Textile machinery

A technology of textile machinery and processing unit, applied in the structural field of textile machinery, can solve the problems of dirtying the package and reducing the quality of the package, and achieve the effect of improving the success rate, preventing the reduction of production efficiency and improving the workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The best embodiment of the present invention will be described below with reference to the accompanying drawings.

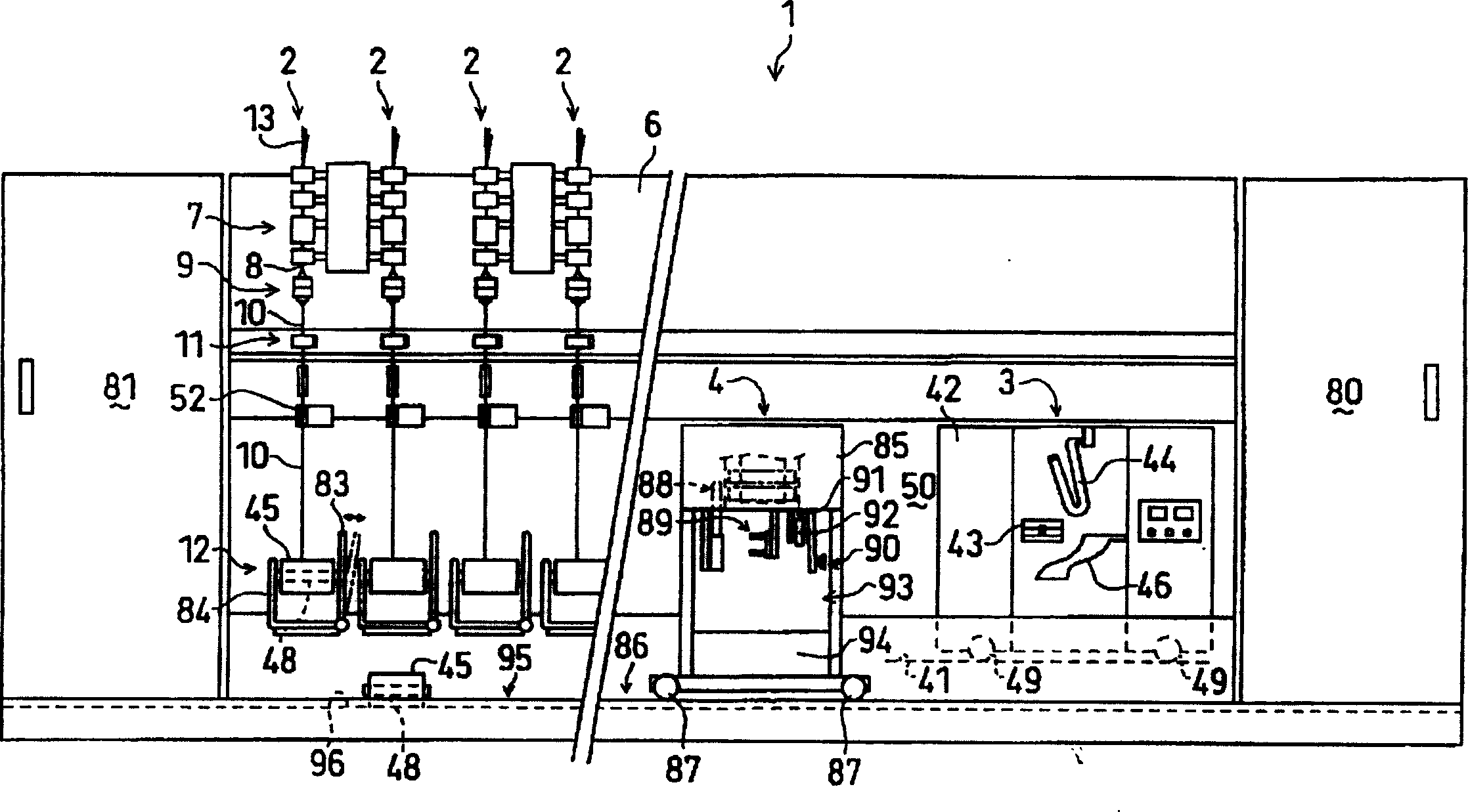

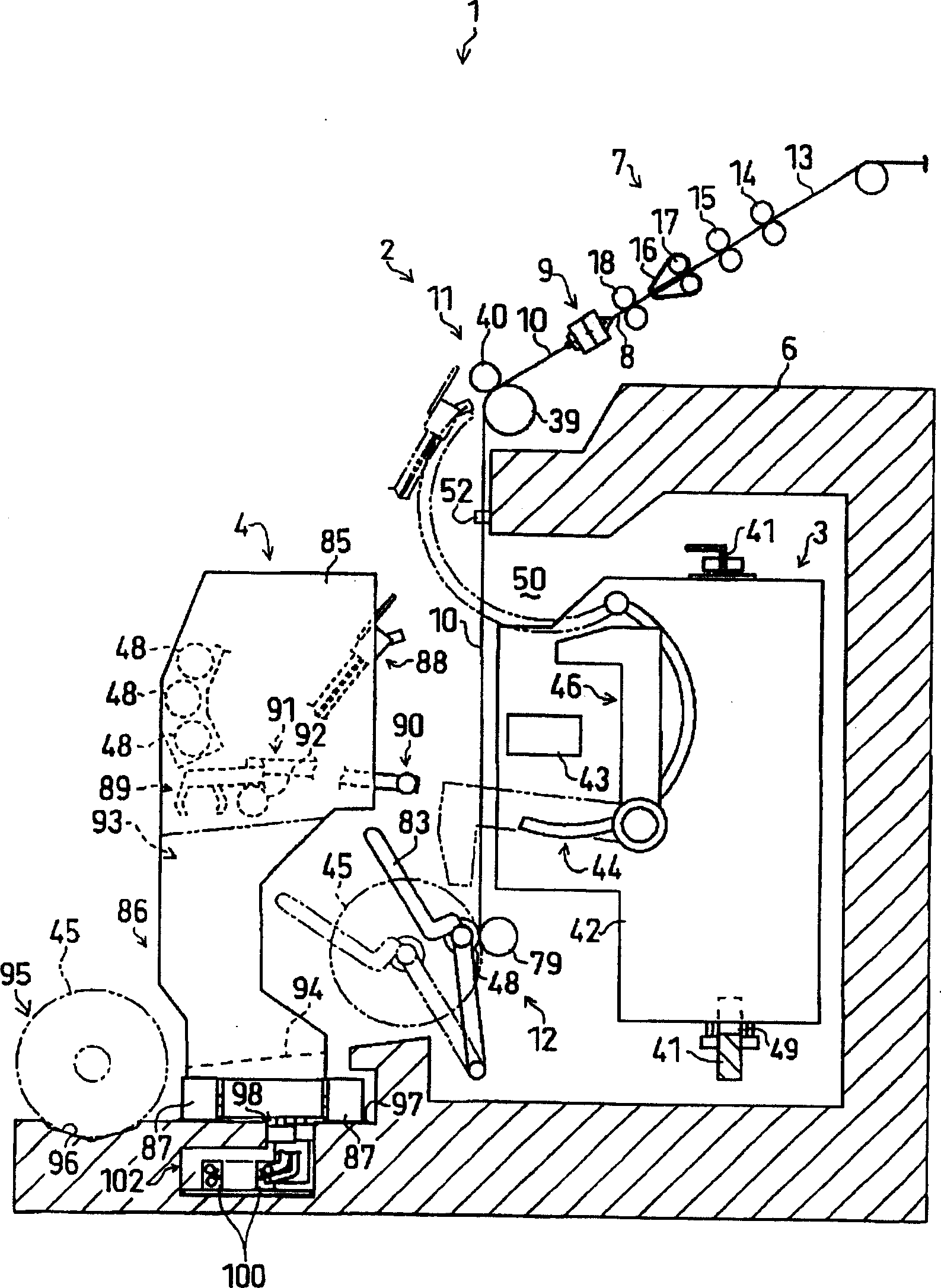

[0034] figure 1 A spinning machine 1 as a spinning machine including a plurality of spinning units (yarn processing units) 2 arranged in parallel is shown. The textile machine 1 includes a piecing cart 3 freely movable along the direction in which the spinning units 2 are arranged, a doffing cart 4 independently of the piecing cart 3 and freely movable, a blower cabinet 80 and a power cabinet 81 .

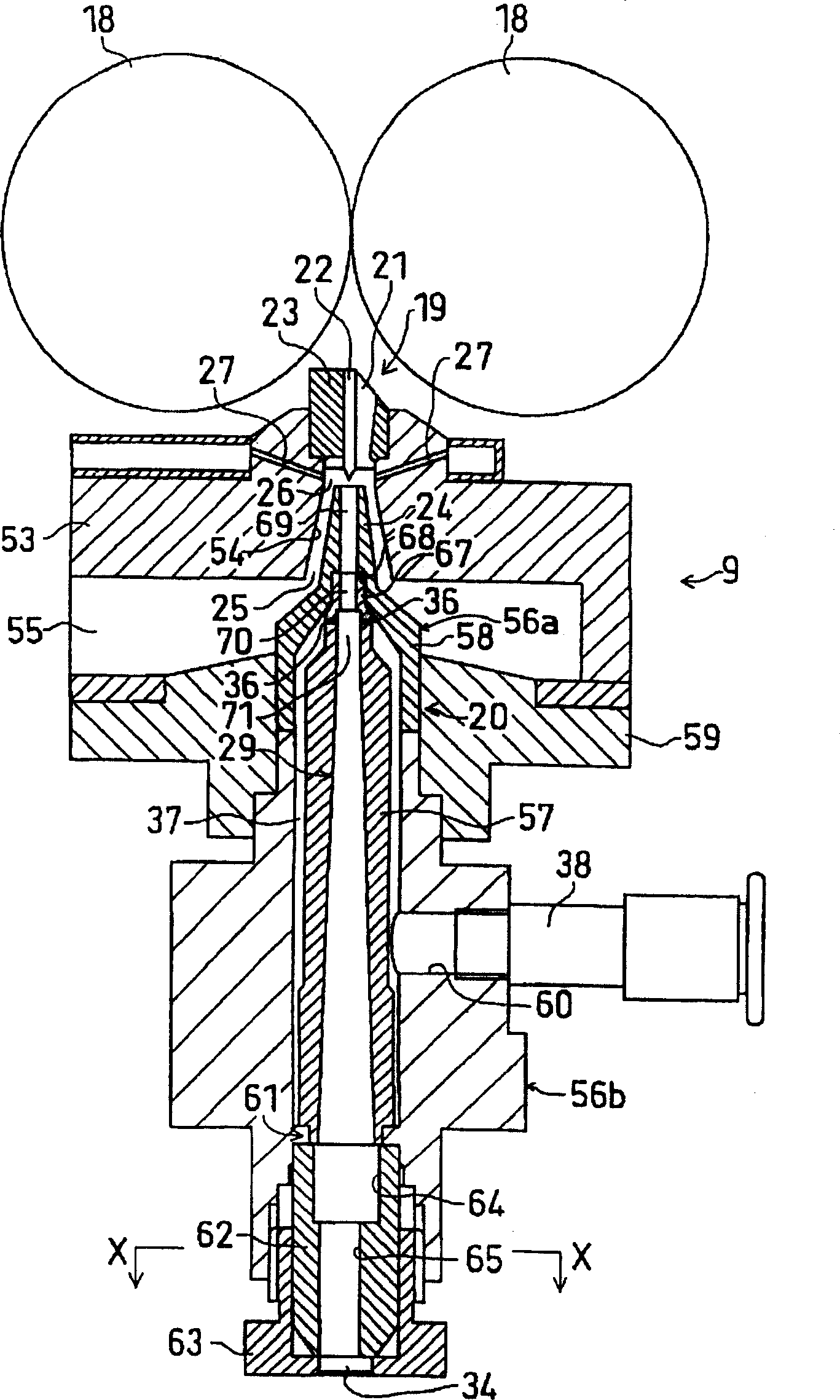

[0035] Such as figure 1 As shown, the main structures of each textile unit 2 include a traction device 7 , a textile component 9 , a yarn feeding device 11 and a winding device 12 . The pulling device 7 is arranged near the upper end of the casing 6 of the main body of the spinning machine 1, and is configured to spin the fiber bundle 8 delivered by the pulling device 7 by the spinning member 9. After passing through a yarn clearer (yarn defect detector) 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com