Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193 results about "Screening procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

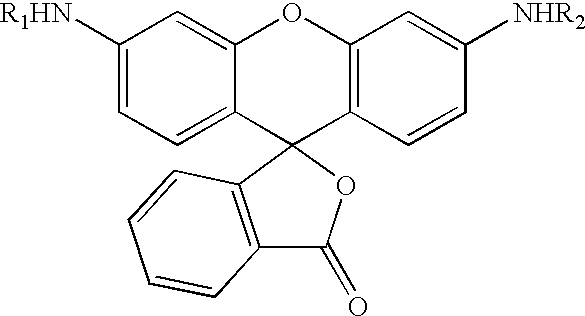

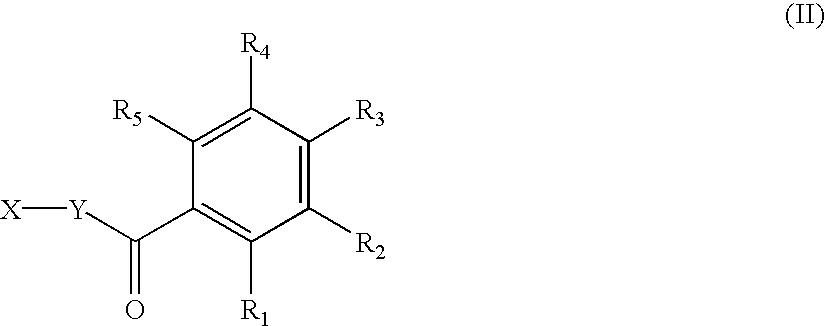

Fluorogenic or fluorescent reporter molecules and their applications for whole-cell fluorescence screening assays for caspases and other enzymes and the use thereof

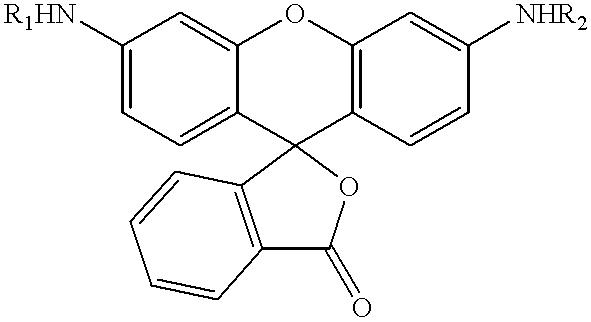

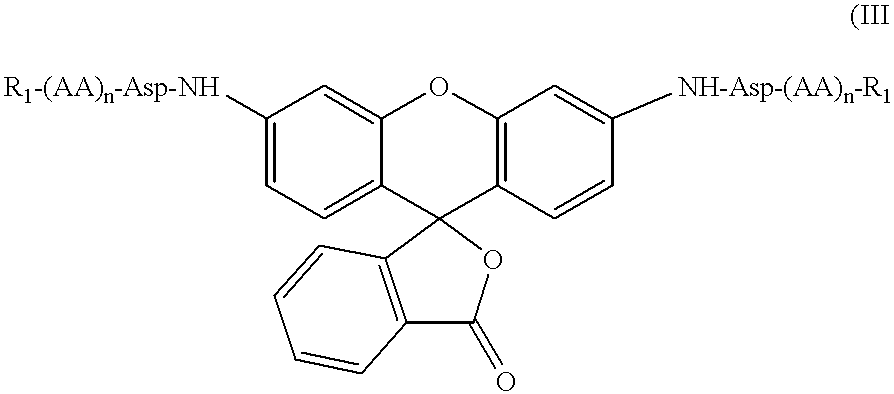

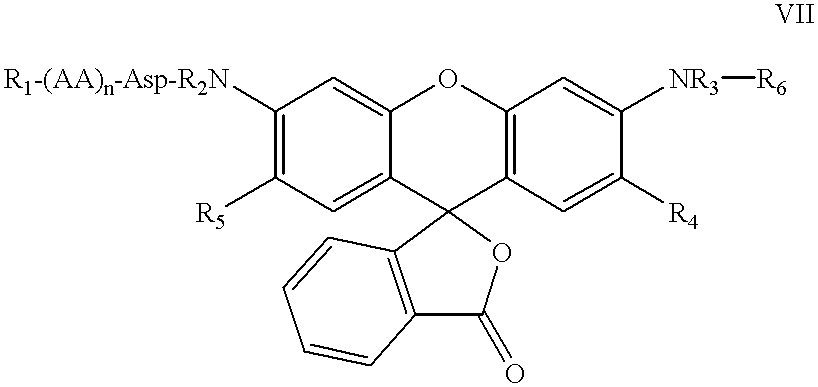

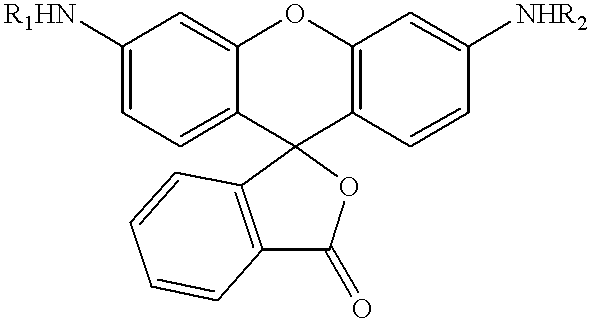

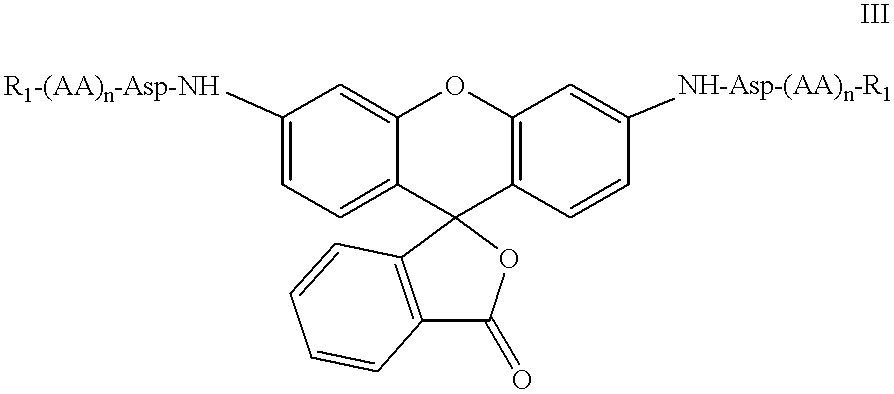

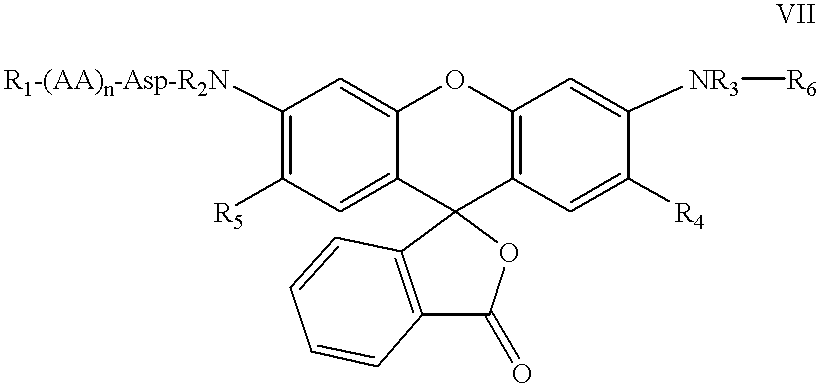

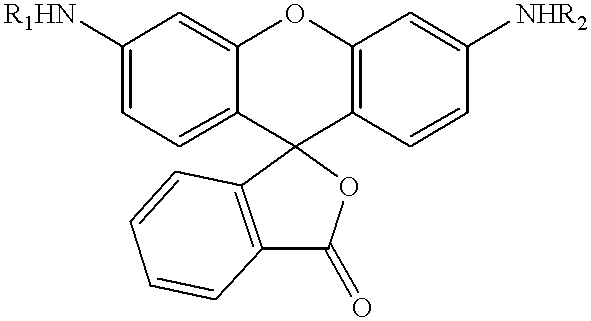

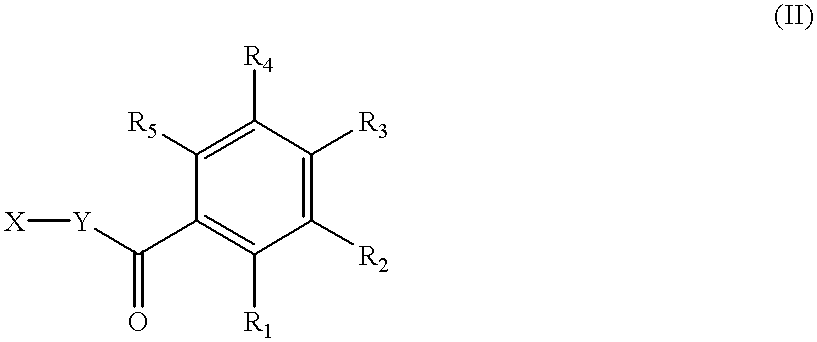

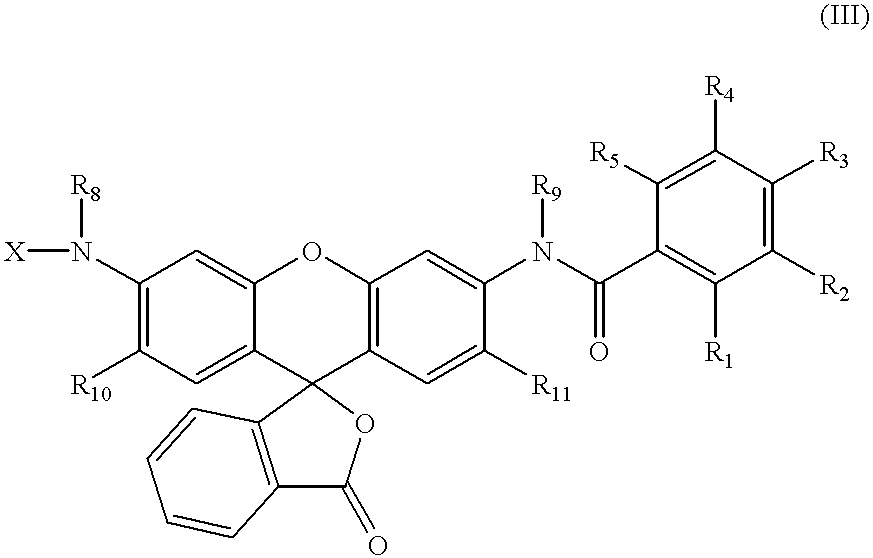

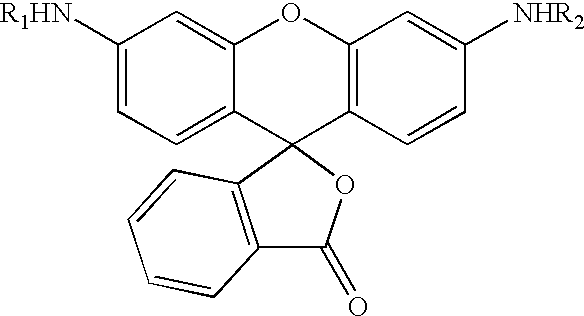

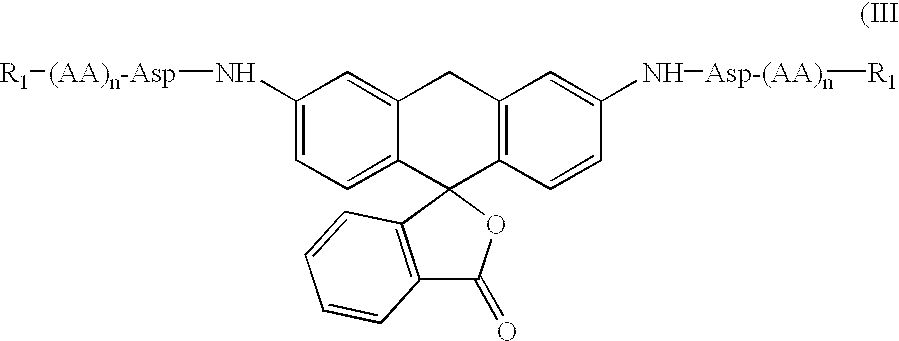

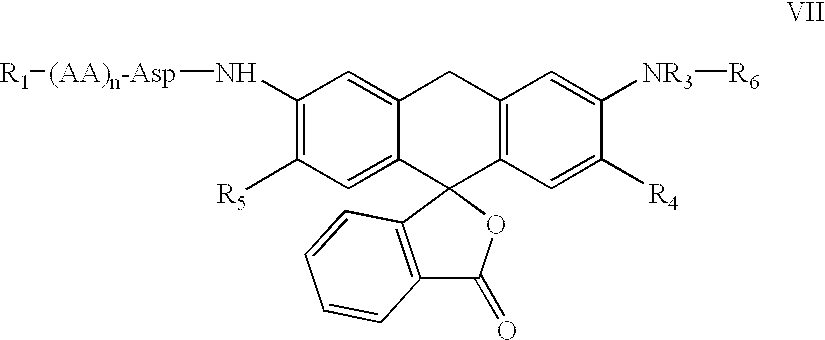

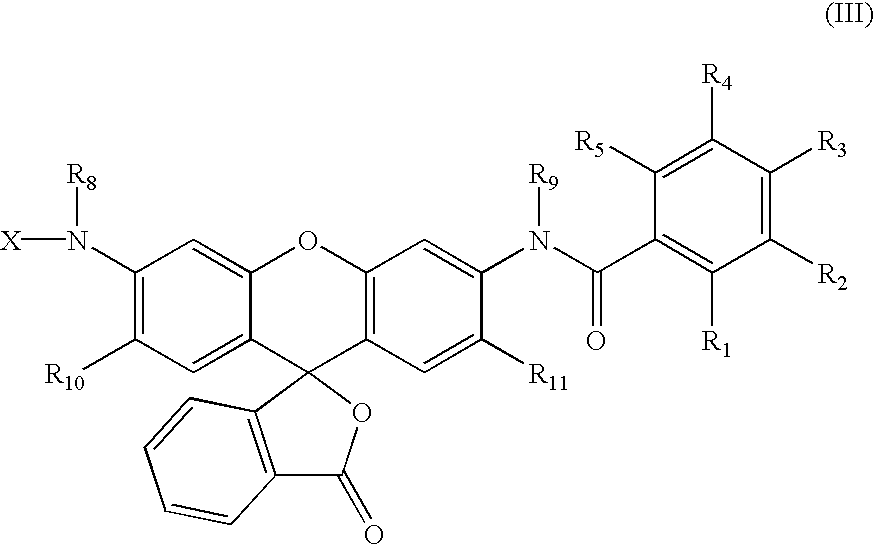

The present invention relates to novel fluorescent dyes, novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of caspases and other enzymes involved in apoptosis in whole cells, cell lines and tissue samples derived from any living organism or organ. The reporter molecules and assay processes can be used in drug screening procedures to identify compounds which act as inhibitors or inducers of the caspase cascade in whole cells or tissues. The reagents and assays described herein are also useful for determining the chemosensitivity of human cancer cells to treatment with chemotherapeutic drugs. The present invention also relates to novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of type 2 methionine aminopeptidase, dipeptidyl peptidase IV, calpain, aminopeptidase, HIV protease, adenovirus protease, HSV-1 protease, HCMV protease and HCV protease.

Owner:CYTOVIA INC

Fluorogenic or fluorescent reporter molecules and their applications for whole-cell fluorescence screening assays for capsases and other enzymes and the use thereof

InactiveUS6342611B1Organic chemistryMicrobiological testing/measurementScreening proceduresApoptosis

The present invention relates to novel fluorescent dyes, novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of caspases and other enzymes involved in apoptosis in whole cells, cell lines and tissue samples derived from any living organism or organ. The reporter molecules and assay processes can be used in drug screening procedures to identify compounds which act as inhibitors or inducers of the caspase cascade in whole cells or tissues. The reagents and assays described herein are also useful for determining the chemosensitivity of human cancer cells to treatment with chemotherapeutic drugs. The present invention also relates to novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of type 2 methionine aminopeptidase, dipeptidyl peptidase IV, calpain, aminopeptidase, HIV protease, adenovirus protease, HSV-1 protease, HCMV protease and HCV protease.

Owner:CYTOVIA INC

Fluorescence dyes and their applications for whole-cell fluorescence screening assays for caspases, peptidases, proteases and other enzymes and the use thereof

InactiveUS6248904B1Microbiological testing/measurementBiological testingScreening proceduresCancer cell

The present invention relates to novel fluorescent dyes, novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of caspases and other enzymes involved in apoptosis in whole cells, cell lines and tissue samples derived from any living organism or organ. The reporter molecules and assay processes can be used in drug screening procedures to identify compounds which act as inhibitors or inducers of the caspase cascade in whole cells or tissues. The reagents and assays described herein are also useful for determining the chemosensitivity of human cancer cells to treatment with chemotherapeutic drugs. The present invention also relates to novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of type 2 methionine aminopeptidase, HIV protease, adenovirus protease, HSV-1 protease, HCMV protease and HCV protease.

Owner:CYTOVIA INC

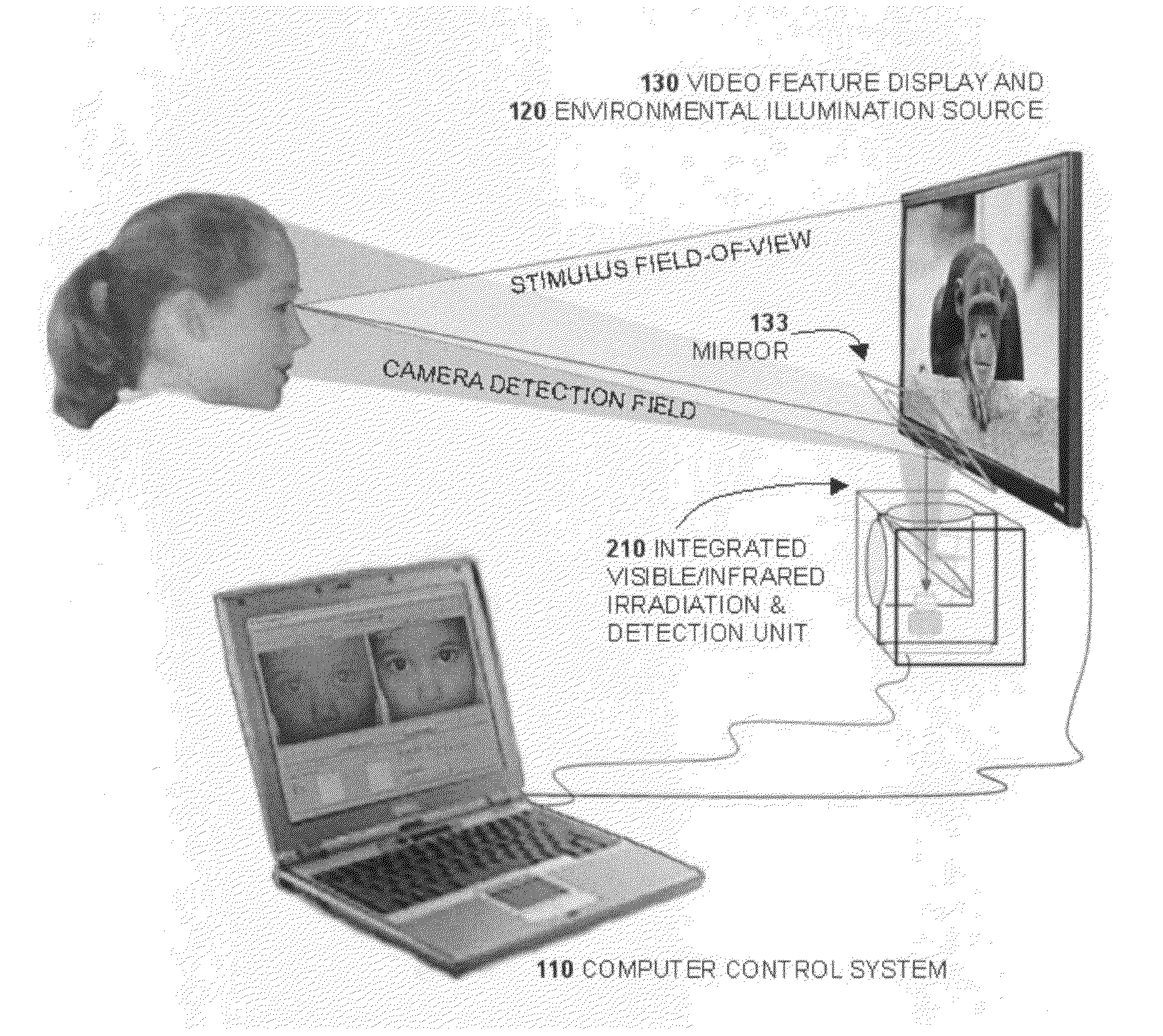

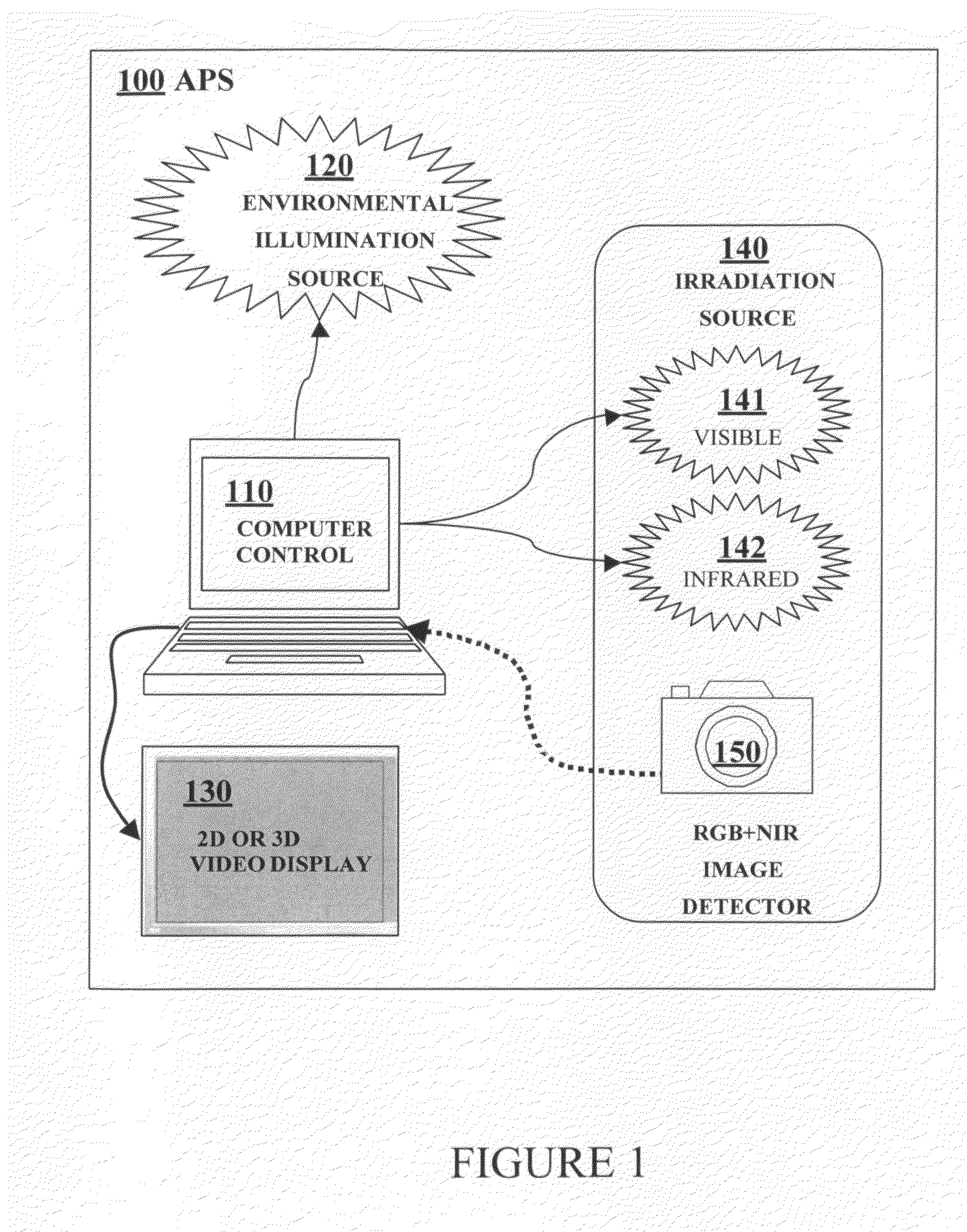

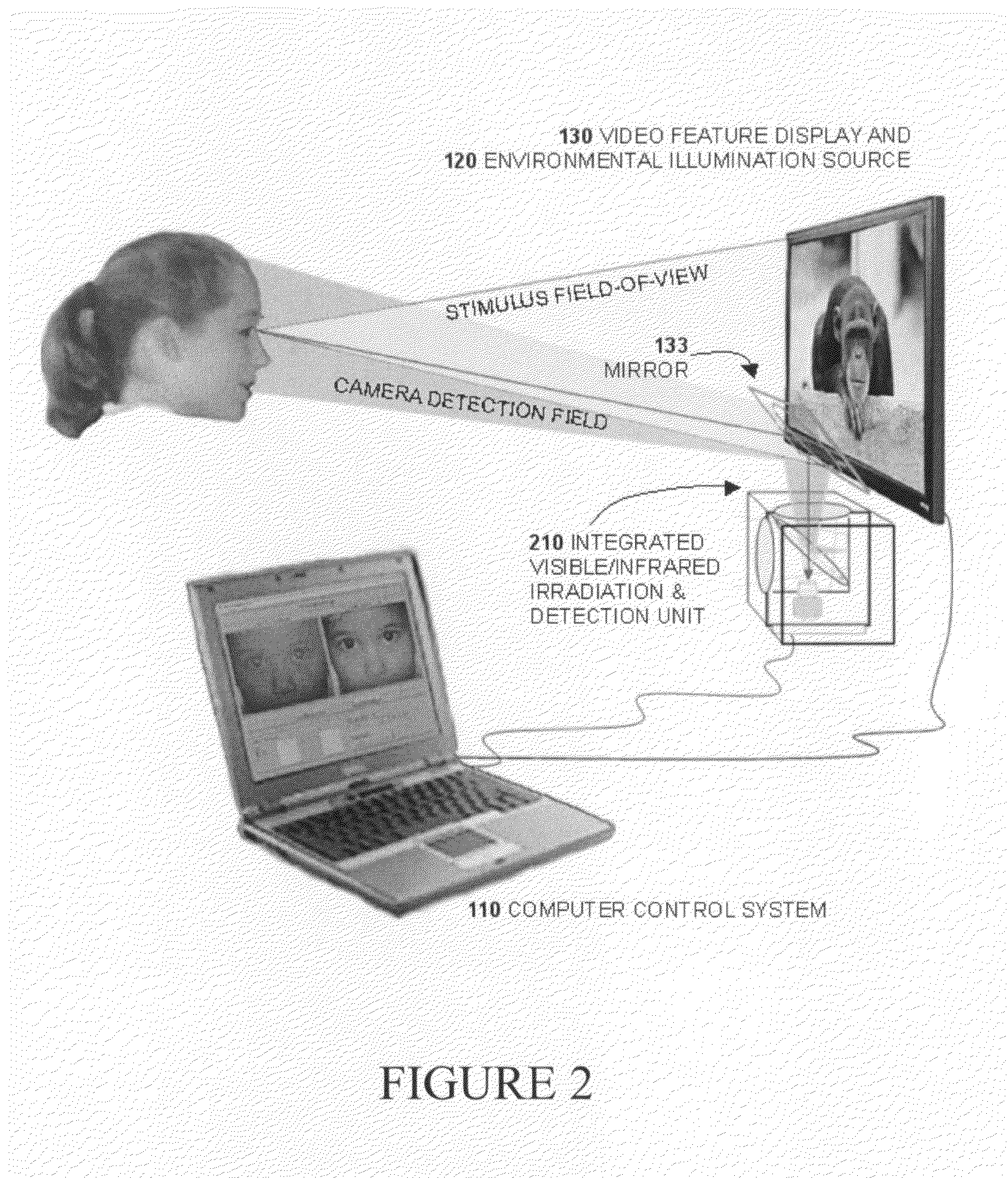

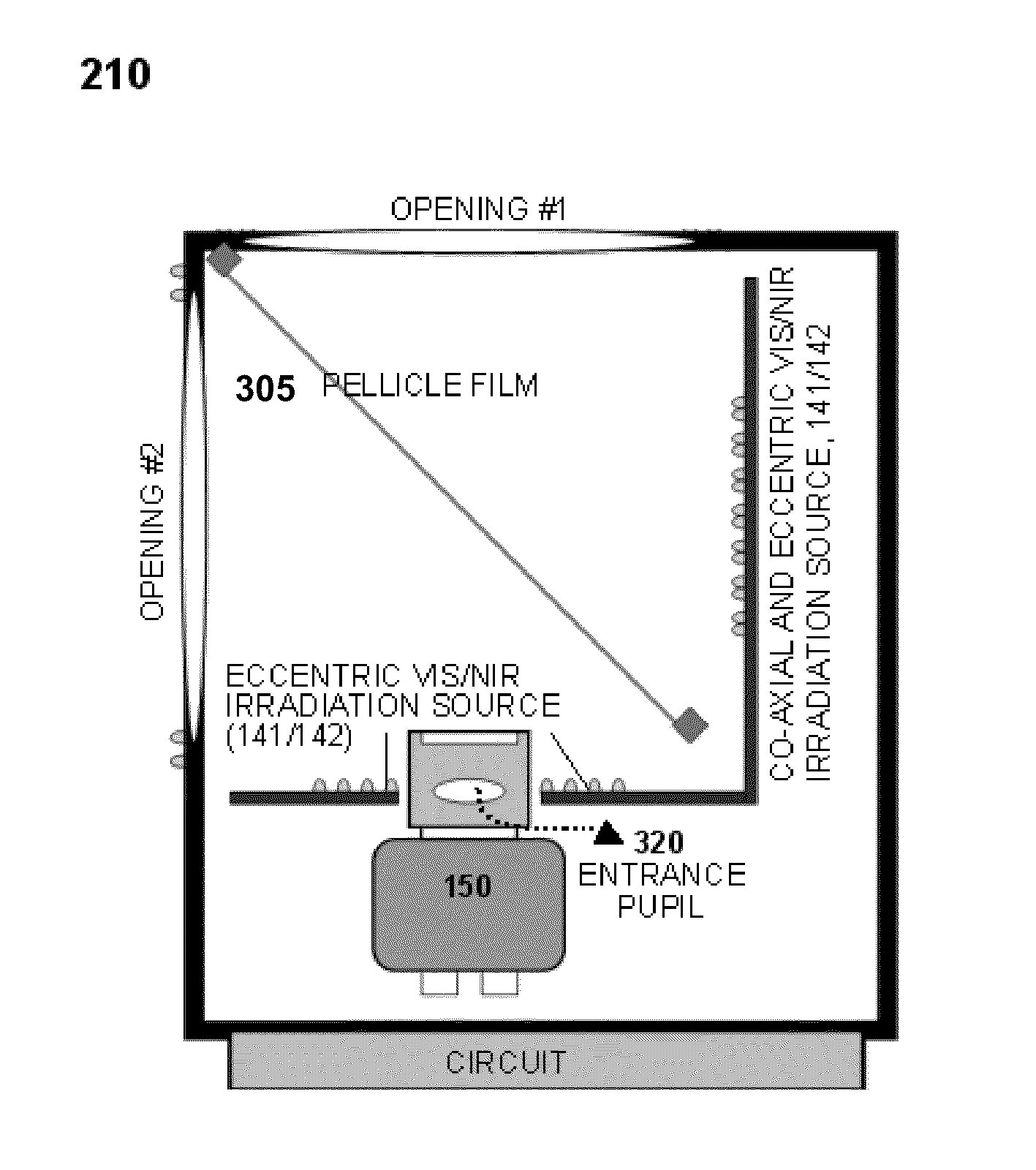

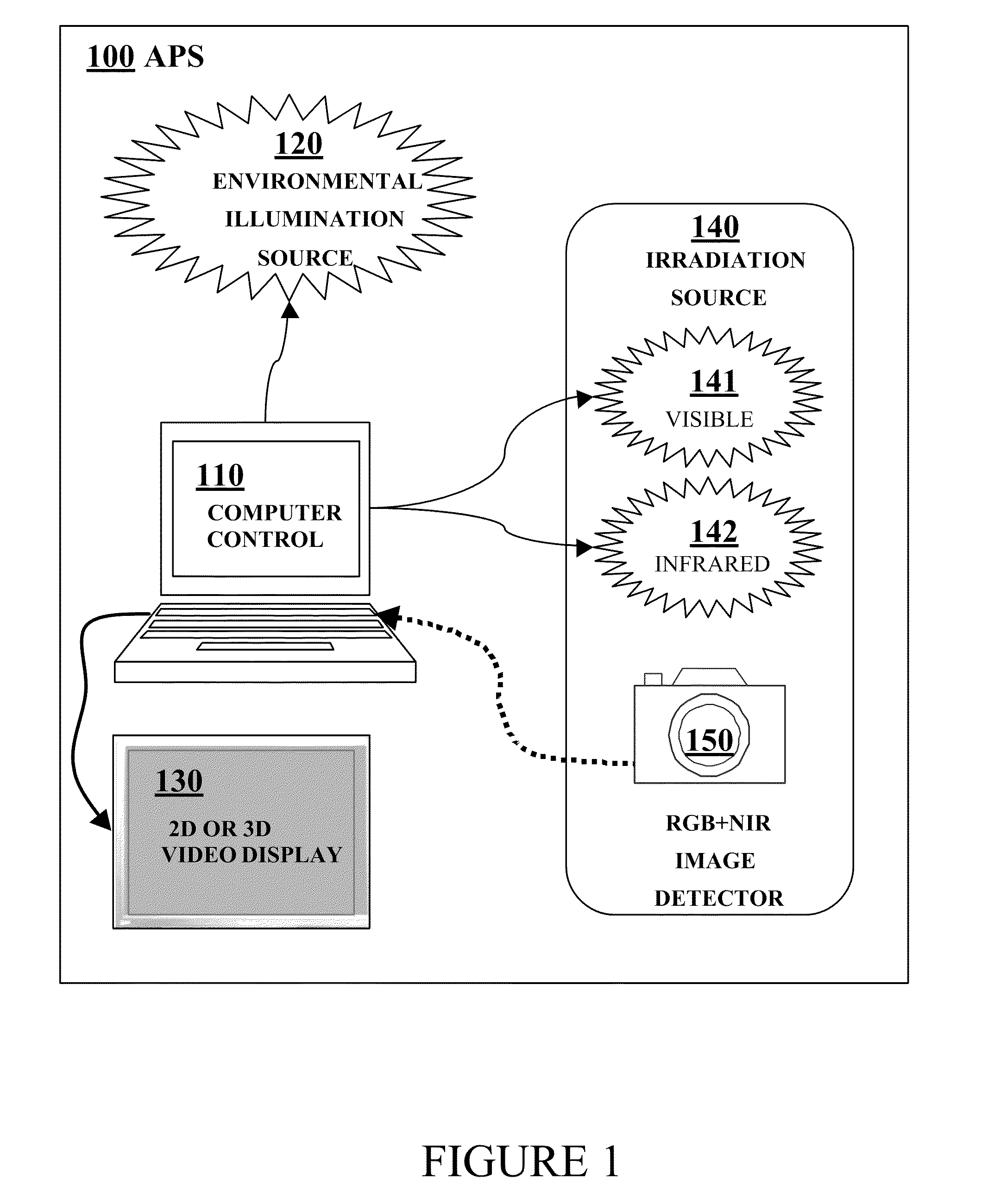

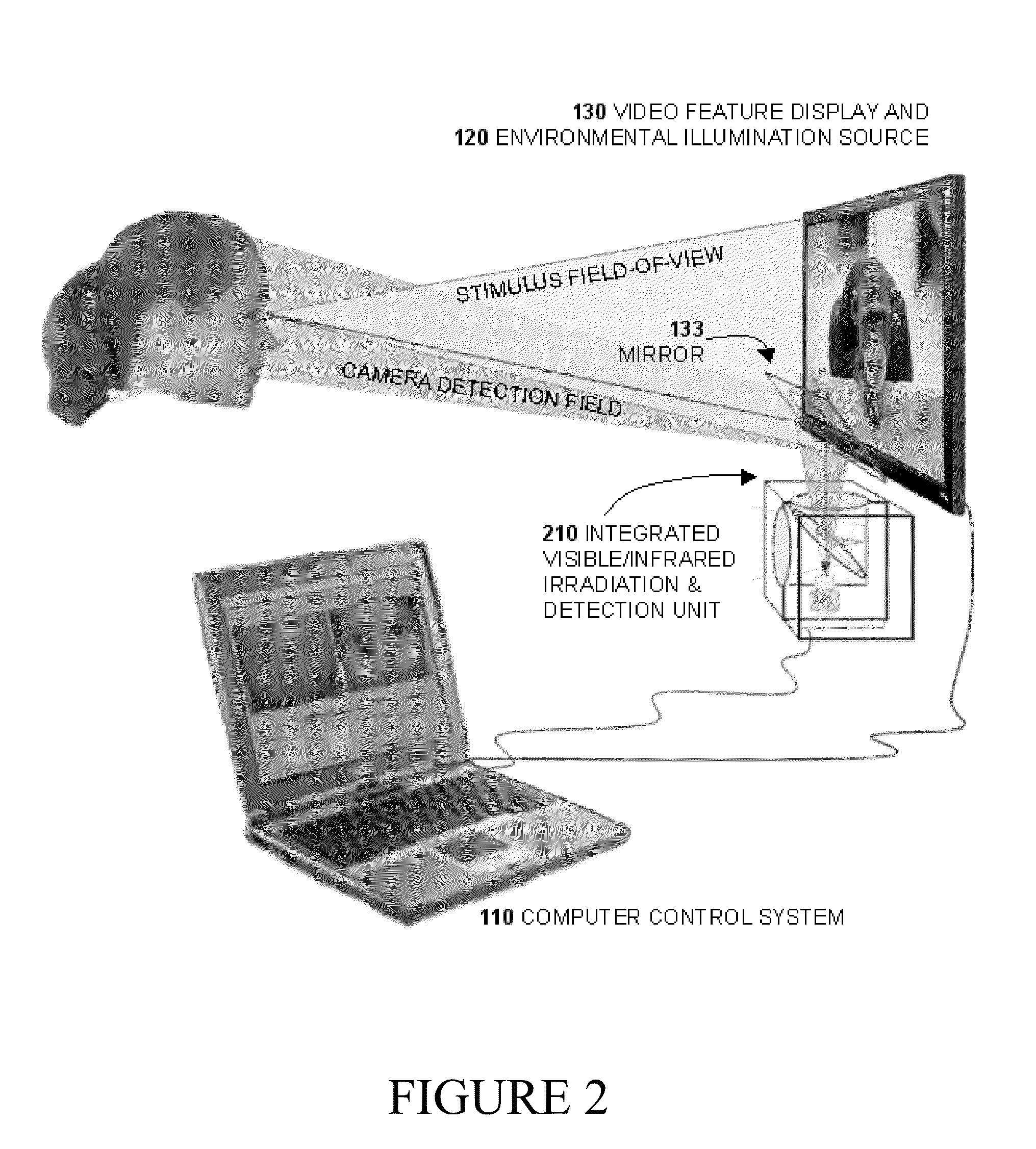

Adaptive photoscreening system

Briefly described, one embodiment of the system, among others, can be implemented as follows. The system includes a computer control system and an environmental light source that is controlled by the computer control system such that an amount of light provided by the environmental light source is adjusted by the computer control so that ocular parameters of an examinee are within a targeted range. Further, the system includes an irradiation system that provides multiple angle and axial eccentricity illuminations and selective wavelength irradiation based upon instructions received from the computer control system, wherein the computer control system instructs the irradiation system to provide different irradiation characteristics for different screening procedures. Also, the system includes an image detection system that captures ocular images of the examinee, wherein the computer control system analyzes captured images and provides results of in-situ analysis. Other systems and methods are also provided.

Owner:UNIV OF TENNESSEE RES FOUND

Adaptive Photoscreening System

InactiveUS20110157550A1Neutralize shiftRefractometersSkiascopesScreening proceduresSpecific population

Briefly described, one embodiment of the system, among others, can be implemented as follows. The system includes a computer control system and an environmental light source that is controlled by the computer control system such that an amount of light provided by the environmental light source is adjusted by the computer control so that ocular parameters of an examinee are within a targeted range. Further, the system includes an irradiation system that provides multiple angle and axial eccentricity illuminations and selective wavelength irradiation based upon instructions received from the computer control system, wherein the computer control system instructs the irradiation system to provide different irradiation characteristics for different screening procedures. Also, the system includes an image detection system that captures ocular images of the examinee, wherein the computer control system analyzes captured images and provides results of in-situ analysis. The system can further include a device, for example a lens or lens system, positioned in the system to be between the eye of the examinee and the image detection system during photoscreening for shifting the neutralization of the system to a desired region for a specific population of examinees. Other systems and methods are also provided.

Owner:UNIV OF TENNESSEE RES FOUND

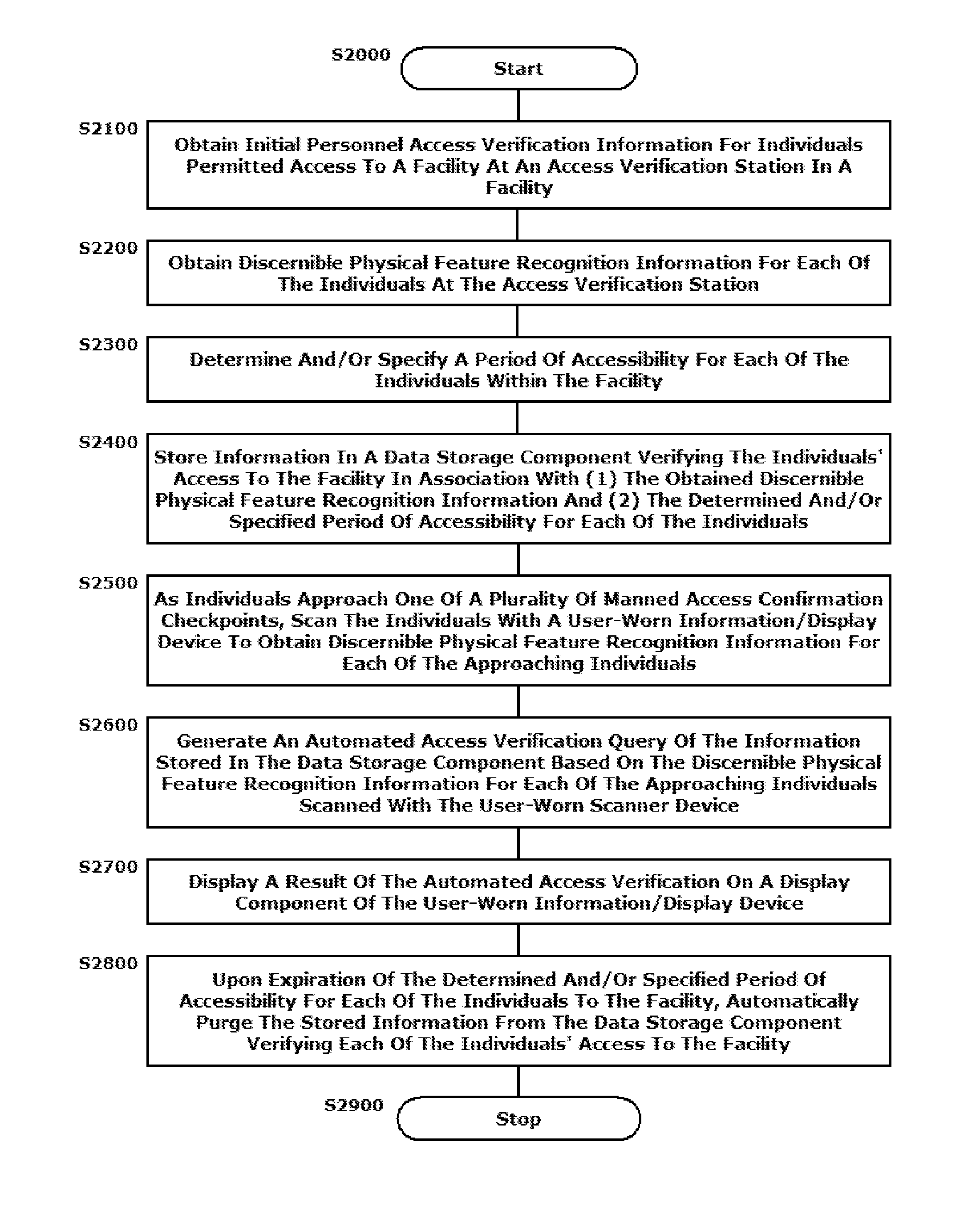

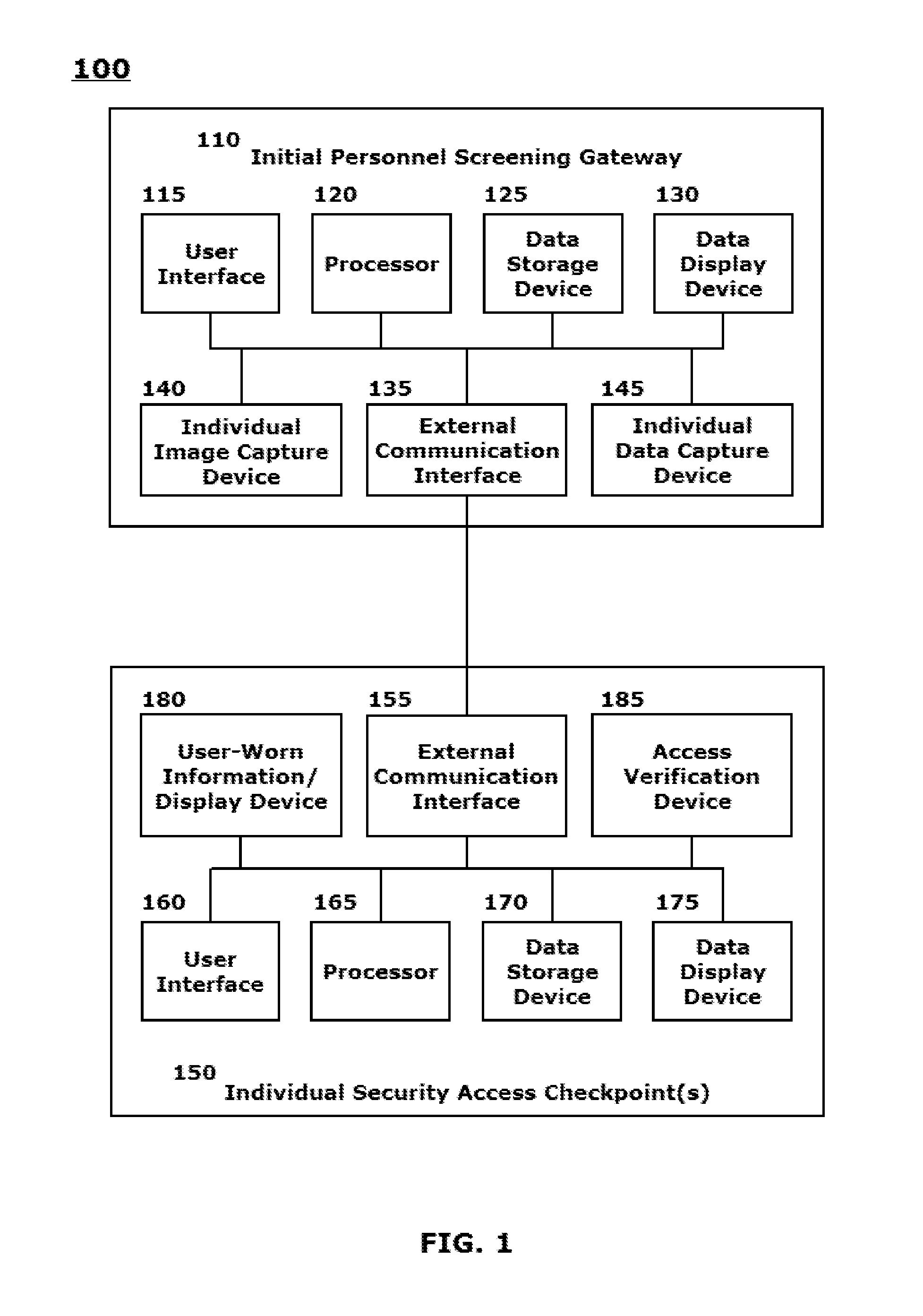

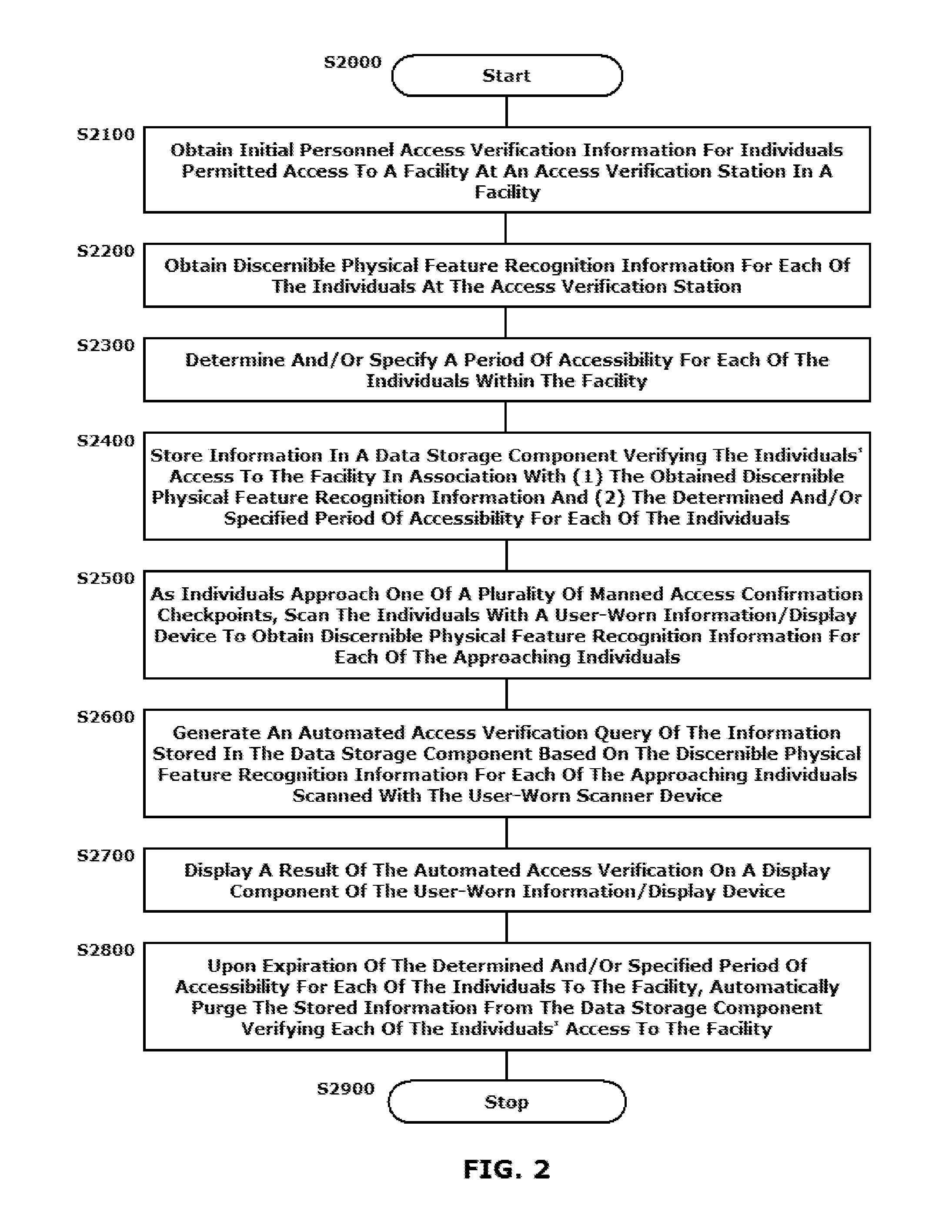

Image capture and individual verification security system integrating user-worn display components and communication technologies

ActiveUS9245175B1Improve securityReduce morbidityProgramme controlComputer controlScreening proceduresHuman interaction

A system and method are provided for integrating user-worn display components and communication technologies into image capture and individual verification security systems. User-worn input / output (I / O) devices are employed to streamline the security screening procedures that continue to require human interaction for visual identification of participating individuals entering secure areas, particularly in large numbers. Individual access credentials and / or permissions are verified for individuals initially upon entry within the facility, and discernible physical feature recognition information, including facial recognition information, to be associated with the access verification for the individuals is collected. The user-worn I / O devices are used by security and screening personnel to observe discernible physical features of individuals presenting themselves at one or more internal security or limited access checkpoints and to initiate comparison analysis of the observed discernible physical features with stored discernible physical feature recognition information to expedite clearance and / or verification procedures.

Owner:ROCKWELL COLLINS INC

Preparation method of aroma rapeseed oil

ActiveCN102936531AStrong fragranceRetain nutrientsFatty-oils/fats refiningFatty-oils/fats productionScreening proceduresAdditive ingredient

The invention discloses a preparation method of aroma rapeseed oil, wherein the preparation method comprises the following main procedures: selecting rapeseeds, removing impurities, and removing macadam and clods, wherein the impurity content is smaller than 0.1% and the rapeseed content in the screen underflow is smaller than 0.5% after the screening procedure; frying the rapeseeds at 140-145 DEG C; squeezing the rapeseeds through a squeezer and controlling the thickness of an oil cake to be smaller than 1.5mm to obtain crude oil; primarily deslagging the squeezed crude oil through an oil clarifying box, and pumping the crude oil in a blade filter to be filtered, wherein the insoluble impurity in the filtered crude oil is smaller than 0.2%; obtaining clean crude oil, controlling the operation temperature at 65-70 DEG C and controlling the water temperature at 70-75 DEG C to perform hydration degumming; washing the clean crude oil twice by virtue of softened water, drying and dewatering at vapor pressure of 4-5 Mpa; stirring the clean crude oil at a rotating speed of 30 r / min (revolutions per minute), and cooling until the oil temperature is lower than 80 DEG C; and filtering the clean crude oil in a frame filter to obtain the aroma rapeseed oil. The prepared rapeseed oil generates full-bodied fragrance, and the nutrition ingredients and physiological active ingredients in the rapeseed oil are kept to the maximum.

Owner:YUNNAN ZHENWEI GREASE

Novel fluorogenic or fluorescent reporter molecules and their applications for whole-cell fluorescence screening assays for caspases and other enzymes and the use thereof

InactiveUS20020150885A1Microbiological testing/measurementChemiluminescene/bioluminescenceScreening proceduresApoptosis

The present invention relates to novel fluorescent dyes, novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of caspases and other enzymes involved in apoptosis in whole cells, cell lines and tissue samples derived from any living organism or organ. The reporter molecules and assay processes can be used in drug screening procedures to identify compounds which act as inhibitors or inducers of the caspase cascade in whole cells or tissues. The reagents and assays described herein are also useful for determining the chemosensitivity of human cancer cells to treatment with chemotherapeutic drugs. The present invention also relates to novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of type 2 methionine aminopeptidase, dipeptidyl peptidase IV, calpain, aminopeptidase, HIV protease, adenovirus protease, HSV-1 protease, HCMV protease and HCV protease.

Owner:CYTOVIA INC

Production method of low melting point spherical metal powder

A production method of low melting point spherical metal powder comprises the following working procedures: melting low melting point metal or alloy, mixing with hot oil, performing primary dispersion under pressure and inert gas, performing high-power ultrasonic dispersion and emulsification, performing filtering separation, etc. The production method of low melting point spherical metal powder is characterized by high production efficiency, narrow particle size distribution of the product, low oxygen content and no screening procedure. The method is suitable for the productions of the low melting point metal and alloy powder thereof of which liquid-phase temperatures are less than 300 DEG C, such as Pb-based alloy, Sn-based alloy, Sn-Zn based alloy or non-ferrous metals such as Bi, In and the like.

Owner:SHENZHEN FITECH

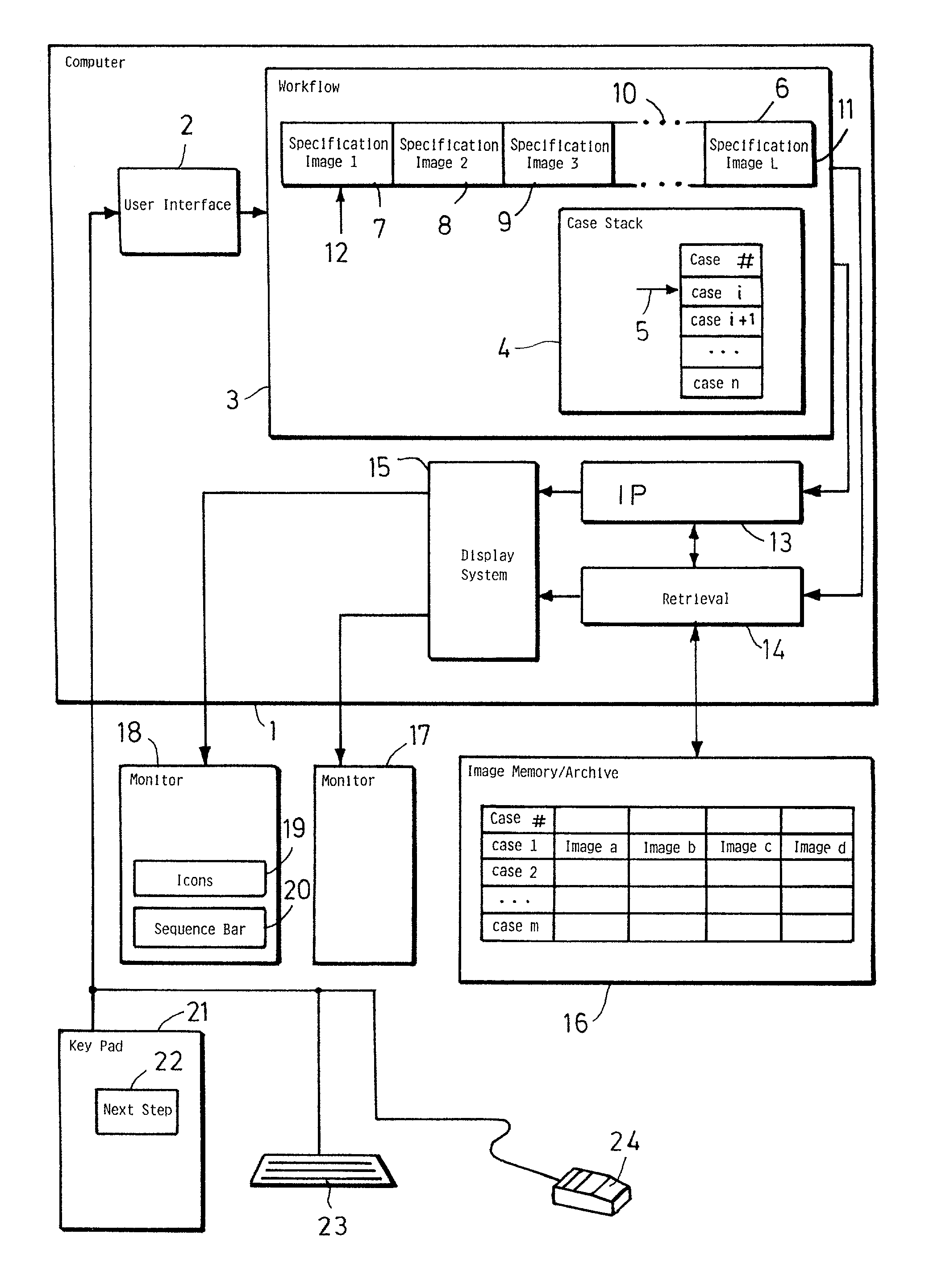

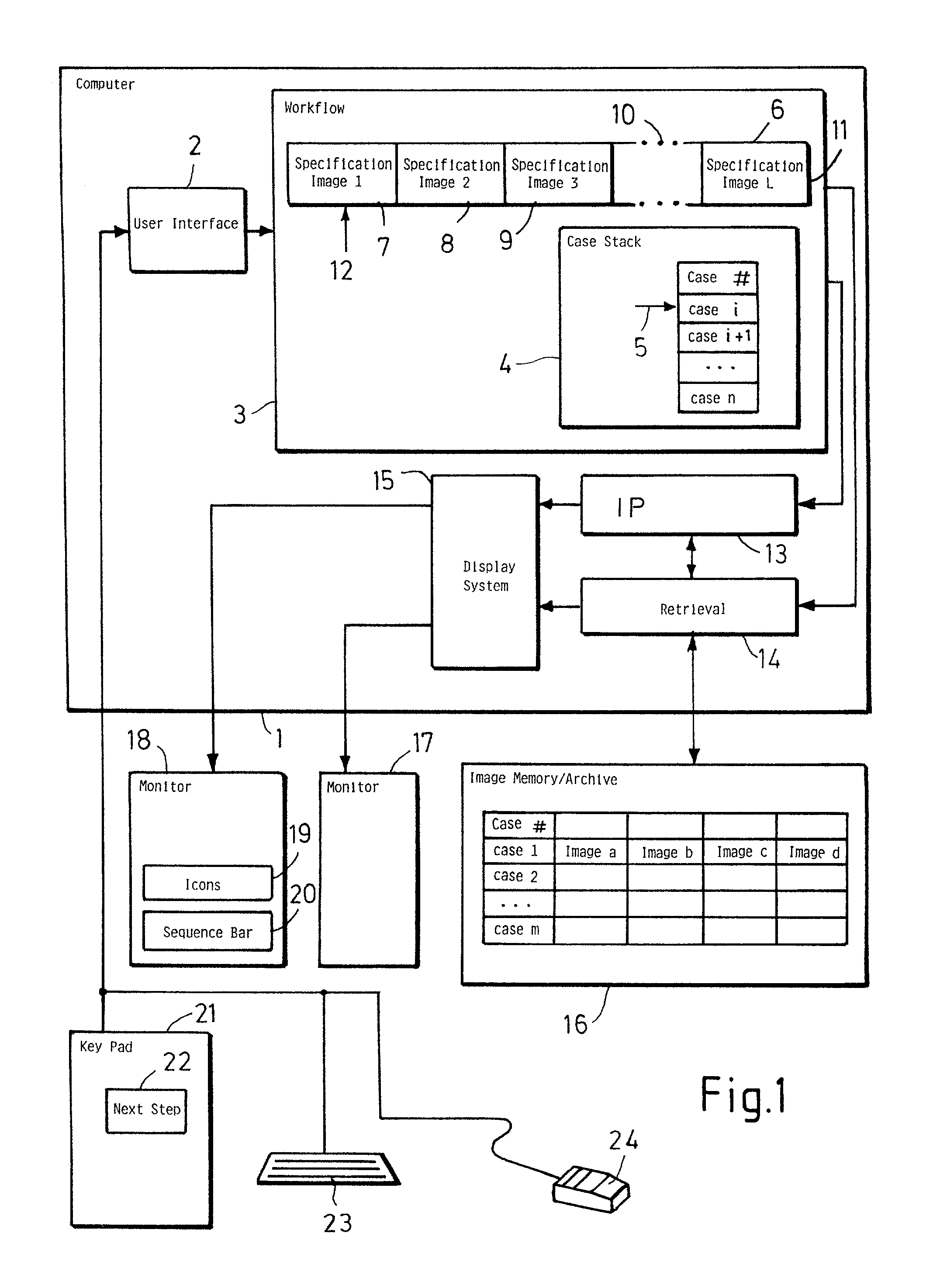

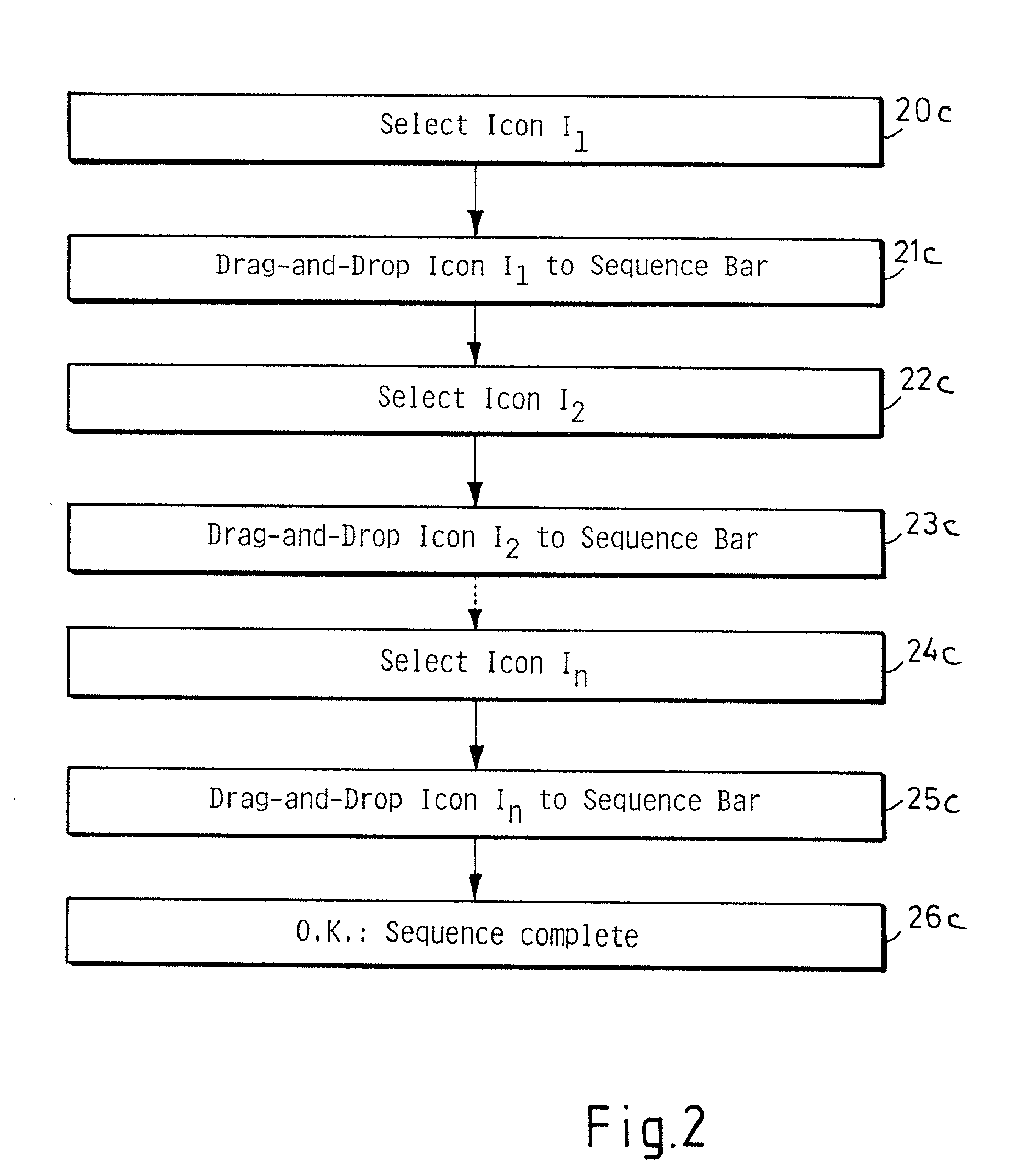

Method and computer system for screening of medical cases

A method and computer system for screening of medical cases in which the computer system has a user interface which enables pre-programming of a sequence of images to be reviewed for each of a group of medical cases. The pre-programming is conducted by means of symbols or icons which are selectable by a user. The pre-programming of the sequence of images is done in a configuration phase of the computer system. During the screening procedure, the user can go from one image to the next by performing a single action input operation, such as, making a mouse click or pressing a next-step button. This has the advantage that the user can fully concentrate on reviewing the medical images without distraction.

Owner:MEVIS BREASTCARE GMBH CO

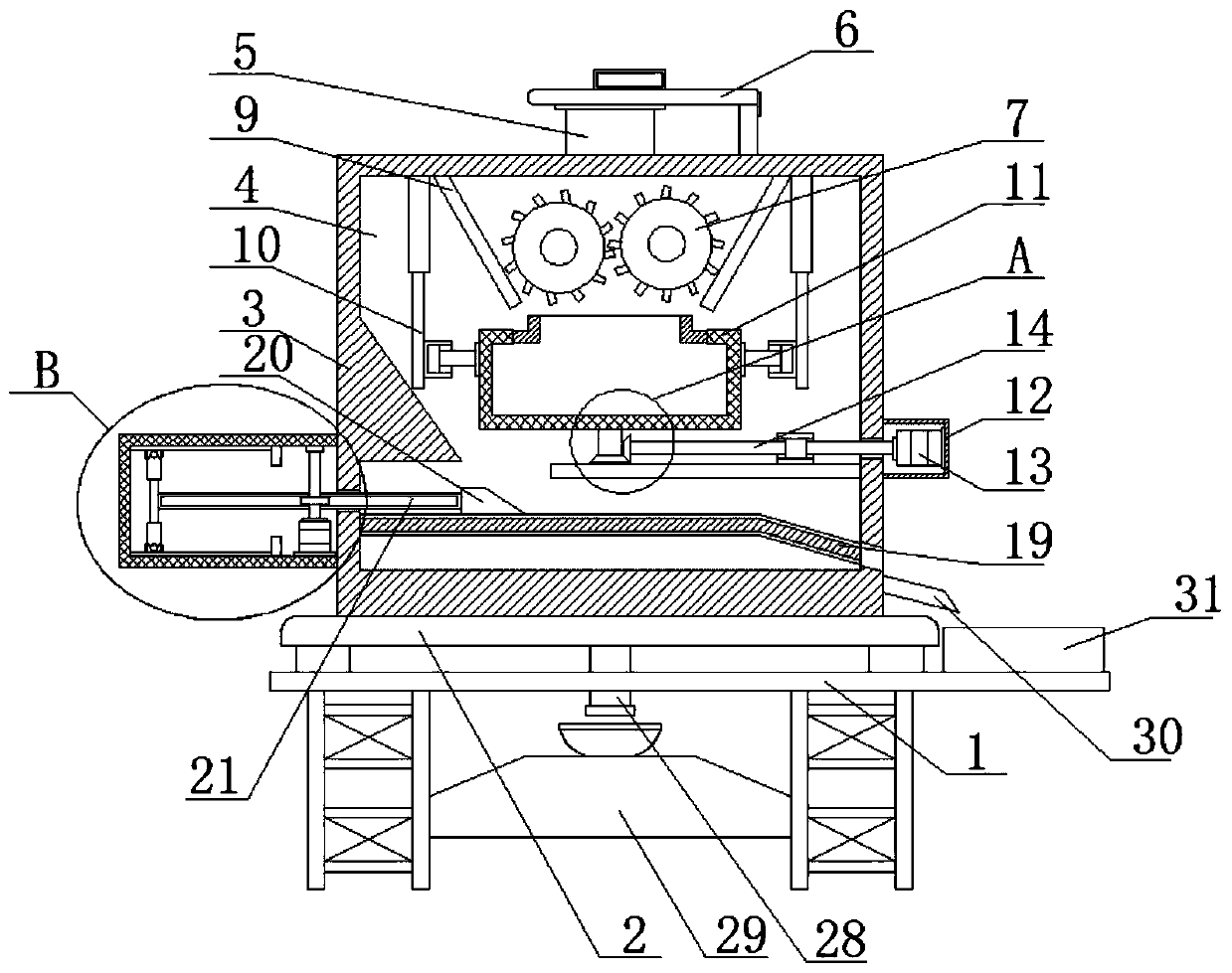

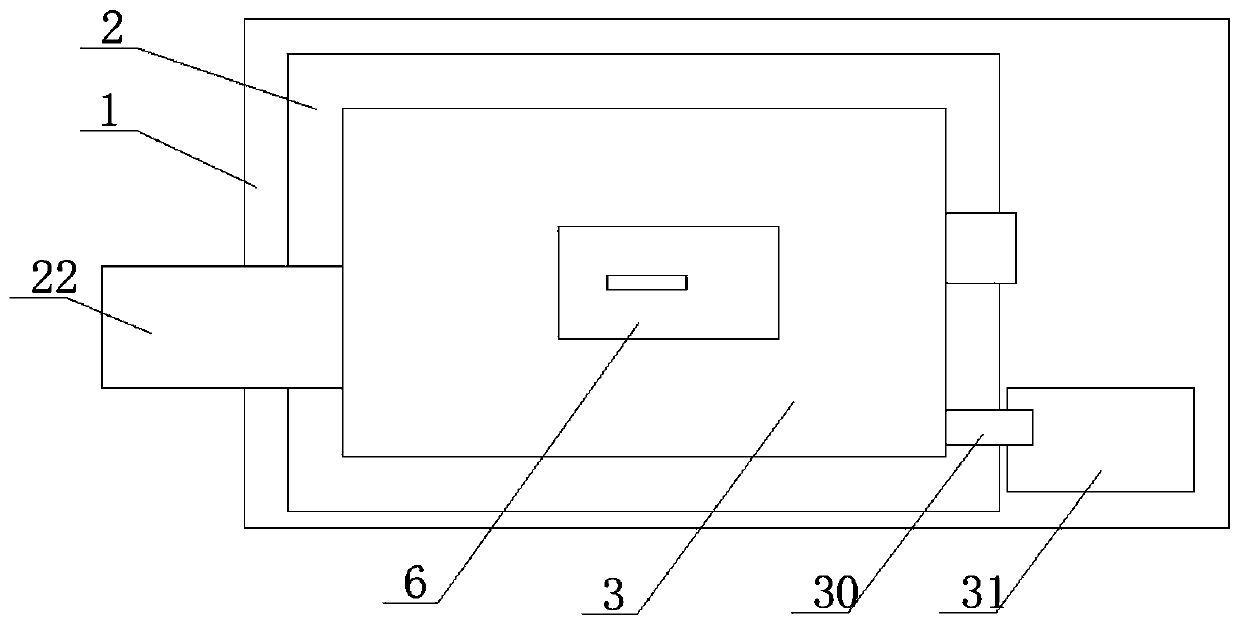

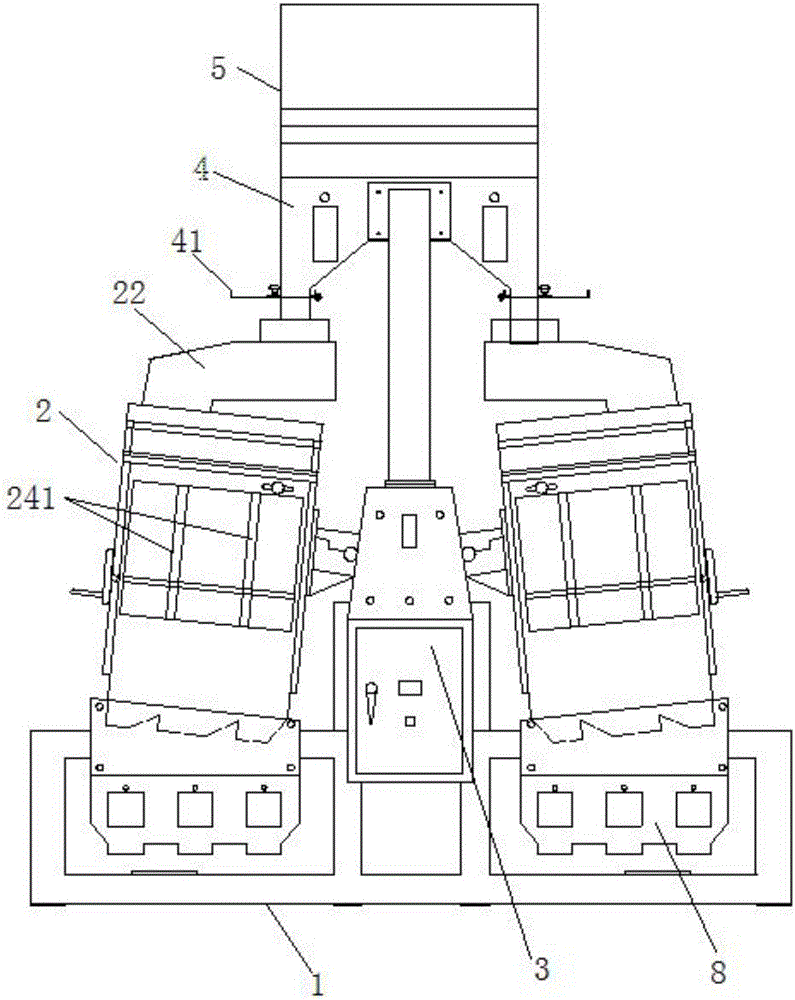

Recycling device of waste lead-acid storage battery and technological process thereof

InactiveCN110180638AReduce processing timeImprove recycling efficiencyWaste accumulators reclaimingGrain treatmentsScreening proceduresDrive motor

The invention belongs to the technical field of waste lead-acid storage battery recycling and discloses a recycling device of a waste lead-acid storage battery and a technological process of the recycling device of the waste lead-acid storage battery. The recycling device of the waste lead-acid storage battery aims to solve the problem that in the prior art, a battery crushing procedure and a screening procedure are separated, so that treatment time is long, and then the recycling efficiency of the waste battery is influenced. The recycling device comprises an installation frame. The top of the installation frame is fixedly provided with a fixing seat, and the top of the fixing base is fixedly provided with a recycling seat. The recycling seat is provided with a recycling cavity, and thetop of the recycling seat is fixedly connected with a feeding pipe. The feeding pipe communicates with the recycling cavity. Two driving motors are symmetrically and fixedly mounted on the inner wallof one side of the recycling cavity, and crushing shafts are fixedly connected to output shafts of the driving motors. The structure of the recycling device is simple, and the recycling device body integrates crushing, screening and collecting of the waste battery, so that the processing time of the waste battery is shortened, and the recycling efficiency of the waste battery is effectively improved.

Owner:安吉绿金金属材料有限公司

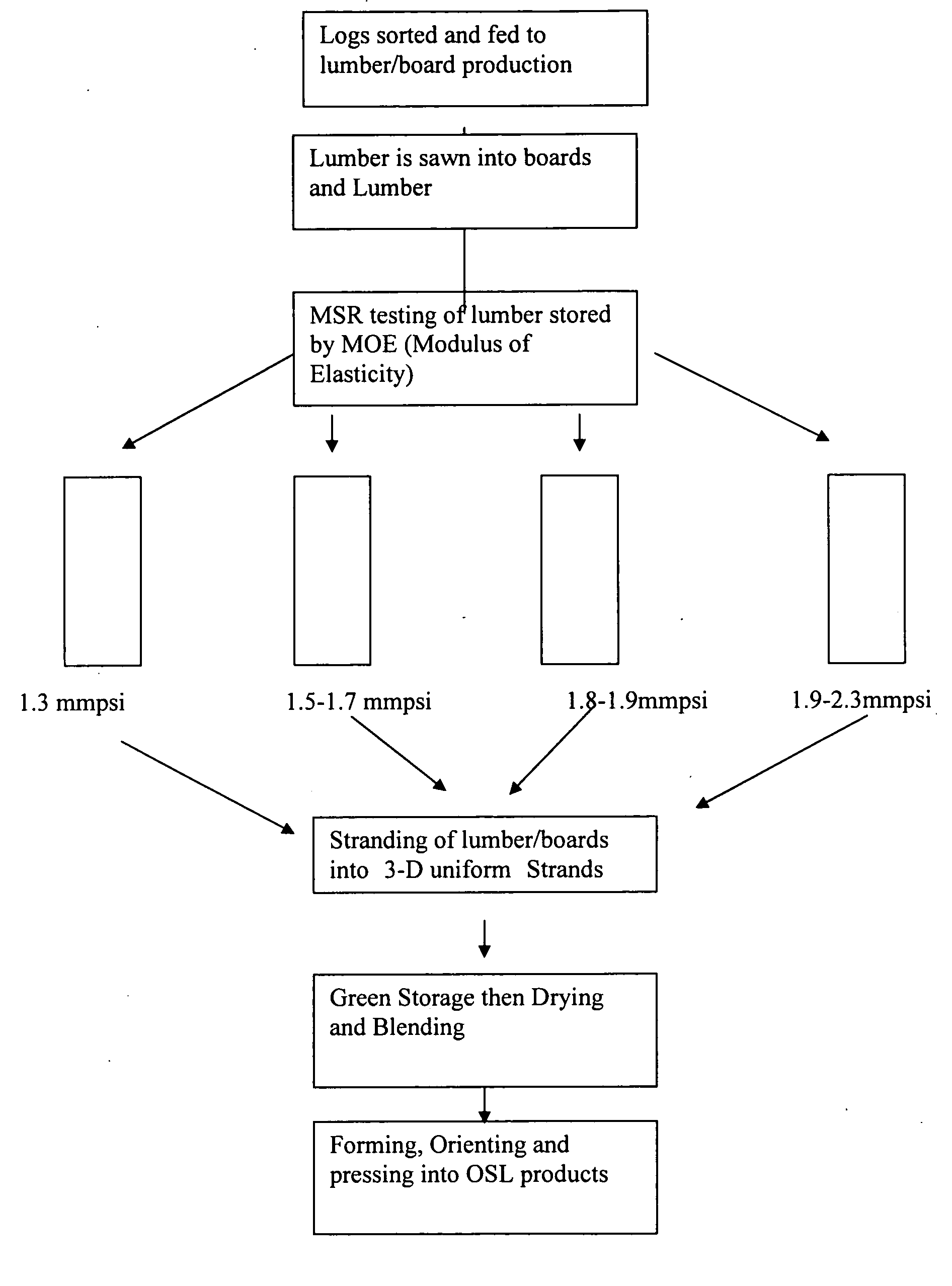

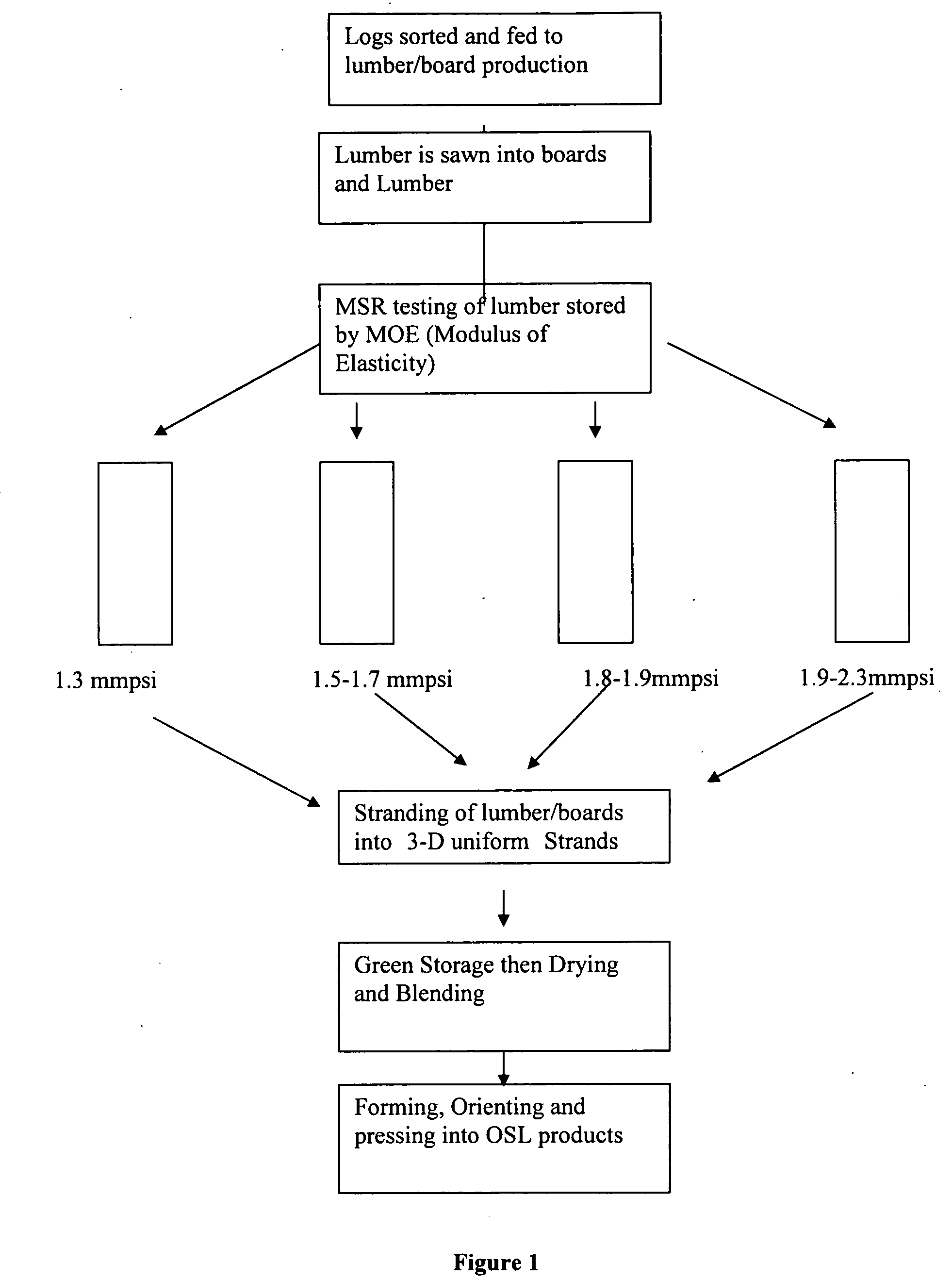

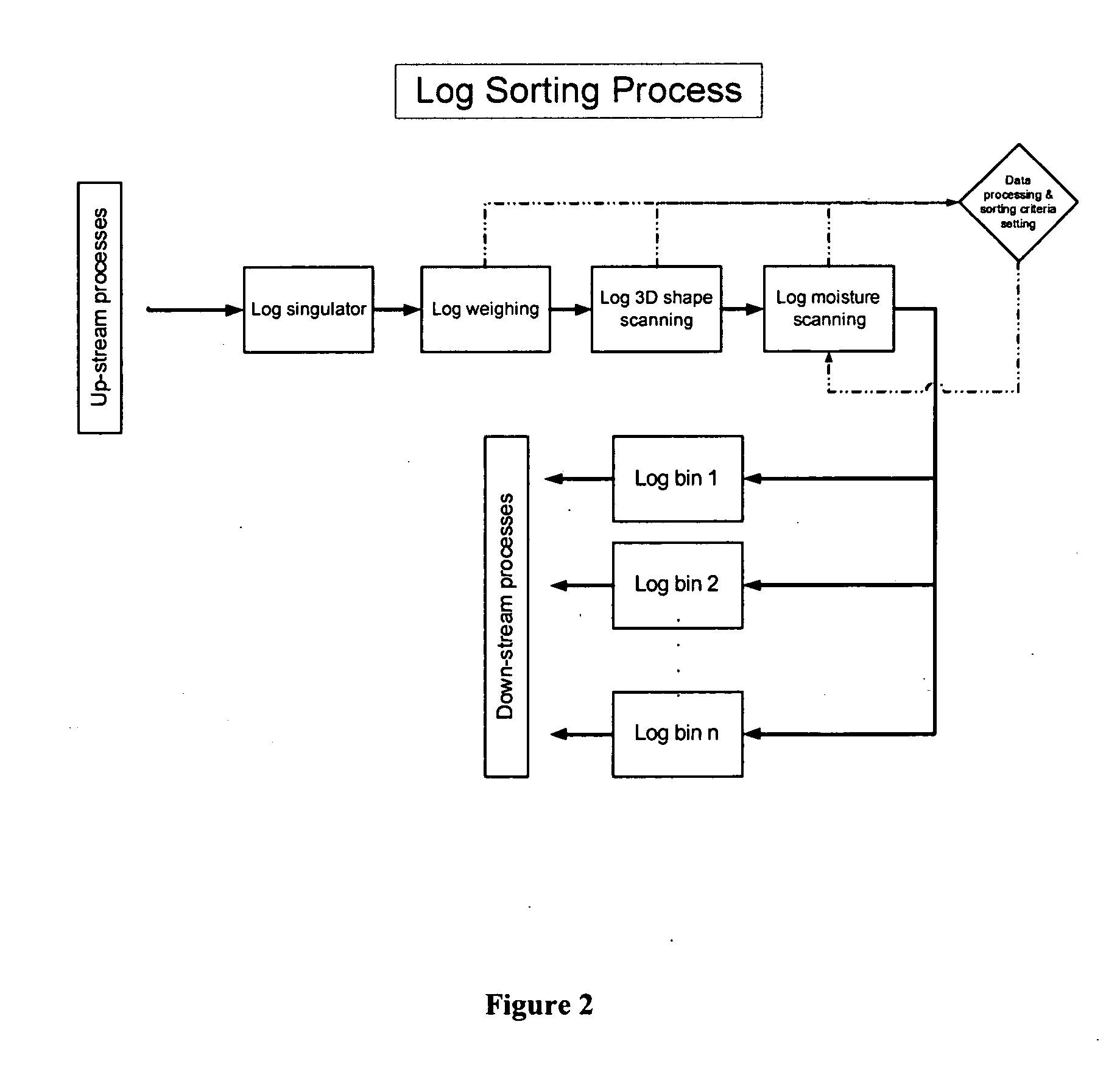

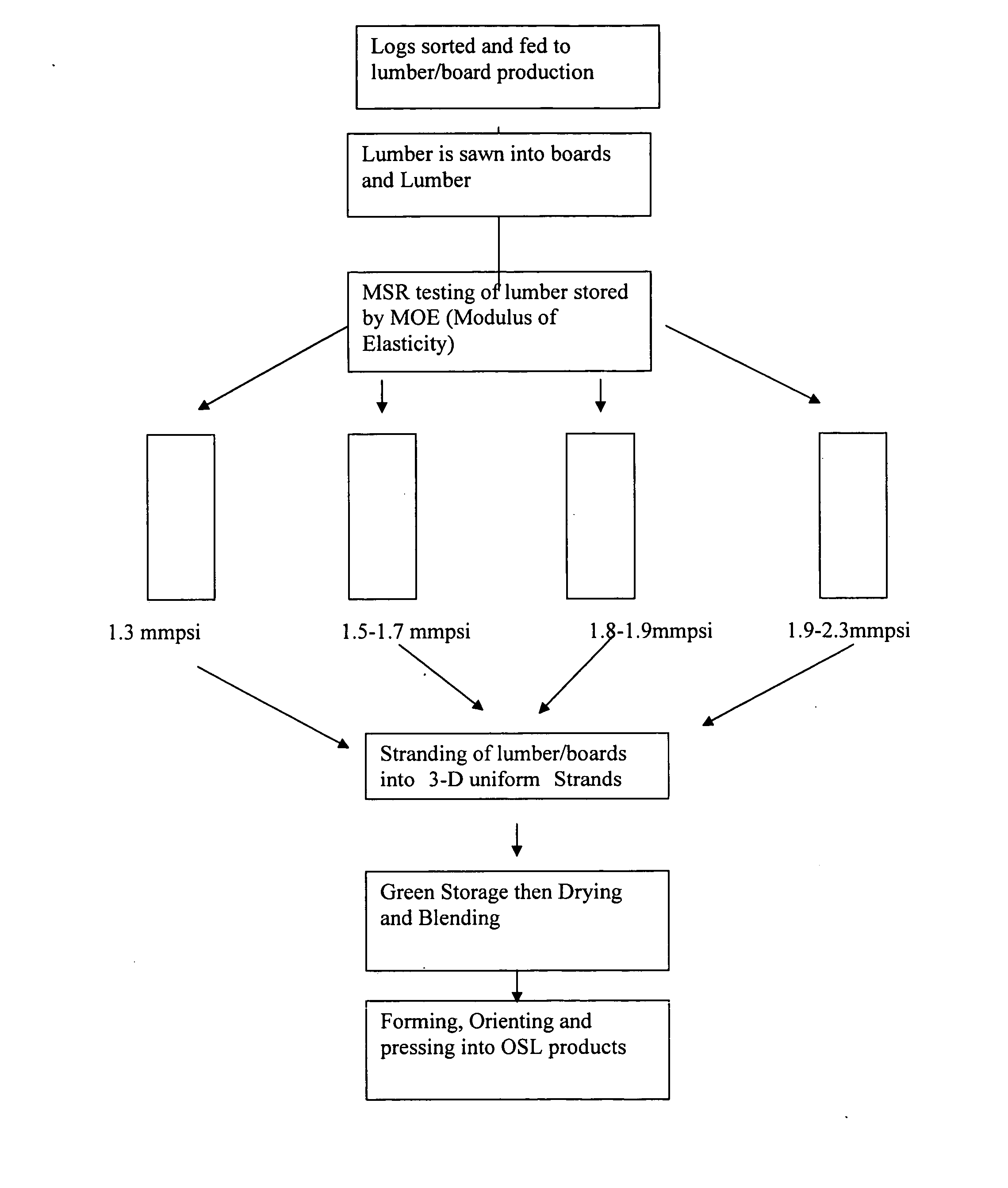

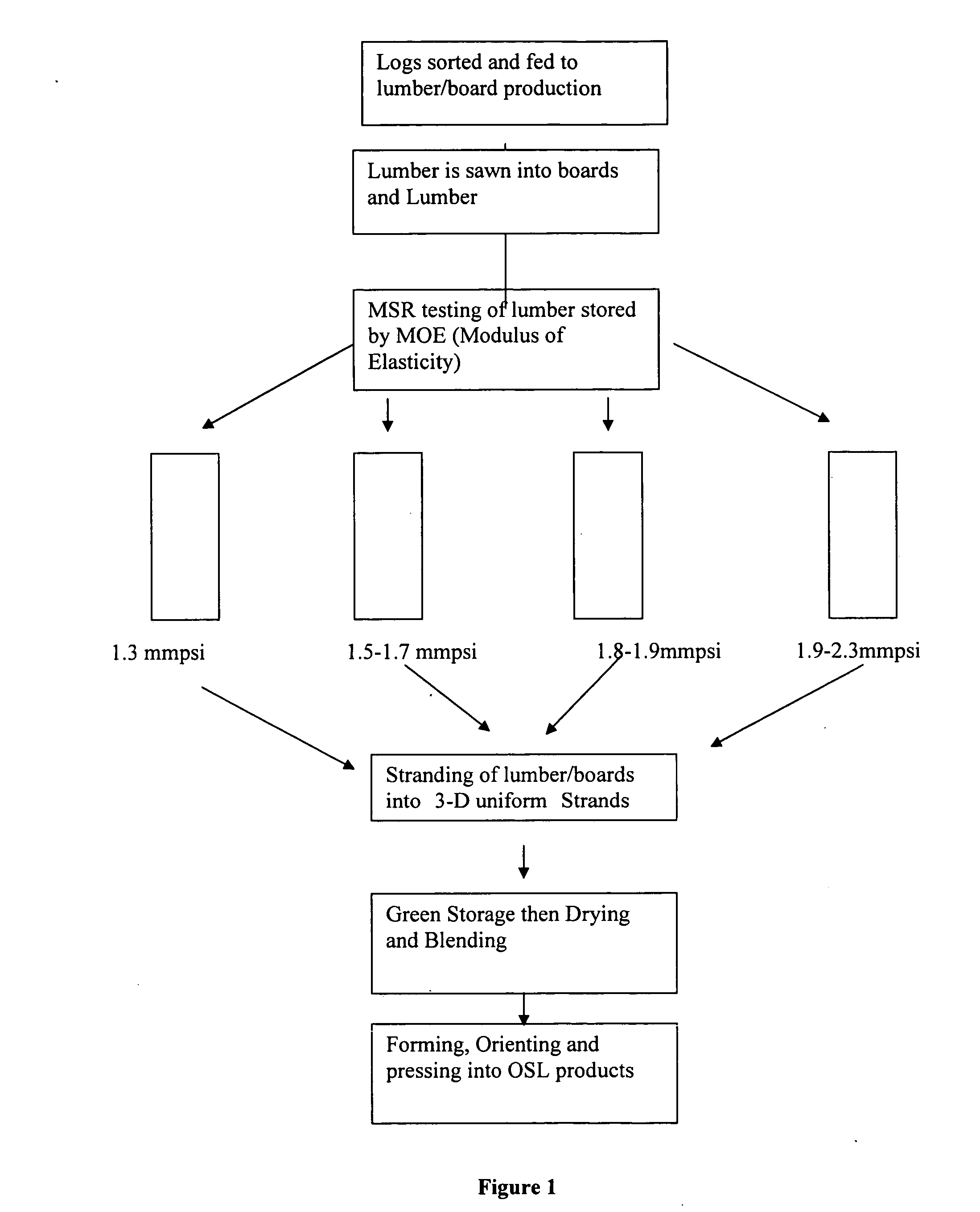

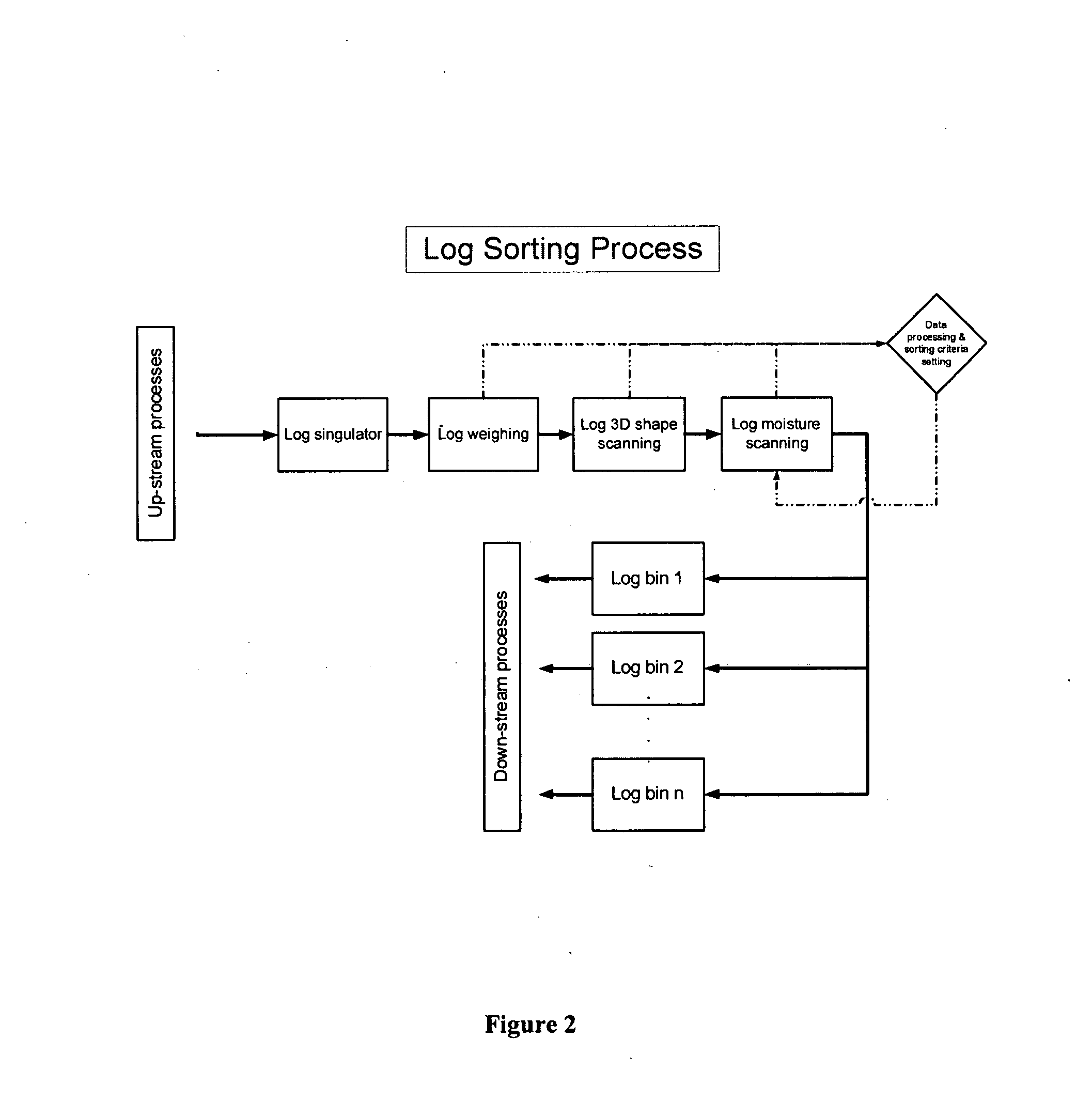

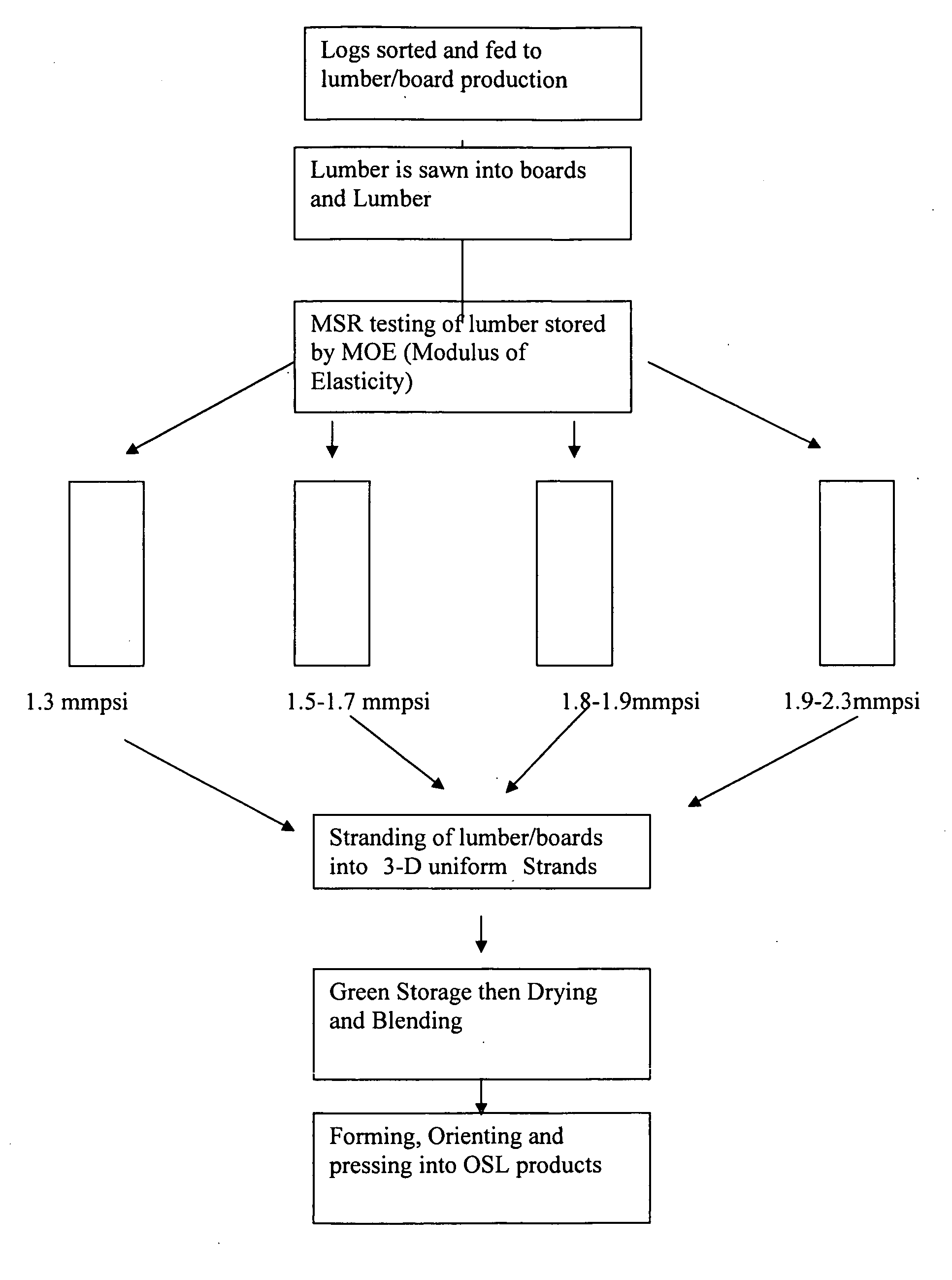

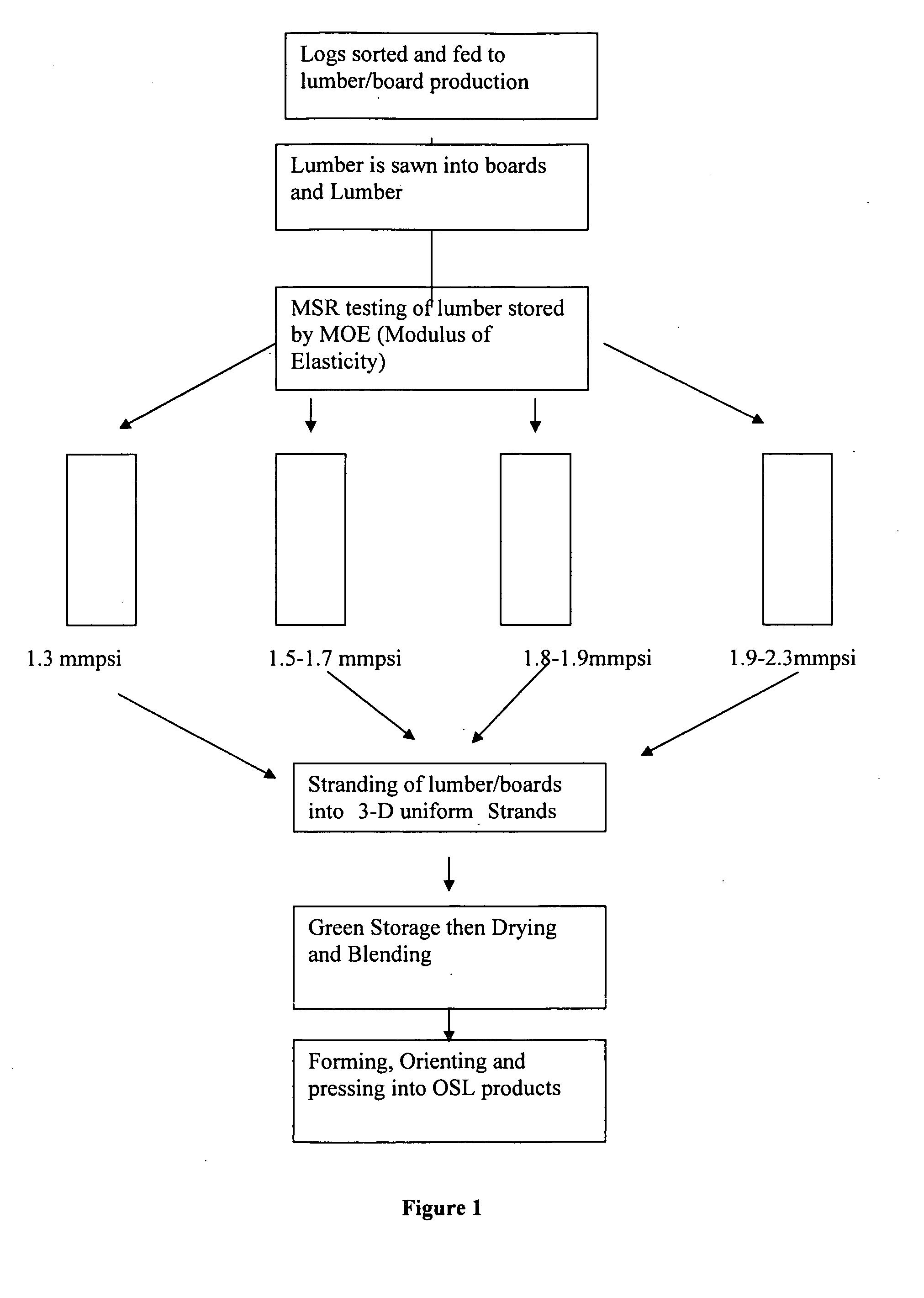

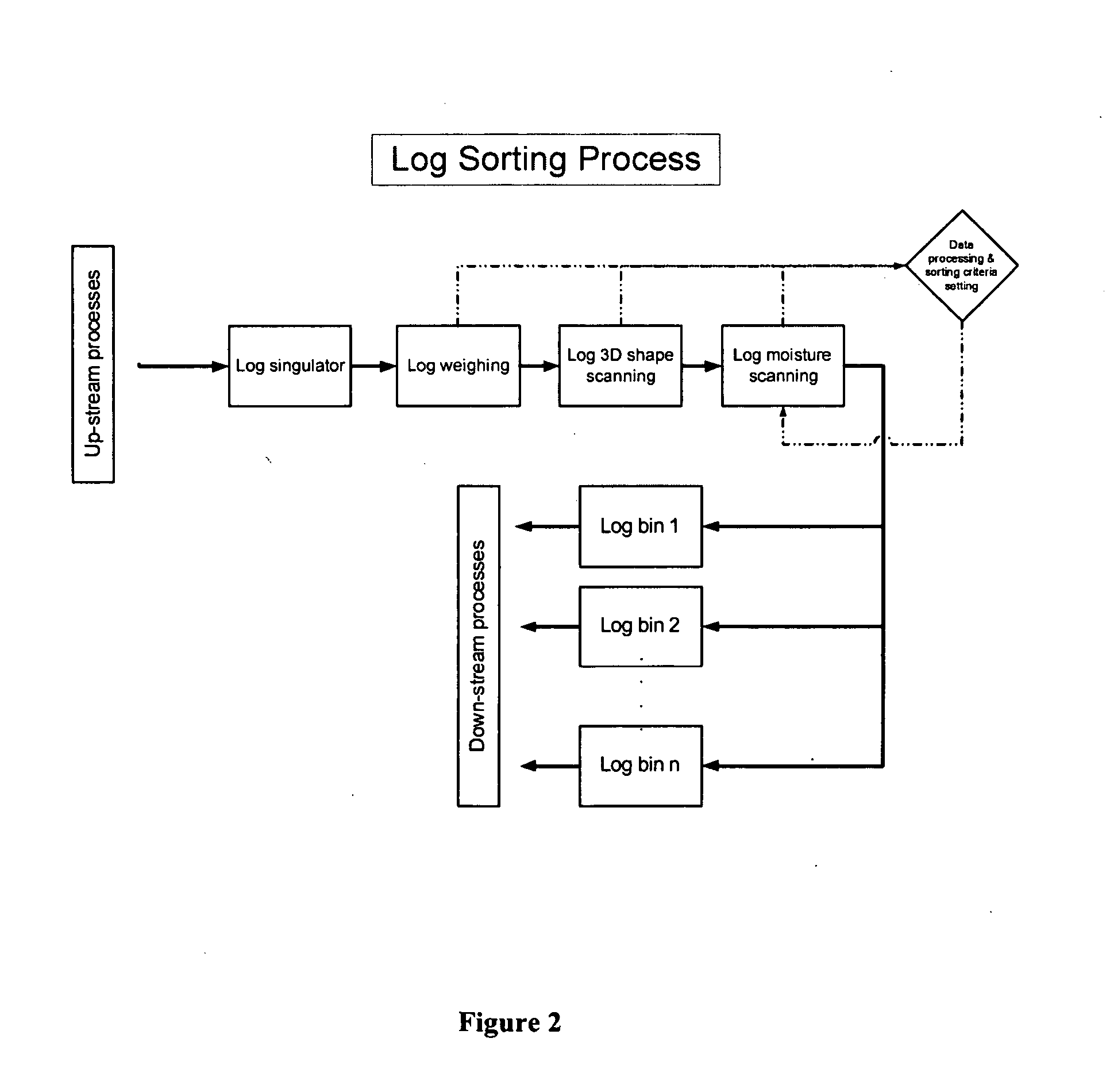

Methods for making improved strand wood products and products made thereby

An overall method of making engineered strand wood products in relation to a number of different possible criteria is provided. Such a method may involve any combination of different screening procedures to determine the best wood sources from which individual strands may be prepared. Such screening procedures may include initial determinations of certain physical characteristics of individual logs, further or initial determinations of certain physical characteristics of portions of sawn logs, further or initial determinations of certain physical characteristics of individual strands, and any combinations thereof. Additionally, after the initial physical characteristic sorting is completed, optionally the wood may be cut into uniformly sized and shaped strands for incorporation within a target strand product. Still further, such strands, in substantially uniform size and shape, as well as substantially uniform physical characteristics, may then be incorporated into a target strand product in specific predetermined configurations. Such various possible combinations of screening procedures and / or selective stranding processes results in strand products (boards, lumber, and the like) of improved properties over previously made strand products. Thus, encompassed within this invention are processes involving each of these procedures either individually or in combination with other sequential processes for the production of desired strand products.

Owner:HUBER ENGINEERED WOODS

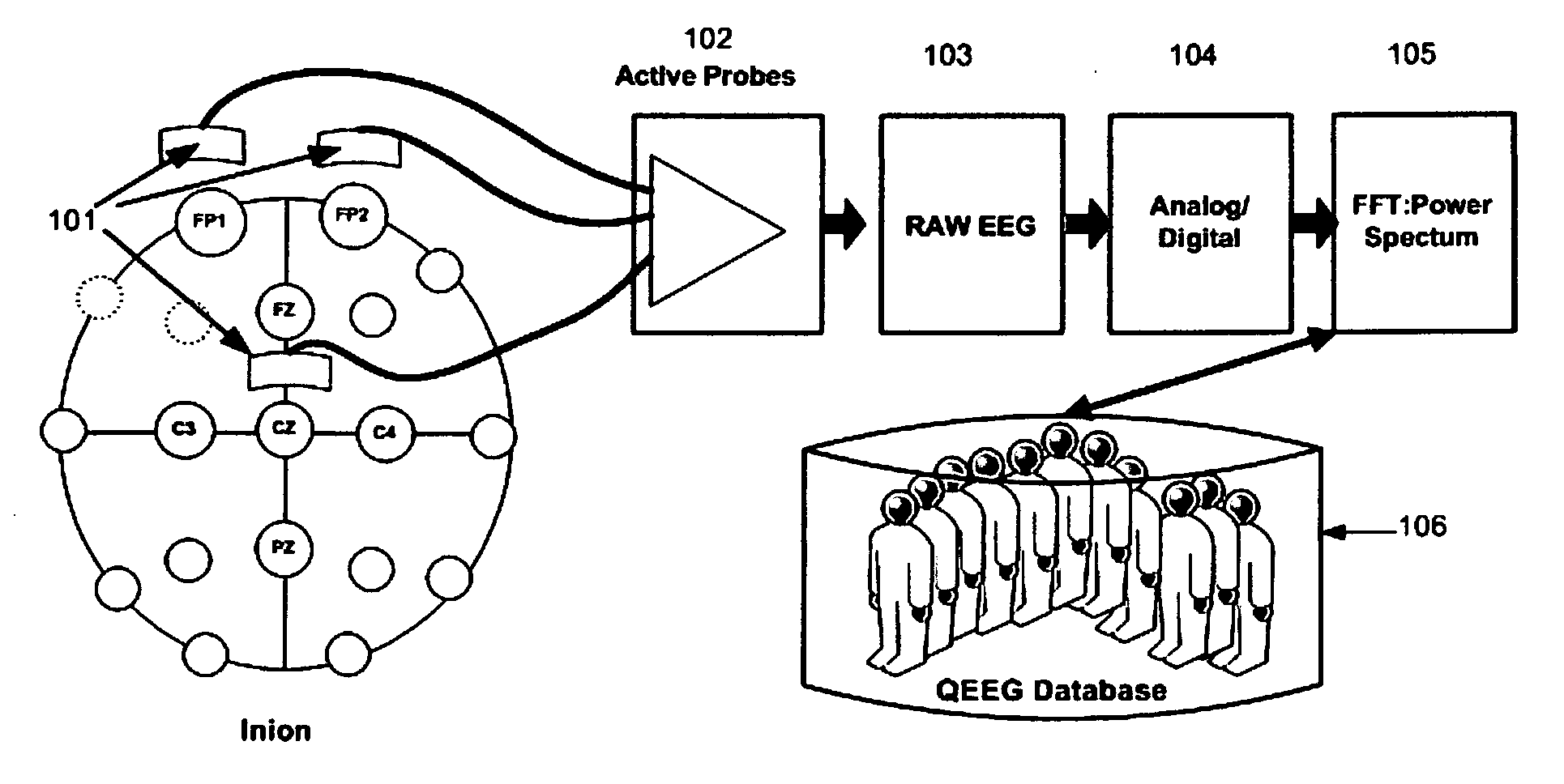

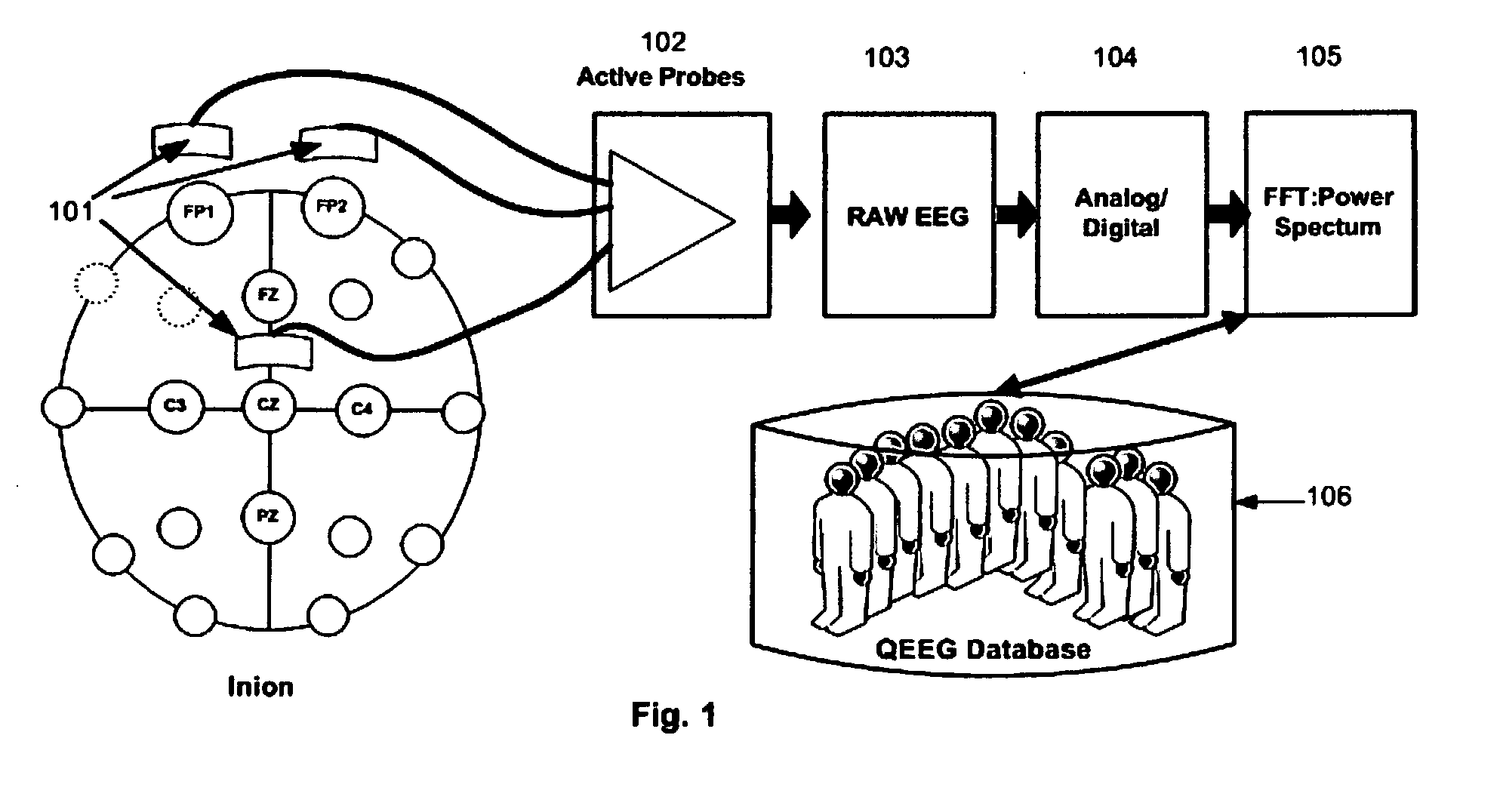

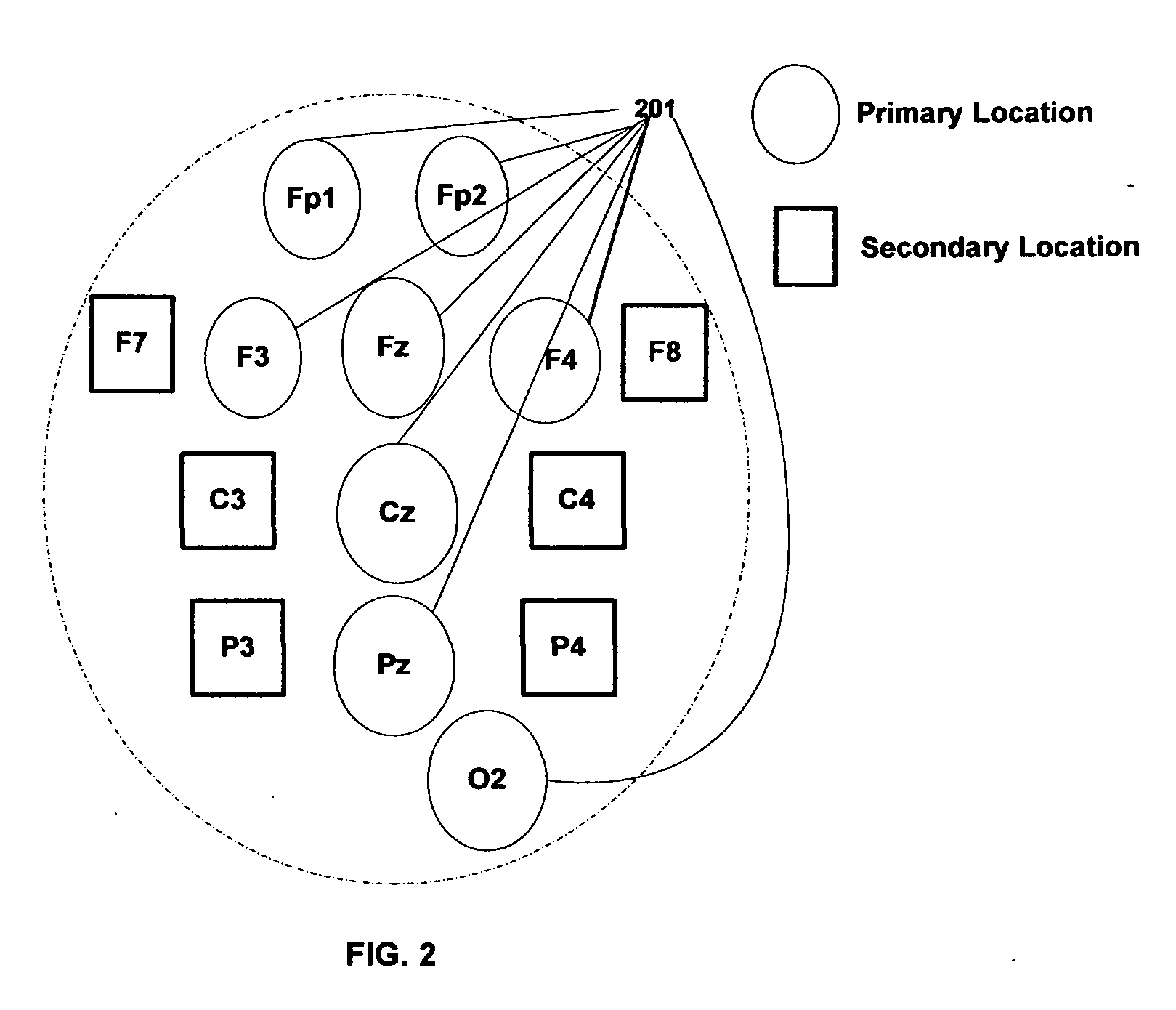

Public Health Screening For Cognitive Health Using Dry Sensor Electroencephalogram Technology

InactiveUS20150157235A1Rapid and easy attachmentImprove signal-to-noise ratioElectroencephalographyComputerised tomographsScreening proceduresPublic health

Systems and methods are provided for performing neurometric evaluation of Quantitative Electro Encephalogram (QEEG) data, derived from Dry Sensor technology, as opposed to the use of any types of conventional paste / gel and silver / silver chloride sensors. The individuals who would be helped by these screening procedures are identified.

Owner:JELEN JAMES J +2

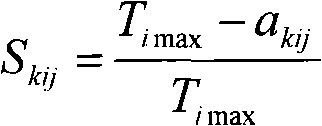

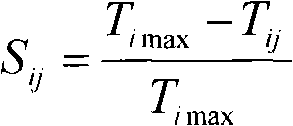

Evaluation method for intensivism use potential of land

The invention belongs to the environment field of agricultural resources, and is an evaluation method for intensivism use of land, comprising, proposing that the intensivism use includes 4 parts of input intensity, utilization degree, output effect and social benefit of land, establishing a evaluation index system and an index determination method of intensivism use of land and proposing the evaluation index and a determination method thereof for intensivism use potential of land. The invention determines a relatively scientific and rational evaluation indicator system by 3-grade screening procedure of frequency analysis, Delphi and multivariate statistics for a lot of primary evaluation indexes and the weight of each index by using the combined method of principal component analysis and hierarchical analysis. The invention improves the single index screening and weight determination to analyze the dynamic change of intensivism use for land and determine the potential at a certain time point, and is a rare quantitative evaluation method for the field of evaluation for regional agricultural resources or quantitative calculation for intensivism use potential of land.

Owner:HEBEI AGRICULTURAL UNIV.

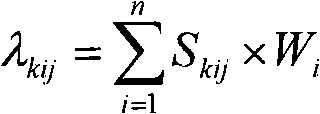

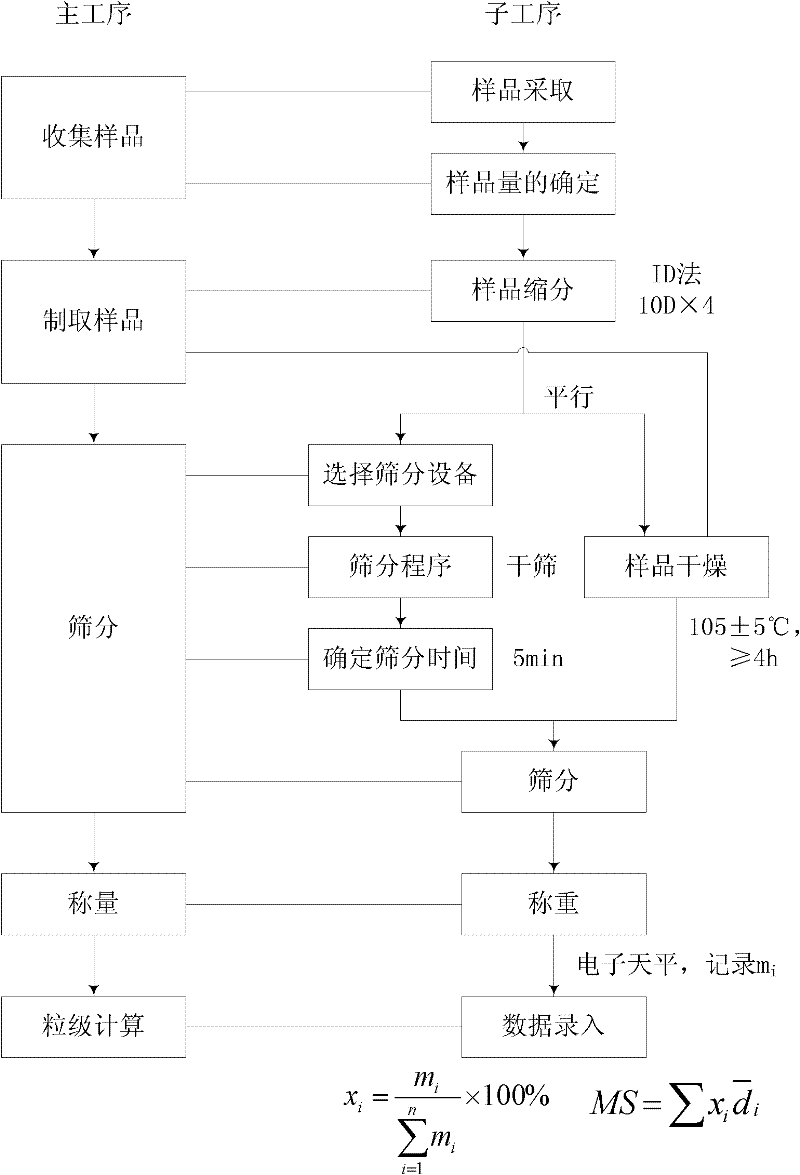

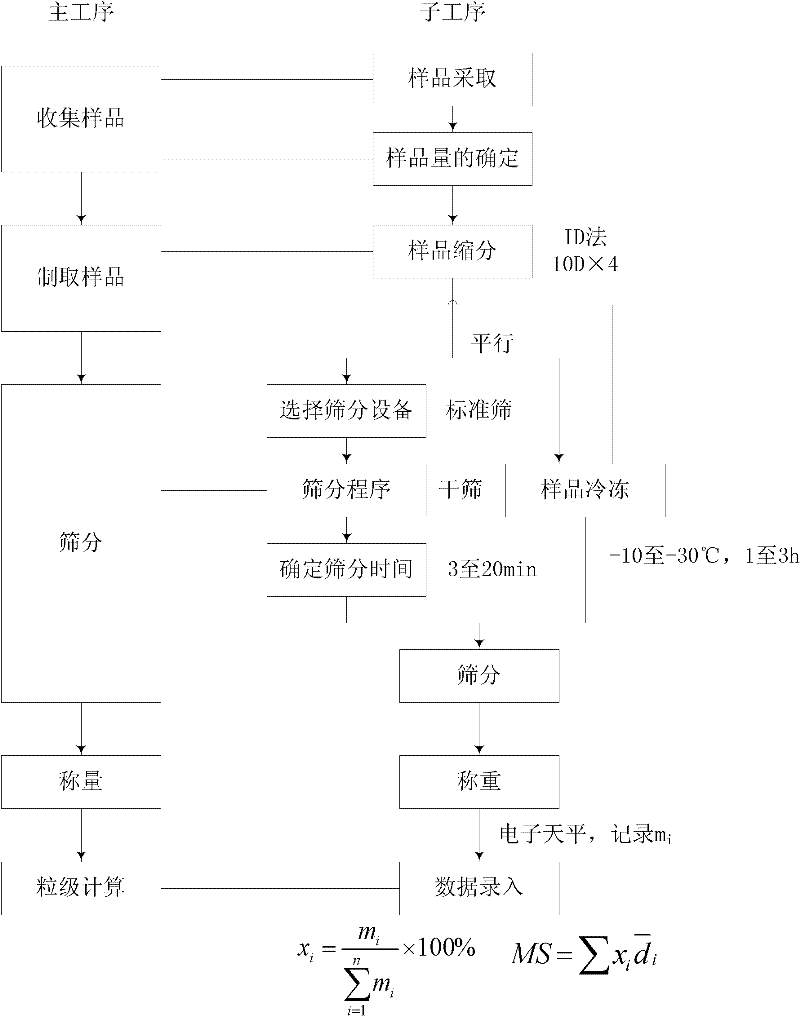

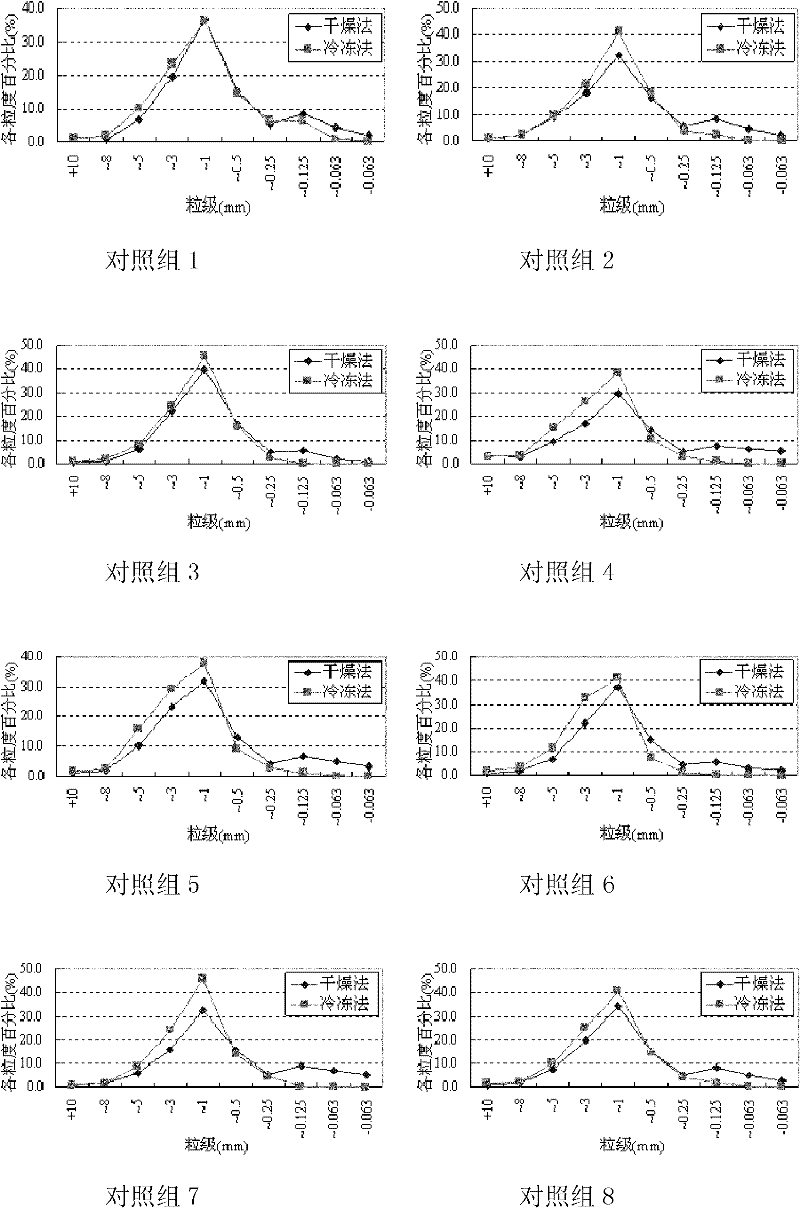

Method for determining sinter mixture granularity

InactiveCN102443695AObjectively reflect the composition of particle sizeThe measurement result is objectiveParticle size analysisScreening proceduresGranularity

The invention provides a method for determining the sinter mixture granularity, which comprises the following steps of: (1) sample collection: sampling samples and determining the sample quantity; (2) sample preparation: reducing, dividing and freezing the samples; (3) screening: selecting screening equipment, determining the screening procedure, determining the screening time and carrying out screening; (4) weighing: weighing the weight of screened materials in all size grades; and (5) size grade calculation: calculating the percentage corresponding to all size grades according to a formula after the weighing completion of the samples in all size grades, recording the percentages, and calculating the average granularity. The method is characterized in that in the second step, the samples are frozen by a refrigerator after reduction and division. When the method is used, the problems that in the existing granularity determining method, the mixture size grade composition under the actual production condition cannot be objectively reflected, the mixed pelletization effect enhancing measure cannot be reasonably evaluated, and the like can be solved. The method has positive effects of effectively improving the proportioning, stabilizing the sinter process and stabilizing and improving the sinter mineral quality on sinter work procedures.

Owner:BAOSHAN IRON & STEEL CO LTD +1

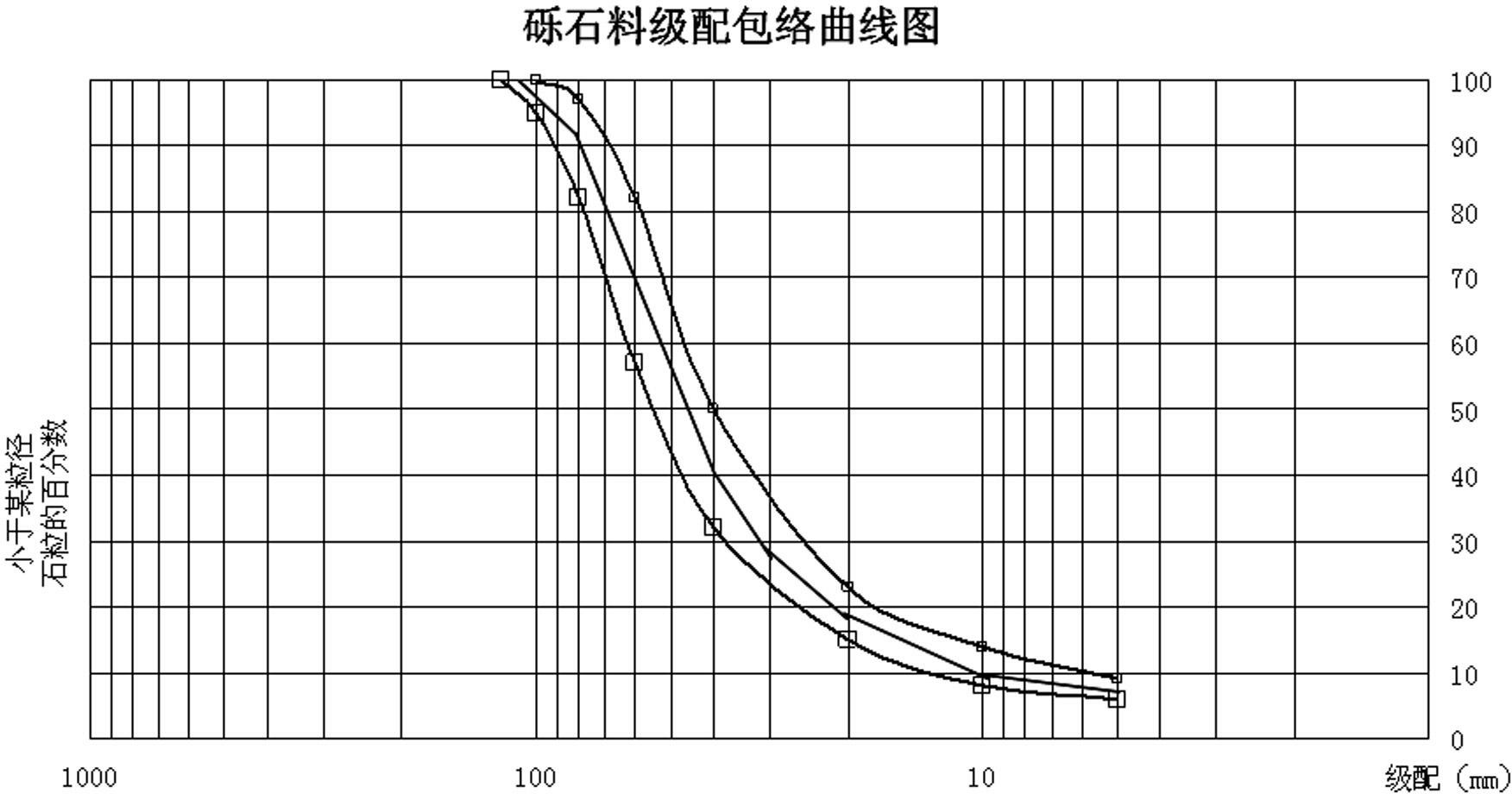

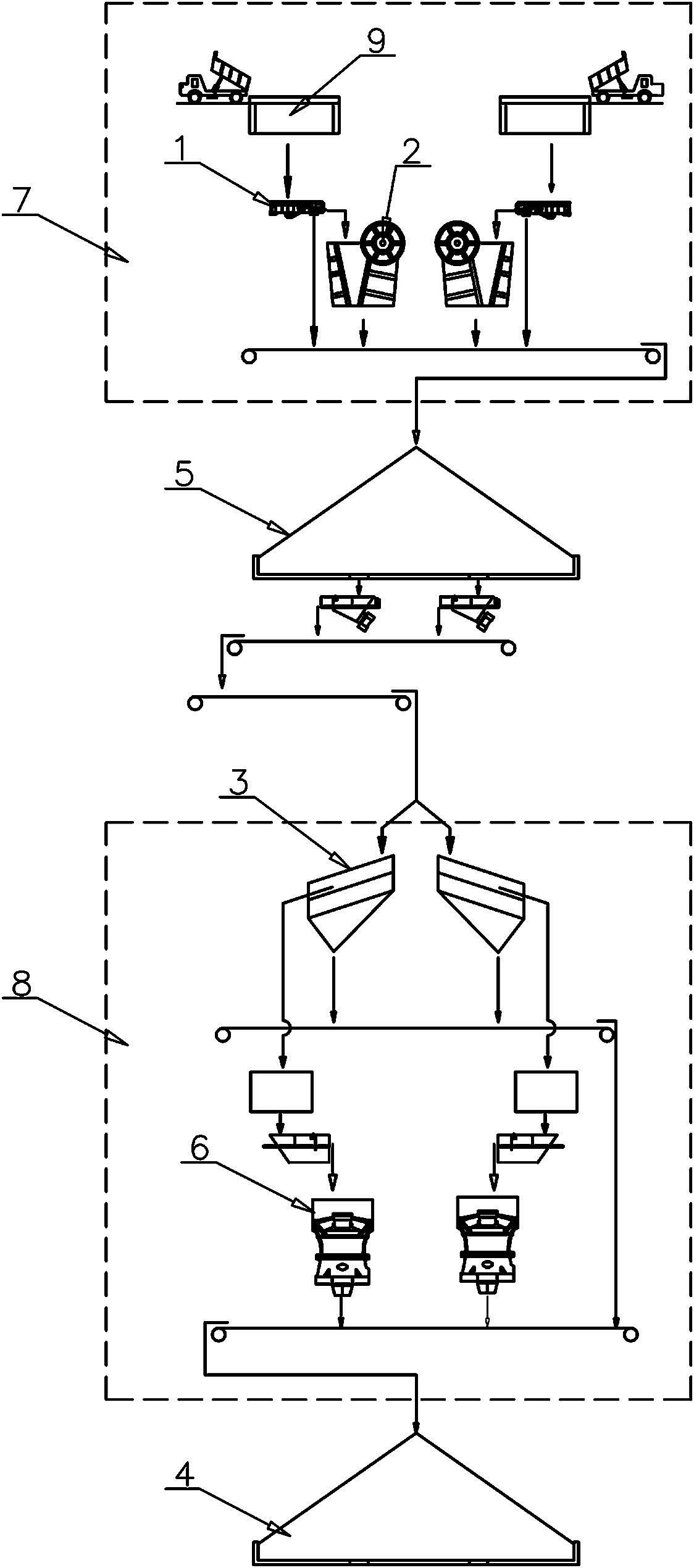

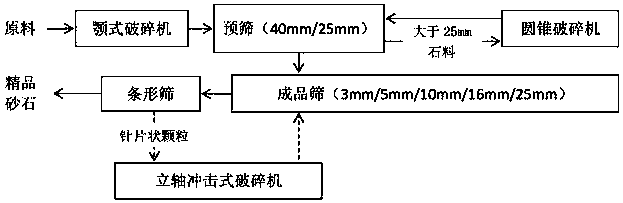

System and method for preparing gravel mixed with dam core wall

InactiveCN102274783AReduce breakageReduce screening processGrain treatmentsScreening proceduresEngineering

The invention relates to a dam core wall gravel-doped stone preparation system. A bar type feeding machine is arranged under a receiving bin; a plus sieve of the bar type feeding machine is connected with a jaw type crusher; a minus sieve of a bar type feeding machine and a discharging opening of the jaw type crusher are connected with a gravel semi-finished product storage yard by a belt conveyor; the gravel semi-finished product storage yard is connected with a screening machine by the belt conveyor; the minus sieve of the screening machine is connected with a gravel finished product storage yard by the belt conveyor; the plus sieve of the screening machine is connected with a cone crusher; and an outlet of the cone crusher is connected with the gravel finished product storage yard by the belt conveyor. The invention realizes the aim of obtaining grading curve gravel meeting the design requirement just by two-stage crushing and one-stage screening by the set matching of rough crushing and intermediate crushing technologies. By reasonably configuring equipment and reducing the crushing and screening procedure, the content of particles smaller than 5mm in a gravel finished product does not exceed 8 percent and meets the process requirement of smaller than 10 percent; and an isolating screen of 5mm is not arranged, and the invention has no discarded materials.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

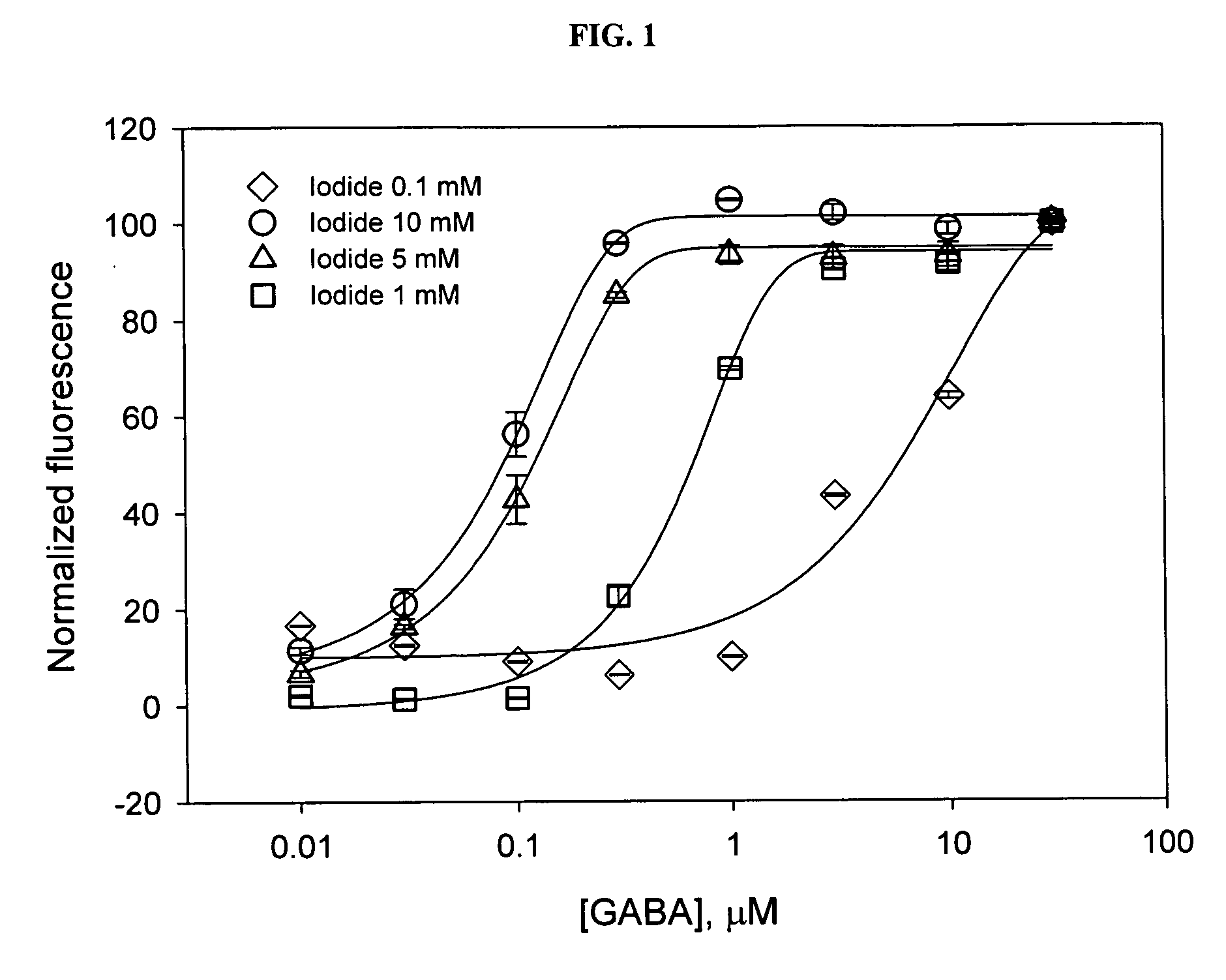

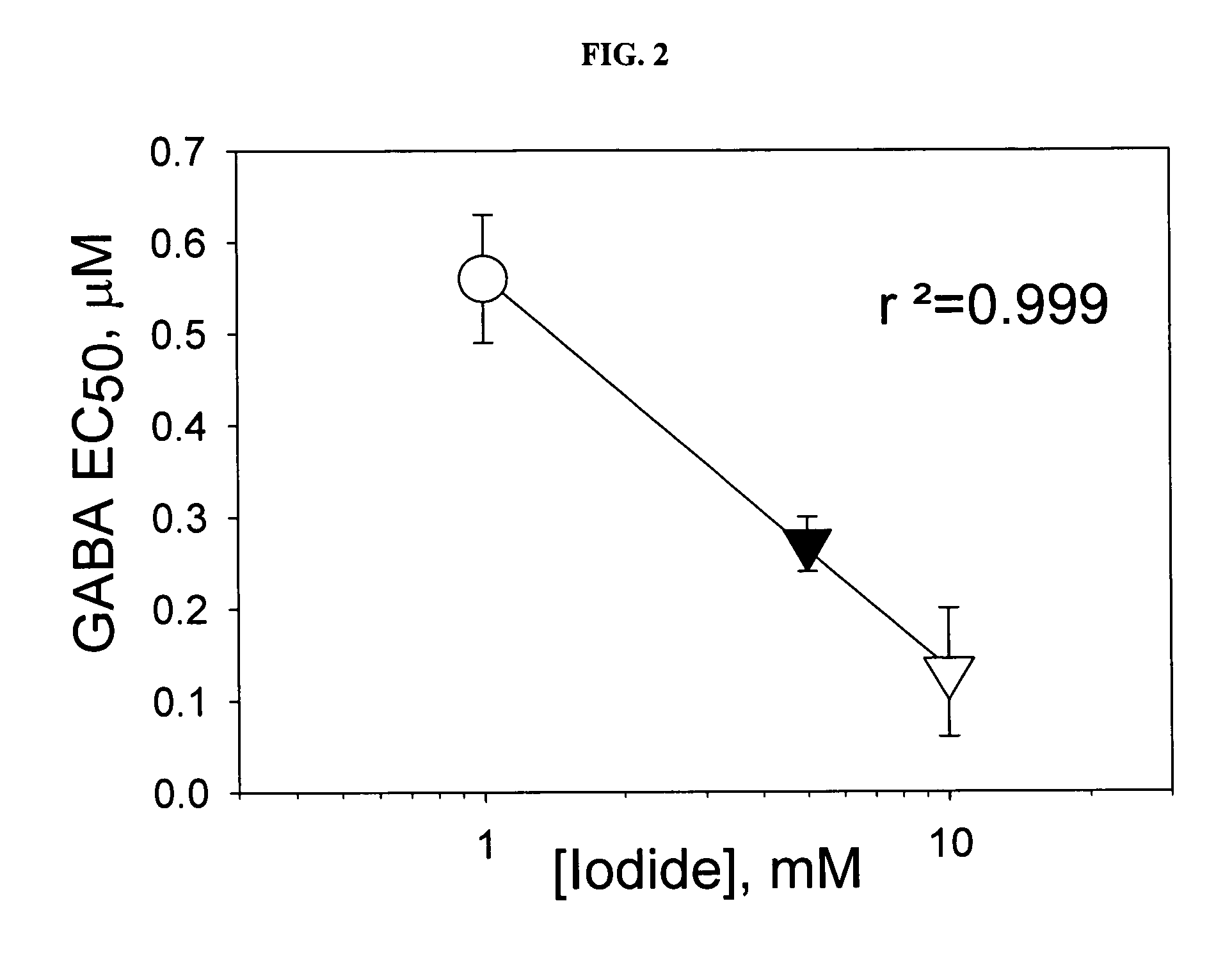

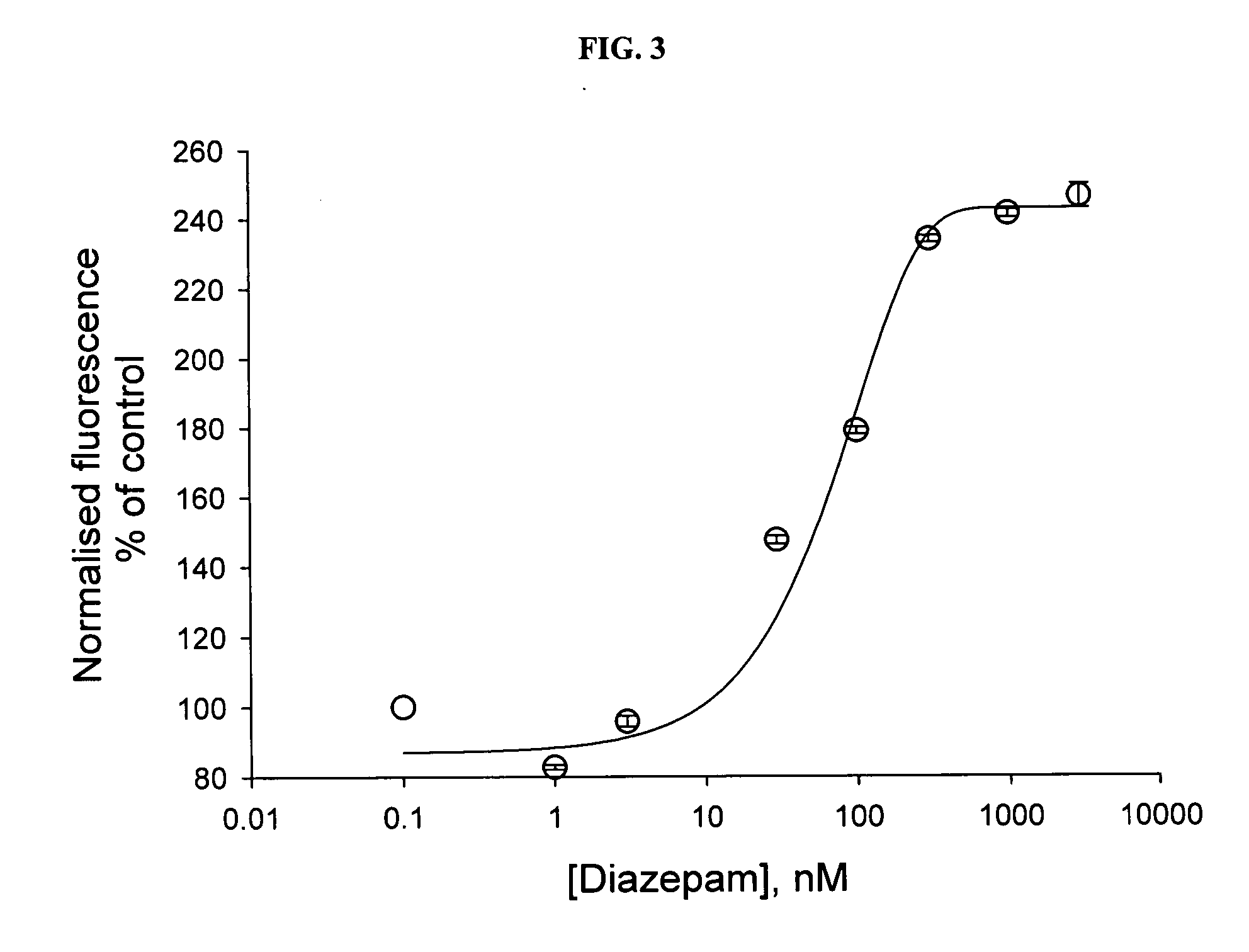

Cell-based assay for the quantitative high throughput screening of gamma-aminobutyric acid-induced halide transport

InactiveUS20060257934A1Compound screeningApoptosis detectionScreening proceduresHigh-Throughput Screening Methods

The present invention is directed to a rapid, quantitative screening procedure of γ-aminobutyric acid (GABA)-mediated halide transport in cells with the use of a conventional 384-well fluorescence plate reader (FLIPR). The halide sensor is a novel yellow fluorescent protein (YFP) with mutations at positions 46 / 148 / 152 that exhibits bright fluorescence at 37° C.

Owner:BRISTOL MYERS SQUIBB CO

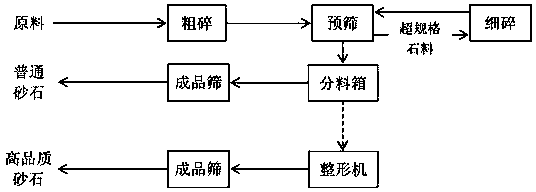

Machine-made gravel processing technology

ActiveCN109290039AEfficient removalPrecise shaping and crushingSievingScreeningScreening proceduresPrill

The invention discloses a machine-made gravel processing technology. The processing technology comprises the steps of firstly crushing stone generally; adding a screening procedure through a strip-type screen in the screening step, screening out elongated and flaky particles from semi-finished products, and achieving precise crushing and squaring of the elongated and flaky particles; performing special composition regulation based on the standard composition requirement after screening of machine-made gravels; and pre-wetting gravels after composition optimization and stacking for at least 24hours, and then washing the gravels with water for removing mud and fines. According to the machine-made gravel processing technology, the effects of precise crushing and squaring of the elongated andflaky particles, precise composition regulation of the gravels, mud and fines removal through combination of pre-wetting and water washing are achieved; the problems of composition, grain shape, mudcontent, water absorption and other quality indexes of the machine-made gravels are solved systematically and economically; and a production technology with certain universality is provided for high-quality machine-made gravels.

Owner:NANJING TECH UNIV +1

Methods for making improved strand wood products and products made thereby

An overall method of making engineered strand wood products in relation to a number of different possible criteria is provided. Such a method may involve any combination of different screening procedures to determine the best wood sources from which individual strands may be prepared. Such screening procedures may include initial determinations of certain physical characteristics of individual logs, further or initial determinations of certain physical characteristics of portions of sawn logs, further or initial determinations of certain physical characteristics of individual strands, and any combinations thereof. Additionally, after the initial physical characteristic sorting is completed, optionally the wood may be cut into uniformly sized and shaped strands for incorporation within a target strand product. Still further, such strands, in substantially uniform size and shape, as well as substantially uniform physical characteristics, may then be incorporated into a target strand product in specific predetermined configurations. Such various possible combinations of screening procedures and / or selective stranding processes results in strand products (boards, lumber, and the like) of improved properties over previously made strand products. Thus, encompassed within this invention are processes involving each of these procedures either individually or in combination with other sequential processes for the production of desired strand products.

Owner:HUBER ENGINEERED WOODS

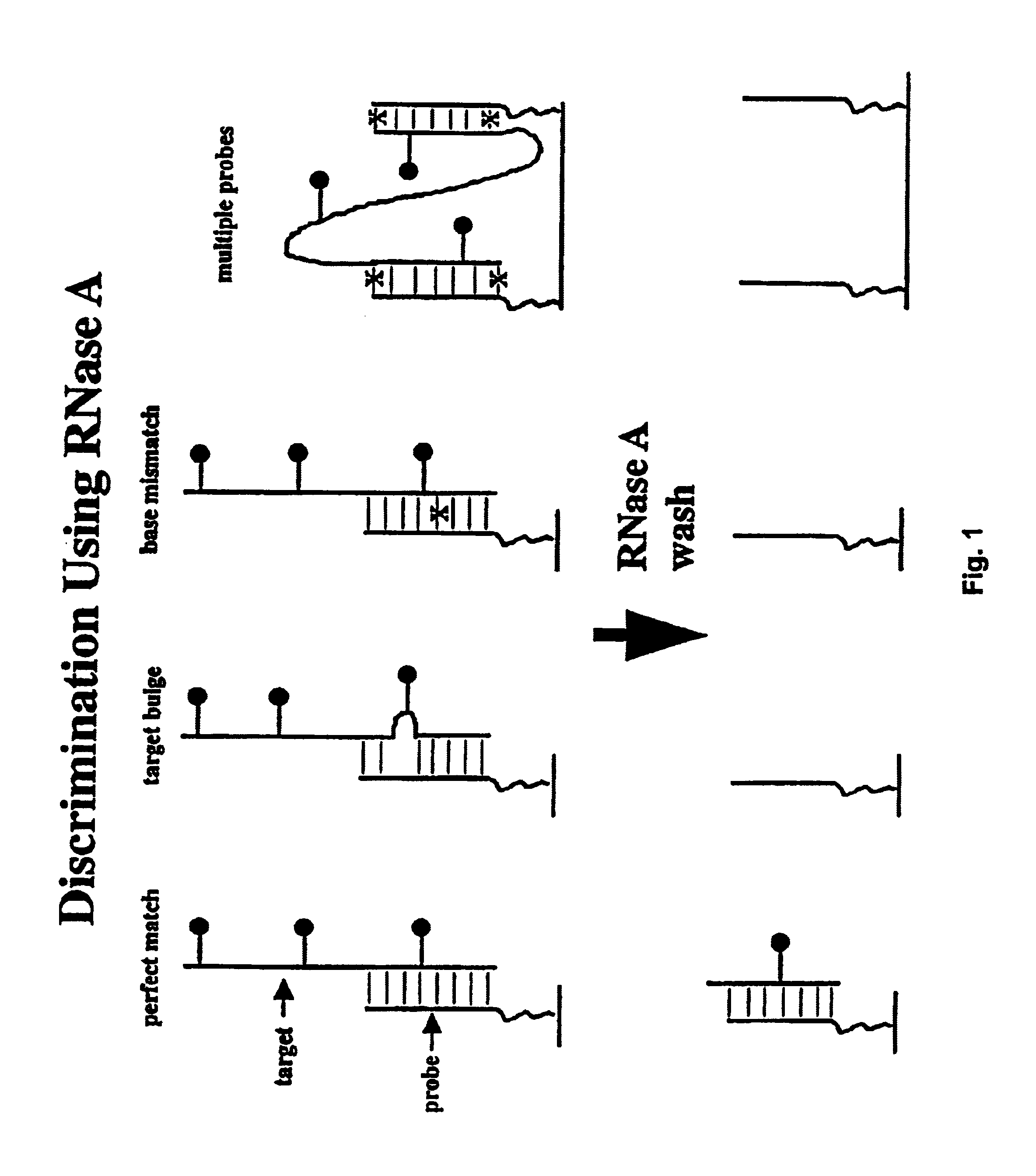

Methods of enzymatic discrimination enhancement and surface-bound double-stranded DNA

InactiveUS6974666B1Quality improvementSure easySequential/parallel process reactionsSugar derivativesScreening proceduresSignal on

Methods for discriminating between fully complementary hybrids and those that differ by one or more base pairs and libraries of unimolecular, double-stranded oligonucleotides on a solid support. In one embodiment, the present invention provides methods of using nuclease treatment to improve the quality of hybridization signals on high density oligonucleotide arrays. In another embodiment, the present invention provides methods of using ligation reactions to improve the quality of hybridization signals on high density oligonucleotide arrays. In yet another embodiment, the present invention provides libraries of unimolecular or intermolecular, double-stranded oligonucleotides on a solid support. These libraries are useful in pharmaceutical discovery for the screening of numerous biological samples for specific interactions between the double-stranded oligonucleotides, and peptides, proteins, drugs and RNA. In a related aspect, the present invention provides libraries of conformationally restricted probes on a solid support. The probes are restricted in their movement and flexibility using double-stranded oligonucleotides as scaffolding. The probes are also useful in various screening procedures associated with drug discovery and diagnosis. The present invention further provides methods for the preparation and screening of the above libraries.

Owner:AFFYMETRIX INC

Methods and compositions for development of drug screening procedures and diagnostic tools

This invention defines novel research and clinical laboratory methodology and compositions related thereto appropriate for use in (a) determining the presence of a neurodegenerative disease selected from the group limited solely to Charcot-Marie-Tooth disease, familial Alzheimer's disease, familial Parkinson's disease, Huntington's disease, spinal muscular atrophy, Friedreich'a ataxia, giant axon neuropathy, juvenile ceroid-lipofuscinosis, familial motor neuron diseases, juvenile diabetic polyneuropathy and Down's syndrome, (b) monitoring the ongoing status of the physiological expression of said disease and (c) screening candidate therapeutic drug agents for possible effectiveness. The invention is based on the new and novel observation that the presence of a neurodegenerative disease can be characterized in part by the expression in cultured fibroblasts obtained from the patient of one or more proteins which are not the product of a defective disease-inducing gene, but which are stress proteins, one or more other proteins modified by conditions of oxidative stress or one or more other disease-related proteins. The invention depends on living cell material, namely fibroblasts, which are readily and, if necessary, repeatedly available from a patient. When adapted as a method and composition useful for the screening candidate therapeutic drug agents for possible effectiveness, this technology offers advantages in terms of (a) providing research opportunities which, in some cases, never existed before, (b) cost effectiveness when compared to alternative technologies, (c) ability to be used readily on a large scale, (d) ability to generate meaningful data in a comparatively short period of time, and (e) providing an early stage opportunity to obtain information based on direct interaction of a candidate drug and a living tissue disease model. Various aspects of diagnostic methods and compositions are also disclosed.

Owner:SHAPIRO HOWARD K

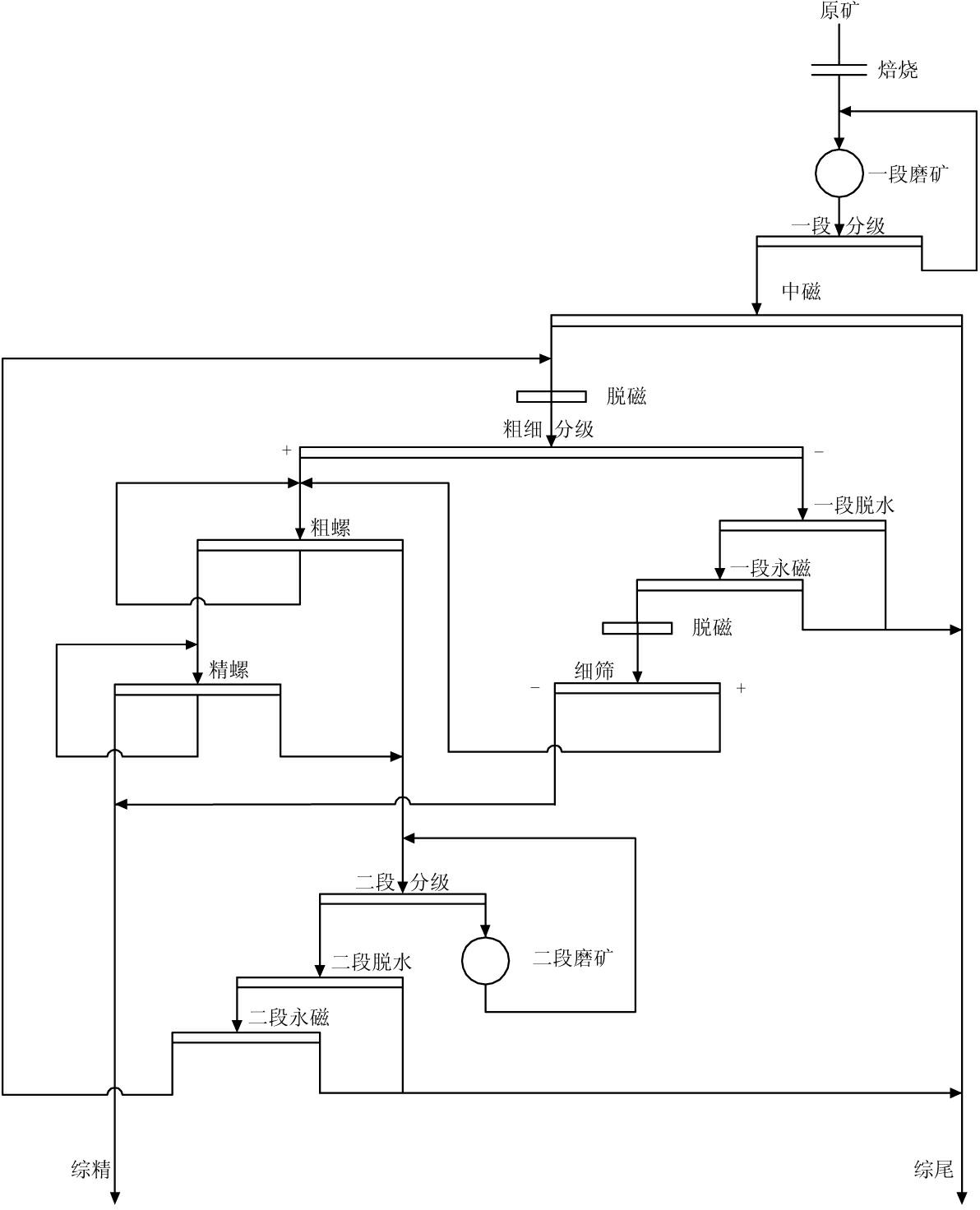

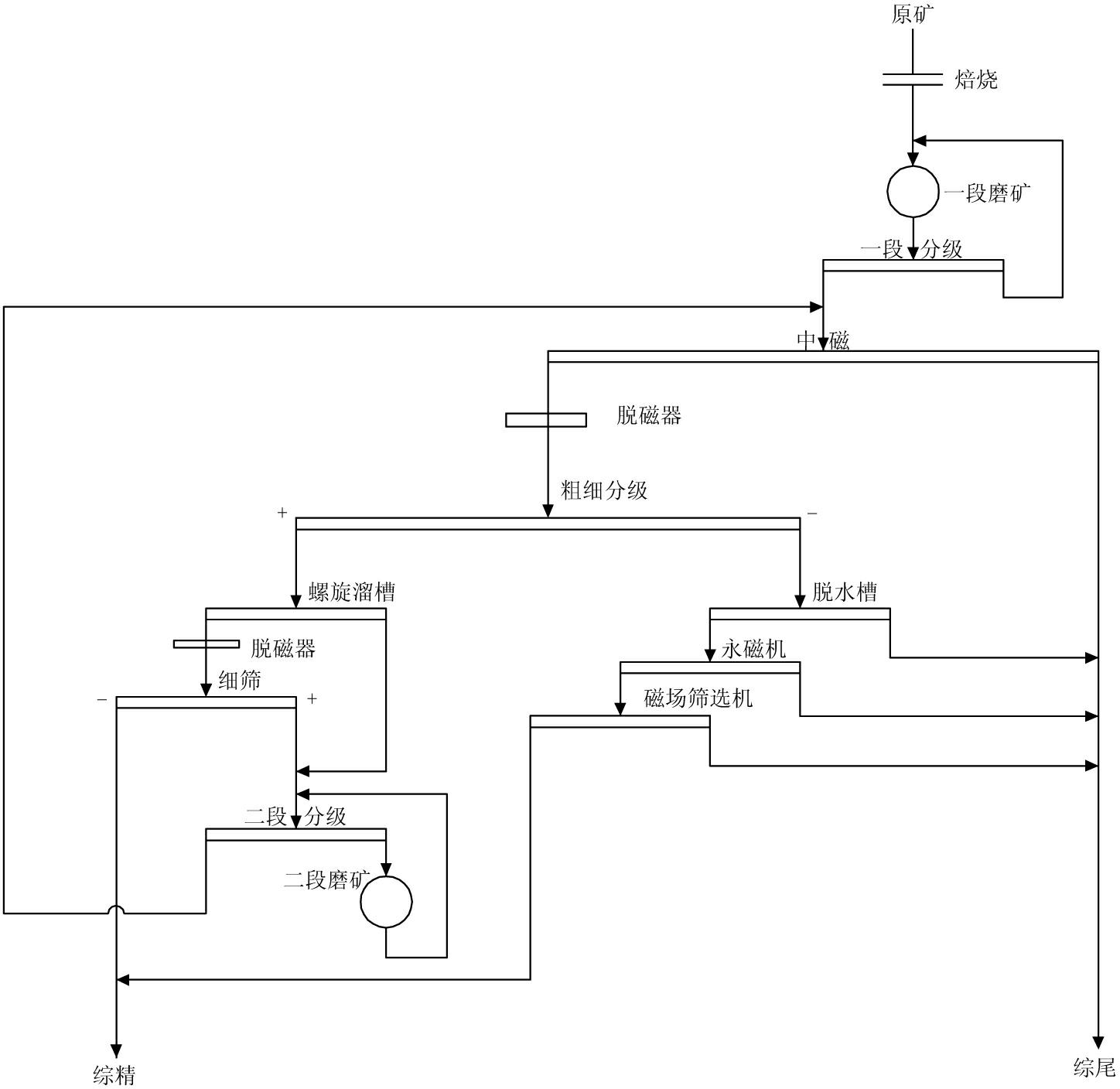

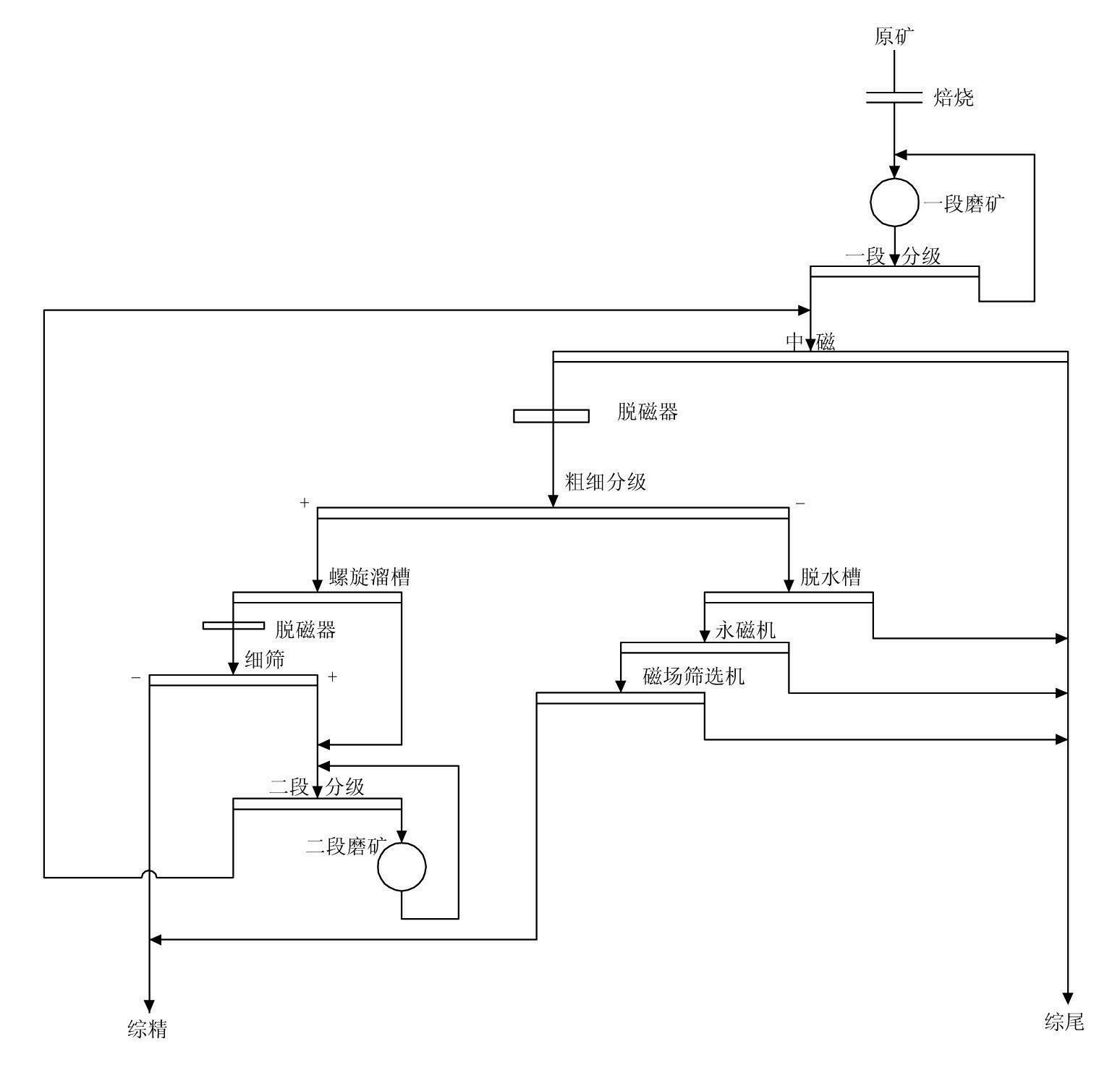

Hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique

ActiveCN102631984AImprove sorting efficiencyImproved technical indicatorsWet separationScreening proceduresClosed loop

The invention belongs to the technical field of iron ore grading and especially relates to a hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique, comprising raw ore roasting, first segment of closed loop grinding, primary grading, intermediate magnetic separation, fineness classifying and gravity concentration-magnetic separation. The technique is characterized by feeding the intermediate magnetic separation concentrate in a demagnetizer, grading the concentrate through fineness classifying, grading the material into rough granule level product and fine granule level product, feeding the rough granule level product in the fineness classifying procedure in a helical chute, demagnetizing the concentrate in the helical chute and performing screening procedure on the concentrate, serving the tailings in the helical chute and the oversize product in the screening procedure as middlings, performing secondary grading and second segment of closed loop grinding procedures on the middlings, and feeding the fine granule parts in the fineness classifying procedure in a dehydration tank, a permanent magnetic machine and a magnetic field screening machine to perform magnetic separation procedure. The comprehensive concentrate is composed of screening concentrate and magnetic field screening machine concentrate, and the compressive tailings are composed of intermediate magnetic separation tailings, dehydration tank tailings, permanent magnetic machine tailings and magnetic field screening machine tailings. The technique has the advantages that the sorting efficiency of the whole procedure is improved, the screening concentrate in rough granule procedure and the magnetic field screening machine concentrate in fine granule procedure can reach 65-67%, the level of the comprehensive concentrate is higher than 65-67%, and the level of the compressive tailings is reduced to 8-10%.

Owner:ANSTEEL GRP MINING CO LTD

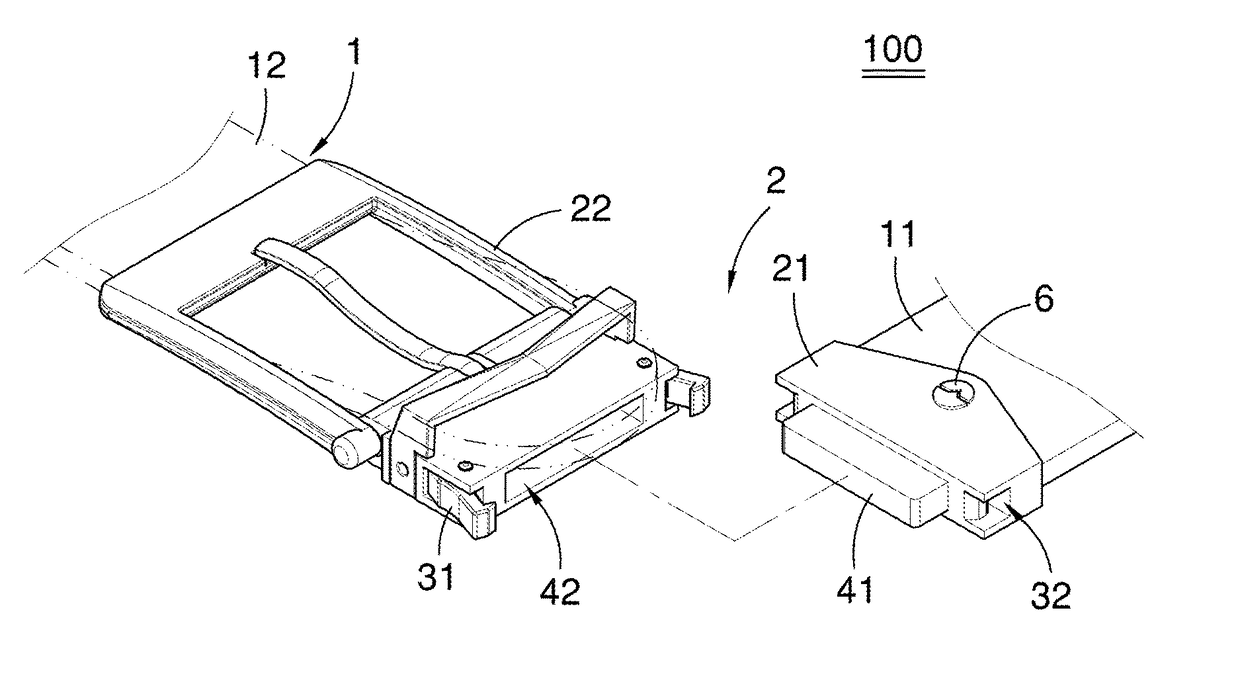

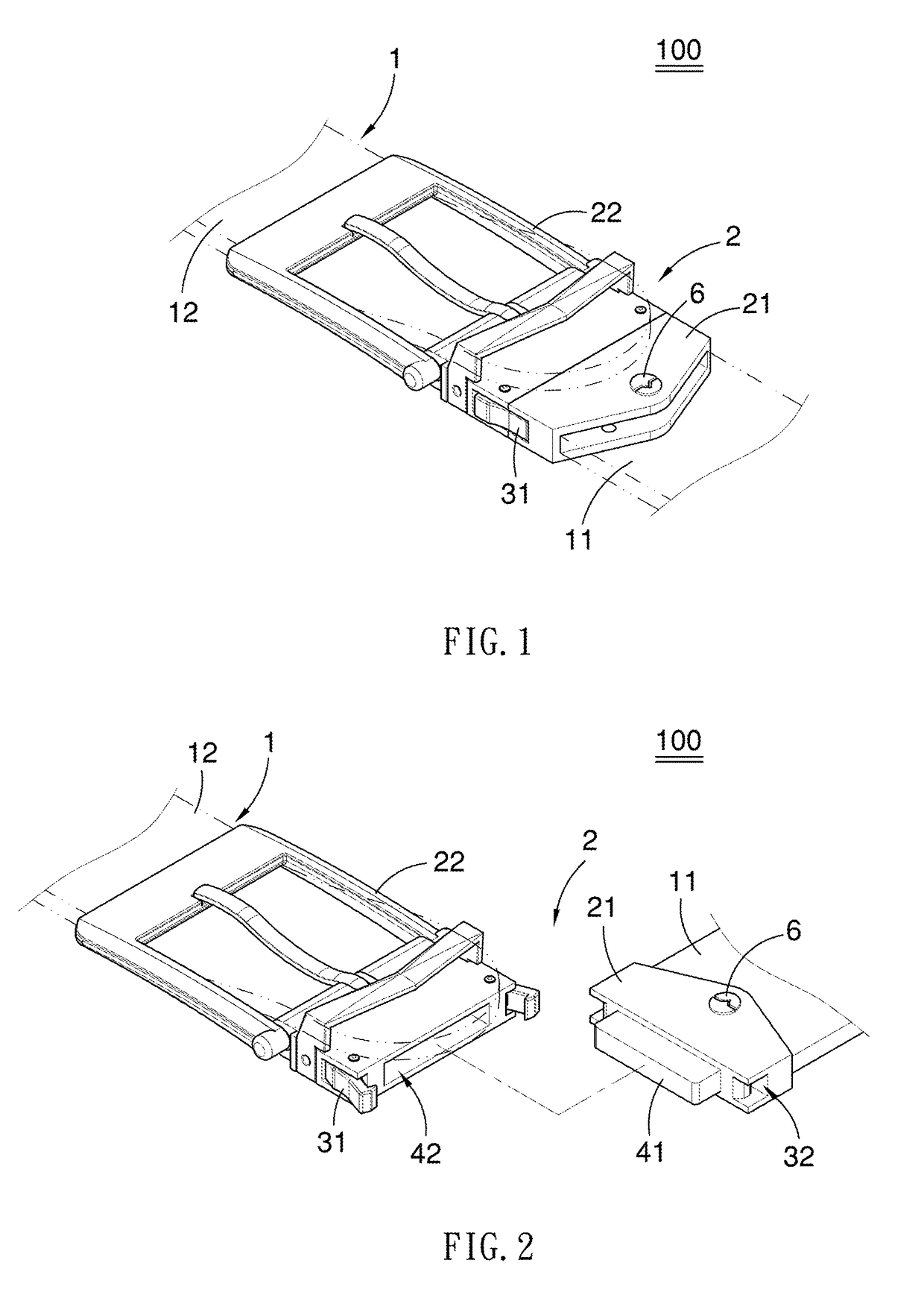

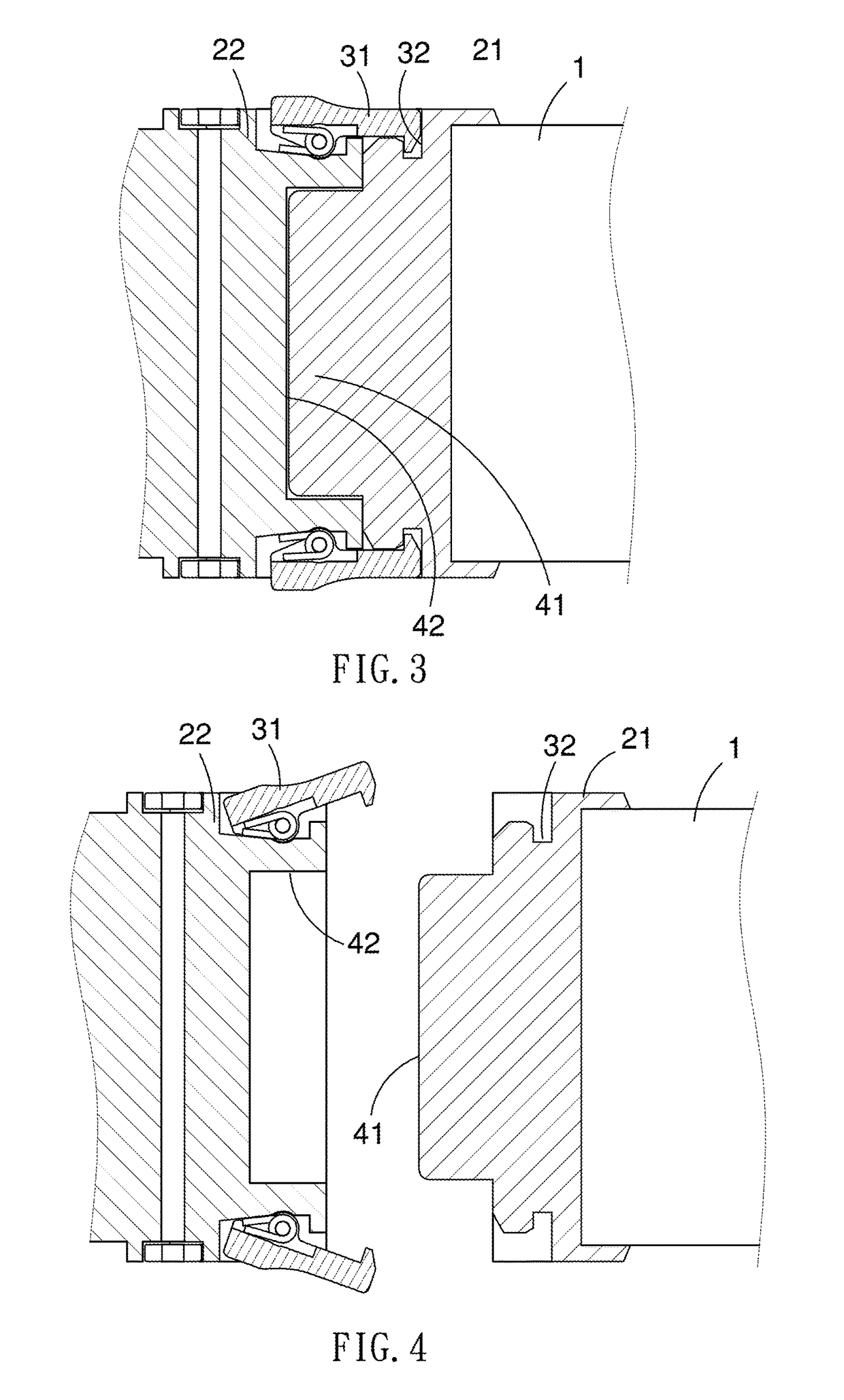

Quick release buckle belt for improving efficiency in security screening procedure and method thereof

InactiveUS9930936B2Improve efficiencyQuick releaseBucklesGarment beltsScreening proceduresMetallic materials

Owner:LIU HSIN TA

Novel fluorescence dyes and their applications for whole-cell fluorescence screening assays for caspases, peptidases, proteases and other enzymes and the use thereof

The present invention relates to novel fluorescent dyes, novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of caspases and other enzymes involved in apoptosis in whole cells, cell lines and tissue samples derived from any living organism or organ. The reporter molecules and assay processes can be used in drug screening procedures to identify compounds which act as inhibitors or inducers of the caspase cascade in whole cells or tissues. The reagents and assays described herein are also useful for determining the chemosensitivity of human cancer cells to treatment with chemotherapeutic drugs. The present invention also relates to novel fluorogenic and fluorescent reporter molecules and new enzyme assay processes that can be used to detect the activity of type 2 methionine aminopeptidase, HIV protease, adenovirus protease, HSV-1 protease, HCMV protease and HCV protease.

Owner:CYTOVIA INC

Apparatus and method of automating arrival and departure procedures in airport

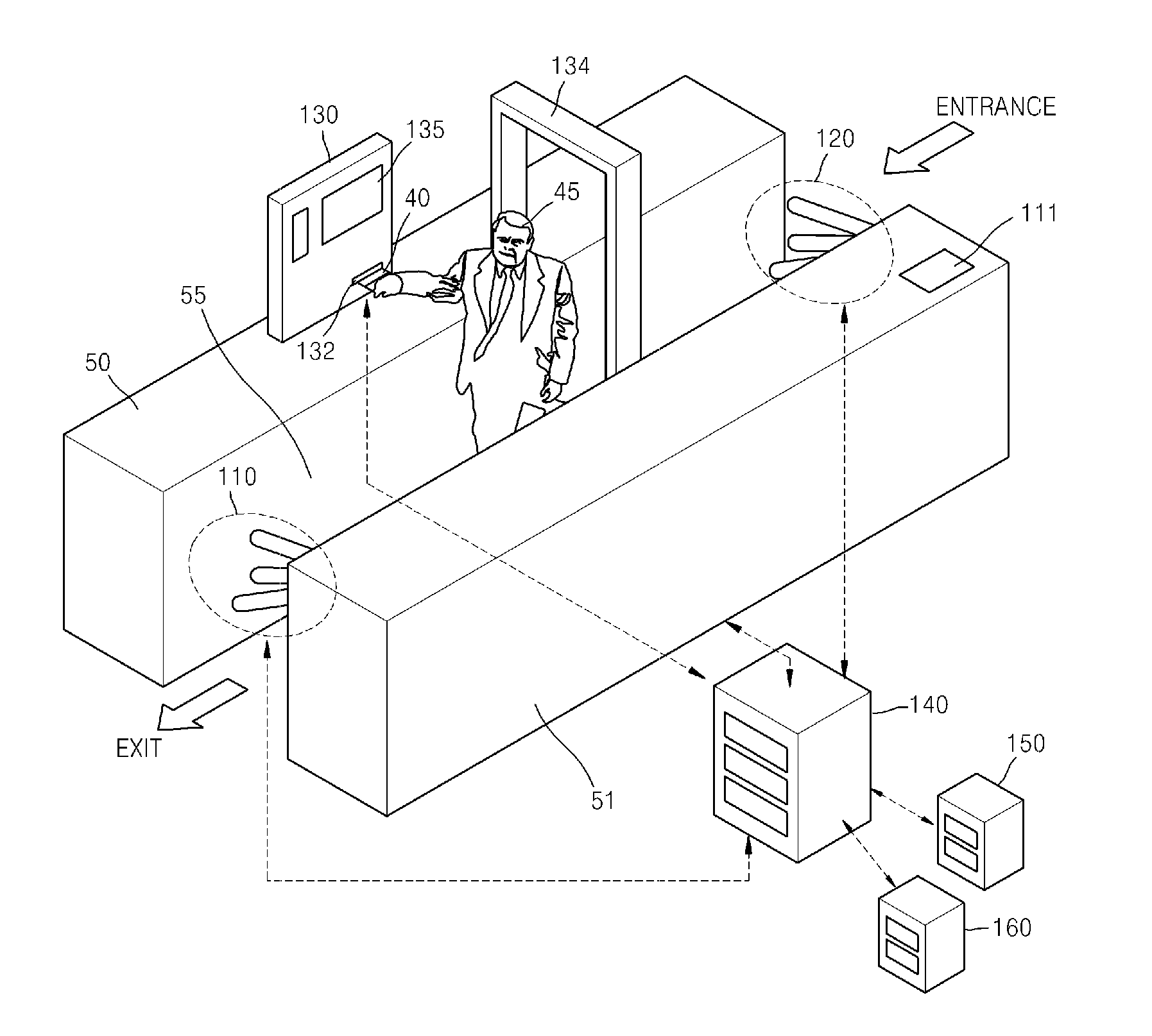

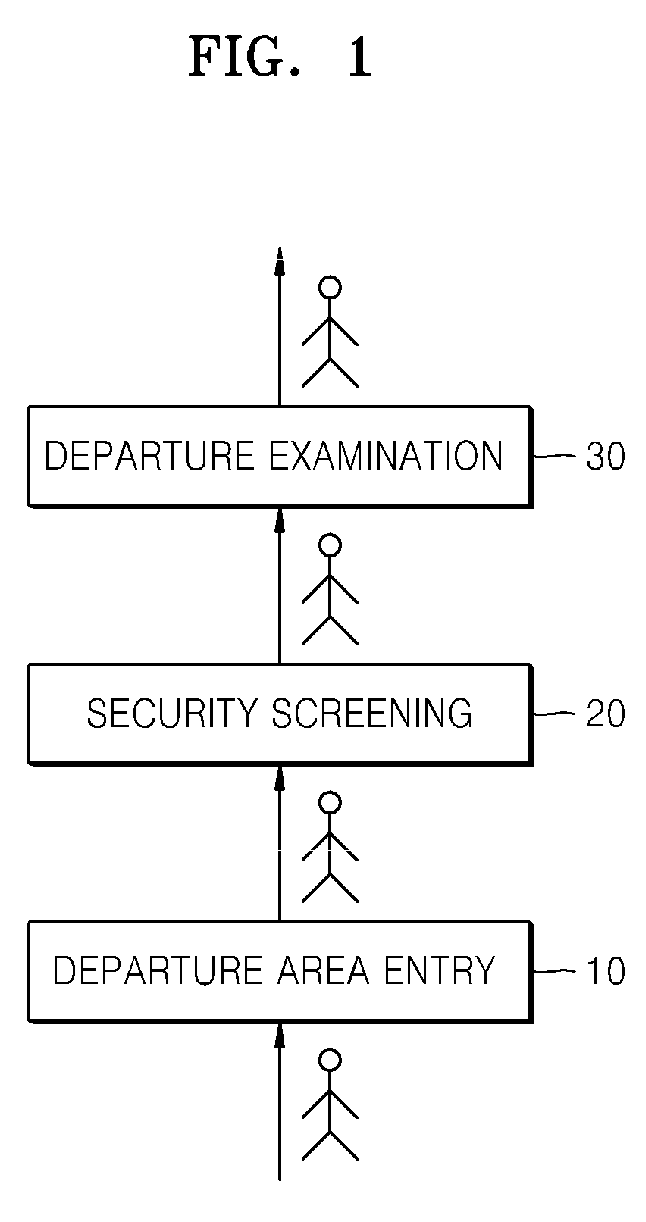

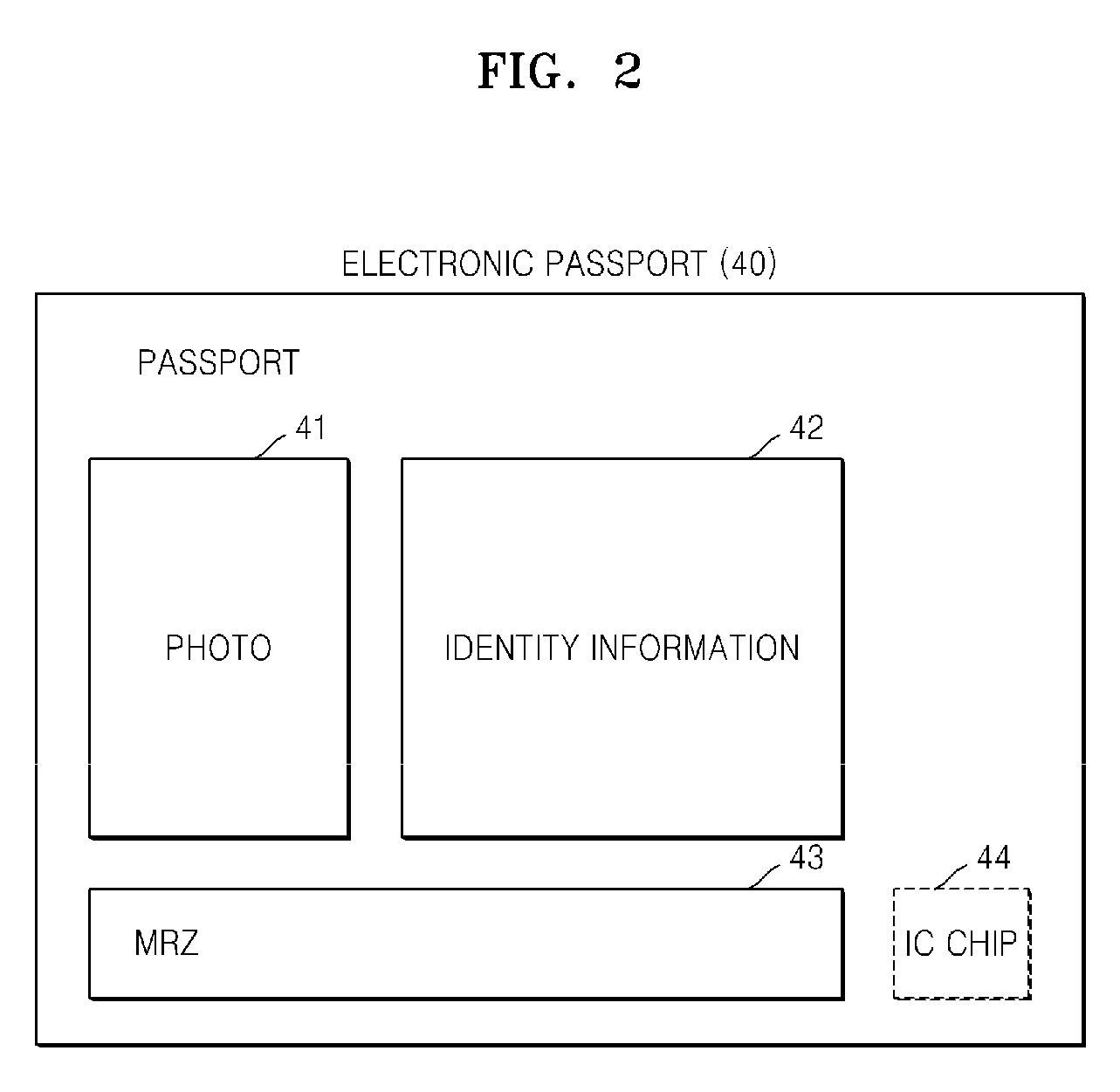

ActiveUS8127989B2Co-operative working arrangementsIndividual entry/exit registersScreening proceduresEngineering

The present invention relates to an apparatus and method of automating arrival and departure procedures in an airport, by which the forgery of a passport, the identity of a passport bearer, the arrival or departure permission according to a result of arrival and departure examinations, and the carry-on of prohibited items on the plane are automatically checked. The apparatus for automating arrival and departure procedures according to the present invention includes an exit gate, a departure automation apparatus, and may further include an entrance gate and a scanner. In the apparatus for automating arrival and departure procedures according to the present invention, a departure area entry procedure, a security screening procedure, and a departure examination procedure for departure passengers, which are conventionally performed separately in different areas, may be incorporated in the same area and performed therein.

Owner:INCHEONINT AIRPORT

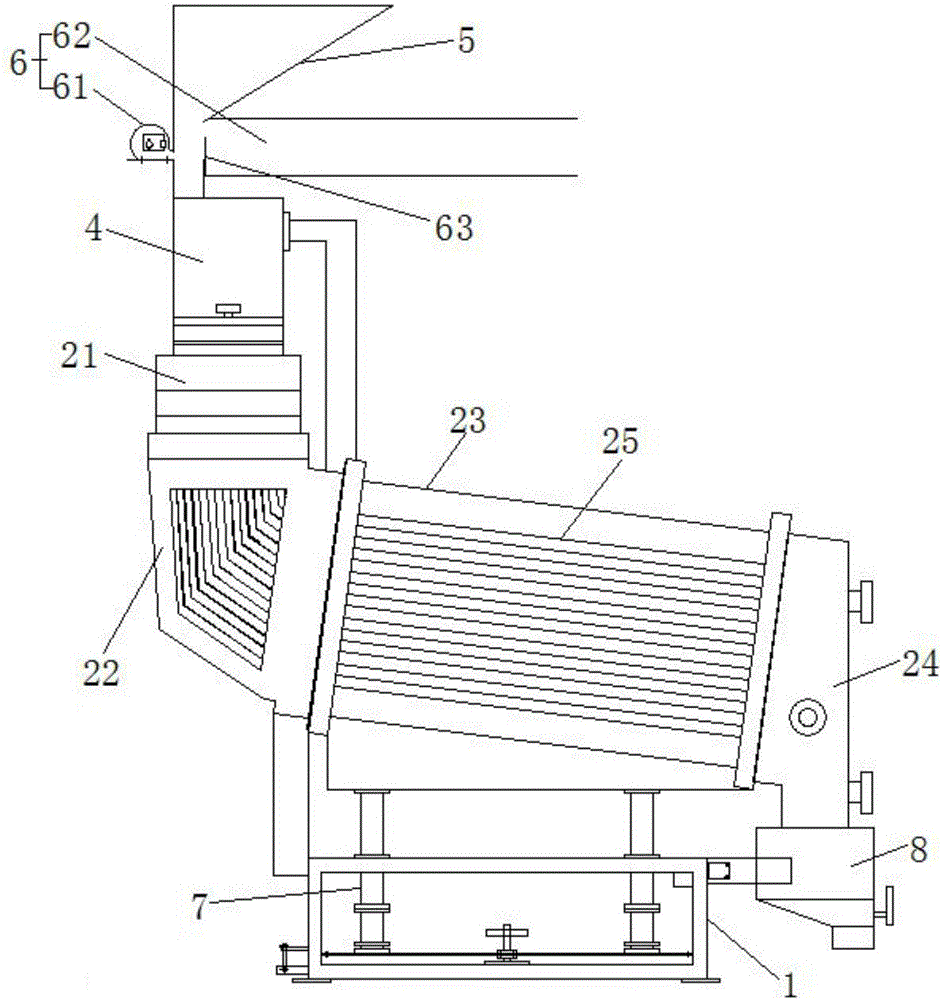

Rice-bran separator

ActiveCN105855169AEffective take outReduce maintenance frequencySievingGas current separationScreening proceduresEngineering

The invention relates to a rice-bran separator which comprises a base, a vibration screening mechanism, a vibration mechanism, a feeding cabin, a feeding funnel and an air separation dust collection system, wherein the vibration mechanism is fixed on the base; the vibration screening mechanism is arranged on one side of the vibration mechanism and is connected with the driving end of the vibration mechanism; the bottom of the vibration screening mechanism is hinged with the base through a plurality of connecting rods; a feeding hole is formed in the upper end of the vibration screening mechanism; a discharge hole is formed in the lower end of the vibration screening mechanism; the feeding cabin is arranged above the feeding hole; the bottom of the feeding cabin is communicated with the feeding hole; the feeding funnel is arranged above the feeding cabin; the bottom of the feeding funnel is communicated with the top of the feeding cabin; and the air selection dust collection system is arranged at the connecting part of the bottom of the feeding funnel and the top of the feeding cabin. The rice-bran separator has the advantages that the structure is simple, bran, dust and impurities can be effectively separated through two screening procedures of air separation and vibration screening, the efficiency is relatively high, problems that dust is adhered to a screening surface and normal use can be affected are avoided, the maintenance overhaul frequency of a machine is reduced, and the cost is reduced.

Owner:武汉竹禾粮食机械有限公司

Metabolite-peptide-aptamer rapid screening method based on molecular docking technology

ActiveCN108197429AAddressing Limiting Factors for Broad ApplicationNo damageProteomicsGenomicsScreening proceduresAptamer

The invention discloses a metabolite-peptide-aptamer rapid screening method based on the molecular docking simulating computation technology. The metabolite-peptide-aptamer rapid screening method includes the steps that (1) a target metabolite is determined; (2) a potential polypeptide library is obtained, wherein binding force exists between the potential polypeptide library and the target metabolite; (3) the potential polypeptide library and the target metabolite are subjected to molecular docking forecasting. The metabolite-peptide-aptamer rapid screening method is high in speed and wide intarget range, a large quantity of manpower and material resources are not required, harm to experimenter bodies is avoided, and limiting factors of wide application of current peptide aptamer are avoided. According to the metabolite-peptide-aptamer rapid screening method based on the molecular docking simulating computation technology, the peptide-aptamer screening procedure can be simplified, the library capacity is increased to a greatest degree, the metabolite peptide aptamer with the suitable specificity and affinity is thus conveniently screened out, and the metabolite-peptide-aptamer rapid screening method is used for designing such as kit and sensor detection, and is applied to detection of the field such as nutriology, biology and clinical diagnosis.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

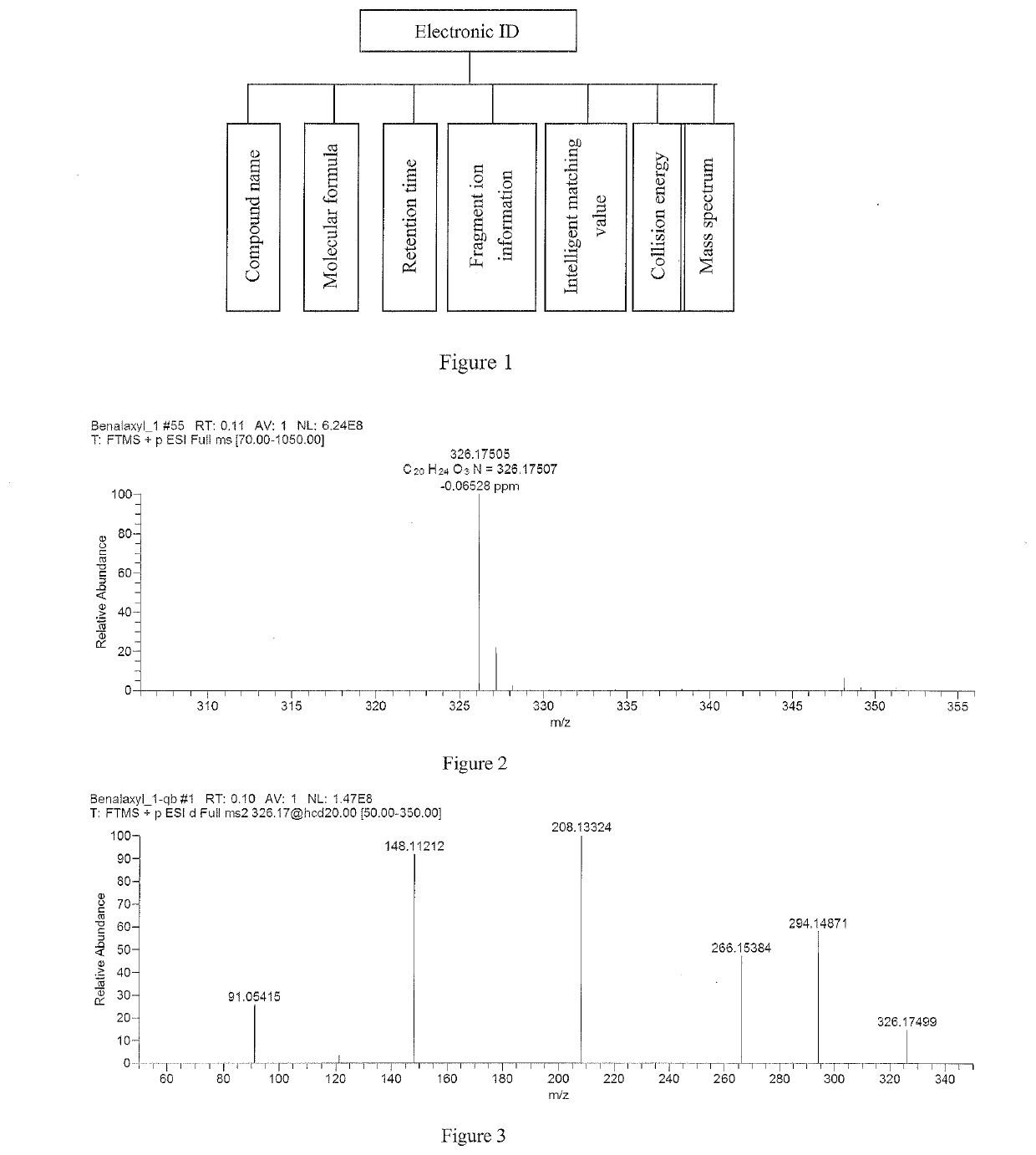

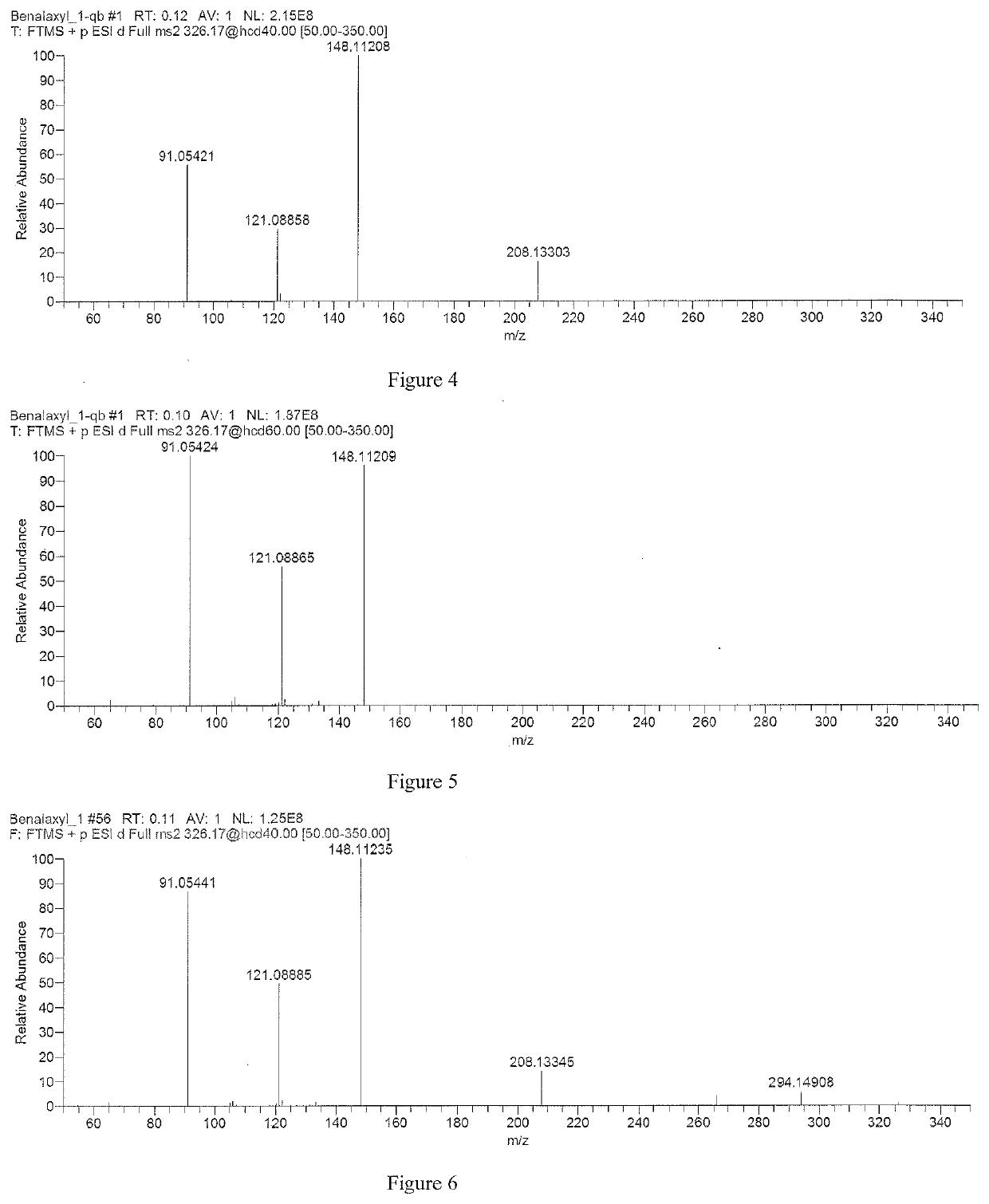

Electronic id database and detection method for pesticide compound in edible agro-products based on lc-q-orbitrap

ActiveUS20210223219A1Improve accuracyDetection technologyParticle separator tubesMolecular entity identificationScreening proceduresPesticide residue

Disclosed is an electronic ID database and detection method for pesticide compound in edible agro-products based on LC-Q-Orbitrap. The electronic ID database includes a collection of various pesticides compound electronic ID information, intelligent matching values and collision energies. It is ordered according to the retention time in the electronic ID. The electronic ID contains pesticide compounds information, retention time, adduct ions information, fragment ions information, collision energies, and the optimal full scan mass spectrum. The detection method includes sample pre-treatment, setting LC-Q-Orbitrap operating conditions and sample pesticide residue screening. Setting LC-Q-Orbitrap operating conditions contain setting suitable chromatography and mass spectrometry conditions. In pesticide residue screening procedures, firstly, the retention time is used to find pesticide compounds electronic ID database. If matching, the corresponding electronic ID information is extracted. Then the intelligent matching value is compared, if it is same, the result is recorded and displayed, and the screening is completed.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE +1

Natural rubber processing technique

The invention discloses a natural rubber processing technique which comprises the following procedures: crushing, creping, pelleting, drying, weighing and packaging. The natural rubber processing technique is suitable for mixing and processing rubber materials of different grades, a screening procedure is additionally set after the crushing procedure, and a hammer-crushing procedure is additionally set after the creping procedure. The invention aims to provide the natural rubber processing technique which is capable of enabling the processed rubber to be relatively high in consistency, stability and cleanness.

Owner:景谷民森橡胶有限责任公司

Methods for making improved strand wood products and products made thereby

InactiveUS20080000547A1Low variabilityDomestic articlesLignocellulosic moulding material treatmentScreening proceduresWire rod

An overall method of making engineered strand wood products in relation to a number of different possible criteria is provided. Such a method may involve any combination of different screening procedures to determine the best wood sources from which individual strands may be prepared. Such screening procedures may include initial determinations of certain physical characteristics of individual logs, further or initial determinations of certain physical characteristics of portions of sawn logs, further or initial determinations of certain physical characteristics of individual strands, and any combinations thereof. Additionally, after the initial physical characteristic sorting is completed, optionally the wood may be cut into uniformly sized and shaped strands for incorporation within a target strand product. Still further, such strands, in substantially uniform size and shape, as well as substantially uniform physical characteristics, may then be incorporated into a target strand product in specific predetermined configurations. Such various possible combinations of screening procedures and / or selective stranding processes results in strand products (boards, lumber, and the like) of improved properties over previously made strand products. Thus, encompassed within this invention are processes involving each of these procedures either individually or in combination with other sequential processes for the production of desired strand products.

Owner:HUBER ENGINEERED WOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com