Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164 results about "Shape optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shape optimization is part of the field of optimal control theory. The typical problem is to find the shape which is optimal in that it minimizes a certain cost functional while satisfying given constraints. In many cases, the functional being solved depends on the solution of a given partial differential equation defined on the variable domain.

Design Optimization System

ActiveUS20110137443A1Geometric CADDesign optimisation/simulationCritical structureTopology optimization

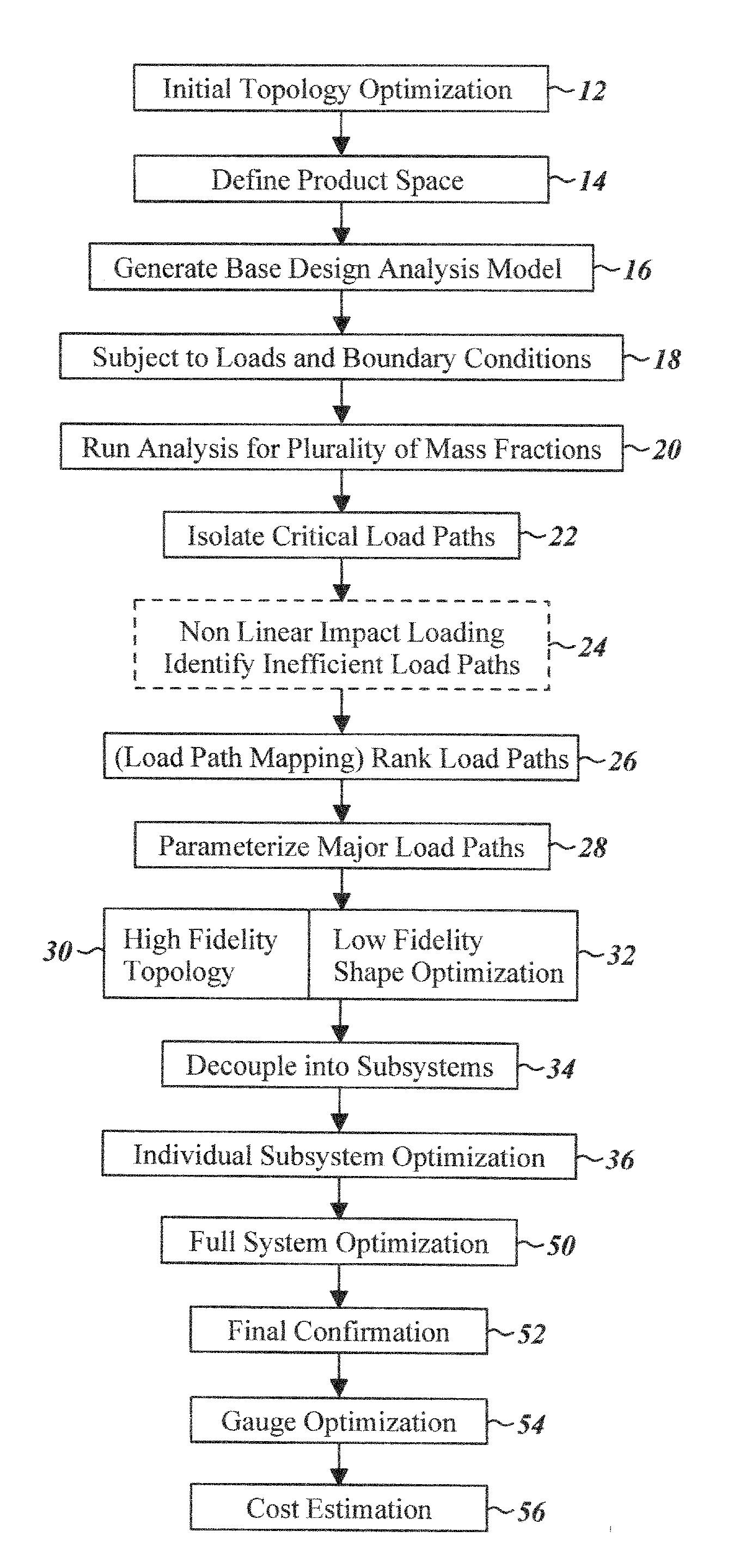

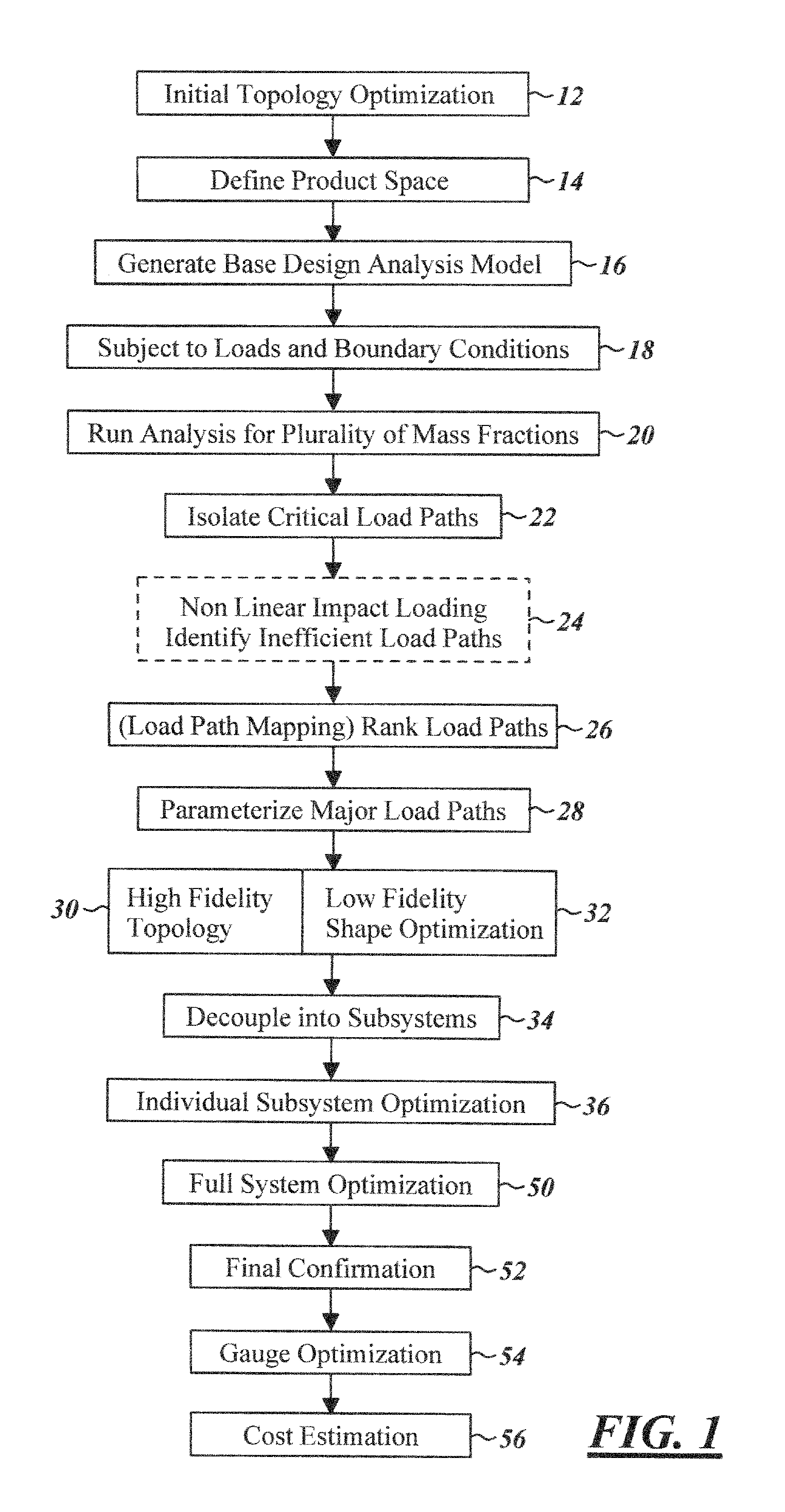

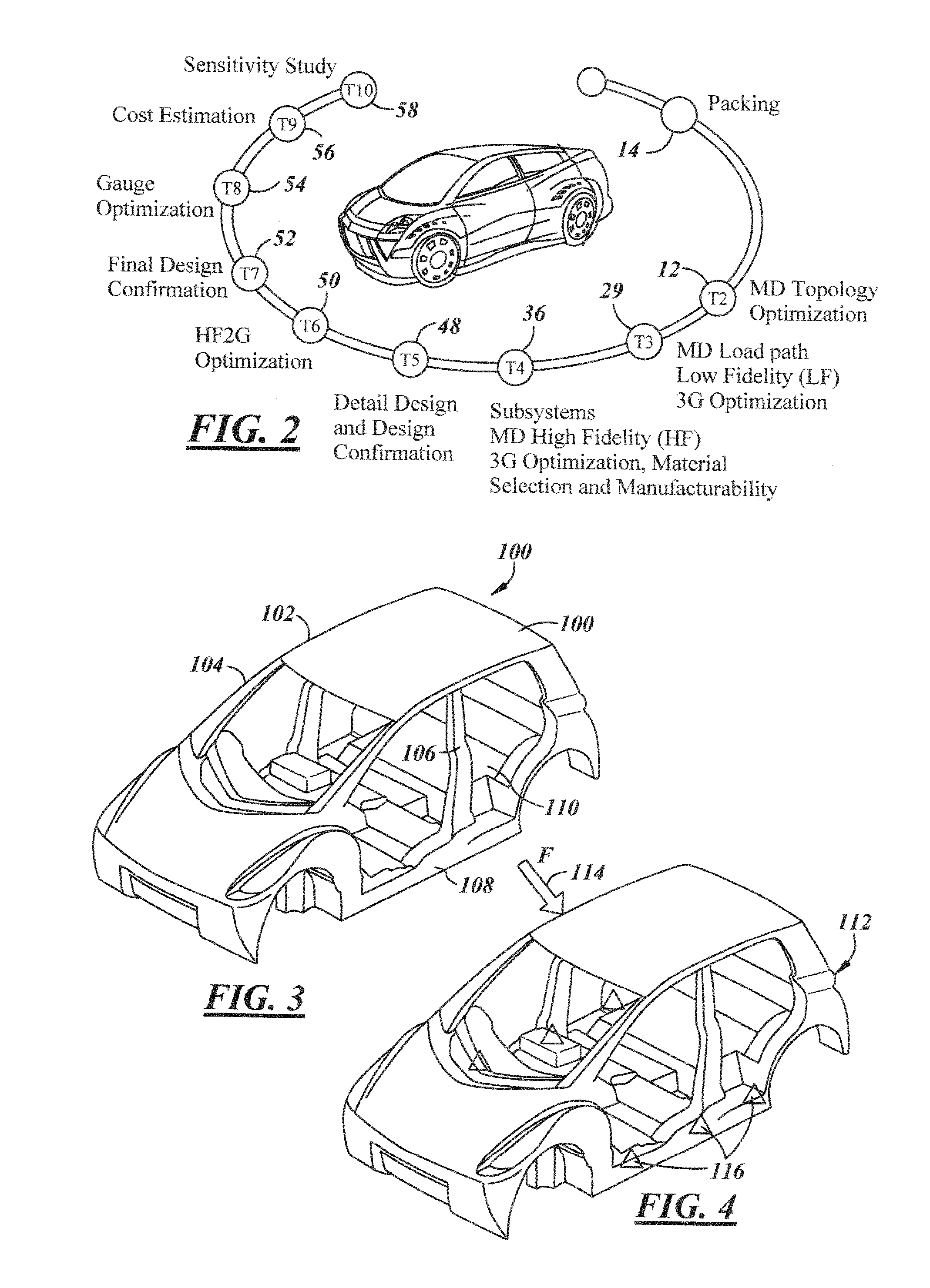

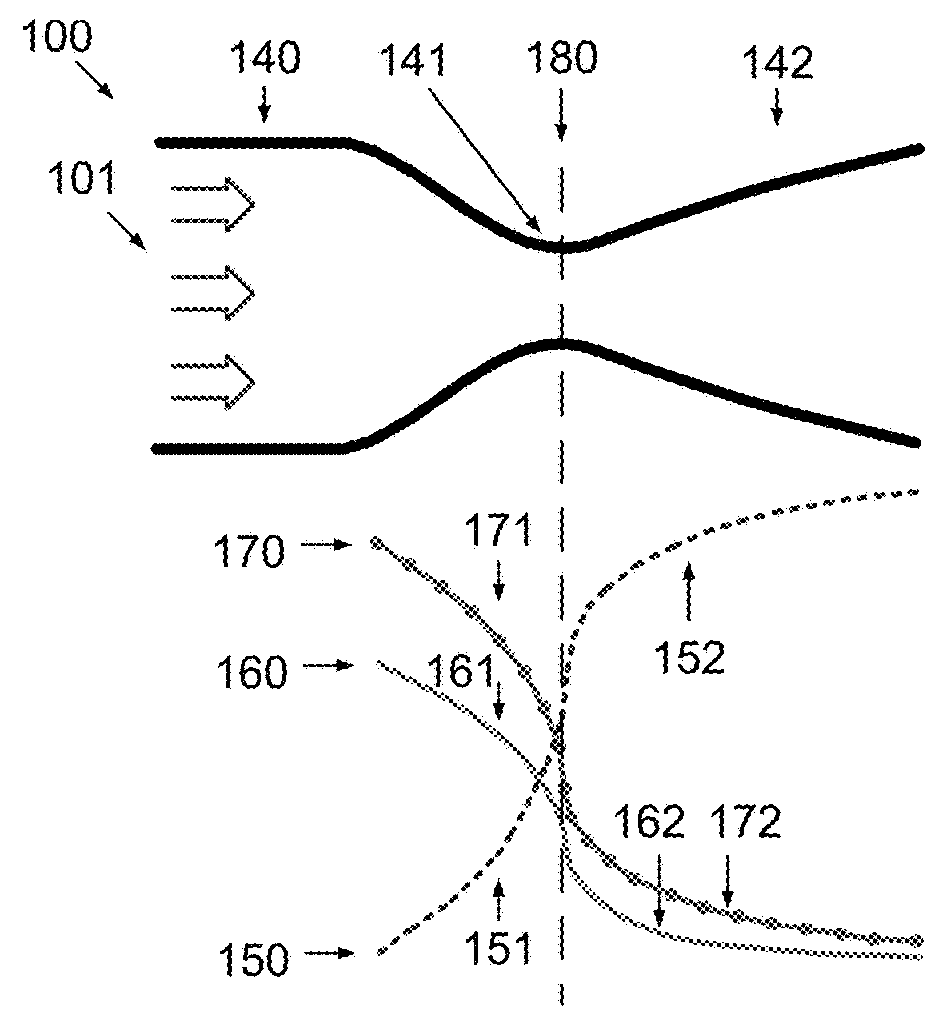

In accordance with the objects of the present invention, a method of complex product design is provided. The method defines a product design space a base design analysis model is then automatically generated within the product design space. A topology optimization of the base design analysis model is performed including solving the topology optimization for multiple mass fractions to identify critical structure areas. The results of the topology optimizations are utilized to identify a plurality of load paths. An optimization of said plurality of load paths is performed to find the optimized load paths. Critical structure areas along the plurality of optimized load paths are then parameterized. An optimization is performed utilizing a multi-disciplinary optimization to optimize geometry, material and thickness along the optimized load paths. A manufacturing analysis of the shape optimized structure is performed and the shape optimized structure is modified to comply with manufacture requirements. An optimization is then performed using multi-disciplinary optimization comprising a gauge and grade optimization.

Owner:NITED STATES STEEL CORP +1

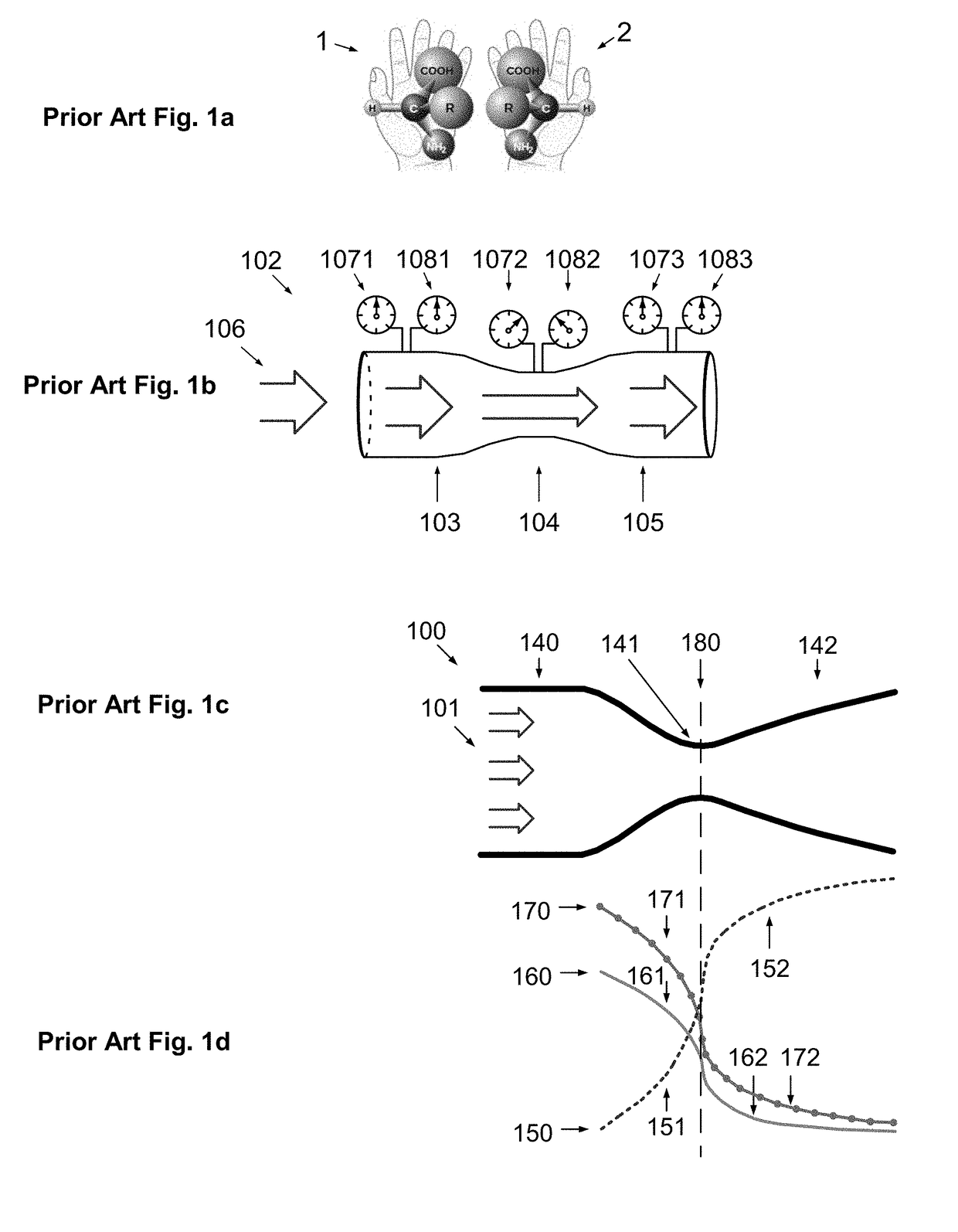

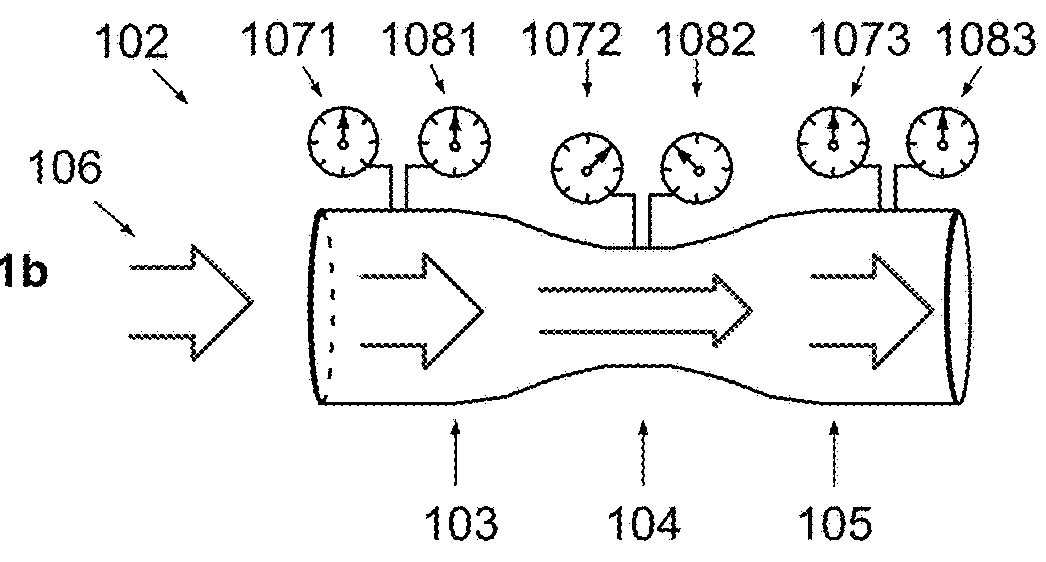

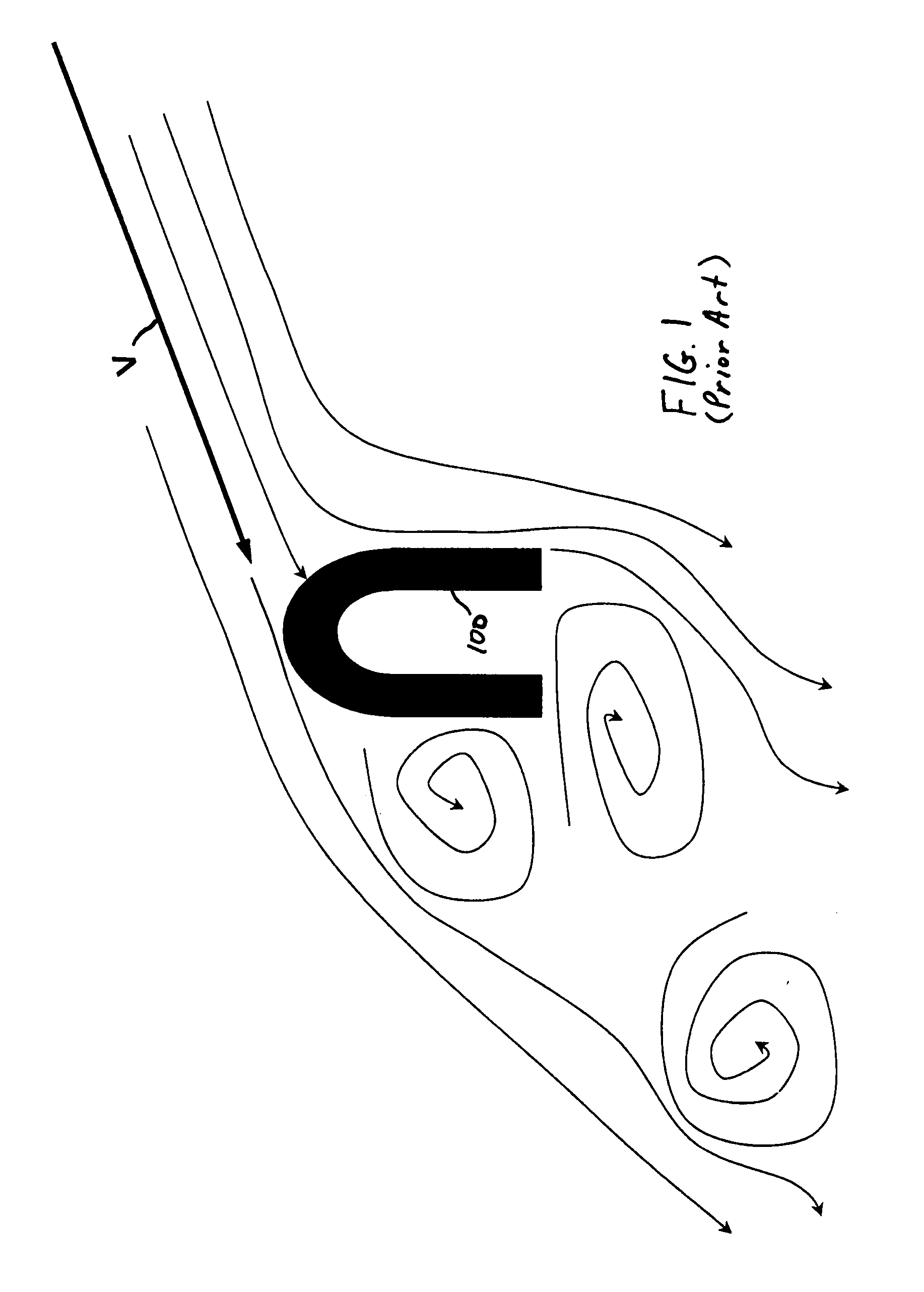

Generalized Jet-Effect

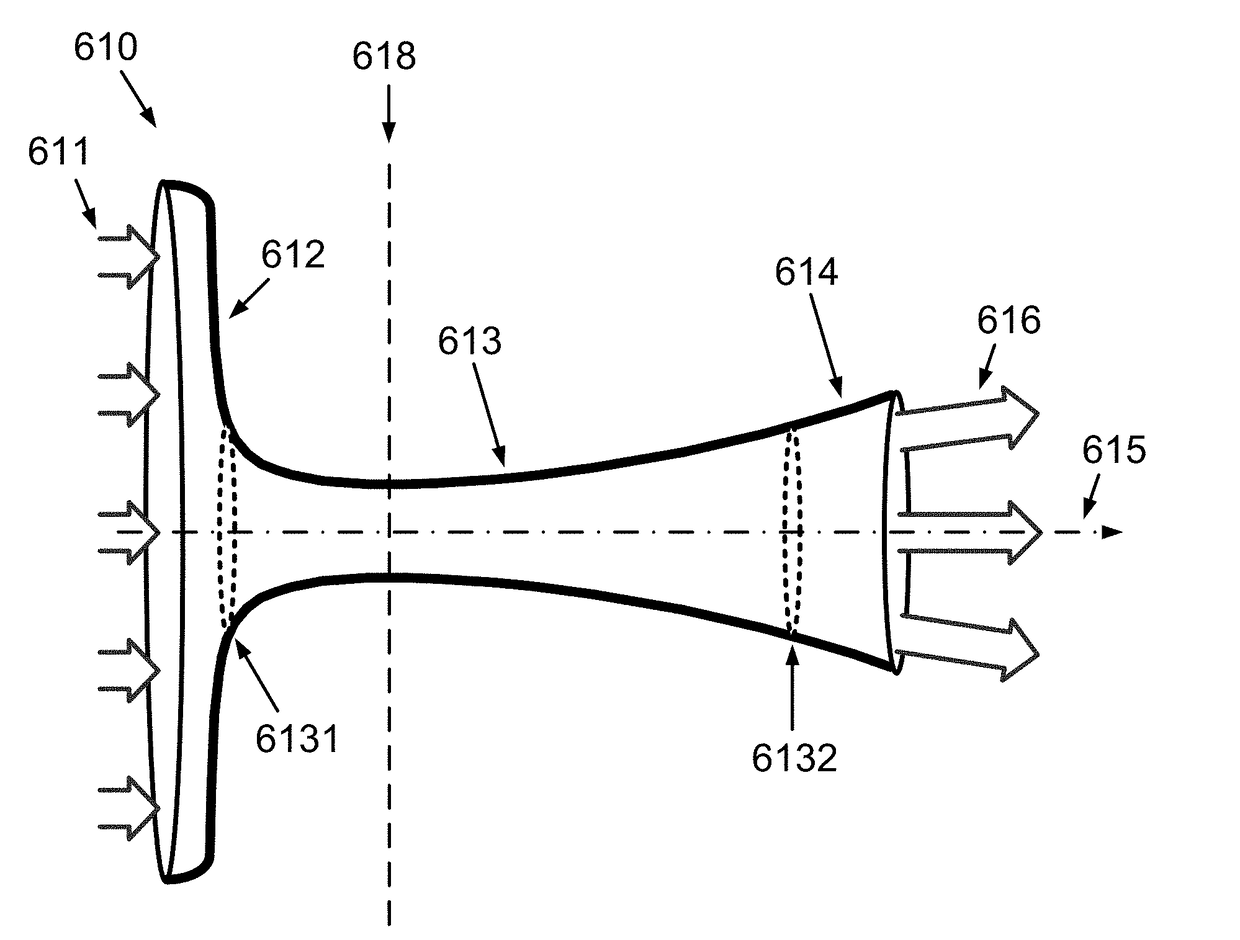

The invention provides a method for computational fluid dynamics and apparatuses making enable an efficient implementation and use of an enhanced jet-effect, either the Coanda-jet-effect, the hydrophobic jet-effect, or the waving-jet-effect, triggered by specifically shaped corpuses and tunnels. The method is based on the approaches of the kinetic theory of matter, thermodynamics, and continuum mechanics, providing generalized equations of fluid motion. The method is applicable for slow-flowing as well as fast-flowing real compressible-extendable fluids and enables optimal design of convergent-divergent nozzles, providing for the most efficient jet-thrust. The method can be applied to airfoil shape optimization for bodies flying separately and in a multi-stage cascaded sequence. The method enables apparatuses for electricity harvesting from the fluid heat-energy, providing a positive net-efficiency. The method enables efficient water-harvesting from air. The method enables generators for practical-expedient power harvesting using constructive interference of waves due to the waving jet-effect.

Owner:SOLITON HLDG CORP DELAWARE CORP

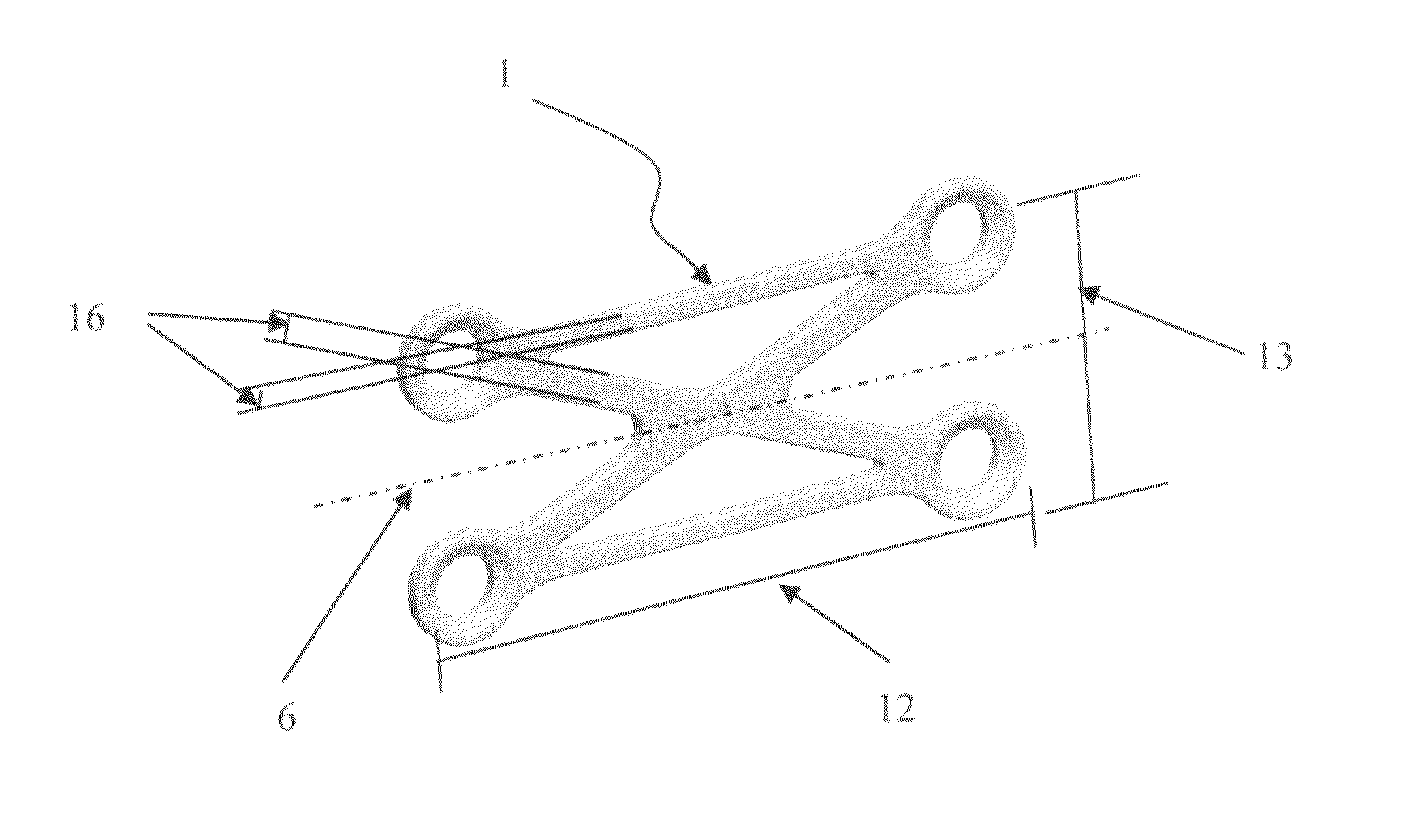

Osteosynthesis plate, method of customizing same, and method for installing same

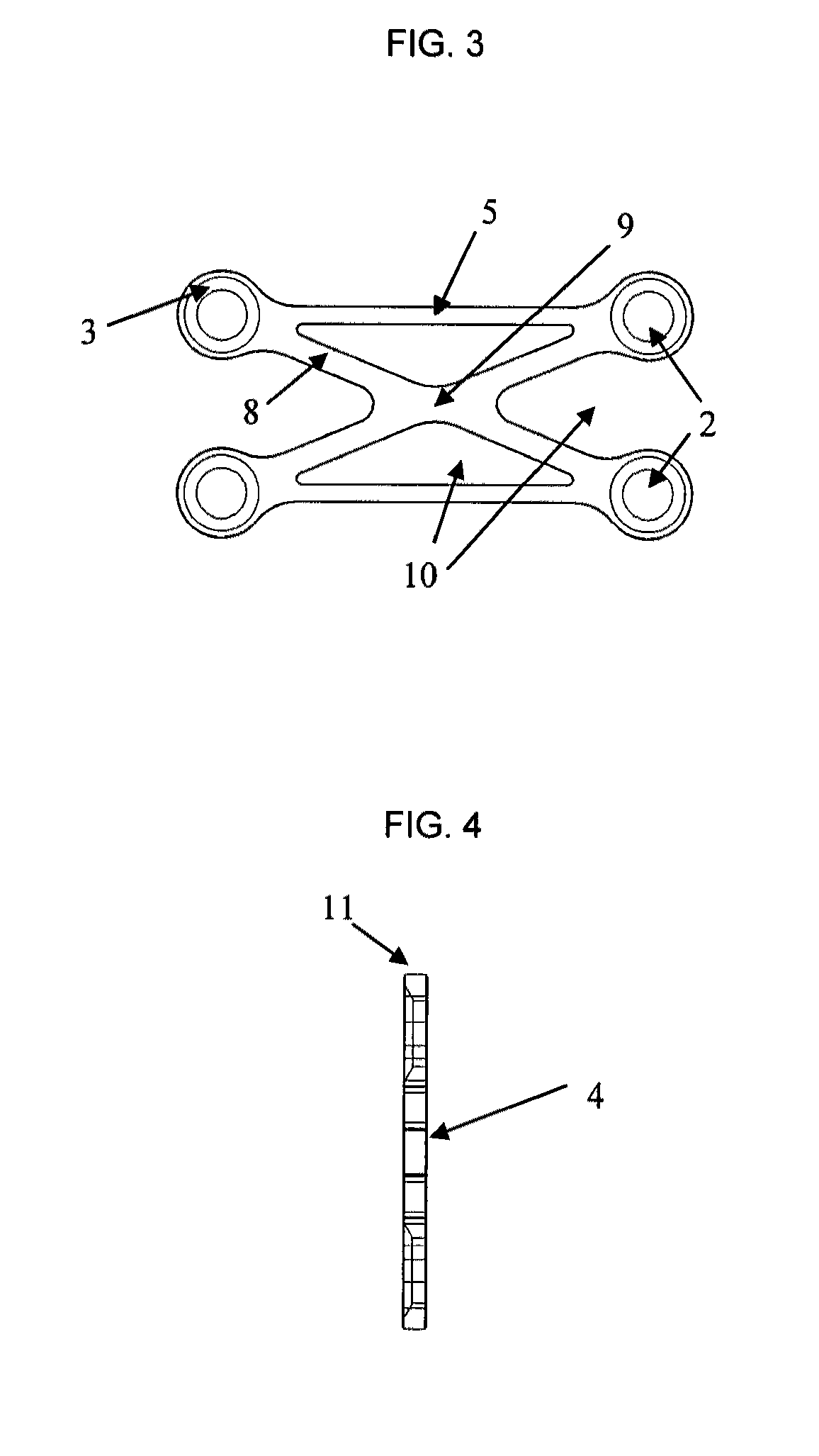

InactiveUS8246663B2Improve stabilityMinimally intrusiveDental implantsJoint implantsAnatomical structuresAcute angle

An implant for osteosynthesis used in the stabilization of fractured bone of the mandible. The plate consists of apertures through which the plate is secured to bone using surgical screws. The apertures are connected by (a) two lateral bar sections running approximately parallel to the long axis of the mandible and (b) two cross bar sections intersecting each other near the centroid of the plate and at acute angles to the lateral bar sections. The plate design can be modified to accommodate patient anatomy depending on the type of bone it is designed to stabilize. Design and size parameters of the fixation plate can be customized to each individual patient using a customization software application to determine the least invasive fixation plate that will provide adequate functioning in stabilizing the bone fracture to a degree that will allow safe bone healing. The invention includes a method of design of osteosynthesis plates using shape optimization for different types and locations of fractures.

Owner:LOVALD SCOTT

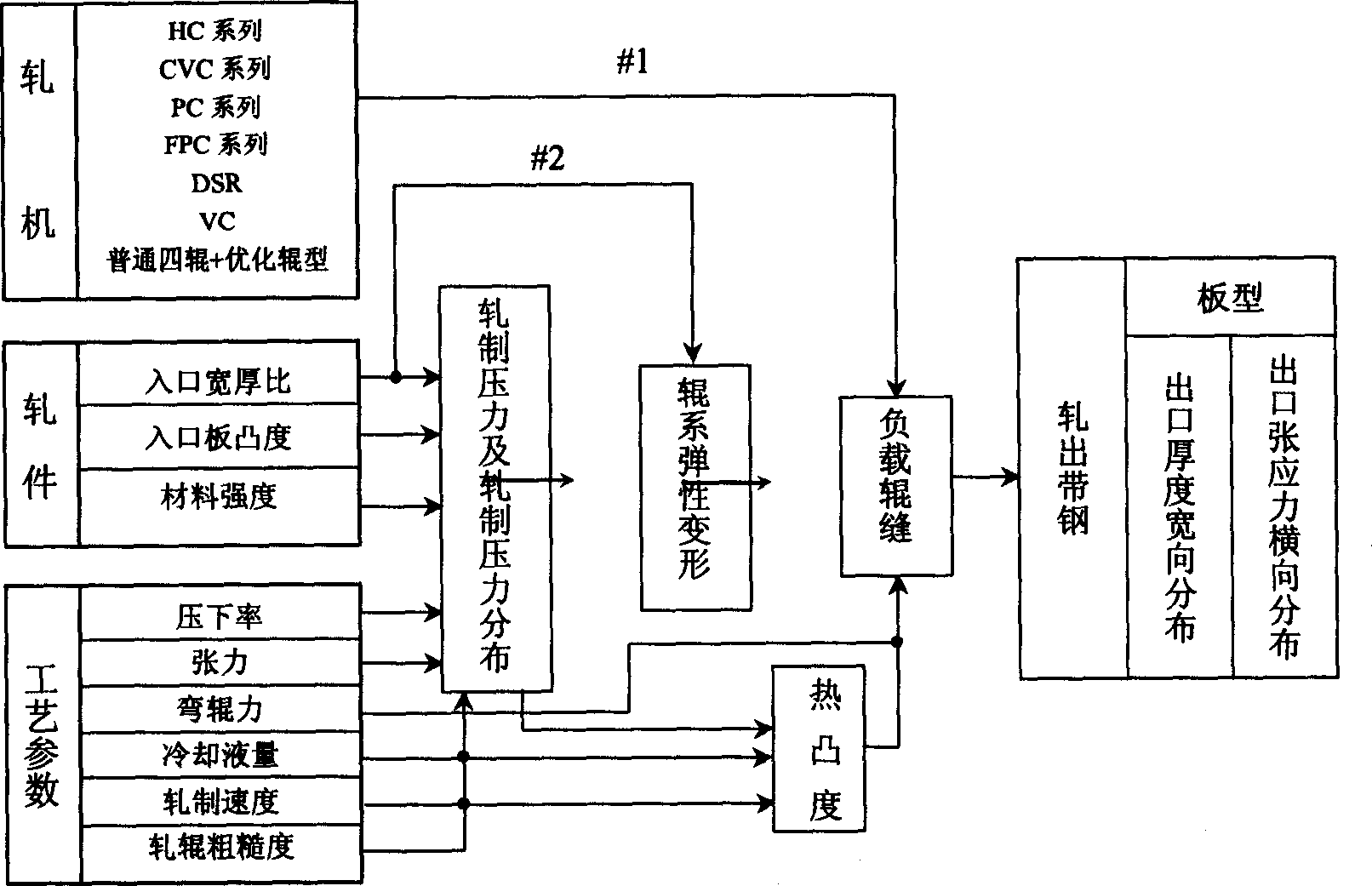

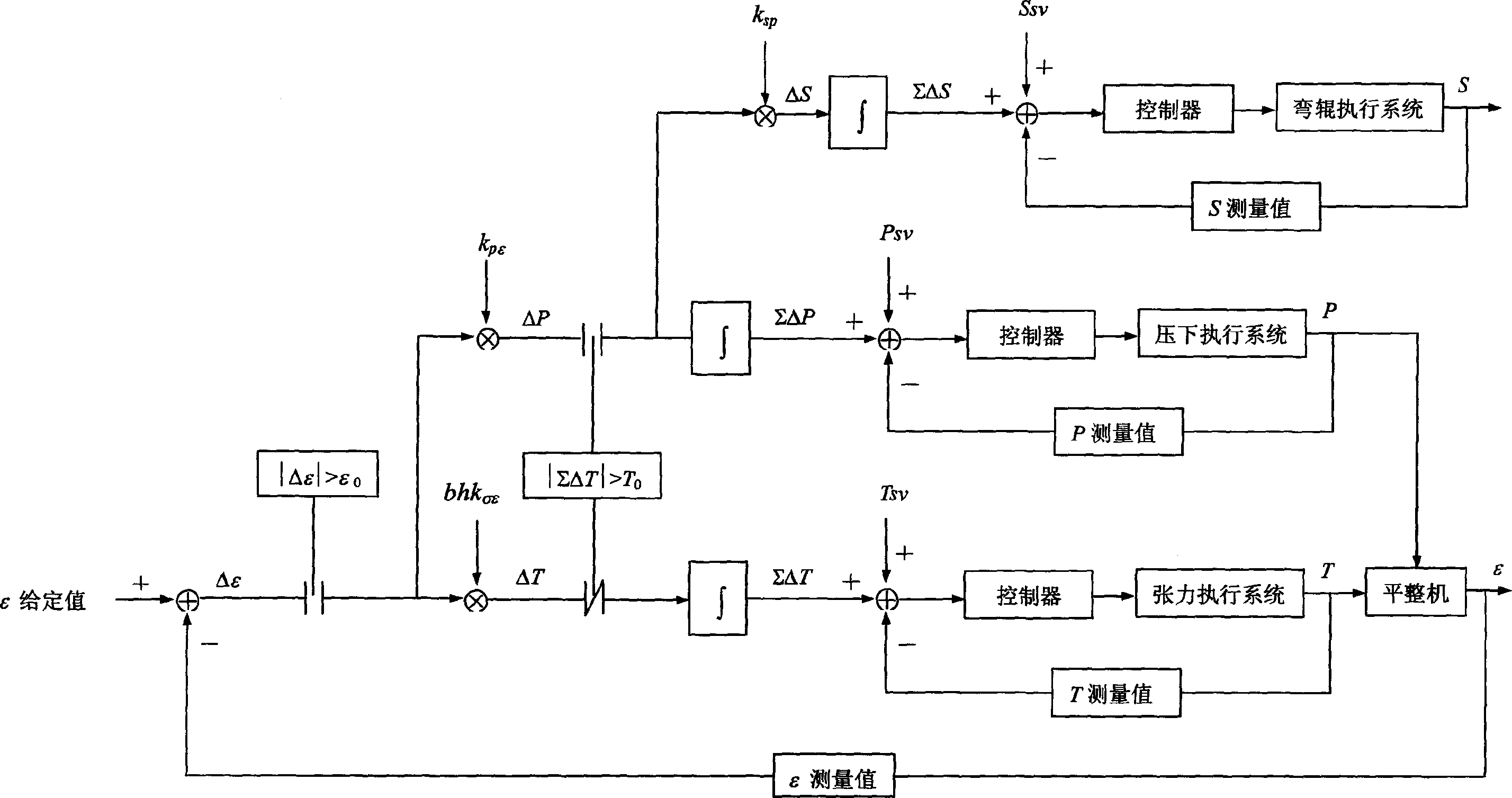

Flattening process for steel strip

The invention discloses a belt steel flattening craft, which is comprised the following parts: flattening roll roll-shape optimization design, flattening processing parameter optimization design initialization and elongation and slab-shaped composite optimization control, therein the craft doesn't need to draft flattener, which can guarantee export belt steel board mold and mechanical property on one common planisher; the invention is fit for hot-dip coating zinc units and annealed flattening; the belt steel slab-shaped guarantee value is 4-6T; the hit ratio is more or equal to 97%; the elongation control accuracy is smaller or equal to +-0.1%.

Owner:BAOSHAN IRON & STEEL CO LTD

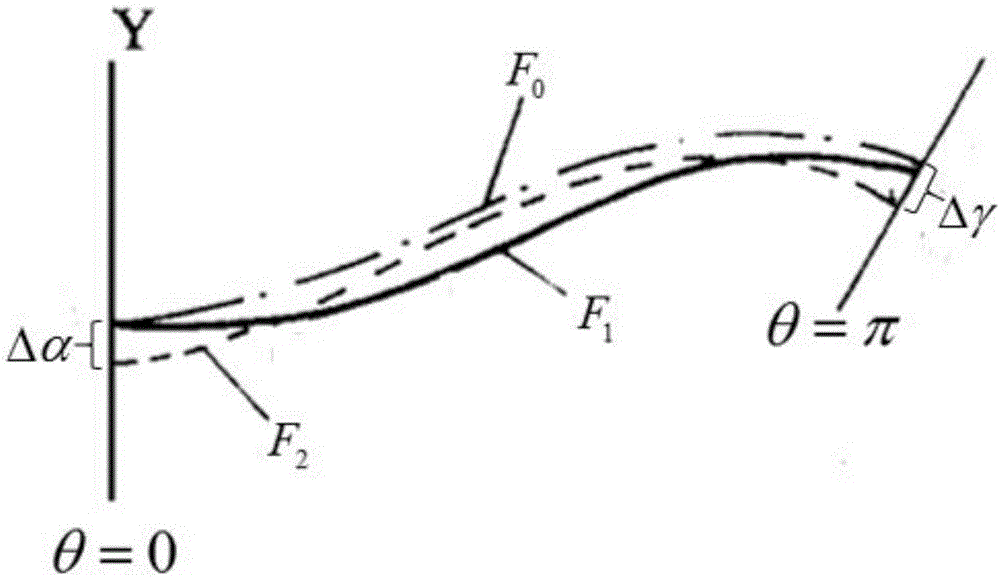

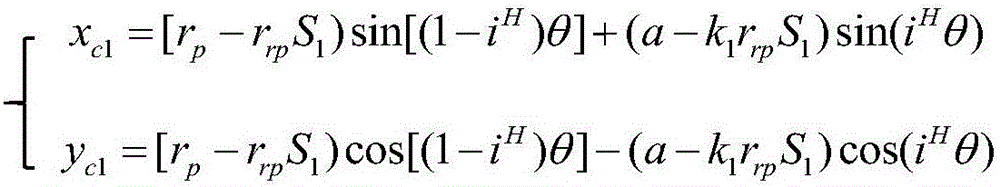

Optimization method of cycloid pin wheel profile modification based on particle swarm algorithm

ActiveCN106227918AShort calculation cycleImprove calculation accuracyGeometric CADArtificial lifeGlobal optimizationShape optimization

The invention discloses an optimization method of cycloid pin wheel profile modification based on particle swarm algorithm, and the method comprises the steps of determining a design variable and an object function according to a basic parameter of a cycloid wheel; re-determining a constrained condition according to a traditional constraint method and constraint requirements to a reshaped cycloid wheel tooth tip gap and a tooth root gap provided by the invention; playing the global optimization ability of particle swarm optimization algorithm in combination with the reshaped characteristics of the cycloid wheel to construct a particle swarm optimization algorithm model after the cycloid wheel shaping optimization; making an optimization object that the reshaped tooth profile can get close to a corner shaping tooth profile maximally and a return difference as small as possible is guaranteed, and further increasing the constraint requirement to the tooth tip gap and the tooth root gap on the basis of the traditional constraint, thereby obtaining a shaping tooth profile with an optimal equidistant and offset. In this way, the invention discloses the optimization method of cycloid needle wheel tooth profile modification based on the particle swarm algorithm with a short calculating period and high calculating precision, and the effect is good.

Owner:BEIJING UNIV OF TECH

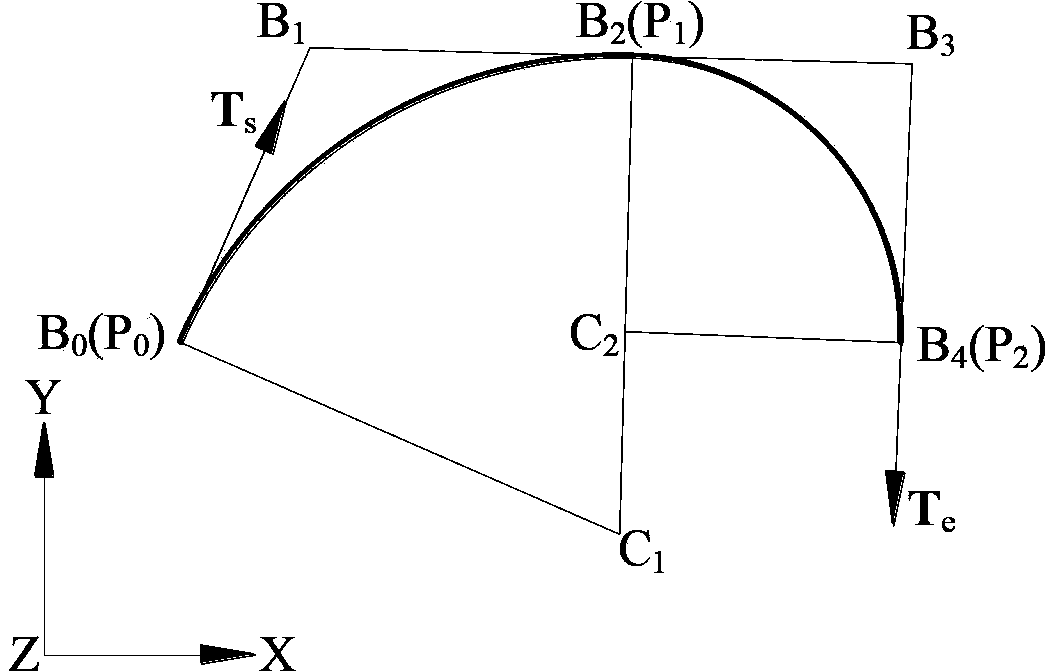

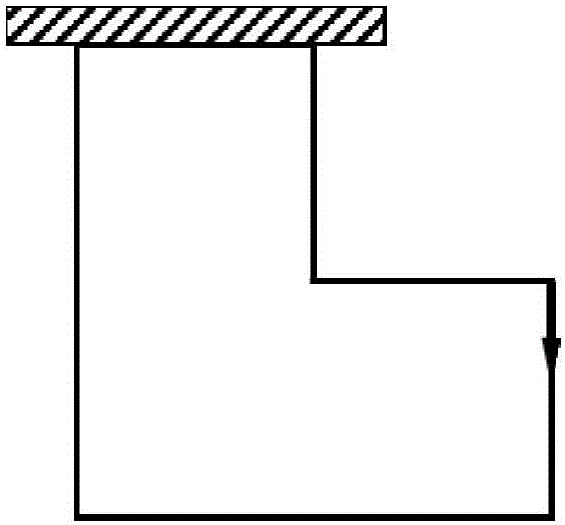

Structural topology-shape combined optimization method based on multi-arc-section curve under pressure load

ActiveCN103425831APracticalSpecial data processing applicationsNumerical controlManufacturing technology

The invention discloses a structural topology-shape combined optimization method based on a multi-arc-section curve under pressure load, and the structural topology-shape combined optimization method based on the multi-arc-section curve under pressure load is used for solving the technical problem that an existing structural topology-shape collaborative optimization method under pressure load is poor in practicality. According to the technical scheme, a NURBS spline interpolation value is adopted to describe the pressure load action boundary curve section, NURBS curve controlling points are shape design variables independent of the topological design variables; structural topology-shape combined optimization is conducted; after the optimization is conducted, the outline boundary needed to be machined and manufactured in a numerical-controlling mode is replaced by the multi-arc-section curve, and fine shape optimization is conducted on the outline of the multi-arc-section curve. The structural topology-shape combined optimization method based on the multi-arc-section curve under pressure load can carry out topology-shape combined optimization in the pressure load working condition, enables the outline of the optimized structure to be a multi-arc-section outline, is suitable for the numerical-control machining manufacturing technology, and is strong in practicality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

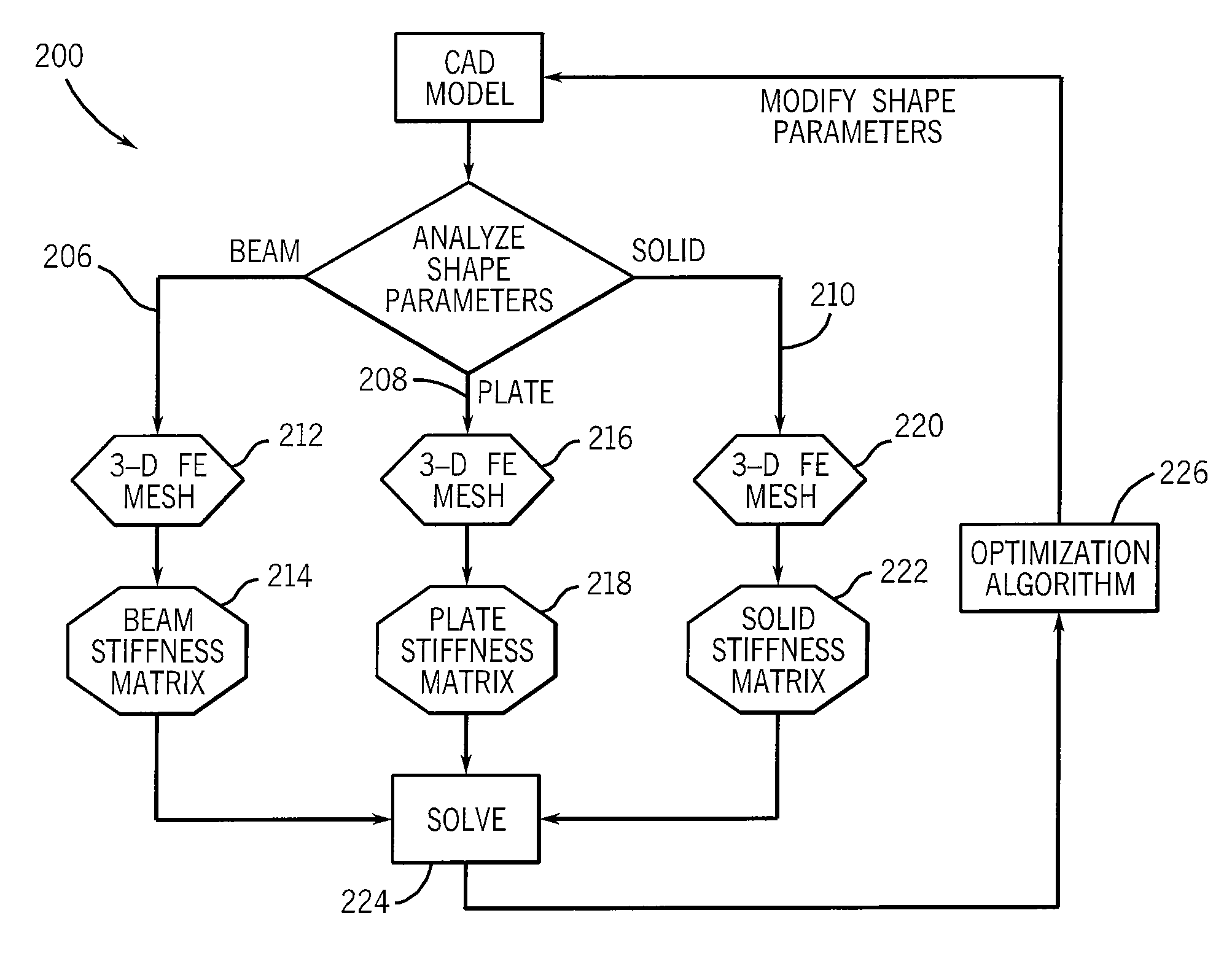

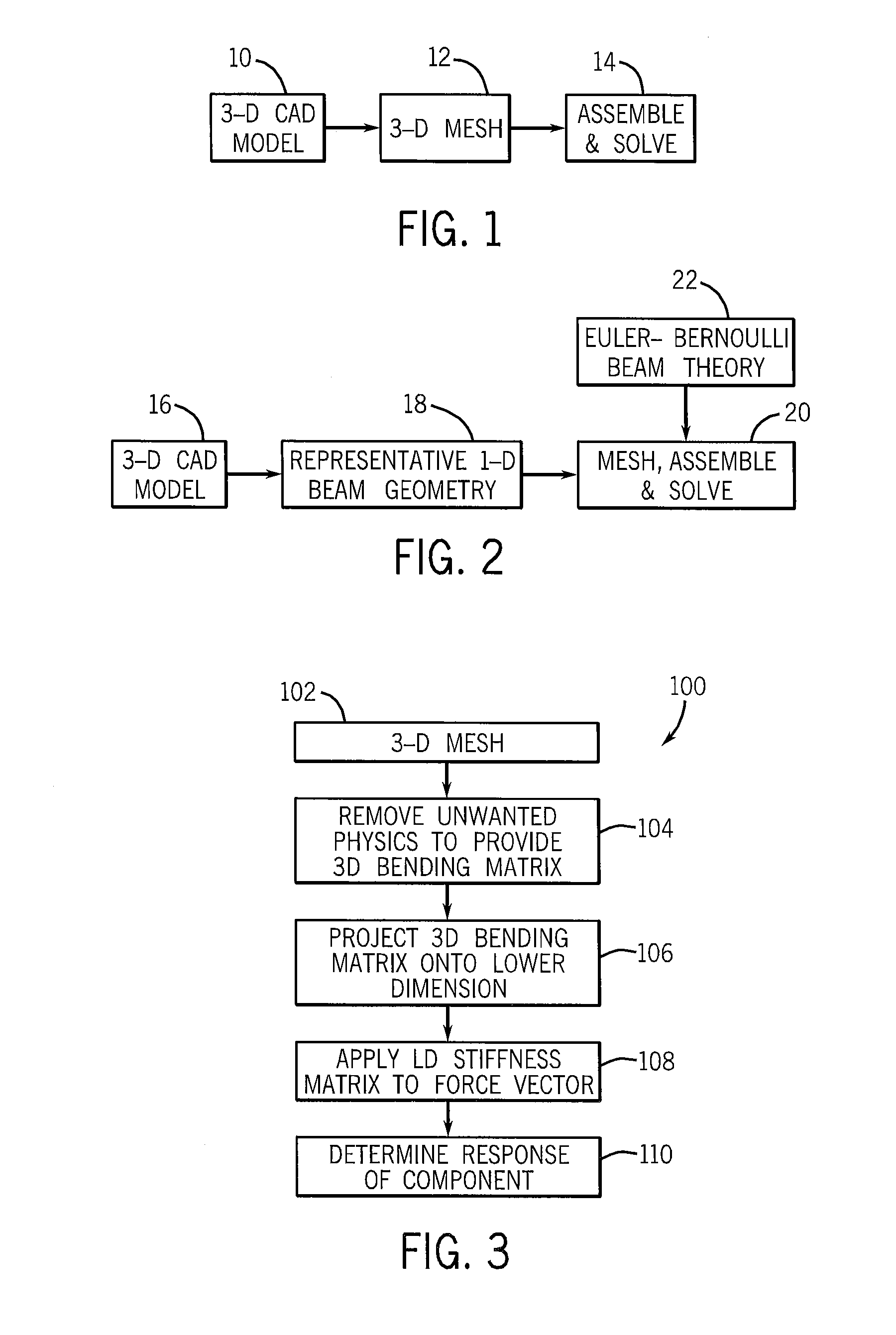

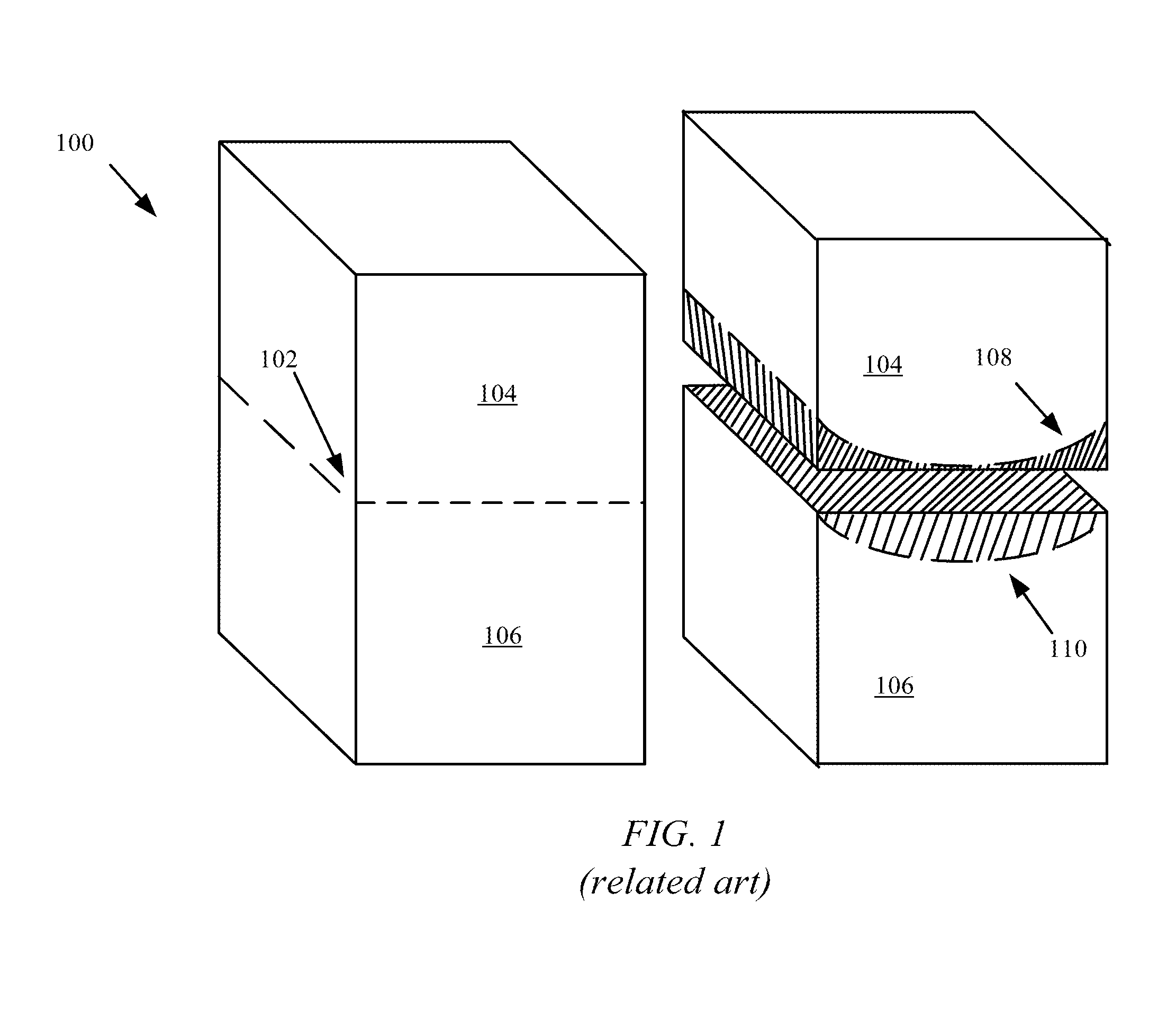

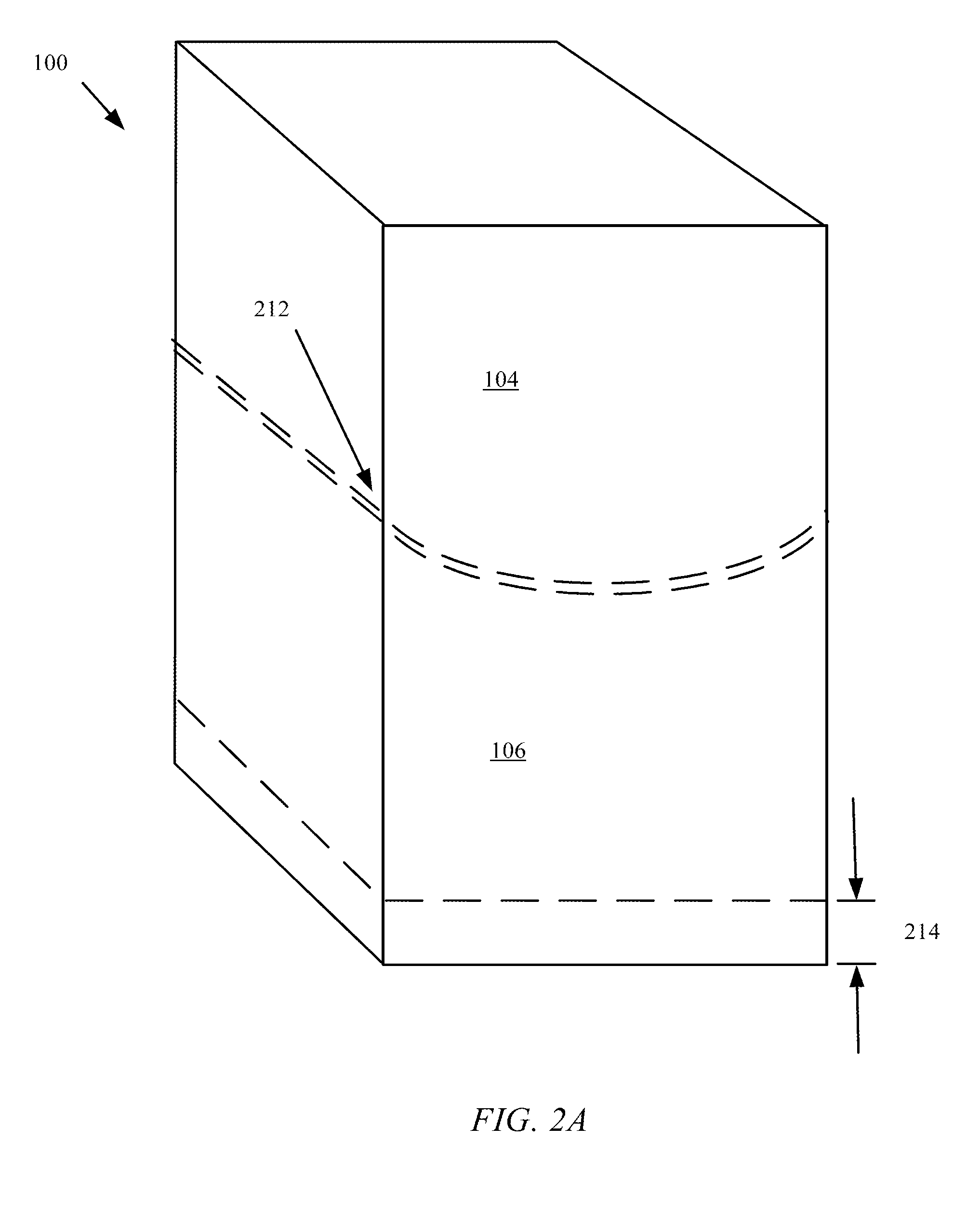

Method And System For Analysis And Shape Optimization Of Physical Structures Using A Computerized Algebraic Dual Representation Implicit Dimensional Reduction

ActiveUS20100153077A1Computation using non-denominational number representationDesign optimisation/simulationData setDimensionality reduction

A method and system for simulating and analyzing the behavior of a structural component of a computerized model in response to a simulated event to determine an optimized shape for the component is disclosed. The shape is optimized using an implicit dimensional reduction rather than an explicit geometric replacement by discarding data of a 3D discretization that has little or no bearing on the performance of the component to a simulated event. The reduced dataset is then collapsed onto a lower dimension projection that is applied over a force vector that is representative of the simulated event to determine the behavior of the component to the simulated event. Optimization tools may then be used to modify the physical attributes of the component and performance of the component once again simulated until an optimized component is determined.

Owner:WISCONSIN ALUMNI RES FOUND

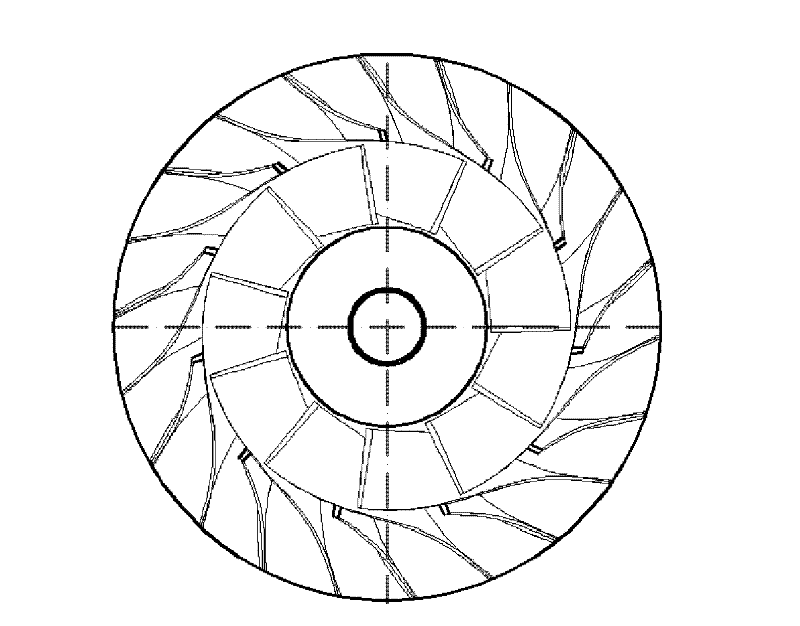

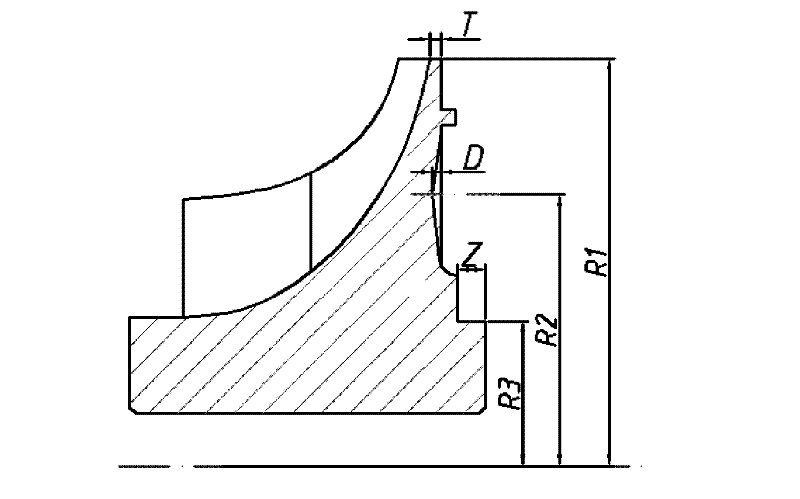

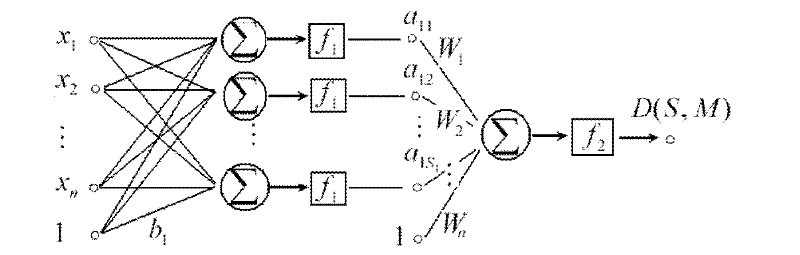

Centrifugal gas compressor impeller disc section shape optimization method

ActiveCN102339351AReduce weightReduce equivalent stressSpecial data processing applicationsImpellerGas compressor

The invention discloses a centrifugal gas compressor impeller disc section shape optimization method. A parametric modeling mode is adopted in the centrifugal impeller disc section shape, the impeller disc section shape is described with fewest design parameters, and the impeller disc section shape is optimized by combining a neural network approximate model and an optimization design method, so that the equivalent stress of the impeller is effectively reduced by over 7.4 percent under the condition of ensuring that the weight of the impeller is not increased, and the work reliability of the impeller is improved. By the design method, the strength design period of the impeller is greatly shortened, the design result is reliable, and the design cost is saved; and the method has high socialbenefit and popularization value.

Owner:XI AN JIAOTONG UNIV

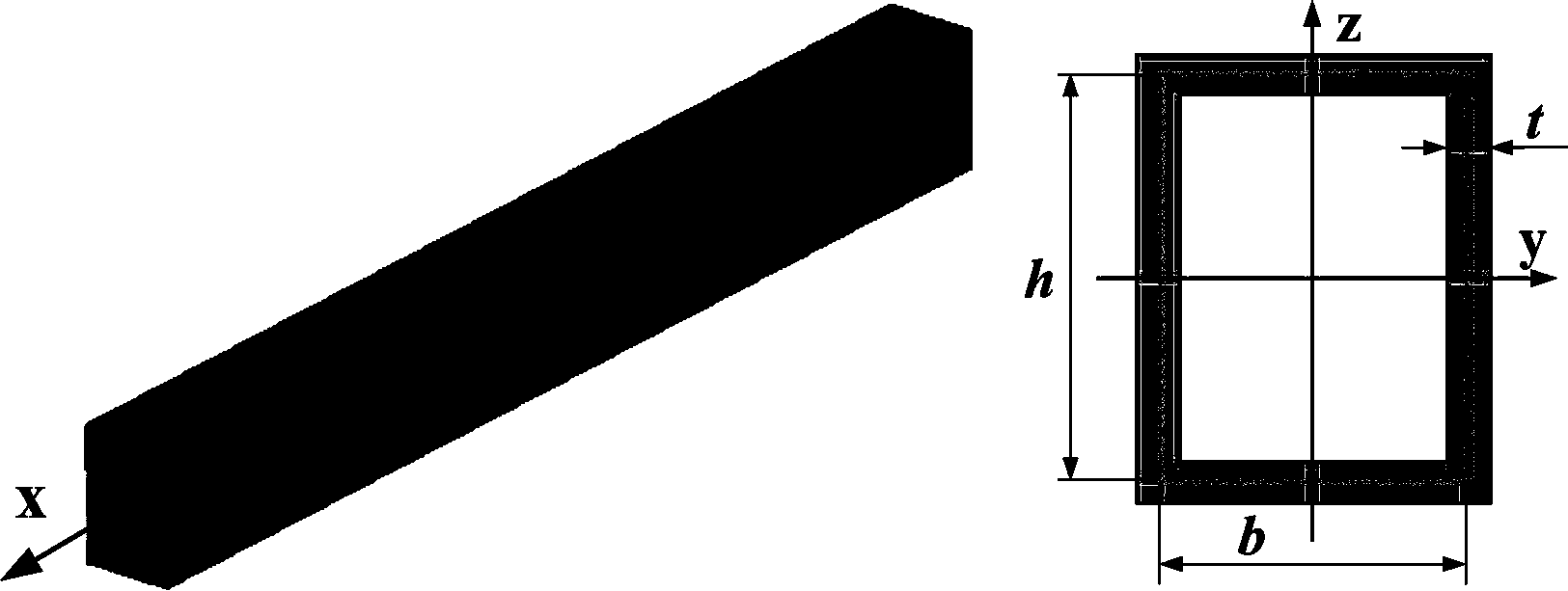

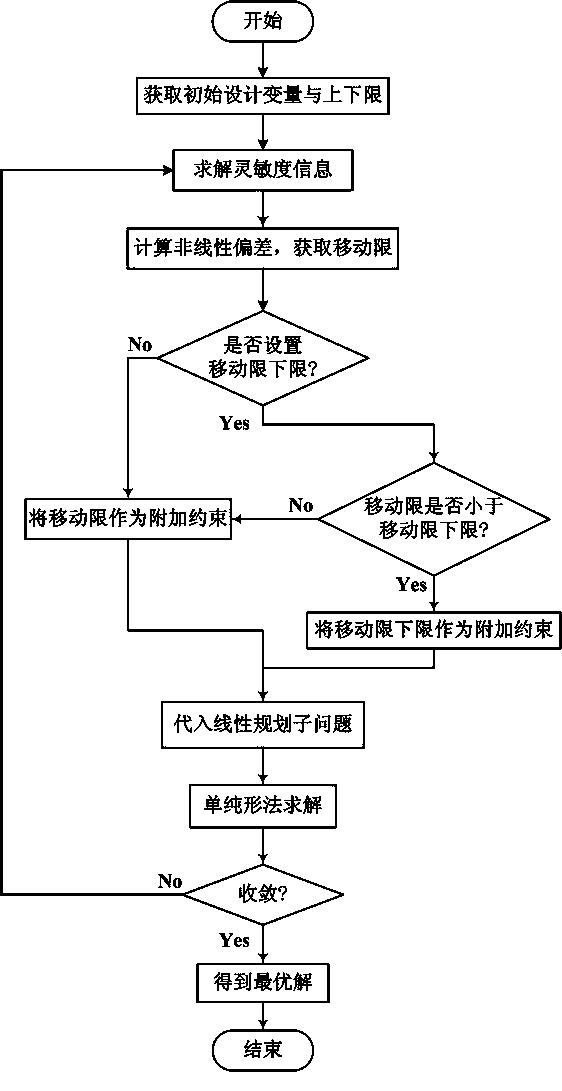

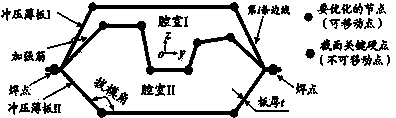

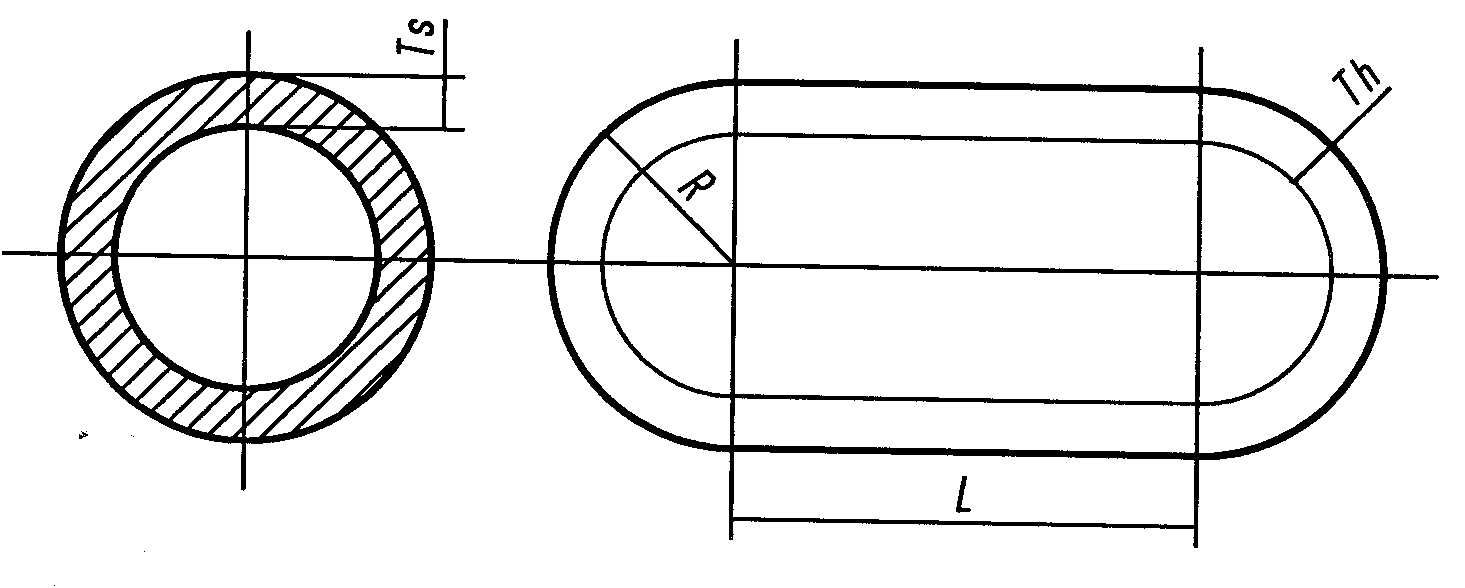

Two-step optimization design method for automotive body section shape

InactiveCN103455692ASolve problems in the field of structural designSolve puzzlesSpecial data processing applicationsShape optimizationSize parameter

The invention discloses a two-step optimization design method for an automotive body section shape. A box-type section is adopted as an intermediate variable to establish two-step collaborative optimization design. The first step of optimization design includes: taking weight of an automotive body as an objective function and high stiffness performance as a constraint condition to build an optimization model in regard to dimension parameters of length, width and thickness of the box-type section; adopting serial linear programming based on component sensitivity information to solve the optimization model so as to obtain the optimal dimension of the box-type section, and further obtaining optimal geometric features of the section. The second step of optimization design includes: taking a minimum sectional area as an objective as well as bending inertia moment, torsional moment of inertia and manufacturing process obtained through first-step optimization as constraint conditions, performing section shape optimization study on sheet thickness and node coordinates of a beam section; adopting a genetic algorithm to solve a polynomial of discrete-continuous variables. By the optimization design method, the complex section shape of the automotive body is determined rationally, and the problem troubling the field of automotive body structure design is solved.

Owner:JILIN UNIV

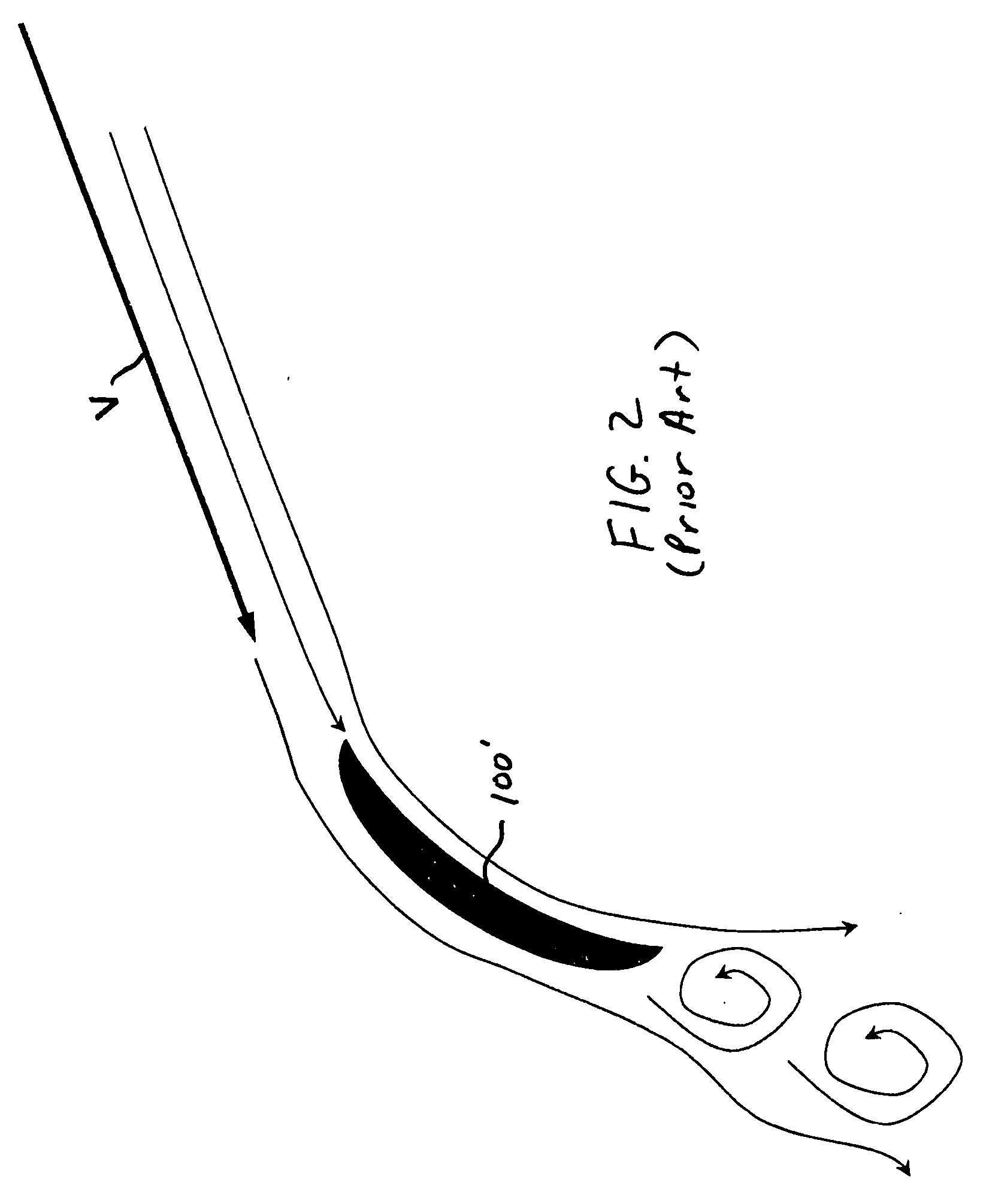

Generalized Jet-Effect and Shaped Tunnel

The invention provides a method for computational fluid dynamics and apparatuses making enable an efficient implementation and use of an enhanced jet-effect, either the Coanda-jet-effect, the hydrophobic jet-effect, or the waving-jet-effect, triggered by specifically shaped corpuses and tunnels. The method is based on the approaches of the kinetic theory of matter, thermodynamics, and continuum mechanics, providing generalized equations of fluid motion. The method is applicable for slow-flowing as well as fast-flowing real compressible-extendable fluids and enables optimal design of convergent-divergent nozzles, providing for the most efficient jet-thrust. The method can be applied to airfoil shape optimization for bodies flying separately and in a multi-stage cascaded sequence. The method enables apparatuses for electricity harvesting from the fluid heat-energy, providing a positive net-efficiency. The method enables efficient water-harvesting from air. The method enables generators for practical-expedient power harvesting using constructive interference of waves due to the waving jet-effect.

Owner:SOLITON HLDG CORP DELAWARE CORP

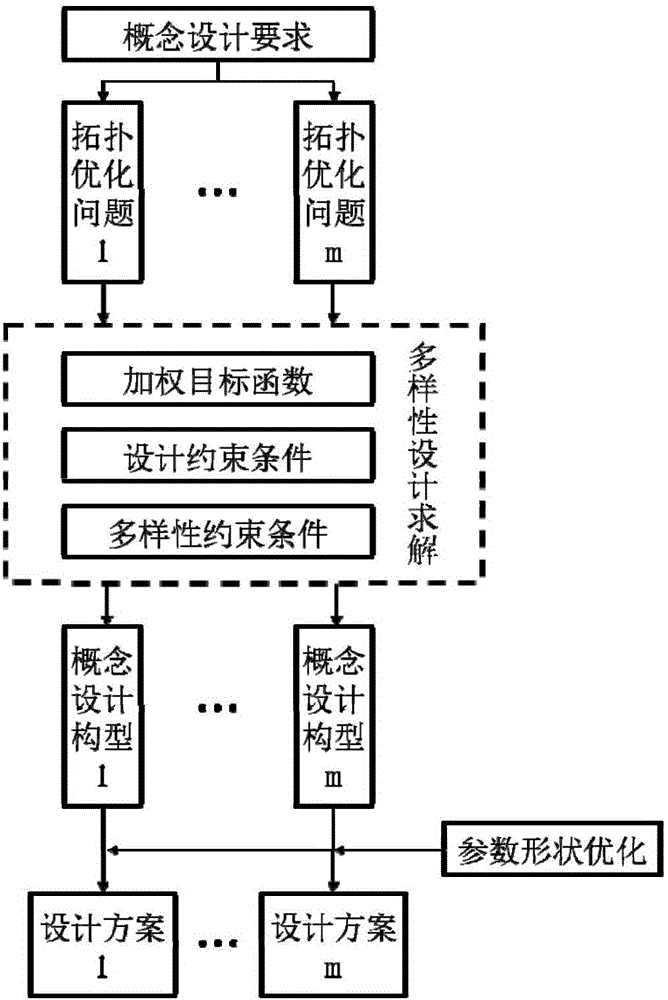

Structure topology optimization method for implementing diversified designs

ActiveCN105760631AShorten design timeGeometric CADSpecial data processing applicationsComputer architectureTopology optimization

The invention relates to the field of optimal designing of engineering structures, and provides a structure topology optimization method for implementing diversified designs. The method comprises the following steps: implementing a structural concept design by virtue of structure topology optimization; proposing diversified design solution methods to obtain a plurality of concept design configurations meeting initial design requirements, comprising: introducing a weighted objective function and proposing diversity constraints, wherein the diversity constraints can be used for describing differences among the topology configurations and driving optimization to obtain a plurality of diversified configurations; evaluating the performance of each concept configuration under detailed design requirements, screening the concept design configurations meeting the design requirements, and performing detailed designing on the concept design configurations by shape optimization and parameter optimization. According to the method, a plurality of diversified initial designs can be obtained, the risk that an initial design solution which cannot meet a subsequent design requirement is forced to be abandoned is reduced, and design iteration times and design time are greatly reduced.

Owner:DALIAN UNIV OF TECH

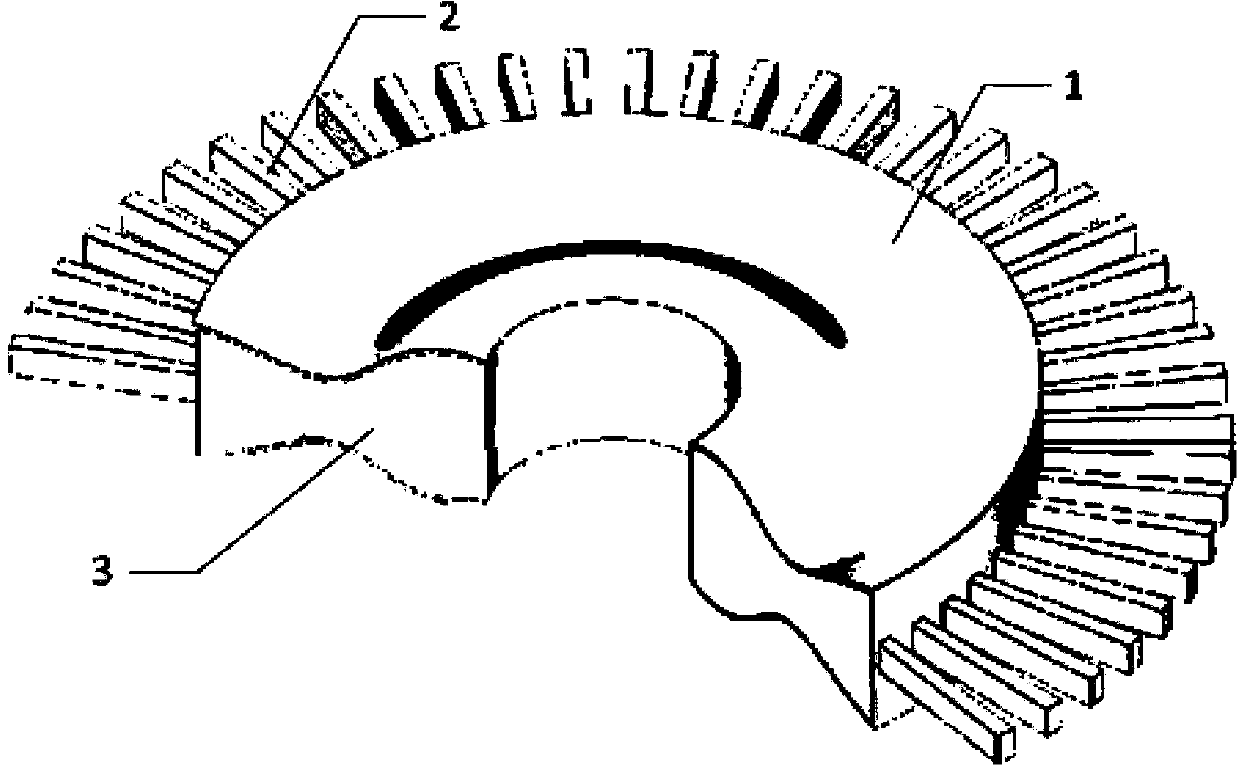

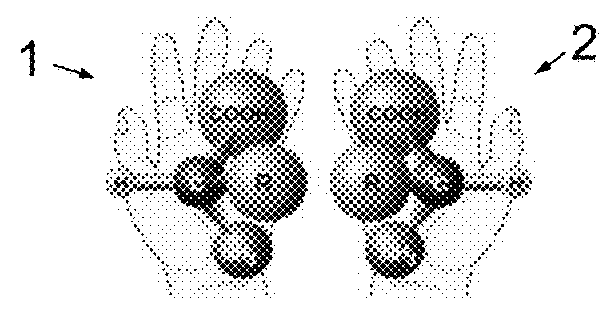

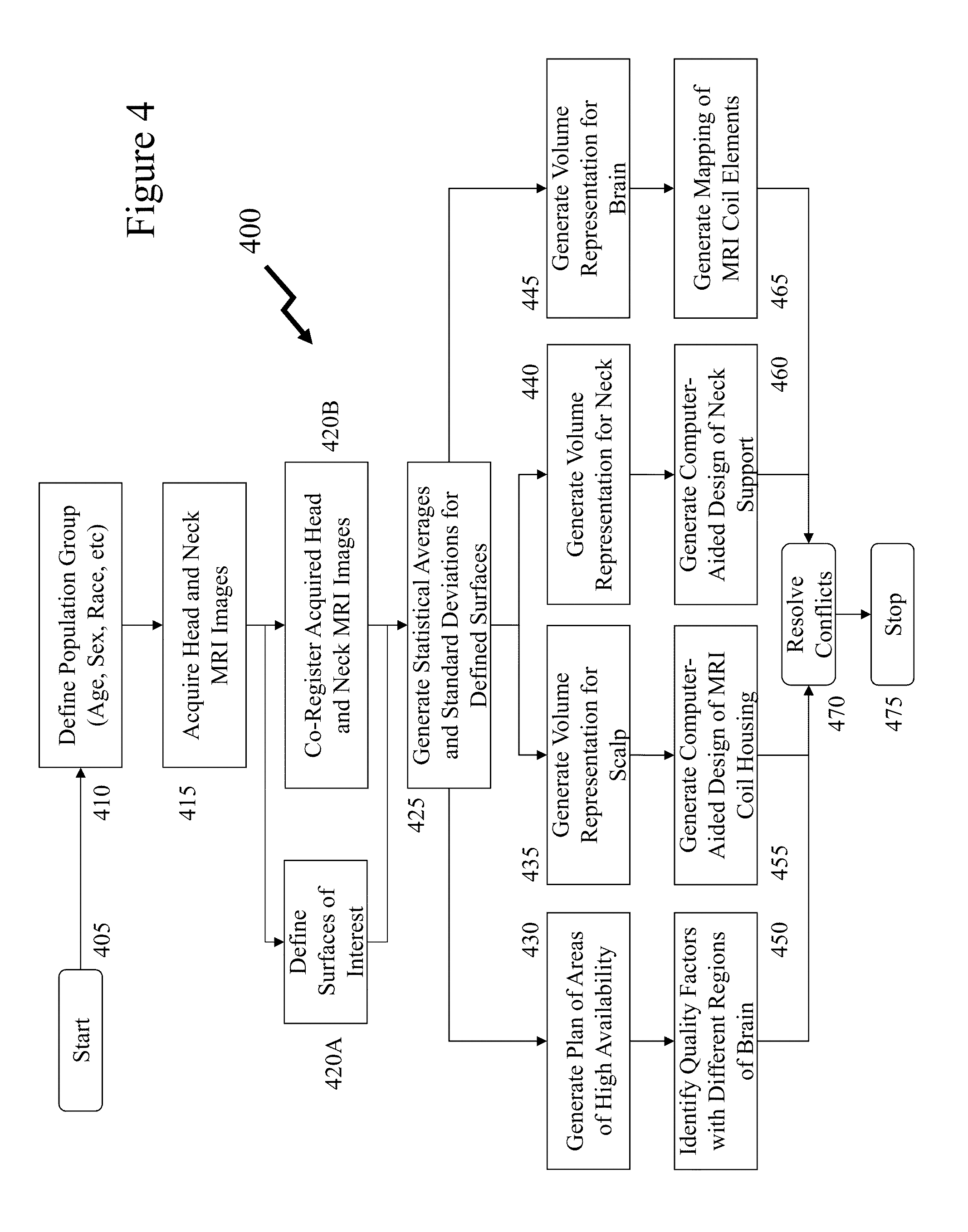

Methods and systems relating to high resolution magnetic resonance imaging

InactiveUS20160018489A1Easy to assembleImprove usabilityDiagnostic recording/measuringMeasurements using NMR imaging systemsShape optimizationSingle shot

The inventors have established design principles for phased-array MRI coils from the considerations of the target region of the anatomy being evaluated and physical anatomy of the patients. Accordingly, the inventors have demonstrated shape-optimized phased array coils with dense packing of 32 channels for posterior-head imaging exhibiting the SNR gains required to realize not only sub-millimeter fMRI BOLD imaging but also allowing single-shot Gradient Echo-EPI imaging to be performed upon general 3 T MRI instruments. At the same time the design techniques address ergonomic considerations of the patient and designing shape-optimized phased-array MRI coils and patient supports that account for variations within the human population arising from factors such as race, gender, etc.

Owner:MCGILL UNIV

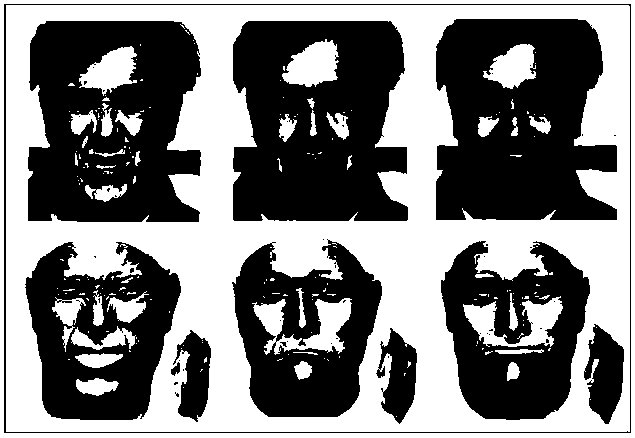

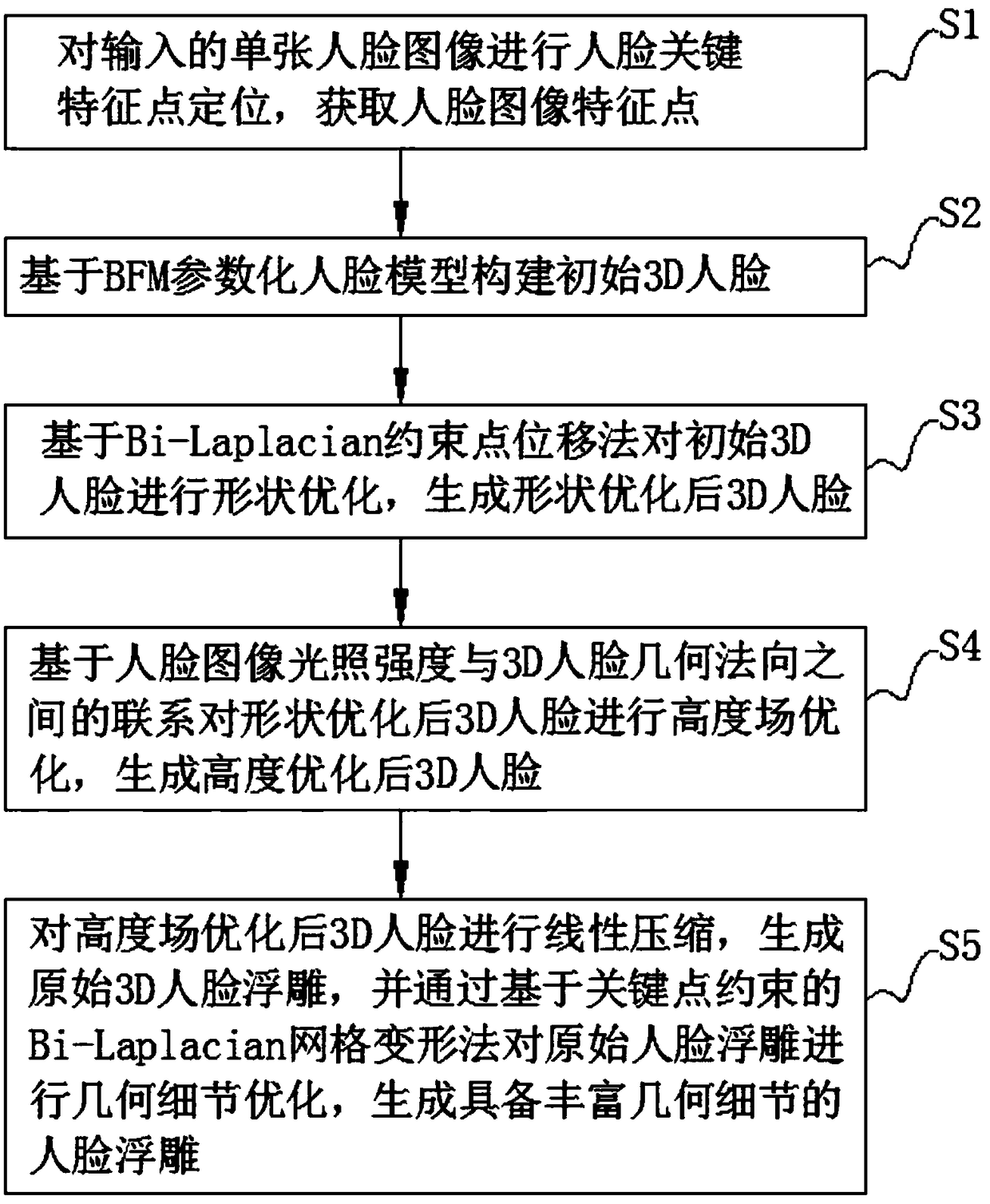

Face relief geometric modeling method

ActiveCN108492373ANo manual interventionImage enhancementImage analysisGrid deformationGeometric modeling

The present invention discloses a face relief geometric modeling method, and belongs to the field of relief modeling. The problems are solved that current portrait relief modeling is low in efficiencyand poor in automation. The method comprises the following steps of: performing face key feature point location for an input single face image, and obtaining face image feature points; based on a BFMparameter face model, constructing an initial 3D face; based on a Bi-Laplacian constrained point displacement method to perform shape optimization of the initial 3D face, and generating a 3D face after shape optimization; performing height field optimization of the 3D face after shape optimization based on a relation of the face image illumination intensity and the 3D face geometric normal, and generating a 3D face after height optimization; and performing linear compression of the 3D face after the height field optimization, generating an original 3D face relief, performing geometric detailoptimization of the original face relief through a Bi-Laplacian grid deformation method based on key point constraint, and generating a face relief with rich geometric details.

Owner:QILU UNIV OF TECH

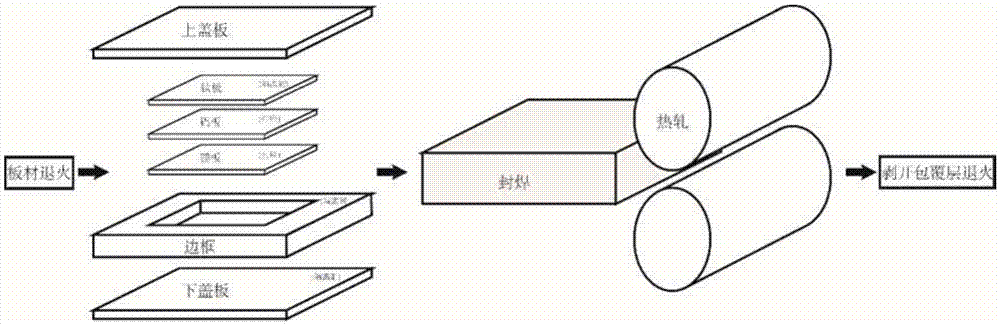

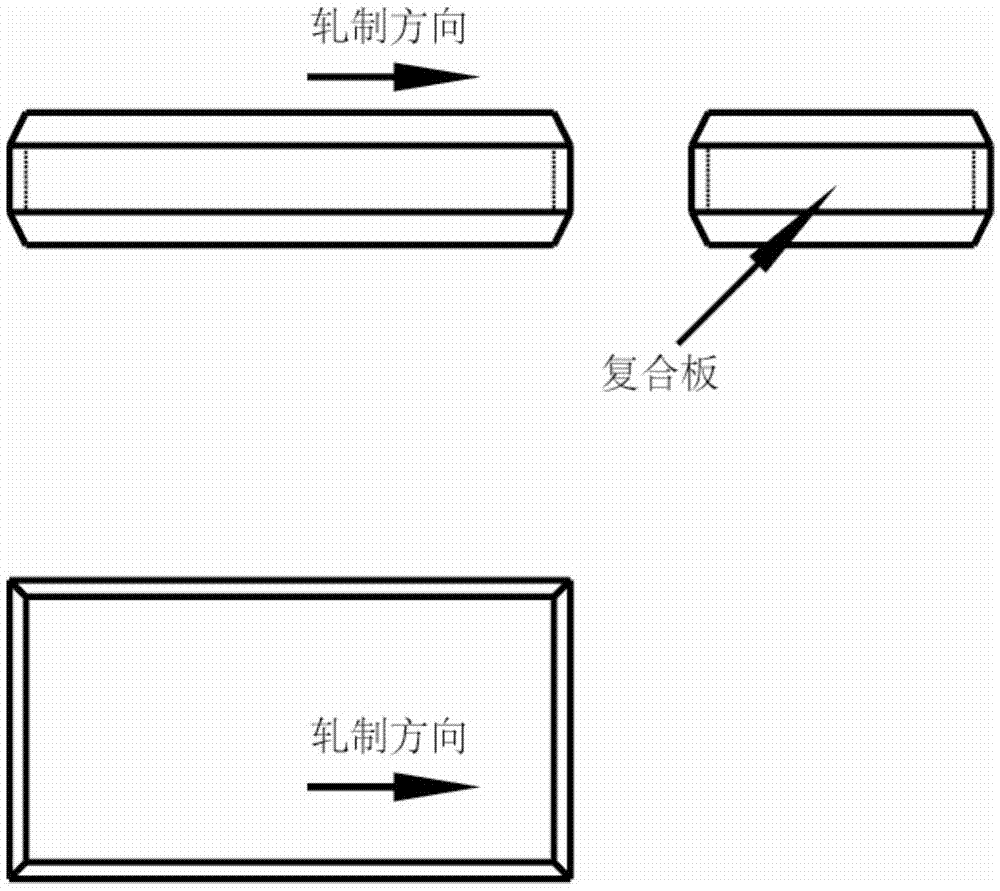

Magnesium/aluminum/titanium composite board cladding-rolling method

InactiveCN105436203AEffectively Constrains Deformation BehaviorEasy to transformForging/pressing devicesMetal rolling arrangementsTitaniumShape optimization

The invention discloses a magnesium / aluminum / titanium composite board cladding-rolling method. According to the method, a cladding layer is used for the composite board during rolling, and through shape optimization of upper and lower cover plates of the cladding layer and design of rolling process parameters, the cladding layer and the cladded composite board can achieve coordinated deformation during rolling, so that the deformation behavior of the cladded composite board can be effectively restrained, the composite interface of the composite board is straight, and the bonding strength of the composite board is improved; the cladding layer can effectively reduce invasion of impurities and harmful gas to the composite interface, so that the bonding strength of the composite board can be further improved; and meanwhile, the use of the cladding layer can slow down loss of heat, so that metal is easy to deform during rolling.

Owner:CHONGQING UNIV

Structure optimization design method for automobile damping board

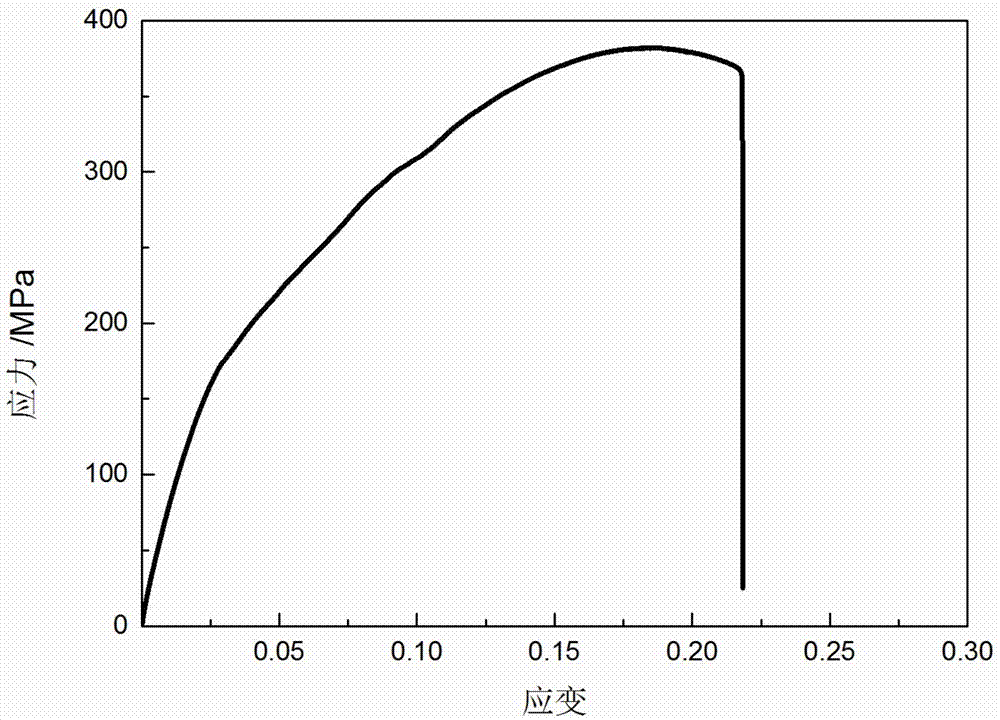

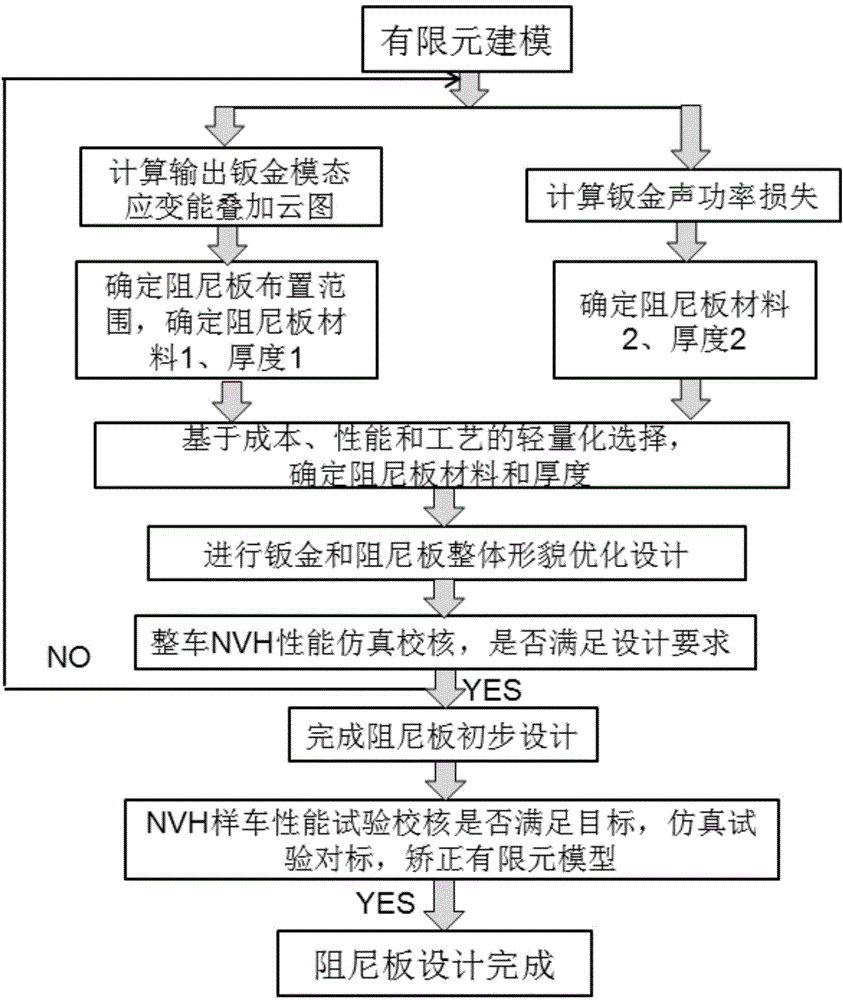

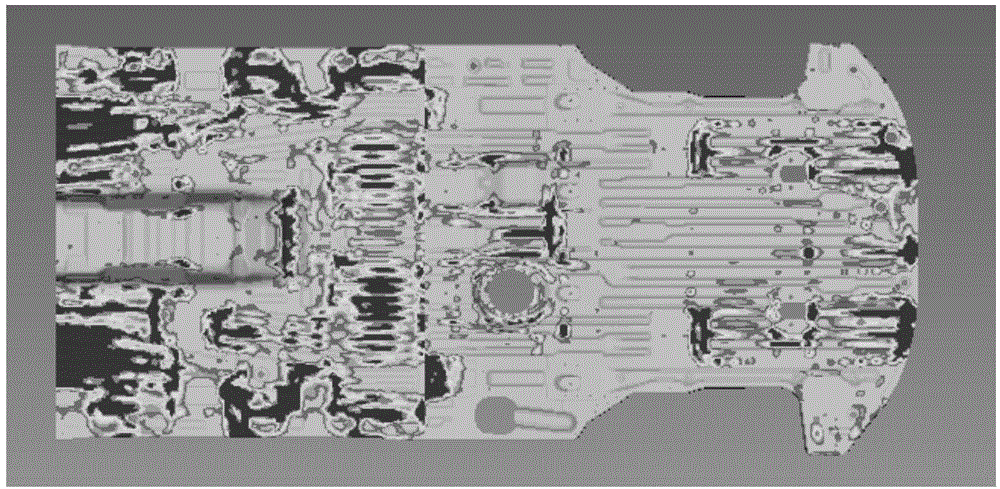

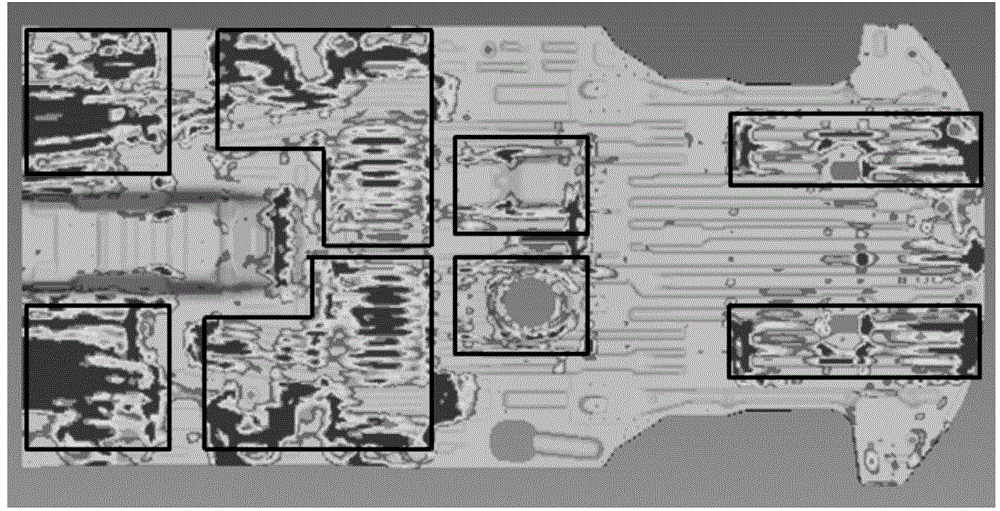

ActiveCN104786957AAchieve lightweight designMeet NVH performanceVehicle componentsCouplingStrain energy

The invention provides a structure optimization design method for an automobile damping board. The structure optimization design method has the advantages that through strain energy overlay analysis and parallel coupling mode design of sound power losses of the damping board and based on light weight option design of cost, performance and the process, the material, the thickness and the arrangement of the damping board are designed, overall shape optimization is conducted on a metal plate and the damping board, and the light weight design of the damping board is achieved on the premise that the NVH performance is achieved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

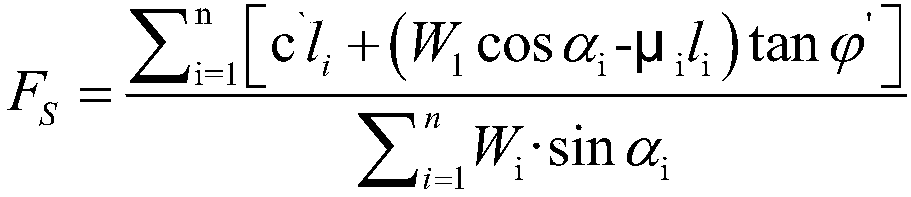

Optimization method for slope shape of end wall of open-pit mine

The invention discloses an optimization method for the slope shape of the end wall of an open-pit mine, and belongs to the field of open-pit mining. The method includes the steps of combining specificconditions of the slope of the end wall of an open-pit mine, qualitatively analyzing stability influencing factors and a potential landslide mode; conducting a mechanical experiment on the rock massof the slope of the end wall of the open-pit mine to obtain physical and mechanical indexes; determining a safety reserve coefficient K of the slope of the end wall of the open-pit mine; dividing theslope of the end wall of the open-pit mine into n stages; adjusting the width of a flat plate at each stage, and when a stability coefficient Fs satisfies |FS-K|< / =0.01, completing the slope shape optimization of each stage; and combining a strength reduction theory algorithm, using FLAC3D finite difference numerical simulation software for simulation test on the optimal slope shape scheme obtained above, and further verifying the feasibility of the optimal slope shape. The method ensures the maximum recovery of the compressed coal under the end wall, provides a basis for the design of the slope shape, and also creates a large number of economic benefits for the open-pit mine.

Owner:LIAONING TECHNICAL UNIVERSITY

Magnetic shape optimization

ActiveUS20130175242A1Metal sawing devicesInductances/transformers/magnets manufactureShape optimizationBiomedical engineering

A method for efficiently machining magnets with curved surfaces is disclosed. The use of machining equipment capable of making curved cuts through magnetic material can allow significant cost and material savings, particularly when machining magnets with complementary surfaces. A process for using a series of cutting wires to simultaneously cut magnetic material into conformally shaped magnets is described.

Owner:APPLE INC

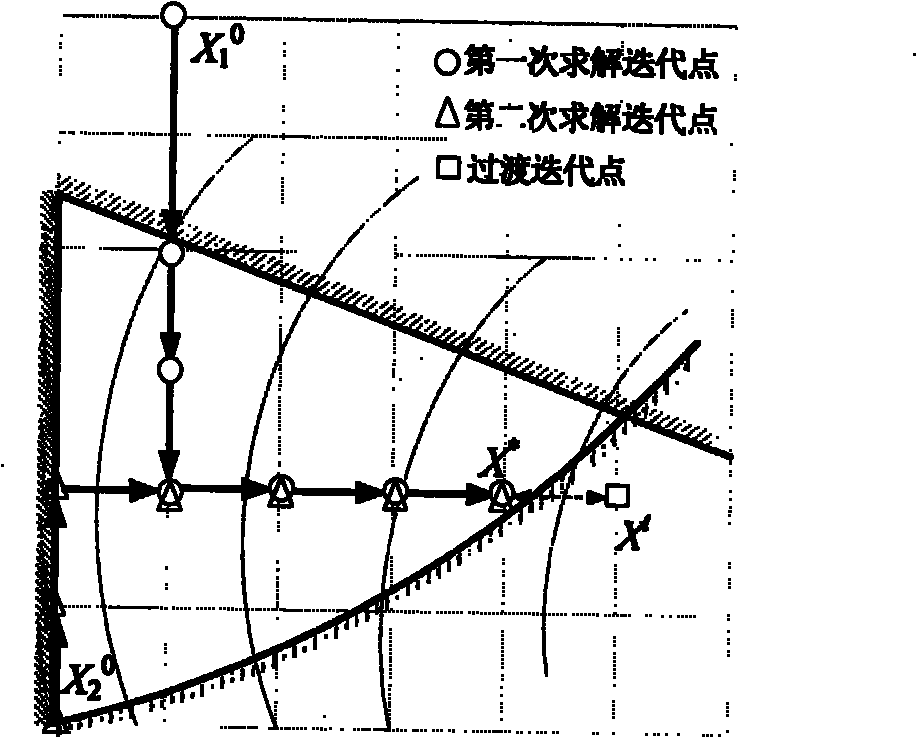

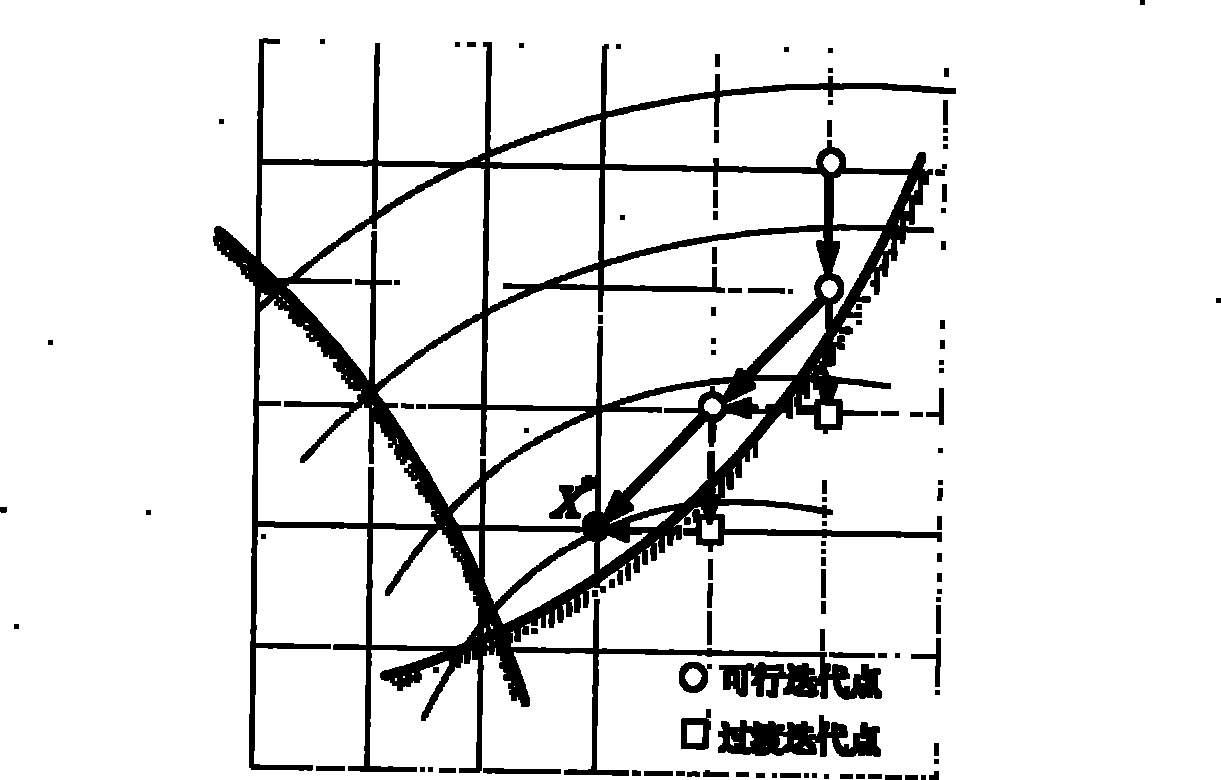

Relative sensitivity method for optimizing shapes of discrete truss structure and continuum structure

InactiveCN101859104AAdvantages of Mixed Discrete Variable Optimization MethodImprove solution efficiencyAdaptive controlCouplingEngineering

The invention discloses a relative sensitivity method for optimizing shapes of a discrete truss structure and a continuum structure. In the method, for the problem of variable coupling optimization of the shapes of the discrete truss structure and the continuum structure containing structure shapes and sectional dimensions, the iteration direction of a mixed discrete optimizing problem is determined according to the relative sensitivity of a target and restriction, and the sectional dimension and structure shape variables which can lead the best target performance of the discrete truss structure and the continuum structure are calculated. The regulation for determining the iteration direction is as follows: in a feasible region, the iteration direction is the coordinate direction which enables a target function to decrease most rapidly and the restriction to increase least; and out of the feasible region, the iteration direction is the coordinate direction which enables the target function to increase least and the restriction to decrease most; and if the variable corresponding to the iteration direction is a continuous variable, the discrete variable value is set to be a constant, and all the continuous variables are optimized according to a continuous variable optimization method.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A construction method of an intelligent fabricated building

PendingCN109684662AFast and accurate generationMeet factory productionGeometric CADSpecial data processing applicationsIntelligent designProcess oriented

The invention relates to the field of fabricated buildings, in particular to an intelligent fabricated building construction method. The method comprises the steps of preliminary model design, whereinspace planning is conducted according to site analysis, building modeling, building landscape and traffic flow lines; Utilizing a BIM technology to form a building full model; Model design is optimized, the whole building model is placed in a specific simulation environment, and the house type, size and orientation of the building are perfected; Carrying out deepening model design, splitting theoptimization model into single components, and carrying out shape optimization, steel bar configuration and collision detection on the single components according to splitting of the components; According to the detection result, all the elements are adjusted, the relation among all the elements is further perfected, a component deepening detail drawing is directly obtained through the BIM model,and the drawing should comprise a component size drawing, a pre-buried positioning drawing and a material list table, and an H-dimensional view is constructed. And an intelligent design technology isutilized, so that the construction of the fabricated building is more standardized, process-oriented, automatic and intelligent.

Owner:唐炳贵

High-quality machine-made sand production process

InactiveCN109365102AReduce pollutionImprove performanceEdge grinding machinesPolishing machinesCrushed stoneEngineering

The invention discloses a high-quality machine-made sand production process. The process comprises step 1, crushed stones are crushed through a crusher, and the crusher is provided with a crushing feeding port and a crushing discharging port, and is used for crushing raw materials; step 2, a vibrating screen is connected with the crushing discharging port, and receives aggregate particles crushedby the crusher, the aggregate particles are conveyed to a grading controller through a conveying device, the grading controller is used for screening the received aggregate particles, and grading machine-made sand and finely controlling grading of the machine-made sand, unqualified materials return to the crusher to be re-crushed, and the vibrating screen is provided with a coarse particle discharging port and a fine particle discharging port; step 3, a particle shape optimization machine is added after the grading controller for optimizing the grain shape of the machine-made sand; and step 4,a wind power powder separator is connected with the fine particle discharging port for wind power powder separation of fine particles, and the wind power powder separator is provided with a machine-made sand discharging port and a stone powder discharging port. According to the process, the production difficulty of the machine-made sand is reduced, so that the performance of the prepared concreteis improved, the use amount of water and the use amount of cement are saved, and the environmental pollution is reduced.

Owner:徐州金盟新型建材有限公司

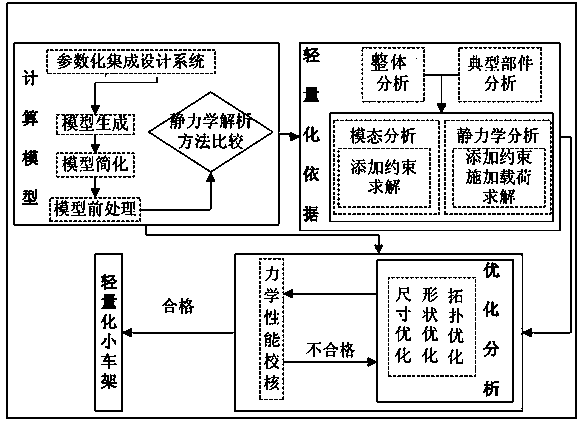

Quantitative method based on engineering machinery structural design

InactiveCN104376177AImprove stress distributionLose weightSpecial data processing applicationsElement analysisTopology optimization

The invention discloses a quantitative method based on engineering machinery structural design. The quantitative method includes the following steps that an engineering machinery structural member parameterization integrating design system is used for fast generating an engineering machinery structural member model; the engineering machinery structural member model on which a statics analytical method is conducted is simplified; finite element analysis is then conducted; an Ansys topological optimization module is combined, a homogenization method for topological optimization is used for conducting optimization analysis on a structural member of the engineering machinery structural member model, size optimization and shape optimization are conducted on the basis of an obtained result, the engineering machinery structural member parameterization integrating design system is used again for generating a design model, the obtained design model is checked, and if it is checked that the design model does not meet the design requirement, the size optimization design and the shape optimization design are conducted again until the design model meets the design requirement. The purposes of saving steel, reducing cost and improving operation stability and safety are achieved.

Owner:LIUZHOU JINMAO MACHINERY

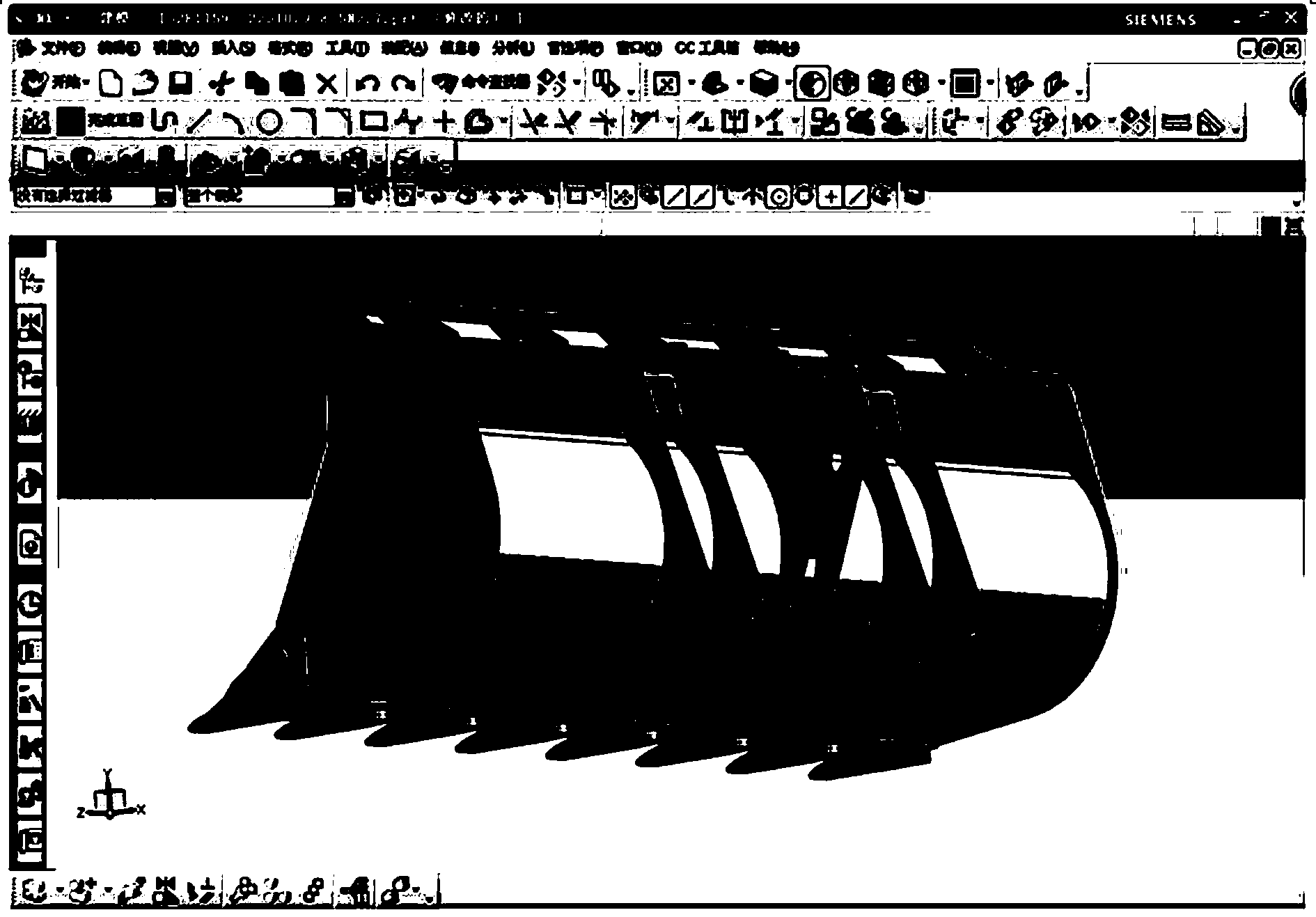

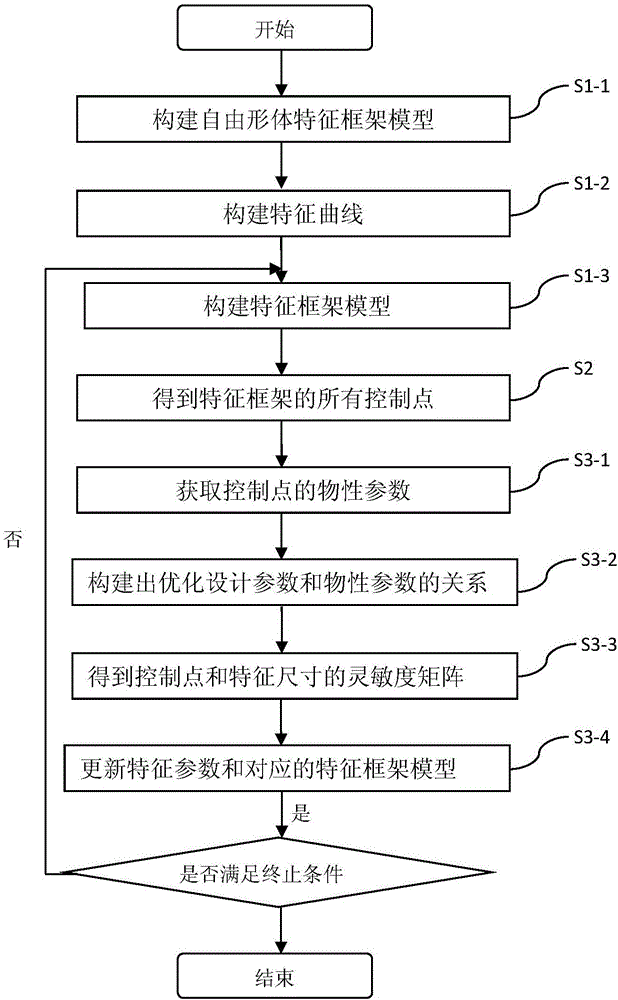

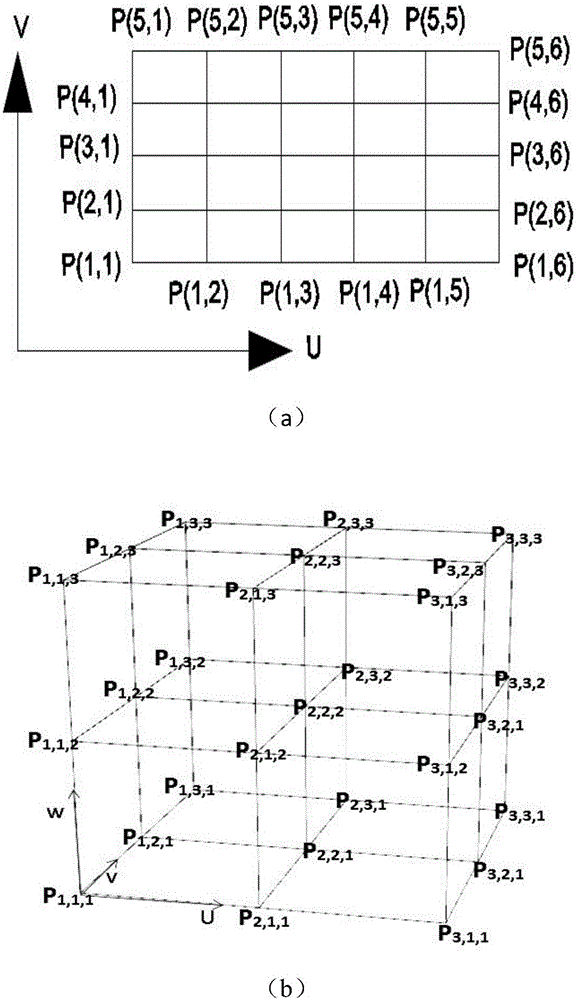

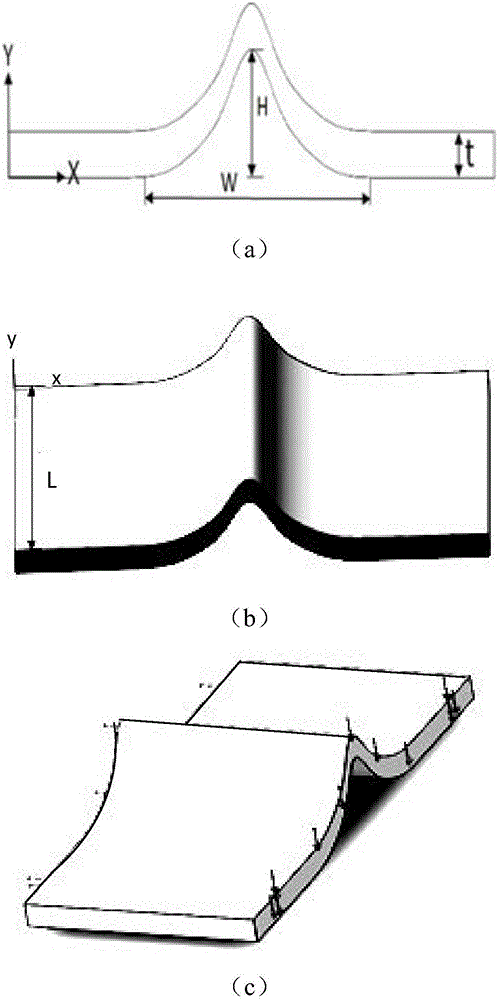

Shape optimization algorithm for three-dimensional product model

ActiveCN106384384AEnhanced interactionMeet design needs3D modellingPattern recognitionFeature Dimension

The invention provides a shape optimization algorithm for a three-dimensional product model, and the method comprises the following steps: firstly constructing a product model which is a feature frame model comprising point, line and surface features through employing a reverse solving method or a size measurement method; adding the constraint between the feature elements, and constructing a parameterized feature frame; employing a multi-drive mode, maintaining the constraint between the features, and achieving the modification of the feature frame model; employing a volume parameterization theory for the feature frame to obtain a volume parameterization model which can be used for geometrical analysis; enabling the feature size of the feature frame to serve as the product size or a shape optimization parameter, deducing the physical performances of a product and the sensitivity matrix of the design parameters, and optimizing the parameters, so as to achieve the optimized design of a product model.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

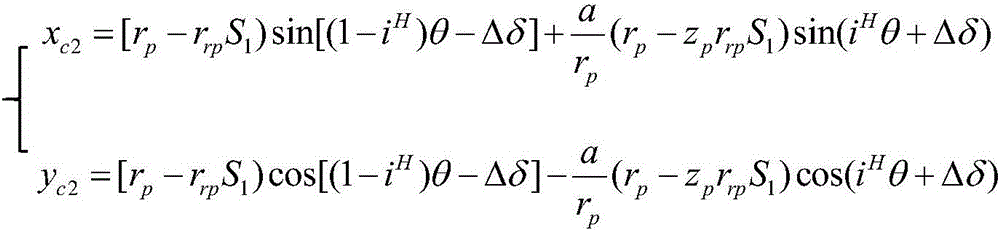

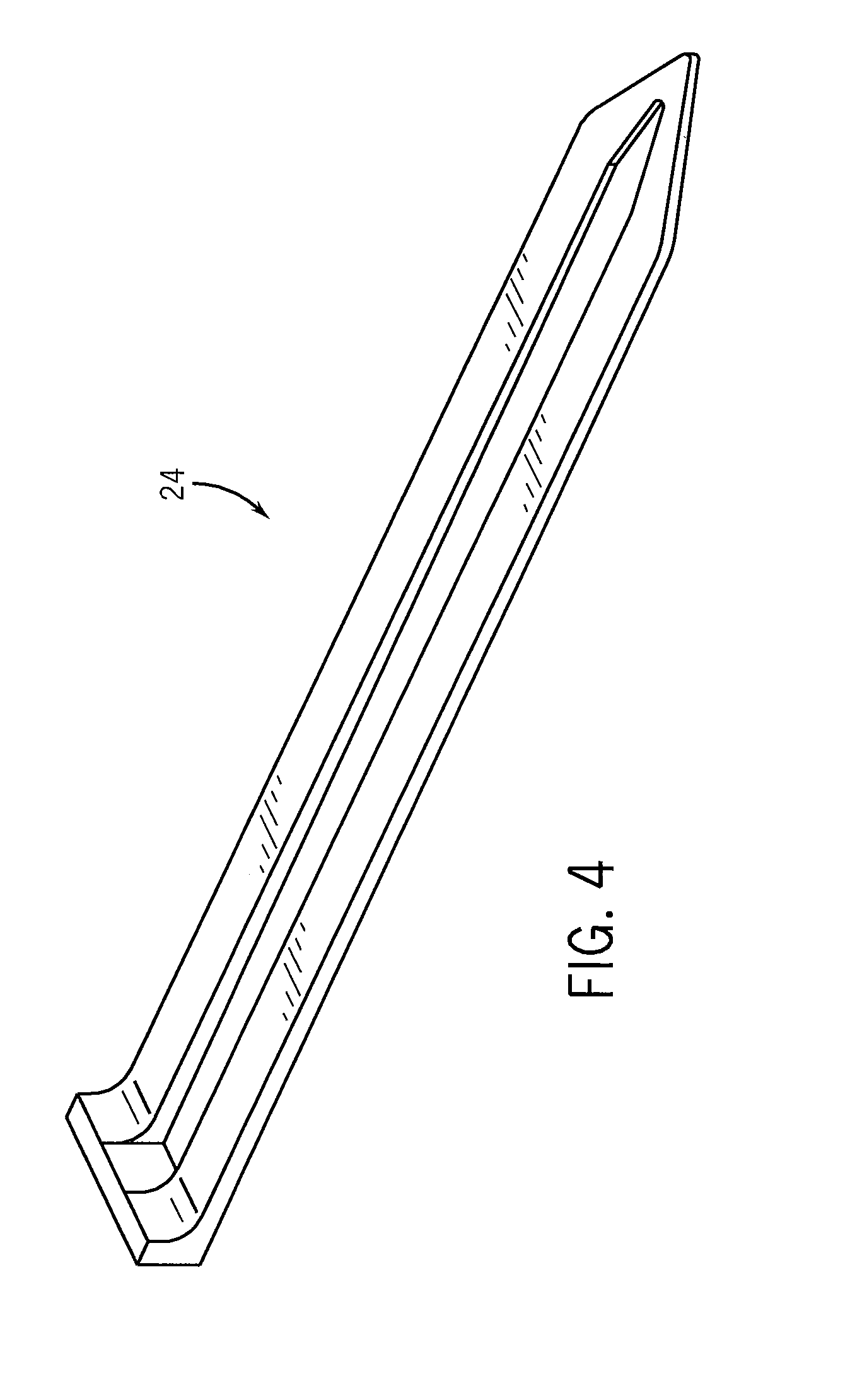

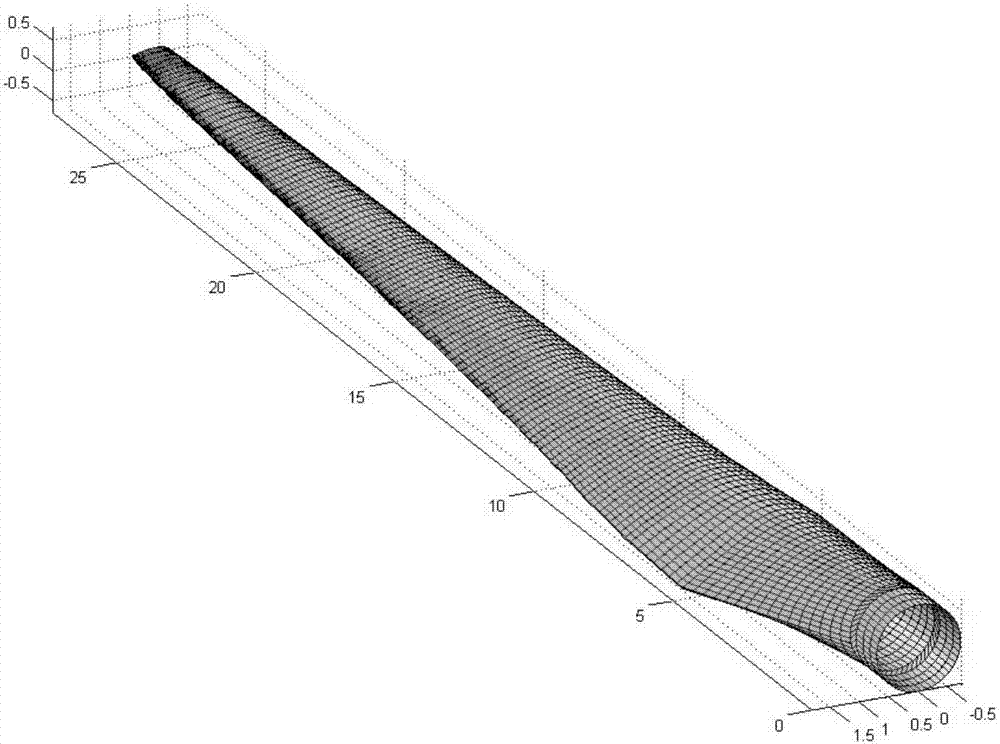

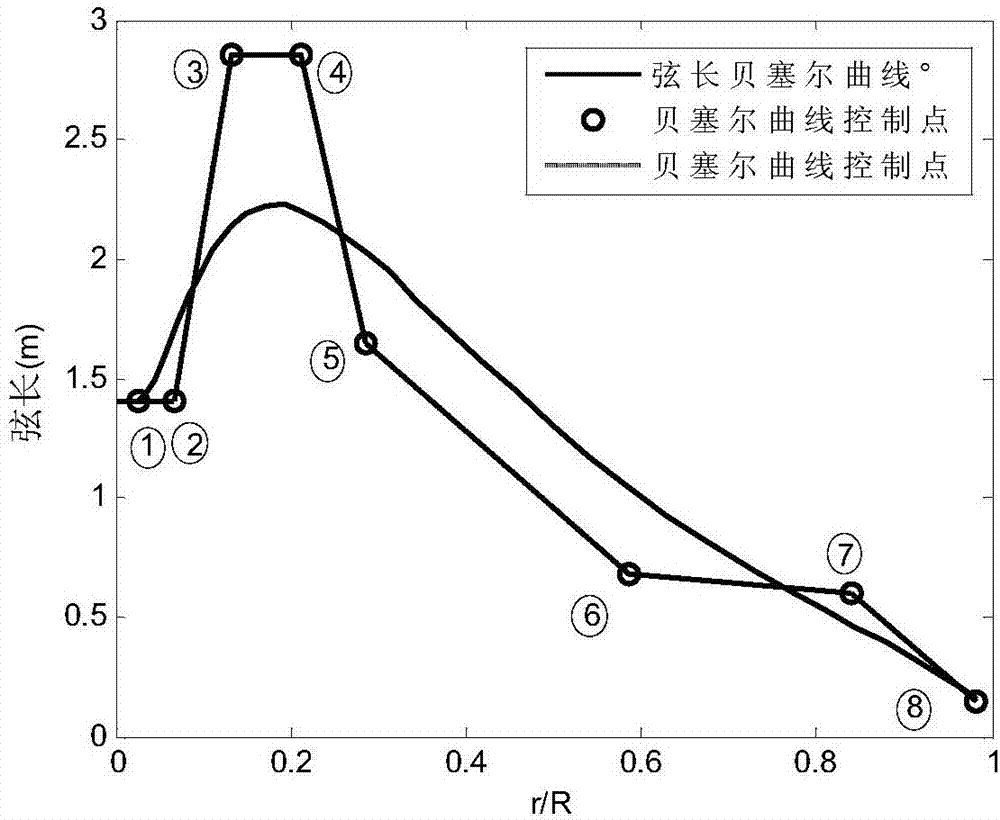

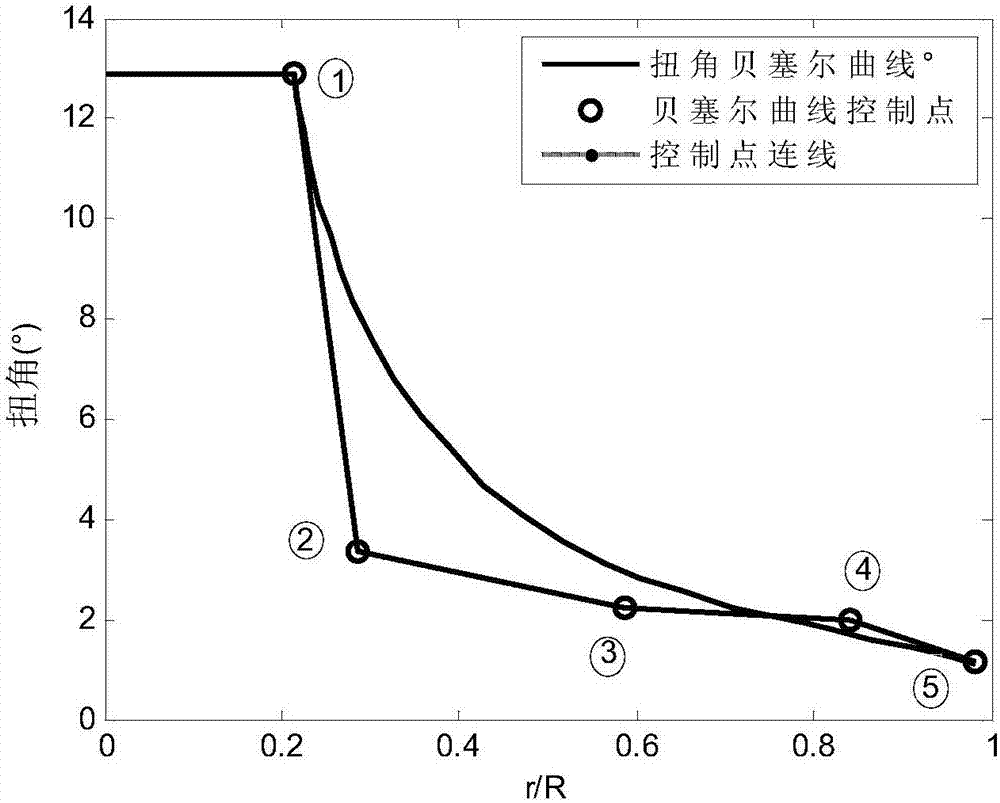

Low-wind-speed variable-speed variable-pitch wind turbine blade optimum design method

InactiveCN106894947ALower chord lengthLow costGeometric CADFinal product manufactureTurbine bladeTorsional angle

The invention relates to a low-wind-speed variable-speed variable-pitch wind turbine blade optimum design method, and belongs to the technical field of wind power generation. According to the low-wind-speed variable-speed variable-pitch wind turbine blade optimum design method, the largest annual energy output and the lowest material cost under the low-wind-speed condition serve as targets, a high order bezier curve is used for defining the chord length and the torsional angle of a blade on the overall length, and optimum control over the best pitch angle and torque-rotating speed is carried out while blade pneumatic shape optimization is carried out. Meanwhile, on the premise that the power generation amount and the lowest material cost are guaranteed, optimal solutions of the chord length and the torsional angle of each cross section of a blade are calculated through an optimization algorithm. The chord length of the wind turbine blade optimized through the method is greatly reduced, the blade area is reduced, the manufacturing material is effectively saved, reduction of the manufacturing cost is facilitates, and meanwhile, the annual energy output is effectively increased.

Owner:CHONGQING UNIV

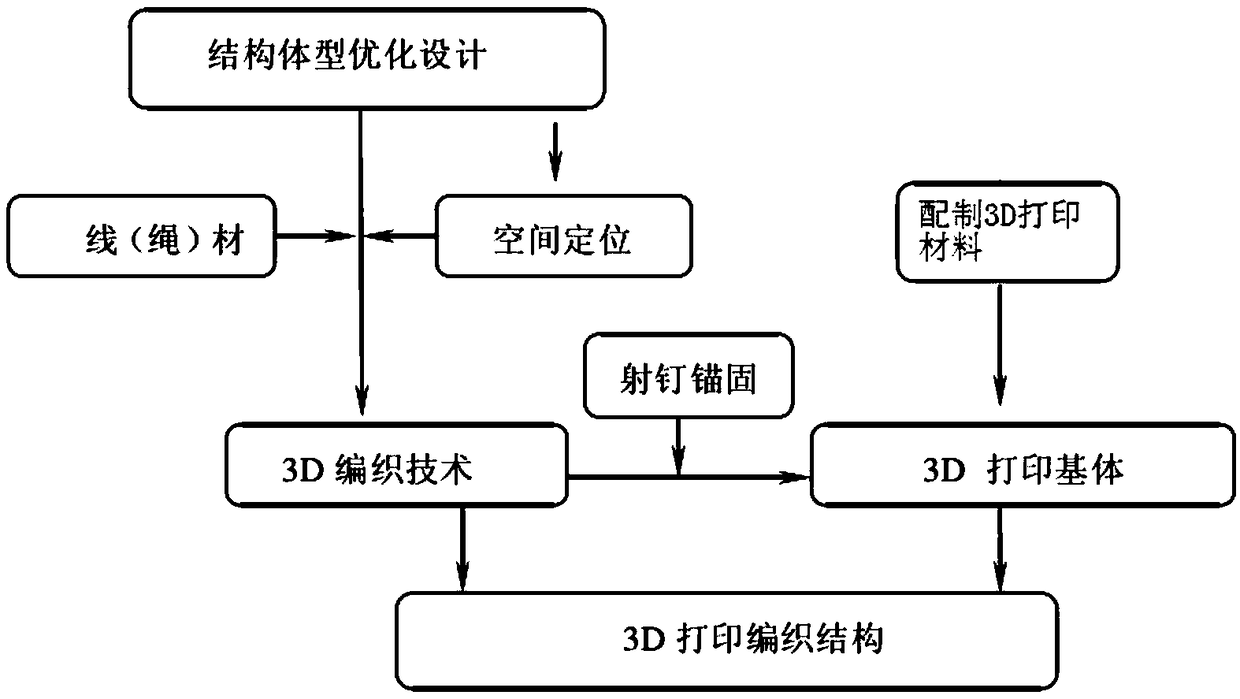

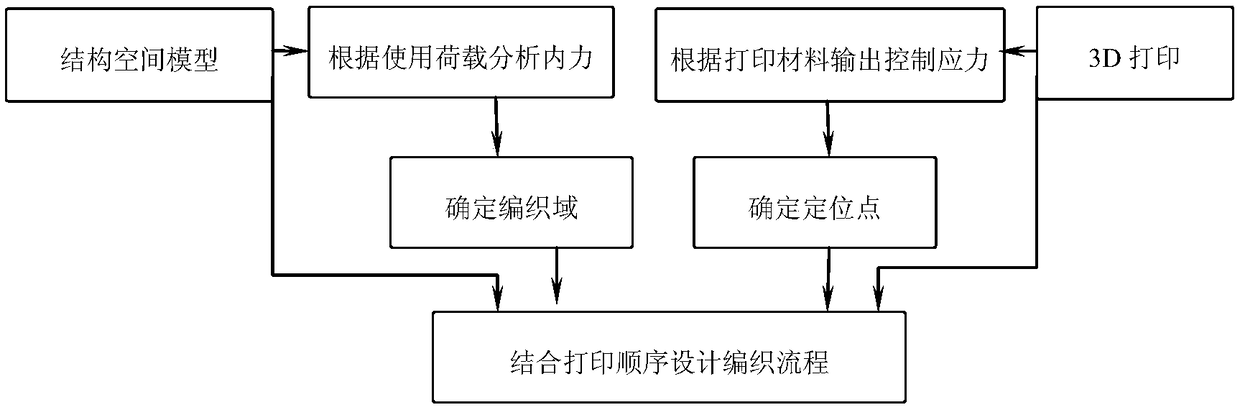

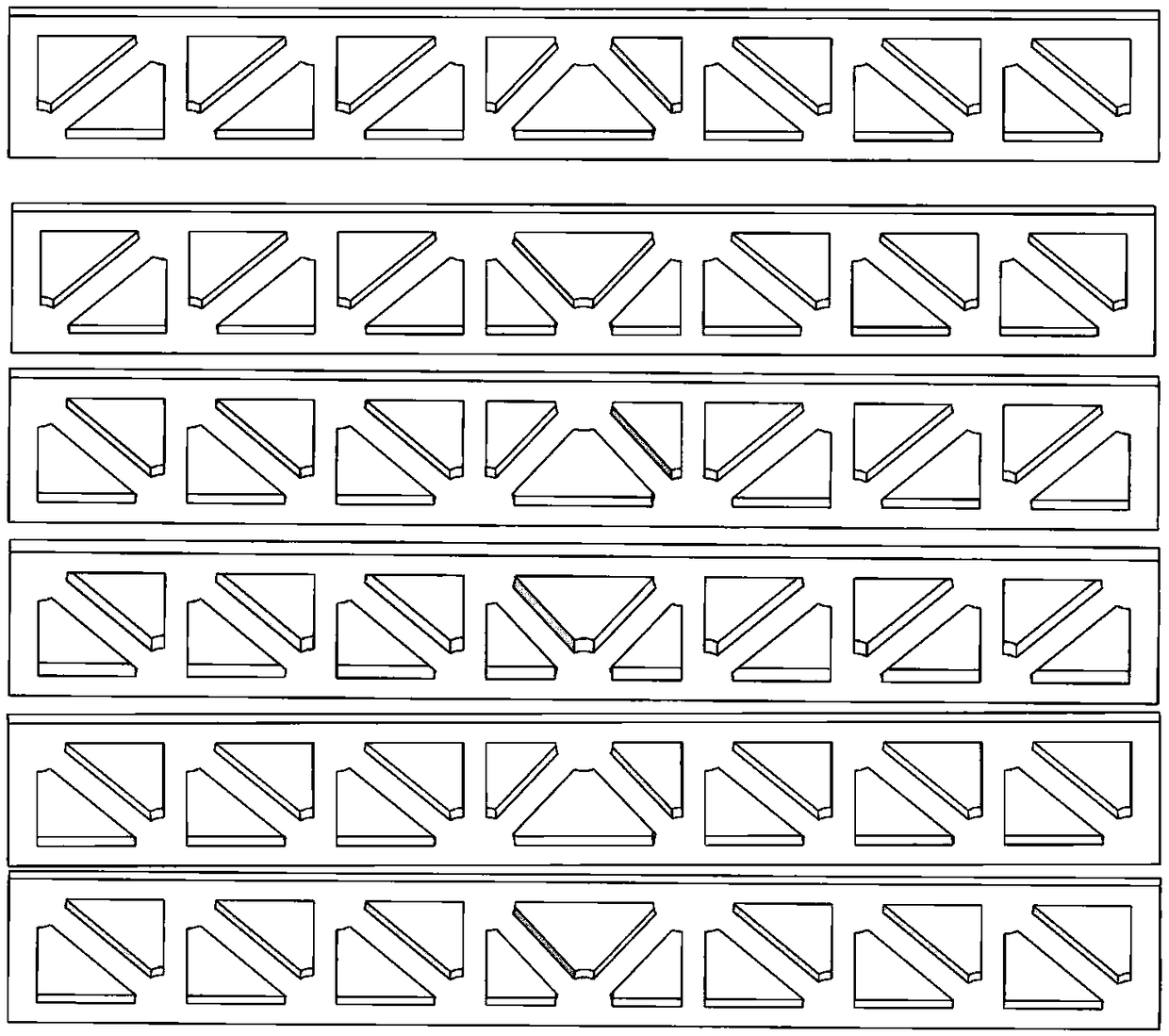

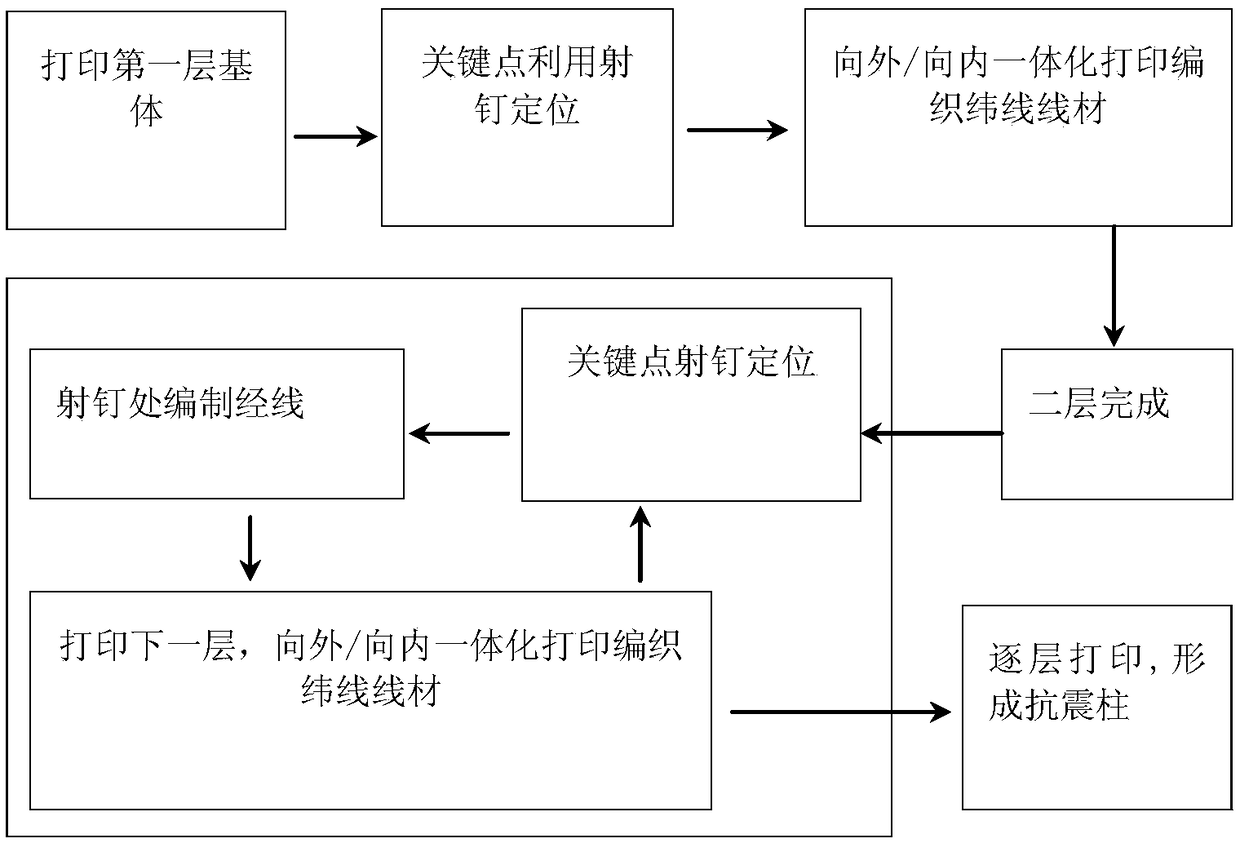

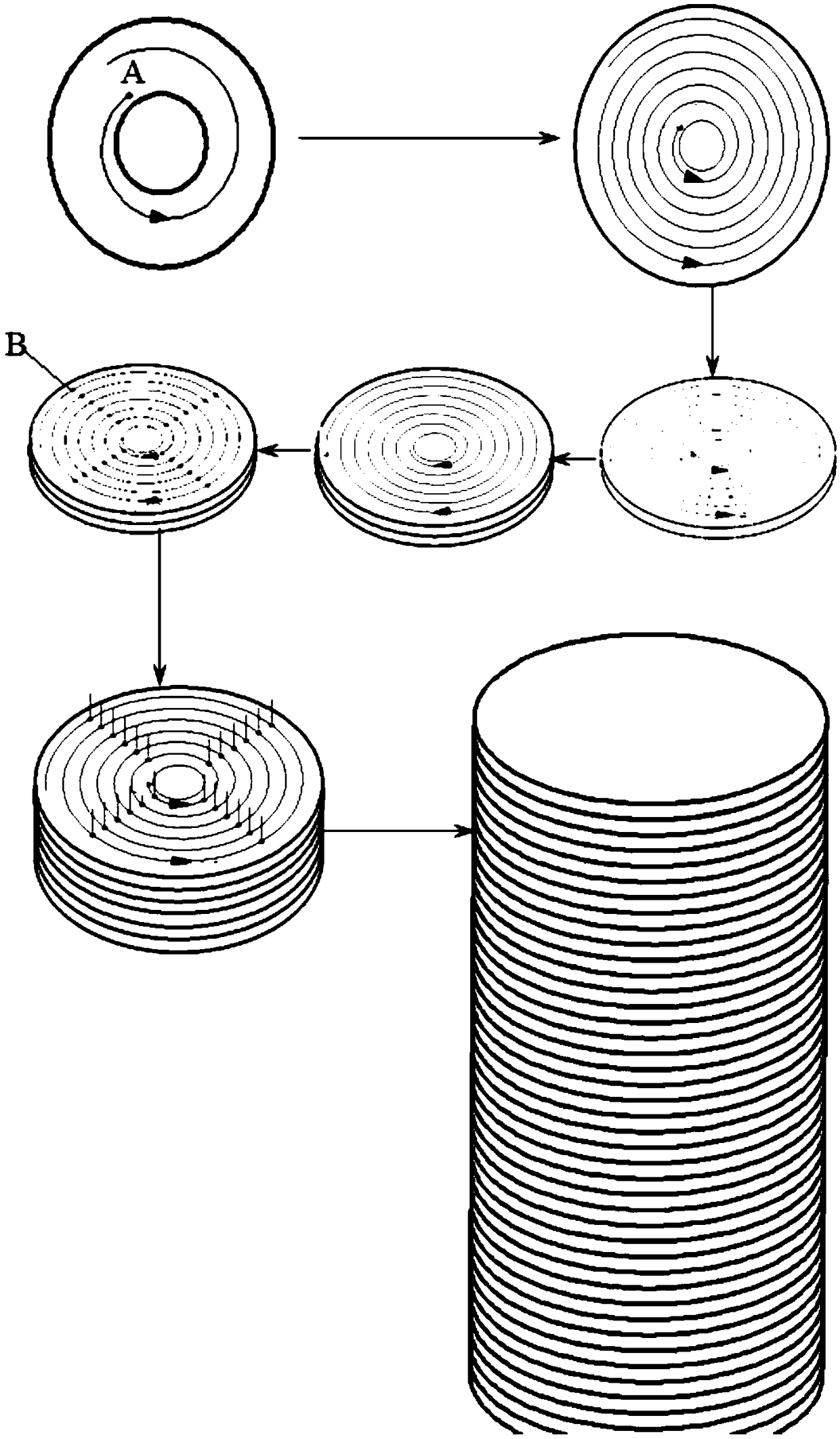

Construction method of composite beam integrally formed by 3D printing and knitting and composite beam

ActiveCN109129818ABeautify the facade of the structureReduce building construction proceduresAdditive manufacturing apparatusCeramic shaping plantsCrack resistanceForce analysis

The invention discloses a construction method of a composite beam integrally formed by 3D printing and knitting and the composite beam. The construction method comprises the steps that modeling is performed for force analysis, beam member spatial shape optimization is performed, and the shape and thickness of a composite beam member skeleton or a composite beam member external mold are determined;a knitting range, the knitting dosage and areas of encryption knitting and ordinary knitting of wires are determined; a knitting process is determined, and the knitting process is combined with a matrix printing process to be jointly designed to form a printing and knitting integrated process; 3D printing materials are prepared; and 3D printing of a matrix and knitting of the wires are performedto obtain the composite beam or a composite beam external mold. A beam member prepared by the construction method is the composite beam, the tensile resistance, shear resistance, abrasion resistance and crack resistance properties of a 3D printing member are effectively improved, the fracture toughness and impact resistance properties of the member are greatly enhanced, the fatigue performance anddurability of the beam member are improved, the space spanning capability is improved, construction is convenient, and quick application is achieved.

Owner:ZHEJIANG UNIV

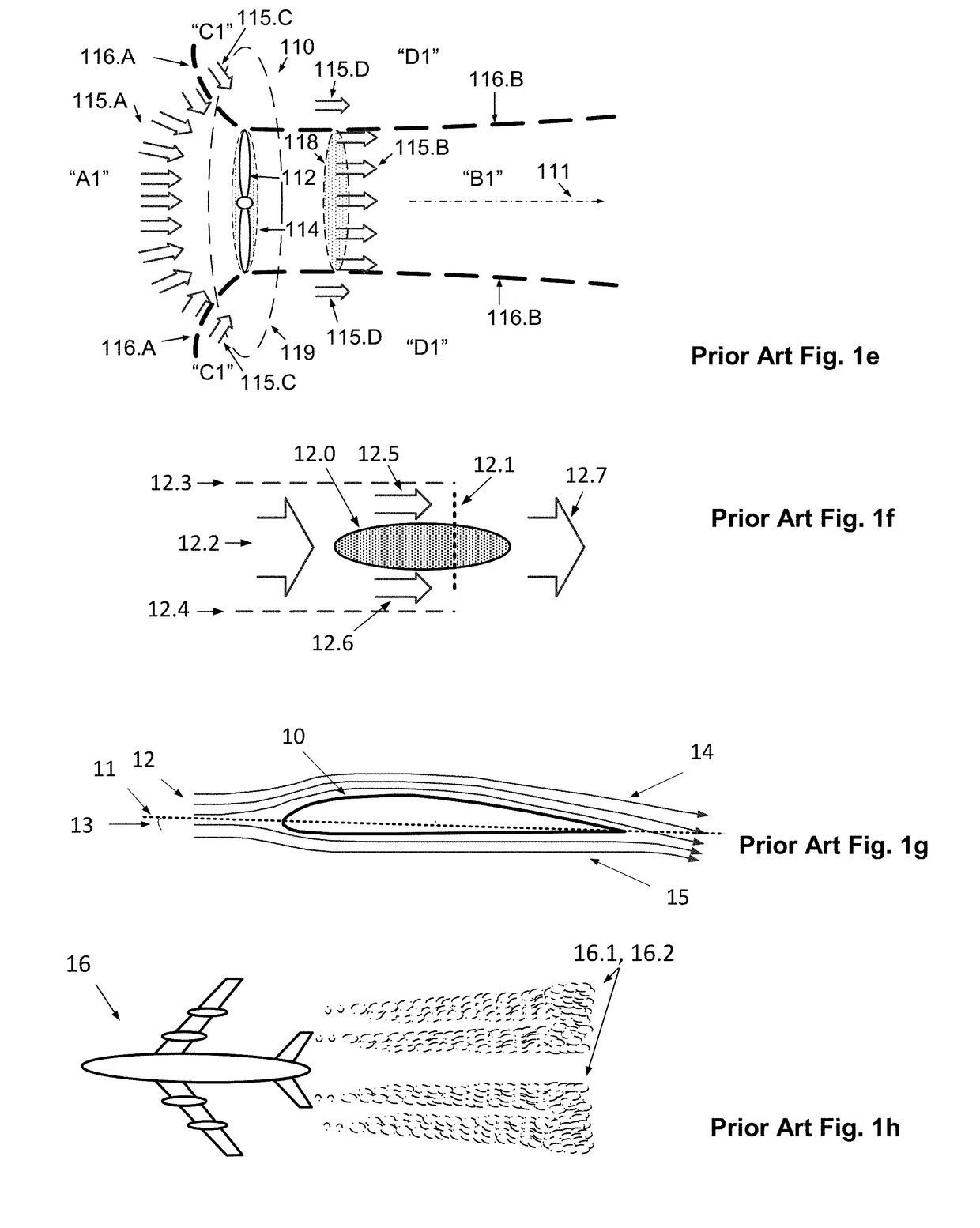

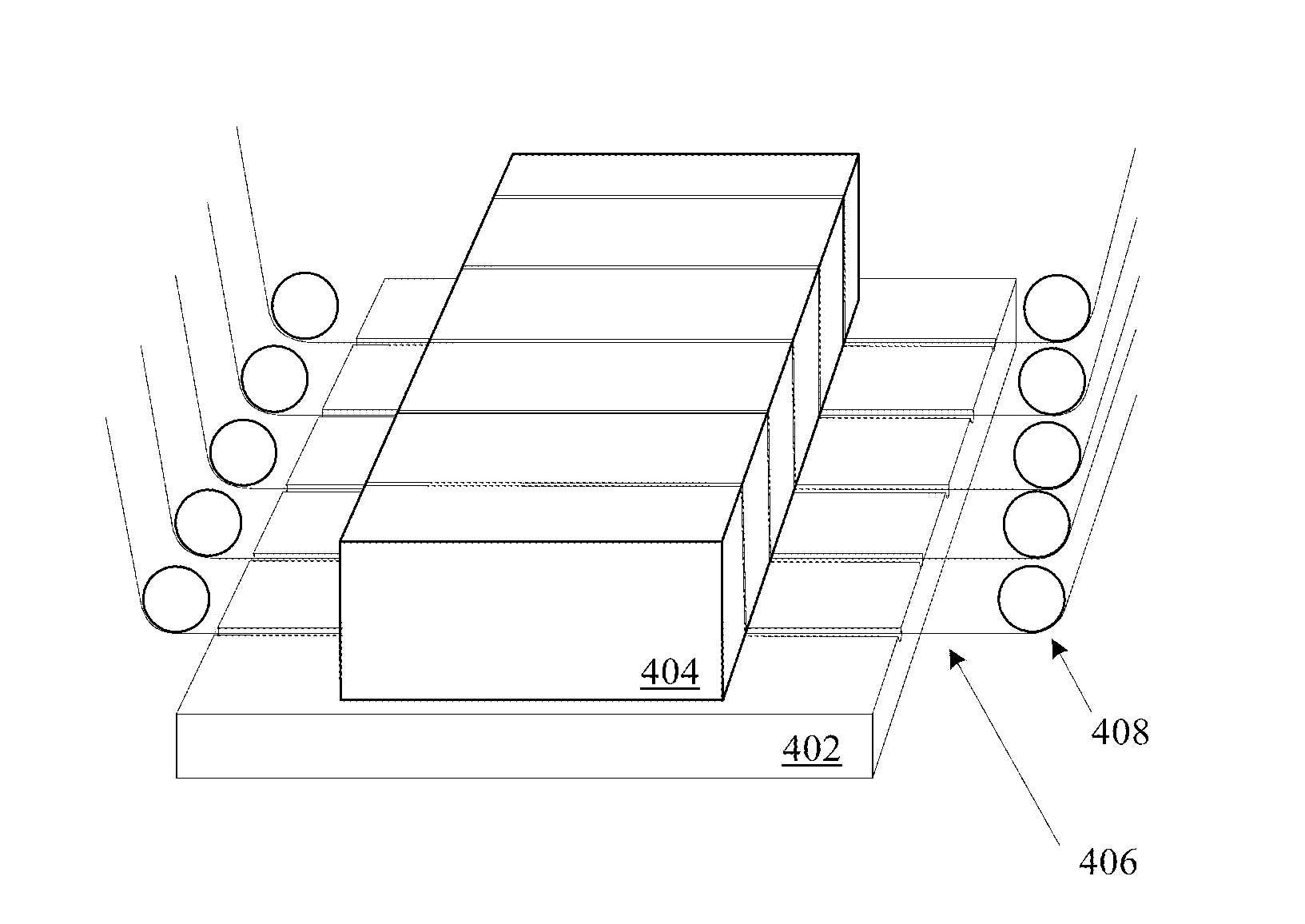

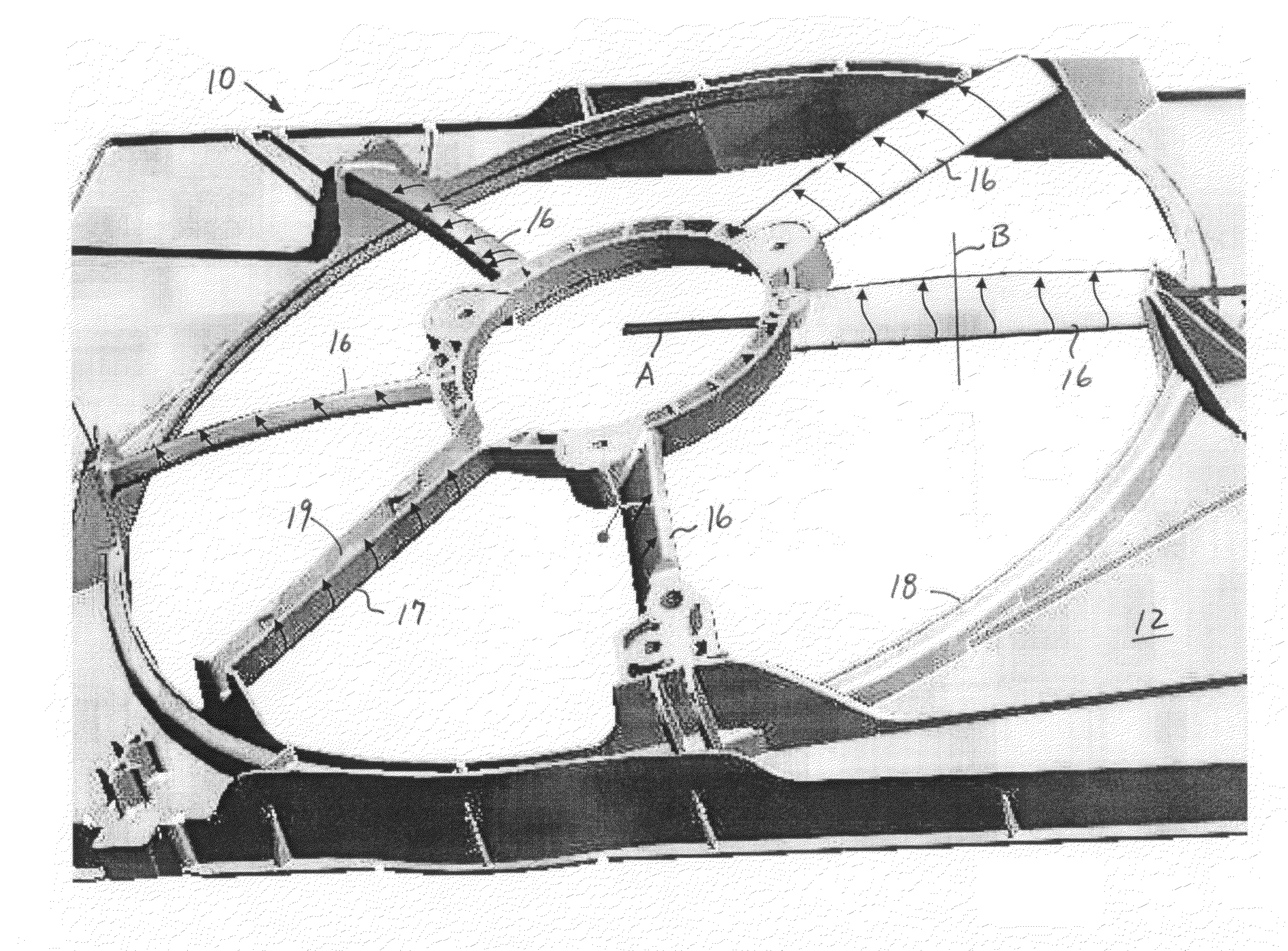

Fan Module motor mont arms with shape optimization

InactiveUS20080078340A1Reduce distractionsCoolant flow controlPump componentsIn vehicleShape optimization

A fan module (10) for mounting a fan of a vehicle includes a base (12), a motor mount (14) constructed and arranged to mount a fan motor thereto, and a plurality of connecting elements (16) each having a radial axis and an axis generally transverse to the radial axis. Each connecting element extends radially between the base and the motor mount, coupling the motor mount to the base. At least one connecting element is oriented about the radial axis thereof in a manner different from an orientation of at least one other connecting element with respect to its radial axis so that the orientation of the at least one connecting element generally reduces interference with in-vehicle air flow patterns.

Owner:SIEMENS VDO AUTOMOTIVE INC

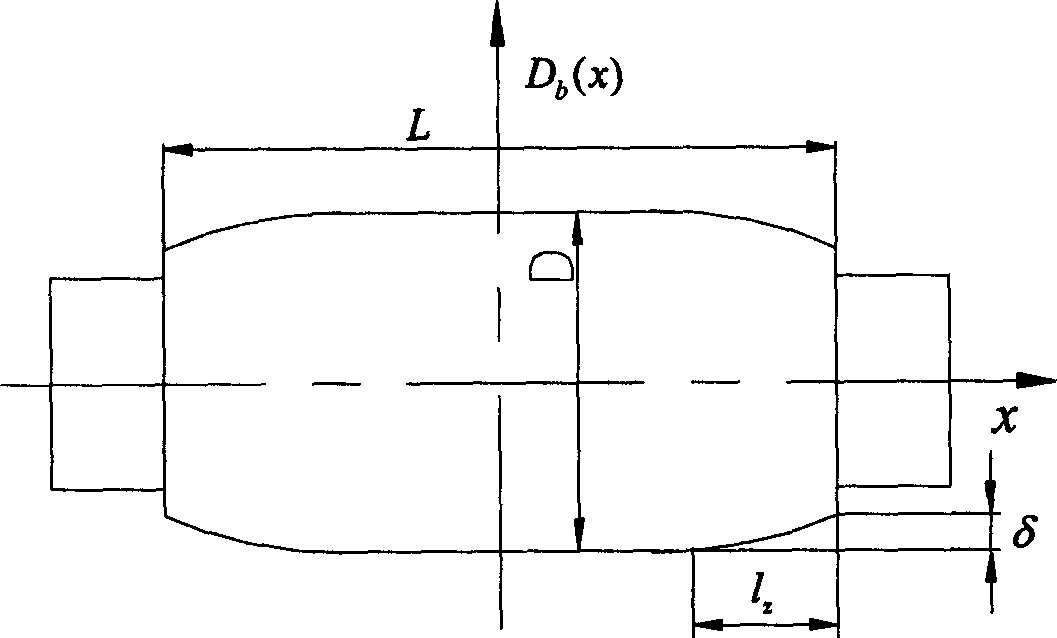

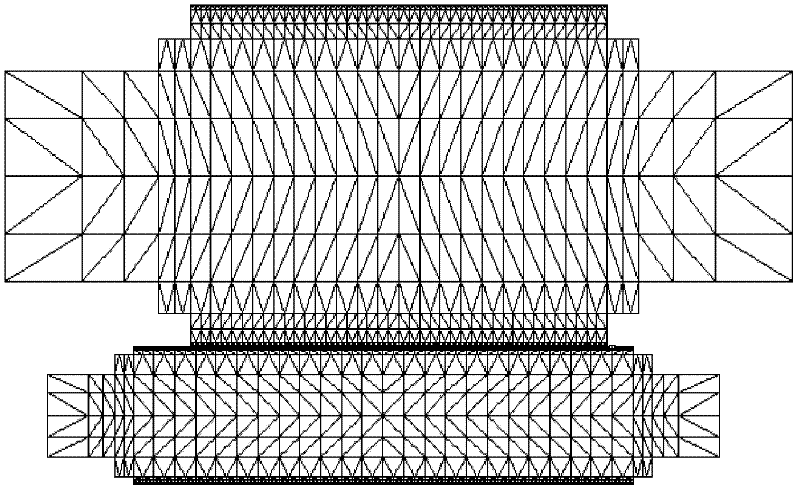

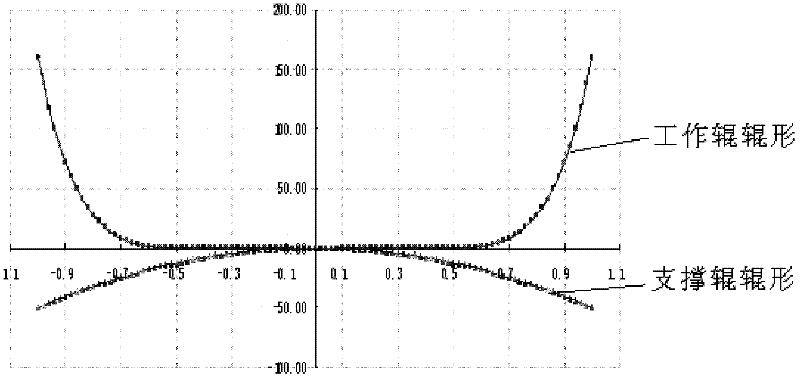

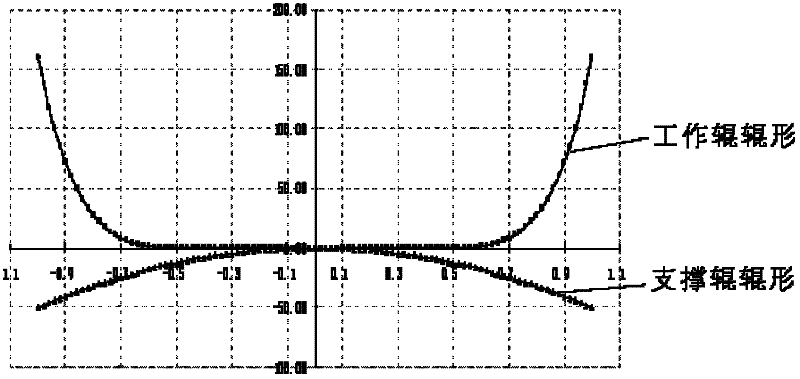

Method for designing and matching roll shape of continuous annealing temper mill

ActiveCN102247993AImprove plate shape adaptabilityImproved shape controlMeasuring devicesRollsElectrical steelEconomic benefits

The invention discloses a method for designing and matching the roll shape of a continuous annealing temper mill. The method comprises the following steps of: for the specification of a main roll, collecting and counting a large number of process parameters, actually measuring sheet shape data at site, and analyzing the sheet shape quality problem of different products; providing a sheet shape target on the design of a roll shape for the requirements of different product users on the sheet shape quality, wherein the width of strip steel is taken as the fundamental quantity in the optimizationprocess; selecting different strip steel widths; and designing a roll shape optimization curve which can synchronously meet different strip steel width specifications and different varieties of steels through the finite element simulation of working condition. By the technical scheme, the sheet shape quality of automobile sheets, household appliance sheets and semi-process electrical steel can beremarkably improved, the precision requirements of users on sheet shape indexes of different products are met, and good economic benefit is created. The stability of rolling is improved, the sheet shape quality of the products is improved, and the method has actual promotion and application value.

Owner:MAANSHAN IRON & STEEL CO LTD

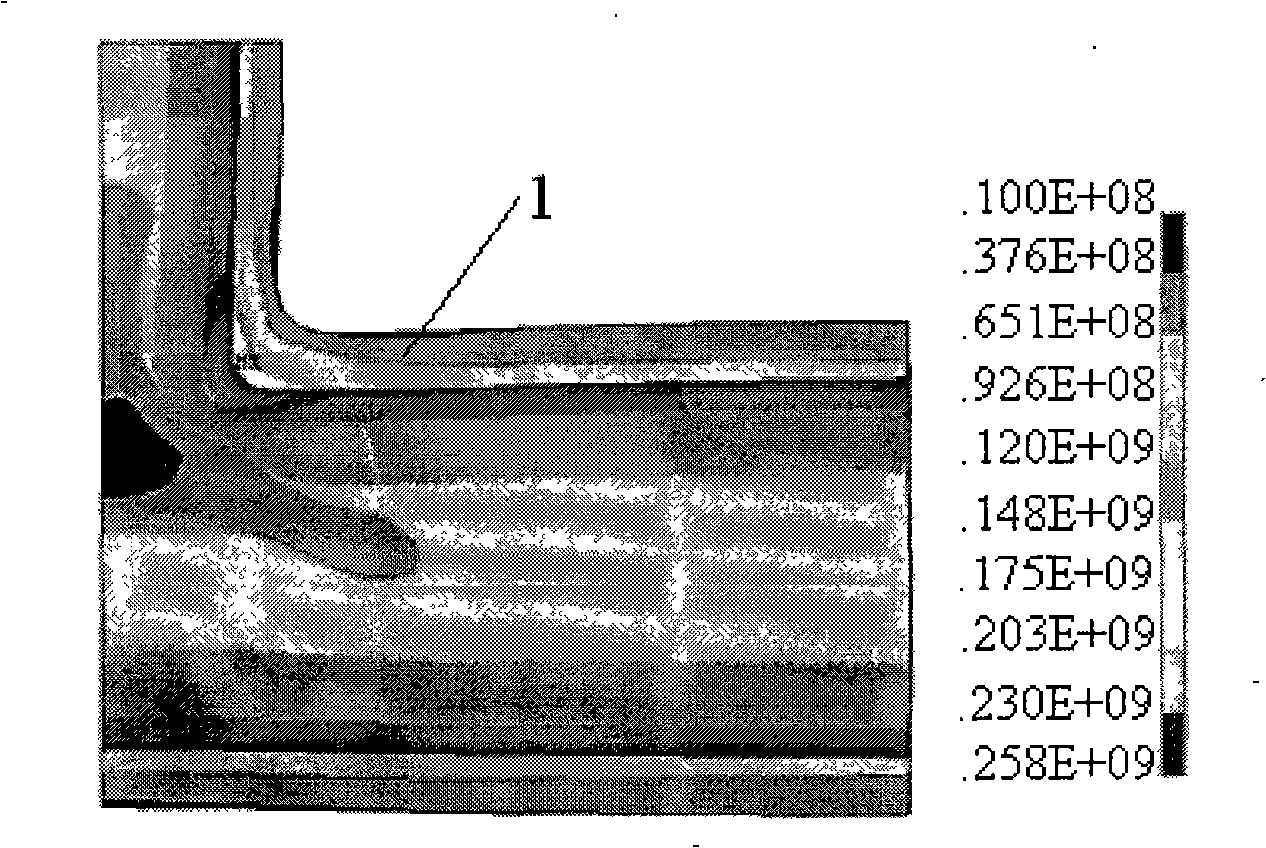

Mechanical part circular bead structure shape optimization method

ActiveCN104268317AImprove structural performanceEasy for CNC machiningSpecial data processing applicationsNumerical controlMechanical components

The invention discloses a mechanical part circular bead structure shape optimization method which is used for solving the technical field that the existing mechanical part circular bead structure shape optimization method is poor in practical. According to the technical scheme, a global rectangular coordinate system is constructed according to the integral structural size of a mechanical part; drawing a multi-arc curve according to starting points and terminal points of double arcs under the global rectangular coordinate system, obtained connecting points, coordinates of a center of a circle and semi-diameter information of the sections of arcs; enabling the drawn double-arc curve to be served as a circular bead curve; selecting coordinate components of coordinates of the starting points and the terminal points of the double arcs and angels of anticlockwise rotation of chord vectors of the double arcs to be coincided with a common tangent of the double arcs to be served as optimization design variable; performing finite element modeling, analysis and sensitivity solution and obtaining an optimized double-arc curve type circular bead structure. The mechanical part circular bead structure shape optimization method can effectively optimize the circular bead structure of the mechanical part, improve the structural performances of the mechanical part and is beneficial to numerical control machining and strong in engineering practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

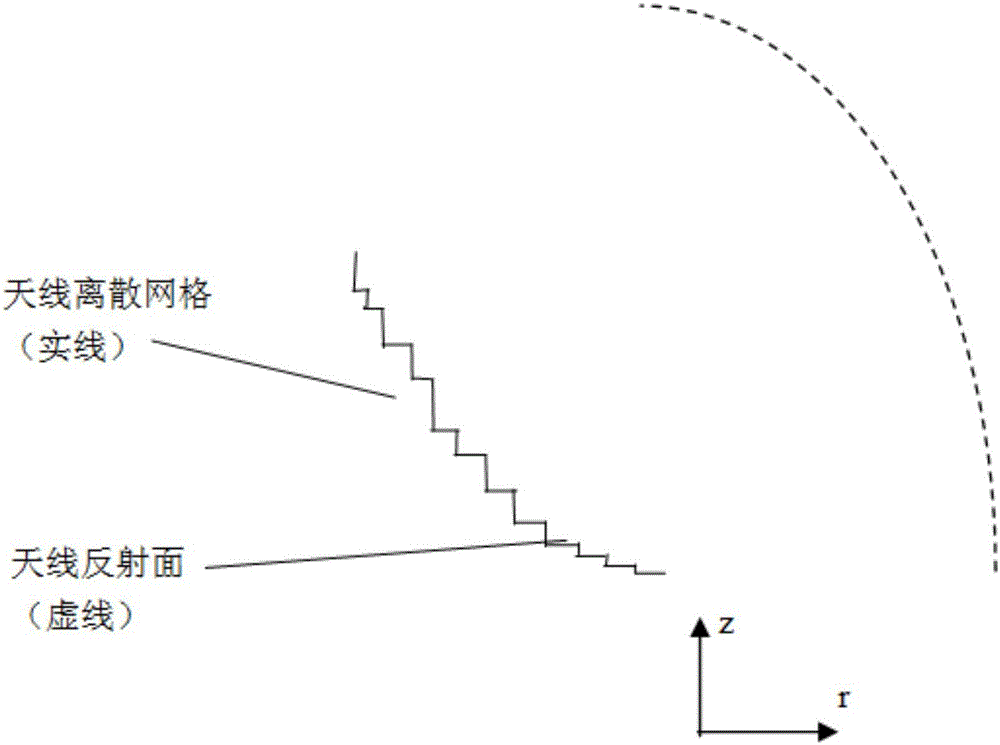

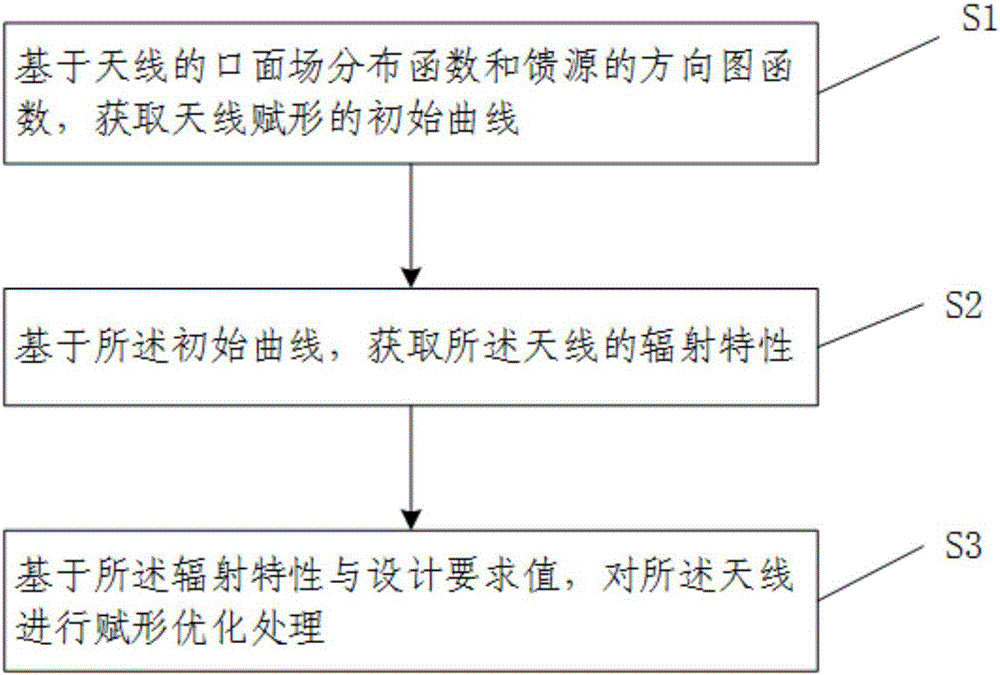

Reflector antenna shape optimization method and device

InactiveCN106816715AImprove efficiencyHighly reflective surfaces indicate accuracyAntennasPower flowGenetic algorithm

The present invention provides a reflector antenna shape optimization method and device. The method comprises the steps of S1 based on an aperture-field distribution function of an antenna and a pattern function of a feed source, obtaining an initial curve of the shape of the antenna; S2 based on the initial curve, obtaining the radiation characteristic of the antenna; S3 based on the radiation characteristic and a design requirement value, carrying out the shape optimization processing on the antenna. According to the present invention, the reflector configuration is fitted by a Zernike polynomial, the shape variable quantity of an antenna shape reflector and a normal vector on the reflector are solved by an analysis relation, and an antenna surface current is solved, on the basis, the design requirement value is compared according to the radiation characteristic of the antenna, and a genetic algorithm is utilized to optimize the shape of the antenna, so that the optimization efficiency is high, after shaping, the reflector presentation precision is high, the test and processing are easy, and the reflector antenna has wide military and civilian prospects.

Owner:北京星网卫通科技开发有限公司

Method for optimum design of tee shape

InactiveCN101329704AReduce stress levelsSpecial data processing applicationsStress concentrationElement model

The invention discloses a design method of shape optimization of a tee, which is carried out according to the following steps: first, a finite element analysis model and a corresponding mathematical expression of static structural analysis are built, then the displacement vector, strain vector and stress vector of a node are calculated; the total correction value and the component at the normal direction at the node are calculated; according to the determined total correction value and the component at the normal direction at the node, the node coordinate is corrected; the structure after correction is carried out stress calculation and test. The design method of shape optimization corrects the existing tee structure design, bases on finite element model, moves a high stress node along the direction of the outer normal on the structure surface by proportion, moves a low stress node along the opposite direction of the outer normal on the structure surface by proportion, and finally obtains a tee structure with a more suitable geometric shape and effective reduction of structure stress concentration.

Owner:XIAN UNIV OF TECH

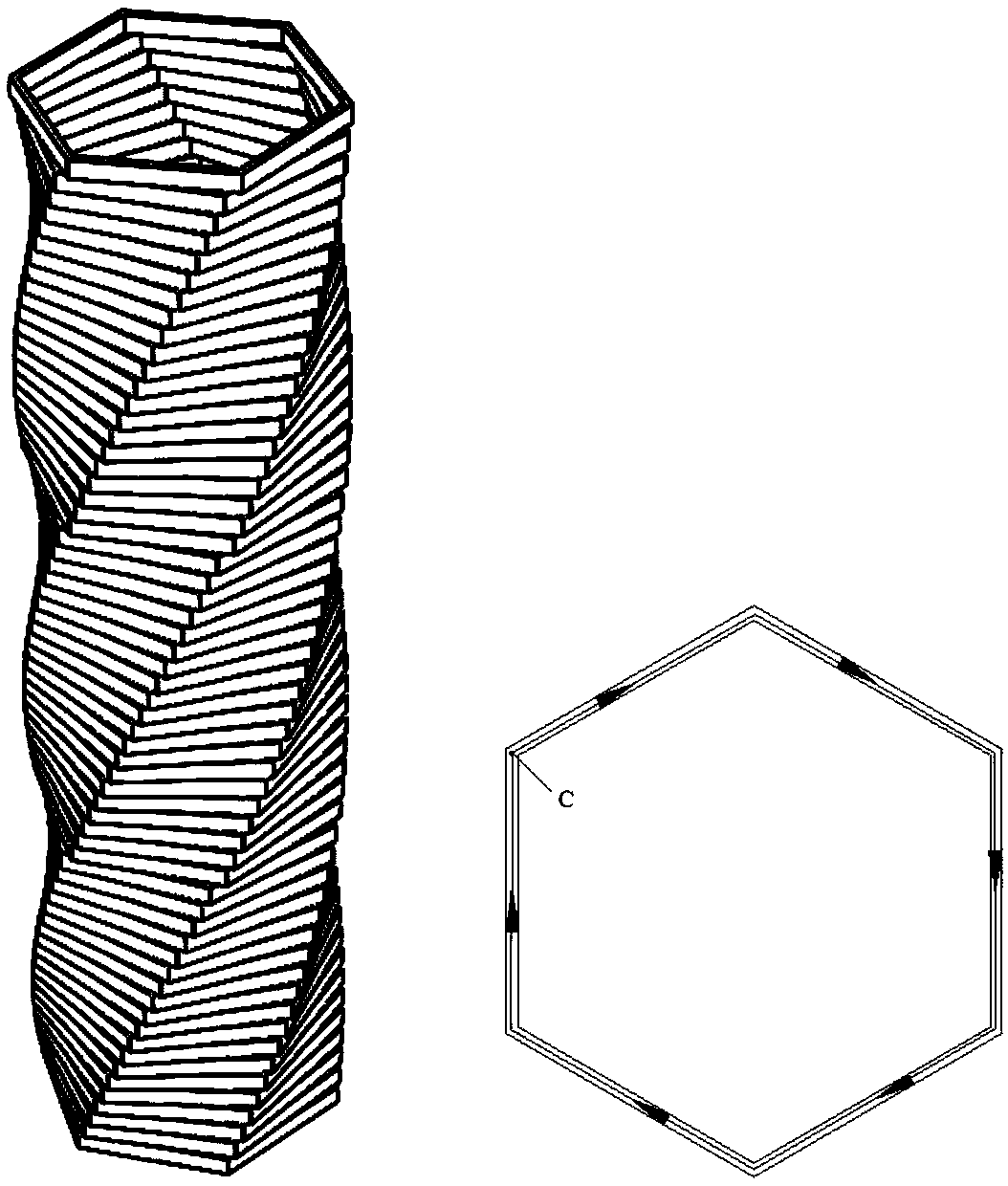

Construction method of composite column integrally formed by 3D printing and knitting and composite column

ActiveCN109129827AReduce building construction proceduresReduce labor intensityAdditive manufacturing apparatusStrutsCrack resistanceEngineering

The invention discloses a construction method of a composite column integrally formed by 3D printing and knitting and the composite column. The construction method comprises the steps that (1) after spatial modeling according to the architectural model, spatial shape optimization is performed according to the functional requirements, and the wire knitting tightness is designed according to the bearing capacity requirements; (2) according to a determined spatial shape and the determined knitting tightness, a matrix printing sequence and anchoring points of wires are arranged to obtain a printing and knitting integrated process, and 3D printing materials are prepared; and (3) according to the printing and knitting integrated process, a solid composite column or a column shell is printed layer by layer. According to the construction method of the composite column integrally formed by 3D printing and knitting, the high-strength wires are knitted in when printing a matrix, and the tensile resistance, shear resistance, abrasion resistance and crack resistance properties of the 3D printing matrix are improved while replacing a steel bar.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com