Smelting method of ultra-low oxygen pure steel

A technology of ultra-low oxygen pure steel and smelting method, applied in the field of smelting, can solve the problems of low purity, channel segregation, large size, etc., and achieve the effect of simple operation process, less quantity, and less inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

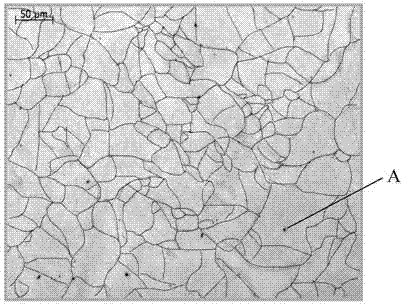

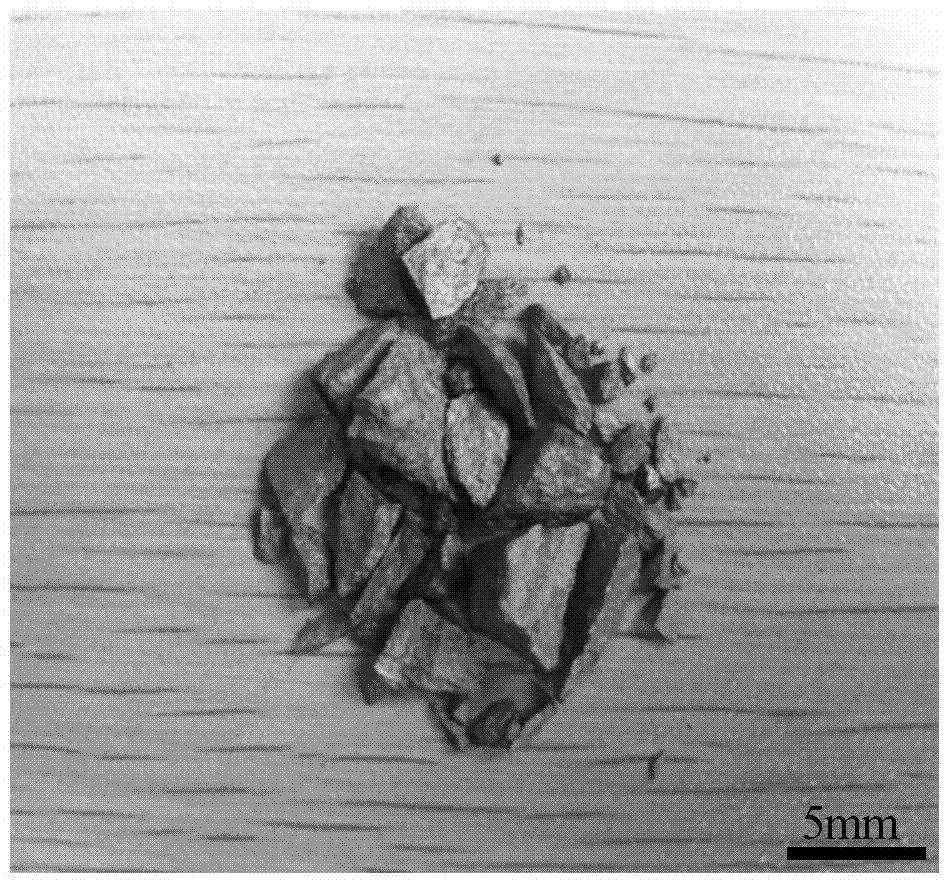

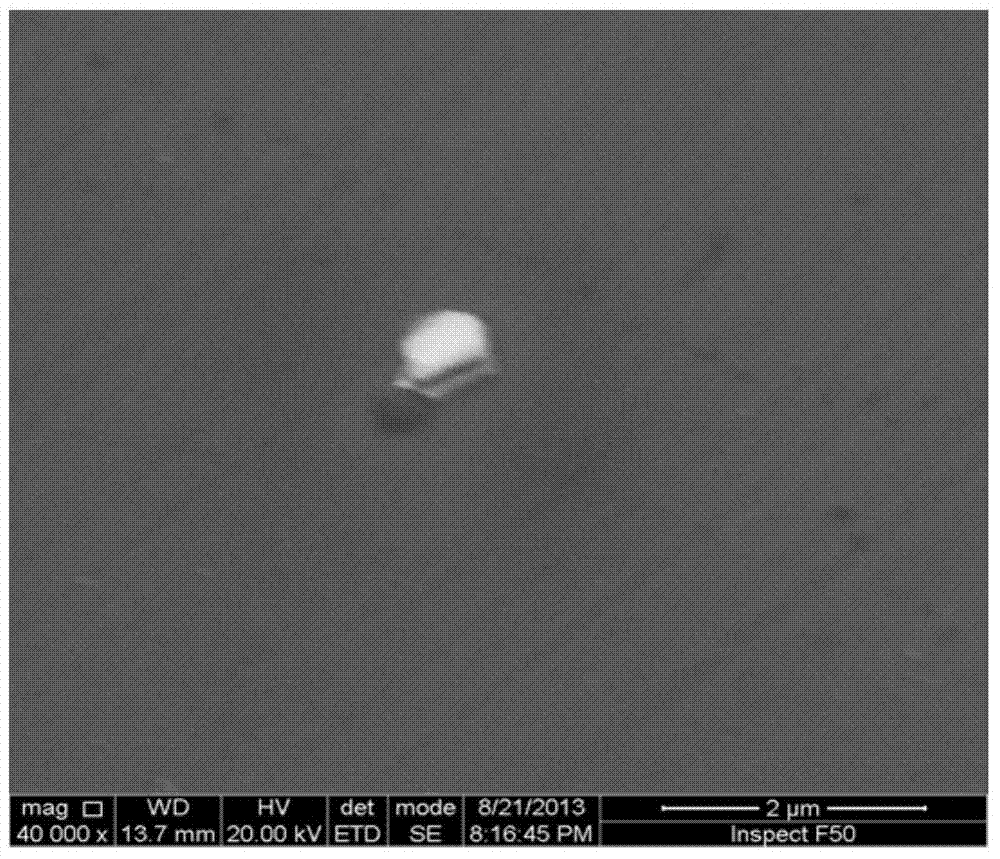

Embodiment 1

[0044] Pouring 50kg steel ingot, the steel ingot material is H13 steel. Vacuum induction furnace is used to smelt and ordinary alloy materials, and the size is 30-60mm. The induction furnace adopts a calcium oxide crucible. After the molten metal is melted, the distance between the molten metal surface and the furnace mouth is 260mm. The vacuum degree of the induction furnace in the smelting process is required to be 10Pa. After the metal material is melted, the molten metal is boiled for 25 minutes at a vacuum of 30 Pa and the temperature is 1540°C. The purpose is to use the reaction of carbon and oxygen under vacuum to form CO to reduce the inclusions in the molten metal. Through the first vacuum carbon-oxygen reaction Reduce the oxygen content to 15ppm without adding any deoxidizing agent or deoxidizing alloy. After standing still for 25 minutes, the molten metal was boiled for another 15 minutes at a vacuum degree of 40 Pa, in order to reduce the content of inclusions and...

Embodiment 2

[0051] Pouring 25kg steel ingot, the steel ingot material is H13 steel. Vacuum induction furnace is used to smelt and ordinary alloy materials, and the size is 20-60mm. The induction furnace adopts a calcium oxide crucible. After the molten metal is melted, the distance between the molten metal surface and the furnace mouth is 270mm. The vacuum degree of the induction furnace in the smelting process is required to be 20Pa. After the metal material is melted, the molten metal is boiled for 20 minutes under a vacuum of 20 Pa, and the temperature is 1550°C. The purpose is to use the reaction of carbon and oxygen under vacuum to form CO to reduce the inclusions in the molten metal. Through the first vacuum carbon-oxygen reaction Reduce the oxygen content to 18ppm without adding any deoxidizing agent or deoxidizing alloy. After standing still for 30 minutes, the molten metal was boiled for another 20 minutes under a vacuum degree of 30 Pa. The purpose was to reduce the content of ...

Embodiment 3

[0053] Pouring 500kg steel ingot, the material of the steel ingot is No. 45 steel. Vacuum induction furnace is used to smelt and ordinary alloy materials, and the size is 40×60×300mm. The induction furnace adopts a magnesia crucible. After the molten metal is melted, the distance between the molten metal surface and the furnace mouth is 320mm, and the vacuum degree of the induction furnace in the smelting process is required to be 25Pa. After the metal material is melted, the molten metal is boiled for 30 minutes under a vacuum of 25 Pa, and the temperature is 1560°C. The purpose is to use the reaction of carbon and oxygen under vacuum to form CO to reduce the inclusions in the molten metal. Through the first vacuum carbon-oxygen reaction Reduce the oxygen content to 14ppm without adding any deoxidizing agent or deoxidizing alloy. After standing still for 20 minutes, the molten metal was boiled for another 20 minutes under a vacuum degree of 35 Pa, the purpose is to reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com