Rotary kiln mineralization agent and method for manufacturing same

A mineralizer and raw material technology, applied in the field of rotary kiln mineralizer and its manufacturing, can solve the problems of low utilization rate, power consumption, large coal consumption, low efficiency, etc., to speed up the formation of clinker minerals, accelerate the solidification Response and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A rotary kiln mineralizer, the raw materials of the rotary kiln mineralizer are as follows by weight:

[0012] Wollastonite 0~5 parts Wollastonite 5~15 parts

[0013] Dolomite 5-45 parts Fayalite 5-15 parts

[0014] Zeolite 10-40 parts Fluorite 0-10 parts

[0015] The invention discloses a method for manufacturing a rotary kiln mineralizer. The rotary kiln mineralizer is crushed separately, mixed with ingredients, and packaged into a finished product.

Embodiment 2

[0017] The optimal ratio of raw materials for rotary kiln mineralizer by weight is as follows:

[0018] Wollastonite 5 parts Wollastonite 10 parts

[0019] Dolomite 40 parts Fayalite 5 parts

[0020] Zeolite 35 parts Fluorite 5 parts

[0021] The invention discloses a method for manufacturing a rotary kiln mineralizer. The rotary kiln mineralizer is crushed separately, mixed with ingredients, and packaged into a finished product.

Embodiment 3

[0023] Another group of optimal ratios of raw materials for rotary kiln mineralizers by weight is as follows:

[0024] Wollastonite 5 parts Wollastonite 5 parts

[0025] Dolomite 35 parts Fayalite 10 parts

[0026] Zeolite 40 parts Fluorite 5 parts

[0027] The invention discloses a method for manufacturing a rotary kiln mineralizer. The rotary kiln mineralizer is crushed separately, mixed with ingredients, and packaged into a finished product.

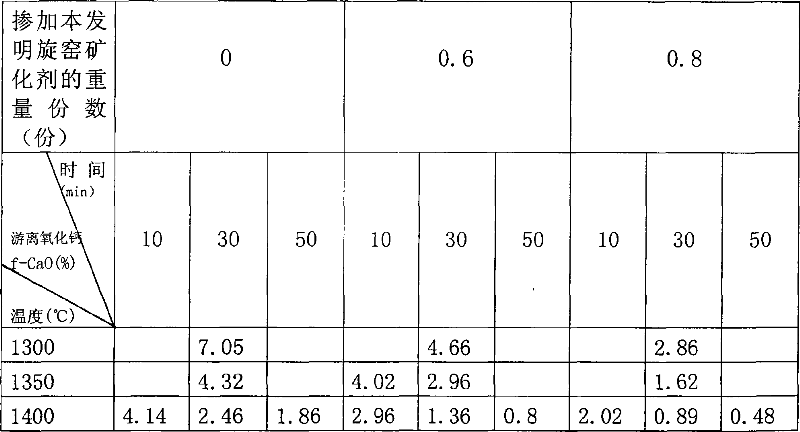

[0028] With the cement raw material that same batching is formed, first calcinate high-quality cement clinker by general method, mix the rotary kiln mineralizer of the present invention and do not mix the rotary kiln mineralizer of the present invention to free calcium oxide (f-CaO) in the cement clinker ) The comparison of the influence of the content is as follows:

[0029]

[0030] Numbering

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com