Modular multi-storeyed overall assembly type steel structural house structure system

A multi-high-rise, prefabricated technology, applied in building components, building structures, wine cellars, etc., can solve the problems of slowing down the construction process, pollution of the surrounding environment, low degree of specialization, etc., to enhance the overall structural performance, Easy to disassemble and transport, to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

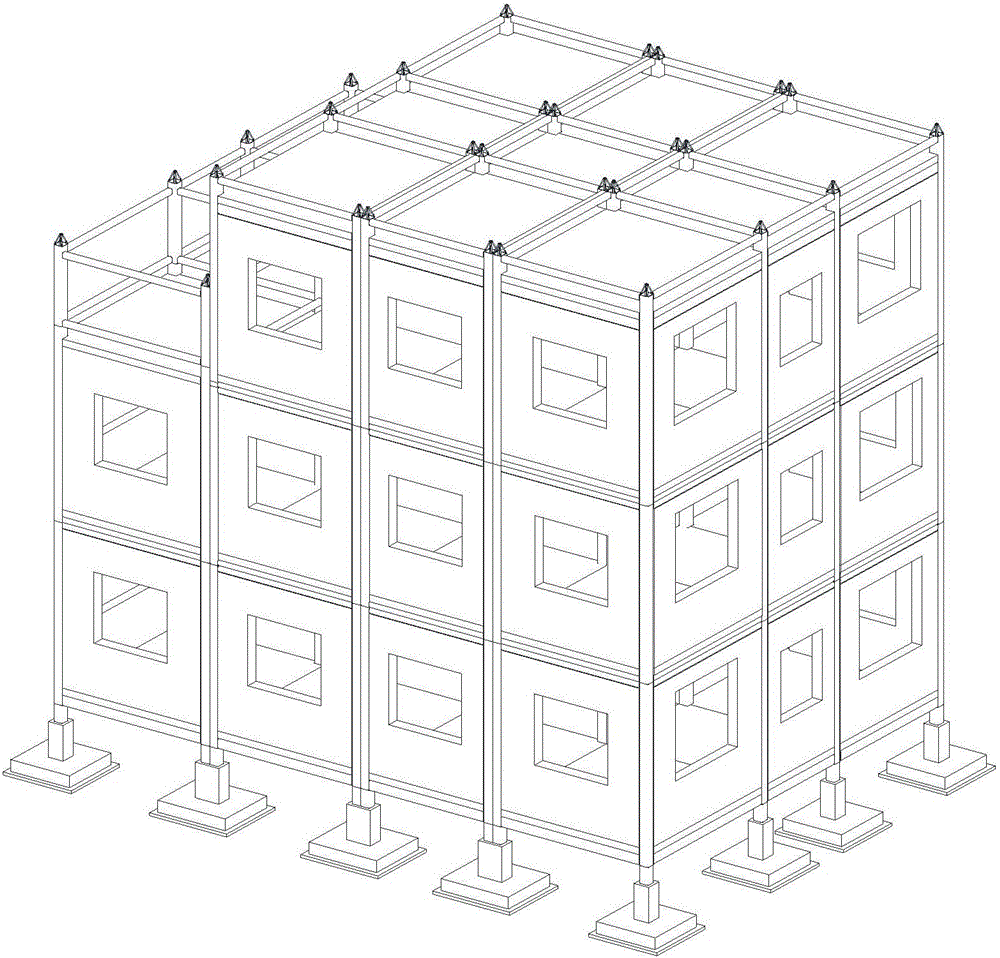

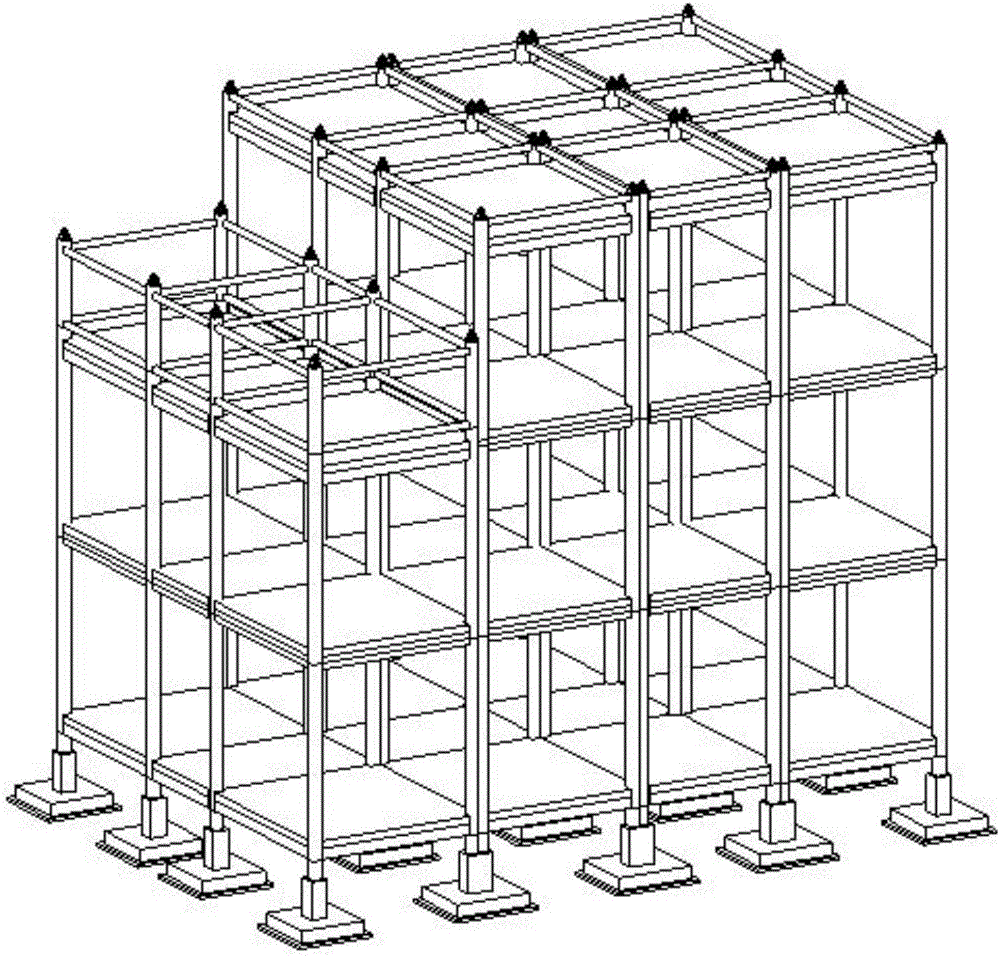

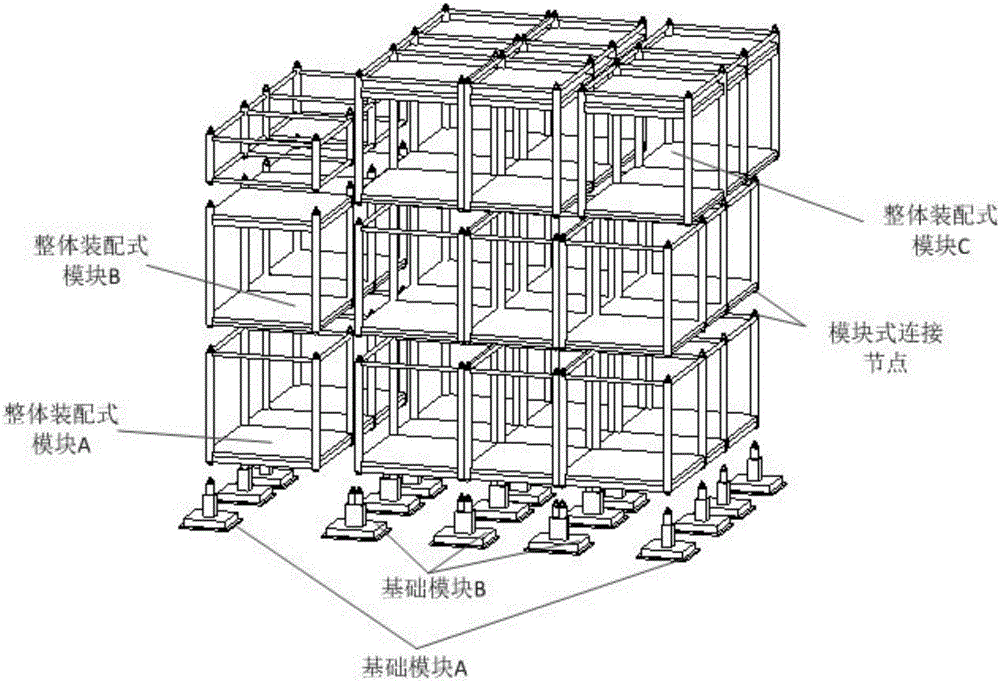

[0032] like figure 1 , 2 As shown, the integral building modules of the present invention are connected by plugging and pouring concrete or welding in the columns, so that the construction work of the steel structure building structural system can be completed. During construction and hoisting, the hook on the top of the column can make the crane hoist smoothly, and the hook and bent plate can play the role of plugging and guiding, which reduces the difficulty of assembly and docking, and greatly improves the construction quality and construction speed .

[0033] In the modular multi-high-rise integrated steel structure building system proposed by the present invention, the prefabricated foundation adopts an independent foundation under a column, and of course the foundation type of the present invention is not limited thereto. The foundation forms are foundation A and foundation B. The foundations mentioned above are all prefabricated in the prefabrication factory, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com