Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

168results about How to "Raise the intensity level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

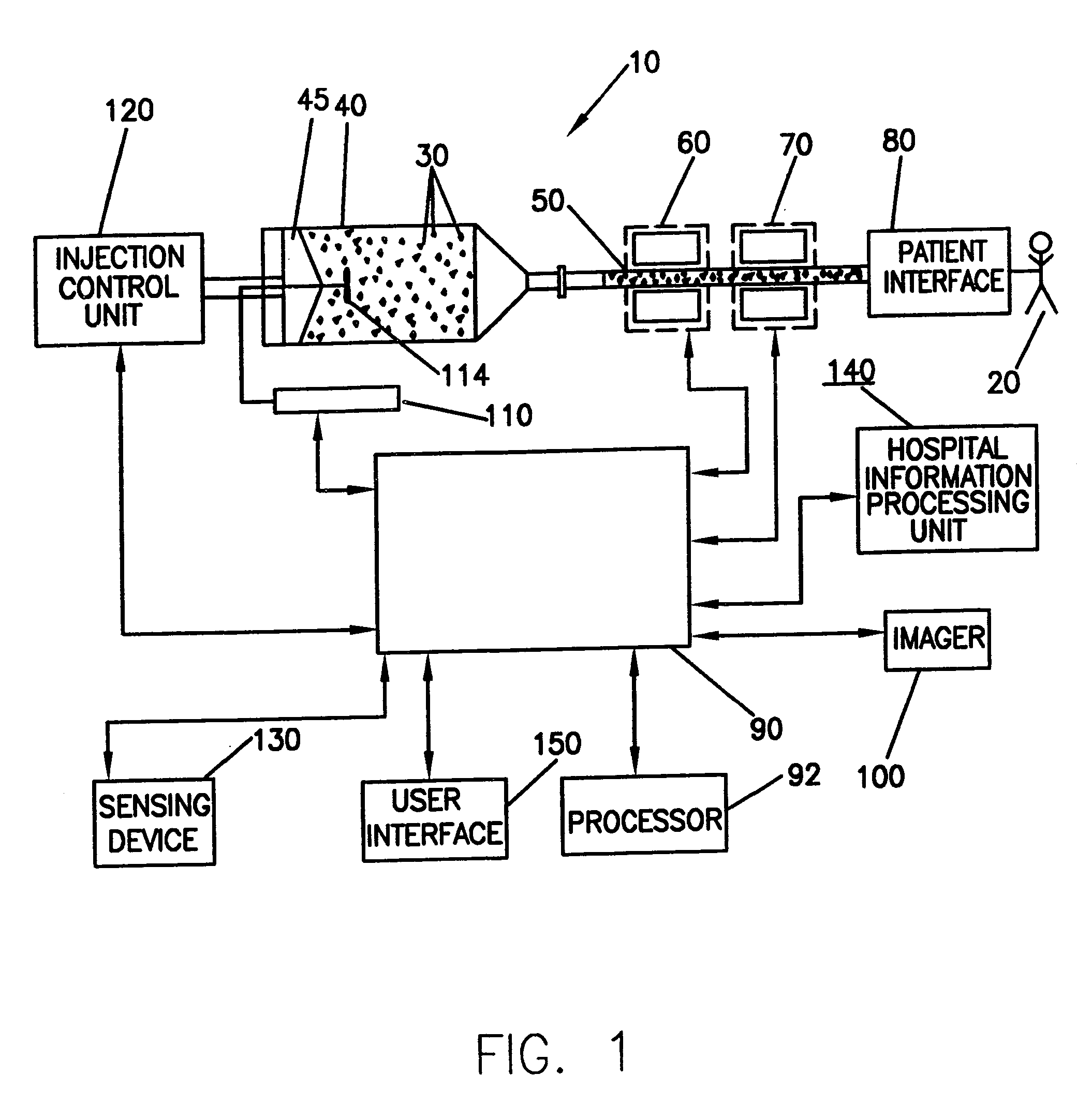

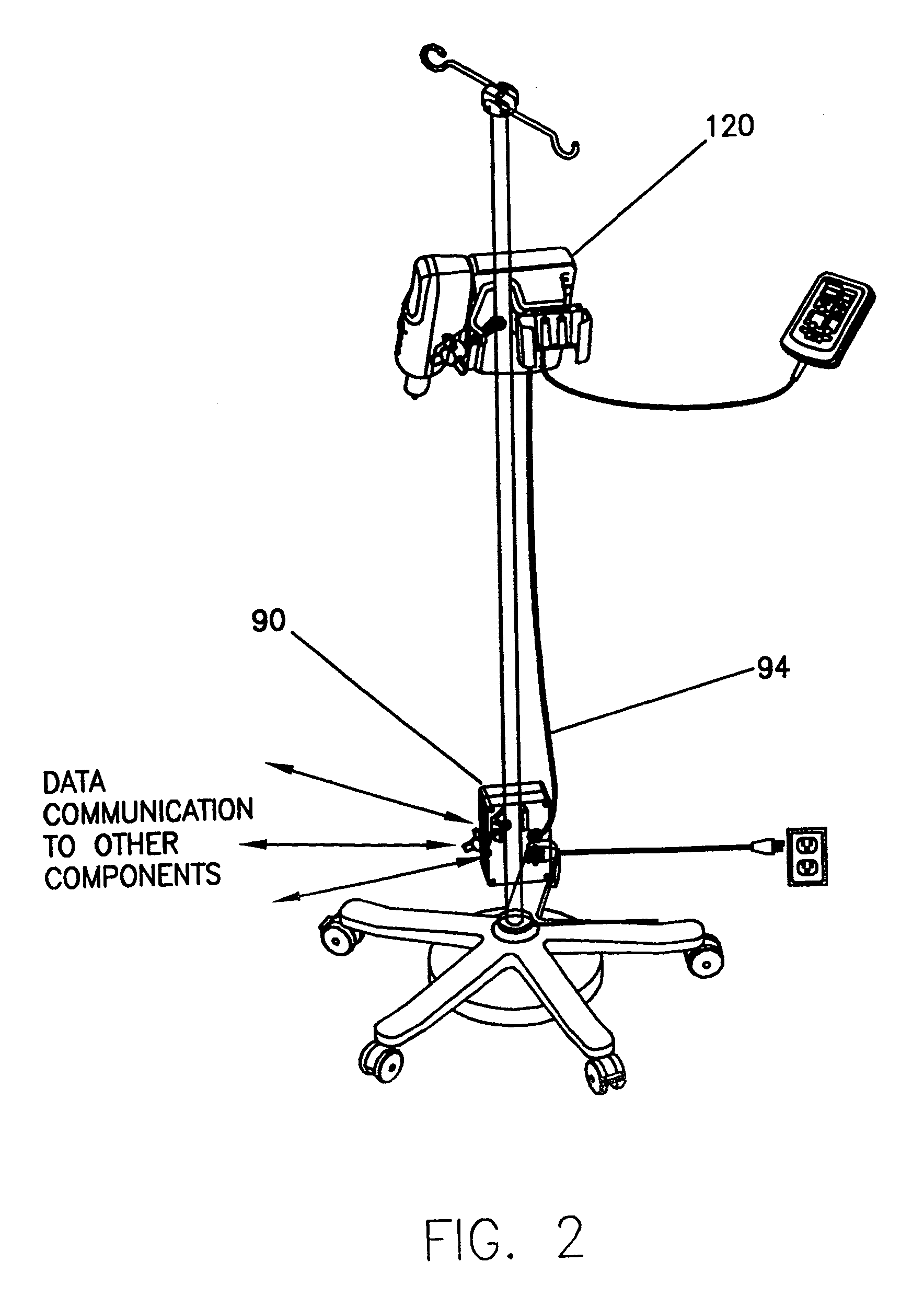

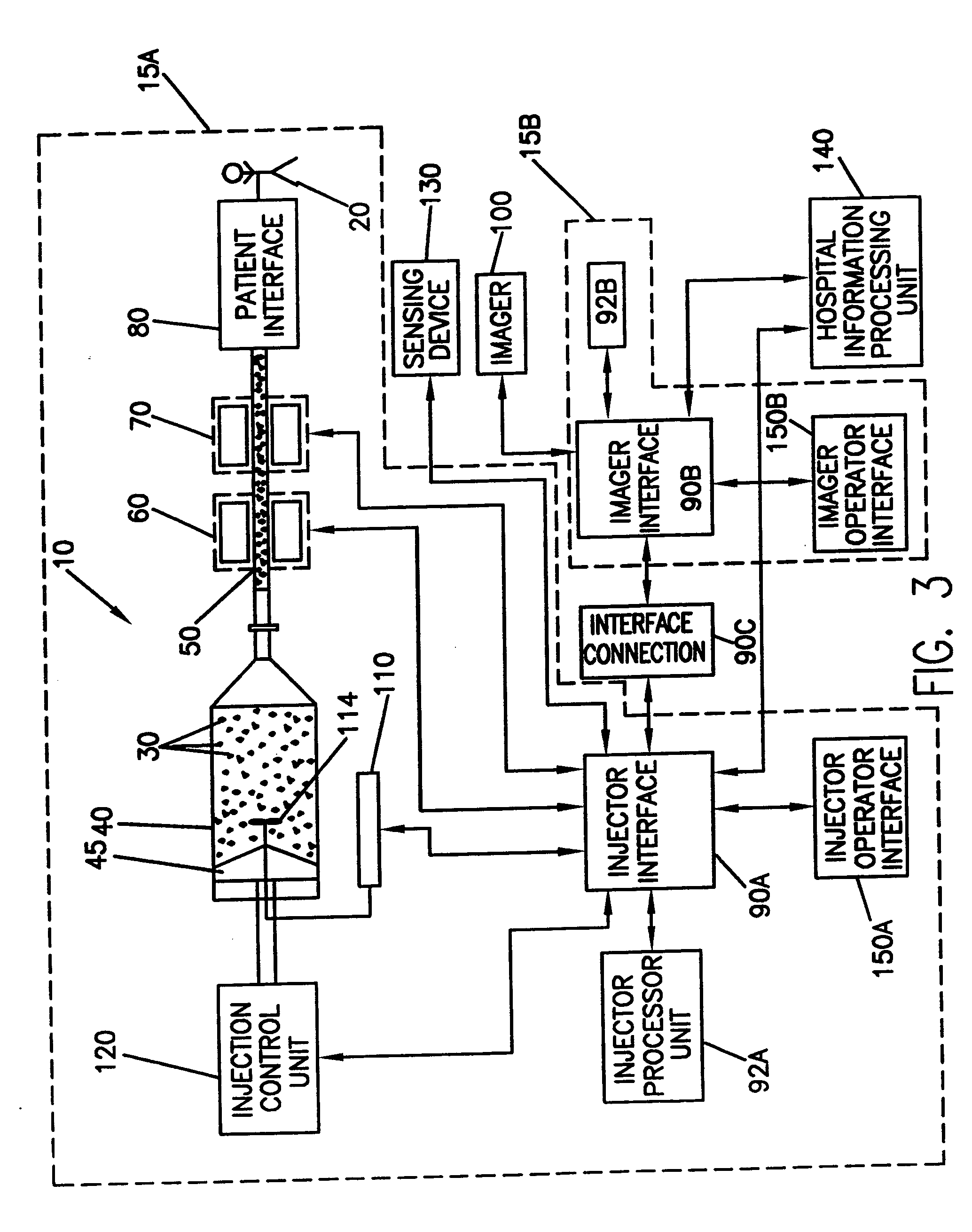

Data communication and control for medical imaging systems

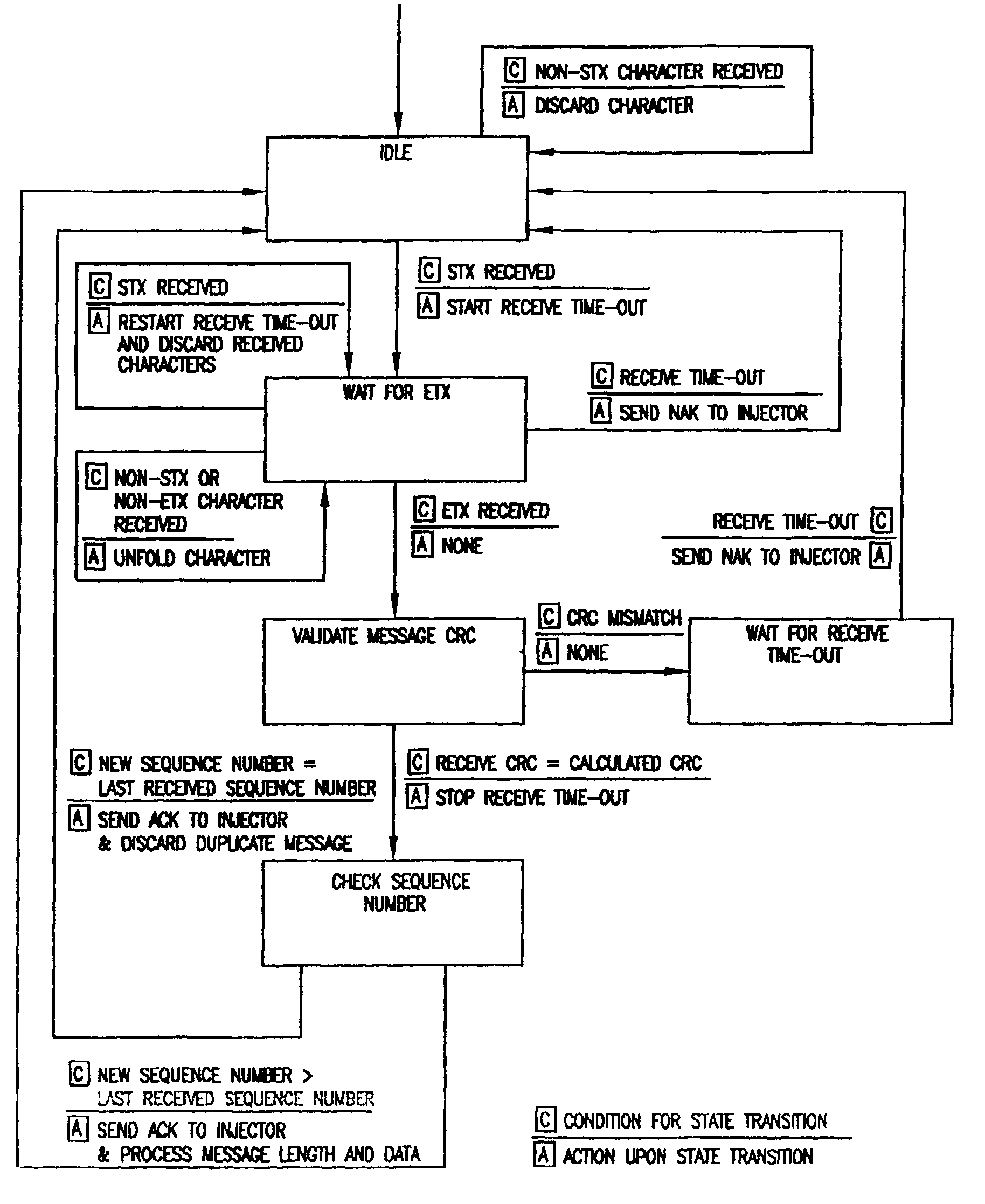

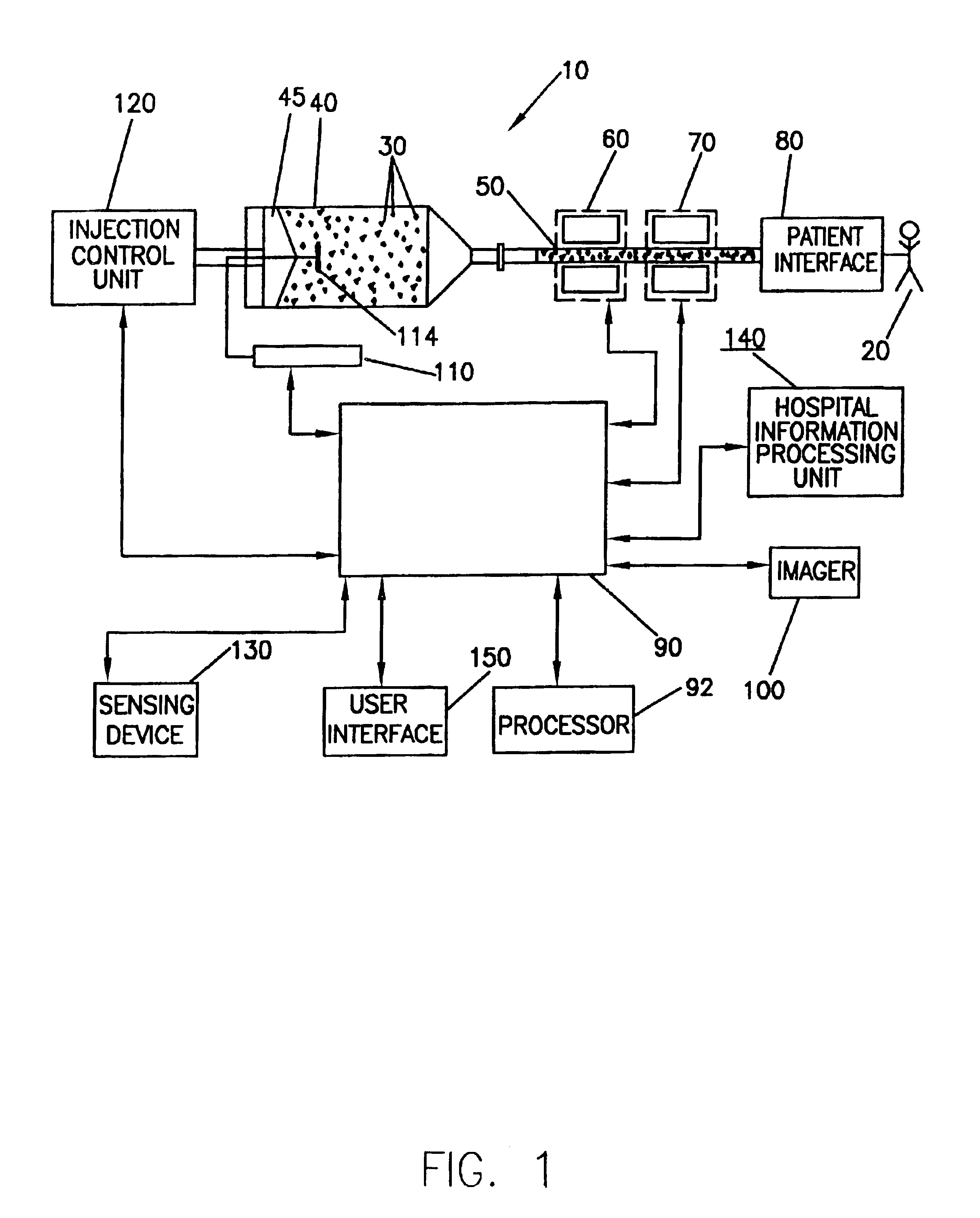

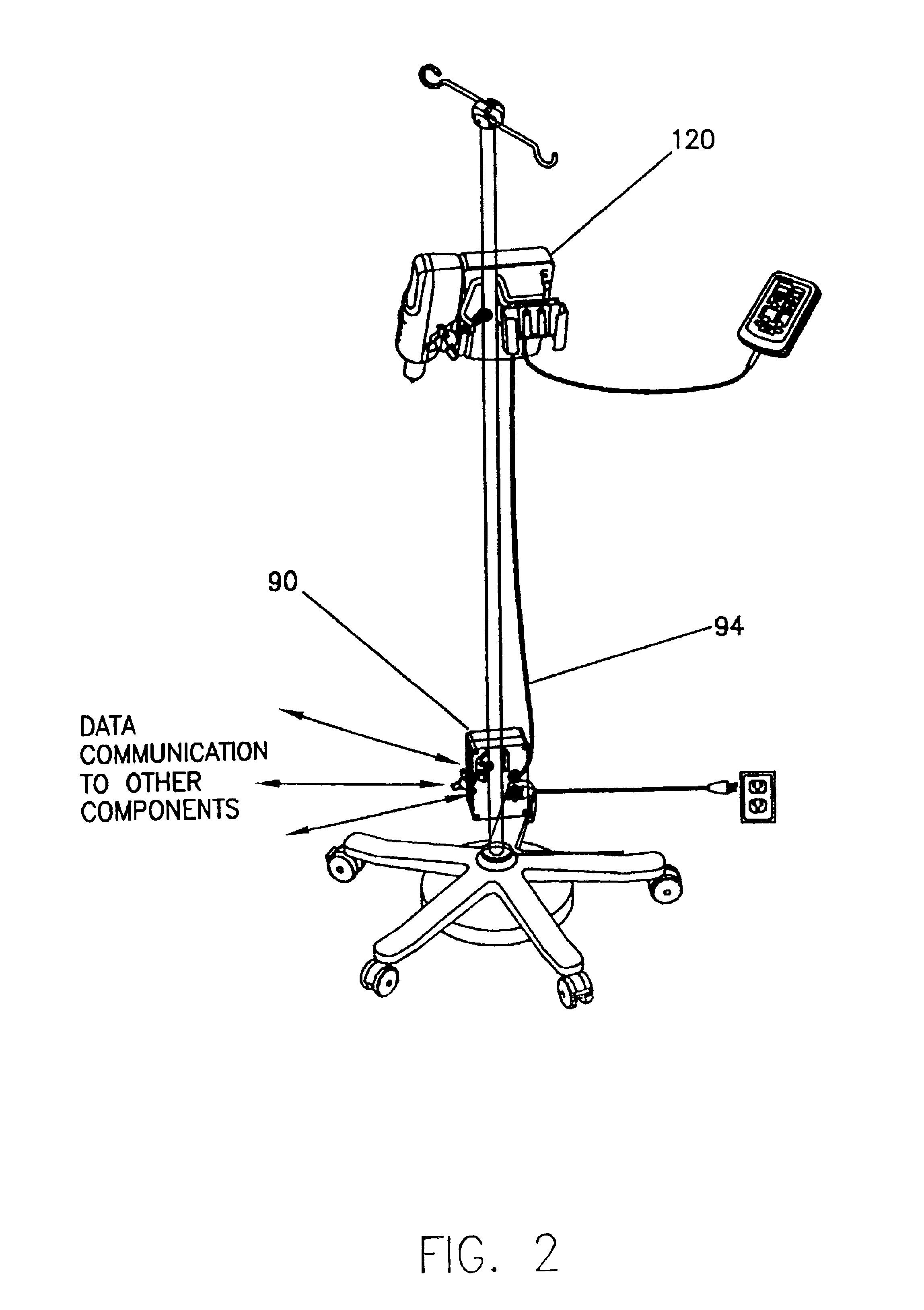

InactiveUS6970735B2Raise the intensity levelDrug and medicationsMedical devicesCommunication interfaceContrast enhancement

A system for producing a contrast-enhanced medical image of a patient includes a source of a contrast or enhancement medium, a pressurizing unit in fluid connection with the source of contrast or enhancement medium, an energy source operable to apply energy to a region of the patient, an imaging unit providing a visual display of an internal view of the patient based upon a signal resulting from the energy applied to the region of the patient, and a control unit. In an embodiment, the signal is affected by a condition of the contrast or enhancement medium in the patient. To control the procedures, the control unit adjusts the condition of the contrast or enhancement medium in the patient based upon the signal. A communication interface preferably enables information between an injector subsystem and an imaging subsystem.

Owner:BAJER MEDIKAL KEHA INK

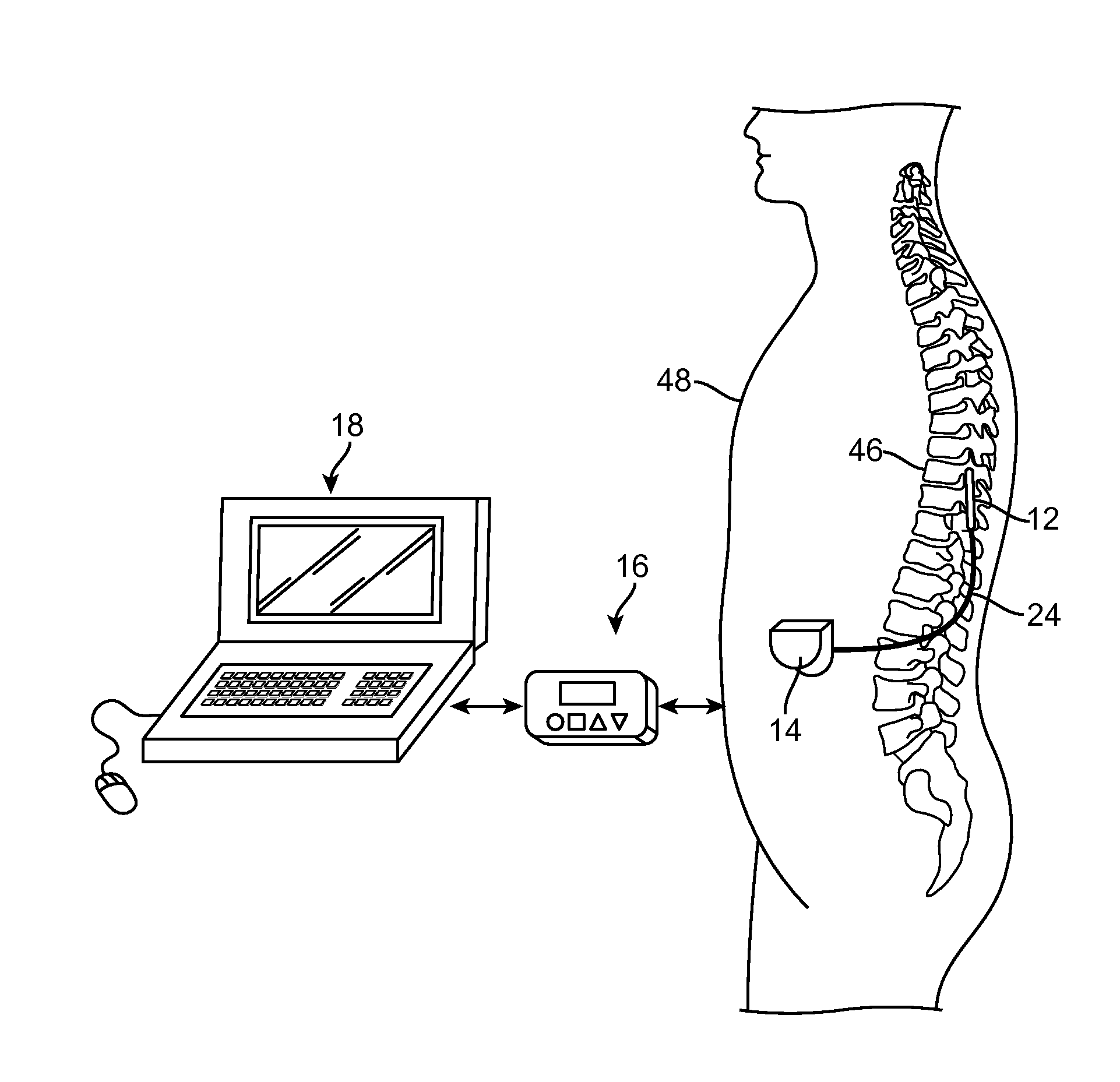

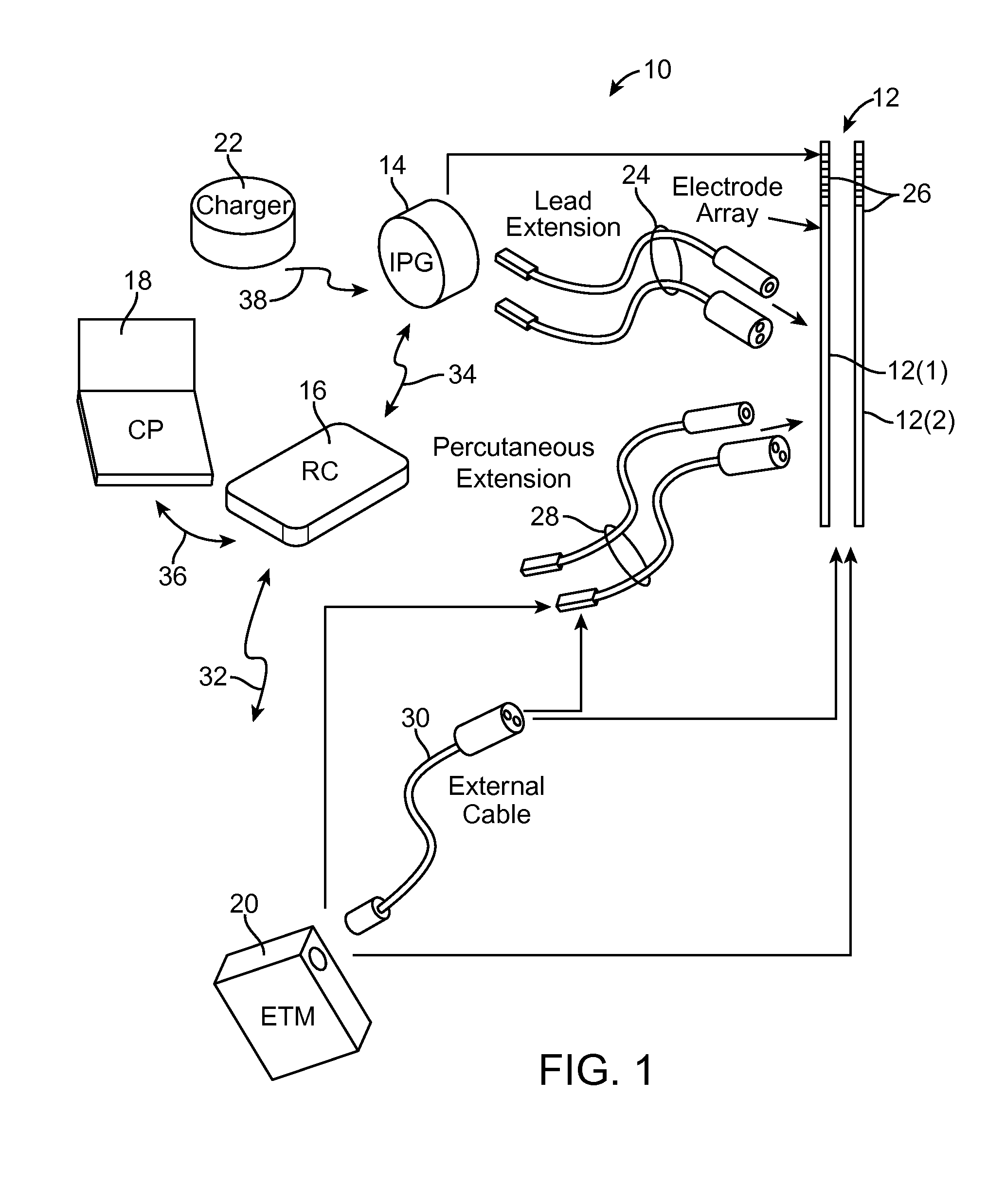

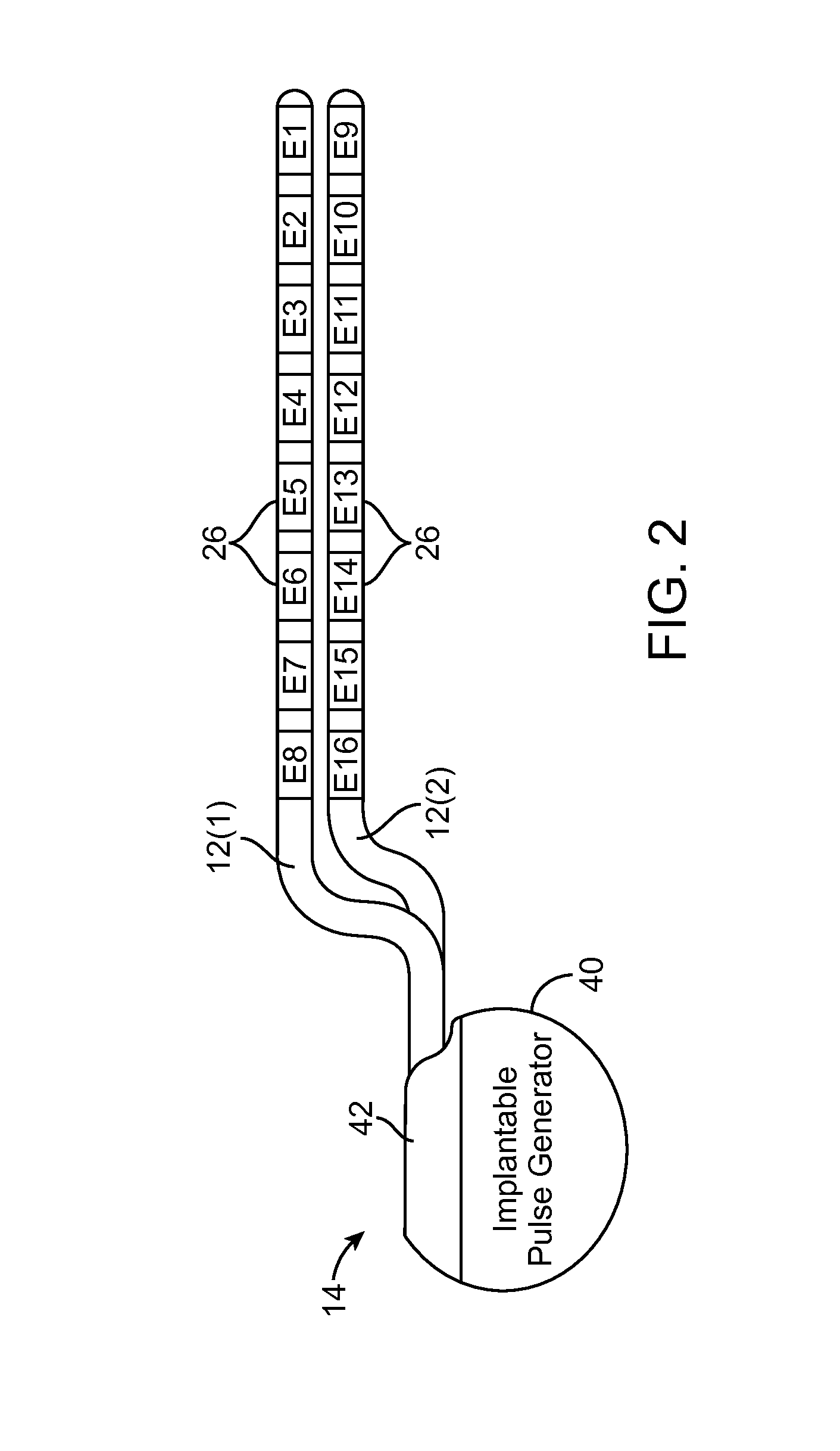

Use of compound action potentials to automatically adjust neurostimulation therapy in response to postural changes of patient

InactiveUS20140277282A1Raise the intensity levelReduce intensity levelElectrotherapyArtificial respirationElectricityMedicine

A neurostimulation system and method of treating a patient. Electrical stimulation energy is delivered to a target tissue site in accordance with a stimulation parameter to treat the patient and evoke at least one compound action potential (CAP) in a population of neurons. A magnitude of the evoked CAP is measured. A function of the measured evoked CAP magnitude(s) is compared to a threshold value. The stimulation parameter is adjusted based on the comparison.

Owner:BOSTON SCI NEUROMODULATION CORP

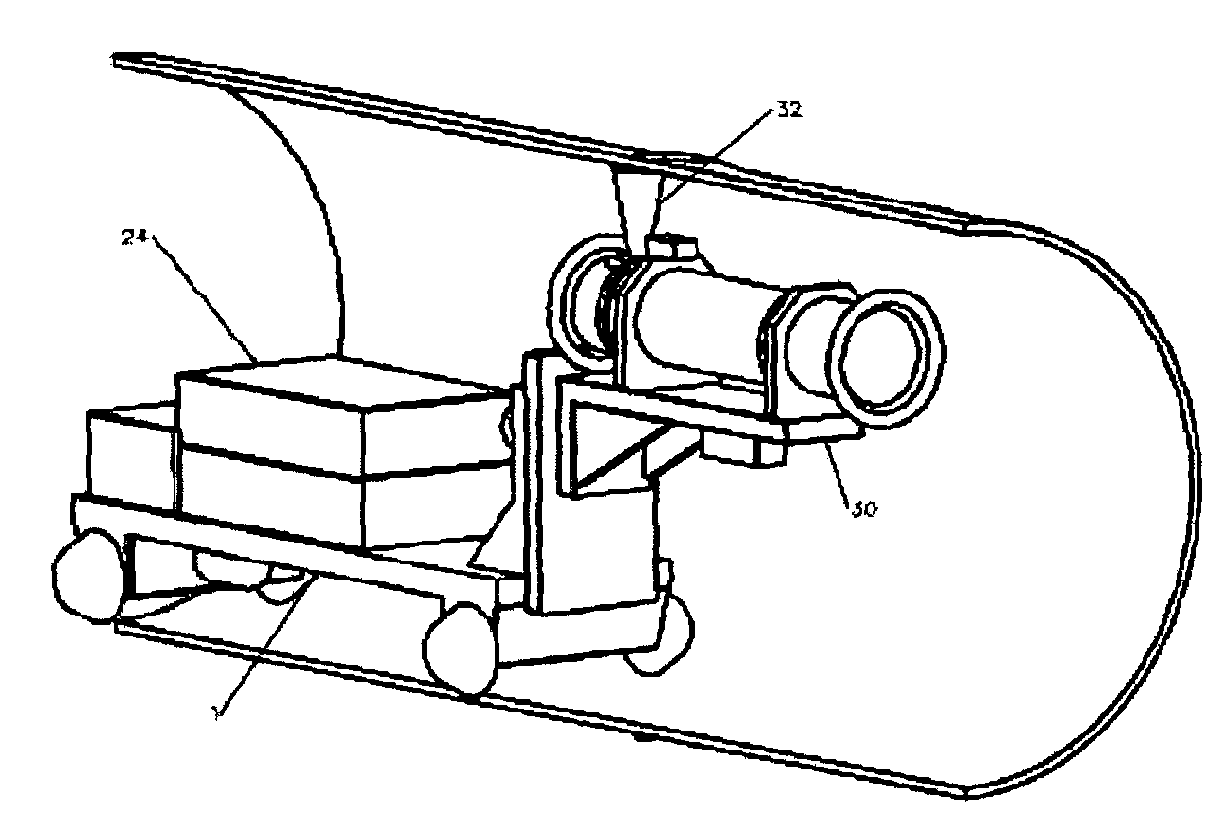

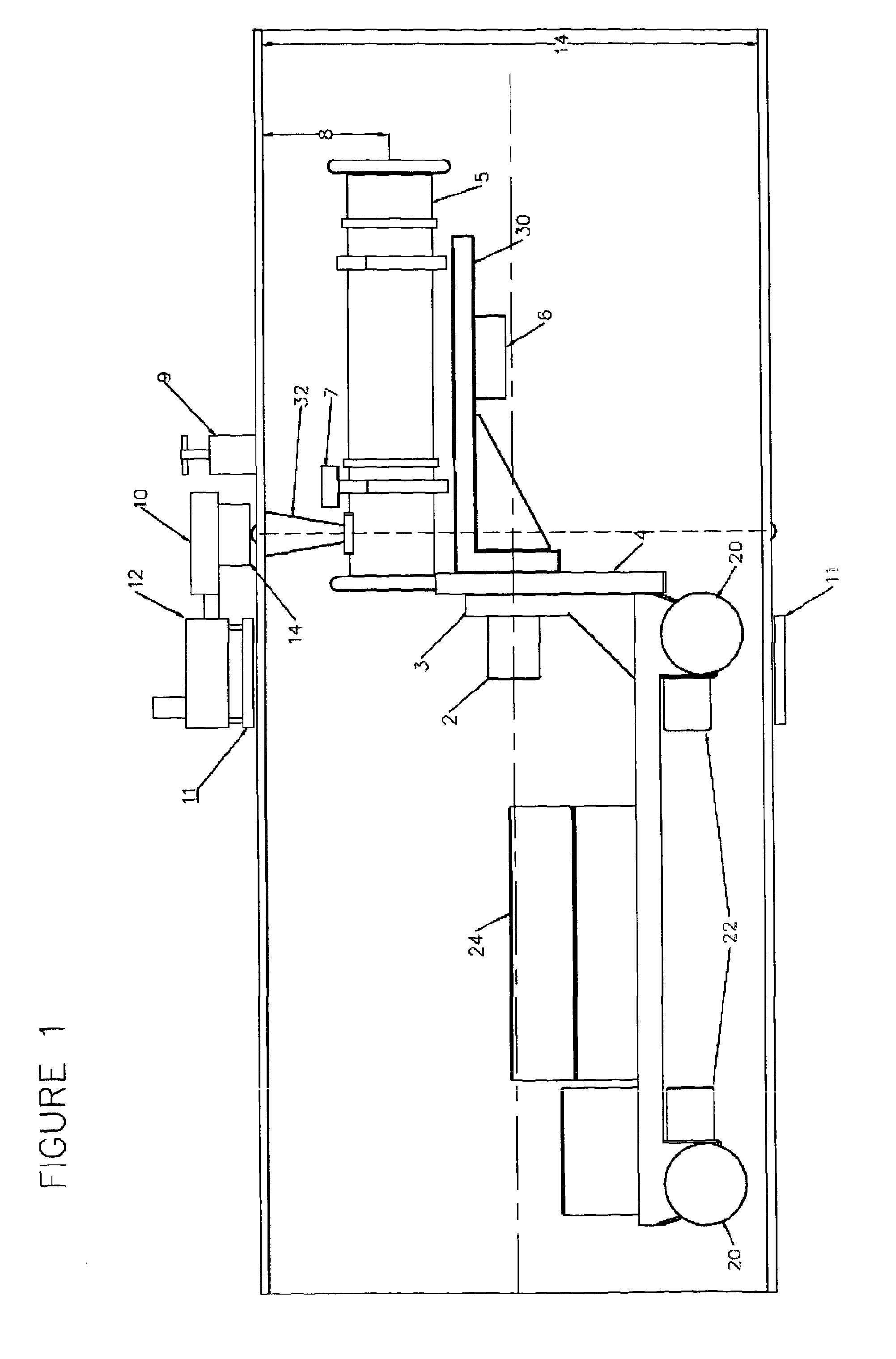

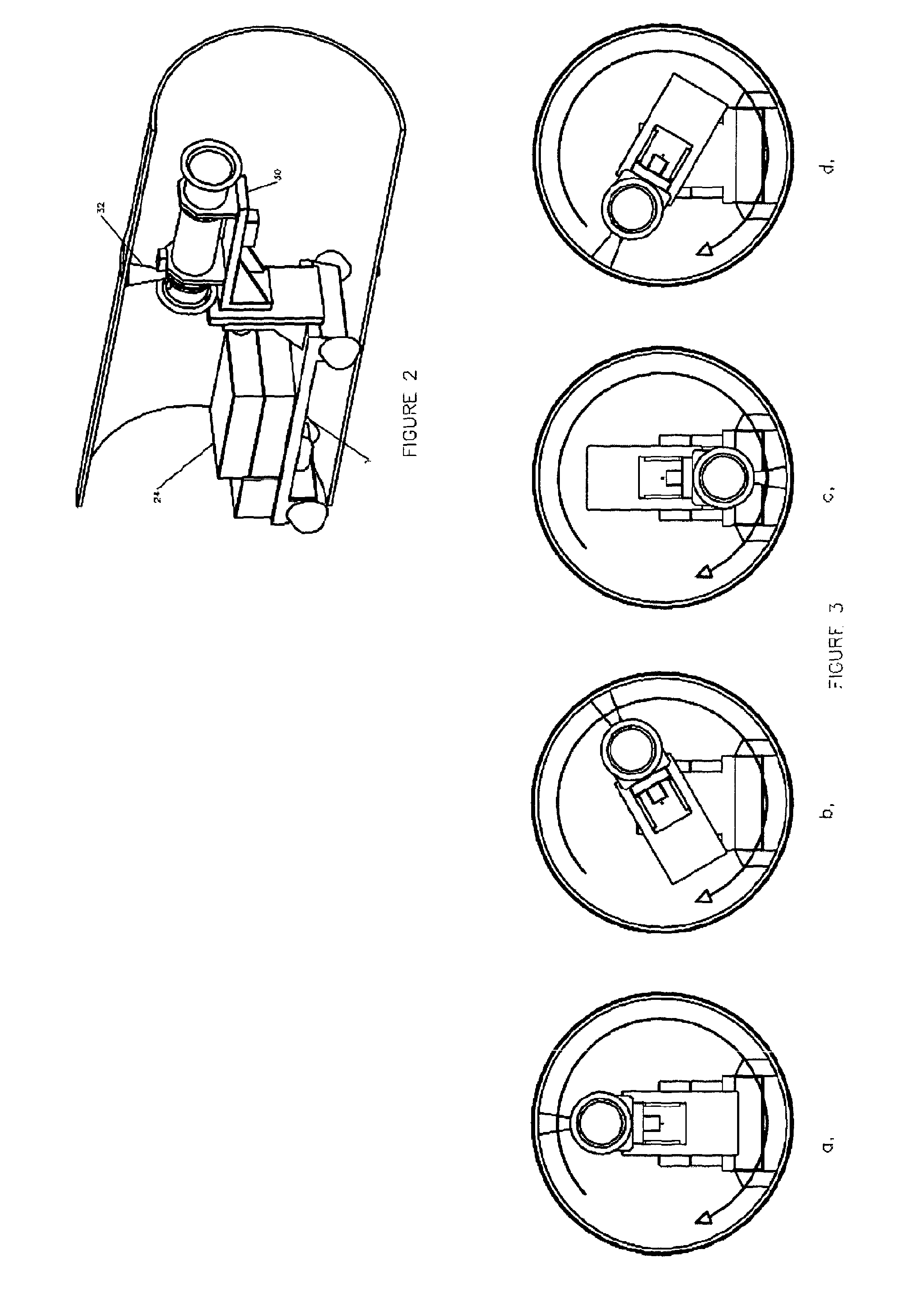

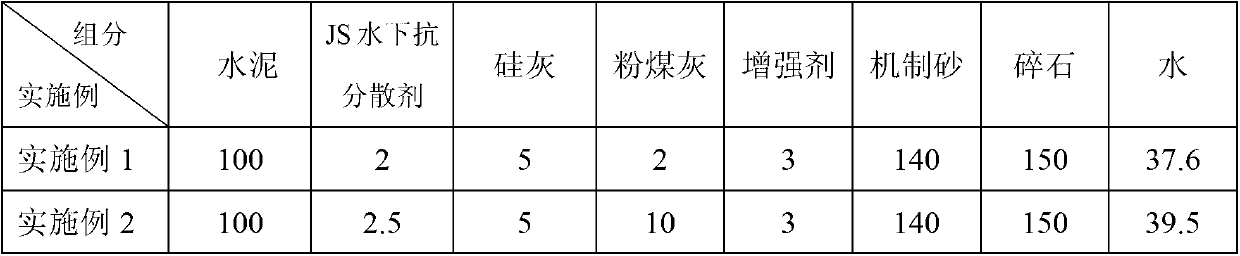

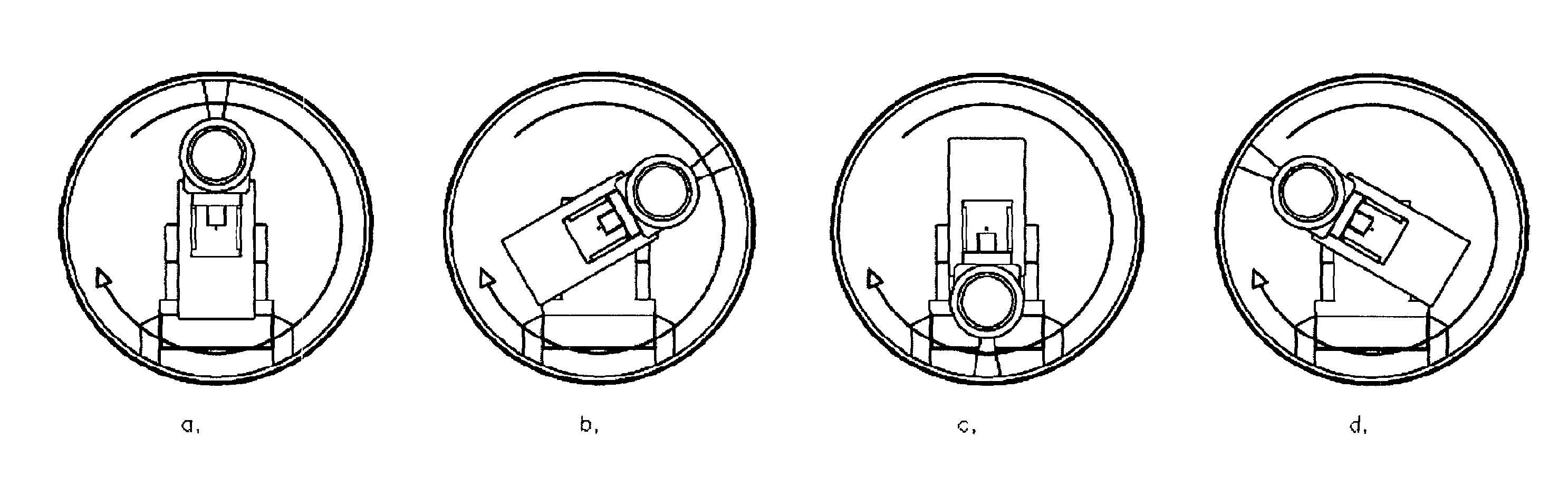

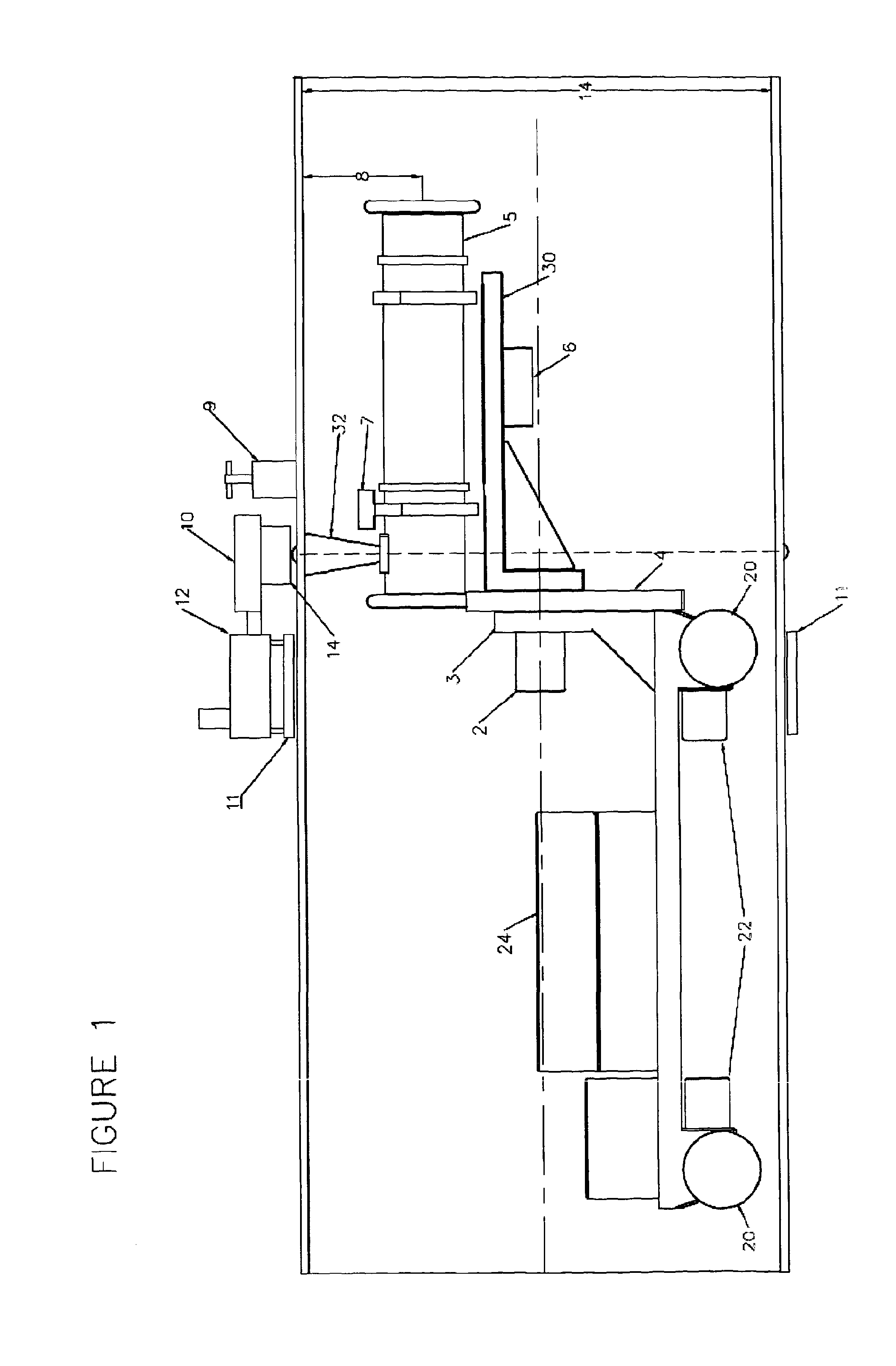

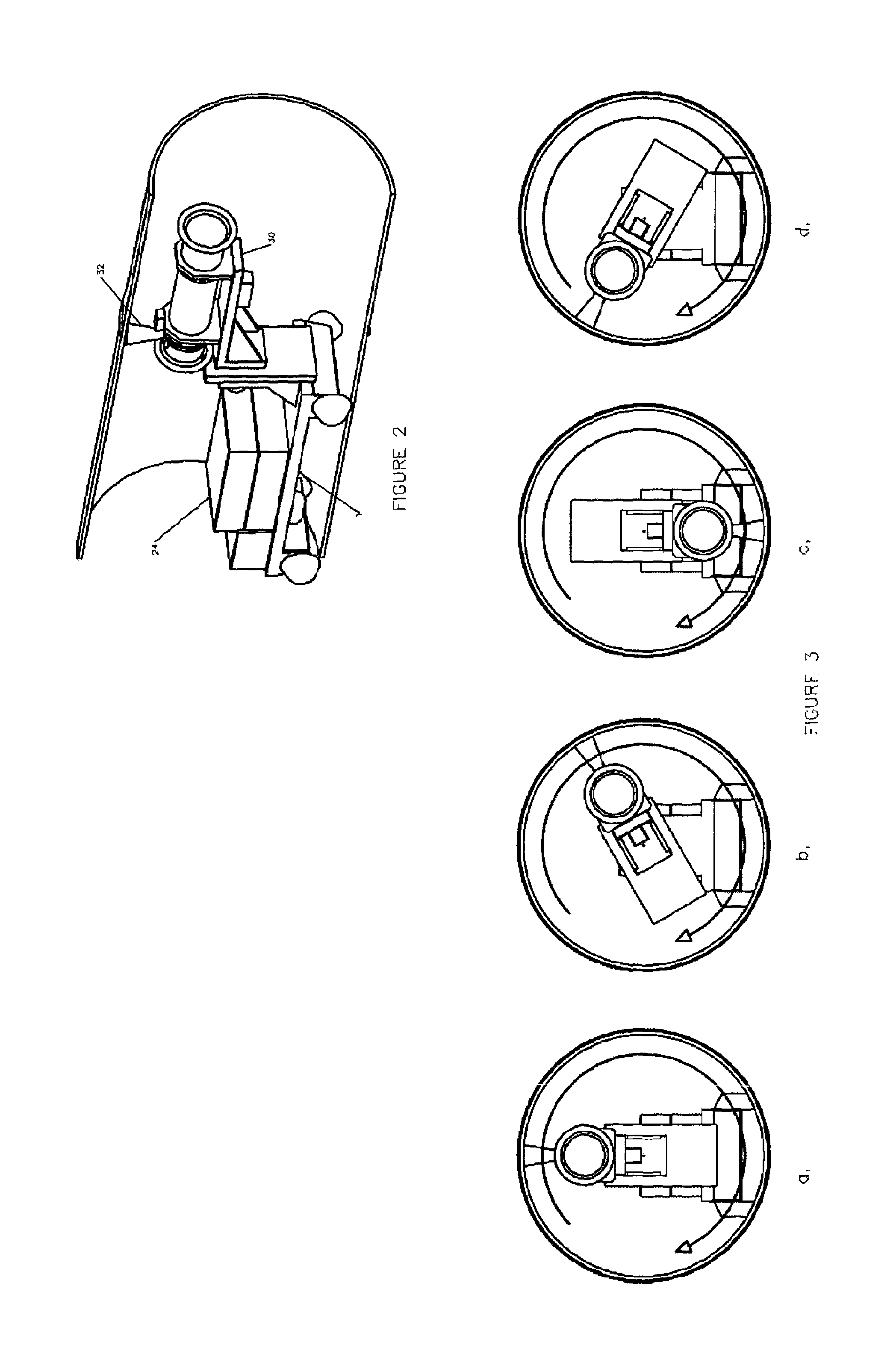

X-ray inspection apparatus for pipeline girth weld inspection

ActiveUS20120201348A1Shorten cycle timePerfect detection systemUsing wave/particle radiation meansMaterial analysis by transmitting radiationX-rayPhysics

An apparatus is provided for x-ray inspection of a pipeline girth weld. This comprises a directional x-ray source 5 which is insertable into a pipeline section and is rotatable within the pipeline. Means are provided to align the directional x-ray source with an external x-ray detector such that both may be rotated through 360 degrees substantially coaxially with the pipeline section. Means for sampling the data detected by the x-ray detector are provided so that it may be further analysed.

Owner:SHAWCOR LTD

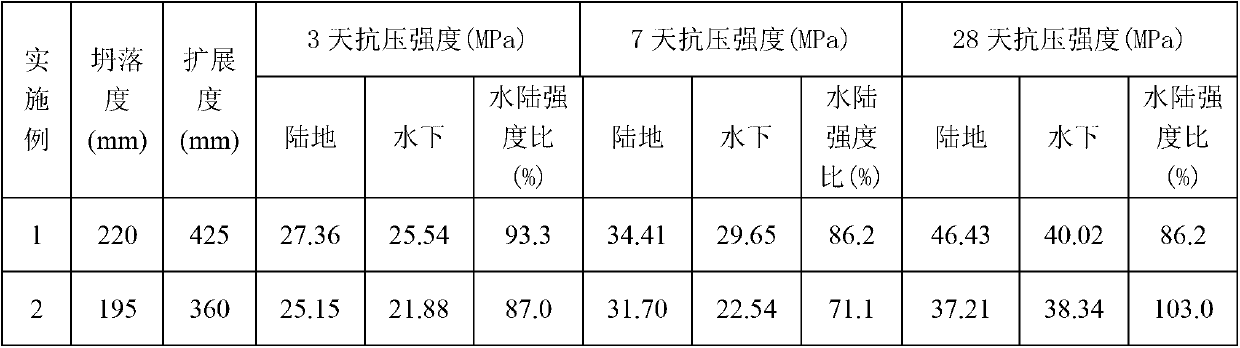

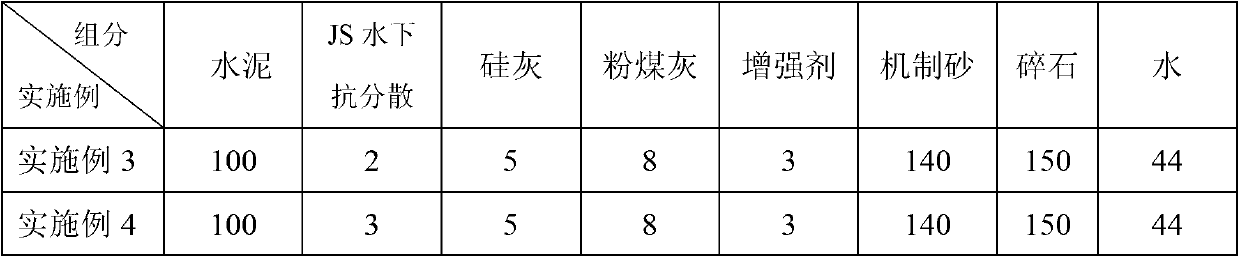

Manufactured sand underwater dispersion resistant concrete and preparation method thereof

The invention relates to a manufactured sand underwater dispersion resistant concrete, which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of underwater dispersion resistant additive, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of an enhancer, 140-200 parts of manufactured sand, 140-200 parts of macadam, and 30-50 parts of water. The preparation method comprises the following steps of firstly putting the manufactured sand, the macadam aggregate, the cement, the enhancer, the coal ash and the silica fume into an agitator, blending through dry mixing, then adding the underwater dispersion resistant additive to further blend through dry mixing, adding water into the material blended through dry mixing previously, stirring for 5-8 minutes, then preparing the manufactured sand underwater dispersion resistant concrete. The manufactured sand underwater dispersion resistant concrete has strong construction mobility, so that the problem of contradiction of mobility and dispersion resistance of the underwater dispersion resistant concrete is better solved, and therefore, the manufactured sand underwater dispersion resistant concrete not only has good dispersion resistance, but also has self-leveling and self-compaction construction mobility.

Owner:江西万年青水泥股份有限公司

Energy-saving consumption-reducing technique for preparing haydite by co-disposing polluted soil and desilting sediment

ActiveCN102173850APromote healthy developmentLow running costCeramicwareExpanded clay aggregateWater content

The invention relates to an energy-saving consumption-reducing environment-friendly method for preparing haydite by co-disposing municipal massive solid wastes, which comprises the following steps: directly mixing polluted soil and polluted desilting sediment (without energy-consuming drying), adding a conditioner, granulating, and firing at 900-1200 DEG C for 15-40 minutes. The test indicates that the prepared haydite product has the following properties: the bulk density is 500-900 kg / m<3>, the cylindrical compressive strength is 5.0-10.0 Mpa, and the water absorptivity is 4.8-9.2%; and the leaching toxicities of typical heavy metals are as follows: Cu<0.26 mg / L, As<0.03 mg / L, Cd<0.0002 mg / L, and Hg<0.0001 mg / L. The method provided by the invention fully utilizes the water-content complementarity of the polluted soil and sewage reservoir sediment as well as the characteristic of mutual catalytic degradation of heavy metal pollutants and organic pollutants, implements energy saving and consumption reduction in the technical field of traditional techniques for preparing haydite from solid wastes, lowers the cost and secondary pollution in solid waste disposal industry, enhances the properties of the solid waste haydite, and widens the application field of the solid waste haydite.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Data communication and control for medical imaging systems

InactiveUS20060030773A1Raise the intensity levelDrug and medicationsMedical devicesCommunication interfaceMedical imaging

A system for producing a contrast-enhanced medical image of a patient includes a source of a contrast or enhancement medium, a pressurizing unit in fluid connection with the source of contrast or enhancement medium, an energy source operable to apply energy to a region of the patient, an imaging unit providing a visual display of an internal view of the patient based upon a signal resulting from the energy applied to the region of the patient, and a control unit. In an embodiment, the signal is affected by a condition of the contrast or enhancement medium in the patient. To control the procedures, the control unit adjusts the condition of the contrast or enhancement medium in the patient based upon the signal. A communication interface preferably enables information between an injector subsystem and an imaging subsystem.

Owner:BAYER HEALTHCARE LLC

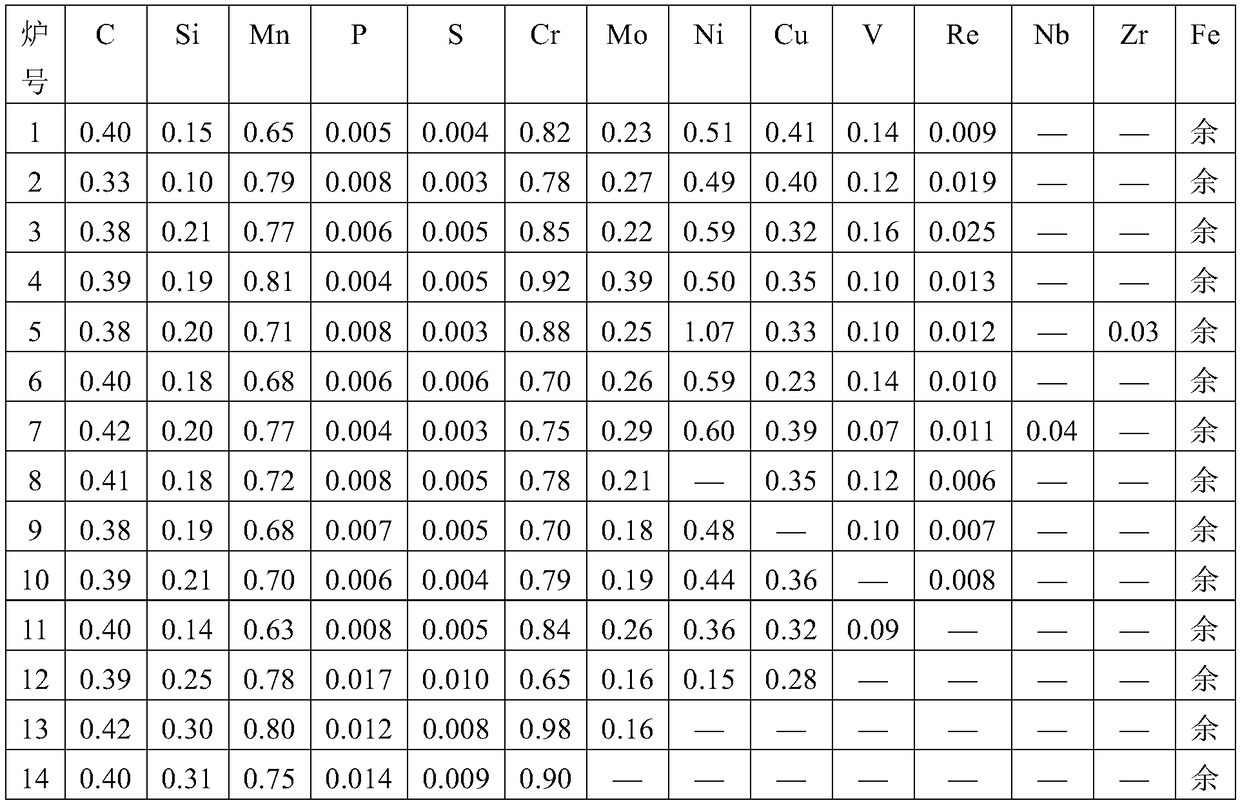

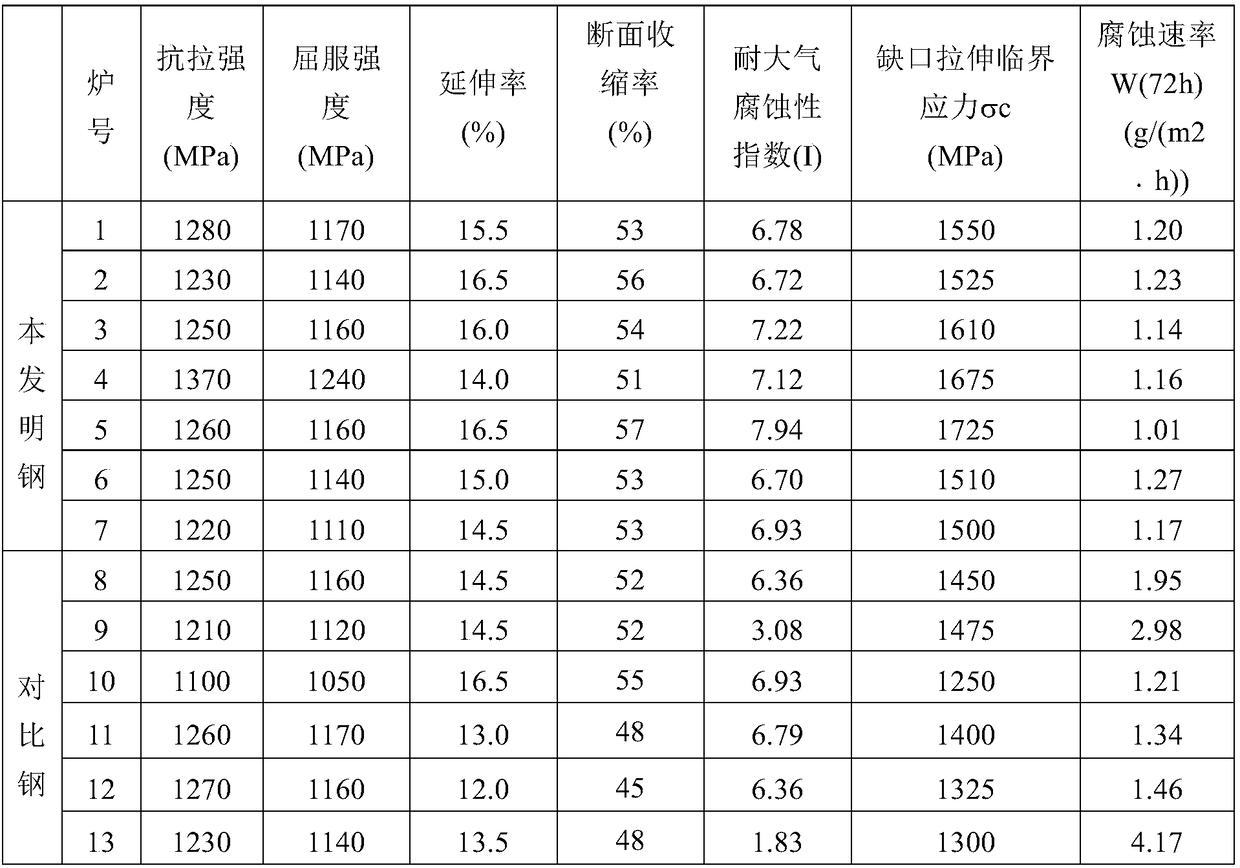

High-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture

PendingCN108754303AAccelerated corrosionImproved delayed fracture resistanceAtmospheric corrosionDelayed fracture

The invention discloses a high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture. The high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture comprises, by mass, 0.30-0.45% of C, below 0.25% of Si, 0.40-1.40% of Mn, below 0.012% of P, below 0.008% of S, 0.40-1.20% of Cr, 0.15-0.50% of Mo, 0.30-1.20% of Ni, 0.20-0.60% of Cu, 0.05-0.20% of V, 0.005-0.030% of Re, and the balance of Fe and inevitable impurity elements. Compared with steels in the prior art, the high-strength bolt steel with excellent resistance to atmospheric corrosion and delayed fracture has the advantages of high strength, excellent resistance to atmospheric corrosion and delayed fracture, and low cost, and can be used to 12.9 level high-strength bolts for bridges and other steel structures.

Owner:BEIJING JIAOTONG UNIV

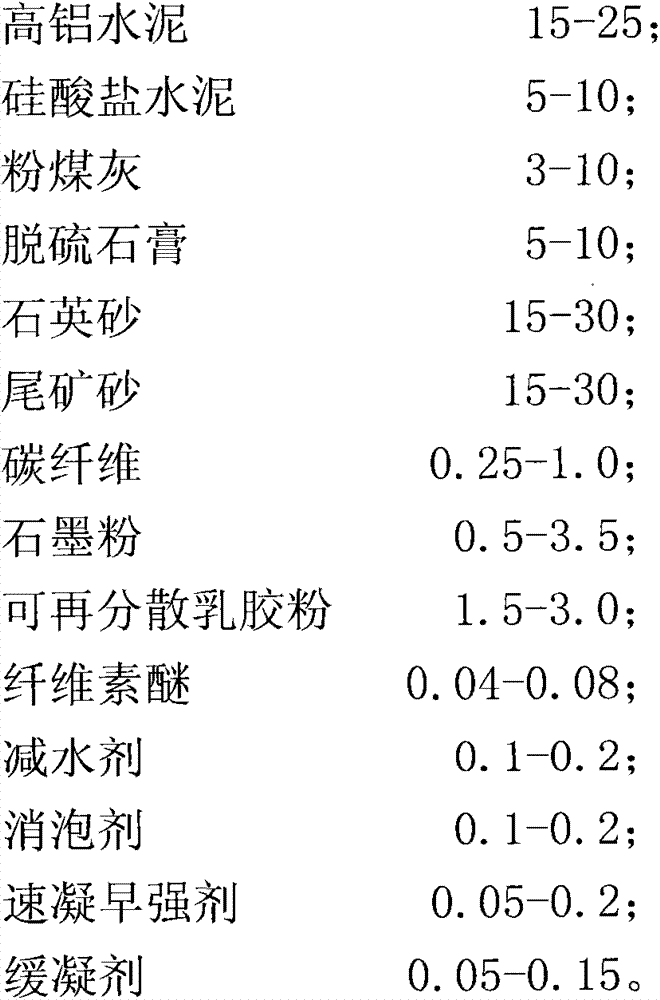

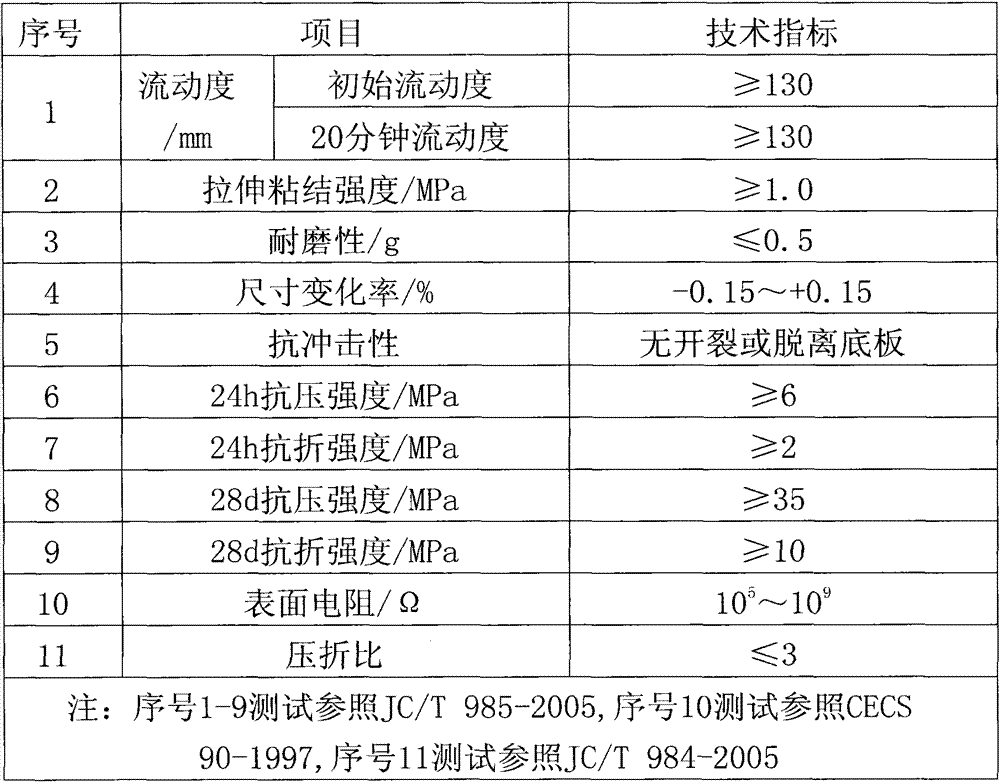

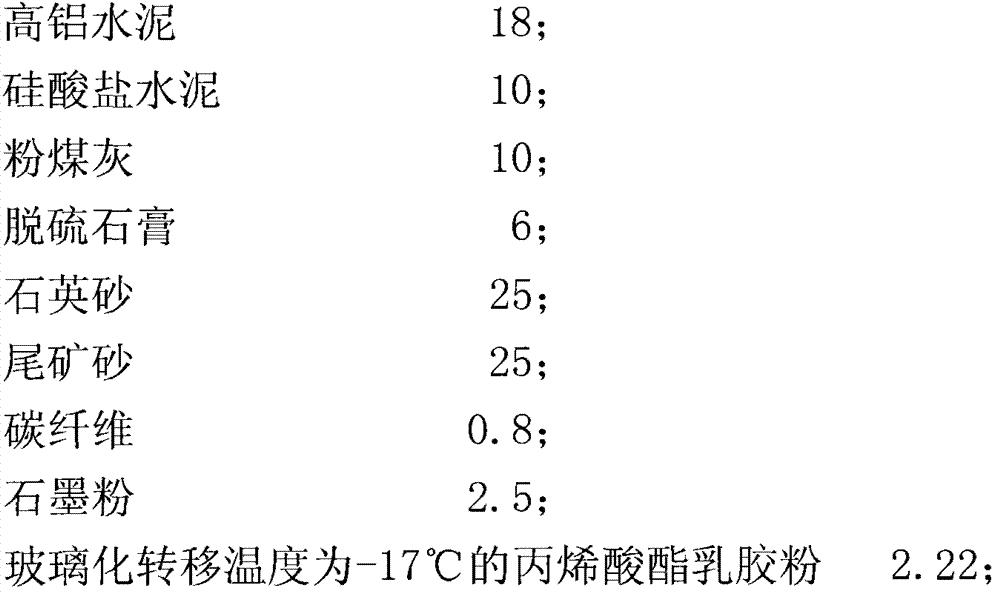

Preparation method for antistatic cement-based self-levelling surface-layer mortar

The invention provides a preparation method for antistatic cement-based self-levelling surface-layer mortar. The preparation method comprises: selecting high-aluminium cement, aluminium cement, Portland cement, fly ash, desulfurized gypsum, quartz sand, mine tailing sand, carbon fiber, graphite powder, redispersible latex powder, cellulose ether, a water reducer, an antifoaming agent, a rapid-setting early-strength agent and a retarder as raw materials, preparing according to a ratio, and uniformly mixing in a high-speed mixer at a rotation speed of 60-200 r / min for 8-10 min, so as to prepare the antistatic cement-based self-levelling surface-layer mortar. By adding a large amount of fly ash and other industrial waste slag, wastes are changed into valuables, a large amount of source is saved, and considerable social economic benefit is brought. Carbon fiber and graphite powder in the raw materials possess electric conductivity and form a stereo point-line-surface interlaced three-dimensional electric-conduction system in a mortar hydrate through combined usage, and exhaust and release of static electricity are facilitated. Additionally, cast self-levelling surface-layer mortar is flat in surface, also is capable of reducing sound of vehicles rolling ground, and is applicable to ground leveling and decoration of a place needing to prevent static electricity.

Owner:北京敬业达新型建筑材料有限公司

Aluminium-magnesium weld filler alloy

InactiveUS6416884B1Improve fatigue performanceFiner and smoother rippleWelding/cutting media/materialsThin material handlingAlloyImpurity

The disclosure relates to an aluminium-base weld filler alloy having the following composition in weight percent: Mg 5.0-6.5, Mn 0.4-1.2, Zn 0.4-<2.0, Zr 0.05-0.3, Cr 0.3 max., Ti 0.2 max., Fe 0.5 max., Si 0.5 max., Cu 0.25 max., balance Al and inevitable impurities. Further, the disclosure relates to a method of manufacturing an aluminium-base weld wire, and to a method of constructing welded constructions.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

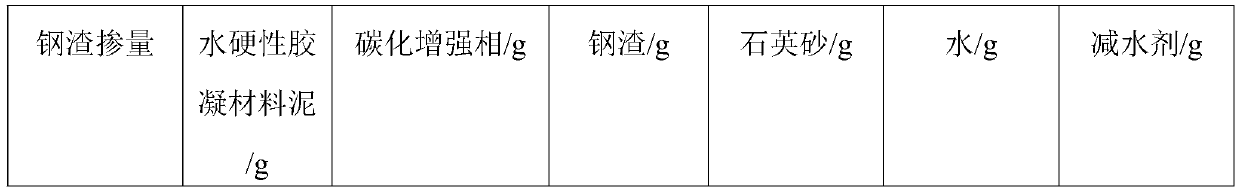

Preparation method of high-performance carbonized reinforced concrete

ActiveCN110818356AHigh strengthGive full play to the carbonization activityCeramic shaping apparatusCompressive resistanceReinforced concrete

The invention discloses a preparation method of high-performance carbonized reinforced concrete, and the method comprises the following steps: mixing steel slag, a hydraulic cementing material, a carbonized reinforced phase and quartz sand, adding water and a water reducing agent, stirring, and carrying out casting molding on the stirred slurry; sealing and maintaining the molded product for 12-24hours, removing a mold, and carrying out drying pretreatment; and putting the dried product into a carbonization kettle with a CO2 atmosphere and an air pressure of 0.1-0.5 MPa, and carrying out carbonization maintenance for 12-24 hours to obtain a steel slag product. The high-performance carbonized reinforced concrete prepared by the invention has excellent working performance; the hydrated andcarbonized synergistic effect of the hydraulic cementing material and the steel slag is fully utilized, the compressive strength can reach 100 MPa within a short time, meanwhile, the utilization rateof the steel slag is remarkably increased, a large amount of CO2 can be solidified and stored, huge environmental benefits are achieved, development of green building materials is facilitated, and a sustainable development road is achieved.

Owner:WUHAN UNIV OF TECH

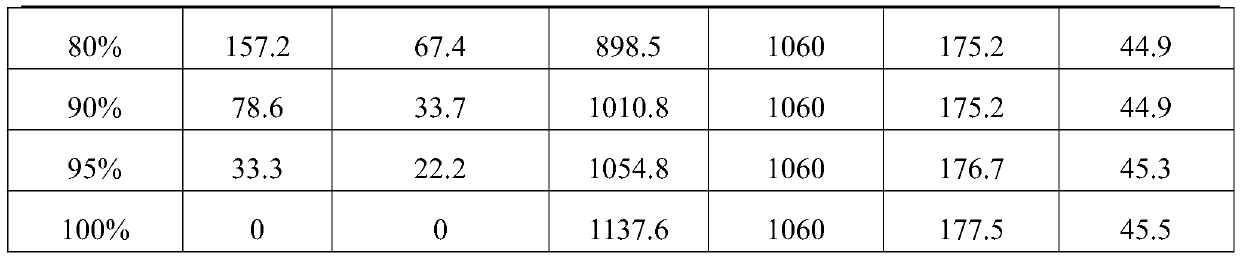

Powder alloy and production technique thereof

The invention relates to the technical field of alloy production, particularly a powder alloy and a production technique thereof. The powder alloy comprises 0.04-0.09% of C, 12-14% of Cr, 7-9% of Co, 3.3-3.7% of W, 3.3-3.7% of Mo, 2.3-3.7% of Al, 3.3-2.7% of Ti, 3.3-3.7% of Nb, 0.006-0.015% of B, 0.03-0.07% of Zr and the balance of Ni. The powder alloy is a highly-alloyed r'-phase precipitation-reinforced nickel-base high-temperature alloy, wherein the r' volume content is 50-55%, and the r' formed element content (atomic) is 28%. The powder alloy is a turbine disk material at the highest strength level under the operating condition of 650 DEG C at present. The powder alloy not only can be used for high / low-pressure turbine disks, but also can be used for gas compressor disks, turbine shafts, turbine baffle rings, high-temperature sealing parts and other high-temperature parts. The powder alloy is prepared by a plasma rotating electrode powder manufacturing apparatus, and the powder quality is greatly enhanced.

Owner:JIANGSU PLAZA PREMIUM ELECTRIC INSTR

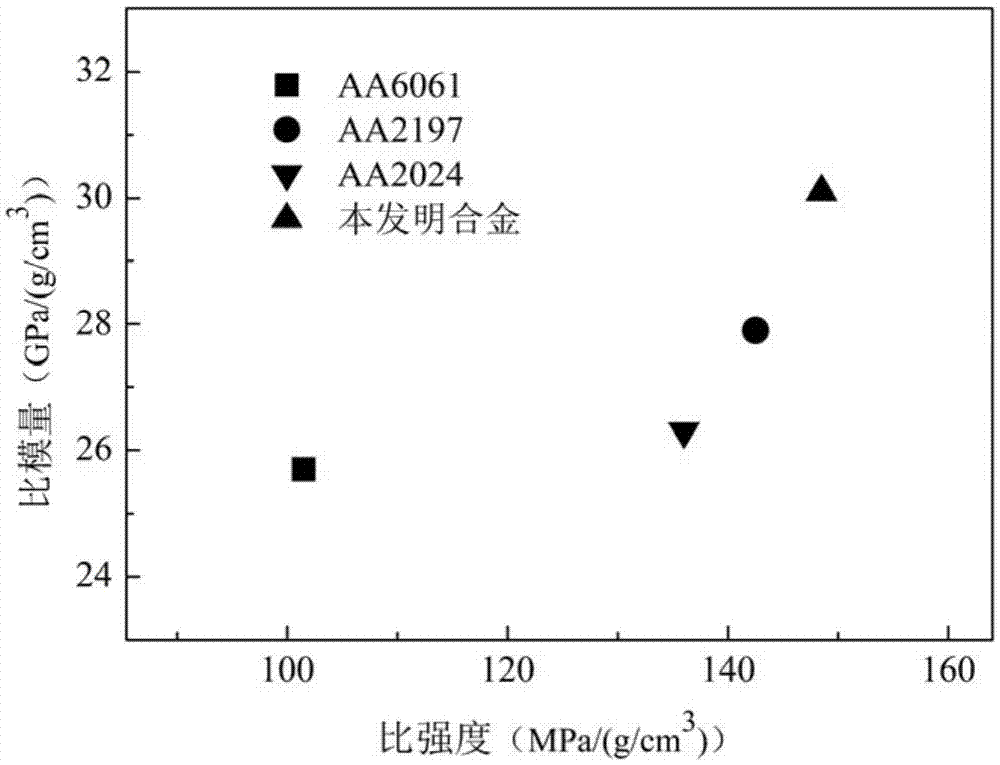

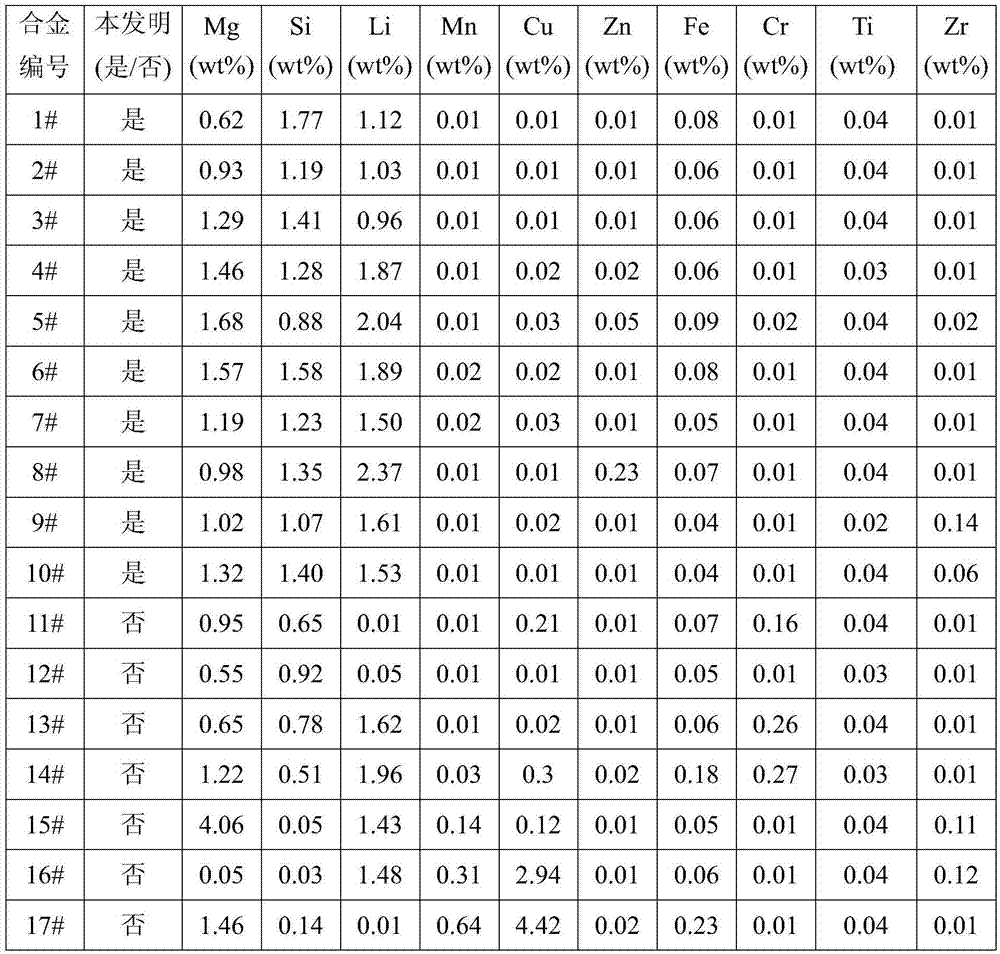

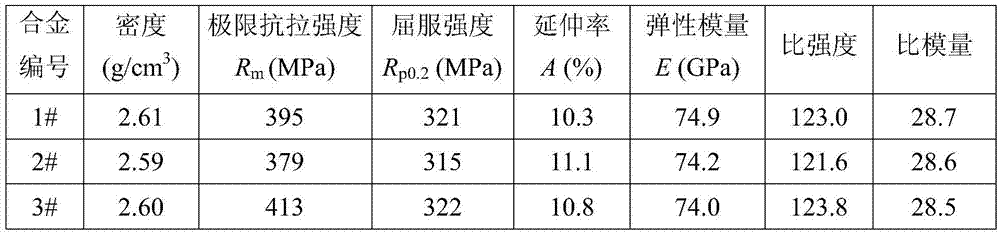

High-specific-strength and high-specific-modulus aluminum alloy material, preparation method thereof and component machined by material

The invention discloses a high-specific-strength and high-specific-modulus aluminum alloy material, a preparation method thereof and a component machined by the material. The aluminum alloy is prepared from, by weight, 0.60-1.70% of Mg, 0.85-1.80% of Si, 0.80-2.40% of Li, no more than 0.50% of Mn, no more than 0.50% of Cu, no more than 0.50% of Zn, 0.50% of Fe, no more than 0.50% of Cr, no more than 0.25% of Ti, no more than 0.25% of Zr, no more than 0.05% of each of other elements, and the balance Al, and the total content of the other elements is no more than 0.15%. The preparation method comprises the steps that an alloy ingot is manufactured, the alloy ingot is subjected to homogenizing heat treatment, deformation machining is conducted on the alloy ingot after the homogenizing heat treatment to obtain the alloy material of a required specification, the alloy material is subjected to solution heat treatment and cooled to the room temperature quickly, and the alloy material is subjected to aging heat treatment to obtain good performance matching. The high-specific-strength and high-specific-modulus aluminum alloy material has excellent specific strength and specific modulus performance and is an ideal material of modern manufacturing structure lightweight components.

Owner:GRIMAT ENG INST CO LTD

Multi-strength regeneration brick aggregate fiber concrete and preparing method thereof

The invention relates to multi-strength regeneration brick aggregate fiber concrete and a preparing method thereof. The multi-strength regeneration brick aggregate fiber concrete is prepared from cement, fine aggregate, natural coarse aggregate, regeneration brick coarse aggregate, polyolefin fiber, steel fiber and water according to the weight ratio of 1: (0.780-1.309) : (0-1.830) : (0.390-1.568) : (0-0.019) : (0-0.161) : (0.33-0.48). The regeneration brick aggregate fiber concrete with the target strength grade of CF30-CF50 can be prepared by means of the raw materials, strength grade is high, and application range is wide. The obtained regeneration brick aggregate fiber concrete has high working performance including peaceability and water-retaining property, compressive strength and splitting-tension strength are high, the preparing process is simple and environmentally friendly, and construction is easy.

Owner:ZHENGZHOU UNIV

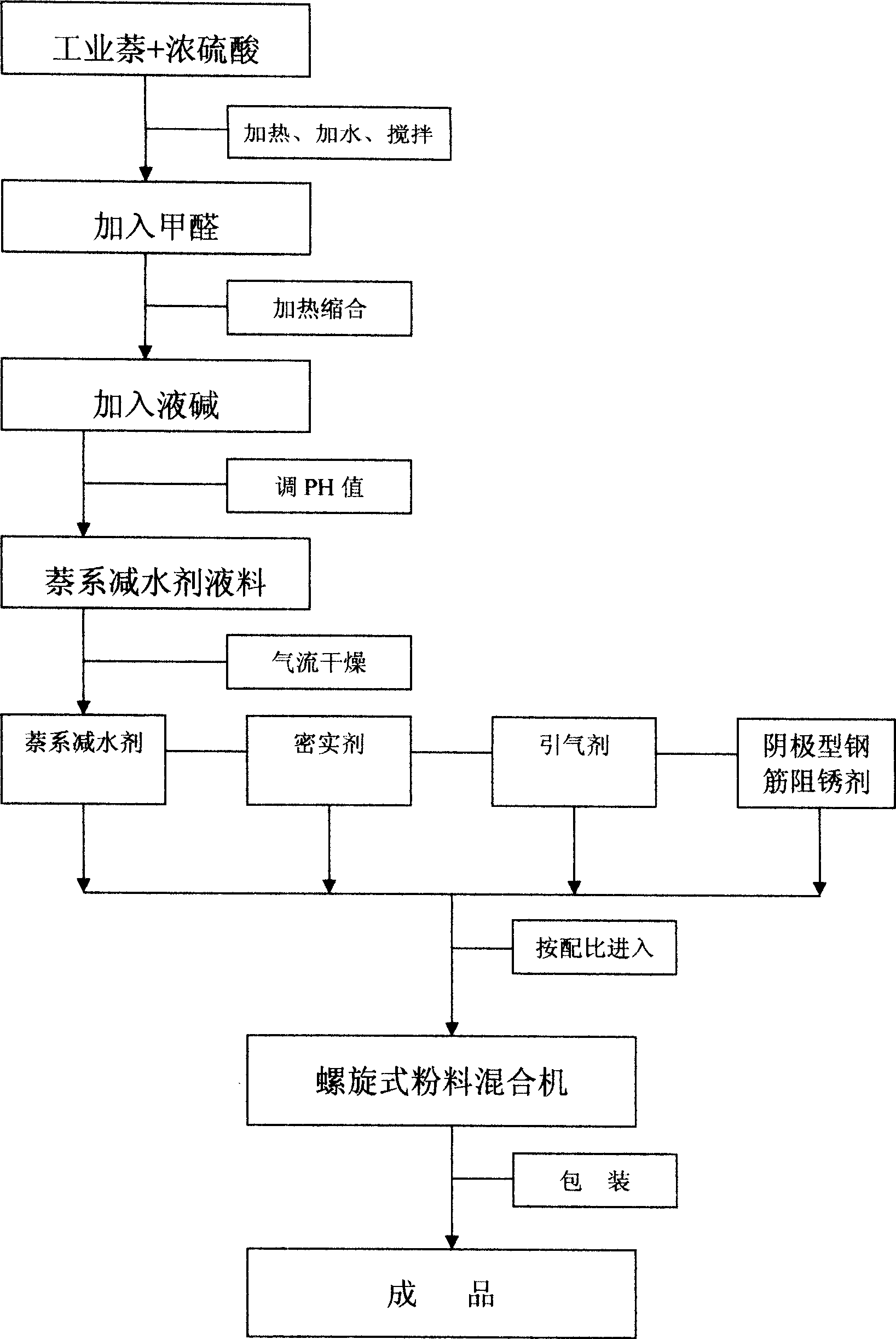

Composite concrete antiseptic agent

The invention relates to a compound concrete corrosion remover. Aiming at the serious hazard brought to concrete by corrosion, the foreign standards and the advanced technical ideas are used for reference so as to improve the anti-corrosive property of the concrete starting from improving four technical points of intensity, compactness, reduction of bleeding and rust resistance of the concrete. The compound concrete corrosion remover changes the prior concrete corrosion prevention thought and technical means. The developed compound concrete corrosion remover can ensure that the concrete has good comprehensive anti-corrosive property. Besides, the compound concrete corrosion remover can improve the construction operation working performance, improve the workability, the cohesive quality and the water preserving capability, and improve the slump and the pumpability. While satisfying the anti-corrosive property, the compound concrete corrosion remover still has the performances of a water reducing agent, a pumping agent and a waterproofing agent. The application of the compound concrete corrosion remover can substantially improve the lasting quality and the comprehensive corrosion resistance of the concrete, remarkably prolong the service life of a building and bring remarkable economic and social benefits.

Owner:YUNNAN INST OF BUILDING RES +1

X-ray inspection apparatus for pipeline girth weld inspection

ActiveUS8923478B2Shorten cycle timePerfect detection systemUsing wave/particle radiation meansX-ray apparatusX-rayPhysics

Owner:SPS ACQUISITION LLC

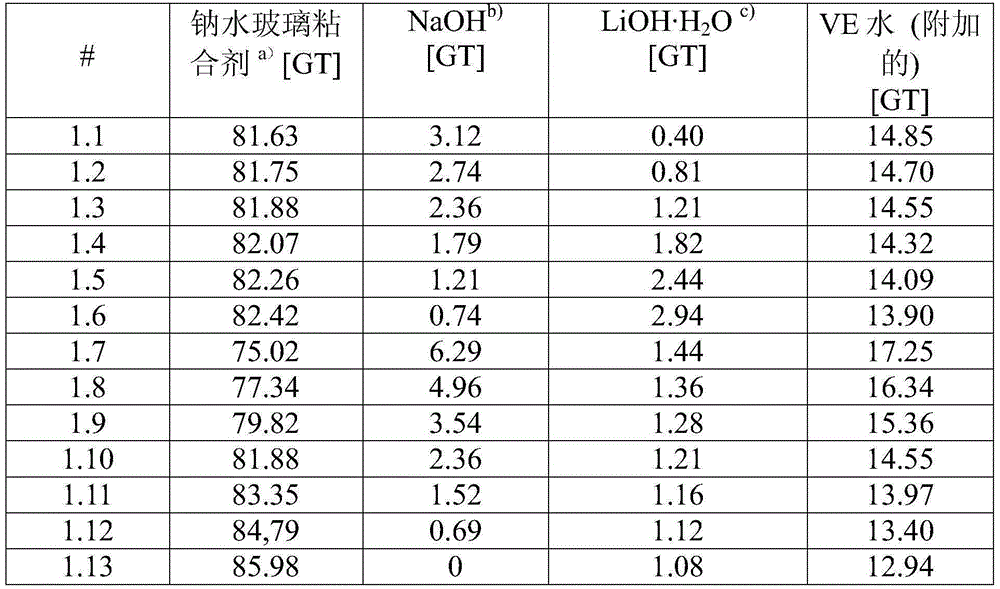

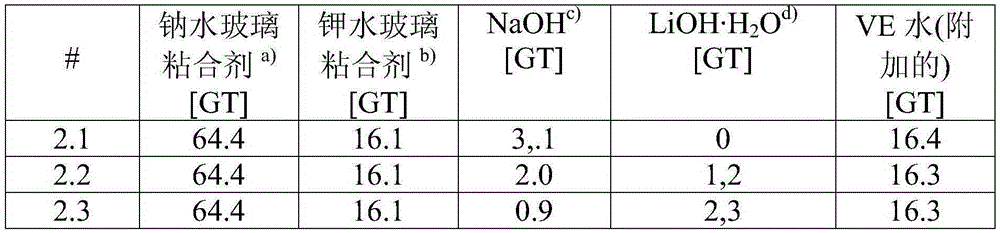

Lithium-containing molding material mixture based on an inorganic binder for producing molds and cores for metal casting

The invention relates to lithium-containing molding material mixtures comprising a refractory main molding material, an inorganic binder, and amorphous silicon dioxide as an additive in the production of molds and cores for metal casting. The invention further relates to a method for producing molds and cores using the molding material mixtures and to molds and cores produced according to the method.

Owner:ASK CHEM LP

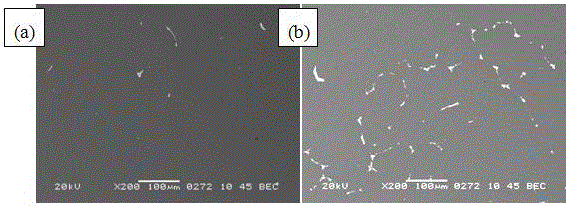

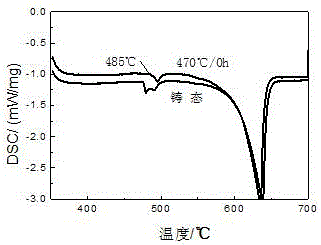

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

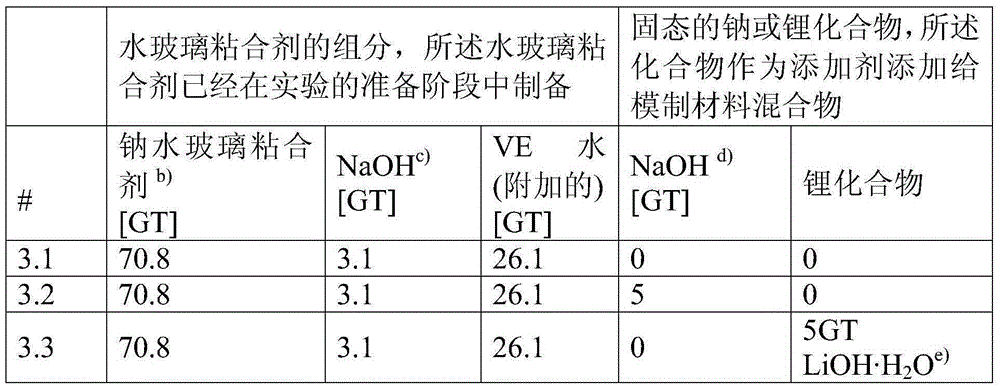

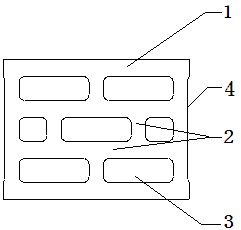

Three-row hole recycled concrete load-bearing energy-saving composite thermal insulation block and preparation method thereof

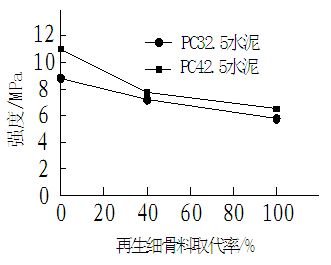

InactiveCN102277924AImprove insulation performanceRaise the intensity levelConstruction materialCeramic shaping apparatusThermal insulationChemistry

The invention discloses a recycled concrete load-bearing thermal insulation block with three rows of holes, which is characterized in that the block is composed of walls and ribs, and the gaps between the walls and ribs are holes. The holes are filled with insulation boards. Crush construction waste into recycled aggregate, and make recycled fine aggregate and recycled coarse aggregate; weigh cement, water, recycled fine aggregate and recycled coarse aggregate according to the formula, and mix cement: water: recycled fine aggregate : Regenerated coarse aggregate = 375: 150: 664: 811 weight ratio mixing, mixing evenly, through the block forming machine to make a three-row hole recycled concrete load-bearing block with a compression ratio of 0.86; fill the insulation board to the three-row hole regeneration In each hole of the concrete load-bearing block, it is verified by experiments that the block of the present invention has higher compressive strength, has increased heat conduction paths and heat preservation materials, and has better heat preservation effect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

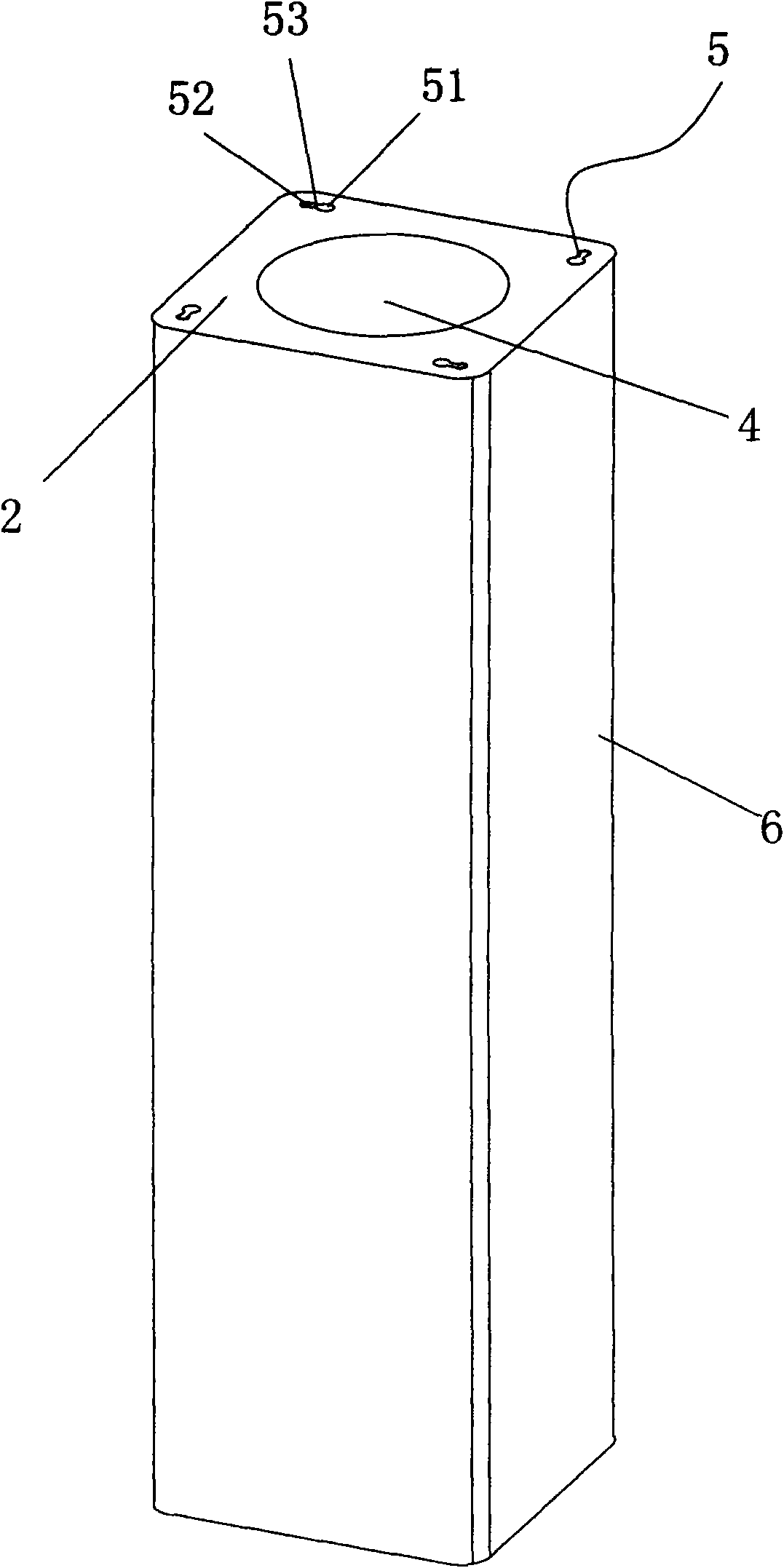

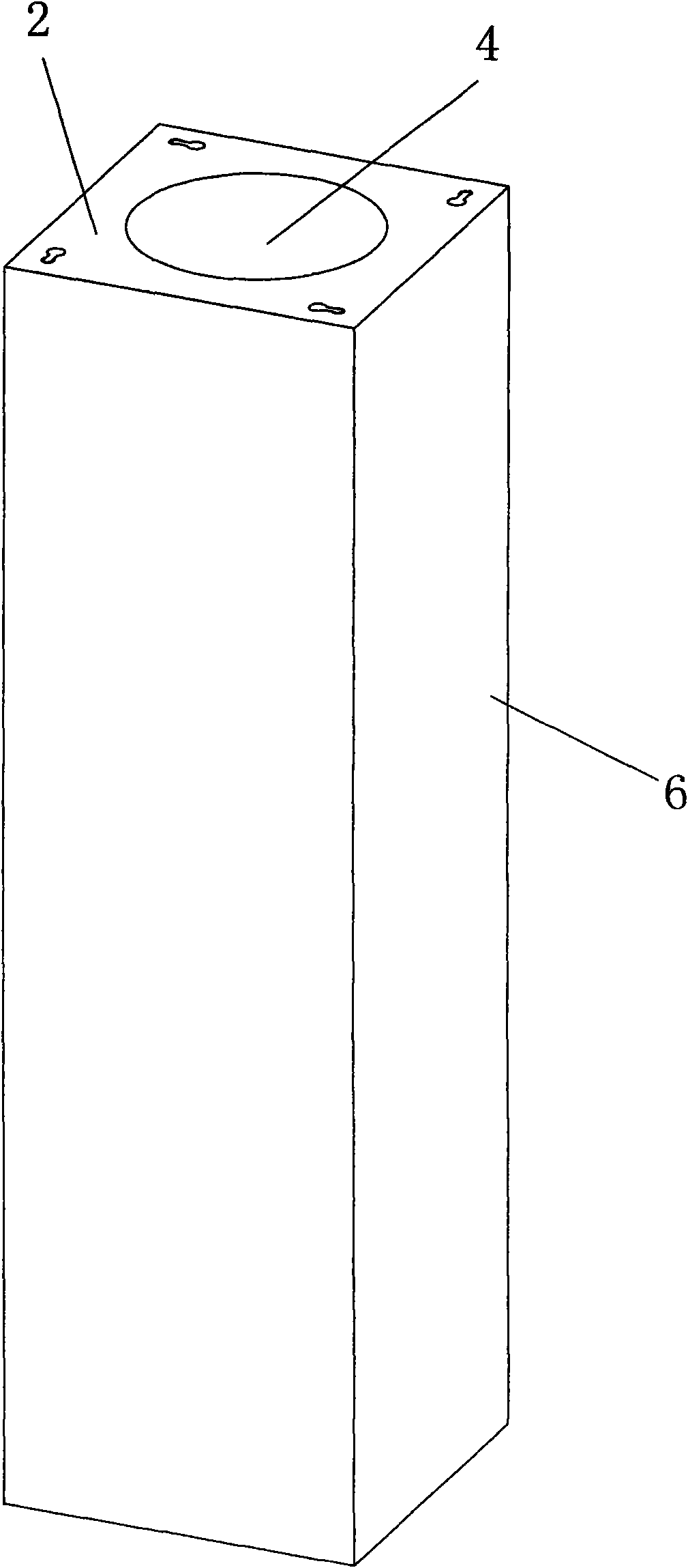

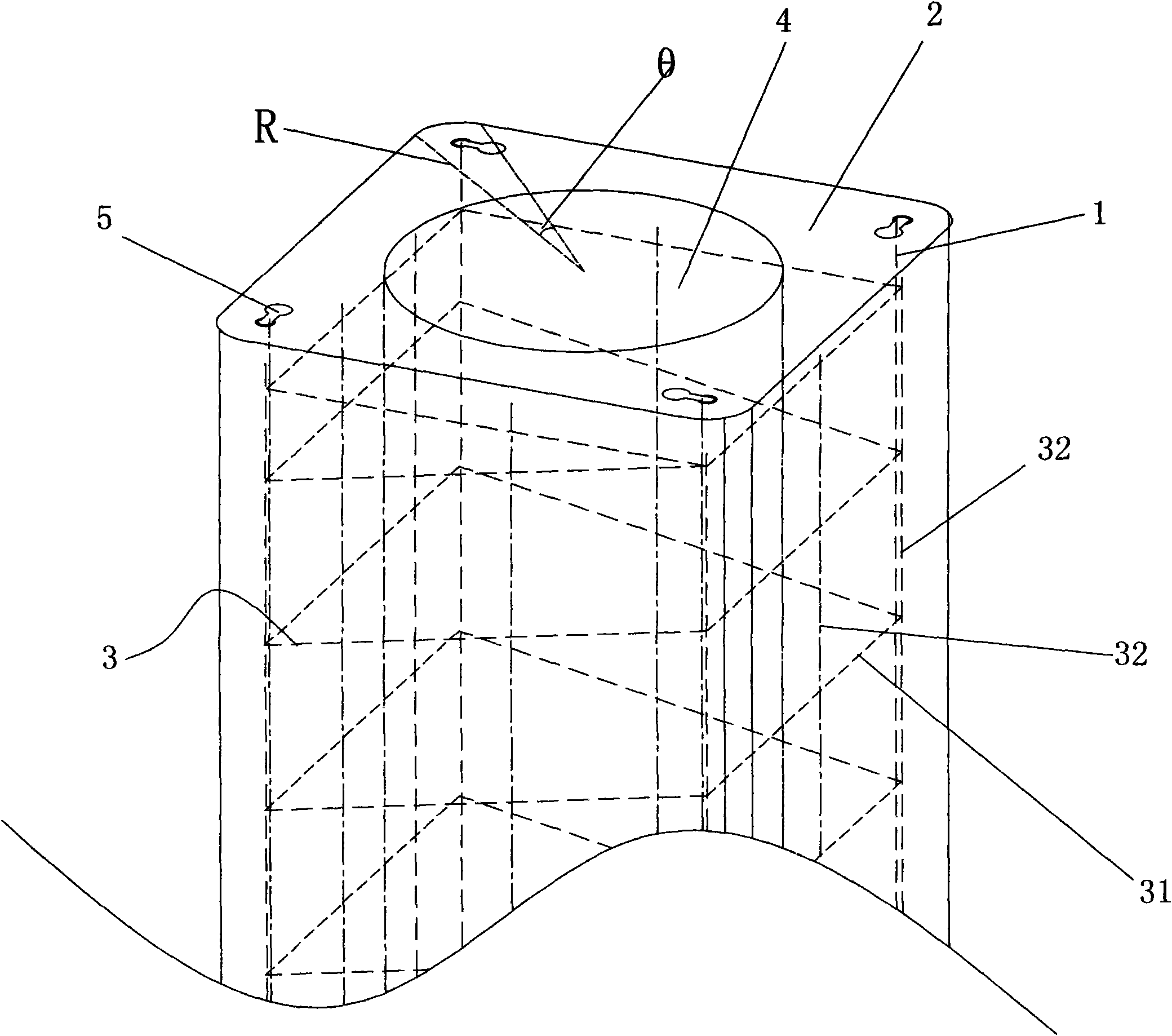

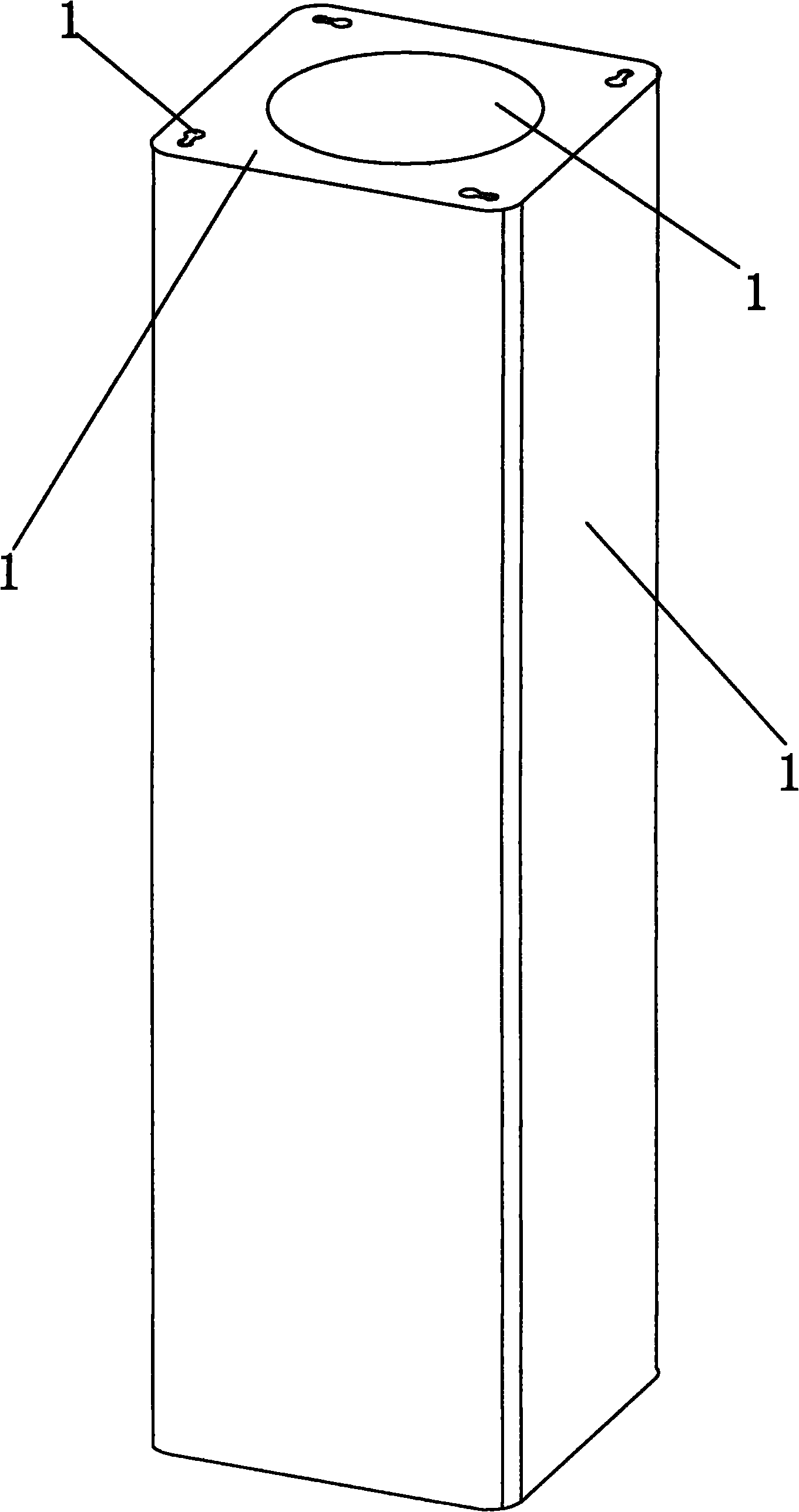

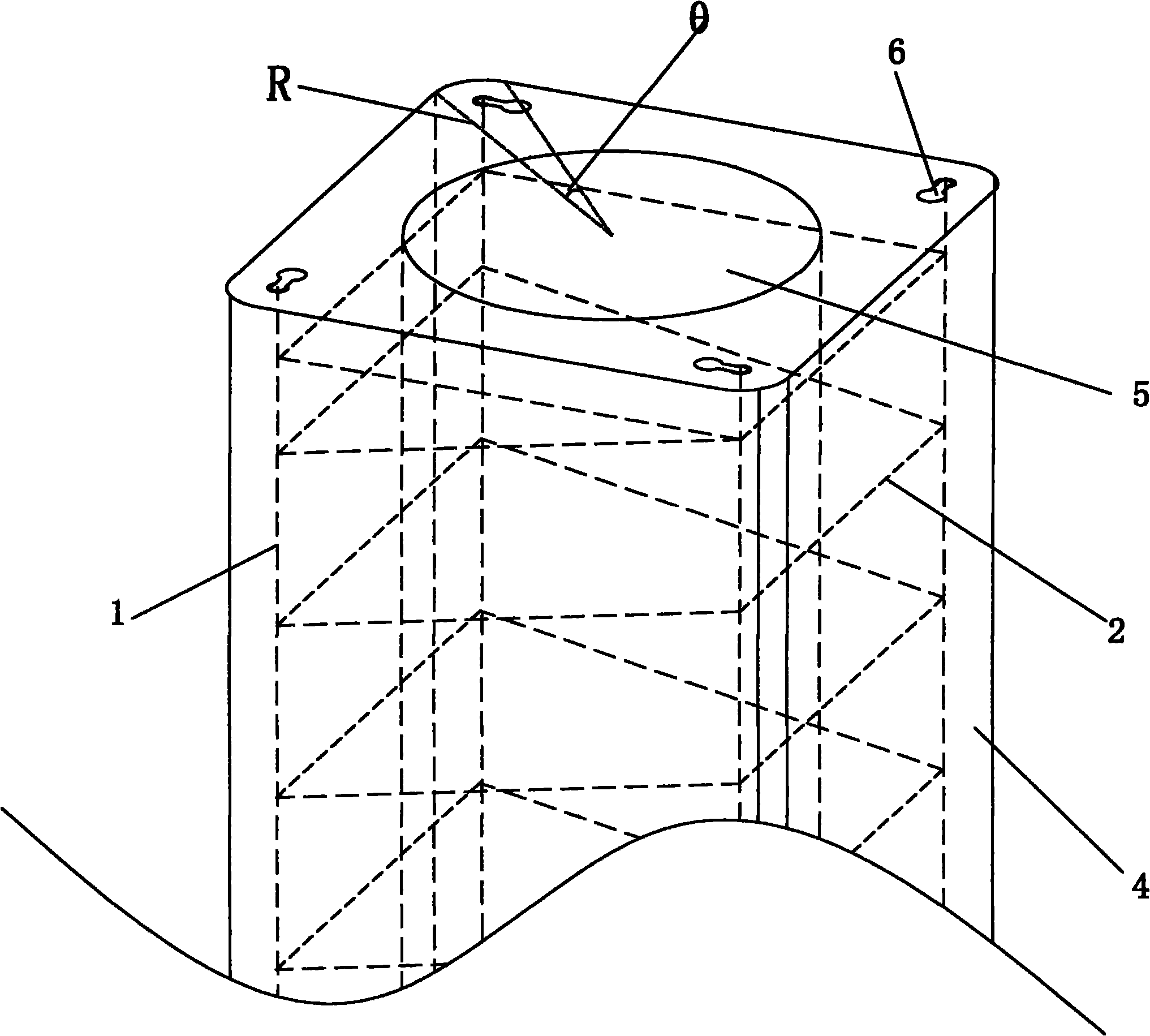

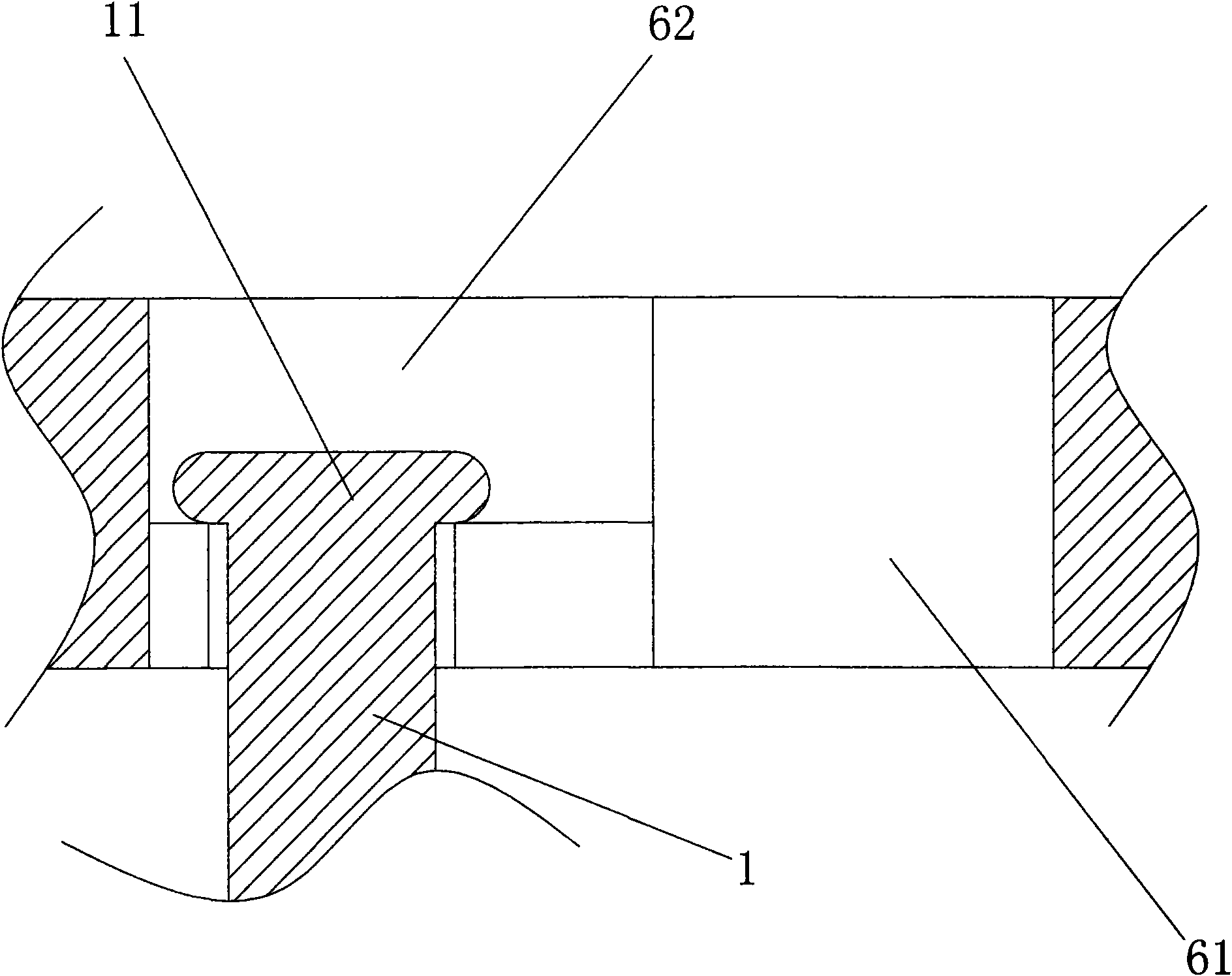

Prestressed concrete hollow square pile and production method thereof

The invention discloses a prestressed concrete hollow square pile comprising a plurality of independent main steel reinforcements. Both ends of each main steel reinforcement are respectively fixedly connected with square end plates; the main steel reinforcements are externally sleeved with steel reinforcement cage racks; each steel reinforcement cage rack comprises a spiral steel reinforcement, and the spiral steel reinforcement is welded with a plurality of auxiliary steel reinforcements; concrete is poured outside the main steel reinforcements and the steel reinforcement cage racks and is combined with the main steel reinforcements and the steel reinforcement cage racks into an integral square pile; and the center of the integral square pile is provided with a central circular hole penetrating through an integral square pile body. The invention aims at providing the prestressed concrete hollow square pile which has the advantages of good molding quality, high single-pile bearing capacity, undamaged steel reinforcement framework before the steel reinforcement framework is used, convenient production, good horizontal anti-bending bearing capacity, high shearing resistant property, convenient stacking and difficult knock damage during pile hoisting, transportation and transferring. The invention also aims at providing a production method of the prestressed concrete hollow square pile.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

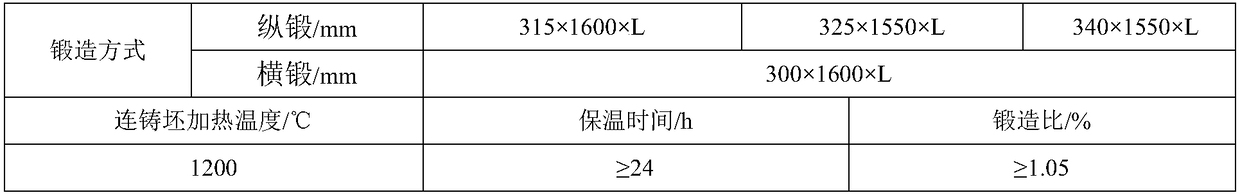

Large-swelling-amount welded tube and manufacturing method thereof

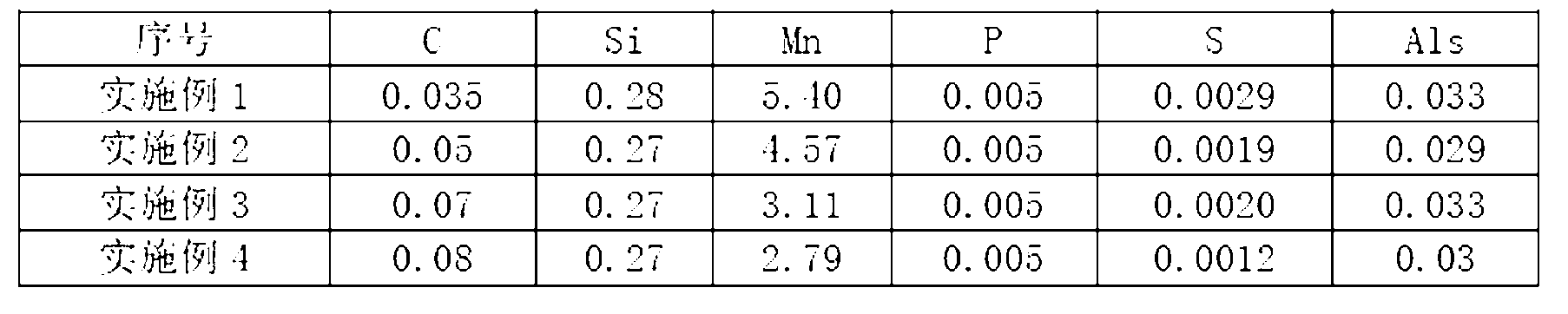

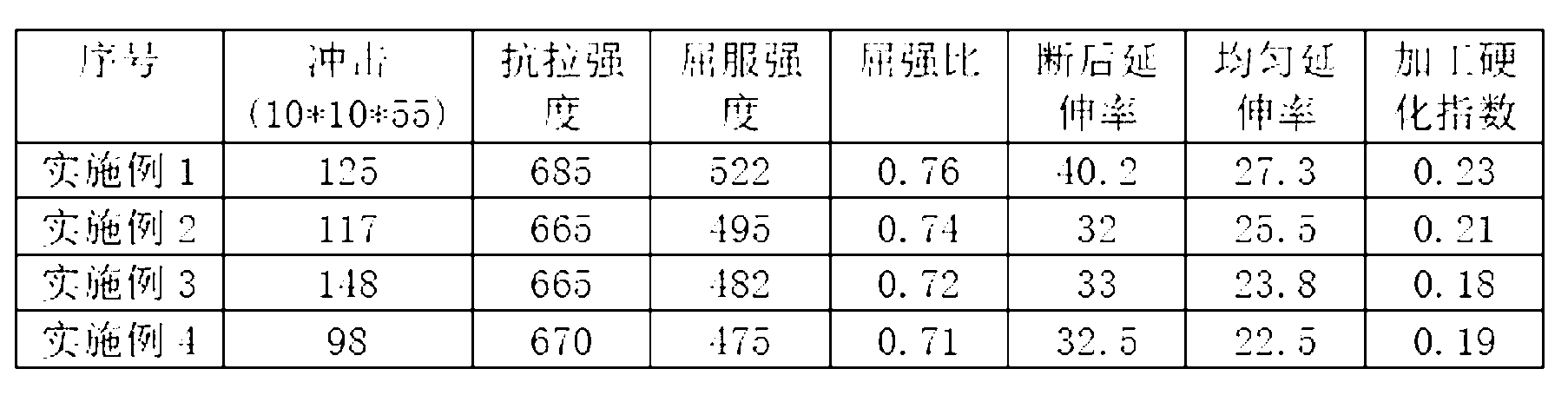

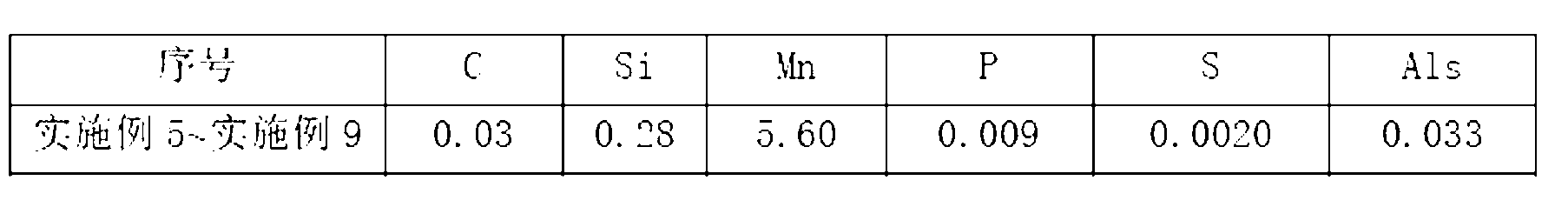

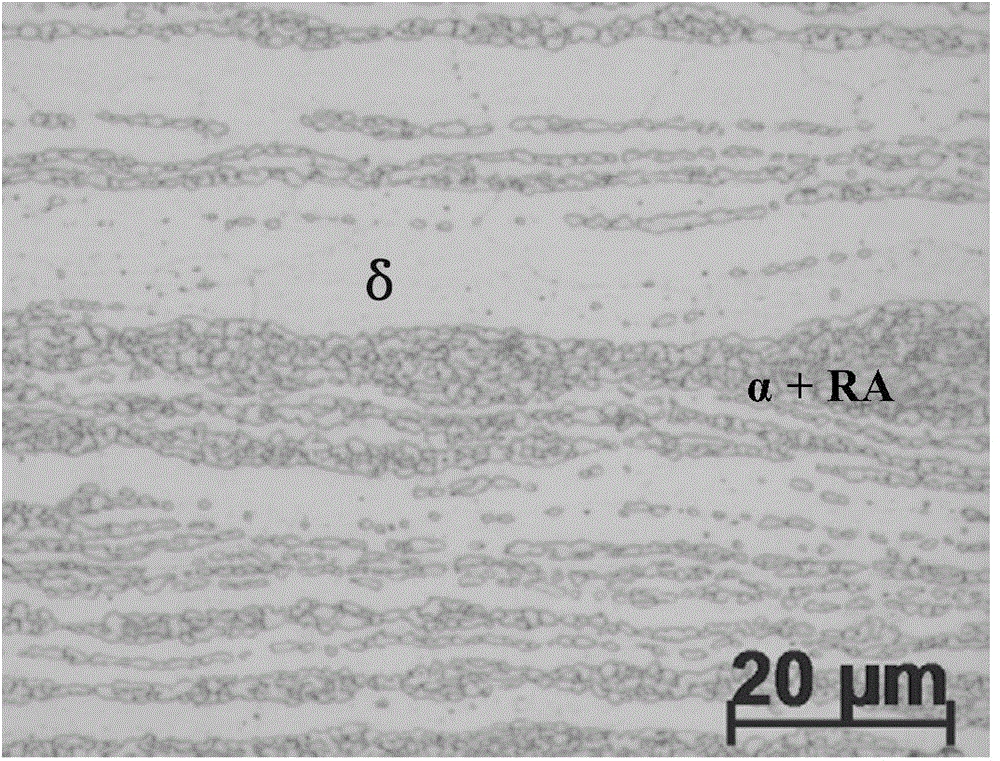

ActiveCN103160730ARaise the ratioMeet different performance requirementsFurnace typesHeat treatment furnacesChemical compositionPerformance index

The invention relates to a large-swelling-amount welded tube and a manufacturing method thereof, belonging to the technical field of welded tube steel. The welded tube contains the following chemical components in percentage by mass: 0.02-0.10wt% of C, 2.0-6.0wt% of Mn, 0.2-1.0wt% of Si, less than 0.01wt% of S, less than 0.02wt% of P and the balance of Fe and inevitable impurities, and can also contain the following one or more chemical components: 0.1-0.6wt% of Ni, 0.1-0.6wt% of Cr, 0.1-0.5wt% of Cu, 0.01-0.1wt% of Nb, 0.01-0.1wt% of V and 0.01-0.02wt% of Ti. The manufacturing method comprises the following steps: performing converter steel making, controlled rolling and controlled cooling; then performing crimping plate processing on steel strips; forming a swollen blank tube through high frequency welding (HFW); and finally performing heat treatment to obtain residual austenite of which the volume fraction is larger than 5% in the structure. The invention ensures that the material has high strength level and simultaneously has high plasticity, the uniform elongation rate is up to 20% or above, and all the mechanical performance indices meet the requirements of API and other relevant standards.

Owner:CENT IRON & STEEL RES INST

Manufacturing method for improving extensibility of commonly-cooled ferrite lightweight steel

ActiveCN104928456AOptimizing the Manufacturing ProcessIncreased elongation and strength-plastic productSteel platesDuctility

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation process of concrete porous brick prepared from tubular pile residual slurry and waste incineration slag

ActiveCN103880464AReduce and eliminate emissionsReduce processing costsSolid waste managementCeramicwareBrickSlag

The invention relates to a preparation process of a concrete porous brick prepared from tubular pile residual slurry and waste incineration slag. The preparation process comprises the following steps: firstly, pretreating raw materials, including delayed coagulation of tubular pile residual slurry, sorting and grinding treatment of domestic waste incineration slag and direct use of fly ash, cement and stone chips; secondly, stirring and mixing according to a set ratio; thirdly, filling a brick mold cavity with the mixed material by adopting a brick making molder and molding in a ramming manner; and finally, carrying out standing curing the molded concrete porous bricks and a bottom supporting plate together in a standing curing chamber for not less than 1 day, then transferring to a maintenance chamber spraying water for maintenance for 10-14 days, and finally transferring to a concrete porous brick stacking field and naturally maintaining for 28 days to obtain a concrete porous brick finished product. By adopting effective components in the tubular pile residual slurry and the waste incineration slag to produce the tubular pile residual slurry-waste incineration slag concrete porous brick, the preparation process has the advantages of not only reducing and avoiding emission of waste slag and waste liquid left over in industrial production so as to prevent secondary pollution, but also saving lots of land stacking cost and treatment expenses.

Owner:TONGXIANG TONGDE WALL BUILDING MATERIALS +2

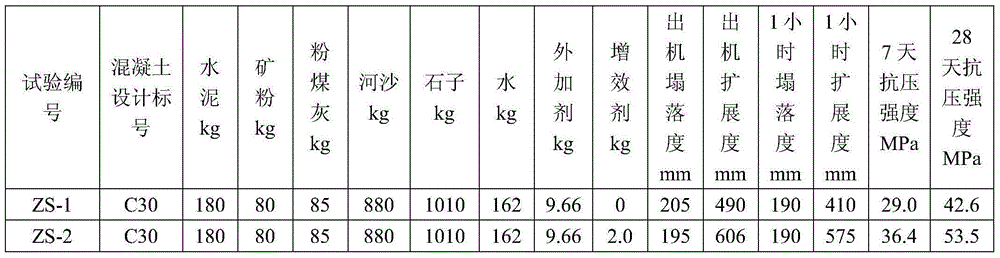

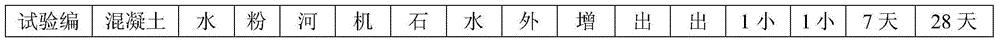

High-efficiency and energy-saving concrete synergistic agent and preparation method thereof

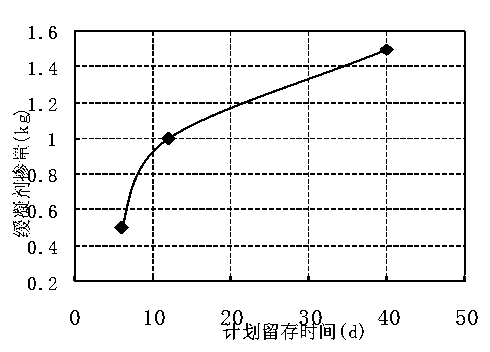

ActiveCN105198264ARaise the intensity levelIntensity level maintenanceWork performanceSodium dodecylbenzenesulfonate

The invention discloses a high-efficiency and energy-saving concrete synergistic agent and a preparation method thereof, and belongs to the concrete technical field. The concrete synergistic agent is prepared from the following raw materials in parts by weight: 10-25 parts of a UFD macromolecular copolymer, 10-15 parts of a water reducing agent mother liquor, 3-5 parts of sodium tripolyphosphate, 2-7 parts of sodium gluconate, 10-15 parts of a stabilizer, and 33-65 parts of water. The UFD macromolecular copolymer is prepared from urea, formaldehyde and sodium dodecylbenzenesulfonate. Through coordinative and promotion effects of the components, the high-efficiency and energy-saving concrete synergistic agent can increase the concrete strength grade, improve the working performance, or reduce the cement use amount under a condition of keeping the concrete working performance and the strength grade basically consistent, so as to achieve the purpose of reducing production cost of the concrete, and then achieve the purposes of saving energy, reducing consumption and reducing environmental pollution. The product production process is simple, and the product storage cycle is as long as one year.

Owner:SHANDONG ZHONGSEN TECH

Waste sintered brick recycled C30 concrete and preparation method thereof

ActiveCN104529333AImprove uniformityImprove quality and tightnessSolid waste managementCompressive resistanceBrick

The invention relates to waste sintered brick recycled C30 concrete and a preparation method thereof. The waste sintered brick recycled C30 concrete is prepared from cement, a waste sintered brick recycled coarse aggregate, a fine aggregate, water and a water reducing agent at a weight ratio of 1 to (1.679-1.737) to (0.653-0.817) to (0.367-0.397) to (0.006-0.01). The C30 concrete prepared by the method disclosed by the invention is qualified and stable in strength, high in compressive strength and split and tensile strength, good in working performances such as workability, fluidity and water retention property, simple and environmentally friendly in preparation process and easy to implement.

Owner:ZHENGZHOU UNIV

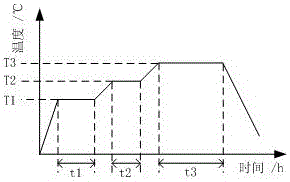

Homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy

The invention relates to a homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy. The homogenization heat treatment method of the Al-Zn-Mg-Cu-Zr aluminum alloy is characterized in that a three-level homogenization heat treatment process for controlling a heating process is used for homogenization heat treatment, and the homogenization heat treatment method comprises the following steps: (1) carrying out low-temperature pre-precipitation, and carrying out a first-level homogenization heat treatment process for promoting precipitation of Al3Zr as a dispersed phase; (2) insulating, and carrying out a second-level homogenization heat treatment process for increasing the overburnt temperature of a structure; and (3) carrying out a long-term uniform insulating process, and carrying out a third-level homogenization heat treatment process for eliminating high-melting-point Al2CuMg. By the heat treatment process, the problem of insufficient soaking in large cast ingots of 7xxx series aluminum alloy can be solved well, a coarse phase does not dissolve in a microscopic structure, an S phase is fully re-dissolved, and meanwhile, uniform precipitation of Al3Zr as the dispersed phase can be regulated and controlled. More importantly, the homogenization heat treatment method is suitable for industrial production of large cast ingots, and has good operability; meanwhile, homogenization heat treatment time can be shortened; and energy consumption of heat treatment is reduced.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Pretensioned prestressed concrete quadrilateral pile and production method thereof

InactiveCN101914913AImprove compactnessRaise the intensity levelCeramic shaping apparatusBuilding reinforcementsPre stressRebar

The invention discloses a pretensioned prestressed concrete quadrilateral pile, which is characterized by comprising a plurality of main reinforcements, wherein the main reinforcements are welded with spiral reinforcements; the heads of the main reinforcements are greater than the diameters of the main reinforcements; both ends of the main reinforcements are connected with quadrilateral end plates respectively; concrete is poured outside a reinforcement cage frame consisting of the main reinforcements and the spiral reinforcements; the concrete is combined with the reinforcement cage frame into an integral quadrilateral pile body; and the center of the quadrilateral pile body is provided with a central round hole passing through the whole quadrilateral pile body. Aiming to overcome the deficiencies in the prior art, the invention provides the pretensioned prestressed concrete quadrilateral pile which has the advantages of high molding quality, high bearing capacity of a single pile, damage resistance during use of the reinforcement frameworks, high bending resistance bearing capacity, high shearing resistance, convenient stacking, and difficult damage during hoisting, transporting and transferring the pile. The invention also aims to provide a production method of the pretensioned prestressed concrete quadrilateral pile.

Owner:句容长江建材有限公司

Thick steel for supporting nuclear steam generator and production method of thick steel

The invention relates to thick steel for supporting a nuclear steam generator and a production method of the thick steel. The thick steel comprises the following chemical components of, by weight percentage, 0.14% to 0.20% of C, 0.25% to 0.40% of Si, 0.30% to 0.40% of Mn, smaller than or equal to 0.008% of P, smaller than or equal to 0.002% of S, 0.30% to 0.60% of Mo, 1.20% to 2.00% of Ni, 0.80% to 1.50% of Cr, 0.01% to 0.03% of V, 0.015% to 0.030% of Al and the balance Fe and inevitable impurities. The thick steel has the advantages that the steel type provided by the invention is relativelyhigh in strength level after being tempered, and the temperature impact absorbed energy and the section fiber fraction of the series of steel type in the tempered state are also kept at a relatively high level.

Owner:ANGANG STEEL CO LTD

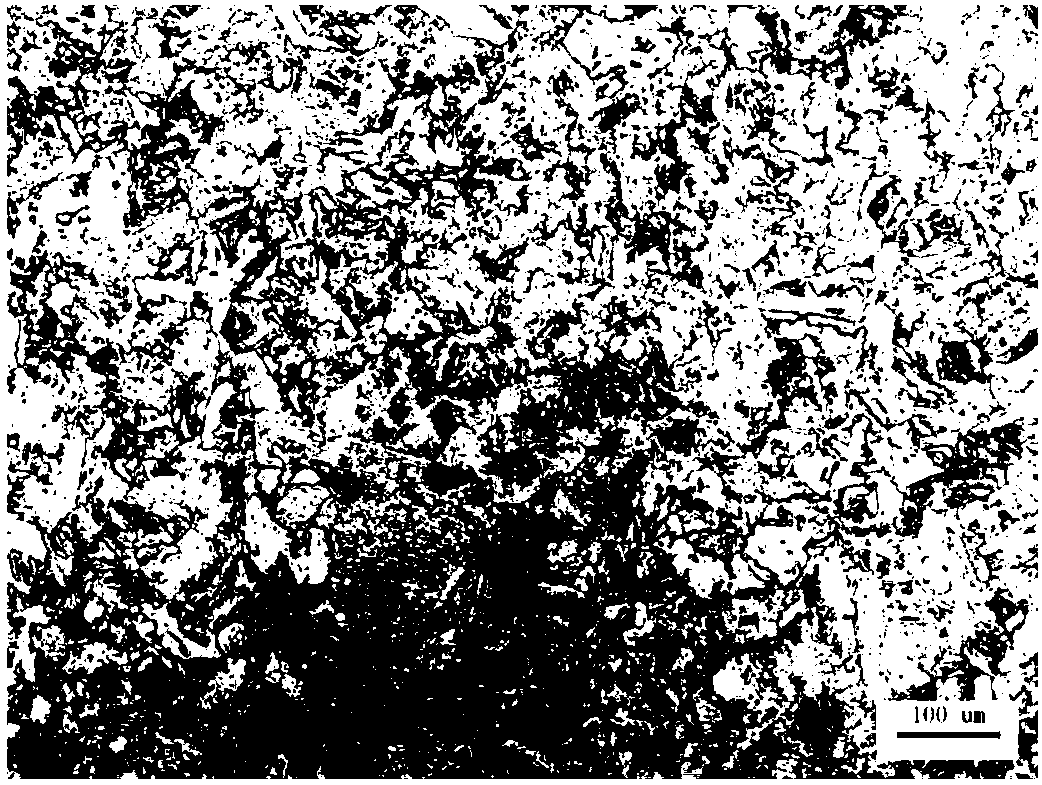

Heat treatment process for improving obdurability of near beta type or metastable beta type titanium alloy

The invention relates to a heat treatment process for improving obdurability of a near beta type or metastable beta type titanium alloy. The process comprises the following steps of: firstly, preserving heat at the temperature of T which is more than or equal to T beta-50 DEG C and less than or equal to T beta-10 DEG C, wherein the heat preservation time T (min) is eta * delta max, the delta max is the maximum section thickness of a forge piece, the unit is mm, the eta is a heating coefficient, and the value of the heating coefficient eta is 0.5 to 1.5min / mm; secondly, discharging the forge piece out of a furnace and cooling the forge piece to room temperature by air or water; thirdly, preserving heat of the cooled forge piece at the temperature of T which is more than or equal to 520 DEGC and less than or equal to 560 DEG C, wherein the heat preservation time T is more than or equal to 20min and less than or equal to 1.5h; fourthly, discharging the forge piece out of the furnace andcooling the forge piece to room temperature by air; fifthly, slowly heating the cooled forge piece to the temperature of T which is more than or equal to 480 DEG C and less than or equal to 540 DEG Calong with the furnace, wherein the heating rate is controlled to be within 5 DEG C / min, and the heat preservation time T is more than or equal to 6h and less than or equal to 12h; and finally, cooling the forge piece along with the furnace or discharging the forge piece out of the furnace and cooling the forge piece to room temperature by air. The process is suitable for heat treatment of the near beta type or metastable beta type titanium alloy with ultrahigh obdurability so as to obtain a tissue with high comprehensive performance and multi-scale precipitated phases, which has the requiredultrahigh strength (Rm is more than or equal to 1,500 MPa), high plasticity (A is more than or equal to 5 percent) and high obdurability (KIC is more than or equal to 45 MPa.m < 1 / 2 >), and meet important bearing structural members with ultrahigh obdurability matching required by airplanes.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

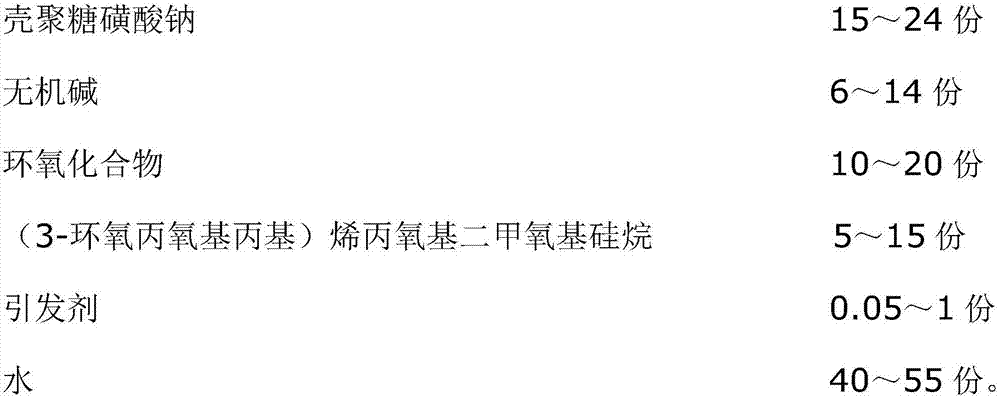

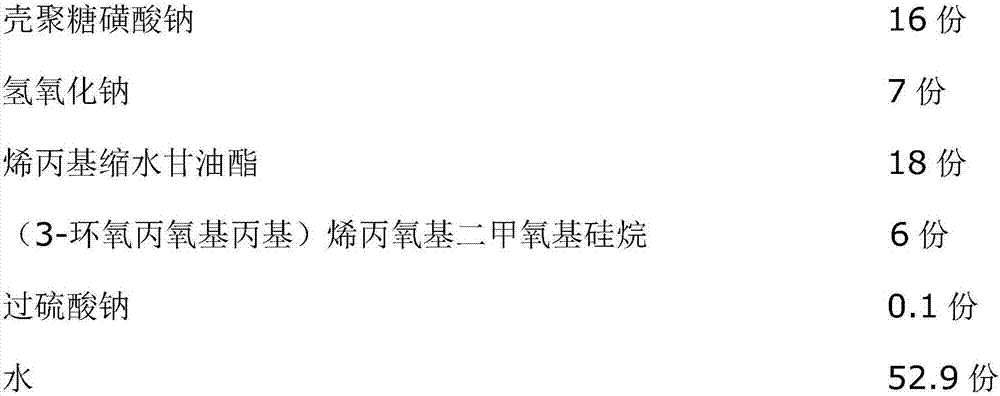

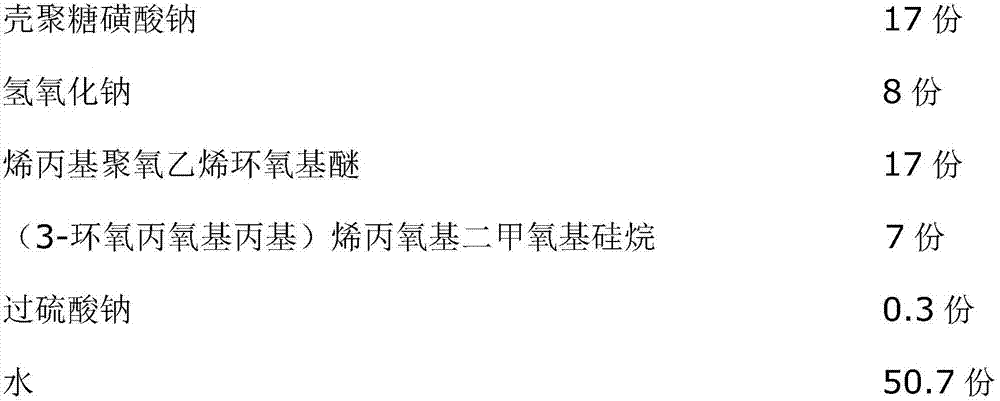

Chitosan sodium sulfonate containing concrete synergist and preparation method thereof

The invention discloses a chitosan sodium sulfonate containing concrete synergist and a preparation method thereof, and belongs to the field of a concrete additive. The synergist comprises chitosan sodium sulfonate, inorganic base, an epoxy compound, (3-epoxy propoxy propyl) allyloxy dimethoxy silicane, an initiator and water, wherein the initiator is a mixture made from one or more than two of sodium persulfate, potassium persulphate or ammonium persulfate. The preparation method comprises: adding weighed chitosan sodium sulfonate, inorganic base and water to a reaction vessel, then adding the epoxy compound and (3-epoxy propoxy propyl) allyloxy dimethoxy silicane to the reaction vessel; and adding the initiator to obtain the concrete synergist. The synergist improves the dispersity of cement particles, stimulates the action of cement, allows the hydration reaction to be fully carried out, improves the comprehensive properties of concrete, raises the strength level of concrete, saves the concrete consumption by about 10%, and reduces the production cost of concrete.

Owner:华海菲菲(河北)混凝土外加剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com