Method for recovering copper, iron and silicon from copper smelting slag

A technology for copper smelting slag and copper recovery, applied in the field of copper smelting, can solve problems such as difficult control, poor practicability, and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

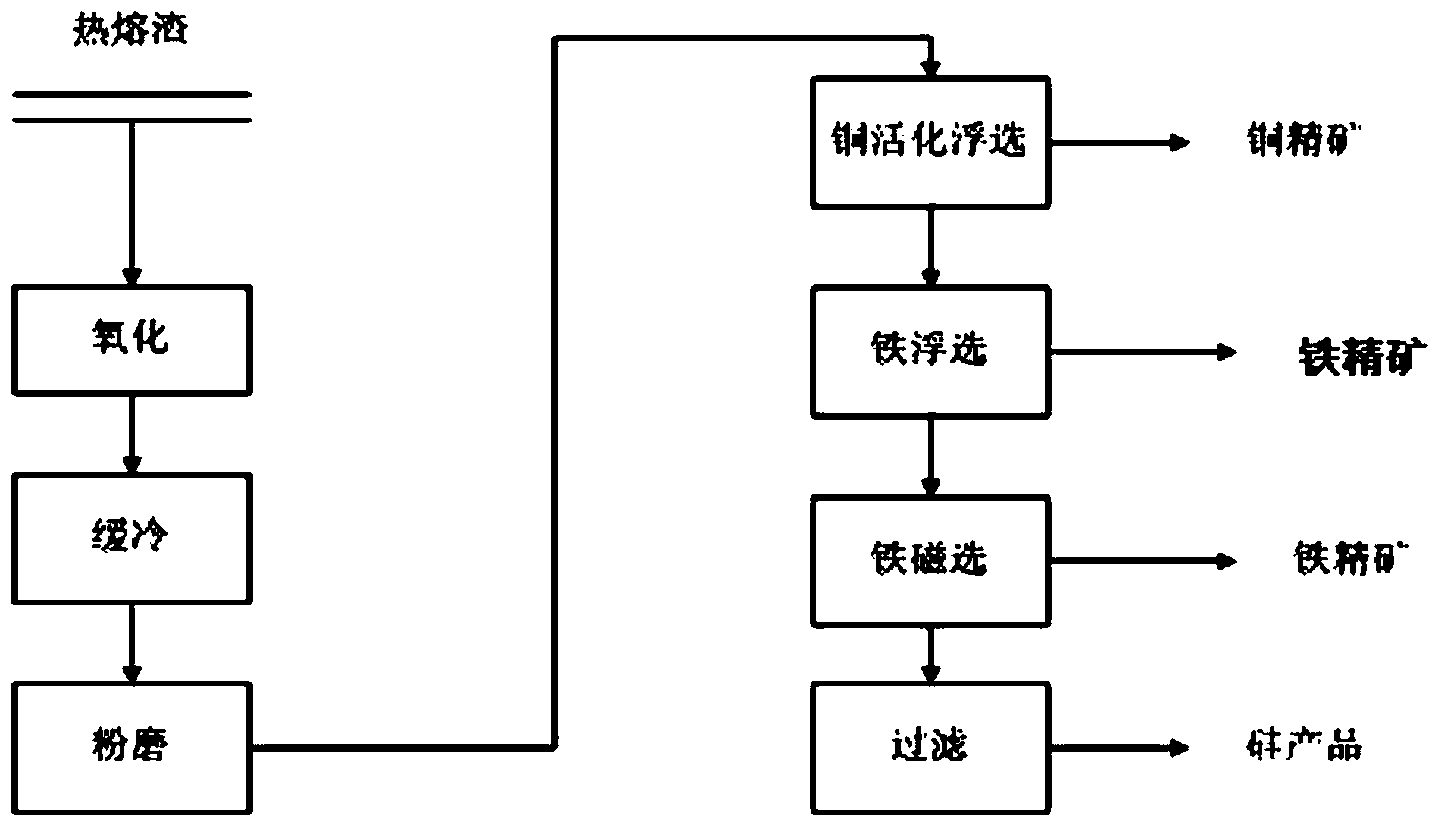

[0064] use figure 1 The process flow shown is the floating magnetic combined process, which is used to recover copper, iron and silicon in hot copper smelting slag. figure 1 It is a process flow diagram for recovering copper, iron and silicon in Example 1 of the present invention.

[0065] The hot-melt slag discharged from the flash smelting furnace is treated as the treatment object, the copper grade of which is 1.0% to 1.6%, and the temperature is within the range of 1000°C to 1350°C. When discharging slag, put hot molten slag into a special slag bag, and oxidize it by passing industrial pure oxygen into the slag in the slag bag. Control the flow rate of oxygen to 18m 3 / min, the oxidation time is 15min, and the mixed slag containing hematite, copper oxide ore and quartz ore is obtained.

[0066] Then, the above-mentioned slag bag is transported to the slag cooling field by a slag bag car, and it is naturally cooled for 24 hours, and then sprayed with water for 36 hours. ...

Embodiment 2

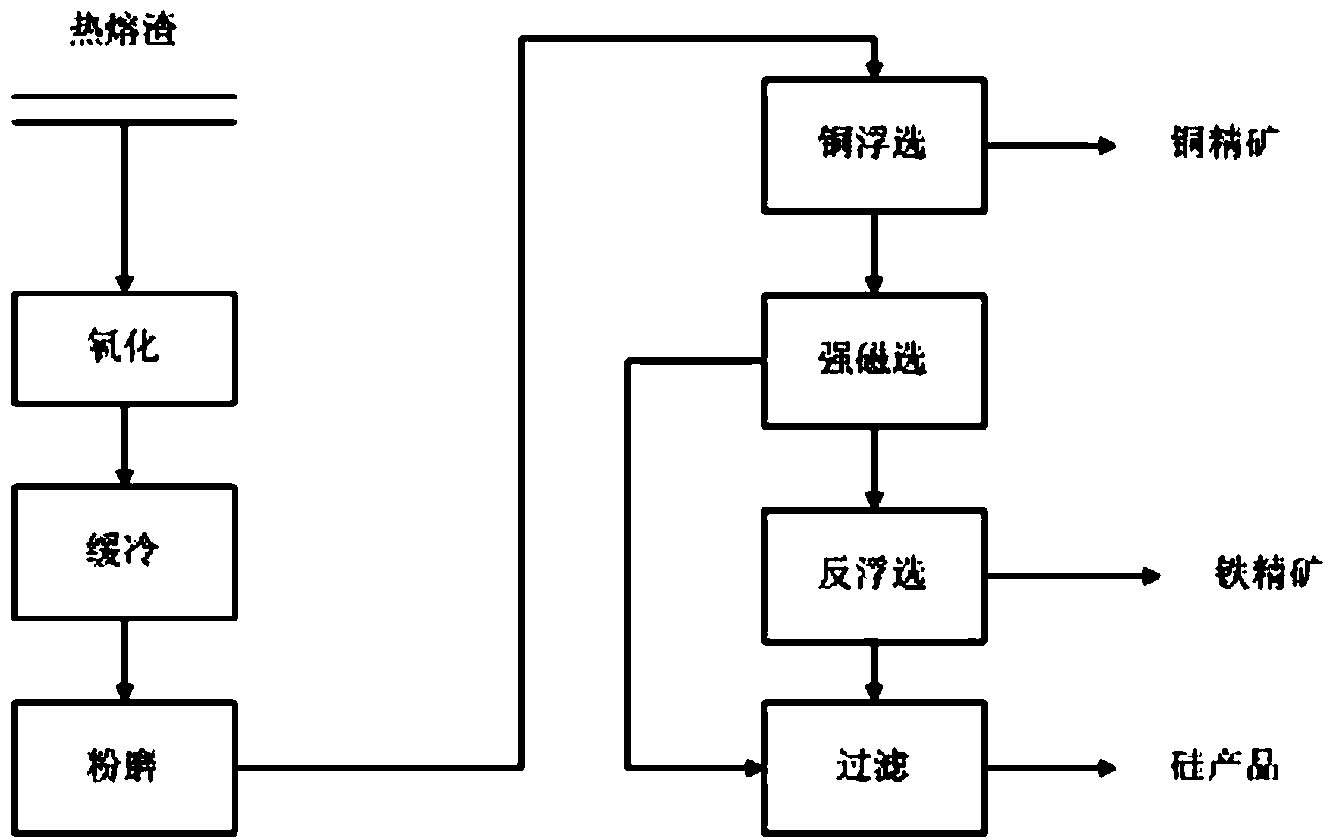

[0072] use figure 2 The process flow shown is the floating magnetic combined process, which is used to recover copper, iron and silicon in hot copper smelting slag. figure 2 It is a process flow chart of recovering copper, iron and silicon in Example 2 of the present invention.

[0073] The hot-melt slag discharged from the flash smelting furnace is treated as the treatment object, the copper grade of which is 1.0% to 1.6%, and the temperature is within the range of 1000°C to 1350°C. When discharging slag, put hot molten slag into a special slag bag, and oxidize it by passing industrial pure oxygen into the slag in the slag bag. Control the flow rate of oxygen to 18m 3 / min, the oxidation time is 15min, and the mixed slag containing hematite, copper oxide ore and quartz ore is obtained.

[0074] Then, the above-mentioned slag bag is transported to the slag cooling field by a slag bag car, and it is naturally cooled for 24 hours, and then sprayed with water for 36 hours. ...

Embodiment 3

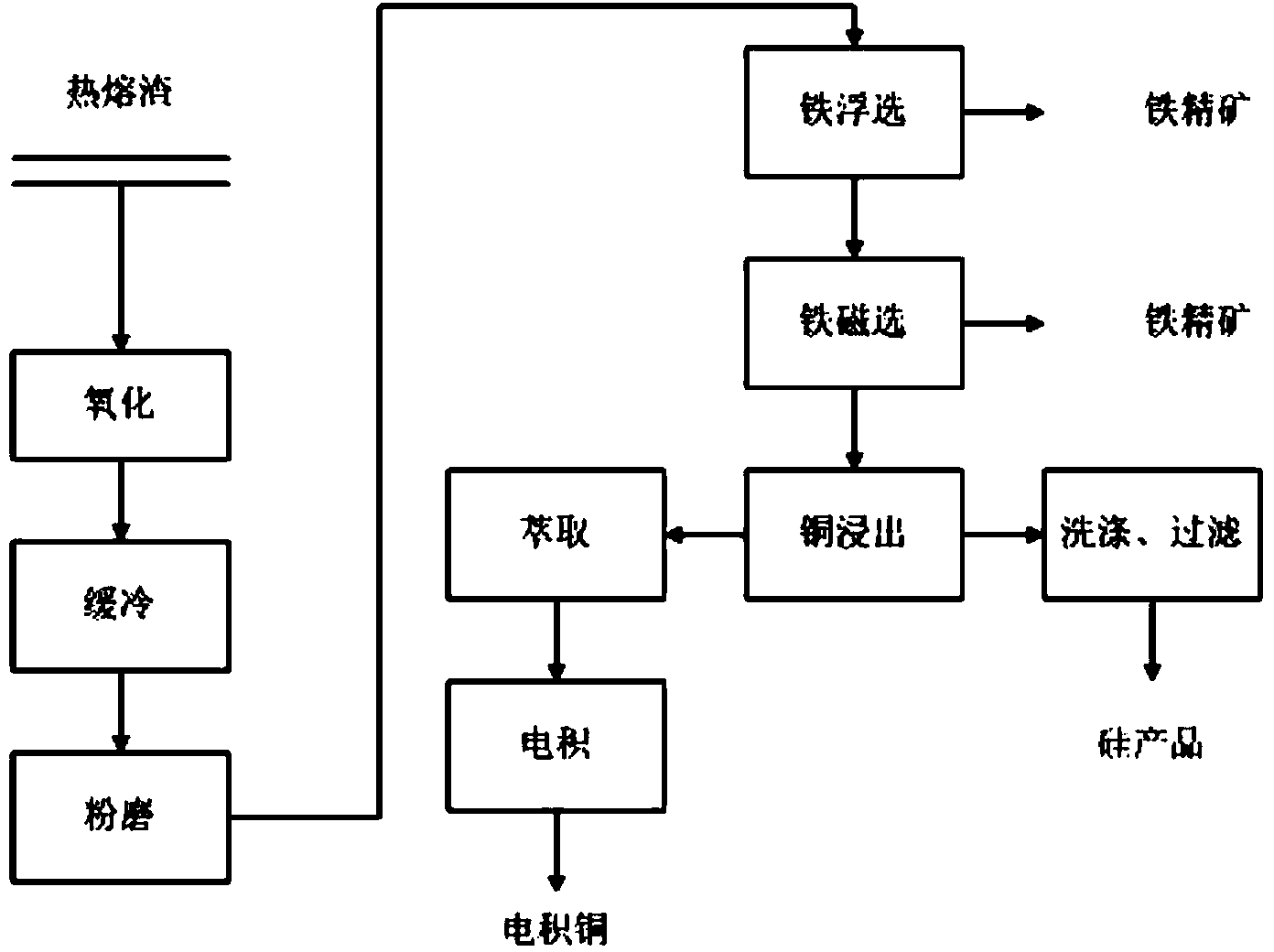

[0080] use image 3 The process flow shown is the process of floating magnetism-leaching-extraction-electrodeposition, which is used to recover copper, iron and silicon in hot copper smelting slag. image 3 It is a process flow chart of recovering copper, iron and silicon in Example 3 of the present invention.

[0081] The hot-melt slag discharged from the one-step copper smelting furnace is used as the treatment object, the copper content of which is 3% to 10%, and the temperature is within the range of 1000°C to 1350°C. When discharging slag, put hot molten slag into a special slag bag, and oxidize it by passing industrial pure oxygen into the slag in the slag bag. Control the flow rate of oxygen to 20m 3 / min, the oxidation time is 20min, and the mixed slag containing hematite, copper oxide ore and quartz ore is obtained.

[0082] Then, the above-mentioned slag bag is transported to the slag cooling field by a slag bag car, and it is naturally cooled for 24 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com