Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

909 results about "Hematite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hematite, also spelled as haematite, is a common iron oxide with the formula Fe₂O₃ and is widespread in rocks and soils. Hematite crystallizes in the rhombohedral lattice system, and it has the same crystal structure as ilmenite and corundum. Hematite and ilmenite form a complete solid solution at temperatures above 950 °C (1,740 °F).

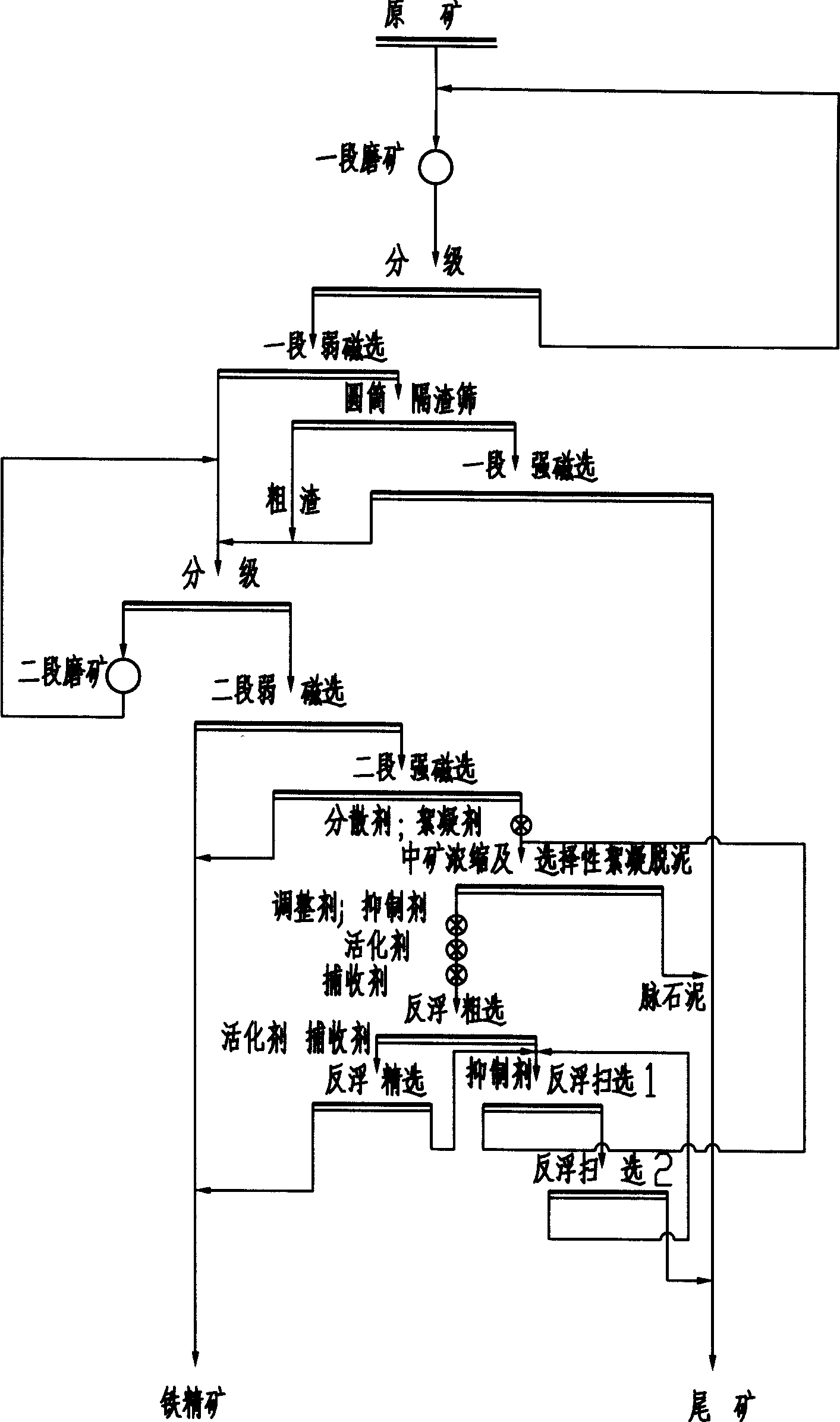

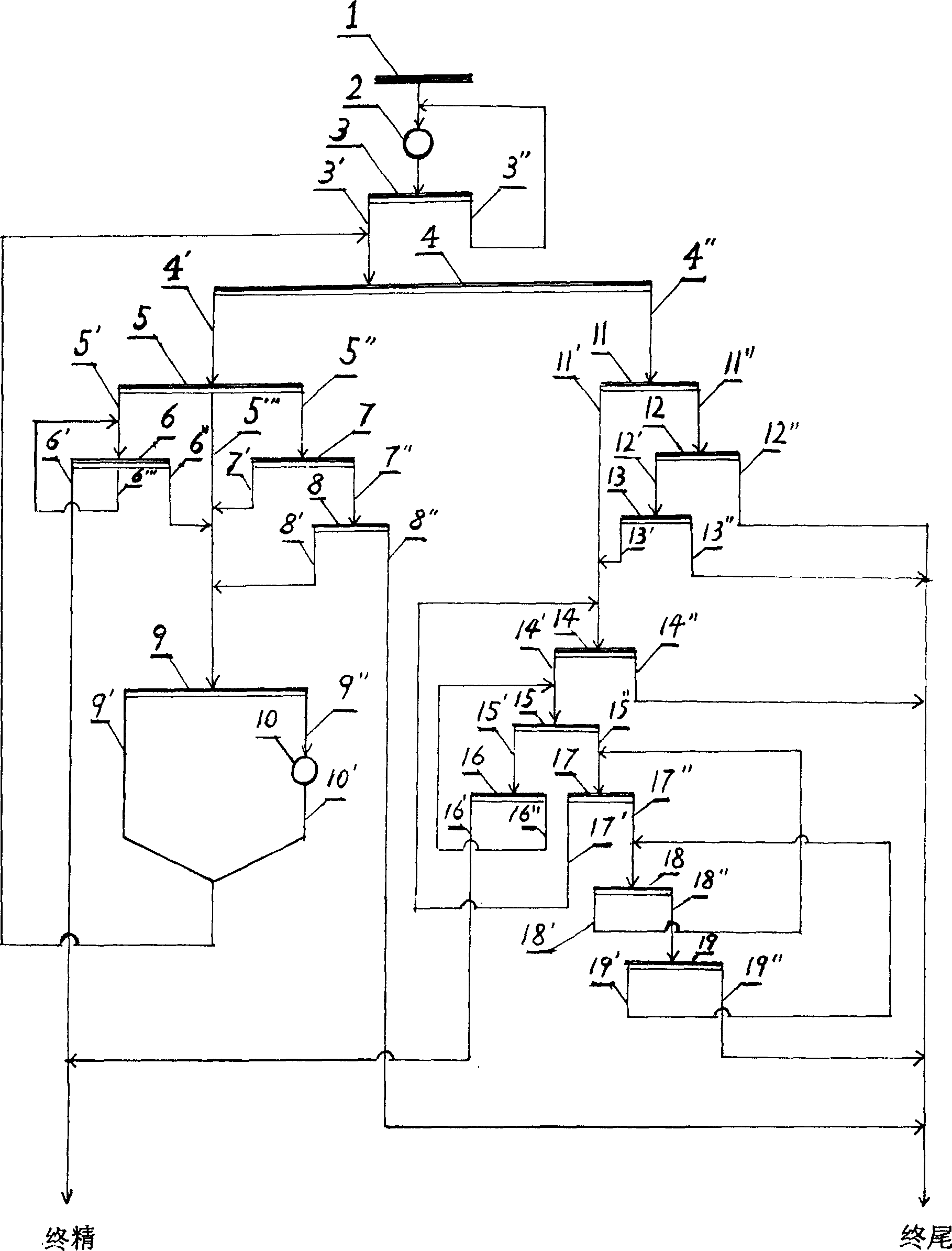

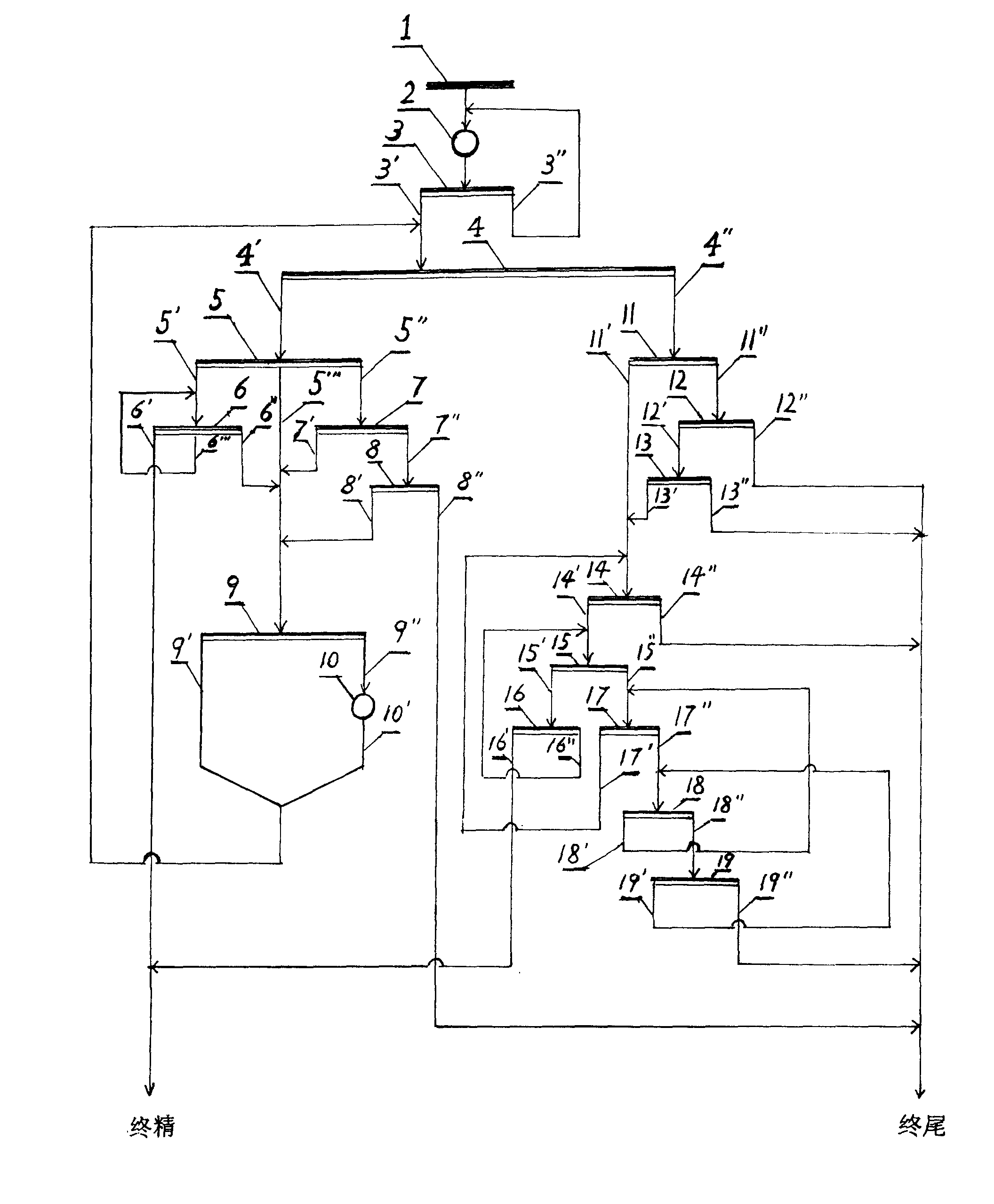

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

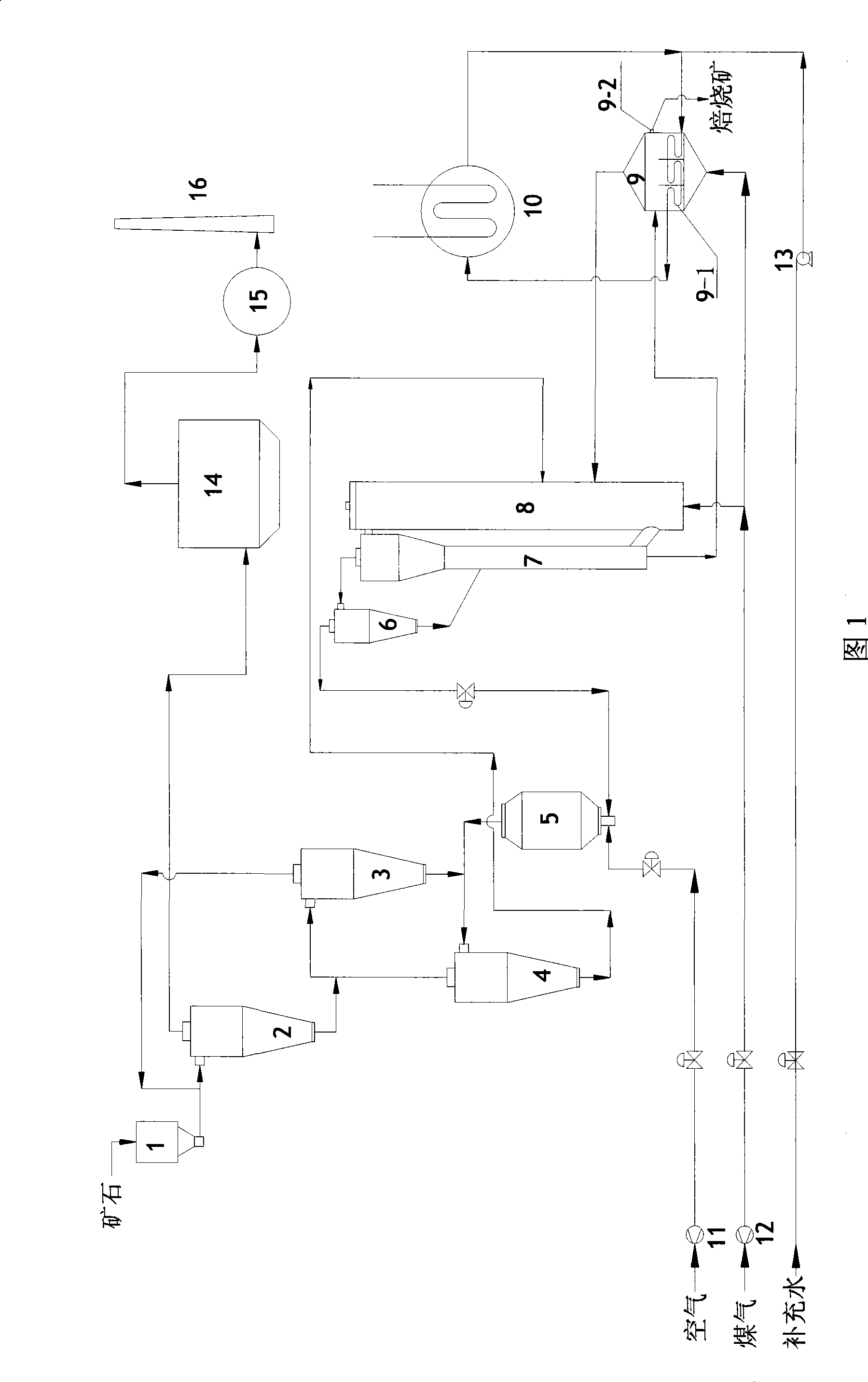

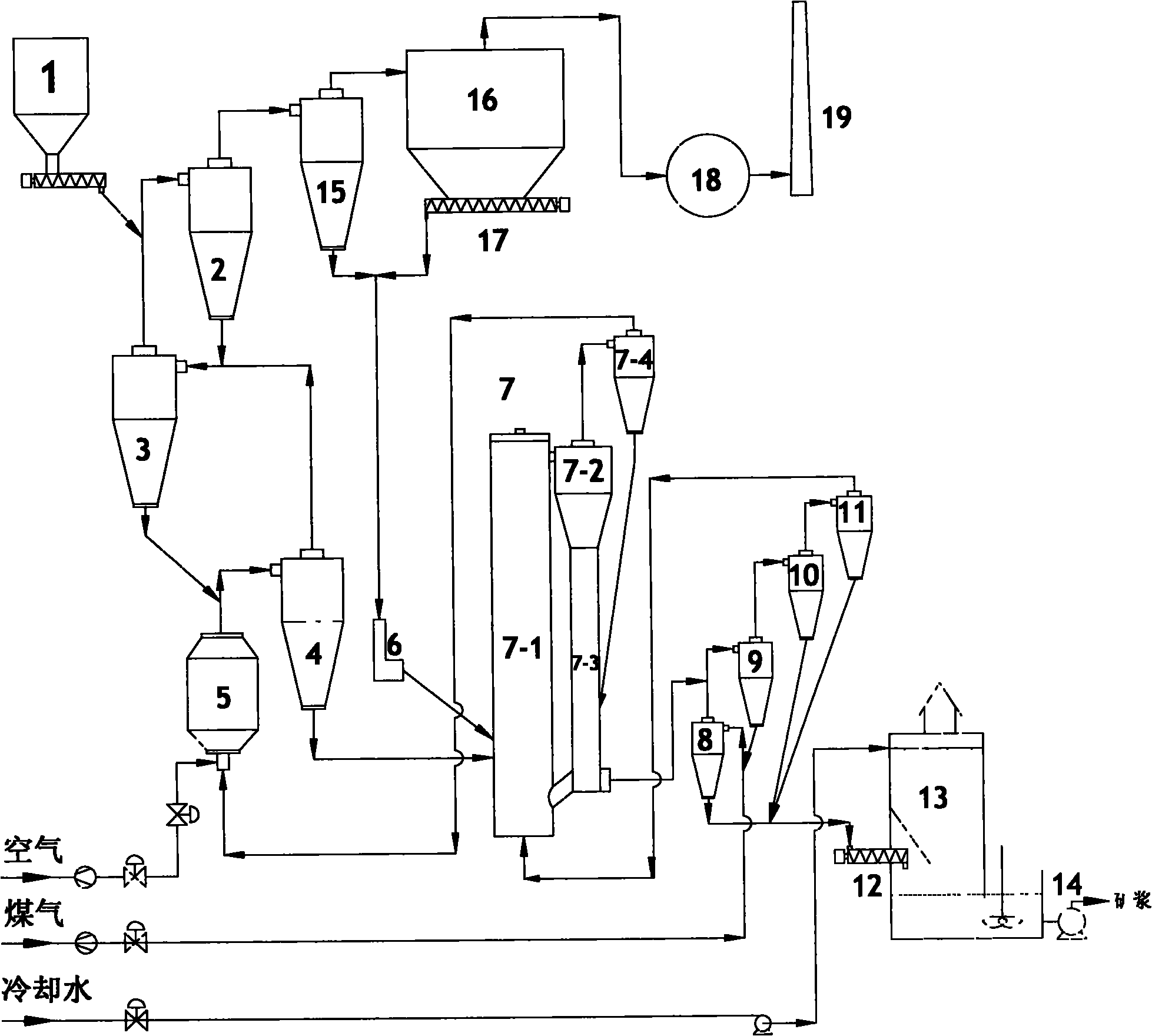

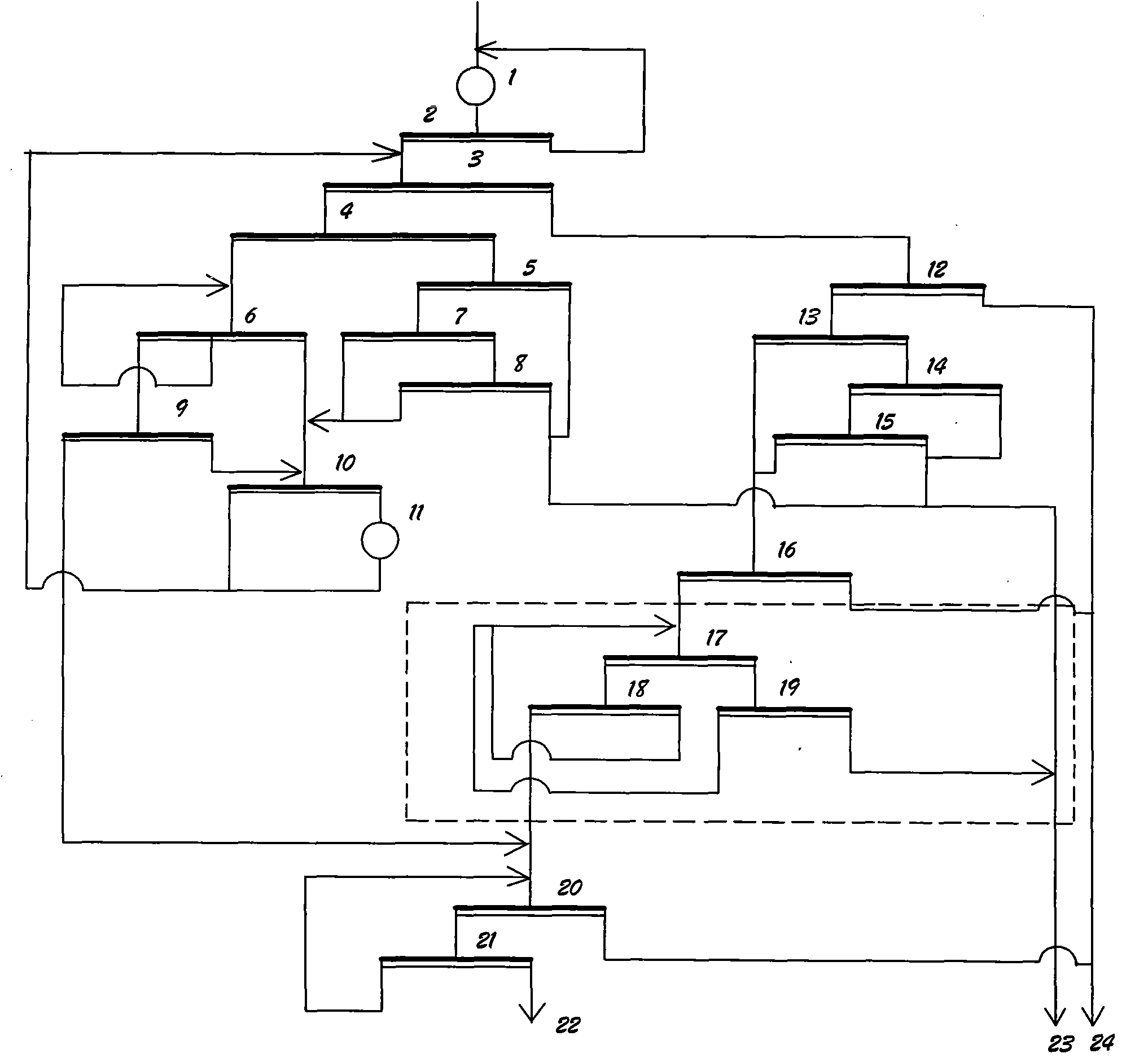

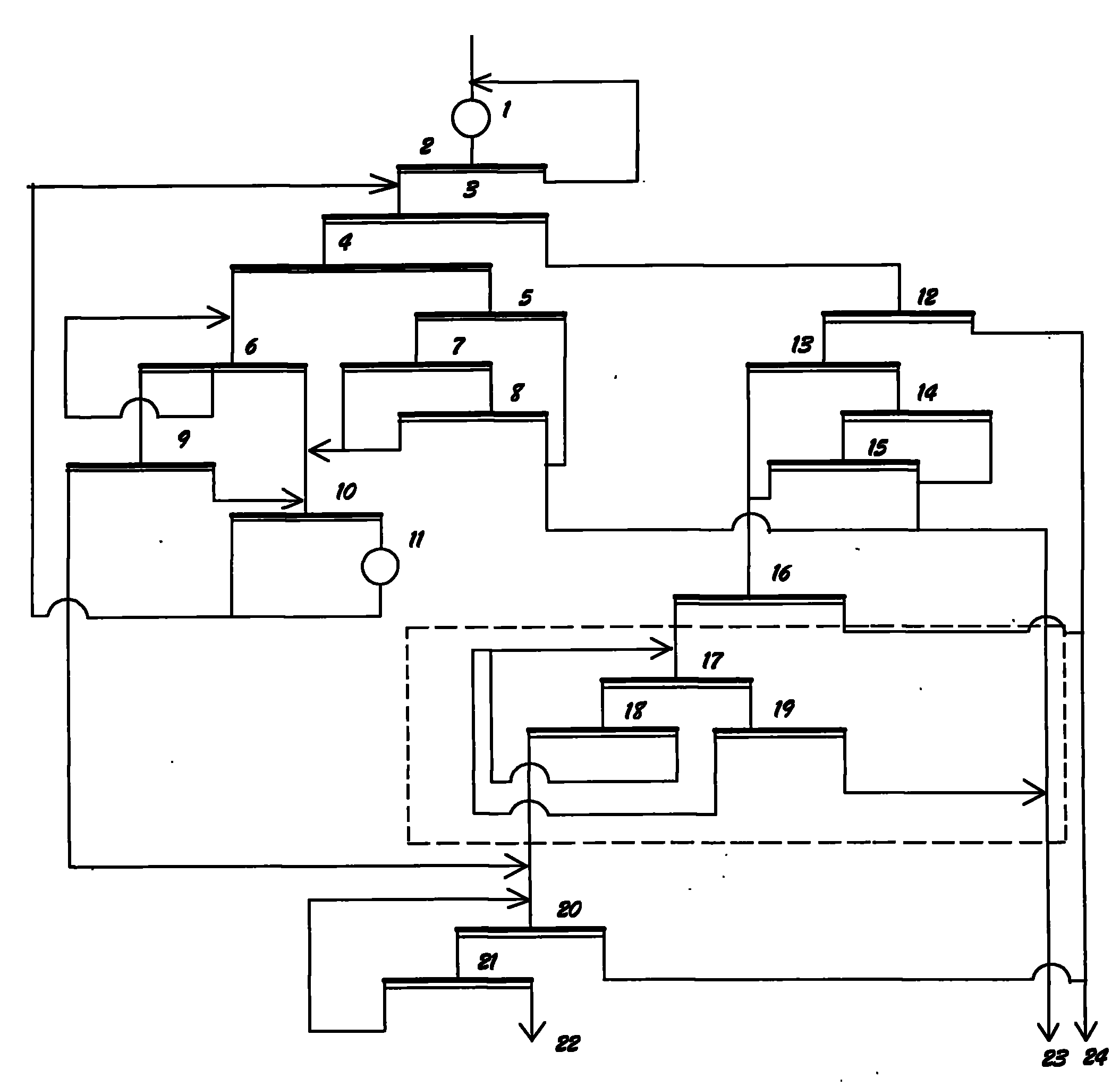

Magnetization roasting technique system for refractory iron ore powder and roasting technology

The invention belongs to the fields of chemical engineering and metallurgy and in particular relates to a process system which adopts a circulating fluid bed to carry out magnetization roasting on limonite, siderite, sedimentary hematite and other refractory iron ore powder bodies. The process system adopts a high-efficiency low-resistance reactor of the circulating fluid bed to carry out the magnetizing roasting to the iron ore powder body; firstly, roasted tail gas in a combustion chamber releases latent heat of unreacted reducing gas through combustion; secondly, the roasted tail gas exchanges heat with the cold iron ore powder body through a multilevel cyclone preheater to reclaim heat; and finally a fluidizing cooler is adopted to reclaim sensible heat of high-temperature roasting ore. The process system has the advantages of high magnetizing roasting efficiency and full heat reclaiming and utilization in the roasting process and the like, can reduce energy consumption of the refractory iron ore powder body in the process of magnetizing roasting and improve the economical efficiency of the refractory iron ore in the process of magnetizing roasting.

Owner:深圳市中科九台资源利用科技产业股份有限公司

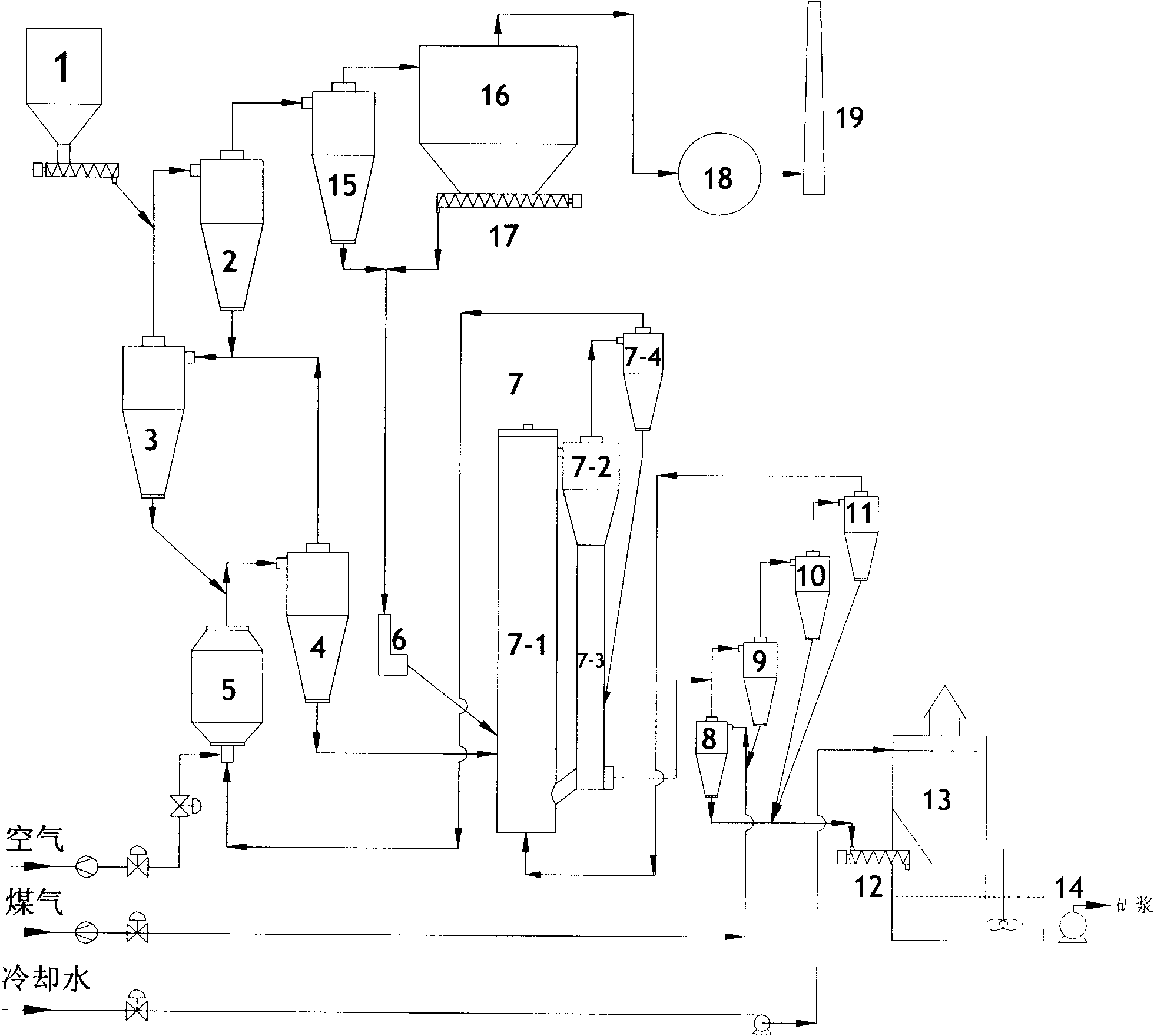

Magnetic roasting system and process for powder of refractory iron ore

The invention belongs to the fields of chemical industry and metallurgy and in particular relates to a magnetic roasting system and process for powder of a refractory iron ore such as limonite, siderite, deposited hematite and the like by using a circulating fluidized bed. The powder of the iron ore is magnetically roasted by using a circulating fluidized bed reactor; the latent heat of unreacted reductive gas in roasting tail gas is released through combustion in a combustion chamber firstly, and then, heat is recovered through the heat exchange between a multistage cyclone preheater and the powder of a cold iron ore; and the sensible heat of the powder of a high-temperature roasted iron ore is recovered in a way that cold coal gas and the powder of the high-temperature roasted iron exchange heat in a cyclone cooler. The magnetic roasting system and process have the advantages of high magnetic roasting efficiency, high heat utilization efficiency in the roasting process and the like and can be used for reducing the energy consumption in the magnetic roasting process of the powder of the refractory iron ore and improving the economical efficiency in the magnetic roasting process of the powder of the refractory iron ore.

Owner:深圳市中科九台资源利用科技产业股份有限公司

Ore dressing process of treating poor hematite

The ore dressing process of treating poor hematite includes staged ore milling, size separating, gravitational dressing, strong magnetic dressing and inverse floating. By means of staged ore milling, early separation between iron containing mineral and gangue, returning the intergrowth to next ore milling for further separation, separating milled material based on size, gravitational dressing of coarse grains, strong magnetic dressing and inverse floating of fine grains, the raw ore of 30 % grade is enriched into high grade concentrated ore up to 67 % in the metal recovering rate over 76 % and SiO2 content lowered from 8-10 % to below 4.5 %.

Owner:鞍钢集团矿业公司研究所

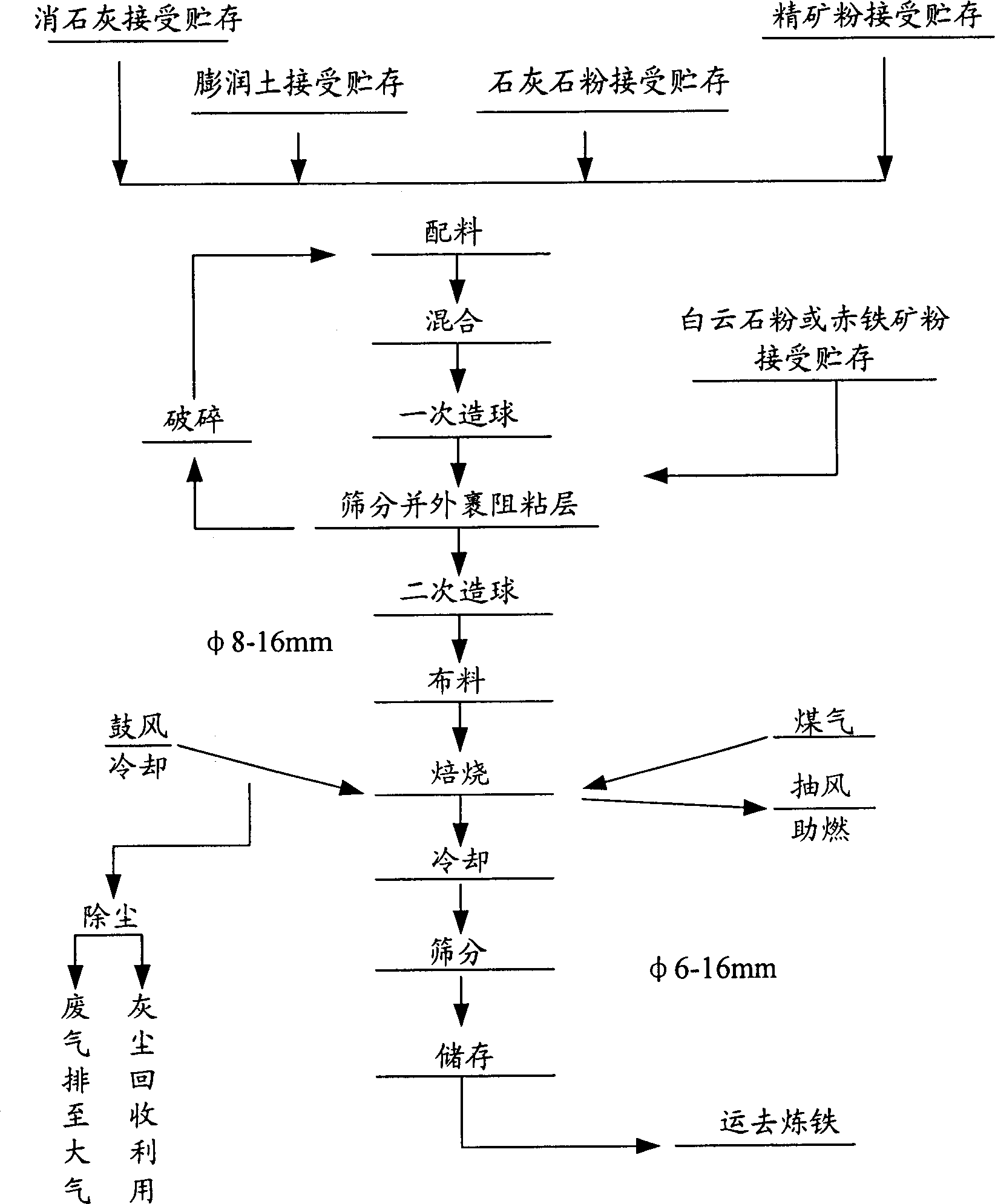

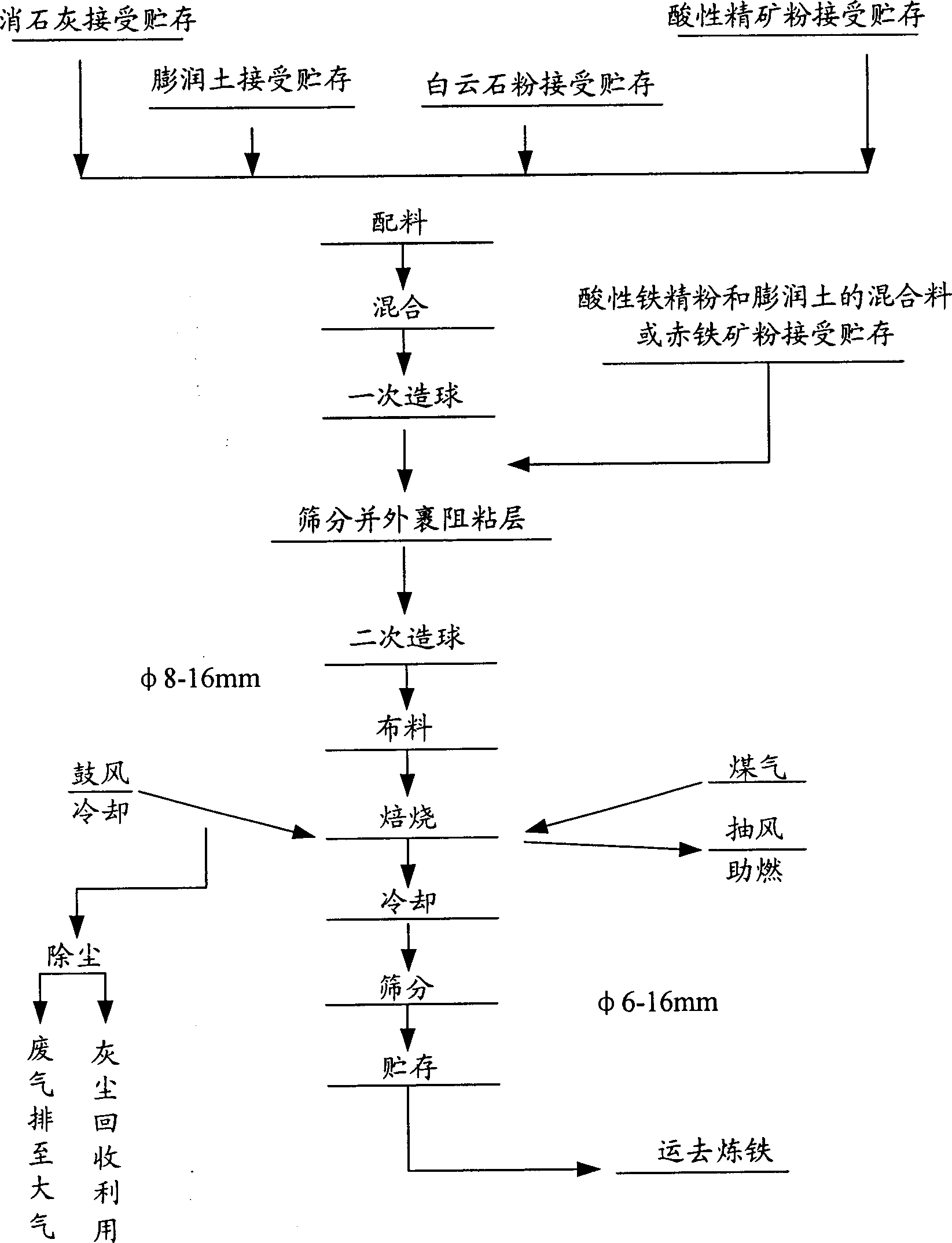

Method for making fluxed iron ore powder composite pellet

The preparation method for a solvent-type iron ore composite aggregate comprises: ensuring the proper CaO and 2-4% MgO with weight o.5-2.0 in the first process; then coming the secondary time, wrapping one block layer evenly of CaCo3 powder, dolomite powder, hematite dried powder or acidic iron concentrate ore; then, baking as the acidic aggregate baking temperature and means to ensure the ore not bond. This invention overcomes bonding problem with low cost and little pollution, and improves blast furnace yield even meets the pH balance or desulfurization request.

Owner:许贵宾

Technique for separating mineral from weak magnetic separation iron tail sand

InactiveCN101219412AProduction process specificationLow costElectrostatic separationFlotationApatiteNon magnetic

The invention relates to a method used for separating minerals from weak magnetic iron tails, which is divided into six stages: primary sorting of strong magnetic minerals, separation of strong magnetic minerals, separation of weak magnetic minerals, separation of non-magnetic minerals, treatment of ore pulp water during the ore dressing process and treatment of finish tail sand. According to the magnetic susceptibility differences, specific gravitydifferences and floating differeces between minerals, magnetite, vanadium titano-magnetite, mixed ore of apatite and xenotime and hematite feldspar concentrate can be separated from the weak magnetic iron by using techniques of crude separation with a strong magnetic separator, refine separation with a weak magnetic separator, gravity separation, floatation, electric separation, etc. The method has advantages of standard production technique, low cost for industrialized production, great variety of separated minerals, stable quality and high separating efficiency, thereby having significant social and economic benefits.

Owner:冯云善

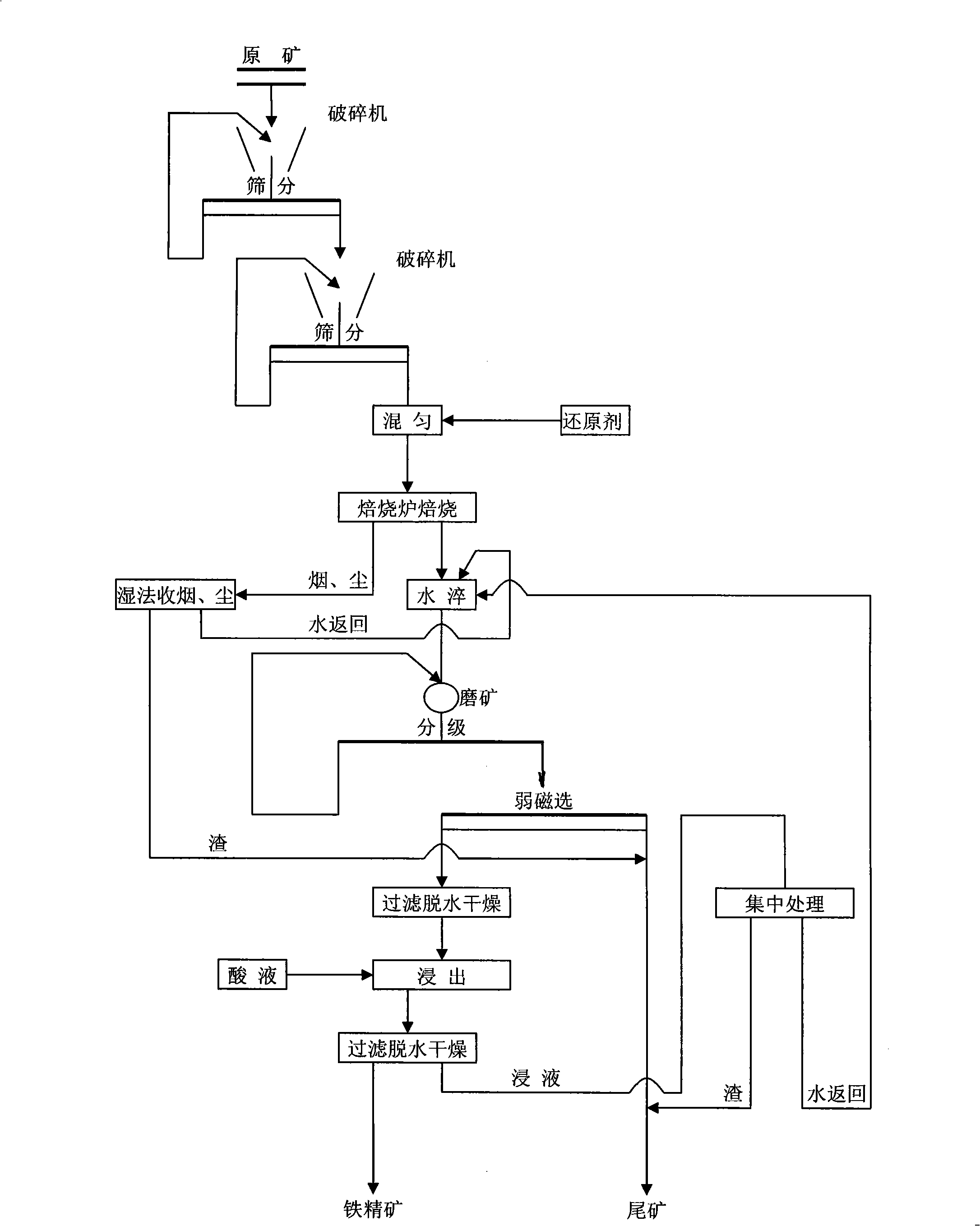

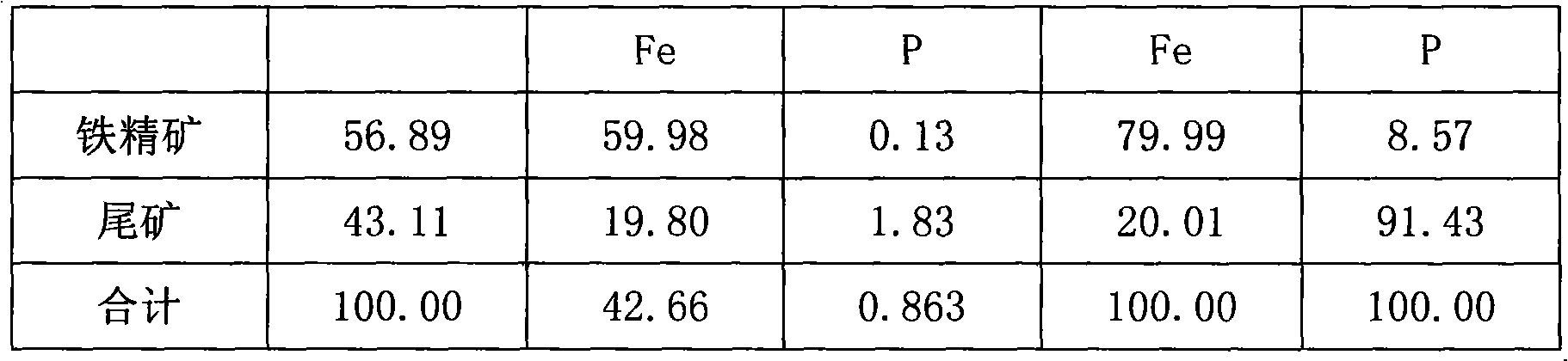

Method for reducing phosphorus in high phosphorus haematite or hematite and limonite ore by magnetization roasting-leaching method

InactiveCN101338361AReduce phosphorus contentProcess efficiency improvementMagnetic separationIronstoneMagnetization

The invention relates to a high phosphorus hematite-hematite-limonite magnetic roasting-extraction phosphorous reduction method, in particular applicable for an extraction phosphorous reduction method for the iron ores which mainly include the hematite-hematite and the limonite and accompany with magnetite, pyrrhotite, iron pyrites, etc. The method of the invention adopts magnetic roasting-wet extraction to reduce phosphorous; after carrying out modifying on high phosphorus iron ore, muriatic acid or vitriol is selected to carry out extraction phosphorous reduction on the iron concentrate obtained by a weak electromagnetic separator which not only can obtain the iron concentrate with an iron grade to be larger than 56 percent; simultaneously the content of the phosphorous in the iron concentrate is lower than 0.30 percent.

Owner:昆明晶石矿冶有限公司

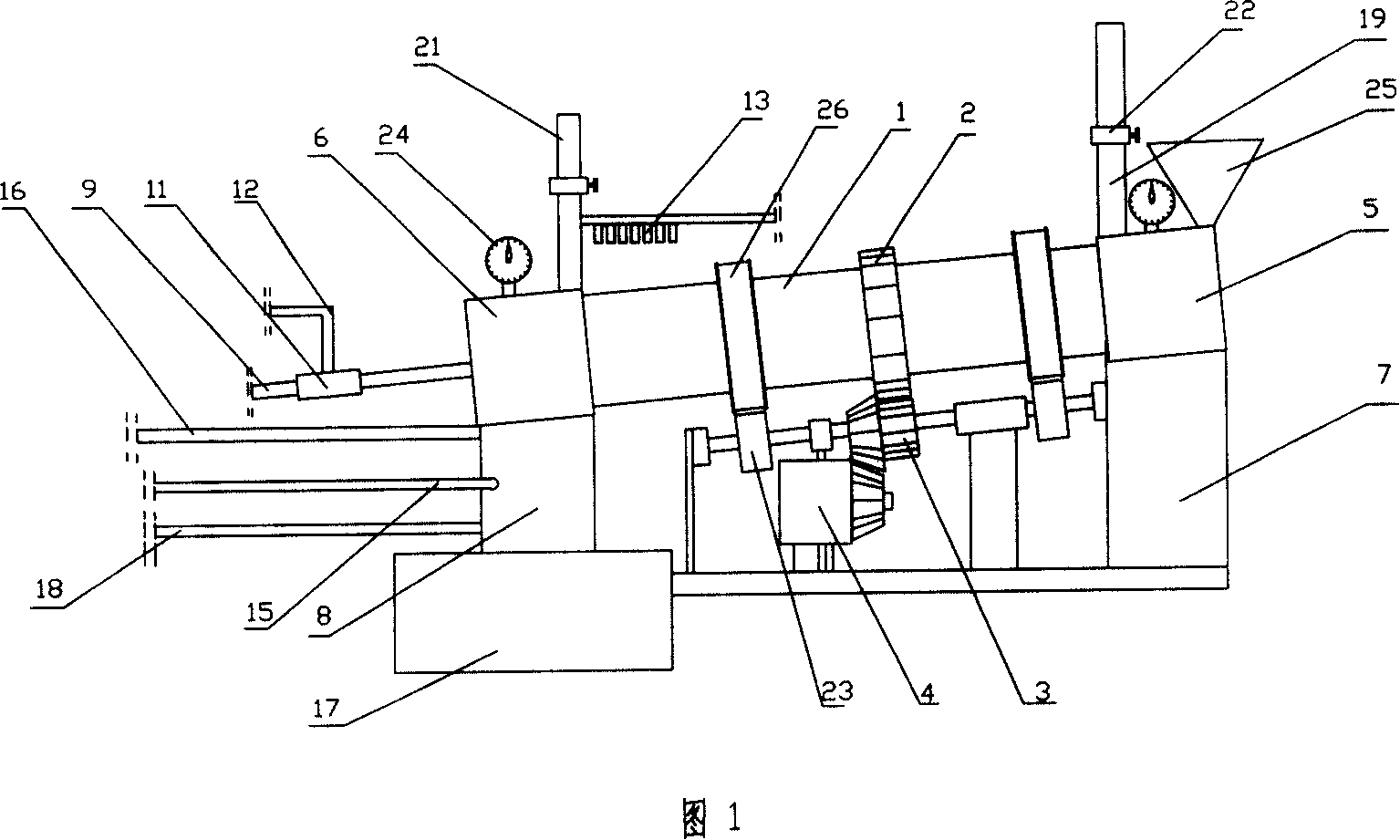

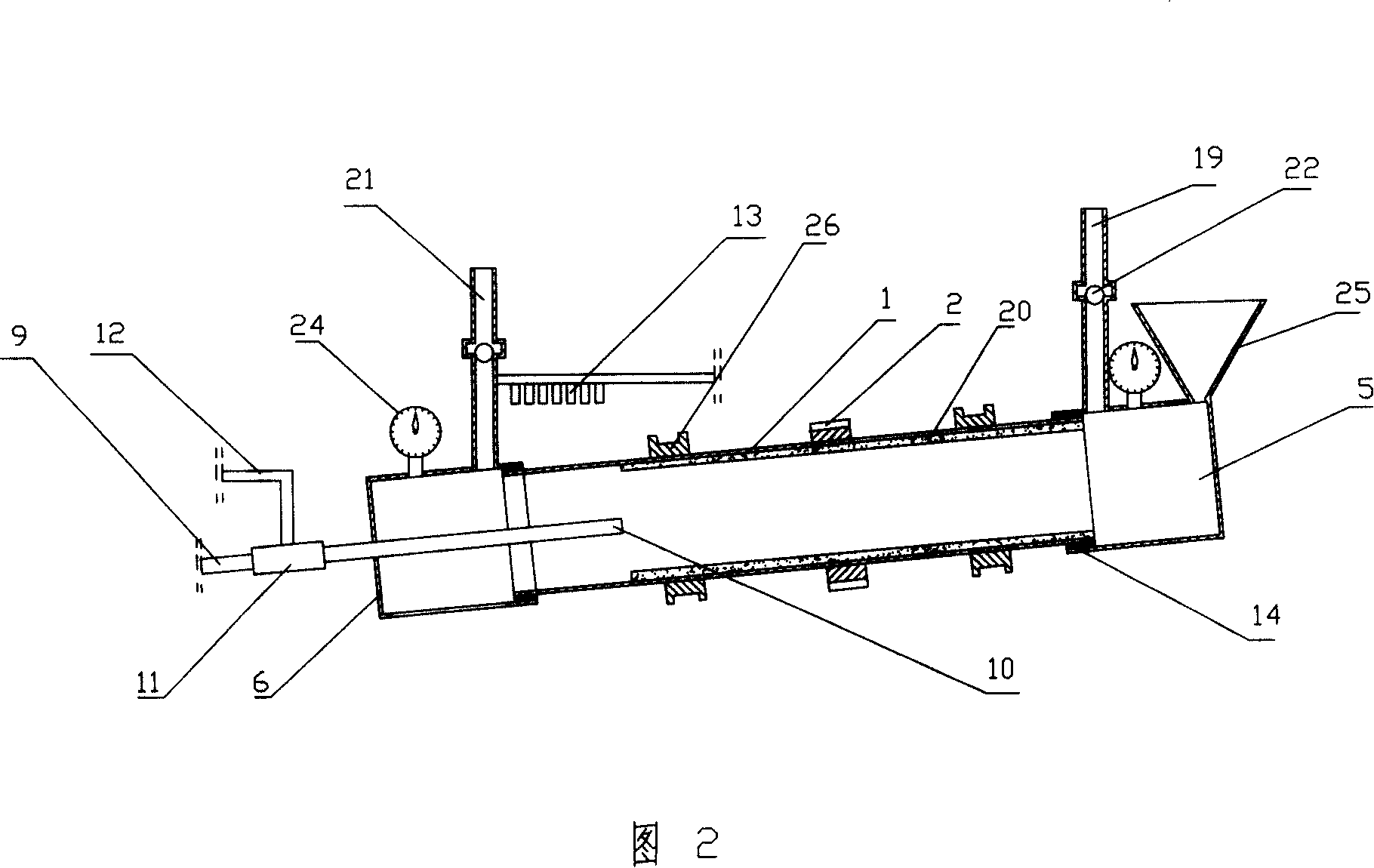

Method for producing iron concentrate by brown hematite and siderite and reduction roaster

The present invention discloses a method for adopting the limonite and the siderite to produce iron powder and a reduction roaster. The material adopts the limonite and the siderite or the specularite, the hematite, and the sulphuric acid slag, the inclined rotary reduction roaster is used, the pressure of the furnace chamber is 250 to 350 Pa, under the deoxidizing atmosphere, the inert solid is rotated and moved to 650 to 900 DEG C from the low temperature, and is cooled and magnetized, and lastly become the iron powder through the dressing by magnetic separation. The present invention is adopted to produce the iron powder, the resources is rich and the production cost is low, and through the utilization of the powder metallurgy art, the iron content of the iron powder is controlled and the activation energy of the iron powder is reduced, and the chemical reaction ability is increased, thereby the output of iron powder is high, the quality is good, the iron powder is loose and porous, the specific surface is big, the apparent density is large, the manufacture cost of pellets sinter and steel smelting can be reduced greatly, and the iron powder can use directly to produce iron oxide red as well as H and N synthetic iron catalyst, or produce ultrapure iron powder.

Owner:郭元杰

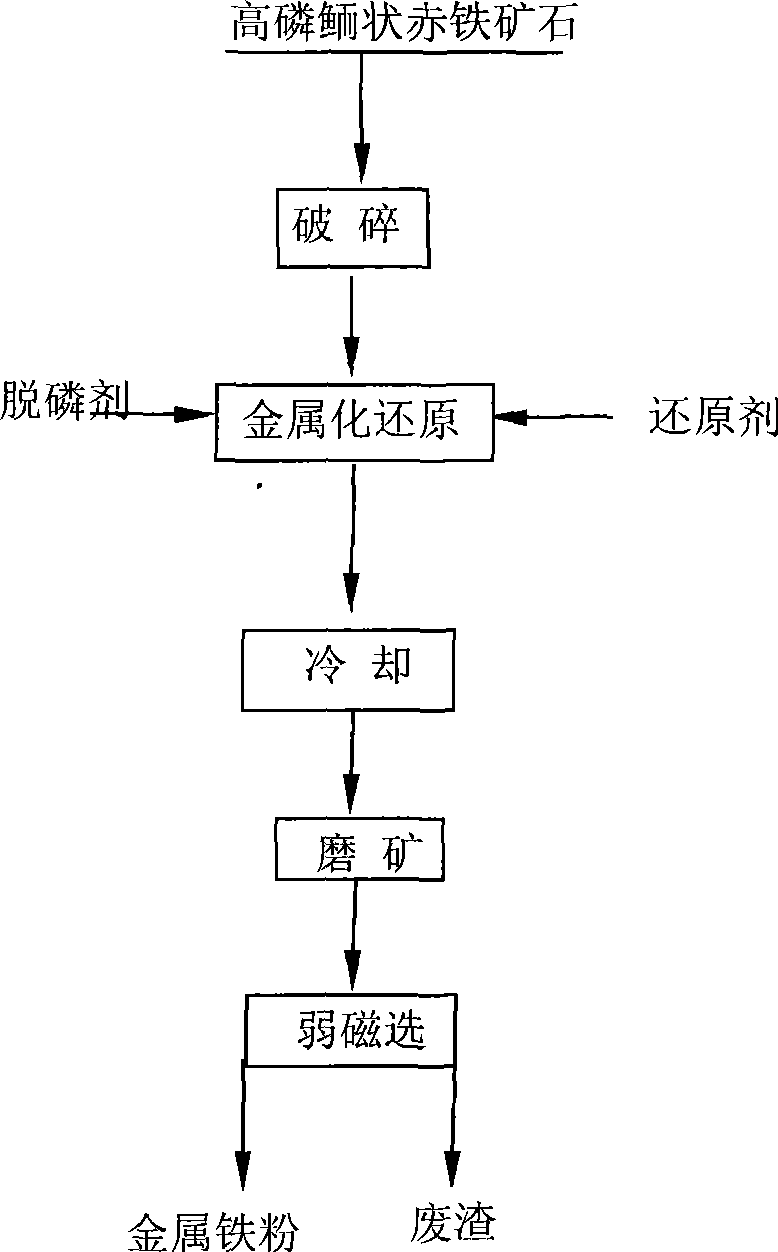

Technological process for directly producing spongy iron from high-phosphor oolitic hematite

InactiveCN101487068AAvoid pollutionEmission reductionProcess efficiency improvementIronstoneResource utilization

A technique method for directly producing spongy iron by using high phosphorus oolitic hematite belongs to the iron making field, and is characterized in that the high phosphorus oolitic hematite is added with a dephosphorizing agent and then is subjected to direct metallization reducing roast by taking coal as a reducing agent, low intensity magnetic separation for raising iron and reducing phosphorus is carried out, thus obtaining the substance with more than 90 percent of iron metal and phosphorus less than 0.08 percent. The invention has the advantages as following: (1) the utilization rate of resource is high, thus shortening the process flow of making raw steel material from iron ore, avoiding from polluting environment in concentrated ore sintering, pelletizing and blast furnace ironmaking in other methods, and having obvious environmental benefits, energy-saving and consumption reduction effects; (2) the technique method is simpler than other methods, the iron raising process and phosphorus reducing process can be completed simultaneously; and (3) coal power with low cost is directly taken as the reducing agent instead of the expensive coke, thus saving the cost in coking process and avoiding from polluting environment; the varieties are simple, the source is rich, the discharging amount of pollutants in the method is less than that in other methods and the pollutants are easy to deal with.

Owner:UNIV OF SCI & TECH BEIJING

Ore dressing process of oolitic high phosphorus hematite

The ore dressing process of oolitic high phosphorus hematite includes the following steps: roasting crushed oolitic high phosphorus hematite in 80-99 wt% with coal powder as reductant in 1-20 wt% inside a shaft furnace or rotary kiln at 700-1050 deg.c for 0.5-2.5 hr and sealed cooling to room temperature; crushing the roasted hematite, grinding and weak magnetic separation; regulating pH value of the coarse concentrate to 8-12, adding iron ore inhibitor sulfonated starch in 0.5-3.0 kg / ton, activator in 0.2-2.0kg / ton and collecting agent in 0.2-3.0kg / ton and final reverse floatation. The process converts the weak magnetic hematite into strong magnetic mineral, concentrates iron mineral via weak magnetic separation and eliminate P, Si and other impurities in reverse floatation, and can obtain iron concentrate with iron grade higher than 63 %, P content less than 0.15 %, and iron recovering rate over 75 %.

Owner:WUHAN UNIV OF SCI & TECH

Dephosphorus iron extraction production method of oolitic high phosphorus red iron ore

The present invention relates to a production method for dephosphorization and extracting iron from oolitic high-phosphorus haematite. Said method includes the following steps: uniformly mixing (by wt%) 60%-90% of oolitic high-phosphorus haematite powder, 8%-20% of coke powder or coal powder and 0-20% of lime hydrate, briquetting or balling, drying, making reduction at 1100 deg.C-1450 deg.C in high-temperature furnace, reduction time is 10-30 min, cooling reduced product, grinding and making magnetic separation, finally making the metal iron granules be separated from phosphorus-rich ganque or slag.

Owner:WUHAN UNIV OF SCI & TECH

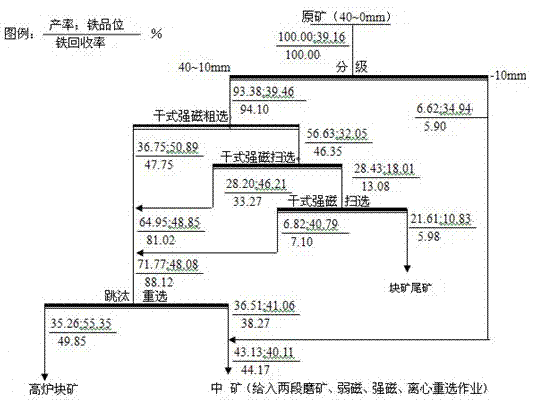

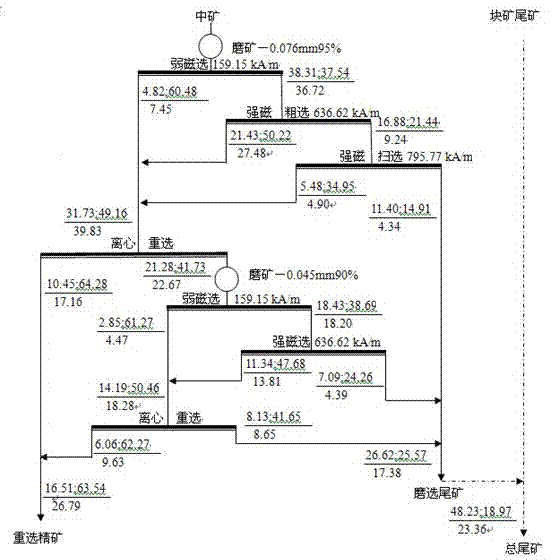

Magnetic-gravity combined ore dressing technology for hematite

InactiveCN102773161AHigh recovery rateThe amount of ball grinding is reducedMagnetic separationIronstoneCrushed stone

The invention discloses a magnetic-gravity combined ore dressing technology for hematite, comprising the following steps of: carrying out dry magnetic separation and jigging gravity separation to obtain blast furnace lump ore, throwing the tailings of the lump ore, carrying out first-stage ore grinding, weak magnetic separation, strong magnetic separation and centrifugal gravity separation on middlings, and carrying out second-stage ore grinding, weak magnetic separation, strong magnetic separation and centrifugal gravity separation. According to the technology, part of qualified blast furnace lump ore (the iron grade is large than 54%) can be obtained in advance, the massive tailings (the iron grade is less than 12%) can be thrown out, the quantity of the ball-milled ore (the middlings) can be greatly reduced, and the grinding and separation energy consumption can be greatly reduced. The massive tailings which are thrown out can replace the macadam and the stone to be taken as the building material, so that the comprehensive utilization of the bulk quantity of the tailings resource can be realized, and the technology is prominent in emission reduction effect; and the whole ore dressing technology is the magnetic-gravity combined ore dressing technological process, so that the flotation reagents can not be consumed, the technology is very friendly to the work environment and the neighboring environment, the environment can be protected, the pollution of the beneficiation reagent to the environment caused by the flotation work can be avoided, and the technology is particularly suitable for the ore dressing of the medium and high-grade (the iron grade is more than or equal to 38%) hematite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Method for separating oolitic hematite

InactiveCN101693222AReduce lossesEconomic beneficiation costHigh gradient magnetic separatorsFlotationSulfateReverse flotation

The invention discloses a method for separating oolitic hematite, and the process of the method comprises discarding tailings of ores by intense magnetic separation through stage grinding and stage separation, and de-phosphorizing and increasing iron to the intense magnetic concentrated by reverse flotation. The intense magnetic separation is functioned of concentrating iron minerals and desliming, thereby preventing smile from influencing flotation. The highly-effective regulator is made from sodium carbonate, sodium silicate and sodium hydroxide, the collecting agent is a composite medicine made from hydroximic acid and alkyl sulfate, and the method for separating oolitic hematite is a key technology for the reverse flotation to further upgrade the concentrate of iron ore. The invention has the advantages of simple technological process, low energy consumption, low cost and good product index, and solves the defects in prior art.

Owner:GUIZHOU UNIV

Ru-kiln celadon ware and preparation process thereof

The invention relates to a Ru-kiln celadon ware and a preparation process thereof. According to the invention, kaolin, flint clay and feldspar are adopted as blank raw materials; the blank raw materials are crushed and are subjected to wet grinding with water; quartz, feldspar, calcite, hematite, ophiolite, bone ashes, and wind cave earth calcined under 900-950 DEG C are adopted as glaze raw materials; the glaze raw materials are crushed and are subjected to wet grinding with water, until a slurry water content is regulated to 80%; a prepared blank is subjected to biscuit firing and is fetched; an obtained glaze is applied on the blank; the blank with the glaze is immediately placed in a kiln and is subjected to stepped heating and firing; after firing, heating is stopped, and the obtained ware is fetched. According to the prepared Ru-kiln ware, cracked-glaze effects with different degrees can be realized. The ware is gentle, delicate, elegant, and natural. The ware is superior among Ru-kiln wares.

Owner:王振宇

Novel rhombohedral iron ore beneficiation technics

InactiveCN101116841AOvercoming processing problemsImprove efficiencyFlotationWet separationPhosphorSilicon

The present invention belongs to the ore separation technical field, in particular to a mill run technics, which includes the smashing and sieving of ores, grinding and classification, dephosphorization treatment and floatation ore separation, ore separation of hematite rich in phosphor of ore powder classification, wherein the present invention is characterized in that the hematite rich in phosphor is smashed and sieved, grinded and classified, and then undergo twice floatation ore separation to eliminate the phosphor and the silicon, then rough separation, fine separation and scavenging is carried out for the ore powder with the cooperation between a spiral chute and a swinging bed, to improve the standard of the iron and decrease content of the phosphor and silicon to obtain the iron core for smelting, which meets the requirement of the metallurgy industry.

Owner:HUBEI YICHANG LINSEN INDAL

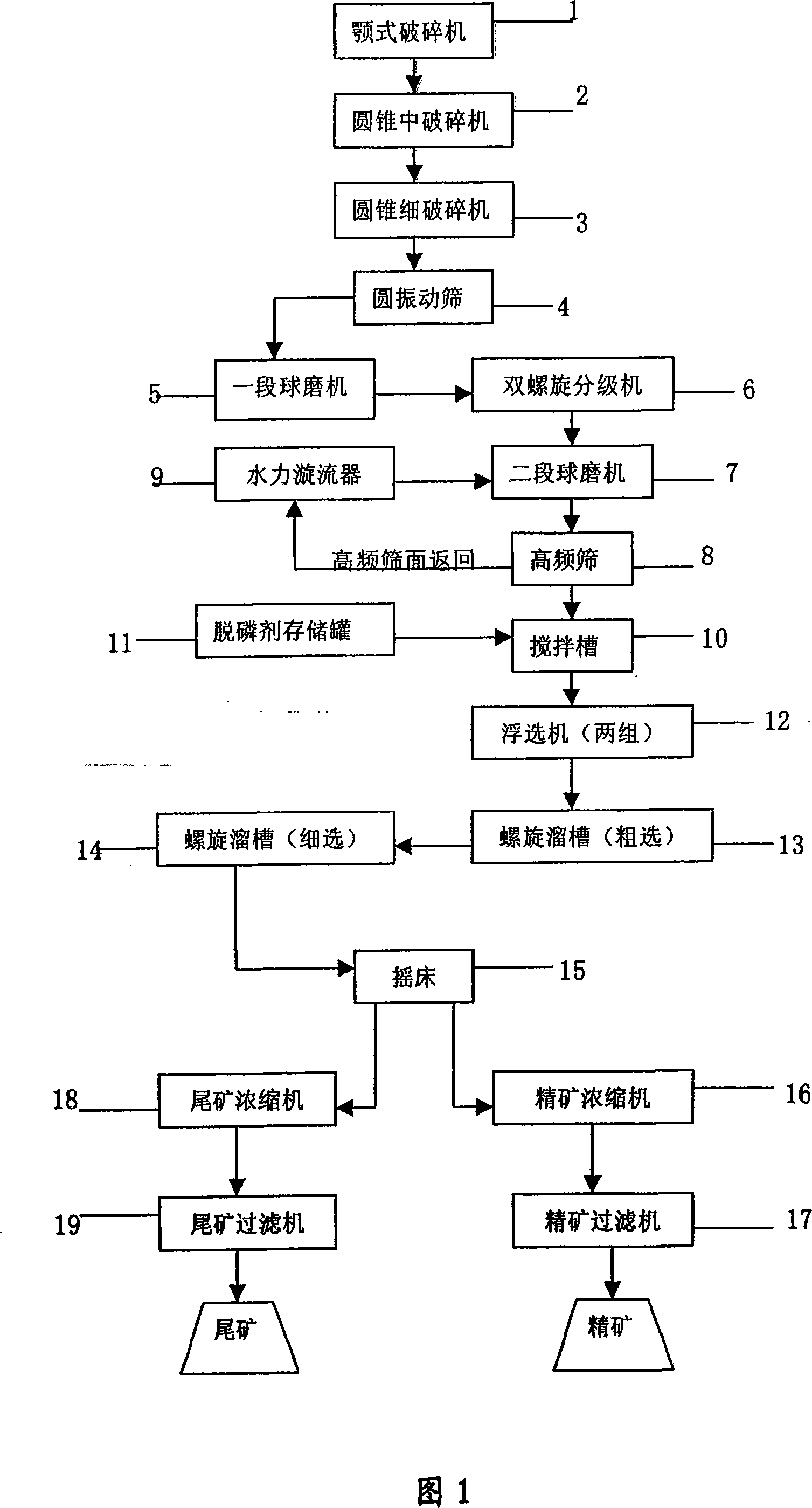

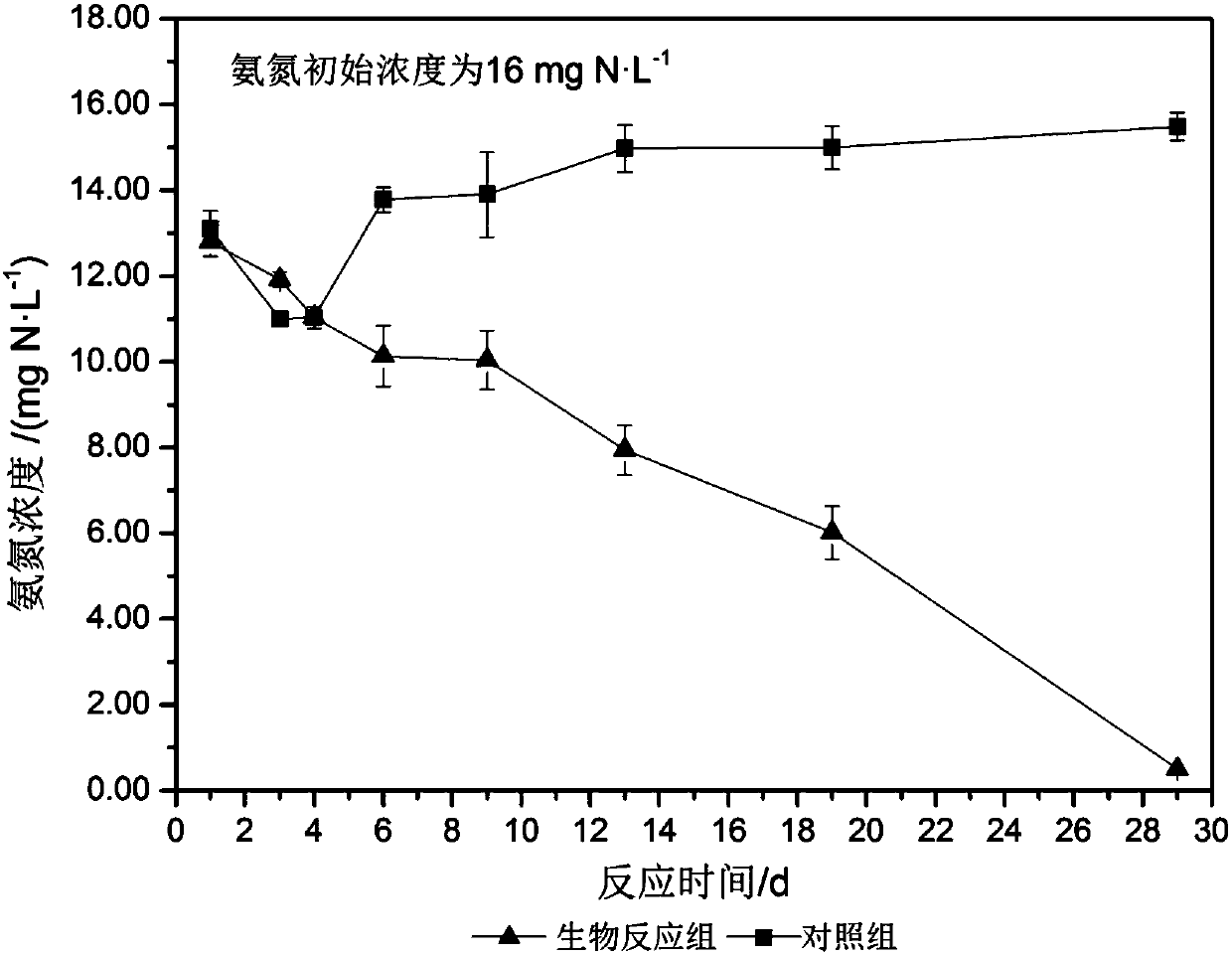

Anaerobic biological oxidation water pollution remediation method with Fe3+ in hematite as electron acceptor

InactiveCN105948280AImprove removal efficiencyLow costWater treatment compoundsTreatment with anaerobic digestion processesMicroorganismBiological oxidation

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

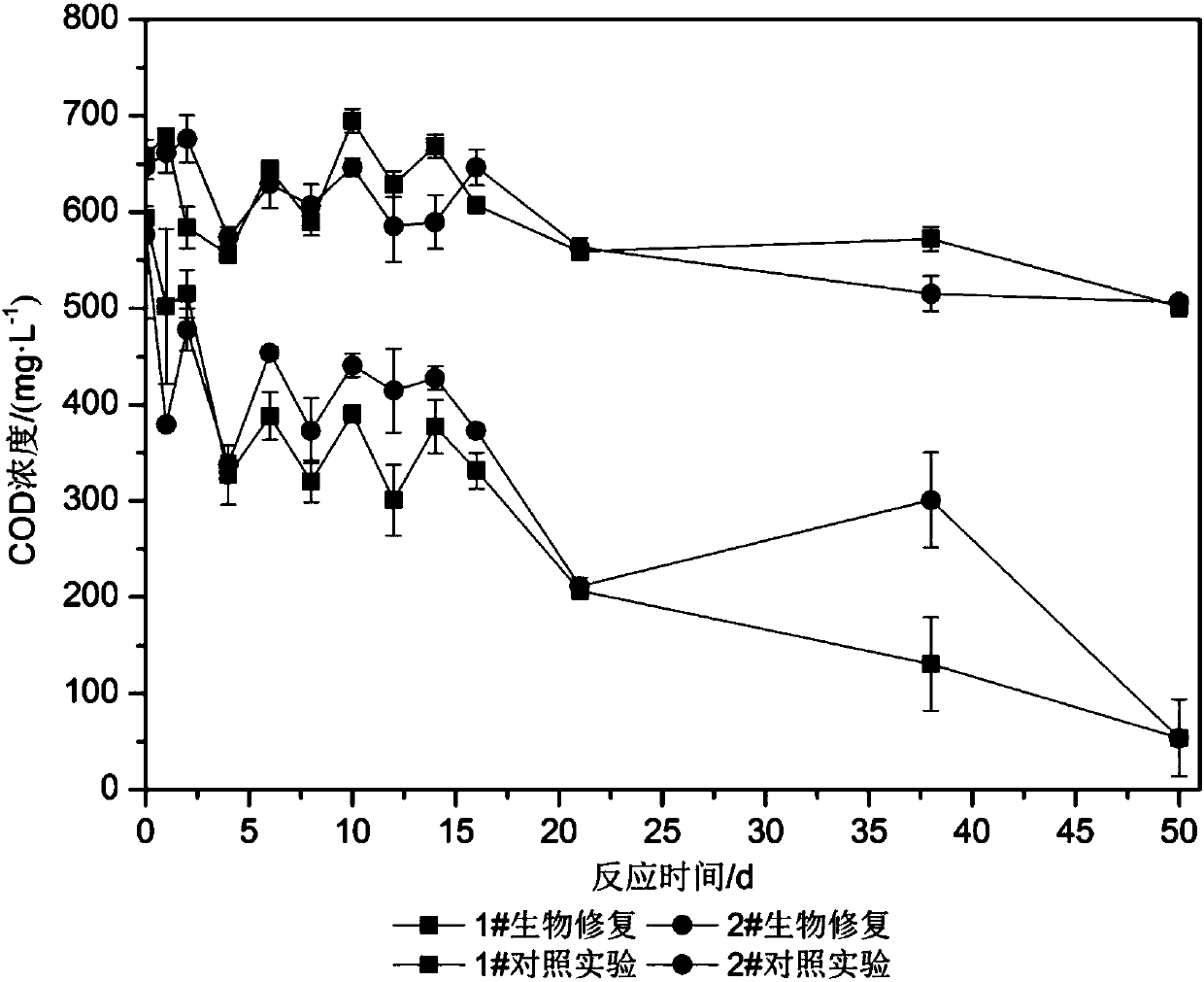

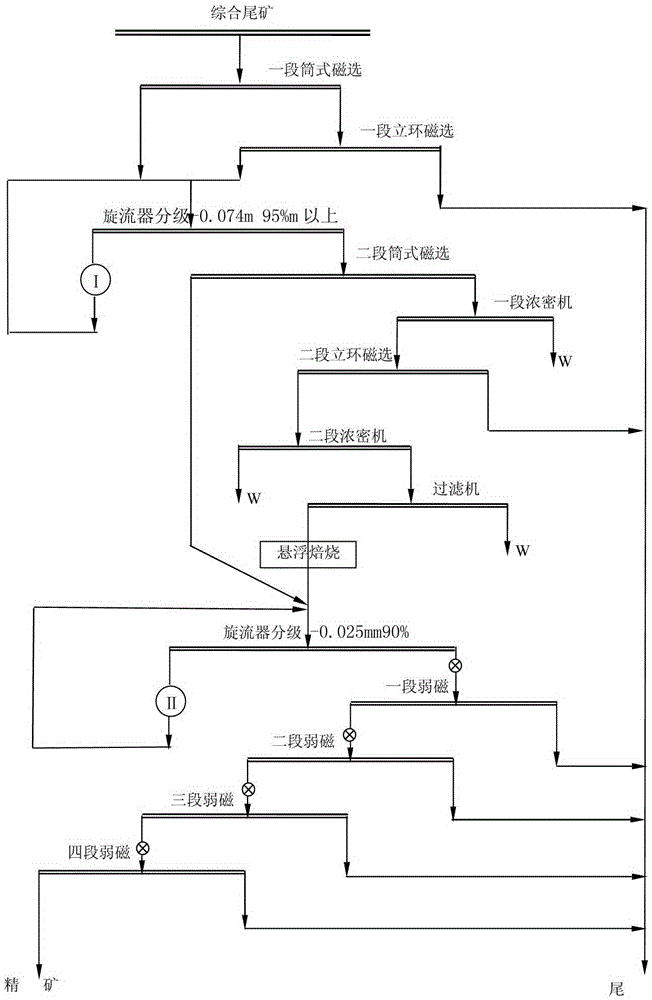

Tailing recovery process adopting preconcentration-roasting-regrinding and magnetic separation method

ActiveCN105233976AEfficient recyclingReduce the processing volume of subsequent grinding and sorting operationsMagnetic separationProcess efficiency improvementMagnetic separatorReducing atmosphere

The invention relates to a tailing recovery process adopting a preconcentration-roasting-regrinding and magnetic separation method. The tailing recovery process is characterized by comprising the following steps: concentrate extraction and tailing discarding are carried out by virtue of a preconcentration process which sequentially comprises first-section drum magnetic separation, first-section vertical ring magnetic separation, ore grinding, second-section drum magnetic separation and second-section vertical ring magnetic separation, so that a rough concentrate grade is increased, and a subsequent operation treatment amount is reduced; suspension roasting is adopted, so that a rotational-flow suspension state of rough concentrate materials in a suspension magnetization roasting furnace under the conditions of a high temperature of 500 DEG C and a reducing atmosphere can be ensured, and micro-and fine-grained hematite, siderite and limonite in the rough concentrate materials are converted to magnetic iron minerals; and meanwhile, multi-section continuous fine separation is carried out by virtue of a regrinding and fourth-section low-intensity magnetic separation machine, thus the good indexes of a concentrate grade of more than 65% and a metal recovery rate of 48-55% are obtained.

Owner:ANSTEEL GRP MINING CO LTD

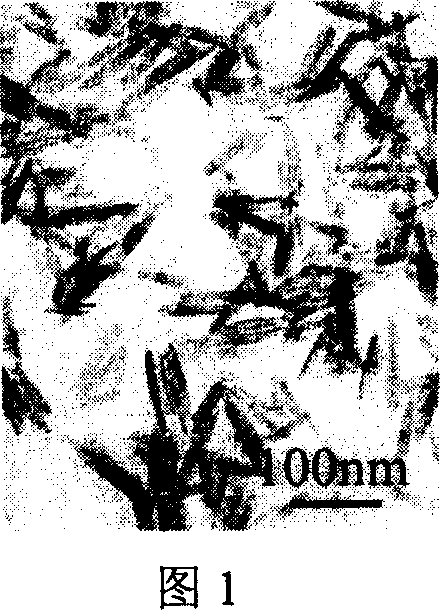

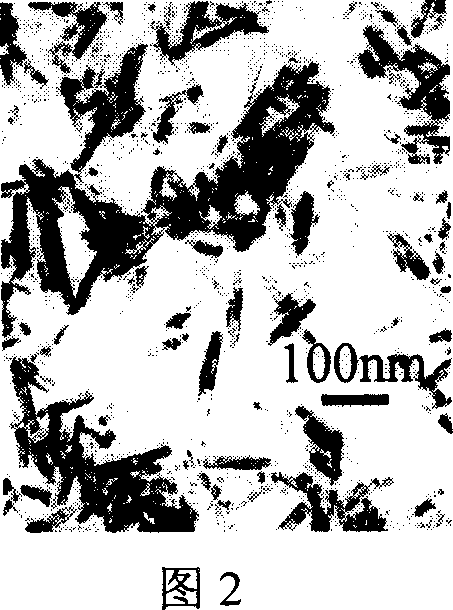

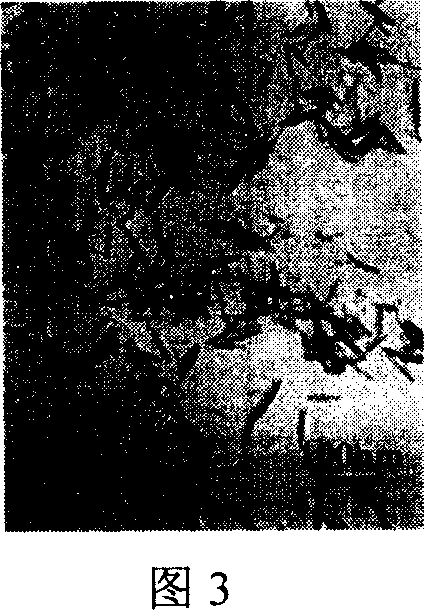

Simple preparation method of alpha-FeOOH and alpha-Fe2O3 nano stick

The invention discloses a green and simple preparing method of alpha-FeOOH (goethite) and alpha-Fe2O3 (hematite) nanometer rod, which comprises the following steps: choosing bivalent soluble ferric saly and hydro peroxide as raw material; choosing simple hydrothermal reaction; selective-synthesizing alpha-FeOOH and alpha-Fe2O3 nanometer rod through controlling temperature; getting alpha-FeOOH nanometer rod under lower temperature; getting alpha-Fe2O3 nanometer rod under higher nanometer rod. This invention possesses simple operation, cheap raw material and wide prospect.

Owner:NANJING UNIV

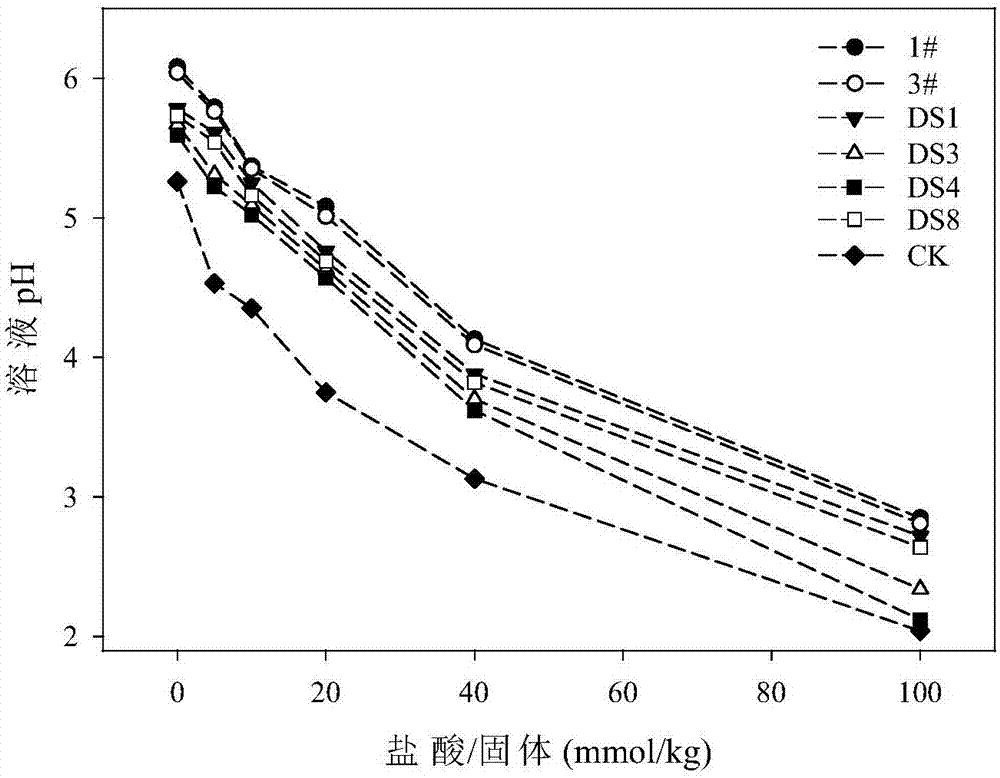

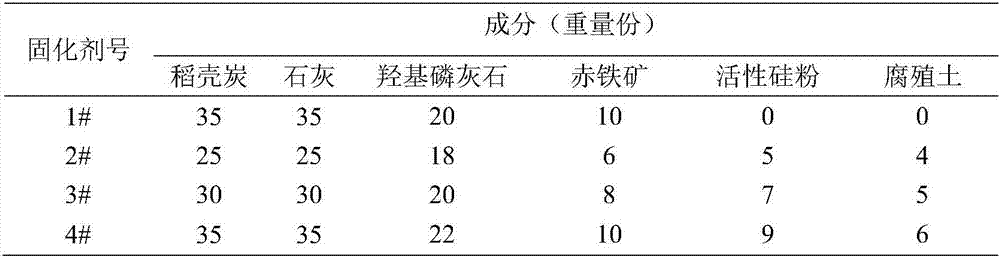

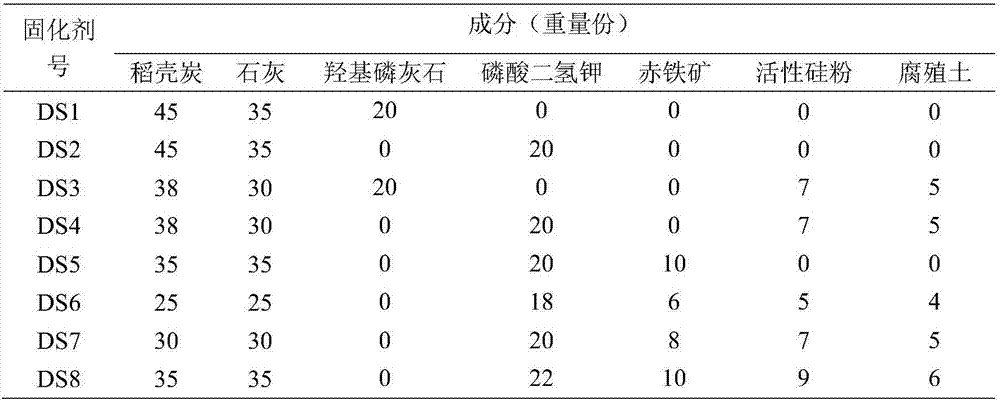

Cadmium (Cd) passivator for acid soil and application thereof

ActiveCN107446589ARaise the pHReduce absorptionAgriculture tools and machinesOther chemical processesEthylic acidBinding state

The invention discloses a cadmium (Cd) passivator for acid soil. The Cd passivator is prepared from the following components of rice hull charcoal, lime, hydroxyapatite and hematite. The Cd passivator for the acid soil, which is provided by the invention, can be used for improving the pH (potential of Hydrogen) of soil and decreasing the content of CaCl2 and ethylic acid extraction state Cd, and is used for promoting the conversion of Cd in the soil from a bioavailable state (an ion exchange state) to a potential available state (a carbonate binding state and a ferromanganese oxide binding state) and an unavailable state (a residue state), reaching the purpose of passivating the activity of the Cd, effectively restoring Cd polluted acid soil, promoting the growth of a plant and decreasing the absorption to the Cd of a crop.

Owner:JIANGXI JIEDI ENVIRONMENTAL TREATMENT & ECOLOGICAL TECH CO LTD

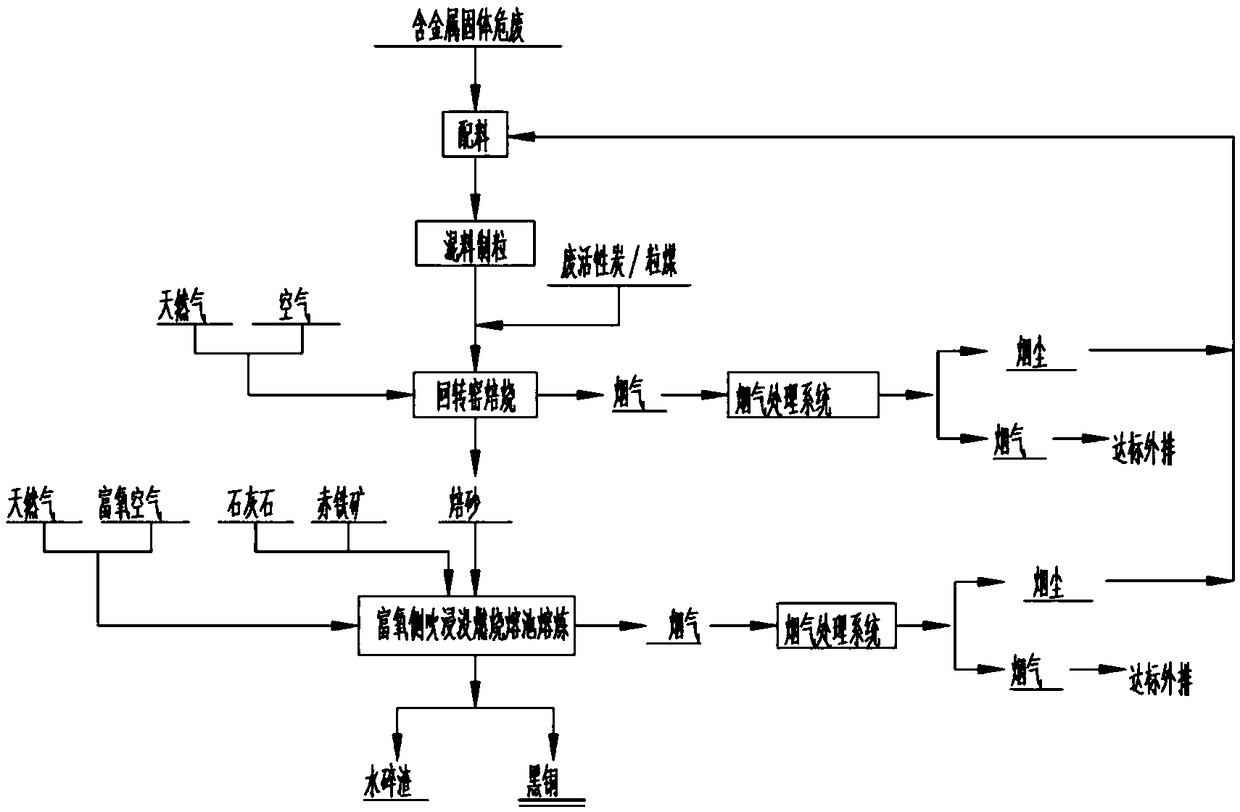

Method for treating hazardous wastes

InactiveCN109402399AAdaptableGood separation and settlingSolid waste disposalProcess efficiency improvementSludgeEngineering

The invention discloses a method for treating hazardous wastes. The method comprises the following steps of: sending hazardous wastes and active carbon into a rotary kiln for roasting, discharging theroasted materials produced by the rotary kiln, sending the roasted materials to a side-blowing submerged combustion molten pool smelting furnace for smelting in a hot charging and hot delivering mode, sending the flue gas of the rotary kiln into a first flue gas treatment system, adding limestone and hematite into a side-blowing submerged combustion molten pool smelting furnace to adjust the slagtype, adopting natural gas as fuel, carrying out submerged molten pool smelting in an oxygen-rich side-blowing mode, crushing the slag produced by molten pool smelting by water to obtain glass-stateharmless slag, and sending the flue gas of the side-blowing submerged combustion molten pool smelting furnace into a second flue gas treatment system. The method for treating hazardous wastes has theadvantages of simple process flow, easy realization of high-level automation, relatively small occupied area, capability of realizing that the recovery rate of valuable metals in solid hazardous wastes containing heavy metal sludge, smoke dust, residues, waste catalysts and the like reaches more than 98 percent, which achieves the comprehensive utilization of resources and energy and the purposesof energy conservation and environmental protection.

Owner:CHINA ENFI ENGINEERING CORPORATION

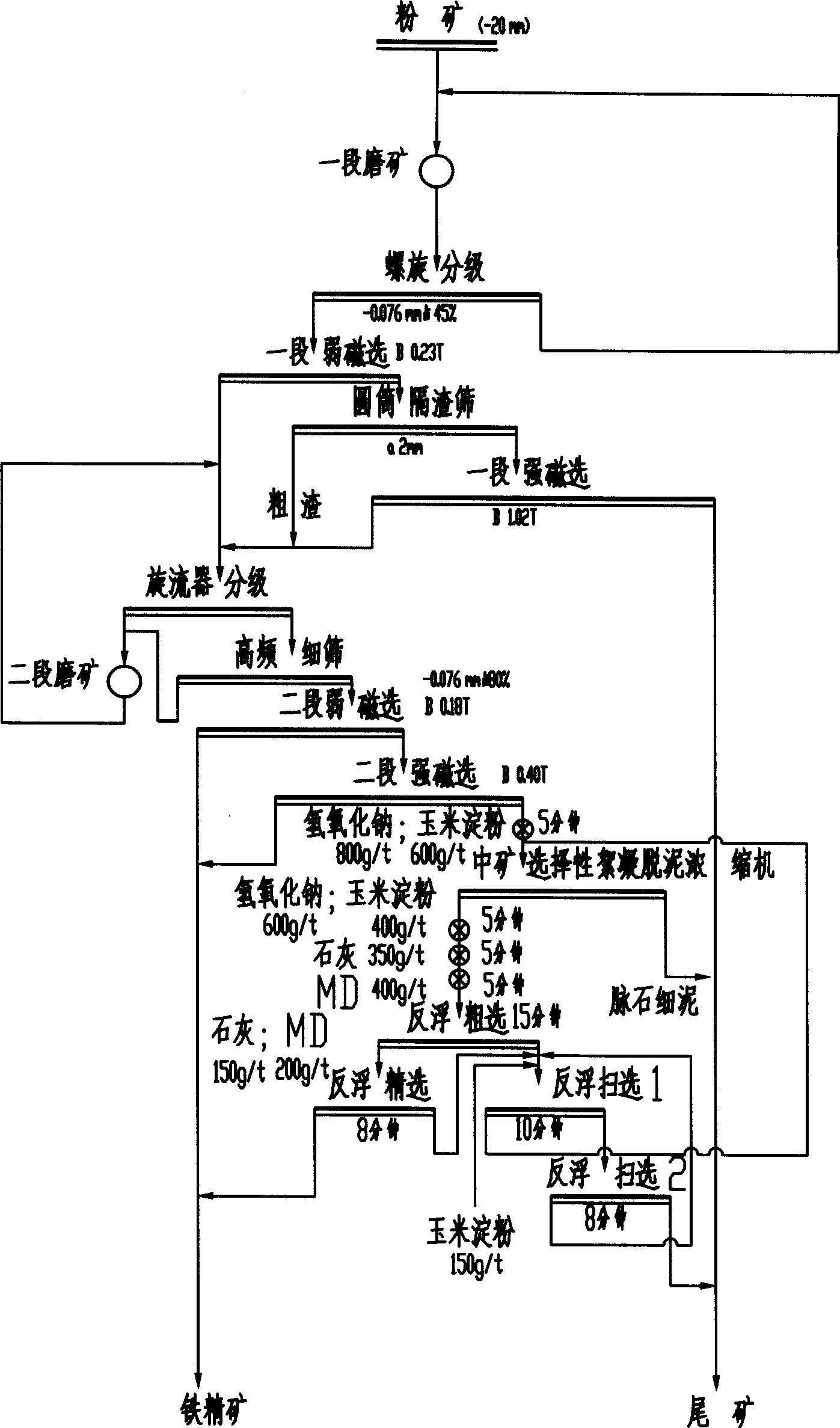

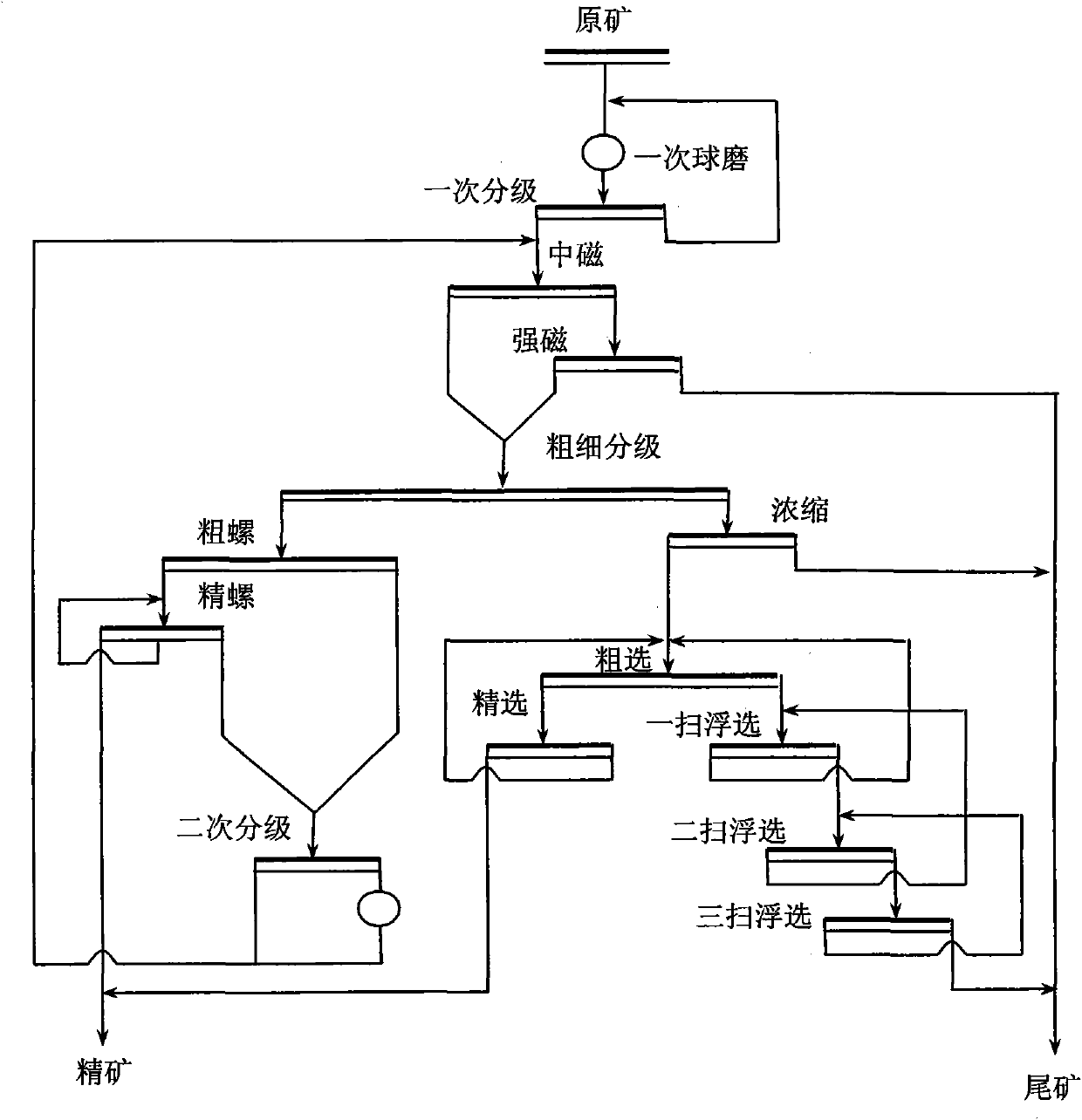

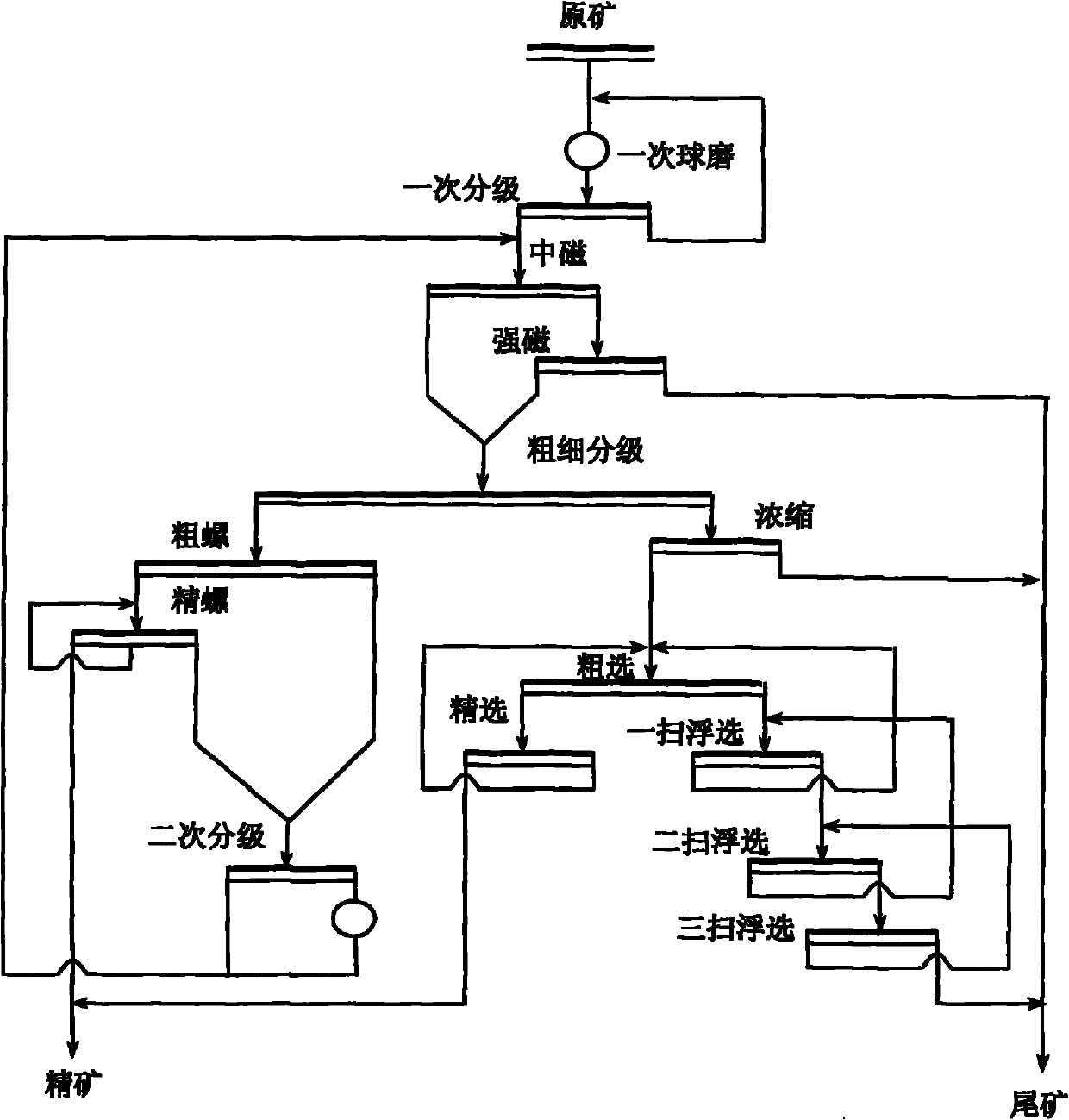

Lean hematite stage grinding and high intensity magnetism, gravity separation, negative ion reverse flotation technique

ActiveCN102019227AReduce loadReduce the cost of beneficiationFlotationMagnetic separationEngineeringHigh intensity

The present invention relates to a lean hematite stage grinding and high intensity magnetism, gravity separation, negative ion reverse flotation technique which includes the following steps of: feeding lean hematite for a first grinding after which a first classification is given; feeding effluence of the first classification under medium intensity magnetism and high intensity magnetism; feeding concentrates into a classification between coarse and fine grits and discarding ore tailings; after the coarse and fine grit classification, feeding the coarse grit products into a coarse snail and fine grit products to concentration; feeding the fine grits from the coarse snail into a fine snail, the fine grits of which are gravity separating fine grits; feeding tailings from the coarse and fine snails into a second classification, the effluence of which goes back to medium intensity magnetism; feeding concentrated underflows into a coarse flotation and discarding the effluents; feeding the fine grits from the coarse flotation into a fine flotation and the tailings into a first sweeping flotation; fine grits from the fine flotation being the fine grits of the flotation and returning the tailings back to the coarse flotation; returning the fine grits from the first sweeping flotation back to the coarse flotation and feeding the tailings into a second sweeping flotation; returning the fine grits from the second sweeping flotation back to the first sweeping flotation and feeding the tailings into a third sweeping flotation; returning the fine grits from the third sweeping flotation back to the second sweeping flotation and discarding the tailings. The technique reduces the work load of the preparation equipment and the cost of mineral separations.

Owner:ANSTEEL GRP MINING CO LTD

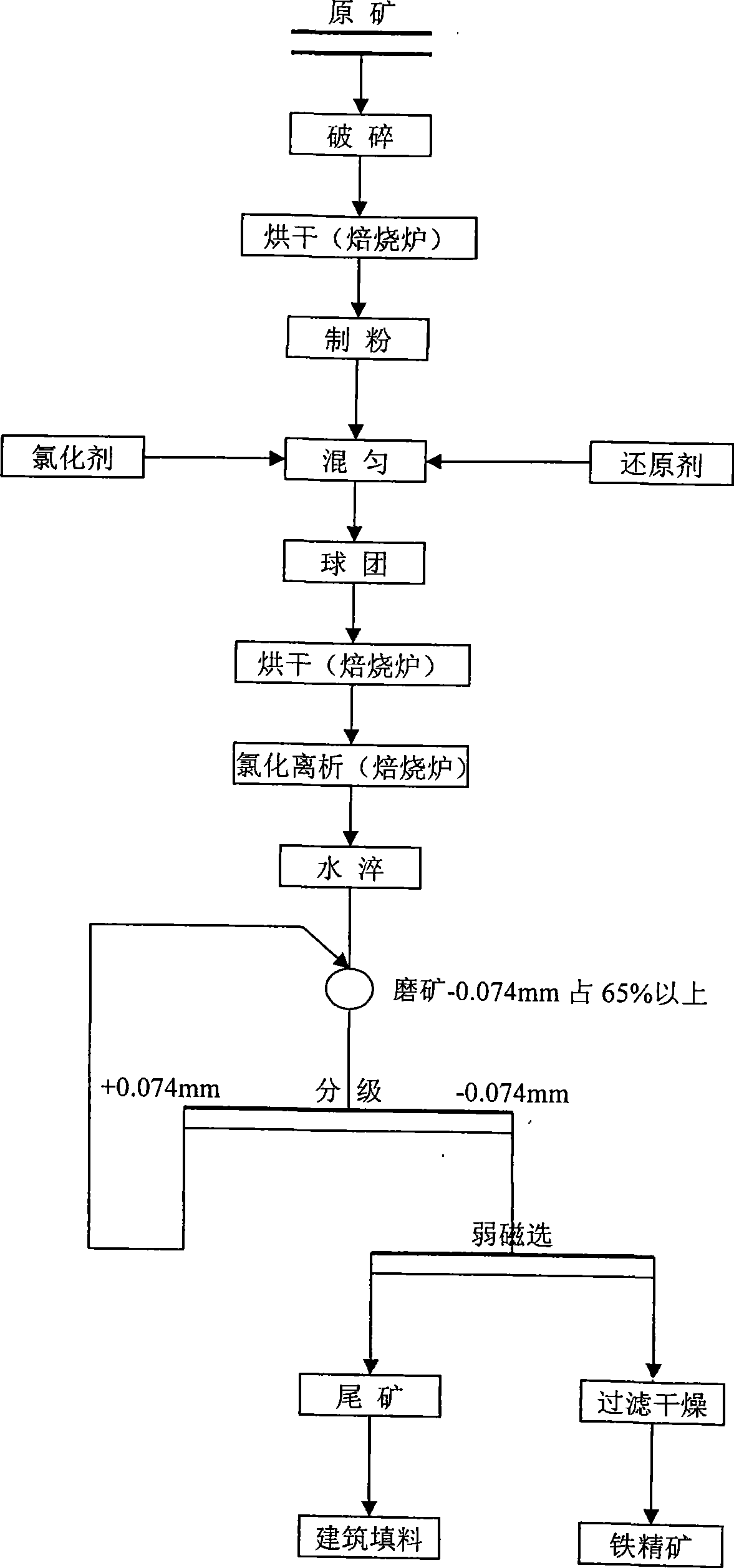

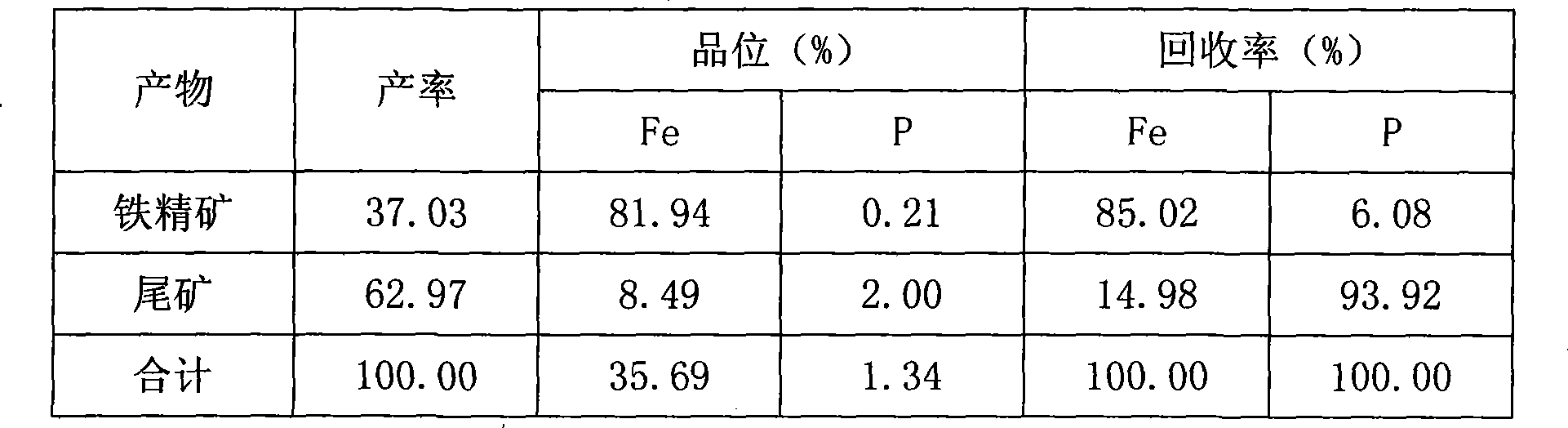

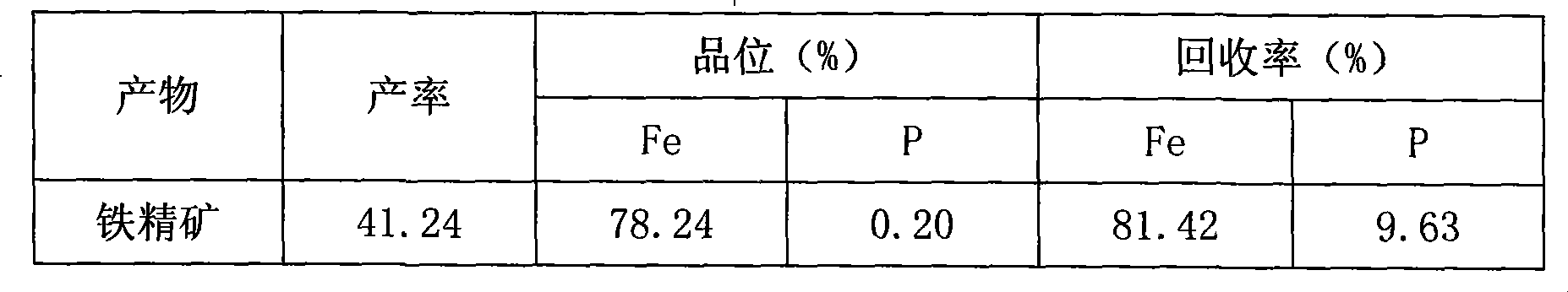

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288AReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

The invention relates to a chloridizing segregation-low-intensity magnetic separation method for reducing phosphorus of a high phosphorus iron ore. A chloridizing segregation-low intensity magnetic separation process is adopted to realize iron increase and phosphorous reduction in the method. A chlorinating agent and a reducing agent coke are added to the high phosphorus iron ore and mixed evenly, then chloridizing segregation roasting is carried out in a roasting furnace; the roasted product is water quenched and ball milled, and then separated by a low-intensity magnetic field magnetic separator, thus being capable of obtaining an iron ore concentrate with the iron grade more than 80%, the iron recovery rate more than 85% and the phosphorous content less than 0.20%. The iron ore concentrate powder can be taken as a raw material for smelting pig iron after being pelletized. Additionally, with regard to high phosphorus iron ores which contain sulfur or contain sulfur and arsenic at the same time, such as hematite, hematite-limonite ore, oolitic hematite-limonite ore, hematite, siderite and the like, the product iron ore concentrate with the sulfur content less than 0.20% and the arsenic content less than 0.04% can also be obtained.

Owner:昆明晶石矿冶有限公司

Oxidation resistant ferritic stainless steels

InactiveUS20050045250A1Reduce surface roughnessImprove antioxidant capacityElectrolysis componentsFuel cells groupingMischmetalRare earth

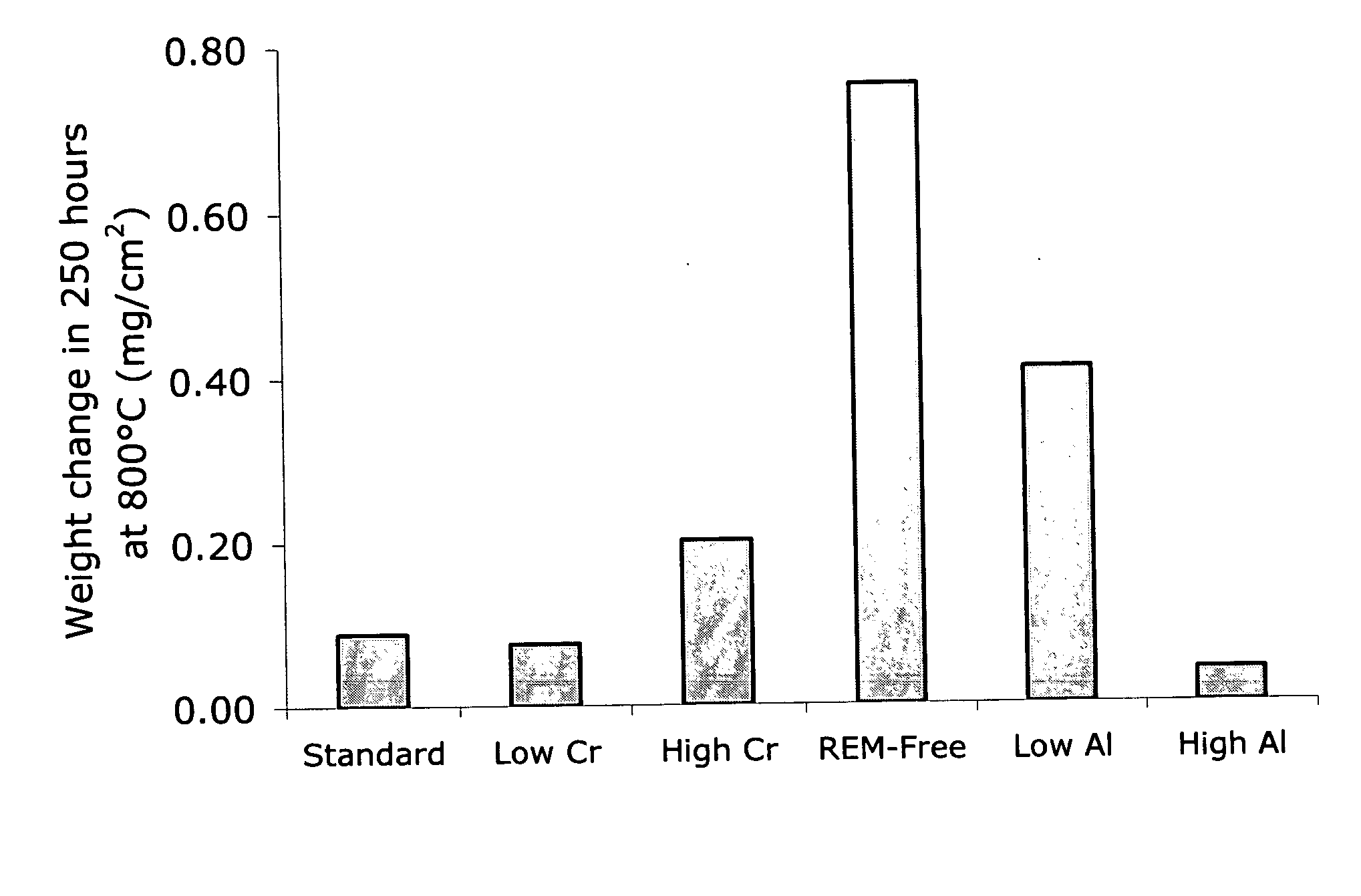

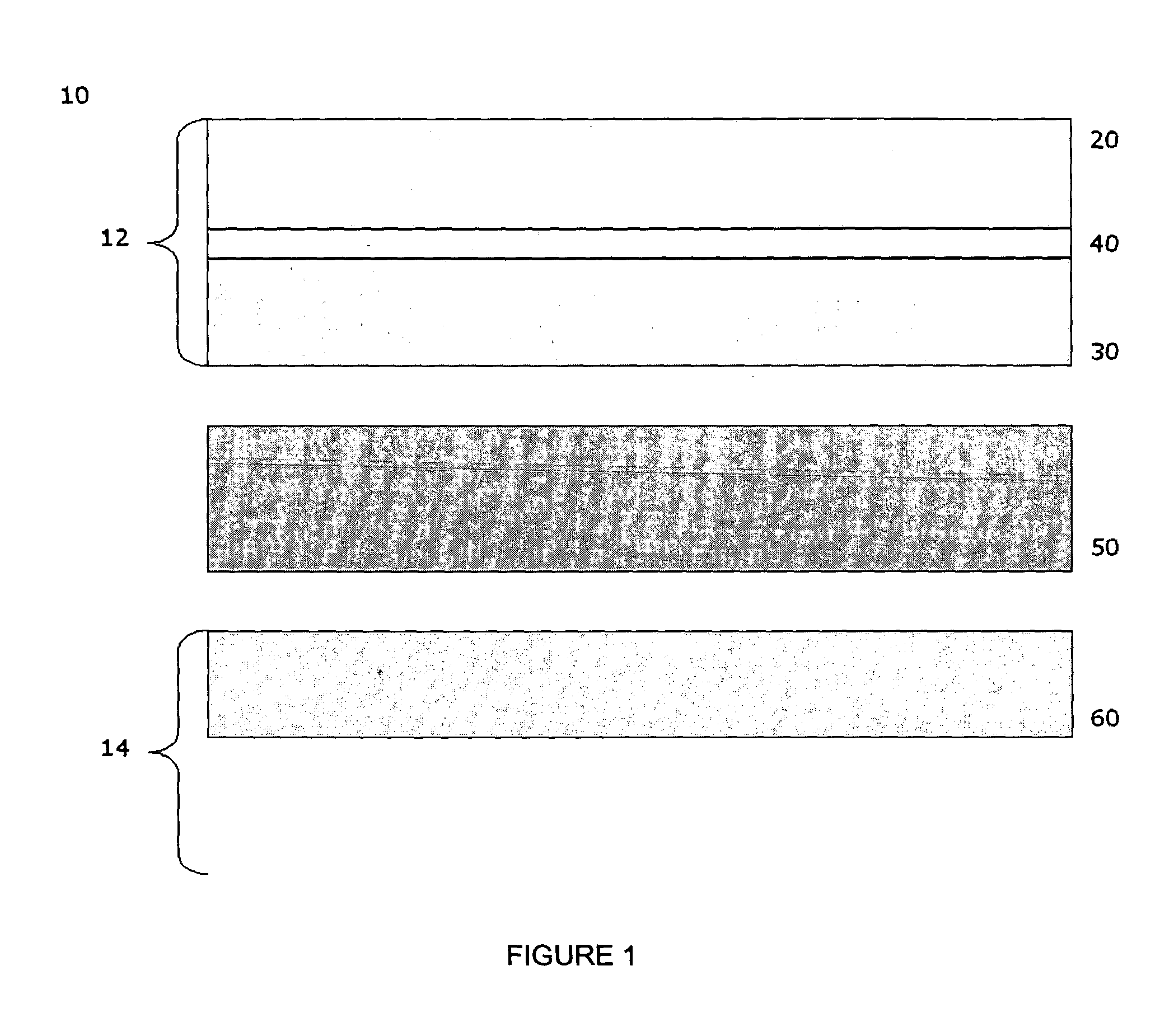

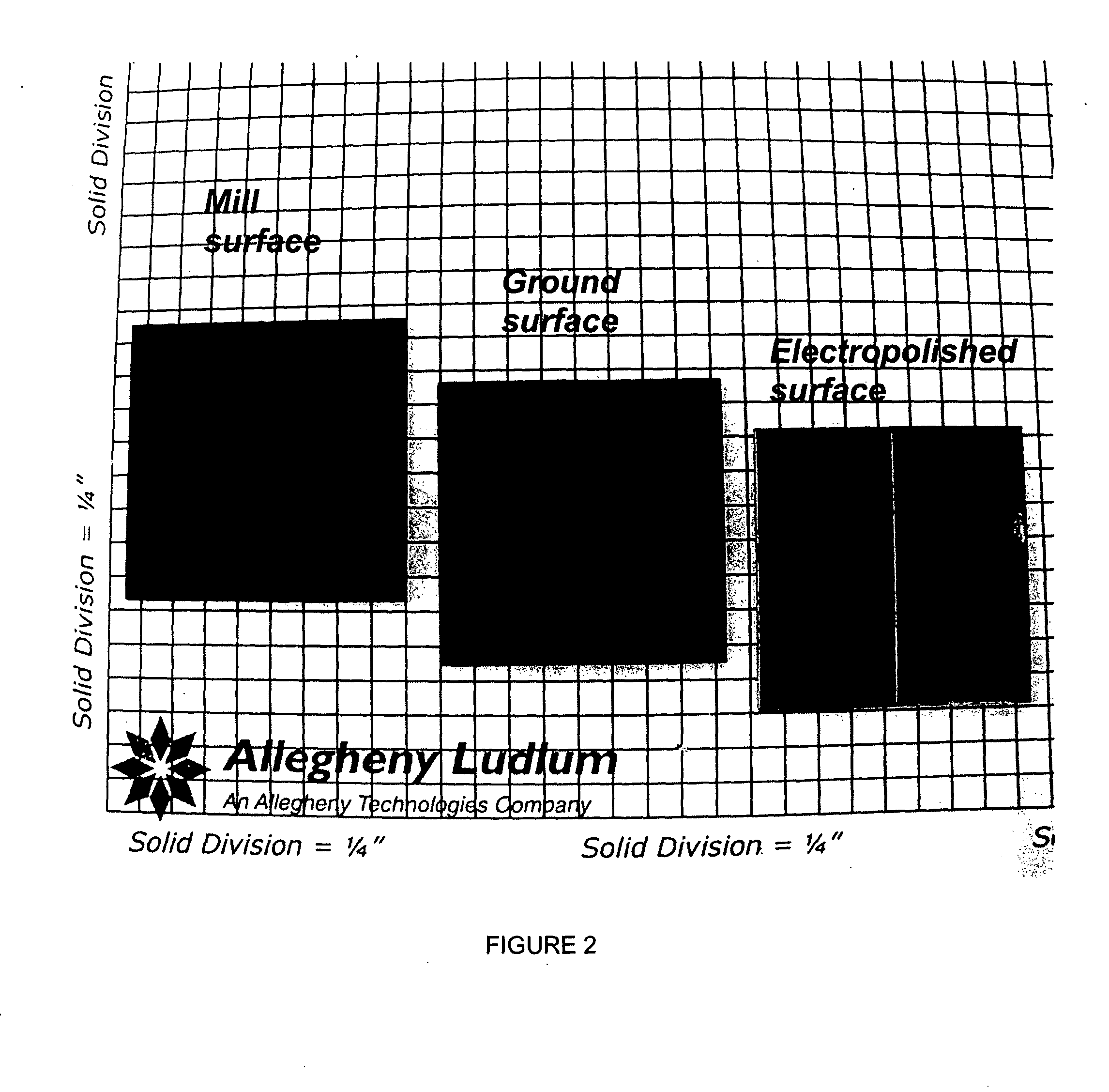

A method for making a ferritic stainless steel article having an oxidation resistant surface includes providing a ferritic stainless steel comprising aluminum, at least one rare earth metal and 16 to less than 30 weight percent chromium, wherein the total weight of rare earth metals is greater than 0.02 weight percent. At least one surface of the ferritic stainless steel is modified so that, when subjected to an oxidizing atmosphere at high temperature, the modified surface develops an electrically conductive, aluminum-rich, oxidation resistant oxide scale comprising chromium and iron and a having a hematite structure differing from Fe2O3, alpha Cr2O3 and alpha Al2O3. The modified surface may be provided, for example, by electrochemically modifying the surface, such as by electropolishing the surface.

Owner:ATI PROPERTIES

Treatment method of oolitic hematite containing phosphorus

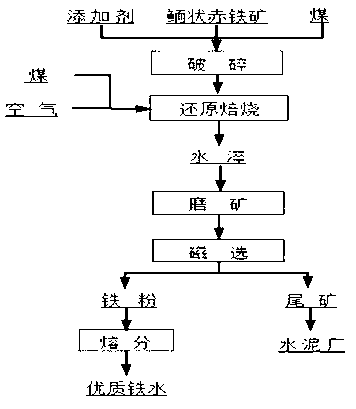

The invention discloses a treatment method of oolitic hematite containing phosphorus and is characterized in that the treatment method sequentially comprising the steps of: (1) evenly mixing raw ore of oolitic hematite, an annexing agent and coal in proportion and then crushing; (2) conducting metallization reducing roasting on crushed ore in the step (1); (3) slowly cooling high temperature roasted products to 400-750 DEG C, then quickly cooling through water quenching, and conducting water quenching roasted product ball milling; (4) conducting magnetic selection after the ball milling to obtain iron powder and tailings; and (5) melting the iron powder obtained in the step (4) to obtain high-quality molten iron with phosphorus less than 0.01%. The raw ore in the treatment method does no need fine grinding, and thickness of the raw ore can be directly crushed to be -5mm, and the raw ore does no need pelletizing, only needs even mixing with the annexing agent and the coal, greatly saves ore grinding and pelletizing cost, special-grade high-quality molten iron with the phosphorus less than 0.01% is produced by melting, the molten iron can serve as a raw material for producing high-quality steel, and a product production value is high.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

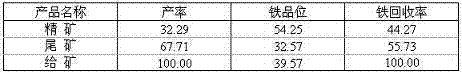

Process for processing low grade hematite ore

ActiveCN101773869ASimplify the flotation processSimple processWet separationSmall footprintFerromagnetism

The invention belongs to the technical field of preparing low grade hematite ore, in particular to a process for processing a low grade hematite ore. The process comprises the following steps: the ore is ground until monomer separation and then coarse and fine classification is carried out on pulp; coarse grain pulp is subject to reselecting, ferromagnetism and sieving to obtain a part of the concentrate; the fine grain pulp is conveyed to a mixing tank for separating sample, and then is conveyed to a second mixing tank to be mixed with medicine for size mixing; the mixture is pumped to a rough flotation column; the under flows of the rough flotation column is fed to a cleaning flotation column, the under flow of the cleaning flotation column is the ultimate iron ore concentrate; foam of the rough flotation column is conveyed to an one-stage scavenging flotation column by a pump; the under flow of the one-stage scavenging flotation column and the foam of the cleaning flotation column are mixed and return to the rough flotation column, and products of the one-stage scavenging flotation column are final tailings. The process has the beneficial effects of smaller occupation area by replacing a flotation machine with the flotation column, can recycle fine-grade valuable mineral effectively, improve the ultimate concentrate grade, provides reference significance for the mineral separation of the ore of the same type in China, and has obvious economic benefits and social benefits.

Owner:ANSTEEL GRP MINING CO LTD

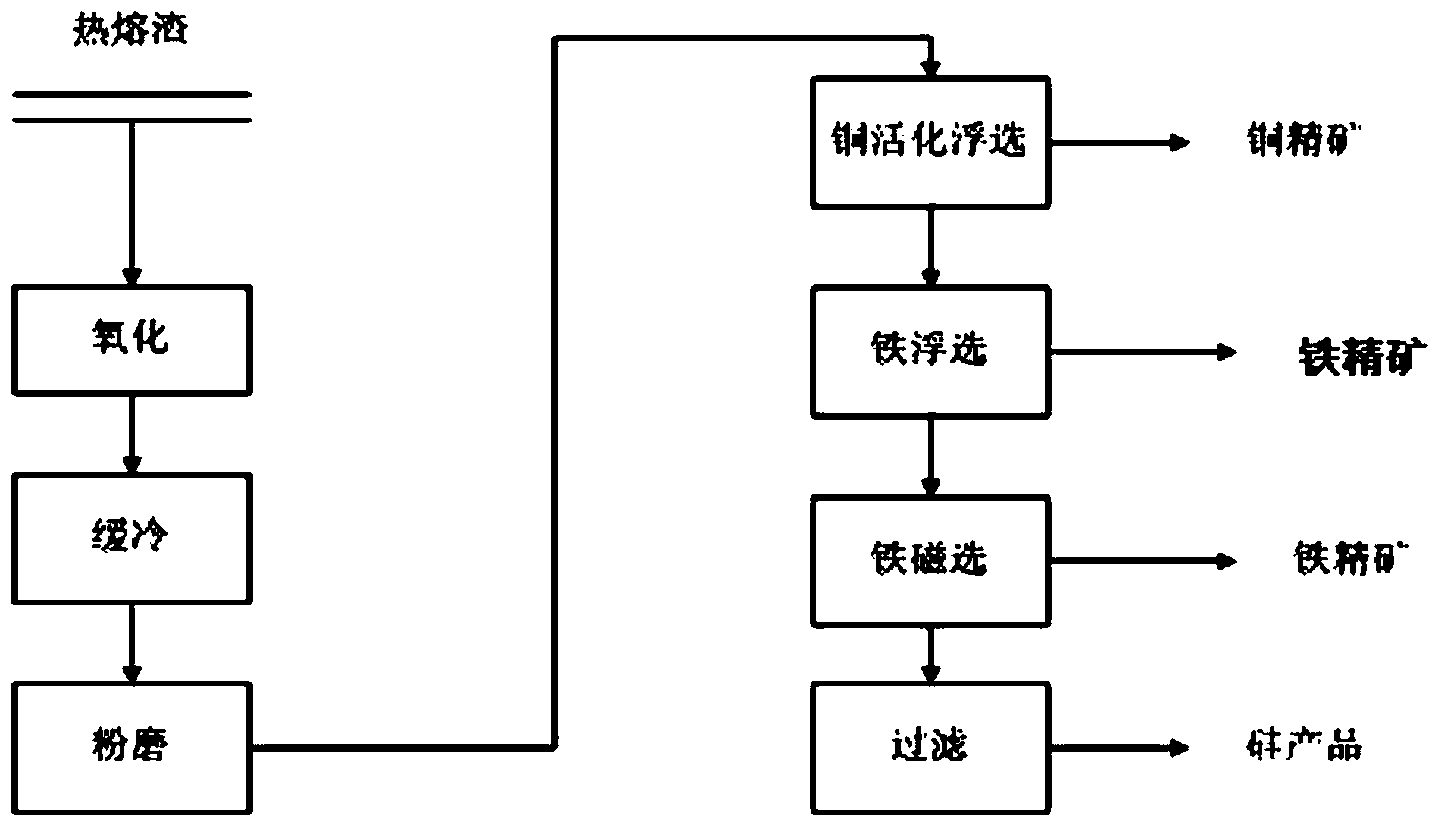

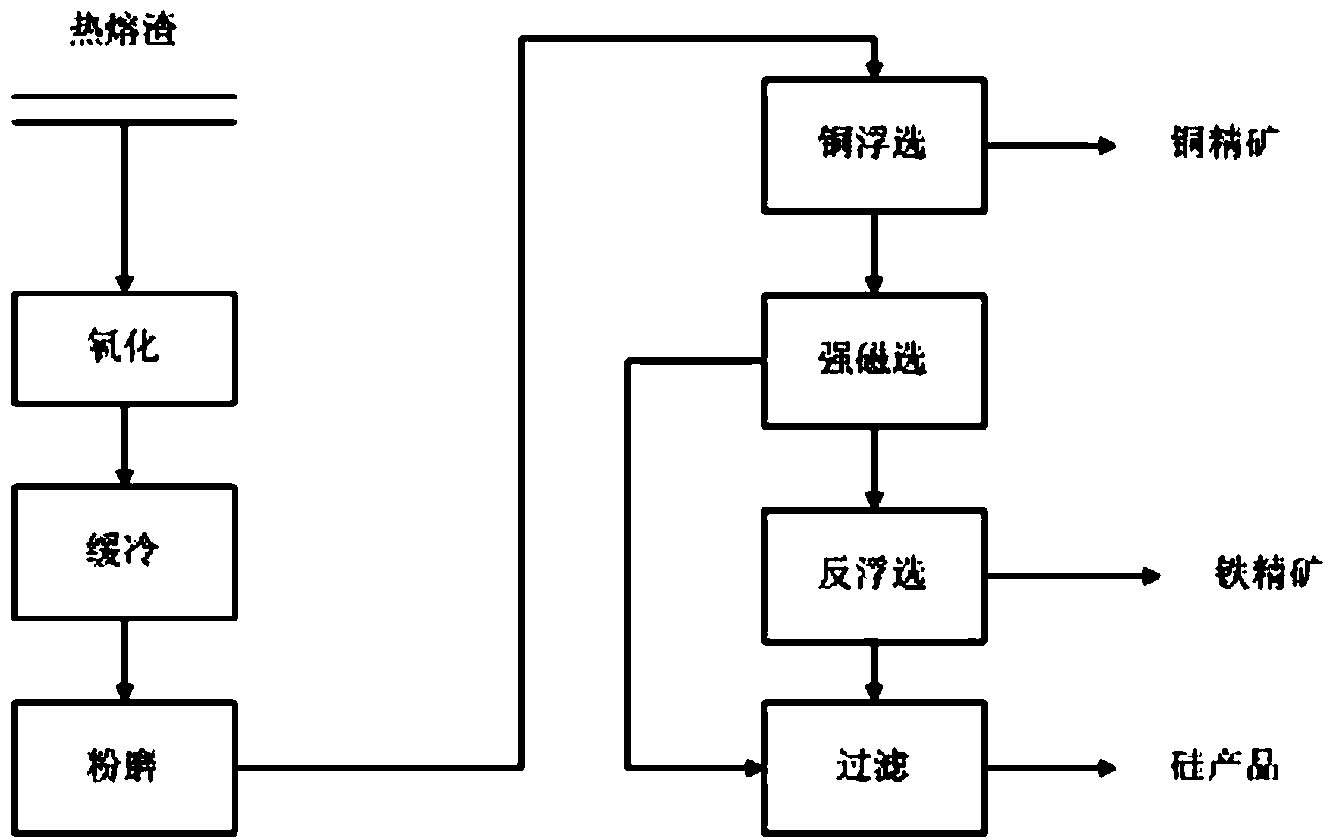

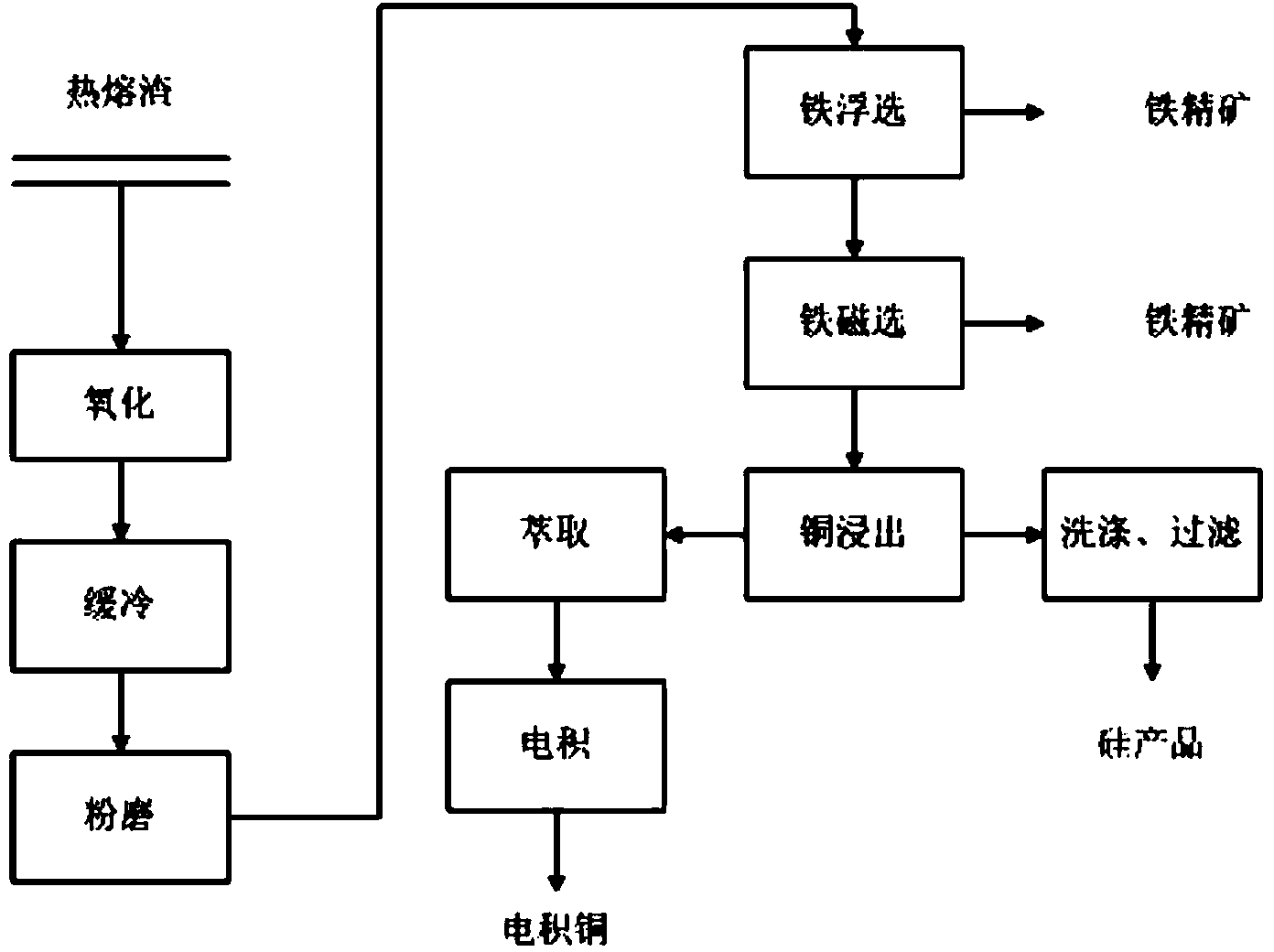

Method for recovering copper, iron and silicon from copper smelting slag

InactiveCN104342561APromote growthMeet the needs of resource processingProcess efficiency improvementSlagCopper oxide

The invention provides a method for recovering copper, iron and silicon from copper smelting slag. The method comprises the following steps: (a) adopting oxygen to oxidize hot copper smelting slag to obtain mixed slag charge, wherein the temperature of the hot copper smelting slag is 1000-1350DEG C, and the mixed slag charge comprises hematite, copper oxide ore and quartz mine, and carrying out slow cooling processing on the mixed slag charge; (b) recovering the hematite from the mixed slag charge subjected to the slow cooling processing in the step (a) through flotation and magnetic separation, receiving a copper-contained product through activation flotation or leaching, and finally filtering tailings subjected to hematite recovery and the copper-contained product to obtain a silicon-contained product. The method provided by the invention has the advantages of short flow, simple technology, easiness in realization and control, wide use range, high practicality and the like and basically meets copper smelting slag resourceful processing requirements of the copper smelting industry. In addition, the method for recovering the copper, the iron and the silicon from the copper smelting slag, which is provided by the invention, does not generate secondary wastes, is free from pollution and has little energy input.

Owner:YANGGU XIANGGUANG COPPER

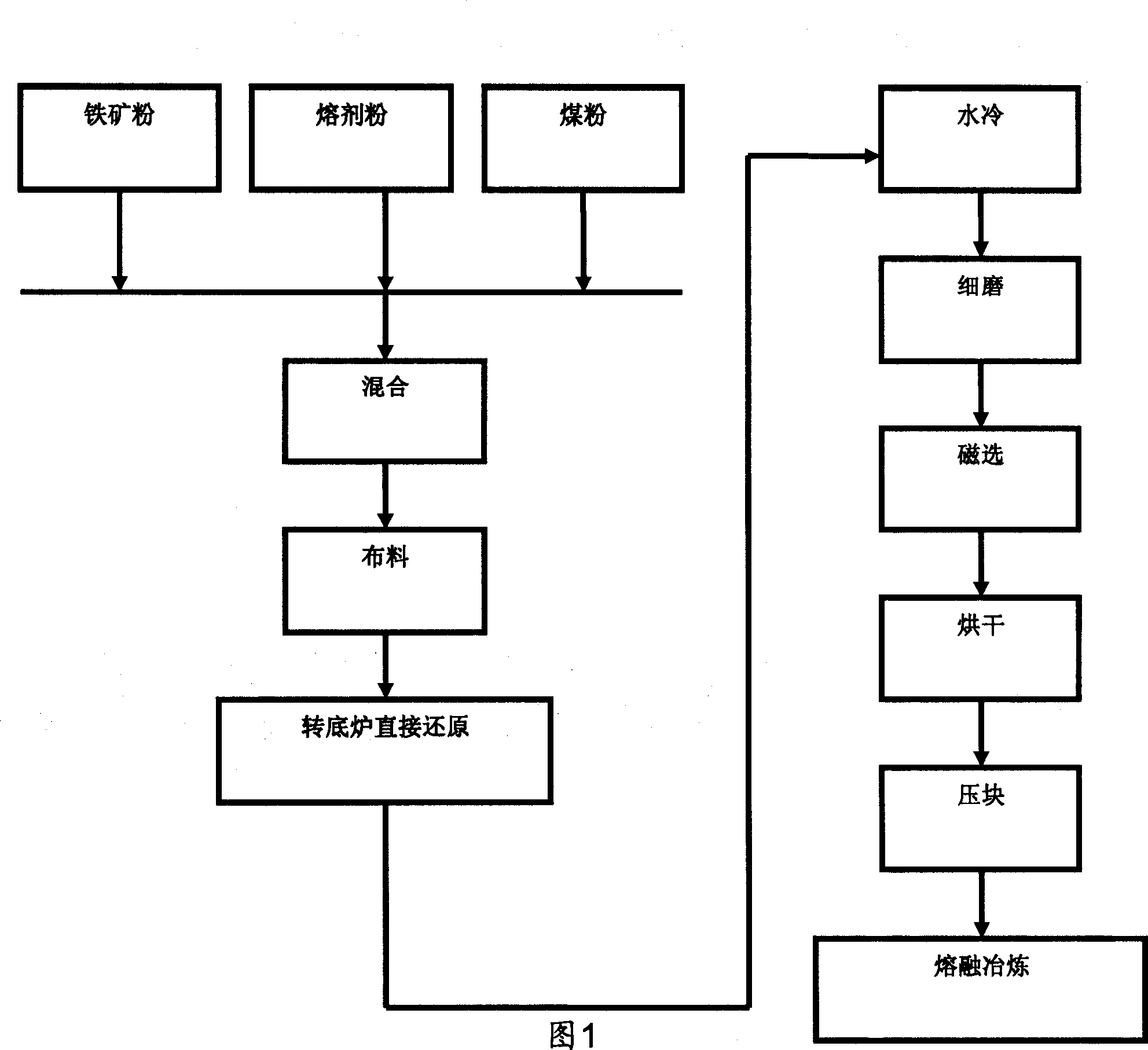

Ore coal, melting ironmaking method after direct reduction-flotation-agglomeration

The invention discloses a method for carrying out direct reduction, sorting, agglomeration, smelting and ironmaking on ore and coal. Firstly, certain amount of the ore, the coal and a solvent are mixed, are placed in a rotary hearth furnace and are heated to the temperature of between 1,100 and 1,350 DEG C, are kept at the temperature for 15 to 40 minutes and are directly reduced to obtain a reduced iron material with metallizing rate of between 80 and 92 percent; the reduced iron material at high temperature of between 800 and 1,100 DEG C is directly transported into water, is cooled and is subjected to fine grinding and sorting; and the iron material after the fine grinding and sorting is subjected to drying and agglomeration by high-temperature oxygen-lost exhaust gas and finally is transported into a submerged arc furnace or other smelting equipment for carrying out slag-iron separation and molten iron production. The method has a simple process, short flow and high efficiency, needs no coke and is suitable for low-grade ore and non-blast furnace ore which is difficult to be used by the prior blast furnaces, such as oolitic hematite, ultrafine particle hematite, limonite, siderite and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

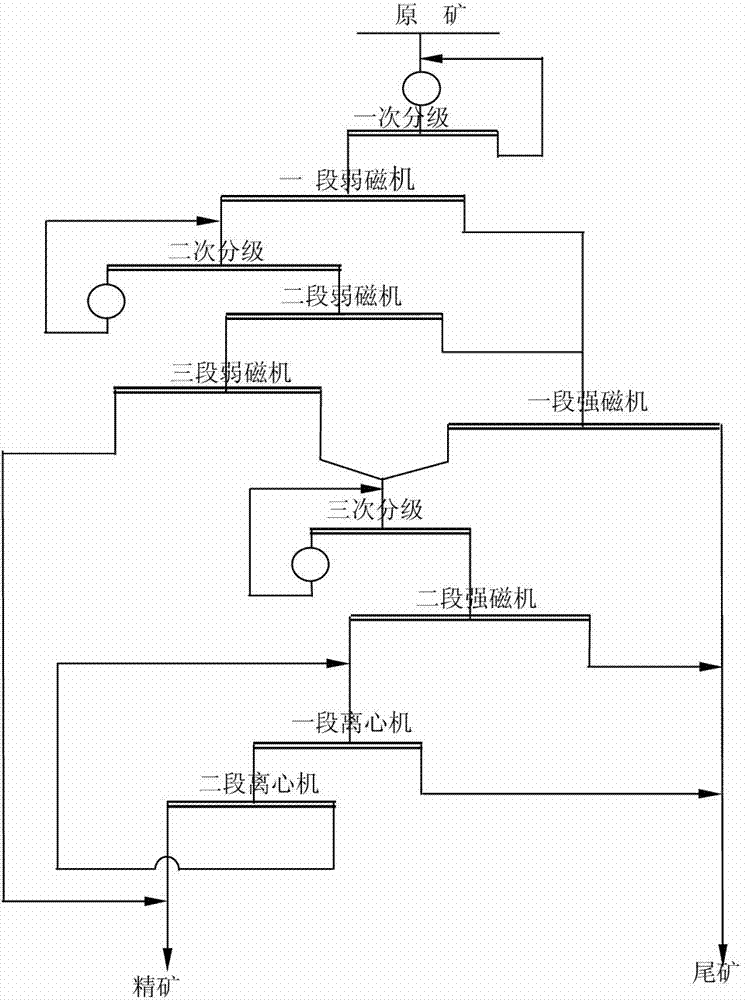

Technique for processing high-iron-carbonate mixed ore

The invention relates to a technique for processing high-iron-carbonate mixed ore. The technique for processing the high-iron-carbonate mixed ore is characterized in that the stage grinding technique and the weak magnetic-strong magnetic-centrifugal machine technique are adopted, and separate grinding and separate screening are carried out on the high-iron-carbonate mixed ore. The technique for processing the high-iron-carbonate mixed ore has the advantages that the weak magnetic technique, the strong magnetic technique and the centrifugal machine technique are allocated flexibly and reasonably according to specific screening indexes of work to recover iron carbonate and hematite in raw ore, environmental pollution is light, the technological process is simple, and qualified iron ore concentrate which has the iron grade of more than 65% after sintering and is capable of meeting smelting requirements can be obtained.

Owner:ANSTEEL GRP MINING CO LTD

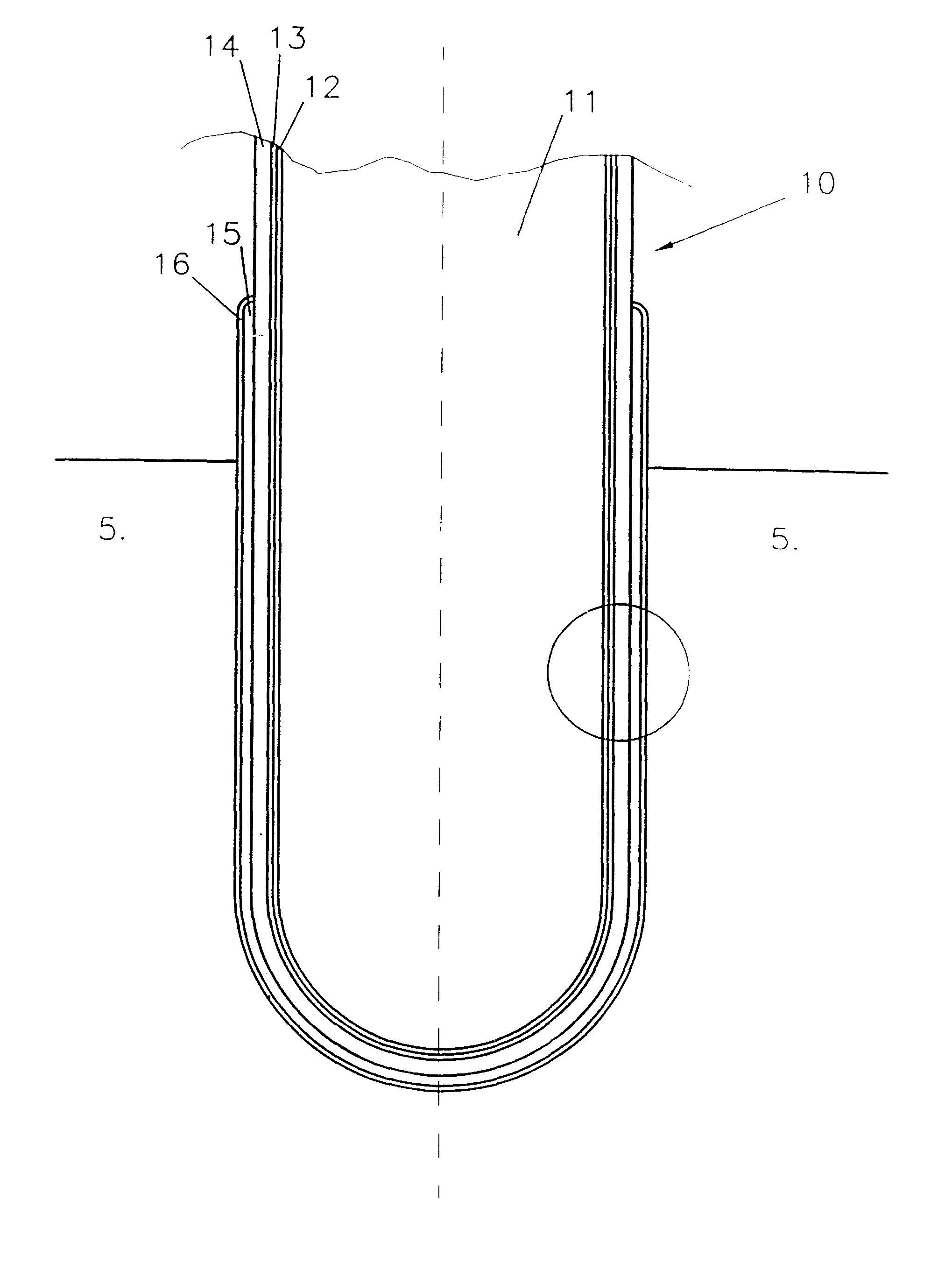

Cells for the electrowinning of aluminium having dimensionally stable metal-based anodes

InactiveUS6372099B1Eliminate pollutionProlong lifeMachining electrodesElectrical-based machining electrodesSolubilityElectrochemistry

A cell for the electrowinning of aluminium comprising one or more anodes, each having a metal-based anode substrate, comprising a metal core covered with an metal layer, an oxygen barrier layer, one or more intermediate layers and an iron layer. The anode substrate is covered with an electrochemically active iron oxide-based outside layer, particularly a hematite-based layer, which remains dimensionally stable during operation in a cell by maintaining in the electrolyte a sufficient concentration of iron species. The cell operating temperature is sufficiently low so the required concentration of iron species in the electrolyte is limited by the reduced solubility of iron species in the electrolyte at the operating temperature, limiting the contamination of the product aluminium by iron to an acceptable level. The iron oxide-based layer is an applied coating or an oxidised surface of a substrate, the surface of which contains iron.

Owner:MOLTECH INVENT

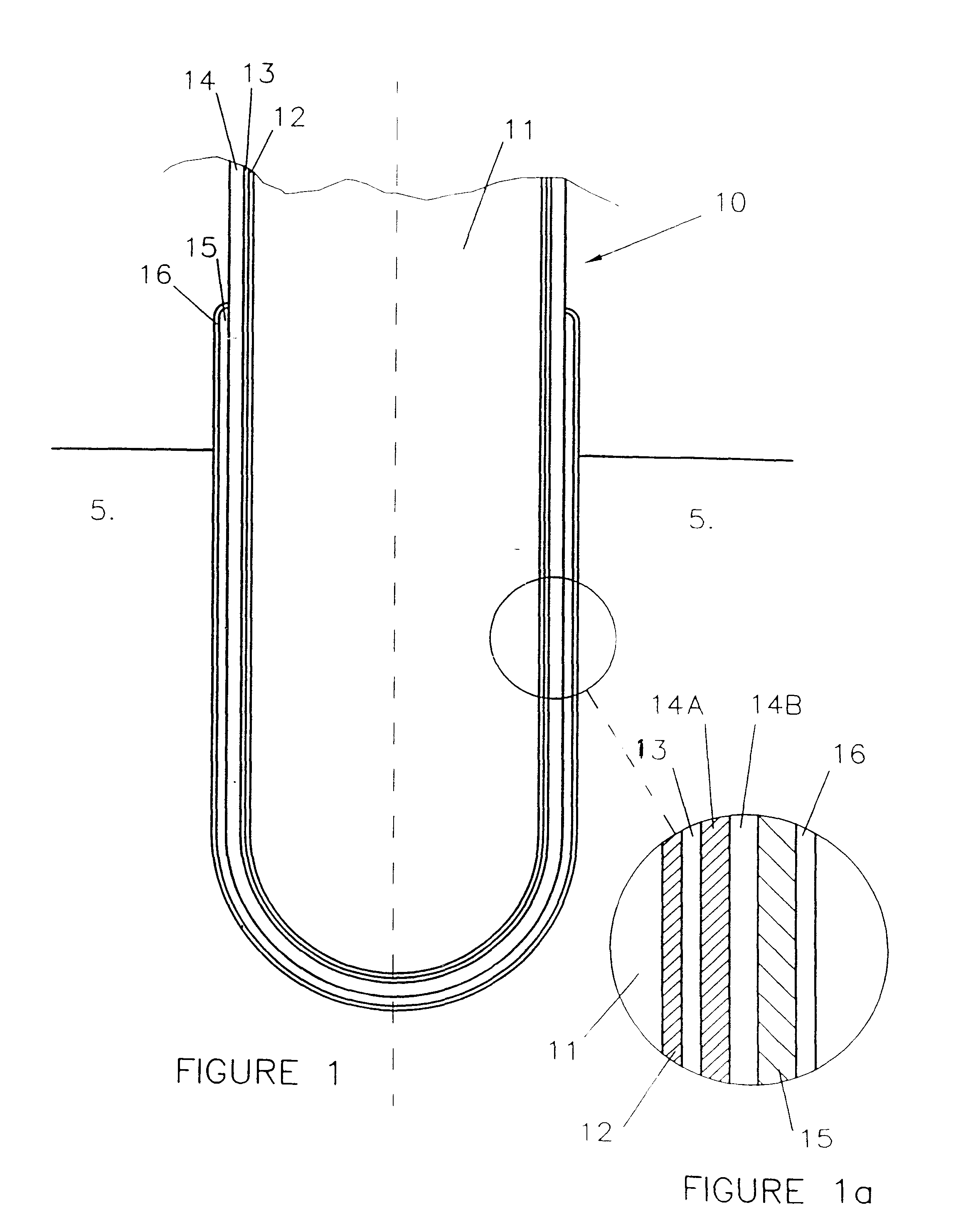

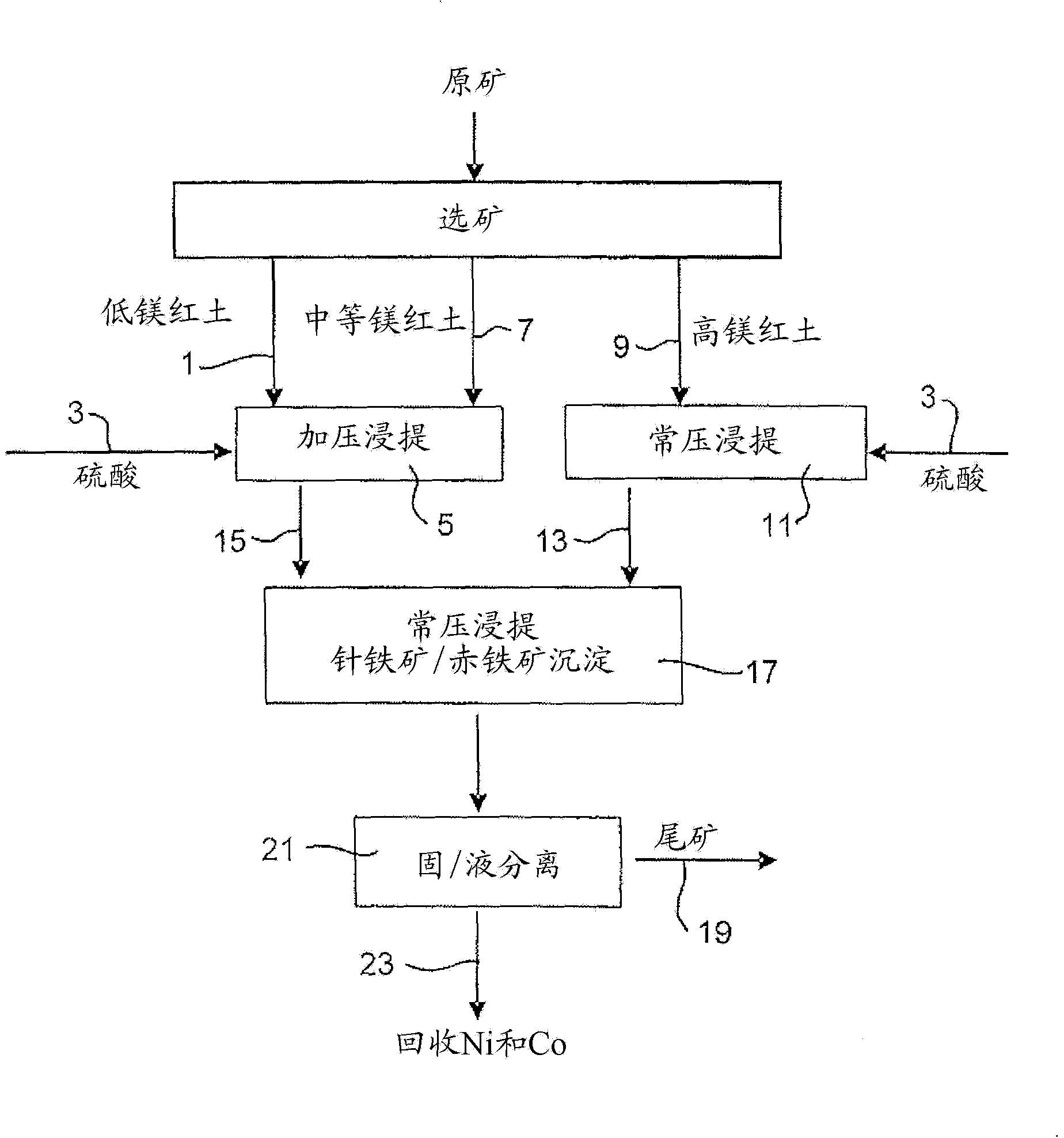

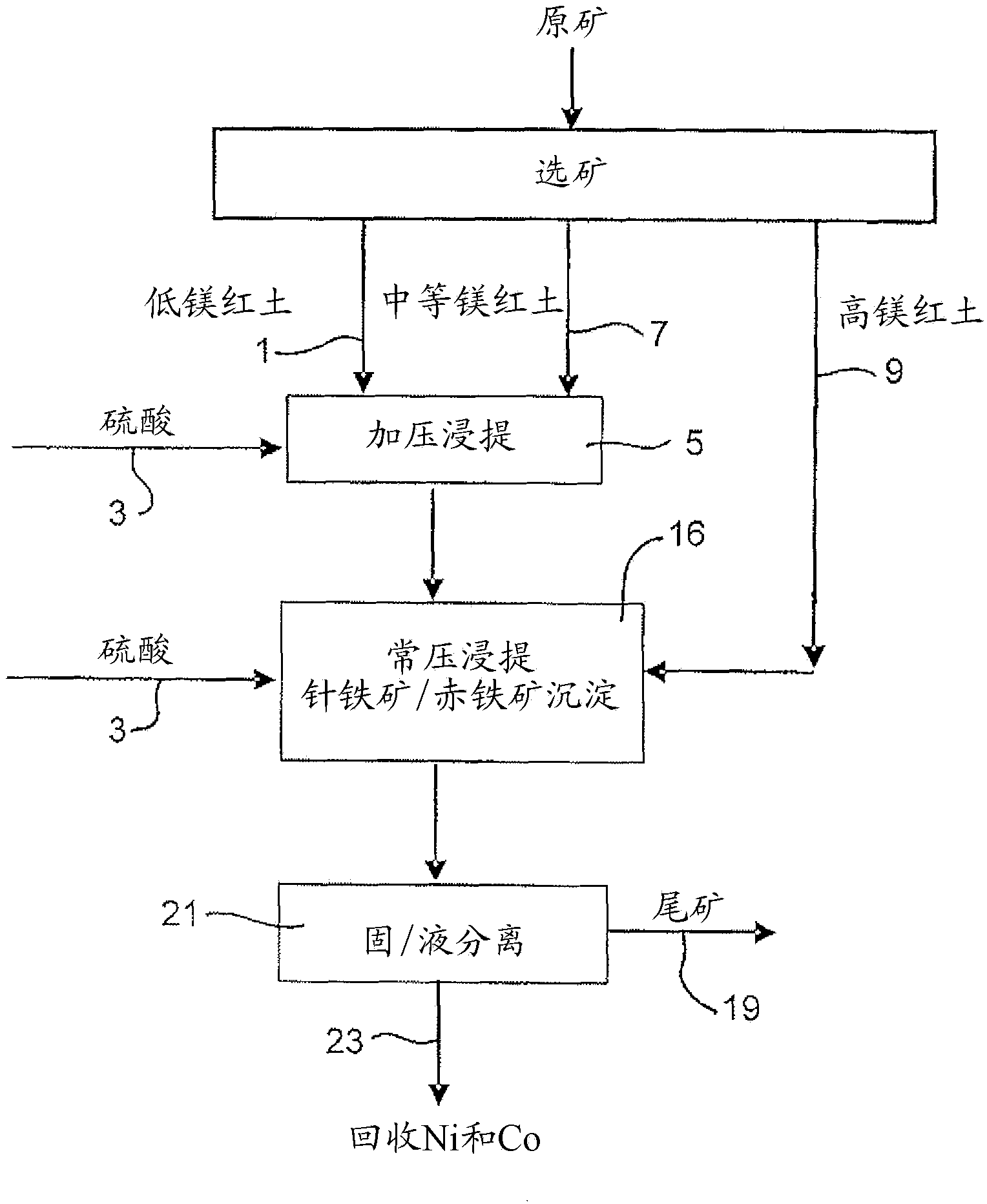

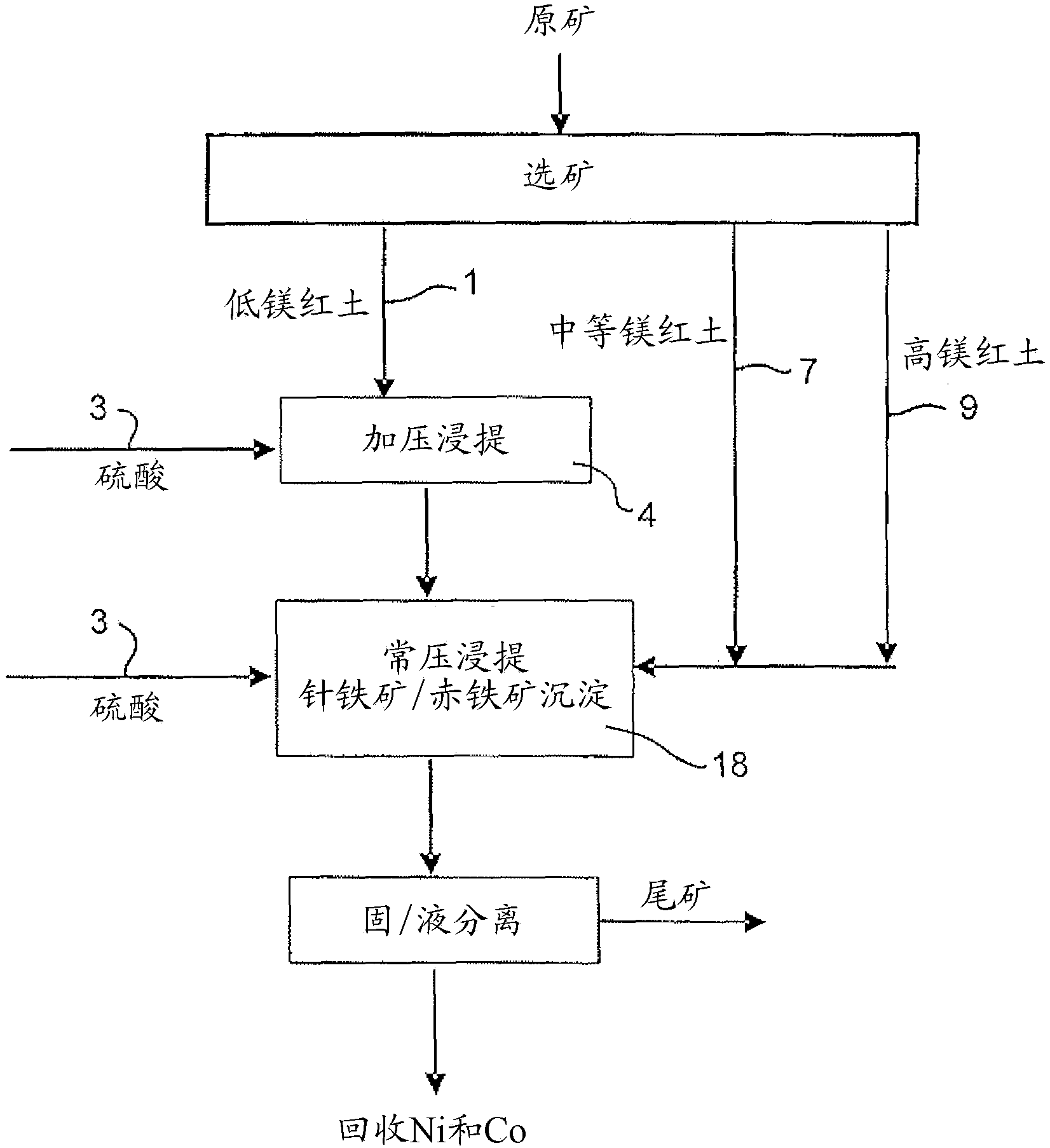

Process for enhanced acid leaching of laterite ores

A process is described for the recovery of nickel and cobalt from a nickeliferous laterite ore including the steps of: a) providing a nickeliferous laterite ore and separating that ore into its low magnesium limonite fraction and high magnesium saprolite fraction; b) treating the limonite fraction in acid solution in a primary high pressure leach step to produce a primary leach slurry; c) adding the saprolite fraction to the primary leach slurry to initiate precipitation of iron as goethite and / or hematite, while simultaneously releasing further acid from the iron precipitation, to effect a secondary atmospheric leach step, producing a secondary leach slurry; wherein all water used to prepare the ore slurries and / or acid solutions has an ionic composition that substantially avoids jarosite formation.

Owner:BHP BILLITON SSM TECH PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com