Machine-made gravel processing technology

A processing technology, sand and gravel technology, applied in the field of machine-made sand and gravel processing technology, can solve problems such as high-pressure water washing or high-pressure air separation effect is not ideal, particle shape optimization is not accurate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

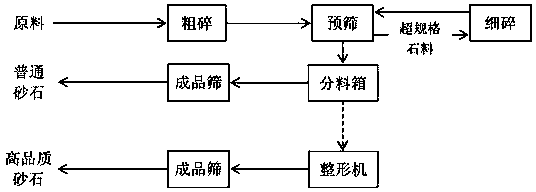

Method used

Image

Examples

Embodiment 1

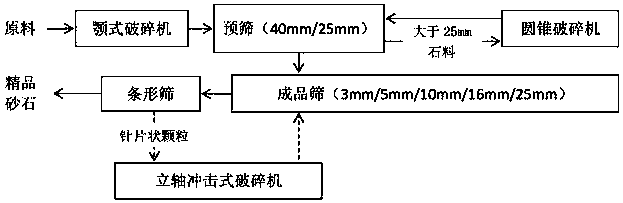

[0056] Application case of a stone mine in Zhenjiang, Jiangsu

[0057] The mine mainly produces high-quality machine-made sand and gravel, which are mainly used for expressway road fabrics and special concrete materials. According to this process, the mine process flow is as follows Image 6 shown. Among them, the screening process is firstly screened into 0-3mm, 3-5mm, 5-10mm, 10--16mm, 16- 25mm and other specifications, 3-5mm, 5-10mm, 10--16mm, 16-25mm are screened through 2*16mm, 3*25, 5*40mm, 8*60mm bar sieves respectively. The needle flake stones screened by the bar screen enter the vertical shaft impact crusher for shaping and crushing, and return to the screening system to realize a closed loop. The needle flake of the product is less than 1%; the installed power of the screening and shaping process is nearly 35% lower than that of the ordinary screening and shaping process.

Embodiment 2

[0059] Application case of a mine in Huzhou, Zhejiang

[0060] The enterprise uses ordinary stone to process high-quality stone. When ordinary stone is processed, it is first moistened with water at a ratio of 8-12%, and then transported to the raw material pile in the high-quality workshop for storage for about 24 hours. The content of high-quality machine-made sand and gravel mud powder is less than 1‰ (< standard 5‰), and the comprehensive water consumption per ton of finished products is 0.52 cubic meters. The products are widely used in high-speed railways, pipe piles, high-rise buildings, etc.

Embodiment 3

[0062] Application case of a mine in Lanzhou, Gansu

[0063] (1) 5-10mm stone gradation optimization

[0064] The company used a two-layer sieve for 5-10mm screening in the early stage. The mesh parameters of the screen are 10*10mm and 5*5mm. Due to the low screening rate of 5mm, the gradation of 5-10mm has not been up to standard. Based on this process, through transformation, a layer of 6.5mm screen is added between the above two layers of screens, and the 5mm screening efficiency is increased by 25%. At the same time, at the discharge end of the vibrating screen, a hydraulic push rod is added to push the baffle plate to divide the material, and part of the 5-6.5mm stone is removed, and the 5-10mm stone gradation is better optimized, such as Figure 7 shown.

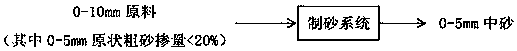

[0065] (2) Optimization of sand making system

[0066] Before the improvement of the sand making system of this enterprise, the raw materials are mainly 5-10mm stone, mixed with no less than 20% of 0-5mm original co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com