has a pneumatic spinning nozzle 27 for generating a rotational gas flow at the vicinity of a tip part 24 of a hollow guide shaft 20 and an assistant nozzle 36 for generating the rotational gas flow in a yarn passage 29 in a hollow guide shaft 20. The assistant nozzle 36 is tilted so as to be directed to the downstream side based on the plane P orthogonal to the yarn passage 29. The tilting angle of the assistant nozzle 36 is preferably 10-35 degrees, more preferably 20 degrees. As a result, the component of the flow directed to the downstream side, and accompanied by the rotational gas flow generated by the assistant nozzle is enlarged, and the sucking power into the yarn passage is enhanced. The balance between the components in the downstream direction and the rotational direction is corrected and the yarn strength of a bound yarn to be discharged is increased to prevent the yarn break or the like.

Owner:MURATA MASCH LTD

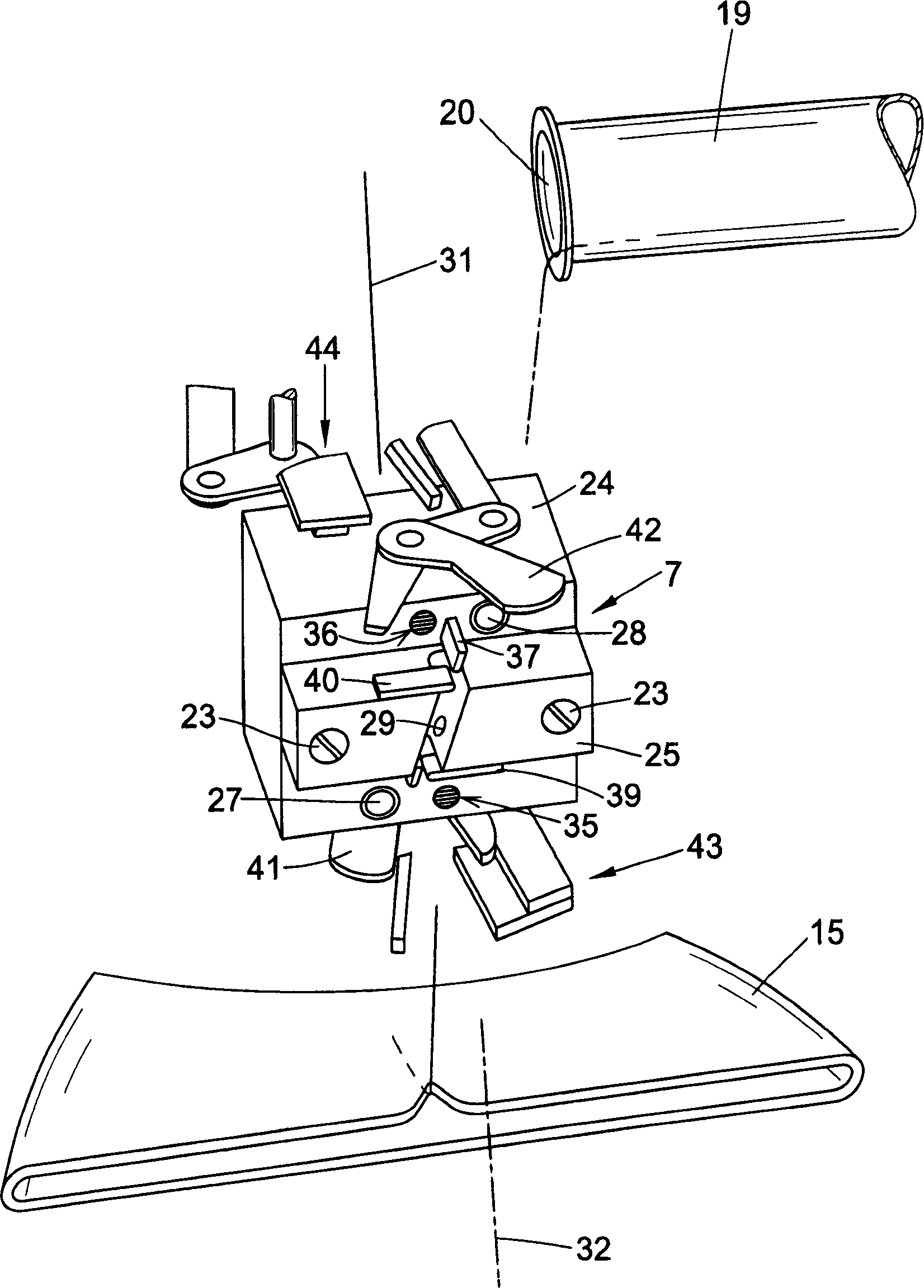

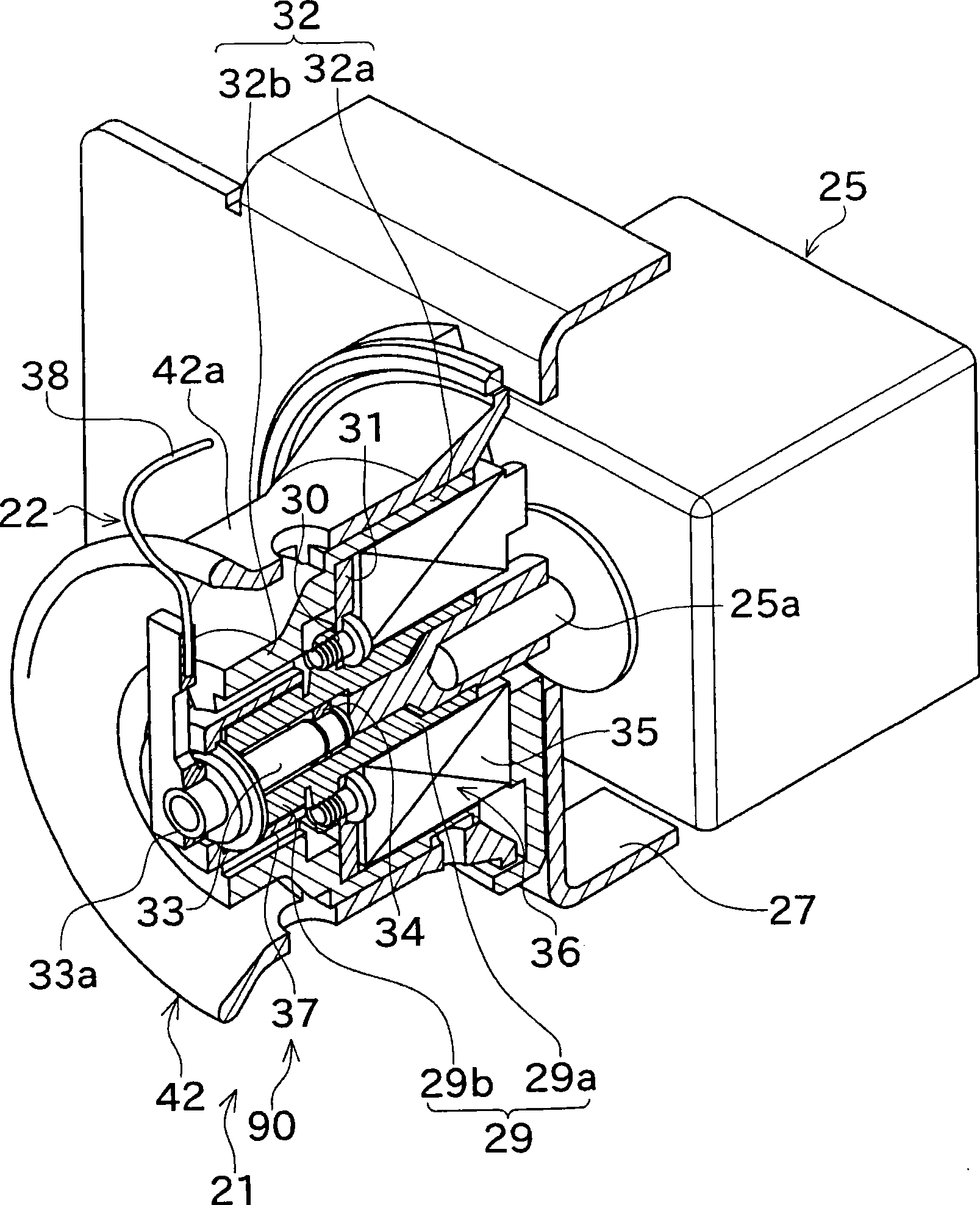

Yarn twisting device

An elastic yarn knot-free yarn splicing device equipped with a prismatic splicing head (25), the splicing head has a splicing groove (26), and at least one compressed air injection hole (29) is provided in the groove. The splicing groove (26) receives the yarns to be spliced with each other and enables airflow splicing of the fibers of the yarns. The splicing device (58) is respectively equipped with a clamping device (43; 44) and a yarn cutting device (41; 42). The splicing device (58) includes pretreatment nozzles (53; 54). In addition to the pretreatment of the yarn ends, the two nozzles are also used as an airflow holding device to fix the mutually spliced yarn ends. According to the present invention, on the yarn path between the clamping device (43; 44) and the pre-treatment nozzle (53; 54), a braking device (49; 50) for airflow acting on the yarn is arranged, so that the yarn is sent to the pre-treatment The retraction distance of the nozzles (53;54) is shortened. By means of the yarn splicing device of the present invention, the number of ineffective yarn splices for splicing elastic yarns on a winder or a combined spinning / winding machine can be reduced.

Owner:OERLIKON TEXTILE GMBH & CO KG

Method for automatic doffing operation and doffing apparatus

The present invention relates to an automatic doffing operation. Conventionally if in spite of a failure in a yarn drawing-out operation, a yarn hooking operation is performed and an empty bobbin is uselessly supplied, an operator is thus forced to remove the bobbin. The present invention includes a full-package taking-out operation step of taking a bobbin with a package out of a cradle, a yarn drawing-out operation step of using a yarn drawing-out device to start drawing out a spun yarn and then catching the spun yarn, and a yarn hooking operation step of supplying an empty bobbin to the cradle and hooking the spun yarn on the bobbin to return a doffing operation to an initial state. If the yarn fails to be caught during the yarn drawing-out operation step, a reverse returning step is executed instead of the yarn hooking operation step to reversely rotate a motor to return the doffing operation to its initial state without executing the yarn hooking operation step.

Owner:MURATA MASCH LTD

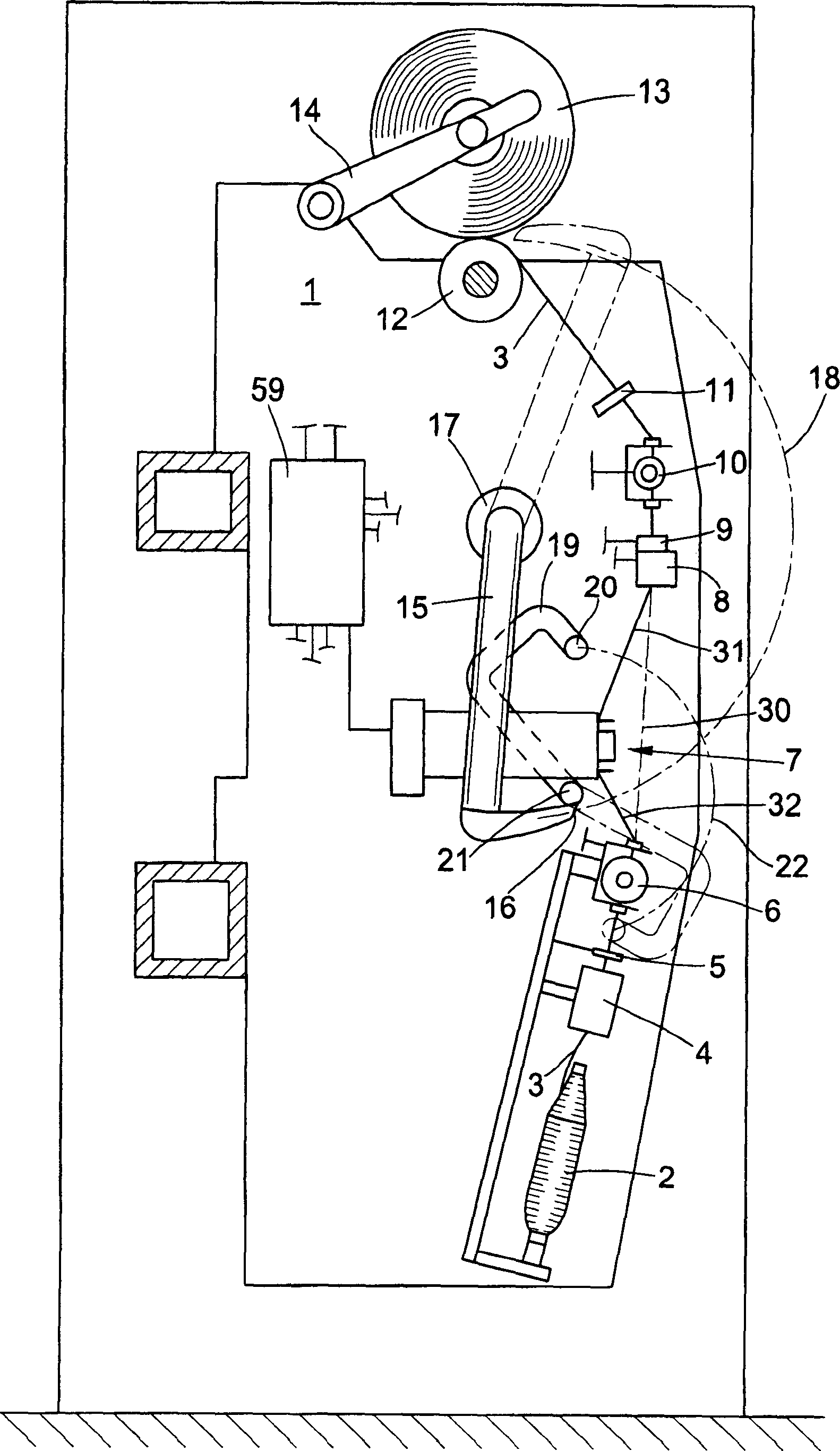

Method for automatically testing yarn breakage and spindle defect and robot for resurrection

The invention discloses a method for automatically testing yarn breakage and a spindle defect and a robot thereof. The invention provides a control system in which a spindle monitoring system (1) and a transportation system (3) are integrated, wherein the system (3) guides and promotes movement of the robot (14) and is used for processing yarn breakage and the spindle defect in monitoring through the monitoring system. Furthermore information related with yarn breakage and the spindle defect is sensed through the monitoring system, and furthermore the information is transmitted to the transportation system (3). The system (3) can carry the robot and a spinning material for advancing along the whole longitudinal axis of a ring spinning machine and is used for processing yarn breakage and other spindle defects, thereby ensuring higher resurrection speed in a yarn spinning process of the ring spinning machine. Furthermore production of the low-quality yarn caused by other spindle defects is prevented.

Owner:PREMIER EVOLVICS PVT LTD

Service trolley for open-end spinning machines

InactiveUS7146792B2Efficient interventionHigh yieldPiercing arrangementsFilament handlingControl unitWaste management

Service trolley for open-end spinning machines equipped with members dedicated to the operations in the intervention cycles and managed by the trolley's own control unit in which each member is independent from the others, being equipped with independent actuation controlled by sensors for the various steps of the intervention cycles.

Owner:SAVIO MACCHINE TESSILI

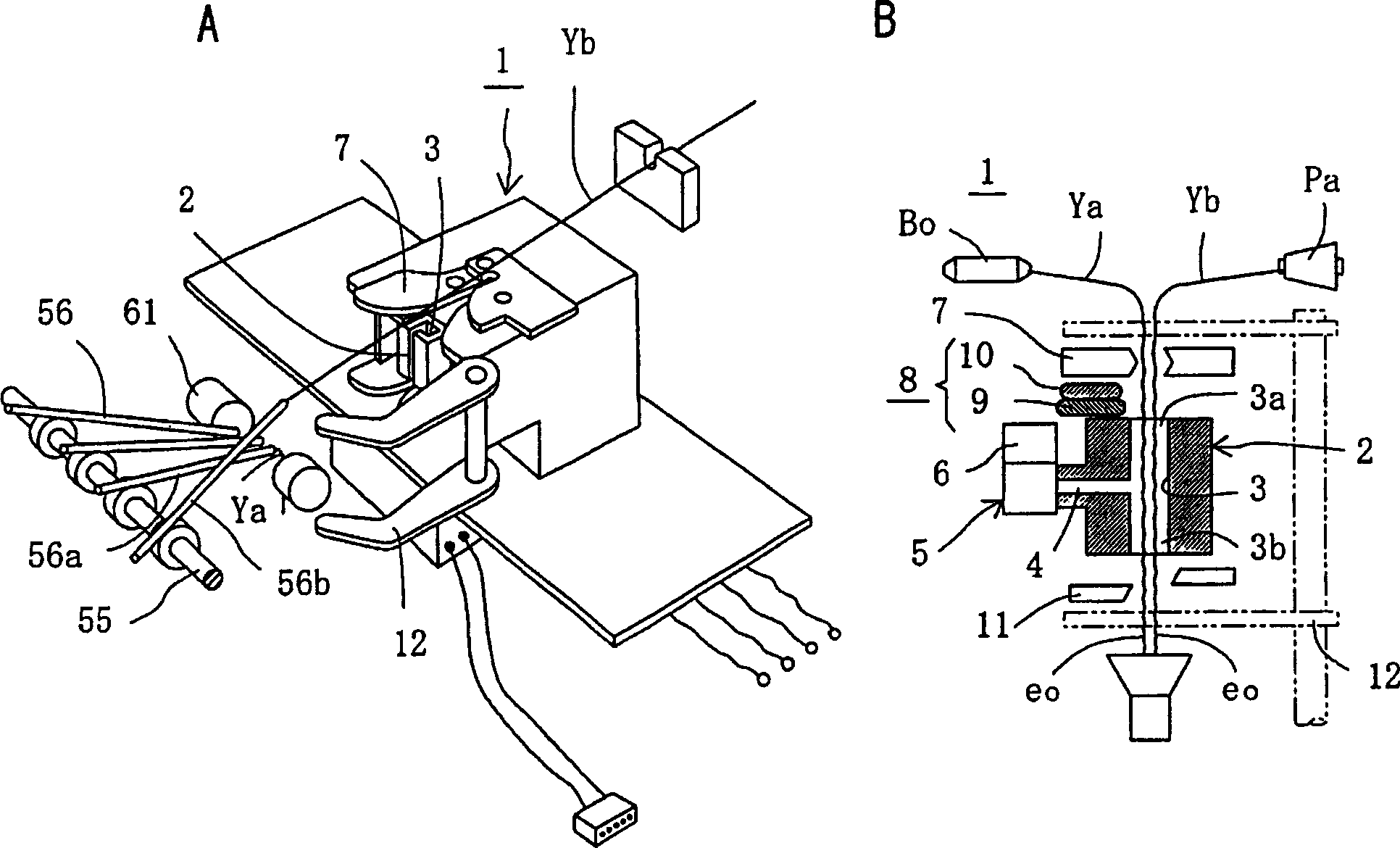

Yarn joining device and handy splicer

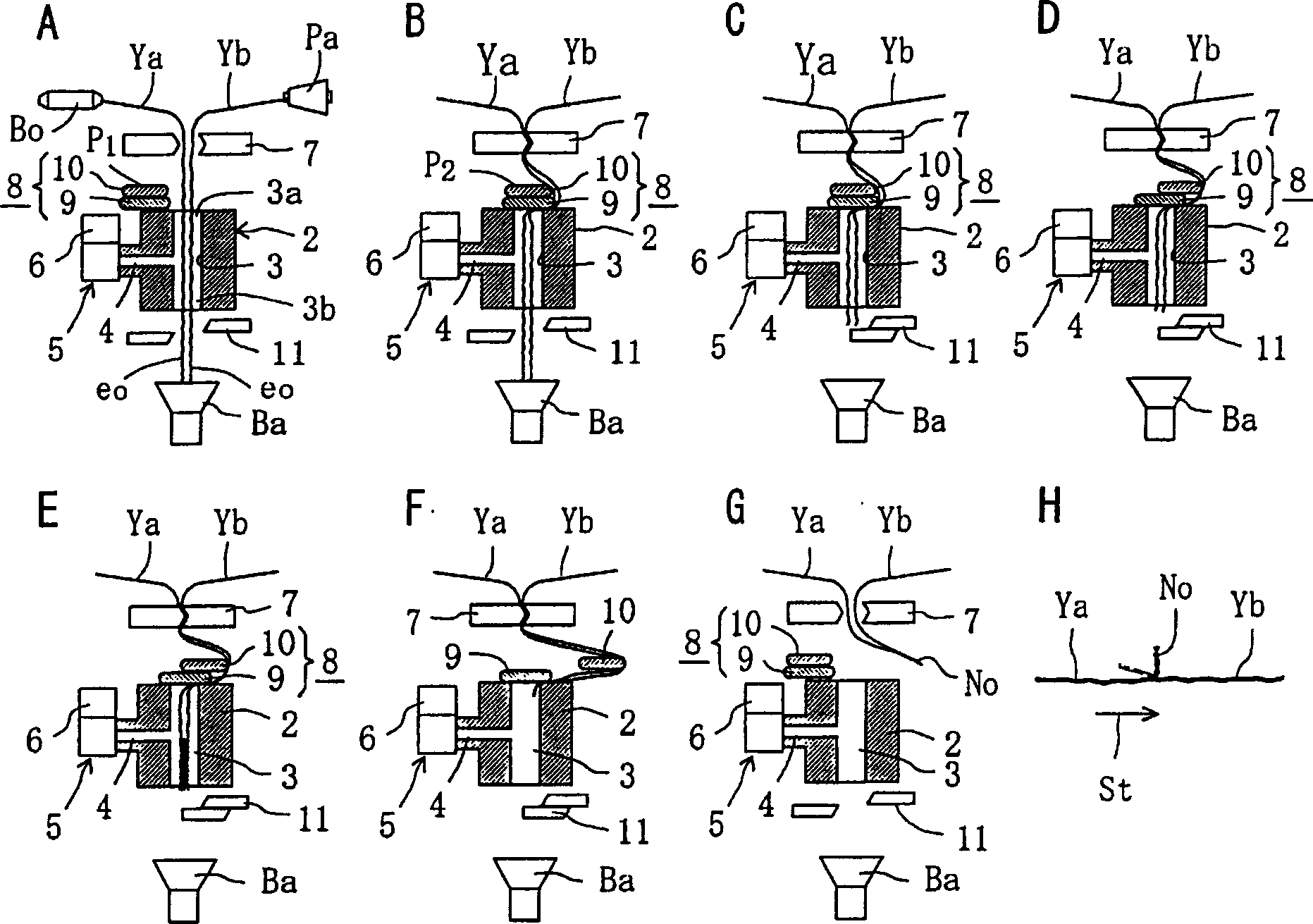

InactiveCN1676698AEffortless and easy untwistingLabor-saving and easy to untwistPiercing arrangementsFilament handlingYarnNozzle

The present invention provides a yarn joining device for joining two yarns (Ya,Yb) with the tail ends (eo) thereof aligned in the same direction. The yarn joining device reduces the size of the joint portion of the yarns even if the yarn joining is successively performed, and also adjusts the yarn joining length, and thereby forms the joint portion of yarns uniformly and reliably. In the yarn joining device for joining tail ends of two yarns with the tail ends aligned in the same direction, loosening and twining of the tail ends of the yarns is performed successively by a single air jet nozzle (2).

Owner:MURATA MASCH LTD

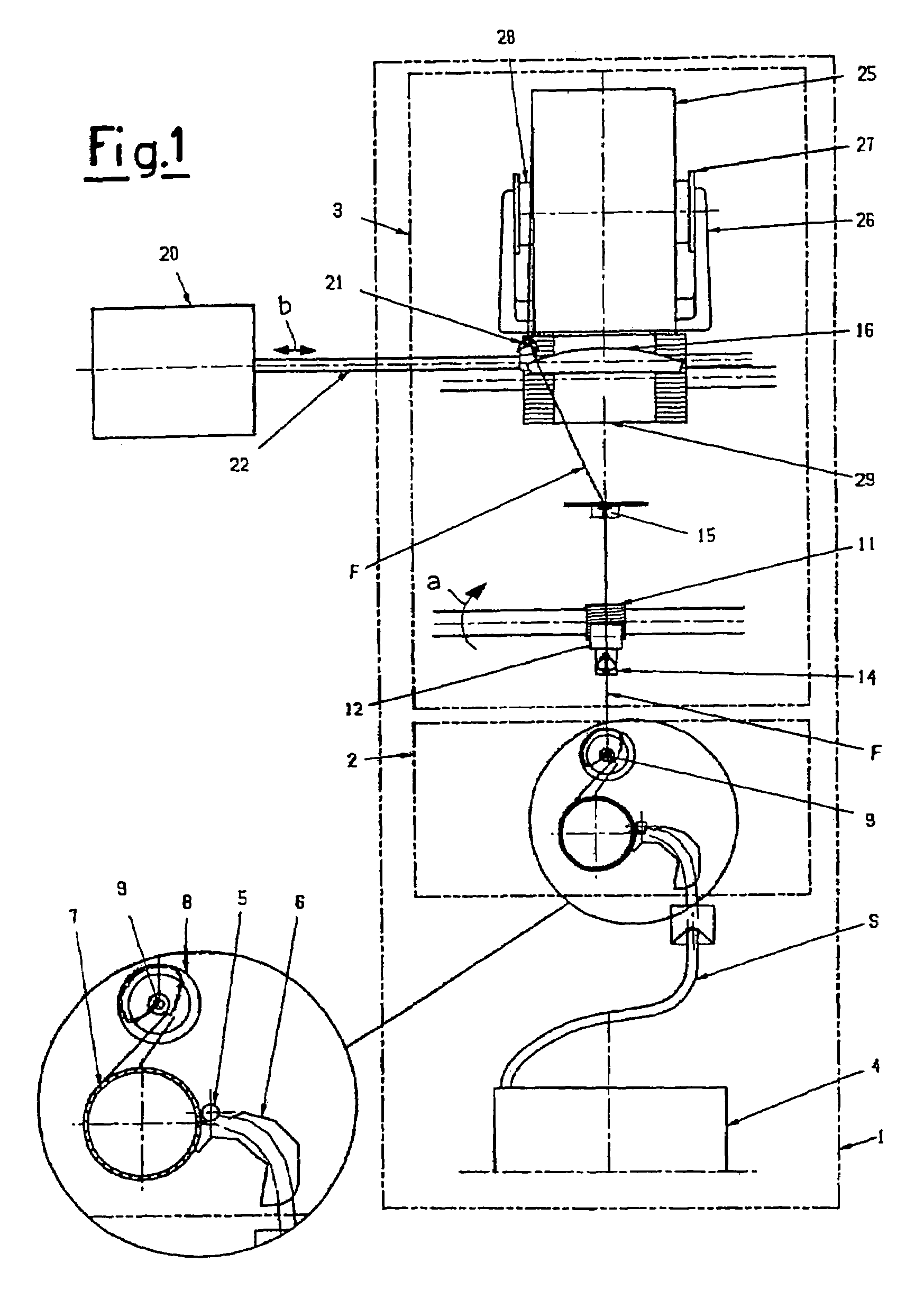

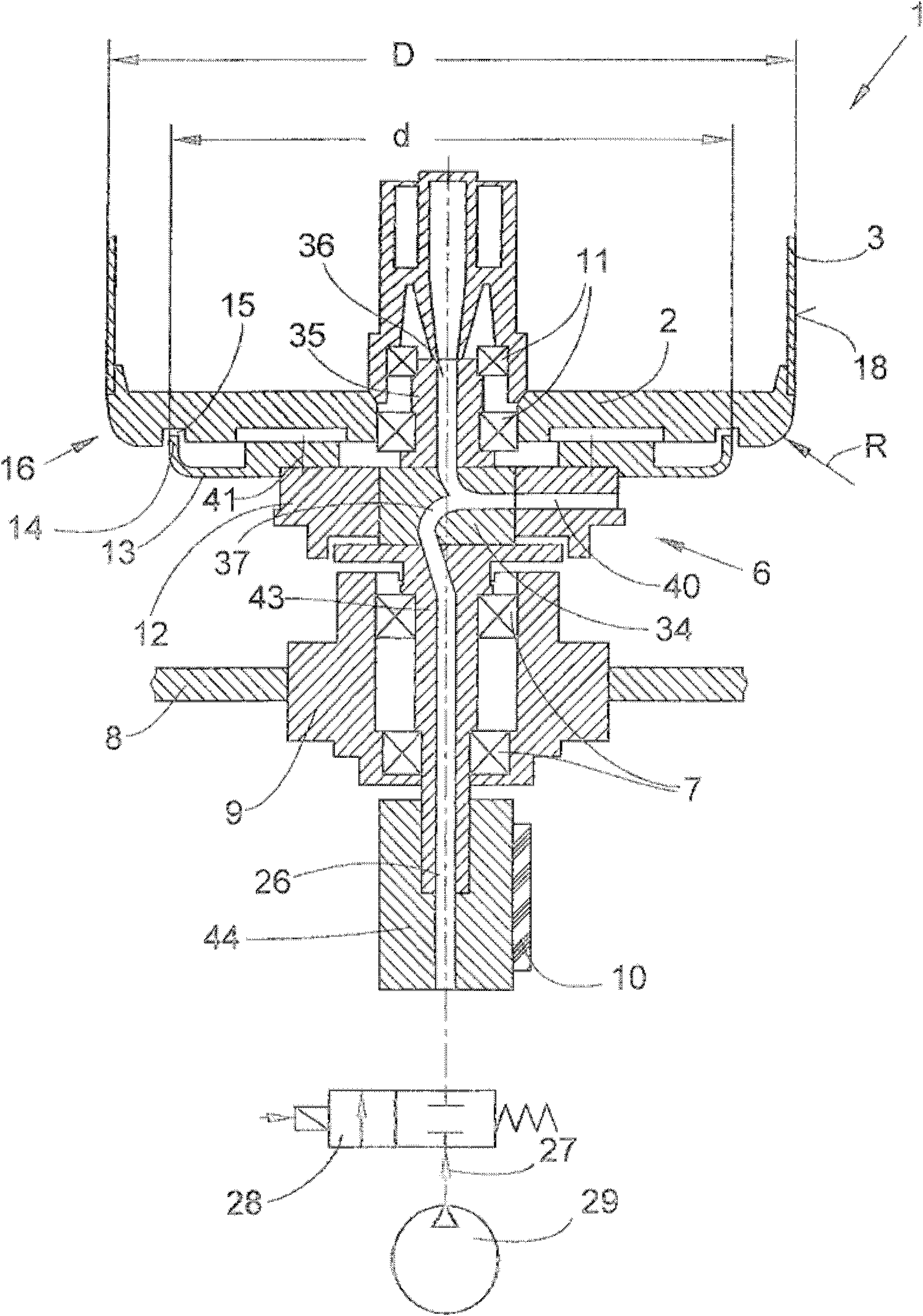

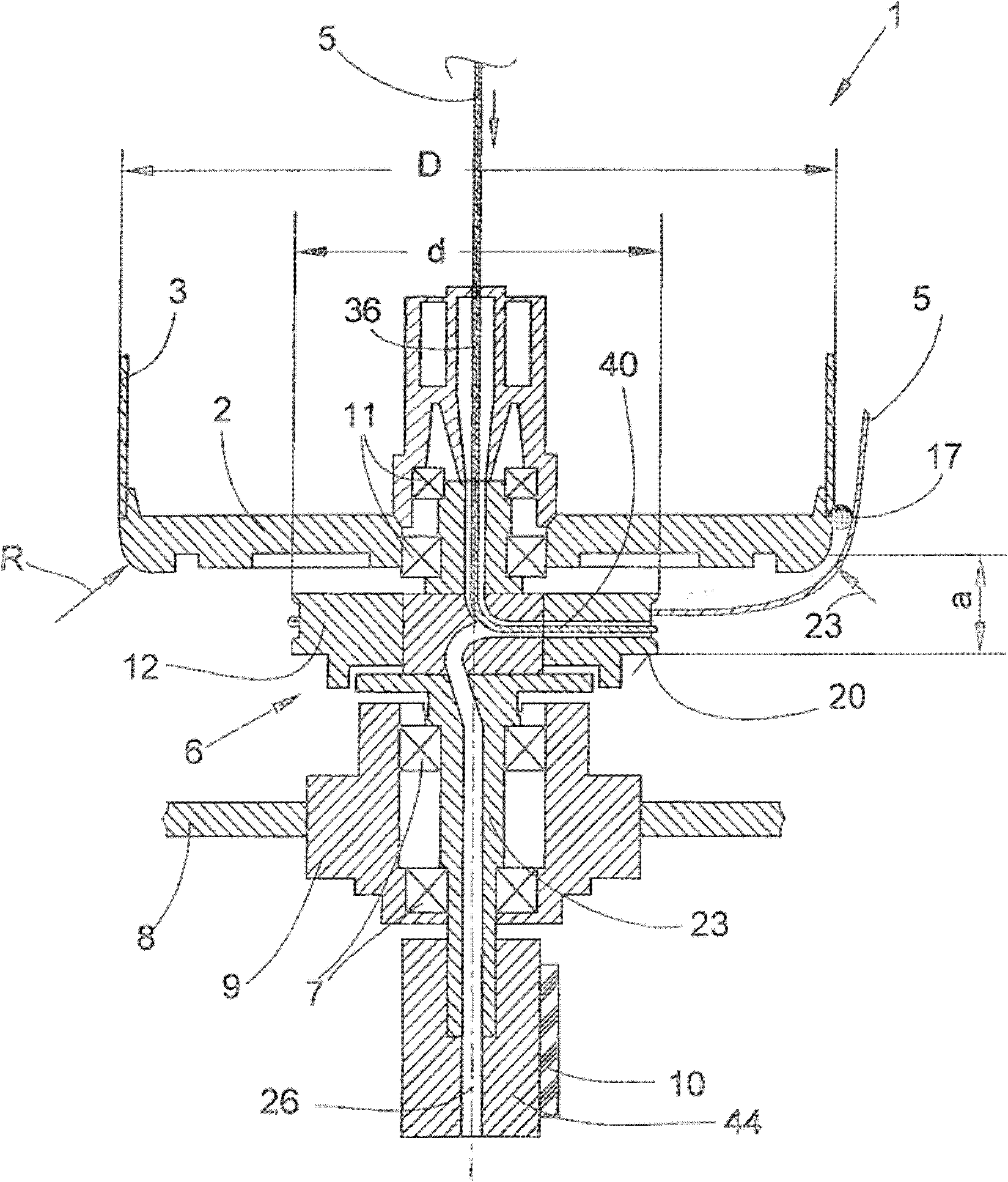

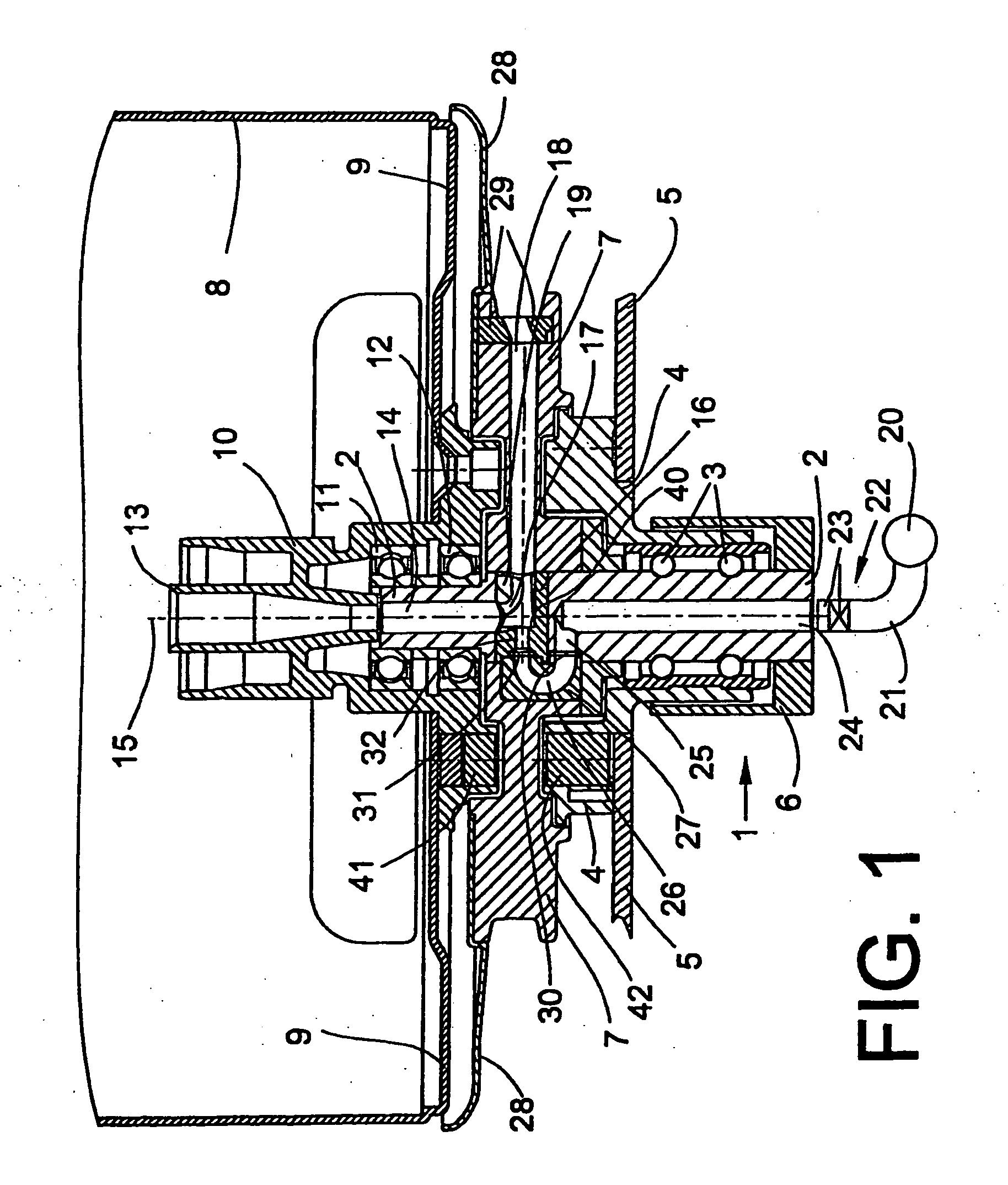

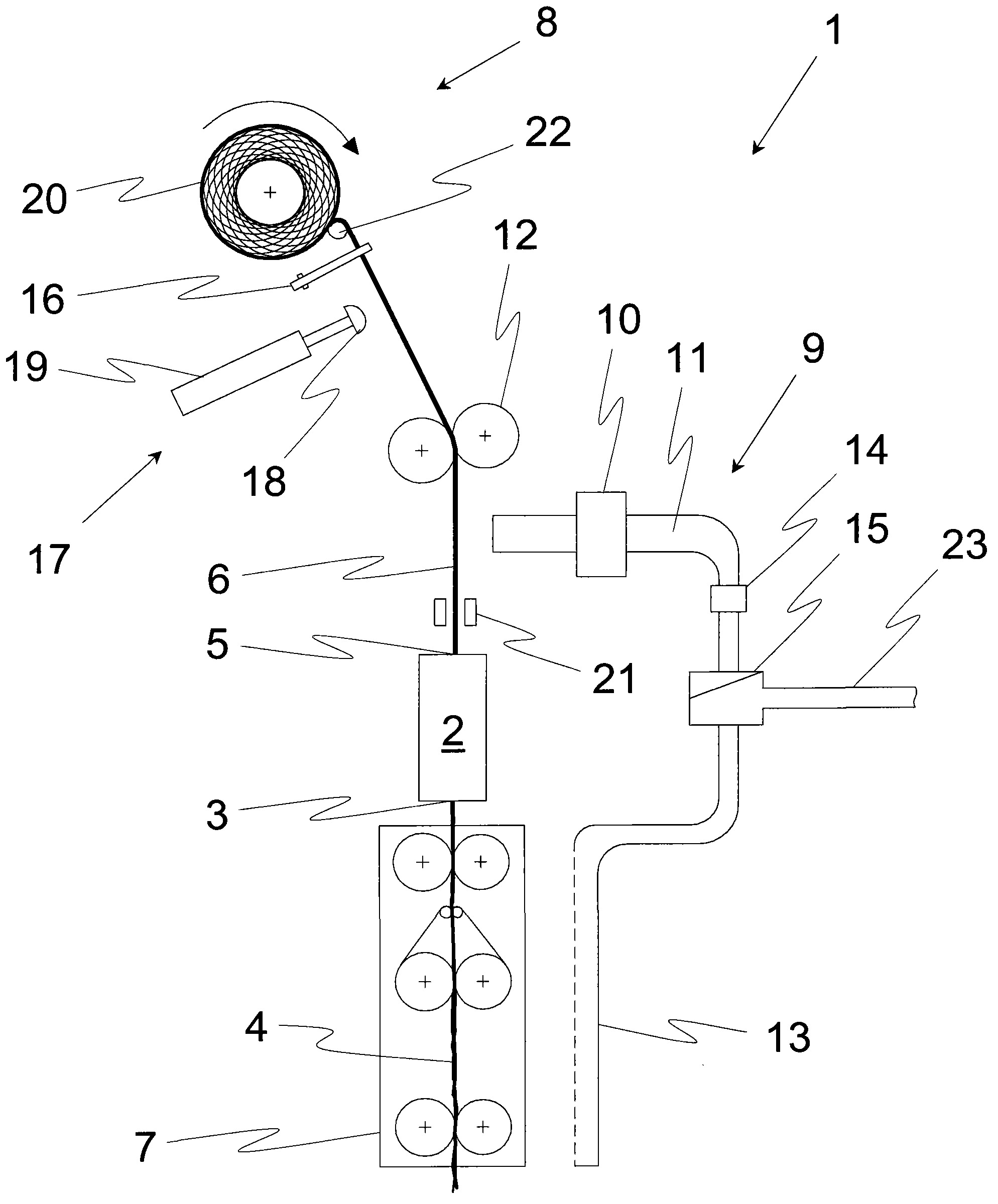

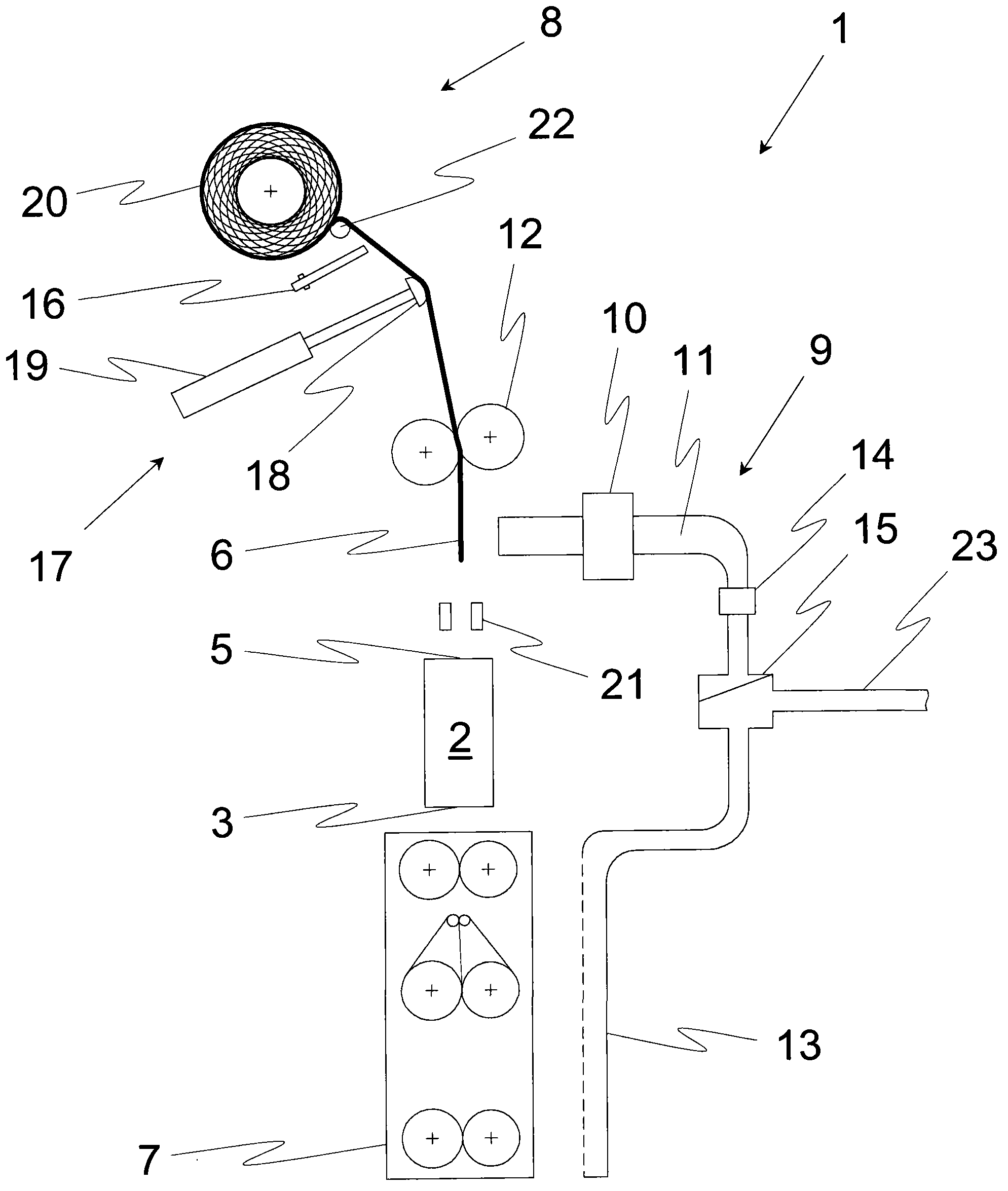

Twin wire twisting or cabling spindle

InactiveCN102212903AReduced ventilation lossesSave drive energyPiercing arrangementsContinuous wound-up machinesYarnBobbin

A two-for-one twisting or cabling spindle apparatus (1) with a supply bobbin (4) mounted on a pot base (2) of a stationary protective pot (3) and a spindle (6) arranged below the protective pot (3) to guide a yarn (5) to be processed during a twisting or cabling process. The spindle (6) is rotatably mounted by a lower bearing device (7) in a bearing housing (9) fixed on a spindle rail (8) and an upper bearing device (11) mounted to the stationary protective pot (3). The largest diameter (d) of the rotatably mounted spindle (6) is at least 10% less than the diameter (D) of a touching line (23) of the pot base (2) of the stationary protective pot (3) with the yarn (5).

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

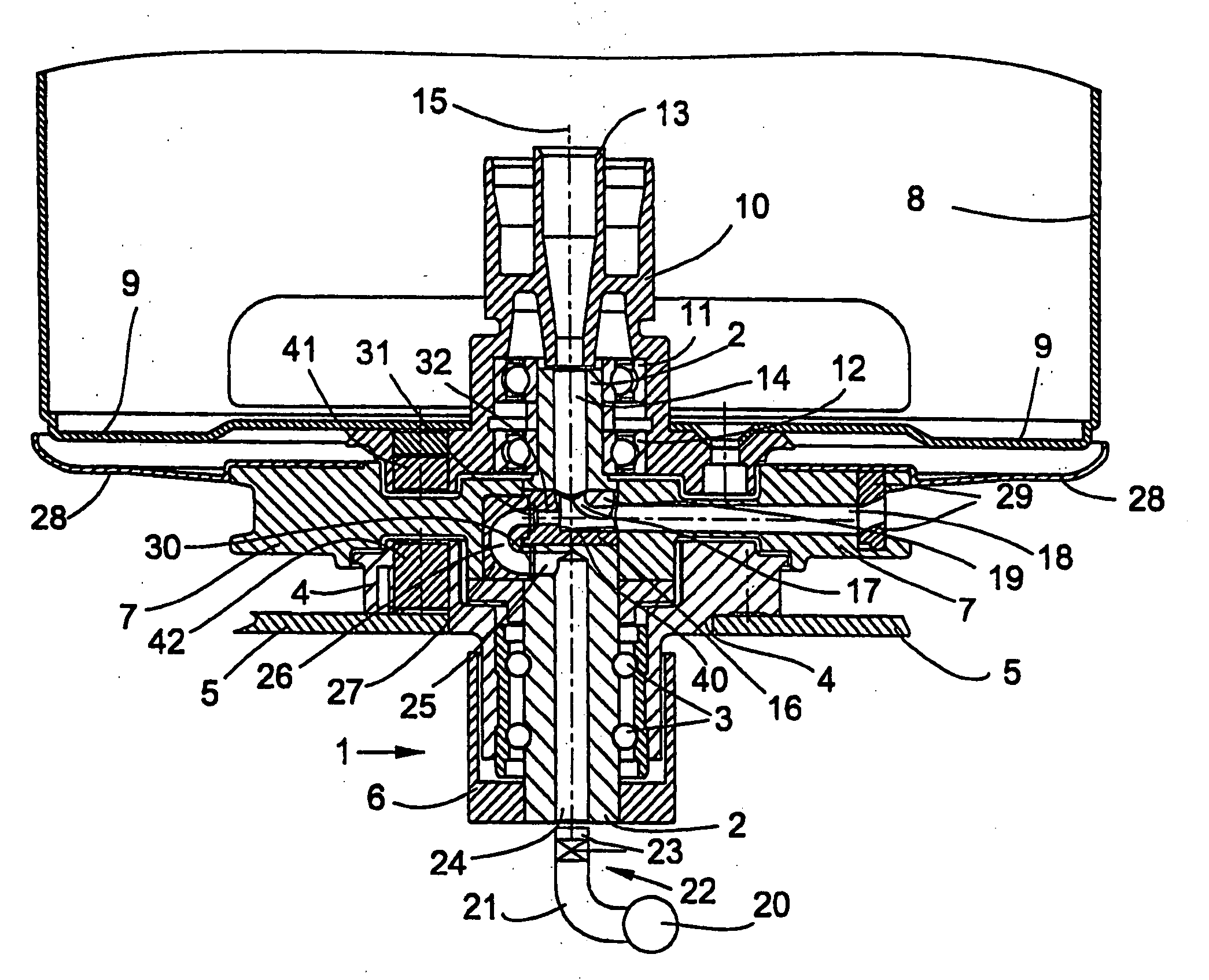

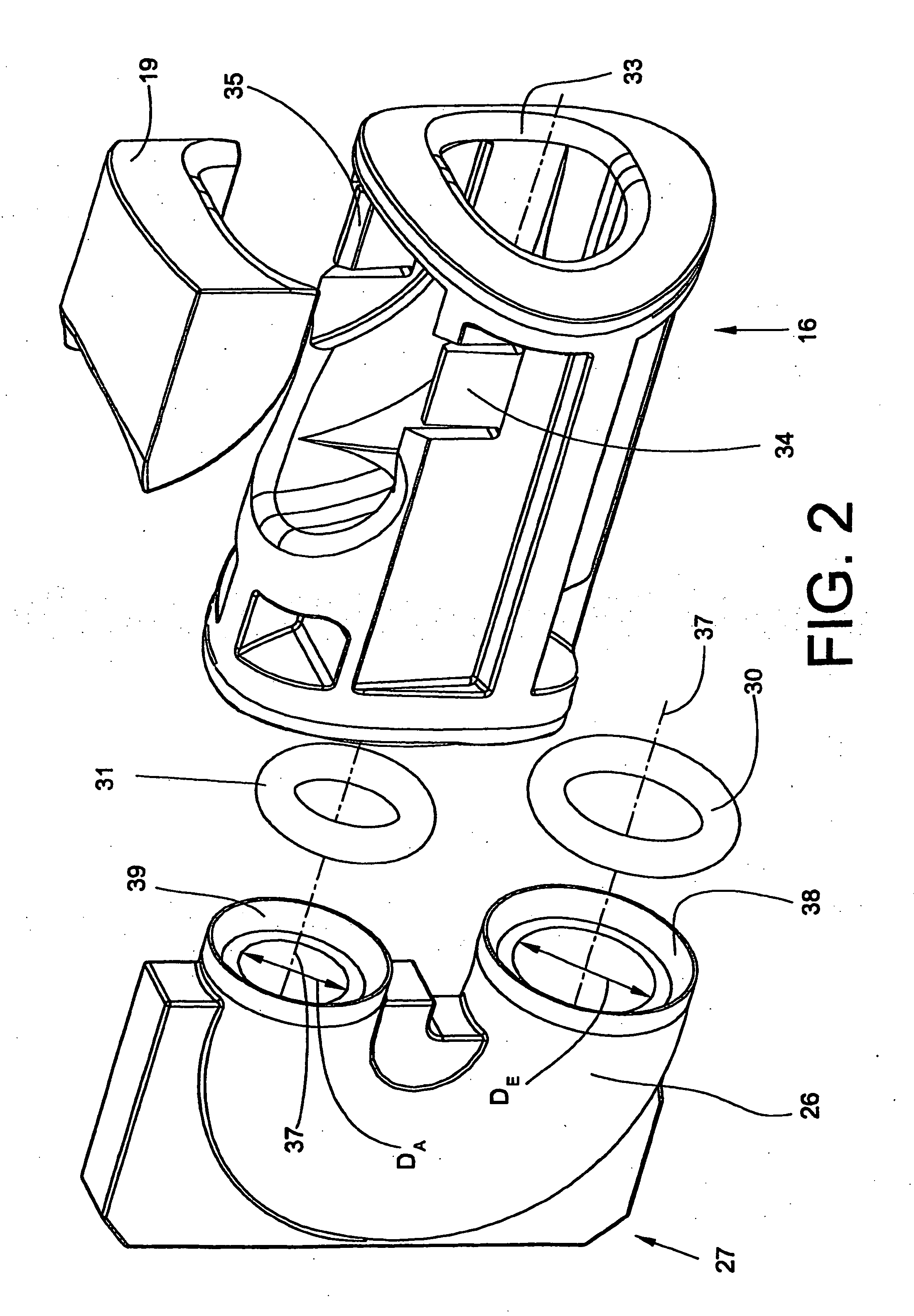

Two-For-One Twisting Spindle Having a Pneumatically Actuated Threading Device

InactiveUS20100018178A1Easy to produceReduce weightPiercing arrangementsDrafting machinesRotational axisEngineering

Two-for-one twisting spindle having a pneumatically actuated threading device, with a spindle shaft rotatable about a vertical axis partially configured as a hollow shaft with a lower feed bore extending coaxially to the rotational axis, and with an injector element opening into a thread guide channel of a thread guide ring temporarily connectable during threading to a compressed air source. Part of the compressed air feed to the injector element is formed by the feed bore. The compressed air feed comprises a connection element (27) with a curved air channel (26), which connects the feed bore (24) to the injector element (16). The connection element (27) is configured as a separate component and the air channel (26) is adapted to the flow requirements.

Owner:SAURER TECH GMBH & CO KG

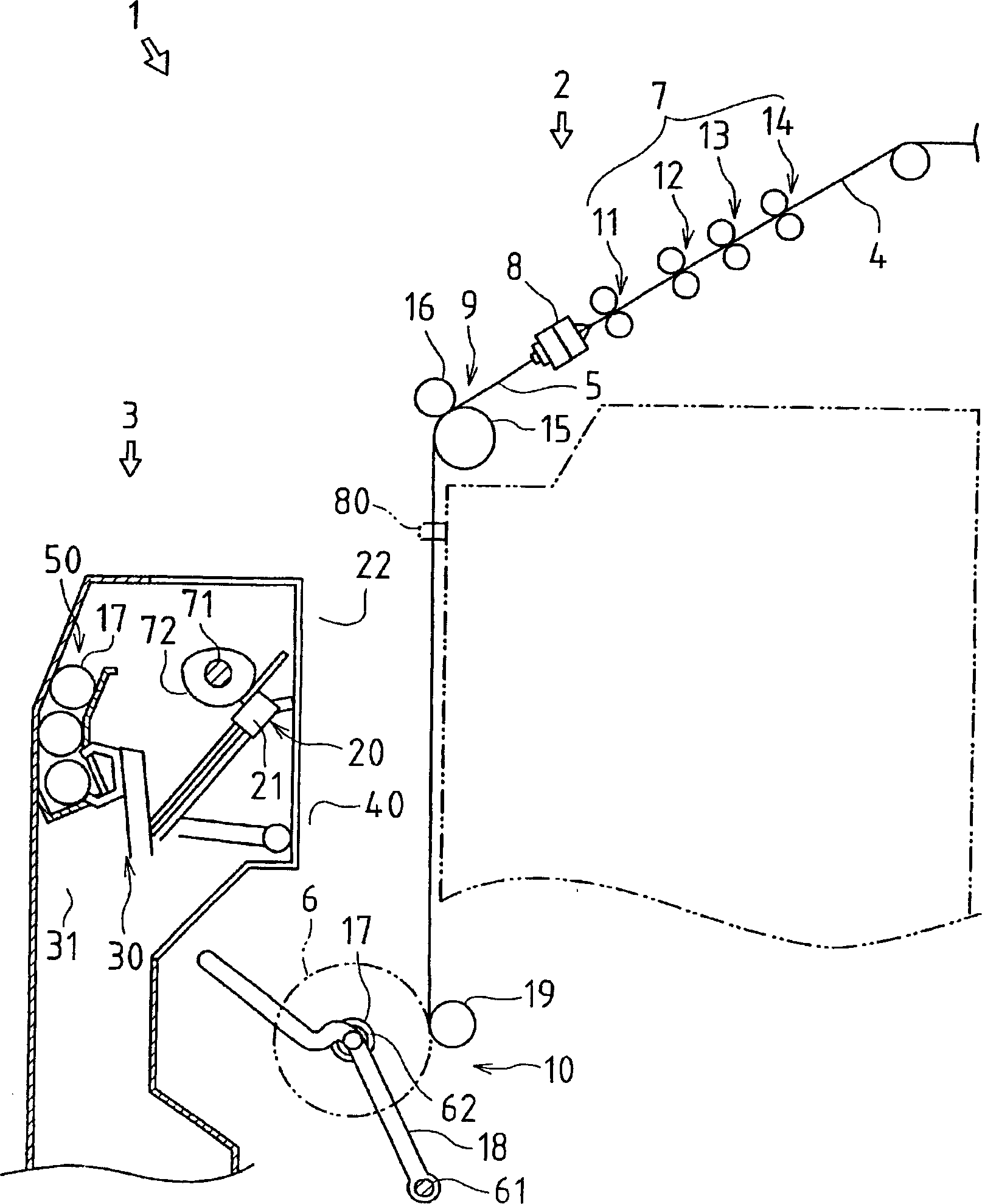

Method and device for operating open-end spinning machine

The invention relates to a method and device for operating an open end rotor spinning machine. The open end rotor spinning machine involves a set of homogeneous workplaces, each provided with a spinning device for producing spinning and a winding device for manufacturing cross winding bobbing. These workplaces are configured that a thread end which is returned from the cross winding bobbing after spinning interruption, prepared for splicing process and placed in the splicing position, is automatically started to spin by the device. Time-critical steps of a spinning start process such as defined return of the thread end in a spinning rotor, exact starting of a thread supply and exact beginning of distraction of a thread from an open end spinning device, are realized by workplace-own devices. Assisting operations before starting the spinning start process are executed by a service assembly automatically operating the workplaces.

Owner:SAURER GERMANY GMBH & CO KG

Yarn processing method and spinning machine

A spinning machine includes a spinning device, a winding device, a yarn accumulating roller, a yarn hooking member, and a yarn removing lever. The yarn accumulating roller winds spun yarn around an outer peripheral surface thereof and rotates with the spun yarn wound around to feed the spun yarn from the spinning device while applying tension to the spun yarn. While being engaged with the spun yarn, the yarn hooking member rotates integrally with the yarn accumulating roller, and thus prevents the spun yarn from being unwound from the outer peripheral surface of the yarn accumulating roller. The yarn removing lever is arranged downstream of the yarn hooking member in a yarn transporting direction, and can be moved between a lowered position where the yarn removing lever does not make contact with the spun yarn and a lifted position where the yarn hooking member makes contact with the spun yarn. At the lifted position, the yarn removing lever removes the spun yarn from the yarn hookingmember.

Owner:MURATA MASCH LTD

Spinning machine and method for discharging an end section of a thread on a spinning machine

ActiveCN103014945AReliable reverse deliveryReduce conveying speedPiercing arrangementsFilament handlingYarnFiber

The invention relates to at least one spinning machine of a spinning table. The spinning point comprises a spinning device which has an input end for fiber material, an output end for yarn manufactured in the spinning device with the fiber material, a conveyance device used for guiding the fiber material to the spinning device, and a winding device for winding the manufactured yarn. The spinning point comprises a yarn end disposal means partly arranged between the input end of the yarning device and the winding device, and with the aid of which an end section of the produced yarn is able to be separated from the rest of the yarn and eliminated. Furthermore, a method for removing an end section of a yarn at a spinning point of a spinning machine prior to the subsequent piecing process is proposed. An end section of a yarn is obtained with the aid of the yarn end disposal means which is a constituent part of the spinning point. The end sections of yarn is disposed from an area of the spinning point after end sections of the rest yarns are separated, and the yarn end disposal means is at least partly arranged between the output end of the spinning device and the winding device.

Owner:MASCHINENFABRIK RIETER AG

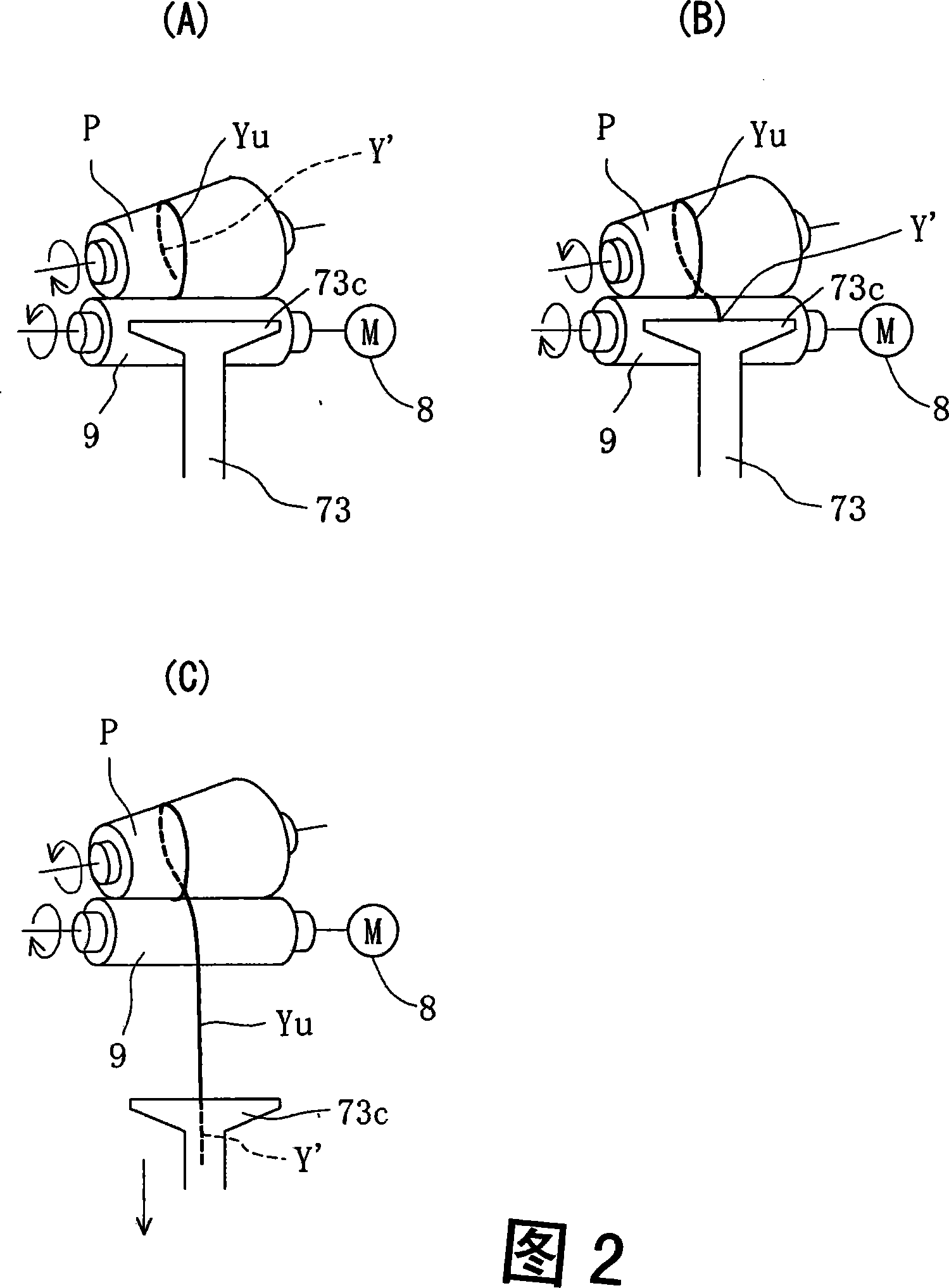

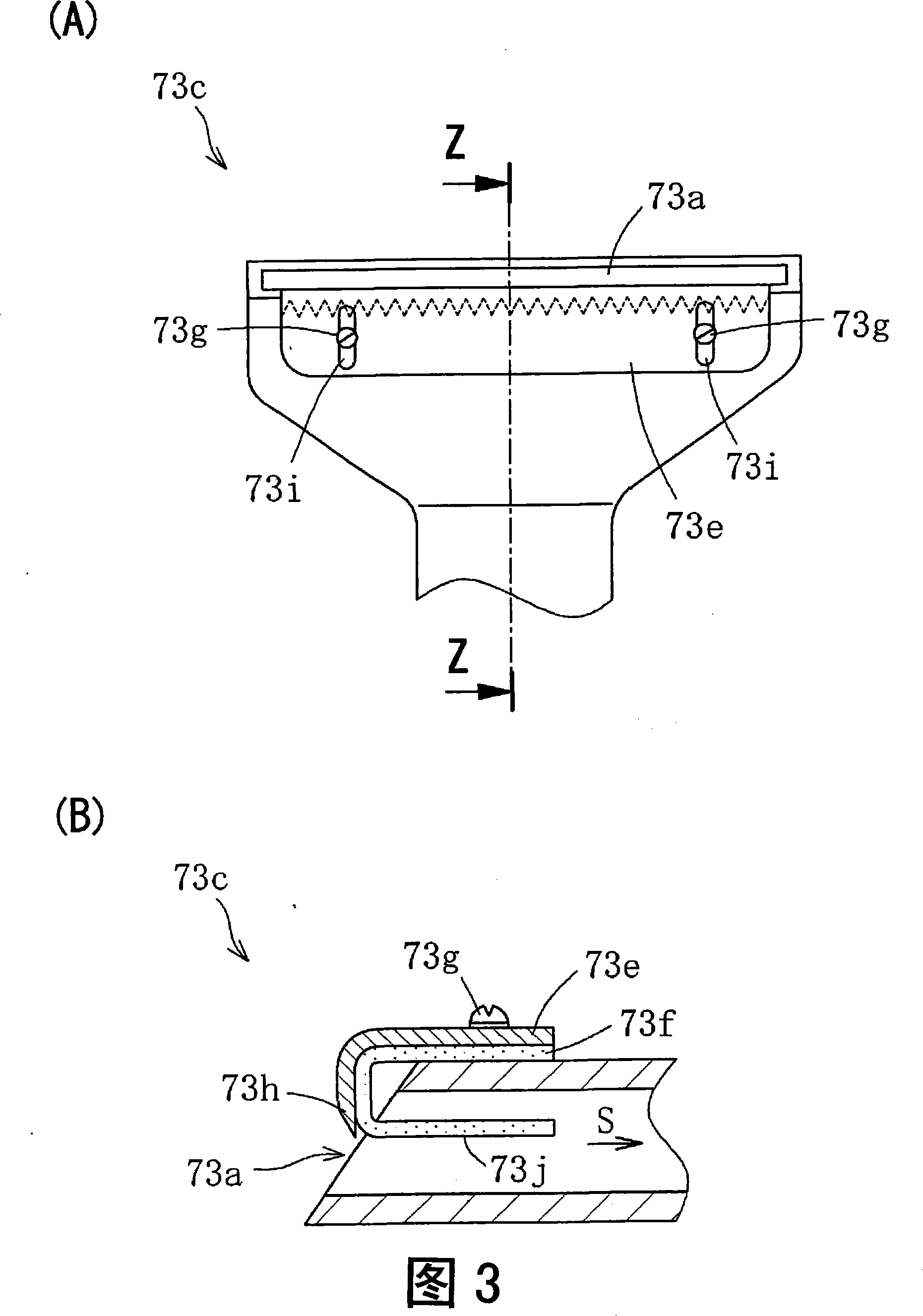

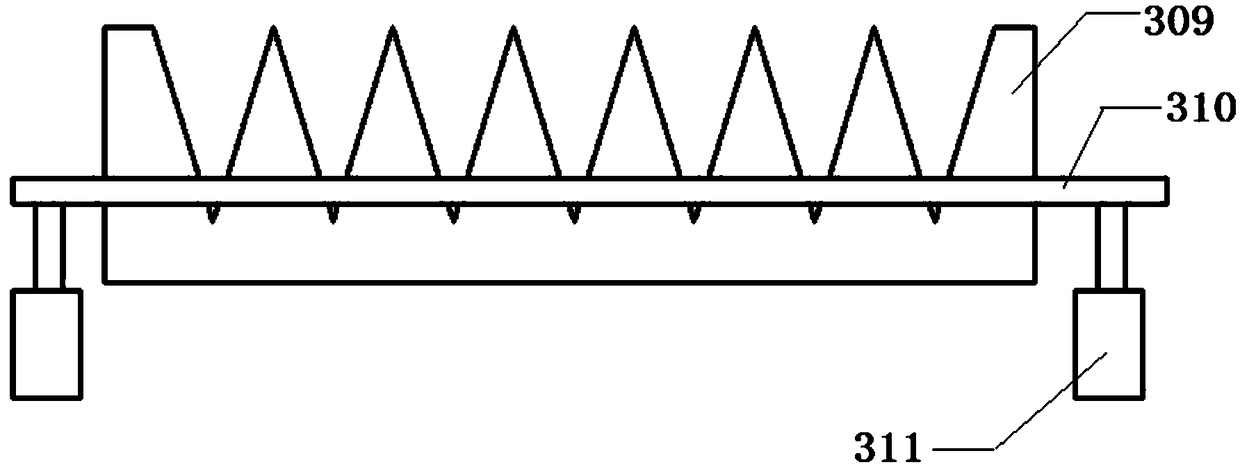

Device for pulling out a yarn end

The present invention provides a yarn end drawing device capable of reliably catching and drawing out a yarn end portion without cutting the yarn end portion. In the yarn end drawing device, a suctioning portion (73c), which includes a suction port (73a) and comb teeth (73h) projecting toward the interior of the suction port (73a), is positioned close to the circumferential surface of a wound yarn package, thereby suctioning a yarn end portion on the wound yarn package and hooking the yarn end portion on a comb tooth (73h) to catch and draw out the yarn end portion. The yarn end drawing device includes a yarn end regulating member (73f) for regulating the suctioned yarn end portion so as not to flutter while being bent at the tip of any comb tooth (73h), and the yarn end regulating member (73f) is arranged at the downstream side in the suction direction of the comb teeth (73h).

Owner:MURATA MASCH LTD

Apparatus for splicing yarns pneumatically

InactiveCN1629375AUniform appearanceAvoid interferenceFilament handlingPiercing arrangementsYarnEngineering

The invention relates to a yarn splicing device for pneumatically joining yarns, especially elastic yarns, with a splicing body having a vacuum-loadable splicing channel which can be operated by means of a The covering element is closed and, moreover, a support is arranged in the region of the splicing channel, which supports the fixing of the yarn ends. According to the invention, it is provided that the supporting element consists of a spring wire (36) and a cover element (23), wherein the spring wire (36) is positioned in an opposite position in the spliced body (19). In the groove (35) that moves angularly in the splicing channel (20), that is, the yarn ends (31, 32) to be spliced are clamped between the covering element (23) and the spring wire ( 36) Between.

Owner:SAURER GMBH & CO KG

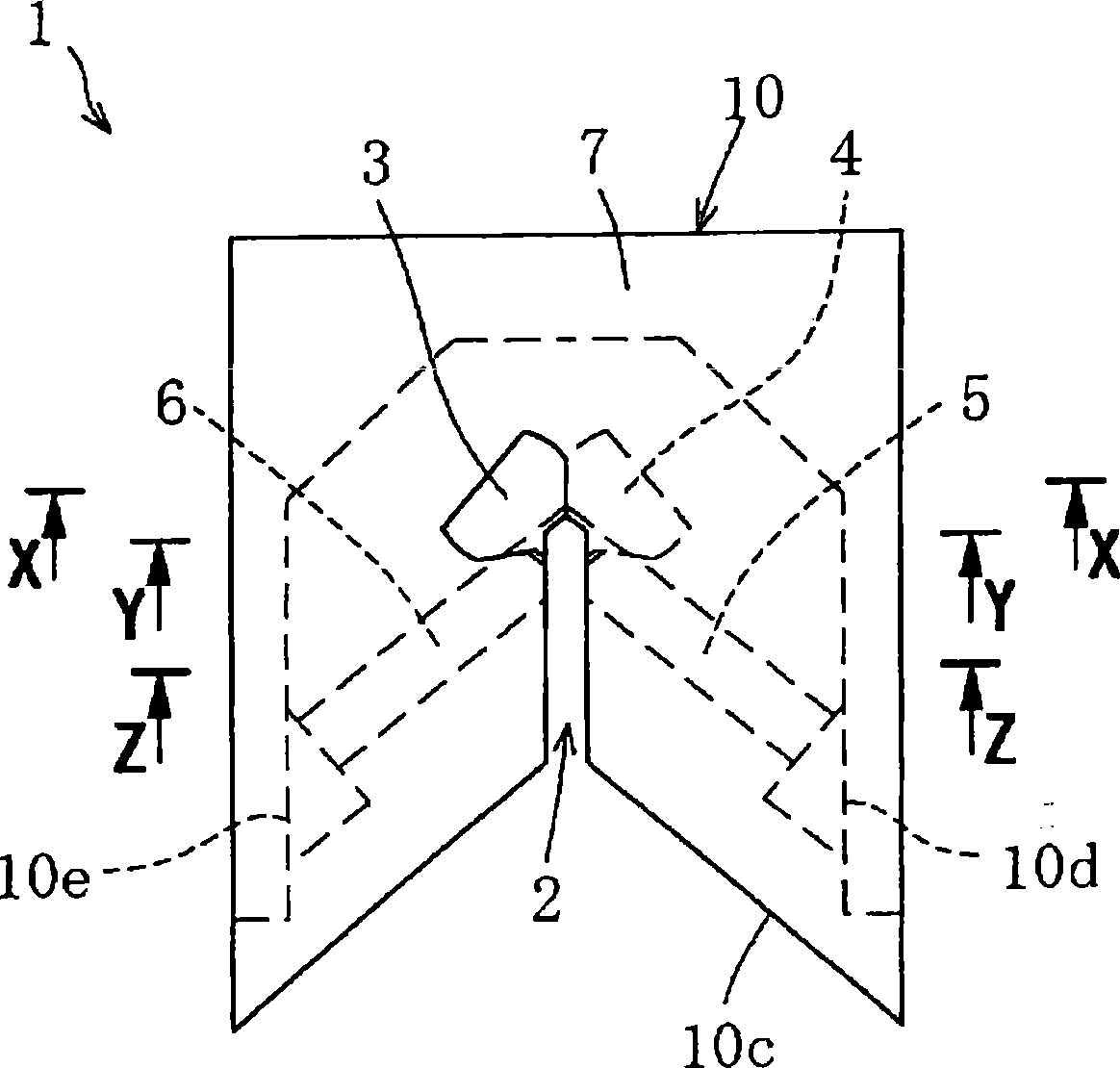

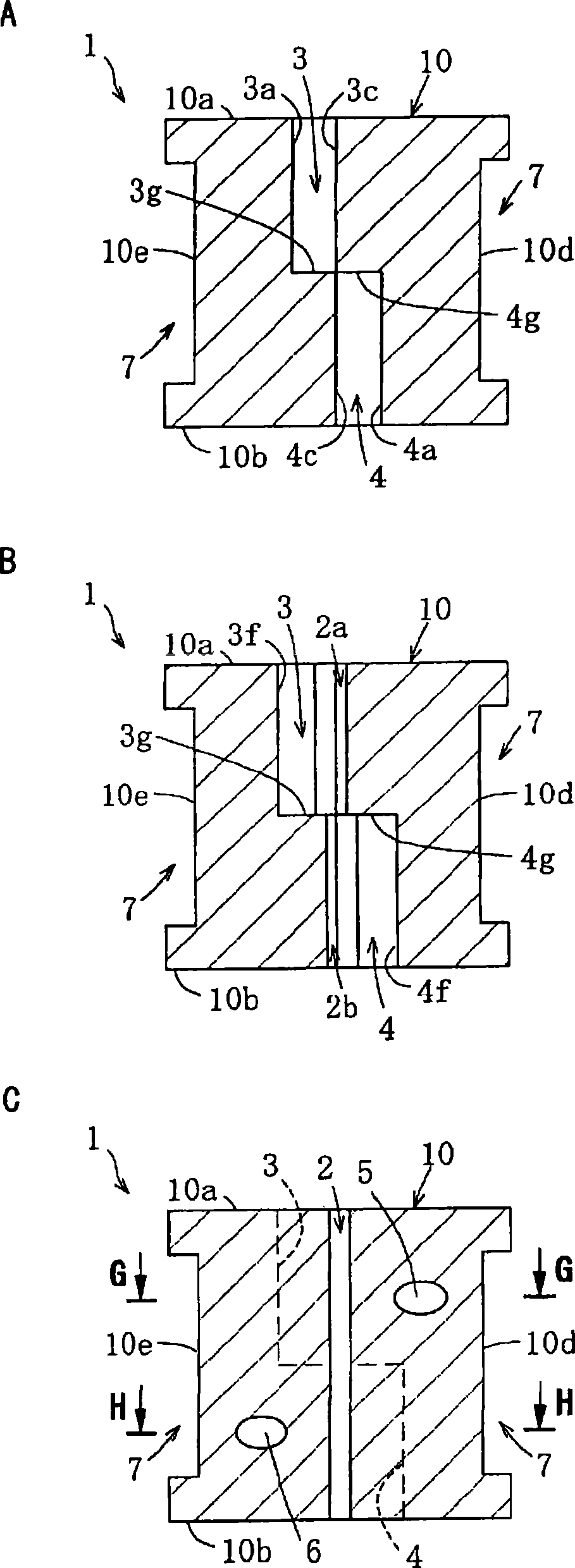

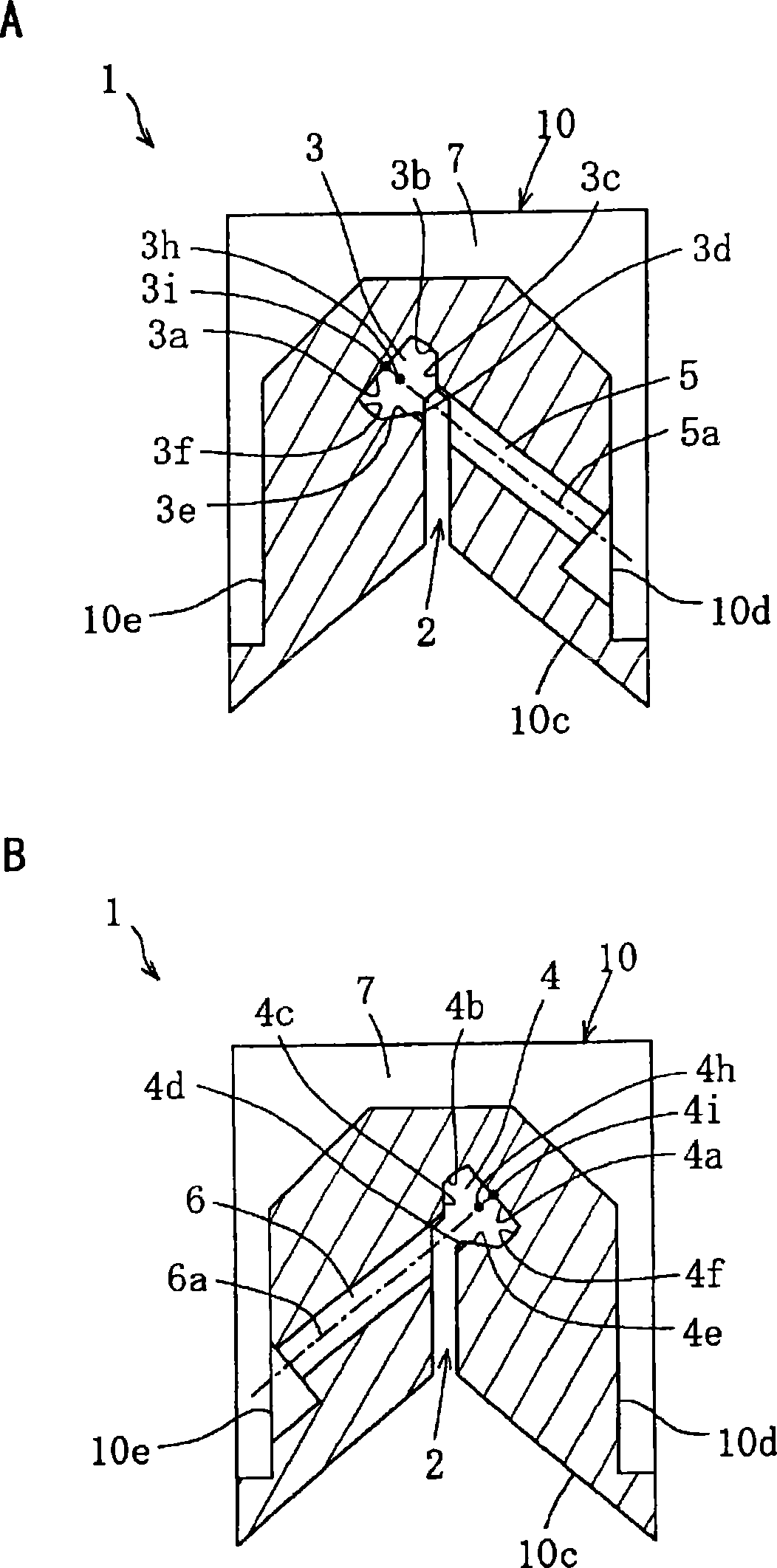

Splicer nozzle

The present invention provides a splicer nozzle (1) characterized in that a yarn splicing hole is divided, in an axial direction, into substantially two yarn splicing chambers (3, 4) formed at positions where axes (3h, 4h) of the yarn splicing chambers (3, 4) are displaced from each other, and a yarn splicing slit (2) common to the yarn splicing chambers (3, 4) is formed over the entire area of the yarn splicing hole, and in that an injection hole (5, 6) is formed for each of the yarn splicing chambers (3, 4) so that compressed air passing through the yarn splicing slit (2) to the axis (3h), (4h) of the yarn splicing chamber (3, 4) is injected through a corresponding one of the injection holes (5, 6), and an inner wall (3a, 4a) of each of the yarn splicing chambers (3, 4) located oppositean air outlet of the corresponding one of the compressed air injection holes (5, 6) is formed to be planar.

Owner:MURATA MASCH LTD

Coiling apparatus of yarn

InactiveCN1530308AInhibition of tension changesEasy maintenanceFilament handlingPiercing arrangementsYarn tensionEngineering

The present invention stabilizes a yarn tension in a yarn winder in which a plurality of winding units are disposed, each of the winging units being provided with a yarn slack eliminating device. A transmitted force adjusting mechanism is provided to adjust a rotative driving force transmitted by a slack eliminating roller of a yarn slack eliminating device to an unwinding tension applying member. The transmitted force adjusting mechanism can be set so that when a load acting on the unwinding tension applying member increases above a predetermined value, the unwinding tension applying member rotates or rotatively moves independently of the slack eliminating roller. When winding tension is weak, the unwinding tension applying member rotates integrally with the slack eliminating roller to tense a yarn. When the winding tension exceeds a predetermined value, the unwinding tension applying member prevents the winding tension from becoming excessive to suppress a variation in tension. When the transmitted force adjusting mechanism is configured so as to vary the force transmitted to the unwinding tension applying member, it is easy to deal with spinning conditions.

Owner:MURATA MASCH LTD

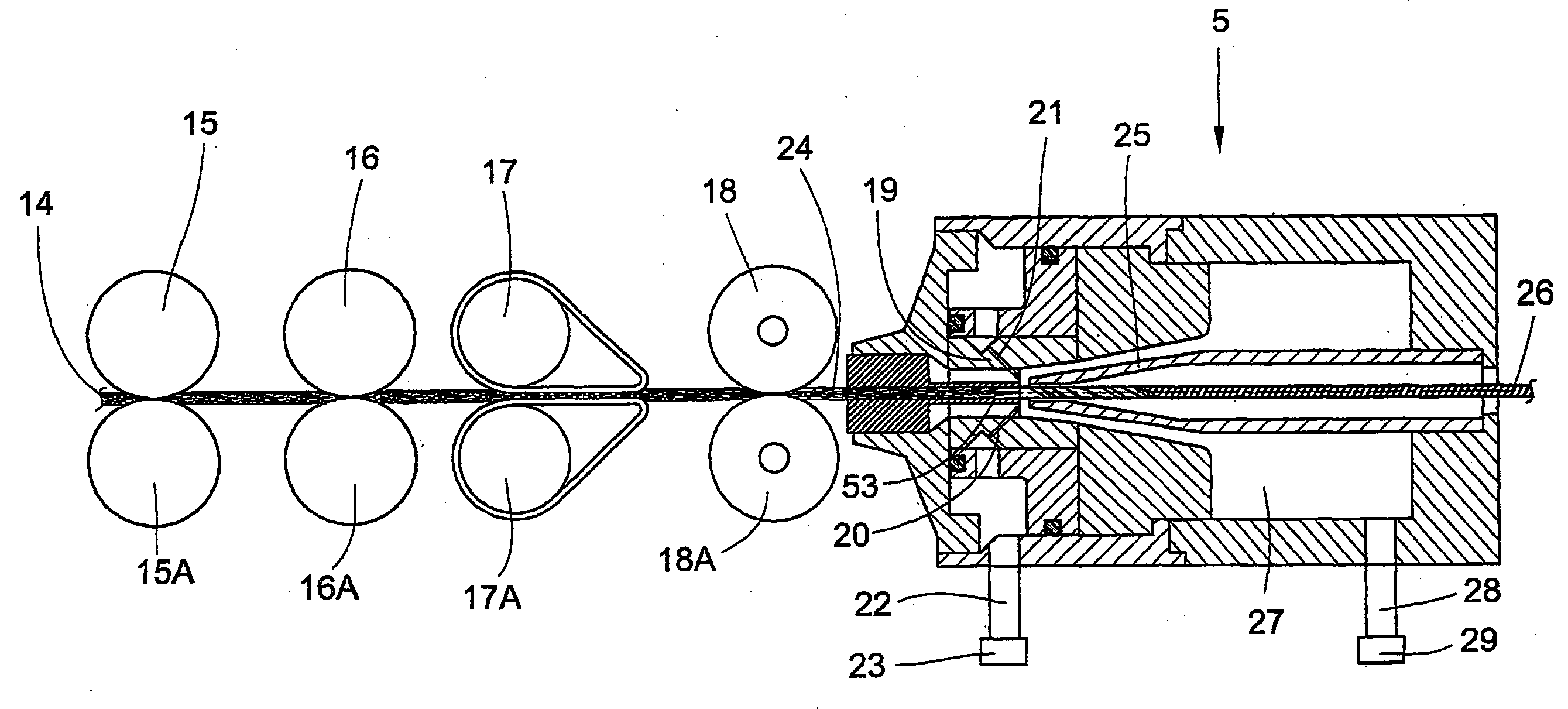

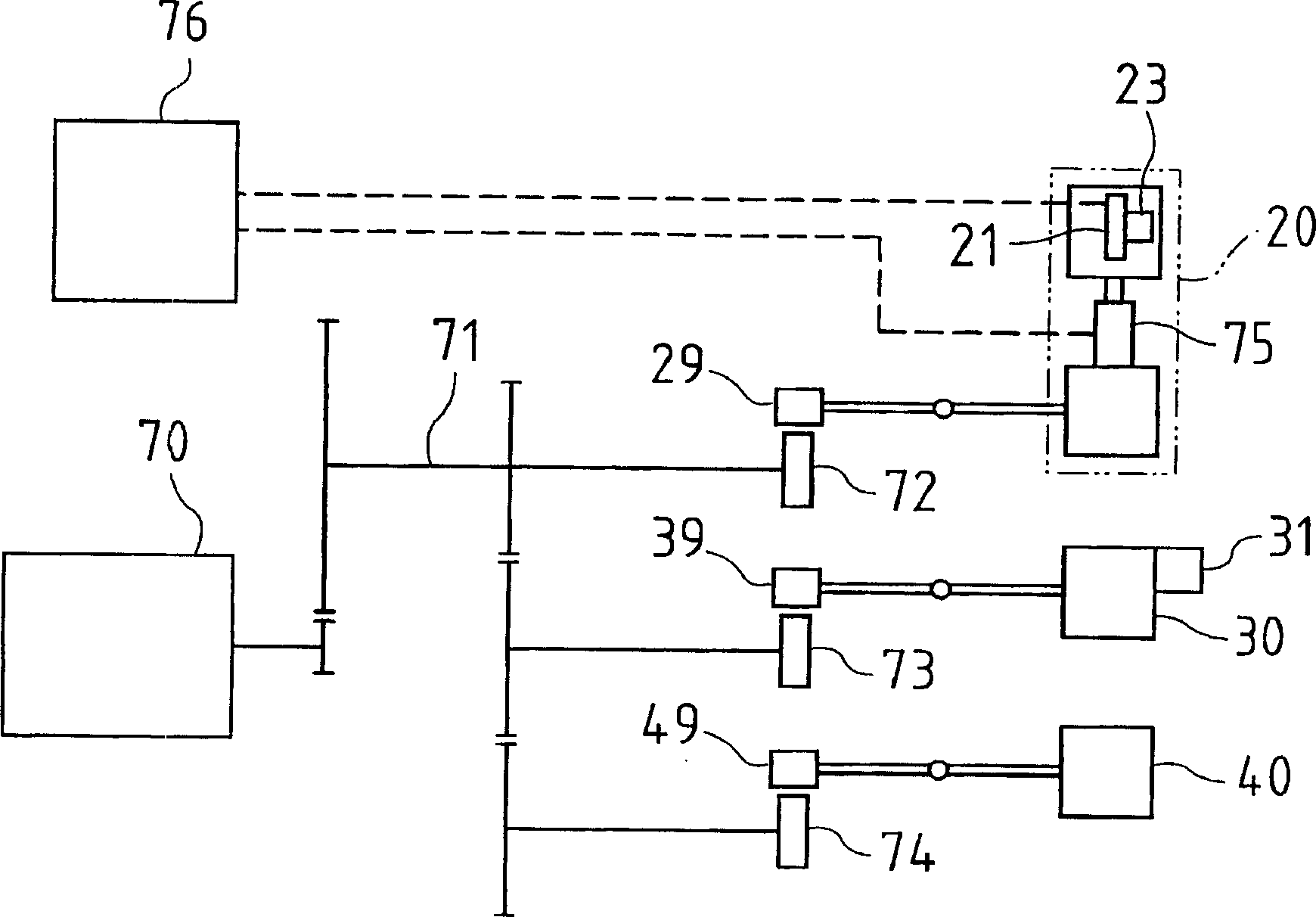

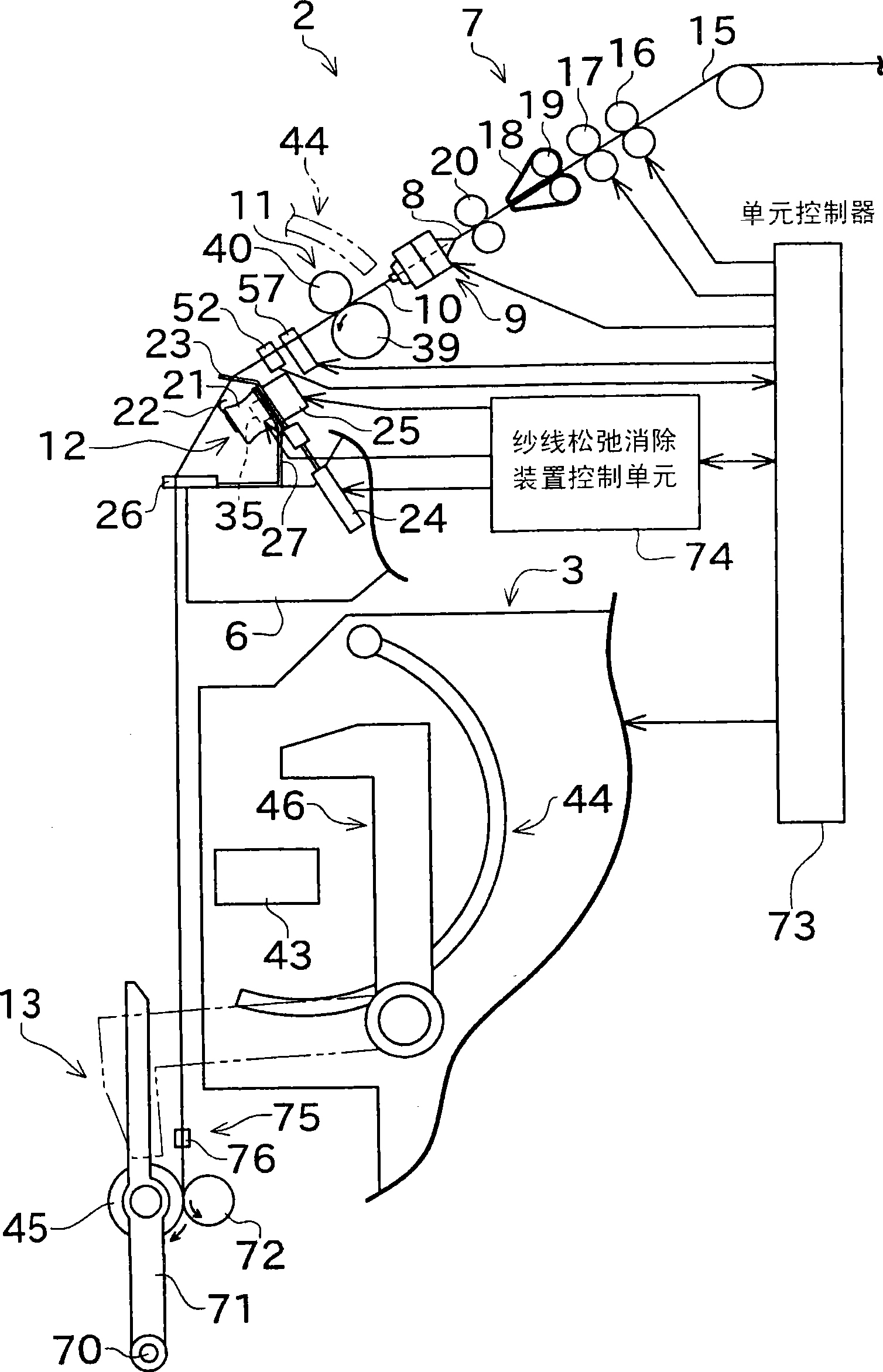

Yarn slack eliminating device and spinning machine

InactiveCN101469469AControl torqueQuality improvementFilament handlingPiercing arrangementsYarnControl theory

An object of the present invention is to provide a yarn slack eliminating device that enables tension applied to a yarn to be controlled while a spinning machine is in operation. A yarn slack eliminating device 12 includes an electric motor 25, a yarn slack eliminating roller 21, a yarn hooking member 22, an electromagnet 36, and a control section 74. The yarn slack eliminating roller 21 is rotationally driven by the electric motor 25. The yarn hooking member 22 is concentrically attached to the yarn slack eliminating roller 21 so as to be rotatable relative to the yarn slack eliminating roller 21. The electromagnet 36 generates a magnetic field to be applied to the yarn hooking member 22. The control section allows the magnetic field to generate a resistance torque resisting the rotation of the yarn hooking member 22 relative to the yarn slack eliminating roller 21. The control section 74 also controls an input to the electromagnet 36 to control the resistance torque.

Owner:MURATA MASCH LTD

Spinning machine and yarn removing method for removing yarn remaining on yarn accumulating roller

ActiveCN101994175AEasy to attractEfficient spinning operationsPiercing arrangementsFilament handlingEngineeringYarn strength

A spinning frame (1) includes a spinning device (9), a yarn clearer (52), a yarn accumulating roller (21), a suction opening (46), a suction device (30), and a unit controller (60). The spinning device produces spun yarn by applying twists to a fiber bundle. The yarn clearer (52) is arranged downstream of the spinning device and detects a yarn defect in the travelling spun yarn. The yarn accumulating roller (21) is arranged downstream of the yarn clearer and accumulates the spun yarn by rotating while winding the spun yarn around an outer peripheral surface thereof. The suction opening of the suction device is arranged near a base end of the yarn accumulating roller (21). The suction device (30) can generate suction airflow at the suction opening (46). The unit controller (60) delays a stoppage timing, which is a timing at which feeding of the spun yarn is stopped, when the yarn clearer (52) detects a prescribed yarn defect in which yarn strength is low, compared with when other type of yarn defect is detected, and stops the yarn accumulating roller (21) after the stoppage timing.

Owner:MURATA MASCH LTD

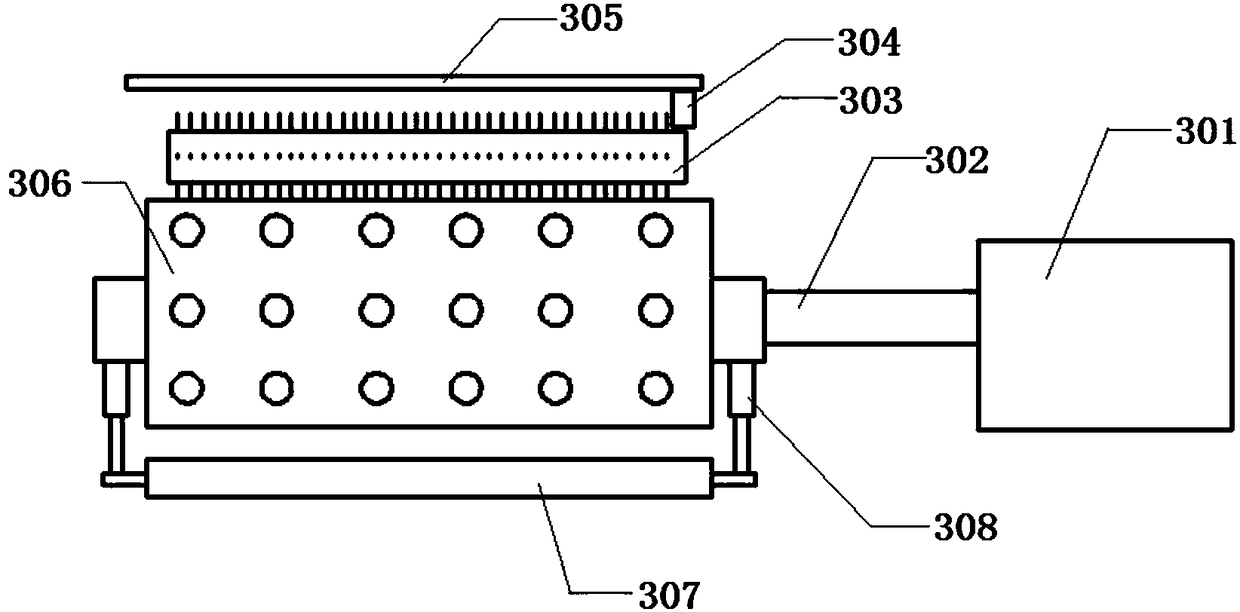

Yarn cleaning device

InactiveCN108060480AGuaranteed cleanlinessPiercing arrangementsFibre cleaning/openingYarnElectrical and Electronics engineering

The invention discloses a yarn cleaning device. The yarn cleaning device comprises a first sliding rail, a sliding block, cleaning devices, pressing devices, yarn detection wire take-up devices and yarn junction devices, the sliding block is slidingly arranged on the first sliding rail, a resetting device is arranged between the first sliding rail and the sliding block, the upper surface of the sliding block is provided with the yarn junction devices, the yarn detection wire take-up devices are arranged between the yarn junction devices, the yarn penetrates through the yarn junction devices and the yarn detection wire take-up devices, the cleaning devices which are used for cleaning yarn flocs are arranged on the sliding block, and the pressing devices are arranged between the yarn junction devices and the cleaning devices. The yarn cleaning device can achieve continuous yarn detection, in the case of continuous yarn movement, cutting off and connecting are conducted, and adsorption processing is conducted on the flocs on the yarn through the cleaning device.

Owner:颍上鑫鸿纺织科技有限公司

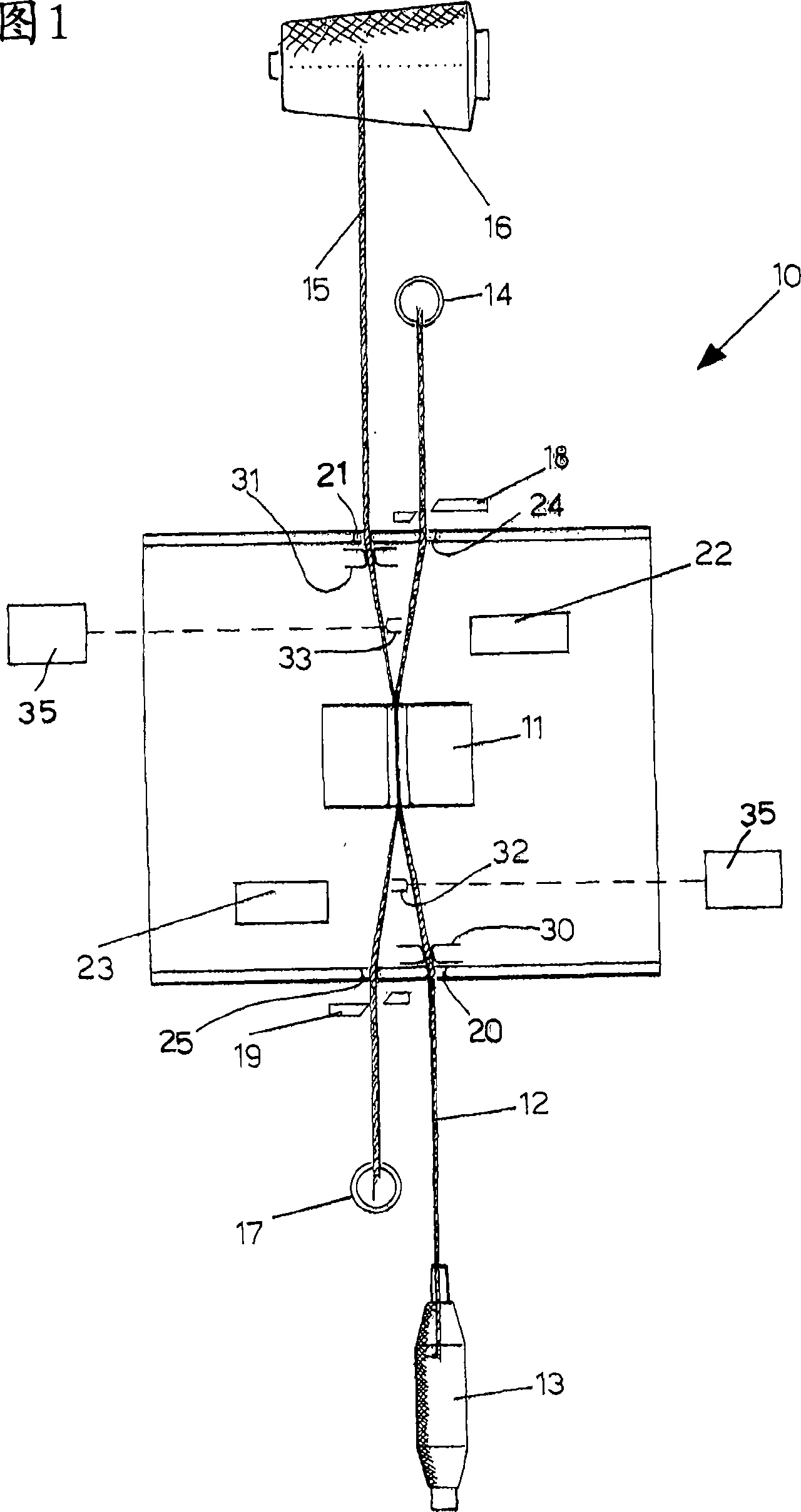

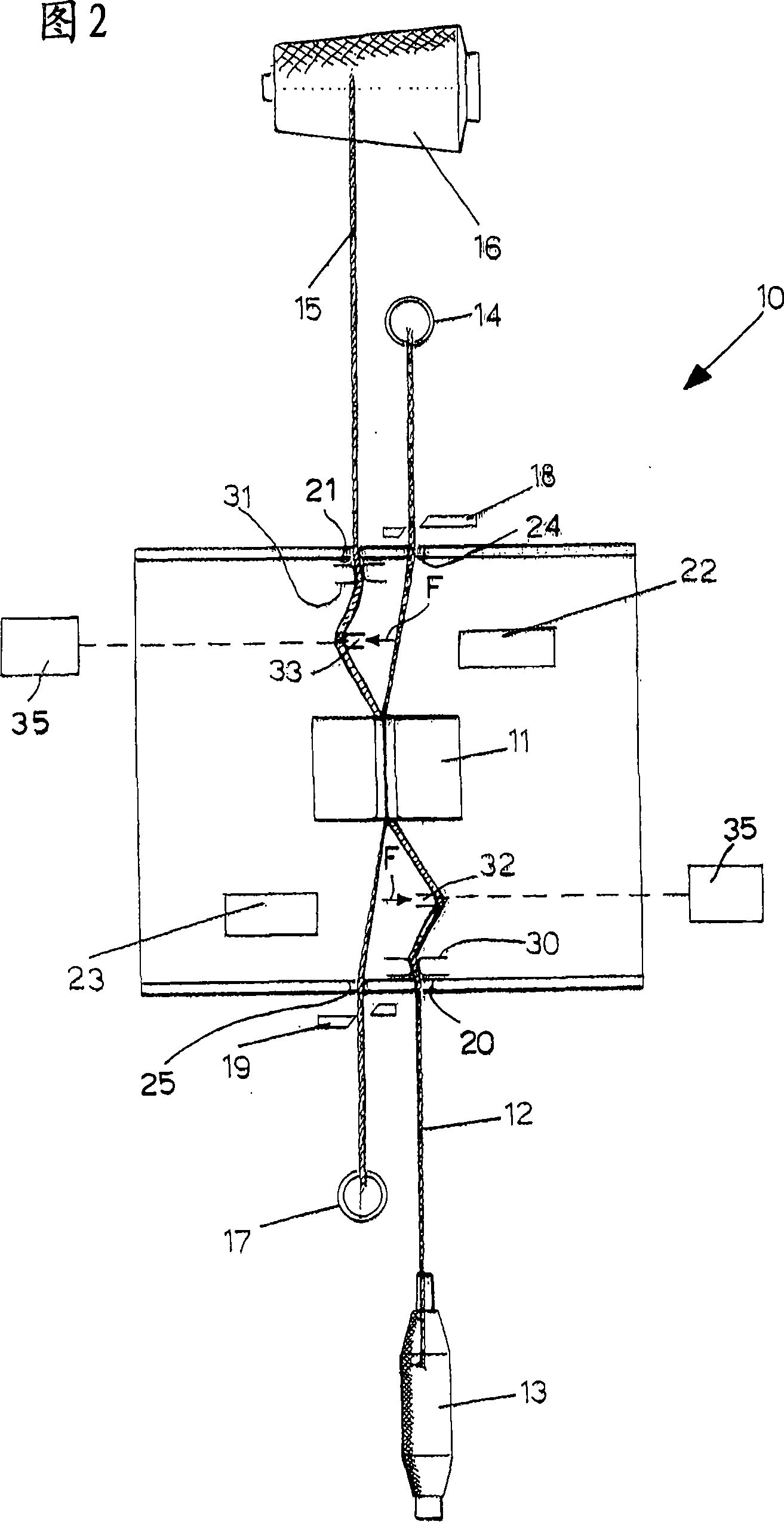

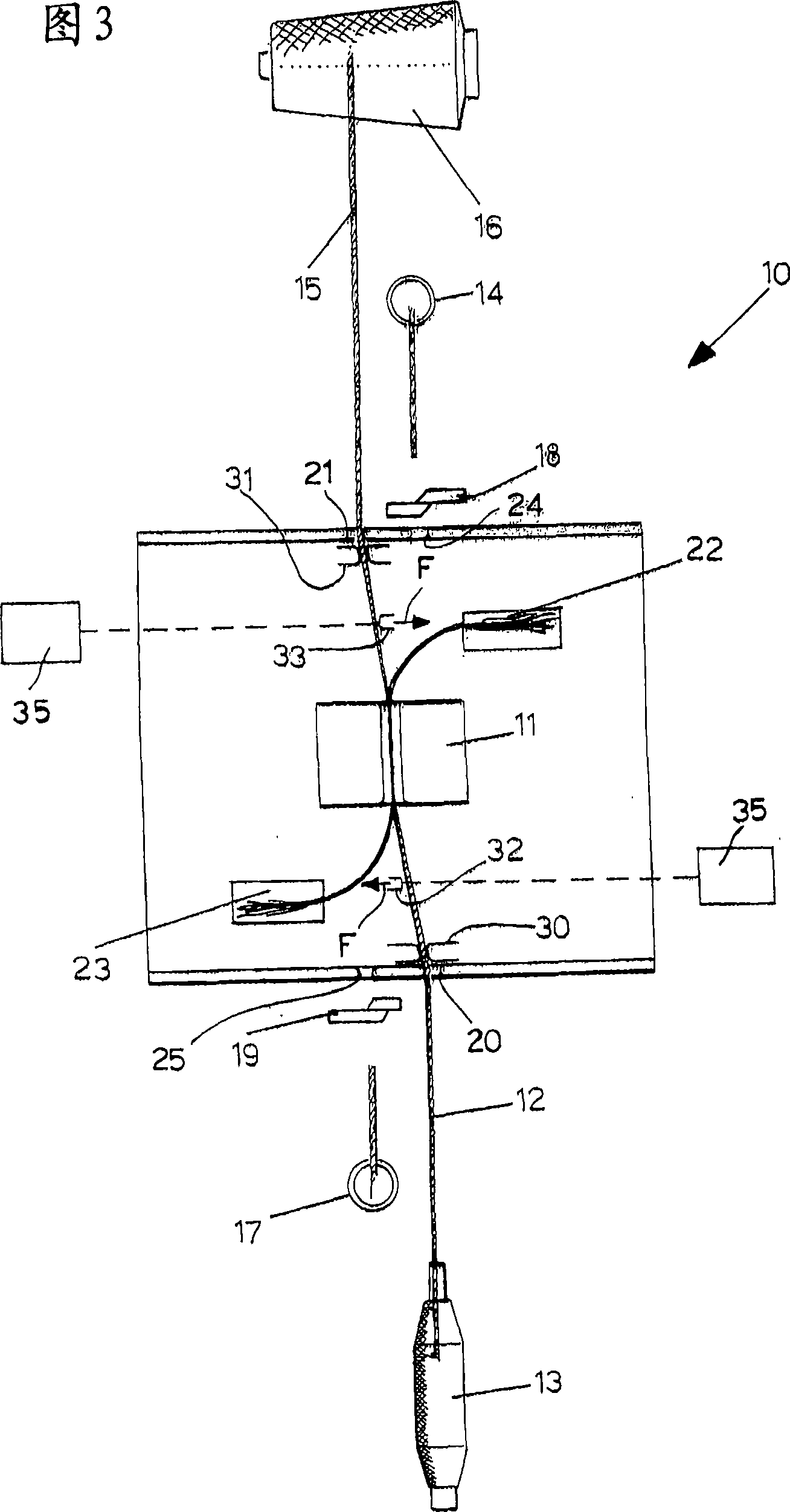

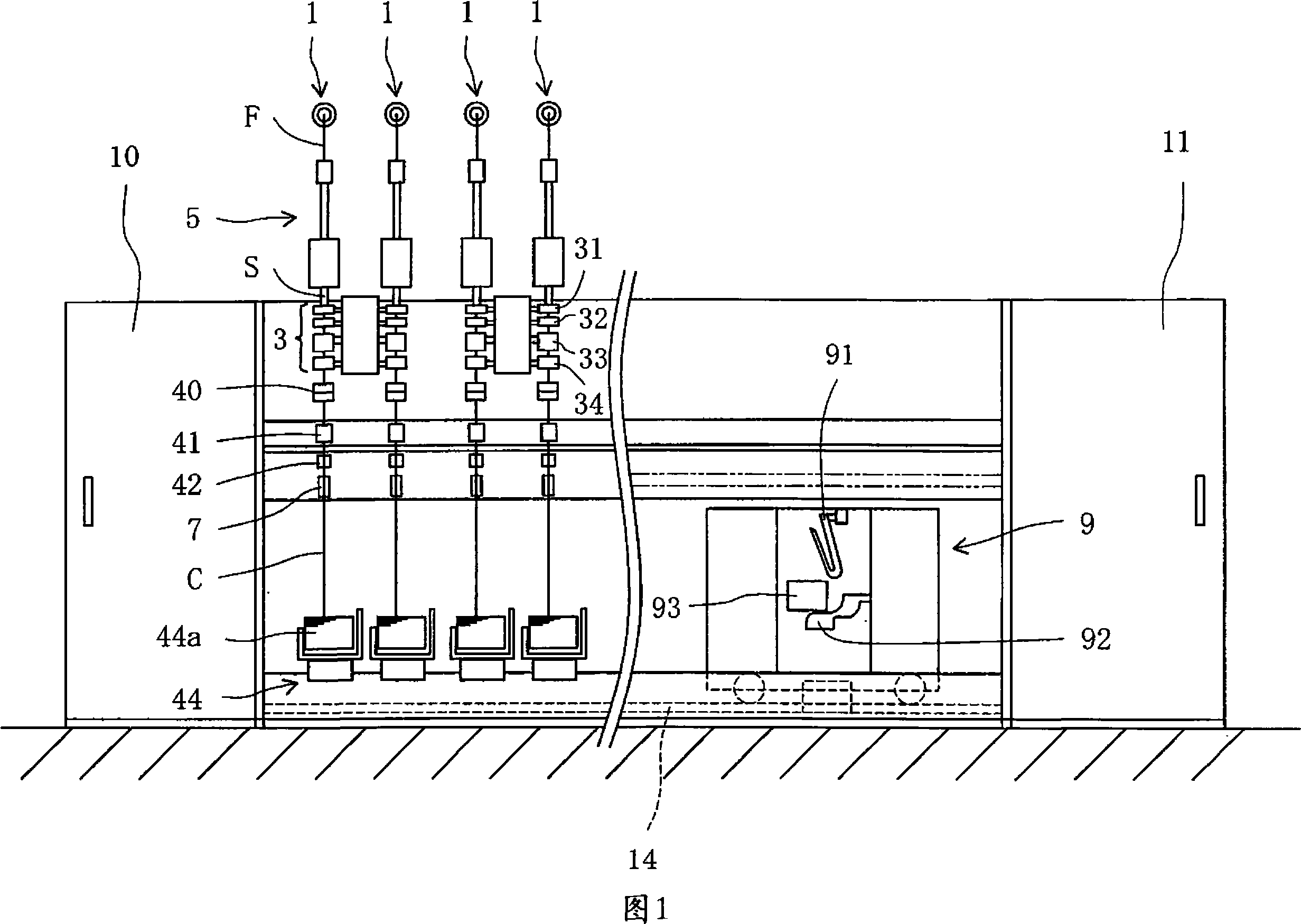

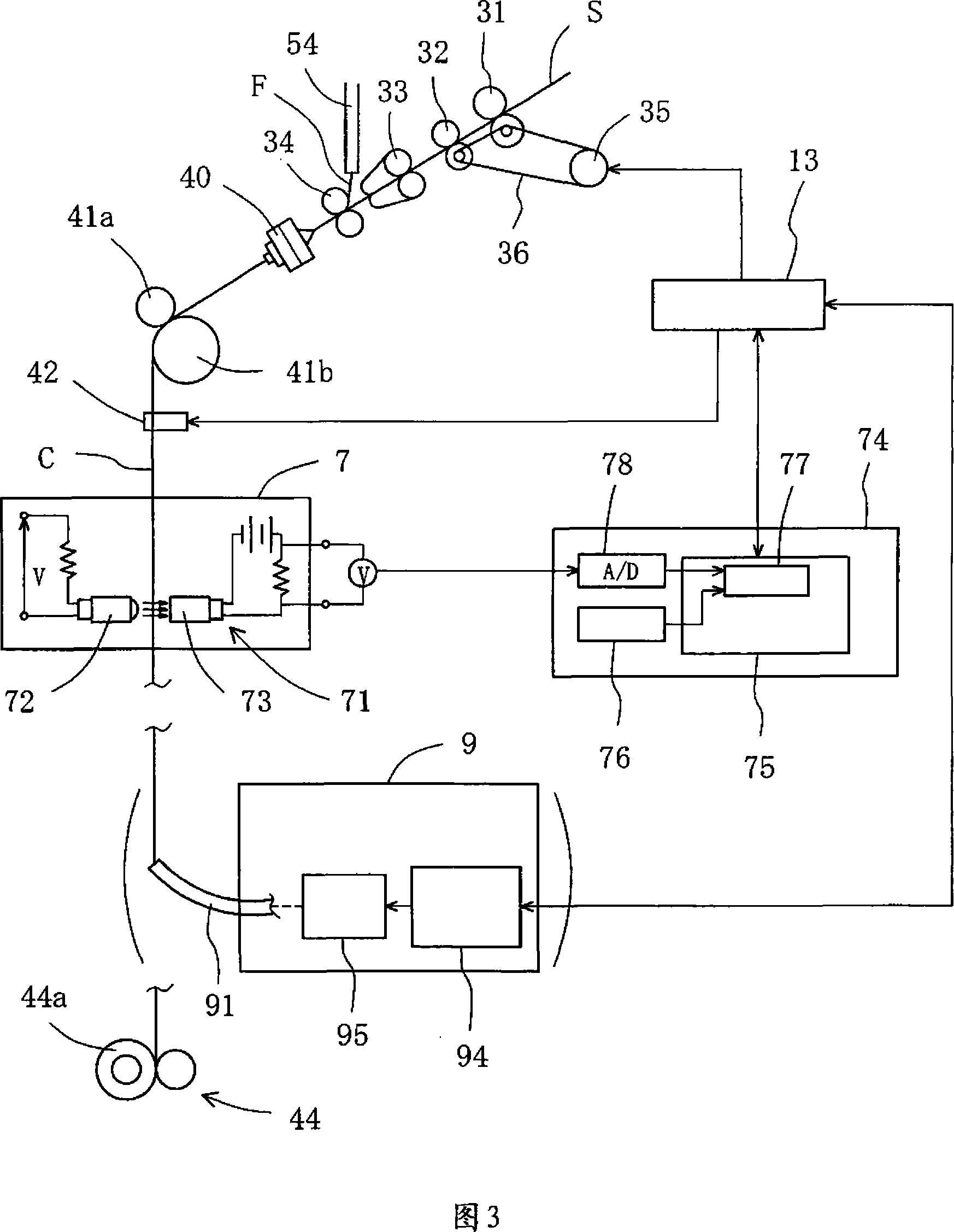

Wadding detecting method and device in core yarn spinning

The object of the invention is to ensure wadding-free core yarn not to be produced by surely sensing the presence / absence of a wadding in core yarn. A method for detecting the presence / absence of a wadding F in core yarn is presented, comprising the following practice: In a process for producing core yarn C by wrapping fiber bundles S around a wadding F, core yarn C with the wadding F content altered from the case with ordinary spinning operation is spun; alternatively, core yarn C containing a wadding consisting of drawn elastic yarn is spun and then slackened to see whether the thickness of the core yarn C is altered.

Owner:MURATA MASCH LTD

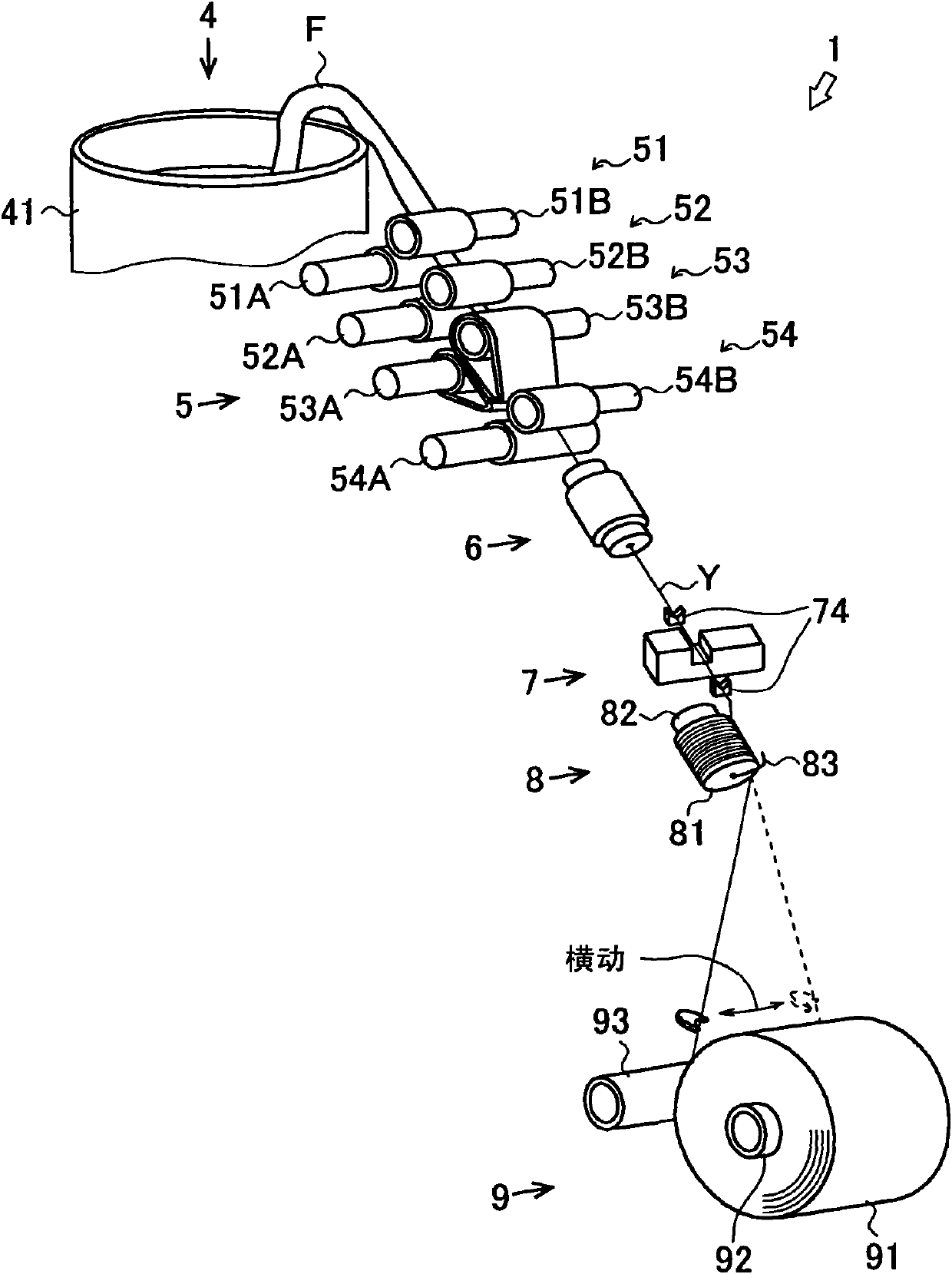

Spinning unit

ActiveCN102031604AStable detectionImprove detection accuracyPiercing arrangementsContinuous wound-up machinesFiberYarn

The invention provides a spinning unit, wherein a drawing-off spinning unit (1) comprises a drawing-off device (5), a spinning device (6), a tension stabilizing device (8), a winding device (9) and a yarn defect detecting device (7).The drawing-off device (5) drafts a fibre bundle (F).The spinning device (6) produces spinnings (Y) from the fibre bundle (F) drafted by the drawing-off device (5).The tension stabilizing device (8) stabilizes the tension of the spinnings (Y) produced by the spinning device (6).The winding device (9) winds a package (91) of the spinnings (Y) fed from the tension stabilizing device (8).The yarn defect detecting device (7) can detect a yarn defect in the spinnings (Y).The yarn defect detecting device (7) is arranged between the spinning device (6) and the tension stabilizing device (8).

Owner:MURATA MASCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com