Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158 results about "Tricalcium aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tricalcium aluminate Ca₃Al₂O₆, often formulated as 3CaO·Al₂O₃ to highlight the proportions of the oxides from which it is made, is the most basic of the calcium aluminates. It does not occur in nature, but is an important mineral phase in Portland cement.

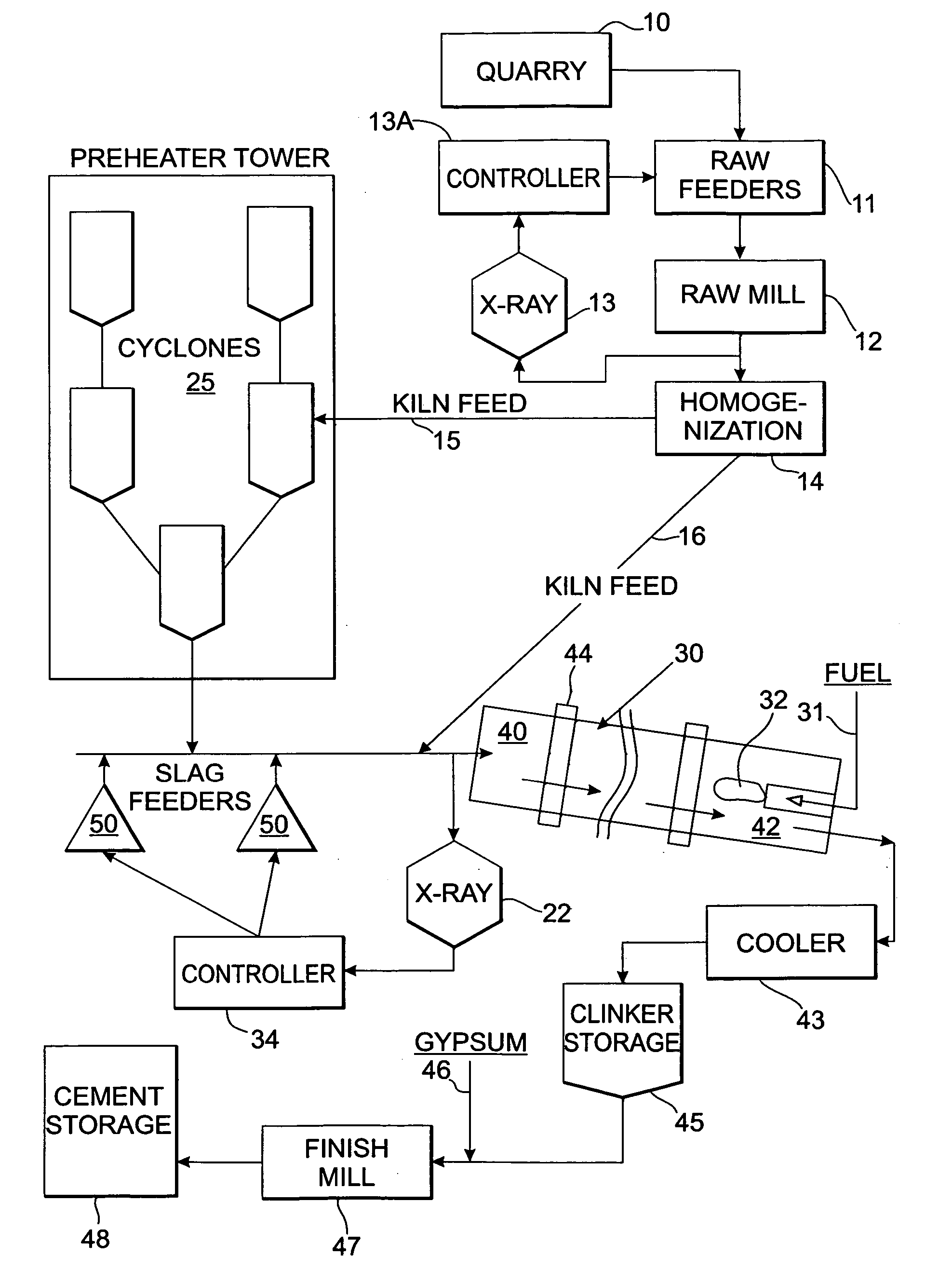

Method and apparatus for control of kiln feed chemistry in cement clinker production

InactiveUS20050132933A1Easy to changeLower the heatTransportation and packagingRotary drum furnacesRefractory wearChemical composition

A method and apparatus for controlling cement clinker production uses a detection device disposed proximate to the feed end of a rotary cement kiln to detect the chemical analysis of a combined additive / kiln feed mixture. A controller changes the feed rate of the additive feeder to adjust for differences between the detected chemical composition and a chemical target specification such as tricalcium silicate, tricalcium aluminate, lime saturation, silica ratio or aluminum to iron ratio. The timely and convenient adjustment of kiln feed chemistry provides more uniform kiln feed chemistry resulting in better kiln operation in terms of productivity, fuel efficiency and less refractory wear. This method and apparatus can provide chemical adjustments for different grades of clinker.

Owner:BLUM BERNARD

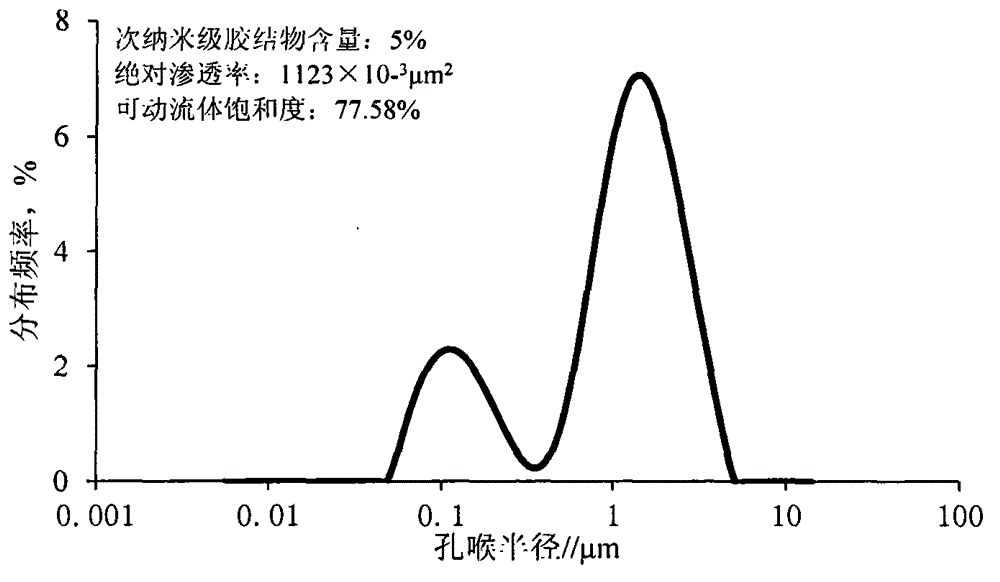

Artificial core containing controllable and movable fluid, and manufacturing method of artificial core

InactiveCN104390825AOvercoming the problem of poor simulation accuracyPrecise pore distributionPreparing sample for investigationEpoxySilicic acid

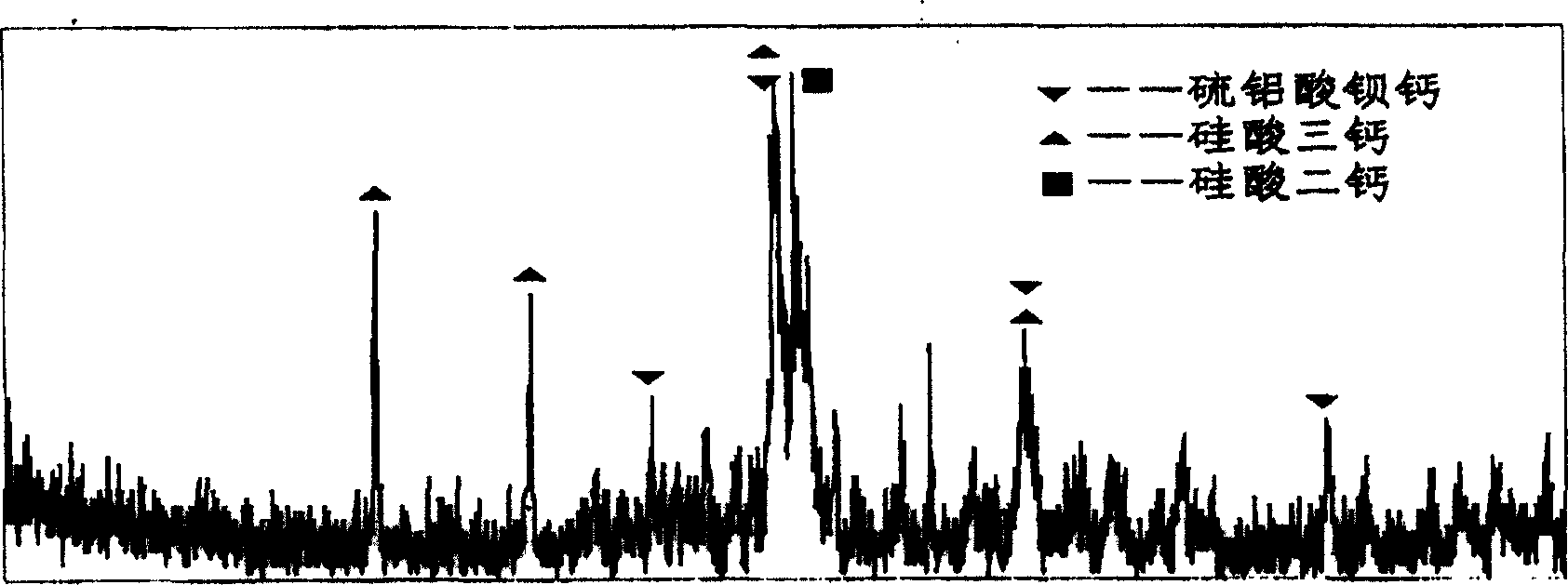

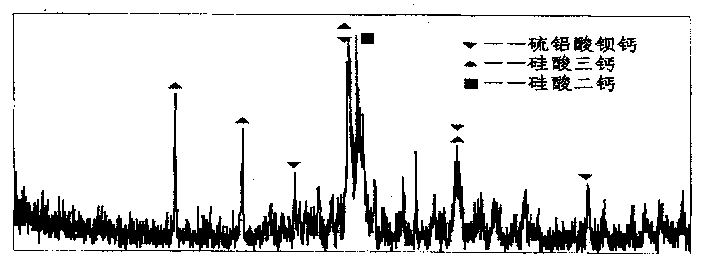

The invention relates to an artificial core containing controllable and movable fluid, and a manufacturing method of the artificial core. The manufacturing method mainly comprises the following steps: firstly, evenly stirring quartz sand, traditional epoxy resin cement and sub-nanoscale powder cement, wherein the median particle diameter of the sub-nanoscale powder cement is within the range from 0.7 to 1.0mu m, and the sub-nanoscale powder cement is formed by tricalcium silicate, dicalcium silicate, tricalcium aluminate and crystallized calcium sulfate according to the mass ratio of (0.20-0.25) to (0.30-0.35) to (0.25-0.35) to (0.20-0.30); putting the mixture into a cylindrical steel mould, pressurizing, and drying at high temperature to obtain the artificial core. Due to the change of proportions of two types of mixtures, the artificial core has better similarity with the natural core in the macroscopic aspects such as porosity and permeability, and the distribution proportion of the movable fluid is changed within the specific range on the basis that different levels of pores in the artificial core reach the specific proportion; furthermore, the artificial core is higher in accuracy, thus meeting the experimental demands such as oil field three-mining chemical flooding optimization, and microscopic use law.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Slow-setting cement for highway roadbeds

ActiveCN102173612AProlong initial setting timeImprove uniformitySolid waste managementSocial benefitsCompressive strength

The invention discloses slow-setting cement for highway roadbeds, which is prepared from the following raw materials in parts by weight: 53 to 60 parts of clinker, 3 to 5 parts of desulfurized gypsum, 1 to 6 parts of desulfurized ash, 15 to 20 parts of limestone, 15 to 25 parts of fly ash, and 0.04 to 0.1 part of slow-setting agent. The clinker mainly contains the following ingredients in percentage by weight: 54 to 62 percent of tricalcium silicate, 15 to 20 percent of dicalcium silicate, 6.7 to l8.7 percent of tricalcium aluminate, and 11 to 13 percent of tetracalcium aluminoferrite. The slow-setting cement provided by the invention is characterized in that: the initial setting time is increased to more than 4 hours, and the final setting time is increased to more than 6 hours; the bending strength (3 days) is more than or equal to 3.6 Mpa, and the compressive strength (3 days) is more than or equal to 17.2 Mpa; the bending strength (28 days) is more than or equal to 6.6 Mpa, and the compressive strength (28 days) is more than or equal to 37.4 Mpa; the performance is better than that of other cement products of the same strength grade and meets the construction requirements for highway roadbeds; and the market prospects are good and the social benefits are increased.

Owner:广州市越堡水泥有限公司

Admixture special for high performance shotcrete

Belonging to the technical field of construction engineering, the invention in particular relates to an admixture special for high performance shotcrete. The special admixture comprises two main components: a cohesive component and an early strength component in a mass ratio of 60-70:30-40. Specifically, the cohesive component is a mixture of modified latex powder and a superfine mineral admixturein a mass ratio of 20-30:70-80, and the early strength component is high activity tricalcium aluminate. Through the synergistic effect of the cohesive component and the early strength component, thespecial admixture provided by the invention effectively improves the cohesiveness and early strength of shotcrete, thereby reducing the resilience of shotcrete and improving the compactness. The material can provide an effective way for really realizing high performance of shotcrete.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

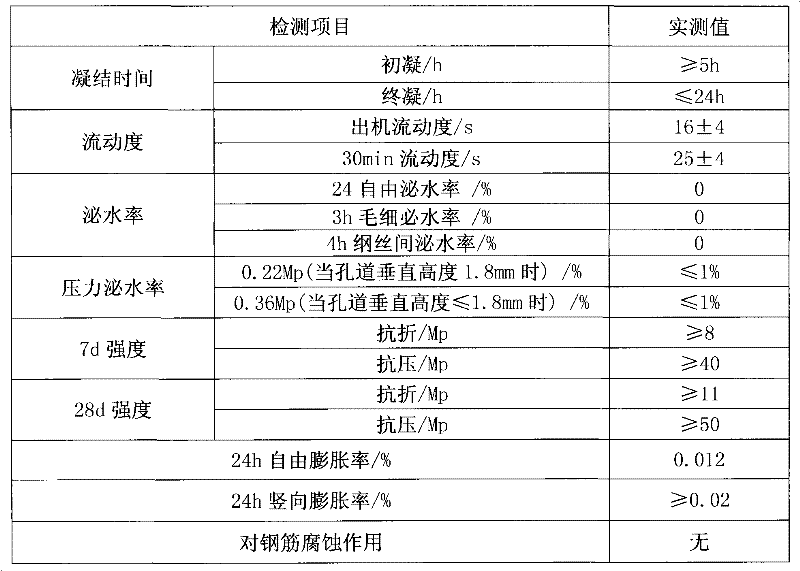

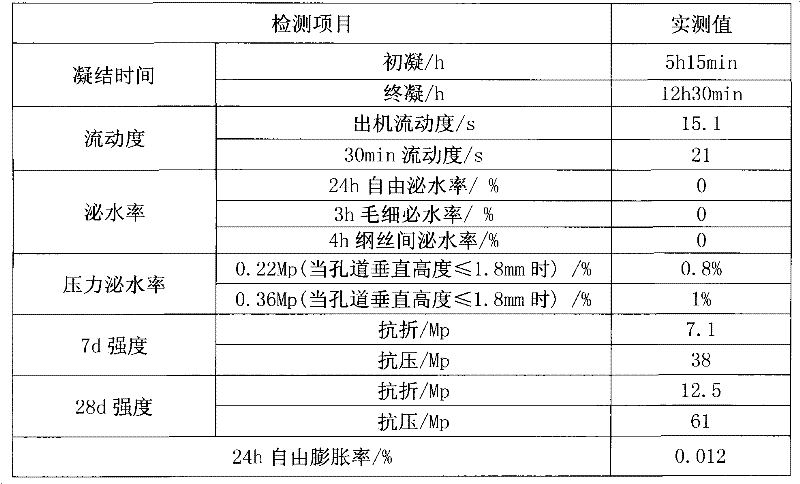

Grouting material, premix of grouting material, and preparation method of premix

The invention relates to a premix of a grouting material. The premix is characterized in that the premix comprises the following components, by weight, 65-90% of ordinary portland cement with the strength level of 42.5MPa or low alkaline cement with the strength level of greater than 42.5MPa, wherein the water demand for normal consistency is less than 25%, and the tricalcium aluminate content is lower than 8%; 2-29.696% of an ultrafine mineral admixture with a specific surface area of greater than 450m<2> / kg, a water demand ratio of less than 95%, and a 28d activity index of greater than 90%; 5-15% of calcium sulphoaluminate; 0.1-1.5% of a melamine water reducer; 0.002-0.2% of a cellulose polymer, an acrylic polymer or polyoxyethylene; 0.1-1.0% of a carbohydrate, a hydroxycarboxylic acid compound and salts thereof, a sulfate, a carbonate, or calcium formate; 0.002-0.1% of vinyl acetate-ethylene copolymerized rubber powder; and 0.1-1.0% of a chromate or a borate.

Owner:王小清

Mineral trioxide aggregate (MTA) composition and use

ActiveUS20120156308A1Good strength developmentFast setting timeHeavy metal active ingredientsBiocideDiseaseHigh fluoride

The present application discloses a fast-setting mineral trioxide aggregate (MTA) with fluoride release for practical treatment of diseases in teeth and bone, e.g. for caries treatment and / or prevention. The cariostatic MTA contain calcia-silica-alumina cement with moderately increased tricalcium aluminate content allowing high calcium hydroxide release. The MTA composition support remineralization and biomineralization, and it is suitable for stimulation of hard tissue regeneration. MTA embodiments contain superplasticizerand nanosilicate for improved mechanical properties. The MTA compositions include optional radiocontrast and nano-enriched leachable fluorine, nitrate, strontium, and phosphate. The fast-setting MTA paste exhibits flow-to-clay-like consistency, which allows new practical applications including cavity lining, temporary restoration, bonding, and cementations in one MTA embodiment. The high calcium hydroxide and high fluoride release are suitable for caries prevention and treatment, and per se inhibition of dental symptoms.

Owner:DENTOSOLVE APS

Cementitous material

A cementitious material is provided that includes a phosphate based component and an alkali earth component. The alkali earth ion component has as a majority source a calcium aluminate calcium ion source of dodeca-calcium hepta-aluminate, or tricalcium aluminate. Magnesium oxide that has been fused and crushed to a size of less than 200 microns, alone or in combination with the calcium aluminate calcium ion source is also provided as the alkali earth ion component. When the phosphate based component and alkali earth ion components are combined in appropriate proportions, a rigid structure is obtained. A cementitious material formulation is also provided having an aqueous acidic phosphate solution as a part B and an alkali earth ion source as a part A that includes calcium aluminate, magnesium oxide or a combination thereof. Other additives include strength enhancing insoluble phosphate additive, an impurity metal reaction suppressant, tackifiers, anti-foaming agents, and the like.

Owner:STELLAR MATERIALS

Negative electrodes of alkaline batteries and their methods of fabrication

InactiveUS20050244714A1Improve cycle lifeLarge capacityNon-metal conductorsFinal product manufactureTricalcium aluminateMaterials science

The present invention discloses negative electrodes for alkaline storage batteries and their methods of fabrication. The material for said negative electrode comprises of an additive that has at least one calcium compound selected from the following: tricalcium silicate, dicalcium silicate, and tricalcium aluminate. The concentration of said additive is between 1 wt % and 15 wt % of the material of said negative electrode. To fabricate said negative electrode, said additive is mixed with an active material for the negative electrode to form a paste, which is then dried. This method of fabrication is simple, convenient and low in cost. An alkaline battery using said material for its negative electrode has long cycle life and a large capacity.

Owner:BYD AMERICA CORP

Hydrated calcium aluminate nano crystal nucleus early strength agent and preparation method thereof

The invention relates to a hydrated calcium aluminate nano crystal nucleus early strength agent and a preparation method thereof. The hydrated calcium aluminate nano crystal nucleus early strength agent is prepared from the following ingredients of tricalcium aluminate, dihydrate gypsum, a dispersion stabilizer and deionized water, wherein a molar ratio of the tricalcium aluminate to the dihydrategypsum is 1 to (1 to 3); the dispersion stabilizer is a mixed solution which is prepared by dissolving a polycarboxylate superplasticizer, triethanolamine and tri-isopropanolamine into water according to the mass ratio as (10 to 30) to 1 to (1 to 3), and the mass concentration of the mixed solution is 10%. The hydrated calcium aluminate nano crystal nucleus early strength agent disclosed by the invention can obviously improve early strength of cement mortar; the hydrated calcium aluminate nano crystal nucleus early strength agent is doped into ordinary Portland cement mortar according to thedoping amount as 1.0 to 2.0%, 1d strength can be improved by 85% or more; the hydrated calcium aluminate nano crystal nucleus early strength agent can be widely applied to concrete prefabricated parts, so that maintenance time with molds is shortened, the turnover rate of the molds is improved, and the production efficiency is effectively improved.

Owner:WUHAN UNIV OF TECH

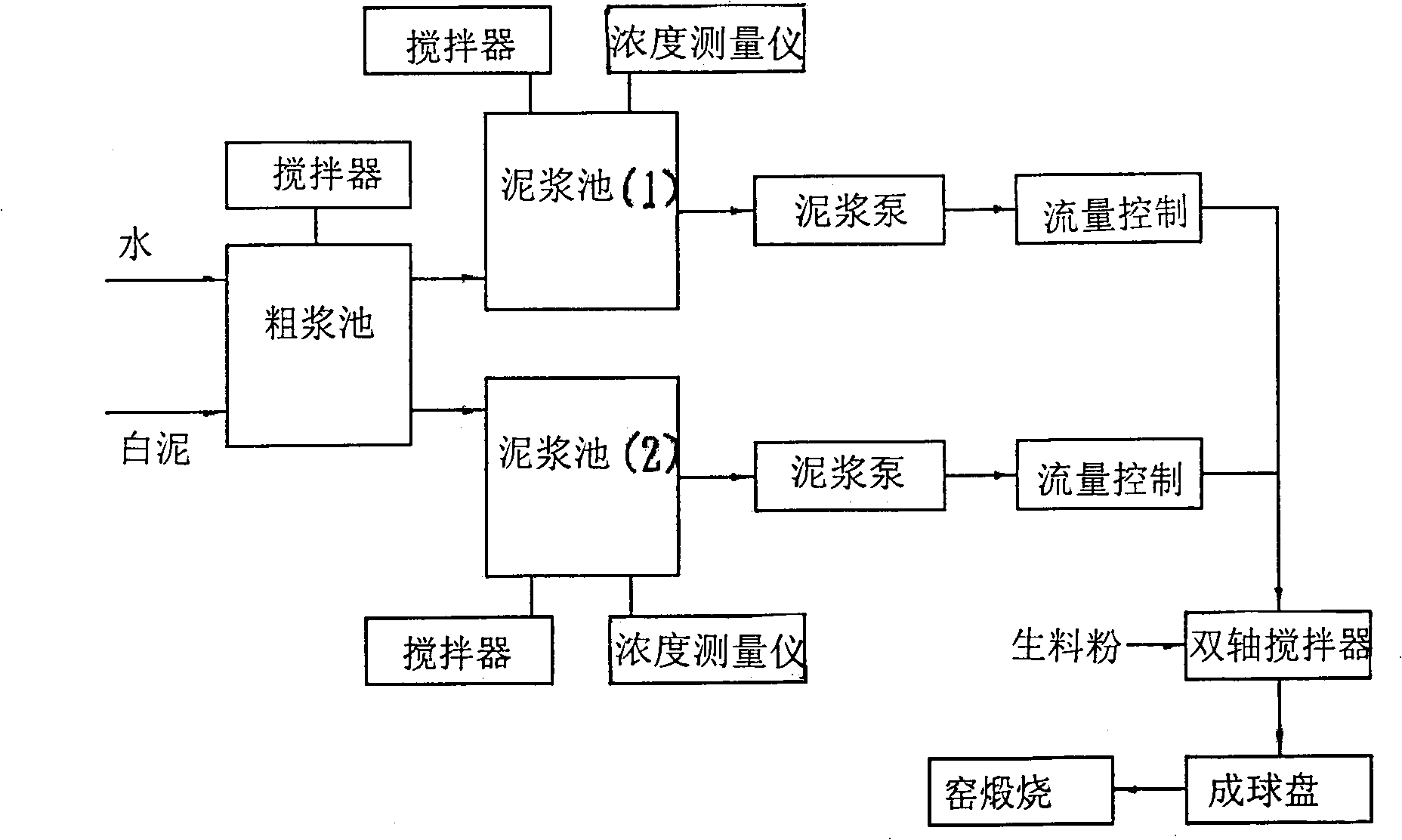

Method for producing cement clinker from paper manufacture waste slag mud

The invention relates to a method for producing cement clinker by using papermaking waste residues and white mud, the process steps are as follows: preparation of raw materials: the consumed raw materials are 1.6 times the clinker; the limestone raw material in the raw materials accounts for 73 percent of the raw materials according to the weight ratio, the limestone raw material is replaced by the white mud, and the white mud accounts for 32.3 percent of the weight of the limestone raw material; the white mud is stirred after the dilution by adding water, then the white mud is sent to a dual-shaft stirring machine via a nozzle by using a high-pressure slurry pump to be mixed with raw material powder, thereby replacing the water for ball shaping, then the mixture is pelletized by a ball shaping disk and then enters a kiln for calcination; the clinker is calcinated; the raw materials are arranged in the cement kiln after the ball shaping for calcination till part of the raw materials are melted, thereby obtaining the silicate cement clinker which takes tricalcium silicate, dicalcium silicate, tricalcium aluminate and tetracalcium aluminoferrite as main ingredients. The method has the advantages that: the white mud replaces the limestone raw material which accounts for 32.3 percent by weight, thereby solving the problems of the environmental pollution and the land occupation caused by the white mud wastes; the method is simple, the drying is not used, the drying investment is saved, the clinker quality can meet the requirements, and the adaptability to the performances of the raw materials is strong.

Owner:缪建通

Alite-barium calcium sulfur aluminate cement

An Alinty-barium calcium thioaluminate cement contains barium calcium thioaluminate (3-38 wt.%), tricalcium aluminate (3-20), tricalcium silicate (30-60), dicalcium silicate (15-40), and ferroaluminate (3-20). Its advantages are low burning temp, high early strength and hardening speed, and low cost.

Owner:UNIV OF JINAN

Concrete-autolysis-type rapid self-repairing system in water environment and preparing method thereof

The invention relates to a concrete-autolysis-type rapid self-repairing system in the water environment. The concrete-autolysis-type rapid self-repairing system comprises a concrete base body and autolysis-type composite microspheres with which the concrete base body is filled, the surfaces of the autolysis-type composite microspheres are coated with autolysis-type protective films, and complex minerals formed by mixing tricalcium silicate and tricalcium aluminate are arranged in the centers of the autolysis-type composite microspheres. Compared with the prior art, the autolysis-type rapid self-repairing system can be widely applied to the hydraulic concrete structure, the marine concrete structure and the underground concrete structure, self healing of concrete cracked in the water environment can be generated, cost is low, the effect is remarkable, the problems that a traditional repairing method is large in cost and poor in effect are solved, and durability of the concrete is improved.

Owner:TONGJI UNIV

Low-heat anti-cracking portland cement

The invention discloses low-heat anti-cracking Portland cement. The cement clinker of the cement consists of the following minerals in percentage by weight: 40 to 70 percent of dicalcium silicate, 10 to 35 percent of tricalcium silicate, 1 to 4 percent of tricalcium aluminate, 15 to 30 percent of tetra calcium aluminoferrite, and 0.1 to 0.8 percent of free calcium oxide, wherein the content of magnesium oxide in the cement is between 3.5 and 5.0 percent, the content of alkali is not more than 0.55 percent, and the content of sulfur trioxide is not more than 3.5 percent. The cement has the main technical indexes that the ignition loss is less than or equal to 3wt%, the specific area is less than or equal to 340m<2> / kg, the stability is qualified, 3-day tensile strength is not required, the 7-day tensile strength is more than or equal to 13MPa, the 28-day tensile strength is between 42.5MPa and 52.5MPa, the 3-day breaking strength is not required, the 7-day breaking strength is more than or equal to 3.5MPa, the 28-day breaking strength is more than or equal to 7.0MPa, the 3-day hydration heat is less than or equal to 220KJ / kg, and the 7-day tensile strength is less than or equal to 250KJ / kg. The cement can be used for remarkably improving the cracking resistance of hydraulic concrete.

Owner:CHINA THREE GORGES CORPORATION

Solidification material prepared from incineration residue material as well as production method and application thereof

The inventon provides a solidification material prepared from incineration residue material as well as a production method and application thereof. The solidification material is prepared by the following components in percentage by weight: 30-40 percent of domestic garbage incineration residue, 30-40 percent of pulverized fuel ash, 10-20 percent of cement clinker, and 5-10 percent of gypsum, wherein the selected incineration residue contains metal objects, the total mount of which is within 1 percent, and is dried to have moisture within 1 percent, the selected pulverized fuel ash contains high-calcium ash and moisture which are both within 1 percent; the selected cement clinker contains tricalcium aluminate and tetracalcium aluminoferrite the contents of which are respectively with 6 percent and above 18 percent; and the selected gypsum contents sulfur trioxide, the content of which is more than 45 percent, and are smashed to below 20 mm. The invention can be used as the solidification material for a road surface subbase course material.

Owner:上海寰保渣业处置有限公司 +2

Method for preparing tricalcium aluminate by aid of spark plasma sintering techniques

ActiveCN105600813AImprove homogeneityImprove compactnessCalcium aluminatesChemical industryAxial pressureMicrometer

The invention relates to a method for preparing tricalcium aluminate by the aid of spark plasma sintering techniques. The method includes analyzing raw materials which are pure calcium carbonate CaCO3 and pure gamma-phase aluminum oxide gamma-Al2O3; carrying out ball-milling on the pure calcium carbonate and the pure gamma-phase aluminum oxide and then controlling the heating rates and the cooling rate of a spark plasma sintering furnace under the conditions of vacuum degrees of (30-50) Pa, pulse ratios (ON / OFF) of (6 / 1-48 / 8) and axial pressures of (1-3) kN; fetching samples out of the spark plasma sintering furnace when the temperatures of the samples are reduced and reach (60-90) DEG C and grinding the samples to obtain particles with the sizes smaller than 20 micrometers so as to obtain the tricalcium aluminate. The method is simple and convenient, and the synthesis efficiency is improved by (10-20) times as compared with the traditional method. The method has the advantages of speediness, high efficiency and energy conservation.

Owner:WUHAN UNIV

Quick-hardening earyly-strenthening cement for oil well

The present invention is characterized by that it is formed from mineral components of tricalcium silicate, tricalcium aluminate, sulful trioxide, dicalcium silicate and tetracalcium iron columinate, when the cement is used, the early-strength agent can be added, and when the clinker prepared and roasted according to the requirements for cement composition is used for grinding to prepare cement, the additive can be added. As compared with existent other oil well cemkent said oil well cement has the excellent performances of high early strength, low water loss, slight expansion and short setting time, etc.

Owner:JIAHUA SPECIAL CEMENT

Method for preparing low-carbon cement clinker by utilizing iron tailings

ActiveCN103373826ARaise the intensity levelReduce intensity levelCement productionCement mortarMaterials science

The invention provides a method for preparing low-carbon cement clinker by utilizing iron tailings. The method for preparing the low-carbon cement clinker comprises the step of firing the iron tailings and limestone as main raw materials at the temperature lower than 1400 DEG C. The low-carbon cement clinker comprises the following mineral compositions: 70-85% of dicalcium silicate, 5-15% of tricalcium silicate, 0-5% of tricalcium aluminate and 4-15% of tetra calcium aluminoferrite. The method has the advantages that the proportion of iron tailings in the raw materials can be up to 32%; in addition, compared with the firing temperature 1450 DEG C of traditional portland cement clinker, the firing temperature is reduced by 50-150 DEG C; compared with the emission of the greenhouse gases in traditional cement production, the emission of CO2 and other NOx-based greenhouse gases is reduced by about 20%. The cement prepared by utilizing the low-carbon cement clinker has the advantages that the 28-day strength can be up to 65-75 MPa; the strength grade is up to 62.5; the cement mortar dispersion degree can be up to 135-200mm; the cement is low in the hydration heat, good in safety and excellent in working performance.

Owner:承德金隅水泥有限责任公司

Functional aggregate and preparation method thereof

The invention belongs to the field of concrete materials, and specifically relates to a functional aggregate and a preparation method thereof. The functional aggregate is characterized in that: the functional aggregate has a core-shell structure, and is composed of a porous core substrate and an alkaline surface active shell. Mullite is a main mineral phase of the porous core substrate, and a continuous phase is formed. Pores are distributed in the continuous phase. The pore sizes of the pores are distributed in a multilevel form. The pores are mainly micron-leveled pores. The mineral phase of the alkaline surface active shell is mainly composed of dicalcium silicate, tricalcium silicate, tricalcium aluminate, and tetracalcium iron aluminate. The functional aggregate provided by the invention has light weight and high strength. The functional aggregate can be internally cured, and has a surface active layer. When the functional aggregate is used in concrete, an interfacial transition zone (ITZ) can be completely enhanced and improved, cement stone structure formation can be regulated, and concrete overall performance can be improved. The preparation process is simple and controllable, and is easy to operate.

Owner:WUHAN UNIV OF TECH

Liquid fine-expansion pumping agent

The invention discloses a liquid micro-expansion pumping agent, comprising the following compositions, in weight percent: polymethylnaphthalene sodium sulfonate: 50 percent to 60 percent; dispersing agent: 5 percent to 10 percent; retarder: 10 percent to 20 percent; initiator: 4 percent to 6 percent; and water: 15 percent to 20 percent. The pumping agent adopts an organosilicon material as an expansion component and utilizes the silanization technique in the organosilicon industry to make silicane have reaction with an active group of a basic material and substitute active hydrogen on an organic molecule, when the silicane is in reaction with tricalcium aluminate, part of hydrogen can be released a plurality of hours later so as to form micro air bubbles in a cement paste, diameters of general air holes are under 0.1mm, thereby the concrete can produce the volume micro-expansion for compensating the volumetric shrinkage of concrete at the stage, in particular to the early-age plastic shrinkage in the high fluidity pumping concrete, so as to reduce plastic cracks.

Owner:浙江大东吴集团建设有限公司

Filtering material for deep treatment of sewage

InactiveCN1435382AVersatileGood effectSustainable biological treatmentFiltration separationPorositySolubility

A filtering material for deeply treating sewage by fixating P, removing N and active filtering by microbes is a granular one or a semi-finished cement clinker, which is prepared from the clay containing tricalcium silicate, dicalcium silicate, tricalcium aluminate and tetracalcium ferroaluminate through sintering. Its advantages are high porosity, self-regeneration and high effect.

Owner:唐文浩

WHDF-type water-reducing, seepage-proof and crack-resistant agent for concrete

ActiveCN102491670AImprove work performanceImprove anti-crack and anti-seepage performanceCalcium hydroxideMicroorganism

The invention relates to a WHDF-type water-reducing, seepage-proof and crack-resistant agent for concrete. The WHDF-type water-reducing, seepage-proof and crack-resistant agent for concrete comprises: by weight, 18 to 28% of a crystallization stimulation component, 12 to 18% of an activity stimulation component, 7 to 15% of a tricalcium aluminate inhibition component, 10 to 20% of a workability adjustment component, 2 to 6% of a microorganism control component and 30 to 40% of a coal ash component. The WHDF-type water-reducing, seepage-proof and crack-resistant agent for concrete can promote a cement hydration degree thereby optimizing hydration products and stimulating secondary hydration action between an active mixed material and calcium hydroxide, and thus the WHDF-type water-reducing, seepage-proof and crack-resistant agent for concrete can effectively improve concrete tensile strength, a ultimate tensile value, compaction performances and a crack-resistant capacity, and can reduce early hydration heat and air shrinkage of concrete and shrinkage-caused cracking. Concrete adopting the WHDF-type water-reducing, seepage-proof and crack-resistant agent for concrete has good seepage-proof and crack-resistant performances.

Owner:武汉天衣新材料有限公司

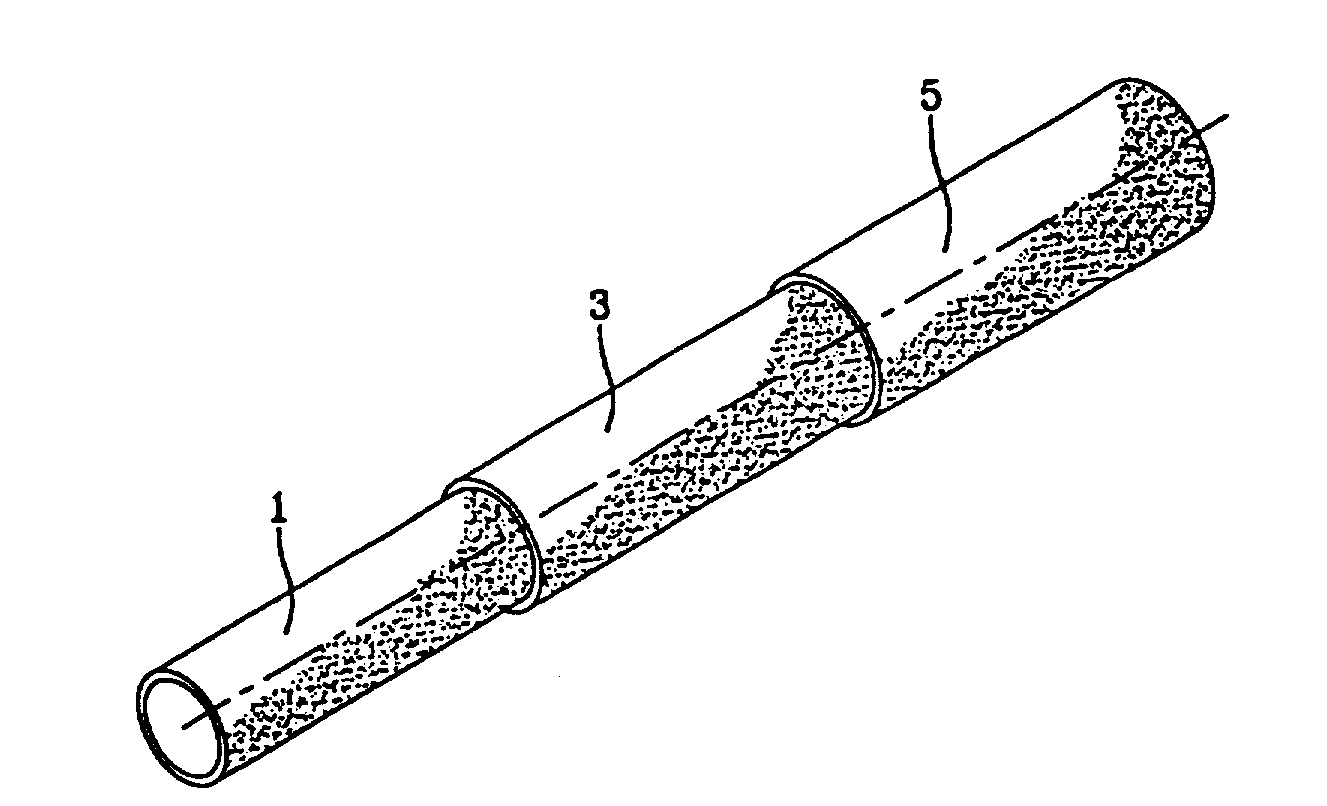

Hose construction containing fluoroelastomer composition and fluoroplastic barrier

The present invention relates to a hose comprising: a thermoplastic fluoropolymer barrier layer; and a rubber layer adjacent to the barrier layer, the rubber layer comprising 100 parts by weight of an elastomer comprising FKM fluoroelastomer; from about 1 to about 15 parts by weight, per 100 parts by weight of elastomer, of at least one acid acceptor selected from the group consisting of magnesium oxide, calcium hydroxide, litharge, dibasic lead phosphite, calcium oxide, and zinc oxide; from about 1 to about 6 parts by weight, per 100 parts by weight of elastomer, of at least one diamine curative; and from about 1 to about 10 parts by weight, per 100 parts by weight of elastomer, of at least one of a hydrotalcite or tricalcium aluminate hexahydrate; wherein the weight ratio of the at least one acid acceptor to the at least one hydrotalcite ranges from about 1 to about 5.

Owner:VEYANCE TECH

Expanded perlite modified activated carbon automobile exhaust desulfurizing agent, and preparation method thereof

InactiveCN103566879AReduce pollutionFast adsorptionOther chemical processesDispersed particle separationFiberHigh concentration

The invention discloses an expanded perlite modified activated carbon automobile exhaust desulfurizing agent which is prepared from the following raw materials in parts by weight: 100-120 parts of activated carbon, 5-7 parts of tricalcium aluminate, 4-6 parts of tetra calcium aluminoferrite, 8-10 parts of dolomite clay, 7-9 parts of montmorillonite, 15-20 parts of expanded perlite, 12-16 parts of calcium hydroxide, 15-20 parts of wood fiber, 4-5 parts of modified diatomite and a suitable amount of water. According to the expanded perlite modified activated carbon automobile exhaust desulfurizing agent disclosed by the invention, the expanded perlite is used for modifying the activated carbon to form loose porous powder, so high adsorption speed and larger adsorption amount are realized; quick and efficient desulfuration as well as longer effect can be realized by using tricalcium aluminate, tetra calcium aluminoferrite, dolomite clay, montmorillonite clay and calcium hydroxide as a desulfurizing agent. The expanded perlite modified activated carbon automobile exhaust desulfurizing agent disclosed by the invention has the advantages of low cost, simple technique, less environmental pollution, high desulfuration speed, easiness for regeneration, and suitability for high-concentration desulfuration of automobile exhaust and the like.

Owner:BENGBU HUAFANG FILTER

Mineral trioxide aggregate (MTA) composition and use

ActiveUS8722100B2Good effectImprove mechanical propertiesHeavy metal active ingredientsBiocideHigh fluoridePhosphate

The present application discloses a fast-setting mineral trioxide aggregate (MTA) with fluoride release for practical treatment of diseases in teeth and bone, e.g. for caries treatment and / or prevention. The cariostatic MTA contain calcia-silica-alumina cement with moderately increased tricalcium aluminate content allowing high calcium hydroxide release. The MTA composition support remineralization and biomineralization, and it is suitable for stimulation of hard tissue regeneration. MTA embodiments contain superplasticizer and nanosilicate for improved mechanical properties. The MTA compositions include optional radiocontrast and nano-enriched leachable fluorine, nitrate, strontium, and phosphate. The fast-setting MTA paste exhibits flow-to-clay-like consistency, which allows new practical applications including cavity lining, temporary restoration, bonding, and cementations in one MTA embodiment. The high calcium hydroxide and high fluoride release are suitable for caries prevention and treatment, and per se inhibition of dental symptoms.

Owner:DENTOSOLVE APS

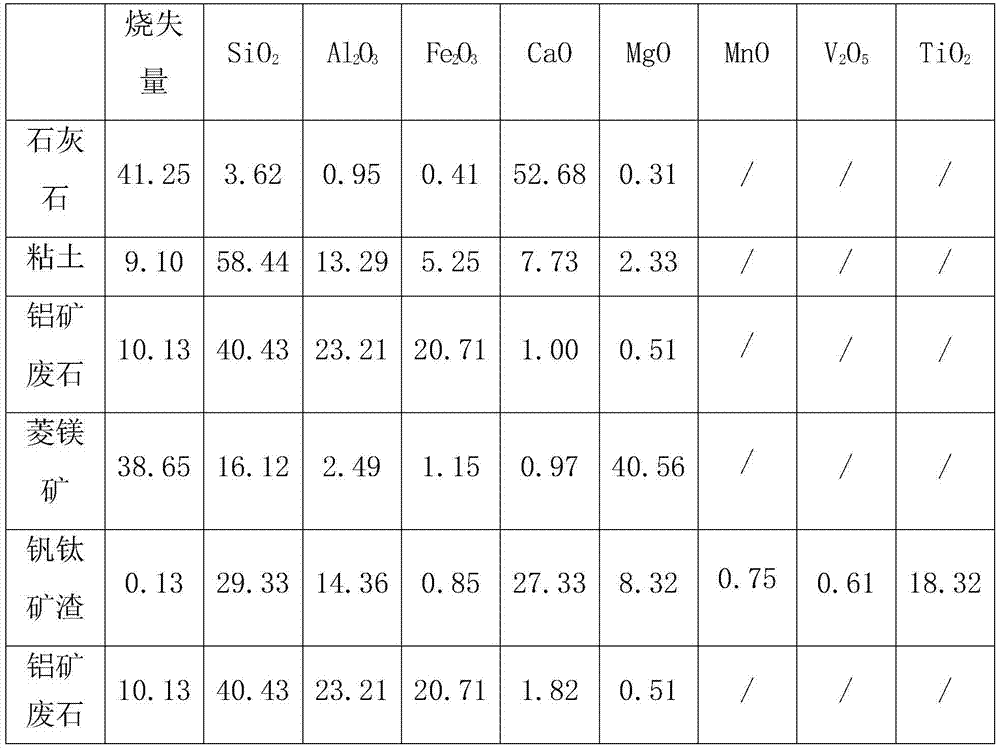

Method for increasing content of periclase in high-magnesium moderate-heat cement clinker

The invention relates to a method for increasing the content of periclase in a high-magnesium moderate-heat cement clinker. The method comprises the following steps: grinding limestone, vanadium-titanium slag, silica, iron tailings and magnesite together to obtain a cement raw material powder; preheating and then calcining the cement raw material powder to obtain a cement clinker; and cooling the cement clinker. The cement clinker comprises the following components in percentage by weight: 48-53% of tricalcium silicate, 20-28% of dicalcium silicate, 1-3% of tricalcium aluminate, 15-18% of tetracalcium aluminoferrite and 3-6% of magnesium oxide. According to the method provided by the invention, metallic elements of manganese, vanadium, titanium and the like in the vanadium-titanium slag are used for replacing magnesium to carry out mineral solid melting and reduce the relative content of solid melting magnesium oxide in clinker liquid, thereby improving the content of free magnesium oxide in the high-magnesium moderate-heat cement clinker.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of inorganic straw composite particle board

InactiveCN107382259AIncrease touch pointsAccelerates and promotes hydration reactionsSolid waste managementAdhesiveSlurry

The invention relates to a preparation method of an inorganic straw composite particle board, and belongs to the technical field of artificial boards. The preparation method comprises the following steps of firstly agitating and mixing chitosan, vital gluten and water, then standing, swelling, afterwards, heating to raise a temperature, agitating and dissolving at a constant temperature, adding an inorganic adhesive after naturally cooling to a room temperature, agitating, mixing, so as to obtain viscous slurry, and afterwards, agitating and mixing a straw particle and a rice hull particle, so as to obtain a mixed particle; atomizing the viscous slurry, then sprinkling into the mixed particle, after the sprinkling is finished, continuously agitating and mixing, so as to obtain a wet material, spreading the wet material to be a board blank, then carrying out hot pressing treatment, then drying after carrying out high-pressure steam curing and natural curing, and discharging. The inorganic adhesive is prepared from dicalcium silicate, tricalcium silicate, tricalcium aluminate, magnesium chloride and the like. The particle board prepared by the preparation method is high in mechanical strength, and can be used as a load-bearing structural component.

Owner:常州水精灵环保设备有限公司

WHDF type concrete inorganic crack-resisting permeability-educing agent

ActiveCN102503214AImprove work performanceImprove anti-cracking performanceCalcium hydroxideMicroorganism

The invention belongs to the technical field of concrete and particularly relates to a WHDF type concrete inorganic crack-resisting permeability-educing agent. The agent comprises the following components by weight percent: 20 to 30 percent of crystallizing exciting components, 10 to 20 percent of activating exciting components, 8 to 16 percent of tricalcium aluminate restraining components, 2 to6 percent of microorganism resisting components and 40 to 60 percent of water or coal ash. The invention has the benefits that the WHDF type concrete inorganic crack-resisting permeability-educing agent is used for promoting the hydrating degree of the concrete, optimizing hydrated products and exciting active mixing material and calcium hydroxide to perform secondary hydration, thereby efficiently increasing the tensile strength, extreme stretching value and compacting property of the concrete, enhancing the capability of resisting cracking, reducing the early hydrating heat and air shrinkage of the concrete, reducing the possibility of cracking caused by the shrinkage, and obtaining excellent crack-resisting permeability-educing property of the concrete.

Owner:武汉天衣新材料有限公司

Curing agent containing modified nano calcium carbonate

The invention discloses a curing agent containing modified nano calcium carbonate. The curing agent is prepared from mixing the following components in parts by weight: 1-2 parts of calcium silicate, 1-2 parts of ammonium chloride, 1.5-2.3 parts of cement, 0.3-0.6 part of sodium sulfate, 0.3-0.7 part of magnesium fluosilicate, 0.4-0.8 part of tricalcium aluminate, 1-2 parts of caustic soda, 1-1.5 parts of potassium carbonate, 2-4 parts of ardealite, 1-2 parts of chitosan, 1-2 parts of alkyl glycoside, 0.6-0.8 part of alum, 0.8-1.3 parts of sodium lignin sulfonate and 1-2 parts of modified nano calcium carbonate. In addition to hardening effect of a common curing agent, the curing agent containing modified nano calcium carbonate disclosed by the invention further has effects of decomposing harmful substances and curing heavy metals; meanwhile, the potassium carbonate and the ardealite in the formula have effects of adjusting a pH value, preventing freezing and preventing ageing, so that the hardening effect is strengthened by the modified nano calcium carbonate.

Owner:HEFEI BAOLI ENVIRONMENTAL PROTECTION TECH

External curing agent for concrete

The invention discloses an external curing agent for concrete. The external curing agent for concrete is prepared from the following raw materials: a modified polyolefin wax emulsion, an organic emulsion, a silane coupling agent, a reinforcing agent and an inorganic densifying component. According to the concrete external curing agent, the modified polyolefin wax emulsion is adopted as a main rawmaterial and contains part of the reinforcing agent; water retention is conducted through the film forming effect of the wax emulsion and the organic emulsion, meanwhile, the reinforcing agent is added to serve as a catalyst, and hydration of the tricalcium aluminate content in concrete and formation of ettringite are accelerated, and a certain reinforcing effect is achieved. According to the concrete external curing agent, the curing cost of concrete is greatly saved, the water retention rate and the compressive strength are greatly improved, and secondary pollution to the surface of the concrete is avoided.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

High-iron-phase Portland cement product and preparation method thereof

ActiveCN113200692AWide variety of sourcesSimple methodCement productionSilicic acidTricalcium aluminate

The invention discloses a high-iron-phase Portland cement product and a preparation method thereof. The preparation method comprises the following steps of mixing high-iron-phase Portland cement clinker and water according to a mass ratio of 1: (0.15-0.25), uniformly stirring to prepare a wet material, putting the wet material into a mold, pressing into a green body, putting the green body into a carbonization curing chamber, and carrying out accelerated carbonization treatment to obtain a high-iron-phase Portland cement product. The high-iron-phase Portland cement clinker is prepared from the following minerals in percentage by weight: 20 to 33 percent of tricalcium silicate, 3 to 8 percent of alpha-dicalcium silicate, 36 to 41 percent of gamma-dicalcium silicate, 1 to 3 percent of tricalcium aluminate and 18 to 35 percent of tetra calcium aluminoferrite. The high-iron-phase Portland cement product is prepared by selecting the cement clinker with specific composition, and the high-iron-phase Portland cement product with ultrahigh strength and corrosion resistance is formed under the combined action of mineral phase carbonization and hydration; and the method is simple, wide in raw material source and short in production period.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com