Spinning machine and method for discharging an end section of a thread on a spinning machine

A spinning machine and yarn technology, which is applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve the problems of unsuitable spinning process and delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

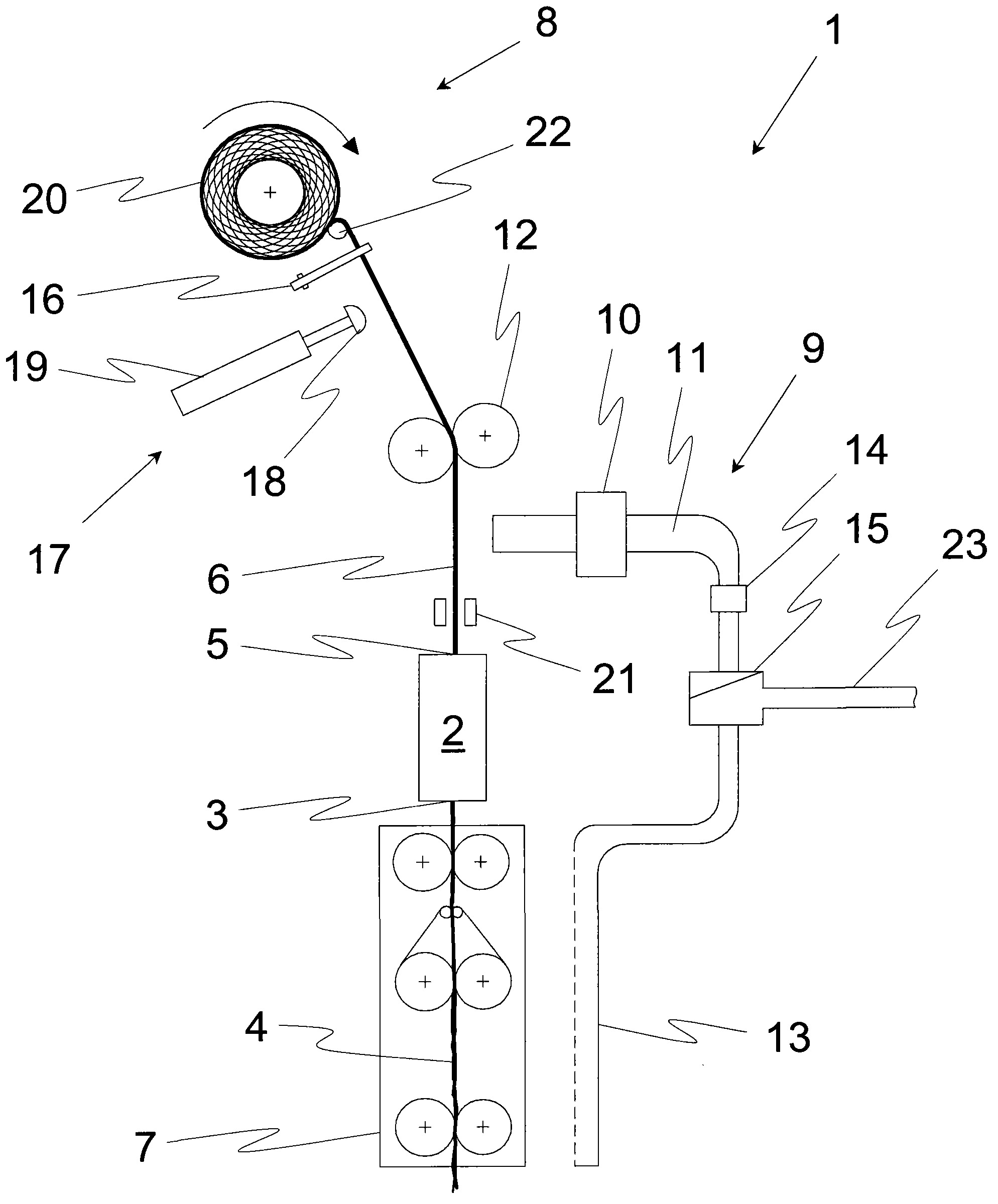

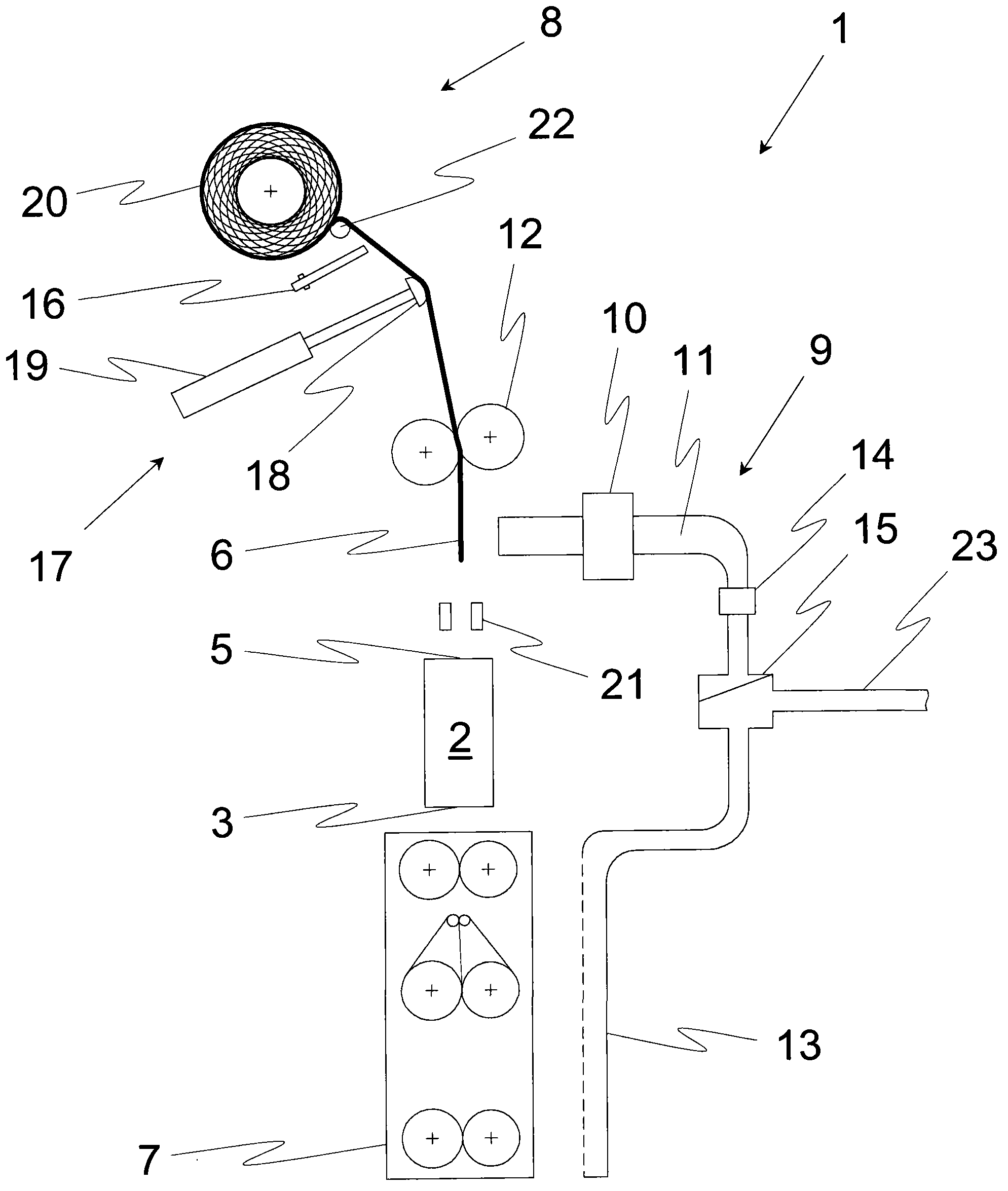

[0039] figure 1 A schematic side view showing the spinning table of a dry spinning machine (as an example of a spinning machine according to the invention) during spinning, wherein the dry spinning machine generally comprises a plurality of continuous perpendicular to the projection plane The spinning station 1 is arranged and preferably similarly assembled.

[0040] exist figure 1 In the example shown, the dry spinning machine has a conveying device 7 designed as a drafting device, which conveys the fiber material 4, for example, in the form of a double-line belt. Furthermore, the shown spinning station 1 comprises a spinning device 2 which is separated from the conveying device 7 and has an input 3 for the fiber material 4 and an inner vortex chamber, not shown.

[0041] Finally, the fibrous material 4 or at least a part of the fibers of the fibrous material 4 is made into the desired yarn 6 inside the vortex chamber by rotation in a known manner. In this case, the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com