Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

458results about How to "Good self-sharpening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal ceramic combination binding agent and combination binding agent diamond wheel

ActiveCN103831740AGood self-sharpeningImprove sharpnessAbrasion apparatusGrinding devicesNumerical controlSilicon dioxide

The invention belongs to the field of diamond wheels and particularly relates to a metal ceramic combination binding agent and a combination binding agent diamond wheel. The metal ceramic combination binding agent is composed of, by weight, 60%-80% of 663 bronze powder and 20%-40% of ceramic powder. The ceramic powder is homemade and composed of, by weight, 45%-60% of silicon dioxide, 20%-30% of boric oxide, 10%-15% of potassium oxide, 5%-10% of magnesium oxide and 2%-5% of calcium oxide. The combination binding agent diamond wheel is composed of, by volume, 25%-40%of diamond abrasive, 55%-75% of combination binding agent and 2%-3% of pore forming agent. When the diamond wheel made of the metal ceramic combination binding agent is applied to a five-axis cnc machine tool, the good sharpness and the good self-sharpening performance of a ceramic binding agent are kept and the advantages of high rigidity and the good shape-maintaining performance of a metal binding agene are obtained. The comprehensive processing efficiency is improved by 100% to 150%.

Owner:江苏赛扬精工科技有限责任公司

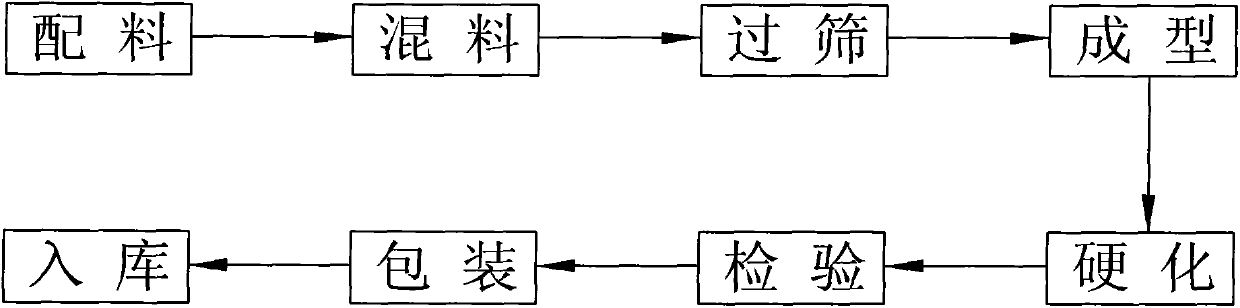

Resin rough grinding wheel and preparation method thereof

ActiveCN103465179AImprove grinding efficiencyIncrease roughnessAbrasion apparatusGrinding devicesPyriteAlumina zirconia

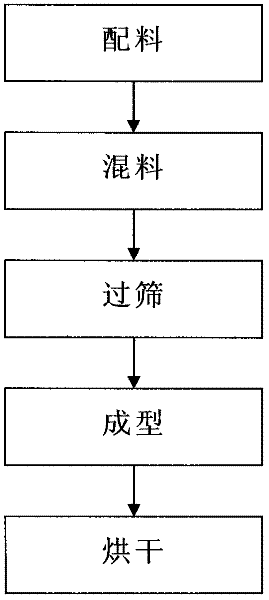

The invention relates to a resin rough grinding wheel and a preparation method thereof. The resin rough grinding wheel comprises a grinding body and reinforcing meshes, wherein the reinforcing meshes are arranged inside the grinding body to enhance the revolving strength of the grinding body. The grinding body is composed of 115-150 parts of grinding materials, 5-15 parts of liquid phenolic resin, 25-45 parts of phenolic resin powder and 15-35 parts of filling, wherein the grinding materials comprise 30-40 parts of microcrystal corundum, 80-100 parts of fused alumina zirconia and 5-10 parts of garnets, the filling is composed of 9-21 parts of pyrite, 1-3 parts of cryolite, 1-3 parts of ferric oxide, 1-3 parts of quick lime and 3-5 parts of fluorite. The resin rough grinding wheel is prepared through the steps of preparation, mixing, sifting, shaping, hardening, testing, packaging and storing, has high strength, good abrasive resistance and self-sharpening performance, high grinding efficiency, good roughness and low workpiece burning possibility; meanwhile, the surface of the grinding wheel is not easy to block and has good breathability, good tenacity and high security performance.

Owner:NINGBO DAHUA GRINDING WHEEL

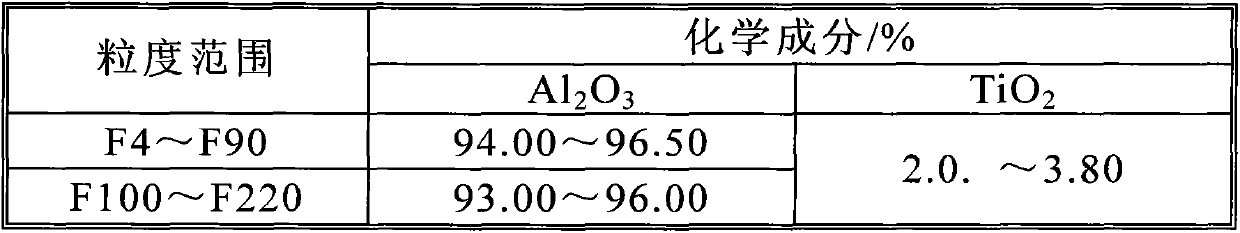

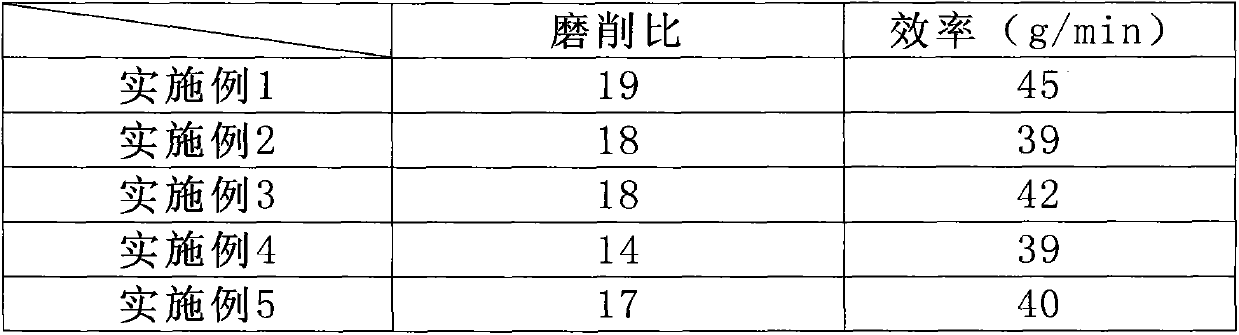

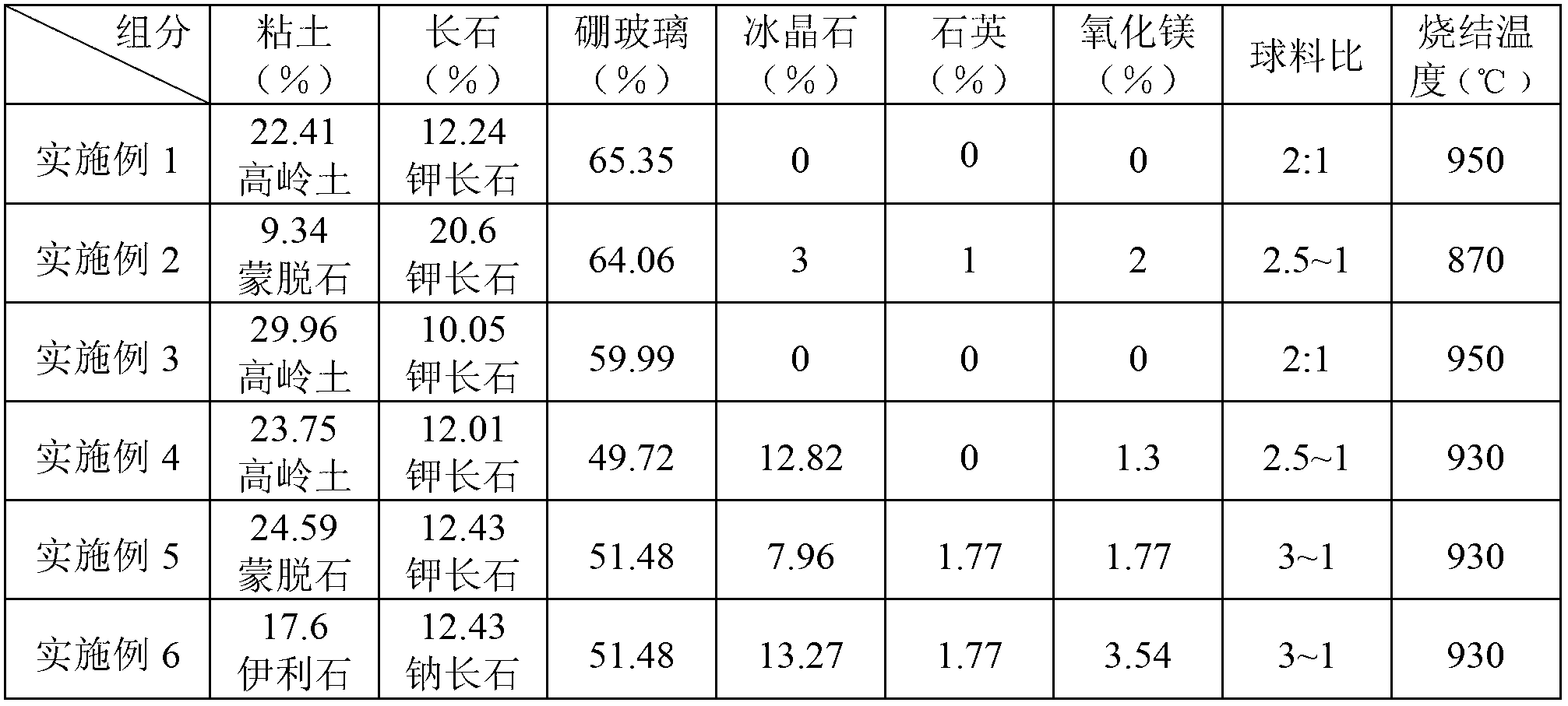

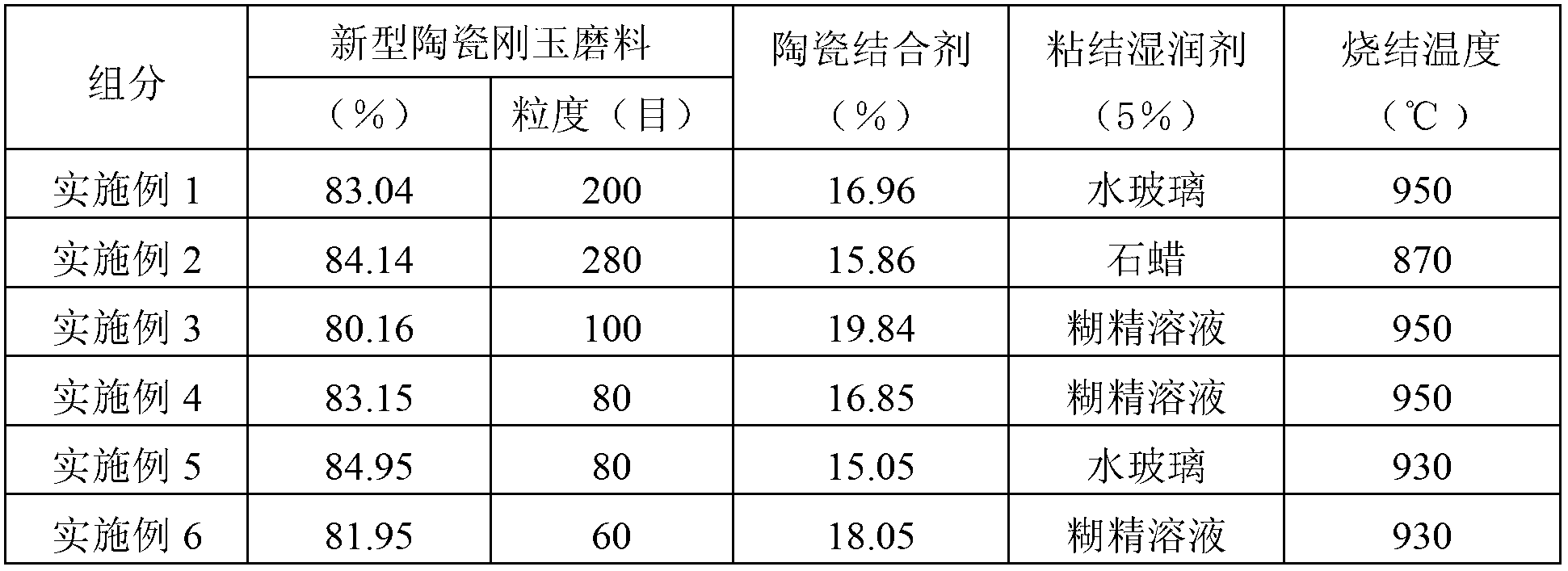

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

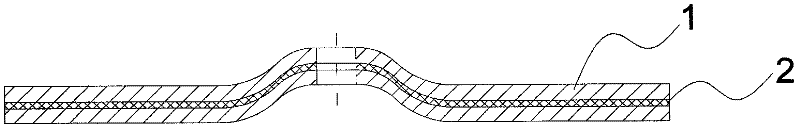

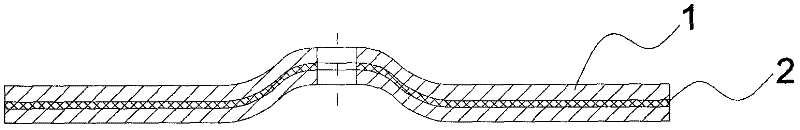

Resin abrasive cutting wheel and manufacturing method thereof

ActiveCN102343558AHigh strengthImprove cutting effectBonded abrasive wheelsGrinding devicesCarbideGrinding wheel

The invention provides a resin abrasive cutting wheel and a manufacturing method thereof, belonging to the field of grinding tools. The resin abrasive cutting wheel solves the problem that the traditional brown corundum resin grinding wheel has low cost but bad cutting performance. The resin abrasive cutting wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body to reinforce the rotation strength of the grinding body, wherein the grinding body comprises the following raw materials in proportions by weight: 62-70% of brown corundum, 4-10% of black silicon carbide, 18-20% of phenolic resin and the balance of packing. The invention also provides a manufacturing method of the resin abrasive cutting wheel. According to the manufacturing method, the cutting performance of the abrasive cutting wheel is increased by increasing a special proportion of black silicon carbide under the condition that the cost is not increased.

Owner:NINGBO DAHUA GRINDING WHEEL

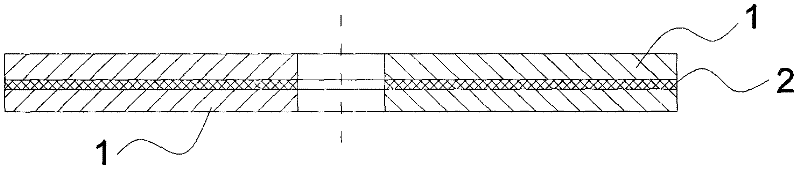

Resin grinding wheel and manufacturing method thereof

ActiveCN102343560AReduce wearAvoid cloggingBonded abrasive wheelsGrinding devicesPyriteGrinding wheel

The invention provides a resin grinding wheel and a manufacturing method thereof, belonging to the field of grinding tools. The resin grinding wheel solves the problem that sulfur dioxide generated by pyrite mine of the traditional resin grinding wheel has corrosiveness. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body to reinforce the rotation strength of the grinding body, wherein the grinding body comprises the following raw materials in parts by weight: 140-200 parts of abrasive material, 50-65 parts of phenolic resin powder, 10-20 parts of phenolic resin liquid, 10-20 parts of quicklime powder, 12-25 parts of pyrite mine powder and 5-10 parts of cryolite powder. The invention also provides a manufacturing method of the resin grinding wheel. According to the manufacturing method, the content of sulfur dioxide generated in the processing process is reduced by using the quicklime powder for reacting with the sulfur dioxide.

Owner:NINGBO DAHUA GRINDING WHEEL

Low-temperature high-strength devitrified glass ceramics bond cubic boron nitride grinding wheel

InactiveCN101362316AHigh hardnessImprove grinding abilityBonded abrasive wheelsNumerical controlBoron nitride

The invention discloses a cubic boron nitride grinding wheel with low-temperature and high-strength microcrystalline glass ceramic binder. The cubic boron nitride grinding wheel consists of a matrix, a binding course and a grinding wheel block. The grinding wheel block is a cubic boron nitride grinding wheel block, and adopts the following raw materials (according to the weight percentage of the content): 45 to 80 percent of cubic boron nitride abrasive, 0 to 20 percent of corundum, and 20 to 35 percent of ceramic binder; the ceramic binder is the microcrystalline glass ceramic binder, and the raw material composition and the weight percentage content is as follows: 40 to 70 percent of SiO2, 5 to 25 percent of B2O3, 2 to 5 percent of Al2O3, 2 to 15 percent of Na2O, 2 to 5 percent of K2O, 2 to 4 percent of MgO, 2 to 4 percent of CaO, 1 to10 percent of Li2O, 2 to 5 percent of ZrO2 and 2 to 5 percent of Sb2O3. The invention provides a high efficiency grinding tool which has the advantages that the using linear speed of the grinding wheel can be 160 m / s, the process precision is high, the service life is long, the environment pollution is avoided, and the high efficiency grinding tool can be matched with a high speed high efficiency numerical control crankshaft grinder and is mainly used in the grinding machining of car crank shafts and various numerical control.

Owner:TIANJIN UNIV

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

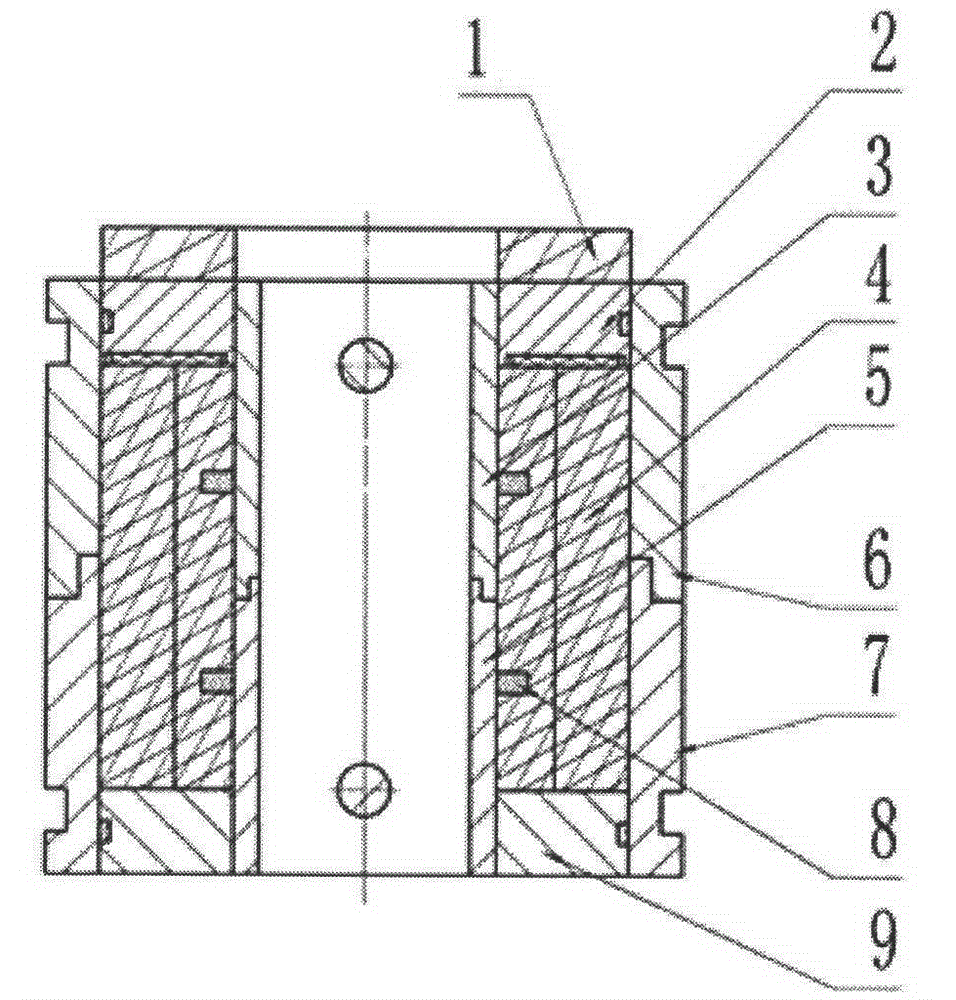

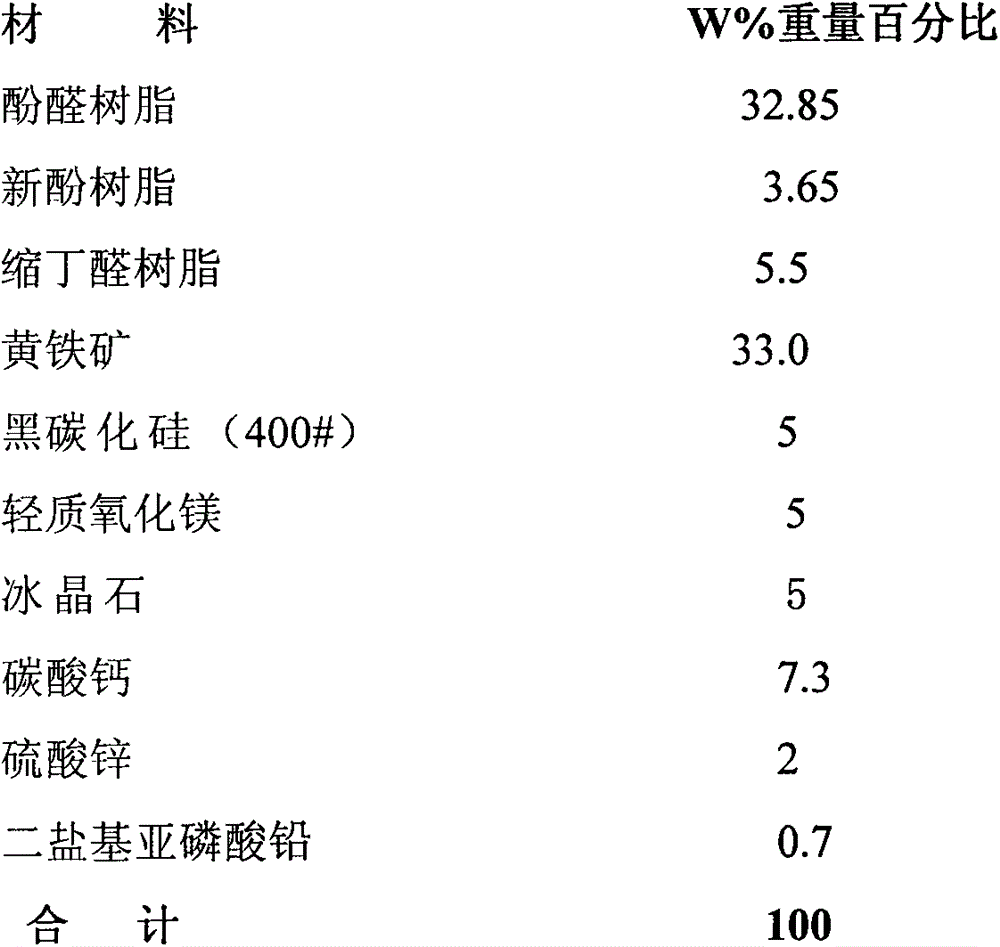

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

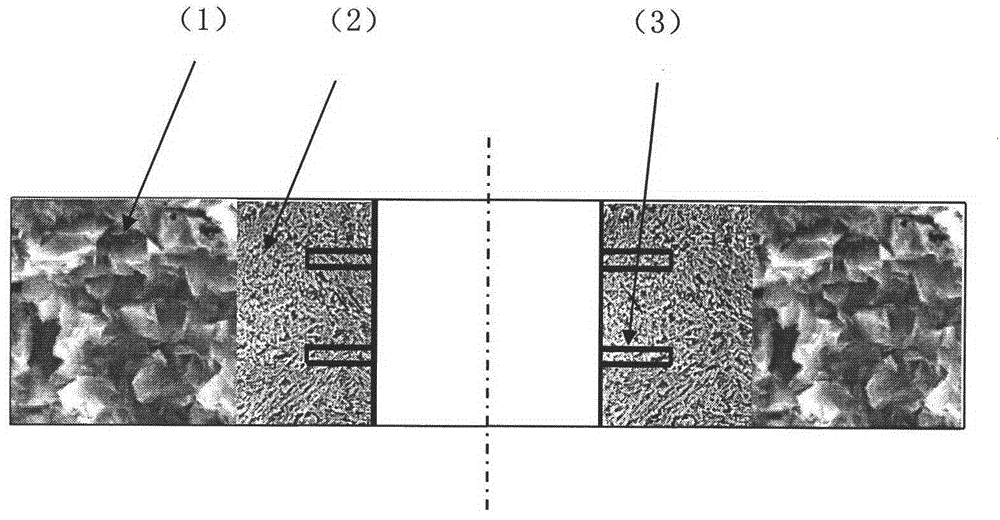

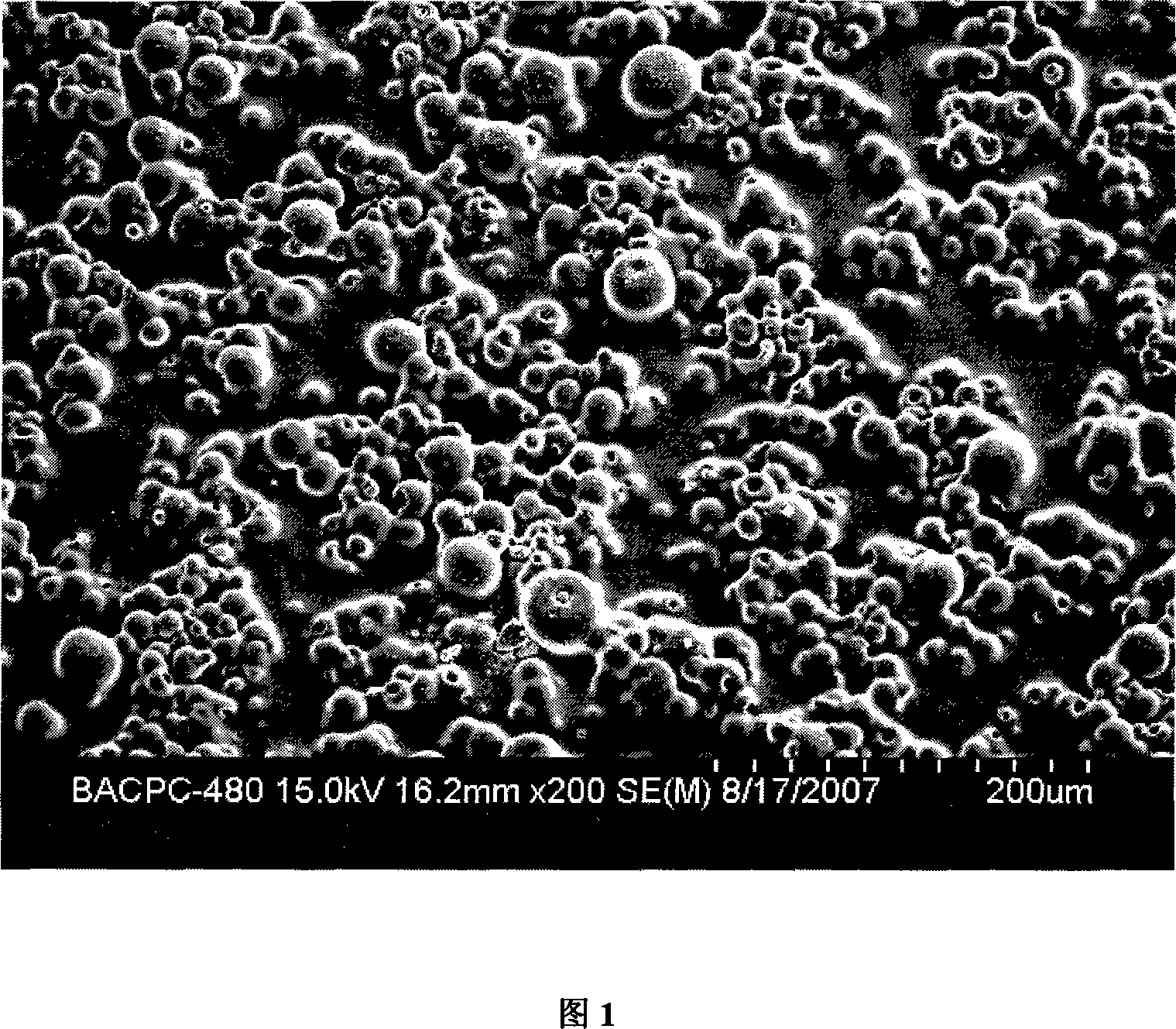

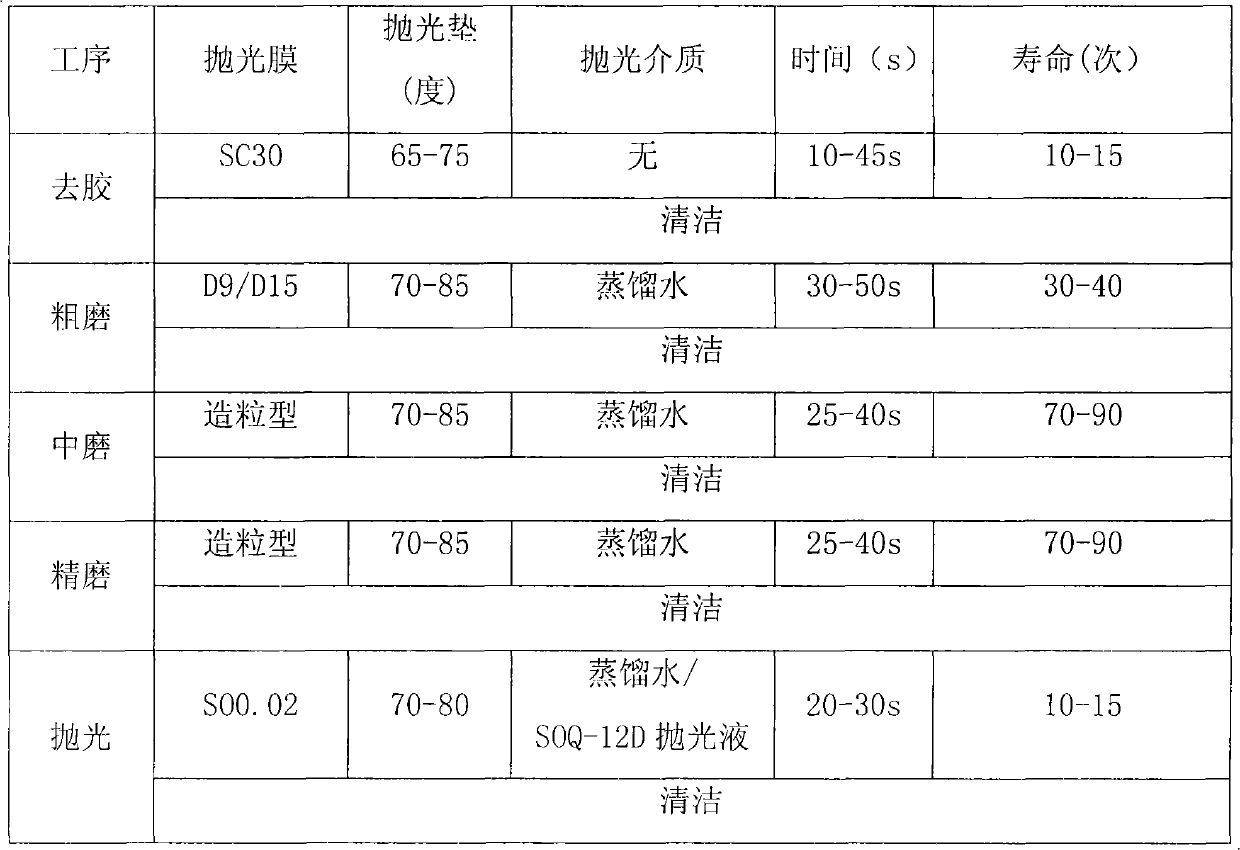

Granulation type pouncing paper, preparation method and application thereof

ActiveCN101219530AEvenly dispersedGrinding force does not decreaseAbrasion apparatusFiberMetal alloy

The invention provides a pelleting emery paper which can sharpen self and has durable grinding property and a preparation method and applications thereof. The invention comprises compound grinding grains which are coated to the surface of a substrate through adhesive and show aggregate ball shape. The grinding powders in the compound grinding grains are dispersed in one or more metal oxide sol which is mixed with organic adhesives or inorganic adhesives. The grain diameter of the grinding powder is not more than 10 micron meters and the diameter of the compound grinding grain is 5-50 micron meters. The emery paper is applicable in the grinding and polishing of most work pieces including metal, metal alloy, ceramic, optical element, fiber connecter, hard disc and semiconductor, etc.

Owner:BEIJING GRISH HITECH

Laser-welding diamond disc and preparation method thereof

ActiveCN101456216AGood self-sharpeningGood edge cutting effectStone-like material working toolsLow speedCobalt

The invention relates to a laser welding diamond round saw blade and a preparation method thereof, which belong to the technical field of powder metallurgy material. The saw blade is used for solving the problem that the laser welding diamond round saw blade has lower speed and easy edge feed when used for cutting hard stones. The material of a cutting head is prepared from the following powder raw materials by weight percentage: 36 to 46 percent of copper, 28 to 38 percent of iron, 10 to 20 percent of cobalt, 3 to 10 percent of nickel, 3 to 9 percent of tin, 1 to 2.5 percent of silicon-chromium alloy, 1 to 1.6 percent of liquid paraffin wax and 1.0 to 2.2 percent of diamond, wherein the silicon-chromium alloy contains 40 percent of silicon, 30 percent of chromium and the balance being iron and small quantities of impurities according to mass proportion. The method adopts a mixed base material of the copper, the iron and the cobalt to improve the service life and the sintering performance of the saw blade and the added silicon-chromium alloy powder is dispersively distributed in a fetal body, thereby effectively improving the sintering performance of the fetal body so as to make the fetal body accelerate an alloying process. At the same time, the self-sharpening performance of the fetal body is improved, the holding force of the fetal body to the diamond is enhanced and the service life and the cutting performance of the saw blade are improved, thereby making the wear performance of the fetal body and the wear performance of the diamond be matched.

Owner:BOSUN TOOLS CO LTD

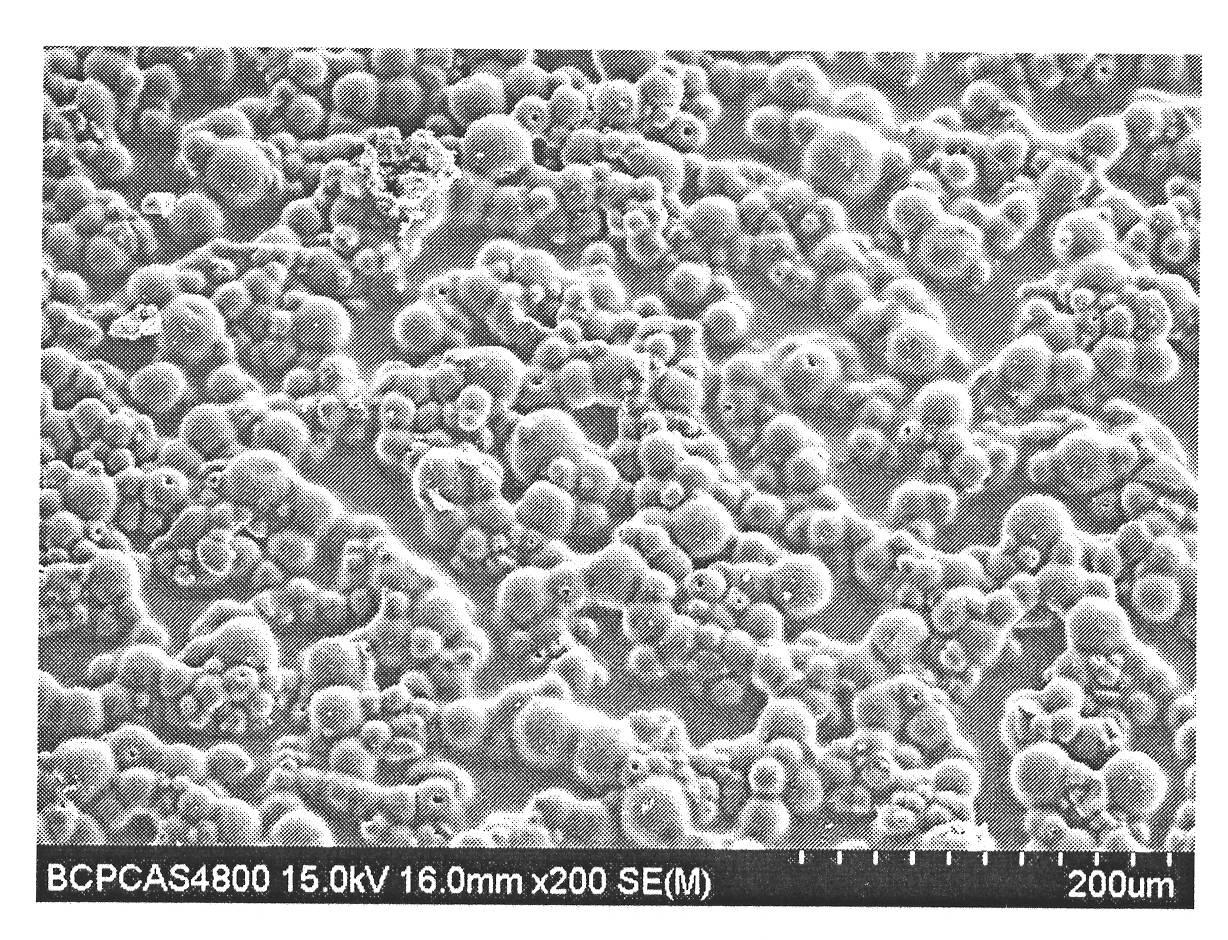

Granulation polishing film, preparing method thereof and application thereof

ActiveCN101767318AImprove surface roughnessImprove grinding efficiencyAbrasion apparatusGrinding machinesPolyesterEpoxy

The present invention provides a for the precise finish of an optical fiber connector with lasting abrasive power and high life time, a preparing method thereof and an application thereof, and can strengthen self-shaping. The granulation polishing film comprises base material and an abrasive layer coated at the surface of the base material, wherein the abrasive layer comprises resinoid bond and composite abrasive grains in global coacervate; the composite abrasive grains are global coacervates prepared by granulating abrasive powder distributed in the mixing liquid of metal oxide sol and organic or inorganic binder; the resinoid bond comprises epoxide resin and epoxide resin toughener, and also comprises one or several kinds of polyester, polyurethane, daiamid, acrylate and polyurea. The granulation polishing film is used for the grinding finish of the optical fiber connector and optical fiber arrays. The life time is one to two times longer than that of the traditional polishing film for the finish of the optical fiber connector, and the processing cost of the optical fiber connector is reduced.

Owner:BEIJING GRISH HITECH

Resin grinding wheel and manufacturing method thereof

ActiveCN102363287AStrong grinding forceImprove grinding forceAbrasion apparatusGrinding devicesPyriteEngineering

The invention provides a resin grinding wheel and a manufacturing method thereof, which belong to the field of grinding tools and are used for solving the problem of the production of harmful sulfur dioxide by pyrite serving as a lubricating agent existing in the conventional resin grinding wheel. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body for enhancing the revolving strength of the grinding body, wherein 90-105 parts by mass of corundum is taken as a grinding material the grinding body; 2-8 parts by mass of phenolic aldehyde resin liquid and 6-25 parts by mass of phenolic aldehyde resin powder are taken as bonding agents; and 1-10 parts by mass of cryolite and 1-5 parts by mass of polytetrafluoroethylene powder are taken as fillers. The invention further provides a manufacturing method of the resin grinding wheel. In the grinding wheel, the polytetrafluoroethylene powder instead of pyrite is taken as a lubricating agent, so that sulfur dioxide is not produced and other pollution is avoided in the using process.

Owner:NINGBO DAHUA GRINDING WHEEL

Metal-ceramic bond diamond grinding wheel and production method thereof

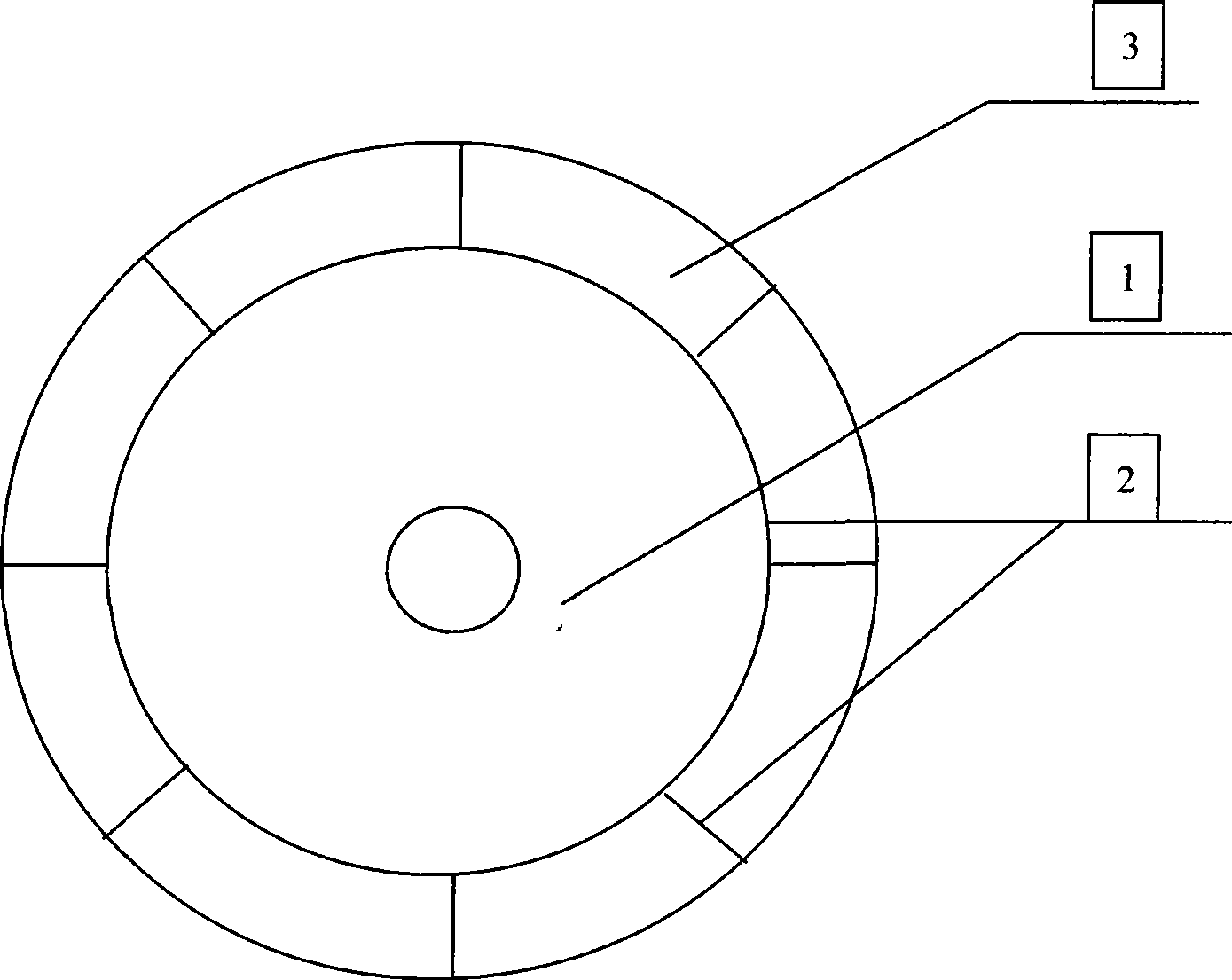

ActiveCN103692371AGood self-sharpeningImprove gripAbrasion apparatusGrinding devicesPowder mixtureCopper plating

The invention discloses a novel metal-ceramic bond diamond grinding wheel having the high strength and form-holding property in metal bond grinding wheels and the high self-sharpening property in ceramic bond grinding wheels, and a production method thereof. The metal-ceramic bond diamond grinding wheel is produced by: 1, preparing powder mixture out of 60-70% of copper-plated diamond powder, 15-20% of (W, Ti)C powder, 5-10% of tin powder, and 5-15% of iron group powders; mixing according to the above components and ratio to obtain the powder mixture; 2, forming, namely pressing the powder mixture into blanks by pressure forming; 3, sintering, namely subjecting the blanks to inert atmosphere low-pressure sintering, heating the blanks to 850-1050DEG C during sintering, and holding the temperature for 10-30 minutes. The copper-plated diamond powder is composed of particles with average particle size of 5-80 micrometers, and the particles are composed of diamond cores and copper coatings covering the diamond cores. Inert atmosphere during sintering is 5-10Mpa.

Owner:长沙市萨普新材料有限公司

Preparation method of composite binding agent diamond grinding wheel

ActiveCN103600308AImprove grinding efficiencyGood self-sharpeningAbrasion apparatusGrinding devicesMaterials scienceTin

The invention discloses a preparation method of a composite binding agent diamond grinding wheel. The method includes the steps of firstly, mixing, by weight, 1-2 parts of phosphorus powder, 10-15 parts of polyimide resin powder, 8-10 parts of tin powder, 35-40 parts of copper powder, 9-11 parts of lead powder and 2-4 parts of zinc powder, and then sieving with a 325-mesh standard sieve to obtain composite binding agent; secondly, mixing, by weight, 10-14 parts of diamond grinding material and 25-45 parts of composite binding agent in a mixing machine, adding, by weight, 1.5-2 parts of acrylic emulsion to continue mixing, and sieving with a 70-mesh standard sieve to obtain grinding wheel mixture; thirdly, placing a steel substrate in a die, filing the grinding wheel mixture in the die, and hot pressing in a hydraulic machine to obtain grinding wheel blank; fourthly, sintering the grinding wheel blank in a sintering furnace; fifthly, machining the sintered grinding wheel blank on a lathe and a grinding machine to obtain the fished composite binding agent diamond grinding wheel. The diamond grinding wheel prepared by the method is high in grinding efficiency, good in self-sharpness, high in rigidity, high in heat resistance, and good in profile maintaining.

Owner:CHANGSHU JULI GRINDING WHEEL

Preparation method of porous metal binding agent braze welding diamond grinding wheel

The invention provides a preparation method of a porous metal binding agent braze welding diamond grinding wheel, comprising the following steps of preparing a grinding wheel segment block and connecting the grinding wheel segment block with a grinding wheel base body. The prepared porous metal binding agent braze welding diamond grinding wheel has 45-70 percent of porosity, and the bending strength of three points of the grinding wheel segment block is 75-200 MPa. Because of the introduction of a pore structure, the trimming and sharpening ability, the grinding material exposure ability and a chips-containing space of the novel grinding wheel are greatly improved compared with the compact metal binding agent grinding wheel, the grinding wheel has favorable self-sharpening property, favorable durability and high processing efficiency, and can bear heavier load when crisp and hard materials are grinded; meanwhile, the grinding wheel segment block has high strength, the metal binding agent has favorable holding force on the grinding material, and the grinding material does not fall off easily and prematurely.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mixed ultra-hard abrasive honing stone

InactiveCN104400614AReduce processing costsEasy to manufactureOther chemical processesAbrasion apparatusNickelHot press

The invention discloses a mixed ultra-hard abrasive honing stone. The mixed ultra-hard abrasive honing stone is characterized by comprising the following components in percentage by weight: 20-40 percent of copper, 2-6 percent of silver, 1-10 percent of aluminum, 2-6 percent of zinc, 2-20 percent of tin, 10-20 percent of iron, 5-10 percent of nickel, 5-30 percent of cobalt, 1-9 percent of lead, 5-10 percent of a bonding agent and the balance of an ultra-hard material, wherein the volume ratio is 60-100 percent; the metal purity of the copper, the silver, the aluminum, the zinc, the tin, the iron, the nickel, the cobalt and the lead is over 99 percent; the granularity of the ultra-hard material is 200-1,000 meshes; the honing stone is prepared by performing mixing, cold press molding and vacuum hot press process on the raw materials according to the mixture ratio. The mixed ultra-hard abrasive honing stone disclosed by the invention has the advantages of sharp grinding, high grinding efficiency, large grinding weight, short grinding time, long service life, superior self-sharpening property, low process cost, easiness and convenience in preparation, and the like.

Owner:YINCHUAN HENGYIDA MACHINERY

Manufacture formula of rail grinding wheel and manufacture method thereof

InactiveCN102241957AGood self-sharpeningImprove grinding effectOther chemical processesAbrasion apparatusIron powderHeat rejection

The invention relates to a wheel, in particular to a rail grinding wheel, which is formed by mixing, sintering, wrapping, drying and hardening the following components in parts by weight: 70-100 parts of zirconia alumina, 5-8 parts of vulcanized iron powder, 4-8 parts of cryolite, 1-3 parts of calcium carbonate, 1-4 parts of gypsum powder and 7-10 parts of phenolic resin. In the invention, the zirconia alumina is selected as the main material of the rail grinding wheel and the vulcanized iron powder, the cryolite, the calcium carbonate, the gypsum powder and the phenolic resin for heat rejection, heat conduction and reinforcement are added on condition that the cutting force is ensured. The wheel manufactured by the invention not only has the advantages of better self-sharpening performance and grinding performance, higher cutting efficiency and low frequency of burn and crackle when a rail is grinded via the wheel, but also has the advantages of higher strength and good breakage proofness.

Owner:李冰湜

Glass grinding fluid and preparation method thereof

InactiveCN103275803AGood cleaning penetration performanceGood self-sharpeningLubricant compositionCamera lensCleansing Agents

The invention discloses a glass grinding fluid and a preparation method thereof. A technical scheme in the invention is characterized in that the glass grinding fluid comprises 5-20wt% of a grinding dust settling agent, 2-8wt% of a cleaning agent, 1-20wt% of a pH stabilizing agent, 1-20wt% of a lubricant, 0.3-2wt% of an organosilicon antifoaming agent, and the balance water. The invention also discloses the preparation method of the glass grinding fluid. The glass grinding fluid has good cleaning and penetrating performances, can effectively prevent grinding tools from passivating, has a good self-sharpening effect on the grinding tools, increases the cutting force of diamond tools, and is suitable for grinding common glass, resin glass, optical glass, flat glass, camera lens, spectacle lens, handset cover plates, sapphire glass, optical products of quartz, high-grade marble or superfine granite.

Owner:HENAN NORMAL UNIV

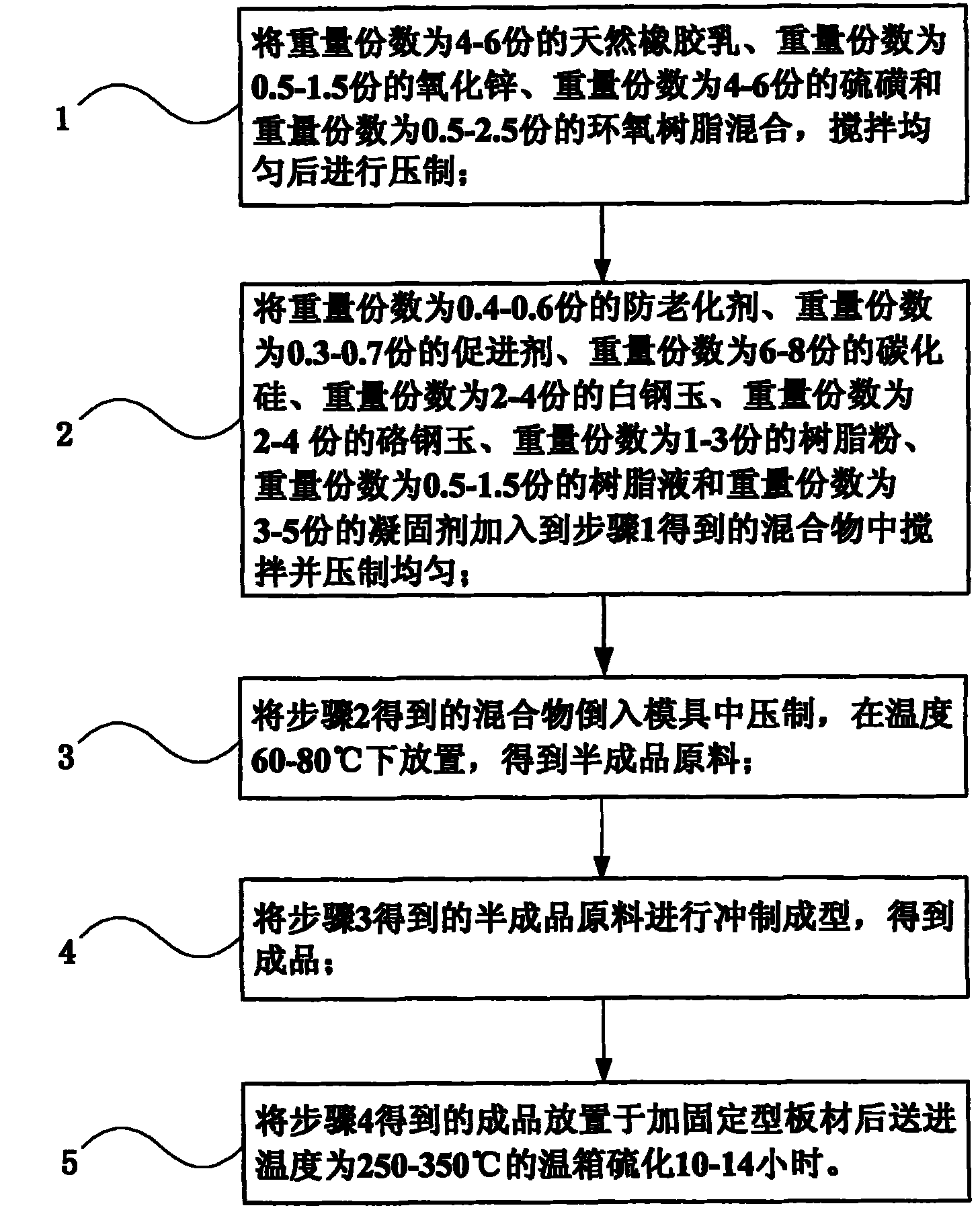

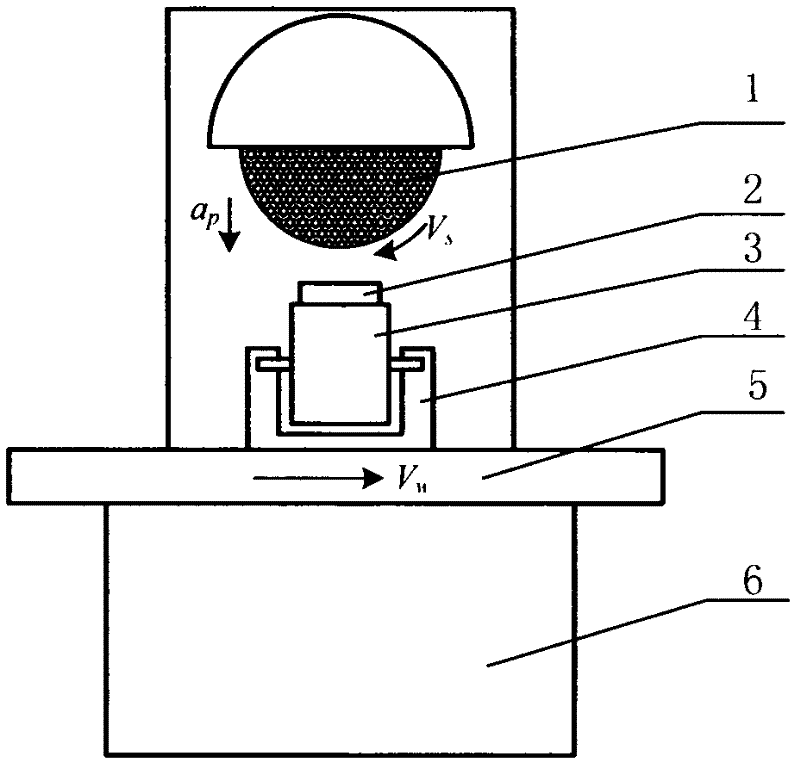

Rubber thin sheet grinding wheel and preparation method thereof

InactiveCN102001057AImprove wear resistanceHigh hardnessAbrasion apparatusGrinding devicesEpoxyPolymer science

The invention relates to a rubber thin sheet grinding wheel and a preparation method thereof. The rubber thin sheet grinding wheel comprises the following raw materials in part by weight: 4 to 6 parts of natural rubber emulsion, 0.5 to 1.5 parts of zinc oxide, 4 to 6 parts of sulfur, 0.5 to 2.5 parts of epoxy resin, 0.4 to 0.6 part of anti-ager, 0.3 to 0.7 part of accelerant, 6 to 8 parts of silicon carbide, 2 to 4 parts of diamantane, 2 to 4 parts of chromium corundum, 1 to 3 parts of resin powder, 0.5 to 1.5 parts of resin liquid and 3 to 5 parts of coagulator. The rubber thin sheet grinding wheel of the invention has the advantages of high wear resistance, heat resistance, self-sharpening property, heat conductivity, corrosion resistance, toughness, hardness and working efficiency and long service life; in addition, the rubber thin sheet grinding wheel prepared by the preparation method of the rubber thin sheet grinding wheel of the invention is very thin and has low loss and high accuracy during cutting.

Owner:施镇源

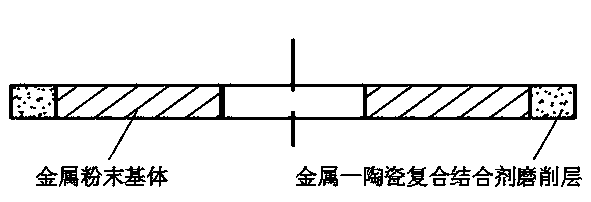

Metal ceramic composite binding agent and composite binding agent diamond grinding wheel

InactiveCN104128892AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesCeramic compositeCopper

The invention discloses a metal ceramic composite binding agent and a composite binding agent diamond grinding wheel manufactured by adoption of the metal ceramic composite binding agent. The metal ceramic composite binding agent is composed of, by weight, 65 percent to 75 percent of metal powder and 25 percent to 35 percent of ceramic powder. The metal powder is composed of, by weight, eight percent to ten percent of tungsten, five percent to eight percent of tin, five percent to eight percent of zinc, three percent to five percent of lead, and the balance copper. The ceramic powder is formed by mixing and melting, by weight, 40 percent to 50 percent of SiO2, 20 percent to 30 percent of Al2O3, 10 percent to 20 percent of K2O, five percent to 15 percent of MgO, and three percent to eight percent of Fe2O3. According to the composite binding agent diamond grinding wheel manufactured by adoption of the metal ceramic composite binding agent, the good sharp and self-sharpness characteristics of a ceramic composite binding agent diamond grinding wheel can be kept, and the high-rigidity and good-shape-maintaining advantages of a metal binding agent diamond grinding wheel are achieved.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

Vitrified bond cubic boron nitride (CBN) grinding wheel for grinding titanium alloy

ActiveCN103223644AHigh grinding temperatureHigh thermal conductivityAbrasion apparatusBoron nitrideTitanium alloy

The invention discloses a vitrified bonded cubic boron nitride (CBN) grinding wheel for grinding titanium alloy, which comprises a basal body, grinding wheel blocks and bonding layers, wherein the grinding wheel blocks comprise the following raw materials in weight percentage: 40-80 percent of cubic boron nitride grinding material, 0-30 percentage of silicon carbide, 14-35 percent of ceramic binder and 6 percent of temporary binder; and the ceramic binder comprises the following raw materials in weight percentage: 15-25 percent of B2O3, 8-15 percent of Al2O3, 46-60 percent of SiO2, 2-8 percent of Li2O, 2-10 percent of Na2O, 2-10 percent of ZnO and 2-10 percent of AlN, and the refractoriness of the ceramic binder is lower than 700 DEG C. The vitrified bound cubic boron nitride grinding wheel can effectively overcome the defects of strong grinding force, high grinding temperature, serious grinding wheel bonding and the like caused during grinding the titanium alloy, and has the advantages of high thermal conductivity, good self-sharpening performance, high grinding efficiency, long service life, low cost and simple process.

Owner:TIANJIN UNIV

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

Protogenic diamond fine particle for precisio machining and production method thereof

ActiveCN102580618AGood self-sharpeningImprove processing efficiencyUltra-high pressure processesOctahedronPyrophyllite

The invention relates to a protogenic diamond fine particle for precision machining and a production method thereof. The diamond particle is 1-30 microns in size, is of the shape of hexahedron, octahedron or hexahedron-octahedron and has a nitrogen content of 200-500 ppm. The production method comprises the steps of: mixing graphite powder, a metal catalyst and a nitrogenous substance at a proportion of 0.4-1: 0.6-1.0: 0.01-0.05 for an isostatic cool pressing treatment; pressing the mixed material into a cylindrical synthesis column for vacuum sintering; then filling pyrophyllite synthetic block and performing a high-temperature and high-pressure treatment in a cubic press; the crushing the synthesis column and separating the crushed synthesis column by a swing bed to obtain the protogenic diamond fine particle for precision machining. The protogenic diamond fine particle has the advantages of being applicable for machining tools, such as fretsaws, ultra-thin saw blades and electroplated grinding wheels, being suitable for efficient precision machining of glass, monocrystalline silicon, polycrystalline silicon, sapphires and silicon carbide crystals and having high machining efficiency as well as long service life. The method, disclosed by the invention, has the advantages of being green, environment-friendly and energy-saving and having steady product performance, low cost and good application performance.

Owner:HENAN UNION ABRASIVES

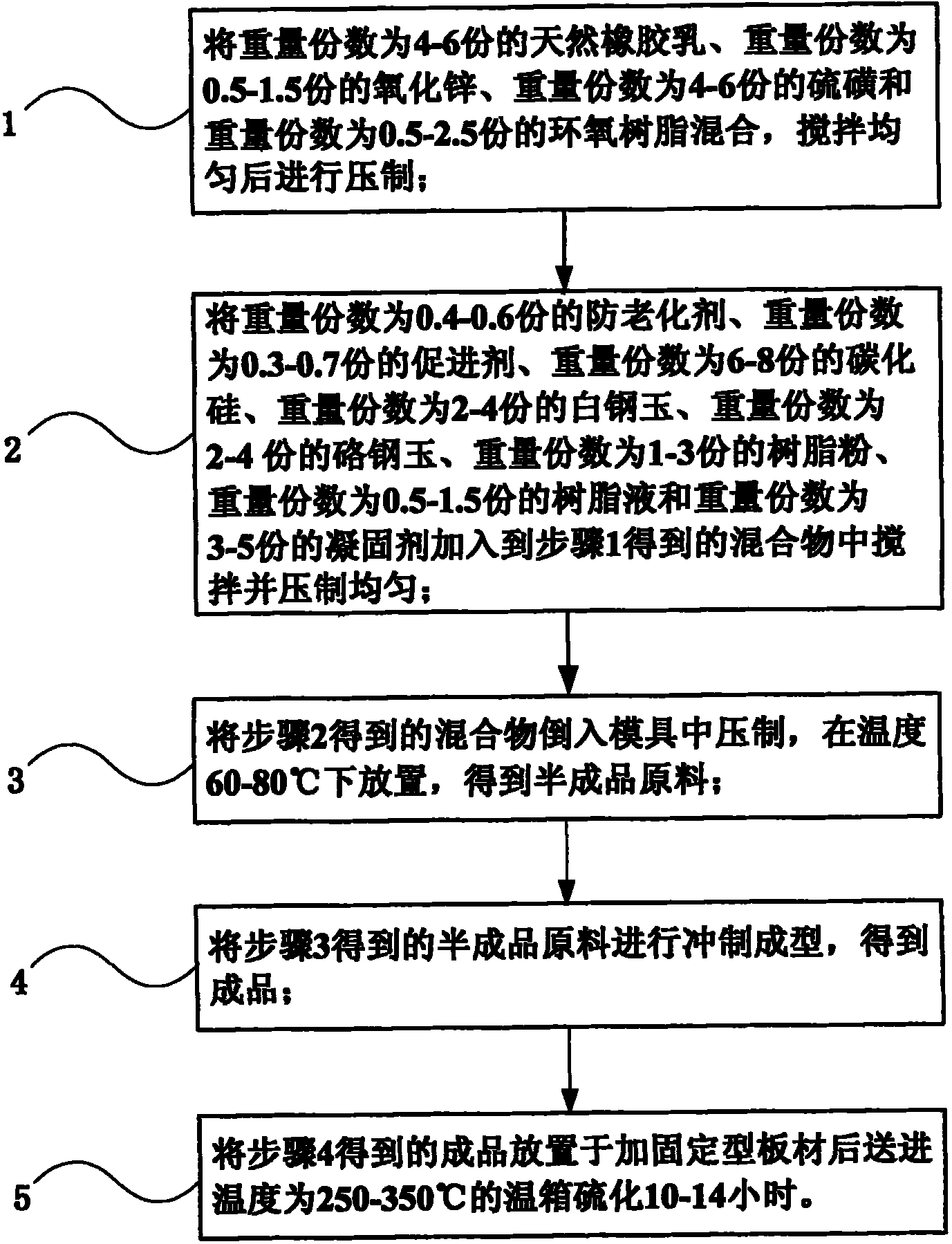

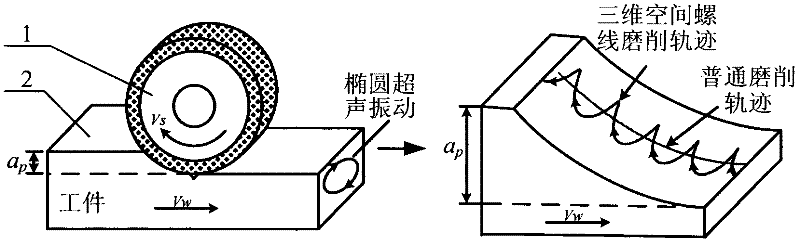

Three-dimensional spiral line grinding method through ultrasonic vibration

The invention provides a three-dimensional spiral line grinding method through ultrasonic vibration, which is applicable to high-efficiency precision machining of difficult-to-cut materials. Two-dimensional ultrasonic vibration is applied to a workpiece in the axial direction of a grinding wheel and in the radial direction of the grinding wheel on a common grinder by an ultrasonic transducer, so that the workpiece is in ultrasonic elliptic vibration. As the grinding direction is perpendicular to a plane of ultrasonic elliptic vibration, cutting tracks of abrasive particles relative to the workpiece are three-dimensional spiral lines. The tracks of the abrasive particles on the surface of the workpiece interfere with each other by the aid of the ultrasonic vibration in the axial direction of the grinding wheel, so that roughness is reduced. Besides, the maximum cutting depth of the abrasive particles is increased by the aid of the ultrasonic vibration in the radial direction of the grinding wheel, and the abrasive particles function in intermittent cutting, so that grinding force is reduced, and material removing rate is increased. The method can be used for improving machining surface quality, decreasing surface damage and improving production efficiency, thereby being applicable to high-efficiency precision machining of the difficult-to-cut materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

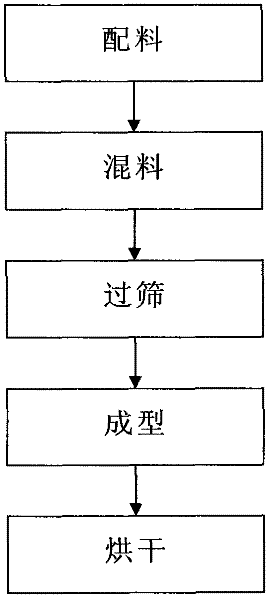

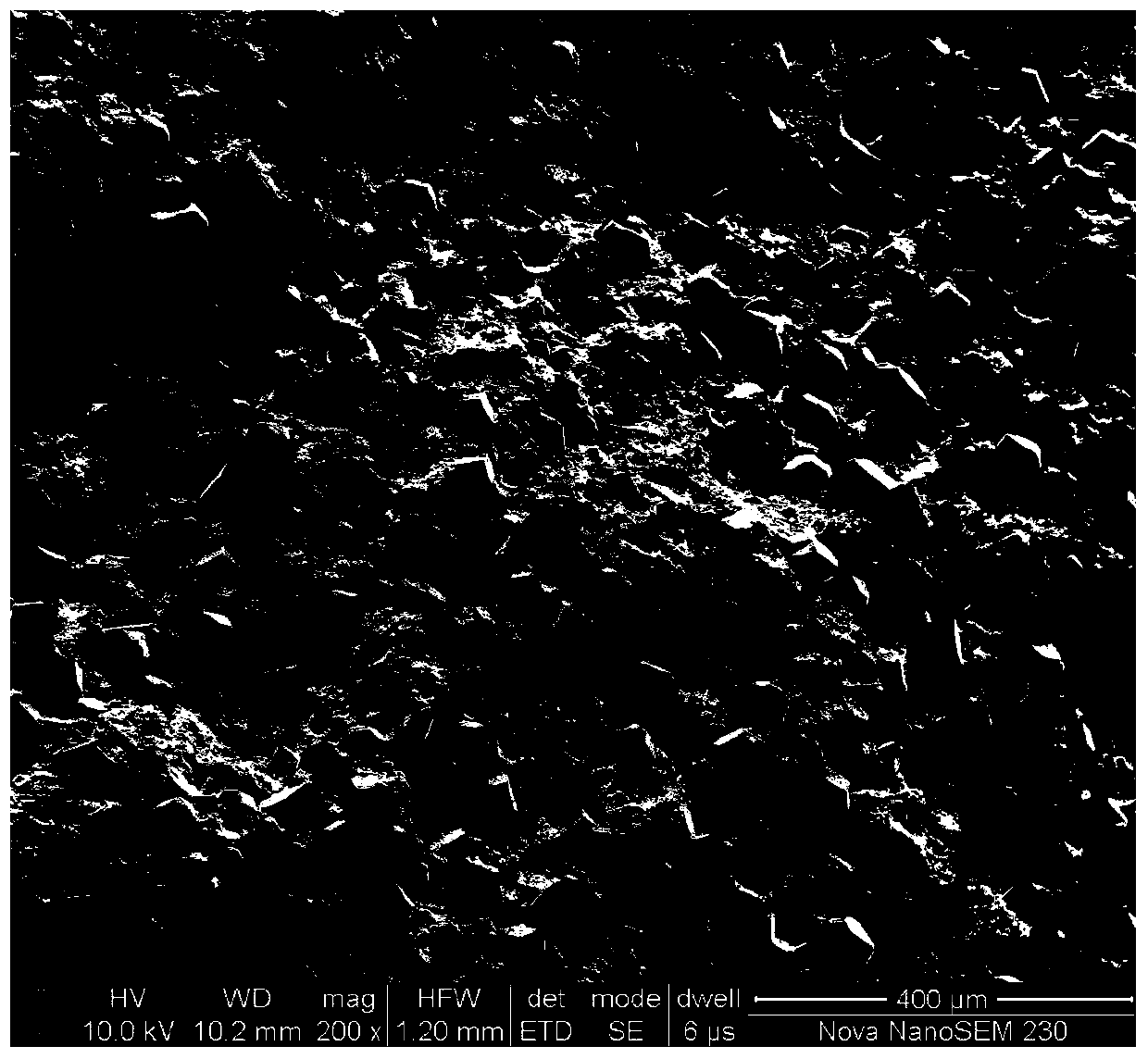

Semi-fixing abrasive grain grinding tool and method of producing the same

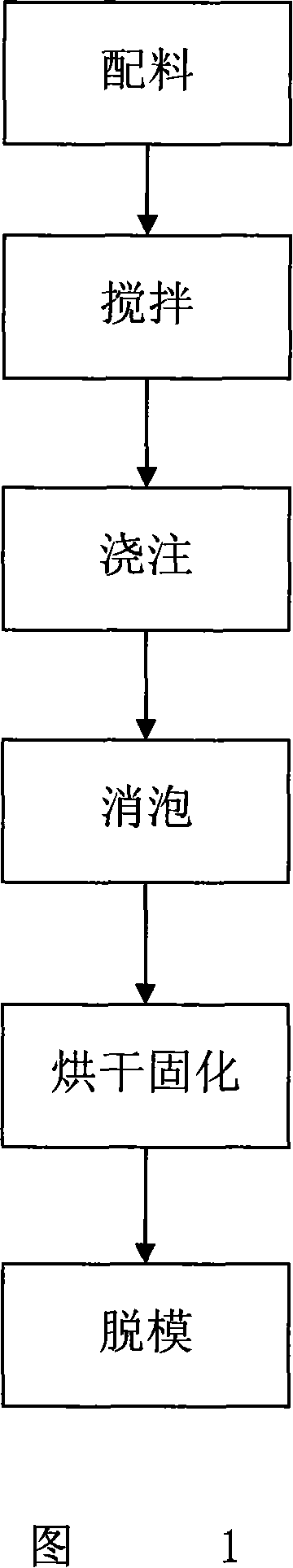

InactiveCN101134298AHigh bonding strengthImprove material removal rateAbrasion apparatusGrinding devicesWear particleAdhesive

The present invention is one kind of grinding tool with semi-fixed abrasive particle and its making process. The grinding tool consists of abrasive grain in 80-90 wt%, adhesive 1-10 wt% and additive 5-15 wt%. Its making process includes the following steps: 1. mixing abrasive grain, adhesive and additive, sieving and mixing with water; 2. molding the mixture in a mold; 3. eliminating bubbles from the molded grinding tool; and 4. stoving the grinding toll in a stove for curing and demolding to obtain the grinding tool with semi-fixed abrasive particle. The present invention has high processing precision and high processing efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

Ultra-thin resin dicing blade for QFN high-quality cutting and preparing method of ultra-thin resin dicing blade

ActiveCN106378714AHigh strengthExtend your lifeBonded abrasive wheelsGrinding devicesGraphiteUltimate tensile strength

The invention discloses an ultra-thin resin dicing blade for QFN high-quality cutting. Burdening of the ultra-thin resin dicing blade comprises a resin bond, diamond and inorganic filler, wherein the volume fraction of the diamond ranges from 12.5% to 30%, the grain size of the diamond ranges from 38 microns to 104 microns, and the volume fraction of the resin bond ranges from 35% to 55%. The inorganic filler is composed of silicon carbide, graphite and chromic oxide, the silicon carbide accounts for 6%-25% of the volume fraction of the total burdening, the graphite accounts for 3%-8% of the volume fraction of the total burdening, and the chromic oxide accounts for 5%-15% of the volume fraction of the total burdening. In the formula, the strength of the dicing blade can be greatly improved through the silicon carbide and the chromic oxide in the formula, meanwhile, the service life of the dicing blade is prolonged, a small amount of graphite is used for assistance, the self-sharpening capability of the blade can be improved, and good cutting quality and stability of the blade are kept. The invention further discloses a preparing method of the above dicing blade. The preparing method comprises the steps that raw materials are mixed through a wetting agent, and hot pressing, secondary curing and machining are conducted. The process is simple, the characters of the raw materials can be brought into full play, and the efficient, high-quality and ultra-thin resin dicing blade suitable for QFN cutting is prepared.

Owner:苏州赛尔科技有限公司

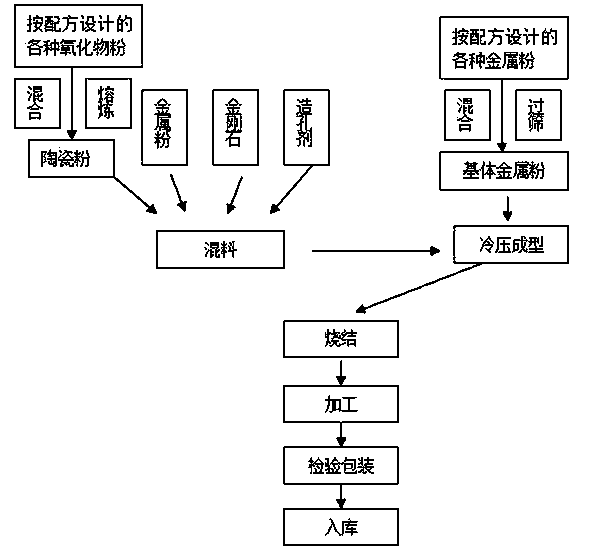

Preparation technology of metal ceramic bonding agent diamond/ cubic boron nitride (CBN) grinding wheel

InactiveCN102363289APrevent oxidationPerformance is not affectedGrinding devicesAir atmosphereHydrogen

The invention discloses a preparation technology of a metal ceramic bonding agent diamond / cubic boron nitride (CBN) grinding wheel. The metal ceramic bonding agent diamond / CBN grinding wheel is sintered by adopting a reducing atmosphere furnace. The technology comprises the following steps of: checking whether the equipment is complete before sintering, and introducing hydrogen if the gas passage is smooth; setting a heating curve, wherein the heating rate is 2 to 3 DEG C per minute from room temperature to 300 DEG C, the heat is preserved for 1 to 1.5 hours at the temperature of 300 DEG C, the heating rate is 1.5 to 2 DEG C per minute from 300 to 750 DEG C, the heat is preserved for 1.5 to 2 hours at the temperature of 750 DEG C, the heating rate is 1 to 1.5 DEG C per minute from 750 to 900 DEG C, and the heat is preserved for 1 to 1.5 hours at the temperature of 900 DEG C; and performing furnace cooling. Compared with the traditional preparation technology, the preparation technology has the advantages that: metal components in the bonding agent can be effectively protected from being oxidized in reducing atmosphere sintering, and the performance of the CBN abrasive particles is protected from being affected at a high temperature. Compared with air atmosphere sintering, the preparation technology has the advantages that: the service life of the grinding wheel is prolonged by about 15 percent, the grinding wheel has good self-sharpening property, and the effect of a machined product is obviously improved.

Owner:广东奔朗新材料股份有限公司

Anti-blocking grinding tool and manufacturing method thereof

ActiveCN104139346AReduce dosageReduce internal stressAbrasion apparatusGrinding devicesAdhesiveUltraviolet lights

The invention discloses a manufacturing method of an anti-blocking grinding tool. The method includes the steps that firstly abrasive powder is added into adhesives and is fully dispersed, then bubbles are removed, and sizing agents are obtained; secondly, a template with the surface provided with a die cavity is coated with the sizing agents obtained in the first step, a sizing agent layer is formed, a preprocessed base material is attached and pressed to the surface of the sizing agent layer, ultraviolet light is used for solidification, die releasing is conducted, and a semi-finished product is obtained; thirdly, the semi-finished product obtained in the second step is solidified at the temperature of 80-90 DEG C, and the anti-blocking grinding tool is obtained. The invention further discloses the anti-blocking grinding tool manufactured through the manufacturing method, the anti-blocking grinding tool has the excellent chip removing capability in the use process, and ground chips can be effectively prevented from being accumulated and agglomerated.

Owner:绍兴自远磨具有限公司

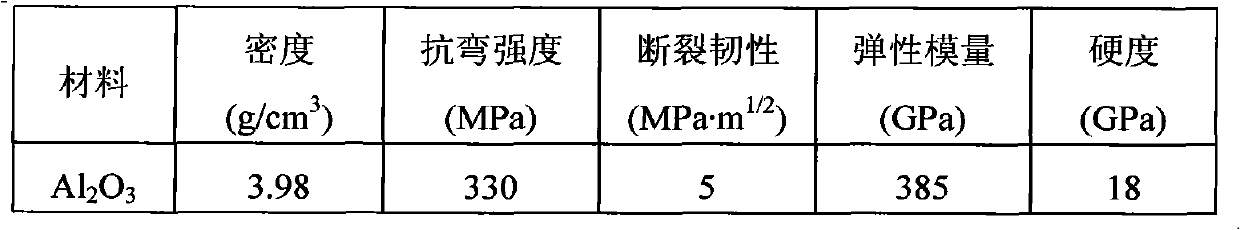

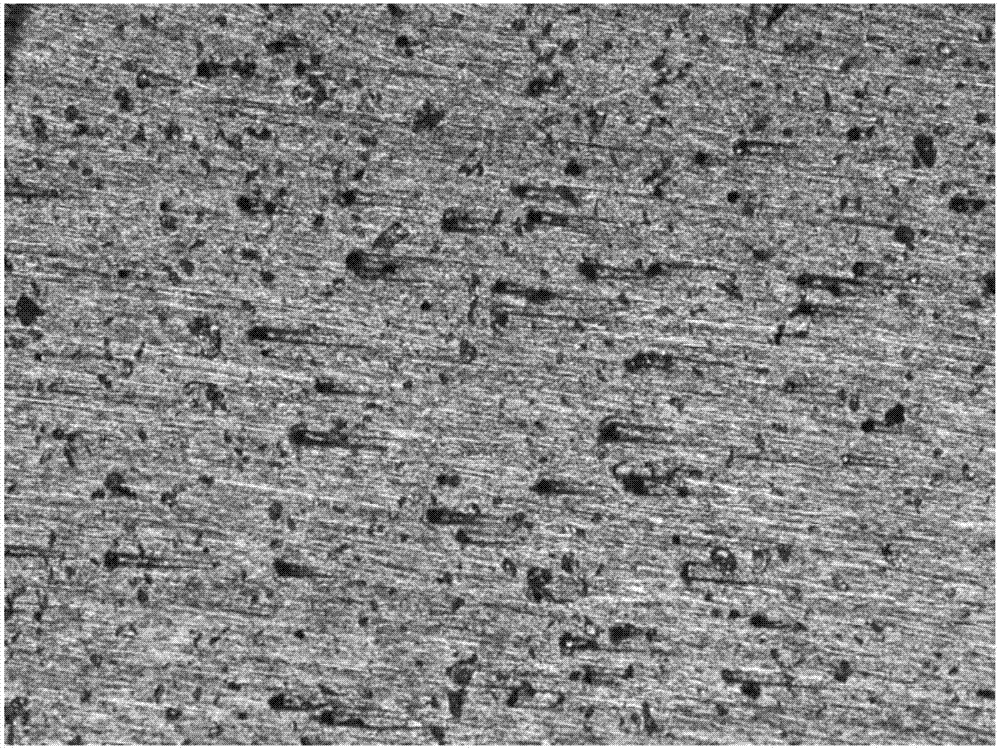

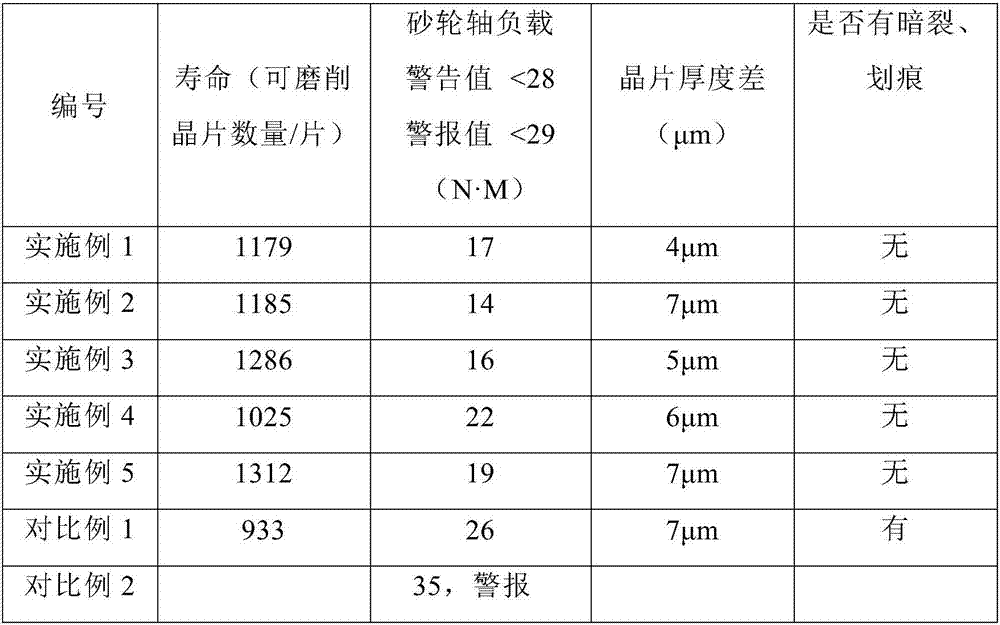

Metallic bond, diamond grinding wheel prepared through bond and preparation method of diamond grinding wheel

The invention relates to a metallic bond, a diamond grinding wheel prepared through the bond and a preparation method of the diamond grinding wheel. The metallic bond comprises, by weight percent, 95%-99% of copper-tin prealloyed powder, 0.5%-3% of graphite powder and 0.5%-2% of nanometer alpha-Al2O3. The copper-tin prealloyed powder, the graphite powder, the nanometer alpha-Al2O3 and diamond are taken according to a certain proportion, procedures of burdening and material mixing, pelletizing, compression, sintering and aftertreatment are carried out in sequence, and tool bits can be prepared. The multiple tool bits are arranged on a matrix at equal distance in the circumferential direction, the cambered surfaces of the tool bits are perpendicular to the matrix, and the diamond grinding wheel is prepared. The above tool bits are uniform in ingredient and good in density, diamond distribution is uniform, and the control effect of the metallic bond on the diamond is good. The grinding wheel has the beneficial effects of being good in ground workpiece surface quality, free of dark cracks and scratches, sharp in grinding and long in service life, facilitating large-scale production and the like and is especially suitable for producing sapphire wafers with the thinning thickness ranging from 100 micrometers to 700 micrometers.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

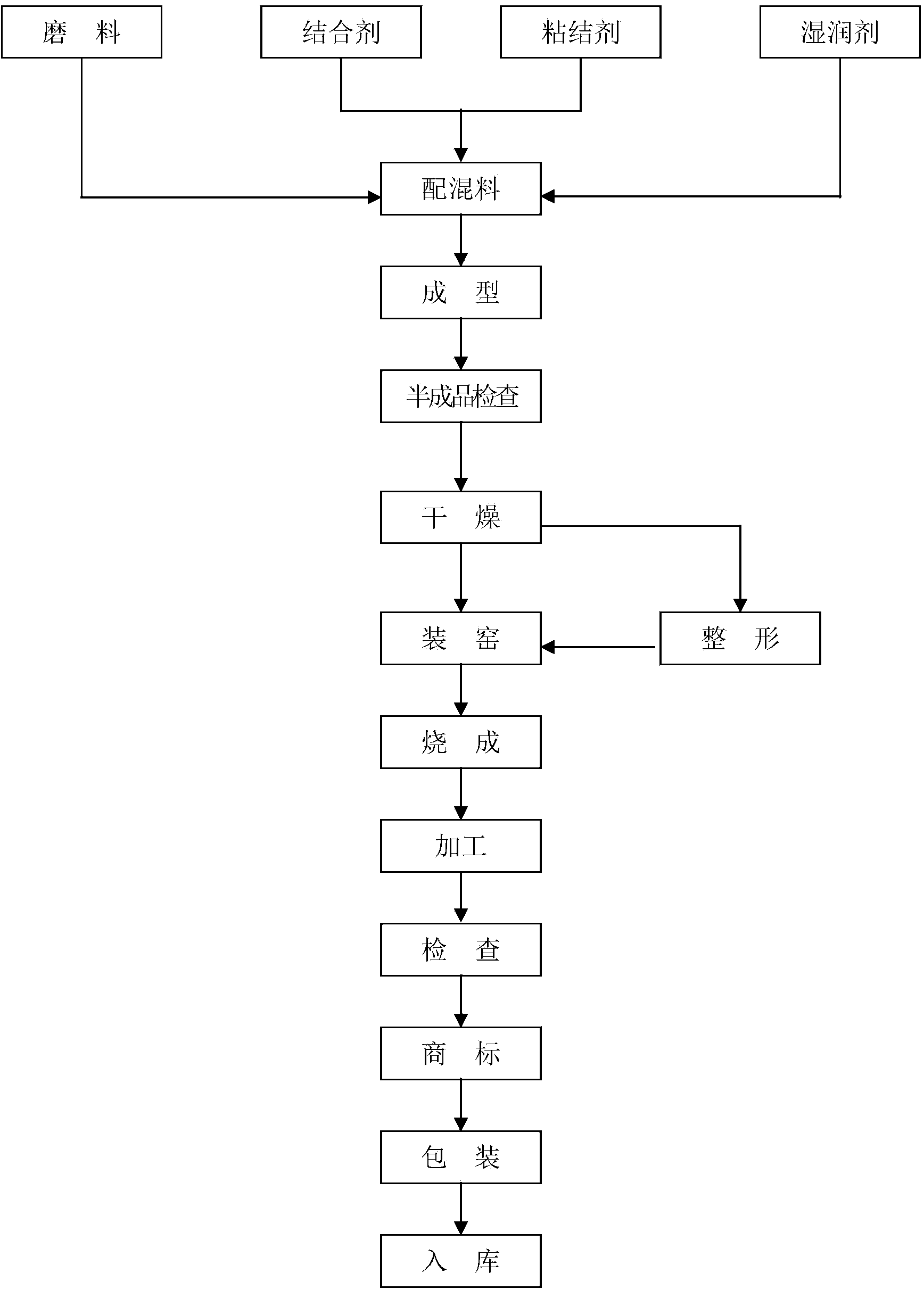

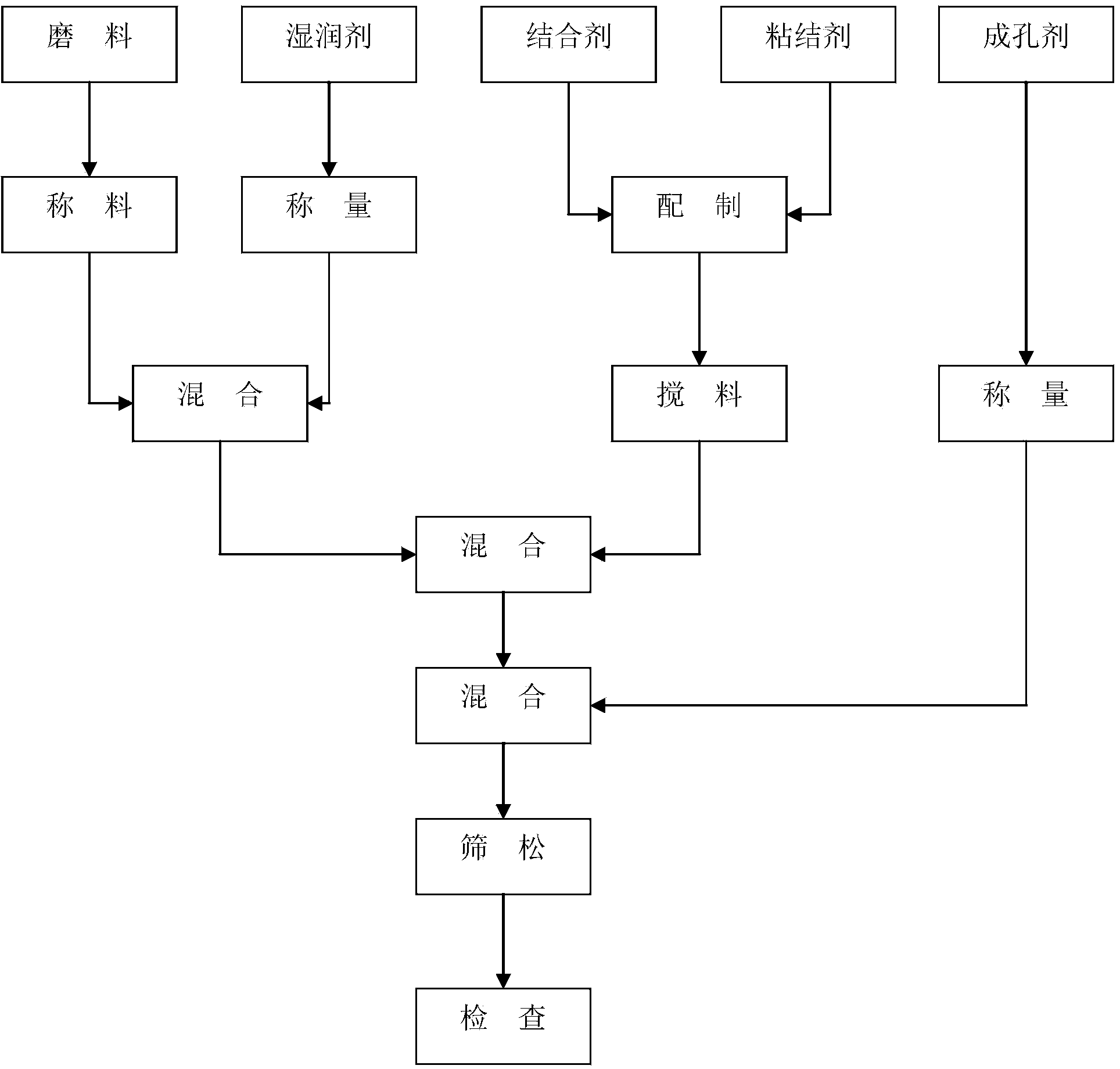

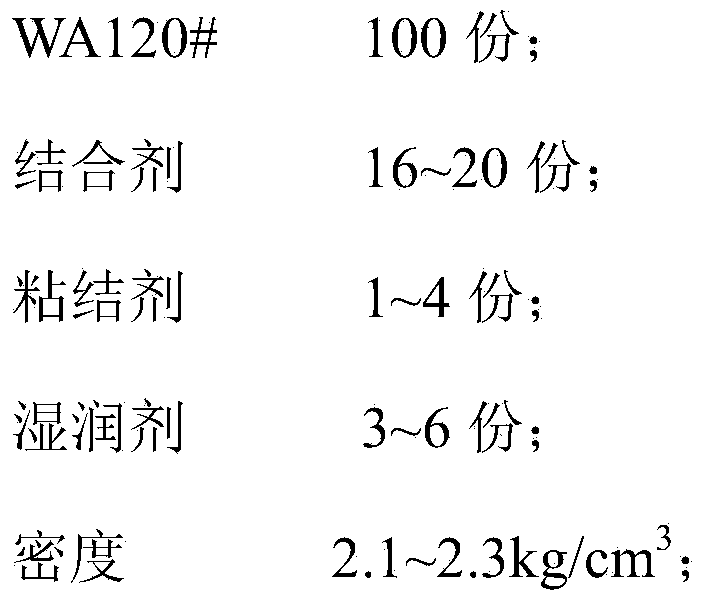

Blade part efficient and precise grinding microcrystal ceramic corundum grinding wheel and machining method thereof

InactiveCN104015131AIncreased durabilityExtended service lifeAbrasion apparatusGrinding devicesMaterials preparationAdhesive

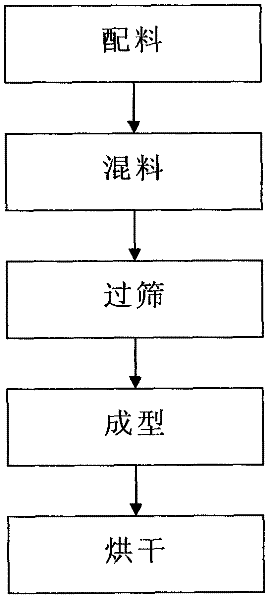

The invention particularly relates to a high-precision blade part efficient and precise grinding microcrystal ceramic corundum grinding wheel and a machining method of the grinding wheel. The grinding wheel comprises a non-grinding layer part and a grinding layer part, and is characterized in that the non-grinding layer part comprises 100 parts of WA No.120, 16-20 parts of binding agents, one to four parts of adhesives and three to six parts of wetting agents; the grinding layer part comprises 50 parts of CA No.60-120, 50 parts of WA No.60-120, 8-14 parts of bonding agents, one to four parts of wetting agents and 6-15 parts of pore-forming agents. The machining method of the grinding wheel is characterized by comprising the following steps of (1), material preparation and mixing, (2), forming, (3), drying and (4), firing. The grinding wheel has the advantages of having the deep cutting performance, large feeding performance, heavy load performance and efficient grinding performance, being high in durability, long in service life, good in self-sharpening performance, free of blocking, low in cost and good in grinding stability and the like.

Owner:LUXIN VENTURE CAPITAL GRP

Diamond grinding wheel for metal binding agent

The invention discloses a diamond grinding wheel for metal binding agent. The diamond grinding wheel for metal binding agent is characterized bu being made up of metal powder, copper-cerium alloys, pore-forming agents, TS-1 titanium silicalite molecular sieves and diamond composite abrasive grains; the metal powder is iron powder, copper powder, nickel powder and tin powder; the pore-forming agents can be PE / CeO2 / Cu compound; and the diamond composite abrasive grains are diamond / cerium oxide nuclear shell composite abrasive grains. According to the invention, the defects of poor self-sharpening property and low efficiency of the diamond grinding wheel for the metal binding agent are overcome; and the diamond grinding wheel for the metal binding agent has good mechanical property and self-sharpening property, and is high in holding force of diamond, good in molding property and long in service life.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com