Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Fayalite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fayalite (Fe₂SiO₄; commonly abbreviated to Fa), also called iron chrysolite, is the iron-rich end-member of the olivine solid-solution series. In common with all minerals in the olivine group, fayalite crystallizes in the orthorhombic system (space group Pbnm) with cell parameters a 4.82 Å, b 10.48 Å and c 6.09 Å.

Method for separating valuable metals from copper slag

InactiveCN104404260AReduce consumptionAchieve recyclingProcess efficiency improvementFayaliteAdhesive

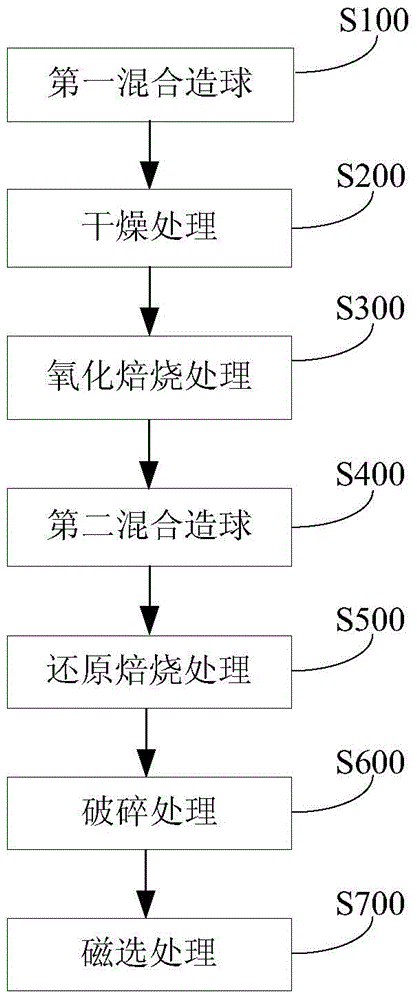

The invention discloses a method for separating valuable metals from copper slag. The method comprises the steps: (1) performing primary mixing palletizing on the copper slag and an adhesive to obtain copper slag pellets; (2) performing drying treatment on the copper slag pellets; (3) performing oxidation roasting treatment on the dried copper slag pellets so as to convert fayalite in the copper slag into ferric oxide; (4) performing secondary mixing palletizing on the copper slag pellets subjected to oxidization roasting and a mixture containing a reducing agent, an additive and an adhesive to obtain a pellet material; (5) performing reducing roasting on the pellet material so as to obtain reduced pellets and smoke containing zinc oxide and lead oxide; (6) smashing the reduced pellets to obtain a mixture containing metal iron powder and tailings; (7) performing magnetic separation on the mixture containing the metal iron powder and the tailings to respectively obtain the metal iron powder and the tailings. According to the method disclosed by the invention, iron, zinc and lead can be effectively separated from the copper slag, and the grade of obtained metal iron is higher.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

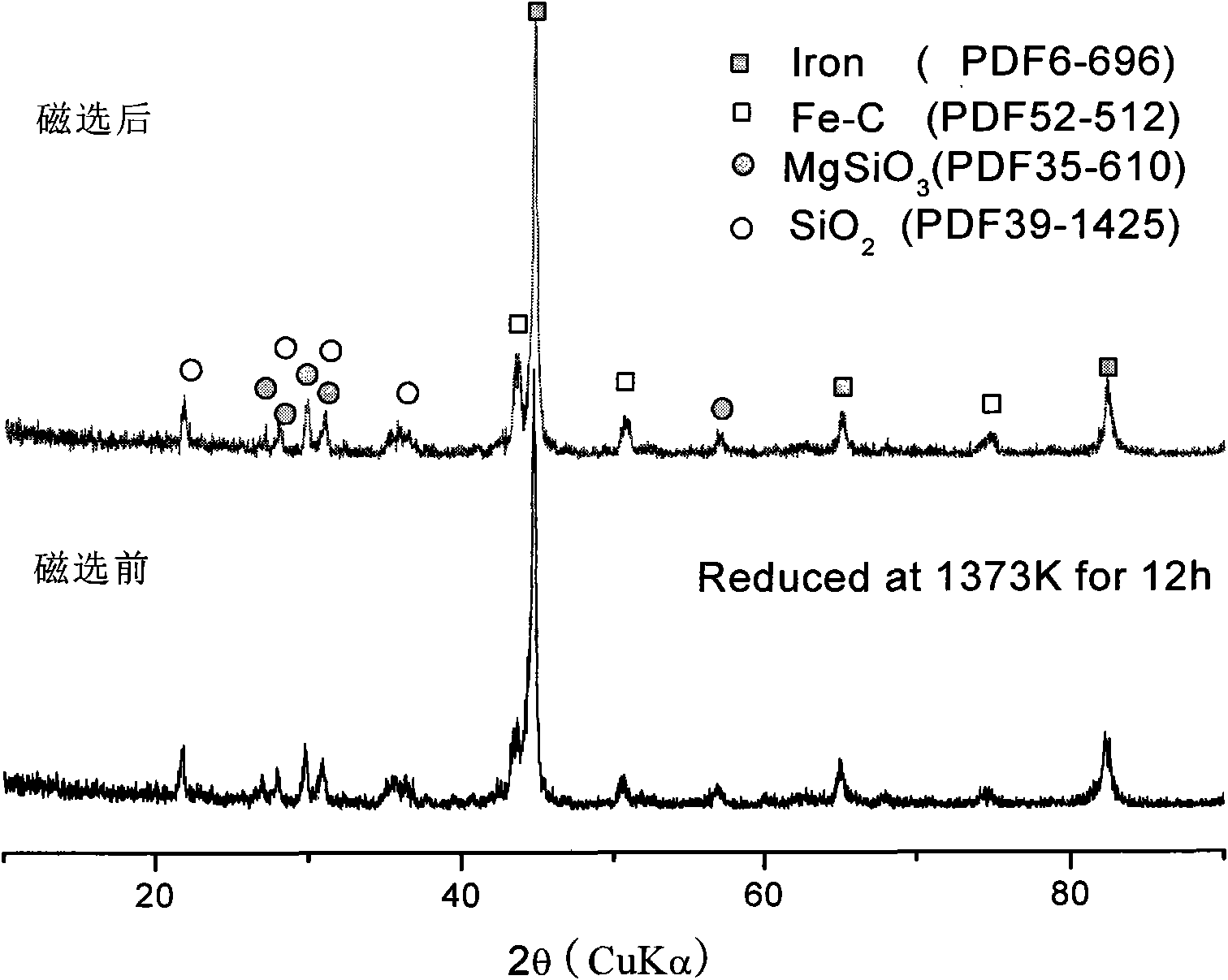

Method for extracting iron from copper smelting waste residue

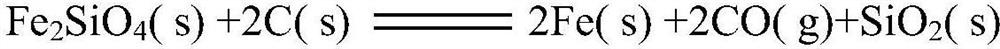

The invention relates to a method for extracting iron from copper smelting waste residue. The method comprises the following steps: pulverizing copper slag, a reductant which is a mixture comprising one or more of anthracite, graphite, petroleum coke and coke, calcium oxide or calcium carbonate into a certain granularity, fully mixing the materials, carrying out mineralogical reconstruction and carbothermal reduction under high temperature to convert fayalite in the residue into iron oxide and then reduce the iron oxide into iron, and recovering the iron by magnetic separation, wherein, nonmagnetic products can be taken as raw materials for burning cement.

Owner:KUNMING UNIV OF SCI & TECH

Method for eliminating magnetic iron oxide furnace accretion produced in copper sulfide concentrate pyrometallurgical process

InactiveCN101871050AReduce the number of timesExtended service lifeProcess efficiency improvementFayaliteSmelting process

The invention relates to a method for eliminating magnetic iron oxide furnace accretion produced in a copper sulfide concentrate pyrometallurgical process. The method is characterized in that a proper amount of scrap copper and quartz are put in a weld pool in the metallurgical process on the basis of a traditional technology, elementary substance copper in the scrap copper replaces FeS in fusant to generate Fe elementary substance, Fe reacts with magnetic iron oxide (main component of furnace accretion) in the weld pool to obtain FeO, the added quartz and the FeO generate fayalite slag and thereby the magnetic iron oxide can be eliminated. The technology can be implemented during smelting, converting, continual copper smelting or the clarification separation process of a slag and sulfide mixed fusant electric furnace. The invention has the advantages that the copper matte grade can be improved, the copper contained in slag is reduced, the furnace condition is improved and the superiority of the separation of copper and impurities in the scrap copper is realized.

Owner:KUNMING UNIV OF SCI & TECH +3

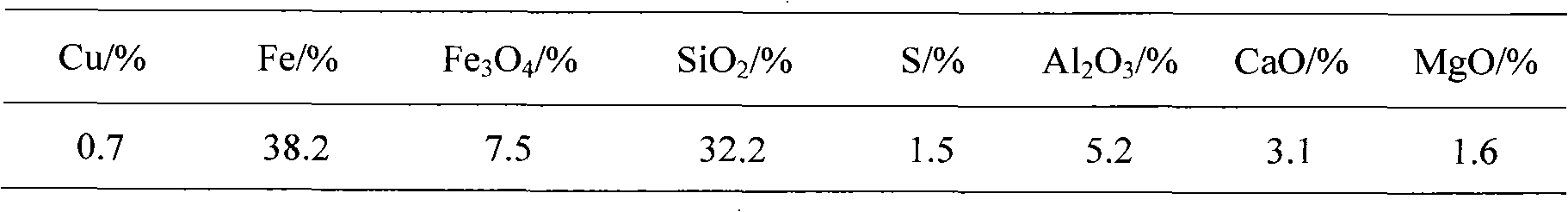

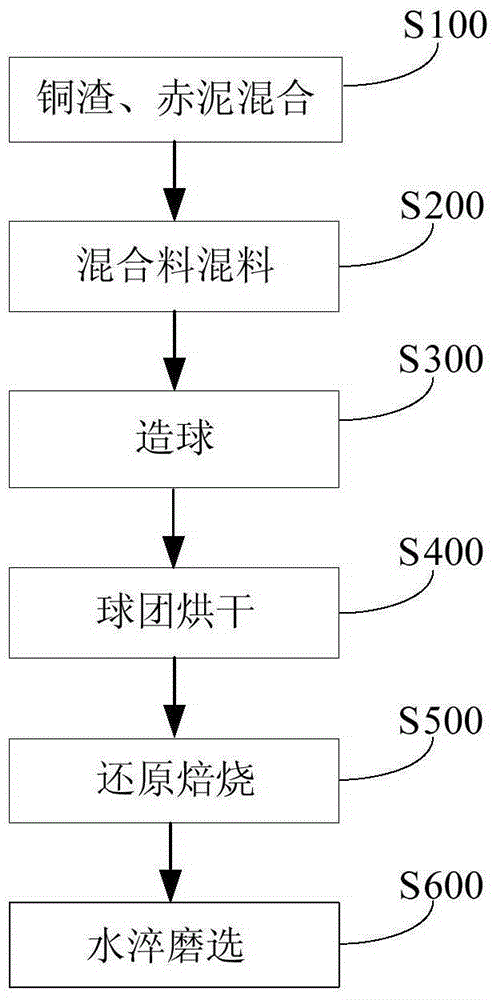

Comprehensive treatment method for red mud and copper slag

The invention provides a comprehensive treatment method for red mud and copper slag. The method comprises the steps that 1, the red mud and the copper slag are mixed to obtain a mixed raw material of the red mud and the copper slag, then a reducing agent is added into the mixed raw material to be evenly mixed, and a mixture is obtained; 2, roasting is conducted; and 3, the mixture is crushed and milled after being cooled, magnetic separation is conducted, and finally metal iron power and tailings are obtained. Through the method, the problems that when the copper slag and the red mud are pelletized independently, pelletizing is difficult, iron particles can not be gathered due to fineness of the iron particles in the independent reduction process of the red mud and fayalite is difficult to restore in the independent reduction process of the copper slag are solved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method and system for treating metallurgical slag

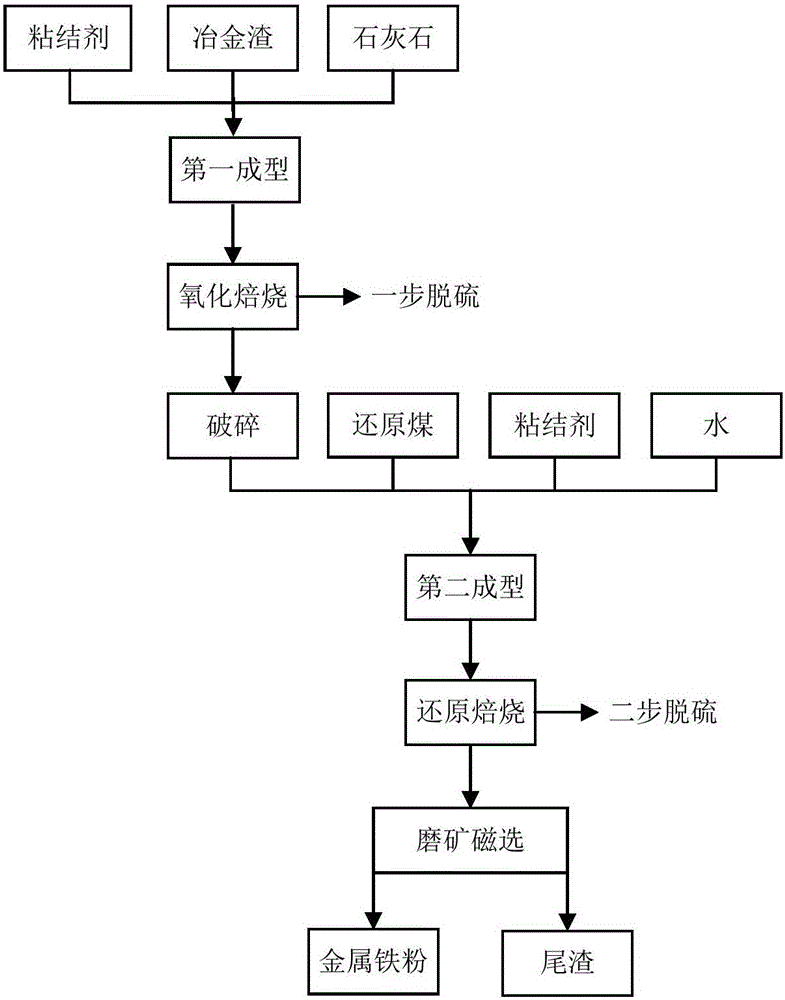

The invention discloses a method and system for treating metallurgical slag. The method comprises the steps that the metallurgical slag, limestone and adhesives are subjected to forming treatment, so that first material pellets are obtained; oxidizing roasting is conducted on the first material pellets, so that fayalite in the metallurgical slag is converted into ferric oxide, and meanwhile oxidizing roasting products are obtained through desulfurization; the oxidizing roasting products are crushed, so that crushed oxidizing roasting products are obtained; the crushed oxidizing roasting products, reducing coal, the adhesives and water are subjected to forming treatment, so that second material pellets are obtained; reducing roasting is conducted on the second material pellets, so that the iron oxide in the second material pellets is converted into iron, and meanwhile reducing roasting products are obtained through desulfurization; and ore grinding and magnetic separation are conducted on the reducing roasting products, so that metal iron powder and tailings are obtained. By the adoption of the method, the problem that reduction of fayalite in the metallurgical slag is difficult is solved, effective separation of the iron element is achieved, and high-quality low-sulfur metal iron powder can be obtained advantageously.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

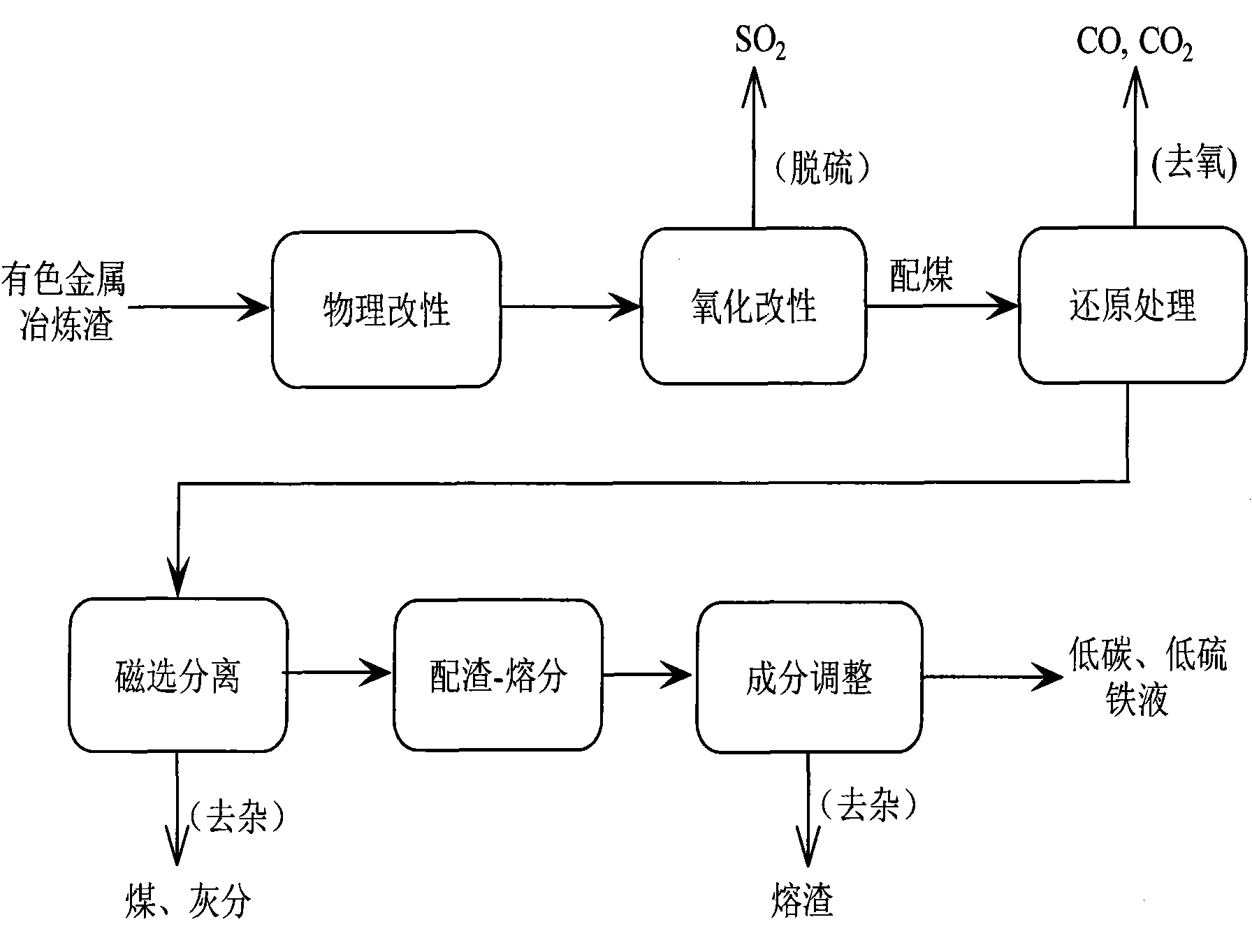

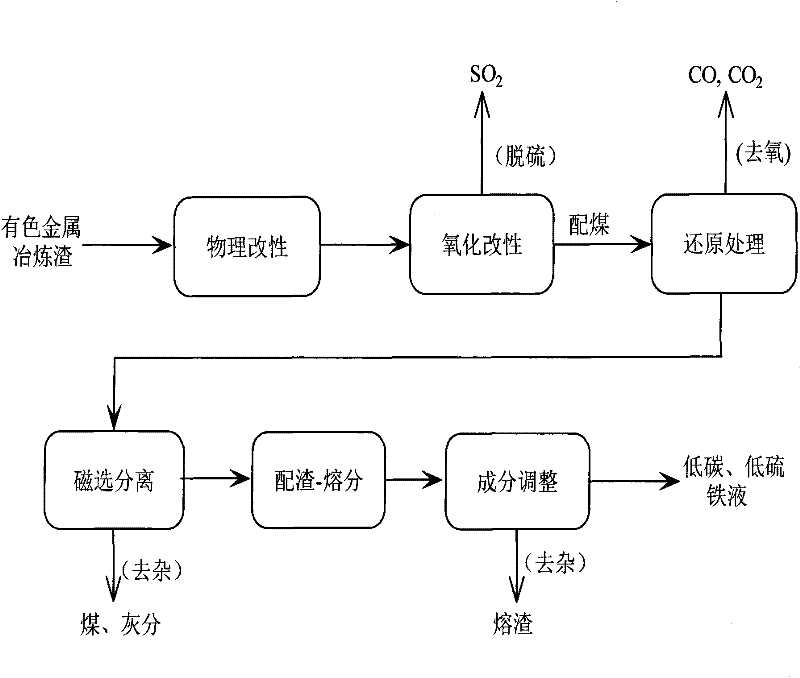

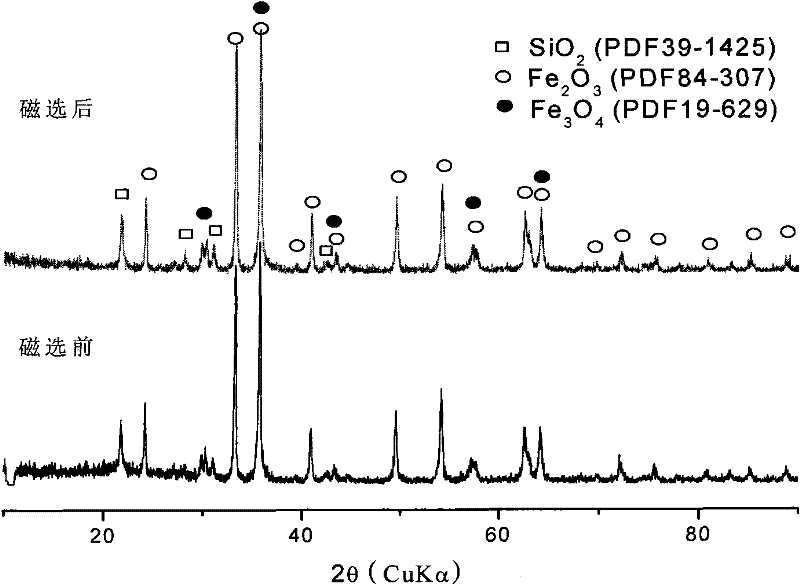

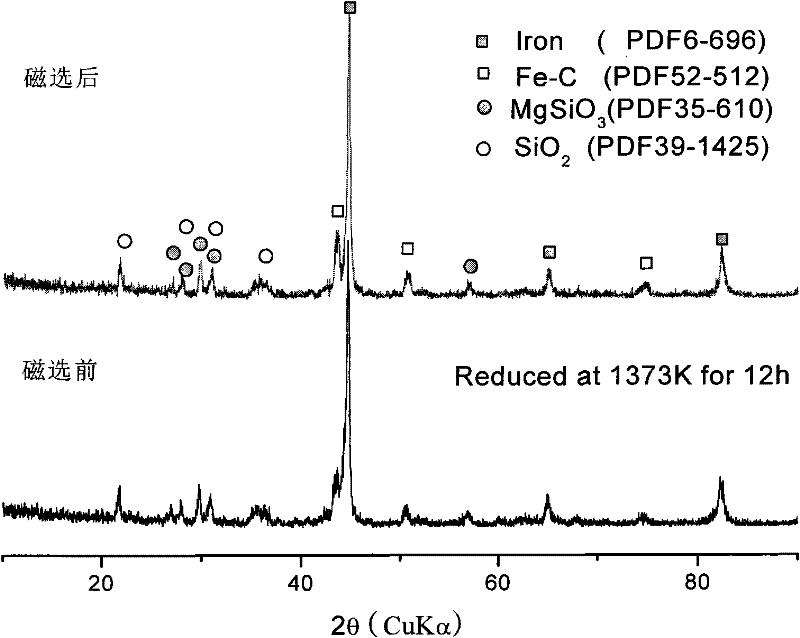

Method for extracting valuable elements from slag of melted high-iron high-silicon nonferrous metal

The invention relates to a method for extracting valuable elements from slag of melted high-iron high-silicon nonferrous metal with fire to produce low-carbon low-sulfur molten iron and directly produce heat-resisting structural steel. The method for extracting valuable elements from slag of melted high-iron high-silicon nonferrous metal comprises the physical modification, the oxidation modification, the reduction and the magnetic separation of the slag of nonferrous metal, the proportion of the slag (the melting of the components) and the adjustment of the components. Adopting the carbonaceous reducing agent and combining the magnetic separation with the FeO oxidation during the proportion of the slag (the melting of the components) and the adjustment of the components, the invention solves the problem of decarbonization after the reduction in the traditional method; adopting the physical modification and the chemical modification, the invention solves the problems that the solid fayalite is difficult to reduce and the finished product contains more sulfur; adopting the proportion of the slag (the melting of the components) after the prereduction of the slag of nonferrous metal, the invention solves the problem of the generation of the foaming slag and the erosion of the furnace lining in the traditional smelting reduction step. According to the characteristics of the valuable elements such as the Fe, the Ni, the Cu and the like in the slag, the valuable elements can be directly used for producing heat-resisting structural steel. The secondary resources are used effectively, and the problem on the environmental protection during smelting the nonferrous metal is solved.

Owner:UNIV OF SCI & TECH BEIJING

Comprehensive utilization method of ferriferous fayalite material

ActiveCN103343225AIncrease response rateEasy to separateProcess efficiency improvementFayaliteLiquid state

The invention discloses a comprehensive utilization method of a ferriferous fayalite material, relates to a processing method of the ferriferous fayalite material, and in particular relates to a method for separating and utilizing iron and silicon in fayalite. The method is characterized by comprising the following steps of: grinding the ferriferous fayalite material; mixing with alkaline liquor for leaching reaction; performing solid-liquid separation on obtained reaction slurry to obtain desilicated concentrate and silicon containing alkaline liquor; and oxidizing the desilicated concentrate in air to goethite. The method disclosed by the invention enriches, separates and extracts iron and silicon elements to form two products: goethite and silicon containing alkaline liquor through alkaline liquor leaching, wherein iron and silicon in ferriferous fayalite exist in solid and liquid states, so that the comprehensive utilization ratio of resources is high and the economic benefit is better.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

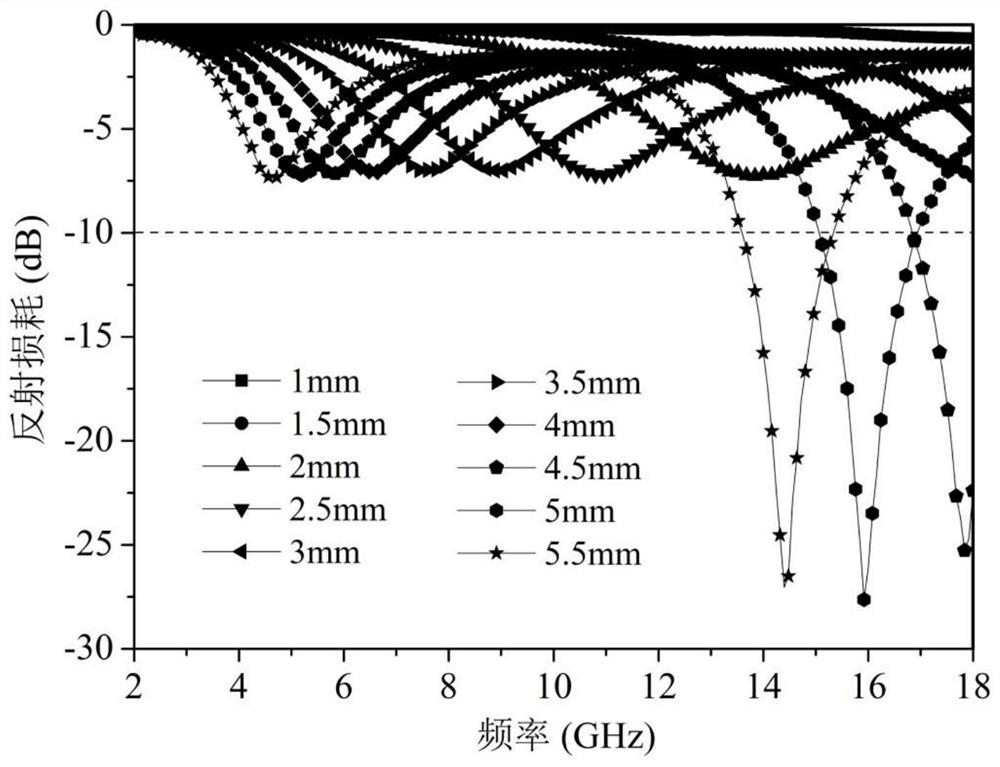

Method for preparing microwave absorbing material from red mud and coal gangue and application of microwave absorbing material

ActiveCN112441815ASimple preparation processImprove microwave absorption performanceOther chemical processesCeramic materials productionFayaliteRed mud

The invention relates to a method for preparing a microwave absorbing material from red mud and coal gangue and application of the microwave absorbing material, belonging to the technical fields of solid waste utilization and microwave absorbing materials. The invention aims to solve the technical problem of efficient and reasonable comprehensive utilization of solid waste red mud and coal gangue.According to a technical scheme in the invention, the method comprises the following steps: subjecting red mud slurry to filter pressing and dispersion so as to obtain dispersed red mud balls; crushing, ball-milling and screening coal gangue to obtain coal gangue powder with moderate granularity; respectively weighing the red mud balls and the coal gangue powder according to a certain ratio, andconducting uniform mixing; and finally, carrying out roasting in an inert atmosphere to obtain the magnetic composite microwave absorbing material loaded with Fe3O4, Fe3O4 / Fe, Fe / FeC or elemental Fe.Main phases of the material include fayalite, nepheline and carbon. According to the invention, the solid waste red mud and the coal gangue are used as raw materials to prepare the composite wave-absorbing material, effective recycling of the red mud and the coal gangue is achieved, and reference is provided for comprehensive utilization of the red mud and the coal gangue.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for extracting valuable elements from slag of melted high-iron high-silicon nonferrous metal

The invention relates to a method for extracting valuable elements from slag of melted high-iron high-silicon nonferrous metal with fire to produce low-carbon low-sulfur molten iron and directly produce heat-resisting structural steel. The method for extracting valuable elements from slag of melted high-iron high-silicon nonferrous metal comprises the physical modification, the oxidation modification, the reduction and the magnetic separation of the slag of nonferrous metal, the proportion of the slag (the melting of the components) and the adjustment of the components. Adopting the carbonaceous reducing agent and combining the magnetic separation with the FeO oxidation during the proportion of the slag (the melting of the components) and the adjustment of the components, the invention solves the problem of decarbonization after the reduction in the traditional method; adopting the physical modification and the chemical modification, the invention solves the problems that the solid fayalite is difficult to reduce and the finished product contains more sulfur; adopting the proportion of the slag (the melting of the components) after the prereduction of the slag of nonferrous metal,the invention solves the problem of the generation of the foaming slag and the erosion of the furnace lining in the traditional smelting reduction step. According to the characteristics of the valuable elements such as the Fe, the Ni, the Cu and the like in the slag, the valuable elements can be directly used for producing heat-resisting structural steel. The secondary resources are used effectively, and the problem on the environmental protection during smelting the nonferrous metal is solved.

Owner:UNIV OF SCI & TECH BEIJING

Method for extracting iron from copper smelting waste residue

The invention relates to a method for extracting iron from copper smelting waste residue. The method comprises the following steps: pulverizing copper slag, a reductant which is a mixture comprising one or more of anthracite, graphite, petroleum coke and coke, calcium oxide or calcium carbonate into a certain granularity, fully mixing the materials, carrying out mineralogical reconstruction and carbothermal reduction under high temperature to convert fayalite in the residue into iron oxide and then reduce the iron oxide into iron, and recovering the iron by magnetic separation, wherein, nonmagnetic products can be taken as raw materials for burning cement.

Owner:KUNMING UNIV OF SCI & TECH

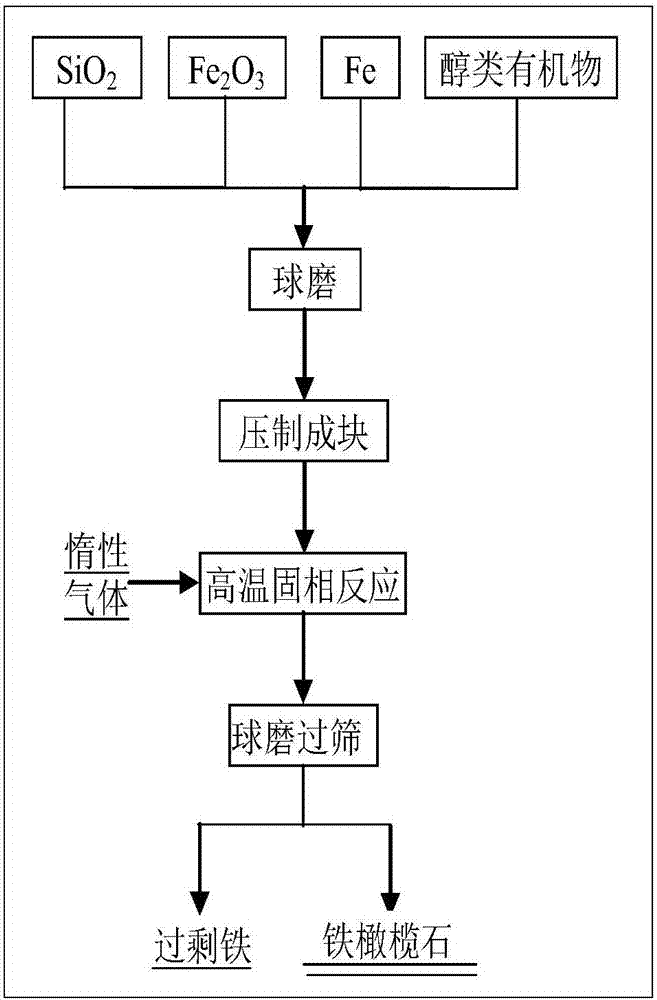

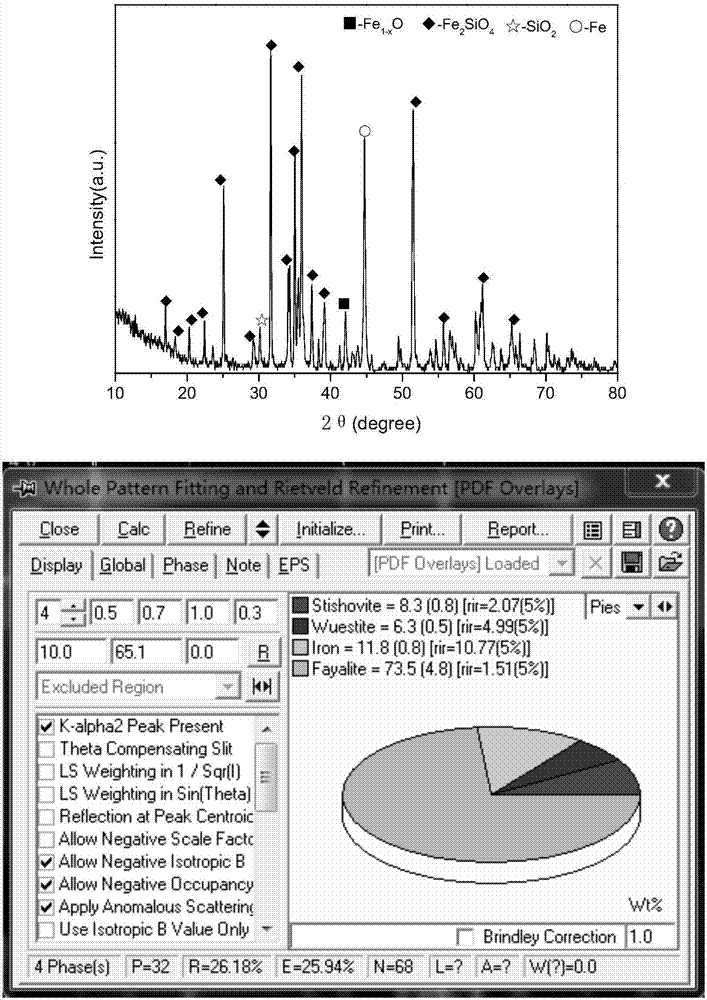

Preparation method of fayalite

The invention discloses a preparation method of fayalite. The method includes steps of mixing and ball-milling Fe, Fe2O3 and SiO2 solid raw materials and lower alcohol, and then pressing into blocks; placing the blocks in a protective atmosphere, and sintering at the temperature of 900-1200 DEG C; performing crushing and magnetic separation on the sintered product, wherein the non-magnetic matter is fayalite with high purity and good crystal form. The method is simple in both technique and equipment, relatively gentle in condition, and free from waste gas pollutant; the shortcomings of compounding the fayalite by high pressure, high temperature and other harsh conditions are overcomein the current method; the method has a great significance in scientific research of geophysics, geology, fireproofing material and other fields, and the post-research of copper quenching slag, nickel slag, fuming slag and other FeO-SiO2 slag to realize the resource utilization.

Owner:CENT SOUTH UNIV

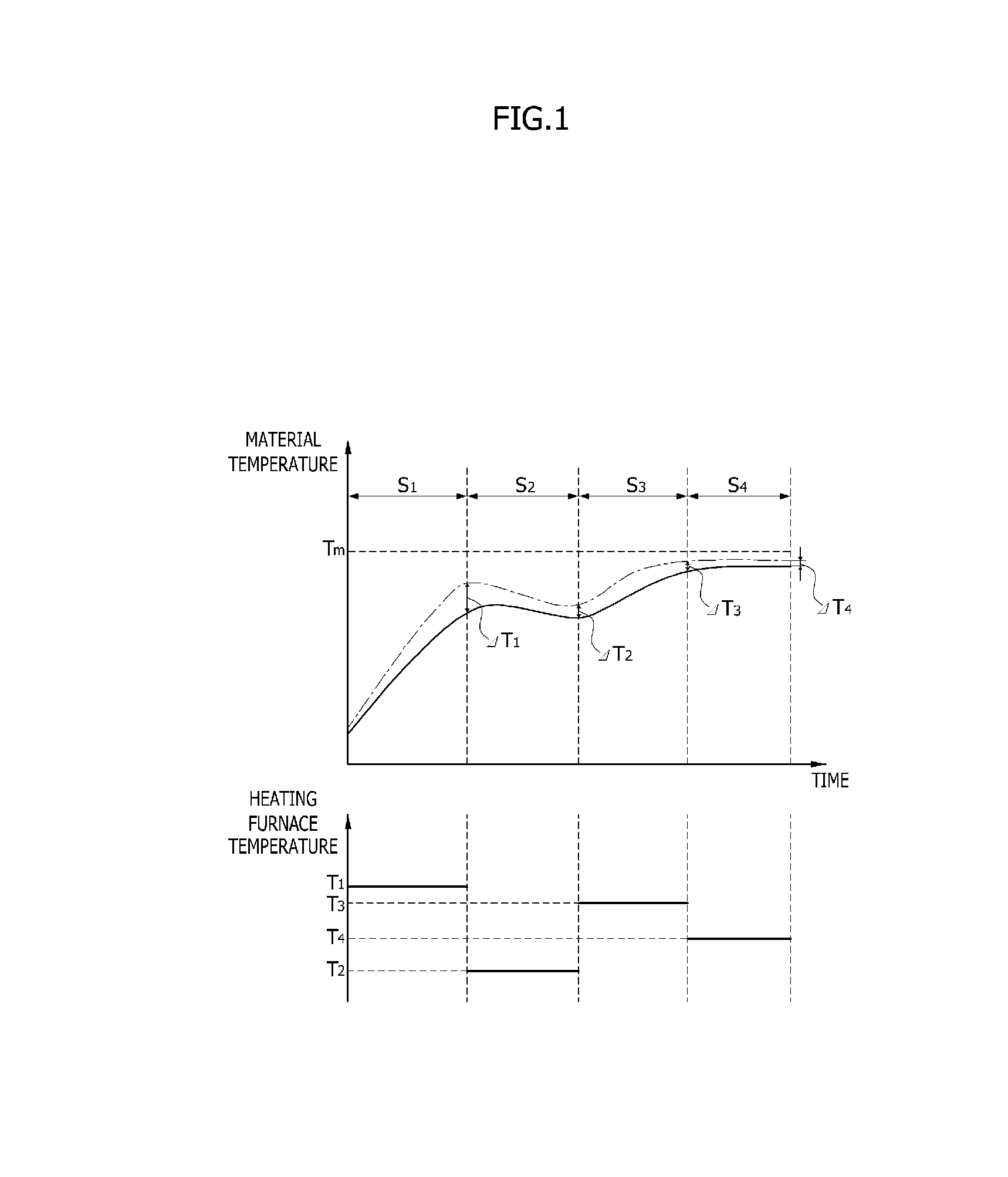

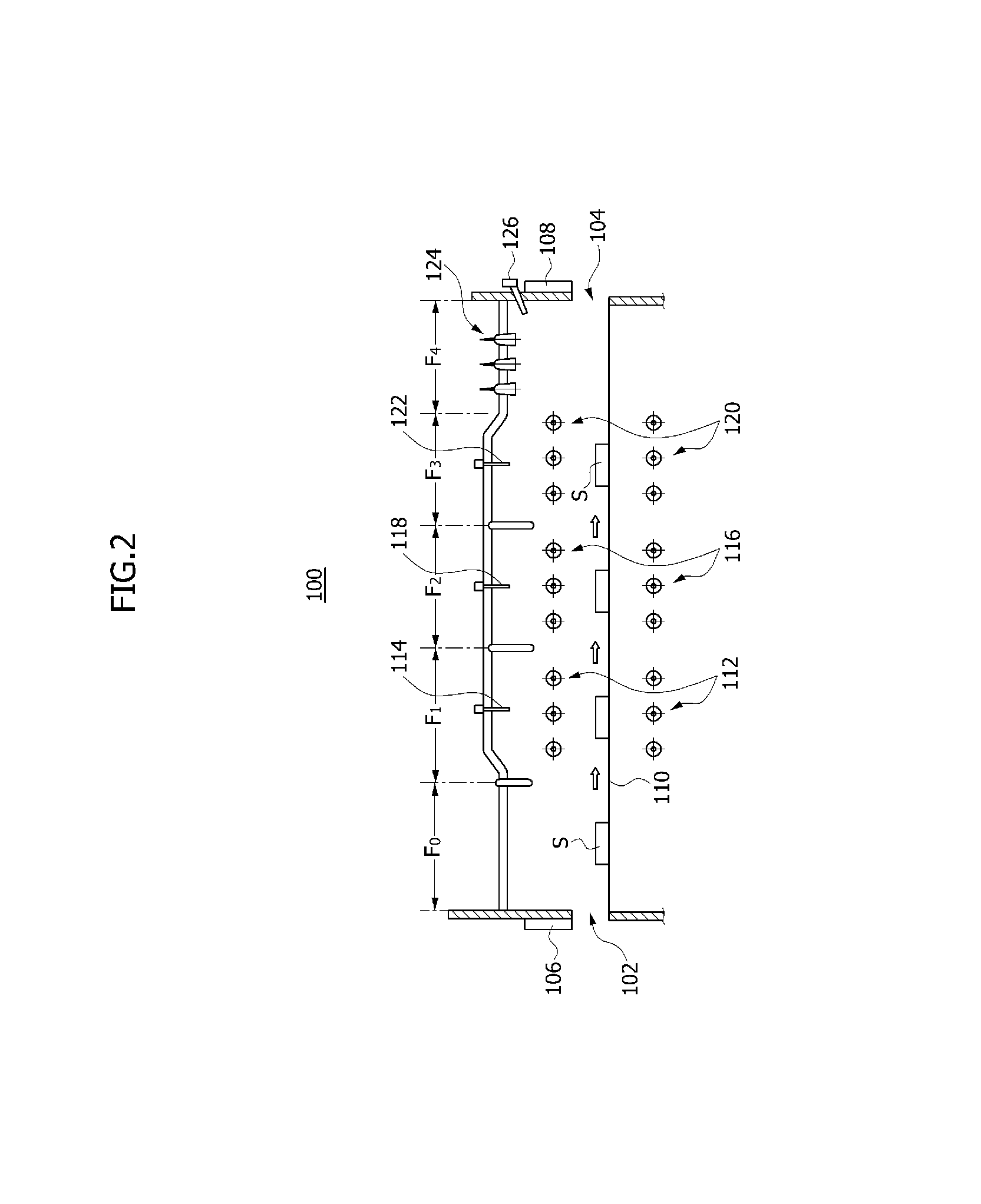

Material heating method

InactiveUS20140065563A1Improve surface qualityEliminate scalingFurnace typesHeat treatment process controlFayaliteTemperature difference

A material heating method includes: a step of charging a silicon-containing carbon steel material into a heating furnace; a step of preheating the material; a first heating step of raising the temperature of the material; a second heating step of lowering the temperature of the material so as to reduce a temperature difference between the surface and inside of the material; a third heating step of raising the temperature of the material; and a soaking step of reducing the temperature difference between the surface and inside of the material. The temperature of the material in the heating furnace is maintained at the melting point of fayalite or lower.

Owner:HYUNDAE STEEL CO LTD

High-temperature surface red rust removal isolating agent for silicon-containing steel and red rust removal method

InactiveCN107903674ADoes not affect the application effectHigh protection temperatureCoatingsFayaliteMullite

The invention relates to the technical field of steel treatment, in particular to a high-temperature surface red rust removal isolating agent for silicon-containing steel and a red rust removal method. The high-temperature surface red rust removal isolating agent for the silicon-containing steel is prepared from dry powder and water; the dry powder adopts vermiculite powder, nano magnesium silicate, nano chromic oxide, mullite powder, coal ash, laterite and cassava starch; the water is 50 to 70 percent of the total weight of the dry powder. The high-temperature surface red rust removal isolating agent for the silicon-containing steel and the red rust removal method are applicable to protection during heating of the silicon-containing steel, and can effectively reduce loss of iron scale, suppress production of fayalite and reduce the red rust area on the downstream hot rolled surface; the adhesive force between scales and a steel matrix is lowered; after the steel is discharged out of afurnace, the scales are removed through high-pressure water, so that the scales and the isolating agent layer can completely fall off; the red rust area of the hot rolled surface is substantially reduced by 50 percent, and the product qualification ratio and the product quality are effectively improved; during production and use, the high-temperature surface red rust removal isolating agent is pollution-free to the environment, and the production cost is low.

Owner:福建省鑫富达铝业有限公司

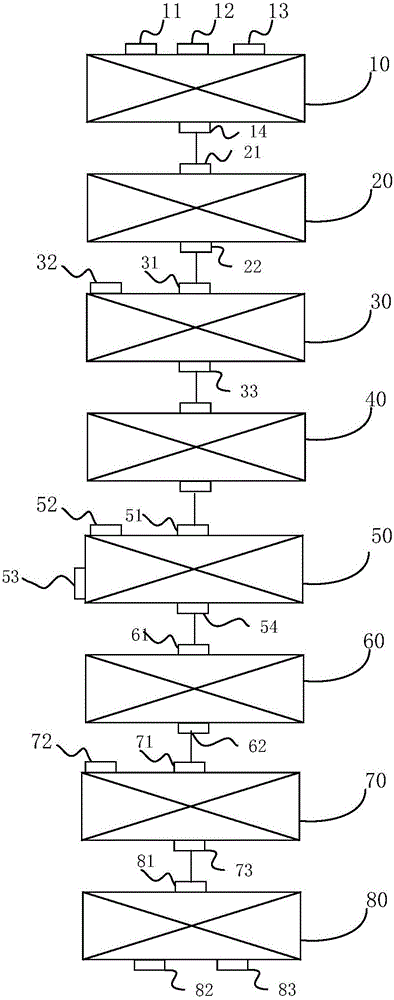

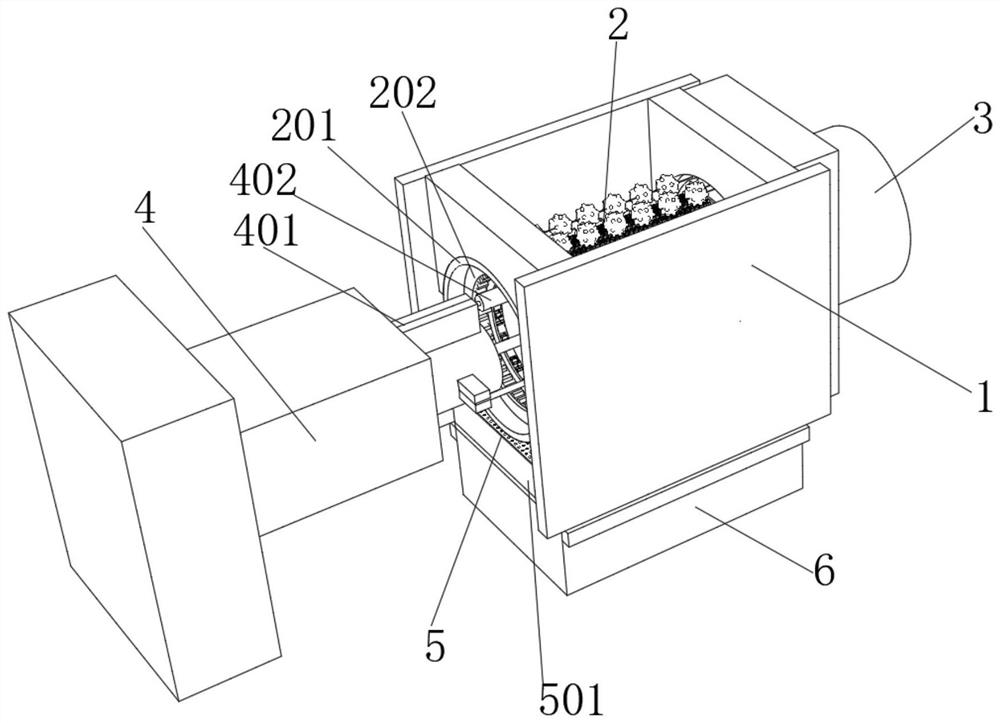

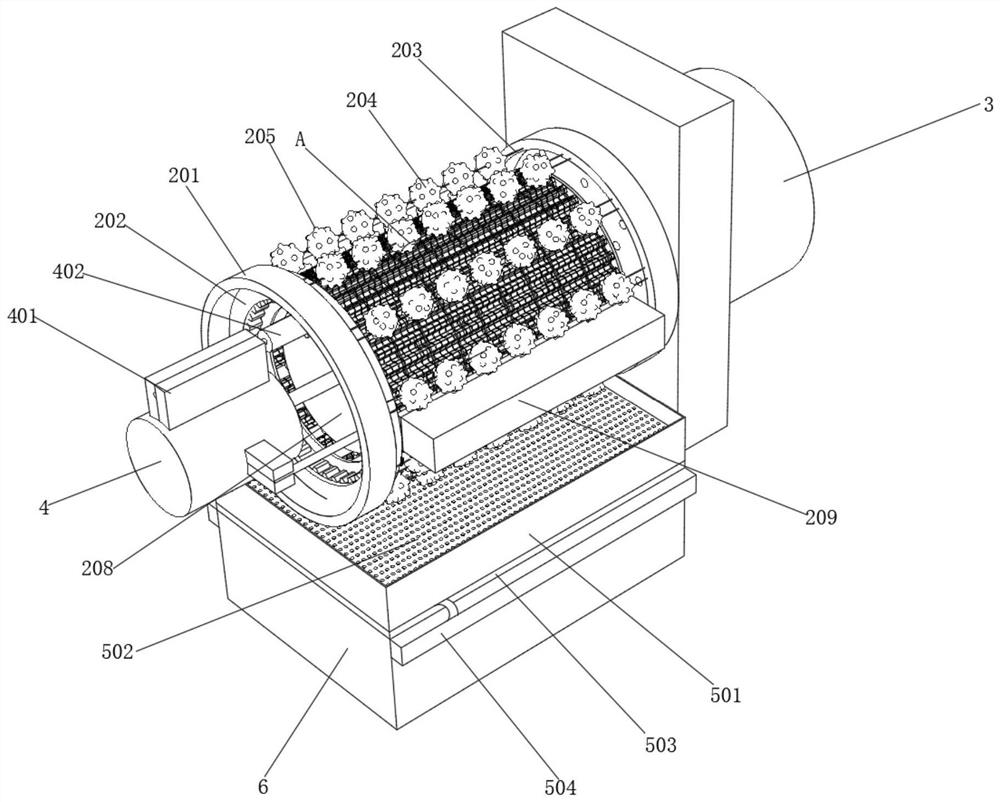

Slag tailing metal recovery system based on big data and recovery process method thereof

The invention provides a slag tailing metal recovery system based on big data and a recovery process method thereof, and relates to the technical field of copper smelting. The slag tailing metal recovery system based on the big data and the recovery process method thereof comprises a shell, a magnetic separation mechanism, a gas supply device, a telescopic driving device, a screening mechanism and a collecting box, the magnetic separation mechanism is arranged in the middle of the interior of the shell and used for screening magnetite in slag, the left side and the right side of the magnetic separation mechanism are fixedly connected with the shell, and the gas supply device is arranged on the right side of the shell. The left side of the air supply device penetrates through the right side of the shell and is fixedly connected with the shell, the telescopic driving device is arranged on the left side of the shell, and the driving end of the telescopic driving device is fixedly connected with the left side of the magnetic separation mechanism, the screening mechanism is movably connected on the bottom end of the shell, the collecting box is movably connected on the bottom end of the screening mechanism. The problem that the magnetite and fayalite are inconveniently and effectively subdivided due to different sizes of tailings particles, the magnetite and the fayalite in copper smelting tailings is solved.

Owner:黄石市泓义城市矿产资源产业研究院有限公司

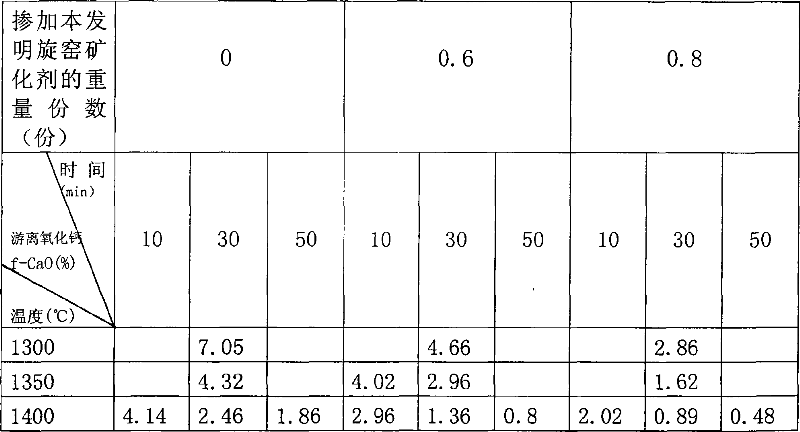

Rotary kiln mineralization agent and method for manufacturing same

The invention discloses an increasing production and energy-saving rotary kiln mineralizer of cement, allocating raw material according to mass percent as: 0-5 wt grammite, 5-15 wt sanbornite, 5-45 wt dolostone, 5-15 wt fayalite, 10-40 wt zeolite and 0-10 wt flour. This invention also discloses a preparing method of rotary kiln mineralizer, which comprises by the following steps: bruising separately; mixing dosage; packing; getting end product.

Owner:翟永生

Comprehensive utilization method of ferriferous fayalite material

ActiveCN103343225BIncrease response rateEasy to separateProcess efficiency improvementFayaliteLiquid state

The invention discloses a comprehensive utilization method of a ferriferous fayalite material, relates to a processing method of the ferriferous fayalite material, and in particular relates to a method for separating and utilizing iron and silicon in fayalite. The method is characterized by comprising the following steps of: grinding the ferriferous fayalite material; mixing with alkaline liquor for leaching reaction; performing solid-liquid separation on obtained reaction slurry to obtain desilicated concentrate and silicon containing alkaline liquor; and oxidizing the desilicated concentrate in air to goethite. The method disclosed by the invention enriches, separates and extracts iron and silicon elements to form two products: goethite and silicon containing alkaline liquor through alkaline liquor leaching, wherein iron and silicon in ferriferous fayalite exist in solid and liquid states, so that the comprehensive utilization ratio of resources is high and the economic benefit is better.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

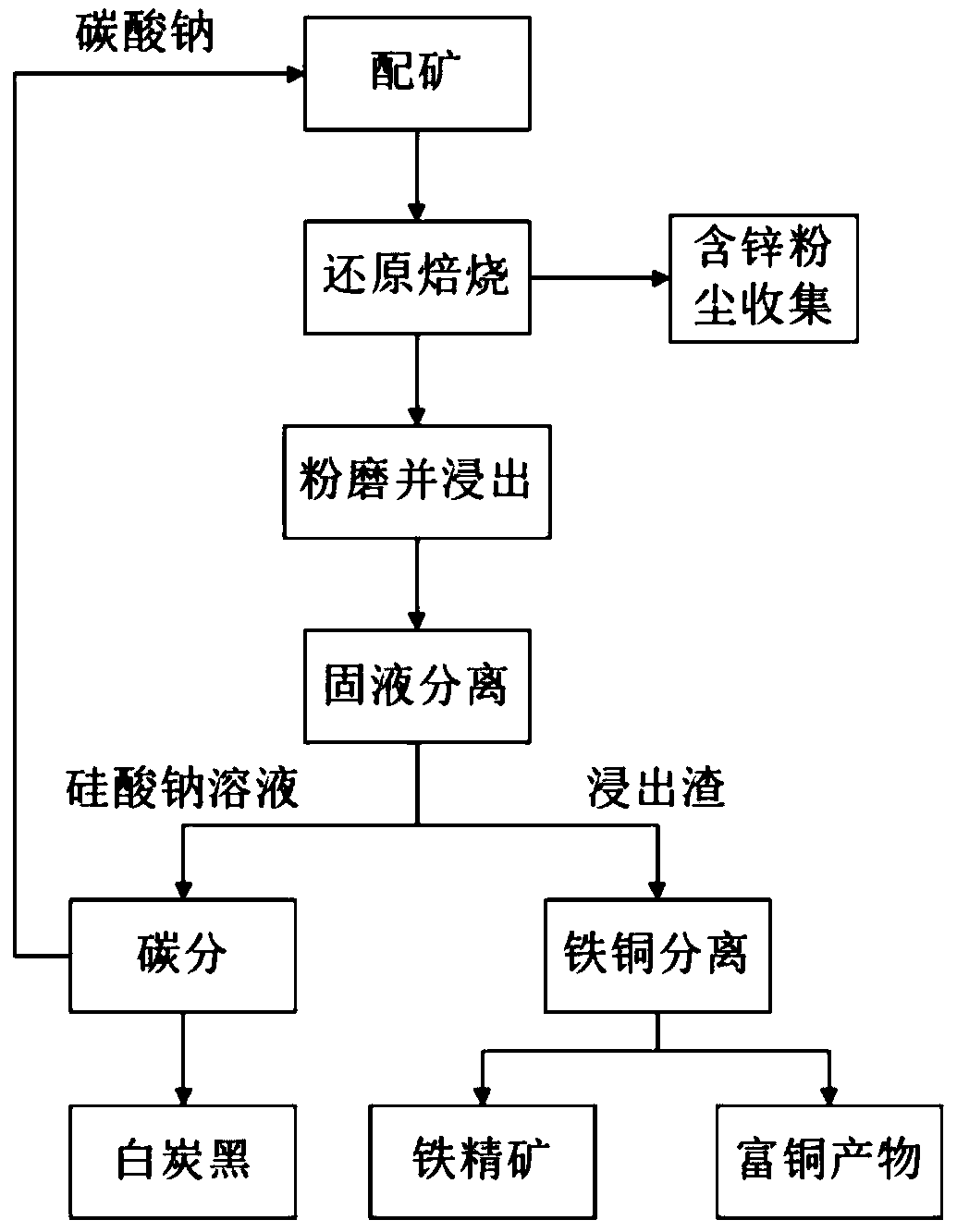

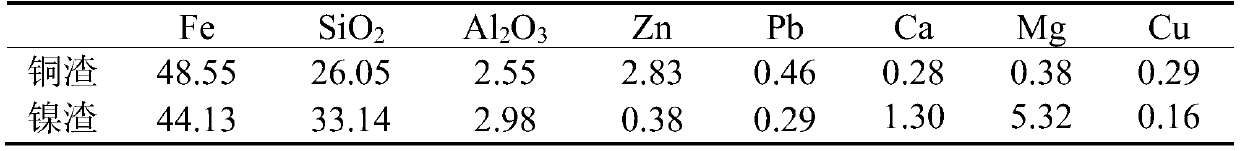

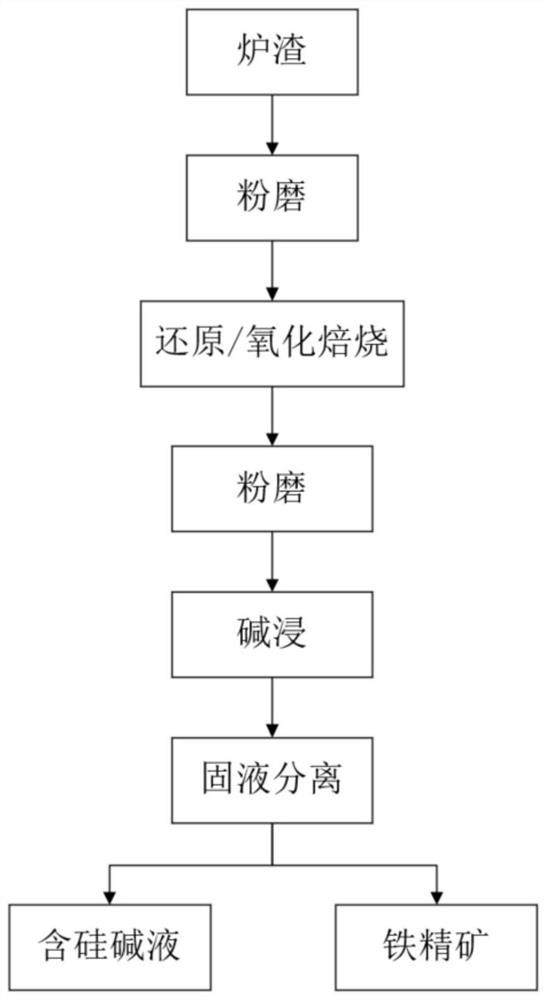

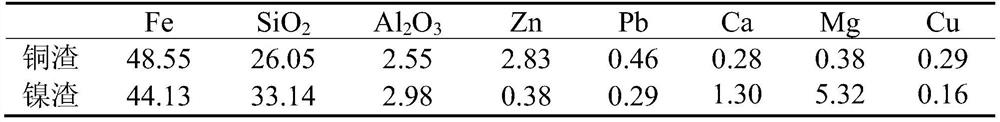

Fayalite type furnace slag resource recycling method

ActiveCN110551902AAchieve separationAchieve recyclingSilicaProcess efficiency improvementFayaliteResource utilization

The invention provides a fayalite type furnace slag resource recycling method, and relates to a mineral engineering technology. The method comprises the following steps of carrying out ore proportioning on furnace slag, sodium carbonate and a reducing agent, grinding and uniformly mixing the mixture to obtain a raw material, wherein the furnace slag comprises at least one of copper slag and nickelslag; carrying out reduction roasting on the raw material to obtain a clinker; grinding the clinker, and then adding the ground clinker into water for leaching; carrying out solid-liquid separation on the leached ore pulp, and separating to obtain a sodium silicate solution and leached residues; carrying out carbon separation on the sodium silicate solution to obtain a white carbon black and a sodium carbonate solution; and carrying out iron-copper separation on the leached residues to obtain iron ore concentrate and a copper-rich product. According to the method, efficient separation of zinc, iron, silicon and copper in the fayalite type furnace slag can be realized, and resource utilization can be performed correspondingly. The fayalite type furnace slag resource recycling method is simple in process flow and low in cost, can realize resource utilization of intractable fayalite type furnace slag such as copper slag, nickel slag and the like, and has a wide application prospect and good economic benefits.

Owner:WUHAN UNIV OF TECH

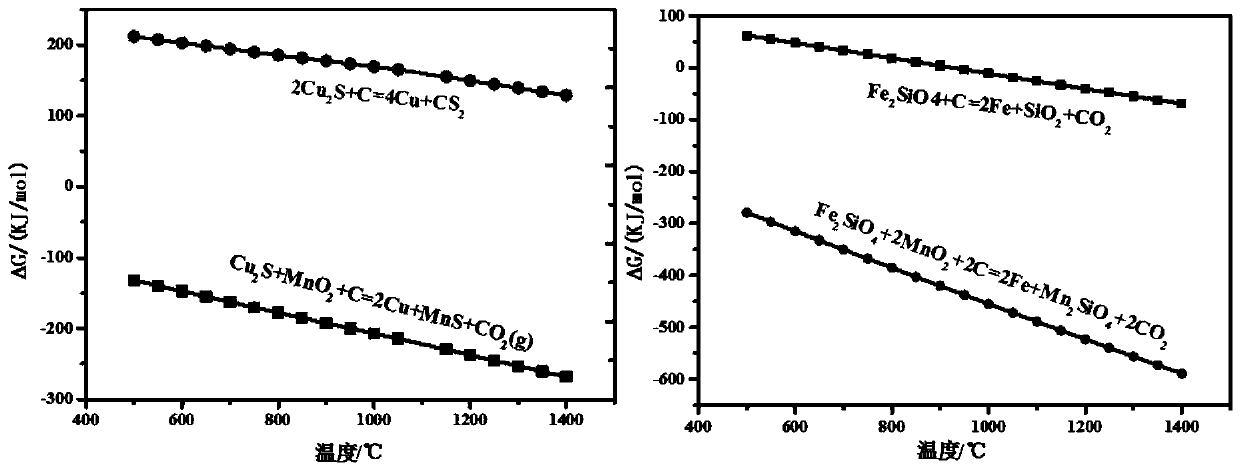

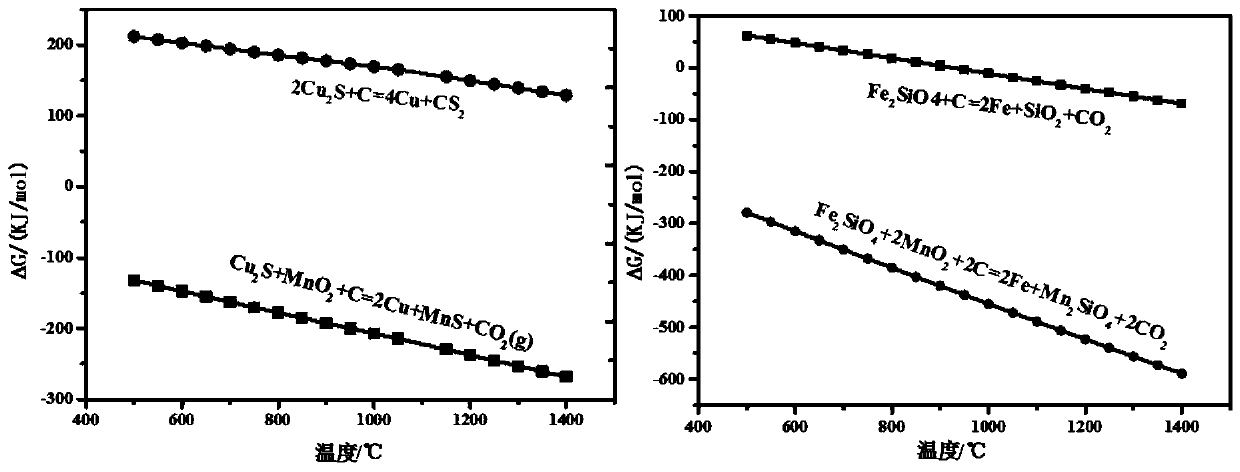

Method for preparing copper-bearing iron powder by synergetic reduction and magnetic separation of high-iron copper slag and high-iron manganese ore

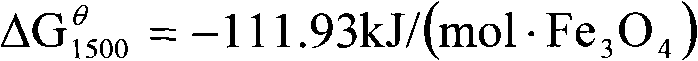

ActiveCN109971907ALower free energyIncrease metallization rateRotary drum furnacesProcess efficiency improvementFayaliteGibbs free energy

The invention discloses a method for preparing copper-bearing iron powder by synergetic reduction and magnetic separation of high-iron copper slag and high-iron manganese ore, and belongs to the technical field of industrial waste slag resource utilization. The method for preparing the copper-bearing iron powder by synergetic reduction and magnetic separation of the high-iron copper slag and the high-iron manganese ore includes the following steps that S1, the high-iron copper slag, the high-iron manganese ore and a composite addition agent are mixed, and pelletizing is conducted to obtain green balls; S2, the green balls are dried and then enter a rotary kiln, reduction coal is added to restore, and thus reduction products are obtained; S3, ore grinding and magnetic separation are conducted on the reduction products to obtain the copper-bearing iron powder; and the composite addition agent is prepared from the components in percentage by mass: 70-90% of limestone and 10-30% of sodiumhumate. According to the method for preparing the copper-bearing iron powder by synergetic reduction and magnetic separation of the high-iron copper slag and the high-iron manganese ore, MnO2 in the high-iron manganese ore is used for participating in the reduction reaction of fayalite and copper sulphide, gibbs free energy of reduction of the fayalite and the copper sulphide is lowered, the reduction reaction is catalyzed, the reduction reaction rate is accelerated, the reduction reaction is facilitated, and thus the metallization ratio and the magnetic separation metal recovery of iron and copper are improved.

Owner:CENT SOUTH UNIV

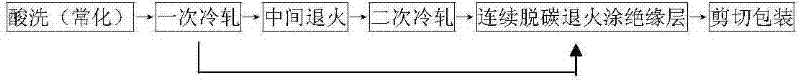

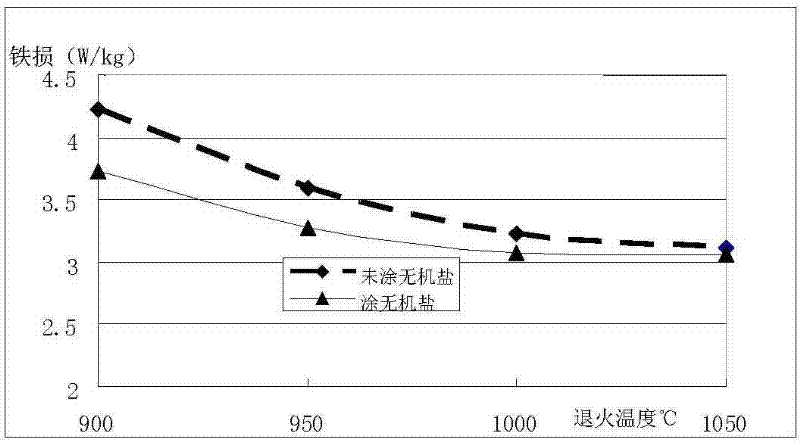

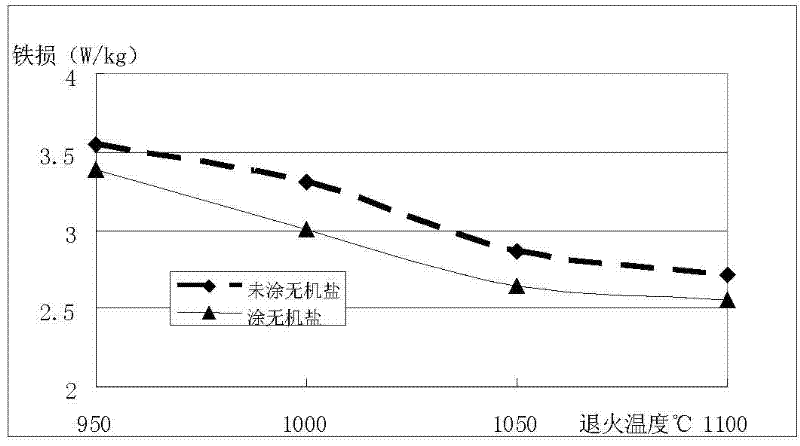

Method for Improving Magnetic Properties of Cold Rolled Non-Oriented Silicon Steel

The invention discloses a method for improving the magnetic properties of cold rolling non-oriented silicon steel, which comprises the following steps of : acid-washing, cold rolling and continuously annealing; the step continuously annealing: adding an inorganic salt coating device in a continuous annealing and washing system, and uniformly coating a layer of inorganic salt solution on a cold-rolled silicon steel strip through the inorganic salt coating device, wherein the inorganic salt solution contains the following components in weight percentage: 0.5-5.0% of K2CO3, l0.5-2% of NaC10, 1-8% of MgO and the rest of H2O, the coating quantity of the inorganic salt solution is 1-50gm<3>, the plate passing speed is 5-400m / min, and the coated silicon steel strip is dried in a hot air drier, and then, a layer of brown-back fayalite film is formed on the surface of the coated silicon steel strip; and carrying out degradation and decarburization to the silicon steel. In the invention, after the cold-rolled silicon steel is coated with the inorganic salt to form the brown-back fayalite film, so that the decarburization effect is improved, the internal oxidation of the silicon strip can be reduced, and the magnetic properties of the silicon steel strip finished product can be stably improved.

Owner:北京中钢贸科技发展有限公司

Novel heat storage brick and preparation method thereof

InactiveCN113716940AFast heat transferCompact structureCeramic materials productionClaywaresSteelmakingFayalite

The invention provides a method for preparing a heat storage brick by taking steelmaking oxidizing slag or copper slag fayalite as a main raw material, cooperatively using a proper amount of a binding agent and carrying out mixing, forming and low-temperature firing. Thus, the heat storage capacity and the volume stability of the heat storage brick are improved, and meanwhile, cost is low.

Owner:SHANDONG KEXIN NEW MATERIALS +1

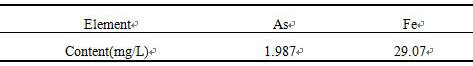

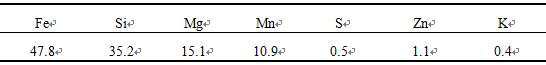

Method for treating arsenic-containing waste acid by taking fayalite as in-situ iron source

PendingCN112028330ALow costReduce dosageWater contaminantsTreatment involving filtrationFayaliteSludge

The invention relates to a method for treating arsenic-containing waste acid by taking fayalite as an in-situ iron source, and belongs to the technical field of heavy metal pollution treatment. The preparation method comprises the following steps: ball-milling fayalite until the particle size is not greater than 45 microns to obtain fayalite powder; adding H2O2 into waste acid, conducting uniformmixing, then adding the fayalite powder, conducting uniform mixing, and conducting stirring and pre-dissolving treatment for 2-6 h at room temperature to obtain a solid-liquid mixture; adjusting the pH value of the solid-liquid mixture to 1.5-4.0, carrying out arsenic removal reaction for 12-24 hours under the conditions of normal pressure and 85-95 DEG C, carrying out solid-liquid separation to obtain an arsenic-containing solid substance and filtrate, carrying out stockpiling treatment on the arsenic-containing solid substance, and carrying out deep arsenic removal treatment on the filtrate.According to the method, natural fayalite is used for removing arsenic, the stockpiling amount of sludge in the waste acid treatment process can be reduced, and meanwhile natural resources can be fully utilized.

Owner:KUNMING UNIV OF SCI & TECH

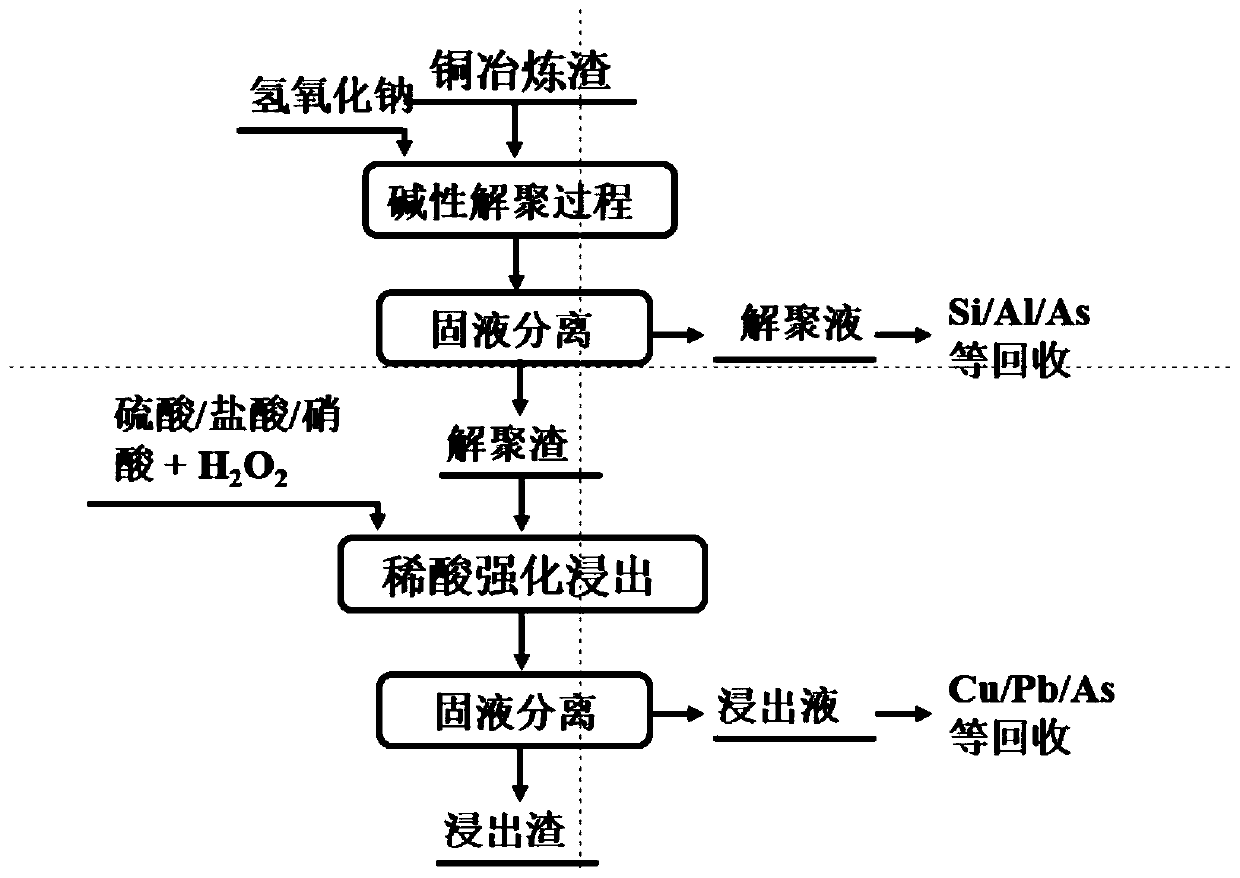

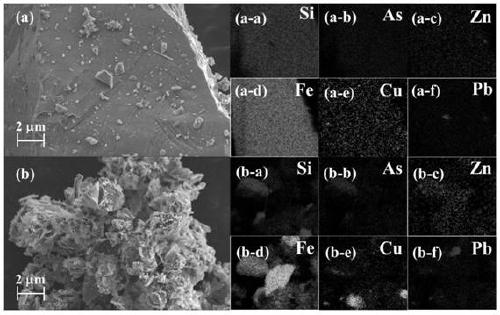

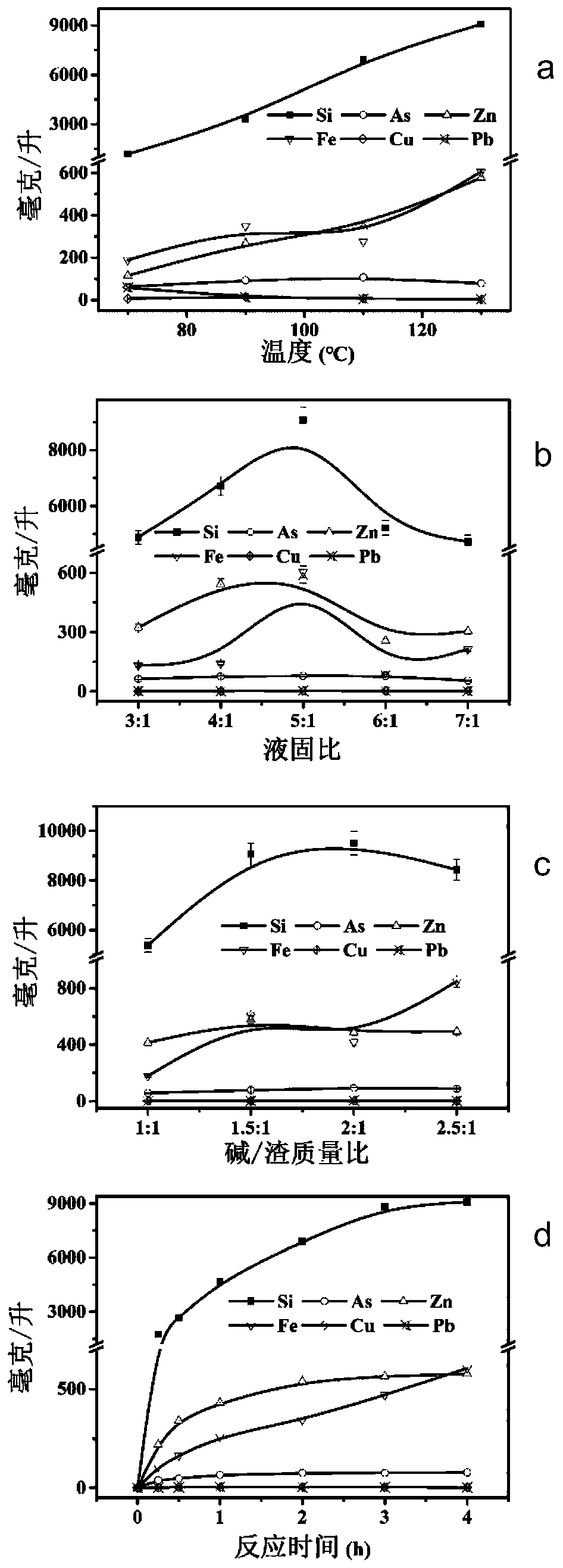

Harmless and reduction method of smelting slag rich in fayalite

InactiveCN111185463AEffective destructionReduce the risk of contaminationSolid waste disposalTransportation and packagingFayalitePregnant leach solution

The invention belongs to the technical field of harmlessness and recycling of metallurgical and bulk industrial smelting slag waste, and discloses a harmless and reduction method of smelting slag richin fayalite. The harmless and reduction method mainly adopts a hot alkali depolymerization-diluted acid enhanced leaching process, and includes the following steps that (1) the smelting slag rich infayalite is crushed and pulverized into powder, and the smelting slag is depolymerized with a hot alkaline solution to obtain depolymerized slag; and the alkaline solution is a sodium hydroxide solution or a potassium hydroxide solution; and (2) the depolymerized slag in the step (1) is subjected to agitation leaching reaction with a mixed system of diluted acid and oxidant to obtain a leaching solution and harmless and reduced slag. The test results show that the harmless and reduction method treats copper smelting slag rich in fayalite, harmful metals in the copper smelting slag are extracted, the leaching rate of the harmful metals As and Pb in the treated copper smelting slag reaches 99.7% and 99.9%, and the reduction rate of the copper smelting slag can reach 57%.

Owner:SOUTH CHINA UNIV OF TECH

Refractories and use thereof

The invention relates to a refractory in the form of a dry, mineral batch of fire-resistant mineral materials combined in such a way that refractories which are long-term resistant to fayalite-containing slags, sulfidic melts (mattes), sulfates and non-ferrous metal melts and are used for refractory linings in industrial non-ferrous metal melting furnaces can be manufactured, said refractory at least containing: - at least one coarse-grained magnesia raw material as the main component; - magnesia (MgO) meal; - at least one fire-resistant reagent which, during the melting process, acts (in situ) in a reducing manner on non-ferrous metal oxide melts and / or non-ferrous metal iron oxide melts and converts same into non-ferrous metal melts.

Owner:REFRATECHNIK HLDG GMBH

Preparation method of high-titanium and high-water-content magnesium fayalite single crystal

ActiveCN113897665AControl silicon activityGood chemical stabilityPolycrystalline material growthFrom solid stateFayaliteSilicic acid

The invention discloses a preparation method of a high-titanium and high-water-content magnesium fayalite single crystal. The method comprises the following steps: preparing a mixture cylinder sample by taking solid magnesium nitrate hexahydrate powder, solid ferric nitrate nonahydrate (III) powder, liquid tetraethyl orthosilicate and liquid tetrabutyl titanate as initial raw materials according to the stoichiometry of magnesium fayalite; preparing a talc and brucite mixture water source round sheet with a weight ratio of 10: 1 by taking solid natural talc powder and solid natural brucite powder as starting raw materials; placing the water source round sheet at two ends of the mixture cylinder sample; and putting the mixture cylinder sample and the water source round sheet into a gold-palladium alloy sample tube, and carrying out high-temperature and high-pressure reaction to prepare high-titanium and high-water-content magnesium fayalite single crystals. According to the invention, the technical blank of preparation of high-titanium and high-water-content Mars mantle magnesium fayalite at present is solved, and a large-particle high-titanium and high-water-content magnesium fayalite single crystal experimental sample is obtained.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Depolymerization method of smelting slag rich in fayalite

InactiveCN111154969AGood depolymerization effectDepolymerization is effectiveProcess efficiency improvementFayalitePregnant leach solution

The invention belongs to the field of harmless and resource-based bulk solid waste, and particularly relates to a depolymerization method of smelting slag rich in fayalite. The depolymerization methodcomprises the following steps that (1) the smelting slag rich in the fayalite is crashed and grinded into powder, obtained smelting slag powder in a hot alkaline solution is subjected to depolymerization reaction, and the alkali solution is a sodium hydroxide solution or a potassium hydroxide solution; and (2) reaction products obtained in the step (1) are separated by solid-liquid separation toobtain a leaching solution and depolymerization slag. According to the depolymerization method of the smelting slag rich in the fayalite, hot alkali depolymerization of the fayalite in the copper smelting slag at a lower temperature is effectively achieved, and thus wrapped harmful and valuable components are exposed; and at the same time, the invention further provides an effective pre-treatmentmethod for harmless treatment and reduction recovery of the smelting slag rich in a fayalite phase.

Owner:SOUTH CHINA UNIV OF TECH

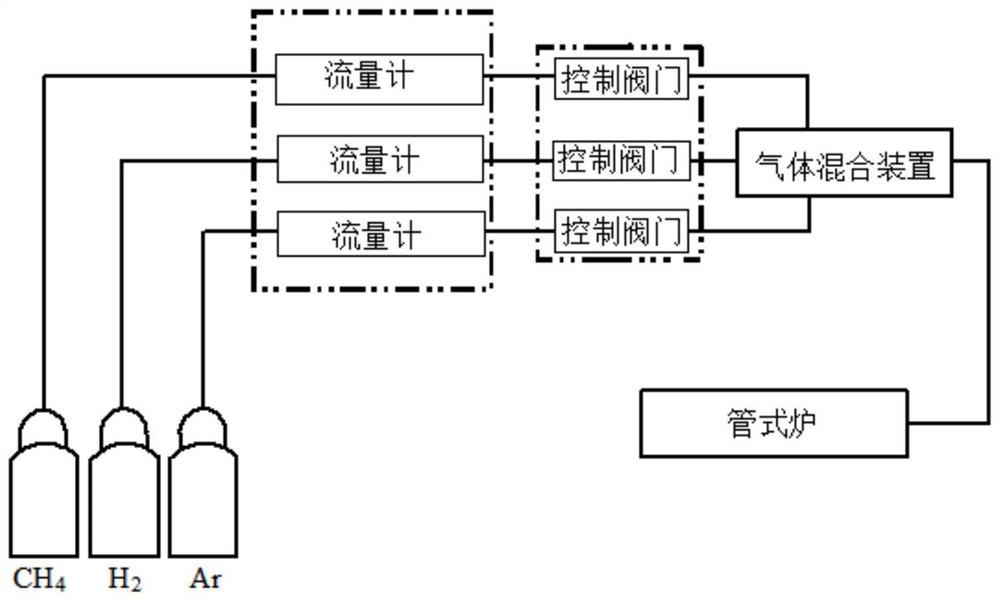

Method for comprehensively recovering various valuable metals in copper slag floating copper tailings

ActiveCN113061738AImprove resource utilizationLow reduction temperatureFlotationMagnetic separationFayaliteMagnetite

The invention discloses a method for comprehensively recovering various valuable metals in copper slag floating copper tailings, and belongs to the technical field of metal element recovery. The method comprises the steps of direct reduction roasting, magnetic separation and reverse flotation. According to the method for comprehensively recovering the various valuable metals in the copper slag floating copper tailings provided by the invention, the mixed gas of methane, hydrogen and argon is introduced for direct reduction roasting, magnetite in the copper slag can be completely converted into metal iron, and a composite additive is matched for dissociating fayalite in the copper slag, so that the purpose of resourceful ore phase reconstruction is achieved; and a phase composition in the copper slag is improved, an iron phase in the slag is subjected to a decomposition reaction, and lead and zinc are gasified in the form of metal steam, so that the various valuable metals in the copper slag are comprehensively recycled. Meanwhile, roasting products are treated through magnetic separation and reverse flotation, so that the iron ore concentrate grade is effectively improved, the effective utilization rate of resources is high, the recycling process is simple, energy consumption is low, and high economic benefits are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Fayalite material with copper slag as main material and preparation method thereof

The invention relates to a fayalite material with copper slag as a main material and a preparation method thereof. The preparation method comprises the following steps: immersing copper slag particles in boiling water for 1-3 h, filtering, drying, and screening; placing the screened copper slag particles into a muffle furnace, and calcining at 700-850 DEG C for 1-3 h to obtain calcined copper slag particles; adding a hydrochloric acid solution to the calcined copper slag particles, stirring, washing and carrying out suction filtration to prepare a precursor copper slag particles; wet-grinding the precursor copper slag particles until the granularity is less than or equal to 60 microns so as to prepare wet-ground copper slag powder; adding the wet-ground copper slag powder and powdered coke into a pug mill, carrying out vacuum extrusion moulding, storing the product for 24-36 h; placing the product into an electric resistance furnace and heating to 1100-1150 DEG C, carrying out thermal insulation for 1-3 h, and cooling with the furnace so as to prepare the fayalite material with copper slag as the main material. The method has advantages of simple process, low energy consumption, low production cost and no special requirement on equipment. The prepared product has good sintering performance and high fayalite conversion rate.

Owner:射阳县金丹实业有限公司

Method for reducing and extracting copper smelting waste slag through microwave carbon heating

The invention relates to a method for reducing and extracting copper smelting waste slag through microwave carbon heating, which comprises the following steps: pulverizing copper slag, reducing agents (one material or a mixture of several materials in anthracitic coal, graphite, refinery coke and coke) and calcium oxide or calcium carbonate; mixing the ingredients; adding binding agents for briquetting; drying the materials; then, carrying out mineral phase reconstruction and carbon heat reduction reaction at the high temperature through using microwaves as heating sources; converting fayalite in the slag into ferric oxide, and reducing the ferric oxide into iron; and then, separating and recovering the iron through pulverization and magnetic selection separation. After further copper recovery, nonmagnetic products can be used as raw materials for firing cement.

Owner:KUNMING UNIV OF SCI & TECH

A kind of fayalite type slag desiliconization method

The invention provides a fayalite type slag desiliconization method and relates to the technical field of mineral engineering. The fayalite type slag desiliconization method comprises the following steps of S1, performing powder grinding on slag, wherein the slag includes at least one of copper slag and nickel slag; step S2, roasting the ground slag to obtain an activated clinker; S3, grinding theactivated clinker into powder, and adding the powder into alkali liquor to be subjected to alkali leaching; and S4, performing solid-liquid separation on ore pulp obtained by alkali leaching to obtain a silicon-contained alkali liquor and iron concentrates. In the fayalite type slag desiliconization method provided by the invention, by controlling appropriate roasting temperature and roasting time, silicon and iron in the slag are thoroughly separated, so that subsequent desiliconization with alkali leaching is facilitated; the silicon oxide removal rate is high, and resource utilization of silicon resources and other valuable metals in the slag is realized at the same time, so that the fayalite type slag desiliconization method is simple in process flow and low in cost, can realize desiliconization of fayalite type slag, such as the copper slag and the nickel slag, which is difficult to treat and has a wide application prospect and good economic benefit.

Owner:WUHAN UNIV OF TECH

Method For Co-Extraction Of Vanadium, Titanium And Chromium From Vanadium Slag

The present disclosure provides a method for co-extraction of vanadium, titanium and chromium from vanadium slag. The method selectively reduces pyroxene and fayalite wrapped on spinel through low-temperature hydrogen reduction, iron removal by ferric chloride, and low-temperature leaching of the vanadium slag by oxalic acid, thereby destroying a structure of the spinel, dissociating a spinel phase and a silicate phase, and fully exposing the spinel phase. The method also directly leaches the vanadium slag at a low temperature by acidity and strong complexation of the oxalic acid, and destroys the structure of the spinel, such that vanadium, titanium, chromium and oxalate are complexed into a solution to co-extract vanadium, titanium and chromium. The present disclosure extracts vanadium, titanium and chromium from the vanadium slag, with a leaching rate each being greater than 99%.

Owner:UNIV OF SCI & TECH BEIJING

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com