Coal bed gas coke deoxidization technique

A technology of coalbed methane and coke, which is applied in the field of deoxidation process, can solve the problems of increased degree of methane cracking, incomplete coke combustion, waste of resources, etc., and achieve the effect of reducing the possibility of explosion, reducing methane cracking, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

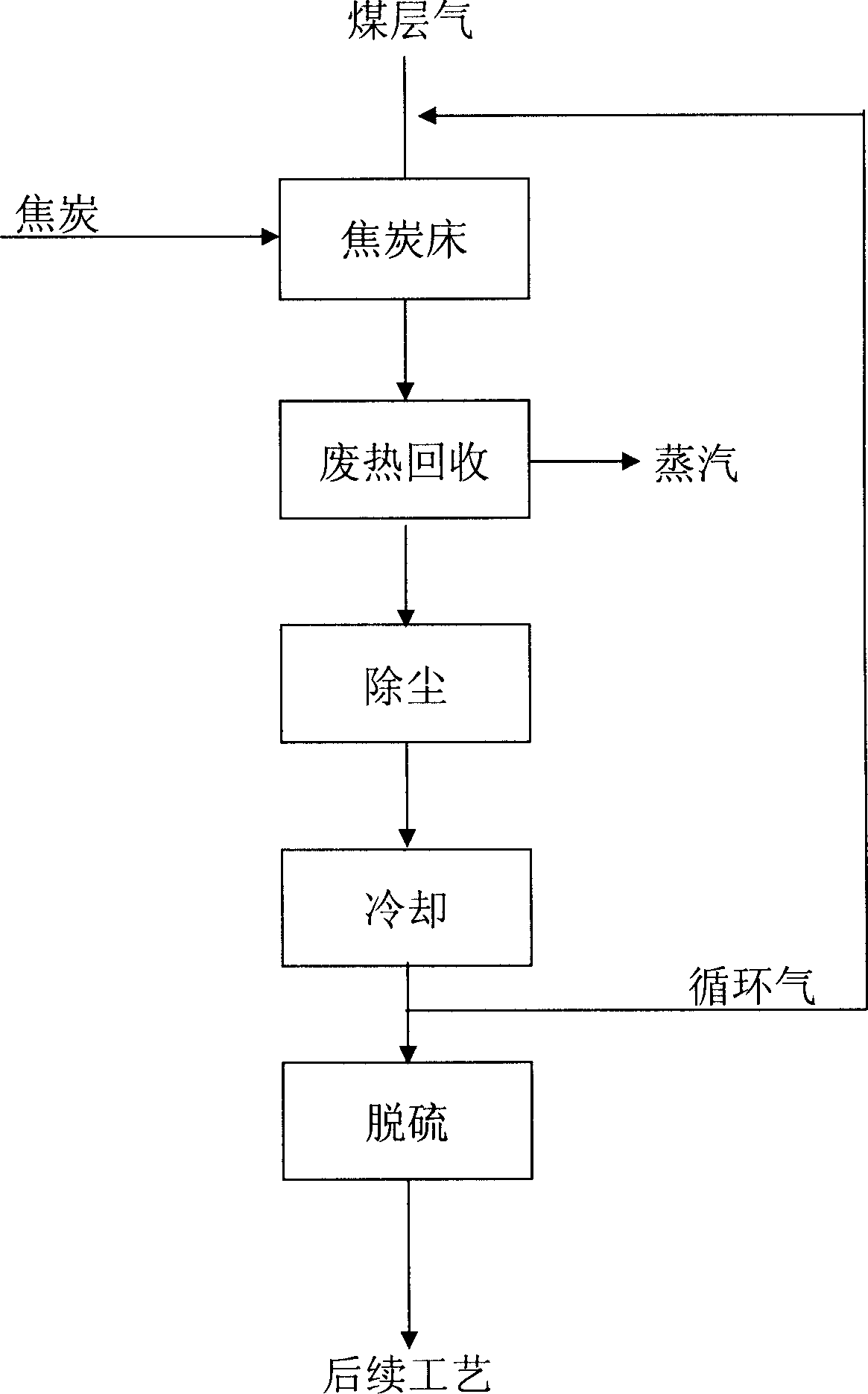

Image

Examples

Embodiment 1

[0023] The coalbed methane coke deoxidation process of this embodiment is as follows:

[0024] In a reactor with a diameter of 32mm, fill 200ml of metallurgical coke, under normal pressure, with 0.5M 3 The flow rate of / hr into the volume composition is O 2 10.5%, N 2 39.5%, CH 4 50% raw material coalbed methane, as the reaction continues, the reaction temperature can be raised to about 1008 ° C, the temperature is too high; through measurement, the composition of coalbed methane after deoxidation (volume percentage, dry basis) is: CH 4 42.98%, N 2 39.8%, O 2 0%, CO 2 5.10%, CO 6.52%, H 2 5.6%.

[0025] In this embodiment, there is no circulating part of the deoxidized and cooled CBM to the raw CBM before deoxidation, and the oxygen content in the raw CBM entering the deoxidation reactor is relatively high, which makes the temperature during the reaction higher than the ideal In the temperature range, the methane cracking loss is relatively large during the rea...

Embodiment 2

[0027] The coalbed methane coke deoxidation process of this embodiment is as follows:

[0028] In a reactor with a diameter of 32mm, fill 200ml of metallurgical coke, under normal pressure, with 0.5M 3 The flow rate of / hr is passed into the raw coalbed methane, and the oxygen content of the reaction gas entering the deoxygenation reactor is adjusted by circulating the partially deoxidized and cooled coalbed methane to the raw coalbed methane before deoxidation, so that the volume composition of each component in it is O 2 7.14%, N 2 26.86%, CH 4 66%, as the reaction continues, the reaction temperature can be controlled at about 780°C, which is an ideal reaction temperature; through measurement, the composition (volume percentage, dry basis) of coalbed methane after deoxidation is: CH 4 64.69%, N 2 26.86%, O 2 0%, CO 2 4.11%, CO 2.84%, H 2 1.5%.

Embodiment 3

[0030] The coalbed methane coke deoxidation process of this embodiment is as follows:

[0031] In a reactor with a diameter of 32mm, fill 200ml of metallurgical coke, under normal pressure, with 0.5M 3 The flow rate of / hr is passed into the raw coalbed methane, and the oxygen content of the reaction gas entering the deoxygenation reactor is adjusted by circulating the partially deoxidized and cooled coalbed methane to the raw coalbed methane before deoxidation, so that the volume composition of each component in it is O 2 6.3%, N 2 23.7%, CH 4 70%, as the reaction continues, the reaction temperature can be controlled at about 670°C, which is an ideal reaction temperature; through measurement, the composition (volume percentage, dry basis) of coalbed methane after deoxidation is: CH 4 68.25%, N 2 23.7%, O 2 0.46%, CO 2 5.08%, CO 1.93%, H 2 0.58%.

[0032] In Example 2 and Example 3, the oxygen content in the raw coal bed gas entering the deoxidation reactor is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com