Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Increase damage tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

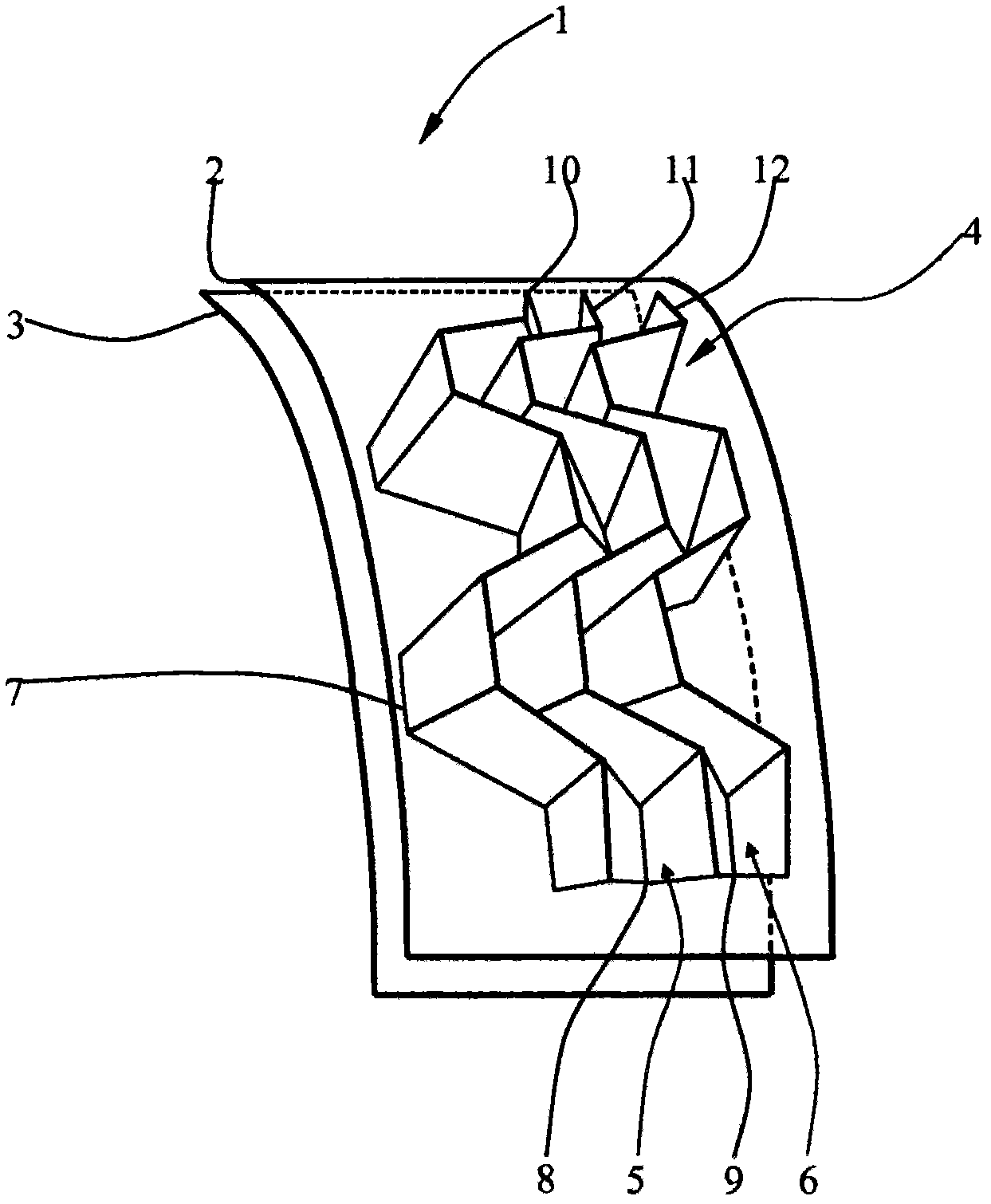

Lightweight structural component in particular for aircraft and method for its production

InactiveUS20080296433A1Efficient productionHigh damage toleranceLoad-supporting pillarsFuselage bulkheadsEngineeringAirplane

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

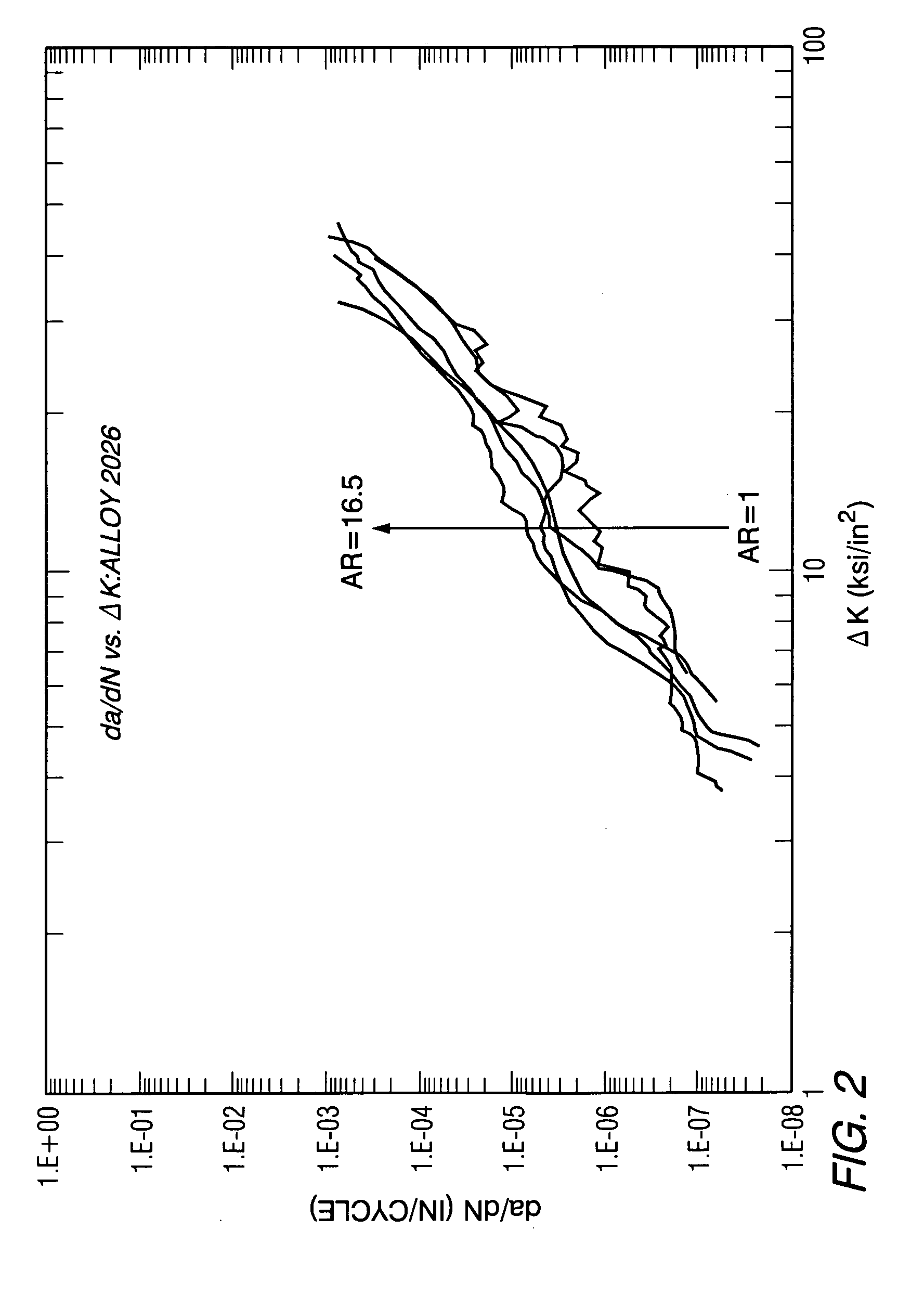

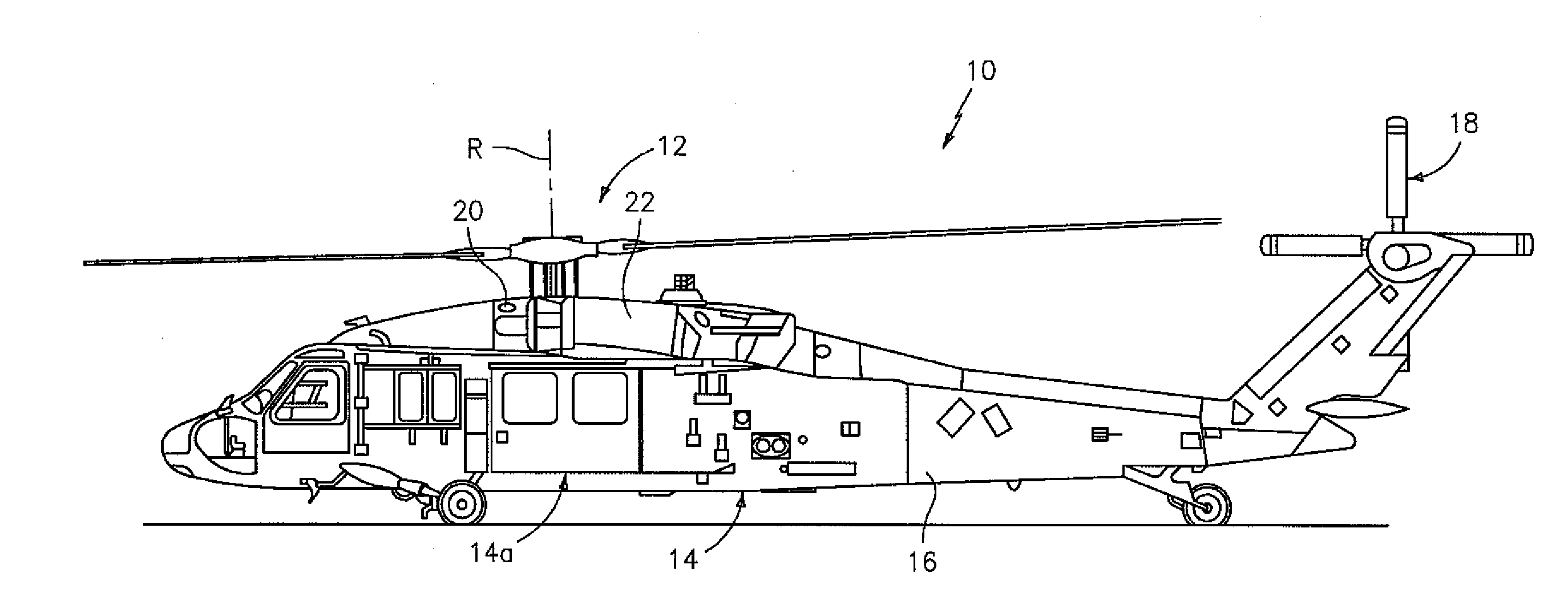

Structural members having improved resistance to fatigue crack growth

InactiveUS20050241735A1High damage toleranceReduce rate of fatigue crack growthLayered productsExtrusion containersFiberDamage tolerance

An extruded structural member having improved damage tolerance containing a base section (6); a stiffening section having at least one pair of structural stiffeners (10), the structural stiffeners integral with the base section (6) and projecting outwardly thereof; and at least one intra-stiffener (90) area positioned between the pair of structural stiffeners (10), the intra-stiffener area (90) having a microstructure with intentionally increased amounts of fiber texture to reduce the rate of fatigue crack growth in the extruded structural member.

Owner:ARCONIC INC

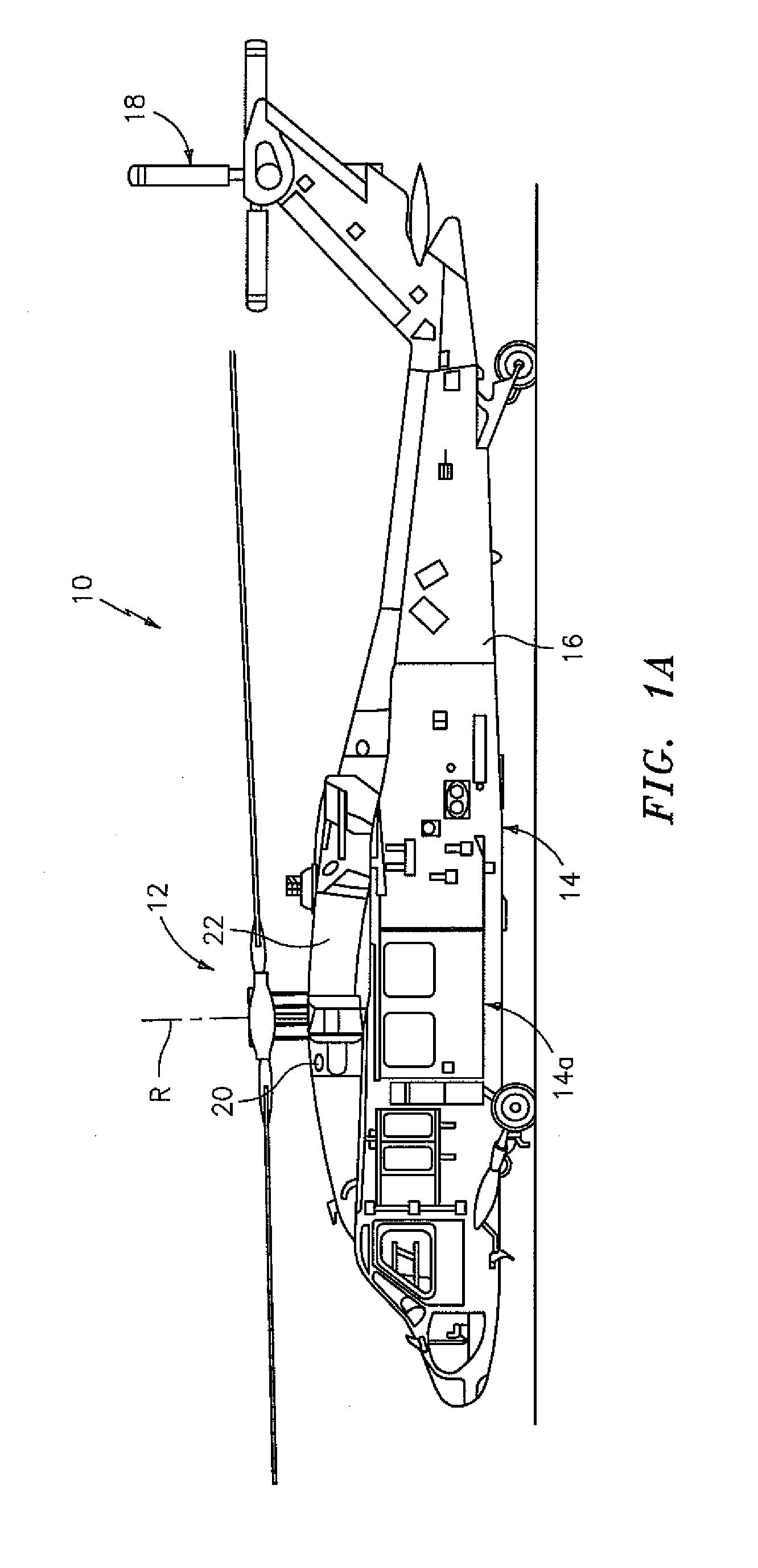

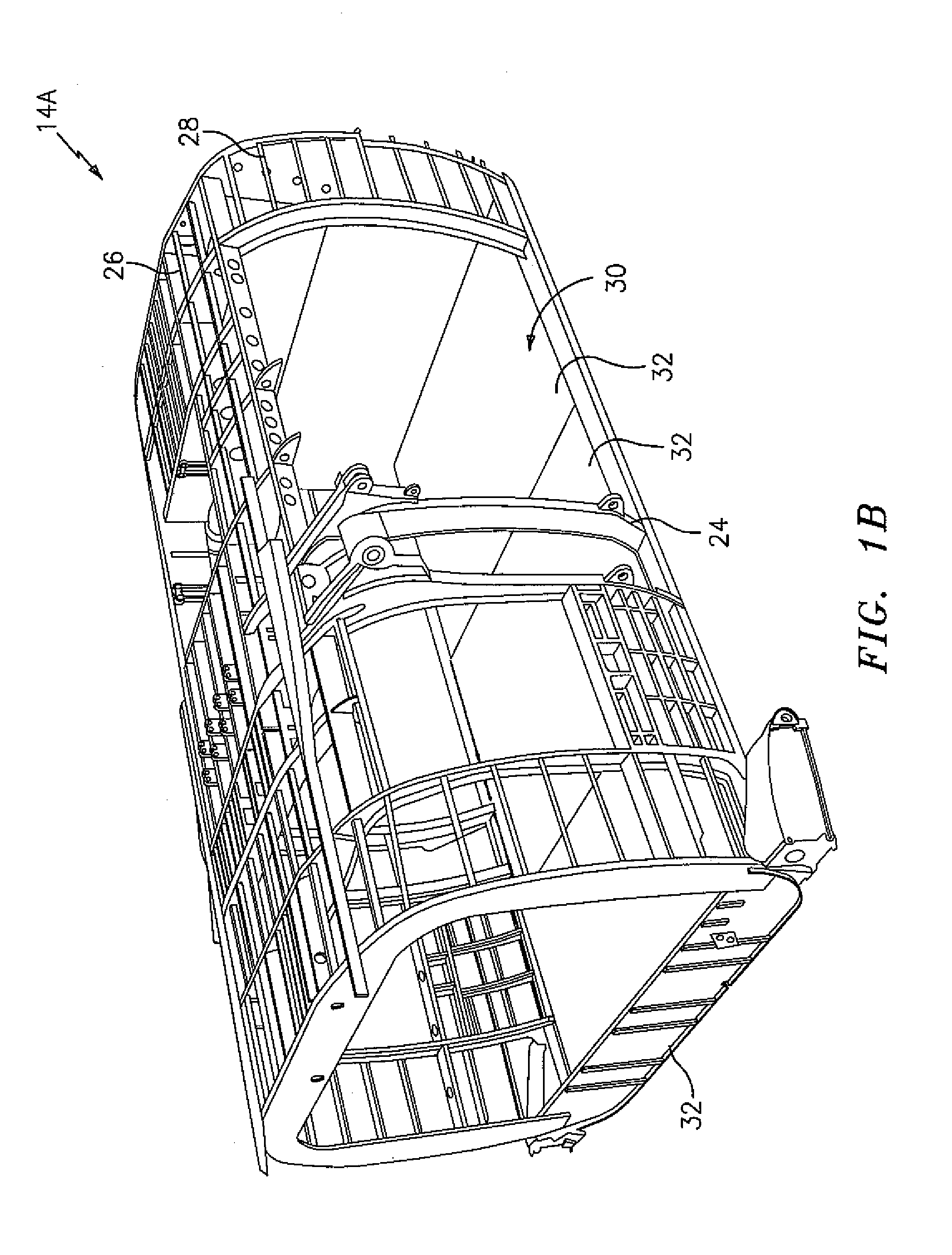

Composite aircraft floor system

InactiveUS20070193146A1Improved structural performanceIncrease damage toleranceBuilding roofsFloorsAirplaneDamage tolerance

An aircraft floor system includes a composite panel which generally includes an inboard layer, an inboard interlock layer, a core layer, an outboard interlock layer and an outboard layer. The advanced sandwich core material may include K-Cor™ or X-Cor™ which is pinned through at least one ply of dry composite reinforcement to provide a mechanical lock between the pins and an inboard and outboard interlock layer. Bonding of the locked-in ply with the inboard and outboard results in improved structural performance and damage tolerance.

Owner:SIKORSKY AIRCRAFT

Preparation method of in-plane isotropic zirconium boride-based ultra-high temperature monolithic structure ceramic with high damage tolerance

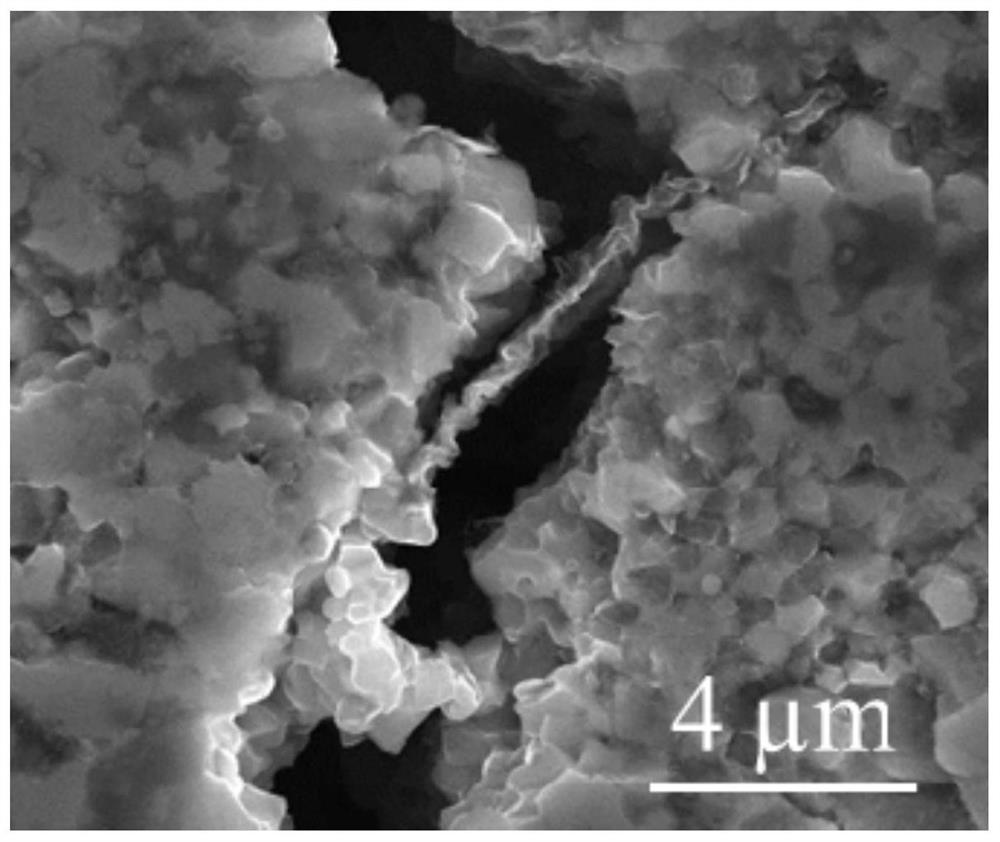

ActiveCN109293384ASolve the problem of in-plane anisotropyImprove fracture toughnessInorganic material artificial filamentsBorideFiber

The invention relates to a preparation method of a zirconium boride-based ultra-high temperature monolithic material, in particular to a preparation method of an in-plane isotropic zirconium boride-based ultra-high temperature monolithic structure ceramic with high damage tolerance, and aims to solve the problems that ZrB2-based ultra-high temperature ceramic has poor damage tolerance and seriousin-plane anisotropy exists in ZrB2-based fiber monolithic ceramic. The preparation method includes: dissolving polyether sulfone in N-methylpyrrolidone, and conducting ball milling mixing with ZrB2 powder and SiC powder to obtain a ZrB2-SiC slurry, and subjecting the ZrB2-SiC slurry to extrusion curing to obtain continuous ZrB2-SiC ceramic fiber; dispersing ZrB2 powder, SiC powder and Graphene indeionized water to obtain a ZrB2-SiC-Graphene slurry; coating the continuous ZrB2-SiC ceramic fiber with the ZrB2-SiC-Graphene slurry, performing drying, and conducting prepressing, high temperature glue discharge and hot pressing sintering. The method provided by the invention solves the in-plane anisotropy problem of uniaxially arranged ZrB2-based fiber monolithic ceramic, and improves the damage tolerance. The method provided by the invention is suitable for preparation of zirconium boride-based ultra-high temperature monolithic structure ceramic.

Owner:HARBIN INST OF TECH

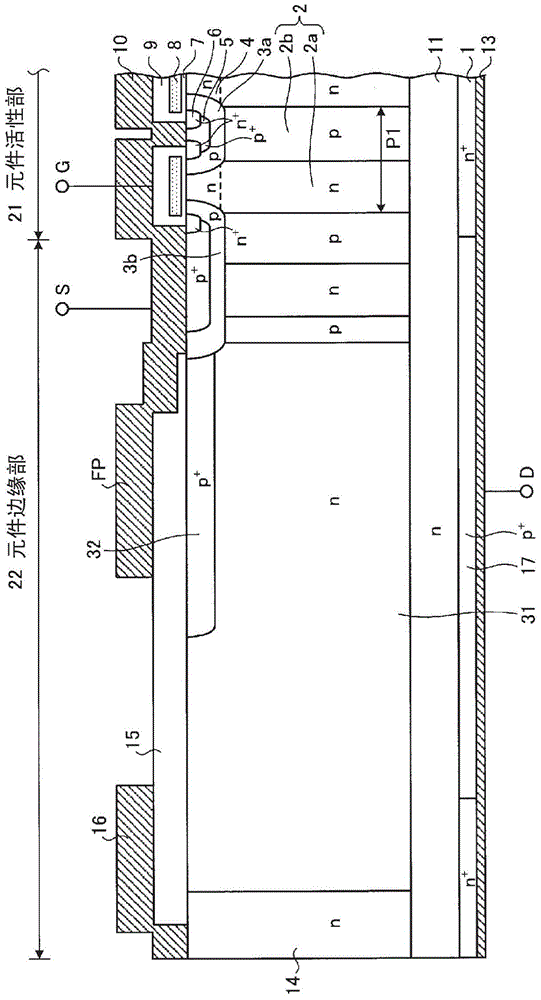

Semiconductor element

InactiveCN104620388AIncrease damage toleranceSemiconductor/solid-state device manufacturingSemiconductor devicesDepth directionOn resistance

A drain / drift section (2) is generally equivalent to a portion directly below a p-base region (3a) which is an element active section (21), and is a first parallel pn structure obtained by repeatedly joining in an alternating manner a first n-type region (2a) and a first p-type region (2b). Around the drain / drift section (2) is an element peripheral edge section (22) comprising a second parallel pn structure obtained by repeatedly joining in an alternating manner a second n-type region (12a) and a second p-type region (12b) oriented continuous with the first parallel pn structure. An n-buffer layer (11) is provided between the first and second parallel pn structures and an n+ drain layer (1). A p+ drain region (17) is selectively provided on the interior of the n+ drain layer (1) of the element peripheral edge section (22), the p+ drain region (17) passing through the n+ drain layer (1) in the depth direction. By this means, damage resistance can be improved in a super-junction semiconductor element capable of significantly improving the tradeoff relationship between on resistance and pressure resistance.

Owner:FUJI ELECTRIC CO LTD

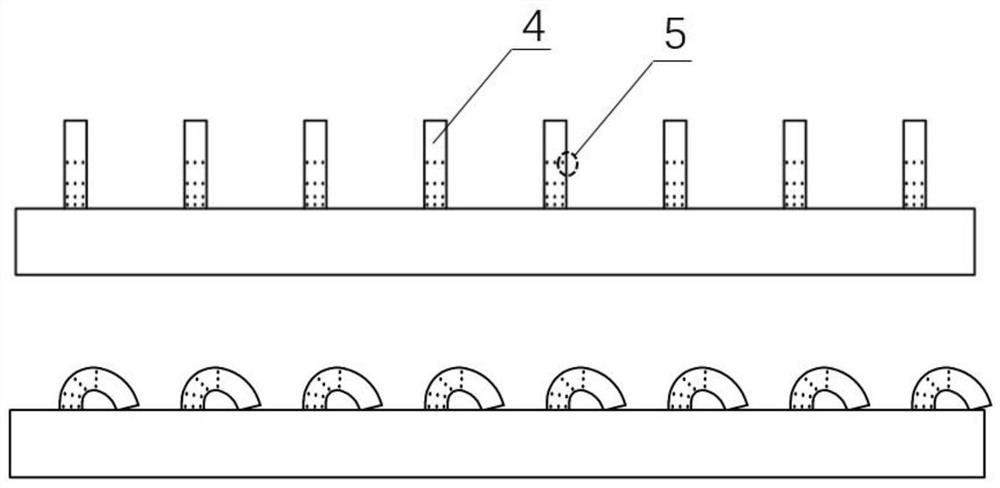

Preparation method of silicon carbide fiber reinforced silicon carbide ceramic-based composite material

InactiveCN112079646AShorten the manufacturing cycleReduce manufacturing costCarbide siliconSic fiber

The invention belongs to the field of composite material preparation, and relates to a preparation method of a silicon carbide fiber reinforced silicon carbide ceramic matrix composite material. The method utilizes an automatic numerical control sewing system to realize automatic sewing of a two-dimensional SiC fiber preform, and adopts a precursor infiltration pyrolysis (PIP) process to prepare atwo-dimensional SiC / SiC composite material. By accurately controlling the tension of the suture lines, the laminated SiC fiber woven fabric is successfully sewn by using the SiC fibers. Compared witha conventional manual sewing method, the method can remarkably improve the sewing efficiency, quality and stability of the two-dimensional laminated SiC fiber woven fabric, and greatly reduces the preparation period and cost of the prefabricated body; meanwhile, SiC fibers are introduced between layers of the composite material, so the layering risk in the technological process can be reduced, and the interlayer mechanical property of the two-dimensional SiC / SiC composite material is effectively improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

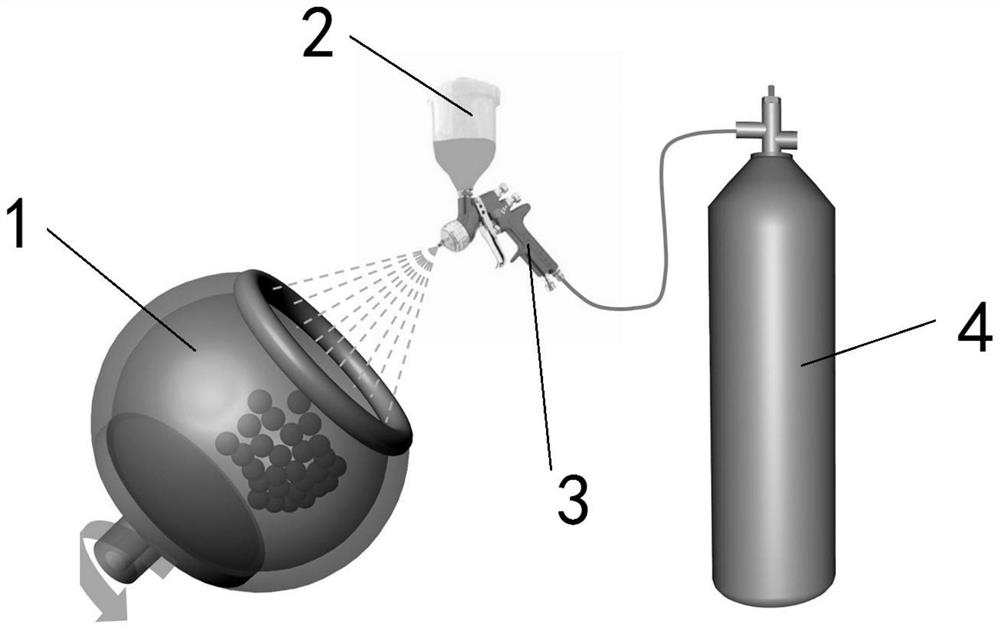

Preparation method of multiscale toughened brick-mud structural super high-temperature ceramic material

The invention provides a preparation method of a multiscale toughened brick-mud structural super high-temperature ceramic material, and relates to the field of preparation of structural ceramic materials, in particular to a preparation method of the brick-mud structural super high-temperature ceramic material. The preparation method aims to solve the problem that the anisotropism of multi-component ZrB2-SiC ceramic is severe and the damage resistant tolerance is poor. The preparation method comprises the steps that 1, a ZrB2-SiC ceramic microsphere is prepared through pelleting; 2, the surfaceof the ZrB2-SiC ceramic microsphere is coated with a ZrB2-SiC-Graphene interface layer through a spraying coating method; and 3, the multiscale toughened brick-mud structural super high-temperature ceramic material is prepared through spark plasma sintering. The preparation method is used for preparing the multiscale toughened brick-mud structural super high-temperature ceramic material, the critical crack size and the fracture work of the material reach 161.8 microns and 150.3 J / m2 respectively, and the critical thermal impact temperature difference is as high as 861 DEG C.

Owner:HARBIN INST OF TECH

Steel reinforced concrete column-steel beam joint locally adopting fiber reinforced concrete

PendingCN107842107AAvoid brittle failureIncreased shear capacityProtective buildings/sheltersShock proofingReinforced concrete columnMetallurgy

The invention discloses a steel reinforced concrete column-steel beam joint locally adopting fiber reinforced concrete. The steel reinforced concrete column-steel beam joint comprises core profile steel, the fiber reinforced concrete, a first steel beam, a second steel beam, a third steel beam and a fourth steel beam; the core profile steel comprises a first profile steel web and a second profilesteel web which are welded to form cross-shaped profile steel, the two ends of the first profile steel web are correspondingly provided with a first profile steel flange and a second profile steel flange, and the two ends of the second profile steel web are correspondingly provided with a third profile steel flange and a fourth profile steel flange; and the first profile steel flange, the second profile steel flange, the third profile steel flange and the fourth profile steel flange are correspondingly connected with the first steel beam, the second steel beam, the third steel beam and the fourth steel beam. The steel reinforced concrete column-steel beam joint locally adopting the fiber reinforced concrete has the characteristics that the fiber reinforced concrete is adopted at a joint core zone, the using amount of stirrups in the core zone can be reduced or even eliminated, the shear resistance capacity of the joint, the rotating capability of the joint and the energy dissipation capability can be remarkably improved, and meanwhile, construction complexity is reduced.

Owner:CHANGAN UNIV

Semiconductor device

InactiveCN1938862AImprove pressure resistanceIncrease damage toleranceSolid-state devicesSemiconductor devicesEngineeringSemiconductor

A semiconductor device having a high withstand voltage is provided. An activation groove (22a) is composed of a long and narrow main groove part (26) and a sub-groove part (27) which is connected with a side plane in a longitudinal direction of the main groove part. On a bottom plane of the main groove part (26), a second conductivity type embedding region (24) having a height lower than a bottom plane of a second conductivity type base diffusion region (32a) is arranged, and in the sub-groove part (27), a second conductivity type activation groove filling region (25) contacting the base diffusion region (32a) is arranged. The embedding region (24) is brought into contact with the base diffusion region (32a) through the activation groove filling region (25). In the one activation groove (22a), since one gate groove (83) is formed at a part upper than the embedding region (24), a gate electrode plug (48) is not interrupted and an electrode pattern is simplified.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Method for making a composite material, composite material and end product

InactiveCN102725131AImprove resistance to damageIncrease damage toleranceSynthetic resin layered productsNon-woven fabricsFiberMechanical engineering

A method is presented for making a composite material from strips comprising longitudinal fibres and a binder or resin, which material comprises a number of layer assemblies one on top of the other. Each layer assembly comprises m sets (with m at least 2) of parallel strips each extending in a different direction, Each layer assembly is manufactured by successive steps of depositing groups of parallel strips according to a well defined pattern (without longitudinally interweaving strips with previously deposited strips). Before completing a layer assembly, with the exception of the last layer assembly, by depositing its last group of parallel strips, the first group of parallel strips of the following layer assembly is already deposited. A composite material manufactured with such a method is presented too.

Owner:STICHTING NAT LUCHTEN RUIMTEVAART LABUM

Hot-pressed light guide plate with high mesh points, backlight, display device and preparation method

PendingCN110412679AReduce in quantityIncrease heightTransfer printingOptical light guidesForeign matterLight guide

The invention provides a hot-pressed light guide plate with high mesh points, a backlight, a display device and a preparation method. The hot-pressed light guide plate comprises a first surface and asecond surface which are opposite to each other, the second surface is provided with a mesh point area composed of a plurality of mesh points, the mesh point area enables light entering the light guide plate to be emitted from the first surface, the average height of annular crater forms of a mold core before hot-press transfer printing of the mesh points is 12-18 micrometers, and the proportion of the annular crater forms the average height of which is greater than or equal to 12 micrometers in the mold core per unit area is 70-100%. According to the hot-pressed light guide plate, under the condition of keeping the annular crater forms of the mold core complete, the mesh point height of the light guide plate is increased, the tolerance degree to the damage caused by tiny foreign matter which cannot be recognized by the human eyes is improved, and the hot-pressed light guide plate is used for reducing the problem of bright white spots or scratches.

Owner:HANBO HIGH TECH MATERIALS (HEFEI) CO LTD

Preparation method of mullite whisker low-temperature growth toughening type aluminum-phosphate-based high-temperature adhesive

The invention provides a preparation method of mullite whisker low-temperature growth toughening type aluminum-phosphate-based high-temperature adhesive. The preparation method comprises the steps ofusing aluminium hydroxide powder, kaolinite powder and an ammonium molybdate tetrahydrate powder prefabricated whisker growth precursor to mix aluminum oxide powder, silicon powder, boron carbide powder and glass powder to prepare a filler, taking a reaction solution of aluminum hydroxide and phosphoric acid as a glue solution, and finally preparing an adhesive by mixing the precursor, the fillerand the glue solution. The preparation method has the effects that the high-temperature adhesive can grow mullite whiskers in situ at 700 DEG C to be strengthened and toughened, and the bonding performance of the high-temperature adhesive can be greatly improved within the range of 700 DEG C to1300 DEG C. Especially after treatment at 1100 DEG C, the adhesive shows excellent bonding effect, compared with a blank sample without whisker growth, the adhesive strength of the adhesive is increased by 79.88% and reaches 49 MPa, and fracture displacement is increased by nearly 164%. In addition, thehigh-temperature adhesive also shows high damage resistant tolerance, and it is fully shown that the high-temperature adhesive has high use safety.

Owner:CIVIL AVIATION UNIV OF CHINA

Power amplifier module

InactiveCN100536323CImprove efficiencyStrong resistanceHigh frequency amplifiersAmplifier modifications to reduce temperature/voltage variationStanding waveEngineering

Provided is a power amplifier module having high efficiency and high damage resistance, and at the same time having a function of protecting an amplifying device from being damaged from a standing wave generated by reflection from an antenna end or the like when a load fluctuates. By detecting and canceling the base overcurrent of the last-stage amplified GaAs-HBT and limiting it, the increase of the collector current can be prevented to prevent damage. In addition, by using both the function of stepping down the reactive current corresponding to the increase of the power supply voltage and the clipping function of the diode connected in parallel with the output stage GaAs-HBT, it is possible to prevent the output stage GaAs-HBT from receiving more than necessary voltage and current. In addition, it is highly resistant to manufacturing variations and temperature fluctuations of the GaAs-HBT and the base current supply source, and the cost is low.

Owner:RENESAS ELECTRONICS CORP

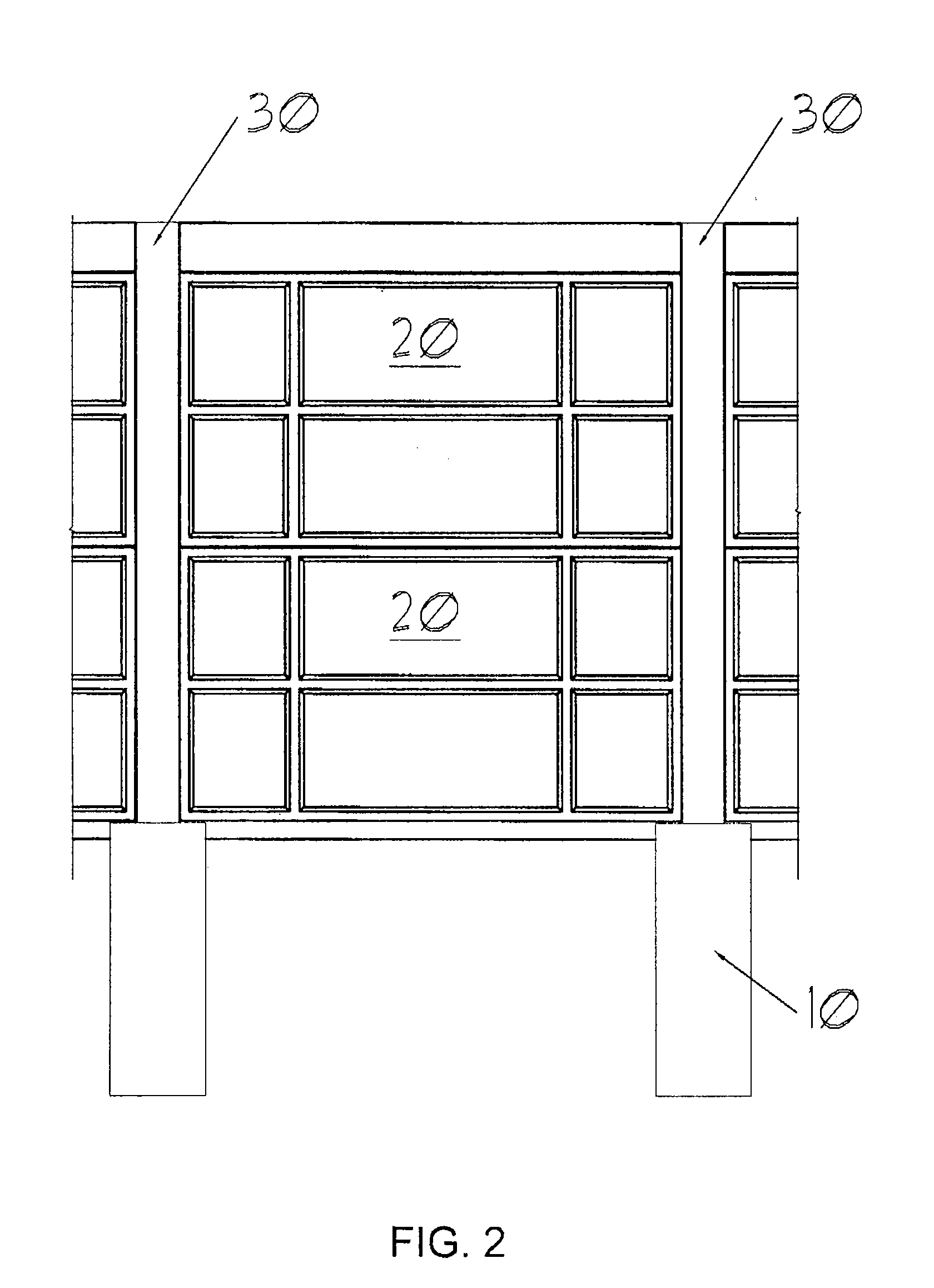

Precast structure and method of construction

InactiveUS20110023394A1Improve structural rigidityIncrease damage toleranceBuilding repairsFoundation engineeringInterior designHangar

Precast structures are formed of precast walls fitted between precast posts extending from cast in place footings, prior to the pouring of a slab. During pouring of the slab, anchors may tie together the panels, posts and slab. Precast concrete, tension fabric or traditional roofing members may be added to form a post and beam construction that spans large open areas providing for flexible manufacturing, storage, hangar, office, schools, institutional, or residential interior design features, due to the structural integrity and cost advantages of structures produced using this method of precast construction.

Owner:DURATEK PRECAST TECH

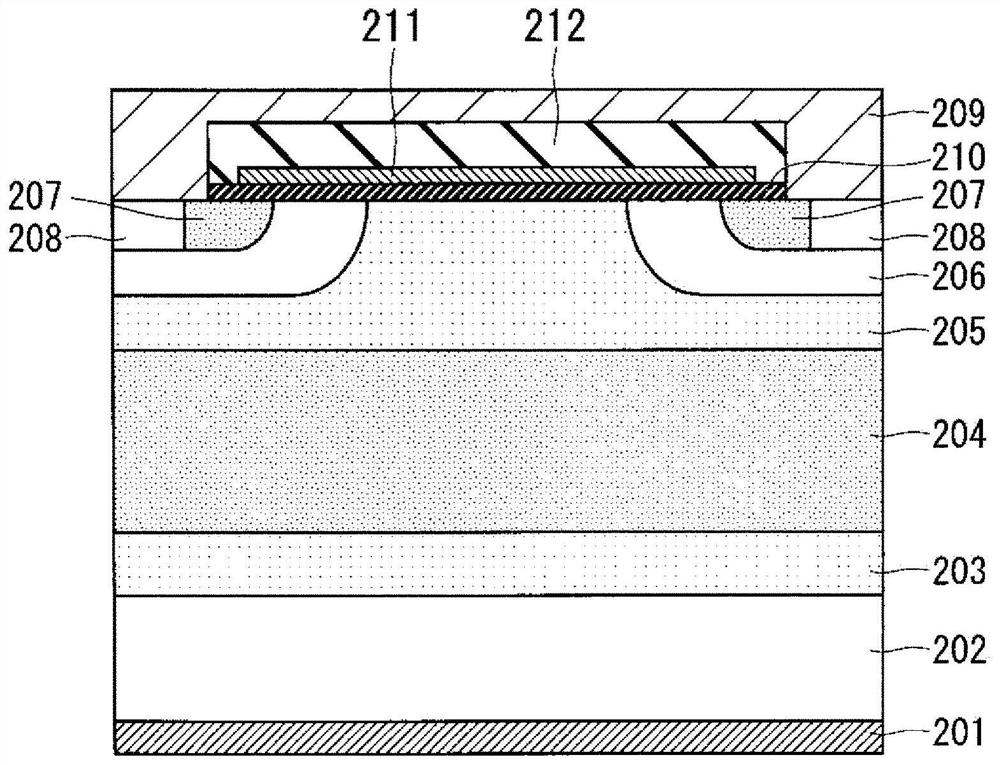

Semiconductor device and manufacturing method thereof

The object is to provide a technique capable of improving the breakdown resistance of the latch. A semiconductor device includes an emitter region, a base contact region, a buried region, and a carrier trapping region. The emitter region and the base contact region are selectively arranged on the upper surface of the base region in a state of being adjacent to each other. The buried region is disposed in the drift region below the base contact region or the emitter region. The carrier trapping region is arranged between the buried region and the base region, and the carrier lifetime is lower than that of the drift region.

Owner:MITSUBISHI ELECTRIC CORP

Semiconductor device

PendingCN113451391AInhibition of inflowIncrease damage toleranceTransistorSolid-state devicesDevice materialSemiconductor

The invention provides a semiconductor device which can enhance the breakdown resistance during the recovery operation. The semiconductor device (100) includes an insulated gate bipolar transistor region (1) and a diode region (2) adjacent to each other, wherein the insulated gate bipolar transistor region (1) includes base layers (9) of a second conductive type provided on the first main surface side, emitter layers (8) of the first conductive type selectively provided in a surface layer of the base layer (9) on the first main surface side, multiple gate electrodes (7a) provided on the first main surface side of the semiconductor substrate, aligned in a first direction extending along the first main surface, and facing the emitter layer (8), the base layer (9), and the drift layer (12) via a gate insulating film (6a), carrier injection suppression layers (10) of the first conductive type selectively provided in a surface layer of the base layer (9) on the first main surface side and sandwiched by the base layers (9) in the first direction.

Owner:MITSUBISHI ELECTRIC CORP

Semiconductor device

PendingCN113451392AIncrease damage toleranceTransistorSolid-state devicesHole injection layerDevice material

The invention provides a semiconductor device which can improve the breakdown tolerance during recovery operation. The semiconductor device according to the present application includes: a semiconductor substrate including a first main surface and a second main surface; a hole injection region including a hole injection layer of a second conductivity type and a semiconductor layer of a second conductivity type provided on the second main surface side; a diode region including: an anode layer of a second conductivity type provided on the first main surface side and a cathode of a first conductivity type on the second main surface side, the diode region having no semiconductor layer of a first conductivity type between the second main surface side end portion of the anode layer and the first main surface of the anode layer; a boundary region including: a boundary portion semiconductor layer of a second conductivity type provided on the first main surface side, a carrier injection suppression layer of a first conductivity type provided in a surface layer of the boundary portion semiconductor layer, and the semiconductor layer of a second conductivity type provided to protrude from the hole injection region on the second main surface side, which are arranged between the diode region and the hole injection region.

Owner:MITSUBISHI ELECTRIC CORP

Method for producing a core composite with double-sided surface layers

ActiveCN102006993BInhibit sheddingIncrease load capacityLamination ancillary operationsLaminationSurface layerHoneycomb

The invention relates to a method for manufacturing flat, single or double curved core composites 1, 23 with at least one folded honeycomb core 4, 19. Prior to applying the initially not yet hardened cover layers 2, 3, 13, 22 a curable and later removable core filler material 15, 16 is introduced into full-length drainage-enabling channels 5, 6 of the folded honeycomb core 4, 19 in order to prevent telegraphing of the cover layers 2, 3, 13, 22 into the channels 5, 6 of the folded honeycomb core when arranging and / or hardening the cover layers 2, 3, 13, 22 and to produce edge-free and polygon-free surfaces of the core composite 1, 23. The core composites 1, 23 made according to the method have optimum structural mechanical properties, an ideal surface quality from the aerodynamic and aesthetic point of view, whereby a direct reprocessing of the core composites 1, 23 is possible without the need for further time and cost-intensive as well as in some circumstances weight-increasing finishing steps. With the method it is possible to manufacture in particular one-piece fuselage sections with wound core composites 1, 23 with a folded honeycomb 4, 19 as well as shell segments with laid cover layers 2, 3, 13, 22 for longitudinally divided (segmented) fuselage sections for large aircraft.

Owner:AIRBUS OPERATIONS GMBH

A preparation method of mullite whisker low-temperature growth toughened aluminum phosphate-based high-temperature adhesive

A method for preparing mullite whisker low-temperature growth toughened aluminum phosphate-based high-temperature glue. It includes using aluminum hydroxide powder, kaolin powder and tetrahydrate ammonium molybdate powder to prefabricate whisker growth precursors, mixing alumina powder, silicon powder, boron carbide powder and glass powder to prepare fillers, and using aluminum hydroxide and phosphoric acid The reaction solution is used as a glue solution, and finally the precursor, filler and glue solution are mixed to prepare an adhesive and other steps. The effect of the present invention: the high-temperature adhesive can grow mullite whiskers in situ at 700°C to be strengthened and toughened, and its bonding performance can be greatly improved in the range of 700°C to 1300°C. Especially after treatment at 1100°C, the adhesive showed excellent bonding effect. Compared with the blank sample without whisker growth, its bonding strength increased by 79.88%, reaching 49MPa, and the fracture displacement increased by nearly 164%. In addition, the high-temperature adhesive also exhibits a high resistance to damage tolerance, which fully demonstrates its high safety in use.

Owner:CIVIL AVIATION UNIV OF CHINA

Semiconductor device

Provided is a semiconductor device having improved breakdown tolerance during a recovery operation. An insulated gate bipolar transistor region (1) of a semiconductor device (100) is arranged in parallel with a diode region (2) in a first direction along a first main surface of a semiconductor substrate, and has: a second conductivity type base layer (9) provided on a surface layer on the first main surface side of the semiconductor substrate; an emitter layer (8) of a first conductivity type, which is selectively provided on a surface layer on the first main surface side of the base layer (9), and which has a higher impurity concentration than the drift layer; a plurality of gate electrodes (7a) arranged in parallel in the first direction and facing the emitter layer, the base layer, and the drift layer with a gate insulating film (6a) therebetween; a counter-doped layer (10) provided on the surface layer of the base layer and having a second conductivity type impurity concentration higher than that of the base layer and a first conductivity type impurity concentration higher than that of the drift layer; and a collector layer of a second conductivity type provided on a surface layer on the second main surface side of the semiconductor substrate.

Owner:MITSUBISHI ELECTRIC CORP

A kind of thermoplastic absorbing material and preparation method thereof

ActiveCN113372638BImprove impact resistanceIncrease damage toleranceChemical industryFiberPolymer science

The invention provides a thermoplastic wave-absorbing material and a preparation method thereof. The thermoplastic wave-absorbing material comprises: reinforced fiber cloth; and a thermoplastic wave-absorbing film, which is located on the upper and lower sides of the reinforced fiber cloth. The thermoplastic wave-absorbing material of the present invention uses a thermoplastic resin with a linear molecular structure as an adhesive matrix material, has good toughness, and can greatly improve the impact resistance and damage tolerance of the thermoplastic wave-absorbing material, and the thermoplastic wave-absorbing material also has It can be processed and shaped many times, and can also be recycled, which is beneficial to protect the environment and save resources; compared with the existing thermosetting absorbing materials, the thermoplastic absorbing materials only need to be stored at room temperature, and the storage period is not as long as limit.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

Semiconductor device

InactiveCN102403358BLower on-resistanceIncrease damage toleranceDiodePower semiconductor deviceElectrical conductor

According to one embodiment, a semiconductor device includes a first major electrode, a first semiconductor layer, a first conductivity-type base layer, a second conductivity-type base layer, a second semiconductor layer, a buried layer, a buried electrode, a gate insulating film, a gate electrode, and a second major electrode. The buried layer of the second conductivity type selectively is provided in the first conductivity-type base layer. The buried electrode is provided in a bottom portion of a trench which penetrates the second conductivity-type base layer to reach the buried layer. The buried electrode is in contact with the buried layer. The gate electrode is provided inside the gate insulating film in the trench. The second major electrode is provided on the second semiconductor layer and is electrically connected to the second semiconductor layer and the buried electrode.

Owner:KK TOSHIBA

A method for preparing in-plane isotropic zirconium boride-based ultra-high temperature monolithic ceramics with high damage tolerance

ActiveCN109293384BSolve the problem of in-plane anisotropyImprove fracture toughnessInorganic material artificial filamentsFiberUltra-high-temperature ceramics

The invention relates to a preparation method of a zirconium boride-based ultra-high temperature monolithic material, in particular to a preparation method of an in-plane isotropic zirconium boride-based ultra-high temperature monolithic structure ceramic with high damage tolerance, and aims to solve the problems that ZrB2-based ultra-high temperature ceramic has poor damage tolerance and seriousin-plane anisotropy exists in ZrB2-based fiber monolithic ceramic. The preparation method includes: dissolving polyether sulfone in N-methylpyrrolidone, and conducting ball milling mixing with ZrB2 powder and SiC powder to obtain a ZrB2-SiC slurry, and subjecting the ZrB2-SiC slurry to extrusion curing to obtain continuous ZrB2-SiC ceramic fiber; dispersing ZrB2 powder, SiC powder and Graphene indeionized water to obtain a ZrB2-SiC-Graphene slurry; coating the continuous ZrB2-SiC ceramic fiber with the ZrB2-SiC-Graphene slurry, performing drying, and conducting prepressing, high temperature glue discharge and hot pressing sintering. The method provided by the invention solves the in-plane anisotropy problem of uniaxially arranged ZrB2-based fiber monolithic ceramic, and improves the damage tolerance. The method provided by the invention is suitable for preparation of zirconium boride-based ultra-high temperature monolithic structure ceramic.

Owner:HARBIN INST OF TECH

Multi-level micro-nano mechanical structure for enhancing damage resistance of functional surface

PendingCN113772616AIncrease the distributionIncrease the carrying areaPiezoelectric/electrostriction/magnetostriction machinesSnap-action arrangementsStress concentrationSpace time domain

The invention discloses a multi-level micro-nano mechanical structure for enhancing damage resistance of a functional surface. The multi-level micro-nano mechanical structure comprises a micro-nano composite structure functional layer, an interconnection network structure functional layer and a mechanical artificial structure functional layer which are connected; the micro-nano composite structure functional layer is of a micro-column array structure which plays a surface function, the interconnection network structure functional layer is of a hard phase and soft interconnection structure, the hard phases are connected through soft phase materials to form an unstable parallelogram, and under the action of plane stress at the tail ends of micro-columns, spontaneous rotation or reconstruction is achieved, and apparent numerical values of stress and strain at the tail ends of the micro-columns are reduced; the mechanical artificial structure functional layer is of an array structure composed of reconfigurable artificial lattices with mechanical properties, and through time-space domain reconstruction of the artificial lattices, a stress transfer path and strain energy density are optimized, and stress concentration of a functional surface is reduced. According to the invention, a dynamic structure is introduced, the damage tolerance of the surface functional layer is improved, the service cycle of the functional surface is prolonged, and the performance of the functional surface is guaranteed.

Owner:XI AN JIAOTONG UNIV

A preparation method of multi-scale toughened brick-mud structure ultra-high temperature ceramic material

The invention provides a preparation method of a multiscale toughened brick-mud structural super high-temperature ceramic material, and relates to the field of preparation of structural ceramic materials, in particular to a preparation method of the brick-mud structural super high-temperature ceramic material. The preparation method aims to solve the problem that the anisotropism of multi-component ZrB2-SiC ceramic is severe and the damage resistant tolerance is poor. The preparation method comprises the steps that 1, a ZrB2-SiC ceramic microsphere is prepared through pelleting; 2, the surfaceof the ZrB2-SiC ceramic microsphere is coated with a ZrB2-SiC-Graphene interface layer through a spraying coating method; and 3, the multiscale toughened brick-mud structural super high-temperature ceramic material is prepared through spark plasma sintering. The preparation method is used for preparing the multiscale toughened brick-mud structural super high-temperature ceramic material, the critical crack size and the fracture work of the material reach 161.8 microns and 150.3 J / m2 respectively, and the critical thermal impact temperature difference is as high as 861 DEG C.

Owner:HARBIN INST OF TECH

Injection mould and manufacturing method thereof

The invention relates to an injection mould for improving a pouring gate and a manufacturing method of the injection mould, and the mould is provided with a detachable pouring core part. The injection mould comprises the pouring core part which is independent of the injection mould, the pouring core part forms the pouring gate and a pouring channel, the pouring core part and the whole mould can be conveniently separated, when the pouring core part is abraded during the working process and plastic molding is further influenced, the pouring core part can be detached from the mould for replacement, thereby being time-saving and labor-saving during actual applications.

Owner:广东邦宝益智玩具有限公司

A method for preparing graphene network toughened zrc-sic ultra-high temperature ceramic material

ActiveCN108178650BGive full play to micro tougheningIncrease damage toleranceCrazingUltra-high-temperature ceramics

A method for preparing a graphene network toughened ZrC-SiC ultra-high temperature ceramic material, and the invention relates to the field of preparation methods of ceramic materials. The present invention aims to solve the technical problem of the existing poor ZrC-SiC damage tolerance. Method: 1. Preparation of graphene oxide aqueous solution; 2. Preparation of graphene oxide dispersion; 3. Directional freezing to prepare PVA-modified graphene network; 4. Thermal reduction and vacuum impregnation to prepare graphene network-wrapped ceramic powder Green body; 5. Spark plasma sintering. The fracture toughness of the ceramic material prepared by the inventive method is by 3.82MPa m 1 / 2 increased to 4.26MPa·m 1 / 2 , the critical crack size increased from 26.8μm to 119.4μm, and the work of fracture increased from 44.7J / m 2 increased to 151.6J / m 2 . The invention is used for preparing ceramic materials.

Owner:HARBIN INST OF TECH

Thermoplastic wave-absorbing material and preparation method thereof

ActiveCN113372638AImprove impact resistanceIncrease damage toleranceChemical industryFiberPolymer science

The invention provides a thermoplastic wave-absorbing material and a preparation method thereof. The thermoplastic wave-absorbing material comprises: a reinforced fiber cloth; and thermoplastic wave-absorbing films positioned on the upper and lower side surfaces of the reinforced fiber cloth. According to the thermoplastic wave-absorbing material disclosed by the invention, the thermoplastic resin with a linear molecular structure is used as an adhesive matrix material, so that the thermoplastic wave-absorbing material has good toughness, the impact resistance and the damage tolerance of the thermoplastic wave-absorbing material can be greatly improved, and the thermoplastic wave-absorbing material can be processed and formed for multiple times and can be recycled, thereby being beneficial to environment protection and resource saving; and compared with the existing thermosetting wave-absorbing material, the thermoplastic wave-absorbing material disclosed by the invention only needs to be stored at normal temperature, and the storage period is not limited.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

Semiconductor device

InactiveCN100573913CImprove pressure resistanceIncrease damage toleranceSolid-state devicesSemiconductor devicesElectrical resistance and conductanceSemiconductor

A semiconductor device having a high withstand voltage is provided. An activation groove (22a) is composed of a long and narrow main groove part (26) and a sub-groove part (27) which is connected with a side plane in a longitudinal direction of the main groove part. On a bottom plane of the main groove part (26), a second conductivity type embedding region (24) having a height lower than a bottom plane of a second conductivity type base diffusion region (32a) is arranged, and in the sub-groove part (27), a second conductivity type activation groove filling region (25) contacting the base diffusion region (32a) is arranged. The embedding region (24) is brought into contact with the base diffusion region (32a) through the activation groove filling region (25). In the one activation groove (22a), since one gate groove (83) is formed at a part upper than the embedding region (24), a gate electrode plug (48) is not interrupted and an electrode pattern is simplified.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Method for producing a core composite with double-sided surface layers

ActiveCN102006993AJia Structural MachineryImprove finishing stepsLamination ancillary operationsLaminationSurface layerHoneycomb

The invention relates to a method for producing, planar, simple or doubly folded core composites (1, 23) with at least one folded honeycomb core (4, 19). A hardening and later removable core filler (15, 16) is introduced into the through drainage channels (5, 6) of the folded honeycomb core (4, 19) before application of the initially unhardened surface layers (2, 3, 13, 22) in order to prevent a penetration of the cover layers, (2, 3, 13, 22) into the channels (5, 6) of the folded honeycomb core on the application and / or hardening of the surface layers (2, 3, 13, 22) and to achieve surfaces of the core composite (1, 23) without edges or polygons.

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com