Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2157results about How to "Improve structural performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

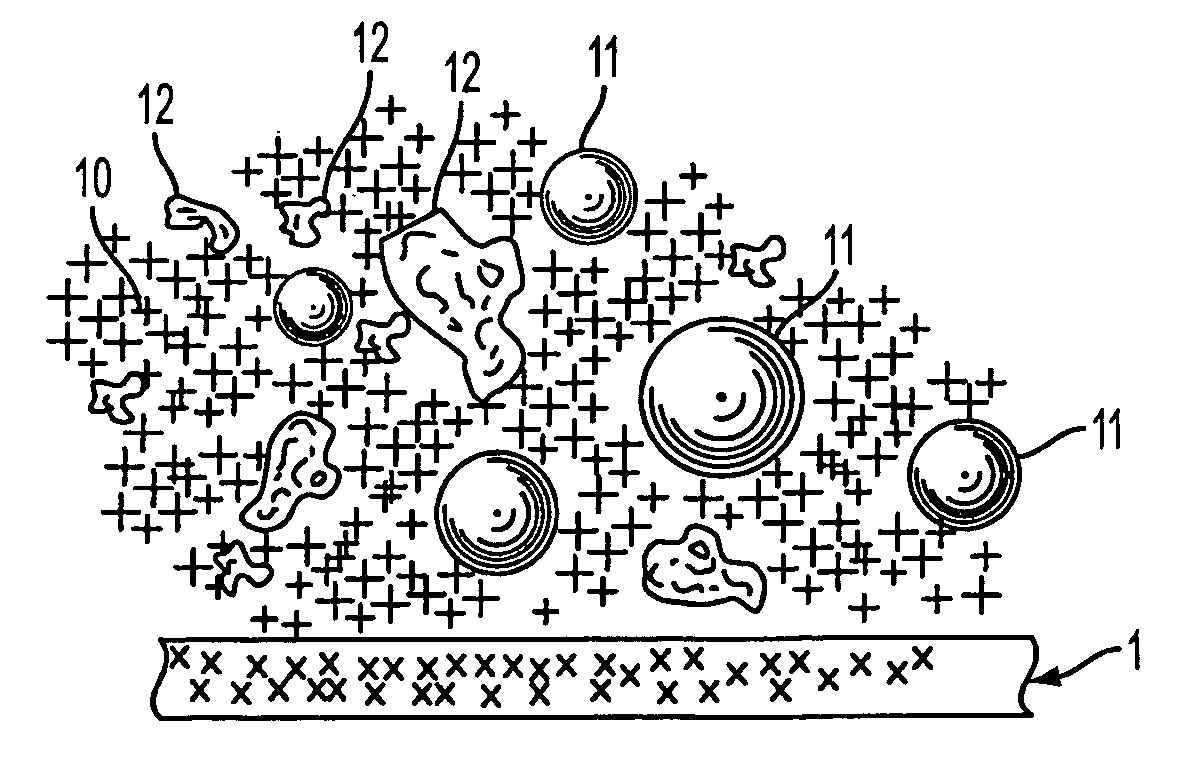

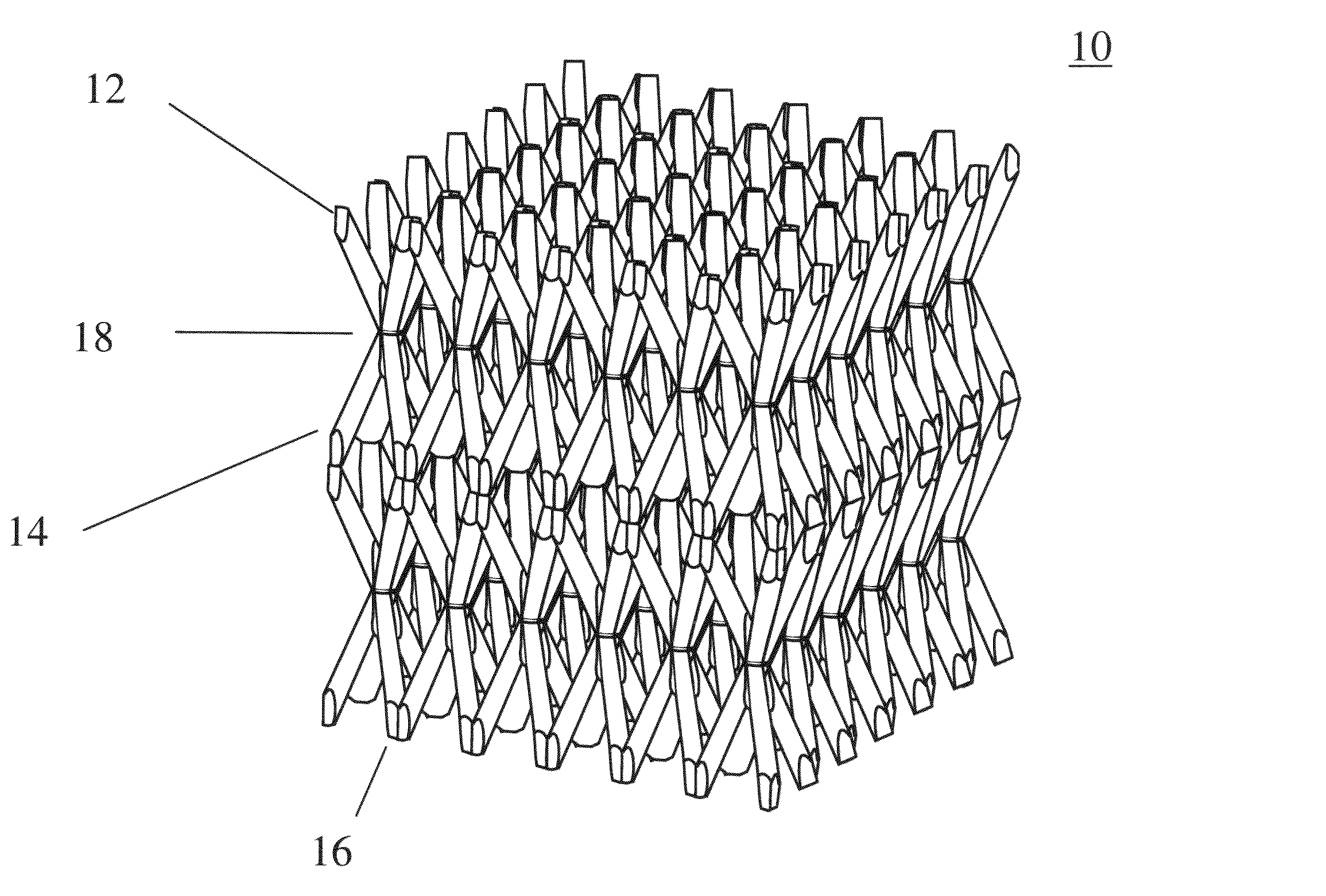

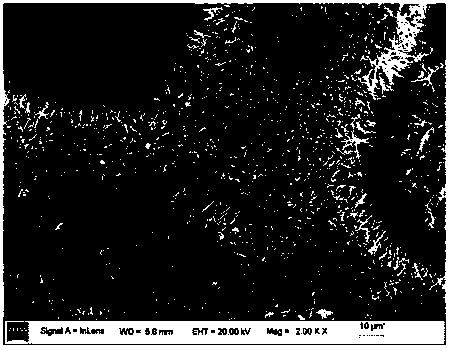

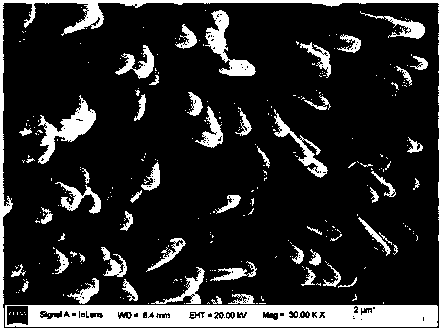

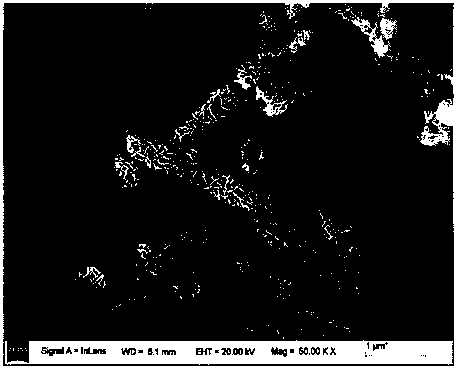

Articles comprising large-surface-area bio-compatible materials and methods for making and using them

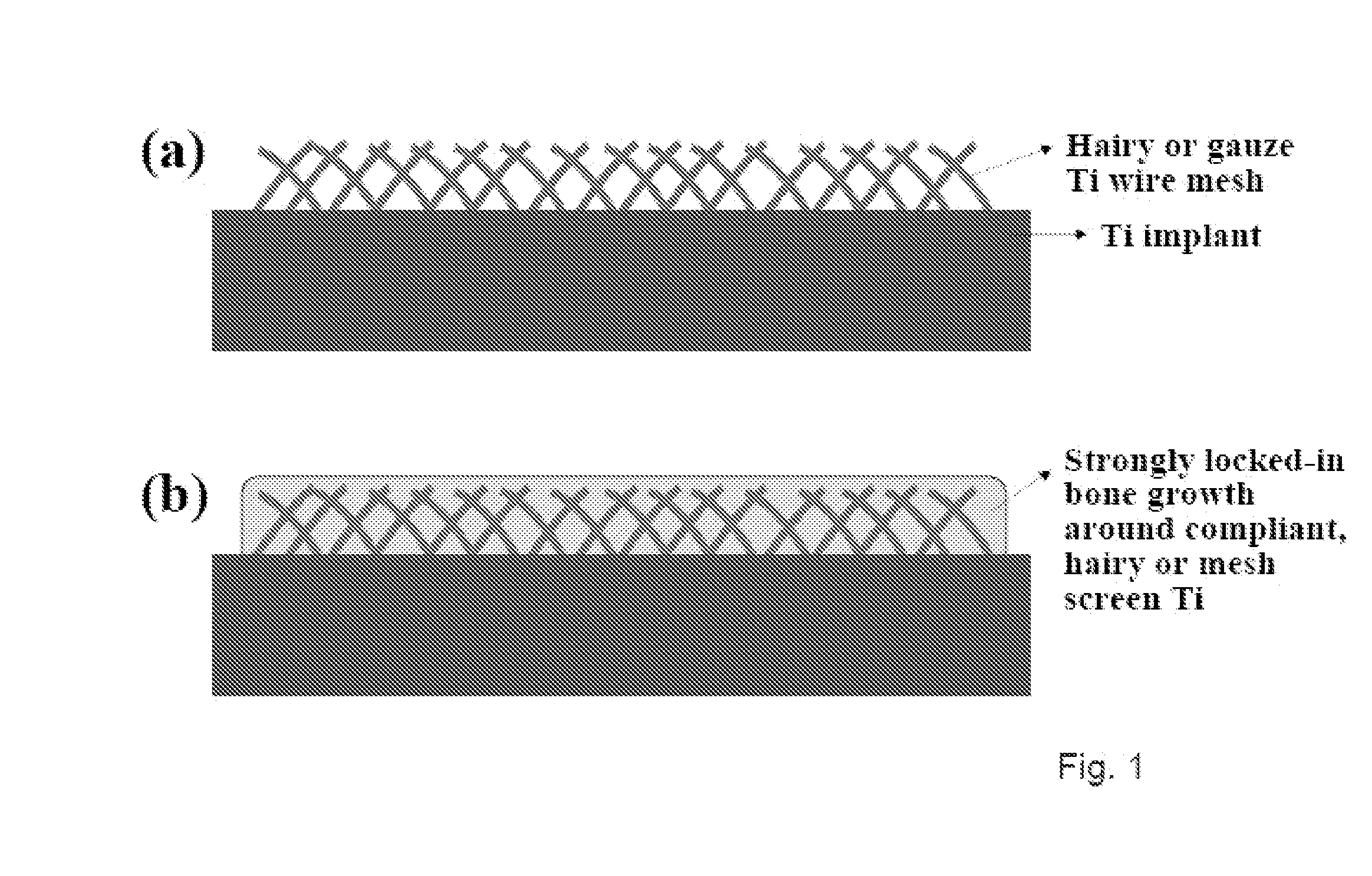

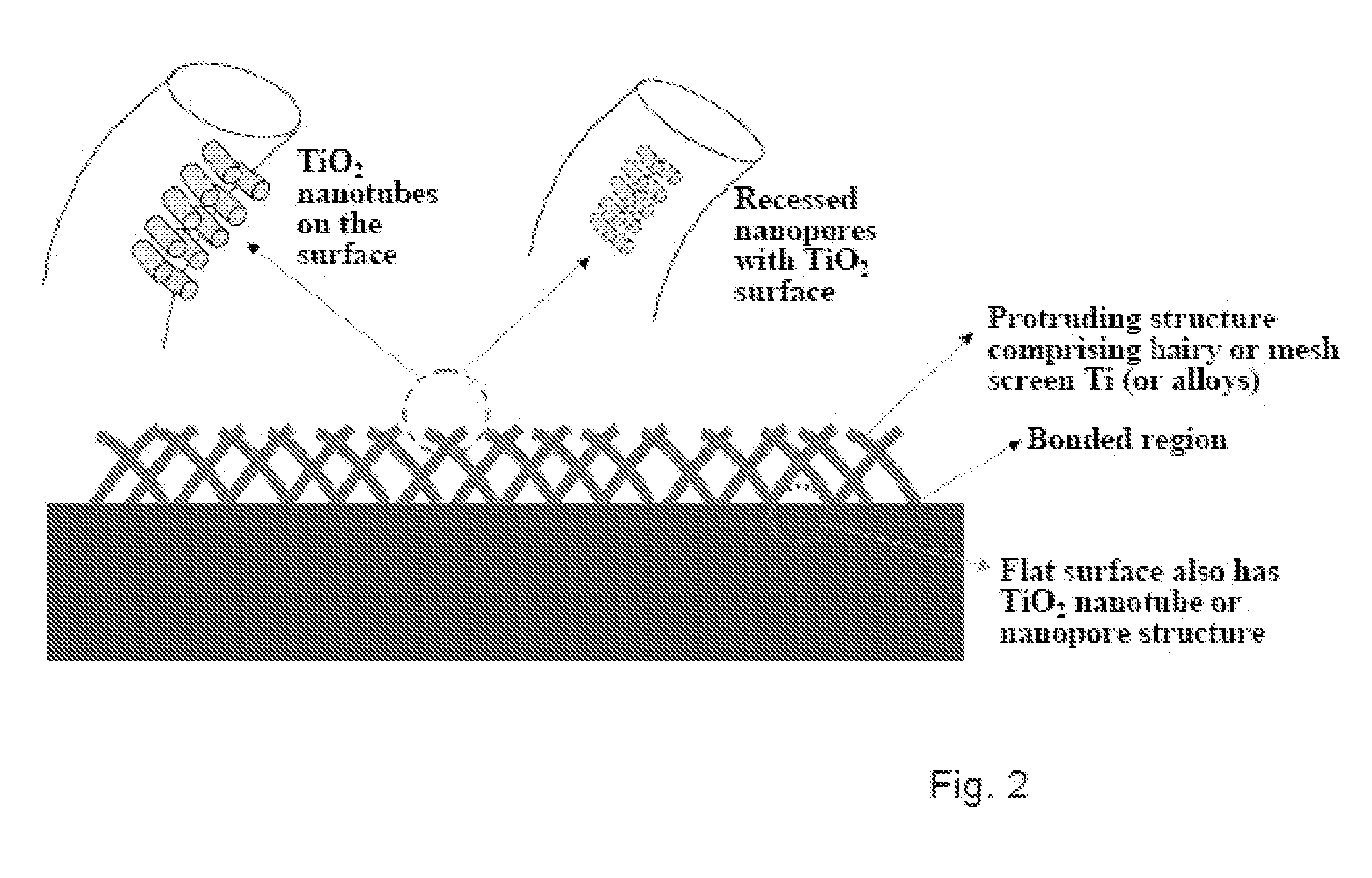

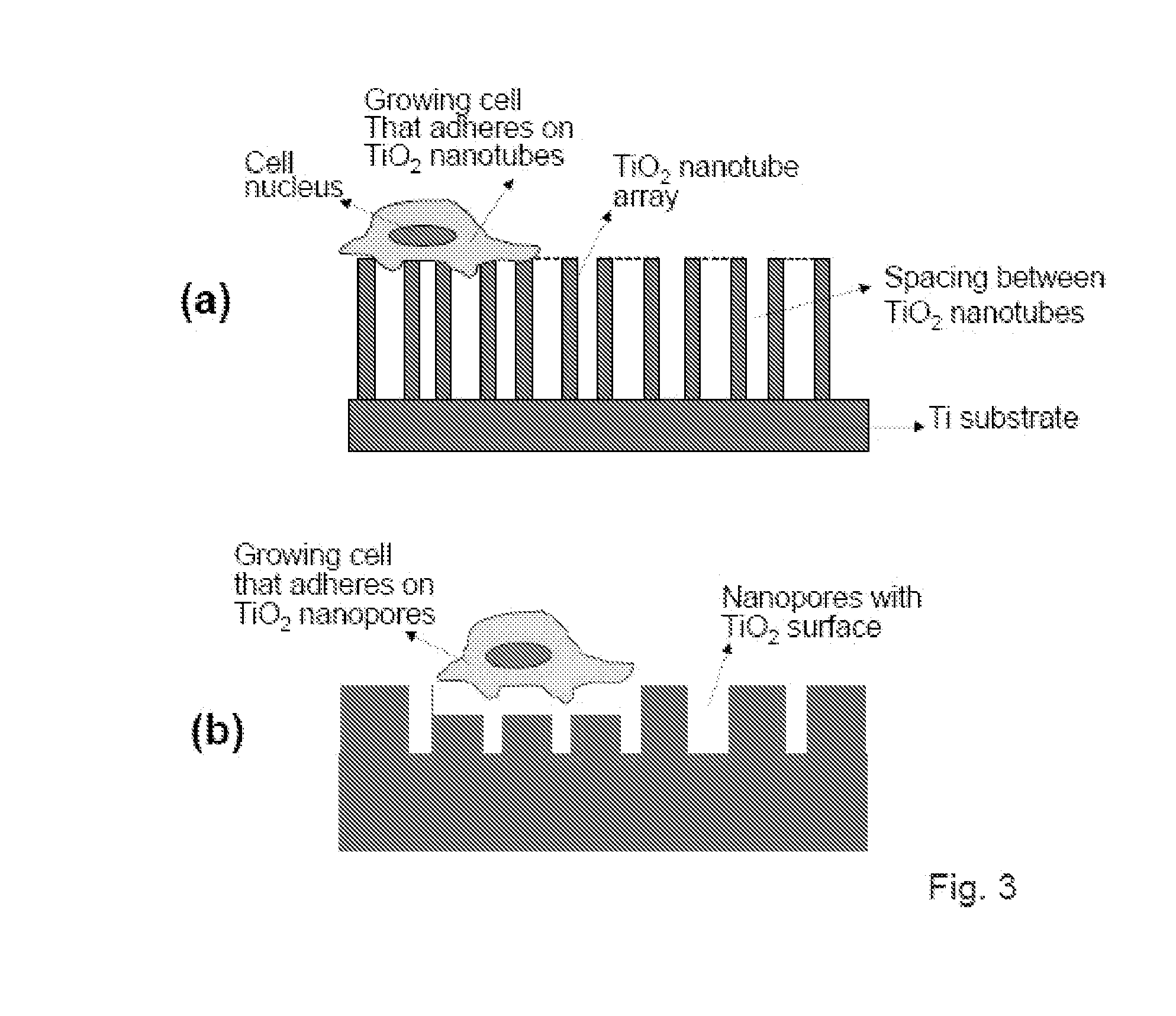

ActiveUS20100303722A1Improve cell adhesionAccelerated cell growth characteristicImmobilised enzymesBioreactor/fermenter combinationsCell culture mediaBone growth

The present invention provides articles of manufacture comprising biocompatible nanostructures comprising significantly increased surface area for, e.g., organ, tissue and / or cell growth, e.g., for bone, tooth, kidney or liver growth, and uses thereof, e.g., for in vitro testing of drugs, chemicals or toxins, or as in vivo implants, including their use in making and using artificial tissues and organs, and related, diagnostic, screening, research and development and therapeutic uses, e.g., as drug delivery devices. The present invention provides biocompatible nanostructures with significantly increased surface area, such as with nanotube and nanopore array on the surface of metallic, ceramic, or polymer materials for enhanced cell and bone growth, for in vitro and in vivo testing, cleansing reaction, implants and therapeutics. The present invention provides optically transparent or translucent cell-culturing substrates. The present invention provides biocompatible and cell-growth-enhancing culture substrates comprising elastically compliant protruding nanostructure substrates coated with Ti, TiO2 or related metal and metal oxide films.

Owner:RGT UNIV OF CALIFORNIA

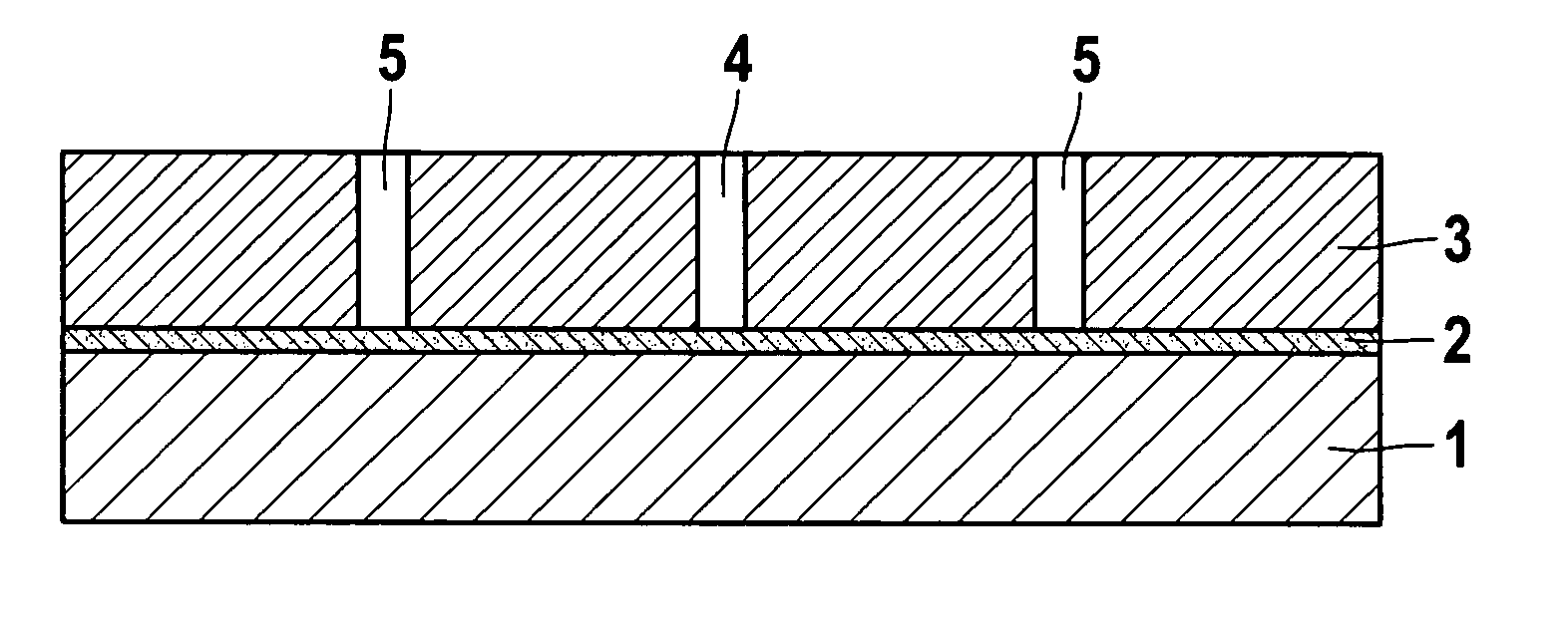

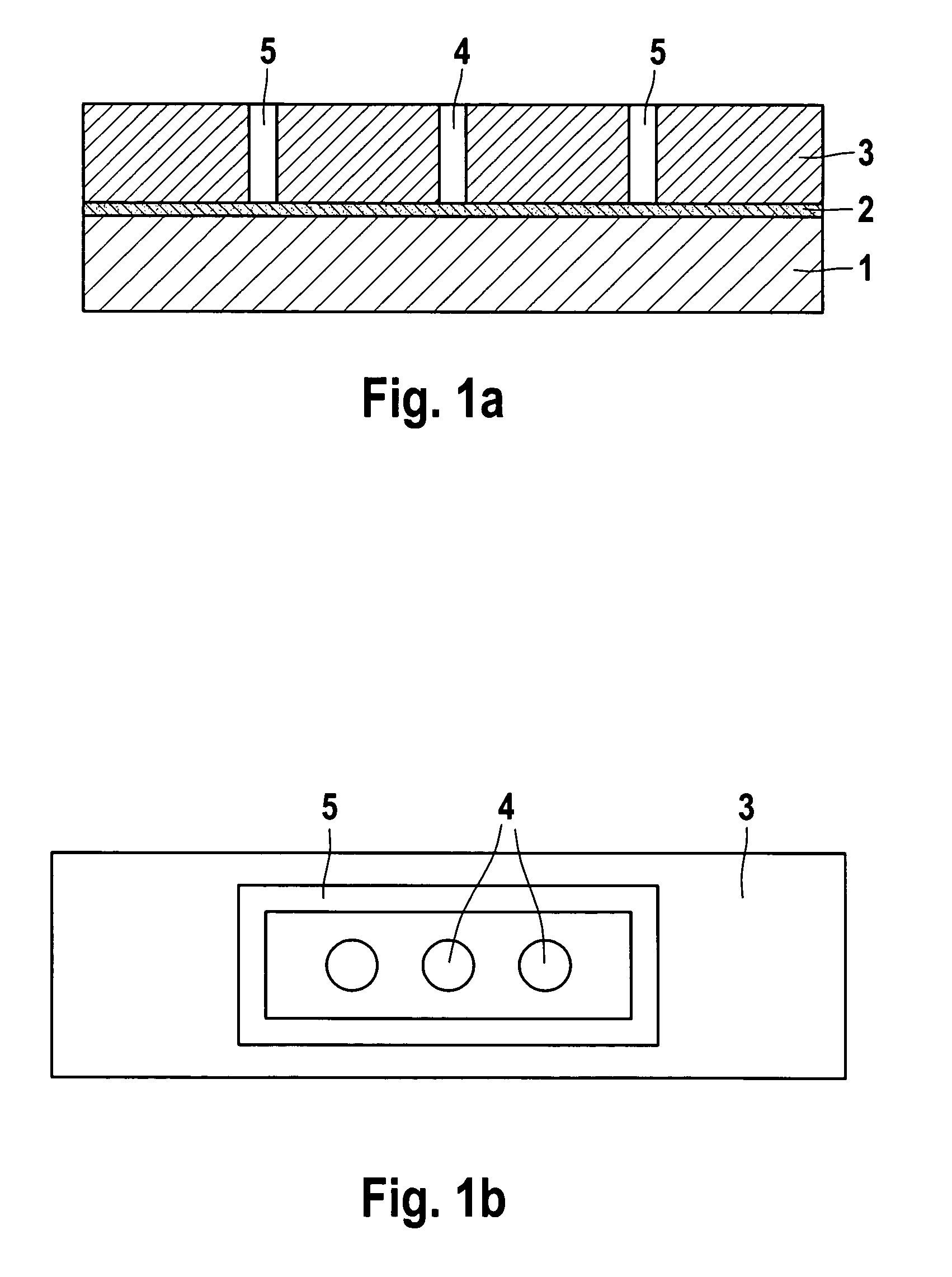

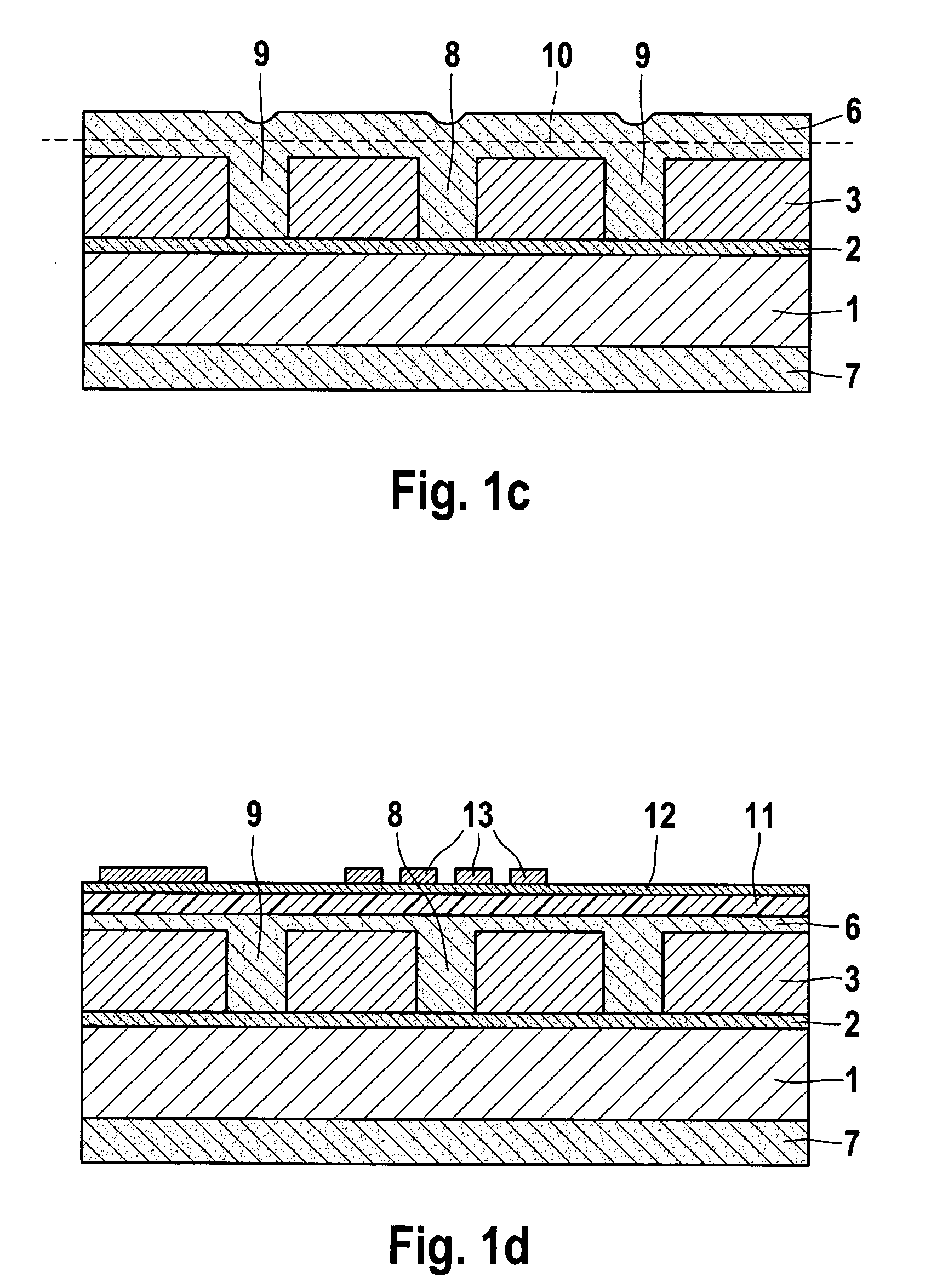

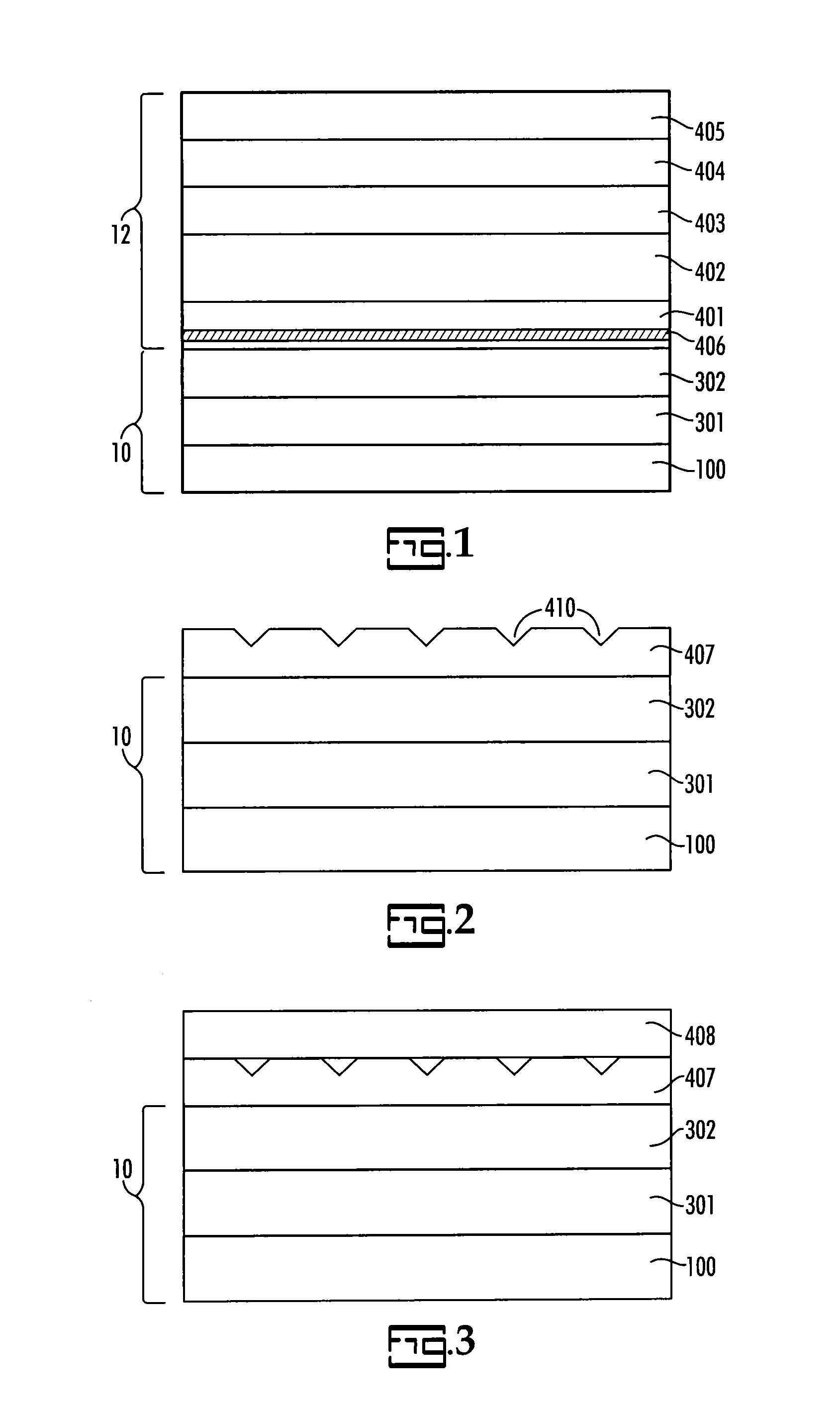

Micromechanical structural element having a diaphragm and method for producing such a structural element

ActiveUS20050098840A1Improve stabilityExtended service lifeDecorative surface effectsFluid pressure measurement using elastically-deformable gaugesEngineeringStructural element

A micromechanical structural element, having a very stable diaphragm, implemented in a pure front process and in a layer construction on a substrate. The layer construction includes at least one sacrificial layer and one diaphragm layer above the sacrificial layer, which is structured for laying bare the diaphragm and generating stabilizing elements on the diaphragm, at least one recess being generated for a stabilizing element of the diaphragm. The structure generated in the sacrificial layer is then at least superficially closed with at least one material layer being deposited above the structured sacrificial layer, this material layer forming at least a part of the diaphragm layer and being structured to generate at least one etch hole for etching the sacrificial layer, which is removed from the region under the etch hole, the diaphragm and the at least one stabilizing element being laid bare, a cavity being created under the diaphragm.

Owner:ROBERT BOSCH GMBH

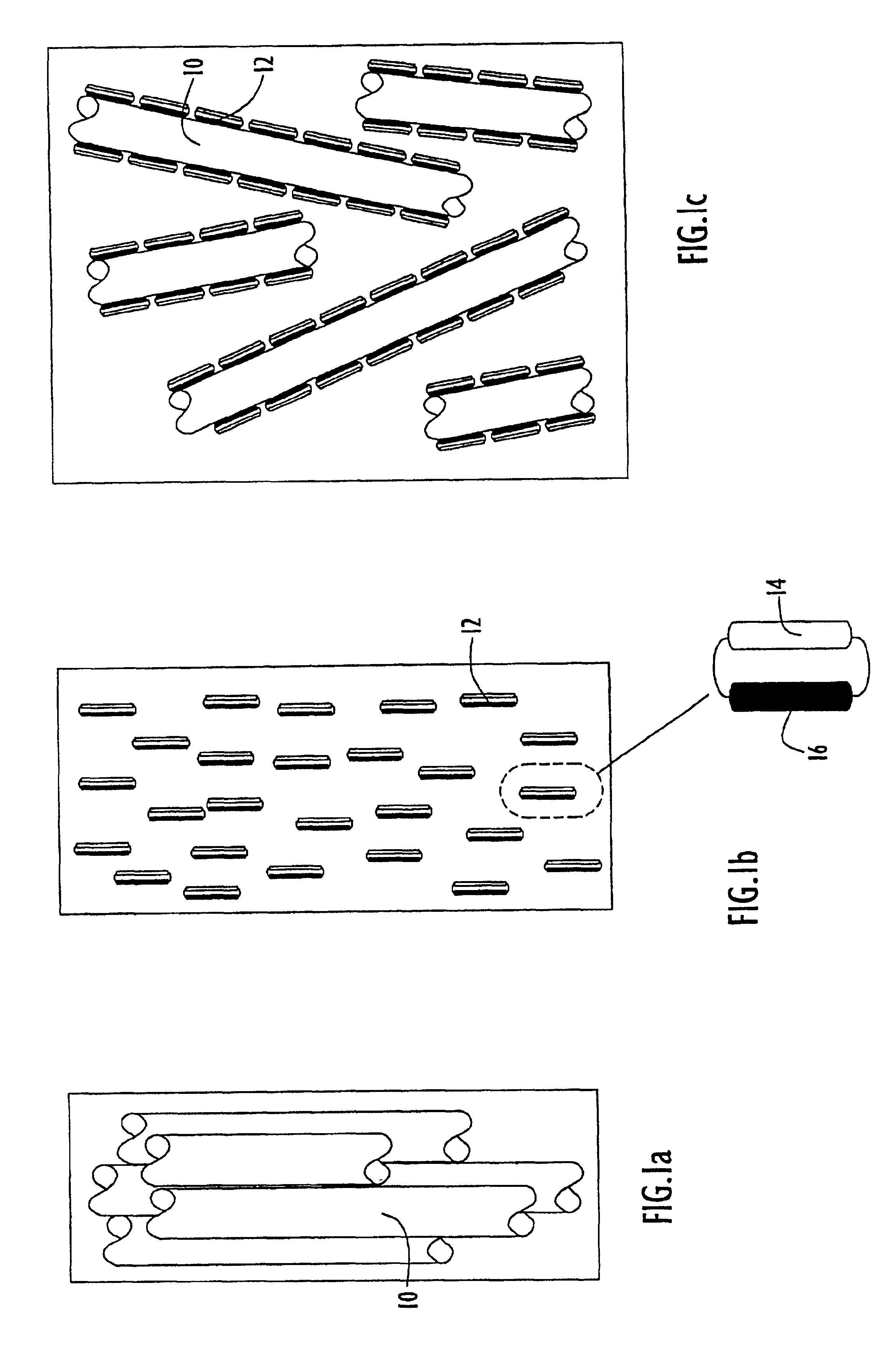

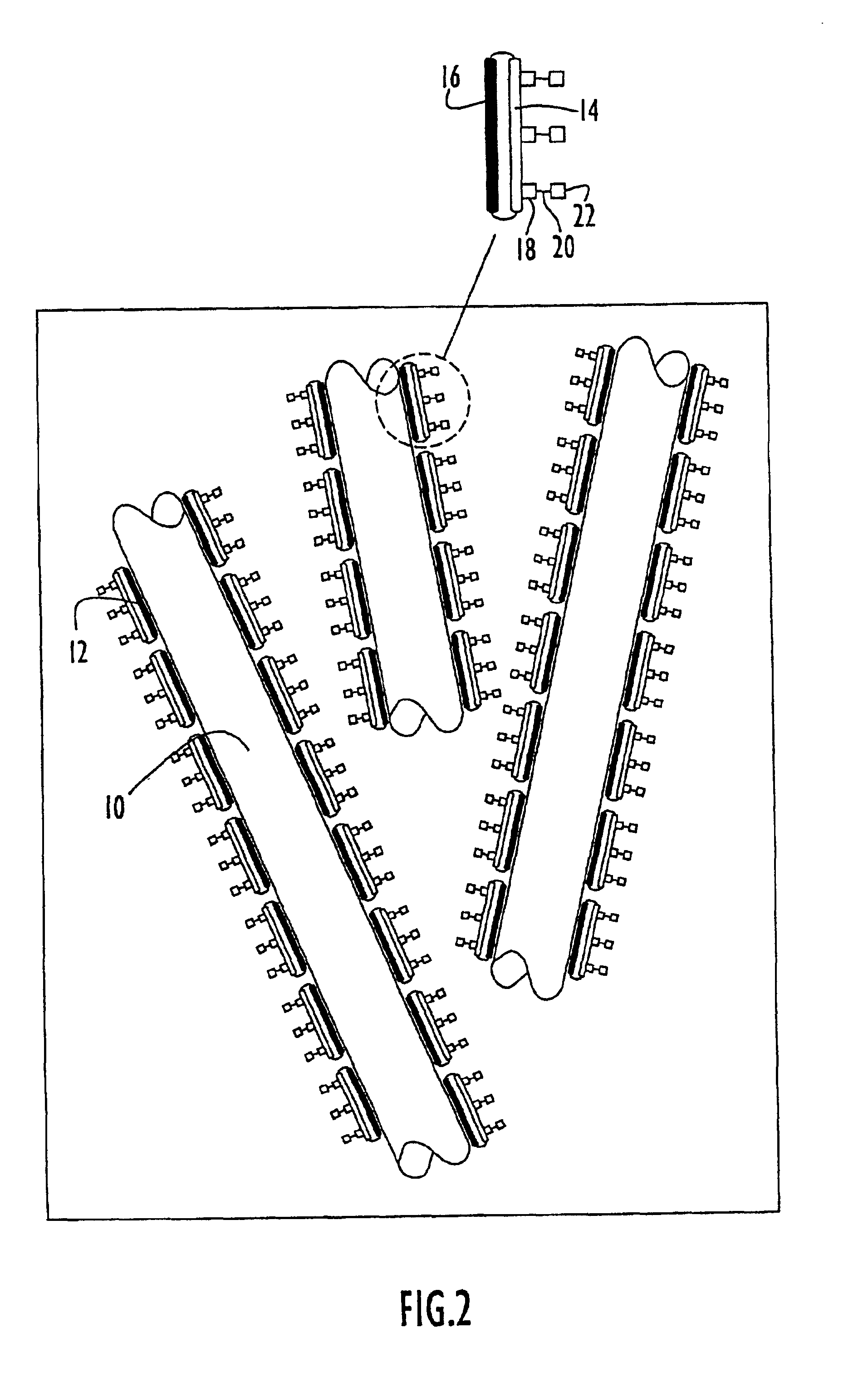

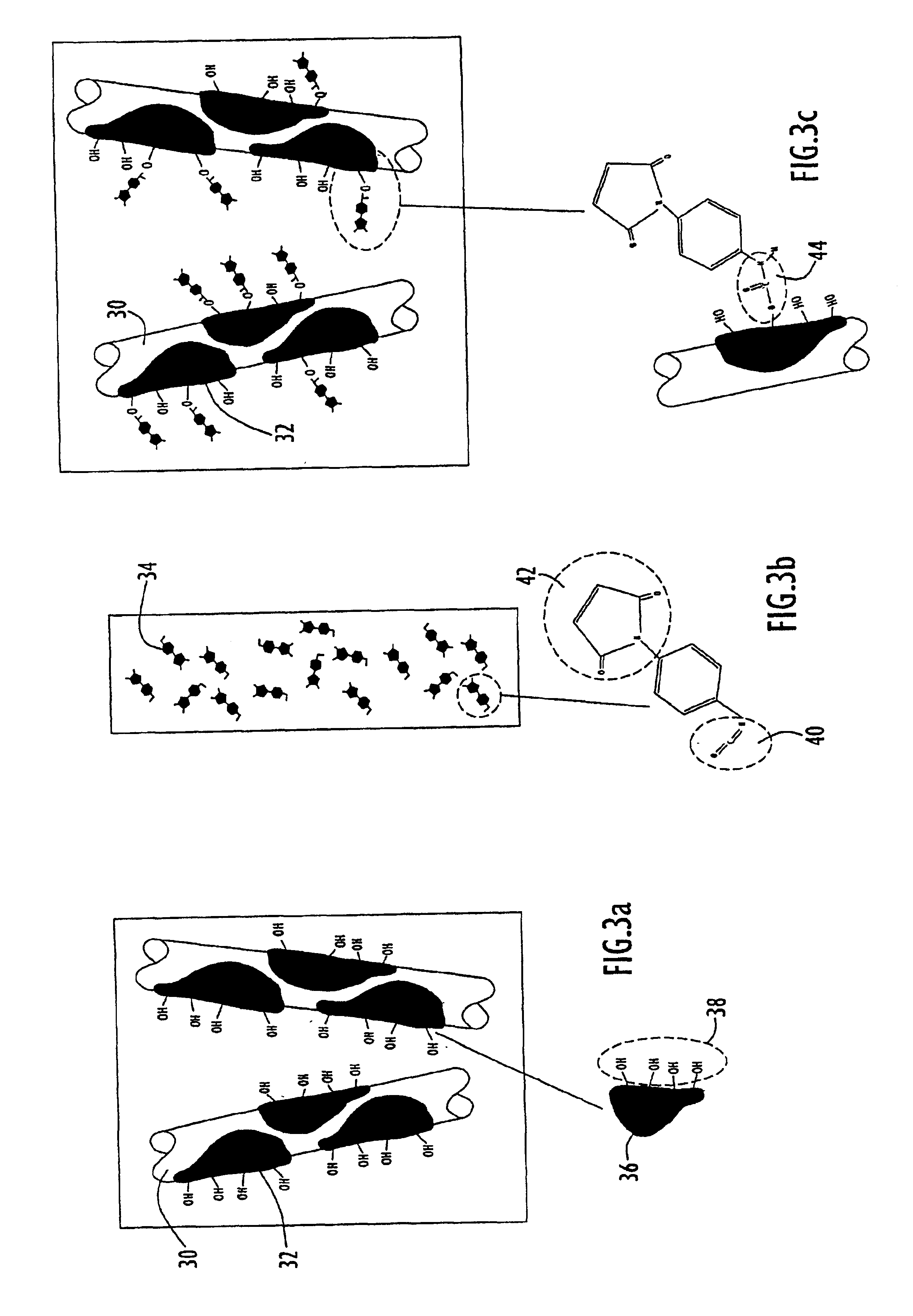

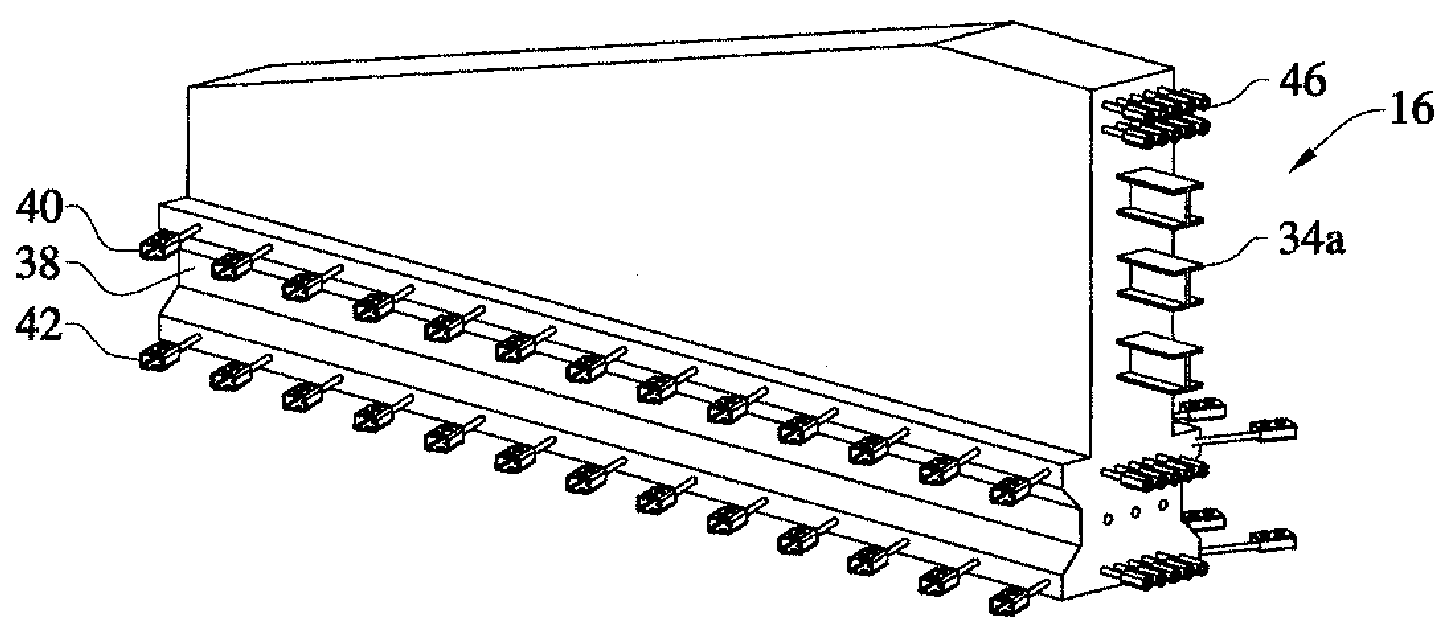

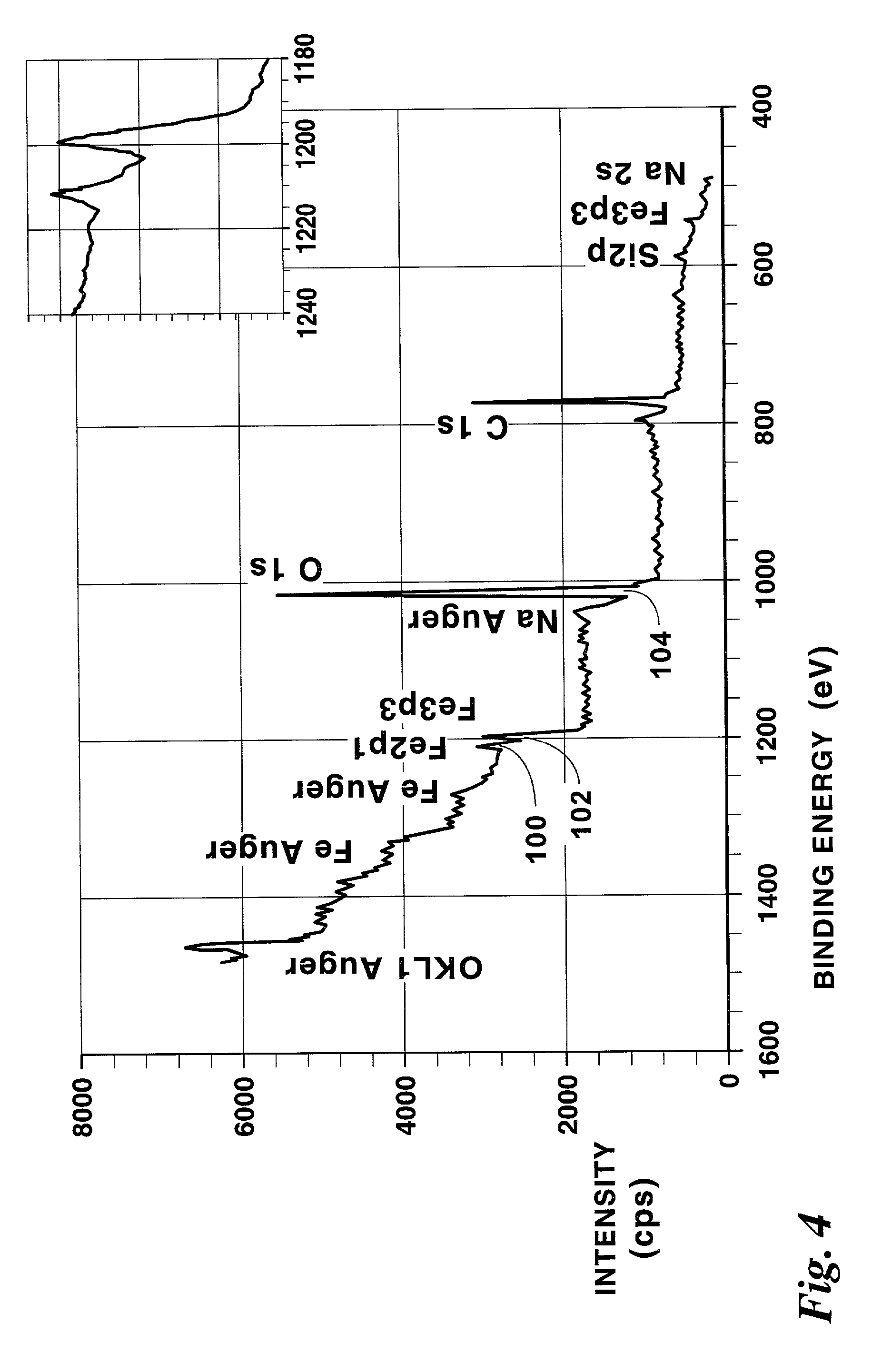

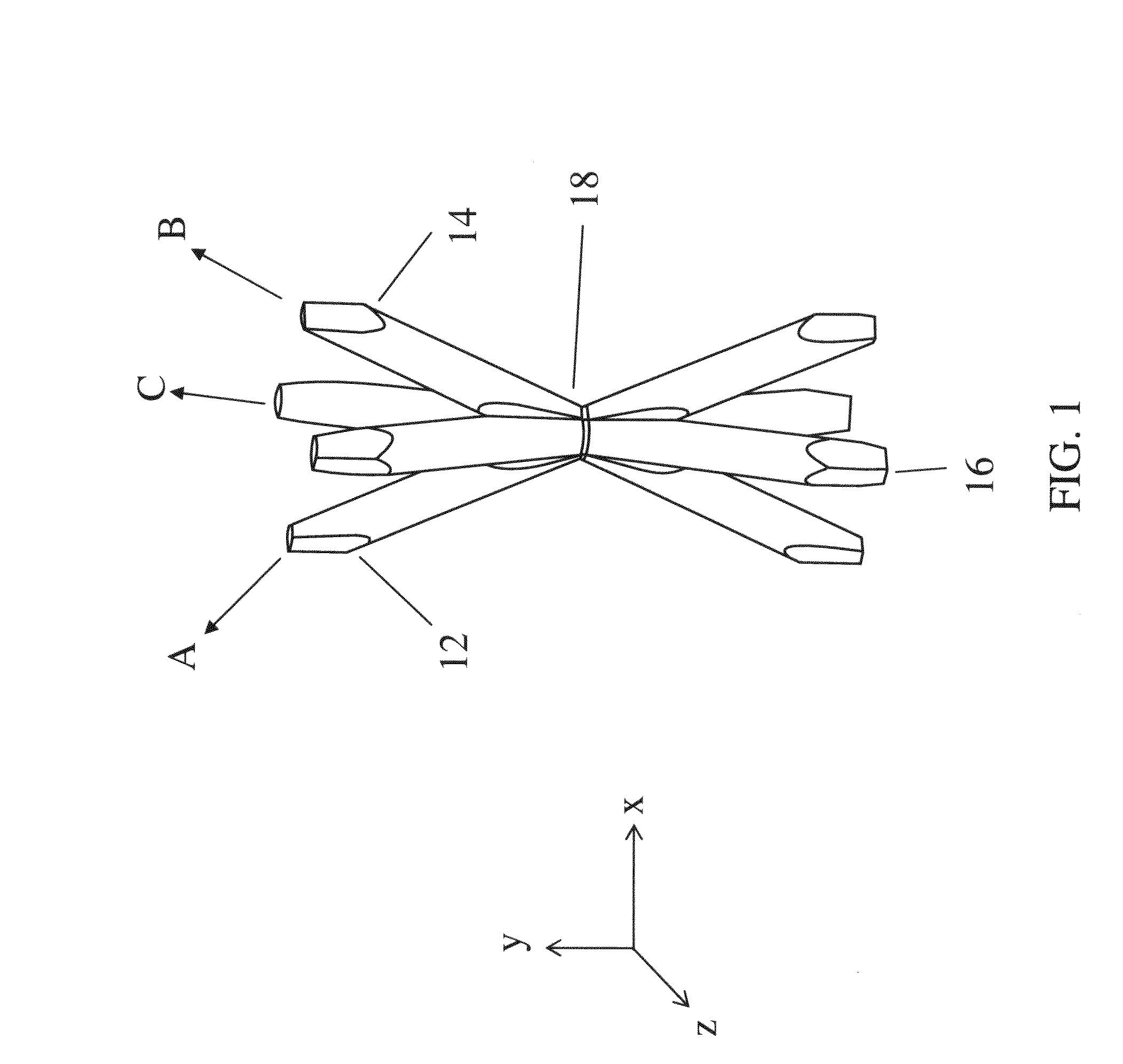

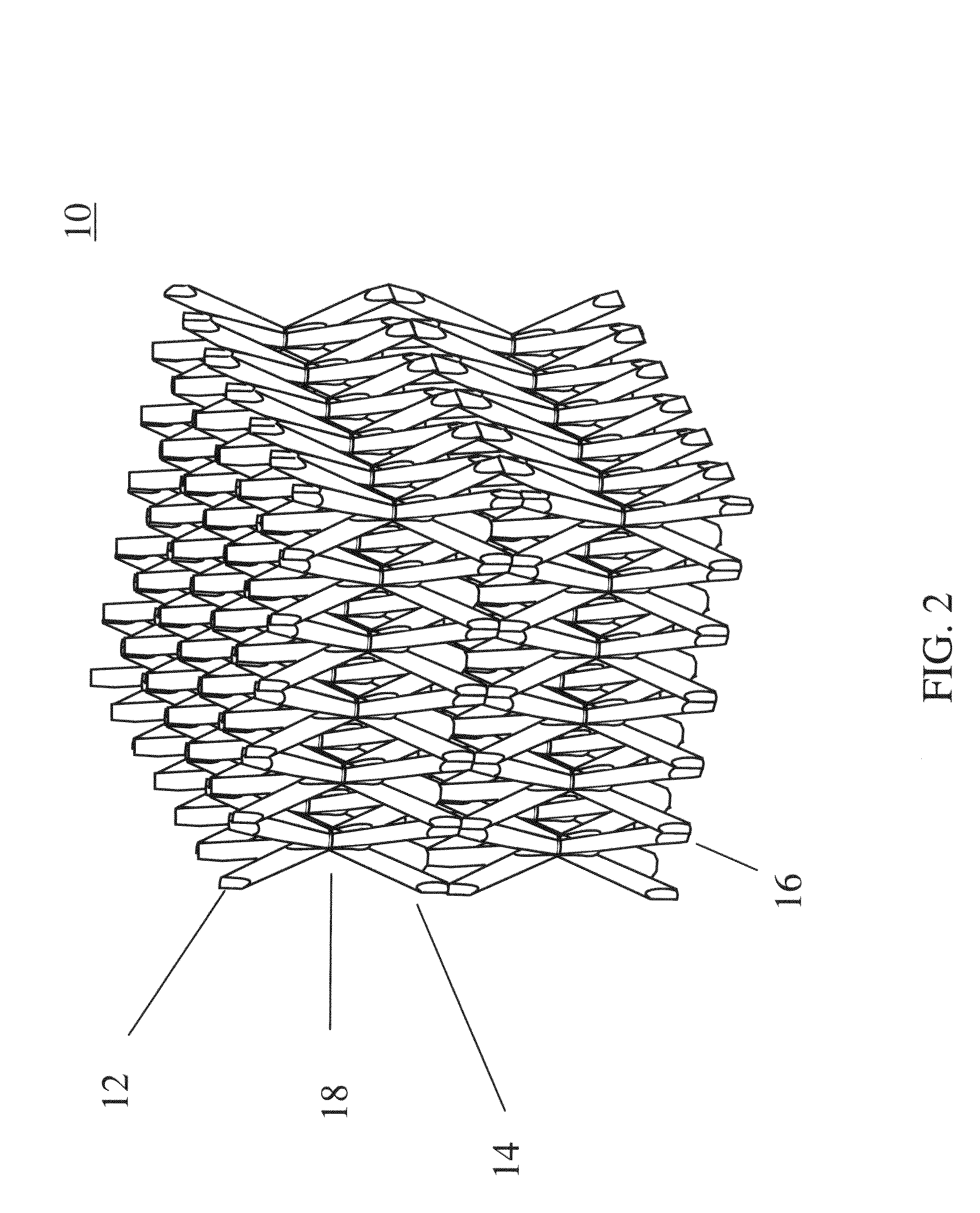

Spatial localization of dispersed single walled carbon nanotubes into useful structures

InactiveUS6896864B2Improve structural performanceMaterial nanotechnologyNanostructure manufactureBinding siteAqueous solution

Methods of aligning single walled carbon nanotube structures into selected orientations for a variety of different applications are achieved by initially dispersing the nanotube structures in aqueous solutions utilizing a suitable dispersal agent. The dispersal agent coats each individual nanotube structure in solution. The dispersal agent may be substituted with a suitable functional group that reacts with a corresponding binding site. Dispersed nanotube structures coated with substituted dispersal agents are exposed to a selected array of binding sites such that the nanotubes align with the binding sites due to the binding of the substituted functional groups with such binding sites. Alternatively, crystalline nanotube material is formed upon deposition of dispersed nanotube structures within solution into channels disposed on the surface of the substrate. Combining dispersal agent chemical modification techniques with deposition of the nanotubes into substrate channels is also utilized to produce useful structures.

Owner:BATTELLE MEMORIAL INST

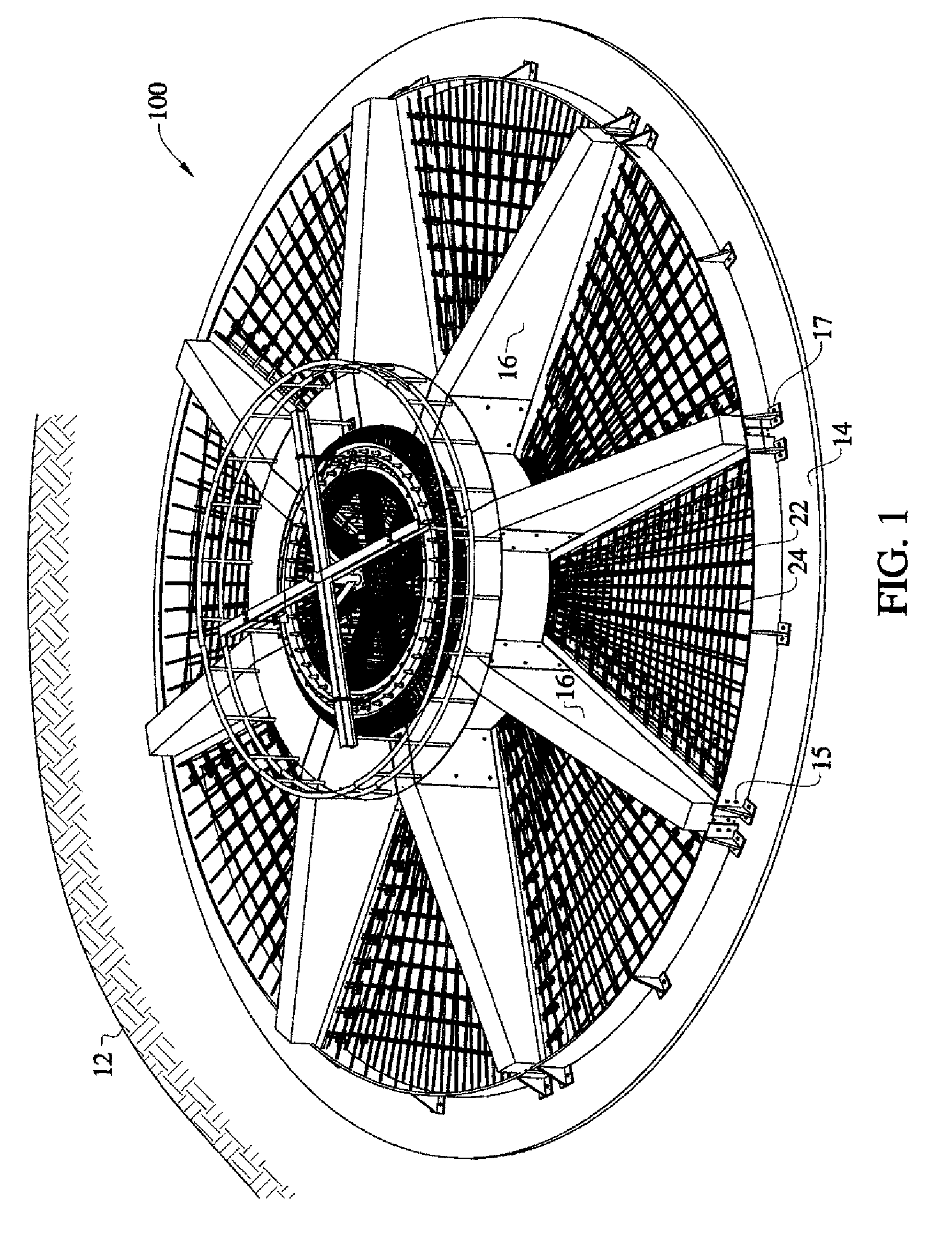

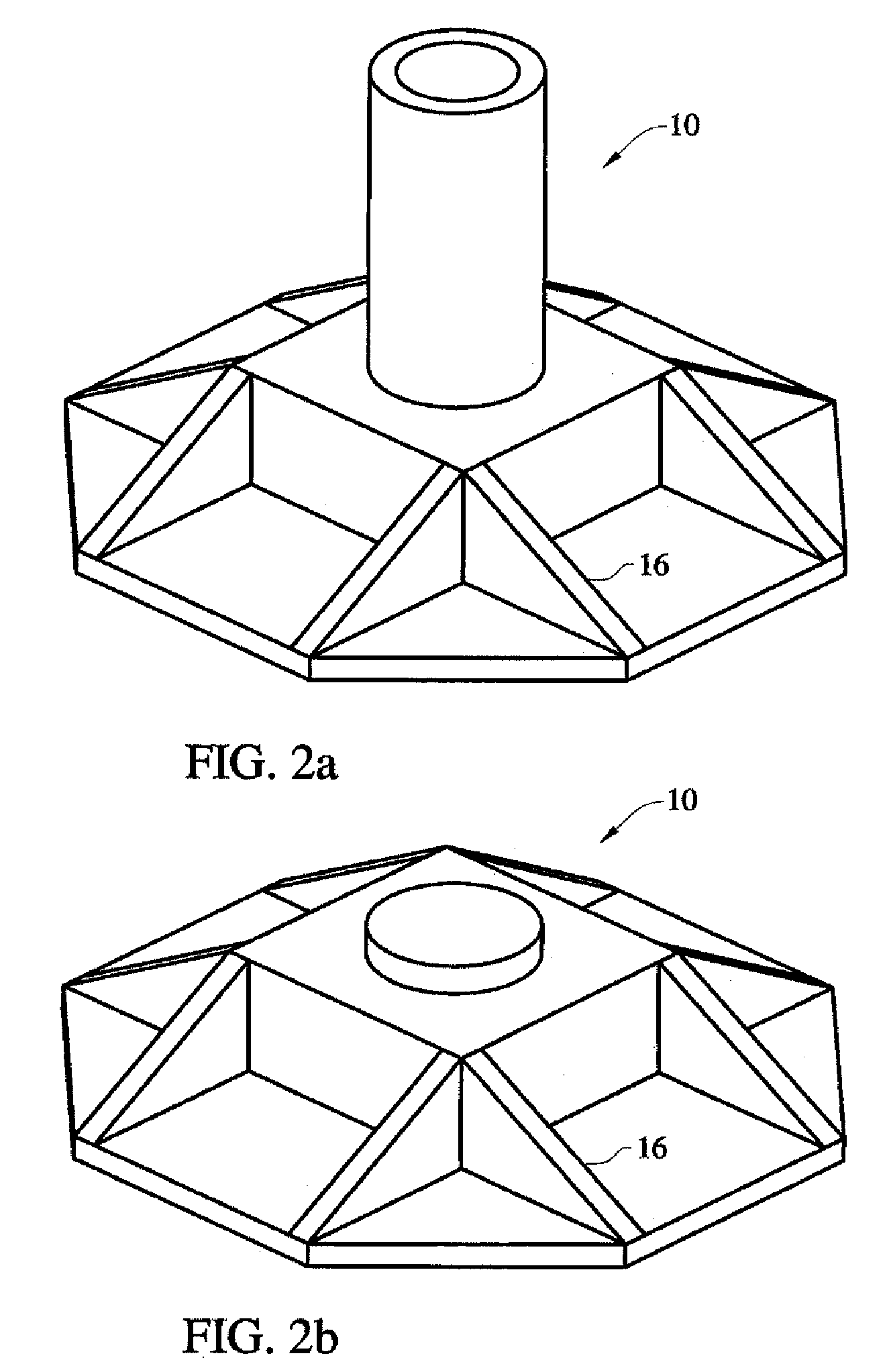

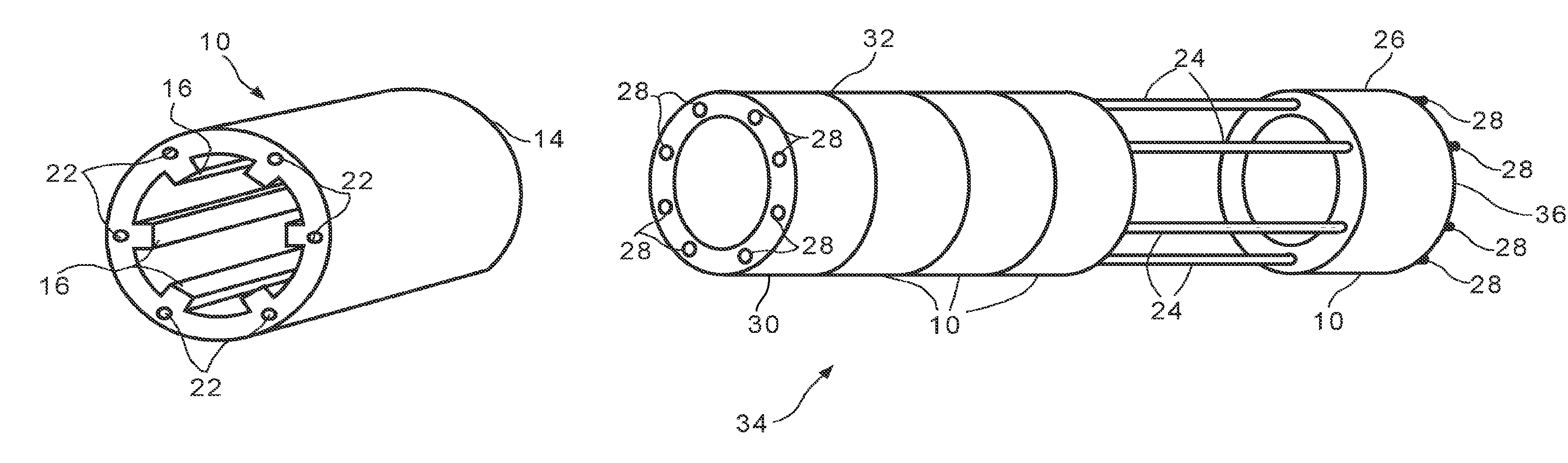

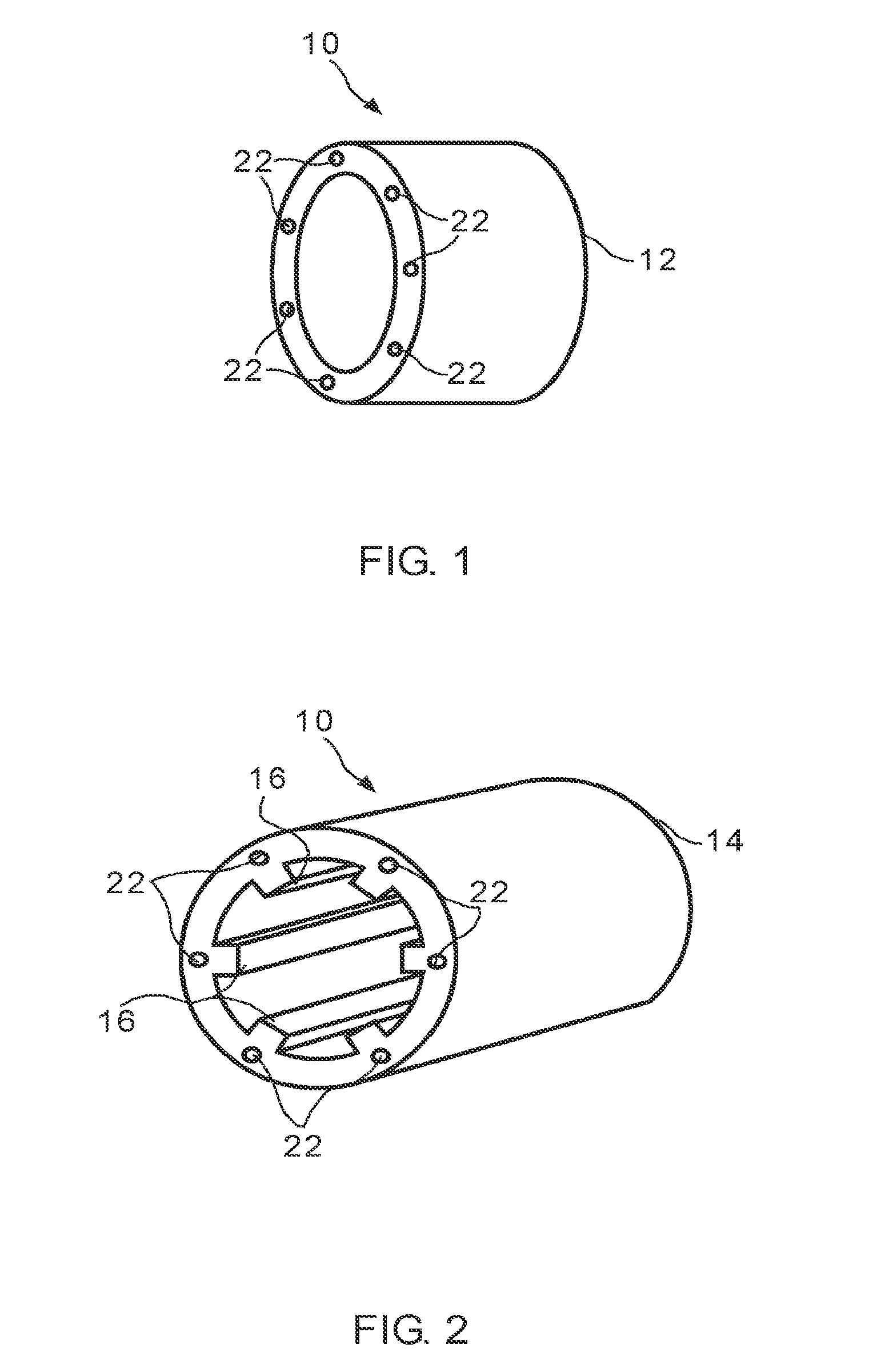

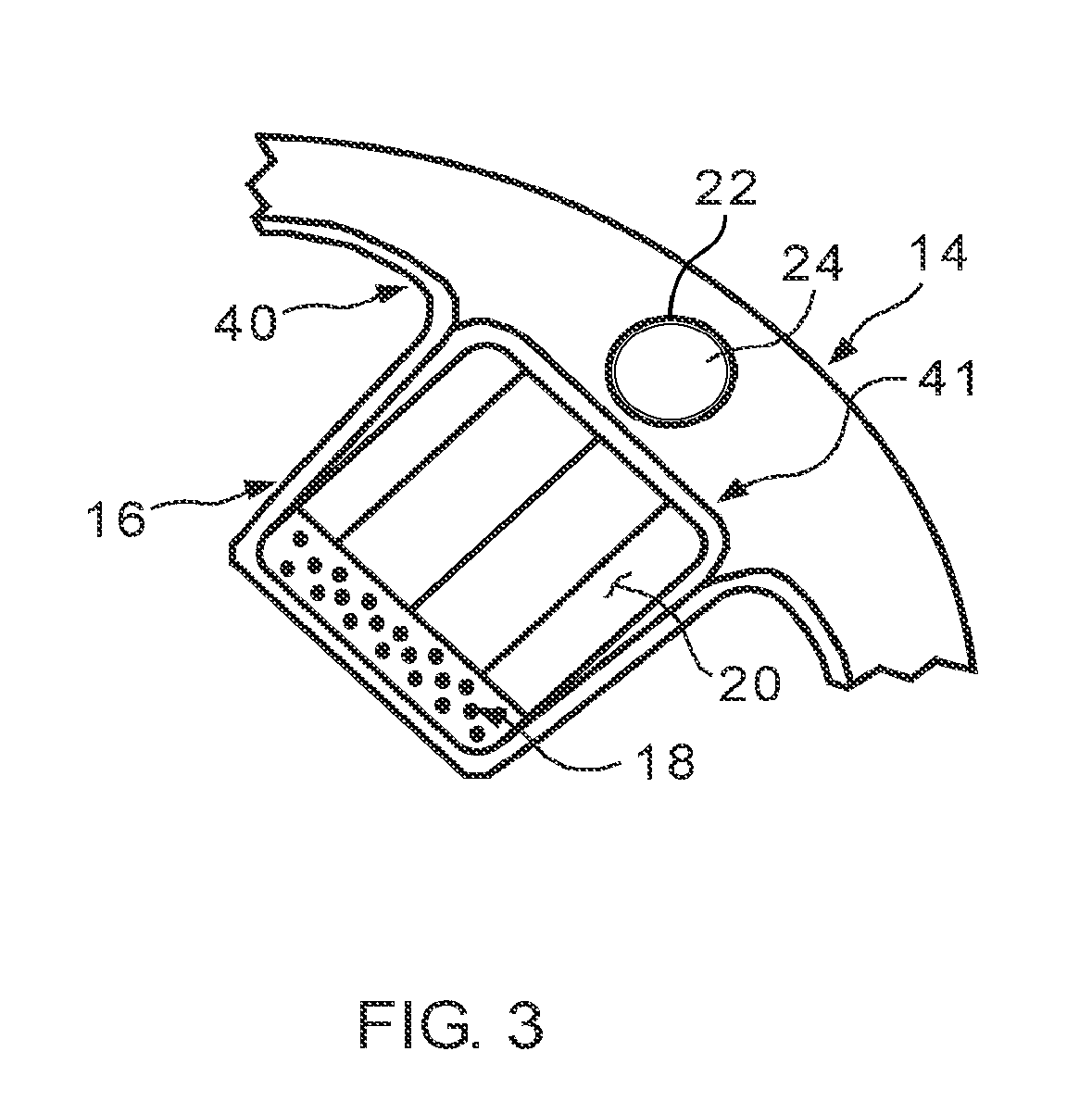

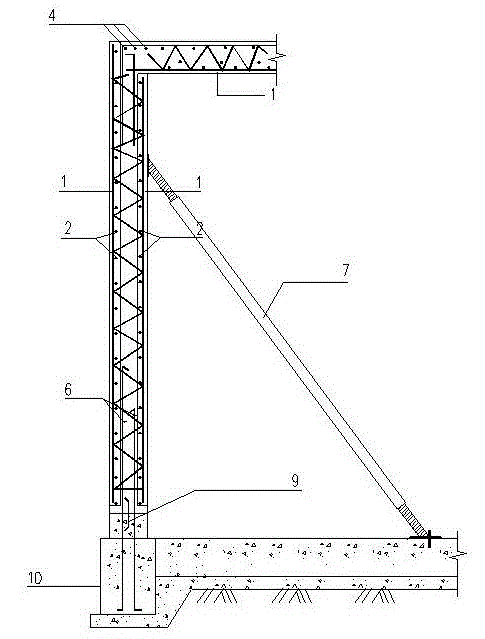

Partially prefabricated modular foundation system

InactiveUS20080072511A1Reliable and readily available designReduce engineering workEngine manufactureFinal product manufactureSteel barTurbine

A wind turbine foundation having a central pedestal, a bottom support slab, and a plurality of prefabricated radial reinforcing ribs. The pedestal and support slab are poured in situ at the site. When the concrete cures the support slab is united to the prefabricated ribs and the ribs are also united to the pedestal. The result is a continuous monolithic foundation wherein loads are carried across the structure vertically and laterally through the continuous structure by doweled and spliced reinforcing steel bars which are integrally cast into the pedestal, ribs and support slab. The slab thus behaves structurally as a continuous slab reducing deflections, improving fatigue conditions and increasing the stiffness of the foundation as well as allowing for the benefits of an economical design.

Owner:AHMED PHULY ENG & CONSULTING

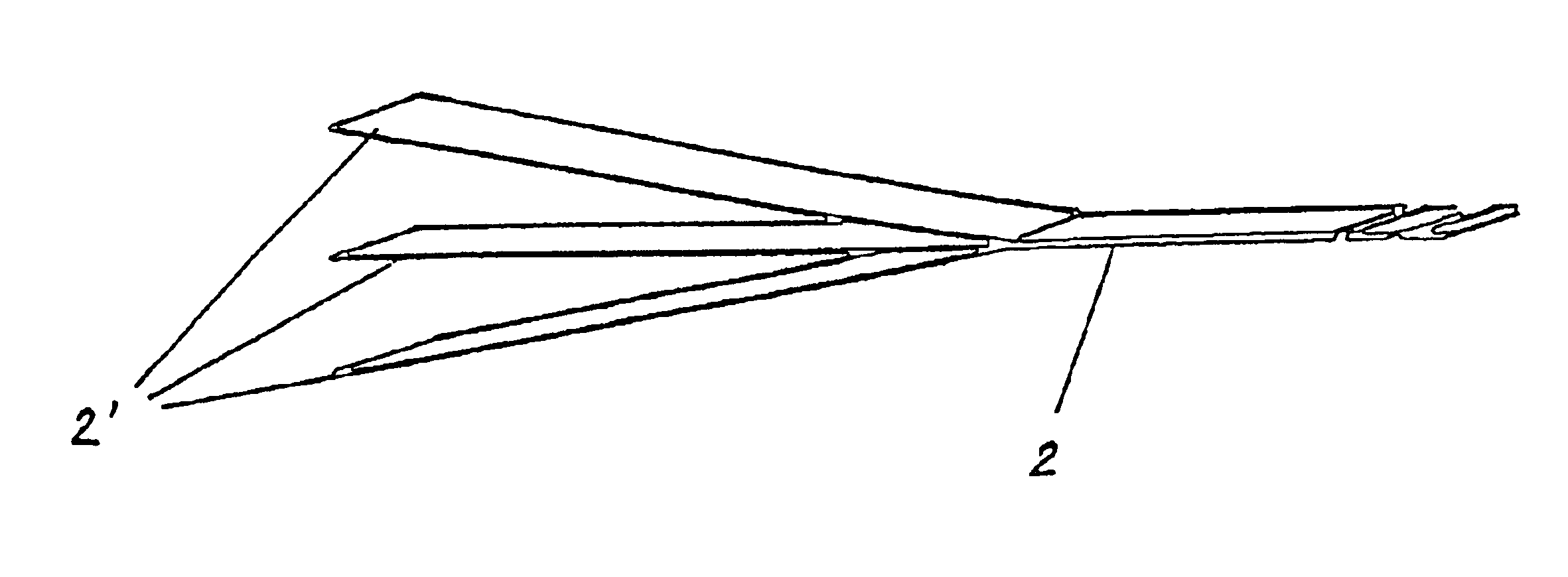

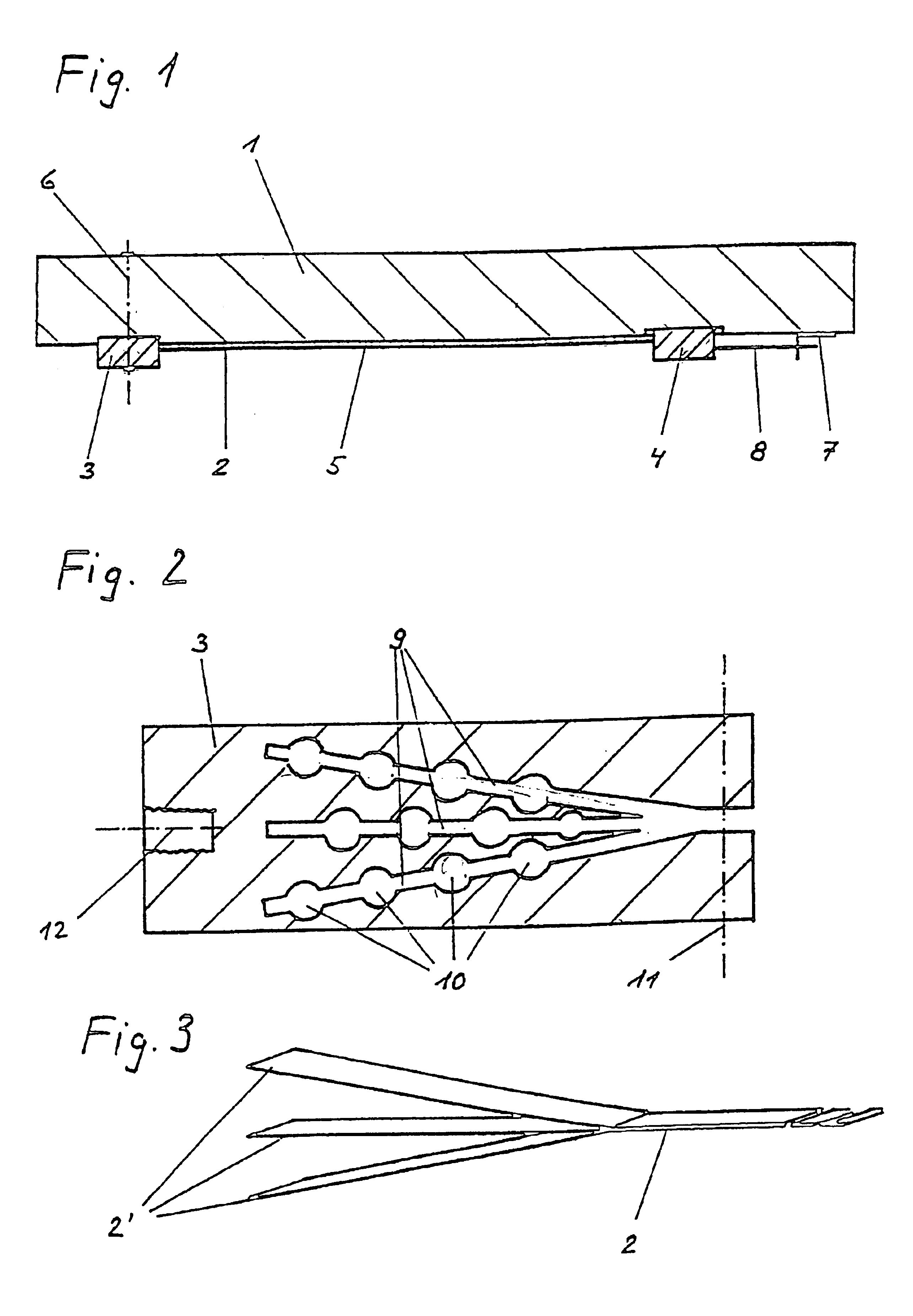

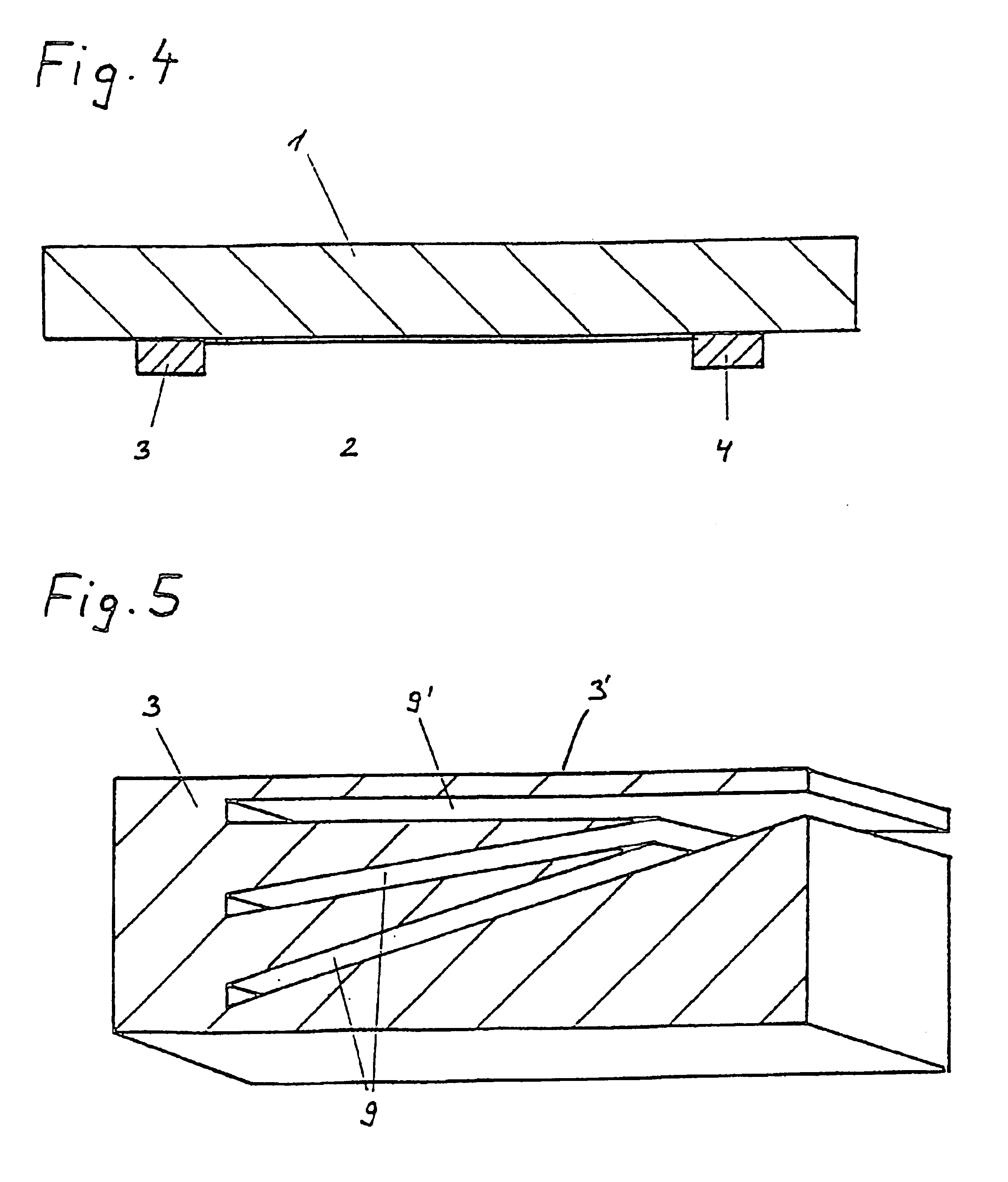

Reinforcement device for supporting structures

InactiveUS6851232B1Smooth connectionGood initiativeLamination ancillary operationsCovering/liningsConcrete beamsStructural engineering

The ends of carbon plates reinforcing supporting elements, such as concrete beams, are divided into at least two splines having approximately the same thickness and are glued in the appropriate retaining slots of a terminal element. The splines form an angle in relation to each other. This assembly is then glued to the traction side of the supporting element, whereby the carbon plates are directly prestressed by the terminal elements in relation to the supporting element. The terminal element can be inserted into an appropriate groove in the supporting element or glued directly on the surface of the supporting element and / or doweled, optionally by using a transverse tensioning device.

Owner:SIKA SCHWEIZ AG

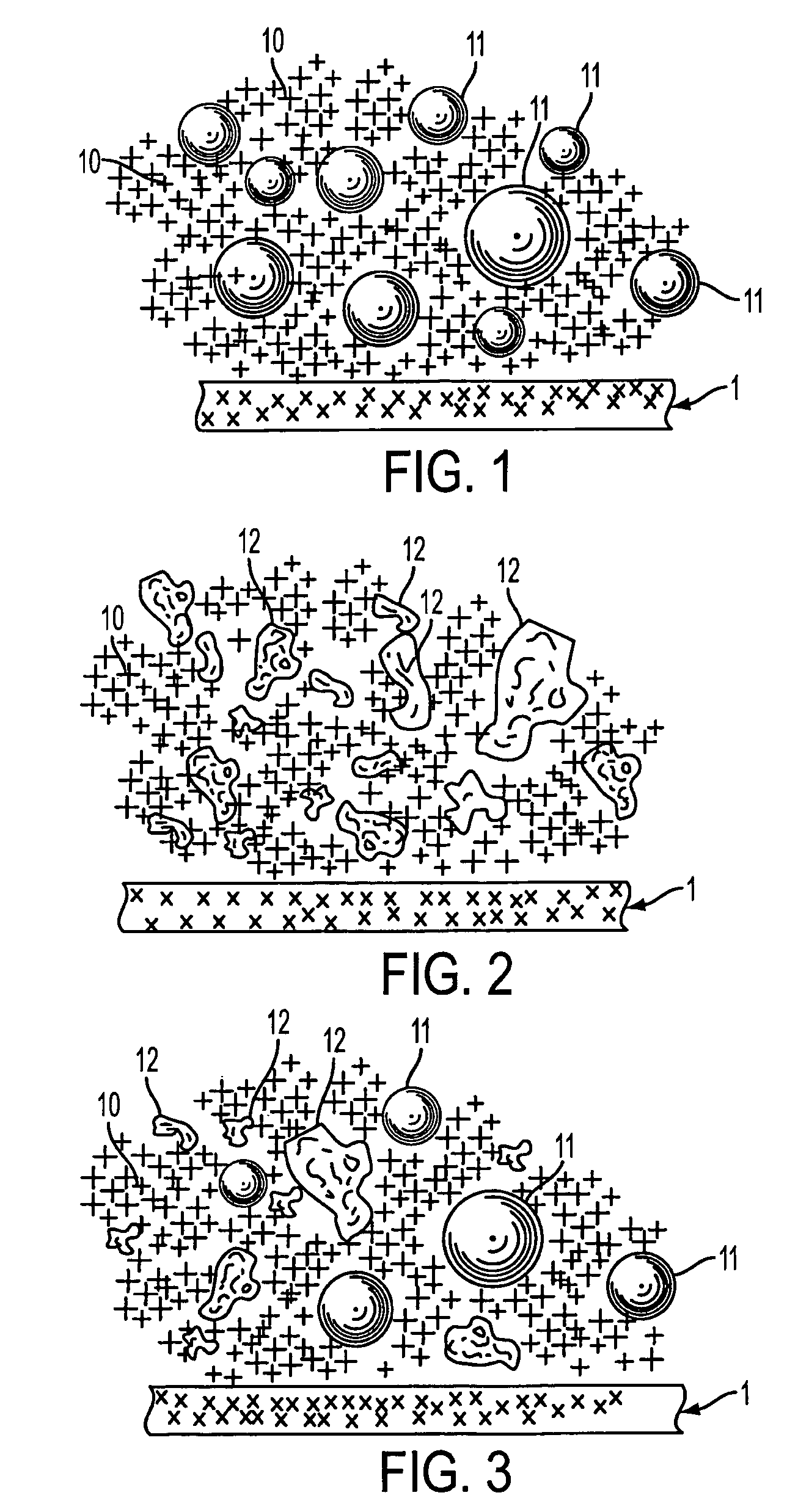

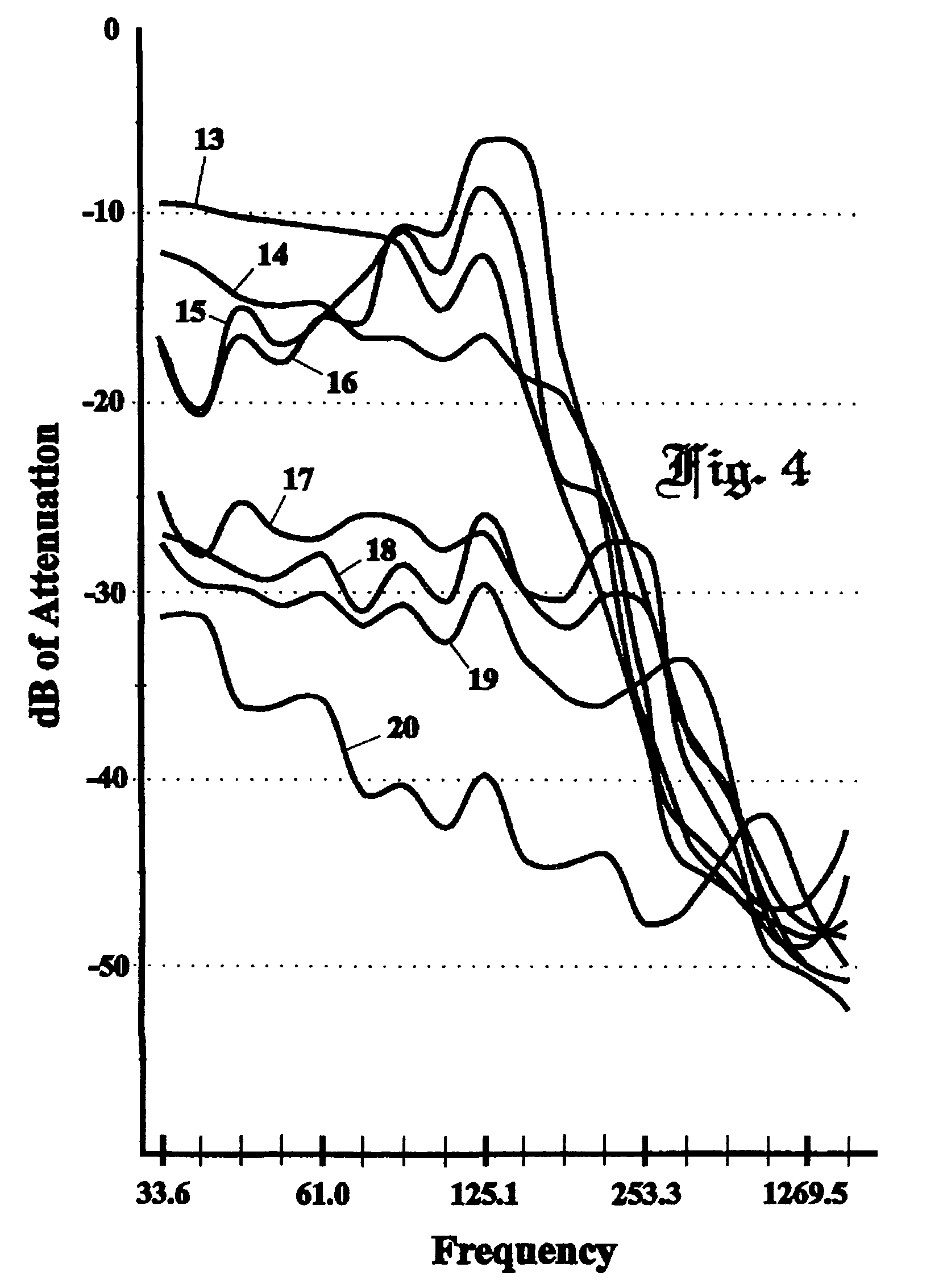

Composite acoustic attenuation materials

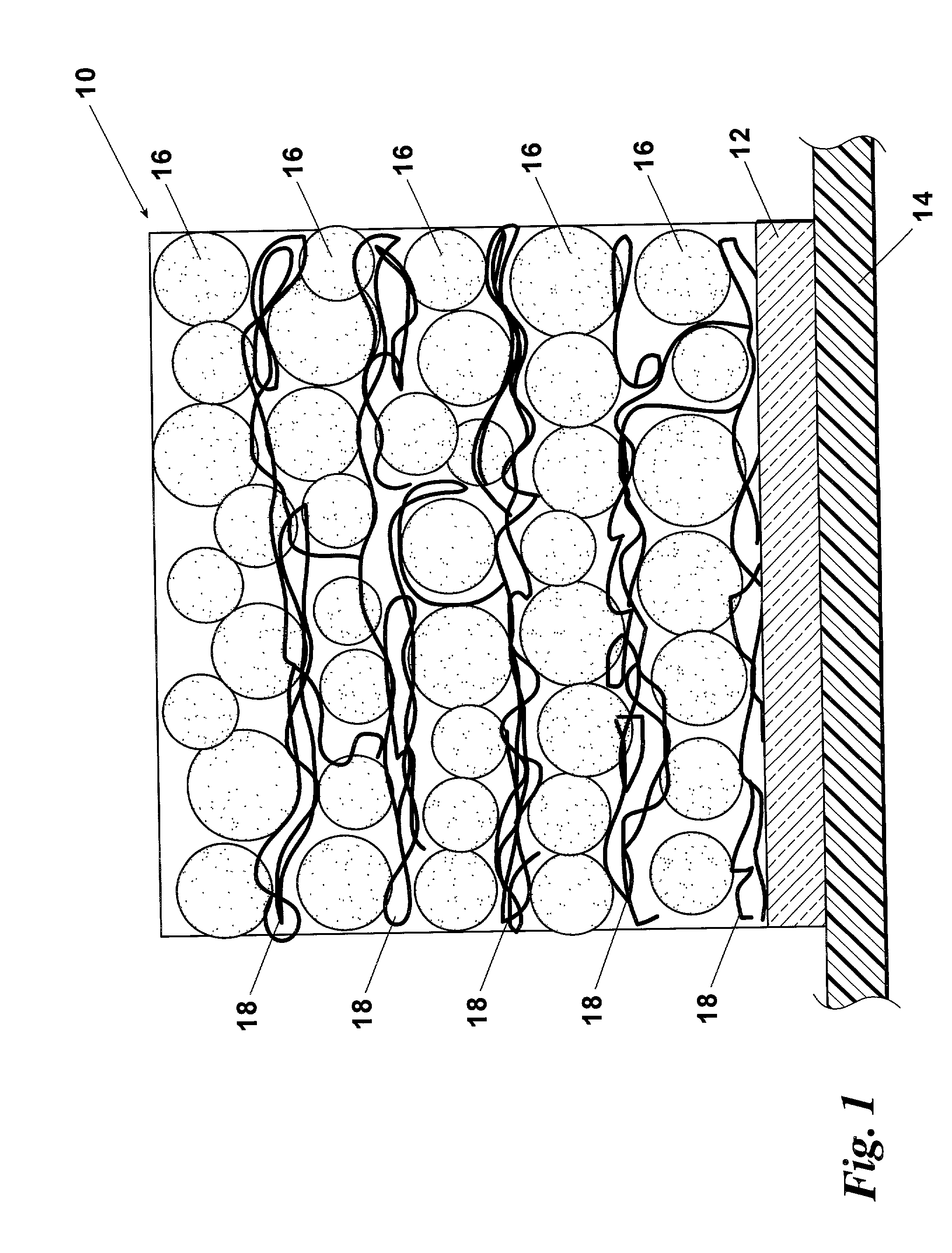

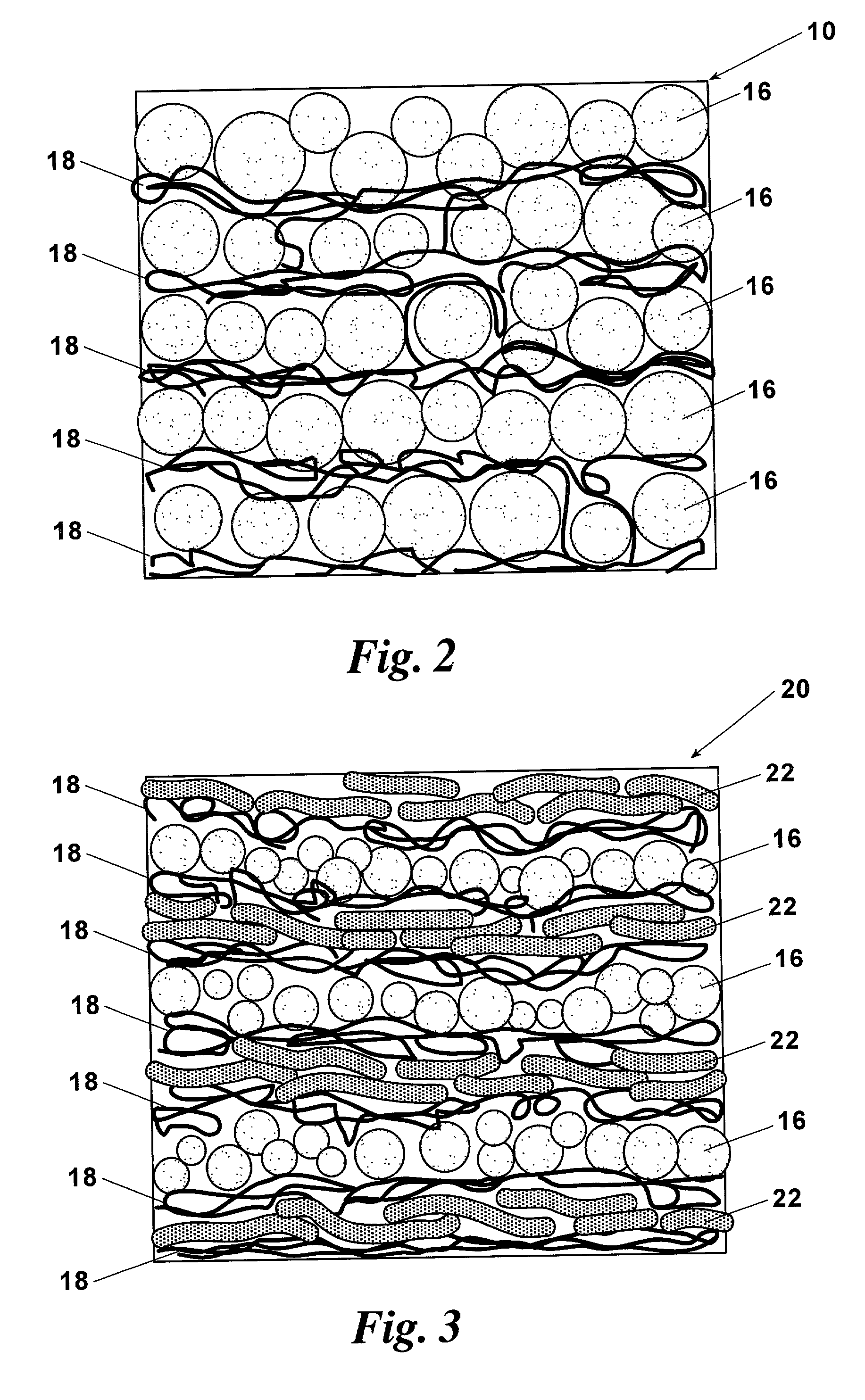

InactiveUS7263028B2Enhancing acoustic attenuation and vibration dampingImprove structural performanceCeilingsWallsAcoustic energyAcoustic impedance

The present invention provides means of enhancing the acoustic attenuation and vibration damping of a material by (1) embedding a plurality of small particles of either a high characteristic acoustic impedance or a low characteristic acoustic impedance or combinations of high and low characteristic acoustic impedance materials to form a matrix material to act as a acoustic attenuator or vibration damper; and (2) combing this matrix material with a second layer of a decoupling material that serves to effectively isolate the matrix material and reduce its tendency to vibrate sympathetically to the impinging acoustic energy. The mass of the resultant material may be very low while retaining excellent acoustic attenuation, vibration damping, and structural characteristics.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON +1

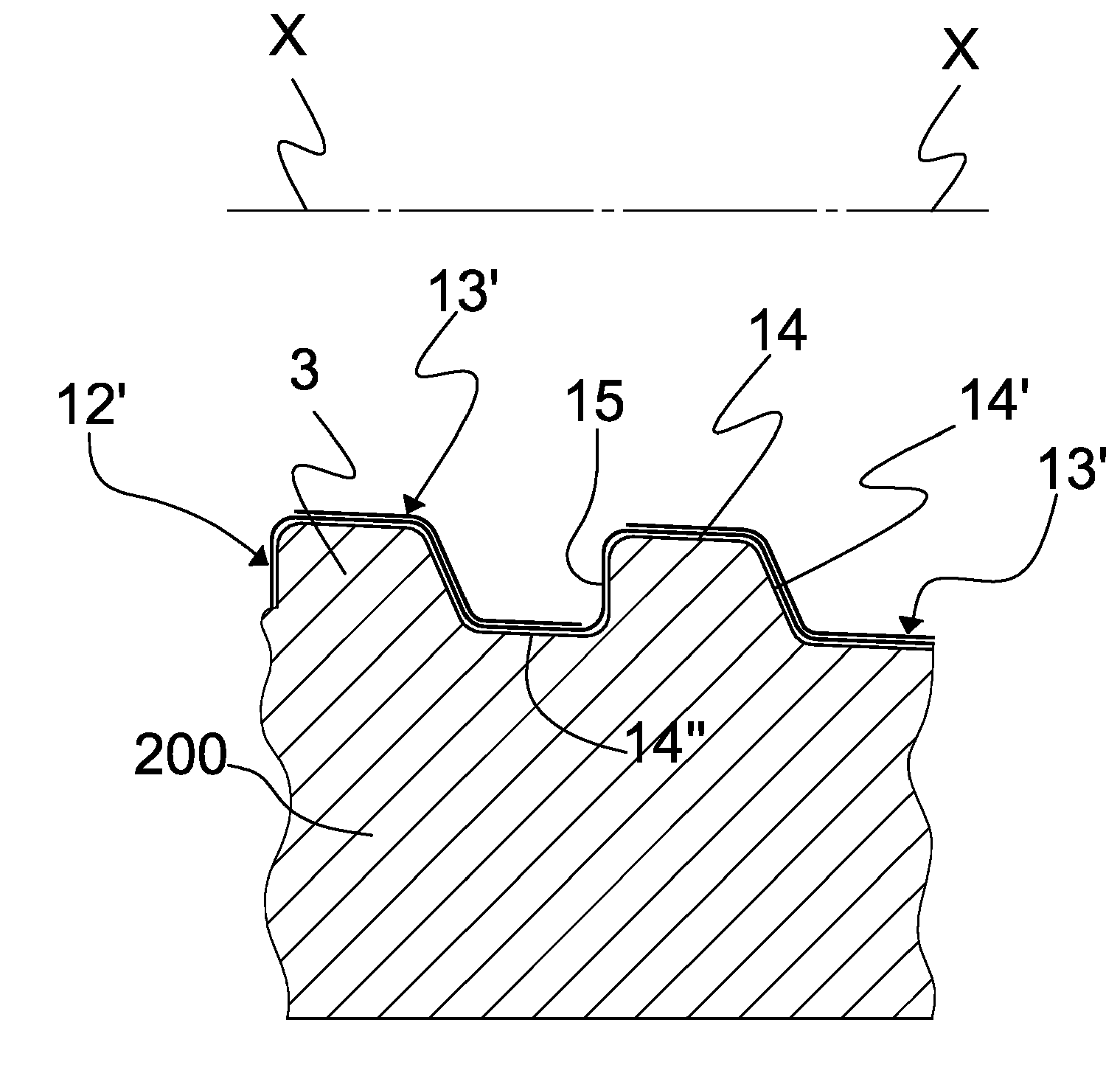

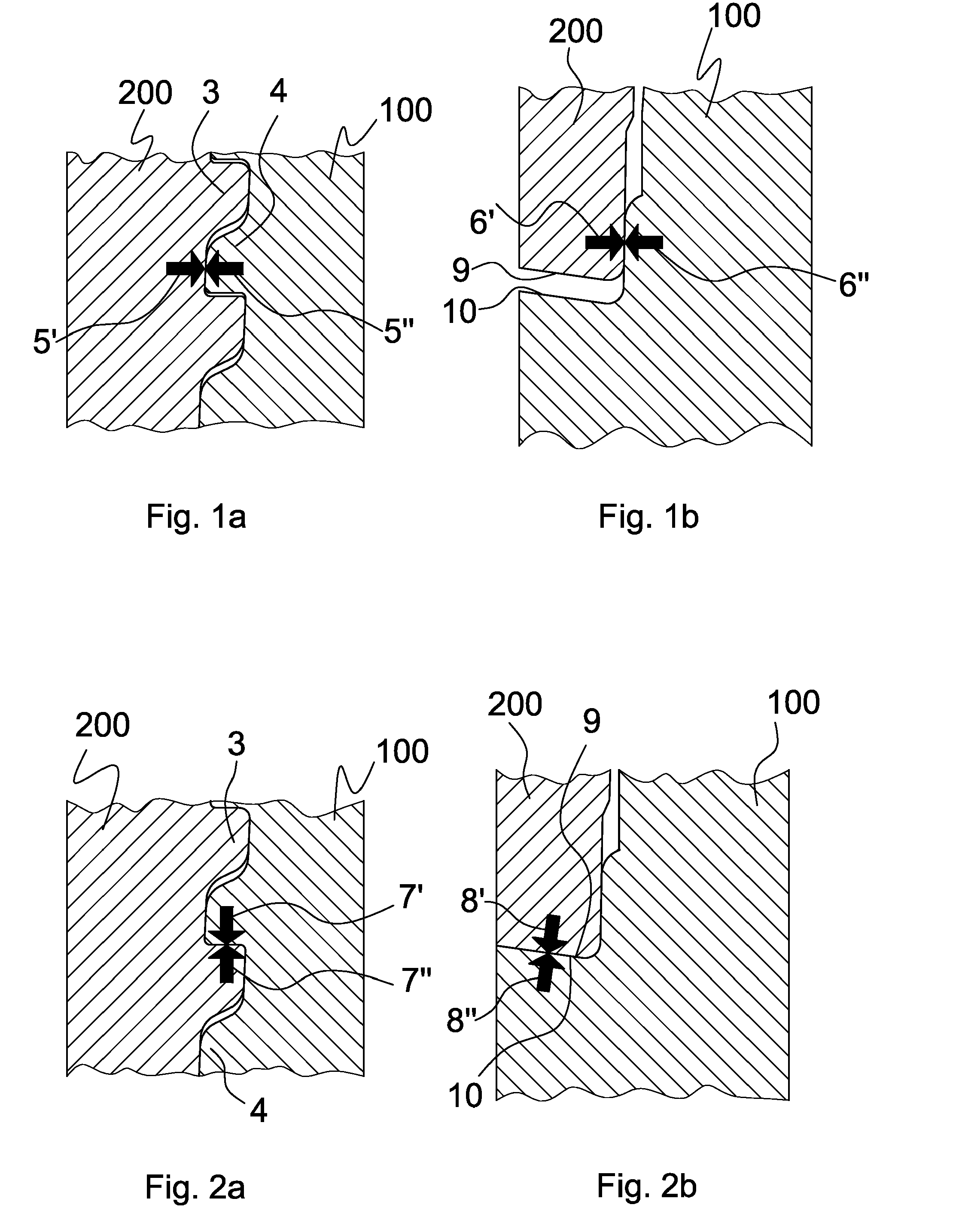

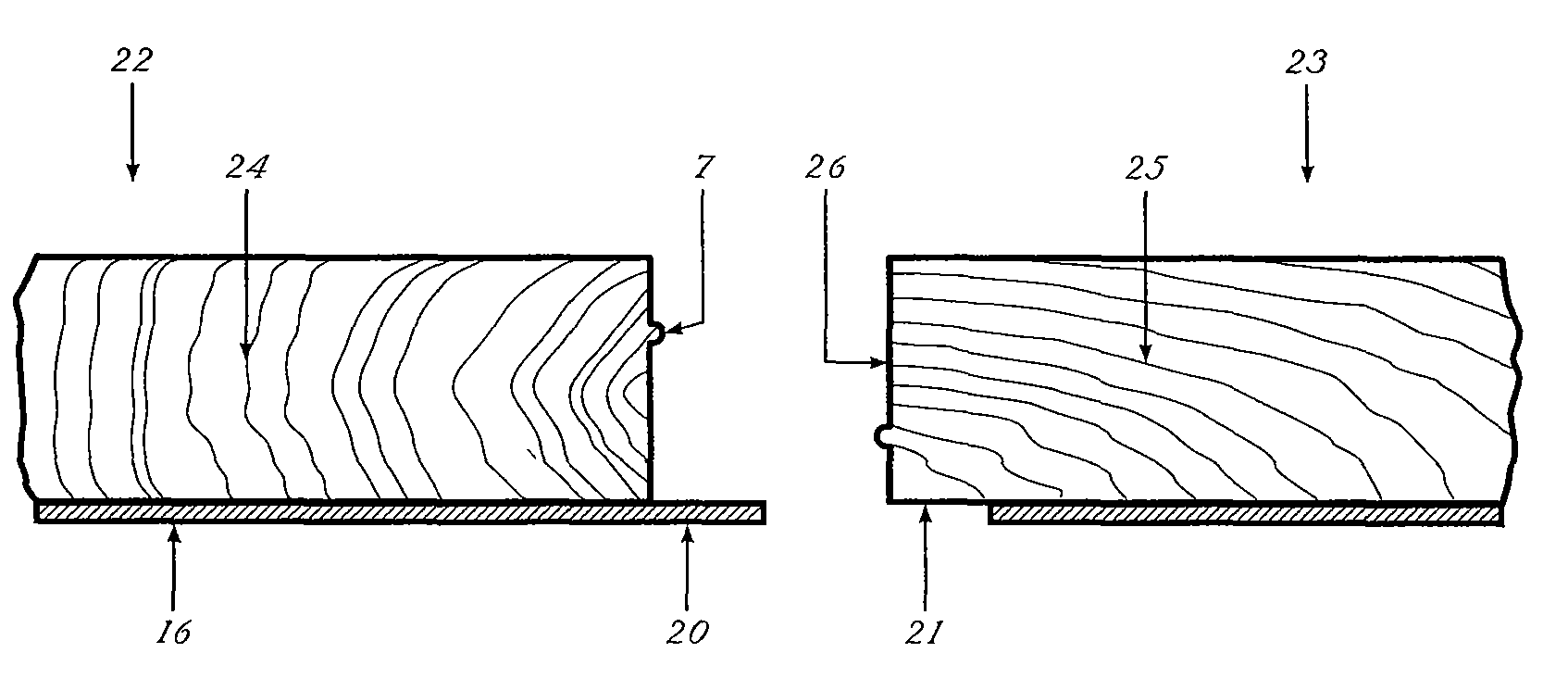

Threaded connections with high and low friction coatings

ActiveUS20090033087A1Increased torsional strengthImprove accuracyDrilling rodsPipe elementsBiomedical engineeringMetal

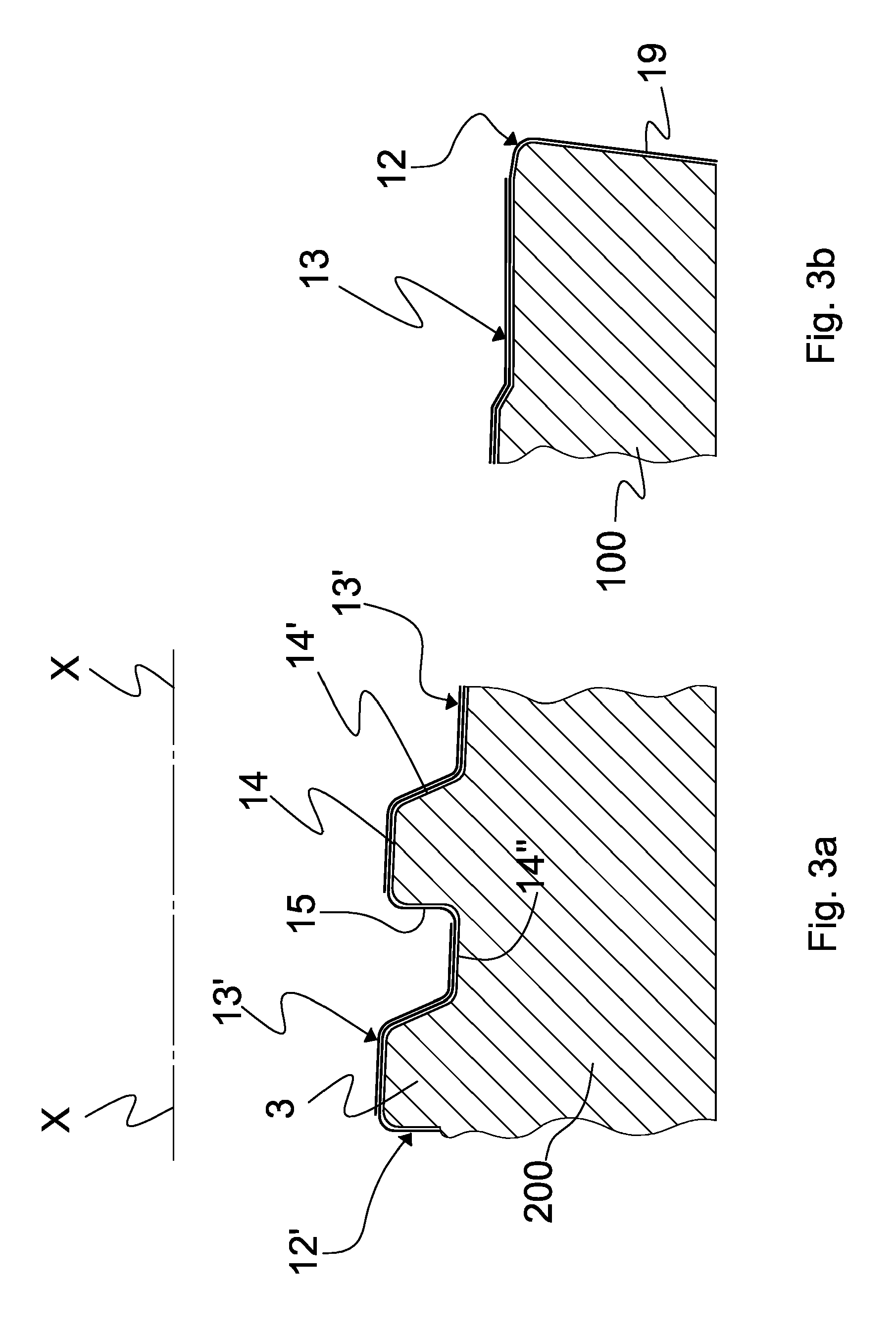

A threaded metallic joint has the thread surface of pin (100) and box (200) covered with a coating comprising a first layer (24) laid on the overall surface of the pin member (100), and a second layer (25) laid on part of the surfaces of either one of the pin or box members. In a first aspect, the coating comprises a first layer with high friction and anti-seize properties laid on the overall surface of the pin member (100), and a second layer (25) with low friction properties laid on specific parts of the surfaces of either one of the pin or box members. Preferably the specific surfaces are those which are in reciprocal radial contact during make-up until pin and box reach the point where shoulders (9, 10) abut. The second layer may contain polytetrafluoroethylene (PTFE). In a second aspect the first layer with a high friction and anti-seize properties laid on the overall surface of the box member (200).

Owner:TENARIS CONNECTIONS

Assembly of free-standing films using a layer-by-layer process

InactiveUS20010046564A1Easy to controlRetain biological activityMaterial nanotechnologyMouldsCross-linkEngineering

A method for the layer-by-layer assembly of a free standing thin film includes the steps of preparing a support with a suitable substrate; forming a thin film having a plurality of layers onto the substrate utilizing a layer-by-layer assembly process; removing the substrate and thin film from the support; and separating the substrate from the thin film. Various compounds improving the strength, flexibility, tension and other mechanical properties may be included in the assembly to improve the structural quality of the film. Similar effect may also be achieved by cross-linking the applied layers.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY +1

Modular blades and methods for making same

ActiveUS7393184B2Reduce weightImprove structural performancePropellersFinal product manufactureEngineeringKnife blades

Owner:GE INFRASTRUCTURE TECH INT LLC

Lightweight sandwich panel heat pipe

ActiveUS8579018B1Easy to manufactureLarge diameterIndirect heat exchangersHeat transfer modificationWorking fluidGas phase

A sandwich panel heat pipe with a three-dimensional ordered open-cellular micro-truss core and a method creating the same. In one embodiment, the sandwich panel heat pipe includes a first face sheet, a second face sheet, the three-dimensional ordered open-cellular micro-truss core between the first face sheet and the second face sheet, and a working fluid in the ordered open-cellular micro-truss core. Here, the three-dimensional ordered open-cellular micro-truss core includes a vapor region and a liquid region, the vapor region is for transporting a vapor phase portion of the working fluid to the liquid region, and the liquid region is for transporting a liquid phase portion of the working fluid to the vapor region.

Owner:HRL LAB

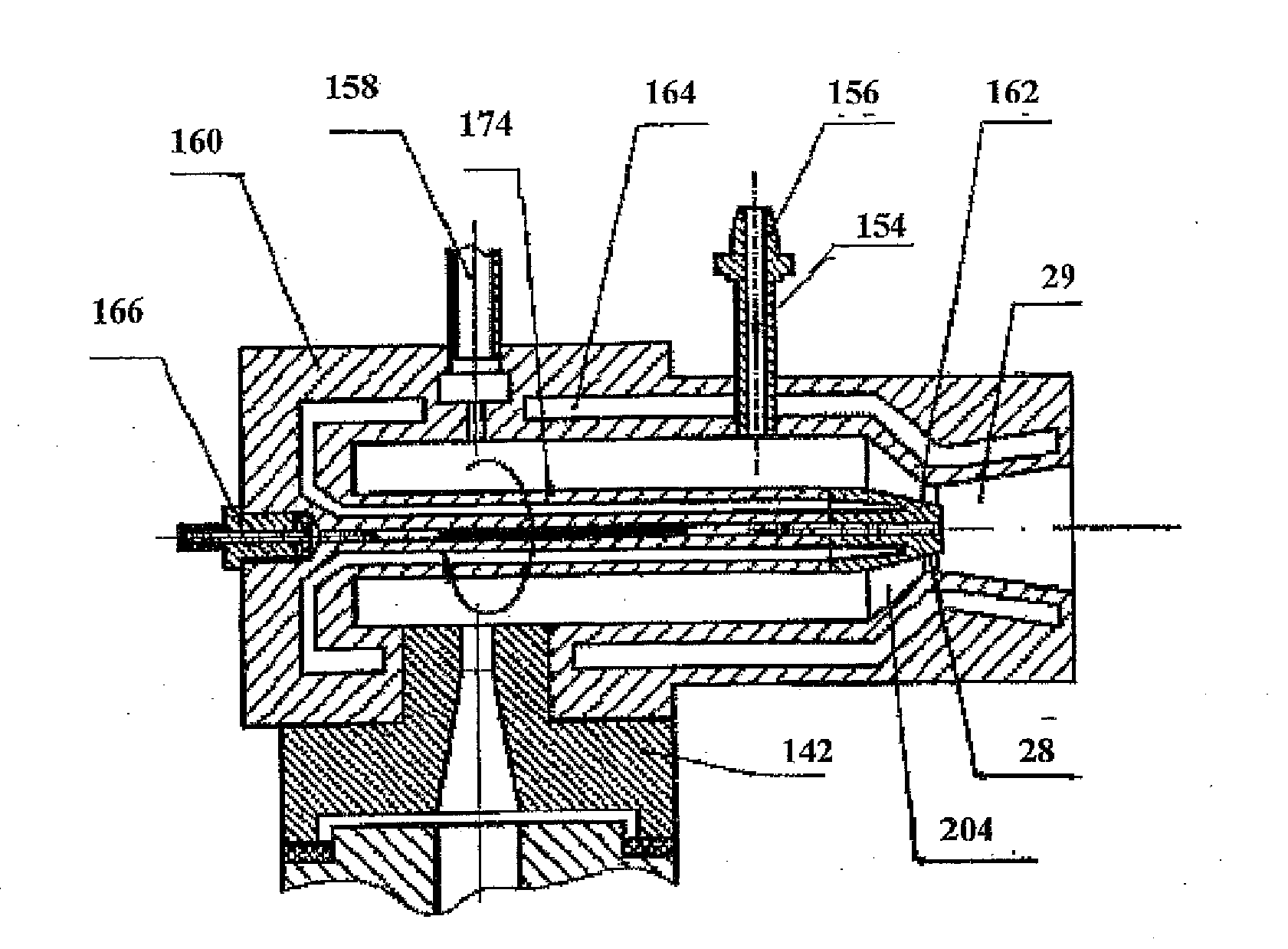

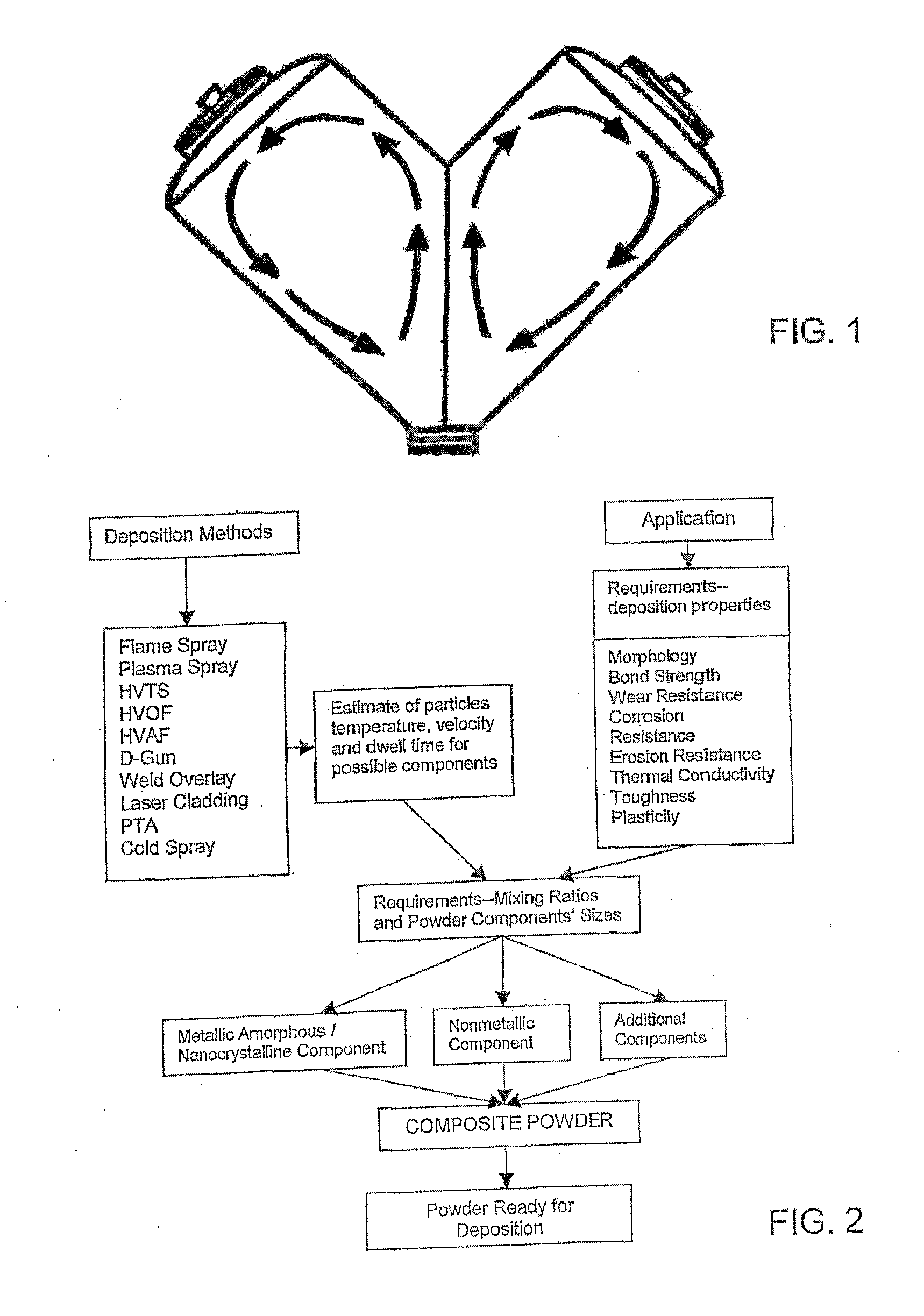

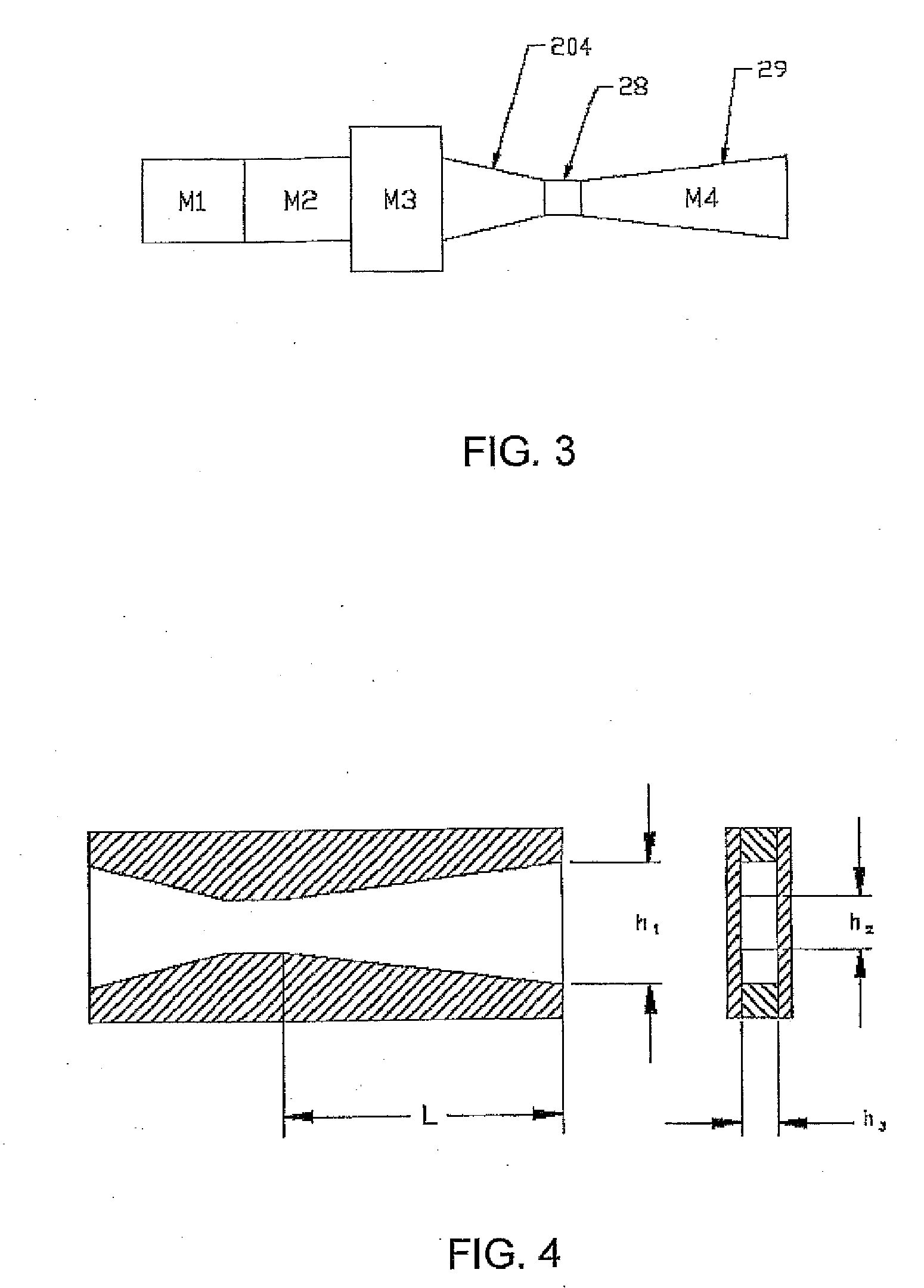

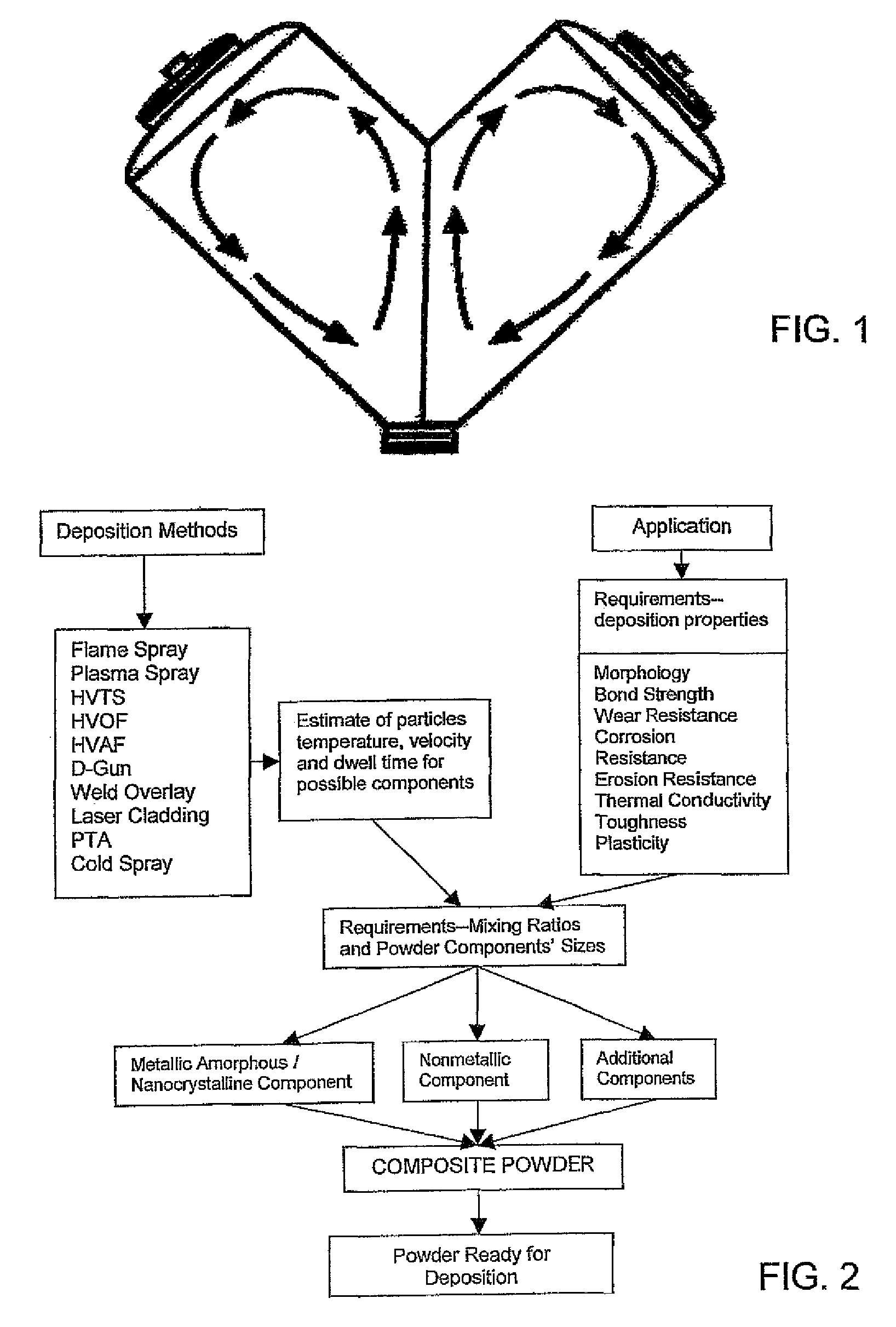

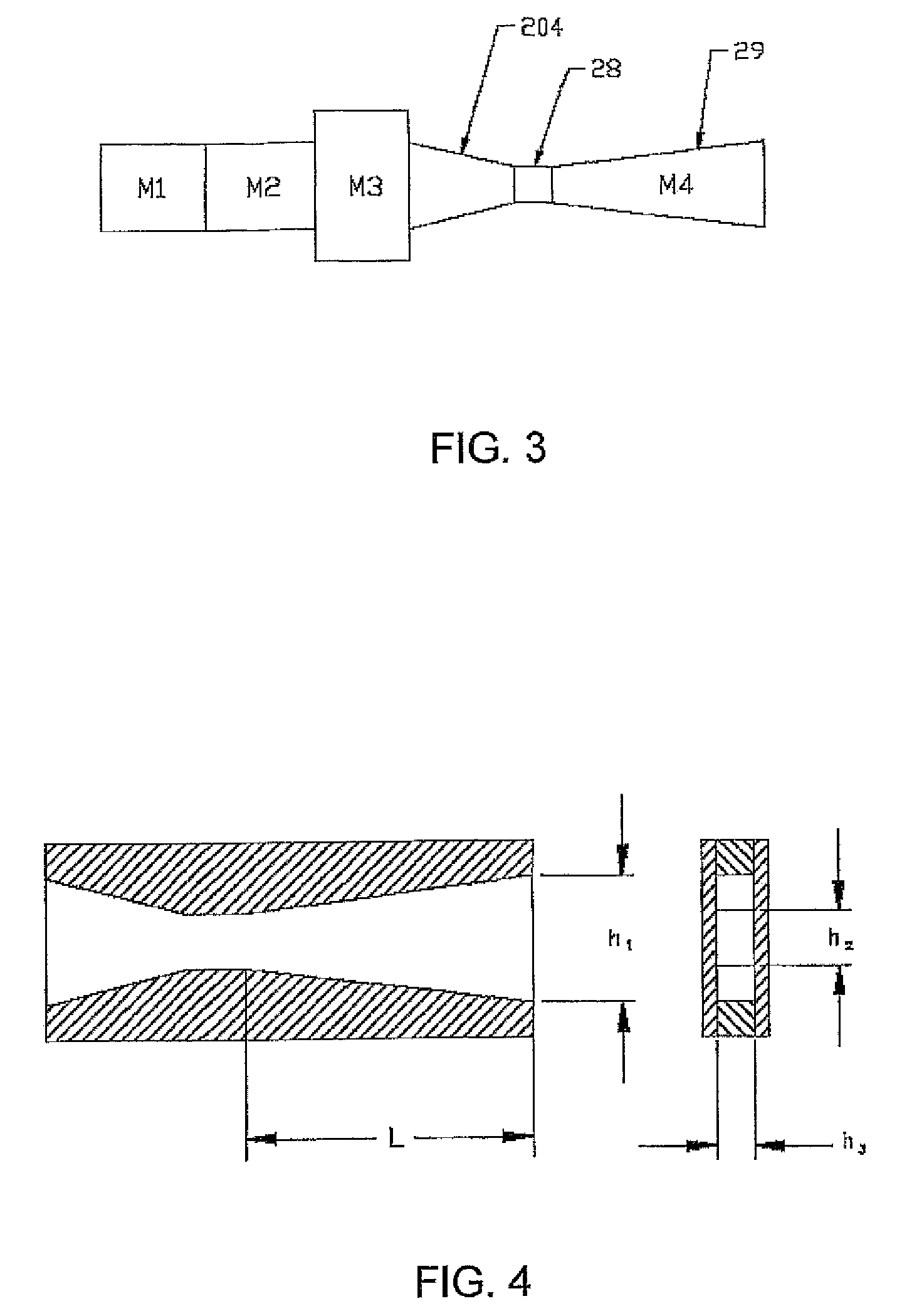

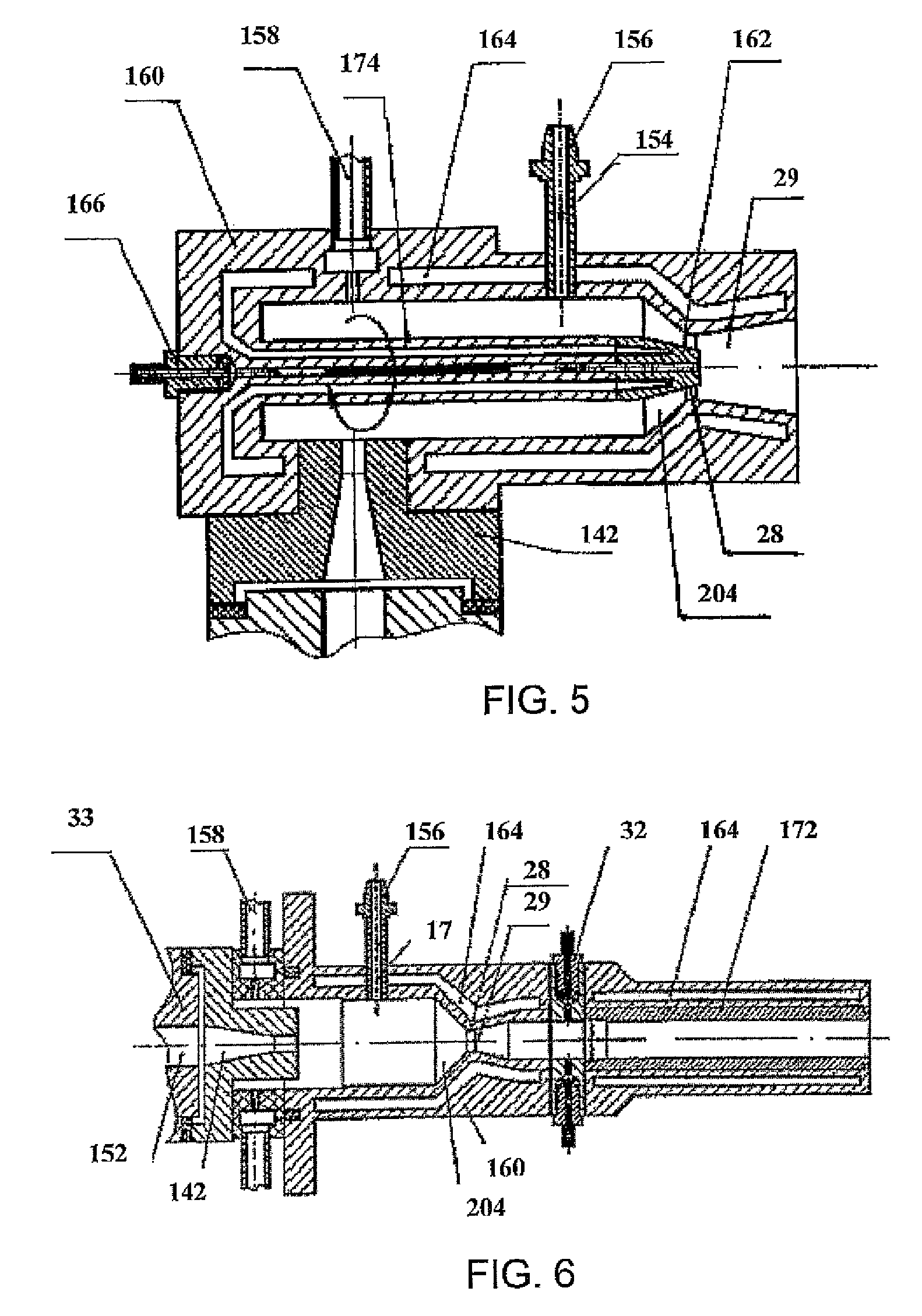

Deposition System, Method And Materials For Composite Coatings

InactiveUS20100189910A1Improve corrosion resistanceImprove structural performanceLiquid surface applicatorsMolten spray coatingHigh wear resistanceNanocrystal

A composite powder for a deposition of a composite coating comprises a nonmetallic component and a metallic component, the metallic component having an amorphous structure or a nanocrystalline structure. The metallic component may include an amorphous metallic alloy. The metallic alloy may include constituents having the amorphous structure. The metallic component may include a combination of the metallic alloy existing in the amorphous state and constituents of the amorphous metallic alloy in the amorphous state. The composite metal-ceramic powders are used for depositing composite coatings on a selected surface. Disclosed are several methods and systems for producing such composite powders. Disclosed are also several methods and systems for depositing composite coatings. Advantageously, the deposited coatings exhibit high corrosion resistance, high wear resistance, and excellent structural properties.

Owner:BELASHCHENKO VLADIMIR E

Deposition system, method and materials for composite coatings

InactiveUS7670406B2Improve corrosion resistanceImprove structural performanceMolten spray coatingMetal-working apparatusHigh wear resistanceNanocrystal

A composite powder for a deposition of a composite coating comprises a nonmetallic component and a metallic component, the metallic component having an amorphous structure or a nanocrystalline structure. The metallic component may include an amorphous metallic alloy. The metallic alloy may include constituents having the amorphous structure. The metallic component may include a combination of the metallic alloy existing in the amorphous state and constituents of the amorphous metallic alloy in the amorphous state. The composite metal-ceramic powders are used for depositing composite coatings on a selected surface. Disclosed are several methods and systems for producing such composite powders. Disclosed are also several methods and systems for depositing composite coatings. Advantageously, the deposited coatings exhibit high corrosion resistance, high wear resistance, and excellent structural properties.

Owner:BELASHCHENKO VLADIMIR E

Modular blades and methods for making same

ActiveUS20070105431A1Reduce weightImprove structural performancePropellersFinal product manufactureEngineeringElectrical and Electronics engineering

Owner:GENERAL ELECTRIC CO

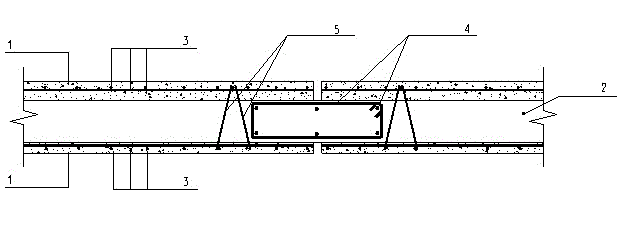

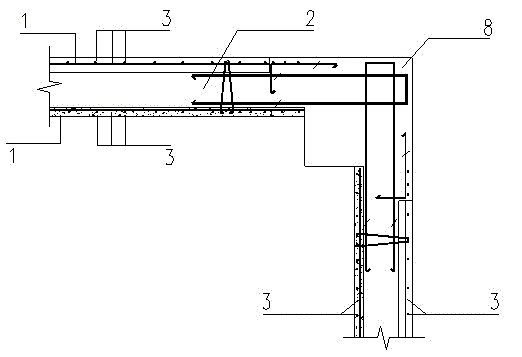

Prefabricated assembled superposed plate type concrete shear wall and construction method thereof

InactiveCN102912900AAchieve standardizationAchieve modularityWallsBuilding material handlingArchitectural engineeringRebar

The invention relates to a prefabricated assembled superposed plate type concrete shear wall and a construction method thereof. The prefabricated assembled superposed plate type concrete shear wall comprises superposed wall plates and a cast-in-place concrete core wall, wherein each superposed wall plate is formed by superposing two prefabricated concrete single wall plates which are of the same specification and are symmetrically arranged at an equal interval; supporting plate steel bar supports are arranged between the two single wall plates; node connection reinforcement steel bars are arranged on end nodes of the superposed wall plates; the superposed wall plates are fixedly integrated with the cast-in-place concrete core wall; and the superposed wall plates, the cast-in-place concrete core wall, the supporting plate steel bars and the node connection reinforcement steel bars are fixedly connected with one another to form the shear wall structure. The invention also provides a construction method for the shear wall structure. By the construction method, when an extensive form building mode is changed, and structural members of a house are standardized and modularized, engineering construction is high in speed, and materials are saved; and the overall structural performance is high.

Owner:ANHUI HUALI CONSTR GRP

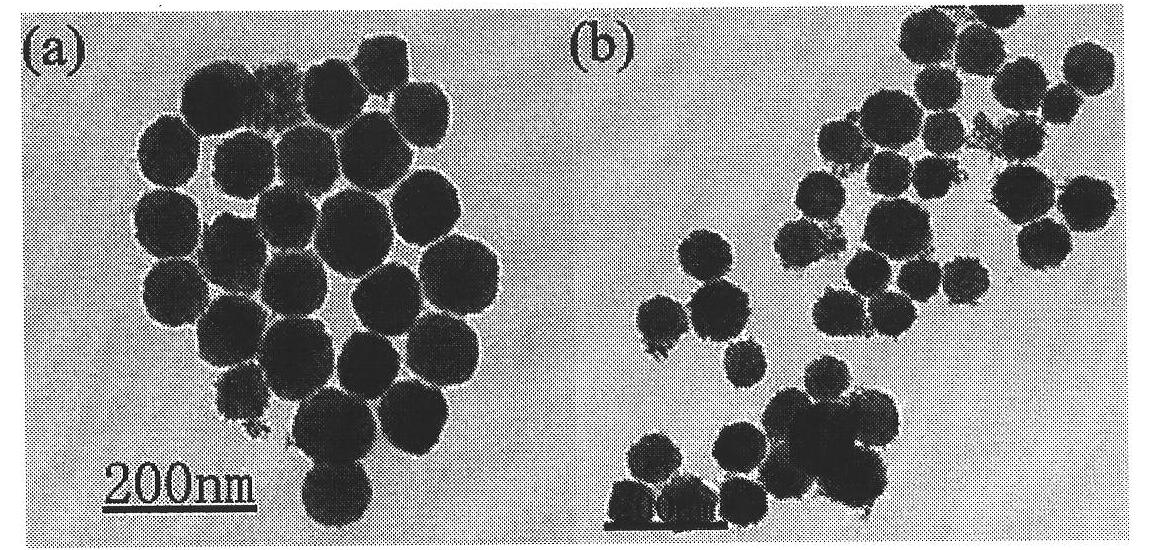

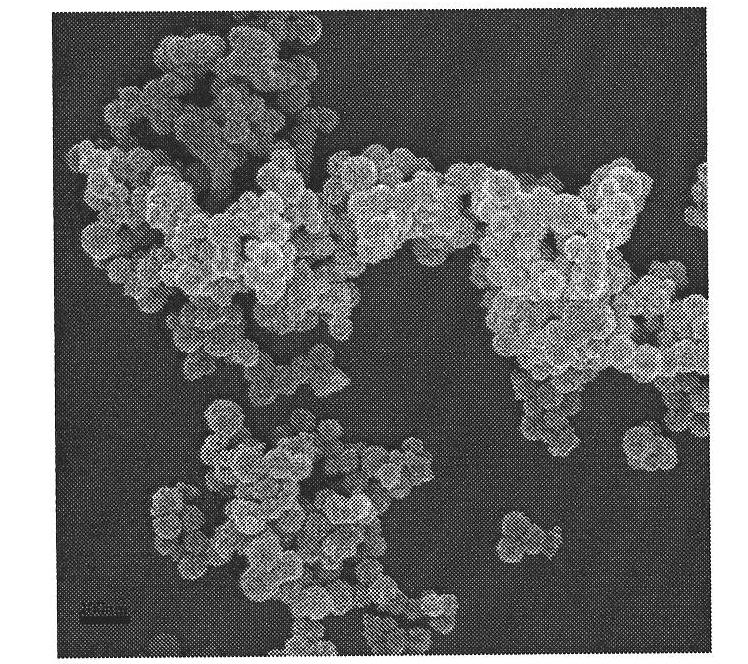

Preparation method of cerium oxide nanoballs

InactiveCN101792171AGood dispersionSmall particle sizeNanostructure manufactureRare earth metal compoundsSolventSolvothermal reaction

The invention relates to a preparation method of cerium oxide nanoballs, and belongs to the technical field of the preparation processes of the inorganic nanomaterials. The key points of the method of the invention include: stirring and mixing cerium salt and a certain amount of surfactant at room temperature, dissolving the mixture in a mixed solution of water and an organic solvent and ultrasonically processing the mixture for 5 to 10 minutes, wherein the cerium salt is optimally cerium nitrate; the surfactant is most preferably polyvinylpyrrolidone; and the belonged organic solvent is most preferably diglycol; then transferring the mixed solution into a high pressure reaction kettle to perform a solvothermal reaction; heating the mixed solution to perform reaction for 24 to 28 hours at the temperature of 100 to 200 DEG C so as to obtain the cerium oxide nanoball sol; evaporating the sol at the temperature of 1500 o 180 DEG C to dryness; and forging the obtained powder for 1 to 4 hours at the temperature of 400 to 600 DEG C; and finally obtaining the cerium oxide nanoballs in the shape of yellow solid powder. The nanoballs have a particle size ranging from 30 to 160nm and high performance and can be applied in fields of ultraviolet light shielding, mechanical polishing and automobile exhaust catalyzation and the like.

Owner:SHANGHAI UNIV

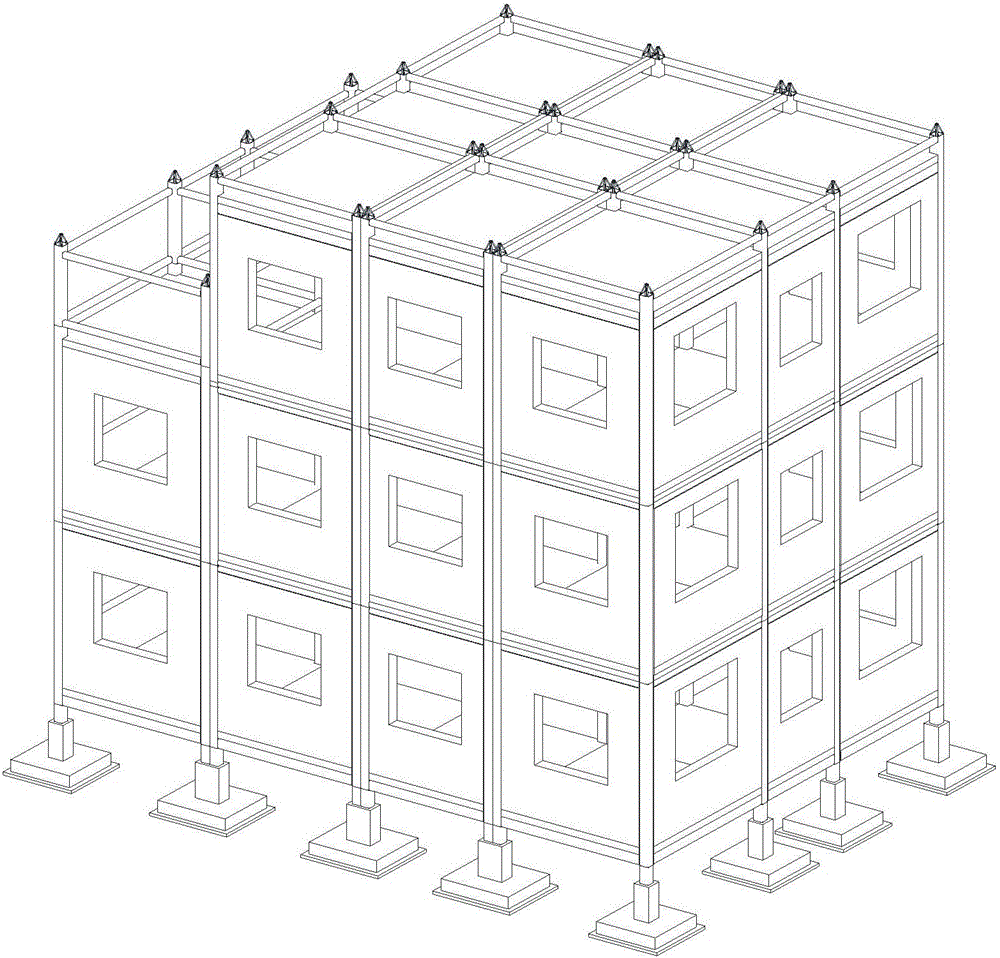

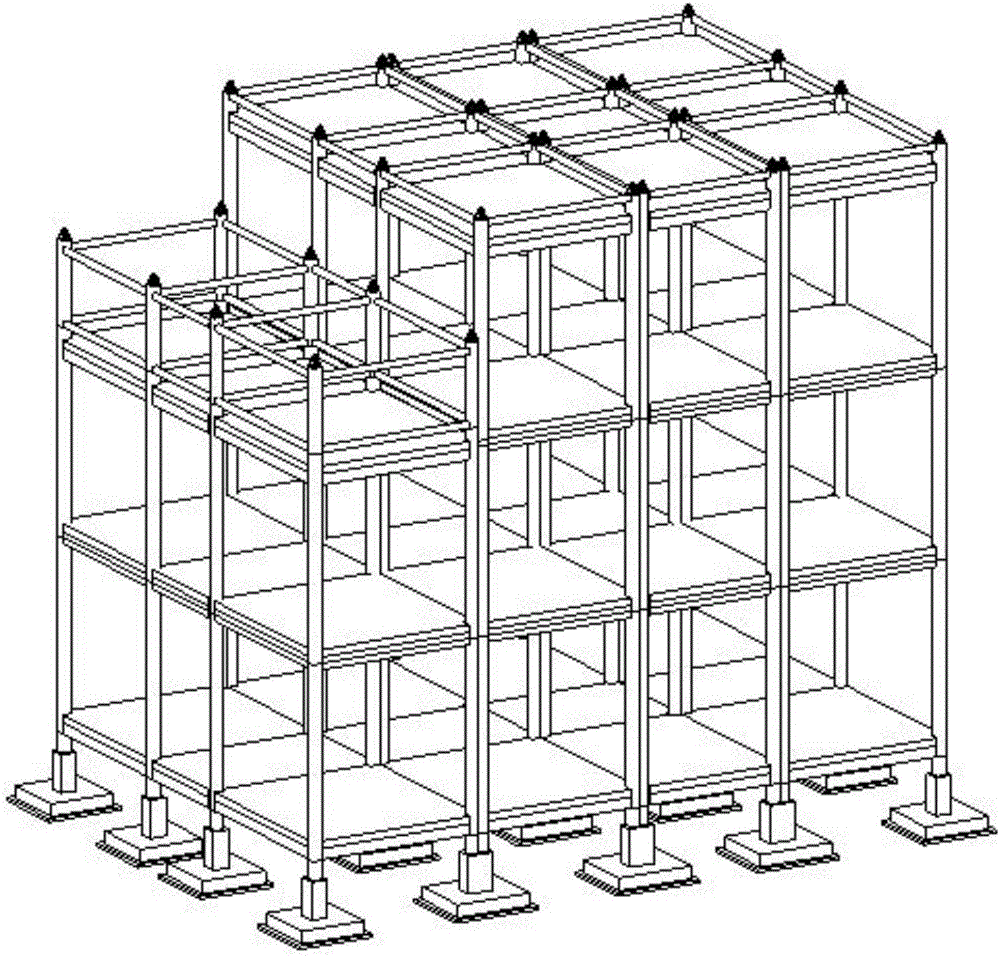

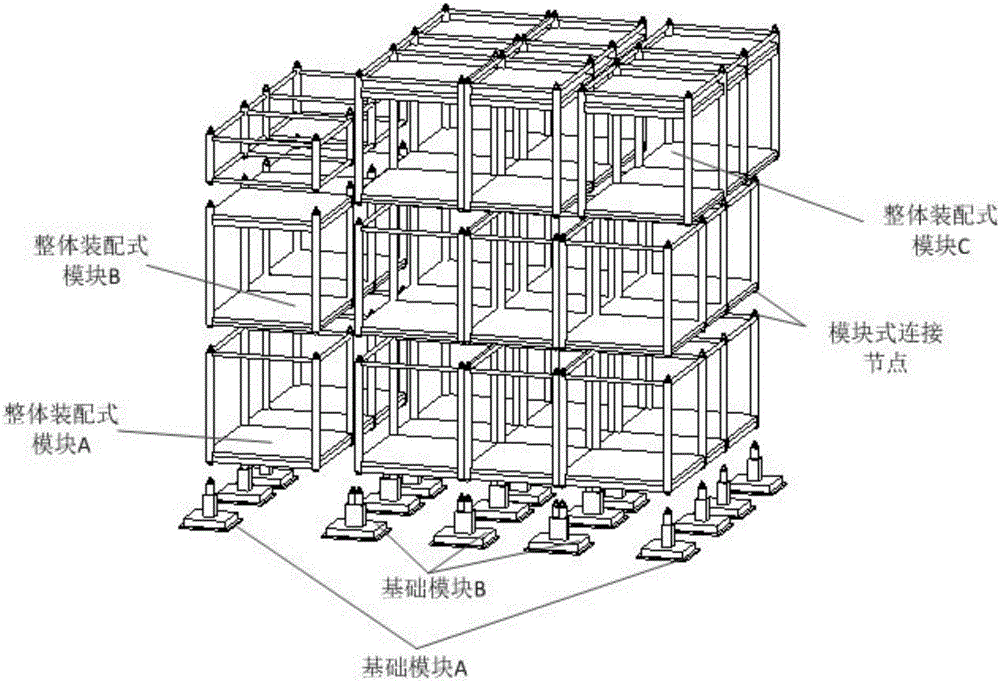

Modular multi-storeyed overall assembly type steel structural house structure system

The invention discloses a modular multi-storeyed overall assembly type steel structural house structure system, and belongs to the technical field of structural engineering. The steel structural house structure system comprises an assembling house module, a foundation module, a hanging hook between modules and a bend plate connector; various modules of the assembling house module are processed and manufactured in a factory, and every module is plugged on construction site through the hanging hook and the bending plate, and then the column is internally poured with concrete or welded, thus the structure building is completed; the hanging plate and the bending plate can plug and guide the module to the place, and anchor with concrete, and enhance the node connection; a dual-column structure is formed between the overall house modules, thus the overall structure performance of the house is strengthened. The house modules can complete the installation of inside and outside wall bodies, floor slabs, doors and windows in the factory, thus all or a part of inside decoration and outside decoration can be completed; thereby significantly reducing the work load on site and improving the construction speed.

Owner:BEIJING UNIV OF TECH

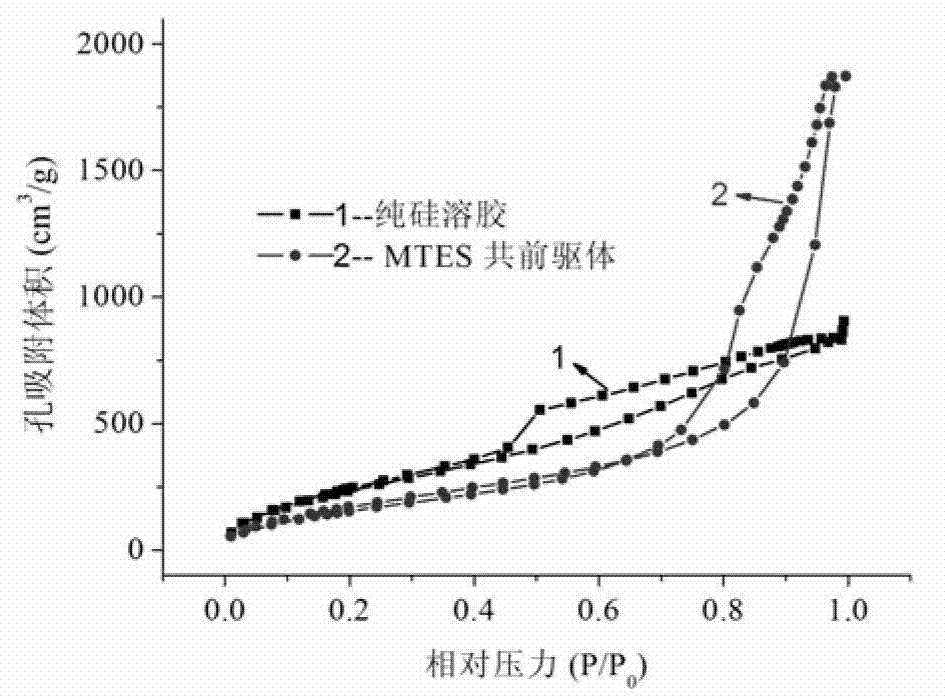

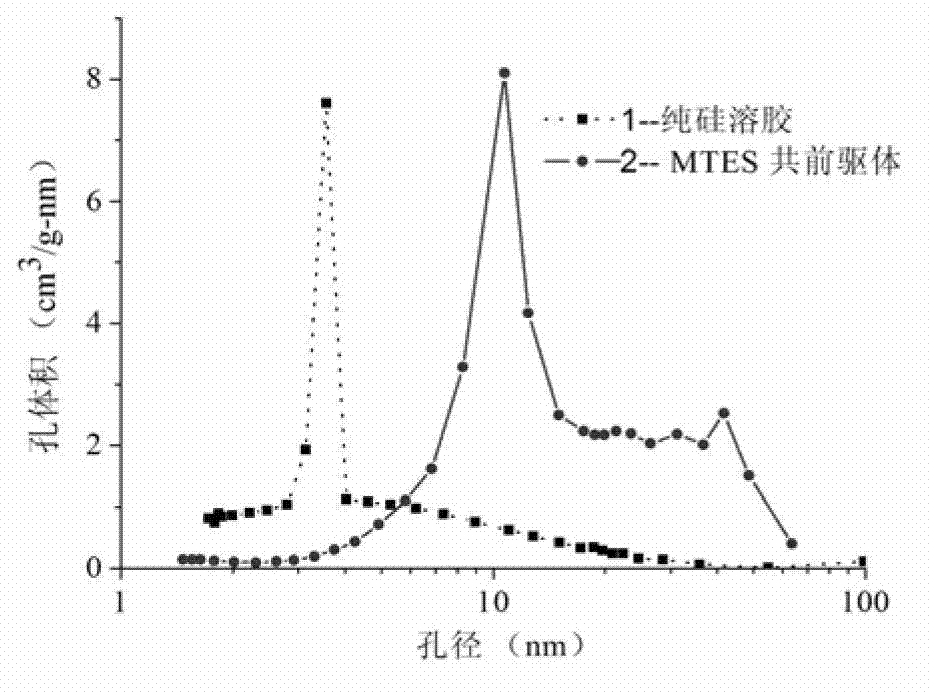

Preparation method of transparent silicon dioxide aerogel

The invention relates to aerogel and provides a preparation method of transparent silicon dioxide aerogel, which has the advantages of low cost, simple process, short production period, controllable reacting process and continuous production and adopts secondary modification process and normal-pressure drying steps. The preparation method comprises the following steps: 1) solution preparation and silicon source co-precursor hydrolysis; 2) ion exchange and silicon dioxide hydrogel preparation by using gel; and 3) aging, alcoholizing, modifying and normal-pressure drying of the silicon dioxide gel.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

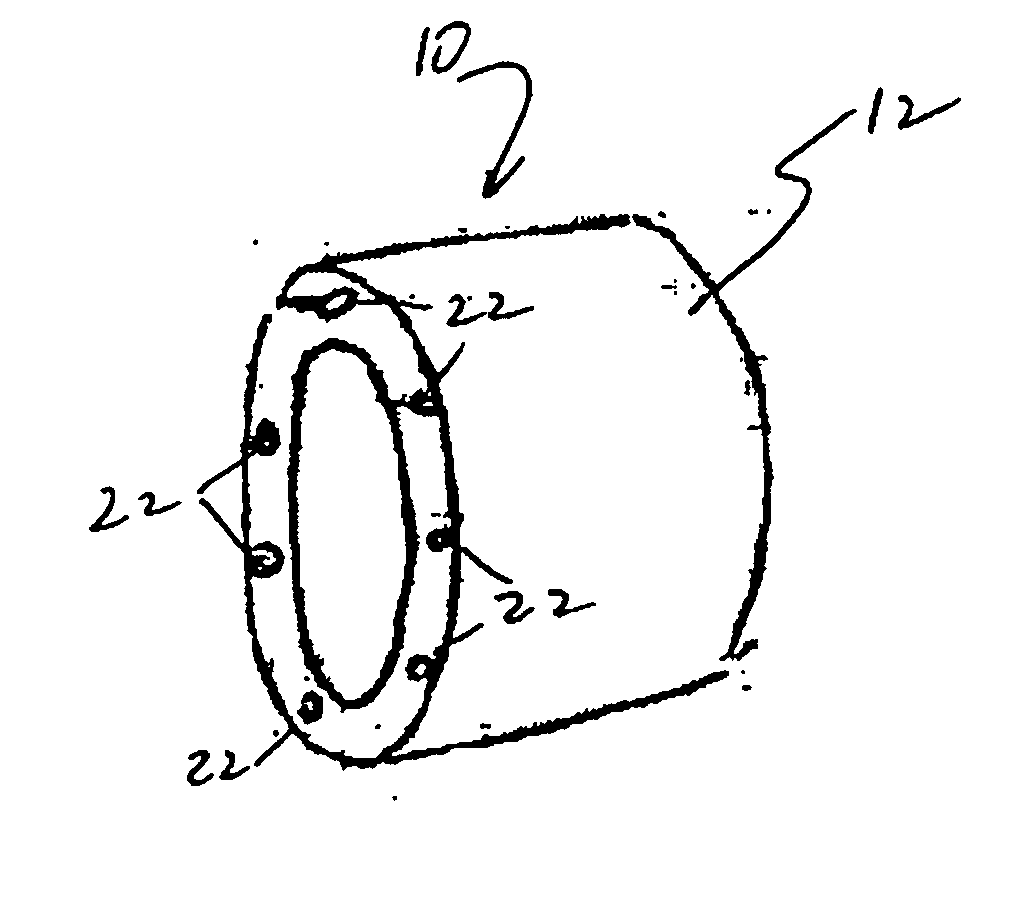

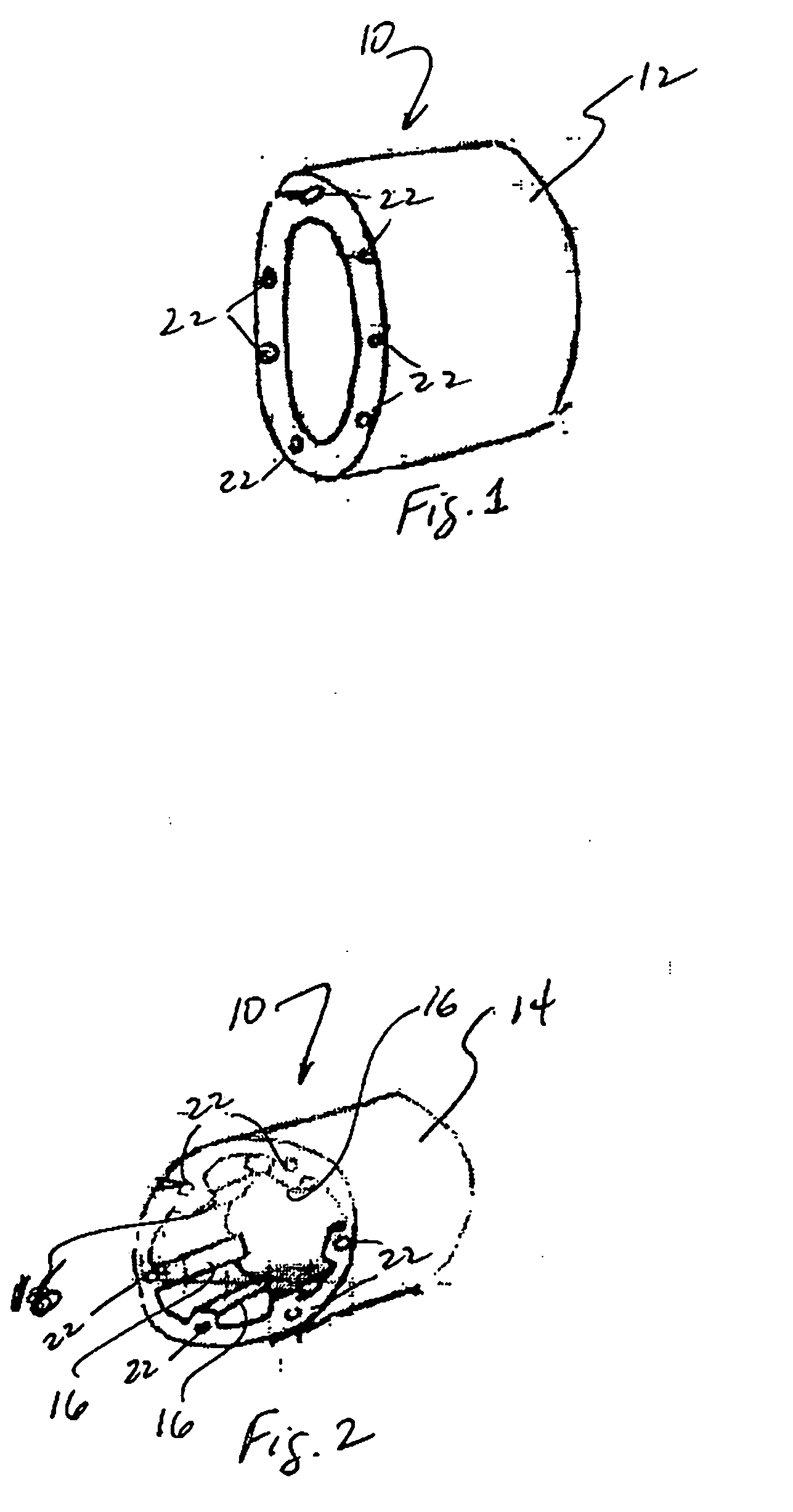

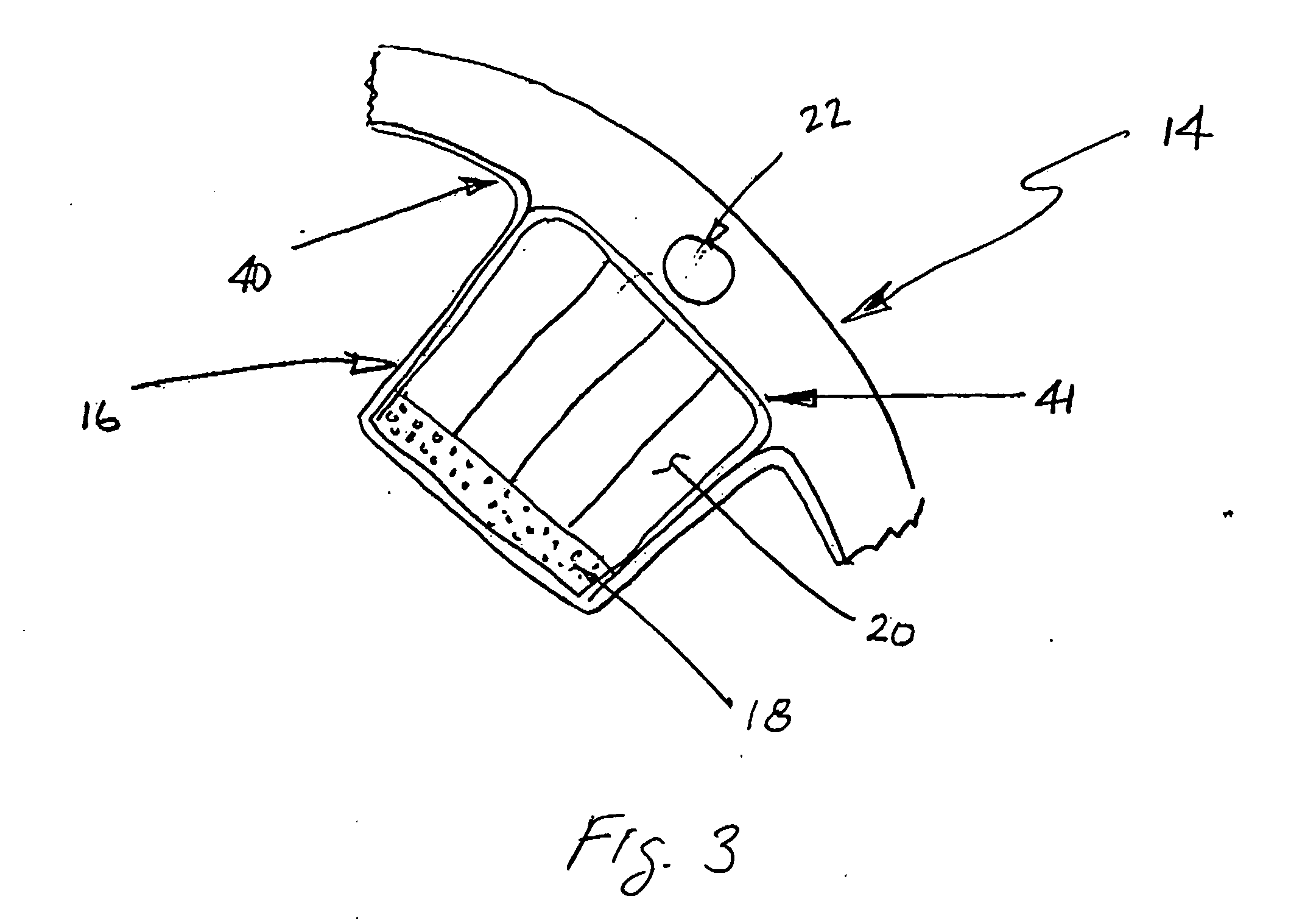

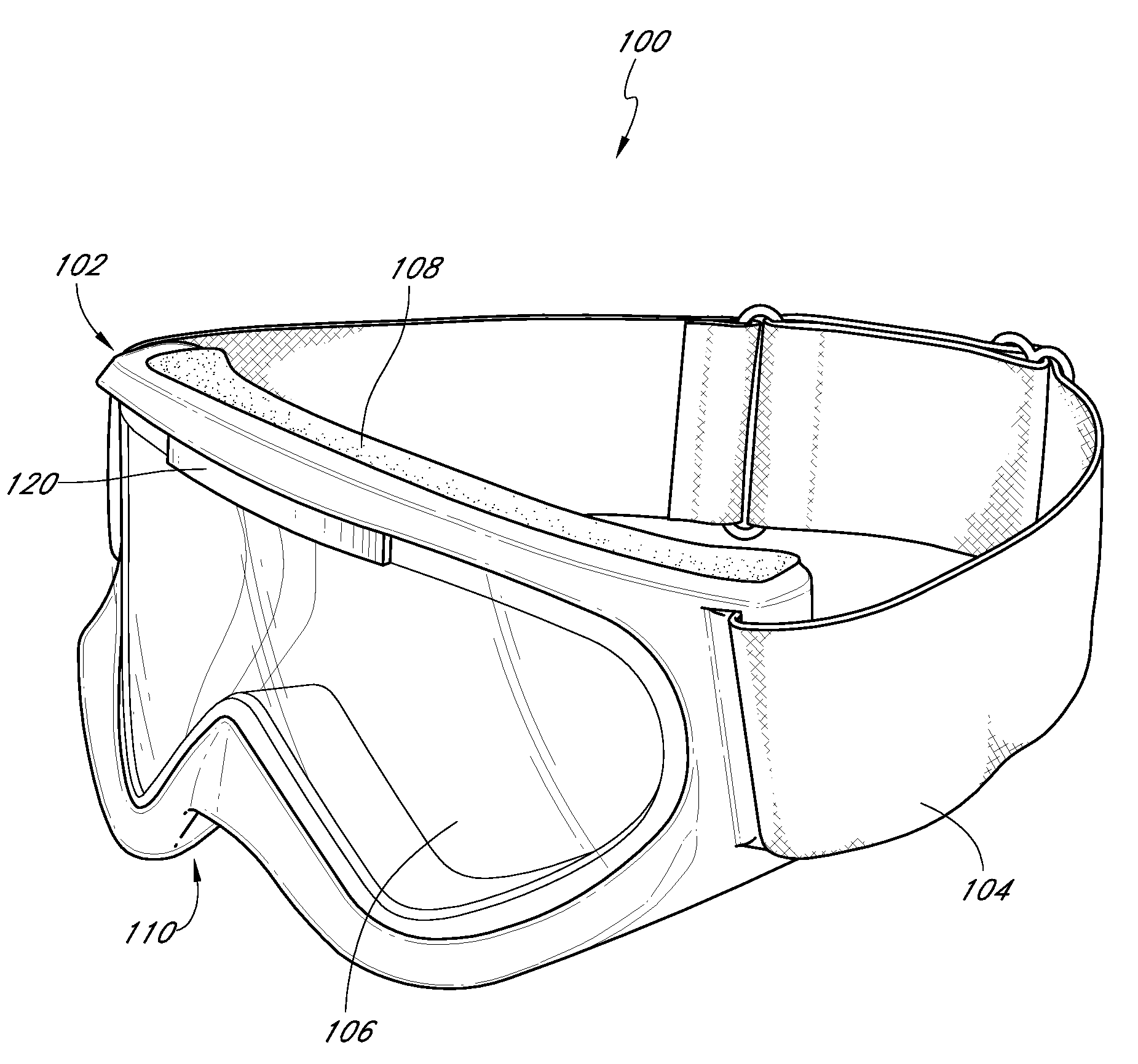

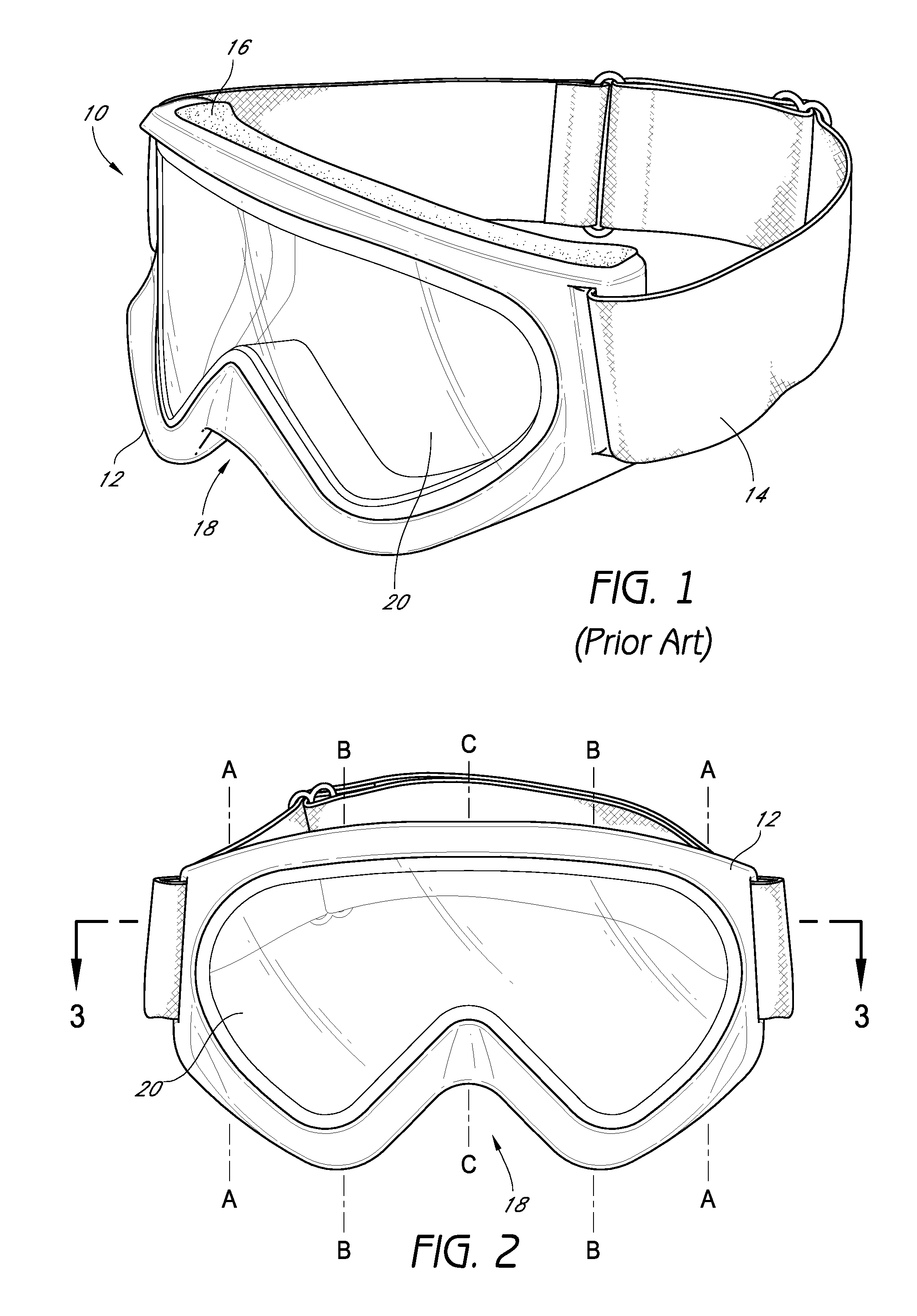

Controlled deflection goggle

ActiveUS20100186153A1Interference fit be createImprove structural performanceGogglesProtective garmentEyepieceFlexural strength

A goggle is provided that can comprise a goggle frame and a bend control component. The goggle frame can define opposing lateral portions and a central portion. The goggle frame can comprise a bridge disposed at the central portion of the goggle frame. The goggle frame can be generally flexible upon exertion of a bending force on the goggle frame. The bend control component can extend along the bridge of the goggle frame. The bend control component can be configured to enhance flexural strength of the goggle at a bridge thereof for reducing preferential bending of the goggle frame at the bridge. In some embodiments, the bend control component is formed separately from the goggle frame. In other embodiments, the bend control component can be secured to the frame using fasteners and / or one or more protrusions and corresponding recesses.

Owner:OAKLEY INC

Electrode material in hollow tubular structure, and preparation method for electrode material

InactiveCN105513831AExcellent supercapacitor performanceIncrease loadHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrochemical corrosion

The invention provides an electrode material in a hollow tubular structure, and the electrode material is in the hollow tubular structure which consists of a composite hydroxide / copper hydroxide / copper-contained metal substrate. The chemical formulation of the composite hydroxide is MxM'y(OH)2, wherein M is Ni2+ or Co2+, M' is Co2+, Al3+, or Fe3+. According to the invention, a method of solution dipping and constant potential deposition, and a copper hydroxide nanowire array grows on the copper-contained metal substrate in an in-situ manner. The composite hydroxide is deposited on a copper hydroxide nanorod in electrolyte containing mixed metal salt solution in a manner of electro-deposition through employing the method of constant potential deposition. Meanwhile, electrochemical corrosion enables the copper hydroxide nanorod to be dissolved in a process of electro-deposition, thereby obtaining the hollow tubular structure of the composite hydroxide / copper hydroxide / copper-contained metal substrate. The electrode material is good in super-capacitance performance, and can be used for a super-capacitor.

Owner:BEIJING UNIV OF CHEM TECH +1

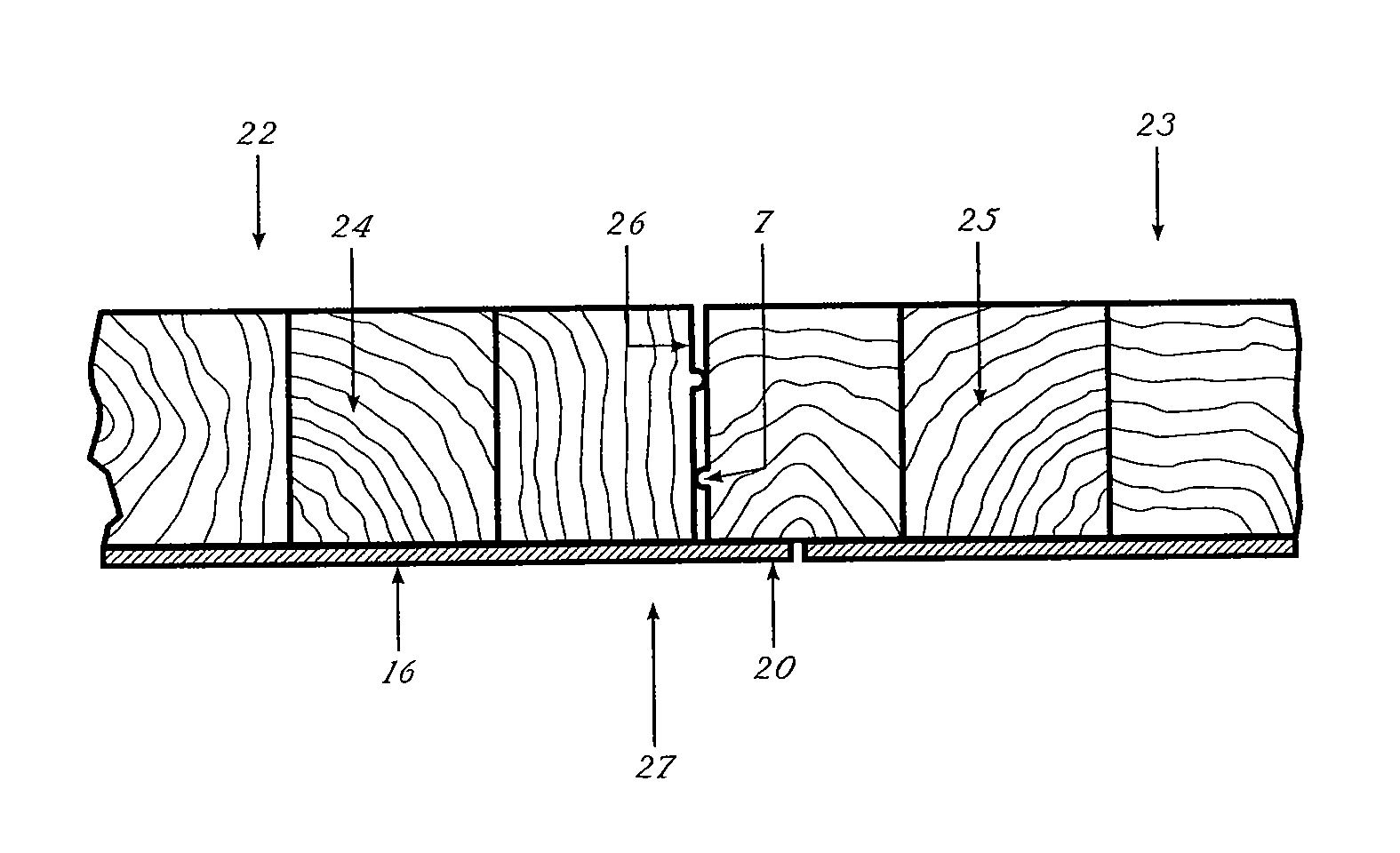

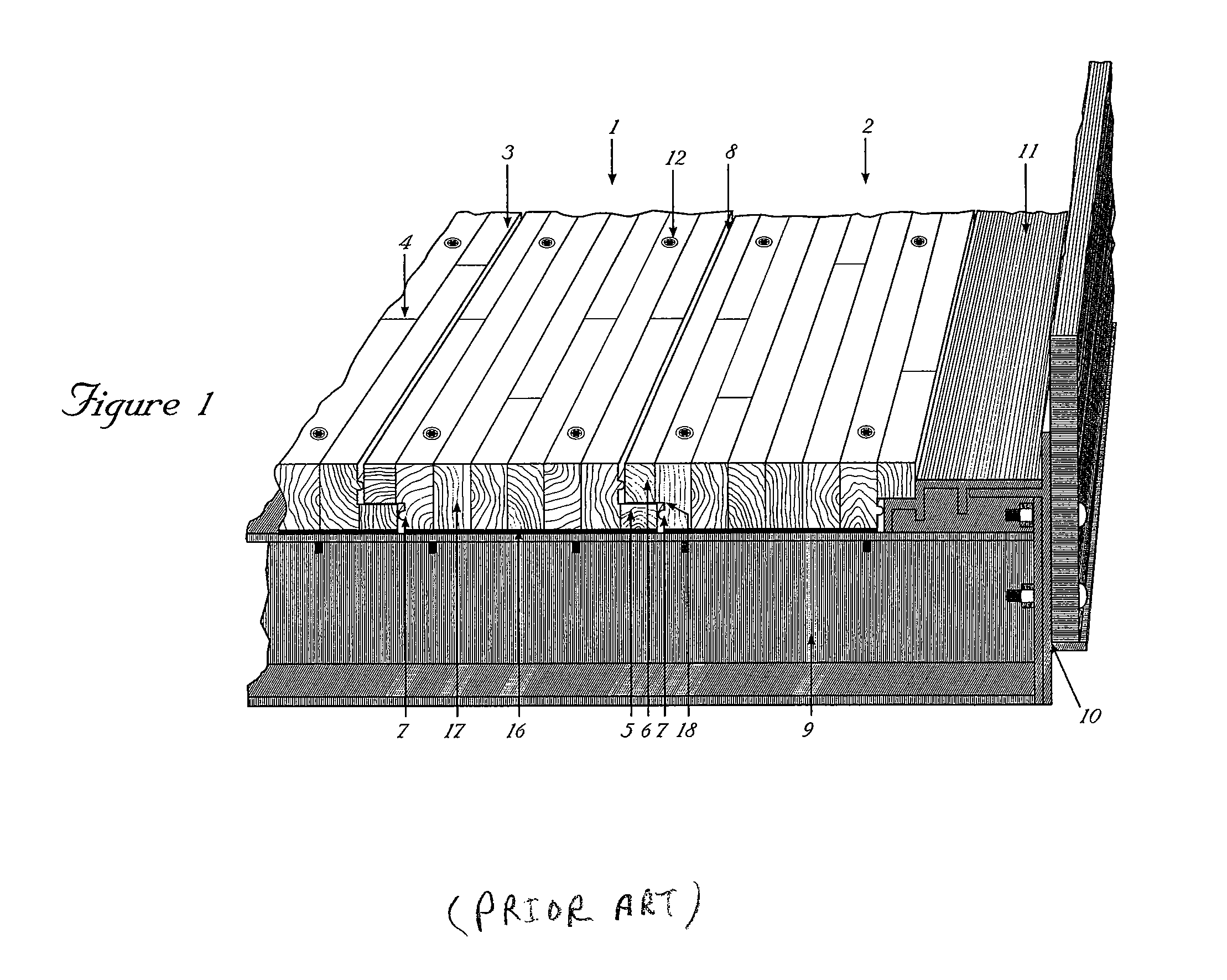

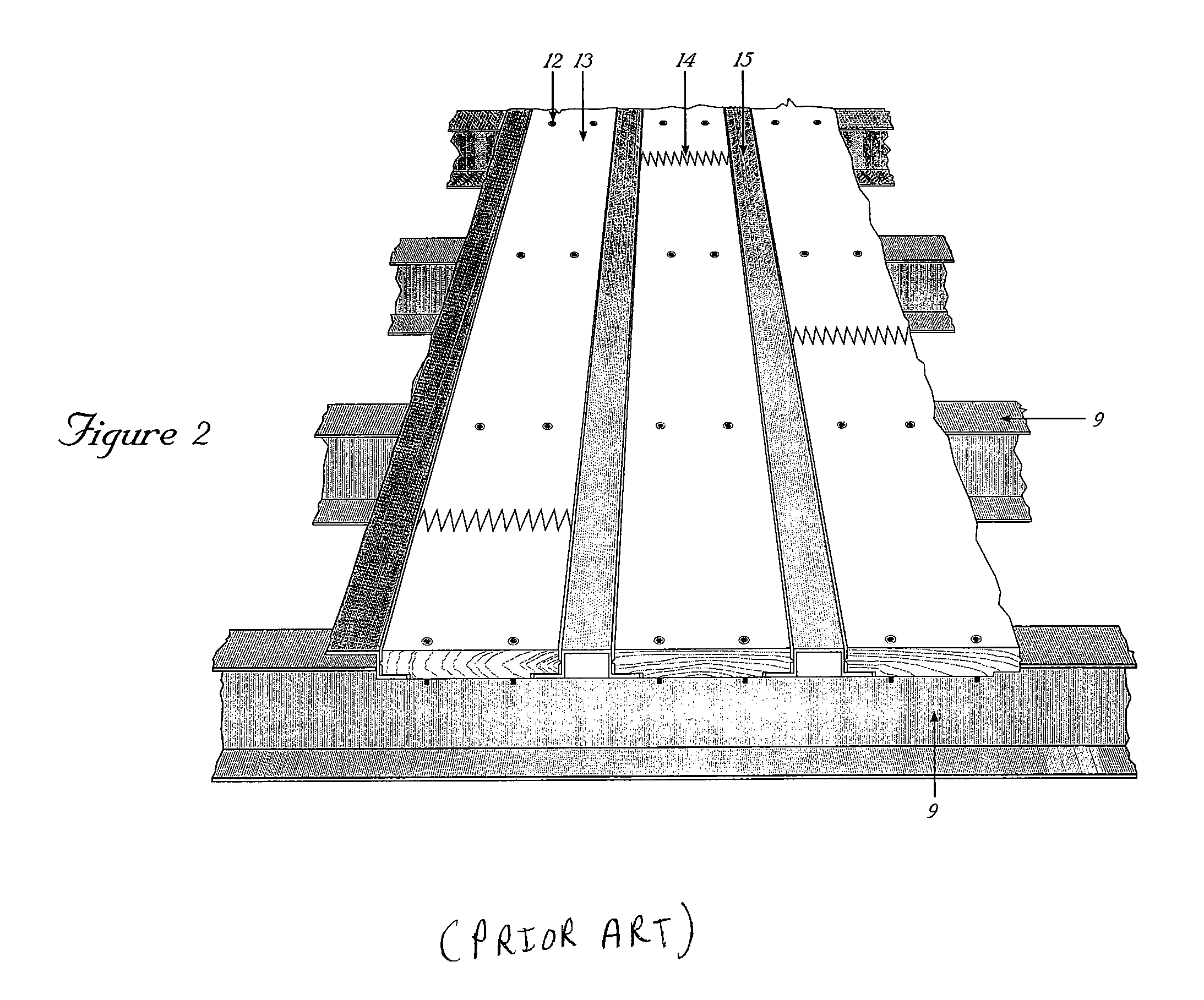

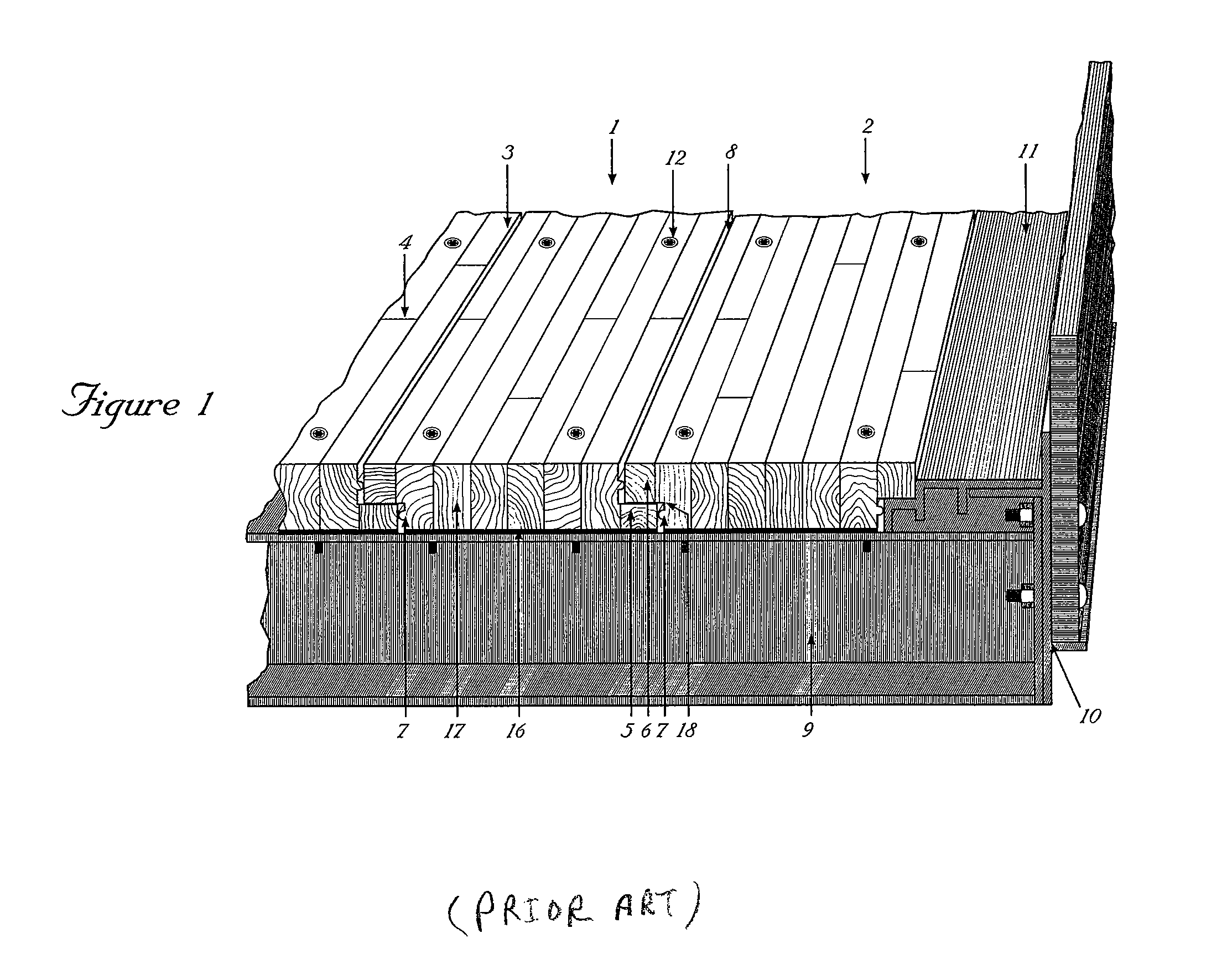

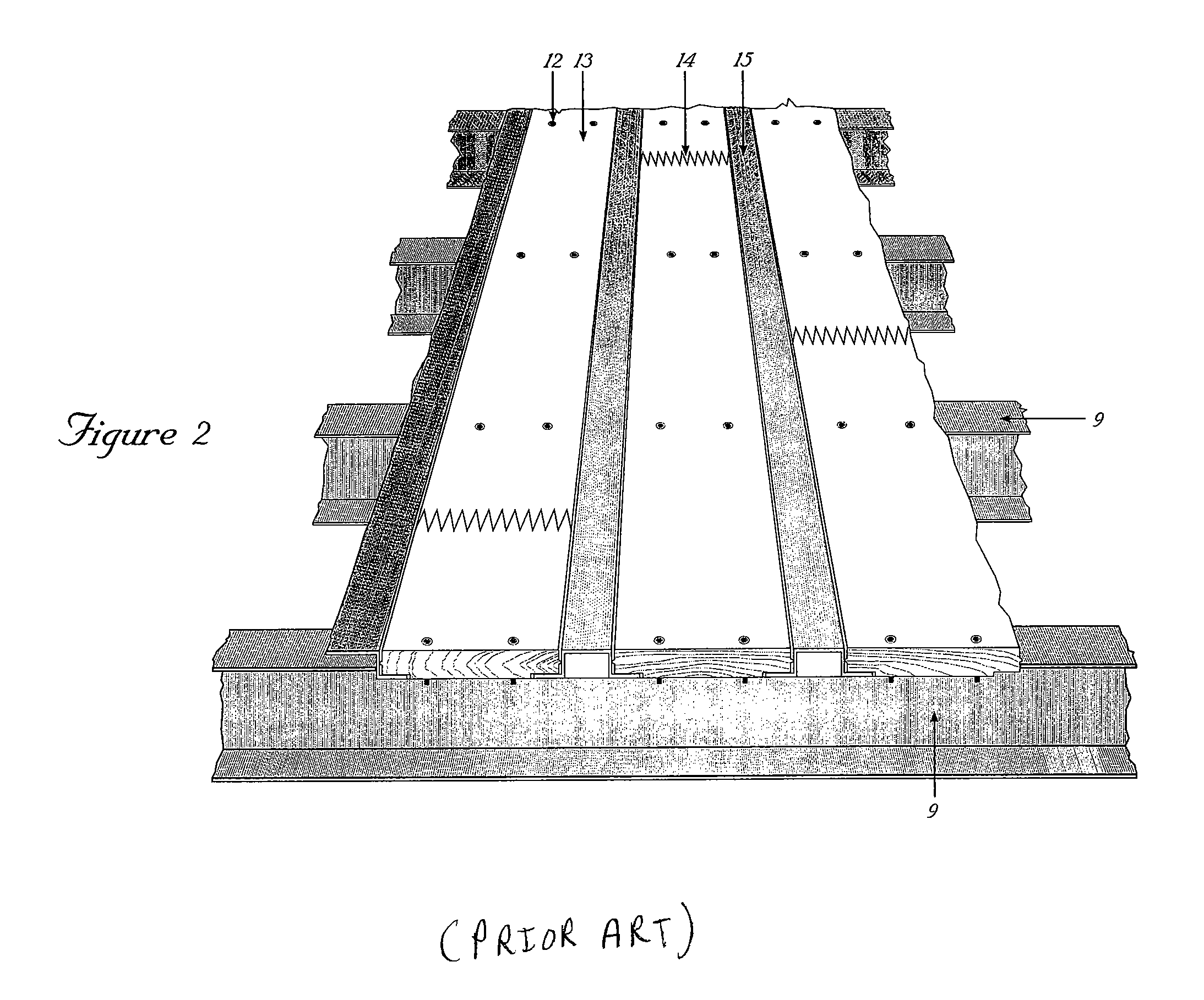

Fleixible composite lap joint for trailer flooring

A composite lap joint for the assembly of a first and a second floor board from a plurality of boards, used to make the floor for a vehicular trailer, each board composed of a layer of wood at the top side and a layer of fiber reinforced composite at the bottom side, wherein the composite layer is at least partly bonded to the wood layer; the composite layer of a first board forming a lip, wherein the lip is a lateral extension of the composite layer and the lip is disposed under the bottom side recess of an adjacent second board to form a composite joint, whereby the joint provides improved flexibility, moisture sealing ability at the seam of the joint and higher strength to the edges of the boards.

Owner:HAVCO WOOD PRODS

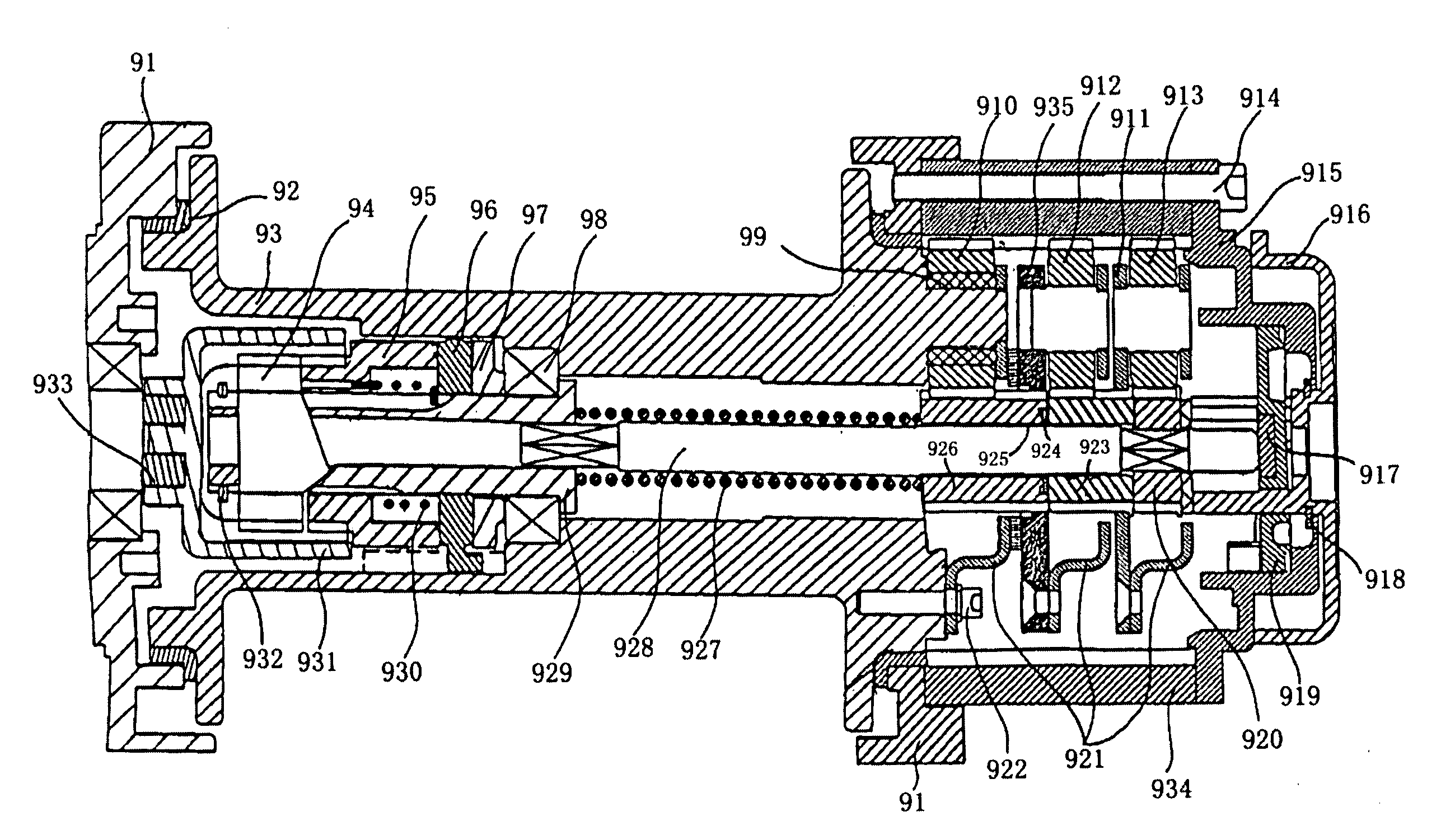

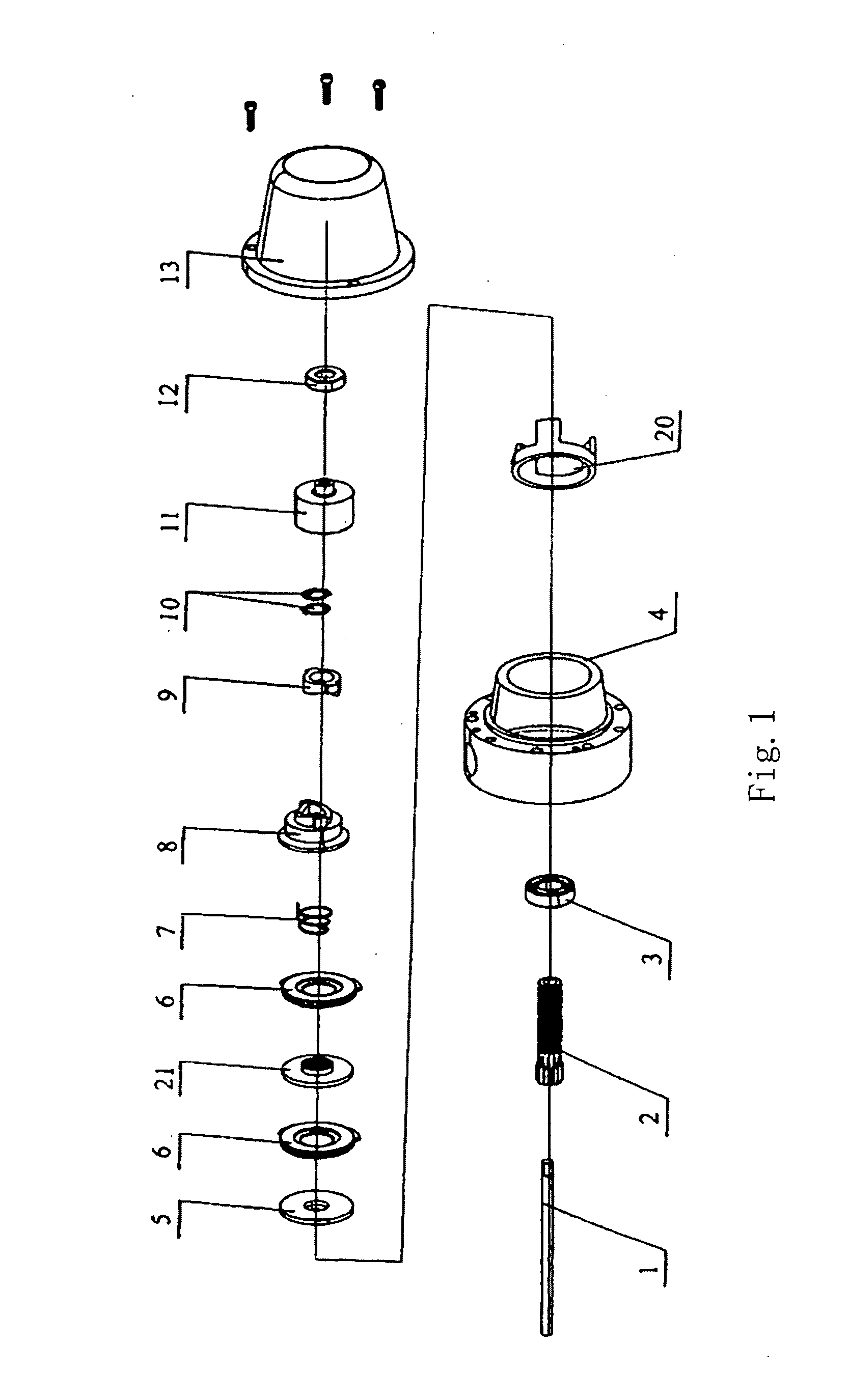

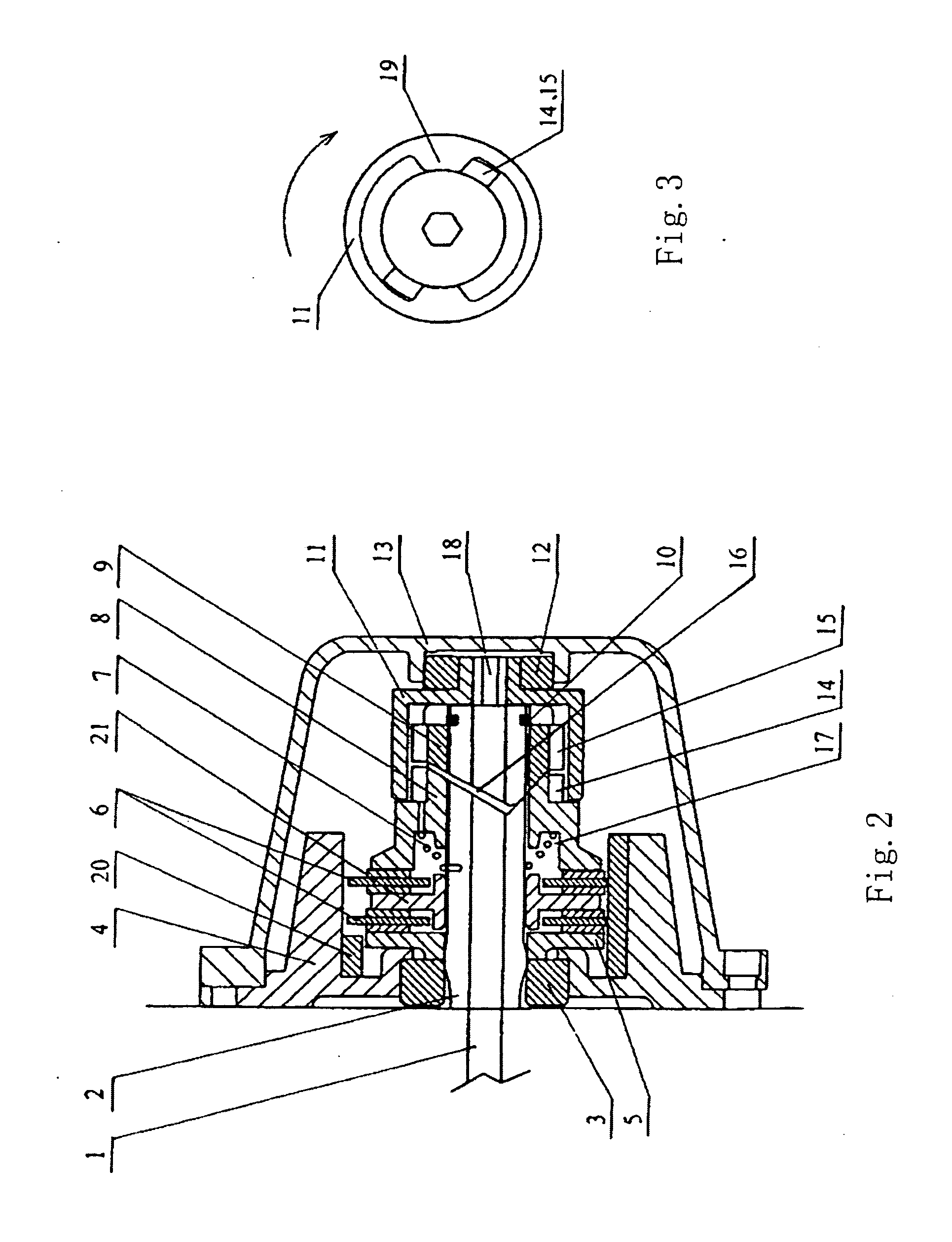

Plane braking device for electric winches and electric winch

The present invention discloses a plane braking device for electric winches and electric winch which disposes a section of hollow gear shaft, a section of core shaft, a fixing ring, a wedge shape support, a stopping piece, a braking plate, an elastic element, a wedge shape piece B, a wedge shape piece A, a braking clutch base and so on in a gear box of an electric winch. When a motor works, the section of core shaft of the motor drives the braking clutch base and the wedge shape pieces A, B to rotate, until a gap is formed between the adjacent braking plate and stopping piece between the braking clutch base and the wedge shape piece B, so that the braking effect disappears. When the motor stops suddenly, a heavy load lifted by a tight wire drum provides a reverse pulling force so that the wedge shape piece B produces a reverse thrust force to push the friction planes of the braking plate and the stopping piece, so the plane braking effect is achieved quickly. Based on the plane braking plate, the present invention can increase the braking area and the braking force and achieve safe braking. Furthermore, when there is wear of parts in long usage, so it only needs to replace the braking plate made of friction materials, which can simplify maintenance, reduce the parts costs and ensure service life of the gear box.

Owner:XIE YUZHI +1

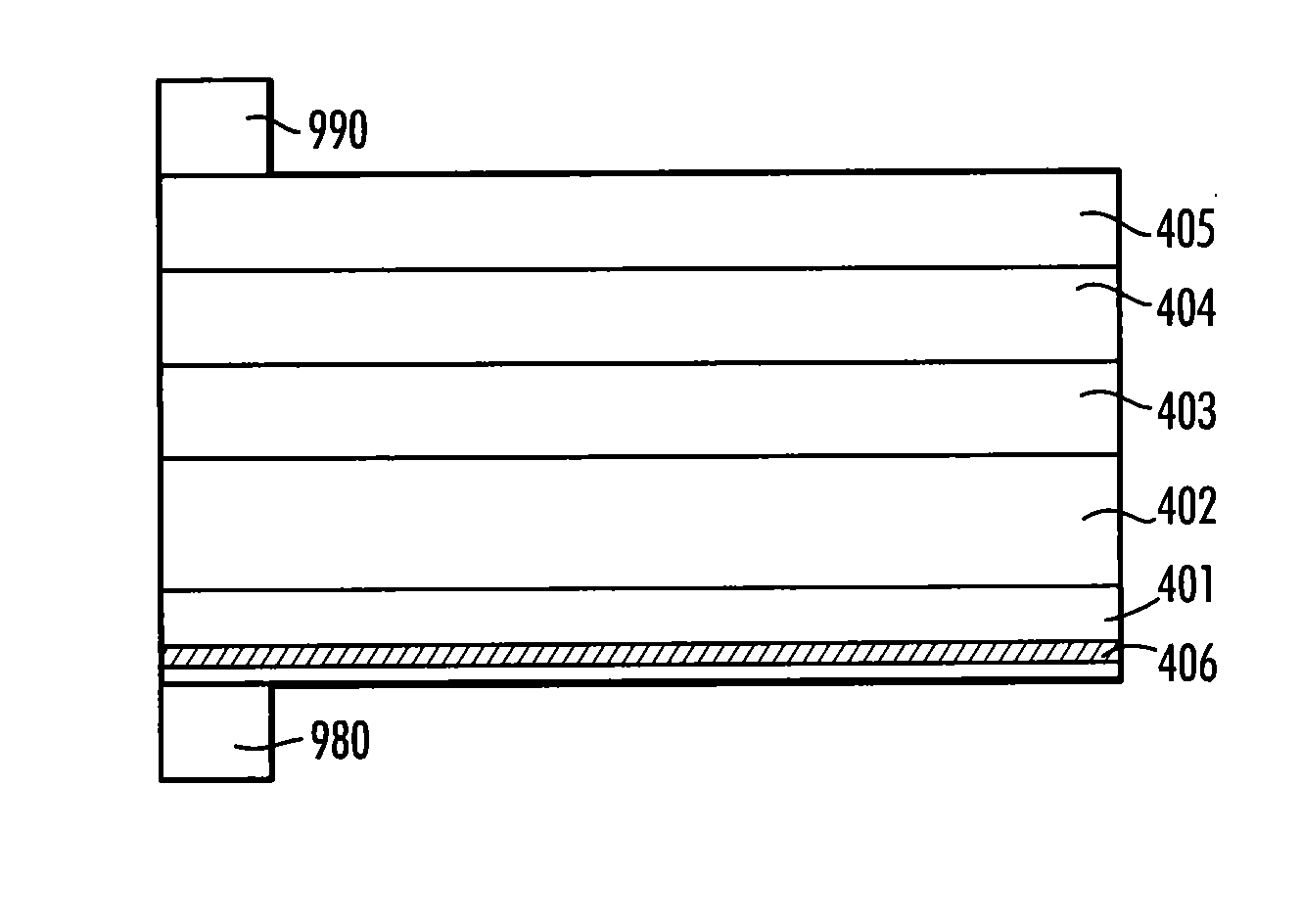

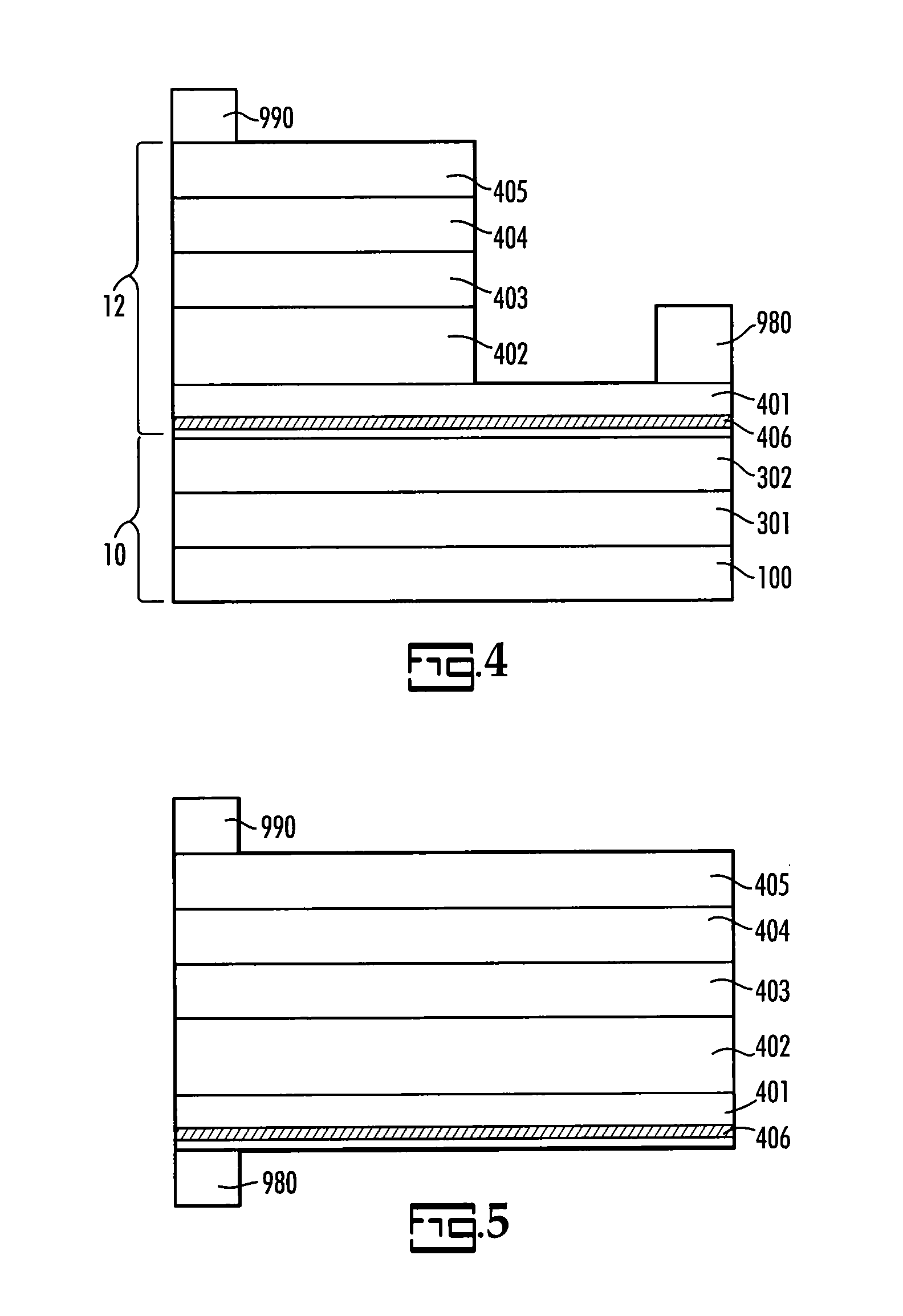

Low resistance ultraviolet light emitting device and method of fabricating the same

ActiveUS20110012089A1Surface roughness and film qualityMore surface mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesSecondary layerIndium

A low resistance light emitting device with an ultraviolet light-emitting structure having a first layer with a first conductivity, a second layer with a second conductivity; and a light emitting quantum well region between the first layer and second layer. A first electrical contact is in electrical connection with the first layer and a second electrical contact is in electrical connection with the second layer. A template serves as a platform for the light-emitting structure. The ultraviolet light-emitting structure has a first layer having a first portion and a second portion of AlXInYGa(1-X-Y)N with an amount of elemental indium, the first portion surface being treated with silicon and indium containing precursor sources, and a second layer. When an electrical potential is applied to the first layer and the second layer the device emits ultraviolet light.

Owner:NIITEK

Complex metallographic structured steel and method of manufacturing same

ActiveUS20090098408A1Castability is degradedFormability deterioratesHot-dipping/immersion processesFurnace typesSheet steelYield ratio

A multi-phase steel sheet having microstructure having in combination ferrite, martensite of between 3% and 65% by volume, and at least one microstructure selected from the group consisting of, bainite and retained austenite, and having fine complex precipitates selected from the group of TiC, NbC, TiN, NbN, (Ti.Nb)C, (Ti.Nb)N, and (Ti.Nb)(C.N) particles having at least 50% smaller than 20 nm in size, and physical properties having tensile strength greater than about 780 megapascals and at least one of the properties of elongation greater than about 10%, yield ratio greater than about 70%, and hole expansion ratio greater than about 50%.

Owner:NUCOR CORP

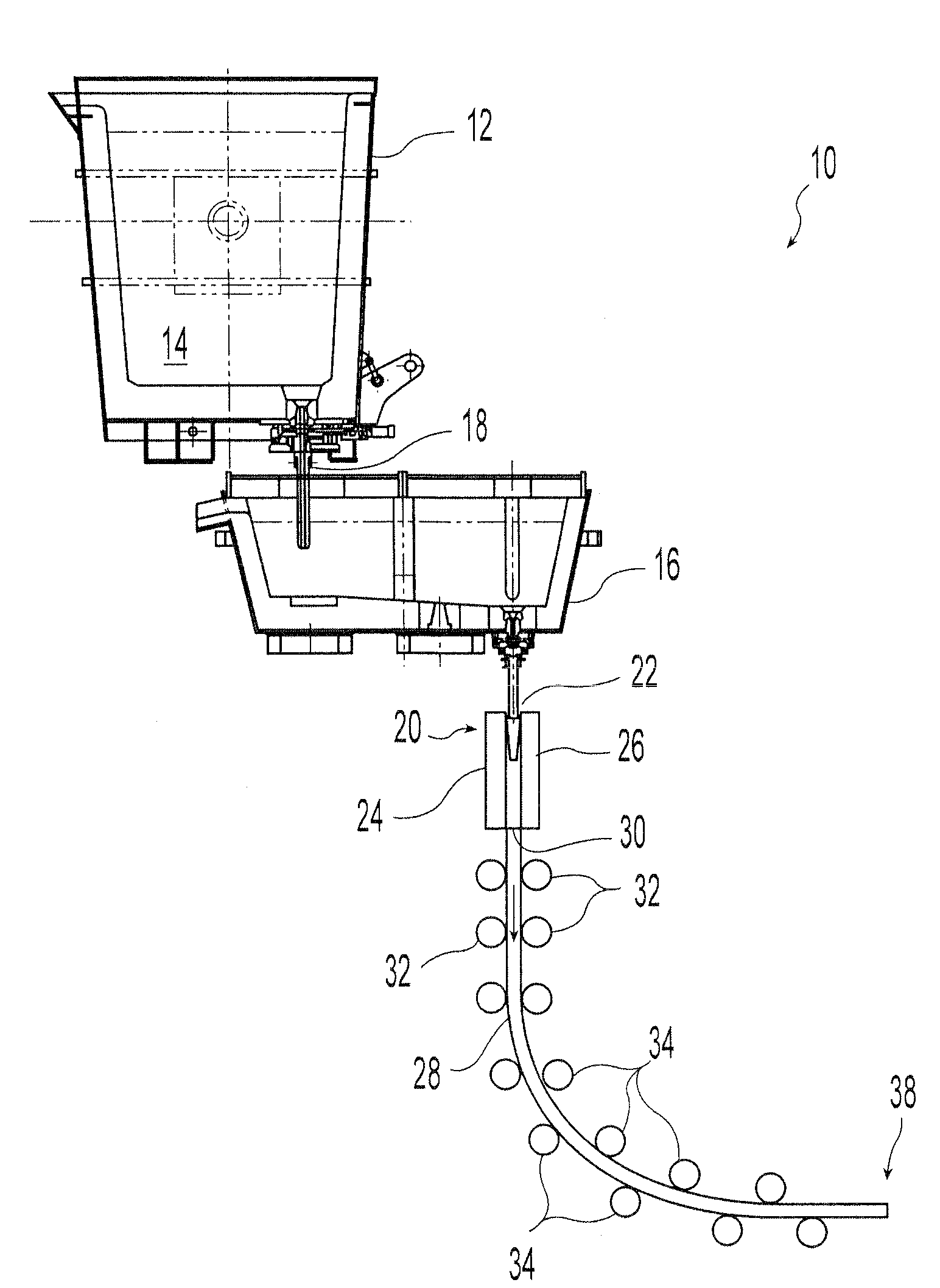

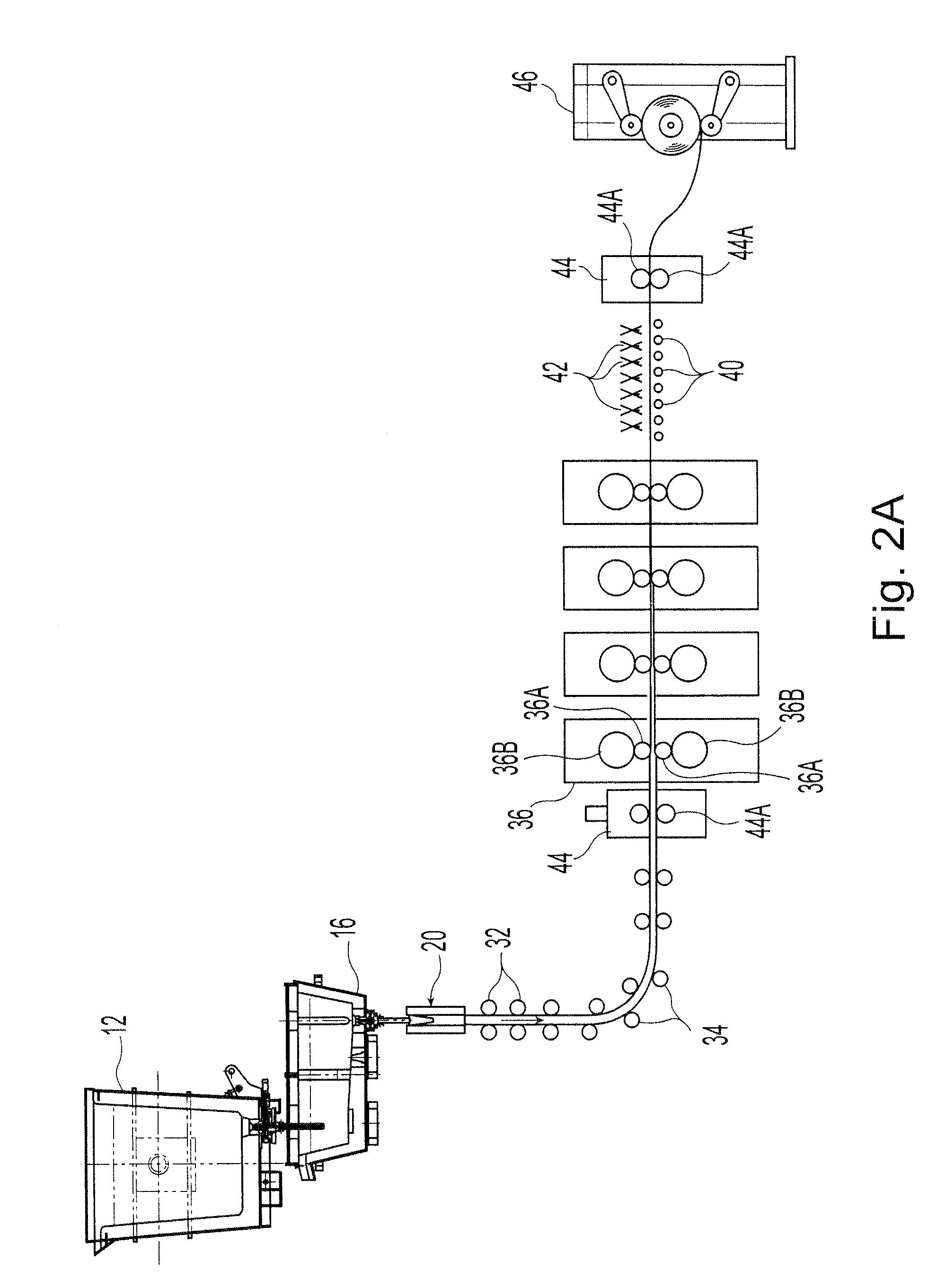

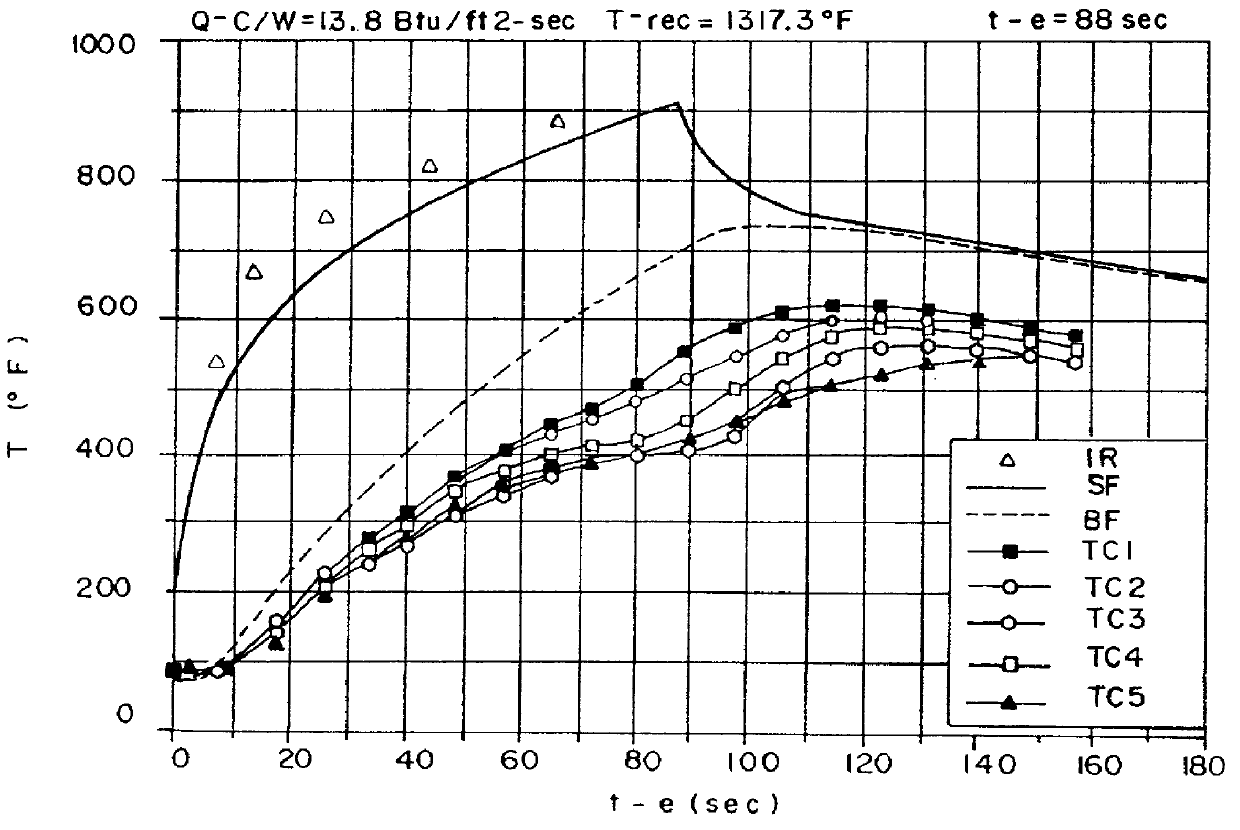

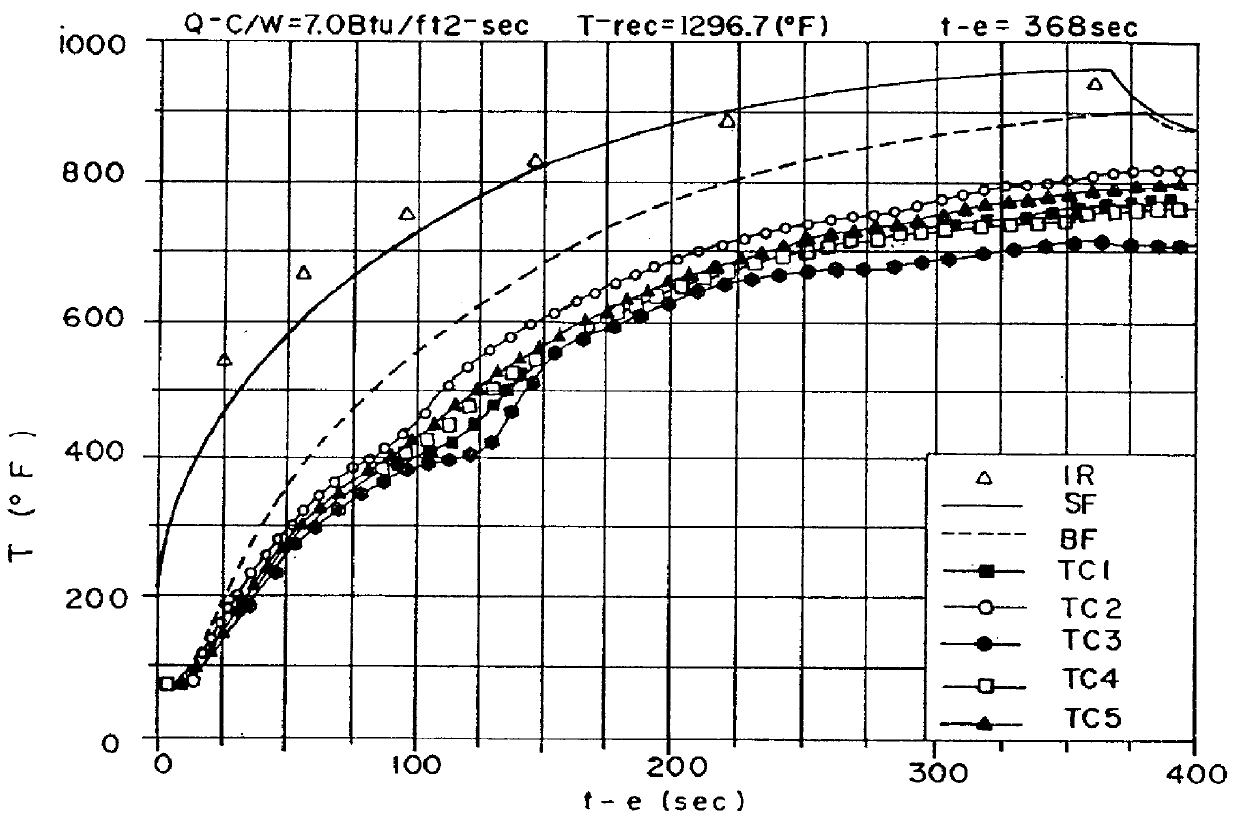

High performance structural laminate composite material for use to 1000 DEG F and above, apparatus for and method of manufacturing same, and articles made with same

InactiveUS6013361ASufficient permeabilityReduce weightCosmonautic vehiclesCosmonautic partsDamage toleranceRefractory

A novel materials technology has been developed and demonstrated for providing a high modulus composite material for use to 1000 DEG F. and above. This material can be produced at 5-20% of the cost of refractory materials, and has higher structural properties. This technology successfully resolves the problem of "thermal shock" or "ply lift," which limits traditional high temperature laminates (such as graphite / polyimide and graphite / phenolic) to temperatures of 550-650 DEG F. in thicker (0.25'' and above) laminates. The technology disclosed herein is an enabling technology for the nose for the External Tank (ET) of the Space Shuttle, and has been shown to be capable of withstanding the severe environments encountered by the nose cone through wind tunnel testing, high temperature subcomponent testing, and full scale structural, dynamic, acoustic, and damage tolerance testing.

Owner:LOCKHEED MARTIN CORP

Flexible composite lap joint for trailer flooring

A composite lap joint for the assembly of a first and a second floor board from a plurality of boards, used to make the floor for a vehicular trailer, each board composed of a layer of wood at the top side and a layer of fiber reinforced composite at the bottom side, wherein the composite layer is at least partly bonded to the wood layer; the composite layer of a first board forming a lip, wherein the lip is a lateral extension of the composite layer and the lip is disposed under the bottom side recess of an adjacent second board to form a composite joint, whereby the joint provides improved flexibility, moisture sealing ability at the seam of the joint and higher strength to the edges of the boards.

Owner:HAVCO WOOD PRODS

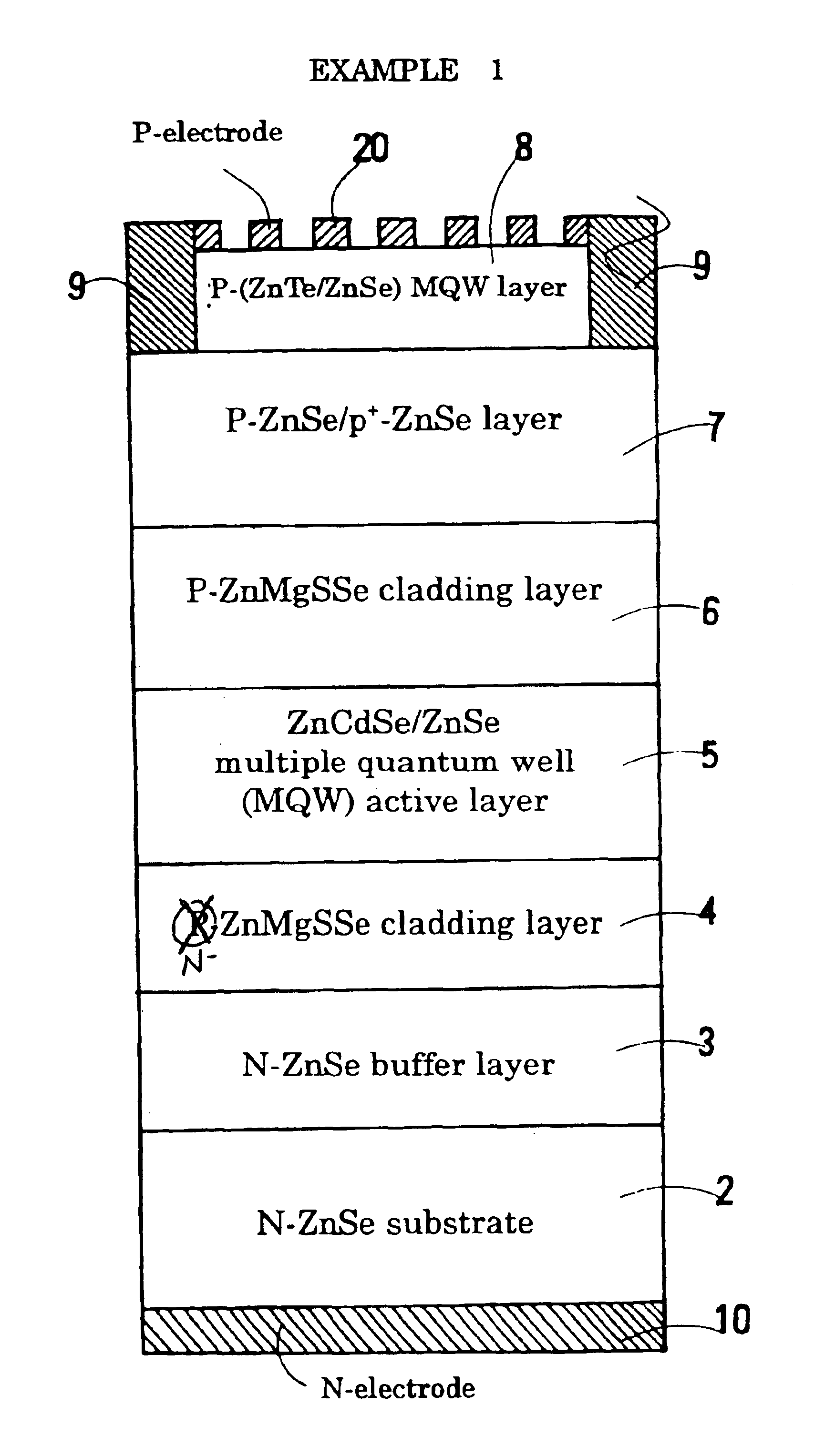

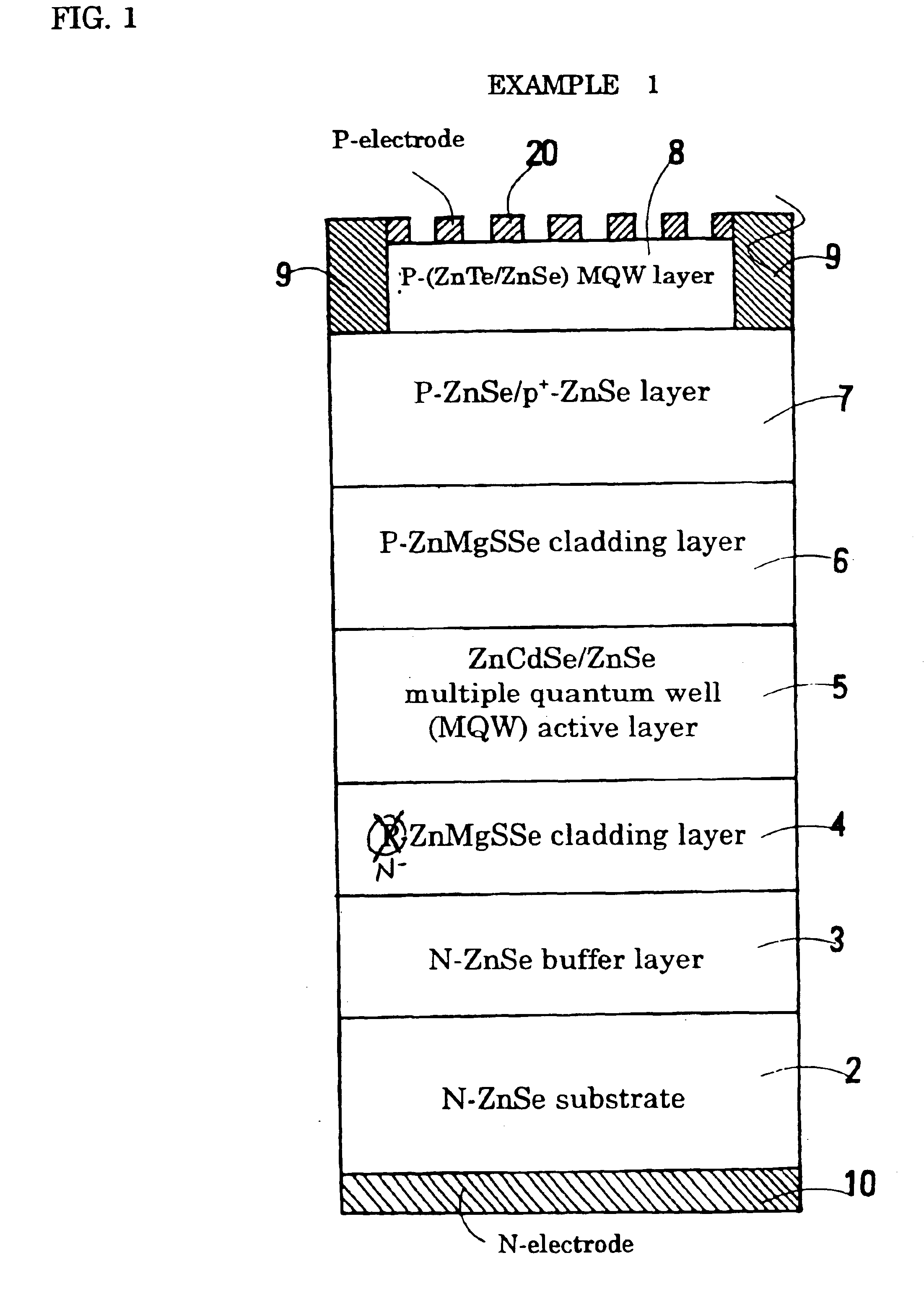

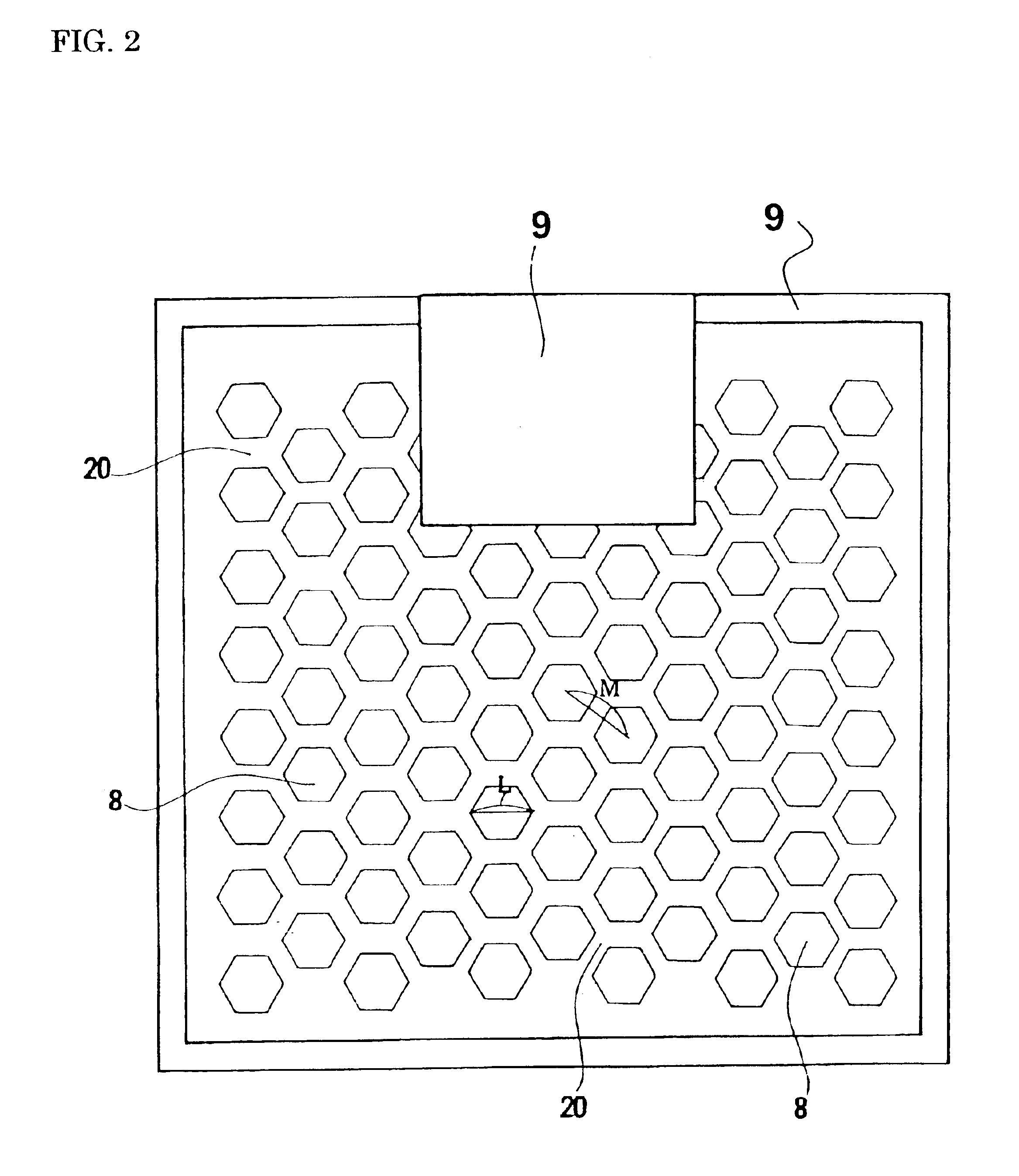

Structure of p-electrode at the light-emerging side of light-emitting diode

InactiveUS6903374B2High light transmittanceImprove light outputSolid-state devicesSemiconductor devicesTransmittanceContact layer

A structure of a p-electrode formed at the light-emerging side of an LED that comprises (a) an n-type semiconductor substrate, (b) an n-type cladding layer, an active layer, a p-type cladding layer, and a p-type contact layer formed on the substrate in this order, and (c) an n-electrode formed on the back face of the substrate. The structure of the p-electrode comprises a mesh-shaped semi-transparent thin-film metal electrode for diffusing electric current formed on the p-type contact layer and a bonding electrode for wire bonding. The metal electrode comprises a covering portion having a transmittance of at least 10% and an opening portion having an opening ratio of at least 20%. The bonding electrode is formed at the periphery of the p-type contact layer and is bonded directly to the mesh-shaped semi-transparent thin-film metal electrode. This structure can increase the intensity of the output light emerging from the p-side.

Owner:SUMITOMO ELECTRIC IND LTD

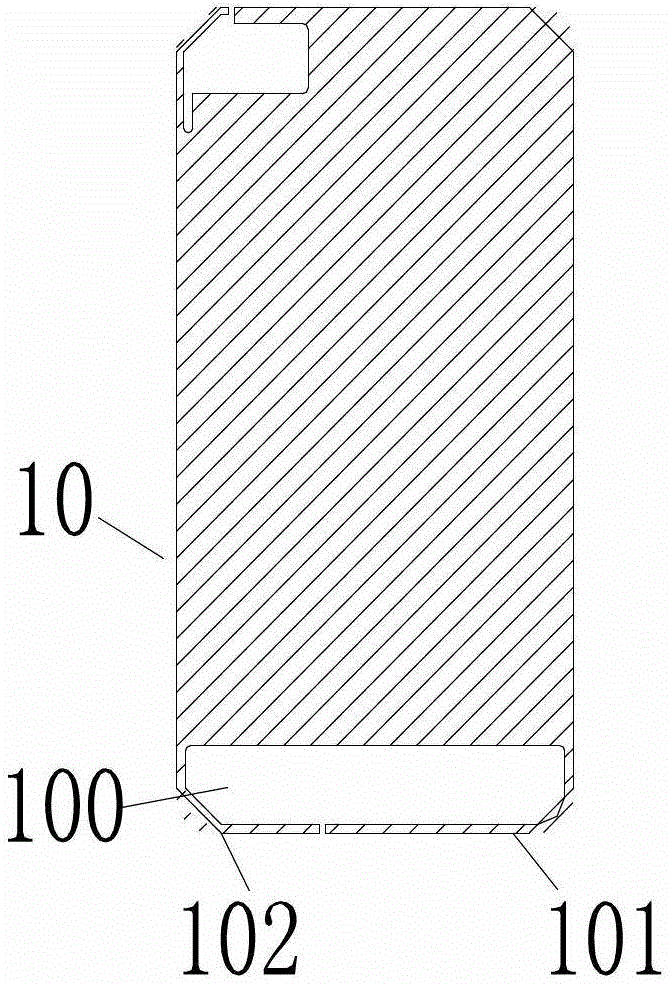

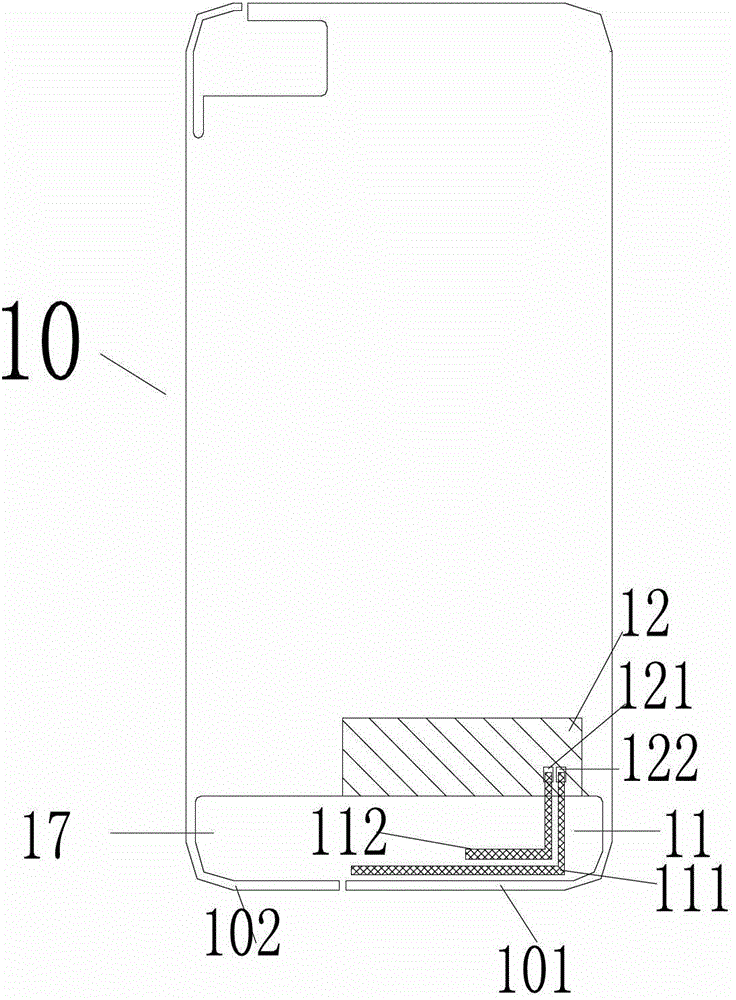

Coupling feed-in type antenna device of mobile terminal

ActiveCN103151613AReduce thicknessImprove structural performanceAntenna supports/mountingsRadiating elements structural formsCommunication qualityCoupling

The invention relates to the field of communication and discloses a coupling feed-in type antenna device of a mobile terminal. The coupling feed-in type antenna device of the mobile terminal comprises a metal shell. A first metal arm and a second metal arm stretch out of the lateral surface of the metal shell, wherein the first metal arm and the second metal arm form a fixed space in a enclosing mode, and a notch is formed in the arm end of the first metal arm and the arm end of the second metal arm. An antenna carrier is arranged inside the fixed space. The antenna is provided with an antenna. The antenna comprises a first antenna branch and a second antenna branch. A main board and an antenna connector are arranged inside the metal shell. The first antenna branch and the second antenna branch are respectively connected with the main board through the antenna connector. Due to the fact that the coupling feed-in type antenna device of the mobile terminal is adopted, the problem that communication quality is decreased when a user grips the mobile terminal is solved, and stronger metal texture is provided for the user.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

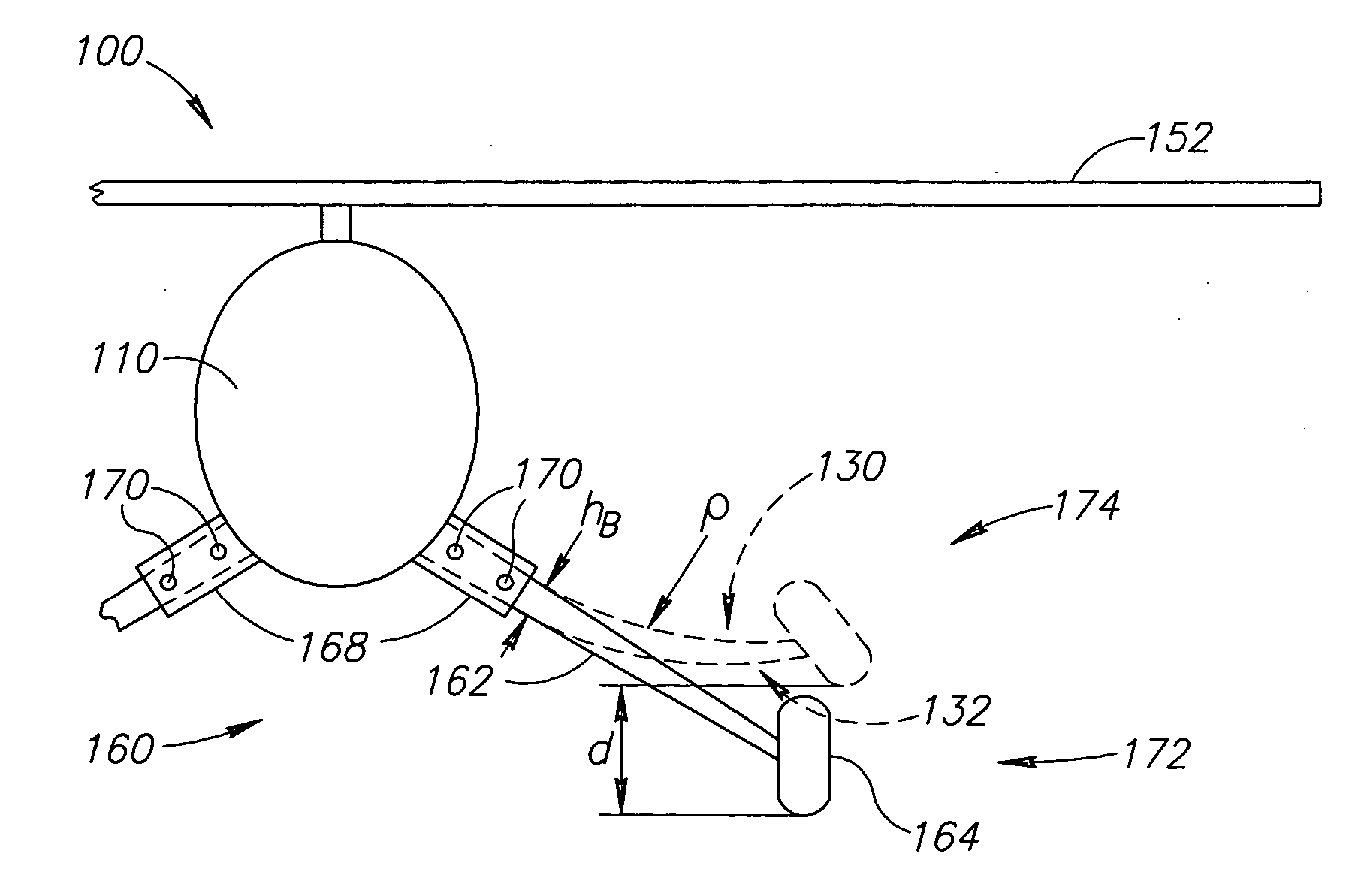

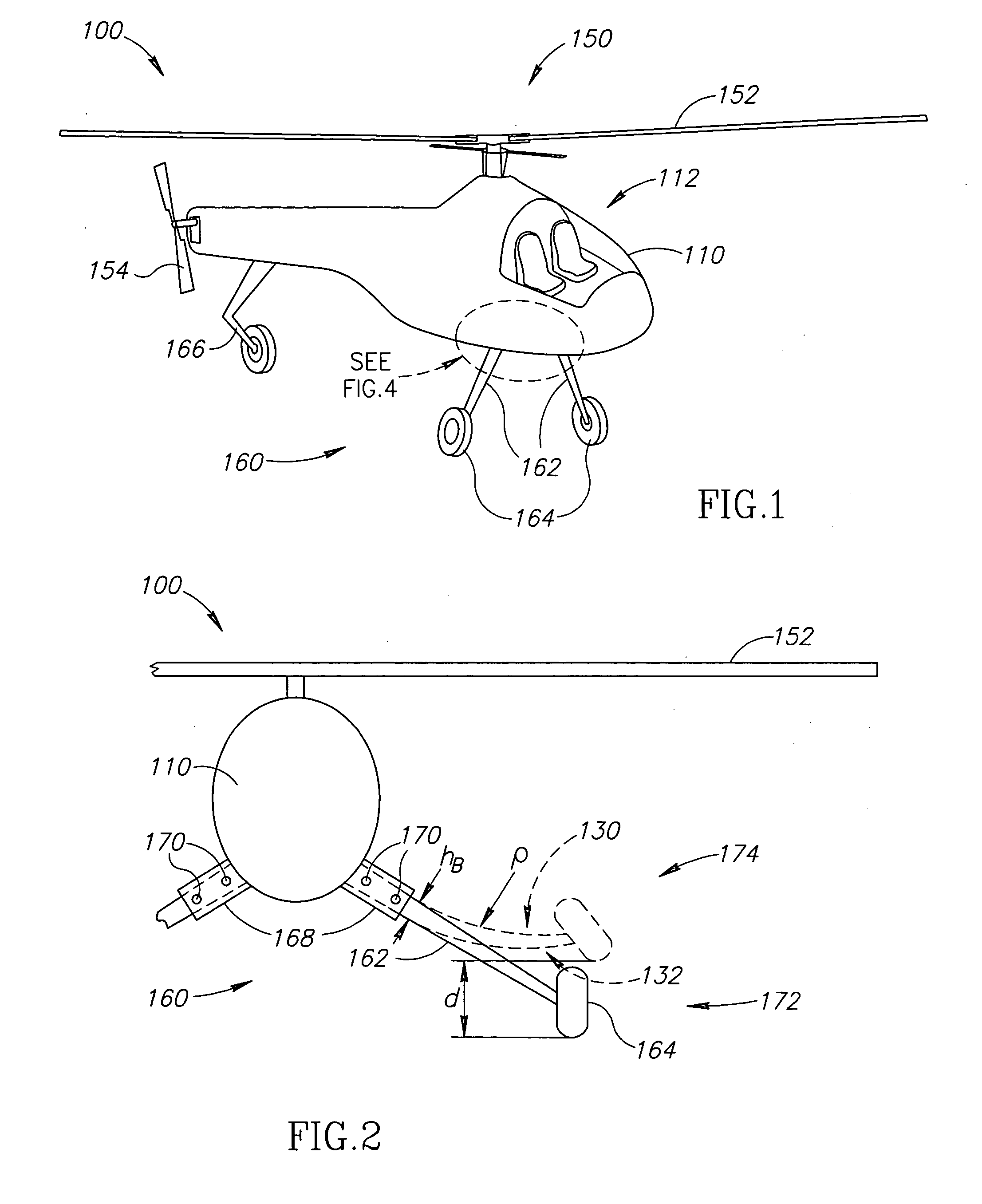

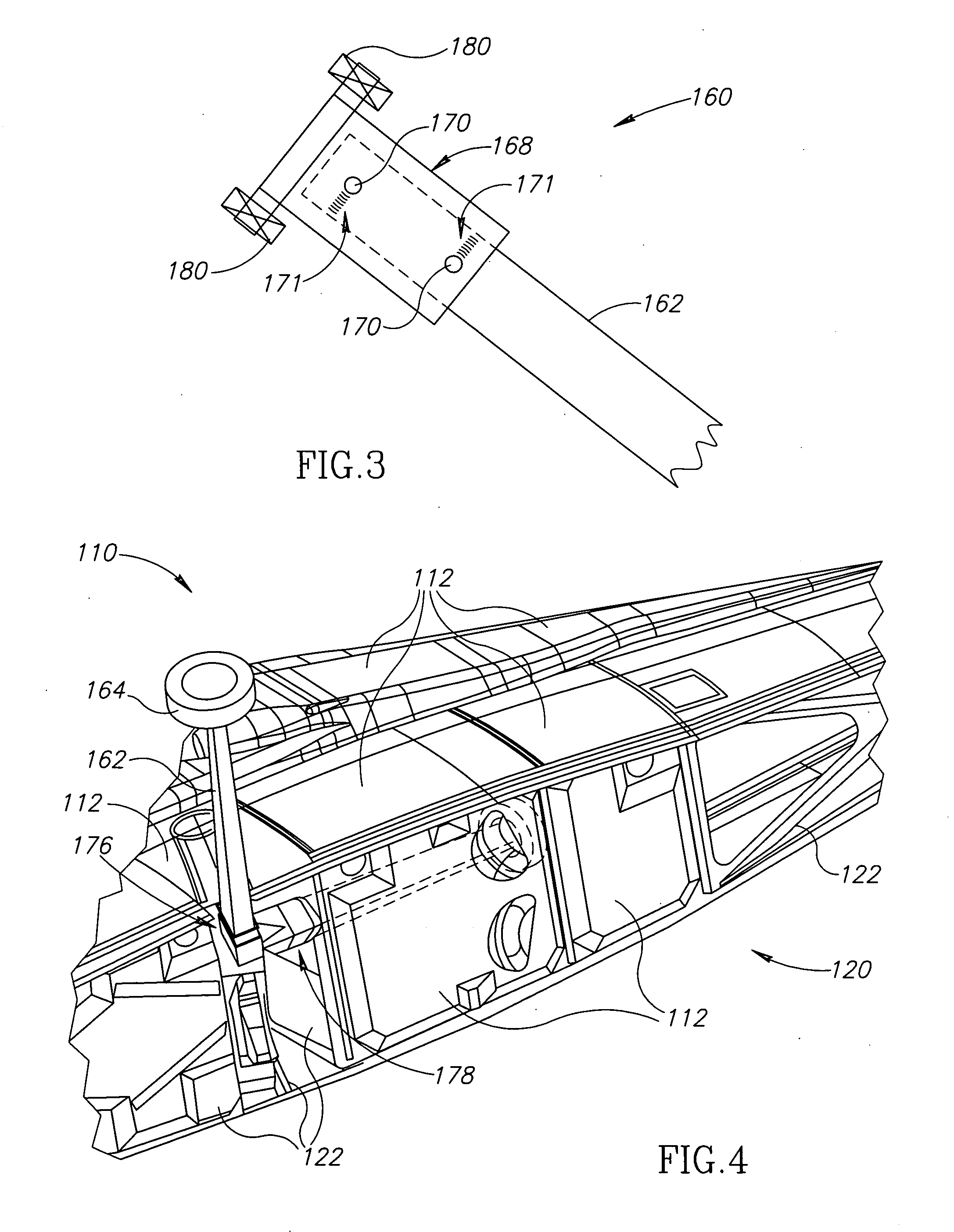

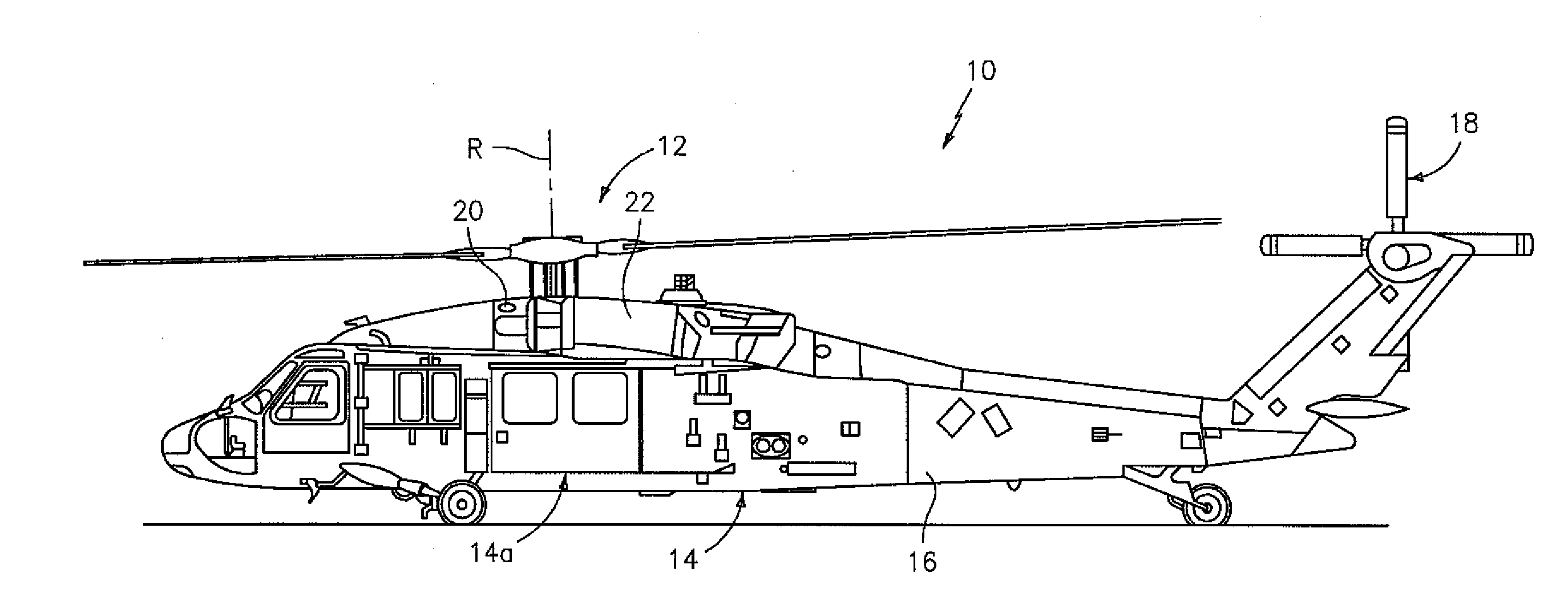

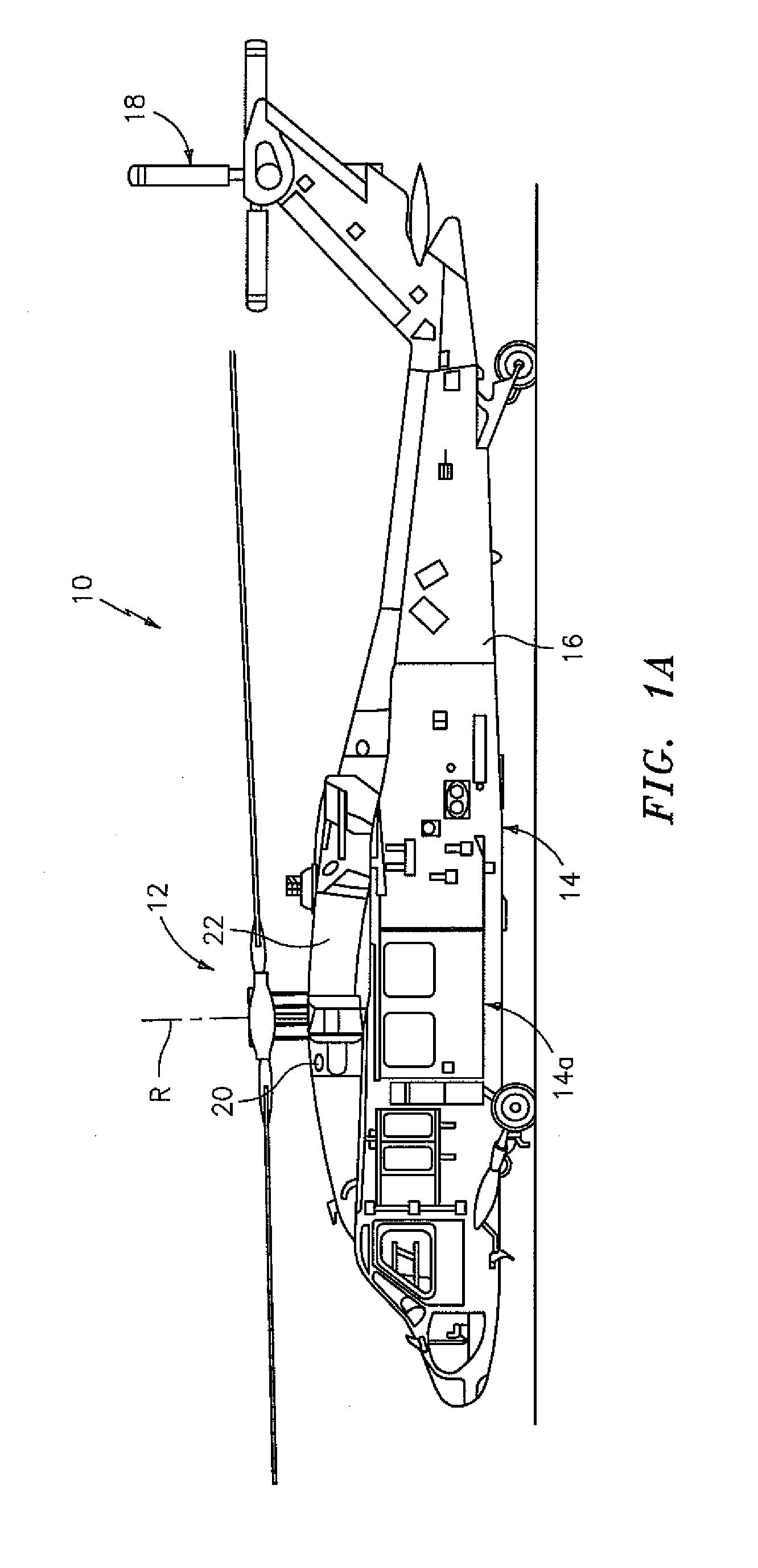

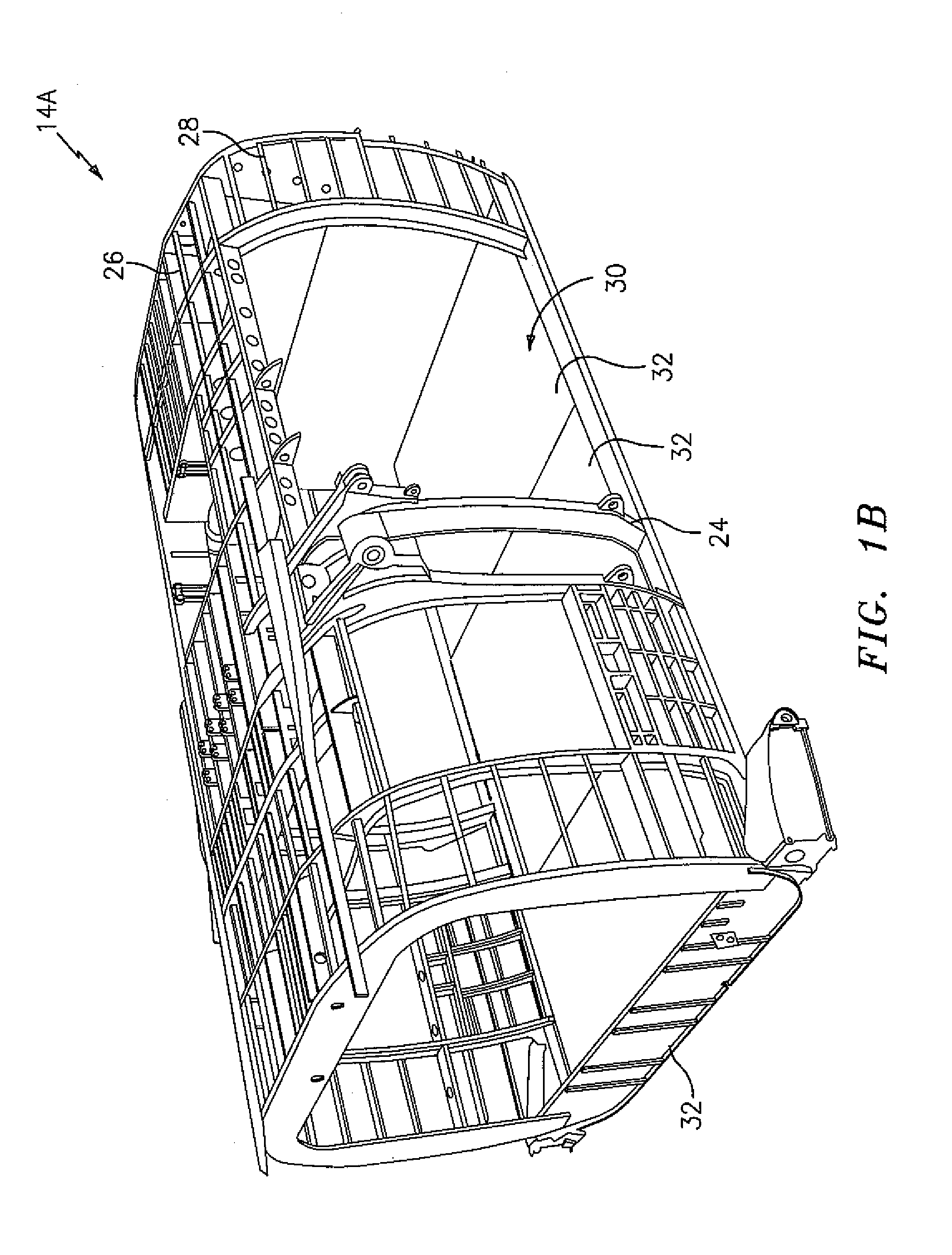

Composite landing gear apparatus and methods

ActiveUS20060284009A1Improve structural performanceReduce weightSkis/runnersUndercarriagesFiberMechanical engineering

Composite landing gear apparatus and methods are disclosed. In one embodiment, a composite component includes an elongated member having a first composite portion coupled to a second composite portion by a pair of composite sidewall portions and forming an elongated cavity therebetween. The first composite portion includes a plurality of first layers, each first layer having a plurality of first fibers disposed therein. Similarly, the second composite portion includes a plurality of second layers, each second layer having a plurality of second fibers disposed therein. The first and second fibers are oriented substantially parallel to a longitudinal axis of the elongated cavity. The composite sidewall portions include a plurality of third layers each third layer having a plurality of third fibers disposed therein, the third fibers being cross-woven and non-parallel with the longitudinal axis.

Owner:THE BOEING CO

Light, simple and efficient cultivation method for cotton

InactiveCN102204469AOvercoming not perishableShorten the fermentation cycleHorticultureTransplantingFilling-in

The invention relates to a light, simple and efficiency cultivation method for cotton. Straw-like light seedling raising medium is filled in paper cylinder and pot or paper plug or nonwoven fabric bags for raising cotton seedlings, and mechanical sowing, transplanting and cotton harvesting can be performed. The light, simple and efficiency cultivation method has the characteristics of labor conservation, cost conservation, high yield and high efficiency, requires small investment, makes operation easy, avoids environment pollution and is a new method for large-scale cotton production with bright promotion and application prospects.

Owner:操宇琳

Composite aircraft floor system

InactiveUS20070193146A1Improved structural performanceIncrease damage toleranceBuilding roofsFloorsAirplaneDamage tolerance

An aircraft floor system includes a composite panel which generally includes an inboard layer, an inboard interlock layer, a core layer, an outboard interlock layer and an outboard layer. The advanced sandwich core material may include K-Cor™ or X-Cor™ which is pinned through at least one ply of dry composite reinforcement to provide a mechanical lock between the pins and an inboard and outboard interlock layer. Bonding of the locked-in ply with the inboard and outboard results in improved structural performance and damage tolerance.

Owner:SIKORSKY AIRCRAFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com