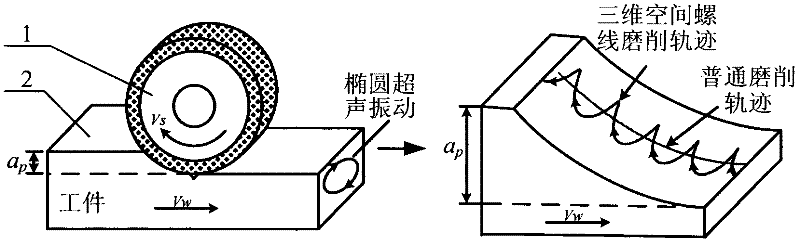

Three-dimensional spiral line grinding method through ultrasonic vibration

An ultrasonic vibration and two-dimensional ultrasonic vibration technology, applied in the field of high-efficiency precision machining, can solve the problems of increased surface roughness and increased grinding wheel wear, and achieve the effect of reducing roughness, increasing grinding depth and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

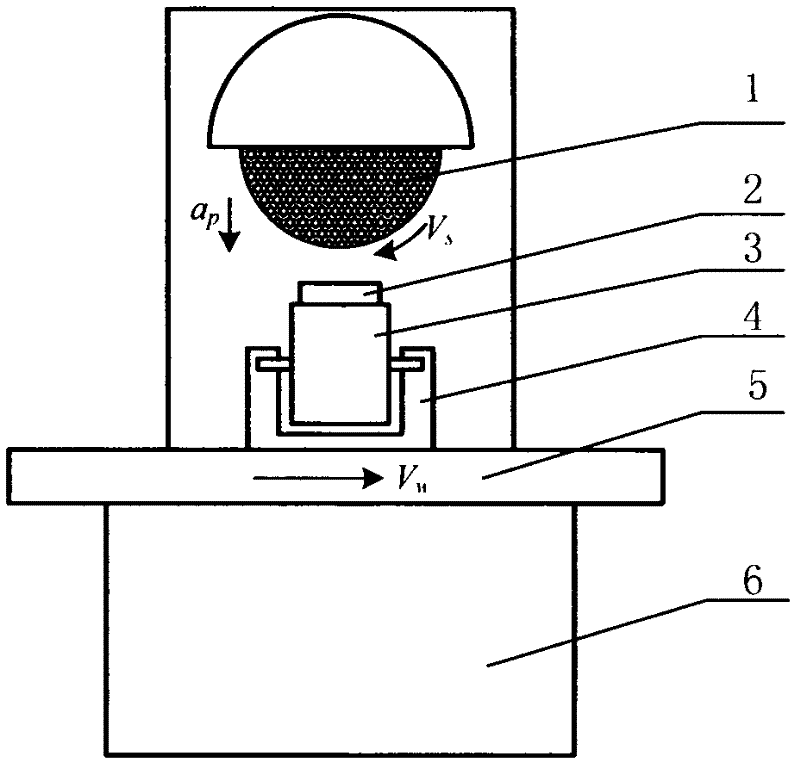

[0010] 1. Fix the workpiece 2 on the top surface of the elliptical ultrasonic vibrator 3 with paraffin, then clamp the elliptical ultrasonic vibrator 3 with the clamp 4, and fix it on the worktable 5 above the machine bed 6.

[0011] 2. Adjust the position of the elliptical ultrasonic vibrator 3 to ensure that its elliptical vibration plane is perpendicular to the direction of the grinding speed.

[0012] 3. Turn on the wave function generator to make it output two AC voltage signals with the same frequency and phase difference. After being amplified by the power amplifier, they are applied to the elliptical ultrasonic vibrator, and the stretching and bending vibration modes of the vibrator are simultaneously excited. At this time, the workpiece vibrates ultrasonically in an elliptical shape along with the elliptical ultrasonic vibrator 3 .

[0013] 4. Set the grinding wheel speed V s and the grinding depth a p , table feed speed V w and other processing parameters for grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com