Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve powder quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

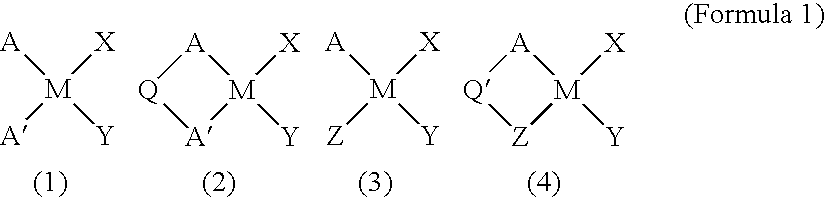

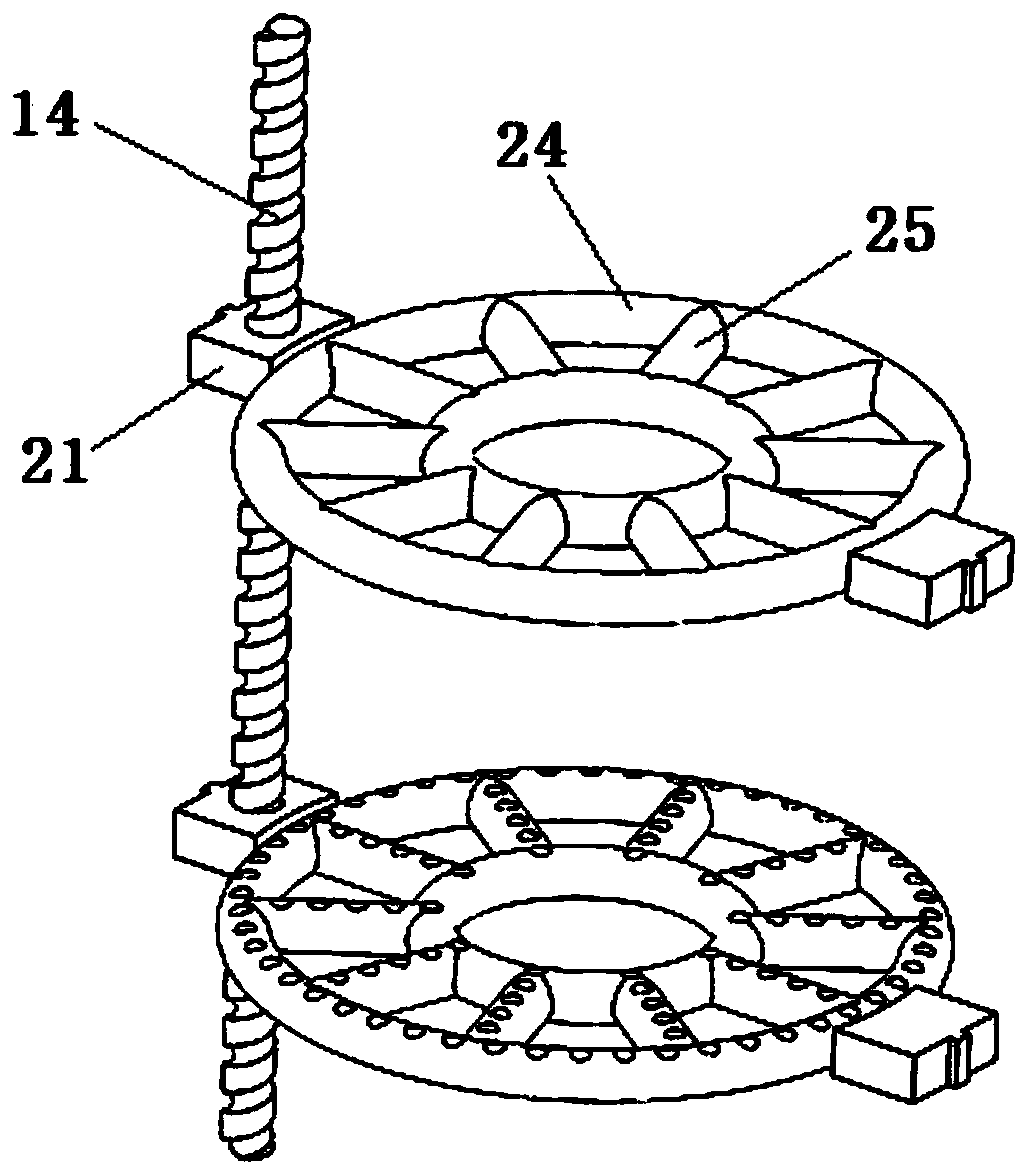

Catalysts for olefin polymerization, process for production of the catalysts, and method for preservation thereof

InactiveUS20090069171A1Energy saveLarge particle sizePhysical/chemical process catalystsOlefin polymerizationPolyolefin

Olefin polymerization catalysts for producing polyolefin resins which can dispense with a melt-kneading step necessitating great energy or a substitute addition step therefor and to which small amounts of antioxidants have been effectively added; and a process for the production of the catalysts. Specifically, a catalyst for olefin polymerization characterized by being prepared by conducting prepolymerization in the presence of [I] a solid catalyst for olefin polymerization having a mean particle diameter of 10 to 200 μm, [II] an antioxidant for resins, and [III] an olefin; and a catalyst for olefin polymerization characterized by containing [IV] an organoaluminum compound in addition to the components [I] to [III].

Owner:JAPAN POLYPROPYLENE CORP

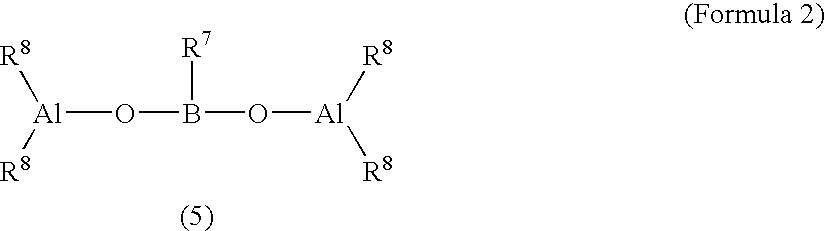

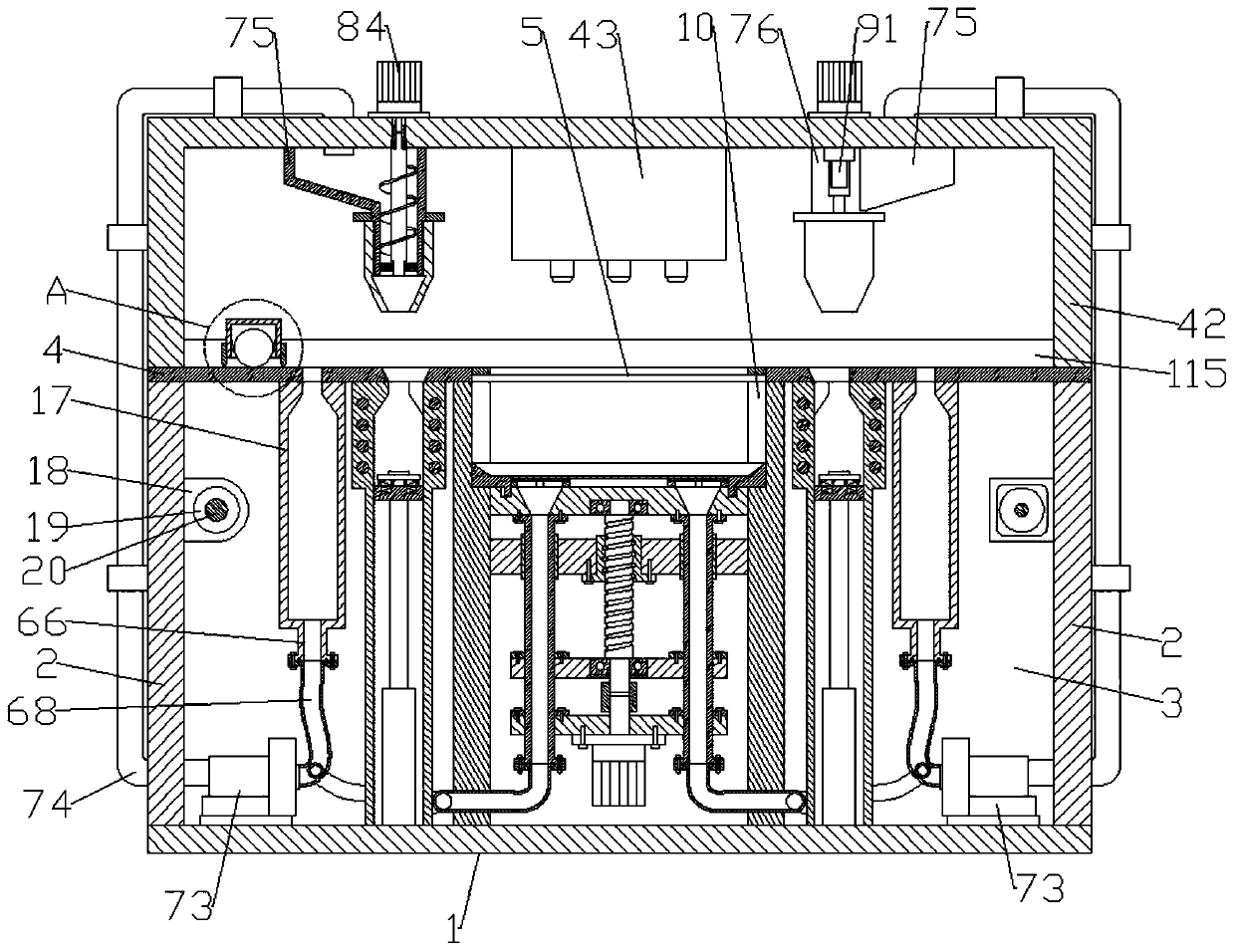

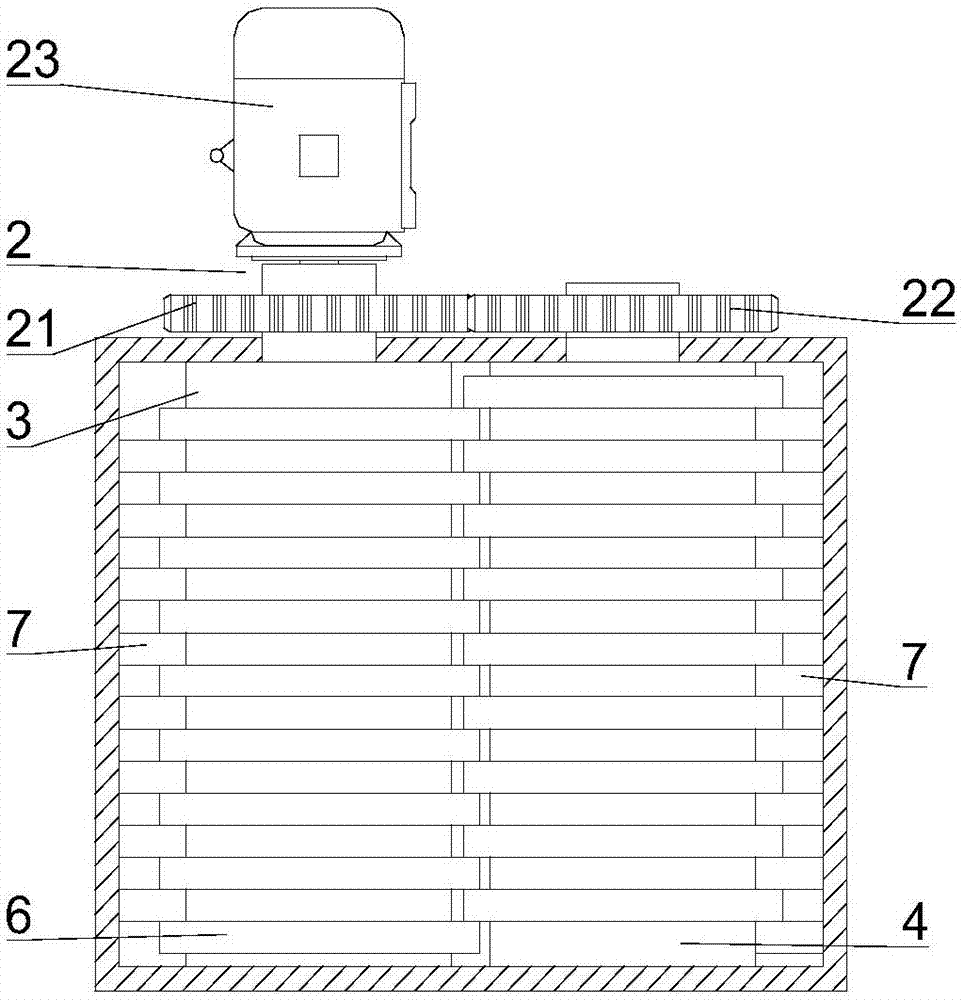

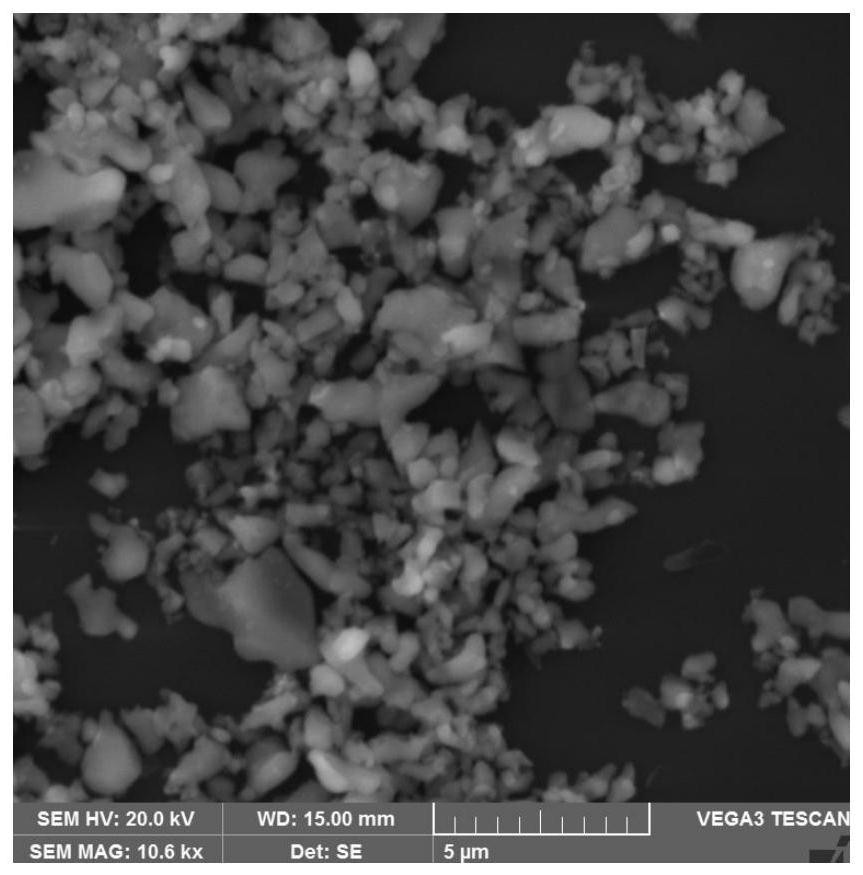

High-pressure smelting atomizing nitrogen-quenching device and method for utilizing device to produce samarium iron nitrogen alloy powder

Provided are a high-pressure smelting atomizing nitrogen-quenching device and a method for utilizing the device to produce samarium iron nitrogen alloy powder. The high-pressure smelting atomizing nitrogen-quenching device comprises a high-pressure control system, a master alloy smelting system and an atomizing nitrogen-quenching system. The high-pressure control system is mainly composed of a high-pressure furnace body, a pressure control device and a vacuum pumping device. The master alloy smelting system is mainly composed of a crucible, an infrared temperature measurement device and an induction heating device. The method for utilizing the high-pressure smelting atomizing nitrogen-quenching device to produce the samarium iron nitrogen alloy powder comprises the steps of high-pressure smelting, atomization into drops, high-pressure nitrogen quenching and powder collection. The high-pressure smelting atomizing nitrogen-quenching device is simple and scientific in structure, the content of nitrogen in the produced powder is high, powder solidification quality is good, and smelting atomization and nitrogen quenching are finished in an identical container rapidly and conveniently.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

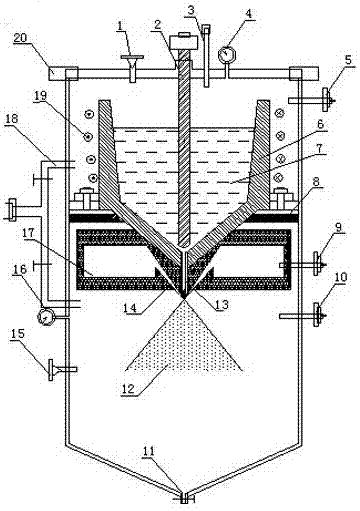

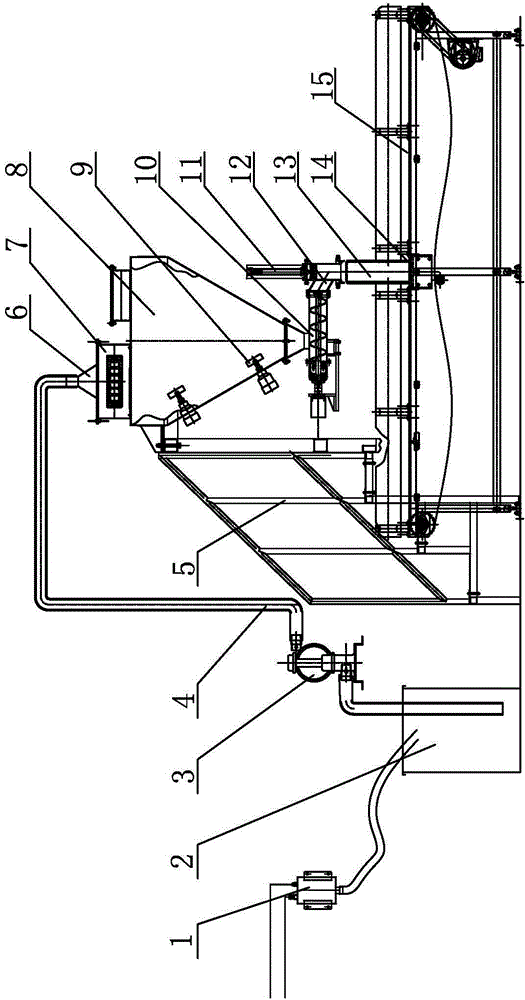

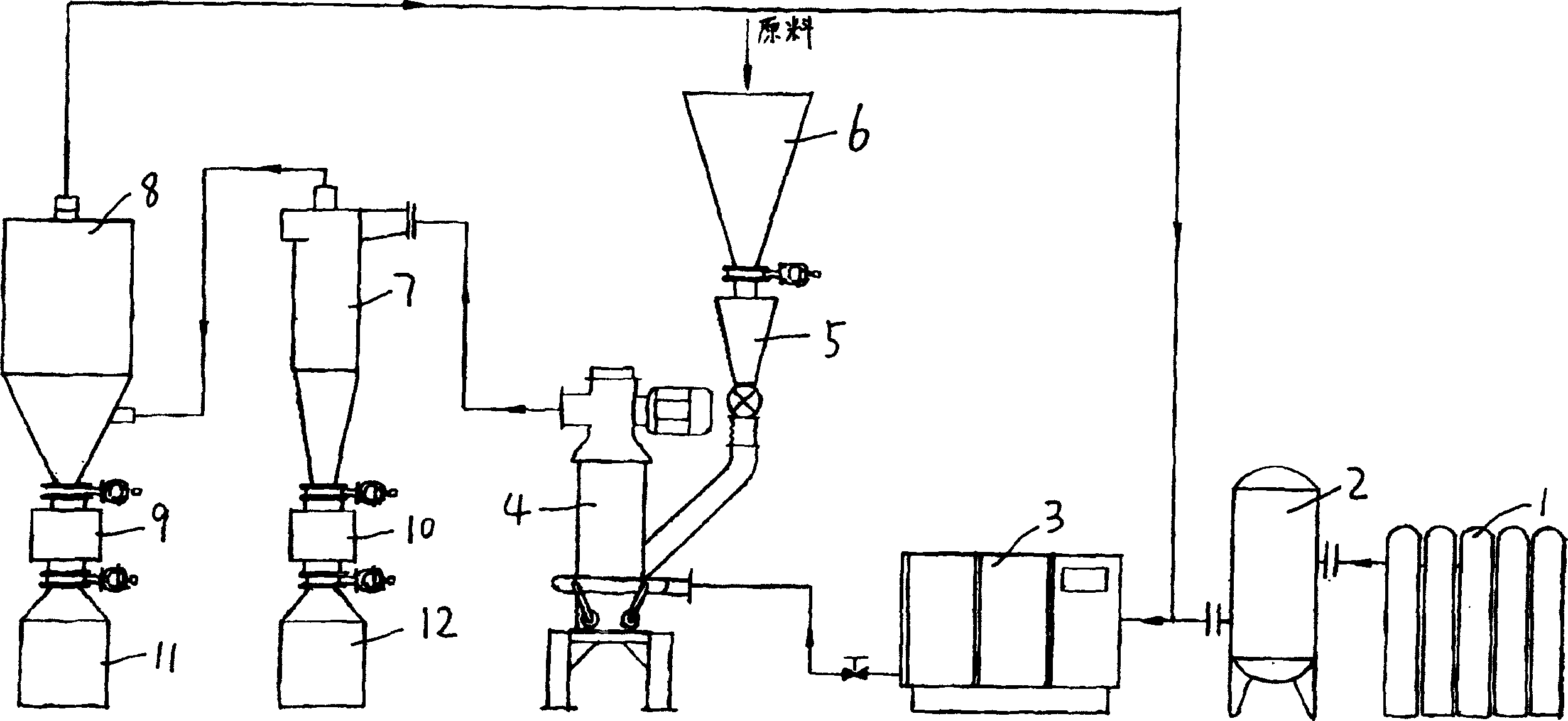

Ultra micro air flow pulverizer set with inert gas shielded

A superfine airflow pulverizer system with inertial gas shielded for pulverizing the material to be oxidized easily is composed of airflow system and pulverizing system. Said airflow system consists of protective gas soorce, gas tank, compressor, fluidized-bed airflow pulverizer, cyclone separator, and dust capture. Said pulverizing system comprises sealed feeder, transition cabin, fluidized-bed airflow pulverzer, cyclone separator, and powder collector.

Owner:MIYOU GROUP

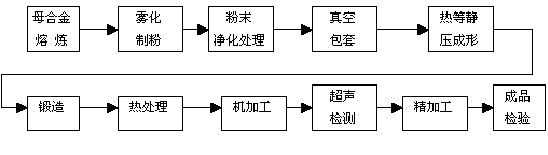

Powder alloy and production technique thereof

The invention relates to the technical field of alloy production, particularly a powder alloy and a production technique thereof. The powder alloy comprises 0.04-0.09% of C, 12-14% of Cr, 7-9% of Co, 3.3-3.7% of W, 3.3-3.7% of Mo, 2.3-3.7% of Al, 3.3-2.7% of Ti, 3.3-3.7% of Nb, 0.006-0.015% of B, 0.03-0.07% of Zr and the balance of Ni. The powder alloy is a highly-alloyed r'-phase precipitation-reinforced nickel-base high-temperature alloy, wherein the r' volume content is 50-55%, and the r' formed element content (atomic) is 28%. The powder alloy is a turbine disk material at the highest strength level under the operating condition of 650 DEG C at present. The powder alloy not only can be used for high / low-pressure turbine disks, but also can be used for gas compressor disks, turbine shafts, turbine baffle rings, high-temperature sealing parts and other high-temperature parts. The powder alloy is prepared by a plasma rotating electrode powder manufacturing apparatus, and the powder quality is greatly enhanced.

Owner:JIANGSU PLAZA PREMIUM ELECTRIC INSTR

3D printer for metal powder

ActiveCN109877322AEasy to paveImprove compactionAdditive manufacturing apparatusMaterial resources3d printer

The invention relates to a 3D printer for metal powder and belongs to the field of 3D printing equipment. According to the 3D printer for the metal powder, the structural design is reasonable, operation is convenient, the powder laying quality is good, the powder is preheated uniformly, the part machining time is greatly shortened, formed parts are taken easily and conveniently, automatic powder adding operation can be achieved, a large quantity of manpower and material resources are saved, and an operator is prevented from inhaling a large amount of the powder. According to the adopted technical scheme, a first electric push rod is mounted on the inner side of a powder outlet sleeve, a lifting device is mounted on the inner sides of a connecting plate and a positioning plate, a conical hole, a shielding plate, a jacking rod and a guiding pipe connected with the conical hole are arranged on a lifting plate to suck the powder around the parts, an electric heating pipe is arranged on theinner side of the upper end of the powder outlet sleeve to preheat the powder, an anti-sticking part is arranged on a powder laying roller, a sealing cover is mounted on an operating panel, and a feeding sleeve, a telescopic sleeve and a feeding screw are arranged at the upper end of a sealing cover to achieve material-adding operation.

Owner:HANGZHOU HIMALAYA INFORMATION TECH

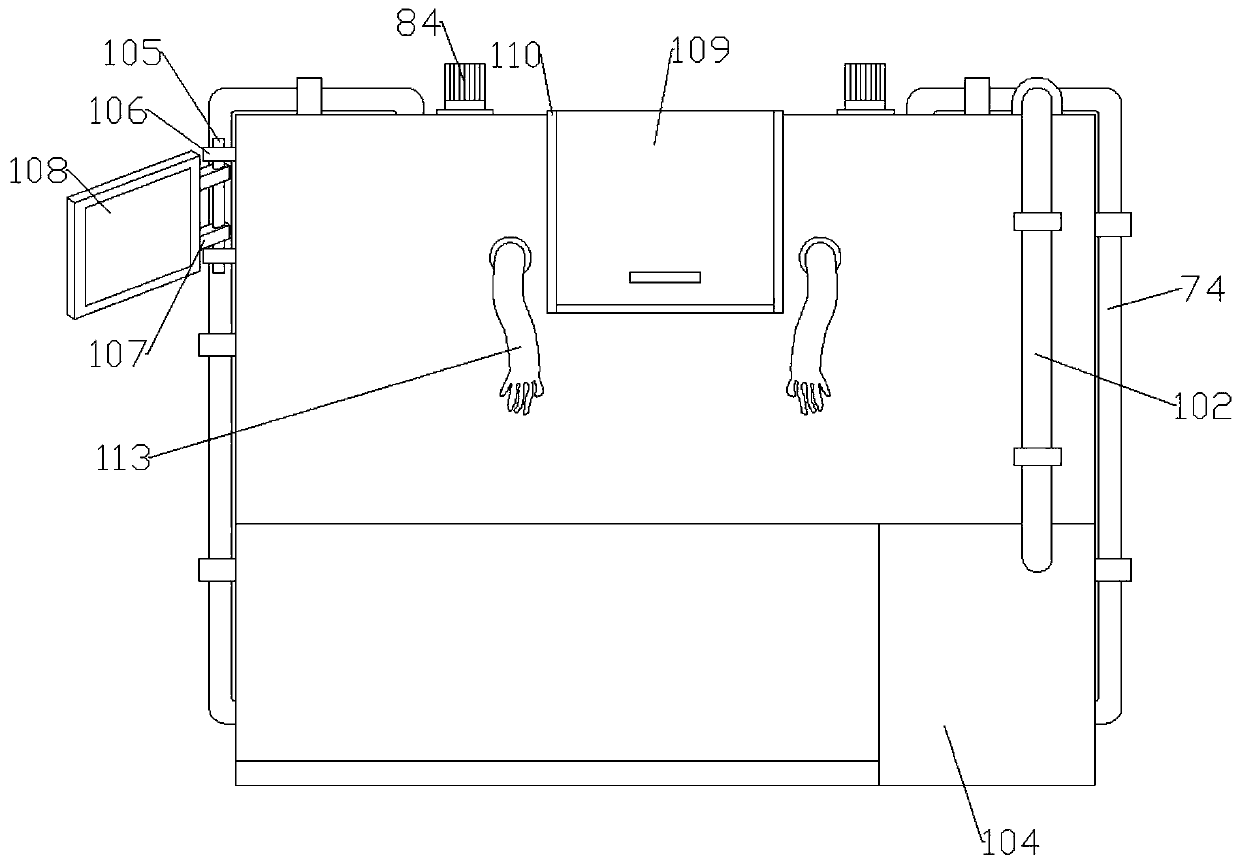

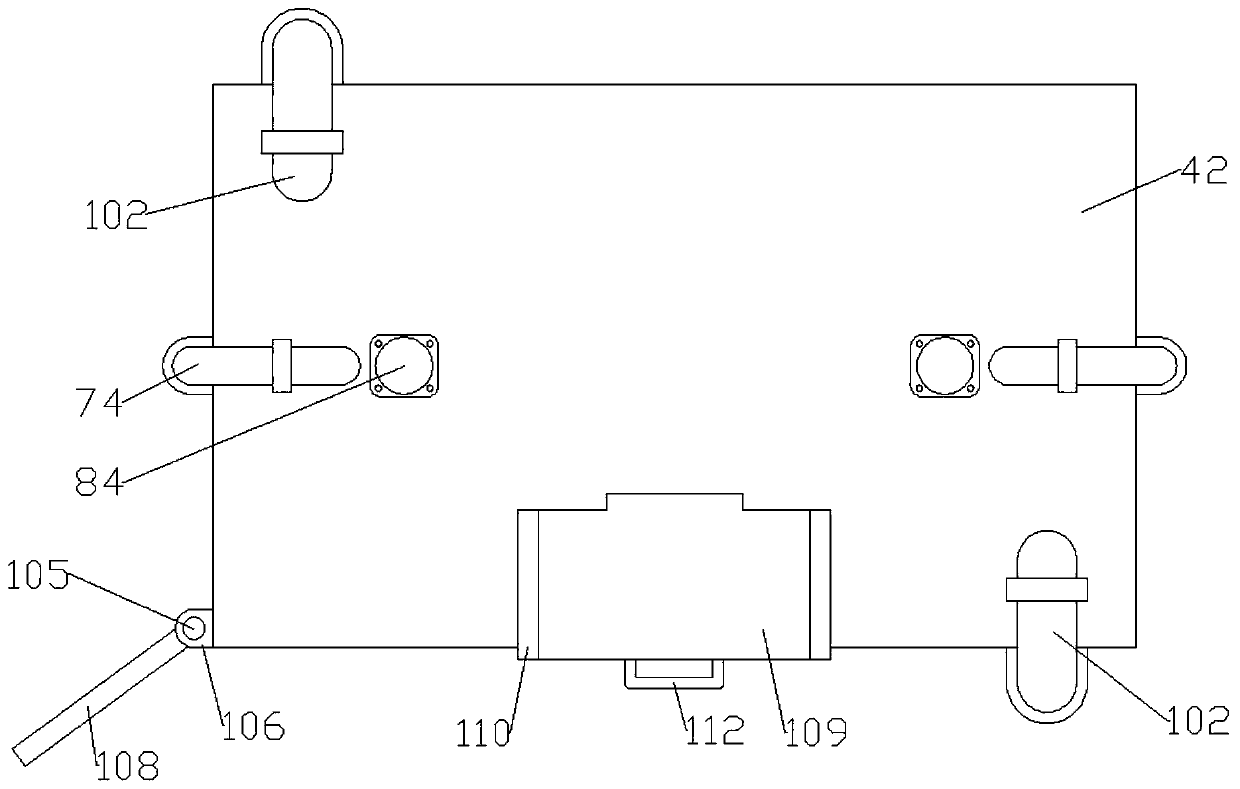

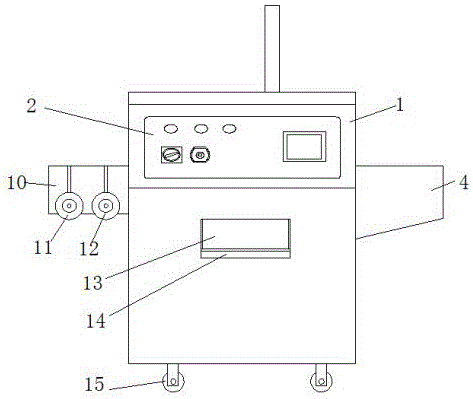

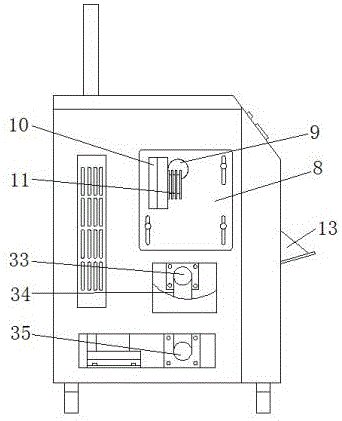

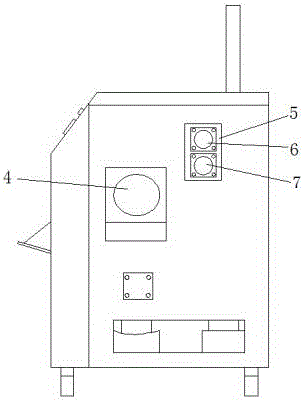

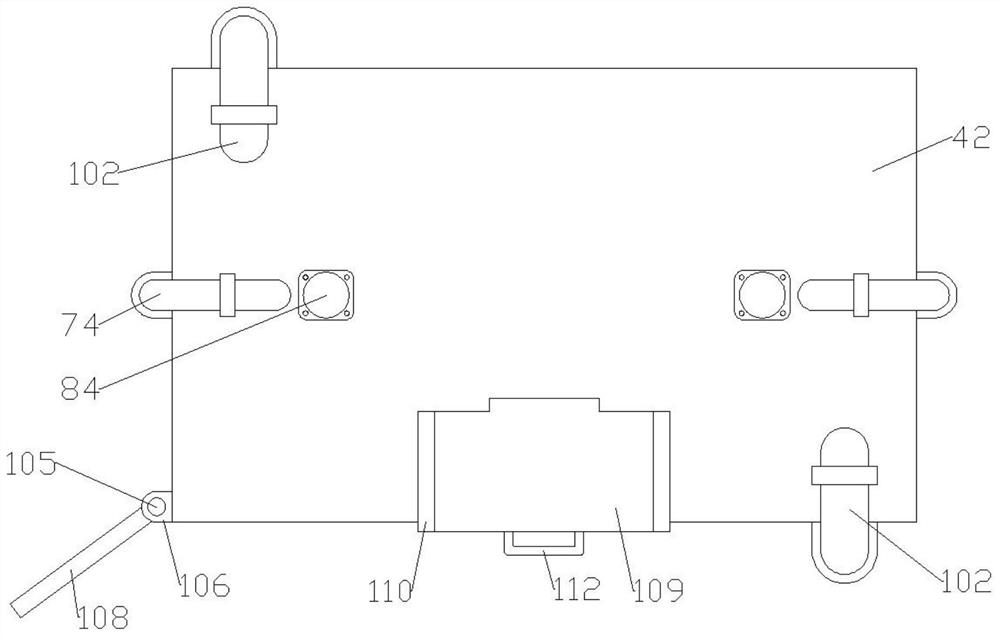

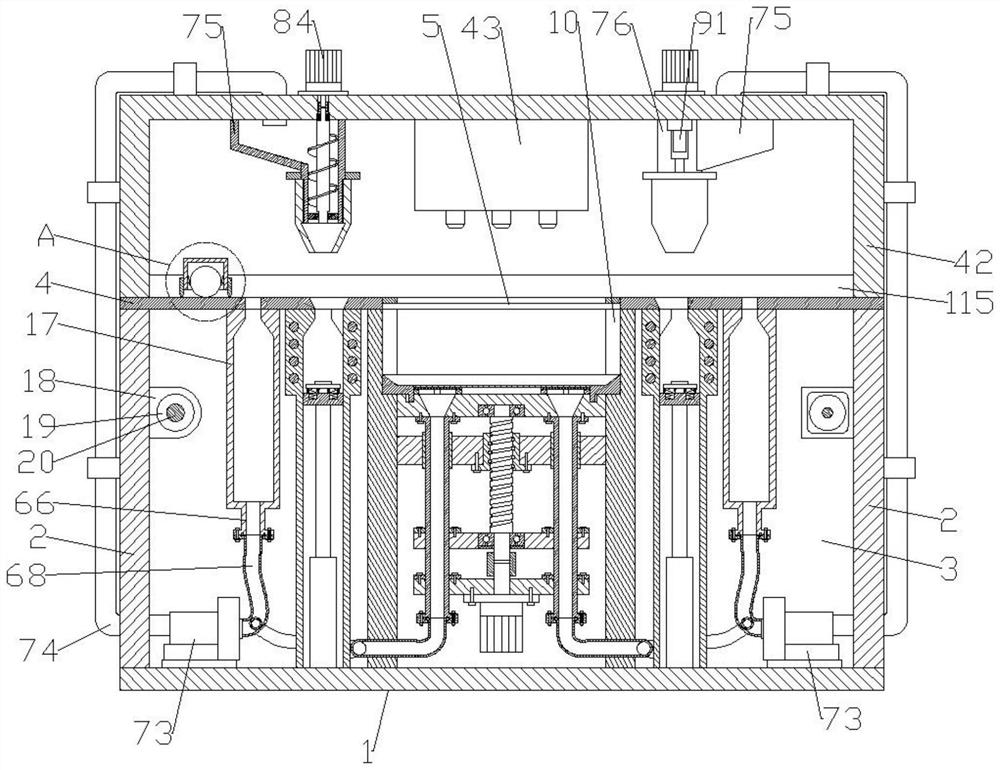

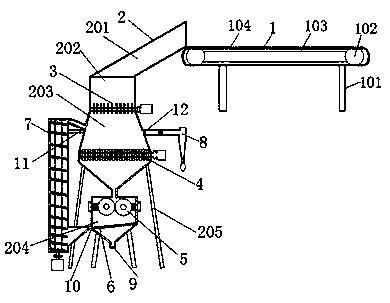

Automatic battery powder filling system

InactiveCN104943882AImprove powder qualityHigh degree of automationPackaging automatic controlSolid materialElectrical batteryWorking environment

The invention relates to the technical field of lithium battery raw material machining equipment, in particular to an automatic battery powder filling system. The automatic battery powder filling system comprises a controller, a conveying part and a filling part, wherein the filling part comprises a feeding pipeline, a storage bin and material tank, a material level detector and a spiral feeding device are disposed in the material tank, the material tank is provided with a feeding inlet and a discharging outlet, the feeding pipeline is communicated with the storage bin and the feeding inlet of the material tank, and the feeding pipeline is provided with a feeding pump; the conveying part comprises a conveying belt mechanism, a loading station is disposed on one side of the conveying belt mechanism, the loading station is located below the discharging outlet, and a material pushing air cylinder and a position sensor are disposed at a position, corresponding to the loading station, of the conveying belt mechanism. The automatic battery powder filling system has the advantages that the system is high in automation level, production efficiency and product quality are increased, raw material waste is reduced, production personnel is reduced, work intensity is lowered, and the work environment is improved.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

Abrasion-resistant straw crushing robot

The invention discloses an abrasion-resistant straw crushing robot, which comprises a casing, wherein an upper opening of the casing is movably connected with a conveying device; a backflow device anda dust removal device are fixedly connected with the two side surfaces of the casing; a reamer device is fixedly connected with the inside of the casing; a double-reamer device is arranged right under the reamer device; a grinding wheel device is fixedly connected with the right lower part of the double-reamer device; a filter sieve is arranged right under the grinding wheel device; the lower side of the filter sieve is fixedly connected with a lower side opening of the backflow device through the casing. The crushing machine has the advantages that through a feeding system, straw is fast conveyed to a feeding opening; through the reamer device, the double-reamer device and the grinding wheel device, the straw in forms of different shapes is reamed and ground into fine powder; the powderdischarging is fast; through the filter sieve, coarse powder is screened out; the reaming and grinding are performed again through the backflow device, so that the work efficiency is improved.

Owner:SUZHOU LINGKEN AGRI TECH CO LTD

Electric wire and cable talcum powder coating machine

ActiveCN106328307AAdjust the rotation speedAdjusting the size of the static electricity can control the rotation speedCable/conductor manufactureElectric machinerySmall footprint

The invention discloses an electric wire and cable talcum powder coating machine which comprises a machine body. A transmission wheel is connected with a driving wheel through a transmission belt, the driving wheel is connected with a stirring motor through a connecting shaft, a high-pressure air blower is arranged at the bottom of the machine body and is connected with a high-pressure motor, and a second air inlet and a second air outlet are formed in the high-pressure air blower. The electric wire and cable talcum powder coating machine does not cause pollution to a working environment, electric wires and cables are evenly coated with powder at 360 degrees during powder coating, the powder coating quality is better, defective products are not produced in the production process due to even powder coating, accordingly the costs of enterprises are reduced, a production environmental is dust-free, the powder coating thickness is adjustable and controllable during production, an application range is wide, and talcum powder can be heated, dehumidified and dried to make the electric wires and cables dry and smooth. When powder attaches to sheaths after powder coating, manual control can be performed, the production efficiency is high, no talcum powder is leaked in the production process, no air pollution is caused to a production environment, and the electric wire and cable talcum powder coating machine is easy to operate, high in automation degree, compact in structure and small in occupied area.

Owner:东莞市泰硕线缆科技有限公司

Phthalic anhydride process

InactiveUS20120259131A1Extension of timeChange timeOrganic chemistryHollow article cleaningEngineeringPhthalic anhydride

Disclosed is an improved process for the production of phthalic anhydride wherein the spent catalyst is removed from the oxidation reactor tubes more effectively by vacuuming from the top and using a vacuum hose having a tip with an increased impact strength and with a maximum hardness. As a result, the new catalyst loading can be made more uniform and the process may be operated with improved stability at higher organics loadings in the reactor feed. Process stability may be further improved by varying the outlet temperature of the phthalic anhydride precondenser over time.

Owner:EXXONMOBIL CHEM PAT INC

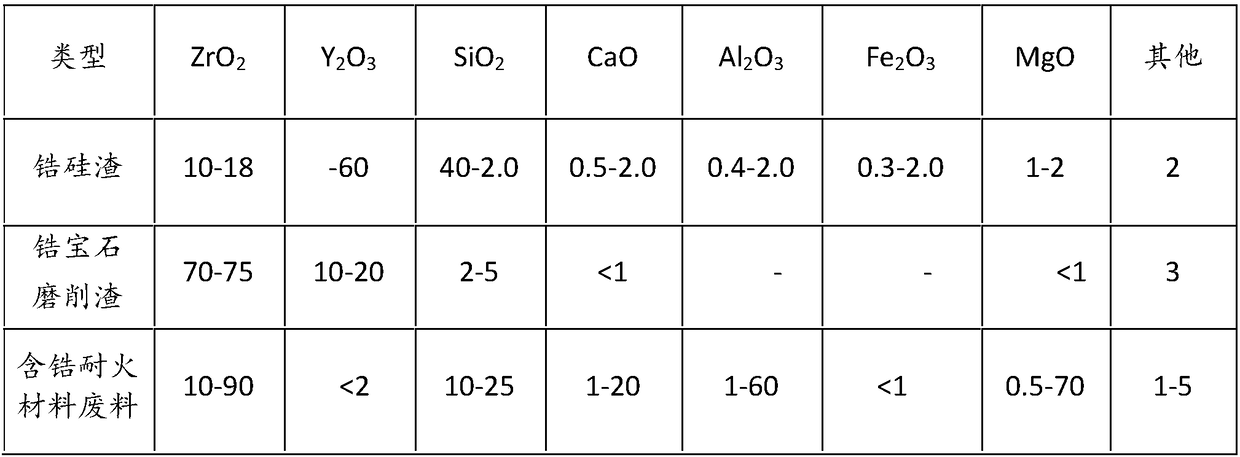

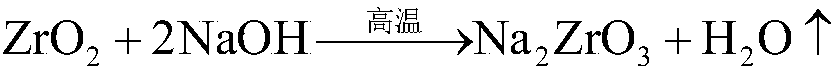

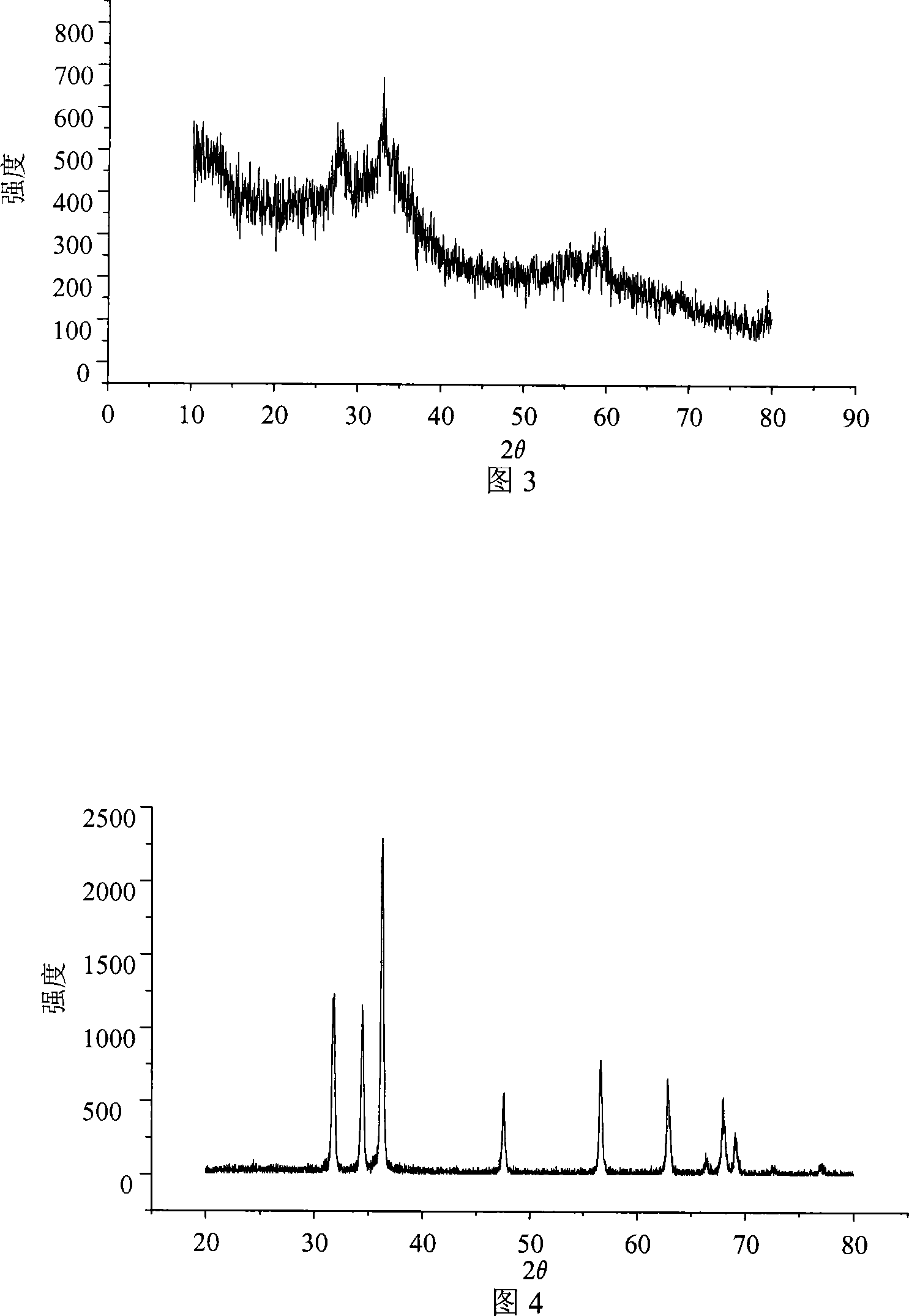

Method for preparing zirconia from solid waste zirconium

InactiveCN108083332AWill not polluteImprove protectionRare earth metal oxides/hydroxidesZirconium oxidesSlagSulfate

The invention provides a method for preparing zirconia from solid waste zirconium. The method comprises the following steps: (1) performing alkalization: after solid waste zirconium are smashed and ground, alkali metal hydroxide is added for roasting, and zirconium salt is obtained; (2) performing extraction and concentration: the zirconium salt is washed with water for impurity removal, subjectedto acidic washing transformation and filtered to remove slag, a transformed solution is obtained and subjected to primary reaction with sulfuric acid, a first precipitate is obtained and subjected tosecondary reaction with sulfuric acid for crystallization and separation of zirconium sulfate, and a zirconium sulfate solution being 0.25-3 mol / L is prepared from zirconium sulfate for standby application; (3) adding dropwise a precipitant to the zirconium sulfate solution for reaction to obtain a second precipitate; (4) washing, drying and calcining the second precipitate to obtain zirconia. The method has the advantages of low equipment requirement, simple process and high powder quality, and recycling of solid waste zirconium is realized.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

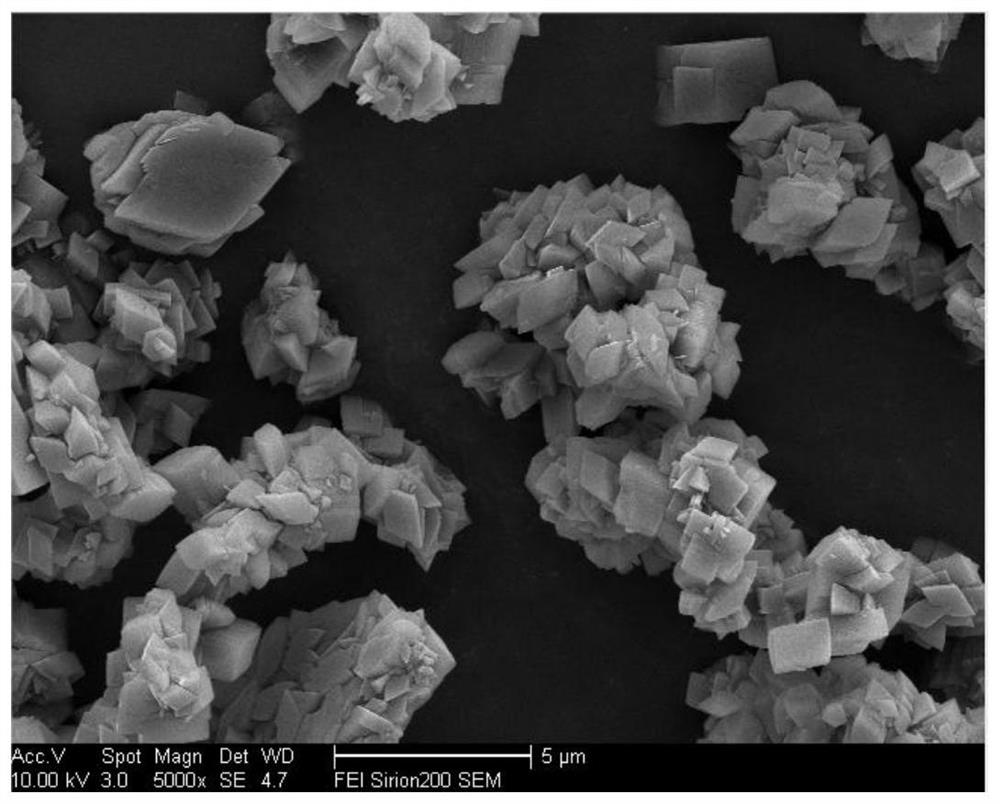

Method for preparing zinc oxide material

InactiveCN101214992AIncrease added valueLow costZinc oxides/hydroxidesDecompositionReaction temperature

The invention relates to a process for preparing zinc oxide material. The preparing process for zinc oxide material is characterized in that the preparing process includes the following steps: 1) selection of material: selecting material containing zinc oxide, urea and water as the mole ratio of zinc oxide and urea is 0.001-0.9 and that of zinc oxide and water is 0.01-1000 as reserve material, 2) blending the material containing zinc oxide, urea and water, grinding the mixture uniformly and obtaining slurry, 3) heating to form colloid: heating the slurry obtained from the step 2) at the temperature between 121-340 DEG C to obtain transparent colloid, 4) employing one of the following two methods to obtain zinc oxide material: a ) heat decompositing filter residue by hydrolysis to obtain zinc oxide material, b ) heat decomposition: heating the colliod obtained from step 3) to the temperature between 420-800 DEG C to obtain zinc oxide material. The method has the advantages of low cost, low reaction temperature and capability of catalyzing urea to heat decomposite to obtain cyanamide. The obtained product is characterized that graininess is small, adulteration is uniform and the product is larger than the specific surface area.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A metal powder 3d printer

ActiveCN109877322BEasy to paveImprove compactionAdditive manufacturing apparatusComputer printingMaterial resources

Owner:HANGZHOU HIMALAYA INFORMATION TECH

Improved flour and preparation method thereof

InactiveCN110050951AHigh viscosityHigh viscosity propertiesFood ingredient as thickening agentFood ingredient as mouthfeel improving agentRoom temperatureHigh pressure

The invention discloses improved flour. The flour is made from, by weight, 80-100 parts of wheat grain, 16-20 parts of superfine wheat bran and 0.6-1 part of improver. The invention also discloses a preparation method of the improved flour, including the following steps: firstly, washing and drying the wheat grain; secondly, pretreating the wheat grain with a wheat grain pretreatment device; thirdly, placing the pretreated wheat grain at room temperature for 12 hours and then grinding the wheat grain and purifying the flour twice to obtain wheat flour; fourthly, mixing all the raw materials evenly. Steam-heat-treated wheat grain is applied to make base flour of the wheat flour, and the wheat flour obtained after pretreatment can not only allow a stronger gluten network to be formed and thegluten strength of the dough to be strong, but also allow the gloss and whiteness of the wheat flour to be improved; cinnamon gum extracted by high pressure and high temperature is applied as an improver, the quality of the wheat flour and the chewing sensation of wheat flour products are improved, and improved wheat flour with high quality and good appearance is obtained.

Owner:安徽正宇面粉有限公司

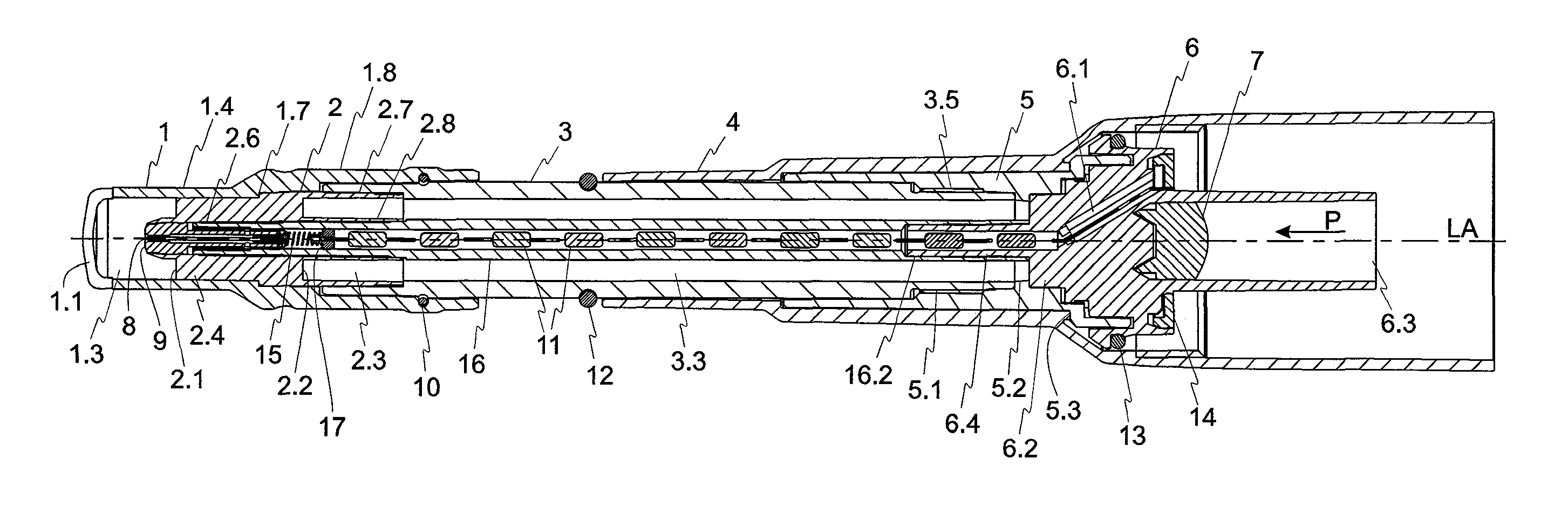

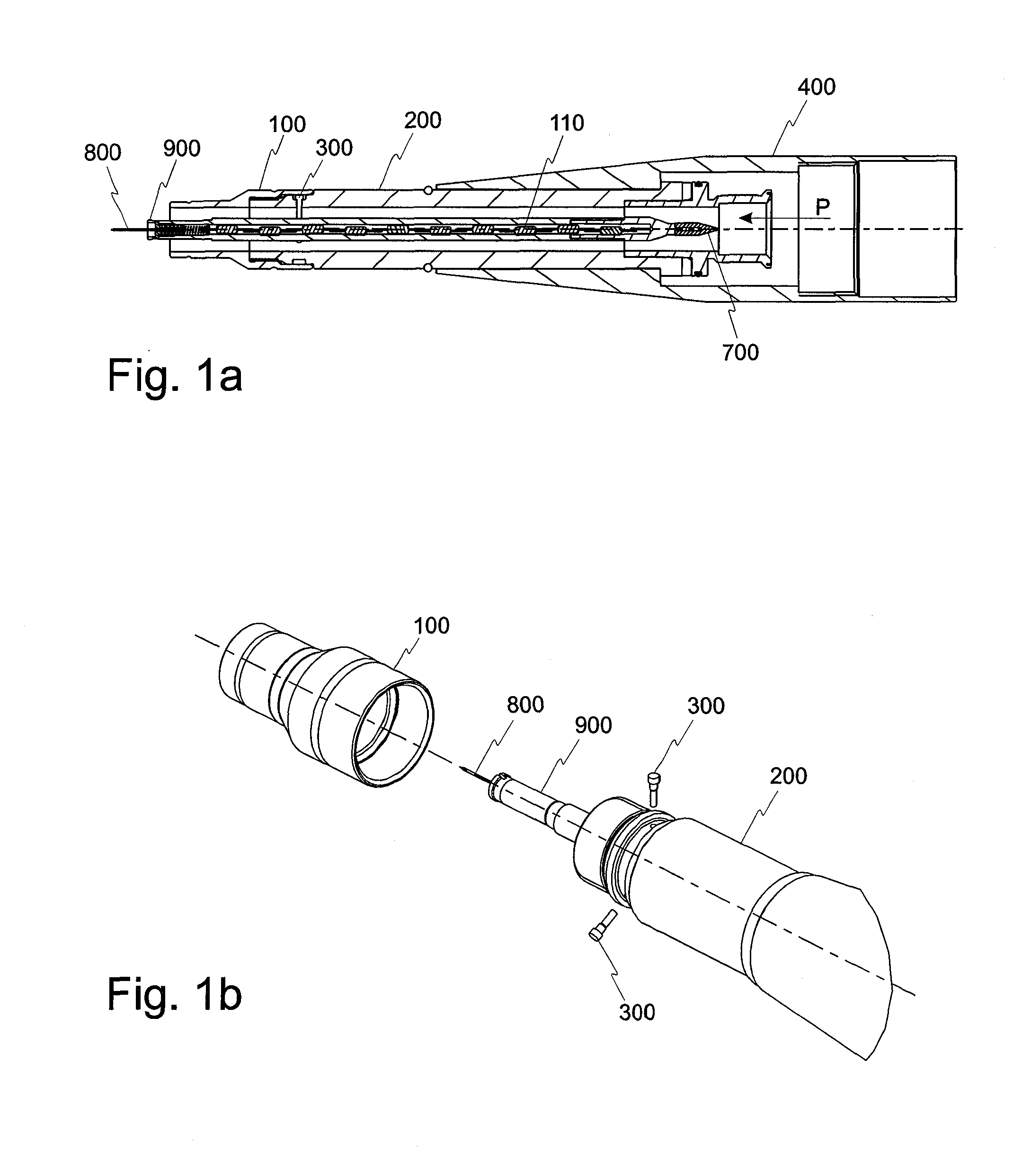

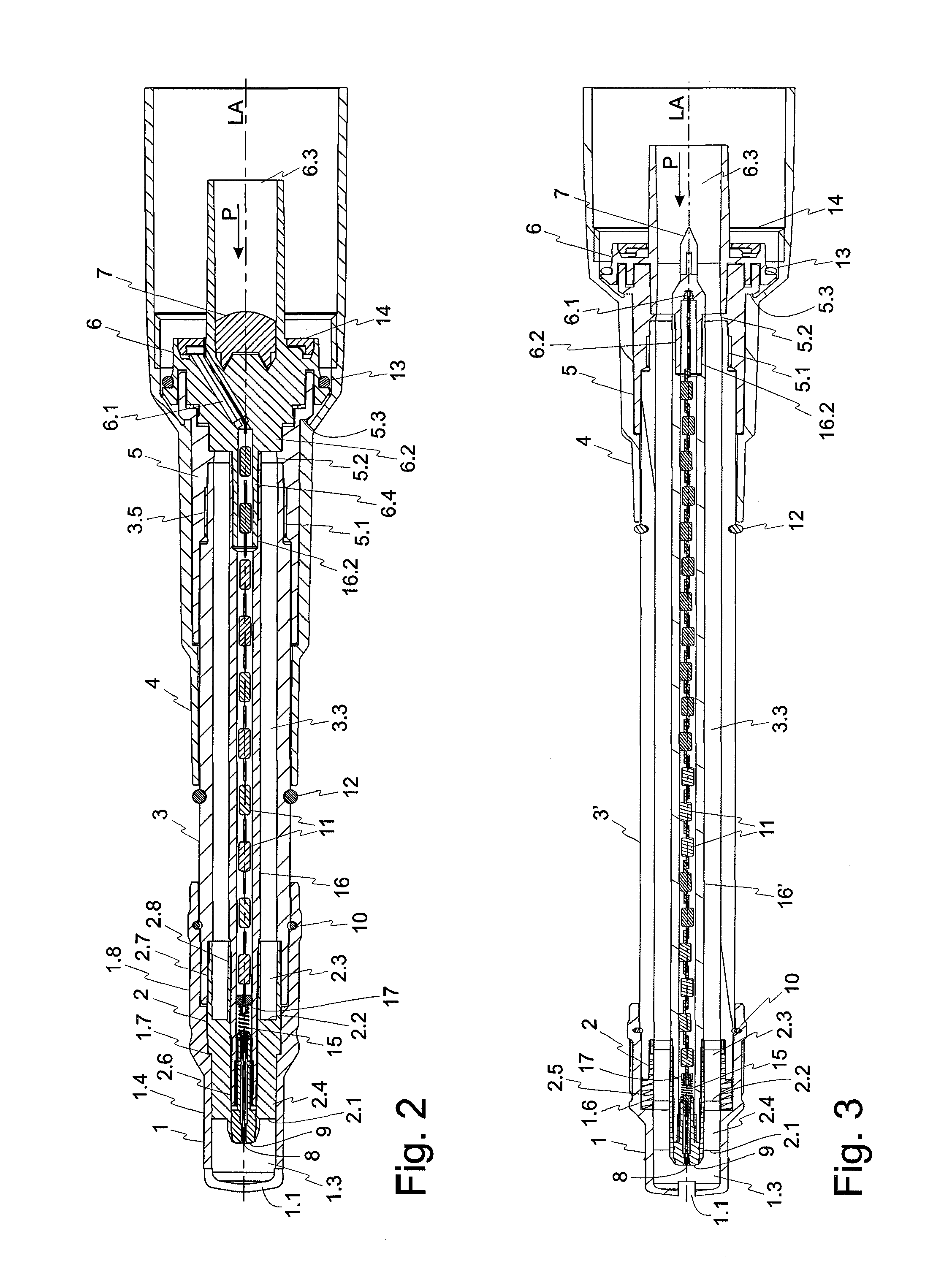

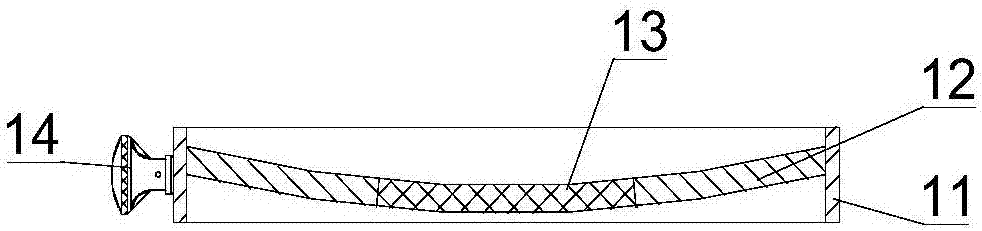

Wedge insert for a powder tube extension of a powder spray gun operable at high voltage, and powder tube extension with wedge insert

InactiveUS20130264395A1Simple and cost-effective solutionImprove powder qualitySpraying power supplyWatering devicesEngineeringHigh pressure

The wedge insert for a powder tube extension of a powder spray gun operable at high voltage comprises a sleeve, wherein the sleeve has a radial web, which is wedge-shaped on the upstream side. In addition, an axially running channel, into which a guide tube, which guides an electrode with a high voltage, can be inserted, is provided in the web.

Owner:J WAGNER GMBH

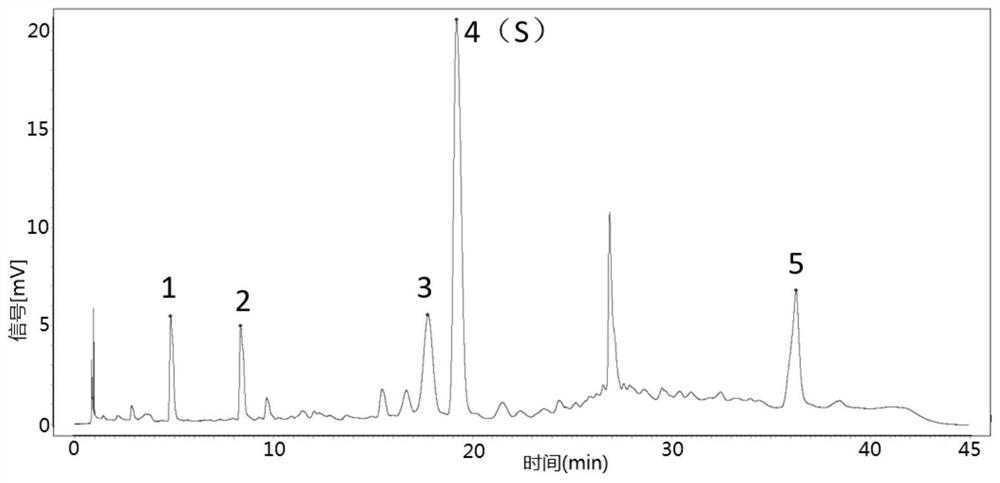

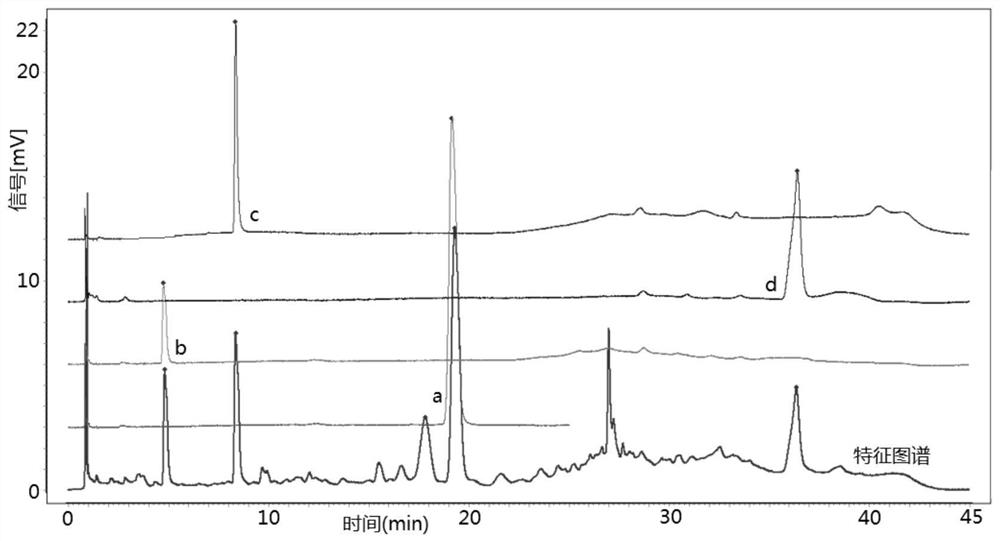

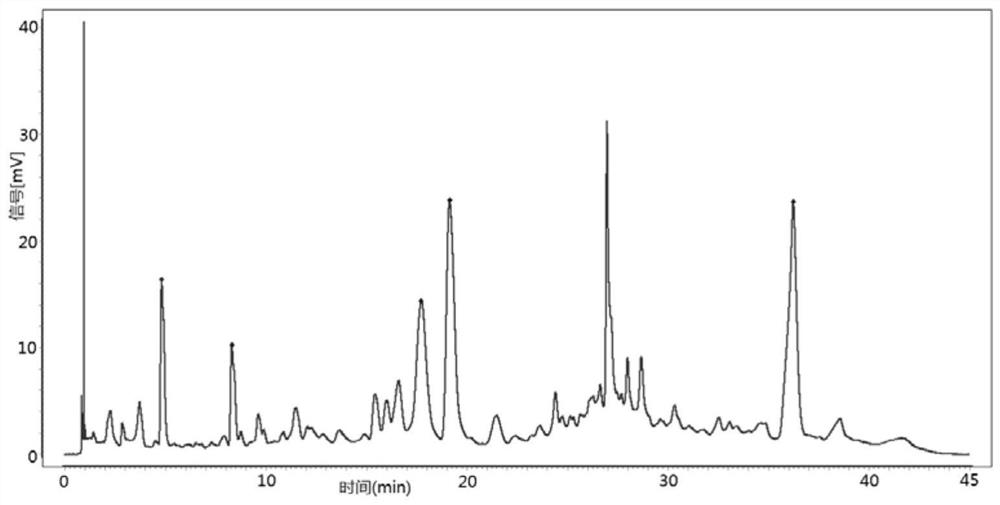

Rosa laevigata formula granules as well as preparation method and quality detection method thereof

InactiveCN113876847AQuality assuranceImprove powder collection rateComponent separationDigestive systemPhysical chemistrySpray dried

The invention belongs to the technical field of preparation of formula granules, and particularly relates to rosa laevigata formula granules as well as a preparation method and quality detection method thereof, in particular to the rosa laevigata formula granules as well as the preparation method thereof, a characteristic spectrum of the Rosa laevigata formula granules and a construction method of the characteristic spectrum, and a method for determining the content of catechin in the rosa laevigata formula granules. According to the method provided by the invention, the powder collecting rate of rosa laevigata spray-dried powder can be ensured to be 80% or above, meanwhile, the main active ingredient namely catechin in rosa laevigata decoction pieces can be fully extracted, and the loss is small in the concentrating and drying links, so that the quality of the rosa laevigata formula granules is ensured. The wall sticking phenomenon in the spraying process is greatly improved by controlling the air inlet temperature of spray drying, and the problems that the spray-dried powder is difficult to dry, powder is difficult to collect and wall sticking is serious due to the fact that the rosa laevigata is high in sugar content and low in softening point are solved.

Owner:BEIJING KANGRENTANG PHARMA

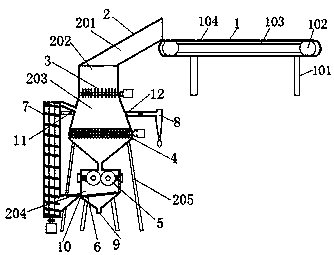

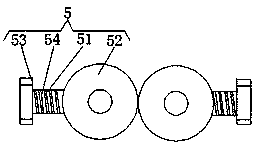

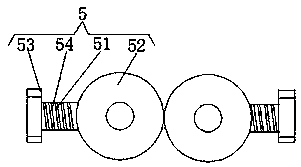

Medical tablet powder squeezing device

InactiveCN107349108AUniform particlesImprove powder qualityOral administration deviceScrapBiomedical engineering

The invention discloses a powder extruding device for medical tablets, which comprises a casing, a driving device, a first extrusion roller, a second extrusion roller, a rib, a scraper and a medicine feeding funnel, and a second extrusion funnel is arranged inside the casing. One extruding roller and the second extruding roller, the first extruding roller and the second extruding roller are arranged in parallel, and the described first extruding roller and the second extruding roller are arranged in parallel; In the process of being involved, the cutting edge between the adjacent ribs cuts the tablet, and the drug is squeezed again by the ribs and the first extrusion roller or the second extrusion roller, so that the tablet is powdered and granulated. Uniformity, improving the powder quality, the scraper scrapes off the powder adhered to the ribs, the first extrusion roller and the second extrusion roller, and finally the powder enters the frame, and the powder particles that do not meet the particle size requirements are filtered Net interception, the invention has simple structure, low manufacturing cost, good powder extrusion effect, and has good practical effects.

Owner:庞明兰

Straw crusher with high efficiency

The invention discloses a straw crusher with high efficiency. The straw crusher comprises a shell, an upper opening of the shell is movably connected with a conveying device, a returning device and adust removing device are fixedly connected to the two side faces of the shell respectively, a reamer device is fixedly connected inside the shell, a double-reamer device is arranged under the reamer device, a pulverizing wheel device is fixedly connected under the double-reamer device, a filtering sieve is arranged under the pulverizing wheel device, and the lower side of the filtering sieve is fixedly connected with a lower side opening of the returning device through the shell. The straw crusher rapidly conveys straw to a feeding port through a feeding system; through the reamer device, thedouble-reamer device and the pulverizing wheel device, the straw which is different in shape is reamed and pulverized into powder, and therefore powder is formed rapidly; through the filtering sieve,the rough powder is sieved out; through the returning device, the powder is reamed and pulverized again, and therefore working efficiency is improved.

Owner:SUZHOU LINGKEN AGRI TECH CO LTD

Drug smashing device

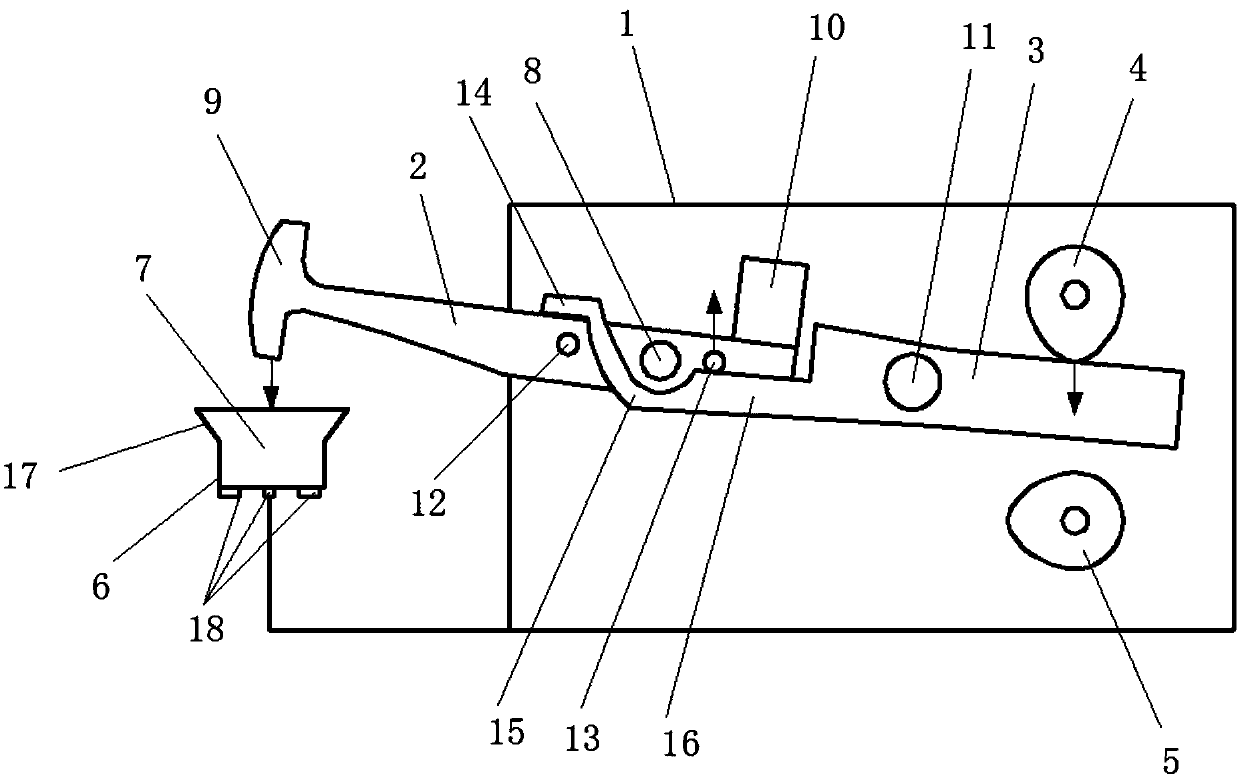

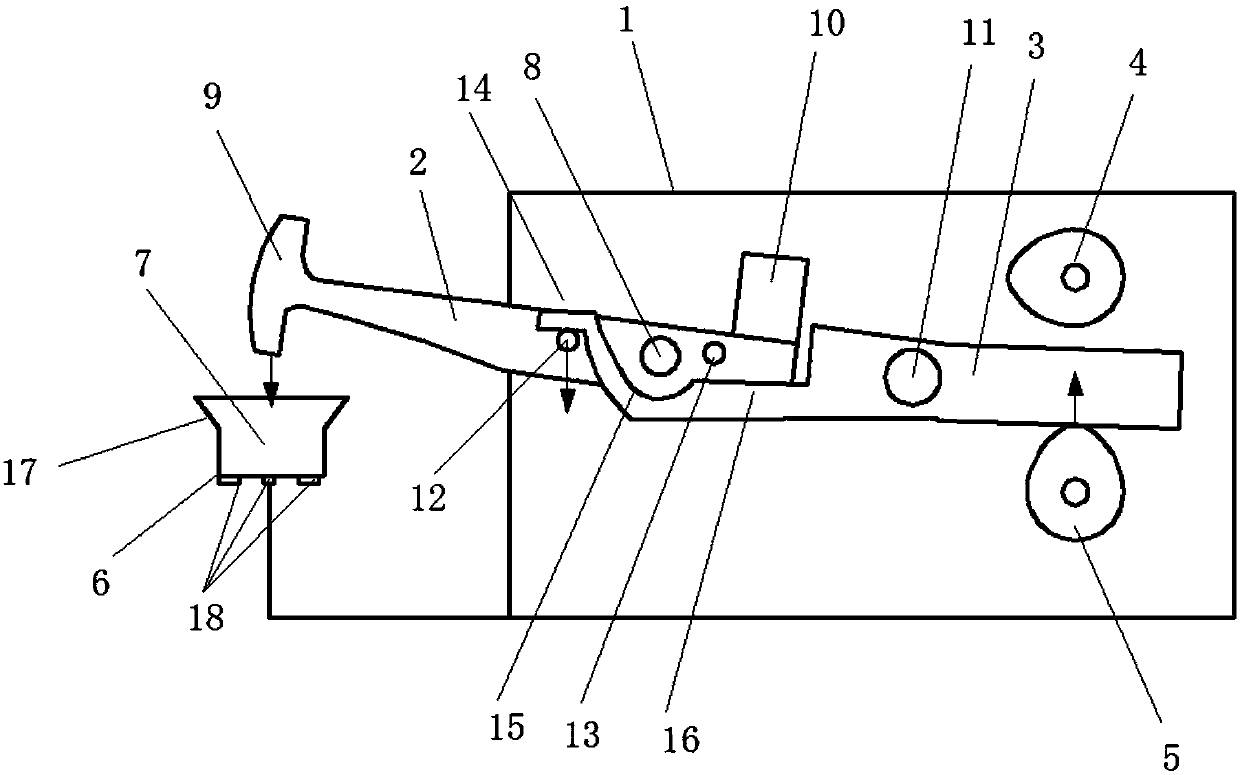

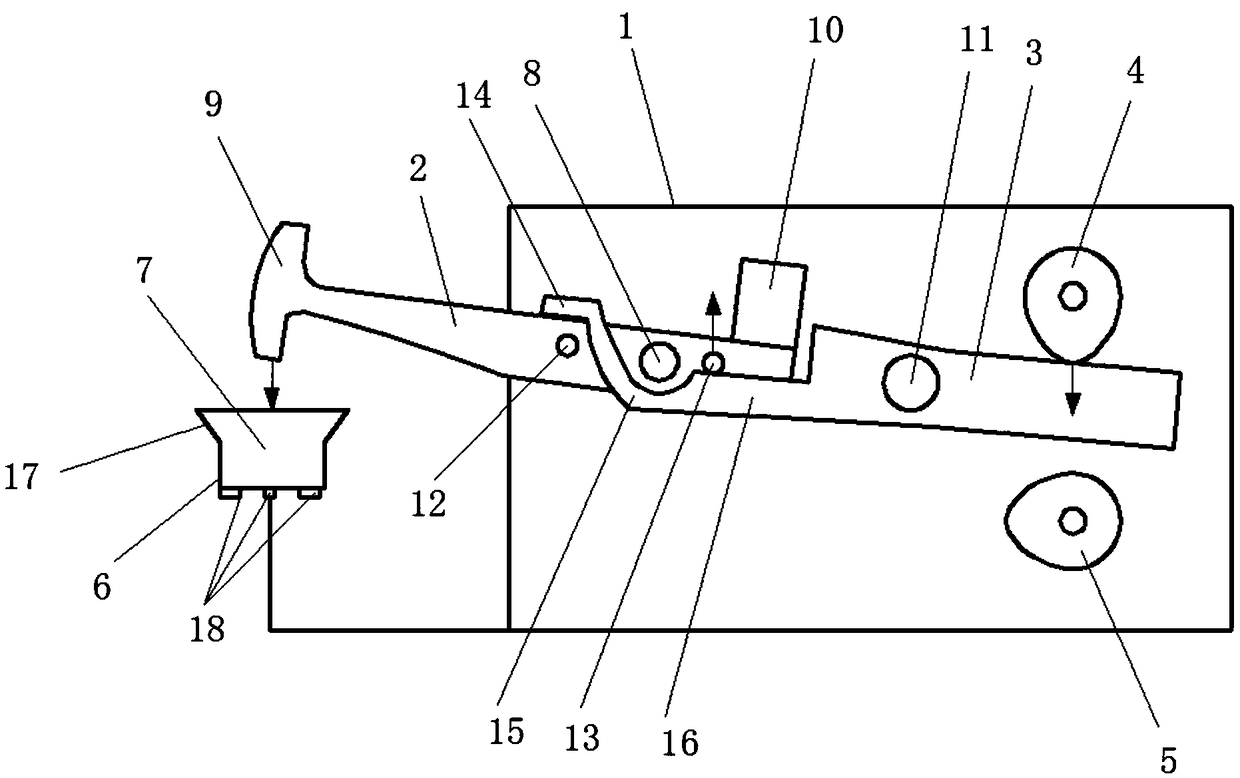

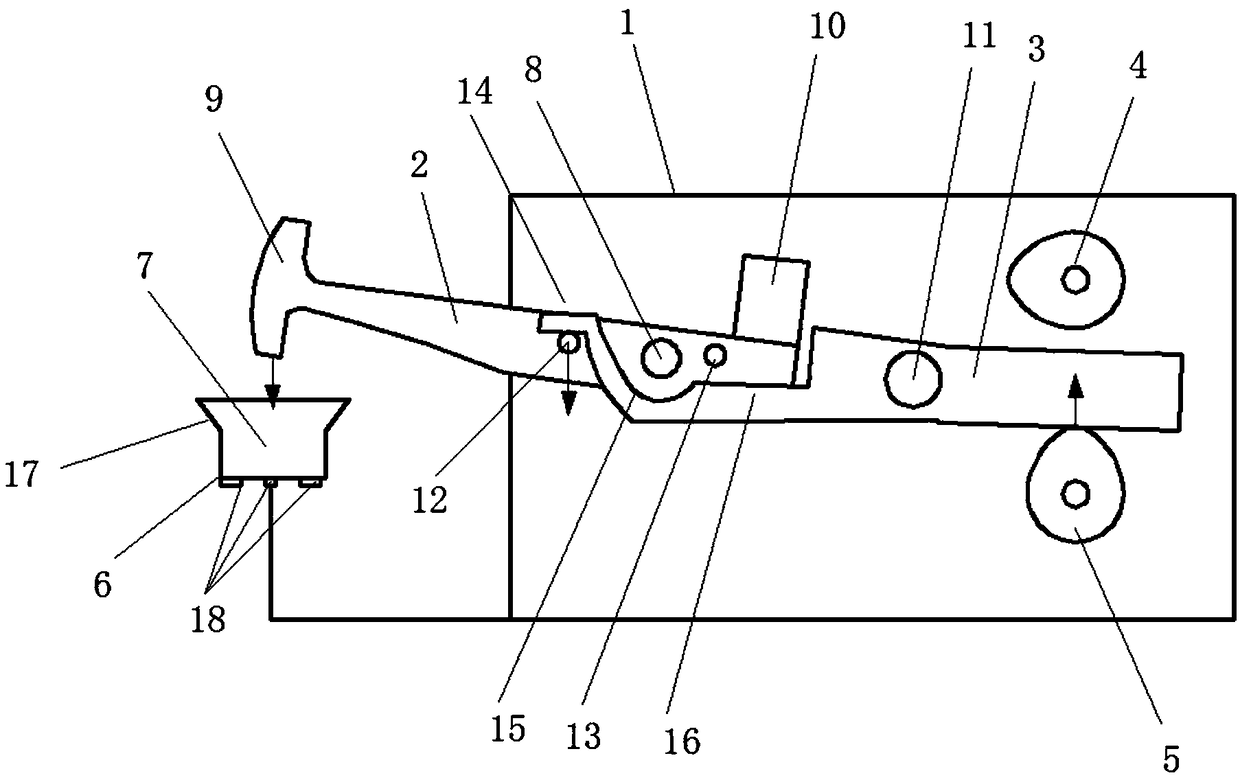

ActiveCN107597264AHit evenlyThe power on the strike rod can make the hammer head strike down evenlyGrain treatmentsEngineeringCam

The invention relates to a drug smashing device. The drug smashing device comprises a shell, a beating bar, a driving rod, a first cam and a second cam. The first cam and the second cam are oppositelylocated above and below the rear end of the driving rod separately. The first cam and the second cam press the rear end of the driving rod downwards or eject the rear end of the driving rod upwards alternately under the driving action of a motor, so that the front portion of the driving rod swings up and down continuously. Therefore, a hammer swings up and down around a first rotating pin so thatthe inside of a beating cavity can be beaten up and down continuously. The drug smashing device replaces manual work to smash drugs, and drug smashing work efficiency is improved. In addition, the drugs in the beating cavity are moved to the two sides from the middle position and then are moved to the middle position from the two sides, cyclic motion is made continuously, the hammer can beat thedrugs more evenly, and the quality of obtained drug powder is made higher.

Owner:江西高馨中药材有限公司

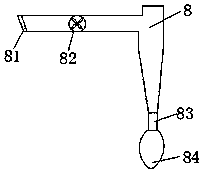

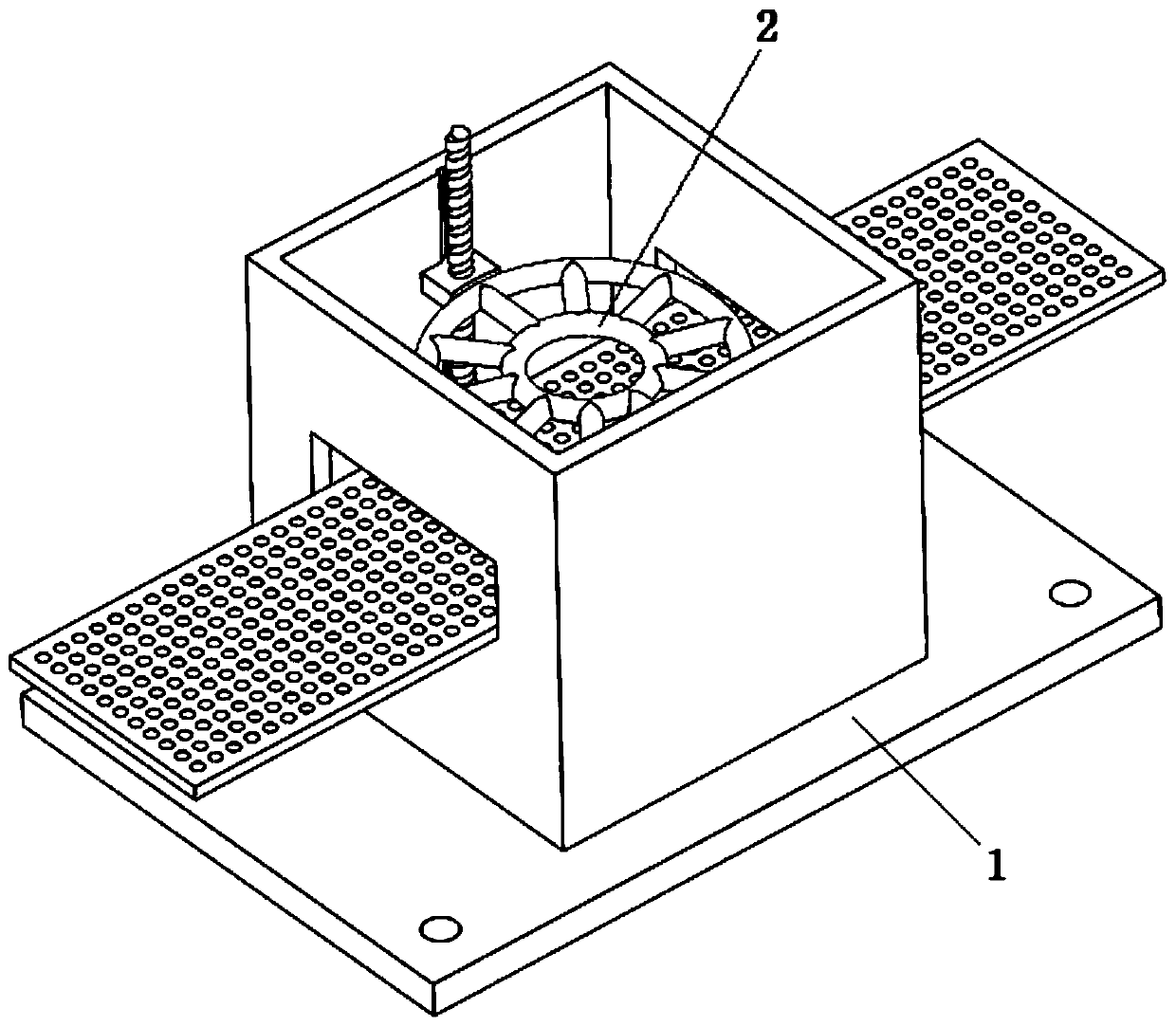

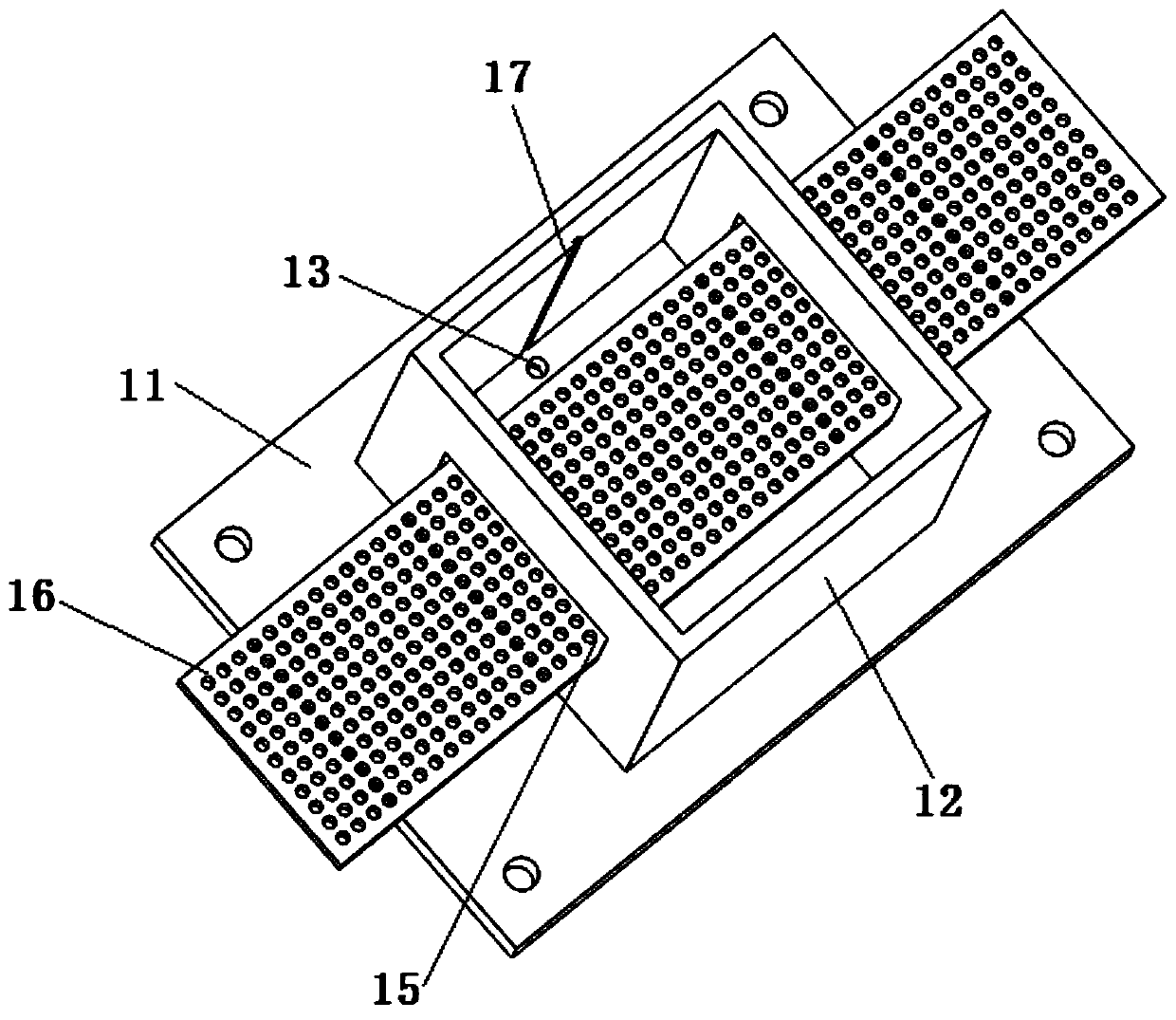

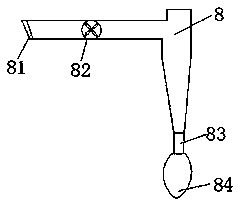

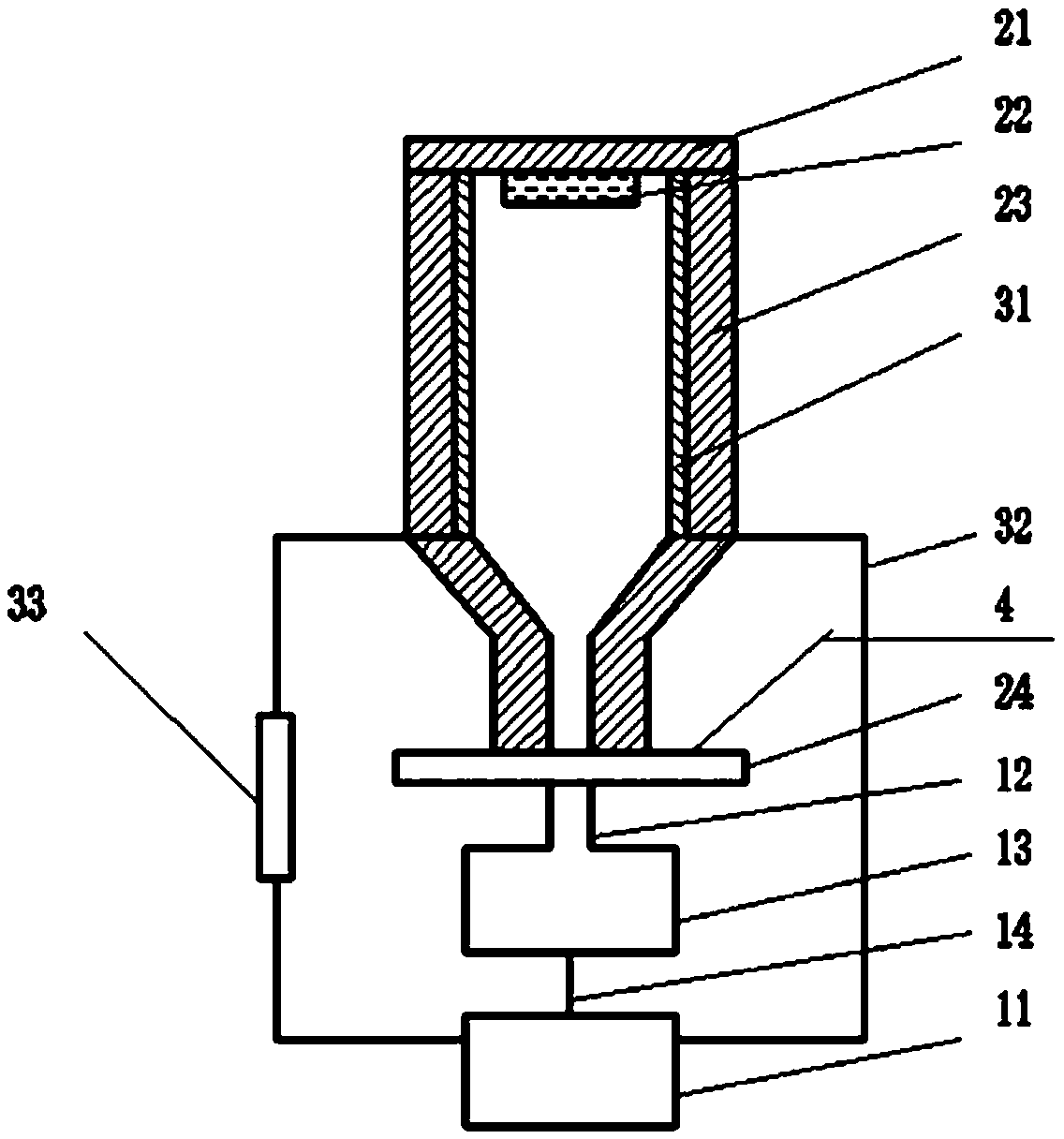

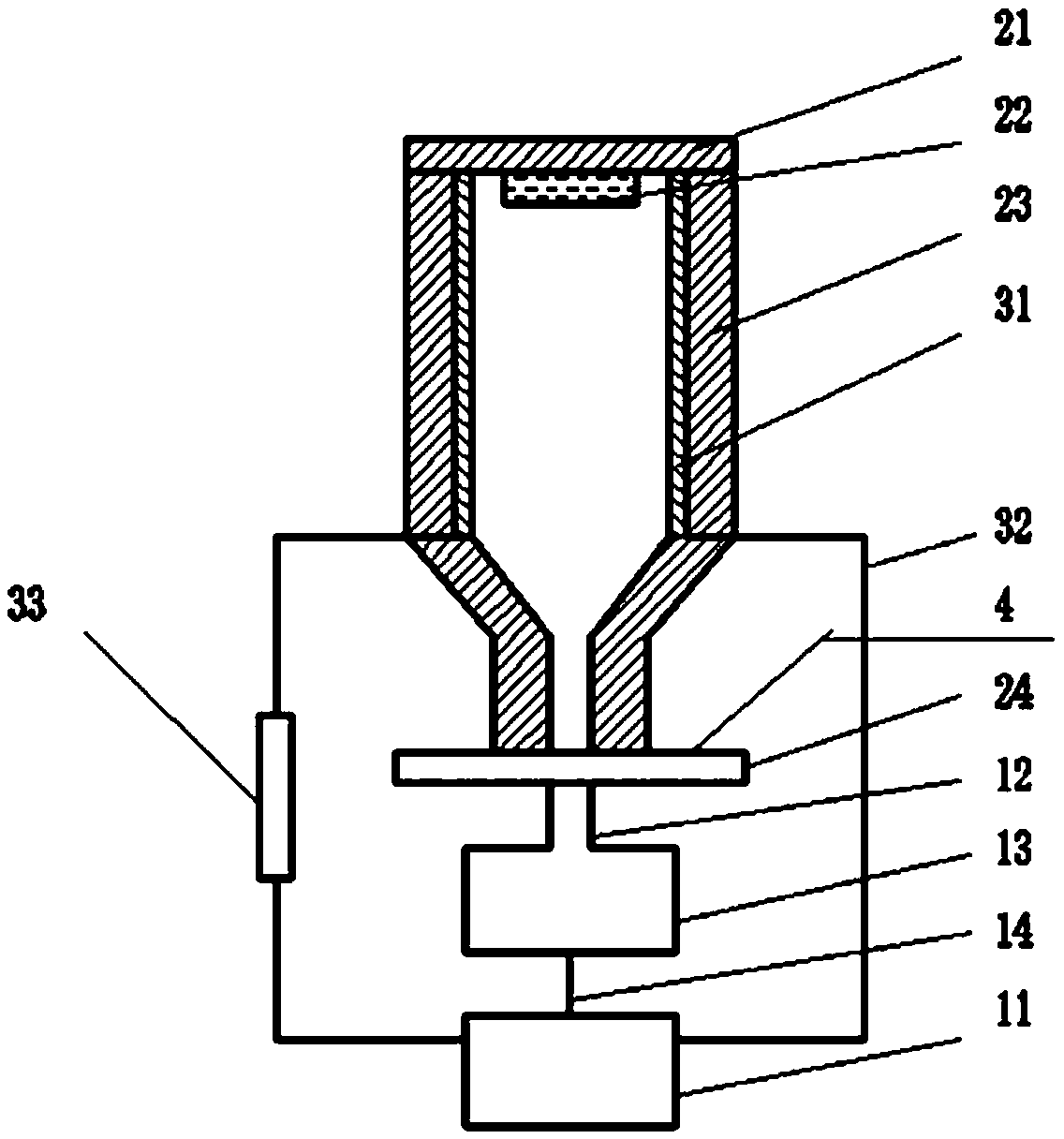

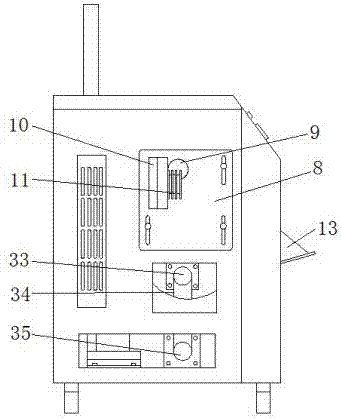

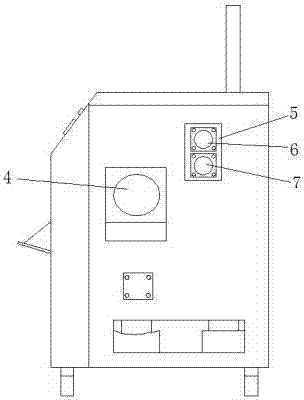

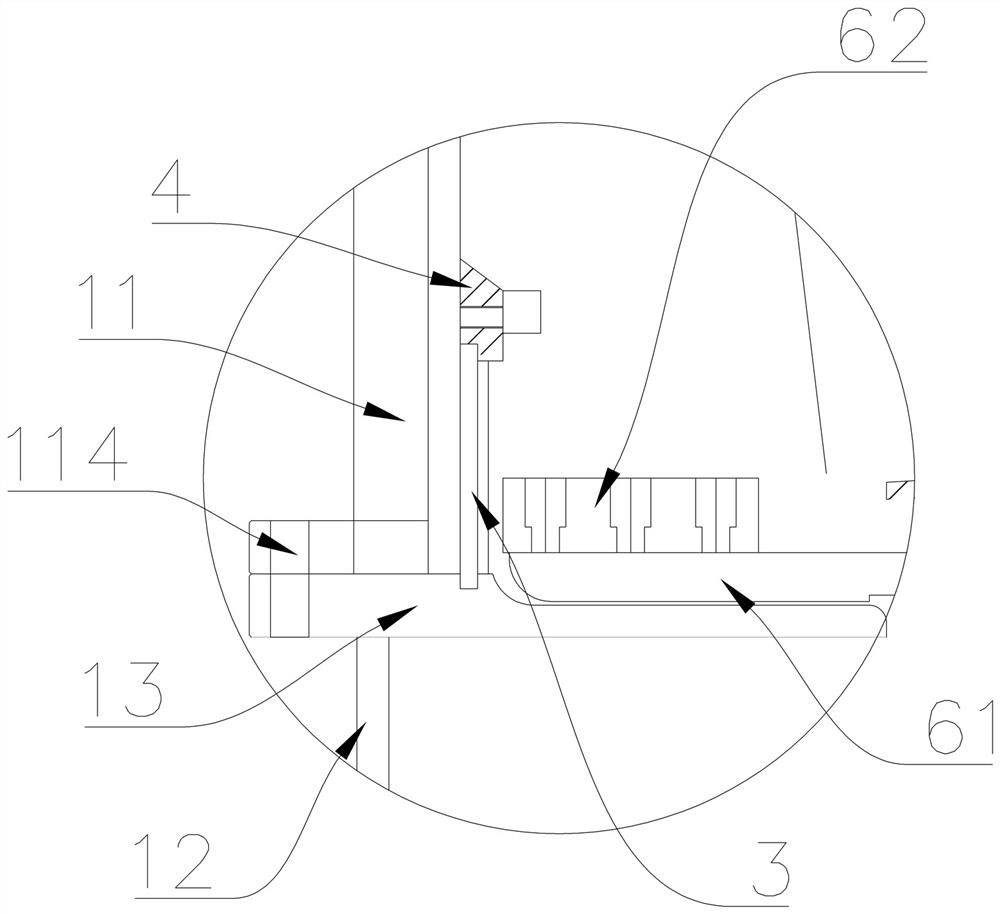

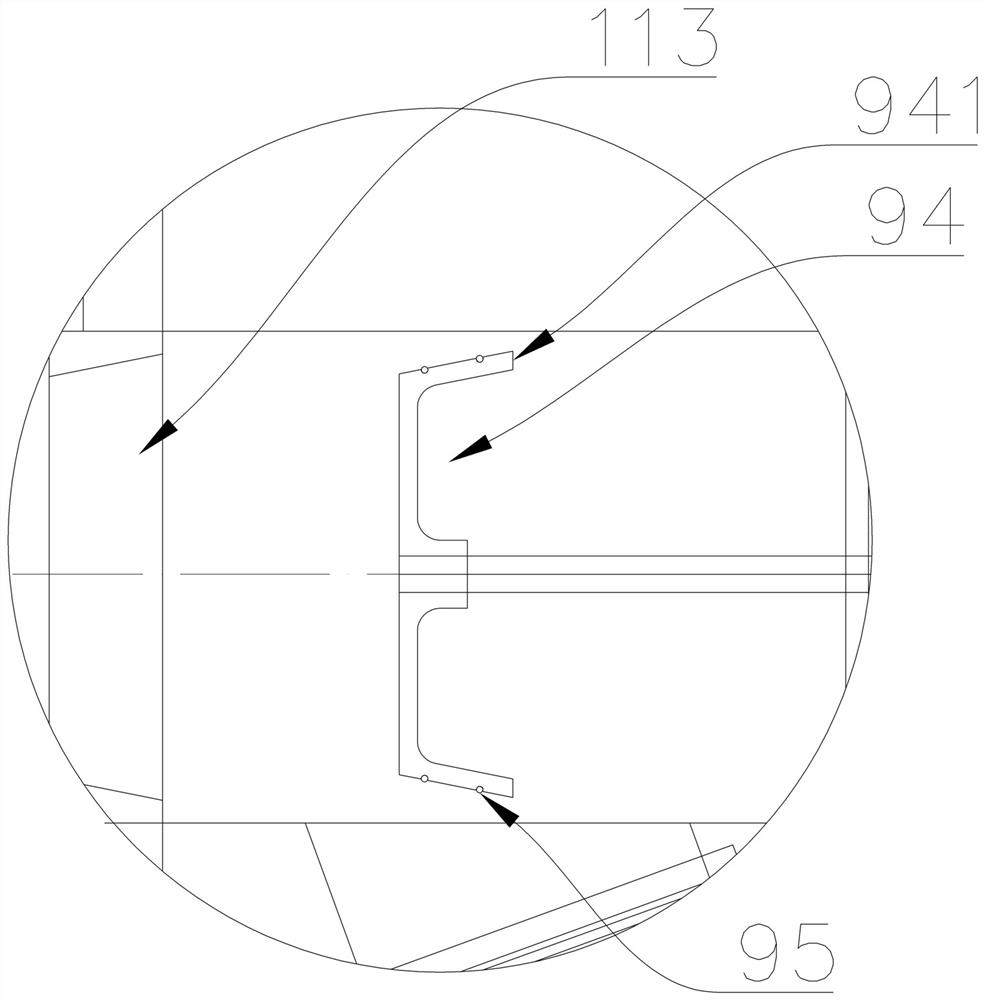

Powder feeder capable of drying and preheating powder based on laser additive manufacturing and powder feeding method

PendingCN109909501AQuality improvementSimple structureAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankControl system

The invention discloses a powder feeder capable of drying and preheating the powder based on the laser additive manufacturing and the powder feeding method. The powder feeder comprises an electrical element, a hopper and a ceramic heating tank, wherein the ceramic heating tank is used for drying and heating the powder; and the electrical element located at the lower part of the powder feeder comprises a control system (11) and a motor (13), and the control system (11) is connected to the motor (13). According to the powder feeder and the powder feeding method, the structure is simple, the timefor independently drying and preheating the powder is saved, and real-time preheating is realized. The quality of the powder fed into a melting tank is better, so that the good quality of a forming part is ensured.

Owner:SHENYANG POLYTECHNIC UNIV

A wire and cable talcum powder electrostatic powder powder machine

ActiveCN106328307BAdjust the rotation speedAdjusting the size of the static electricity can control the rotation speedCable/conductor manufactureDrive wheelSmall footprint

The invention discloses an electric wire and cable talcum powder coating machine which comprises a machine body. A transmission wheel is connected with a driving wheel through a transmission belt, the driving wheel is connected with a stirring motor through a connecting shaft, a high-pressure air blower is arranged at the bottom of the machine body and is connected with a high-pressure motor, and a second air inlet and a second air outlet are formed in the high-pressure air blower. The electric wire and cable talcum powder coating machine does not cause pollution to a working environment, electric wires and cables are evenly coated with powder at 360 degrees during powder coating, the powder coating quality is better, defective products are not produced in the production process due to even powder coating, accordingly the costs of enterprises are reduced, a production environmental is dust-free, the powder coating thickness is adjustable and controllable during production, an application range is wide, and talcum powder can be heated, dehumidified and dried to make the electric wires and cables dry and smooth. When powder attaches to sheaths after powder coating, manual control can be performed, the production efficiency is high, no talcum powder is leaked in the production process, no air pollution is caused to a production environment, and the electric wire and cable talcum powder coating machine is easy to operate, high in automation degree, compact in structure and small in occupied area.

Owner:东莞市泰硕线缆科技有限公司

Efficient negative-pressure crusher for preparation of ultra-fine powder

PendingCN112774822AReduce the degree of oxidationRealize repeated crushingGrain treatmentsStructural engineeringCrusher

The invention relates to the field of crushing equipment, in particular to an efficient negative-pressure crusher for preparation of ultra-fine powder. The efficient negative-pressure crusher for preparation of the ultra-fine powder comprises a case with a crushing cavity, a fixed grinding head arranged on the inner wall of the crushing cavity and a grinding disc rotationally arranged in the crushing cavity, wherein a movable grinding head is arranged on the grinding disc; the movable grinding head and the fixed grinding head are matched to be used for crushing materials; the case comprises a case body and a matching disc which is fixed onto the case body and encloses the crushing cavity with the case body; the matching disc and the grinding disc are in vertical sealing fit; and the case is provided with a negative-pressure connector which is communicated with the crushing cavity and connected with a negative pressure source to exhaust air from the crushing cavity. According to the efficient negative-pressure crusher for preparation of the ultra-fine powder provided by the invention, the negative-pressure connector is arranged, and the crushing cavity is subjected to air exhaust through the negative-pressure connector, so that the vacuum degree in the crushing cavity is guaranteed, the powder oxidation degree can be reduced in the crushing process, the powder quality can be improved, and meanwhile, combustion explosion is not likely to happen under the high-temperature condition.

Owner:岳杰

Phthalic anhydride process

InactiveUS8729278B2Extension of timeChange timeOrganic chemistryHollow article cleaningEngineeringPhthalic anhydride

Disclosed is an improved process for the production of phthalic anhydride wherein the spent catalyst is removed from the oxidation reactor tubes more effectively by vacuuming from the top and using a vacuum hose having a tip with an increased impact strength and with a maximum hardness. As a result, the new catalyst loading can be made more uniform and the process may be operated with improved stability at higher organics loadings in the reactor feed. Process stability may be further improved by varying the outlet temperature of the phthalic anhydride precondenser over time.

Owner:EXXONMOBIL CHEM PAT INC

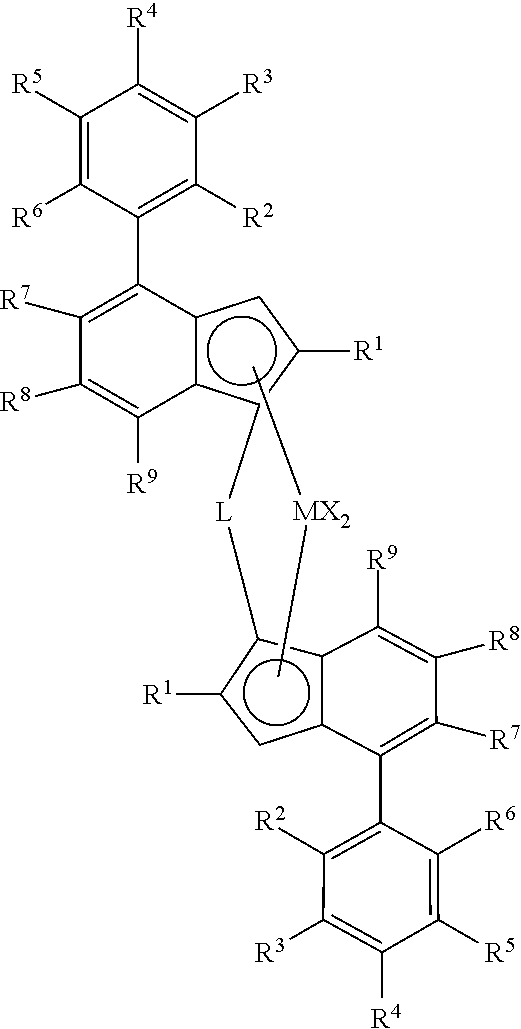

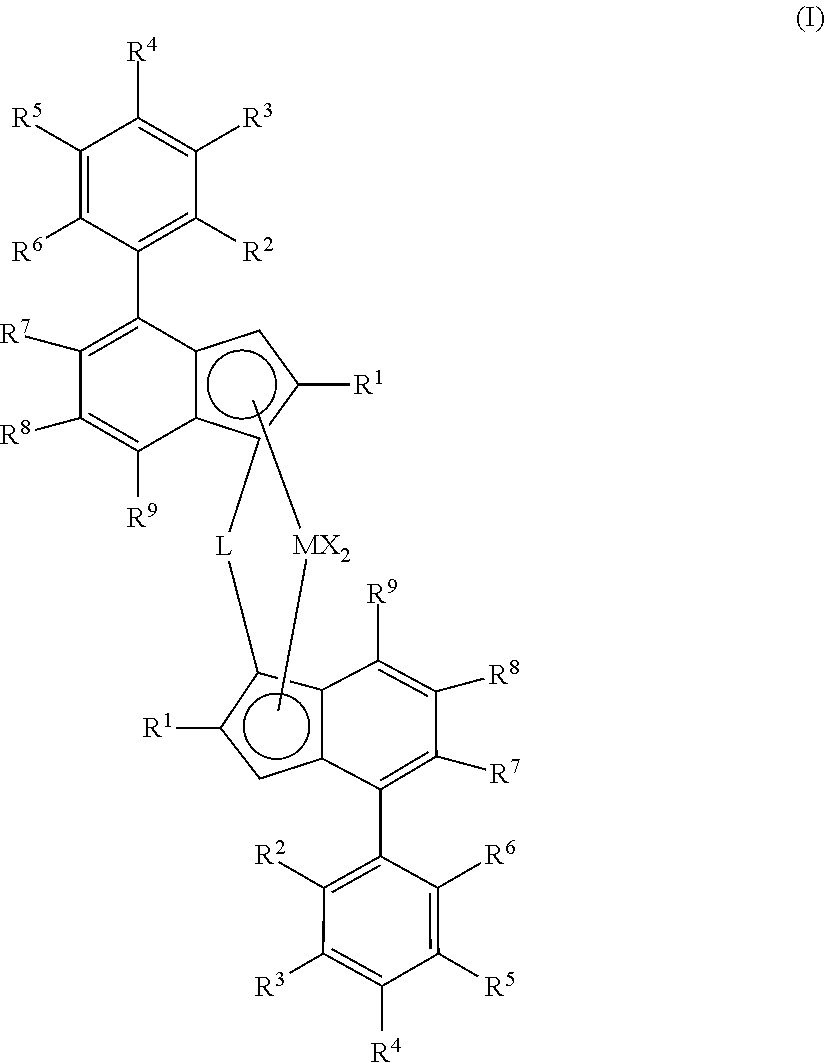

Polypropylene pipe composition

PendingUS20210108058A1Easy to processHigh impact strengthChemical/physical/physico-chemical stationary reactorsPolypropyleneHexene

Polypropylene composition having a melting temperature Tm of 135° C. to 140° C. (DSC according to ISO 11357 / part 3), —an MFR2 of 0.05 to 0.50 g / 10 min (2.16 kg, 230° C., IS01133), a XS according to IS016152 of 0.2 to 2.5 wt.-%, and a molecular weight distribution Mw / Mn of at least 2.8 and less than 6.0, wherein Mn is the number average molecular weight and Mw is the weight average molecular weight both being determined by Gel Permeation Chromatography (GPC) according to ISO 16014-4:2003, and ASTM D 6474-99, whereby the polypropylene composition comprises units derived from 1-hexene in an amount of 1.80 wt.-% to 5.0 wt.-%.

Owner:BOREALIS AG

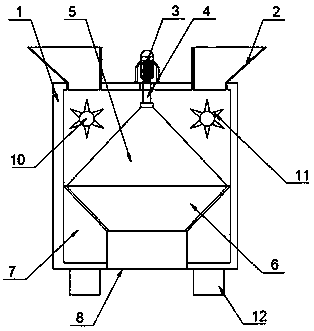

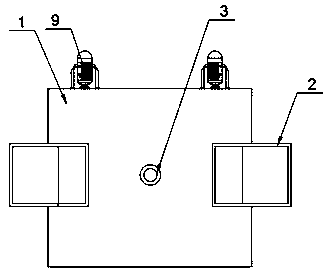

Powder making device for feed machining and production

InactiveCN110813500AImprove powder qualitySimple structureFeeding-stuffGrain treatmentsElectric machineryScrew thread

The invention discloses a powder making device for feed machining and production, and particularly relates to the technical field of feed machining and production. The powder making device comprises abox body, wherein two feeding hoppers are fixedly connected to the top of the box body, the two feeding hoppers are distributed symmetrically, a first motor is arranged on the inner side of the two feeding hoppers, an output shaft of the first motor penetrates through the top of the box body and extends into the box body, a threaded rod is fixedly connected to the output shaft of the first motor,and a supporting block is fixedly connected to the bottom end of the threaded rod. According to the powder making device, by arranging the two second motors, two rotating shafts and a plurality of blades arranged on the rotating shaft, feed input into the box body can be cut first, and then by arranging the first motor, the threaded rod, the supporting block, a grinding head and a grinding ring,and the preliminary cut and crushed feed can be further ground and crushed; the powder making device is simple in structure, the operation is convenient, the quality of the powder made by the feed ishigher, and the powder making efficiency is improved.

Owner:徐州三禾饲料有限公司

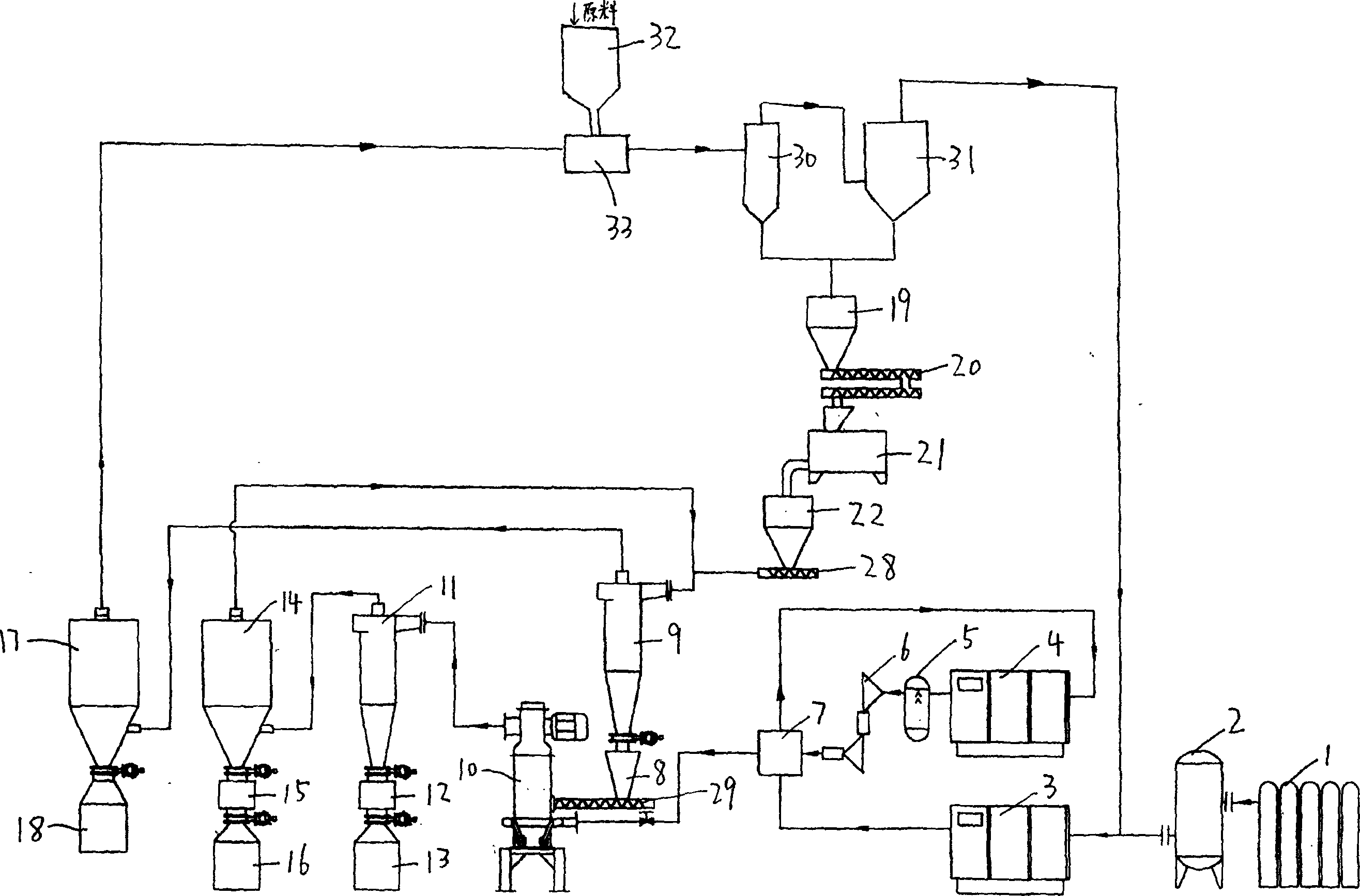

Apparatus for grinding chinese herb medicines into super-fine powder using chillness

InactiveCN1229180CFine particleImprove powder qualityPharmaceutical product form changeGrain treatmentsCycloneGas compressor

The invention discloses a cryogenic traditional Chinese medicine ultrafine pulverization device, which is used for pulverizing materials. It is composed of a refrigeration exchange system, a coarse pulverization system and a low-temperature air flow pulverization system; 1. Two gas compressors, refrigerators, and heat exchangers; the coarse crushing system mainly includes sealed feeders, the first and second spiral precoolers, coarse grinders, the third cyclone separator, and the third dust collector; The low-temperature airflow pulverization system mainly includes a compressor, a fluidized bed airflow pulverizer, the first and second cyclone separators, the first and second dust collectors; the raw materials are subjected to low-temperature treatment during coarse pulverization, and the gas and solid are subjected to gas treatment after coarse pulverization. Solid separation pre-cools the coarsely crushed material again, and then enters the fluidized bed jet mill for fine grinding, so that the material is more refined. Therefore, the present invention has high crushing capacity, fine particles of the crushed material, and high powder quality. At the same time, the cold air is recycled and reused in the fully enclosed system, which saves energy and further reduces costs.

Owner:MIYOU GROUP

Ultra micro air flow pulverizer set with inert gas shielded

A superfine airflow pulverizer system with inertial gas shielded for pulverizing the material to be oxidized easily is composed of airflow system and pulverizing system. Said airflow system consists of protective gas soorce, gas tank, compressor, fluidized-bed airflow pulverizer, cyclone separator, and dust capture. Said pulverizing system comprises sealed feeder, transition cabin, fluidized-bed airflow pulverzer, cyclone separator, and powder collector.

Owner:MIYOU GROUP

Preparation method of alumina polishing powder

InactiveCN113563801AGood self-sharpeningImprove toughnessPolishing compositions with abrasivesAluminium hydroxideCerium

The invention discloses a preparation method of aluminum oxide polishing powder. The preparation method comprises the following steps of: S1, preparing aluminum hydroxide; S2, adding silicon dioxide, cerium oxide, ferric oxide and the aluminum hydroxide in the step S1 into a ball mill according to the mass ratio of (12-8): (3-1): (3-1): (2-1), crushing the added materials so as to obtain a crushed material; and S3, carrying out coarse treatment on the crushed material. According to the preparation method, the prepared aluminum oxide polishing powder is rhombic crystals, while the aluminum oxide polishing powder prepared through a traditional process is flocculent crystals, the aluminum oxide polishing powder prepared through the preparation method has good self-sharpening performance and toughness, the wear resistance of the aluminum oxide polishing powder can be greatly improved, the polishing time is prolonged to 5-5.5 hours from 3 hours, the whiteness is also improved, and the conventional whiteness is 89-92, while the whiteness of the product prepared by the process of the invention is 98 or above.

Owner:HANGZHOU ZHIHUAJIE TECH

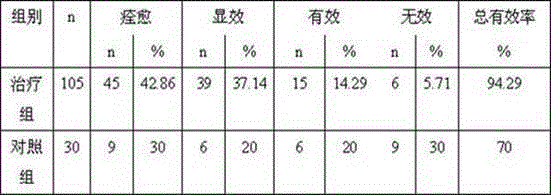

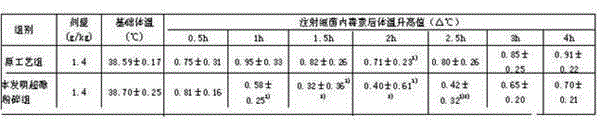

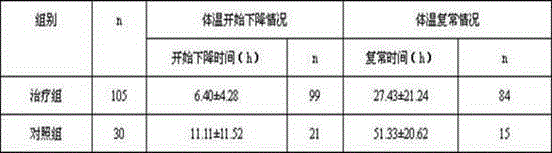

A kind of Xiaoer Qingrening traditional Chinese medicine granule

ActiveCN103006773BSmall effective particle sizeNarrow particle size distributionAntipyreticAnalgesicsBiotechnologyMedicinal herbs

The present invention disclosed a kind of children's Qing Rein Chinese medicine particles, which belong to the field of traditional Chinese medicine.It is made of gold and silver flowers, scutellaria baicalensis, Bupleurum, Banlangen, Antelope horn powder, beef, cattle horn concentrated powder, and borneol as raw materials., Improve the powder quality of the material; effectively protect the thermist component of spray drying technology, which is not destroyed, and overcomes the problems of traditional drying difficulties, large hygroscopicity, poor liquidity, long drying time, and uneven pink pink. In a short time, in a short timeInternal granules with good liquidity, low water content, and uniform size are consistent, which greatly improves the quality of Qing Ning Ning Granules.And to increase the measurement items of the content of drugs such as Huangpinyl, custodonin, tinyl flowers, and beef and bilirubin in the formula, so that the quality control of the children's clearing the Jining particles is significantly improved.After clinical application, the total effective rate reached 94.29%, and the significant efficiency reached 80%.

Owner:HENAN FURENTANG MEDICINES +2

A drug crushing device

The invention relates to a drug smashing device. The drug smashing device comprises a shell, a beating bar, a driving rod, a first cam and a second cam. The first cam and the second cam are oppositelylocated above and below the rear end of the driving rod separately. The first cam and the second cam press the rear end of the driving rod downwards or eject the rear end of the driving rod upwards alternately under the driving action of a motor, so that the front portion of the driving rod swings up and down continuously. Therefore, a hammer swings up and down around a first rotating pin so thatthe inside of a beating cavity can be beaten up and down continuously. The drug smashing device replaces manual work to smash drugs, and drug smashing work efficiency is improved. In addition, the drugs in the beating cavity are moved to the two sides from the middle position and then are moved to the middle position from the two sides, cyclic motion is made continuously, the hammer can beat thedrugs more evenly, and the quality of obtained drug powder is made higher.

Owner:江西高馨中药材有限公司

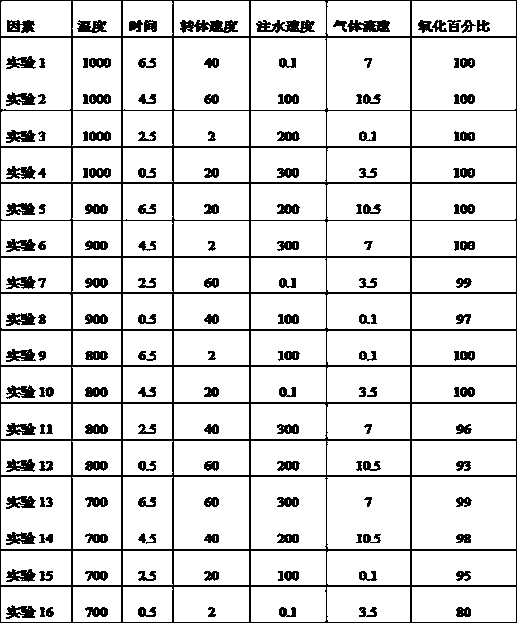

A high-efficiency and energy-saving oxidation method for waste cemented carbide

ActiveCN106947865BHigh recovery rateSimple processProcess efficiency improvementThermal insulationAlloy

The invention relates to a high-efficiency energy-saving oxidation method of a waste hard alloy. The method comprises the steps of sorting the waste WC-Co hard alloy according to differences of Co content, using aqueous solution which is prepared from sodium hydroxide with the concentration being 80g.L <-1>, , sodium carbonate with the concentration being 30g.L <-1> and trisodium phosphate with the concentration being 60g.L <-1> to remove impurities and oil on the surface of the waste WC-Co hard alloy at the temperature of 80 DEG C, conducting oxidation of the hard alloy in the conditions of oxygen enrichment, rotation, and wetness increasing, specifically, the temperature is 700-1000 DEG C, the time for thermal insulation is 0.5-6.5 hours and the gas flow speed is 0.1-10.5m3, / h, and the wet oxidizing atmosphere is used for driving an injector through a pump to inject water into a forge at the injection speed of 0.1-300ml / min. The high-efficiency energy-saving oxidation method of the waste hard alloy is easy to operate, short in process, low in energy consumption, has no specific requirement for production equipment, and can prolong the service life of the equipment; the recovery rate is high, and by adoption of the method, the prepared oxide precursor power has good quality, therefore the high-efficiency energy-saving oxidation method of the waste hard alloy has high market application value and economic value, and is suitable for industrial production.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com